Silicon-carbon negative electrode material of lithium ion battery and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as deterioration, electrode material pulverization, poor battery cycle performance, etc., and achieves easy operation, low cost, and preparation technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

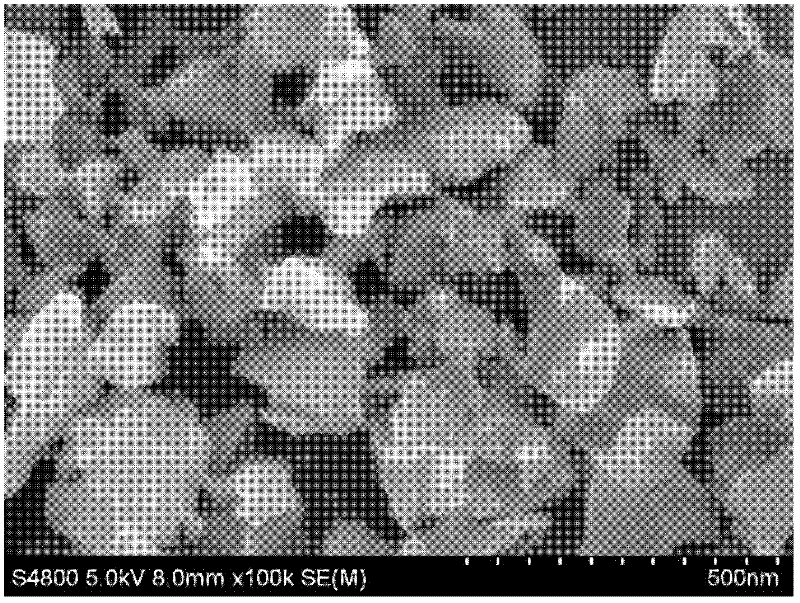

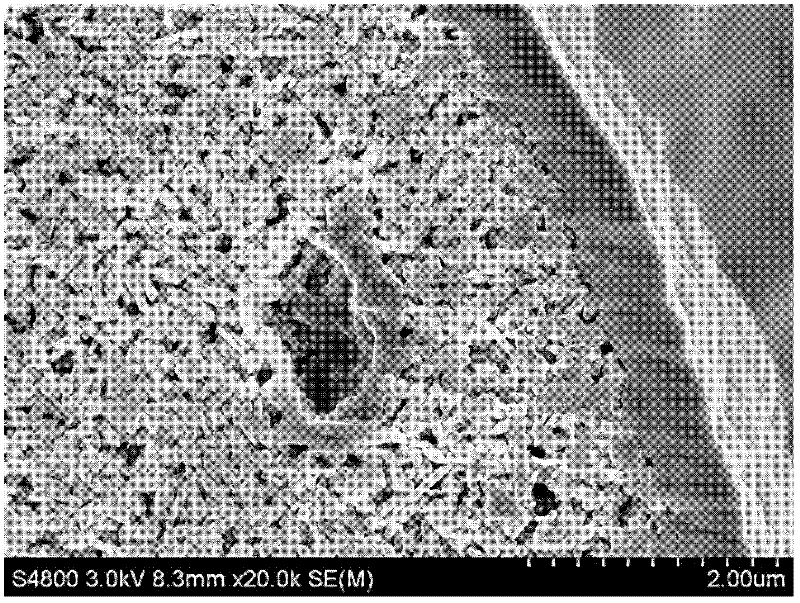

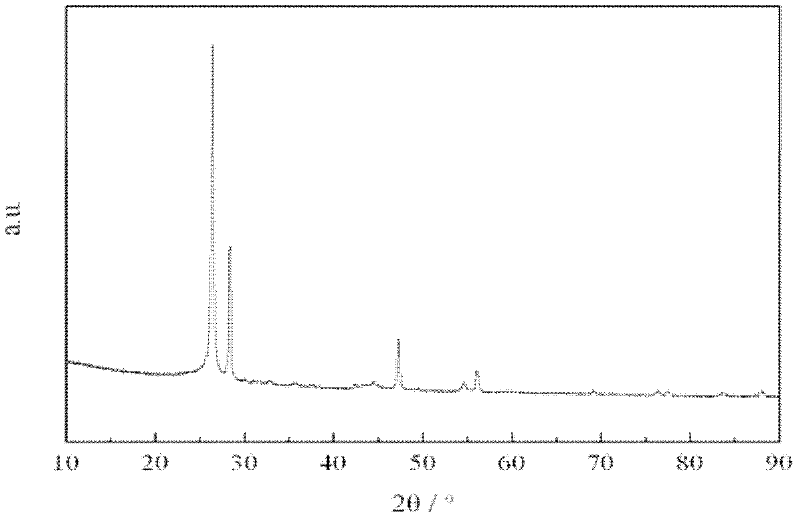

[0014] The preparation method of the lithium-ion battery silicon-carbon negative electrode material of the present invention obtains the required lithium-ion battery silicon-carbon negative electrode material through the steps of nano-silicon powder, chemical vapor deposition, coating and roasting, and mixing, and specifically includes the following steps:

[0015] 1. To prepare ultra-fine and nano precursor silicon powder, 2-8% of catalyst, 2-10% of soluble organic carbon, 82-95% of particle size of 1-5 μm, and purity of 99.9% or more are prepared according to mass percentage Elemental coarse silicon powder and absolute ethanol, control the mass solid content to 5-30%, pour it into a nano-sand mill for closed grinding, the nano-grinder first performs wet ball milling at a speed of 1850rpm for 25-30 hours, and then ball mills at a low speed 1~3h, the rotation speed is 500~800rpm, and then take the material into the ultrasonic disperser for ultrasonic vibration for not less than...

Embodiment 1

[0025] Example 1, the high-purity elemental coarse silicon powder with an average particle size of 1 to 5 μm weighed 100 g, which was 91% of the total design ingredients, and dissolved it in absolute ethanol; weighed 2% of the total weight of the material Catalyst nickel acetate, soluble organic carbon glucose accounting for 7% of the total weight of the material, adding absolute ethanol to control its solid content to 20%, pouring it into a high-energy nano grinder for closed ball milling. The high-energy mill performs wet ball milling at a speed of 1850rpm for 25 hours, and then conducts ball milling at a low speed of 500rpm for 2 hours, and then takes the material into an ultrasonic disperser for ultrasonic vibration for 30 minutes. The ultrasonic vibration frequency is 30KHz and the power density is 1.0W / cm 2 . The silicon micron powder is dried by drying equipment, and the precursor powder with a particle size of 8-12um is prepared. After heating up to 460°C at a heating...

Embodiment 2

[0031] Example 2, the high-purity elemental coarse silicon powder with an average particle size of 1 to 5 μm weighed 100 g, which was 93% of the total design ingredients, and dissolved it in absolute ethanol; weighed 3% of the total weight of the material Catalyst nickel acetate, soluble organic carbon glucose accounting for 4% of the total weight of the material, adding absolute ethanol to control its solid content to 20%, pouring it into a high-energy grinder for closed ball milling. The high-energy mill performs wet ball milling at a speed of 1850rpm for 25 hours, and then conducts ball milling at a low speed of 600rpm for 2 hours, and then takes the material into an ultrasonic disperser for ultrasonic vibration for 30 minutes. The ultrasonic vibration frequency is 30KHz and the power density is 1.0W / cm 2 . Drying equipment is used for powder making, wherein the precursor powder with a particle size of 8-15 um is prepared. After heating up to 460°C at a heating rate of 3°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com