Method for preparing nanoscale silica hollow microspheres

A technology of silicon dioxide and hollow microspheres, applied in the directions of silicon dioxide, silicon oxide, nanotechnology, etc., can solve the problems of high cost and complicated preparation process, and achieve complete yield, simple operation, uniform size and shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

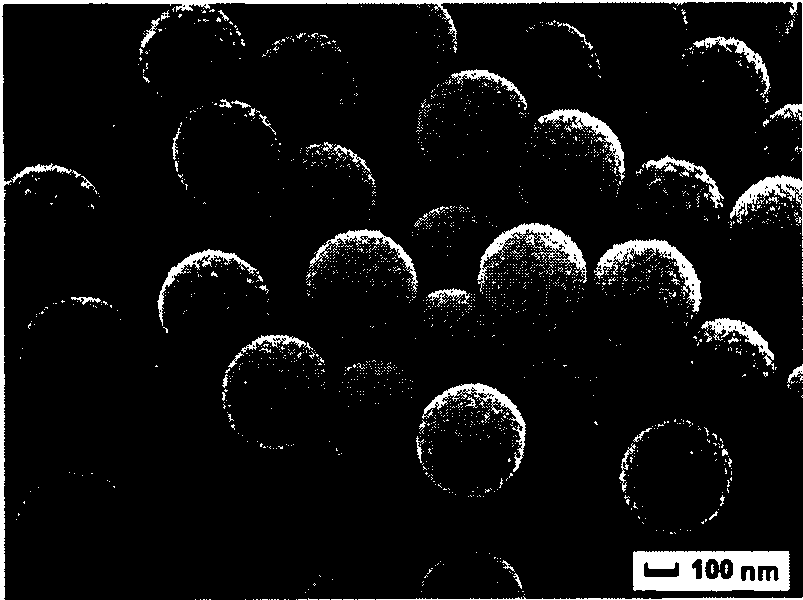

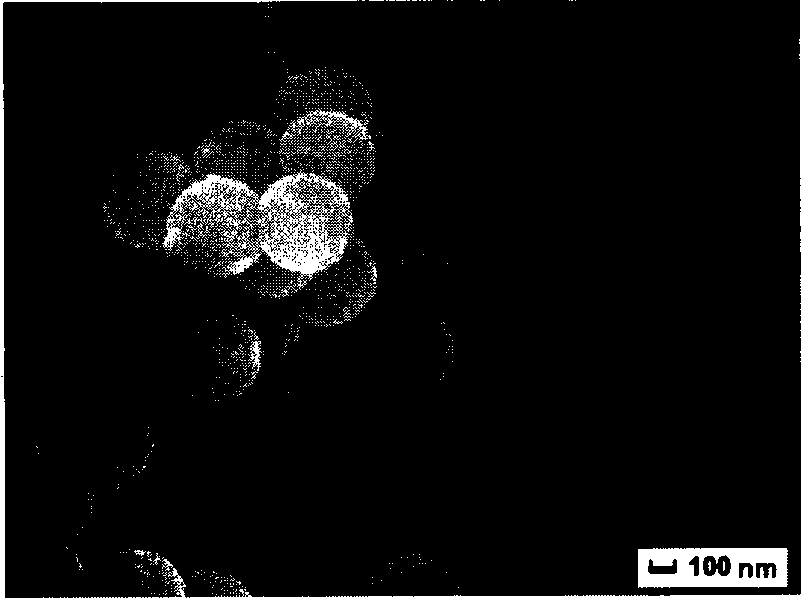

[0020] In a water bath environment at 70°C, 50ml of styrene, 5ml of methacrylic acid, and 450ml of distilled water were added to a 1000ml four-necked flask (the volume ratio of styrene to methacrylic acid was 10:1), mechanically stirred, and 10ml of 25g K of / L 2 S 2 o 8 Aqueous solution was added to initiate the reaction. After reacting for 24 hours, a styrene-methacrylic acid copolymerized microsphere emulsion was obtained. The emulsion is centrifuged and washed to obtain a styrene-methacrylic acid copolymer colloid template with a diameter of about 380 nm.

[0021] 5 g of the prepared template microspheres were added to 150 ml of distilled water, and ultrasonically dispersed for 20 minutes to obtain a stable dispersed suspension. The suspension was transferred to a large 1000ml beaker and placed in a water bath at 80°C. Then 5 ml of aqueous CTAB solution (50 g / L) was added and stirring was maintained for 1 hour.

Embodiment 2

[0026] In a water bath environment at 70°C, add 50ml of styrene and 450ml of distilled water into a 1000ml four-neck flask, stir mechanically, and add 10ml of 20g / L K 2 S 2 o 8 Aqueous solution was added to initiate the reaction. After reacting for 12 hours, a pure polystyrene microsphere emulsion was obtained. The emulsion was centrifuged and washed to obtain a simple polystyrene colloid template with a diameter of about 650 nm.

[0027] 5 g of the prepared template microspheres were added to 150 ml of distilled water, and ultrasonically dispersed for 20 minutes to obtain a stable dispersed suspension. The suspension was transferred to a large 1000ml beaker and placed in a water bath at 80°C. Then 5 ml of aqueous CTAB solution (50 g / L) was added and stirring was maintained for 1 hour.

[0028] 600 ml of sodium silicate solution (0.1 mol / L) was added dropwise into the reaction liquid within 3 hours by using a constant flow pump, and the coating amount of silicon dioxide w...

Embodiment 3

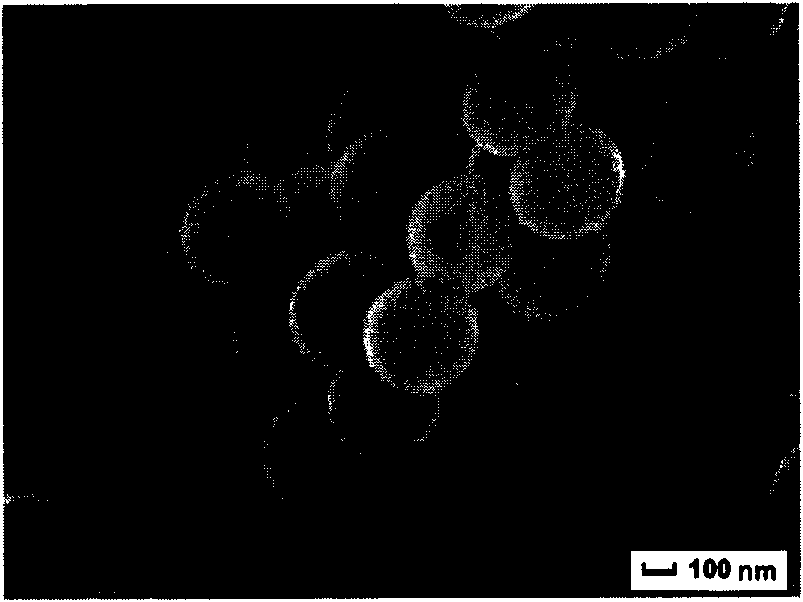

[0033] In a water bath environment at 70°C, add 50ml of styrene, 5ml of methacrylic acid, and 450ml of distilled water into a 1000ml four-neck flask, mechanically stir, and add 10ml of 20g / L K 2 S 2 o 8 Aqueous solution was added to initiate the reaction. After reacting for 12 hours, a styrene-methacrylic acid copolymerized microsphere emulsion was obtained. The prepared styrene-methacrylic acid copolymerized microsphere emulsion is added to a 500ml beaker and placed in a water bath at 40°C, then 200ml of vitriol oil (98wt%) is added dropwise and kept stirring to obtain a sulfonated polystyrene Microspheres. The emulsion is centrifuged and washed to obtain a sulfonated polystyrene colloid template with a diameter of about 440 nm.

[0034] 5 g of the prepared sulfonated polystyrene template microspheres were added to 150 ml of distilled water, and ultrasonically dispersed for 20 minutes to obtain a stable dispersed suspension. The suspension was transferred to a large 1000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com