Patents

Literature

339 results about "Single injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

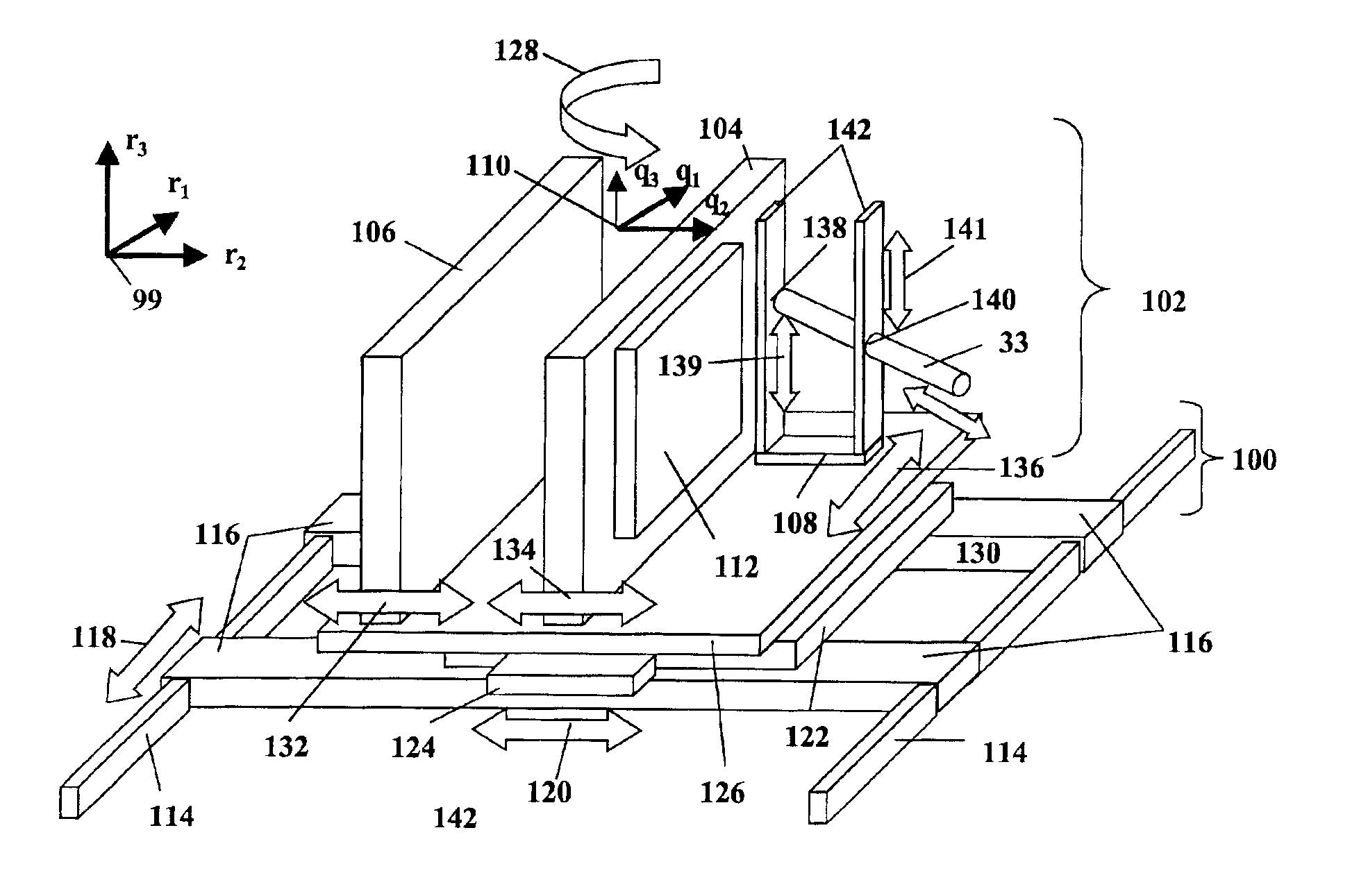

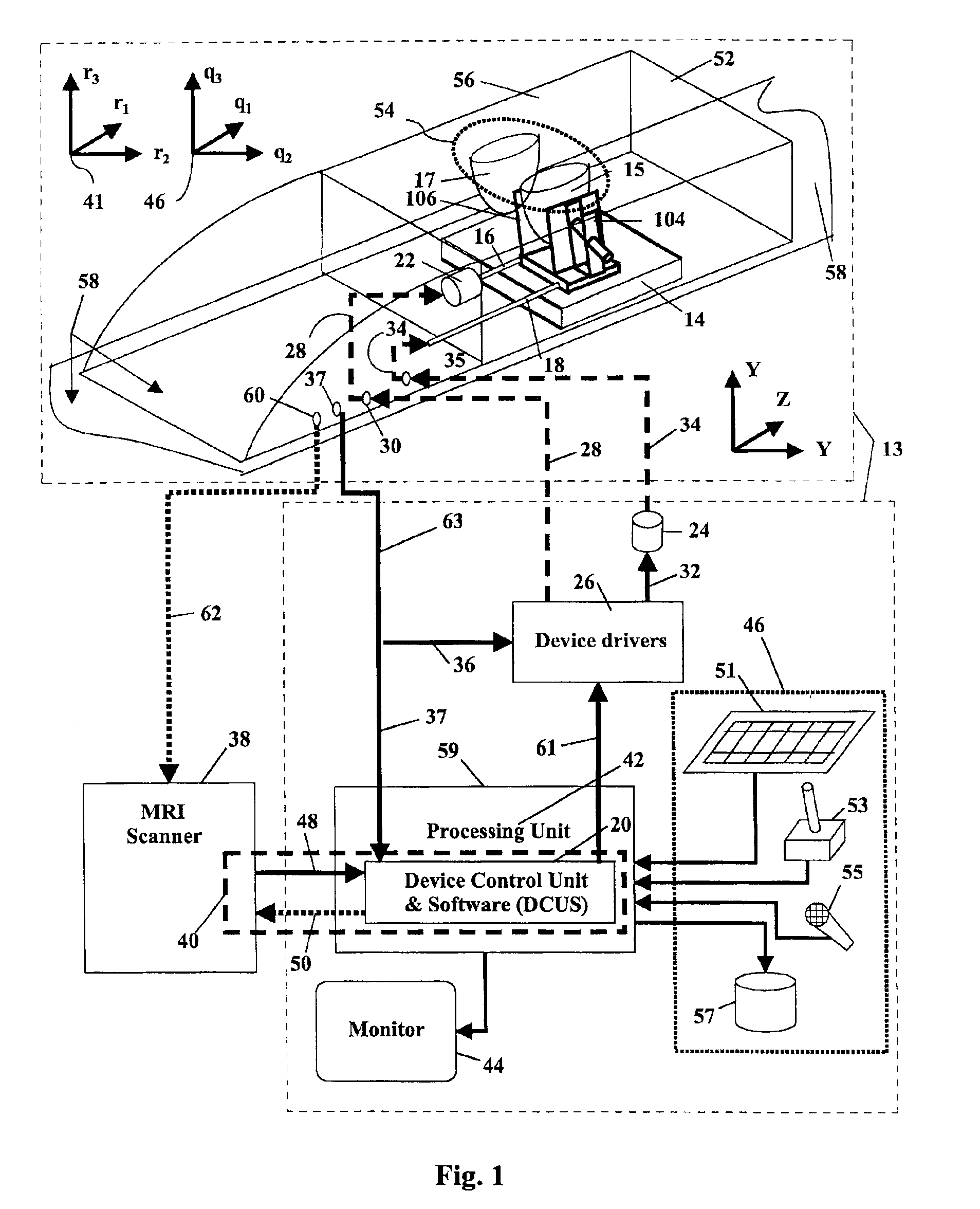

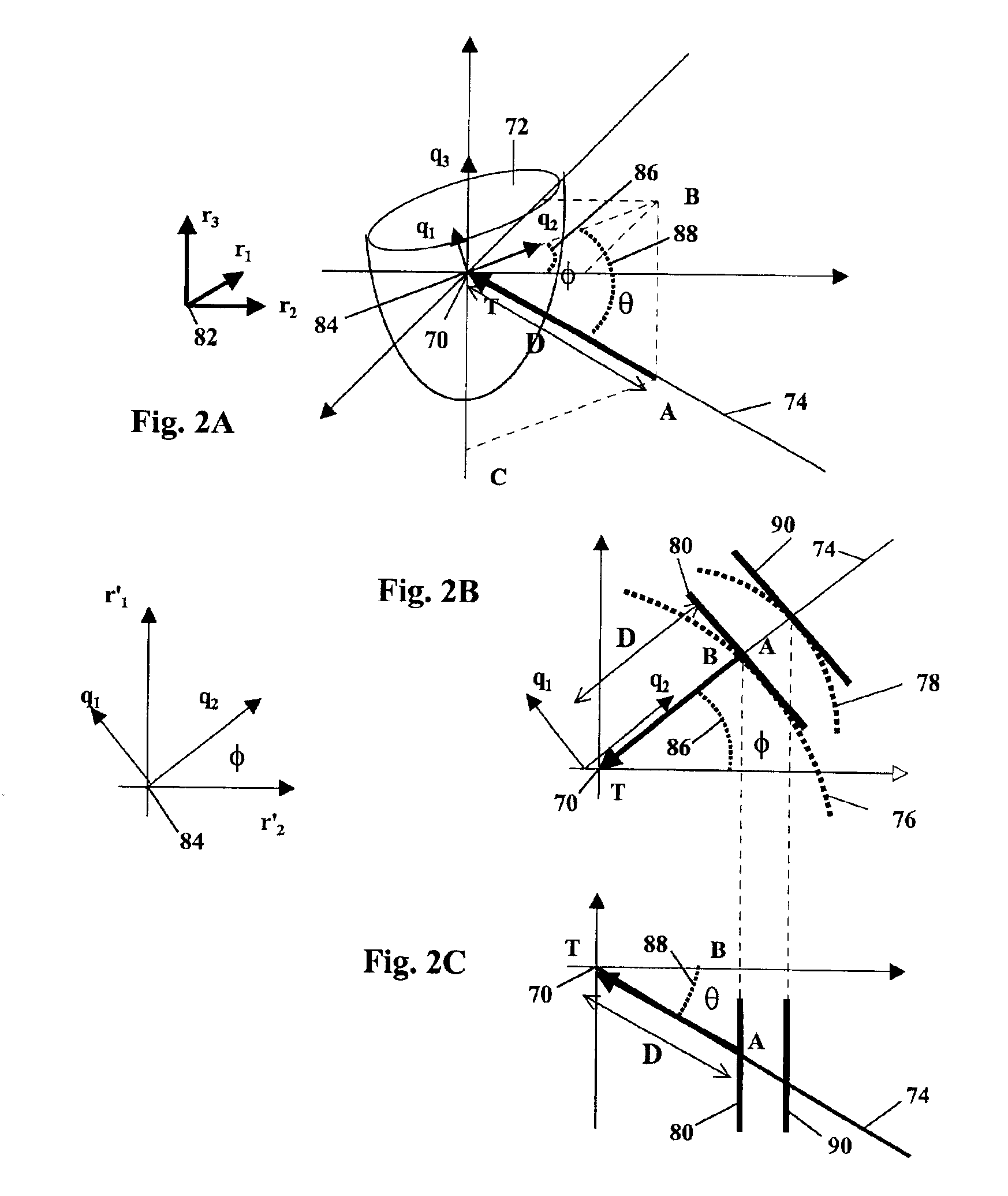

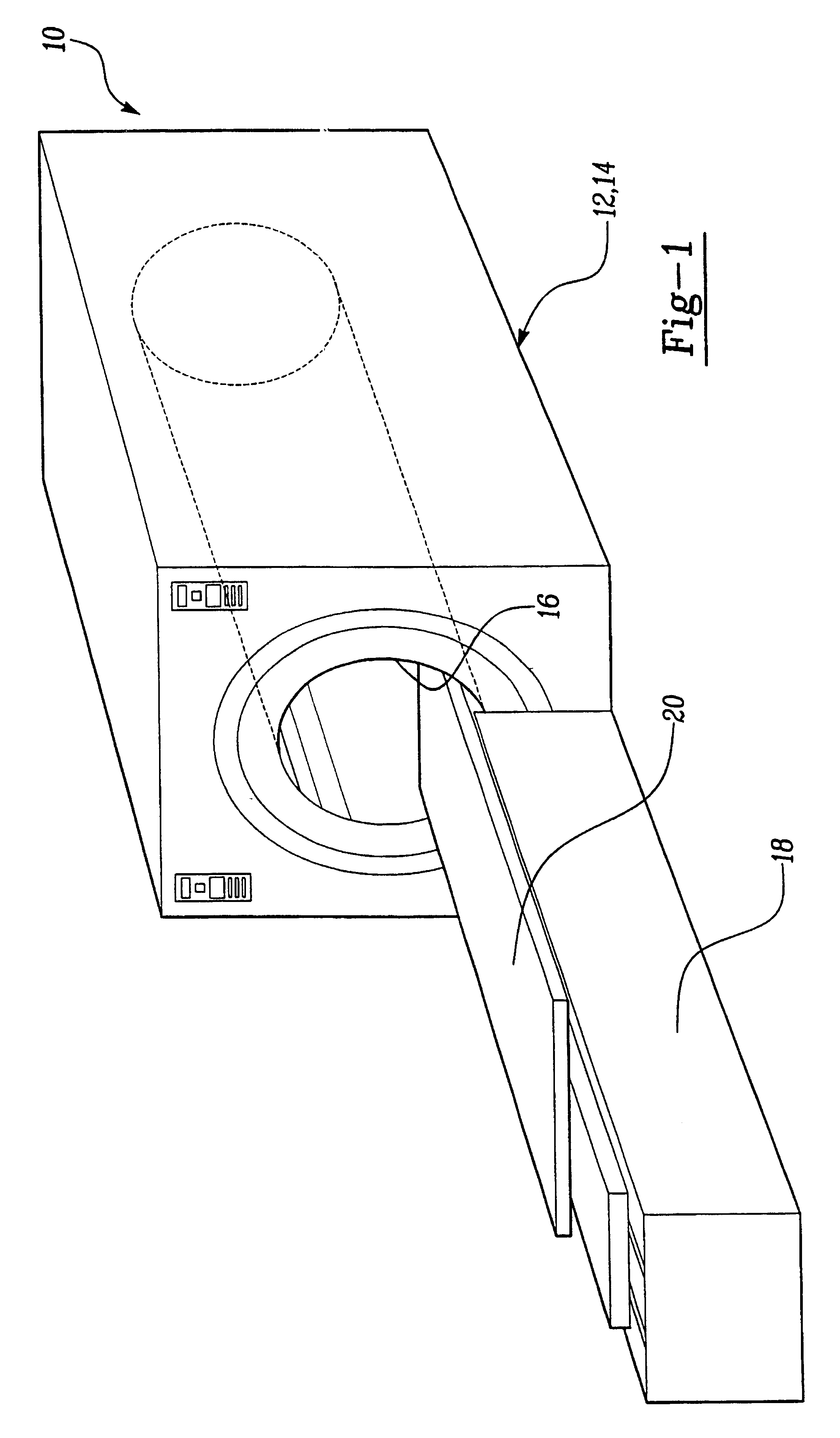

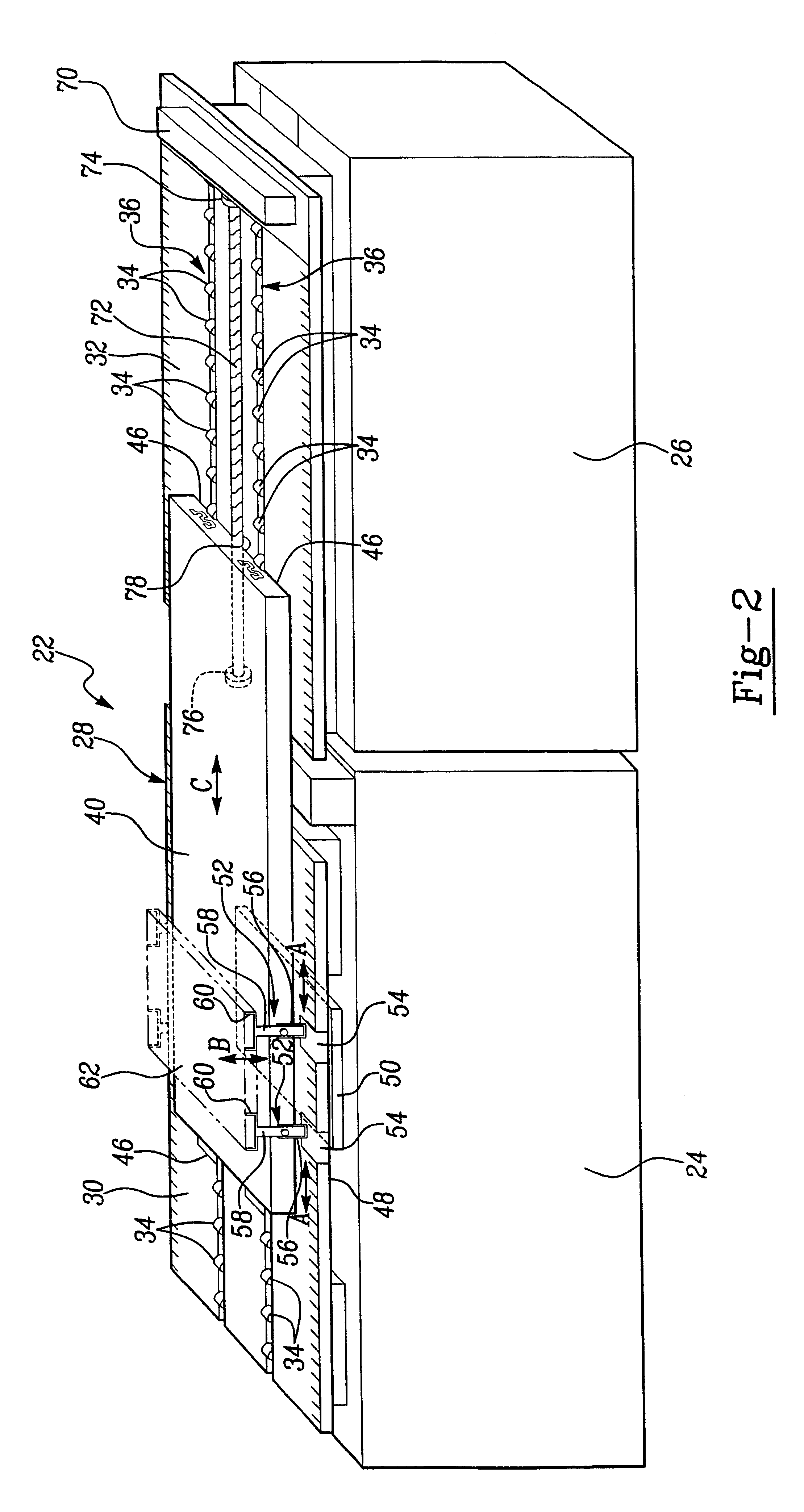

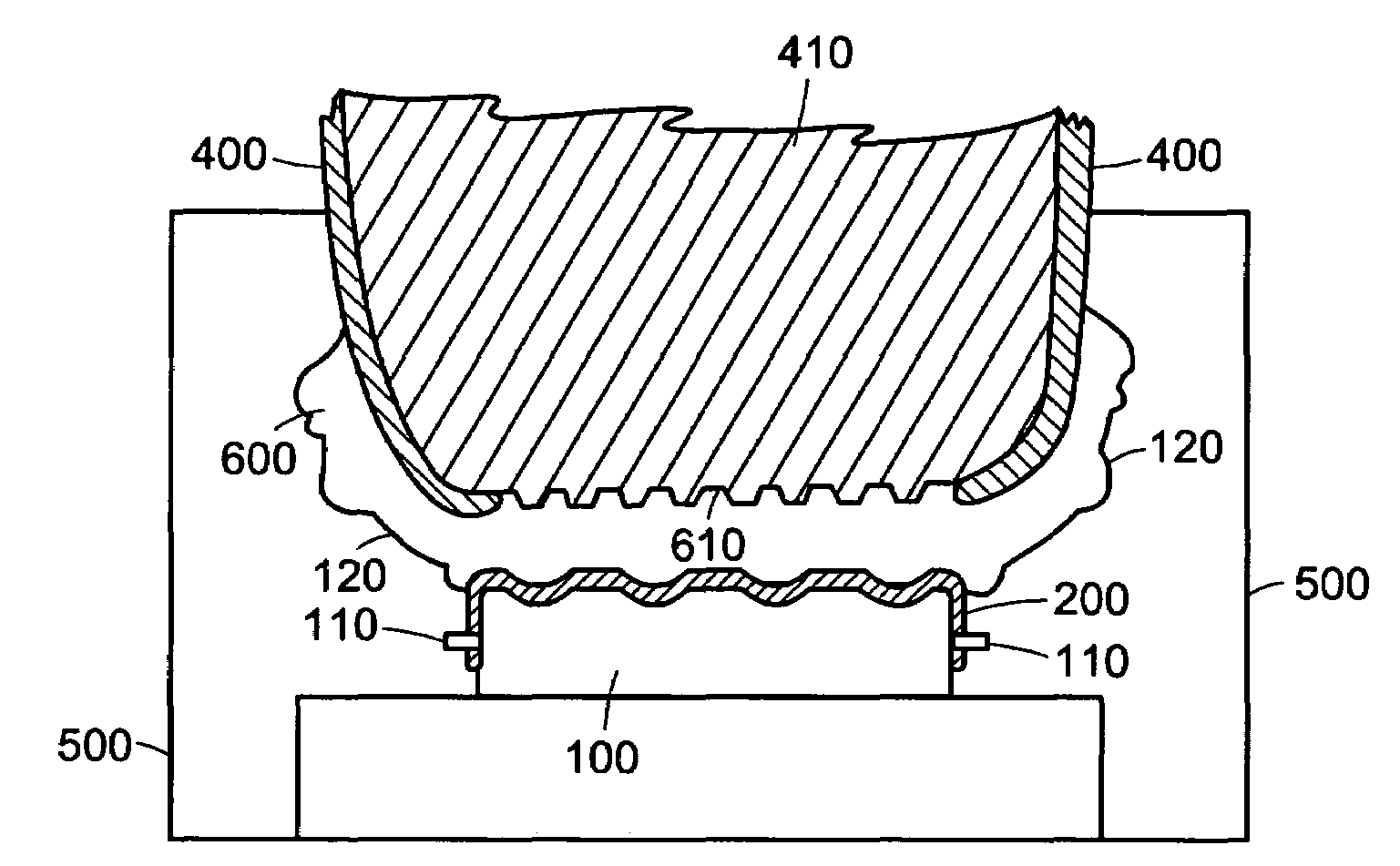

System for MRI-guided interventional mammary procedures

InactiveUS6904305B2Enhanced magnetic resonance imagingProvide flexibilitySurgical needlesVaccination/ovulation diagnosticsContrast-enhanced Magnetic Resonance ImagingSingle injection

The combination of contrast enhanced magnetic resonance imaging (MRI) and MR-guided subcutaneous core biopsy can be used as a robust approach for the diagnosis and treatment of breast cancer. MRI provides the means to accurately position and monitor interventional procedures such as biopsy, removal of tissue or other transcanular procedures. MRI may also be used in this invention to position and monitor the progress of breast conserving therapies (BCT), such as laser photo-ablation, cryoablation and localized hyperthermia. The general practice of this invention is to provide a remotely controlled apparatus for MR-guided interventional procedures in the breast. The apparatus allows the practice of a method that provides flexibility in conditioning the breast, i.e. orientation and degree of compression, and in setting the trajectory of the intervention. To that end, a robust conditioning / positioning device, fitted with the appropriate degrees of freedom, enhances the efficacy and efficiency of breast interventions by providing the flexibility in planning and executing an appropriate procedure strategy that better suits interventional procedures, either those in current use or yet to be developed. The novelty and potential commercial success of the device originates from its high maneuverability to set and perform the procedure strategy and its adaptability to accommodate an array of interventional probes. Remote control of this device can allow planning the operation and performing the relevant tasks in a short period, for example, within the contrast window provided by a single injection of a contrast agent, and this feature can be operator-independent.

Owner:RGT UNIV OF MINNESOTA

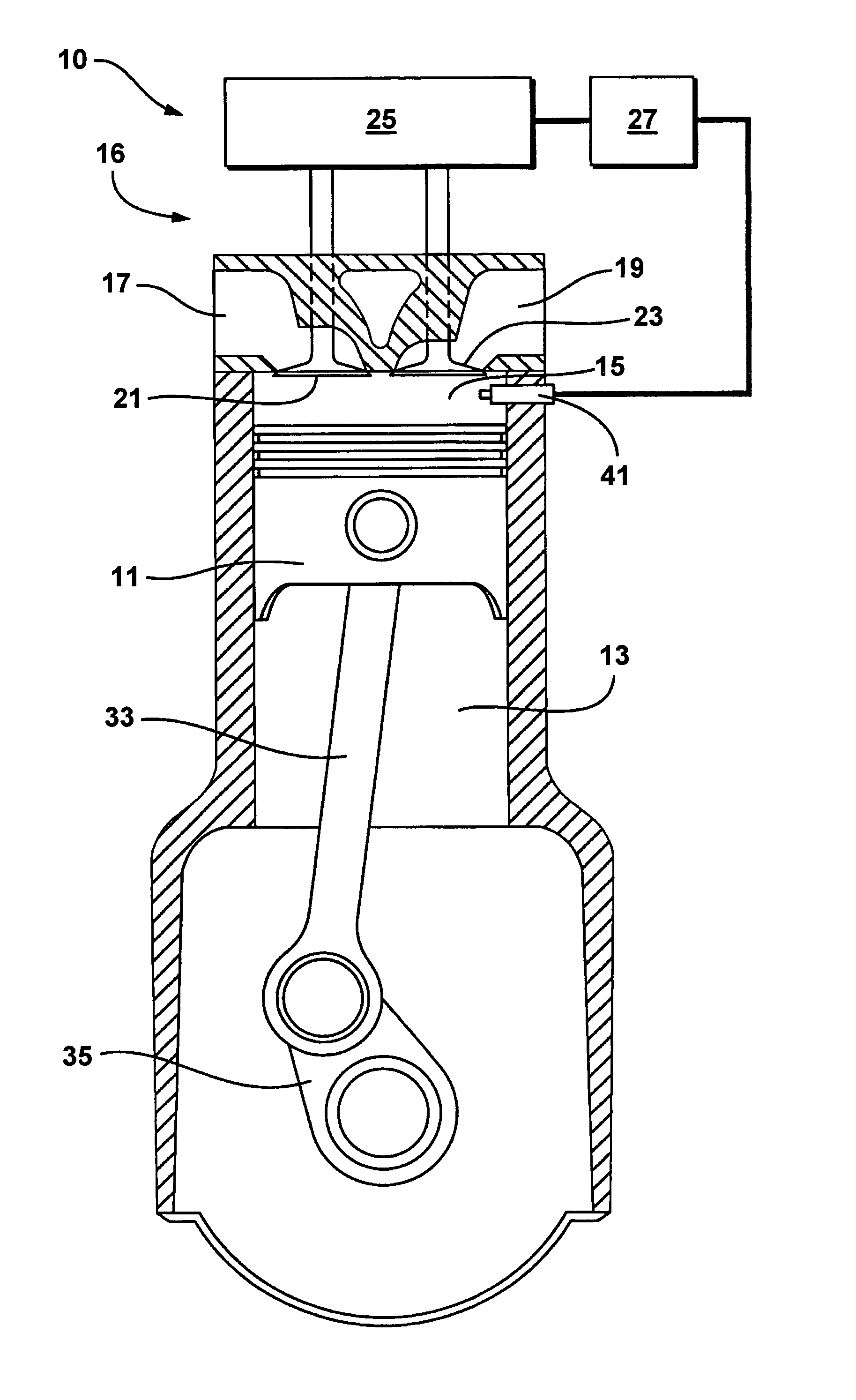

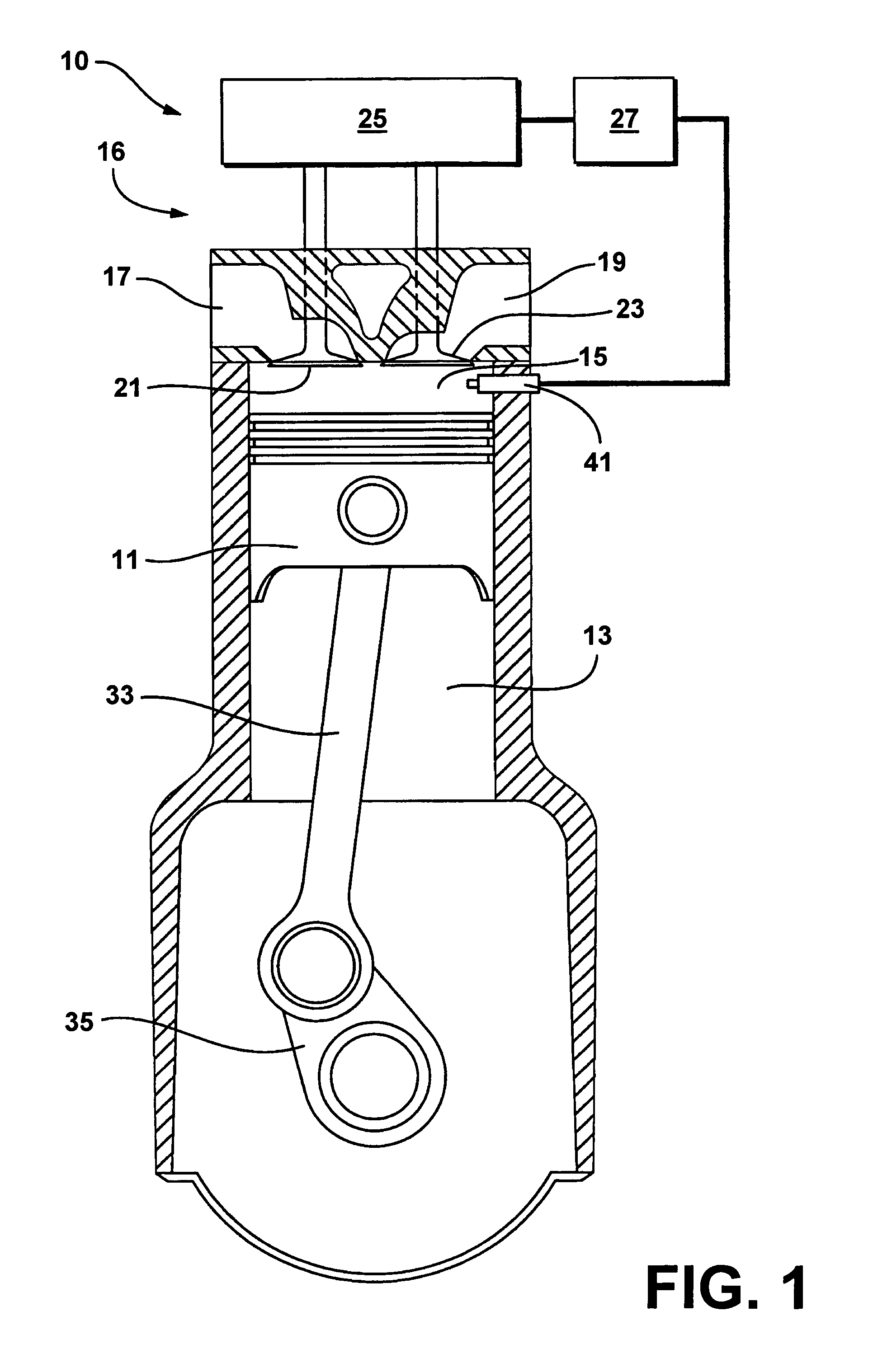

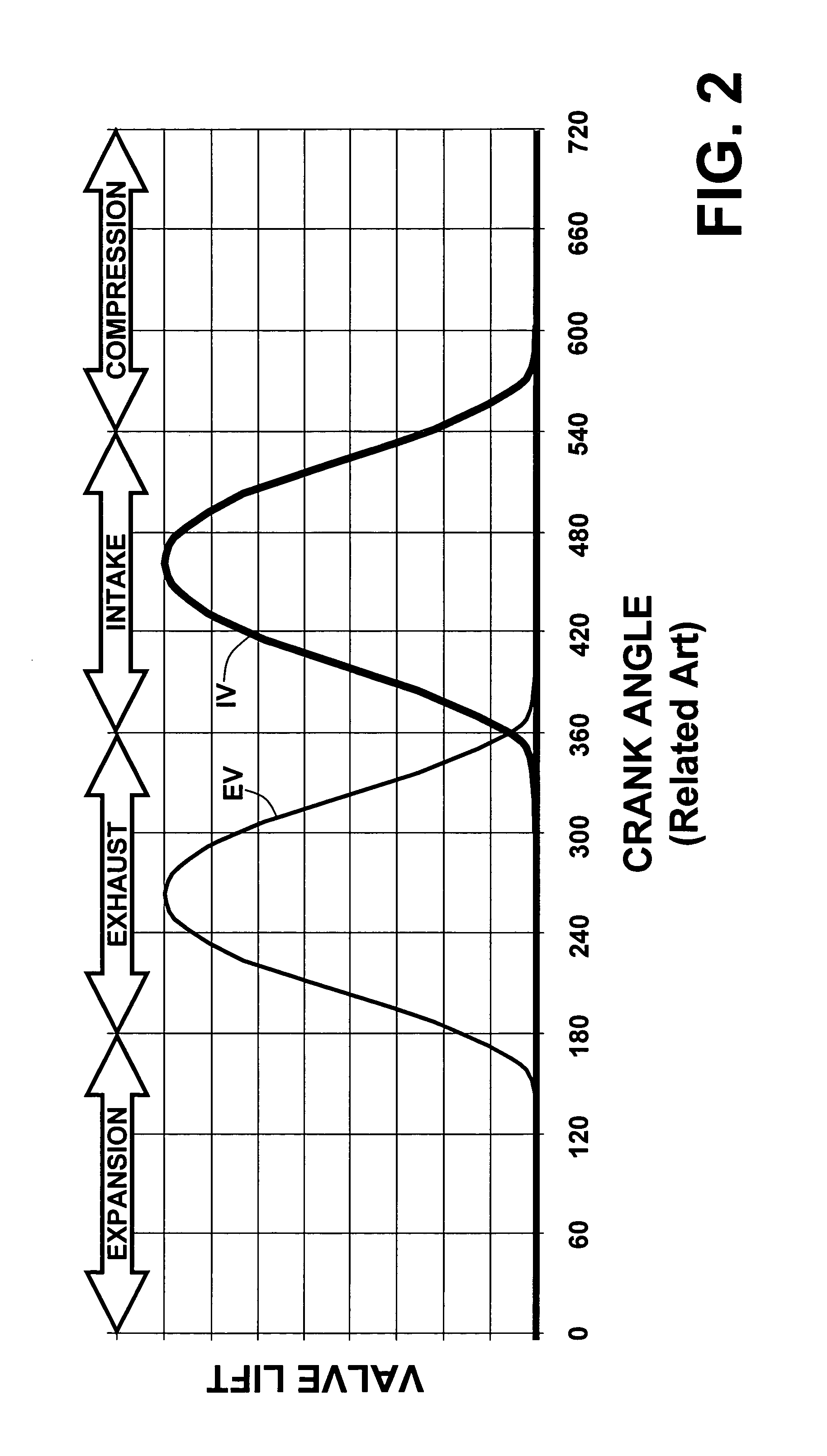

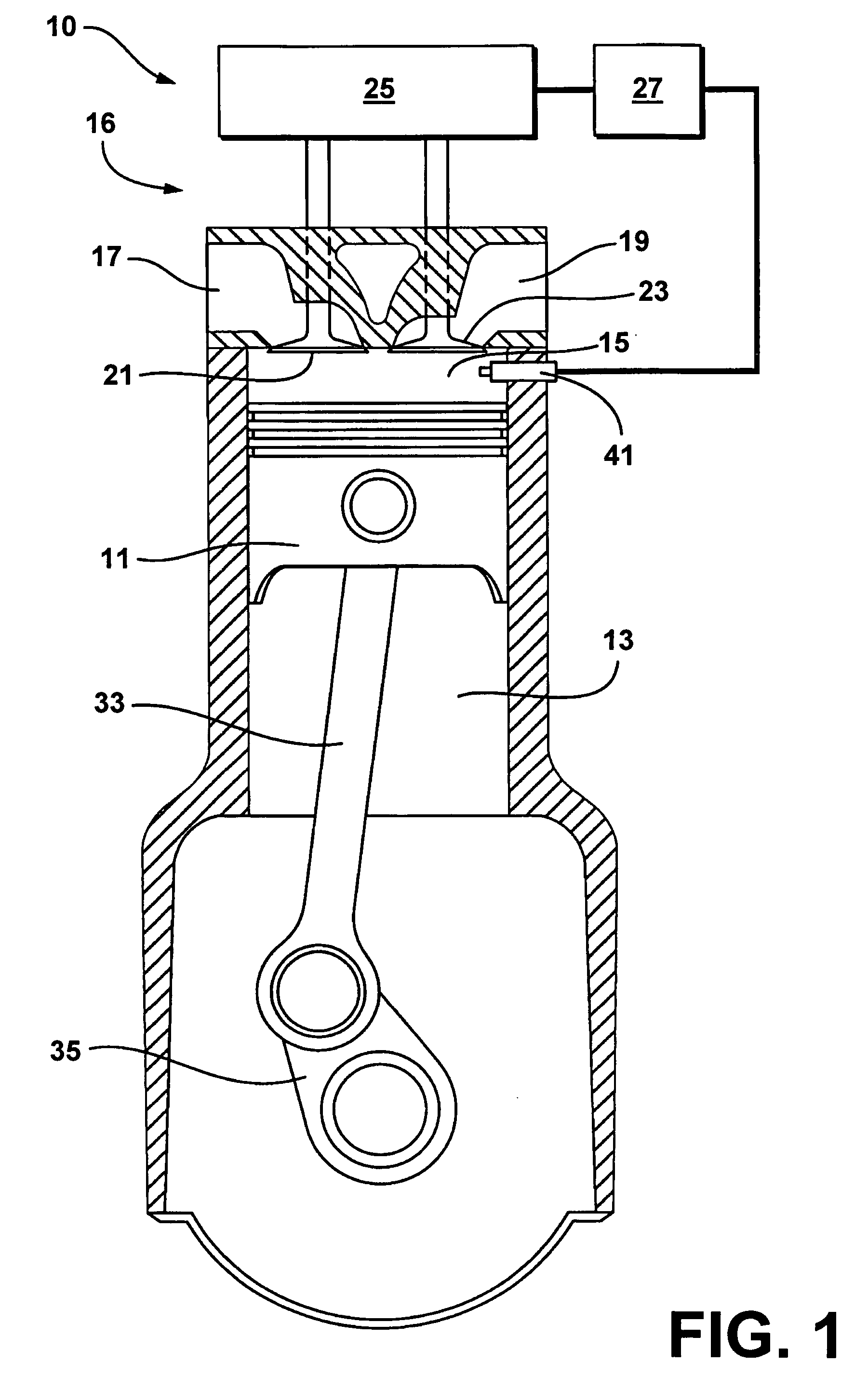

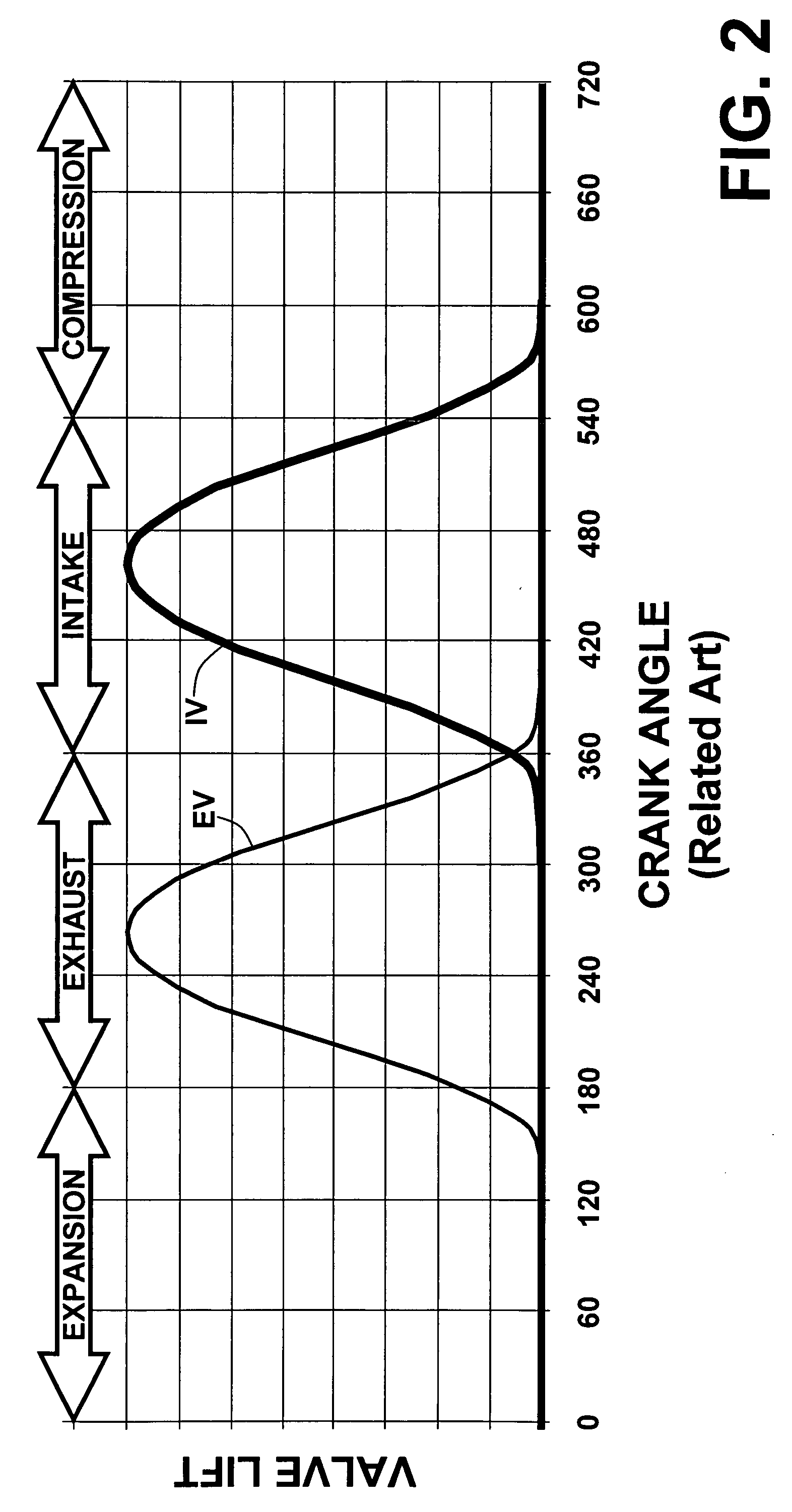

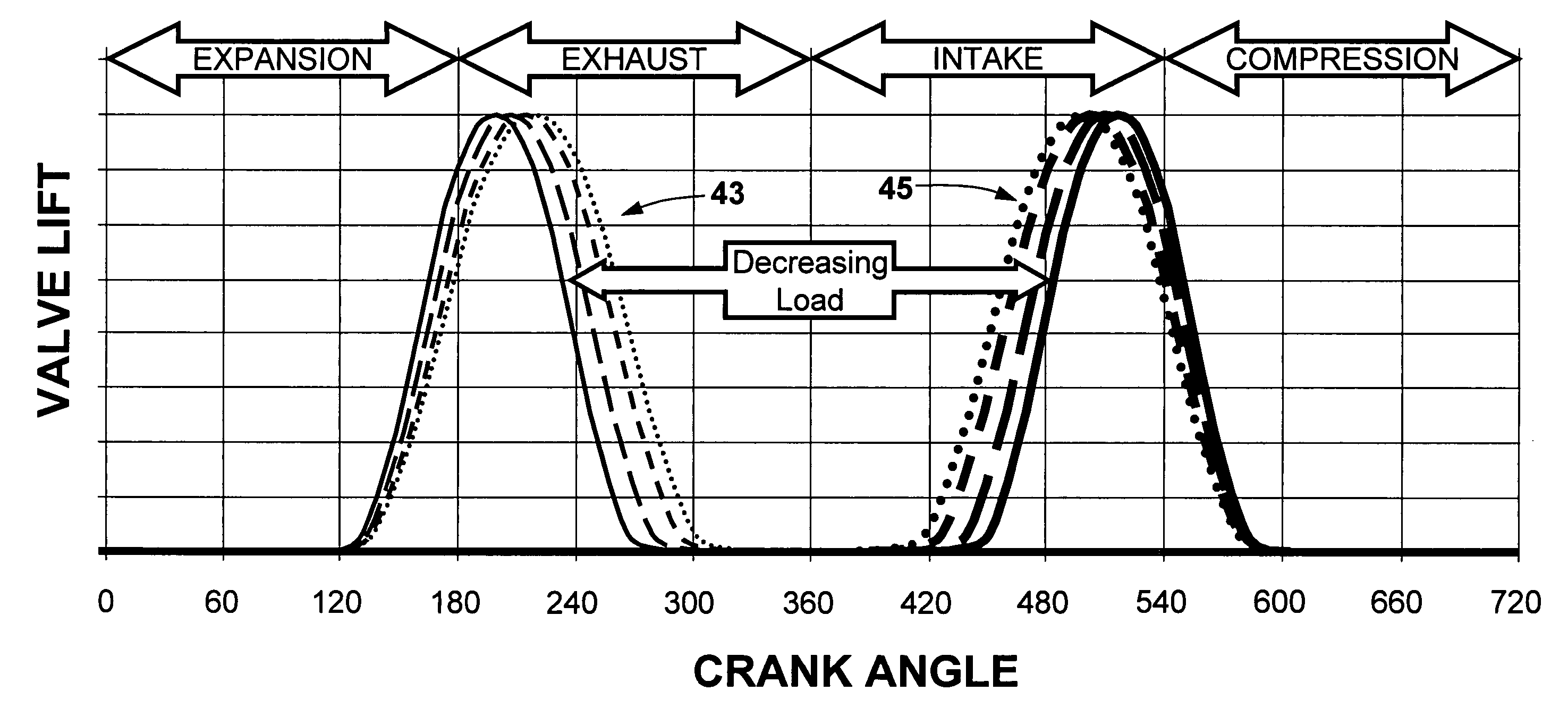

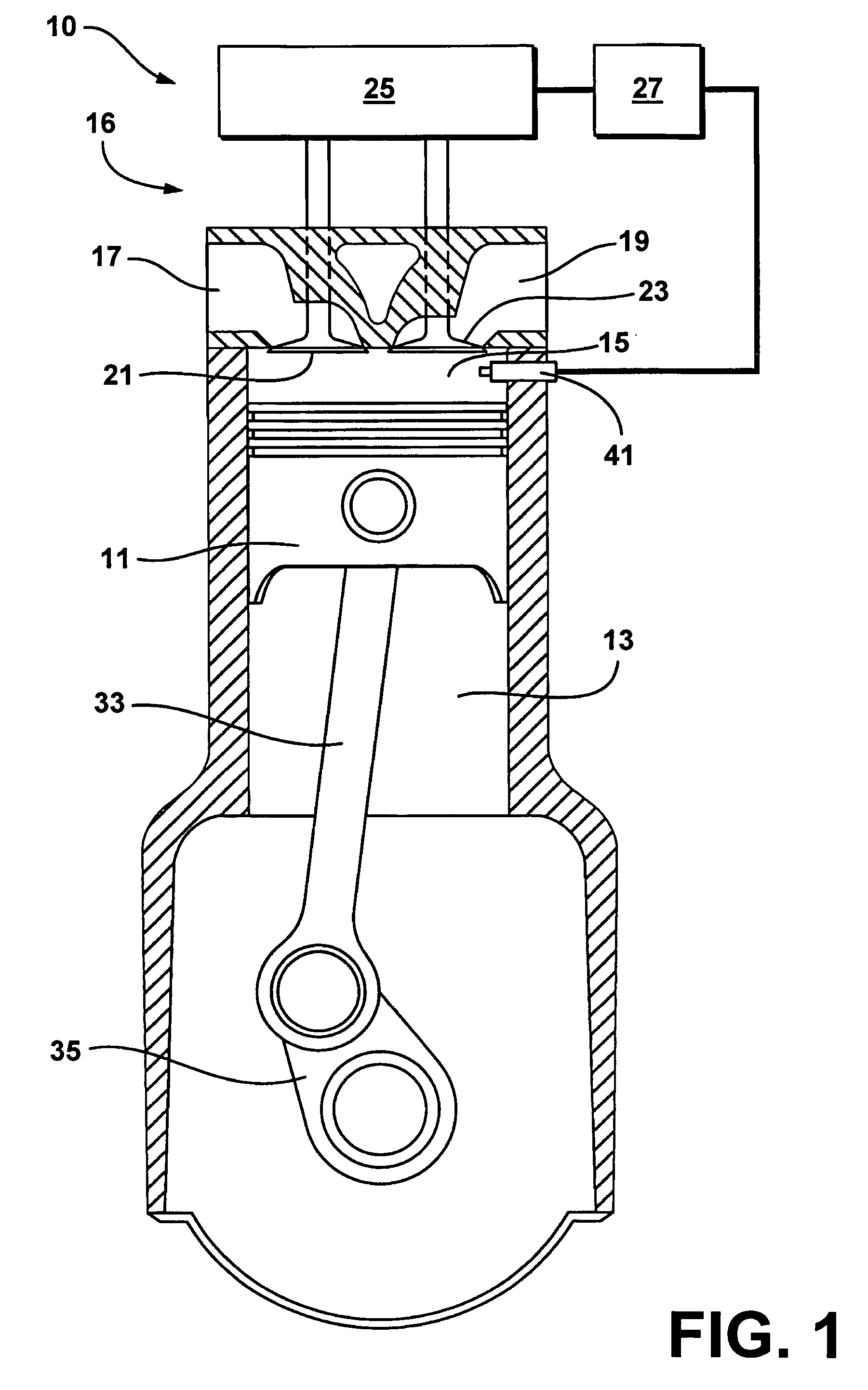

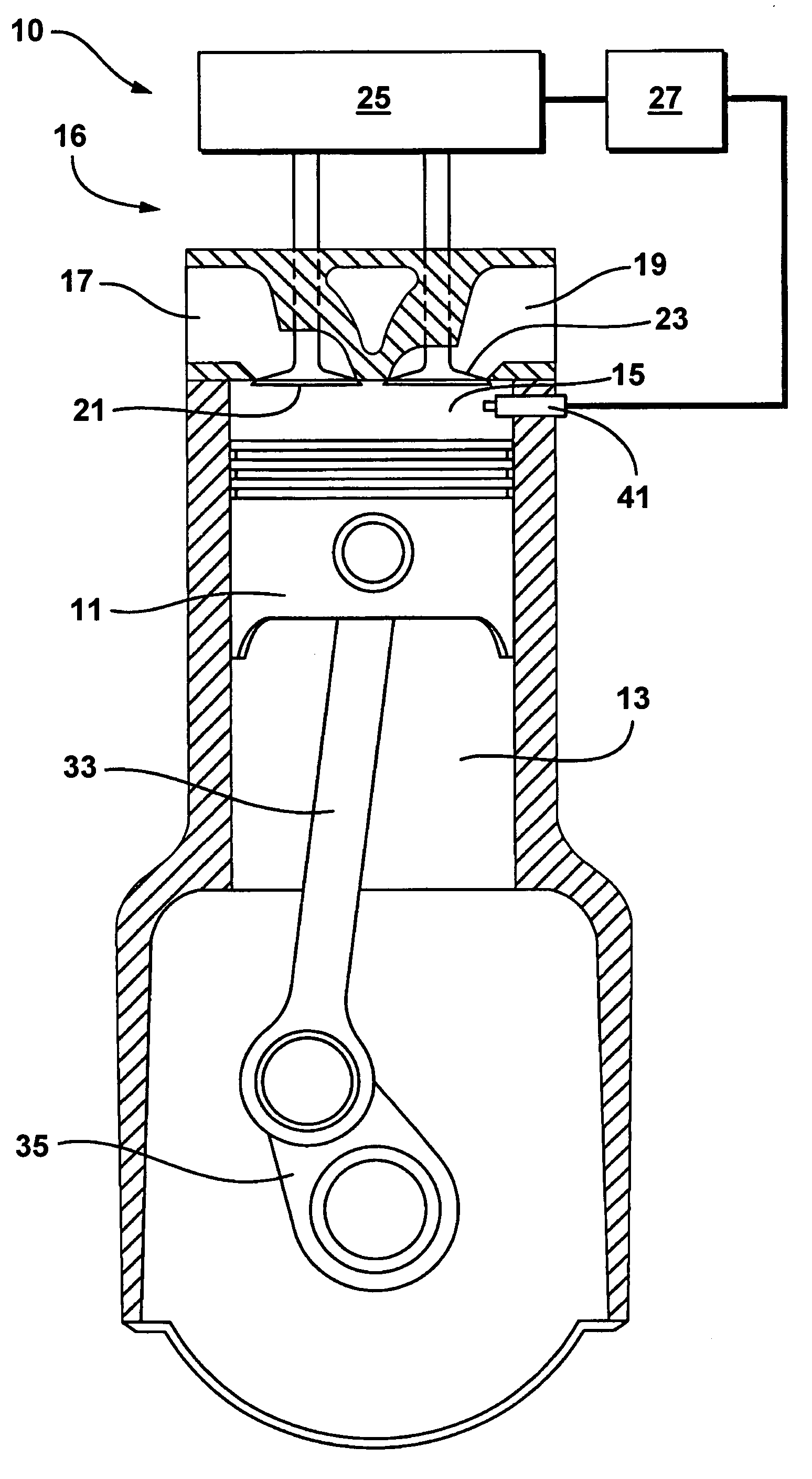

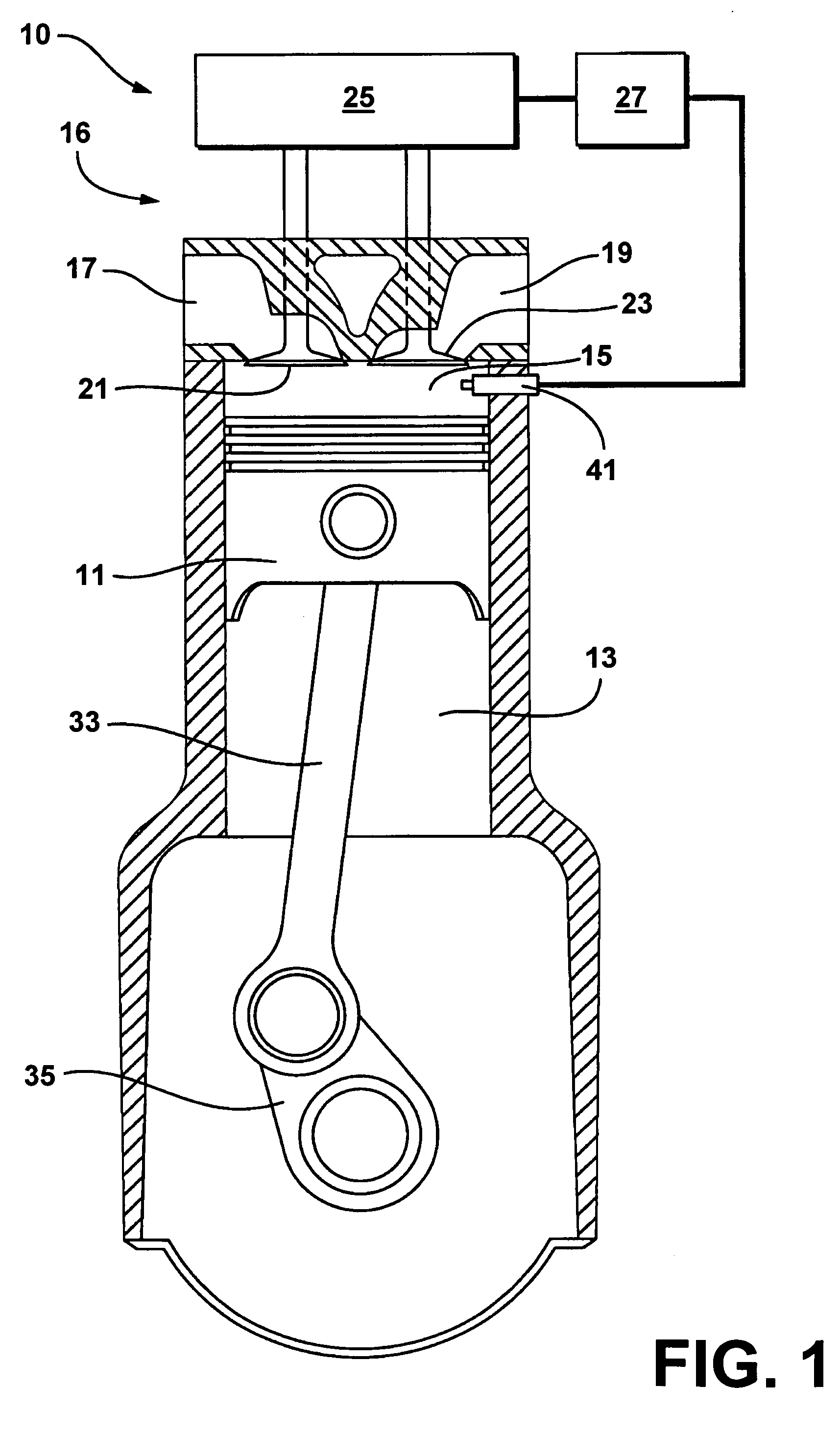

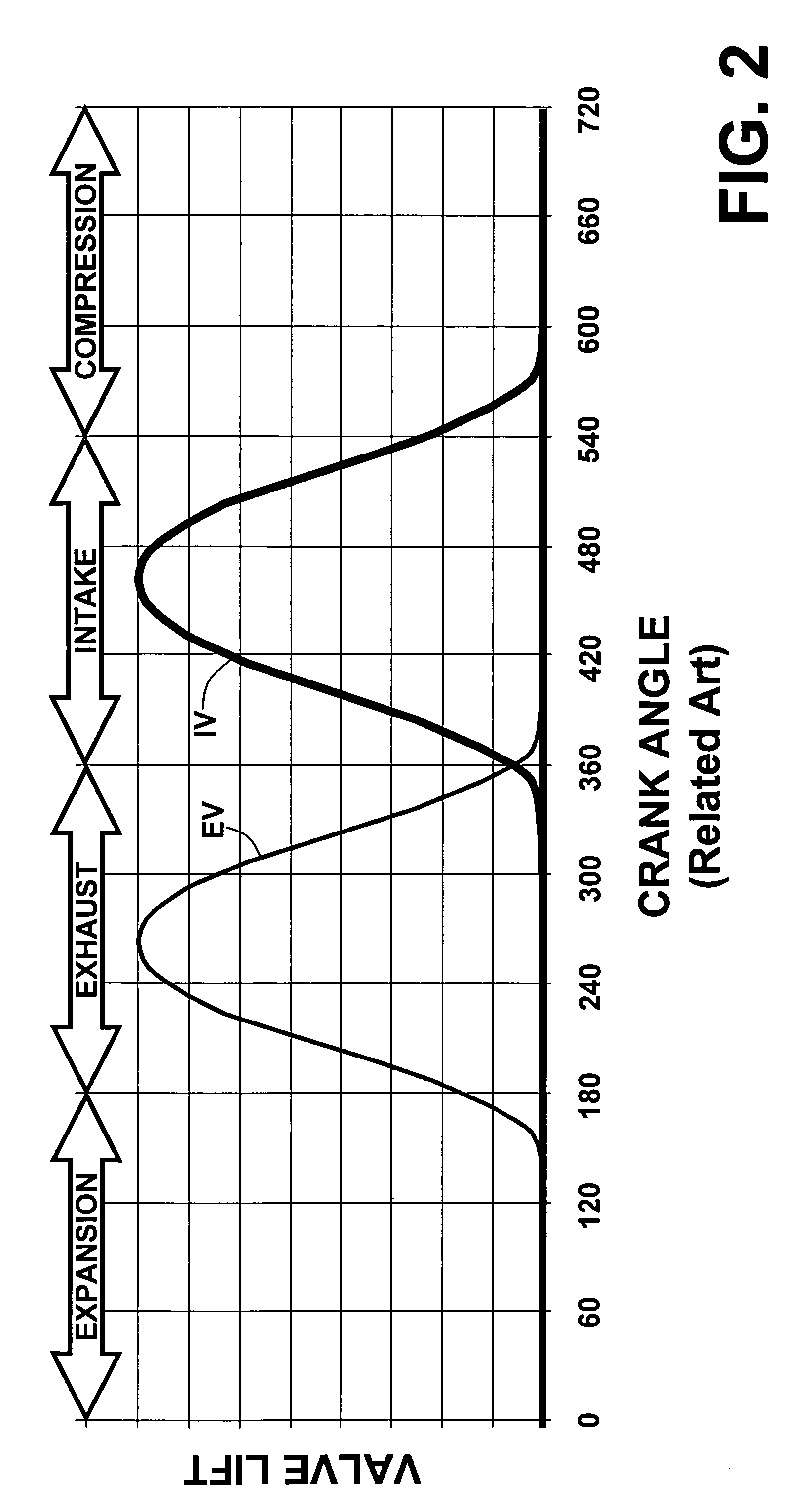

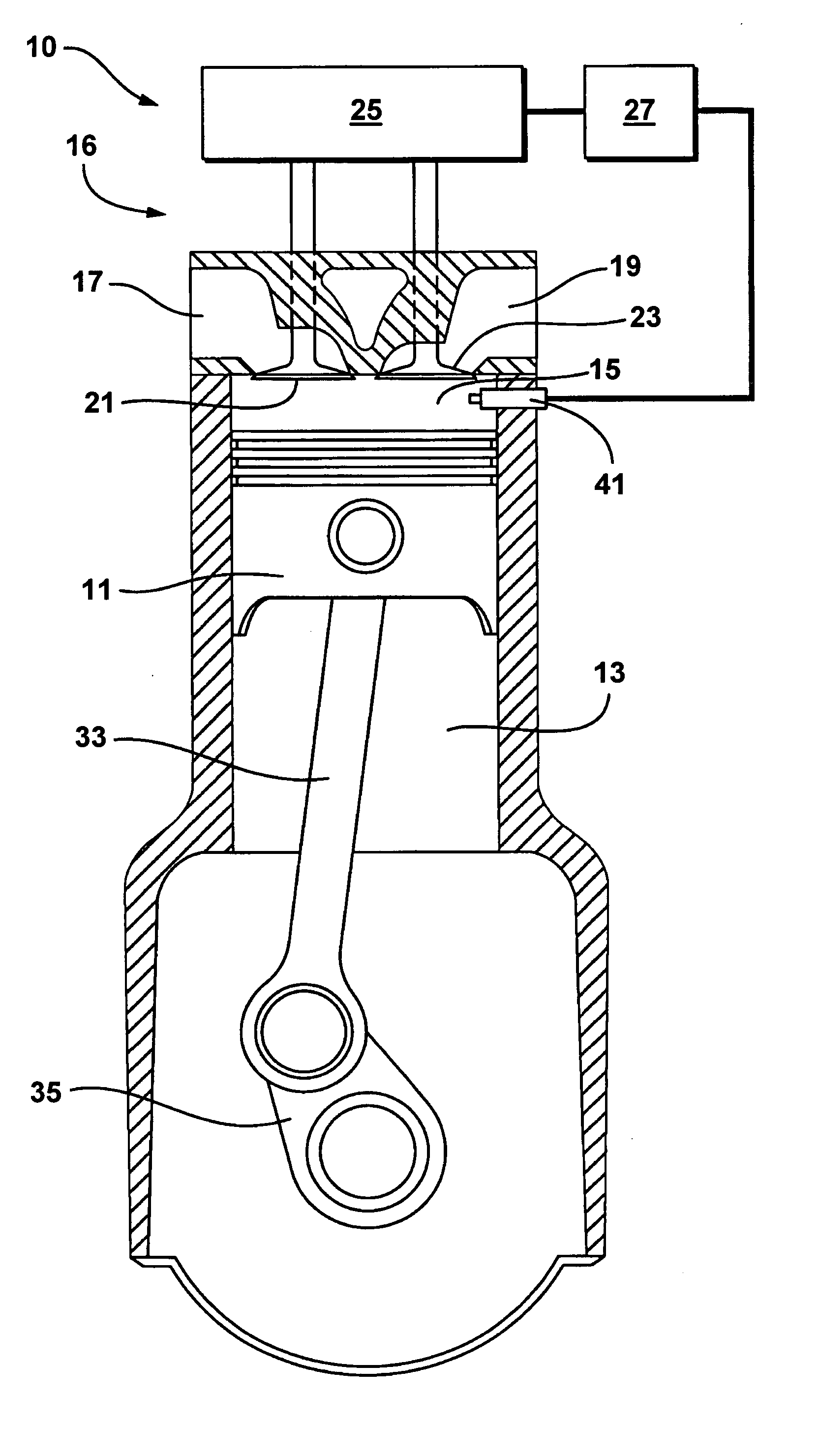

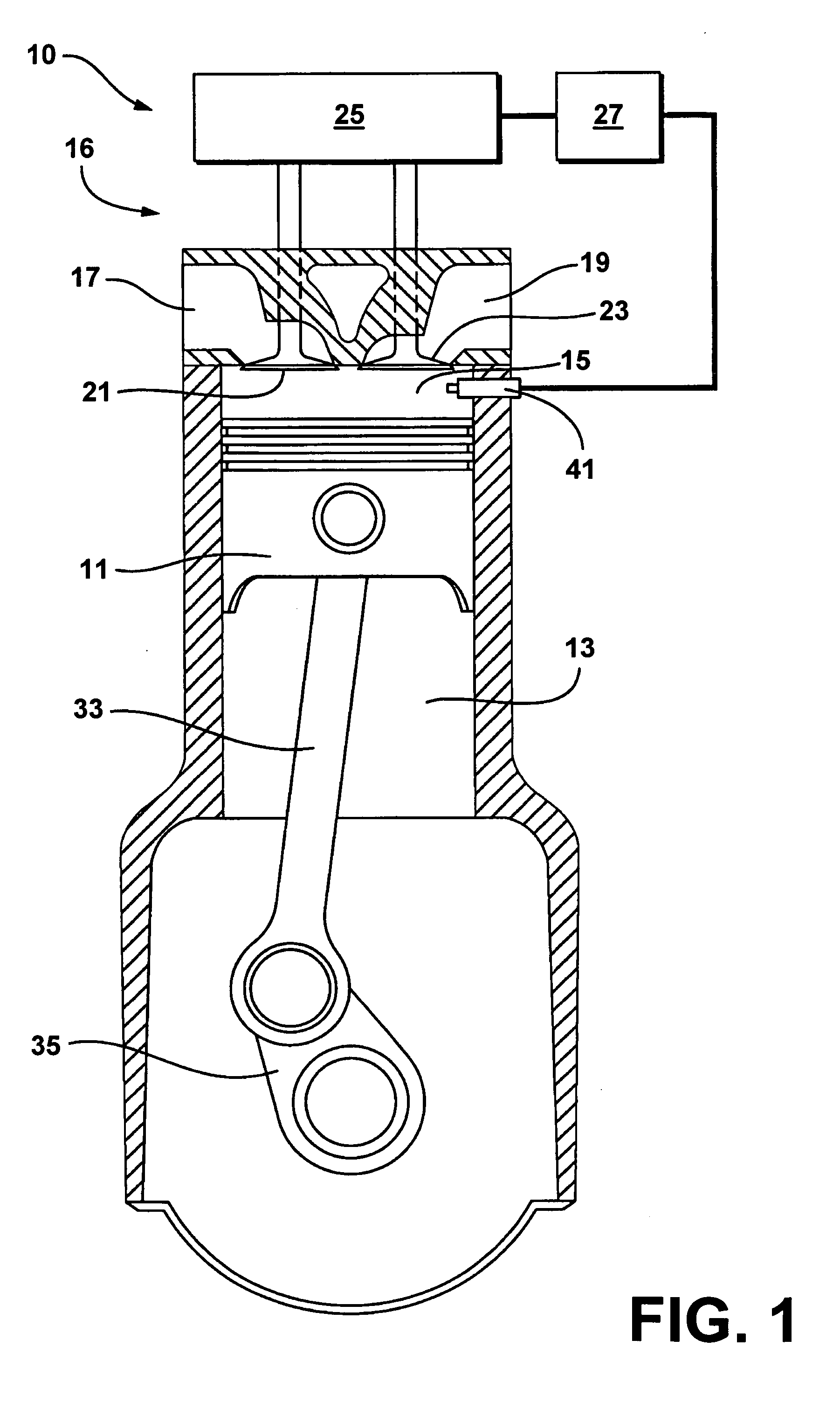

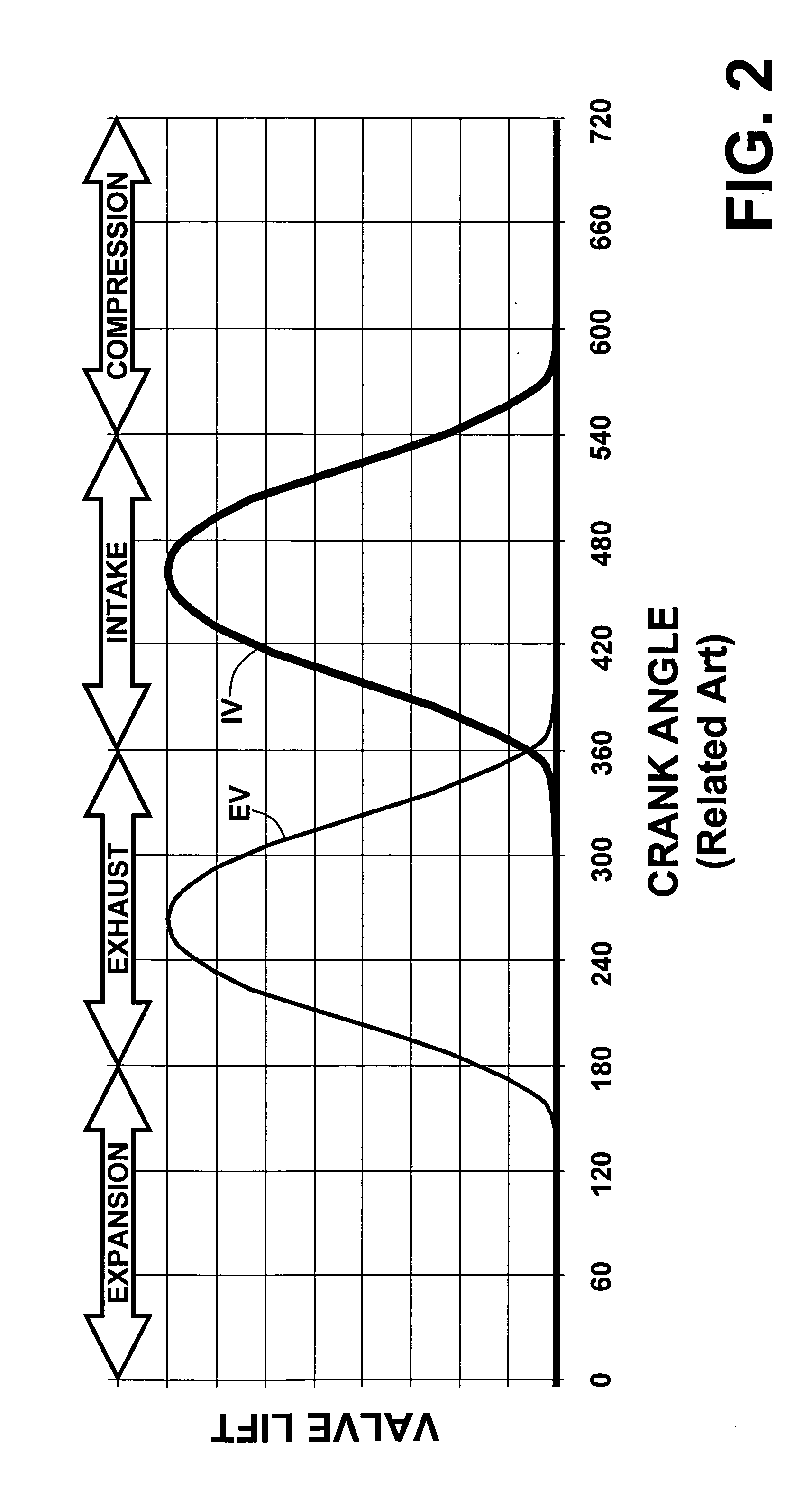

Valve and fueling strategy for operating a controlled auto-ignition four-stroke internal combustion engine

ActiveUS7021277B2Improve abilitiesReduce decreaseValve arrangementsElectrical controlCombustionOperating point

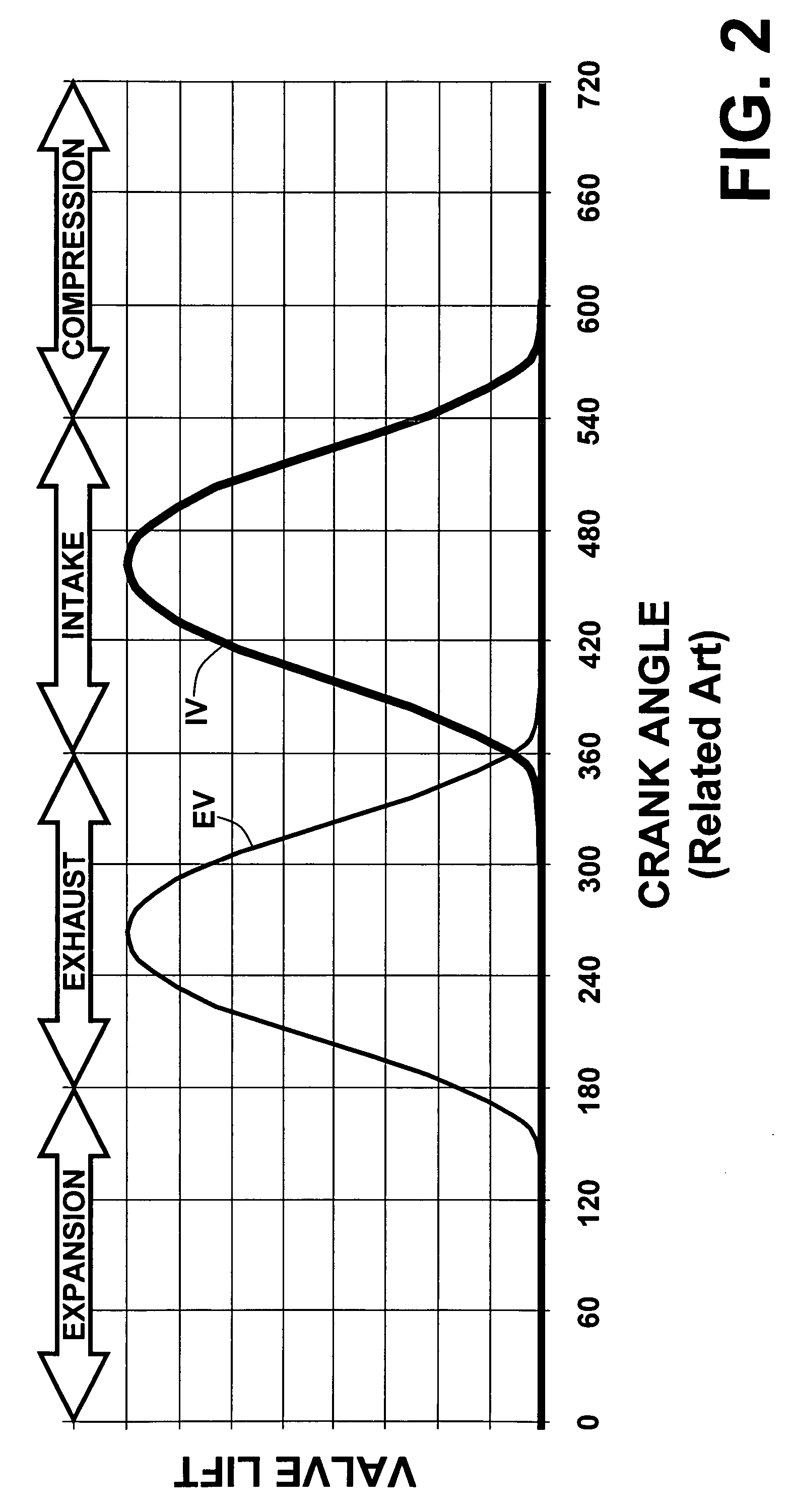

Part load operating point for a controlled auto-ignition four-stroke internal combustion engine is reduced without compromising combustion stability through load dependent valve controls and fueling strategies. Optimal fuel economy is achieved by employing negative valve overlap to trap and re-compress combusted gases below a predetermined engine load and employing exhaust gas re-breathing above the predetermined engine load. Split-injection fuel controls are implemented during low and intermediate part load operation whereas a single-injection fuel control is implemented during high part load operation. Split-injections are characterized by lean fuel / air ratios and single-injections are characterized by either lean or stoichiometric fuel / air ratios. Controlled autoignition is thereby enabled through an extended range of engine loads while maintaining acceptable combustion stability and emissions at optimal fuel economy.

Owner:GM GLOBAL TECH OPERATIONS LLC

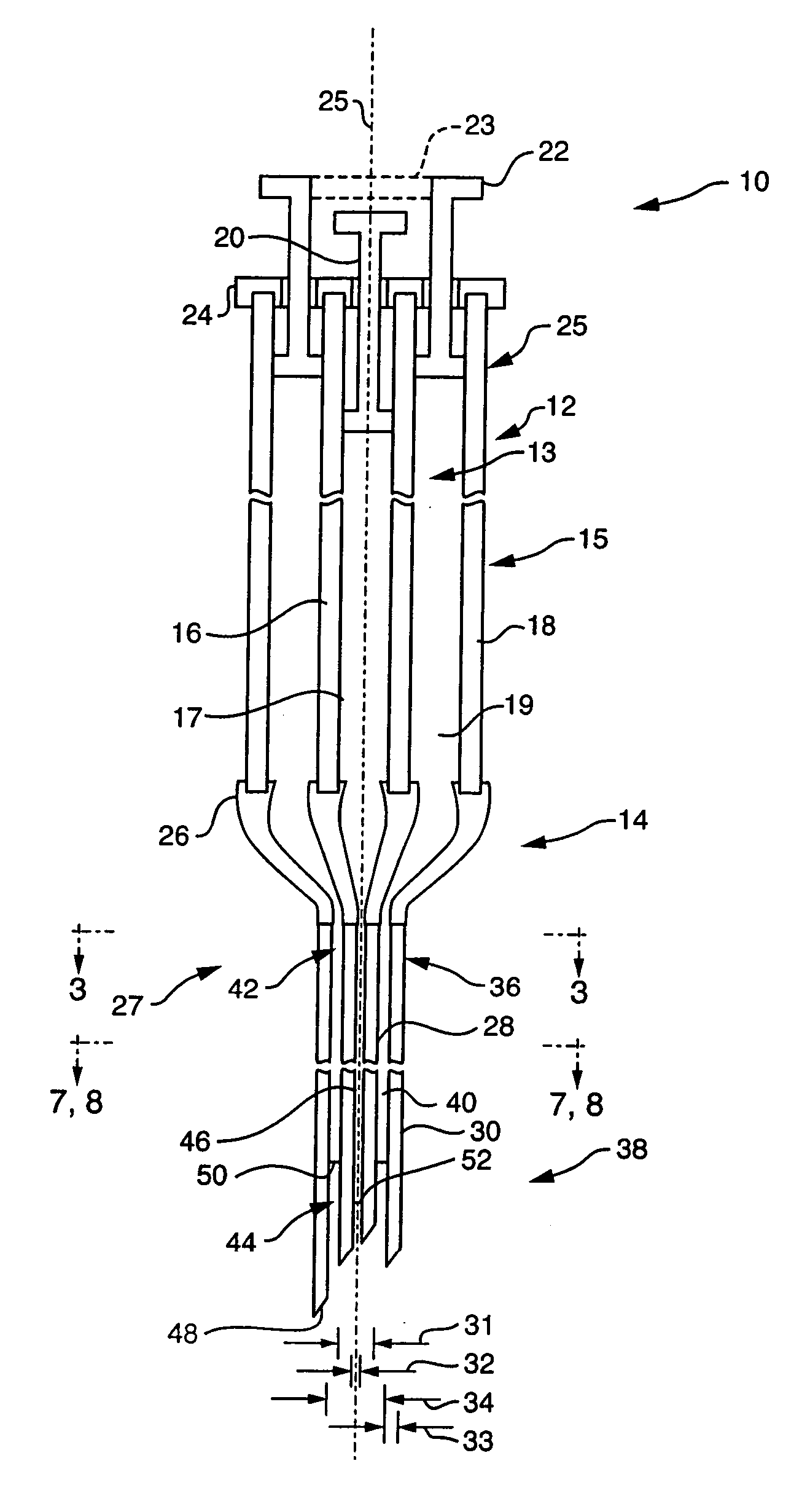

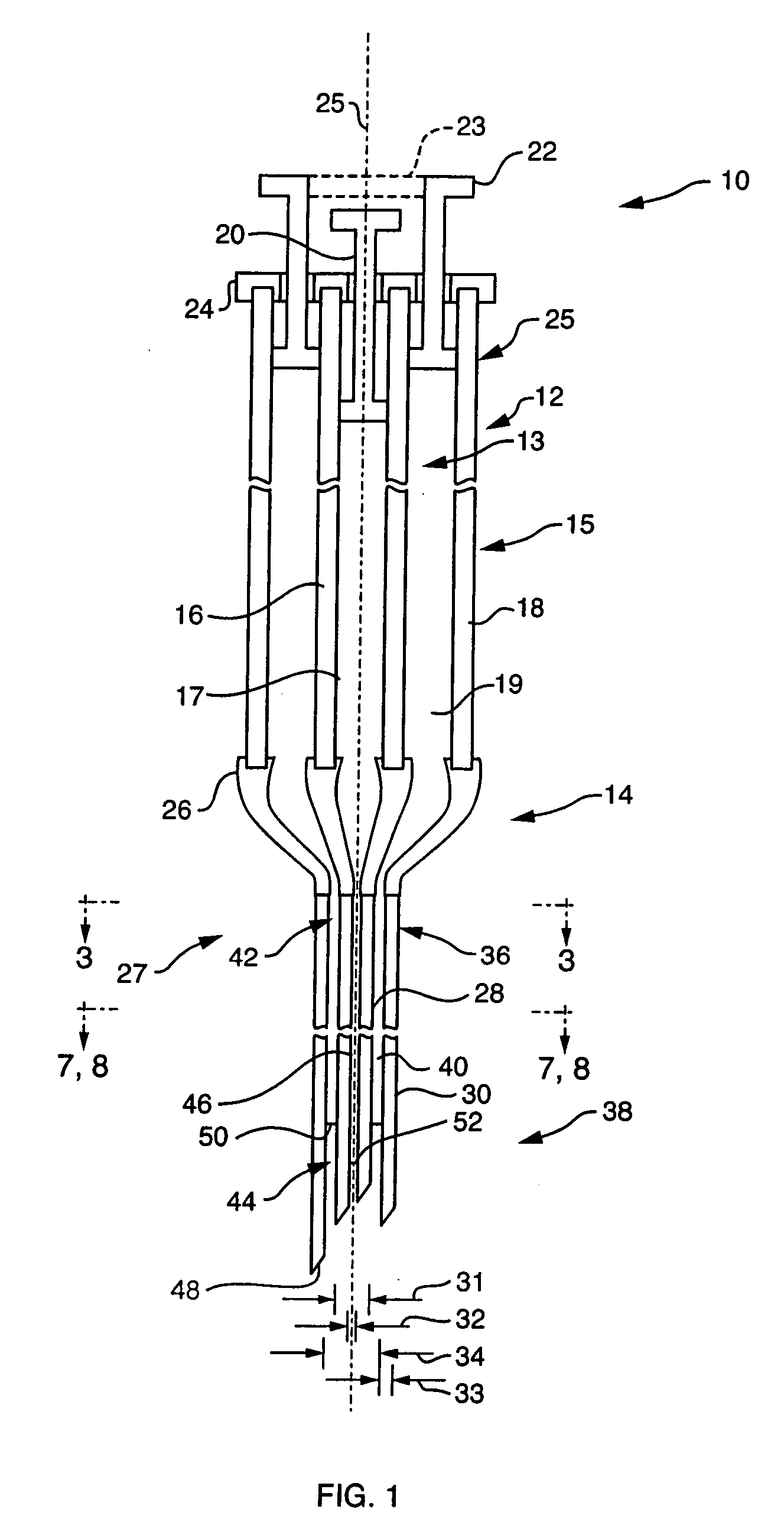

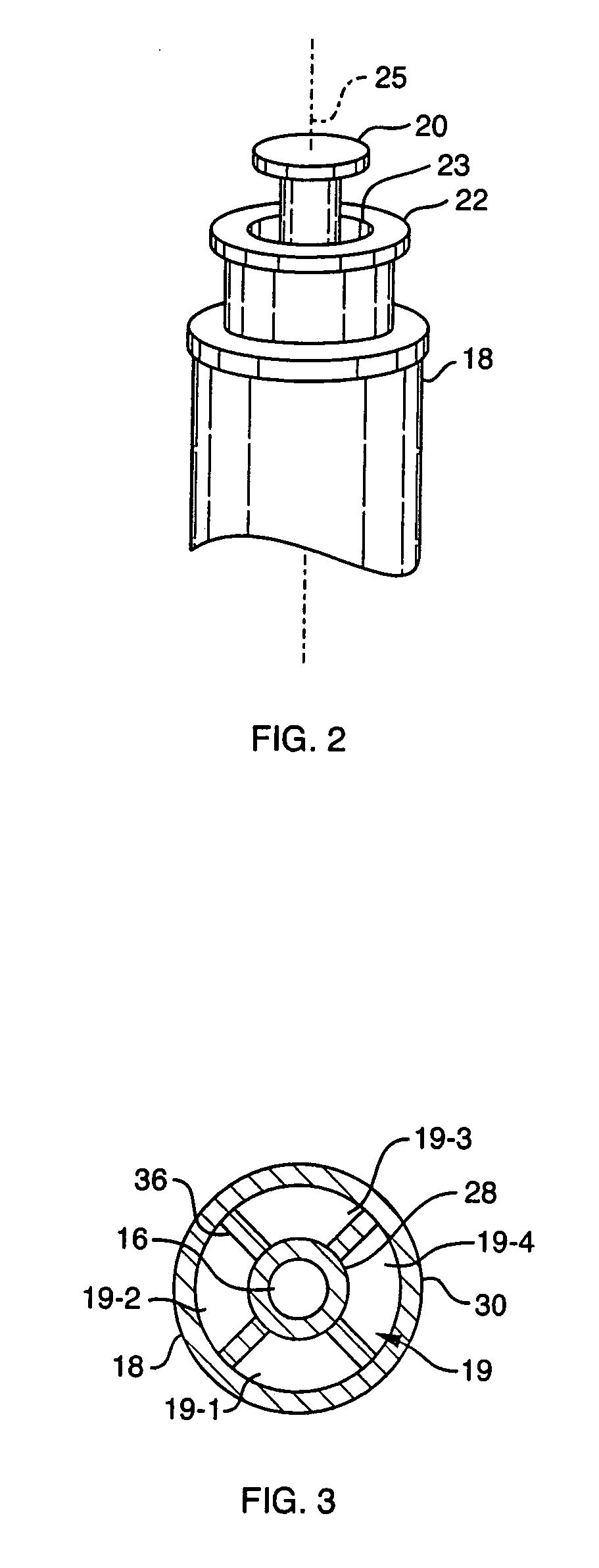

Low-loss multi-lumen injection apparatus

InactiveUS20070073267A1Reduce residual lossInfusion syringesMedical devicesDrug reservoirInjection site

Injection devices, systems and methods are disclosed for injecting two or more medicaments to a patient at a single injection site while preferably minimizing any mixing of the medicaments prior to delivery to the patient. The invention can also be used to sequentially deliver the medicaments to the patient in a repetitive manner. For example, the injection apparatus can sequentially provide a first medicament and then a second medicament to the patient during a first injection procedure. During a second injection procedure, the injection apparatus can again sequentially provide the first medicament and the second medicament to the patient either at the injection site of the first injection procedure or at a different injection site. Multi-lumen manifolds are disclosed for coupling to conventional drug ampoules, to permit the user to sequentially delivery different medicaments via a single skin penetration and to reduce losses associated with usage. Systems including multiple drug reservoirs and filling adaptors are also disclosed.

Owner:MILE CREEK CAPITAL

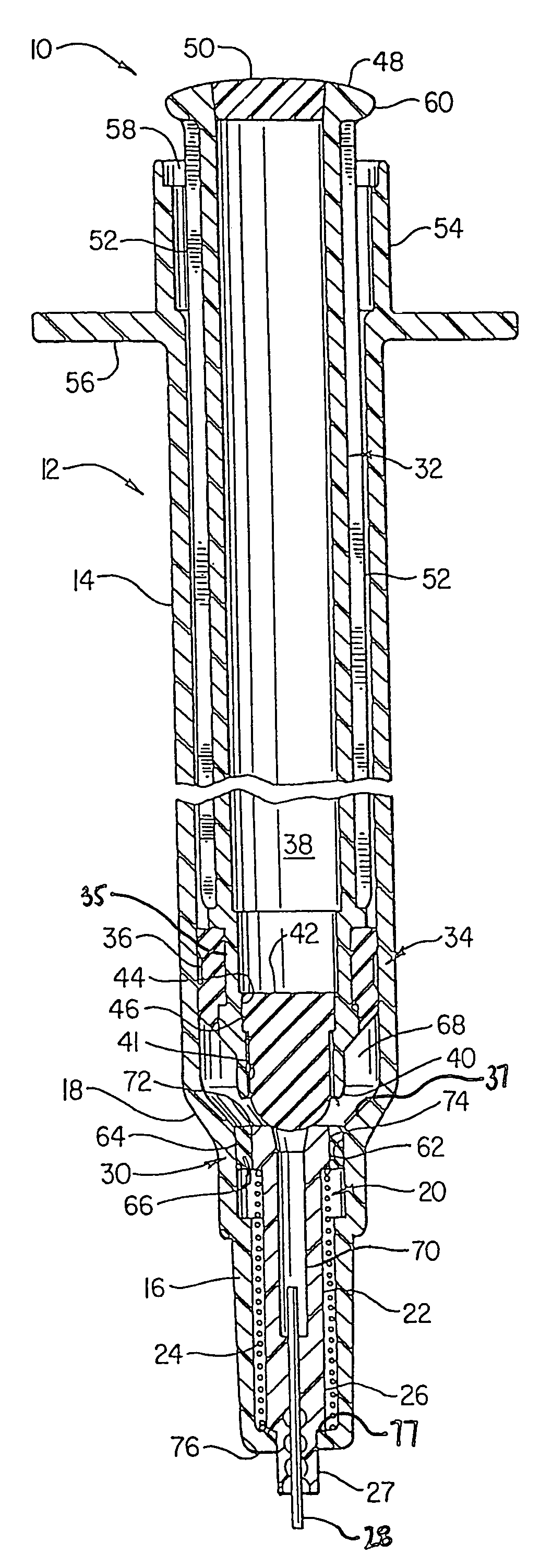

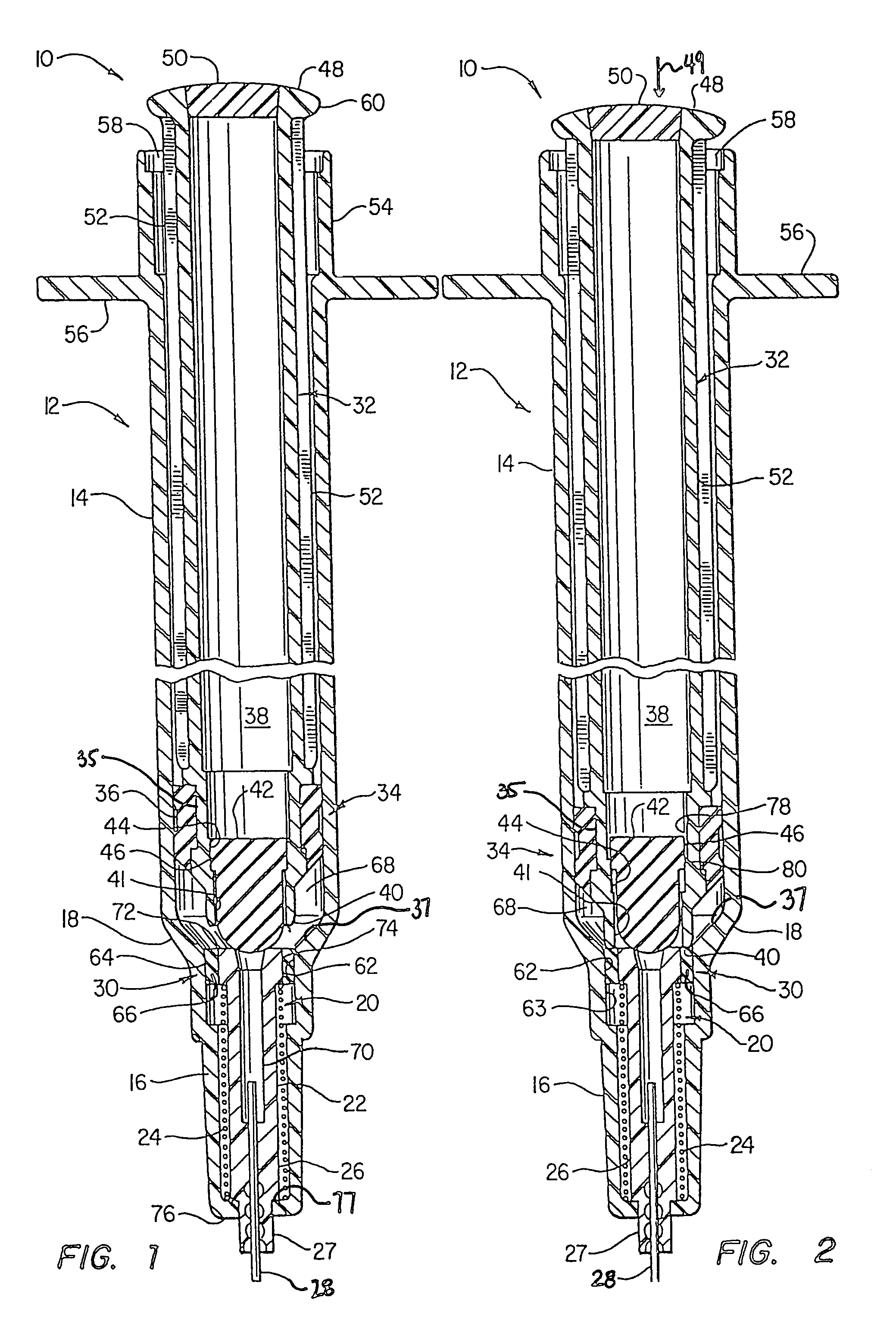

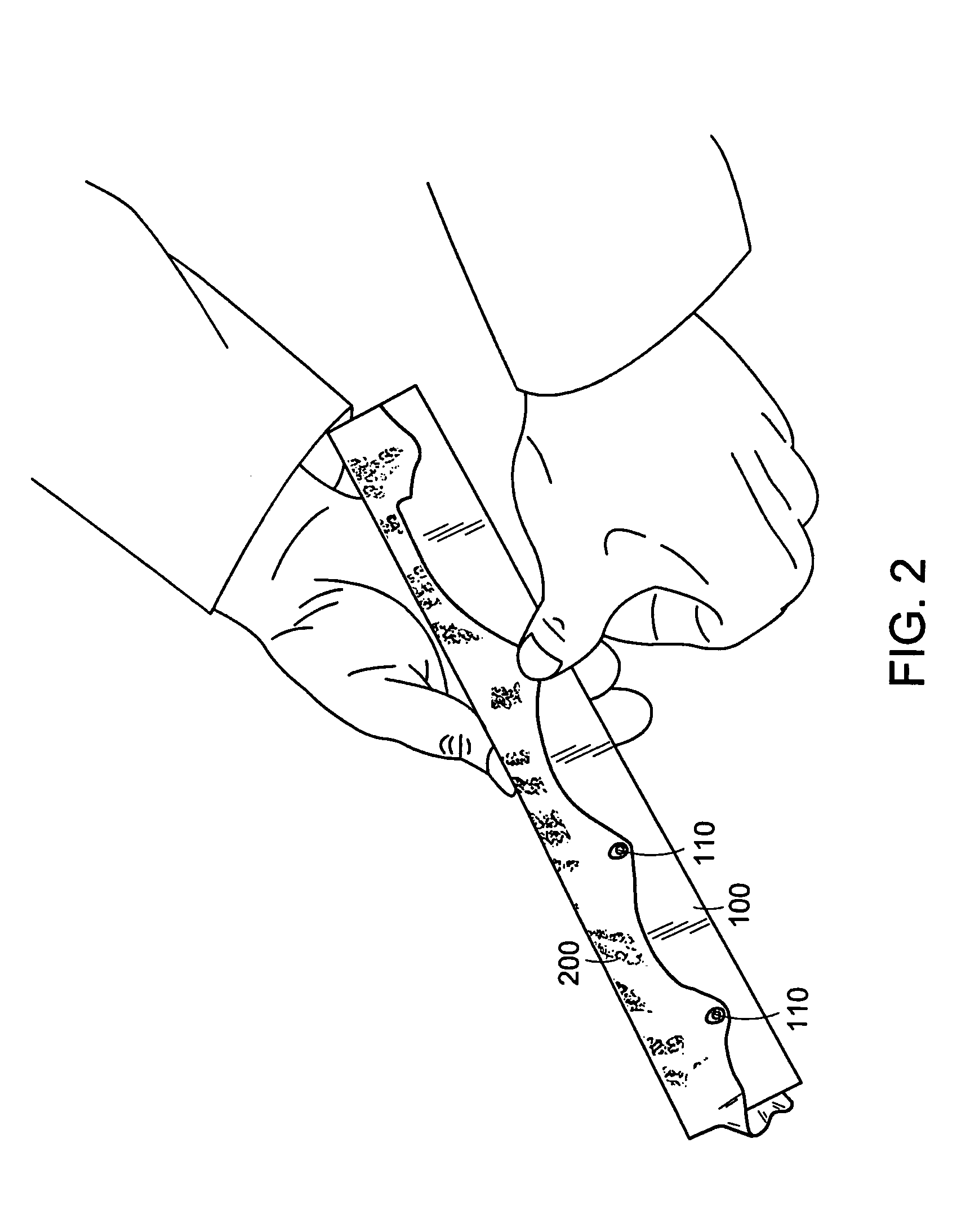

Retractable syringe assembly designed for one use

InactiveUS7351224B1Prevent retractionReduce clamping forceInfusion syringesInfusion needlesSingle injectionSyringe needle

A syringe assembly having a retractable needle, the syringe assembly being rendered unusable after a single injection and having a hollow syringe body, a retraction mechanism with a spring disposed in the front portion of the syringe and an inner head, a continuous retainer member surrounding the inner head, and a bridging portion disposed between the continuous retainer member and the inner head, wherein the bridging portion couples the continuous retainer member and the inner head to form a fluid seal between a fluid passageway and the barrel prior to retraction, and a plunger reciprocally disposed inside the barrel and forming a variable chamber between the plunger and the needle holder prior to and during retraction, wherein the continuous retainer member is releasable from the inner head of the needle holder when the plunger is further depressed inside the barrel following injection.

Owner:SHAW CO

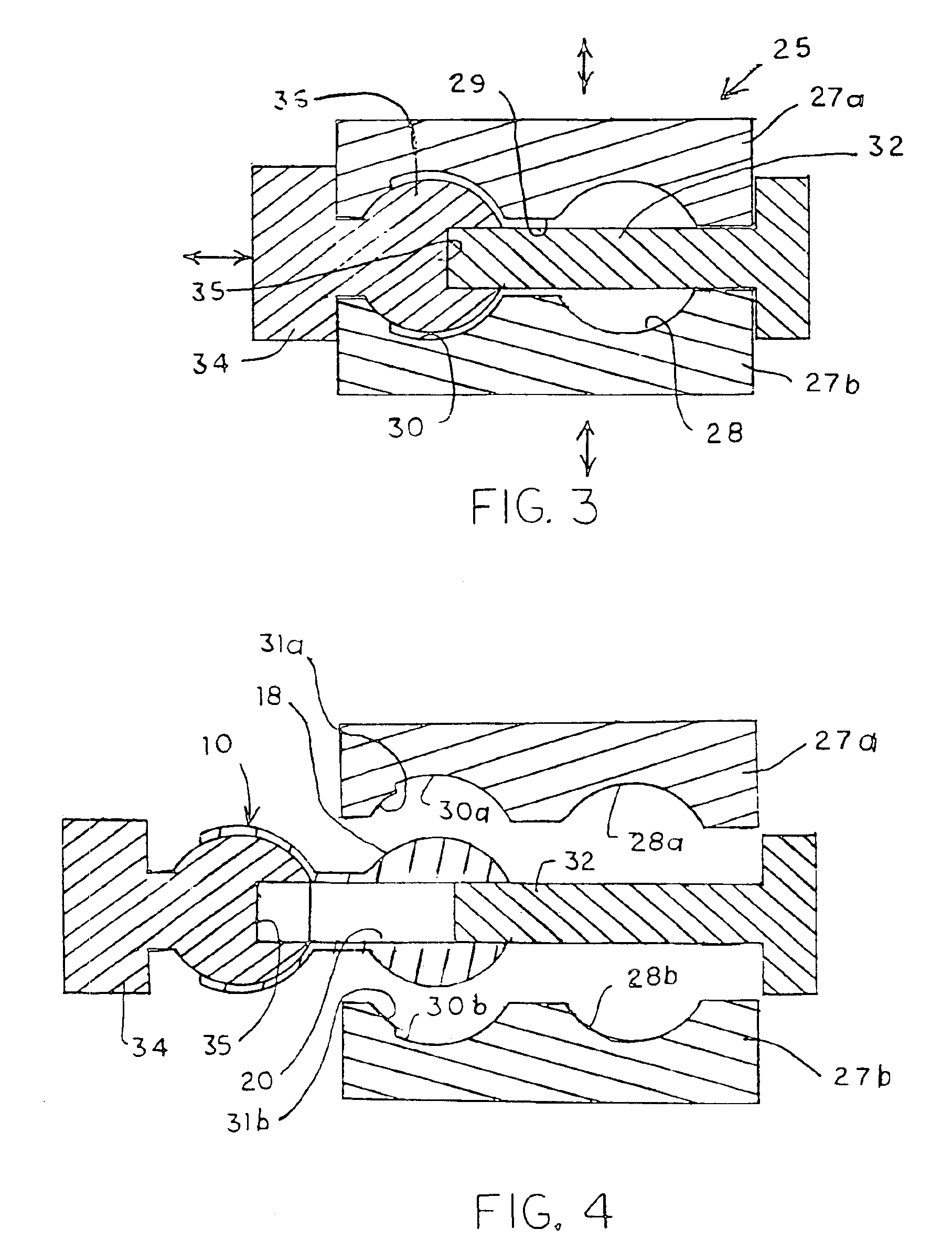

Injection molding method for manufacturing plastic parts

InactiveUS20060068206A1Quality improvementImprove replicationMouldsLayered productsInjection pointSingle injection

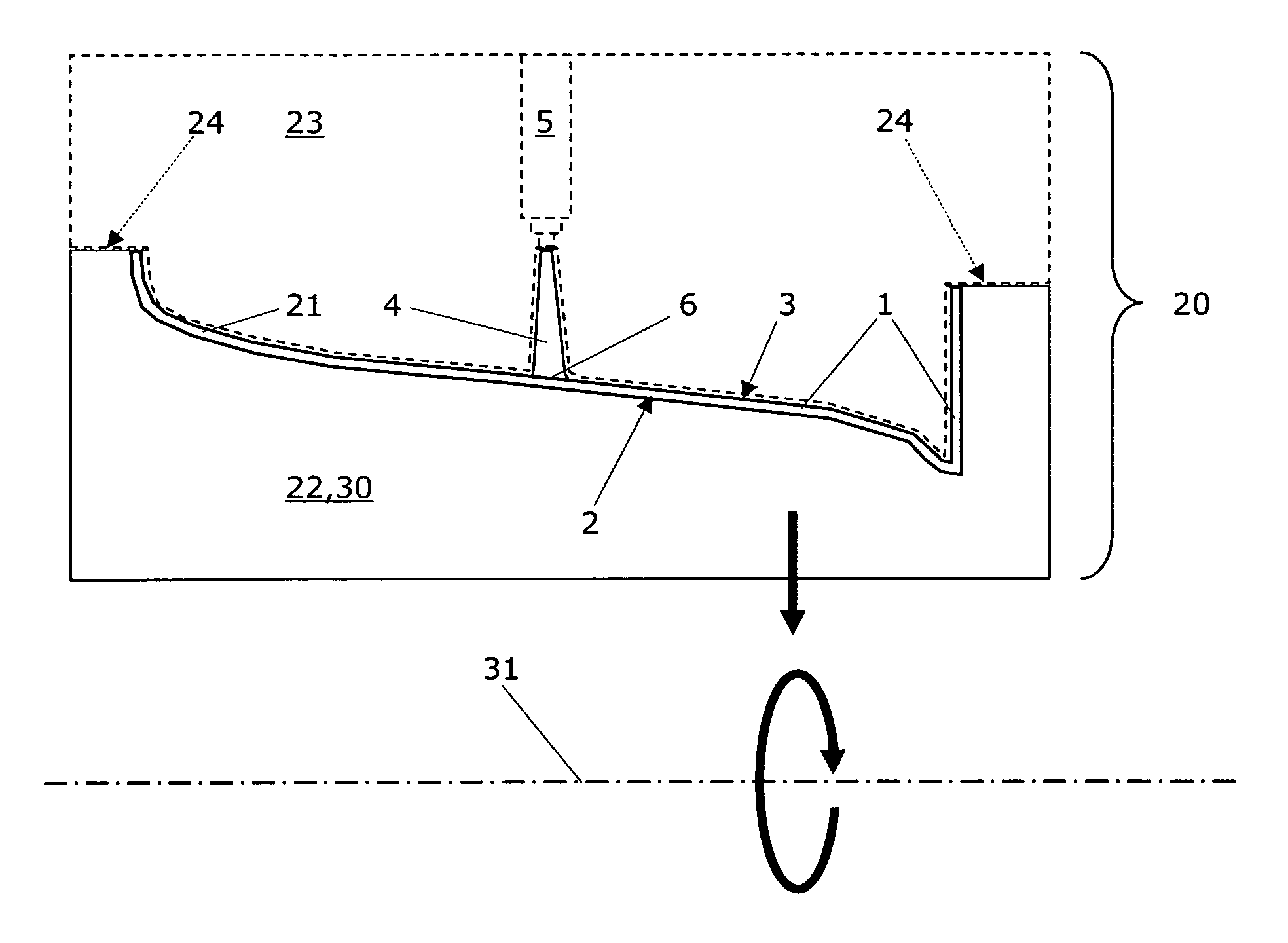

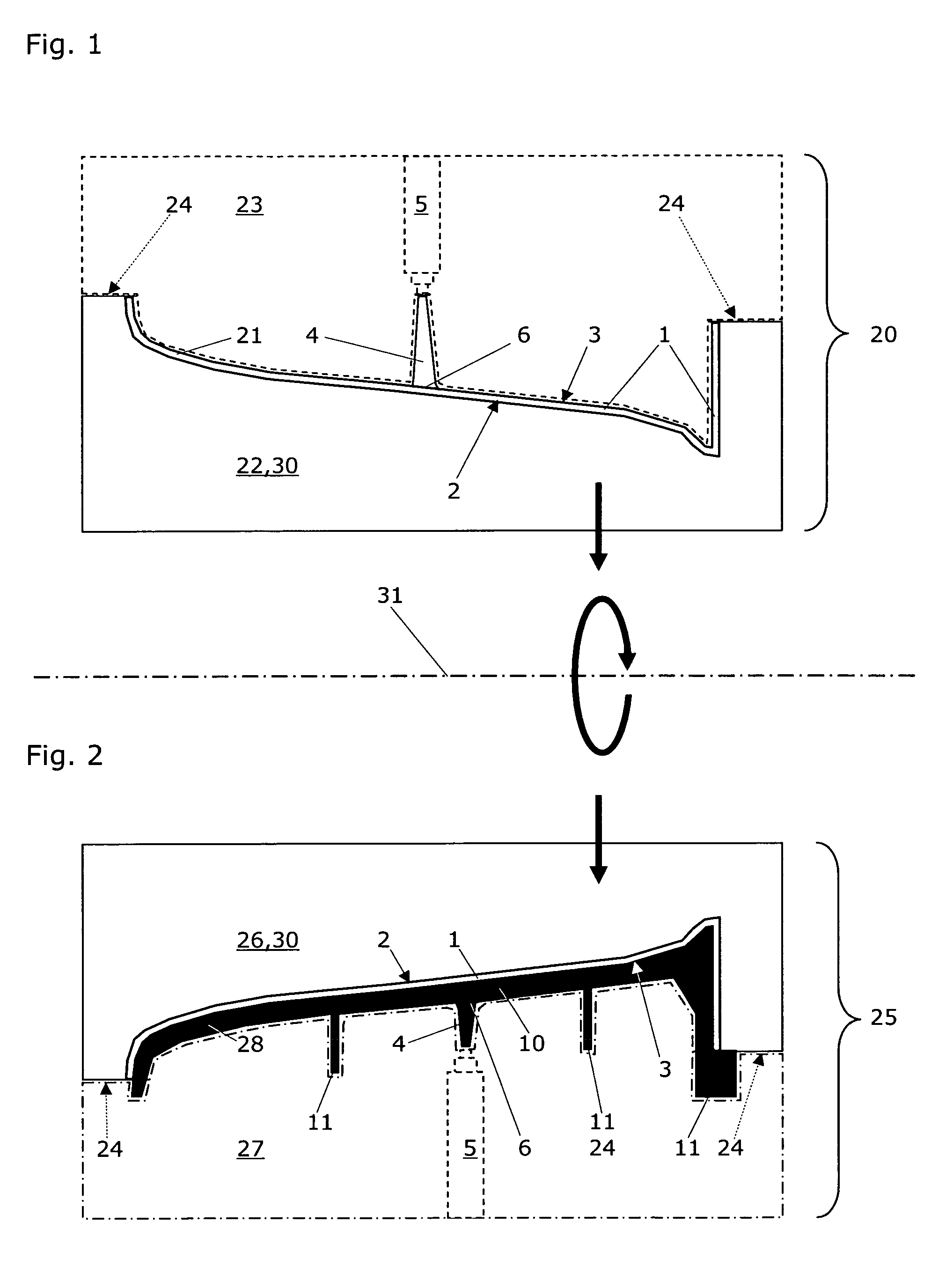

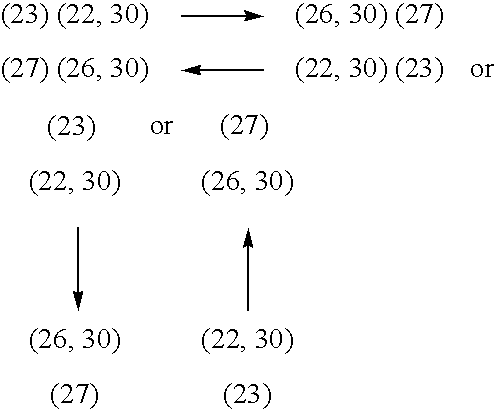

Disclosed is an injection molding method for manufacturing plastic parts from thermoplastically processible plastic molding materials with at least one exposed part (1) and at least one functional part (10), whereby the plastic molding material for the exposed part (1) comprises a transparent or translucent matrix with added effect pigments, and whereby the functional parts (10) can exhibit different physical and / or chemical plastic properties to the exposed parts (1). The injection molding method comprises the following steps: a) injection molding and solidification of the plastic molding material of the at least one exposed part (1) with an exposed surface (2) and a core surface (3) facing away from the latter in a first mold (20) with a first cavity (21); b) opening of the first mold (20) along a parting line or plane (24); c) closing of a second mold (25) with the at least one exposed part (1) in a second cavity (28); d) injection molding and solidification of the plastic molding material of the functional part (10) on the core surface (3) of the at least one exposed part (1); and e) opening of the second mold (25) and removal of the part. The injection molding method according to the invention is characterized in that for each exposed part (1)—to prevent irregularities such as flow marks and / or knit lines—a single injection nozzle (5) positioned to optimize the flow or at least two injection nozzles in a cascaded injection molding method are used, and that the plastic molding material for the exposed part (1) comprises at least one transparent polymer. The corresponding plastic parts manufactured by injection molding exhibit an exposed surface (2) and a core surface (3) facing away from the latter with at least one injection point (6), whereby the functional part (10) of the plastic part is injection molded onto the core surface (3) of the previously solidified exposed part (1).

Owner:EMS CHEM AG

Environment-friendly, cushioning and well-wrapping popcorn bridging shoes and production process thereof

InactiveUS20180103719A1Simple materialIncrease elasticitySolesLastingEnvironmental resistanceCushioning

A pair of environment-friendly popcorn bridging shoes and a production process thereof are provided. The upper of each bridging shoe comprises an inner bootie, which is composed of a lining and an inner pad formed by single injection molding, and a vamp; the collar of the inner bootie is fixedly connected with that of the vamp, and the lower edge of the vamp wrapped by a PU bridging layer extends to the bottom surface of the inner pad fixedly connected with the same; the upper and a popcorn sole made of mixed PU and TPU popcorn particles are integrally connected by the PU bridging layer. The shoe making process is simpler, and firmer bonding and better shock absorbing performance of the shoes are achieved; the vamp and the sole can well wrap the foot; and the dissolution proportion of shoes is increased by increasing the consumption of the PU material.

Owner:CHEN MAOSHUANG

Valve and fueling strategy for operating a controlled auto-ignition four-stroke internal combustion engine

ActiveUS20060016423A1Improve abilitiesMaintaining and improving combustion qualityElectrical controlNon-fuel substance addition to fuelCombustion chamberOperating point

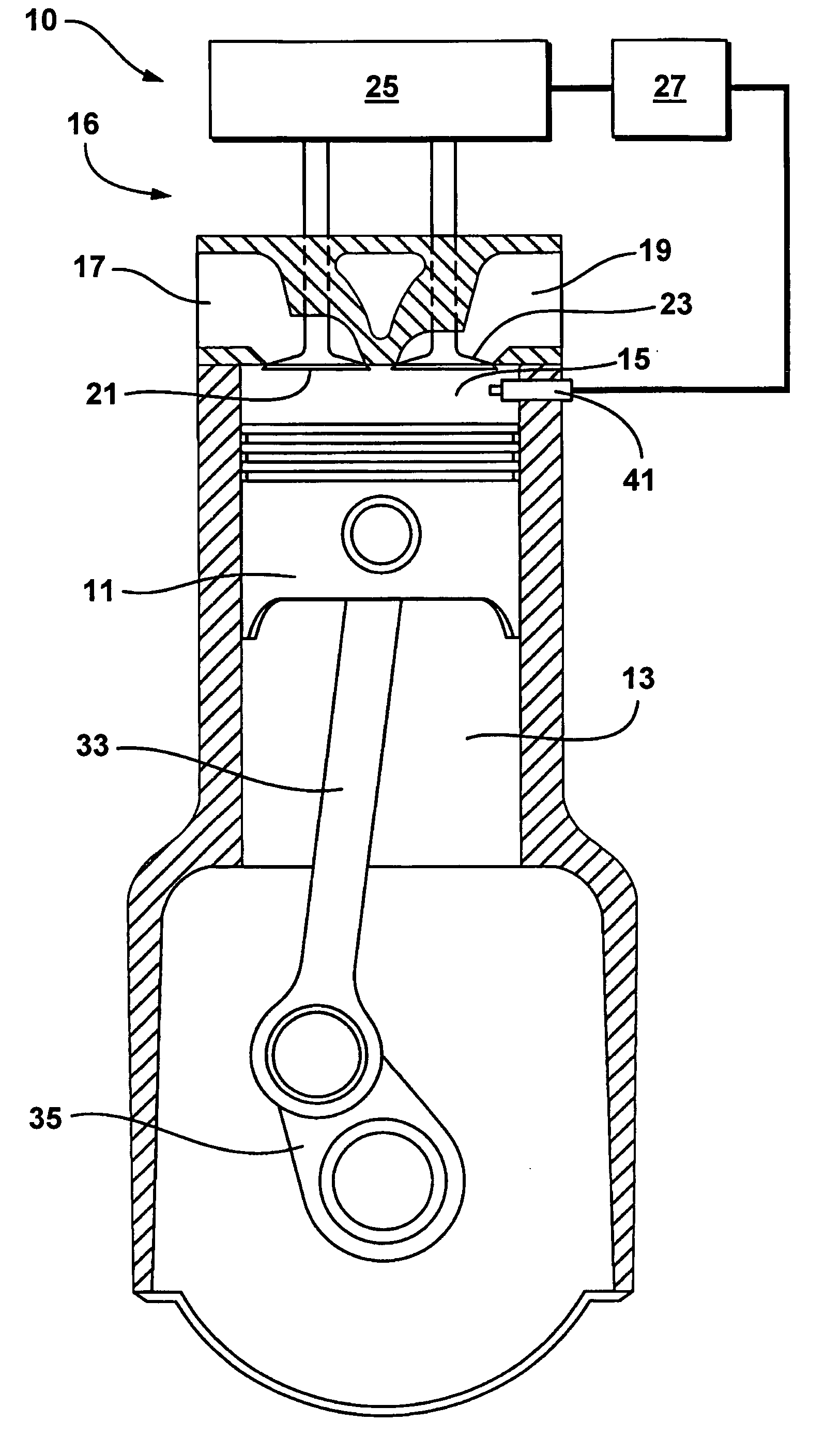

Part load operating point for a controlled auto-ignition four-stroke internal combustion engine is reduced without compromising combustion stability through negative valve overlap control operative to retain and compress combusted gases within the combustion chamber into which fuel is introduced. Combustion chamber pressures and temperatures are increased as engine load decreases. Various split-injection fuel controls are implemented during low and intermediate part load operation whereas a single-injection fuel control is implemented during high part load operation. Split-injections are characterized by lean fuel / air ratios and single-injections are characterized by either lean or stoichiometric fuel / air ratios. Controlled autoignition is thereby enabled through an extended range of engine loads while maintaining acceptable combustion stability and emissions.

Owner:GM GLOBAL TECH OPERATIONS LLC

Valve and fueling strategy for operating a controlled auto-ignition four-stroke internal combustion engine

ActiveUS7128047B2Improve abilitiesReduce decreaseElectrical controlInternal combustion piston enginesOperating pointExternal combustion engine

Part load operating point for a controlled auto-ignition four-stroke internal combustion engine is reduced without compromising combustion stability through negative valve overlap control operative to retain and compress combusted gases within the combustion chamber into which fuel is introduced. Combustion chamber pressures and temperatures are increased as engine load decreases. Various split-injection fuel controls are implemented during low and intermediate part load operation whereas a single-injection fuel control is implemented during high part load operation. Split-injections are characterized by lean fuel / air ratios and single-injections are characterized by either lean or stoichiometric fuel / air ratios. Controlled autoignition is thereby enabled through an extended range of engine loads while maintaining acceptable combustion stability and emissions.

Owner:GM GLOBAL TECH OPERATIONS LLC

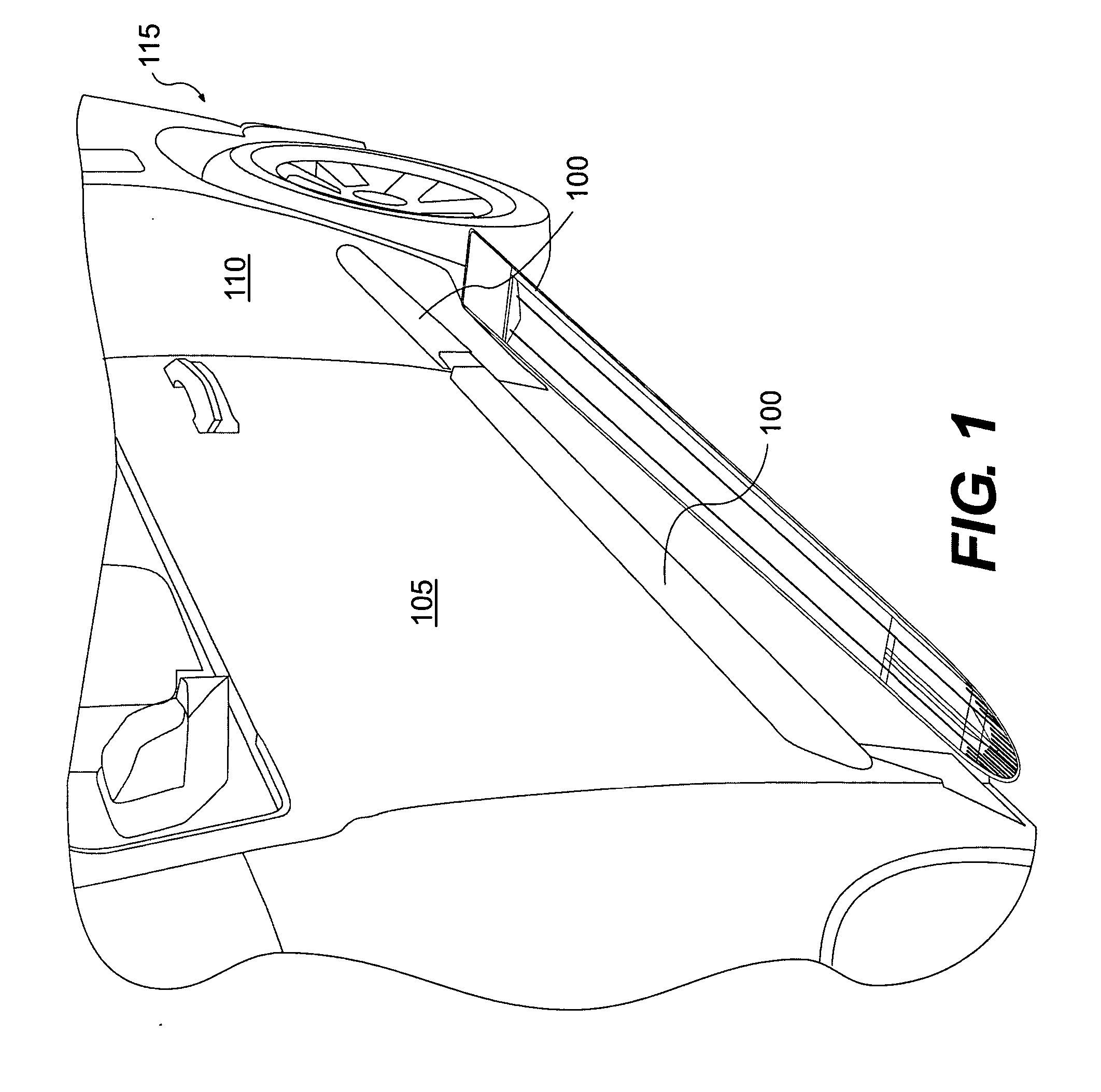

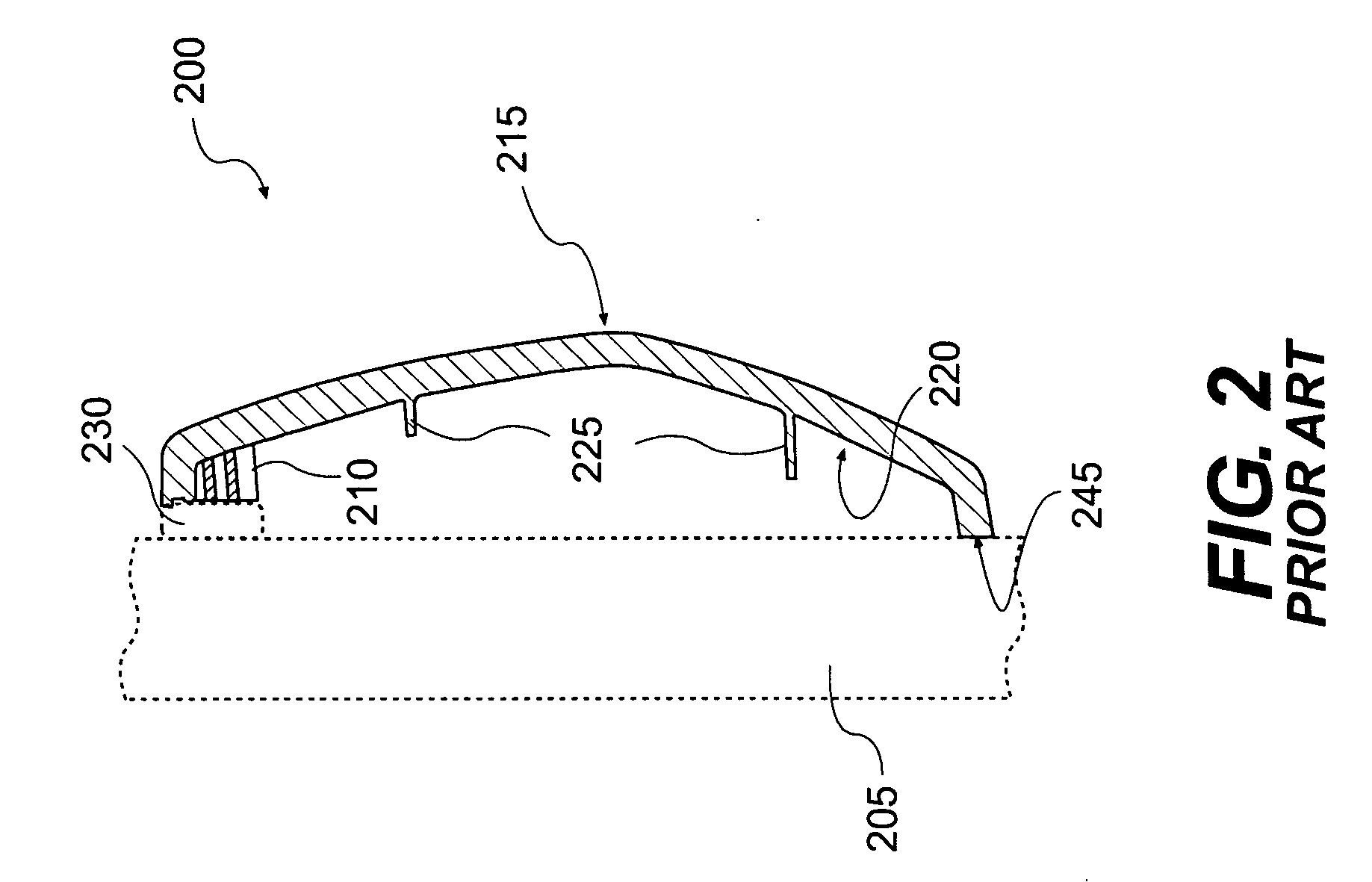

Injection molded parts for vehicles and other devices

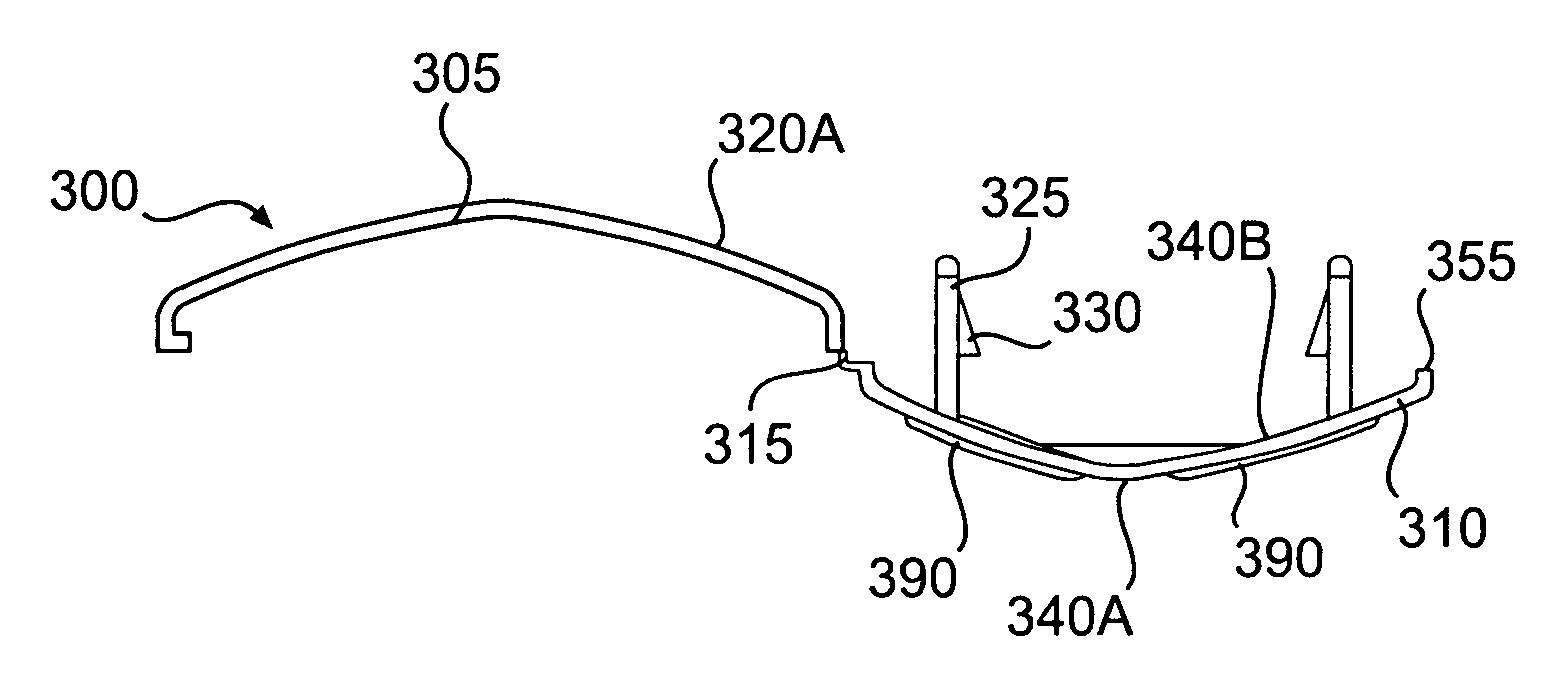

InactiveUS20070085361A1Promotes relative motionLow costSuperstructure subunitsMonocoque constructionsSingle injectionSupport surface

A vehicle part such as a body molding includes a trim piece connected to a bearer piece by a flexible and foldable hinge, which is preferably integrally molded with the trim and bearer pieces in a single injection mold. The trim piece and bearer piece are folded about the molded hinge to rotate towards each other and are snap-fitted together to form an integral body side molding that can be adhesively and / or clippedly affixed to a support surface, such as a vehicle body side panel. Methods for manufacturing and installing such vehicle parts are also disclosed.

Owner:REHAU INC

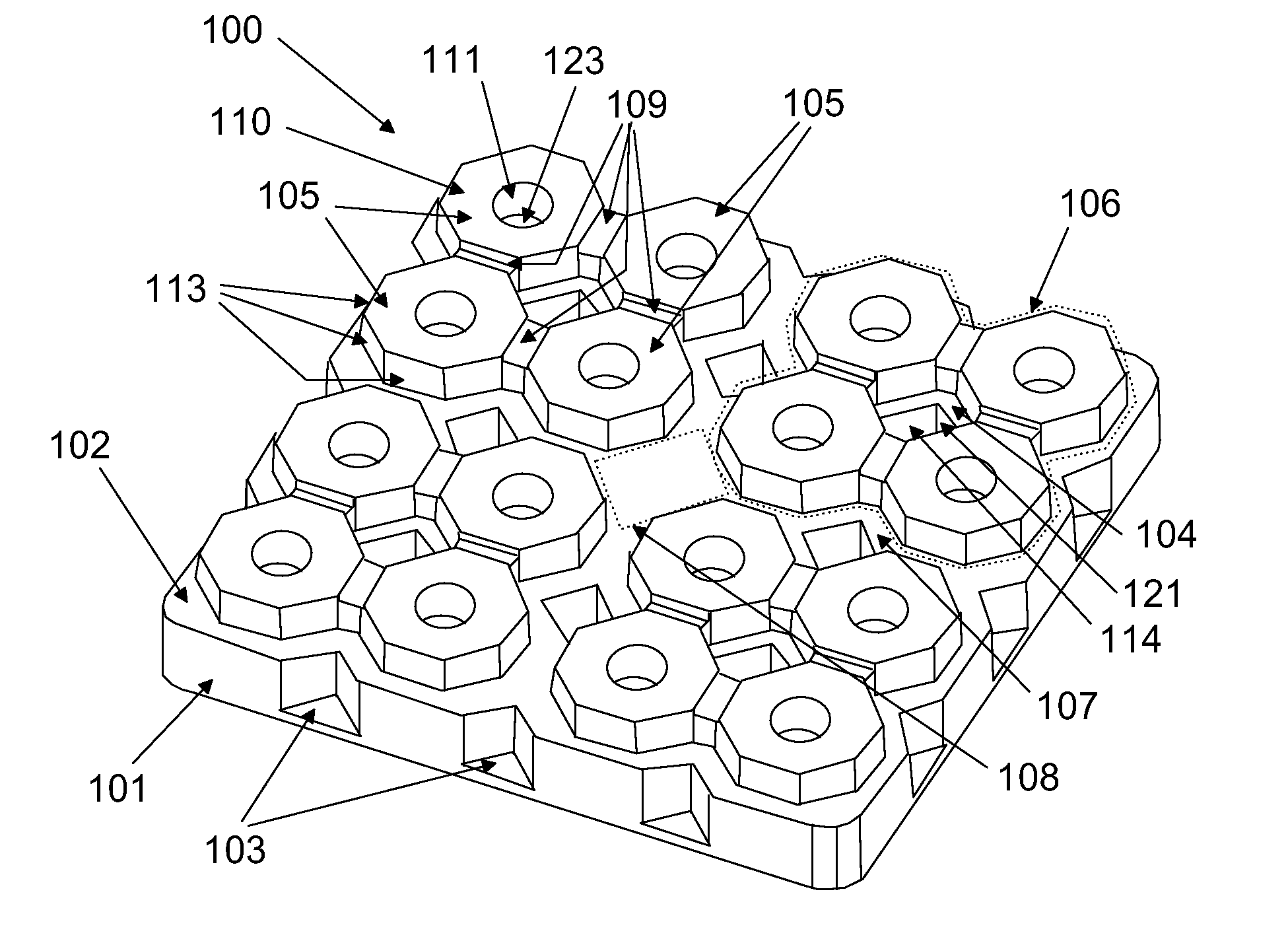

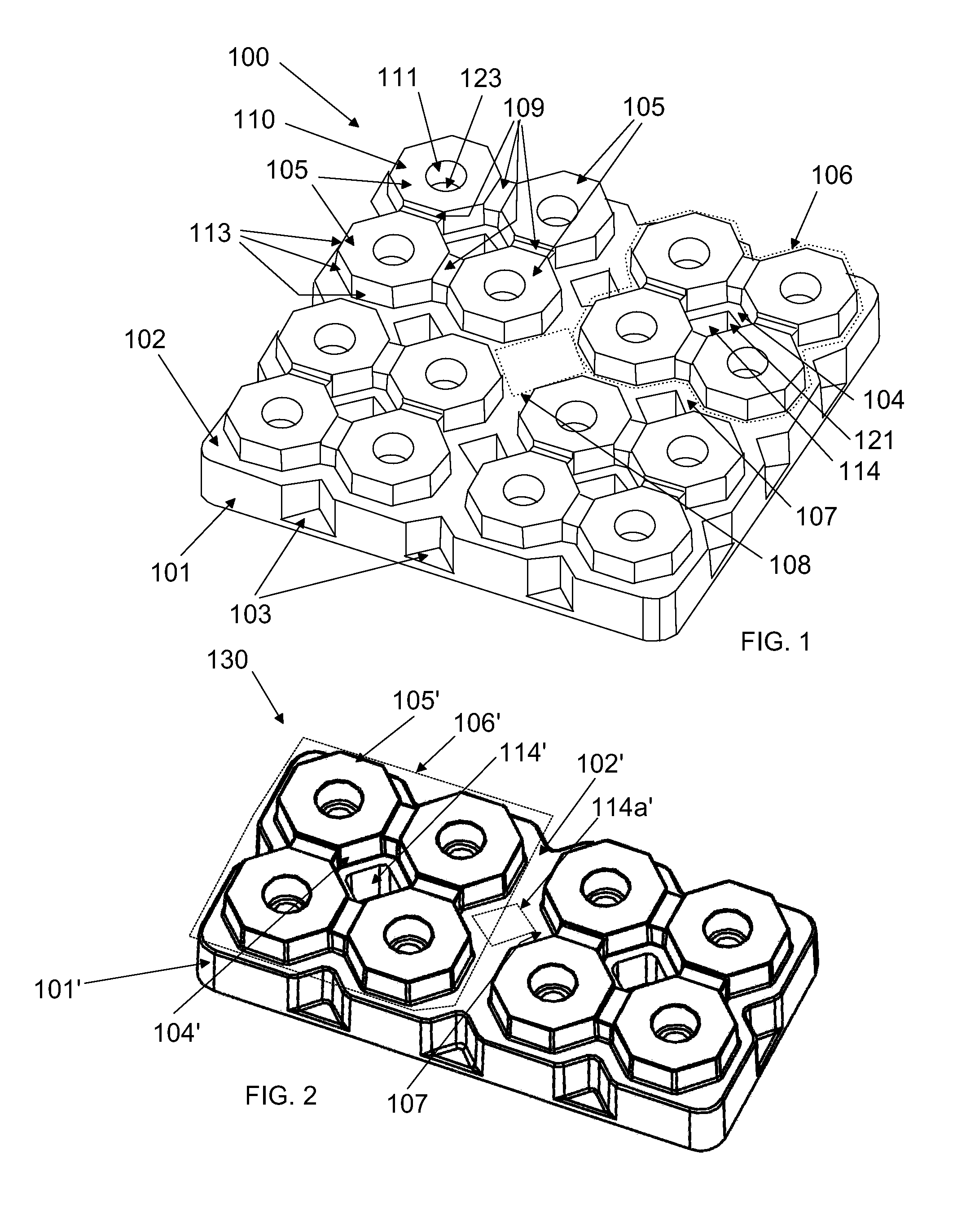

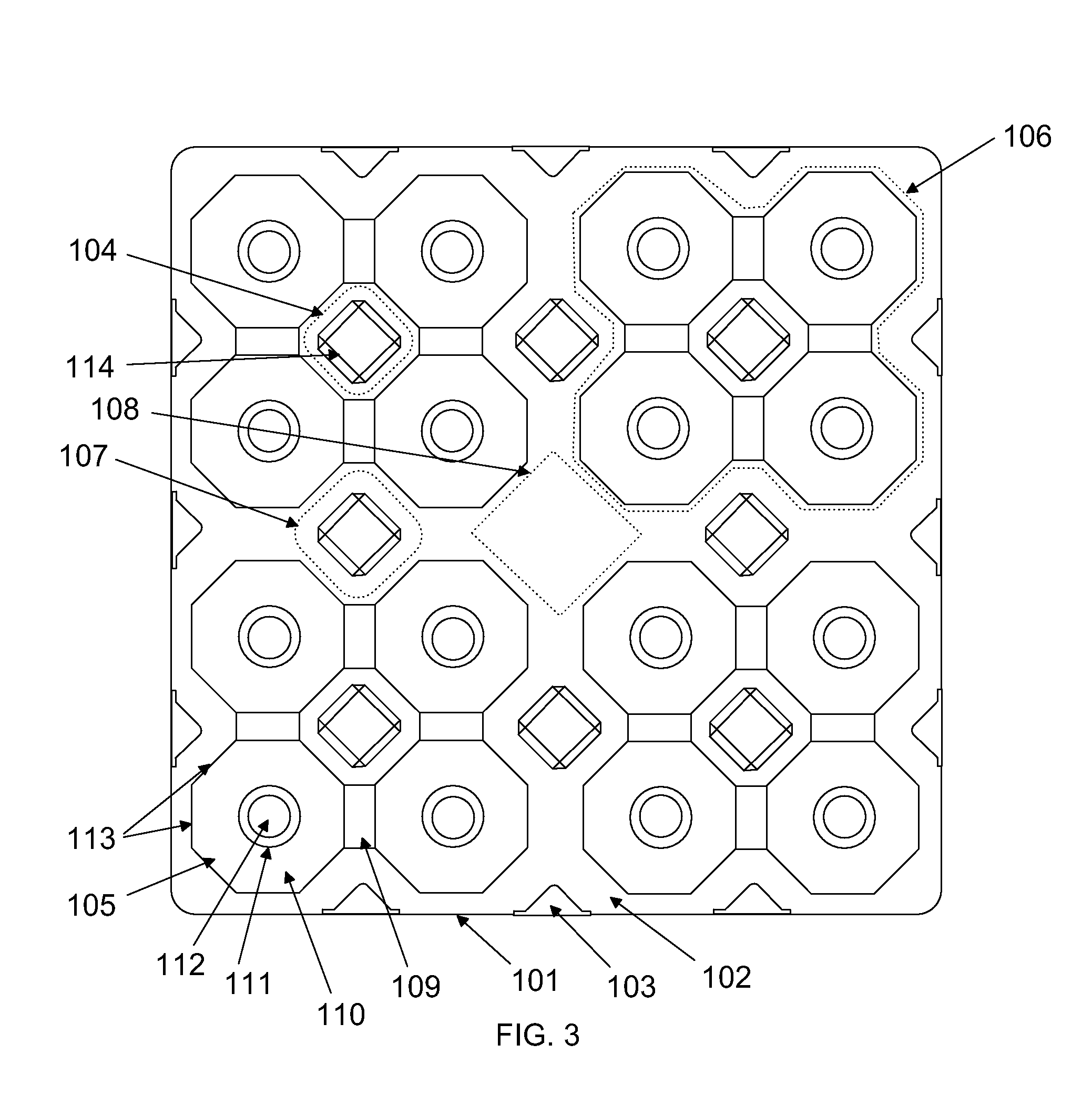

Half block for multi-level interlocking blocks

ActiveUS8002241B1Effective forceStrong and stable structureVehicle with pivoted armsInclined ship-liftingPolystyreneSingle injection

The present invention is a unitary piece block formed of polymers (such as polystyrene or other high strength polymer) by a single injection molding step which are assembled into a recreational vehicle leveler. The invention ramp provides four sets of four connectors at a top of a floor plate, which are adapted to interlock in cavity structures formed within a cavity on the underside of the block. Two adjacent blocks are secured together by applying to their top surfaces the securing cavity structure of an underside of a third such block. Such blocks can be stacked in an interlocking manner to reduce storage space.

Owner:SHAW ANNE

Rapid magnetic resonance imaging and magnetic resonance angiography of multiple anatomical territories

InactiveUS6493571B1Reduce osmotic pressureHigh resolutionBedsDiagnostic recording/measuringIodinated Contrast AgentSingle injection

A procedure and apparatus are provided which allow rapid positional change in the patient centering in order to facilitate the imaging of blood vessels in a series of different views. This procedure and apparatus can also facilitate the imaging of other tissues of the body at different spatial locations as well. The procedure and apparatus reduce the time required for obtaining the necessary images for a medical imaging examination using a single injection of an MRI or iodinated contrast agent.

Owner:WILLIAM BEAUMONT HOSPITAL

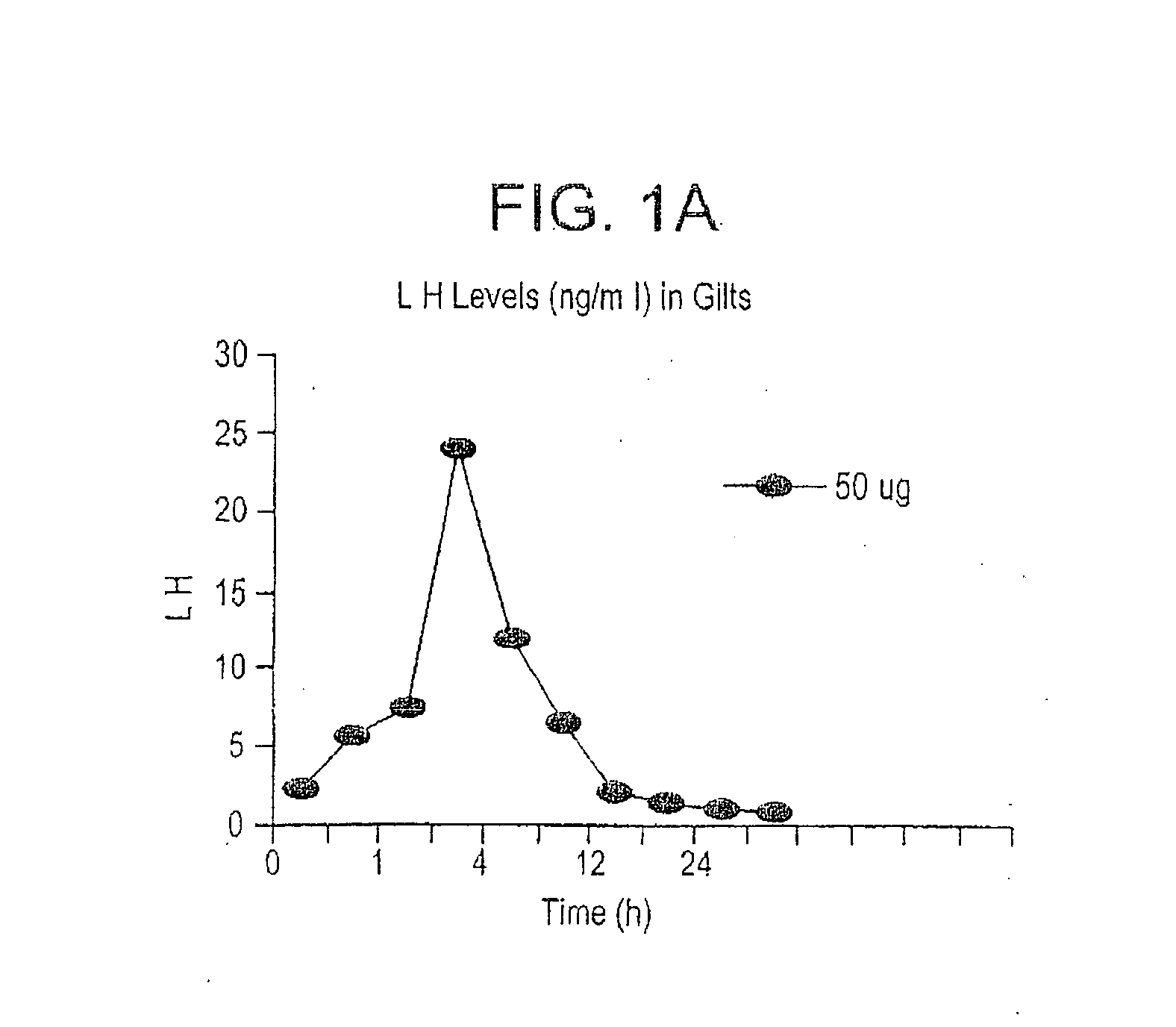

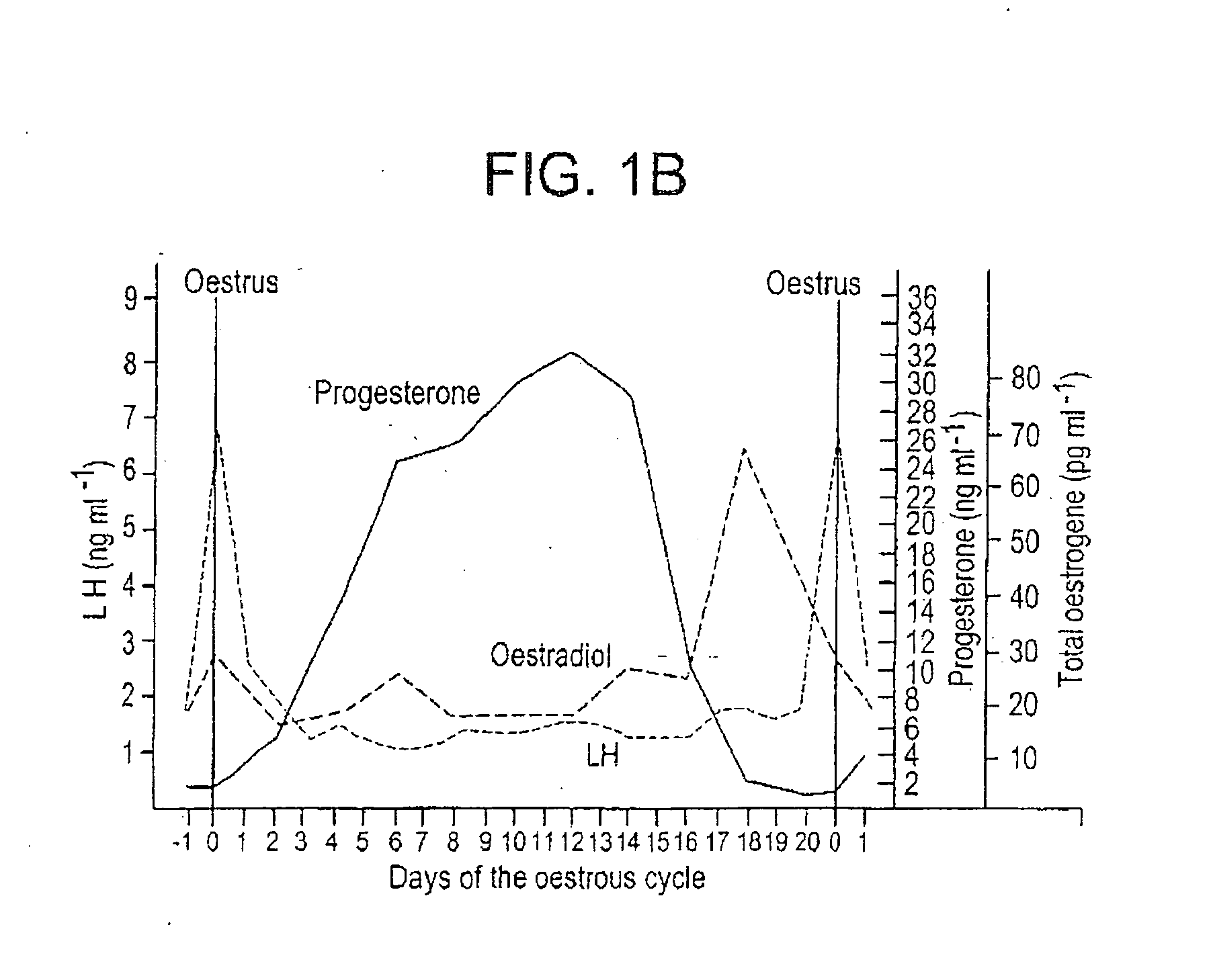

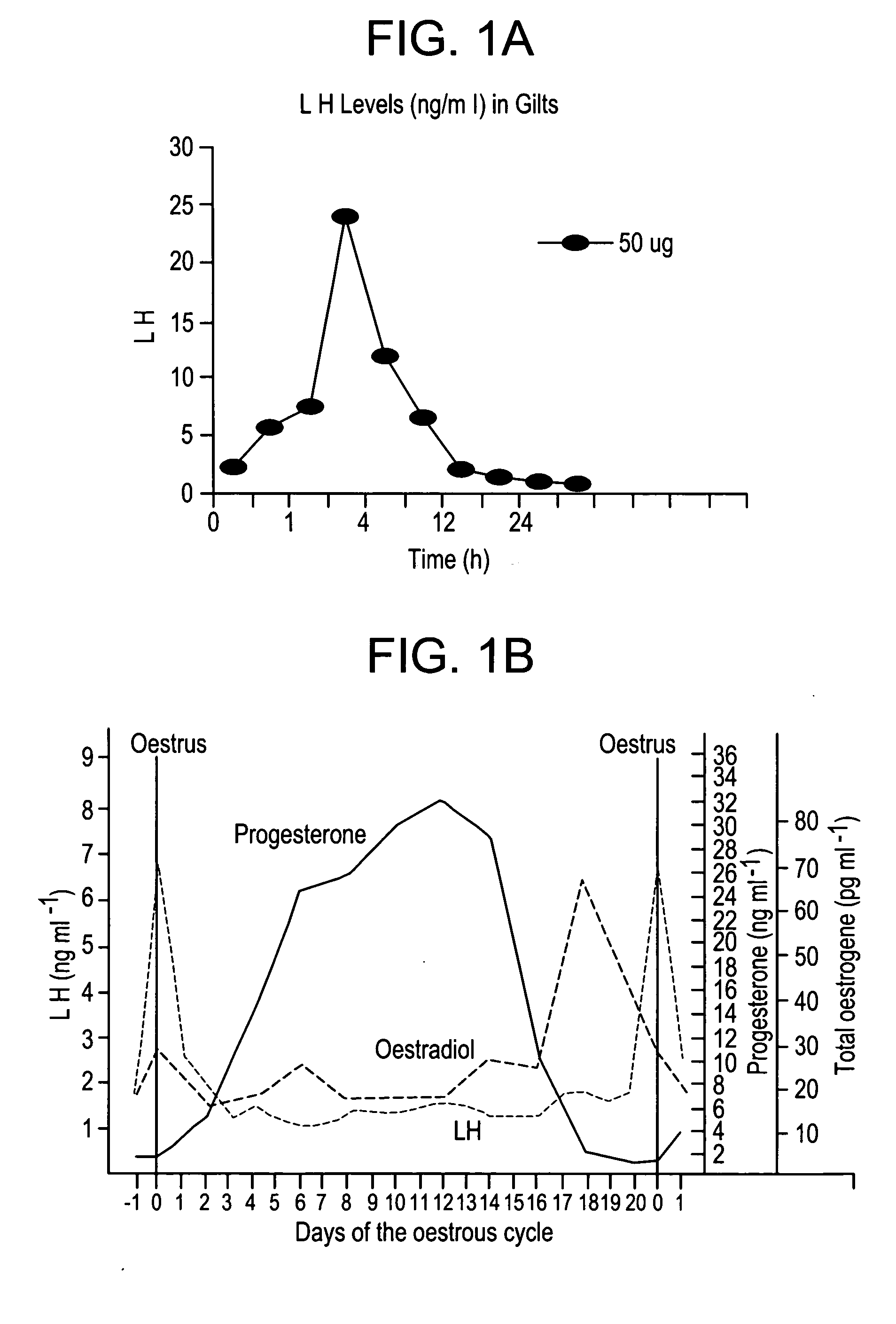

Process for the synchronization of ovulation for timed breeding without heat detection

InactiveUS20070197435A1Efficient methodPeptide/protein ingredientsDepsipeptidesSingle injectionBiology

A method for synchronizing ovulation in sows and gilts by a single injection of hormones is disclosed. A hormone, gonadotropin releasing hormone (GnRH), luteinizing hormone (LH), follicle stimulating hormone (FSH), human chorionic gonadotropin (hCG), analogues, derivatives, agonists or combinations thereof is administered to an open sow post weaning at a specific time to stimulate ovulation of mature responsive follicles. The sow is then bred, without heat detection, at a specific subsequent timed interval after injection with hormone, with one or two artificial or natural breedings. In gilts, the hormone is injected at a timed interval from onset of estrus or at a specific timed interval following Prostaglandin F2a for those gilts which have been held in a state of pseudopregnancy.

Owner:JBS UNITED

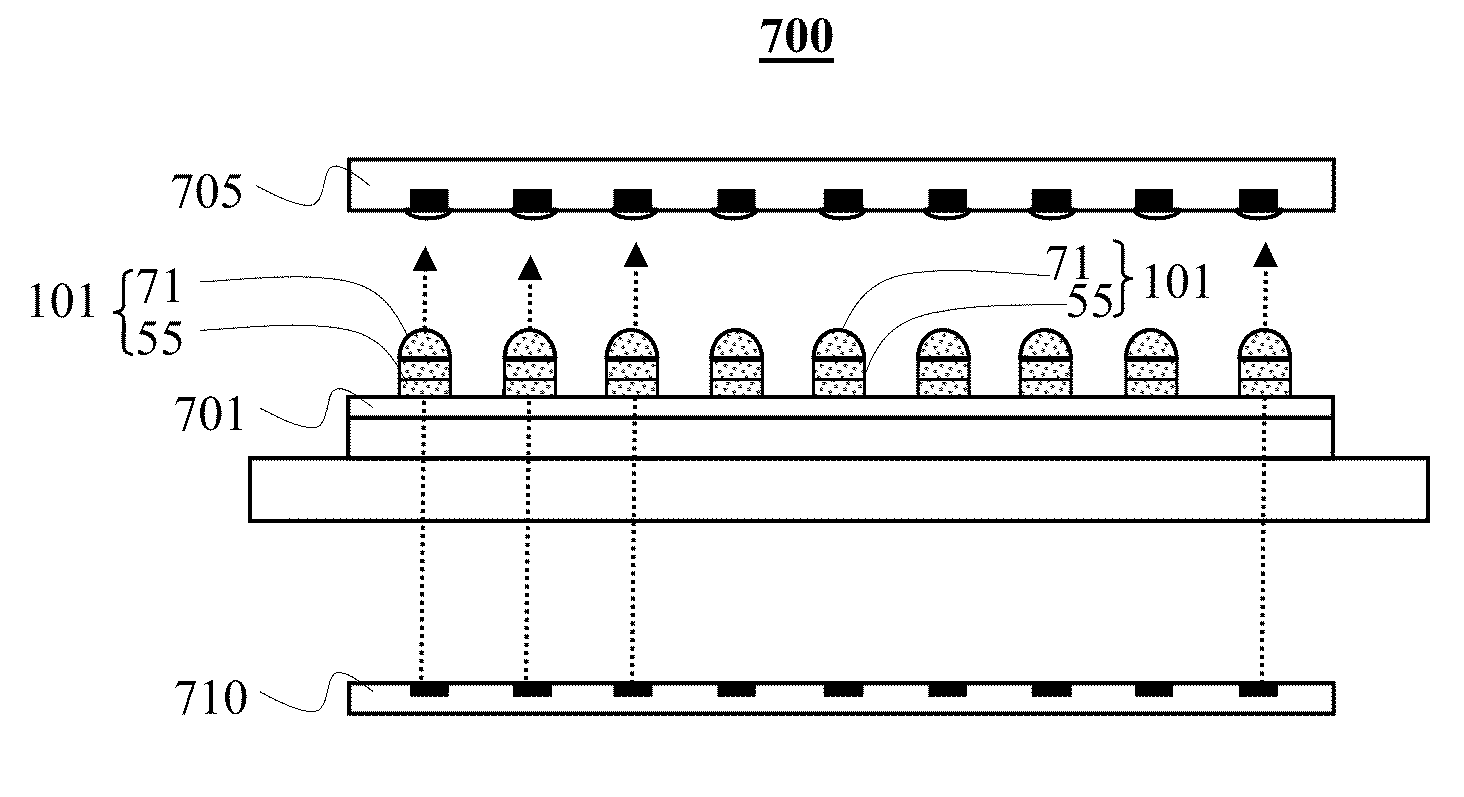

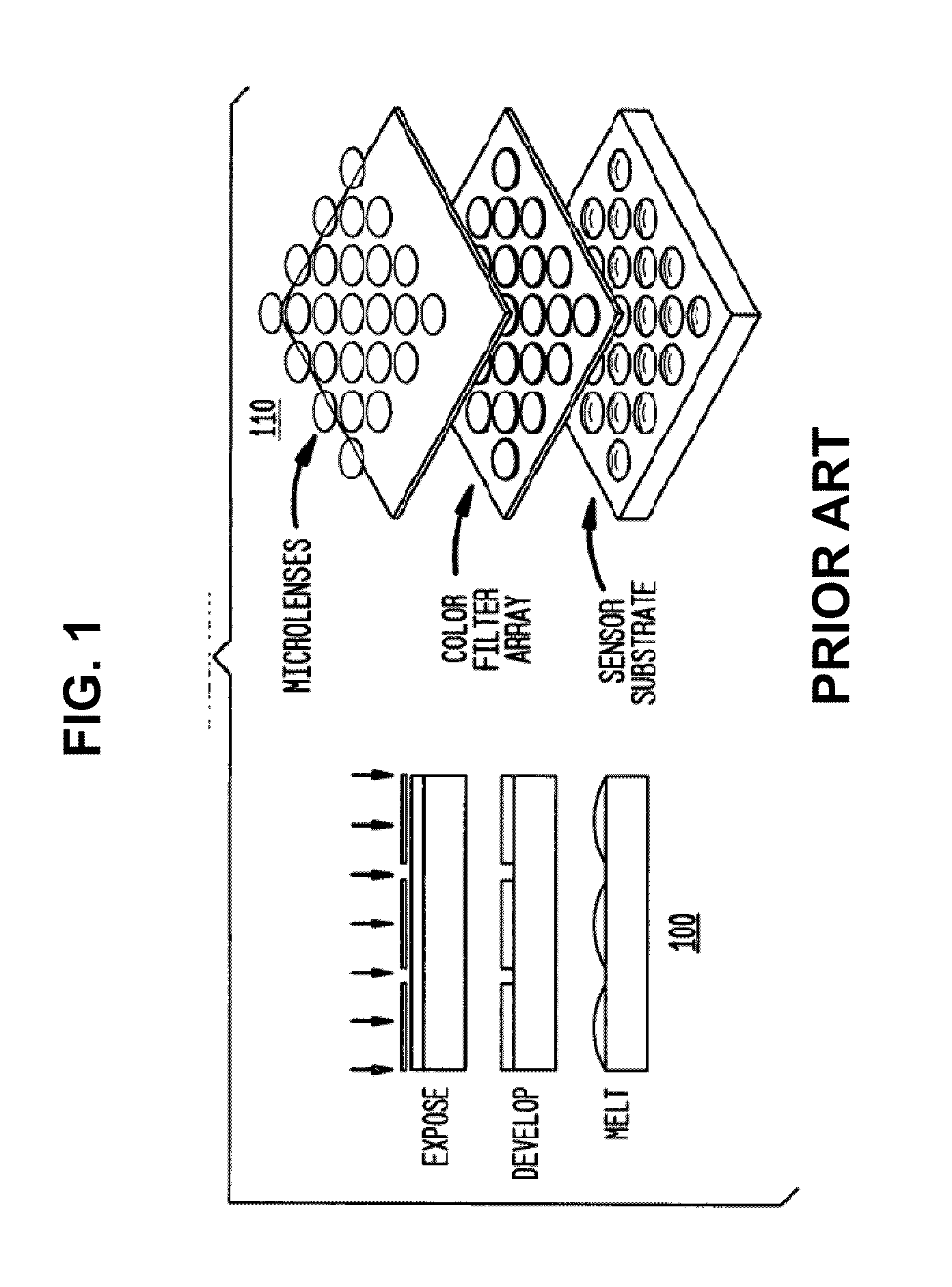

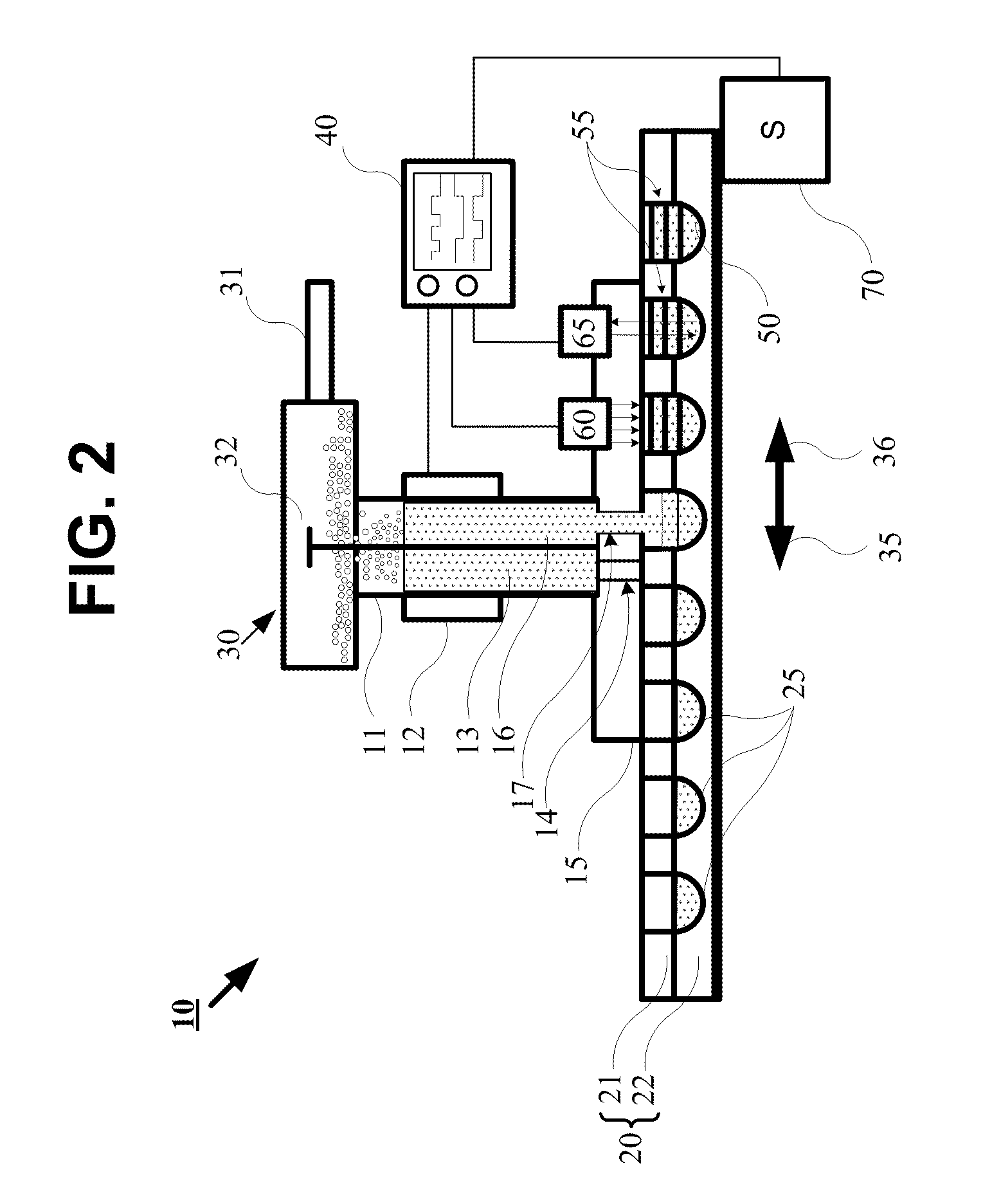

Fabrication of optical filters integrated with injection molded microlenses

InactiveUS20110090570A1Low costLow production costOptical articlesAuxillary shaping apparatusSingle injectionInjection moulding

Injection molding of monolithically integrated optical components is disclosed. In one embodiment, an injection molding system includes a moldplate having an array of specially designed cavities. In at least one cavity, different types of photo-curable optical materials are injected in an ordered sequence. In a first instance, a lens material is injected into the cavity and subsequently cured to form a predetermined lens element at the base of the cavity. In a second instance, a filter material is injected into the cavity above the already formed lens element. The filter material is also cured, and an optical filter is formed stacked onto the lens element and contained within sidewall of the cavity. In this manner, a complex optical component having an optical filter automatically aligned with, and monolithically integrated into, a lens element is readily formed in a single injection molding process.

Owner:GLOBALFOUNDRIES INC

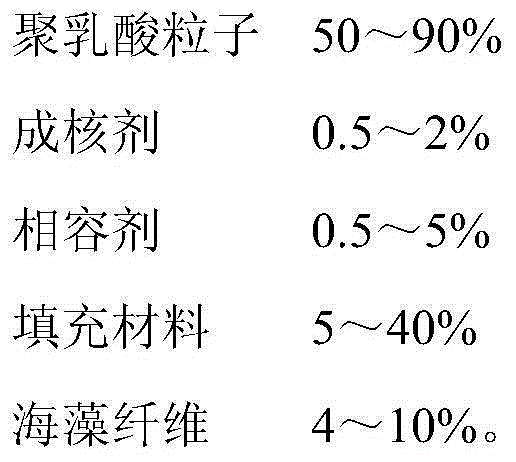

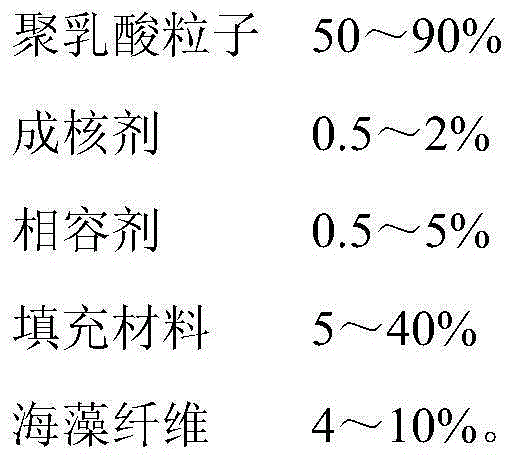

Heat resistant polylactic acid composite material and preparation method thereof

The invention belongs to the technical field of polymer materials and in particular relates to a heat resistant polylactic acid composite material and a preparation method thereof. The heat resistant polylactic acid composite material is prepared from the following raw materials by mass percent: 50-90% of polylactic acid particles, 0.5-2% of nucleating agents, 0.5-5% of compatilizer, 5-40% of filling material and 4-10% of alginate fibers. The heat resistant polylactic acid composite material has the advantages that by preferably selecting the polylactic acid nucleating agents, the crystallization process can be effectively completed in a drying oven and dimensional change in the baking process is small; the density of polylactic acid can be adjusted, the texture can be promoted and the cost can be reduced by adopting the filling material; meanwhile, the compatilizer is preferably selected, so that the mechanical properties of the highly filled heat resistant polylactic acid product are better; full crosslinking of reactive groups of all the components is promoted by adding the alginate fibers, thus further improving the mechanical properties and heat resistance of the material; crystallization outside molds is achieved through adjustment of a formula and the process; and the single injection molding cycle is shortened within 10 seconds.

Owner:SHENZHEN LYUYI PACKAGING CO LTD

Injection-molded footwear having a textile-layered outer sole

An article of textile-soled footwear and method of making employ a simple fabrication process and apparatus that allows fabrication of the footwear outer shell via a single injection-molding step. The article of footwear has a textile layer at the ground-contacting surface of the outsole, the textile layer being moldably and integrally attached, in a common mold, to the molded outsole as it is being created during the injection process. Fasteners are set along the side of the sole plate of the injection mold to secure the textile layer across the sole plate and prevent it from being moved during injection of the moldable compound to form the outsole. The sole plate and the sidewalls of the injection mold are assembled in place for the injection process. The shoe upper is fitted onto the shoe last and set in place in the mold, the mold is closed, and the moldable compound is injected into the mold. Once injection is complete, the mold side walls are opened, the injected shoe is removed, and the excess textile layer is trimmed. In the preferred embodiment, the molded outsole layer is made of a thermoplastic resin and the ground-contacting textile layer is a combination of cotton, polyester, and Lycra®.

Owner:PARATORE STEPHEN L +1

Valve and fueling strategy for operating a controlled auto-ignition four-stroke internal combustion engine

ActiveUS7152559B2Improve abilitiesReduce decreaseValve arrangementsElectrical controlOperating pointExternal combustion engine

Part load operating point for a controlled auto-ignition four-stroke internal combustion engine is reduced without compromising combustion stability through a valve control operative to establish low pressure conditions within the combustion chamber into which fuel and exhaust gases are introduced. Combustion chamber pressures during the intake cycle are controlled lower as engine load decreases. Combusted gases are recirculated into the combustion chamber through a variety of internal and external recirculation mechanizations. A split-injection fuel control is implemented during low part load operation whereas a single-injection fuel control is implemented during intermediate and high part load operation. Split-injections are characterized by lean fuel / air ratios and single-injections are characterized by either lean or stoichiometric fuel / air ratios. Controlled autoignition is thereby enabled through an extended range of engine loads while maintaining acceptable combustion stability and emissions.

Owner:GM GLOBAL TECH OPERATIONS LLC

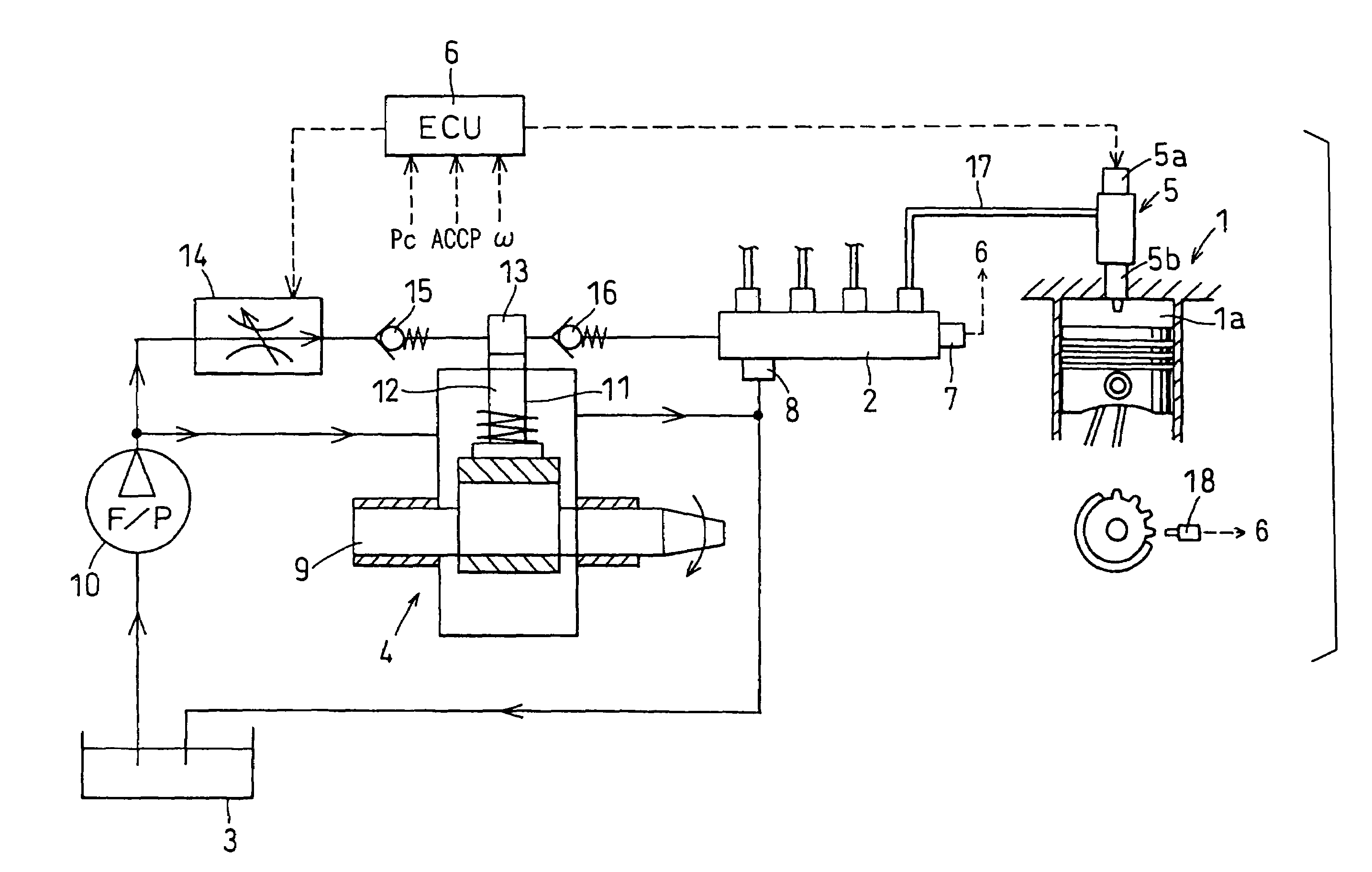

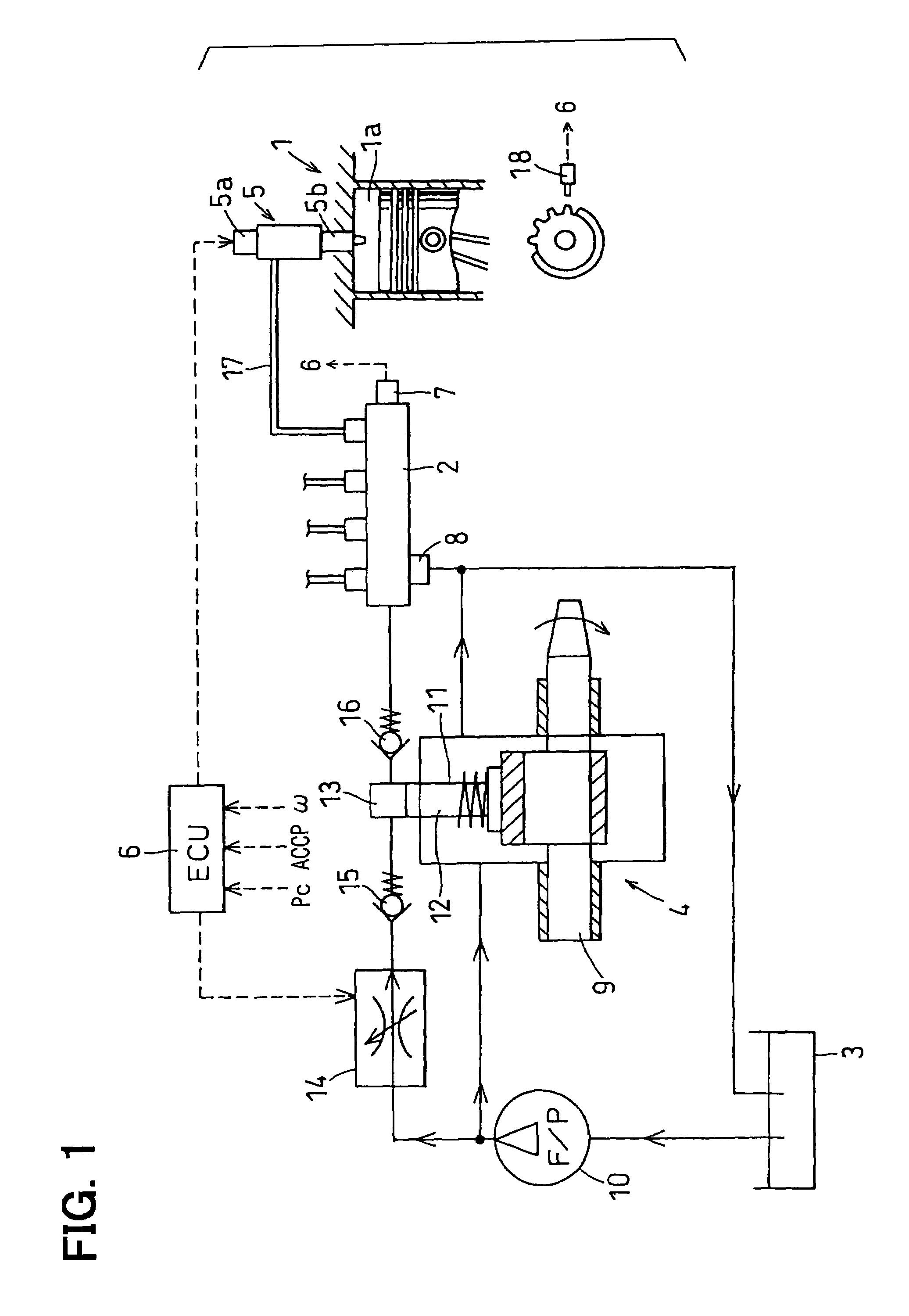

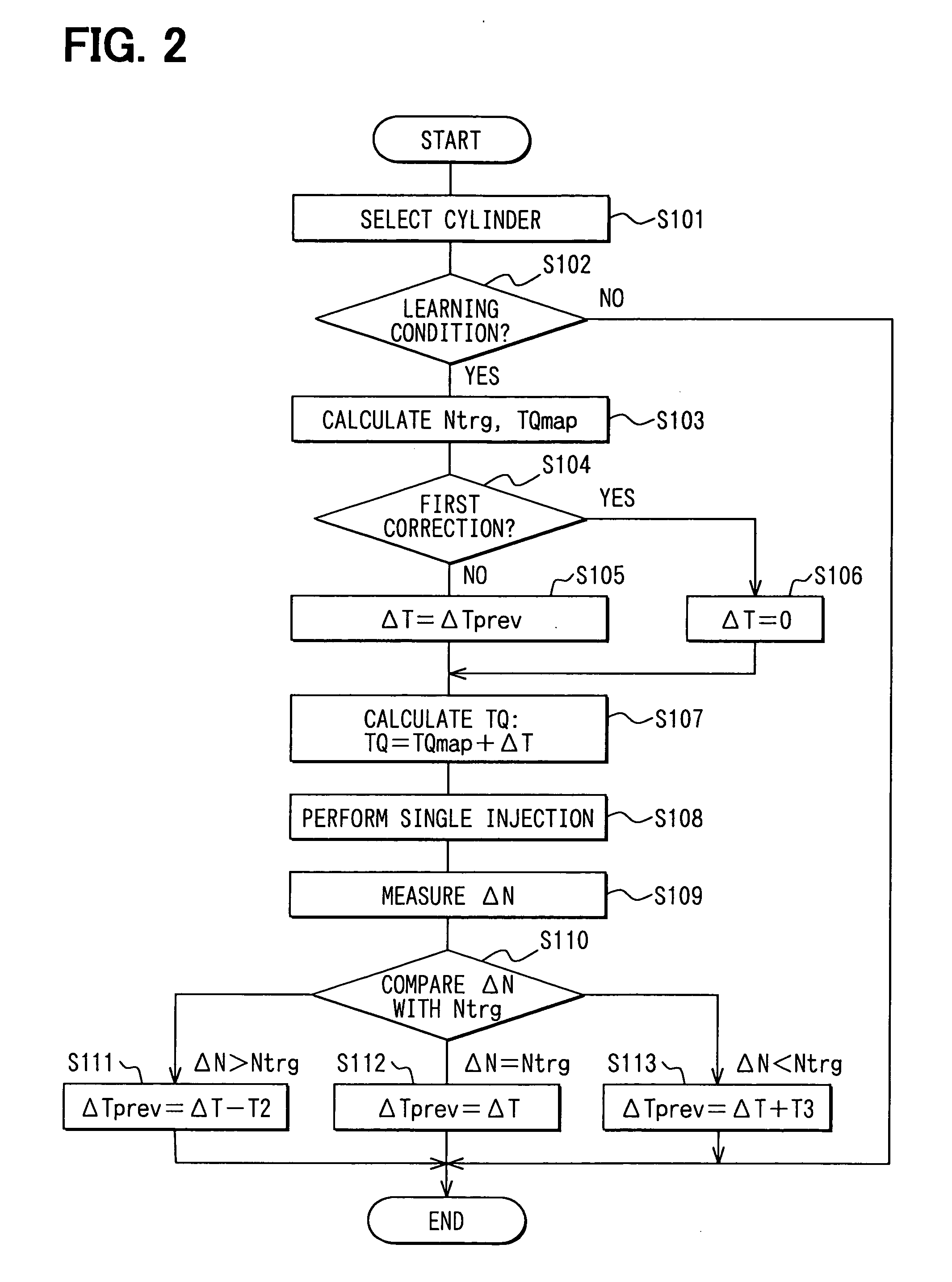

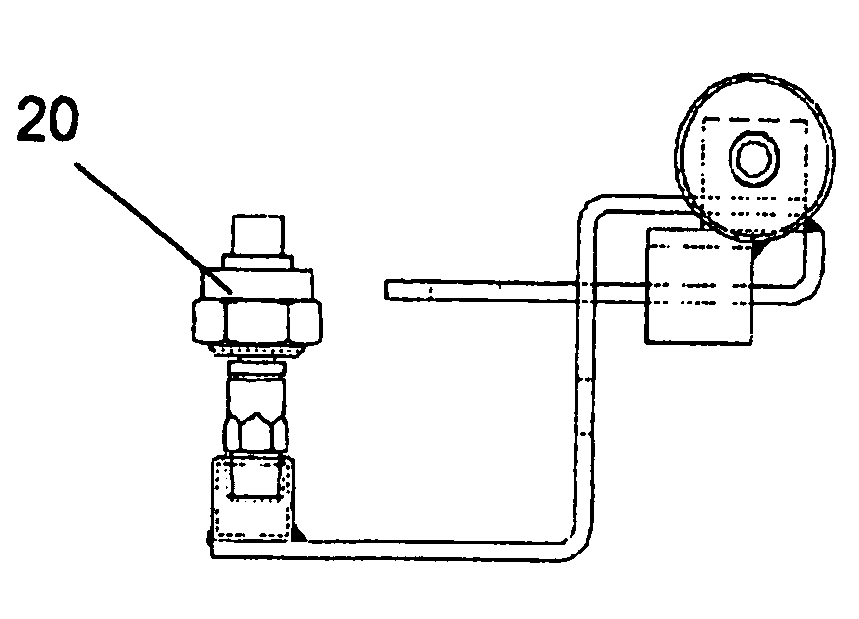

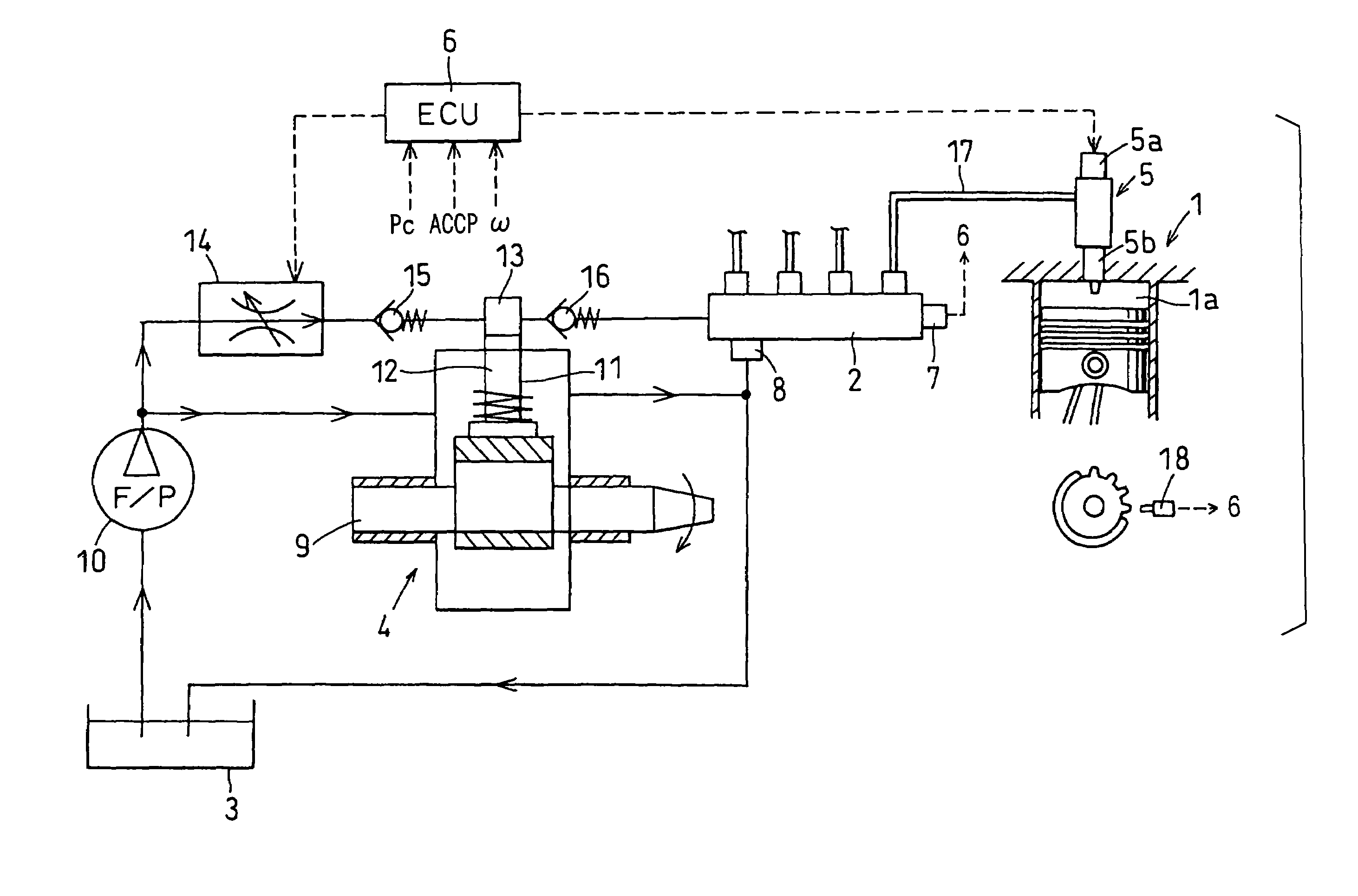

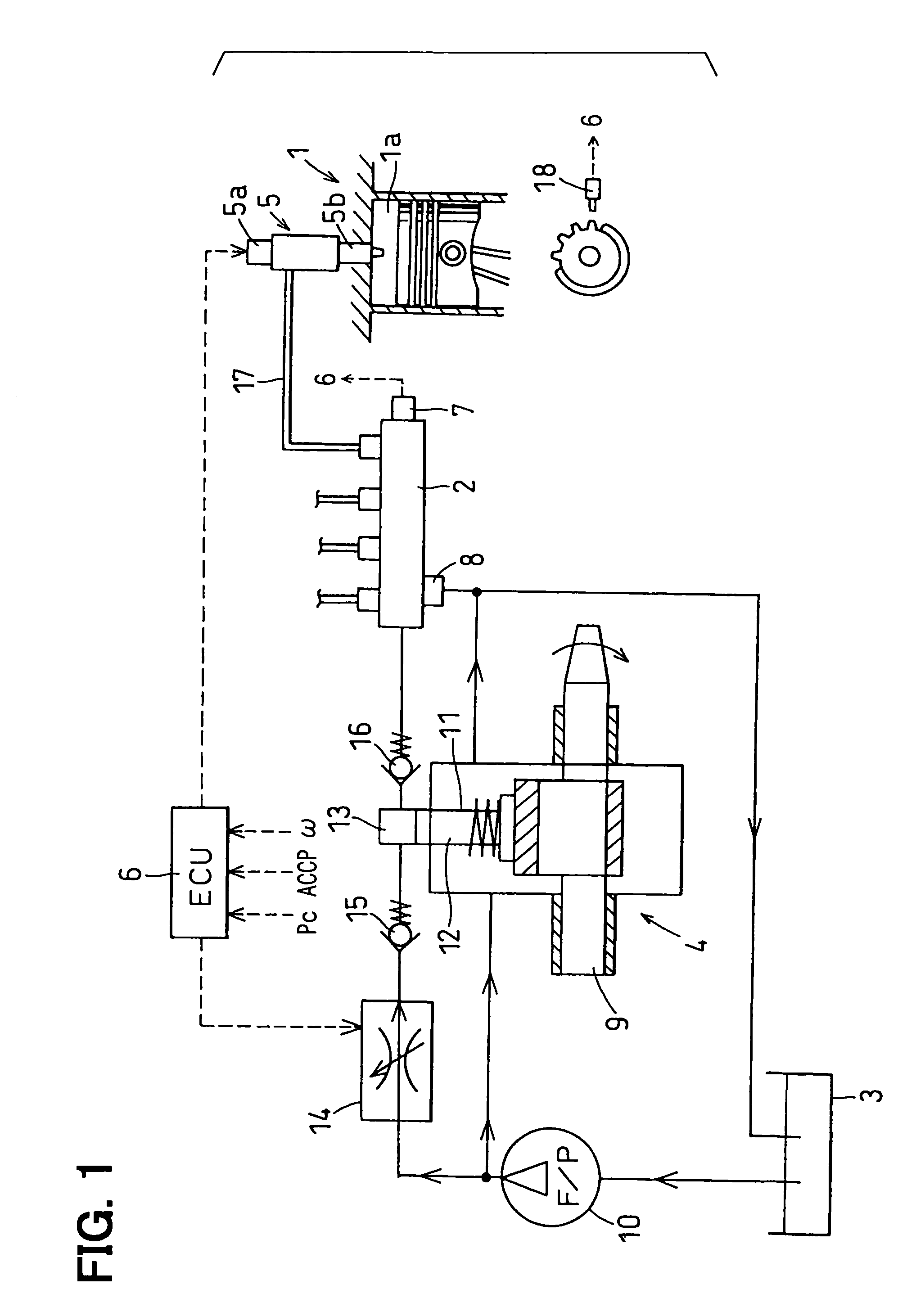

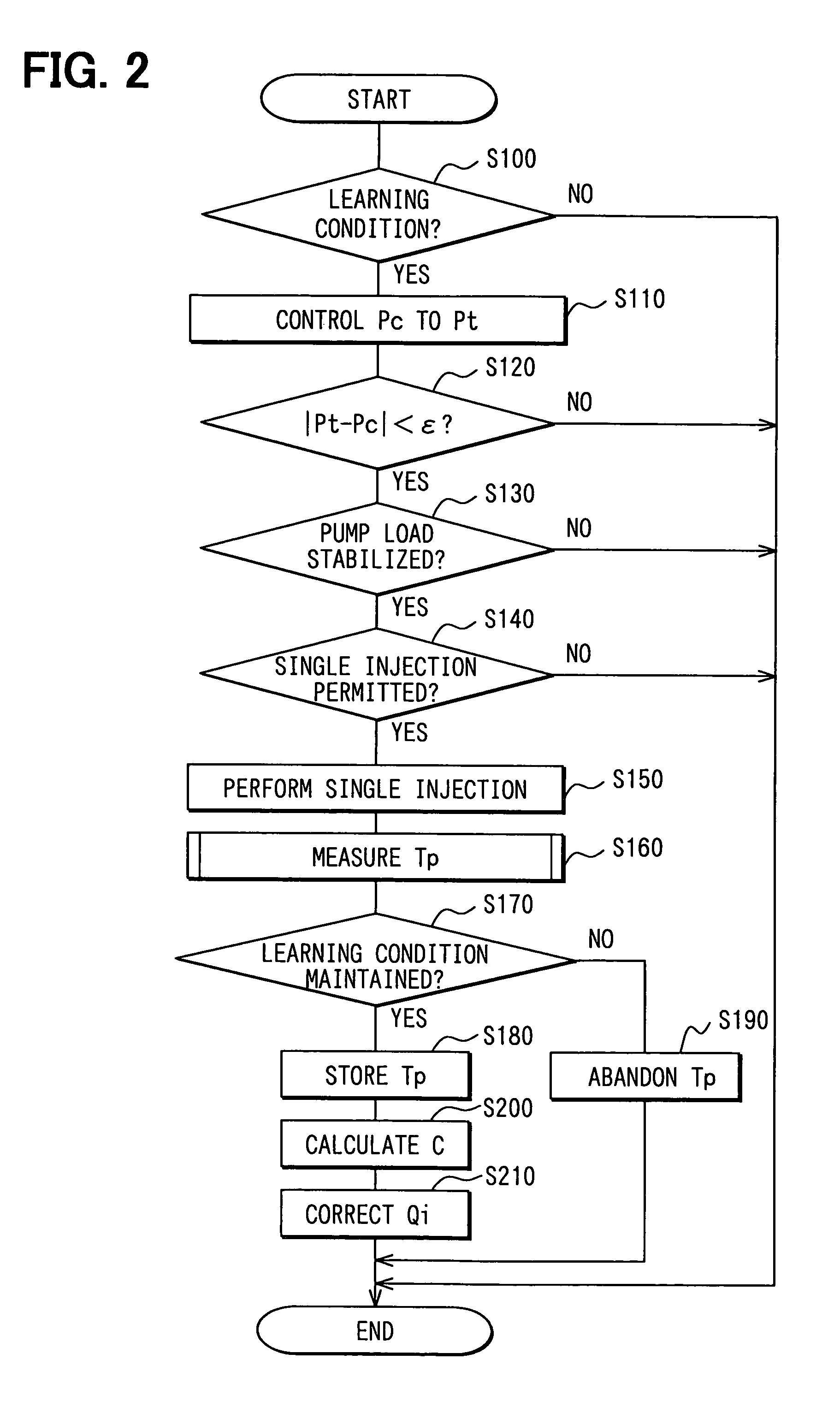

Injection control system of internal combustion engine

ActiveUS6988030B2Shorten the overall cycleAvoid emissionsAnalogue computers for vehiclesElectrical controlState variationControl system

Owner:DENSO CORP

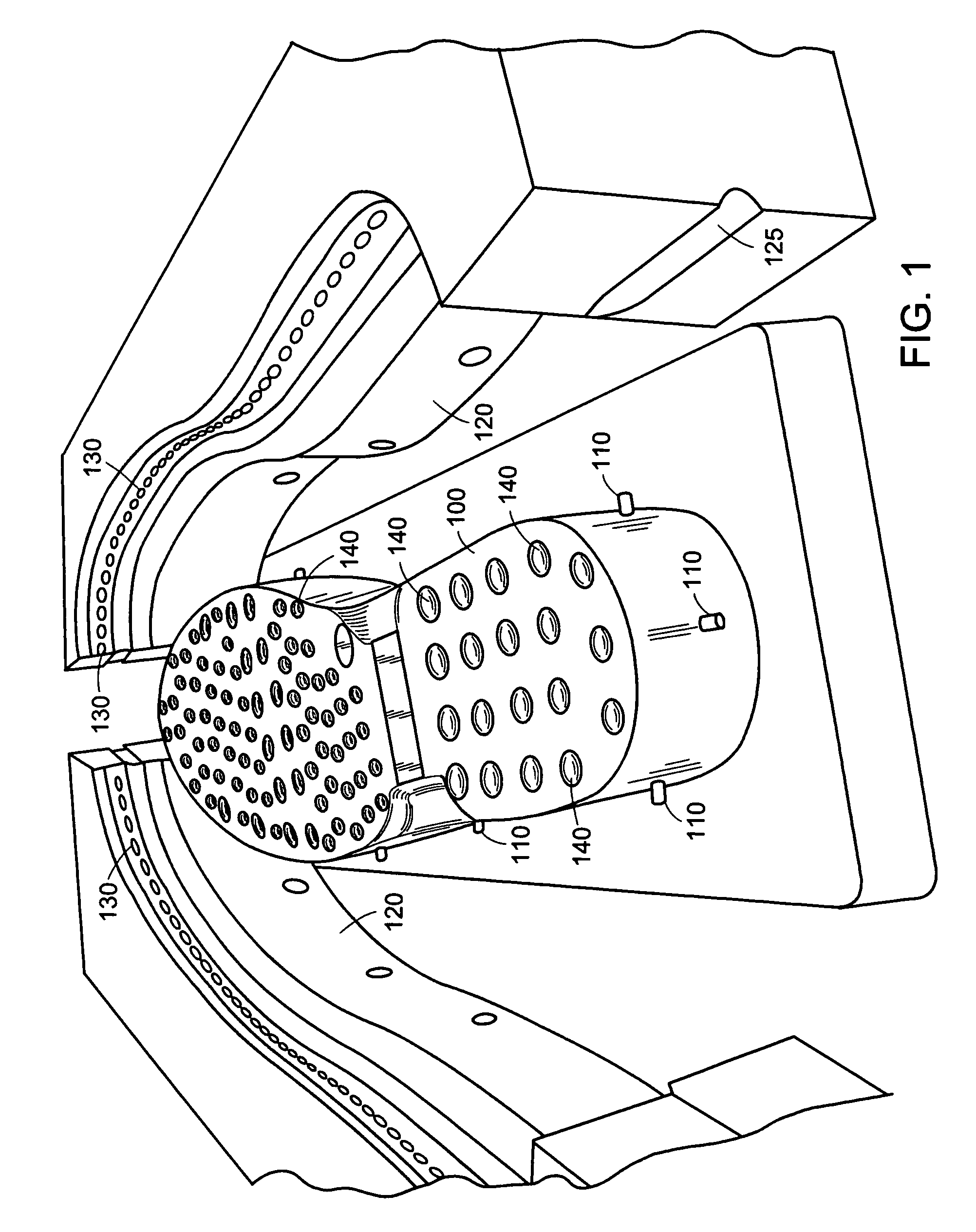

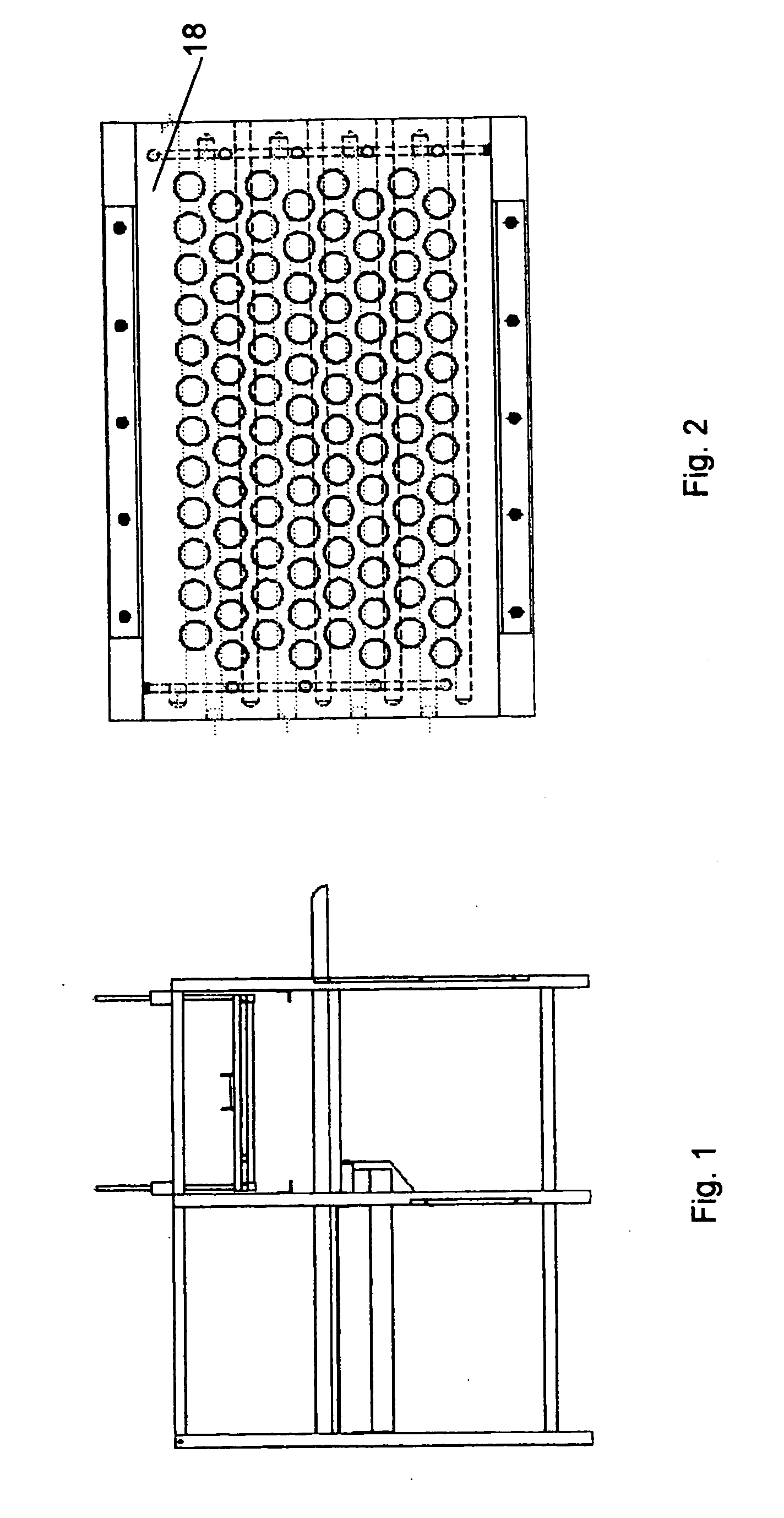

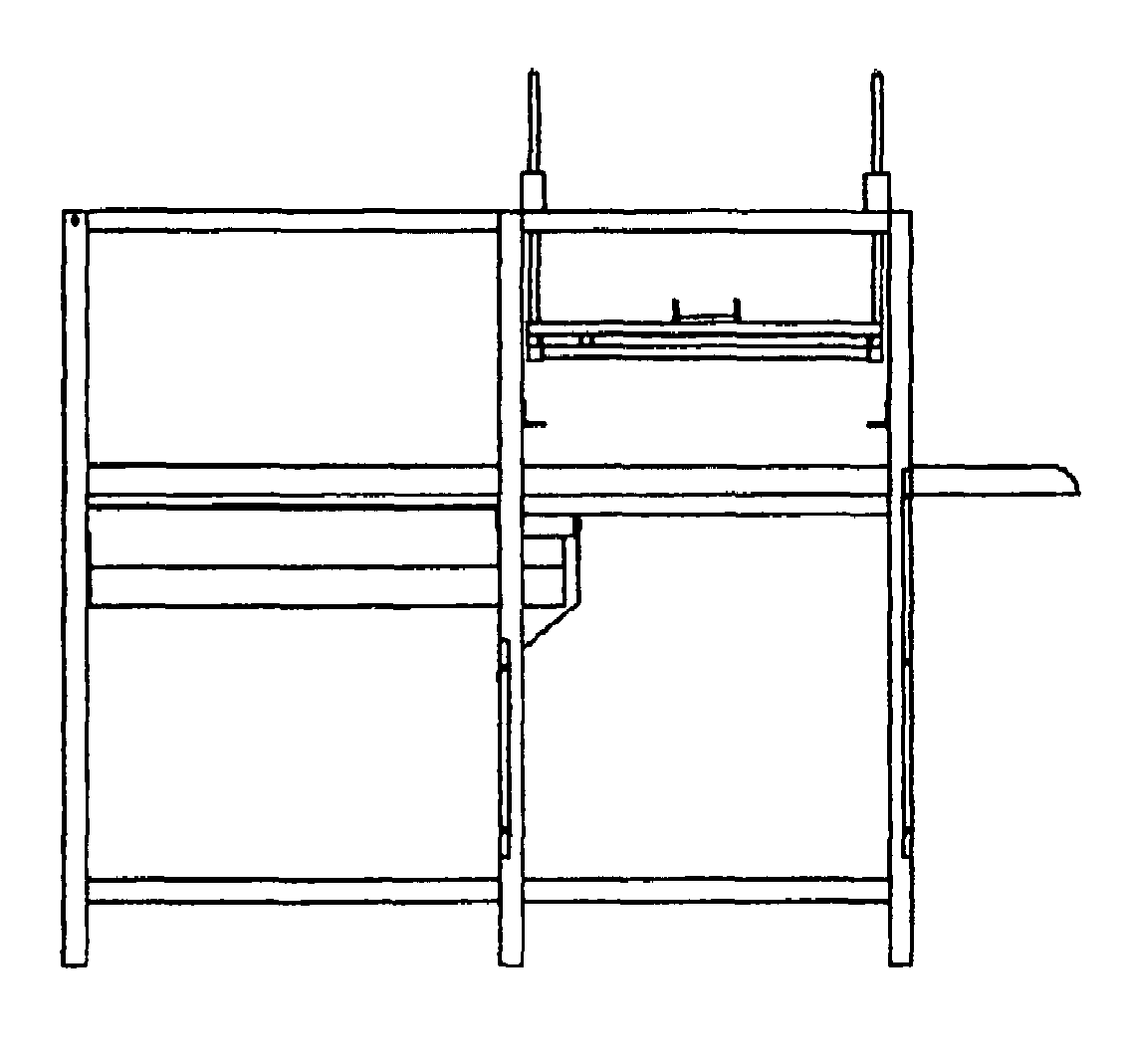

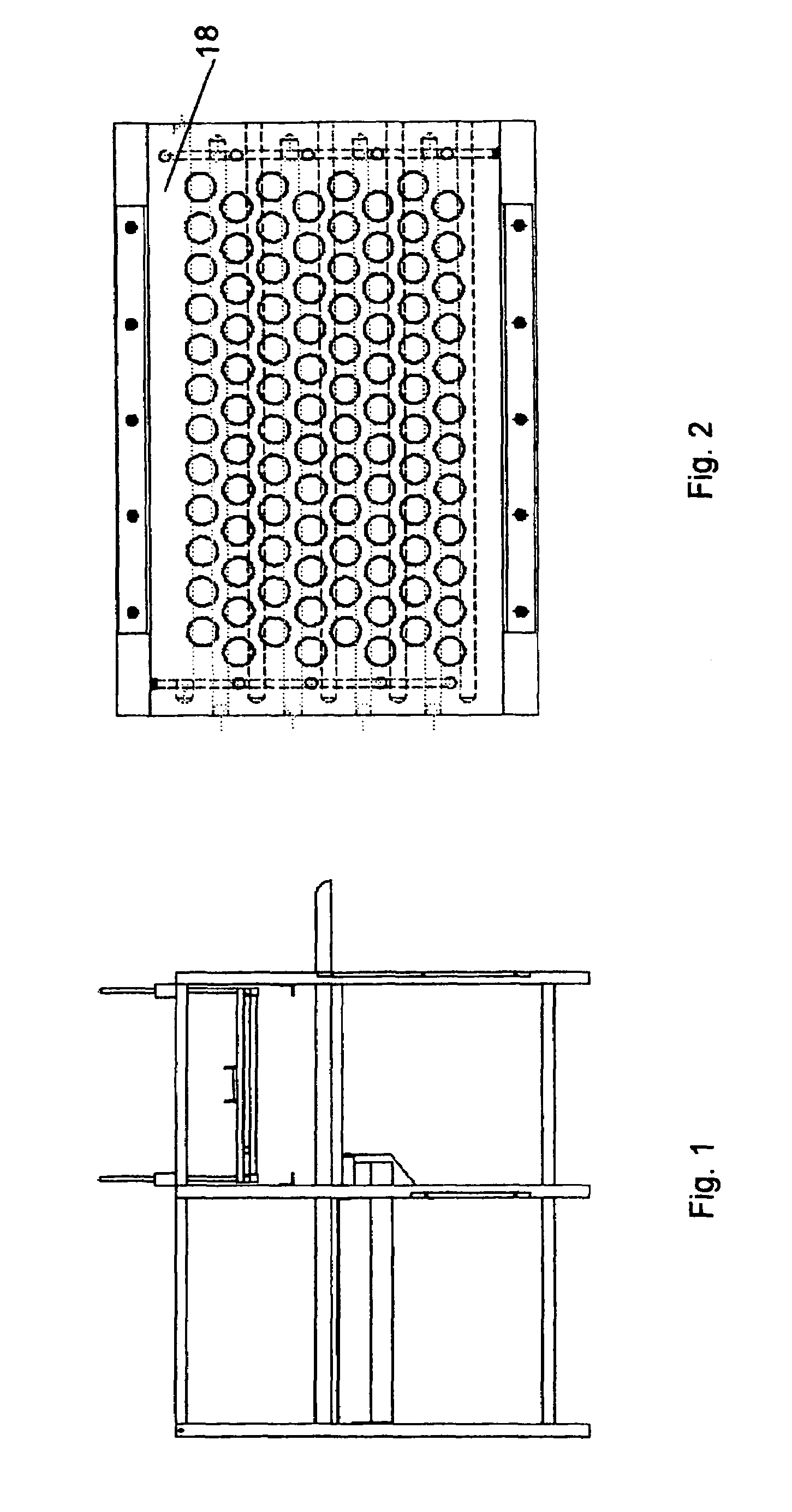

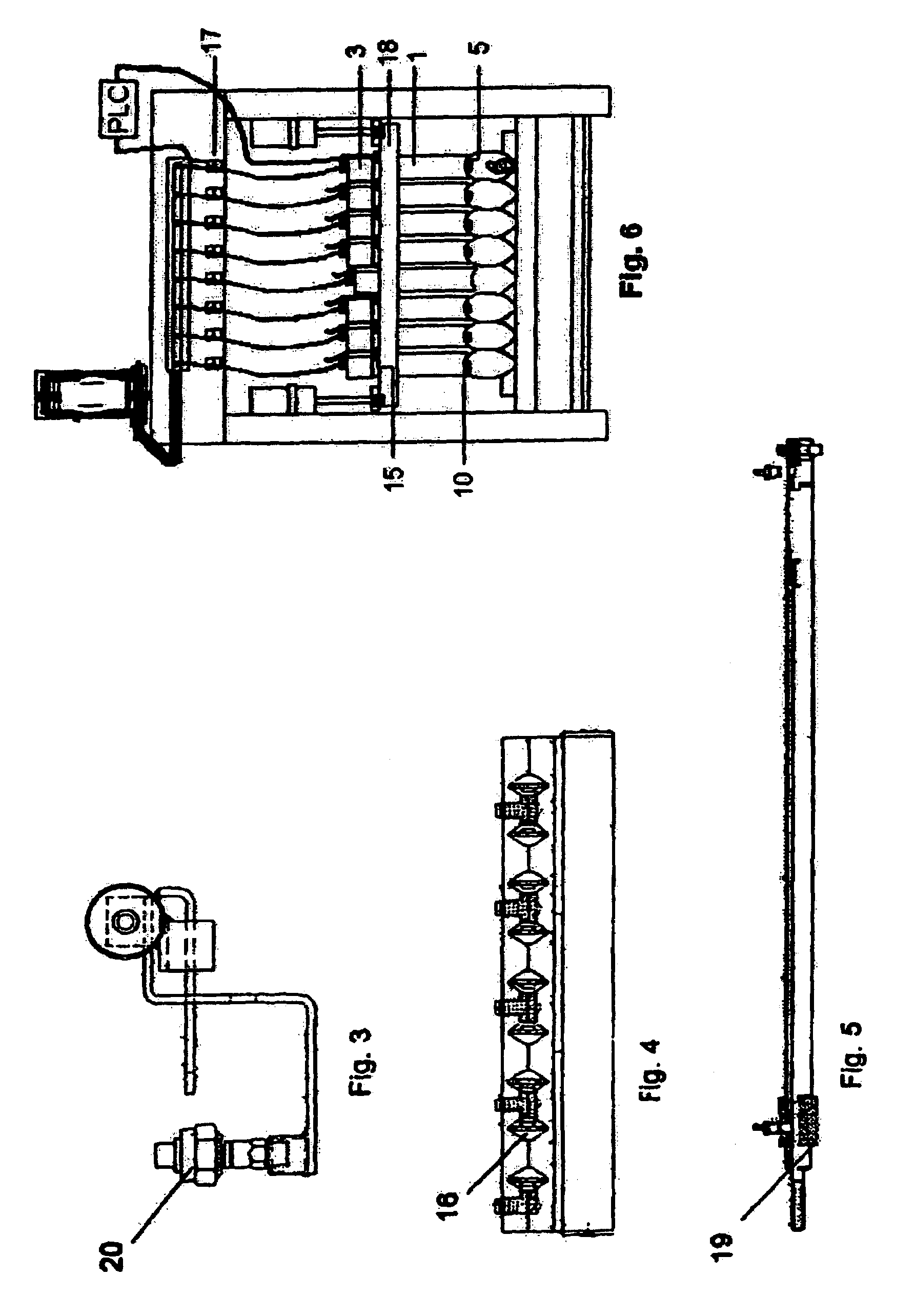

Automatic egg vaccinator

The invention relates to a system of automatic vaccination of eggs, developed for the purpose of vaccinating large quantities of fertile eggs in order to reduce the costs and labor involved, reduce embryonic mortality by increasing protection from diseases and reduce the stress in the first day of life of poultry chicks by eliminating the process of manually vaccinating each chick. The invention comprises an automatic system controlled by a PLC (programmable logic controller), using an injector that has a cylindrical body and cap made from high density non-corrosive plastic and together they form a pneumatic chamber, the cap containing an electronic contact sensor to signal empty egg spaces and avoiding wasting vaccine. The injector's pneumatic chamber contains a plasticized fiber sleeve to permit smooth movement of the pneumatic plunger. A needle passes through the plunger and a double acting spring in addition to securing the plunger in its starting position and returning it to the original position after the injection of vaccine, reduces the pressure on the needle after it breaks the egg shell to avoid harming the embryo. The injection platform that has conical holes for the injectors to permit lateral movements that allows the injectors to accommodate eggs that are tilted, with the injectors locked into position by a series of air bladders located within the platform and running parallel to the injectors. The sanitization system which disinfects the needle and the part of the injector in contact with the egg after every single injection is coupled with the removal of the incubator trays from the vaccination area to economize on production time.

Owner:MERIAL INC

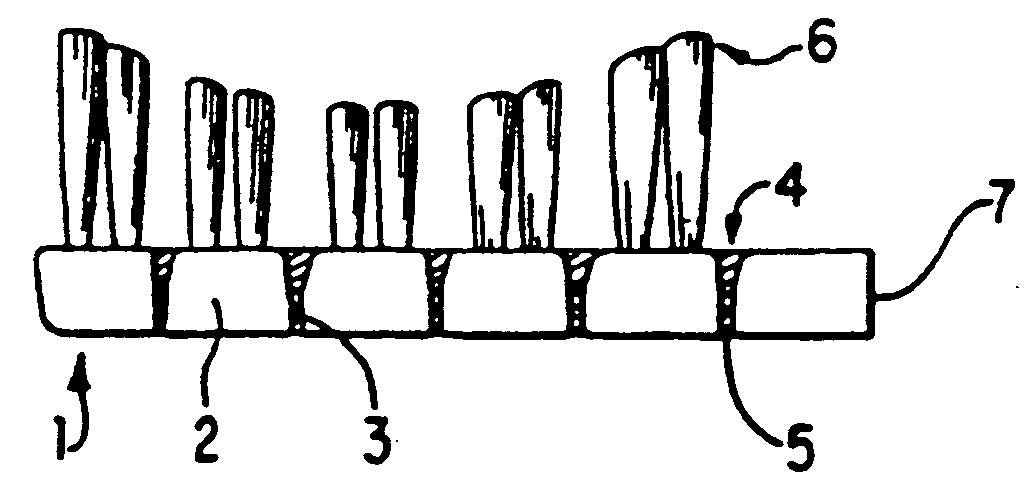

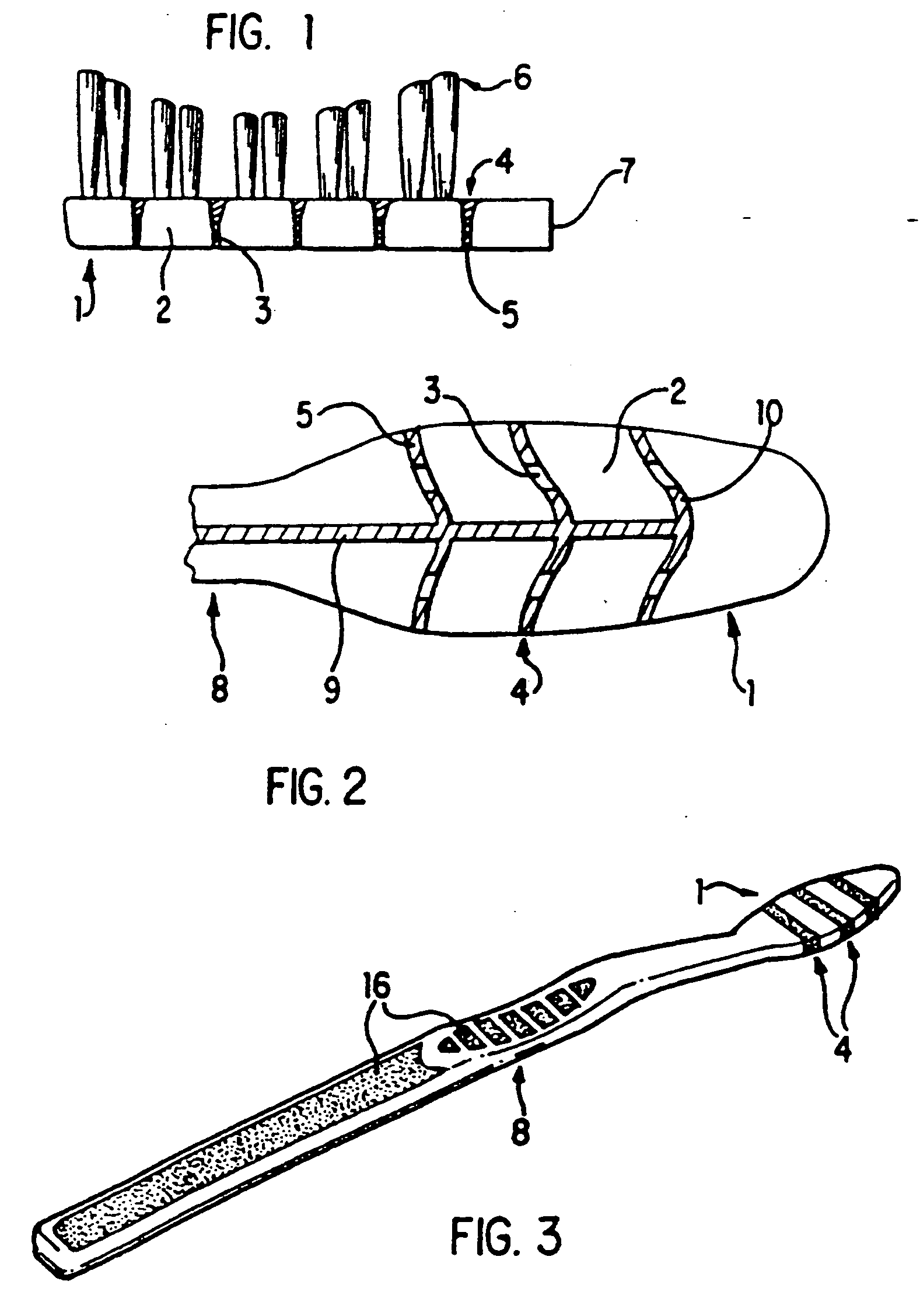

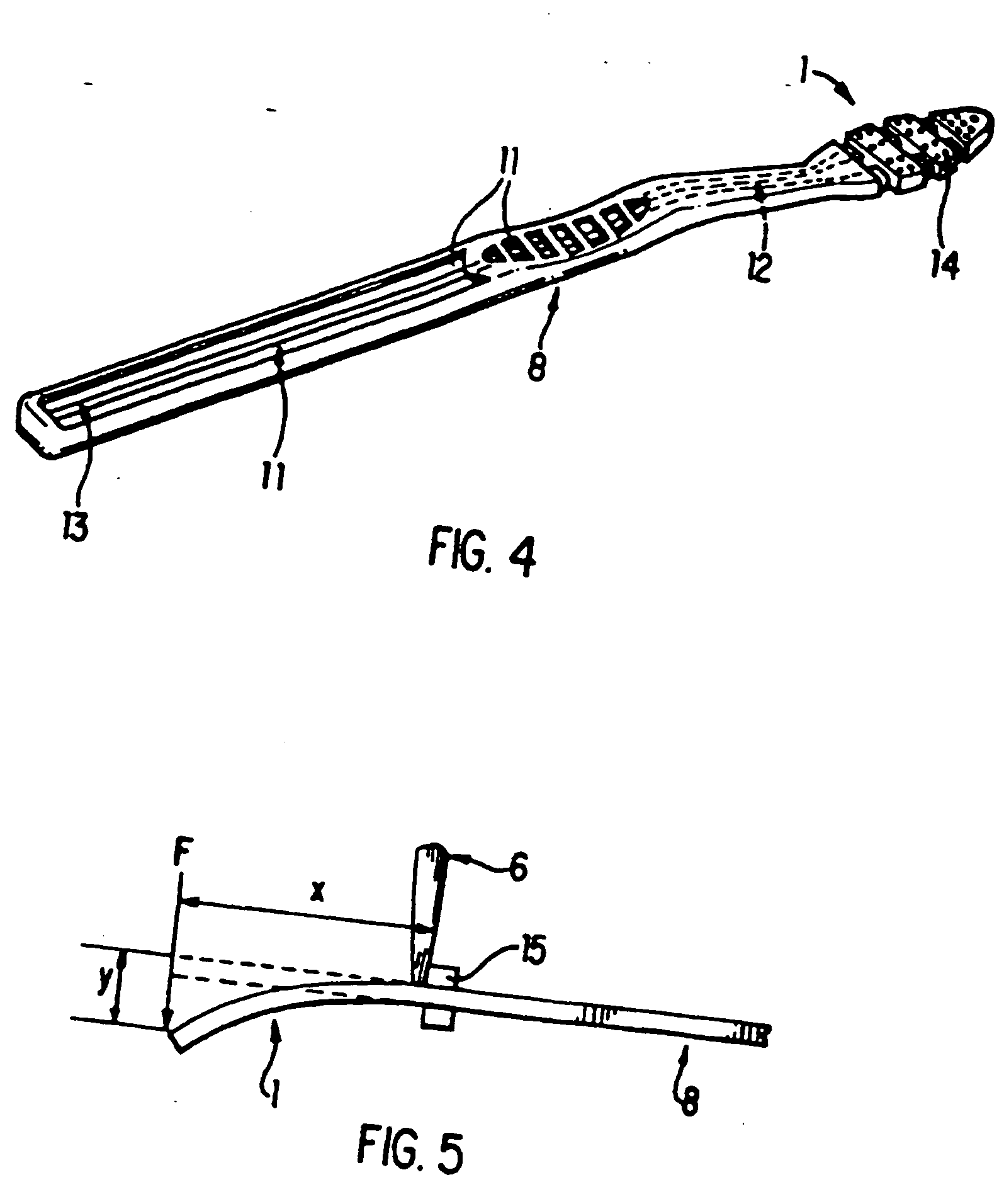

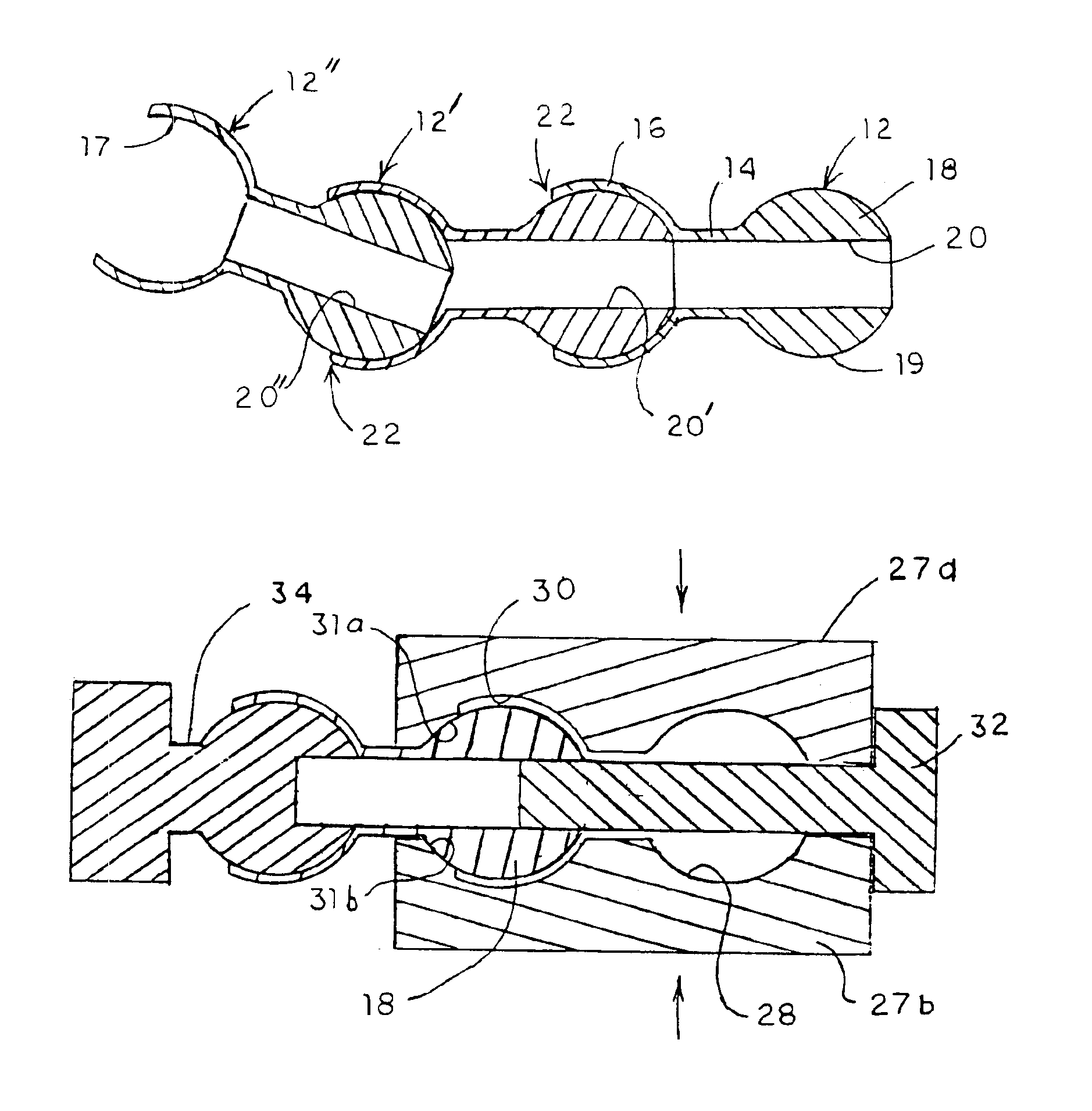

Toothbrush with elastomer filled flexible head

The invention relates to a toothbrush comprising: i) an elongated handle having distal and proximal ends and one or more elastomeric handle regions therein; and ii) a resiliently flexible head attached to the proximal end of the handle, the head including a pair of opposing faces, one of the pair being a bristle-bearing face with bristles attached to and extending from the face, wherein at least one of the pair has one or more elastomer-containing, transverse grooves therein; and iii) one or more elastomer supply channels extending between the elastomeric handle regions and the transverse grooves. Whereby at least one of the elastomeric handle regions and the traverse grooves can be filled with elastomer from a single injection point. The elastomeric regions in the head can be used to make the head flexible and the whole brush can conveniently be made on conventional machines.

Owner:THE PROCTER & GAMBLE COMPANY

Injection control system of diesel engine

An electronic control unit (ECU) of an injection control system of an internal combustion engine determines that a load of a fuel pump is stabilized when a pressure-feeding operation delay elapses since a command pressure-feeding quantity outputted to the fuel pump reaches a certain pressure-feeding quantity necessary to maintain a target injection pressure. The ECU permits a single injection when a waiting period necessary to measure rotation speeds once for each cylinder before the single injection is performed elapses since the load of the fuel pump is stabilized. Thus, the single injection timing is determined based on the time point when the command pressure-feeding quantity is stabilized, the pressure-feeding operation delay, and the waiting period. Therefore, an injection quantity learning operation can be performed highly accurately in a short period.

Owner:DENSO CORP

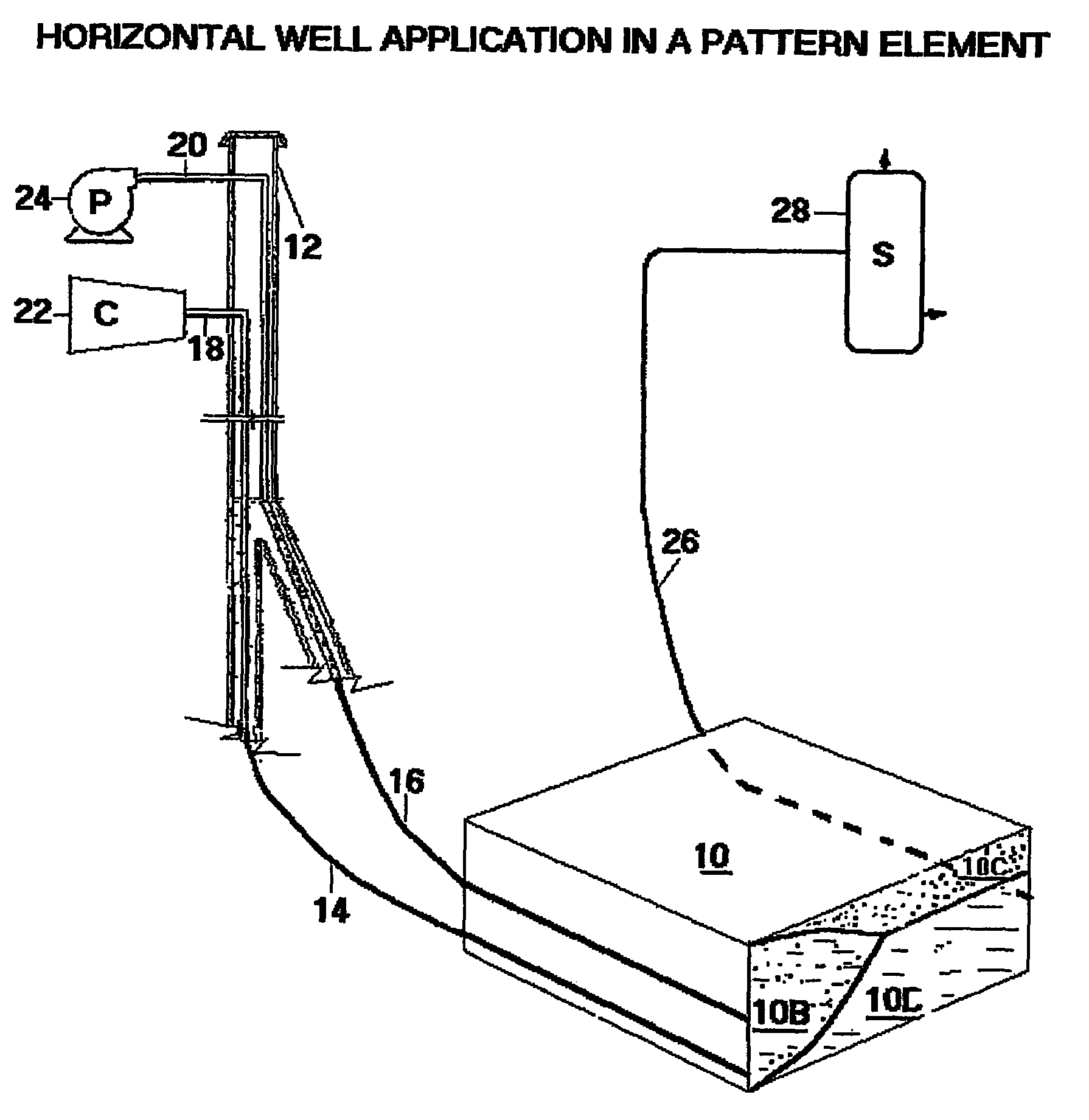

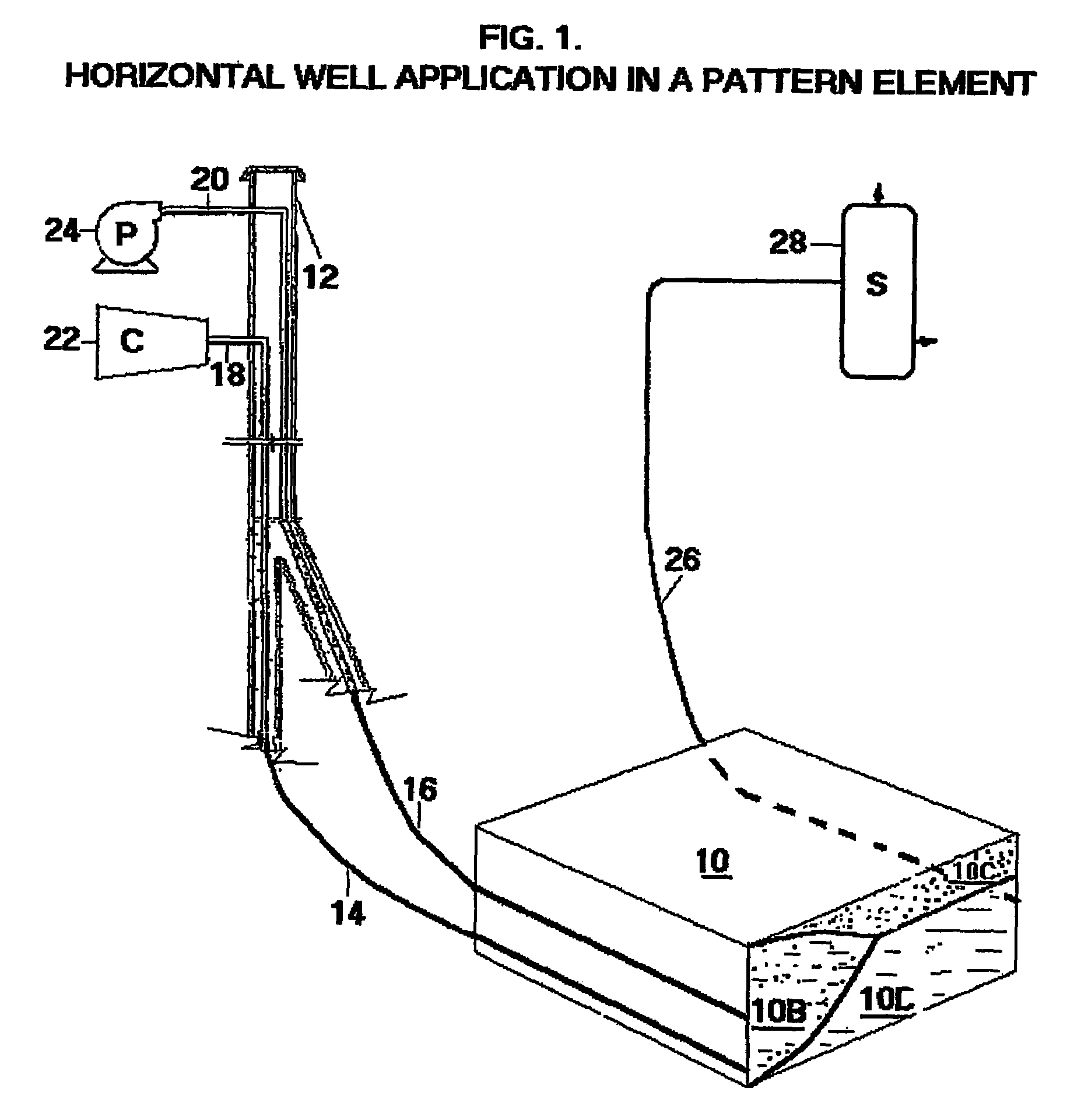

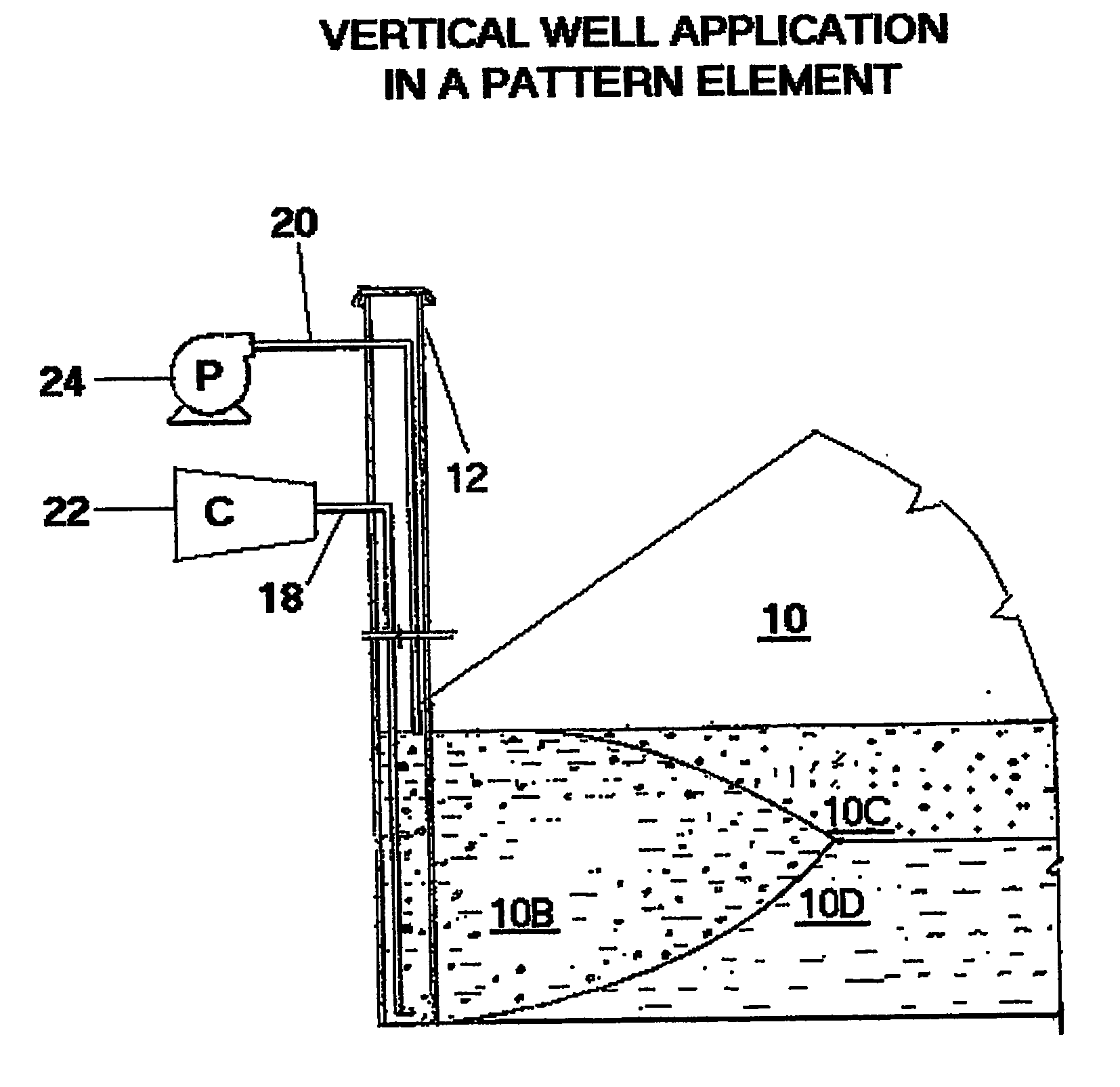

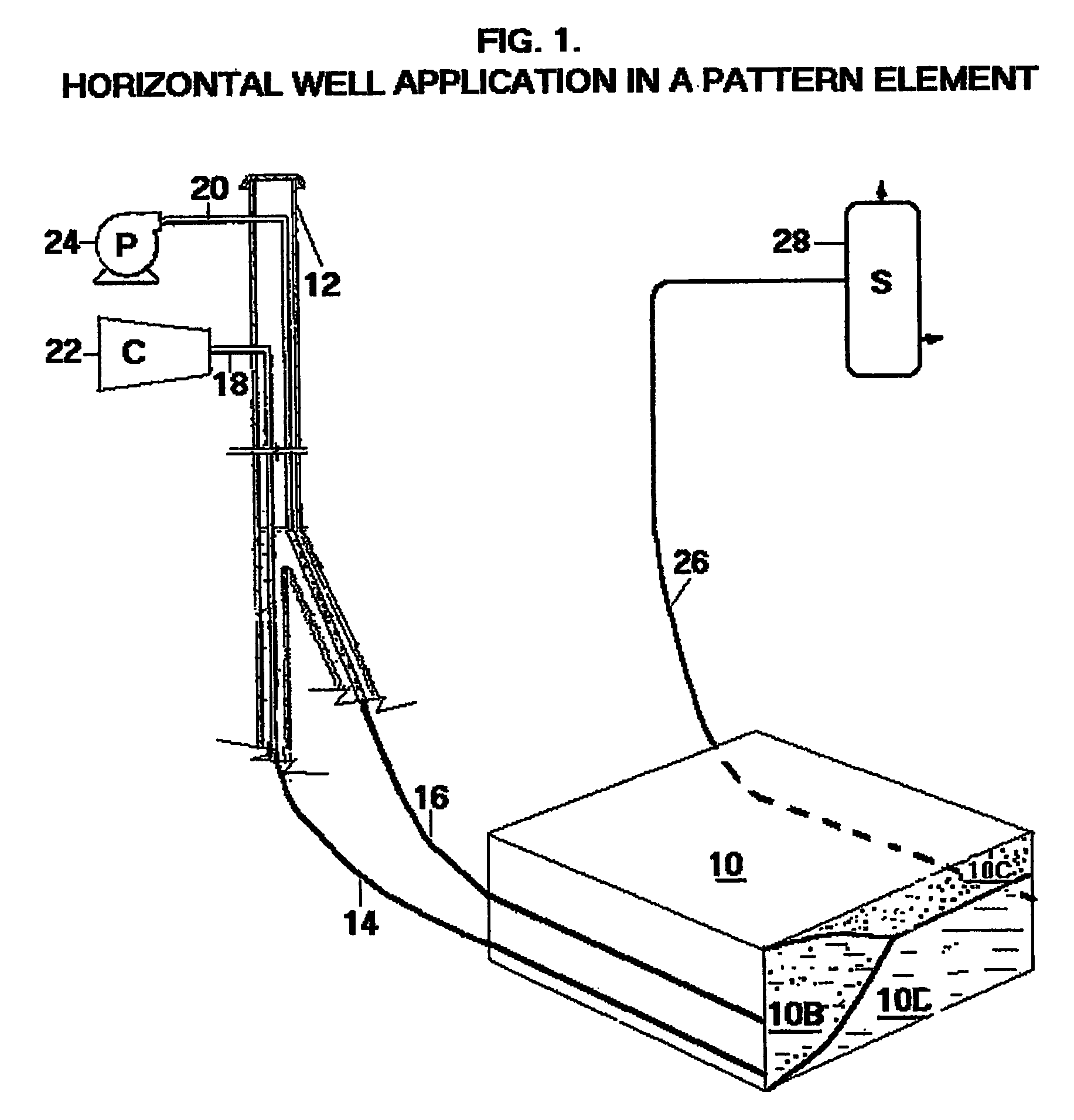

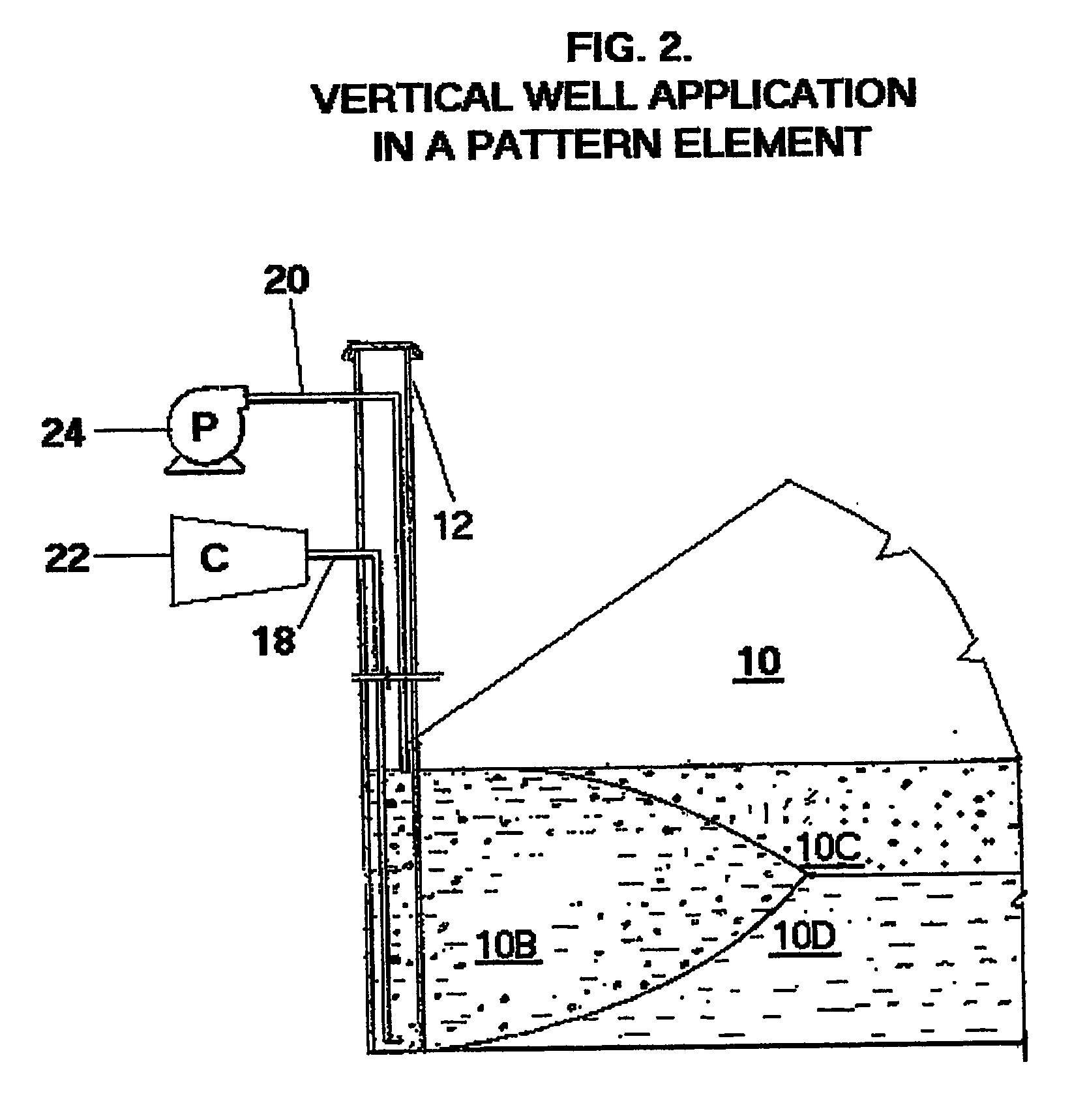

Method for improved vertical sweep of oil reservoirs

InactiveUS7303006B2Promote recoverySlow and control segregationSurveyFluid removalSweep efficiencySingle injection

In a WAG flood oil is displaced from a subterranean formation by injecting water alternately with gas into a single injection completion per pattern. The ratio of water to gas injected is the WAG ratio. In this invention, two separate injection completions are used in each pattern, with one placed directly above the other. A very low WAG ratio is used for injection into the bottom extremity of the formation. A very high WAG ratio is injected into the upper interval, at as high a rate as can safely be used without fracturing the formation. In the preferred embodiment, two horizontal well bores serve as the two completion intervals. Proper design of this method gives a vertical sweep efficiency of the gas that is several-fold greater than the best of previous WAG flood designs, especially in thin formations.

Owner:STONE HERBERT L

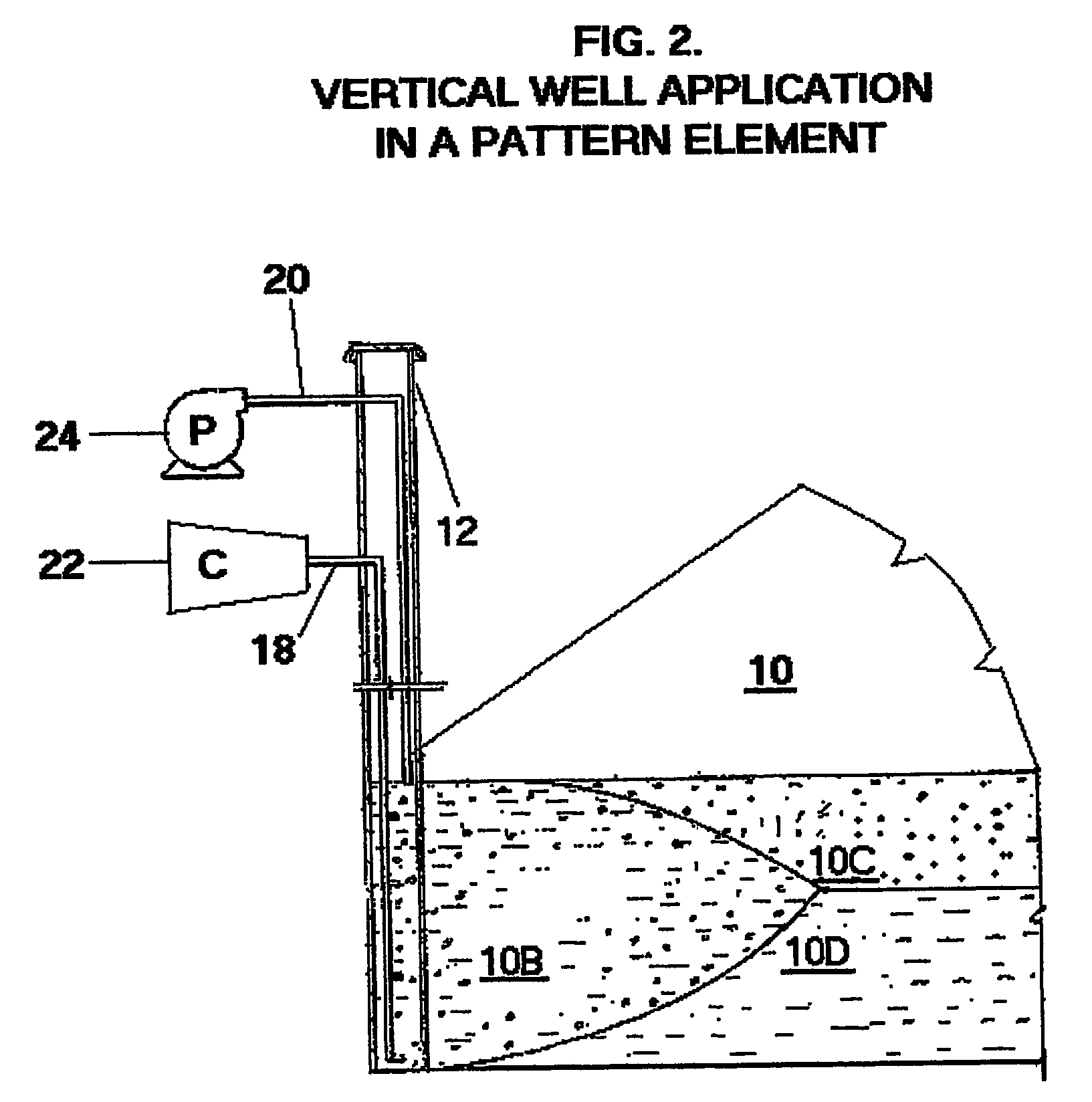

Fluid conduits and method of manufacturing same

InactiveUS6854768B2Even abilityLikelihood evenSleeve/socket jointsClosuresJoint componentSingle injection

A continuous flexible conduit is formed from like-configured components, each having a male joint member and a female joint member with a passageway extending therethrough. The female joint member is over-molded about a corresponding male joint member to form a substantially fluid-tight articulating joint. In a method of producing the flexible conduit, a single-shot molding process is used to form each like-configured component, with each newly formed component indexed within the single-shot mold so that the male joint member is within the female mold cavity for the formation of the next component. In an alternative embodiment, a continuous conduit is formed of two different sets of like configured components—one set having only female joint members and the other set having only male joint members. A two-shot molding process is described for continuous production of the flexible conduit using these two sets of components.

Owner:INNATECH

Automatic egg vaccinator

The invention relates to a system of automatic vaccination of eggs, developed for the purpose of vaccinating large quantities of fertile eggs in order to reduce the costs and labor involved, reduce embryonic mortality by increasing protection from diseases and reduce the stress in the first day of life of poultry chicks by eliminating the process of manually vaccinating each chick. The invention comprises an automatic system controlled by a PLC (programmable logic controller), using an injector that has a cylindrical body and cap made from high density non-corrosive plastic and together they form a pneumatic chamber, the cap containing an electronic contact sensor to signal empty egg spaces and avoiding wasting vaccine. The injector's pneumatic chamber contains a plasticized fiber sleeve to permit smooth movement of the pneumatic plunger. A needle passes through the plunger and a double acting spring in addition to securing the plunger in its starting position and returning it to the original position after the injection of vaccine, reduces the pressure on the needle after it breaks the egg shell to avoid harming the embryo. The injection platform that has conical holes for the injectors to permit lateral movements that allows the injectors to accommodate eggs that are tilted, with the injectors locked into position by a series of air bladders located within the platform and running parallel to the injectors. The sanitization system which disinfects the needle and the part of the injector in contact with the egg after every single injection is coupled with the removal of the incubator trays from the vaccination area to economize on production time.

Owner:MERIAL INC

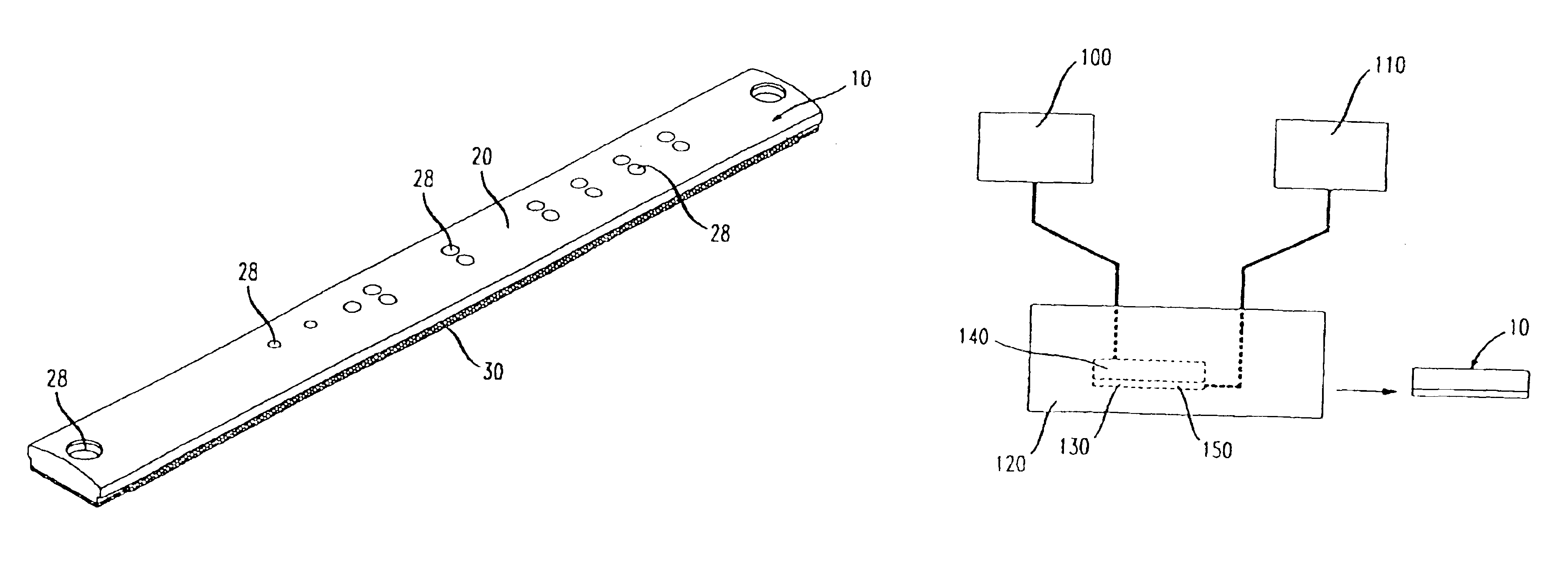

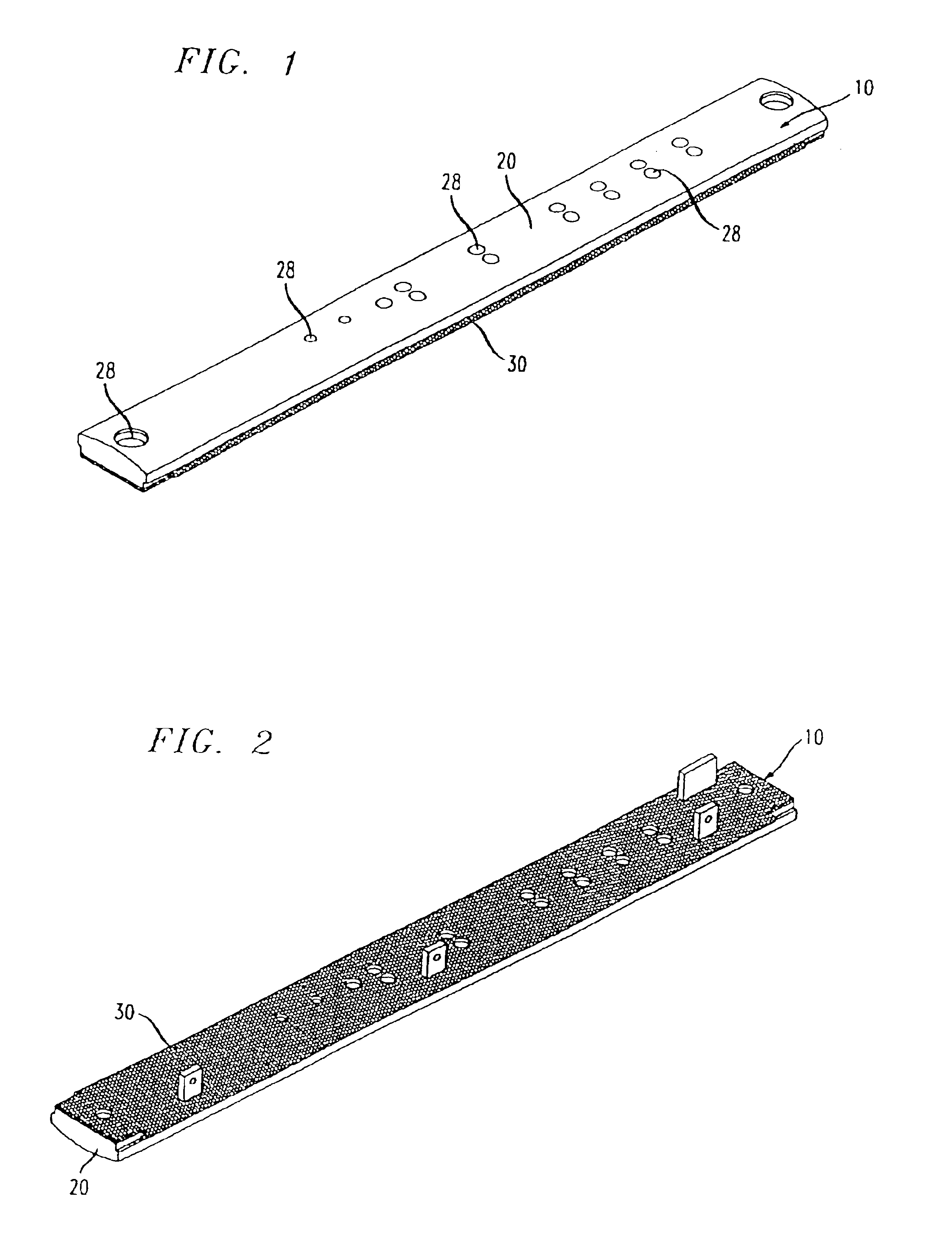

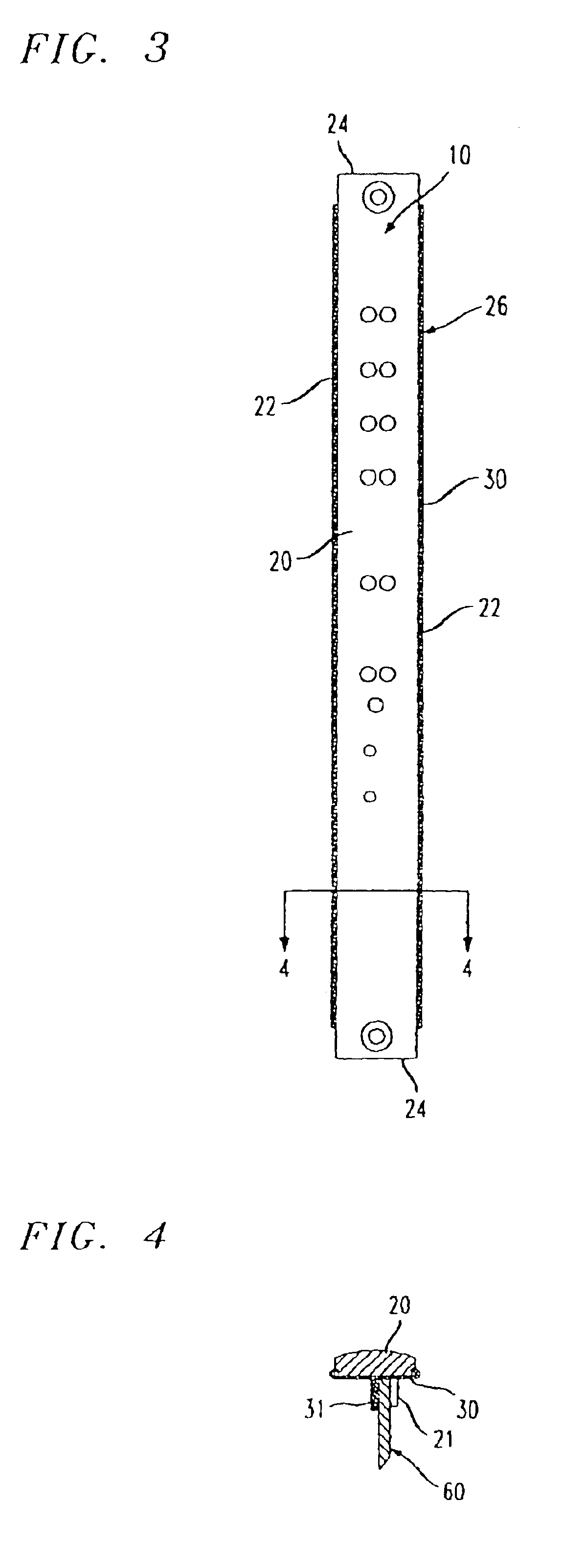

Device and method of forming a unitary electrically shielded panel

InactiveUS6865805B2Less-costly to fabricatePrinted circuit assemblingScreening gaskets/sealsSingle injectionEngineering

A device and method of unitarily forming an electrically shielded panel for use in electromagnetically sealing an opening defined in an electronic enclosure. The unitary electrically shielded panel is formed of an electrically non-conductive rigid thermoplastic panel part and a substantially planar, electrically conductive elastomeric gasket bonded together to form the unitary panel in a single tool during a single injection-molding operation.

Owner:LUCENT TECH INC

Method to prevent fertilization in mammals by administering a single dose of zona pellucida derived antigens, liposome and adjuvant

InactiveUSRE37224E1Extended maintenance periodReduce deliveryPeptide/protein ingredientsSnake antigen ingredientsAntigenAdjuvant

A vaccine for the immunocontraception of mammals is described. The vaccine consists of zona pellucida antigens and an adjuvant encapsulated in a liposome delivery system. The liposome delivery system allows for the slow release of antigen resulting in a prolonged immune response. In particular, after a single injection of the vaccine, levels of anti-zona pellucida antibodies were detected for up to 22 months in seals. Thus, the vaccine according to the present invention is effective after a single dose and is therefore very useful in immunocontraceptive protocols.

Owner:IMMUNOVACCINE TECH INC

Valve and fueling strategy for operating a controlled auto-ignition four-stroke internal combustion engine

ActiveUS20060016420A1Improve abilitiesReduce decreaseValve arrangementsElectrical controlCombustion chamberOperating point

Part load operating point for a controlled auto-ignition four-stroke internal combustion engine is reduced without compromising combustion stability through a valve control operative to establish low pressure conditions within the combustion chamber into which fuel and exhaust gases are introduced. Combustion chamber pressures during the intake cycle are controlled lower as engine load decreases. Combusted gases are recirculated into the combustion chamber through a variety of internal and external recirculation mechanizations. A split-injection fuel control is implemented during low part load operation whereas a single-injection fuel control is implemented during intermediate and high part load operation. Split-injections are characterized by lean fuel / air ratios and single-injections are characterized by either lean or stoichiometric fuel / air ratios. Controlled autoignition is thereby enabled through an extended range of engine loads while maintaining acceptable combustion stability and emissions.

Owner:GM GLOBAL TECH OPERATIONS LLC

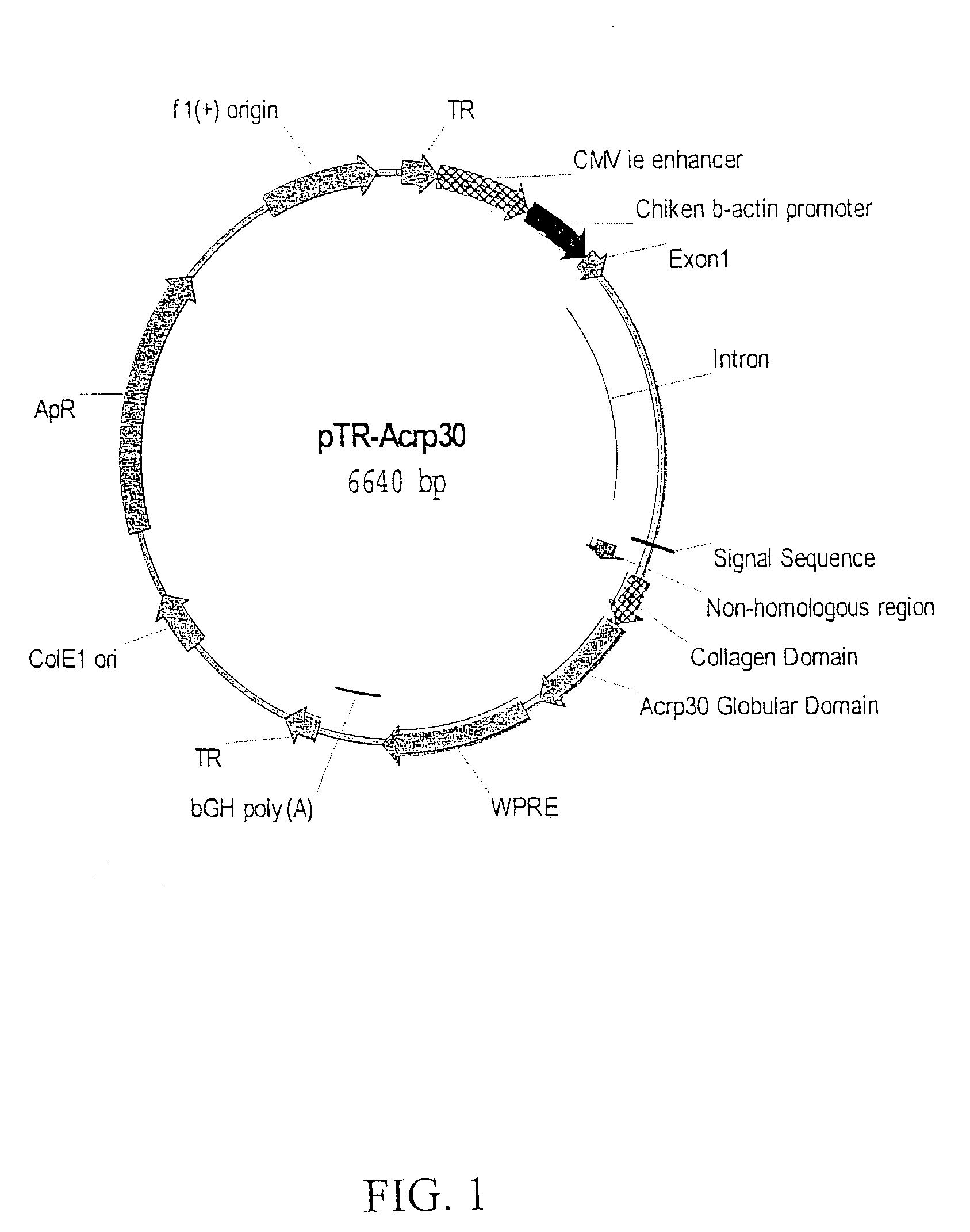

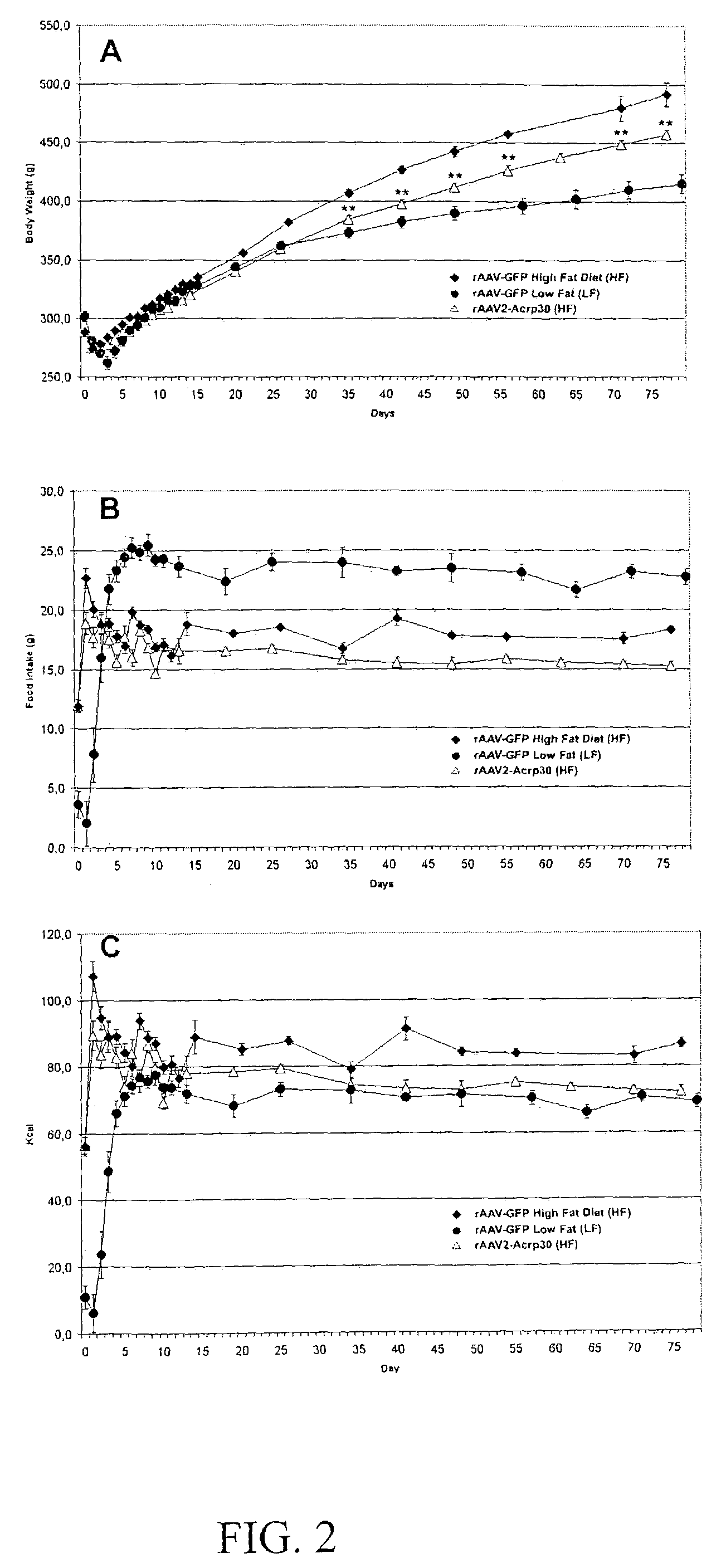

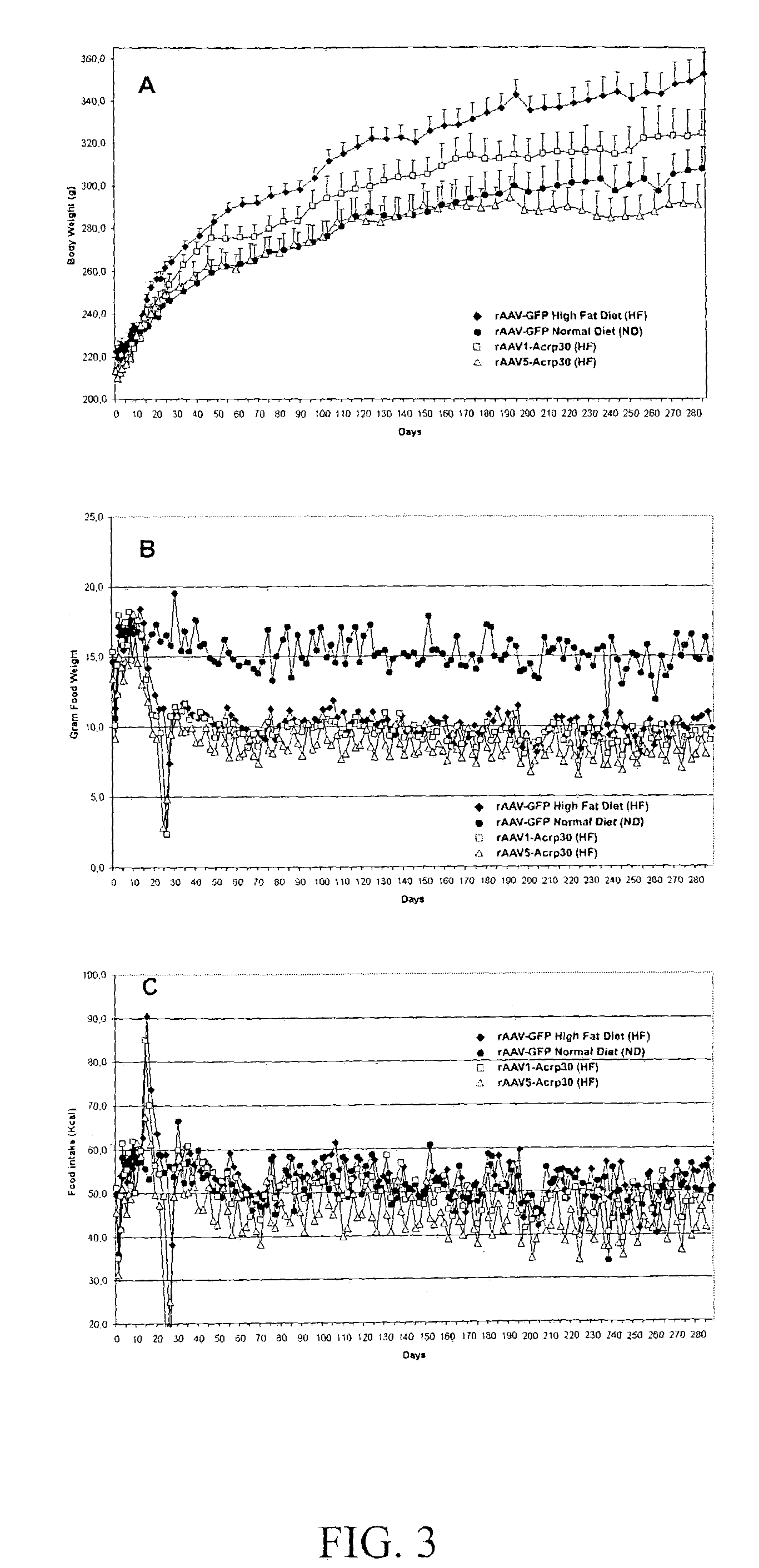

Adiponectin gene therapy

InactiveUS6967018B2Increase body weightIncrease insulin sensitivityBiocideVectorsSide effectControl animal

Adiponectin cDNA was cloned into AAV serotypes 1, 2, and 5-based expression vectors. Virions containing these vectors were administered to the livers of rat subjects via portal vein injection. A single injection of 6×1011 virions of the vector caused a sustained and statistically significant reduction in body weight of the treated animals compared to the control animals. This occurred in the absence of side effects. Compared to control animals, the subject rats also exhibited reduced adipose tissue mass, reduced appetite, improved insulin sensitivity, and improved glucose tolerance.

Owner:APPL GENETIC TECH CORP

Process for the synchronization of ovulation for timed breeding without heat detection

ActiveUS20050130894A1Efficient methodAnimal reproductionPeptide/protein ingredientsOvulation timesSingle injection

A method for synchronizing ovulation in sows and gilts by a single injection of hormones is disclosed. A hormone, gonadotropin releasing hormone (GnRH), luteinizing hormone (LH), follicle stimulating hormone (FSH), human chorionic gonadotropin (hCG), analogues, derivatives, agonists or combinations thereof is administered to an open sow post weaning at a specific time to stimulate ovulation of mature responsive follicles. The sow is then bred, without heat detection, at a specific subsequent timed interval after injection with hormone, with one or two artificial or natural breedings. In gilts, the hormone is injected at a timed interval from onset of estrus or at a specific timed interval following Prostaglandin F2a for those gilts which have been held in a state of pseudopregnancy.

Owner:THORN BIOSCI

Method for improved vertical sweep of oil reservervoirs

InactiveUS20060180306A1Promote recoverySlow and control segregationSurveyFluid removalSweep efficiencySingle injection

In a WAG flood oil is displaced from a subterranean formation by injecting water alternately with gas into a single injection completion per pattern. The ratio of water to gas injected is the WAG ratio. In this invention, two separate injection completions are used in each pattern, with one placed directly above the other. A very low WAG ratio is used for injection into the bottom extremity of the formation. A very high WAG ratio is injected into the upper interval, at as high a rate can safely be used without fracturing the formation. In the preferred embodiment, two horizontal well bores serve as the two completion intervals. Proper design of this method gives a vertical sweep efficiency of the gas that is several-fold greater than the best of previous WAG flood designs, especially in thin formations.

Owner:STONE HERBERT L

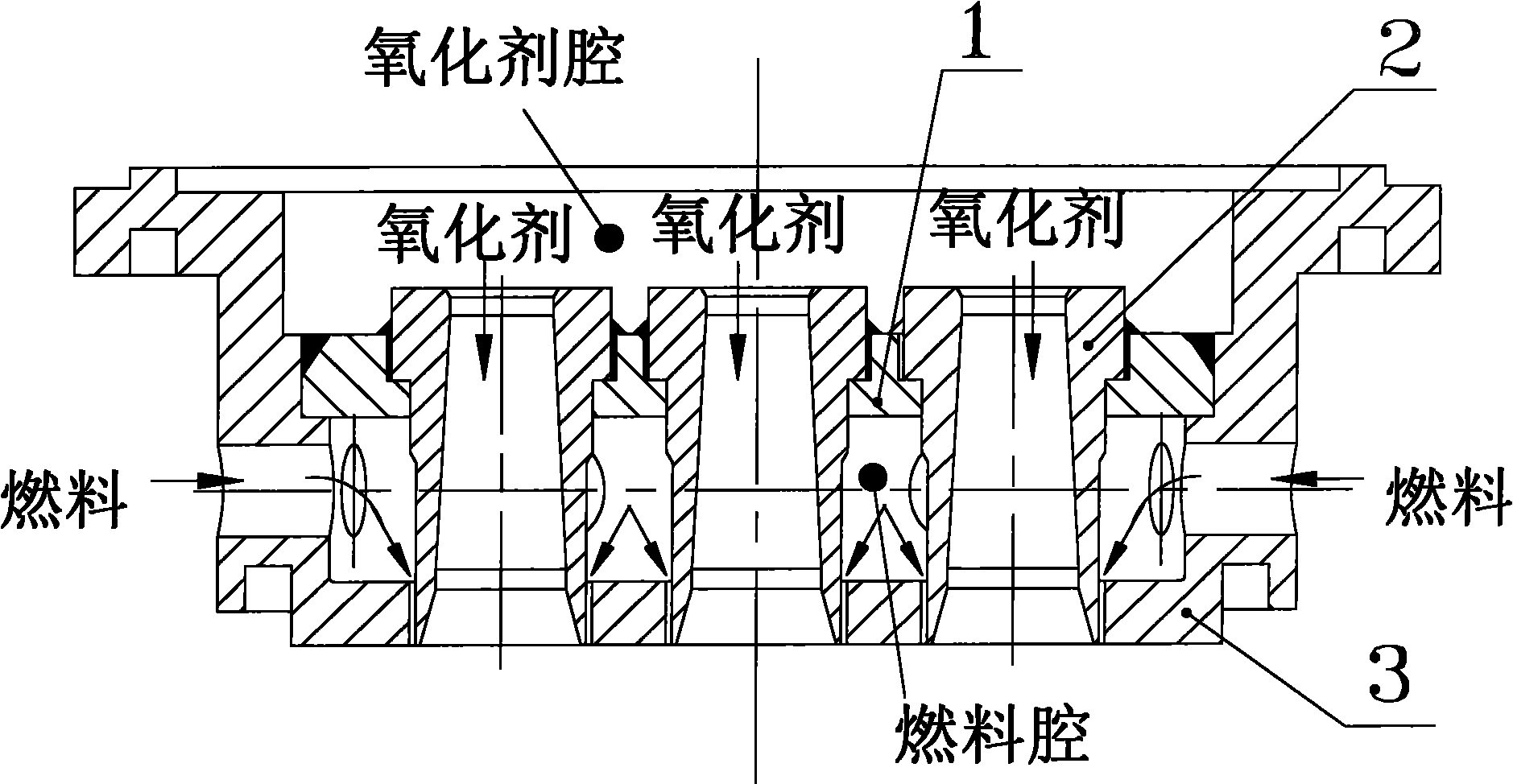

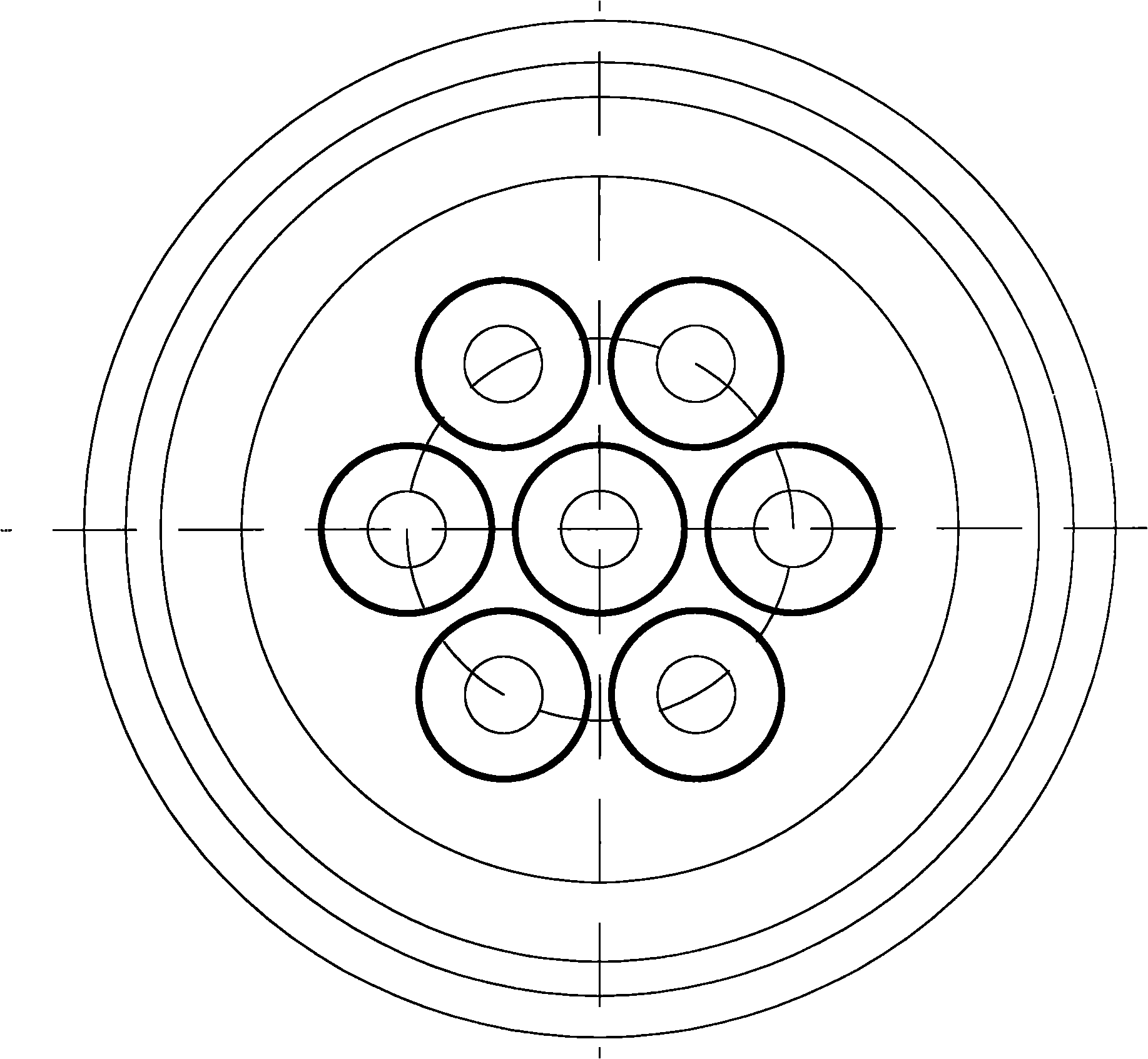

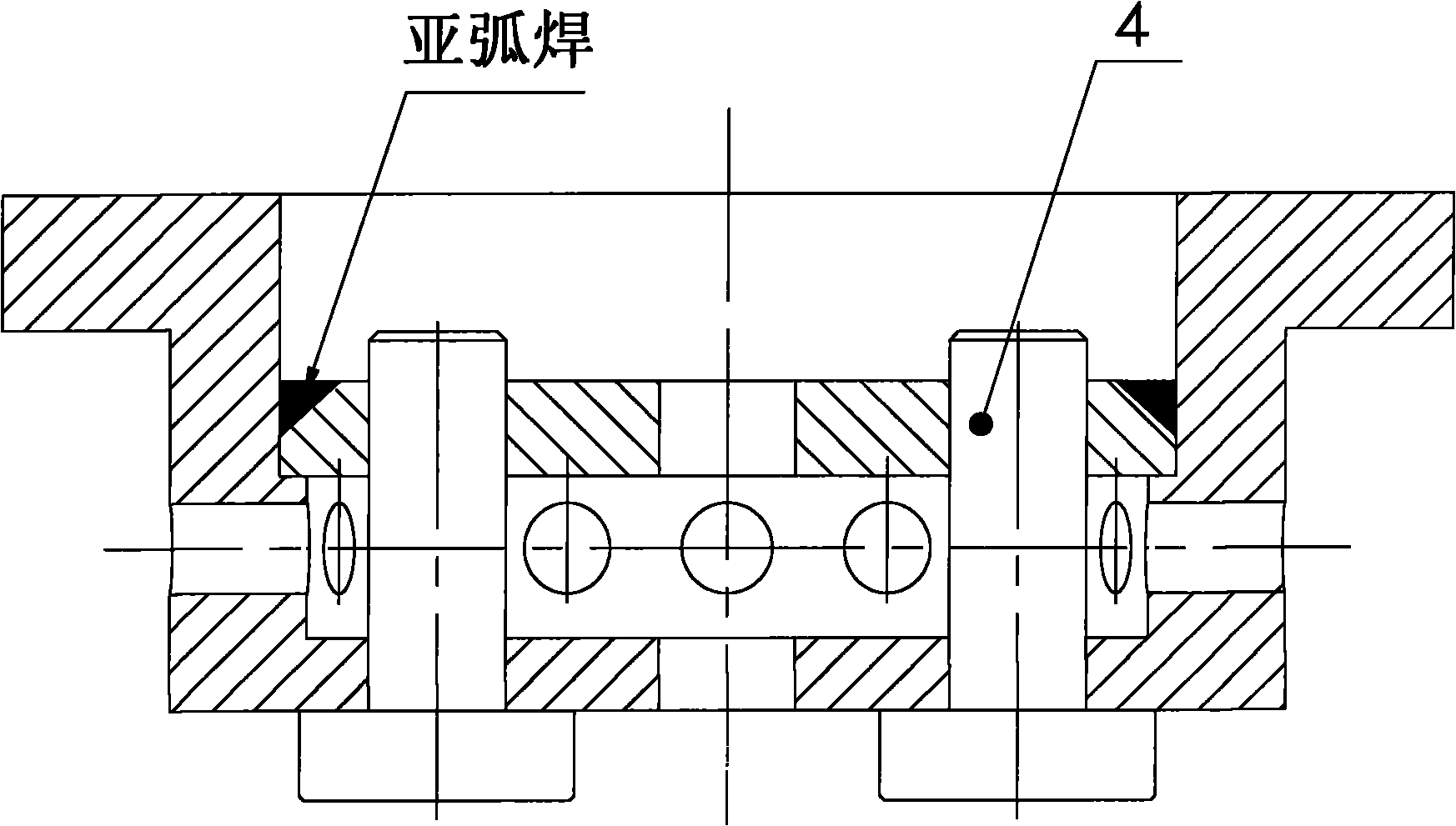

Multiunit coaxial injector component for test and manufacturing method

InactiveCN101782030AReduce processing difficultyProcessing Difficulty GuaranteeRocket engine plantsSingle injectionDesign methods

The invention discloses a multiunit coaxial injector component for a test, which comprises an upper plate, an oxidant nozzle and an outer framework. A single injection unit only comprises the oxidant nozzle without a fuel nozzle component, wherein an annular fuel nozzle is formed between the lower end of the oxidant nozzle and an injector hole on the lower plate of the outer framework; the oxidant nozzle is in sealed connection with the upper plate through braze welding; the upper plate is in sealed connection with the outer framework through sub-arc welding; the periphery of the outer framework is designed in a porous form; a tool is adopted when injection holes are machined on the upper plate and the outer framework jointly; and the tool is also needed when the oxidant nozzle is brazed with the upper plate. In the multiunit coaxial injector component for the test, a design method for the multiunit injector used for the test is directly provided; a nozzle structure which generally needs external fuel is saved; the multiunit coaxial injector component has a simple structure and low cost, can avoid the leakage between an oxidant chamber and a fuel chamber, and can strictly ensure the coaxiality of coaxial injector units; and the fuel chamber can be designed lower.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com