Patents

Literature

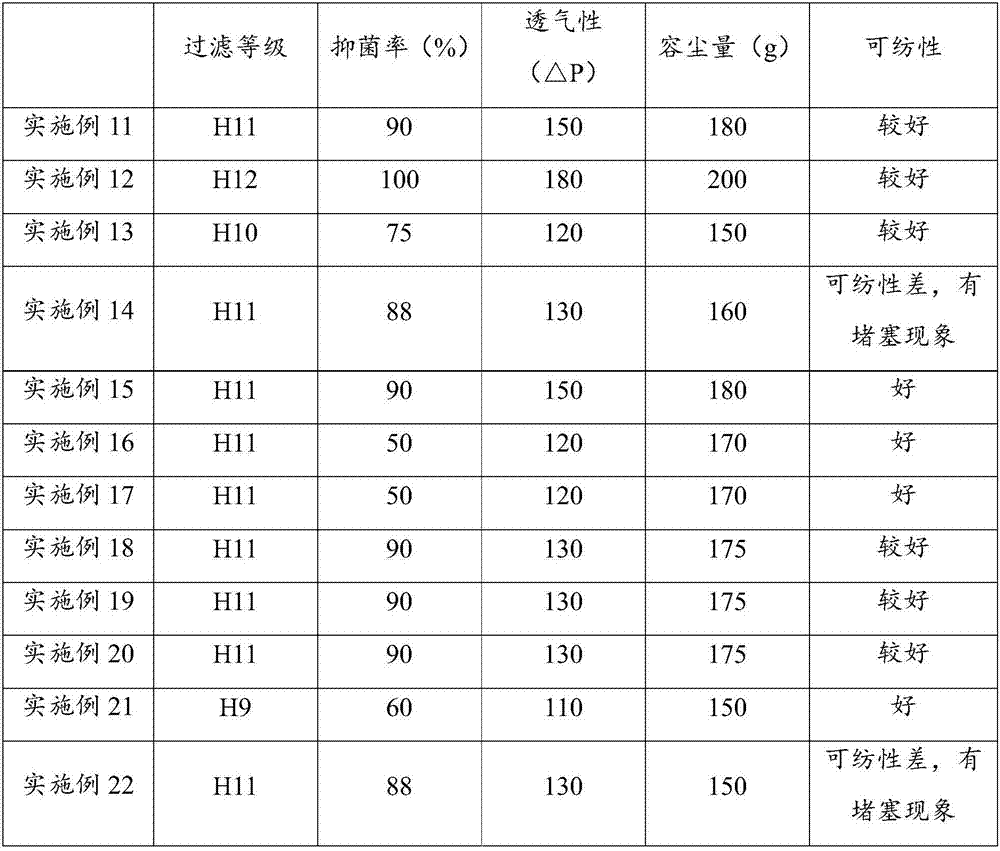

2380results about How to "Improve spinnability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monofilament suture and manufacturing method thereof

InactiveUS7070610B2Increase flexibilityExcellent knot securitySuture equipmentsFilament/thread formingMedicineYoung's modulus

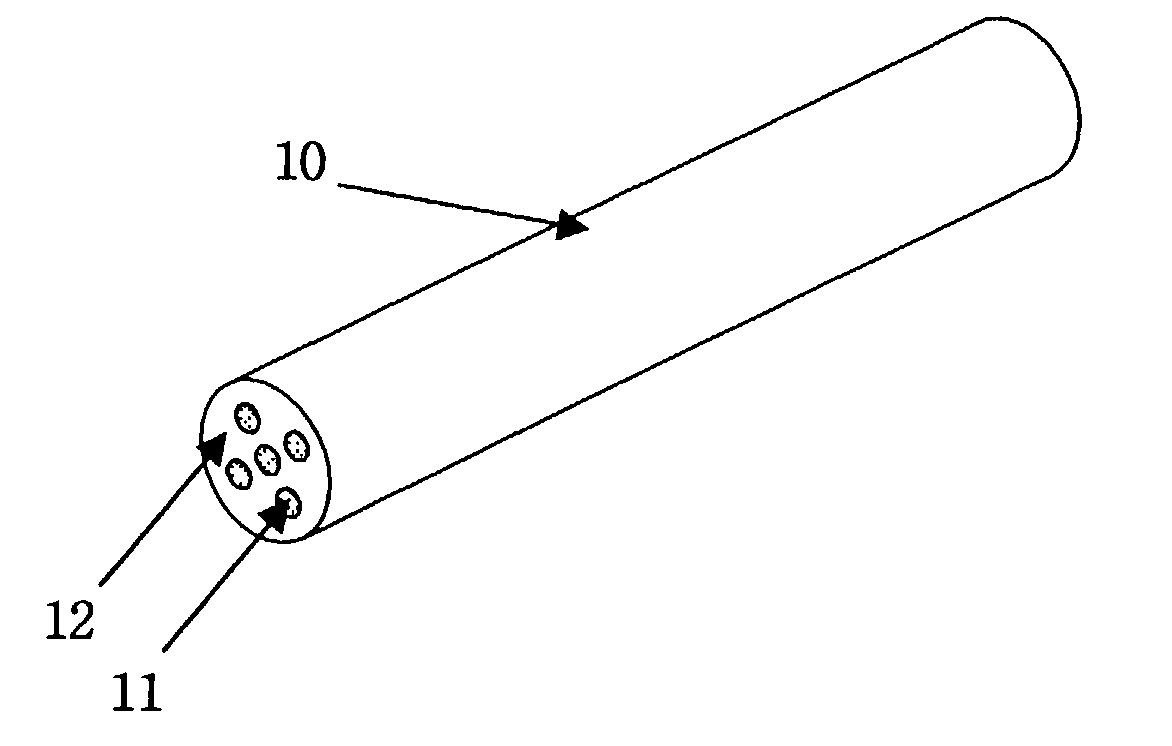

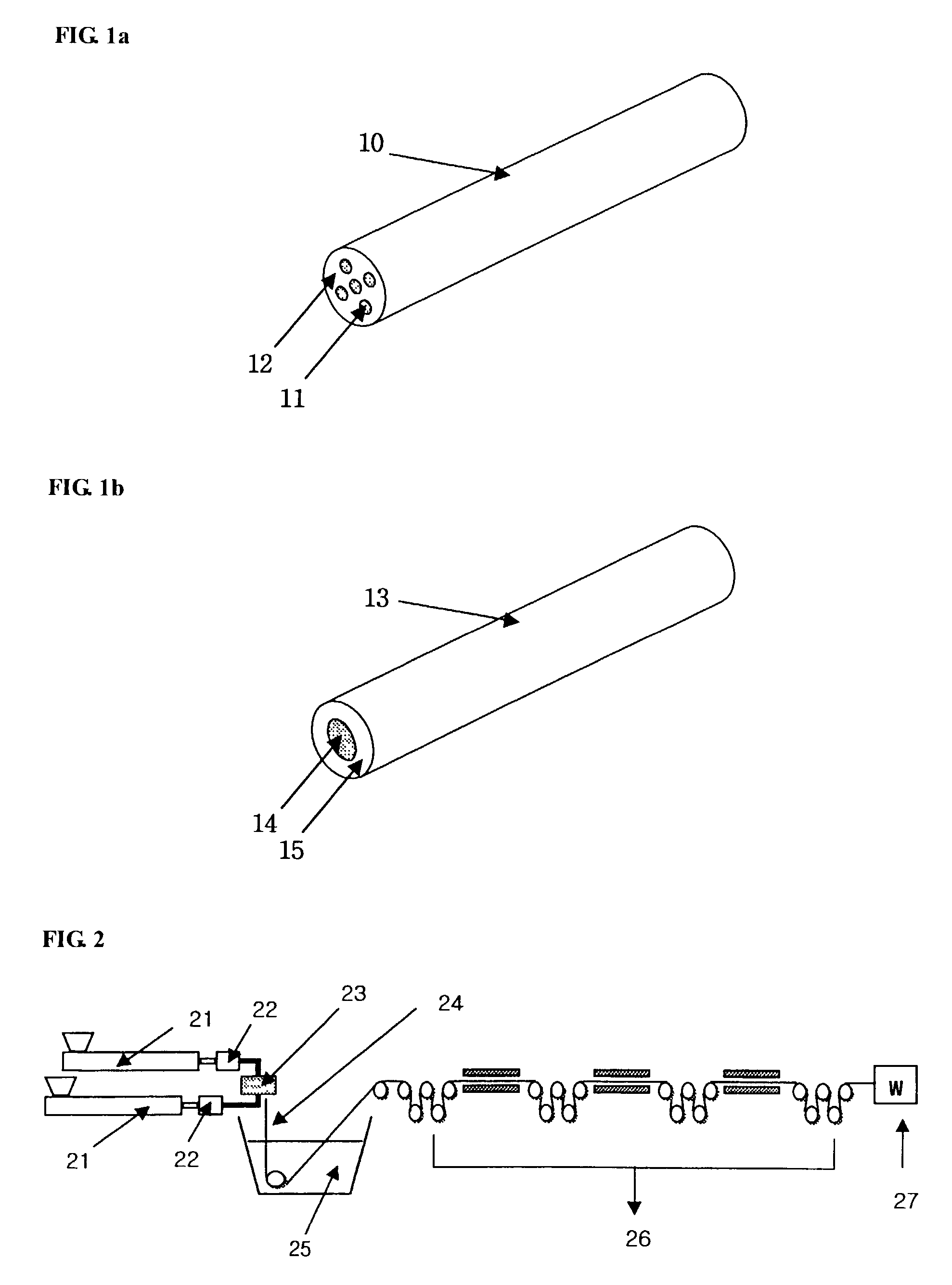

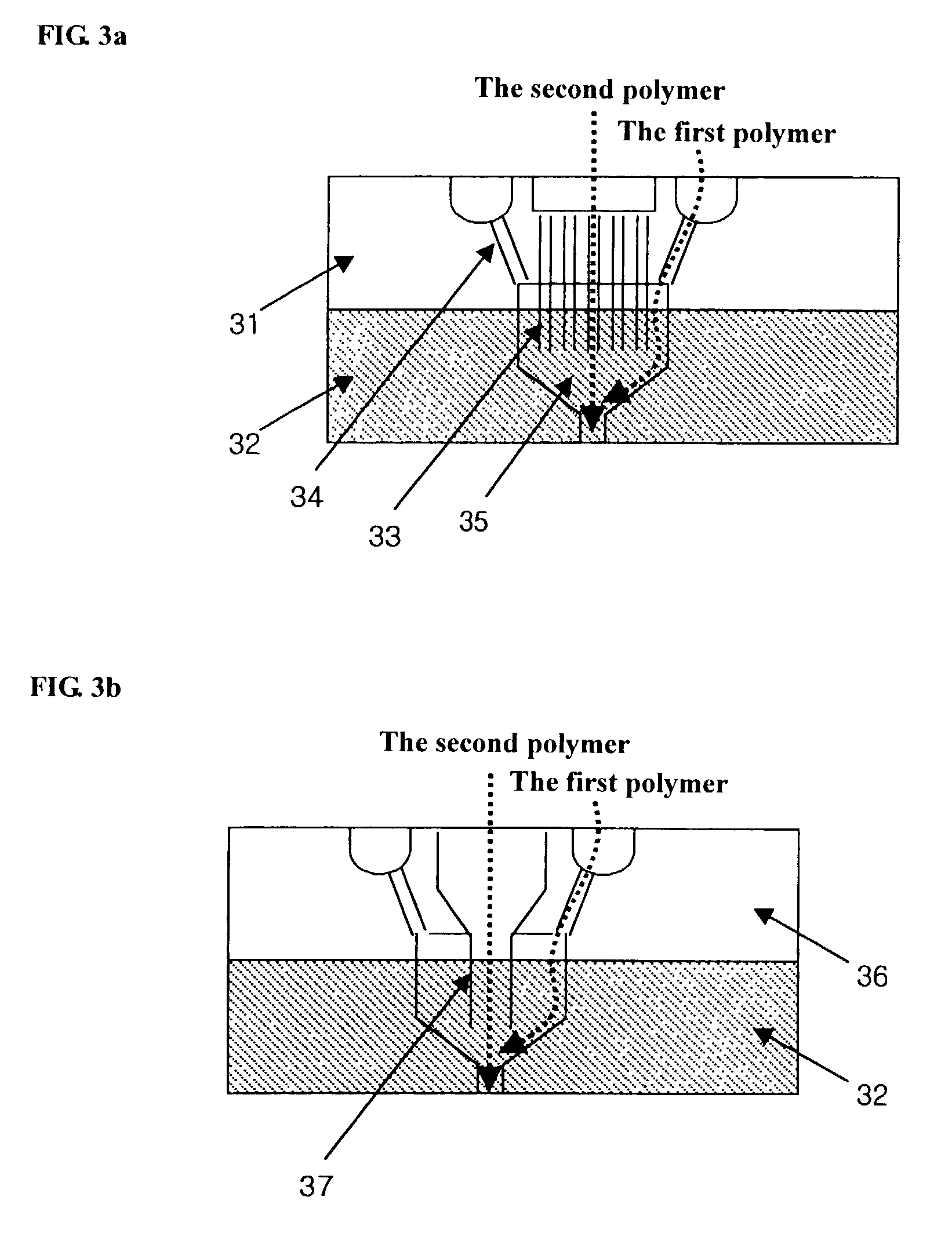

The present invention relates to a monofilament suture prepared by co-extruding polymers having different Young's moduli and to a process for preparing the same. The suture is prepared in such a form that a polymer having a high Young's modulus surrounds a polymer having a low Young's modulus. The monofilament suture prepared by the present invention has excellent knot security, flexibility and / or knot strength.

Owner:SAMYANG HLDG CORP

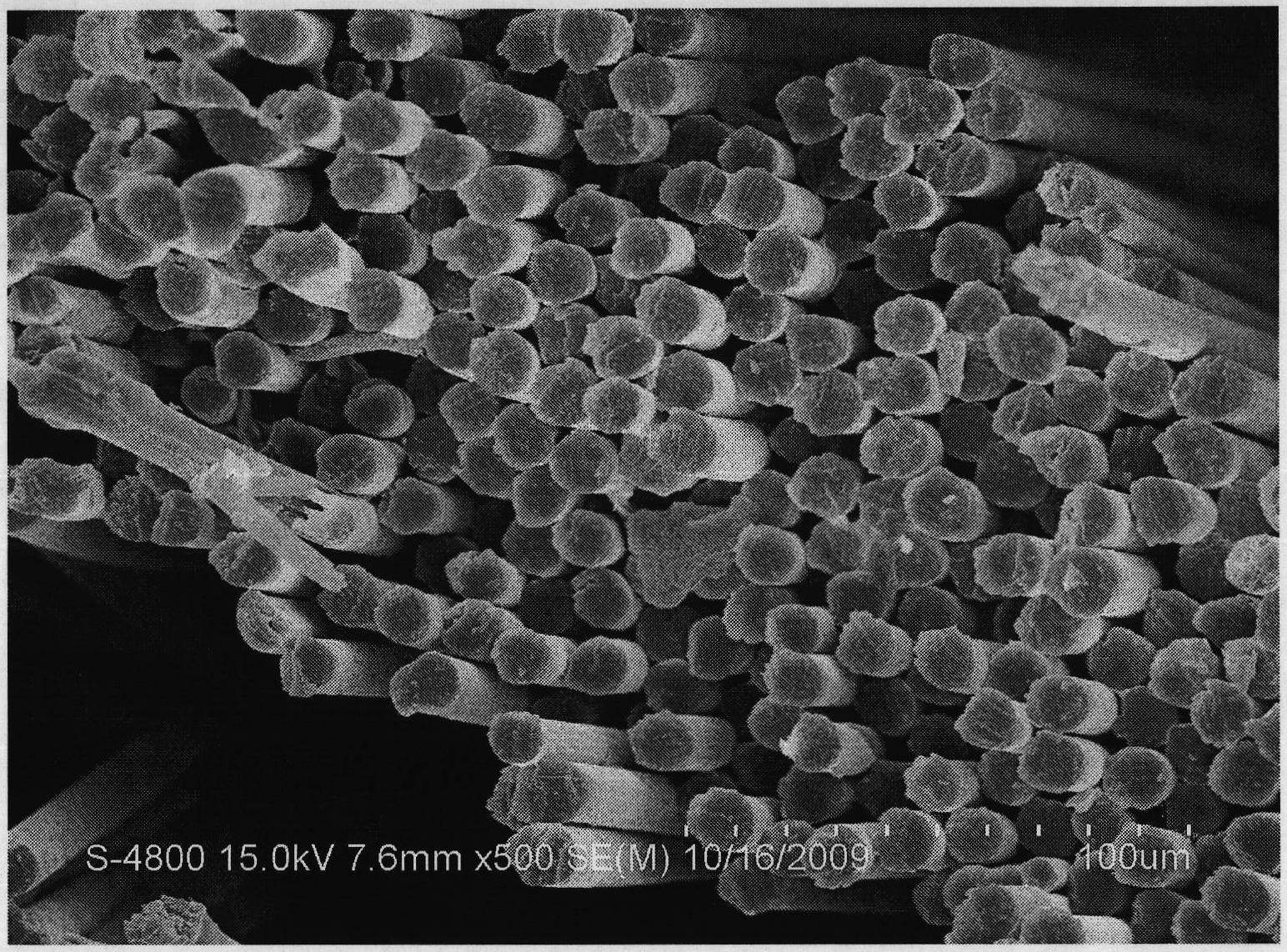

Lignin carbon nanofiber and preparation method thereof

ActiveCN101768799AImprove spinnabilityGuaranteed reliabilityFilament/thread formingFibre chemical featuresFiberCarbon fibers

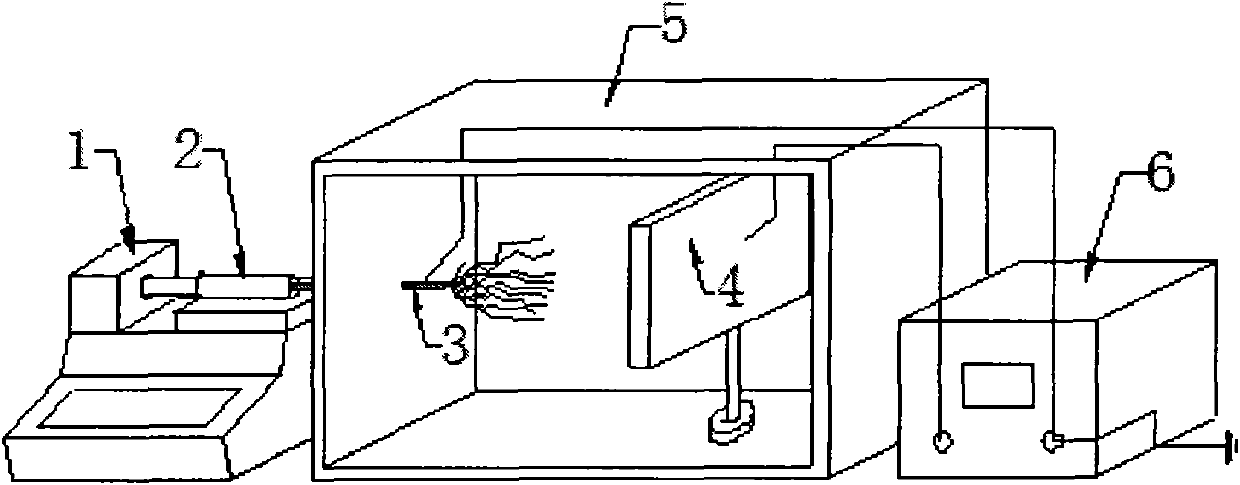

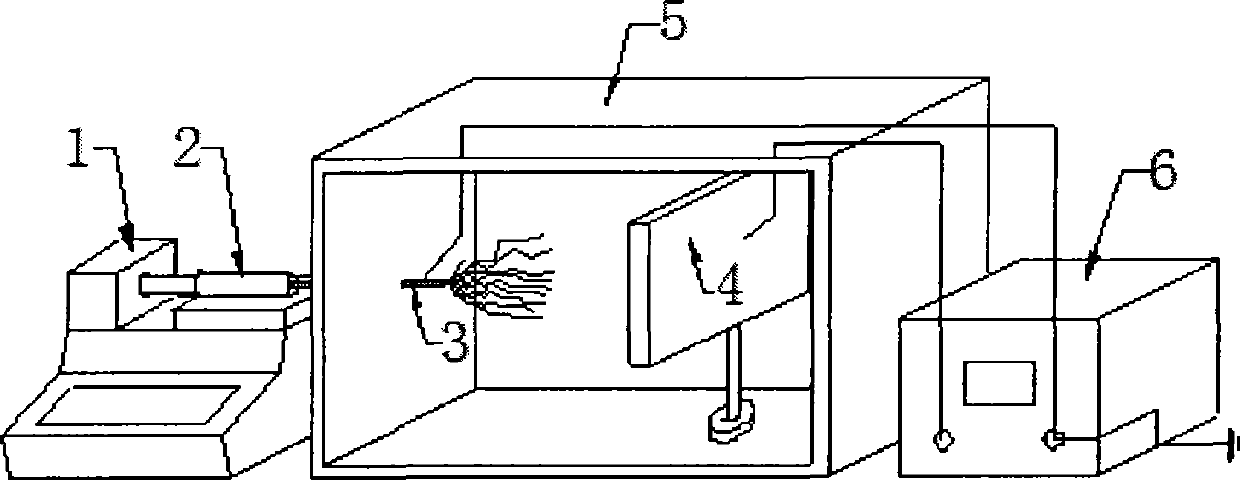

The invention discloses a lignin carbon nanofiber and a preparation method thereof, belonging to the field of materials. The preparation method comprises 5 steps of lignin pretreatment, preparation of spinning solution, electrostatic spinning, pre-oxidation and carbonization. The preparation method is characterized in that the lignin pretreatment means that lignin with the relative molecular mass within 5,000 to 50,000 is selected, and then the treatment of removing carbohydrate and inorganic salt is respectively carried out on alkali lignin and acetic acid lignin (or formic acid lignin). The diameter of the obtained carbon nanofiber is within 50 to 300nm and the length is within 1 to 10mum. As the obtained lignin has good spinnability, the nanofiber can be spun and further processed into the carbon nanofiber without synthetic macromolecules. In addition, the method adopts simple electrospinning equipment for electrospinning, the diameter of a spinning nozzle is large, the blockage cannot easily occur, and the working reliability of the spinning equipment is ensured.

Owner:SOUTH CHINA UNIV OF TECH

Sea-island typed conjugate multi filament comprising dope dyeing component and a process of preparing for the same

InactiveUS6838172B2Improve shrinkageImprove fastnessFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterYarn

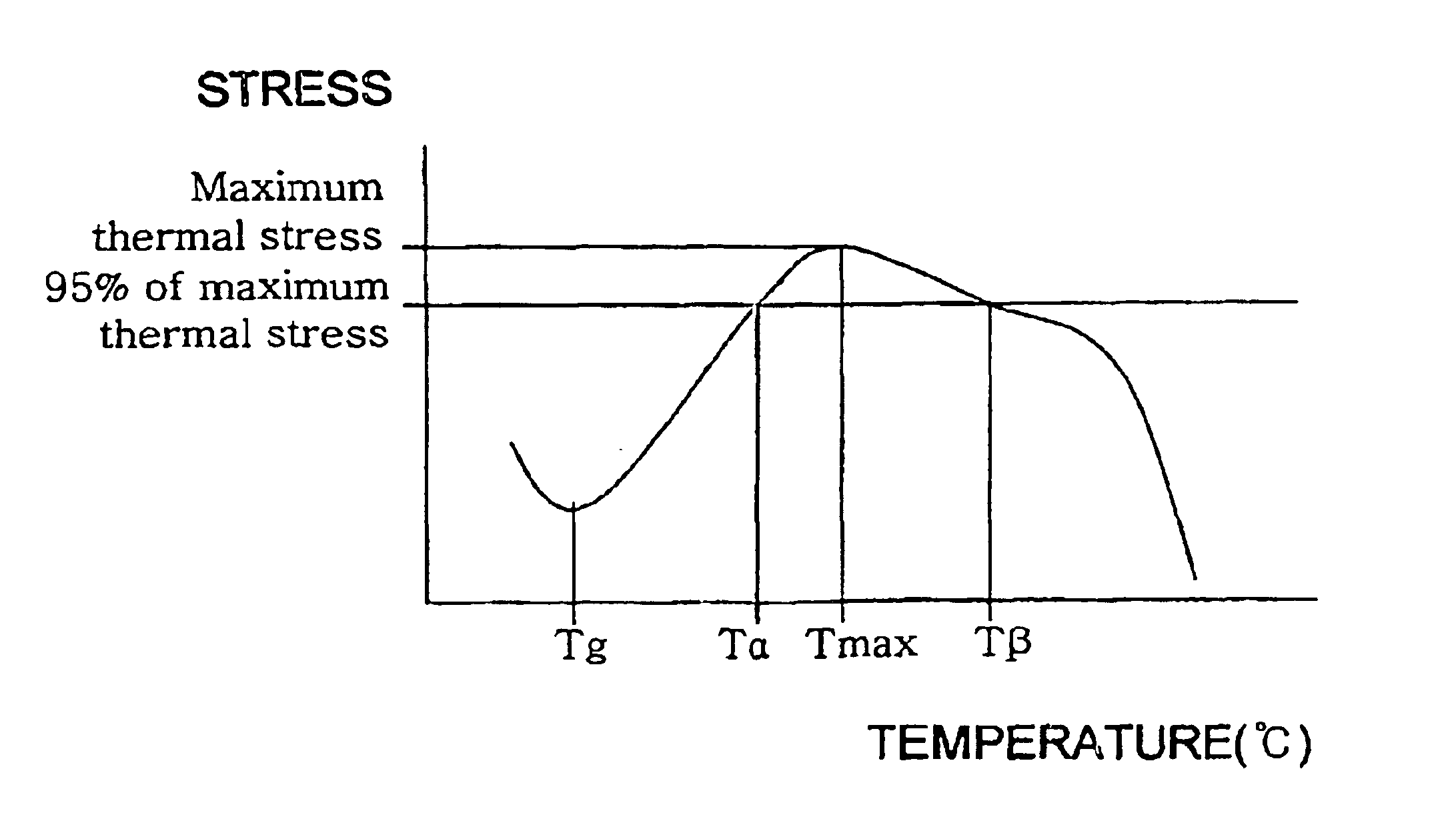

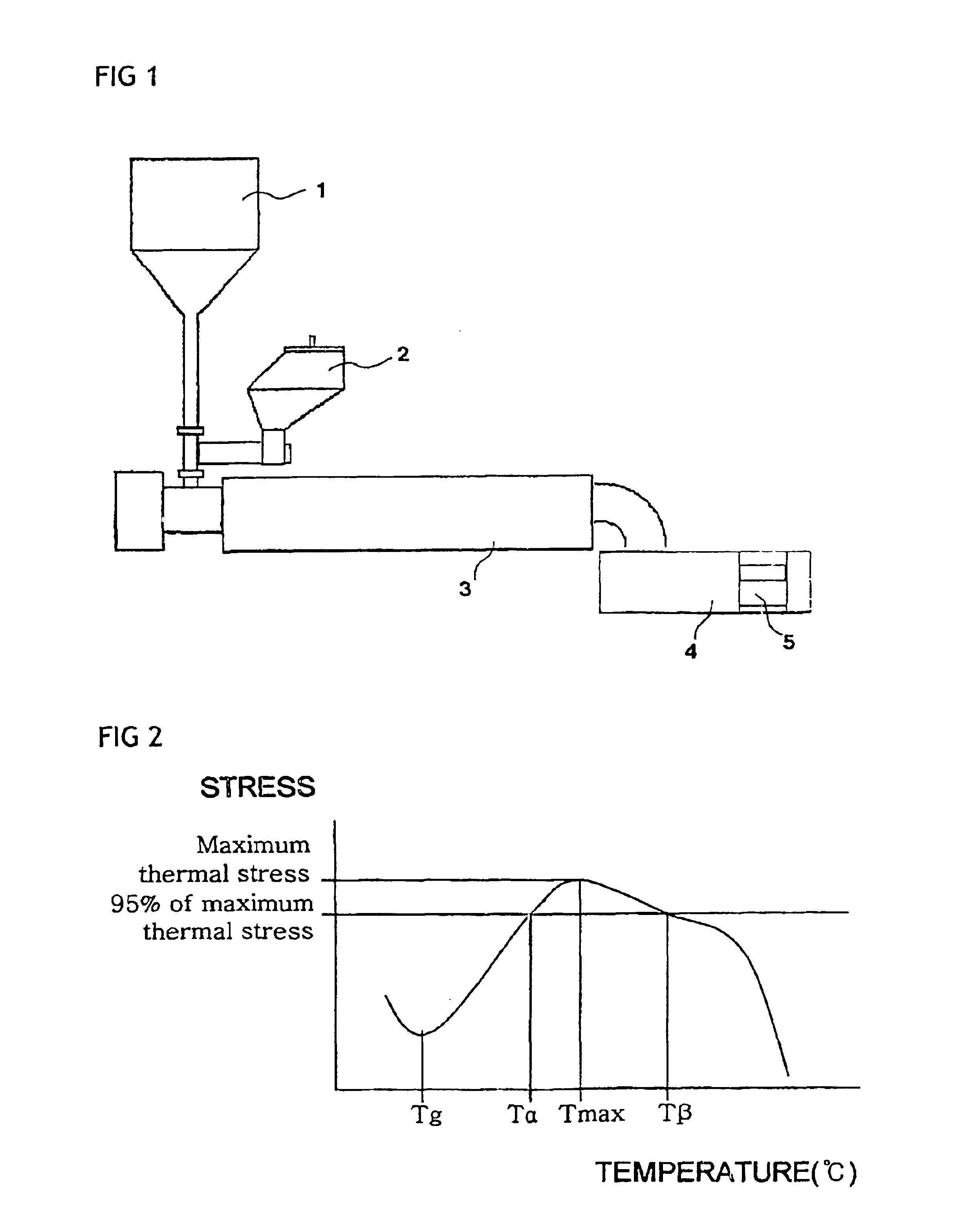

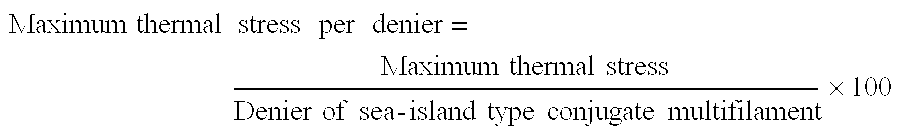

The present invention relates to a dope dyed sea-island type conjugate multifilament. In the dope dyed sea-island type conjugate multifilament, which comprises easy soluble polymer as a sea component and polyester as an island component, the island component contains a dope dyed component selected from the group consisting of carbon black, pigments and dyestuffs and the temperature range (Tα-Tβ) showing more than 95% of the maximum thermal stress of yarns is from 120° C. to 210° C. The dope dyed sea-island type conjugate multifilament of the present invention has an excellent thermal shrinkage property and excellent wash fastness and light fastness, and the dyeing process thereof can be omitted after producing a woven or knitted fabric because a dope dyed component is contained in the island component (ultra fine yarn). The dope dyed sea-island type conjugate multifilament of the present invention is useful as yarns for warp knit fabrics used in production of women's apparel.

Owner:KOLON IND INC

High-temperature resistant flame-retarding textile

The invention aims to provide high-temperature resistant flame-retarding textile. The high-temperature resistant flame-retarding textile is weaved by high-temperature resistant flame-retarding yarns, and the high-temperature resistant flame-retarding yarns are blended with preoxidized fibers, high tenacity flame-retarding fibers and common flame-retarding fibers; and conducting fibers can also be used to weave the high-temperature resistant flame-retarding textile when the high-temperature resistant flame-retarding textile is prepared. The high-temperature resistant flame-retarding textile overcomes the drawback that the preoxidized fiber is difficultly spun, low in tenacity and only has single color of blackness; and the high-temperature resistant flame-retarding textile also has the advantages of high high-temperature resistance, high tenacity, good wearing comfortability, rich color, proper price and safety and reliability for the human body and is reasonable high-temperature resistant flame-retarding textile.

Owner:汕头市奥山服饰有限公司

Graphene oxide/cellulose compound material as well as preparation method and application of same

ActiveCN102489259AImprove toughnessGood film formingOther chemical processesWater/sewage treatment by sorptionFiberCellulose compounds

The invention belongs to the field of material science and particularly relates to a graphene oxide / cellulose compound material as well as a preparation method and application of the material. The compound material is prepared by mixing graphene oxide suspension and alkaline solution of cellulose, and forming a compound structure of the graphene oxide and the cellulose under the action of mechanical stirring, shearing, ultrasonic or the like. In the preparation method, raw materials are cheap and easy to obtain, a water system is simple and free of pollution, equipment is simple and low in cost, and the industrial preparation is easy to realize; and the prepared compound material has the properties of fiber and the graphene oxide and is widely applied.

Owner:HENAN UNIVERSITY

Electrically conductive composite fibre containing carbon nanotube and method for making same

InactiveCN1840750AGood electrical propertiesIncreased durabilityFilament/thread formingArtifical filament manufactureFiberConductive polymer

The disclosed conductive composite fiber with carbon nano tube comprises a conductive core layer with 60~99.5wt% thermoplastic polymer, 0~5% carbon nano tube, 0~15% conductive carbon black, and 0.5~20% dispersant; and a shin layer with fiber-forming polymer. Wherein, the preparation method comprises mixing, extruding for granulation, and mixed spinning. This invention improves product performance.

Owner:DONGHUA UNIV

Antistatic, antibacterial and graphene-reinforced composite polyester fiber and preparation method thereof

InactiveCN103710790AGood spinnabilityGood electrical conductivityFilament/thread formingConjugated synthetic polymer artificial filamentsCvd grapheneChemistry

The invention provides an antistatic, antibacterial and graphene-reinforced composite polyester fiber, which is characterized in that the composite polyester fiber comprises a component A and a component B, wherein the component A is polyester excluding graphene, and the component B is polyester including 0.3-3.0wt% of graphene. The invention also provides a preparation method of the composite polyester fiber. The composite polyester fiber provided by the invention is low in cost, high in strength, and high in antistatic and antibacterial properties.

Owner:厦门翔鹭化纤股份有限公司

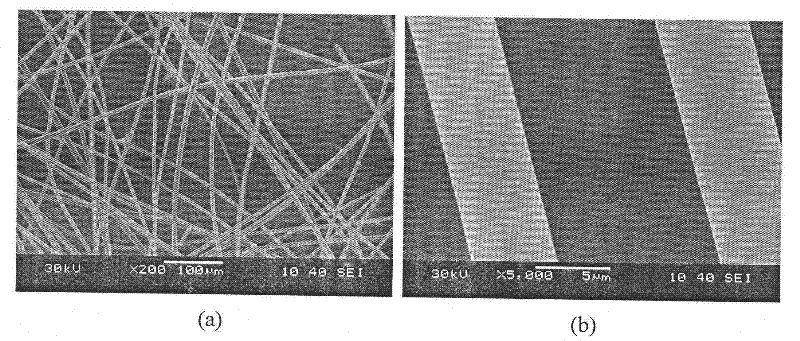

Method for preparing nitrogen-doped porous carbon nanofiber cloth

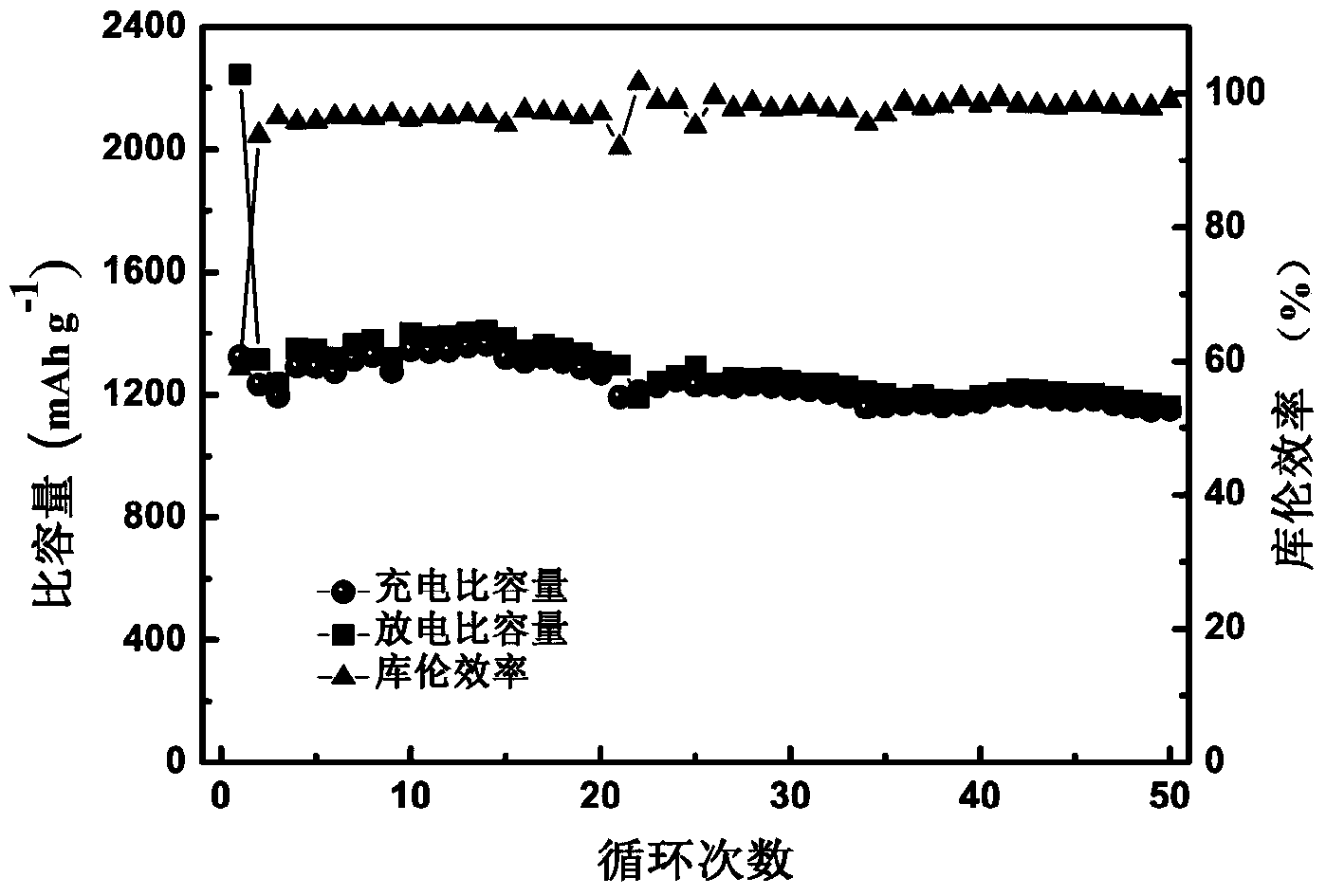

ActiveCN103855361ALow costGood spinnabilityMicroscopic fiber electrodesSecondary cellsLithium electrodeCarbon nanofiber

The invention relates to a method for preparing nitrogen-doped porous carbon nanofiber cloth. The nitrogen-doped porous carbon nanofiber cloth is prepared by adding a nitrogen-rich compound into an organic solution, electrospinning and subsequent carbonizing-activating, has a self-support structure, omits preparation steps of size mixing, coating and the like, needs no conductive agent or binder, and can be directly used as the negative electrode of a lithium ion battery. The electrochemical performance of the negative electrode material of the lithium ion battery is improved by doping nitrogen and activating and forming pores; compared with a commercial graphite lithium ion battery negative electrode material, the nitrogen doping porous carbon nanofiber cloth used as the negative electrode material of the lithium ion battery has simple steps for preparing the electrode, has higher specific capacity, good power performance and circulatory stability. The method also can be used as the electrode material of super capacitors and other novel batteries.

Owner:TSINGHUA UNIV

Method for preparing continuous polymerization directly-spun high-shrinkage polyester filaments

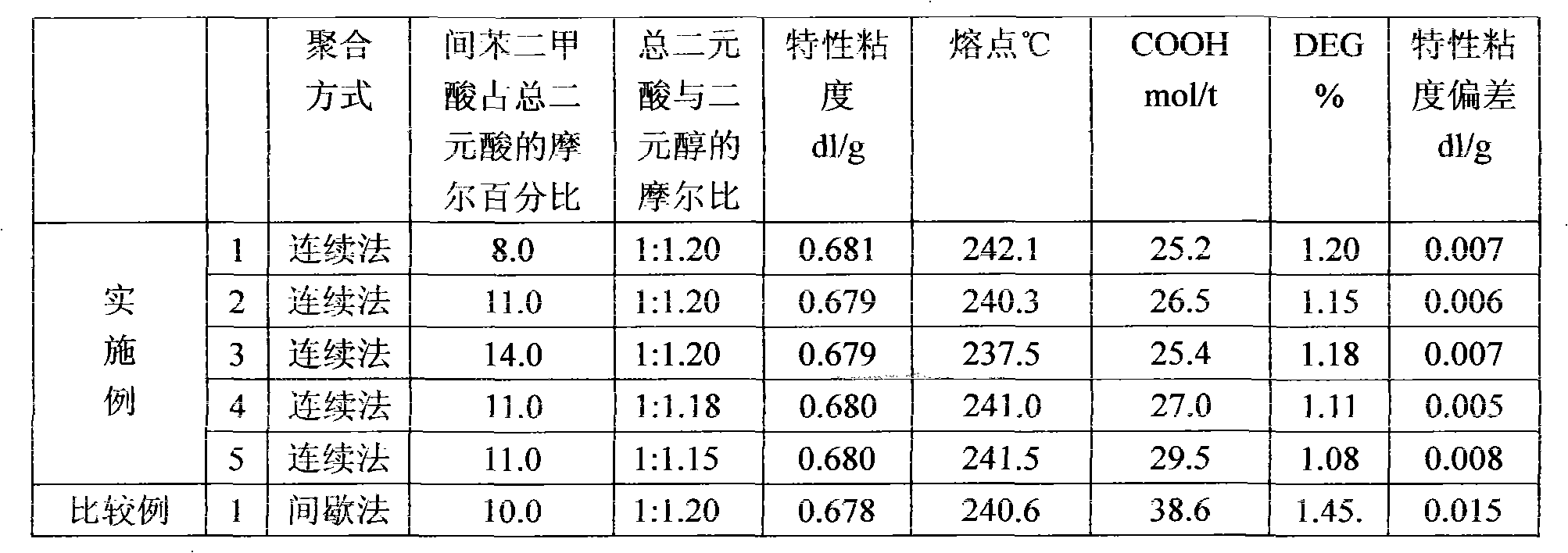

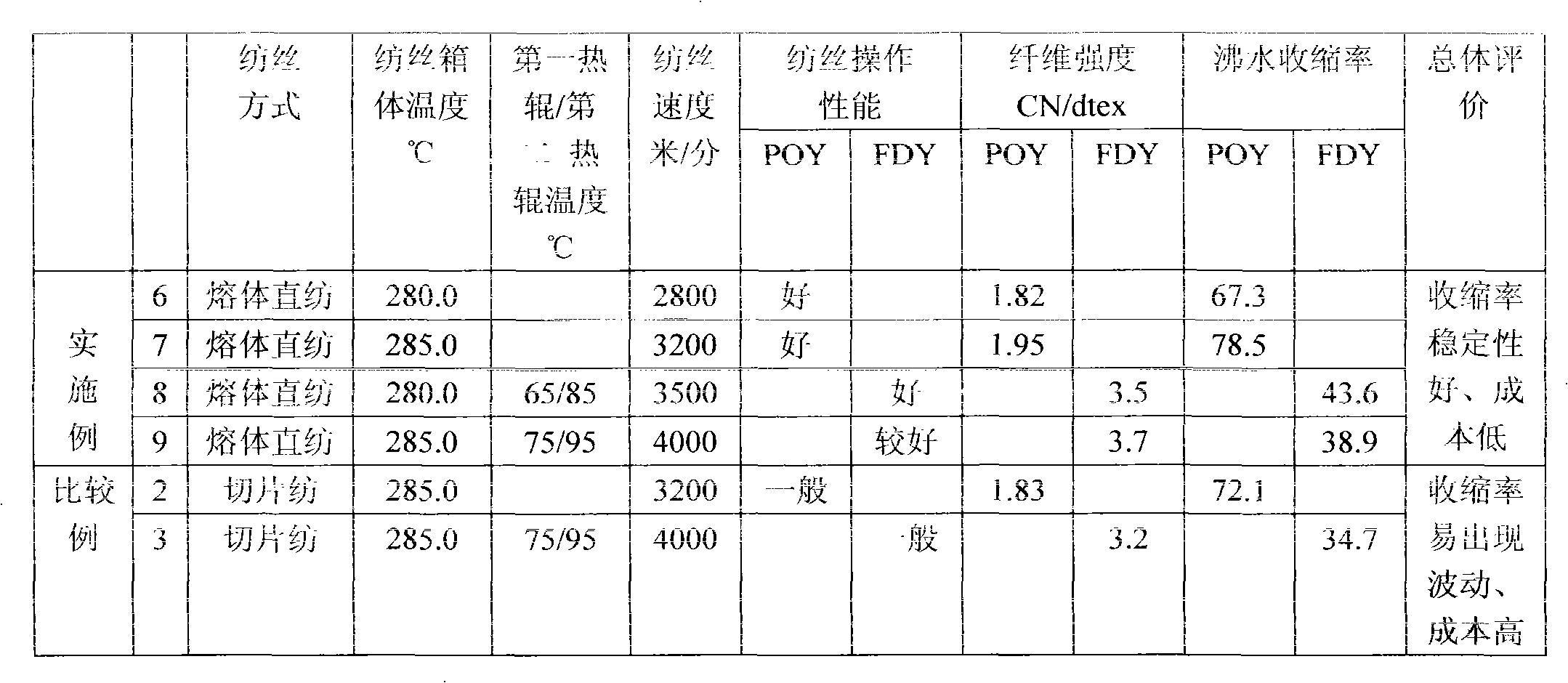

InactiveCN101787583AShrinkage stableShort processSpinning head liquid feederMonocomponent copolyesters artificial filamentYarnFiber

The invention discloses a method for preparing continuous polymerization directly-spun high-shrinkage polyester filaments, which comprises a process for preparing continuous polymerization modified copolyester melt and a process for preparing directly-spun cation-dyeable high-shrinkage polyester filaments. In the process for preparing the continuous polymerization modified copolyester melt, purified terephthalic acid, isophthalic acid and glycol monomers are taken as raw materials to prepare the modified copolyester melt; and the copolyester melt directly passes through a melt conveying piping equipment, and is metered, extruded, blown to be cooled, drawn for heat shaping, and wound to prepare one of high-shrinkage polyester preoriented yarns and high-shrinkage polyester drawn yarns. The method has the advantages of short flow, less working procedures, reasonable process, stable melt quality, and good spinning performance; and the prepared high-shrinkage fibers have good shrinkage stability and even dyeing, and the production cost is reduced obviously.

Owner:ZHEJIANG SCI-TECH UNIV +1

Modified polypropylene master batch, melt-blow cloth, preparation method and application thereof

InactiveCN107286473ALarge specific surface areaHigh conductivityFiltration separationNon-woven fabricsGraphene derivativesAntioxidant

The invention provides a modified polypropylene master batch, melt-blow cloth, a preparation method and an application thereof. The modified polypropylene master batch is mainly produced from, by weight, 77-90% of polypropylene, 5-20% of a graphene material and 1-5% of an additive. The graphene material includes any one or more of graphene, graphene oxide and graphene derivative. The additive includes any one or more of a coupling agent, a dispersant and an antioxidant and preferably includes the coupling agent, the dispersant and the antioxidant. The modified polypropylene master batch, when being used for manufacturing the melt-blow cloth, not only improves antibacterial and electrification property but also increases the filtering efficiency and dust capacity of the melt-blow cloth.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Method and equipment of preparing high performance zirconium oxide continuous fiber

InactiveCN1459418AGood effectHigh molecular weightInorganic material artificial filamentsZirconium oxidesFiberStructure and function

A process for preparing high-performance continuous fibre of zirconium oxide includes such steps as synthesizing acetylacetone-zirconium polymer as precursor from acetylacetone and zirconium oxychloride as main materials, dissolving in methanol to obtain the spinning solution, drying spinning to obtain continuous fibre of precursor, heat treating in a multifunctional sintering furnace by special atmosphere and high-temp. airflow spraying for stretching. Its advantages are high tensile strength (over 2.6 GPa) and long length up to several kilometers.

Owner:绍兴市圣诺超高温晶体纤维材料有限公司

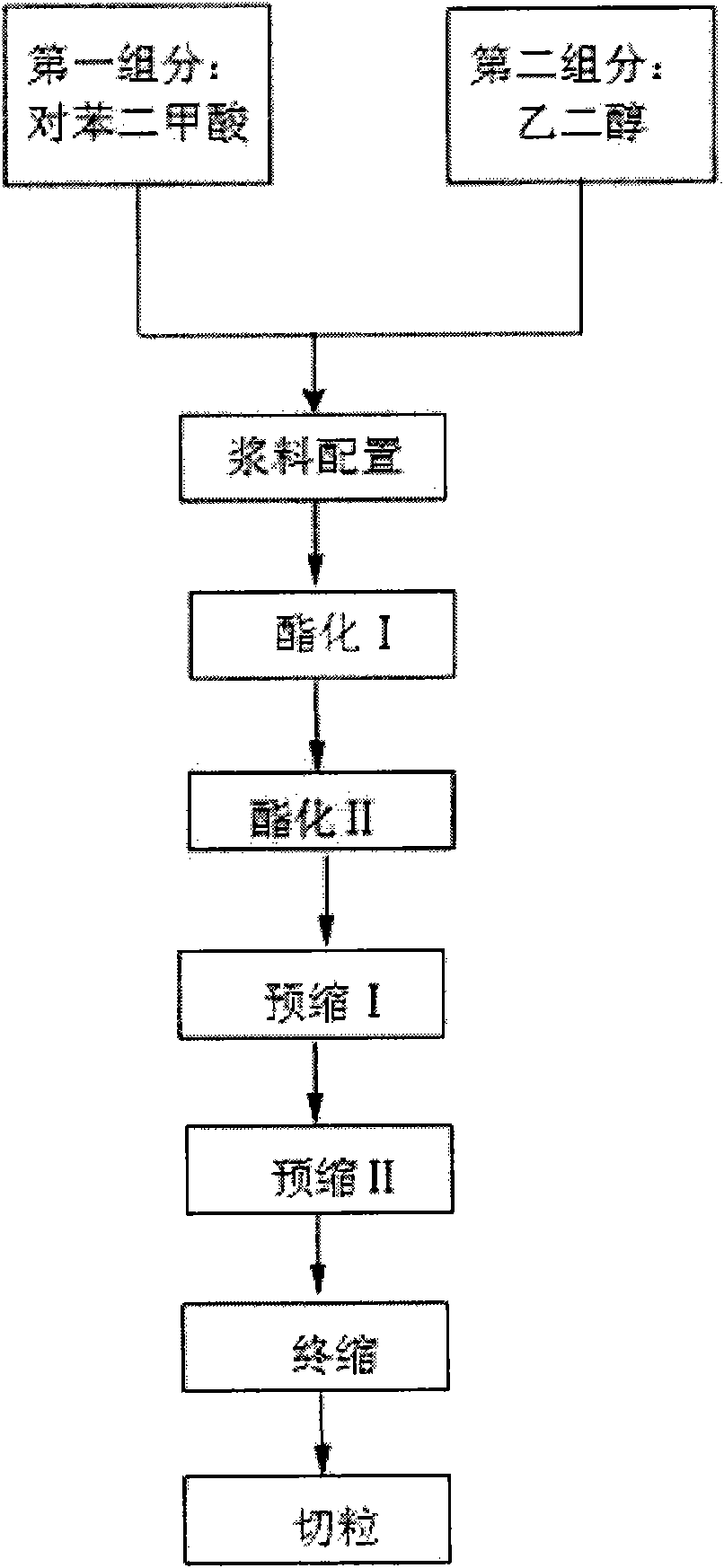

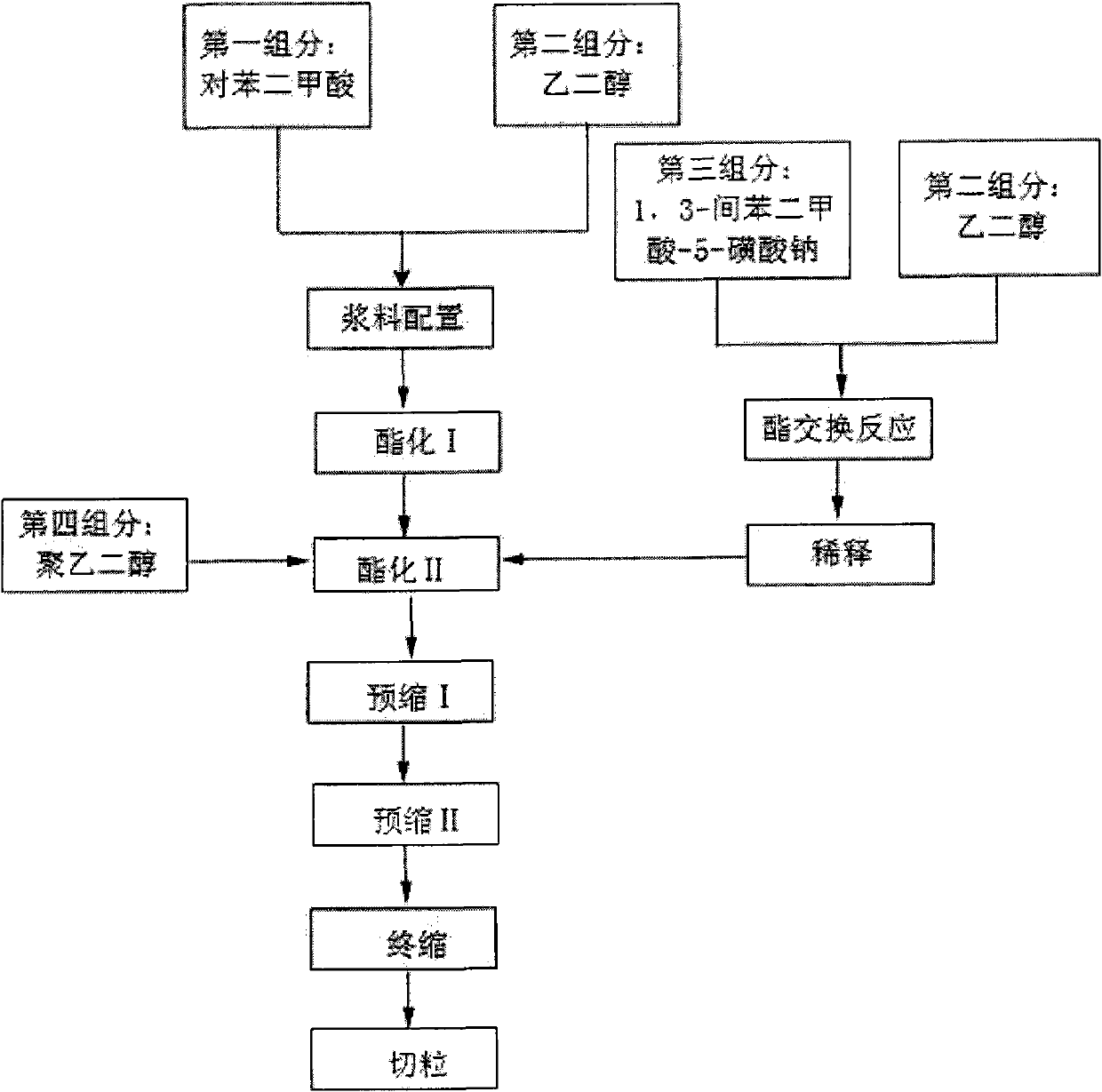

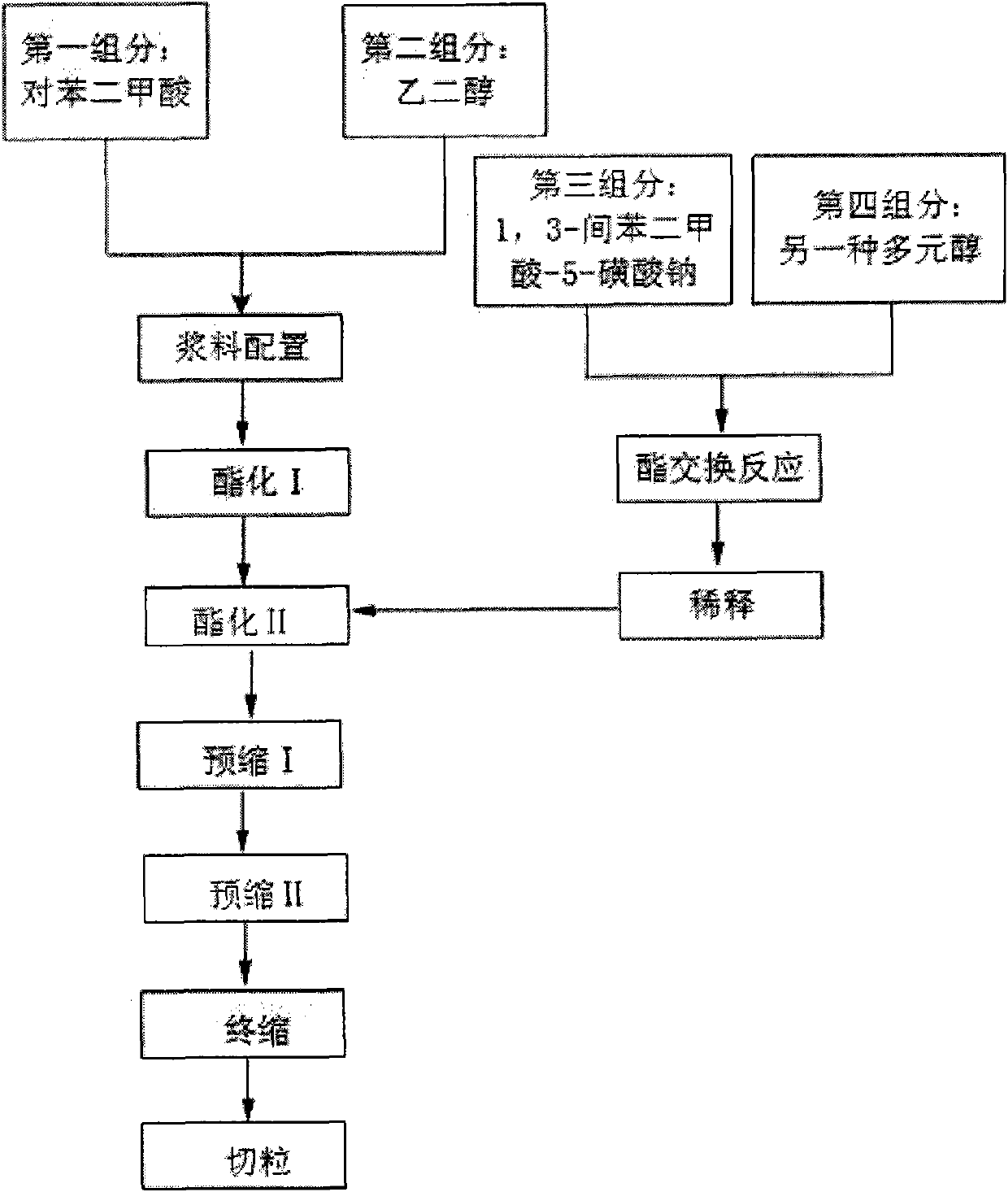

Preparation method of polyol copolyester

InactiveCN102086261AIncrease the chances of participating in a responseAchieve mass ratioDyeing processSlurryPhotochemistry

The invention discloses a preparation method of polyol copolyester. The preparation method comprises the following steps of carrying out slurry preparation, esterifying I, esterifying II, pre-condensing I, pre-condensing II, final condensing and pelletizing on terephthalic acid and glycol. The preparation method also comprises: carrying out ester exchange reaction on 1,3-isophthalic acid-5-sodium sulfonate and another polyol; diluting with the glycol, and then performing the esterifying II. In the preparation method, 1,3-isophthalic acid-5-sodium sulfonate and another polyol react in advance, thereby increasing the reaction probability of another polyol and ensuring that another poyol can reach the required mole ratio in a finished product. The preparation method is mainly applied to production of dye modified polyester by using various dihydric alcohols at normal temperature and normal pressure. The modified polyester is dyed by mainly using anode pigment, the used dye chromatograph is more than that of common polyester, dye-uptake rate can reach above 99%, colour fastness reaches 4-5 grade of European standard, and the color is more flamboyance and beautiful. When filament yarns are subjected to spinning, full-package rate is up to 95%-100%.

Owner:SHANGHAI DEFULUN CHEM FIBER

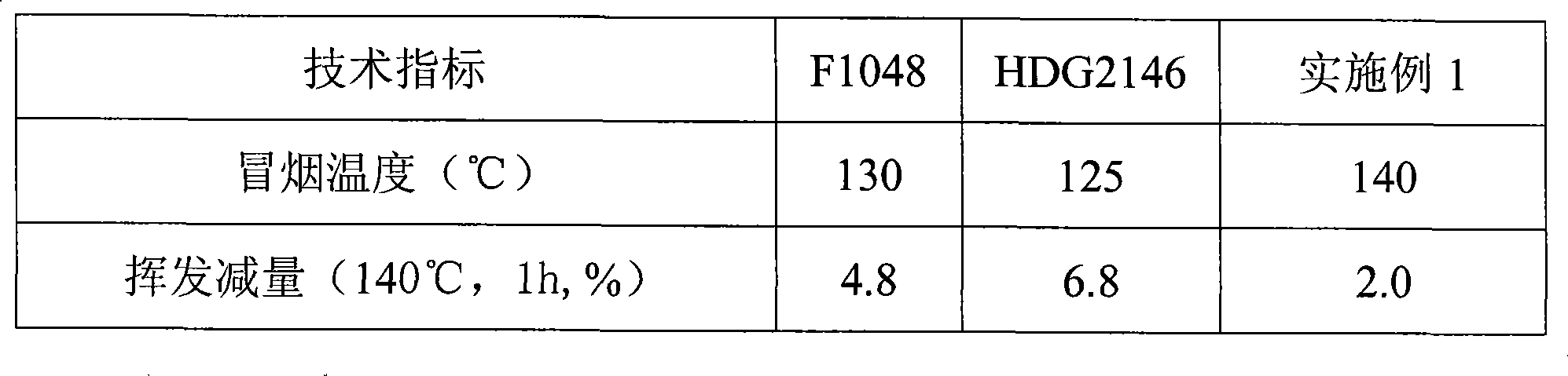

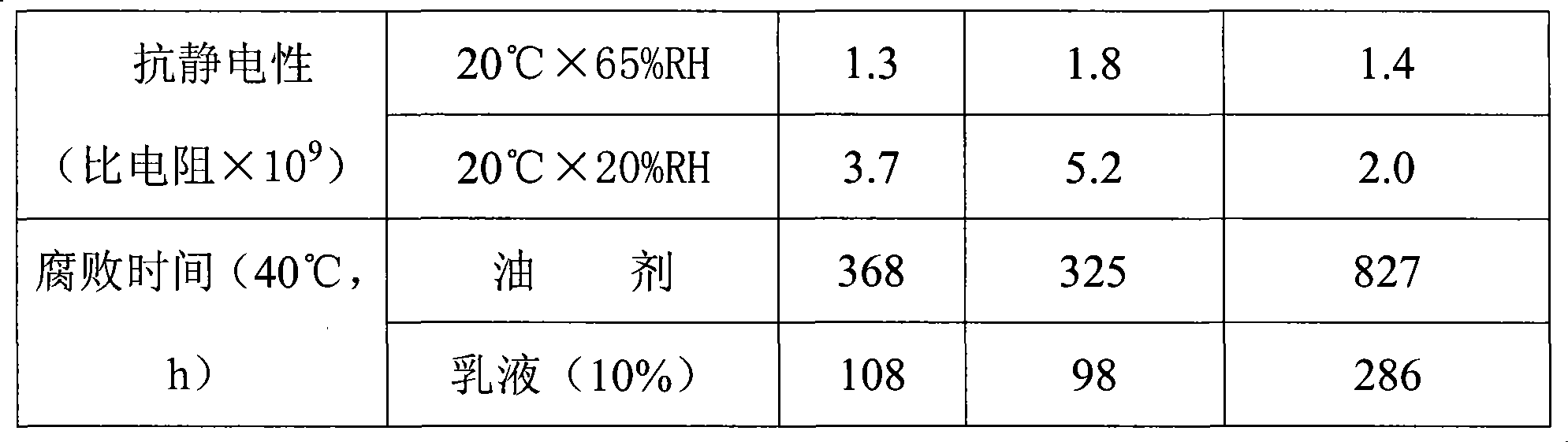

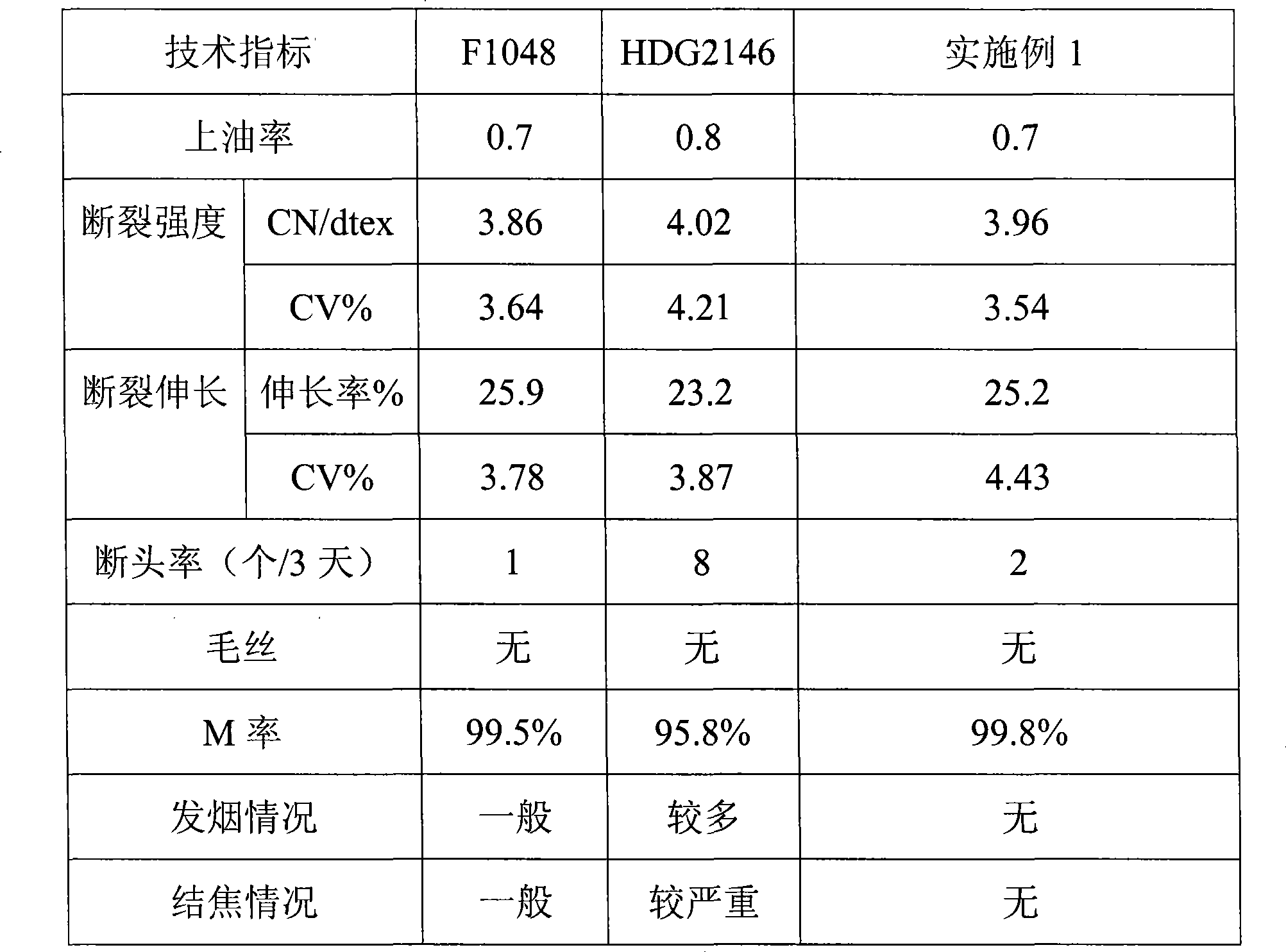

Terylene FDY oil and preparation method thereof

The invention discloses a polyester FDY oil agent and a preparation method thereof. The heat resistance of the existing oil agent is poor with serious volatilization, which results in heavy smog in the workshop and seriously affects the working environment and the body health of the workers; also the oil agent has serious coking phenomena and causes yarn waste and broken ends. The ingredients of the invention and the weight percentages are as follows: 55-65% of high-temperature smoothing agent, 15-25% environment-friendly emulsifying agent, 3-10% binder, 5-8% compound anti-static agent and the rest is additive; and the high-temperature smoothing agent contains special polyether. The invention has good heat resistance and is suitable for the high-speed spinning technique of various polyester fibers (including the high denier); and the oil agent provided by the invention does not generate smoke and does not coke on the hot roll.

Owner:HANGZHOU TRANSFAR CHEM LTD

Carpet Fiber Polymeric Blend

ActiveUS20080157425A1Improve fire resistanceImprove spinnabilityFlame-proof filament manufactureCeramic shaping apparatusYarnPolymer chemistry

The invention provides carpet fibers prepared from a blend of polymeric components, said fiber exhibiting improved properties, such as improved spinnability and improved fire resistance. The carpet fibers particularly comprise a majority of polytrimethylene terephthalate (PTT) and a minority of polyethylene terephthalate (PET). The invention further provides yarns and carpets prepared from the inventive fibers, said yarns and carpets likewise exhibiting improved properties. The invention also provides methods of improving various physical properties (such as fire resistance, spinnability, and elongation) of a polymeric composition.

Owner:ALADDIN MFG CORP

Zirconium oxide fabrics prepared from organic polyzirconium fore spinning solution by silk process

InactiveCN1584155AGood effectRaw materials are cheap and easy to getInorganic material artificial filamentsFuranSolvent

The manufacture method of a kind of zirconia fibre cotton relates to the field of resistance of fire fibre material. We compose van-style acetamide acetone zirconium polymer according to chloridze zirconia, acetamide acetone and three-ethylamine. We use methanol as the dilute impregnant, we mix round them to let hloridize zirconia, acetamide acetone and three-ethylamine react at 40-20 deg.C, and we can receive poly-acetamide acetone zirconium van-substance. Four-hydrogen furan filtrate and remove the outgrowth hydrochloric three-ethylamine. The offspring dissolve in the filature liquid made of methanol. After centrifugal swing, we can receive van-substance fibre. After we do special hear treatment, the zirconia fibre cotton we receive has the characteristic of good filature ability, high content of zirconium, equality andclarity and jarles capability. It can be used as industrial stove, roomage fusion stove, atomic energy reactor and the high temperature heat insulation material used in aviation and military. The material of the invention cost low, the method is easy, the impregnant can be recycled, the preparation of fibre cost low.

Owner:绍兴市圣诺超高温晶体纤维材料有限公司

Preparation method of nanometer carbon fiber material containing iron oxide

InactiveCN102634872ALow costImprove performanceElectro-spinningSpinning solutions preparationFiberCarbon fibers

The invention relates to a preparation method of a nanometer carbon fiber material containing iron oxides, which is characterized in that wood fiber resources are used as raw materials, and the method comprises the following steps: extracting lignin from wood fibers by a boiling process, removing impurities in the lignin by an organic solvent extraction method, mixing the purified lignin, high-molecular polymer, the organic solvent, and ferric acetylacetonate and dissolving, continuously injecting the mixed solution into a high pressure electrostatic spinning device, performing spinning to obtain nanometer fibers, finally preoxidizing the obtained nanometer fibers in air, and performing high temperature carbonization in the presence of protective gas to obtain the C / Fe3O4 nanometer fibers. The invention has cheap and easily available raw materials, a simple preparation process, easy operations, and good repeatability, and is easy to realize large scale production.

Owner:李翠花

Technology of preparing aluminium oxide based continuous fibers by sol-gel process

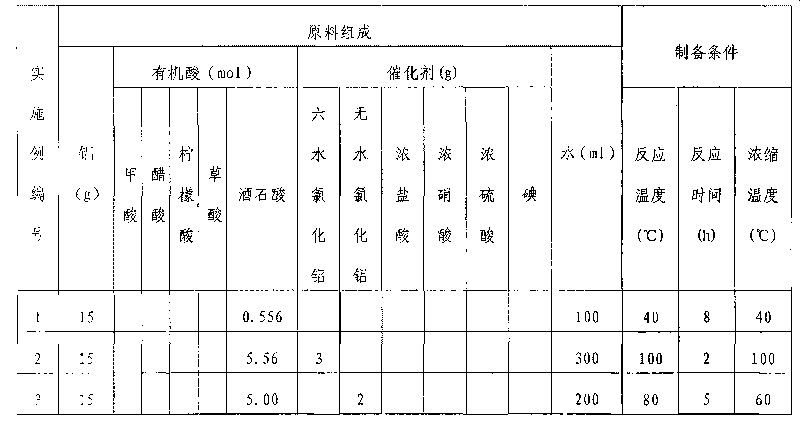

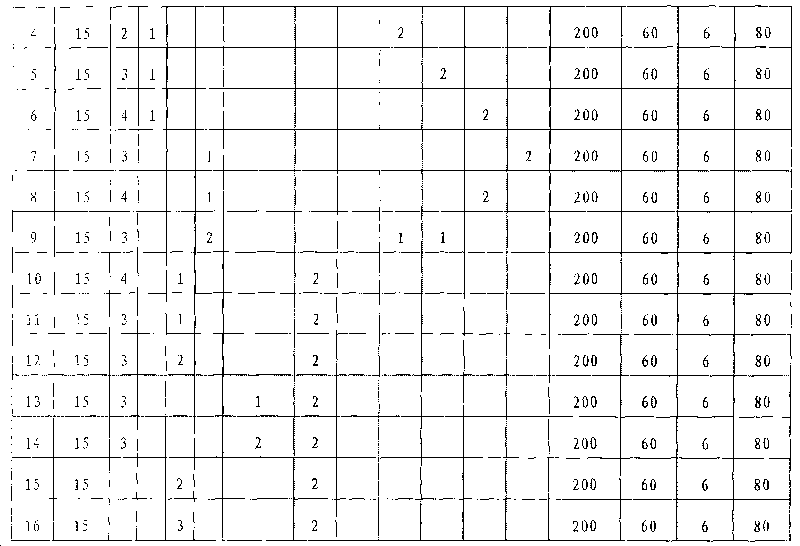

The invention discloses technology of preparing aluminium oxide based continuous fibers by a sol-gel process, which is characterized by adding one or more organic acid containing 1-8 carbon atoms into distilled water, adding aluminum powder and a catalyst after the mixture is evenly mixed and ensuring the mixture to react under the conditions of continuous stirring and reflux condensation under certain temperature to obtain transparent aluminum carboxylate solution; evaporating redundant organic acid in the aluminum carboxylate solution and then adding a solvent, a silicon-containing additive and a given quantity of spinning assistants to obtain precursor solution of aluminium oxide based fibers; concentrating the solution to obtain precursor sol of spinnable aluminium oxide based fibers; spinning by a dry or wet method to obtain aluminium oxide based continuous precursor fibers containing organics; and drying and sintering the precursor fibers to obtain the aluminium oxide based fibers. The aluminium oxide based continuous fibers prepared by the technology can be used in reinforcement in the composite, further improve the strength, ductility and heat resistance of the material and are widely applied in the fields of aerospace, automobile and the like.

Owner:XI AN JIAOTONG UNIV

Modified polylactic acid fiber and preparation method thereof

ActiveCN103225125ASave raw materialsRich sourcesMelt spinning methodsMonocomponent polyesters artificial filamentEnvironmental resistanceCellulose diacetate

The invention discloses a modified polylactic acid fiber and a preparation method thereof. The modified polylactic acid fiber is prepared through blending polylactic acid, a cellulose derivative, a cellulose diacetate grafted polylactic acid copolymer, a lubricant, inorganic nanoparticles, a nucleating agent and an antioxidant. The preparation method comprises the following steps: adding partial polylactic acid slices and all other raw materials to a high speed mixer according to a mass component ratio, carrying out high speed dispersion, and carrying out melt blending and extrusion through a double screw extruder to obtain modified polylactic acid master batch slices; and carrying out dry mixing of the modified polylactic acid master batch slices and residual polylactic acid slices in the high speed mixer, carrying out melt spinning through a melt spinning machine, and stretching to obtain the modified polylactic acid fiber. The prepared polylactic acid fiber has the advantages of low cost, complete biodegradation, environmental protection, good spinning performance, stable filament bundle quality, excellent flexibility, excellent antifriction, excellent dyeing property and excellent comfortableness, and is a very good high-performance environmentally-friendly fiber material. The preparation method has the advantages of simplicity, low equipment requirement, and environmental protection in the production process, and is in favor of the industrialized production.

Owner:长沙乐远化工科技有限公司

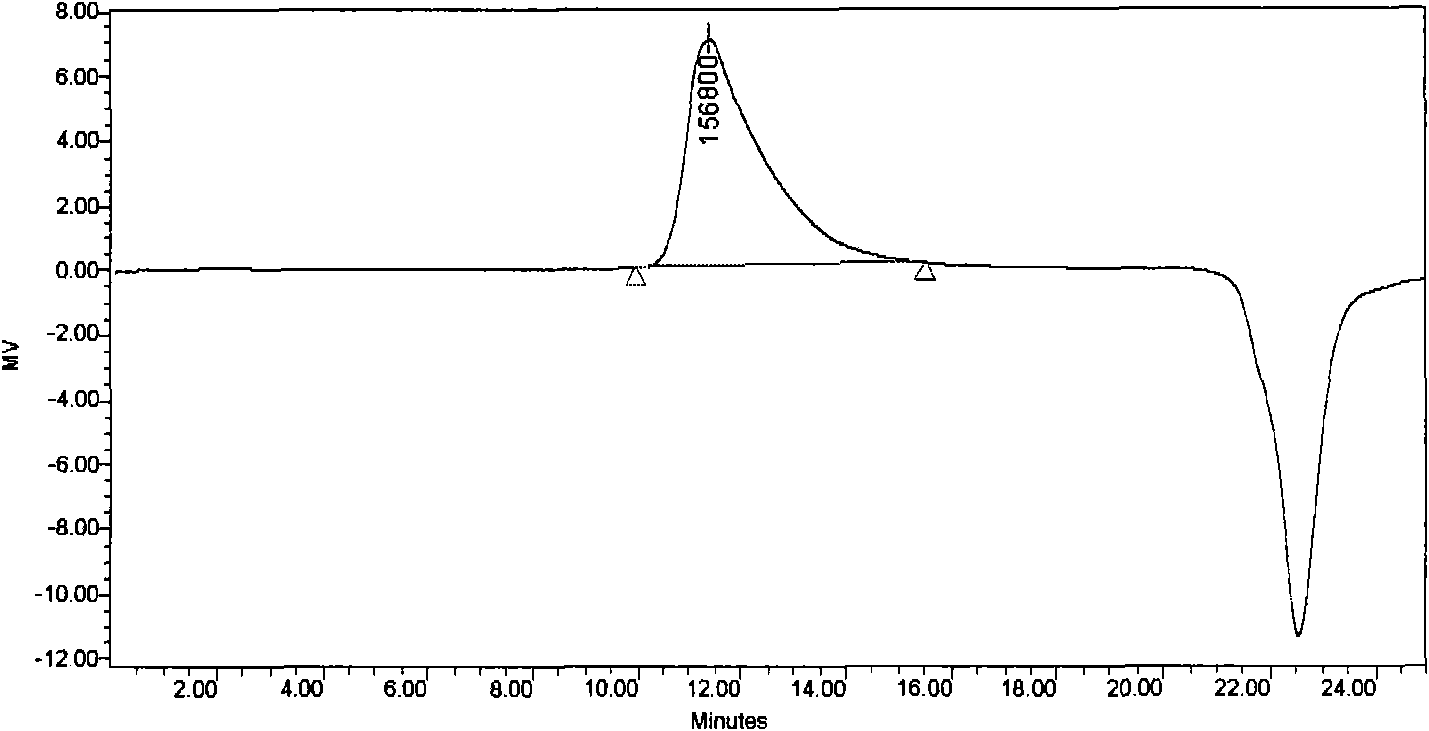

Process for preparing water-soluble copolyester

The water soluble copolyester is prepared with polytetrahydrofuran in number average molecular weight of 350-20000 as the fourth component, and metaphthalate-5-sodium sulfonate, metaphthalate dihydroxyethyl-5-sodium sulfonate, metaphthalate dimethyl-5-potassium sulfonate, or other metaphthalate type sulfonate as the third component, and through polycondensation in PTA or DMT path. Compared with the copolyester with polyglycol and other aliphatic flexible compound as the fourth component, the present invention is water soluble and has better crystallizing performance. The product produces no adhesion during drying, and may be blended with conventional polyester slice to obtain POY sea island cotton with flexible elastic process to raise the spinnability and processibility of sea island fiber.

Owner:SINOPEC YIZHENG CHEM FIBER

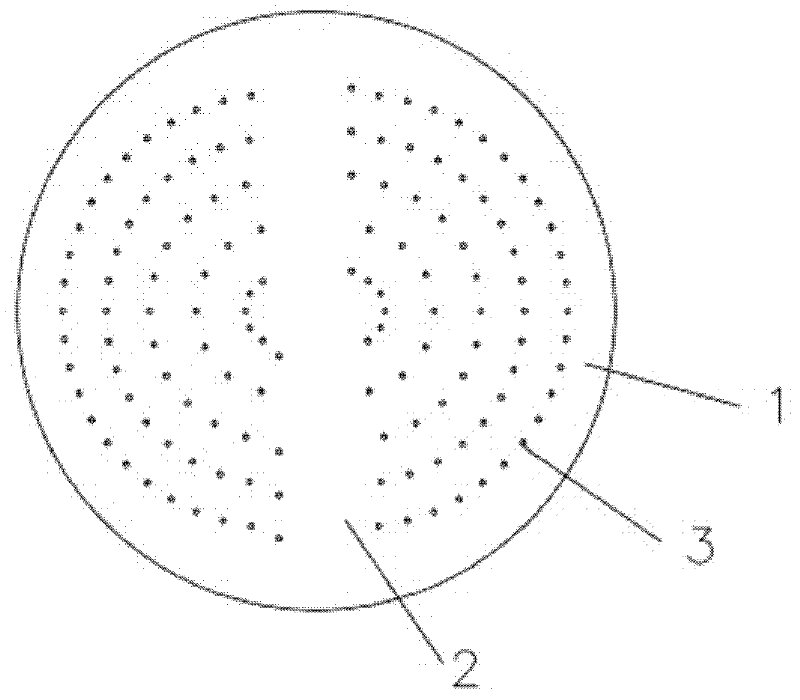

Method for preparing thin-diameter zirconium oxide fibers and fiber board thereof

ActiveCN102181962ALow costHigh purityFibreboardInorganic material artificial filamentsYttriumAdhesive

The invention relates to a method for preparing thin-diameter zirconium oxide fibers and a fiber board thereof. The method comprises the following steps of: preparing poly zirconium sol spinning solution by adopting basic zirconium carbonate, glacial acetic acid, water and yttrium nitrate as raw materials, obtaining thin-diameter poly zirconium sol fibers by ultrahigh-speed centrifugal swinging and high-speed hot airflow blowing and drafting, and performing thermal treatment and sintering on the thin-diameter poly zirconium sol fibers to obtain the thin-diameter zirconium oxide fibers; and performing vacuum suction molding and pressure leveling to prepare a wet fiber board blank by adopting the thin-diameter zirconium oxide fibers as a raw material and adopting poly zirconium sol spinningsolution diluted by adding water as adhesive, and drying and calcining the wet blank to obtain the zirconium oxide fiber board. The raw materials are easily obtained, the preparation of the adhesive is simple and convenient, and the method has low cost and no pollution and is suitable for large-batch industrialized production; the prepared thin-diameter zirconium oxide fibers have good bending flexibility; and the prepared zirconium oxide fiber board has uniform thickness, flat surface, accurate and controllable thickness, and good mechanical property and high-temperature bending resistance.

Owner:南京理工宇龙新材料科技股份有限公司

Polyester POY spinning finish and production method thereof

The invention discloses a polyester POY spinning finish, comprising 81-88% of lubricating agent, 3-5% of emulsifying agent, 4-7% of tow collecting agent, 3-5% of antistatic agent and 2-4% of additive by weight. The invention also discloses a production method of the polyester POY spinning finish. The product not only can endow the fibers with good processability but also is environment-friendly, overcomes the phenomenon that the finish corrodes equipment and can ideally solve the problem of easy cohesion on guide rolls during apparent cohesion and reduce fluff and broken yarns.

Owner:绍兴市上虞皇马化学有限公司

Artificial leather sheet substrate and production method thereof

InactiveUS20050118394A1Improving entangling stateImprove propertiesLayered productsFibre treatmentHigh densityEngineering

The artificial leather sheet substrates of the invention comprise a united laminate structure of a nonwoven fabric layer A and a knitted or woven fabric layer B and an elastic polymer C impregnated into the united laminate structure. The nonwoven fabric layer A and the knitted or woven fabric layer B are strongly bonded to each other by entanglement. A portion of the microfine fibers constituting the knitted or woven fabric layer B are exposed to the outer surface of the nonwoven fabric layer A. Therefore, the artificial leather sheet substrates exhibit excellent mechanical properties such as resistance to tear stress. Having a high density as compared with conventional artificial leathers, the artificial leather sheet substrates have feel and densified feel similar to those of natural leathers.

Owner:KURARAY CO LTD

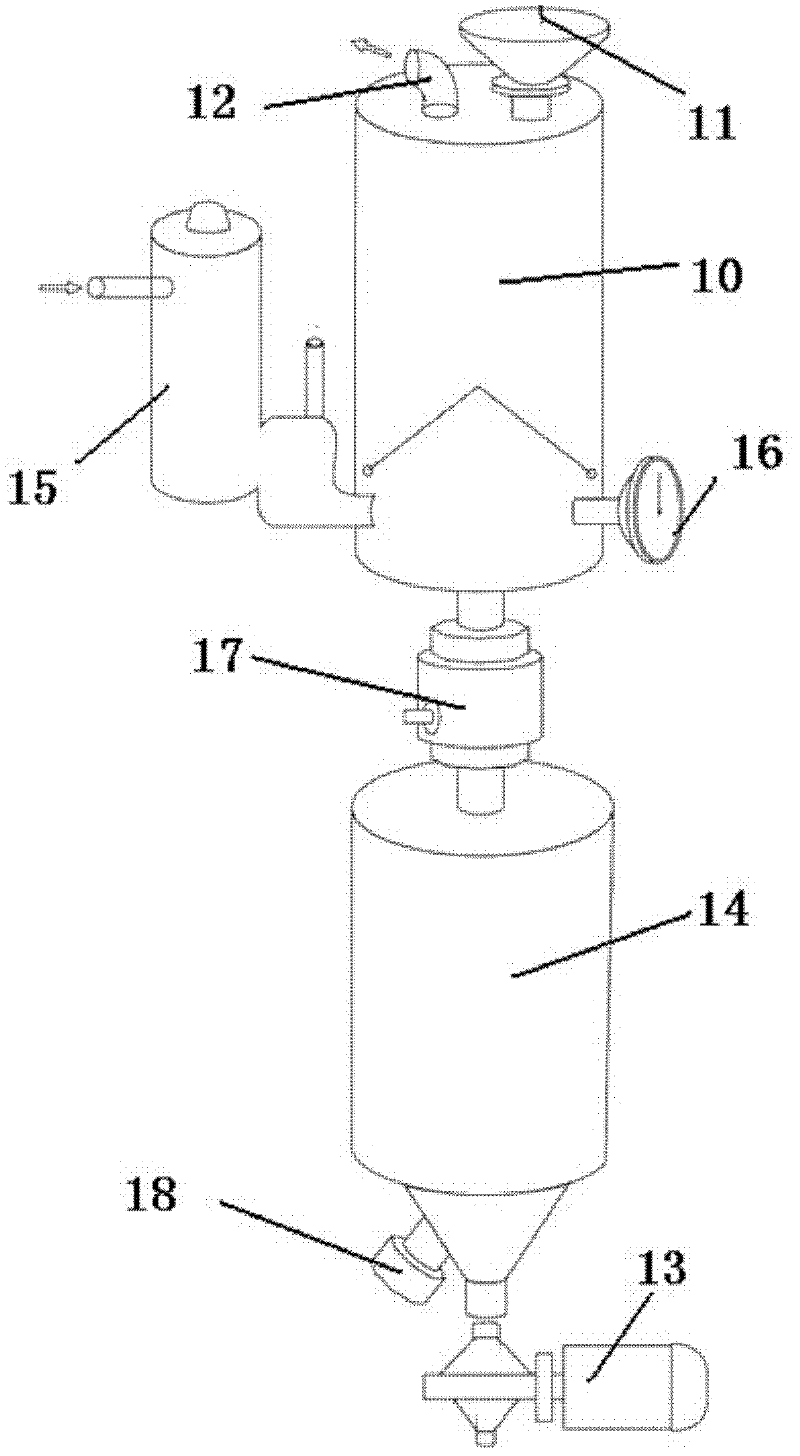

Production method of fine-denier porous POY black yarn

InactiveCN102443859AImprove spinnabilityReduced stabilitySpinnerette packsMelt spinning methodsProduction rateYarn

The invention discloses a production method of a fine-denier porous POY black yarn. The method comprises the following steps of: drying semi-dull slices, drying black masterbatch, adding the slices and the black masterbatch material into a screw extruder, fusing the added materials in the screw extruder, respectively processing the fused materials in a metering pump and a spinning beam, spinning on a pack, cooling the materials by lateral blowing, applying oil on strands, processing the strands in draw-off godets GR1 and GR2, winding and shaping, and inspecting products. The method is characterized in that the step of drying the black masterbatch comprises the following sub-steps of: based on a continuous drying mode, firstly, adding the black masterbatch into a crystallization and drying tank, introducing heated dry air from the lower part of the crystallization and drying tank, and blowing out the heated dry air from the top of the crystallization and drying tank so as to dry the black masterbatch, wherein the drying time is 2 hours, the dried black masterbatch falls into an intermediate material storage bin for storage under the crystallization and drying tank, and the black masterbatch is further injected by a masterbatch injector under the intermediate material storage bin. The production method of the fine-denier porous POY black yarn has high masterbatch spinnability and better cooling effect, and can improve the oil application uniformity of spinning cakes and the productivity.

Owner:桐乡市中洲化纤有限责任公司

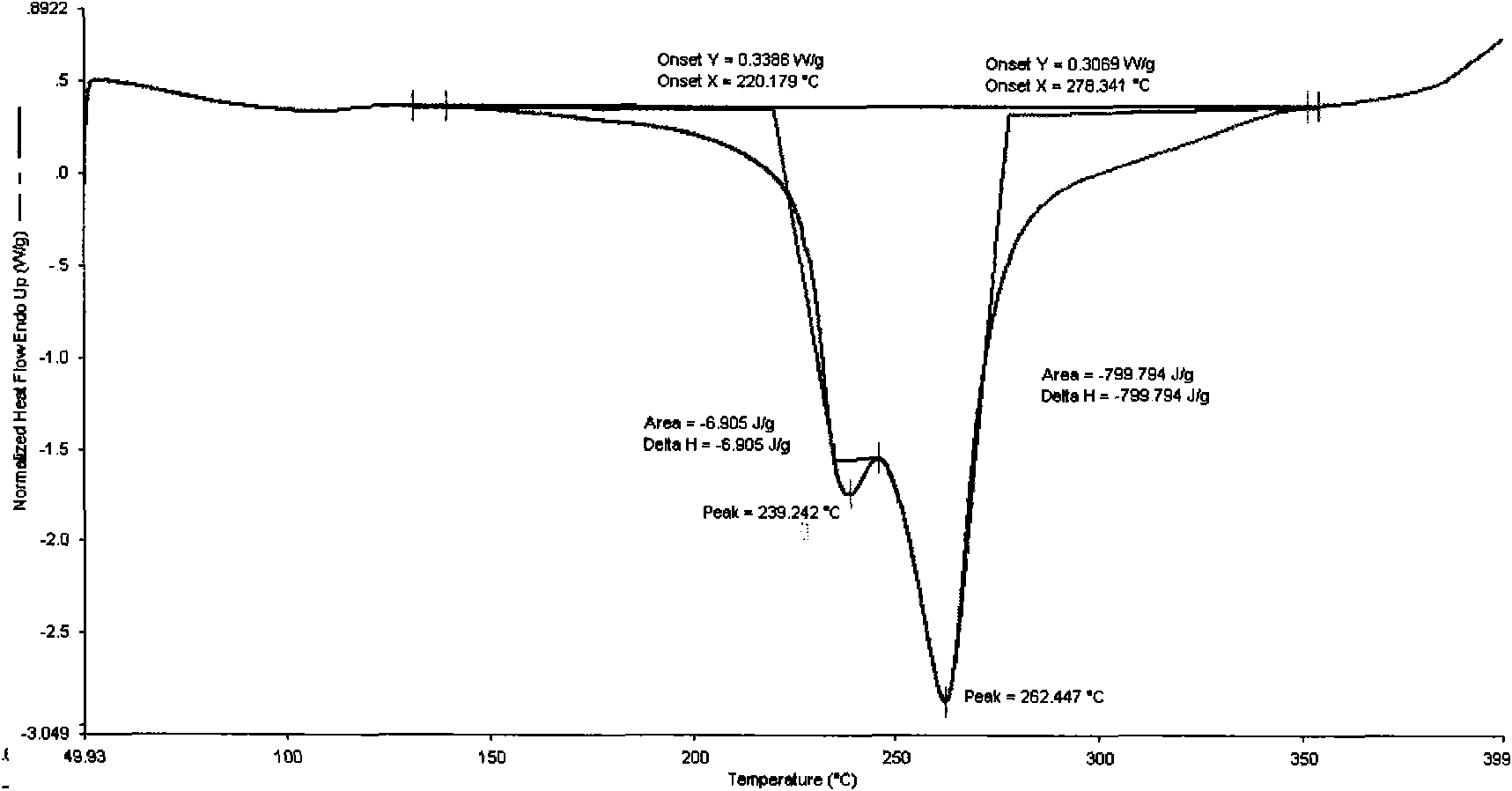

Acrylonitrile copolymer spinning solution with high molecular weight and narrow distribution and preparation method thereof

InactiveCN101805936AHigh molecular weightHigh solid contentMonocomponent synthetic polymer artificial filamentPolymer scienceAlcohol

The invention discloses an acrylonitrile copolymer spinning solution and a preparation method thereof. The spinning solution is a mixed solvent solution of an acrylonitrile copolymer; the acrylonitrile copolymer is formed by polymerization of a first acrylonitrile monomer and a comonomer, and the comonomer comprises unsaturated carboxylic acid monomers; the mass of the first acrylonitrile monomer is 90-99.5% of the total mass of monomers, and the mass of the comonomer is 0.5-10% of the total mass of monomers; the mixed solvent is a mixture comprising dimethyl sulfoxide and at least one of water, alcohol solvents and ketone solvents; and the mass percent concentration of the monomers in the spinning solution is 15-30%. In the invention, the mixed solvent of the dimethyl sulfoxide is adopted in the process of acrylonitrile copolymerization, and the proportion of each solvent is controlled to carry out copolymerization reaction in homogeneous phases; and meanwhile, the second comonomer is continuously replenished in a certain time of reaction to stabilize the instantaneous composition of the acrylonitrile copolymer to obtain the polyacrylonitrile copolymer spinning solution with high molecular weight, narrow molecular weight distribution and uniform chain structure.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Protein cellulose viscose and preparing method thereof

ActiveCN101298708AGood protein contentImprove spinnabilityConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentSpinningPROTEIN S HEERLEN

The invention relates to a protein viscose fiber and a preparation method thereof, belonging to the textile field and aiming at solving a technical problem about how to provide a method for adopting different animal and plant proteins as materials to prepare the protein viscose fiber. The preparation method of the protein viscose fiber includes the following steps: 1. the animal and plant proteins are degreased, decolored and deodorized to obtain animal-plant protein powder; 2. alkalization: the animal-plant protein powder is dissolved in alkaline liquor to obtain protein alkaline solution; 3. cross-linker is added into the protein alkaline solution to obtain a protein spinning liquor; 4. the protein spinning liquor is blended with a glue to be spun to obtainprotein filaments; 5. the protein filaments are washed by peroxide solution and are oiled, dried and formed into cylinder form to get the protein viscose fiber. The protein viscose fiber preparation method of the invention does not adopt any acetalation treatments to the protein filaments after spinning so as to avoid the remaining of methanal, etc. harmful matters, the technique steps are simple and can be easily operated and the manufacturing can be realized with the existing viscose fiber preparation equipment.

Owner:YIBIN GRACE GROUP CO LTD

Novel composite nanofiber membrane as well as preparation method and application thereof

The invention relates to a nanofiber membrane and particularly relates to a novel composite nanofiber membrane as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) dissolving any one of polyvinyl alcohol, polylactic acid and regenerated silk fibroin in an organic solvent to prepare a spinning solution with the mass fraction of 5-20 percent; (2) adding polyphenol substances to the spinning solution, and uniformly stirring to obtain a mixed spinning solution which accounts for 1-7 percent of the total mass of the polyphenol substances and the organic solvent, wherein the polyphenol substances are one or more of vegetable tannin, apple polyphenol and grape polyphenol; (3) carrying out ultrasonic treatment on the mixed spinning solution for 1-600 minutes; and (4) carrying out electrostatic spinning on the mixed spinning solution and collecting to obtain the required composite nanofiber membrane. After subjected to electrostatic spinning, the composite nanofiber membrane is smooth in surface, continuous and uniform, has the diameter of between 100nm and 800nm and can be applied to the fields of medical dressing, makeup facial masks, tea bags, controlled release of targeted drugs, food preservation and sewage purification.

Owner:HEYE HEALTH TECH CO LTD

Method for preparing universal pitch charcoal fibre

InactiveCN101135074AHigh residual carbon valueSmall discreteFibre chemical featuresCarbon fibersNitrogen

The process of universal asphalt carbon fiber includes setting ethylene bottom oil into a reaction kettle, introducing air in the oil weight and air flow rate ratio of 1800-2000 g to 0.2-0.4 cu m / hr while stirring, heating in the rate of 0.5-1.5 deg / min to 260-330 deg.c and maintaining for 1-7 hr, heating to 320-380 deg.c under protection of nitrogen and maintaining for 0.5-4 hr to obtain spinning asphalt, melt spinning and carbonizing to obtain universal asphalt carbon fiber. The present invention has simple technological process and low cost, and is suitable for industrial production.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

Functionalized polypropylene fibre and its preparation method

InactiveCN1766184AWith deodorizing functionSolve reunionMonocomponent polyolefin artificial filamentArtifical filament manufactureNatural substanceSilicon dioxide

The invention discloses a functional polypropylene fibre contained and fused a plurality of natural inorganic materials and polypropylene, which comprises: tourmaline, alumina, zirconium phosphate carried-Ag antibacterial agent, silicon dioxde, and titania. The preparation method comprises: breaking and mixing the materials, fusing and mixing said materials with polypropylene slice to obtain mother grain; then, using common fusion spinning method to treat said grain and slice. This product has well spinnability, high strength, and deodorization function.

Owner:上海依福瑞实业有限公司

Improved preparation of cellulose spinning solution with ion liquid as solvent

InactiveCN101476166AImprove solubilityReduced gel particle contentArtificial filaments from cellulose solutionsSpinning solutions preparationApparent viscosityDistillation

The invention provides a method for preparing an improved fibrino spinning original solution that ion liquid is used as solvent, which includes: two phases of swelling and dissolution, namely, placing dried fibrino dissolving pulp and 1-butyl-3-methyl imidazole villaumite with 1%-20% water ratio into a dissolution device for uniform mixing, firstly, leaving and swelling in 70-100 DEG. C, then stronger stirring for swelling to plasm shape without dissolution; secondly, raising temperature to 80-125 DEG. C slowly in stirring state, stirring and reducing pressure distillation for removing water component, fibrino can be dissolved completely after 2-8h; finally, reducing stirring speed, and reducing temperature of plasm to 90-100 DEG. C and keeping 30-60 min for obtaining straw yellow spinning original solution. The method provided by the invention has advantages that the spinning original solution is more uniform, dissolution is more fully, gelatin particle in the spinning original solution is reduced, the spinning original solution quality is increased; apparent viscosity of the spinning original solution is reduced, accordingly, solid content in the spinning original solution is increased further.

Owner:DONGHUA UNIV

Technology for producing poly(p-phenylene benzobisoxazole) (PBO) fibers

ActiveCN102943316AEfficient transferAchieving Scale AggregationWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to a technology for producing poly(p-phenylene benzobisoxazole) (PBO) fibers, and belongs to the field of high performance fiber production. The technology comprises the steps: A, degassing, pre-polymerizing and defoaming; B, post-polymerizing and defoaming; C, spinning and solidifying; D, post-treating; and E, heat-treating and the like. Through optimizing equipment and controlling parameters, a plurality of problems of the prior art are solved. The technological process, equipment cooperation and parameter control of the basic technical scheme are taken as an integral system, are cooperated with each other and are dispensable, materials can be effectively transferred, the scale polymerizing and subsequent scale spinning of the PBO polymer are realized, and a high-quality PBO fiber product is obtained.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com