Preparation method of highly air-permeable polylactic acid non-woven diapers

A technology of polylactic acid and non-woven fabrics, which is applied in the field of hygiene, can solve the problems of affecting the air permeability of products, easy to get diaper rash, etc., and achieve the effects of not easy side leakage, good isolation, and good moisture conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

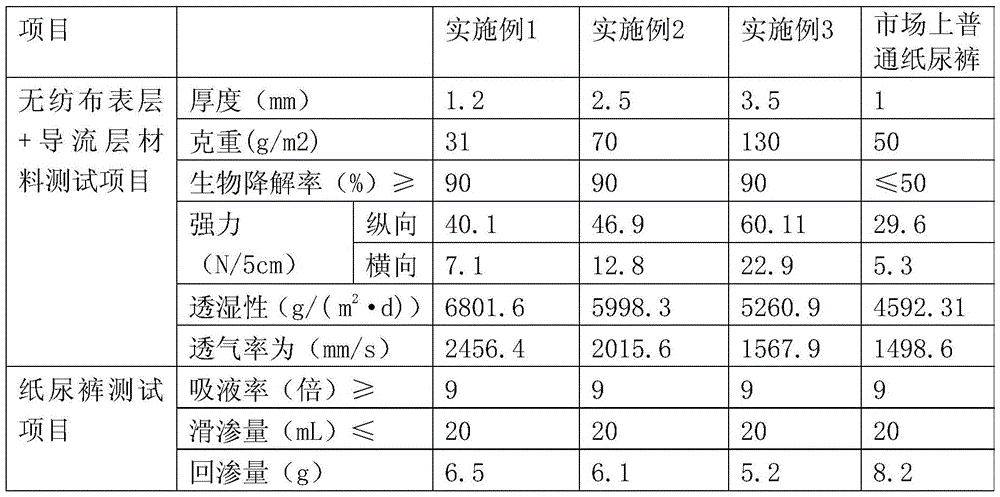

Embodiment 1

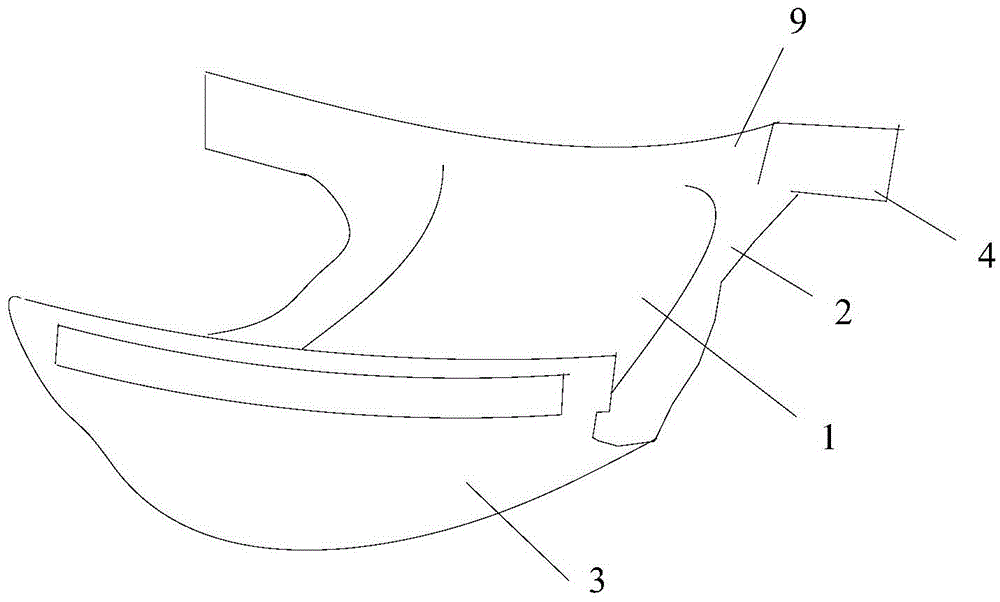

[0043] Such as figure 1 The diapers proposed by the present invention are approximately rectangular when flattened, and the four corners are provided with adhesive parts 4 (the trade name is a nylon hook and loop). The diapers surround the buttocks, and the adhesive parts bond together to form shorts. The "inside" of the diaper refers to the side that is in contact with the body; when it is spread out, it is the "up" direction. The waist is provided with a curved elastic waistline 9 .

[0044] The diapers include a surface material 1, a water-absorbent core layer, and a bottom film 3 from the inside to the outside. The surface material 1 has a three-layer structure of an upper layer, a middle layer, and a lower layer. Woven cloth and lower polylactic acid short fiber net. The polylactic acid long-fiber non-woven fabric is distributed with diversion holes with a diameter of 20 mesh. The diversion holes are in the shape of a large top and a small bottom.

[0045] The polylac...

Embodiment 2

[0056] The preparation of the same paper diaper of structure and embodiment 1:

[0057] A PLA fiber with a linear density of 3.3dtex and a length of 51mm is used. First, a hydrophilic agent is sprayed on the surface of the fiber. The concentration of the hydrophilic agent is 10%, so that the fiber surface contains a hydrophilic agent with a concentration of 0.8%. After the polylactic acid staple fiber is fed, opened, mixed, roller carding machine and finely carded by the work roll, it is stripped by double doffers and transferred to the upper and lower layers of fiber webs. The upper and lower layers of polylactic acid short fibers The weight of the fiber net is 20 grams per square meter, and the thickness is 1.1mm; the active unwinding device located in the middle of the double doffer unwinds the 100% polylactic acid filament non-woven fabric, and sandwiches the upper and lower layers of polylactic acid short fiber In the middle of the net, the three-layer fiber net is sent t...

Embodiment 3

[0066] The preparation of the same paper diaper of structure and embodiment 1:

[0067] Using a PLA fiber with a linear density of 4.4dtex and a length of 65mm, first spray a hydrophilic agent on the surface of the fiber, the concentration of the hydrophilic agent is 8%, so that the fiber surface contains a hydrophilic agent with a concentration of 1%. After the polylactic acid staple fiber is fed, opened, mixed, roller carding machine and finely carded by the work roll, it is stripped by double doffers and transferred to the upper and lower layers of fiber webs. The upper and lower layers of polylactic acid short fibers The weight of the fiber net is 40 grams per square meter, and the thickness is 1.5mm; the active unwinding device located in the middle of the double doffer unwinds the 100% polylactic acid filament non-woven fabric, and sandwiches the upper and lower layers of polylactic acid short fiber In the middle of the net, the three-layer fiber net is sent to the flat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com