Efficient in-situ preparation method of graphene reinforced copper-based composite material

A copper-based composite material and an in-situ preparation technology, which is applied in the field of preparing graphene-reinforced copper-based composite materials, can solve the problems of poor uniform dispersion of graphene, poor structural integrity, complicated process, etc., and achieves short preparation time, low cost, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

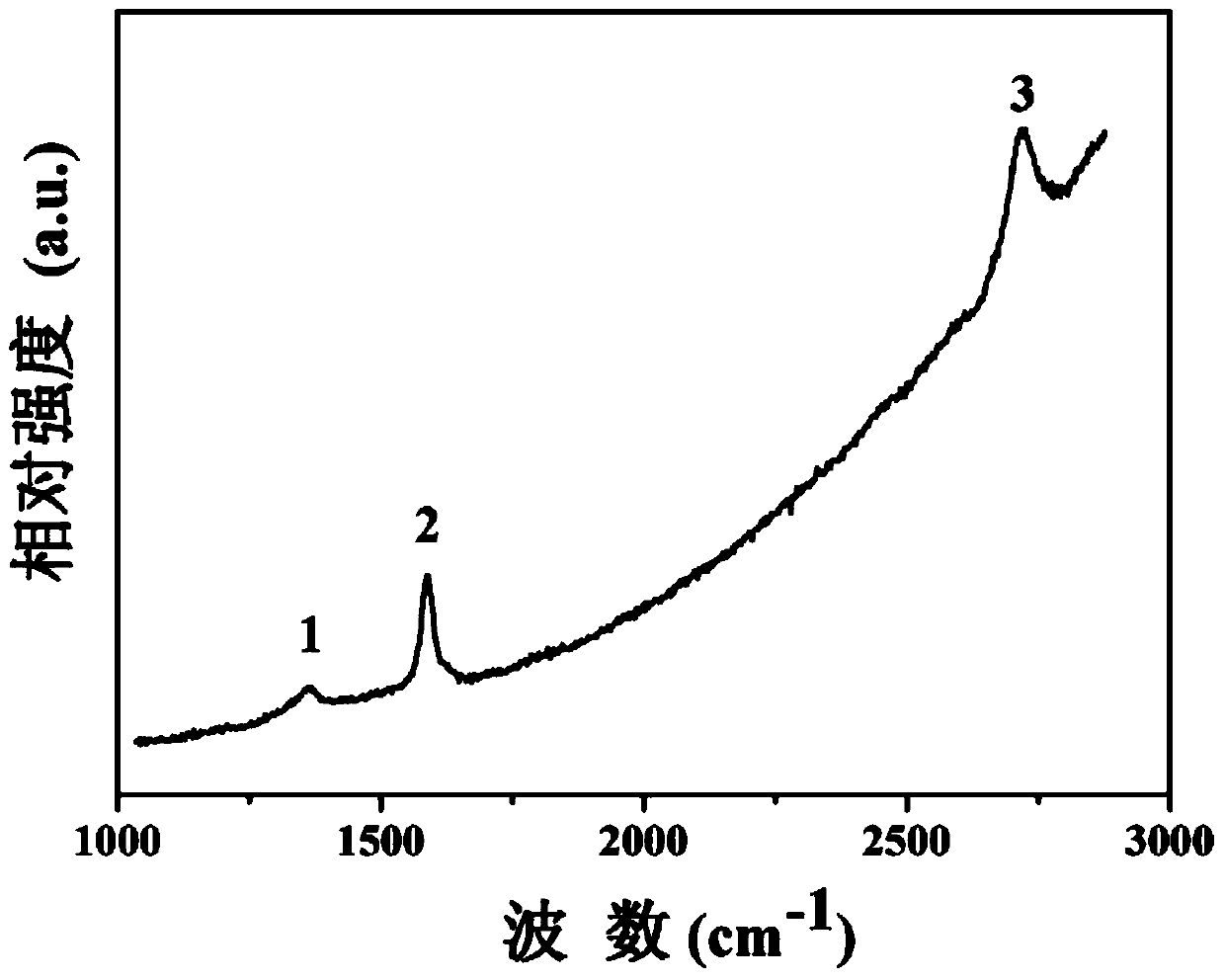

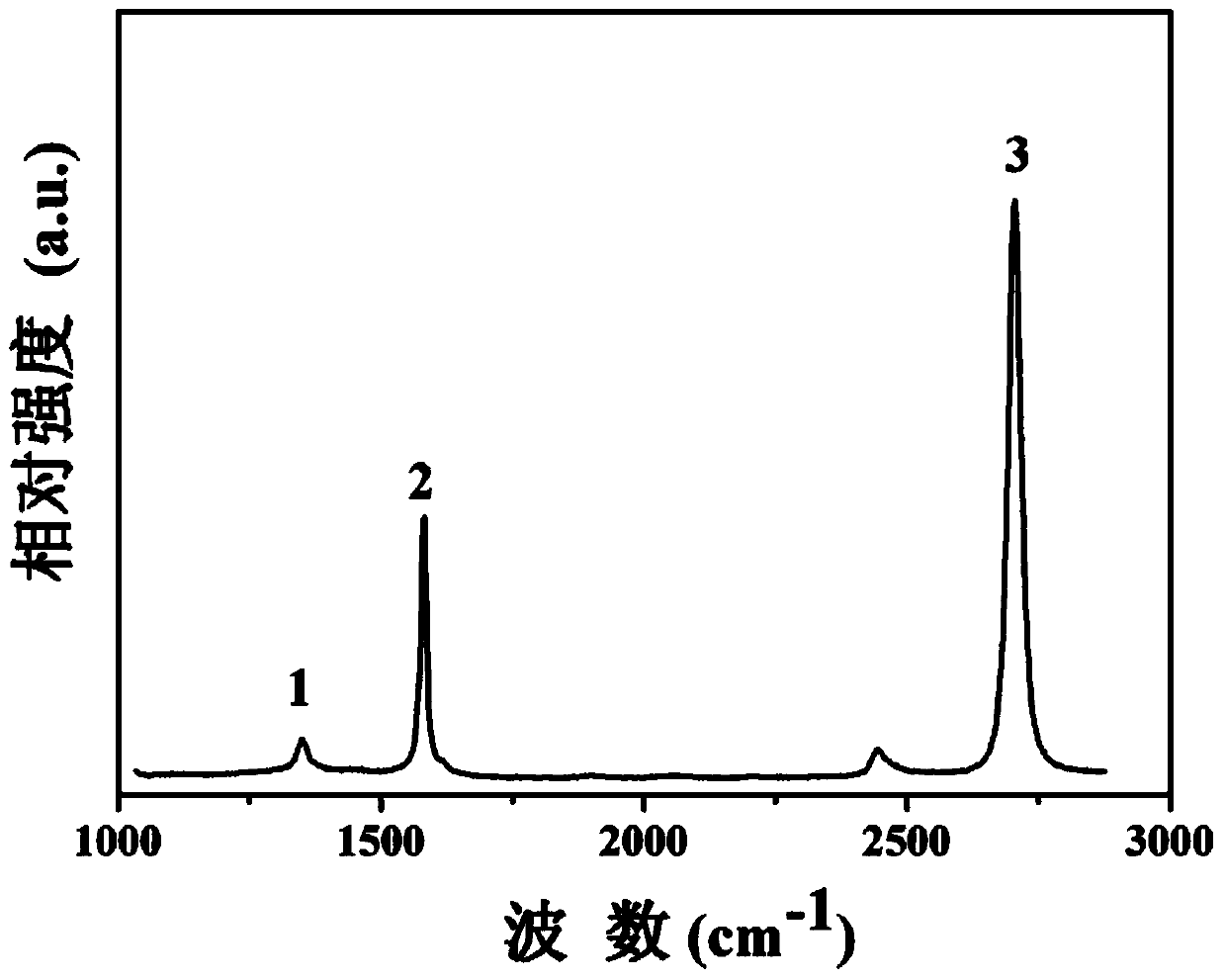

[0017] Specific embodiment one: a kind of efficient in-situ preparation method for graphene-reinforced copper-based composite material described in this embodiment is specifically carried out according to the following steps:

[0018] 1. Put the copper powder in the plasma-enhanced chemical vapor deposition vacuum device, evacuate until the pressure is below 5Pa, feed hydrogen gas with a gas flow rate of 18sccm-22sccm, and adjust the vacuuming speed to put the plasma-enhanced chemical vapor deposition in the vacuum device. The pressure is controlled at 190Pa to 210Pa, and the temperature is raised to 500°C to 700°C within 40 minutes under the pressure of 190Pa to 210Pa and hydrogen atmosphere, and the temperature is 500°C to 700°C for 25min to 35min;

[0019] 2. Introduce argon and carbon source gas, adjust the gas flow of hydrogen to 40 sccm, argon gas to 80 sccm, and carbon source gas to 1 sccm to 8 sccm, and adjust the vacuuming speed to vacuum the plasma-enhanced chemical v...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that the copper powder described in Step 1 has a purity of 99%-99.99%, and a particle diameter of 100 nm-100 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the carbon source gas described in step 2 is methane. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com