Patents

Literature

311results about How to "Small size change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

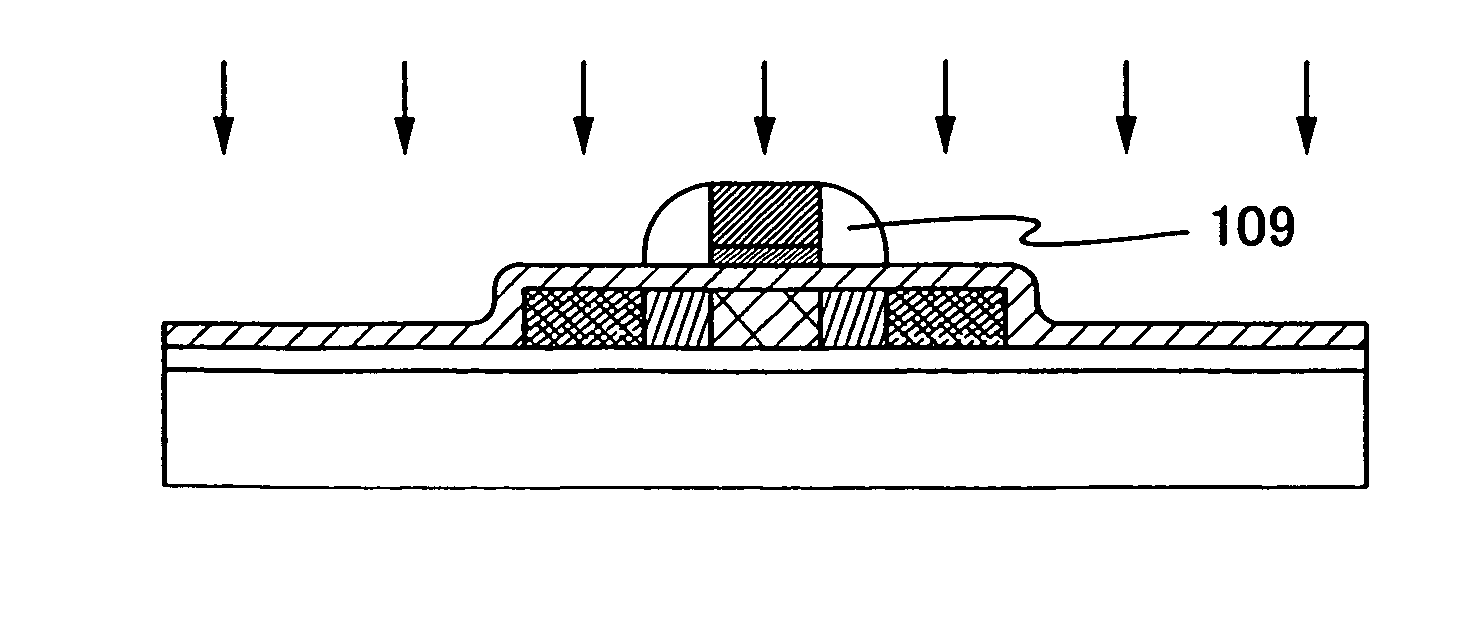

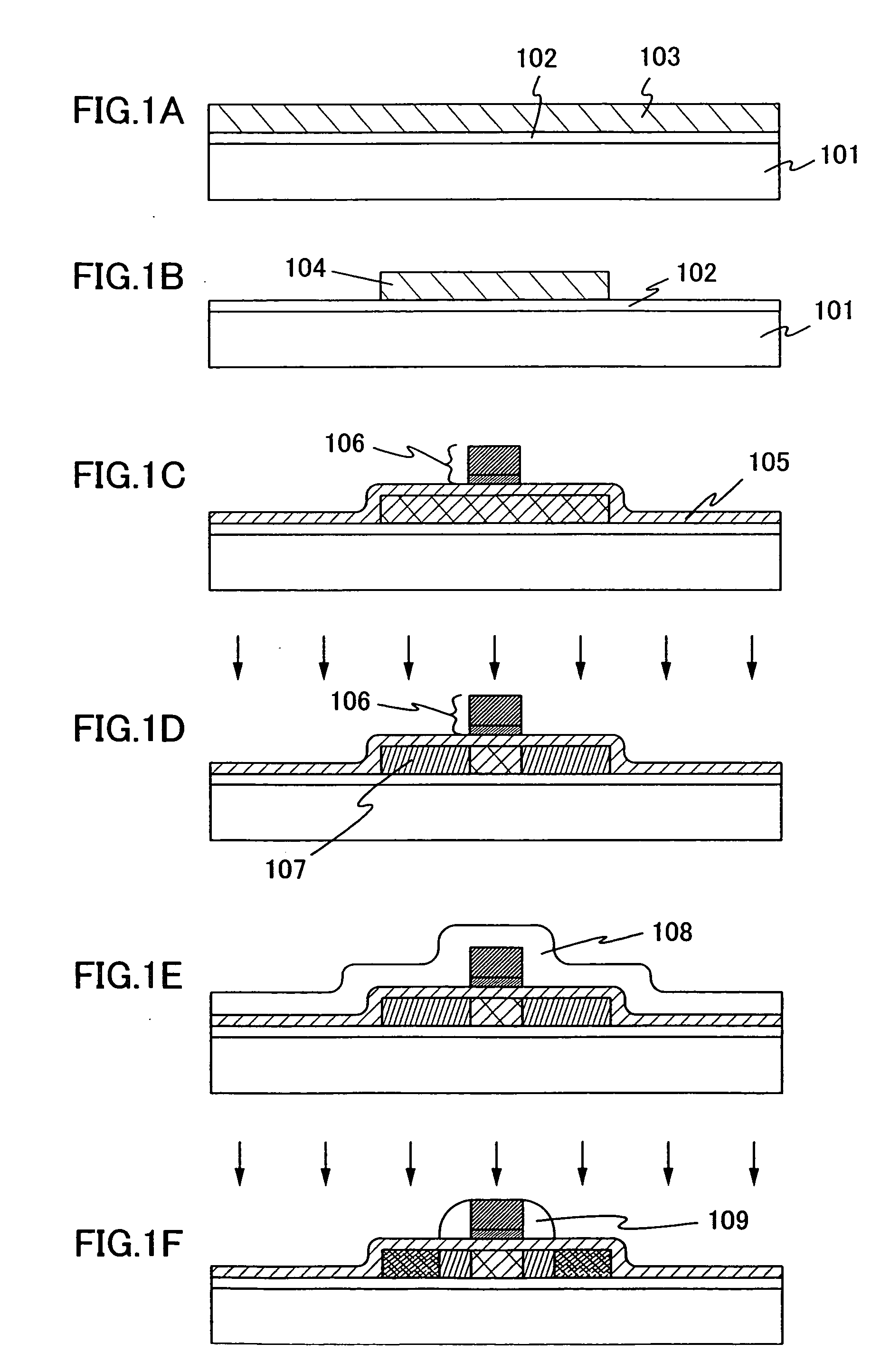

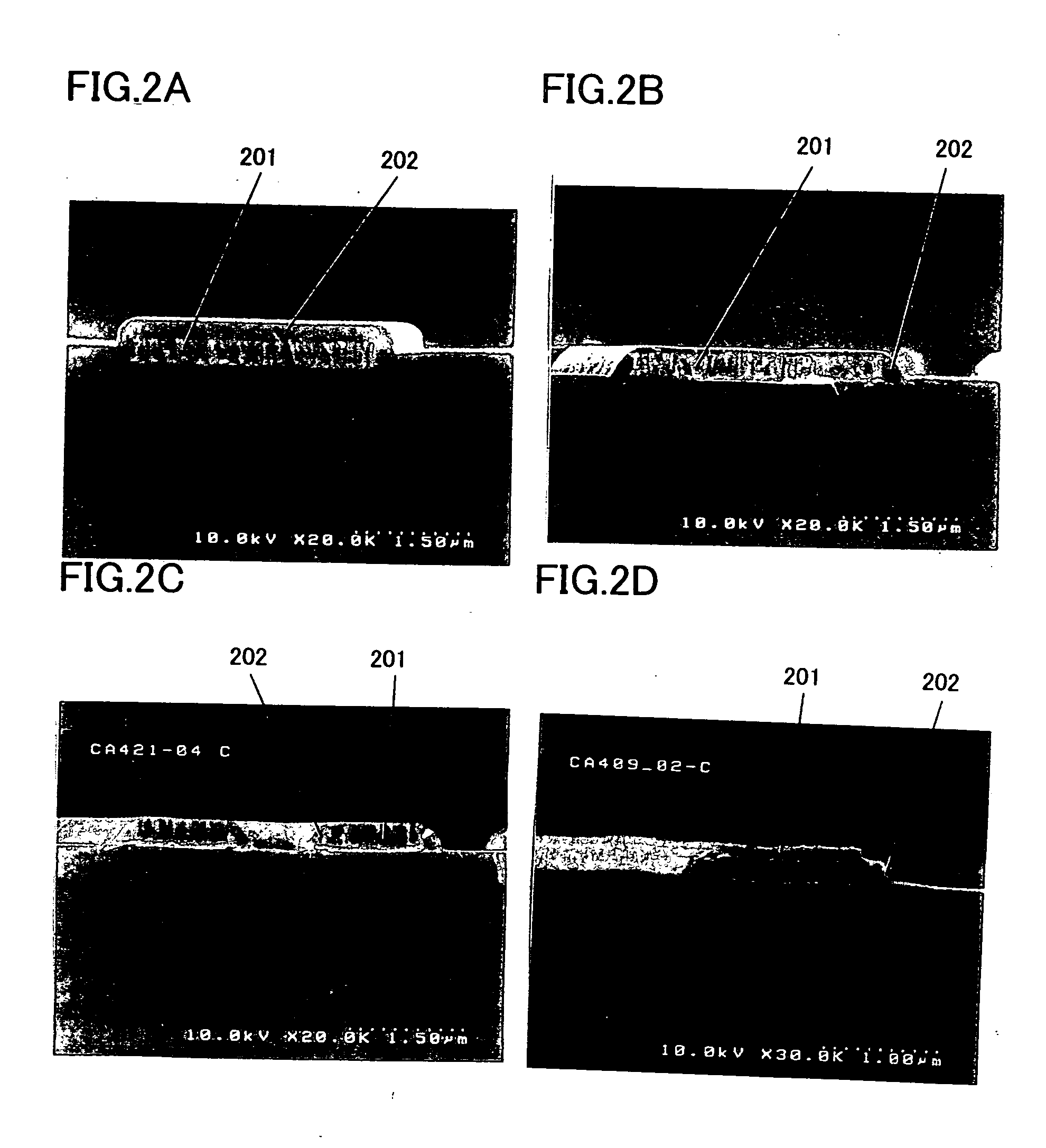

Method for manufacturing semiconductor device

InactiveUS20060205129A1Avoid changeAvoid low process precisionSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialInductively coupled plasma

In a gas containing a fluorine atom in the molecule, etching of a SiN film is performed isotropically; therefore, the width of a sidewall gets smaller and it is difficult to widen the width of an LDD region. A silicon nitride film is formed over a gate electrode, a hydrogen bromide is mainly used as an etching gas, the silicon nitride film only over the gate electrode and the surface of a substrate are removed by an etching method such as ICP (Inductively Coupled Plasma), and the silicon nitride film is simultaneously left only on the side surface part of the gate electrode.

Owner:SEMICON ENERGY LAB CO LTD

Thermoplastic olefin compositions, processes and articles

A thermoplastic olefin (TPO) composition comprises (1) a major amount by weight of (a) a substantially linear homopolymer or copolymer of a C2-C10 α-olefin in major proportion to (b) a long chain branched a linear homopolymer or copolymer of a C2-C10 α-olefin, (2) a minor amount by weight of a cross linkable elastomer, and (3) at least one thermally decomposing free radical generating agent present in an amount sufficient to promote an increase in melt strength of the composition over that of the melt strength of the linear homopolymer or copolymer of a C2-C10 α-olefin alone and insufficient to substantially degrade the α-olefinic polymers. The TPO composition is prepared by melt blending the components at a temperature sufficient to melt said homopolymers or copolymers of a C2-C10 α-olefin and thermally decompose said agent. Articles are thermoformed from the thermoplastic olefin.

Owner:EXOUSIA IP LLC

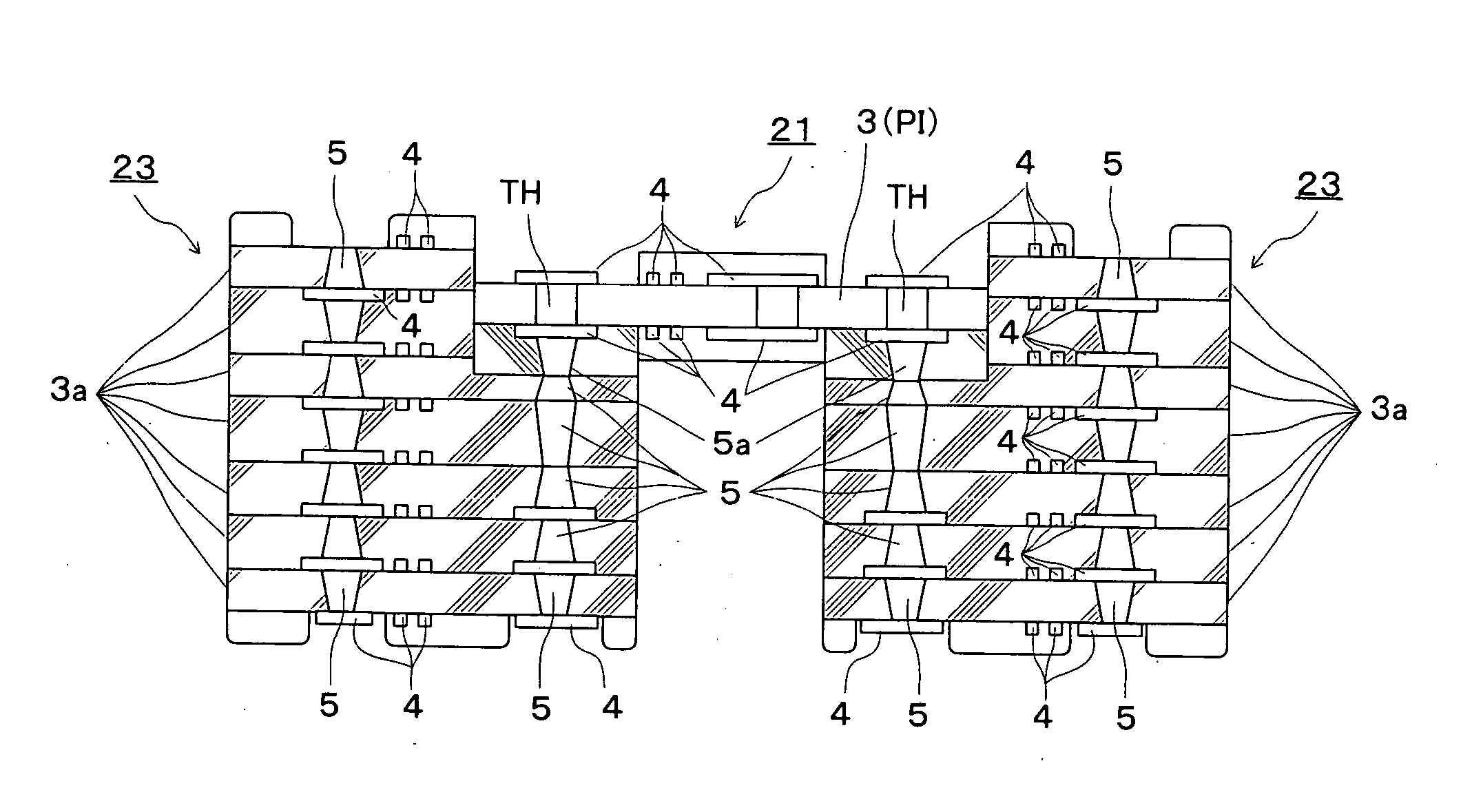

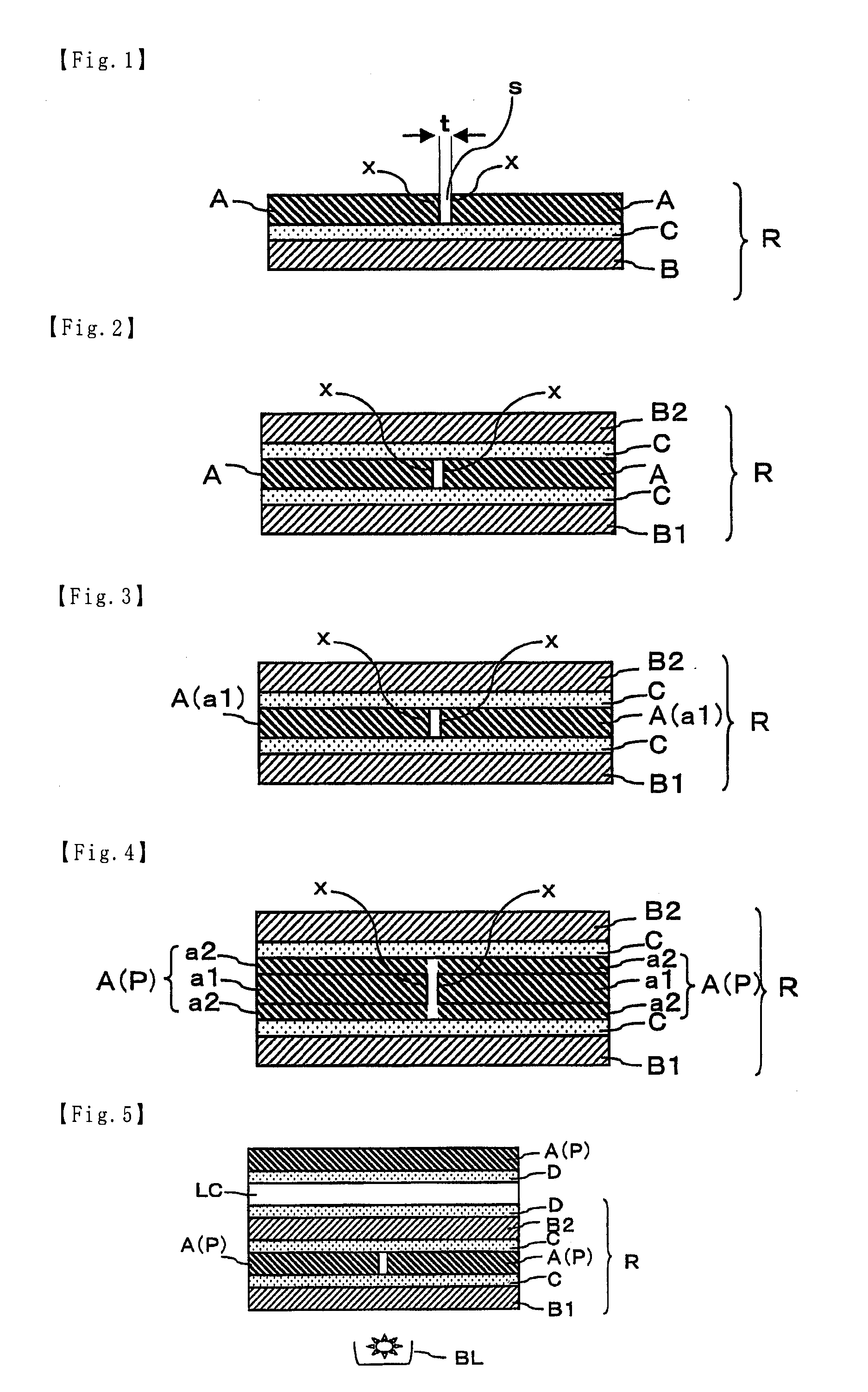

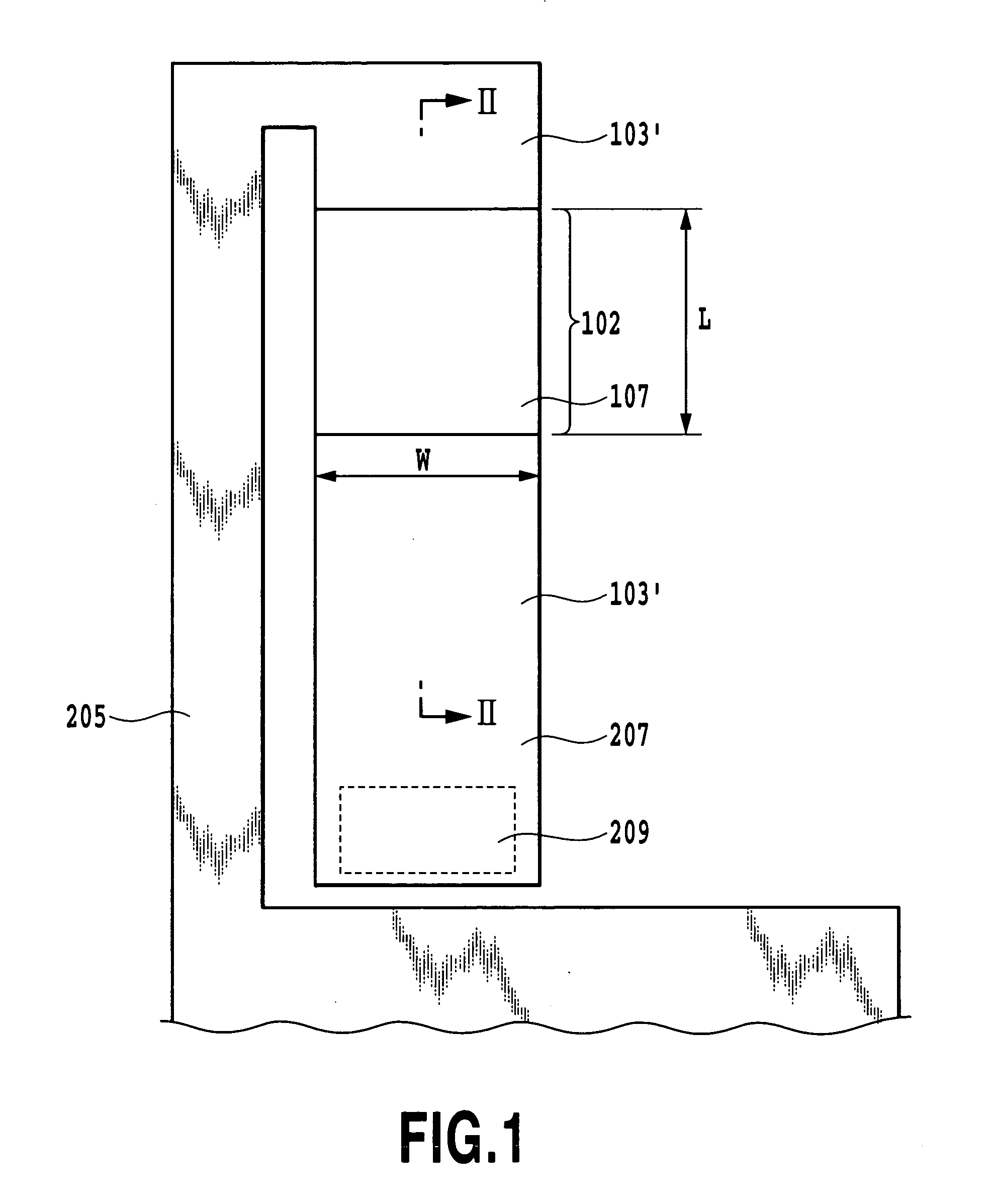

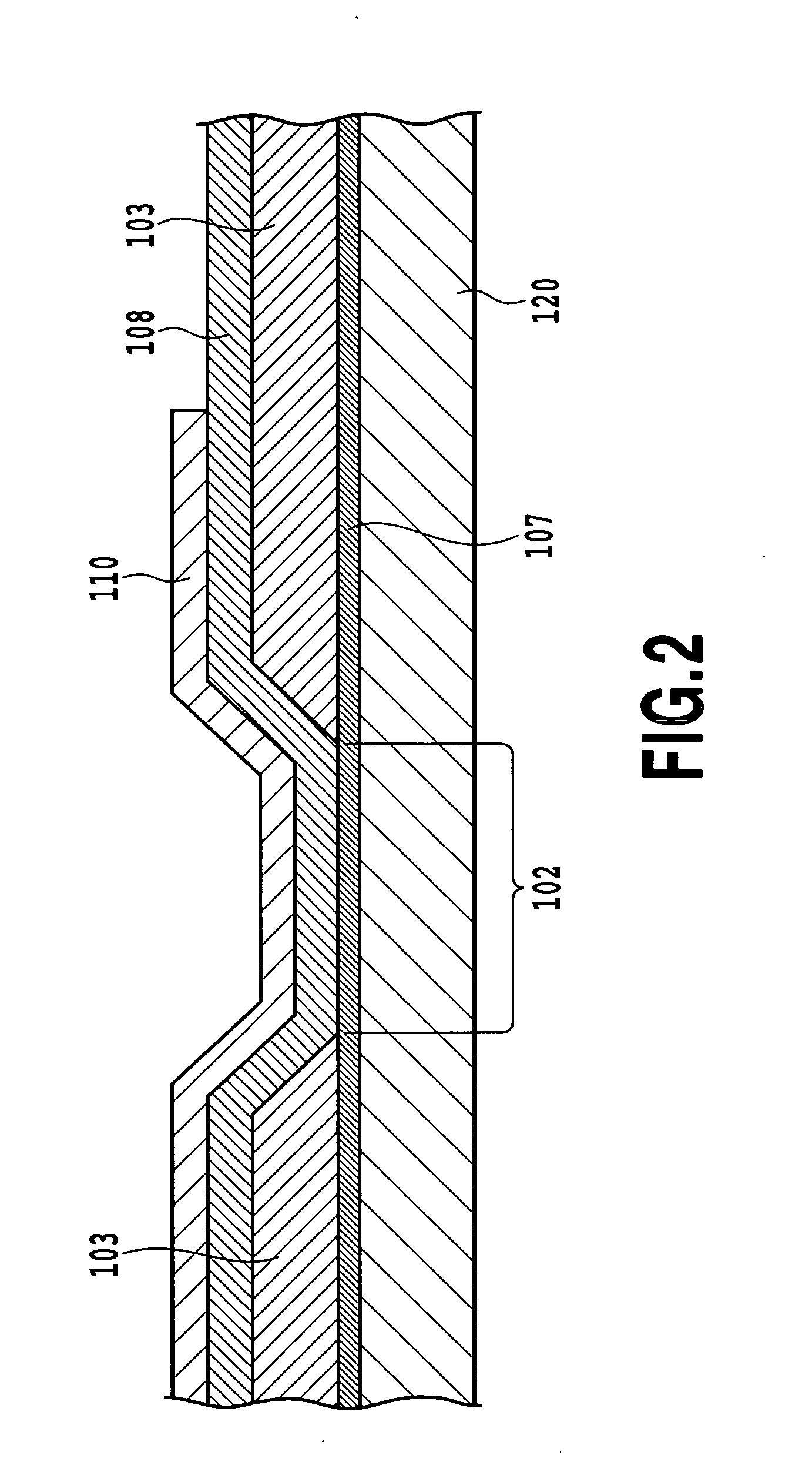

Rigid-Flexible Board and Method for Manufacturing the Same

InactiveUS20070281505A1High aspect ratioSimple molding processPrinted circuit assemblingLamination ancillary operationsEngineeringYield ratio

A rigid-flexible board and a method for manufacturing the same can be provided, whereby the material yield ratio can be enhanced and the productive yield can be also enhanced. A rigid board with a step for connection and a flexible board with a connector at the edge thereof are formed independently. Then, the connecting area is spot facing processed so that the depth of the thus obtained depressed portion is equal to or lower than the thickness of the flexible board. The connector of the flexible board is electrically connected to the vertical wiring area of the depressed portion.

Owner:DAI NIPPON PRINTING CO LTD

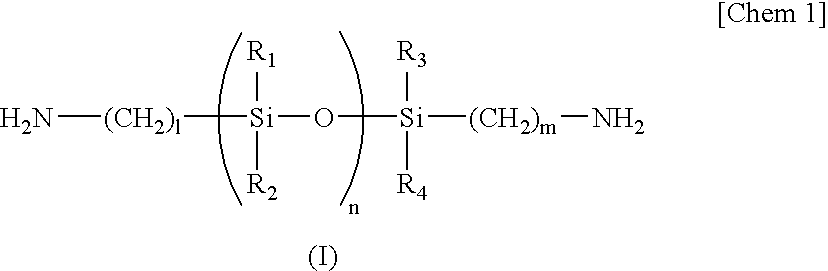

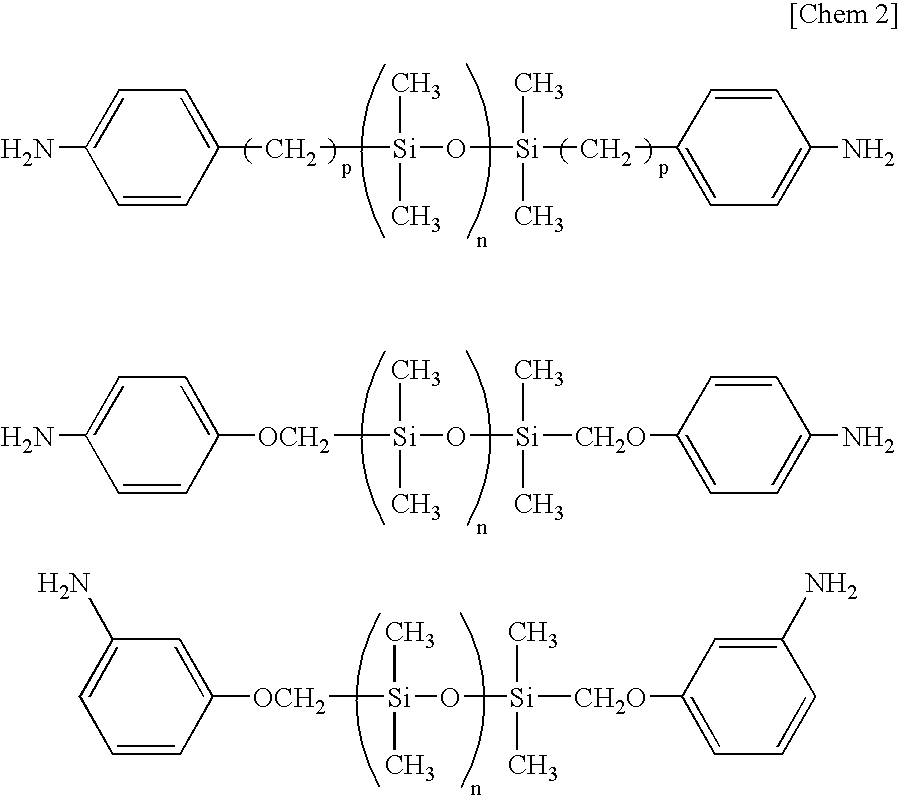

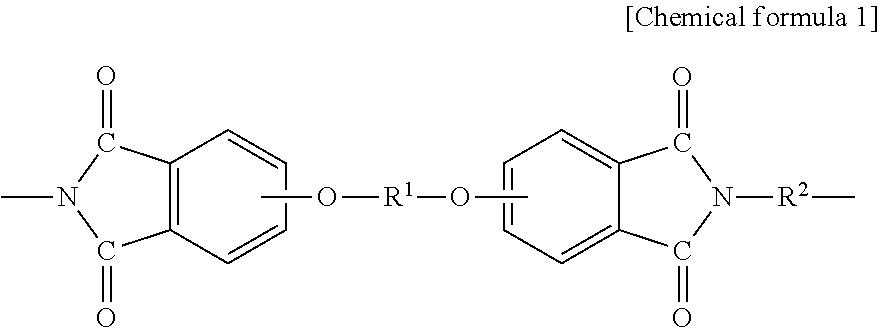

Block Copolymerized Polyimide Ink Composition for Printing

InactiveUS20080275181A1Strong adhesionLow modulusPrinted circuit aspectsSemiconductor/solid-state device manufacturingBenzoic acidSolvent

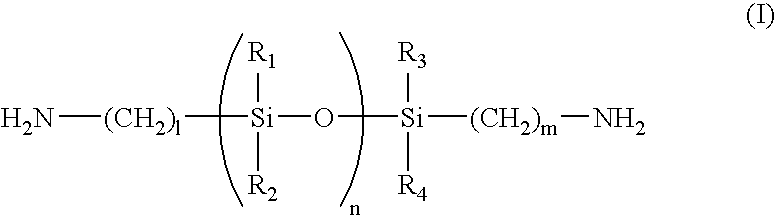

The object is to provide a polyimide ink composition having good printing properties and good continuous printing properties, which composition can be dried at a low temperature of not higher than 220° C., and which composition gives a coating film, after being dried, having excellent dimensional stability, heat resistance, low modulus of elasticity, flexibility, resistance to warping, chemical resistance, adhesiveness with substrates, and plating resistance. This object is accomplished by a polyimide ink composition for printing, comprising a mixed solvent containing an benzoic acid ester solvent and a glyme solvent, and a polyimide soluble in the mixed solvent; wherein the polyimide is obtained by polycondensing a polyimide oligomer with a tetracarboxylic dianhydride component(s) and / or a diamine component(s) having no siloxane bond in molecular skeleton thereof the polyimide oligomer being prepared by polycondensing a tetracarboxylic dianhydride component(s) and a diamine component(s) having siloxane bonds in molecular skeleton thereof in the presence of a base catalyst(s), or a mixed catalyst including a lactone(s) and / or an acidic compound(s) and a base(s); the content of the diamine component(s) having siloxane bonds based on the total diamine components being 15 to 85% by weight.

Owner:PI R & D +1

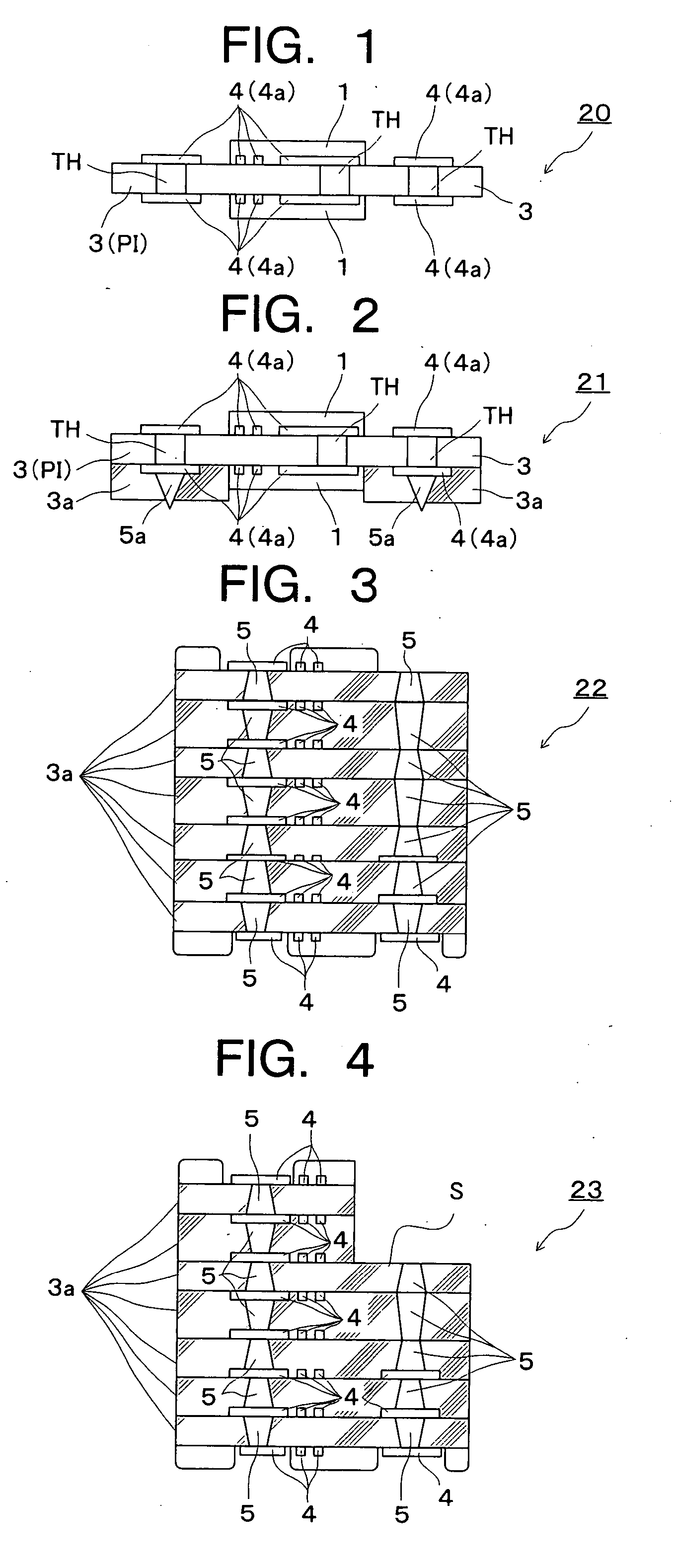

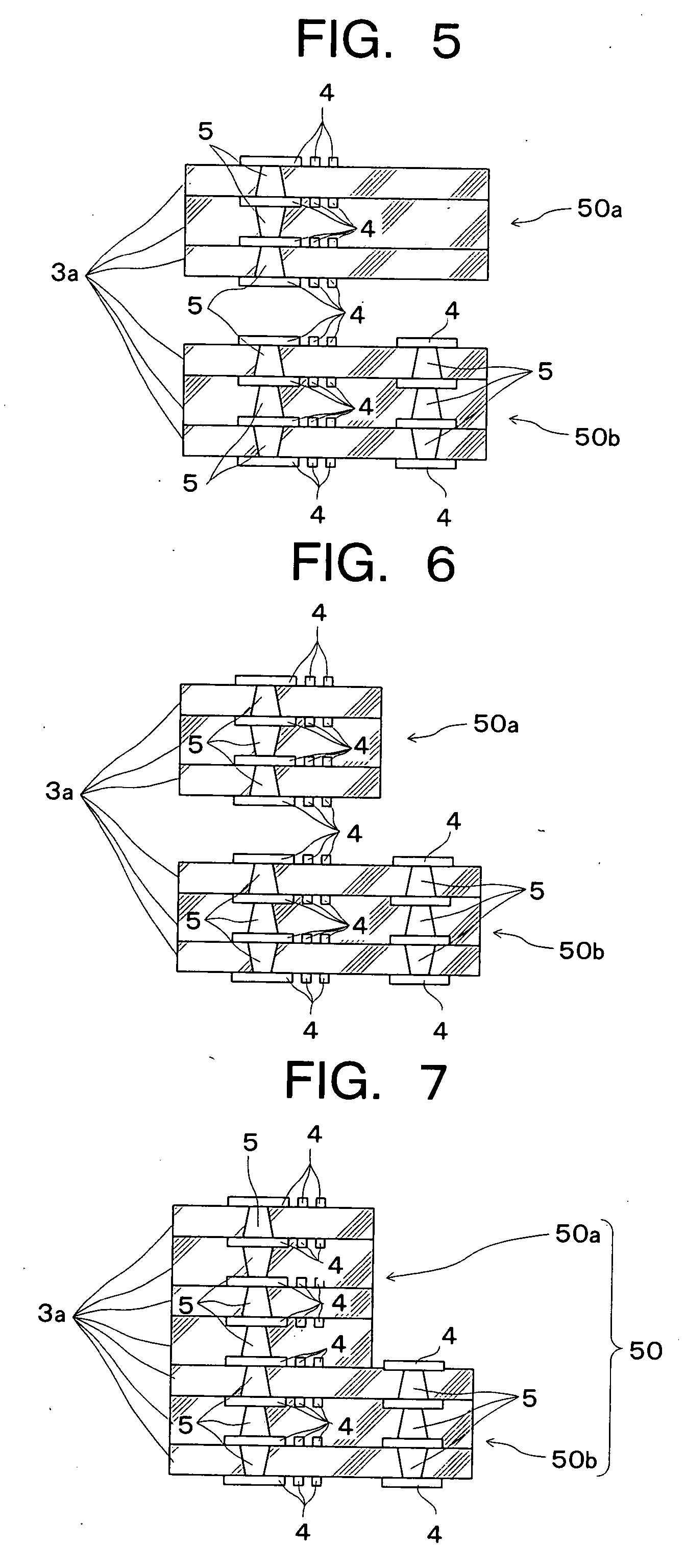

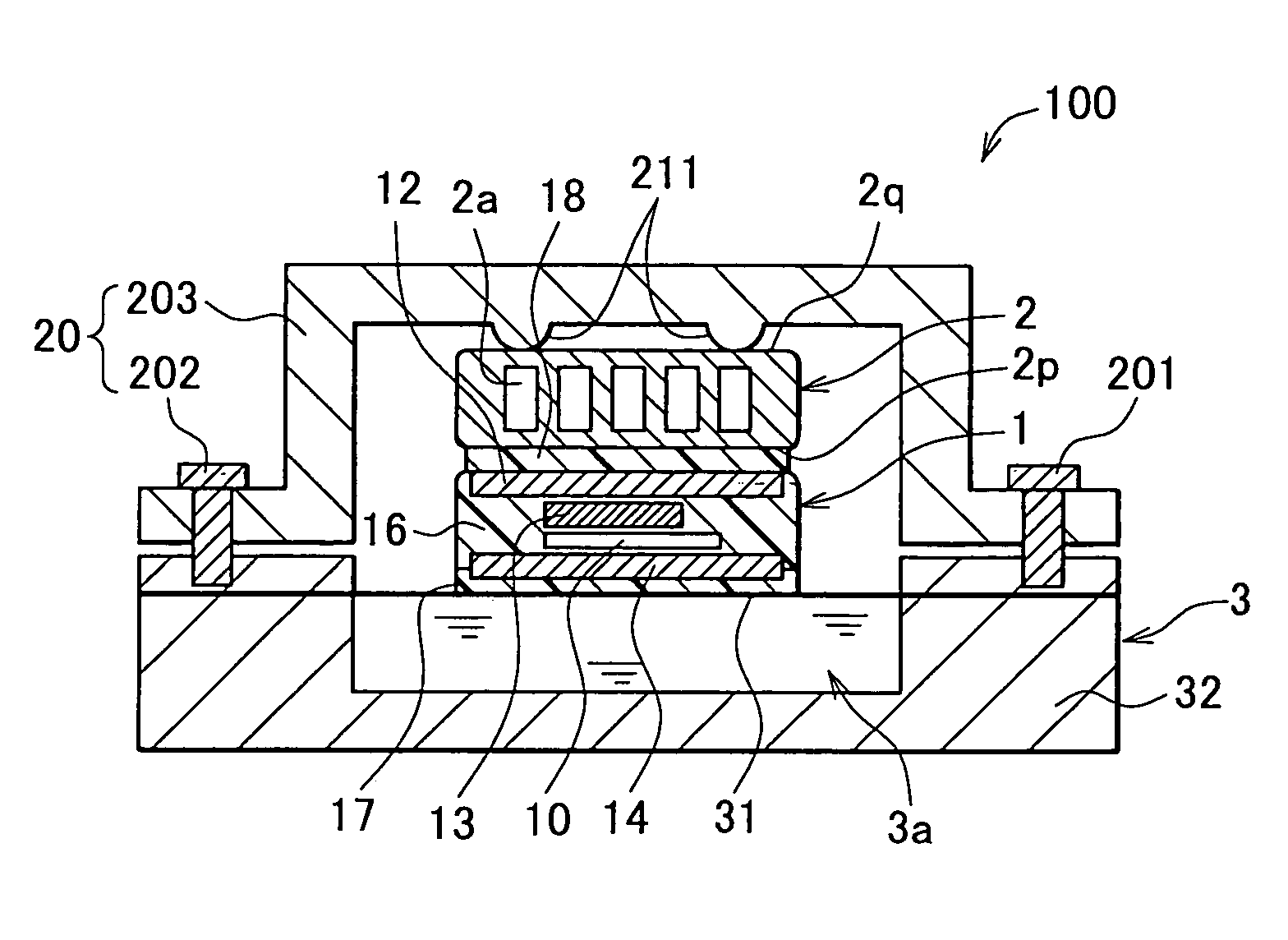

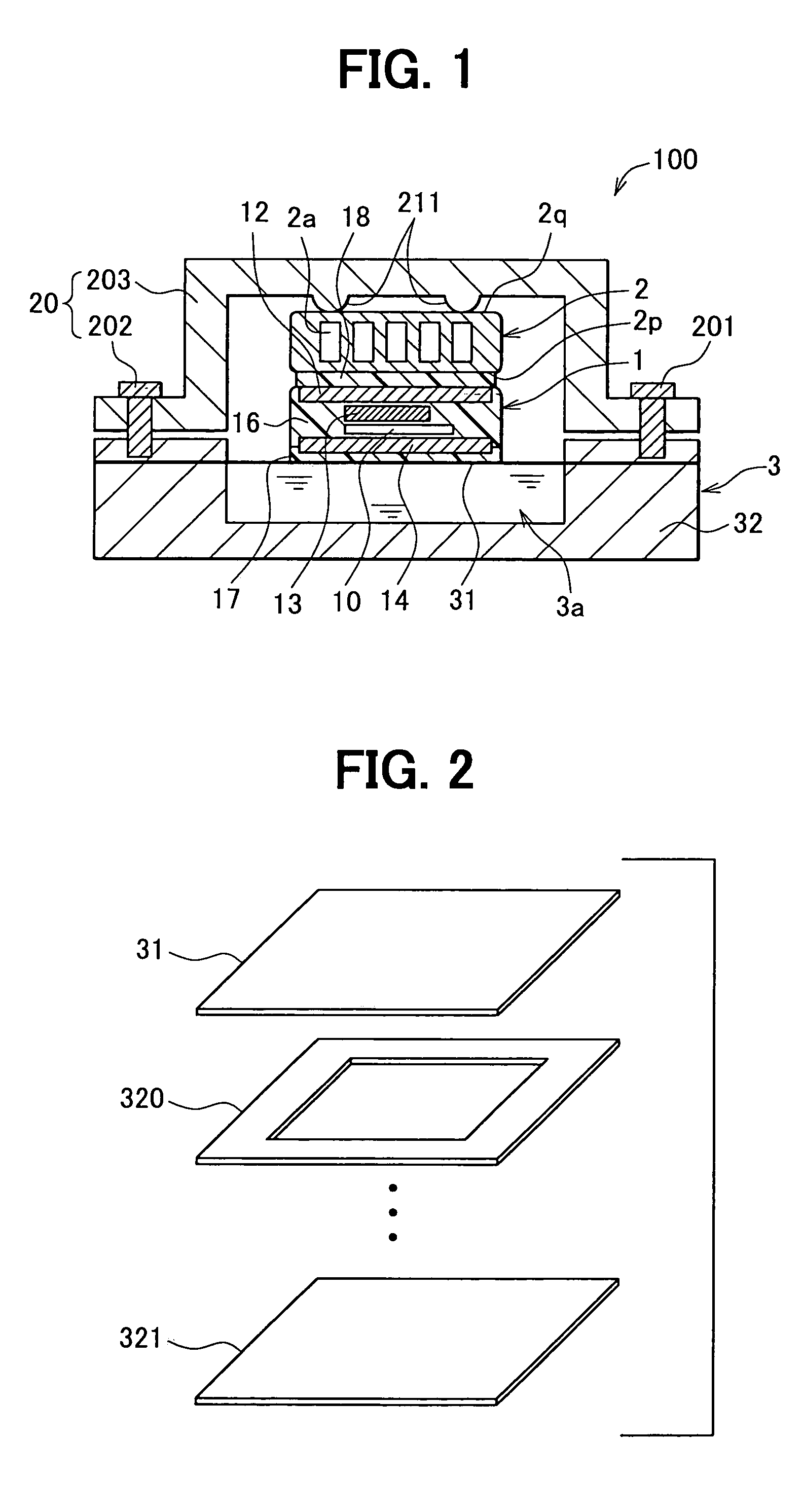

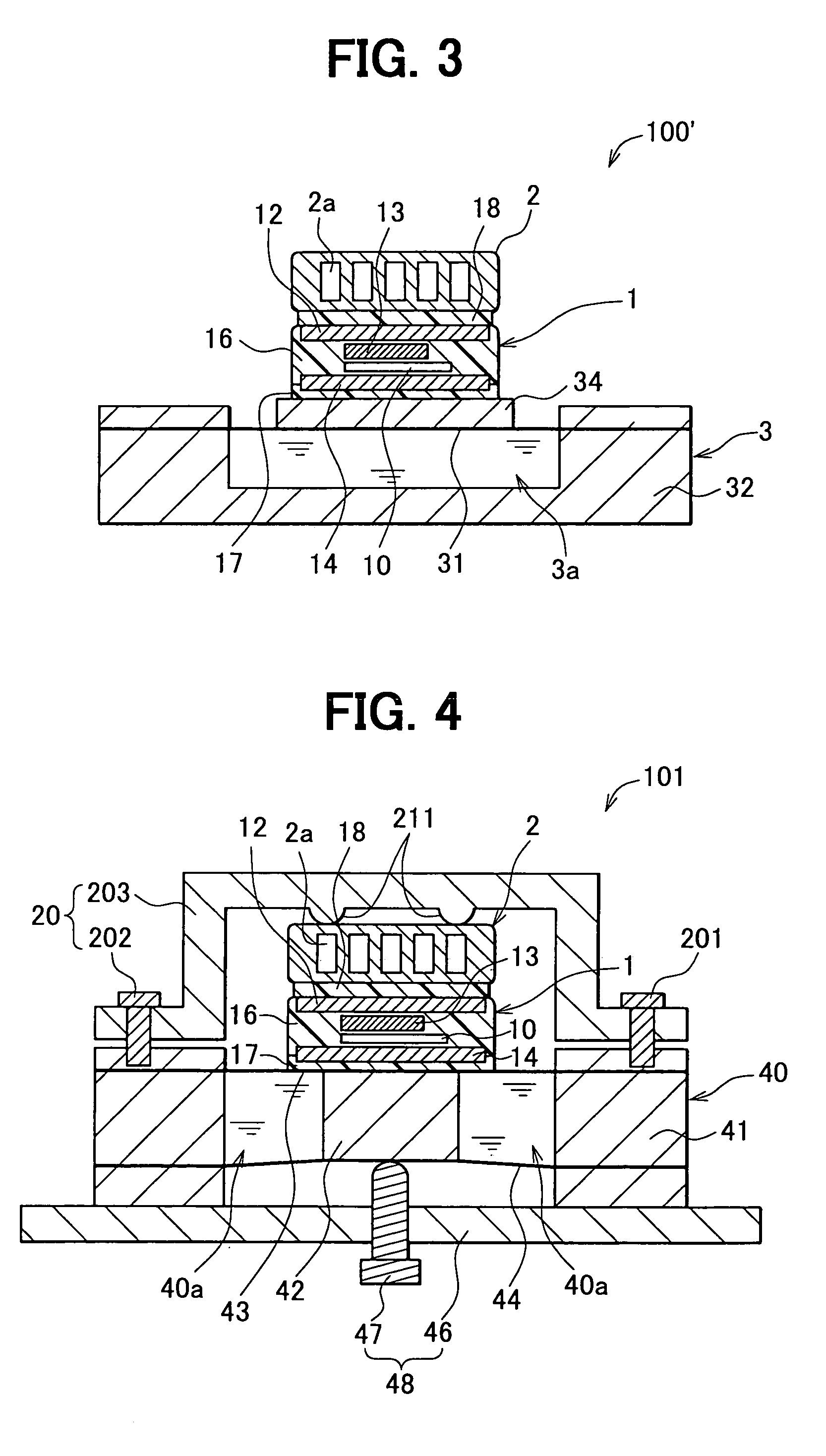

Double-sided cooling type semiconductor module

ActiveUS7019395B2Reduce heat resistance requirementsSmall size changeSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageMetal sheet

A semiconductor module includes a fixed type and transformable type coolers and a flat semiconductor package sandwiched between the coolers. A relative positional relationship of the semiconductor package is fixed with the fixed type cooler, but variable with the transformable type cooler. The transformable type cooler includes a transformable member of a metal thin plate covering a coolant chamber. The semiconductor module includes a sandwiching mechanism causing the fixed type cooler to be pressed toward the transformable type cooler. Fastening adjustment screws of the sandwiching mechanism causes a pressing frame to approach a cooler body of the transformable type cooler. Therefore, the semiconductor package is pressed via the fixed type cooler while the transformable member is slightly transformed. This enhances a degree of contact between the semiconductor package and transformable member via an insulating member.

Owner:DENSO CORP

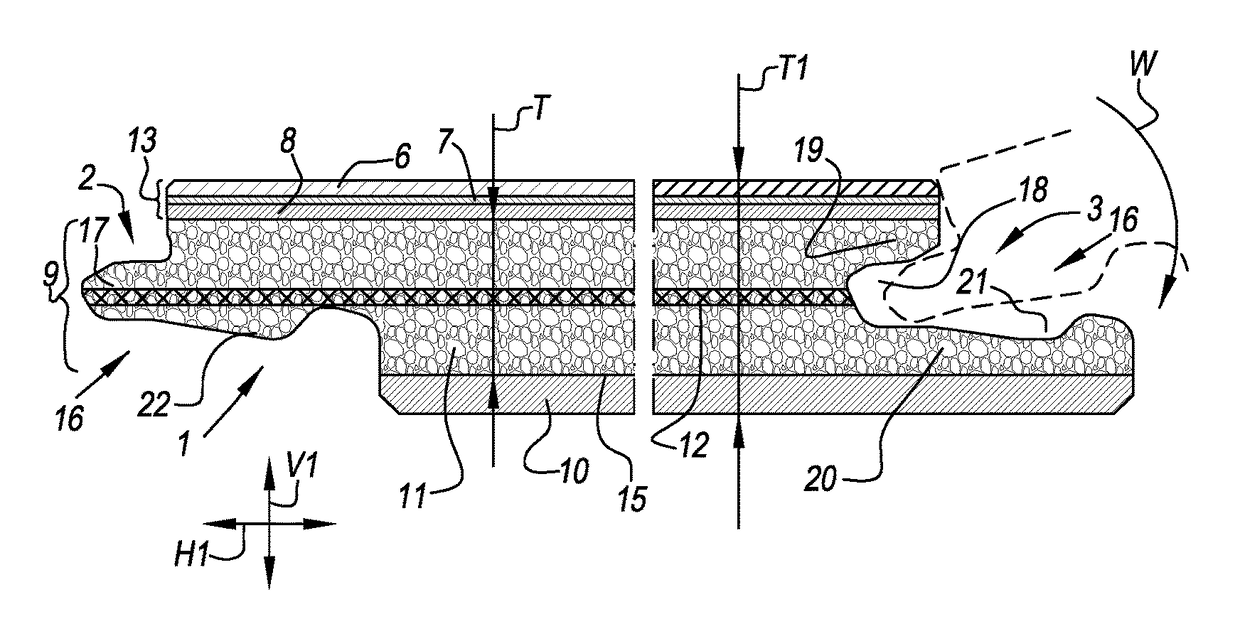

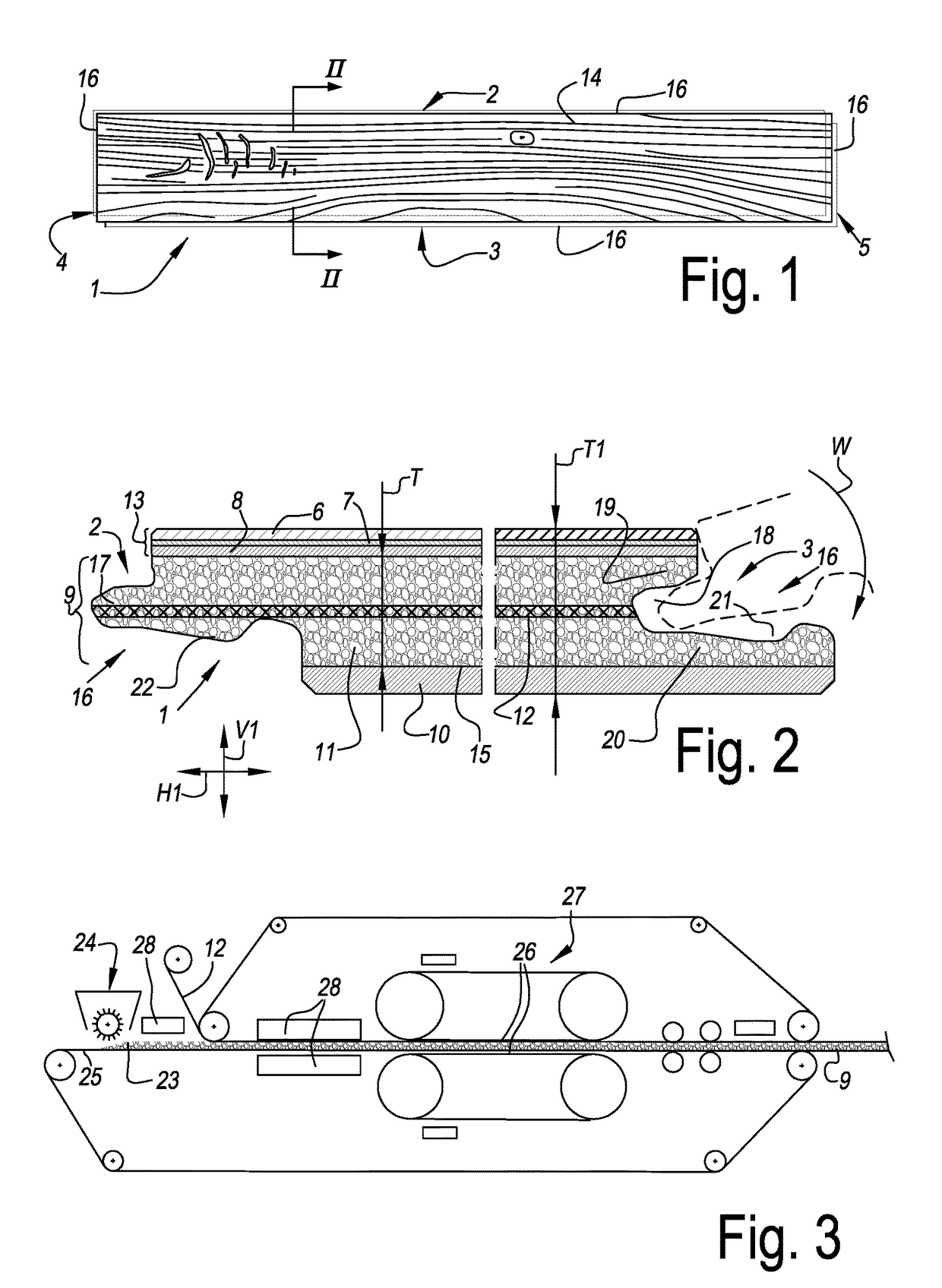

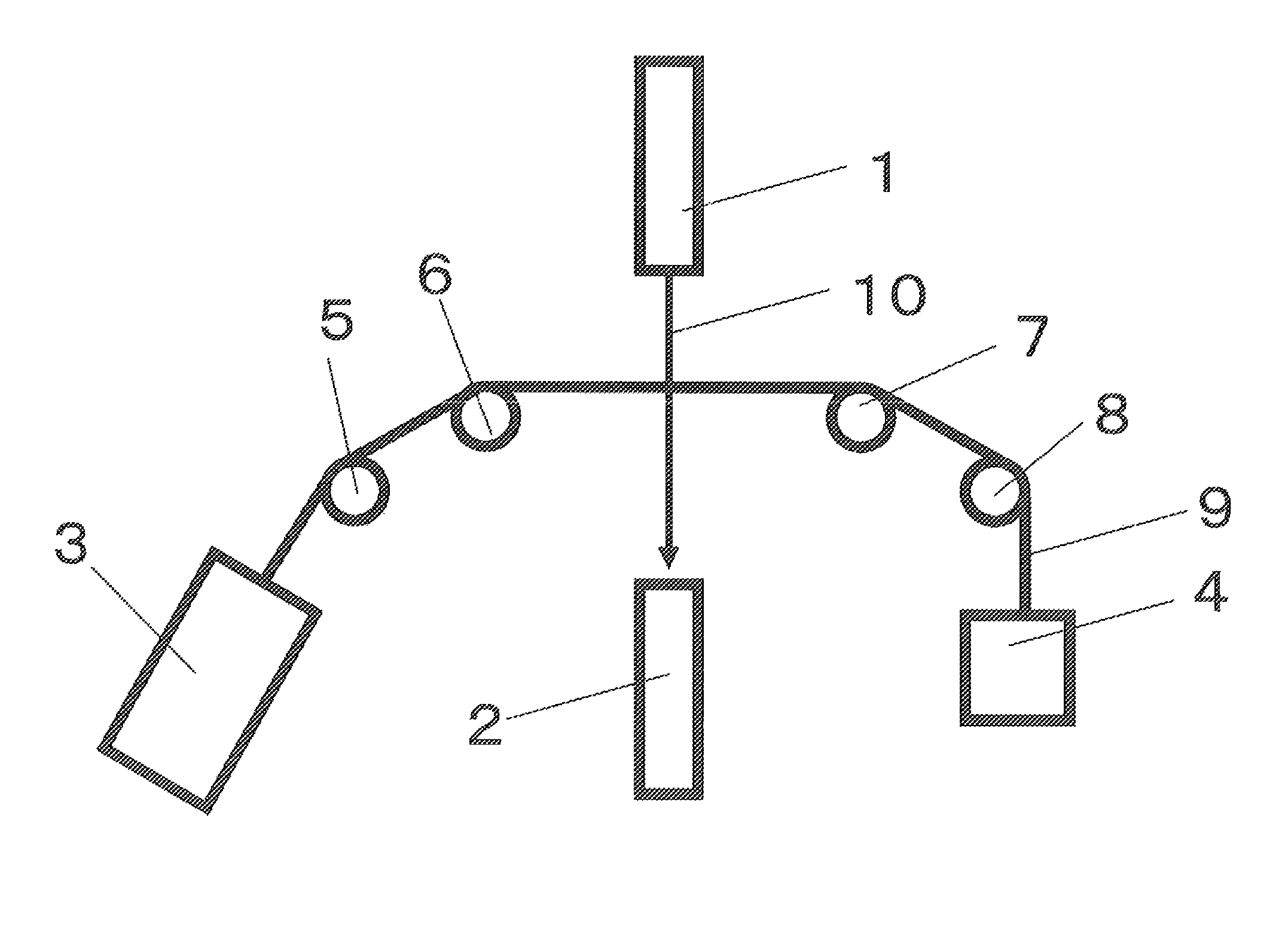

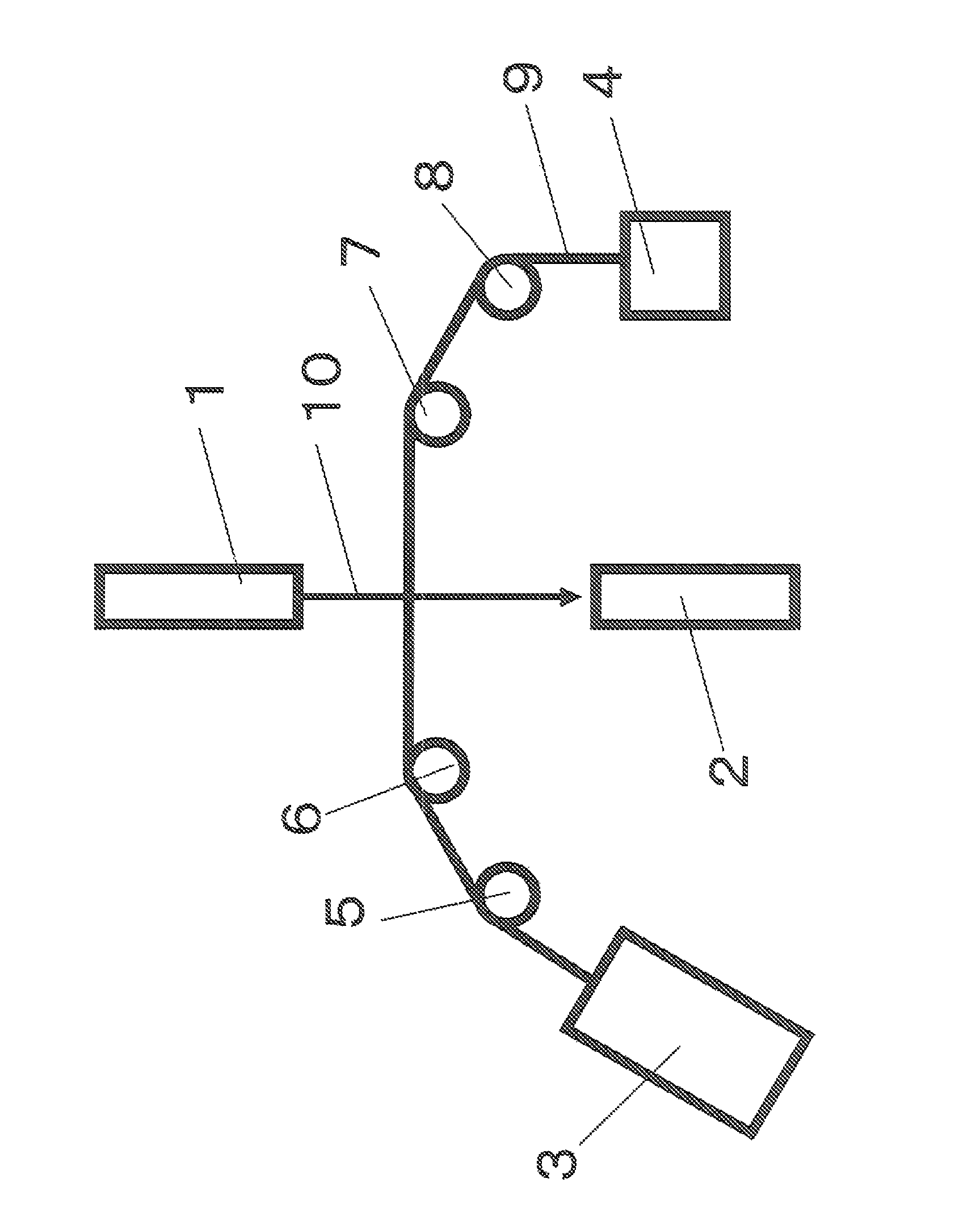

Panel for forming a floor covering, method for manufacturing such panels and granulate applied herewith

ActiveUS9758973B2Good dimensional stabilityLimited extentWood working apparatusThin material handlingFiberEngineering

Panel for forming a floor covering, wherein this panel comprises at least a layer of thermoplastic material, wherein said layer also comprises at least individual fibers having a length greater than 1 millimeter.

Owner:FLOORING IND LTD

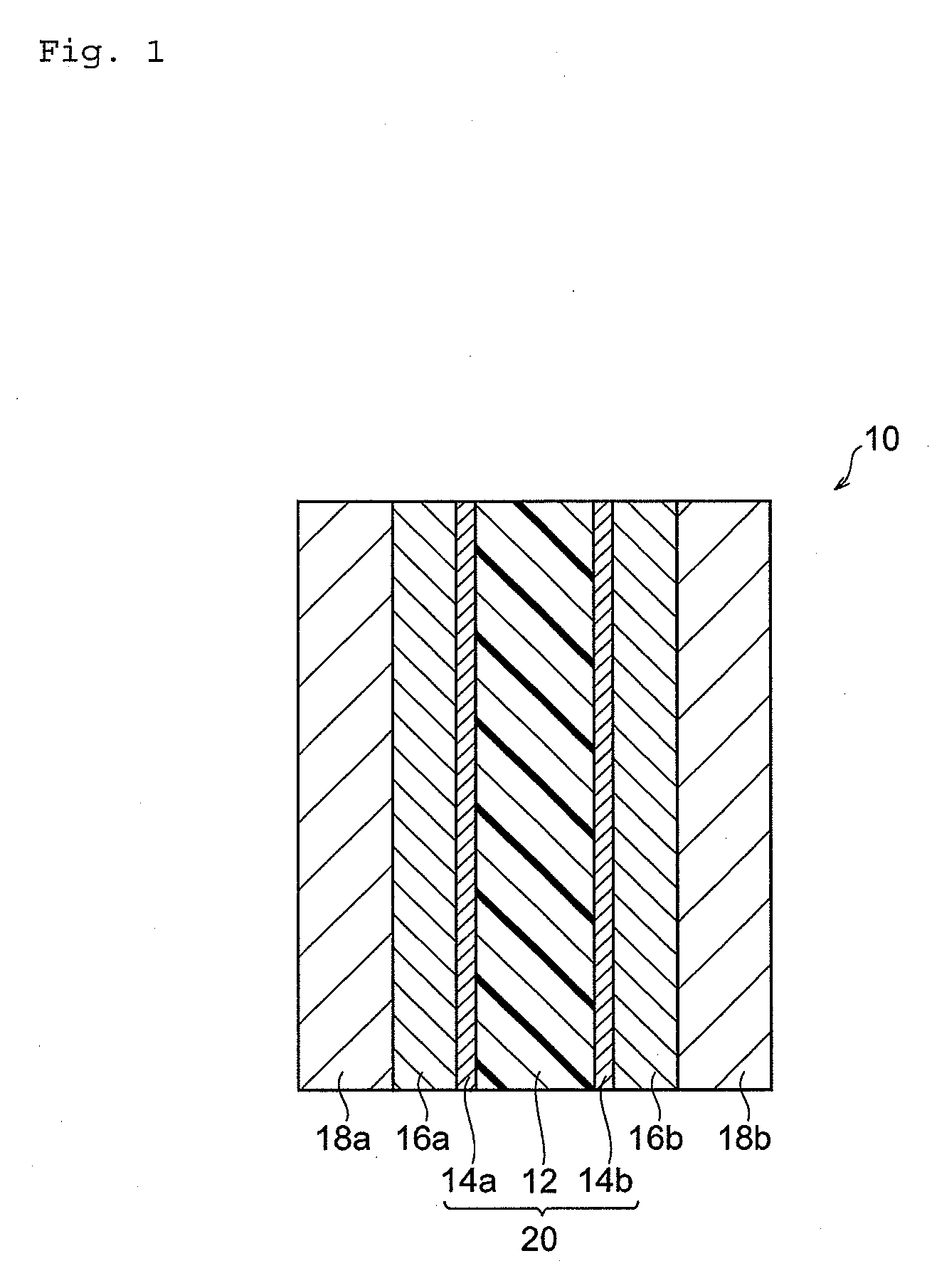

Biaxially oriented polyester film and magnetic recording medium

ActiveUS8609264B2Excellent in stiffness and dimensional stabilityLittle abrasionMagnetic materials for record carriersSynthetic resin layered productsPolyesterHigh density

[Problem to be solved] To provide a biaxially oriented polyester film, which suffers only small dimensional changes due to changes in environmental temperature and humidity and due to storage, ensures low error rates, and can little abrade the magnetic head and the magnetic tape, when used as a base film of a magnetic recording medium, and which can be used to provide a high density magnetic recording medium excellent in running durability.[Solution] A biaxially oriented polyester film having an islands-in-sea structure, an average island domain size of 30 to 200 nm, and a coefficient of hygroscopic expansion of 0 to 6.0 ppm / % RH at least either in the machine direction or in the transverse direction of the film.

Owner:TORAY IND INC

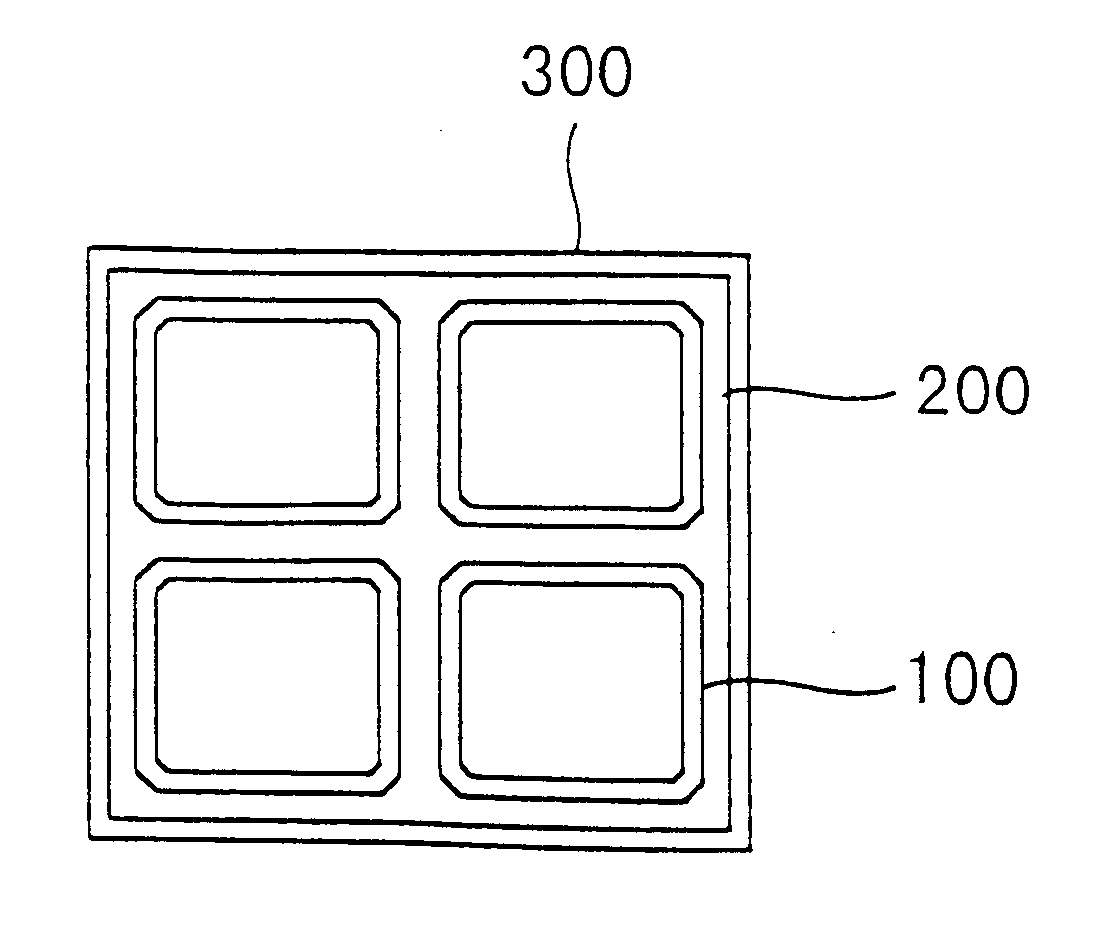

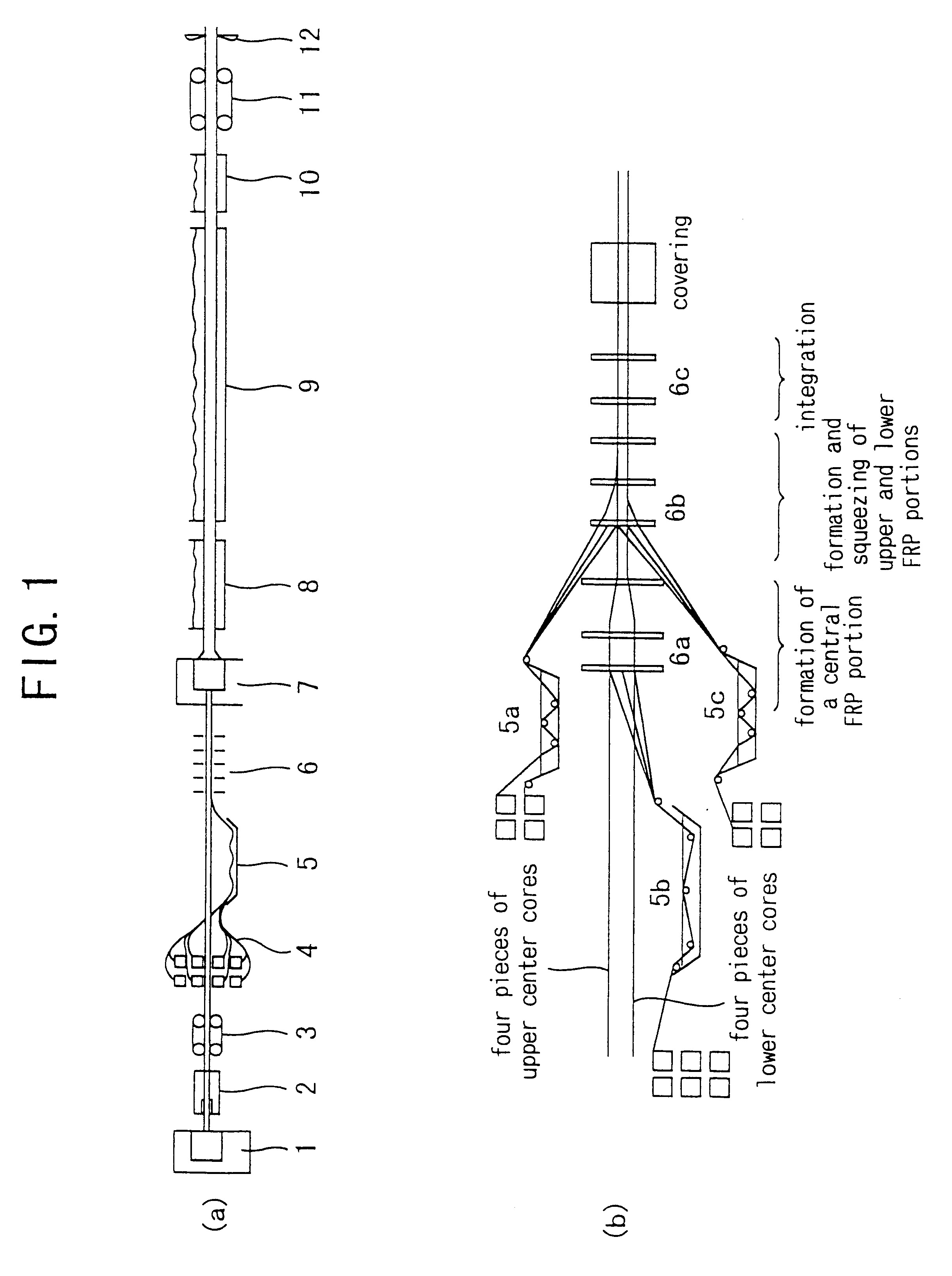

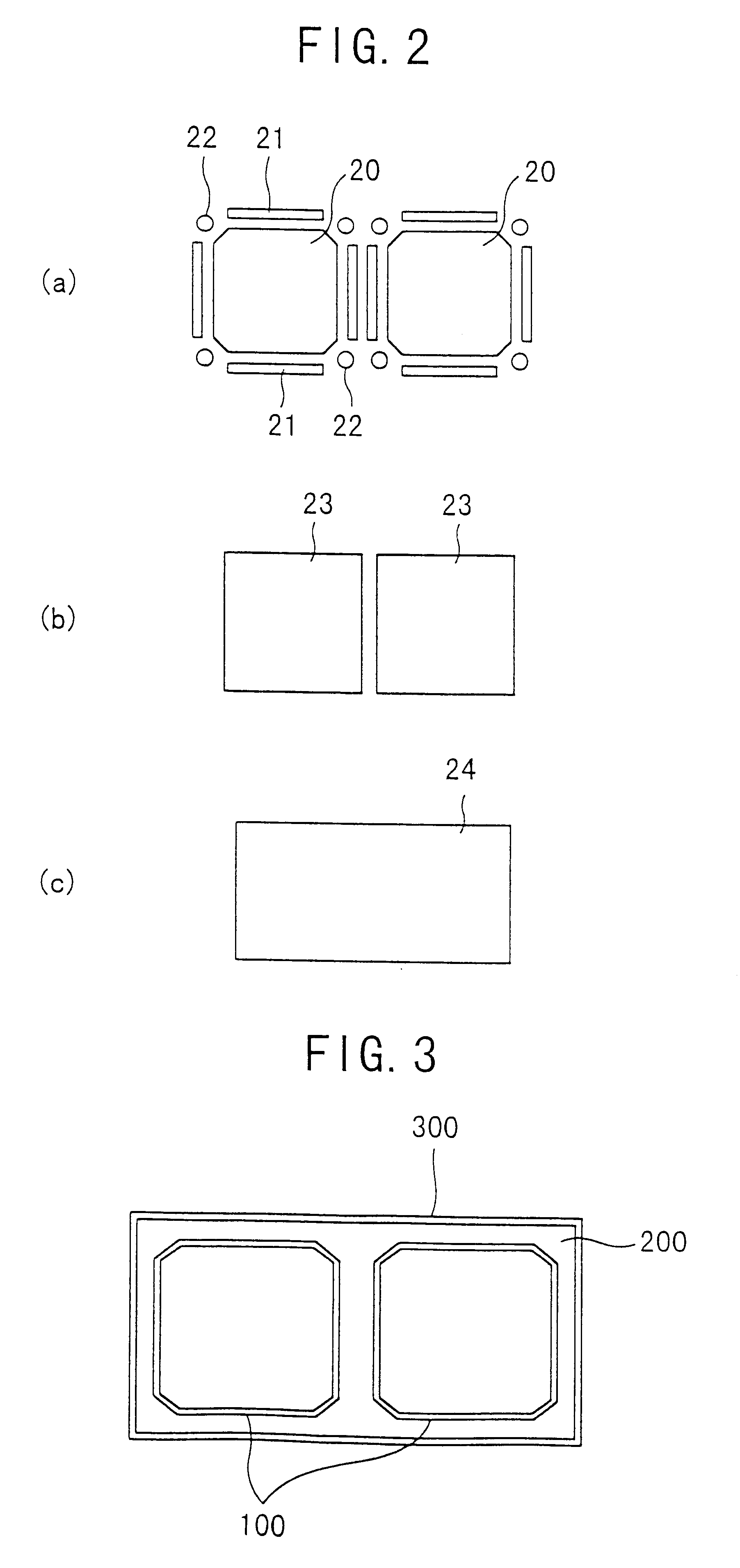

Fiber-reinforced composite hollow structure, method for production thereof, and apparatus therefor

InactiveUS6607798B1Prevent saggingUniform coverageEnvelopes/bags making machineryWrappers shrinkageEngineeringFiber-reinforced composite

Center cores are formed by extrusion-molding ABS resin. Seven pieces of the center cores, which are juxtaposed to each other in the horizontal direction, are supplied by a pultruder, and reinforcing long-fibers impregnated with an unsaturated polyester resin are allowed to pass through dispersion guides and squeezing nozzles, to thus squeezing-mold a fiber-reinforced composite hollow structure having FRP made legs. A final squeezing nozzle is disposed in a cross head die through a cooling jacket, and the hollow structure thus molded is allowed to pass therethrough to be covered with the ABS resin in a state in which the outer periphery of the hollow structure is heated. The hollow structure thus covered is subjected to cooled-sizing through a plurality of horizontal and vertical pairs of rollers, and then cured in a hot curing tank. The surface covered with the ABS resin is subjected to a surface-treatment of imparting irregularities for giving an antislipping function to the surface. A thermoplastic resin-made protective cap is fitted to an end of the center core. The apparatus for manufacturing a composite hollow structure has a plurality of pairs of rotatable and heat-resisting sizing rollers. The plurality of pairs of the sizing rollers are disposed in the pultruding direction while being gradually cooled in the order from those positioned on the upstream side to those positioned on the downstream side for sizing the softened outer layer covering the outer periphery of the intermediate layer.

Owner:UBE NITTO KASEI CO LTD

Cathode header optic for x-ray tube

ActiveUS7529345B2Reduced cross sectionImprove electronic efficiencyX-ray tube electrodesCathode ray concentrating/focusing/directingEngineeringElectron

A cathode header optic for an x-ray tube includes an elongate trench with opposite trench walls. A cup recess is formed in the trench between the opposite trench walls, and has a bounded perimeter. A cathode element is disposed in the trench at the cup recess. The cathode element is capable of heating and releasing electrons. A secondary cathode optic defining a cathode ring can be disposed about the header optic. The cathode optics can form part of an x-ray tube.

Owner:MOXTEK INC

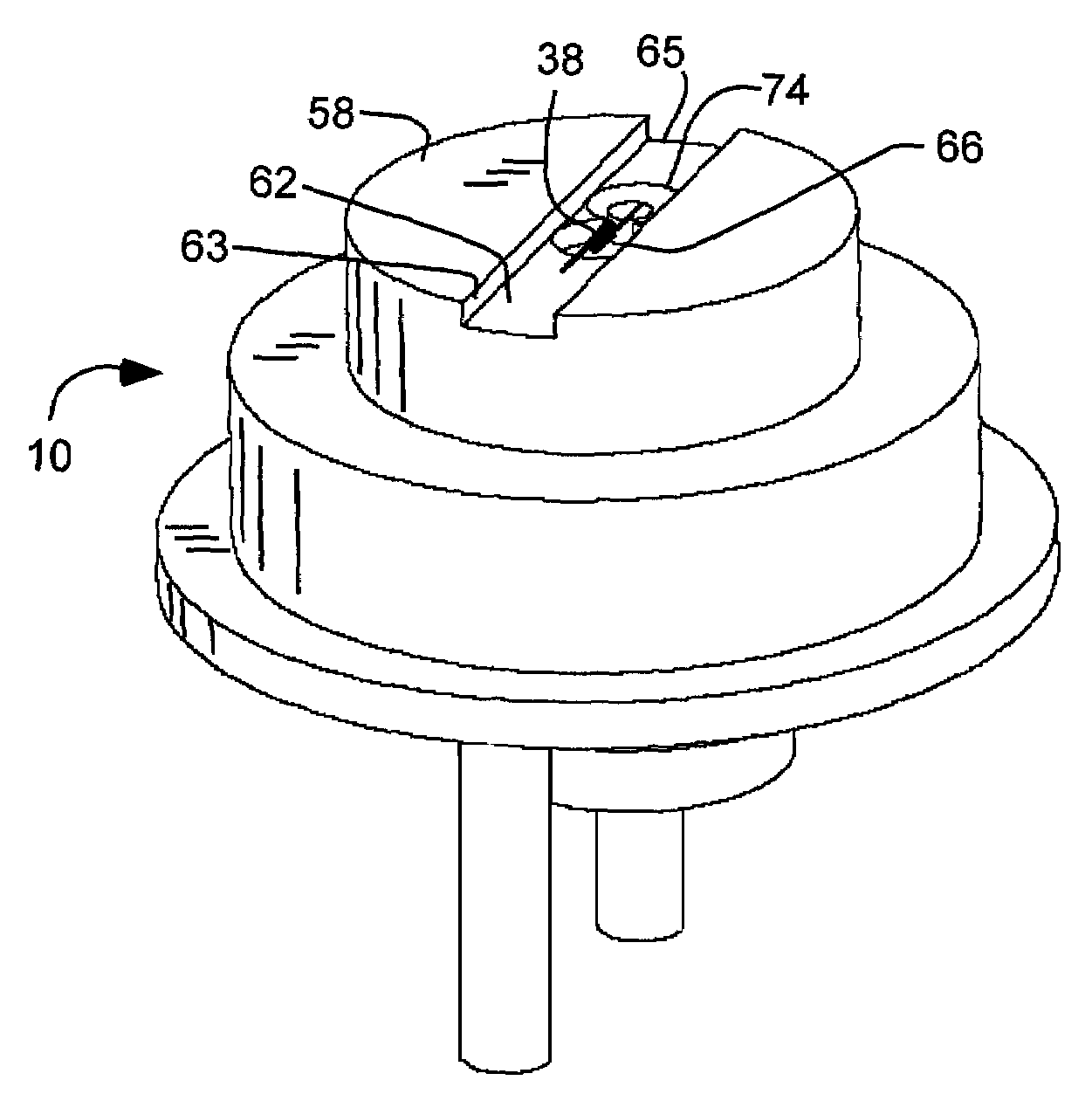

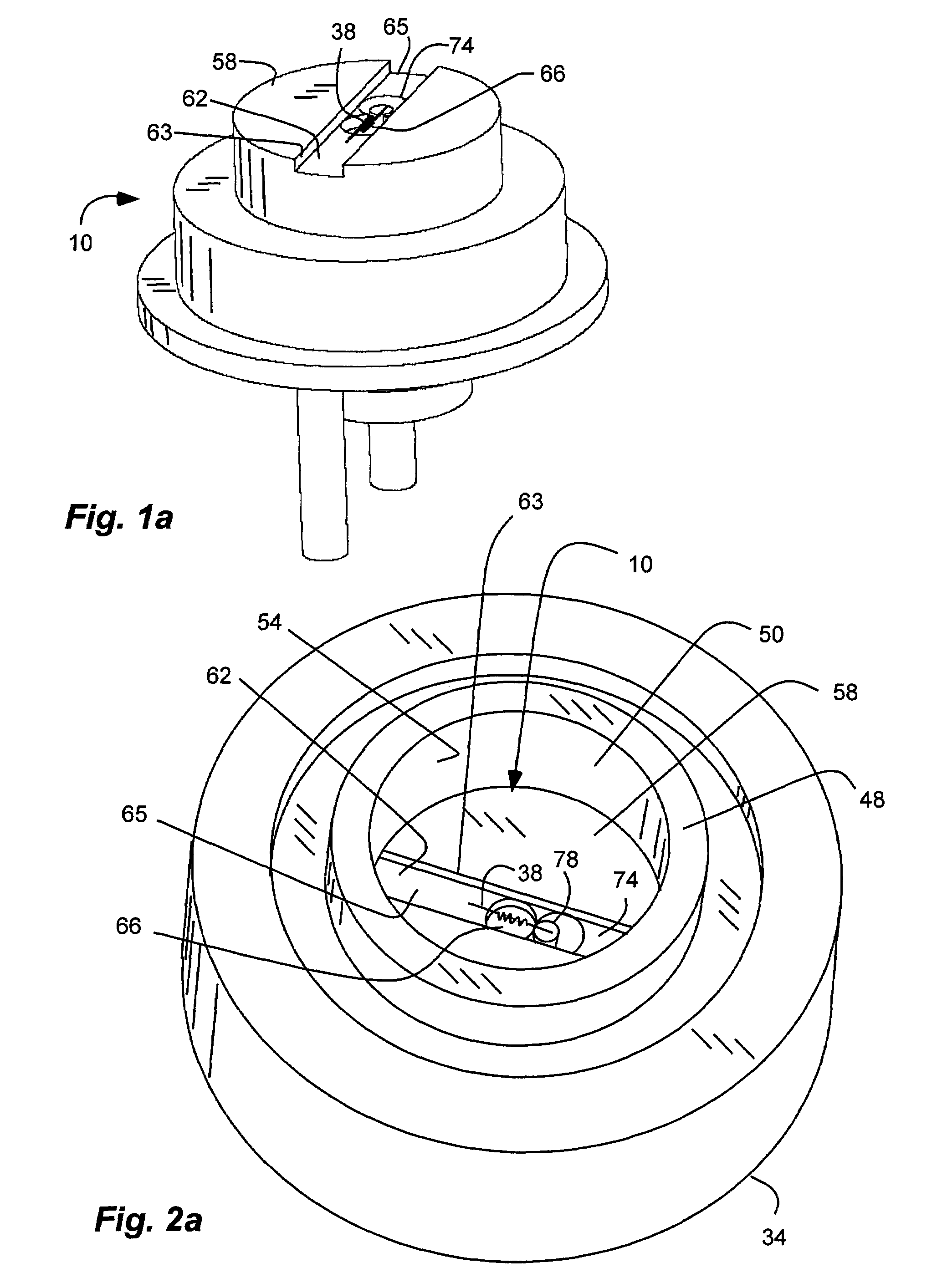

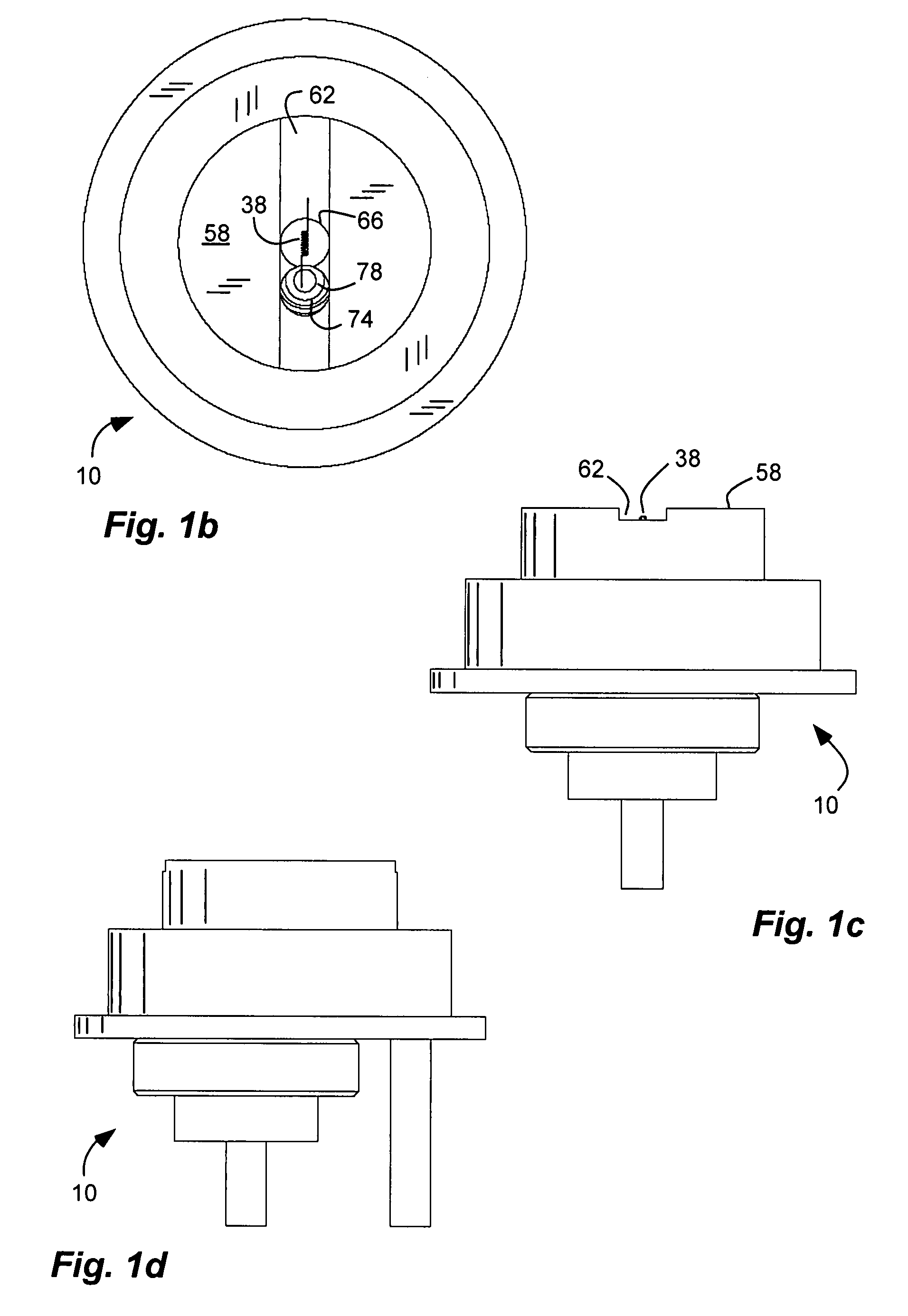

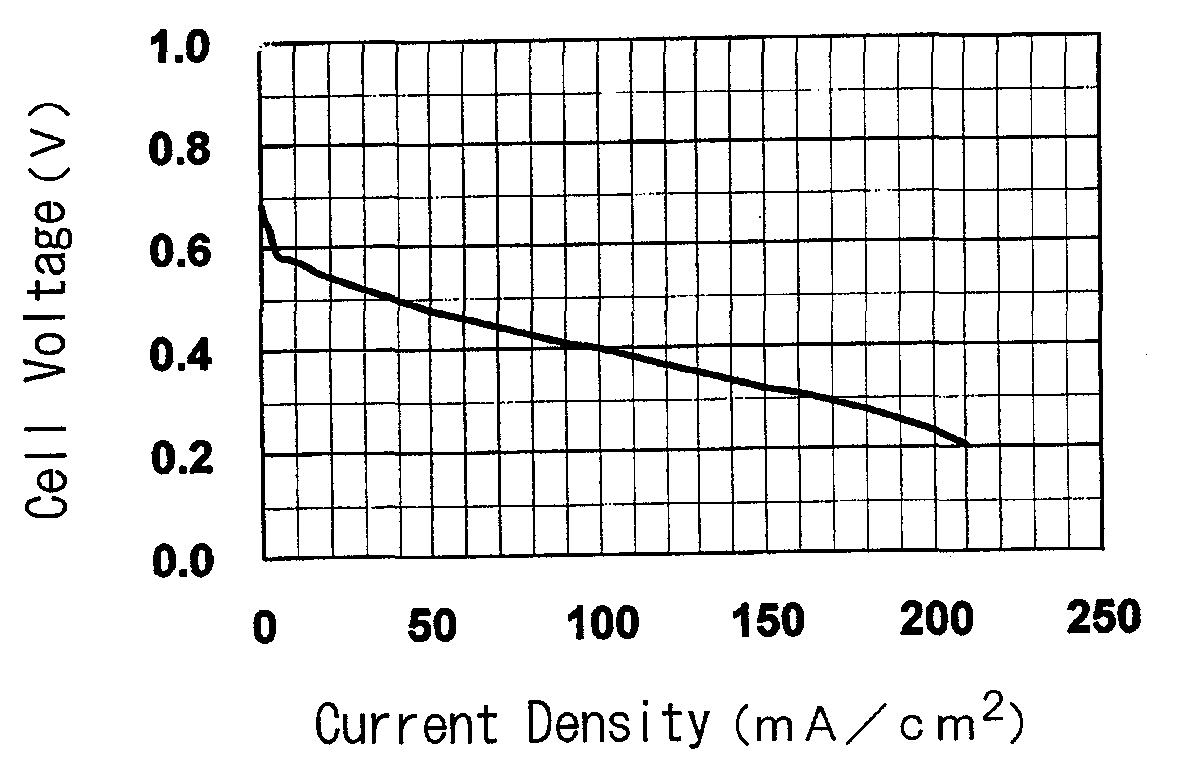

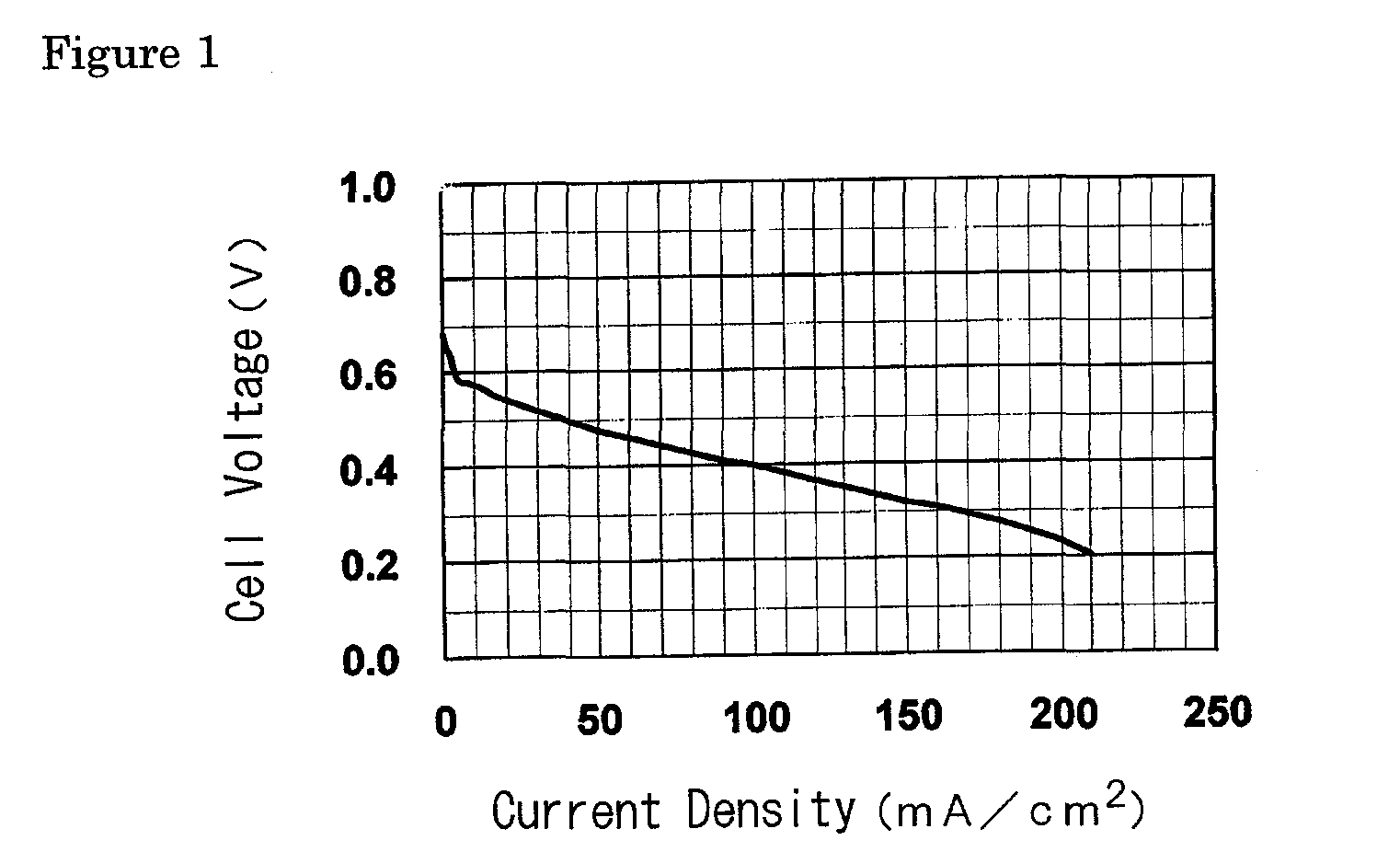

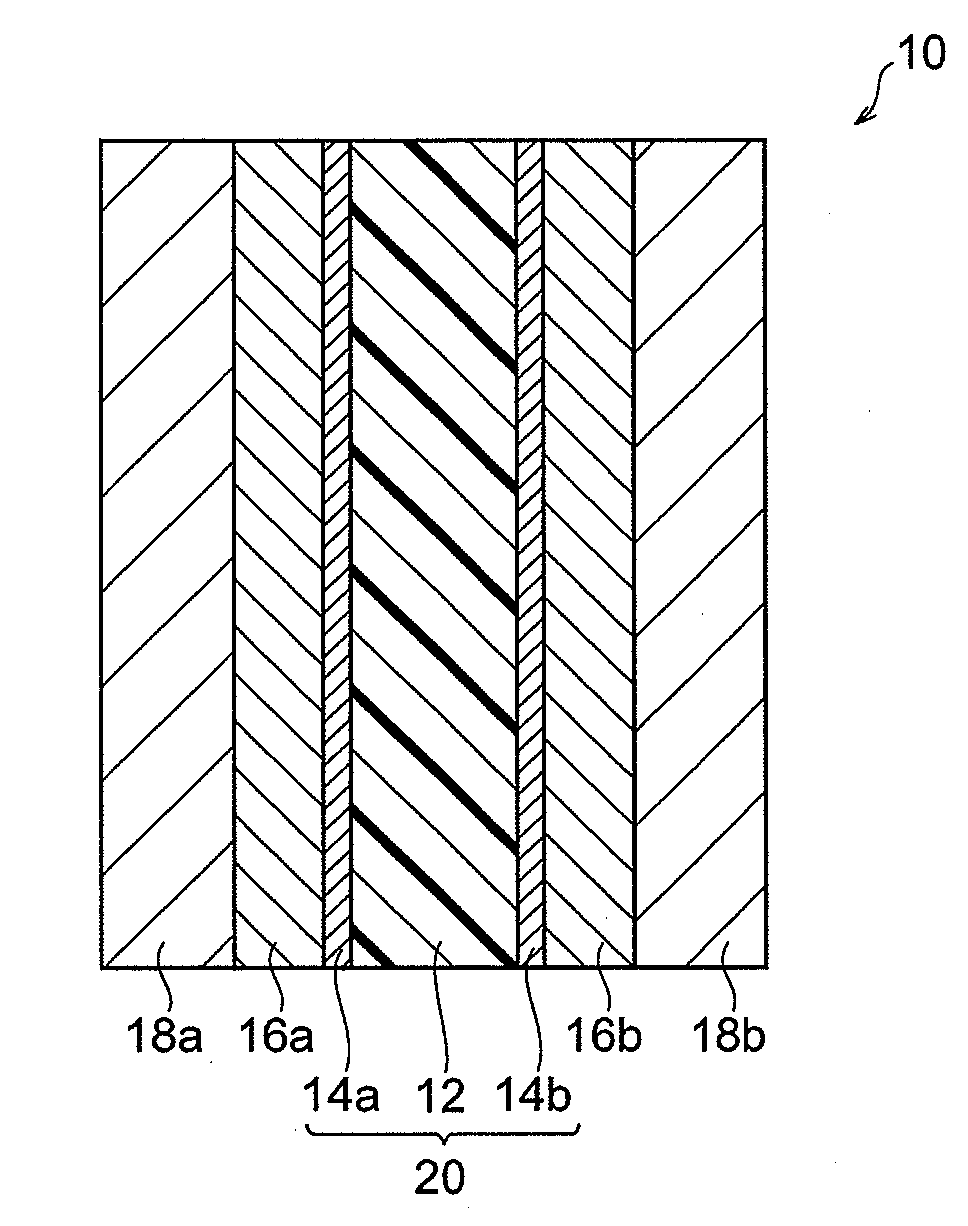

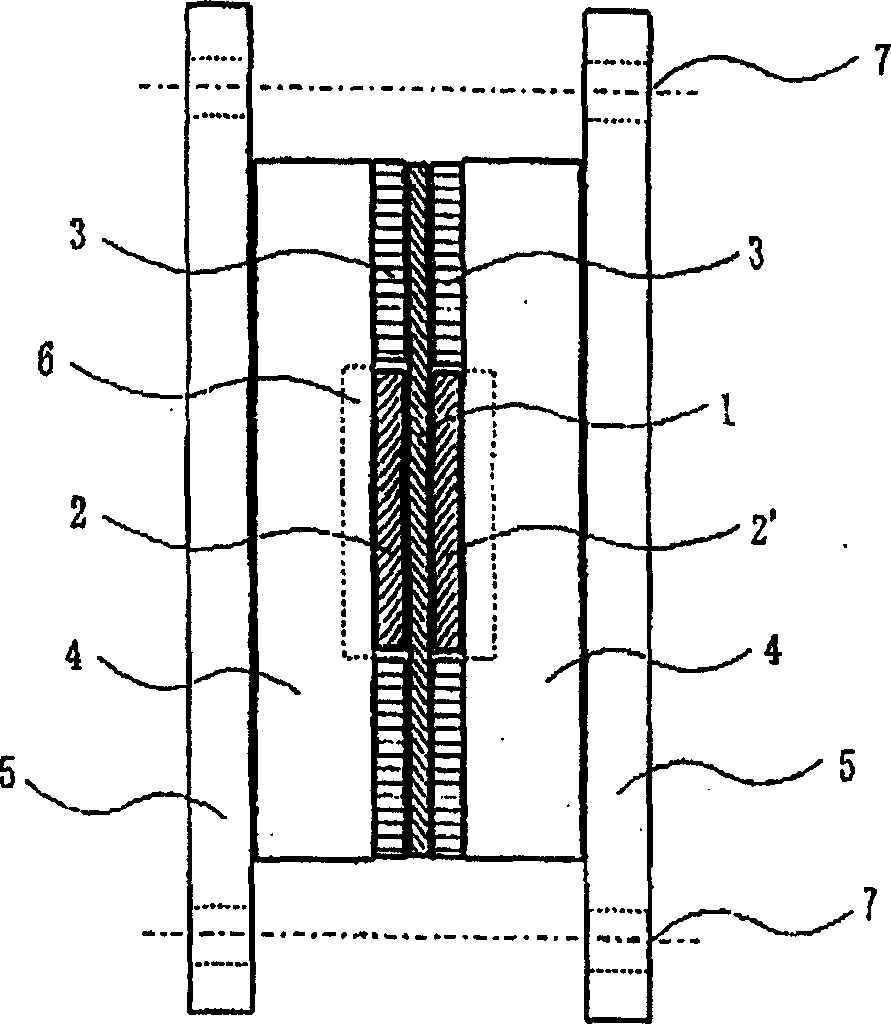

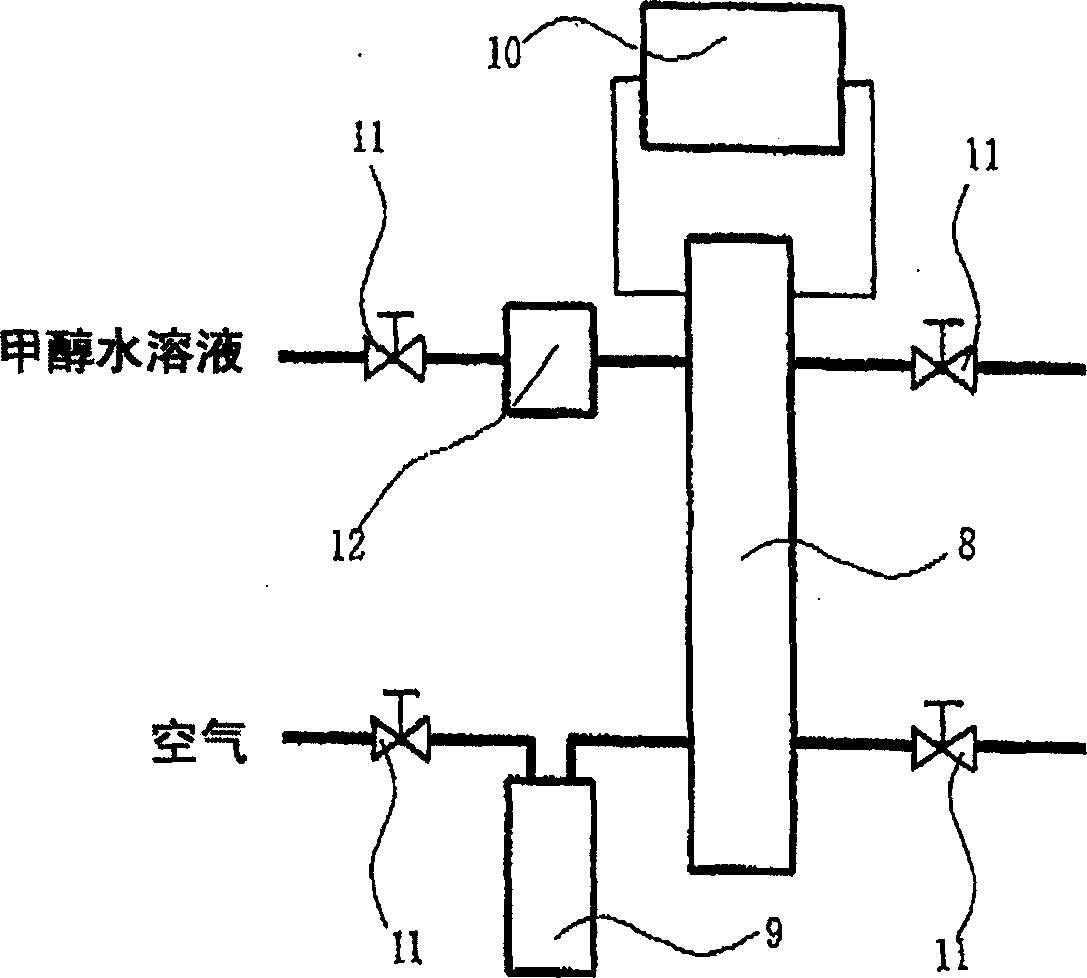

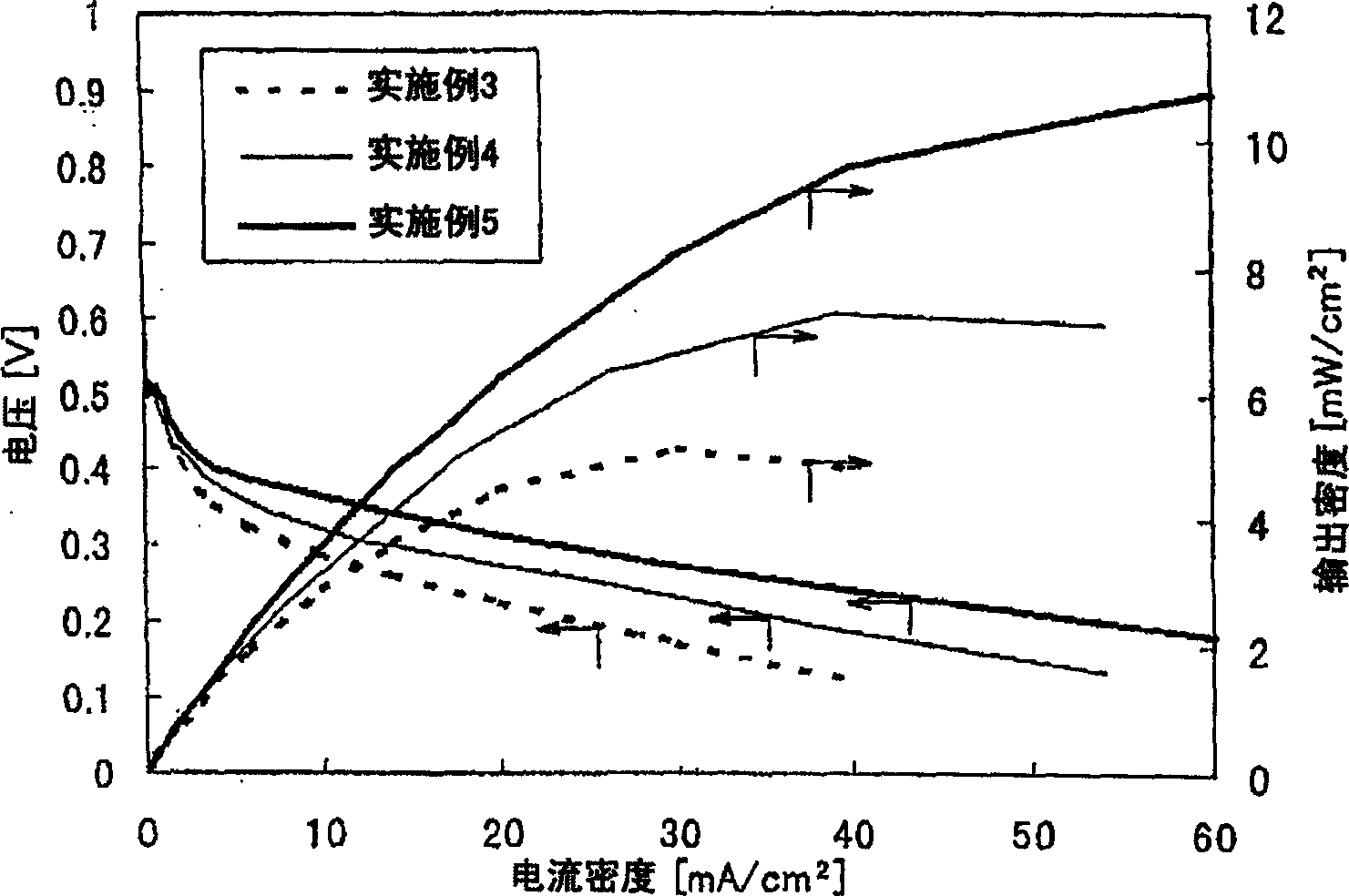

Polyelectrolyte film, film-electrode assembly, and solid-polymer-type fuel cell

InactiveUS20100167159A1Excellent moldabilityExcellent performanceSolid electrolytesConductive materialIonPolymer electrolytes

A polymer electrolyte membrane comprising as a main ingredient a block copolymer which comprises, as its constituents, a polymer block (A) having as a main unit an aromatic vinyl compound unit and a polymer block (B) forming a flexible phase, and has ion-conducting groups on the polymer block (A), said aromatic vinyl compound unit being such that the hydrogen atom bonded to the α-carbon atom is non-replaced or replaced with an alkyl group or an aryl group optionally having substituent(s), and at least one of hydrogen atoms directly bonded to the aromatic ring is replaced with an alkyl group; and a membrane electrode assembly and a polymer electrolyte fuel cell both of which uses it. The polymer block (A) can have a restraining phase, and / or can be cross-linked. The electrolyte membrane is mild to the environment, has a high ion conductivity and good bonding properties to electrodes, is excellent in moldability, and is not easily influenced by methanol; and displays excellent performance in polymer electrolyte fuel cells, particularly direct methanol fuel cells.

Owner:KURARAY CO LTD

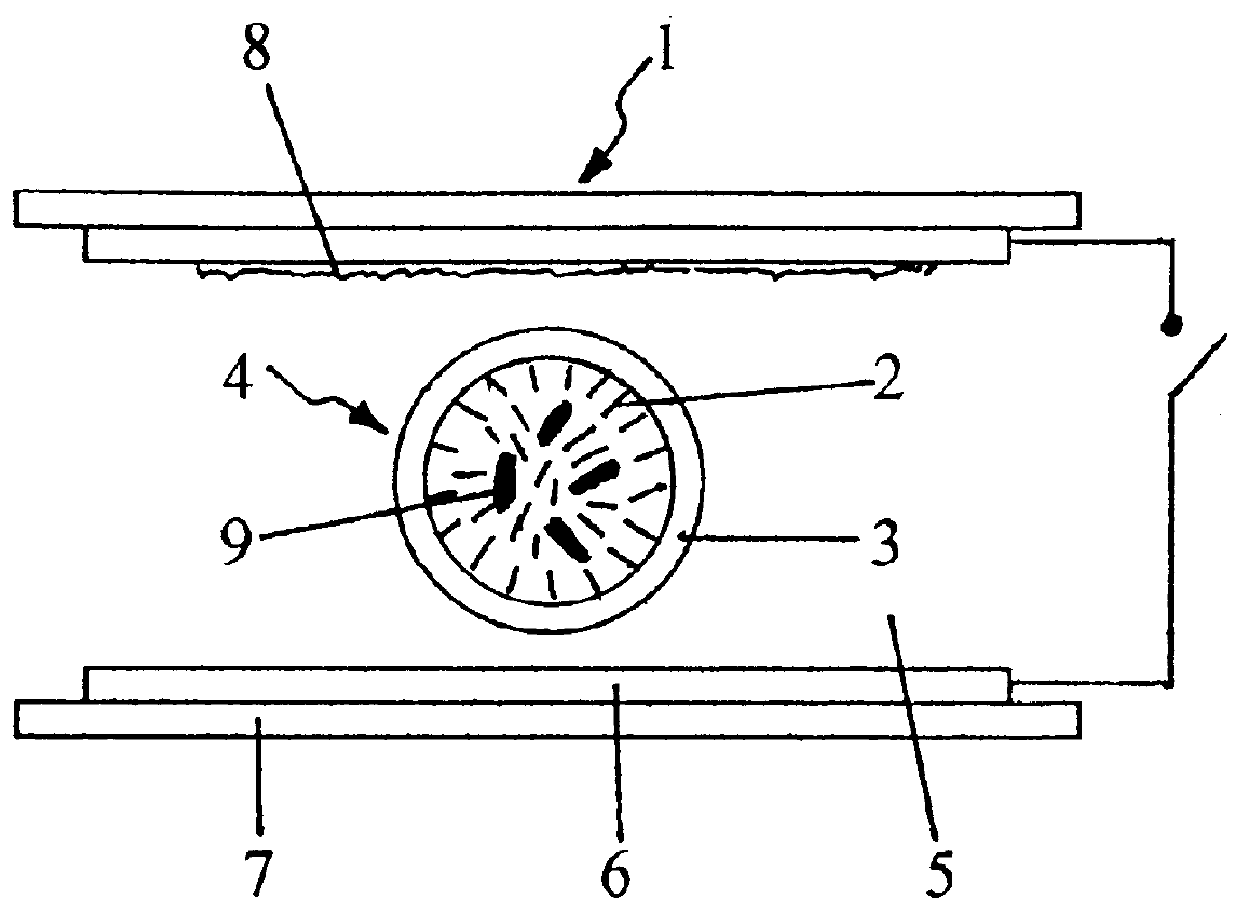

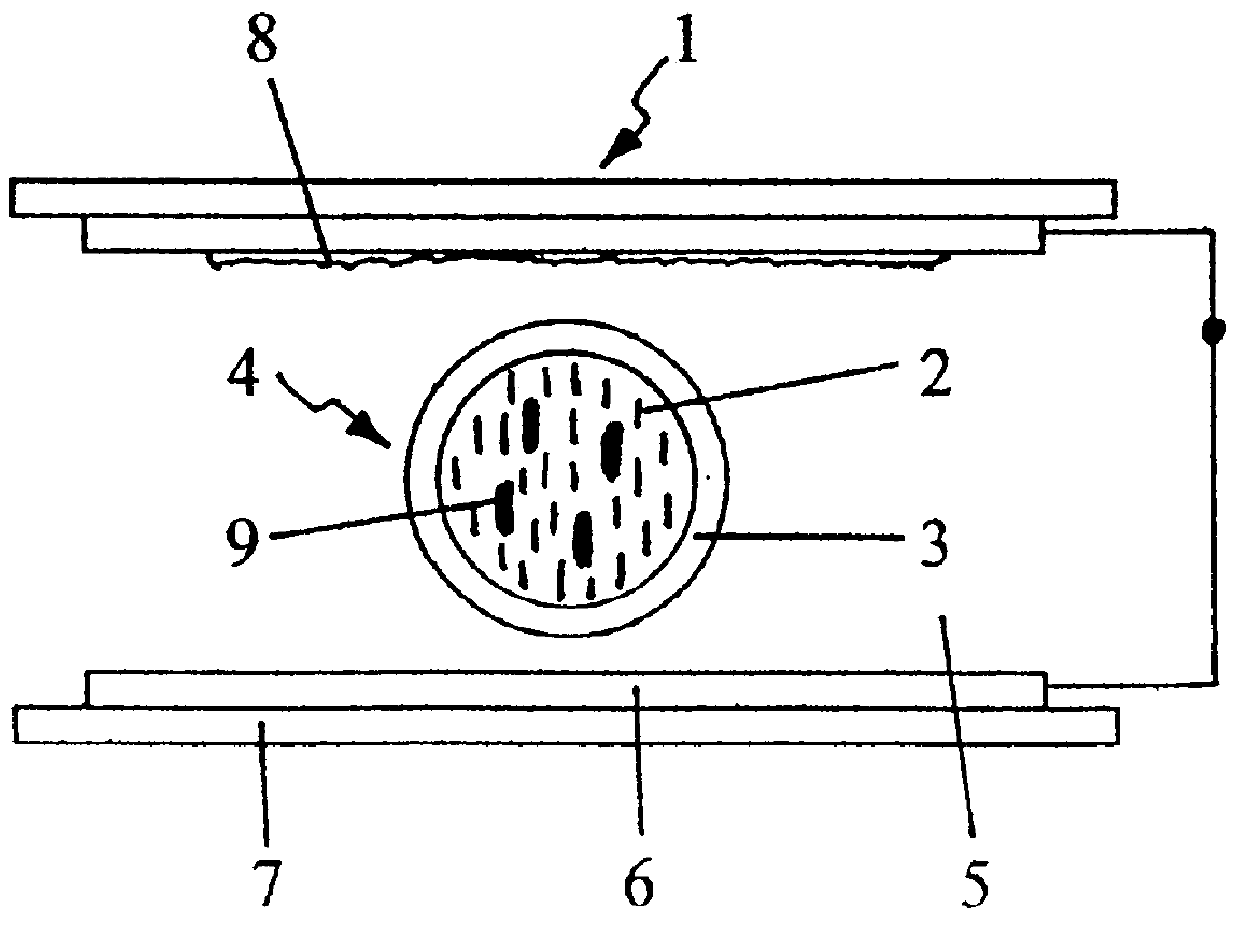

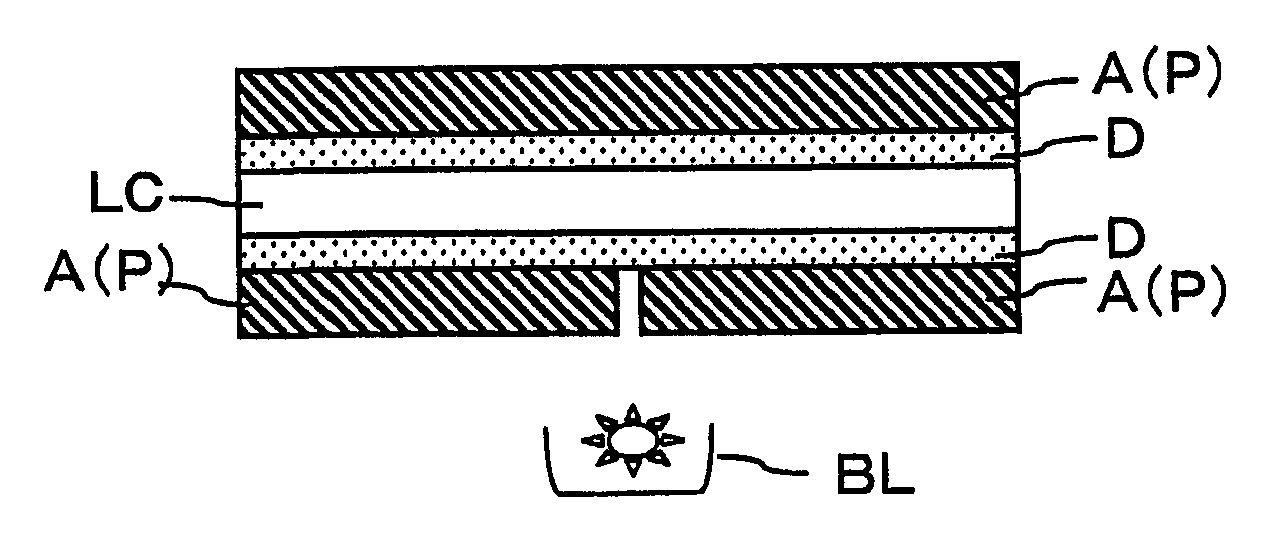

Microencapsulated liquid crystal and a method and system for using same

InactiveUS6204900B1Increase display contrastExtended service lifeNon-linear opticsEngineeringLiquid crystal devices

A liquid crystal device, materials for making the device, and method of making and using the device, and several applications of the device, having memory is responsive to respective inputs to assume respective optical responses; the liquid crystal may be liquid crystal microencapsulated in a containment medium; the memory capability of the device allows the device to hold a prescribed optical response condition even though one of the inputs changes between respective states or values.

Owner:FERGASON PATENT PROPERTIES

Treatment method of black hard microarc oxidation ceramic membrane on surface of magnesium alloy

InactiveCN102021631AUniform colorImproved color stabilityAnodisationElectrolysisPlasma electrolytic oxidation

The invention belongs to the treatment technology of a black hard ceramic membrane on the surface of magnesium alloy, in particular relating to a treatment method of a black hard microarc oxidation ceramic membrane on the surface of magnesium alloy. The invention mainly solves the technical problems that the colour of a ceramic membrane treated by magnesium alloy microarc oxidation is white or grey white mostly and the deep colour and even black ceramic membranes can not be obtained in the prior art. The method provided by the invention comprises the steps that sodium phosphate, sodium fluoride, sodium hydroxide, sodium molybdate, potassium carbonate, sodium tungstate, copper sulphate and potassium dichromate are added into water and prepared into an alkaline electrolytic solution, and the solution is stirred for later use; and then magnesium alloy and a stainless steel plate are immersed into the alkaline electrolytic solution, the magnesium alloy is taken as an anode, the stainless steel plate is taken as a cathode, and microarc oxidation treatment is carried out until a compact black hard ceramic membrane grows in situ on the surface of the magnesium alloy.

Owner:杭州意来客电器设备有限公司

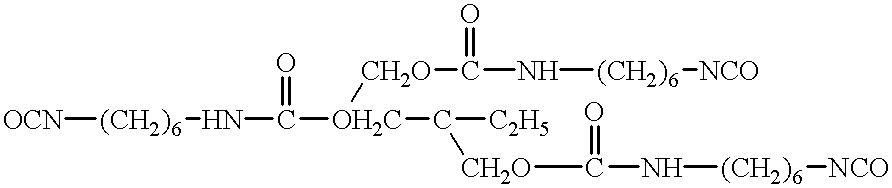

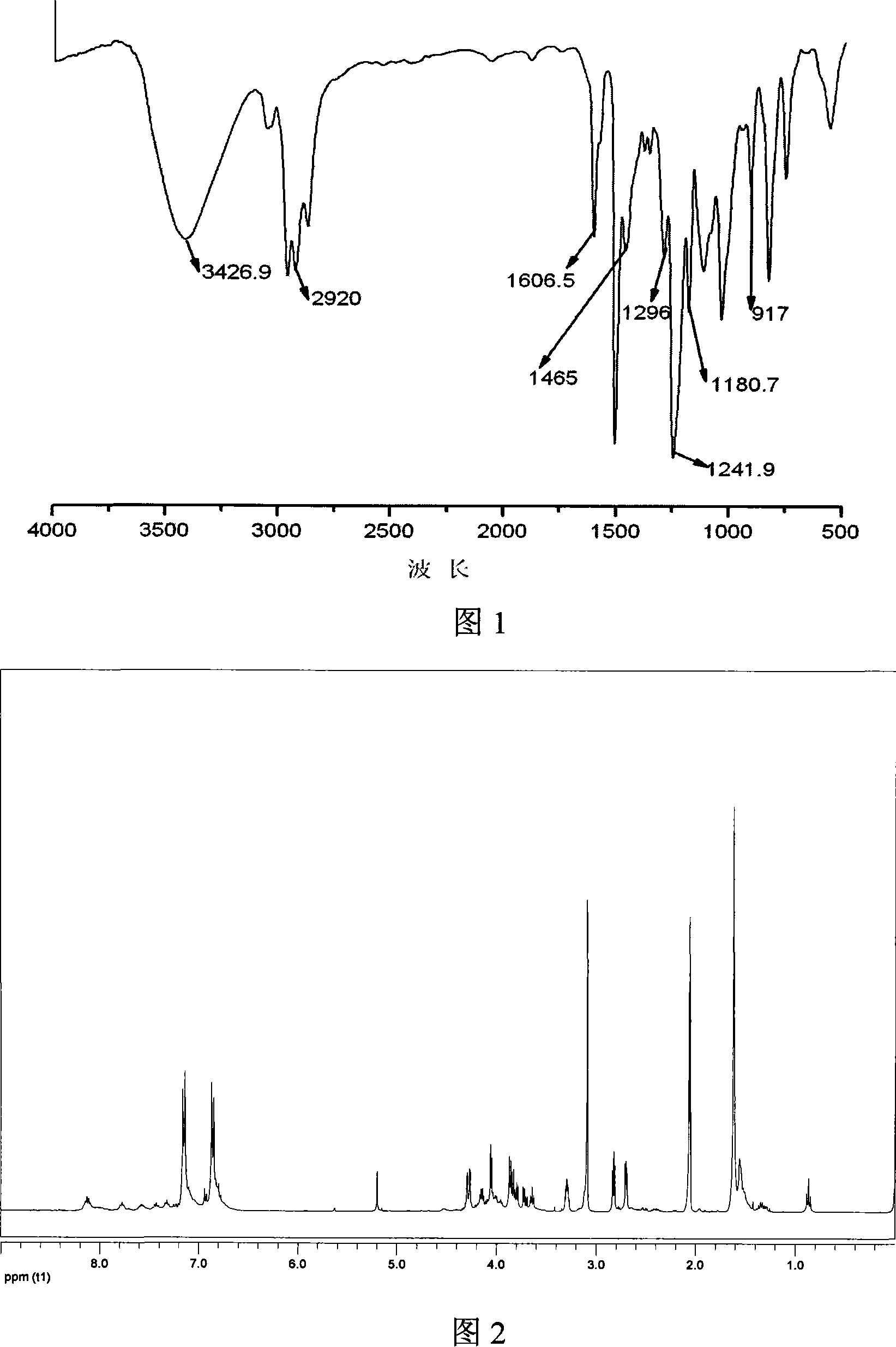

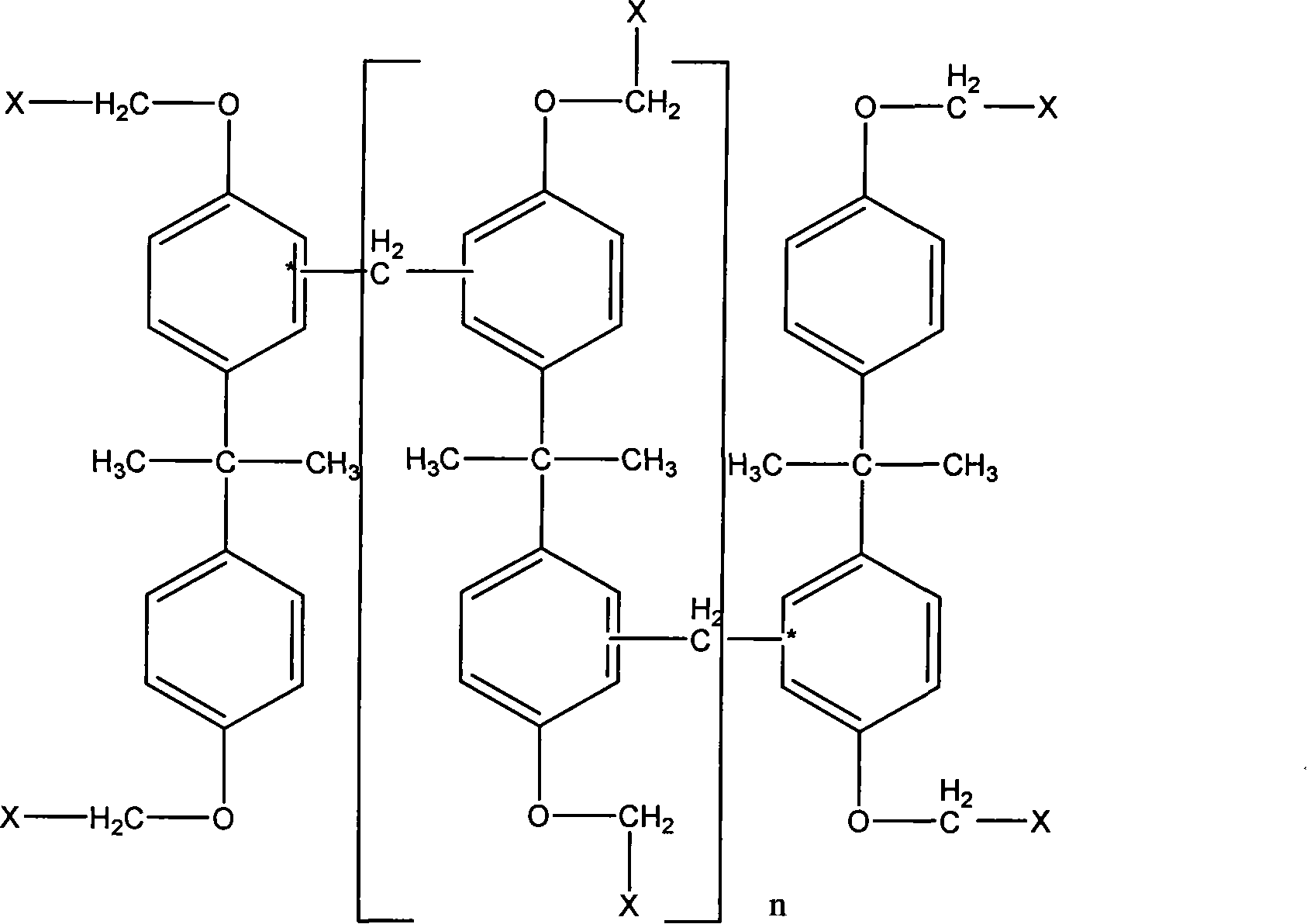

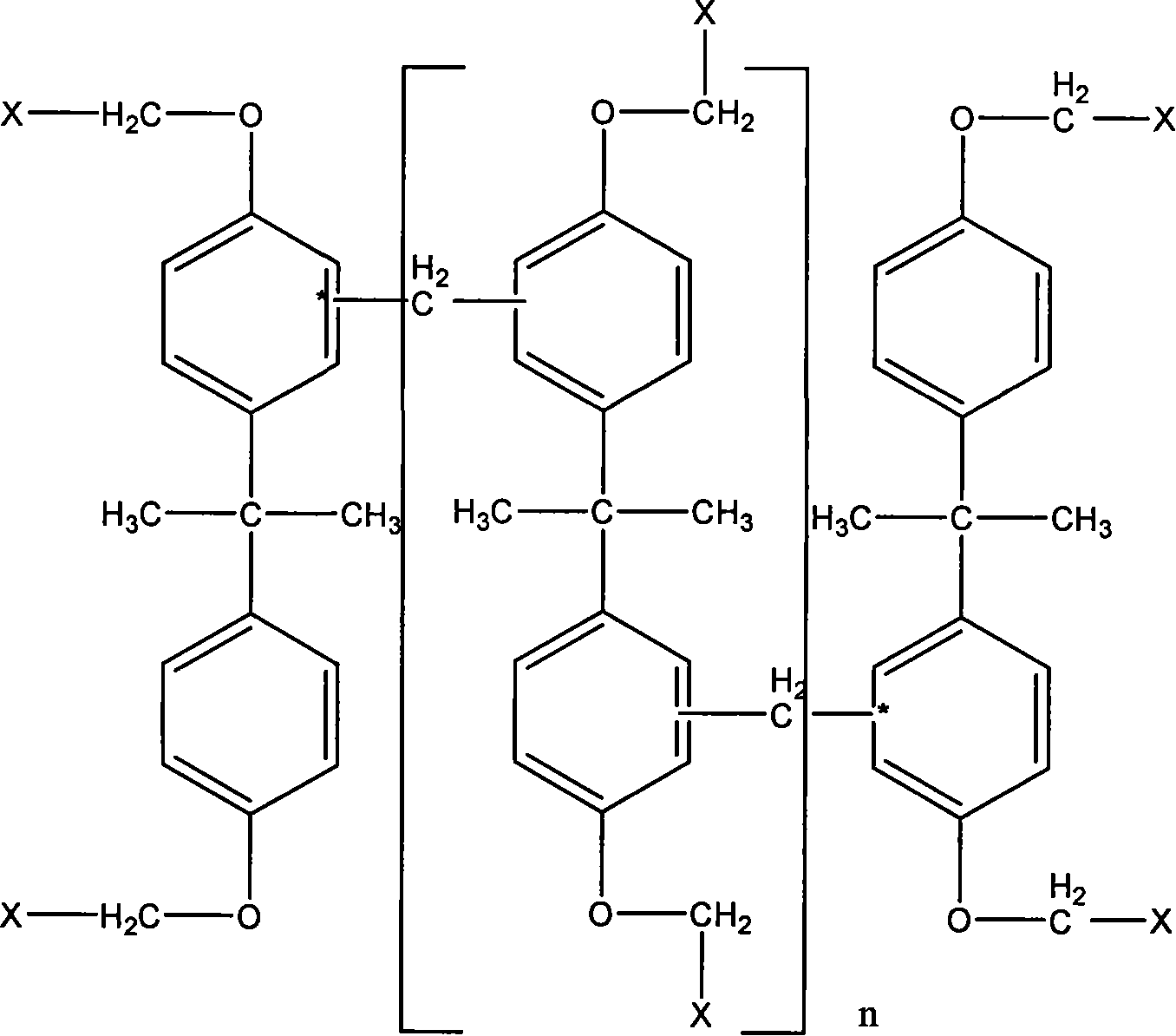

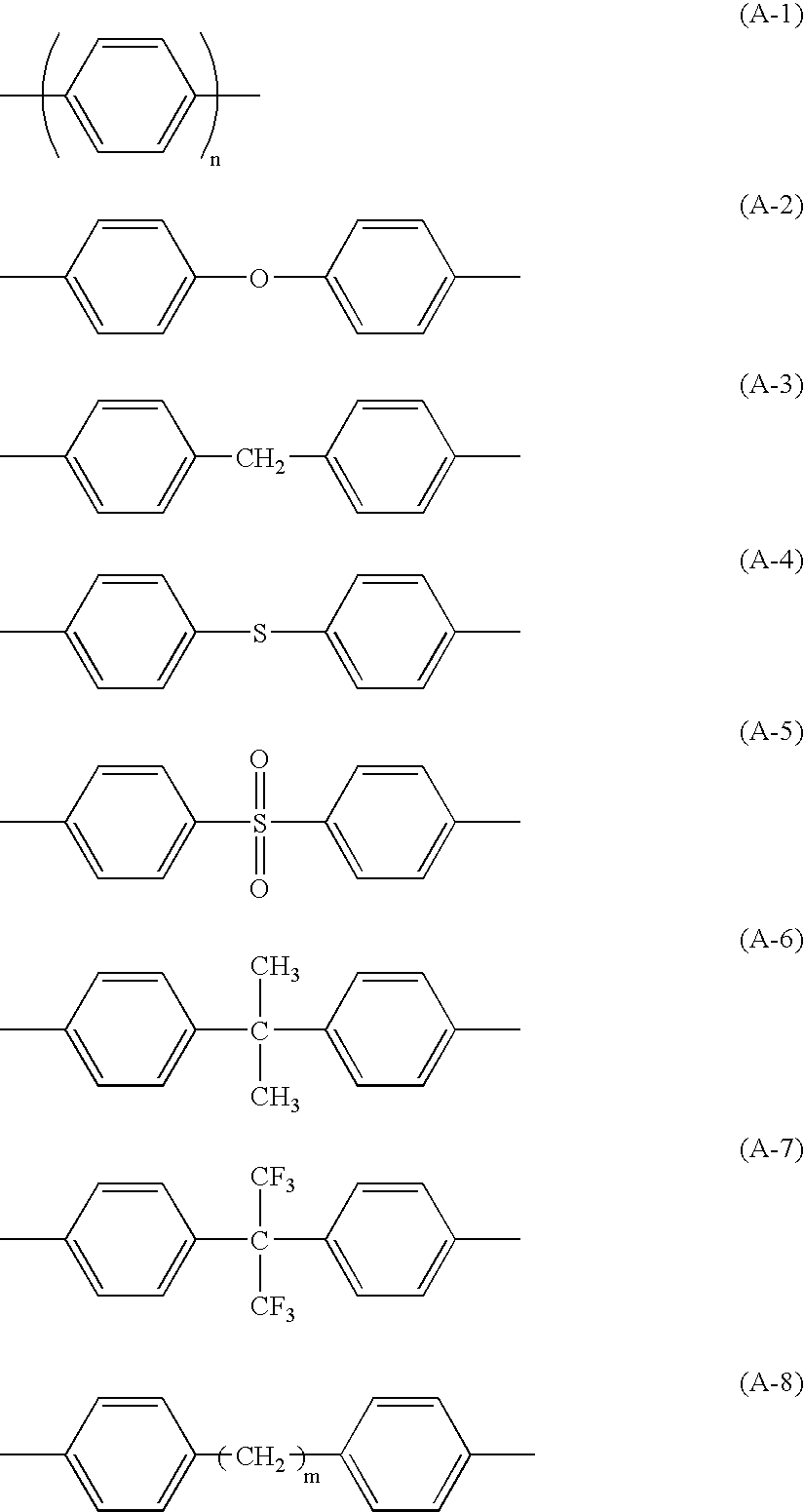

Phosphor A containing novolac epoxy and method for producing the same

InactiveCN101195676AImprove heat resistanceReduce the impactPlastic/resin/waxes insulatorsOrganophosphorous compoundsMechanical property

The invention relates to the technical field of novolac epoxy resin, in particular to a bisphenol A novolac epoxy resin containing phosphorous and a relative preparation method, wherein the compound formula is represented as below, n is 0-7. The invention condensates formaldehyde or cavaform and bisphenol A in the presence of acid catalyst to prepare phenol resin compound, processes etherification with epichlorohydrin in the presence of phase transfer catalyst, generates bisphenol A novolac epoxy resin in the presence of alkal catalyst, and reacts the bisphenol A novolac epoxy resin with organic phosphorous compound in the presence of catalyst to obtain bisphenol A novolac epoxy resin containing phosphorous. The solid product has good thermal resistance, flameproof, mechanical property and wide application in the technical fields of laminated board, insulated material, semi-conductor package and composite material.

Owner:DONGGUAN UNIV OF TECH

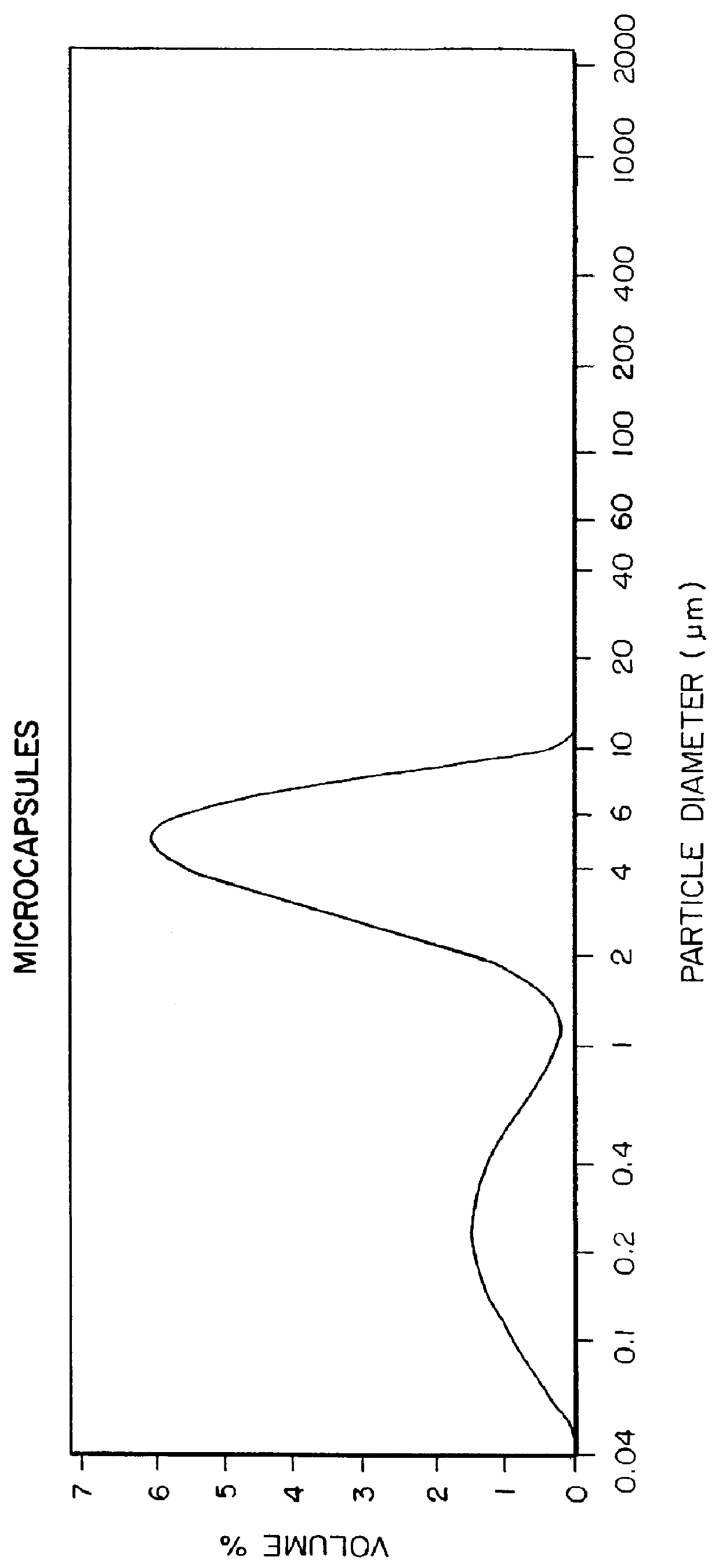

Microencapsulated liquid crystal and a method and system for using same

InactiveUS6120701AIncrease display contrastExtended service lifeLiquid crystal compositionsThin material handlingCrystallographyLiquid-crystal display

Briefly, according to one aspect of the invention, liquid crystal material is microencapsulated by a method utilizing an interfacial polymerization reaction which creates a combination of polyurethane and polyurea polymers which form the capsule walls surrounding the discrete liquid crystal droplets. The formed capsule walls are designed to have an adjustable refractive index so as to allow for the matching of the refractive index to that of the liquid crystal and polymeric binder materials. This allows for the production of a liquid crystal droplet surrounded by polymer film, which is optically clear when the liquid crystal director is aligned with the electric field. The microencapsulated liquid crystal droplets improves the dye stability of a dichroic dye and enhances the contrast of a liquid crystal display.

Owner:HSU YING YEN

Connection combination type optical film, liquid crystal panel, image display device, and liquid crystal display device

InactiveUS20100103353A1Improve leakageEasy to transformPolarising elementsNon-linear opticsLiquid-crystal displayDisplay device

An object of the invention is to prevent light leakage over time in a combined optical film including a plurality of optical films whose end faces are allowed to abut against each other. The invention is directed to a combined optical film, including: a plurality of optical films each having at least one end face, wherein the end faces abut against each other; and a transparent connection film that is adhered to at least one side of each of the optical films through a pressure-sensitive adhesive layer or an adhesive layer so that the optical films are joined by the transparent connection film.

Owner:NITTO DENKO CORP

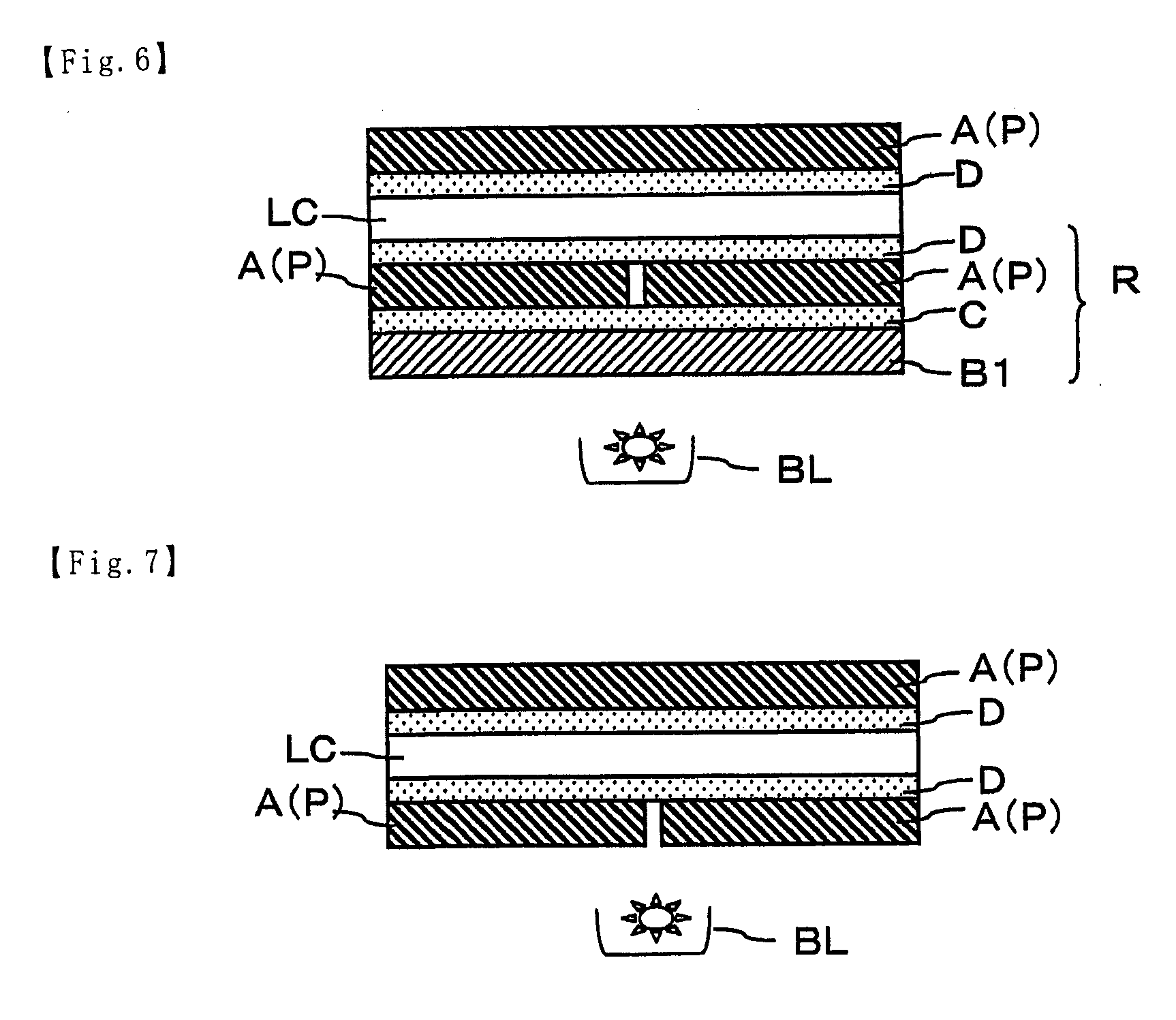

Method for producing plastic pipe fitting with insert made from polyphenylene sulfide alloy material

The invention relates to a method for making a plastic pipe with an insert made from a PPS alloy material. Materials such as PPS, nylon, etc. are treated with steps of blending, extrusion, strip stretching, cooling, pelletizing, homogenization, injection molding, etc. so as to obtain the plastic pipe with the insert made from the PPS alloy material. The making method of the invention has simple and easy technique; the alloy material has the advantages of small specific weight, good heat and corrosion resistance as well as good dimensional stability; in addition, the obtained pipe has good sealing, high notched impact strength, etc. The plastic pipe provided by the invention has wide range of application and can be applicable to water supply and drainage systems and drinking water pipe systems, gas transmission systems and industrial pipe systems, heating systems and agricultural pipe systems.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS +1

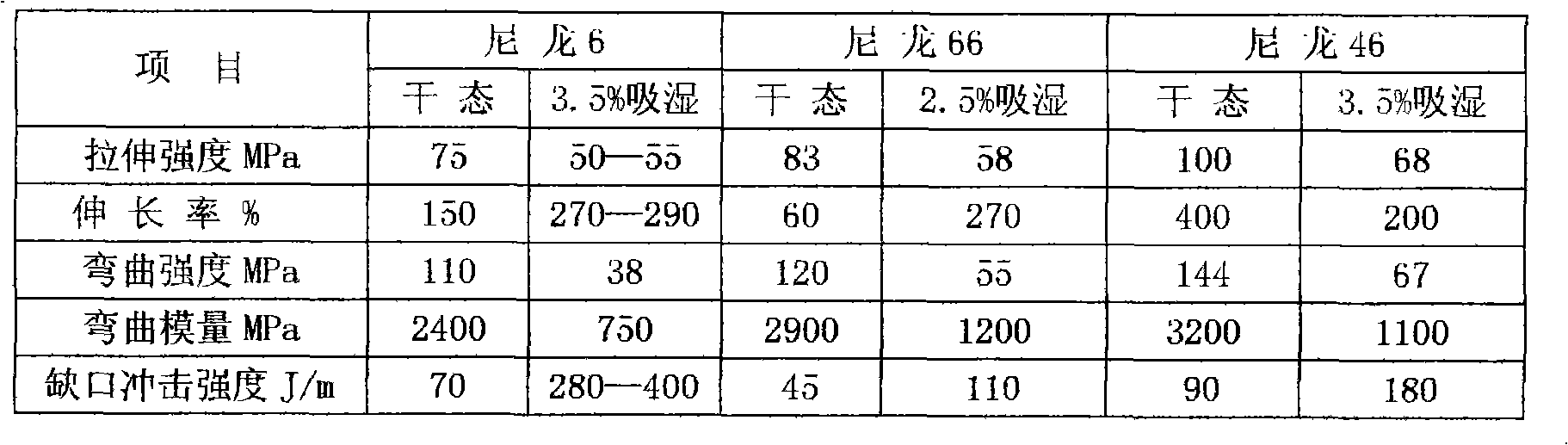

Method for preparing C/C-SiC composite part and product prepared through method

ActiveCN106927846AEvenly distributedAvoid damageAdditive manufacturing apparatusFiberSolvent evaporation

The invention belongs to the field of composites, and discloses a method for preparing a C / C-SiC composite part and a product prepared through the method. The method comprises the following steps that firstly, carbon fiber / phenolic resin composite powder is prepared by using a solvent evaporation method; secondly, according to a three-dimensional model of the part, the carbon fiber composite powder is molded into an initial molded blank by means of the 3D printing technology; thirdly, the initial molded blank is subjected primary densification and a C / C porous body is obtained; fourthly, the C / C porous body is subjected to a molten silicon infiltration reaction, high-temperature desilication and secondary densificaiton, and the final C / C-SiC part is obtained. By means of the method, the C / C-SiC composite part with a complex structure can be shaped in a near-net mode, the method is short in production period and low in cost, and the C / C-SiC composite part obtained through the method is low in residual silicon content and has excellent performance.

Owner:HUAZHONG UNIV OF SCI & TECH

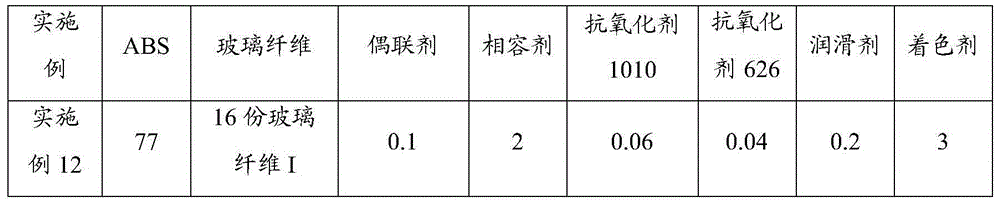

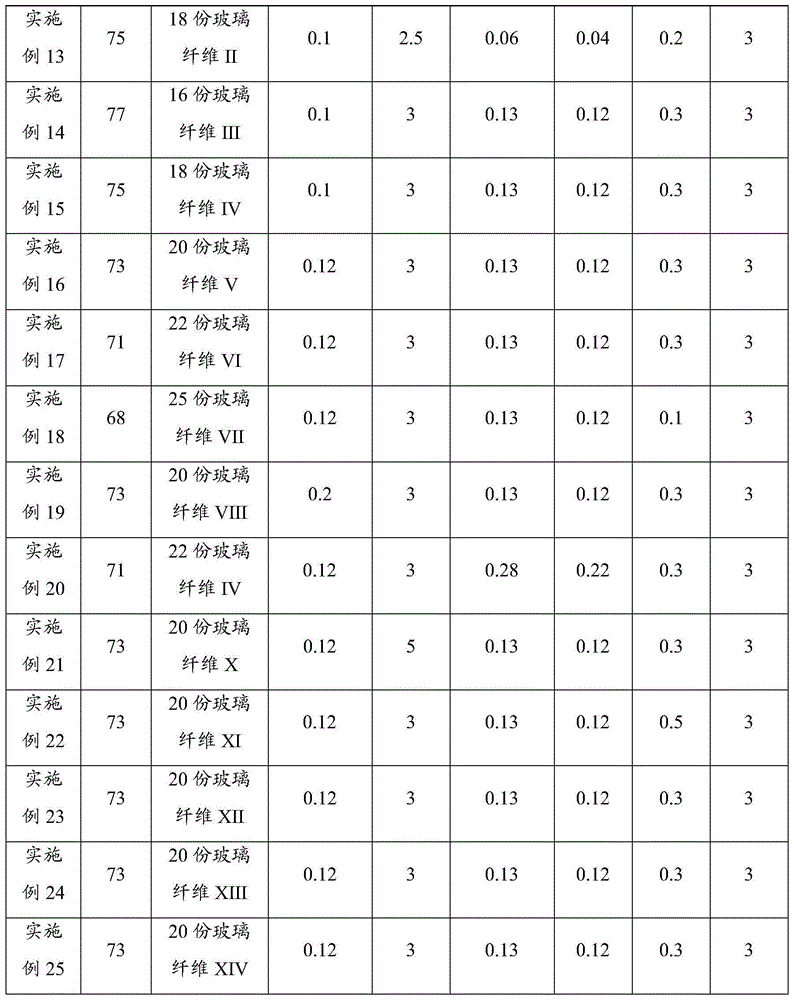

Glass fiber, surface treatment method of glass fiber, plastic and shell

InactiveCN104310803ALow coefficient of linear expansionImprove impact resistanceGlass fiberFlat glass

The invention relates to the technical field of materials, and particularly relates to a glass fiber, a surface treatment method of the glass fiber, a plastic and a shell, which are used for improving the capacity, of combining with ABS, of the glass fiber. The surface treatment method of the glass fiber comprises the following steps: putting the glass fiber to be treated in corrosive liquid to carry out corrosive treatment for 30-40 seconds, wherein the corrosive liquid comprises a corrosion inhibitor and an acidic water solution with mass fraction of 0.05-0.5% and 99.5-99.95%; putting the corroded glass fiber in a coupling agent to carry out infiltration; and drying the infiltrated glass fiber. Through the surface treatment, the capacity, of combining with ABS, of the glass fiber is relatively high; being added into ABS plastics, the glass fiber is capable of effectively enhancing the linear expansion coefficient of the ABS; and when the glass fiber is flat glass fiber, the shock resistance of the ABS plastics can be improved.

Owner:GUANGDONG HISENSE ELECTRONICS CO LTD

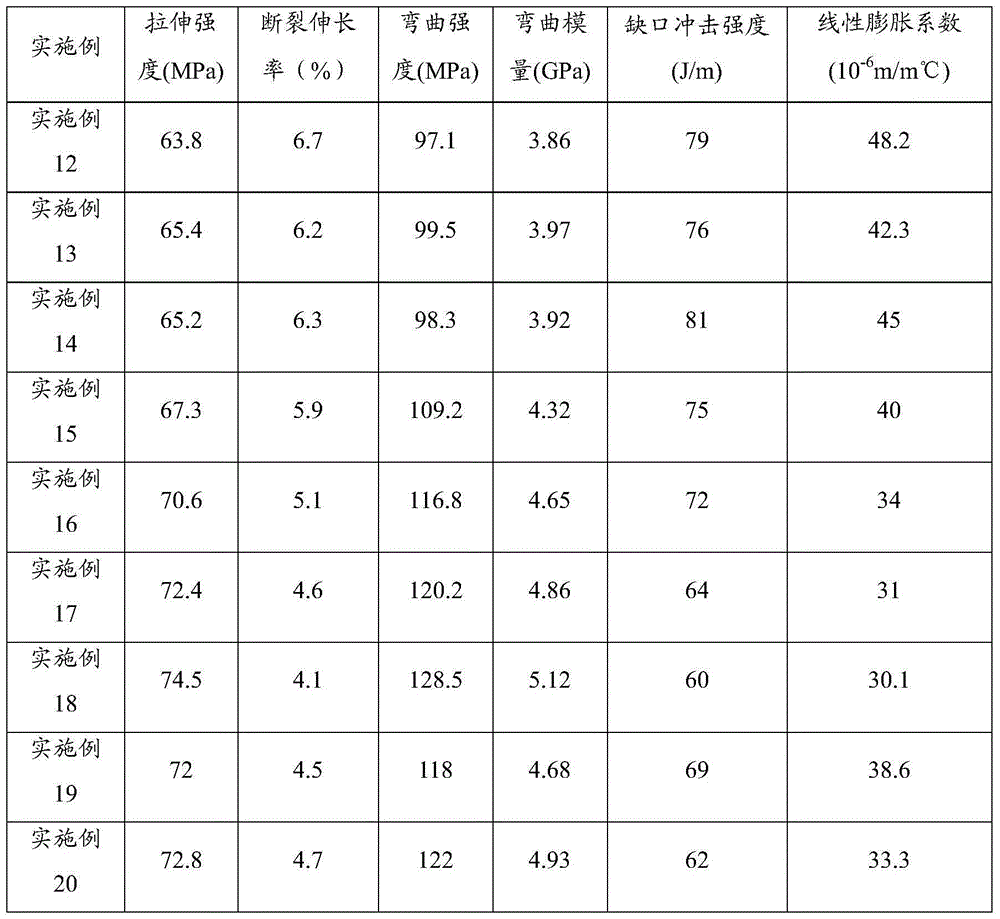

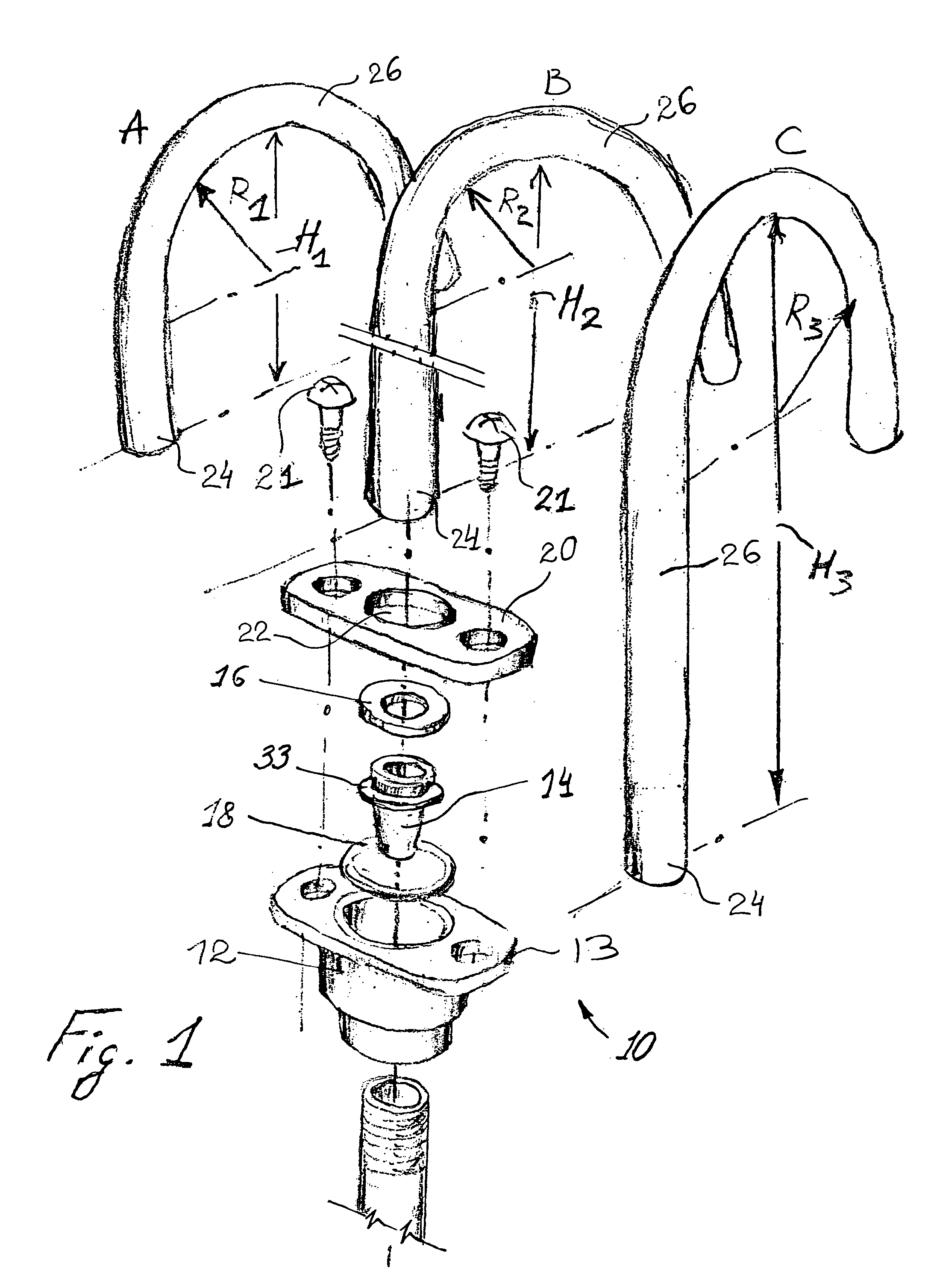

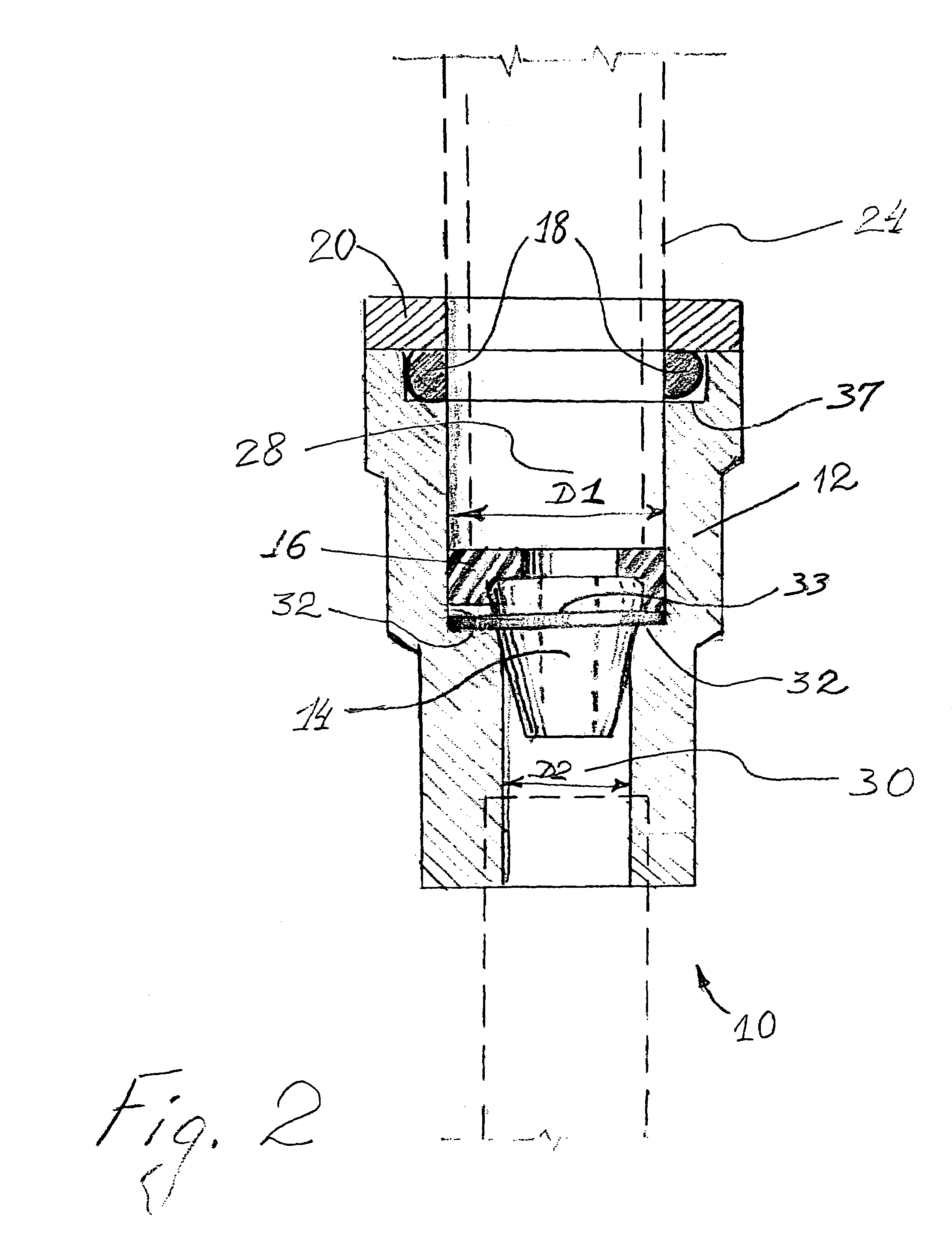

Interchangeable gooseneck faucet

InactiveUS7207075B2Easily interchangeable spoutEasily interchangeable spoutsSleeve/socket jointsFlanged jointsCheck valveEngineering

A faucet spout assembly providing multiple spouts with different heights and curvature which are interchangeable within the same faucet. Laminar flow from the spout is achieved with a flow control device upstream of the spout outlet A check valve is optionally used in the inlet to the spout to promote greater flexibility in placement of the flow control device within the assembly.

Owner:SPEAKMAN

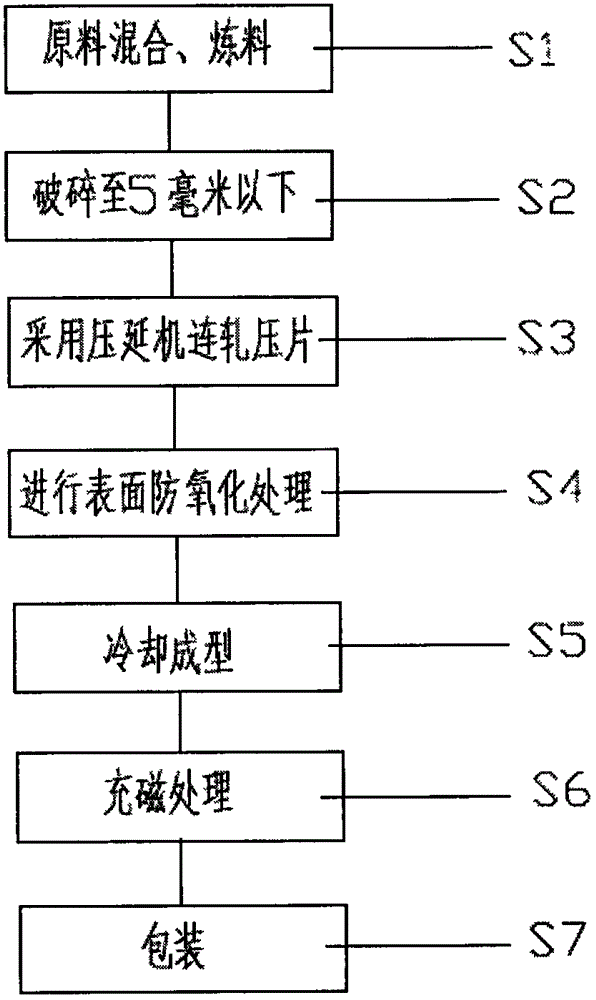

Bonded NdFeB (neodymium, ferrum and boron) strong magnet and preparation method thereof

ActiveCN102723165ALow densityUniform and stable magnetismPermanent magnetsInorganic material magnetismBoronFerric

The invention provides a bonded NdFeB (neodymium, ferrum and boron) magnet. The magnet comprises the following raw materials in percentage by weight: 80-95 percent of NdFeB powder, 0-20 percent of ferrite rubber magnetic powder, 0-20 percent of rubber, 0-20 percent of functional plastic, and the balance of assistant. The invention further provides a preparation method of the bonded NdFeB strong magnet. With the adoption of the bonded NdFeB strong magnet and the preparation method thereof, the produced product is soft, small in brittleness, high and stable in magnetic property, easy to be assembled, and various specifications and dimensions can be easily formed, and meanwhile, the preparation cost is low, the efficiency is high, the energy is saved the consumption is reduced; and moreover, the magnet and the method are environment-friendly and halogen-free, and are pollution-free for the environment.

Owner:金华市磁莱福磁铁科技有限公司

Polymer electrolyte, and polymer electrolyte membrane, membrane-electrode assembly and fuel cell that are using the polymer electrolyte

InactiveUS20090117438A1Improve proton conductivitySmall size changeSolid electrolytesFinal product manufactureSulfolaneN dimethylformamide

The present invention provides polymer electrolyte that has the ion-exchange capacity of 1.7 meq / g or more and has the reduced viscosity of 160 mL / g or more at 40° C. when being made to be 1% by weight solution with at least one kind of solvent selected from the group consisting of N,N-dimethylformamide, N-methyl-2-pyrrolidone, dimethyl sulfoxide, N,N-dimethylacetamide, sulfolane, and γ-butyrolactone, and polymer electrolyte that has the ion-exchange capacity of 1.7 meq / g or more and the reduced viscosity of 160 mL / g or more at 40° C. when being made to be 1% by weight solution with at least one kind of solvent selected from the group consisting of N,N-dimethylformamide, N-methyl-2-pyrrolidone, and dimethyl sulfoxide.

Owner:SUMITOMO CHEM CO LTD

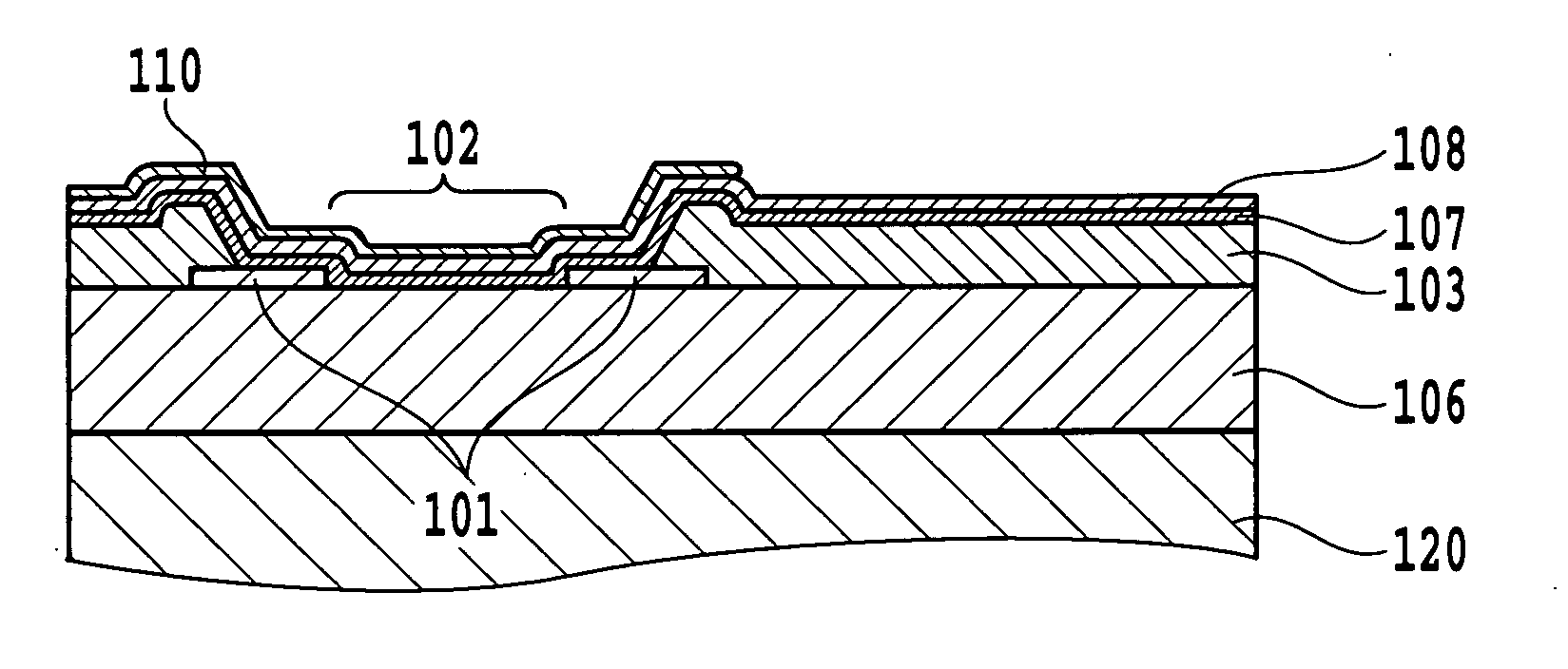

Ink jet head circuit board, method of manufacturing the same and ink jet head using the same

InactiveUS20060033779A1Improve accuracyImprove the immunityPrintingThermal energyElectrical resistance and conductance

An ink jet head circuit board is provided which has heaters to generate thermal energy for ink ejection. This board has the heaters formed with high precision to reduce their areas. It has provisions to protect the electrode wires against corrosion and prevent a progress of corrosion. The substrate is deposited with the thin first electrodes made of a corrosion resistant metal. Over the first electrodes the second electrodes made of aluminum are formed. The second electrodes are deposited with a resistor layer. The heater is formed in the gap between the first electrodes. With this construction, the heaters are formed without large dimensional variations among them. Should a defect occur in a protective layer above or near the heaters, a progress of corrosion can effectively be prevented because the material of the resistor layer is more resistant to encroachment than aluminum and the first electrodes are corrosion resistant.

Owner:CANON KK

Sintered zirconia, and sintering composition and calcined object therefor

ActiveCN103080045ACheap manufacturingInhibition of low temperature deteriorationZirconium oxidesX-rayMaterials science

Provided is sintered zirconia which can be inhibited from deteriorating at low temperatures. Also provided are a sintering composition and a calcined object which are precursors for the sintered zirconia. The burned surface of the sintered zirconia gives an X-ray diffraction pattern in which the ratio of the height of the peak present around the location where a [200] peak assigned to the cubic system is to appear to the height of the peak present around the location where a [200] peak assigned to the tetragonal system is to appear is 0.4 or more, and a region located at a depth of 100 [mu]m or more from the burned surface gives an X-ray diffraction pattern in which the ratio of the height of the peak present around the location where a [200] peak assigned to the cubic system is to appear to the height of the peak present around the location where a [200] peak assigned to the tetragonal system is to appear is 0.3 or less.

Owner:NORITAKE CO LTD

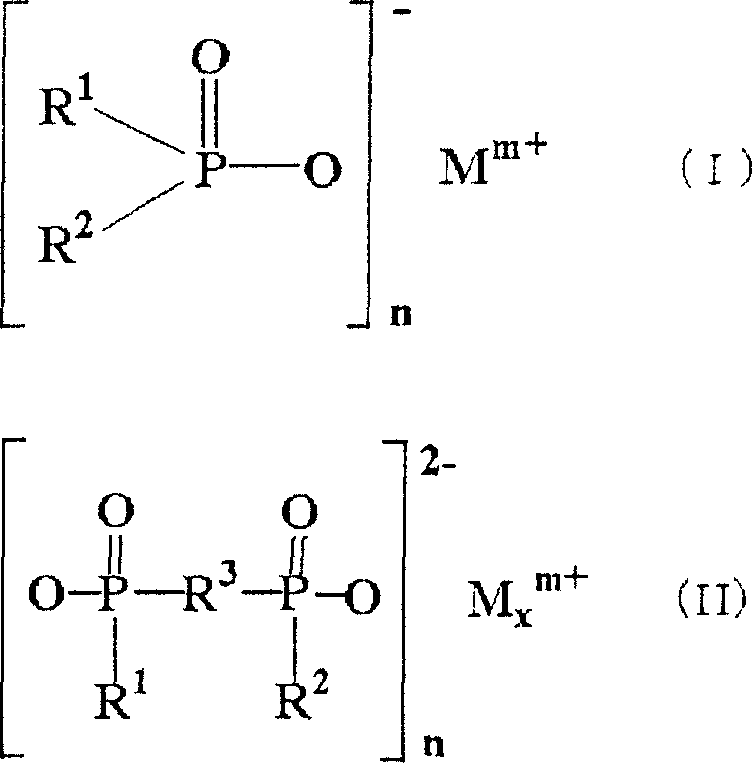

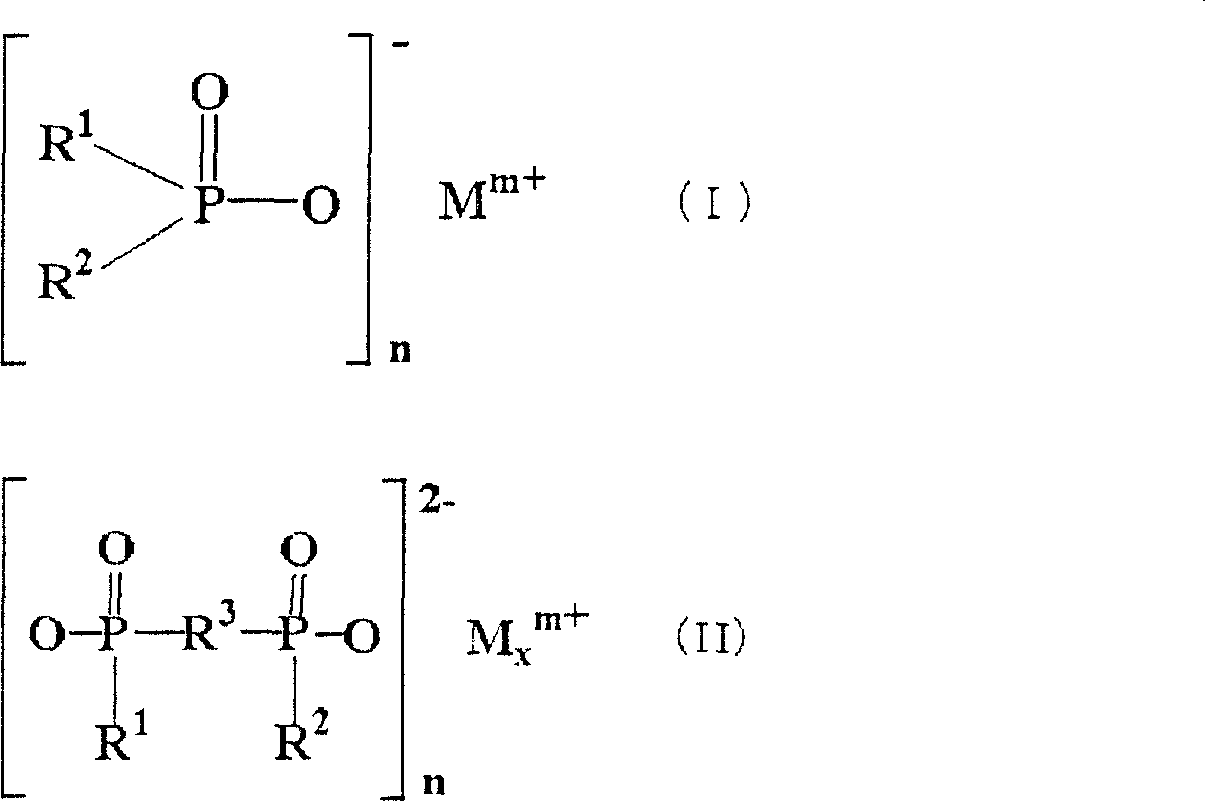

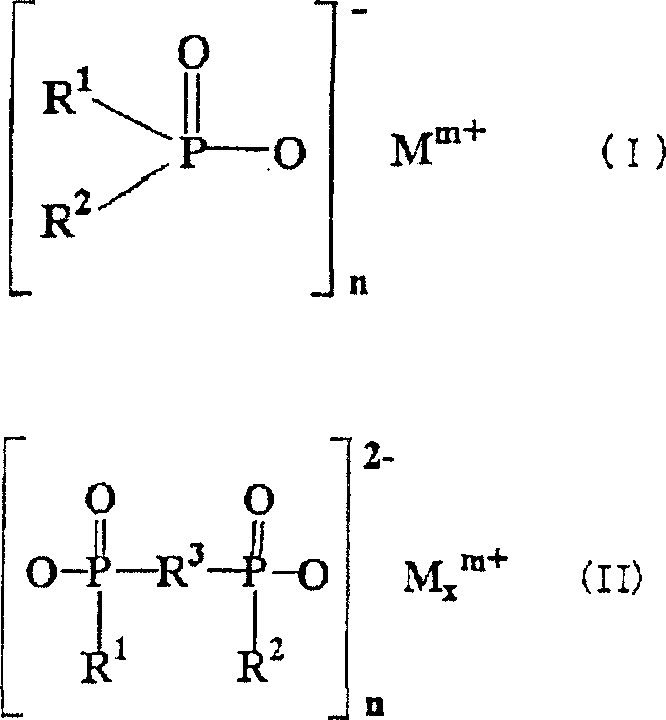

Flame-retardant resin composition

InactiveCN1950455AImprove flame retardant performanceStrong water absorptionPolyamidePhosphinic Acids

There is provided a flame-retardant resin composition which is excellent in flame retardancy and excellent in low water-absorbing property and exhibits a small dimensional change and a small decrease in insulating properties. A flame-retardant resin composition containing: (A) an aliphatic polyamide resin; (B) an aromatic polyamide resin; (C) a flame retardant containing (c1) a phosphinic acid salt represented by the following formula (I) and / or (c2) a diphosphinic acid salt represented by the following formula (II) and / or a polymer containing at least one of these (c1) and (c2) as a component C1 and containing (c3) a melamine condensation product and / or (c4) a reaction product of melamine with phosphoric acid and / or (c5) a reaction product of a melamine condensation product with phosphoric acid and / or a mixture containing at least two of these (c3) to (c5) as a component C2; and (D) an inorganic filler.

Owner:UBE IND LTD

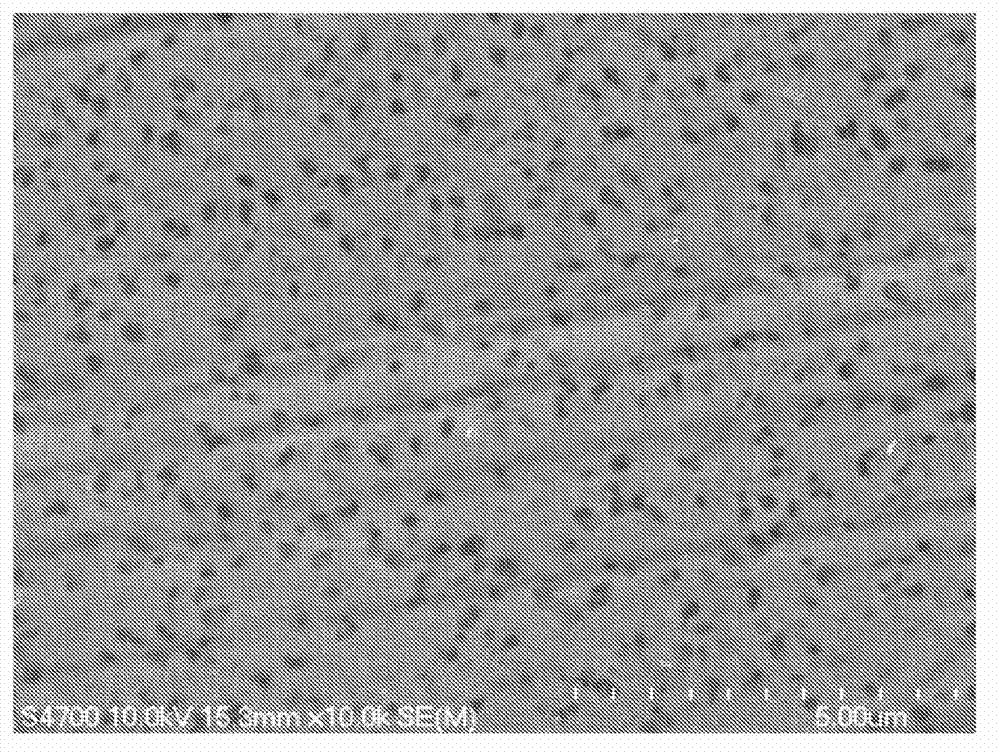

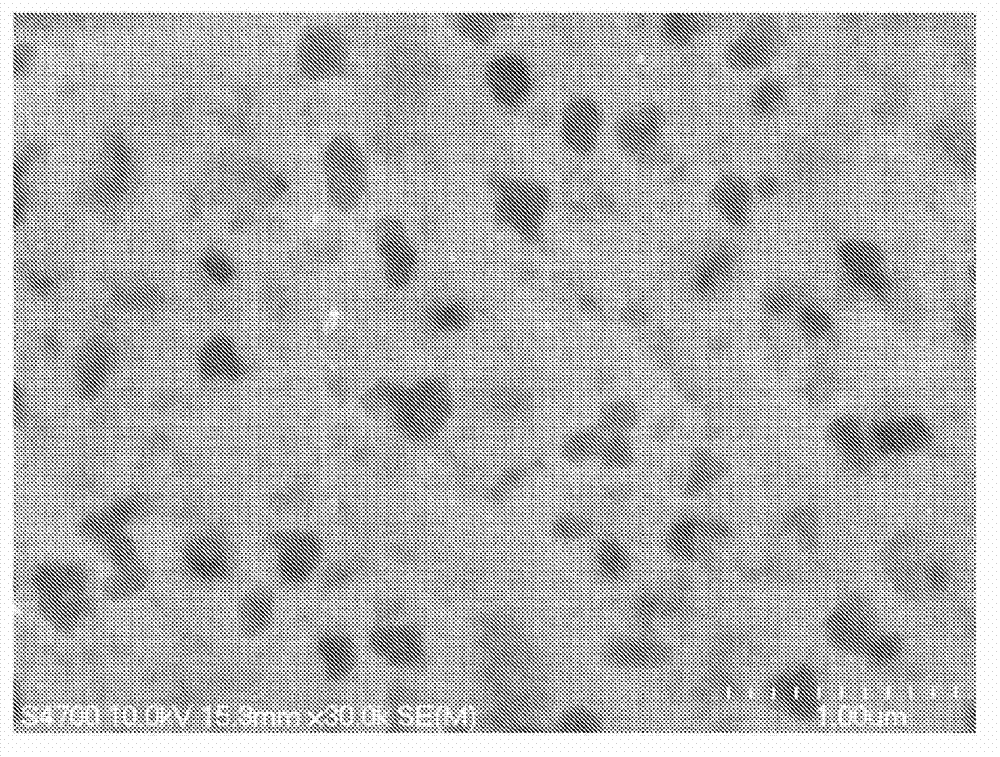

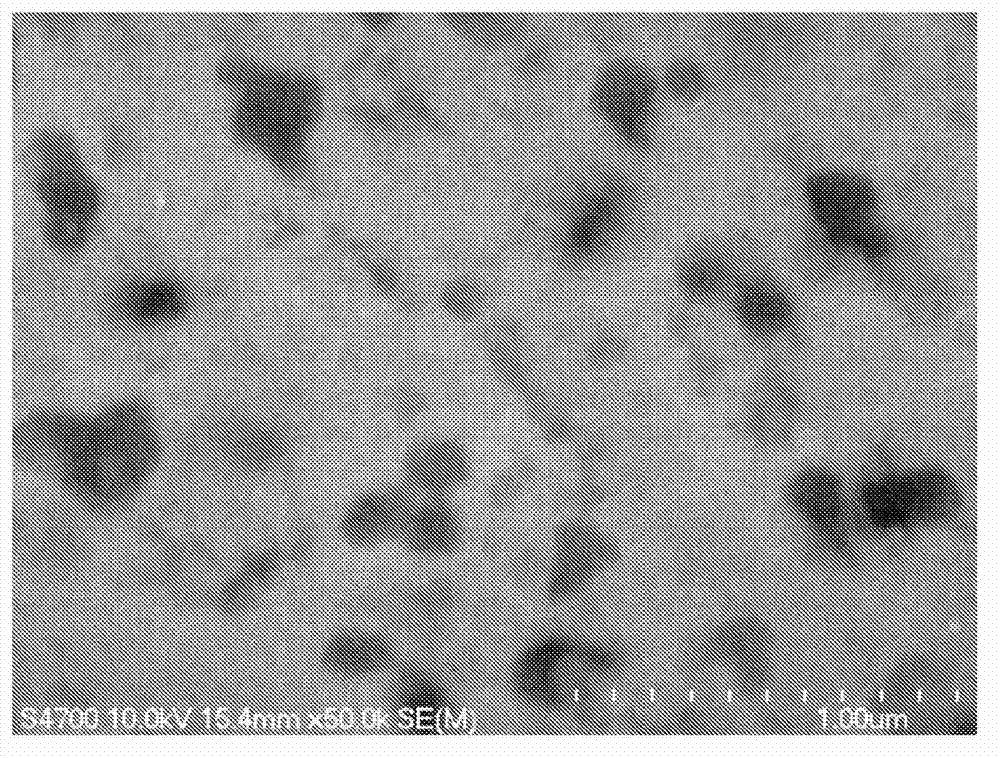

Separator for energy device and energy device having the same

InactiveUS20100003588A1Small pore diameterUniform fiber densityHybrid capacitor separatorsDouble layer capacitorsEngineeringElectrolyte

Disclosed is a separator for energy devices, which hardly allows an internal short circuit, while excellent in electrolyte solution retention. Also disclosed is an energy device comprising such a separator. Specifically disclosed is a separator for energy devices, which comprises a nonwoven fabric laminate composed of two or more melt-blown nonwoven fabric layers arranged on top of one another. Each of the melt-blown nonwoven fabric layers has an average fiber diameter of 0.5-3 μm, and the weight per square meter of the nonwoven fabric laminate is not more than 50 g / m2. This separator for energy devices has a surface centerline roughness (Rt value) of not more than 35 μm.

Owner:MITSUI CHEM INC

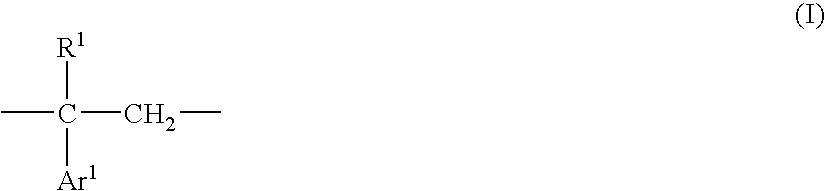

Liquid crystalline polymer cpmposition and use thereof

InactiveUS20070293633A1Little warpageSmall size changeLiquid crystal compositionsLiquid crystallinePolymer science

The present invention provides a liquid crystalline polymer composition comprising (A) a polymer including units of formula (I), and units of formula (II) and / or units of formula (III), the units of formula (I) being included in 15-80% by mol, based on the total units [(I)+(II)+(III)]; and (B) a polymer (B) including units of formula (IV), formula (V) and the formula (VI), each of units being included in 30-80% by mol, 10-35% by mol and 10-35% by mol, respectively, based on the total units [(IV)+(V)+(VI)], the component (B) being included in 5-80% by weight based on the total weight of the components (A) and (B); wherein (I) —(VI) are —OC—Ar1-0-, —O—Ar2—O—, —OC—Ar3—CO—, —OC—Ar4—O—, —O—Ar5—X— and —OC—Ar6—CO—, respectively.

Owner:SUMITOMO CHEM CO LTD

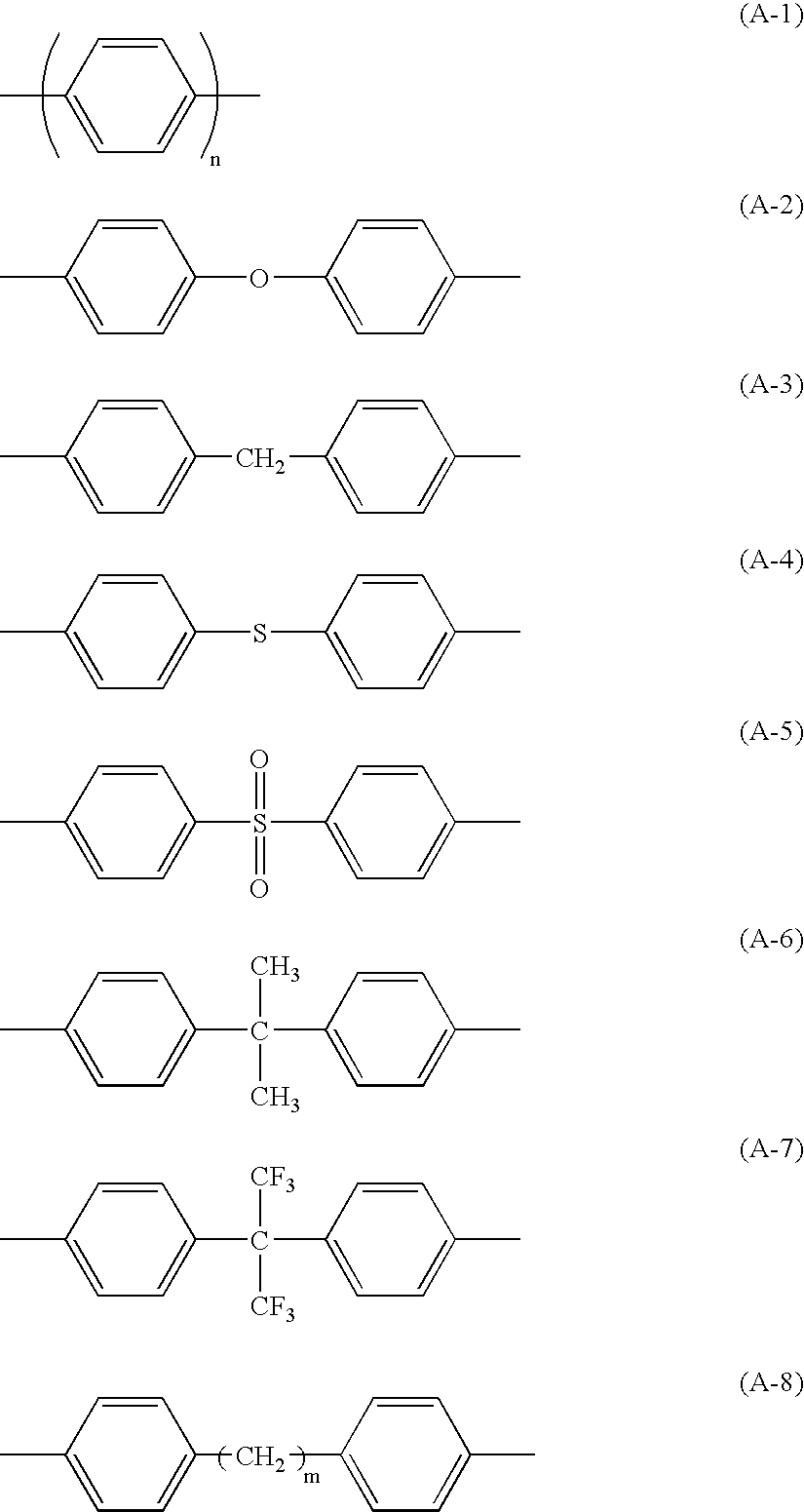

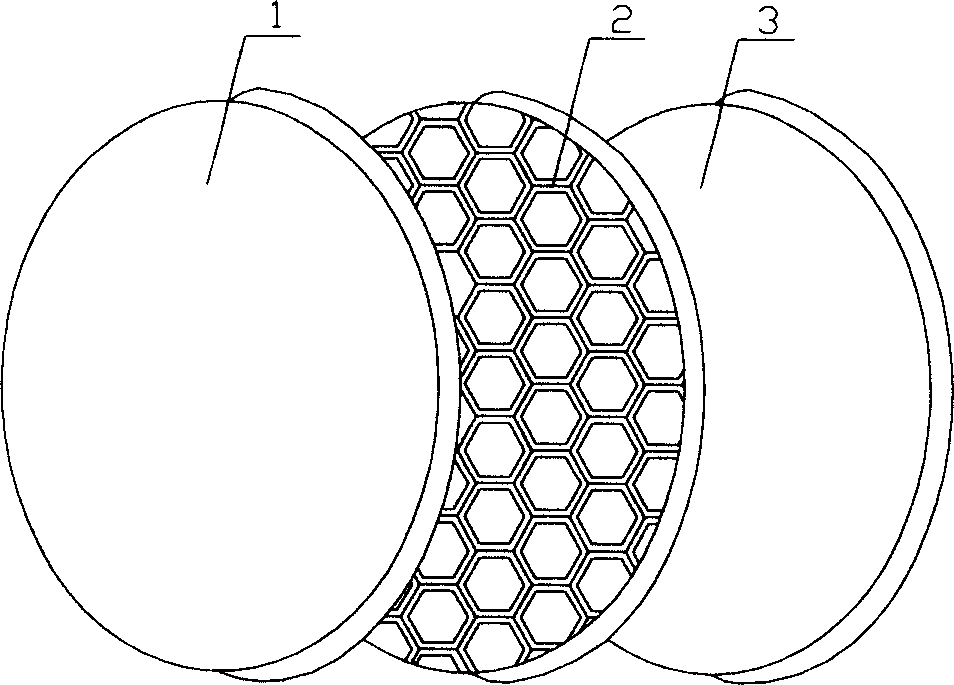

Reflection mirror with honeycomb sandwiched structure silicon carbide base composite material and its preparation method

The present invention relates to a silicon carbide base composite material reflector with honeycomb sandwich structure. It is characterized by that after the upper cover plate, sandwich layer with honeycomb structure and lower cover plate are bonded, then they are undergone the processes of siliconing and sintering treatment so as to obtain the invented reflector whole body with the characteristics of light weight, high rigidity and good workability, etc. Besides, said invention also provides its preparation method and concrete steps.

Owner:NAT UNIV OF DEFENSE TECH

Rapidly assembled bamboo wood barrack

InactiveCN101338622AFast growthCorrosion resistanceBuilding constructionsProtective buildings/sheltersThermal insulationEngineering

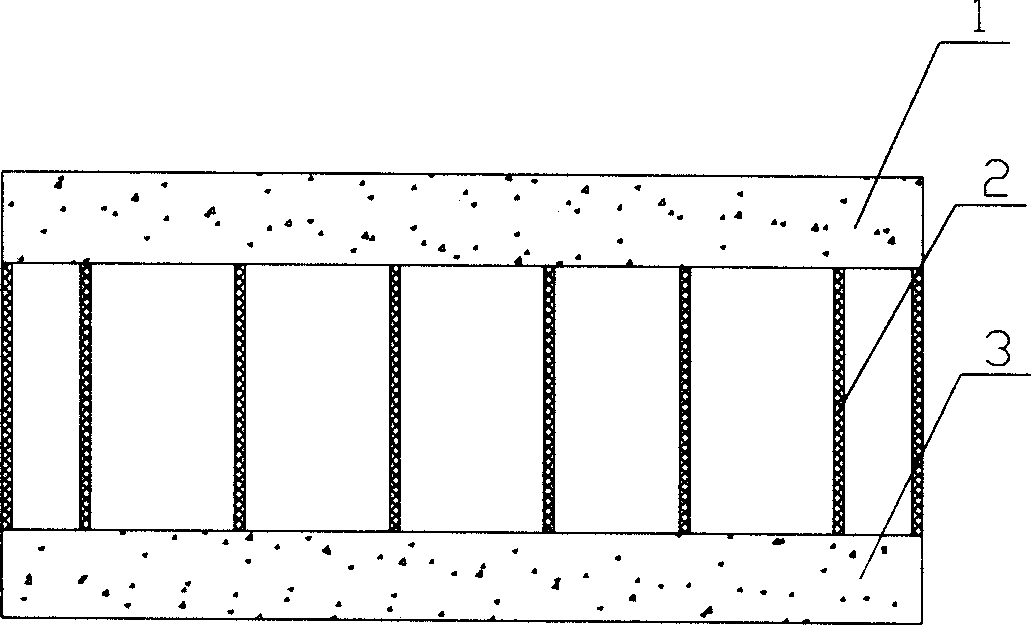

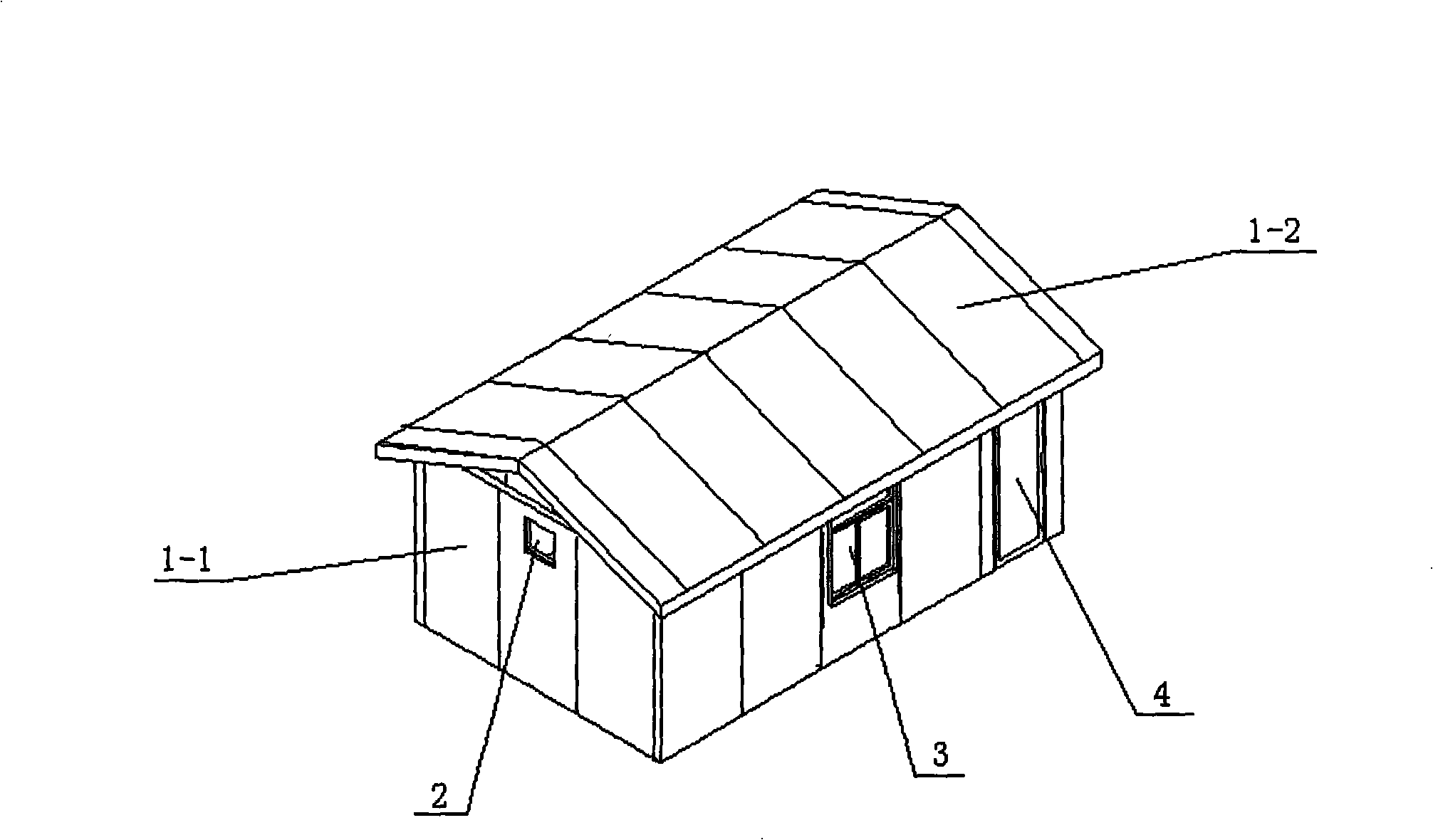

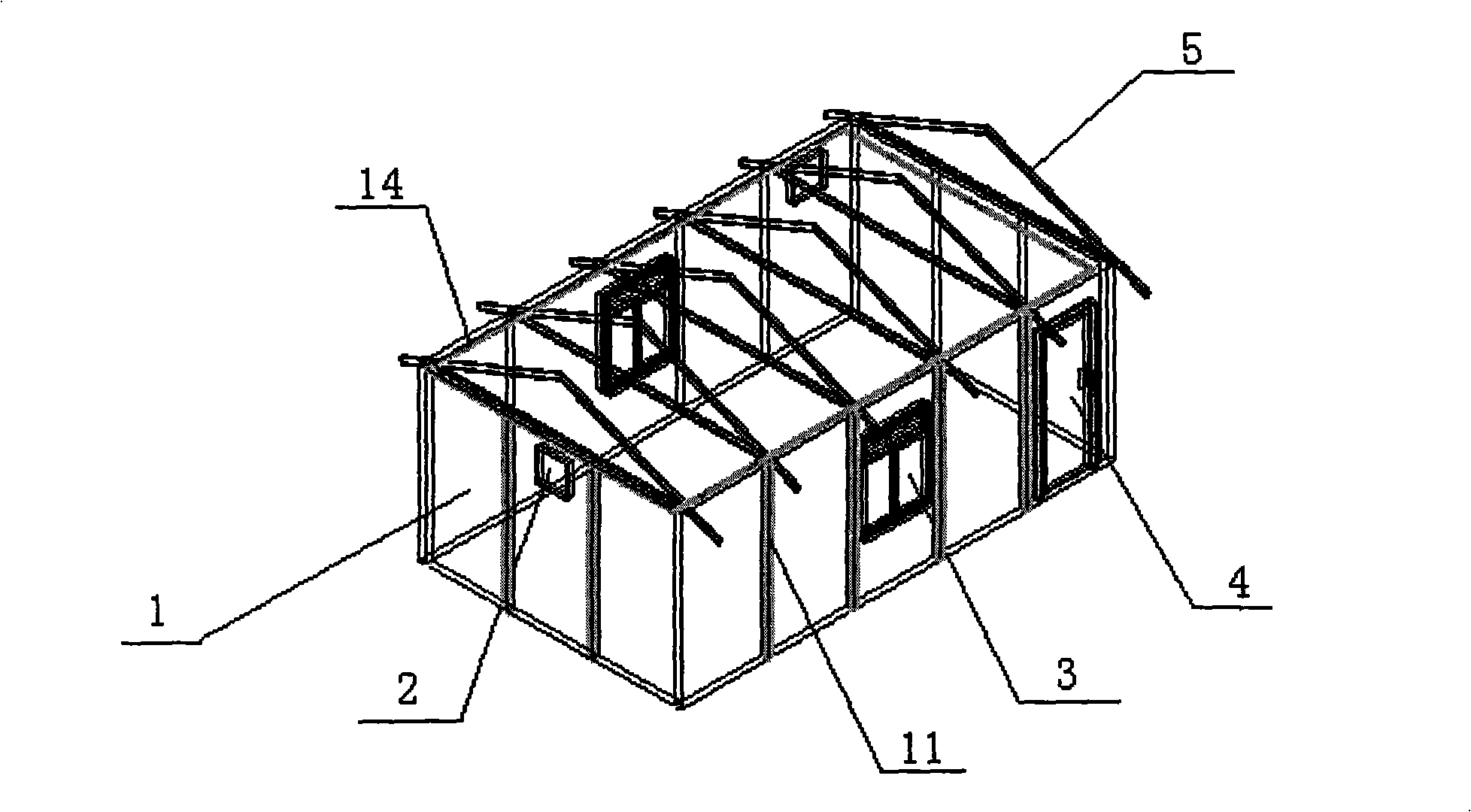

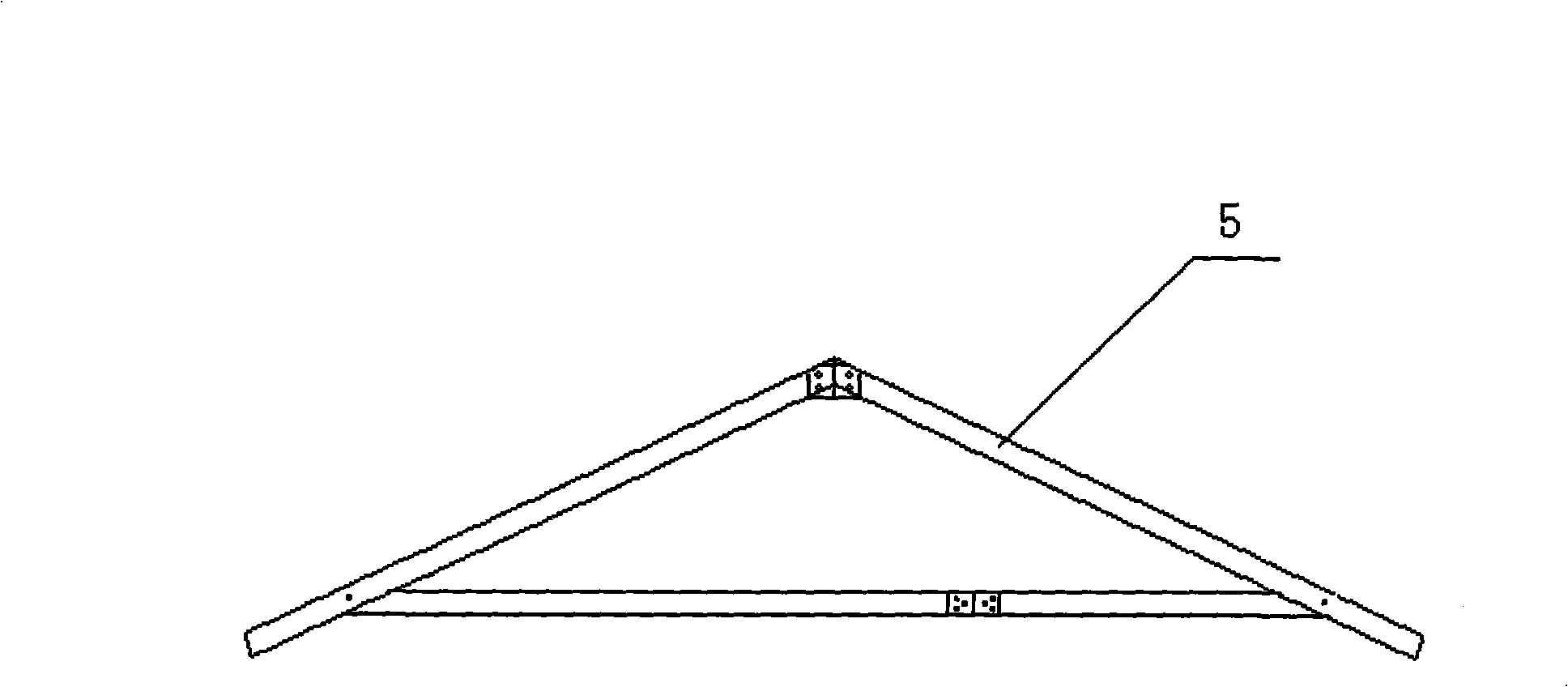

The invention relates to a quickly assembled bamboo frame house which comprises plate units, bamboo house frames, connecting pillars and connecting beams; wherein, the frame of the plate unit is made of bamboo veneers or wood beams; the external plate of the plate unit is made of bamboo veneers; the internal plate of a wall plate unit is made of gypsum plates or bamboo veneers or light wooden plates; the internal plate of a house plate unit is made of gypsum plates; and thermal-insulation material or sound-insulation material is filled between the external plate and the internal plate. The connecting pillars and the connecting beams are made of bamboo veneers; the connecting beam is connected with the side of the wall plate unit by bolts; and the wall plate units are connected with each other by the connecting pillars and bolts. The wall plate units at the corners of a house are connected with each other by bolts and angle steel. With excellent quakeproof performance and good thermal-insulation effect, the frame house provided by the invention can be processed and assembled quickly and can be dismounted and reused; moreover, the main construction material is environmental friendly and the material source is wide; therefore, the frame house has low manufacturing cost.

Owner:HUNAN UNIV

Polyvinyl alcohol-based film, production method thereof and polarizing film produced from polyvinyl alcohol-based film

ActiveCN107200977AGuaranteed drying uniformityGuaranteed Optical ConsistencyPolarising elementsAntioxidantPlasticizer

The invention relates to a composition of a high molecular compound, and particularly discloses a polyvinyl alcohol-based film, a production method thereof and a polarizing film produced from the polyvinyl alcohol-based film. The polyvinyl alcohol-based film comprises the following components as raw materials in parts by mass: 80-95 parts of PVA (polyvinyl alcohol), 5-20 parts of EVOH, 5-25 parts of a plasticizer, 0.001-0.1 part of surfactant and 0.001-0.1 part of an antioxidant; the polyvinyl alcohol-based film is annealed for 2 hours at the temperature of 80 DEG C and the RH (relative humidity) of 50-95%; the crystallinity change of any region of the polyvinyl alcohol-based film is smaller than or equal to 5%. The polyvinyl alcohol-based film is good in size stability, the size change in any direction of the film during swelling can be reduced, the processability of the polyvinyl alcohol-based film is enhanced, the obtained polyvinyl alcohol-based film is good in optical consistency, and bending spots generated during staining are less.

Owner:CHINA PETROCHEMICAL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com