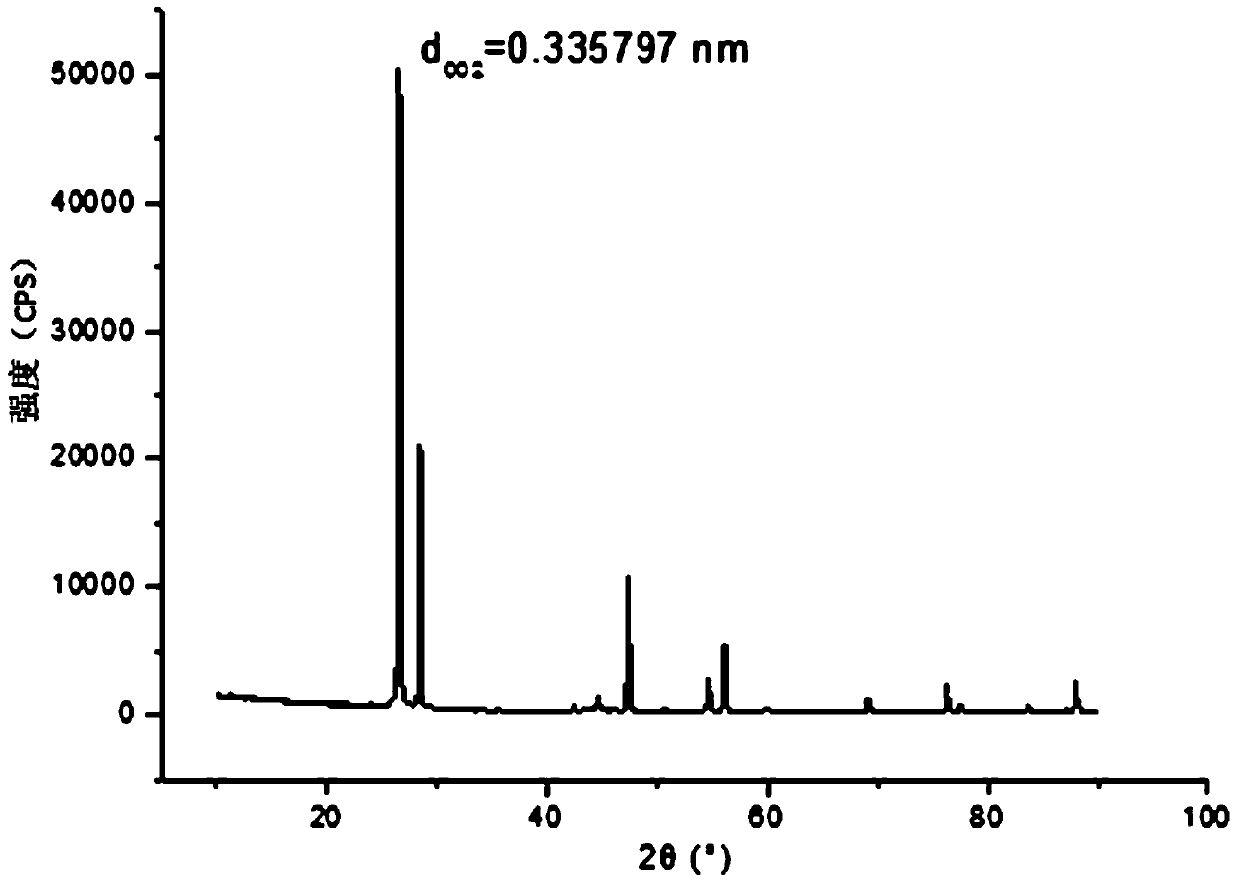

Modification method of natural graphite ball-milling machinery and modified natural graphite anode material

A technology of natural graphite and negative electrode material, applied in the direction of graphite, battery electrodes, electrical components, etc., can solve the problems of undisclosed first discharge efficiency, irreversible capacity and cycle performance, poor high current charge and discharge performance, and poor electrolyte compatibility. and other problems, to achieve the effect of high cost performance, environmentally friendly production methods and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add 1 kg of natural spherical graphite powder with an average particle size of 16 to 19 μm and a carbon content of ≥99.95%, 0.25 L of water and 2 kg of zirconia balls into the ball mill pot, set the ball mill’s rotation speed to 100 rpm and revolution speed to 50 rpm points, ball milled for 10min. After ball milling, the circulating water type multipurpose vacuum pump is used for suction filtration to remove the filtrate. The filter residue is dried in an electric blast drying oven, and then sieved to obtain a ball-milled mechanically modified natural graphite negative electrode material.

Embodiment 2

[0042] Add 0.5 kg of natural spherical graphite powder with an average particle size of 16 to 19 μm and a carbon content of ≥99.95%, 0.625 L of water and 3 kg of zirconia balls into the ball mill tank, and set the rotation speed of the ball mill to 50 rpm and revolution speed to 50 rpm / min, ball milled for 30min. After ball milling, the circulating water type multipurpose vacuum pump is used for suction filtration to remove the filtrate. The filter residue is dried in an electric blast drying oven, and then sieved to obtain a ball-milled mechanically modified natural graphite negative electrode material.

Embodiment 3

[0044] Add 0.8kg of natural spherical graphite powder with an average particle size of 16-19μm and a carbon content of ≥99.95%, 1L of water and 2kg of zirconia balls into the ball mill pot, set the ball mill’s rotation speed to 300 rpm and revolution speed to 120 rpm points, ball milled for 10min. After ball milling, the circulating water type multipurpose vacuum pump is used for suction filtration to remove the filtrate. The filter residue is dried in an electric blast drying oven, and then sieved to obtain a ball-milled mechanically modified natural graphite negative electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com