Patents

Literature

14805 results about "Environmental resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental resistance. noun. : the sum of the environmental factors (such as drought, mineral deficiencies, and competition) that tend to restrict the biotic potential of an organism or kind of organism and impose a limit on numerical increase.

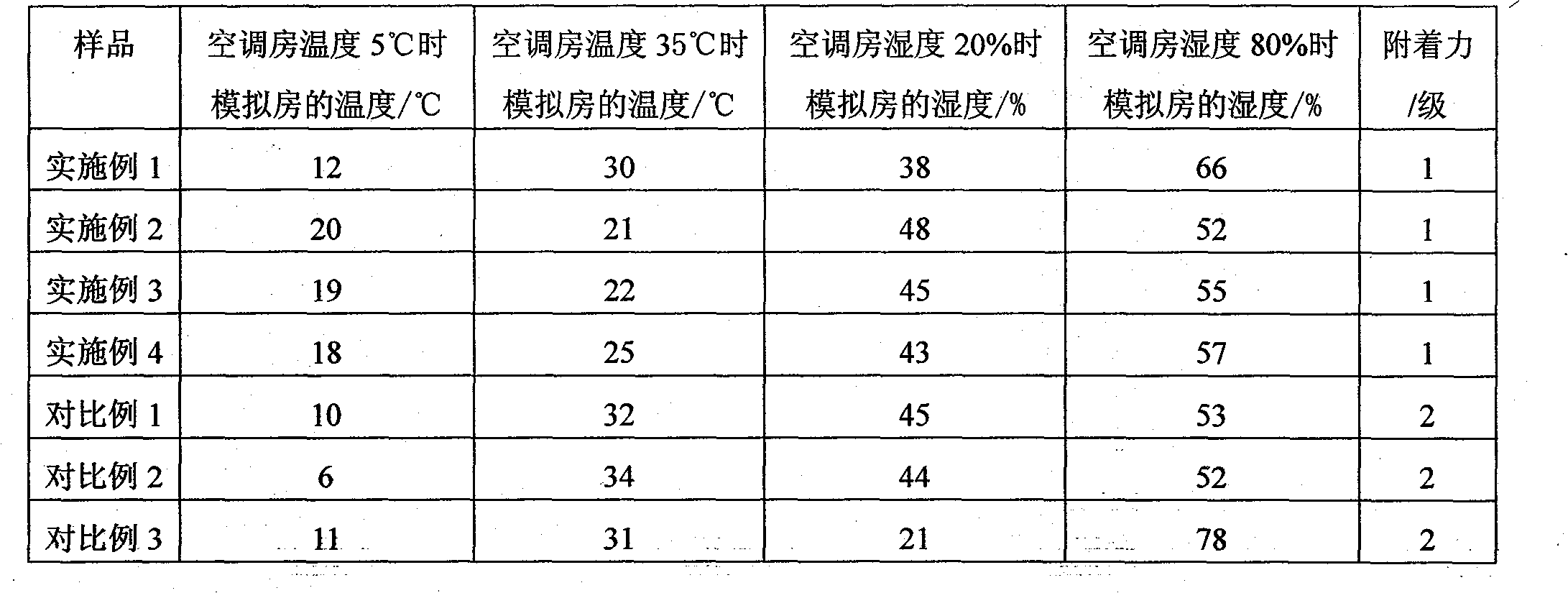

Temperature adjusting humidity adjusting coating and preparation method thereof

InactiveCN103159437ALower room temperatureTurn up the room temperatureEnvironmental resistanceThermal insulation

The invention relates to temperature adjusting humidity adjusting coating and a preparation method thereof. The temperature adjusting and humidity adjusting coating comprises thermal insulation undercoat, phase transition energy storage intermediate coat and heat conduction humidity adjusting finish. The undercoat insulates heat, and the phase transition energy storage intermediate coat transmits indoor energy through the finish and stores energy through the phase transition, and thereby effectively adjusting indoor temperature. The phase transition energy storage intermediate coat and the humidity adjusting function of the finish impart the whole coating temperature adjusting and humidity adjusting function. In addition, the temperature adjusting and humidity adjusting coating has the advantages of being fireproof, waterproof, antifouling, mechanical, capable of eliminating peculiar smell, sterilizing, insulating heat, removing sound, protecting environment and the like. The temperature adjusting and humidity adjusting coating is applicable to various kinds of constructional coating.

Owner:LUNAN RES INST OF COAL CHEM

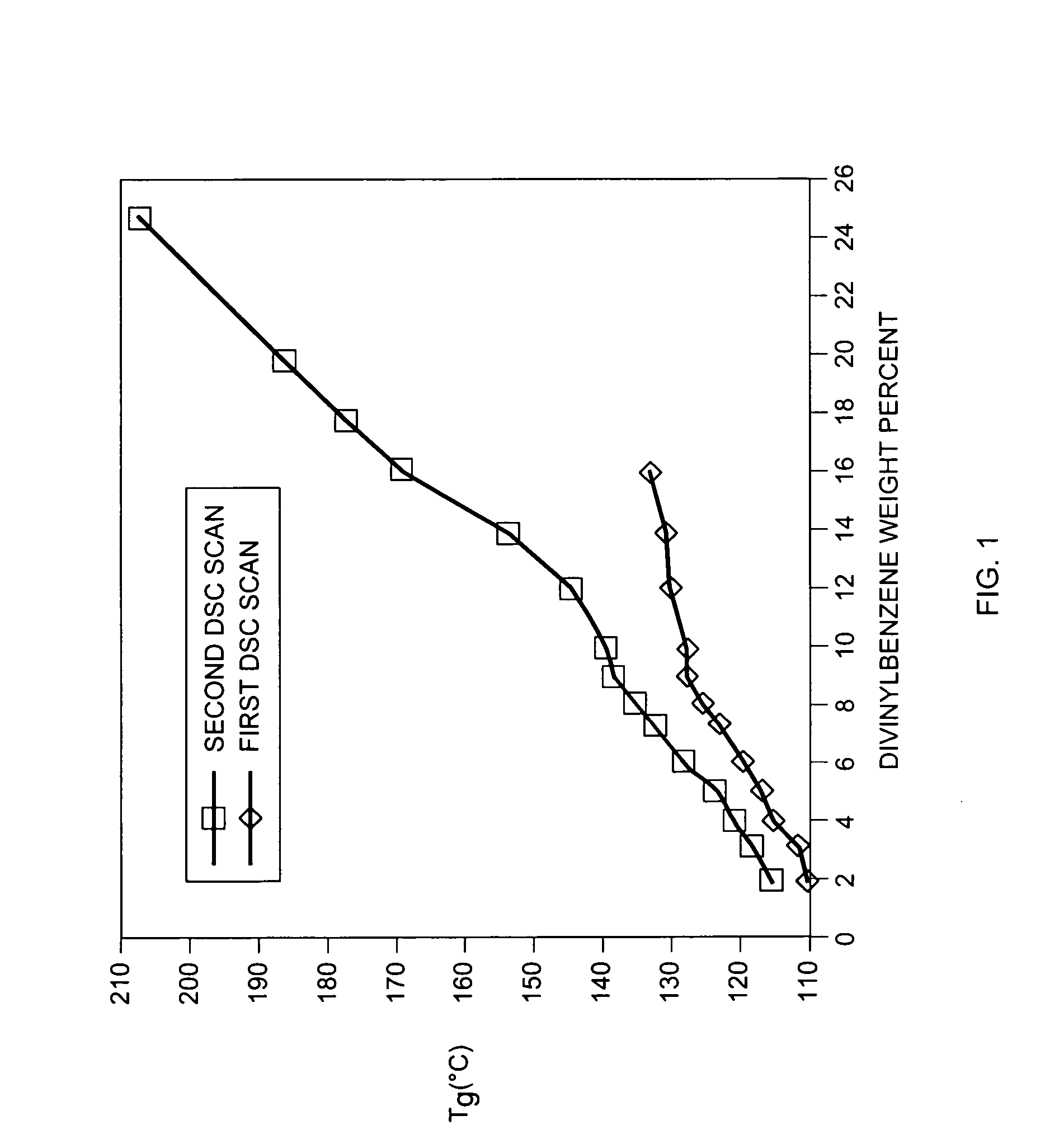

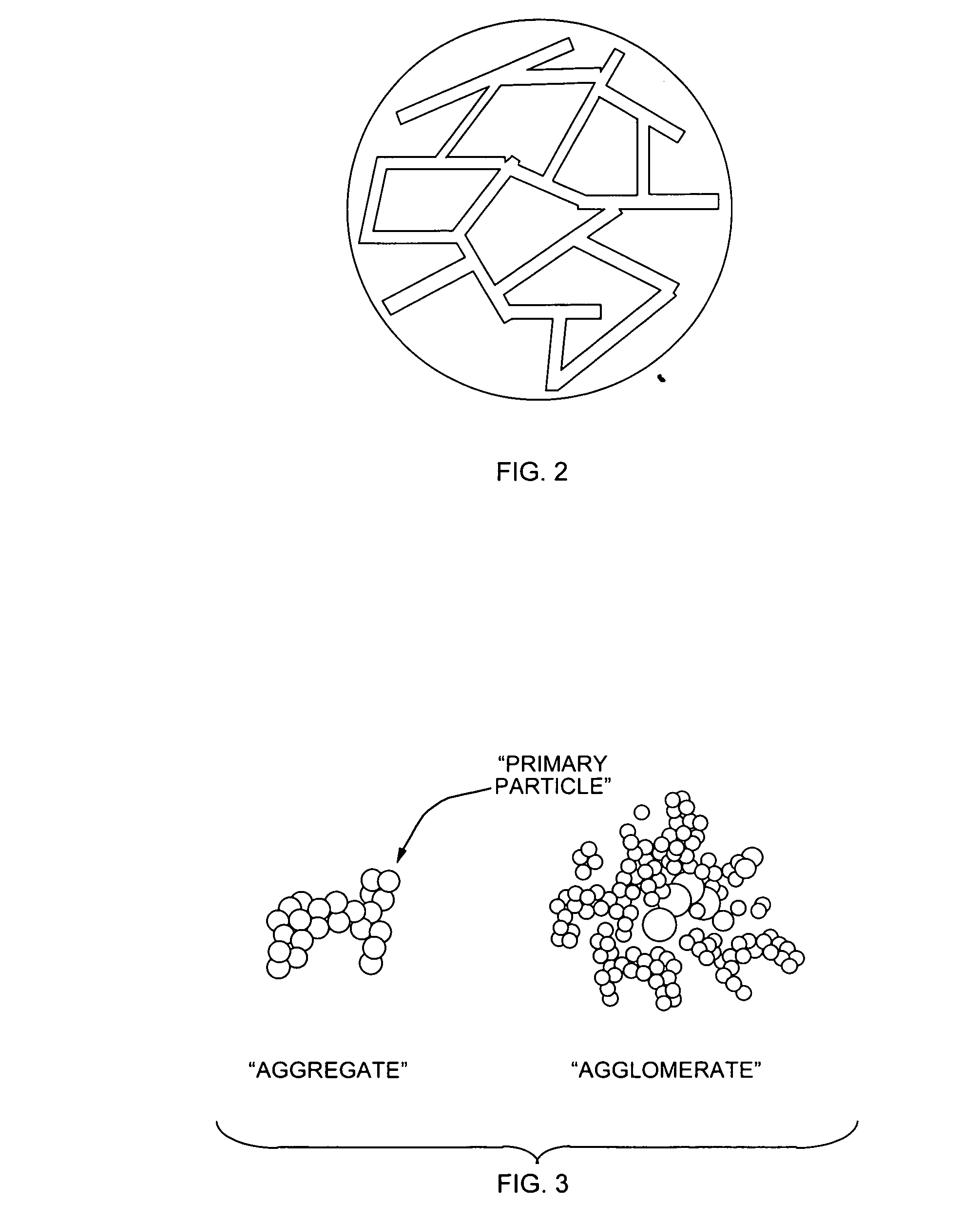

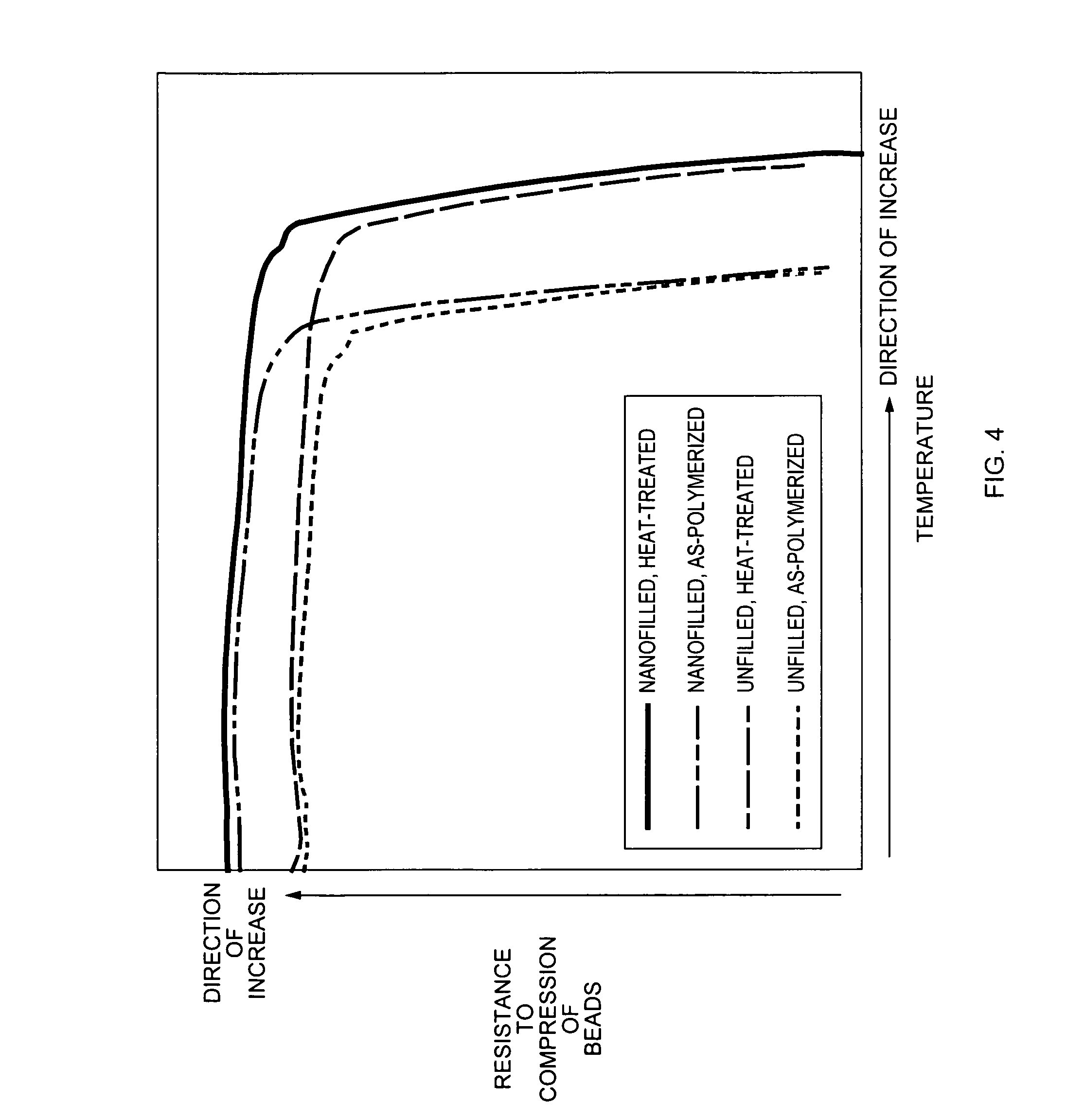

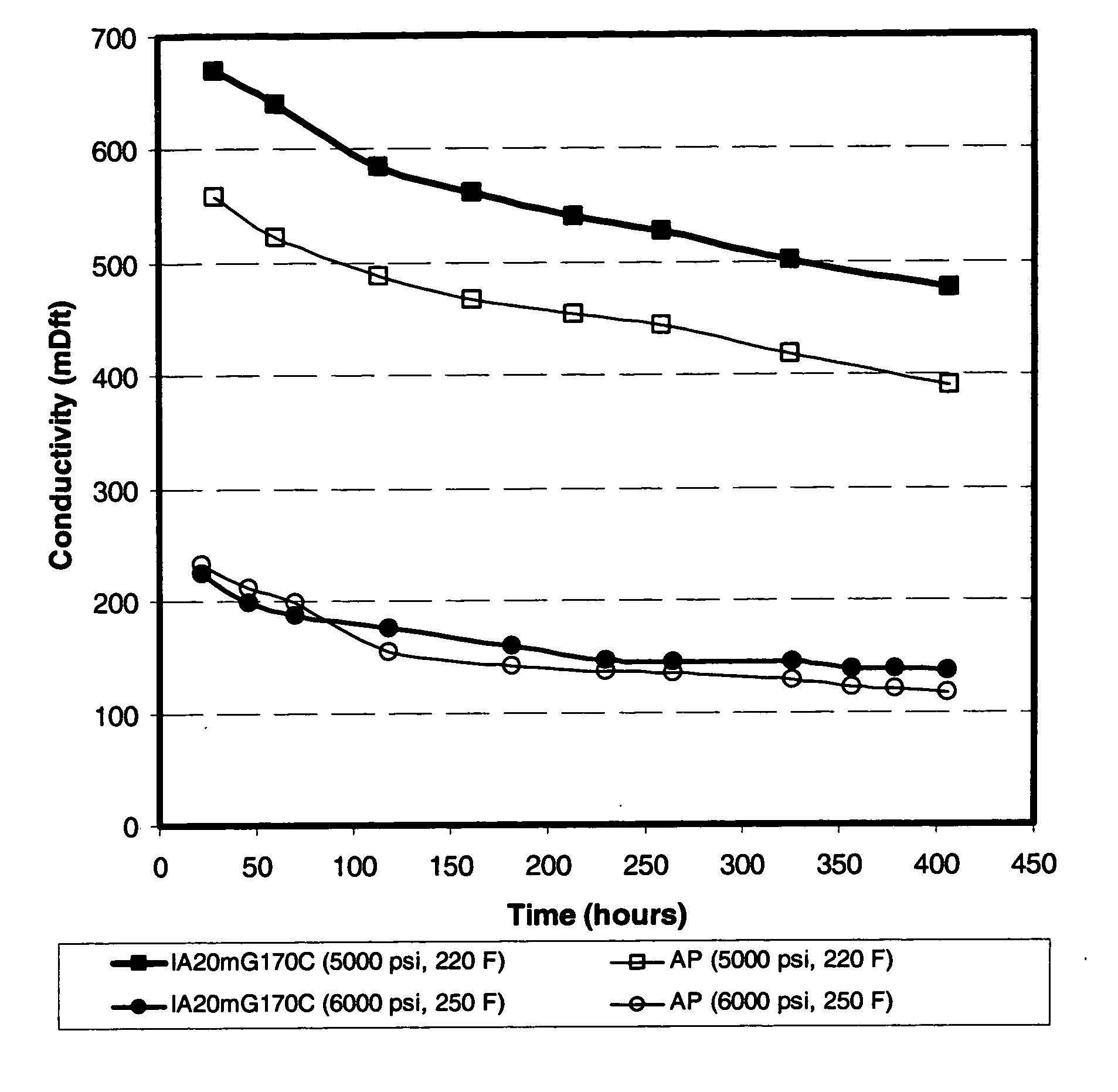

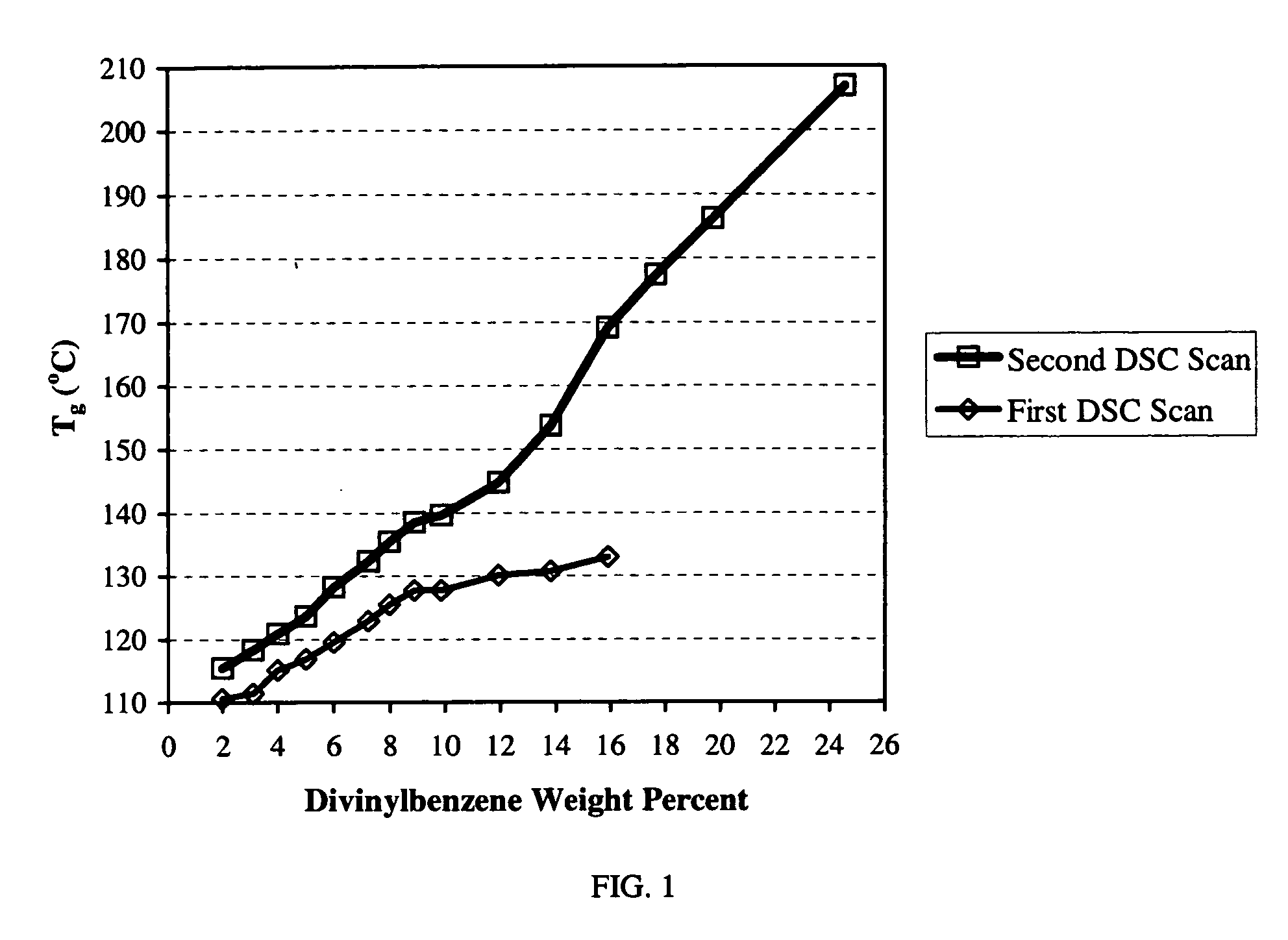

Thermoset nanocomposite particles, processing for their production, and their use in oil and natural gas drilling applications

ActiveUS20070066491A1Improve curingImprove heat transfer performanceMaterial nanotechnologySynthetic resin layered productsEnvironmental resistanceBall bearing

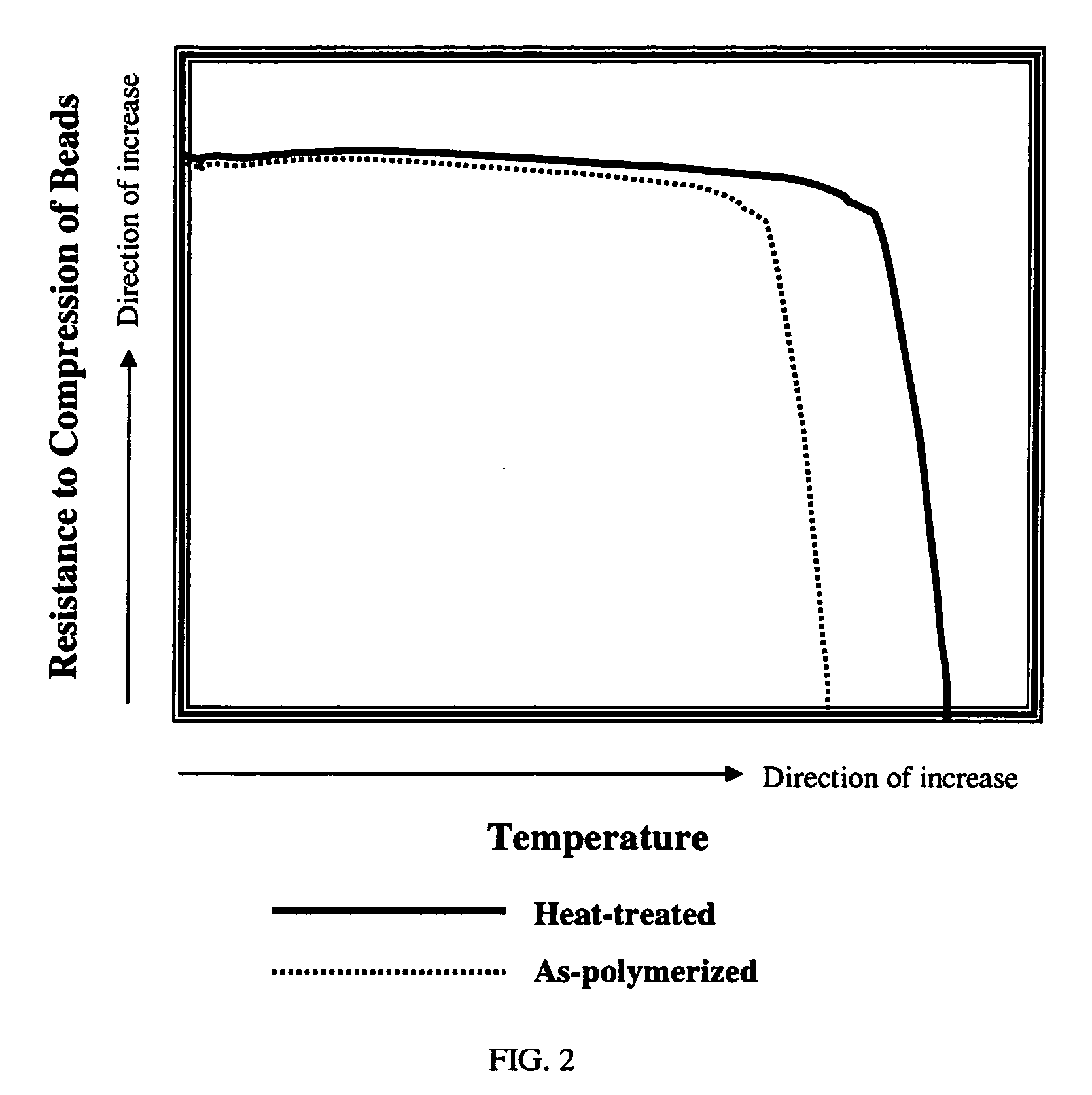

Thermoset polymer particles are used in many applications requiring lightweight particles possessing high stiffness, strength, temperature resistance, and / or resistance to aggressive environments. The present invention relates to the use of two different methods, either each by itself or in combination, to enhance the stiffness, strength, maximum possible use temperature, and environmental resistance of such particles. One method is the application of post-polymerization process steps (and especially heat treatment) to advance the curing reaction and to thus obtain a more densely crosslinked polymer network. In general, its main benefits are the enhancement of the maximum possible use temperature and the environmental resistance. The other method is the incorporation of nanofillers, resulting in a heterogeneous “nanocomposite” morphology. In general, its main benefits are increased stiffness and strength. Nanofiller incorporation and post-polymerization heat treatment can also be combined to obtain the benefits of both methods simultaneously. The present invention relates to the development of thermoset nanocomposite particles. It also relates to the optional further improvement of the heat resistance and environmental resistance of said particles via post-polymerization heat treatment. Furthermore, it also relates to processes for the manufacture of said particles. Finally, it also relates to the use of said particles in the construction, drilling, completion and / or fracture stimulation of oil and natural gas wells; for example, as a proppant partial monolayer, a proppant pack, an integral component of a gravel pack completion, a ball bearing, a solid lubricant, a drilling mud constituent, and / or a cement additive.

Owner:SUN DRILLING PRODS

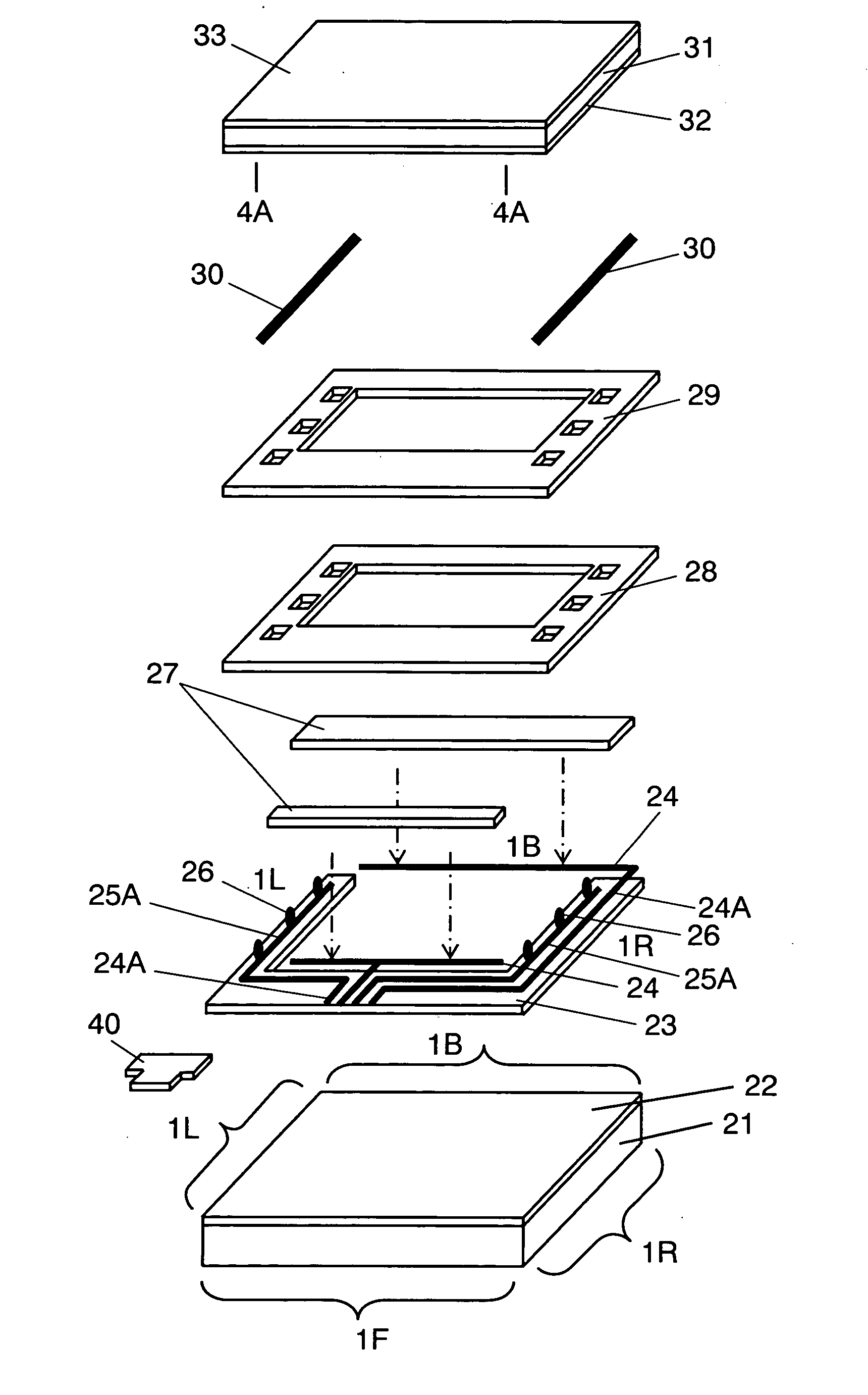

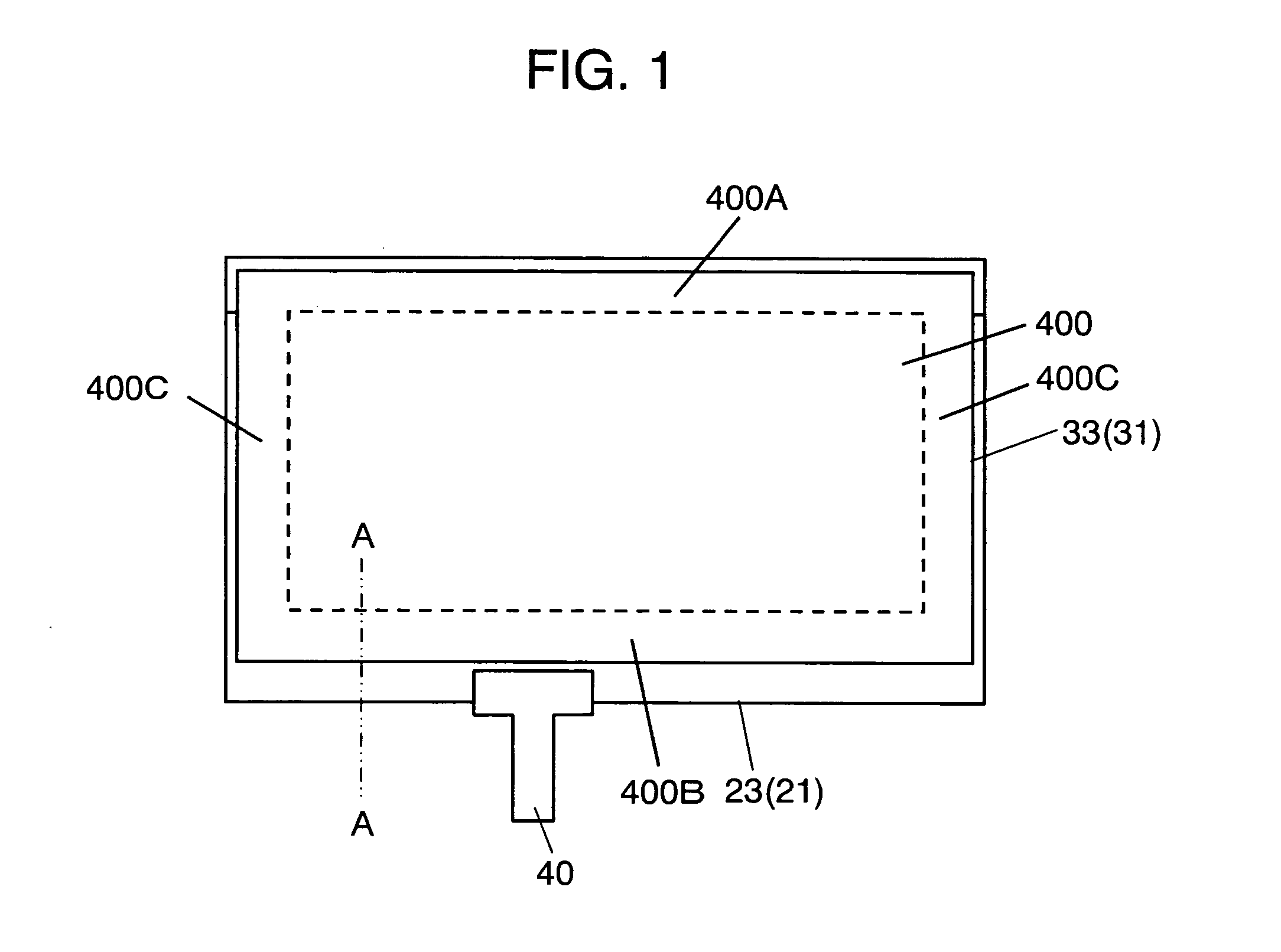

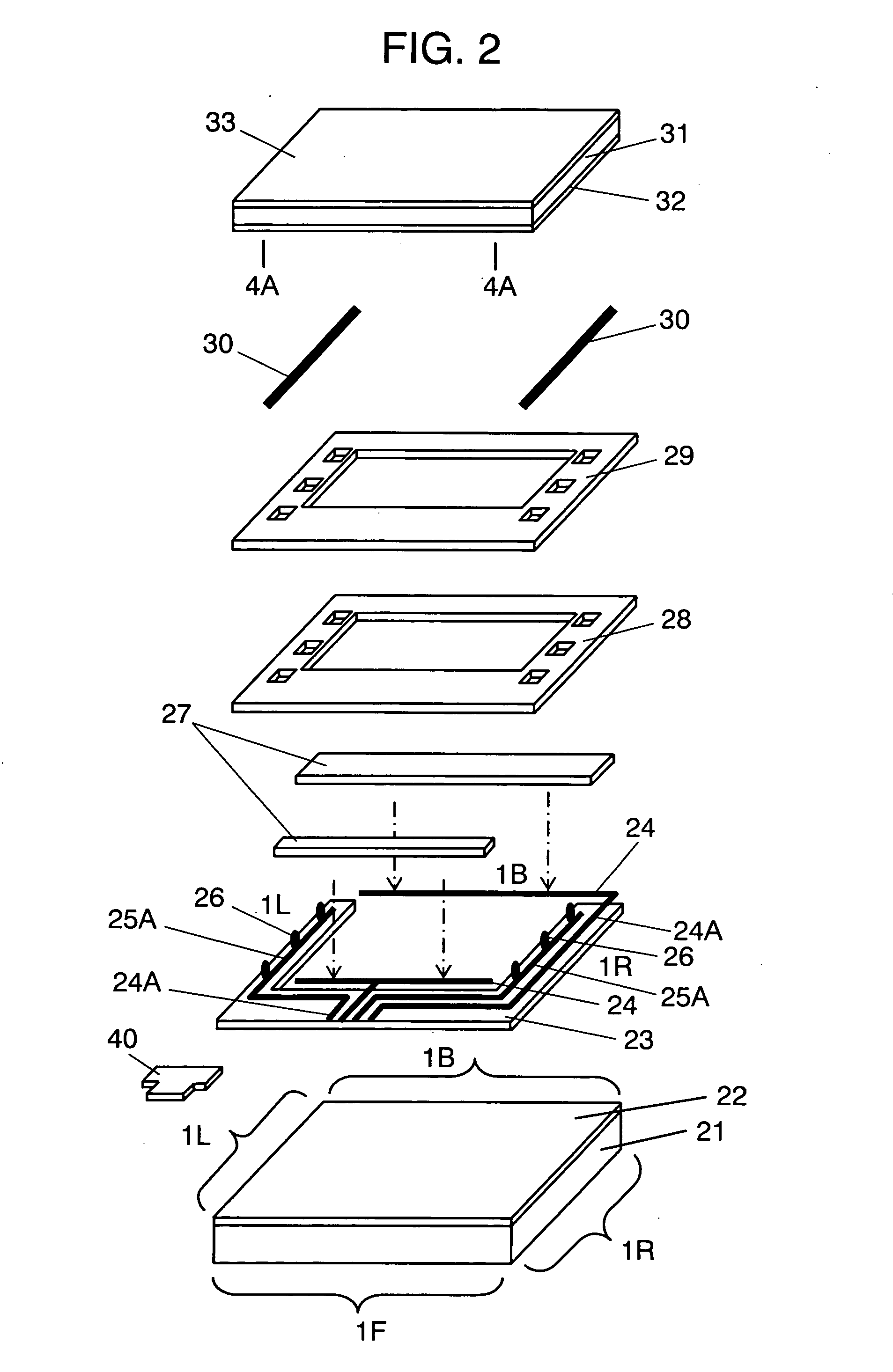

Touch panel and electronic device using the same

InactiveUS20050046622A1Avoid contactWell formedCathode-ray tube indicatorsInput/output processes for data processingEnvironmental resistanceLiquid-crystal display

The invention presents a touch panel disposed at the display screen side of a liquid crystal display device or the like, and excellent in surface smoothness and environmental resistance. In marginal outer circumferential part 400B for adhering and fixing first transparent substrate 21 and second transparent substrate 31 face to face, insulating layer 27 for correction of step difference is disposed in order to make uniform the film thickness. Adhesive layer 29 is disposed on insulating layer 27, and first transparent substrate 21 and second transparent substrate 31 are adhered to each other. As a result, the adhesion fixing state if stabilized, and the adhesion strength is enhanced, and a touch panel suitable for car-mount unit excellent in surface smoothness and environmental resistance can be presented.

Owner:PANASONIC CORP

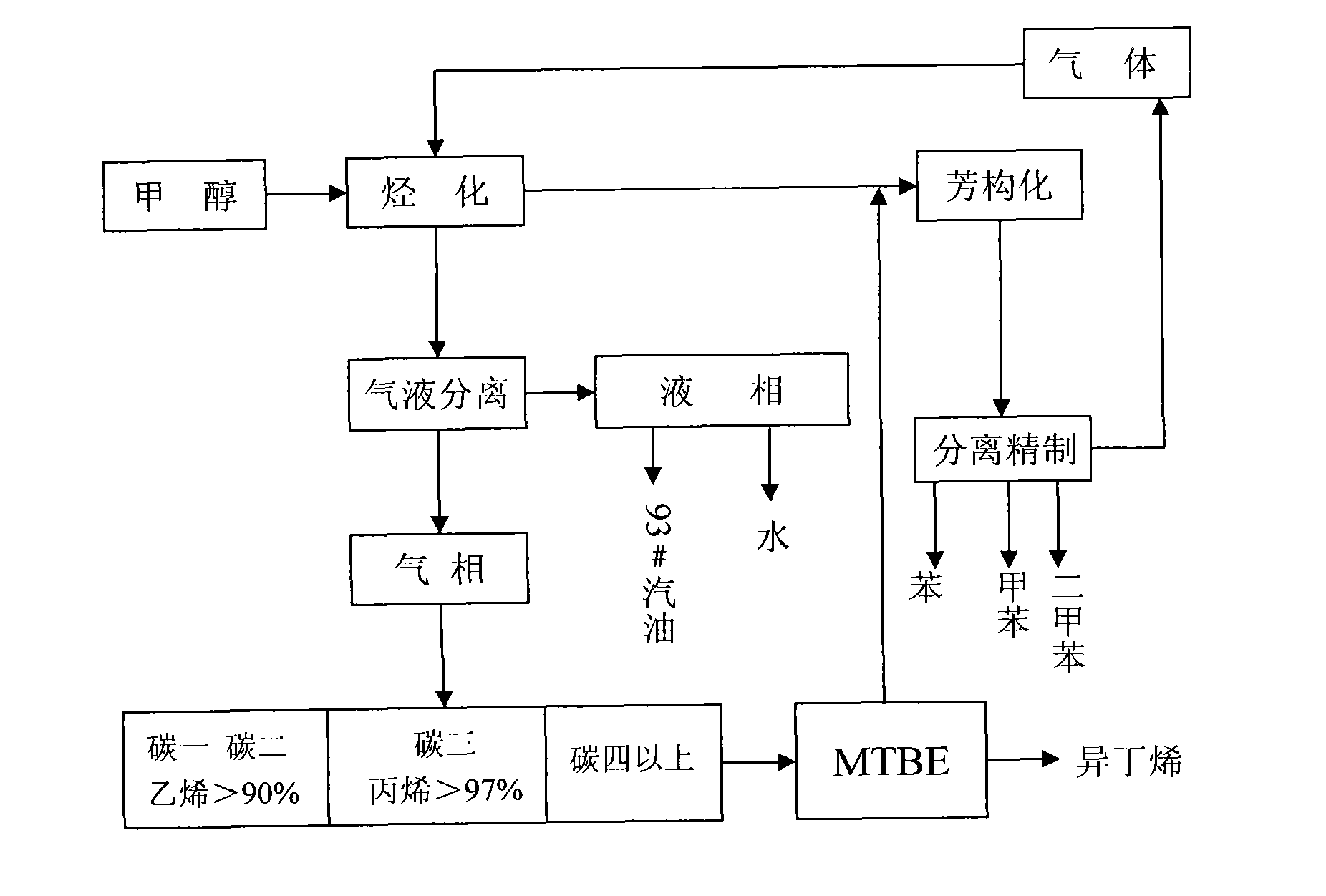

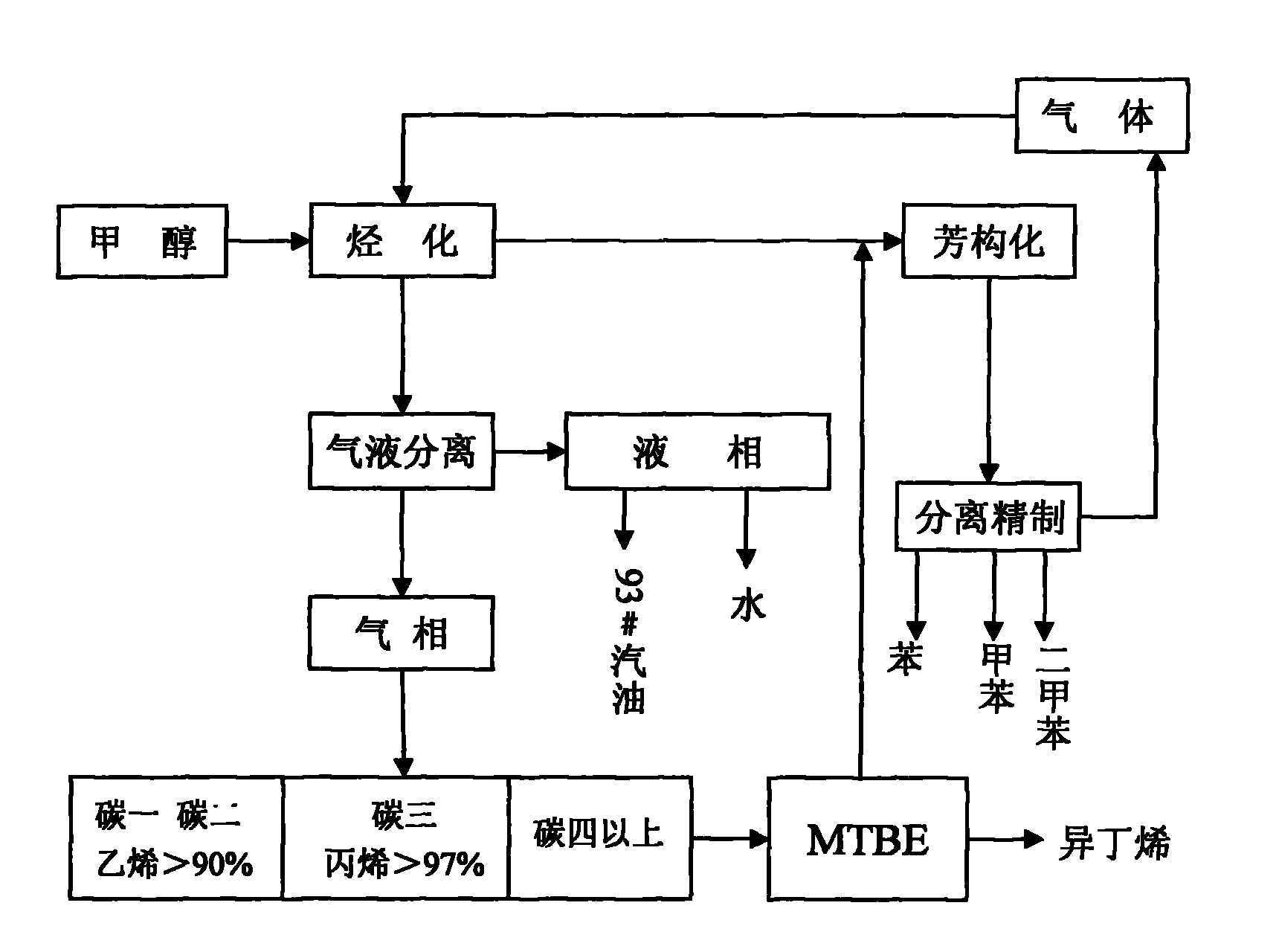

Process for producing low carbon olefin and arene parallel cogeneration gasoline by using methanol as raw material

InactiveCN102146010ALow costReduce energy consumptionHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionEnvironmental resistanceCogeneration

The invention discloses a process for producing low carbon olefin and arene parallel cogeneration gasoline by using methanol as a raw material. In the process, the methanol is used as the raw material and a molecular sieve catalyst is adopted to produce the low carbon olefin and arene parallel cogeneration gasoline by a methanol alkylation reaction and aromatization. In the process, the coal-based methanol is used as the raw material and can replace the conventional petroleum raw material to cogenerate a basis organic chemical raw material, and thus, the dependence degree of the conventional petrochemical industry on the petroleum can be reduced. Meanwhile, the process is also beneficial for reducing the foreign dependence degree of national petroleum, the strategic safety of energy and resources is improved, the production process of the process has low discharge, low pollution and low energy consumption, the requirements on green and environment protection are met, and the process has the advantages of low production cost and strong market competitiveness.

Owner:江苏煤化工程研究设计院有限公司 +2

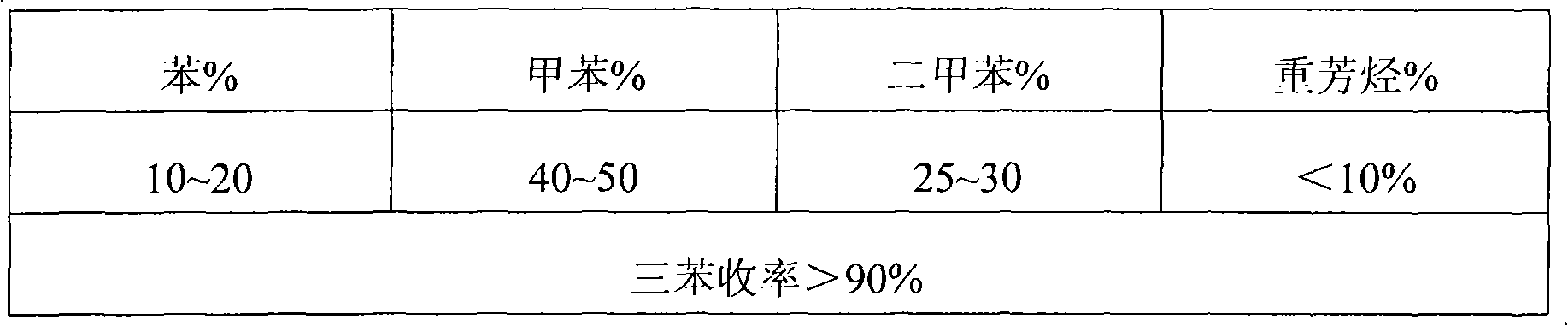

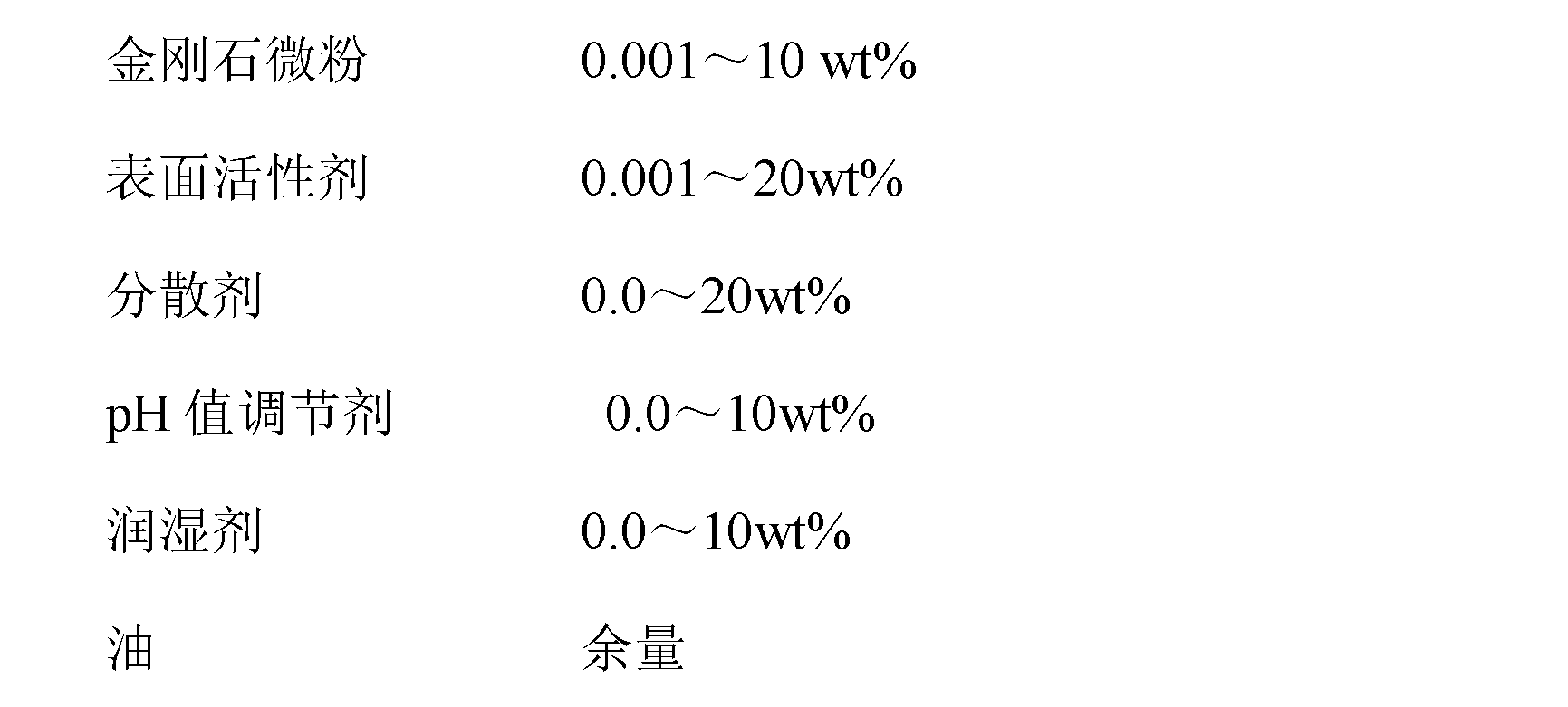

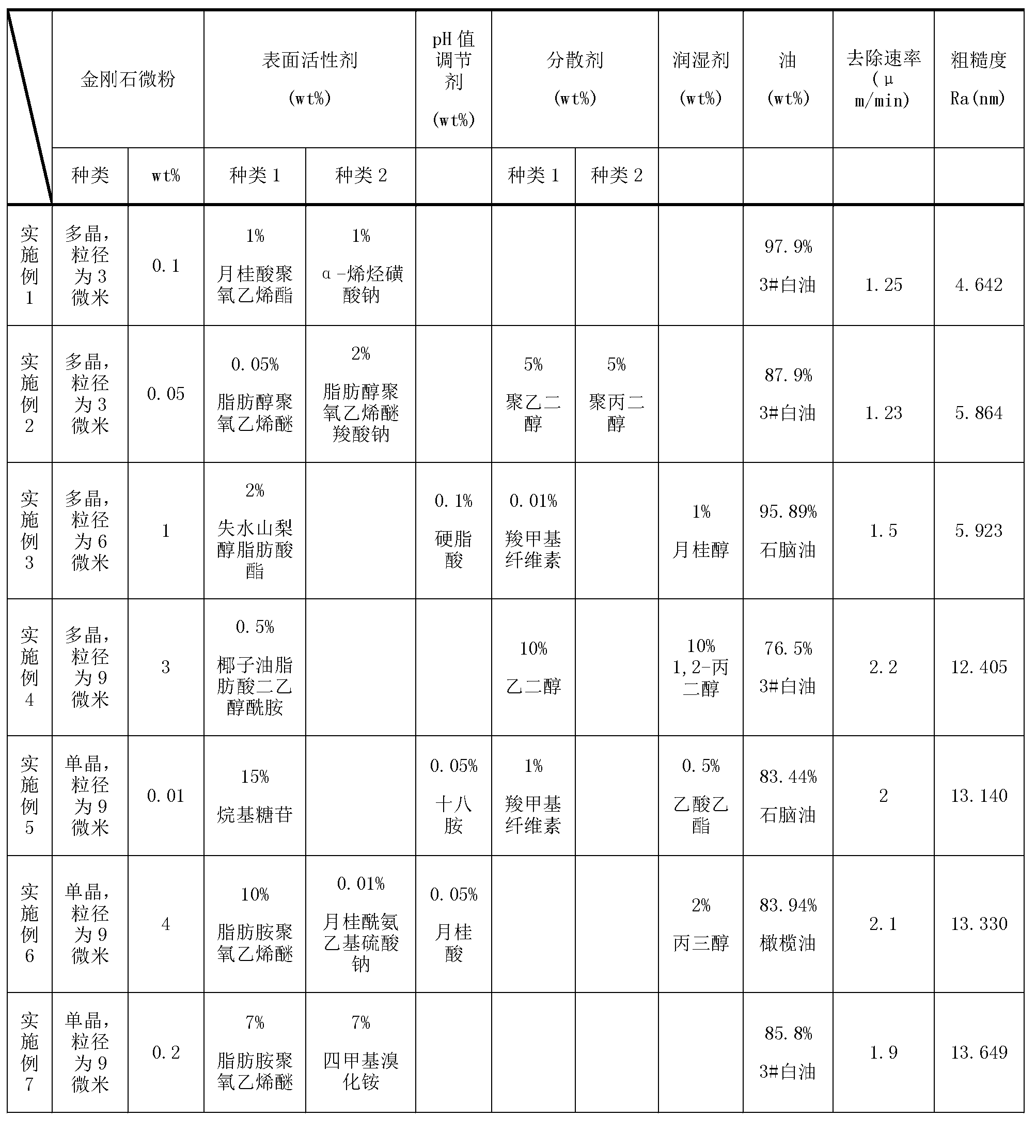

Oily diamond grinding liquid and preparation method thereof

InactiveCN103013345AImprove polishing efficiencyImprove matchPolishing compositions with abrasivesStable stateEnvironmental resistance

The invention discloses an oily diamond grinding liquid and a preparation method thereof, and belongs to the technical field of surface superfine grinding. The grinding liquid comprises the following components by weight percent: 0.001%-10% of diamond micro powder, 0.001%-20% of surface active agent, 0-20% of dispersant, 0-10% of pH value regulator, 0-10% of wetting agent and oil in balancing amount. The oily diamond grinding liquid is mainly applied to surface grinding and polishing of silicon carbide wafers, LED sapphire substrate slices, ceramic, optical fiber, dies, semi-conductor compound wafers and the like. By the use of the oily diamond grinding liquid provided by the invention, the polishing efficiency can be greatly improved; the dispersing performance is good; a uniform and stable state can be kept for a long time; the degree of finish of products polished with the oily diamond grinding liquid is high; the polishing effect is good; no ingredient harmful to human body is contained; the cleaning is easy; and the environmental protection is facilitated.

Owner:TSINGHUA UNIV +2

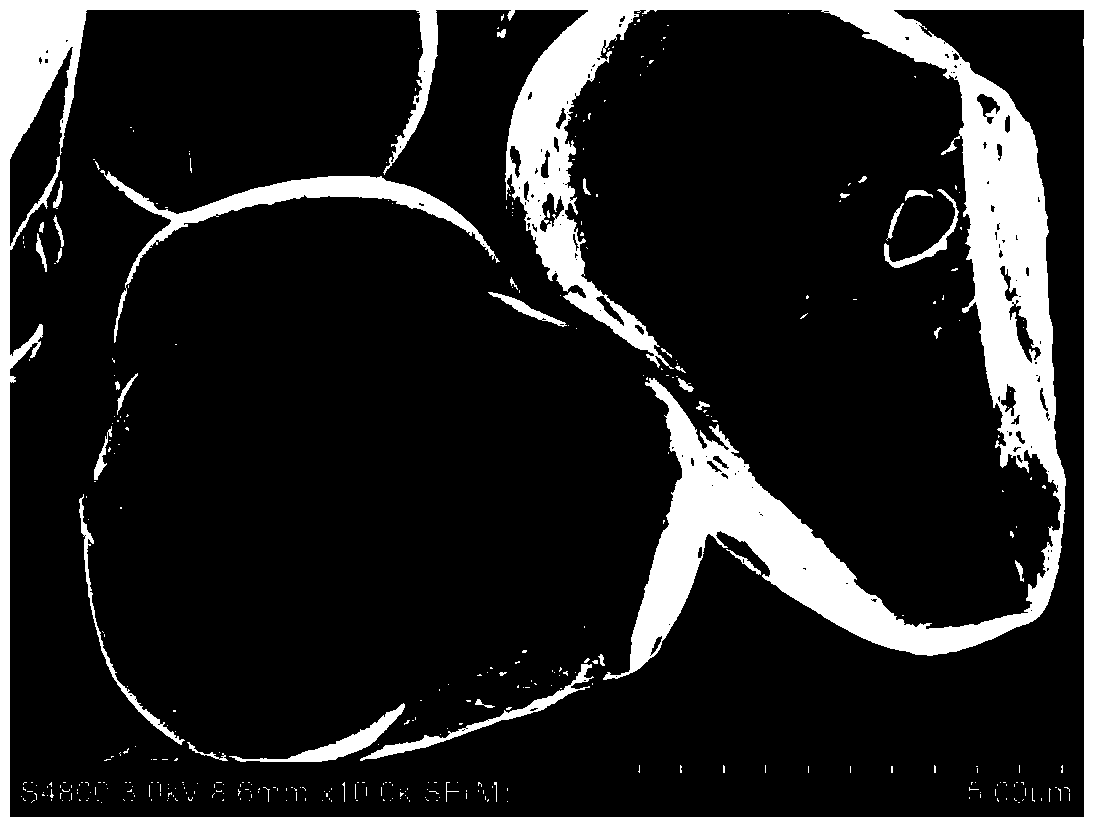

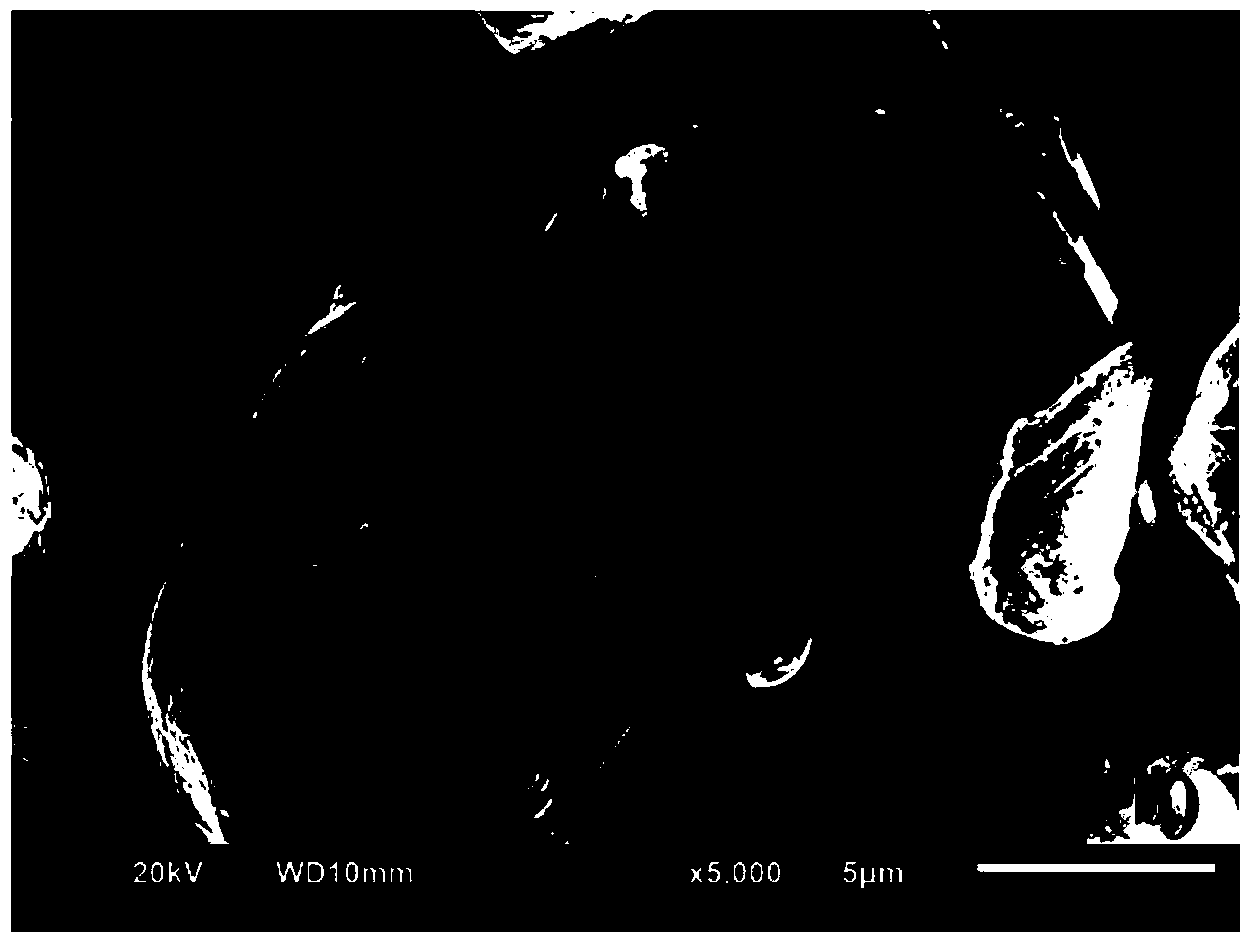

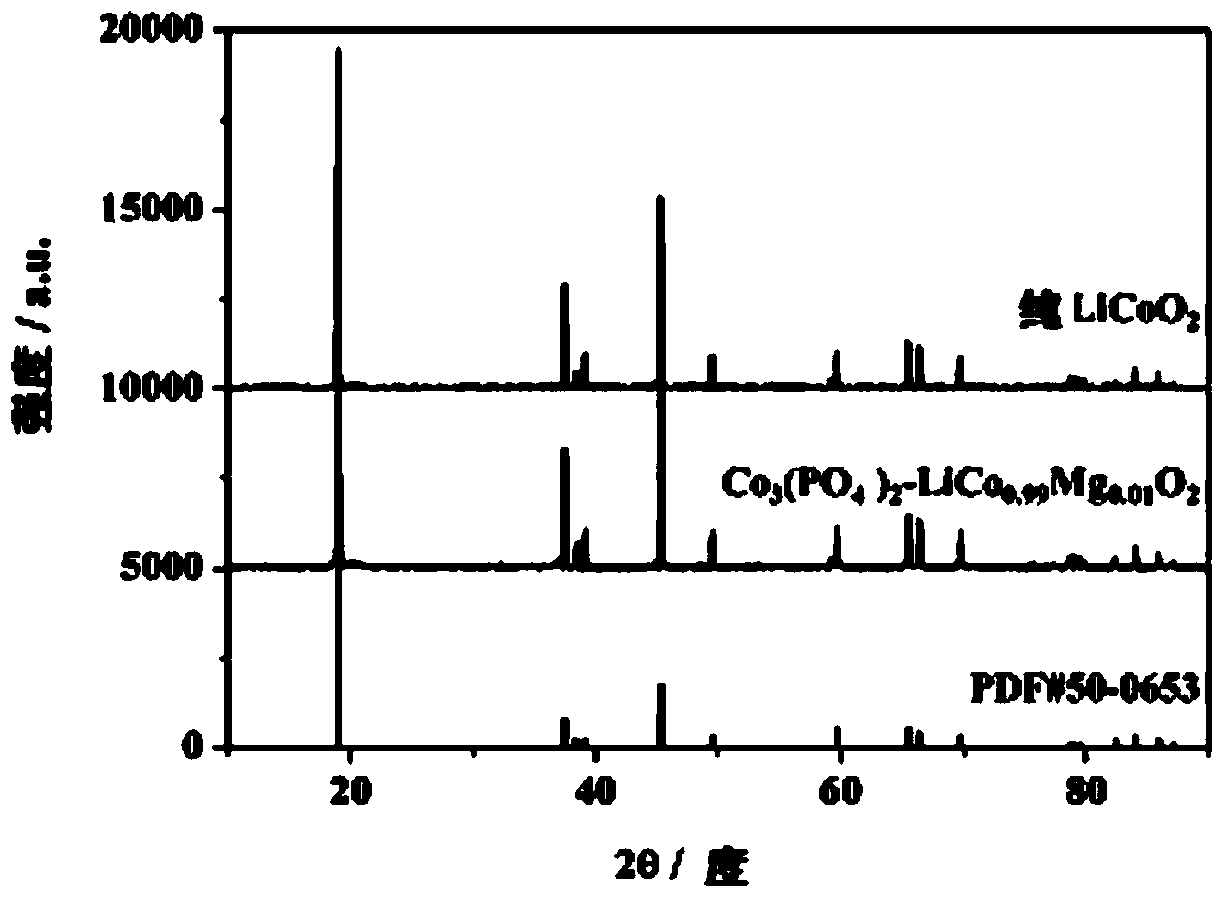

Doped and surface coating co-modified anode material for lithium ion battery and preparation method thereof

InactiveCN103779556APromote circulationEasy to operateSecondary cellsPositive electrodesEnvironmental resistancePhosphate

The invention discloses a doped and surface coating co-modified anode material for a lithium ion battery and a preparation method thereof. The anode material uses doped lithium cobalt oxide as a matrix, the surface of which is coated with Co3(PO4)2, AlPO4, Mn3(PO4)2, FePO4, Ni3(PO4)2, Mg3(PO4)2 and other phosphates, therefore, the electric conductivity, the circulating performance, the high temperature and high pressure resistance and other performances are improved. The preparation method has the advantages that the coating material is uniformly coated on the surface of the anode material to be beneficial to improving the electrochemical performance; the method is simple to operate, is green and environment-friendly and has industrial applicability.

Owner:北京盟固利新材料科技有限公司

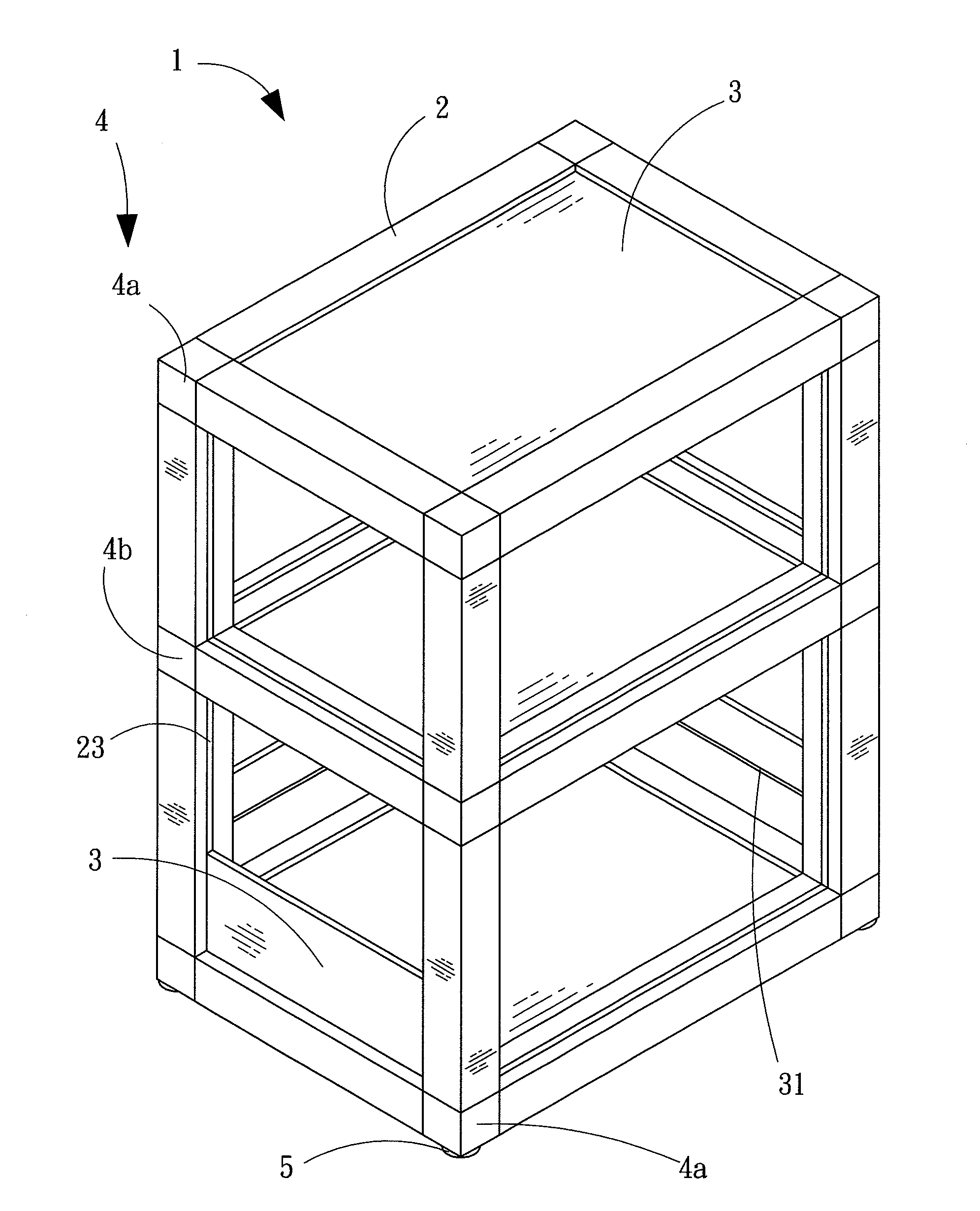

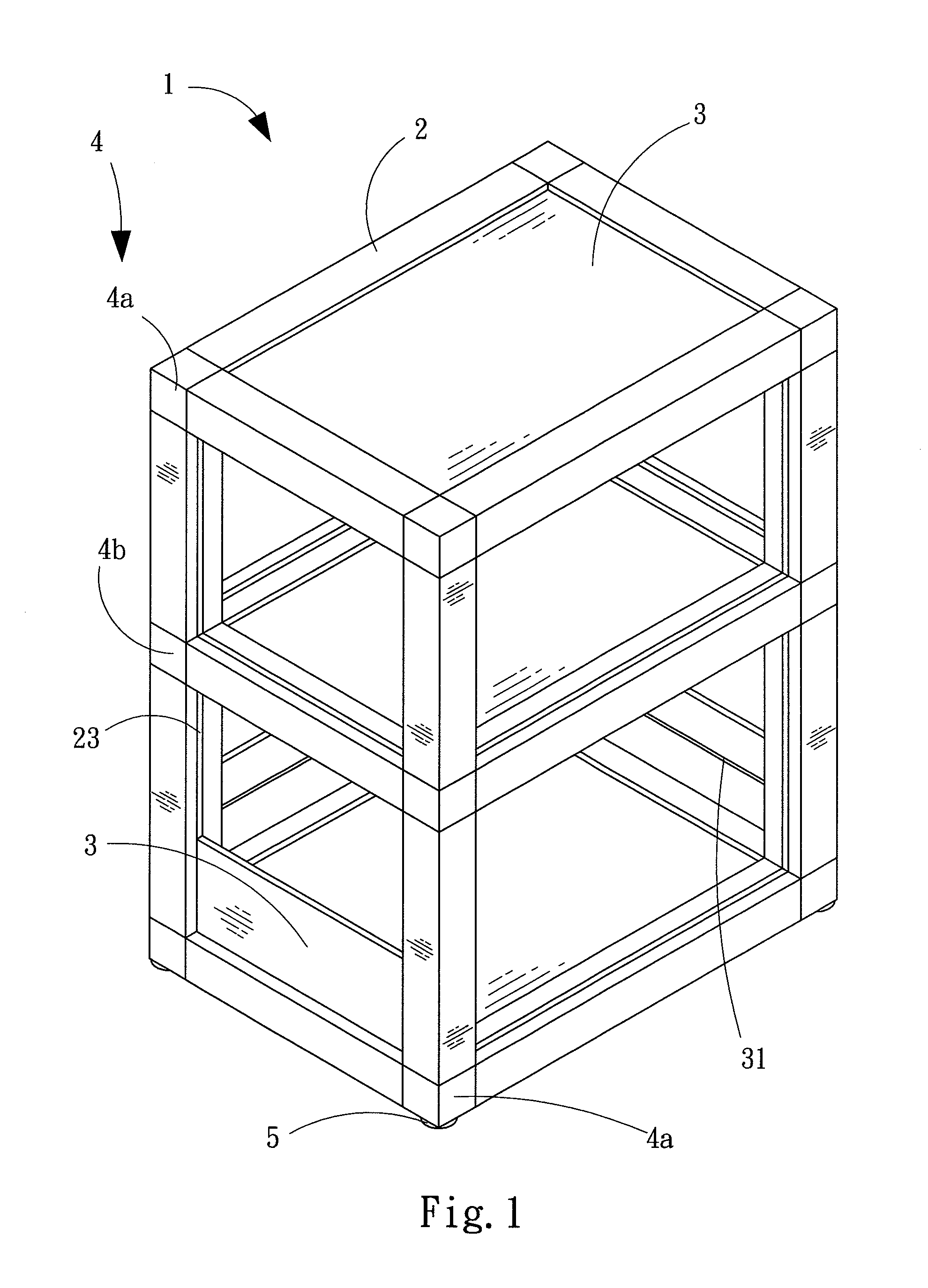

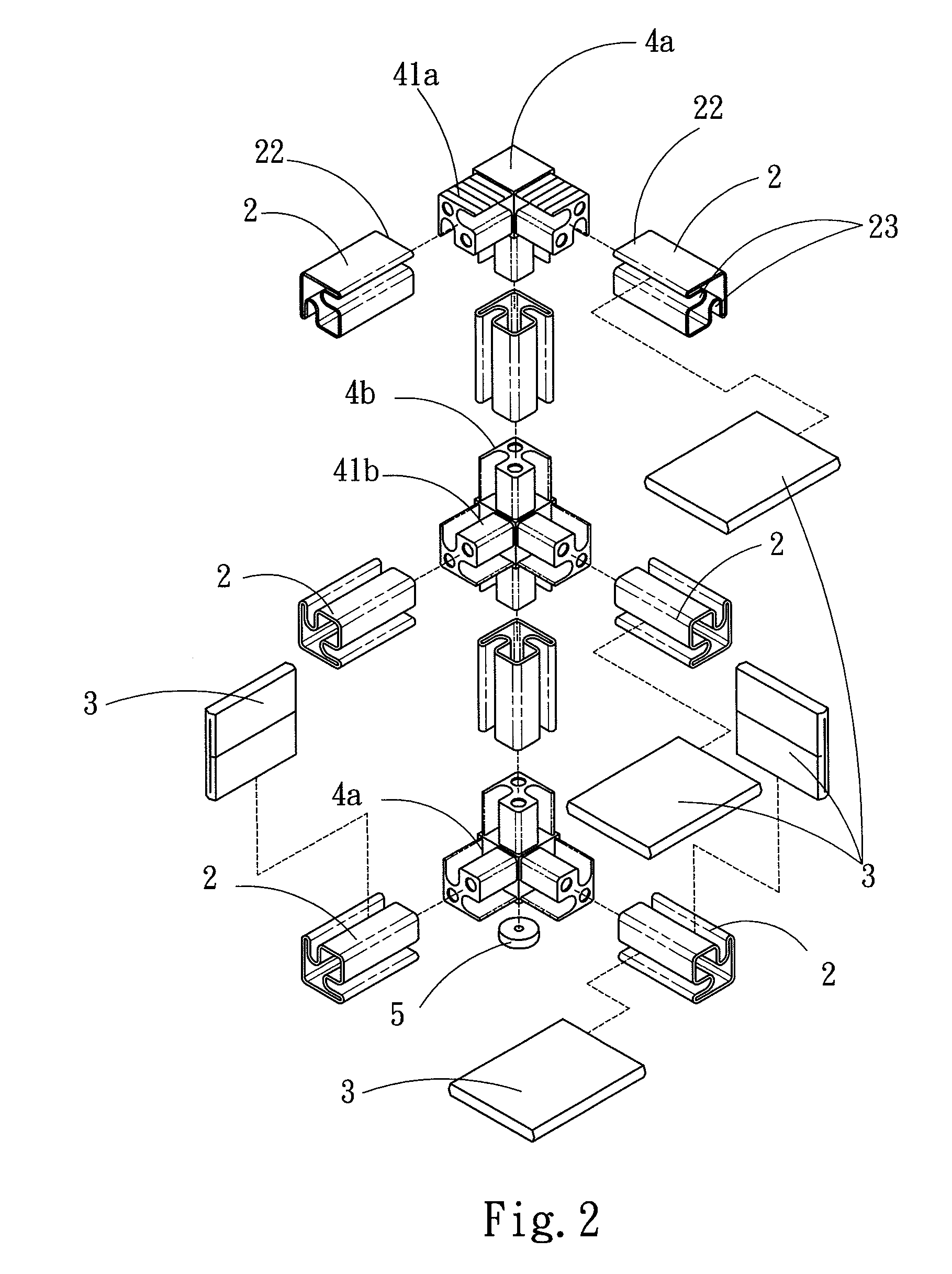

Environmental protection shelving combination

InactiveUS20110017691A1Easy constructionEasy to processFurniture partsFolding cabinetsEnvironmental resistanceMetal framework

The environmental protection shelving combination of the present invention includes sleeves and panels made of corner protection paper for support and plastic connector sets used for coupling the sleeves. Therefore, in accordance with different requirements, the assembly thereof can be altered as desired. Furthermore, since the corner protection paper is formed by pressing Kraft paper and the sand tube paper into a supporting structure, it can provide bearing and pressure capability, so that can replace the conventional wood, plastic or metal framework. Accordingly, not only the costs of material, conveying and assembly can be reduced, the pollution to the environment also can be minimized.

Owner:WU CHUAN CHING

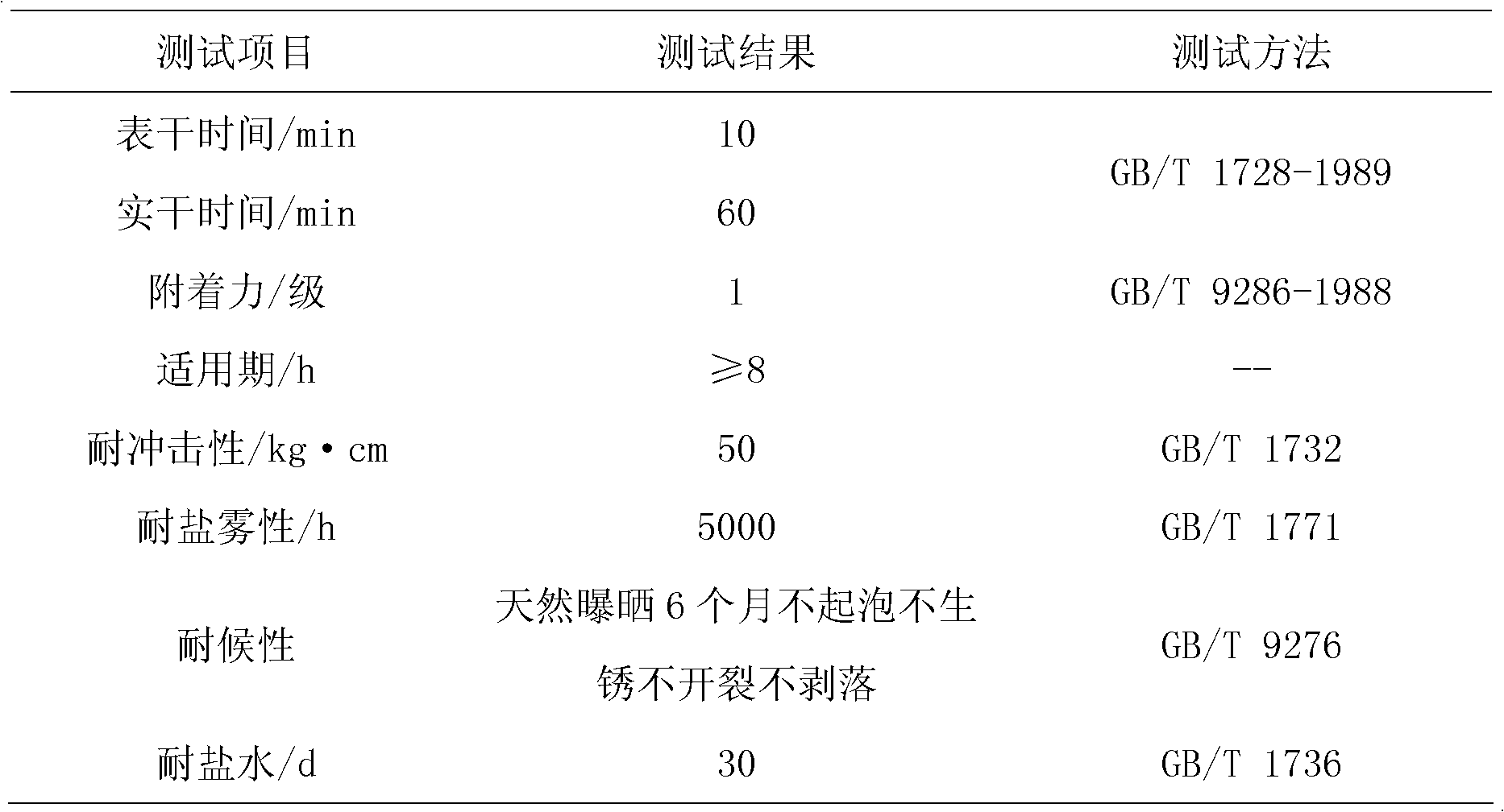

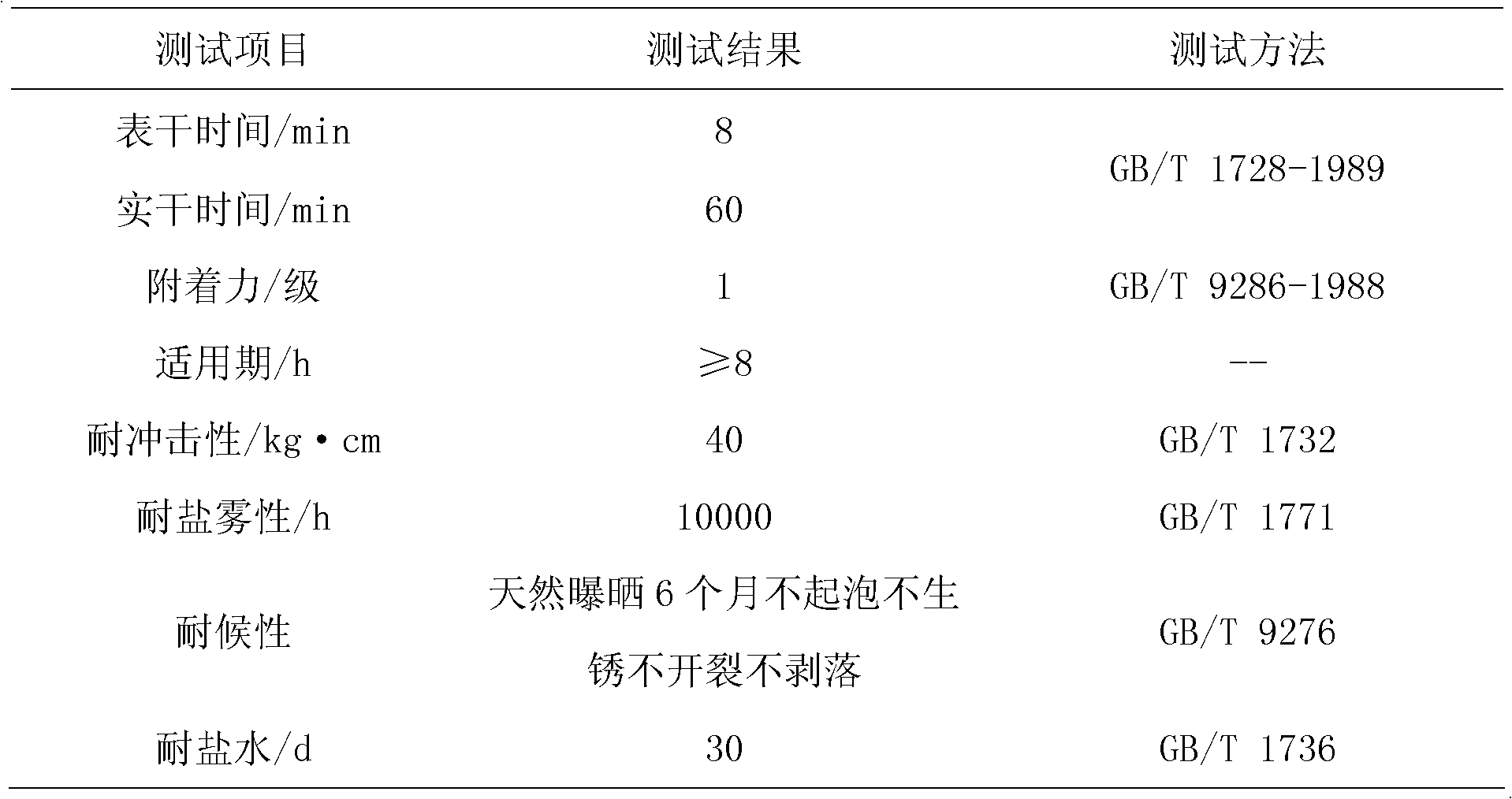

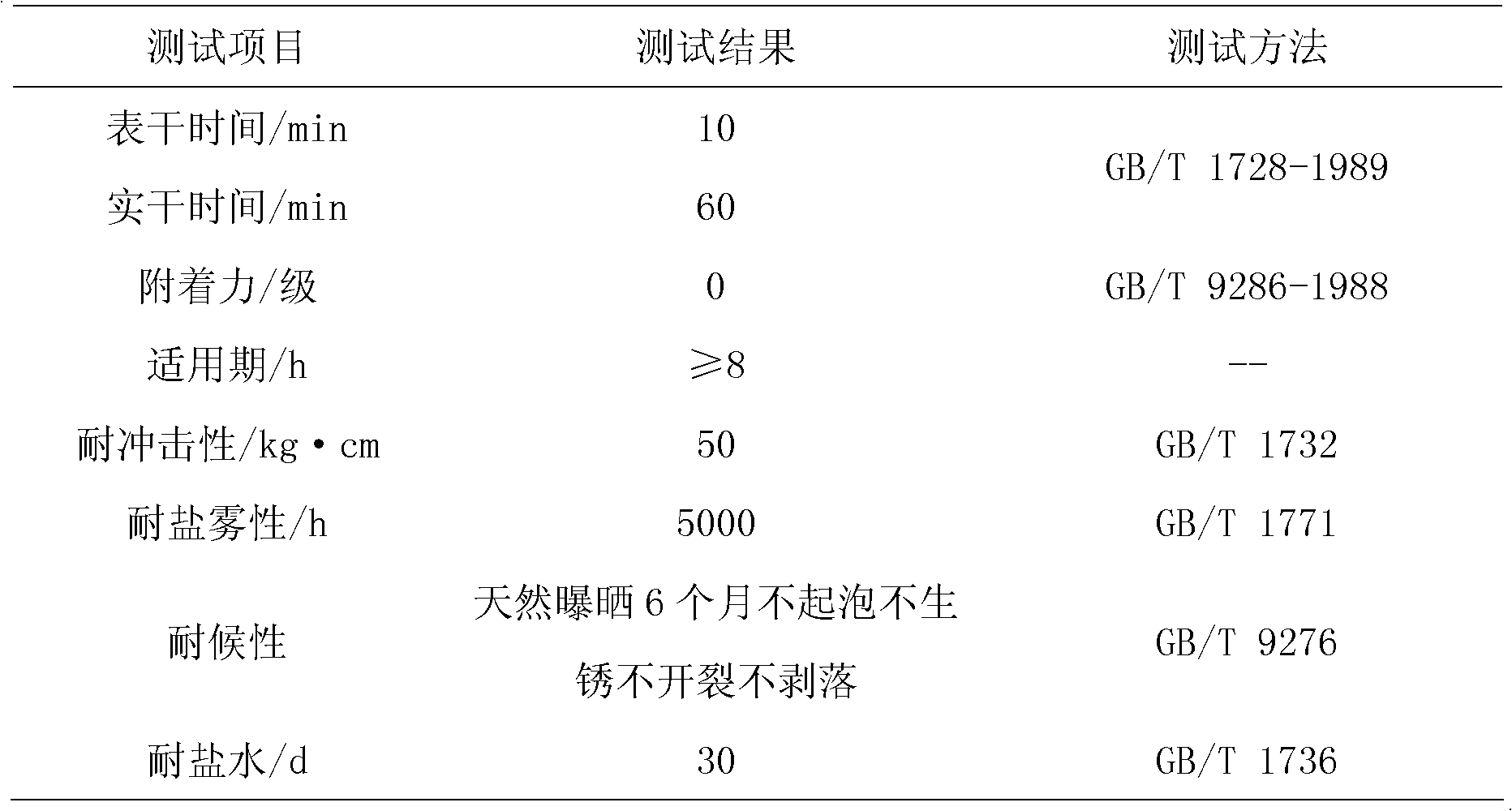

Waterborne room-temperature self-curing inorganic zinc rich coating

ActiveCN102146225AStrong adhesionHigh modulusAlkali metal silicate coatingsAnti-corrosive paintsEnvironmental resistanceMaterials science

The invention discloses waterborne room-temperature self-curing inorganic zinc rich coating. The coating is prepared by uniformly mixing a prepared base stock and powder in a mass ratio of 1:1.5-3.5, wherein the process of preparing the base stock comprises the following steps of: adding 5 to 10 parts of water into alkali metal silicates solution with the mode number of 2.5 to 3.7 and stirring the mixture at low speed; then adding silica sol drops with the grain diameter of 7 to 20nm and the solid content of 25 to 32 percent, dripping 1 to 10 parts of silane coupling agent and adding 0.5 to 2parts of stabilizing agent; and filtering out precipitates to obtain the transparent base stock. The inorganic zinc rich coating has high drying speed and good early-period waterproofness and can resist to washing with certain pressure after being dried for 20 minutes, has good salt spray corrosion resistance due to the adoption of multiple anticorrosion mechanisms and can resist to the high temperature of 400 DEG C. Meanwhile, the constructability of the conventional waterborne inorganic zinc rich coating is greatly improved; and the corrosion resistance year limit can reach over 15 years. The paint is prepared at normal temperature under normal pressure and has low production cost. The environmental protection requirement is met.

Owner:SOUTH CHINA UNIV OF TECH +1

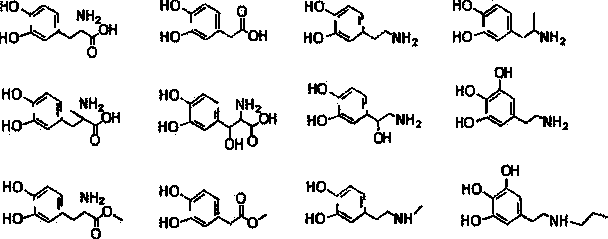

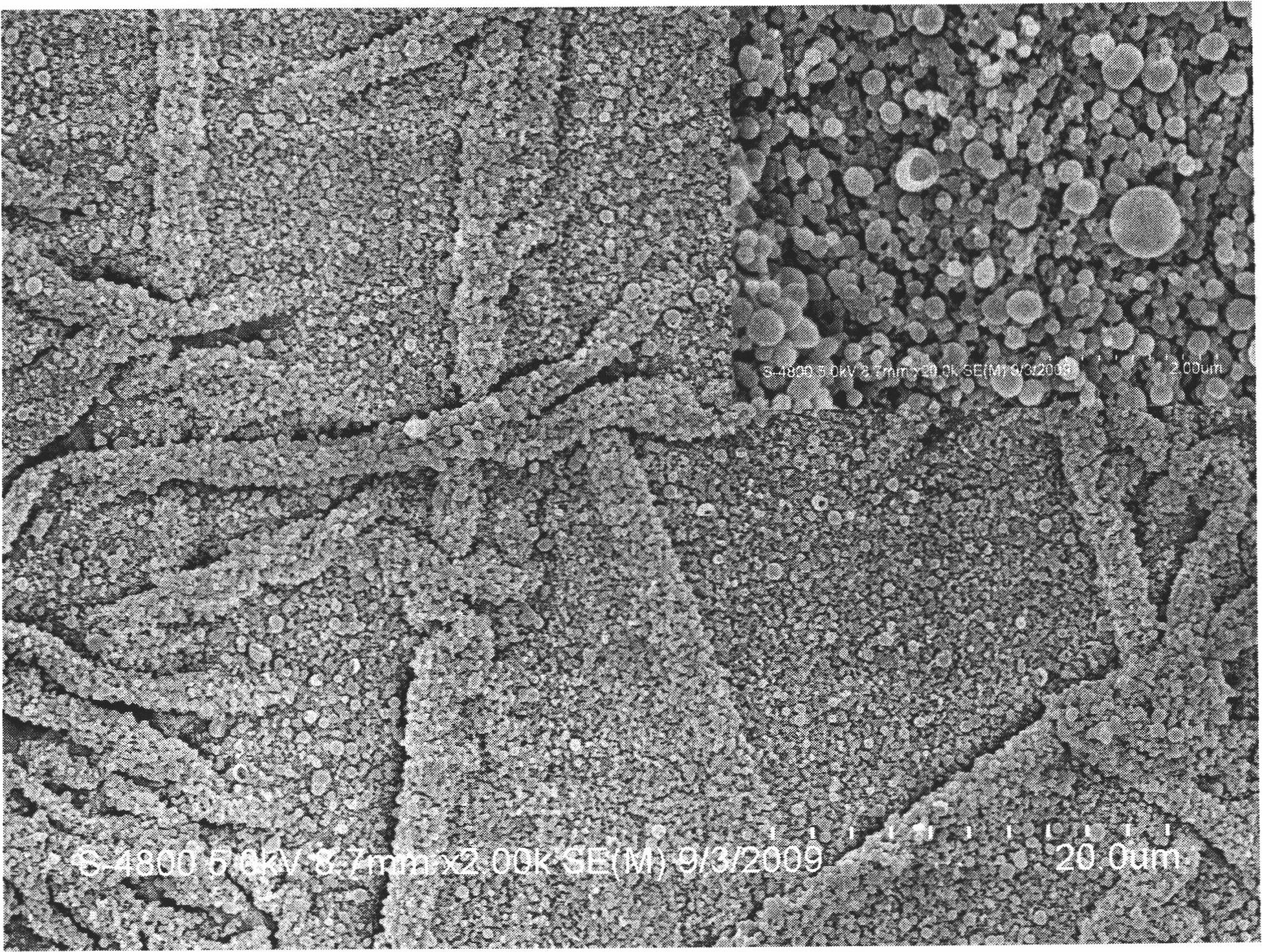

Method of in-situ generation of nano particle on separating membrane surface

The invention relates to the technical field of separating membranes, and in particular to a method of in-situ generation of a nano particle on a separating membrane surface. The method comprises the following steps: conducting surface modification on a basic separating membrane surface for more than once, and conducting in-situ generation of the nano particle for more than once on the separating membrane surface subjected to the surface modification, wherein the special points are that the surface modification refers to the following steps: soaking the basic separating membrane in dopamine buffer salt solution with the concentration of 0.001 mg / mL-100 mg / mL and the PH value of 7-12, modifying for 1 min-7 d under the condition that oxygen or oxidant is participated to form a poly-dopamine layer on the basic separating membrane surface; the in-situ generation of the nano particle refers to the following steps: soaking the separating membrane with the poly-dopamine layer generated on the surface in metal salt solution with the concentration of 0,001-10,000 mM / L for 1 min-300 d to generate the nano particle in situ, or accelerating the in-situ generation of the nano particle under the action of reducer. Compared with the prior art, the preparation method is simple and easy to be operated, economic, efficient and environmental-friendly, and facilitates industrialisation.

Owner:山东净泽膜科技有限公司

Environment-friendly, cushioning and well-wrapping popcorn bridging shoes and production process thereof

InactiveUS20180103719A1Simple materialIncrease elasticitySolesLastingEnvironmental resistanceCushioning

A pair of environment-friendly popcorn bridging shoes and a production process thereof are provided. The upper of each bridging shoe comprises an inner bootie, which is composed of a lining and an inner pad formed by single injection molding, and a vamp; the collar of the inner bootie is fixedly connected with that of the vamp, and the lower edge of the vamp wrapped by a PU bridging layer extends to the bottom surface of the inner pad fixedly connected with the same; the upper and a popcorn sole made of mixed PU and TPU popcorn particles are integrally connected by the PU bridging layer. The shoe making process is simpler, and firmer bonding and better shock absorbing performance of the shoes are achieved; the vamp and the sole can well wrap the foot; and the dissolution proportion of shoes is increased by increasing the consumption of the PU material.

Owner:CHEN MAOSHUANG

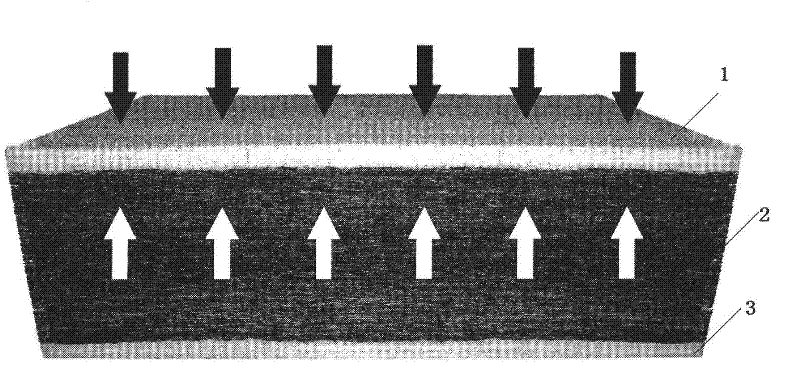

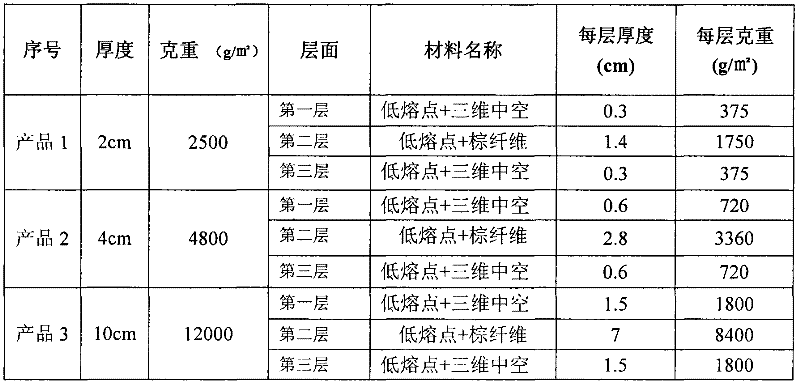

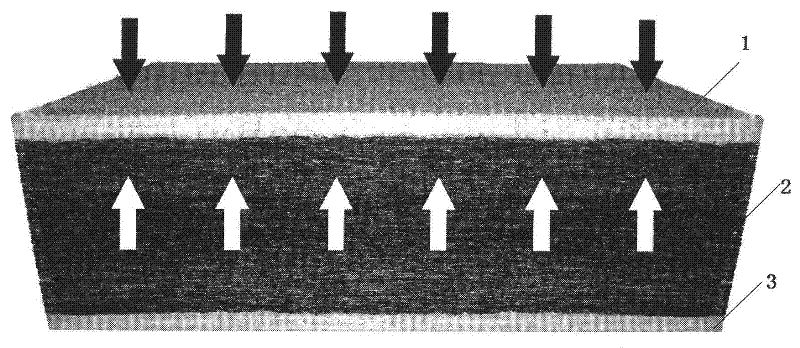

Polyester fiber coconut fiber plate and preparation method thereof

The invention discloses a polyester fiber coconut fiber plate and a preparation method thereof. The polyester fiber coconut fiber plate is characterized by including three layers, wherein the upper and lower layers are made from same materials which are low melting point double-component sheath core fiber and three-dimensionally coiled round hollow fiber, the middle layer is made from low melting point double-component sheath core fiber and coconut fiber, and the three layers are molded integrally through a process. The coconut fiber plate is formed by heat-melting hot-air penetration, melting, bonding and cooling technologies. The polyester fiber coconut fiber plate is environmental-friendly, formaldehyde-free, odorless, temperature-difference-resistant, deformation-free, elastic, strong in tension, impact-resistant, uniform in thickness, and good in sound insulation effect; three layers are molded integrally through the process, the upper and lower layers made from polyester fiber cotton have strong tension, the lining is formed by combining the low melting point polyester fiber with the coconut fiber; and under stress, each layer orderly buffers pressure so as to avoid deformation.

Owner:昆山吉美川纤维科技有限公司

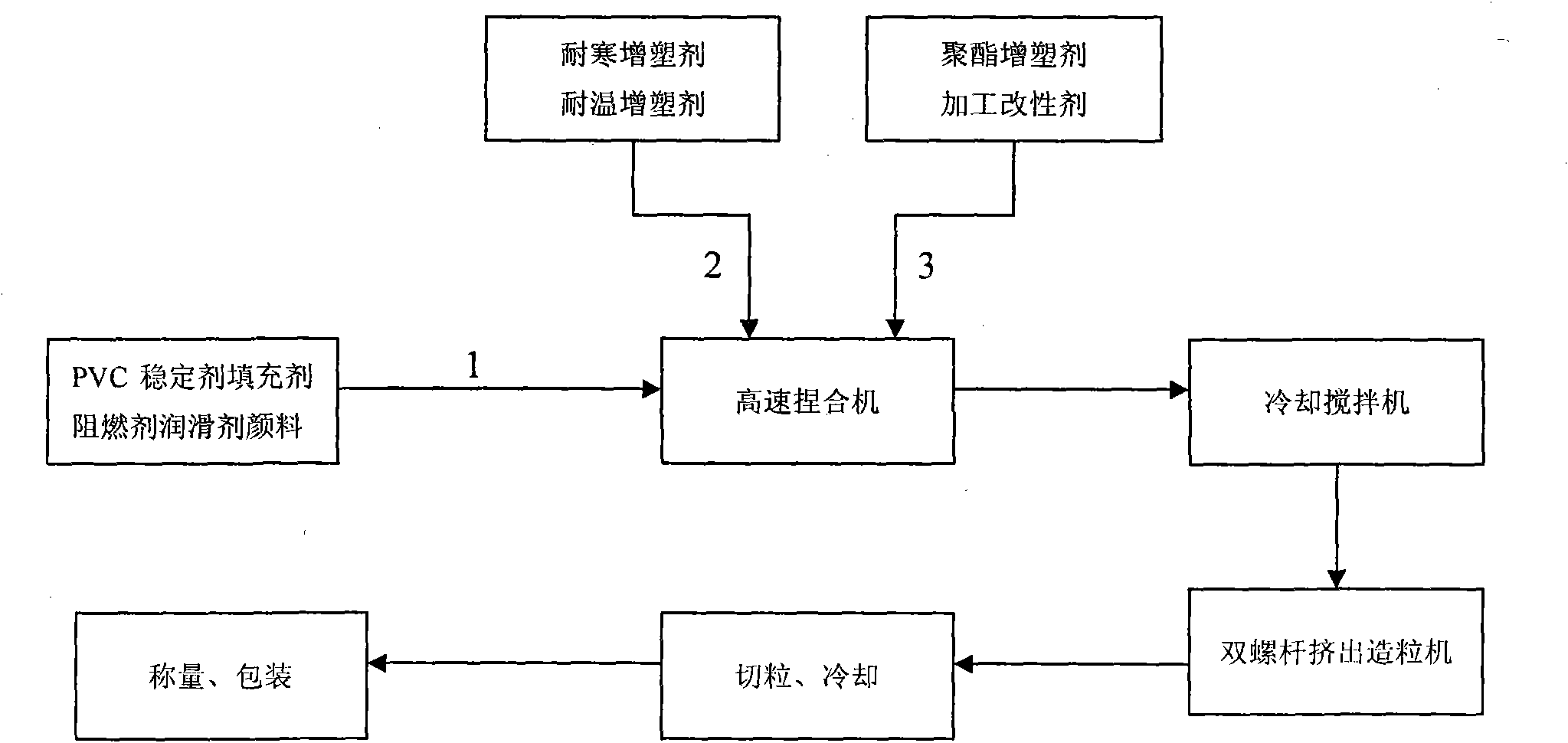

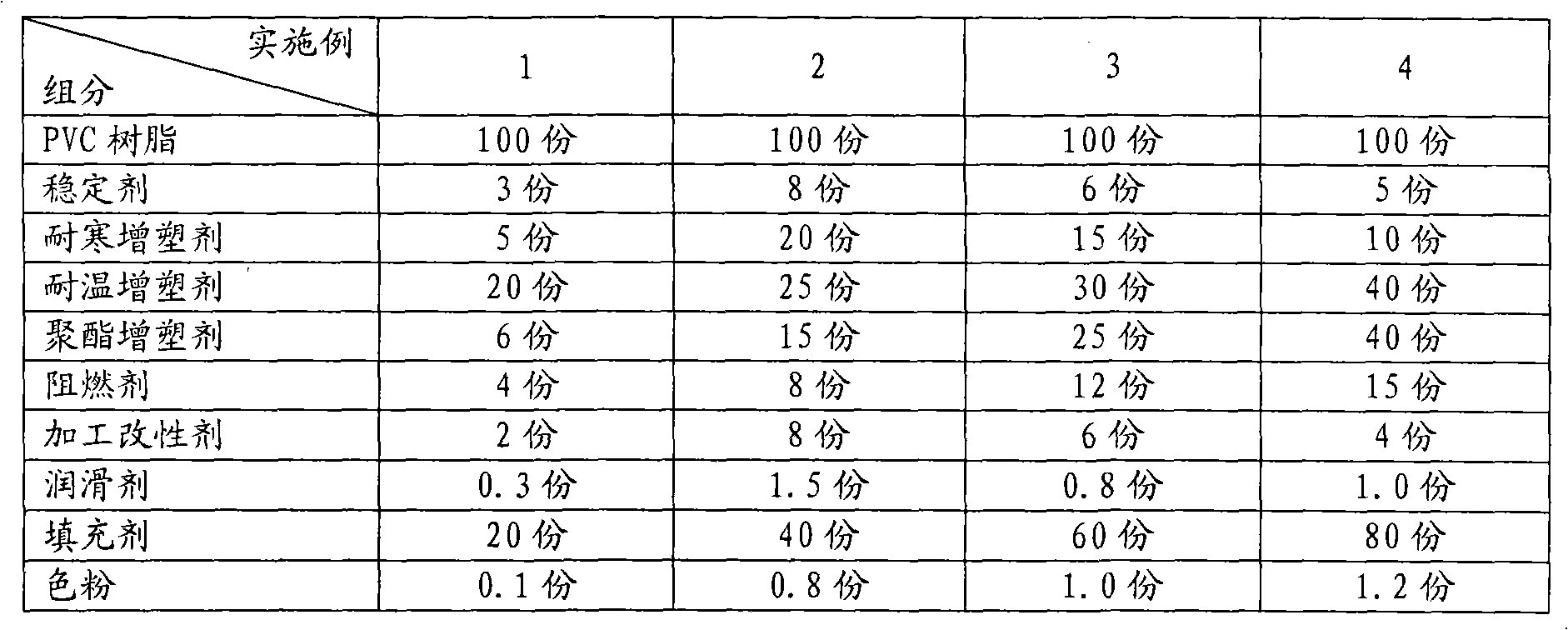

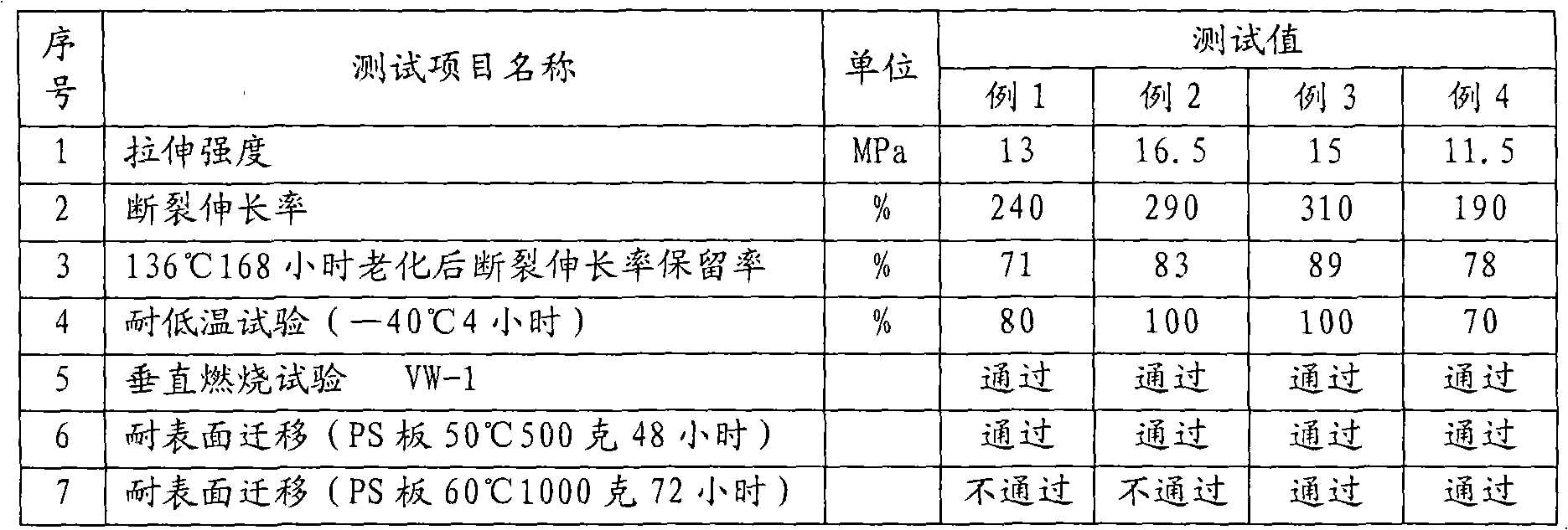

Cold-resistant temperature-resistant flame-retardant surface migration-resistant polrvinyl chloride insulating material

InactiveCN101967250AWon't breakNo migrationPlastic/resin/waxes insulatorsPolyesterEnvironmental resistance

The invention discloses a cold-resistant temperature-resistant flame-retardant surface migration-resistant polrvinyl chloride insulating material. The material comprises the following components in part by weight: 100 parts of polrvinyl chloride (PVC) resin, 5 to 20 parts of cold-resistant plasticizer, 20 to 40 parts of temperature-resistant plasticizer, 6 to 40 parts of polyester polymer plasticizer, 3 to 8 parts of environmentally-friendly heat stabilizer, 20 to 80 parts of filler, 4 to 15 parts of fire retardant, 2 to 8 parts of processing modifier, 0.3 to 1.5 parts of lubricant and 0.1 to 1.2 p[arts of toner. The polrvinyl chloride composite material of the invention has the comprehensive performance, such as low temperature embrittlement resistance, low temperature compact resistance, high temperature aging resistance, fire resistance, surface migration resistance and the like.

Owner:王长明

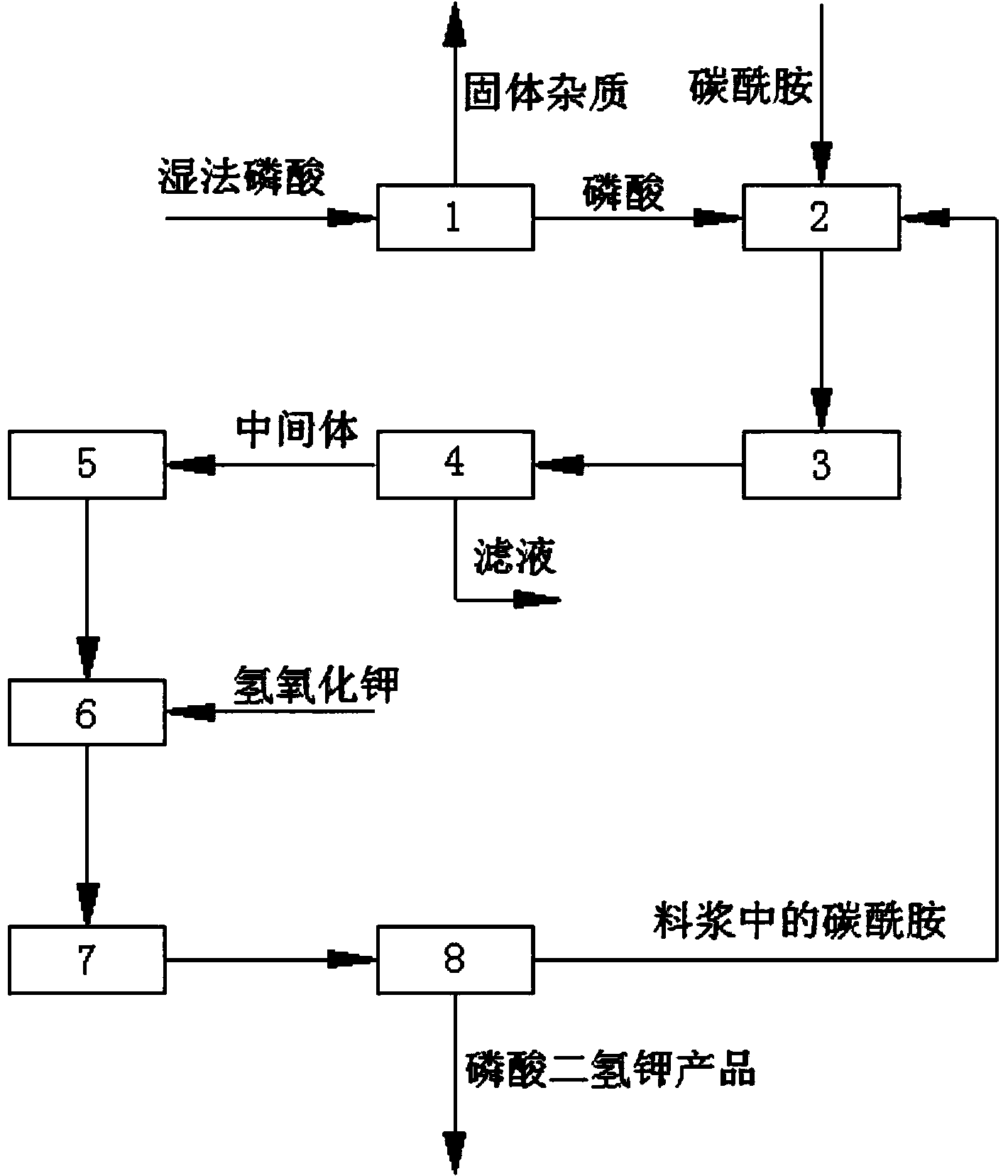

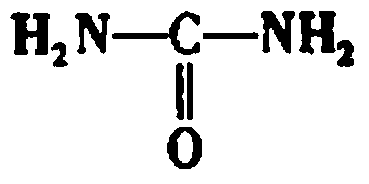

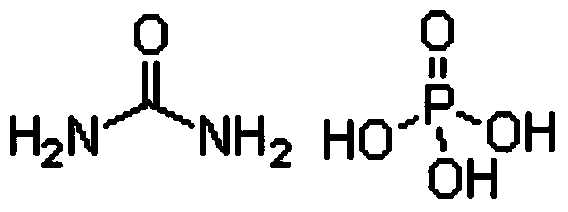

Method for preparing monopotassium phosphate by using wet-process phosphoric acid

InactiveCN103803518AReduce manufacturing costNo pollution in the processPhosphorus compoundsFertilizer mixturesEnvironmental resistanceHigh energy

The invention discloses a method for preparing monopotassium phosphate by using wet-process phosphoric acid. The method comprises the following steps: reacting carbonyl diamide and wet-process phosphoric acid to obtain an intermediate; reacting the intermediate and potassium hydroxide to prepare a monopotassium phosphate product. The method has the advantages of short process route, low energy consumption, stable product quality, low production cost, convenience in operation and safety in production. A side product, namely, slurry can be recycled completely, an entire production process is environment-friendly, clean and free from pollution, and no waste gas, waste water or waste residues are discharged. A response is made to the policy calling of energy saving, emission reduction and clean production, the problems of complex process, instable product quality, high energy consumption and environmental pollution existing in the prior art are solved, and the purity of the obtained monopotassium phosphate product is more than or equal to 98 percent.

Owner:GUIYANG KAILIN FERTILIZER CO LTD +1

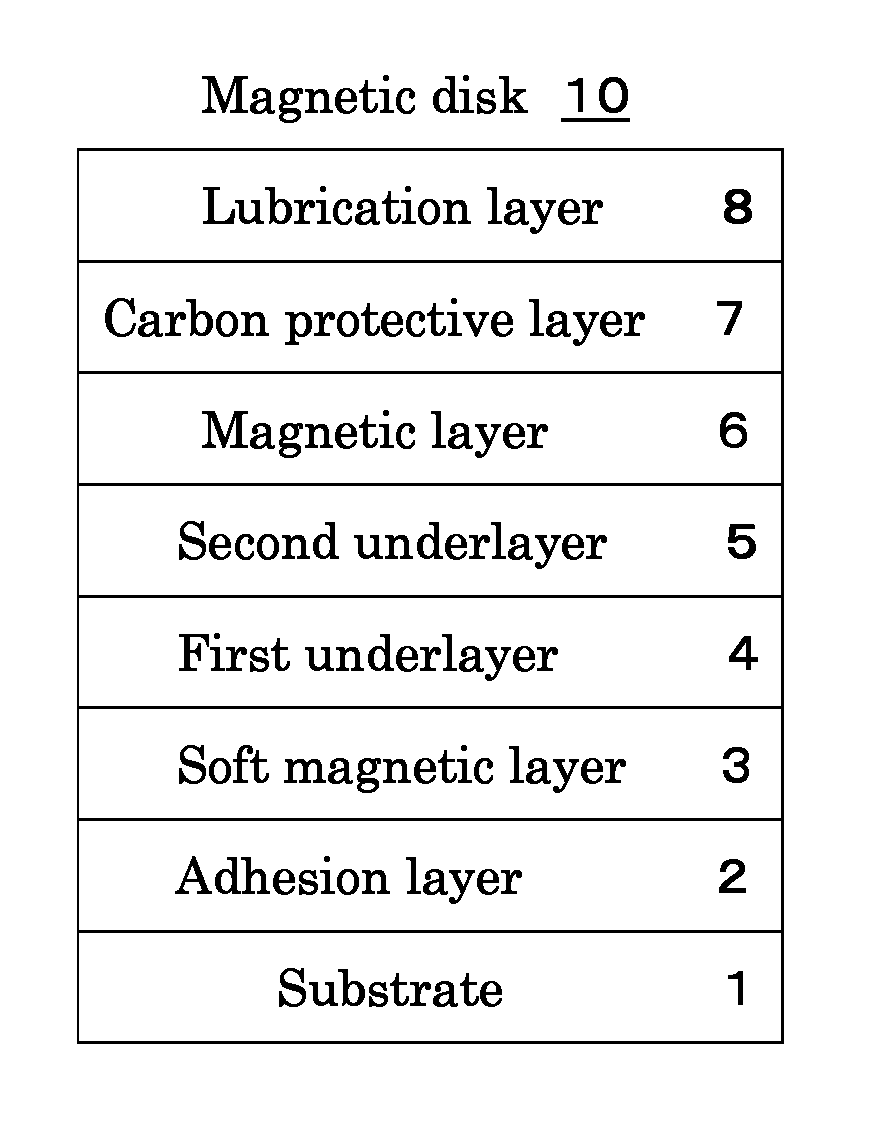

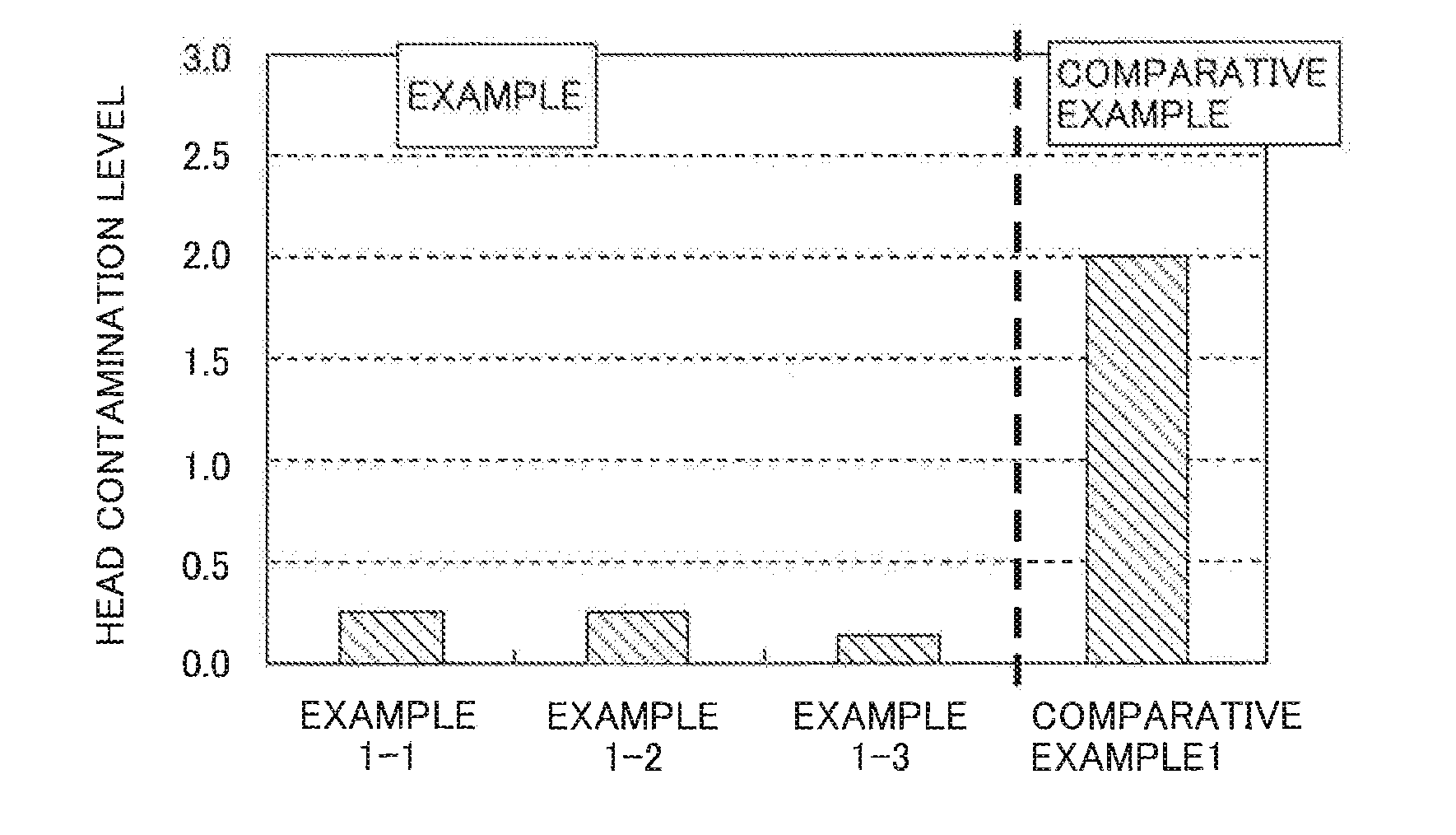

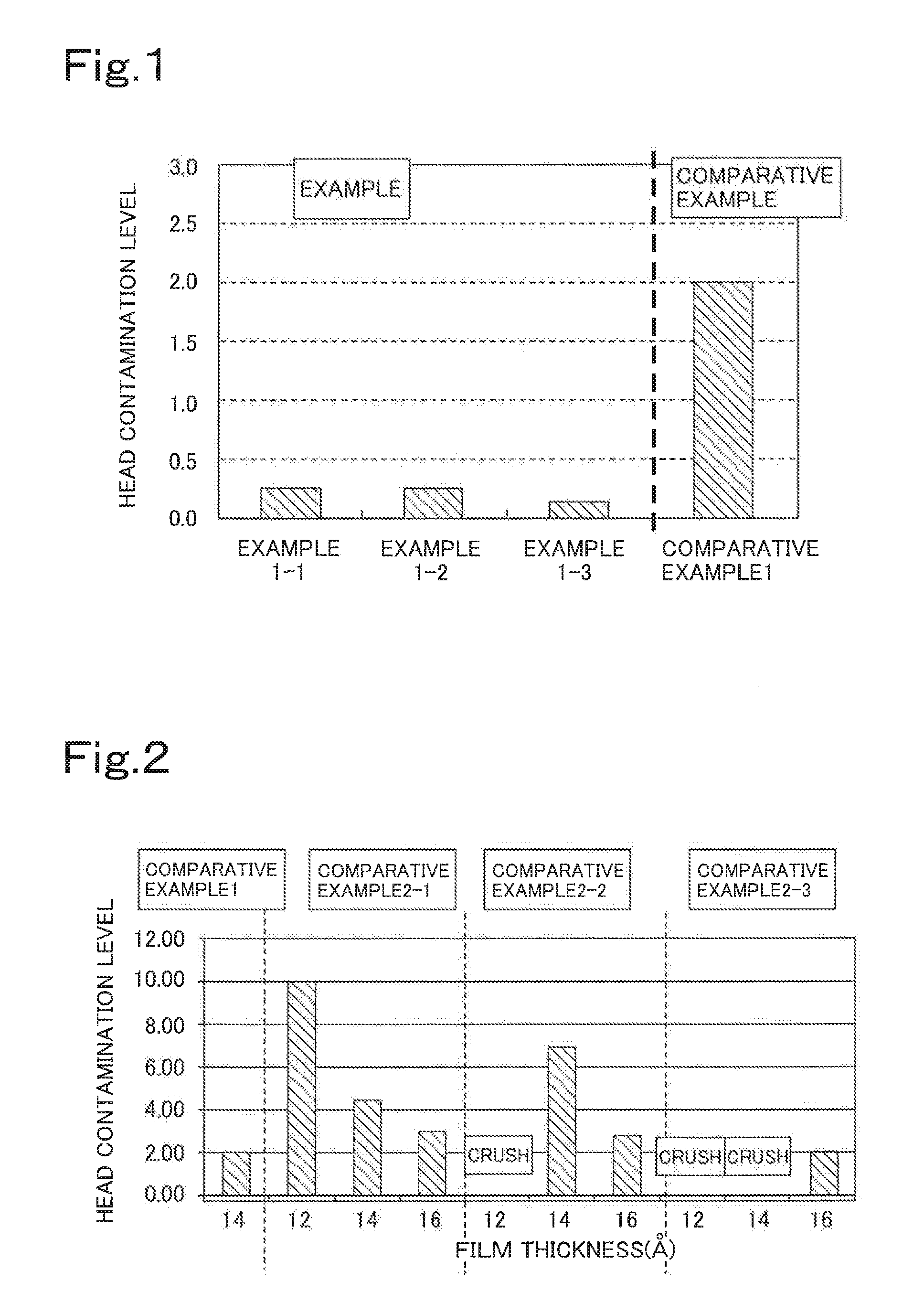

Lubricant for magnetic disc, magnetic disc and method of producing the same

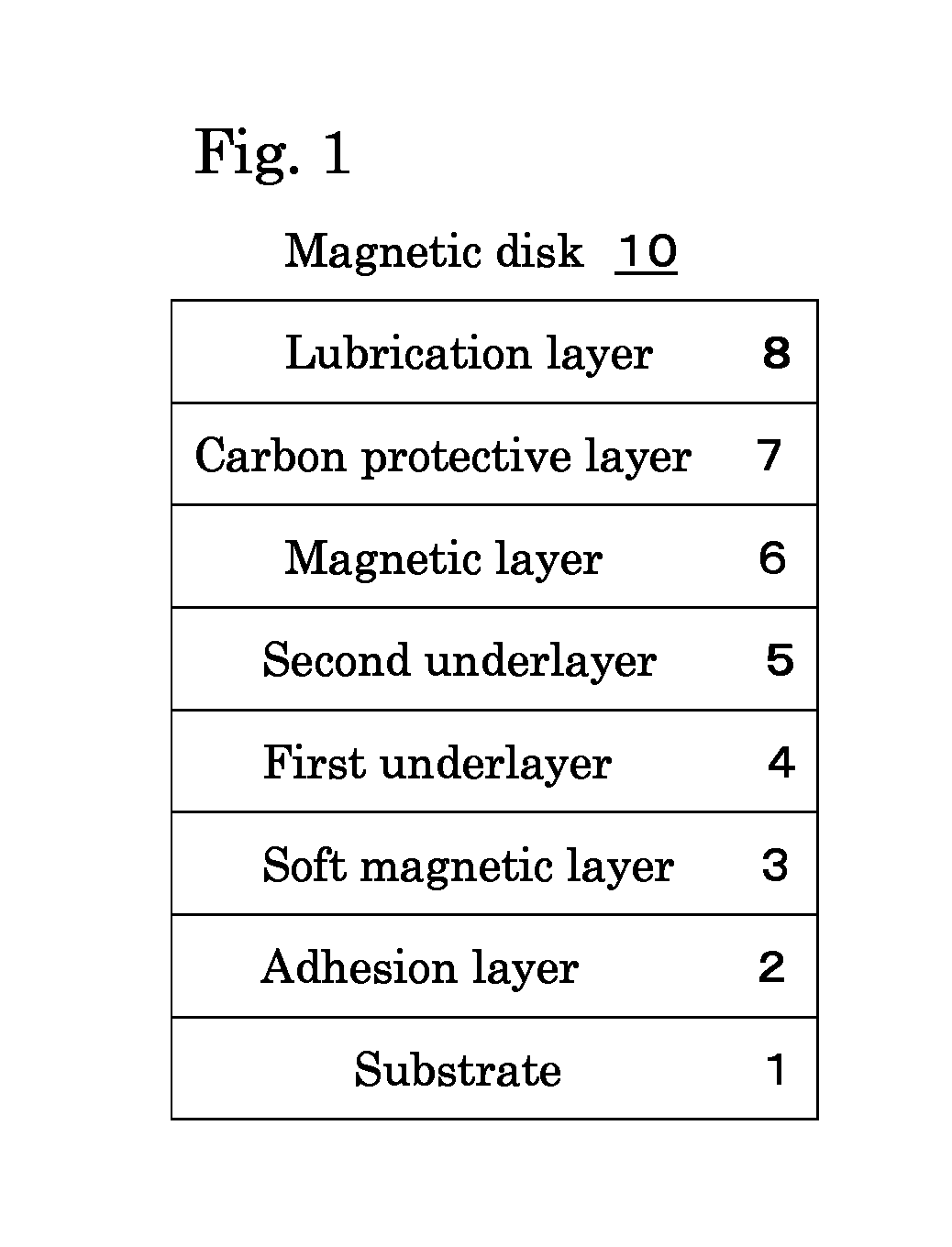

ActiveUS20120148875A1Organic chemistryRecord information storageEnvironmental resistancePerfluoropolyether

A magnetic disk with which further reduction of magnetic spacing can be realized and which has high reliability under such circumstances of a lower floating amount of a magnetic head involved in the recent rapid increase in recording density and of extremely severe environmental resistance involved in diversification in use applications is provided.In a magnetic disk in which at least a magnetic layer, a protective layer, and the lubrication layer are sequentially provided on a substrate, the lubrication layer contains a lubricant compound for a magnetic disk, having a perfluoropolyether main chain in the molecular structure and a structure indicated as follows at a position close to the center of the molecule:-0-CH2—CH(OH)—CH2—CH2—CH(OH)—CH2-0-or-0-CH2—CH(OH)—CH(OH)—CH2-0-

Owner:WESTERN DIGITAL TECH INC

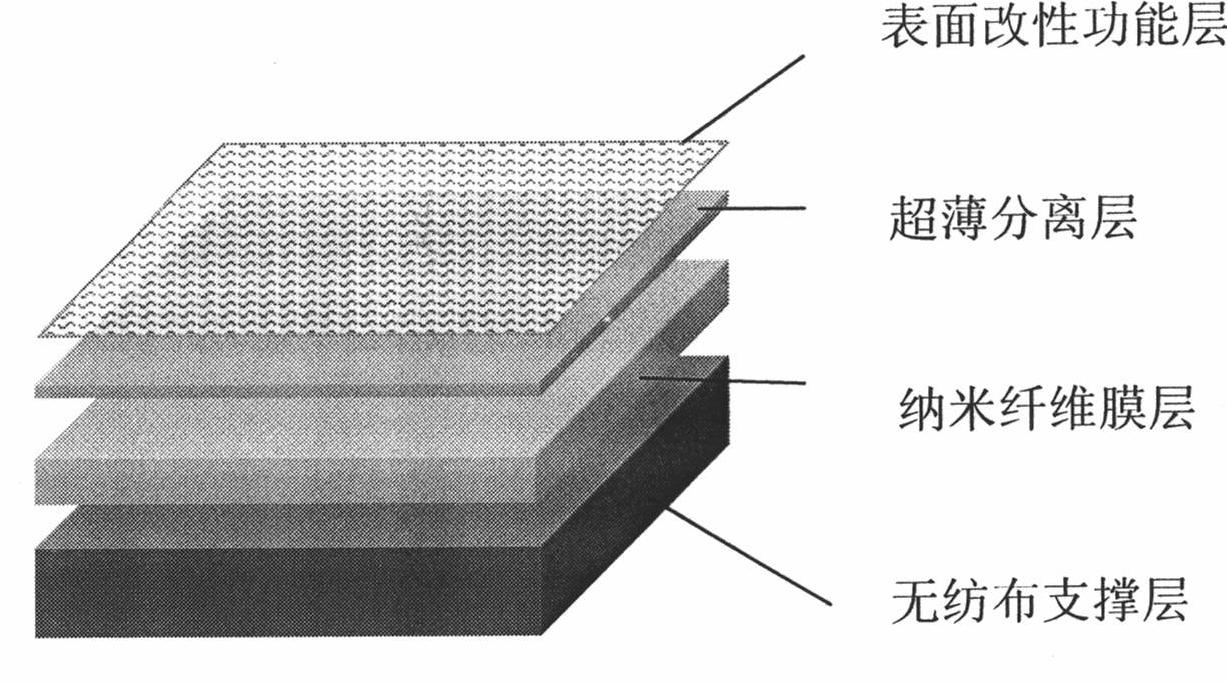

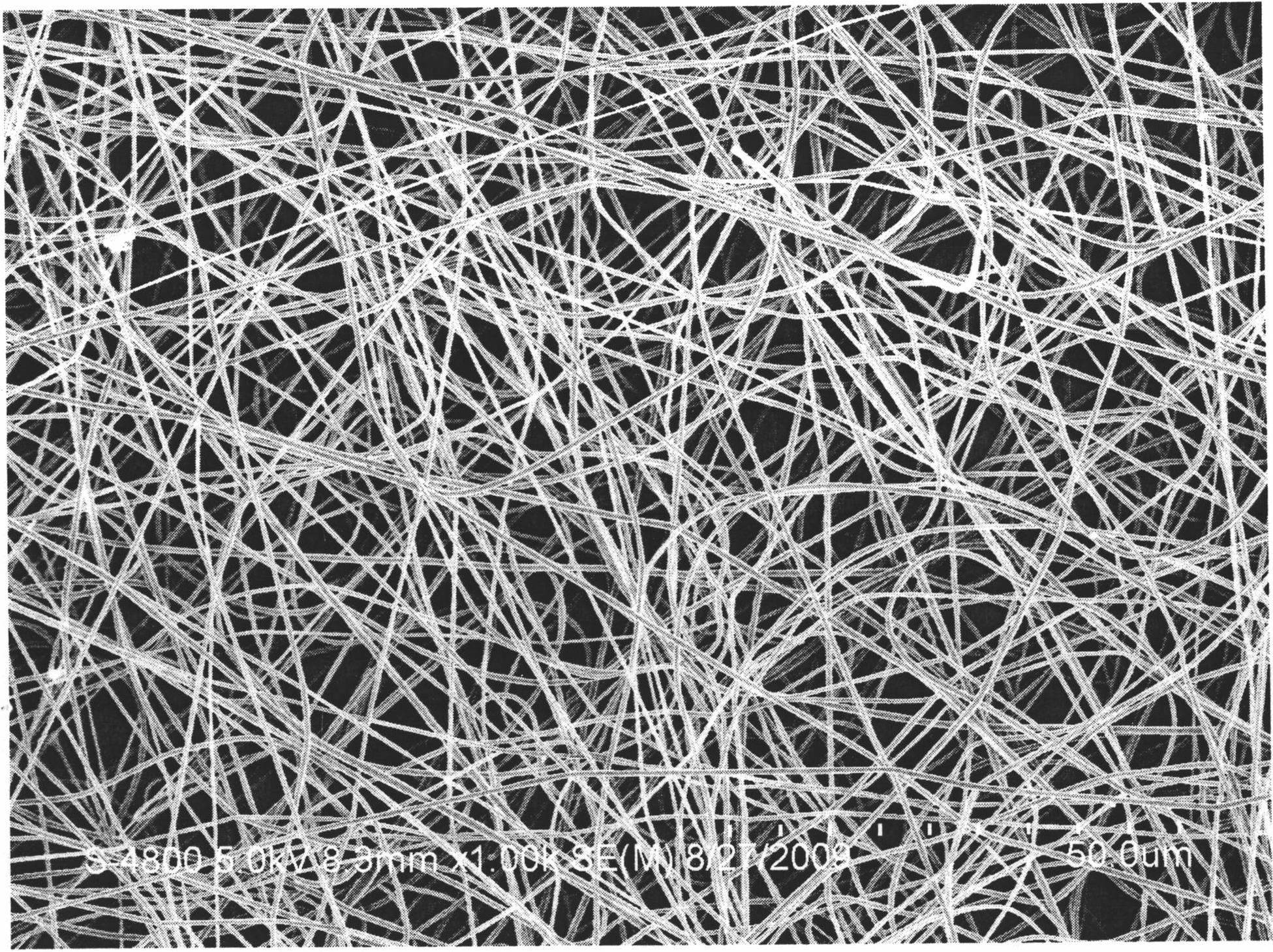

Hyperfiltration membrane or nanofiltration membrane with multi-layered composite structure and preparation method thereof

InactiveCN102139187AIncrease water fluxHigh retention rateSemi-permeable membranesEnvironmental resistanceHydrophilic polymers

The invention relates to a hyperfiltration membrane or nanofiltration membrane with a multi-layered composite structure and a preparation method thereof. The hyperfiltration membrane or nanofiltration membrane is a polymer electrostatic spinning nanofiber membrane layer characterized in strong chemical resistance prepared through an electrostatic spinning method, a hydrophilic polymer ultra-thin separation layer obtained through interfacial polymerization, and a functional group surface modification functional layer formed through the grafting reaction of reactant gases on the surfaces of hydrophilic polymers, or a long-chain polymer surface modification functional layer formed through the grafting reaction of the reaction gases on the surfaces of the hydrophilic polymers, or a functionalgroup-containing long-chain polymer surface modification functional layer through the grafting reaction of the reaction gases with the functional groups on the surfaces of the hydrophilic polymers. The hyperfiltration membrane or nanofiltration membrane with the multi-layered composite structure has the advantages of high water flux, high cutting rate and stable chemical performances. The filtration membrane can be used for the production of domestic water, drinking water or water in special conditions, and is suitable for the medical field, food field, environmental protection field and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method of ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption

InactiveCN103756006ASolve the defect of strong hydrophilicityLow densityCoatingsEnvironmental resistanceCellulose

The invention discloses a preparation method of an ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption, and relates to a preparation method of cellulose aerogel. The method disclosed by the invention aims to solve the problem that existing cellulose aerogel which is lower in oil absorption multiplying power and strong in hydrophilicity is not suitable for oil-water separating materials. The method comprises the following steps: I, preparing cellulose aqueous liquor; II, preparing a nano fibrillated cellulose aqueous dispersion liquid; III, preparing a strongly gelatinous nano fibrillated cellulose aqueous dispersion liquid; IV, freezing and drying; and V, carrying out hydrophobic modification to obtain the ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption. The preparation method of the ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption is simple in preparation process, wide in source of raw materials, low in cost and environment-friendly and green. The invention relates to the preparation method of the ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption.

Owner:NORTHEAST FORESTRY UNIVERSITY

Magnetic disk and manufacturing method thereof

ActiveUS20120127599A1Guaranteed uptimeImprove reliabilityDriving/moving recording headsProtective coatings for layersEnvironmental resistanceCompound a

A magnetic disk is provided which is excellent in durability of the magnetic disk or particularly in LUL durability and CFT characteristics and has high reliability under a decreased floating amount of the magnetic head accompanying the recent rapid increase in a recording density and extremely severe environmental resistance accompanying diversification of the applications.The magnetic disk of the present invention is a magnetic disk having at least a magnetic layer, a carbon protective layer, and a lubrication layer sequentially provided on a substrate, and the lubrication layer is a film formed by a lubricant that contains two types of compounds having a perfluoropolyether main chain in the structure, a molecular weight distribution of the two types in total being within a range of 1 to 1.2, the two types of compounds including a compound a having a hydroxyl group at the end and a compound b having a number average molecular weight smaller than the number average molecular weight of the compound a and not more than 1500, and a content of the compound b in the two types of compounds being not more than 10%.

Owner:WESTERN DIGITAL TECH INC

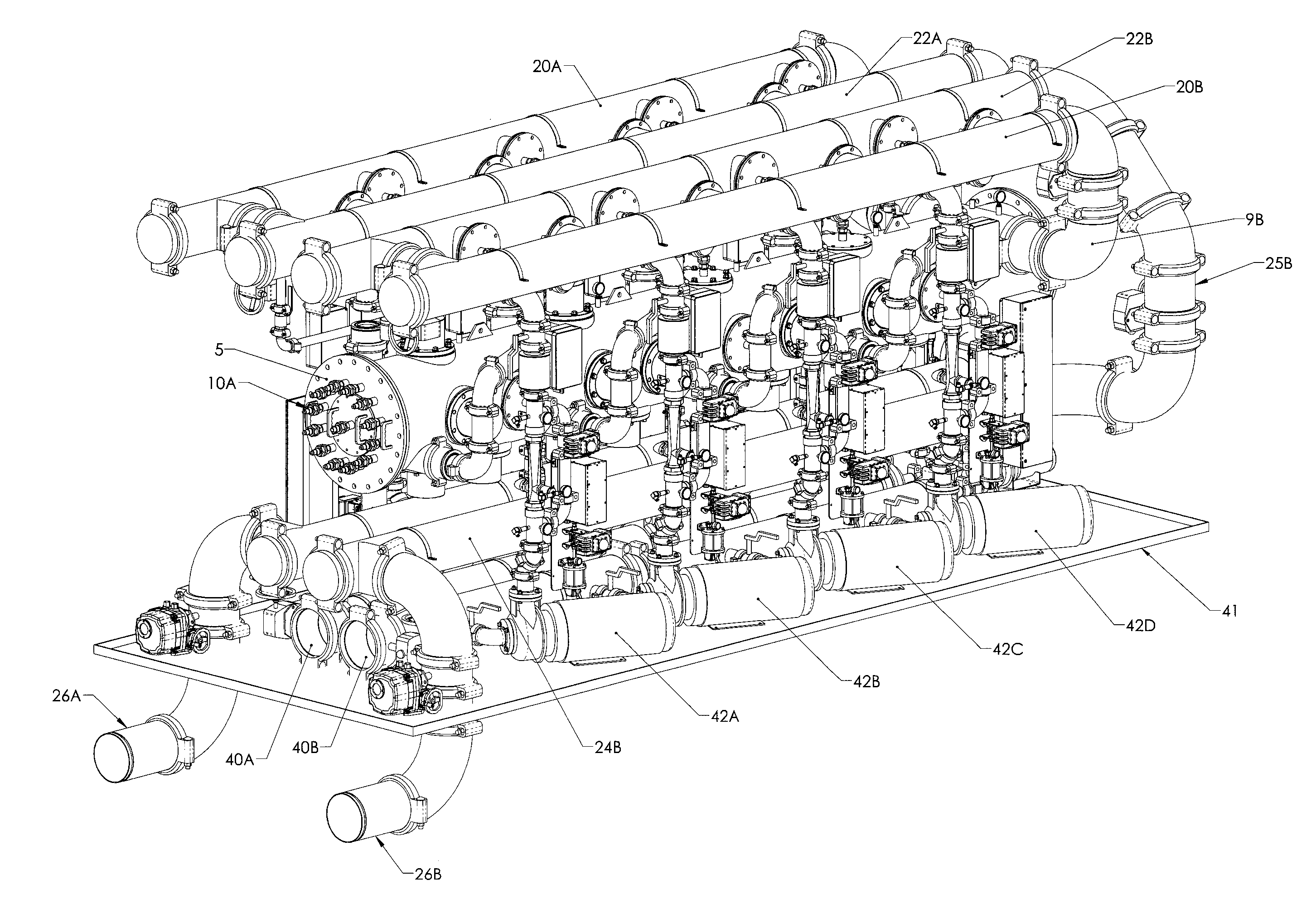

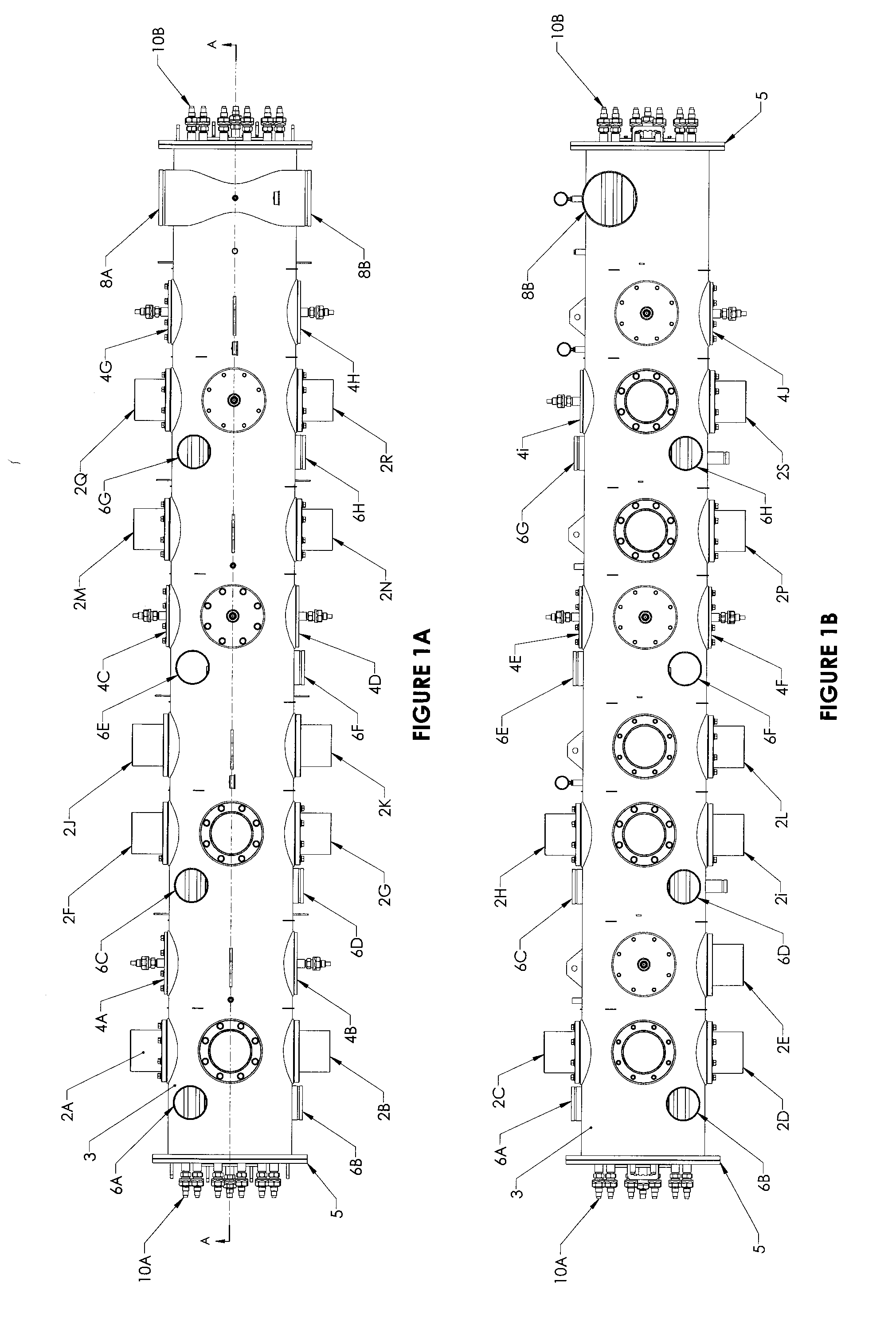

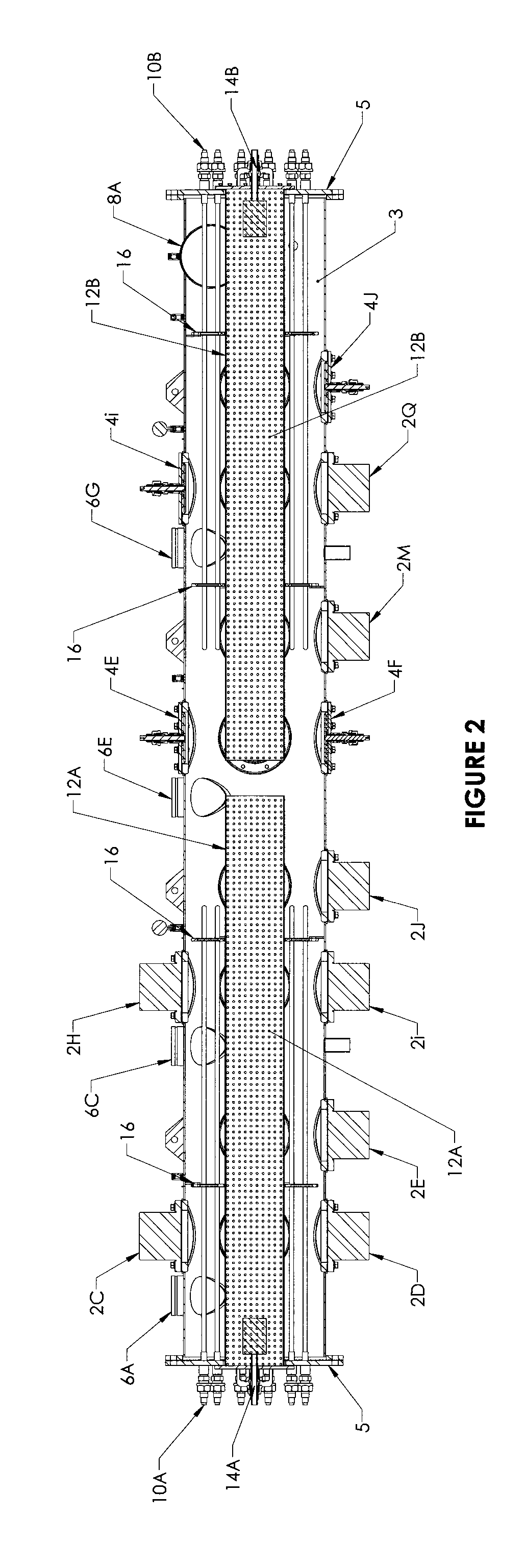

Apparatus for treating fluids

InactiveUS20120205301A1Enhanced mass transferFaster rateGeneral water supply conservationWater treatment compoundsTruck-trailerChemical treatment

The treatment apparatus is pressurized and operates on a continuous flow of fluids which are subjected to hydrodynamic waves, acoustic ultrasonic waves in combination with injected ozone and electro chemical treatment. The treatment system provides a cost efficient and environmentally friendly process and apparatus for cleaning and recycling fluids as contaminated as frac water, used to stimulate gas production from shale formations, as well as other types of fluids having various levels of contaminants such as aerobic and anaerobic bacteria and suspended solids. The calcium carbonate scaling tendency is reduced to an acceptable level without the use of acids, ion exchange materials, or anti scaling chemicals which is of economical and environmental significance and benefit. The treatment apparatus is modular in construction and compact in overall configuration. The treatment apparatus and associated equipment and electrical power generator is sized and configured to be mounted within a truck trailer body.

Owner:ECOSPHERE TECH

Lubricant compound for magnetic disk and magnetic disk

ActiveUS20120127601A1Reduction of magnetic spacingImprove reliabilityProtective coatings for layersMagnetic materials for record carriersEnvironmental resistanceRecording density

A lubricant compound for a magnetic disk is provided which can realize further reduction of the magnetic spacing and moreover, has high reliability under a lower floating amount of the magnetic head involved with the recent rapid increase in the recording density and under extremely severe environmental resistance involved with diversification of the applications.A lubricant compound is contained in a lubrication layer of a magnetic disk in which at least a magnetic layer, a protective layer, and a lubrication layer are sequentially provided on a substrate, and the lubricant compound contains a component A and a component B expressed by the following chemical formula:[Chemical formula]1 Component A: X=OHComponent B: X=OCH2CH(OH)CH2OHand a component C made of a specific compound having a phosphezene ring in the structure thereof.

Owner:WESTERN DIGITAL TECH INC

Thermoset particles with enhanced crosslinking, processing for their production, and their use in oil and natural gas driliing applications

InactiveUS20070021309A1Increase compressive elastic modulusReduced deformabilitySynthetic resin layered productsCellulosic plastic layered productsEnvironmental resistancePetroleum

Thermoset polymer particles are used in many applications requiring lightweight particles possessing high stiffness, strength, temperature resistance, and / or resistance to aggressive environments. The present invention relates to the use of methods to enhance the stiffness, strength, maximum possible use temperature, and environmental resistance of such particles. One method of particular interest is the application of post-polymerization process step(s) (and especially heat treatment) to advance the curing reaction and to thus obtain a more densely crosslinked polymer network. The most common benefits of said heat treatment are the enhancement of the maximum possible use temperature and the environmental resistance. The present invention also relates to the development of thermoset polymer particles. It also relates to the further improvement of the key properties (in particular, heat resistance and environmental resistance) of said particles via post-polymerization heat treatment. Furthermore, it also relates to processes for the manufacture of said particles. Finally, it also relates to the use of said particles in the construction, drilling, completion and / or fracture stimulation of oil and natural gas wells; for example, as a proppant partial monolayer, a proppant pack, an integral component of a gravel pack completion, a ball bearing, a solid lubricant, a drilling mud constituent, and / or a cement additive.

Owner:SUN DRILLING PRODS

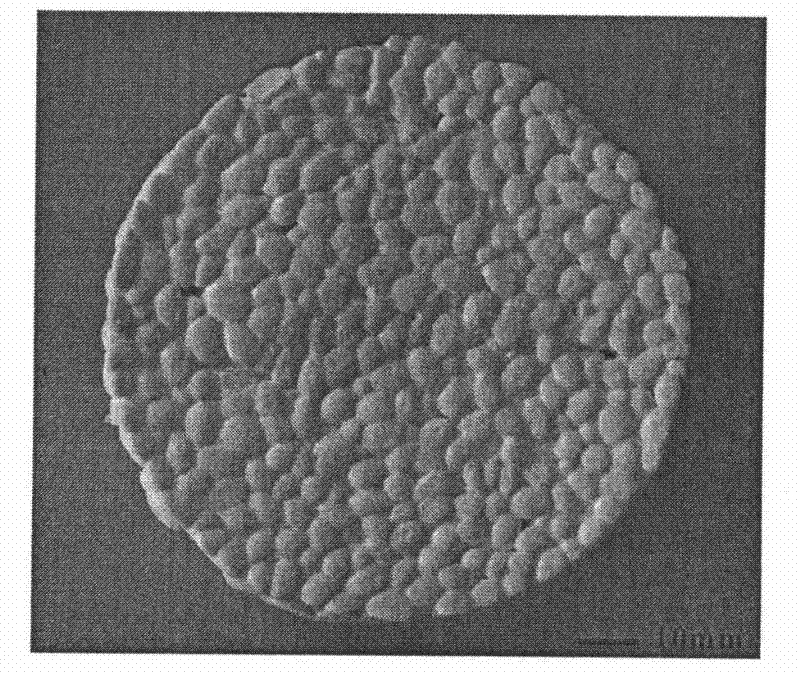

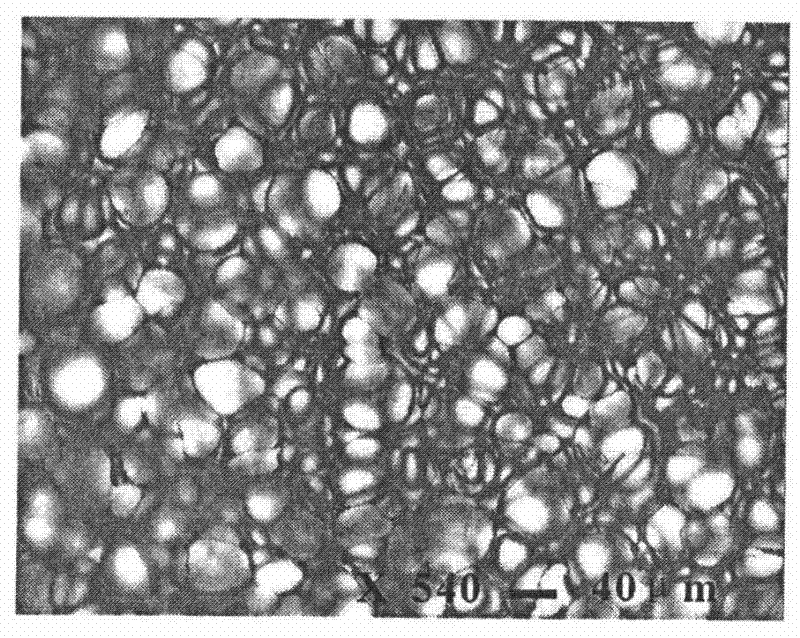

Spherical porous light haydite for treating waste water and its production method

InactiveCN1380137AHigh economic valueSolve the way outOther chemical processesSustainable biological treatmentPorosityEnvironmental resistance

The present invention relates to a kind of spherical porous loight-ceramsite produced by using industrial waste slag, steel-smelting rod mud and flyash as main raw material, using clay as binding agent, adding proper quantity of pore-forming agent and adopting high-temp., sintering process. Said invention also provides its production method, and said product can be specially used as filtration material for water treatment. Its product quality is as follows: specific surface area is 4-10 sq.m / g, average pore size is 50-250 micrometers, apparent density is 1.40-1.80 g / cu.cm and its voidage is 30-40%.

Owner:HUAQI ENVIRONMENT PROTECTION SCI & TECH

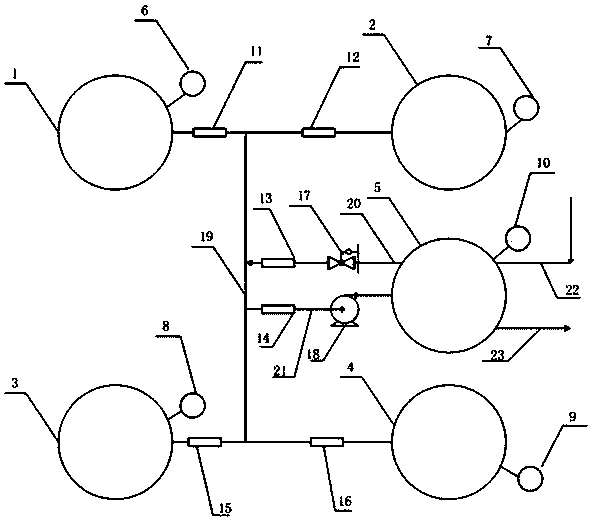

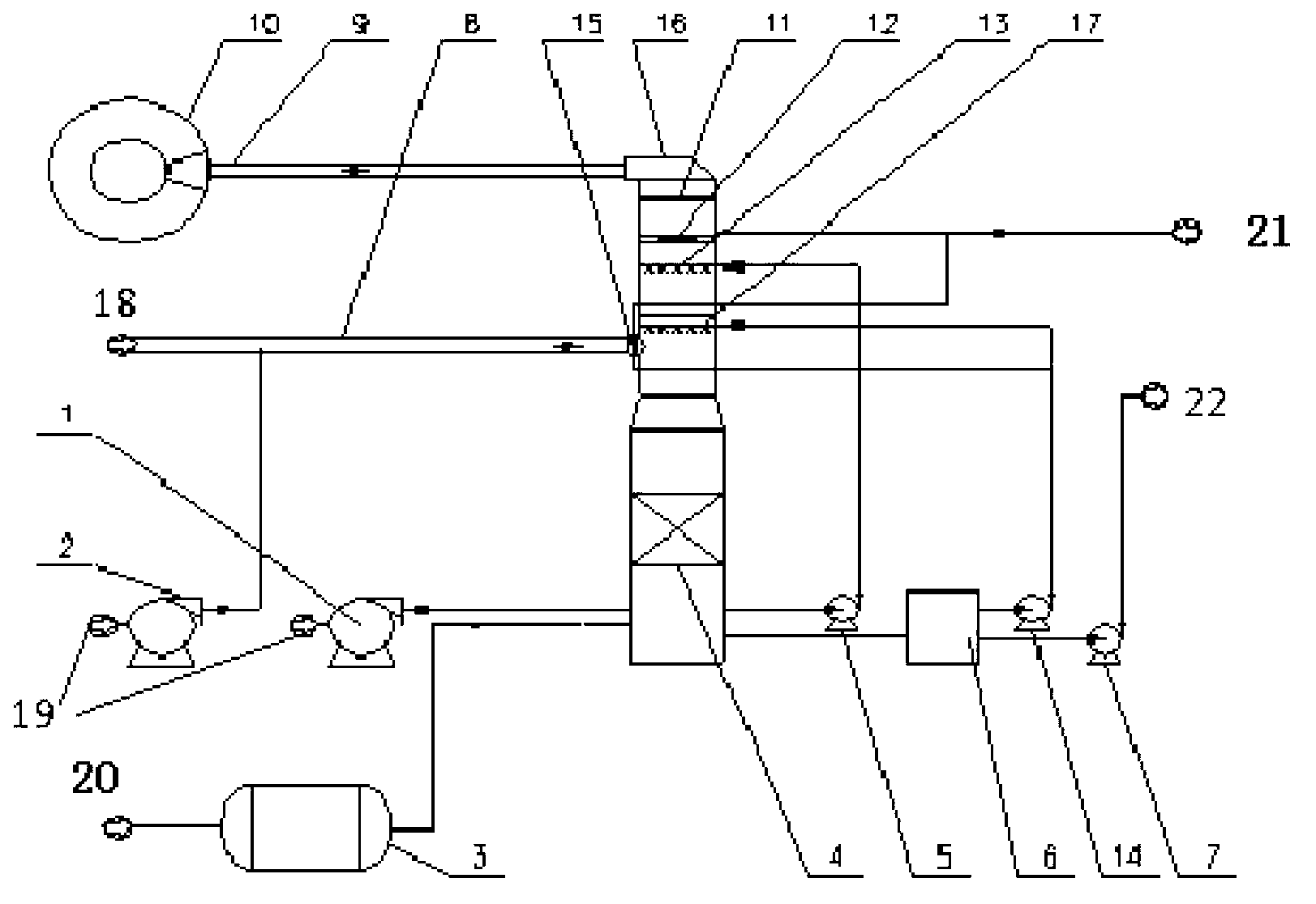

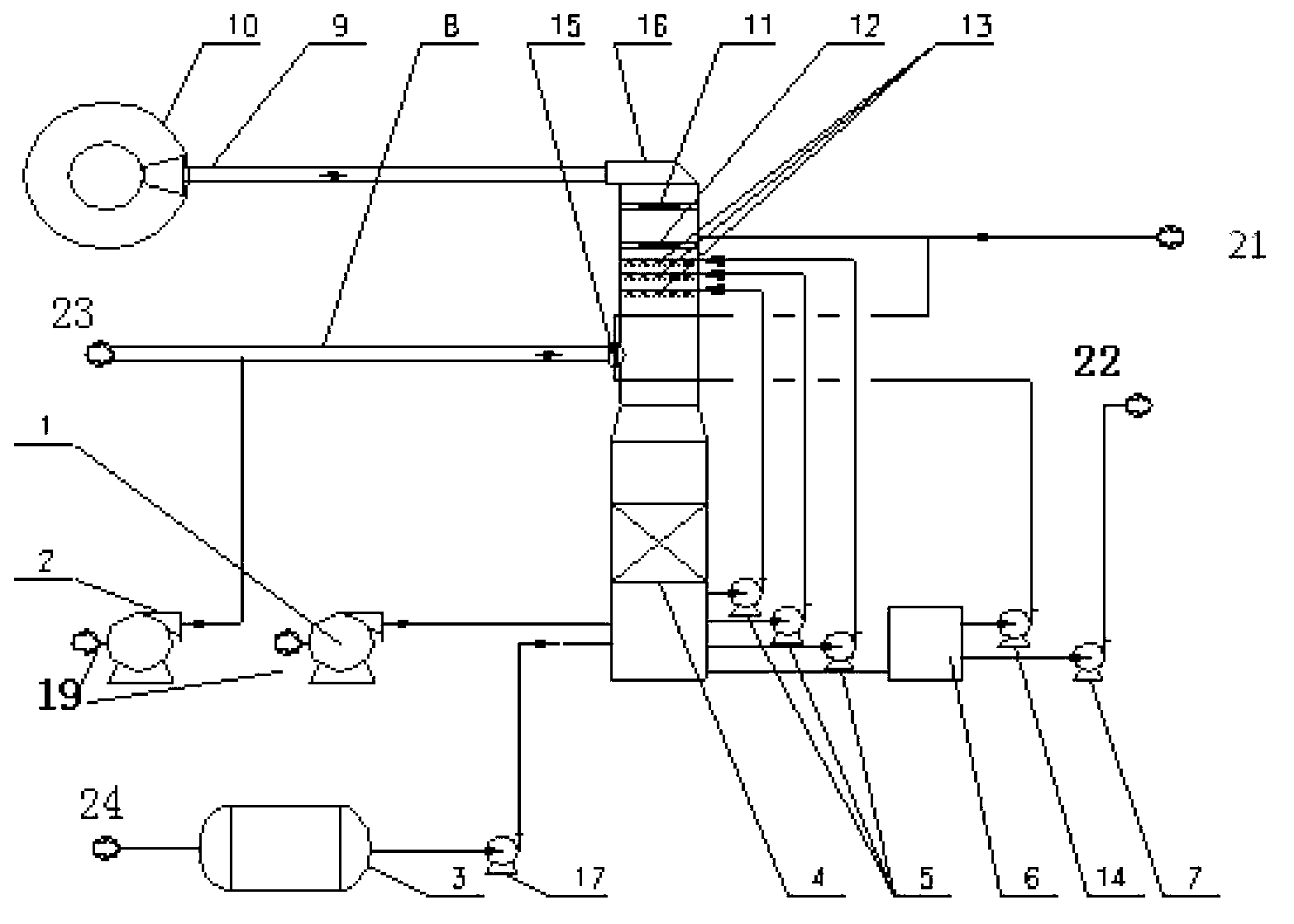

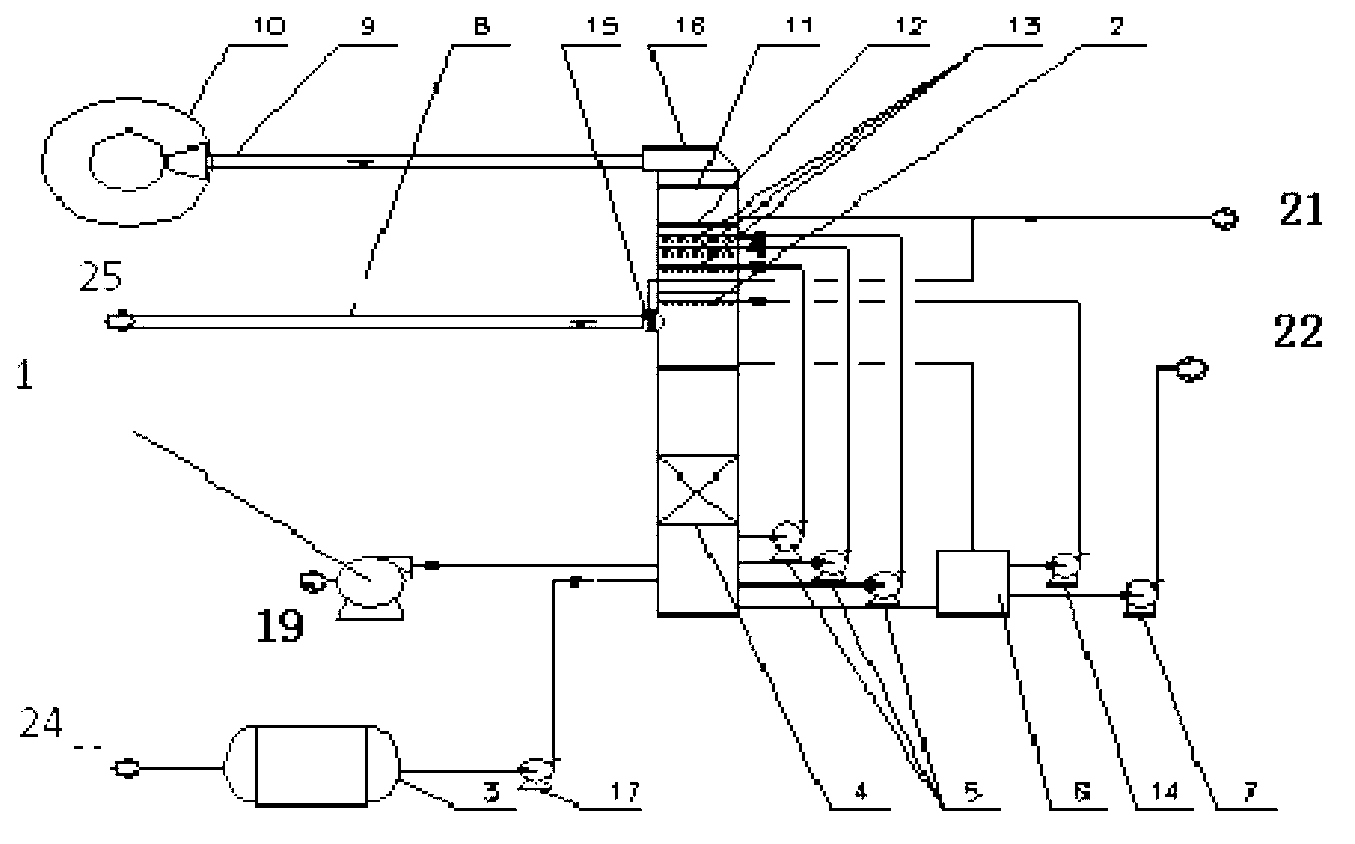

Safe and environment-friendly method for protecting storage tanks

InactiveCN104370000AShort processReduce dosageLarge containersEnvironmental resistancePositive pressure

The invention relates to a safe and environment-friendly method for protecting storage tanks to mainly solve the problems that in the prior art, the gas consumption of nitrogen protection is excessively large, cost is high, and sulfur-containing gas and other peculiar smell gas are hard to treat. According to the safe and environment-friendly method for protecting the storage tanks, the gas produced by liquid in the storage tanks enters a compressor (18) through a main gas pipe (19) and an inflation pipe (21), the gas is pressurized by the compressor (18) and stored in a buffering tank (5) to serve as one part of positive-pressure protection gas, when the gas stored in the buffering tank (5) cannot meet the positive-pressure protection of all storage tanks, the nitrogen from a nitrogen inlet pipeline (22) is used for performing supplementation, and when the pressure stored in the buffering tank (5) exceeds the designed pressure, the residual gas is sent to a torch or combustion furnace through a torch or combustion furnace leading pipeline (22), the problems are well solved through the technical scheme, and the method can be used in storage tank protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

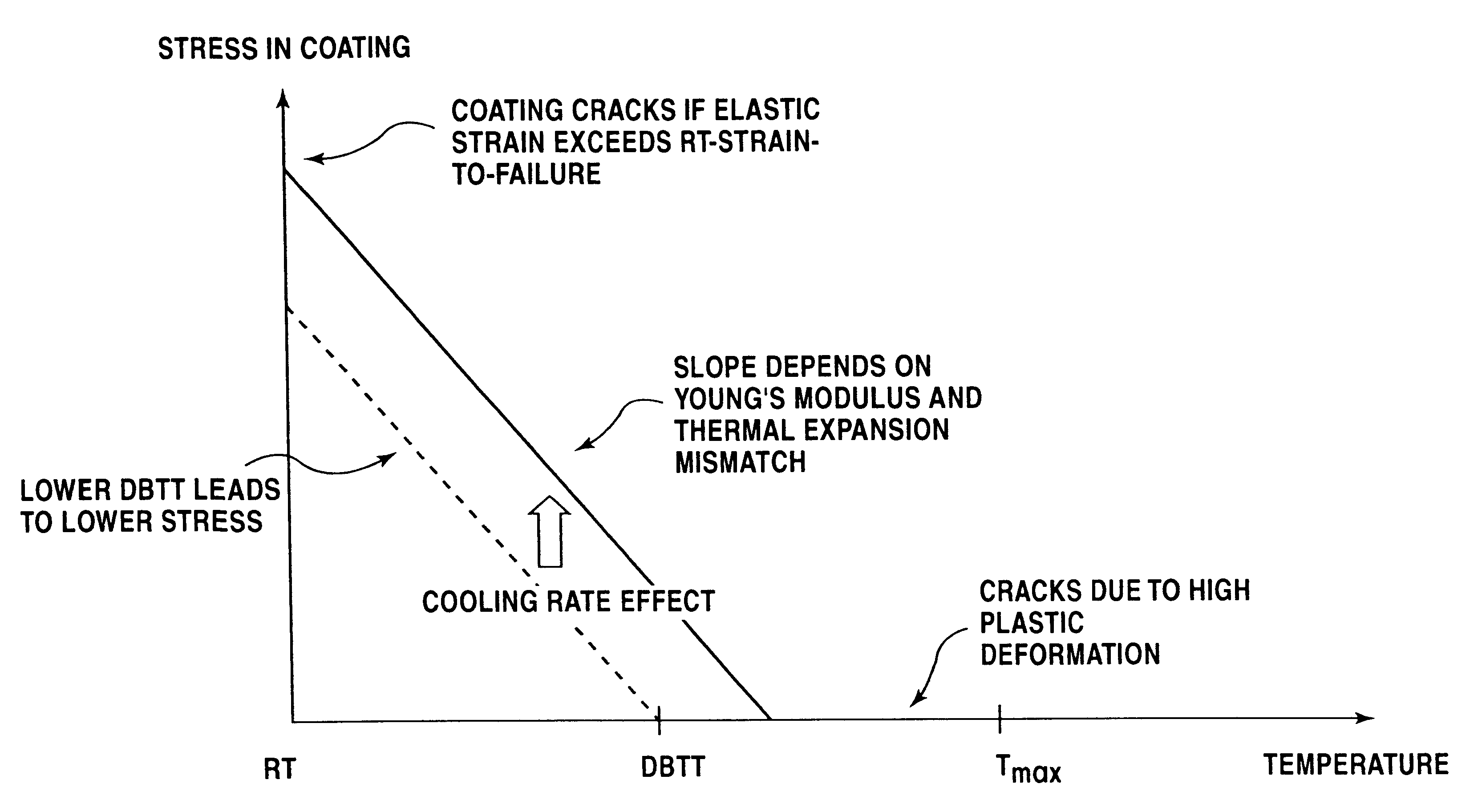

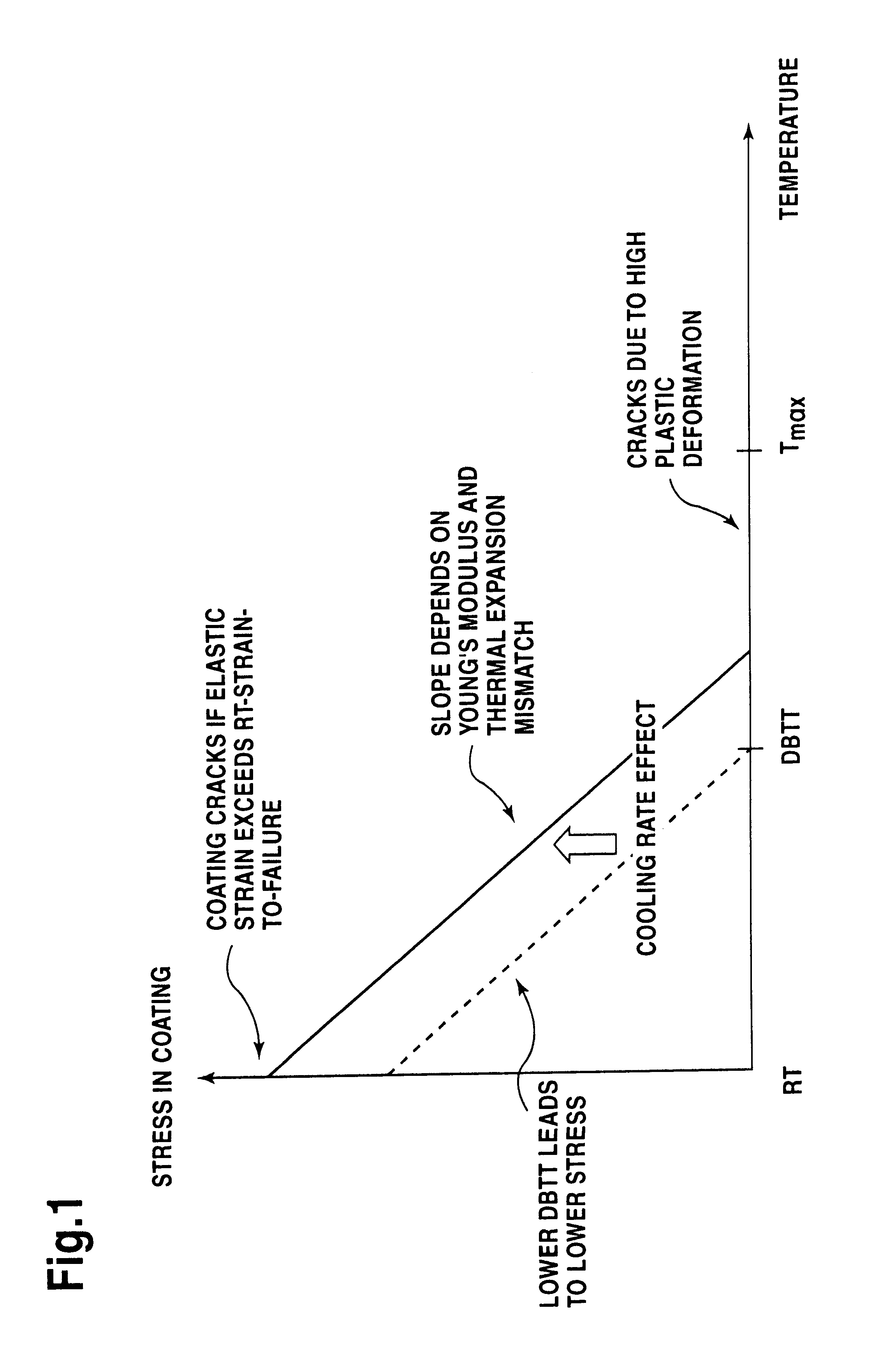

Coating composition for high temperature protection

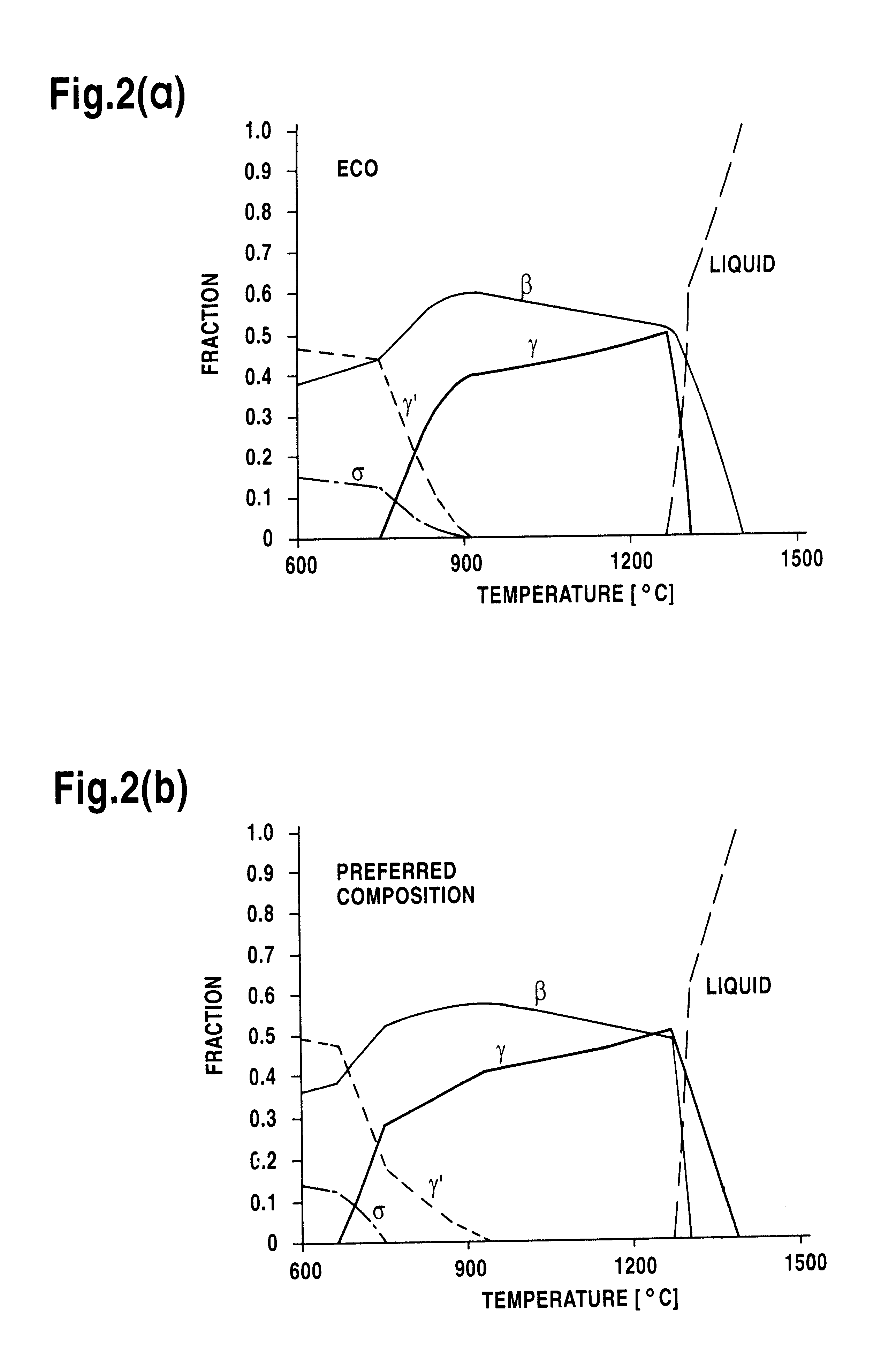

InactiveUS6221181B1Improve mechanical propertiesLower resistanceSuperimposed coating processThin material handlingEnvironmental resistanceSuperalloy

The invention relates to a coating composition for superalloy structural parts, especially for gas turbine vanes and blades, which provides simultaneously excellent environmental resistance and highly improved thermomechanical behavior. The coating consists essentially of, by weight, 28-35% Co, 11-15% Cr, 10-13% Al, 0-1% Re, 1-2% Si, 0.2-1% Ta, 0.005-0.5% Y, 0-5% Ru, 0-1% Ca, 0-1% Mg, 0-0.5% La (or elements from the La series), 0-0.1% B, balance Ni and incidental impurities.

Owner:ANSALDO ENERGIA IP UK LTD

Ammonia process flue gas treatment method for acidic tail gas and device

ActiveCN103223292AIncreased self-concentrationGood desulfurization absorptionDispersed particle separationAmmonium sulfatesEnvironmental resistanceAmmonia storage

The invention relates to an ammonia process flue gas treatment method for acidic tail gas. The method includes the steps of: 1) controlling the sulfur dioxide concentration of tail gas entering an absorption tower at a level of less than or equal to 30000mg / Nm<3>; 2) arranging process water in an absorption tower entrance flue or in the absorption tower or cooperating with a ammonium sulphate solution to perform spray cooling; 3) disposing an oxidation section in the absorption tower, setting an oxidation distributor at the oxidation section to achieve oxidation of a desulfurized absorption liquid; 4) arranging an absorption section in the absorption tower, utilizing an absorption liquid distributor in the absorption section to realize desulfurization spray absorption by an ammonia-containing absorption liquid, which is fed through an ammonia storage groove; 5) arranging a water washing layer at an absorption section upper part in the absorption tower, washing the absorption liquid in the tail gas by the water washing layer and reducing the absorption liquid escape; and 6) setting a demister at the upper part of the water washing layer in the absorption tower to control the mist drop content in the purified tail gas. Employment of the Claus sulfur recovery and ammonia process desulfurization integrated desulfurization technology in the coal chemical industry can reduce the investment cost of after-treatment, the process can be simpler, and factory environmental protection treatment can form an intensive advantage.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Nontoxic, odorless and recoverable environmentally-friendly polyurethane foaming material and preparation method thereof

ActiveCN102229709ANo chemical reactions involvedHuge energy savingCoatingsEnvironmental resistanceHuman health

The invention discloses a nontoxic, odorless and recoverable environmentally-friendly polyurethane foaming material and a preparation method thereof. The foaming material is characterized in that a raw material of polyurethane is adopted and is directly subjected to a physical gas foaming in the presence of a physical gas foaming agent to prepare the foaming material. The foaming material has a foaming density of 0.08-0.80 g / cm<3>, a foaming ratio of 1.5-15 times, a average pore diameter of 10-100 [mu]m, uniform distribution of cells, wherein diameter deviations of 95% of the cells do not exceed 10% of the average pore diameter. In addition, the foaming material has no surface structure and can be the foaming material with any shape. The foaming material has an adjustable softness and hardness and excellent performance, and can be widely applicable for the fields of packaging, human protector, shoe product, automobile inner garnish, amortization cushion, building energy conservation, acoustic insulating material and the like. According to the present invention, the following problems that: harmful gas is discharged during the production process of the polyurethane foaming material, and monomer residues are harmful to human health and cause environmental pollution, are thoroughly solved from the source, such that a practicable development approach is provided for green environmental protection, energy saving and emission reduction of the foaming material.

Owner:浙江博发新材料股份有限公司

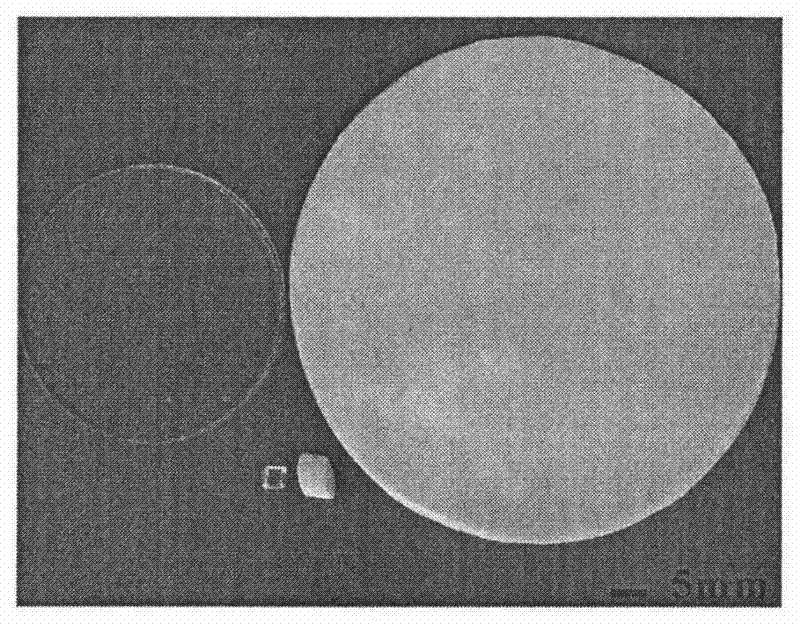

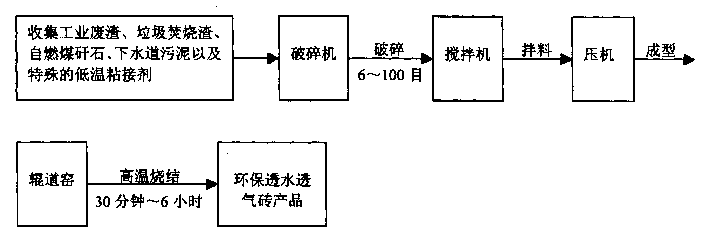

Fast baking process of environment protecting water and air permeable brick in roller kiln

InactiveCN1436750AReduce the temperatureStable water tableSolid waste managementSolid waste disposalEnvironmental resistanceCooking & baking

Owner:广东唯美新技术实业有限公司

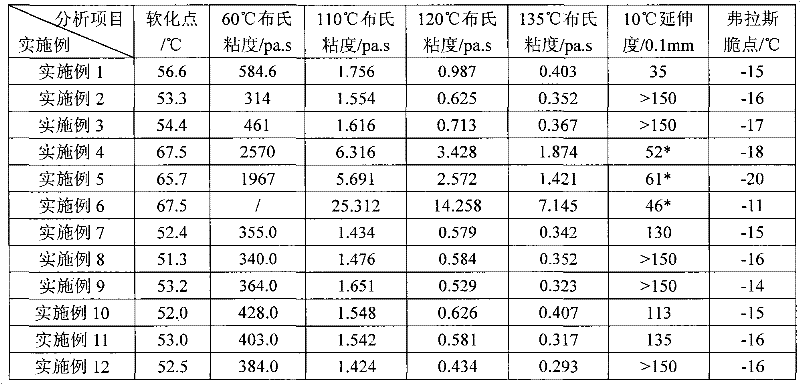

Warm mixed asphalt cement and preparation method thereof

ActiveCN102532920AWith viscosity reducing effectHas a lubricating effectIn situ pavingsClimate change adaptationEnvironmental resistanceChemical industry

Owner:PETROCHINA CO LTD +1

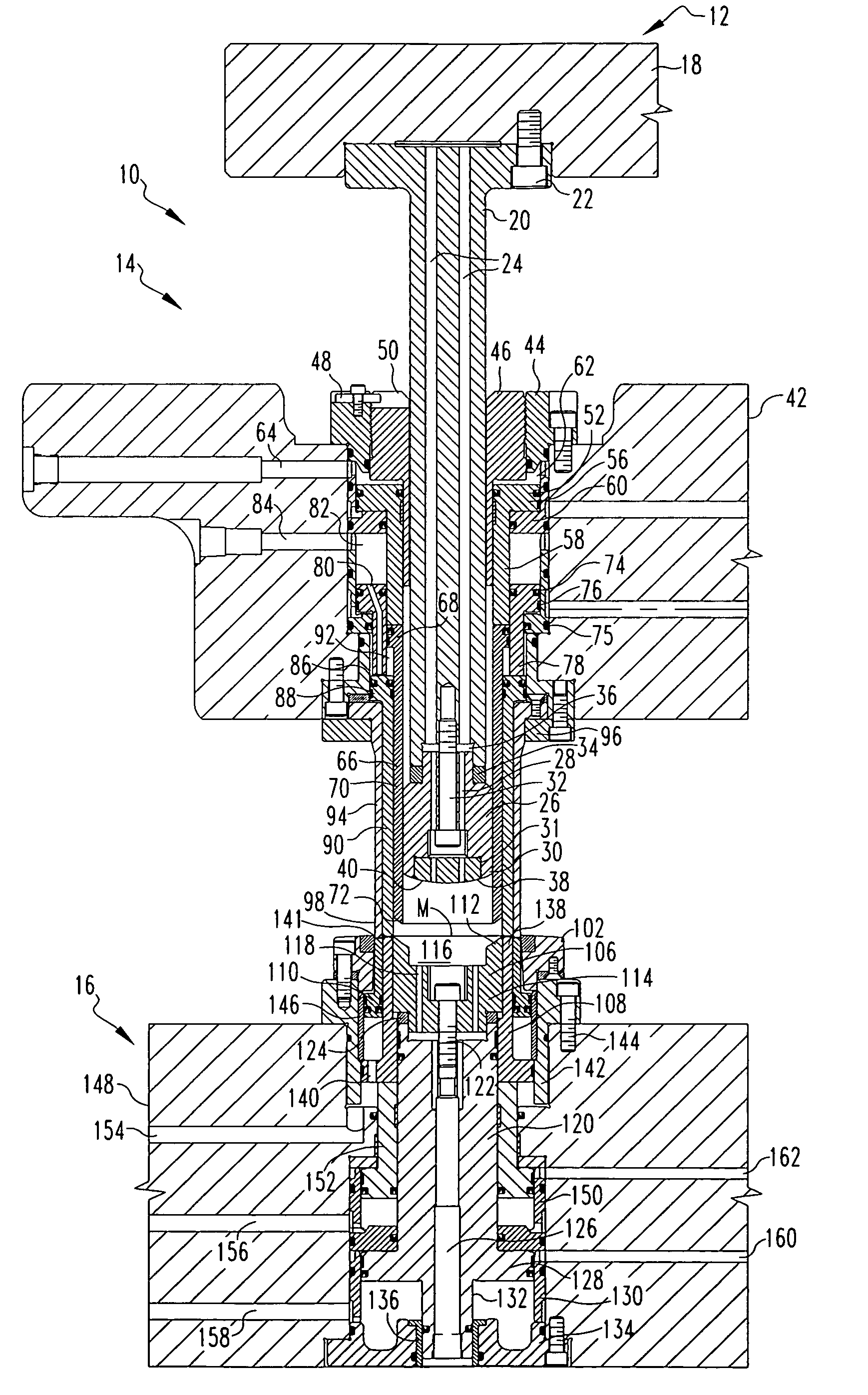

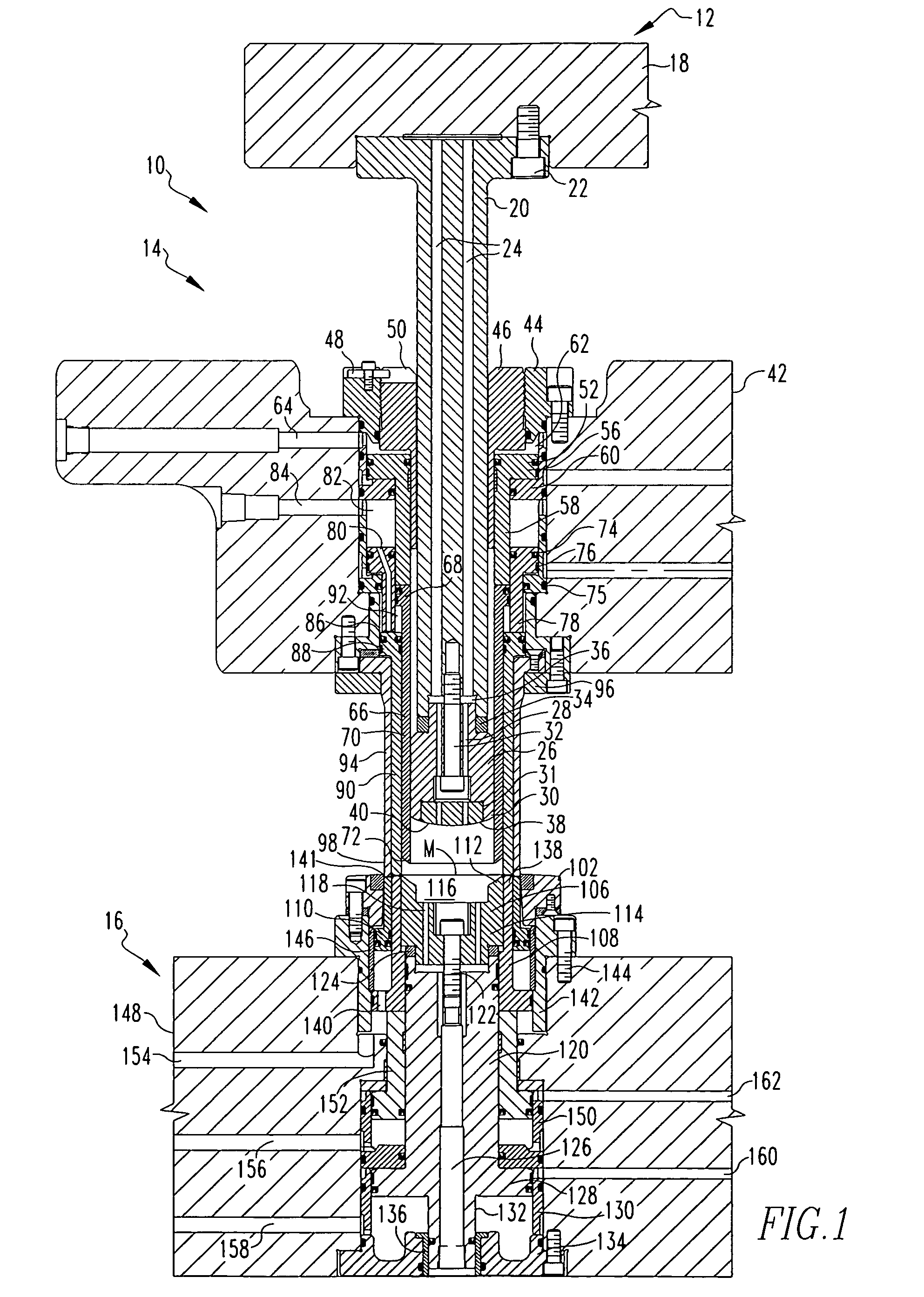

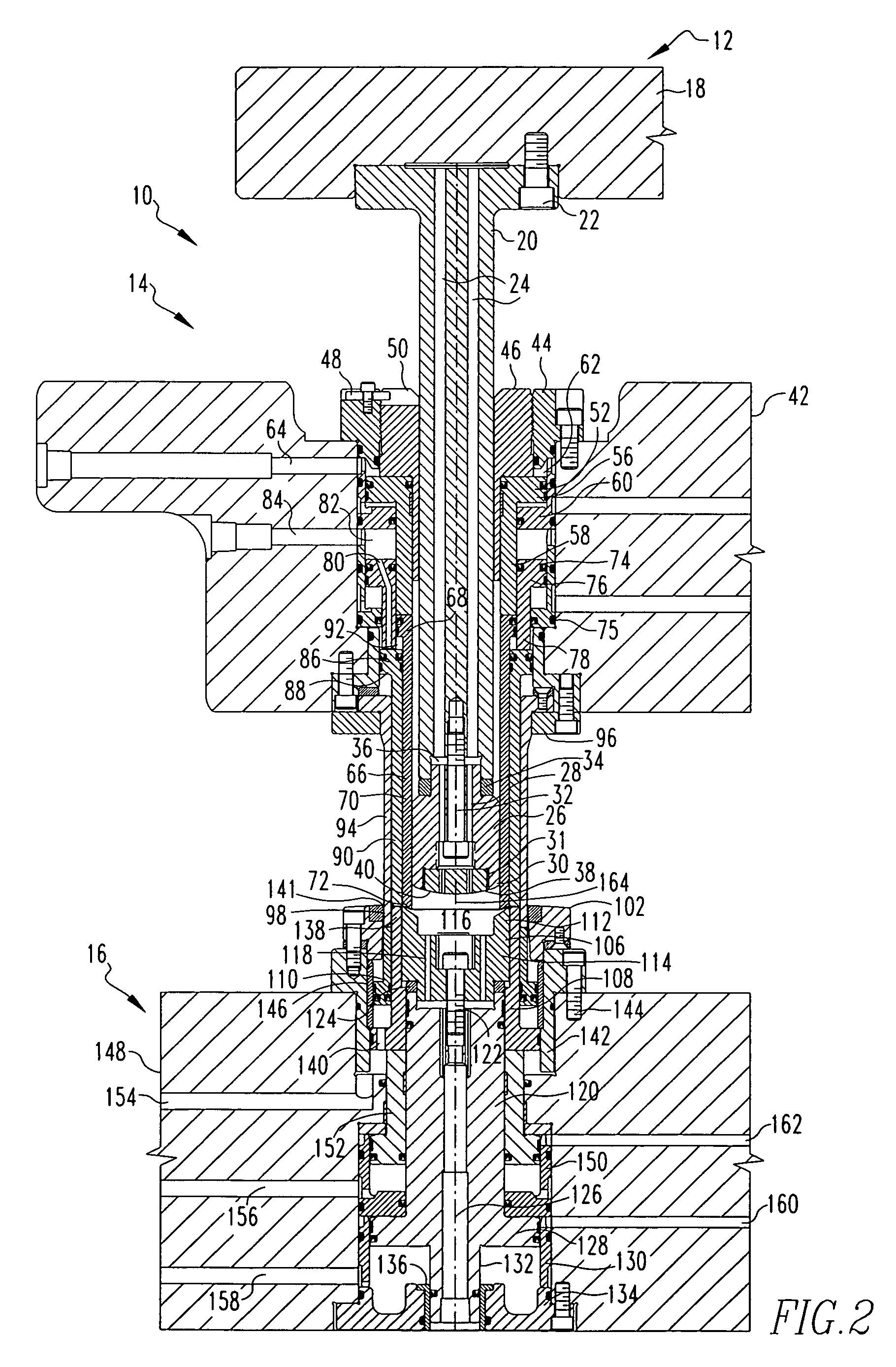

Press and method of manufacturing a can end

An apparatus and method for forming a can end having an annular ridge and a central panel and a can body with a can bottom is provided that exhibits reduced wrinkling in the material used to form the can end and can body. The method of the invention uses a two step doming process wherein material is first drawn or stretched and then held by a punch core ring and then further drawn, stretched or domed and then held by a punch core. The apparatus and method of the invention also include a lower piston located above an upper pressure sleeve and radially outward from a punch core ring wherein the lower piston has a bore and the lower piston, punch core ring and upper pressure sleeve define a gap to which pressurized gas may be supplied through the bore to selectively axially actuate the punch core ring.

Owner:STOLLE MACHINERY

Nano-composite environment-friendly water permeable brick and production method thereof

InactiveCN103290753AGuaranteed compression performanceGood water permeabilitySingle unit pavingsCeramic shaping apparatusEnvironmental resistanceBrick

The invention discloses a nano-composite environment-friendly water permeable brick and a production method thereof. The nano-composite environment-friendly water permeable brick comprises a concrete bottom layer and a mortar surface layer arranged on the concrete bottom layer, wherein the concrete bottom layer and the mortar surface layer are compounded to form an integrated structure; the concrete bottom layer is prepared from the following raw materials in parts by weight: 20-40 parts of cement, 10-20 parts of water, 5-15 parts of fly ash, 50-65 parts of recycled aggregate, 50-65 parts of natural coarse aggregate, 65-85 parts of sand and 0.05-0.2 part of water-reducing agent; and the mortar surface layer is prepared from the following raw materials in parts by weight: 70-100 parts of cement, 5-20 parts of nano-TiO2, 30-60 parts of water, 200-400 parts of sand and 0.1-1.0 part of water-reducing agent. The nano-composite environment-friendly water permeable brick disclosed by the invention is integrally formed and has the advantages of high compressive strength, high flexural strength, good water permeability and good water retention, and a ground surface laid by the nano-composite environment-friendly water permeable bricks can timely dredge and drain rainwater, is conductive to growth of surrounding vegetation and can effectively supplement groundwater, reduce the pressure of a municipal drainage system and reduce the influence of surface gathered water on the traffic; and the nano-composite environment-friendly water permeable brick has a photocatalytic self-cleaning function and can decompose and remove organic stains on the surface of the brick and beautify the urban environment.

Owner:CHINA STATE CONSTR HAILONG TECH CO LTD

Waterborne epoxy modified emulsified asphalt concrete for steel bridge surface and preparation method thereof

ActiveCN102173663AReduce energy consumptionSolve the problem of energy consumptionEnvironmental resistanceEpoxy

The invention provides a waterborne epoxy modified emulsified asphalt concrete for a steel bridge surface and a preparation method thereof. The waterborne epoxy modified emulsified asphalt concrete for the steel bridge surface is prepared by the following steps of: adding waterborne epoxy resin, a curing agent, and a stabilizing agent into modified emulsified asphalt, continuously stirring until the mixture is uniform, and shearing to obtain waterborne epoxy resin modified emulsified asphalt emulsion; and stirring coarse aggregate and fine aggregate in a container, adding the waterborne epoxyresin modified emulsified asphalt and then stirring, adding a filler and then mixing and stirring, and adding cement and stirring to obtain the waterborne epoxy modified emulsified asphalt concrete. A paving material prepared by the method has the characteristics of environment-friendliness, low volatile organic compound (VOC), low energy consumption, high bonding strength with a steel plate, high cryogenic stabilization, excellent water stability performance, high tenacity, and high fatigue resistance performance.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com