DTY (Draw Textured Yarn) oiling agent and DTY

An oil and lubricant technology, applied in the field of chemical fiber spinning, can solve the problems of oil splash, broken ends, filaments, etc., and achieve the effect of improving the oiling rate, ensuring uniformity, and reducing filaments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

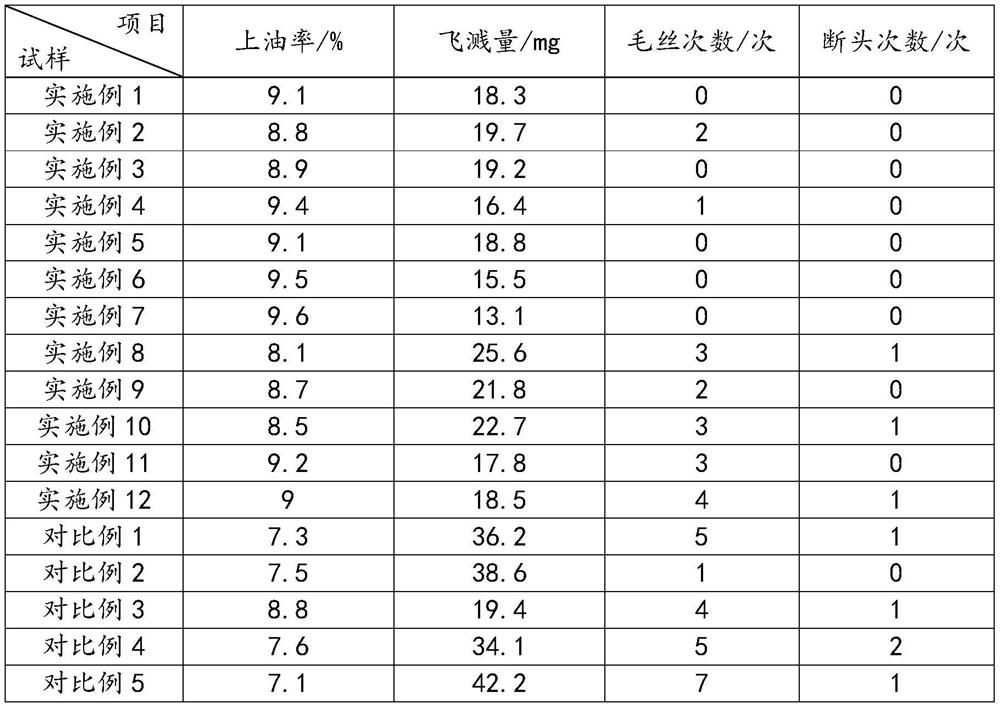

Examples

preparation example 1

[0037] Preparation example 1, a polydimethylsiloxane emulsion, was prepared according to the following method:

[0038] S101: Dissolve 30g of sodium dodecylsulfonate and 9g of OP-10 in 3L of water under stirring, continue to stir and heat up to 70°C, add 400g of octamethylcyclotetrasiloxane and 100g of tetramethyl tetrasiloxane The mixed solution composed of vinyltetrasiloxane was stirred for 2 hours at a speed of 200 rpm to obtain a pre-emulsion;

[0039] S102: Add 5g of p-toluenesulfonic acid (initiator) to the pre-emulsion, stir and heat up to 80°C, stir at a constant temperature and react for 7h to obtain a reaction solution, then drop to room temperature, add sodium bicarbonate solution (buffer) to adjust The pH value was 7, and a polydimethylsiloxane emulsion with a viscosity (at 25° C.) of 350 mm2 / s was obtained.

preparation example 2

[0040] Preparation example 2, a polydimethylsiloxane emulsion, was prepared according to the following method:

[0041] S101: Dissolve 60g of sodium dodecylsulfonate and 15g of OP-10 in 5L of water under stirring, continue to stir and heat up to 80°C, add octamethylcyclotetrasiloxane with a mass ratio of 450g and 90g A mixed solution composed of tetramethyltetravinyltetrasiloxane was stirred for 3h at a rotating speed of 500rpm to obtain a pre-emulsion;

[0042] S102: Add 8g of p-toluenesulfonic acid (initiator) to the pre-emulsion, keep a constant temperature at 85°C and stir for 10h to obtain the reaction solution, then drop to room temperature, add sodium bicarbonate solution (buffer) to adjust the pH value 7. Obtain a polydimethylsiloxane emulsion with a viscosity (at 25° C.) of 900 mm2 / s.

preparation example 3

[0043] Preparation example 3, a polydimethylsiloxane emulsion, was prepared according to the following method:

[0044] S101: Dissolve 20g of sodium dodecylsulfonate and 7g of OP-10 in 3L of water under stirring, continue to stir and heat up to 70°C, add 420 g of octamethylcyclotetrasiloxane and 80 g of tetramethyl tetrasiloxane The mixed solution composed of vinyltetrasiloxane was stirred for 2 hours at a speed of 200 rpm to obtain a pre-emulsion;

[0045] S102: Add 5g of p-toluenesulfonic acid (initiator) to the pre-emulsion, stir and heat up to 80°C, stir at a constant temperature and react for 6h to obtain a reaction solution, then drop to room temperature, add sodium bicarbonate solution (buffer) to adjust The pH value was 7, and a polydimethylsiloxane emulsion with a viscosity (at 25° C.) of 200 mm2 / s was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com