Patents

Literature

676 results about "Phosphinic Acids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hypophosphorous acid is a phosphorus oxoacid and a powerful reducing agent with molecular formula H3PO2. Inorganic chemists refer to the free acid by this name (also as "HPA"), or the acceptable name of phosphinic acid. It is a colorless low-melting compound, which is soluble in water, dioxane, and alcohols.

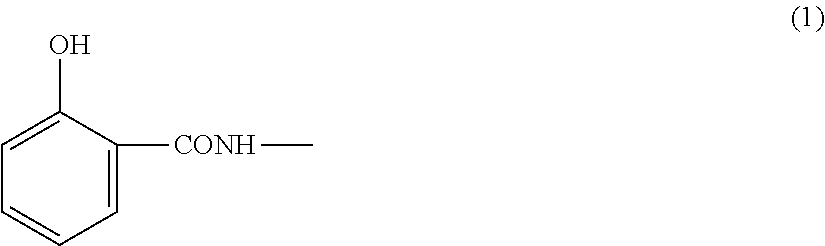

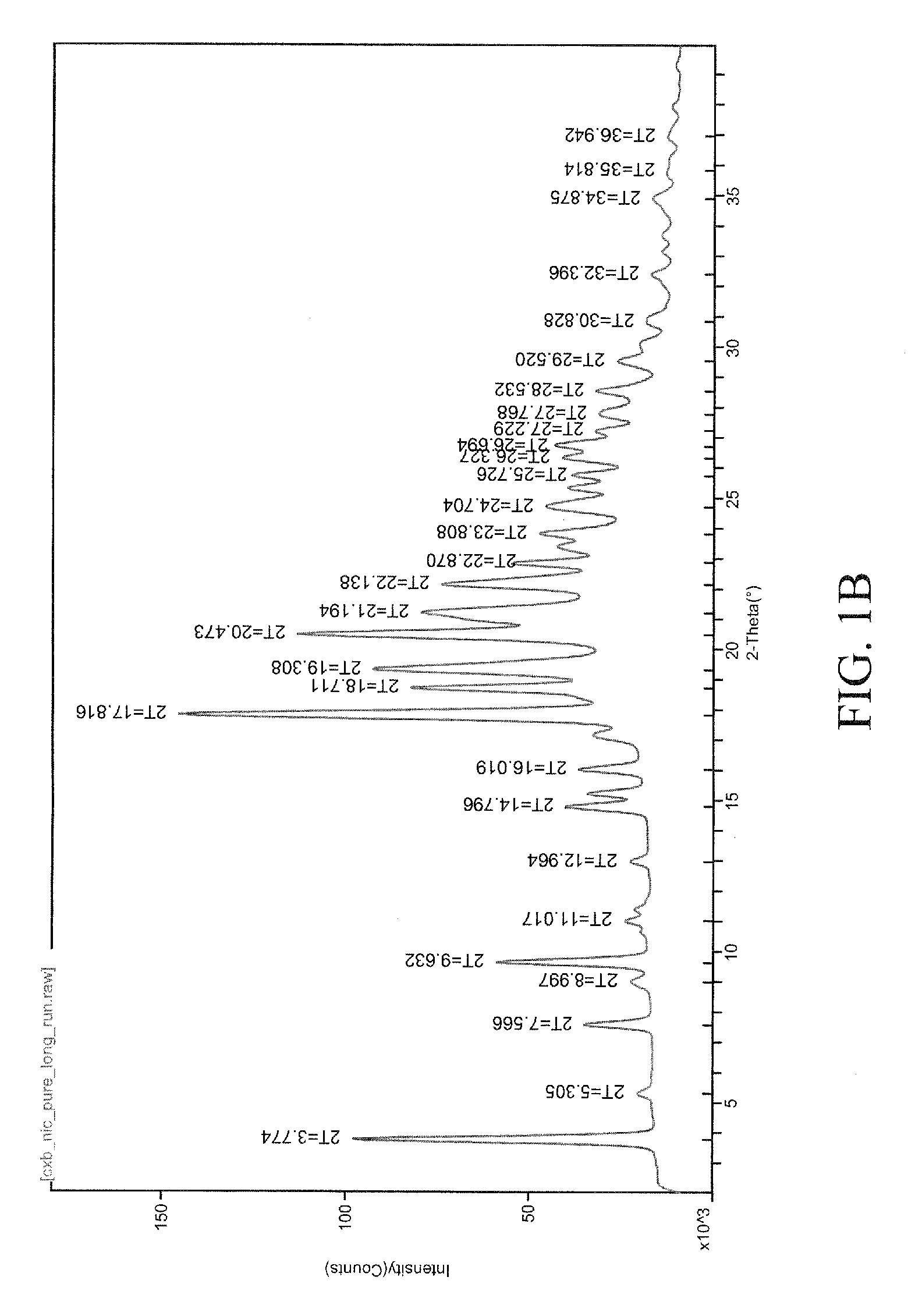

Pharmaceutical co-crystal compositions

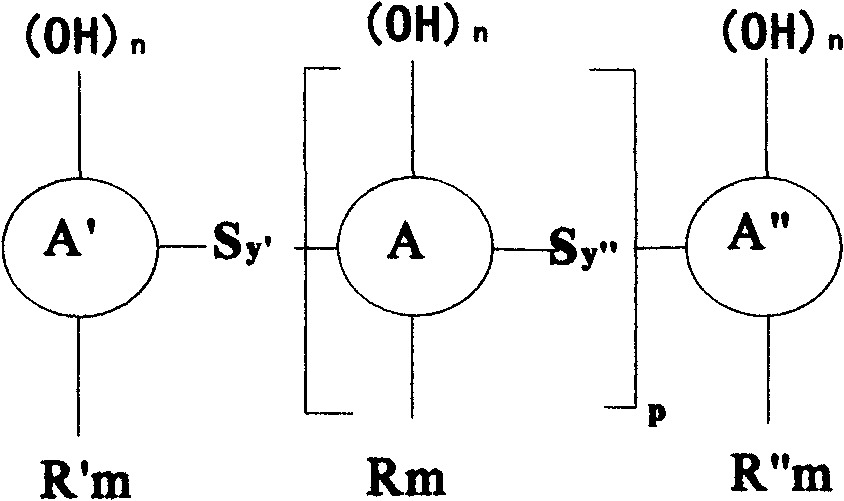

A pharmaceutical composition comprising a co-crystal of an API and a co-crystal former; wherein the API has at least one functional group selected from ether, thioether, alcohol, thiol, aldehyde, ketone, thioketone, nitrate ester, phosphate ester, thiophosphate ester, ester, thioester, sulfate ester, carboxylic acid, phosphonic acid, phosphinic acid, sulfonic acid, amide, primary amine, secondary amine, ammonia, tertiary amine, sp2 amine, thiocyanate, cyanamide, oxime, nitrile diazo, organohalide, nitro, s-heterocyclic ring, thiophene, n-heterocyclic ring, pyrrole, o-heterocyclic ring, furan, epoxide, peroxide, hydroxamic acid, imidazole, pyridine and the co-crystal former has at least one functional group selected from amine, amide, pyridine, imidazole, indole, pyrrolidine, carbonyl, carboxyl, hydroxyl, phenol, sulfone, sulfonyl, mercapto and methyl thio, such that the API and co-crystal former are capable of co-crystallizing from a solution phase under crystallization conditions.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES +2

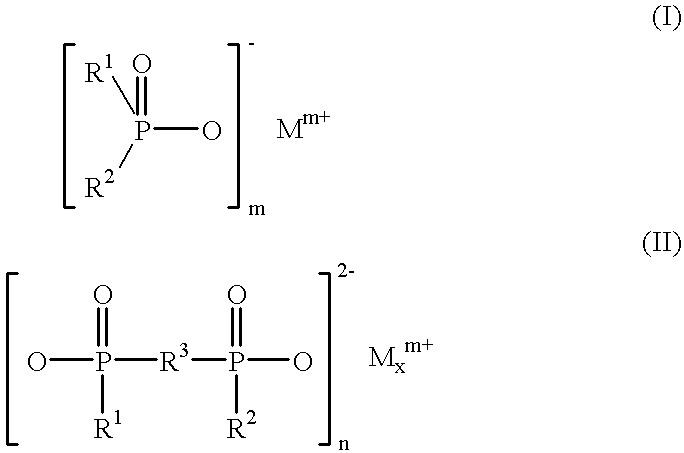

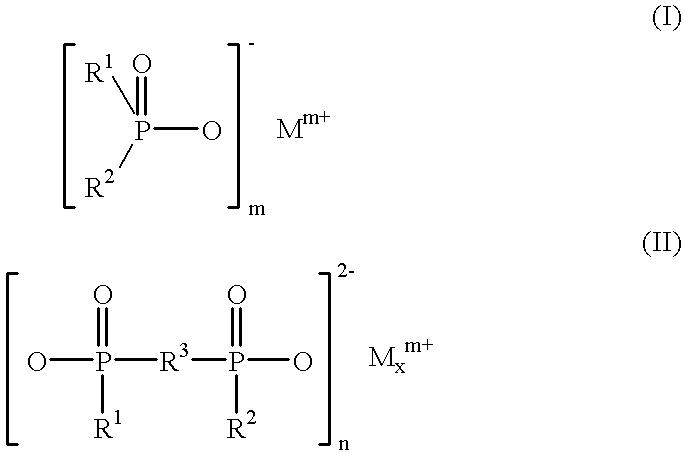

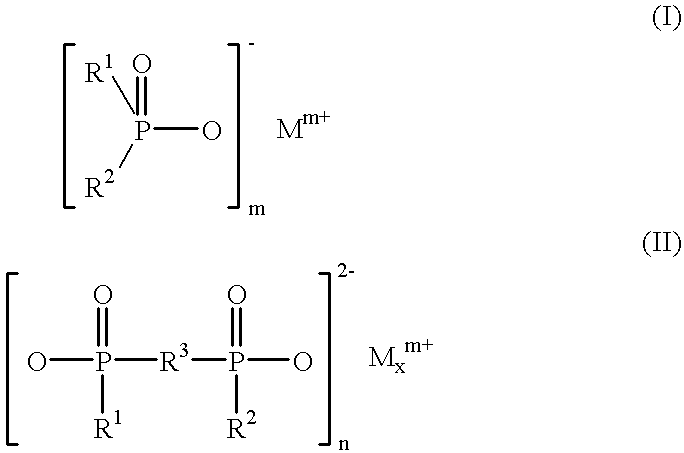

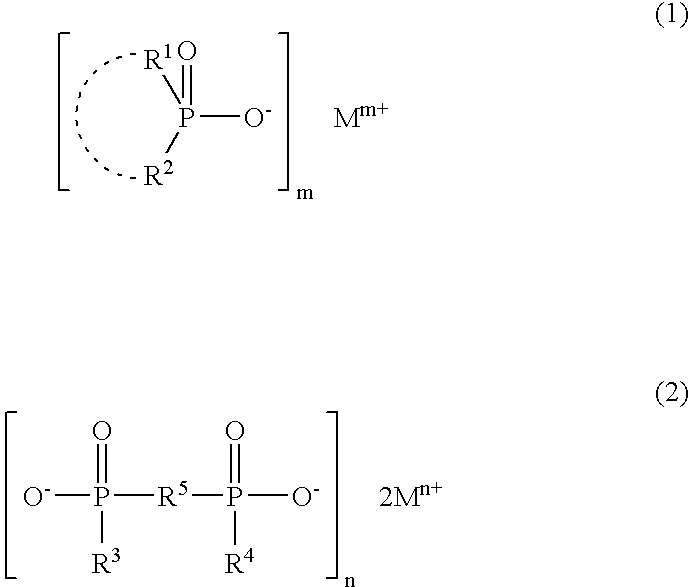

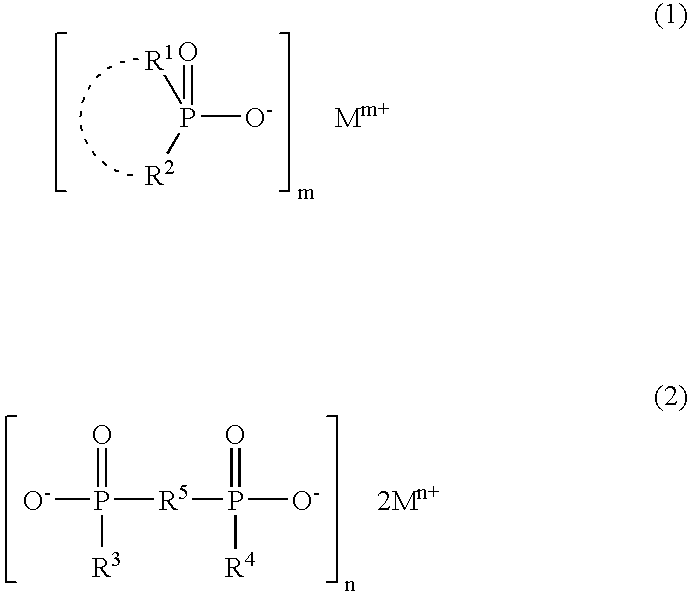

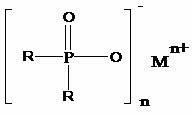

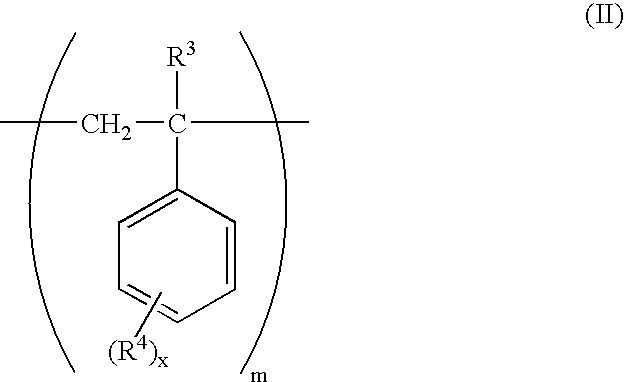

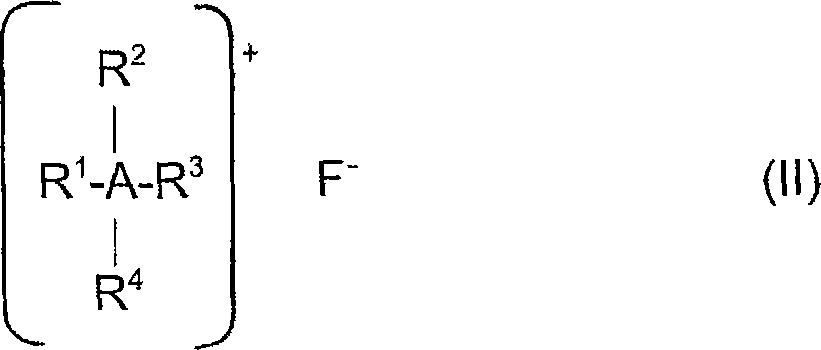

Synergistic flameproofing combination for polymers

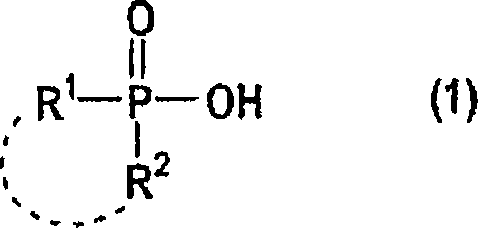

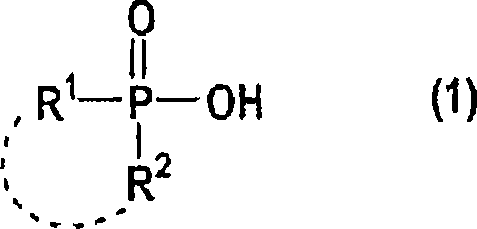

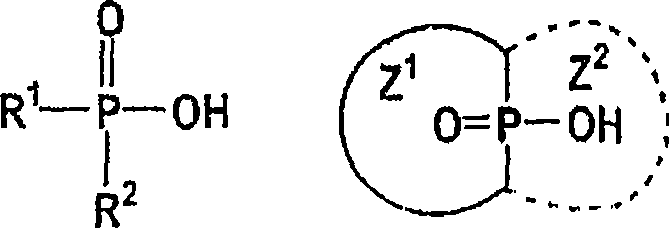

The present invention relates to a synergistic flameproofing combination for polymers, in particular for ABS, which contains, as component A, a phosphinic acid salt of the formulae (I) defined in the description and / or a diphosphinic acid salt of the formula (II) and / or polymers thereof and which contains, as component B, a nitrogen-containing phosphate or a mixture of the compounds defined by the formulae.

Owner:CLARIANT PROD DEUT GMBH

Pharmaceutical co-crystal compositions

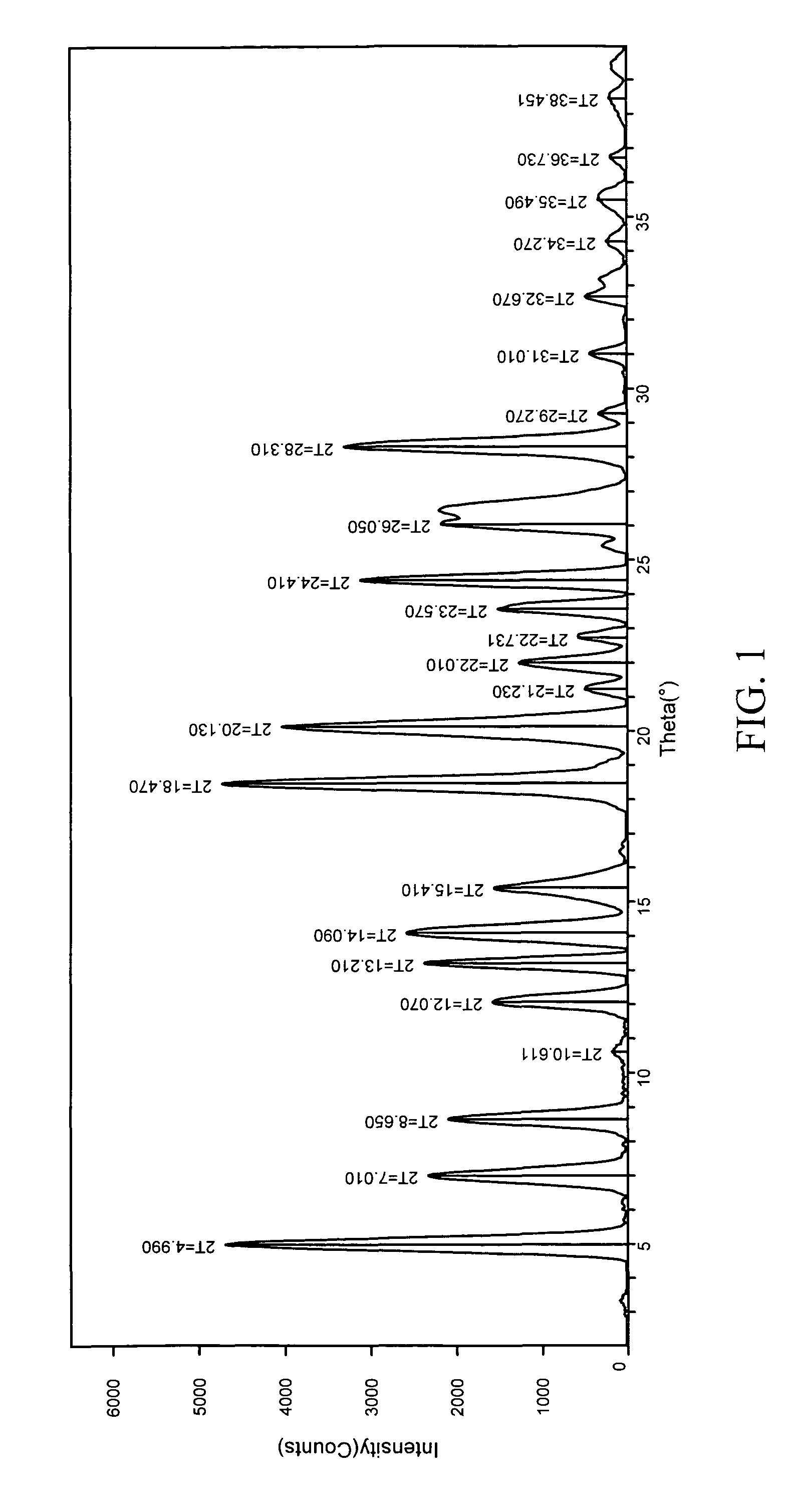

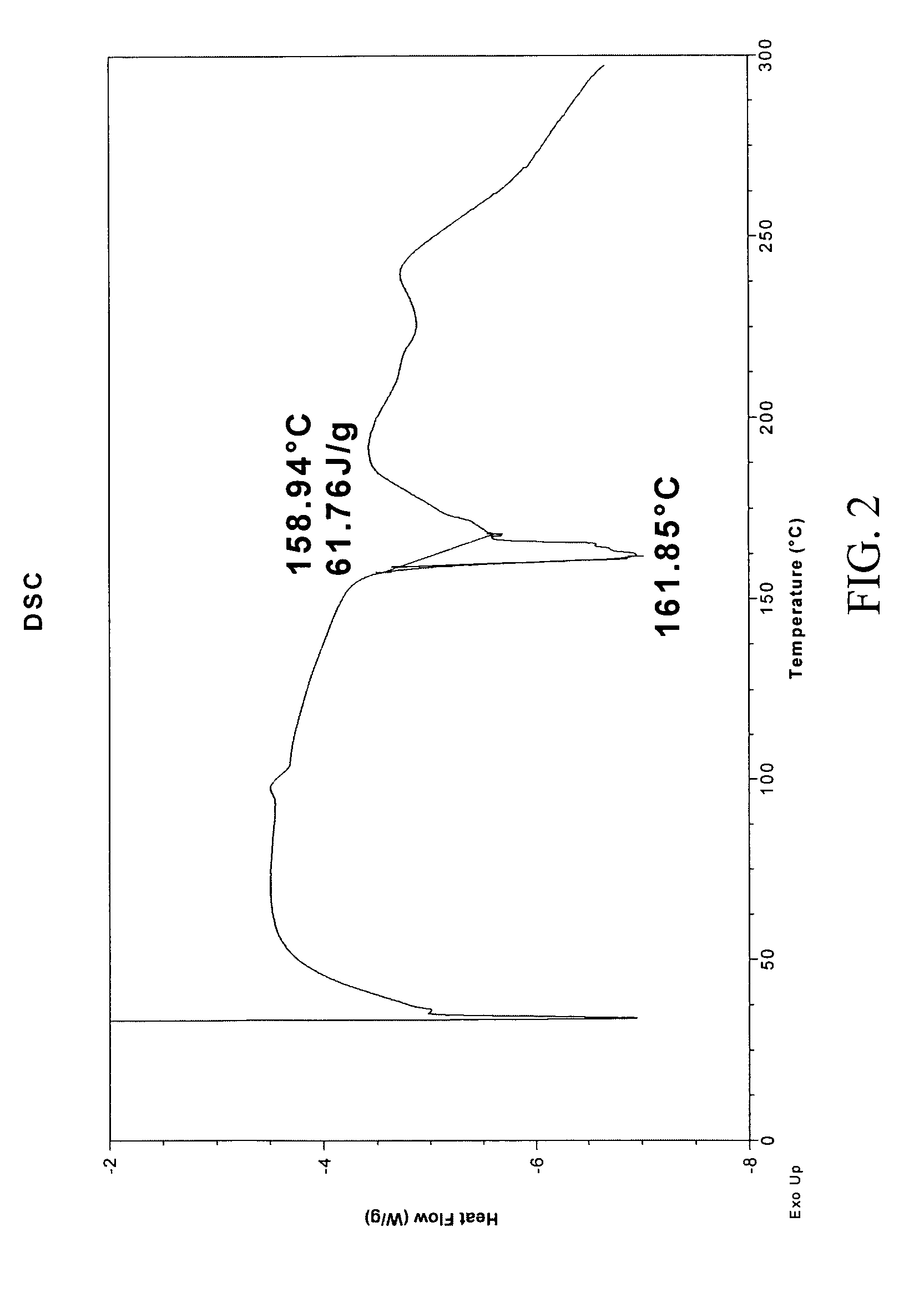

InactiveUS20070026078A1Improve solubilityLow hygroscopicityBiocidePowder deliveryThioketoneHydroxamic acid

A pharmaceutical composition comprising a co-crystal of an API and a co-crystal former; wherein the API has at least one functional group selected from ether, thioether, alcohol, thiol, aldehyde, ketone, thioketone, nitrate ester, phosphate ester, thiophosphate ester, ester, thioester, sulfate ester, carboxylic acid, phosphonic acid, phosphinic acid, sulfonic acid, amide, primary amine, secondary amine, ammonia, tertiary amine, sp2 amine, thiocyanate, cyanamide, oxime, nitrile diazo, organohalide, nitro, s-heterocyclic ring, thiophene, n-heterocyclic ring, pyrrole, o-heterocyclic ring, furan, epoxide, peroxide, hydroxamic acid, imidazole, pyridine and the co-crystal former has at least one functional group selected from amine, amide, pyridine, imidazole, indole, pyrrolidine, carbonyl, carboxyl, hydroxyl, phenol, sulfone, sulfonyl, mercapto and methyl thio, such that the API and co-crystal former are capable of co-crystallizing from a solution phase under crystallization conditions.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES +2

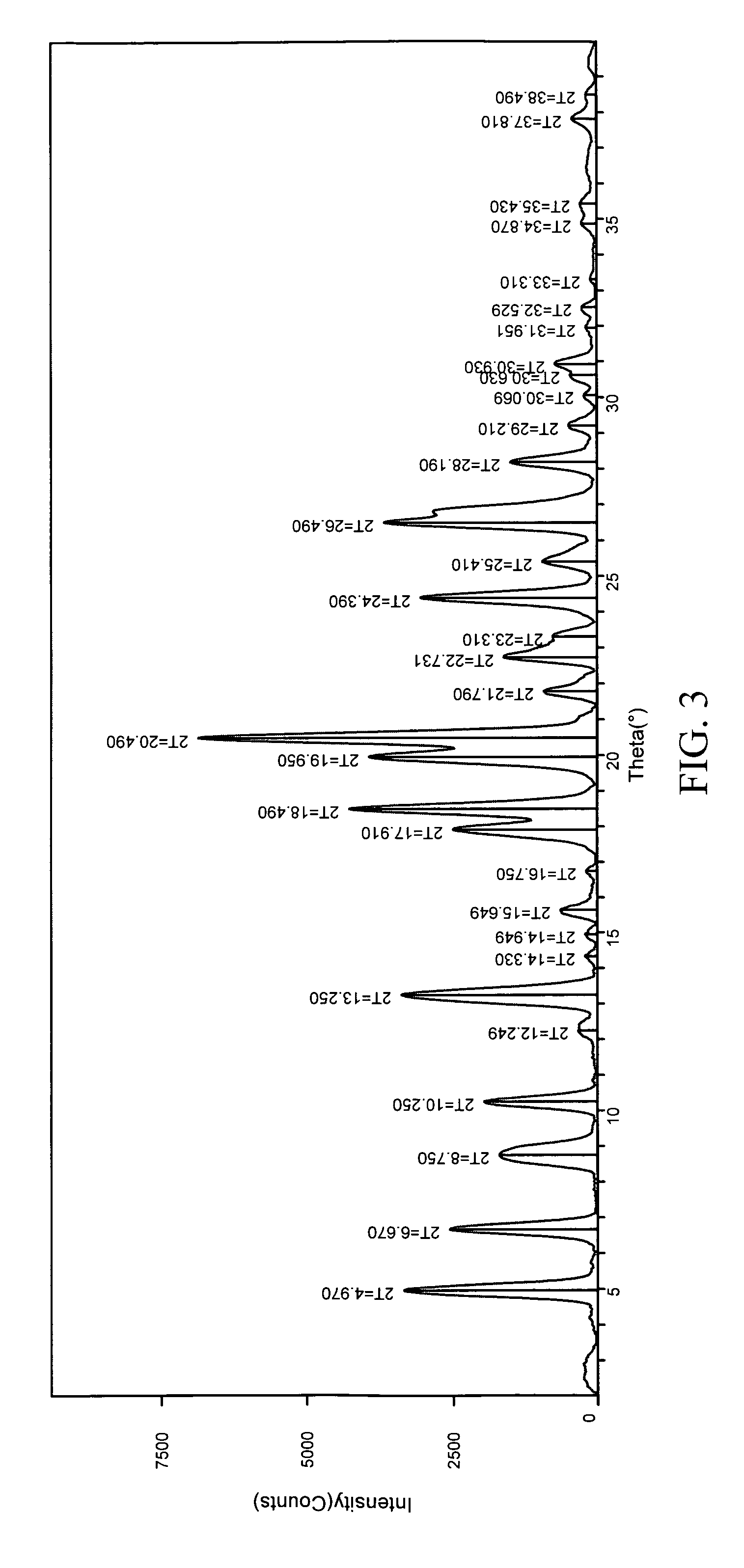

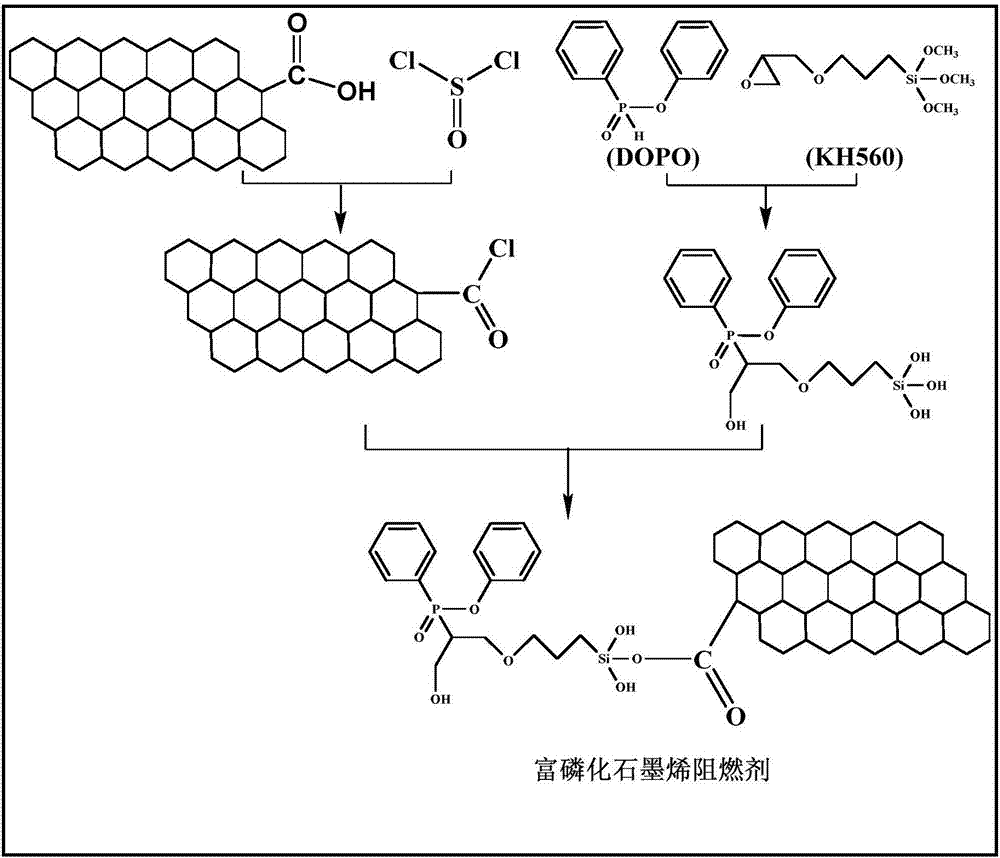

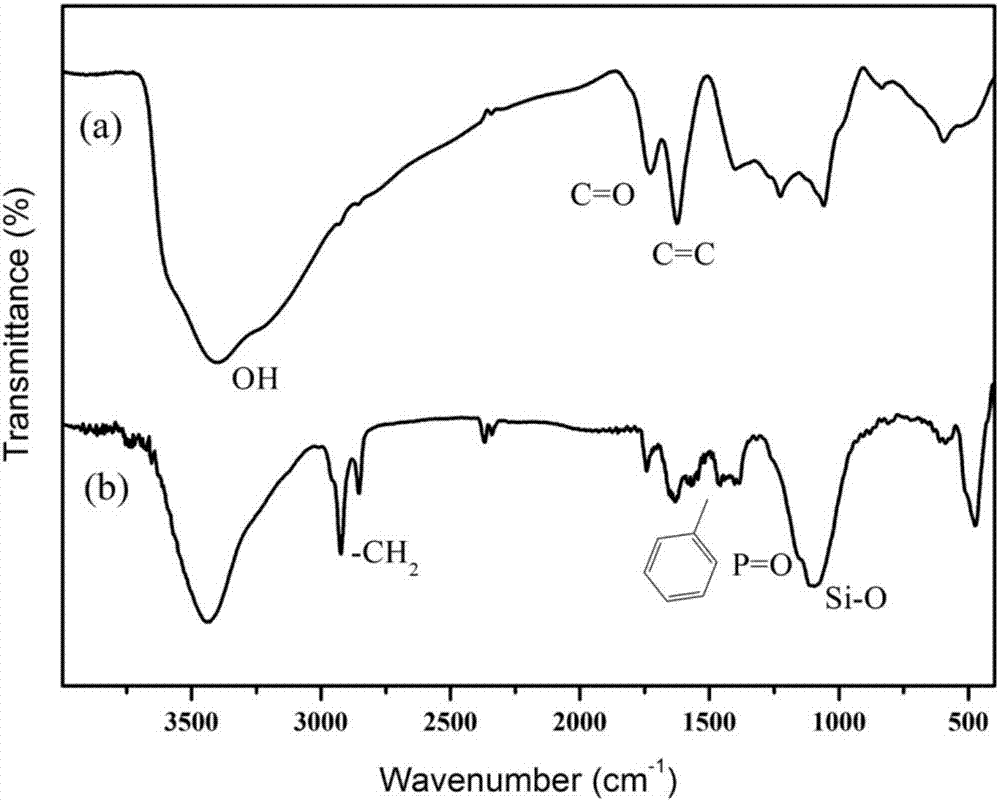

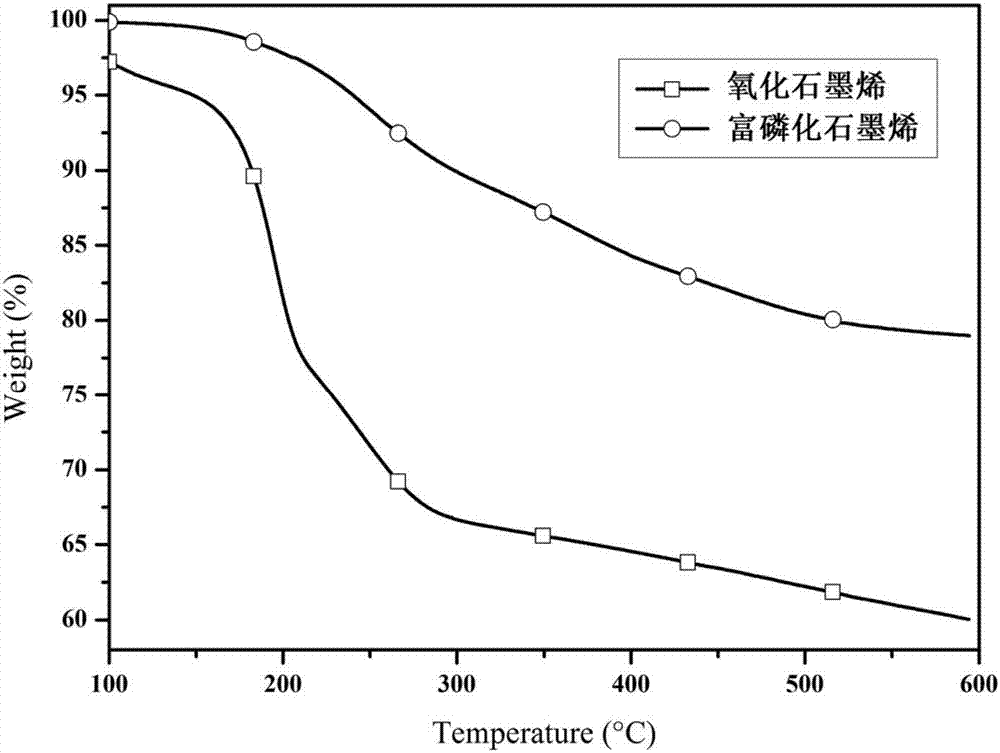

Phosphor-rich graphene flame-retardant agent and preparation method thereof

ActiveCN106883450AHigh flame retardant efficiencyConducive to synergistic flame retardantFireproof paintsPolyurea/polyurethane coatingsCarbon layerSilanes

The invention provides a phosphor-rich graphene flame-retardant agent with a structural formula shown in the description. The invention also provides a preparation method of the phosphor-rich graphene flame-retardant agent. The preparation method is characterized in that graphene oxide is used as a basic raw material, reactive groups at both ends of a silane coupler containing a silicon carbon layer improving agent are fully utilized, one end of the silane coupler is connected with acid source components, such as CEPPA (carboxyethyl phenyl phosphinic acid), DOPO or derivatives, and the other end of the silane coupler is connected with the graphene oxide, so as to obtain a macromolecular flame retardant integrating a physical carbon layer, an acid source and the carbon layer improving agent. The phosphor-rich graphene flame-retardant agent has the advantages that the flame-retardant efficiency is high, the polarity is low, the moisture absorbing property is little, and the mechanical property of the material can be well maintained; by not containing halogen, the flame-retardant agent is friendly to the human body and environment, and meets the green development direction of future flame-retardant agents.

Owner:宿迁聚萃功能复合材料研究所有限公司 +1

Flame-retardant thermoplastic resin composition and molded article

A flame-retardant thermoplastic resin composition that has a largely decreased corrosiveness to metals while maintaining a high degree of flame retardancy is provided, which is produced by adding a phosphinic acid salt and a compound having a specific structure to a thermoplastic resin, and molded articles with largely decreased corrosiveness to metals are also provided, so that useful molded articles can be provided as materials for mechanical machine parts, electric / electronic components, and automotive parts. The flame-retardant thermoplastic resin composition includes 65 to 99 wt % of (A) a thermoplastic resin, 1 to 35 wt % of (B) at least one phosphinic acid salt selected from the group of phosphinic acid salt, diphosphinic acid salt, polymer of phosphinic acid salts, and polymer of diphosphinic acid salts, and 0.001 to 0.70 wt % of (C) a compound having a specific, and molded articles produced therefrom.

Owner:TORAY IND INC

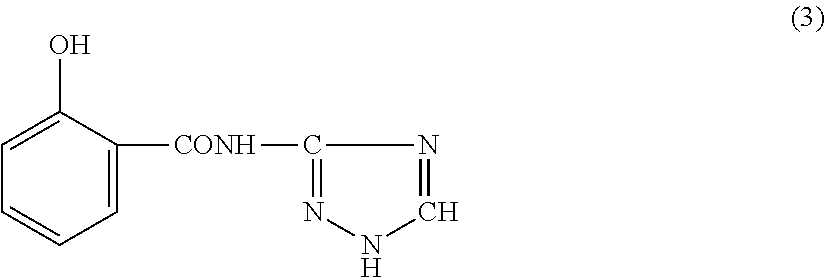

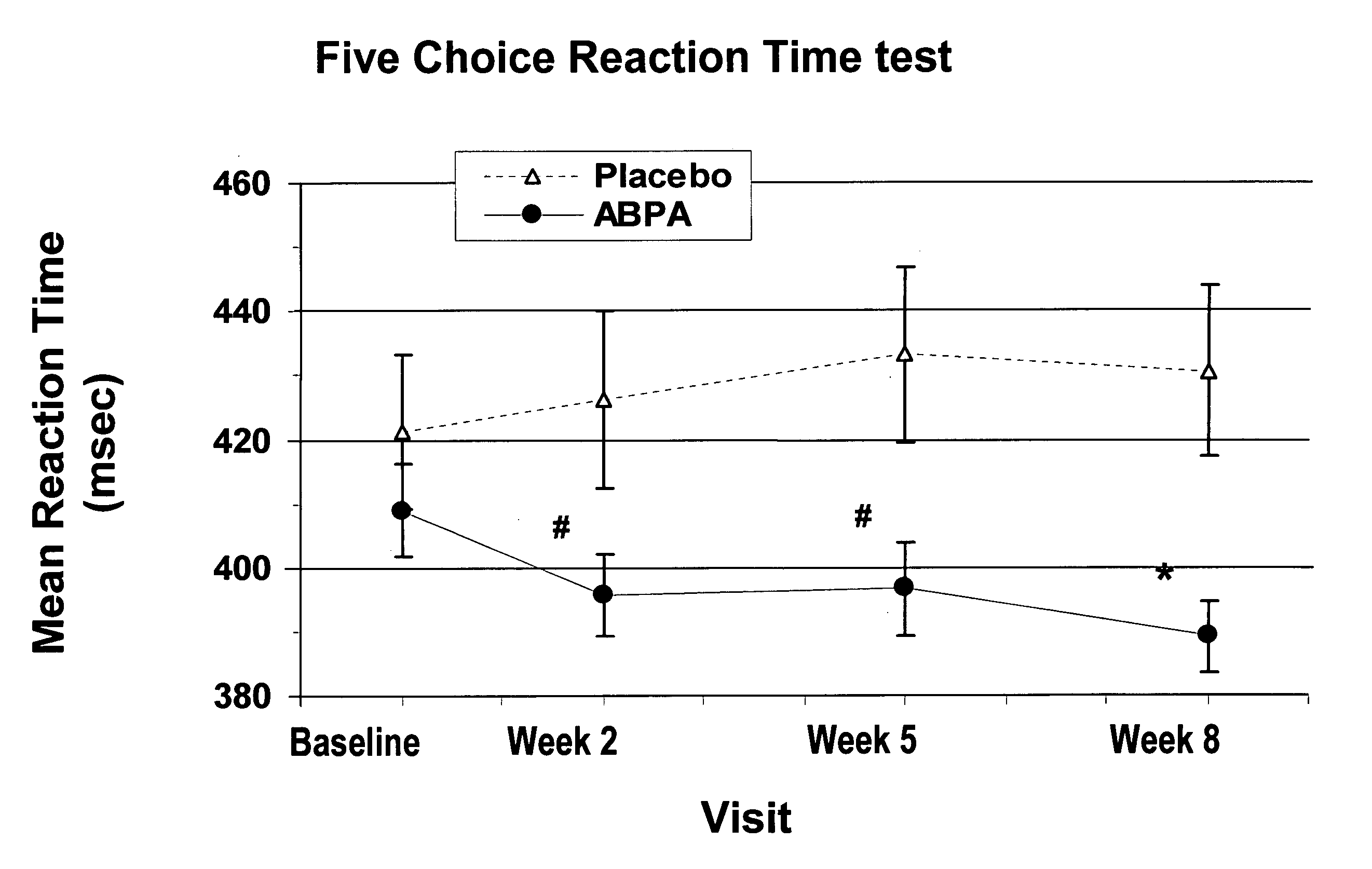

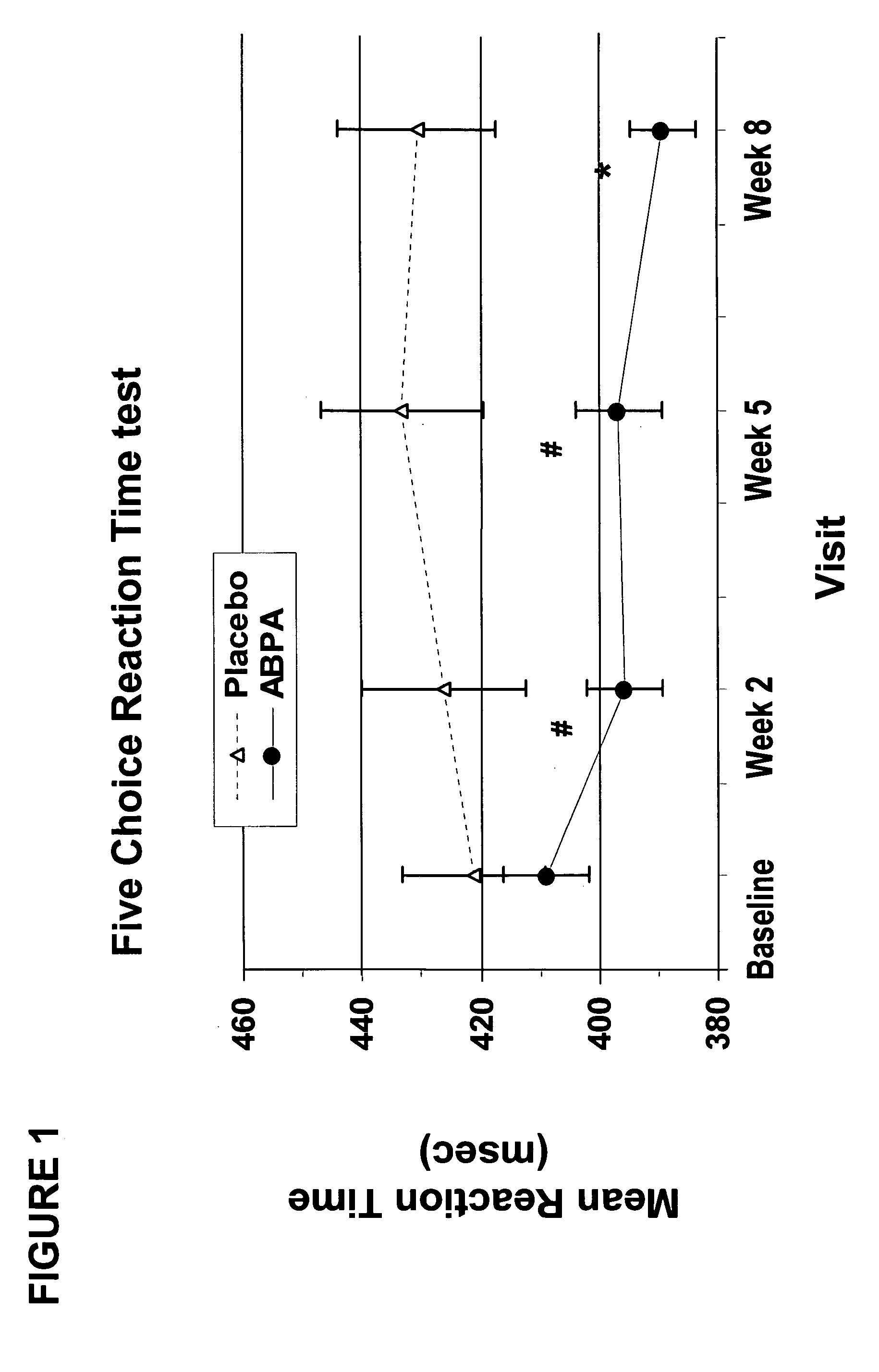

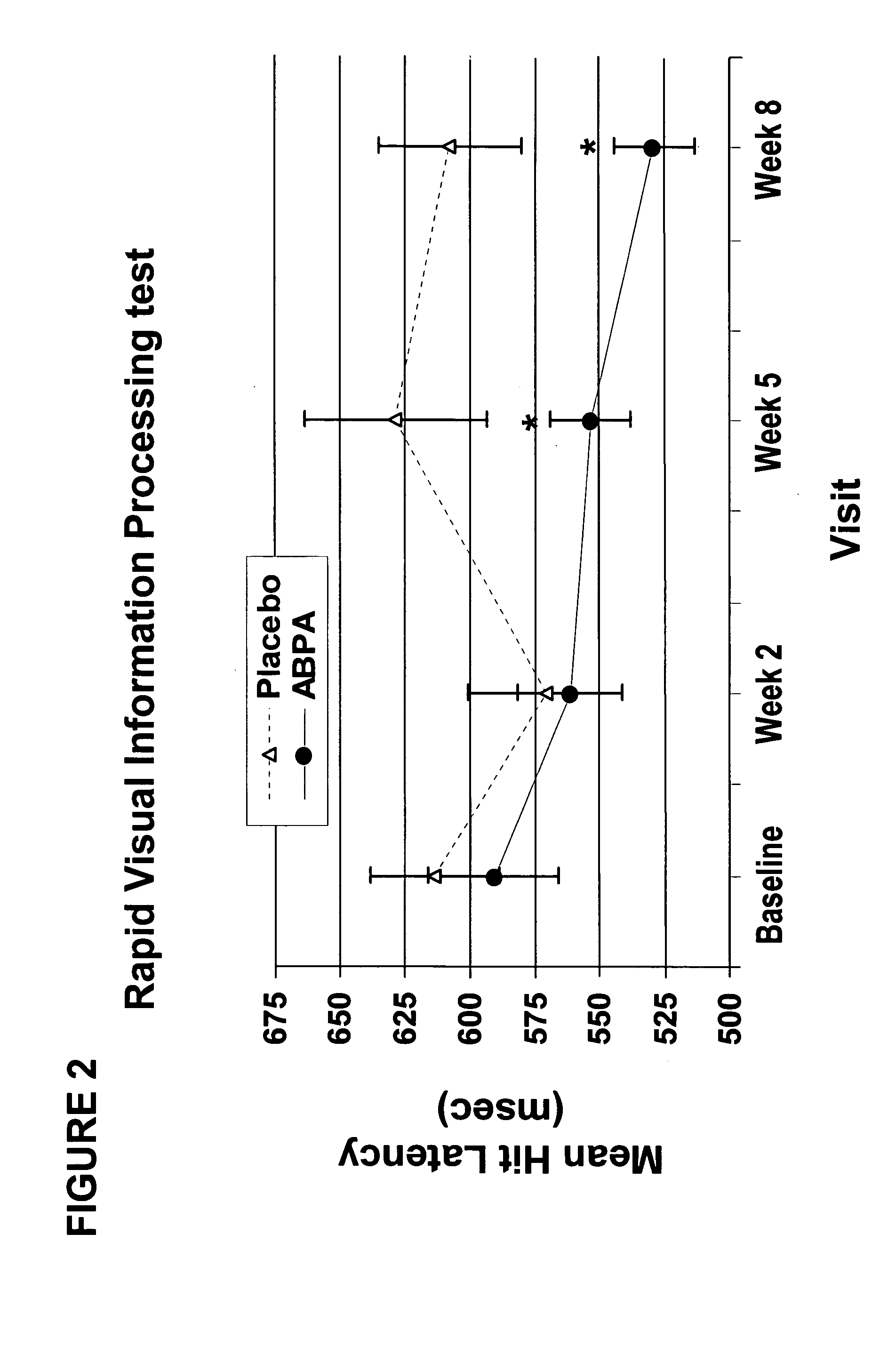

Treatment of attention disorders

InactiveUS20050187196A1Raise attentionBiocidePhosphorous compound active ingredientsPhosphinic AcidsAttention disorders

The invention provides methods and medicaments for improving attentiveness in humans, including subjects diagnosed with attention disorders. In one aspect, a GABAB receptor antagonist, such as 3-aminopropyl-(n-butyl)-phosphinic acid (ABPA), is used to improve attention.

Owner:SAEGIS PHARMA

Flame-retardant resin composition

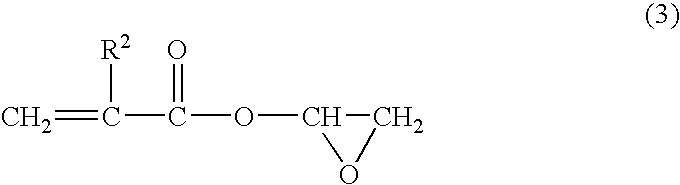

ActiveUS20080167406A1Improve flame retardant performanceImprove machinabilityGroup 5/15 element organic compoundsPolytetramethylene terephthalateElastomer

A flame-retardant resin composition comprises 25 to 150 parts by weight of (B) a thermoplastic polyester elastomer, 5 to 40 parts by weight of (C) a phosphinic acid compound comprising a salt of at least one member selected from the group consisting of a phosphinic acid, a diphosphinic acid, and a polymerized product thereof, and 0.5 to 20 parts by weight of (D) an epoxy compound, relative to 100 parts by weight of (A) a polybutylene terephthalate-series resin. Such a flame-retardant resin composition is useful for various molded products and for covering the surface of an electric wire, or the like. The present invention provides a halogen-free flame-retardant resin composition which has a high heat resistance and a high flame retardancy and is excellent in hydrolysis resistance, abrasion resistance, and moldability (e.g., extrusion properties).

Owner:WIN TECH POLYMER LTD

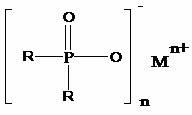

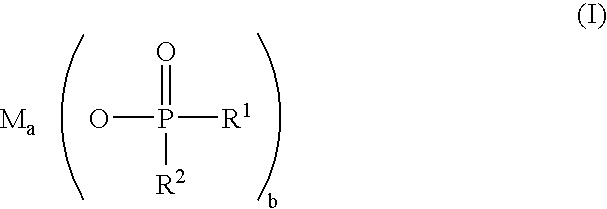

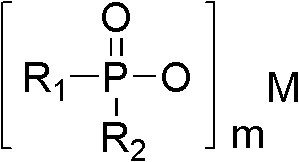

Preparation method of dialkyl hypophosphite

InactiveCN102050835AHigh purityAvoid it happening againGroup 5/15 element organic compoundsPhosphorous acidOrganic solvent

The invention discloses a preparation method of dialkyl hypophosphite. The structure of the dialkyl hypophosphite is disclosed as a Formula (I). The preparation method of the dialkyl hypophosphite comprises the following steps: preparing a Grignard reagent from alkylogen, magnesium powder and organic solvent, preparing dialkyl phosphorus oxide from the Grignard reagent and diethylester phosphite,carrying out reaction on the dialkyl phosphorus oxide and an oxidant, acidifying to obtain a dialkyl phosphinic acid solution, and carrying out reaction on the dialkyl phosphinic acid solution and a metal salt to obtain the corresponding dialkyl hypophosphite. The preparation method of dialkyl hypophosphite has the advantages of high yield and simple synthesis technique, is convenient to operate,greatly lowers the production cost, simplifies the production equipment and enhances the safety of the production process.(I).

Owner:GUANGZHOU KINGSKY MATERIAL

Flame retardant resin composition

InactiveCN101128541AImprove flame retardant performanceExcellent electrical propertiesMeth-Phosphate

Disclosed is a resin composition improved in flame retardance and electrical characteristics. Specifically disclosed is a flame retardant resin composition which is improved in electrical characteristics and composed of a base resin, a halogen flame retardant (namely, a bromine-containing flame retardant such as a brominated polybenzyl (meth)acrylate resin or brominated styrene resin), an organic phosphinic acid (such as dialkylphosphinic acid, alkylenephosphinic acid or cycloalkylenephosphinic acid) or a salt thereof (such as a metal salt or a salt with a nitrogen-containing compound having an amino group), and a flame retardant assistant which are different from the base resin (namely, an antimony-containing compound such as an antimony oxide or an antimonate, a fluorine-containing resin, a silicon-containing compound, an aromatic resin and / or a phosphorus-containing compound except for (fused) aminotriazine phosphates). This resin composition may further contain an olefin resin and an electrical characteristics improver assistant. Per 100 parts by weight of the base resin, there may be contained 3-30 parts by weight of a halogen flame retardant, 1-30 parts by weight of an organic phosphinic acid or a salt thereof, and 0.1-30 parts by weight of a flame retardant assistant.

Owner:POLYPLASTICS CO LTD

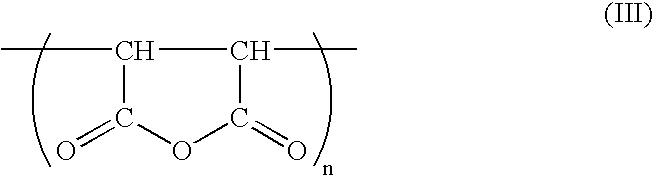

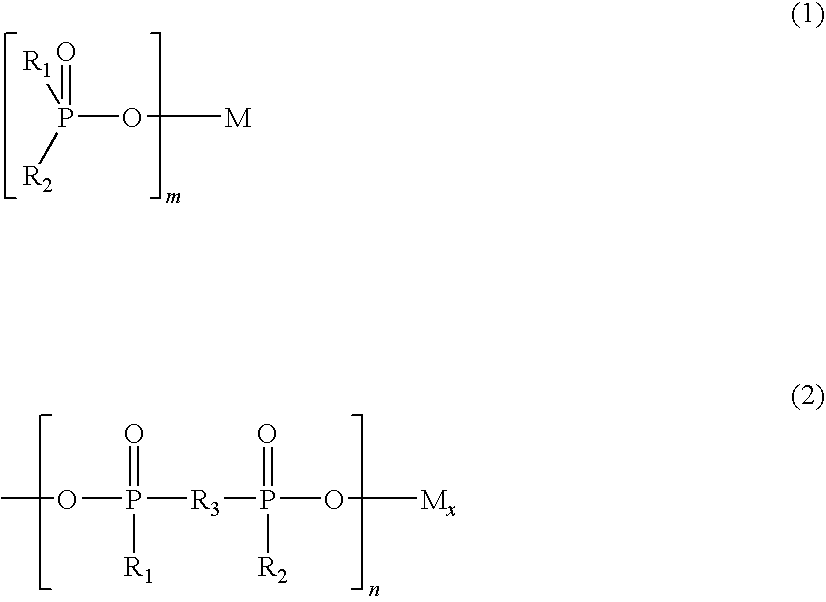

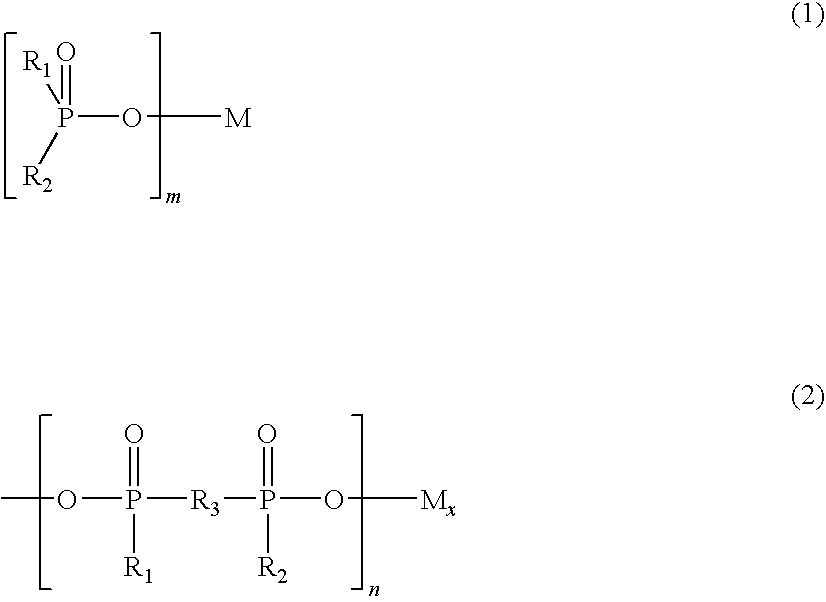

Thermosetting resin composition and prepreg and laminated sheet using the same

InactiveUS20050234173A1Synthetic resin layered productsPrinted circuit manufactureMedicinePhosphinic Acids

The present invention relates to a thermosetting resin composition comprising: (1) a metal salt of a disubstituted phosphinic acid, and (2) a resin having a dielectric constant of 2.9 or less at a frequency of 1 GHz or more, and a prepreg and a laminated board using the same.

Owner:HITACHI CHEM CO LTD

Method for mfg of anode foil of aluminium electrolytic capacitor

InactiveCN1484259ALarge capacityReduce leakage currentAnodisationElectrolytic capacitorsPhosphorous acidCapacitance

This invention relates to a method for manufacturing electrode foils of aluminium electrolytic condensers including pure water boiling, formation, depolarization and reformation in which, the formation liquid electrolyte includes one of solutions of mineral acid containing boric acid or phosphoric acid or organic acid with oxalic acid or their saline material characterizing in adding soppm~5000ppm hypophosphorous acid, phosphorous acid, or their saline materials as the active material added by 100ppm~10000ppm citric acid, tartaric acid or their saline material as the complexant suppressing solution of the foil to reduce attenuation of capacitance.

Owner:深圳市东阳光化成箔股份有限公司

Flame retardant polybutylene terephthalate resin composition

InactiveUS20090124733A1Improve performanceExcellent characteristicsOrganic dyesPolytetramethylene terephthalateGlass fiber

The invention provides a resin composition which gained flame-retardancy by a non-halogen based flame-retardant, having excellent small-warping performance without deteriorating excellent moldability and various characteristics (mechanical characteristics, electrical characteristics, and long-term environmental characteristics) which are inherent advantageous properties of polybutylene terephthalate resin. Specifically, to (A) 100 parts by weight of polybutylene terephthalate-based resin, there are mixed: (B) 10 to 100 parts by weight of a polymer of one or more types selected from the group consisting of modified polyester and styrene-based resin; (C) 10 to 100 parts by weight of specific phosphinic acid salt and / or diphosphinic acid salt and / or a polymer thereof; and (D) 20 to 200 parts by weight of glass fiber having an average cross-sectional area ranging from 100 to 300 square micrometers.

Owner:WIN TECH POLYMER LTD

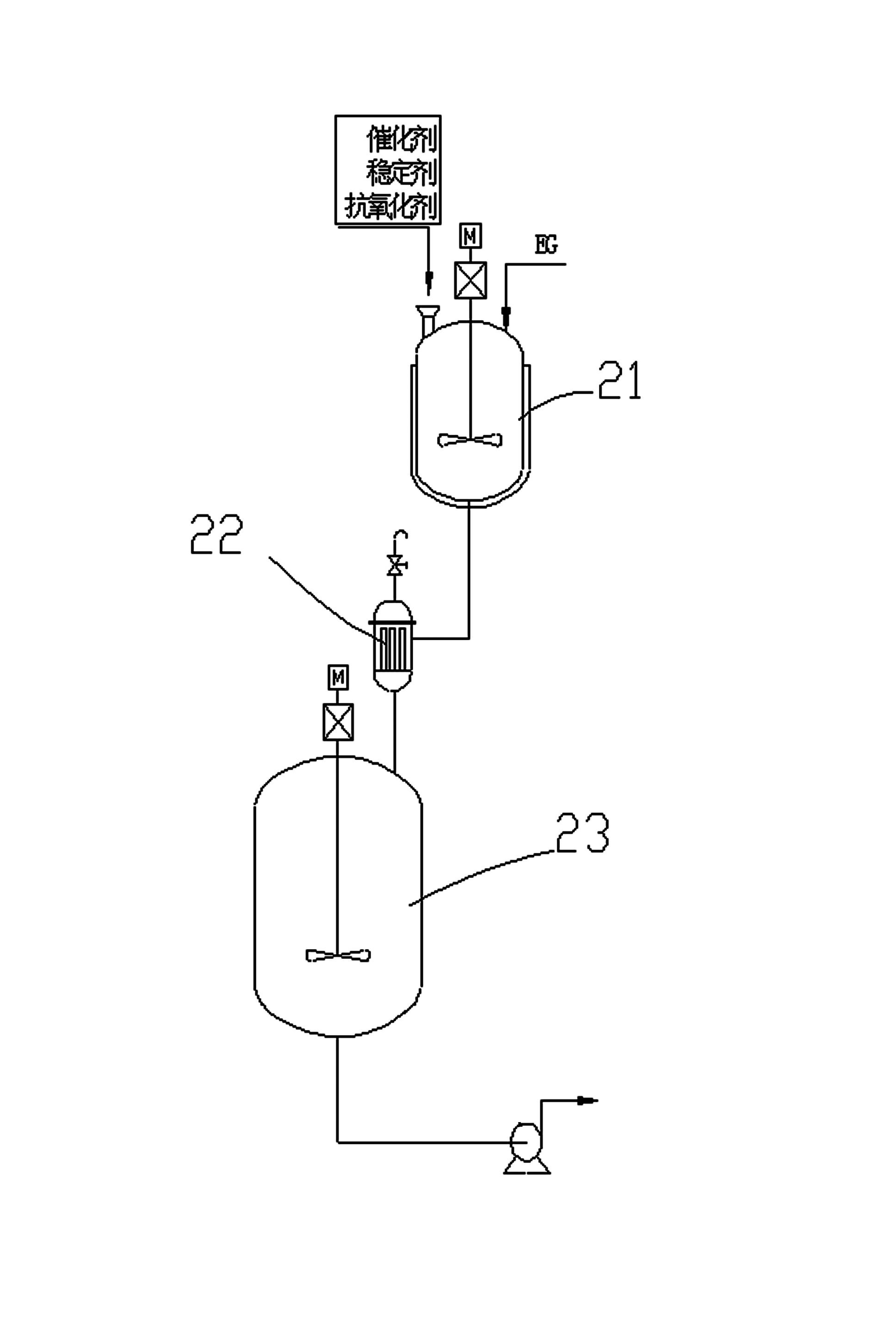

Preparation method of titanium series catalyst for polyester

The invention discloses a preparing method of titanium-system catalyst of polyester, which is characterized by the following: reacting titanic acid ester and 2-hydroxy carboxylic compound and organic phosphonic acid compound; making the product react with at least one phosphorus compound of phosphoric acid, phosphorous acid, hypophosphorous acid, phosphate ester or phosphite ester; fitting for polyester industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

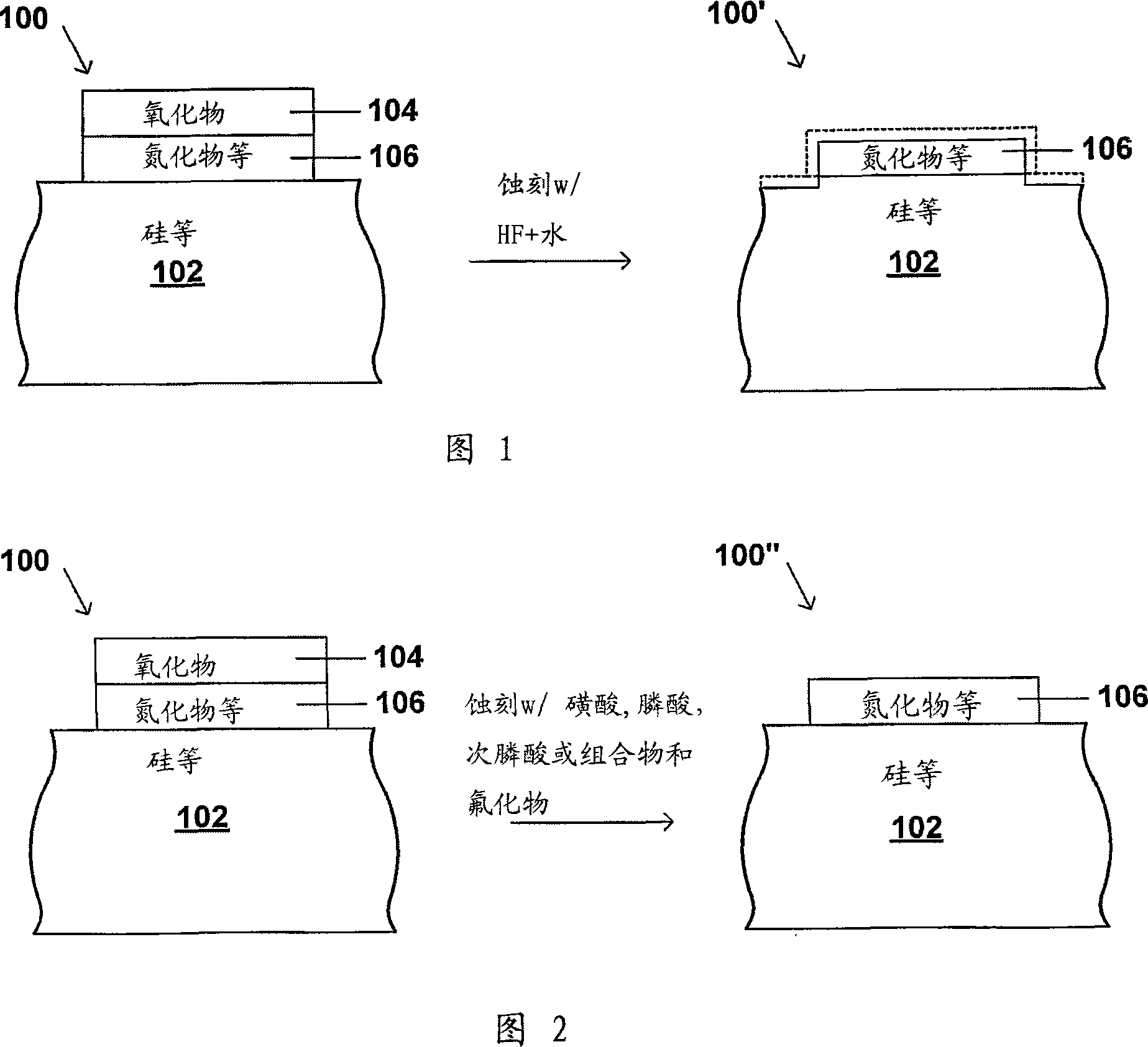

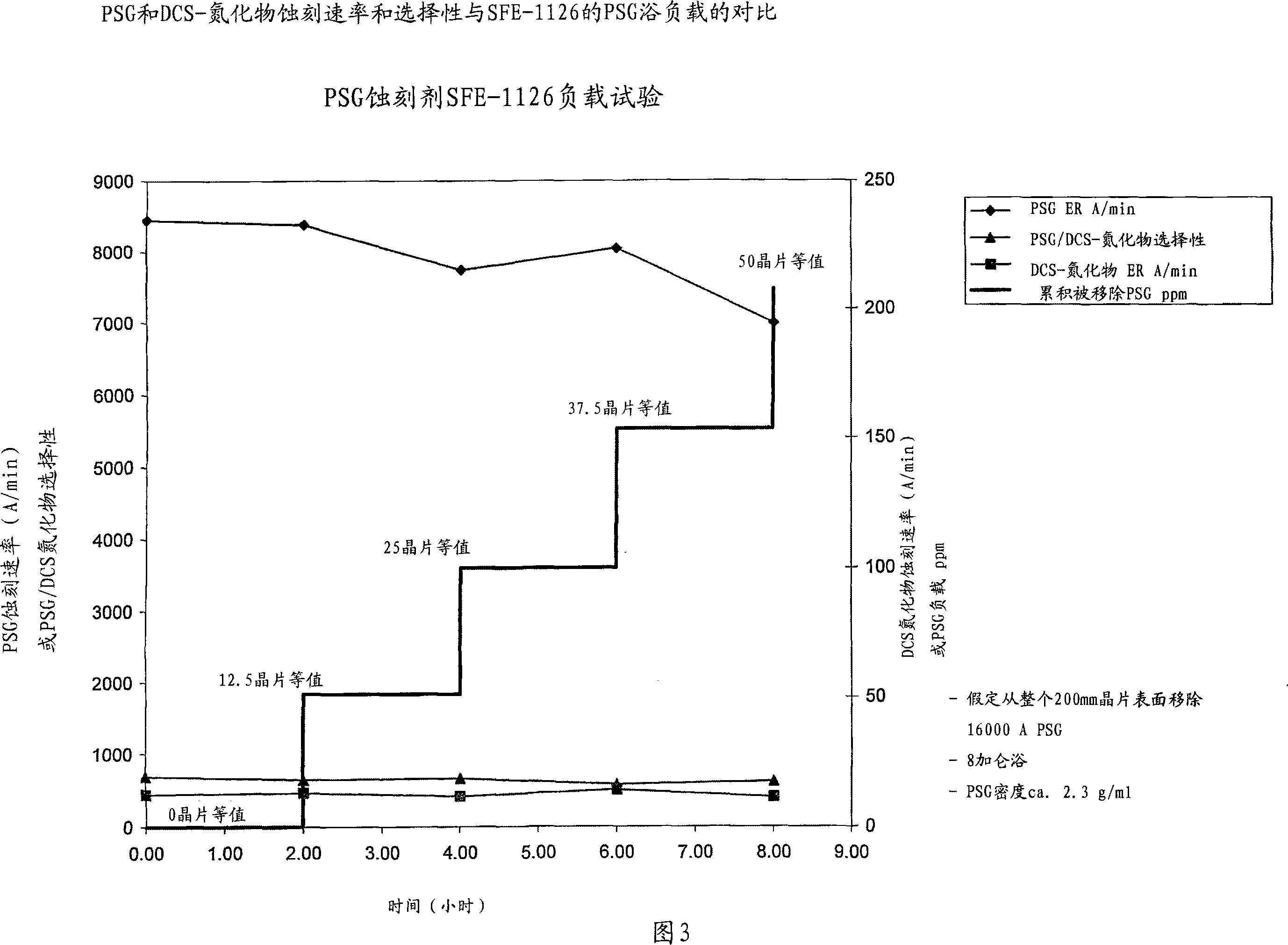

Selective wet etching of oxides

The present invention relates to a wet etching composition including a sulfonic acid, a phosphonic acid, a phosphinic acid or a mixture of any two or more thereof, and a fluoride, and to a process of selectively etching oxides relative to nitrides, high-nitrogen content silicon oxynitride, metal, silicon or silicide. The process includes providing a substrate comprising oxide and one or more of nitride, high-nitrogen content silicon oxynitride, metal, silicon or silicide in which the oxide is to be etched; applying to the substrate for a time sufficient to remove a desired quantity of oxide from the substrate the etching composition; and removing the etching composition, in which the oxide is removed selectively.

Owner:SACHEM INC

Method for preparing flame-proof polyester fiber

ActiveCN101200820AImprove flame retardant performanceImprove flame retardant stabilityFlame-proof filament manufactureFilament/thread formingFiberPositive pressure

The invention relates to a flame retardant polyester fiber preparation method. Pure terephthalic acid, ethylene glycol and phenyl-(ethylene glycol propionate) phosphinic acid are used for the esterification under the positive pressure and for the polycondensation, the belt casting and the granulation under the negative pressure to obtain fire retardant polyester slices. The phenyl-(ethylene glycol propionate) phosphinic acid is phosphor series fire retardant. The content of phosphor in the slices is controlled to be 0.5 to 1 percent. The fire retardant polyester slices are put in a vacuum drum dryer. The dried slices are put on a spinning machine for the spinning to obtain the fire retardant polyester fiber. The fire retardant property is stable. No free flame retardant agent monomer exists. The utilization rate of the fire retardant is improved. The corrosion, toxic gas and the smoke releasing amount of the polyester fiber and the textile are lowered. The production technological process is simplified at the same time. The used raw material categories are reduced. The production cost of the fire retardant polyester fiber is reduced. The oxygen index is 32 to 34 percent.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

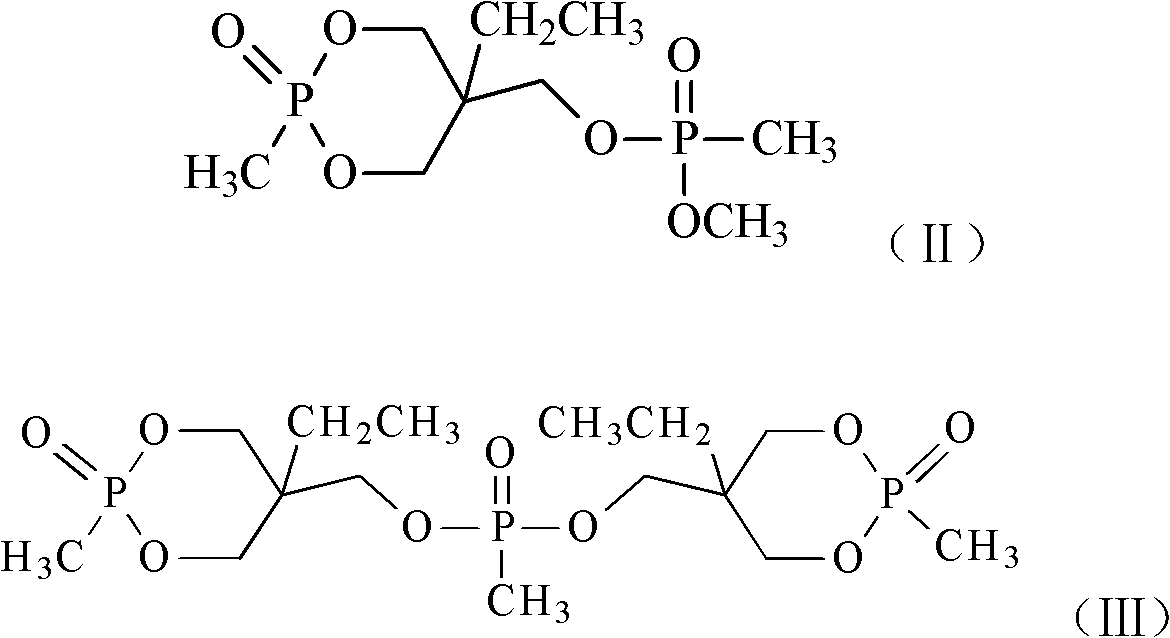

Halogen-free high-efficiency flame retardant composition and preparation method thereof

InactiveCN102337034AImprove thermal stabilityImprove liquidityFibre treatmentPolyolefinPolymer science

The invention discloses a halogen-free high-efficiency flame retardant composition and a preparation method thereof. The halogen-free high-efficiency flame retardant composition is prepared from the following components in percentage by mass: 10-80% of phenyl melamine carboxyethyl phenyl phosphinic acid condensation compound, 15-70% of melamine and / or derivative thereof and 5-20% of organic phosphate. The halogen-free flame retardant composition can be used for flame retarding of various polyolefin, nylon, polyurethane, polyester and other synthetic materials and textiles, and is particularly suitable for polyester and nylon engineering plastic; and by the addition of 12wt% of the flame retardant composition to polybutylene terephthalate (PBT) resin, the flame-retarding level can reach UL 94 V-0 (1.6 mm). The flame retardant composition has the characteristics of high flame retarding efficiency, good fluidity, no precipitation and the like, and can meet the use requirements of flame-retardant resin for electric appliance shells and supports, electronic and electric device connectors and the like.

Owner:DONGHUA UNIV

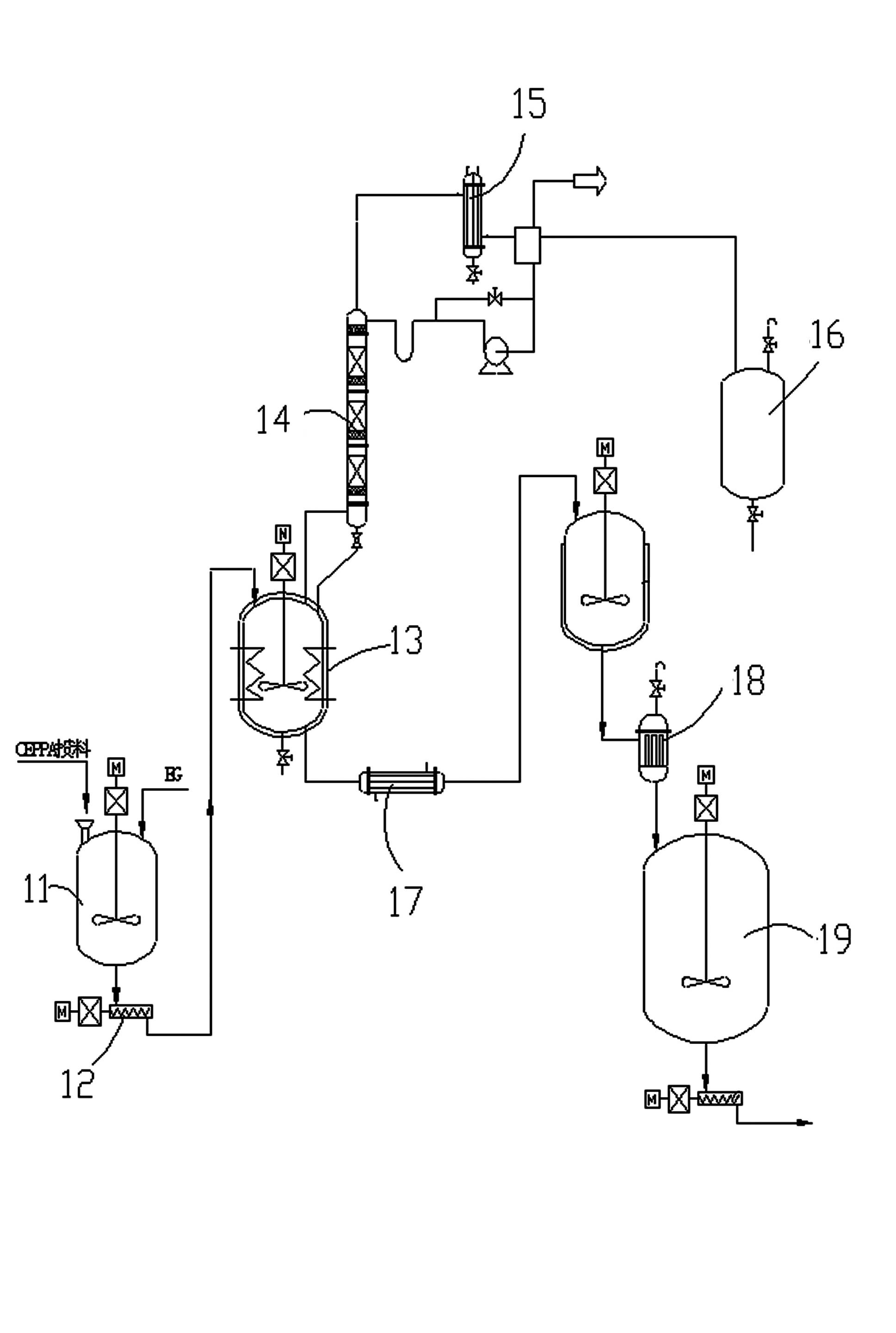

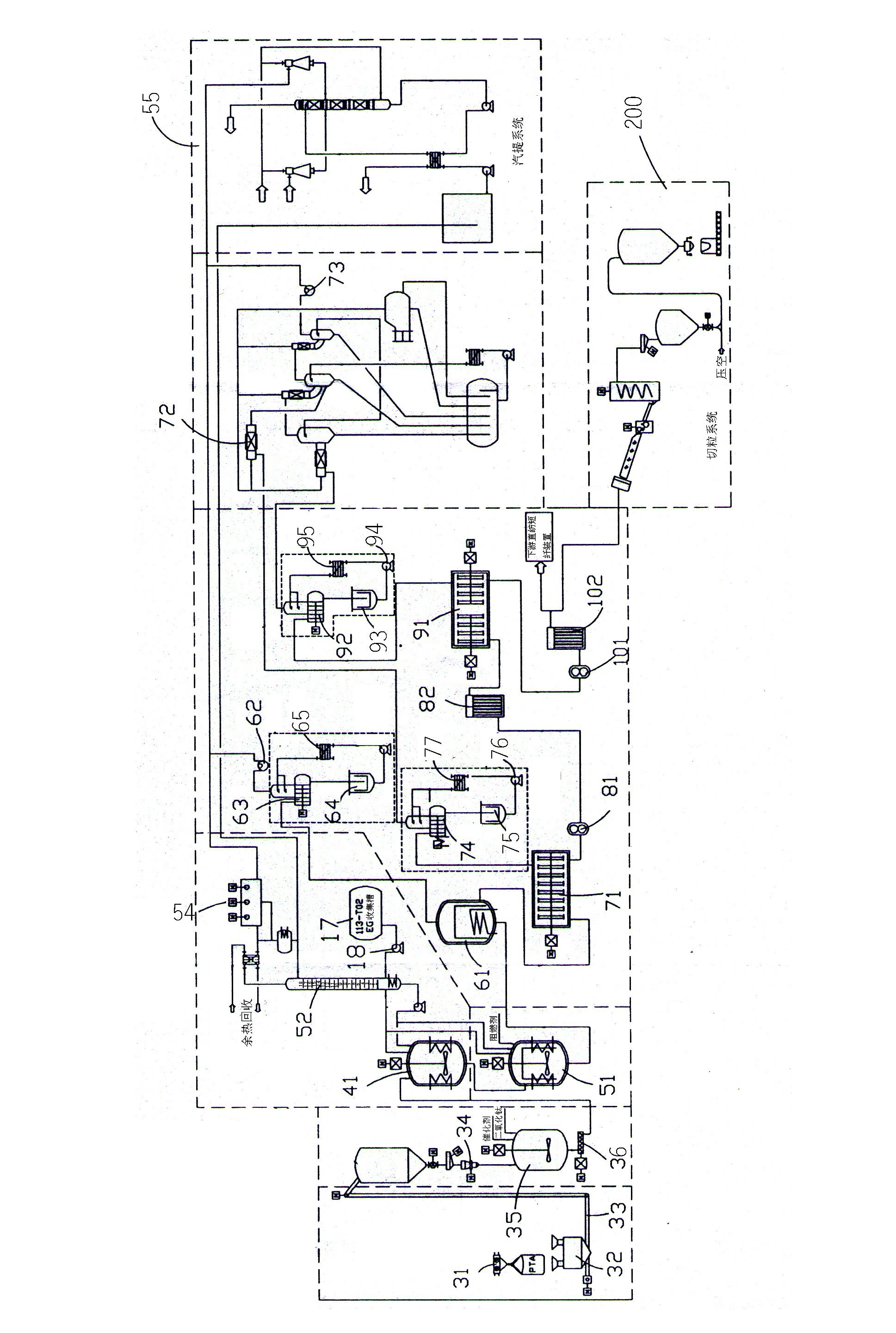

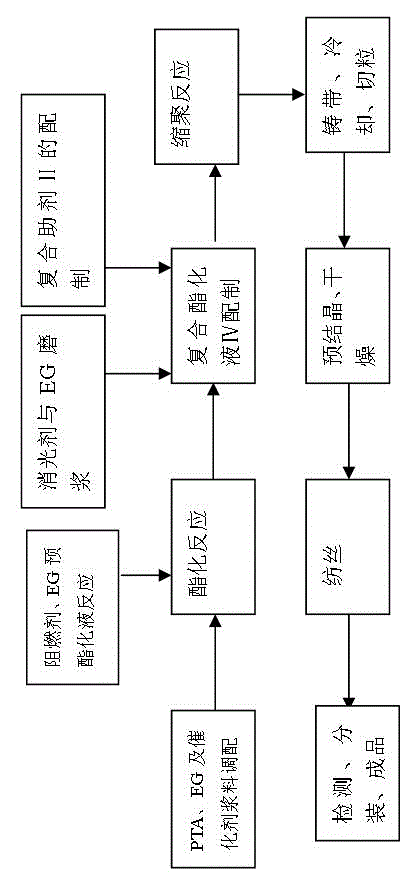

Process for manufacturing fire-retardant polyester fiber

ActiveCN102691130AIncrease productivityReduce consumptionFlame-proof filament manufactureSpinning head liquid feederFiberPolyester

The invention provides a process for manufacturing fire-retardant polyester fiber. The process comprises the steps of: fire retardant preparation, catalyst and promoter preparation, size preparation, two grading esterification reactions, two pre-polycondensation reactions, pre-polymer conveying and filtering, final polycondensation reactions, final polymer conveying and filtering, spinning melt conveying and distributing, spinning and drafting. According to the invention, phosphorus-based non-toxic fire retardant 2-carboxyethyl (phenyl) phosphinic acid-ethylene glycol (CEPPA-EG) esterifying liquid is adopted to ensure that the heat resistance is better; compared with a conventional generally-adopted two-step fiber producing process of firstly producing chips through batch or semicontinuous polymerization and then carrying out chip spinning, the process adopts an one-step fiber producing process of a continuous polymerization melt direct spinning method and therefore has the advantages of high production efficiency, low consumption and loss and low production cost; the manufactured fire-retardant polyester fiber has the advantages of excellent spinnability and fiber physical property and excellent fire retardation of polymer per se; and the fabric manufactured by adopting the fire-retardant polyester fiber has the advantages of more excellent and lasting fire retardation, high limit oxygen index (LOI) which is more than 34, excellent washing durability and safety and no harm to human body.

Owner:福建经纬新纤科技实业有限公司

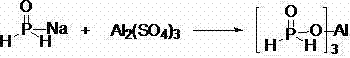

Method for preparing aluminum hypophosphite

The invention relates to a method for preparing aluminum hypophosphite. The method includes the following steps of firstly, preparing sodium hypophosphite solution with concentration of 2-6mol / L, adjusting pH (potential of hydrogen) to be 3-5 preferentially within 3-6.5; secondly, preparing aluminum sulfate solution; and thirdly, subjecting the sodium hypophosphite solution and the aluminum sulfate solution to reaction by heating on the acid condition to generate aluminum hypophosphite. The aluminum sulfate is added into the sodium hypophosphite solution for reaction within a certain temperature range, so that harms caused by volatilization of hypophosphorous acid during preparing of the aluminum hypophosphite are avoided, operation is simplified, yield of products is high, cost is low and industrialization is easy to realize.

Owner:NANJING NORMAL UNIVERSITY

Method for chemically synthesizing high-dielectric constant electrode foil

InactiveCN101030483AIncrease profitImprove oxidation efficiencyAnodisationElectrolytic capacitorsDielectricO-Phosphoric Acid

The invention is concerned with the converting technique of the high dielectric constant electrode foil, it is: infuses the high dielectric constant electrode foil into the phosphoric acid or phosphate liquor, cleans with pure water, processes the first level anodic oxidation; processes the infusion and the cleaning again; then processes the anodic oxidation; processes heat treatment in high temperature; progresses the anodic oxidation, infuses into the phosphoric acid or phosphate liquor; finally, cleans with pure water and drying. The invention is high producing efficiency, and stable production quality.

Owner:DONGGUAN HEC CONDENSER CO LTD

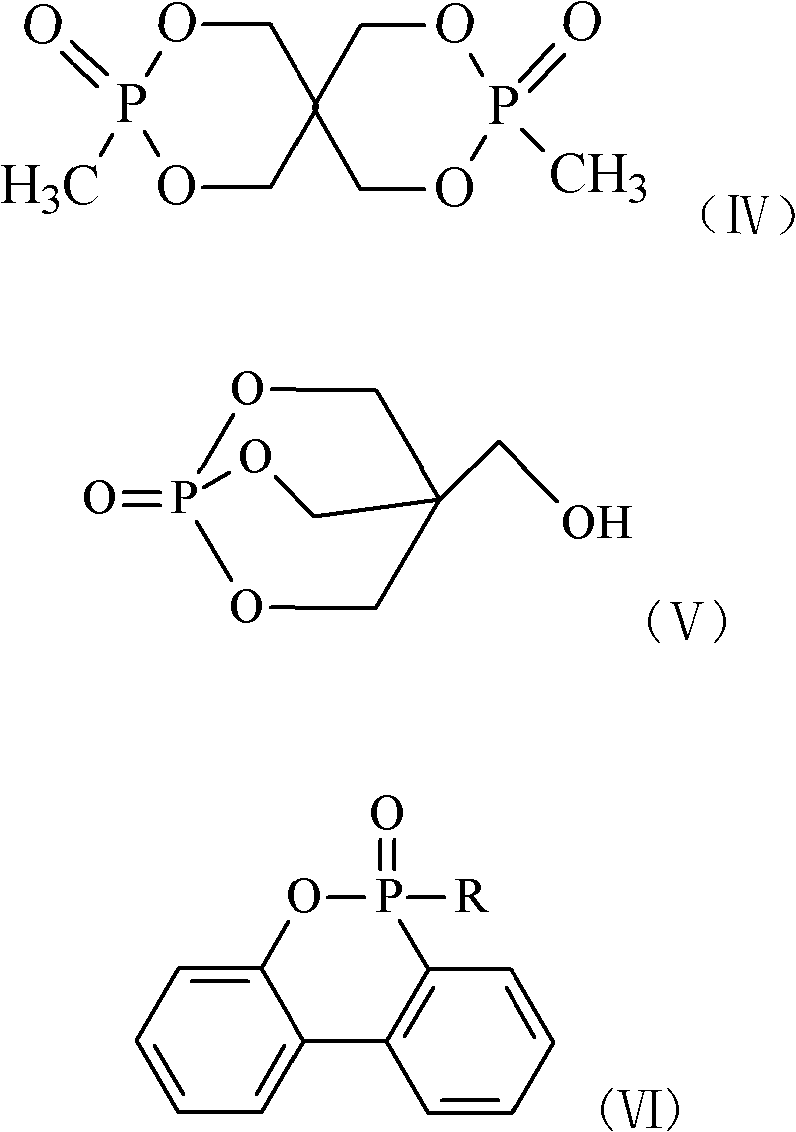

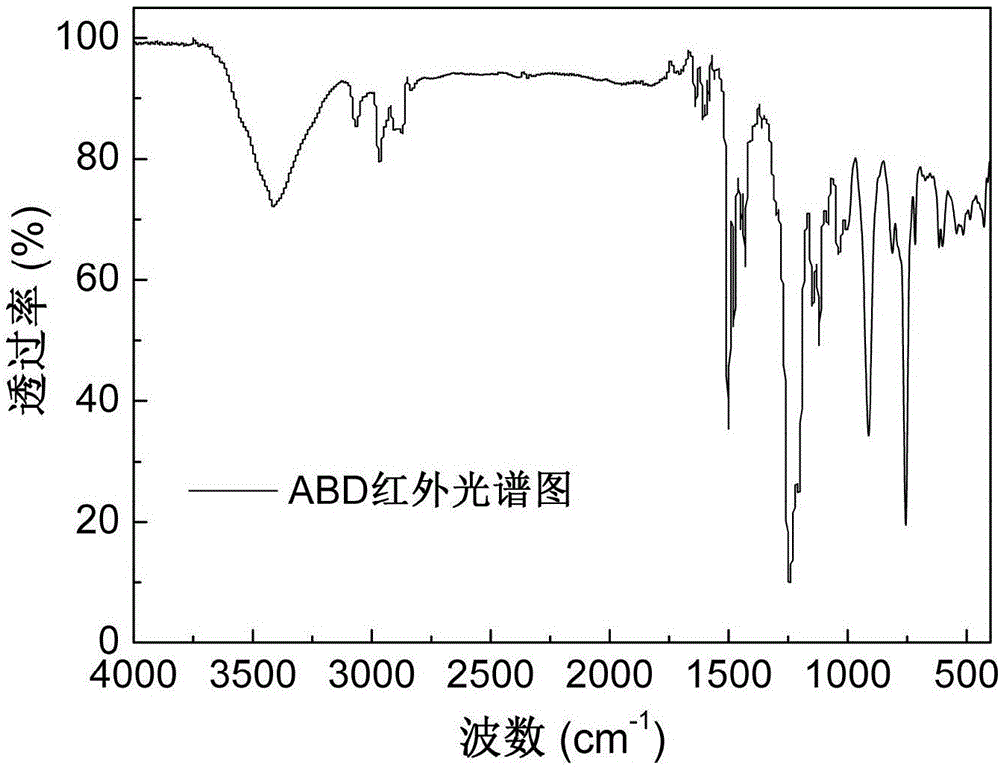

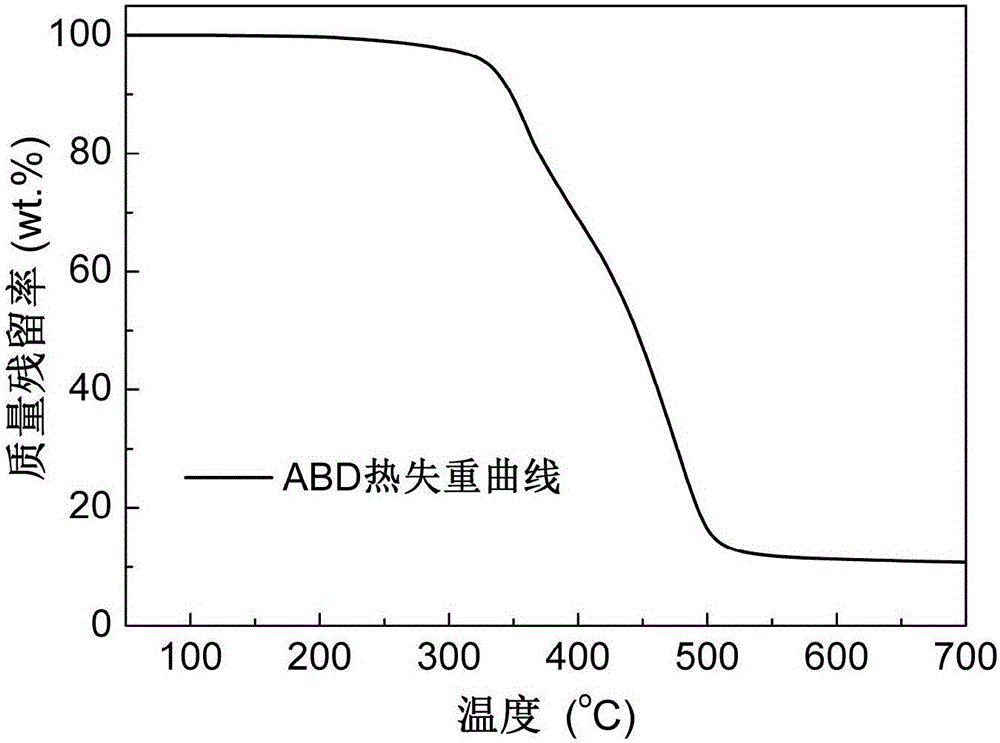

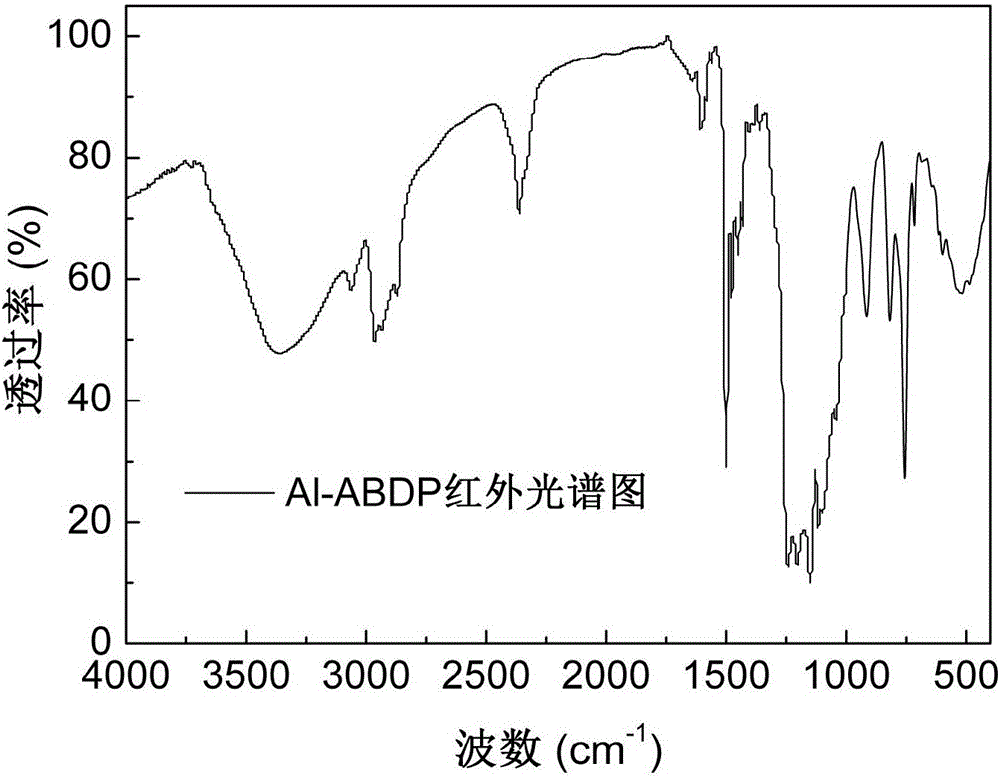

Alkylphosphinate derivative fire retardant containing phosphaphenanthrene group and preparation method thereof

The invention discloses an alkylphosphinate derivative fire retardant containing a phosphaphenanthrene group. A preparation method of the fire retardant is as follows: fusion or solution system addition reaction is carried out for P-H bonds on 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and epoxide groups and C=C double bonds on o-diallyl bisphenol A diglycidyl ether, in order to obtain a primary intermediate ABD; an addition reaction is carried out between hypophosphorous acid and / or P-H bond on salt thereof and residual C=C double bonds of the primary intermediate ABD initiated by free radicals, in order to obtain a secondary intermediate ABDP and / or salts thereof; metallic compounds and / or protonated nitrogen base are added, an alkaline substance is added for neutralization of acids in the reaction system, a target material is salified and separated, and alkylphosphinate M-ABDP containing the phosphaphenanthrene group is prepared. The M-ABDP has good application prospects, and can be widely applied to flame retardation modification of polyester, polyamide and thermosetting resin, and other high-molecular resin materials.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Method for preparing flame-retardant and anti-dripping polyester fiber

InactiveCN101851811AWill not affect other performanceImprove spinnabilityMonocomponent polyesters artificial filamentArtifical filament manufactureFiberPolymer science

Owner:JIANGYIN BOLUN CHEM FIBER

Finish for nylon FDY and preparation method

The invention relates to the technical field of auxiliary manufacturing in the fiber processing technology, in particular to finish for nylon FDY and a preparation method. The finish for nylon FDY comprises the following components: 55-60% of isooctyl stearate, 5-7% of scouring agents, 5-7% of oleic acid, 8-10% of coconut oil diethanolamine, 5-7% of hydrogenated castor oil polyoxyethylene ether, 5-7% of fatty alcohol polyoxyethylene ether 4, 1-2% of oleic acid sarcosine, 0.5-1% of hypophosphorous acid, 1-1.5% of potassium hydroxide and 5-7% of wetting agent. The preparation method comprises the process steps of mixing, stirring and testing. The finish for nylon FDY has good thermal stability, is less in volatilization and free of coking and has low coefficient of dynamic friction in the drawing stage and good cohesion.

Owner:JIAXING NEW & HIGH TECH FIBER

Preparation method of negative ion release, far-infrared and fire retardation composite function polyester fibers

ActiveCN104988594AImprove flame retardant performanceGood far-infrared radiation performanceFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolyesterEnvironmental resistance

The present invention relates to a preparation method of negative ion release, far-infrared and fire retardation composite function polyester fibers with effects of permanent negative ion release and good far-infrared radiation performance, wherein ethylene glycol (EG) and refined p-phthalic acid (PTA) are adopted as main materials, a phosphorus-based polymerization type fire retardation agent 2-carboxyethyl(phenyl) phosphinic acid (CEPPA), negative ion powder (such as nano-scale tourmaline and the like), far-infrared nano-scale ceramic powder, a catalyst, a matting agent and other auxiliary agents are added, and esterification, condensation polymerization and spinning are performed to prepare the modified polyester fibers. According to the present invention, the fire retardation property is good, the environmentally friendly and permanent fire retardation is provided, the P content is up to 7000-14000 PPm, and the fire retardation property of the woven fabric can meet the fabric fire retardation grade 1; the fibers have the permanent negative ion release function, and the released negative ion amount is 800-5000 / cm<3>; and the far-infrared radiation property is good.

Owner:浙江真北纺织新材料研究院有限公司 +1

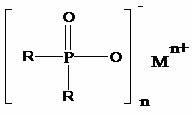

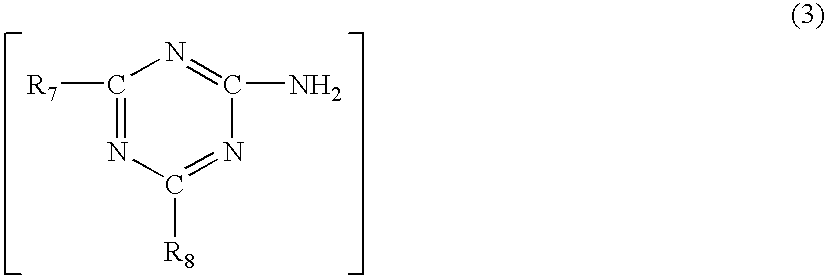

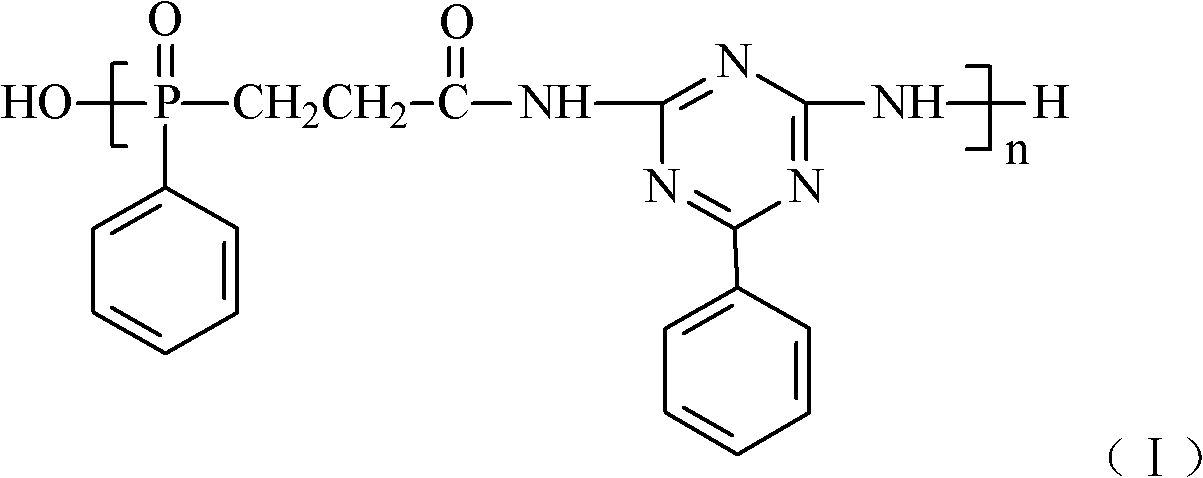

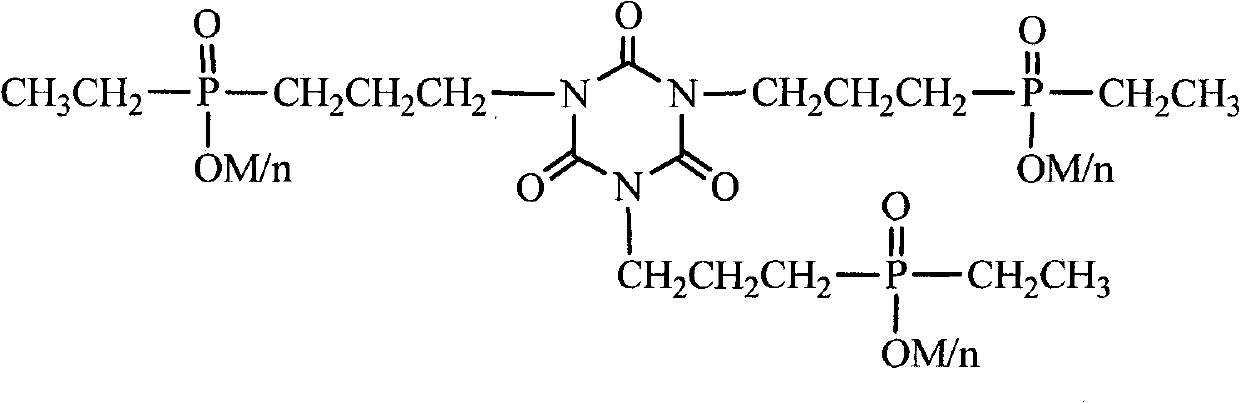

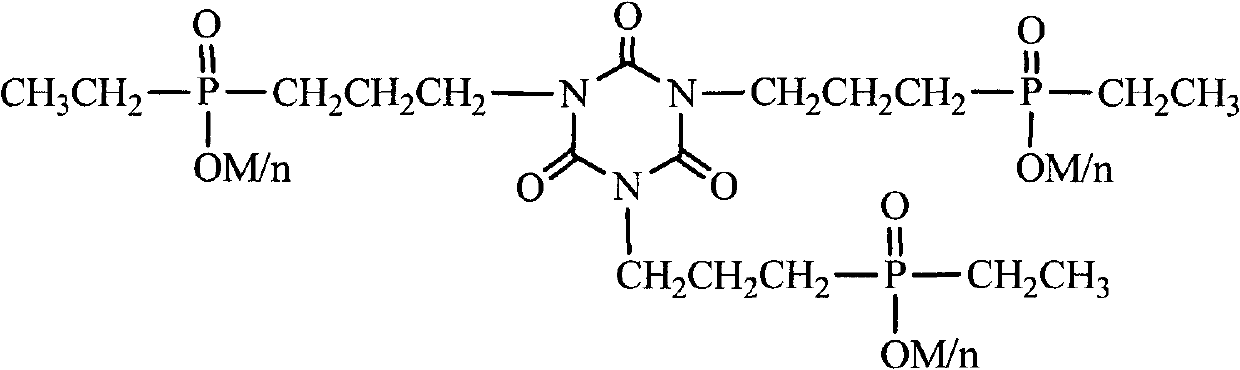

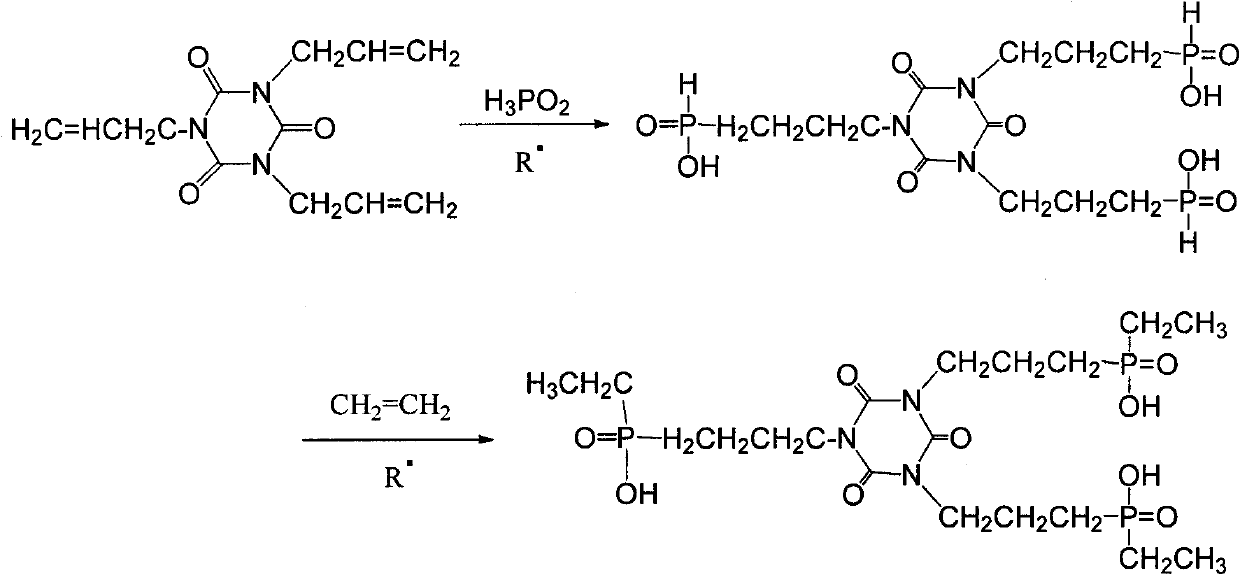

Organic phosphinic acid metal salt containing triazine ring and preparation method thereof

ActiveCN102229622AImprove mechanical propertiesHigh molecular weightGroup 5/15 element organic compoundsCoatingsEpoxyPolyester

The invention relates to organic phosphinic acid metal salt containing a triazine ring and a preparation method thereof. The structure of the compound is represented as follows: FORMULA, wherein M is a metal ion of Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Ce, Sn, Fe, Mn, Li, Na or K; and n is a valence of the M. The preparation method comprises the following steps of: reacting the phosphinic acid or alkali metal salt of the phosphinic acid with triallyl isocyanurate and ethylene in the presence of a radical initiator so as to obtain organic phosphinic acid or alkali metal salt of the organic phosphinic acid containing the triazine ring; and then, reacting with a metal compound of Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Ce, Sn, Fe and Mn so as to obtain the relative organic phosphinic acid salt containing the triazine ring. The compound can be used as a fire retardant of nylon, polyester, polyurethane, epoxy resin, glass fibre reinforced resin, coat and the like. The preparation method is simple in process and easy to perform industrial production.

Owner:昆山卡帝德塑料制品有限公司

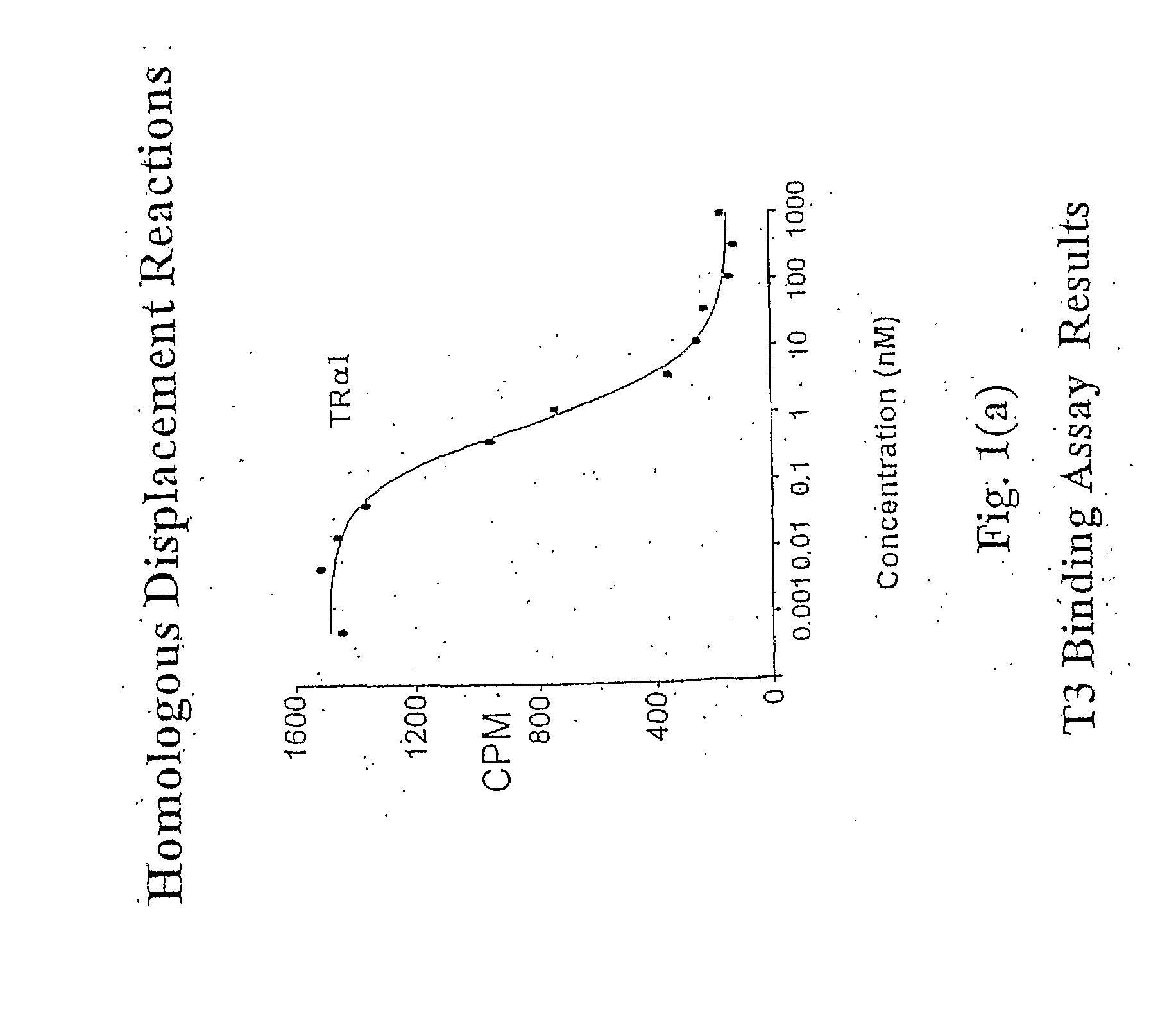

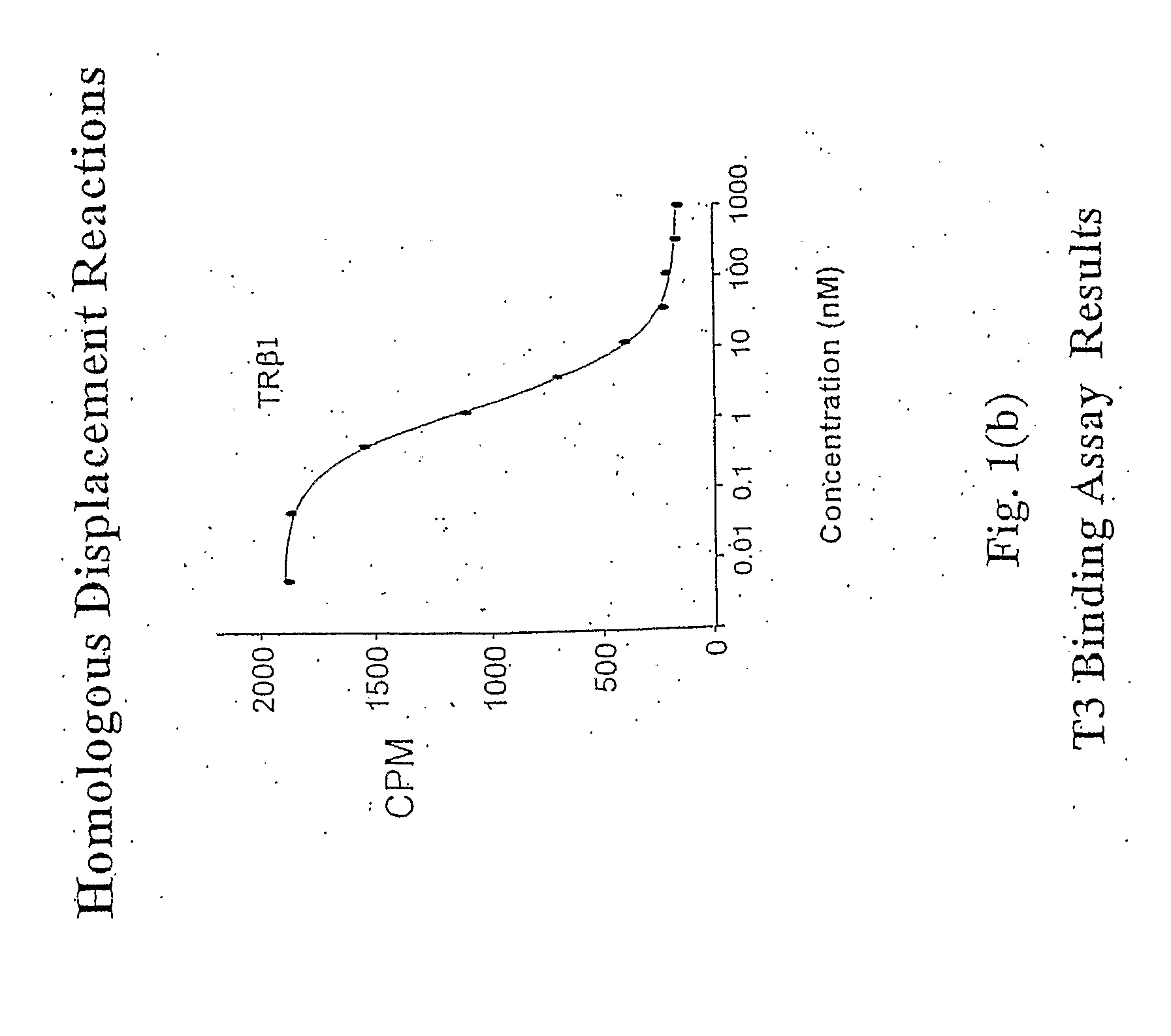

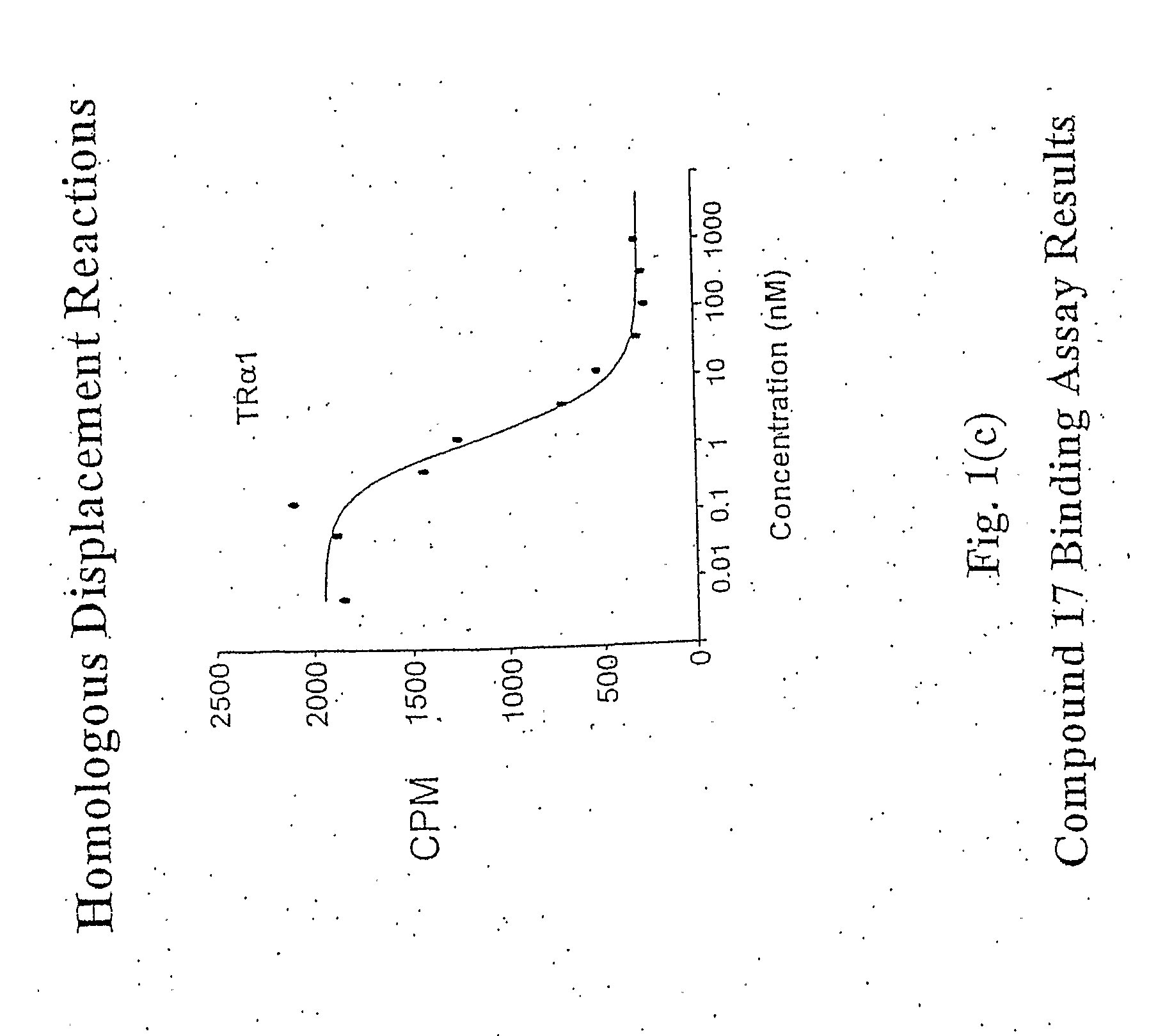

Novel Phosphinic Acid-Containing Thyromimetics

InactiveUS20090028925A1Good curative effectDecreasing non-liver toxicityBiocideMetabolism disorderDiseaseHyperlipemias

The present invention relates to compounds of phosphonic acid-containing T3 mimetics and monoesters thereof, stereoisomers, pharmaceutically acceptable salts, co-crystals, and prodrugs thereof and pharmaceutically acceptable salts and co-crystals of the prodrugs, as well as their preparation and uses for preventing and / or treating metabolic diseases such as obesity, NASH, hypercholesterolemia and hyperlipidemia, as well as associated conditions such as atherosclerosis, coronary heart disease, impaired glucose tolerance, metabolic syndrome x and diabetes.

Owner:METABASIS THERAPEUTICS INC

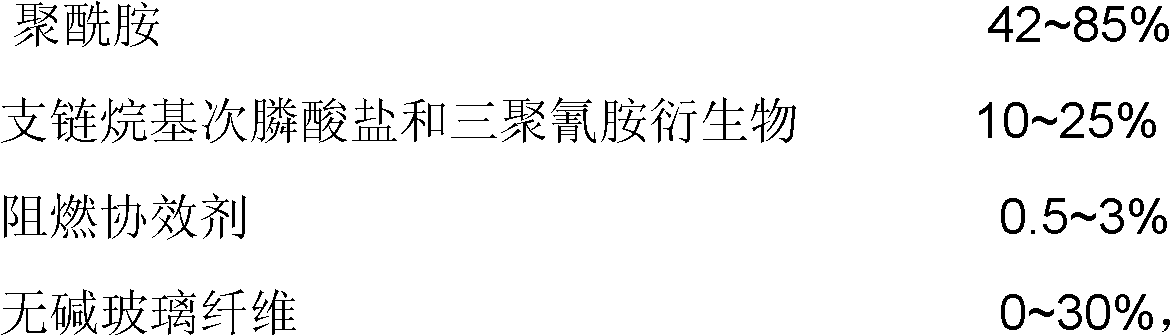

High-retardant polyamide

The invention discloses high-retardant polyamide which is prepared from the following components in percentage by weight through cross blending fusion: 42-85% of polyamide, 10-25% of branched chain alkyl phosphinic acid and melamine derivatives, 0.5-3% of fire-retardant synergist, and 0-30% of alkali-free glass fiber, wherein the mass ratio in percentage of branched chain alkyl phosphinic acid tothe melamine derivatives is (2:1)-(4:1), or the mass percentage of the melamine derivatives is 0, the oxygen index of the high-retardant polyamide is 27.3-32.2%, and the vertical flame UL-94 of a test sample with the thickness of 1.6mm is V-1, and the vertical flame UL-94 of a test sample with the thickness of 0.8mm is NR-(V-0). The high-retardant polyamide provided by the invention is obtained through adding a retardant system of a novel branched chain alkyl phosphinic acid fire retardant, a nitrogen or phosphorous compound and the formulation of the synergist, not only has an excellent fireretardant effect, but also can be used for lowering the cost through reducing the additive amount of the fire retardant.

Owner:SICHUAN UNIV

Composite catalyst and its application in preparing light-colored rosin esters

ActiveCN101264454APrevent oxidationPlay a bleaching roleOrganic-compounds/hydrides/coordination-complexes catalystsNatural resin chemical modificationPhosphinic AcidsRosin

The invention provides a compound catalysis used for preparing pale rosin ester, reducing the production cost and simplifying production technique as well as an application thereof. The compound catalysis comprises components of the following mass ratios: 1 to 200 portions of hypophosphorous acid and / or hypophosphite, 1 to 100 portions of sulfur-containing metal salt and 2 to 100 portions of organic disproportionation catalyst. The compound catalysis of the invention can prepare the pale rosin ester using common resin as the raw material to produce the pale rosin ester with solid garner color no larger than 2.

Owner:江西科茂林化科技有限公司

Pharmaceutical Co-Crystal Compositions

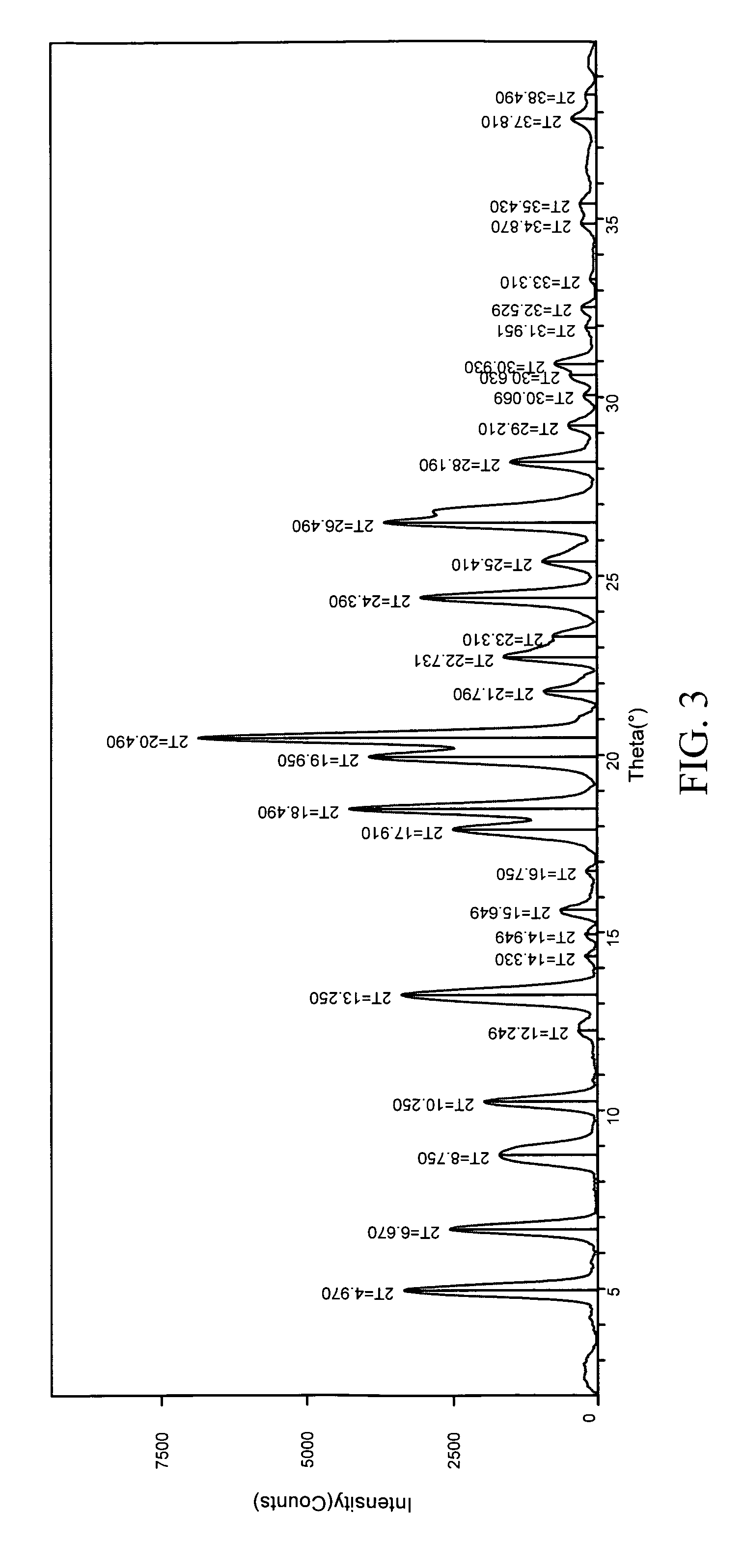

InactiveUS20100311701A1Improve solubilityLow hygroscopicitySalicyclic acid active ingredientsBiocidePhosphinic AcidsKetone

A pharmaceutical composition comprising a co-crystal of an API and a co-crystal former; wherein the API has at least one functional group selected from ether, thioether, alcohol, thiol, aldehyde, ketone, thioketone, nitrate ester, phosphate ester, thiophosphate ester, ester, thioester, sulfate ester, carboxylic acid, phosphonic acid, phosphinic acid, sulfonic acid, amide, primary amine, secondary amine, ammonia, tertiary amine, imine, thiocyanate, cyanamide, oxime, nitrile diazo, organohalide, nitro, S-heterocyclic ring, thiophene, N-heterocyclic ring, pyrrole, O-heterocyclic ring, furan, epoxide, peroxide, hydroxamic acid, imidazole, pyridine and the co-crystal former has at least one functional group selected from amine, amide, pyridine, imidazole, indole, pyrrolidine, carbonyl, carboxyl, hydroxyl, phenol, sulfone, sulfonyl, mercapto and methyl thio, such that the API and co-crystal former are capable of co-crystallizing from a solution phase under crystallization conditions.

Owner:MCNEIL PPC INC

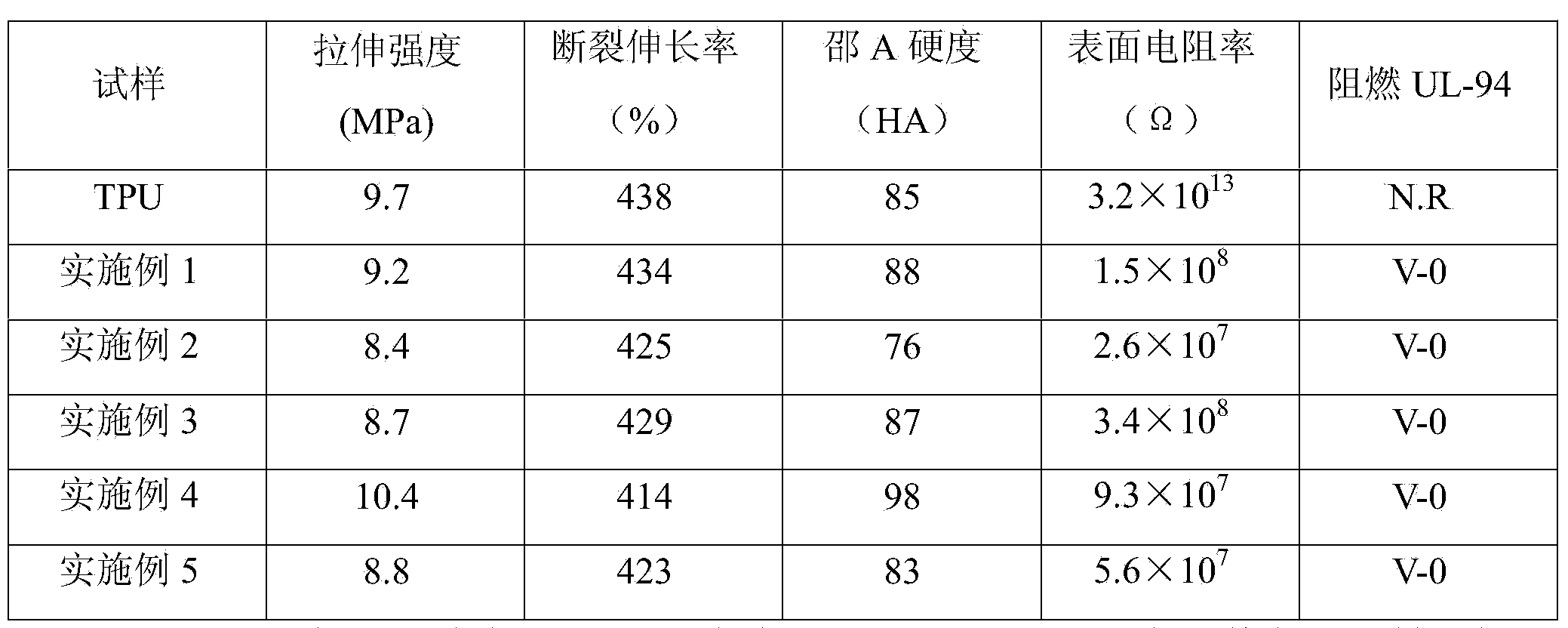

Halogen-free flame-retardant antistatic TPU (thermoplastic polyurethane) material and preparation method thereof

The invention the invention discloses a halogen-free flame-retardant antistatic TPU (thermoplastic polyurethane) material which is composed of 60-90 parts of thermoplastic polyurethane elastomer, 5-40 parts of flame retardant, 1-5 parts of antistatic agent, 0.1-0.5 part of antioxidant and 0.2-1 part of lubricant. The Shore hardness A of the TPU elastomer is 70-95HA, and the flame retardant is composed of one or more of alkyl hypophosphorous acid metal salts or hypophosphorous acid metal salts. The method comprises the following steps: proportionally selecting raw materials, uniformly mixing the selected raw materials, melting, compounding, and granulating by extrusion. The halogen-free flame-retardant antistatic TPU material has obviously lower surface resistivity and obviously higher flame-retardant grade under the condition of not influencing the tensile strength, fracture strength and Shore hardness A of the TPU substrate, is free of halogens, and has excellent flame-retardant and antistatic functions.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

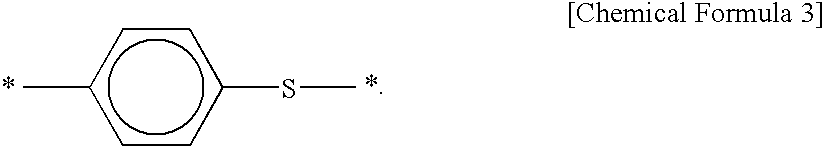

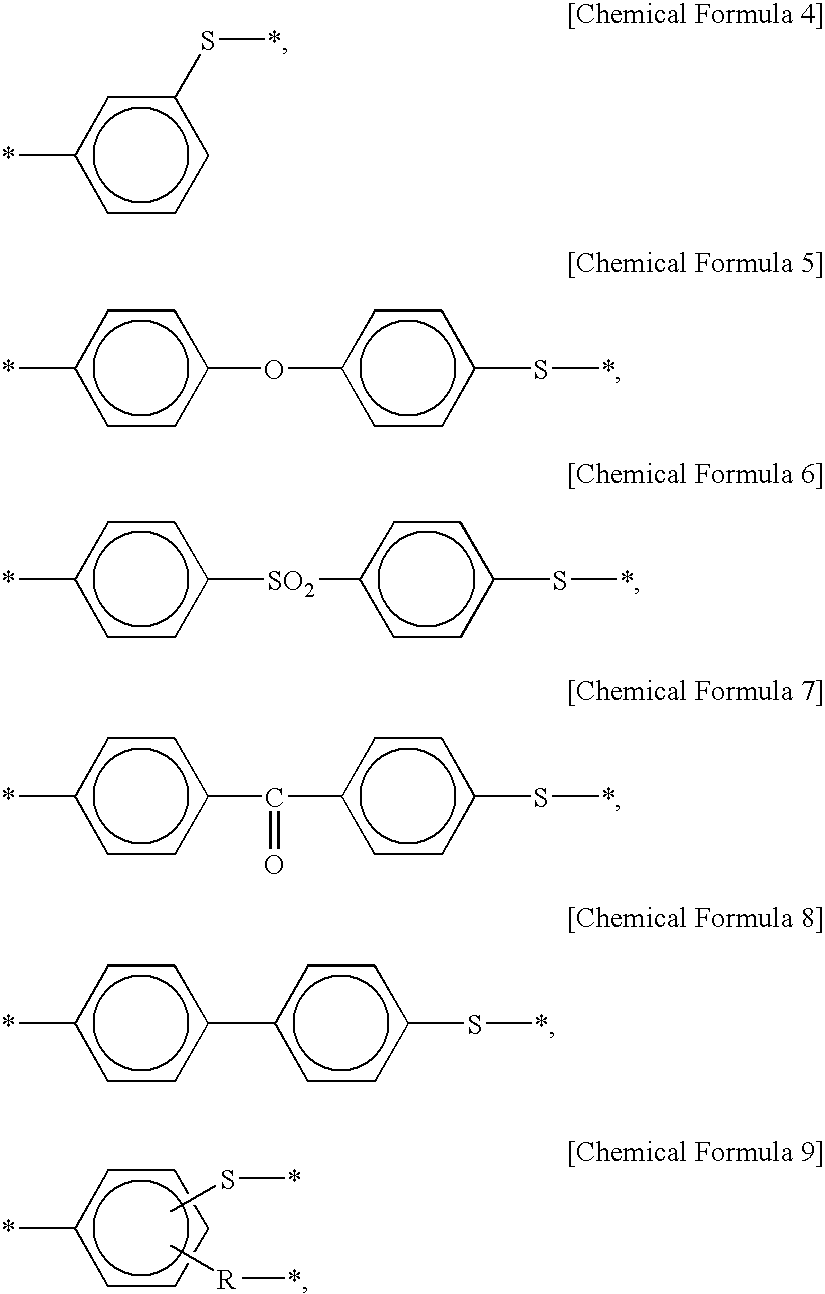

Flame Retardant Thermoplastic Resin Composition

Disclosed is a flame retardant thermoplastic resin composition that includes about 100 parts by weight of a mixed resin (A) including about 10 to about 90 wt % of an aromatic polyamide resin (A-1) and about 10 to about 90 wt % of a polyphenylene sulfide resin (A-2), about 0.5 to about 30 parts by weight of a phosphinic acid metal salt flame retardant (B), and about 10 to about 100 parts by weight of a filler (C).

Owner:CHEIL IND INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com