Preparation method of negative ion release, far-infrared and fire retardation composite function polyester fibers

A flame-retardant composite and polyester fiber technology, which is applied in the field of polyester fiber manufacturing, can solve the problems of not having far-infrared radiation and flame-retardant functions, and achieve good flame-retardant and radiation performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

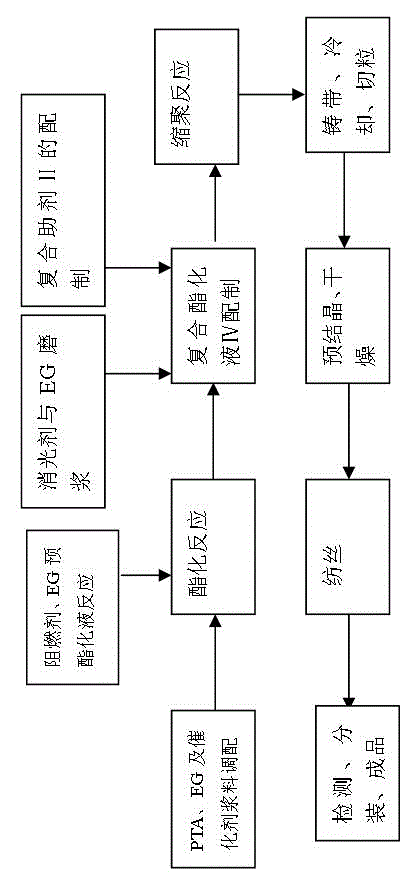

[0008] Embodiment 1: with reference to attached figure 1 . A preparation method for releasing negative ions, far-infrared and flame-retardant composite functional polyester fibers. Add 2-carboxyethylphenylphosphinic acid, a copolymerized phosphorus-based flame retardant, into the pre-esterification reaction kettle, and slowly raise the temperature to 140-160°C under the conditions of vacuuming to a constant value of 0.002-0.012Mpa and stirring , keep the esterification for 2 to 5 hours; generate H during the esterification process 2 O, separated H 2 O metering, supplementing EG with the same mass fraction of separated water to prepare 2-carboxyethylphenylphosphinic acid diethylene glycol ester flame retardant pre-esterification solution I for later use, and its acid value is not greater than 65mgKOH / g; (2) Preparation of composite additives: Stir and disperse 0.8 to 1.2 parts by mass of nanoscale natural tourmaline negative ion powder, 0.8 to 1.2 parts by mass of nanoscale ...

Embodiment 2

[0009] Example 2: On the basis of Example 1, a preparation method for releasing negative ions, far-infrared and flame-retardant composite functional polyester fibers, (1) Preparation of flame-retardant pre-esterification liquid: 1 mass part of ethylene glycol , 0.8 parts by mass of the copolymerized phosphorus-based flame retardant 2-carboxyethylphenylphosphinic acid was added to the pre-esterification reaction kettle, and the temperature was slowly raised to 140 under the condition of vacuuming to a constant value of 0.002-0.012Mpa and stirring. ~160℃, keep esterification for 2~5 hours; generate H during esterification 2 O, separated H 2 O metering, supplementing EG with the same mass fraction of separated water to prepare 2-carboxyethylphenylphosphinic acid diethylene glycol ester flame retardant pre-esterification solution I for later use, and its acid value is not greater than 65mgKOH / g; (2) Preparation of composite additives: Stir and disperse 0.8 mass parts of nano-scal...

Embodiment 3

[0010] Example 3: On the basis of Example 1, a preparation method for releasing negative ions, far-infrared and flame-retardant composite functional polyester fibers, (1) Preparation of flame-retardant pre-esterification liquid: 1.5 parts by mass of ethylene glycol , 1.2 parts by mass of the copolymerized phosphorus-based flame retardant 2-carboxyethylphenylphosphinic acid was added to the pre-esterification reaction kettle, and the temperature was slowly raised to 140 under the condition of vacuuming to a constant value of 0.002-0.012Mpa and stirring. ~160℃, keep esterification for 2~5 hours; generate H during esterification 2 O, separated H 2O metering, supplementing EG with the same mass fraction of separated water to prepare 2-carboxyethylphenylphosphinic acid diethylene glycol ester flame retardant pre-esterification solution I for later use, and its acid value is not greater than 65mgKOH / g; (2) Preparation of composite additives: Stir and disperse 1.2 mass parts of nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com