Composite carbon negative electrode material of lithium ion power battery and its preparation method

A power battery and negative electrode material technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of increasing battery internal resistance, small reaction area, electrode structure damage, etc., and achieves low cost, simple preparation process, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the lithium-ion power battery composite carbon negative electrode material of the present invention comprises the following steps: 1. Graphite powder with a particle size of 0.1 μm to 40 μm and a fixed carbon content ≥ 94%, additives accounting for 0.1 to 5% of the weight of the graphite powder, The binder accounting for 1 to 50% of the weight of the graphite powder is mixed and granulated. First, add the graphite powder, then add additives, and then add the binder after mixing; 2. Extrude the mixed pellets, and the density after molding is 1.6~1.75g / cm 3 , followed by roasting and impregnation, using the conventional graphite electrode roasting and impregnation process, roasting in a staged heating method, the roasting temperature is 130°C-1300°C, the heating rate is 1.3-10°C / h, and the roasting time is 320h-420h; Add hot asphalt at 160°C to 180°C, immerse the product, pressurize at 1.18 to 2.5MPa, and keep it for 2 to 4 hours. When the densit...

Embodiment 1

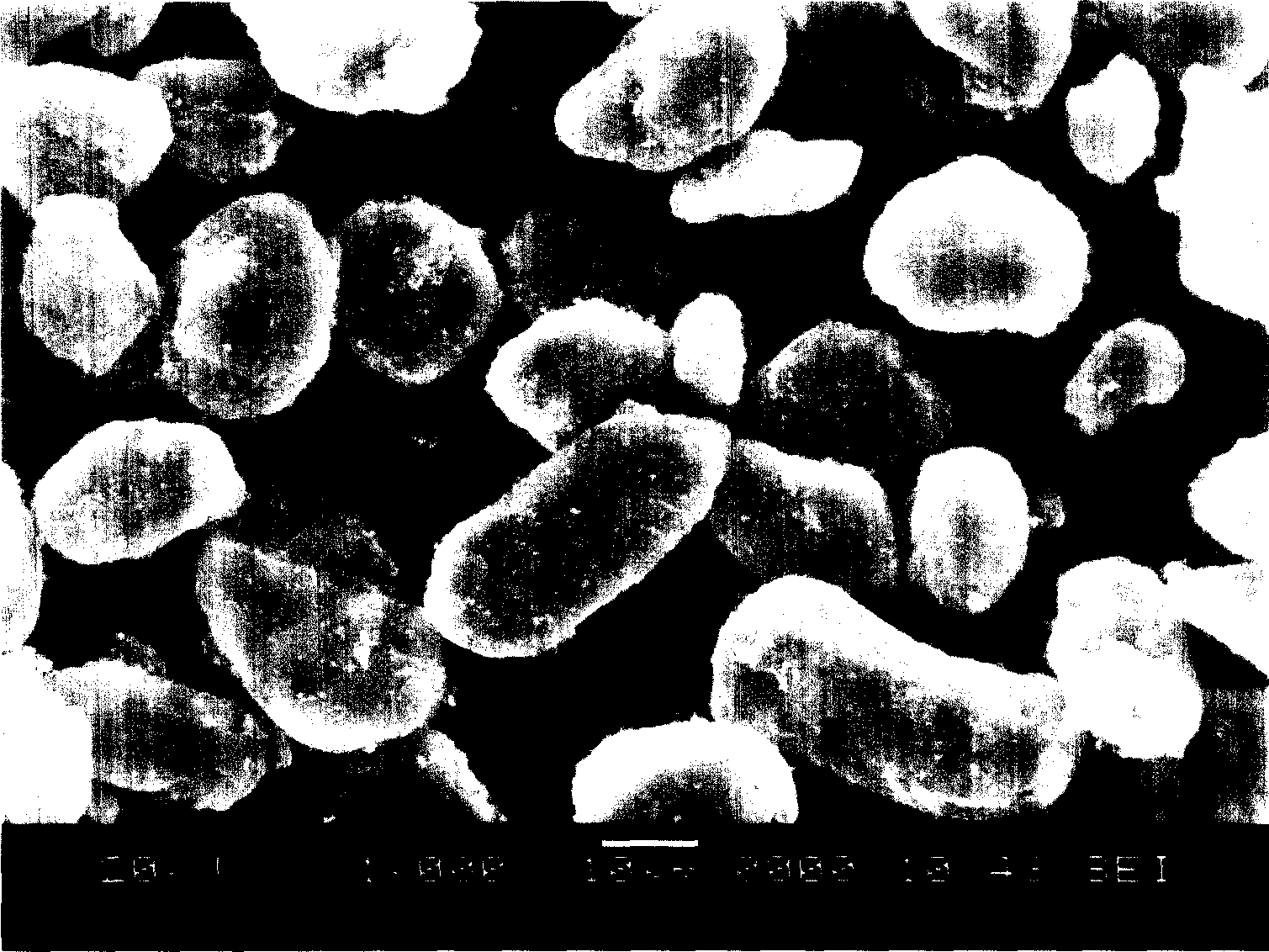

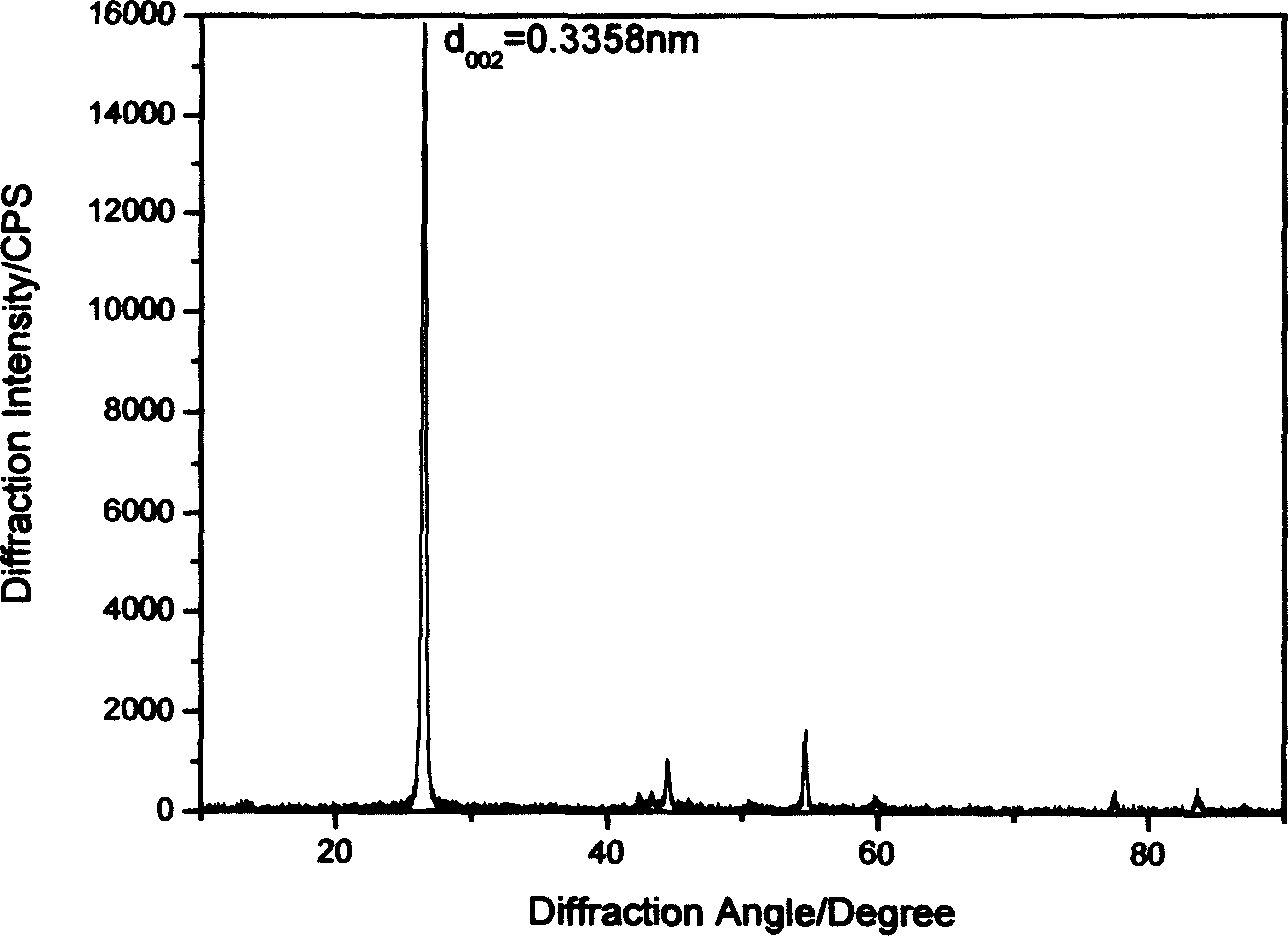

[0041] Example 1, with 100 parts by weight of spherical natural graphite powder with an average particle size of 8 μm and a carbon content of 95%, add 2 parts by weight of conductive carbon black as an additive, 10 parts by weight of an organic binder thermosetting phenolic resin, and mix an appropriate amount of solvent absolute ethanol Evenly, evaporate the solvent to dryness. Density after pressing: 1.65g / cm 3 , the mixture was graphitized at a temperature of 2800° C. for 4 hours, then cooled to room temperature, and pulverized by a high-pressure pulverizer to obtain composite carbon particles with an average particle size of 20 μm. Such as figure 2 As shown in the scanning electron microscope photos, it can be seen that the composite carbon particles are composed of spherical graphite and carbon materials coated on the surface. The long The diameter ratio is 1.6, and the d of graphite crystal is obtained by powder X-ray wide-angle diffraction method. 002 It is 0.3358nm...

Embodiment 2

[0043]Example 2, 50 parts by weight of natural graphite powder with an average particle size of 10 μm and a carbon content of 99.9% is mixed evenly with 50 parts by weight of artificial graphite powder of the same particle size and carbon content, and 10 parts by weight of binder pitch is added, and the additive VGCF 1.5 Parts by weight were mixed and coated at a temperature of 150°C, and the mixture was carbonized at a temperature of 1000°C for 4 hours, then lowered to room temperature, and pulverized by a low-speed impact ball mill to obtain composite carbon particles with an average particle size of 20 μm. From the scanning electron microscope photos of the composite carbon particles, it can be seen that the composite carbon particles are composed of spherical graphite and the carbon material coating on the surface, and the aspect ratio of the composite carbon material is 3.6 through image analyzer analysis and testing. The d of graphite crystals obtained by powder X-ray wid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com