Production method of fine-denier porous POY black yarn

A production method and technology of black silk, applied in the directions of melt spinning, spinneret assembly, filament forming process, etc., can solve the problem that porous fine denier or ultra-fine denier fibers cannot be produced, and the product quality cannot be recognized by customers. , the tow is not fully cooled, etc., to achieve the effect of reducing instability, good moisture absorption and perspiration and deodorization, and good masterbatch spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The production method of the fine-denier porous POY black silk described in this example includes the following production steps: semi-dull chip drying-black masterbatch drying-chip and black masterbatch adding screw extruder-screw extruder melting-metering pump -Spinning box-component spinning-side blowing cooling-oiling of tow 9-GR1, GR2 godet-winding forming-finished product inspection, characterized in that:

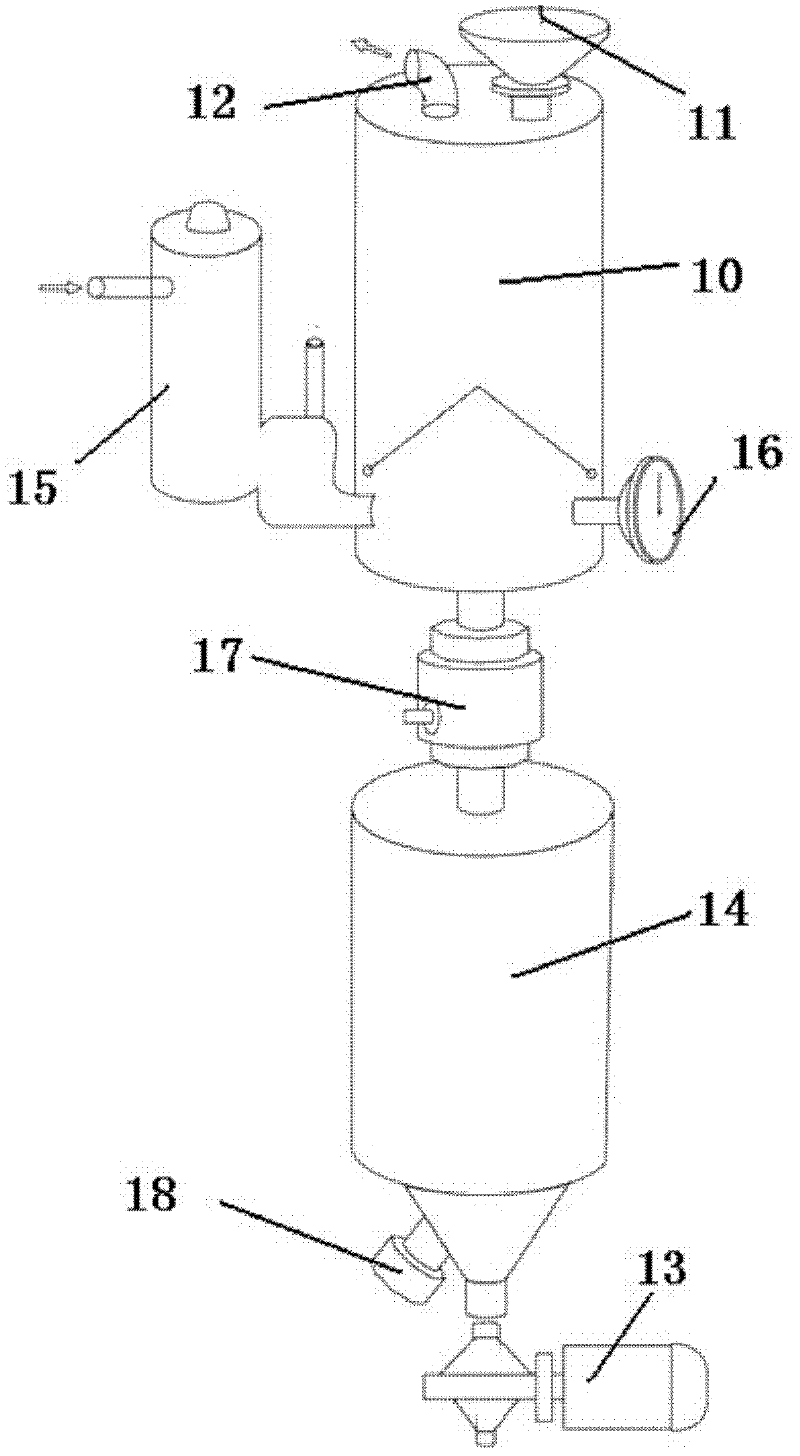

[0045] In the black masterbatch drying step: adopt continuous drying mode (such as figure 1 As shown), the black masterbatch is first added to the crystallization drying tank 10, and the heated dry air enters from the bottom of the crystallization drying tank 10 and blows out from the top to dry the black masterbatch. The drying time is 2 hours. After the drying is completed, the black masterbatch The material falls into the intermediate silo 14 below the crystallization drying tank 10 for storage, and is injected by the masterbatch injector 13 below the inter...

Embodiment 2

[0050] The production method of the fine-denier porous POY black silk described in this embodiment is different from Example 1 in that:

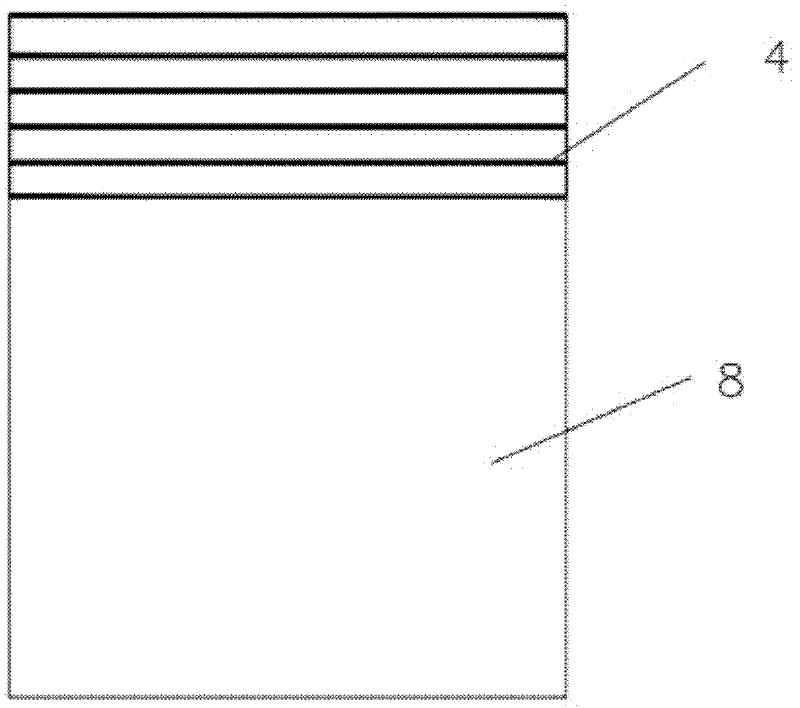

[0051] Such as figure 2 As shown, an arc-shaped guide piece 7 is arranged on the arc of the arc-shaped notch 6, and the arc-shaped guide piece 7 guides the horizontal side blowing to the center of the tow 9. Can form the effect of a ring blowing like this, and side blowing can cool it almost from around the tow 9, and the cooling effect is better.

Embodiment 3

[0053] The production method of the fine-denier porous POY black silk described in this embodiment is different from Example 1 in that: the steps of adding the slicing and black masterbatch to the screw extruder include the following measures: masterbatch injector 13 black masterbatch The injection frequency is related to the working status of the metering pumps assigned to different spinning positions. Different types of metering pumps for different spinning positions have their own operating frequencies. When the metering pump for a certain spinning position is not working, the masterbatch injector 13 The injection frequency is overall minus the corresponding frequency. Because the control frequency of the existing masterbatch injector 13 adopts the average distribution method, that is, each part is assigned the same color masterbatch frequency, the corresponding masterbatch frequency is reduced when the stop is stopped, and the masterbatch supply is reduced; if the spinning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com