Patents

Literature

37results about How to "Reduce head breaks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of fine-denier porous POY black yarn

InactiveCN102443859AImprove spinnabilityReduced stabilitySpinnerette packsMelt spinning methodsProduction rateYarn

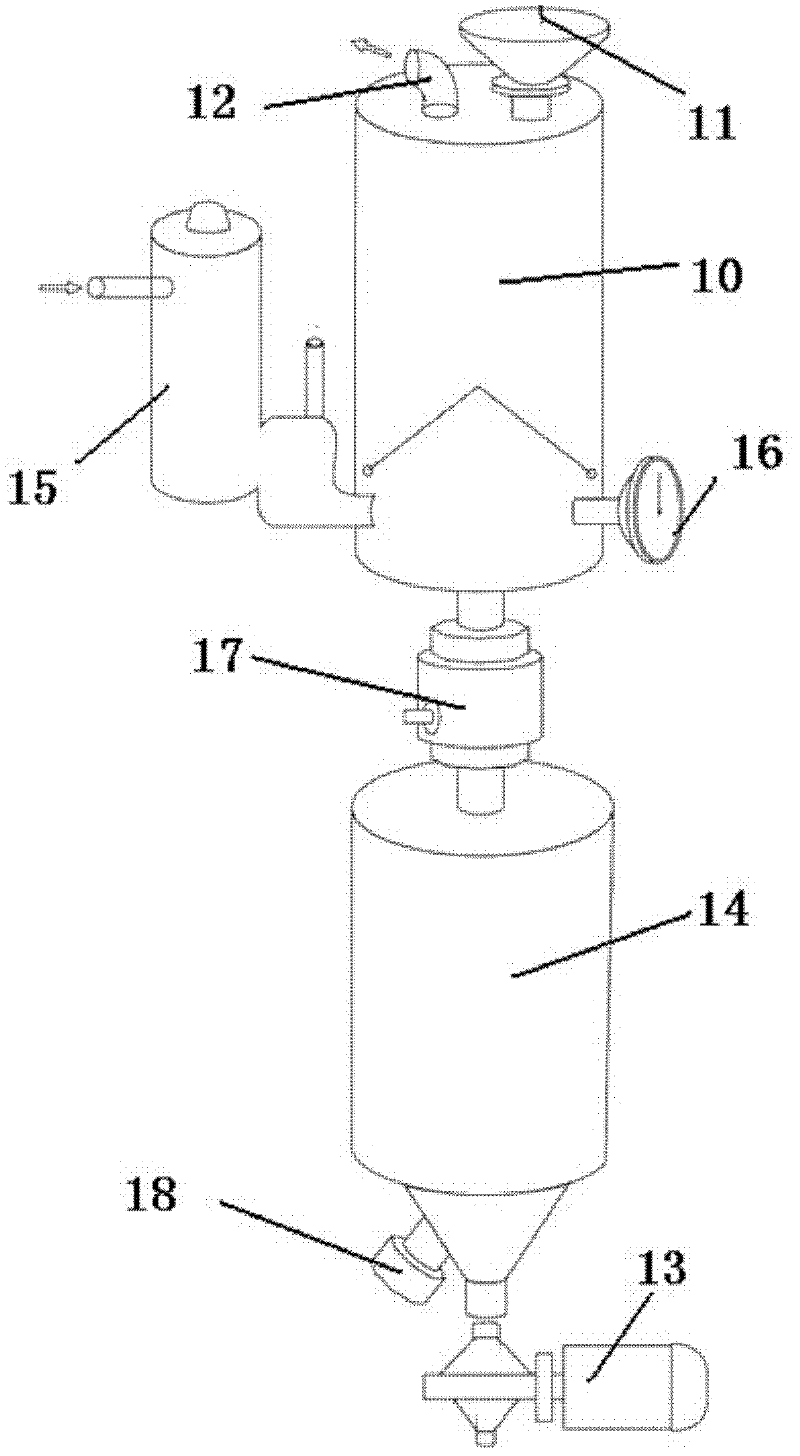

The invention discloses a production method of a fine-denier porous POY black yarn. The method comprises the following steps of: drying semi-dull slices, drying black masterbatch, adding the slices and the black masterbatch material into a screw extruder, fusing the added materials in the screw extruder, respectively processing the fused materials in a metering pump and a spinning beam, spinning on a pack, cooling the materials by lateral blowing, applying oil on strands, processing the strands in draw-off godets GR1 and GR2, winding and shaping, and inspecting products. The method is characterized in that the step of drying the black masterbatch comprises the following sub-steps of: based on a continuous drying mode, firstly, adding the black masterbatch into a crystallization and drying tank, introducing heated dry air from the lower part of the crystallization and drying tank, and blowing out the heated dry air from the top of the crystallization and drying tank so as to dry the black masterbatch, wherein the drying time is 2 hours, the dried black masterbatch falls into an intermediate material storage bin for storage under the crystallization and drying tank, and the black masterbatch is further injected by a masterbatch injector under the intermediate material storage bin. The production method of the fine-denier porous POY black yarn has high masterbatch spinnability and better cooling effect, and can improve the oil application uniformity of spinning cakes and the productivity.

Owner:桐乡市中洲化纤有限责任公司

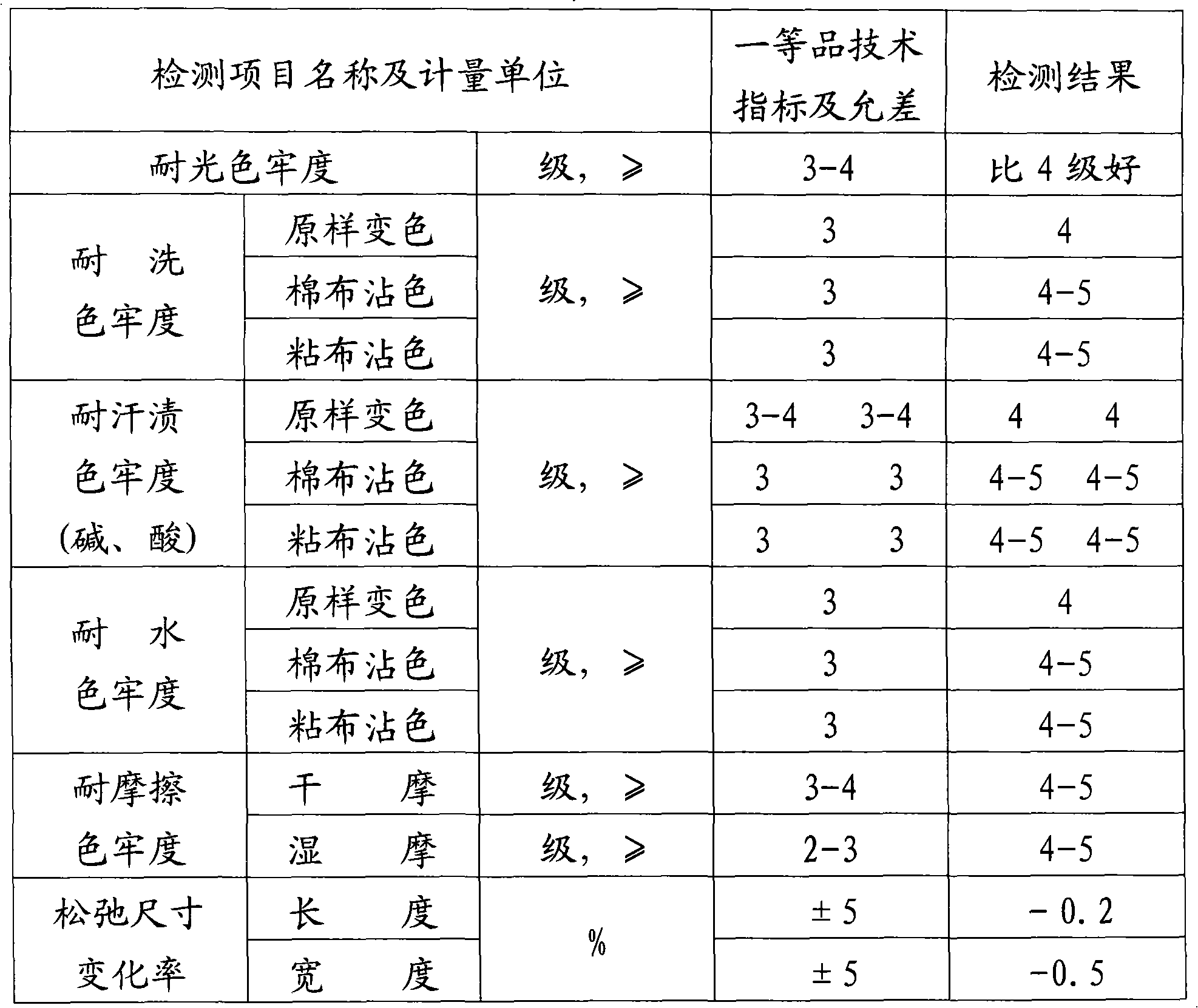

Woollen sweater and production thereof

The invention discloses a knitted sweater and the production technology thereof. The raw material of the knitted sweater is yarn blended with spun silk, Modal fiber, milk fiber and cashmere. The weight ratio of the spun silk ranges from 50 to 60 percent, that of the Modal fiber ranges from 20 to 30 percent, that of milk fiber ranges from 10 percent to 15 percent and that of cashmere is between 5 to 15 percent. The production technology for knitted silk comprises (1) selection of raw white yarn, (2) dyeing, (3) rewinding, (4) panel knitting, (5) linking, (6) stitches, (7) hand sewing, (8) rinsing, (9) drying and (10) ironing. The knitted sweater has natural wrinkle resistance, higher hygroscopicity and warmth, and soft handfeel.

Owner:周婉

Pearl fiber blended yarn and application thereof

InactiveCN101545156AReasonable weaving process conditionsReduce head breaksGarmentsConjugated synthetic polymer artificial filamentsFiberYarn

The invention provides a pearl fiber blended yarn, which is prepared from 35 to 45 percent of tencel, 35 to 45 percent of modal fiber and 15 to 25 percent of pearl fiber by weight percentage through blended spinning. The invention also provides a slippery ventilated comfortable sweater woven from the pearl fiber blended yarn and a method for producing the same. The sweater or an underwear product also has the characteristics of the tencel, the modal fiber and the pearl fiber, is slippery and soft in hand feeling and ventilated, has good hygroscopicity, is not toxic and irritative to a human body, and can make pearl particles give play to functions of caring skin, beautifying, clearing fever and whitening after contacting with skin for a long time. The calcium carbonate content in the pearl fiber blended yarn has far infrared emission function and ultraviolet resistant function, and can not only accelerate human body microcirculation and promote metabolism, but also prevent skins from being hurt by ultraviolet, thus the pearl fiber blended yarn has certain health care and protective effects on the human body.

Owner:JIANGYIN XIANGFEI APPAREL

Ring spinning fully numerical control system and control method implemented by same

InactiveCN108315841AAchieve stabilityMeet the precision requirementsContinuous wound-up machinesYarnControl system

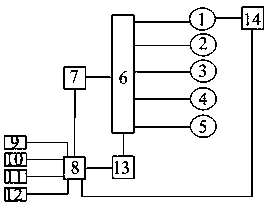

The invention discloses a ring spinning fully numerical control system and a control method implemented by the same. The ring spinning fully numerical control system comprises a drafting system and awinding forming system. The drafting system comprises rear rollers, middle rollers and front rollers which can be driven by drafting driving devices to rotate, the winding forming system comprises main shaft spindles and ring rails which can be driven by winding driving devices, the drafting driving devices and the winding driving devices are connected with an IGPT centralized control unit, the IGPT centralized control unit is connected with a central control system, data can be transmitted between the central control system and a data computation control system by the aid of KAN communicationtechnologies, the data computation control system is connected with a parameter input device, rotation speeds of the main shaft spindles can be acquired by a detection device in real time, and rotation speeds which are acquired by the detection device can be transmitted to the data computation control system in real time. The ring spinning fully numerical control system and the control method have the advantages that ring spinning frames can be fully digitally controlled by the aid of the ring spinning fully numerical control system and the control method, spinning technological parameters can be adjusted in an interface manner by the aid of the ring spinning fully numerical control system and the control method, high-speed spinning procedures are stable, and the stability of the qualityof resultant yarns can be improved.

Owner:JIANGNAN UNIV

Antibacterial composite short fiber and preparation method thereof

InactiveCN110565203ALow rewetGood overall performanceFilament/thread formingConjugated synthetic polymer artificial filamentsSuper absorbentSodium polyacrylate

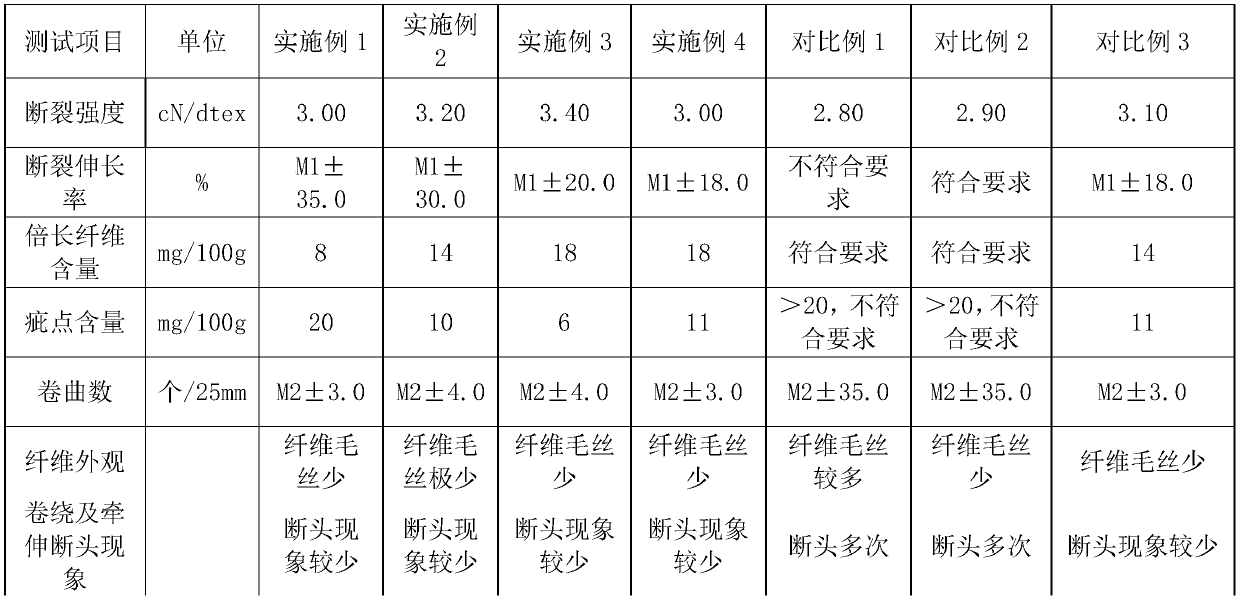

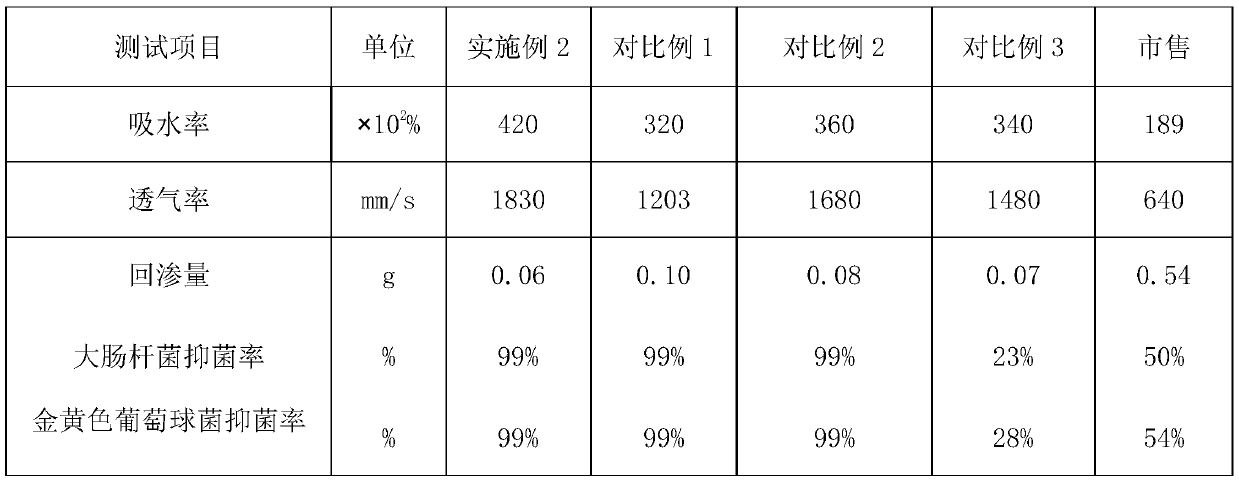

The invention discloses an antibacterial composite short fiber and a preparation method thereof. The PP / PE composite short fiber is composed of a core layer and an outer layer; the core layer and theouter layer are concentric circles; the core layer is prepared from, by mass, 40-50 parts of polypropylene, 5-9 parts of an ethylene-propylene copolymer, 4-6 parts of a propylene block copolymer, 8-9parts of starch-acrylic acid super-absorbent resin, 2-3 parts of titanium dioxide and 4-8 parts of zinc oxide; the outer layer is prepared from, by weight, 20-30 parts of linear low-density polyethylene, 20-30 parts of high-density polyethylene, 20-30 parts of antibacterial polyethylene particles, 10-15 parts of methyl-methacrylate-grafted modified polyethylene, 10-12 parts of ethylene-grafted methyl methacrylate and 12-17 parts of sodium polyacrylate super-absorbent resin. The PP / PE composite short fiber has the following advantages that the short fiber has few curls and defects, and preparedproducts have a small back infiltration amount after absorbing water, excellent air permeability, an excellent bacteriostatic effect and excellent comprehensive performance.

Owner:嘉兴市新丰特种纤维有限公司

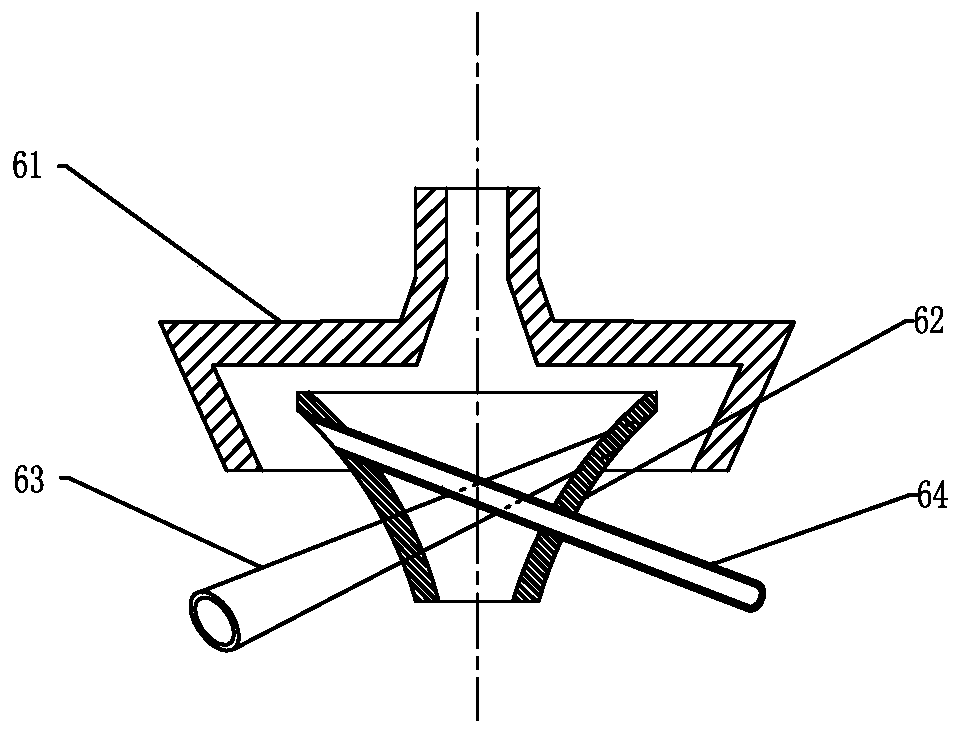

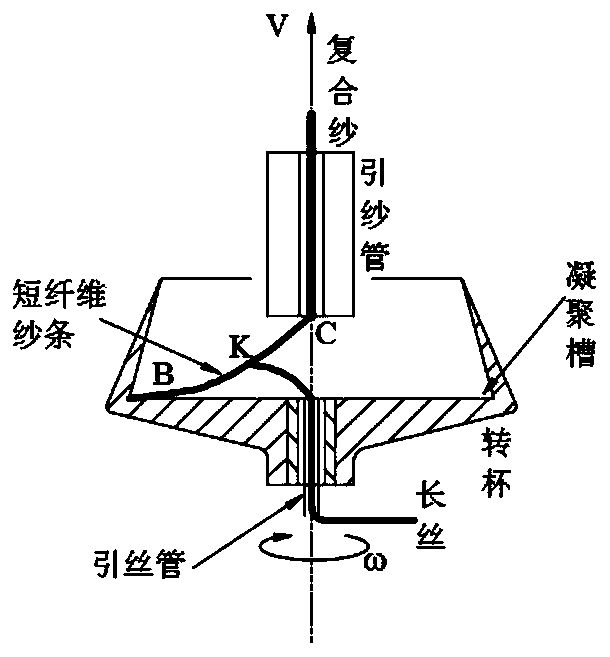

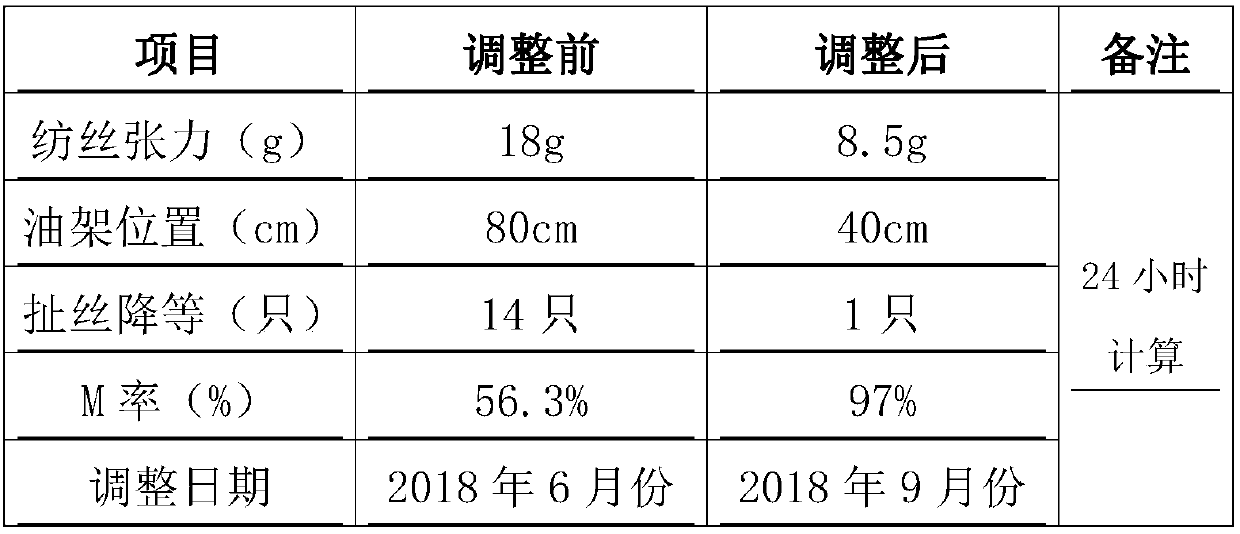

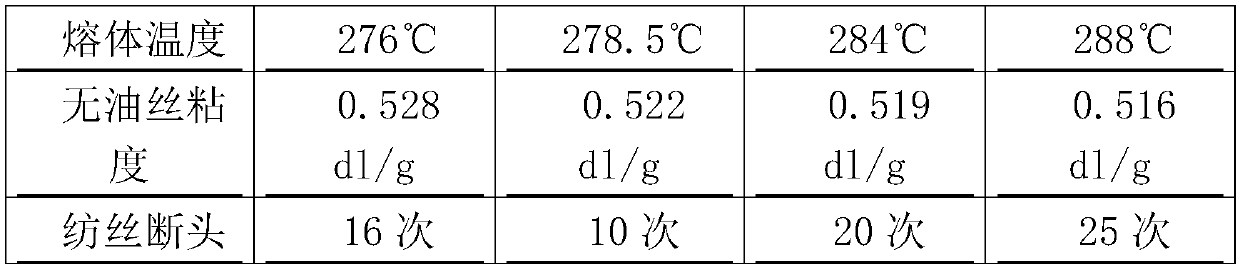

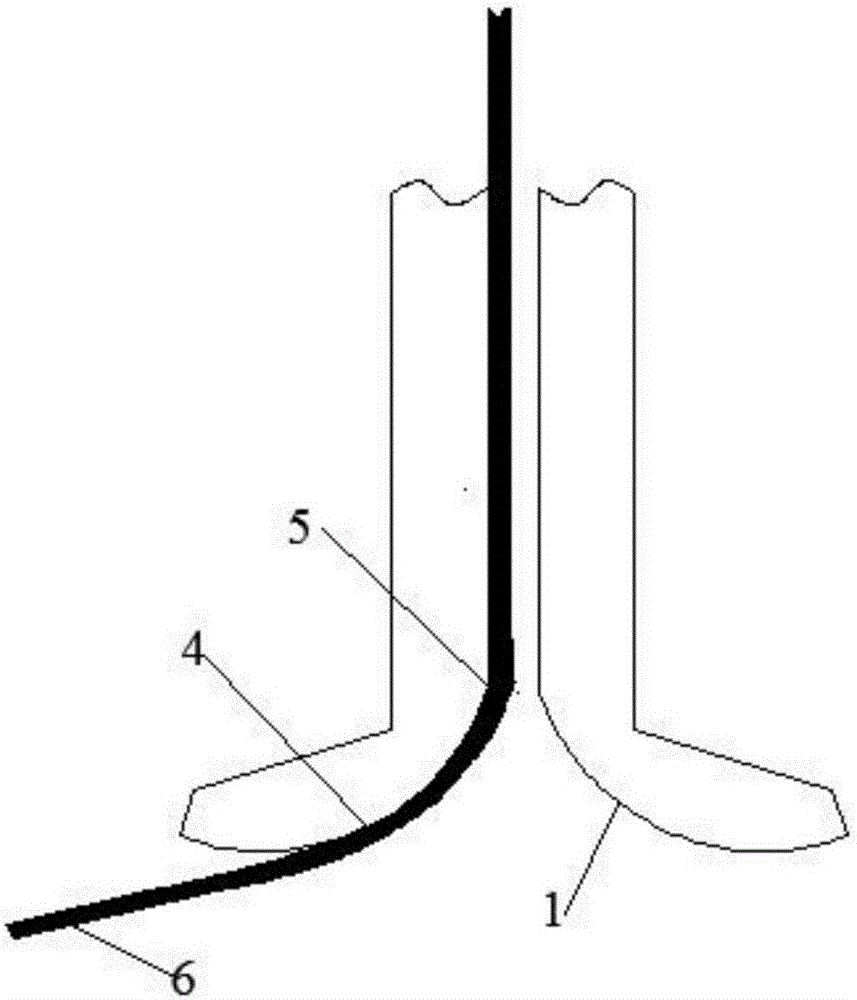

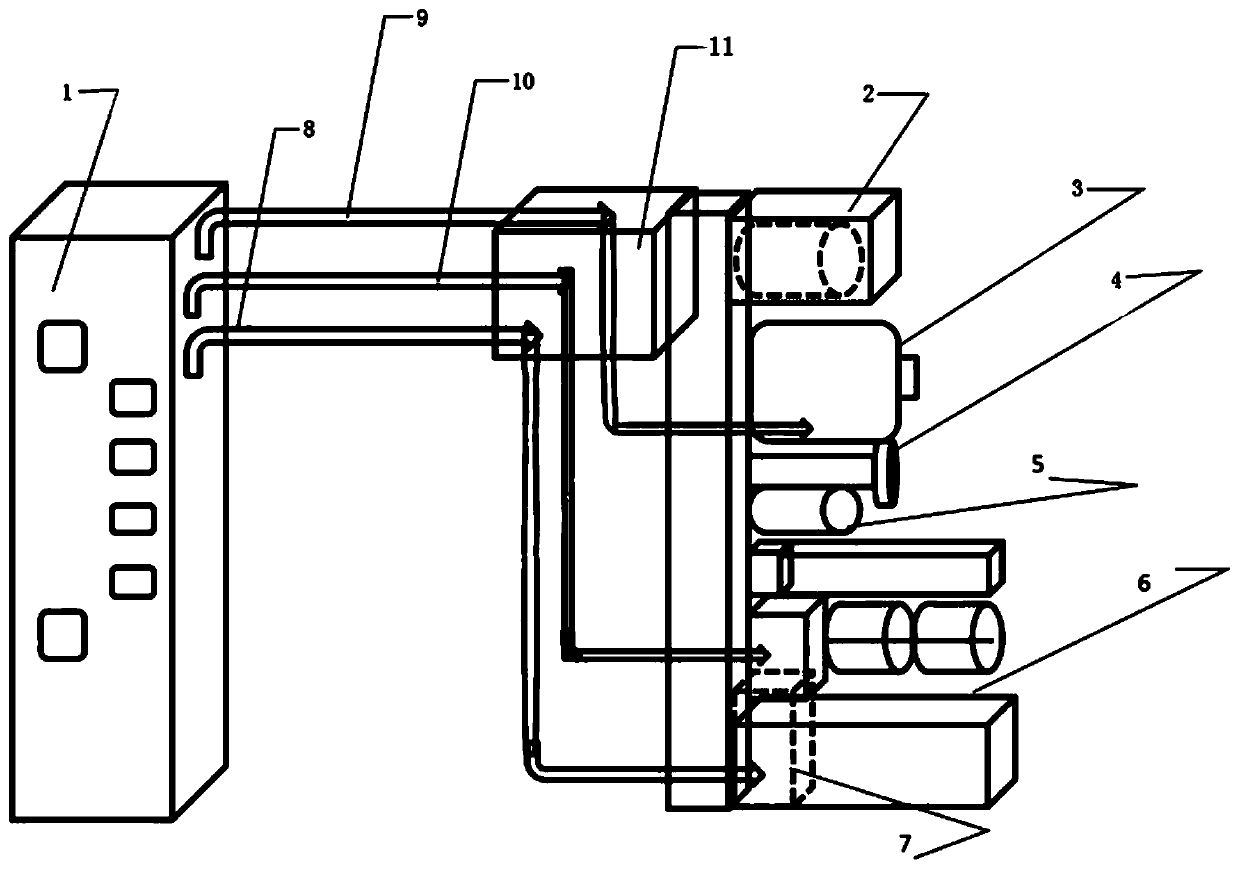

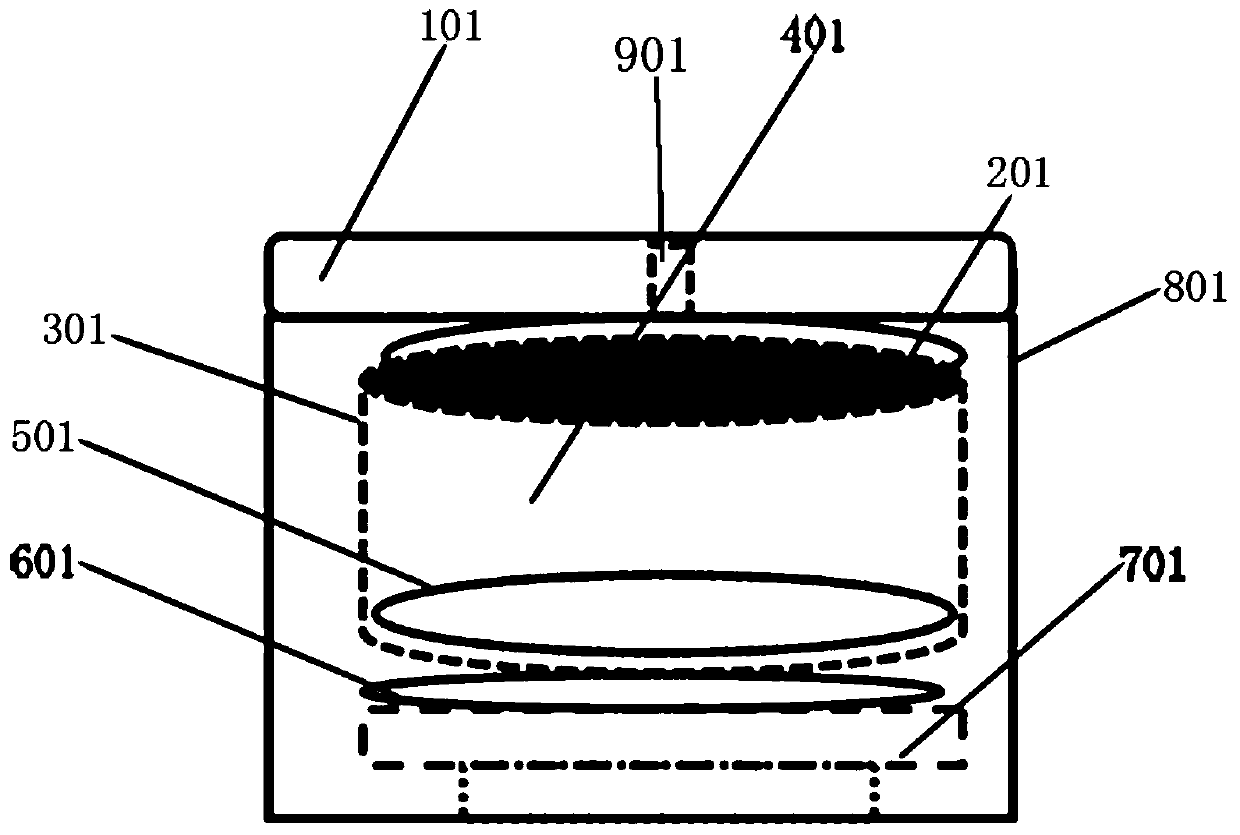

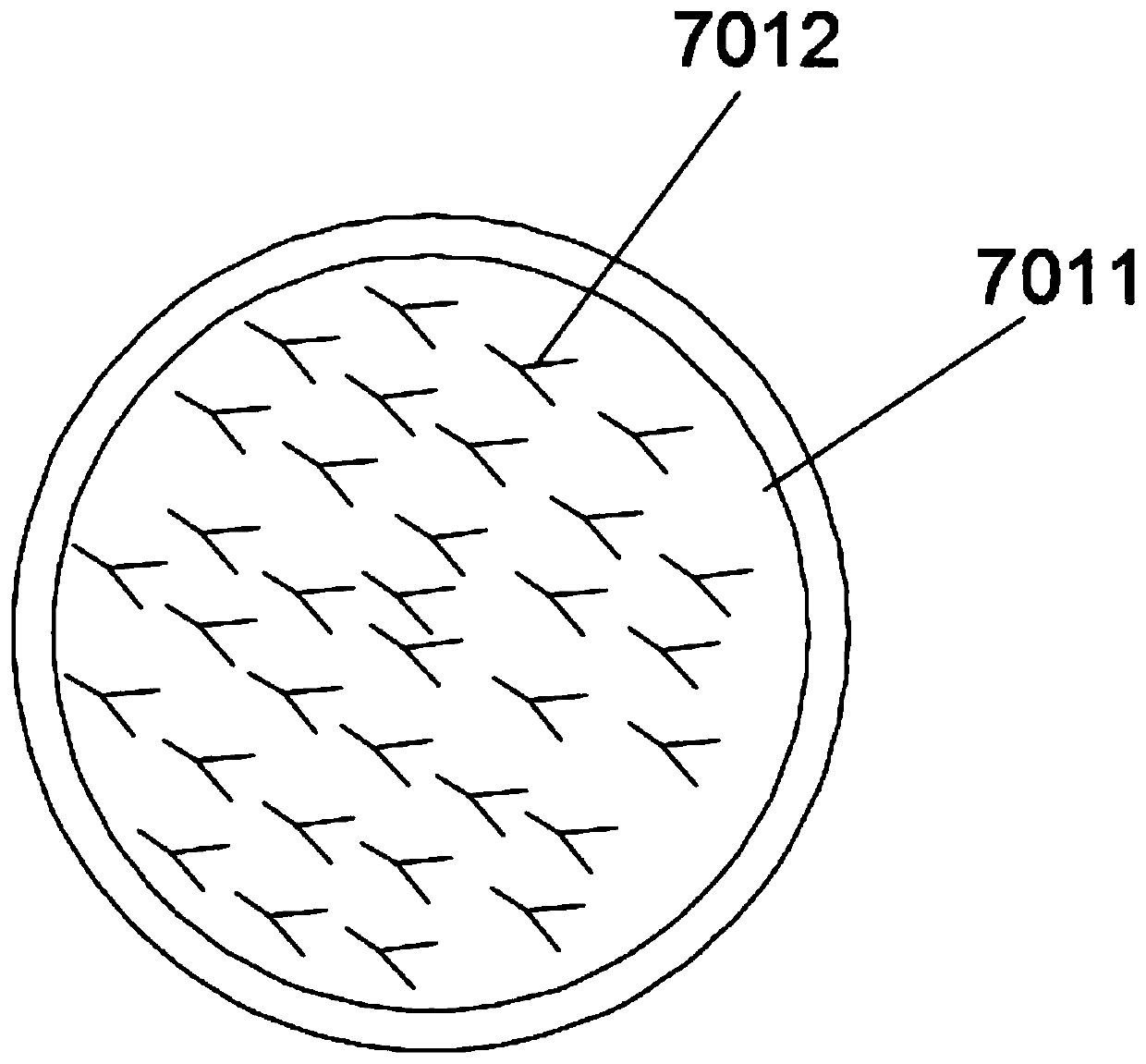

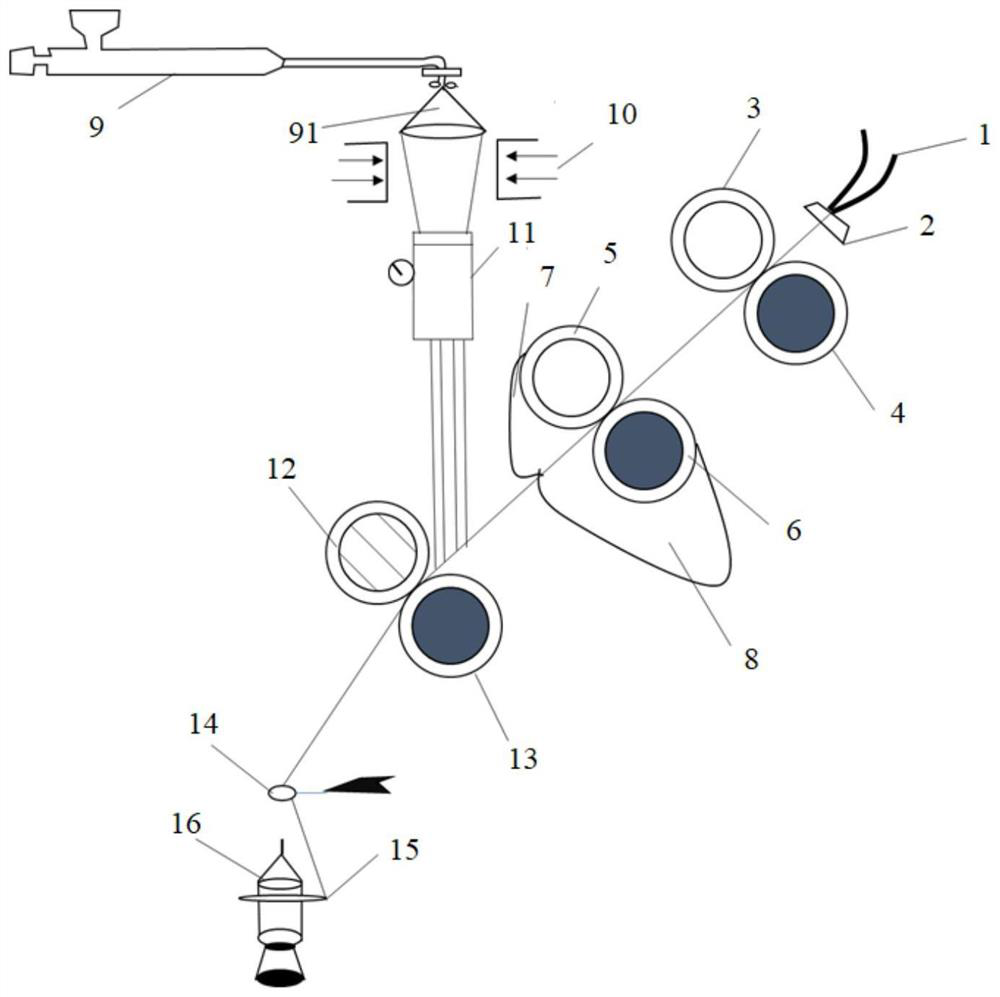

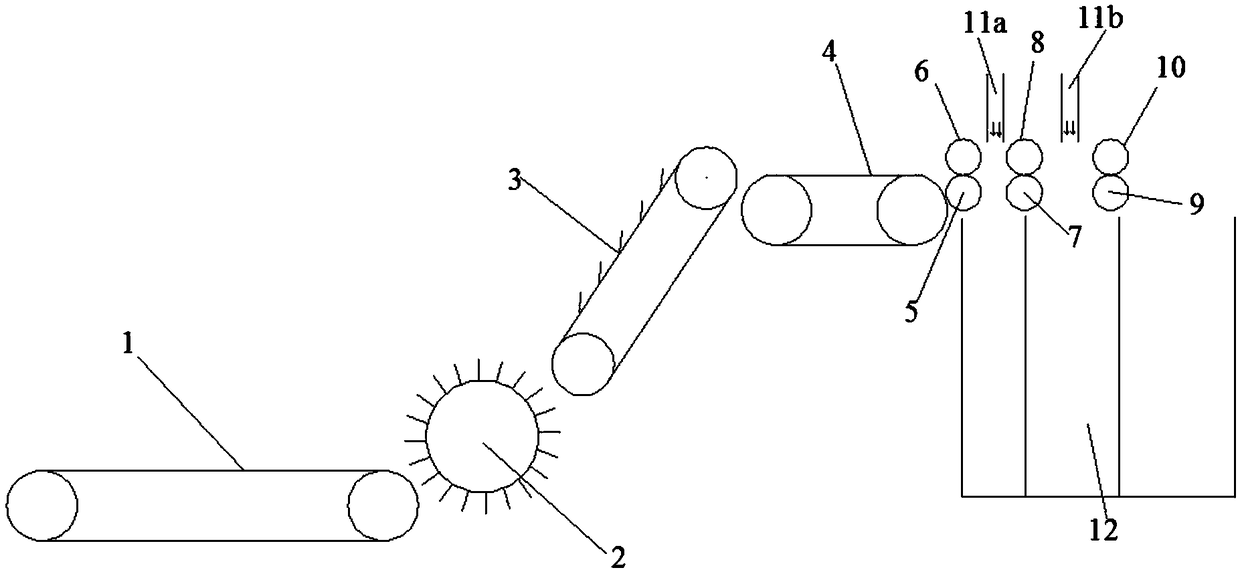

Production device and process of rotor-spun filament as well as short-fiber core-spun yarn and covered yarn

PendingCN110144660AReduce broken endsImprove efficiencyContinuous wound-up machinesOpen-end spinning machinesEngineeringFilament yarn

The invention relates to a production device and process of a rotor-spun filament as well as a short-fiber core-spun yarn and a covered yarn, and belongs to the technical field of spinning. The production device comprises a filament frame, a filament drum, yarn guide rods, yarn guides, filament guides, a yarn forming device, yarn introducing rollers and a spindle, wherein the filament drum is arranged on the filament frame; a plurality of yarn guide rods are arranged below the filament frame; the yarn guides are arranged on the yarn guide rods; the filament frame and the yarn guide rods are fixed above a vehicle body; the filament guides are arranged below the yarn guides; the filament guides are connected with the yarn forming device; the yarn introducing rollers and the spindle are arranged in turn above the yarn forming device. The production device has the advantages of high composite yarn forming efficiency, adjustable tension over a relatively wide range and the like, can producethe core-spun yarn with relatively large tension and the covered yarn with relatively small tension, and can produce the covered yarns with different filament coating effects by controlling the tension of the filaments.

Owner:JIANGNAN UNIV

High-concentration color masterbatch for deep-dyed bright red fiber and preparation method thereof

InactiveCN107964223ASolve the problem of dyeing spinnabilityReduce driftPigment addition to spinning solutionMonocomponent polyesters artificial filamentHigh concentrationFiber

The invention provides a high-concentration color masterbatch for a deep-dyed bright red fiber; the high-concentration color masterbatch consists of, in parts by weight, 10-50 parts of PET, 0-40 partsof PBT, 30-42 parts of a dye A or pigment a, 5-15 parts of a dye B or pigment b, 0.5-1.5 parts of a thermal stabilizer, and 1-2 parts of a rheology modifier, wherein the intrinsic viscosity of PET is0.66-0.82 dl / g, the intrinsic viscosity of PBT is 0.82-1 dl / g, the melting point of the dye A or pigment a is greater than that of PET and PBT, and the melting point of the dye B or pigment b is greater than that of PET and PBT. The invention also provides a preparation method of the high-concentration color masterbatch for the deep-dyed bright red fiber. The color masterbatch is suitable for thedeep-dyed bright red fiber, can solve the problems of coloring and spinnability before spinning at present, reduces wire floating and head breaking, and prolongs the service cycle of spinning components.

Owner:POLY PLASTIC MASTERBATCH SUZHOU

Production method of blended fabric of water-soluble fiber and racoon dog fur

The invention belongs to the technical field of textiles and relates to a production method of blended fabric of water-soluble fiber and racoon dog fur. A technical process of mixing, carding, spinning, spooling, plying and double-twisting is provided; water-soluble fiber is added to raccoon dog fur in a certain ratio, so that fewer broken ends occur during spinning of racoon dog fur products, andspinnability is improved. In addition, finished textile fabric finally made can retain the original style of raccoon dog fur products after special afterfinishing and removal of the water-soluble fiber in the textile fabric.

Owner:CONSINEE GRP CO LTD

Color masterbatch for fibers suitable for high-temperature rinsing and disinfection and preparation method of color masterbatch

InactiveCN108017885AExtend the life cycleSolve the problem of substandard color fastness and poor spinnabilityConjugated synthetic polymer artificial filamentsArtifical filament manufactureMasterbatchFiber

The invention provides color masterbatch for fibers suitable for high-temperature rinsing and disinfection. The color masterbatch is prepared from components in parts by weight as follows: 10-90 partsof PET, 0-40 parts of PBT, 0-35 parts of pigment and 0-5 parts of an assistant, wherein the intrinsic viscosity of PET is 0.66-0.82 dl / g, and the intrinsic viscosity of PBT is 0.82-1 dl / g. The invention further provides a preparation method of the color masterbatch. With adoption of the color masterbatch for the fibers suitable for high-temperature rinsing and disinfection, the problems about mass dyeing and spinnability can be solved, drift filaments and broken filaments can be reduced, the service cycle of a spinning assembly can be prolonged, and the problems that dyeing fastness cannot meet the standard, the environment is polluted and the like can be solved. In order to guarantee the spinnability (fewer drift filaments and broken filaments and slow boosting of the assembly), relatedindicators of the masterbatch are controlled strictly, the intrinsic viscosity of the masterbatch is controlled at 0.35-0.55 dl / g, and the FPV (filtering performance) of the masterbatch is controlledat 0.01-1.00 MPa.

Owner:POLY PLASTIC MASTERBATCH SUZHOU

Production process of energy-saving and environmentally-friendly direct-spinning FDY fine-denier cationic polyester filament

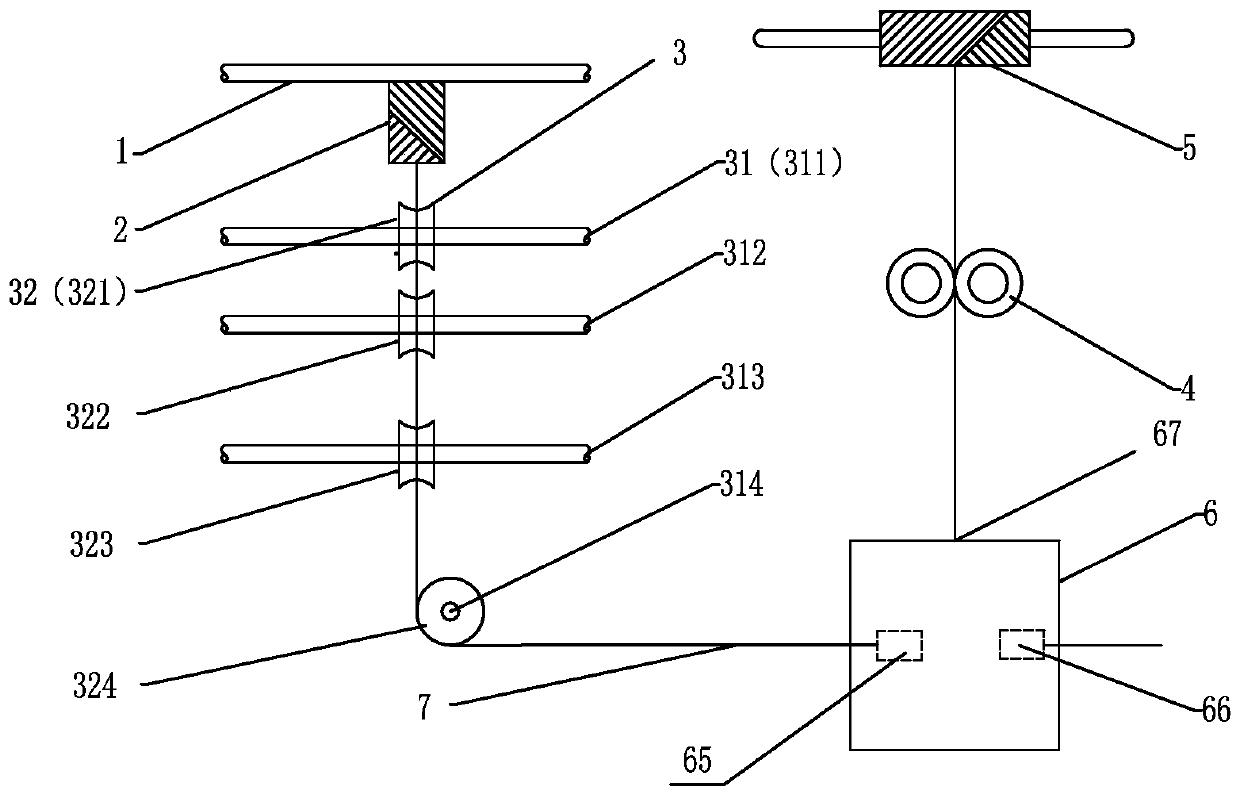

ActiveCN109629022AImprove productivity and qualityEnergy savingNew-spun product collectionArtificial thread manufacturing machinesChemistryDyeing

The invention discloses a production process of an energy-saving and environmentally-friendly direct-spinning FDY fine-denier cationic polyester filament. The process flow comprises the steps of polymerization three-cylinder flow->melt distributor->booster pump->melt transport->cooler->static mixer->melt distribution valve->spinning box->metering pump melt extrusion->spinning assembly->ring blowing drum->cooling forming->magnetic ring->oil nozzle oiling->spinning shaft->yarn guide->GR0 ->first heat roll->second heat roller->third heat roller->fourth heat roller->fifth heat roller->GR1->GR2->main network->GR3->yarn guide->broken wire detector ->winder->fully automatic doffer->sky rail transportation->dyeing and classification->quality inspection packaging->stereo warehouse automatic storage. The production process of the energy-saving and environmentally-friendly direct-spinning FDY fine-denier cationic polyester filament not only achieves energy saving and environmental protection, butalso guarantees spinning quality.

Owner:TONGKUN GRP

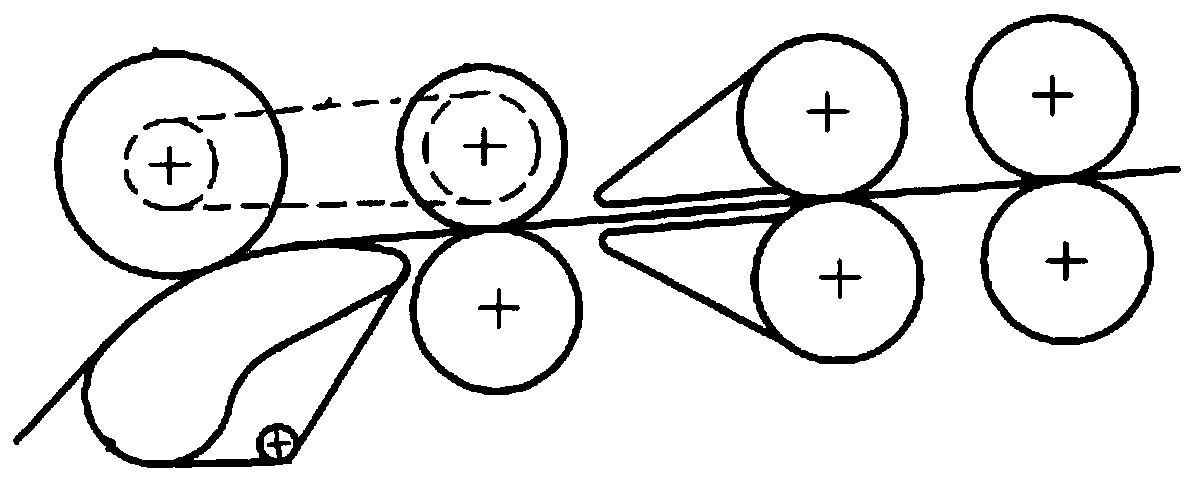

Jade fiber/bamboo fiber/modal functional sweater and manufacturing method thereof

The invention relates to a jade fiber / bamboo fiber / modal functional sweater and a manufacturing method thereof. The jade fiber / bamboo fiber / modal functional sweater is characterized in that the fabric weave of the sweater is single jersey; and three Sirospun yarns which has the yarn count of 40S and comprise 40 percent of jade fiber, 40 percent of bamboo fiber and 20 percent of modal fiber are stranded to form a yarn, the yarn twist is 320 twist / meter, and the gram weight is 290 grams / square meter. The manufacturing process comprises the following steps of Siro-spinning three kinds of fibers; rewinding; knitting pieces; linking; flat sewing; hand sewing; water washing; drying; pressing; packing; and warehousing. In the process of Siro-spinning the three kinds of fibers, on a spinning frame, main rough yarns do not pass through a rear roller, auxiliary rough yarns pass through the rear roller and are fed intermittently, and the radial run-out of the roller is controlled to be less than 0.03mm. The product has the functions of good antibacterial property, coolness, humidity absorption and elimination, high air permeability and the like.

Owner:JIANGYIN XIANGFEI APPAREL

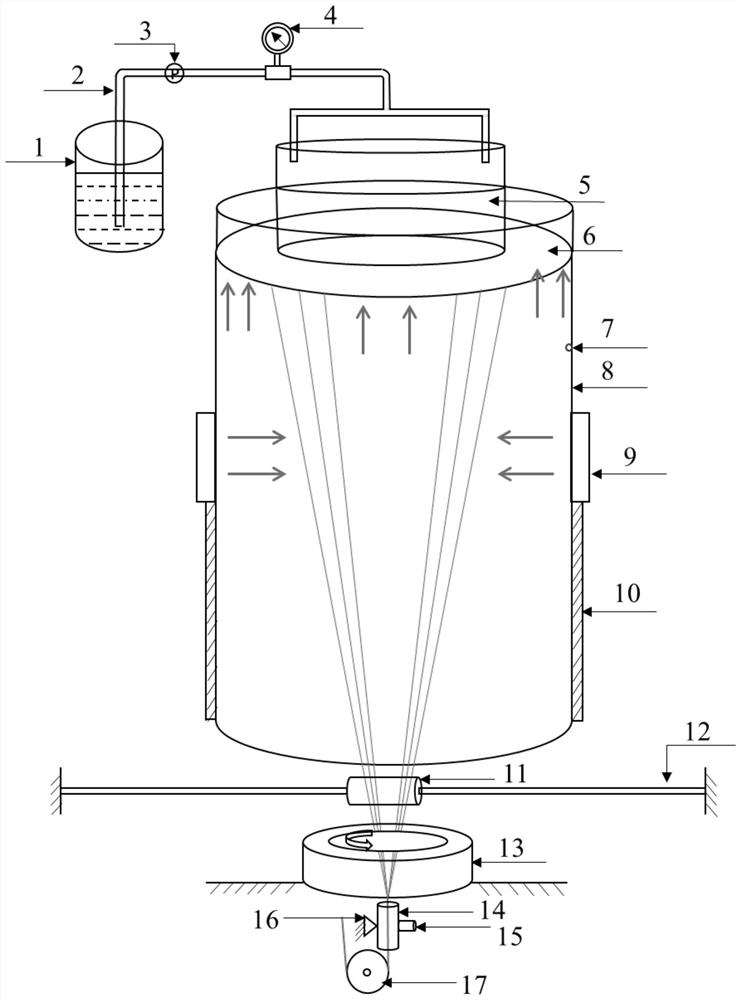

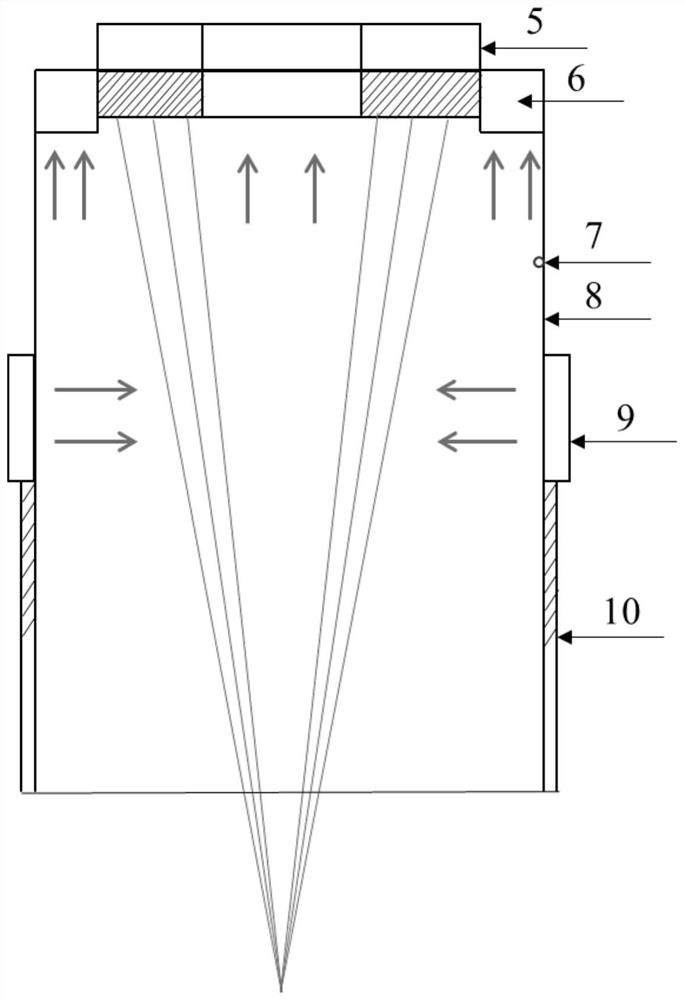

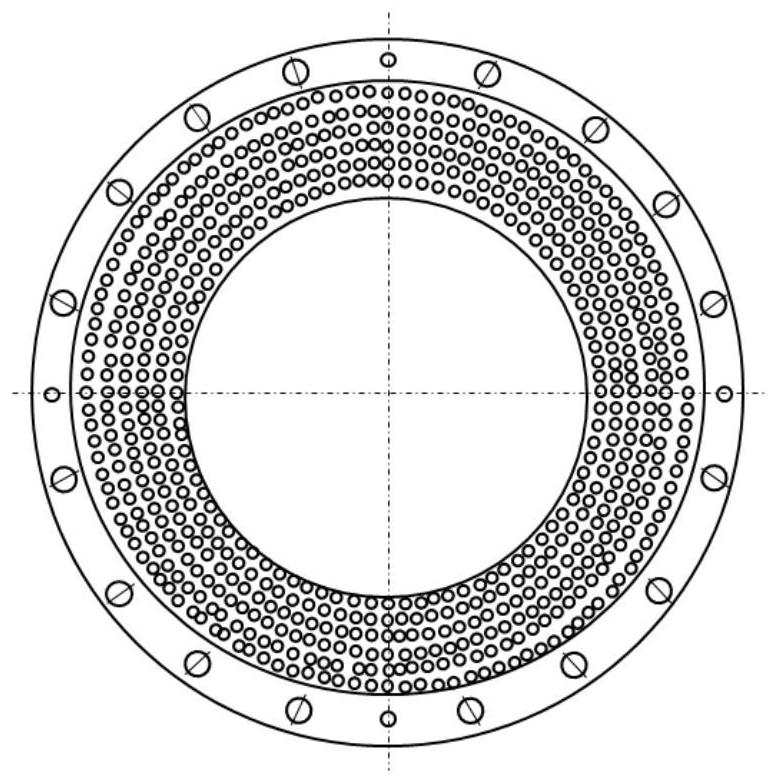

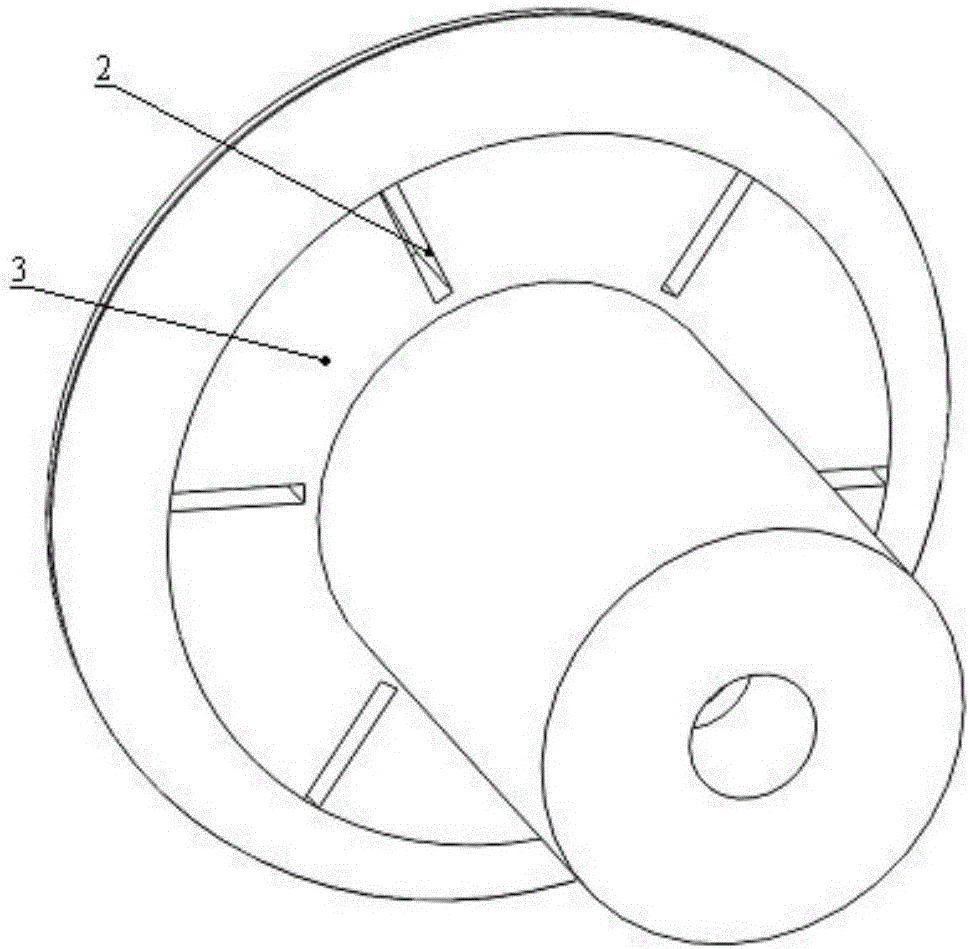

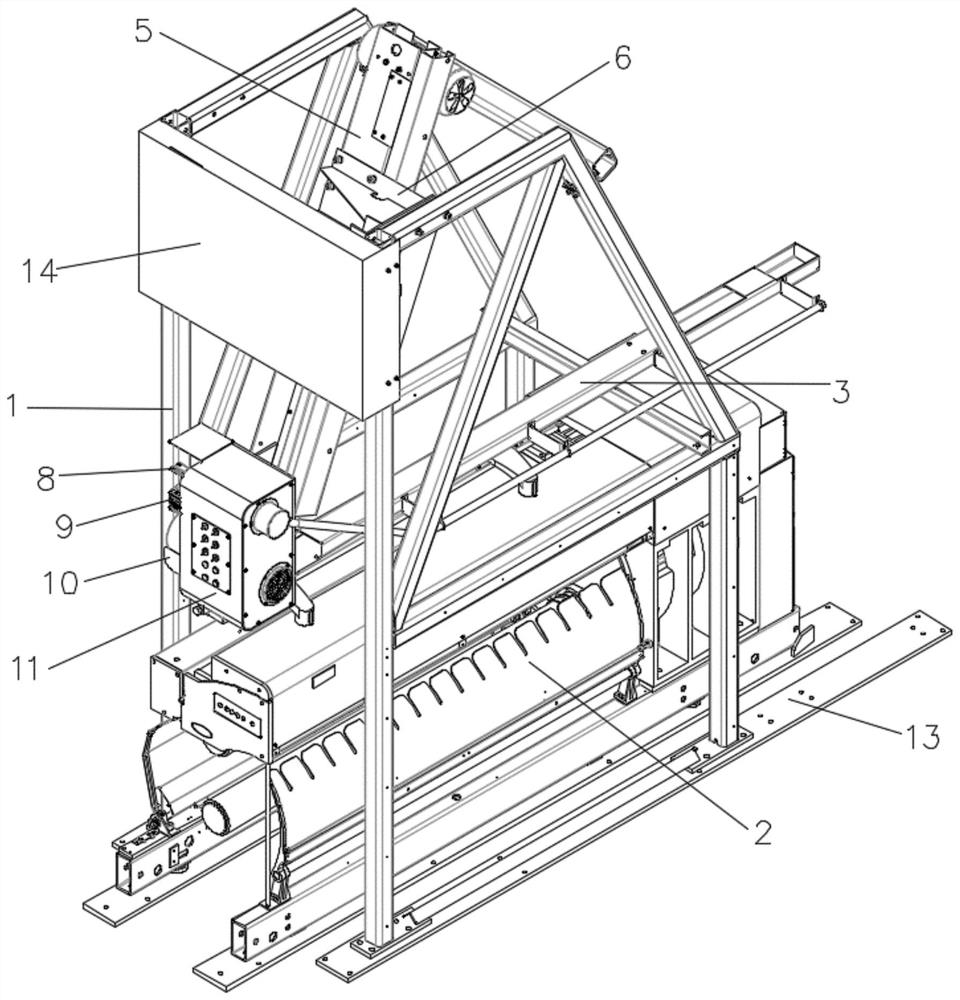

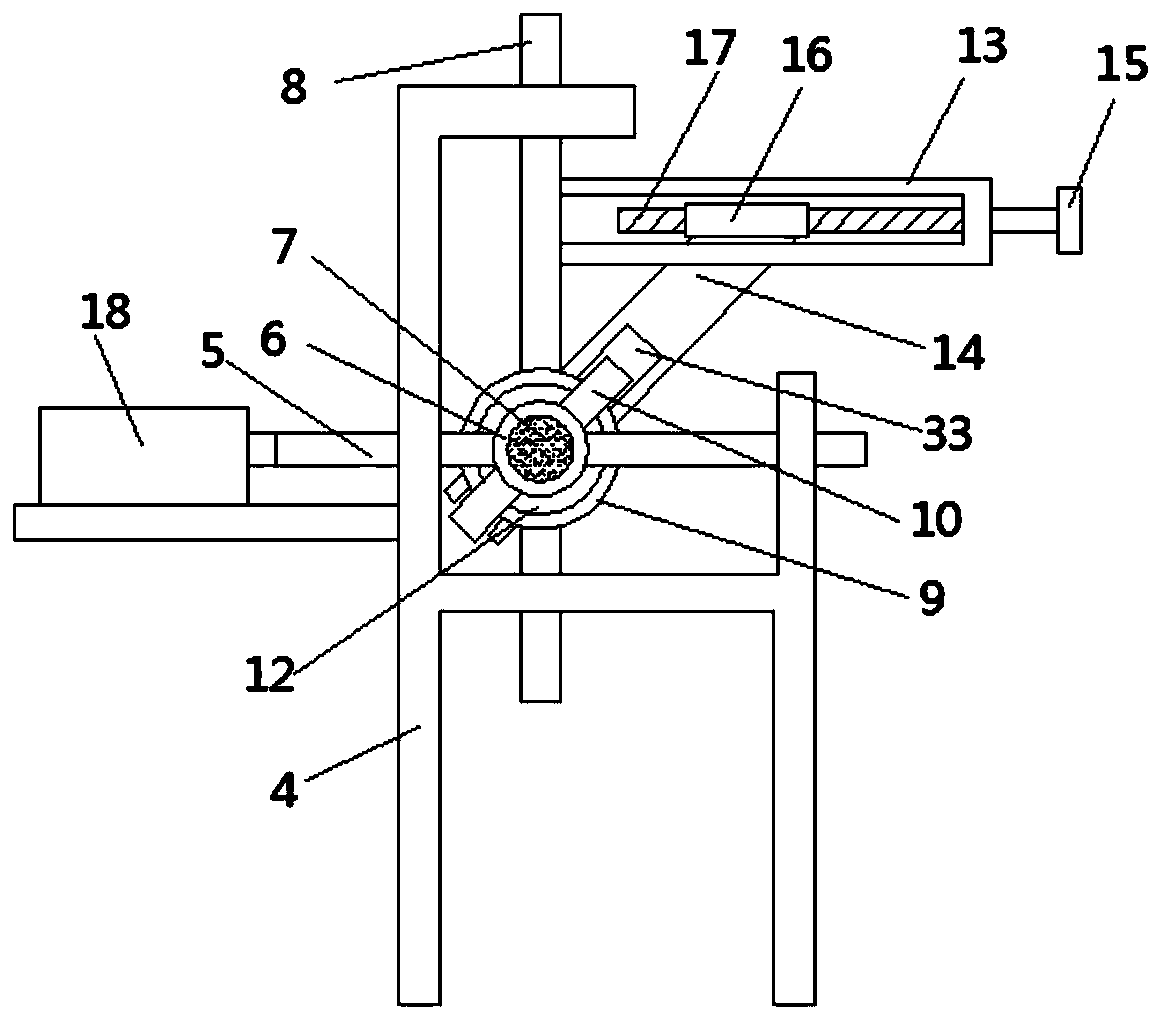

Industrial-grade aluminum oxide continuous fiber thousand-hole spinning channel and bundling device

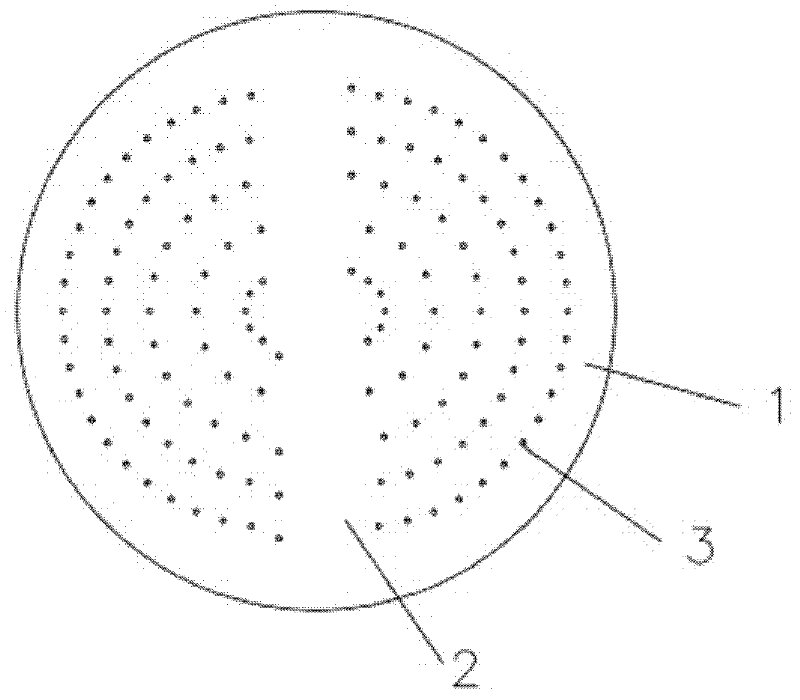

PendingCN112501701ASolve the problem of internal humidity and external drynessGuaranteed uniformitySpinnerette packsInorganic material artificial filamentsFiberYarn

The invention discloses an industrial-grade aluminum oxide continuous fiber thousand-hole spinning channel and bundling device, and belongs to the technical field of aluminum oxide spinning equipment.According to the industrial-grade aluminum oxide continuous fiber thousand-hole spinning channel and bundling device, one end of a liquid suction device is connected with a liquid feeding device, andthe other end of the liquid suction device is connected with a spinneret plate assembly; the spinneret plate assembly and an upper-side annular air blowing device are located on the upper portion ofa channel body, and the upper-side annular air blowing device is located on the outer side of the spinneret plate assembly; a side annular air blowing device and an annular heating device are locatedon the two sides of the channel body, and the side annular air blowing device is located on the upper portion of the annular heating device; a central shaft of an oiling device and a central shaft ofa cross rod are on the same straight line; and a twisting device is located on the lower portion of the oiling device, an air supply device is located on the lower portion of the twisting device, anda drafting device is located on the lower portion of the air supply device. By means of the industrial-grade aluminum oxide continuous fiber thousand-hole spinning channel and bundling device, the average diameter of fibers can be controlled to reach the level of 9+ / -1.5 [mu]m, and the problems of yarn drifting and yarn breaking which cannot be solved all the time in the spinning process are solved.

Owner:上海榕融新材料科技有限公司

Polyamide filament elastic yarn processing process applicable to sizing of short fiber sizing machine

A polyamide filament elastic yarn processing process applicable to sizing of a short fiber sizing machine relates to the technical field of weaving polyamide filament elastic yarn sizing. The process comprises performing a warping step through the creel of a small V-type column tensioner arranged on a warping machine, wherein the weight of the tension bars of the tensioner is 2.6 g, and the single yarn tension of the tension bars of the tensioner is 9 g; performing a sizing step through the short fiber sizing machine, during which applied sizing agent contains low-polymerization degree PVA (polyvinyl alcohol) and polyacrylate adhesives, the sizing temperature is 50-60 DEG C, and yarns in every area are straight and flat without twisting. The polyamide filament elastic yarn processing process applicable to sizing of the short fiber sizing machine facilitates sizing of the polyamide filament elastic yarns through the short fiber sizing machine, effectively avoids yarn scraping and breakage and further ensures subsequent normal production of polyamide filament elastic fabric.

Owner:JIANGSU LIANFA TEXTILE

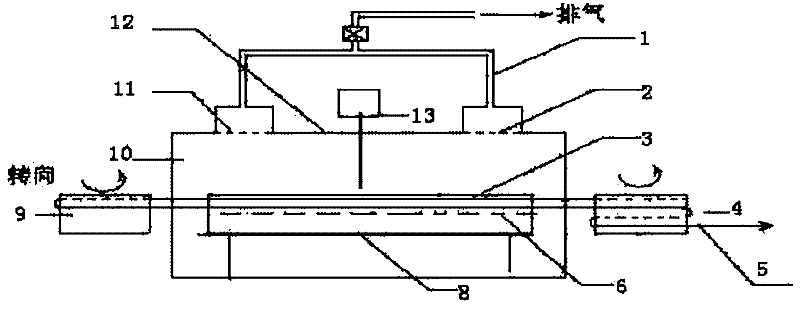

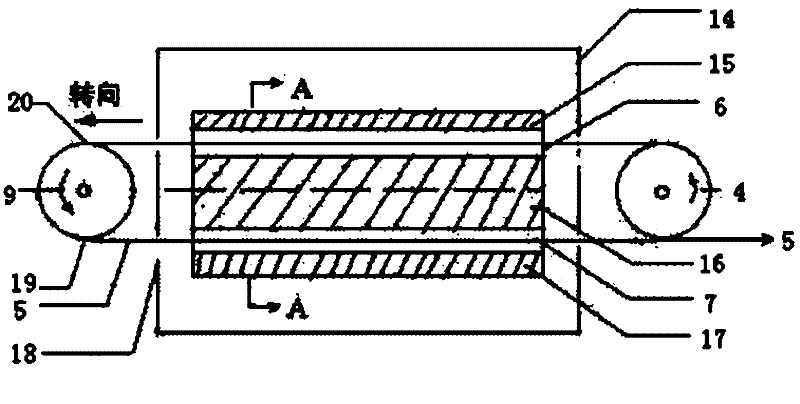

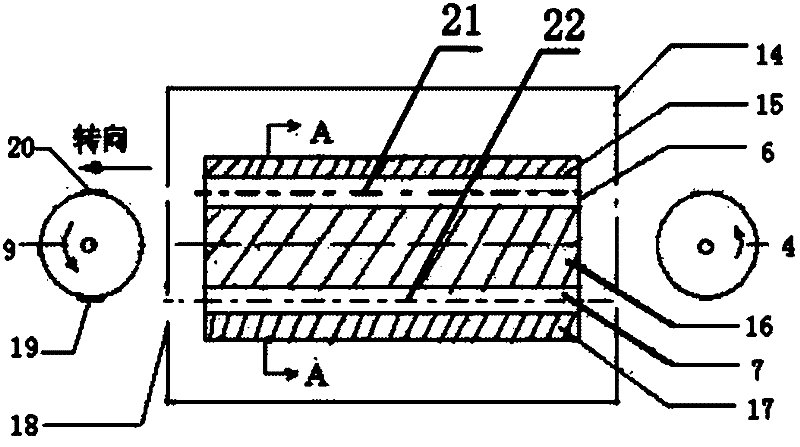

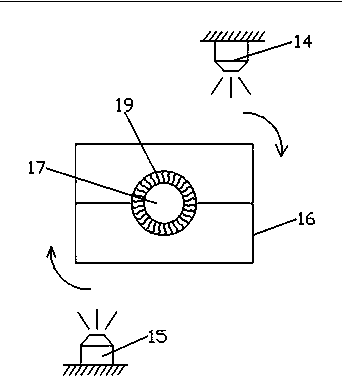

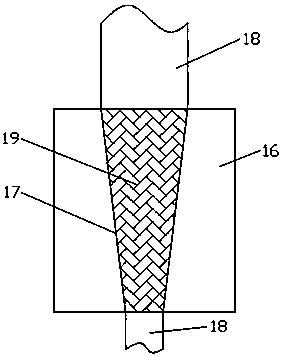

Microwave sintering and drafting device for pasty polytetrafluoroethylene extruded fibers

ActiveCN102493007AIncrease productivityAvoid breakingArtificial filament heat treatmentStretch-spinning methodsSteering wheelControl system

The invention discloses a microwave sintering and drafting device for pasty polytetrafluoroethylene extruded fibers, which comprises a microwave heating system, a sintering device, a temperature measuring system, a control system and an exhaust system. The microwave sintering and drafting device for pasty polytetrafluoroethylene extruded fibers is characterized in that a left area and a right area at the top of the microwave heating cavity are provided with exhaust pores with aperture smaller than wavelength of microwave, and a microwave generator comprises magnetrons with adjustable heating power. The temperature measuring system comprises an infrared temperature measuring instrument, and the control system is connected with the infrared temperature measuring instrument and the microwave generator. The sintering device comprises a two sintering tank disposed side by side and a filling medium, and the filling medium is disposed between the two sintering tanks disposed side by side and outside the two sintering tanks. A driven steering wheel and a drive steering wheel are arranged on the left and the right of the outer side of the microwave heating cavity respectively. An exhaust cover covers the exhaust pores and in joint with the exhaust pores. The microwave sintering and drafting device for pasty polytetrafluoroethylene extruded fibers is simple in operation, stable in heating temperature and high in sintering efficiency, and strength and ductility of sintered fibers are high.

Owner:XIAMEN BARON FLUORIDE MATERIALS TECH

Natural colored cotton slashing technology

InactiveCN101177854AReduce head breaksImprove permeabilityLeasingTextile treatment by pouringYarnEngineering

The invention provides a novel concept of natural colored cotton sizing and a method thereof. When the natural colored cotton is clear-starched, penetration of serous fluid to the yarn is improved; after the yarn enters a drying area, the holding and control of a serous film to the yarn is enhanced; unwinding tension is properly enhanced, and the coverage of serous material to the yarn is improved so as to lead the weaving efficiency of the yarn on a weaving machine to be greatly improved; few broken ends exist during the clear-starching process; sizing junk can meet requirement; clear-starching rate of the yarn is as high as 7.5 percent plus or minus 0.5 percent; sizing hairs adhesiveness and the strength of the yarn are improved obviously; the efficiency of the weaving machine is over 96.4 percent and the production value of the product is increased.

Owner:SHENGHONG GRP CO LTD

Kapok fiber, modal and cotton fiber light-weight and thermal sweater and manufacture method thereof

InactiveCN103160995ASolve the problem of poor cohesion of yarnReduce fuzzWoven fabricsBursting strengthKapok fiber

The invention relates to a kapok fiber or modal or cotton fiber light-weight and thermal sweater and a manufacture method of the kapok fiber or modal or cotton fiber light-weight and thermal sweater. The kapok fiber or modal or cotton fiber light-weight and thermal sweater and the manufacture method of the kapok fiber or modal or cotton fiber light-weight and thermal sweater are characterized in that fabric weave of the sweater is single-face plain weave. Yarn adopts three 40S and comprises, by weight, 30% of the kapok fiber, 30% of the modal and 40% of the cotton fiber siro spinning yarn twisted yarn. Twist of the yarn is 300 twiddles / meter, and gram weight of the yarn is 260g / m<2>. The manufacture method comprises: at first adopting a siro spinning technique to manufacture the kapok fiber, the modal and cotton fiber siro spinning yarn twisted yarn, and then carrying out weaving process: twisting the yarn, rewinding, weaving slice, covering ports, flat machine, sewing by hands, washing by water, drying, pressing, packaging and entering warehouse. The product is light in weight and thermal, color of the appearance is bright, cloth cover is bright and clean, flexibility and elasticity are good, and a visual effect is remarkable. The intrinsic requirement of being good in a moisture absorption performance and a moisture discharge performance, good in air permeability, bacteriostatic and antifungus, free of fuzziness, free of pilling, and bursting strength meets a criterion.

Owner:JIANGYIN XIANGFEI APPAREL

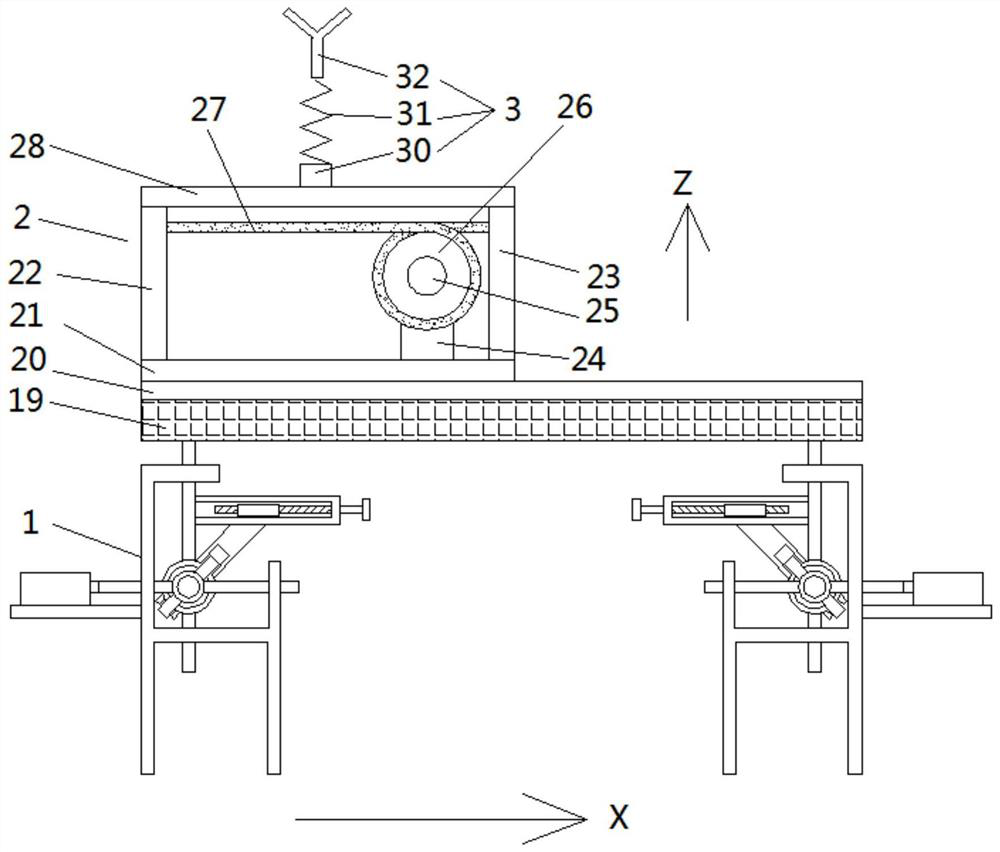

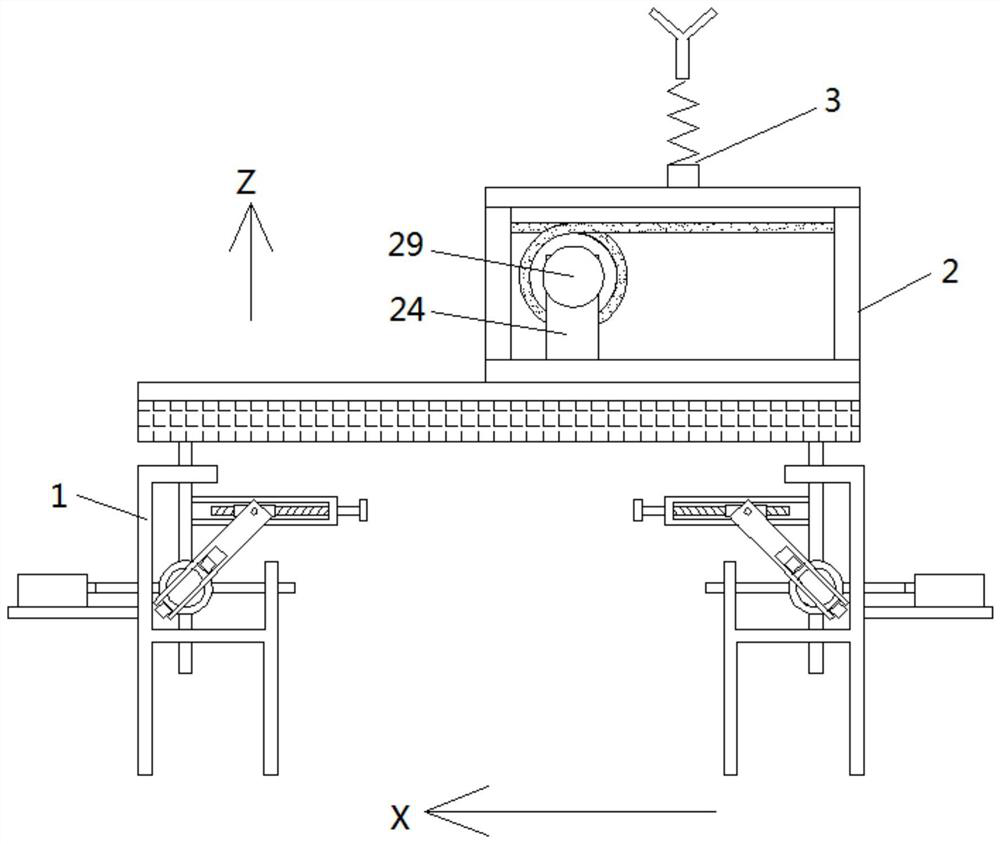

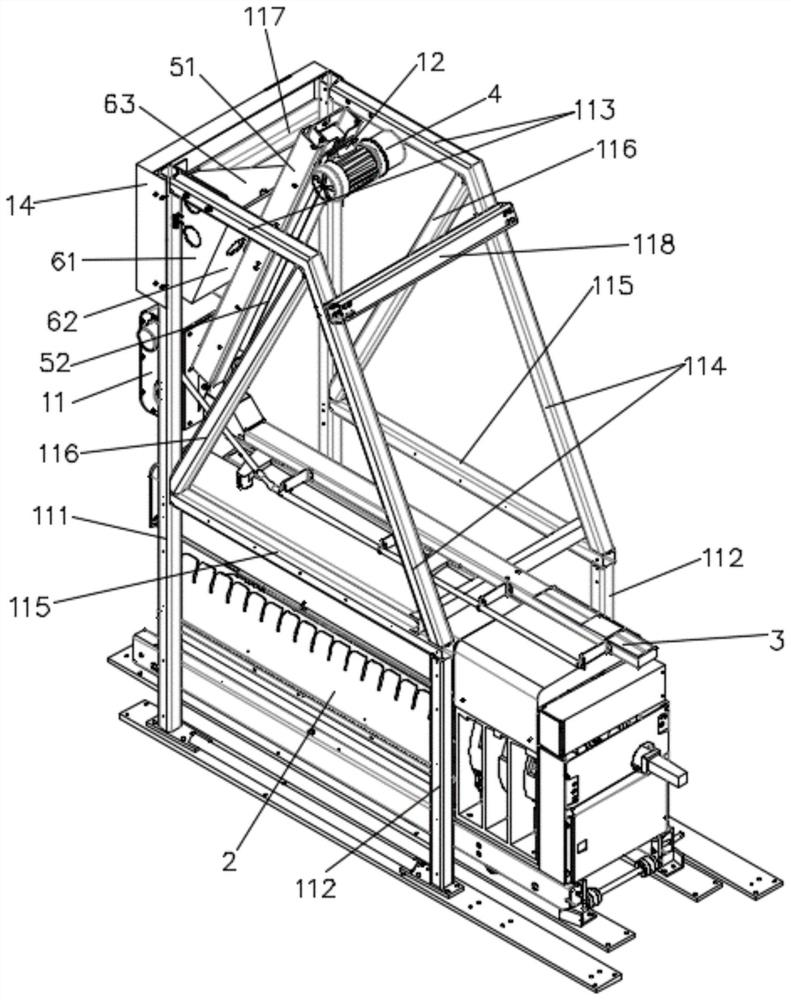

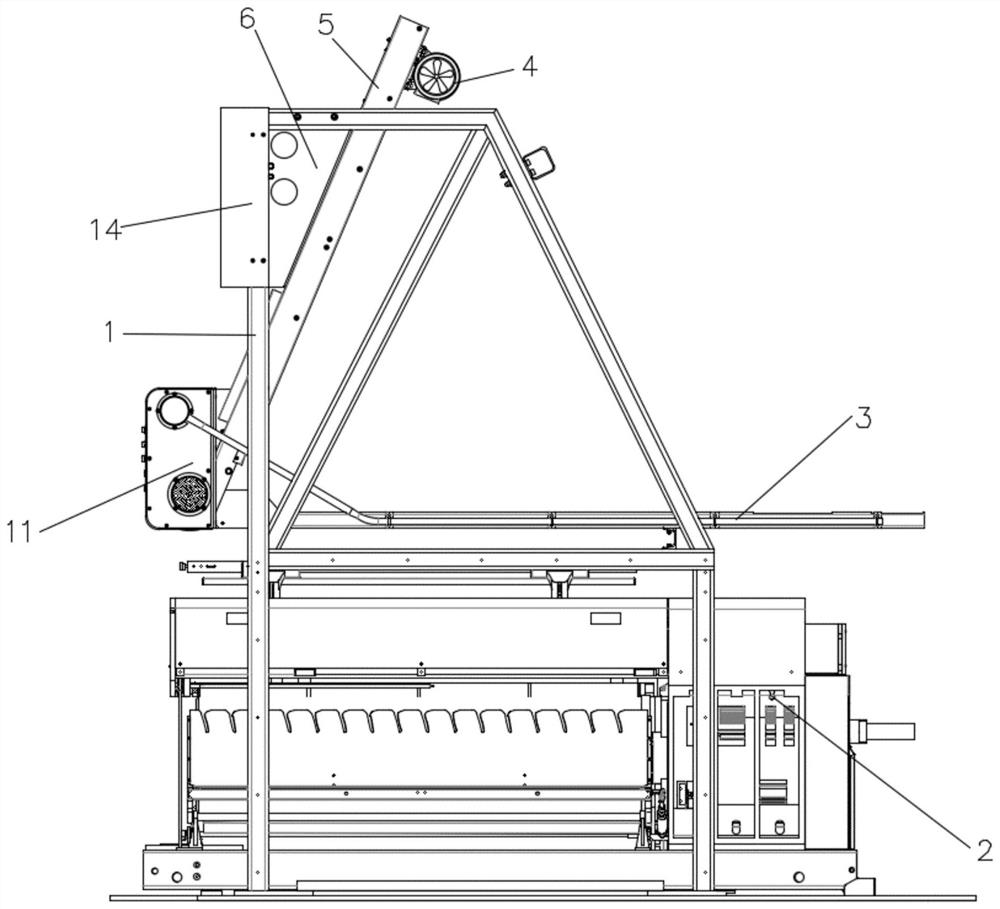

A double twister yarn guide device

The invention provides a yarn guide device for a two-for-one twister, which solves the problem that the tension of the existing yarn guide device cannot be adjusted, and the textile yarn is prone to splitting and end breakage, which seriously affects the work quality; The adjustment component drives the position of the yarn guide component to be adjusted in the X-axis and Z-axis directions. The adjustment is simple and convenient, so that the textile thread is in a tensioned state and avoids the splitting of the textile thread; the drive rod is pushed by the cylinder to move in the X-axis direction, and the drive plate follows the direction of the X-axis. The drive rod moves in the X-axis direction, the transmission block A cooperates with the drive groove, and the transmission rod moves in the Z-axis direction to complete the adjustment of the position of the yarn guide assembly in the Z-axis direction; the motor drives the main shaft to rotate, the pulley rotates with the main shaft, and the cable and Friction is generated between the pulleys to move the cable to complete the adjustment of the yarn guide assembly in the X-axis direction; the product quality is improved through the yarn guide assembly, and the spring is used as a buffer to reduce tension fluctuations and reduce the phenomenon of textile thread breakage.

Owner:江苏维迅纺织实业有限公司

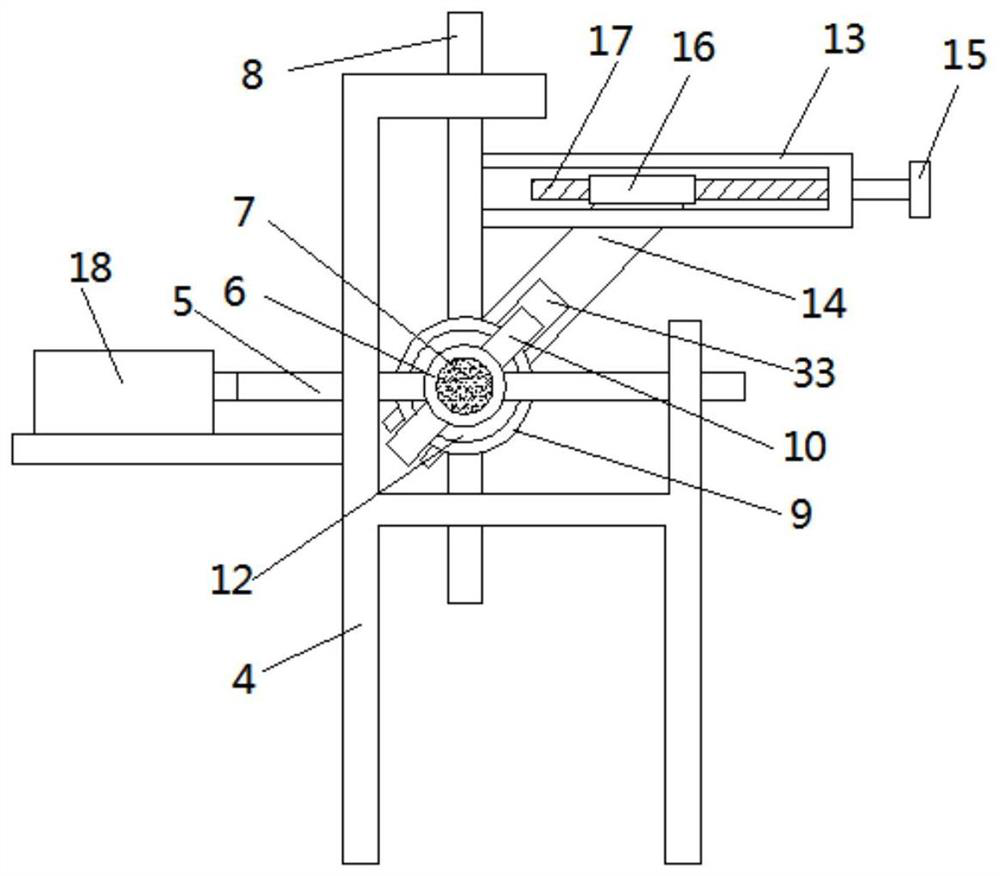

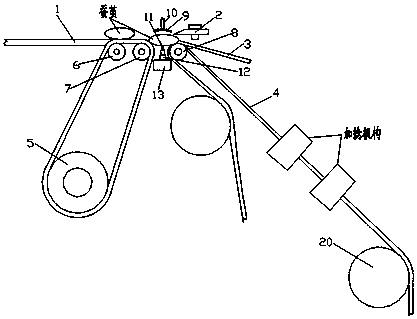

Rotor spinning false twister

InactiveCN106319696AReduce broken endsGood industry upgradeContinuous wound-up machinesOpen-end spinning machinesCombingYarn

The invention discloses a rotor spinning false twister. Narrow slits penetrating a cambered surface are formed in the cambered surface of a false twister body and connected with external fans, and air exhaust functions are achieved. When yarns are spun in a rotor spinning manner, the yarns can be adsorbed on the narrow slits by external negative pressure, friction action among the spun yarns and the cambered surface of the false twister body can be increased, so that false twisting action of the false twister is enhanced, and end breakage is decreased when the yarns are spun in the rotor spinning manner. The rotor spinning false twister can effectively solve the problem of end breakage in rotor spinning of combed noil yarns below 14.7tex, and can help enterprises to effectively upgrade industries and save production cost.

Owner:JIANGSU PUMEI TEXTILE CO LTD

Nylon BCF (bulked continuous filament) superfine fiber and preparation method thereof

The invention discloses a nylon BCF (bulked continuous filament) superfine fiber and a production method thereof; the method comprises the steps of firstly taking slices, carrying out melt extrusion,carrying out spinning through a special-shaped 105-hole trilobal spinneret plate, cooling and setting, oiling, drafting, deforming, making lapping points and winding to obtain the nylon BCF superfinefiber. According to the invention, the special-shaped trilobal spinneret plate is adopted, a high polymer melt or a solution in a viscous flow state sticks to the spinneret plate and is converted intoa thin flow with a specific cross section through micropores, and the thin flow is solidified through a solidification medium such as air or a solidification bath to form a filament. By controlling the whole post-treatment process, the occurrence of fiber filaments is avoided, and the generation of end breakage is greatly reduced. The prepared fiber is fine and smooth to touch, has the special properties of high strength, small elongation, small curling degree and the like, and allows spooled yarns to be easy to spin and process. The obtained superfine fiber is good in quality, completely meets market requirements, and has good economic and social benefits for enterprises.

Owner:SHEN MA INDUSTRY CO LTD

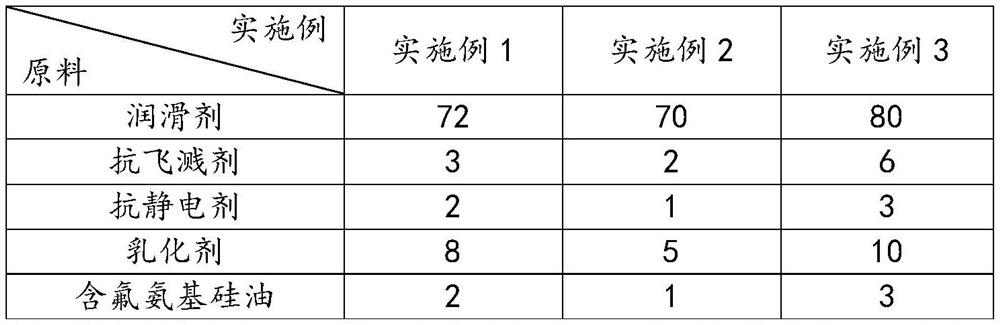

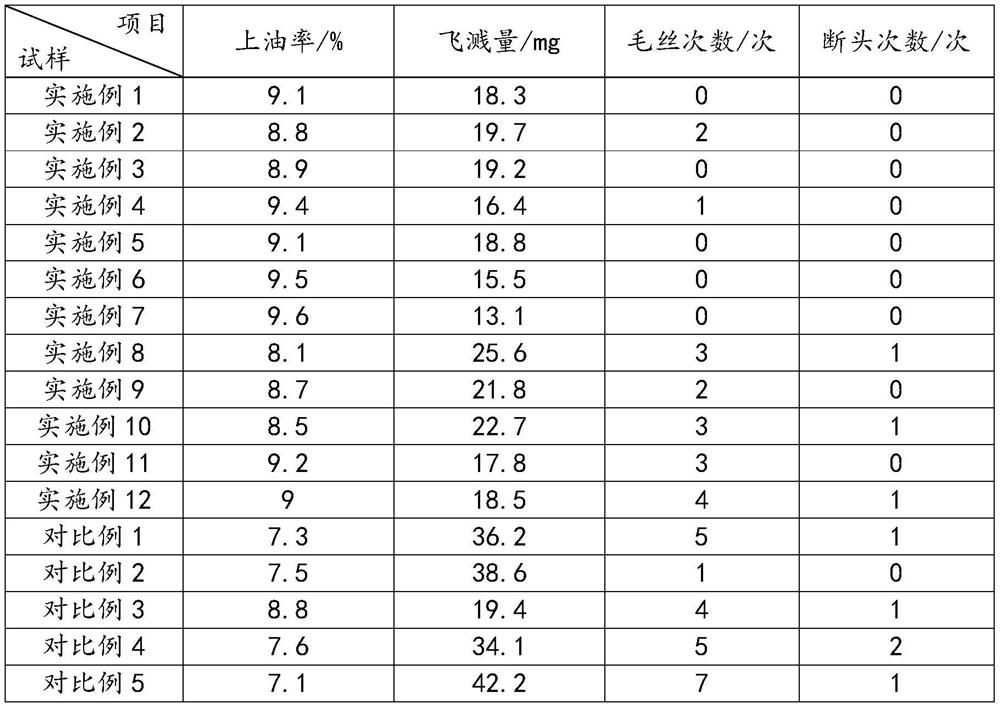

DTY (Draw Textured Yarn) oiling agent and DTY

The invention discloses a DTY (Draw Textured Yarn) oiling agent and DTY filaments. The DTY oiling agent comprises the following raw materials in parts by mass: 70-80 parts of a lubricant; 2-6 parts of an anti-splashing agent; 1-3 parts of an antistatic agent; and 5-10 parts of an emulsifier. The lubricant is prepared from industrial white oil and polydimethylsiloxane emulsion in a mass ratio of (15-18): 1; the viscosity of the industrial white oil is 3-10 mm < 2 > / s; and the viscosity of the polydimethylsiloxane emulsion is 300 to 1000 mm < 2 > / s. According to the DTY oiling agent disclosed by the invention, the lubricant is obtained by compounding the industrial white oil and the polydimethylsiloxane emulsion, so that the oiling rate and the splashing resistance of the DTY oiling agent can be effectively improved, the oiling uniformity of the oiling agent is guaranteed, and the phenomena of broken filaments and broken ends are reduced.

Owner:杭州朗平纺织有限公司

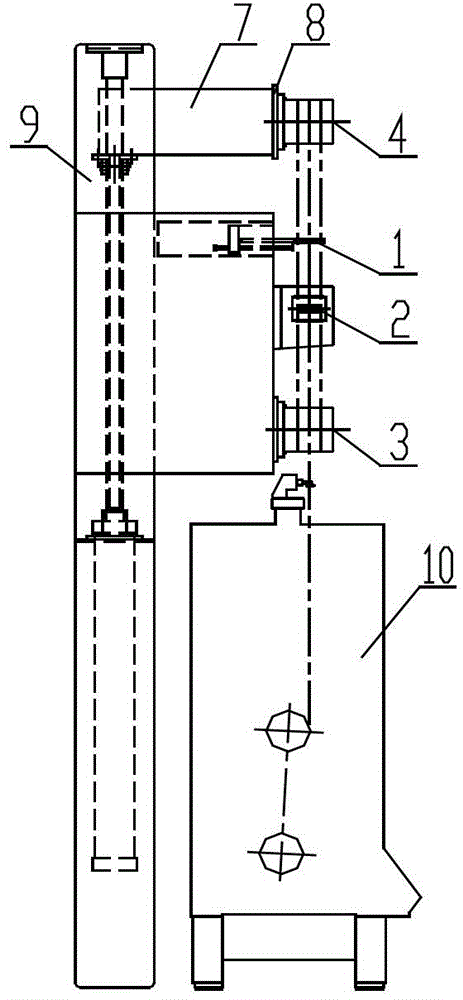

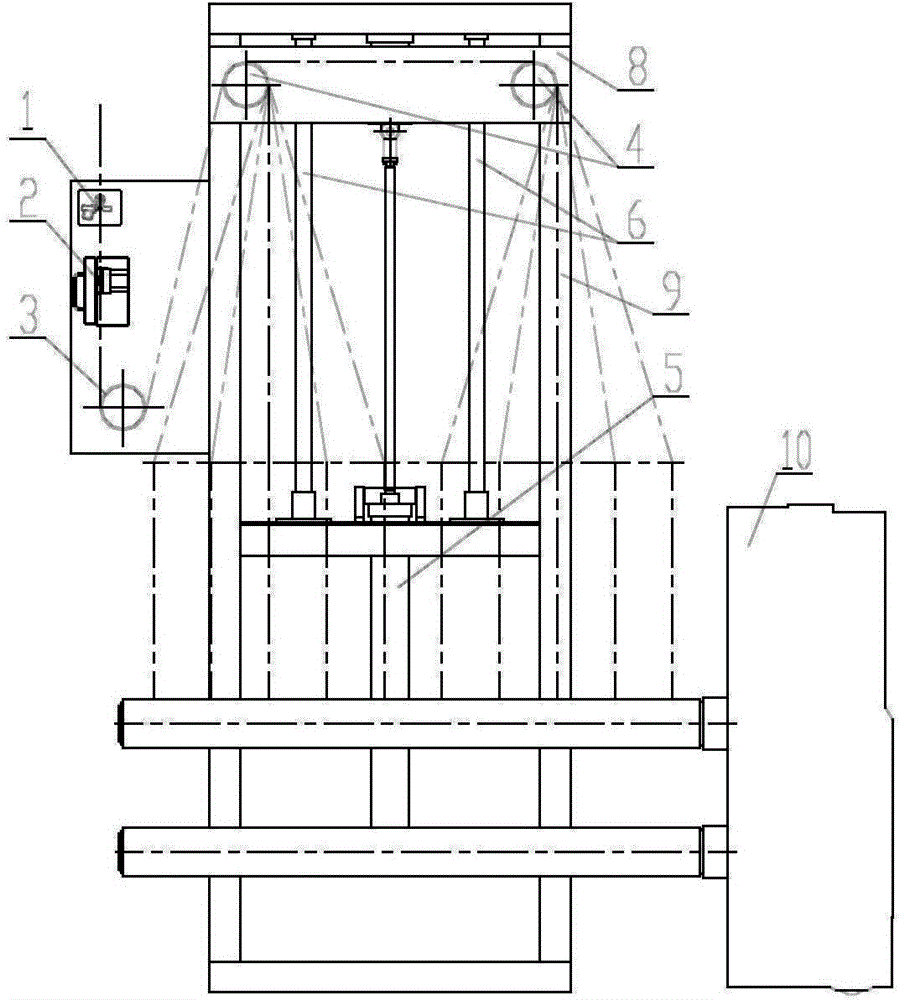

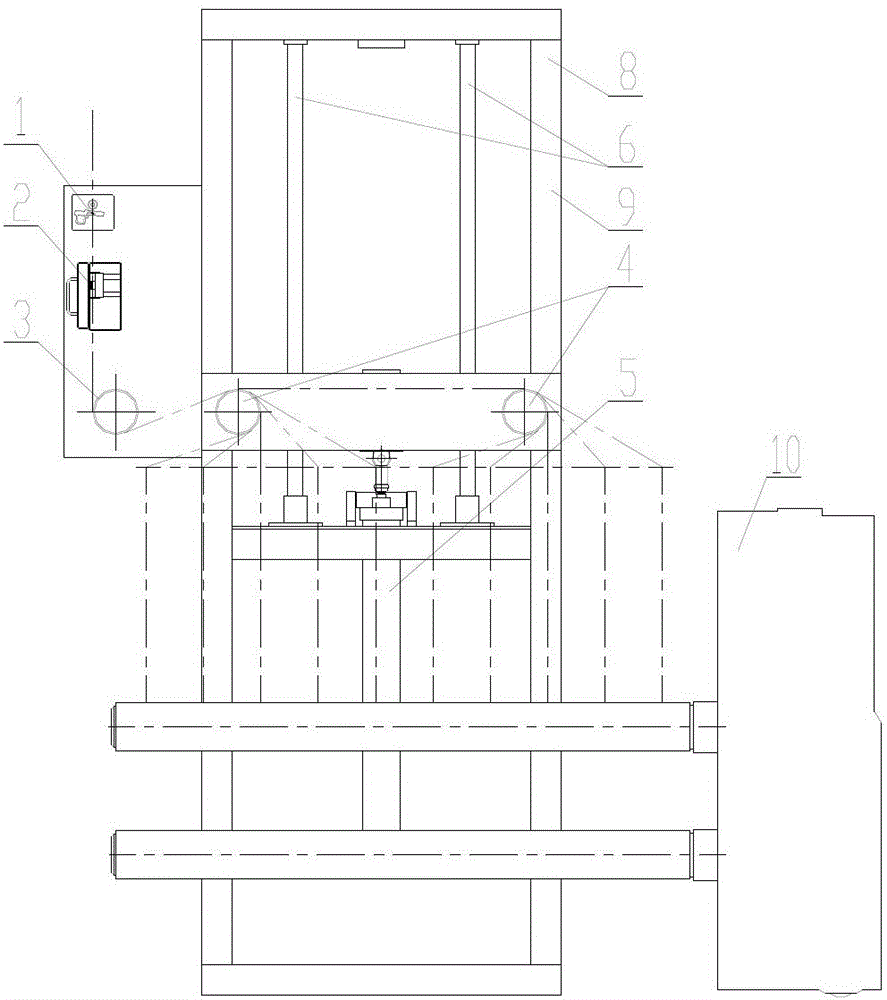

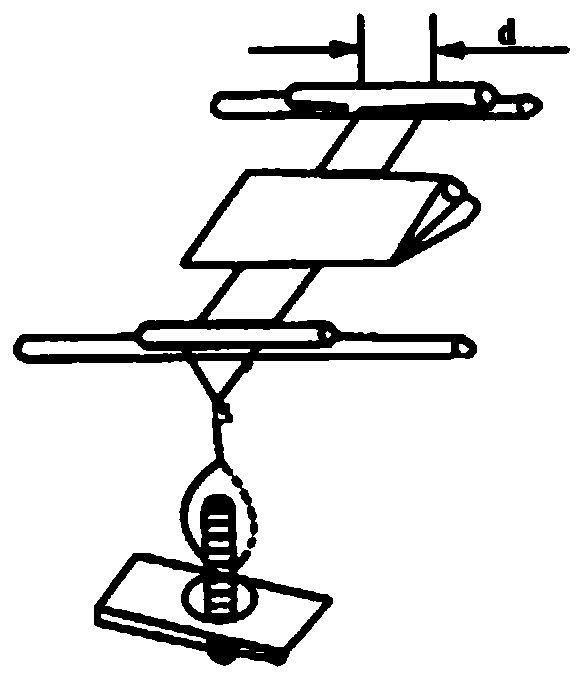

Filament POY (Pre-Oriented Yarn) drafting and winding device

ActiveCN103361752BReduce infrastructure costsReduce the overall heightNew-spun product collectionArtificial filament physical treatmentGuide wiresFilament yarn

Disclosed is an apparatus for drawing and winding POY filament yarn. The drawing and winding apparatus comprises: a yarn cutting and suctioning apparatus, a pre-interlacing device, a first yarn guide plate, a second yarn guide plate, a lifting mechanism, a lifting seat, a machine frame and a winder, wherein the yarn cutting and suctioning apparatus, the pre-interlacing device and the first yarn guide plate are provided in succession on one side of the machine frame based on the direction of travel of a tow; the lifting mechanism is provided on the machine frame, the lifting seat is linked to the lifting mechanism, and the lifting seat makes a reciprocal movement in a vertical direction under the drive of the lifting mechanism; the second yarn guide plates are two in number and are provided horizontally on the lifting seat; the winder is provided below the second yarn guide plates; after passing through the yarn cutting and suctioning apparatus, the pre-interlacing device and the first yarn guide plate, the tow is divided into two bundles respectively reeled on the two second yarn guide plates and then entering the winder to be wound. The present invention simplifies the structure and also increases the quality of the yarn, and enables more spinning station equipment to be installed in the same factory, increasing production capacity and reducing engineering construction costs.

Owner:BEIJING CHONGLEE MACHINERY ENG

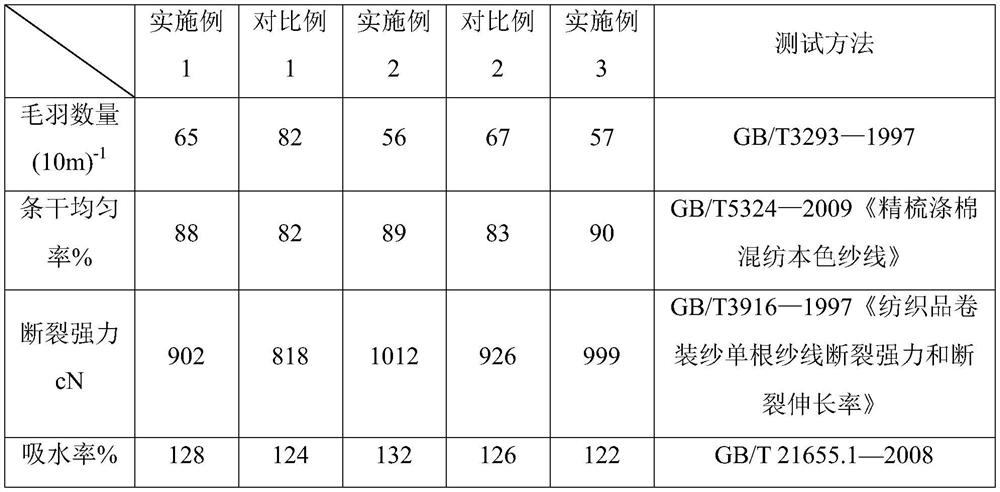

Blended yarn and preparation method and application thereof

ActiveCN114717701AStrong and goodImprove wear resistanceDrafting machinesTextile/flexible product manufactureYarnPolymer science

The invention discloses a blended yarn and a preparation method and application thereof.The preparation method of the blended yarn comprises the steps that in the siro spinning process, multiple roving strips are subjected to multiple times of siro spinning drafting and twisting through a siro spinning method, and siro spinning primary yarn is obtained; stranding the siro spinning primary yarn and a fiber bundle which is spun through melt spinning and is not completely cooled, and then jointly carrying out siro spinning drafting and twisting for at least one time to obtain a blended yarn; in the plying process, the fiber bundles which are not completely cooled adhere siro spinning primary yarn through the softened and adhesive surfaces of the fiber bundles, siro spinning is adopted in the method, but the defects existing in the conventional siro spinning process are overcome, the broken end phenomenon of single yarn fiber strands in the siro spinning process is reduced, and the yarn quality is improved. And the prepared blended yarn has better effects in the aspects of strength, wear resistance, hairiness quantity and the like.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

Anti-pilling wool fabric

An anti-pilling wool fabric includes 100% merino superfine wool, Sunn crotataria fiber, cashmere, milk fiber, acrylic fiber, modal fiber, combed cotton, and real silk. The wool fabric is blended by various fibers, and uniqueness of various fibers can be stuck out through reasonable fiber composition; the advantages of various fibers are integrated to the wool fabric, the wool fabric has a smooth hand feeling of the real silk fiber, and excellent heat retention property and water absorption capability, shows a style of softness with toughness, brightness, and colorfulness, has the characters of smoothness and good overhanging feel of the milk fiber, and has moisturizing factors which can achieve comfort of wearing; the cashmere can allow abundant suede of fabric and smooth hand feeling; the modal fiber has excellent elastic and toughness, and then end-down phenomenon can be reduced during processing; fresh bright color can kept after multi-time washing due to excellent dyeing property; the wool fabric has good stability of shape and size, has natural wrinkle resistance, can prevent pilling, and has soft sweat inhibition functions.

Owner:NANTONG JIANWEI YARN DYED CLOTHING CO LTD

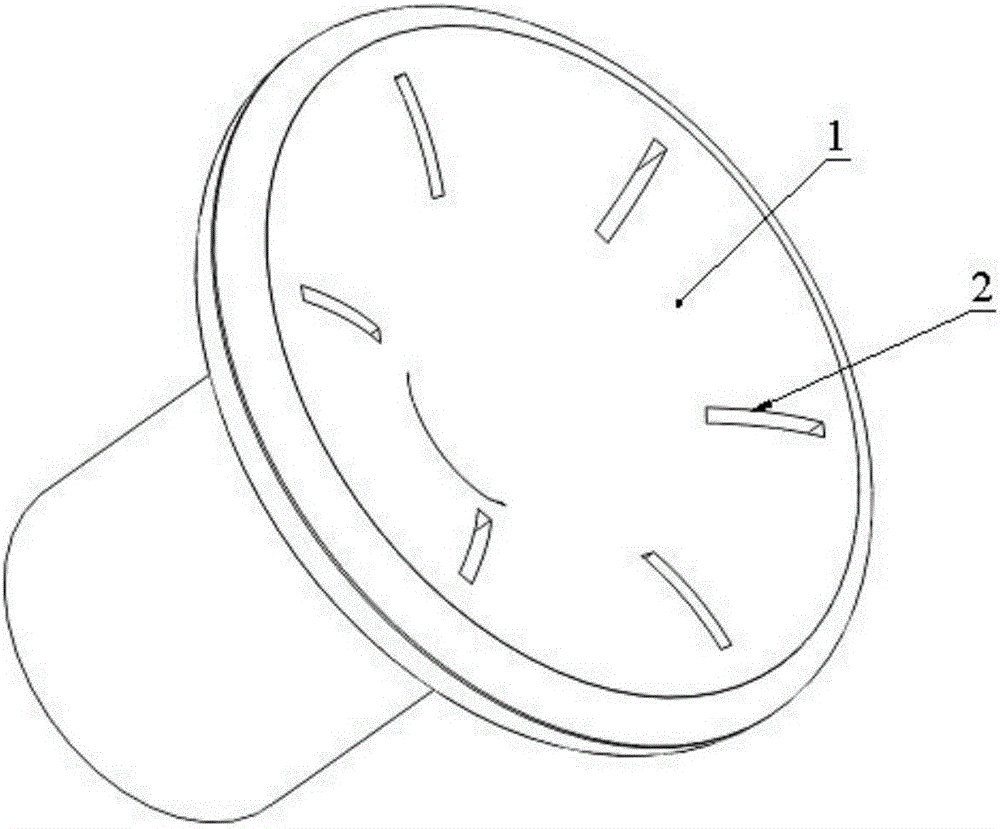

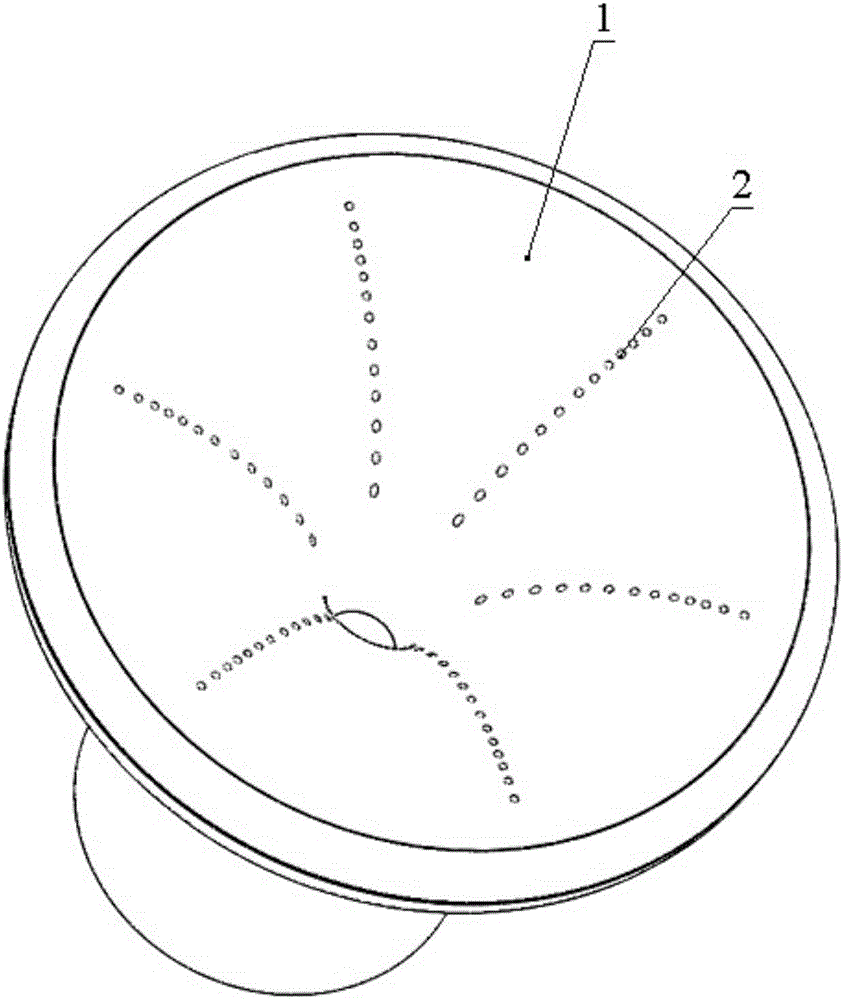

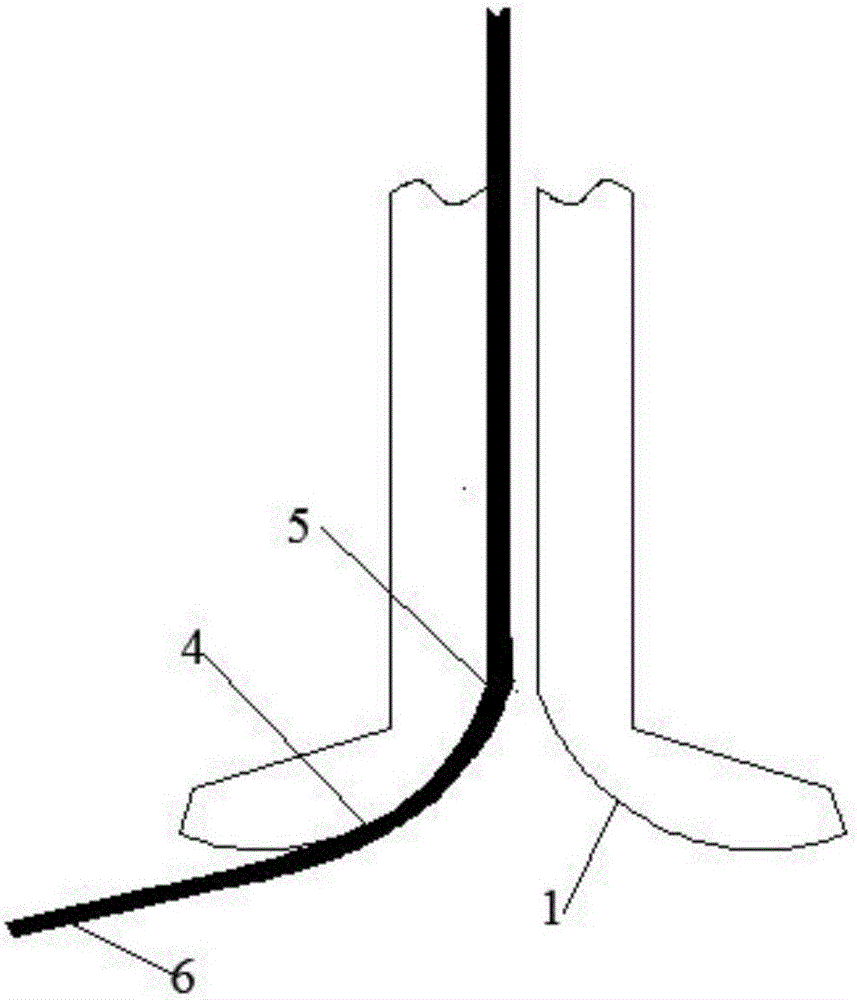

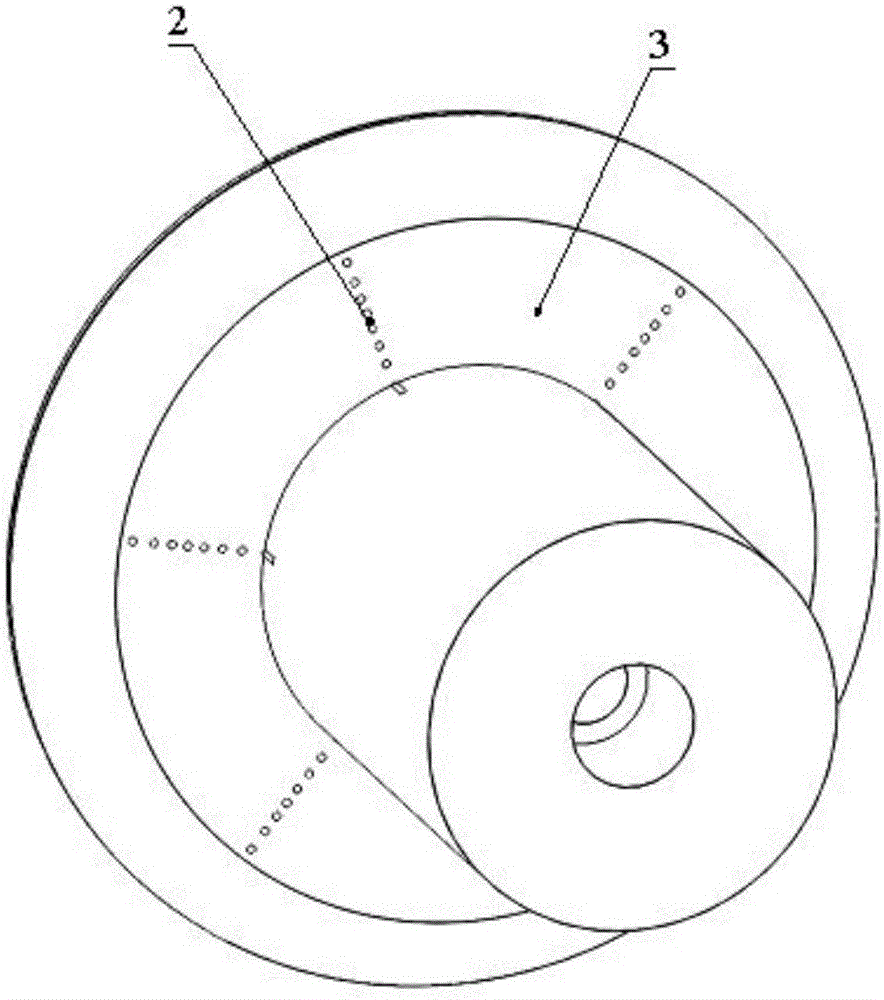

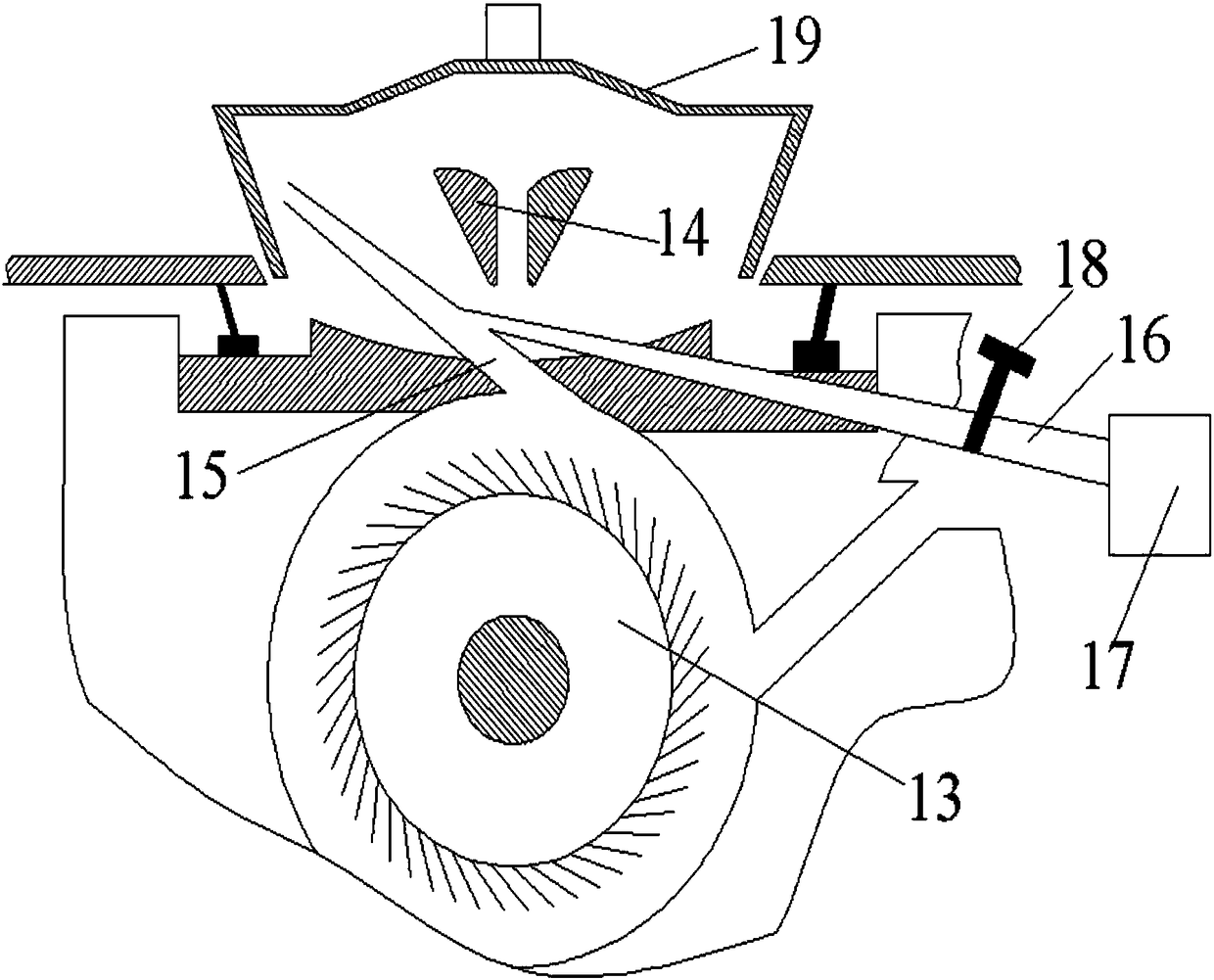

Preparation method of pure spun blended yarn of horn gourd fiber

The invention relates to a preparation method of calotropis gigantean fiber pure spinning blended yarn. Through strip forming, drawing, rough yarn and fine yarn processes of calotropis gigantean fiber, the calotropis gigantean fiber pure spinning blended yarn is prepared. Strip forming is conducted in the mode that the calotropis gigantean fiber is combed by metal card clothing on the surfaces ofa feeding stabbing roller and an opening roller, is divided into a single-fiber state, is transmitted and enters a strip forming cylinder which rotates under the effect of negative pressure airflow which is generated by an exhaust fan, is parallelly arrayed along the inner side of the cylinder wall of the strip forming cylinder in the circumferential direction, and slides into a strip forming groove and is stacked into annular fiber strands under the effect of centrifugal force; the strip forming cylinder is a rotation body and is composed of a cylinder body and a cylinder shaft, an opening isformed in one end of the cylinder body, and the cylinder body is composed of a cylinder bottom, a cylinder wall and the strip forming groove which makes the cylinder bottom connected with the cylinder wall; the diameter of the cylinder body is gradually increased from the cylinder opening to the strip forming groove, and the cylinder shaft is located on the outer side of the cylinder body and isvertically connected with the center of the cylinder bottom. According to the preparation method, strip forming is successfully conducted under the situation that the fiber is less damaged, and the prepared calotropis gigantean fiber is low in short fiber content and high in quality.

Owner:上海魔树生物科技有限公司

Pearl fiber blended yarn and application thereof

InactiveCN101545156BReasonable weaving process conditionsReduce head breaksGarmentsConjugated synthetic polymer artificial filamentsYarnSpinning

The invention provides a pearl fiber blended yarn, which is prepared from 35 to 45 percent of tencel, 35 to 45 percent of modal fiber and 15 to 25 percent of pearl fiber by weight percentage through blended spinning. The invention also provides a slippery ventilated comfortable sweater woven from the pearl fiber blended yarn and a method for producing the same. The sweater or an underwear productalso has the characteristics of the tencel, the modal fiber and the pearl fiber, is slippery and soft in hand feeling and ventilated, has good hygroscopicity, is not toxic and irritative to a human body, and can make pearl particles give play to functions of caring skin, beautifying, clearing fever and whitening after contacting with skin for a long time. The calcium carbonate content in the pearl fiber blended yarn has far infrared emission function and ultraviolet resistant function, and can not only accelerate human body microcirculation and promote metabolism, but also prevent skins from being hurt by ultraviolet, thus the pearl fiber blended yarn has certain health care and protective effects on the human body.

Owner:JIANGYIN XIANGFEI APPAREL

Rotor spinning false twister

InactiveCN106319697AReduce broken endsHigh false twist efficiencyContinuous wound-up machinesOpen-end spinning machinesCombingYarn

The invention discloses a rotor spinning false twister. Through holes penetrating a cambered surface are formed in the cambered surface of a false twister body and connected with external fans, and air exhaust functions are achieved. When yarns are spun in a rotor spinning manner, the yarns can be adsorbed at the through holes by external negative pressure, friction action among the spun yarns and the cambered surface of the false twister body can be increased, so that false twisting action of the false twister is enhanced, and end breakage is decreased when the yarns are spun in the rotor spinning manner. The rotor spinning false twister can effectively solve the problem of end breakage in rotor spinning of combed noil yarns below 14.7tex, and can help enterprises to effectively upgrade industries and save production cost.

Owner:JIANGSU PUMEI TEXTILE CO LTD

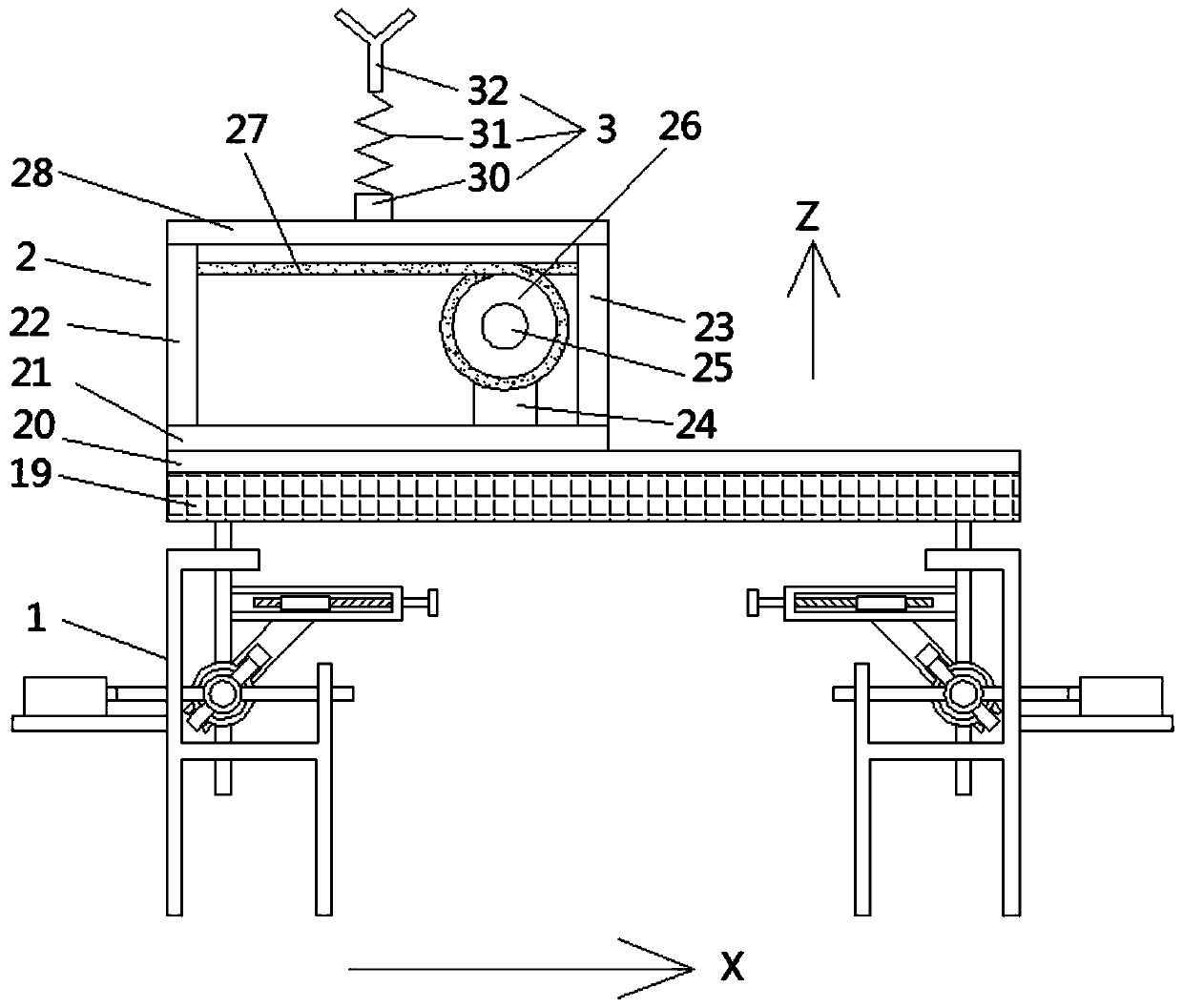

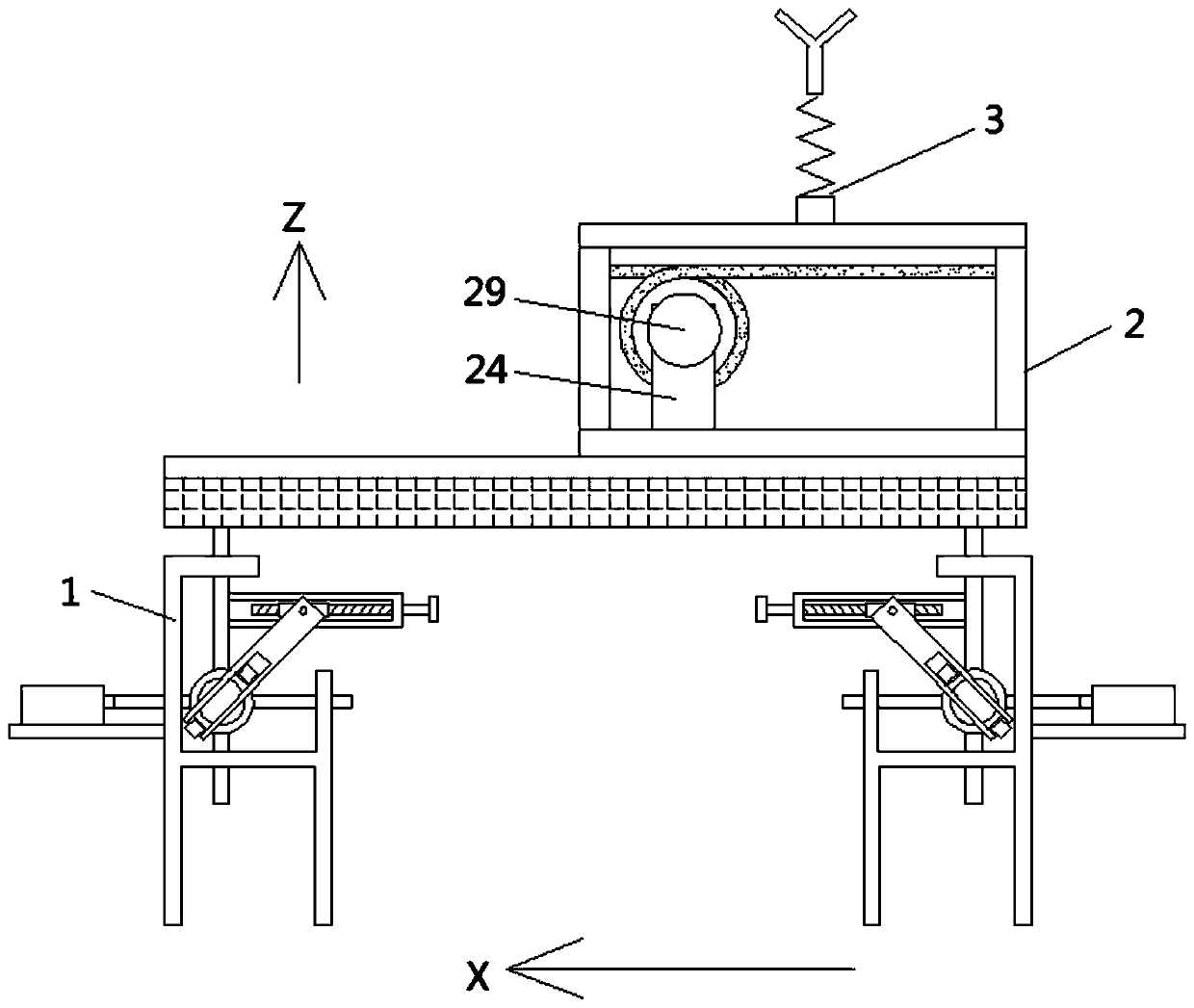

Synthetic fiber integrated winding device

PendingCN112209165AReduce the number of peopleReduce labor costsFilament handlingTextiles and paperYarnSynthetic fiber

The invention discloses a synthetic fiber integrated winding device. The synthetic fiber integrated winding device comprises a rack, a winding head, a side support, a lifting mechanism, a yarn shearing and sucking device, a pre-interlacing device, a lower guide disc, an upper guide disc and a lifting base, the winding head is located in the rack, the side support is fixed to the side surface of the rack and comprises a supporting part, the lifting mechanism comprises a supporting frame and a lifting driver, the lower end of the supporting frame is fixed to the top of the winding head, the upper end of the supporting frame is fixed to the supporting part, the lifting driver is arranged in the supporting frame, the wire shearing and sucking device, the pre-interlacing device and the lower guide disc are located at the lower end of the support frame, the lifting base is fixed to the movable end of the lifting driver, and the upper guide disc is fixed to the lifting base. The operations ofa drafting unit and a winding unit are combined from two layers to one layer so that the device is greatly reduced, and the occupied area is reduced.

Owner:BEIJING CHONGLEE MACHINERY ENG

Yarn guiding device of double-twisting machine

The invention provides a yarn guiding device of a double-twisting machine. The yarn guiding device solves the problems that the tension of existing yarn guiding devices cannot be adjusted, textile threads are easily split into strands and broken at the ends, and the working quality is seriously affected. The position of a yarn guiding assembly is adjusted in the X-axis direction and the Z-axis direction through driving of vertical adjusting assemblies and a horizontal adjusting assembly easily and conveniently to make textile threads in a tension state and prevent the textile threads from being split into strands; driving rods are pushed by air cylinders to move in the X-axis direction, driving discs follow the driving rods to move in the X-axis direction, transmission blocks A and drivinggrooves cooperate with each other, transmission rods move in the Z-axis direction, and the adjustment of the position of the yarn guiding assembly in the Z-axis direction is completed; a main shaft is driven by a motor to rotate, a belt pulley follows the main shaft to rotate, friction is generated between a cable and the belt pulley to make the cable move, and the adjustment of the position of the yarn guiding assembly in the X-axis direction is completed; the product quality is improved through the yarn guiding assembly, a buffering function is achieved by utilizing springs, the tension fluctuation is reduced, and the end breakage phenomenon of the textile threads is reduced.

Owner:江苏维迅纺织实业有限公司

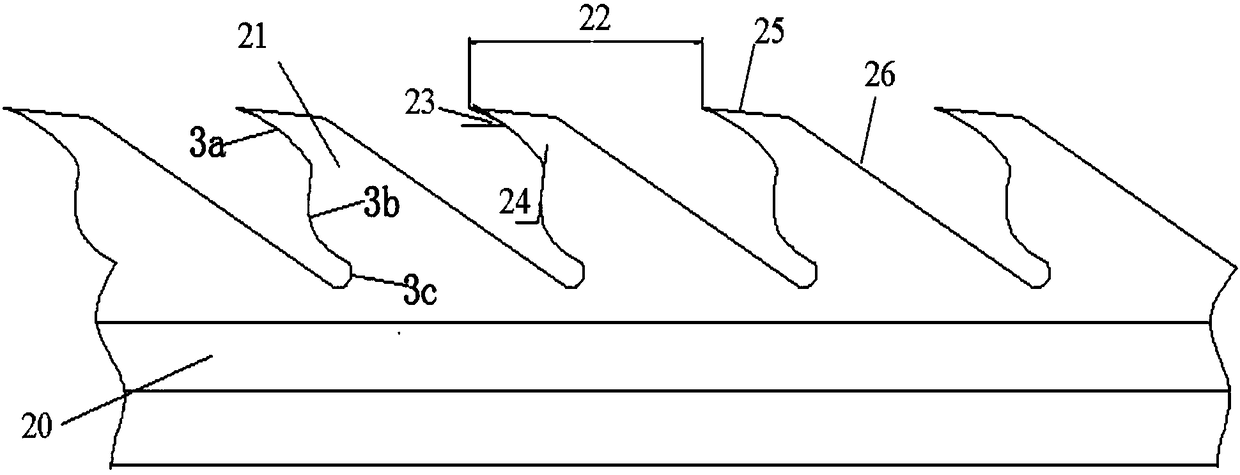

Silkworm-peeling device for silk fabrics

PendingCN107587198AGuaranteed uniformityReduce head breaksSilk filament obtainingEngineeringSilk fabric

The invention relates to the technical field of silk fabric production equipment and especially relates to a silkworm-peeling device for silk fabrics. The silkworm-peeling device comprises a silkwormcocoon conveyer belt, wherein a silkworm-peeling mechanism is arranged at one end of the silkworm cocoon conveyer belt; a silkworm-peeling scraper is arranged on one side of the upper part of the silkworm-peeling mechanism; a naked silkworm conveyer belt is arranged at the lower end of the silkworm-peeling scraper; a silkworm coat conveyer belt is arranged on one side of the naked silkworm conveyer belt; a plurality of twisting mechanisms are arranged on the middle part of the silkworm coat conveyer belt. The silkworm-peeling device for silk fabrics can guarantee the stable sequential performance of the process of peeling the silkworm coat from the silkworm cocoon; the twisting mechanisms are adopted for simply twisting the peeled silkworm coat; the uniformity of the subsequent formed silkis guaranteed; the head-breaking phenomenon is reduced; the silk forming quality is guaranteed; the overall production efficiency is increased.

Owner:湖州卓宇丝织有限公司

A method for spinning combed noil by rotor spinning

ActiveCN106567166BReduce head breaksIncrease productivityCarding machinesContinuous wound-up machinesCombingEngineering

Owner:JIANGSU PUMEI TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com