Patents

Literature

5435 results about "Sodium-ion battery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The sodium-ion battery (NIB) is a type of rechargeable battery analogous to the lithium-ion battery but using sodium ions (Na⁺) as the charge carriers. Its working principle and cell construction are identical with that of the commercially widespread lithium-ion battery with the only difference being that the lithium compounds are swapped with sodium compounds: in essence, it consists of a cathode based on a sodium containing material, an anode (not necessarily a sodium-based material) and a liquid electrolyte containing dissociated sodium salts in polar protic or aprotic solvents. During charging, Na⁺ are extracted from the cathode and inserted into the anode while the electrons travel through the external circuit; during discharging, the reverse process occurs where the Na⁺ are extracted from the anode and re-inserted in the cathode with the electrons travelling through the external circuit doing useful work. Ideally, the anode and cathode materials should be able to withstand repeated cycles of sodium storage without degradation.

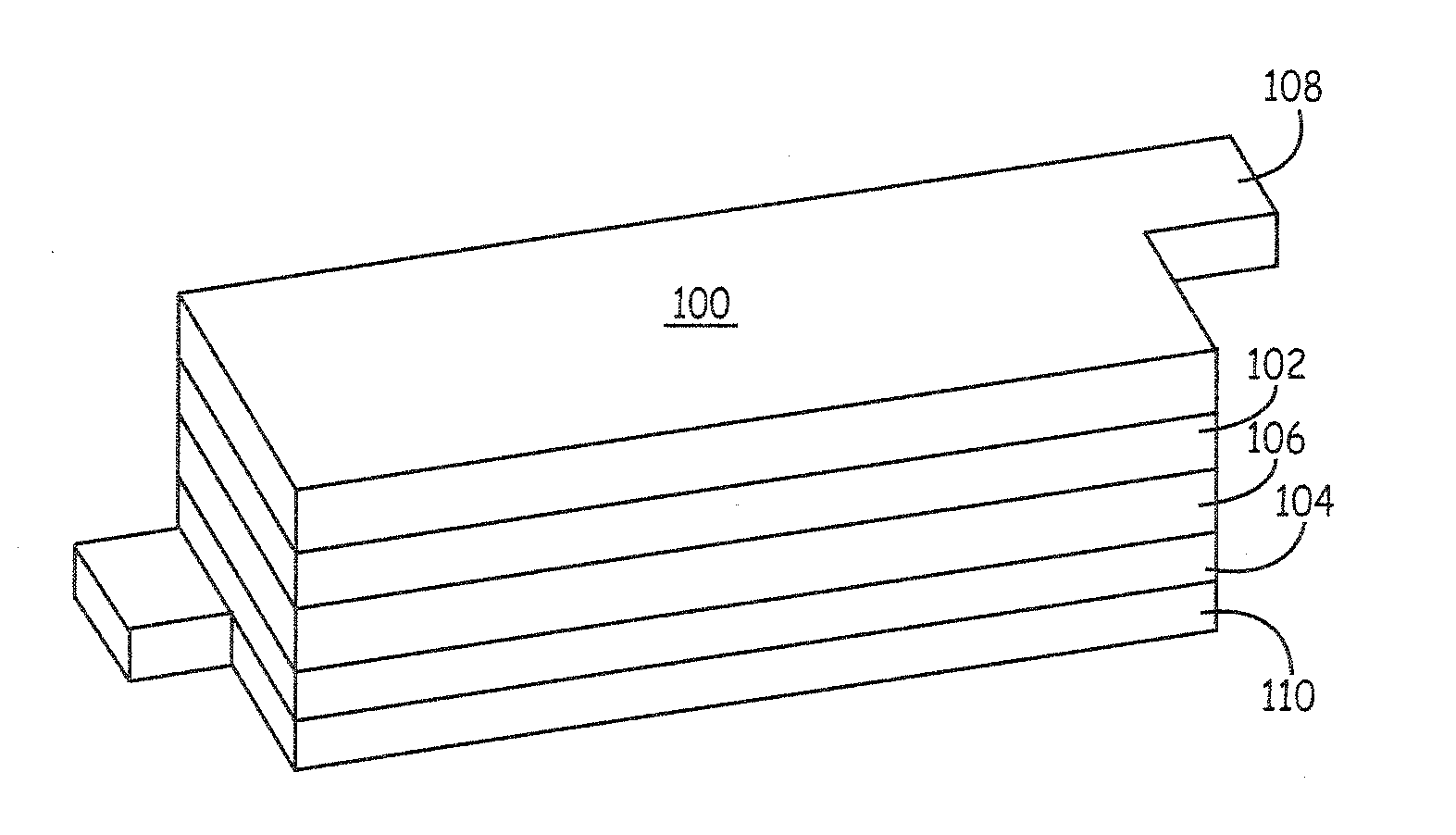

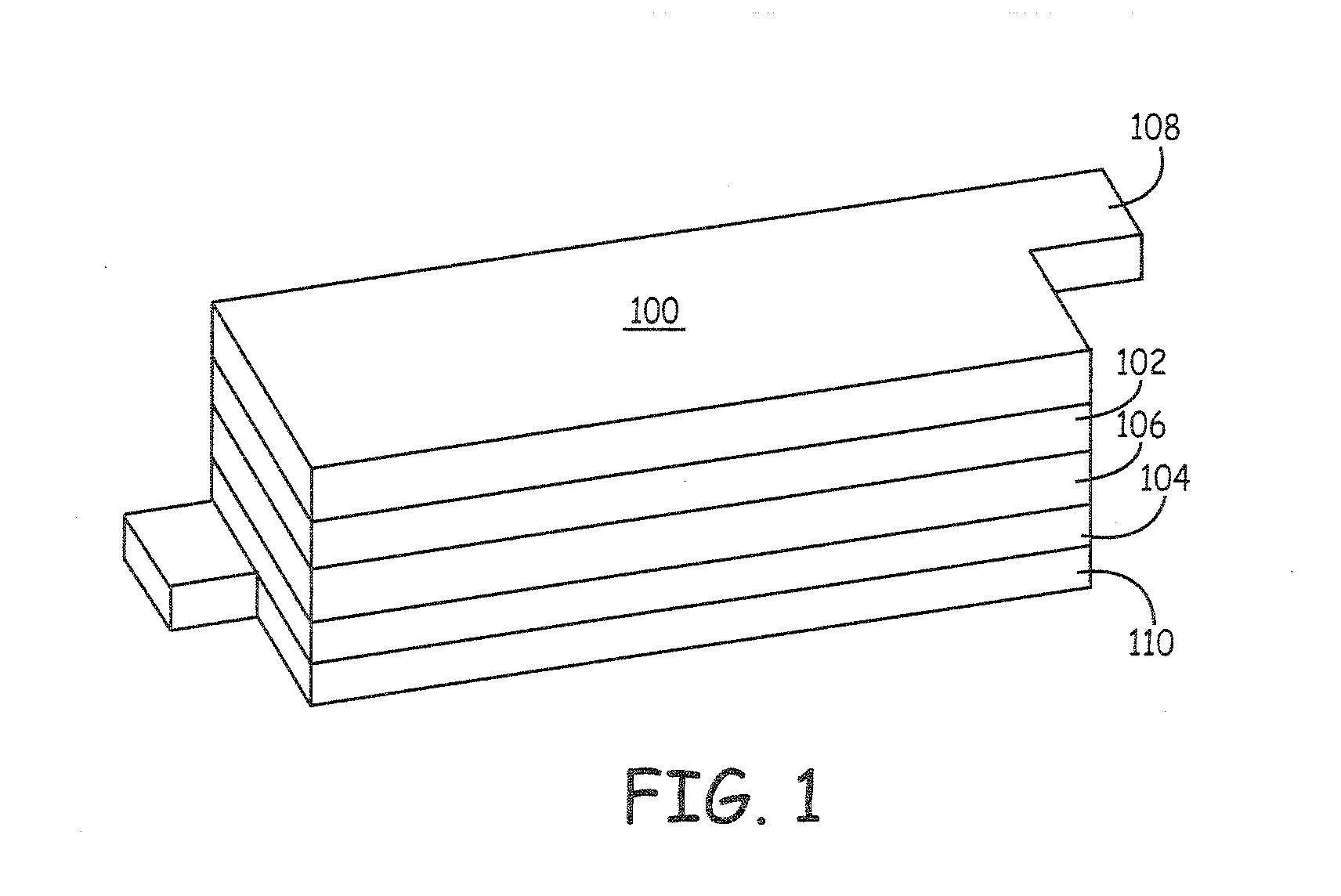

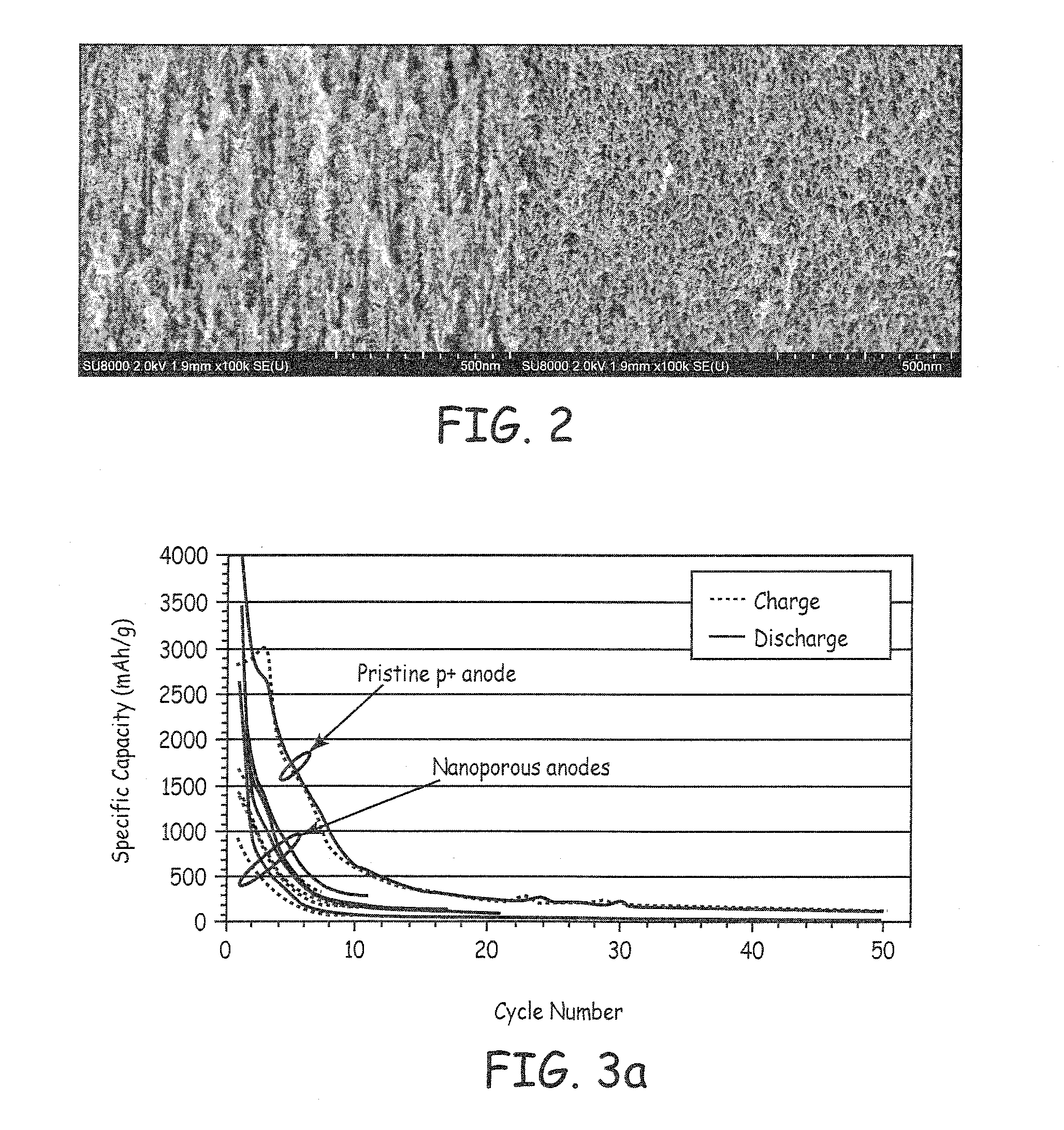

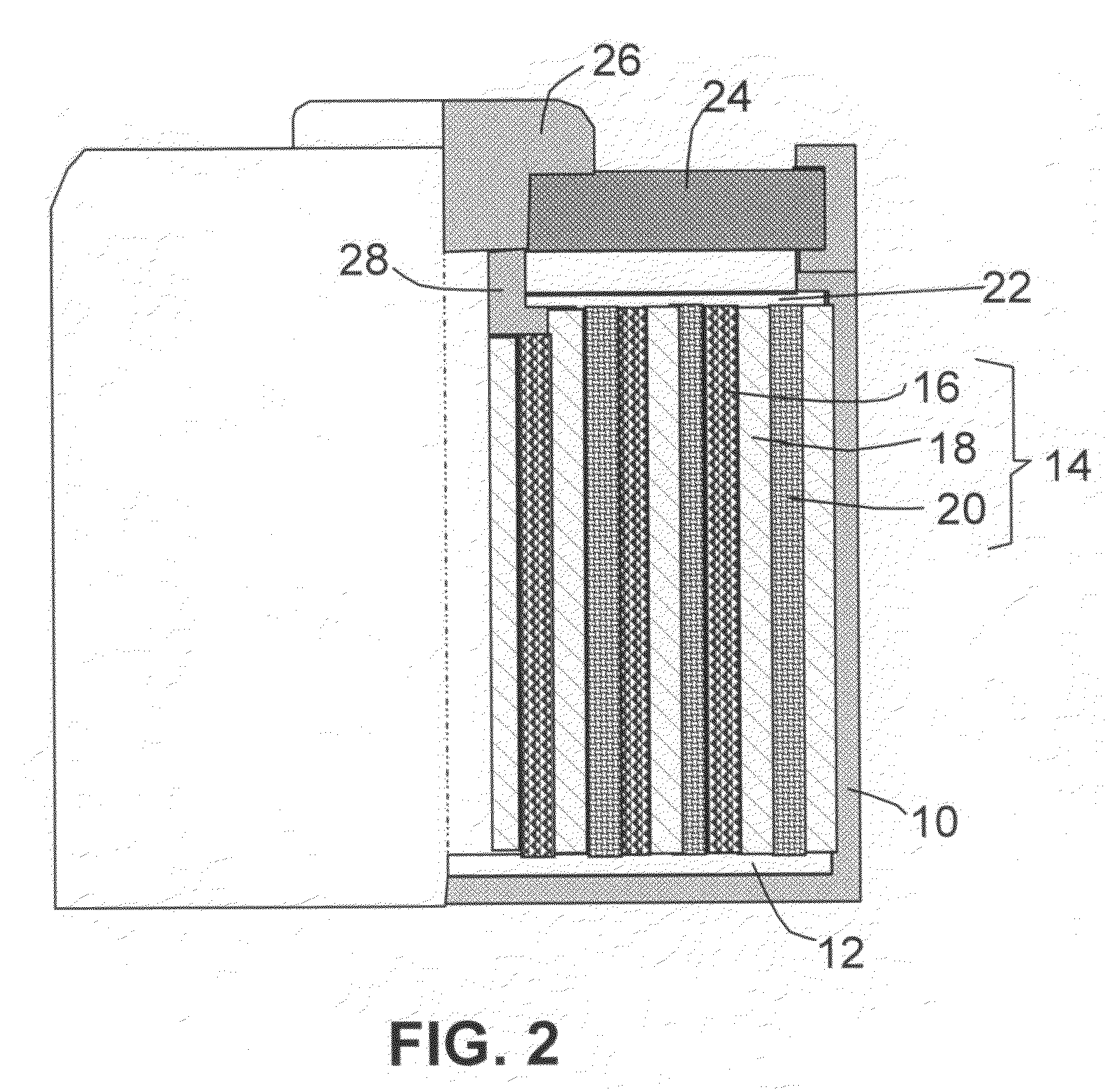

High Capacity Anode Materials for Lithium Ion Batteries

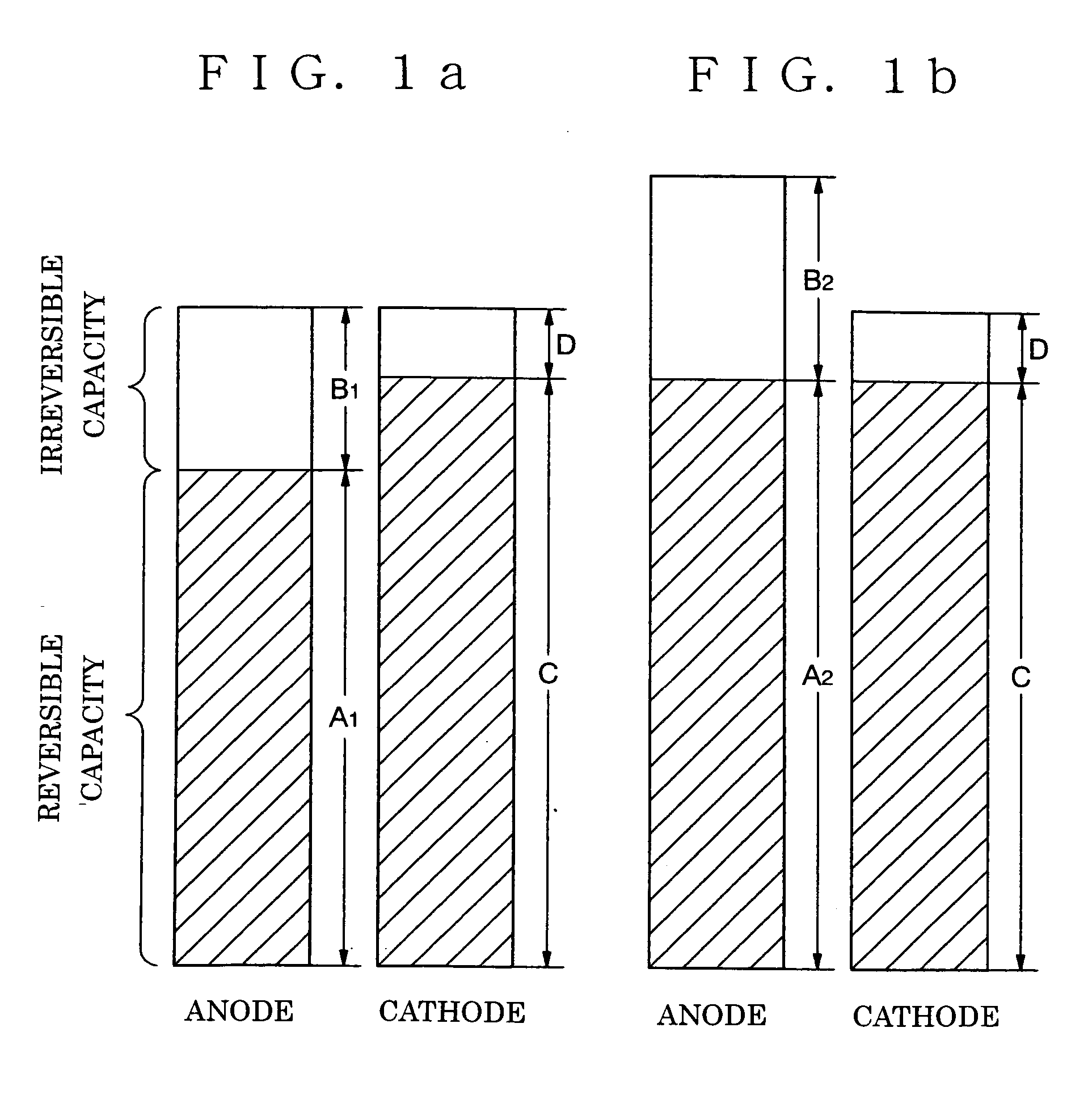

High capacity silicon based anode active materials are described for lithium ion batteries. These materials are shown to be effective in combination with high capacity lithium rich cathode active materials. Supplemental lithium is shown to improve the cycling performance and reduce irreversible capacity loss for at least certain silicon based active materials. In particular silicon based active materials can be formed in composites with electrically conductive coatings, such as pyrolytic carbon coatings or metal coatings, and composites can also be formed with other electrically conductive carbon components, such as carbon nanofibers and carbon nanoparticles. Additional alloys with silicon are explored.

Owner:IONBLOX INC

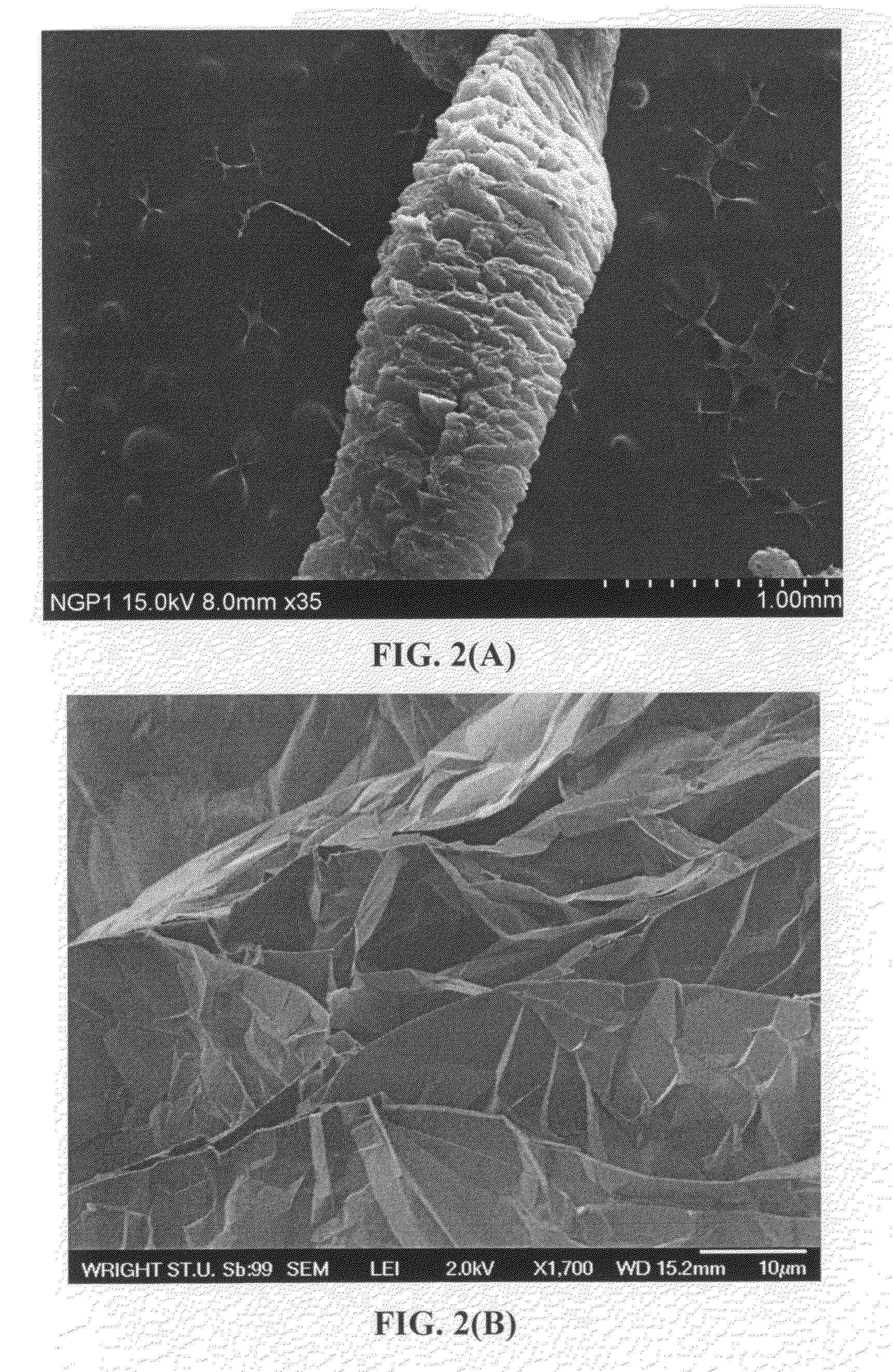

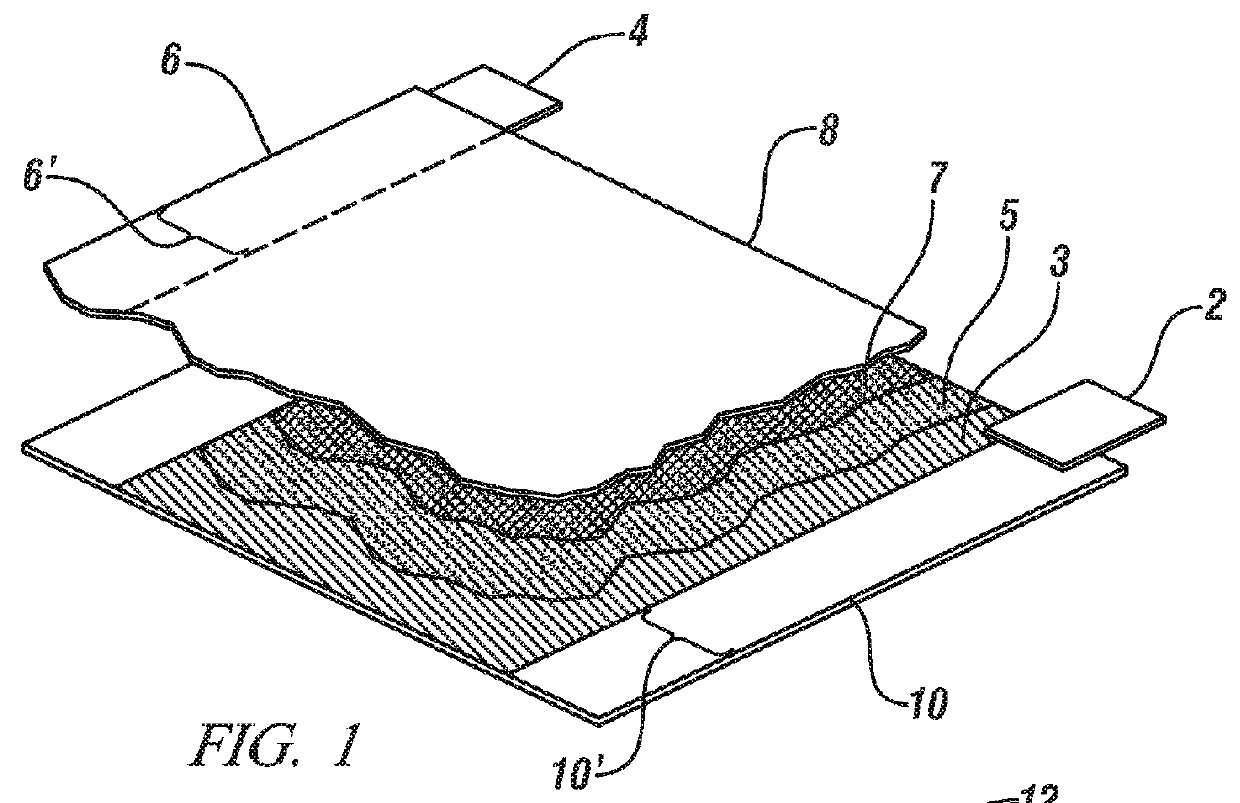

Hybrid anode compositions for lithium ion batteries

ActiveUS20090117466A1Superior multiple-cycle behaviorSmall capacity fadeAlkaline accumulatorsConductive materialHybrid materialSodium-ion battery

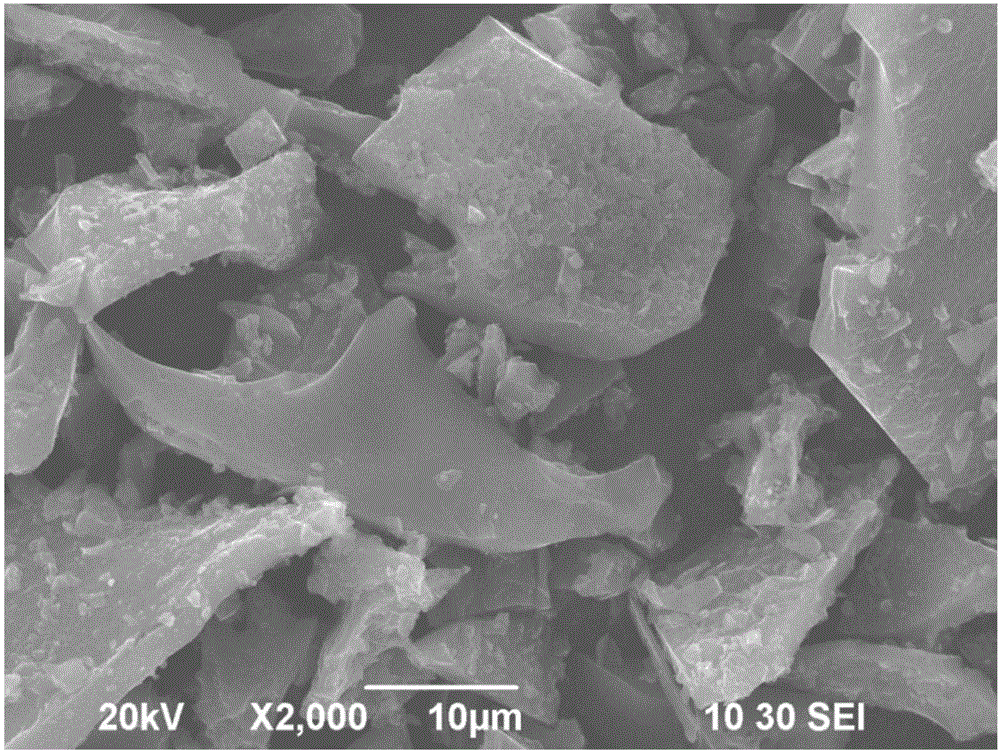

The present invention provides an exfoliated graphite-based hybrid material composition for use as an electrode, particularly as an anode of a lithium ion battery. The composition comprises: (a) micron- or nanometer-scaled particles or coating which are capable of absorbing and desorbing alkali or alkaline metal ions (particularly, lithium ions); and (b) exfoliated graphite flakes that are substantially interconnected to form a porous, conductive graphite network comprising pores, wherein at least one of the particles or coating resides in a pore of the network or attached to a flake of the network and the exfoliated graphite amount is in the range of 5% to 90% by weight and the amount of particles or coating is in the range of 95% to 10% by weight. Also provided is a lithium secondary battery comprising such a negative electrode (anode). The battery exhibits an exceptional specific capacity, excellent reversible capacity, and long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

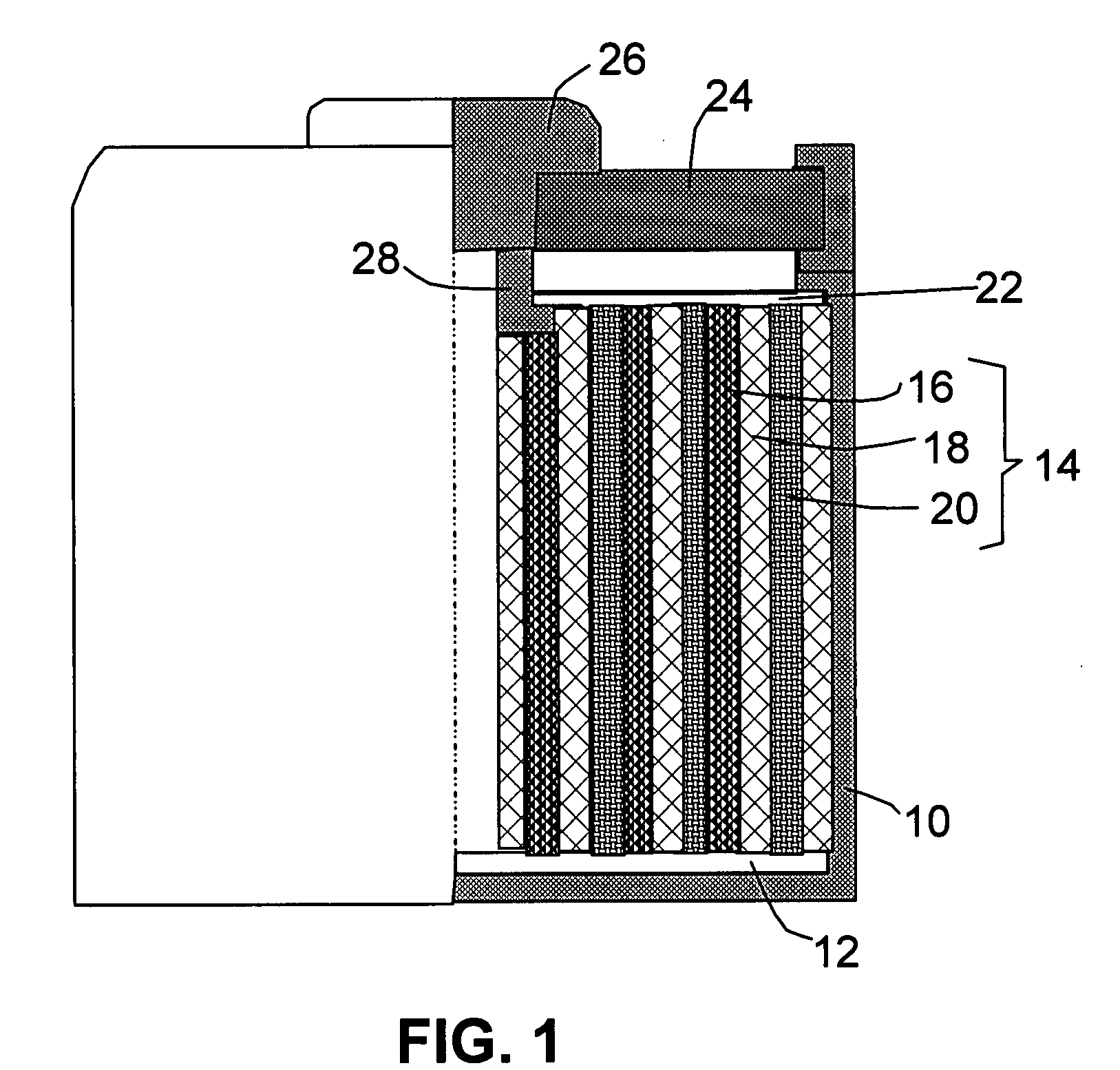

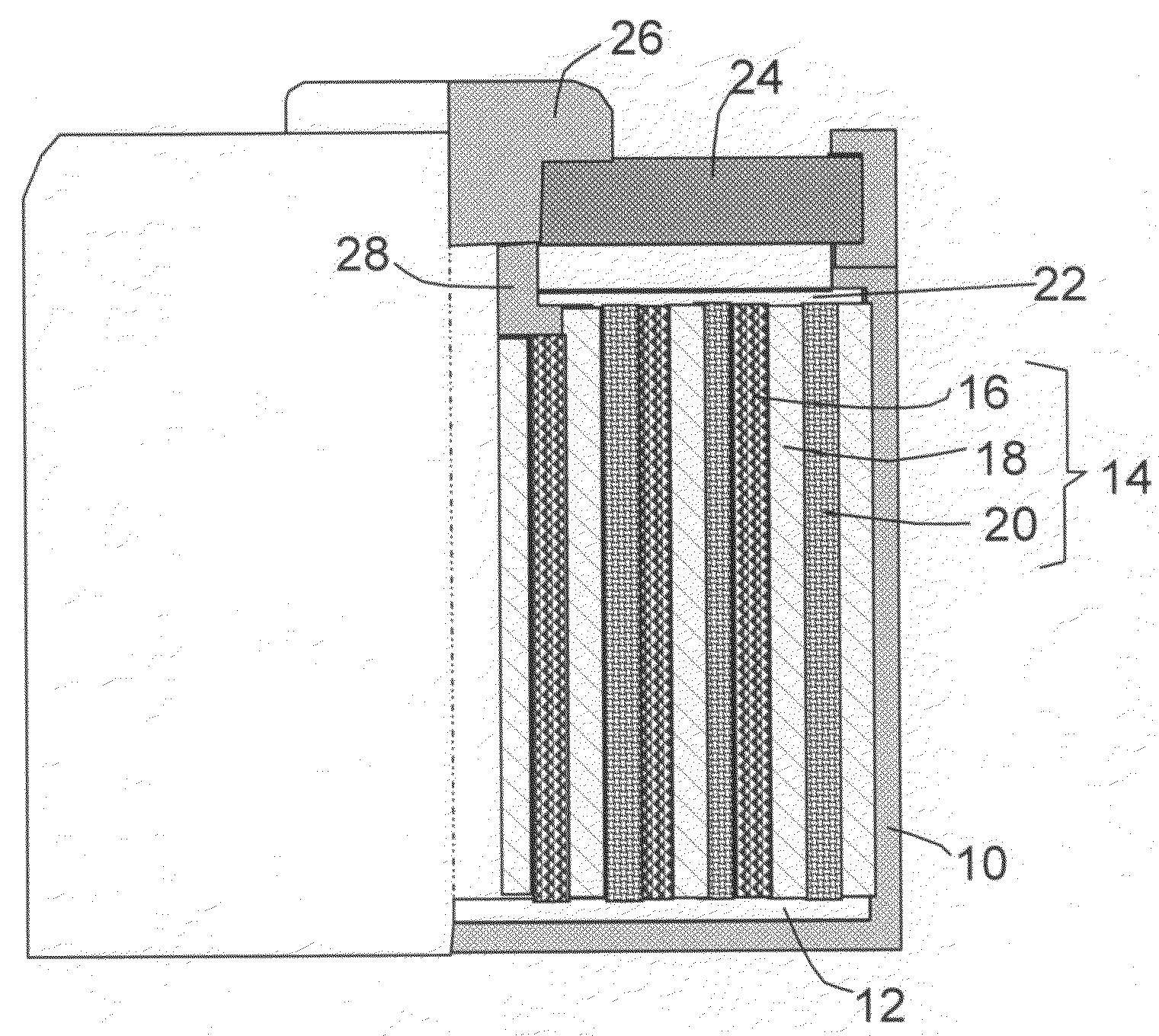

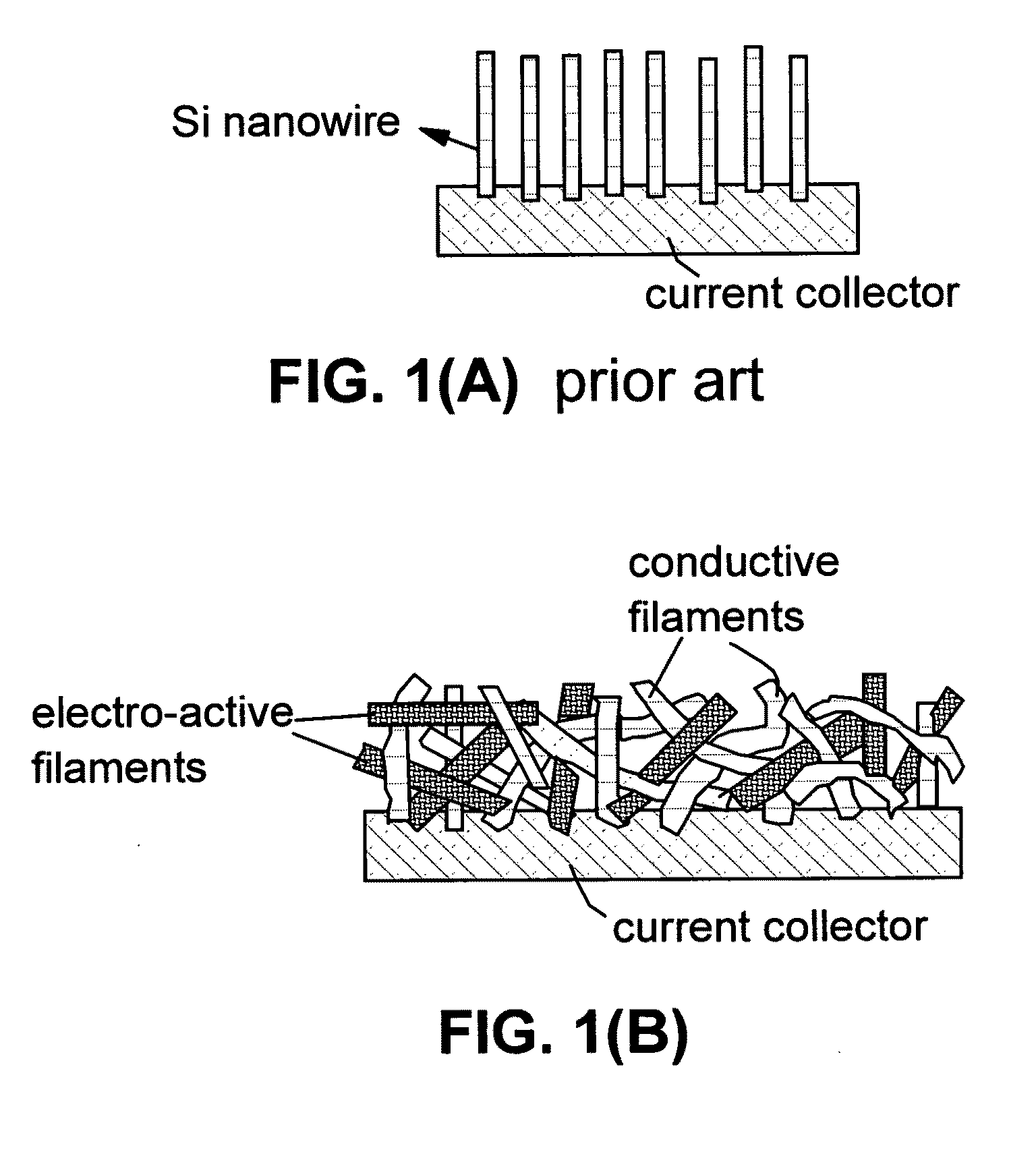

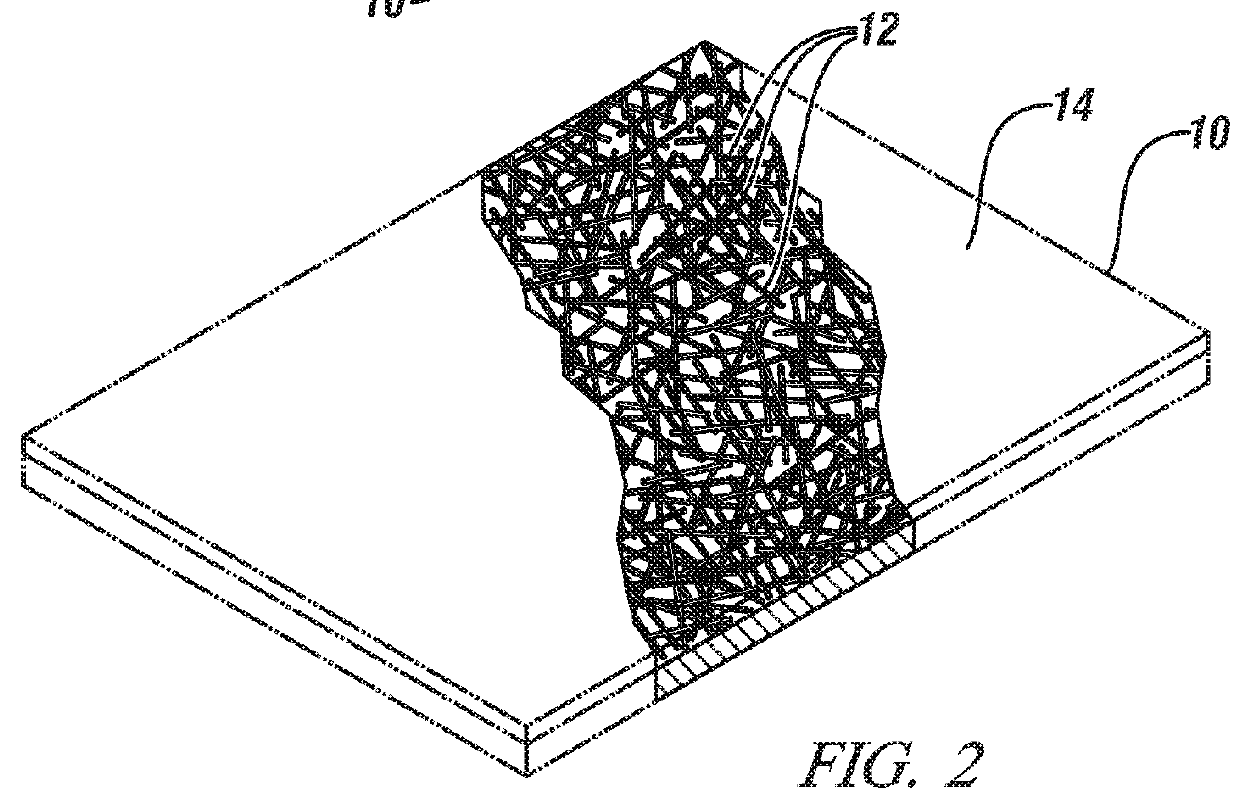

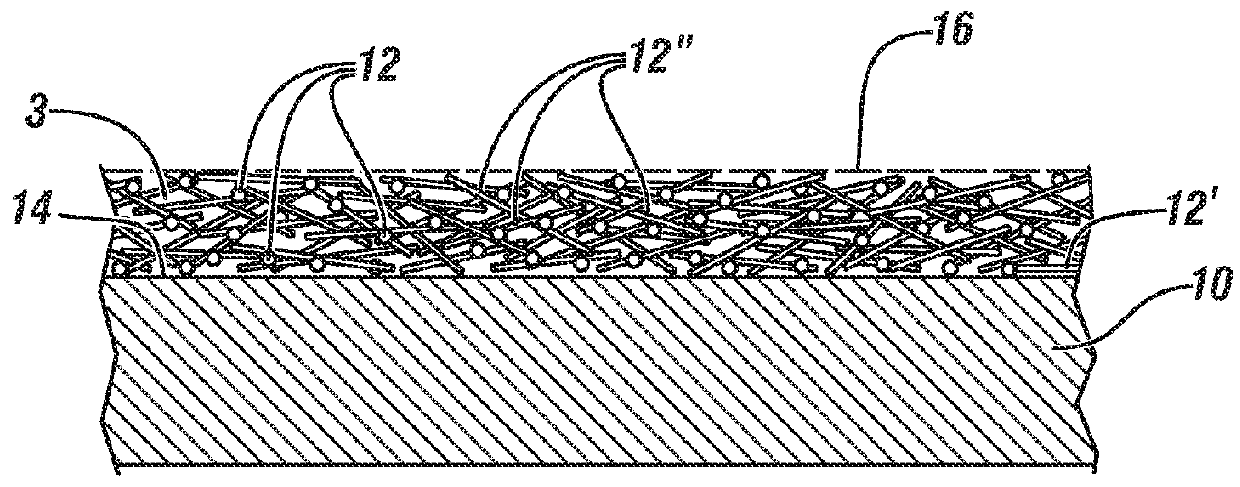

Mixed nano-filament electrode materials for lithium ion batteries

ActiveUS20090176159A1Improve conductivityEasy to collectActive material electrodesSecondary cellsFiberNanowire

This invention provides a mixed nano-filament composition for use as an electrochemical cell electrode. The composition comprises: (a) an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, or percolated to form a porous, electrically conductive filament network, wherein the filaments have a length and a diameter or thickness with the diameter / thickness less than 500 nm (preferably <100 nm) and a length-to-diameter or length-to-thickness aspect ratio greater than 10; and (b) Multiple nanometer-scaled, electro-active filaments comprising an electro-active material capable of absorbing and desorbing lithium ions wherein the electro-active filaments have a diameter or thickness less than 500 nm (preferably <100 nm). The electro-active filaments (e.g., nanowires) and the electrically conductive filaments (e.g., carbon nano fibers) are mixed to form a mat-, web-, or porous paper-like structure in which at least an electro-active filament is in electrical contact with at least an electrically conductive filament. Also provided is a lithium ion battery comprising such an electrode as an anode or cathode, or both. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Graphene/metal oxide composite cathode material for lithium ion battery and preparation

InactiveCN102646817APromote circulationExcellent rate performanceCell electrodesHigh energyIn situ polymerization

The invention belongs to the fields of material synthesis and energy technology, and especially relates to a graphene / metal oxide composite cathode material for lithium ion batteries and a preparation method thereof. Grapheme is dispersed into various metal oxide precursor salt solutions; a graphene / metal oxide compound is obtained directly by a hydrothermal method, or an graphene / metal oxide compound is obtained by a liquid in-situ polymerization method or a coprecipitation process; and the graphene / metal oxide compound is obtained by heat treatment or hydrothermal treatment. In the invention, the novel three-dimensional composite cathode material of graphene-coated metal oxide or graphene-anchored metal oxide is prepared by carrying metal oxide particles with graphene as a carrier. The obtained composite material can be used as a lithium ion battery cathode, which has a high specific capacity, excellent cycle stability and rate capability, and is expected to be used as a lithium ion battery cathode material with a high energy density and a high power density.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

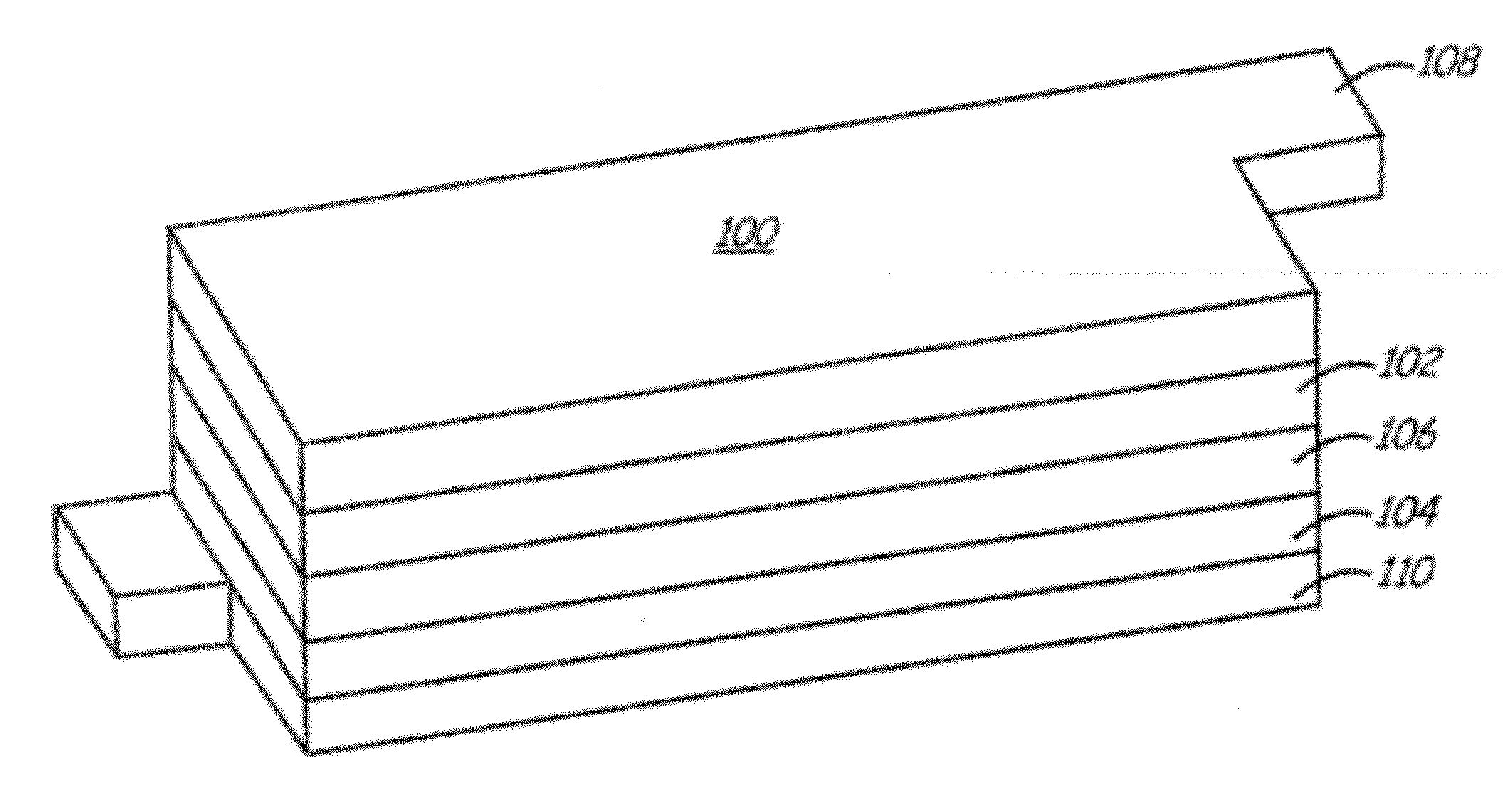

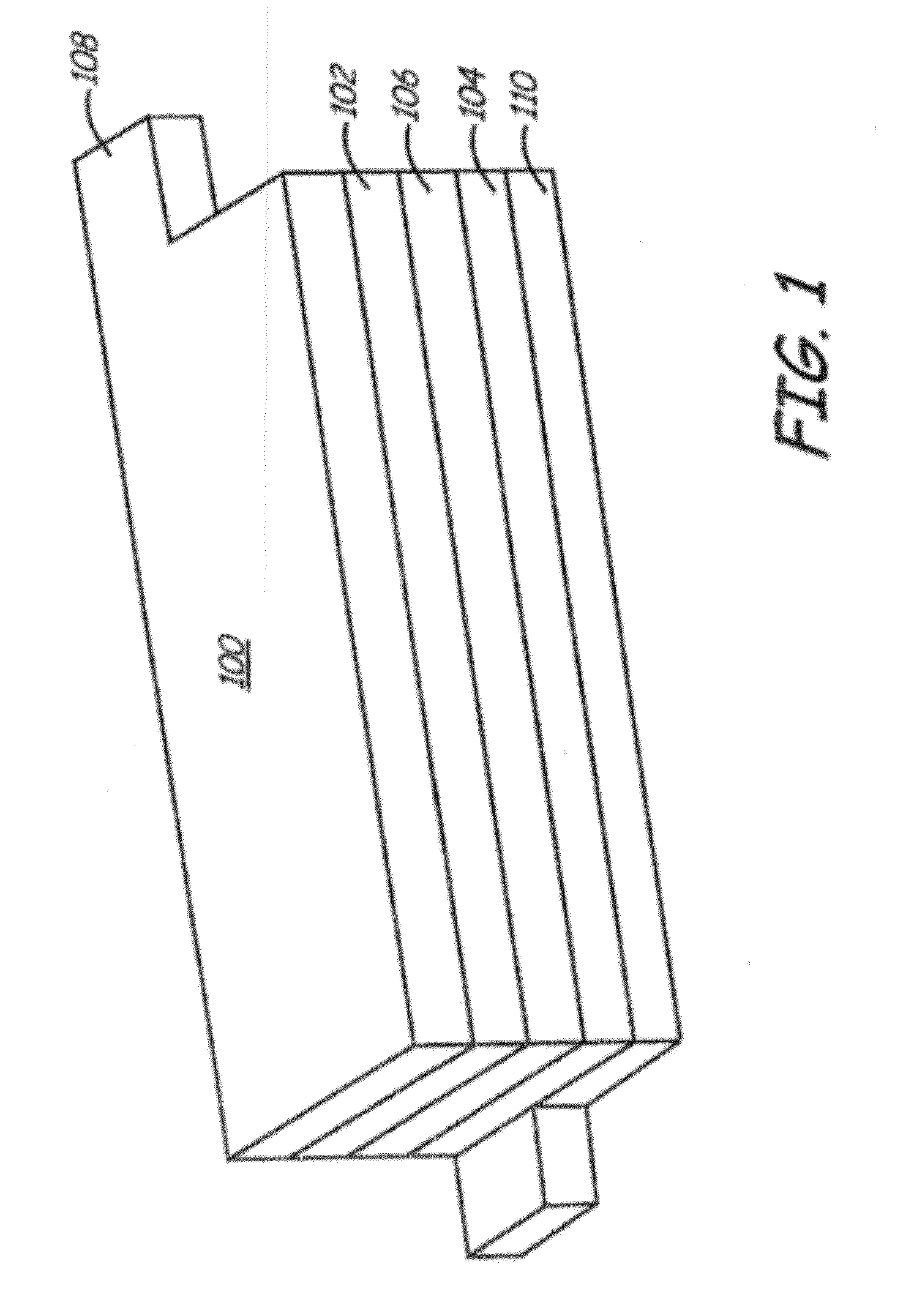

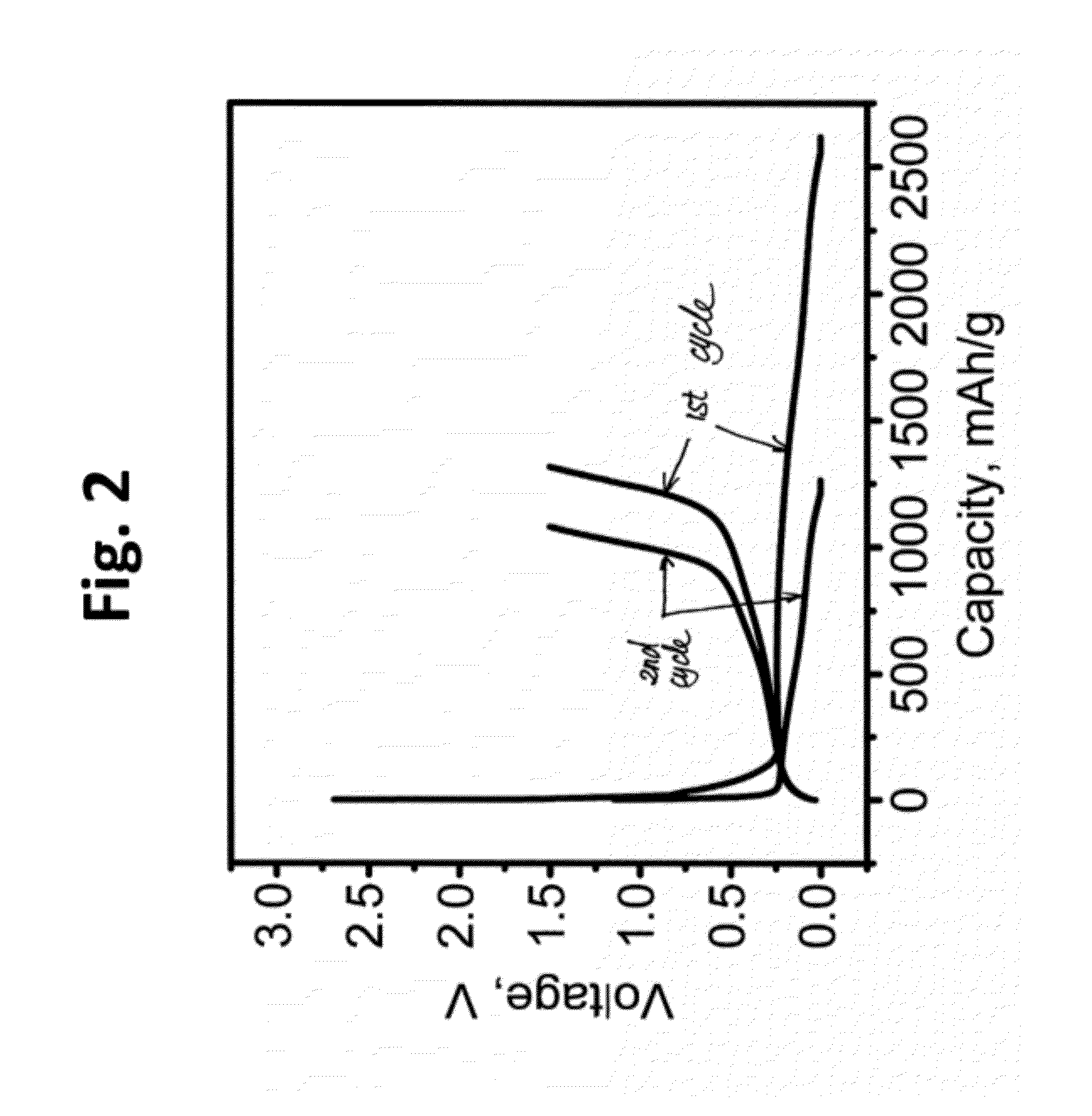

Silicon oxide based high capacity anode materials for lithium ion batteries

Silicon oxide based materials, including composites with various electrical conductive compositions, are formulated into desirable anodes. The anodes can be effectively combined into lithium ion batteries with high capacity cathode materials. In some formulations, supplemental lithium can be used to stabilize cycling as well as to reduce effects of first cycle irreversible capacity loss. Batteries are described with surprisingly good cycling properties with good specific capacities with respect to both cathode active weights and anode active weights.

Owner:IONBLOX INC

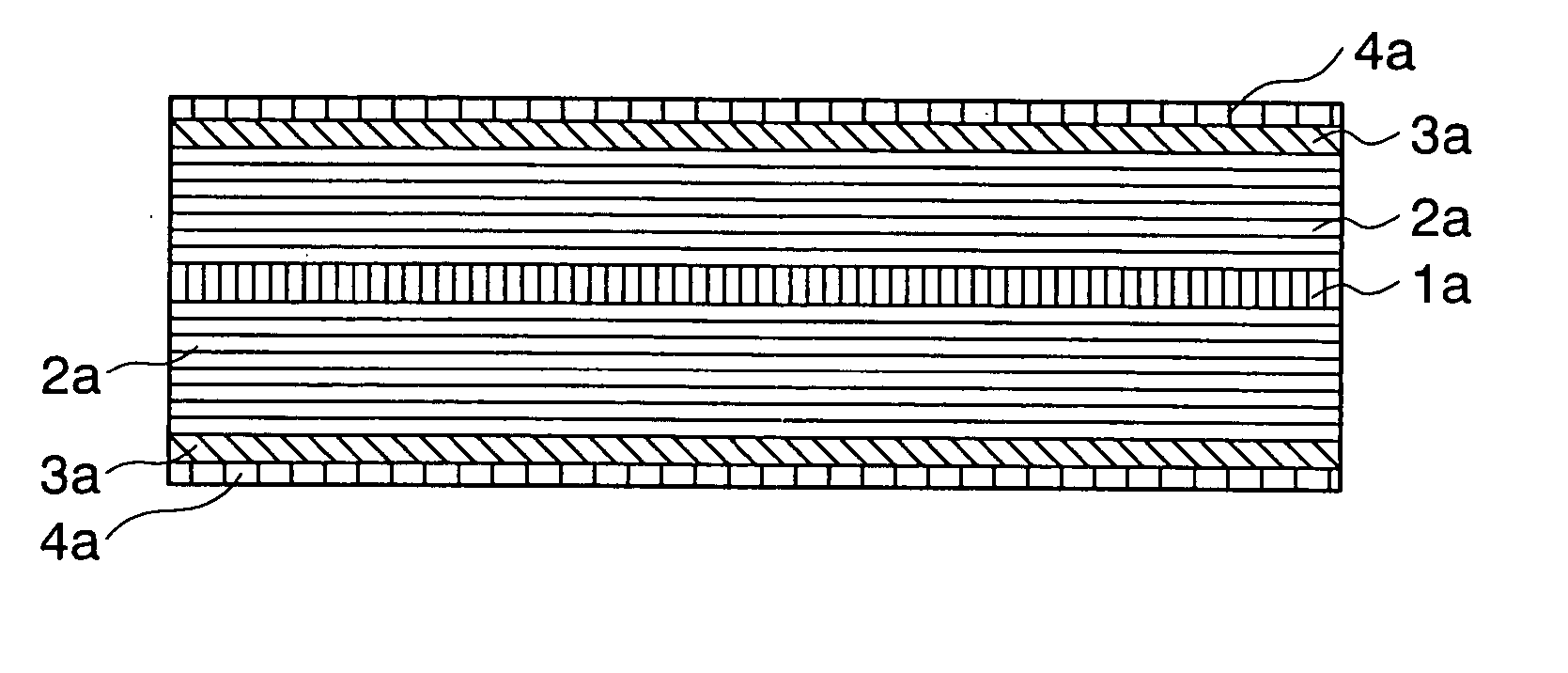

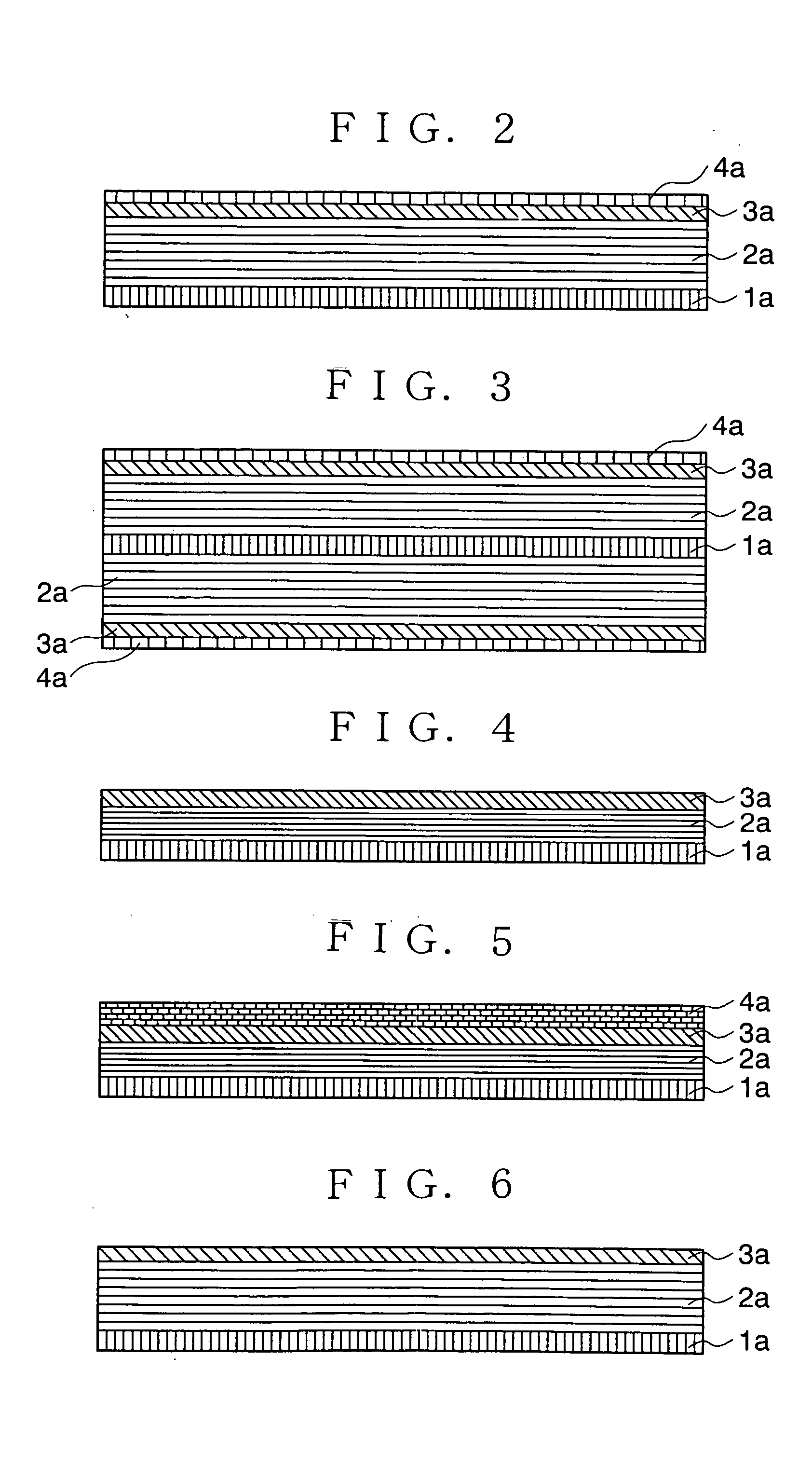

Negative pole for a secondary cell, secondary cell using the negative pole, and negative pole manufacturing method

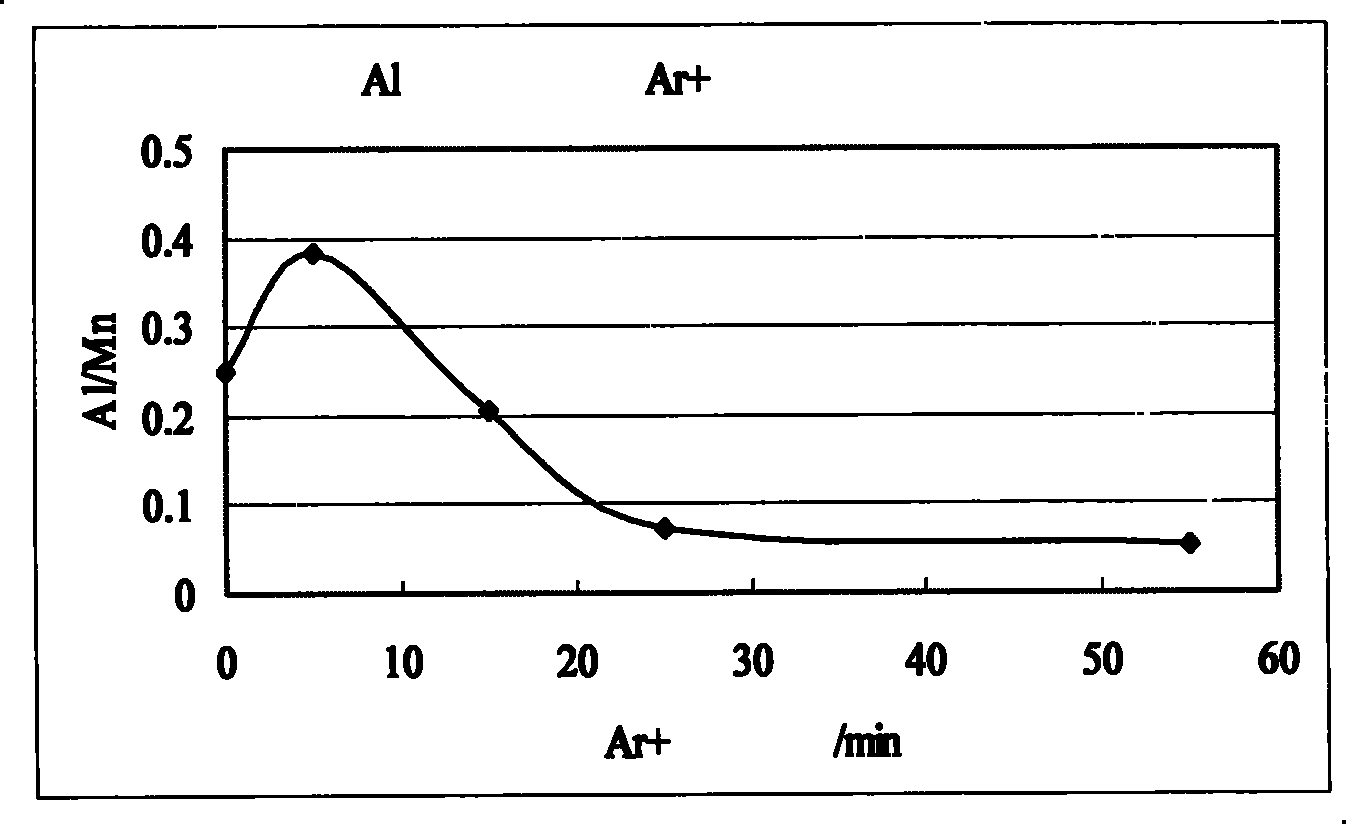

ActiveUS20040175621A1High reversible capacityImprove cycle performanceVacuum evaporation coatingSputtering coatingDischarge efficiencySodium-ion battery

An anode for a secondary battery capable of inserting and extracting a lithium ion having a multi-layered structure including a first anode layer (2a) containing carbon as a main component; a second anode layer (3a) made of a film-like material through which a lithium component passes; and a third anode layer (4a) containing lithium and / or a lithium-containing compound as a main component. The battery capacity of the lithium ion battery is substantially increased while the higher charge-discharge efficiency and the stable cycle performance are maintained.

Owner:NEC CORP

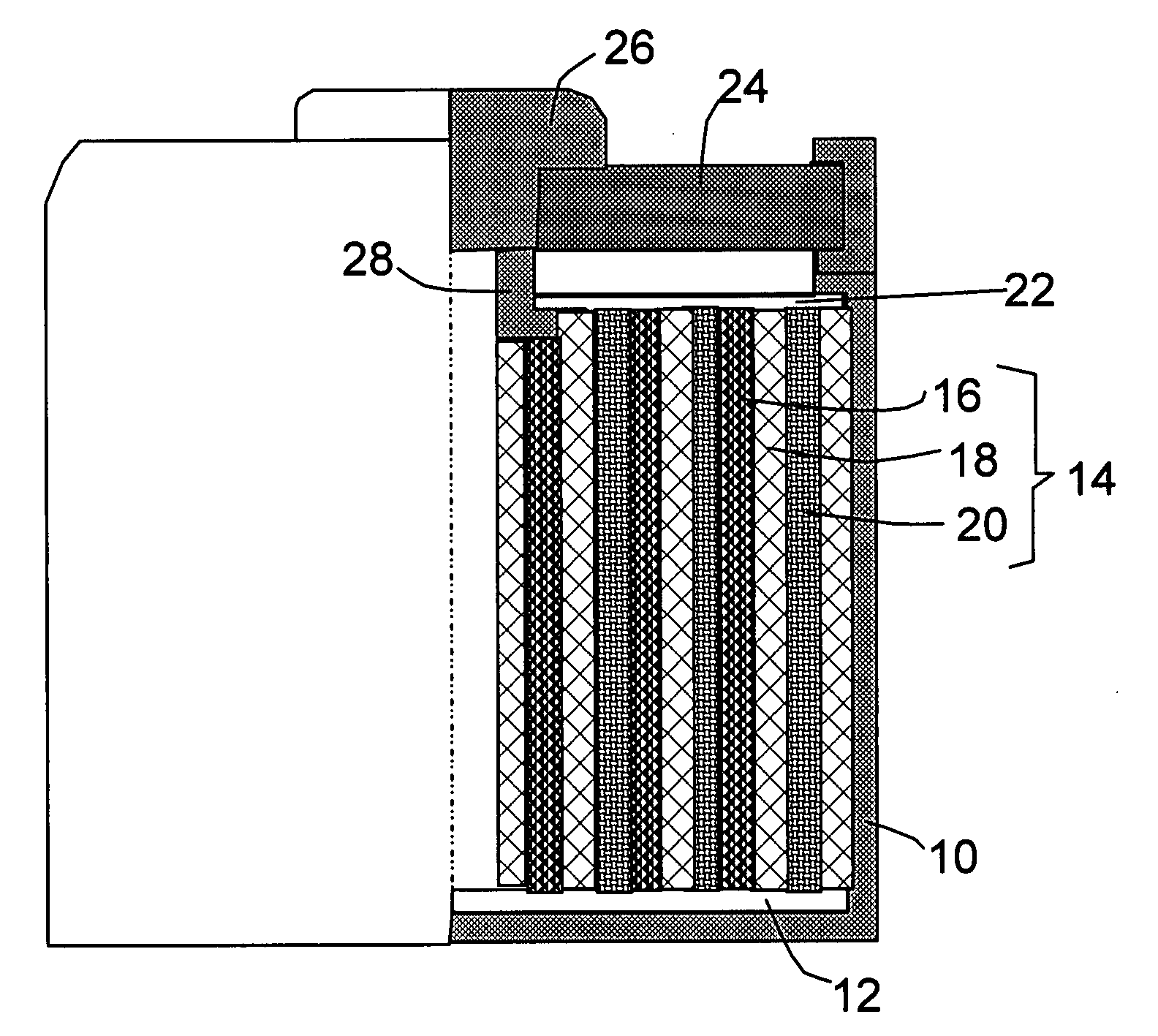

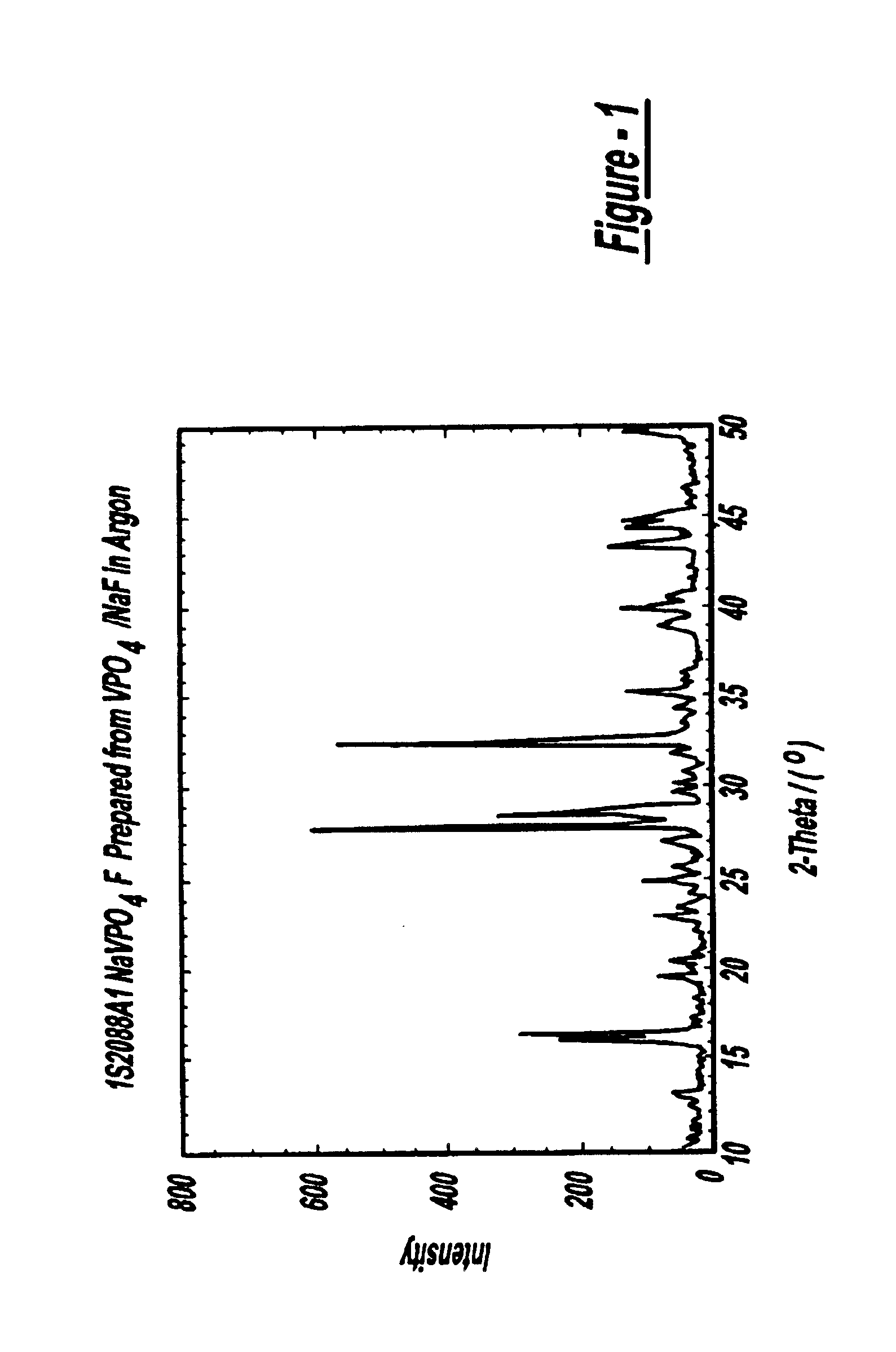

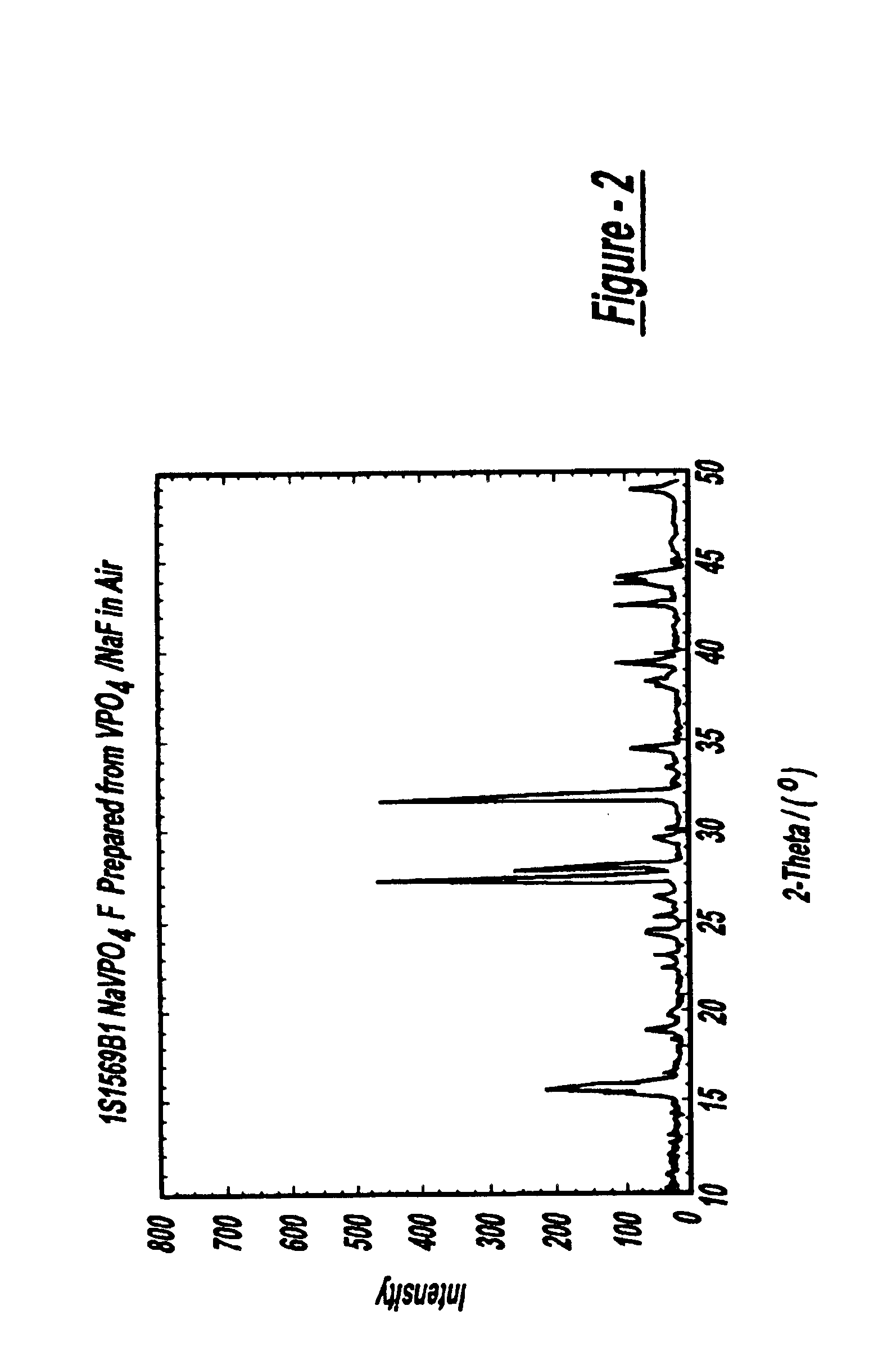

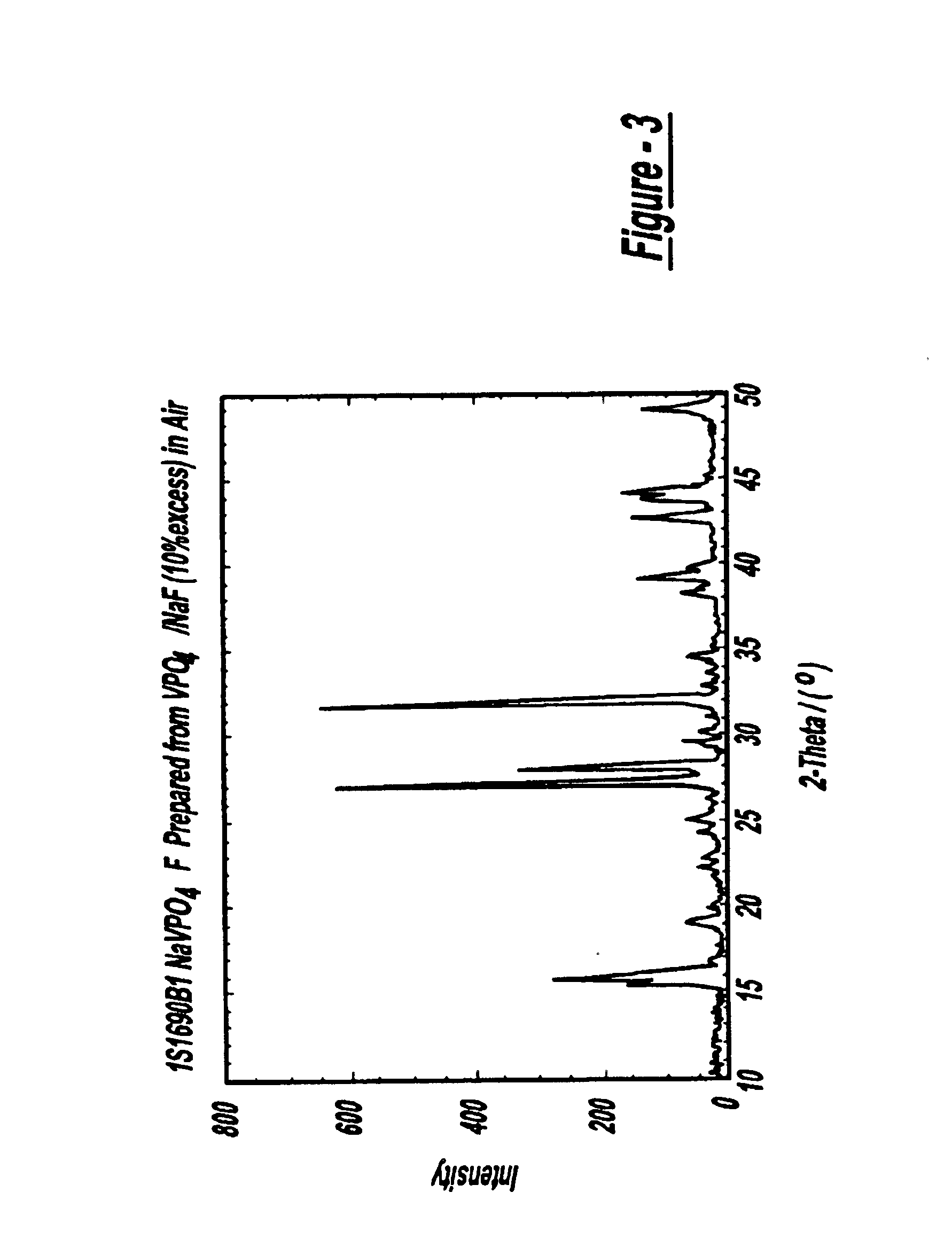

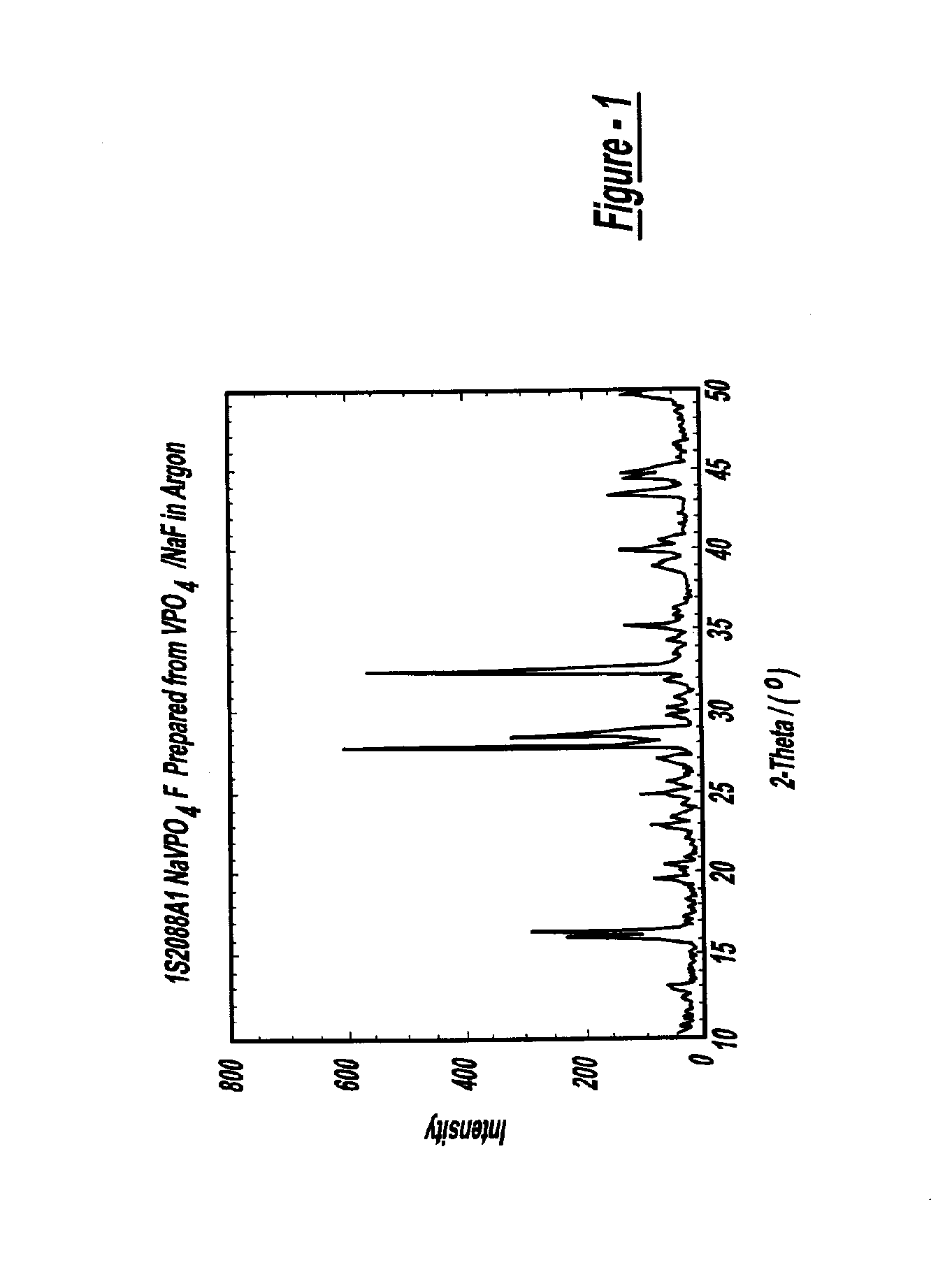

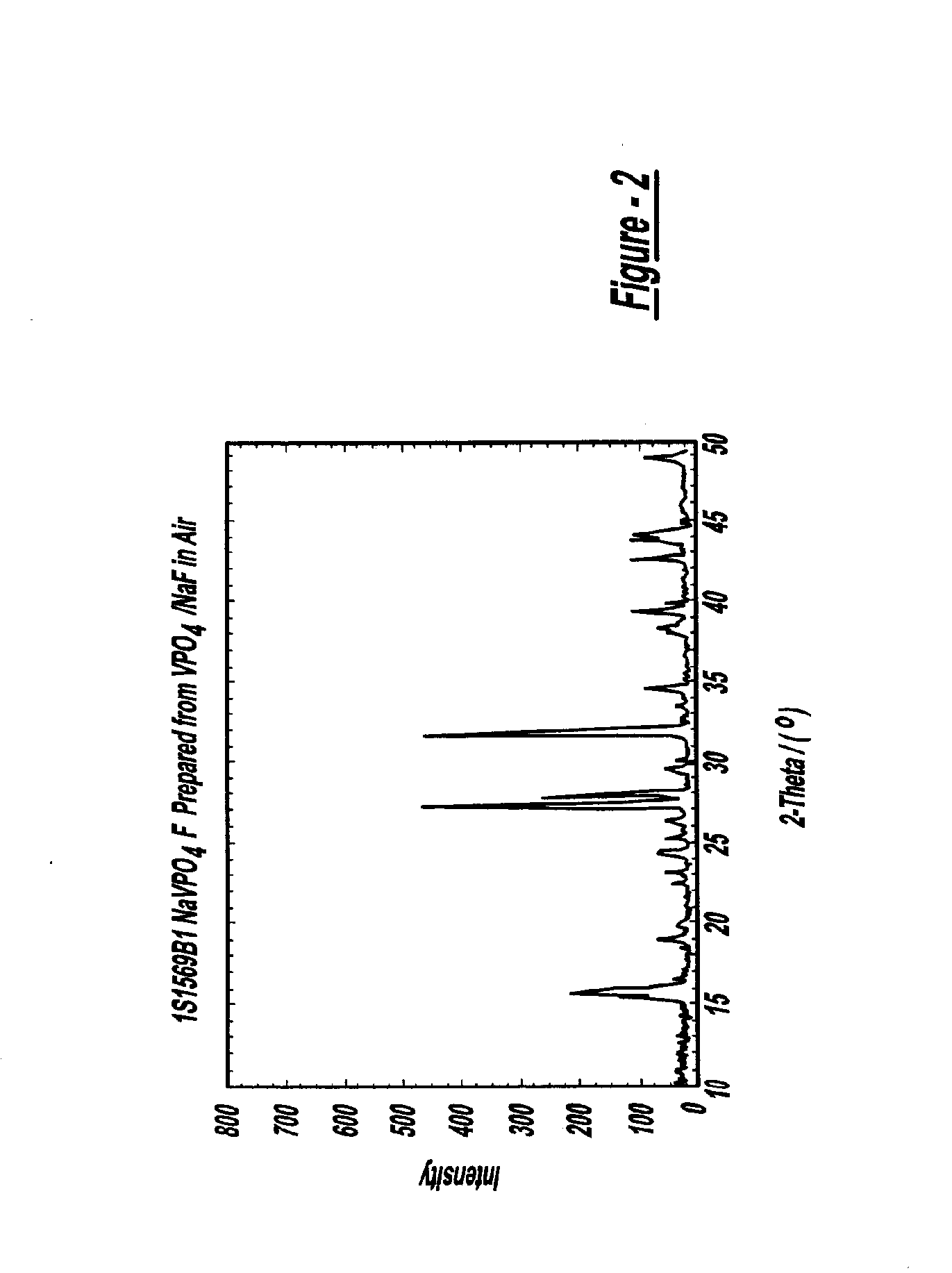

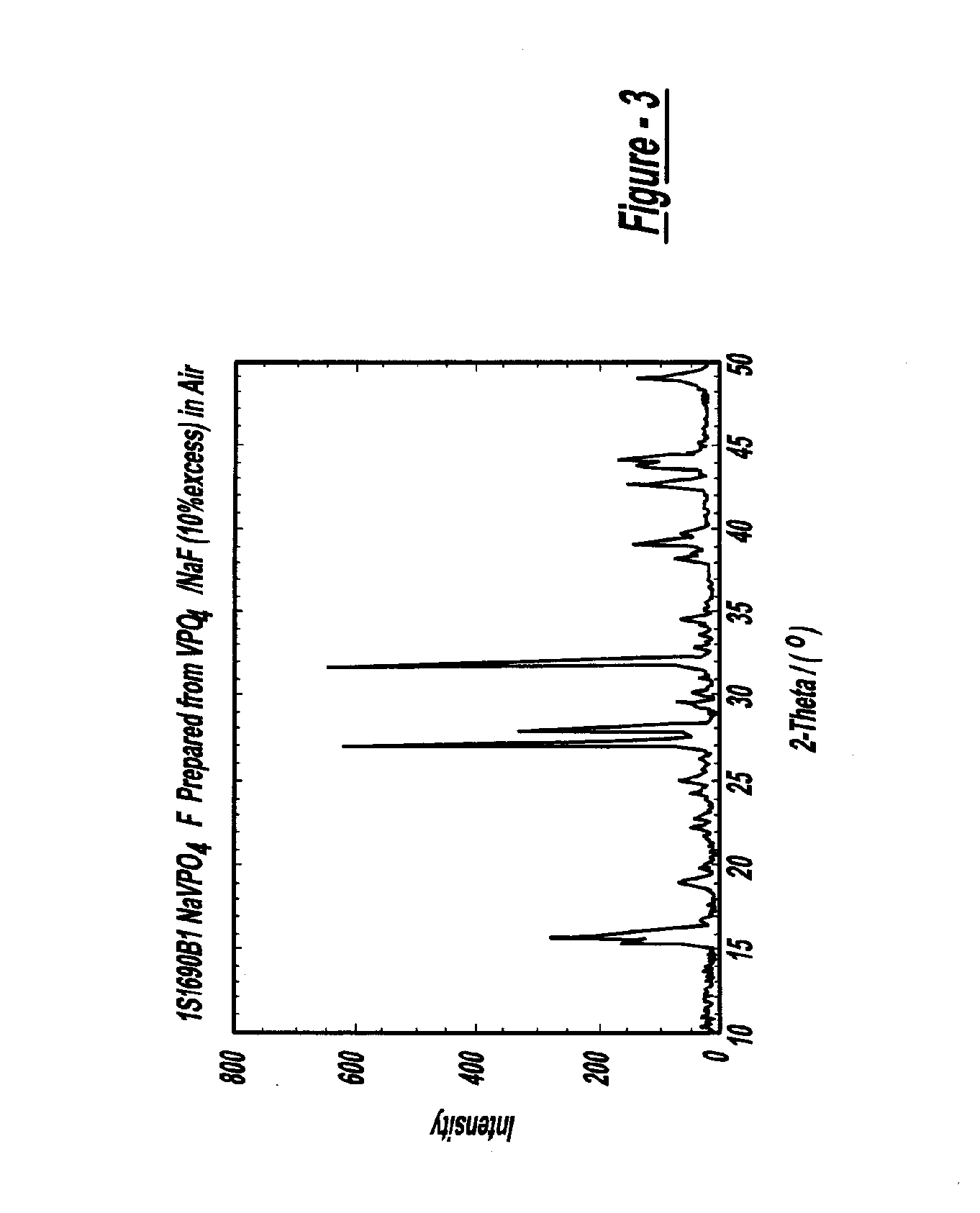

Sodium ion batteries

InactiveUS6872492B2High operation potentialHigh specific capacityOrganic electrolyte cellsSecondary cellsPhosphateSodium-ion battery

Sodium ion batteries are based on sodium based active materials selected among compounds of the general formula:AaMb(XY4)cZd,wherein A comprises sodium, M comprises one or more metals, comprising at least one metal which is capable of undergoing oxidation to a higher valence state, Z is OH or halogen, and XY4 represents phosphate or a similar group. The anode of the battery includes a carbon material that is capable of inserting sodium ions. The carbon anode cycles reversibly at a specific capacity greater than 100 mAh / g.

Owner:VALENCE TECH INC

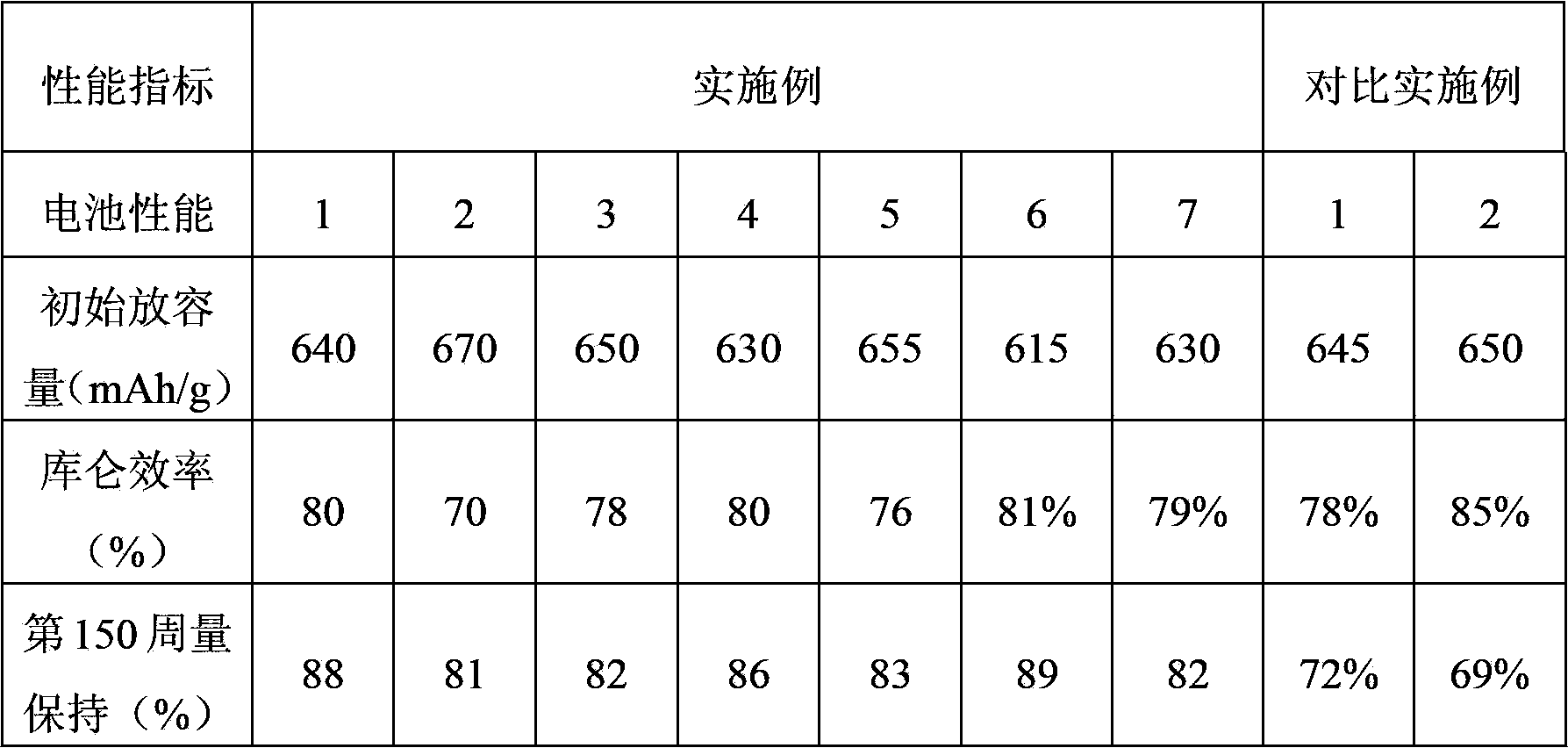

Multicomponent material with multilayer coating structure for lithium ion battery and preparation method thereof

InactiveCN101997113AIncrease capacityReduce bloatElectrode manufacturing processesSecondary cellsSodium-ion batteryLithium-ion battery

The invention discloses a multicomponent material for a lithium ion battery and a preparation method thereof, and particularly relates to a multicomponent material with a multilayer coating structure for a lithium ion battery and a preparation method thereof. The multicomponent material with the multilayer coating structure comprises an inner core and coating layers, wherein both the inner core and the coating layers comprise lithium-containing metallic oxides; and the number n of the coating layers is 1 to 5. The multicomponent material with the multilayer coating structure has a simple preparation process, relatively low cost and high processability; and the lithium ion battery made of the material has a small amount of swelling, high capacity, high high-temperature cyclical stability and high safety.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Full-component resource reclamation method for waste positive electrode materials of lithium ion batteries

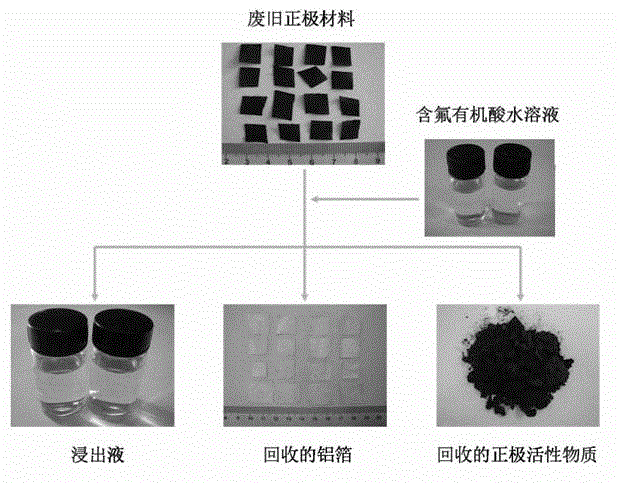

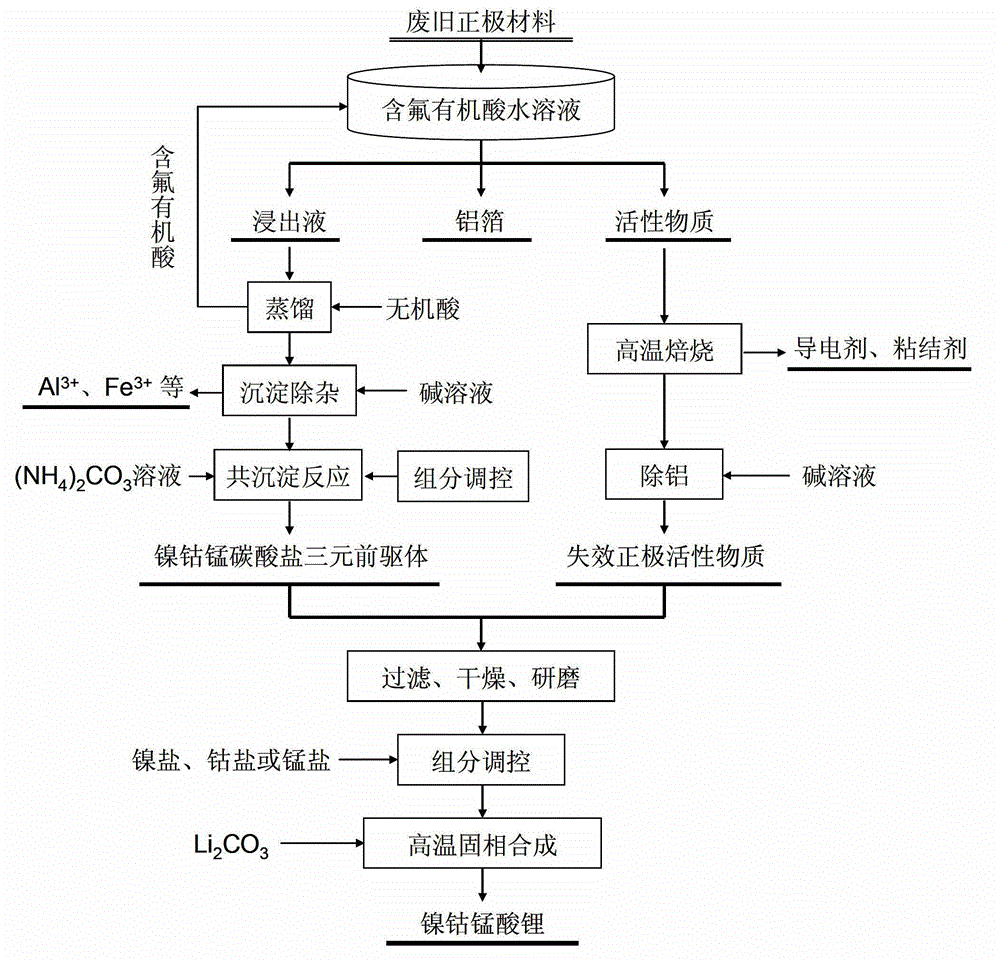

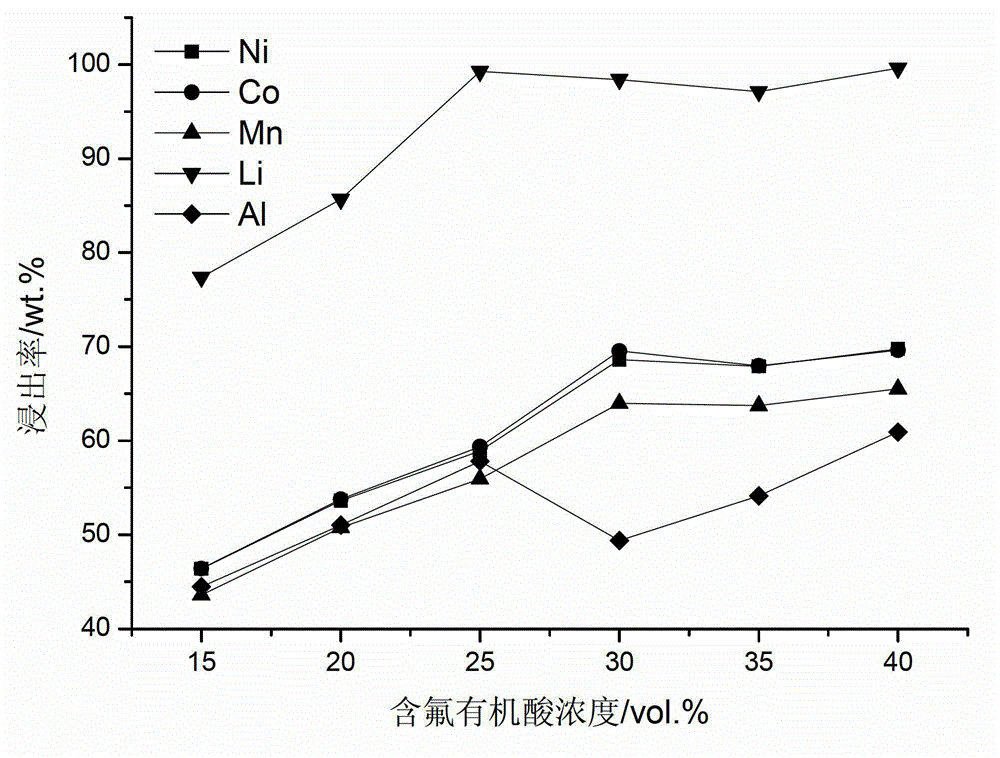

ActiveCN102751549AAvoid secondary pollutionImprove separation efficiencyWaste accumulators reclaimingBattery recyclingRecovery methodDistillation

The invention provides a full-component resource reclamation method for waste positive electrode materials of lithium ion batteries. The method comprises the following steps: 1) separating active substances and aluminum foils in waste positive electrode materials of lithium ion batteries by using an aqueous solution of fluorine-containing organic acid and carrying out liquid-solid-solid separation so as to obtain leachate, the lithium-containing active substances and the aluminum foils; 2) respectively carrying out high temperature roasting and impurity removal with alkali liquor on the lithium-containing active substances; 3) respectively carrying out recovery of the fluorine-containing organic acid through addition of acid and distillation, deposition of impurity ions through addition of alkali and ammonium carbonate coprecipitation on the leachate so as to prepare nickel-cobalt-manganese carbonate ternary precursor; and 4) carrying out component regulation on a mixture of the treated active substances and the nickel-cobalt-manganese carbonate ternary precursor, adding lithium carbonate in a certain proportion and carrying out high temperature solid phase sintering so as to prepare a lithium nickel cobalt manganese oxide ternary positive electrode material. The method provided in the invention has the following advantages: the application scope of the method is wide; separation efficiency of the lithium-containing active substances and the aluminum foils is high; short-flow direct re-preparation of positive electrode materials in waste lithium ion batteries is realized; and the method is applicable to large-scale resource reclamation of waste lithium ion batteries.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

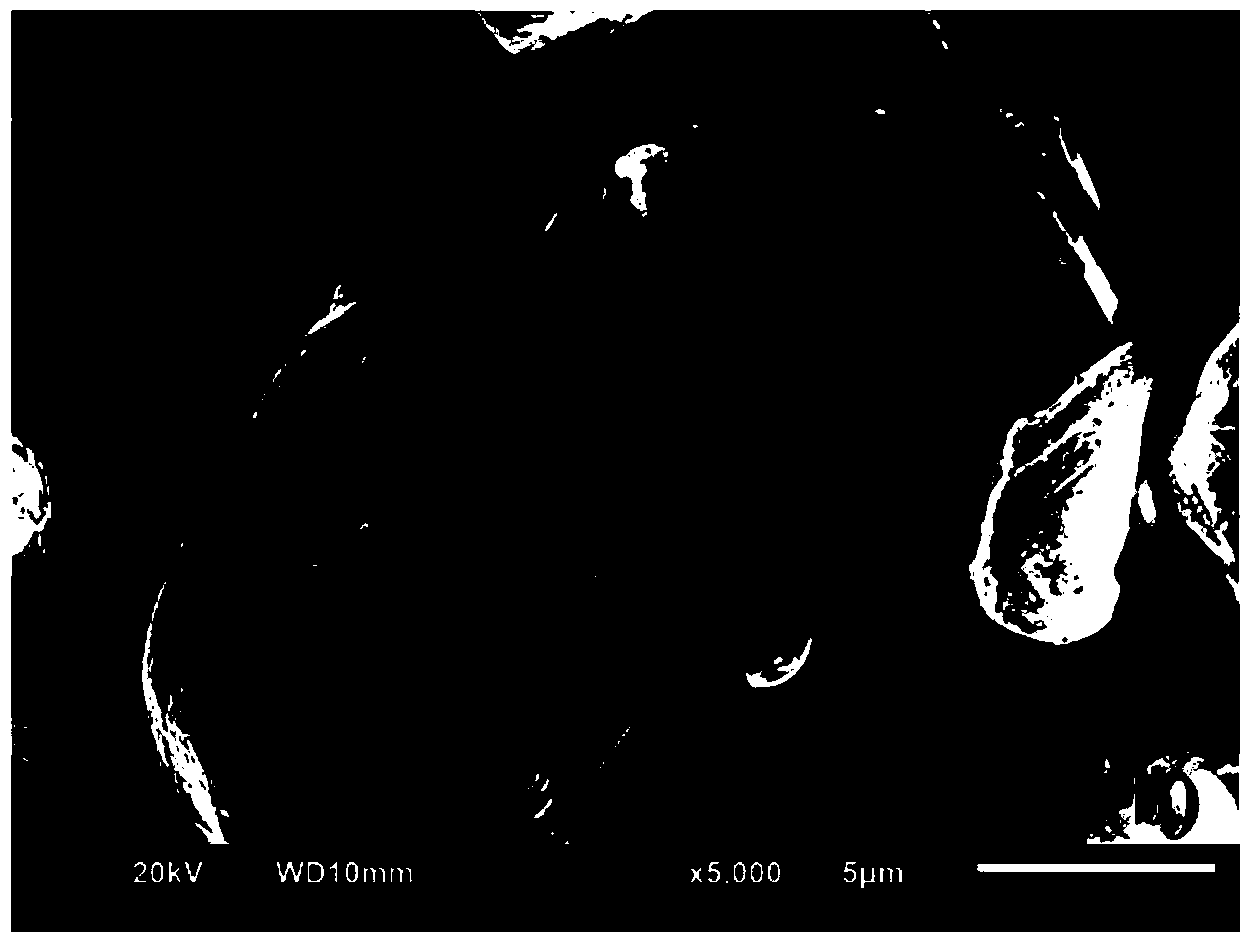

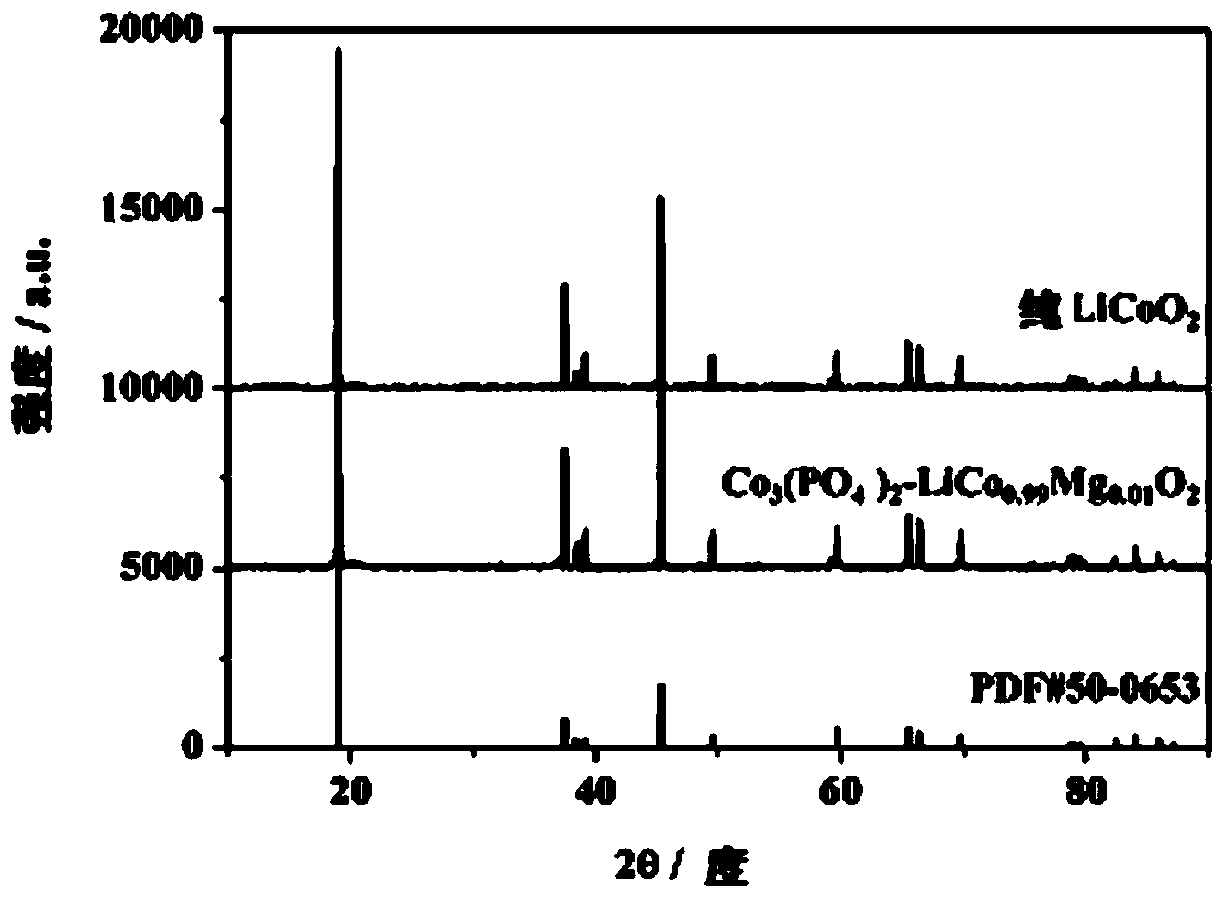

Doped and surface coating co-modified anode material for lithium ion battery and preparation method thereof

InactiveCN103779556APromote circulationEasy to operateSecondary cellsPositive electrodesEnvironmental resistancePhosphate

The invention discloses a doped and surface coating co-modified anode material for a lithium ion battery and a preparation method thereof. The anode material uses doped lithium cobalt oxide as a matrix, the surface of which is coated with Co3(PO4)2, AlPO4, Mn3(PO4)2, FePO4, Ni3(PO4)2, Mg3(PO4)2 and other phosphates, therefore, the electric conductivity, the circulating performance, the high temperature and high pressure resistance and other performances are improved. The preparation method has the advantages that the coating material is uniformly coated on the surface of the anode material to be beneficial to improving the electrochemical performance; the method is simple to operate, is green and environment-friendly and has industrial applicability.

Owner:北京盟固利新材料科技有限公司

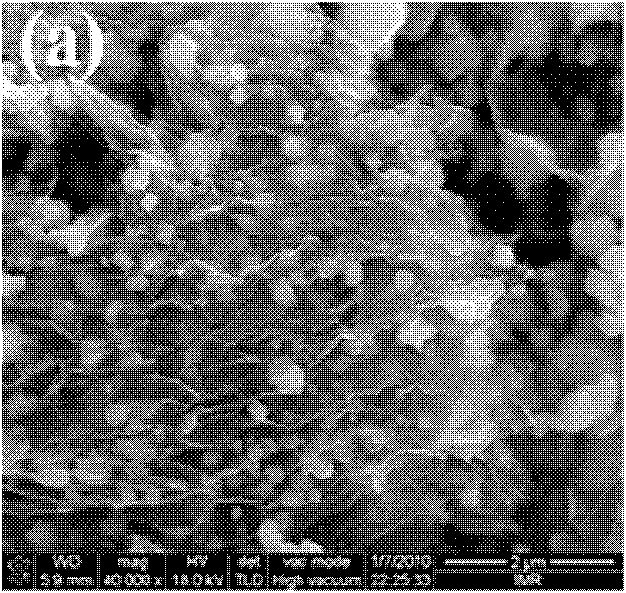

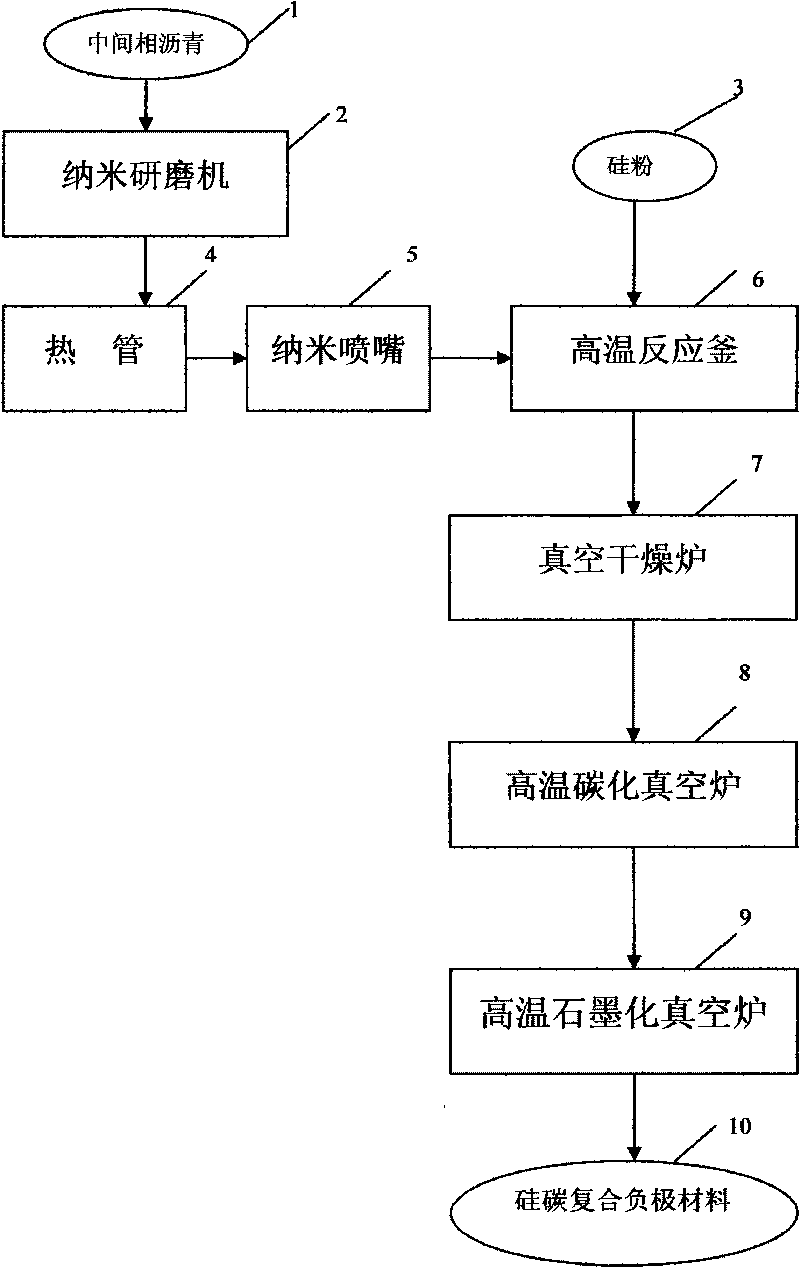

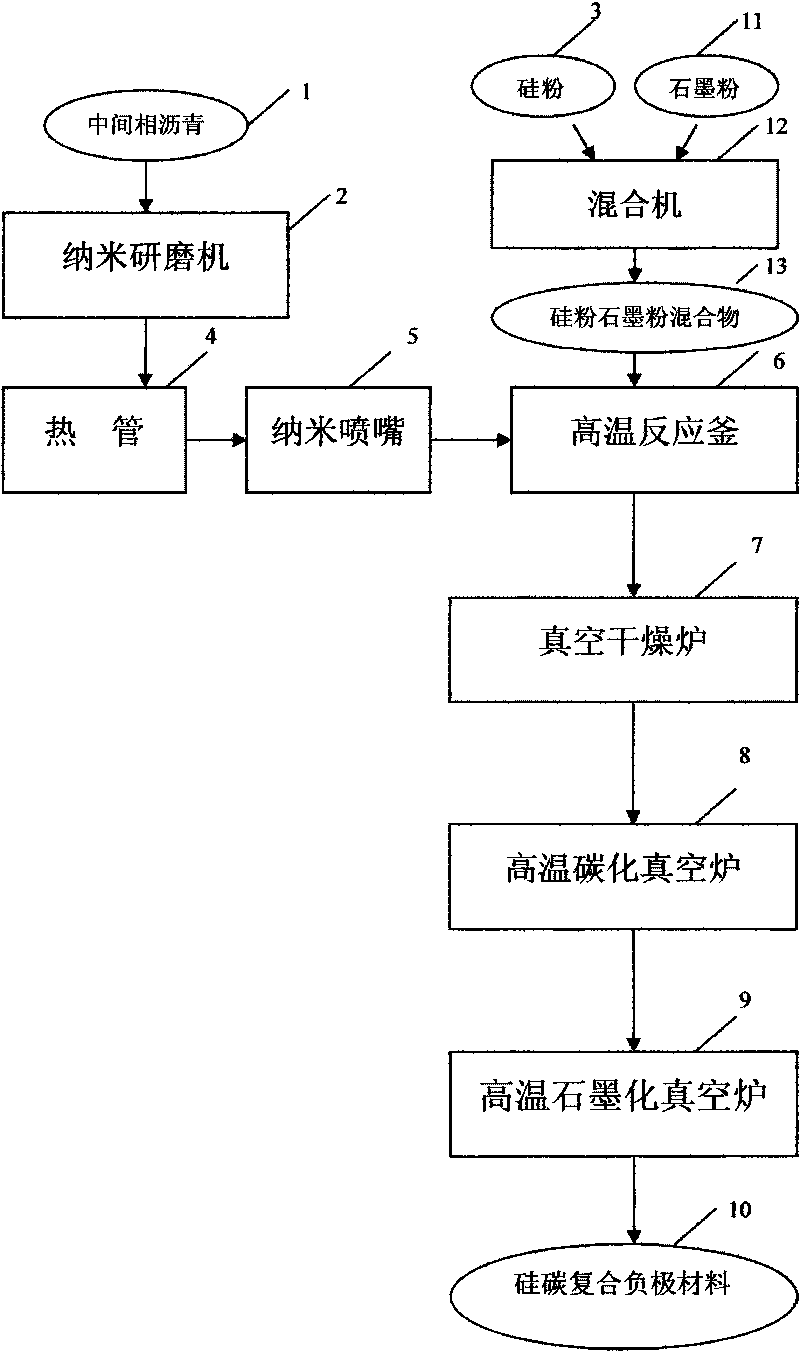

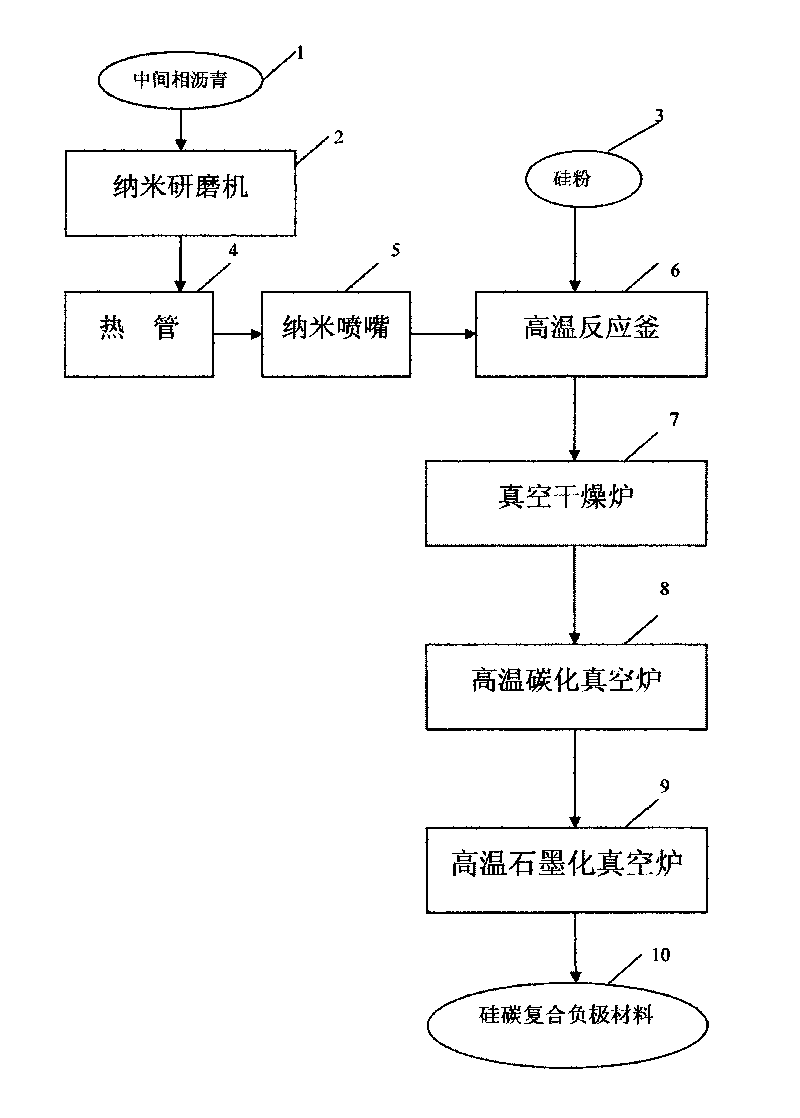

Silicon-carbon negative electrode material of lithium ion battery and preparation method thereof

ActiveCN102394287AExcellent intercalation and delithiation abilityImprove cycle stabilityCell electrodesFiberCarbon composites

The invention discloses a silicon-carbon negative electrode material of a lithium ion battery and a preparation method thereof, and solves the technological problem of improving the charge and discharge cycling stability of the electrode material. The silicon-carbon negative electrode material is prepared by mixing a silicon-carbon composite material and a natural graphite material, wherein the weight of the silicon-carbon composite material is 7-20% and the silicon-carbon composite material is prepared by depositing carbon nanotube and / or carbon nanofiber on the surface of nanometer silica fume and / or embedding into the nanometer silica fume to form core, the surface of which is covered with 3-15wt% of a carbon layer. The preparation method provided by the invention comprises steps of: precursor silicon powder preparation; chemical vapor deposition; liquid-coating roasting; crushing; and mixing. In comparison with the prior art, the reversible specific capacity of the silicon-carbon composite negative electrode material is greater than 500mAh / g; the coulombic efficiency for a first cycle is greater than 80%; the capacity conservation rate of cycling for 50 weeks is greater than 95%. The preparation method is simple, is easy to operate, requires low cost and is suitable for a high-volume negative electrode material of lithium ion batteries used for various portable devices.

Owner:BTR NEW MATERIAL GRP CO LTD

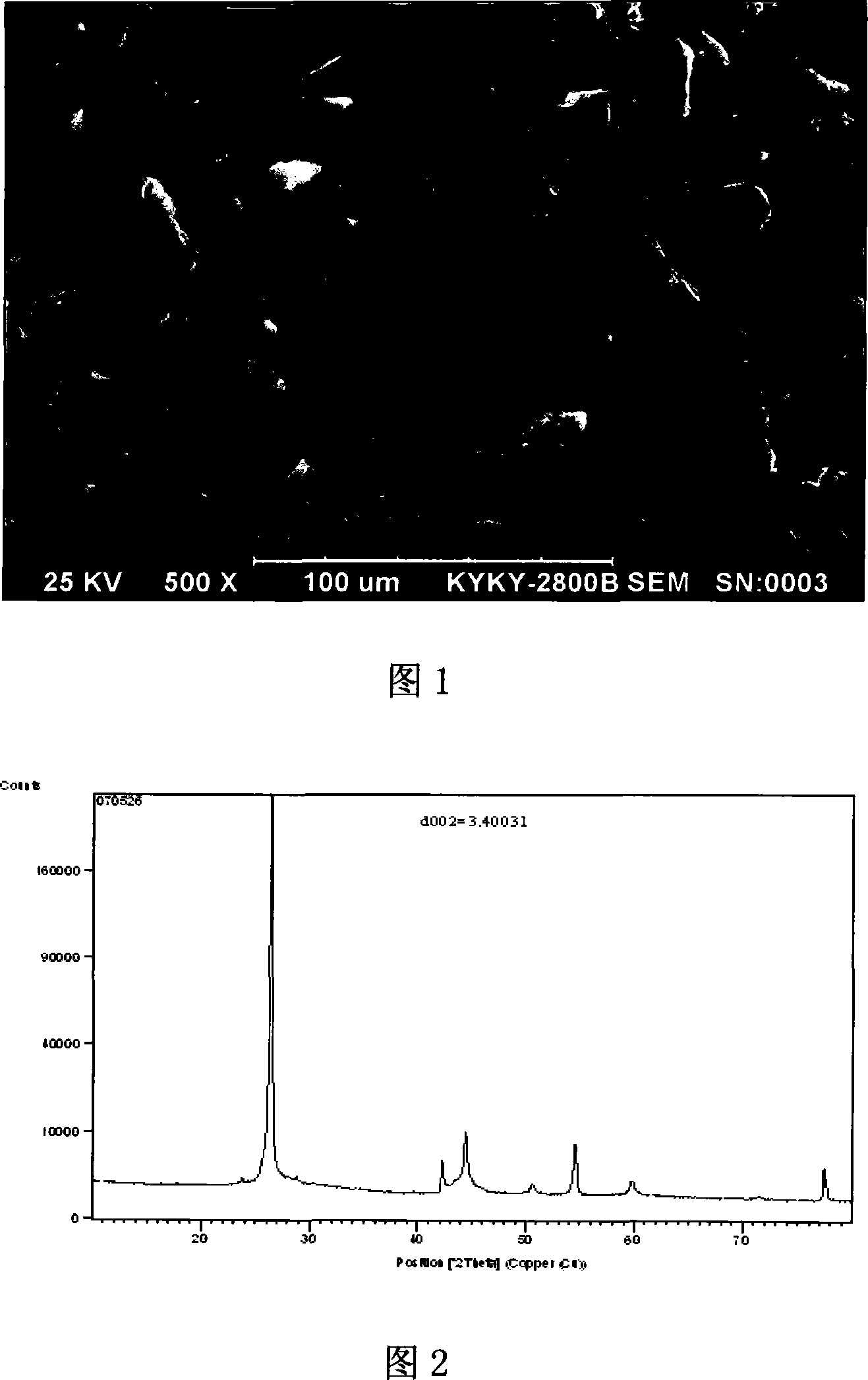

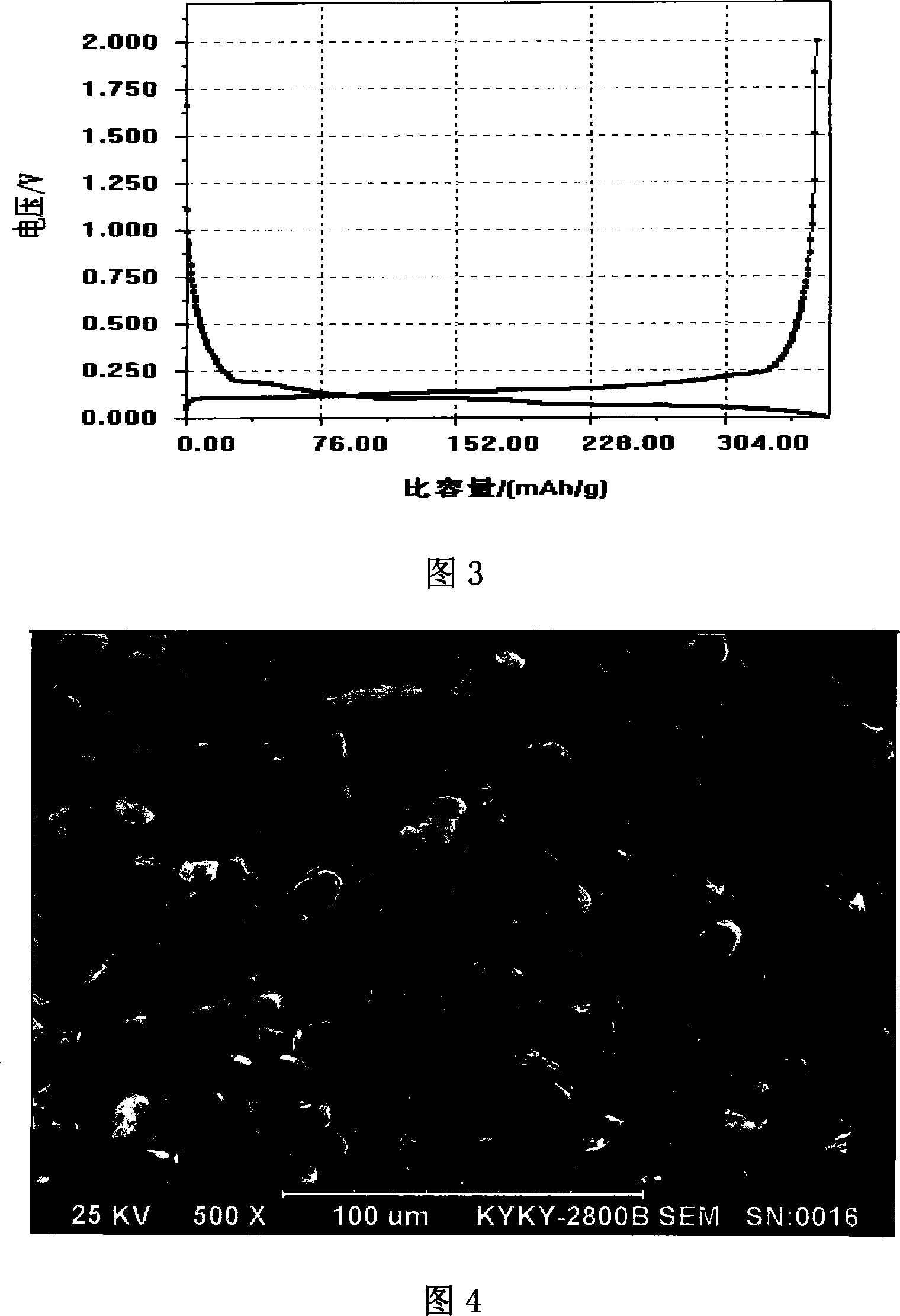

Man-made graphite cathode material for lithium ion battery and its making method

ActiveCN101087021AImprove discharge capacityPromote circulationCell electrodesAluminium-ion batteryElectrical battery

The invention discloses a preparing method of an artificial graphite cathode material used in lithium ion battery; it aims at resolving problems that cathode material possesses higher discharging capacity, coulomb efficiency and long circle life. The preparing method includes following steps: coal or petroleum needle-type coke is comminuted, and hot processed for 1-48 hours at 800deg.C-3000deg.C, comparing with current technique, the cathode material adopts needle-type coke to be comminuted, and hot process, defect that high crystallinity graphite material can not be circled in electrolyte system of PC solvent stably, and it can discharge in big times, it can be used in lithium ion drive battery, and craft is easy, and it fits for industrialization production.

Owner:BTR NEW MATERIAL GRP CO LTD

Lithium manganese oxide material and preparation method thereof

InactiveCN102054985AEasy to prepareNormal temperature is goodCell electrodesHigh temperature storagePhysical chemistry

The invention discloses a lithium manganese oxide material and a preparation method thereof, in particular to a high-crystallinity lithium manganese oxide material and a preparation method thereof, wherein the high-crystallinity lithium manganese oxide material is used for coating a lithium ion battery. The lithium manganese oxide material is obtained by being coated on a lithium manganese oxide precursor with the one-time crystal particle of 0.01-20mum and has the general formula of LiaMn2-b-cMbGcO4-d-eXdZe, wherein M and X are doped elements, G and Z are coating elements of which the concentration is distributed in a decreasing gradient from outside to inside, a is not less than 0.9 and is not more than 1.2, b is not less than 0 and is not more than 0.2, c is more than 0 and is not more than 0.2, d is not less than 0 and is not more than 0.2, and e is not less than 0 and is not more than 0.2. The material serves as the positive pole material of the lithium ion battery, has better normal-temperature and high-temperature cycle performance and excellent high-temperature storage performance, is simple in preparation and easy to operate, control and carry out industrial production.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

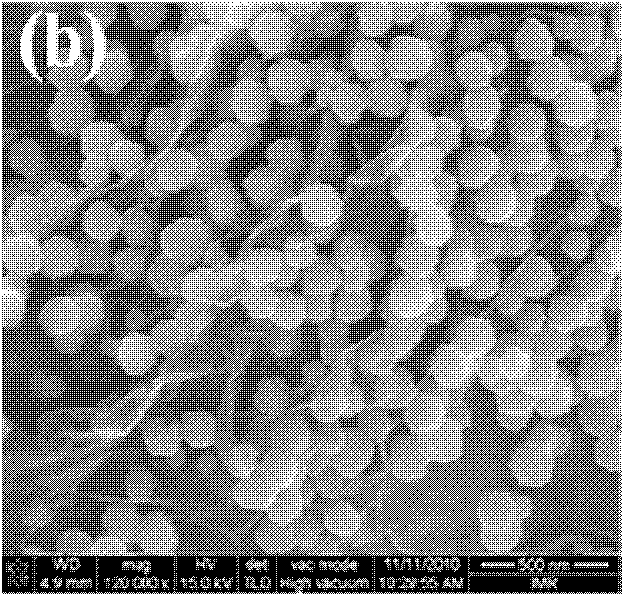

Silicon-carbon composite material, lithium ion battery, and preparation method and application of silicon-carbon composite material

ActiveCN103633295AAlleviate volume expansionAvoid direct contactCell electrodesSecondary cellsCarbon compositesSilicon monoxide

The invention discloses a silicon-carbon composite material, a lithium ion battery, and a preparation method and application of the silicon-carbon composite material. The preparation method of the silicon-carbon composite material comprises the steps: uniformly mixing silicon powder and silicon monoxide powder, then mixing with a solution containing an organic carbon source dispersant, and performing wet-process ball milling to obtain a slurry; uniformly mixing the slurry, graphite and a conductive agent, and performing spray drying to obtain spherical-like particles, wherein graphite is synthetic graphite and / or intermediate-phase graphite; mixing the spherical-like particles and asphalt, performing cladding processing under the inert atmosphere to obtain a cladded material; and then performing carbonizing processing to obtain the silicon-carbon composite material, wherein silicon powder, silicon monoxide powder, graphite and asphalt respectively accounts for 5-15%, 3-10%, 45-75% and 5-40% by weight of the sum of the above materials, and the organic carbon source dispersant and the conductive agent both accounts for 0.1-2% by weight of the sum of silicon powder, silicon monoxide powder and graphite. The silicon-carbon composite material has relatively good cycle performance, and can be directly used as a cathode material of the lithium ion battery. The preparation method is simple in technology, low in cost and applicable to industrial production.

Owner:SHANGHAI SHANSHAN TECH CO LTD

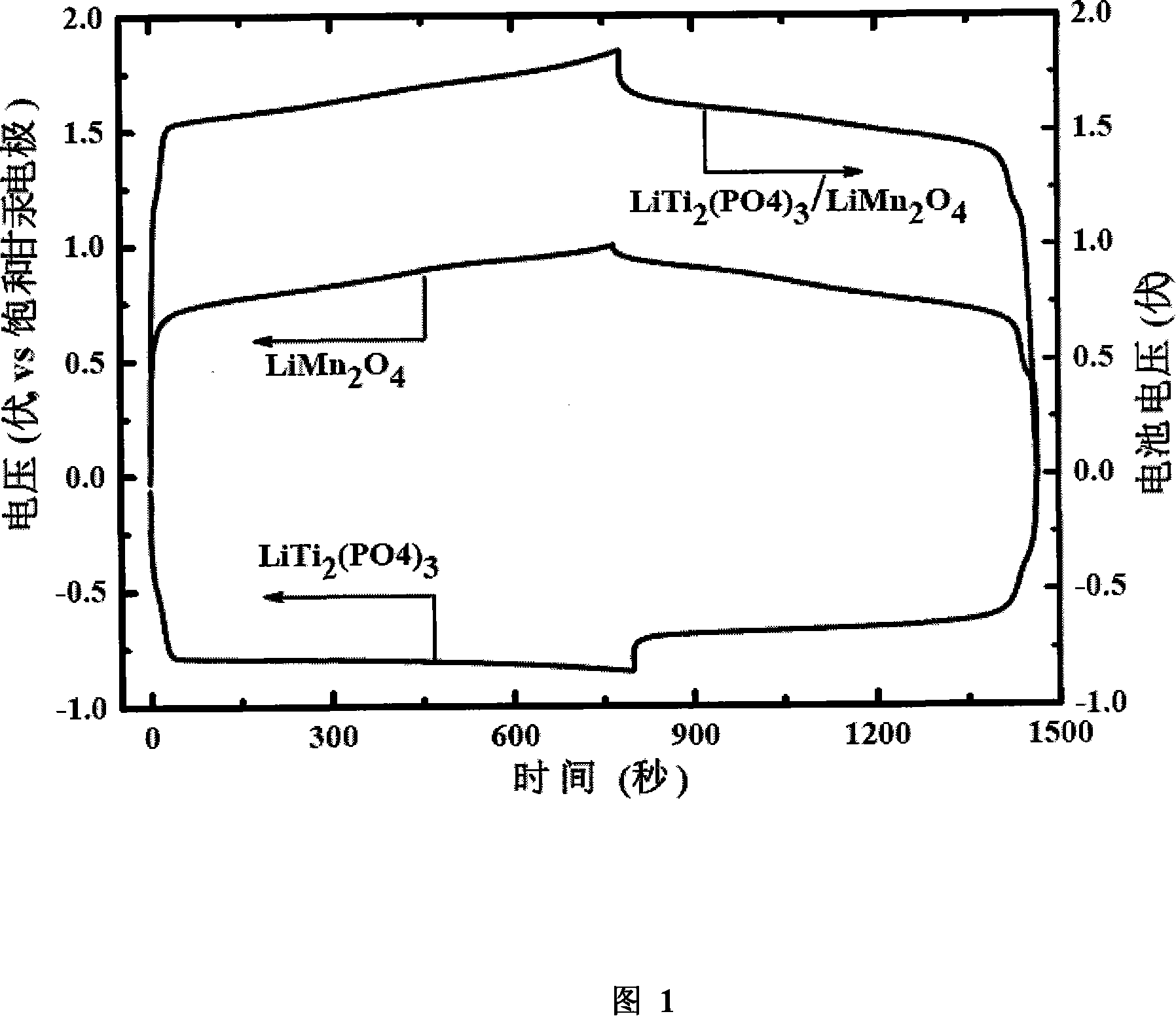

Hydrographical rechargeable lithium or sodium ion battery

InactiveCN101154745ALow costGuaranteed cycle performanceAlkaline accumulatorsCell electrodesPower batteryIon transfer

The invention belongs to electrochemical technical field, in particular to a novel high performance water system lithium ion battery. The invention adopts an ion embedding in-out mechanism used by an organic system lithium ion battery in an energy storage element which uses a water solution as an electrolyte. The embedding-in reaction ion mainly includes lithium ion composite and sodium ion composite. In the invention, the positive pole adopts a material containing the positive ion embedding-in composite while the negative pole adopts a shell structure material of LiTi2(PO4)3; the electrolyte adopts a water system electrolyte of the positive ion. The electric charging and discharging process only relates to the ion transfer between the two electrodes, and the invention can still has the characteristic of a rocking-chair type organic system lithium ion battery; the invention is of long cycling service life, big power, safety, low cost and no pollution, and is particularly suitable to be used as an ideal power battery of electric vehicle.

Owner:FUDAN UNIV

High energy lithium ion batteries with particular negative electrode compositions

Combinations of materials are described in which high energy density active materials for negative electrodes of lithium ion batteries. In general, metal alloy / intermetallic compositions can provide the high energy density. These materials can have moderate volume changes upon cycling in a lithium ion battery. The volume changes can be accommodated with less degradation upon cycling through the combination with highly porous electrically conductive materials, such as highly porous carbon and / or foamed current collectors. Whether or not combined with a highly porous electrically conductive material, metal alloy / intermetallic compositions with an average particle size of no more than a micron can be advantageously used in the negative electrodes to improve cycling properties.

Owner:IONBLOX INC

Composite hard carbon cathode material of lithium ion battery and preparation method thereof

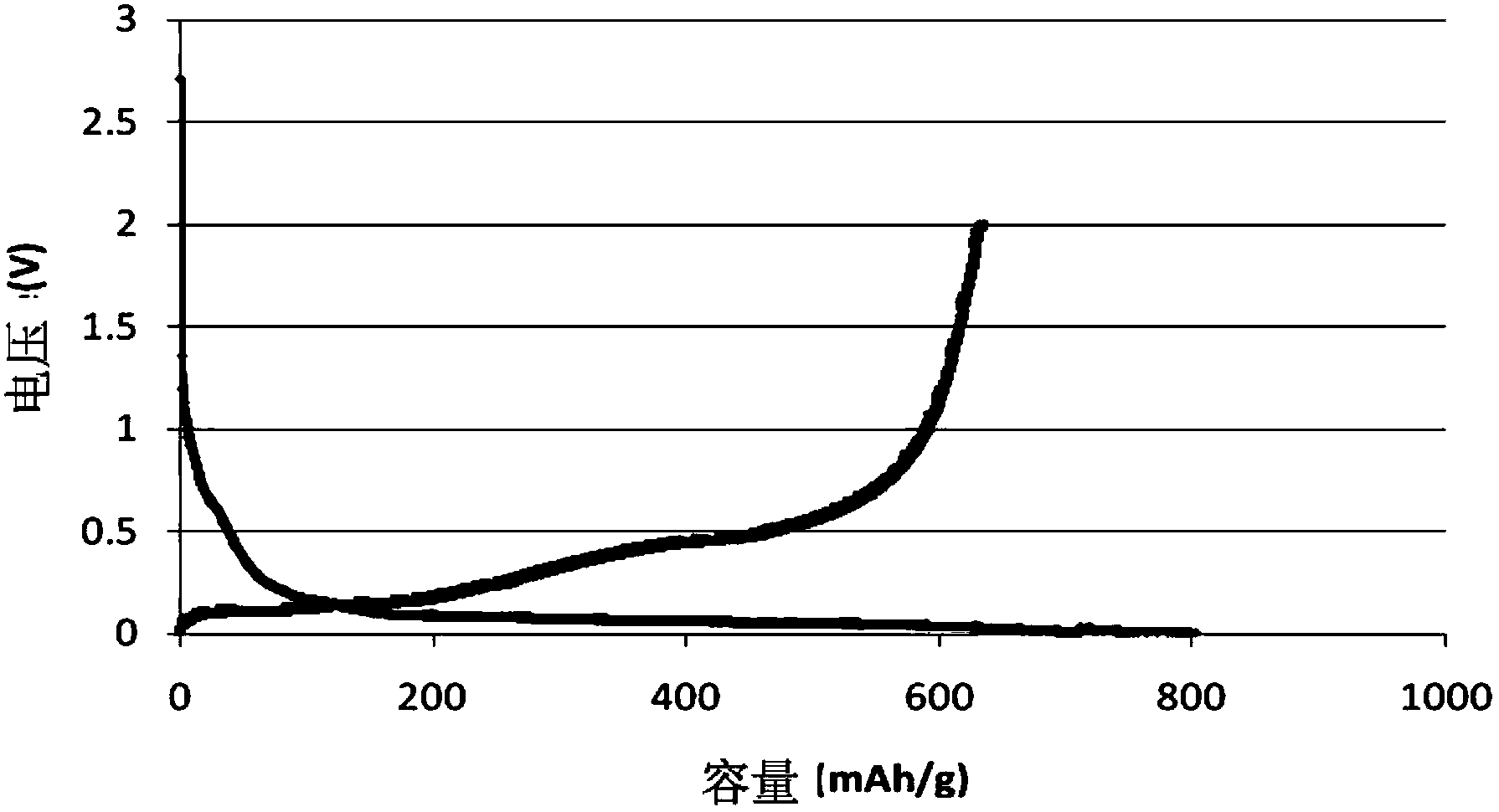

ActiveCN101887966AIncrease capacityImprove the first Coulombic efficiencyCell electrodesSodium-ion batteryCharge discharge

The invention discloses a composite hard carbon cathode material of a lithium ion battery and a preparation method thereof, aiming at improving the first coulombic efficiency. In the composite hard carbon cathode material, a coating object is coated outside a hard carbon matrix, a precursor of the hard carbon matrix comprises a thermoplastic resin which forms the hard carbon matrix by pyrolysis, and a precursor of the coating object is an organic matter. The preparation method comprises the steps of curing, pyrolyzing, pulverizing and coating. Compared with the prior art, a curing agent and adopant are added to the resin for curing, the cured mixture is taken as a carbon source, and then the carbon source is pyrolyzed and coated to finally obtain the composite hard carbon cathode material; and the first reversible capacity of the obtained composite hard carbon cathode material is more than 455.2mAh / g and the first coulombic efficiency thereof is more than 79.4% in the case of 0.2C, thus the obtained composite hard carbon cathode material has high capacity and high first coulombic efficiency, meets the requirement of the lithium ion battery with high capacity, high multiplying power and excellent high and low temperature cycle performance on the charge-discharge performances of the cathode material, has low production cost and is suitable for industrial production.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +2

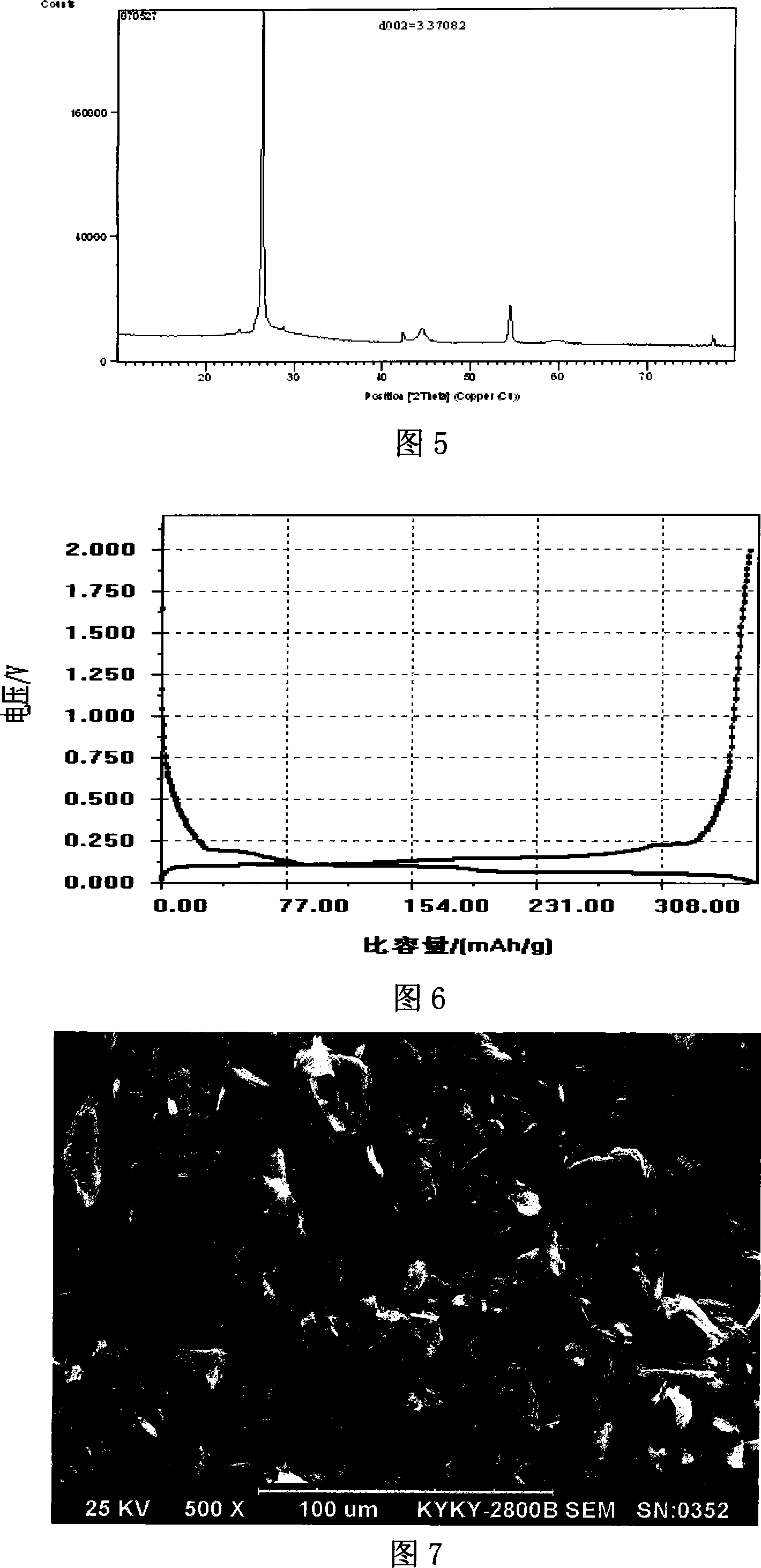

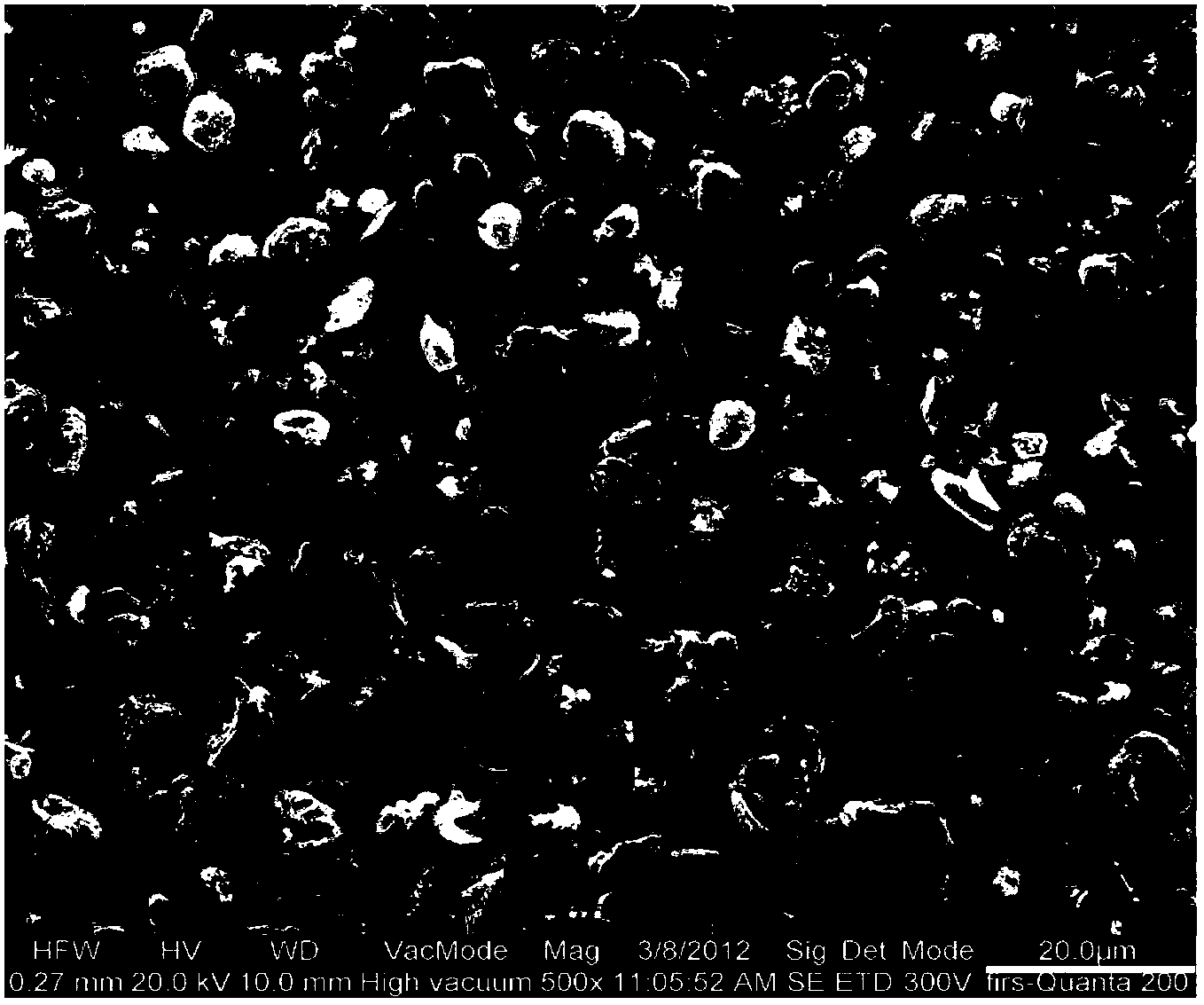

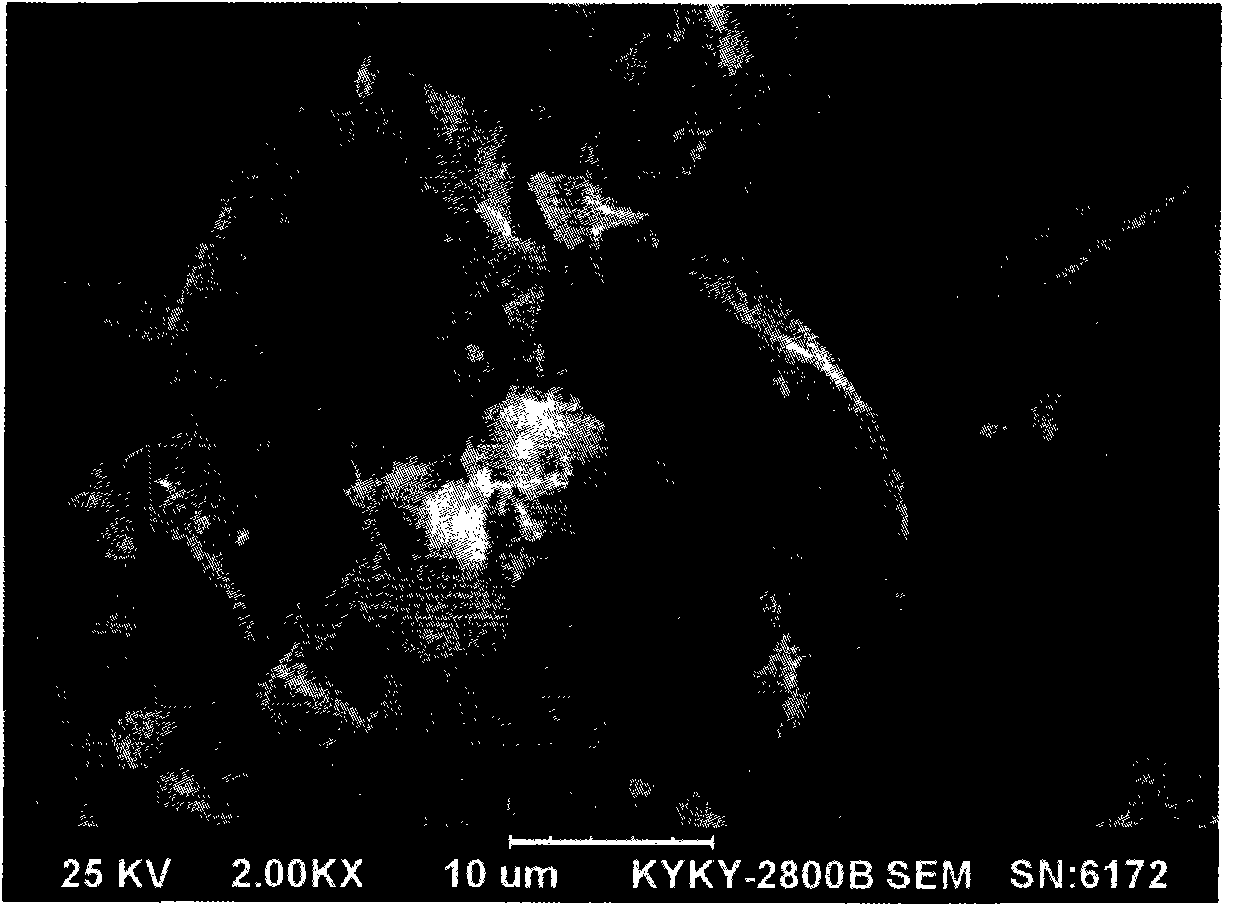

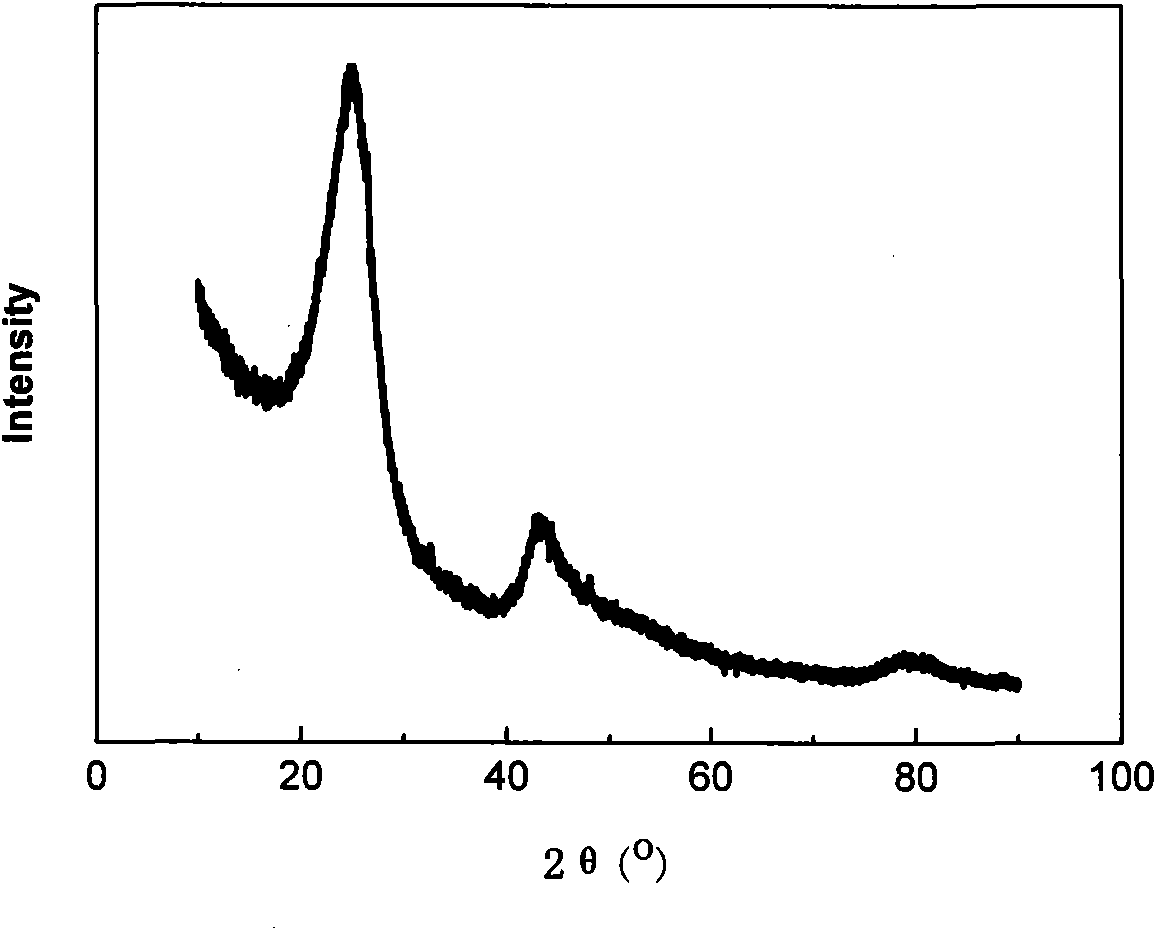

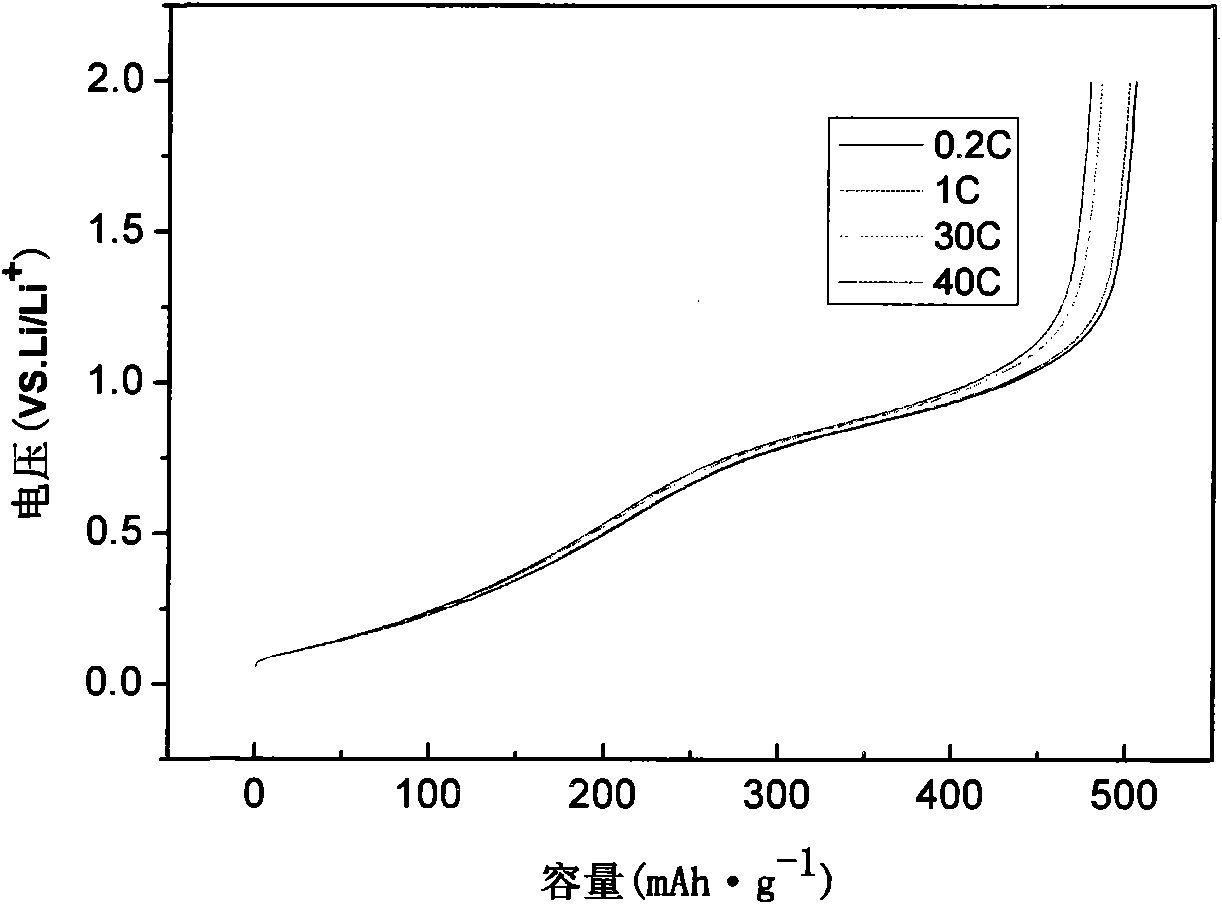

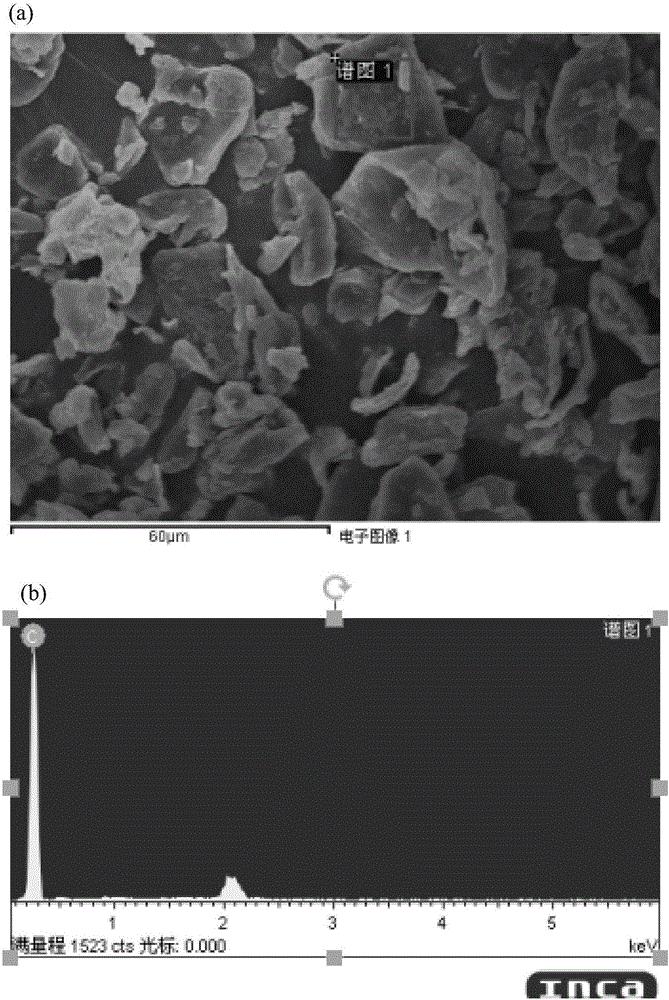

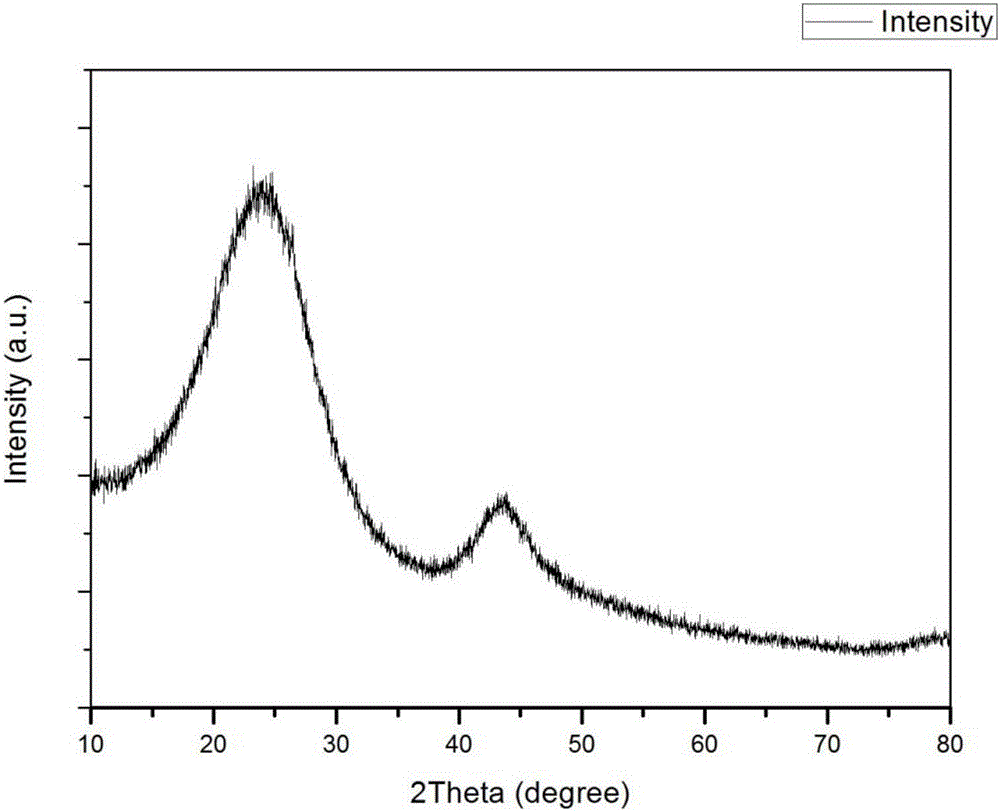

Biomass hard carbon negative electrode material for sodium ion battery, preparing method and sodium ion battery

ActiveCN106299365AImprove the first charge and discharge efficiencyImprove electrochemical performanceNon-aqueous electrolyte accumulatorsCell electrodesSodium-ion batteryLithium-ion battery

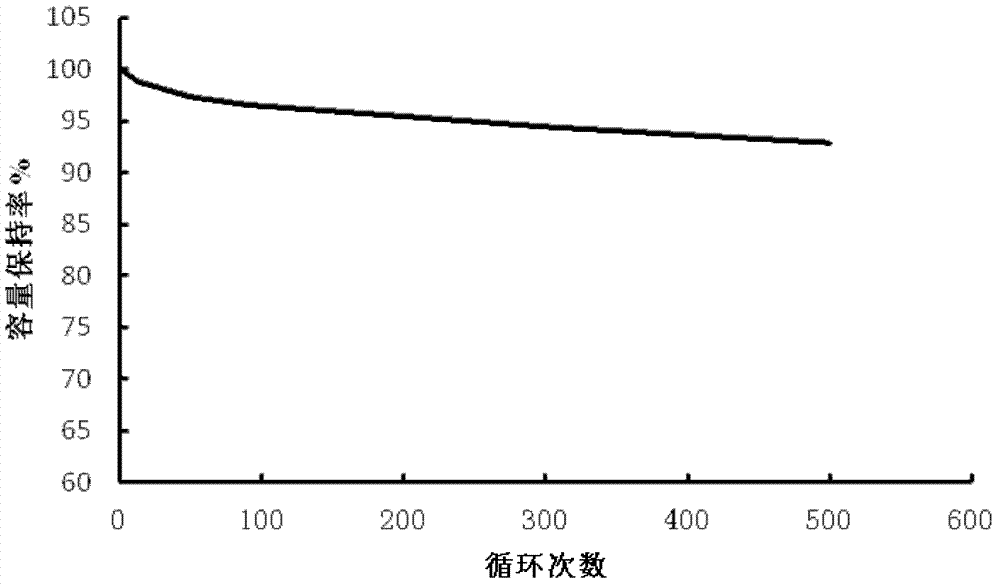

The invention relates to a biomass hard carbon negative electrode material for a sodium ion battery, a preparing method and the sodium ion battery and belongs to the technical field of sodium ion energy storage equipment. The biomass hard carbon negative electrode material is prepared through the method including the following steps that firstly, a biomass raw material is smashed, and precursor particles are obtained; secondly, in a protection atmosphere, the precursor particles are heated to 400-600 DEG C to be pre-sintered for 1.5-2.5 h, then cooled to the room temperature along with a furnace, then heated to 800-1600 DEG C to be sintered for 2-5 h and cooled, and an intermediate is obtained; thirdly, the intermediate is put into an alkali solution to be soaked, taken out, then put into an acid solution to be soaked, then washed with water to be neutral and dried, and a purified product is obtained; fourthly, the purified product is subjected to microwave vacuum activation for 3-15 s at the power of 1000-2000 W, and then the biomass hard carbon negative electrode material is obtained. The first-time charging and discharging efficiency of the obtained biomass hard carbon negative electrode material reaches up to 90% or above, the circulation stability is good, the reversible specific capacity is 300 mAh / g or above, and the biomass hard carbon negative electrode material has a good electrochemical property.

Owner:浙江瓦司特钠科技有限公司

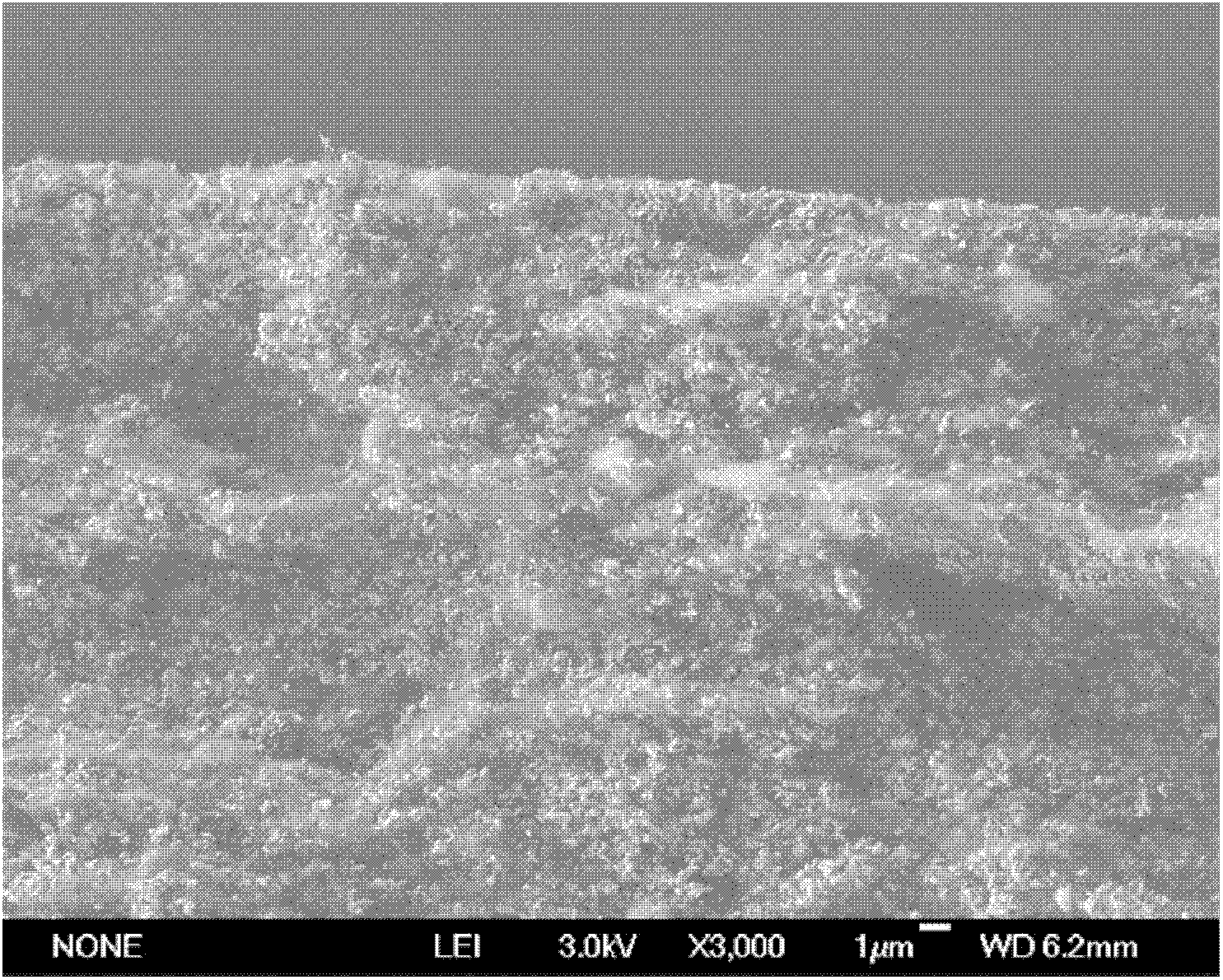

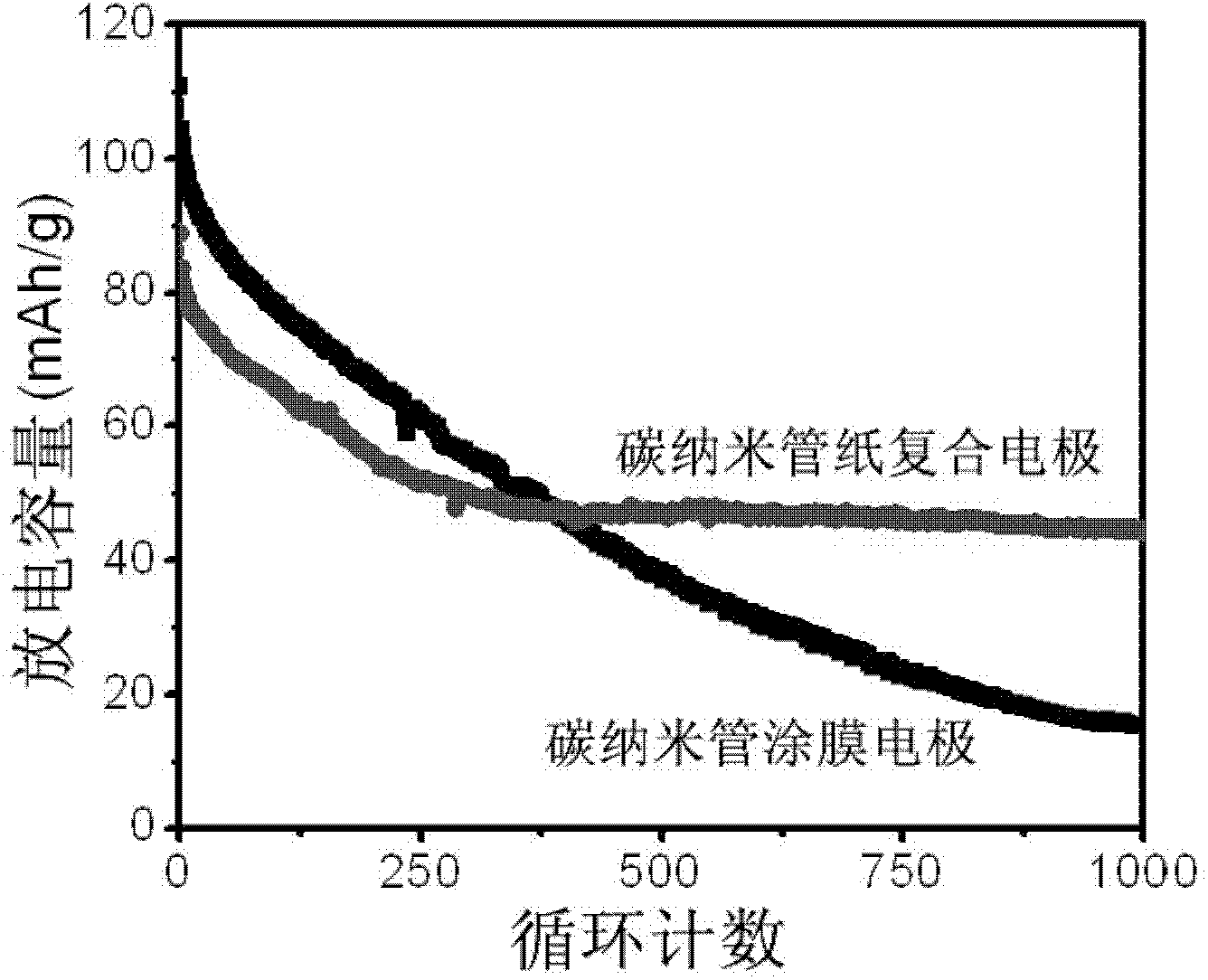

Self-supporting flexible carbon nano-tube paper composite electrode material for lithium ion battery

InactiveCN102593436AImprove performanceGood electronicsCell electrodesCarbon nanotubeSodium-ion battery

The invention discloses a self-supporting flexible carbon nano-tube paper composite electrode material for a lithium ion battery. A carbon nano-tube paper network of the material is formed by using interlaced carbon nano-tubes, and active anode material particles or cathode material particles of the lithium ion battery are compounded with carbon nano-tube paper to form the carbon nano-tube paper composite electrode material. In the electrode material, the carbon nano-tubes form an efficient three-dimensional conductive network, so that a better electron channel is provided for active material particles with low electrical conductivity. Because a bonding agent and a current collector are not needed, the electrode material has a higher active material ratio, and the performance of the electrode material is further improved. Meanwhile, the high mechanical property of the carbon nano-tube paper makes the composite electrode material show flexible characteristics, and as a flexible electrode material, the self-supporting flexible carbon nano-tube paper composite electrode material is hopeful to be widely used in next-generation flexible electronic equipment.

Owner:TSINGHUA UNIV

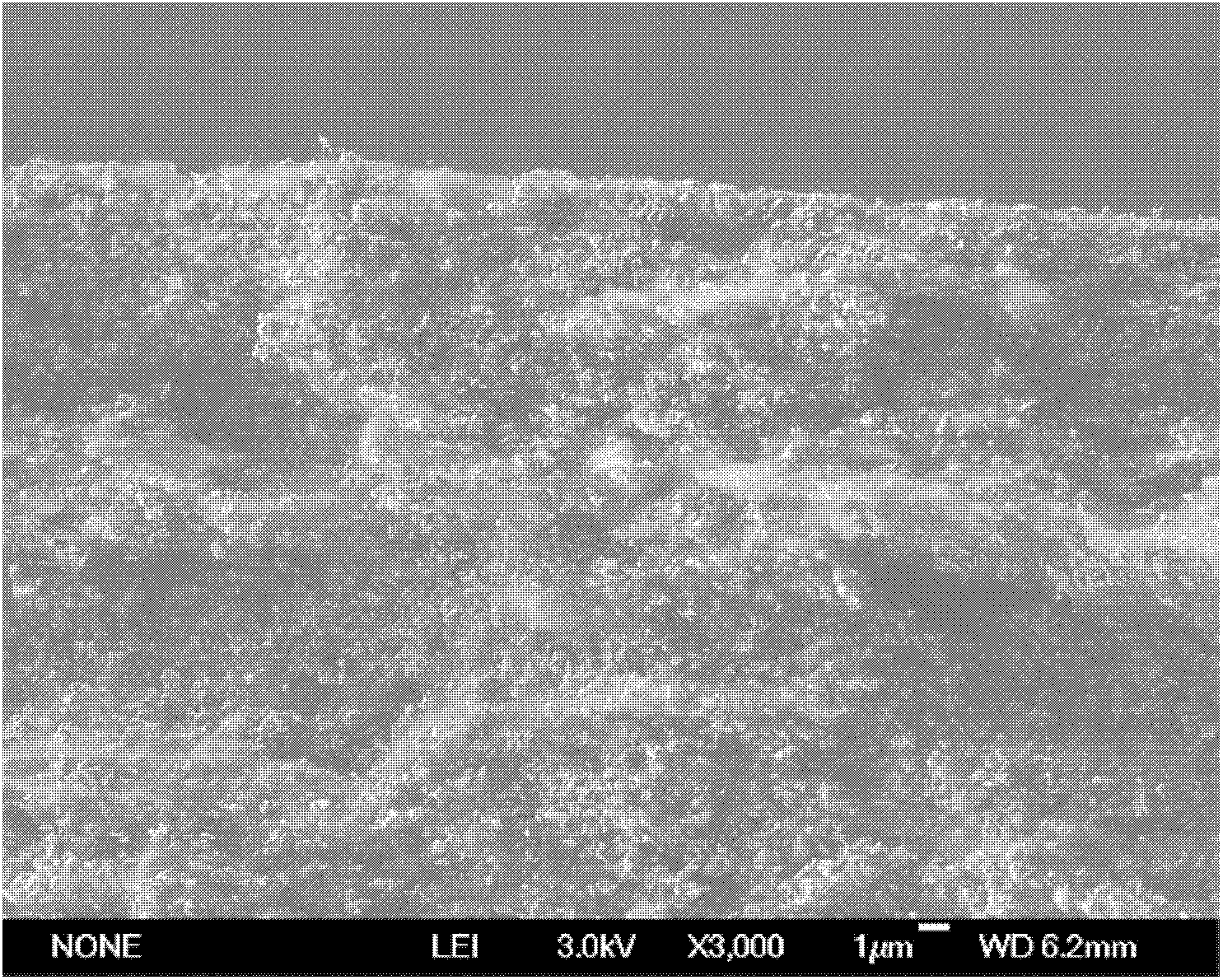

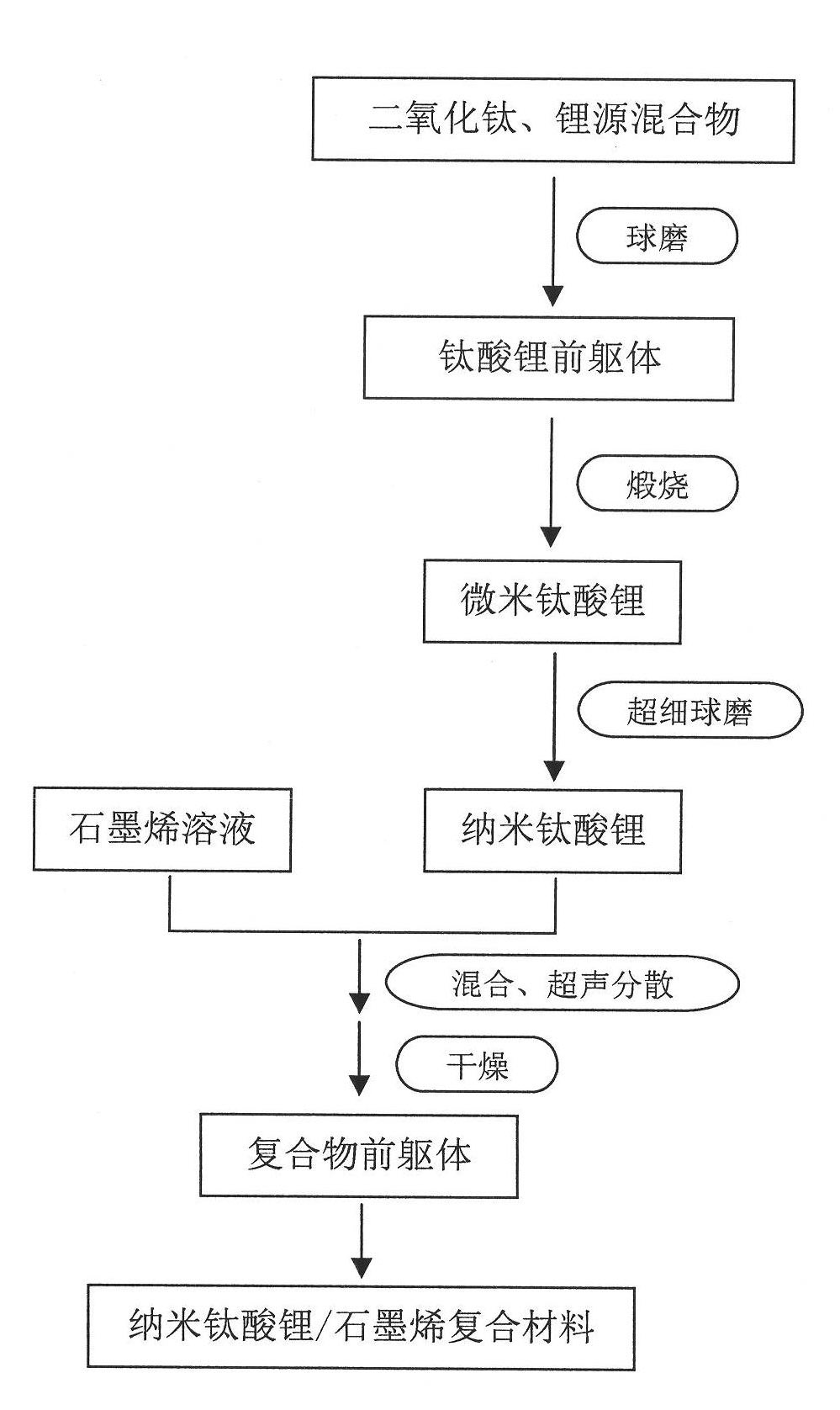

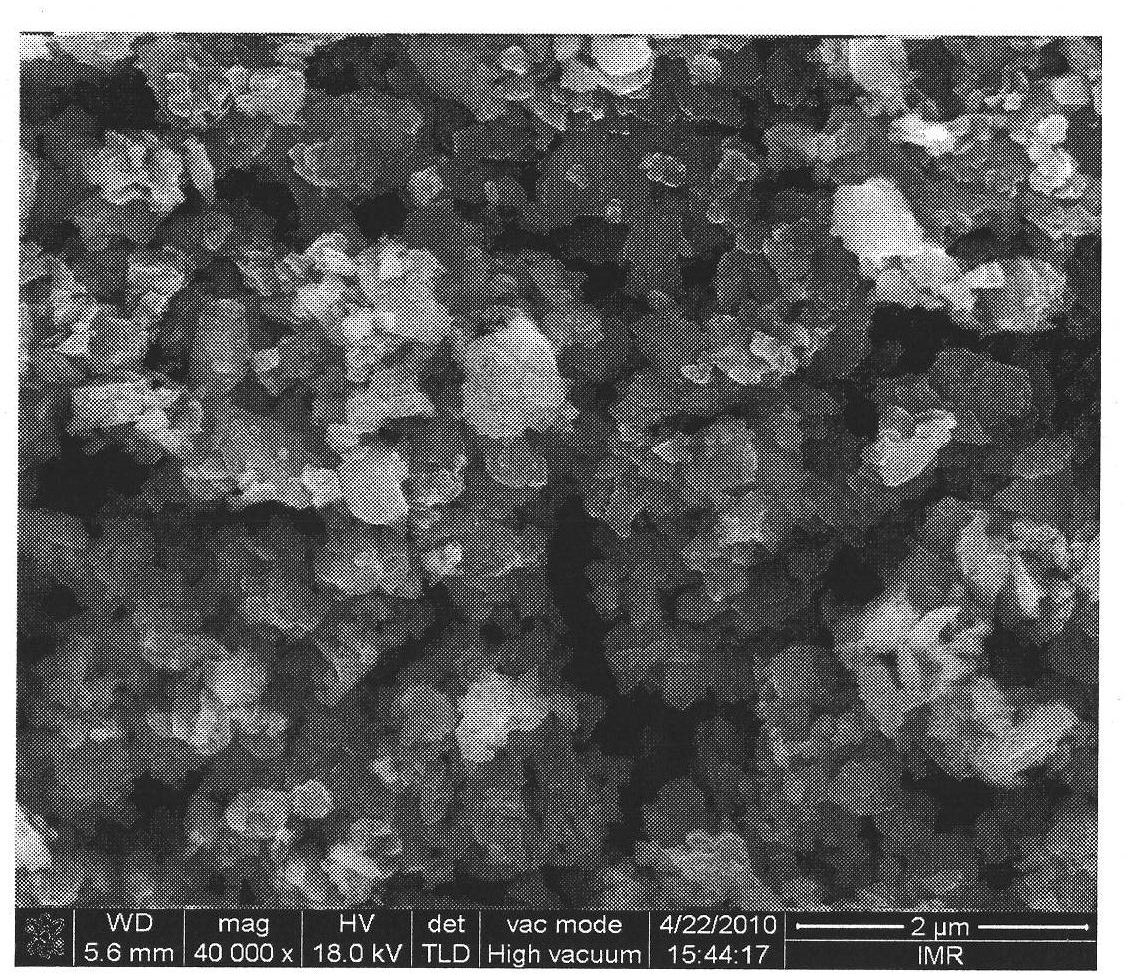

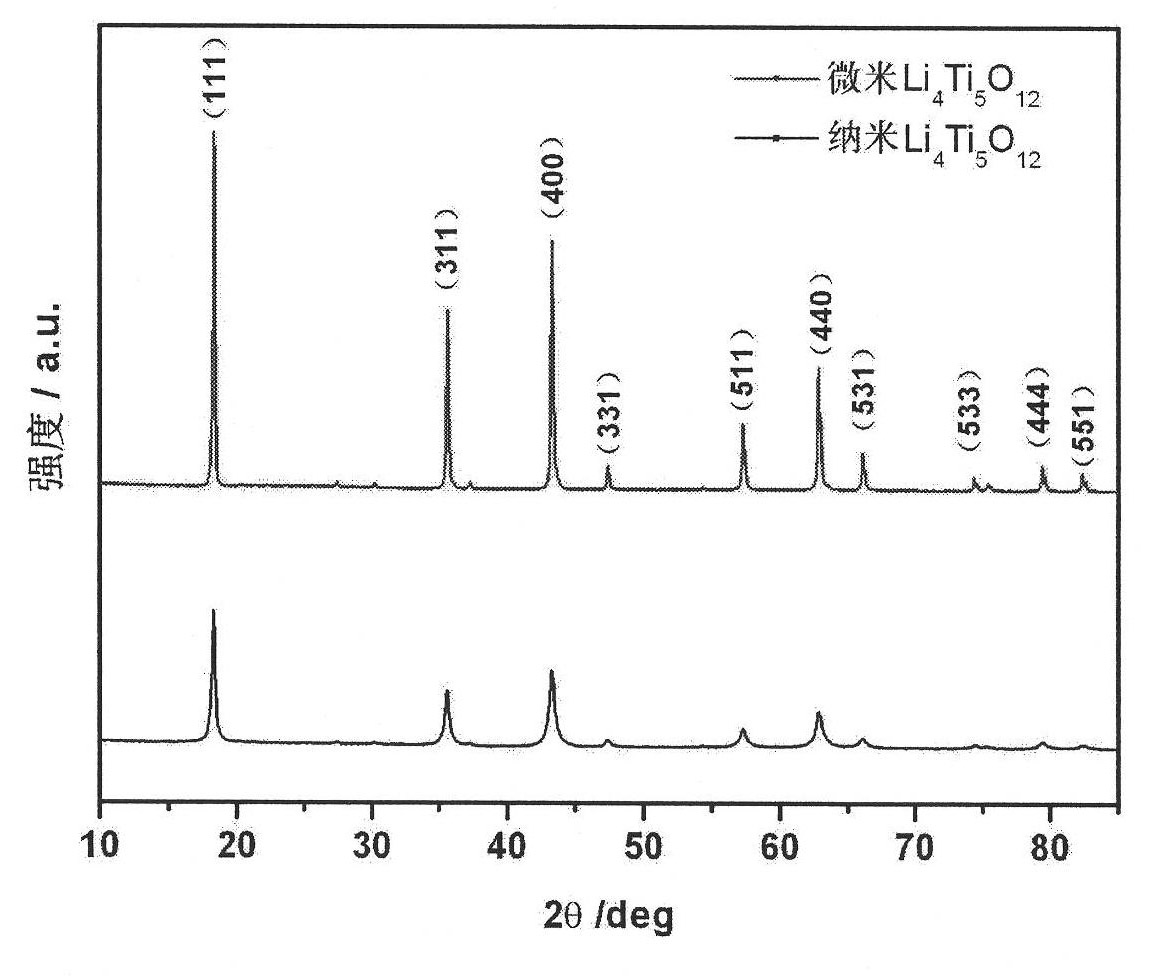

Nanometer lithium titanate/graphene composite negative electrode material and preparation process thereof

InactiveCN102376937AImprove electrochemical performanceAvoid defectsNon-aqueous electrolyte accumulator electrodesGrain treatmentsSodium-ion batteryCvd graphene

The invention relates to the field of negative electrode materials of lithium ion batteries, and specifically to a nanometer lithium titanate / graphene composite negative electrode material and a preparation process thereof. According to the invention, micron-sized lithium titanate prepared by the solid phase method is subjected to ultrafine ball milling to obtain nanometer powder, and the nanometer lithium titanate powder and graphene are uniformly compounded and subjected to heat treatment so as to obtain a high performance lithium ion battery negative electrode material; the invention is characterized in that uniform distribution of graphene in the nanometer lithium titanate powder is realized through in situ compounding; the weight of graphene in the composite negative electrode material accounts for 0.5 to 20%, and the weight of lithium titanate accounts for 80 to 99.5%. The lithium ion battery negative electrode material has good electrochemical performance, 1C capacity greater than 165 mAh / g, 30C capacity greater than 120 mAh / g and 50C capacity greater than 90 mAh / g. Nanometer lithium titanate in the lithium ion battery negative electrode material prepared in the invention has high phase purity; the preparation process of the material is simple and is easy for industrial production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method for negative electrode active material of lithium ion battery

ActiveCN103474666AImprove conductivityImprove structural stabilityElectrode thermal treatmentSecondary cellsCarbon compositesCarbon layer

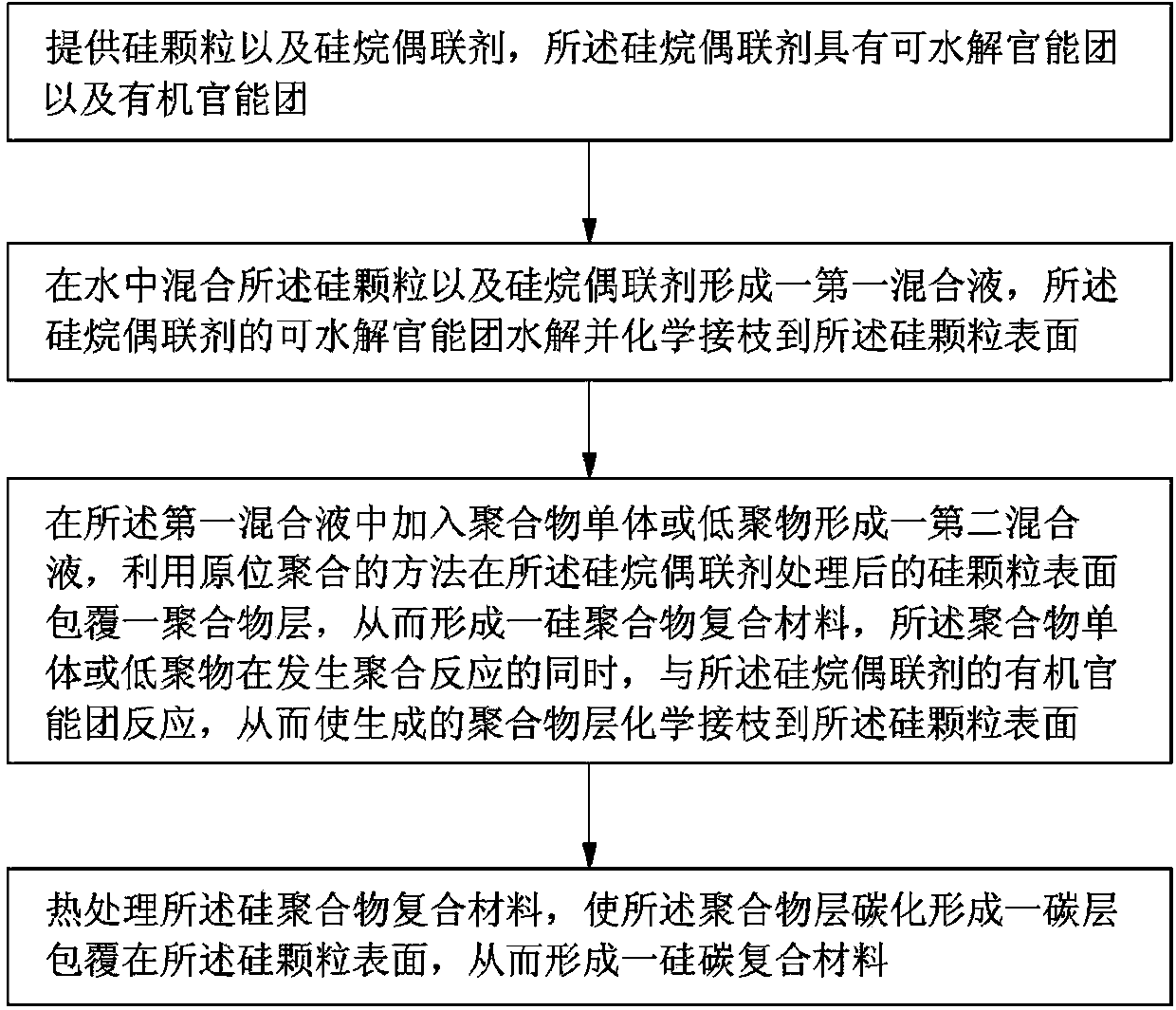

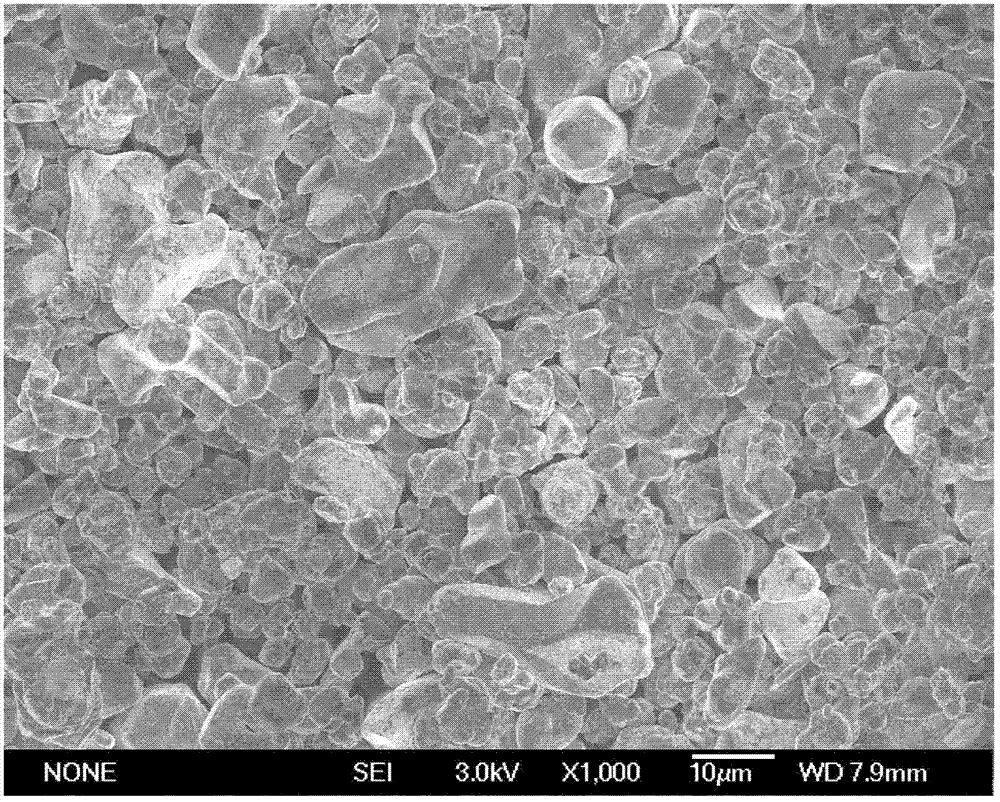

The invention relates to a preparation method for a negative electrode active material of a lithium ion battery. The preparation method comprises the following steps: providing a silicon particle and a silane coupling agent which has a hydrolyzable functional group and an organic functional group; mixing the silicon particle with the silane coupling agent in water to form a first mixed liquor, wherein the hydrolyzable functional group of the silane coupling agent is hydrolyzed and chemically grafted onto the surface of the silicon particle; adding a polymer monomer or oligomer into the first mixed liquor to form a second mixed liquor, coating a polymer layer on the surface of the silicon particle by using in situ polymerization so as to form a silicon / polymer composite and allowing the polymer monomer or oligomer to react with the organic functional group of the silane coupling agent during polymerization so as to allow the generated polymer layer to be chemically grafted onto the surface of the silicon particle; and subjecting the silicon / polymer composite to heat treatment to carbonize the polymer layer so as to form a carbon layer coated on the surface of the silicon particle, thereby forming a silicon carbon composite.

Owner:JIANGSU HUADONG INST OF LI ION BATTERY +1

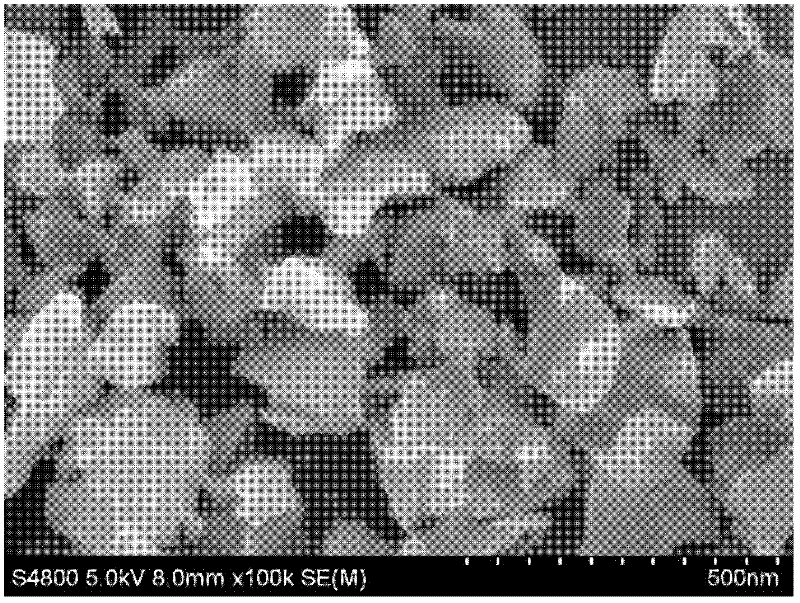

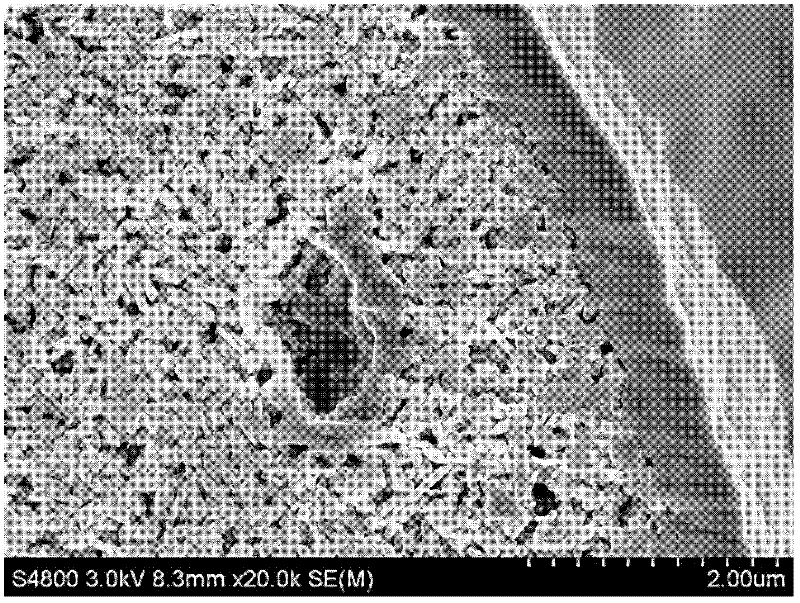

Preparation method of cathode material of LCO (lithium cobaltate)-based lithium ion battery

ActiveCN102779976AImprove cycle performanceImprove securityCell electrodesDissolutionSodium-ion battery

The invention discloses a preparation method of cathode material of an LCO (lithium cobaltate)-based lithium ion battery, which includes the following steps of: respectively preparing LCO material A with a median particle diameter of 10-25micrometers and LCO material B with a median particle diameter of 1-10micrometers which contain doping element of M; mixing the material A with the material B according to a certain proportion, adding secondary surface doping element M', carrying out ball milling and mixing, roasting and grinding to obtain material C with median particle diameter of 7-15micrometers; and finally coating an element G on the surface of the material C, drying and then conducting heat treatment to obtain the cathode material of the LCO-based lithium ion battery. Through the grading of the LCO materials with different particle diameters, the space utilization rate and the compacted density of the material are effectively improved; through the treatment of secondary surface doping, the stability of the surface structure of the material is improved; and through the coating treatment, the contact area between the LCO and the electrolyte is reduced, and the dissolution of the Co contained in the material in the electrolyte is reduced. Therefore, the cycle performance and the safety performance of the lithium ion battery are improved.

Owner:PULEAD TAIAN TECH IND

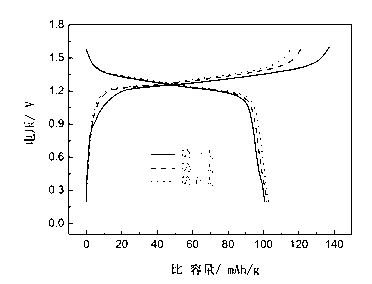

Water system chargeable sodium-ion battery

InactiveCN103022577AIncrease energy densityImprove cycle lifeCell electrodesSecondary cellsElectrolytic agentElectrical battery

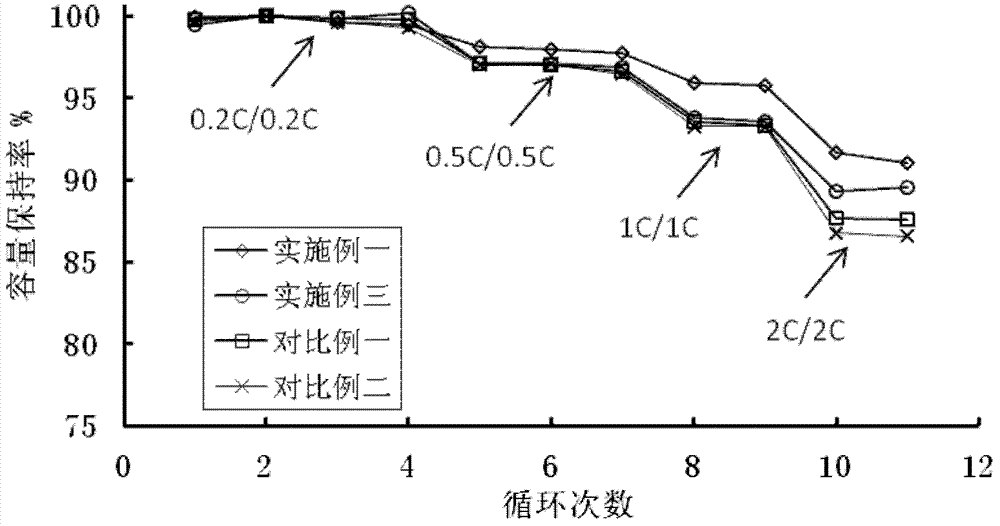

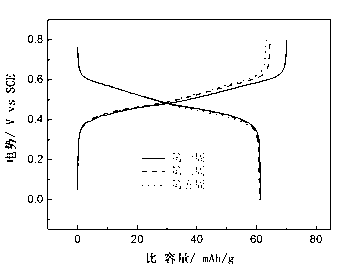

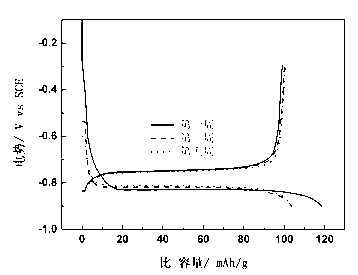

The invention discloses a water system chargeable sodium-ion battery system. The system uses a concept of a 'rocking chair battery' of a lithium ion battery; and the entire battery system is formed by using sodium-based prussian blue matter as an embedded anode, titanium sodium phosphate as an embedded cathode, and sodium-contained inorganic salt solution as electrolyte. The system has the advantages of high discharge voltage, large specific capacity, good rate capability, long cycle life and the like, and further has the characteristics of green and environmental friendliness, and high security and no pollution. The system very hopefully becomes an electrochemical stored energy system with low price and environmental friendliness.

Owner:WUHAN UNIV

Method for preparing anode material lithium nickle cobalt manganic acid of lithium ion battery

InactiveCN101510603AConducive to neutralizing the balanceGood effectElectrode manufacturing processesNickel compoundsLithium hydroxideNew energy

The invention relates to a preparation method of Ni-Co lithium manganate which is a cathode material for a lithium ion battery, which pertains to the field of new energy material and preparative technique. The preparation method comprises the following steps: 1. a sulfate mixture solution of nickel, cobalt and manganese is prepared in accordance with a certain concentration; 2. the mixture solution, NH3 water and a sodium hydroxide solution are continuously injected into a reactor and stirred, and a spherical or quasi-spherical multiple hydroxide A of Ni, Co and Mn is obtained after the filtration, washing and drying are conducted over the mixture; 3. the dry multiple hydroxide A of Ni, Co and Mn is presintered to obtain a spherical multiple oxide B of Ni, Co and Mn; and 4. after being added with a right quantity of alcohol, the product B is evenly mixed with lithium hydroxide and the mixture is sintered, smashed and screened to obtain a spherical LizNixCoyMnxO2 cathode material C for the lithium ion battery. With the preparation method, the particle size and distribution of the product A and product B are easy to control and the spherical Ni-Co lithium manganate C with stable quality, high density, high capacity and high discharge plateau is obtained; therefore, the preparation method is applicable to stabilizing industrial production.

Owner:JILIN JIEN NICKEL IND

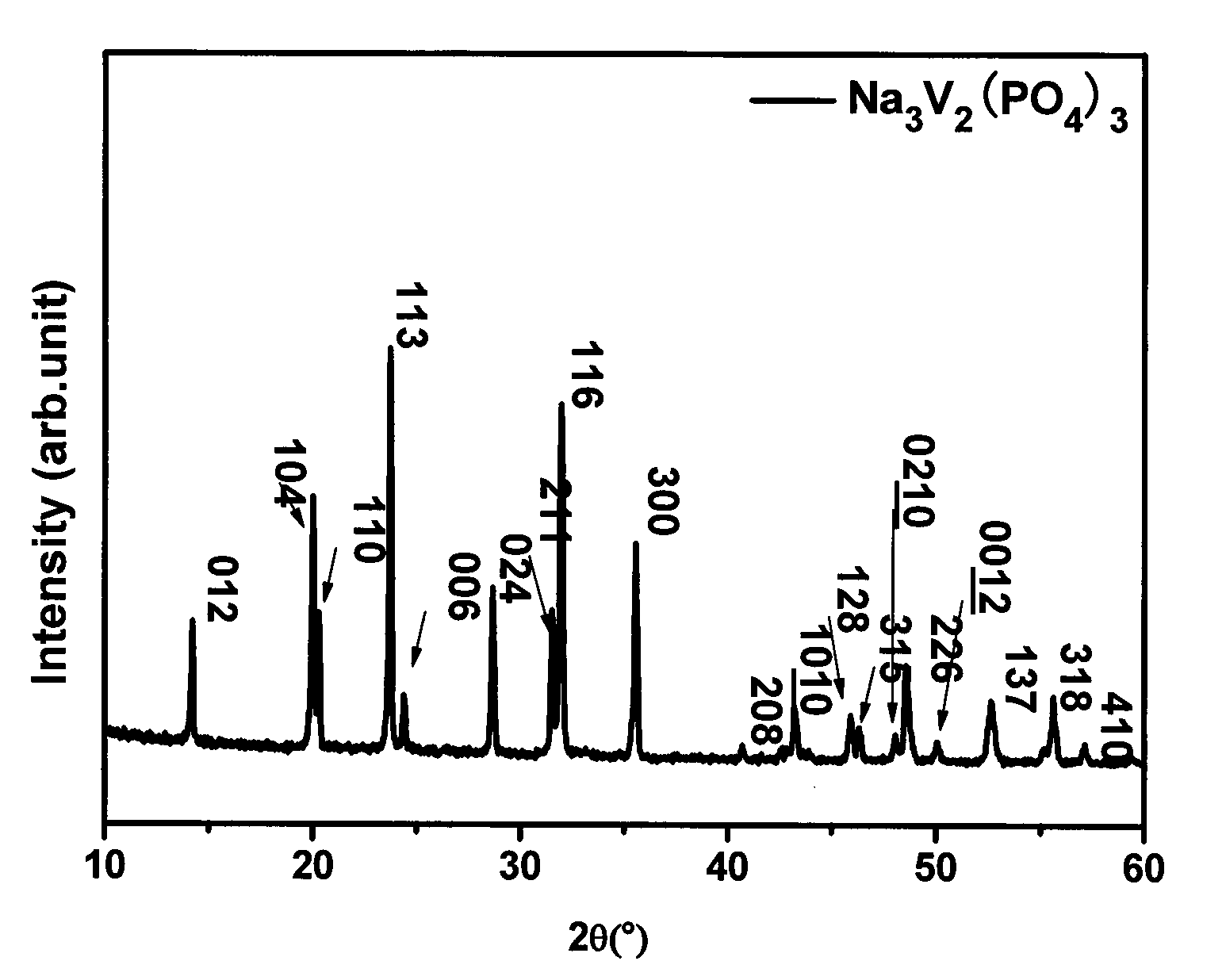

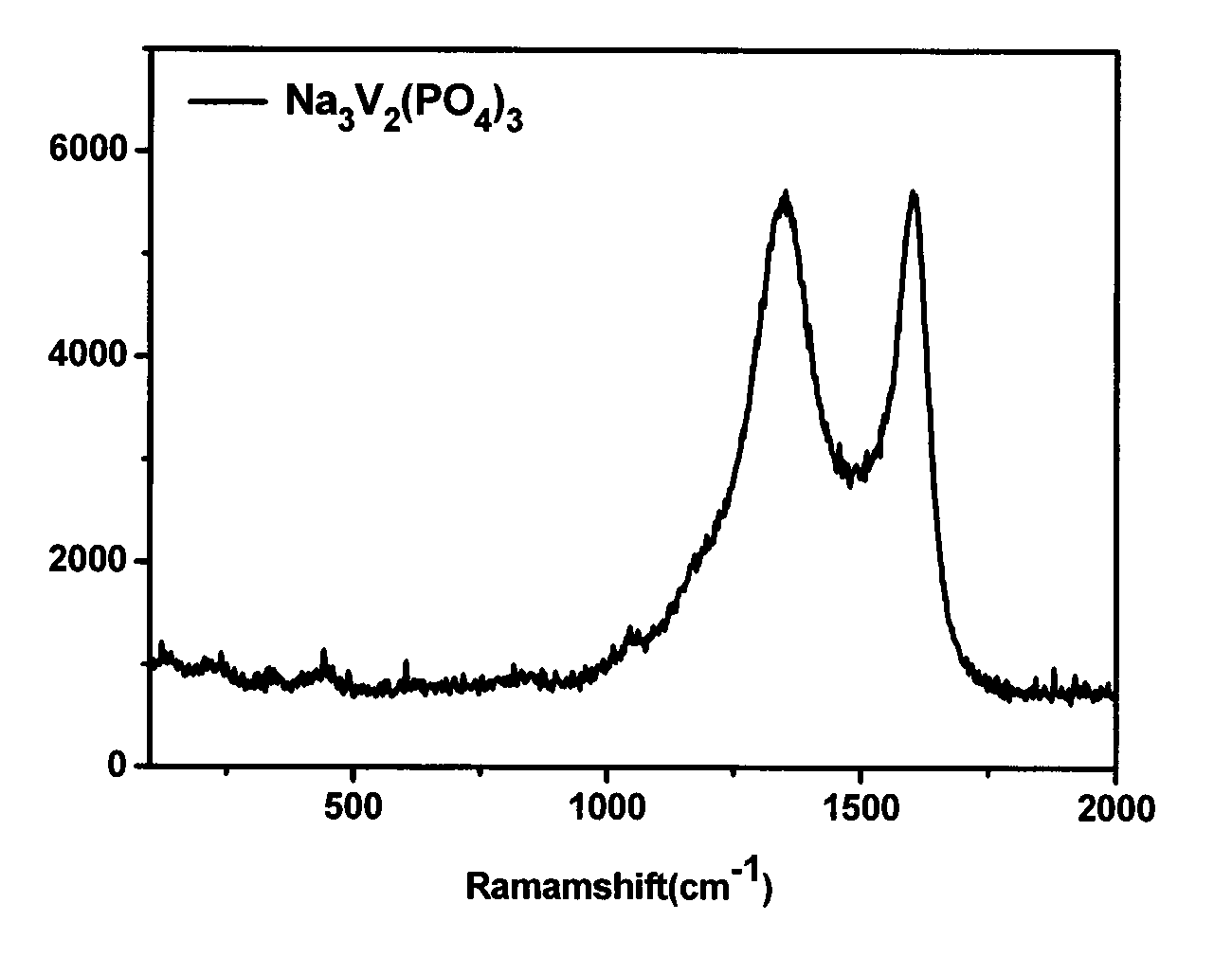

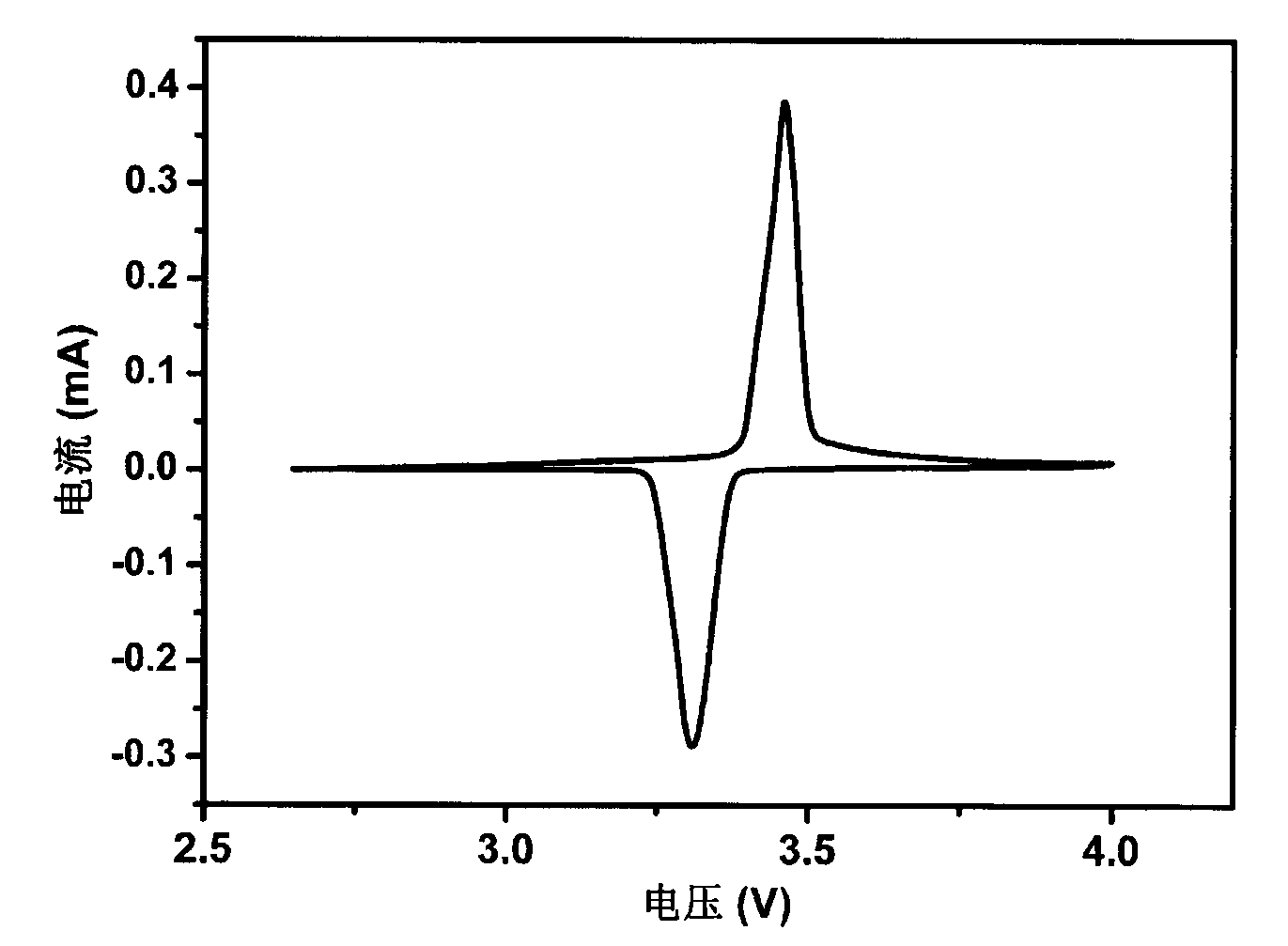

Vanadium sodium phosphate composite material as well as preparation method and application thereof

InactiveCN103000884AImprove cycle performanceImprove securityCell electrodesSodium phosphatesNitrogen

The invention relates to a vanadium sodium phosphate composite material as well as a preparation method and an application thereof. The general formula of the composite material provided by the invention is C1-xNx-LaNabMcVd(PO4)3, wherein C1-xNx is carbon or carbon doped with nitrogen, L is one or two selected from Li and K; M is one or more than one selected from Mg, B, Al, Ca, Ti, Cr, Mn, Fe, Co, Ni, Cu, Zn, Ce, Y, Zr, Nb, Mo, Sn, La, Ta and W; and x, a, b, c and d are mol percents, wherein x is more than or equal to 0 and less than 1, a is more than or equal to 0 and less than 2, b is more than 1 and less than or equal to 3, c is more than or equal to 0 and less than or equal to 1, and d is more than or equal to 1 and less than or equal to 2. The invention also provides a preparation method and an application of the composite material. The vanadium sodium phosphate composite material can be taken as cathode or anode material of a secondary sodium-ion battery, especially vanadium sodium phosphate composite material coated with carbon and nitrogen has higher coulombic efficiency and ion and electron conductivity and better cycling performance, is high in safety, low in price, simple in process and wide in application range and can be applied to energy storage equipment, a backup power supply, a spare power supply and the like.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

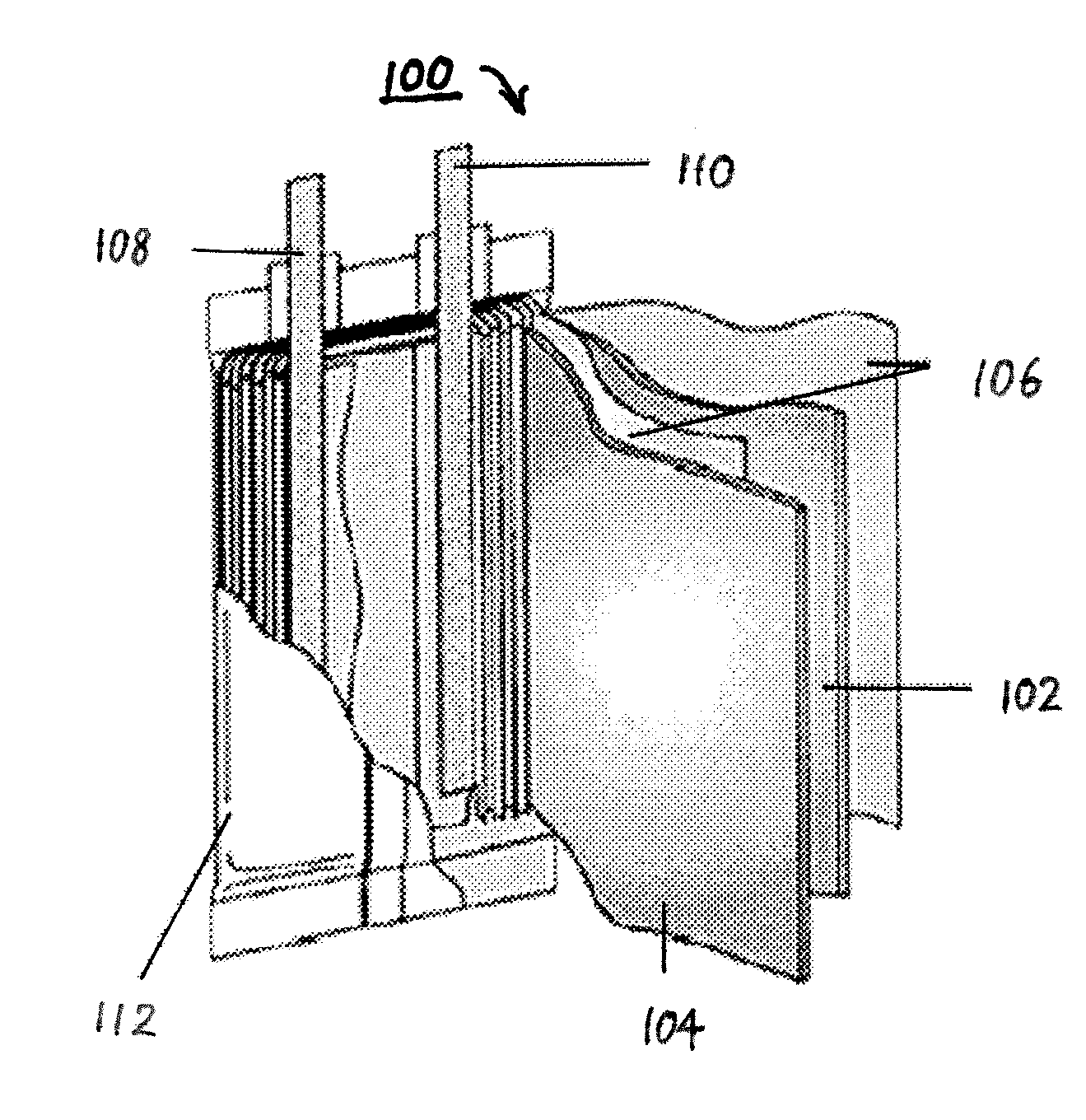

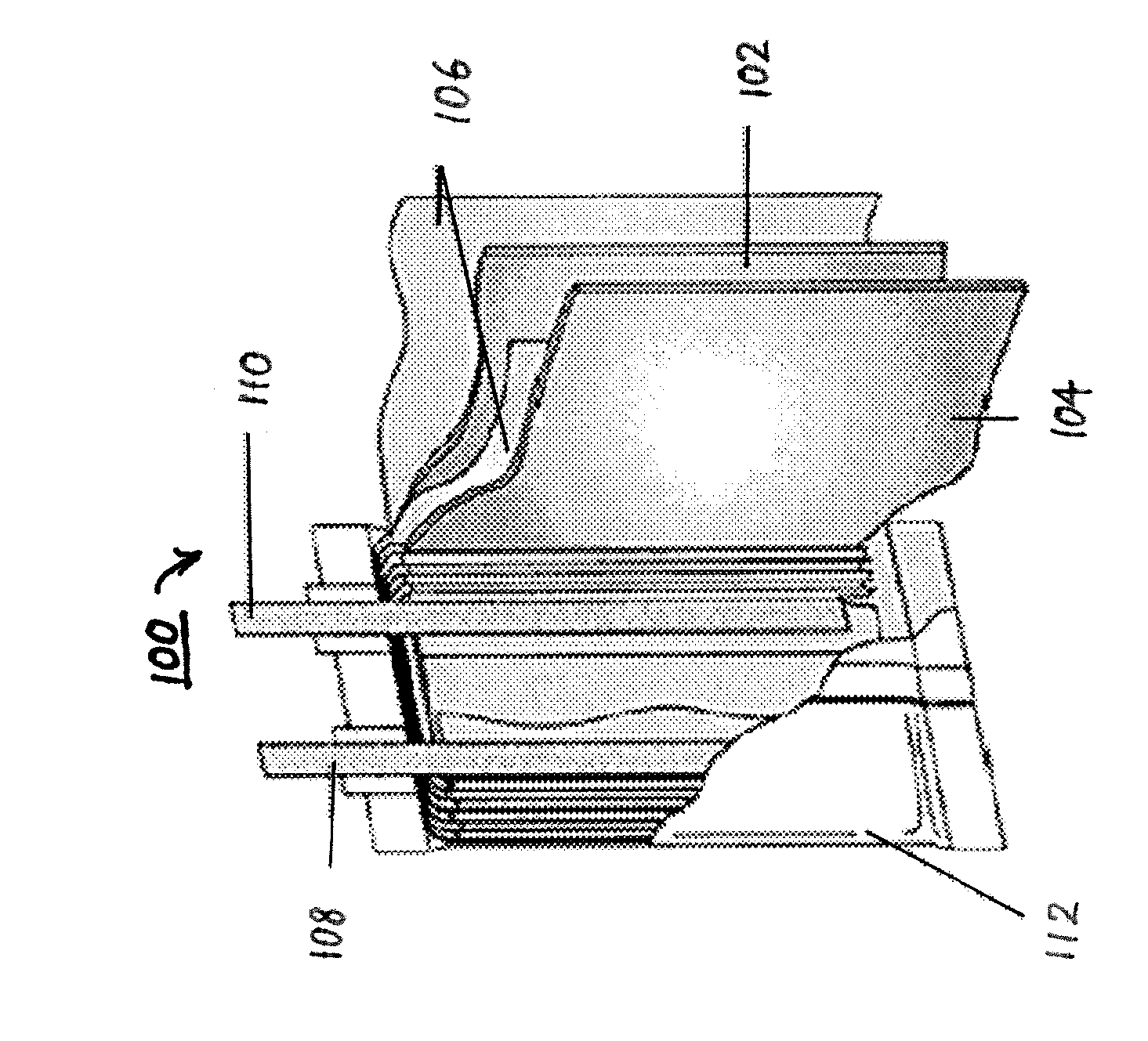

Reinforced battery electrodes

ActiveUS9362551B2Avoid strainMaintain electrical continuityElectrode carriers/collectorsActive material electrodesElectrical batteryShape-memory alloy

The gravimetric and volumetric efficiency of lithium ion batteries may be increased if high capacity materials like tin and silicon may be employed as the lithium-accepting host in the negative electrode of the battery. But both tin and silicon, when fully charged with lithium, undergo expansions of up to 300% and generate appreciable internal stresses which have potential to spall off material from the electrode on each discharge-charge cycle, resulting in a progressive reduction in battery capacity, also known as battery fade. A method of reinforcing such electrode materials by incorporating within them fiber reinforcements or shaped, elongated reinforcements fabricated of shape memory alloy is described. Electrode materials incorporating such reinforcements are less prone to damage under applied stress and so less prone to battery fade.

Owner:GM GLOBAL TECH OPERATIONS LLC

Sodium ion batteries

InactiveUS20050238961A1High operation potentialHigh specific capacityOrganic electrolyte cellsSecondary cellsPhosphateSodium-ion battery

Sodium ion batteries are based on sodium based active materials selected among compounds of the general formula AaMb(XY4)cZd, wherein A comprises sodium, M comprises one or more metals, comprising at least one metal which is capable of undergoing oxidation to a higher valence state, Z is OH or halogen, and XY4 represents phosphate or a similar group. The anode of the battery includes a carbon material that is capable of inserting sodium ions. The carbon anode cycles reversibly at a specific capacity greater than 100 mAh / g.

Owner:VALENCE TECH INC

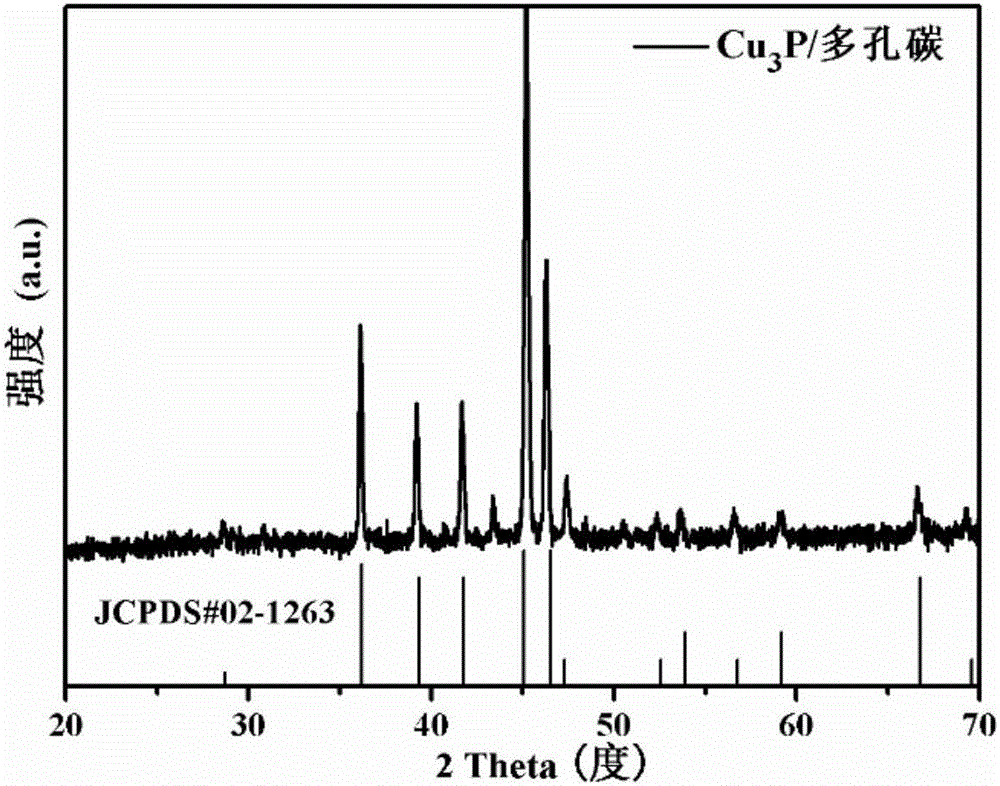

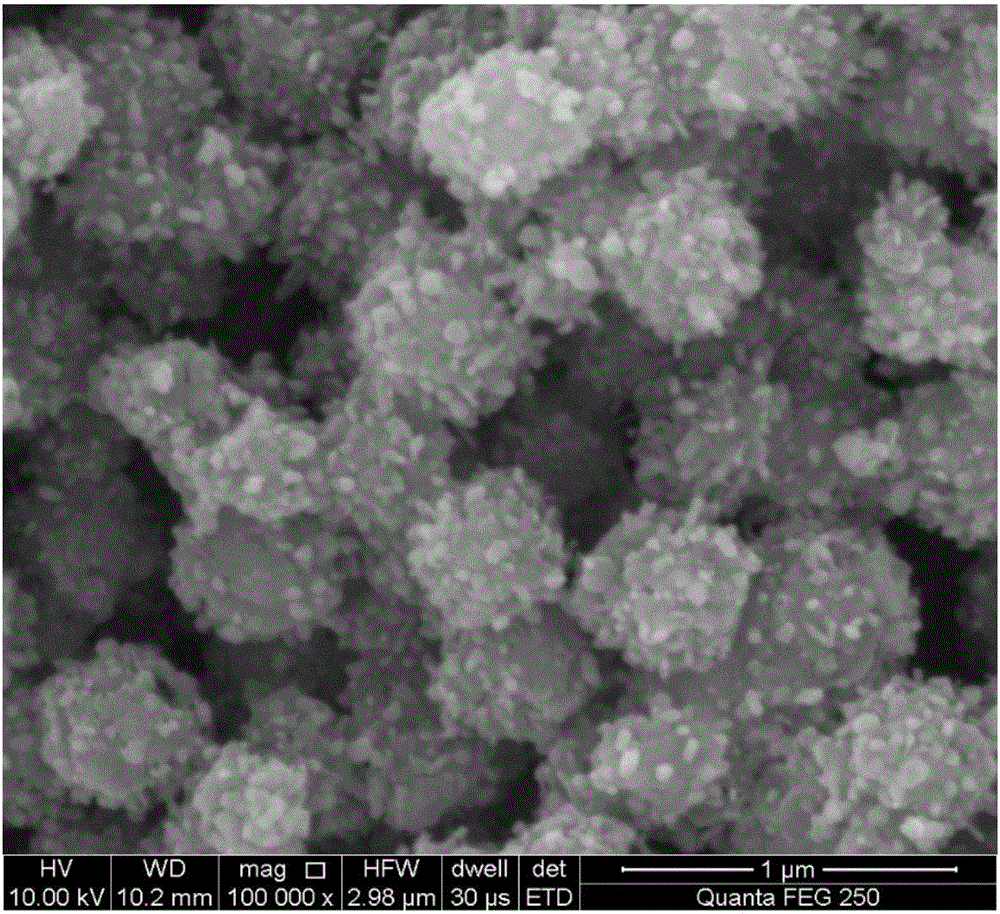

Transition metal phosphide/porous carbon anode composite material for sodium-ion battery and preparation method thereof

InactiveCN105895886AImprove conductivityImprove cycle stabilityMaterial nanotechnologyCell electrodesPorous carbonTube furnace

The invention discloses a transition metal phosphide / porous carbon anode composite material for a sodium-ion battery and a preparation method thereof. The composite material is formed by dispersive distribution of transition metal phosphide nano-particles in a porous carbon material. A preparation process of the composite material comprises the following steps of preparing a transition metal organic frame structure by transition metal salt and organic ligands through an in-situ growth method; respectively placing the transition metal organic frame structure and a phosphorus source on two ends of a tube furnace, heating the tube furnace, and meanwhile, circulating liquid inert gas into one end of the tube furnace with the inorganic phosphorus source to carry out heat treatment; and washing and drying a heat treatment product in sequence to obtain the composite material. The prepared transition metal phosphide / porous carbon anode composite material used as the anode material of the sodium-ion battery has high specific capacity, good rate capability, simple preparation method, low cost and wide industrial application prospect.

Owner:CENT SOUTH UNIV

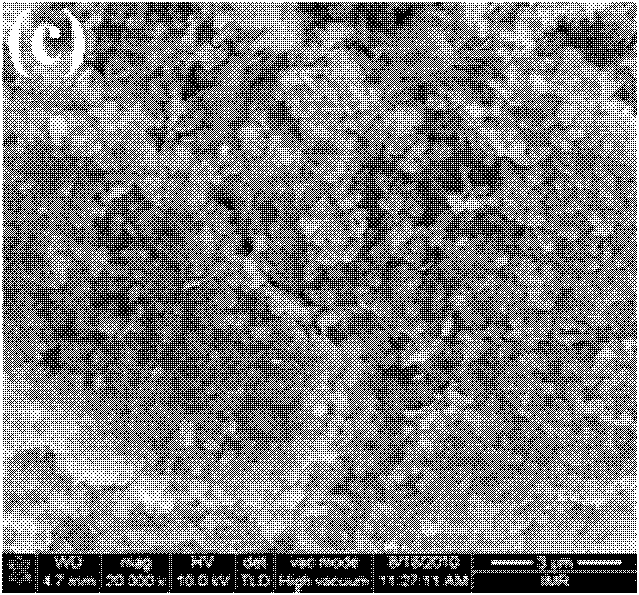

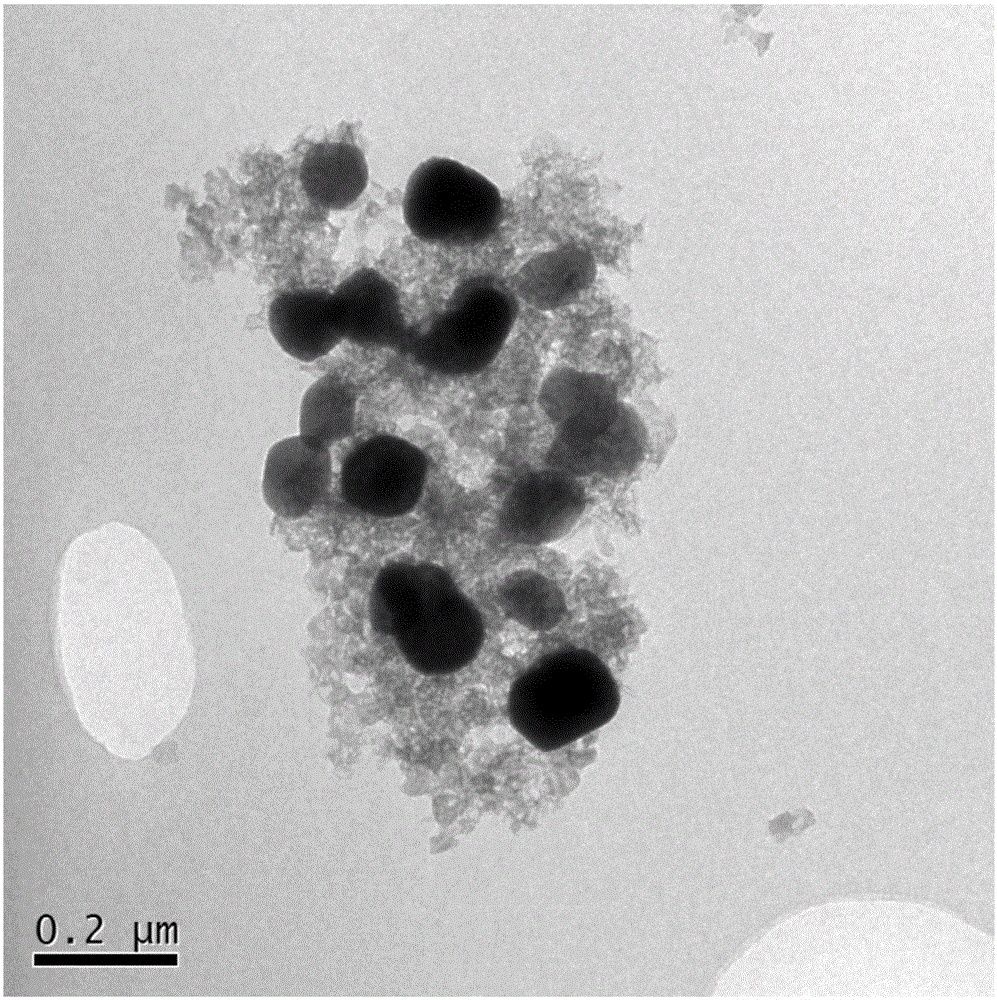

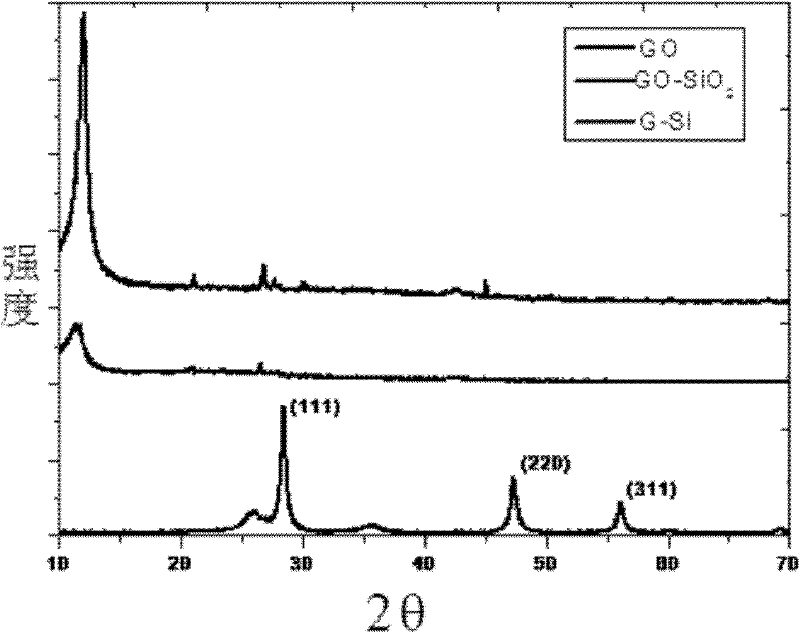

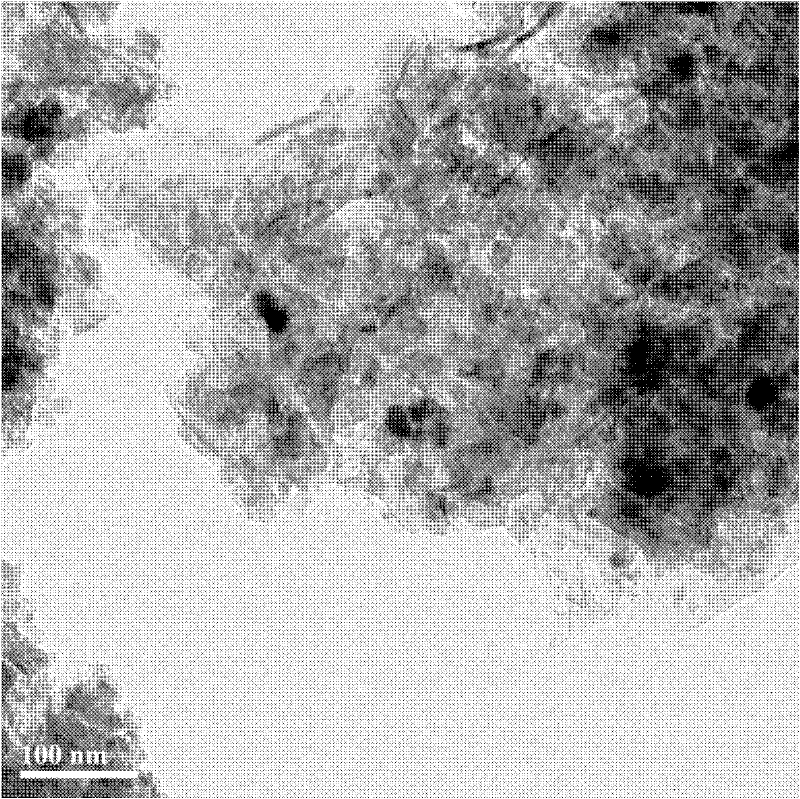

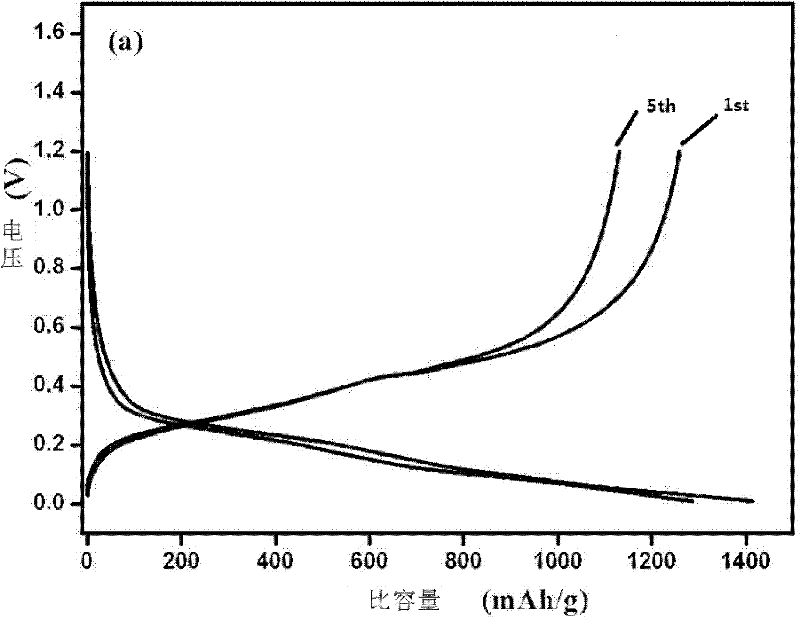

Preparation method of silicon/graphene nanocomposite material for cathode of lithium ion battery

ActiveCN102569756ASimple methodRaw materials are easy to obtainMaterial nanotechnologySilicaGraphene nanocompositesSodium-ion battery

The invention relates to a preparation method of a silicon / graphene nanocomposite material for a cathode of a lithium ion battery, which comprises the steps of: preparing oxidized graphite; preparing a silica / graphene nanocomposite material under the existence of a surfactant; then preparing the silicon / graphene nanocomposite material for the cathode of the lithium ion battery through the magnesiothermic reduction reaction. Compared with the prior art, the graphene in the composite material, prepared by the invention, can better inhibit volumetric expansion of silicon material in the insertion and separation process of lithium ions so as to improve the circulating performance of the composite material greatly, so that the volume of the material after 30 circulations under the current of 200mA / g is still maintained to be above 1100mAh / g.

Owner:SHANGHAI JIAO TONG UNIV

High-energy silicon-carbon composite negative electrode material for lithium ion battery and manufacturing process thereof

InactiveCN101710617AImprove cycle stabilityGive full play to the characteristics of high specific capacityElectrode manufacturing processesCarbon compositesHigh energy

Owner:DALIAN LICHANG NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com