Patents

Literature

437 results about "Large aspect ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

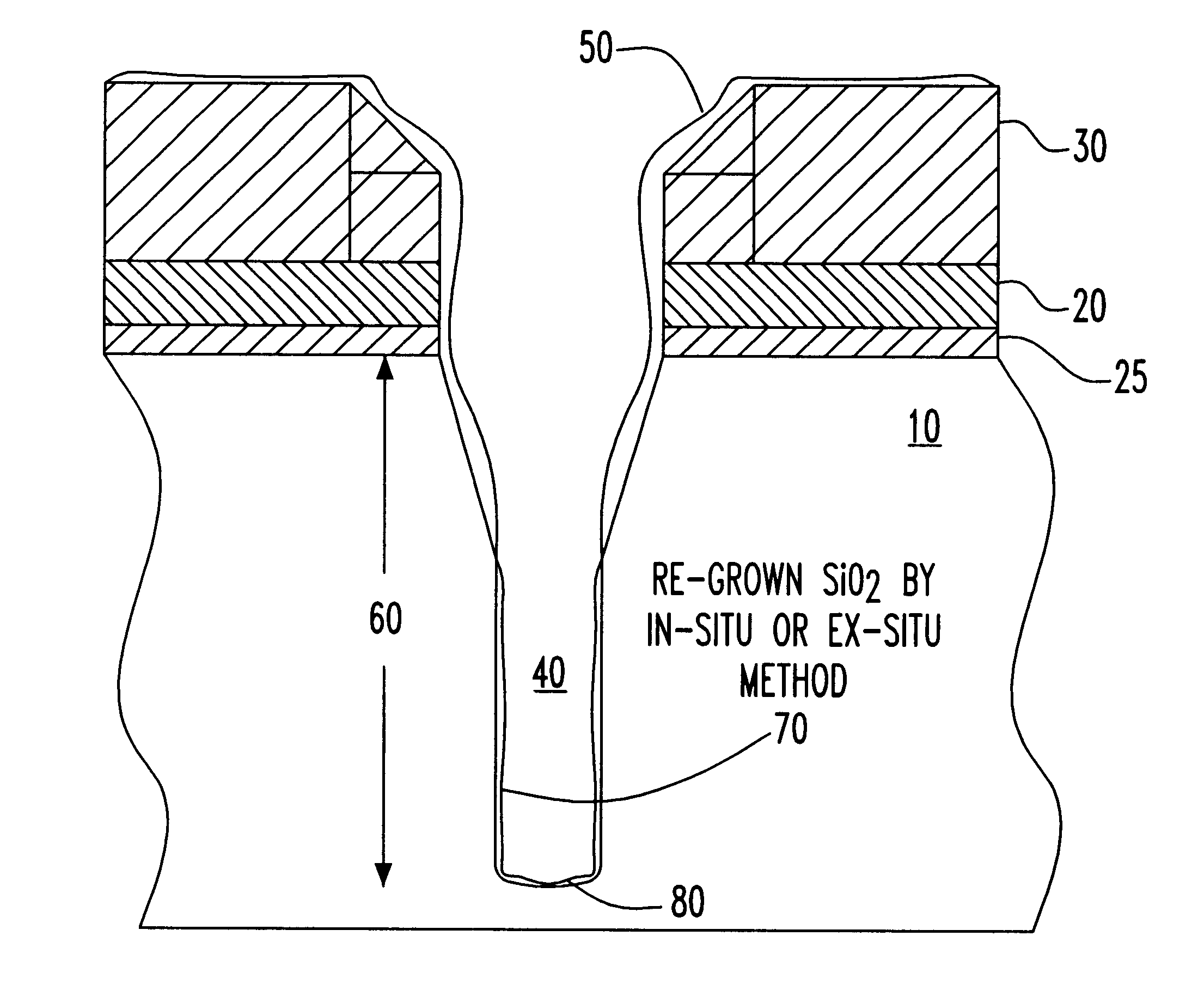

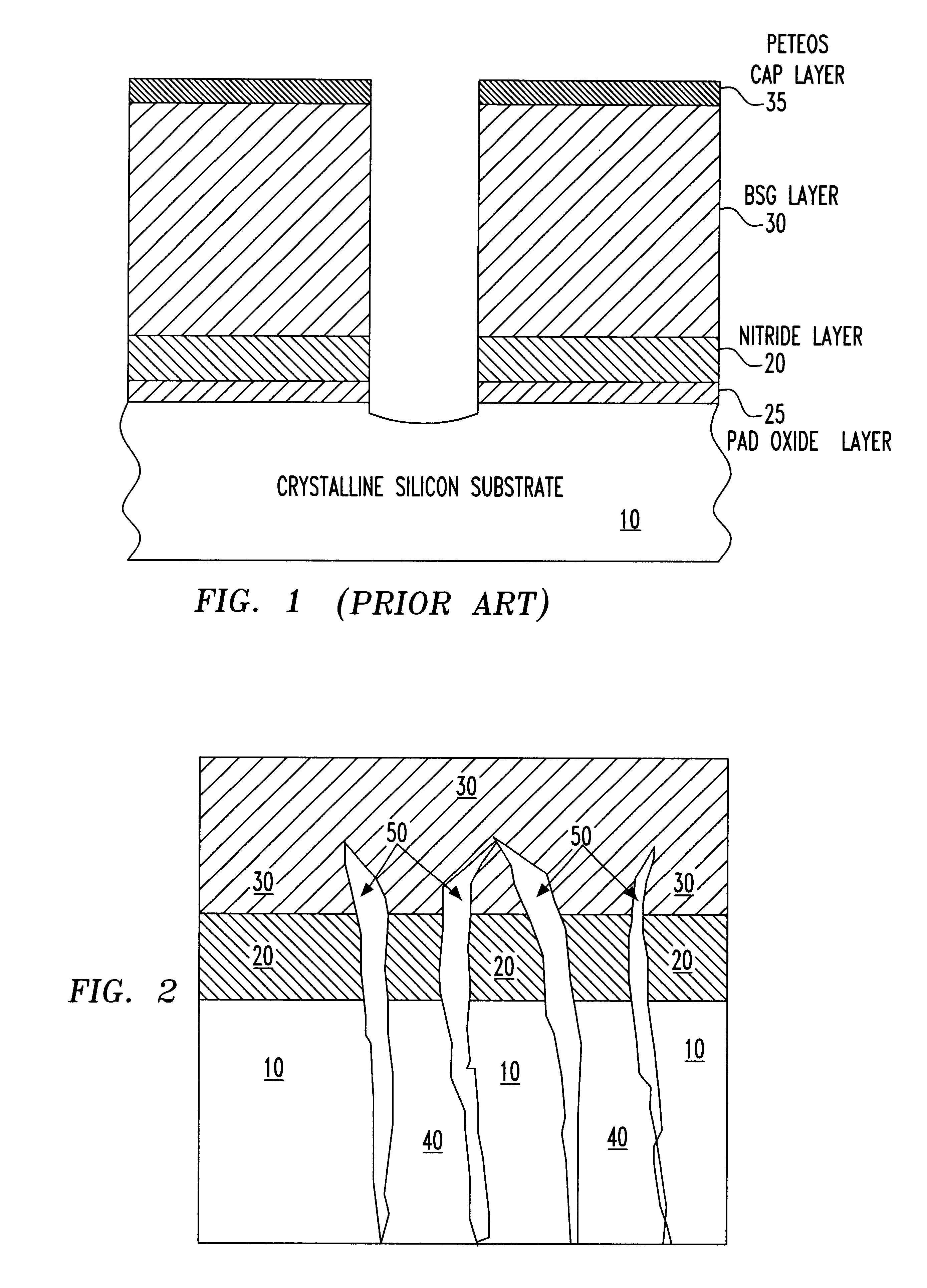

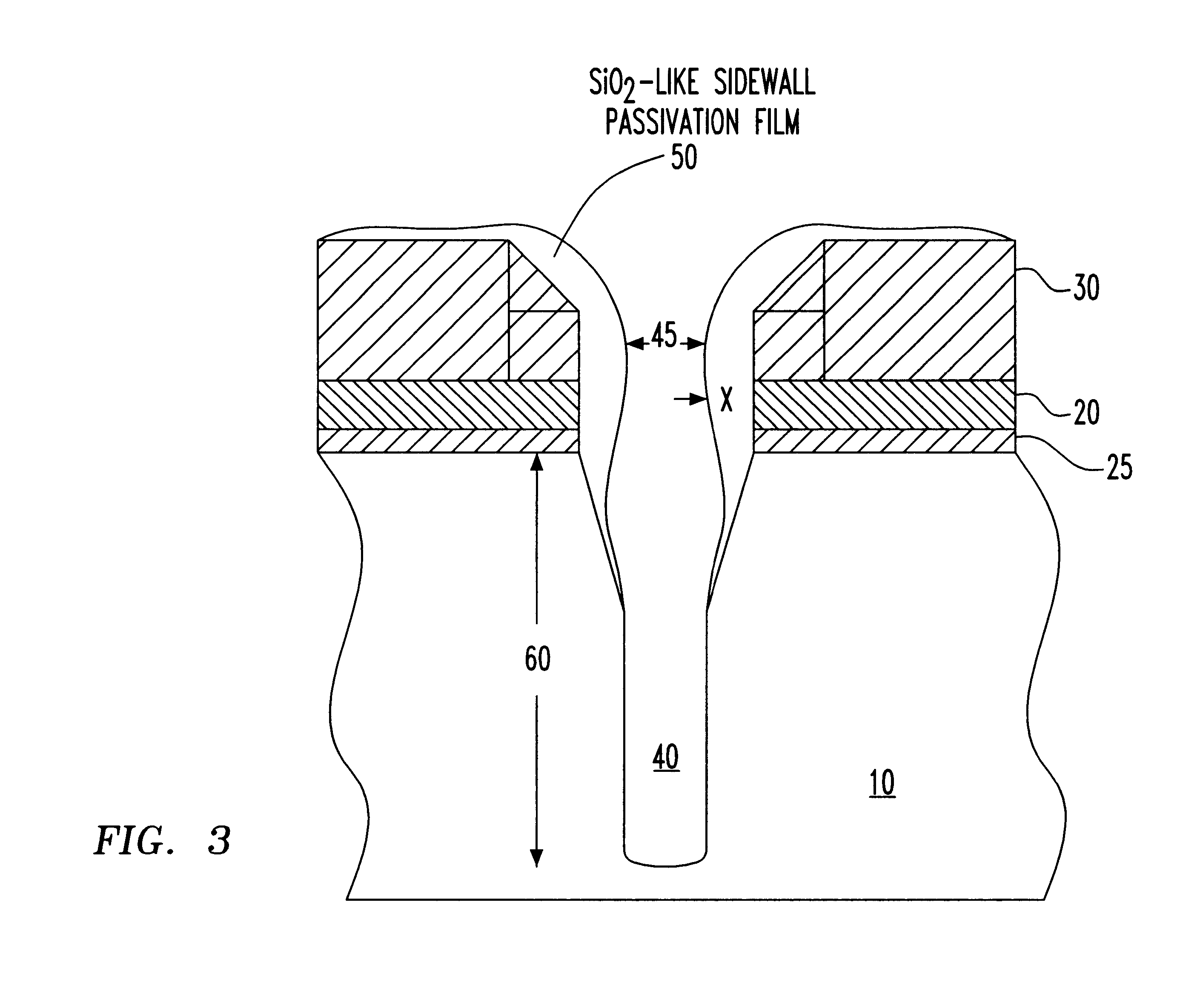

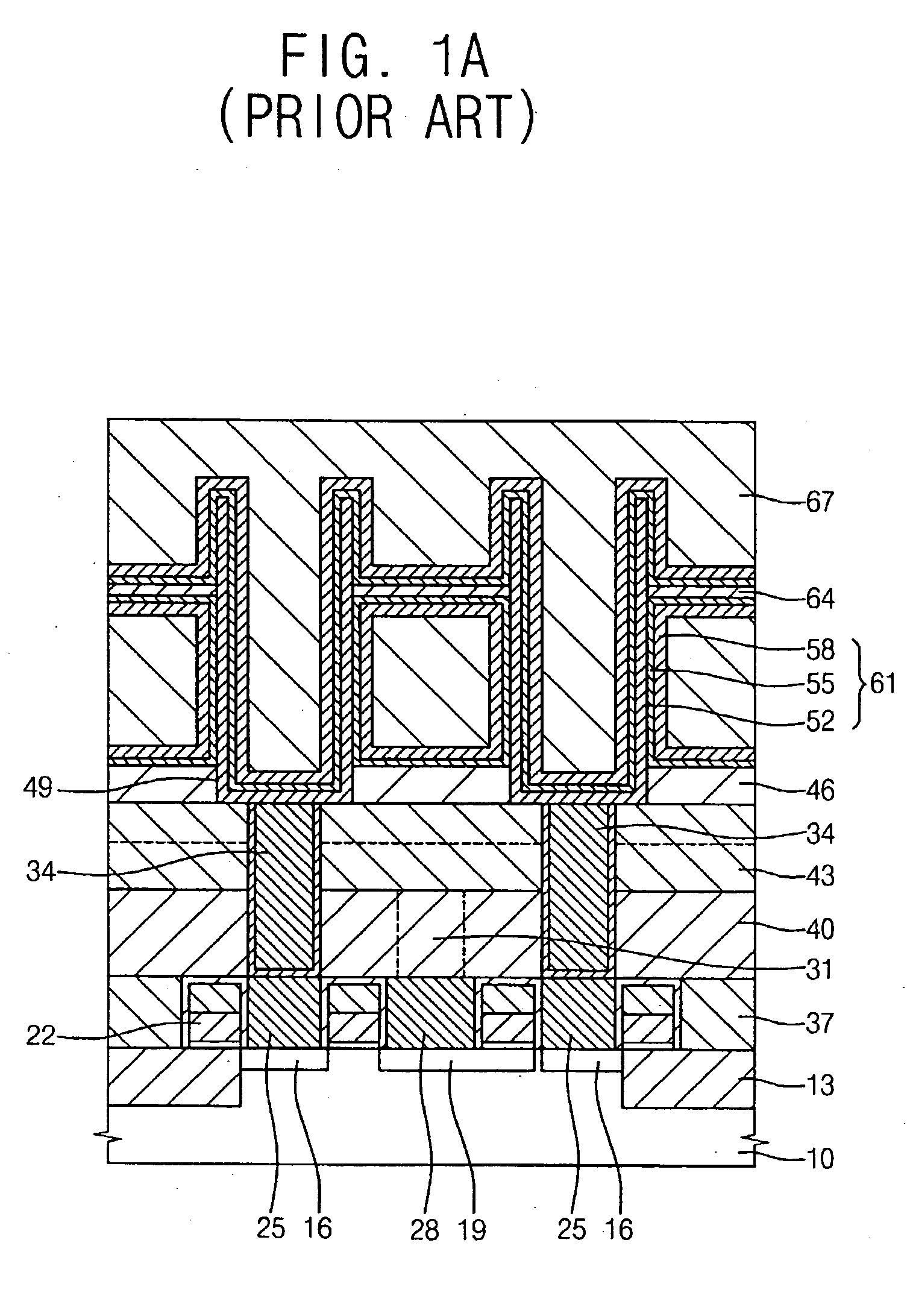

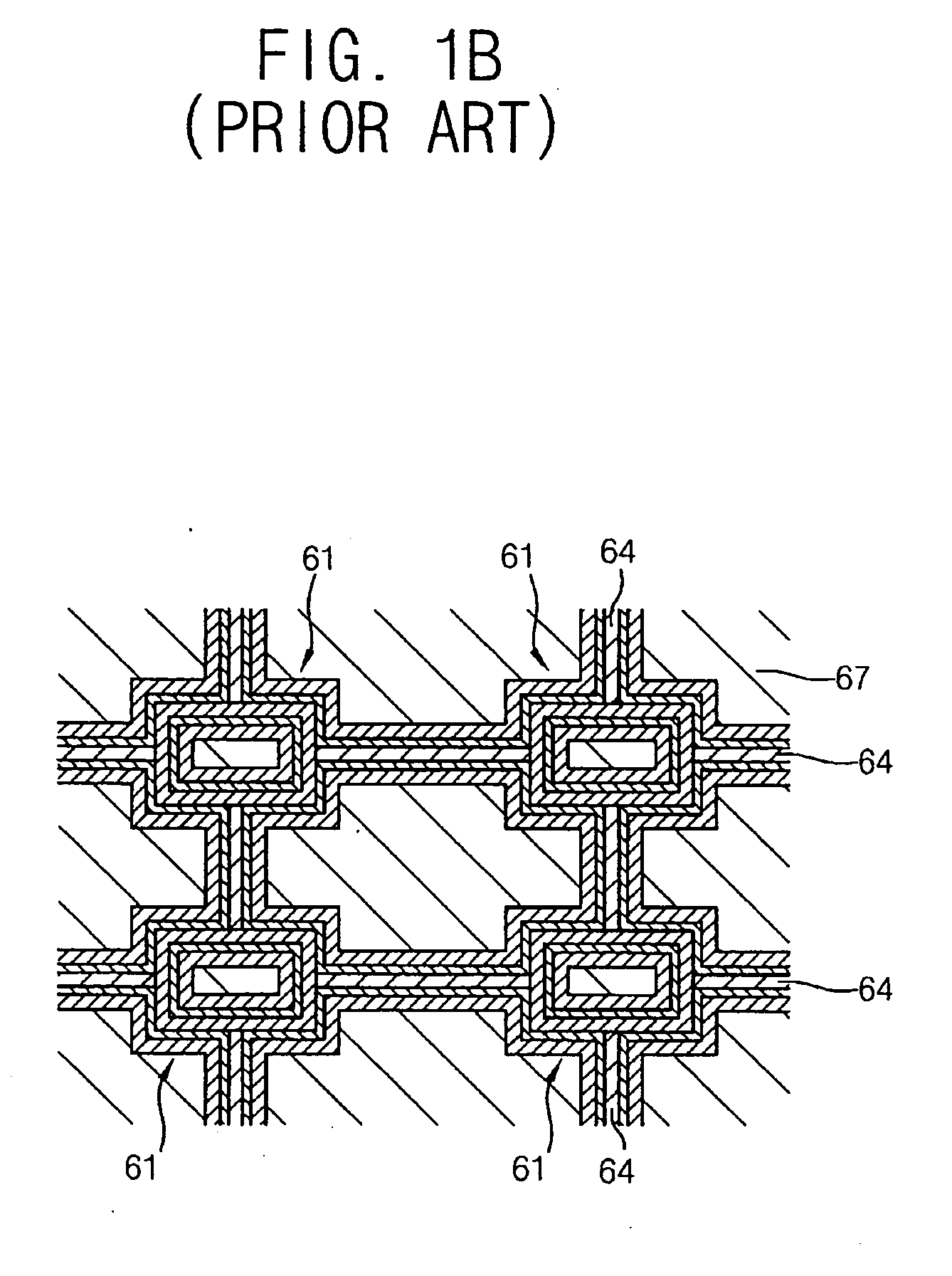

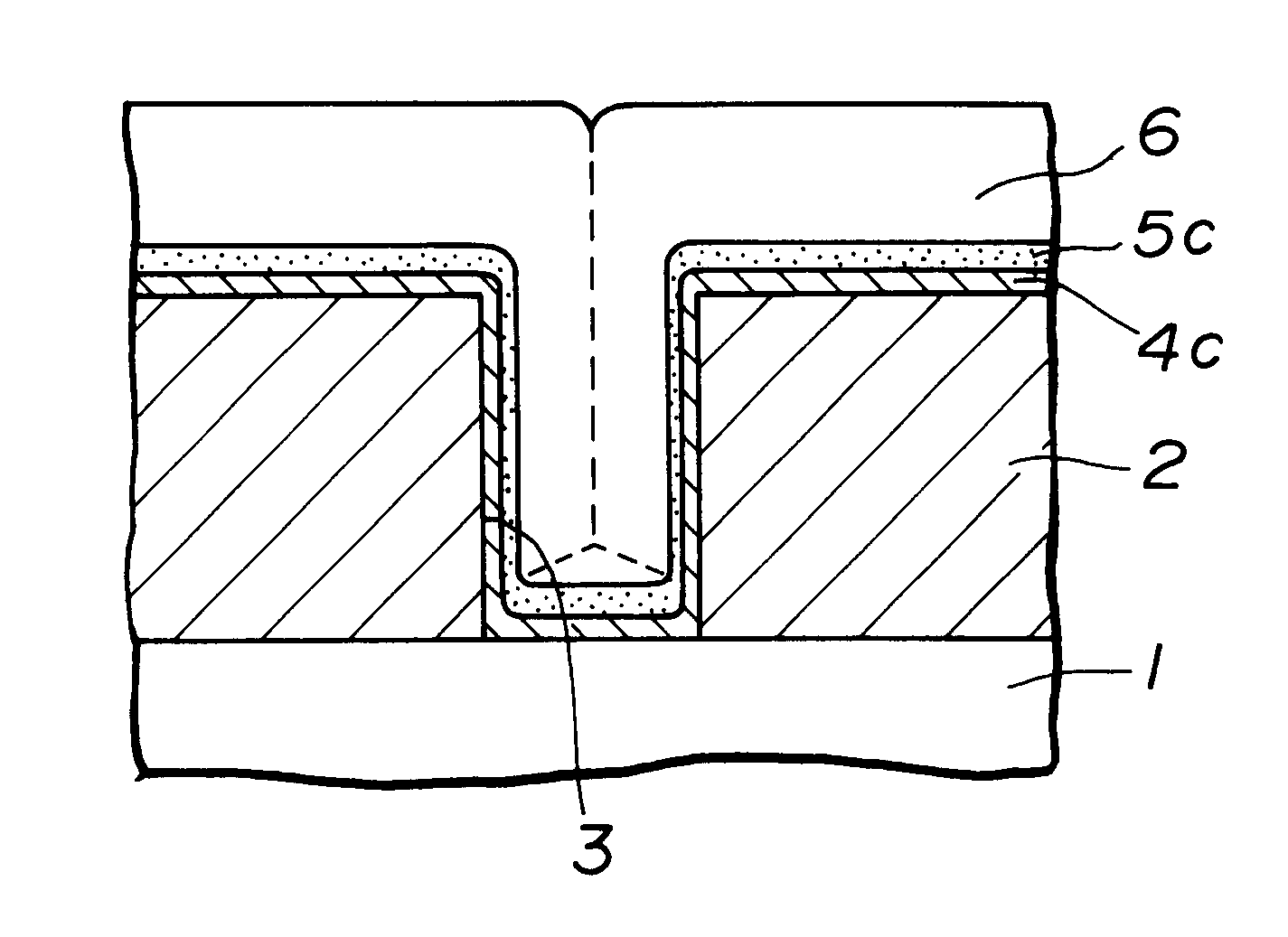

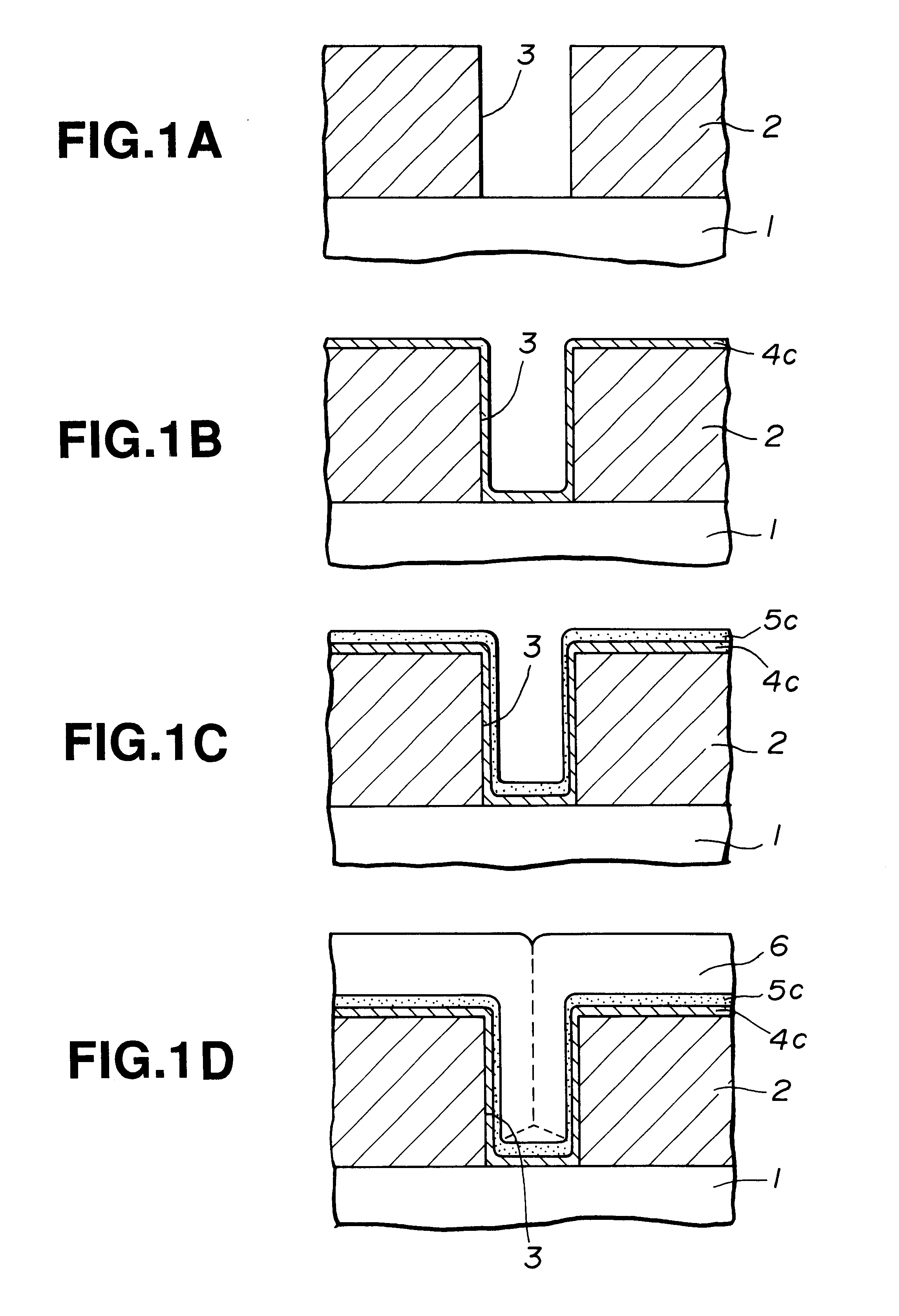

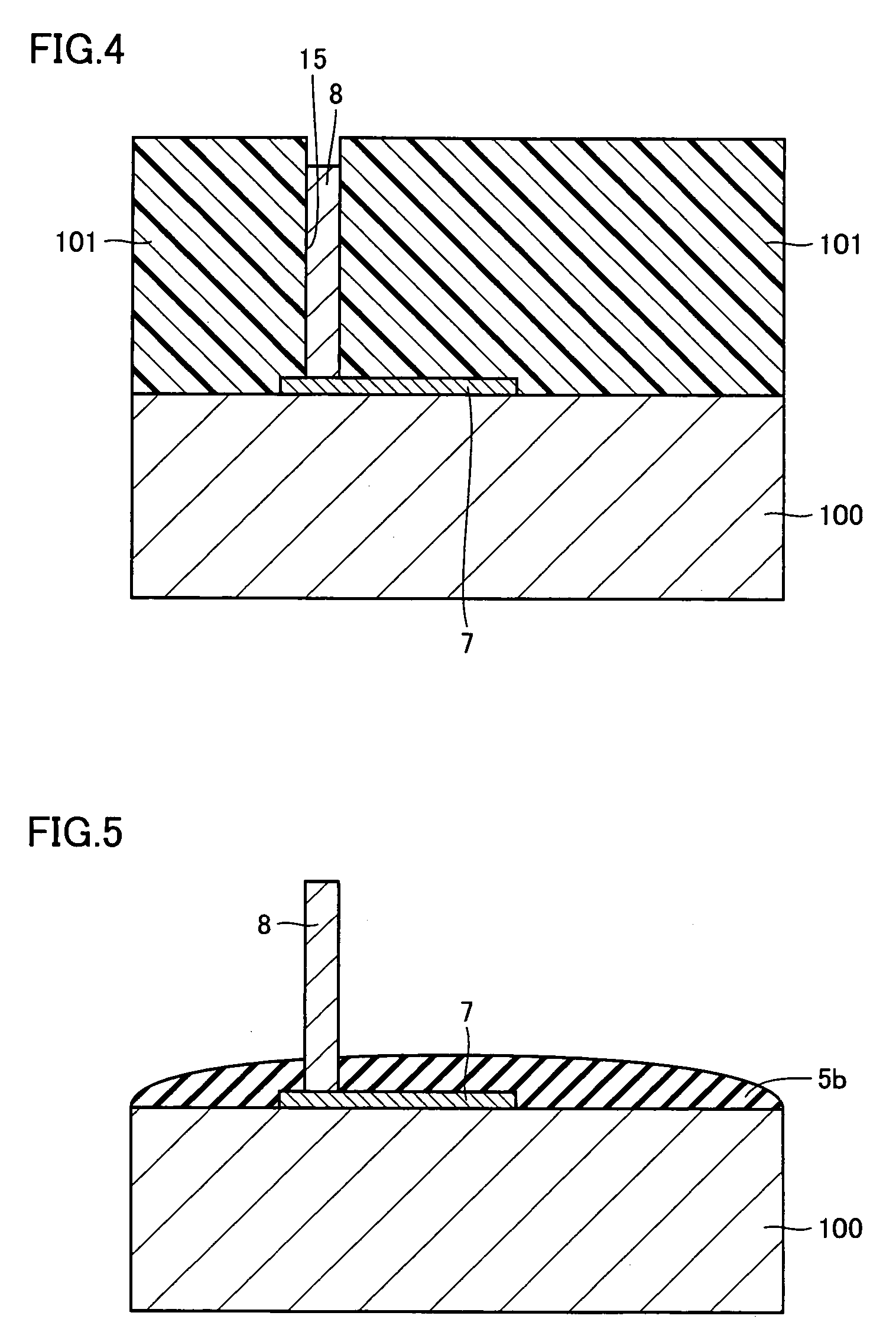

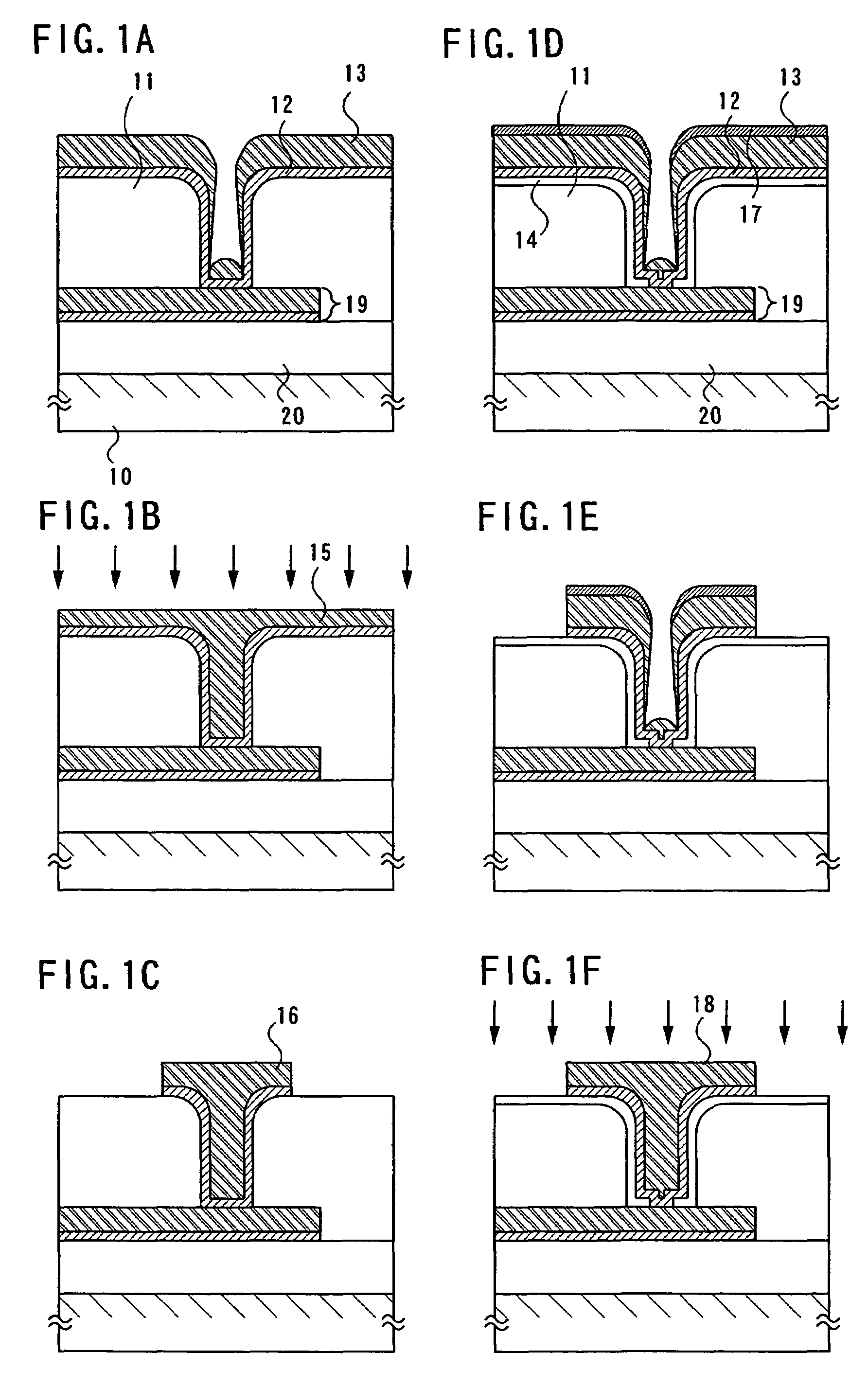

Method of reducing RIE lag for deep trench silicon etching

InactiveUS6284666B1Eliminating and at least minimizing RIE lagEliminating or at least minimizing RIE lagTransistorSemiconductor/solid-state device manufacturingHydrofluoric acidGas phase

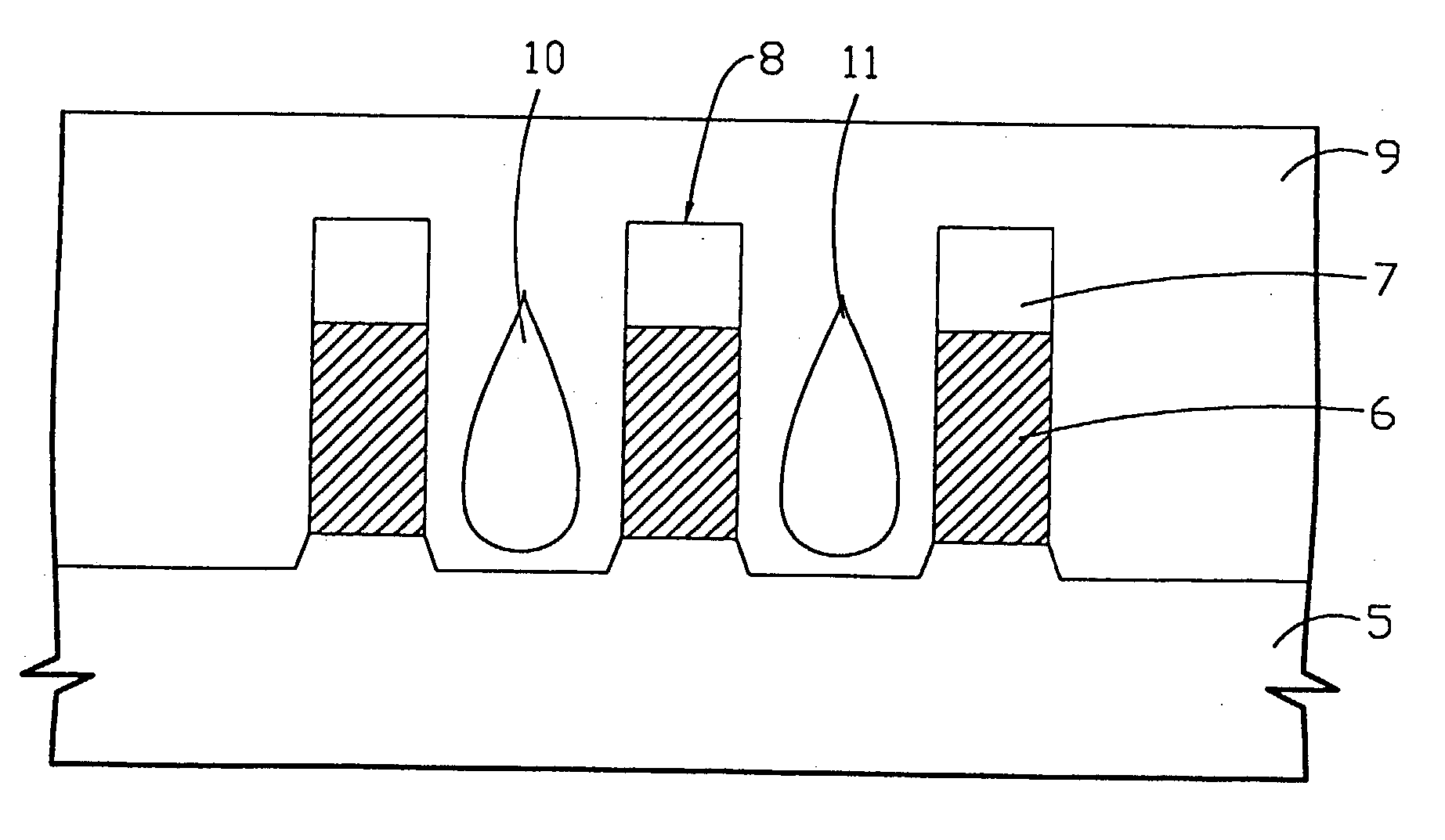

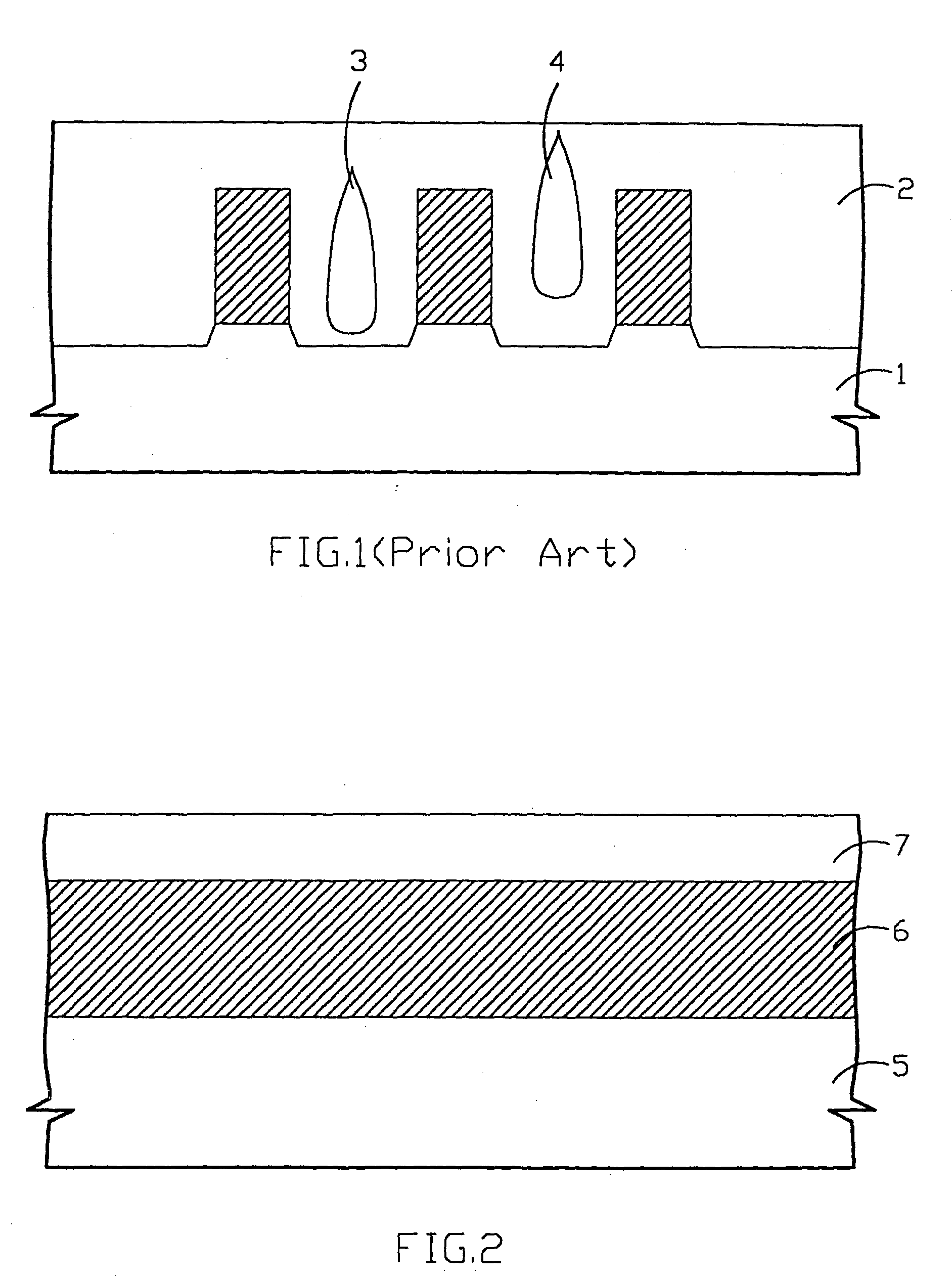

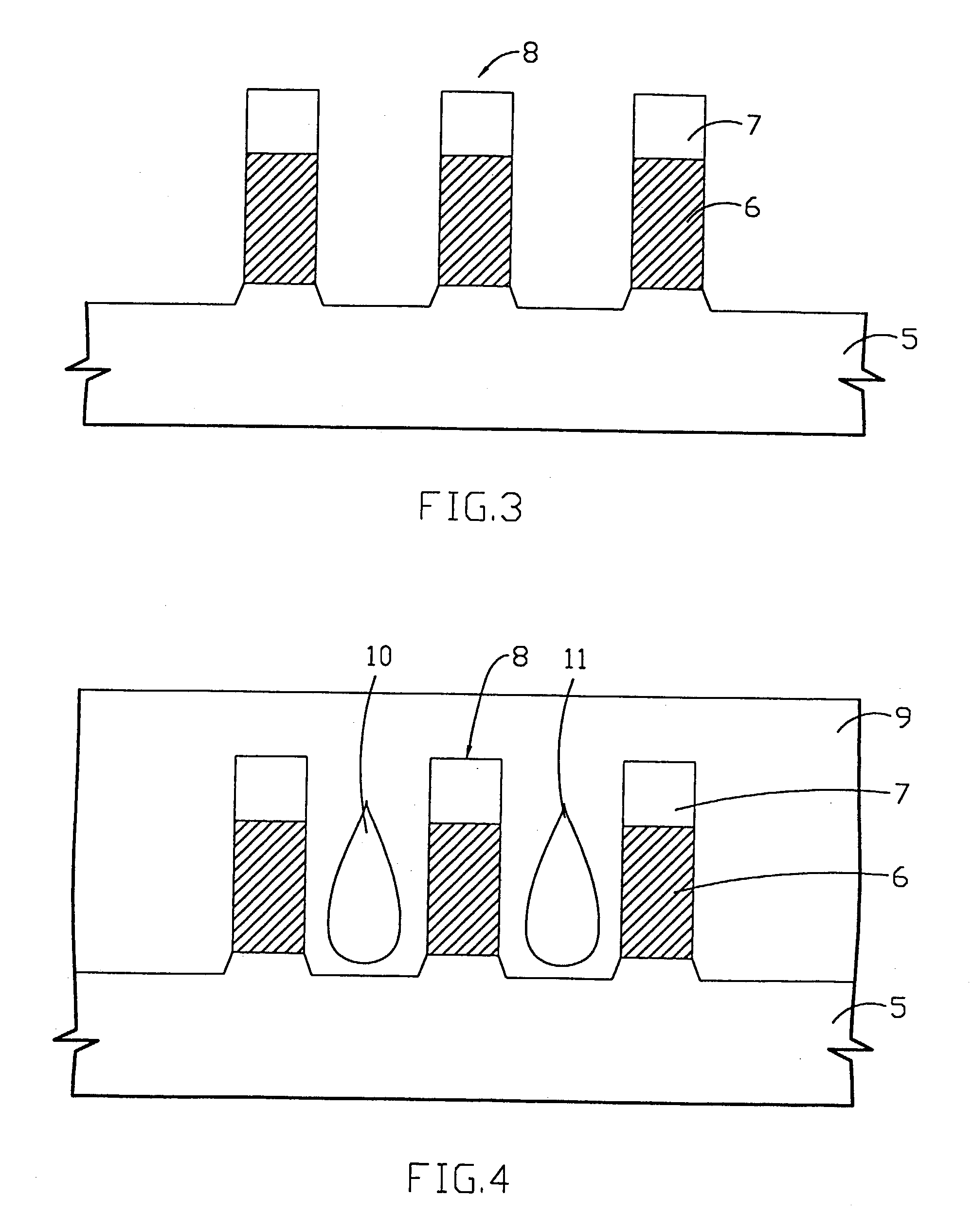

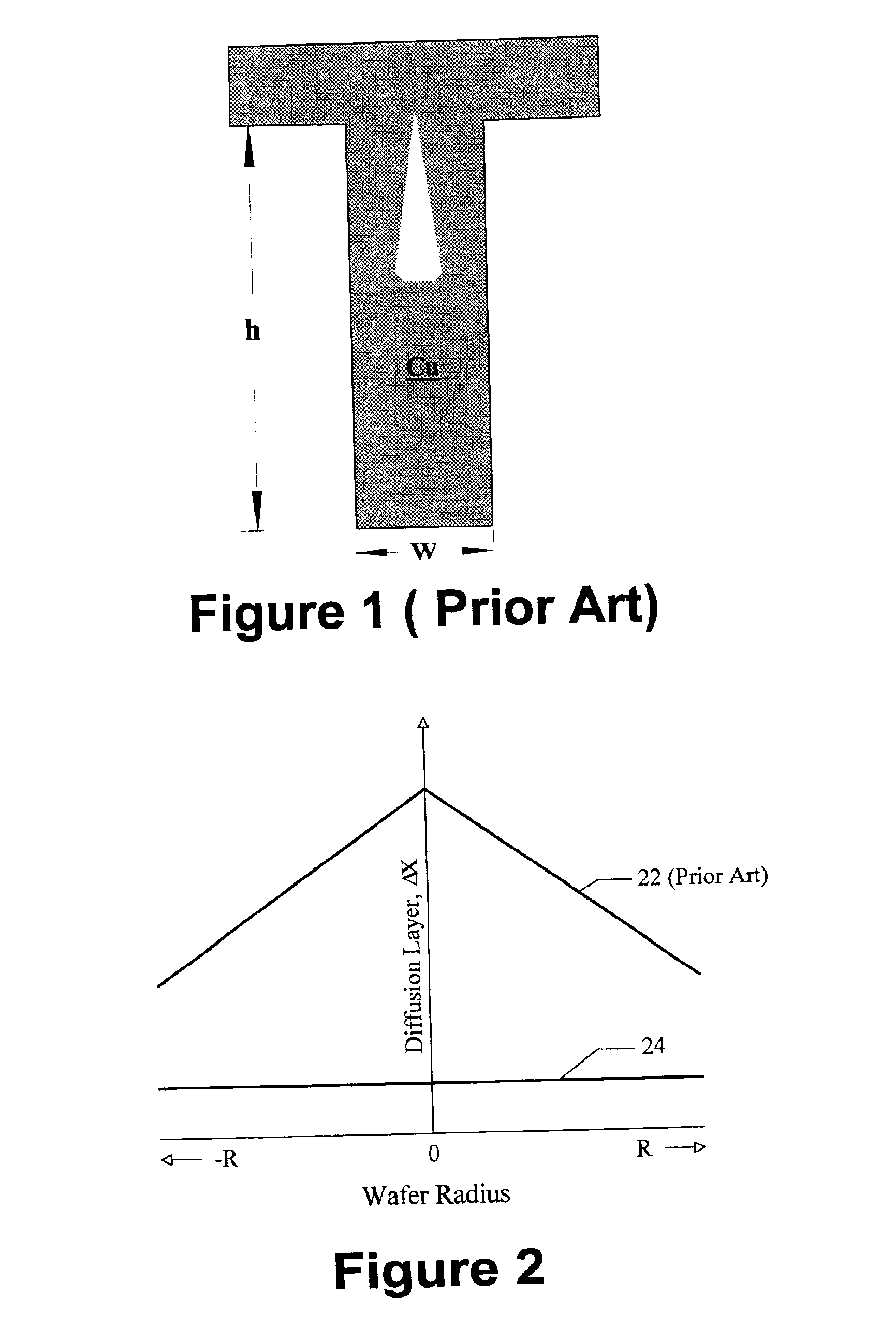

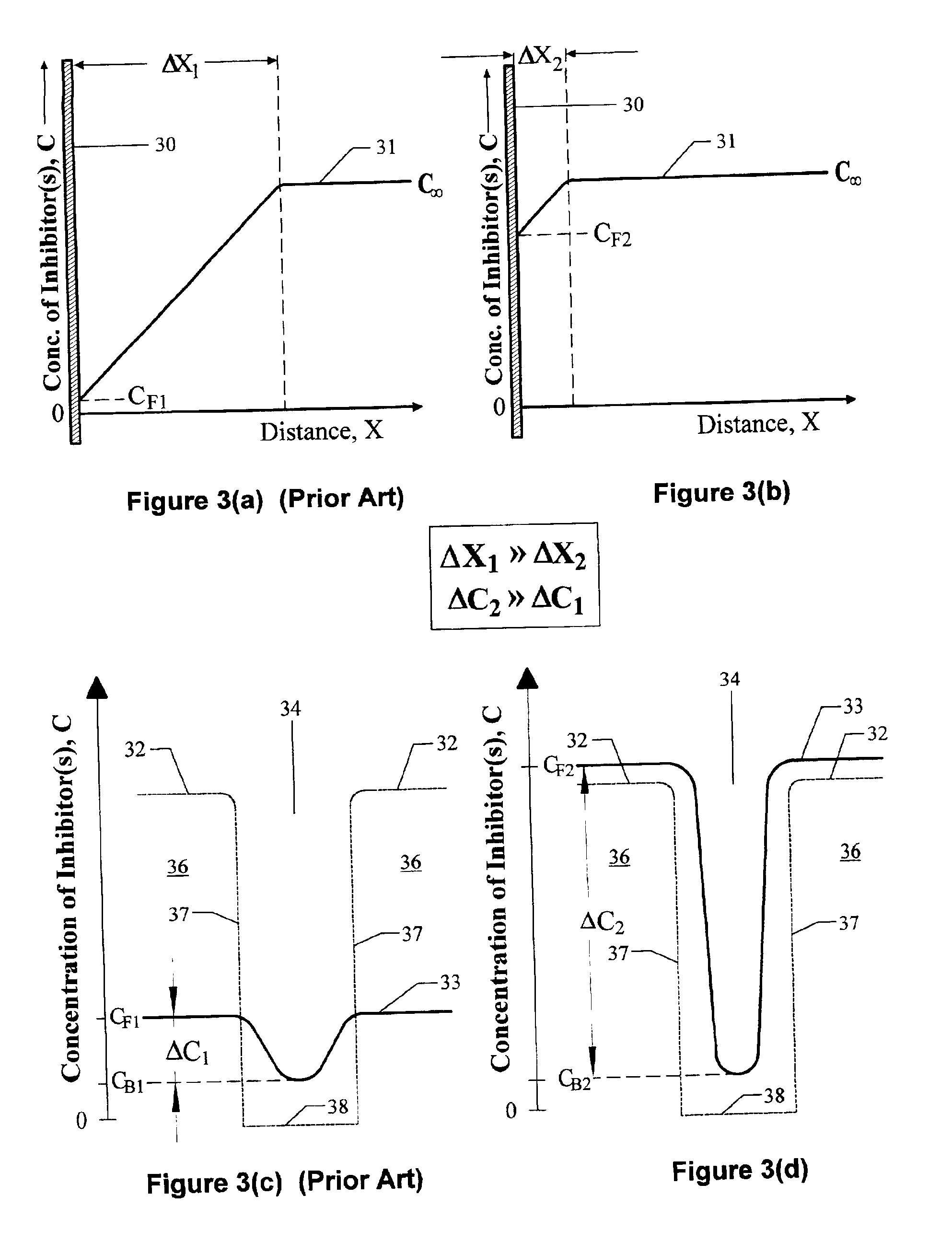

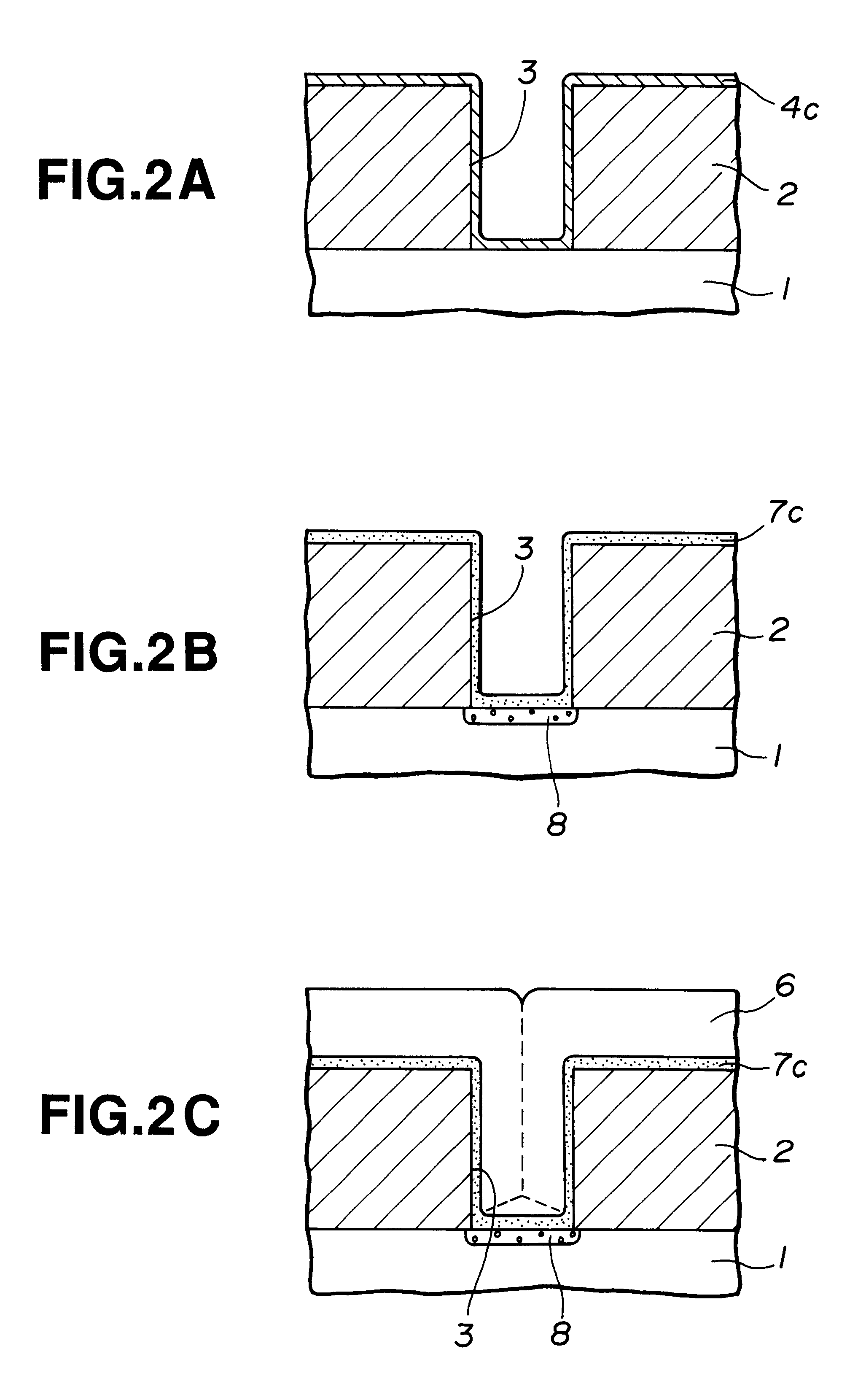

A method of minimizing RIE lag (i.e., the neutral and ion fluxes at the bottom of a deep trench (DT) created during the construction of the trench opening using a side wall film deposition)) in DRAMs having a large aspect ratio (i.e., <30:1) is described. The method forms a passivation film to the extent necessary for preventing isotropic etching of the substrate, hence maintaining the required profile and the shape of the DT within the substrate. The RIE process described provides a partial DT etched into a substrate to achieve the predetermined depth. The passivation film is allowed to grow to a certain thickness still below the extent that it would close the opening of the deep trench. Alternatively, the passivation film is removed by a non-RIE etching process. The non-RIE process that removes the film can be wet etched with chemicals, such as hydrofluoric acid (buffered or non buffered) or, alternatively, using vapor phase and / or non-ionized chemicals, such as anhydrous hydrofluoric acid. The controlled thickness of the film allows achieving a predetermined DT depth for high aspect ratio structures.

Owner:INFINEON TECH AG +1

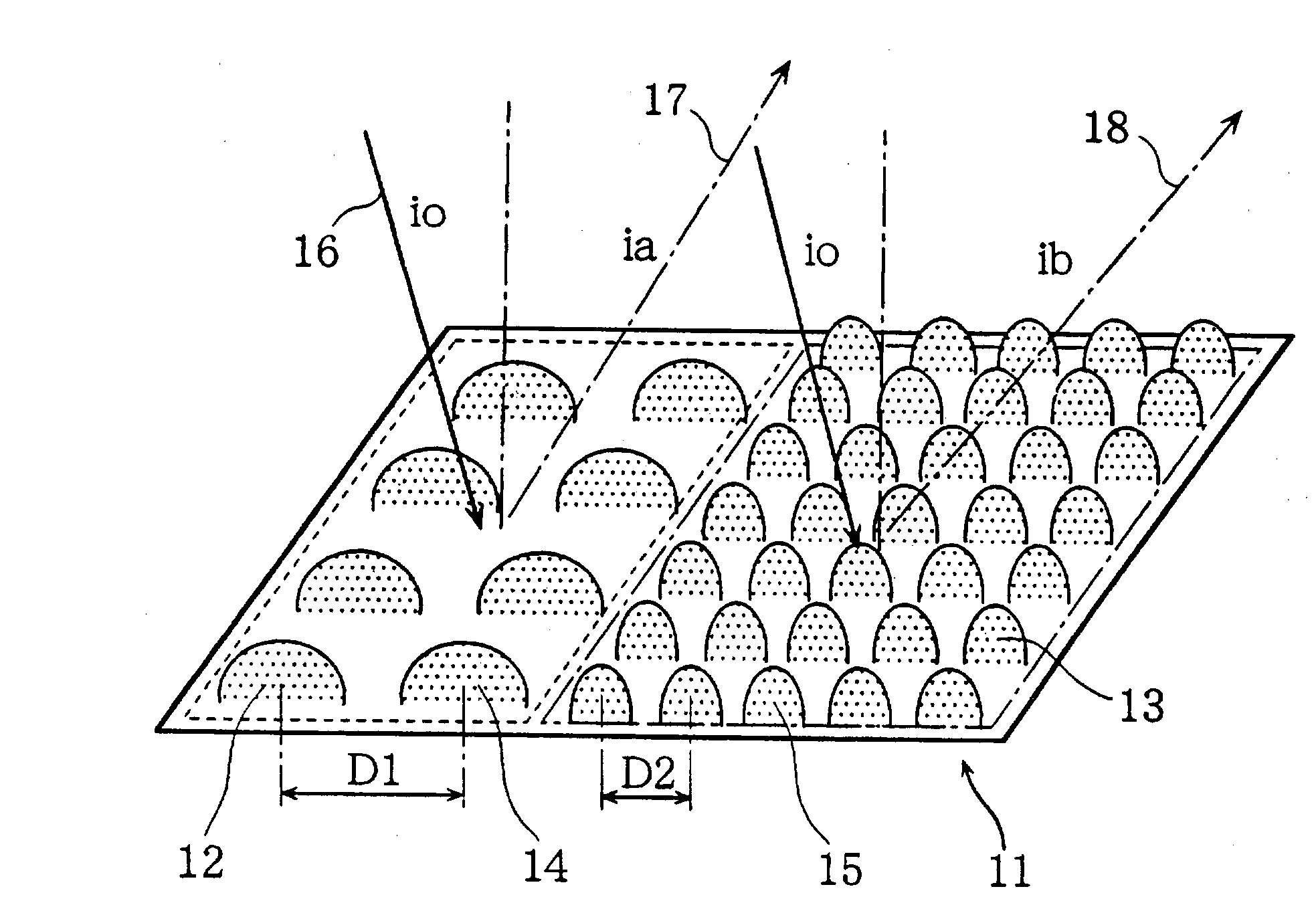

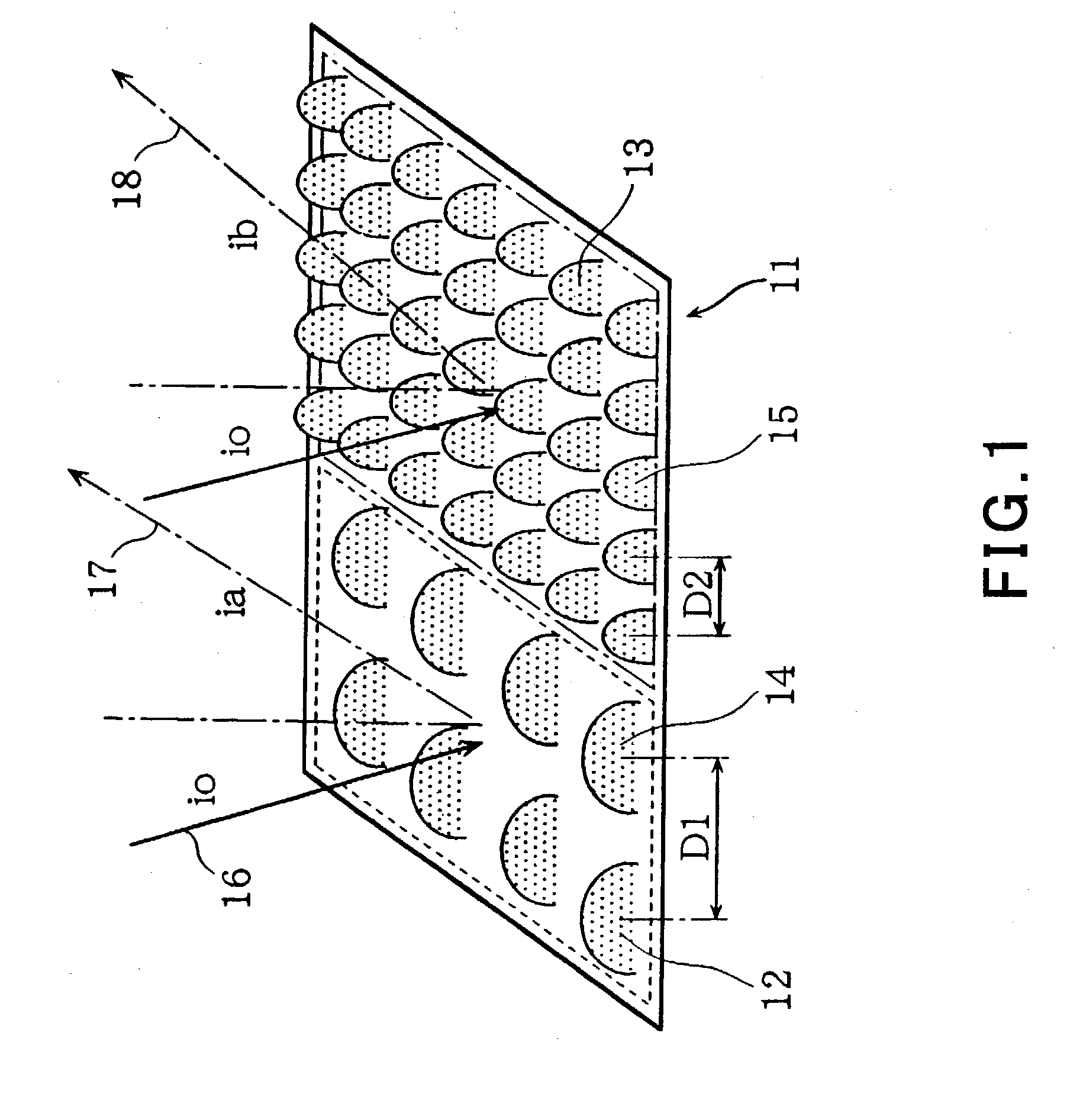

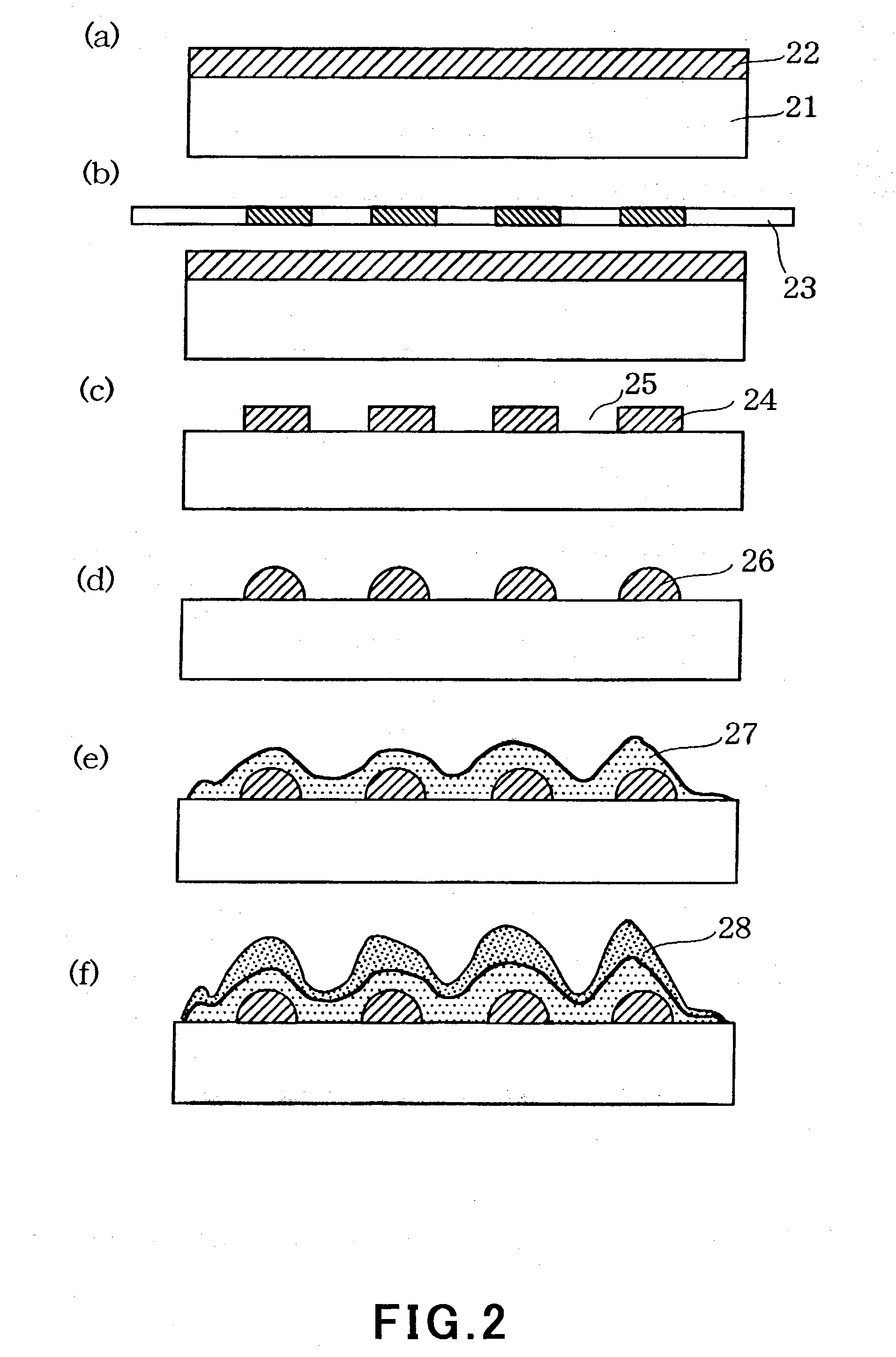

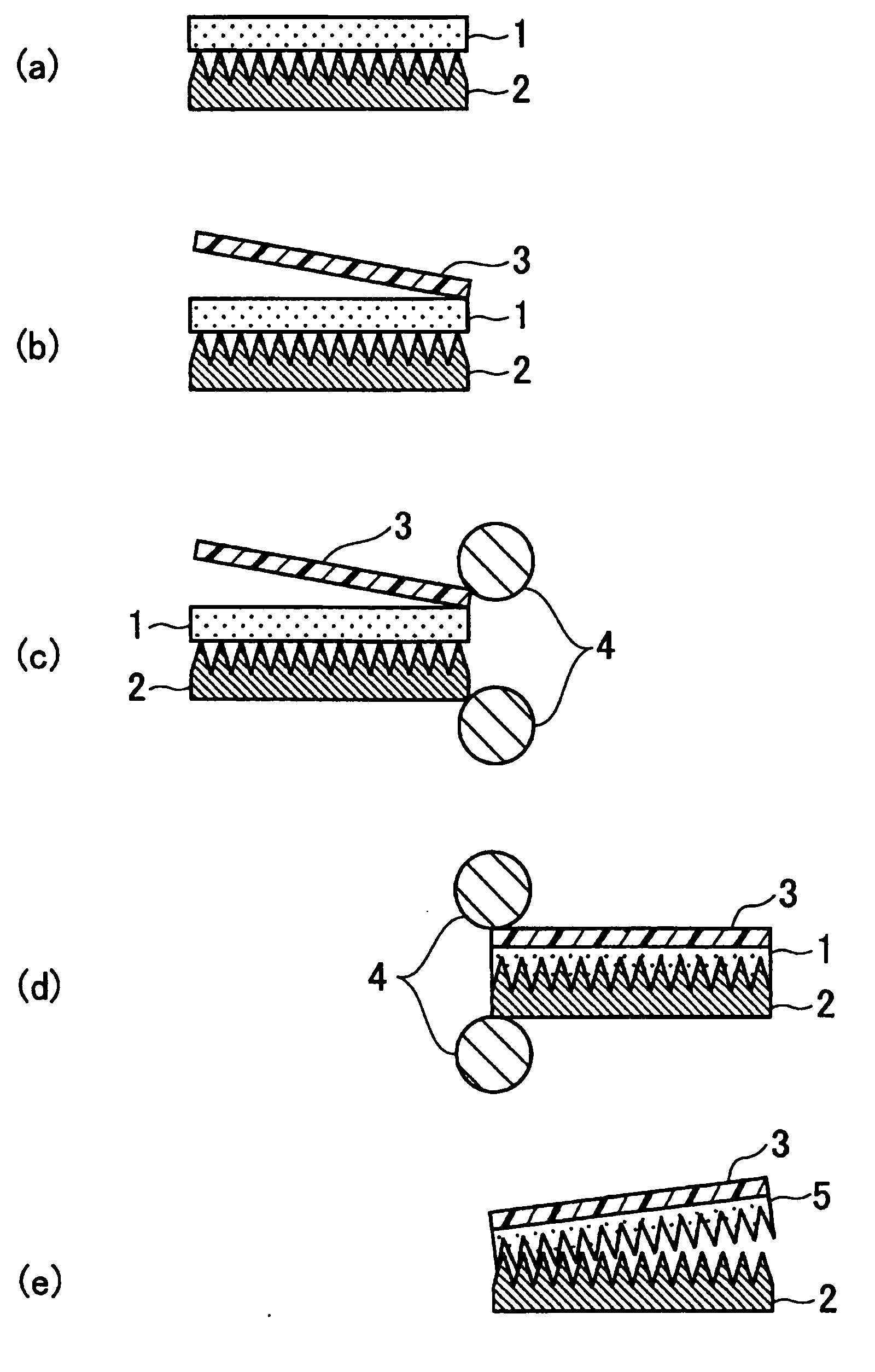

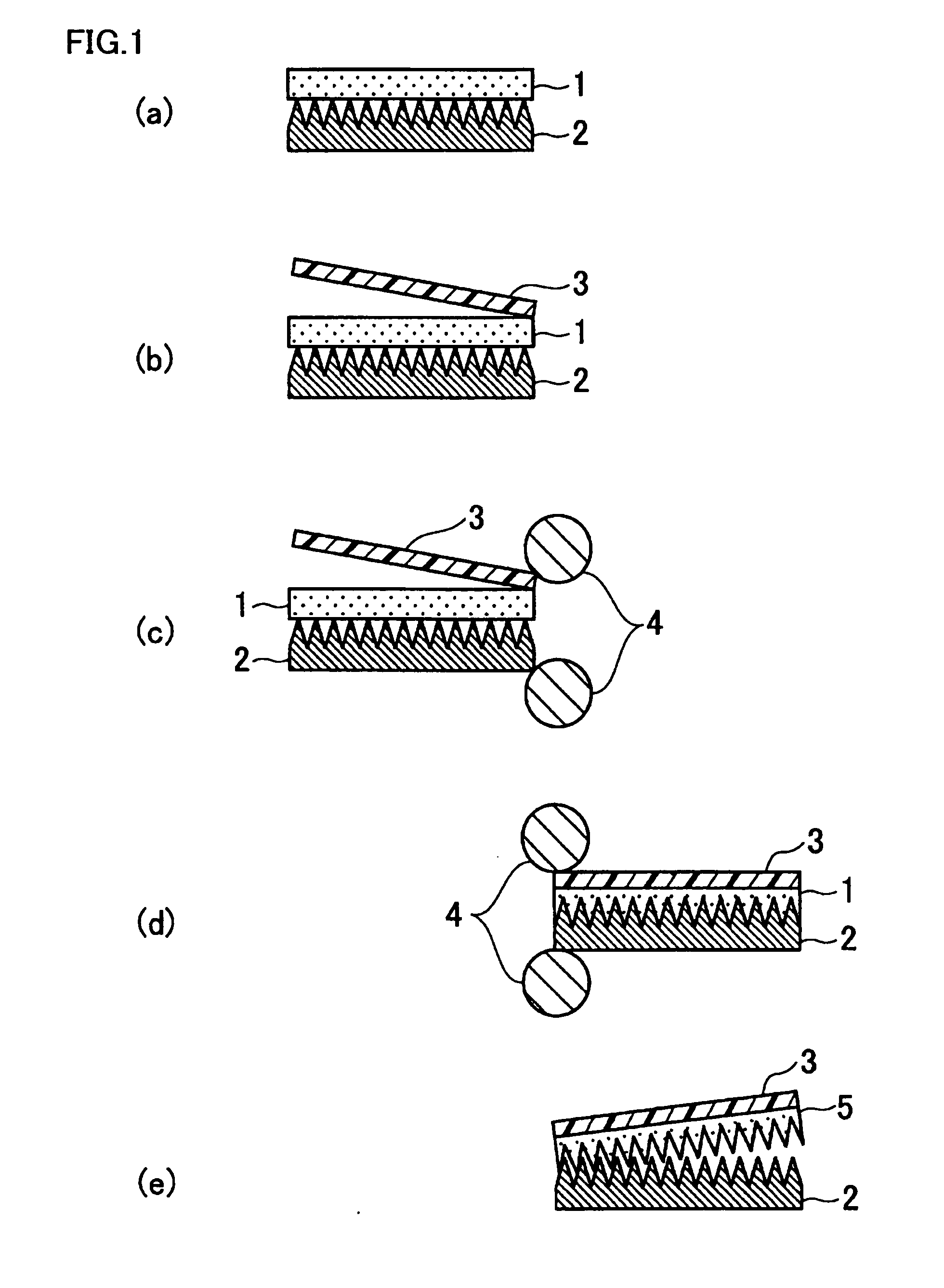

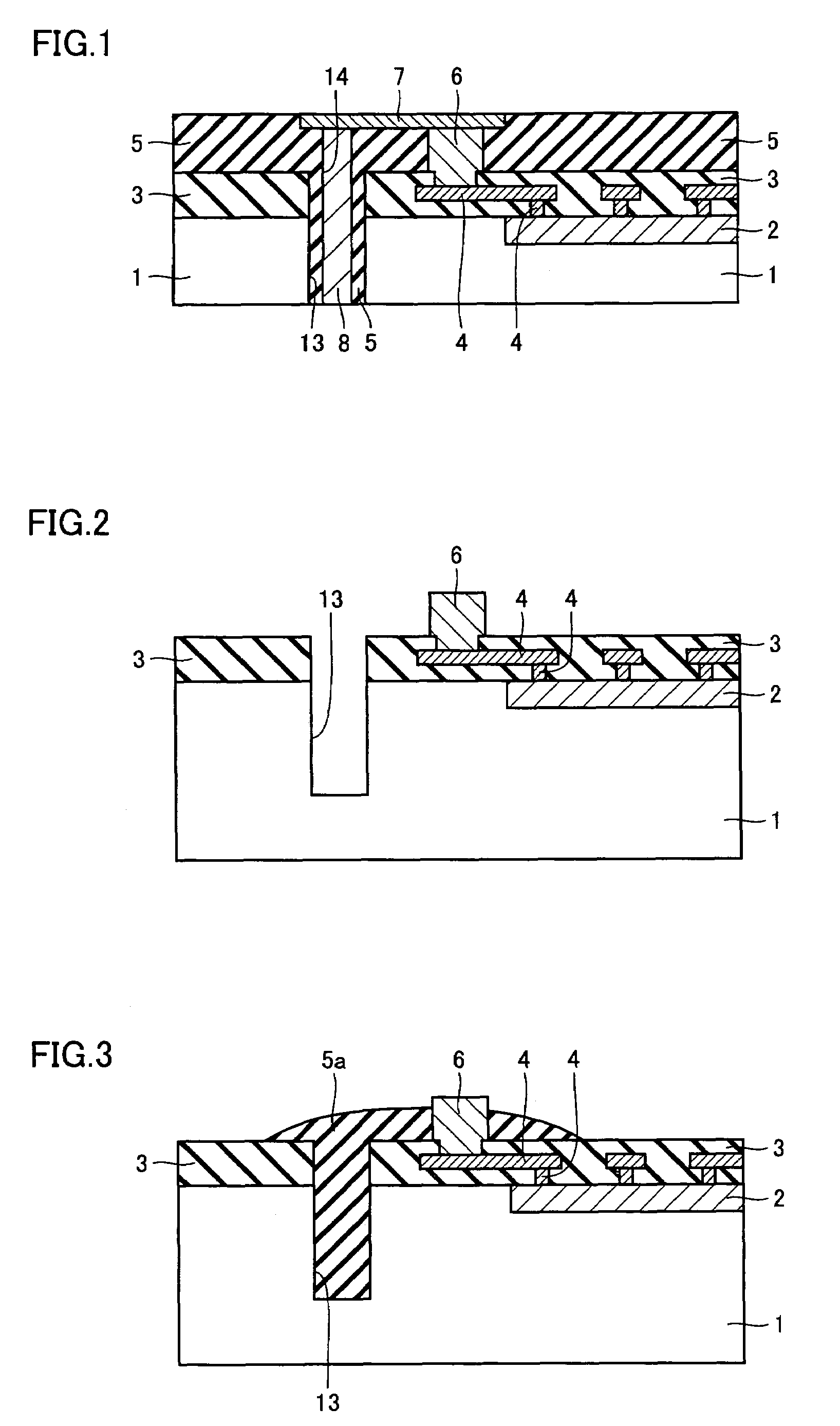

Irregular-shape body, reflection sheet and relection-type liquid crystal display element, and production method and production device therefor

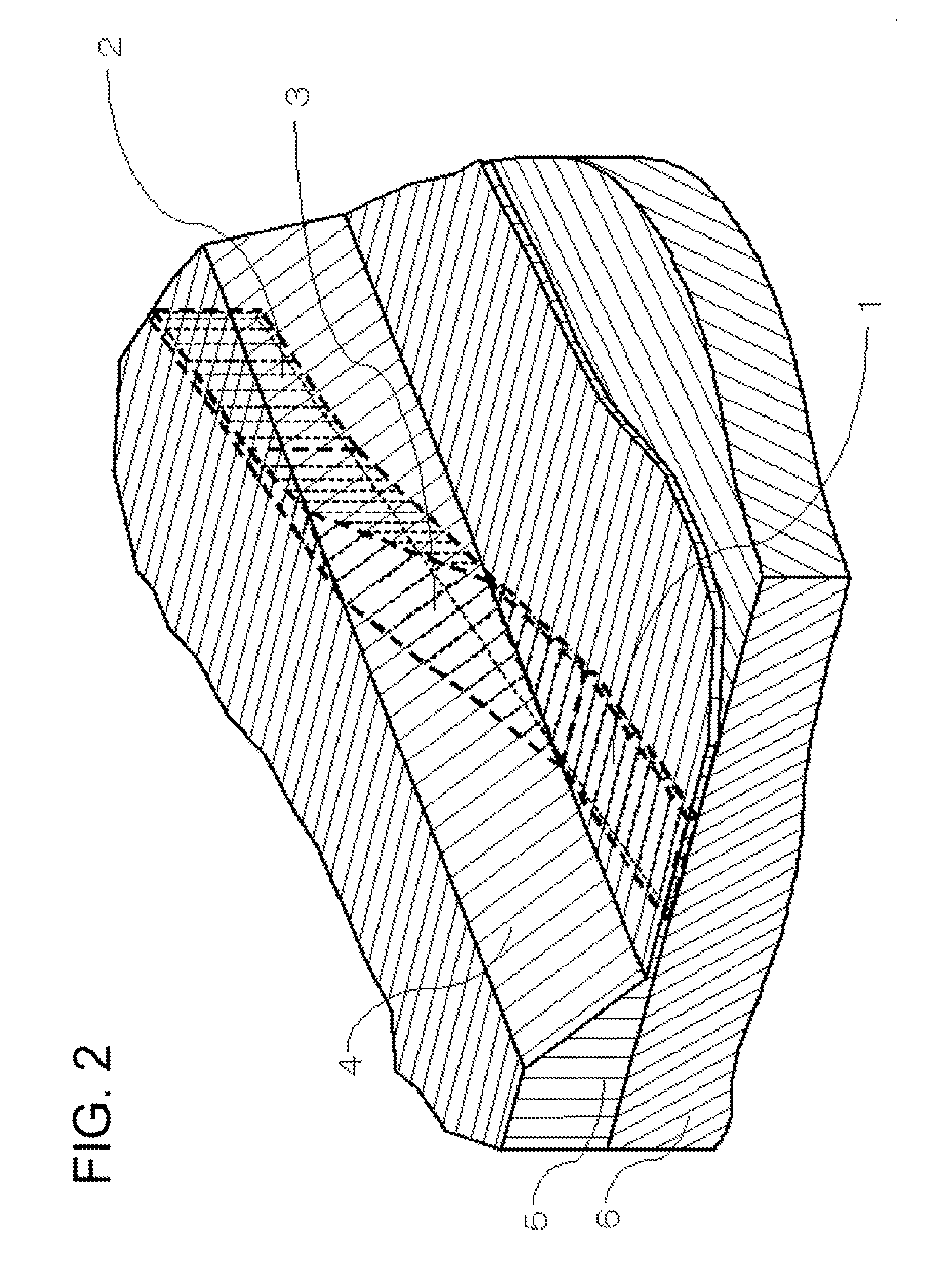

In a method for manufacturing a reflector having a plurality of convex portions 4 that are obtained by means of melt deformation of column-shaped bodys 15 formed of a photosensitive resin material, the photosensitive resin material has aspect ratio vs. average tilt angle characteristics in which an average tilt angle theta reaches a maximum value through an incremental change process and then converges to a certain value through a decremental process when an aspect ratio is gradually increased from a value close to zero, provided that the average tilt angle of the convex portion is an angle of elevation from the outer periphery of the bottom surface of the convex portion 4 to an apex of the convex portion and that the aspect ratio is a ratio of the height of said column-shaped body 15 with respect to the width thereof. A set value for the aspect ratio of the column-shaped body 15 that is obtained after the development step is determined to be a larger aspect ratio than a starting point from which convergence to said certain value begins. This configuration provides a reflector having good contrast characteristics and PAPER WHITE APPEARANCE, and a reflective liquid crystal display panel that uses the above-mentioned reflector.

Owner:JAPAN DISPLAY CENT INC

Polarization rotator and method for manufacturing the same

InactiveUS20100002989A1Eliminate trade-off relationshipHighly integratedCoupling light guidesOptical waveguide light guideLarge aspect ratioWaveguide

An optical circuit comprises a first waveguide; a second waveguide; and a third waveguide that converts mode field and direction of polarization of light of said first waveguide at the same time to perform wave guiding to said second waveguide; wherein large aspect ratio directions of corresponding ends of a core of said first waveguide and a core of said second waveguide differ from each other.

Owner:NEC CORP

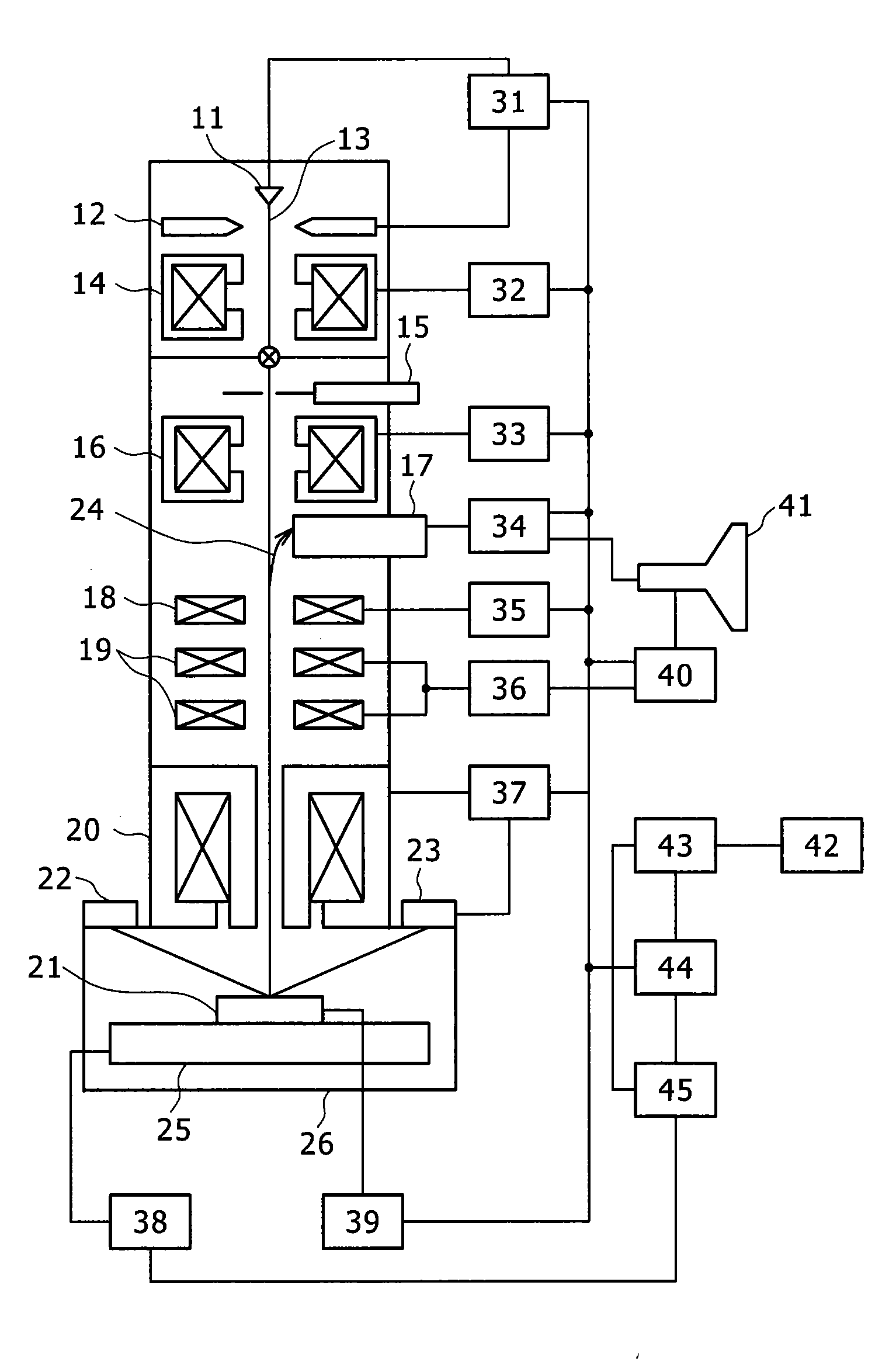

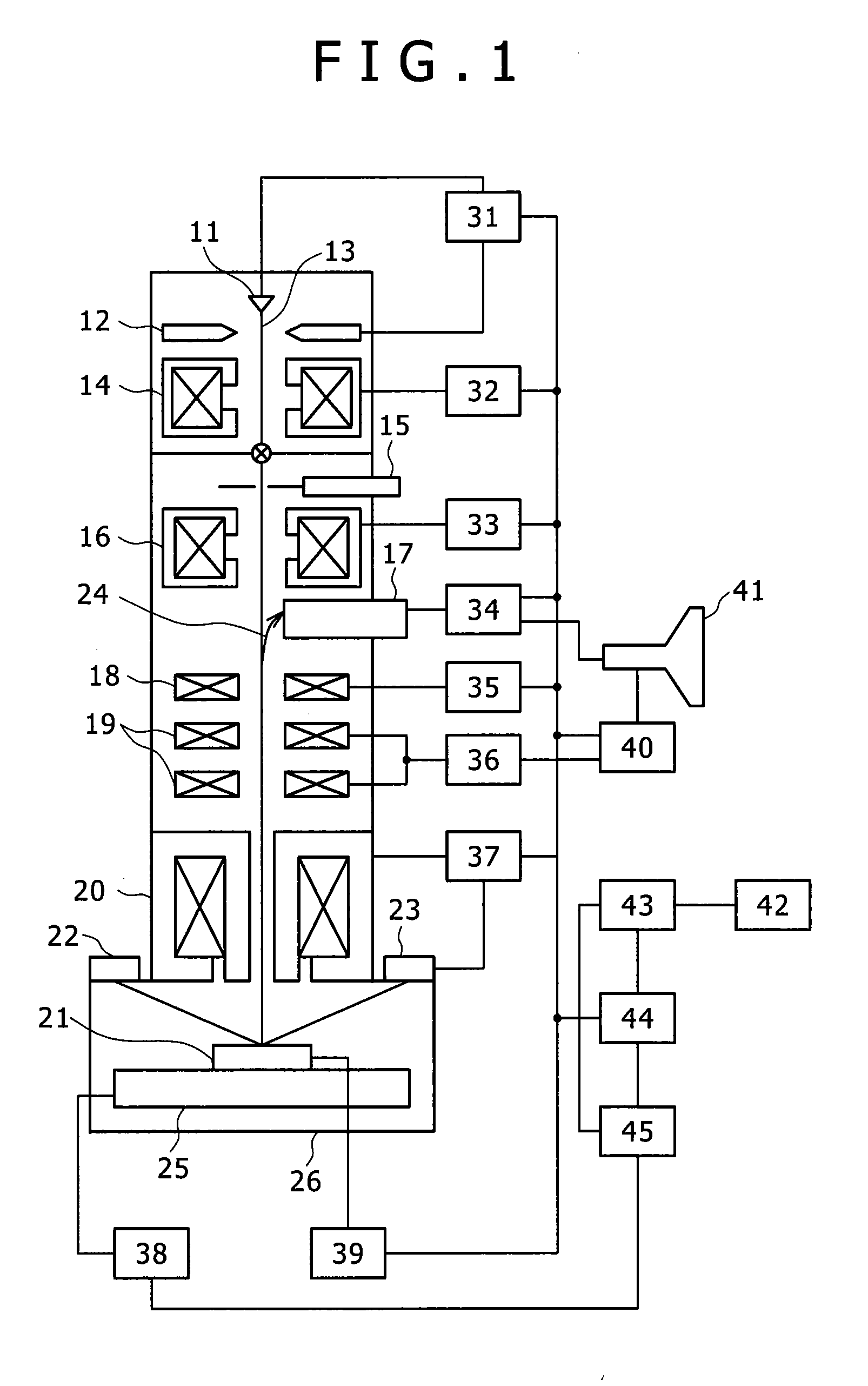

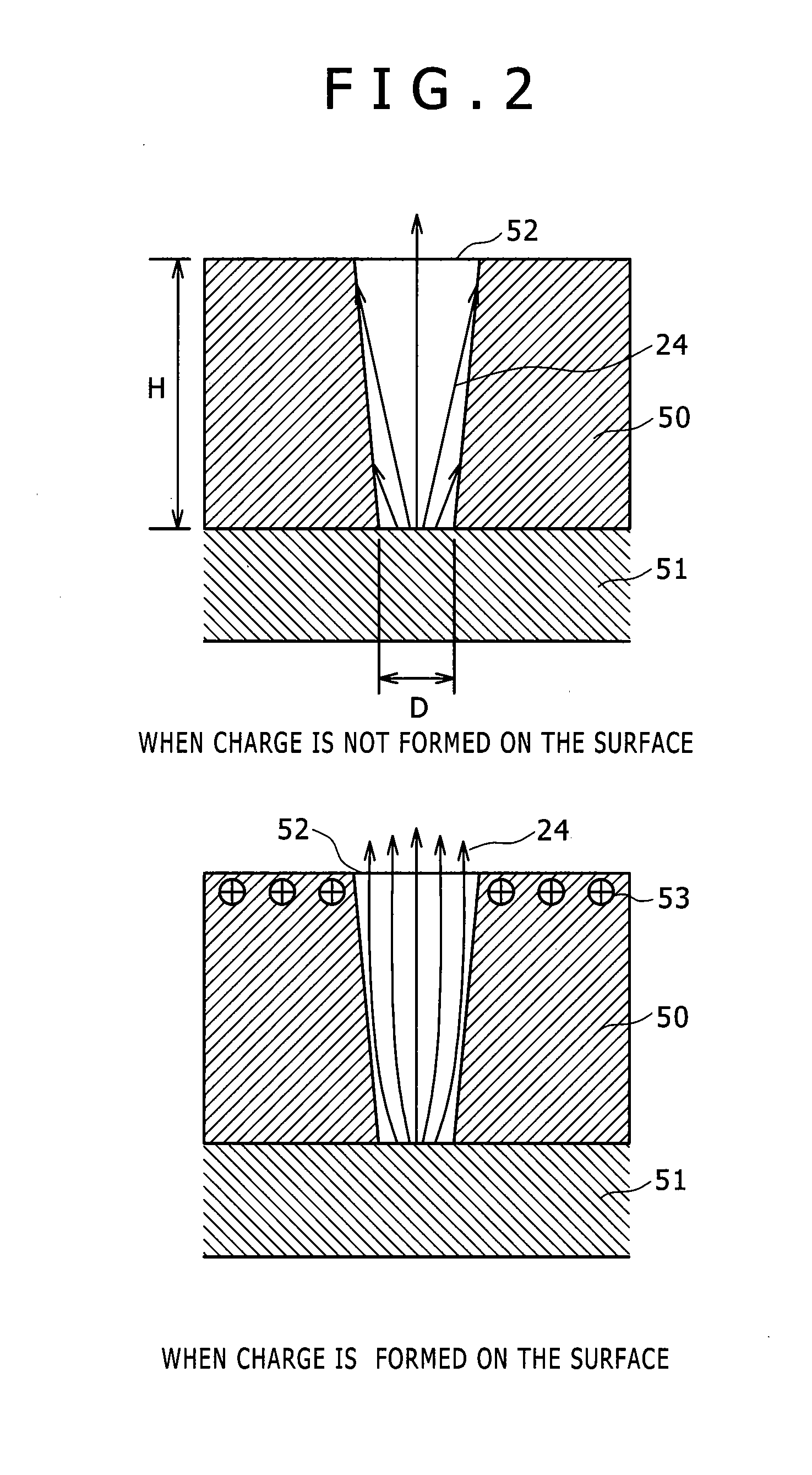

Method for inspecting and measuring sample and scanning electron microscope

ActiveUS20090084954A1Improve spatial resolutionInhibition of variationMaterial analysis using wave/particle radiationElectric discharge tubesScanning tunneling microscopeBeam diameter

As an aspect for realizing accurate observation, inspection, or measurement of the contact hole with large aspect ratio, a method and a device to scan a second electron beam after scanning a first electron beam to a sample to charge the sample are proposed wherein the beam diameter of the first electron beam is made larger than the beam diameter of the second electron beam.

Owner:HITACHI HIGH-TECH CORP

Method and structure for reducing capacitance between interconnect lines

InactiveUS20030176055A1Semiconductor/solid-state device detailsSolid-state devicesCapacitanceEngineering

A method and structure for reducing capacitance between interconnect lines, characterized in that a pad oxide layer is added on each of metal lines over a substrate, having a plurality of semiconductor elements and one dielectric layer for isolating the semiconductor elements formed thereon, to form an interconnect line. The pad oxide layer added on each of metal lines increases intra-metal aspect ratio and facilitates air gap formation in each of the spacings between the adjacent interconnect lines having larger aspect ratios. Moreover, each of air gaps is formed below the pad oxide layer, while the top end and lower end thereof respectively exceed the top end and bottom end of the adjacent metal lines. The distance from the portion of the air gap between the top end and bottom end of the adjacent metal lines to the sidewall of the adjacent metal lines is more consistent and smaller. Therefore, a better low K effect between the adjacent metal lines is obtained.

Owner:UNITED MICROELECTRONICS CORP

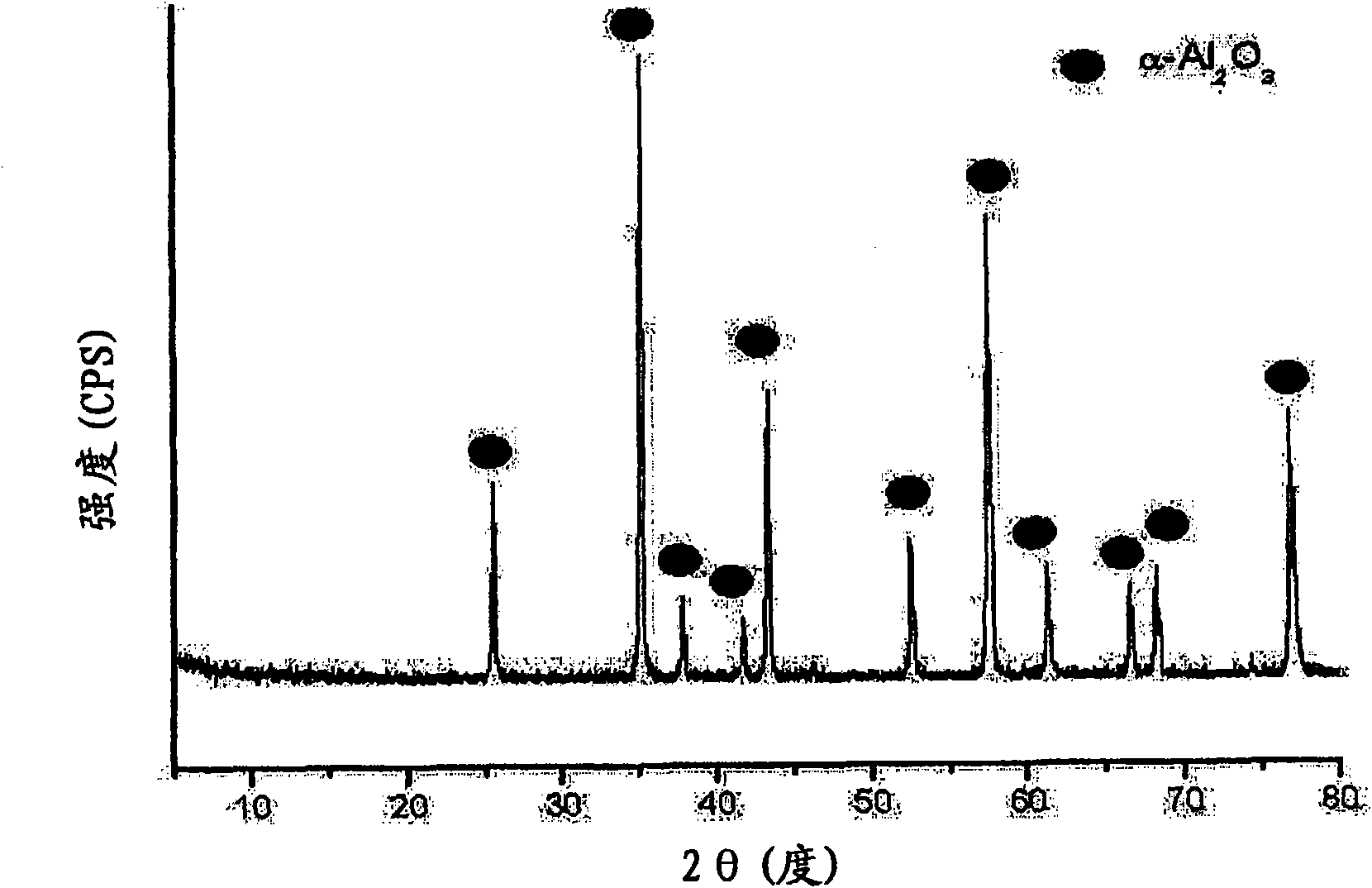

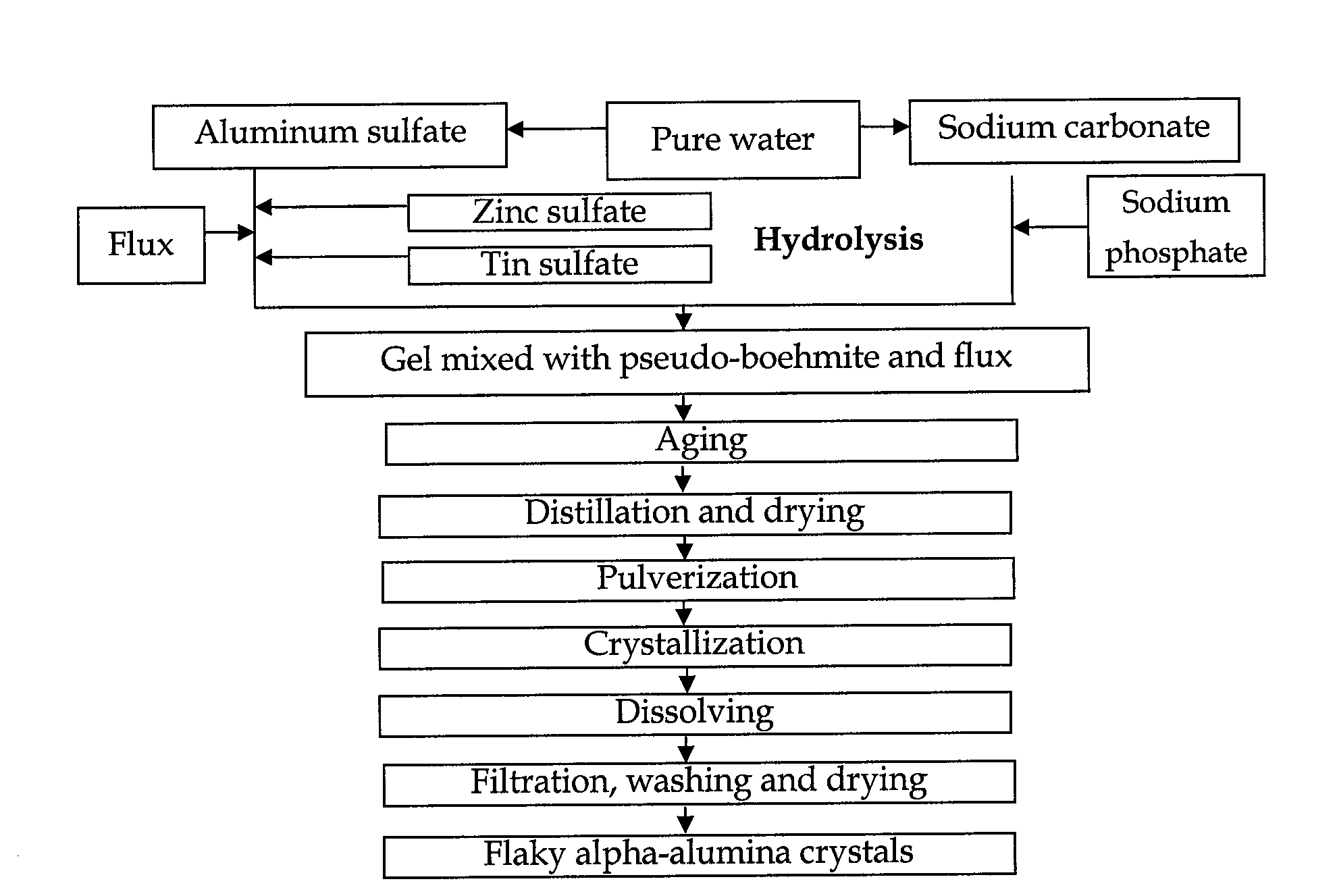

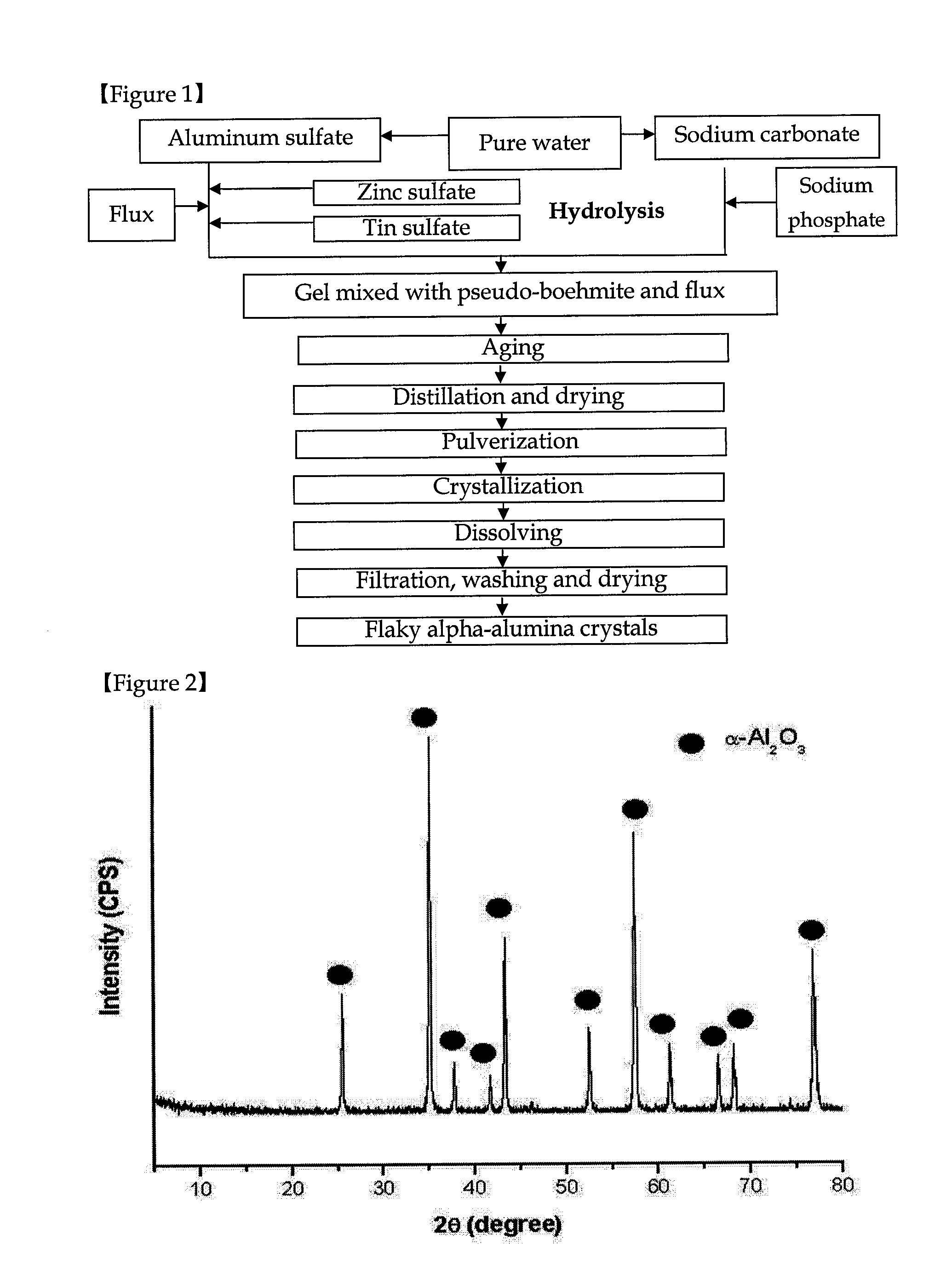

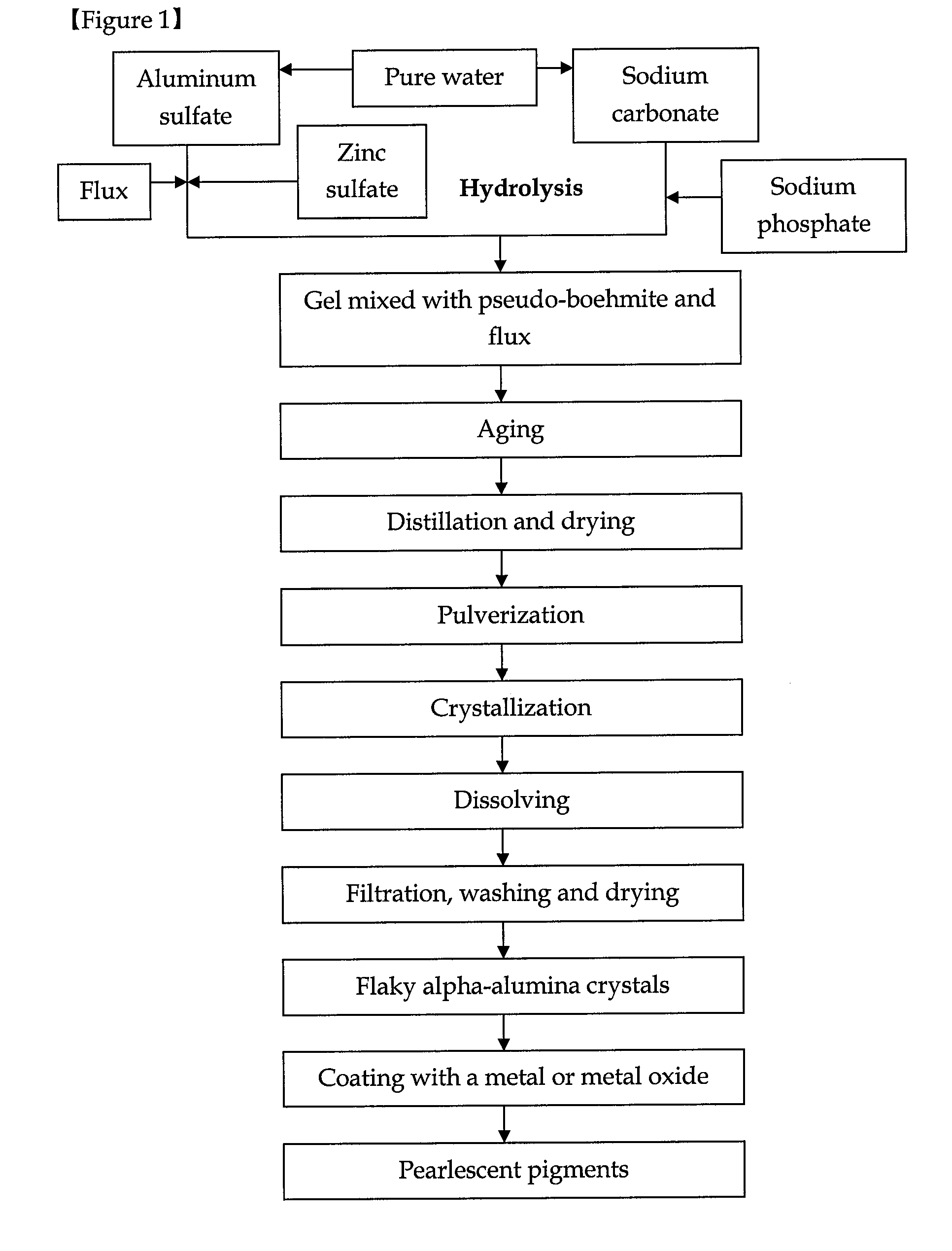

Flaky alpha-alumina crystals with large aspect ratio and a preparation method of the same

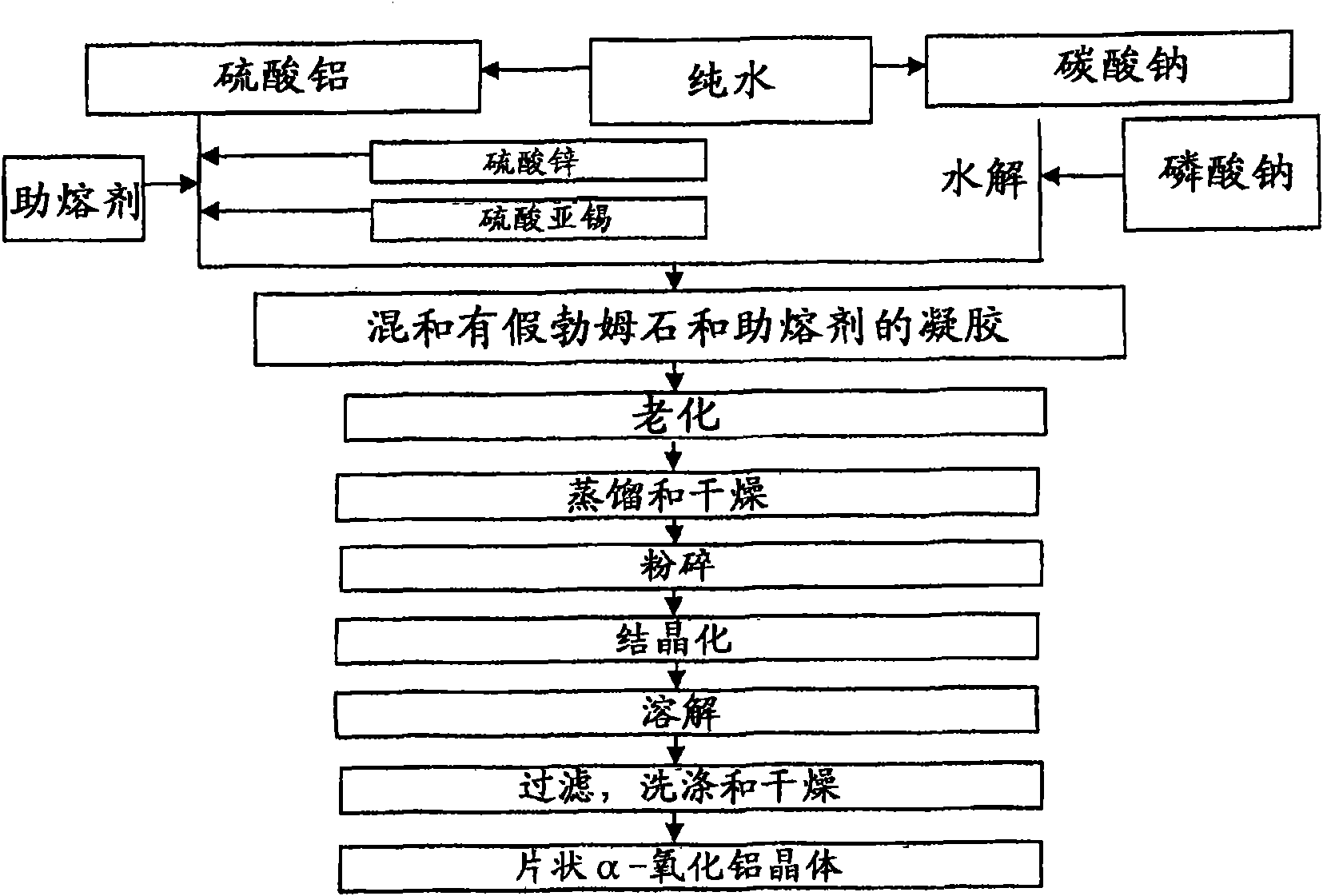

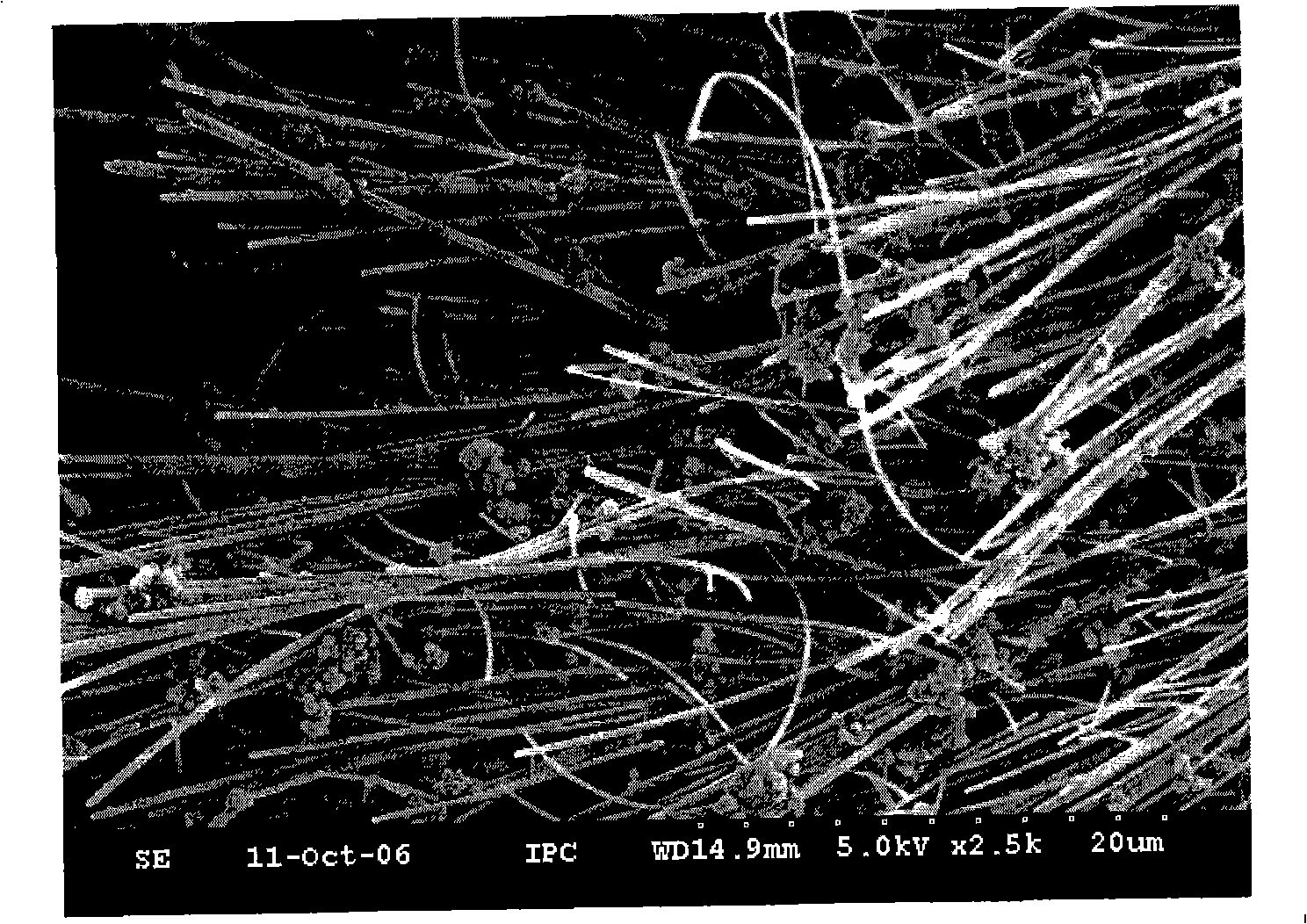

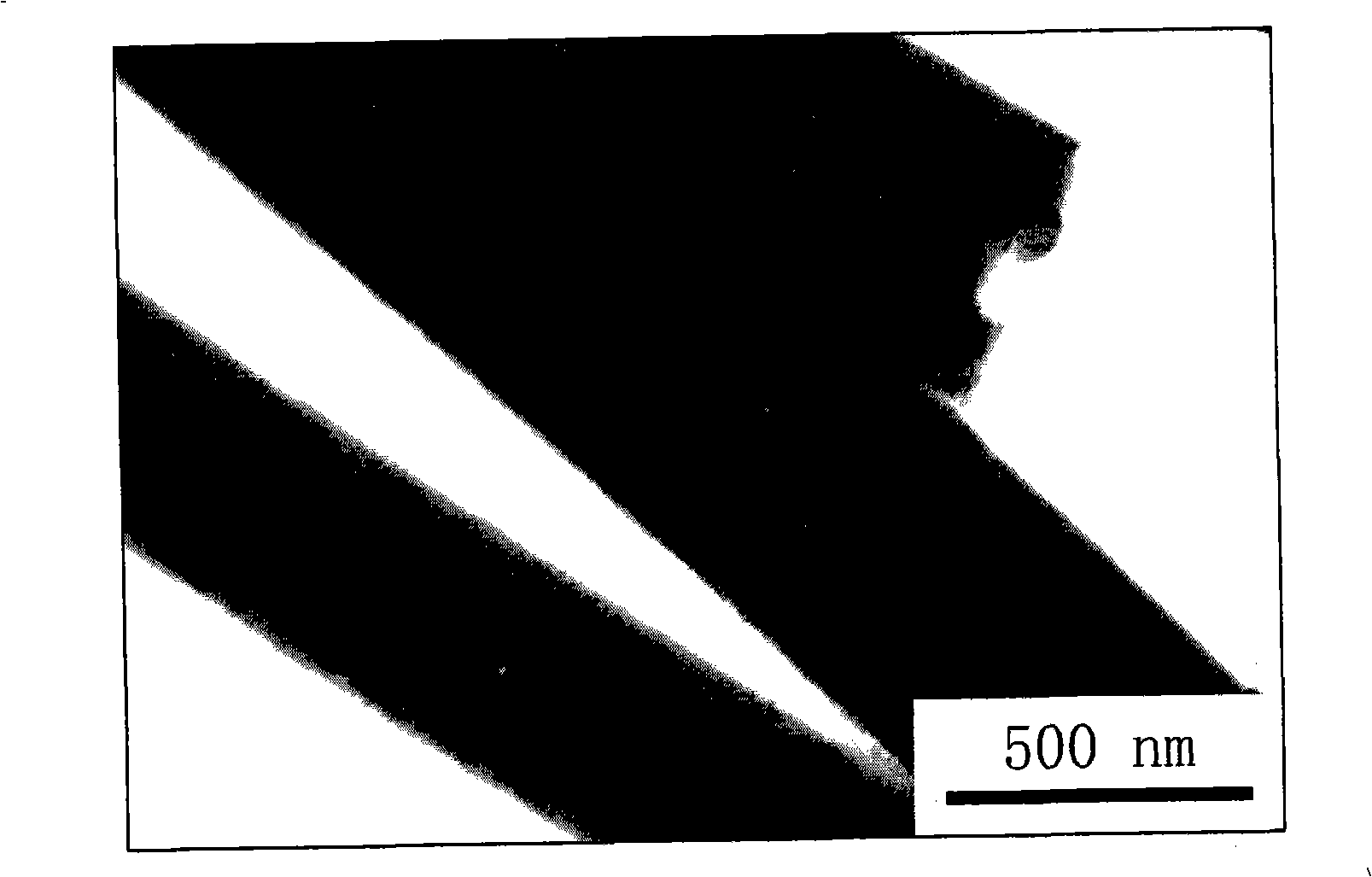

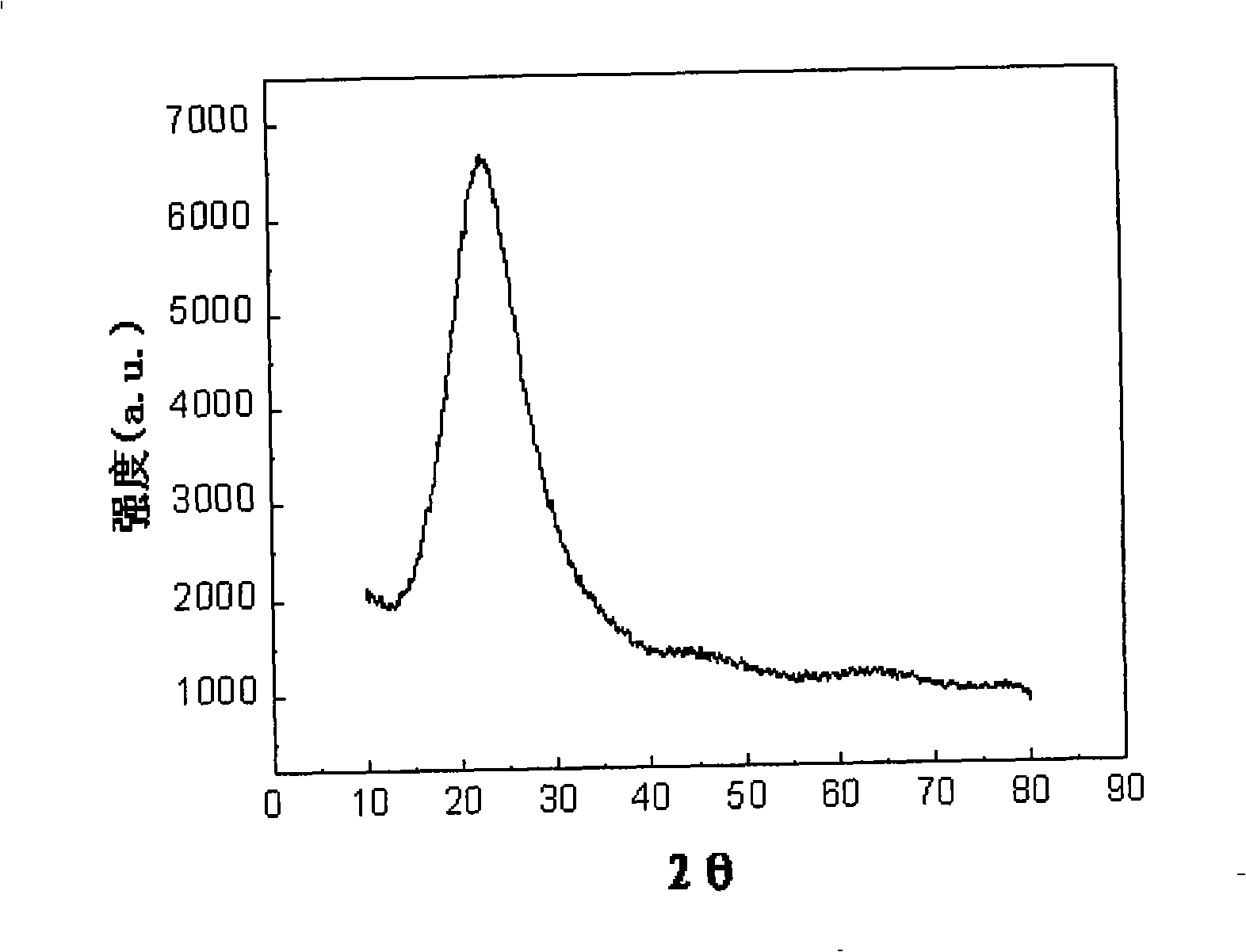

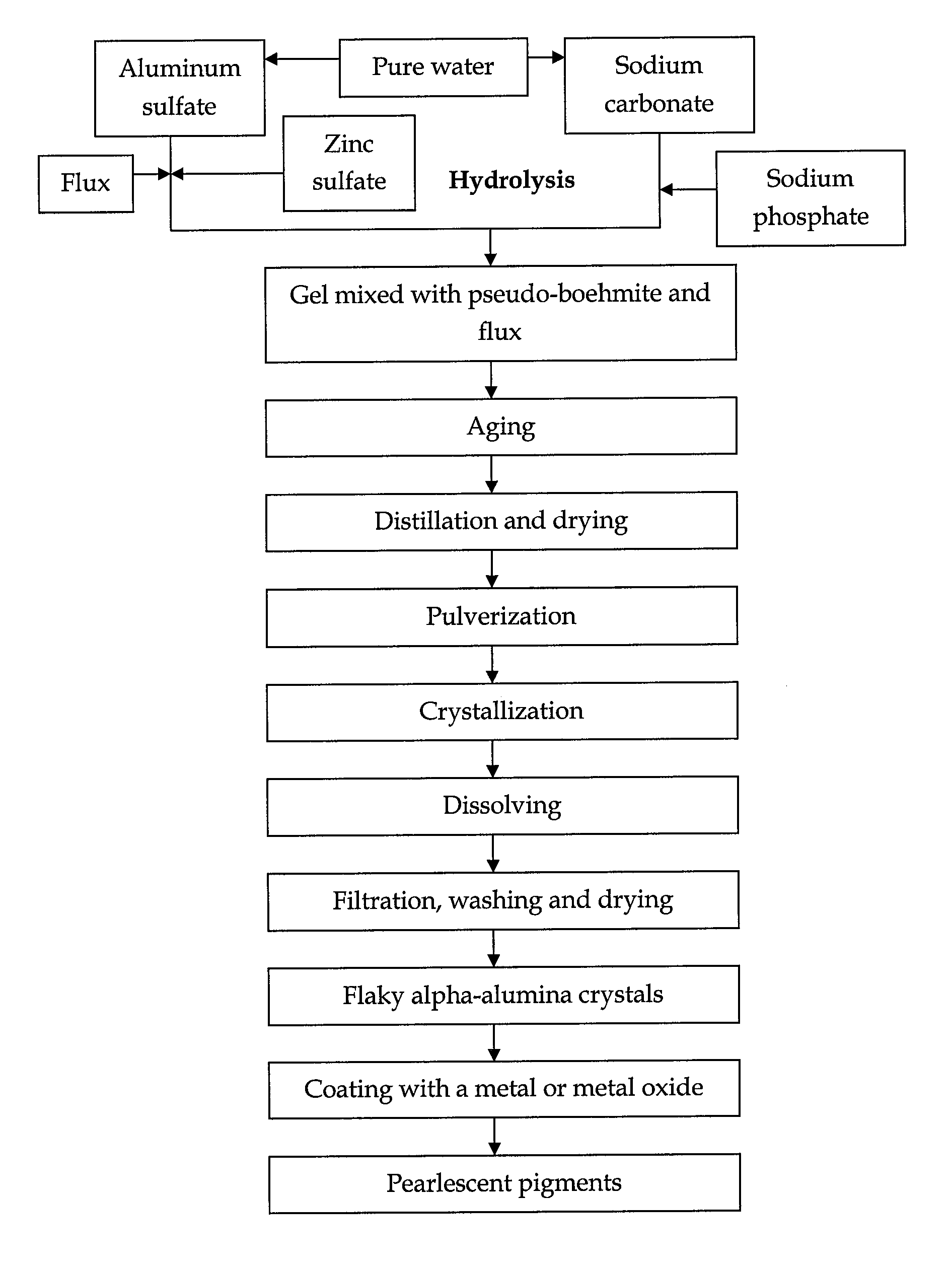

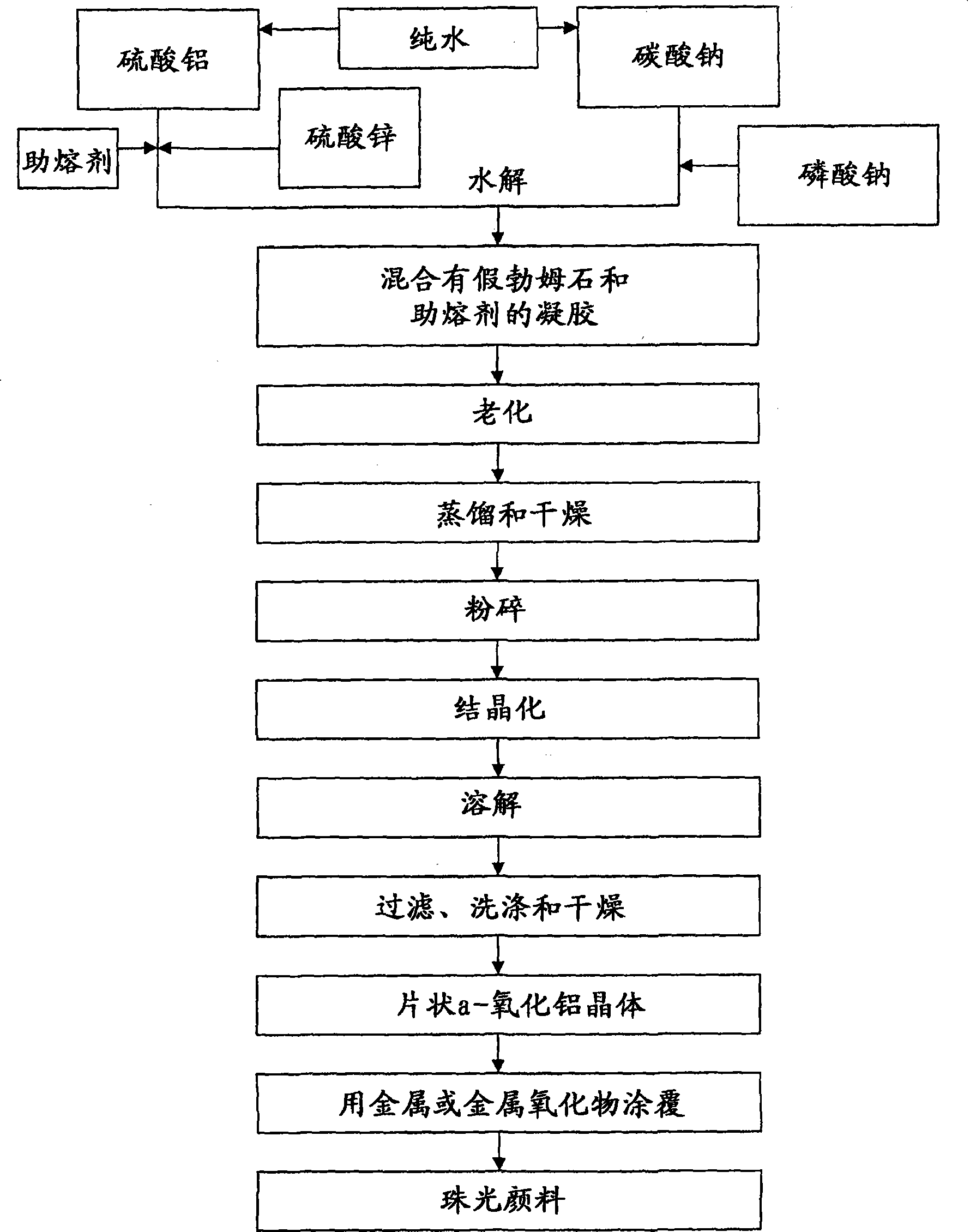

The present invention relates to flaky alpha-alumina crystals with large aspect ratio and its preparation method, and particularly to flaky alpha-alumina crystals comprising aluminum oxide, zinc oxide and tin oxide, which are prepared by obtaining a mixed gel which are prepared by obtaining a mixed gel by means of hydrolysis of an aqueous aluminum precursor solution comprising aqueous flux, aqueous zinc precursor solution and tin precursor aqueous solution, followed by aging, drying and crystallization processes. The crystals herein have an average particle thickness of 0.5 [mu]m or less, an average particle diameter of 30 [mu]m or higher and an aspect ratio of 100 or higher, thus being useful as a substrate of high quality pearlescent pigments, an abrasive, ceramic material and a filling material.

Owner:KOREA RES INST OF CHEM TECH +1

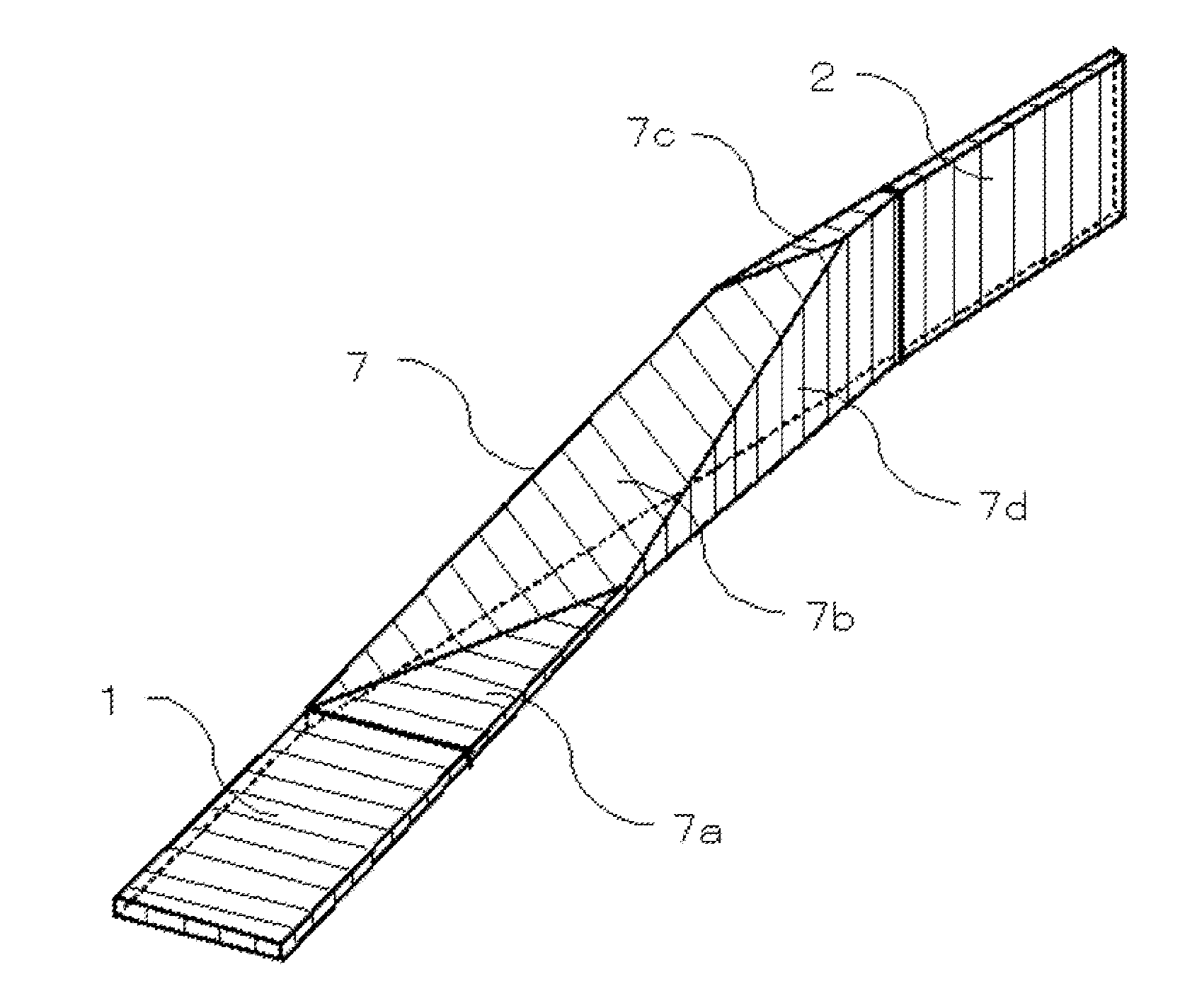

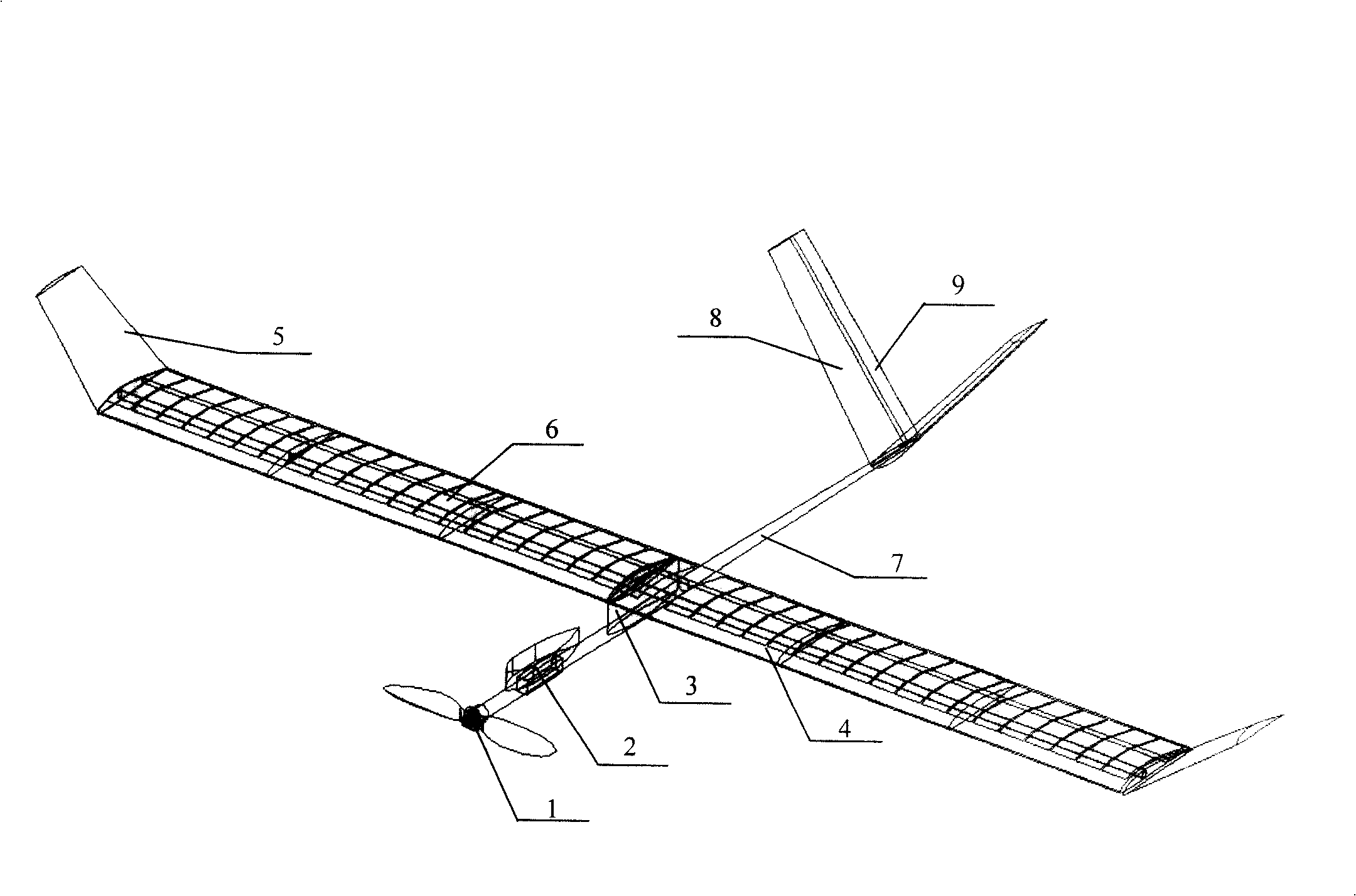

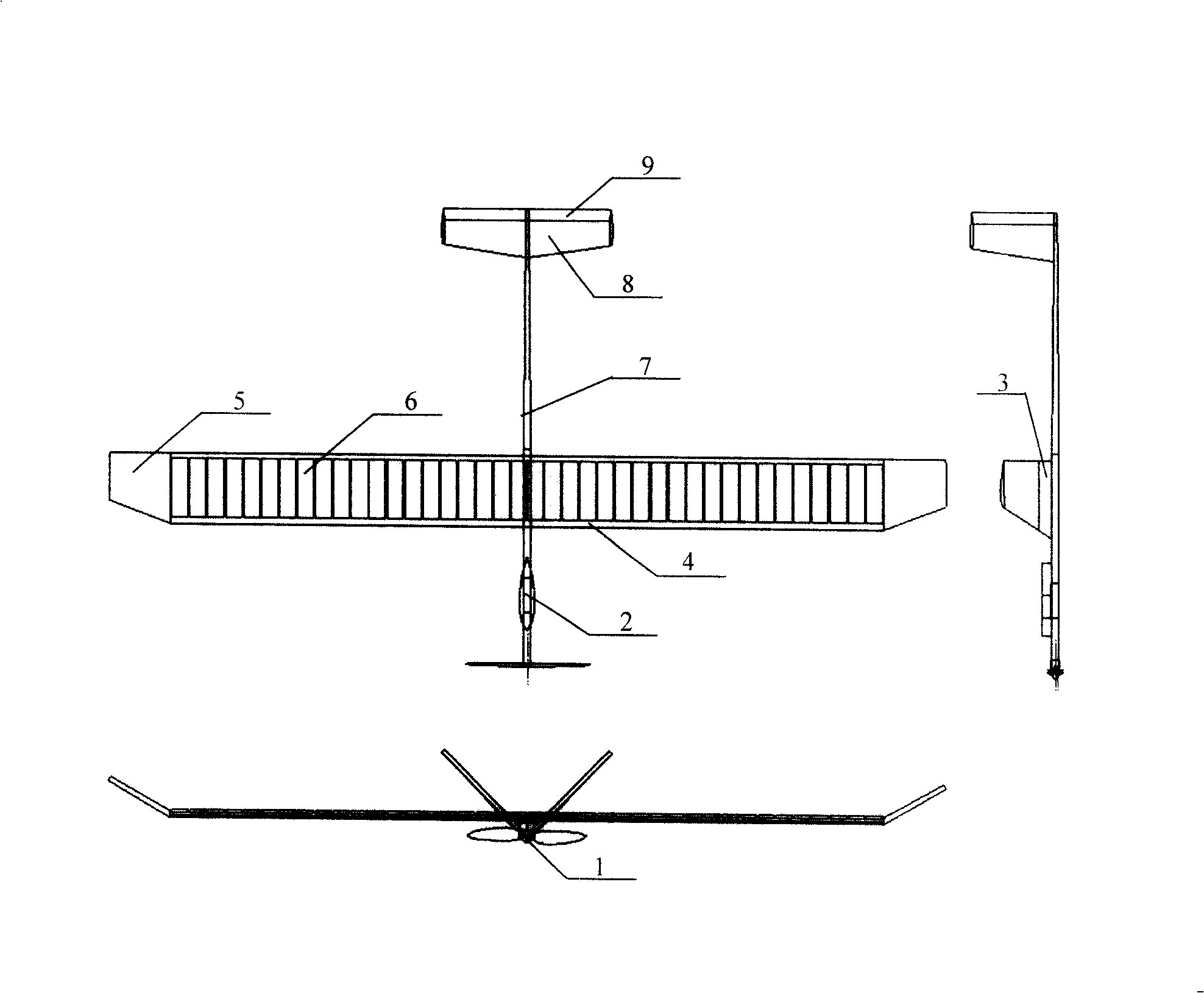

Solar pilotless plane

InactiveCN101254753AImprove the lift-to-drag ratioImprove hovering performanceToy aircraftsVehicular energy storageVertical stabilityHigh energy

The invention relates to a solar unmanned aircraft. In order to overcome the problems of difficult flight control and bad stability of the flying wing solar unmanned aircrafts, the invention adopts the configuration of tip winglets(5) arranged at the outer segments of a large aspect-ratio high wing, a V shaped empennage and a wing(4); the wing(4) is connected with and a fuselage(7) through a bridge wing(3) and a controlling rudder(9) is arranged on the V shaped empennage(8) to realize the pitching and yawing control of the aircraft. Combining the characteristic of the high energy conversion efficiency of a flexible thin film solar battery, the invention lays the flexible thin film solar battery(6) on the wing(4). An engine and propeller propulsion system (1) adopts a haul-in-type, and an equipment cabin (2) is arranged at the front part of the fuselage(7). The solar unmanned aircraft improves the lift-drag ratio of the aerial vehicle, prolongs the operation time and effectively improves the horizontal and the vertical stabilities and maneuverability of the aircraft, thus relieving the problems of bad stability and bad maneuverability of the flying wing configuration.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

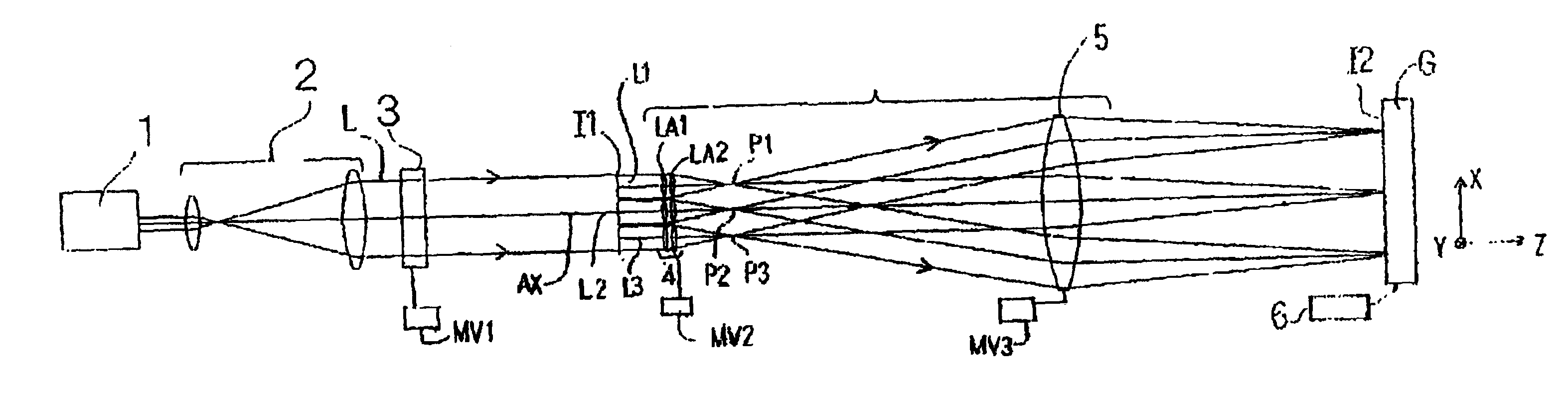

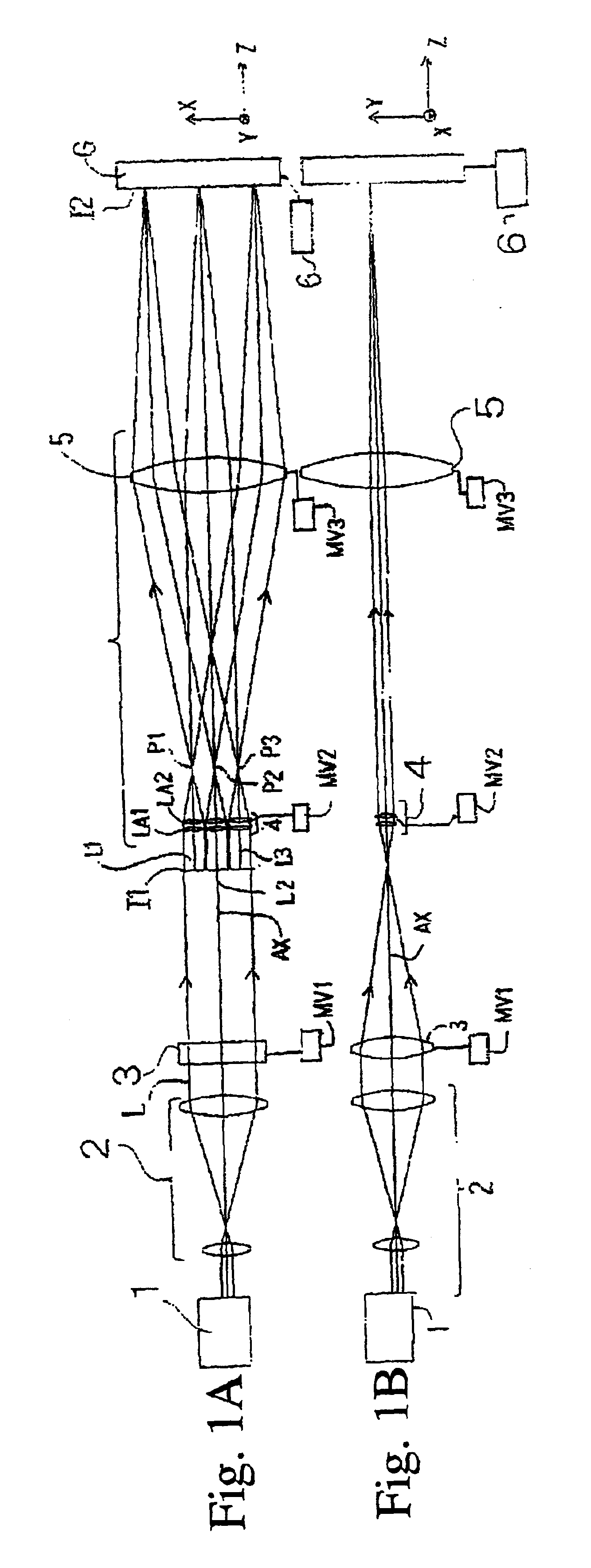

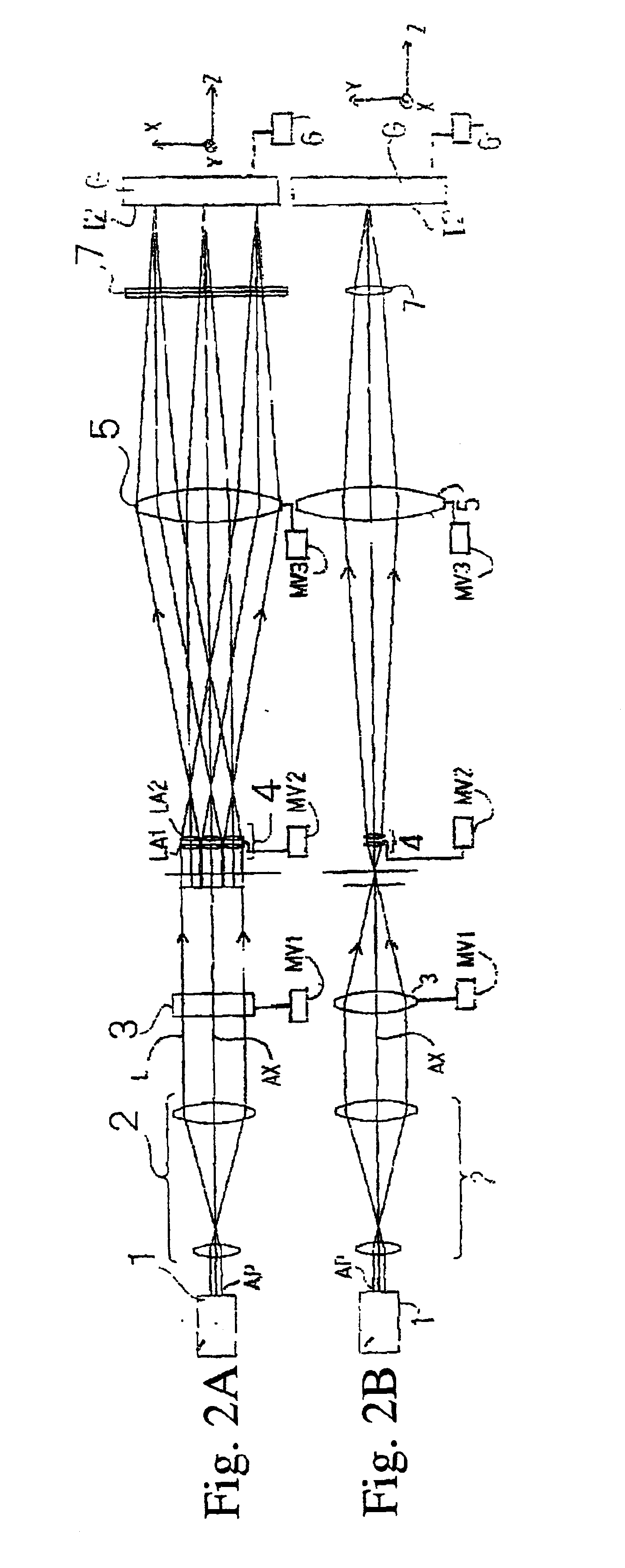

Illumination optical system and laser processor having the same

InactiveUS6894839B2Superior image formationImprove light uniformityPhotomechanical exposure apparatusMicrolithography exposure apparatusBeam expanderLine width

An illumination optical system has superior image formation capabilities, and can radiate a linear beam with excellent illumination uniformity and a narrow line width having a large aspect ratio; the illumination optical system comprises an afocal beam expander system which expands an beam illuminated from a laser light source; a linear beam-forming lens system having at least refractive power in a second direction which is substantially at a right angle to at least a first direction, the linear beam-forming lens system converting the beam, illuminated from said beam expander system, to a linear beam having its long side in said first direction; a lens array section having a plurality of element lenses, arranged along said first direction; and a condenser optical system which illuminates a processed face by reconnecting images of said linear beam from each of said element lenses thereon.

Owner:IHI CORP

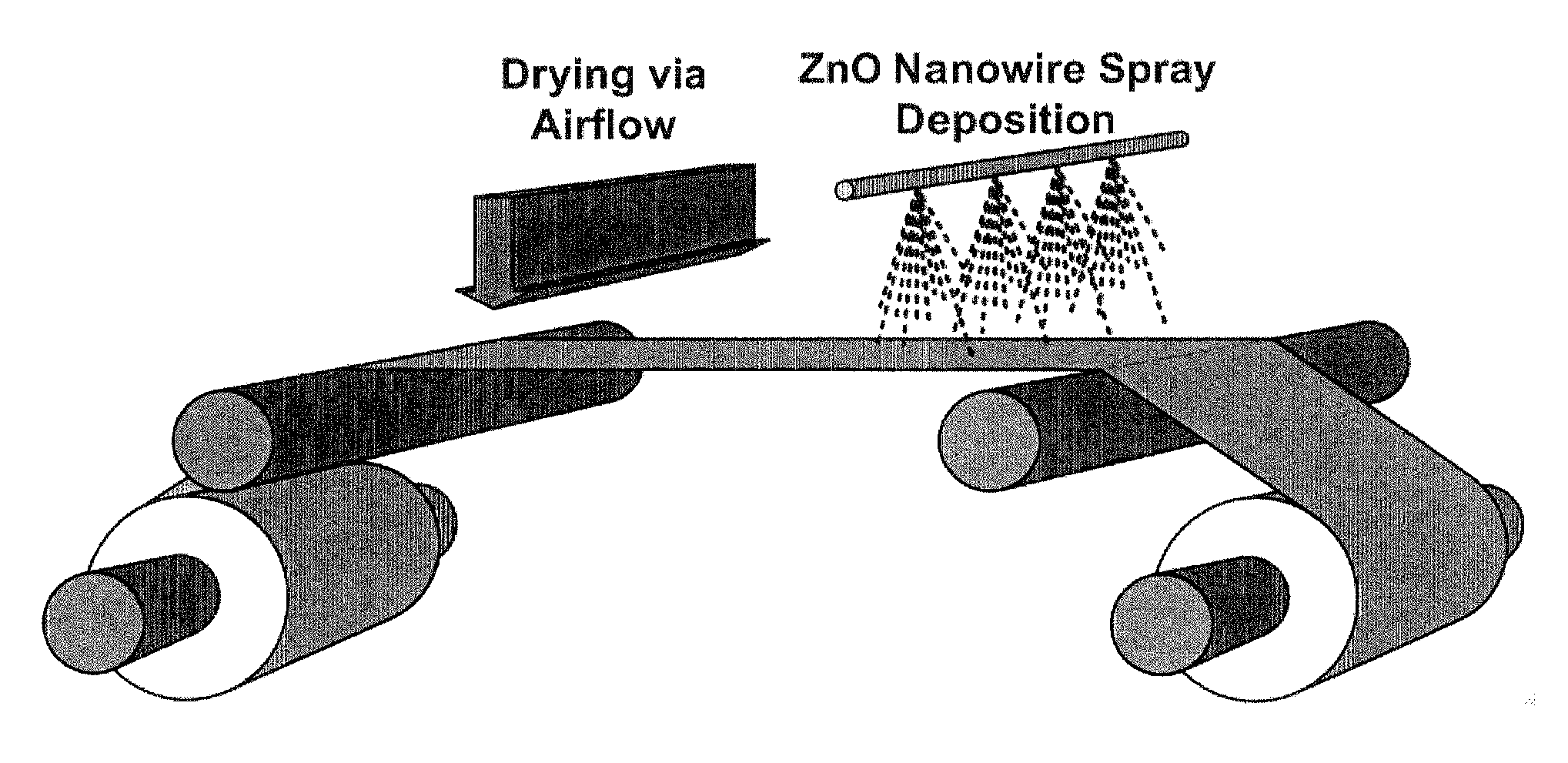

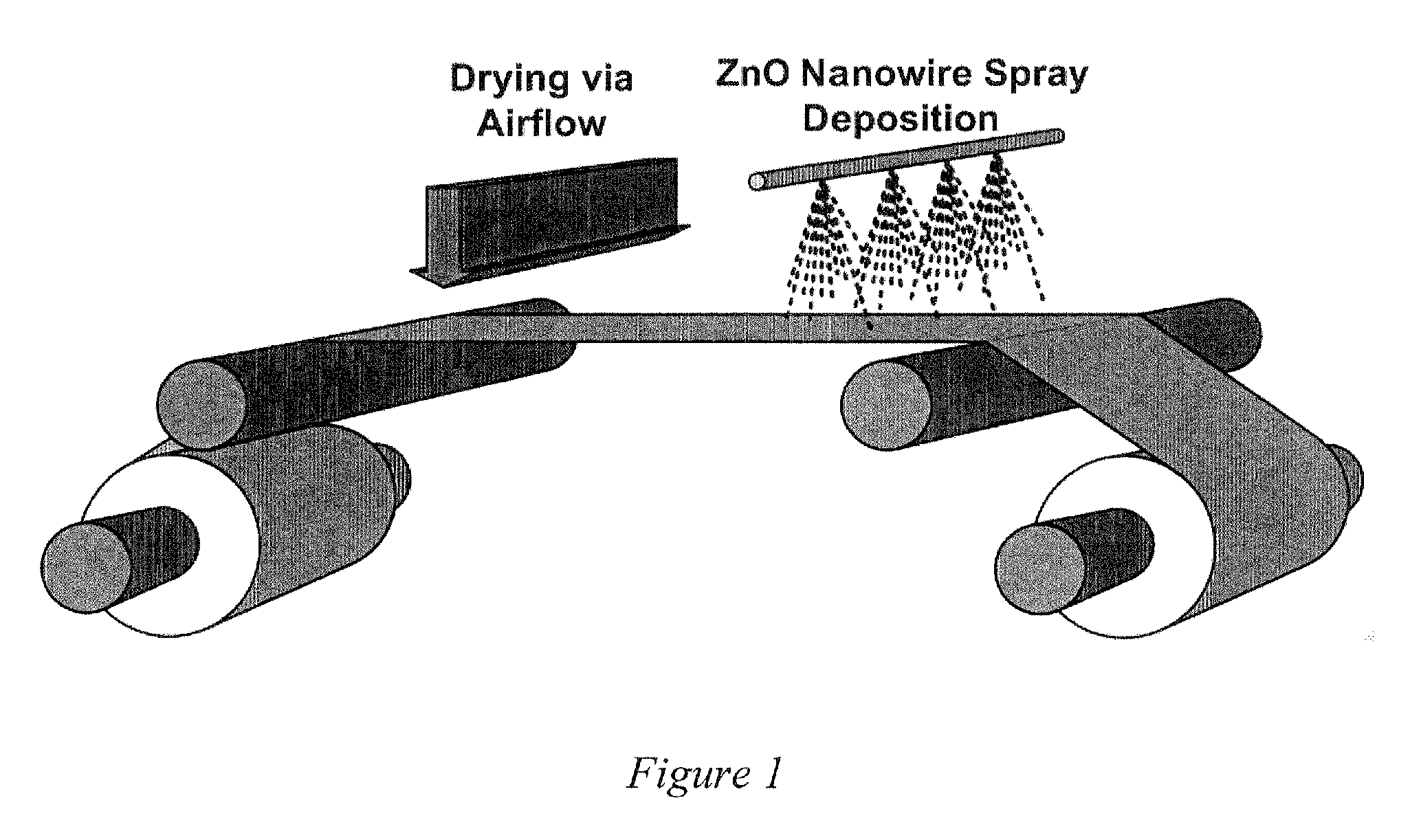

Interlaminer reinforced composite structures

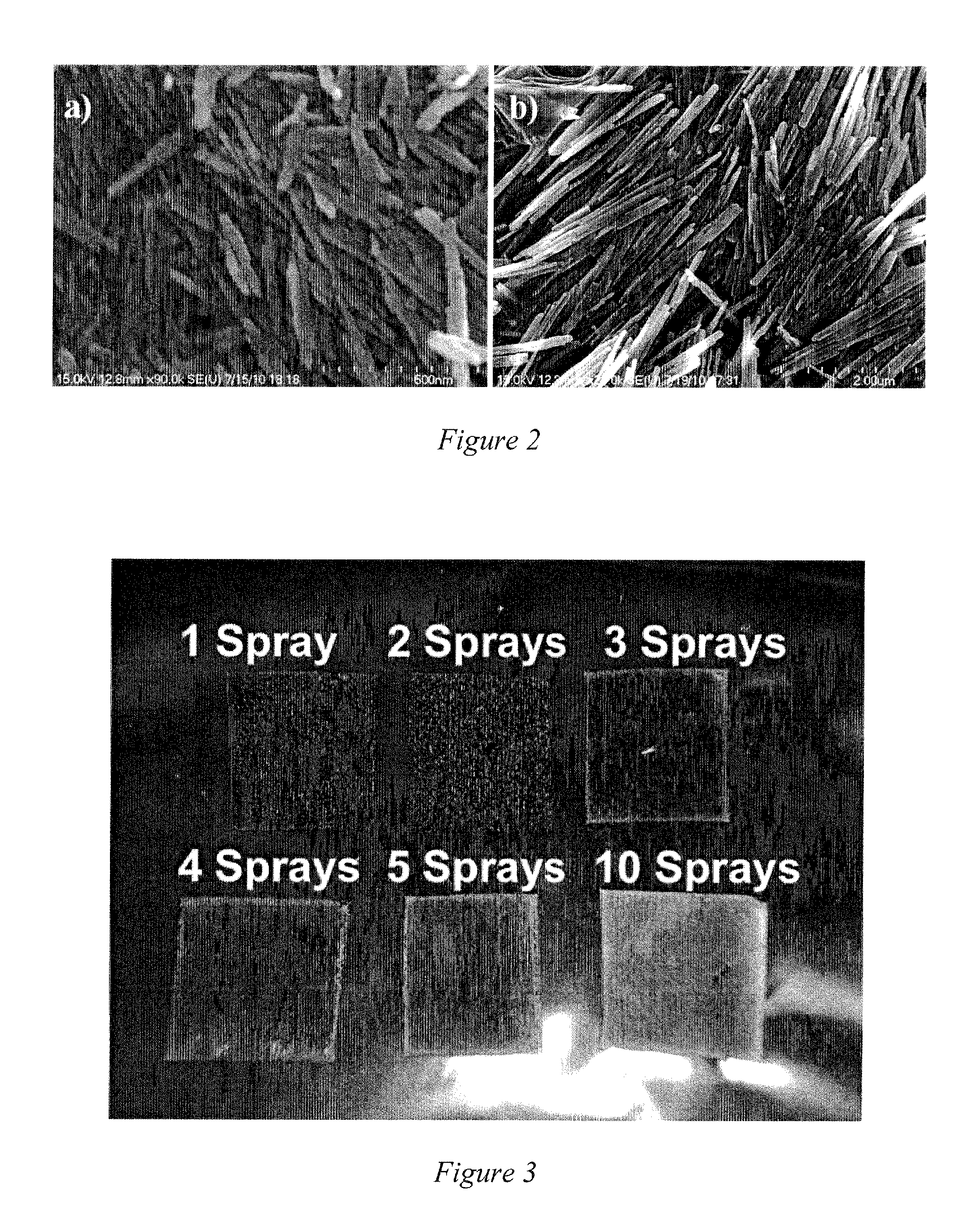

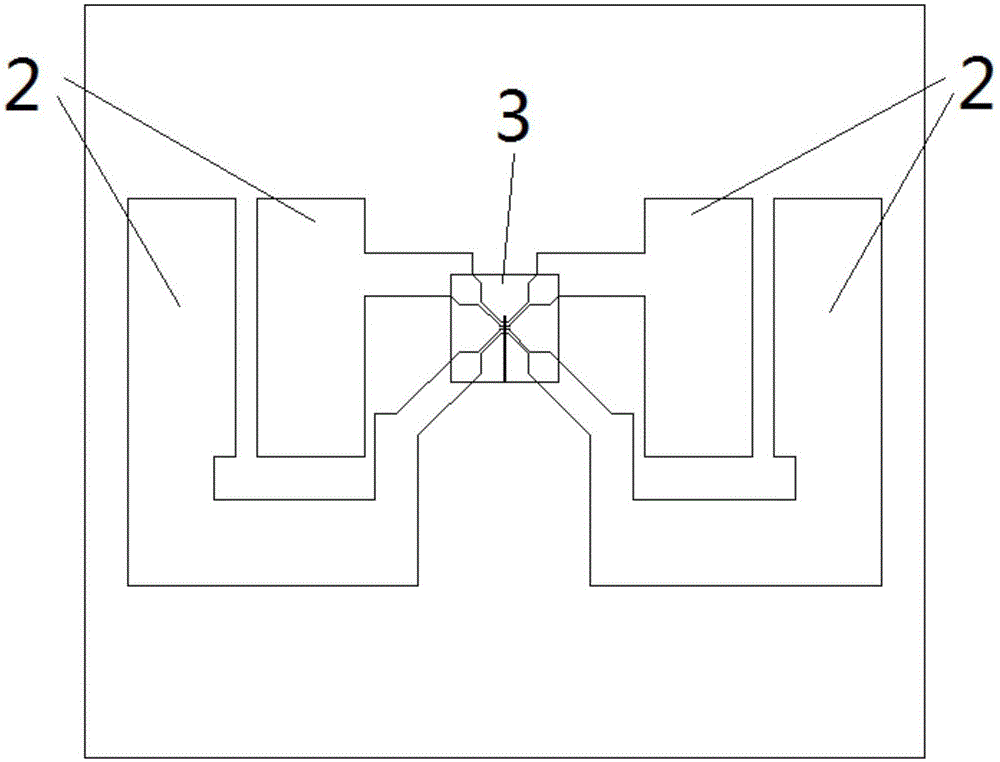

ActiveUS20130034724A1Promotes mechanical interlockingMaterial nanotechnologyLaminationNanoparticleLarge aspect ratio

In an embodiment of the invention, a laminar composite has at least one interlaminar reinforced interface comprising a dispersion of binding-agent-treated low-dimensional nanoparticles with a large aspect ratio fixed between adjacent lamina by residues of the binding agents. In another embodiment of the invention, a method to prepare a laminar composite having reinforced interfaces involves the deposition of binding-agent-treated low-dimensional nanoparticles from a solution or suspension onto the surface or a prepreg sheet, where, optionally, after removal of the liquid that comprises the solution or suspension, sheets of the prepreg are layed-up and cured to form the laminar composite.

Owner:SODANO HENRY

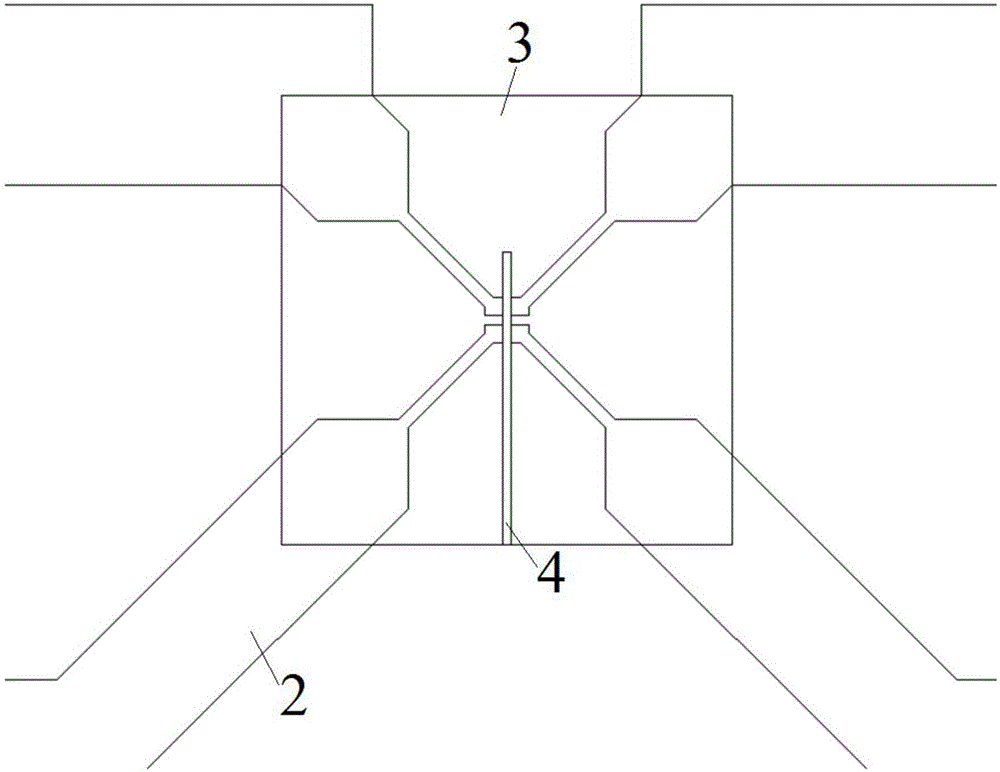

Nanometer material transmission electron microscope in-situ testing chip, preparation method and applications thereof

ActiveCN105136822AReduce the conditions of useReduce use costTelevision system detailsMaterial analysis using wave/particle radiationHeterojunctionElectron

The present invention discloses a nanometer material transmission electron microscope in-situ testing chip, a preparation method and applications thereof, and belongs to the technical field of nanometer material performance in-situ testing. The chip comprises a silicon substrate, insulating layers and a film window, wherein the insulating layer respectively grows on both surfaces of the silicon substrate, a metal film or device or a semiconductor function film or device grows on the chip front surface insulating layer so as to apply various physical and chemical effects on a sample, the center of the chip is provided with the film window, and the film window region is provided with a electron beam penetrating long hole or electron beam penetrating long groove having a large aspect ratio. According to the present invention, the transmission electron microscope sample can be subjected to in-situ measurement under the atomic scale resolution, the nano-wire samples and the nano-tube samples can be subjected to in-situ characterization, the bulk samples and the heterojunction interface samples can be subjected to in-situ characterization, the placement of the sample through the micro manipulator in the focused ion beam system and the laboratory can be achieved, and the sample transferred and fixed on the chip can be continuously processed by using the ion reduction equipment.

Owner:NANJING UNIV

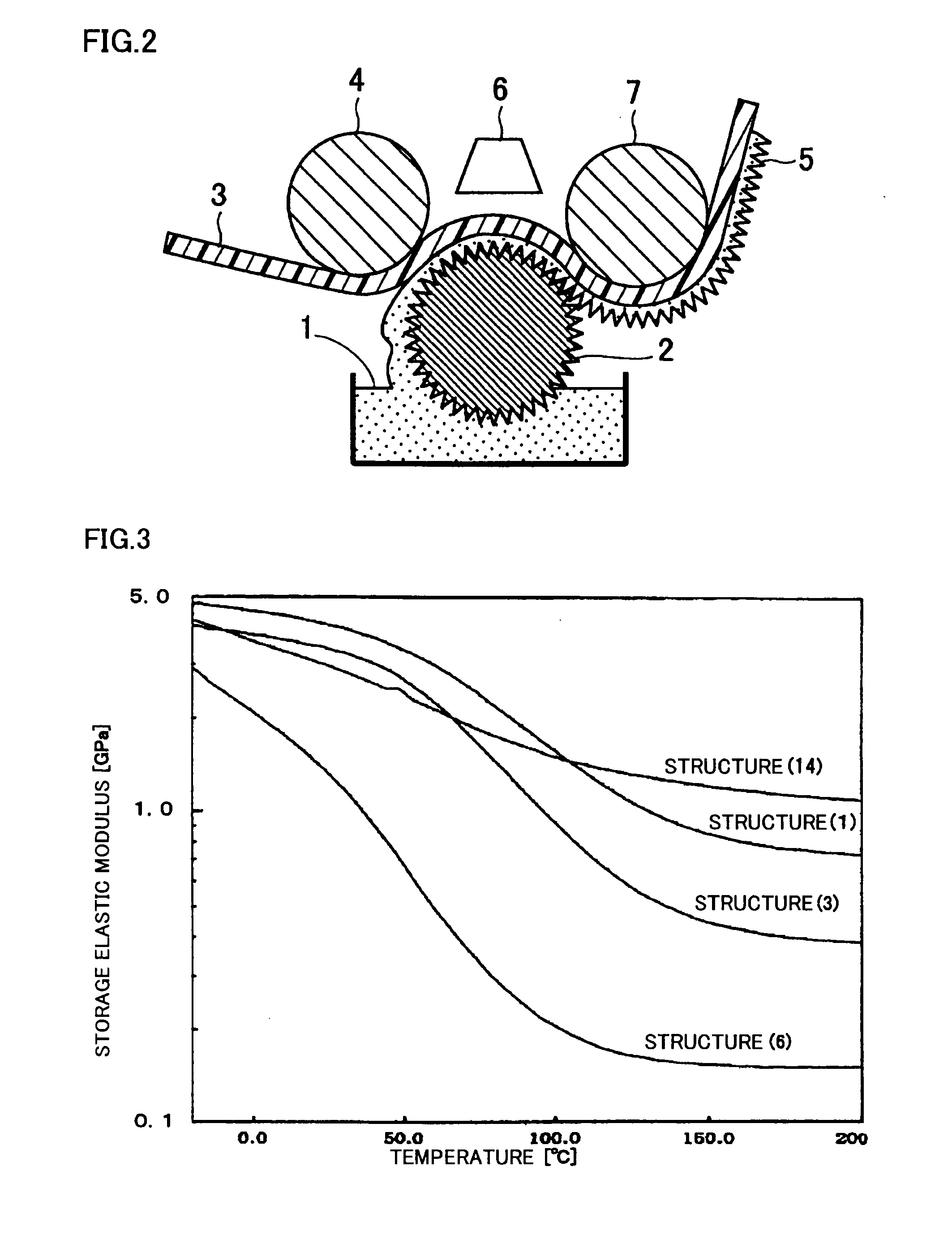

Structure having specific surface shape and properties and (METH)acrylic polymerizable composition for formation of the structure

InactiveUS20090246494A1Excellent in antireflection performance of lightSimple structureSynthetic resin layered productsOptical articlesLight irradiationEngineering

A surface shape and physical properties required for a structure having an antireflection performance of light and an improved performance of light permeability have been found, particularly the structure having surface scratch resistance is provided, a composition capable of forming the structure having such a particular structure and physical properties is provided, and further a composition which can easily form the structure which is excellent in antireflection performance of light and an improved performance of light permeability and has a large aspect ratio is provided. That is, the present invention is the structure having convex parts with an average height of 100 nm or more and 1000 nm or less or concave parts with an average depth of 100 nm or more and 1000 nm or less on its surface wherein the convex parts or the concave parts are present at an average cycle of 100 nm or more and 400 nm or less in at least one direction, characterized in that the structure is obtained by polymerizing a (meth)acrylic polymerizable composition by light irradiation, electron beam irradiation and / or heating and a storage elastic modulus at 180° C. or above is 0.5 GPa or more.

Owner:THE INCTEC INC

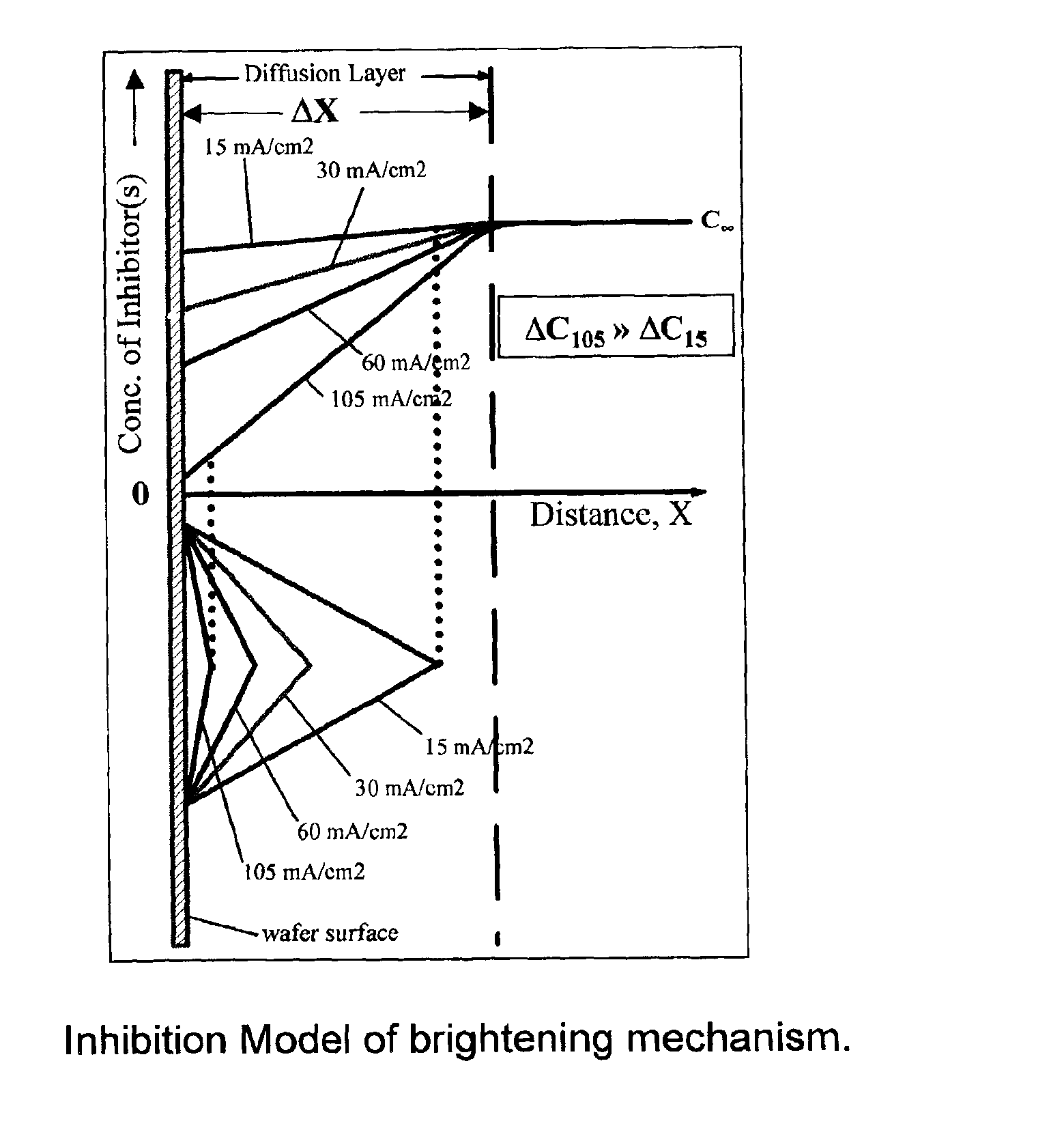

Enhanced electrochemical deposition (ECD) filling of high aspect ratio openings

InactiveUS6869515B2Increase inhibition (or suppression) differentiationEnhancing void-free superfilling mechanismCellsSemiconductor/solid-state device detailsJet flowHigh pressure

Embodiments of the present invention provide methods for enhancing void-free metallic filling of narrow openings by electrochemical deposition (ECD). The methods provide enhanced replenishment of plating inhibitor at the field, while depleting the inhibitor inside narrow openings. The resulting inhibitor gradients facilitate void-free ECD filling of narrow openings with large aspect ratios. The inventive methods utilize vigorous electrolyte agitation at the field and top corners of the openings, while maintaining a relatively stagnant electrolyte inside the openings. Vigorous agitation is produced, for example, by high pressure jets flow and / or by mechanical means, such as brush (or pad, or wiper blade) wiping, or by a combination of jets and wiping brushes.

Owner:COHEN URI

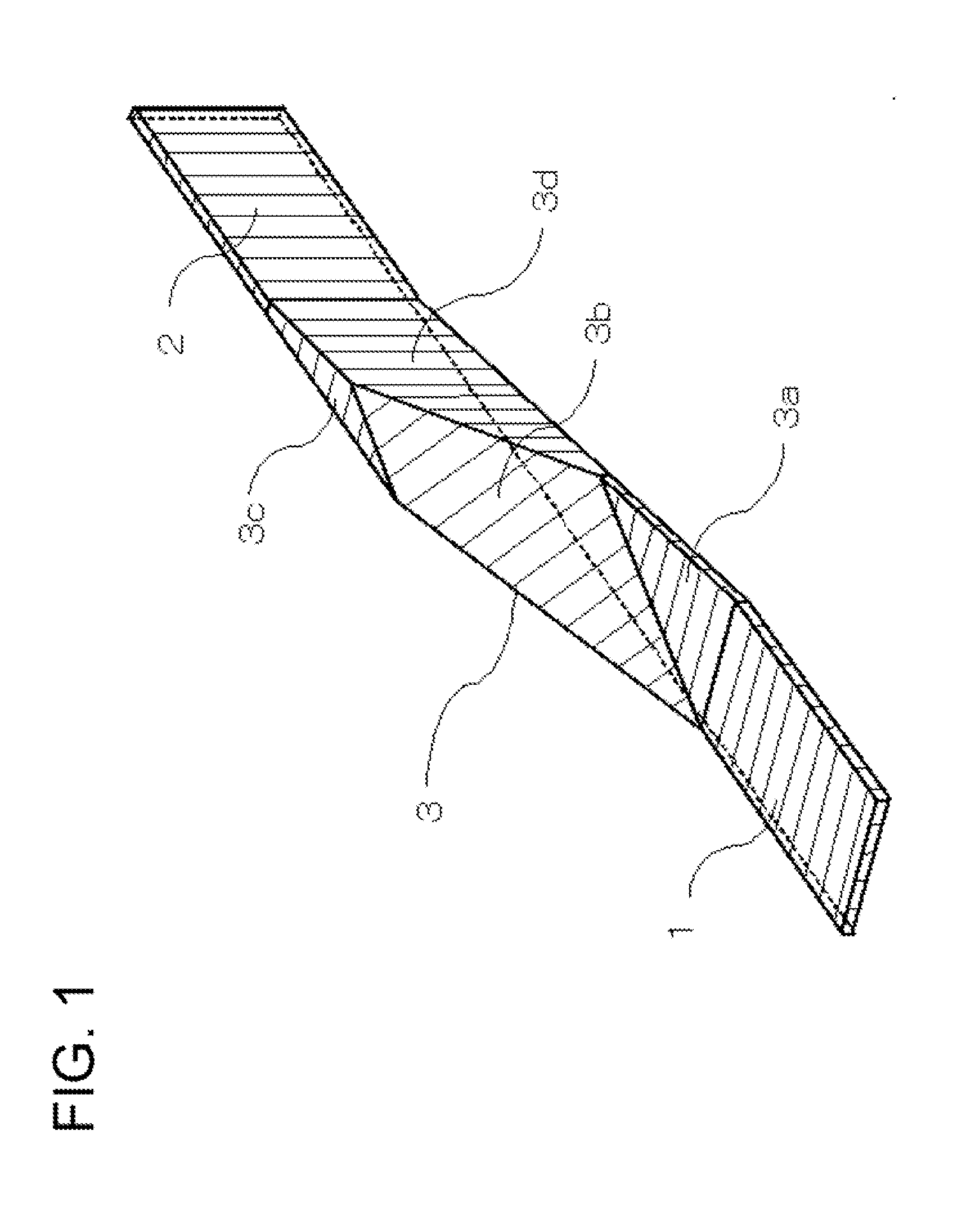

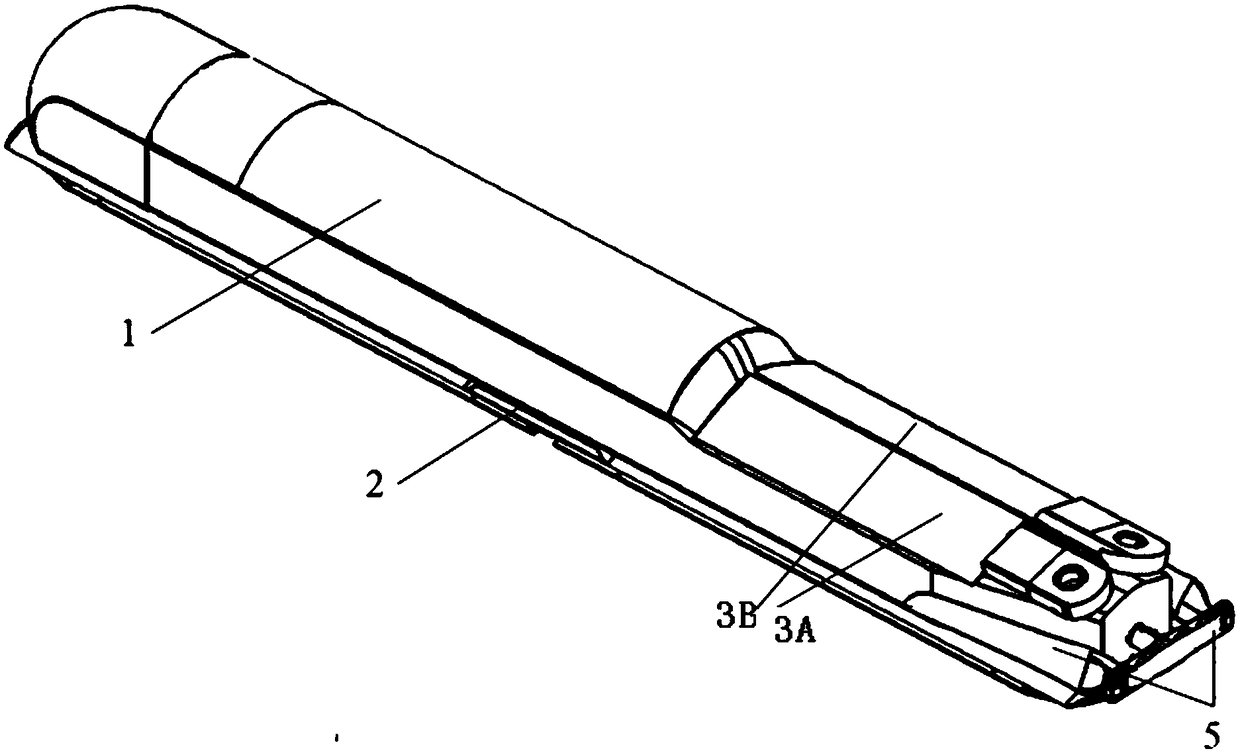

Cylinder type launch folding wing unmanned aerial vehicle and launch method thereof

PendingCN109436296AImprove aerodynamic characteristicsSmall footprintPropellersLaunching/towing gearLarge aspect ratioAerospace engineering

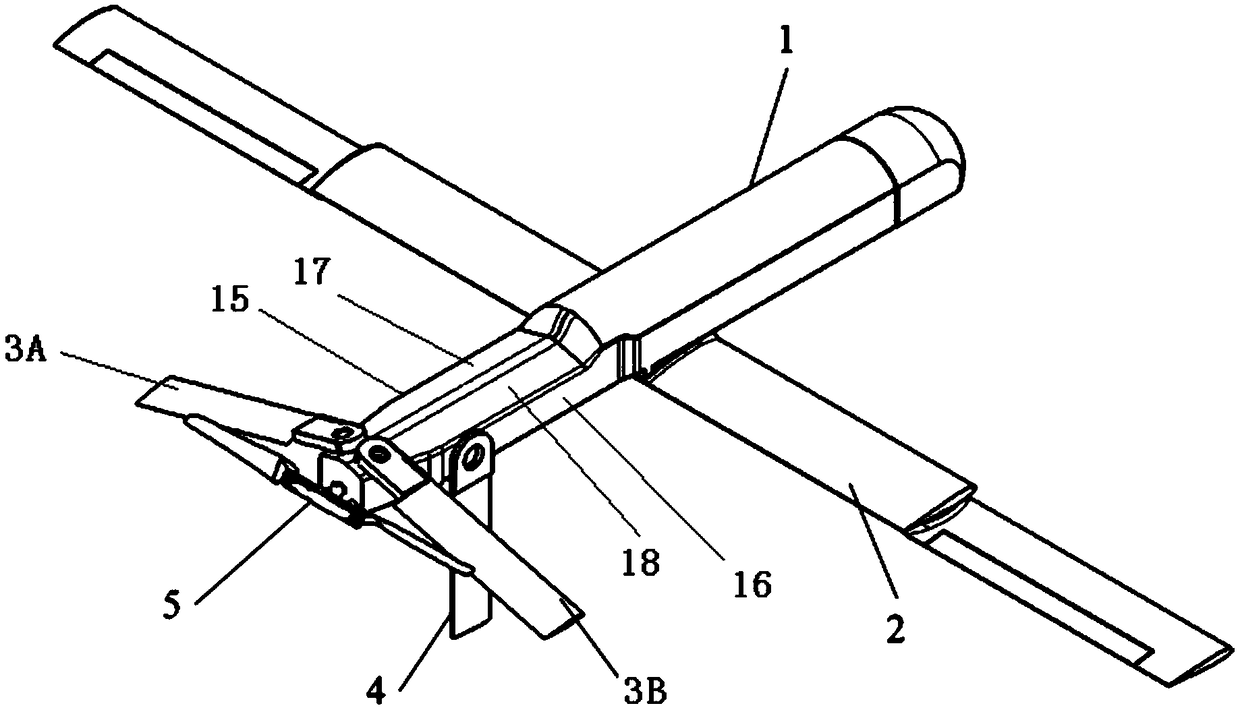

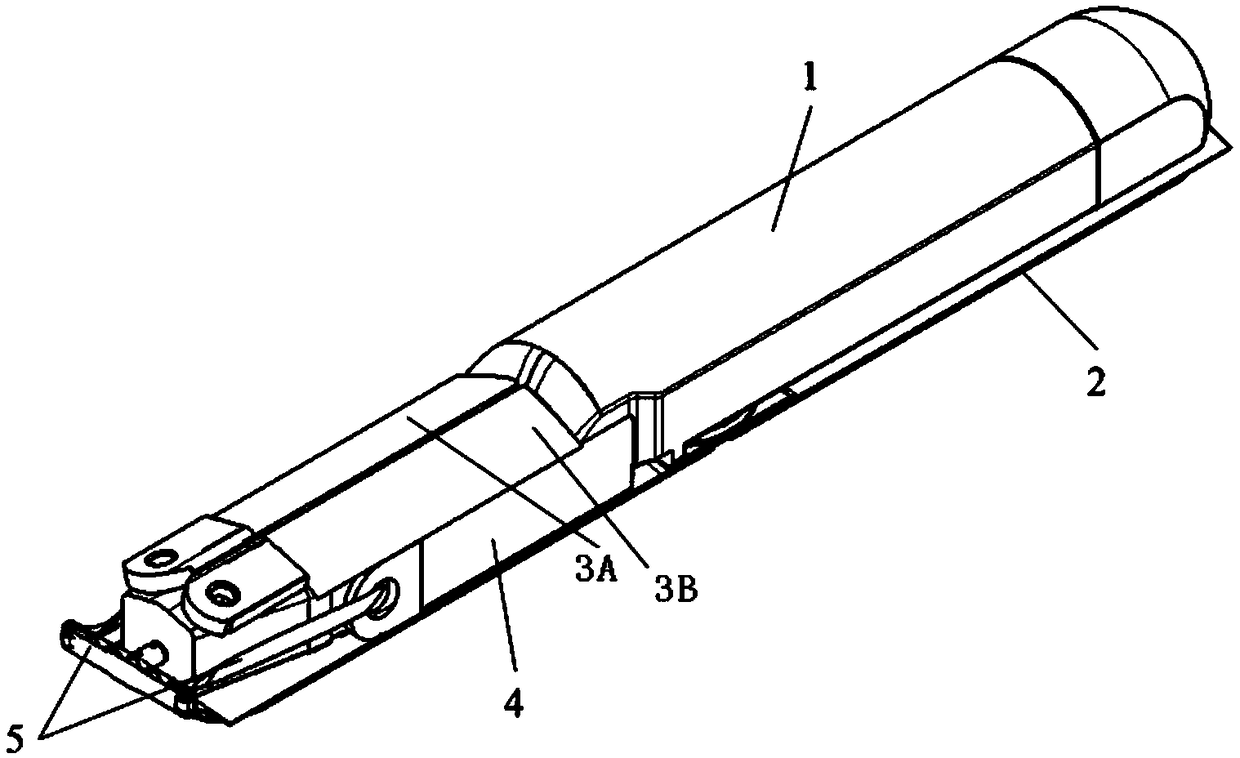

The invention provides a cylinder type launch folding wing unmanned aerial vehicle and an launch method thereof. The cylinder type launch folding wing unmanned aerial vehicle comprises a folding wingunmanned aerial vehicle (7) and a launch cylinder (6), wherein the folding wing unmanned aerial vehicle (7) is in a complete folding state and is arranged in the launch cylinder (6); when the launch cylinder (6) launches the folding wing unmanned aerial vehicle (7), the folding wing unmanned aerial vehicle (7) is ejected out of the launch cylinder (6), and climbs up to enter a complete unfolding loitering task state after a gradually unfolding varying process. The cylinder type launch folding wing unmanned aerial vehicle has the characteristics of simple structure, light weight and high engineering feasibility. Meanwhile, a Z-shaped folding elastic wing with the advantages of small land occupation in a folding state, big wing area in an unfolding state, large aspect ratio and the like is used to effectively improve the space use ratio and the aerodynamic performance of the cylinder type launch folding wing unmanned aerial vehicle in the loitering task state.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

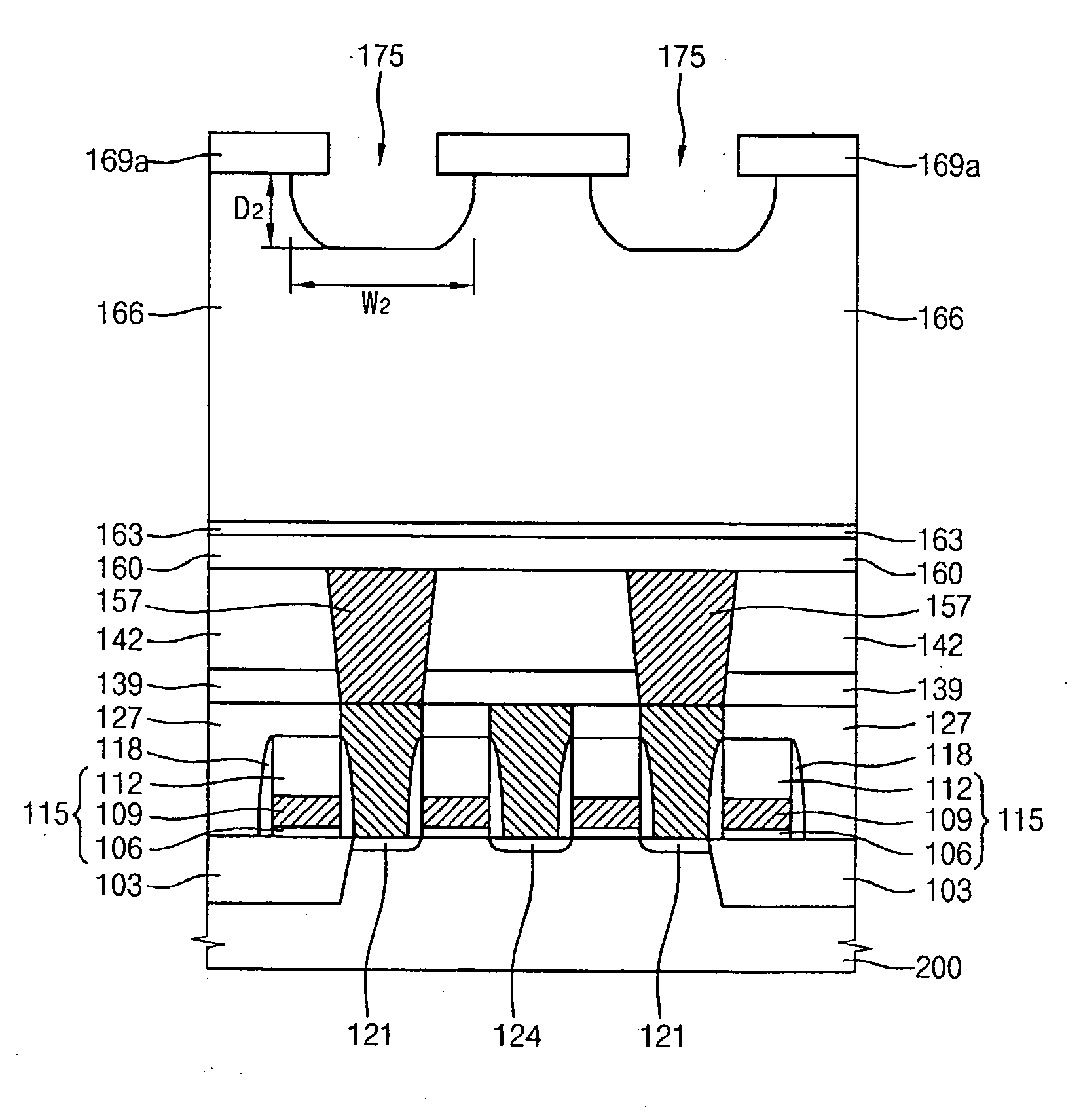

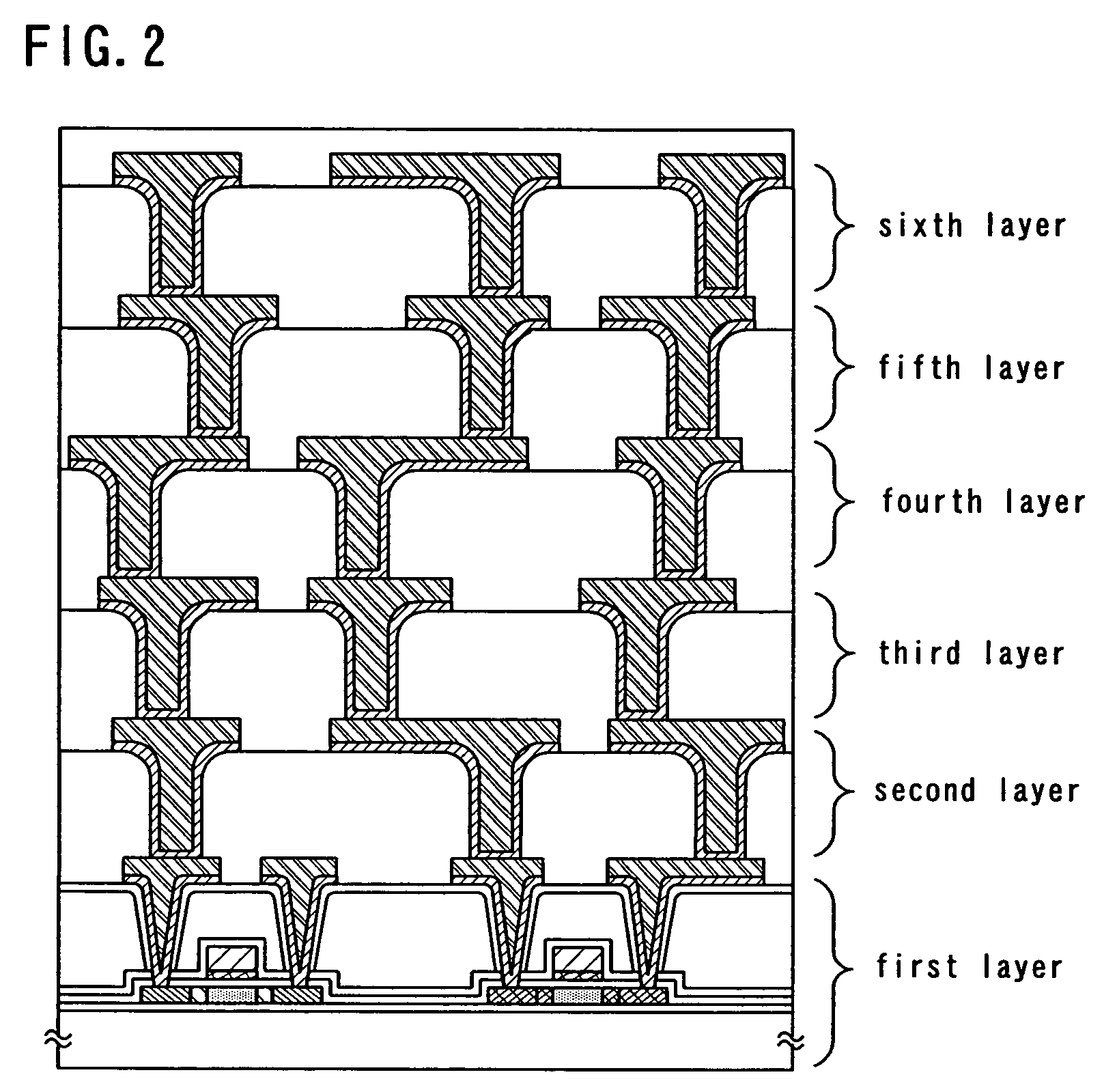

Semiconductor device including an improved capacitor and method for manufacturing the same

InactiveUS20050099760A1Improve structural stabilityIncrease capacitanceTransistorSolid-state devicesCapacitanceDevice material

In a semiconductor device according to embodiments of the invention, a capacitor includes a storage electrode having a cylindrical storage conductive layer pattern and connecting members formed on the upper portion of the cylindrical storage conductive layer pattern. The connecting member connects to an adjacent connecting member of another storage electrode. A dielectric layer and a plate electrode are successively formed on the storage electrode. All of the capacitors are connected by one another by forming cylindrical storage electrodes so that the storage electrode does not fall down when the capacitors have an extremely large aspect ratio. Thus, the capacitance of the capacitors may be improved to the desired level. A semiconductor device that includes these capacitors may have improved reliability and the throughput of a semiconductor manufacturing process may be increased.

Owner:SAMSUNG ELECTRONICS CO LTD

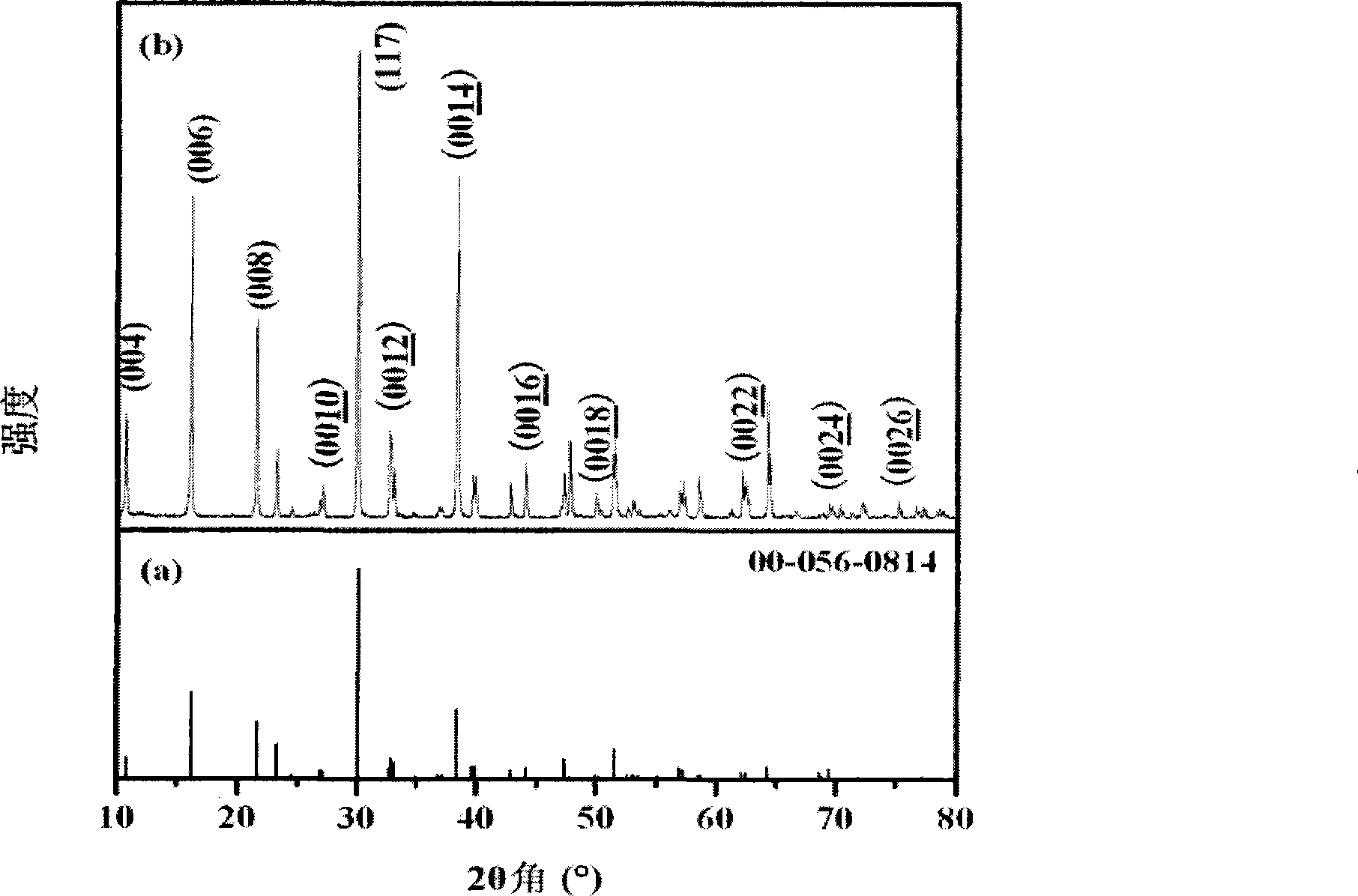

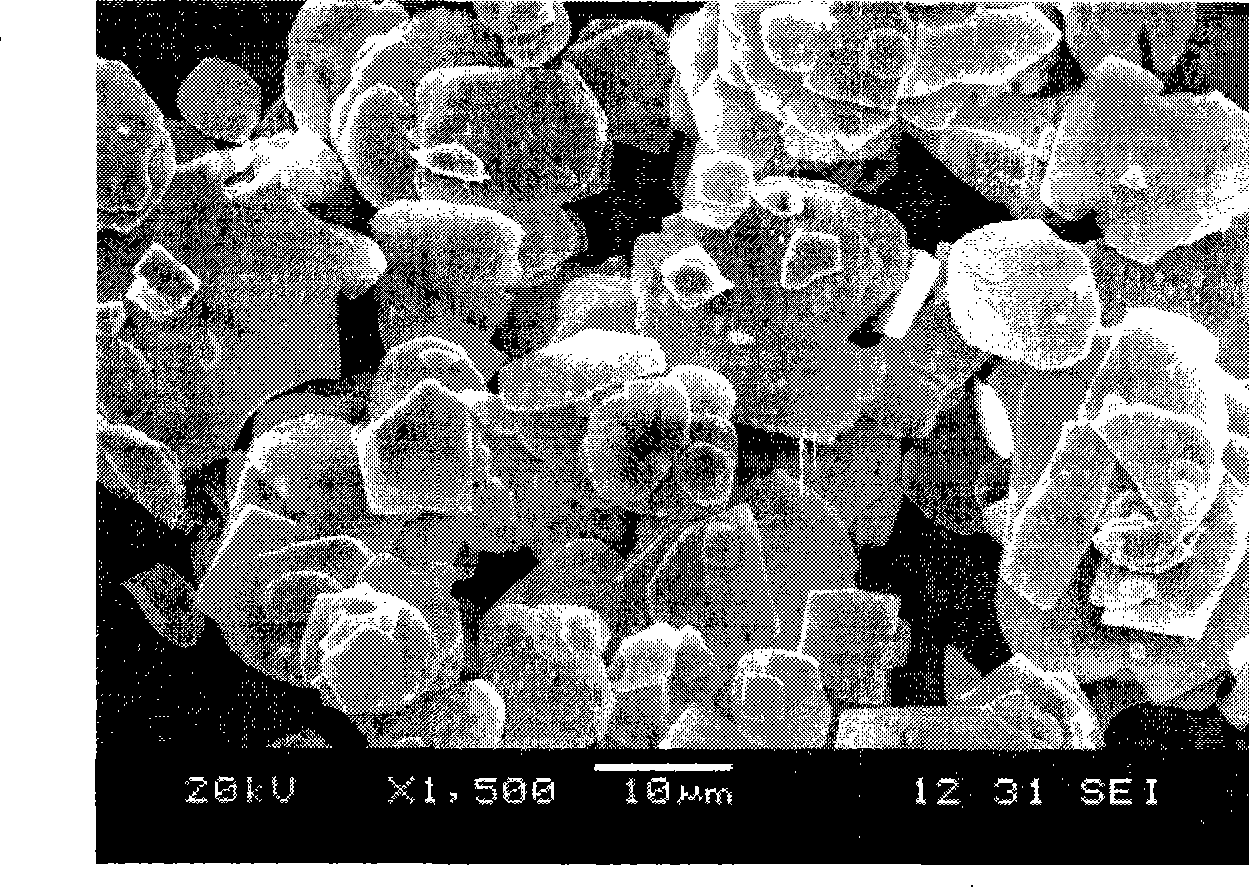

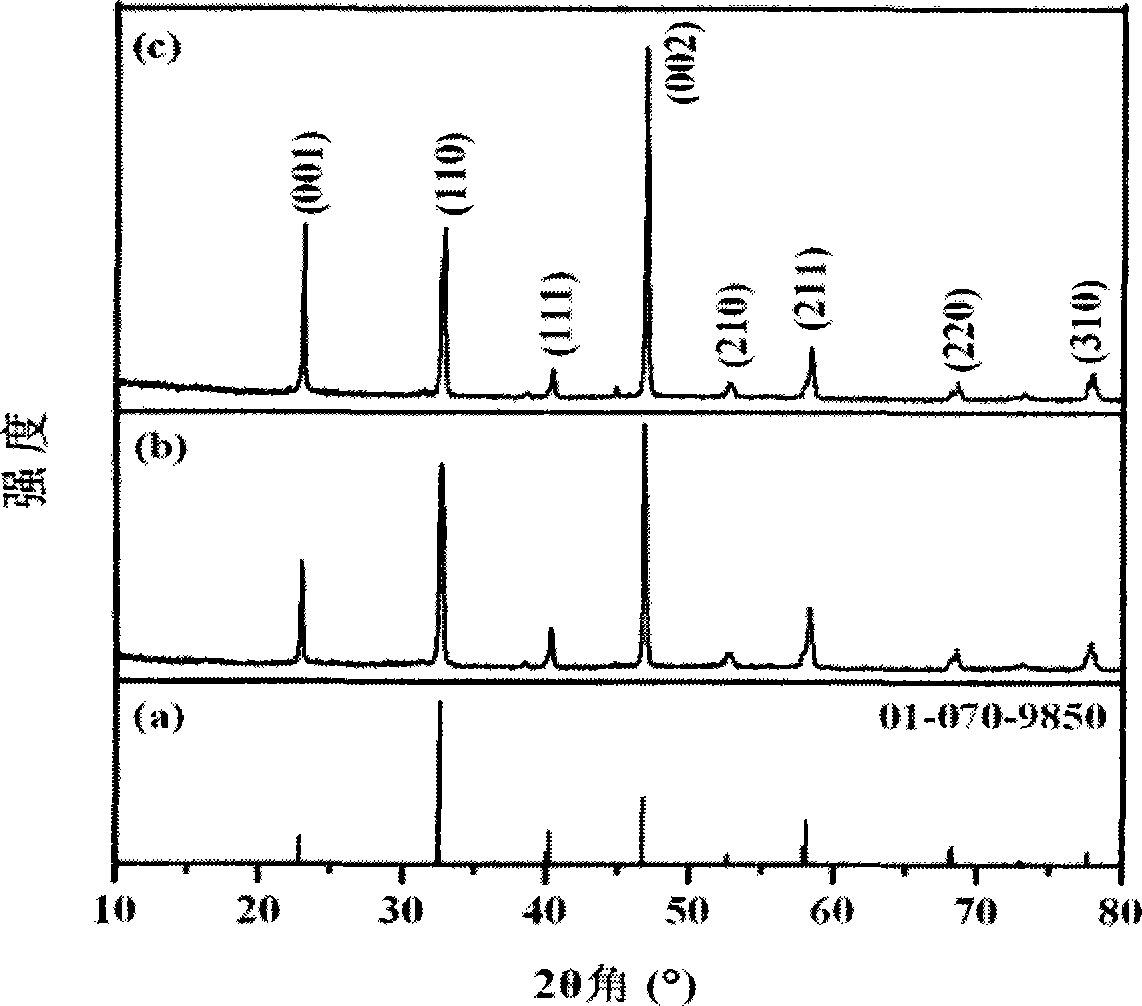

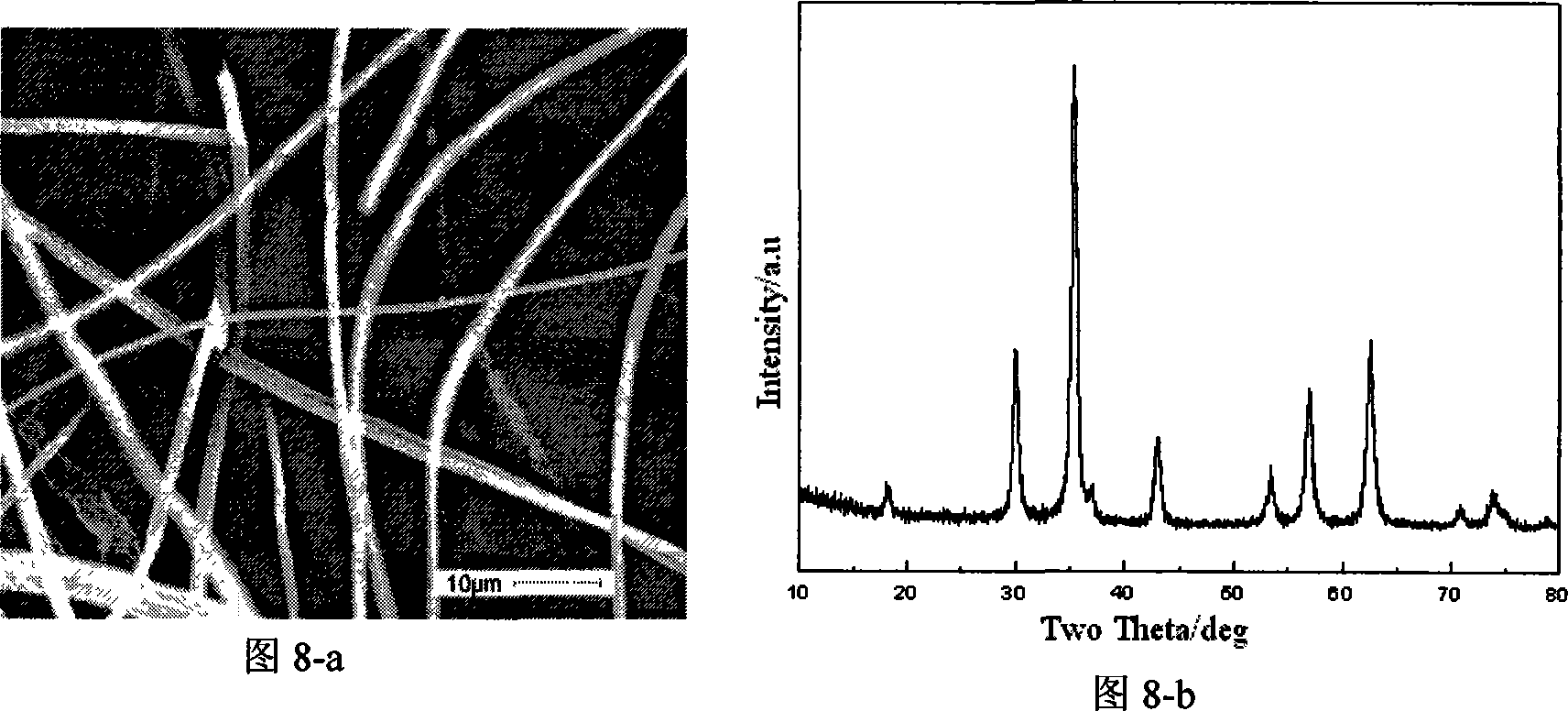

Sheet bismuth sodium titanate mould plate grain and manufacture method thereof

The invention relates to a schistic bismuth sodium titanate template crystal grain and a preparation method thereof, belonging to the preparation field of textured non-lead piezoelectric ceramic template crystal grain, the chemical formula of the template grains is Na0.5Bi0.5TiO3, the appearance of the crystal grain is schistic, the radial length is 5 to 15Mum, the thickness is 0.5 to 1.0Mum, the crystal grain has large aspect ratio and strong orientation, which is an ideal template crystal grain. The crystal grain adopts schistic Bi4Ti3O12 as a precursor which is synthesized by molten salt method, in the molten salt system of NaCl, the crystal grain can have topological chemical reaction with Na2CO3, TiO2 so as to produce schistic polycrystalline Na0.5Bi0.5TiO3 template crystal grain and the crystal grain can be regarded as the template for various textured bismuth sodium tianate non-lead piezoelectric ceramics, which has positive effect for improving the density, the orientation and piezoelectric properties of textured bismuth sodium tianate non-lead piezoelectric ceramics.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

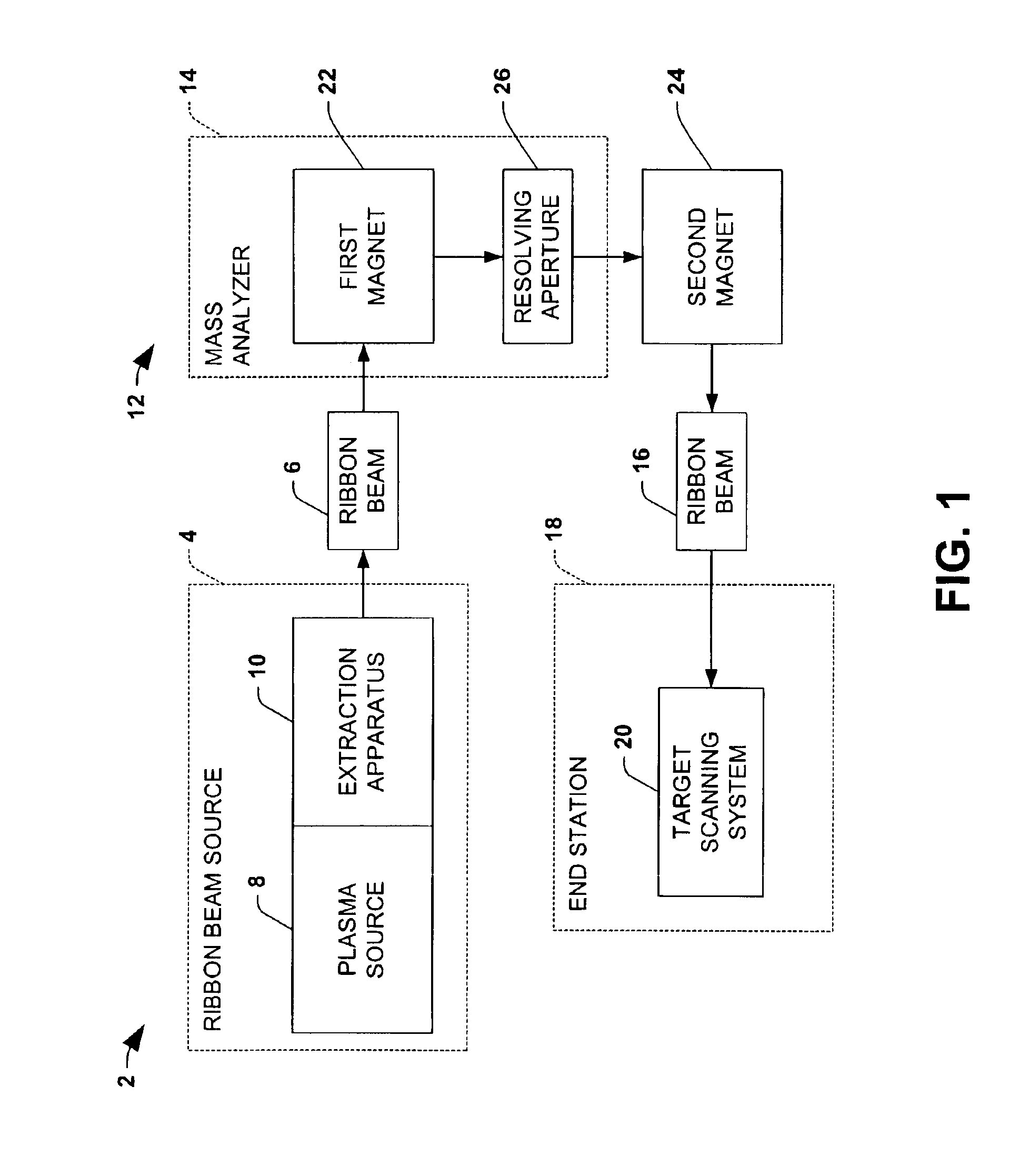

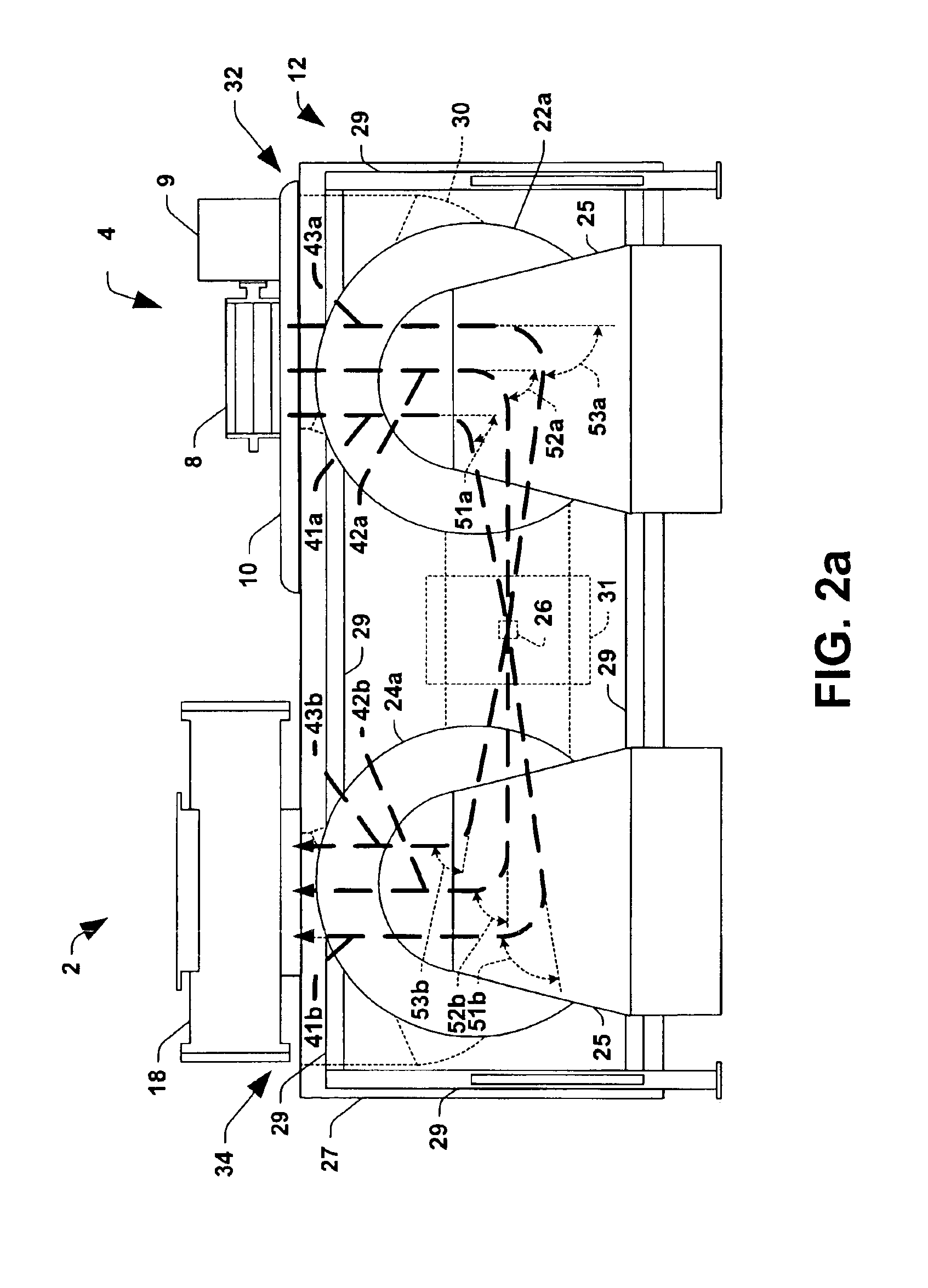

Symmetric beamline and methods for generating a mass-analyzed ribbon ion beam

InactiveUS6885014B2Conducive to simplificationEasy maintenanceThermometer detailsBeam/ray focussing/reflecting arrangementsBeam trajectoryBand shape

Ion implantation systems and beamlines therefor are disclosed, in which a ribbon beam of a relatively large aspect ratio is mass analyzed and collimated to provide a mass analyzed ribbon beam for use in implanting one or more workpieces. The beamline system comprises two similar magnets, where the first magnet mass analyzes the ribbon beam to provide an intermediate mass analyzed ion beam, and the second magnet collimates the intermediate beam to provide a uniform mass analyzed ribbon beam to an end station. The symmetrical system provides equidistant beam trajectories for ions across the elongated beam width so as to mitigate non-linearities in the beam transport through the system, such that the resultant mass analyzed beam is highly uniform.

Owner:AXCELIS TECHNOLOGIES

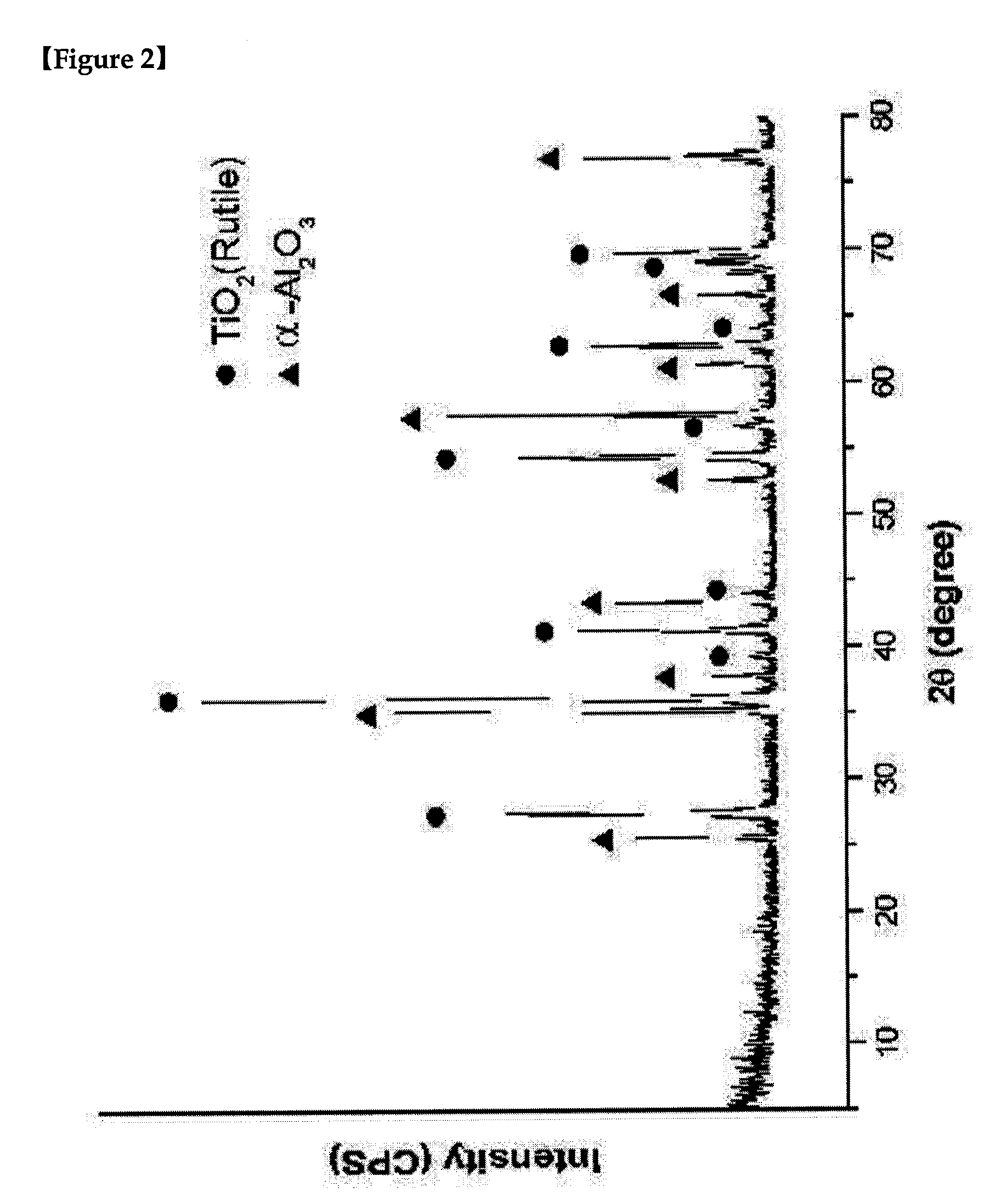

Flaky alpha-alumina crystals with large aspect ratio and a preparation method of the same

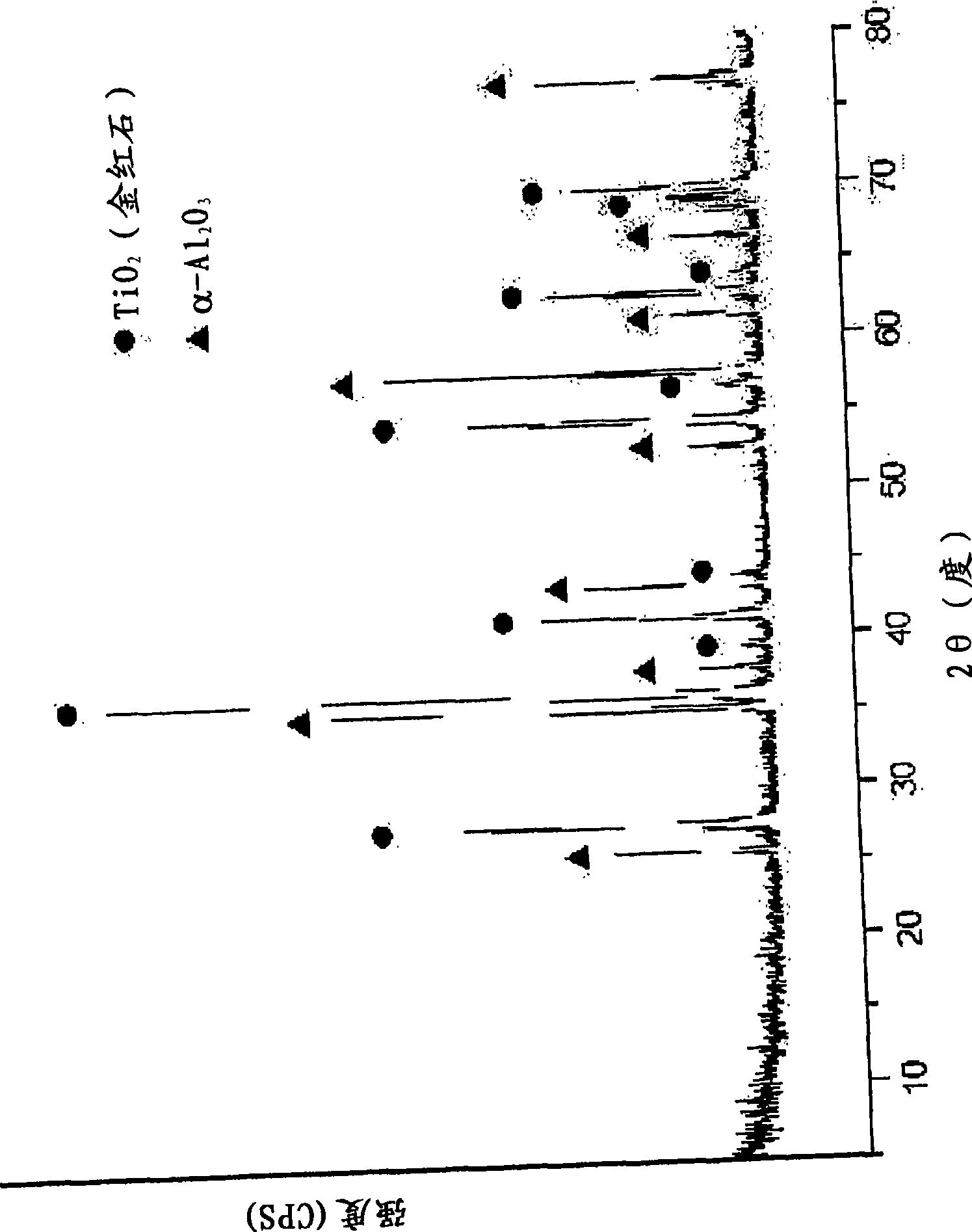

ActiveUS20100015445A1High aspect ratioOvercome problemsPigmenting treatmentSynthetic resin layered productsHydrolysisTin

The present invention relates to flaky alpha-alumina crystals with large aspect ratio and its preparation method, and particularly to flaky alpha-alumina crystals comprising aluminum oxide, zinc oxide and tin oxide, which are prepared by obtaining a mixed gel which are prepared by obtaining a mixed gel by means of hydrolysis of an aqueous aluminum precursor solution comprising aqueous flux, aqueous zinc precursor solution and tin precursor aqueous solution, followed by aging, drying and crystallization processes. The crystals herein have an average particle thickness of 0.5 um or less, an average particle diameter of 30 μm or higher and an aspect ratio of 100 or higher, thus being useful as a substrate of high quality pearlescent pigments, an abrasive, ceramic material and a filling material.

Owner:KOREA RES INST OF CHEM TECH +1

Preparation of silicon dioxide nano-tube

InactiveCN101280457AAvoid disadvantages such as uneven hydrolysisHigh yieldPolycrystalline material growthSilicon oxidesAmmonium hydroxideLarge aspect ratio

The invention provides a preparation method of silicon dioxide nano-tubes, which includes the following steps. (1) The ethanol solution of tartrate is in preparation. The ultrasonic is implemented until the tartrate is dissolved completely, so that a the first solution can be obtained, wherein the concentration of tartrate is 0.01 to 0.04mol / L. (2) The ammonia solution with the weight percentage concentration of 24% to 28% is added to the first solution obtained from the first step, thus a the second solution is obtained, wherein the volume ratio of the ammonia solution and the first solution is 0.2 to 0.6. (3) In a state of agitation, the silicon ester is dropped into the second solution obtained from the second step within 0 to 2 hours, which then stands for 0 to 24 hours after the dropping is completed. Thereby a white gel is obtained, wherein the volume ratio of the silicon ester and the second solution is 0.05 to 0.2. (4) The white gel obtained from the third step is repeatedly washed with the deionized water ultrasonic. Afterwards, the white floc obtained from the washing is dried, so that the silicon dioxide nano-tubes are obtained. Therefore, the method of the invention has the advantages of high yield ratio, large aspect ratio, uniform size and so on.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Pearlescent pigments with large aspect ratio and a method of their preparation

ActiveUS20090320719A1High glossOvercome problemsPigment preparation by wet methodsZinc compoundsInterference colorLarge aspect ratio

The present invention relates to a pearlescent pigment with large aspect ratio and a method of their preparation, and particularly to pearlescent pigments prepared by coating a metal or metal precursor on the flaky alpha-alumina crystals obtained by using an aluminum precursor aqueous solution and a zinc precursor aqueous solution as main ingredients. The crystals herein has an average particle thickness of 0.5 μm or less, an average particle diameter of 15 μm or higher and a large aspect ratio of 50 or higher, thereby being superior in gloss. The crystals show metal colors and interference colors of silver, gold, red, purple, blue and green.

Owner:KOREA RES INST OF CHEM TECH +1

Method for preparing carbon fiber reinforced inorganic polymer based composite material

InactiveCN101182152AOvercome reunionOvercome the problem of breakingCement productionFiberPolymer science

A preparation method of carbon fiber reinforced inorganic polymer composite relates to a preparation method of inorganic polymer composite. The method solves following problems: low mechanical strength, low ductility, low bearing capacity, low application reliability of the inorganic polymer composite; large aspect ratio, easiness to be winded and agglomerated even be fractured during the preparation process, uneven distribution in an inorganic polymer composite matrix and low strengthening effect of existing carbon fiber. The preparation method of the invention is: firstly, to prepare batch of the inorganic polymer and regulate the viscosity of the batch through deionized water; secondly, to prepare chopped carbon fiber prefabrication; thirdly, to prepare a composite green body which includes a plurality of carbon fiber prefabrication layers; fourthly, to add vacuum pressure on the green body and dry the green body to produce the carbon fiber reinforced inorganic polymer composite. The invention overcomes the carbon fiber agglomeration and fracture problems of a conventional strong agitation method. The composite prepared through the invention has the advantages of high carbon fiber content, even distribution, high material strength and good ductility.

Owner:HARBIN INST OF TECH

Method of producing semiconductor device

InactiveUS6331485B1Good shape retentionImprove contact reliabilitySemiconductor/solid-state device detailsSolid-state devicesConductive materialsLarge aspect ratio

A method for producing semiconductor device for reducing a gas of halogenated product of a group IVB element with H2 by the ECR plasma CVD method to form a thin film of the group IVB element on a substrate is disclosed. This method includes forming an adhesion layer of the group IVB element in a contact hole, including walls, to be in contact with the exposed substrate, the adhesion layer being formed by reducing with H2 a gas of a halogenated product of the group IVB element in an ECR plasma CVD process, the group IVB element and H2 being used at a flow ratio of 0.4 and greater; forming a barrier layer in contact with the adhesion layer; and filling the contact hole with an electrically conductive material. The stable barrier metal is formed and an upper-layer metallization material is filled within the minute contact hole having a large aspect ratio.

Owner:SONY CORP

Pearlescent pigments with large aspect ratio and a method of their preparation

ActiveCN101535419AHigh glossPigment preparation by wet methodsZinc compoundsInterference colorLarge aspect ratio

The present invention relates to a pearlescent pigment with large aspect ratio and a method of their preparation, and particularly to pearlescent pigments prepared by coating a metal or metal precursor on the flaky alpha-alumina crystals obtained by using an aluminum precursor aqueous solution and a zinc precursor aqueous solution as main ingredients. The crystals herein has an average particle thickness of 0.5 [mu]m or less, an average particle diameter of 15 [mu]m or higher and a large aspect ratio of 50 or higher, thereby being superior in gloss. The crystals show metal colors and interference colors of silver, gold, red, purple, blue and green.

Owner:KOREA RES INST OF CHEM TECH +1

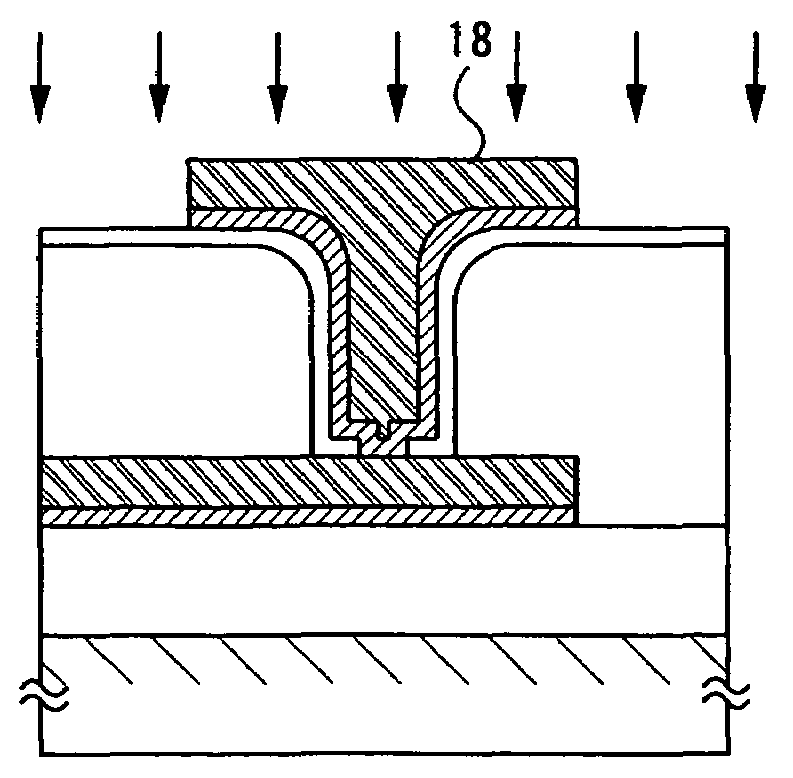

Semiconductor device having through electrode and method of manufacturing the same

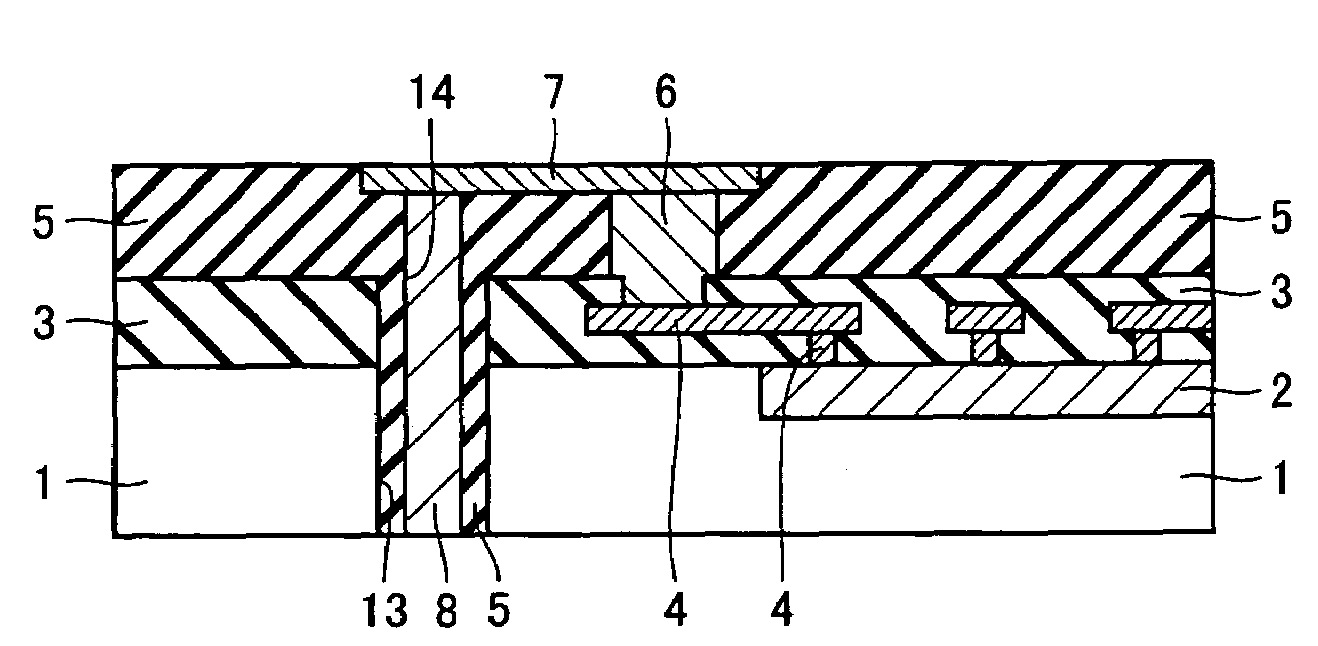

ActiveUS7288481B2Improve reliabilityWell formedSemiconductor/solid-state device detailsSolid-state devicesEngineeringInterconnection

With a fluid insulating material applied on a convex substrate and a fluid insulating material applied on a concave substrate, a columnar conductive portion of the convex substrate is inserted into a hole of the concave substrate. With this, a conductive portion and an internal interconnection are electrically connected with each other via a bump. Therefore, a semiconductor device having a through electrode which enables a size reduction, has high reliability and is easily formed even with a large aspect ratio, and a method of manufacturing the same are obtained.

Owner:RENESAS ELECTRONICS CORP

Method for manufacturing semiconductor device

InactiveUS7211502B2Low costIncrease coverageSemiconductor/solid-state device manufacturingNon-linear opticsCapacitanceEngineering

A method for manufacturing a semiconductor device in which lower cost can be realized, a wiring with favorable coverage can be formed in a contact hole having a large aspect ratio, wiring capacitance can be reduced and a multilayer wiring can be formed, can be provided. In order to obtain the semiconductor device, the following steps are required; forming a first conductive film which serves as a barrier so as to be in contact with an organic insulating film with an opening portion formed; forming a second conductive film including aluminum so as to be in contact with the first conductive film; or forming a nitride film so as to be in contact with the organic insulating film with the opening portion formed; patterning the nitride film; forming a first conductive film which serves as a barrier so as to be in contact with the nitride film; forming a second conductive film including aluminum so as to be in contact with first conductive film; and thereafter selectively performing a heat treatment under reduced pressure or in normal pressure, and flattening the second conductive film.

Owner:SEMICON ENERGY LAB CO LTD

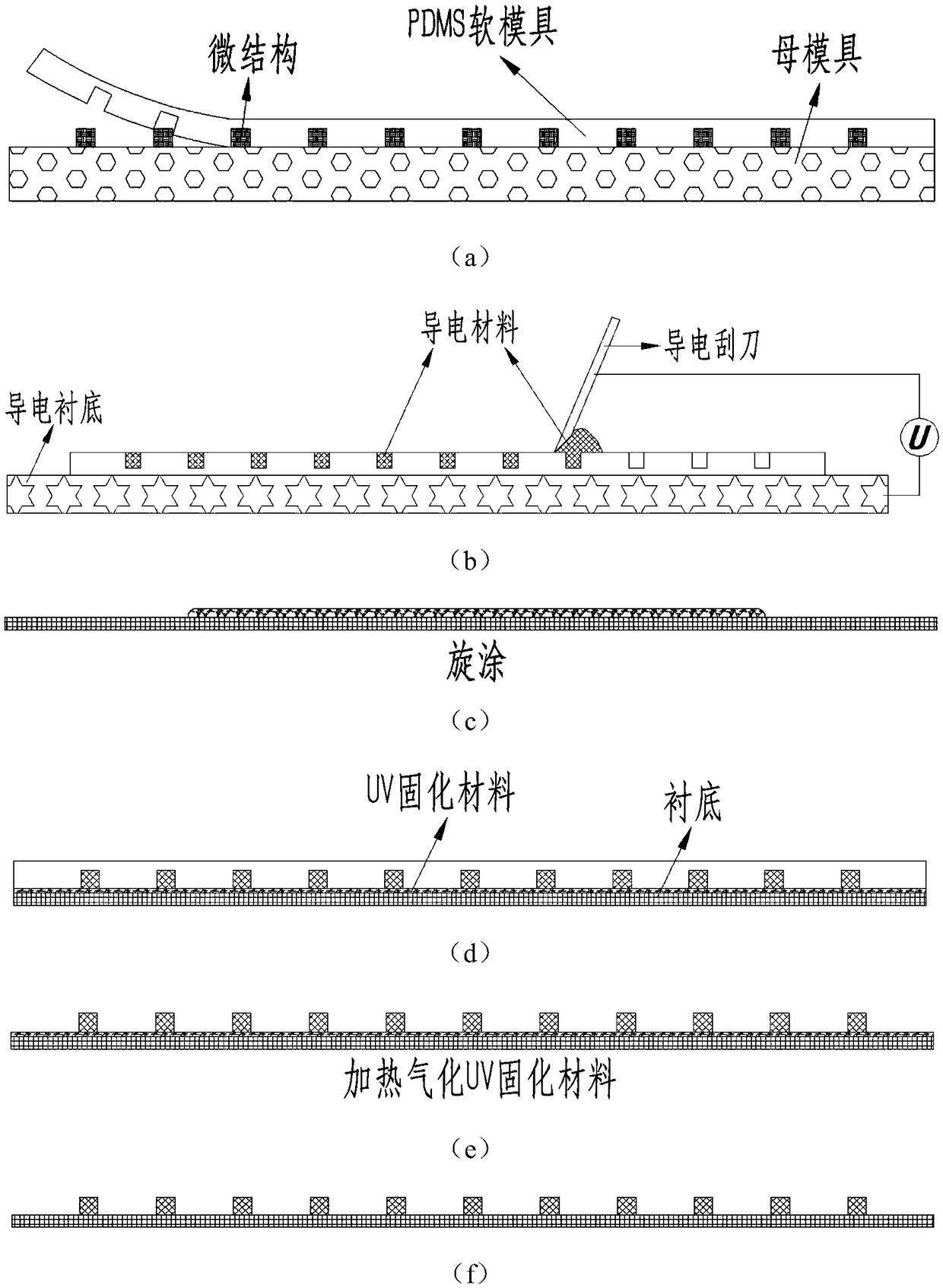

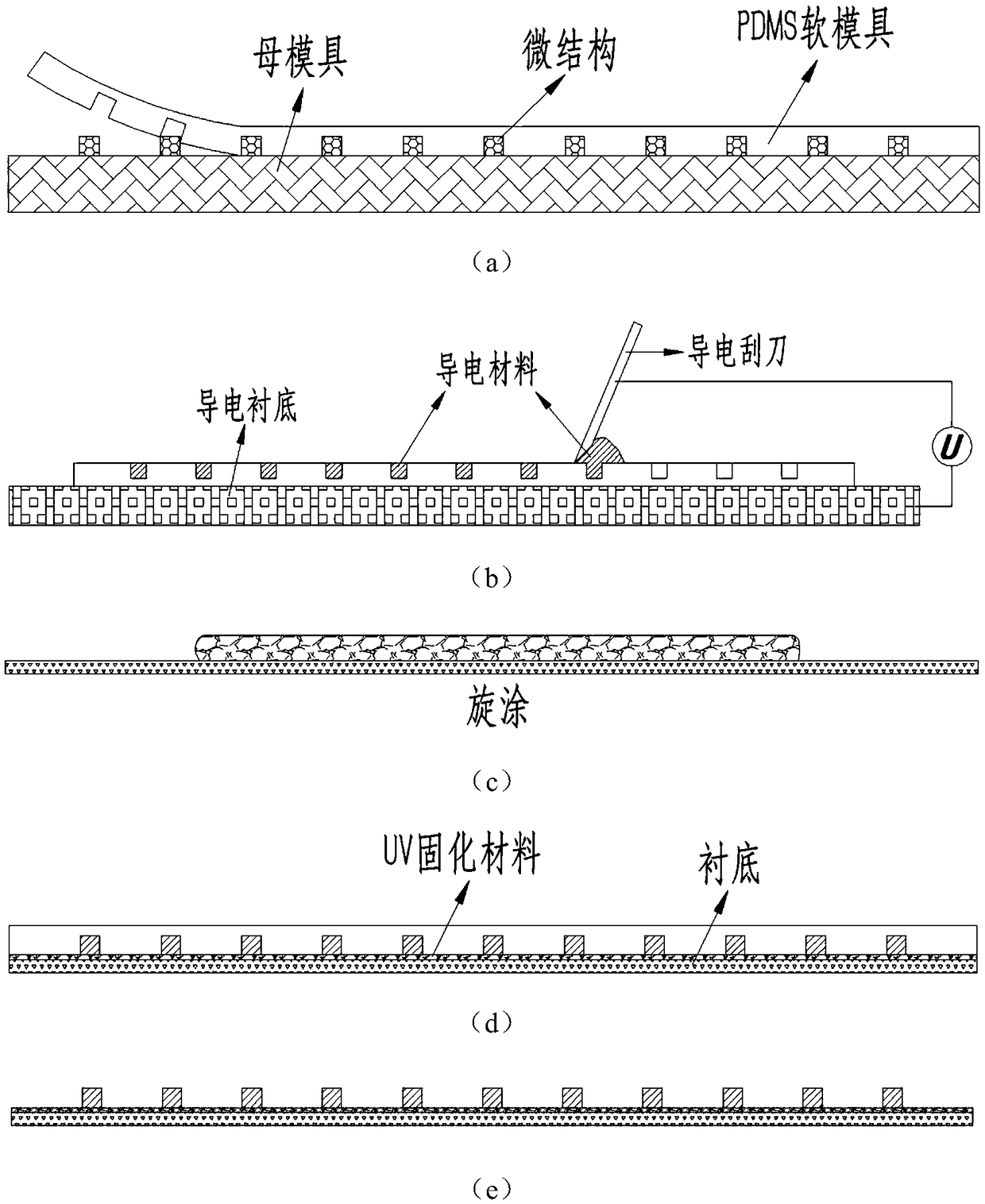

Large-height-width-ratio microstructure transfer printing method

PendingCN109483780AEffective transferWide range of choicesNanotechnologyCoatingsMicro nanoElectricity

The invention relates to a large-aspect-ratio microstructure transfer printing method. According to the method, the template with the convex micro-nano structure is used as a mother mold, the liquid polydimethylsiloxane(PDMS) is poured to the mother mold, and heating is carried out to manufacture the PDMS soft die; a liquid conductive material is filled into the groove of the PDMS soft die throughan electric wetting auxiliary scraping and coating mode, and the conductive material is pre-cured at a certain temperature; the conductive material is transferred to the target substrate through a UVauxiliary transfer printing technology; the conductive structure on the target substrate is further processed to obtain the conductive structure which is good in consistency, high in precision and excellent in electric conduction performance.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

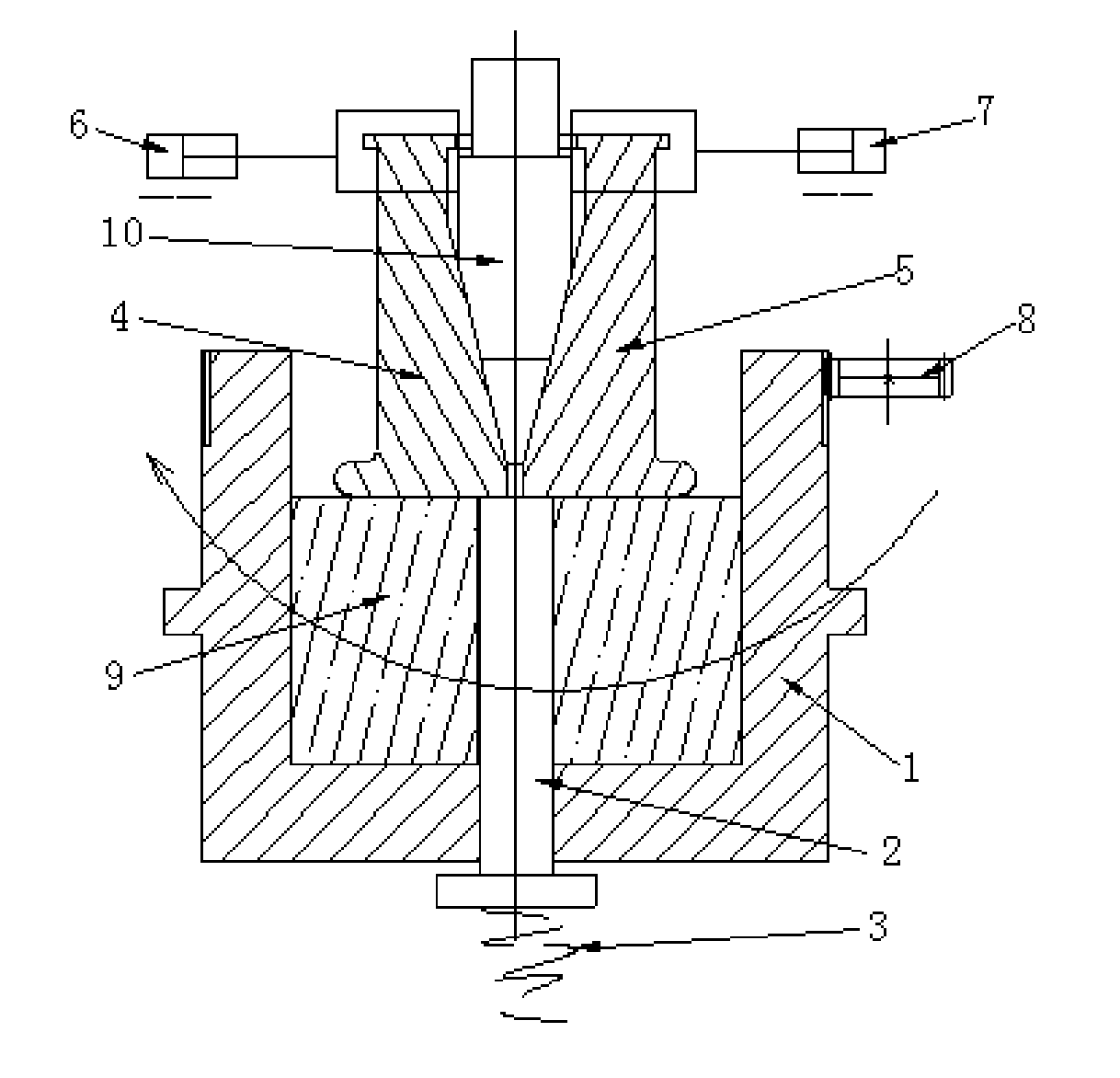

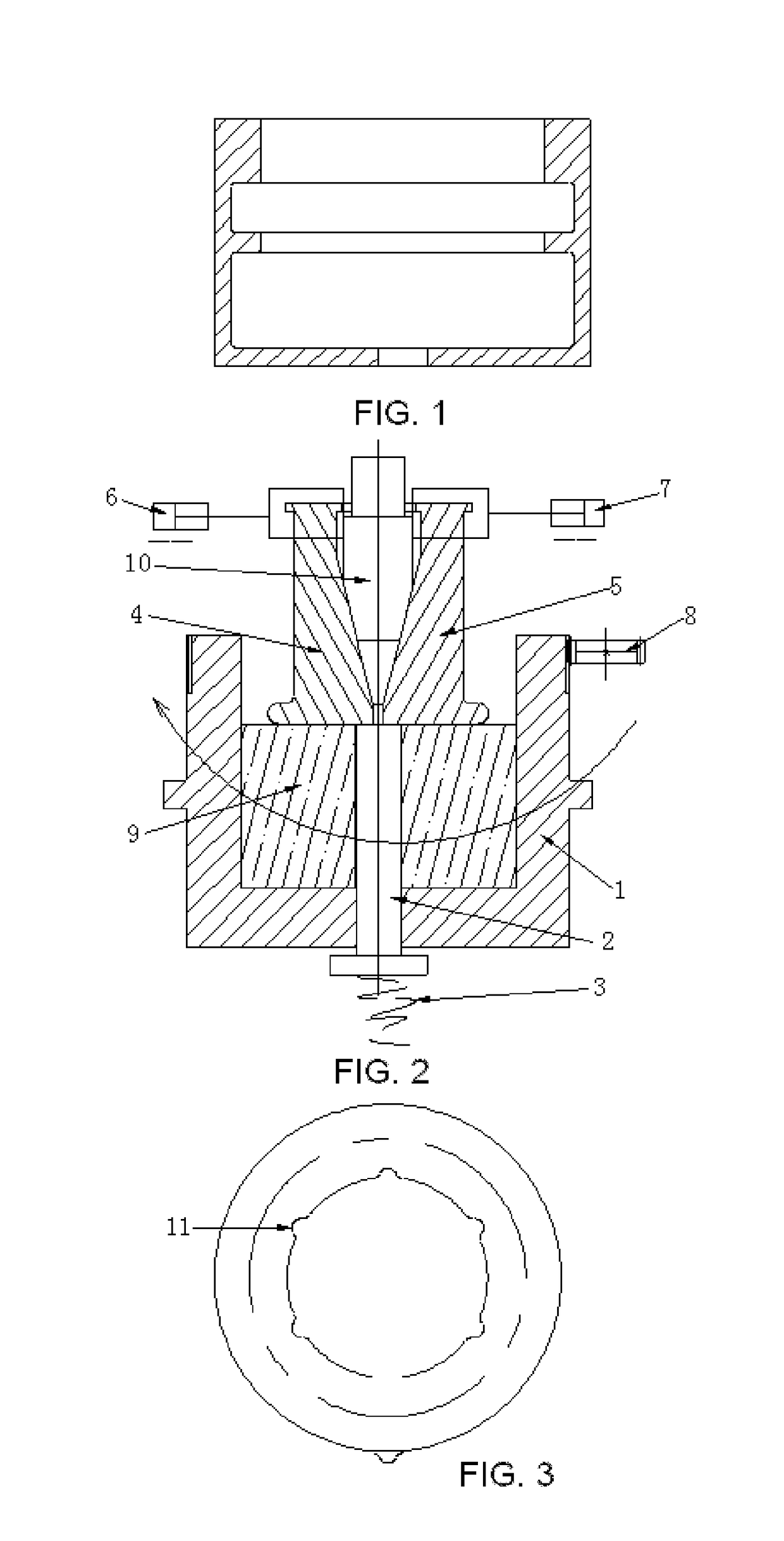

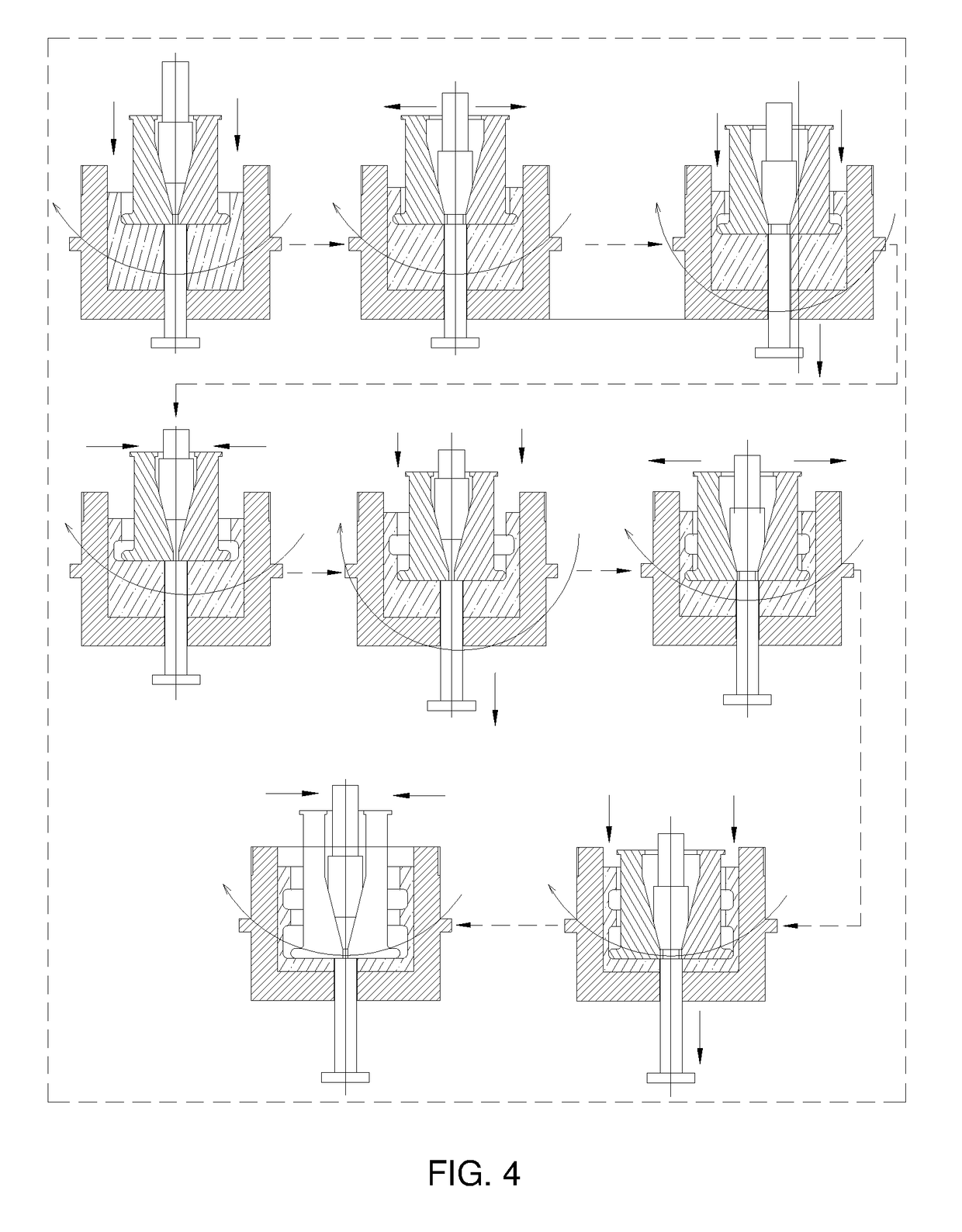

Rotary Extrusion Producing Method for Producing Inner Ring Rib with Large Aspect Ratio Formed of Hollow Billet

ActiveUS20180056351A1Easy to useEasy to operateExtrusion diesExtrusion mandrelsHydraulic cylinderEngineering

The present invention discloses a rotary extrusion producing method for producing an inner ring rib with a large aspect ratio formed of a hollow billet, which includes: combining, at an initial stage of rotary extrusion, two convex dies together and driving, by a slider on a press machine, left and right half convex dies to extrude a blank downward to form an initial profile of a transverse rib; dragging respectively, by left and right horizontal hydraulic cylinders, the left and right half convex dies to move in a radial direction, to form an initial cylindrical wall, so as to achieve a purpose of forming the transverse rib, once the blank is extruded downward by a certain depth, where a head of a mandrel is set to be at a certain conical degree, and a certain number of processed pits are distributed on an inner cavity of a concave die.

Owner:ZHONGBEI UNIV

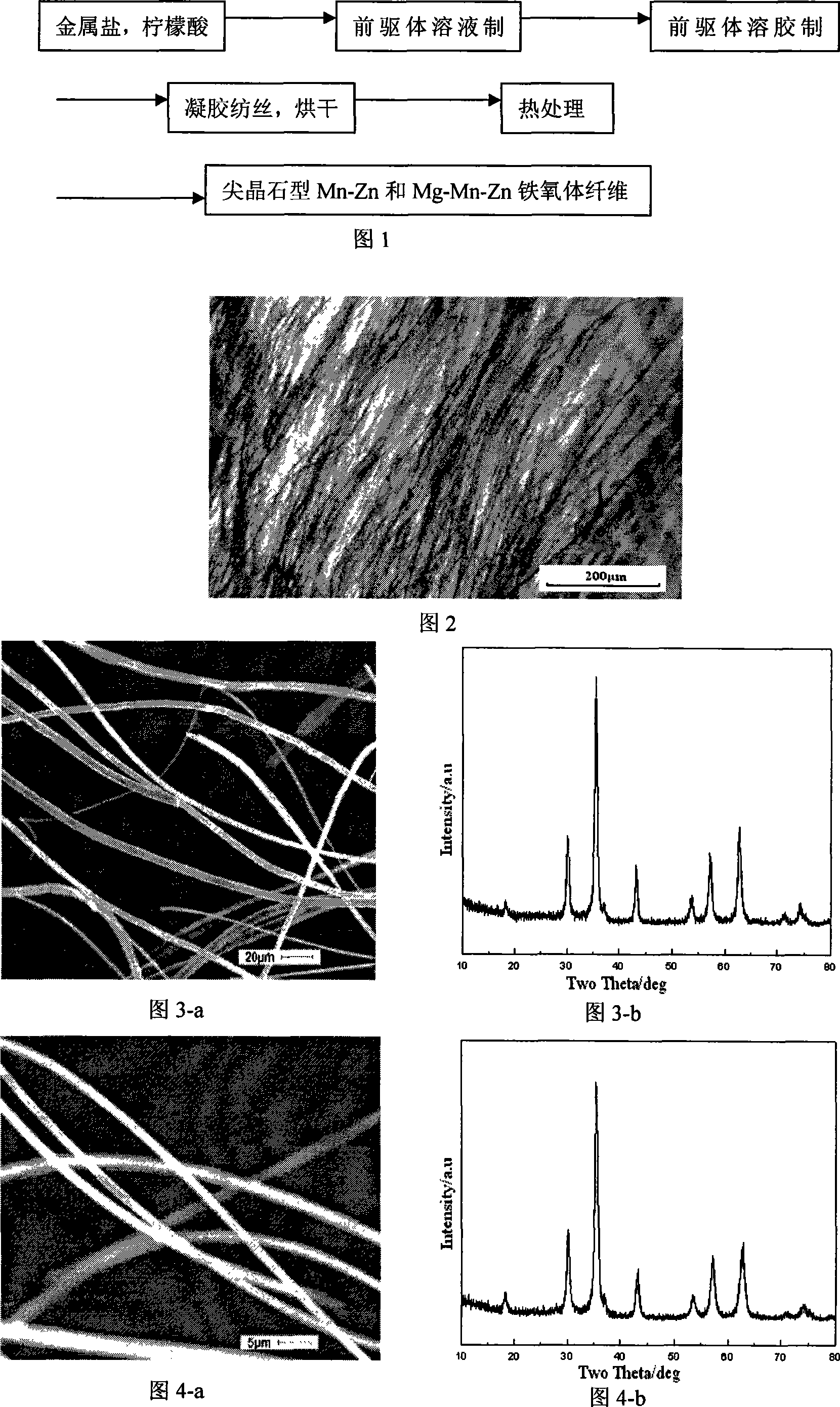

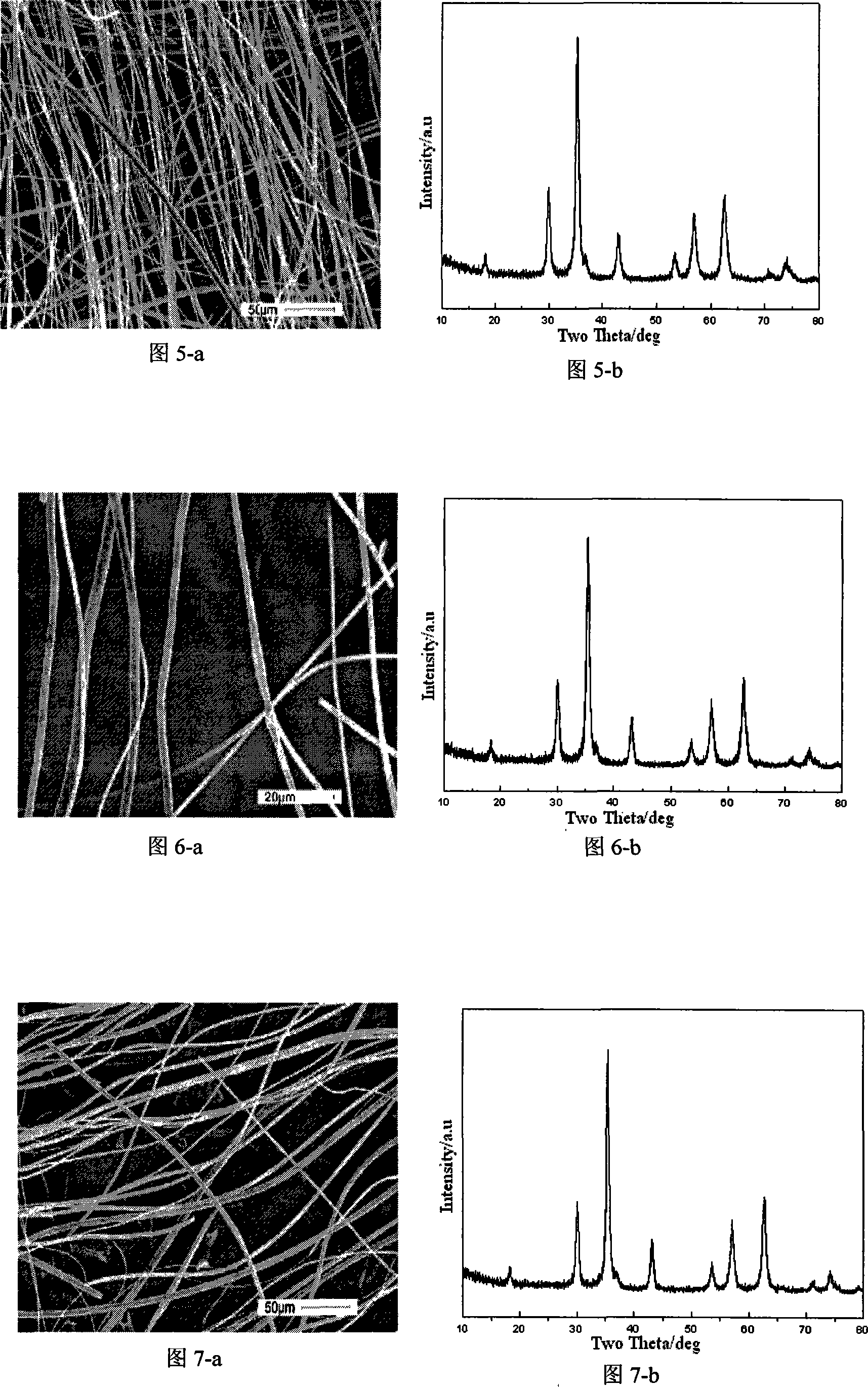

Mn-Zn ferrite fibre and preparing process thereof

InactiveCN101104556AReduce the impactSynthesis temperature is lowInorganic material magnetismCelluloseFiber

A Mn-Zn ferrite fiber and the preparation method relate to the inorganic non-metallic materials and the preparation technical field. The present invention uses citric acid and metal salts of magnesium, manganese, zinc and iron as raw materials to get precursor solution through chemical reactions, and then precursor gel is obtained through decompression and dehydration to get the gel cellulose filament through spinning; the gel cellulose filament will then be baked to get spinel-type Mg1-x-yMnxZnyFe2O4 series ferrite ceramic fibers, wherein, x is less than 1 but more than 0, y is less than 1 but more than 0, -xy is less than 1 but more than or equal to 0. Through organic complexation gel precursor conversion, Mn-Zn ferrite ceramic fibers with uniform diameter, smooth surface and larger aspect ratio are obtained at low sintering temperature, therefore, the invention has the advantages of simple process, low equipment requirements, low cost and short operation cycle.

Owner:JIANGSU UNIV

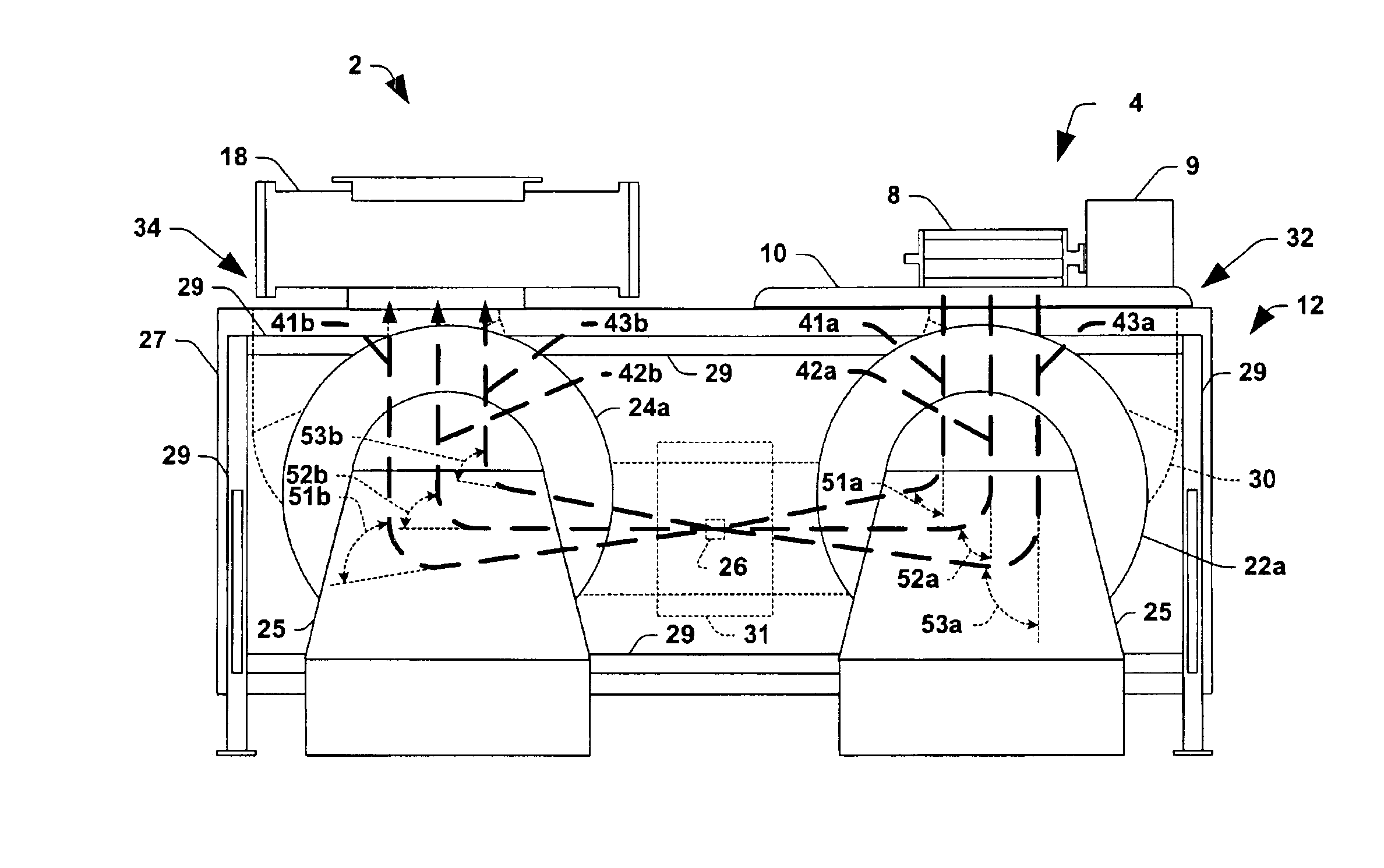

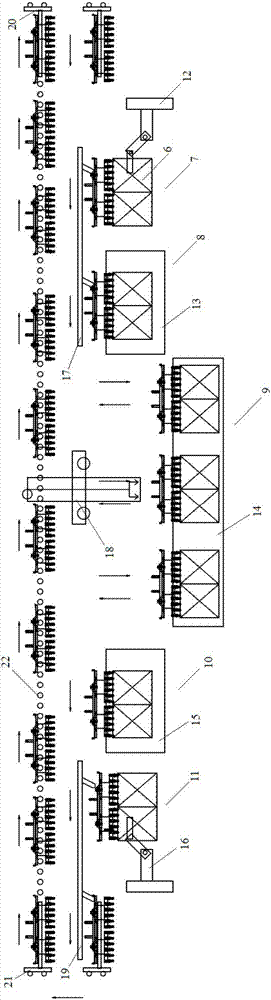

Full automatic electroplating production line

InactiveCN107012496AUniform plating qualityRealize automatic loading and unloading operationElectrolysis componentsSemiconductor devicesProduction lineEngineering

The invention discloses a full automatic electroplating production line which comprises a plurality of plating piece loading mechanisms, an electroplating device and a pass back mechanism. The plating piece loading mechanisms comprise a conductive rod, a swing support and a swing driving piece, the conductive rod is assembled on the swing support, and the swing driving piece is connected with the swing support; the electroplating device comprises a feeding station, an electroplating pretreatment station, an electroplating station, an electroplating aftertreatment station, a discharging station and a plating piece conveying mechanism; the feeding station is provided with a feeding mechanical arm, the electroplating station is provided with a plurality of electroplating grooves capable of containing a plurality of plating pieces, and a discharging mechanical arm is arranged on the discharging station; and the pass back mechanism runs from the outside side of the discharging station to the inlet side of the feeding station, and the discharged plating piece loading mechanisms are sent from the discharging station to the feeding station. According to the embodiment, full automatic electroplating is achieved, the unified electroplating quality of all plating pieces can be kept, the full automatic electroplating production line is suitable for plating pieces with large aspect ratio, automatic feeding and discharging operation is achieved, the labor intensity is reduced, and the working efficiency is improved.

Owner:DONGGUAN WERY DOOD CIRCUIT BOARD EQUIP

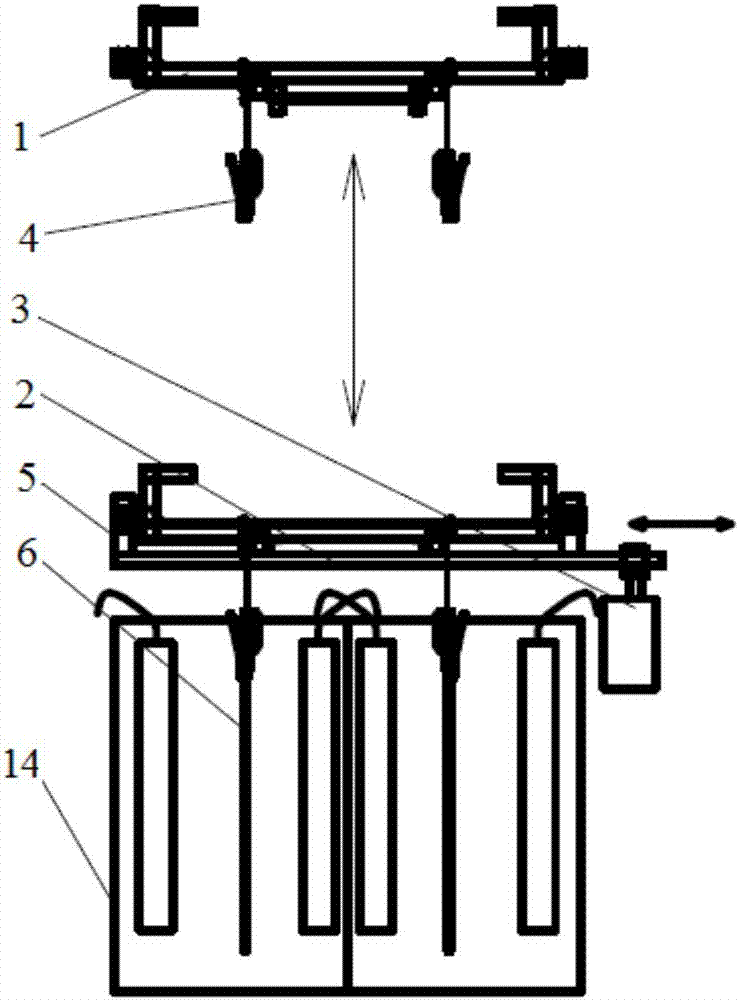

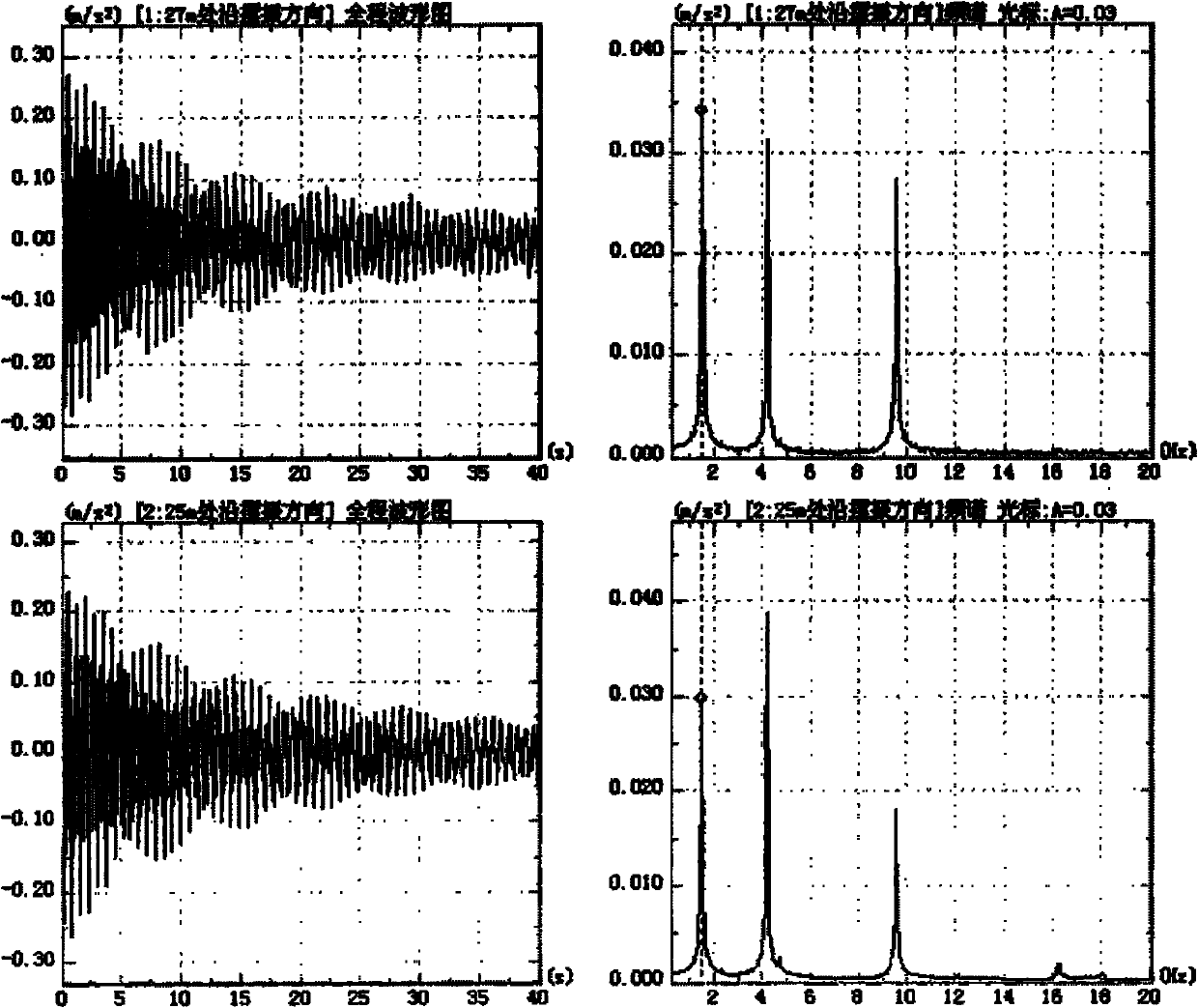

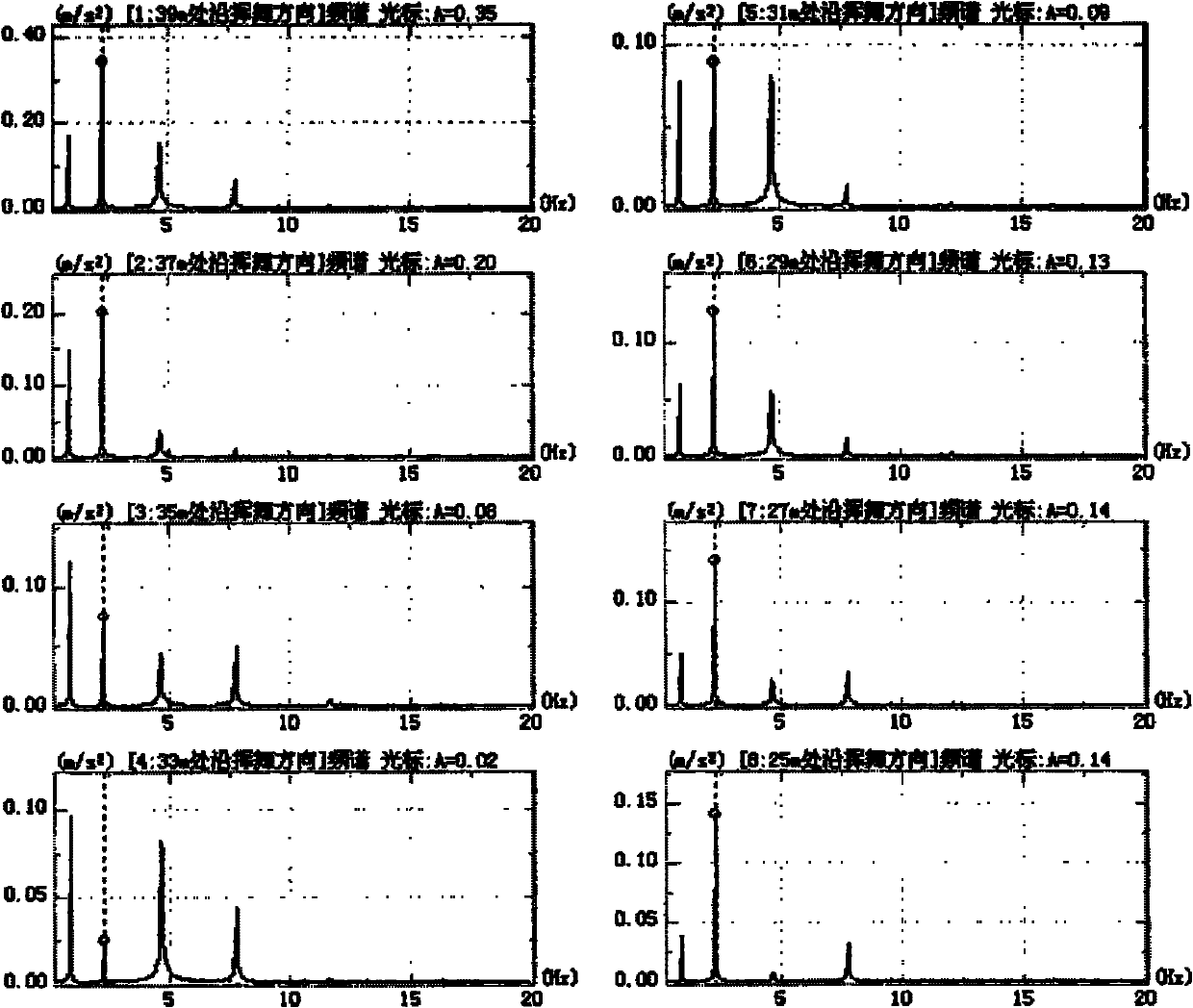

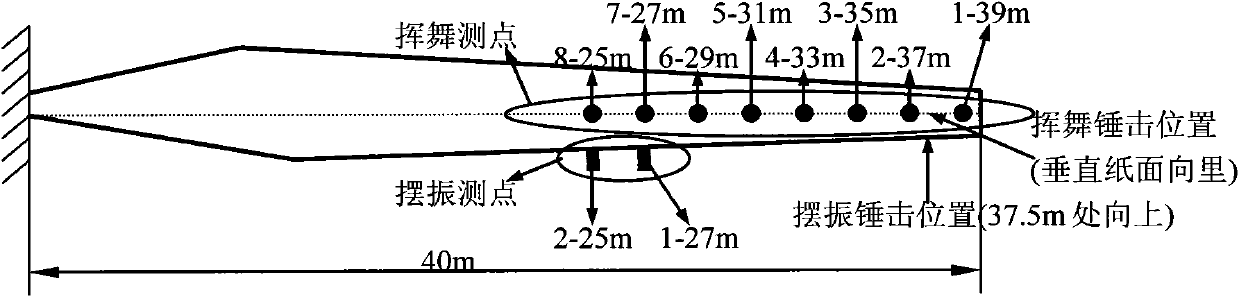

Method for testing high-order frequency of large wind-power blades

ActiveCN101949731ASolve problems that are susceptible to external environmental factorsOvercome Difficult Motivational ProblemsVibration measurement in solidsElectricityEngineering

The invention discloses a method for testing high-order frequency of large wind-power blades. The method comprises the following steps of: firstly determining a reasonable test point arrangement scheme, exciting the blades by utilizing a high elastic energy-collecting hammer, testing a vibratory response of the blades by utilizing an acceleration sensor, collecting the blade frequency through a data collecting system, and finally recognizing modal parameters of the large wind-power blades through a rear-end server and determining the natural frequency of each order of the large wind-power blades. In the invention, the high-order frequency of the large wind-power blades is tested by using an improved non-weighing method, the characteristic of difficult excitation due to large aspect ratio, big mass, low natural frequency (first-order waving frequency is designed to be lower than 1Hz) of the large wind-power blades is overcome, and the high-order frequency of the large glass-steel wind-power blades more than 40m can be intuitively and effectively tested.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

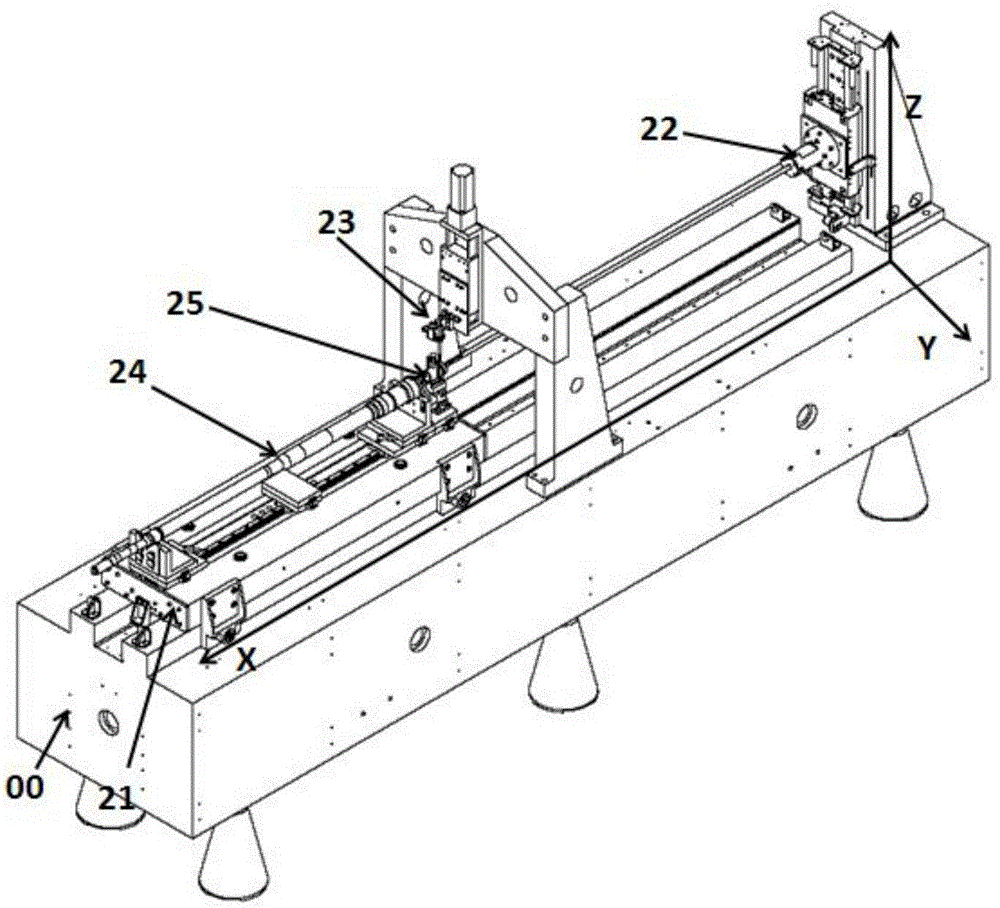

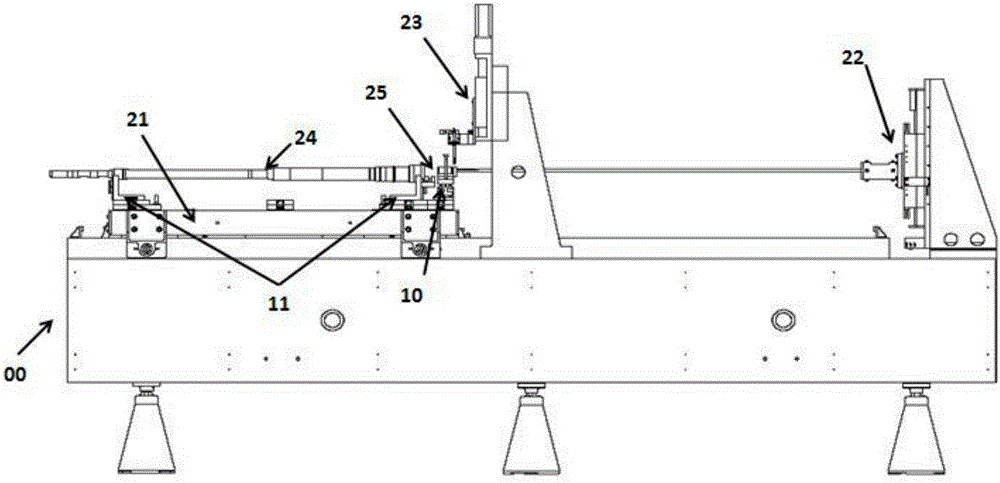

Large-aspect-ratio hollow-thin-wall thin and long shaft precision detection equipment and detection method thereof

ActiveCN106568387AMeasurement data is stableThe measurement method is reasonableUsing optical meansHead movementsEngineering

The invention belongs to the large-aspect-ratio deep hole inner type cavity and external diameter form and location tolerance precision detection equipment filed and relates to large-aspect-ratio hollow-thin-wall thin and long shaft precision detection equipment and a detection method thereof. The detection equipment comprises a pedestal, a measuring bar, an inner measuring head and a movement mechanism, an outer measuring head and the movement mechanism, a workpiece-support mobile platform, a calibration ring, a measured workpiece and a control processing unit. The workpiece-support mobile platform can drive the measured workpiece to move along an X direction. The inner measuring head and the isntalled movement mechanism, and the outer measuring head movement mechanism move along a Z direction. The calibration ring is used for establishing connection between the inner and outer measuring head. The control processing unit is used for compiling and measuring the program, collecting measured data and carrying out data processing so as to acquire a demanded workpiece form and location tolerance. By using the large-aspect-ratio hollow-thin-wall thin and long shaft precision detection equipment and the detection method thereof, measurement accuracy is high, a measurement length is long, measuring efficiency is high and usage is convenient.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com