Patents

Literature

2645 results about "Uniform size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

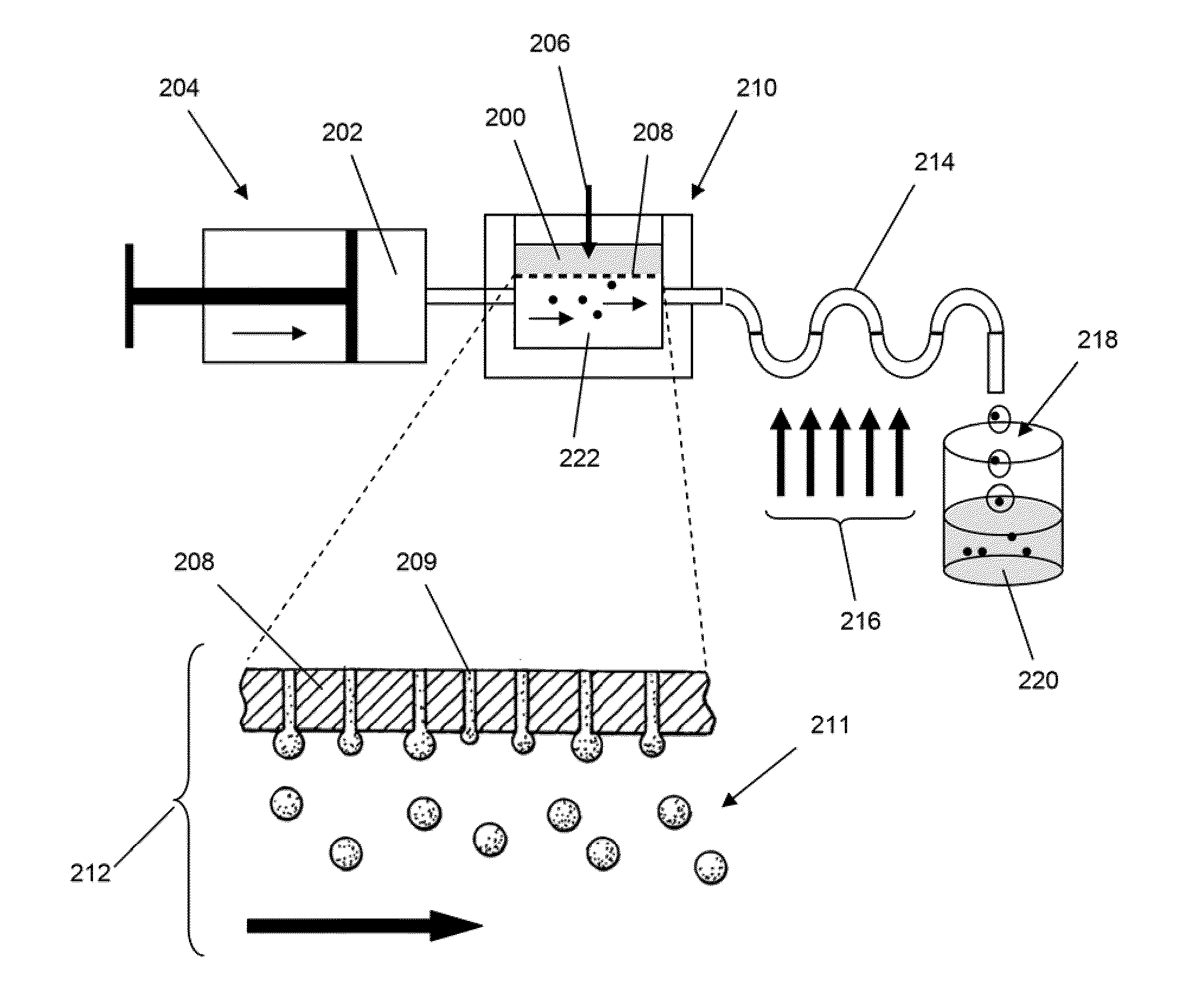

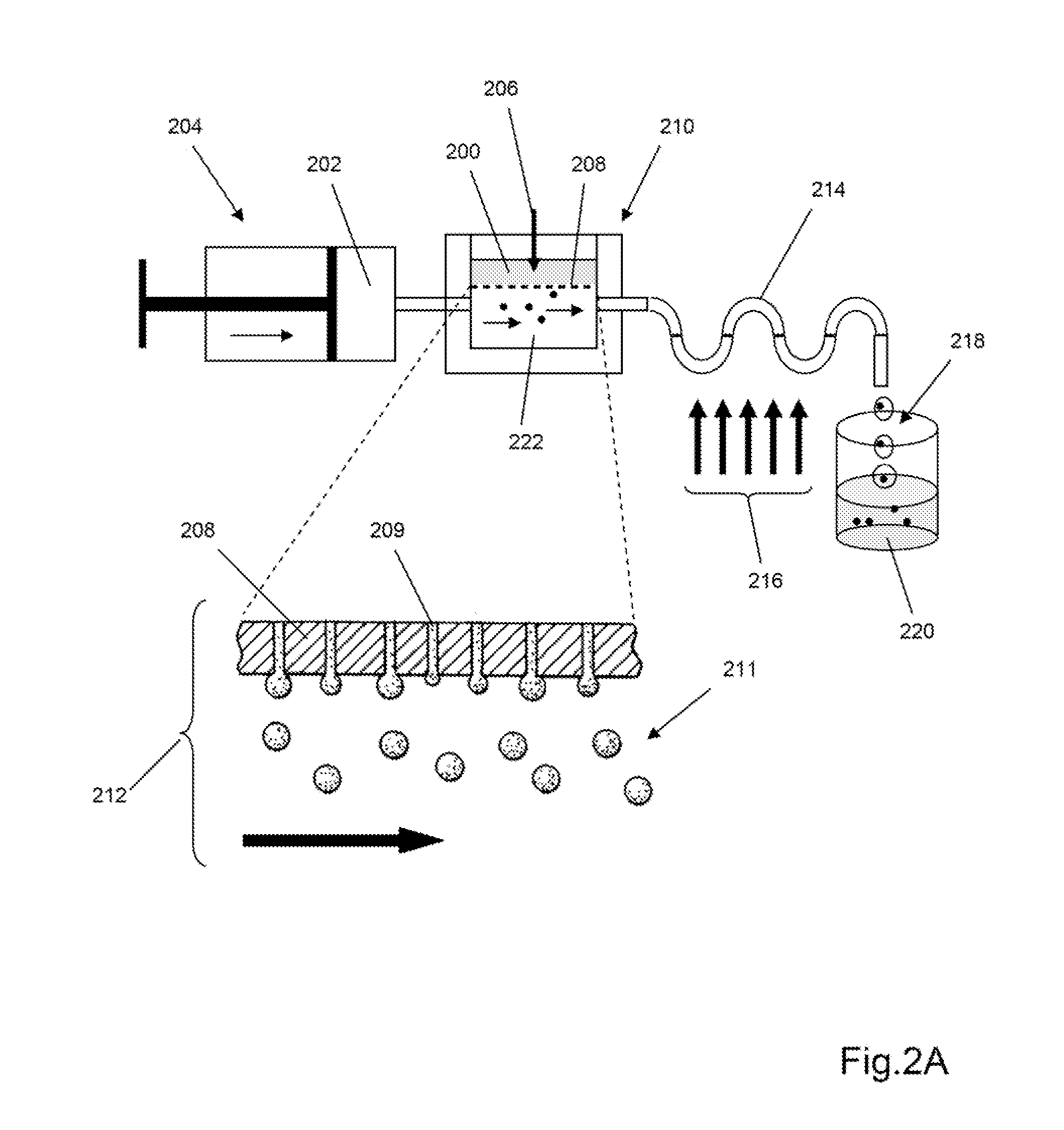

Methods for producing droplets for use in capsule-based electrophoretic displays

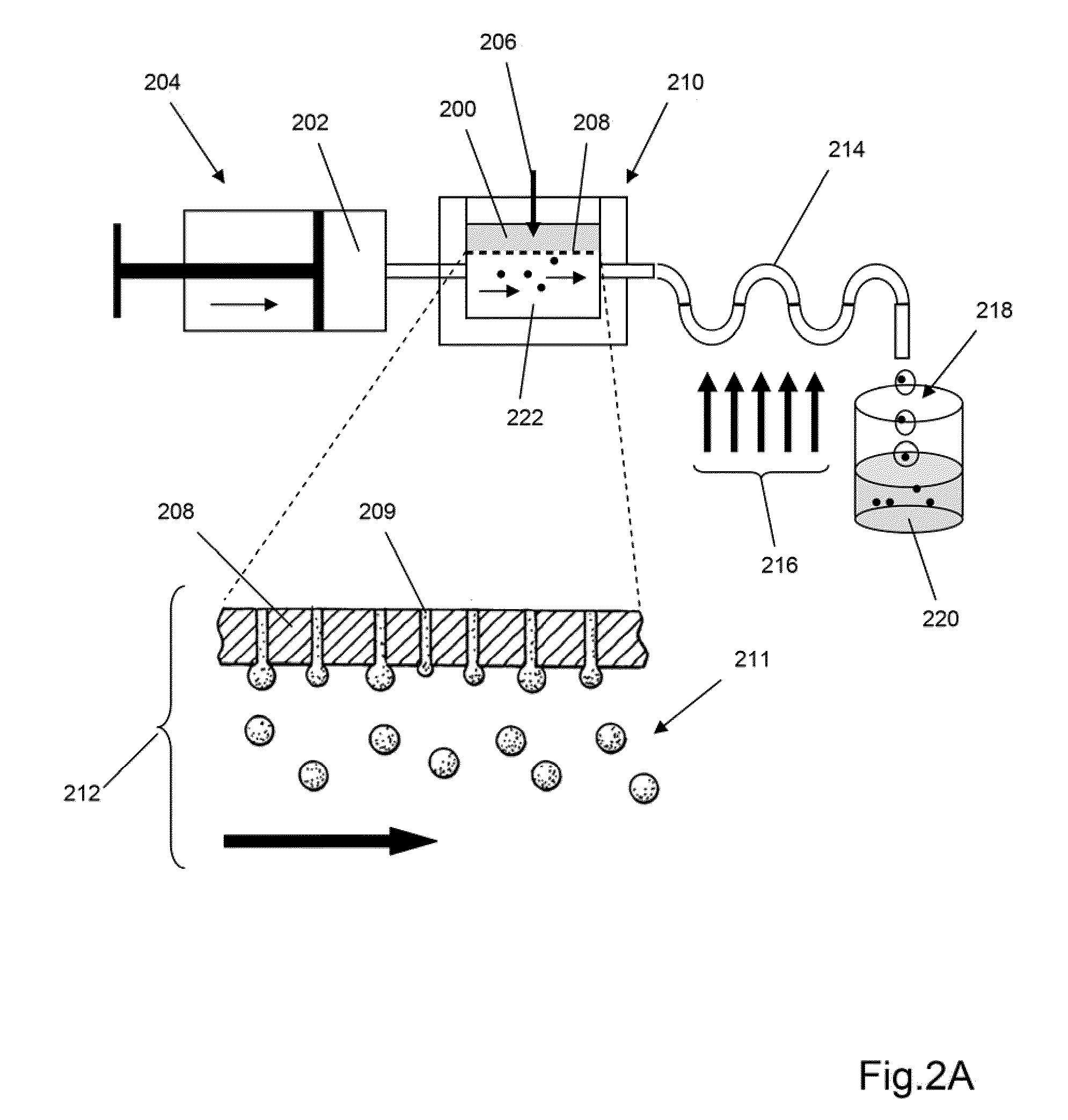

Methods are provided for forming a dispersion of substantially uniform droplets. An internal phase that includes a plurality of particles suspended in a first fluid is provided and an external phase including a second fluid is provided. The internal phase is vibrated and the internal phase is applied to the external phase. Either the internal phase or a combination of the internal and external phases form a series of droplets or complex droplets of substantially uniform size.

Owner:E INK CORPORATION

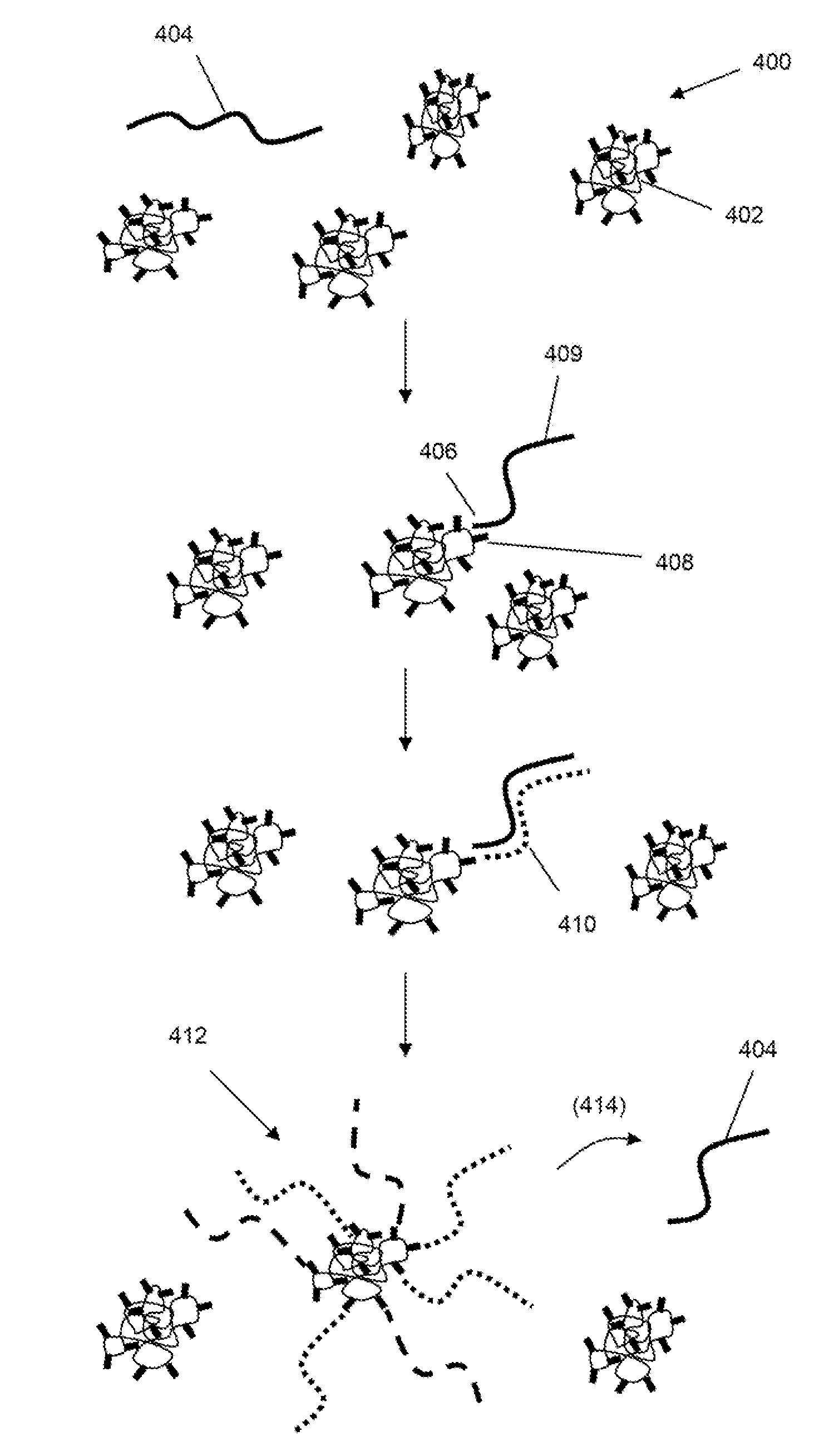

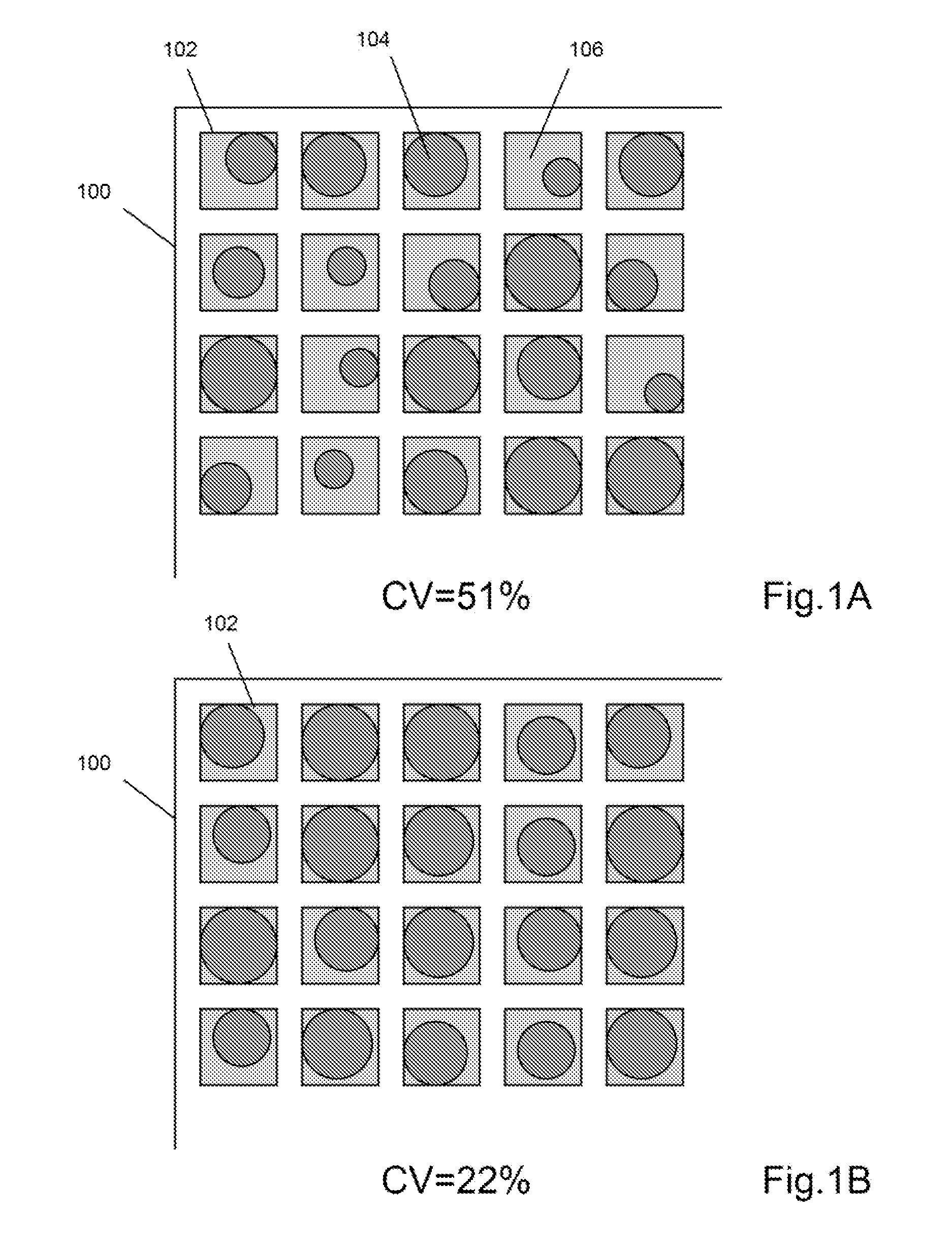

Scaffolded nucleic acid polymer particles and methods of making and using

ActiveUS20100304982A1Bioreactor/fermenter combinationsSequential/parallel process reactionsParticle compositionPolynucleotide

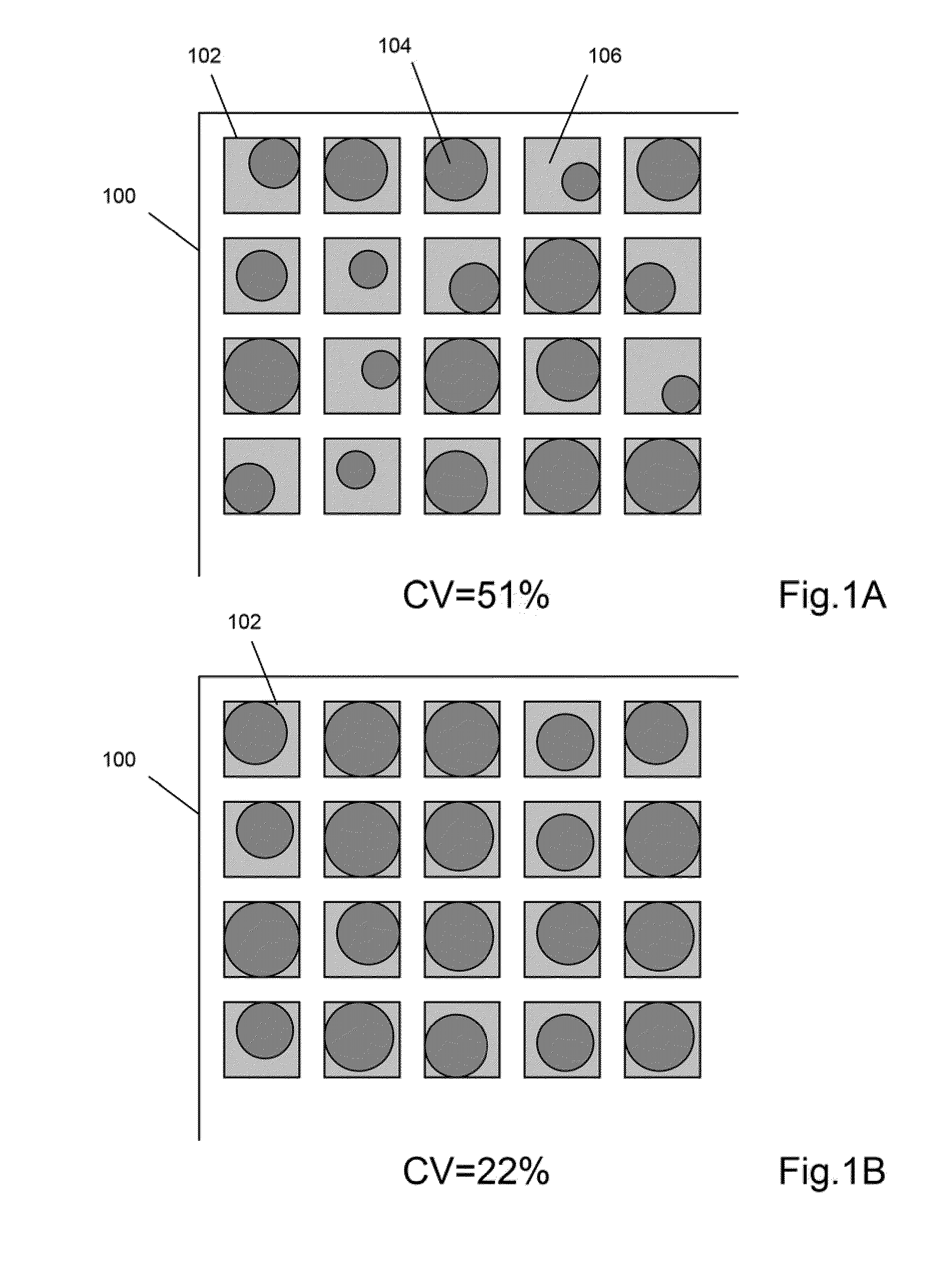

The invention provides particle compositions having applications in nucleic acid analysis. Nucleic acid polymer particles of the invention allow polynucleotides to be attached throughout their volumes for higher loading capacities than those achievable solely with surface attachment. In one aspect, nucleic acid polymer particles of the invention comprise polyacrylamide particles with uniform size distributions having low coefficients of variations, which result in reduced particle-to-particle variation in analytical assays. Such particle compositions are used in various amplification reactions to make amplicon libraries from nucleic acid fragment libraries.

Owner:LIFE TECH CORP

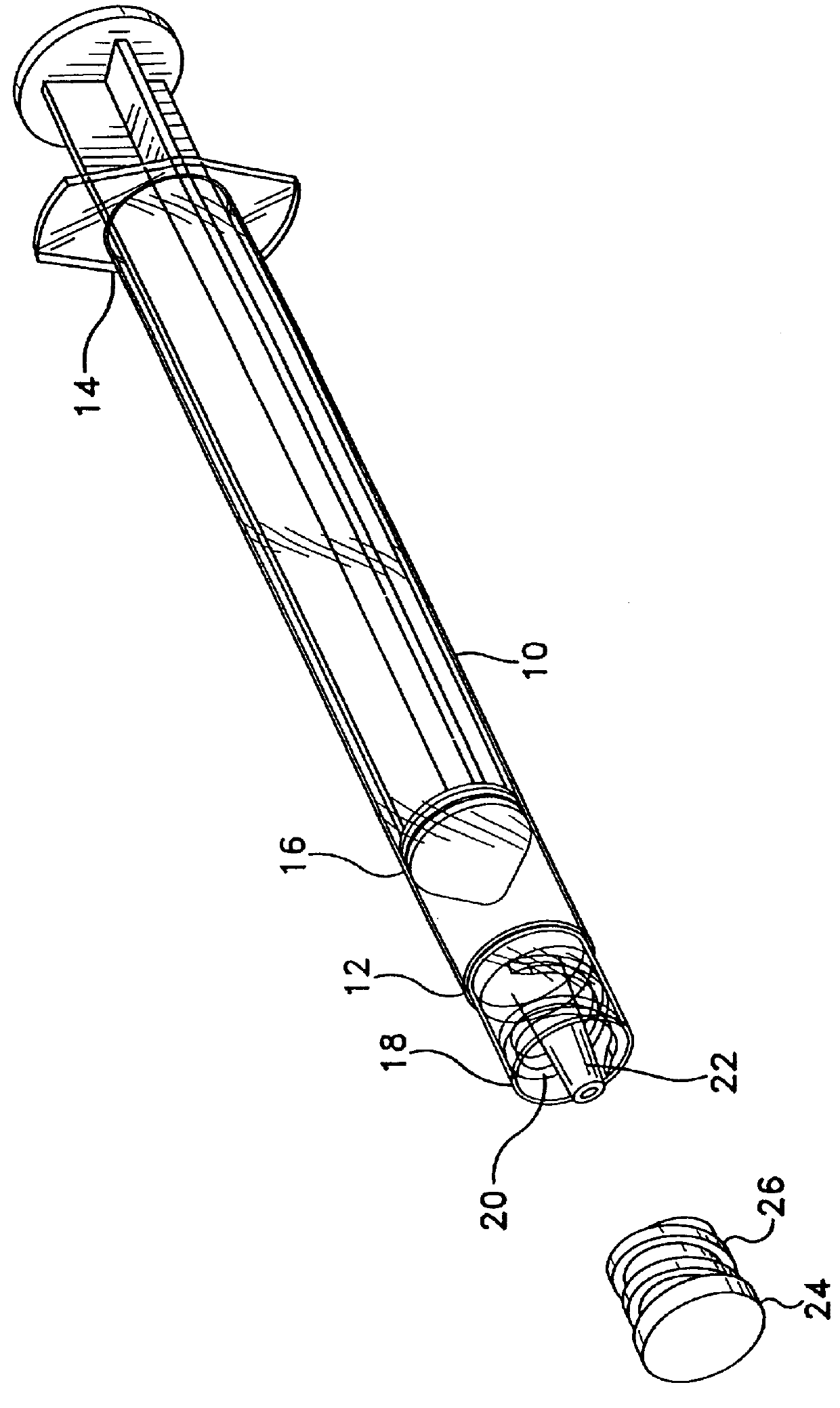

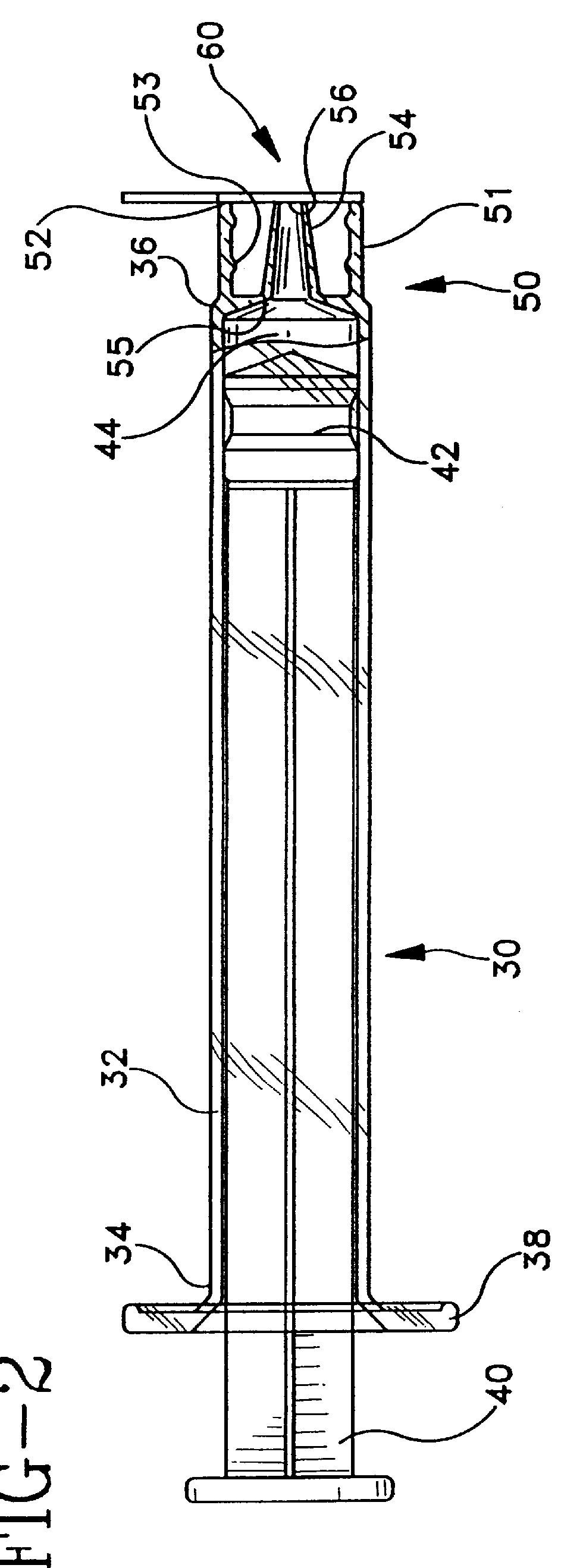

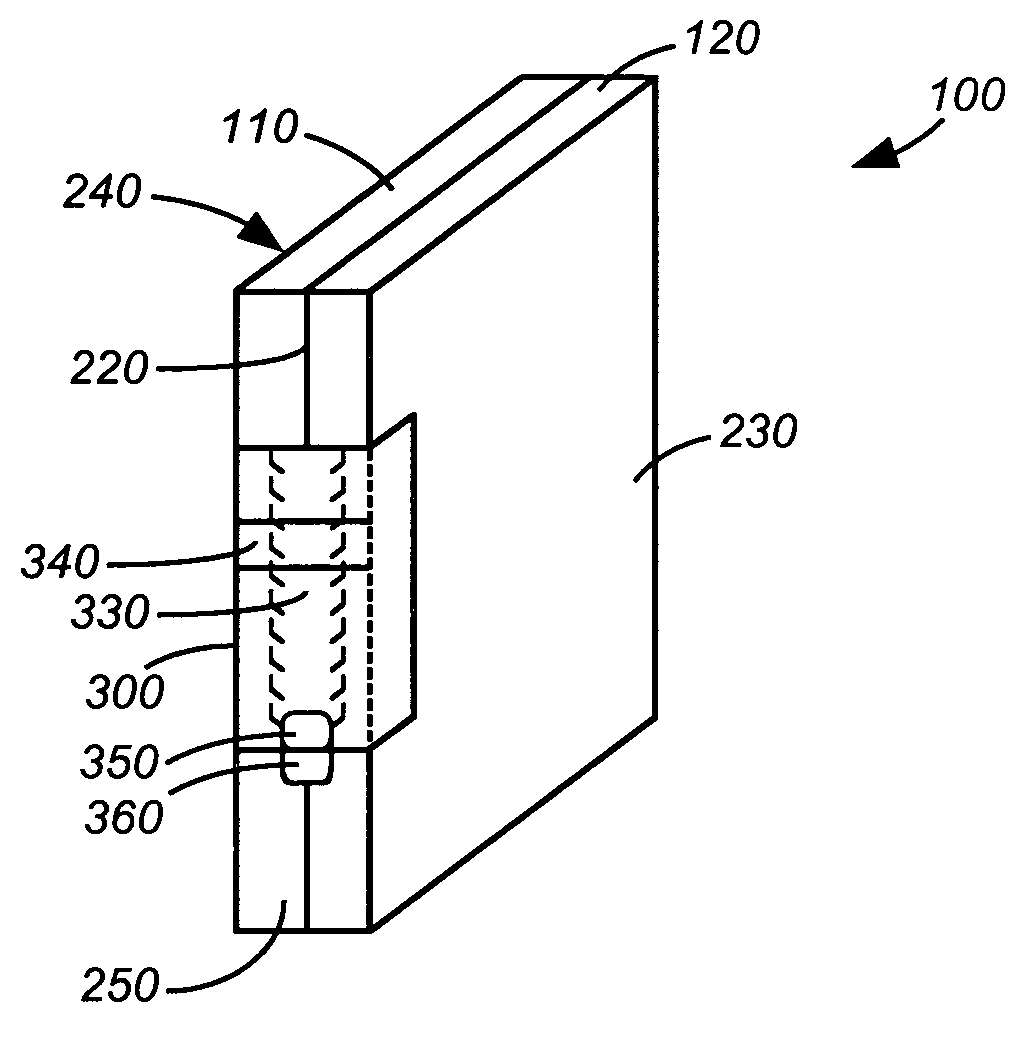

Protective sealing barrier for a syringe

InactiveUS6126640AEasy disposalEasy to operateInfusion syringesInfusion needlesBiomedical engineeringMembrane configuration

A protective sealing barrier for a syringe is disclosed. The protective sealing barrier can be configured to safeguard the sterility of the syringe and any contents held therein, as a barrier against leakage of any contents held within the syringe, or both. The syringe includes a luer tip and a collar having terminal ends which are preferably substantially co-planar with one another. The barrier consists of a membrane which is disposed in substantially entire surface contact with the terminal ends of both the luer tip and the collar. The membrane can be selected from a material permitting the syringe to be irradiated or heat sterilized. Likewise, the membrane can be chosen from a material permitting the syringe to be sterilized by various gas sterilization procedures. The membrane provides good tamper evidence of the syringe, can be stocked in a uniform size adaptable to various sizes of syringes, reduces the storage space required for the syringes, and can serve as a platform for printing information regarding contents held within the syringe.

Owner:BECTON DICKINSON & CO

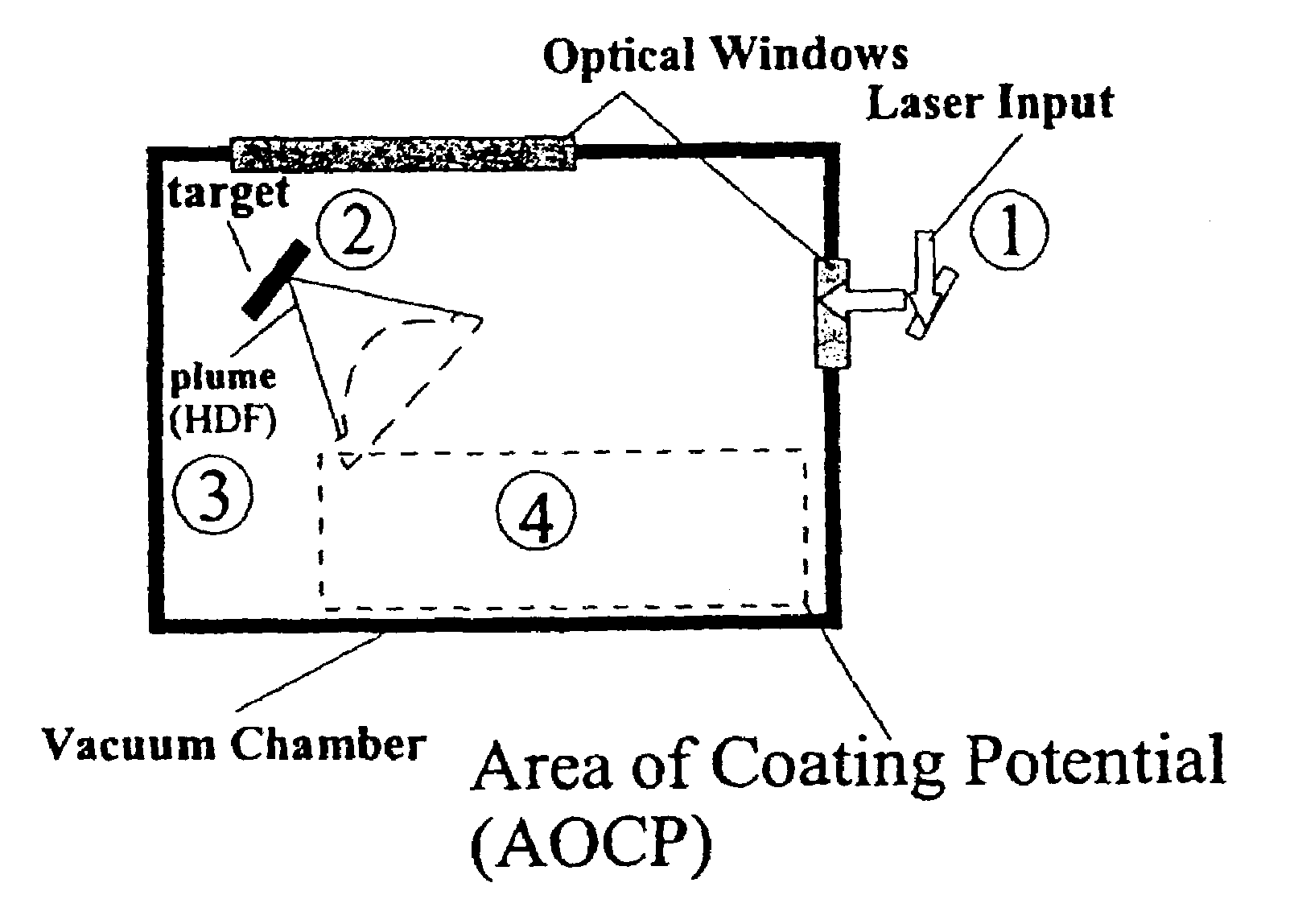

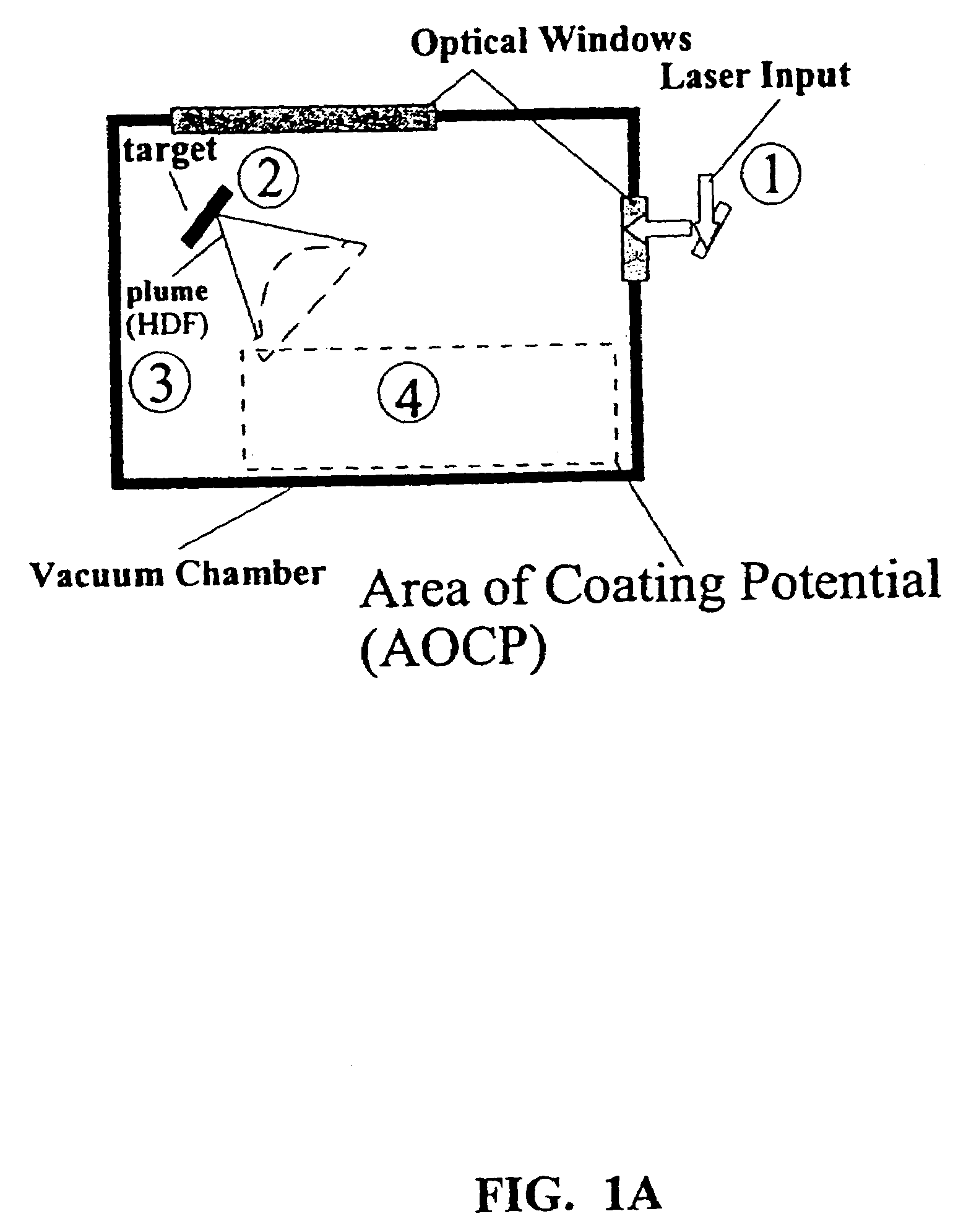

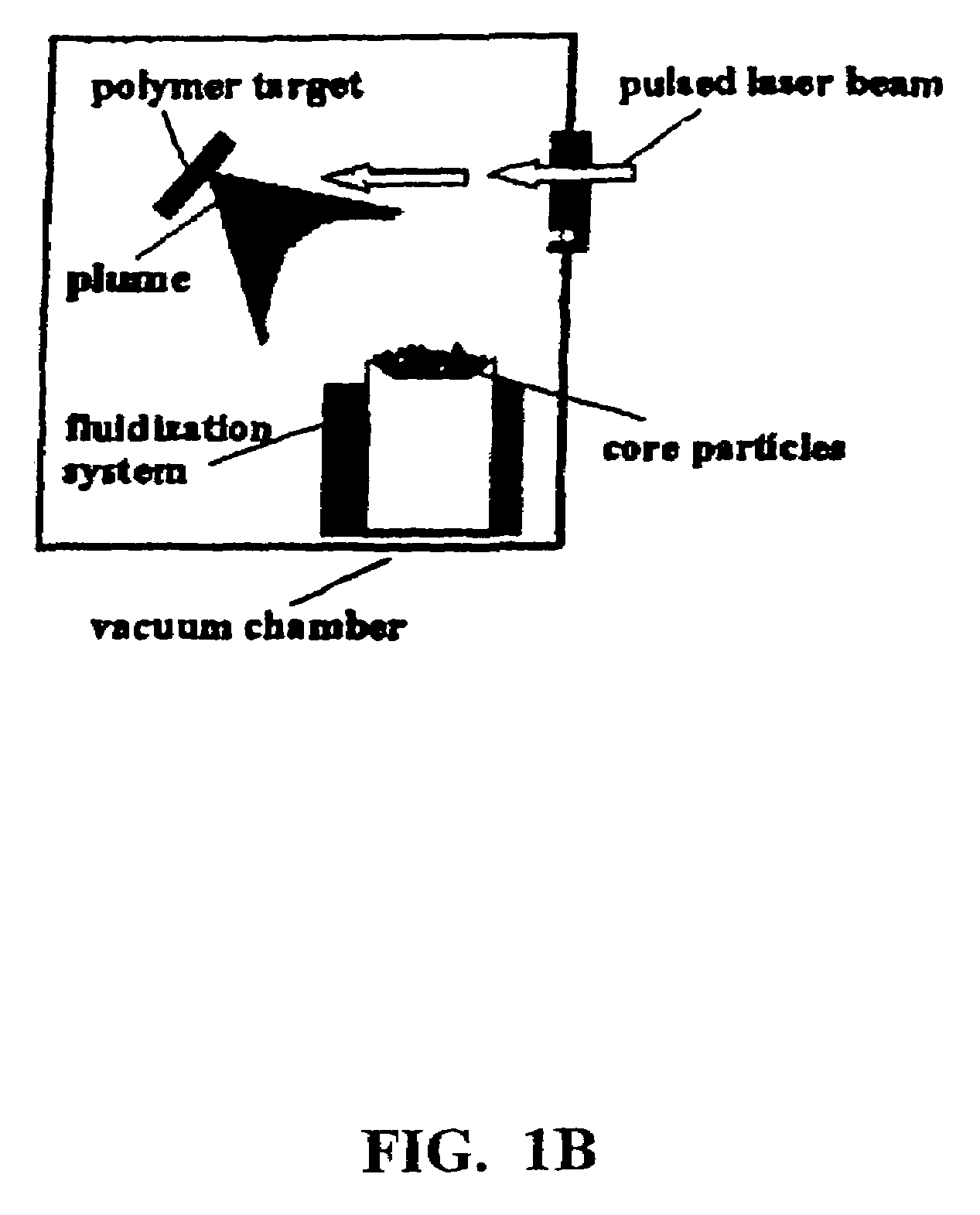

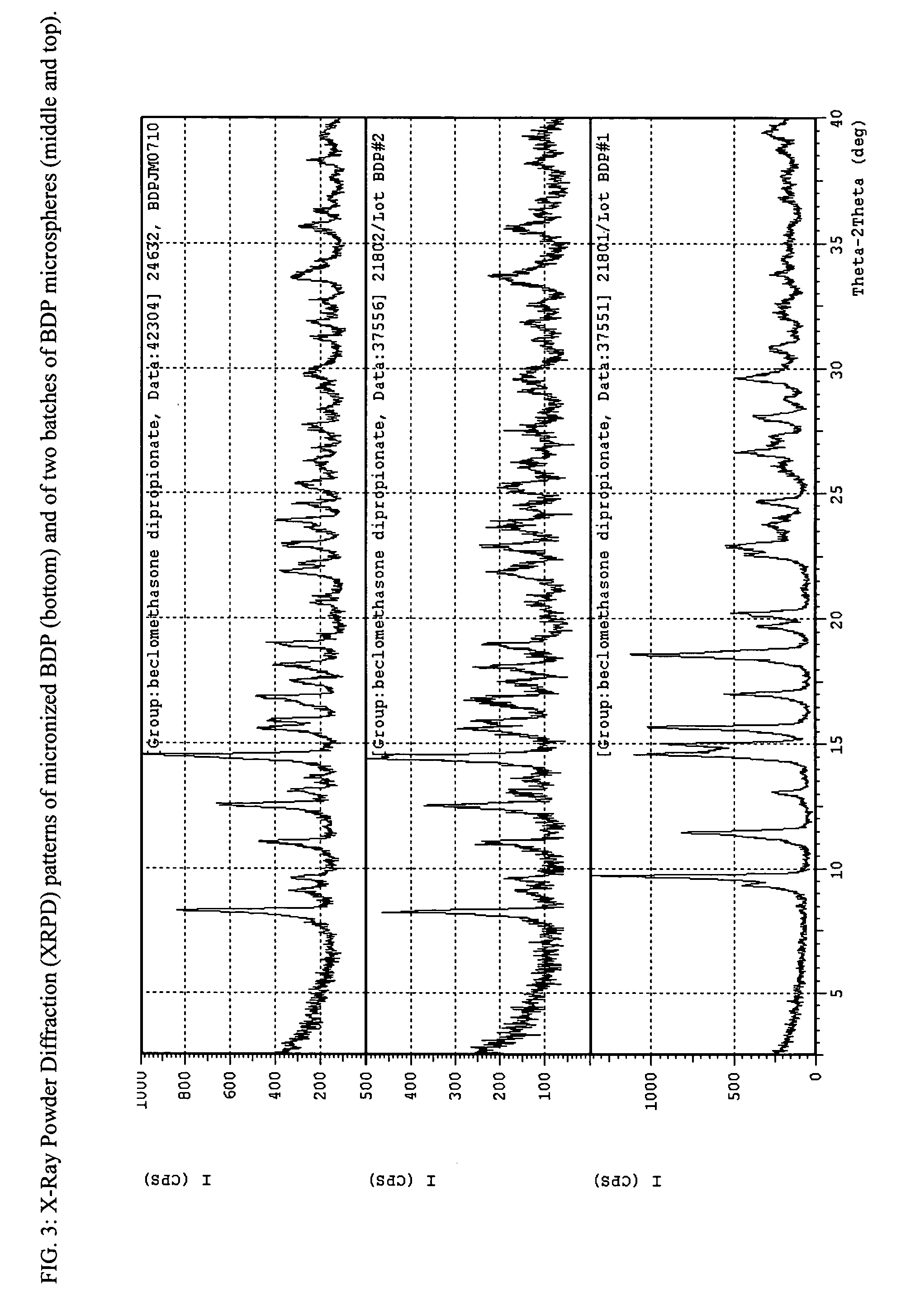

Methods for preparing coated drug particles and pharmaceutical formulations thereof

Disclosed are methods using pulsed laser ablation to prepare coated drug particles of uniform size and thickness. The coated drug particles ranged in size from several nanometers to several millimeters in diameter size, and were coated with organic polymer particle having average diameter sizes from about 1 to 50 nm. In illustrative embodiments, coated drug particles or drug delivery particles are disclosed comprising a biodegradable or biocompatible polymer coating having controlled thickness and controlled coating uniformity, that offer superior pharmaceutical properties for controlled delivery and increased bioavailability.

Owner:FLORIDA UNIV PF +2

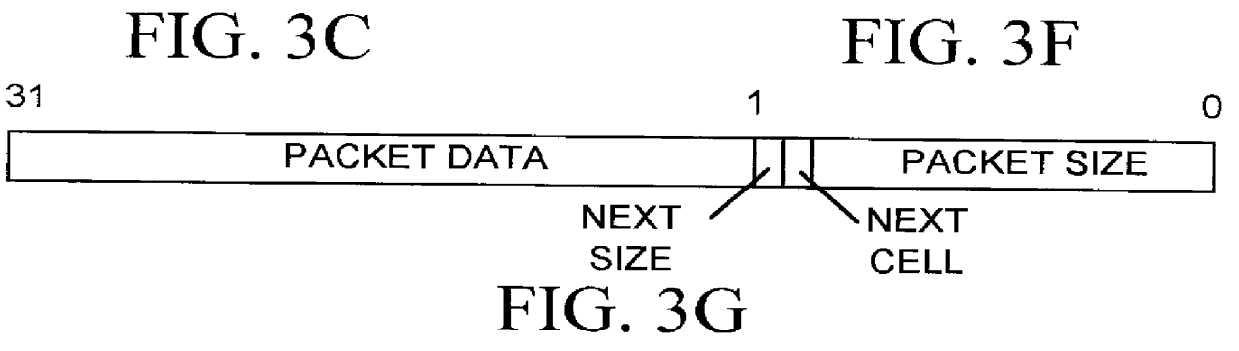

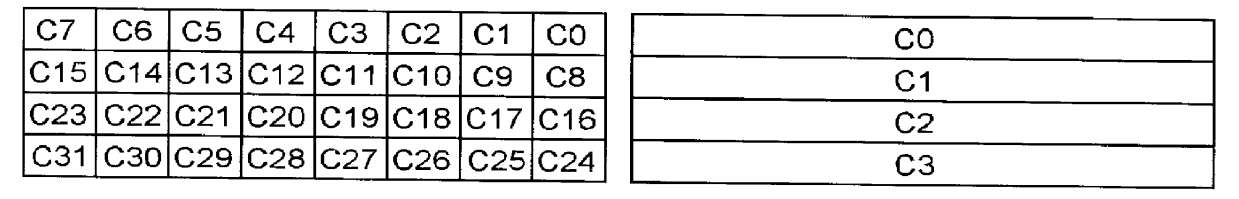

Dynamically configurable buffer for a computer network

A dynamically configurable network buffer includes a buffer manager organizing a buffer memory into a set of uniform sized packet buffers, each of which is large enough to store the largest possible data packet that may be transmitted through the network switch. The buffer manager further subdivides each packet buffer into a set of smaller packet cells of uniform size. When an incoming data packet arrives at the network buffer, the buffer manager determines its size. If the packet is too large to be stored in a single packet cell, the buffer manager stores the packet by itself in an unoccupied packet buffer. If the packet is small enough to be stored in a single packet cell, the buffer manager stores the packet in an unoccupied packet cell. The network buffer can increase or decrease packet cell size in response to input configuration data.

Owner:RPX CORP

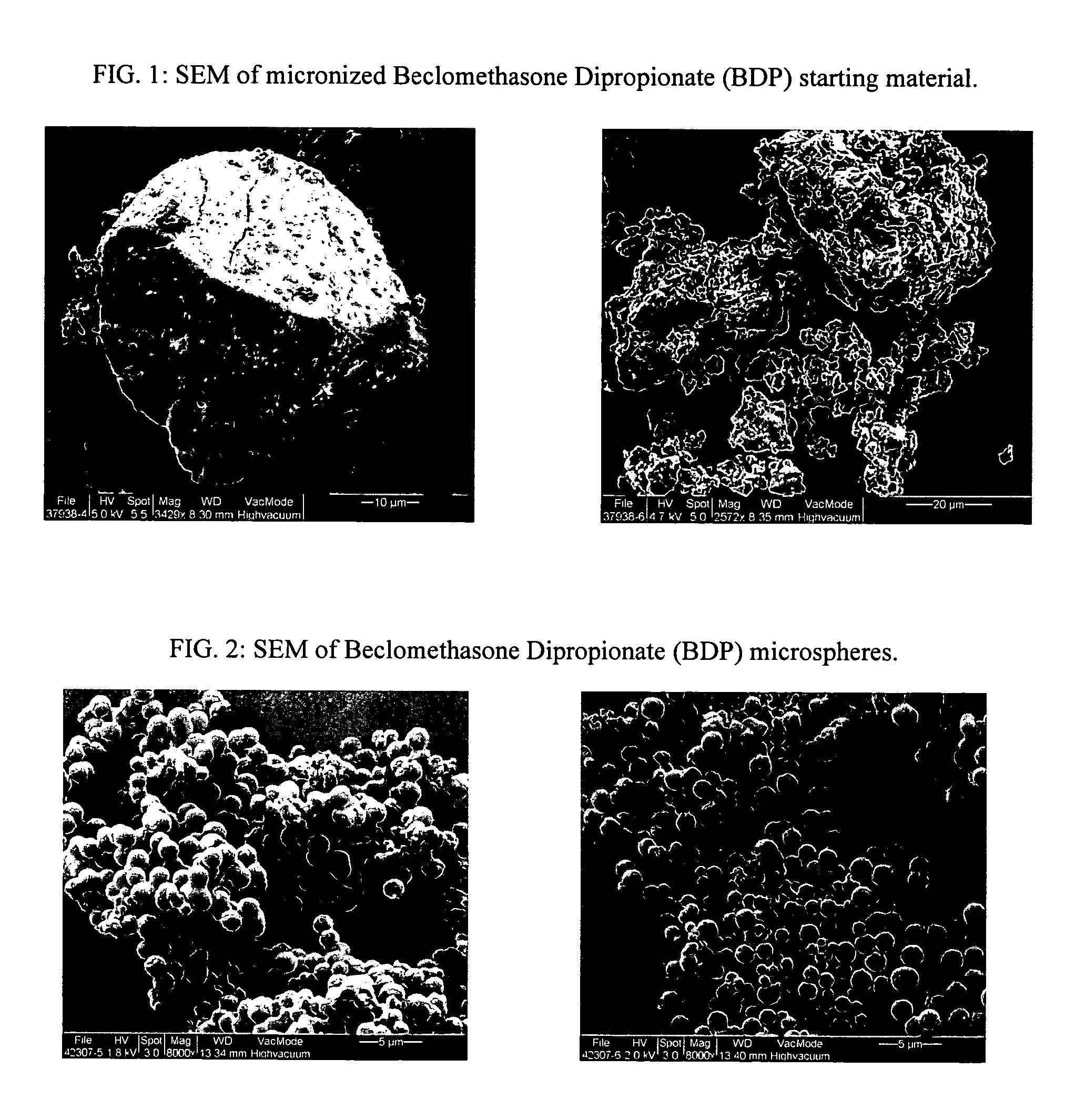

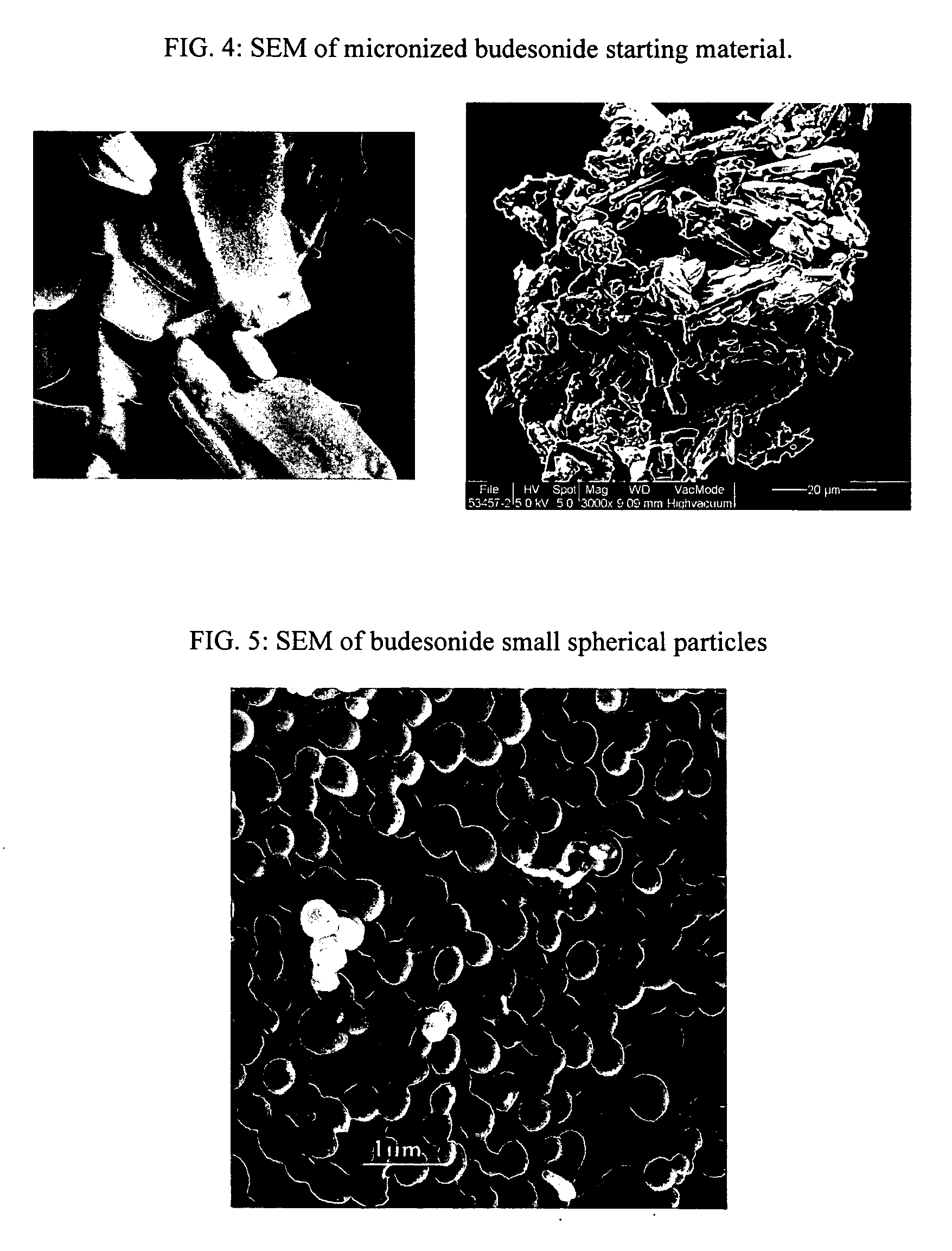

Small spherical particles of low molecular weight organic molecules and methods of preparation and use thereof

InactiveUS20050048127A1Uniform sizeHigh ratio of surface areaPowder deliveryChemical physicsNanosized particle

The invention provides homogeneous small spherical particles of low molecular weight organic molecules, said small spherical particles having a uniform shape, a narrow size distribution and average diameter of 0.01-200 μm. The invention further provides methods of preparation and methods of use of the small spherical particles. These small spherical particles are suitable for applications that require delivery of micron-size or nanosized particles with uniform size and good aerodynamic or flow characteristics. Pulmonary, intravenous, and other means of administration are among the delivery routes that may benefit from these small spherical particles.

Owner:BAXTER INT INC +1

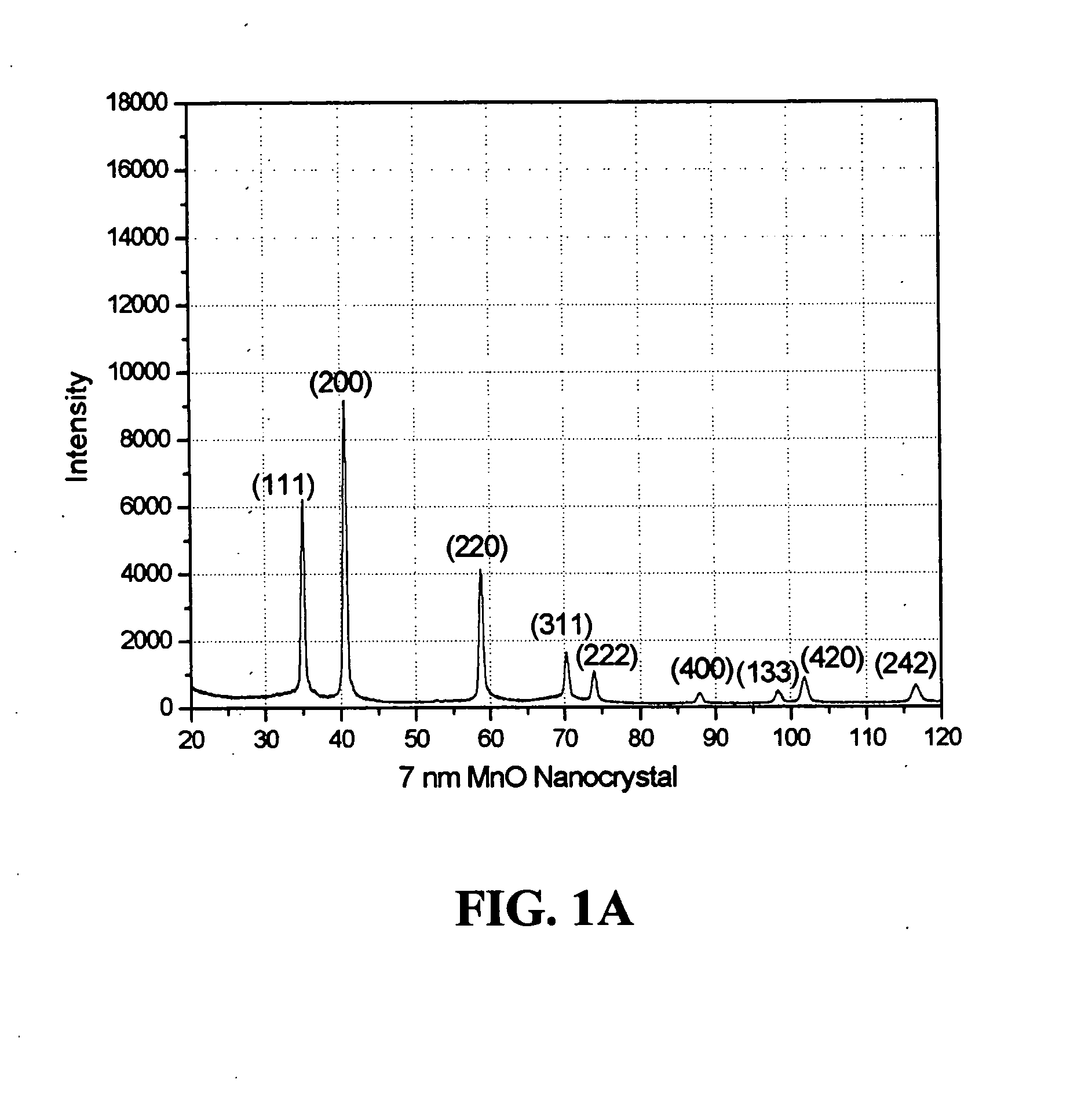

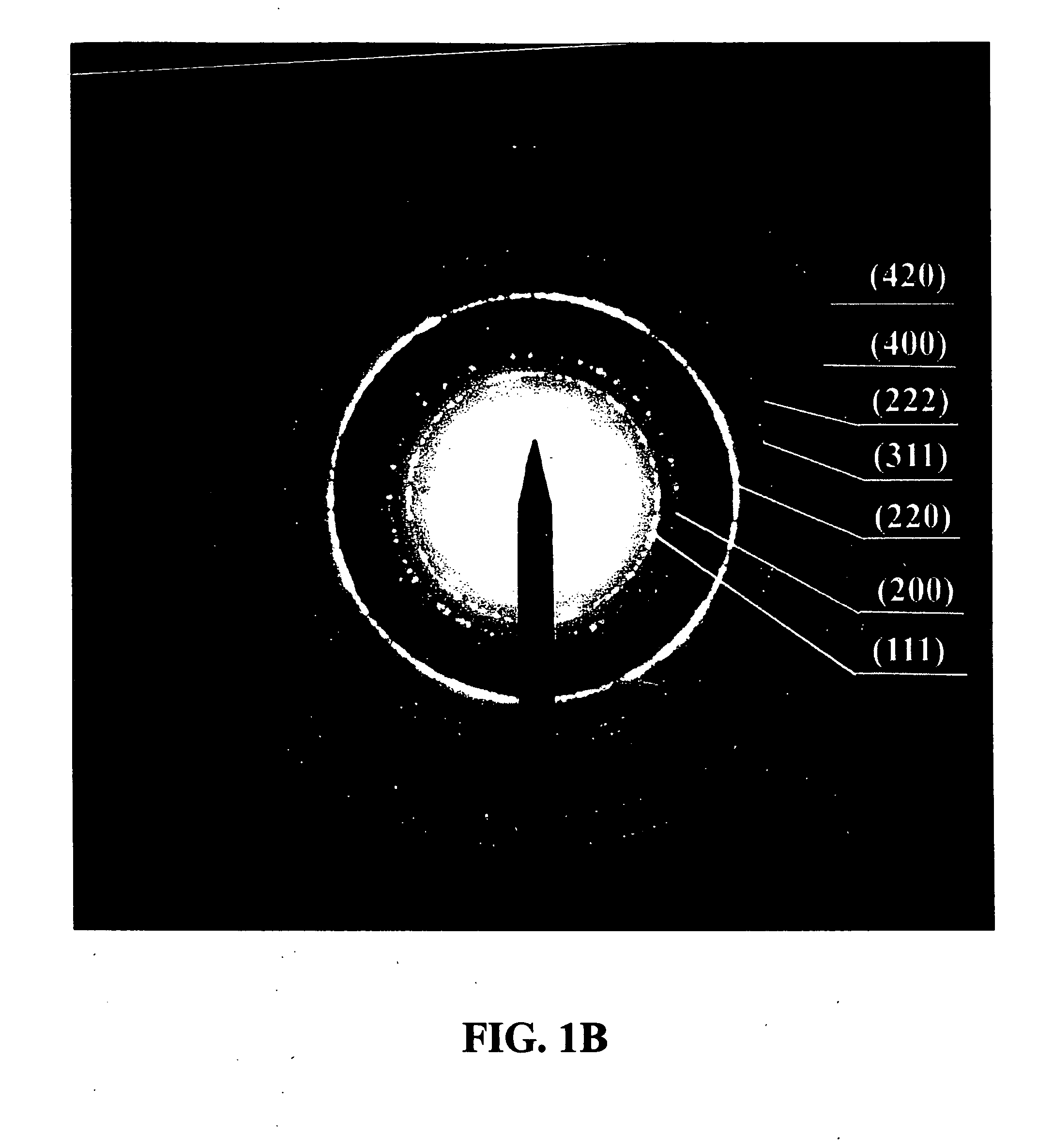

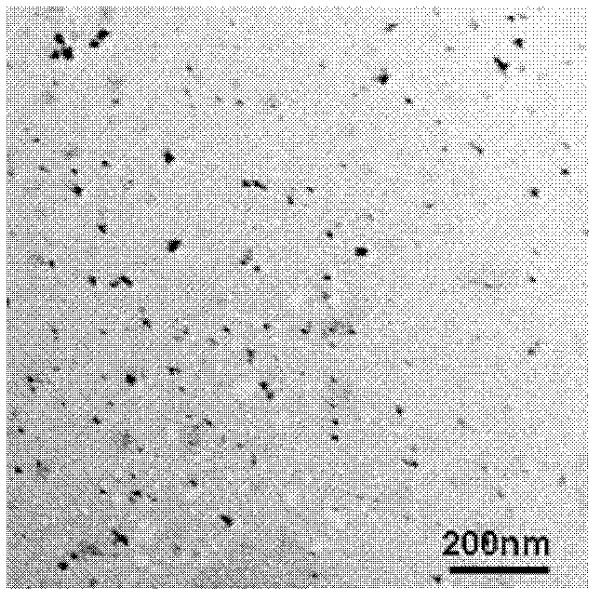

Nano-sized particles, processes of making, compositions and uses thereof

InactiveUS20070140951A1Economical and efficientQuality improvementMaterial nanotechnologyToilet preparationsSolventPharmaceutical formulation

The present invention describes methods for preparing high quality nanoparticles, i.e., metal oxide based nanoparticles of uniform size and monodispersity. The nanoparticles advantageously comprise organic alkyl chain capping groups and are stable in air and in nonpolar solvents. The methods of the invention provide a simple and reproducible procedure for forming transition metal oxide nanocrystals, with yields over 80%. The highly crystalline and monodisperse nanocrystals are obtained directly without further size selection; particle size can be easily and fractionally increased by the methods. The resulting nanoparticles can exhibit magnetic and / or optical properties. These properties result from the methods used to prepare them. Also advantageously, the nanoparticles of this invention are well suited for use in a variety of industrial applications, including cosmetic and pharmaceutical formulations and compositions.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

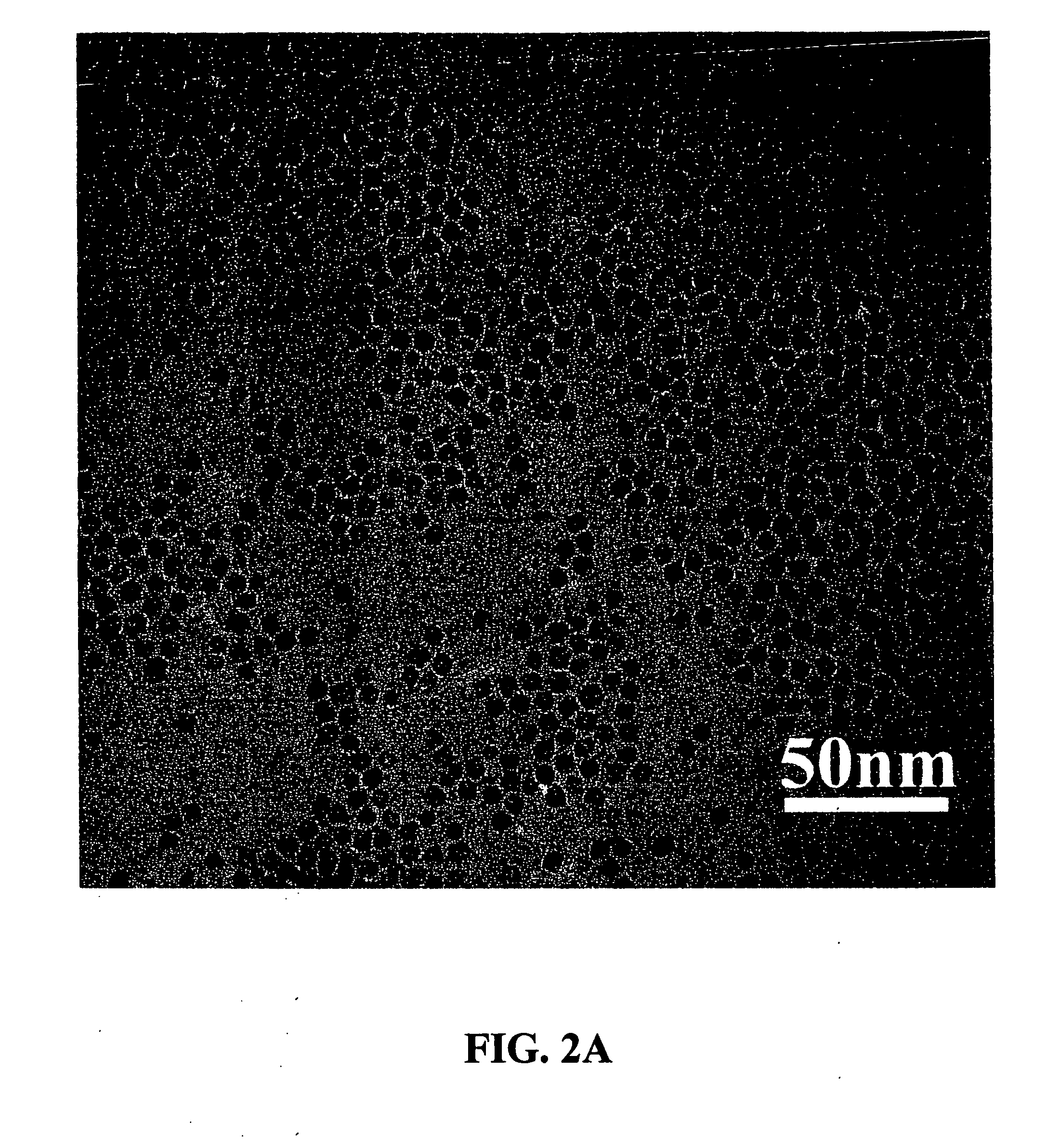

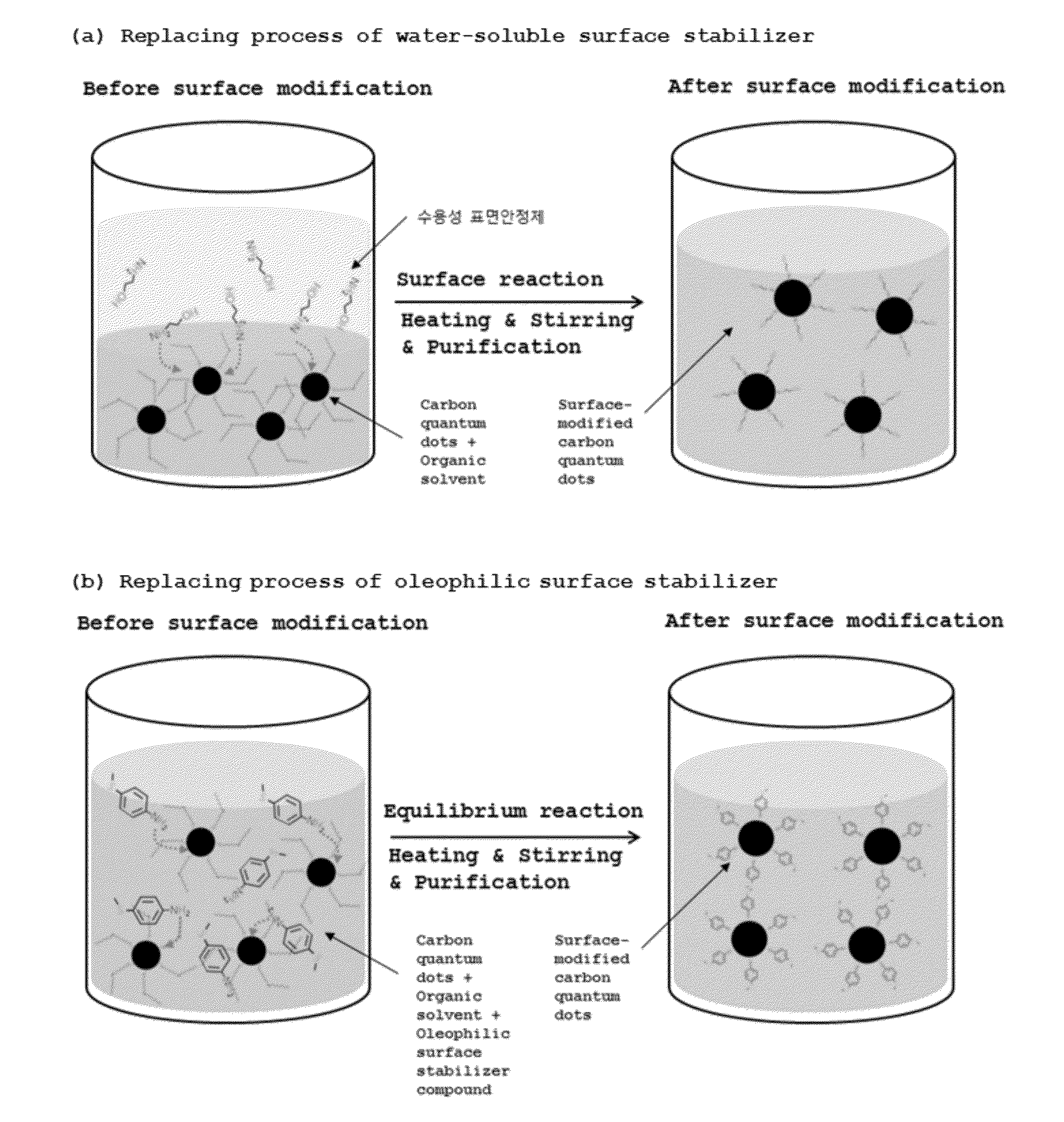

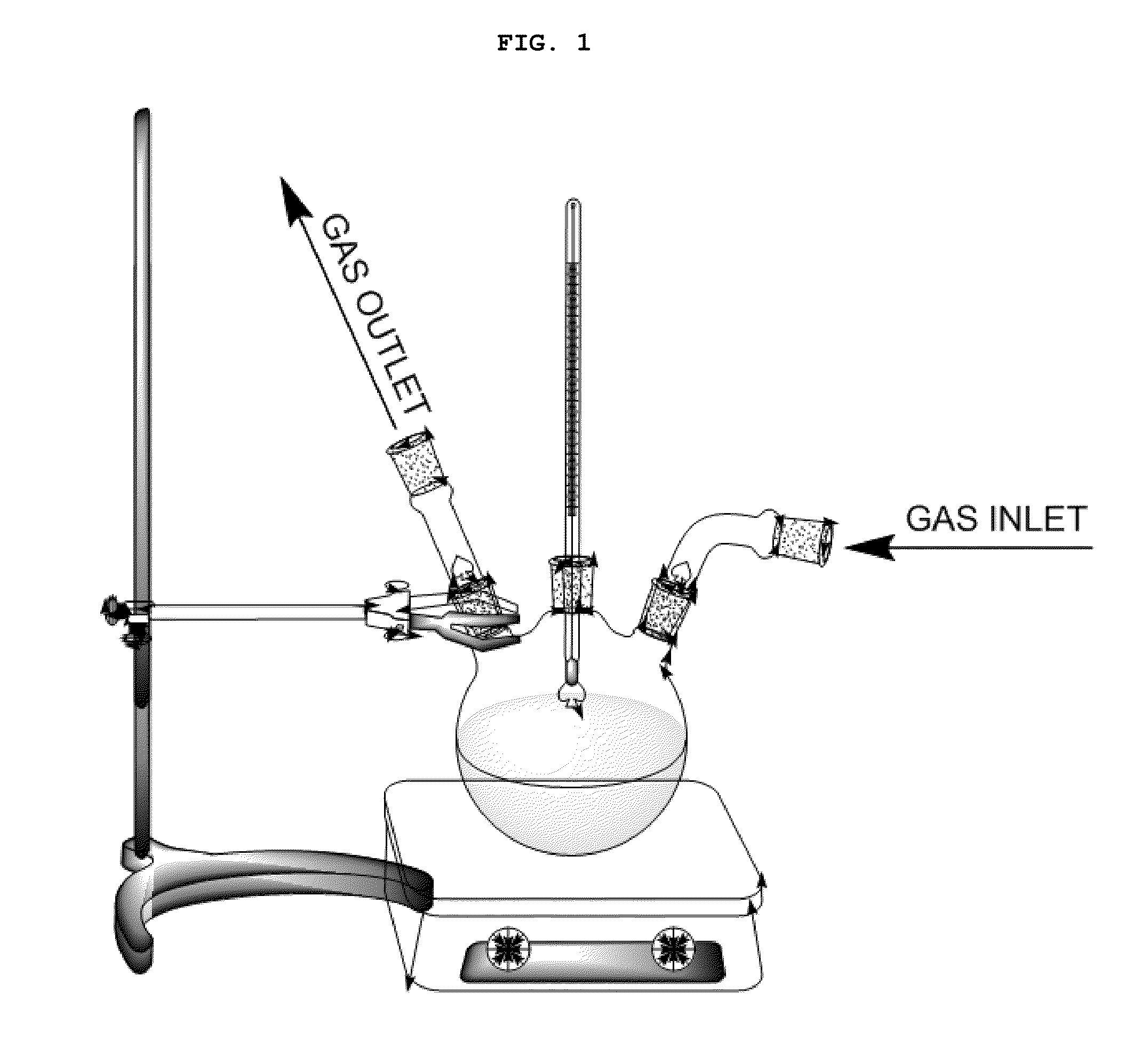

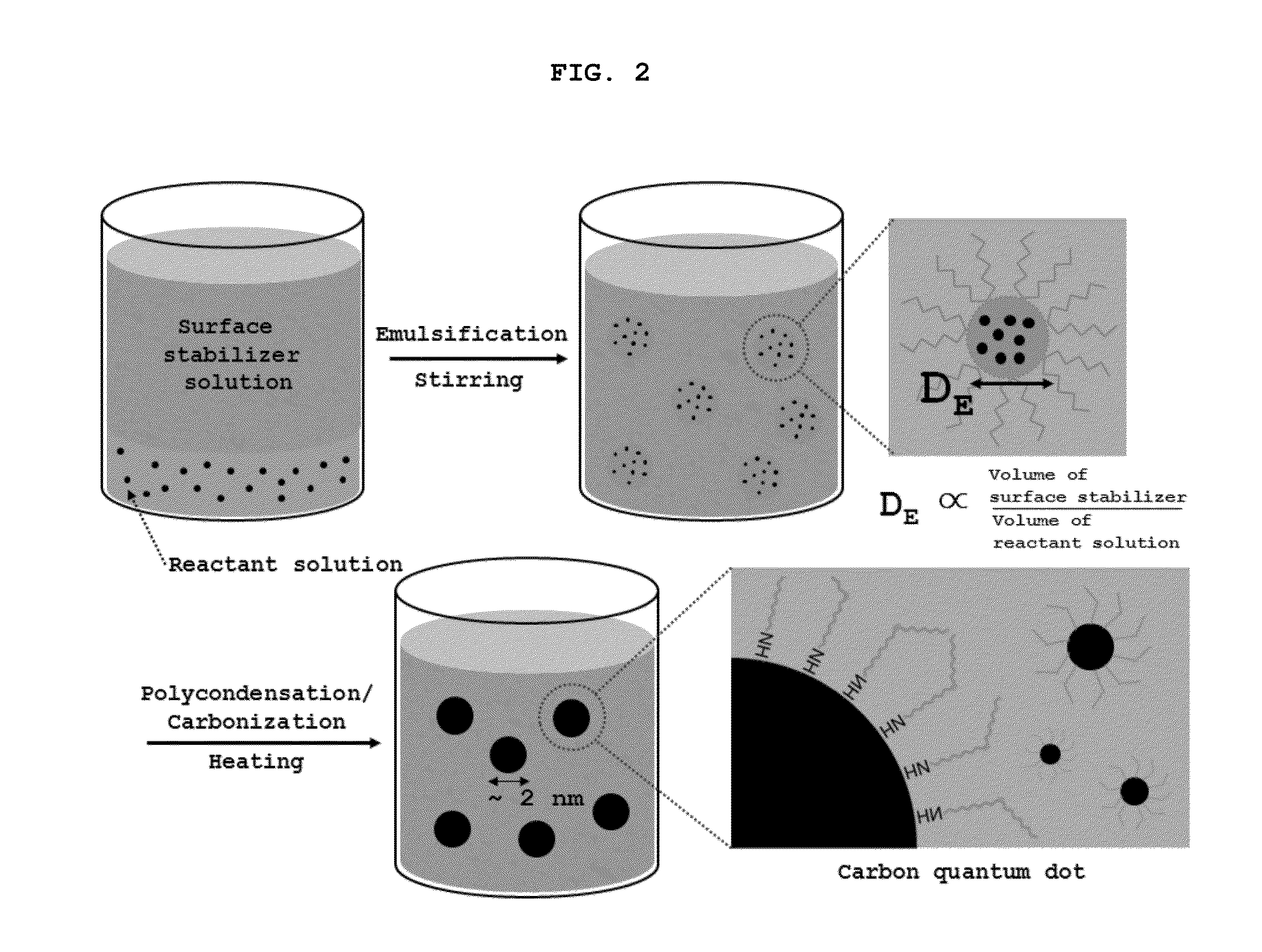

Process for preparing carbon quantum dots using emulsion

InactiveUS20150361334A1High reaction yieldEffective controlOrganic chemistryNano-carbonQuantum yieldEmulsion

The present invention provides a process for preparing carbon quantum dots having uniform size by using emulsion, and a process for doping the inside of the carbon structure with other element or replacing the surface with a surface stabilizer having a specific chemical functional group different from existing stabilizers in order to control the properties of the carbon quantum dots. The process for preparing the carbon quantum dots according to the present invention makes a mass production possible and the process thereof is simple. Furthermore, the process is easy to control the size of the quantum dots and the reaction yield rate of the method is excellent. In addition, according to the present invention, it is possible to synthesize carbon quantum dots having uniform size and superior quantum yield rate and it makes it possible to embody the color as equivalent to existing molecular chromophores or heavy metal quantum dots by changing the structure of the chromophore.

Owner:POSTECH ACAD IND FOUND

Scaffolded Nucleic Acid Polymer Particles and Methods of Making and Using

InactiveUS20110195253A1Sequential/parallel process reactionsMicrobiological testing/measurementParticle compositionPolynucleotide

The invention provides particle compositions having applications in nucleic acid analysis. Nucleic acid polymer particles of the invention allow polynucleotides to be attached throughout their volumes for higher loading capacities than those achievable solely with surface attachment. In one aspect, nucleic acid polymer particles of the invention comprise polyacrylamide particles with uniform size distributions having low coefficients of variations, which result in reduced particle-to-particle variation in analytical assays. Such particle compositions are used in various amplification reactions to make amplicon libraries from nucleic acid fragment libraries.

Owner:LIFE TECH CORP

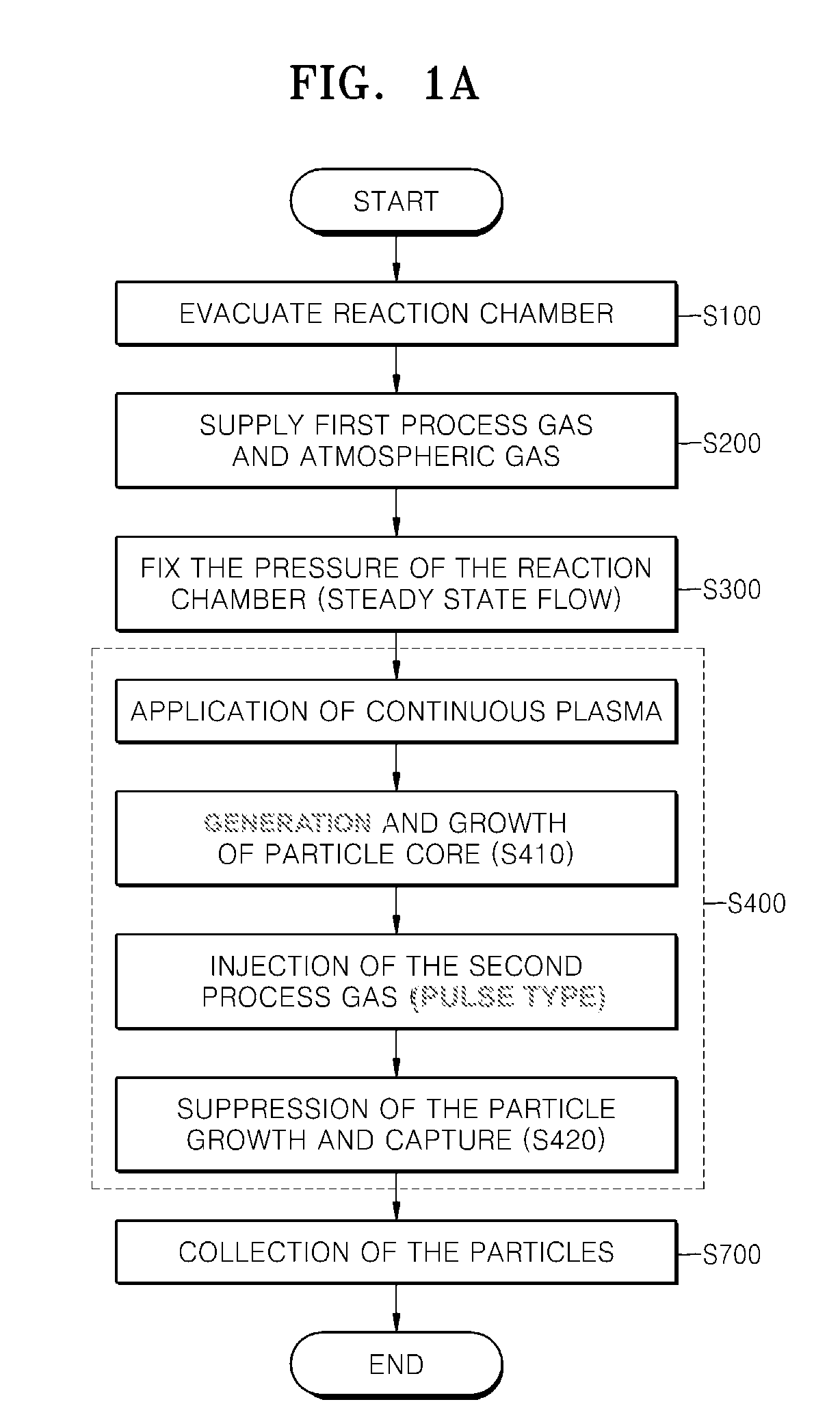

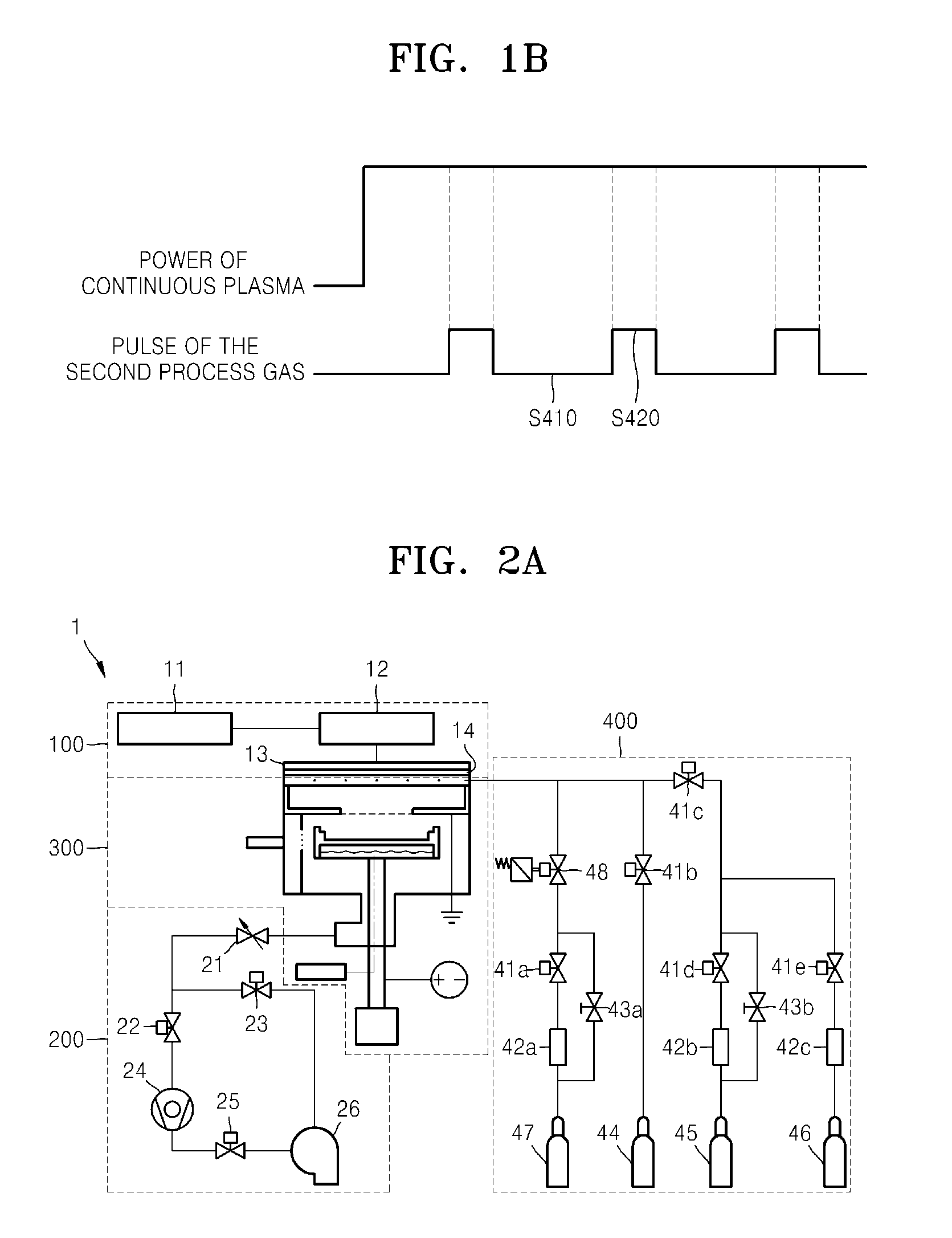

Method of producing nanoparticles, nanoparticles, and lithium battery comprising electrode comprising the nanoparticles

ActiveUS20090253037A1Material nanotechnologyNanostructure manufactureNanoparticleLow temperature plasma

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

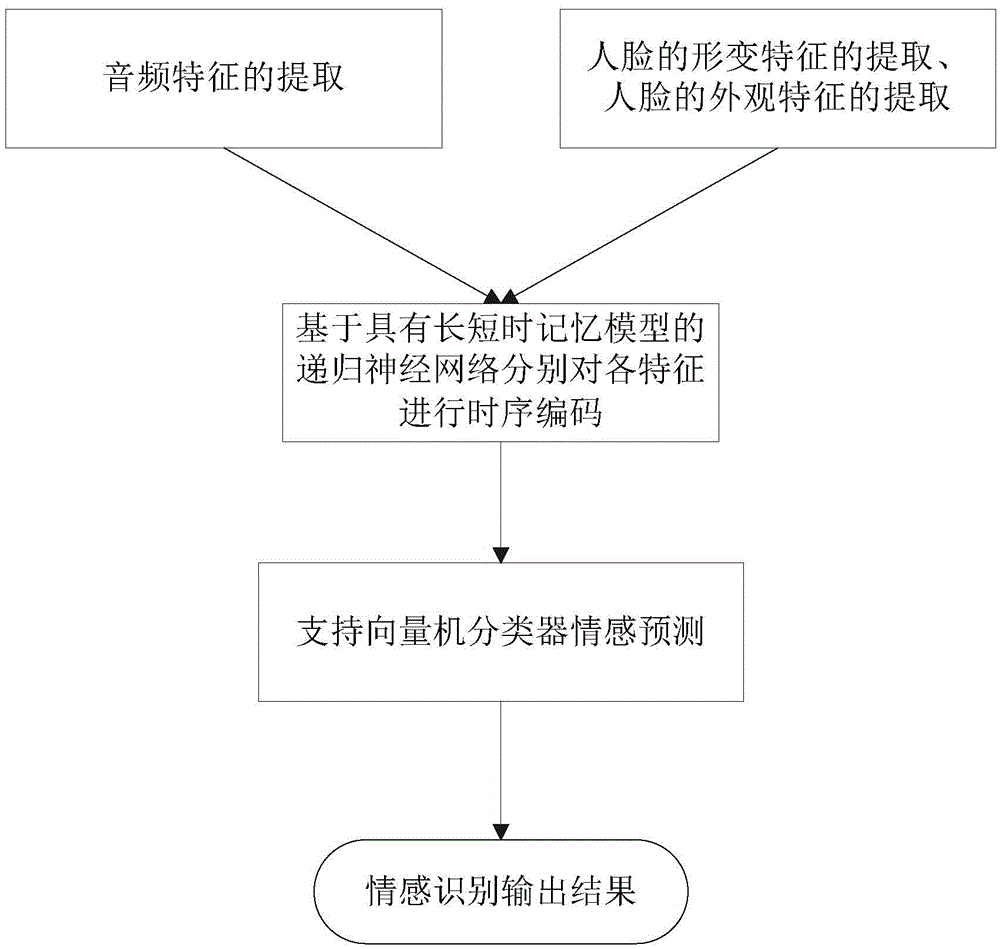

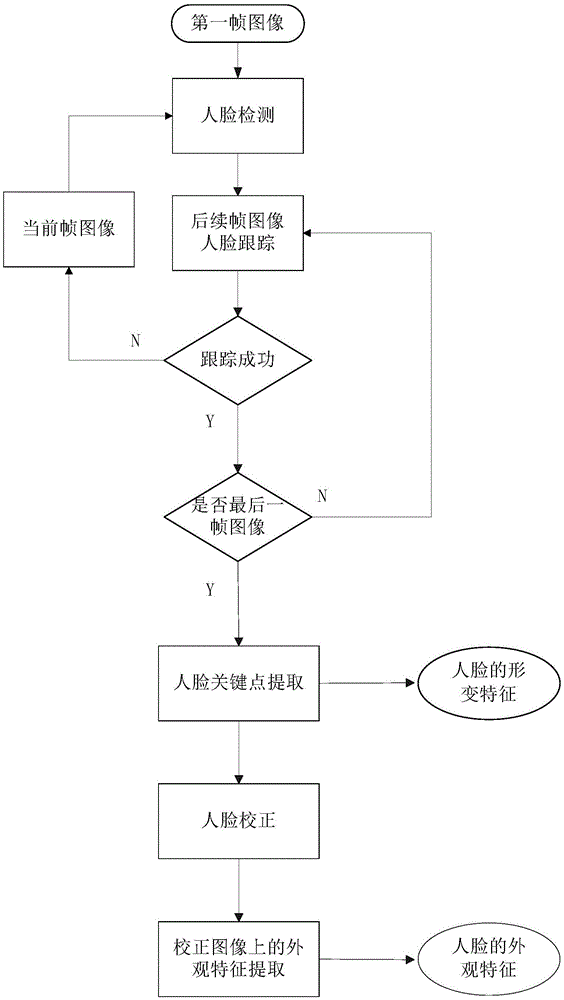

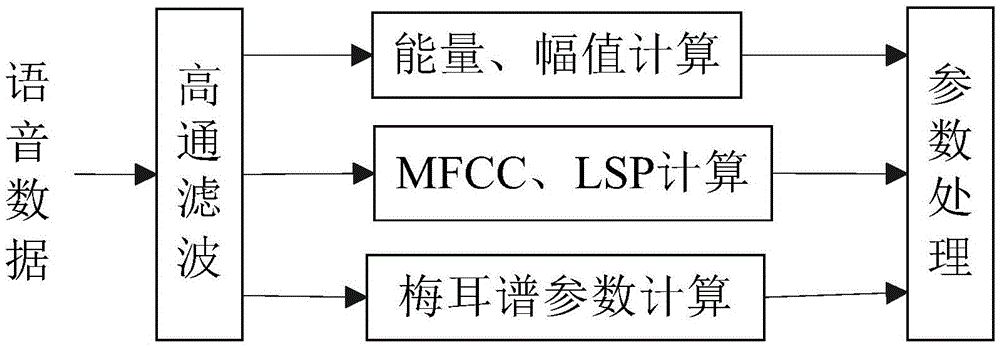

Recurrent neural network-based discrete emotion recognition method

ActiveCN105469065AModeling implementationRealize precise identificationCharacter and pattern recognitionDiscrete emotionsSupport vector machine classifier

The invention provides a recurrent neural network-based discrete emotion recognition method. The method comprises the following steps: 1, carrying out face detecting and tracking on image signals in a video, extracting key points of faces to serve as deformation features of the faces after obtaining the face regions, clipping the face regions and normalizing to a uniform size and extracting the appearance features of the faces; 2, windowing audio signals in the video, segmenting audio sequence units out and extracting audio features; 3, respectively carrying out sequential coding on the three features obtained by utilizing a recurrent neural network with long short-term memory models to obtain emotion representation vectors with fixed lengths, connecting the vectors in series and obtaining final emotion expression features; and 4, carrying out emotion category prediction by utilizing the final emotion expression features obtained in the step 3 on the basis of a support vector machine classifier. According to the method, dynamic information in the emotion expressing process can be fully utilized, so that the precise recognition of emotions of participators in the video is realized.

Owner:北京中科欧科科技有限公司

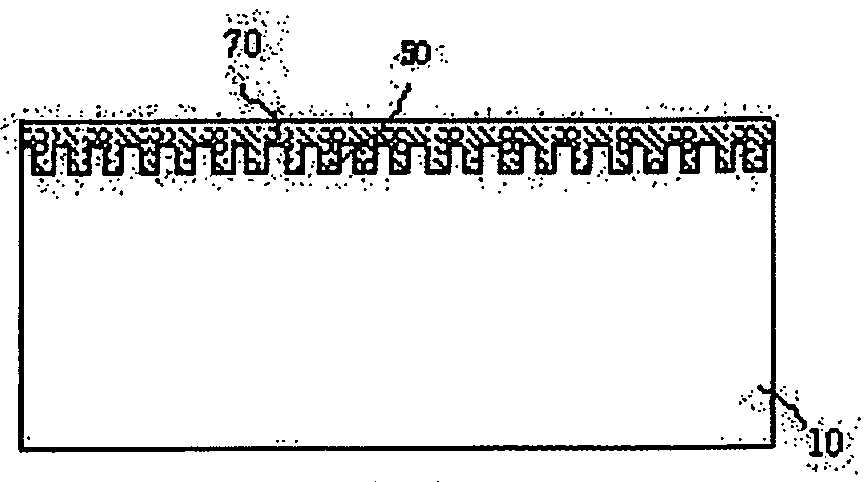

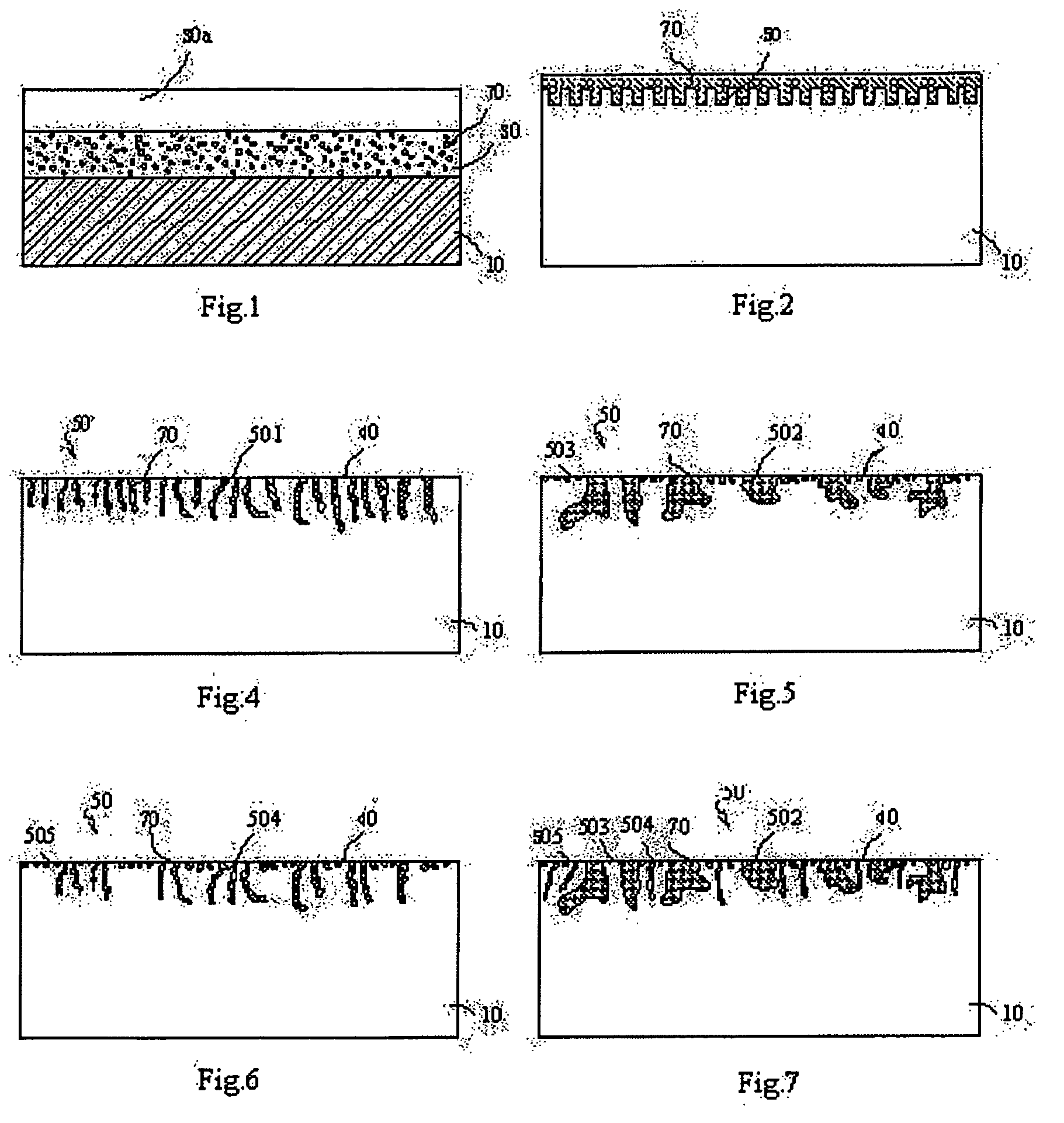

Nanoporous Drug Release Structure for Drug Elute Instruments and the Preparation Method Thereof

InactiveUS20090112310A1Reduce riskNo effect on mechanical propertySurgeryPharmaceutical delivery mechanismMicro arc oxidationPercent Diameter Stenosis

The present invention relates to a nanoporous configuration for drug release used in a drug-eluting device and its preparation, employing acid corrosion or anode oxidation to prepare pores, or employing acid corrosion to prepare pores firstly, then employing anode oxidation or micro-arc oxidation combined with micro-arc nitridation to prepare single sized or two sized or multiple sized nanopores, as well as a uniform size distributed or two or more nonuniform size distributed in pore diameter or pore depth h nanopores on the raw material of device body directly. The preparation process includes: ① Pre-treating the surface of the device body, ② Preparing pore, ③ Post-treating the surface of the device body, ④preparing drug, ⑤ Spraying drug etc. The nanoporous configuration lowers the risk of forming thrombus after the drug-delivery device with polymer carrier is implanted into the tissue. The device also controls the release rate of drug efficiently and lowers the incidence of restenosis significantly.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

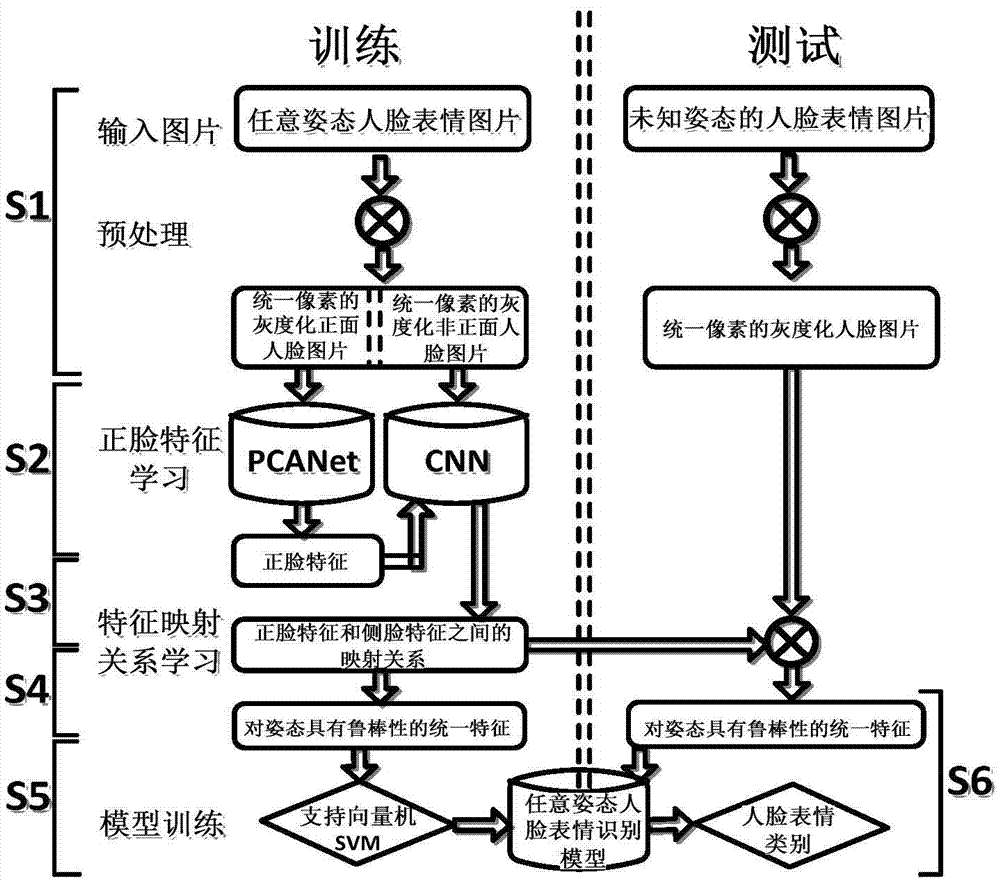

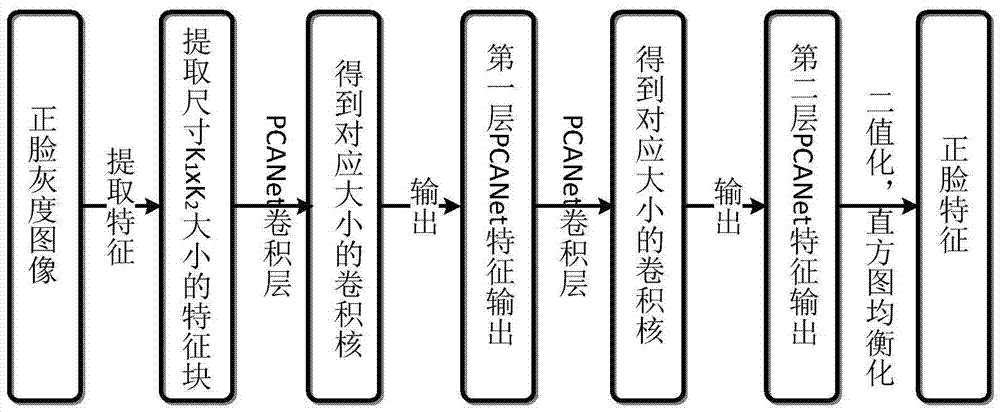

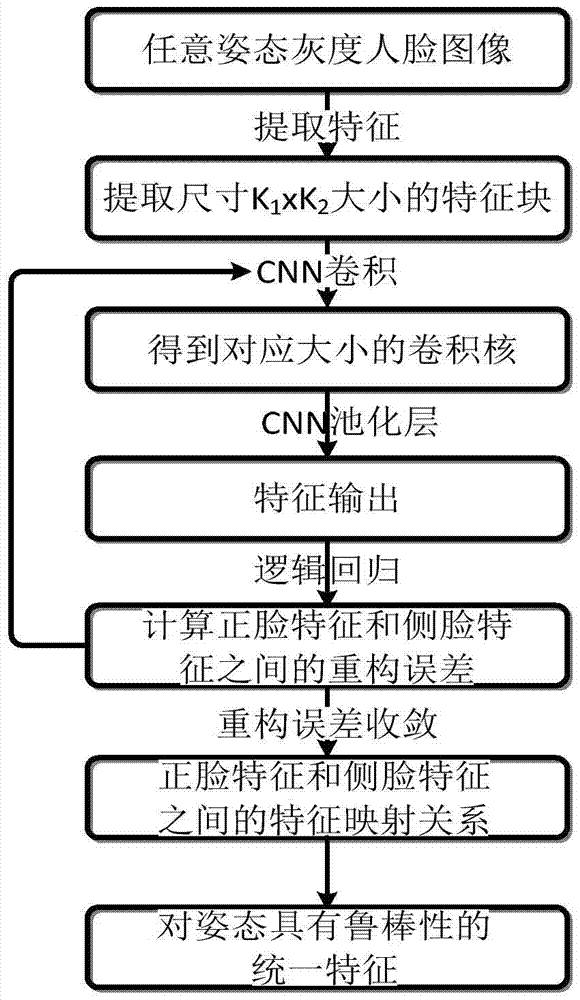

PCANet-CNN-based arbitrary attitude facial expression recognition method

ActiveCN105447473AImprove efficiencyEasy to identifyAcquiring/recognising facial featuresGray levelFacial characteristic

The invention discloses a PCANet-CNN-based arbitrary attitude facial expression recognition method. The method comprises the following steps: firstly pre-processing the original images to obtain gray level facial images with uniform size, wherein the gray level facial images comprise front facial images and side facial images; inputting the front face images into an unsupervised characteristic learning model PCANet and learning to obtain characteristics corresponding to the front facial images; inputting the side facial images into a supervised characteristic learning model CNN, and training by taking the front facial characteristics obtained through the unsupervised characteristic learning as labels so as to obtain a mapping relationship between the front facial characteristics and the side facial characteristics; and obtaining uniform front facial characteristics corresponding to the facial images at arbitrary attitudes through the mapping relationship, and finally sending the uniform front facial characteristics into SVM to train so as to obtain a uniform recognition model in allusion to arbitrary attitudes. According to the method provided by the invention, the problem of low model recognition rate caused by the condition of respectively modeling for each attitude in the traditional multi-attitude facial expression recognition and the factors such as attitude and the like is solved, and the correctness of the multi-attitude facial image expression recognition can be effectively improved.

Owner:JIANGSU UNIV

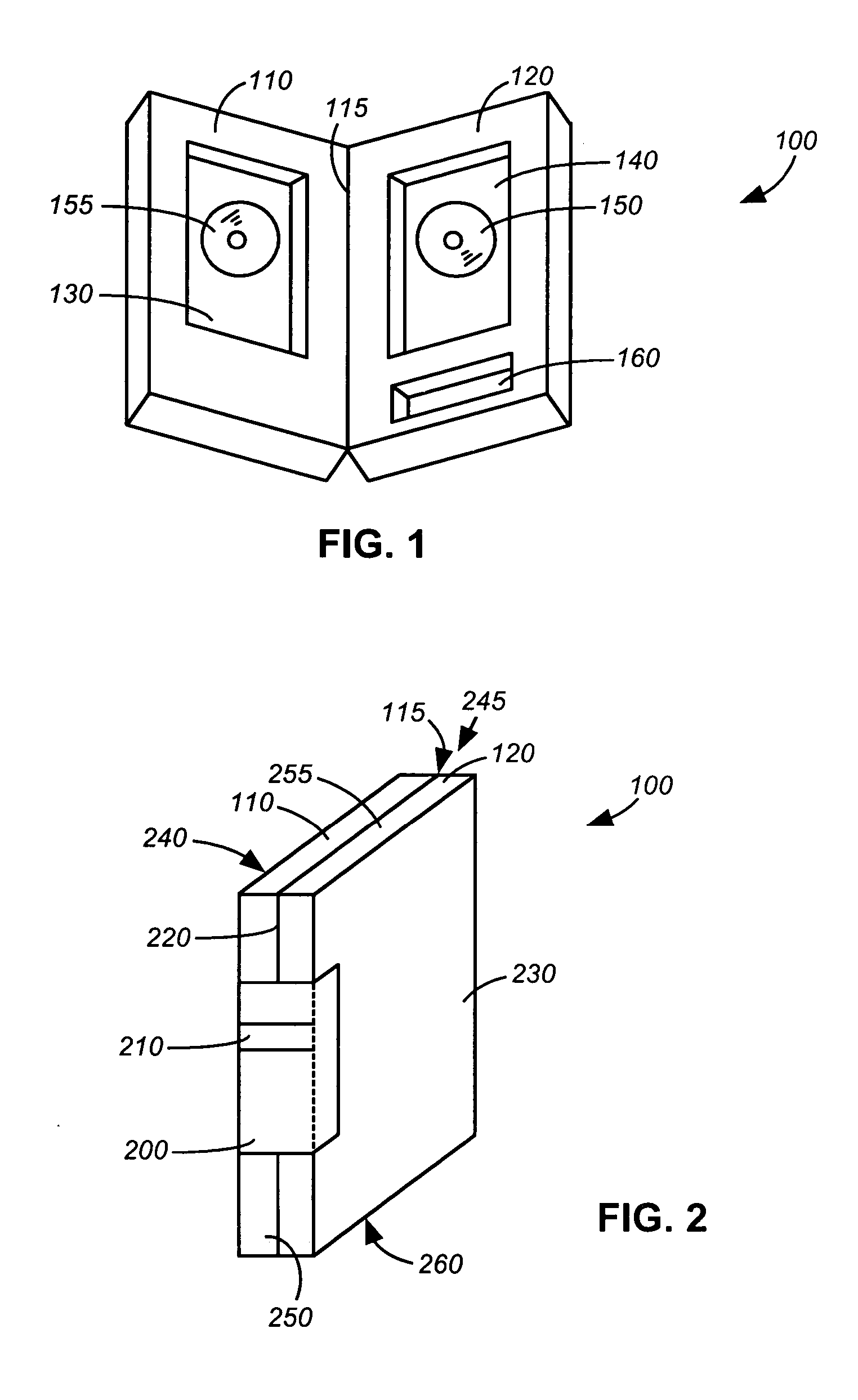

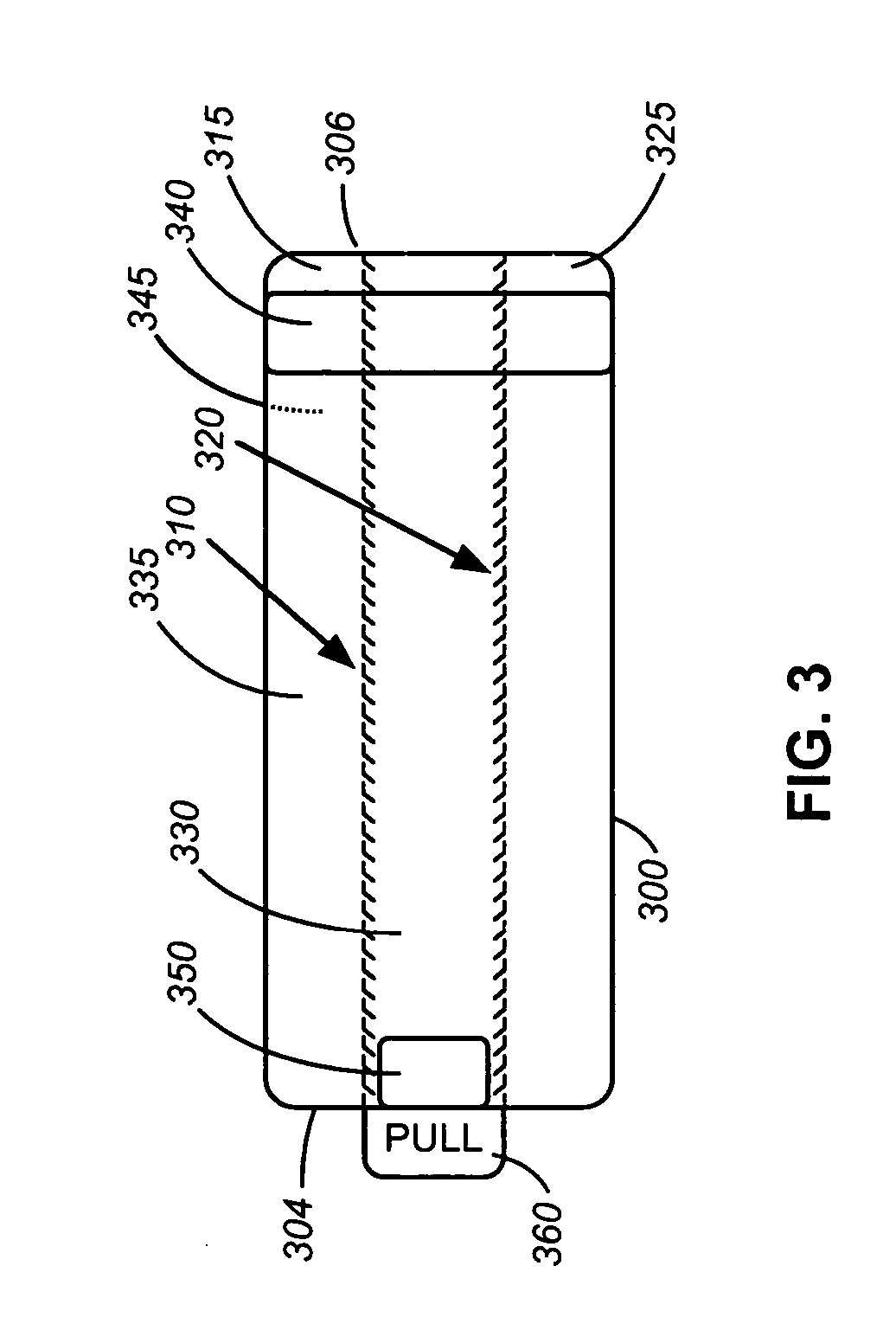

Package closure device

A convenient, effective closure device for use on packages such as those used to enclose games distributed on CDs, DVDs, or similar media. A preprinted edge label is selectively coated with adhesive and affixed to a package in such a manner that the package may not be opened without violating the edge label. To facilitate opening, a tear strip is at least in part defined by two rows of obtuse perforations. The obtuse perforations, or at least a subset of them, are formed to be of uniform size and shape of a pair of slits that intersect at their respective end points, forming the obtuse angle.

Owner:NOKIA CORP

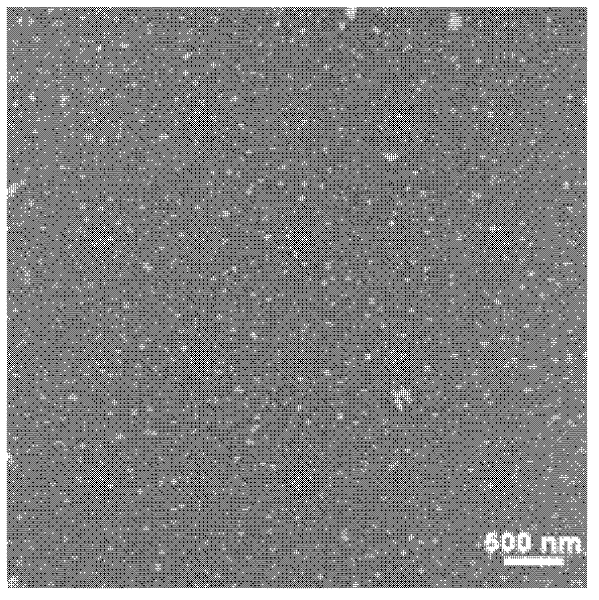

Method for preparing Ag-carrying bacterial cellulose hydrogel antimicrobial dressing and product thereof

The invention discloses a method for preparing an Ag-carrying bacterial cellulose hydrogel antimicrobial dressing and a product thereof. The method comprises the following steps of: soaking a bacterial cellulose hydrogel film in solution of silver metal precursor; then heating the film to be between 121 and 135 DEG C in a high-pressure sterilizing pot, and pressurizing between 0.205 and 0.313MPa; standing bacterial cellulose for 5 to 30min; and then taking the treated bacterial cellulose out for washing, partial dehydration, packaging and sterilization to obtain an Ag-carrying bacterial cellulose hydrogel antimicrobial dressing which is formed by compounding silver metal nano-particles and bacterial cellulose and is attached with 0.01 to 10 weight percent of the silver metal nano-particles in a bacterial cellulose three-dimensional porous network structure. The preparation process of the invention has the advantages of simplicity, easiness, convenient operation, controllable preparation technology, no pollution and low cost; and the prepared nano-particles have the advantages of high purity, small particle size, uniform size and good dispersity. The obtained Ag-carrying bacterial cellulose hydrogel antimicrobial dressing has the characteristics of good antimicrobial property, high water content, good water-retaining property, strong toughness, good air permeability and the like, and can meet the requirements of treating various wounds by a wet method.

Owner:DONGHUA UNIV +1

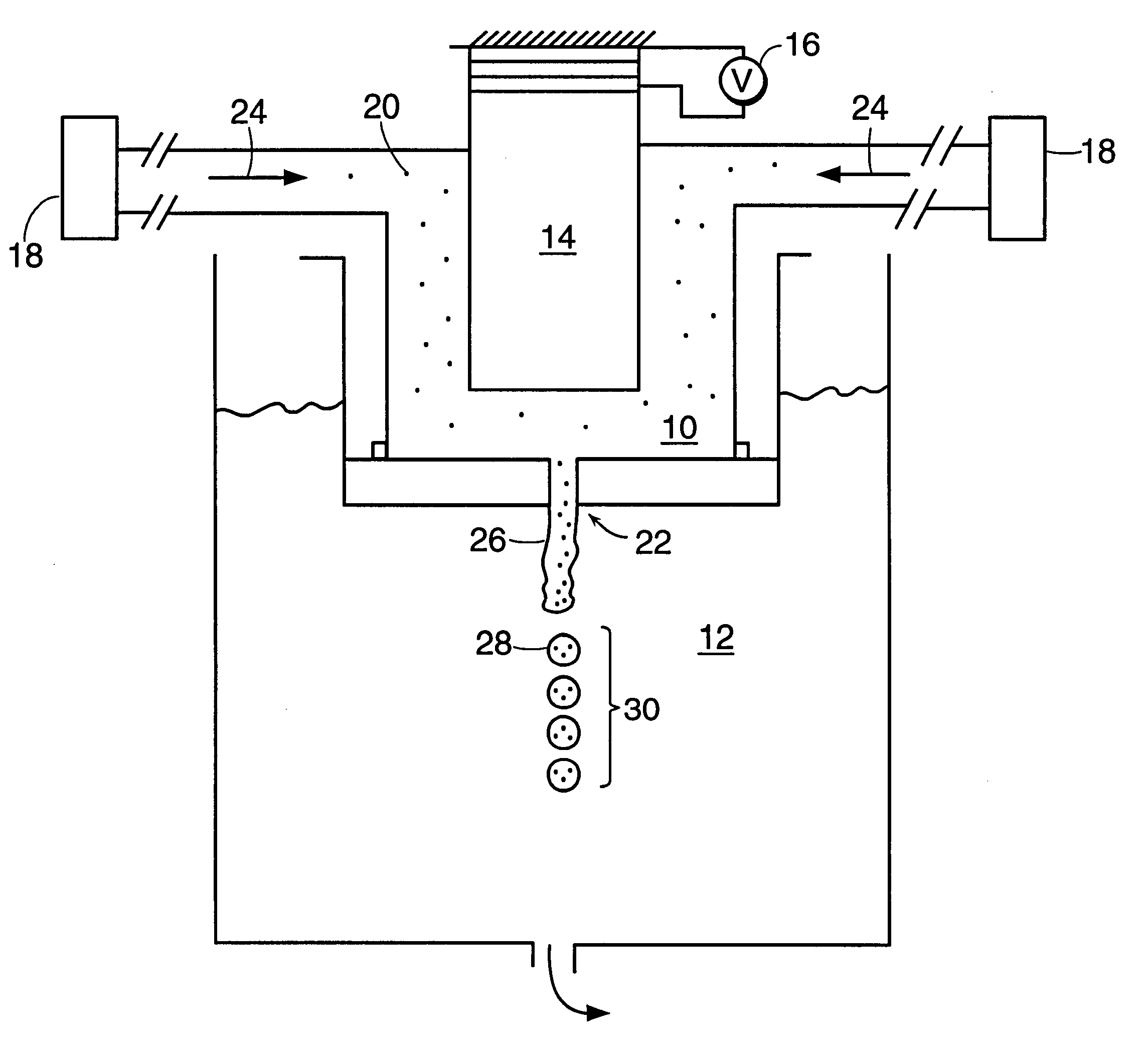

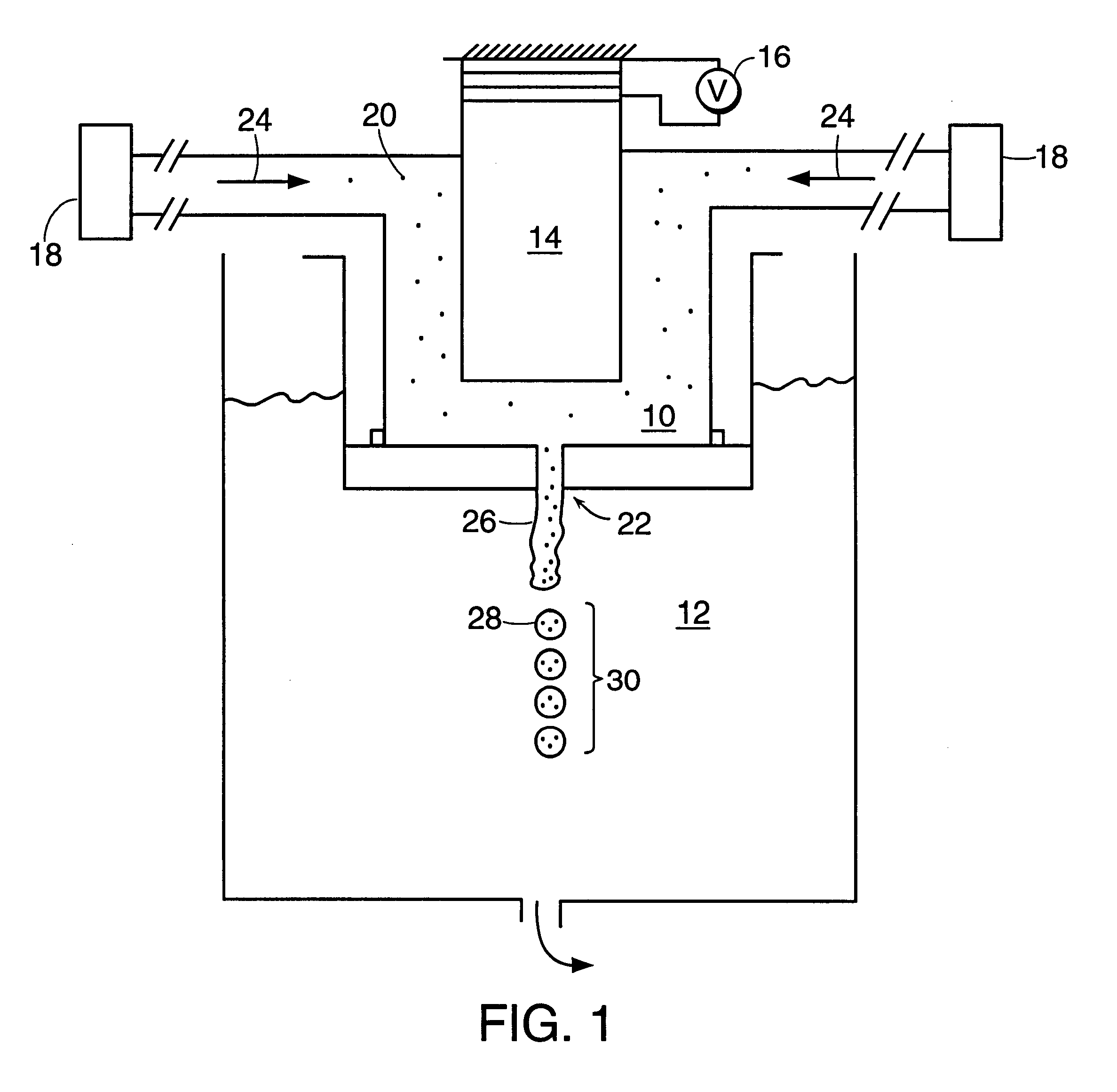

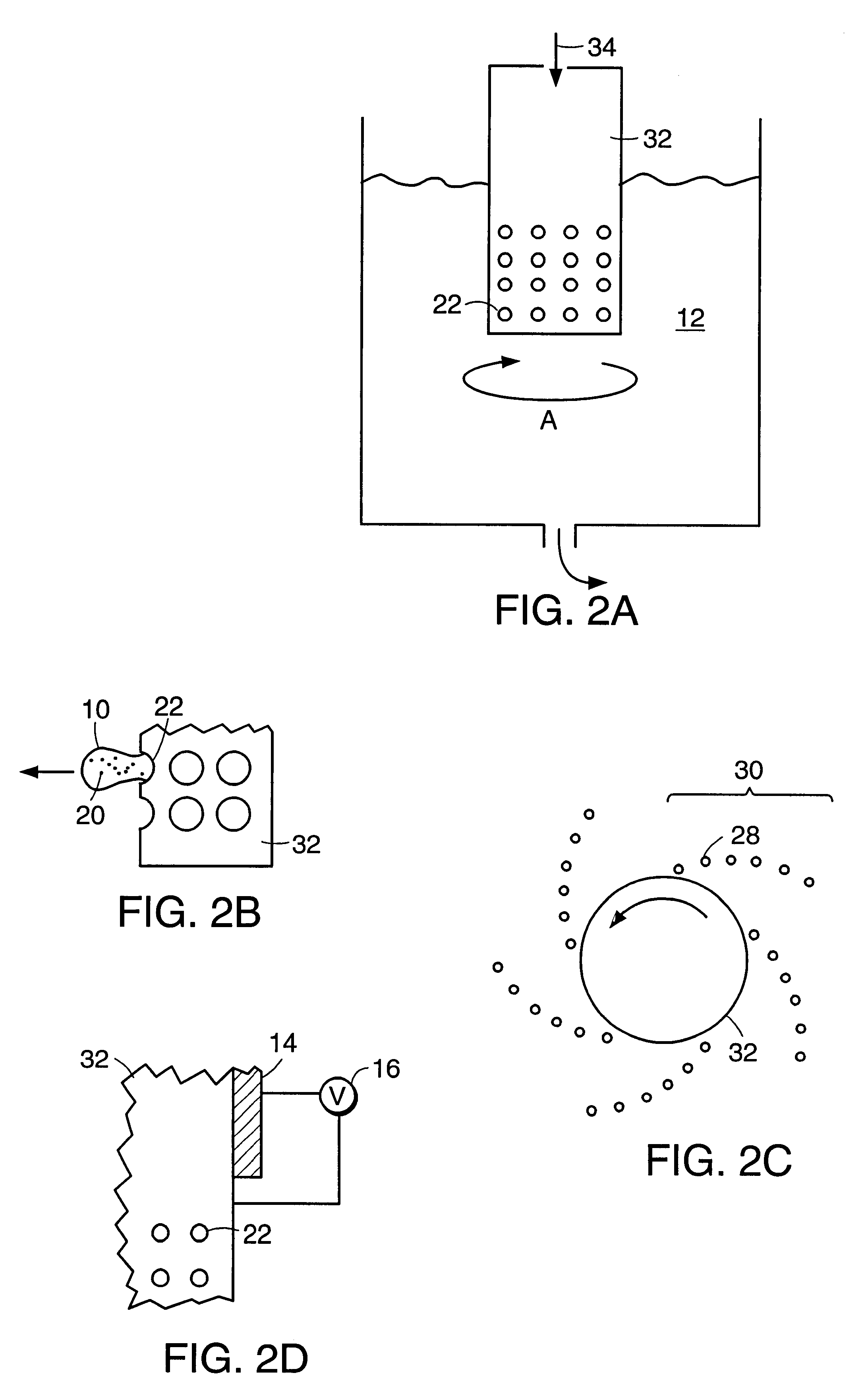

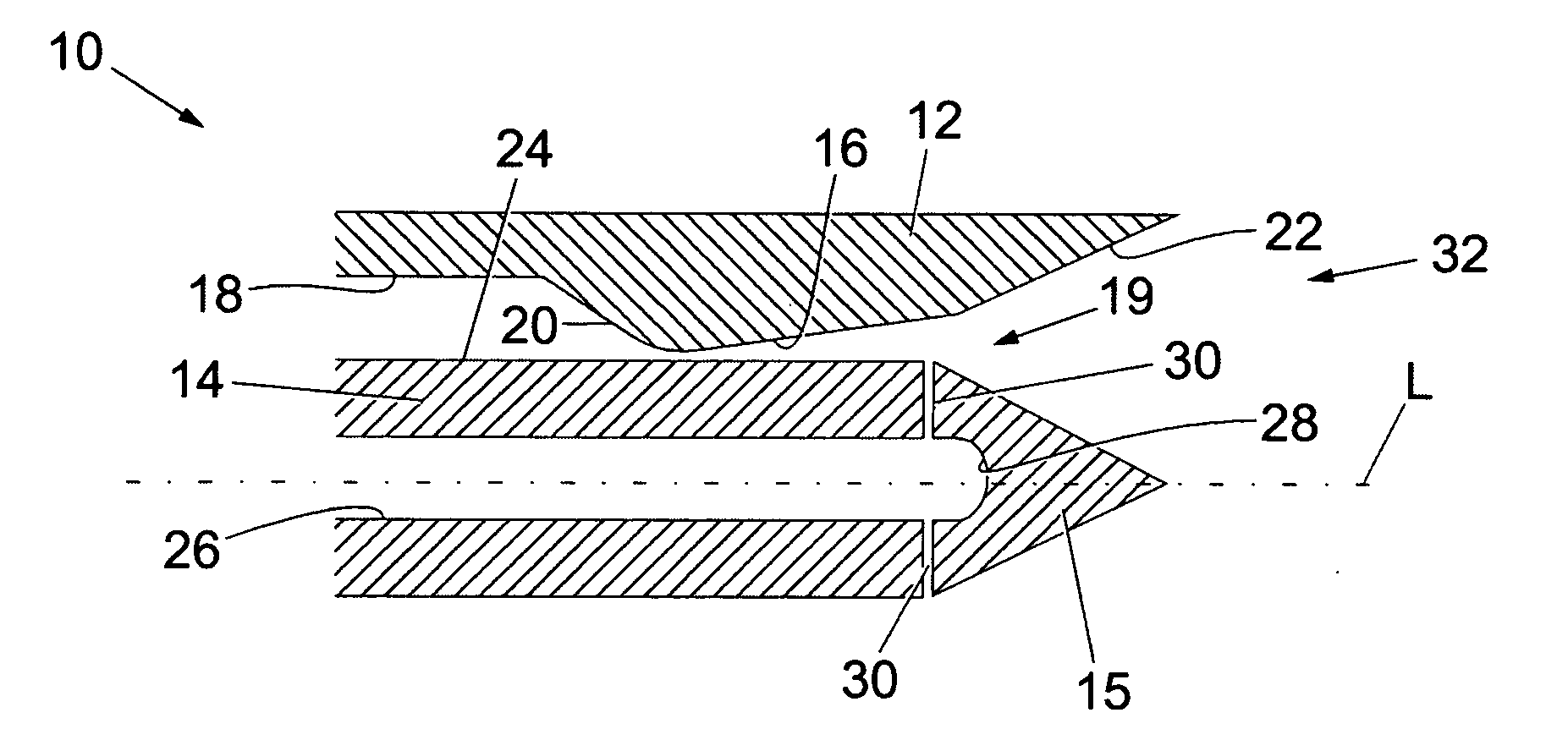

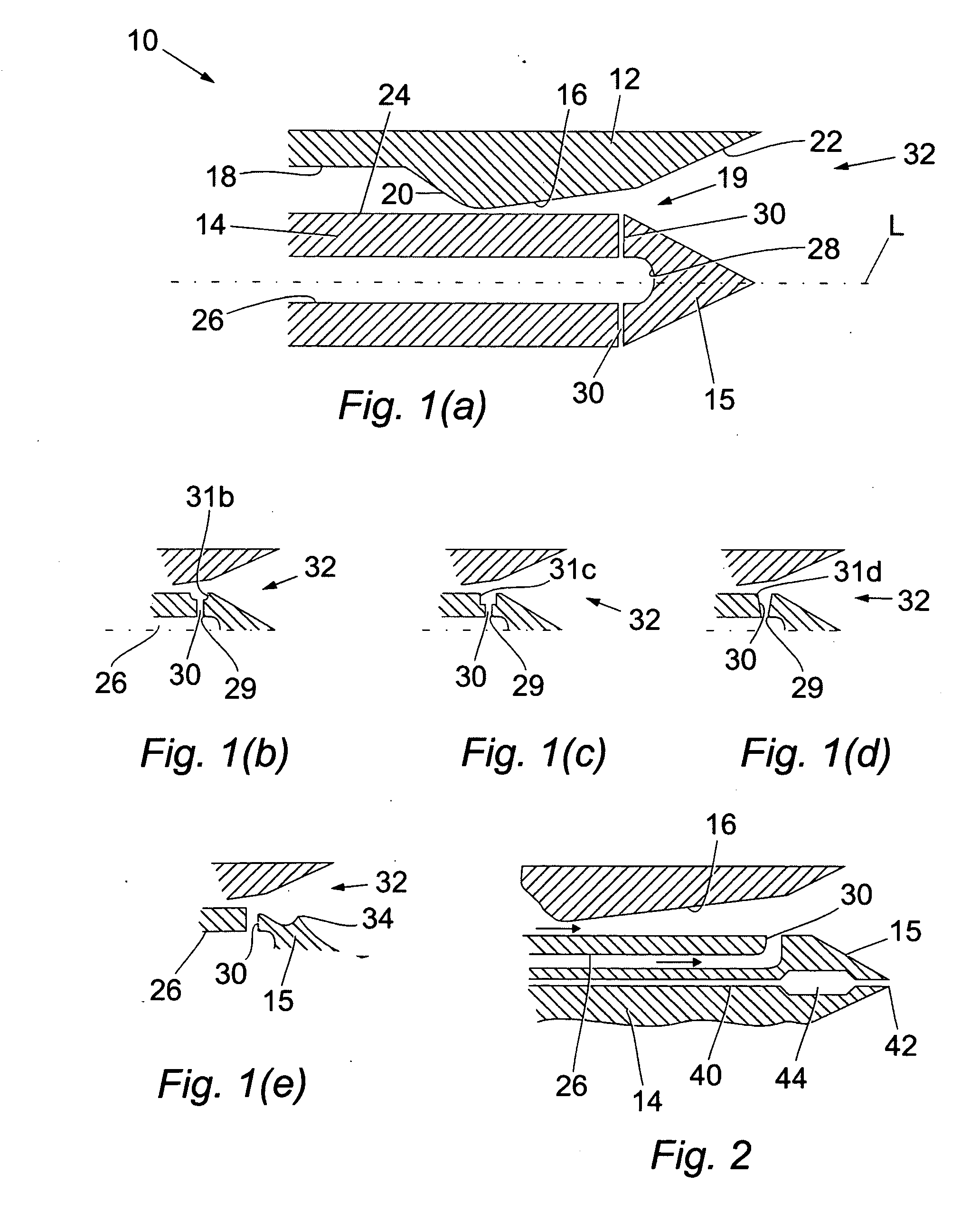

Mist generating apparatus and method

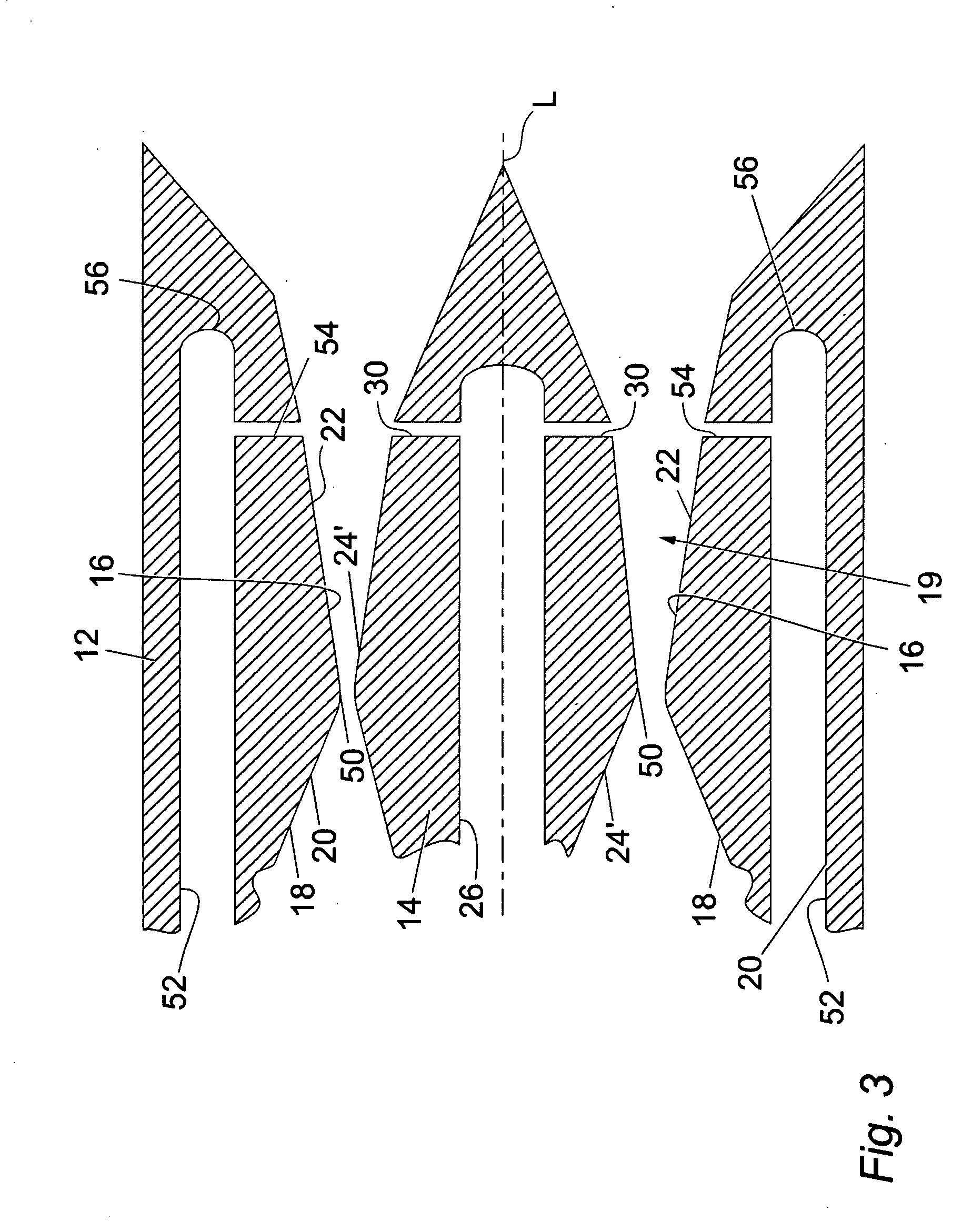

Apparati for generating a mist are disclosed. One apparatus is disclosed, which has an elongate hollow body (12) and an elongate member (14) located within the body (12). A transport fluid passage (16) and a nozzle (32) are defined between the body (12) and the elongate member (14). The transport fluid passage (16) has a throat portion of reduced cross-sectional area and is in fluid communication with the nozzle (32). The elongate member (14) includes a working fluid passage (26) and one or more communicating openings, such as for example, bores, annuli, and combinations thereof, (30) extending radially outward from the working fluid passage (26). The openings (30) permit a working fluid (e.g. water) to be passed into the transport fluid passage (16), whereupon the working fluid is subjected to shear forces by a high velocity transport fluid (e.g. steam). The shearing of the working fluid results in the generation of a mist formed from droplets of substantially uniform size. Methods of generating a mist using such apparati are also disclosed. Also provided are mists for fire suppression produced using an apparatus disclosed herein, as well as fire suppression systems that include any of the apparati disclosed herein. Further provided are devices, methods, and mists for various other applications including turbine cooling and decontamination.

Owner:TYCO FIRE PRODS LP

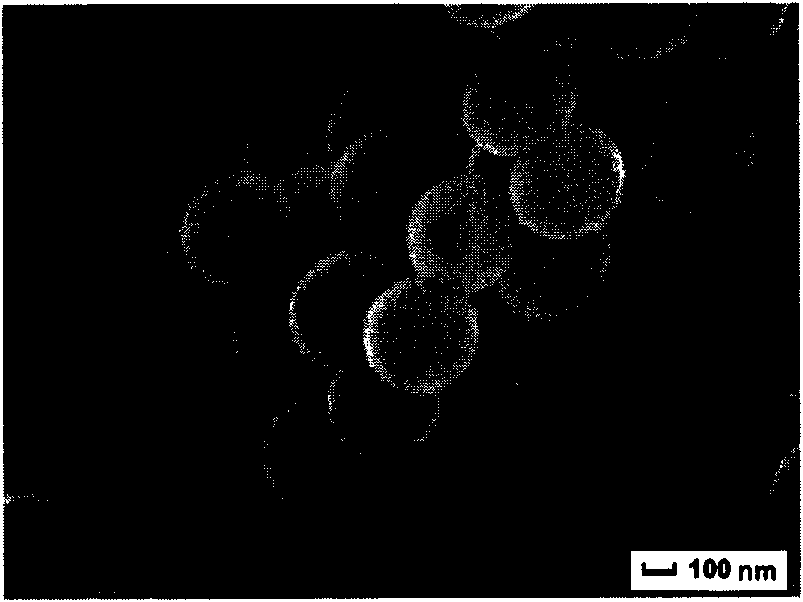

Method for preparing mono-disperse microemulsion, liposome and microsphere based on microfluidic technology

InactiveCN102068409ABest size rangeHigh activityImmobilised enzymesGranular deliveryDispersion stabilityOil phase

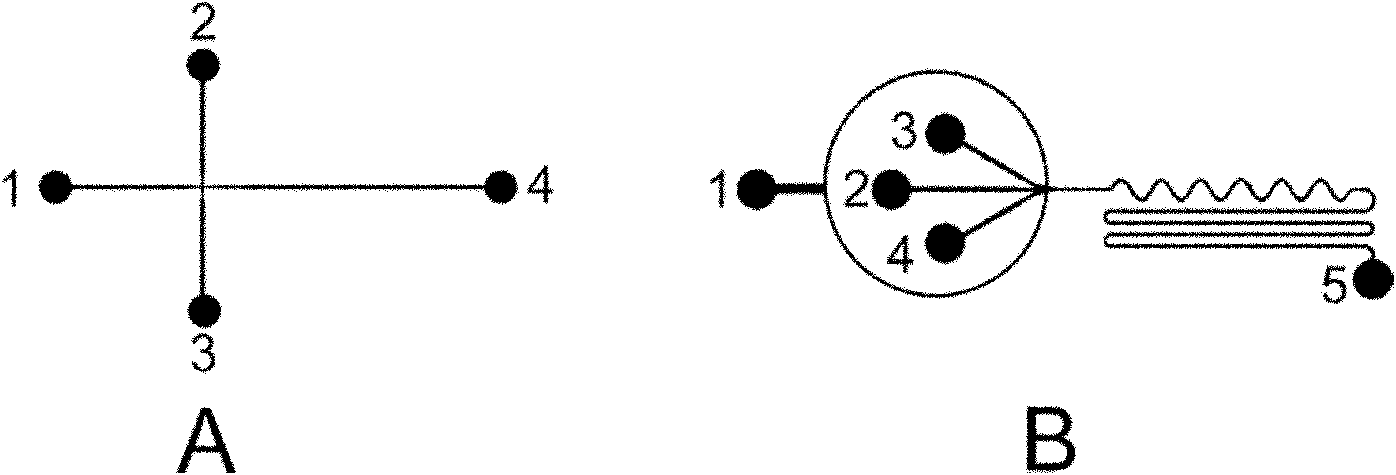

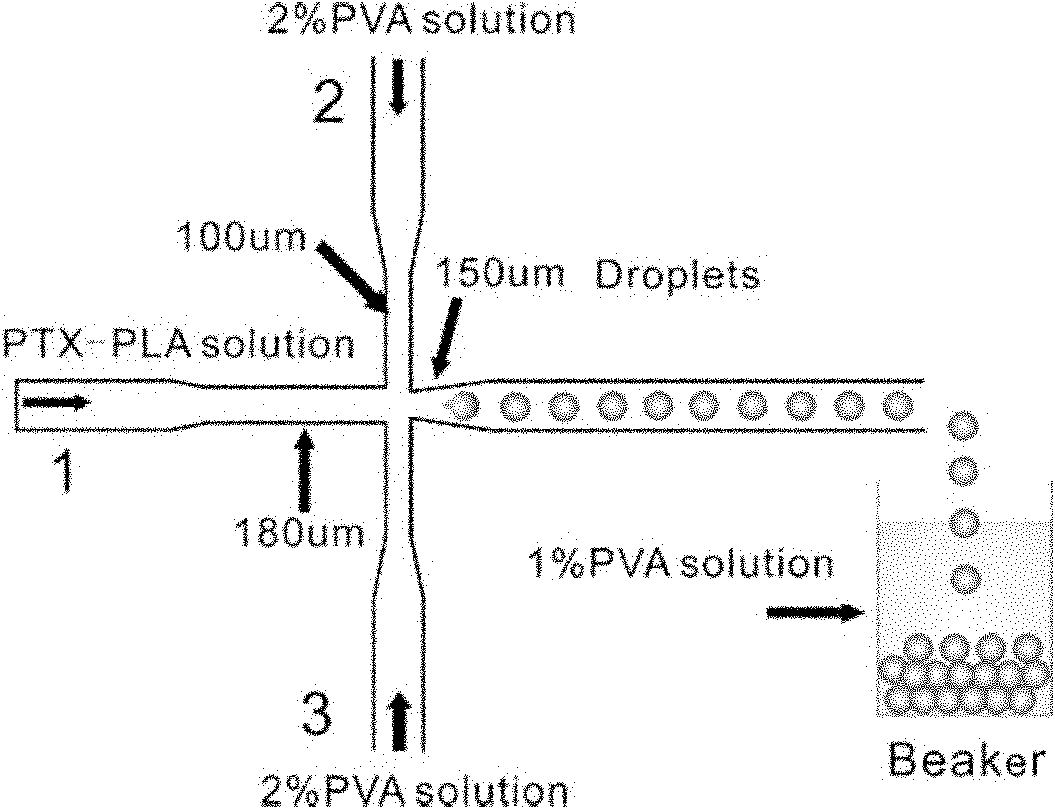

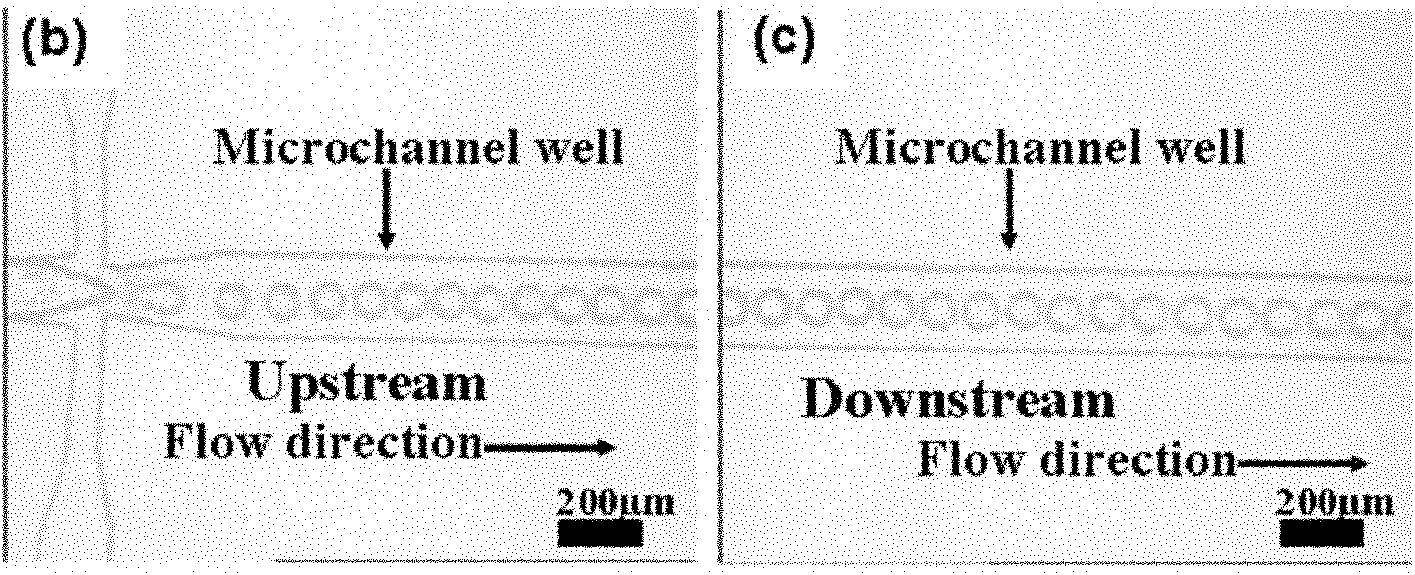

The invention discloses a method for preparing mono-disperse microemulsion, liposome and microspheres based on a microfluidic technology. The method comprises the following steps: taking aqueous solution (or oily solution) of a hydrophilic medicine (or a lipid-soluble medicine) as a disperse phase; taking an oil phase (or an aqueous phase) as a continuous phase; and respectively conveying the disperse phase and the continuous phase into corresponding micro-channels of a microfluidic chip device, shearing the phases into mono-disperse liquid drops of the encapsulated medicine, then curing the liquid drops by a certain curing method, and finally obtaining the medicine-carrying liposome, microspheres or the biodegradable microspheres with uniform size and dispersion stability. Under an optimum condition, the diameter distribution coefficients of the microemulsion and the microspheres can be less than 5%, and the diameter is 10-500microns. By utilizing the method, the problems such as uneven size, low embedding rate, poor dispersibility, poor targeting property, low bioavailability, low bioactivity of enzyme and cells, immune suppression and the like of the medicine-carrying microemulsion, the liposome and the microspheres prepared by the traditional ultrasonic method, agitation emulsification method and film hydration-dispersion method are solved.

Owner:TSINGHUA UNIV

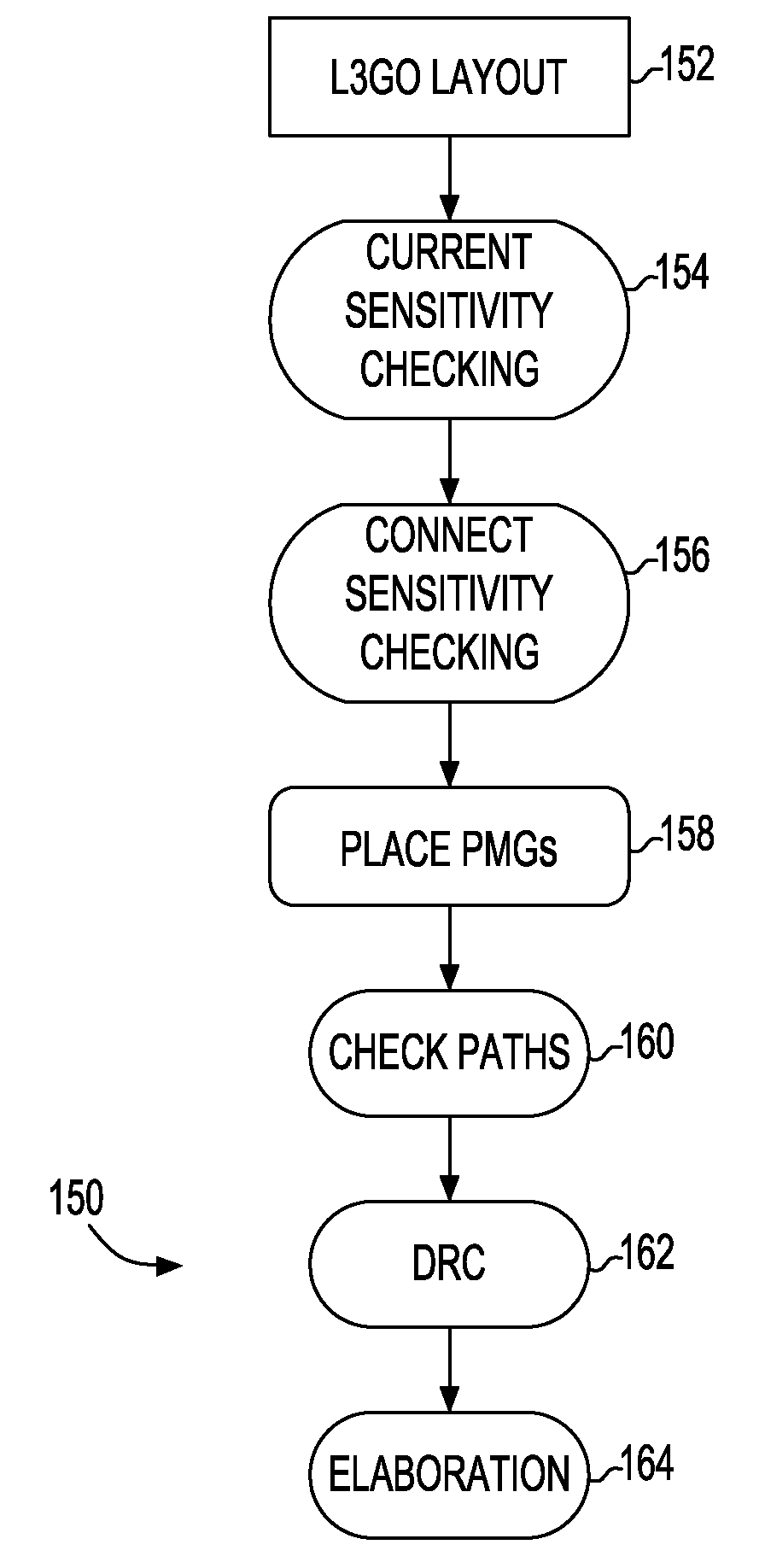

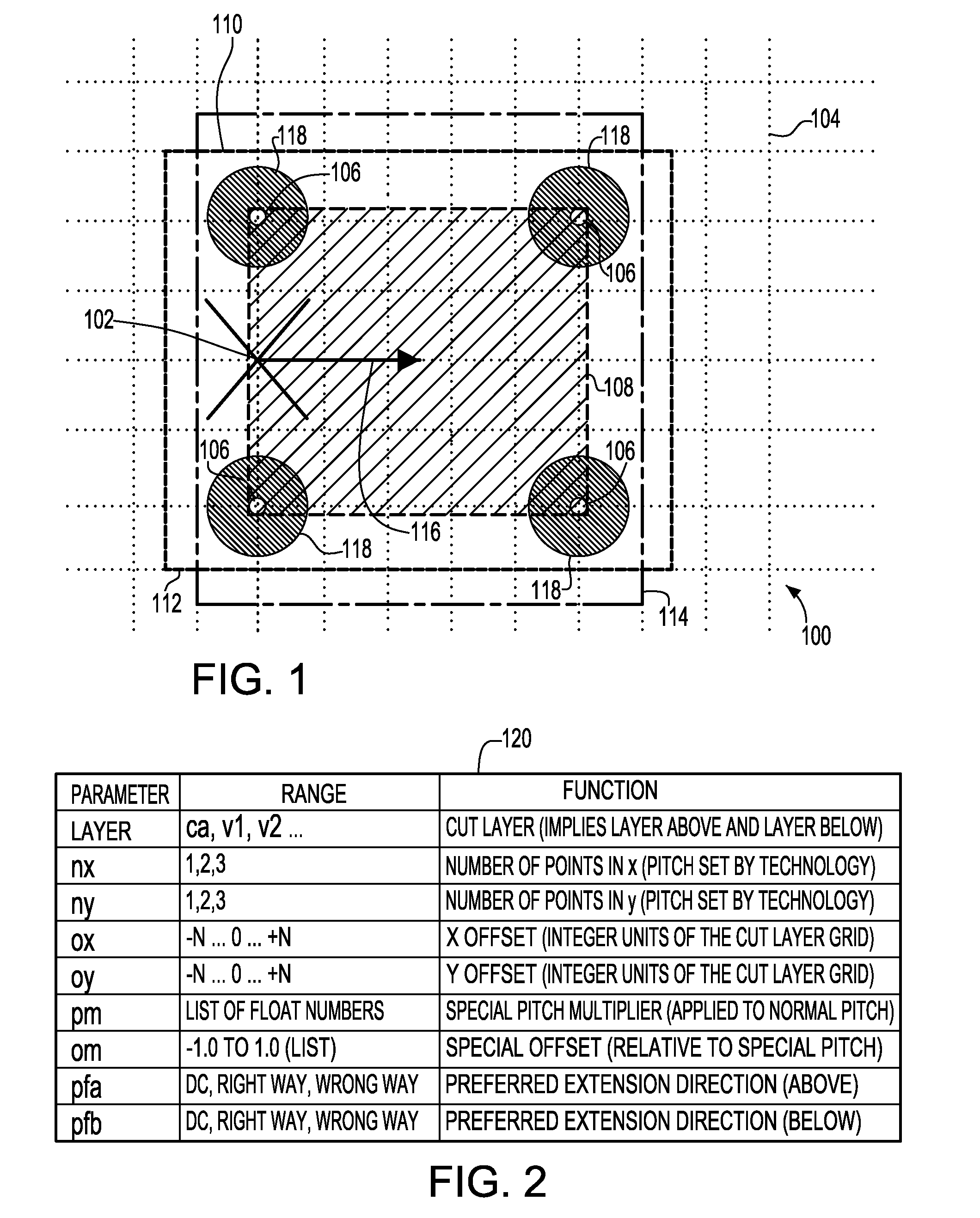

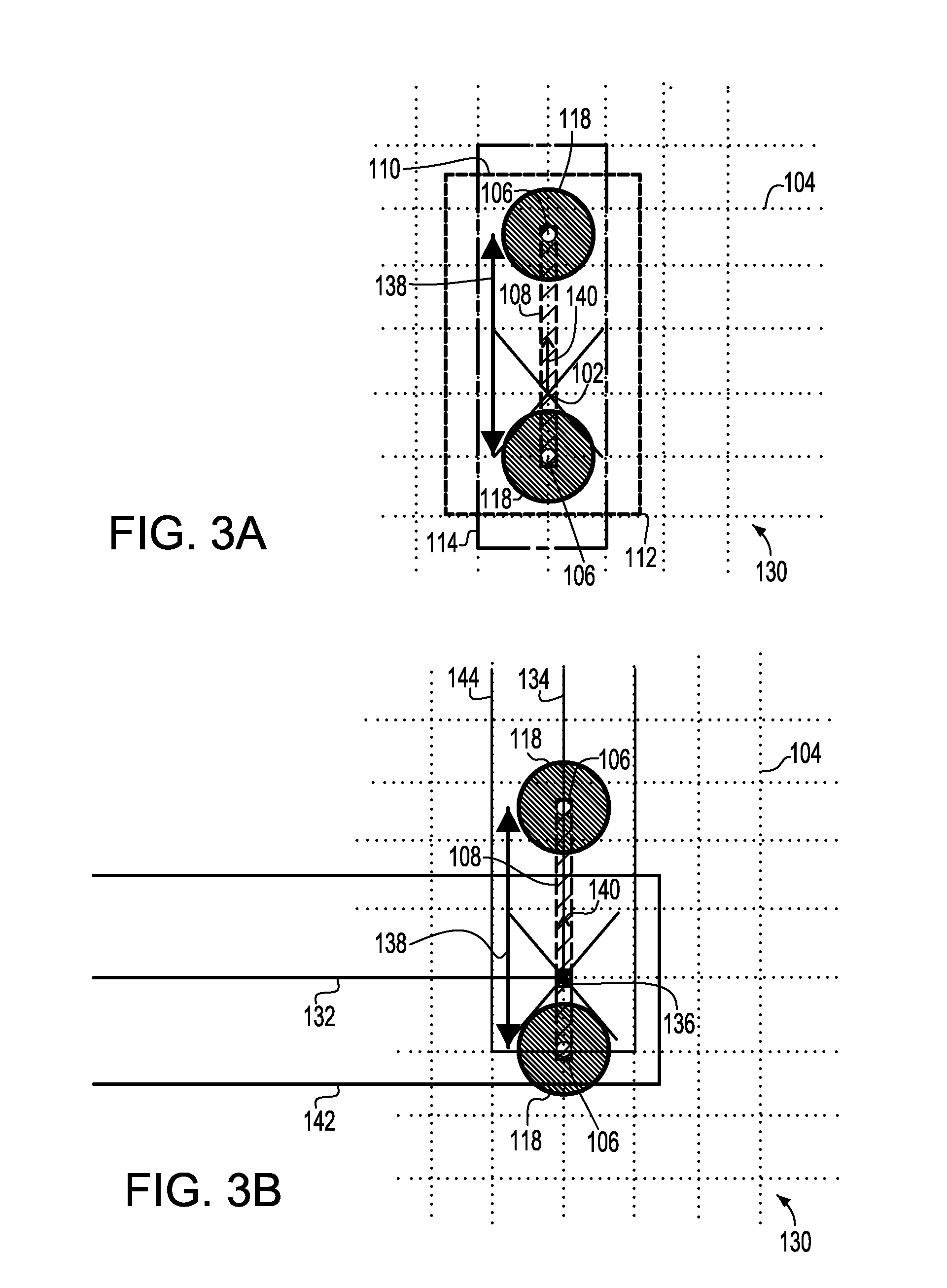

Gridded glyph geometric objects (L3GO) design method

InactiveUS20090235215A1Low costReduce riskDetecting faulty computer hardwareComputer aided designElectrical conductorComputer graphics (images)

A method of gridded glyph geometric objects (L3GO) integrated circuit (IC) design, wherein at least one inter-level connect in a L3GO circuit design is represented as a point matrix glyph (PMG) on a L3GO grid. Each PMG connects a pair of conductors on the next adjacent (above and below) layer and includes an array (one or two dimensional) of point glyphs contained within a cage. The point glyphs may have uniform size and may be on minimum pitch. Each PMG may also include a flange on the above and below layer. A default flange insures adequate coverage of cut shapes represented by the point glyphs.

Owner:GLOBALFOUNDRIES INC

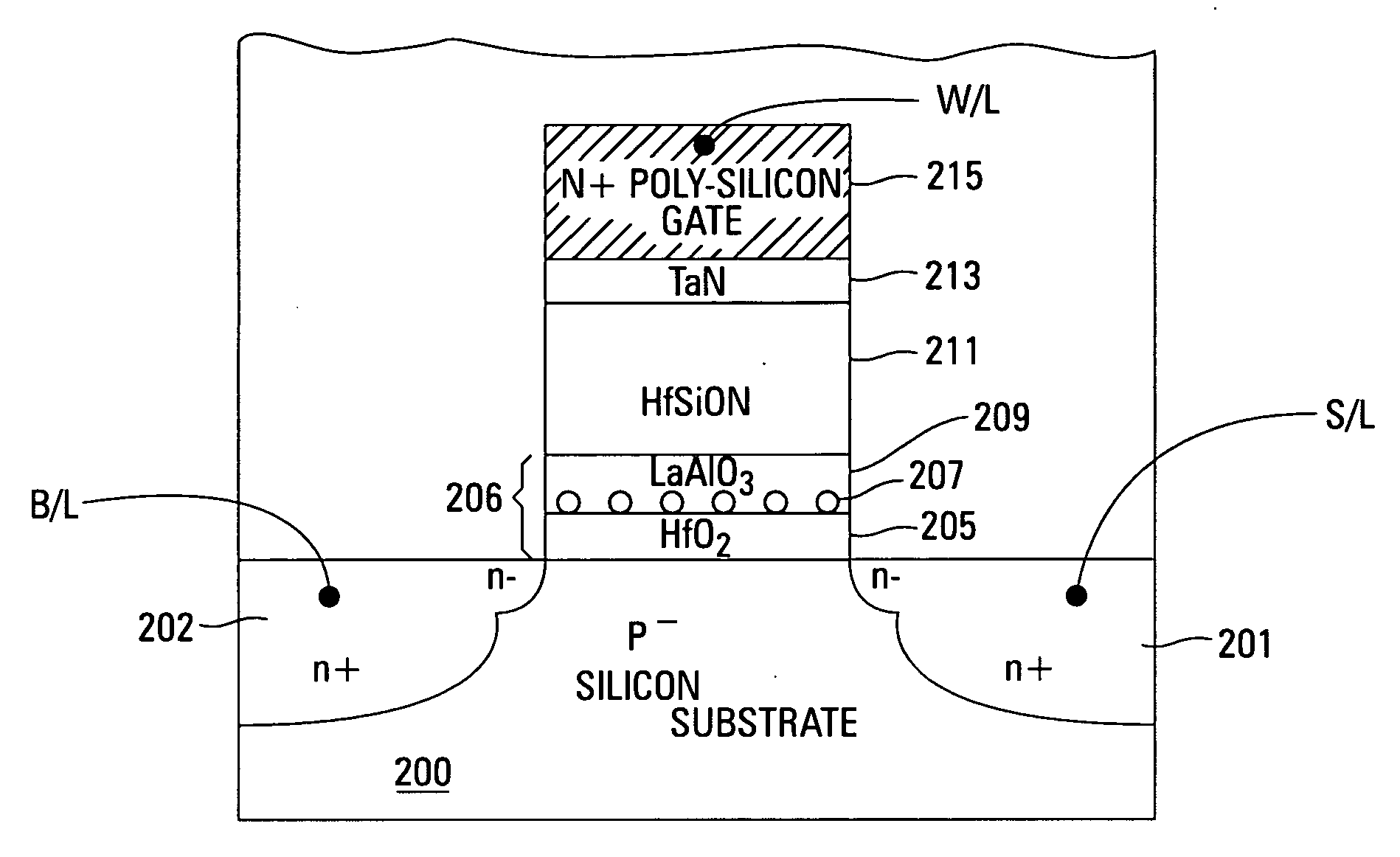

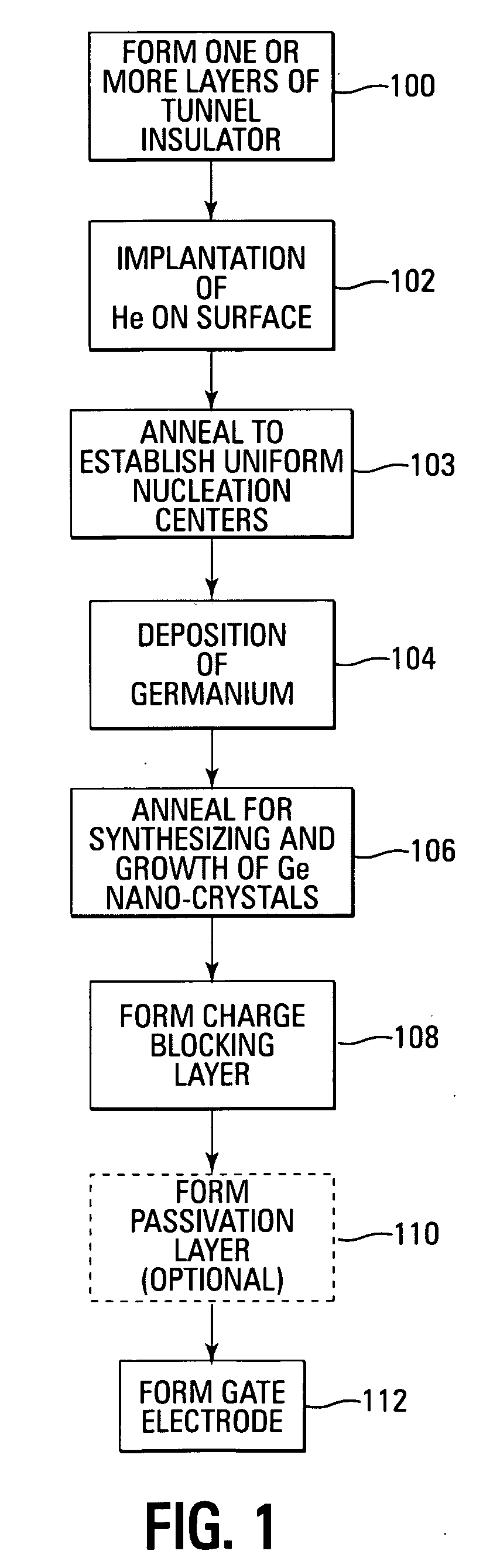

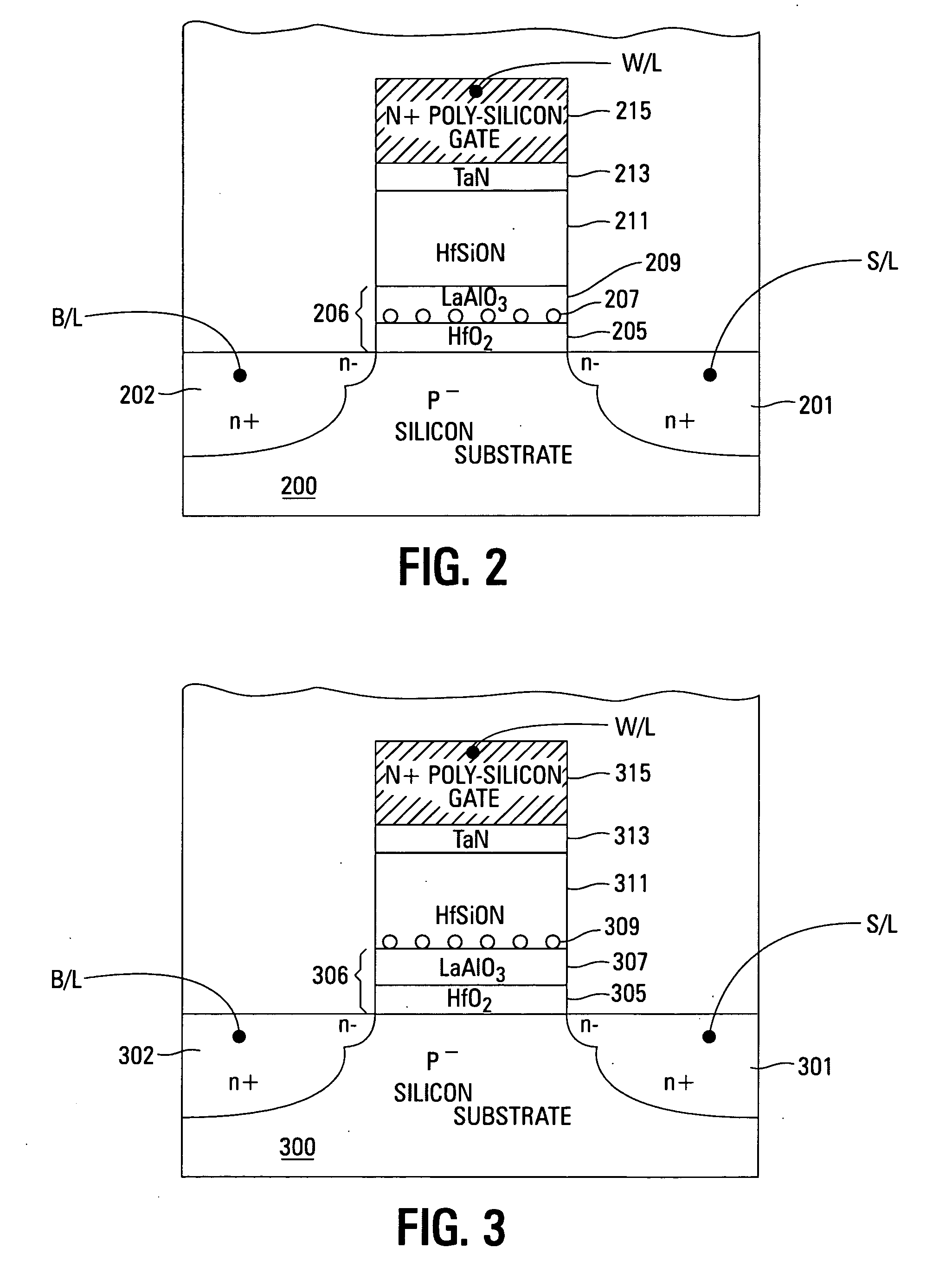

Scalable multi-functional and multi-level nano-crystal non-volatile memory device

ActiveUS20070052011A1Great non-volatilityEvenly distributedNanoinformaticsSolid-state devicesTrappingMultilevel memory

A multi-functional and multi-level memory cell is comprised of a tunnel layer formed over a substrate. In one embodiment, the tunnel layer is comprised of two layers such as HfO2 and LaAlO3. A charge blocking layer is formed over the tunnel layer. In one embodiment, this layer is formed from HfSiON. A control gate is formed over the charge blocking layer. A discrete trapping layer is embedded in either the tunnel layer or the charge blocking layer, depending on the desired level of non-volatility. The closer the discrete trapping layer is formed to the substrate / insulator interface, the lower the non-volatility of the device. The discrete trapping layer is formed from nano-crystals having a uniform size and distribution.

Owner:MICRON TECH INC

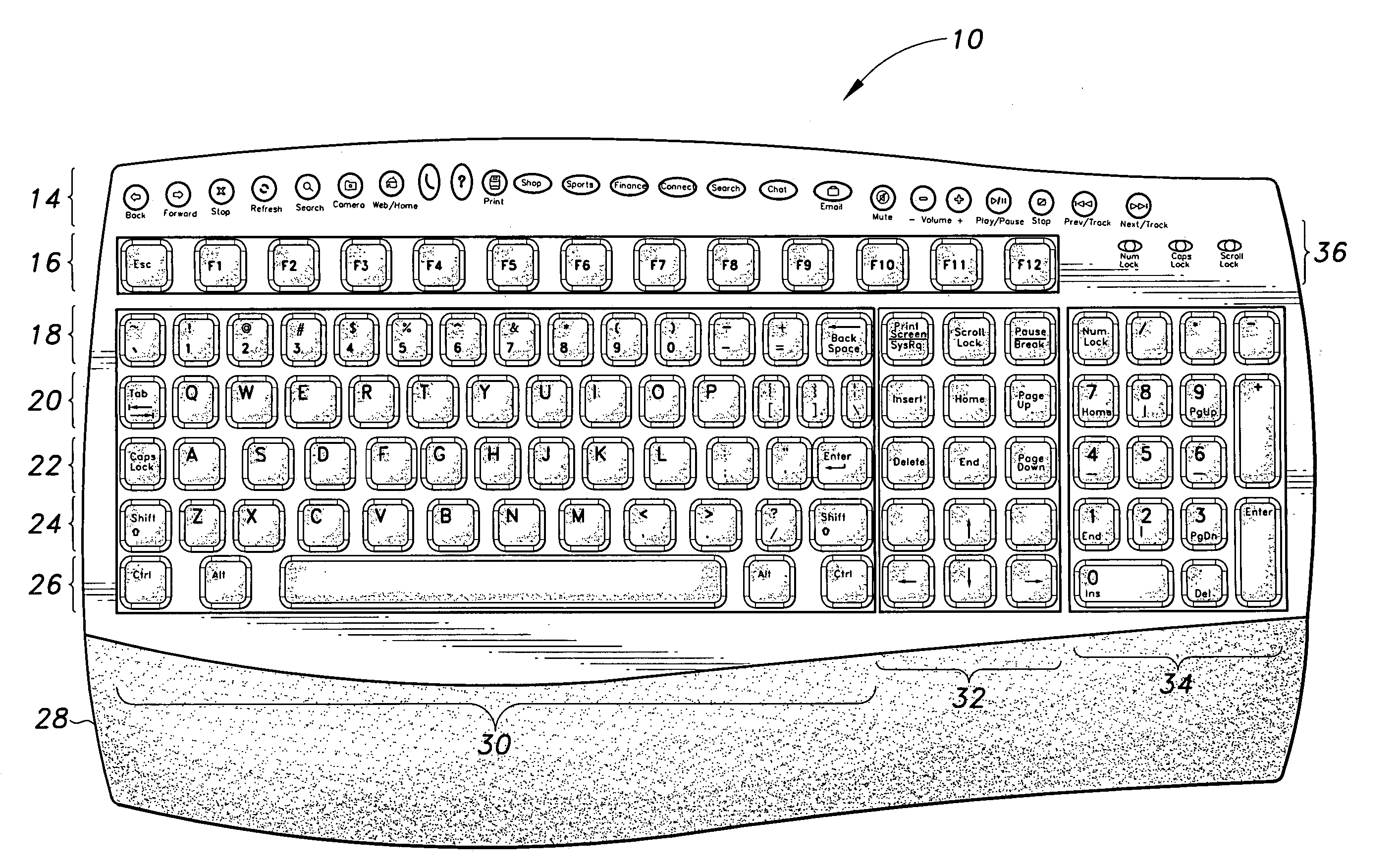

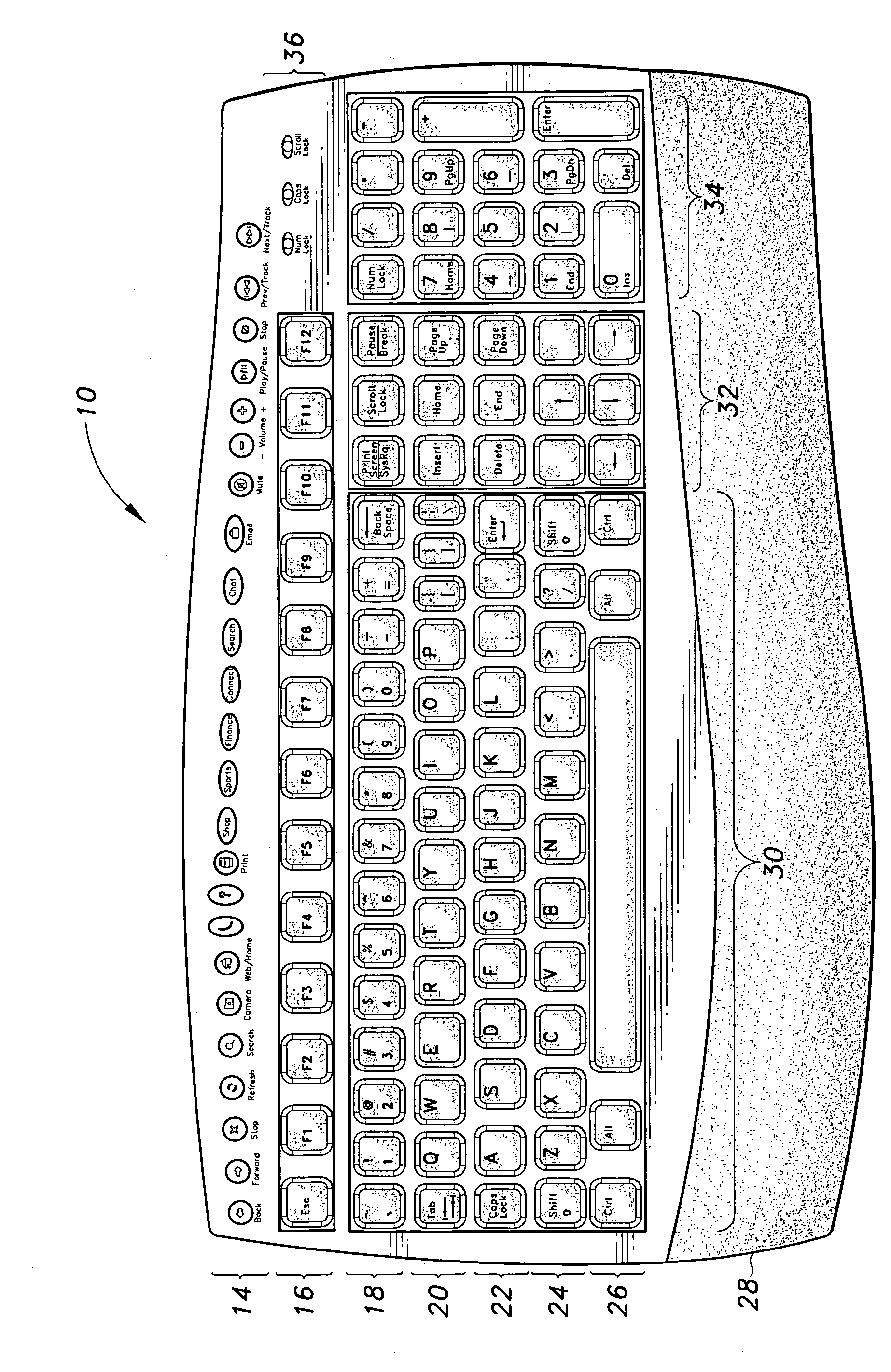

Computer keyboard

InactiveUS20050207817A1Other printing apparatusInput/output processes for data processingComputer scienceLettering

A computer keyboard comprises a typewriter section containing lettered keys corresponding to letters of an alphabet. The lettered keys are positioned in a standard order, but are of non-uniform size with respect to one another.

Owner:JENKINS KARLA R

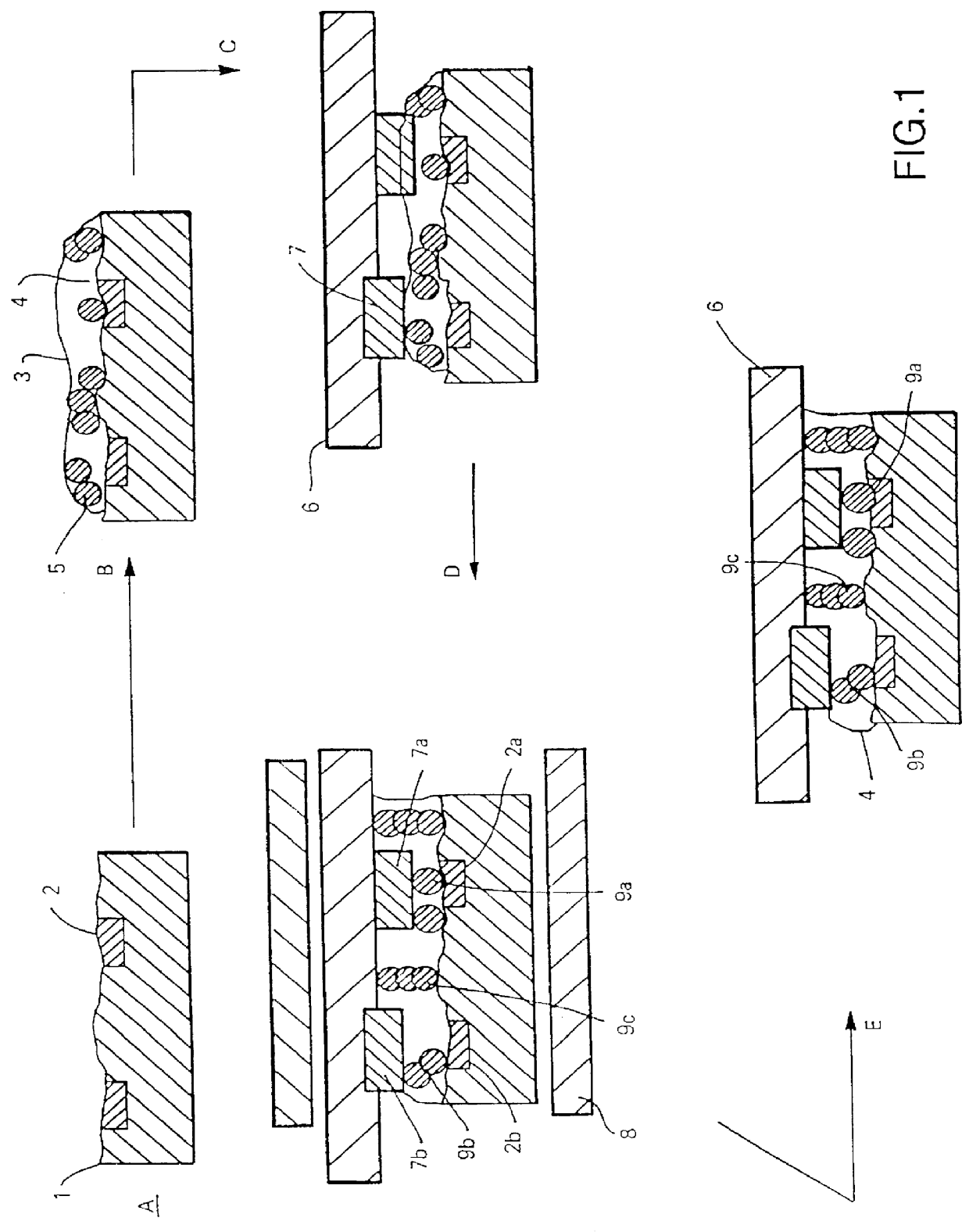

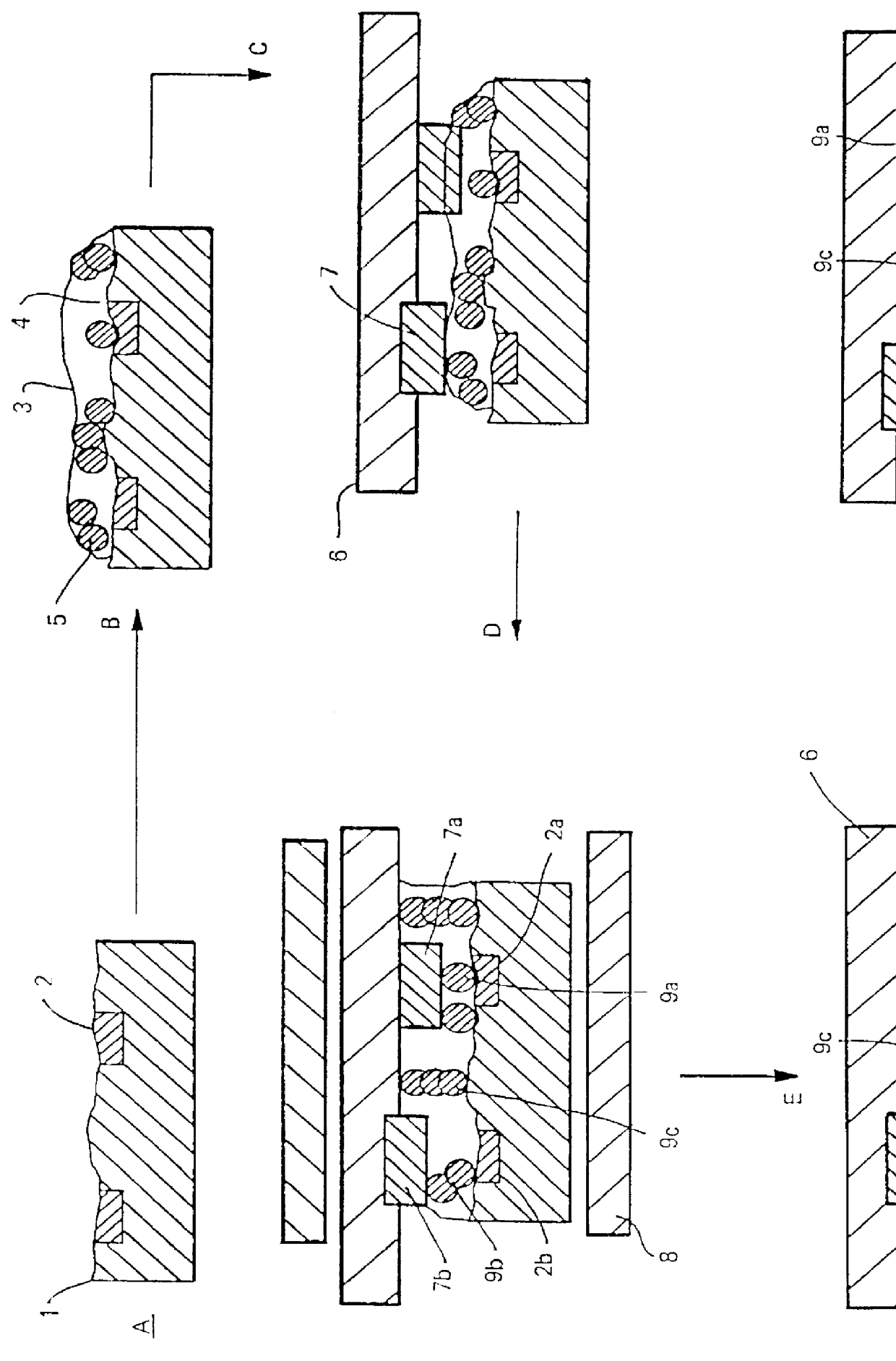

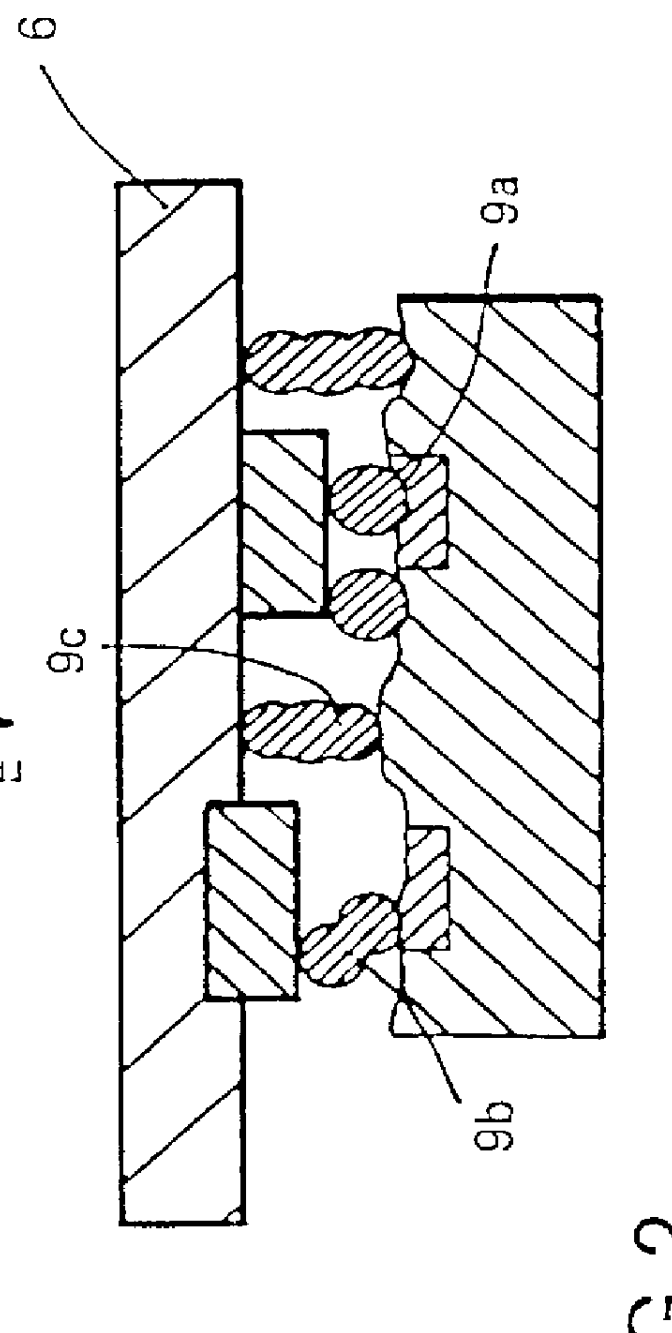

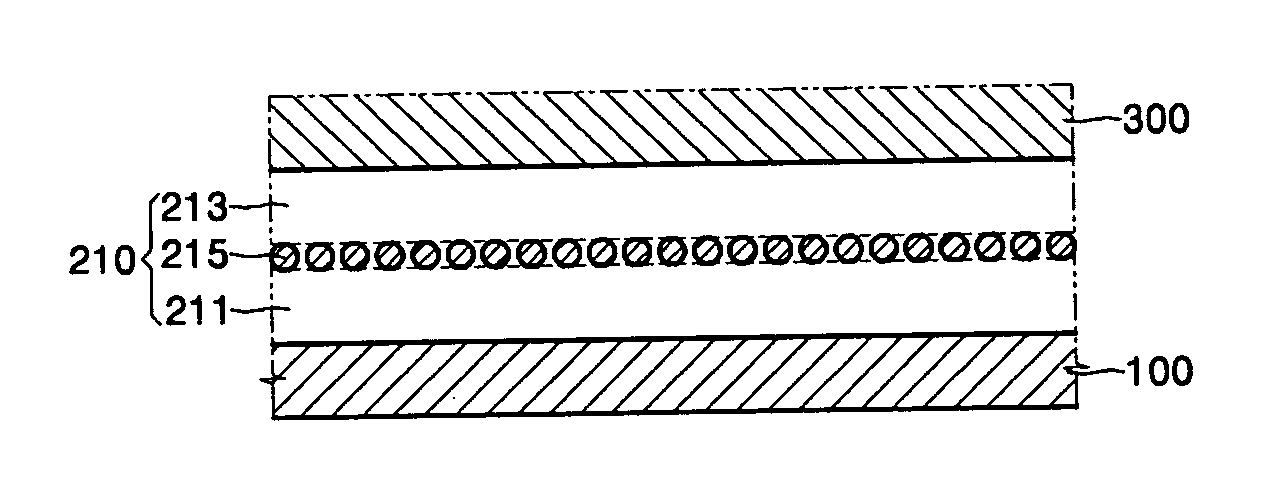

Compositions and method for providing anisotropic conductive pathways and bonds between two sets of conductors

InactiveUS6110399ASimple processImprove electrical contact reliabilityNon-insulated conductorsNon-macromolecular adhesive additivesRegular patternElectrical conductor

The invention provides a composition (3) comprising: (i) a ferrofluid comprising a colloidal suspension (4) of ferromagnetic particles in a non-magnetic carrier liquid, and (ii) a plurality of electrically-conductive particles (5) having substantially uniform sizes and shapes, dispersed in the ferrofluid. Various types of substantially non-magnetic electrically-conductive particles (5) are described. Application of a substantially uniform magnetic field by magnet means (8) to the composition (3) causes the electrically-conductive particles (5) to form a regular pattern (9). The composition is used for providing anisotropic conductive pathways (9a, 9b) between two sets of conductors (2a, 2b; 7a, 7b) in the electronics industry. The composition may be a curable adhesive composition which bonds the conductors. Alternatively or in addition the electrically-conductive particles may have a latent adhesive property e.g. the particles may be solder particles. The ferrofluid may be a colloidal suspension of ferromagnetic particles in a liquid monomer.

Owner:LOCTITE (R&D) LIMITED

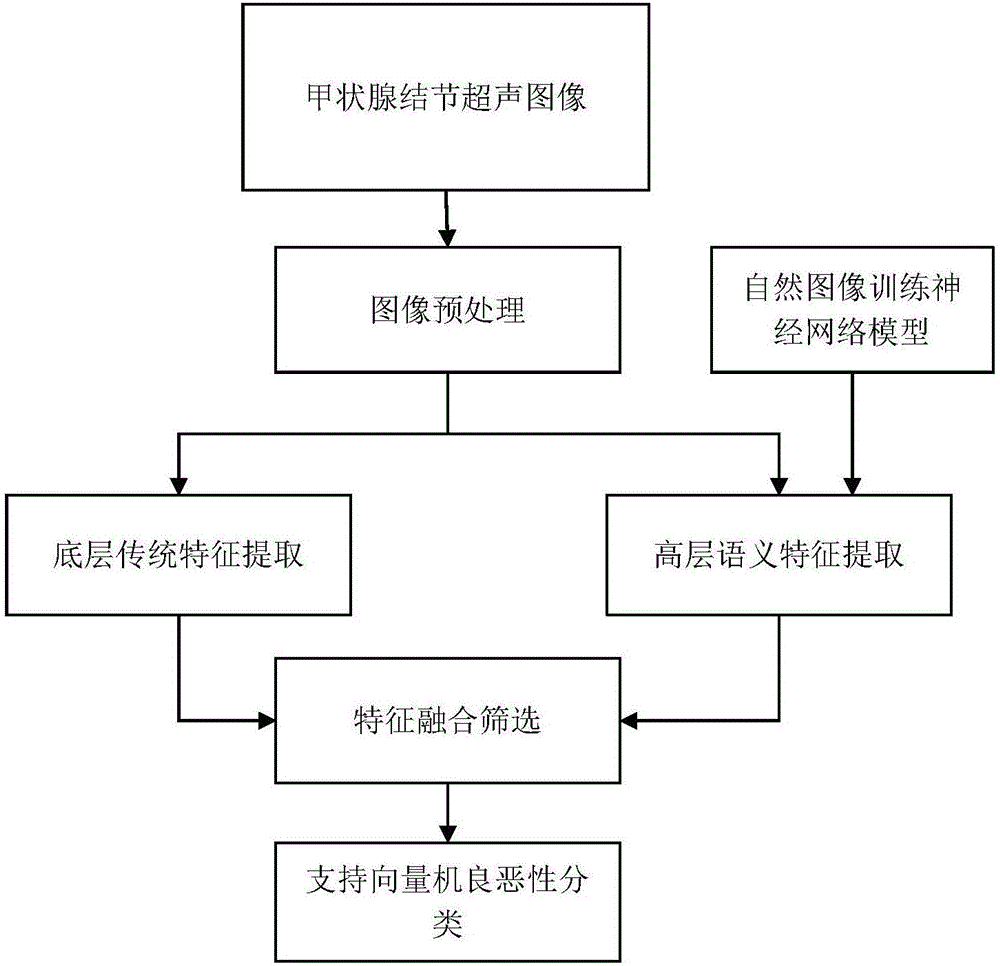

Transfer learning and feature fusion-based ultrasonic thyroid nodule benign and malignant classification method

ActiveCN106780448ADescribe the characteristics of the caseAvoiding Obstacles That Cannot Train Convolutional Neural NetworksImage enhancementImage analysisSonificationSupport vector machine classifier

The invention discloses a transfer learning and feature fusion-based ultrasonic thyroid nodule benign and malignant classification method. The method comprises the following steps of firstly preprocessing an ultrasonic image and zooming the ultrasonic image to a uniform size; extracting traditional low-level features of the ultrasonic image; extracting high-level semantic features of the ultrasonic image by using a model obtained in a natural image through deep neural network training through a transfer learning method; fusing the low-level features with the high-level features; carrying out feature screening by utilizing distinction degree of benign and malignant thyroid nodules so as to obtain a final feature vector which is used for training a support vector machine classifier; and carrying out final thyroid nodule benign and malignant classification. According to the method disclosed by the invention, the low-level features and the high-level features are fused, and salient feature screening is carried out, so that the problem that the ability of single features for describing thyroid nodule features on the level of semantic meaning is insufficient is solved, and the classification precision is effectively improved; and through importing the transfer learning, the problems that the medical sample images are few and the deep features can not be obtained by direct training are solved.

Owner:TSINGHUA UNIV +1

Method of preparing cadmium sulfide nanocrystals emitting light at multiple wavelengths, and cadmium sulfide nanocrystals prepared by the method

A method for preparing cadmium sulfide nanocrystals emitting light at multiple wavelengths. The method comprises the steps of (a) mixing a cadmium precursor and a dispersant in a solvent that weakly coordinates to the cadmium precursor, and heating the mixture to obtain a cadmium precursor solution, (b) dissolving a sulfur precursor in a solvent that weakly coordinates to the sulfur precursor to obtain a sulfur precursor solution, and (c) feeding the sulfur precursor solution to the heated cadmium precursor solution maintained at a high temperature to prepare cadmium sulfide crystals, and growing the cadmium sulfide crystals. Further, cadmium sulfide nanocrystals prepared by the method. The cadmium sulfide nanocrystals have uniform size and shape and can emit light close to white light simultaneously at different wavelengths upon excitation. Due to these characteristics, the cadmium sulfide nanocrystals can be applied to white light-emitting diode devices.

Owner:SAMSUNG ELECTRONICS CO LTD

Nanowire based non-volatile floating-gate memory

InactiveUS20070029600A1Easy shape controlGood size controlTransistorNanoinformaticsNanowireSingle crystal

A non-volatile memory transistor with a nanocrystal-containing floating gate formed by nanowires is disclosed. The nanocrystals are formed by the growth of short nanowires over a crystalline program oxide. As a result, the nanocrystals are single-crystals of uniform size and single-crystal orientation.

Owner:IBM CORP

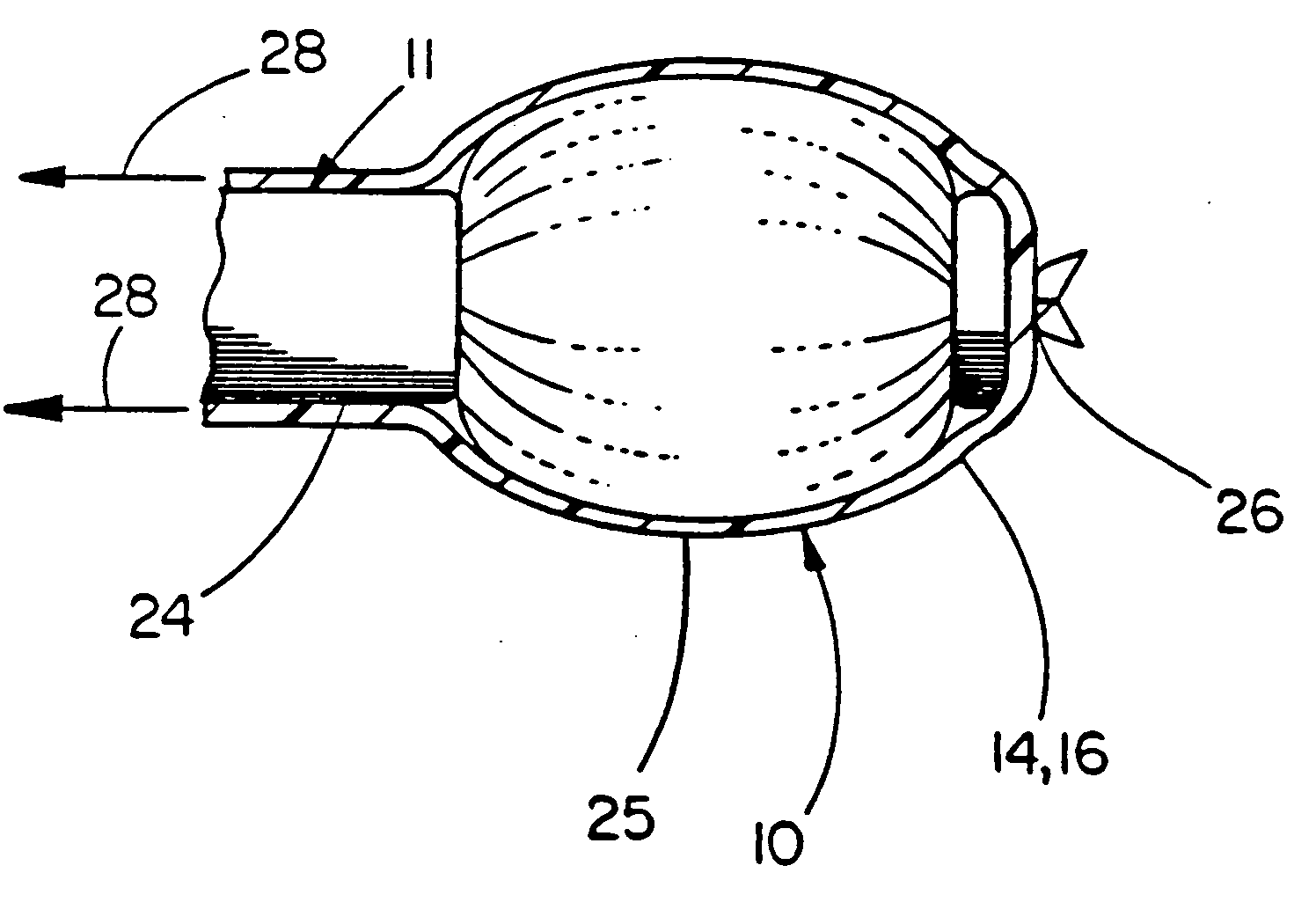

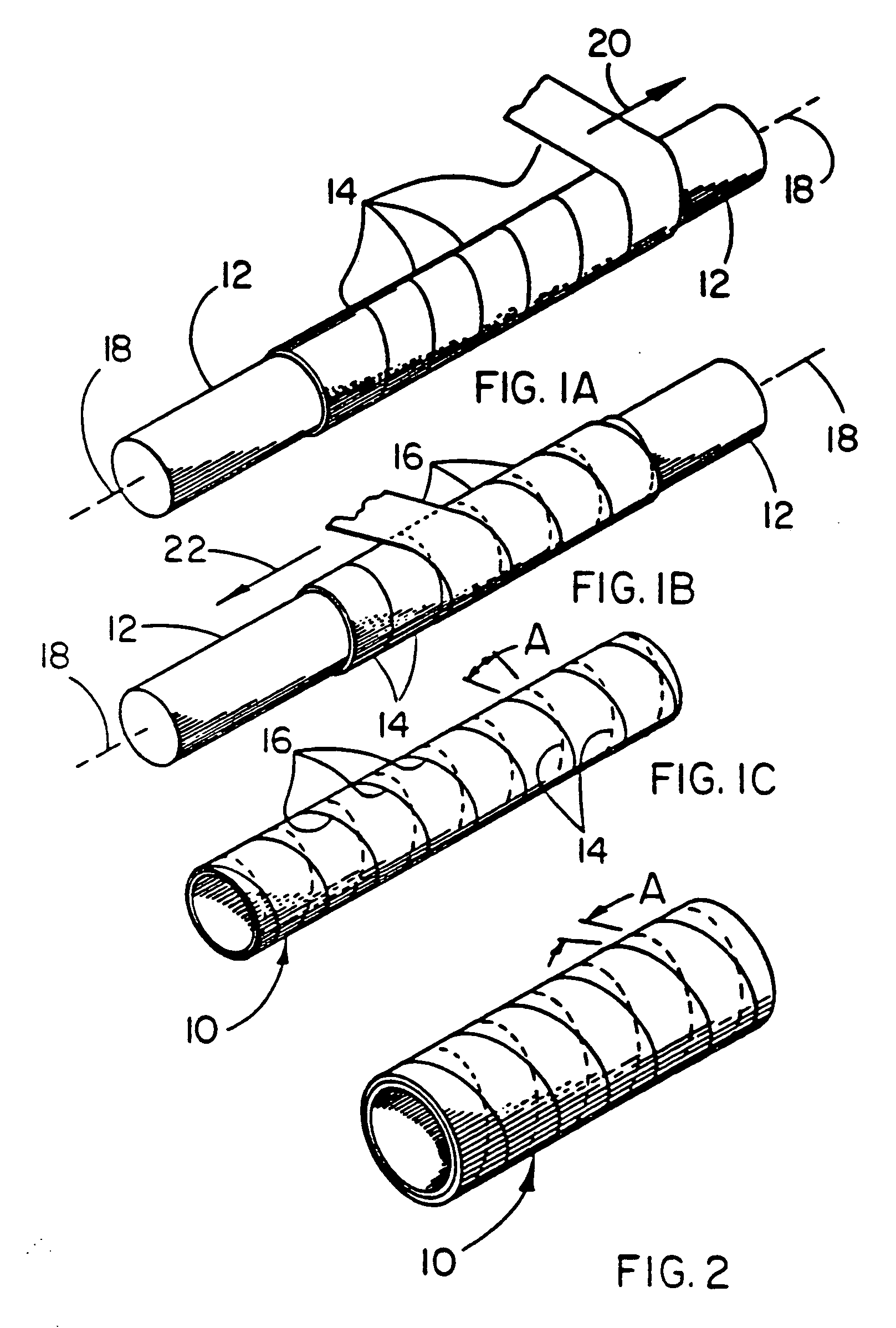

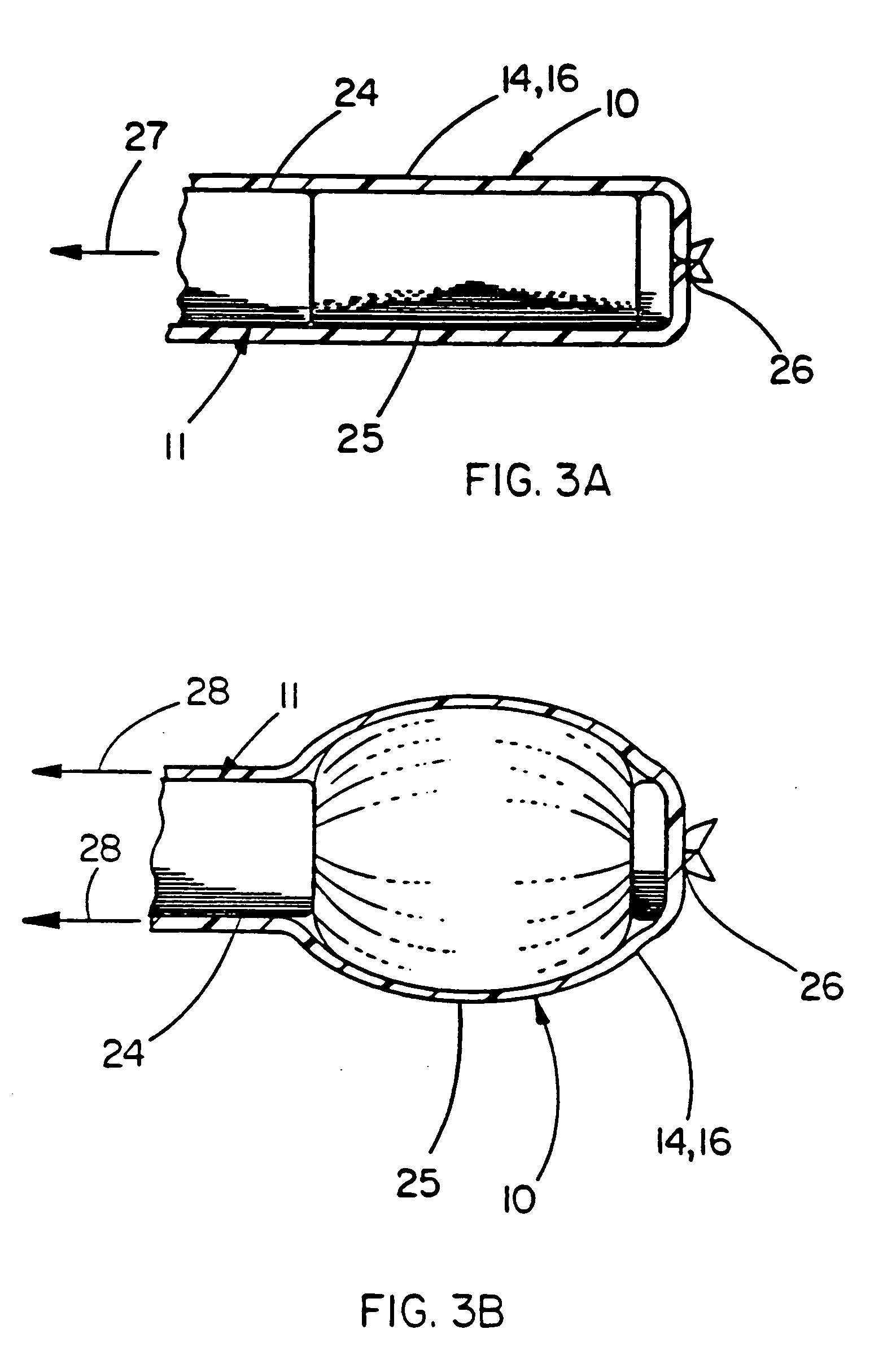

Balloon catheter device

InactiveUS20060271091A1Increase profitBursting strengthStentsBalloon catheterMedicineBalloon catheter

Balloon catheters are provided having the balloon length is substantially surrounded by an elastic cover. The balloon and the cover maintain a substantially and circular cross-section along the balloon length during inflation. The cross section is able to maintain a uniform size down the length of the balloon during inflation.

Owner:WL GORE & ASSOC INC

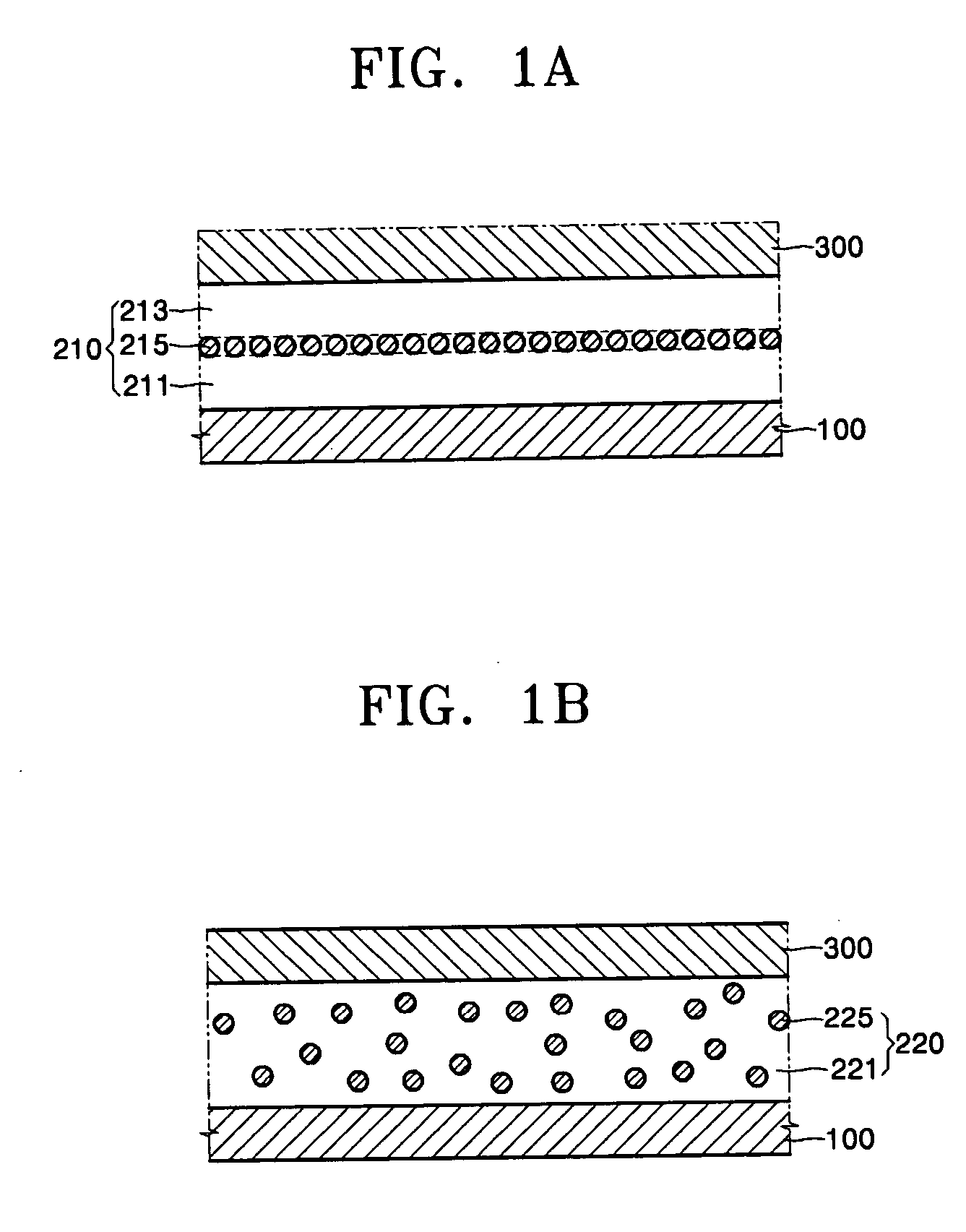

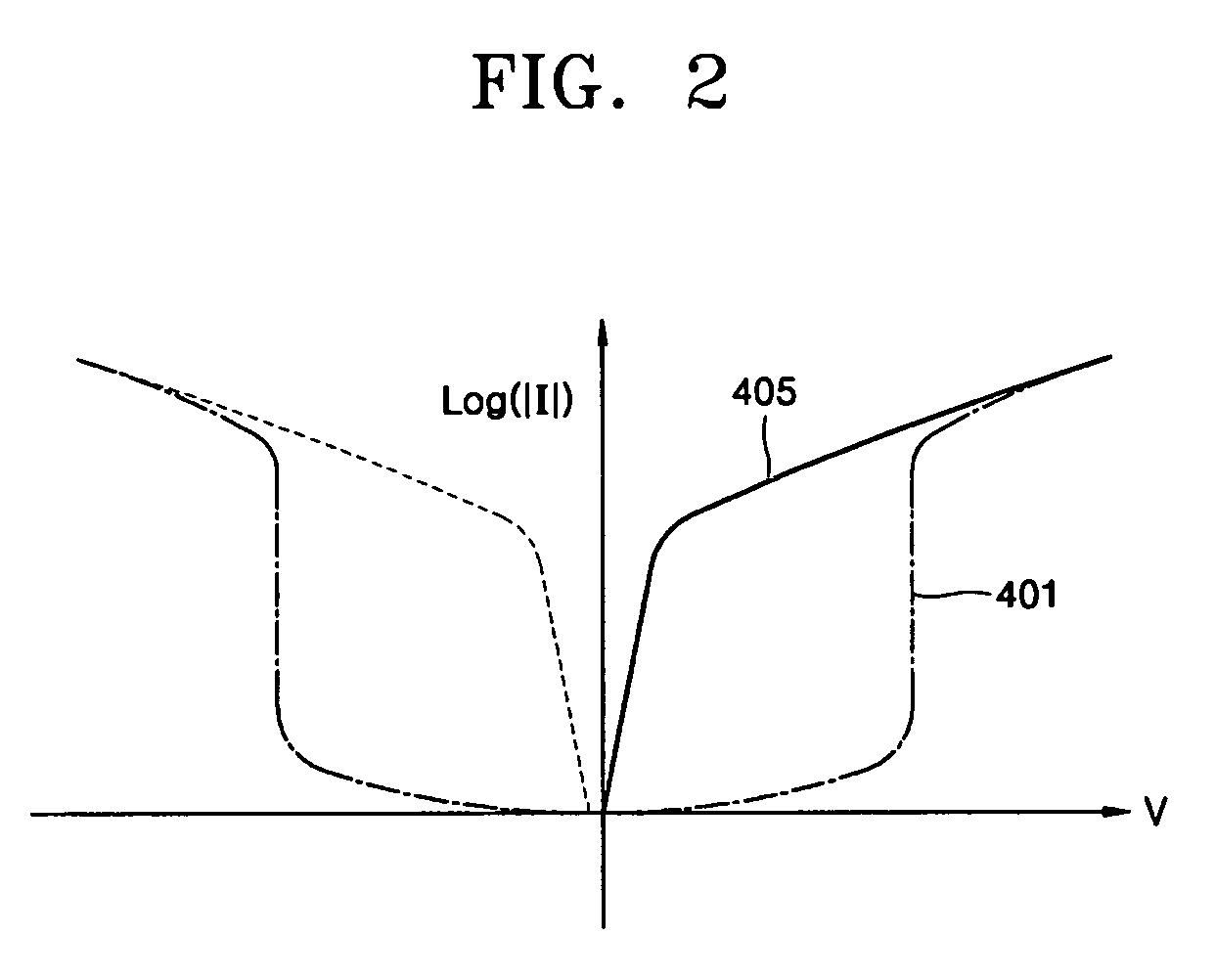

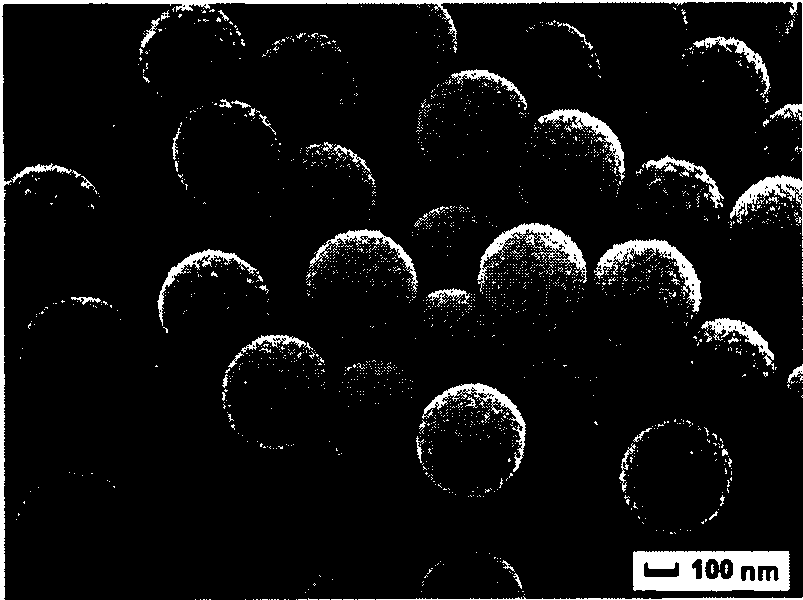

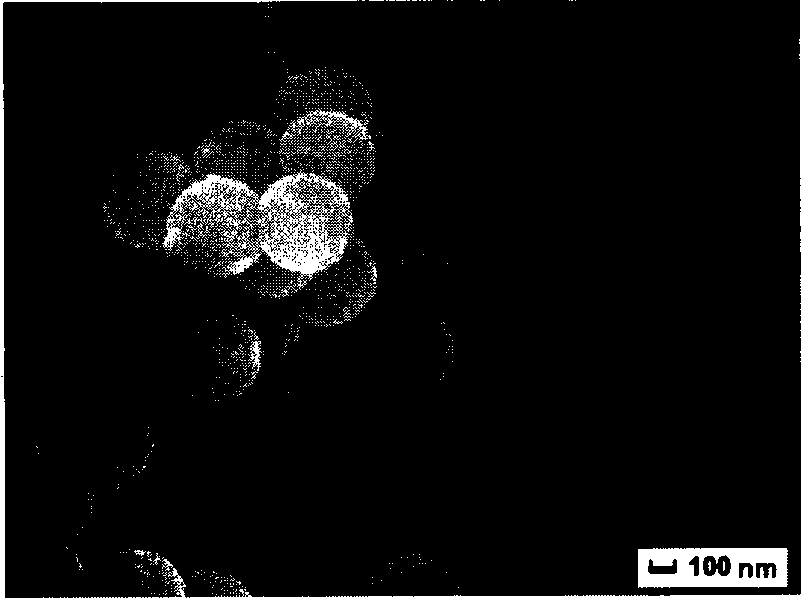

Organic memory device and method of manufacturing the same

InactiveUS20060131569A1Small sizeImprove uniformityTransistorSemiconductor/solid-state device detailsOrganic memoryManufacturing technology

An organic memory device and a method of manufacturing the same are disclosed. The organic memory device includes an electron channel layer including an organic layer, in which nano particles of a uniform size are dispersed, interposed between metal electrodes, thus having electrical bistability. The organic memory device uses a change of electrical conductivity which results from a substantial change of the electrical structure of the electron channel layer when a voltage is applied. The organic memory device can be integrated using a simple manufacturing process, and ensures uniformity between devices due to the threshold voltage characteristics, even when highly miniaturized.

Owner:ELECTRONICS & TELECOMM RES INST

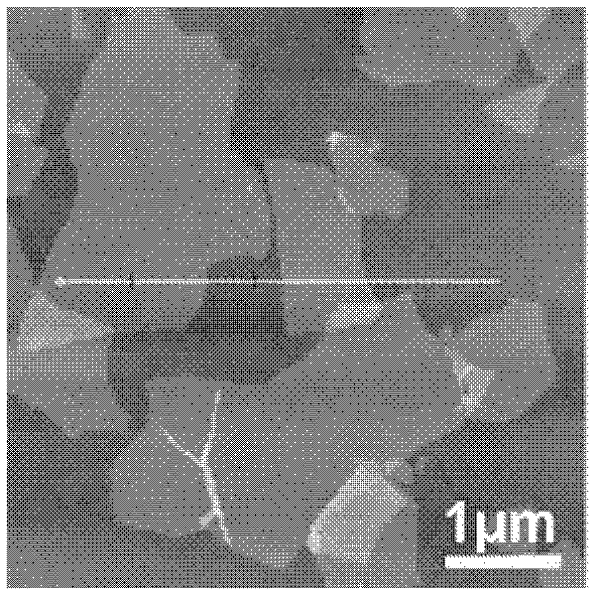

Method for preparing nanoscale silica hollow microspheres

The invention discloses a method for preparing nanoscale silica hollow microspheres, which uses sodium silicate solution and modified polymer respectively as the silicon source and template. Nanoscale silica hollow microspheres are prepared by a sacrificial template method by the following steps: (1) preparing polymer colloidal template microspheres; (2) preparing silicon dioxide-colloidal template complex microspheres; and (3) roasting the complex microspheres to obtain nanoscale silica hollow microspheres. Nanoscale silica hollow microspheres prepared by the invention have the characteristics of uniform size and appearance, fine integrity and high rate of productivity. The method can realize low cost and easy operation by using sodium silicate solution as the silicon source. Therefore, with easy operation and low cost, the method has certain instructing value for the industrialized production of silica hollow microspheres in the future.

Owner:JIANGSU UNIV

Preparation method of graphene oxide quantum dot based on photocatalytic oxidation

ActiveCN102336404ASimple and fast manufacturing methodSimple systemNanotechnologyUltraviolet lightsQuantum dot

The invention relates to a preparation method of graphene oxide quantum dot based on photocatalytic oxidation. In the method, graphite oxide is dispersed in deionized water, under the act of ultrasonic, and the graphite oxide is stripped and dispersed into single layers so as to prepare a graphene oxide aqueous solution. The oxidant H2O2 and the catalyst Fe3+ are added in the graphene oxide solution, the mixture is stirred at room temperature, and simultaneously, the ultraviolet light radiates on the mixture system to prepare the graphene oxide quantum dot. In comparison with the prior art, the preparation method provided by the invention has the advantage of being simple and efficient in preparation process, simple in system and capable of preparing the graphene oxide quantum dots with uniform size.

Owner:上海碳源汇谷新材料科技有限公司

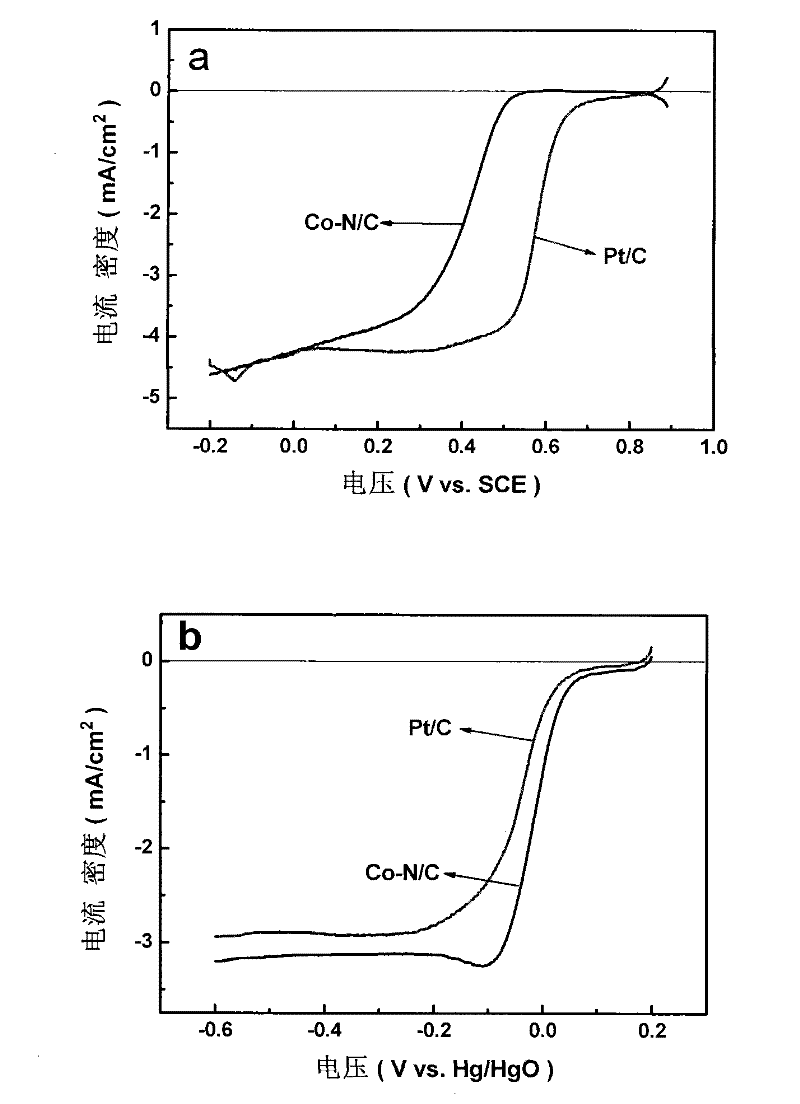

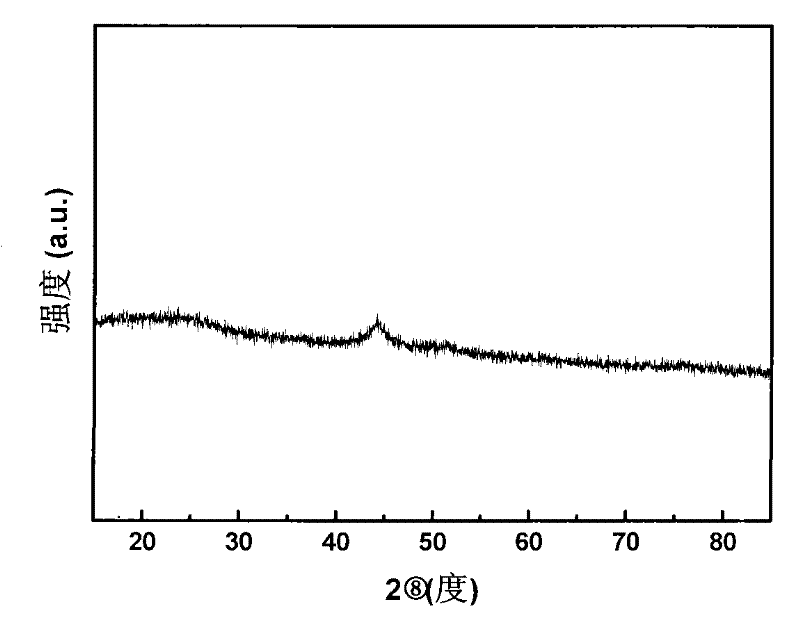

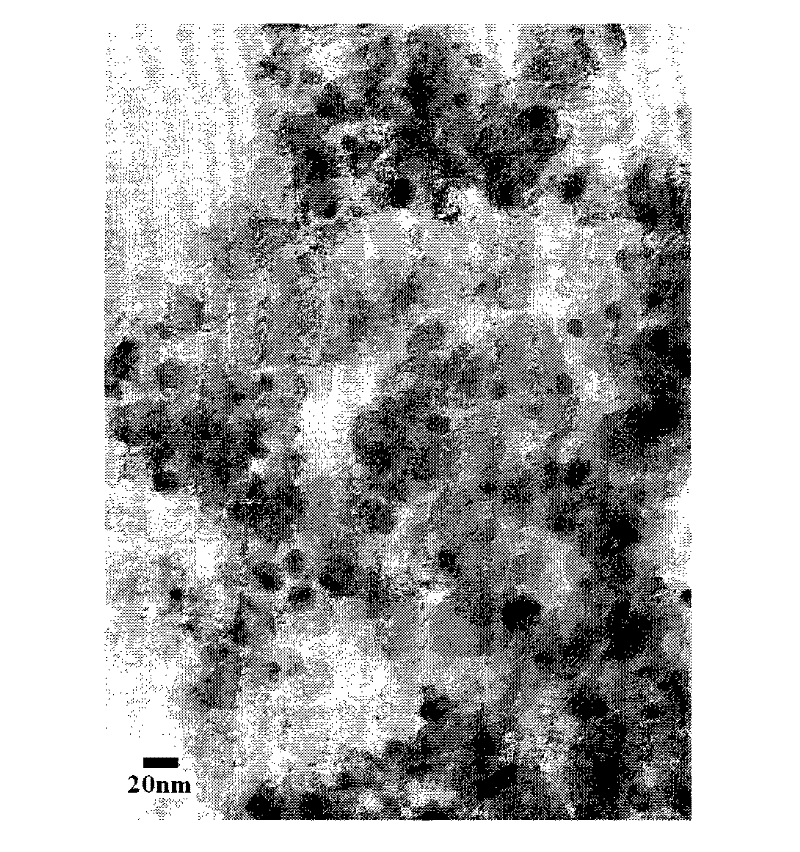

Application of a Catalyst in Alkaline Fuel Cell

InactiveCN102299347AHigh activityGood application effectPhysical/chemical process catalystsCell electrodesFuel cellsActive component

The present invention relates to alkaline fuel cell catalysts, specifically the application of a highly active catalyst in alkaline fuel cells; the active component of the catalyst is composed of N and metal components, and the metal components are Fe, One or more of Co, Ni, Ti, V, Cr, Mn, Cu, Zn, Zr, Nb, Mo, Cd, W, Sn, Pb, Pd, Ir, Ru, W and their oxides; The atomic ratio of N and other metal components in the catalyst is 20:1-0.1:10, the mass percentage of active components in the catalyst is 10-80%, and the balance is C carrier. The catalyst of the invention has small particles and uniform particle size distribution. Compared with Pt, the catalyst has the advantages of low price and rich resources, and its activity in an alkaline system is equivalent to that of Pt, thereby greatly reducing the catalyst cost.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

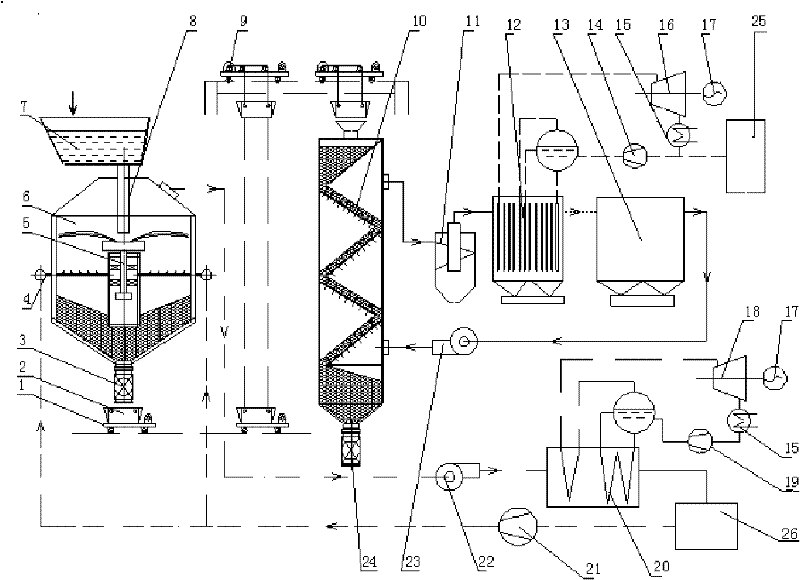

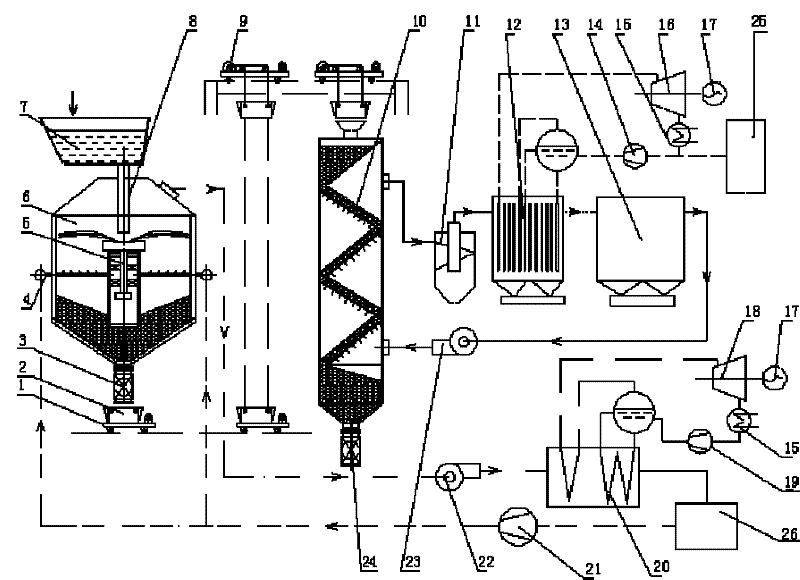

Blast furnace slag granulation and waste heat utilization process technology and equipment

ActiveCN102268495ASmall and uniformSmall sizeProcess efficiency improvementSteam generation using hot heat carriersMolten slagBlast furnace

The invention provides a process technology for granulating blast-furnace slag and utilizing waste heat. The process technology is characterized by comprising the following steps of: performing primary cooling and triple granulation on high-temperature molten slag from a blast furnace in a slag primary cooling device to form fine granules with diameter of less than 3mm and temperature of about 800-1,000 DEG C; discharging the fine granules through a high-temperature slag discharge valve; entering a slag basket and conveying to the upper part of a slag secondary cooling device; falling to the lower part of the slag secondary cooling device along a plurality of layers of baffle heat exchange components which are arranged in the slag secondary cooling device; and cooling to about 200 DEG C and discharging through a low-temperature slag discharging valve, wherein waste heat of normal pressure steam of 200 DEG C can be recovered by the slag primary cooling device; and waste heat of hot circulating air of over 600 DEG C can be recovered by the slag secondary cooling device. The invention provides equipment for granulating blast-furnace slag and utilizing waste heat. The equipment mainlycomprises the slag primary cooling device, the slag secondary cooling device, a waste heat boiler and the like. The process technology and the equipment have the advantages of good granulation effectof the molten slag, small and uniform size of slag granules, almost zero new water consumption and low environmental pollution.

Owner:北京中冶设备研究设计总院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com