Patents

Literature

621 results about "Copper matrix composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Short fiber-particle synergetically-reinforced copper-based composite material and preparation method thereof

The invention relates to a copper-based composite material, and particularly relates to a short fiber-particle synergetically-reinforced copper-based composite material which is prepared through powder metallurgy. Short fibers and particles are used as reinforced phases, the content of the short fiber is 0.1-0.1 wt%, and the content of reinforcement particles is 0.1-10 wt%. The short fibers can be carbon nanotubes, carbon nanofibers, ceramic short fibers, and the like, and the particles used as reinforced phases can be aluminum oxide, zirconium oxide, magnesium oxide, titanium dioxide, silicon carbide, titanium carbide, tungsten carbide, silicon nitride, aluminum nitride, titanium nitride, titanium diboride, Ti3SiC2, and the like. The composite material is prepared through the steps of mixing, forming, sintering and processing, and the room temperature and the high temperature strength of the composite material can be increased by more than 3 times in comparison with those of pure copper; the electrical conductivity of the composite material can reach more than 80% of that of pure copper; the thermal conductivity of the composite material can reach more than 70% of that of pure copper; the coefficient of friction of the composite material can be reduced to be below 70% of that of pure copper; and the wear rate of the composite material can be reduced to be below 50% of that of pure copper.

Owner:UNIV OF SCI & TECH BEIJING

High-strength and high-conductivity graphene copper-based composite material and preparation method thereof

The invention discloses a high-strength and high-conductivity graphene copper-based composite material and a preparation method thereof, wherein the graphene copper-based composite material comprises 0.01wt.%-6.0wt% of graphene and the balance of copper; the preparation method comprises the following steps: firstly, adding graphene oxide to a copper sulfate solution, adding a hydrazine hydrate solution to reduce nano-copper powder and graphene, drying and then reducing in H2 atmosphere, and finally, preparing the graphene copper-based composite material from the reduced composite powder by use of the Spark Plasma Sintering (SPS) technology. The graphene copper-based composite material shows excellent electric conductivity and thermal conductivity and outstanding wear resistance and corrosion resistance, and thus has a wide application prospect in the field of the frame leads and the electrical contact materials.

Owner:JIANGXI UNIV OF SCI & TECH

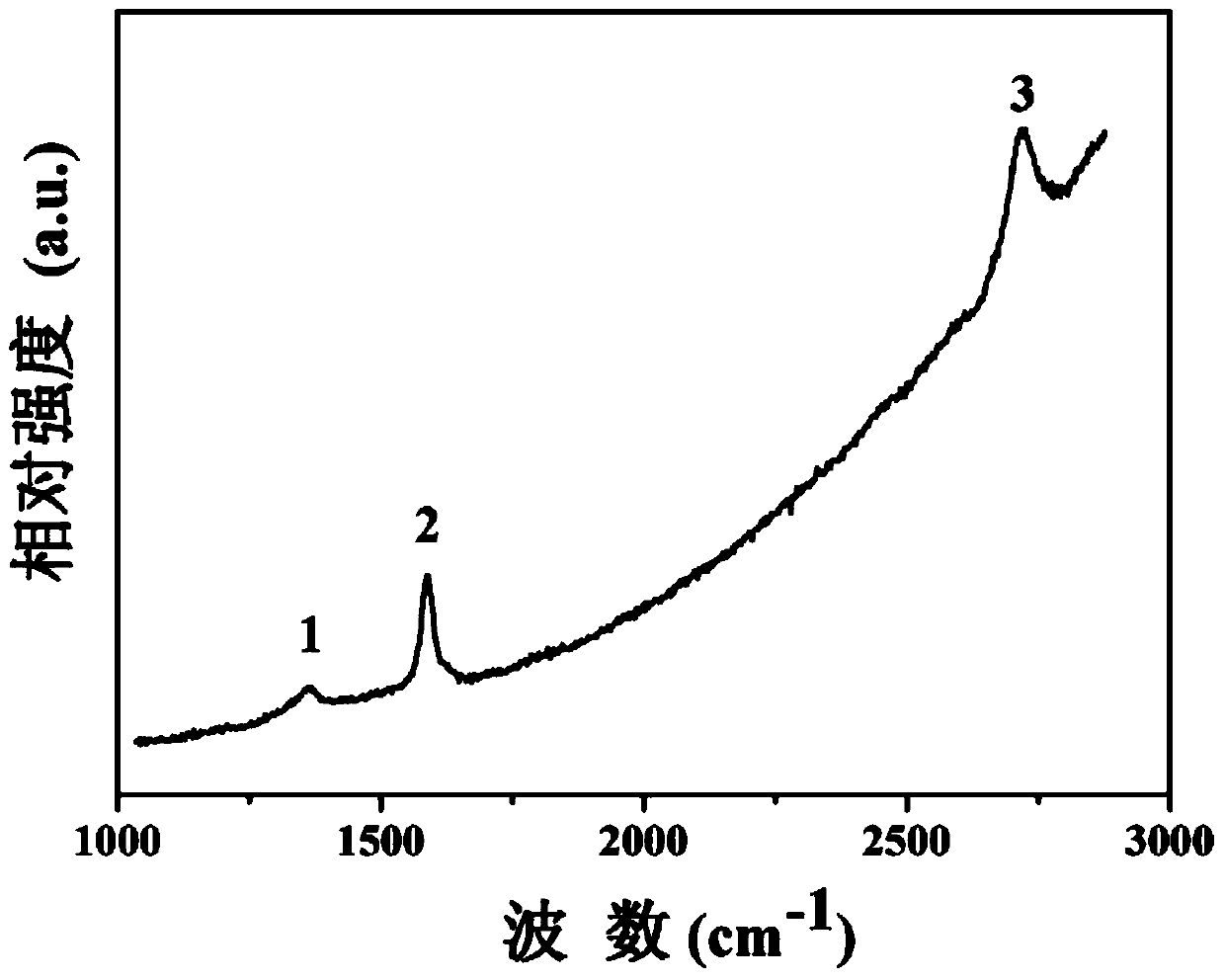

Efficient in-situ preparation method of graphene reinforced copper-based composite material

The invention discloses an efficient in-situ preparation method of a graphene reinforced copper-based composite material, and relates to a method for preparing a graphene reinforced copper-based composite material and the method can be used for solving the problems of poor uniform dispersion, poor structure integrity of grapheme and complex process in the existing preparation method of the graphene reinforced copper-based composite material. The efficient in-situ preparation method of the graphene reinforced copper-based composite material comprises the following steps: putting copper powder in a plasma reinforced chemical vapor deposition vacuum device, introducing hydrogen, preserving heat at high temperature, then introducing argon and carbon source gas, depositing, stopping introducing the carbon source gas after ending the deposition, and finally, cooling below the room temperature to obtain grapheme / copper composite powder, and then primarily pressing, sintering and secondarily pressing the grapheme / copper composite powder to obtain the graphene reinforced copper-based composite material. The method is an efficient in-situ preparation method of a graphene reinforced copper-based composite material.

Owner:HARBIN INST OF TECH

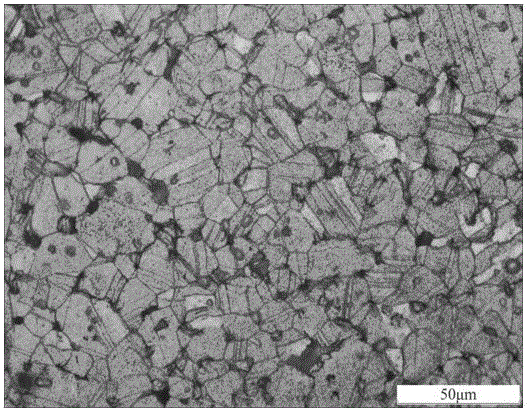

Multiple dispersion strengthening copper-base composite material prepared in situ and preparation method thereof

InactiveCN101613816APromote generationImprove organizational structureTitanium carbideSelf generation

The invention discloses a multiple dispersion strengthening copper-base composite material produced in situ and a preparation method thereof; the reinforced phase comprises at least three of the following substances: titanium carbide, zirconium carbide, alumina, titanium boride, aluminum carbide, chromium oxide, zirconia, graphite and copper; wherein, the contents of titanium carbide, zirconium carbide, alumina, titanium boride, chromium oxide and zirconia are not less than 0.3% and not more than 5%, the content of aluminum carbide is not less than 0.1% and not more than 5%, the content of graphite is not less than 0.1% and not more than 1% and the balance is copper. The particle size of the reinforced phase is between 10nm to 10mu m. The preparation method adopts ball milling; pressing, sintering and squeezing processes and the technological parameters are optimized and controlled properly to obtain the multiple dispersion strengthening copper-base composite material. Because the in situ self-generation technology is adopted and various reinforced phase methods are combined, the material of the invention has higher high-temperature strength and better electroconductibility and anti-creep property compared with the traditional ceramic particle strengthening copper-base composite material.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

High heat conductivity copper-base composite material and preparation method thereof

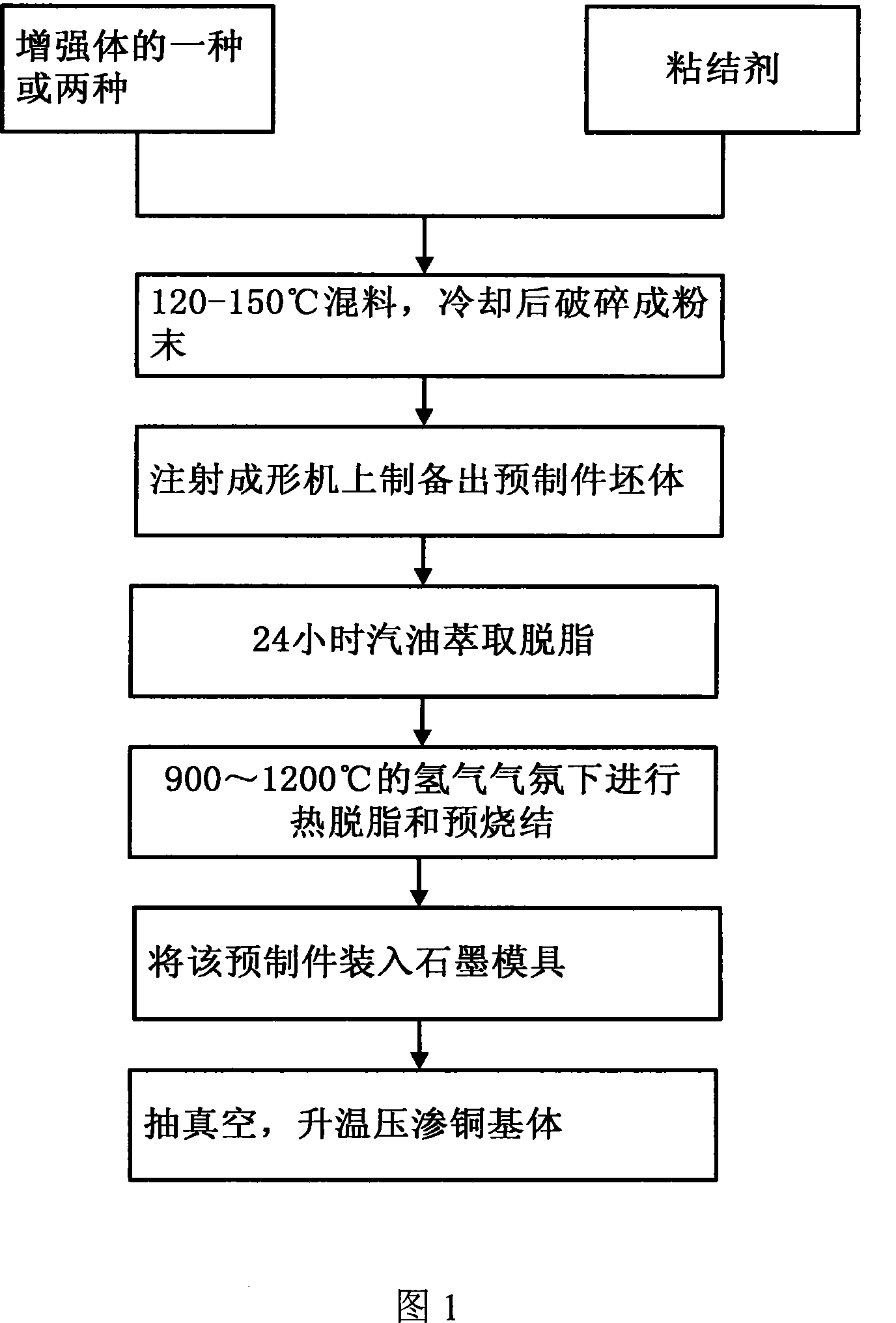

The invention belongs to the technical field of preparation of electronic packaging materials, and particularly designs a copper-based composite material with high thermal conductivity and a preparation method thereof. The copper-based composite material is made of a reinforcement and a binder through a prefabricated injection molding process to make a reinforcement prefabricated part, wherein the size of the reinforcement particle is 7-60 μm, and it is composed of silicon carbide particles, diamond particles or aluminum nitride particles. One or two of them; the copper matrix is directly placed on the reinforcement preform, wherein the copper matrix is electrolytic copper or oxygen-free copper, and the volume ratio of the reinforcement to the copper matrix is 50-75%: 25-50 %, made by pressure infiltration process. The preparation method adopts the injection molding process of the prefabricated part and the pressure impregnation process to prepare the high thermal conductivity copper matrix composite material. The thermal conductivity of the copper-based composite material in the present invention is higher than that of the aluminum-based composite material with the same reinforcement system, the material itself has low density and small thermal expansion coefficient, which meets the requirement of light weight of the packaging material.

Owner:GRIMAT ENG INST CO LTD

Method for preparing high volume-fraction carborundum granule-reinforced copper-based composite material

ActiveCN101157993AHigh densityThermophysical property adjustmentVolumetric Mass DensityParticle-size distribution

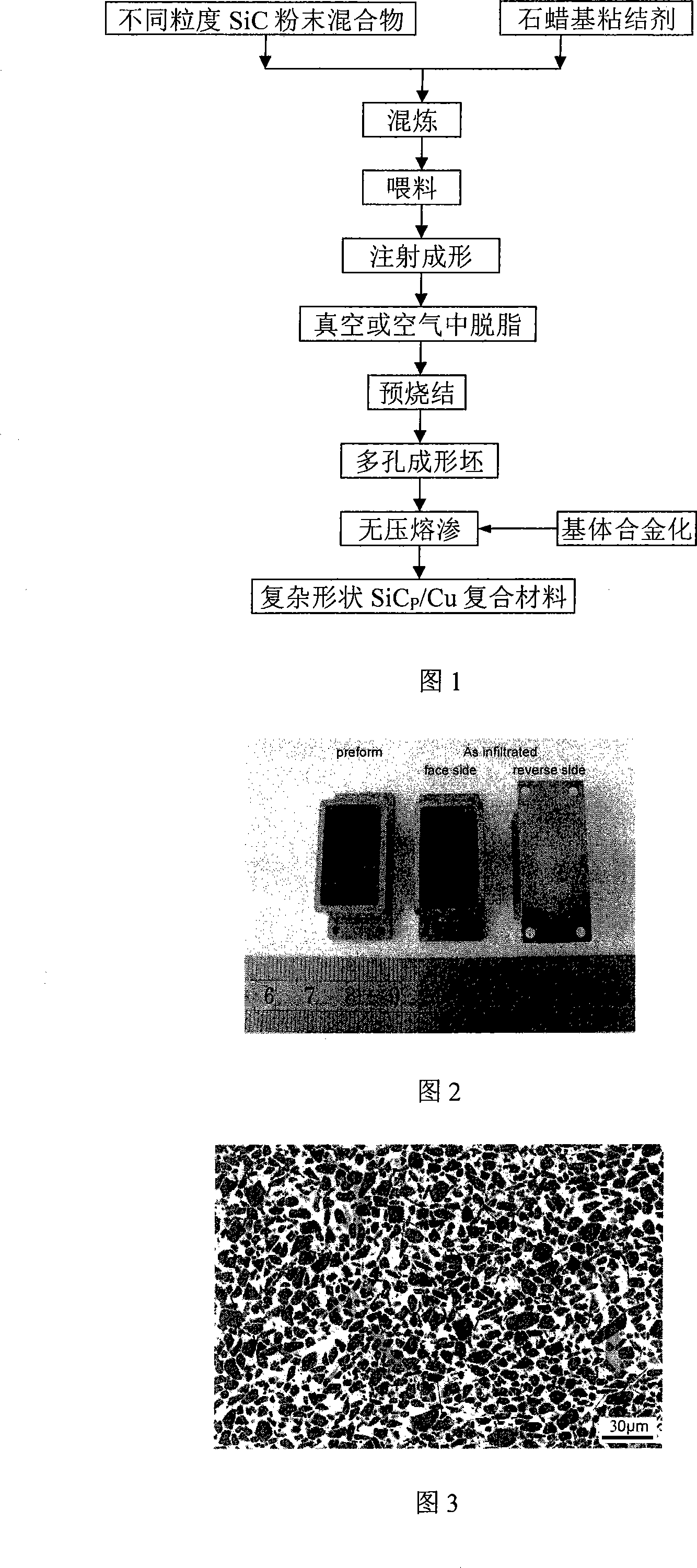

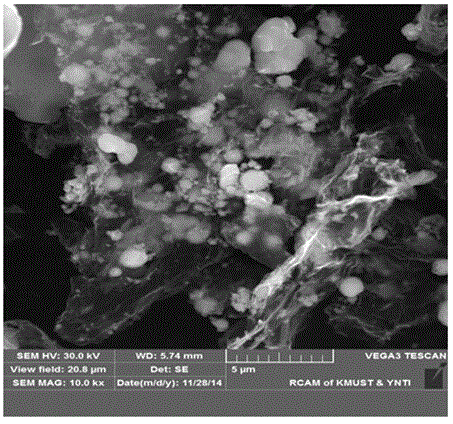

The invention relates to a method to prepare high volume fraction silicon carbide particle to enhance copper matrix composite, belonging to the field of metal matrix composites. The technique is that: proper blended particle size distributed SiC powder is mixed with polymer component paraffin base binder in a volume proportion of 57-68% load in sudarpress, fine blended feedstock is obtained; injection mold in powder injection molding machine in the injection temperature of 150-175 DEG C and the injection pressure of 75-125MPa to obtain a required billet, the billet is degreased in a solution-doff + thermal-doff process, and is first sintered in 600-1120 DEG C to obtain pre-molded billet of porous SiC. Infiltrate copper alloy to the porous SiC pre-molded billet in the temperature of 1400-1450 DEG C in vacuum via non-pressure infiltration. So the high volume fraction SiCp / Cu composite is obtained. The invention can prepare intricate shaped thin wall SiCp / Cu composite parts, enhance the content of phase as high as 57-67% volume fraction, the density of the composite is high, the microstructure is evenly distributed, and the invention has the advantages of high utilization rate of material, high productivity, and low production cost.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of graphene-reinforced copper-based composite

ActiveCN105624445AImprove performanceEasy to organizeTransportation and packagingMetal-working apparatusSlurryCobalt

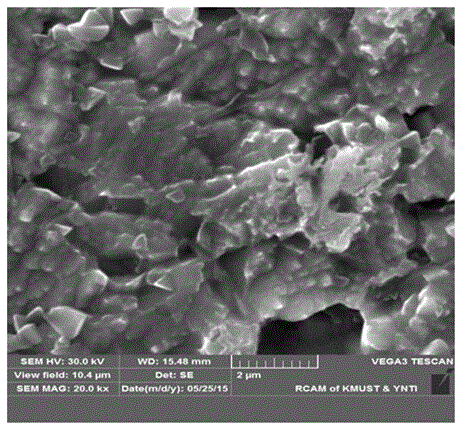

The invention discloses a preparation method of a graphene-reinforced copper-based composite and belongs to the field of preparation of high-strength and high-conductivity composites. The method comprises steps as follows: graphene, nano copper powder and cobalt powder in the required mass ratio are mixed in absolute ethyl alcohol, the mixture is physically dispersed under electromagnetic stirring, and then physically dispersed mixed slurry is added to a ball milling tank for mechanical ball milling; after evenly mixed slurry is centrifugally dried, obtained mixed powder is annealed and then subjected to hot-pressing SPS (spark plasma sintering) forming; an obtained block blank is annealed and then subjected to hot extrusion, and the graphene-reinforced copper-based composite is obtained. The graphene-reinforced copper-based composite prepared through the method has the good mechanical property, uniform structure and good heat and electricity conductivity.

Owner:KUNMING UNIV OF SCI & TECH

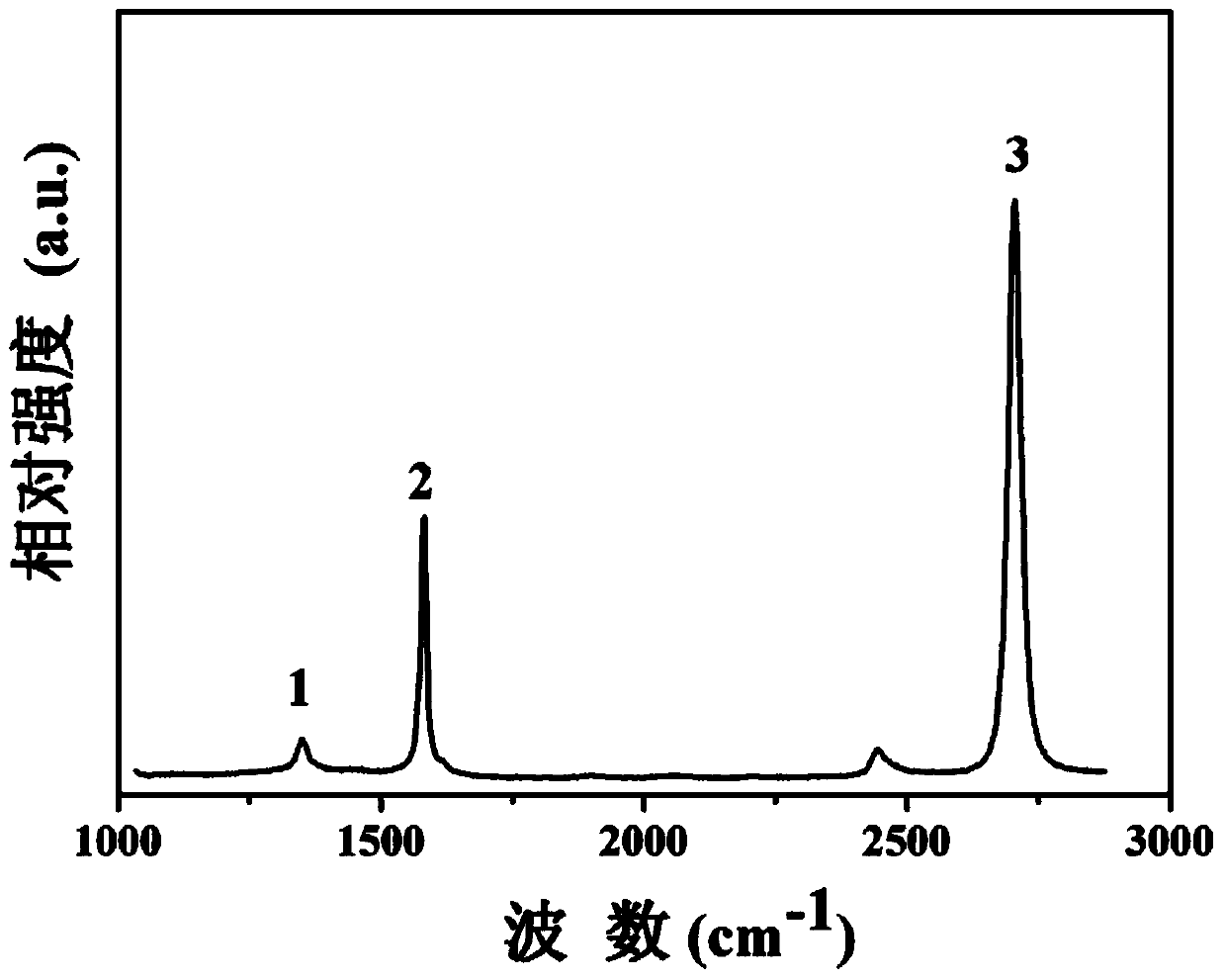

Method for preparing graphene/copper composite material by in-situ catalysis of solid carbon source on surfaces of copper powders

The present invention relates to a method for preparing a graphene / copper composite material by in-situ catalysis of a solid carbon source on surfaces of copper powders. The method comprises the steps of: adding steel balls, the copper powders and polymethyl methacrylate at the mass ratio of 150: 10: (0.1-0.3) into a ball milling tank, and filling argon as protective atmosphere after vacuum pumping; after ball milling, preparing cooper-polymethyl methacrylate powders which are uniformly dispersed; performing reduction treatment in a tubular furnace to catalyze the polymethyl methacrylate into graphene, and obtaining graphene / copper composite powders with graphene in-situ growth; and then preparing a graphene copper-based composite material block. Tensile property of the graphene reinforced copper-based composite material prepared by the method is better than tensile property of that prepared by a traditional adding method, that is a method of adding reduction-oxidation graphene or graphene sheets. Reinforcement of a cooper-based material is achieved, and high-strength copper materials have a better application prospect on electronic devices.

Owner:TIANJIN UNIV

High heat-conducting copper-based composite material and preparation method thereof

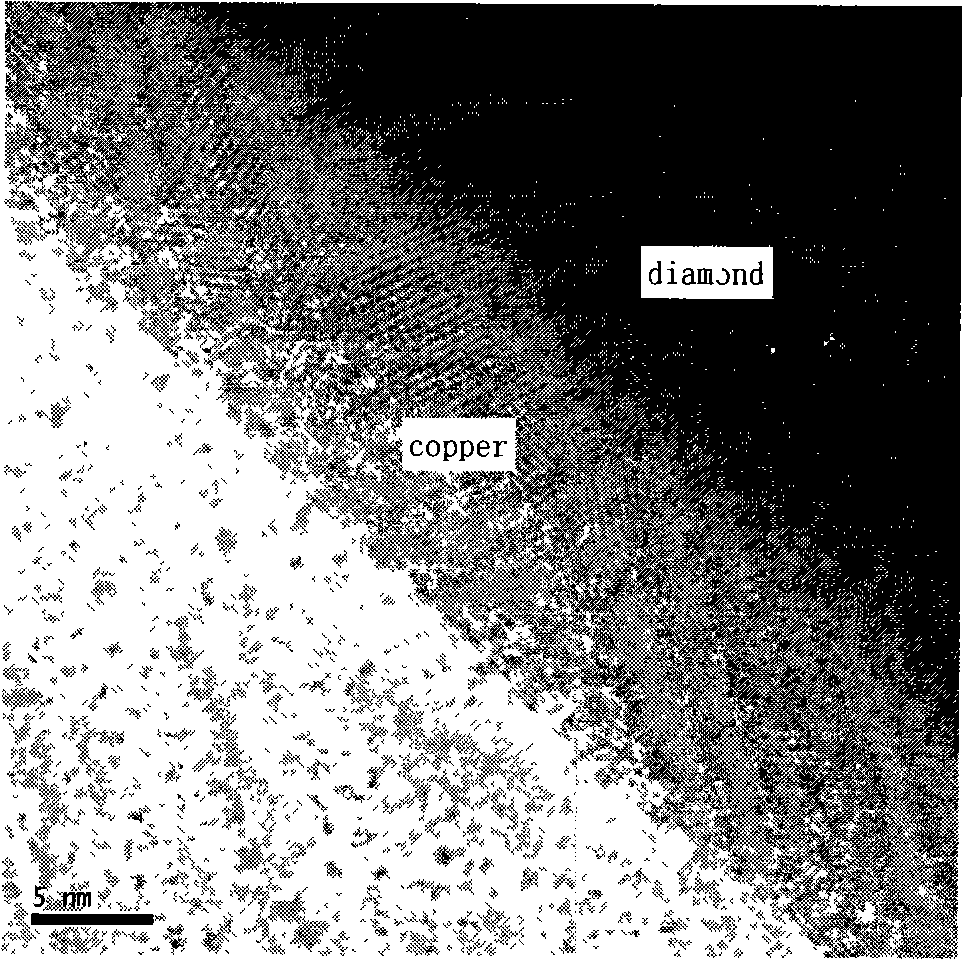

InactiveCN101831584ALow densitySmall coefficient of thermal expansionVacuum evaporation coatingSputtering coatingInterfacial thermal resistanceThermal expansion

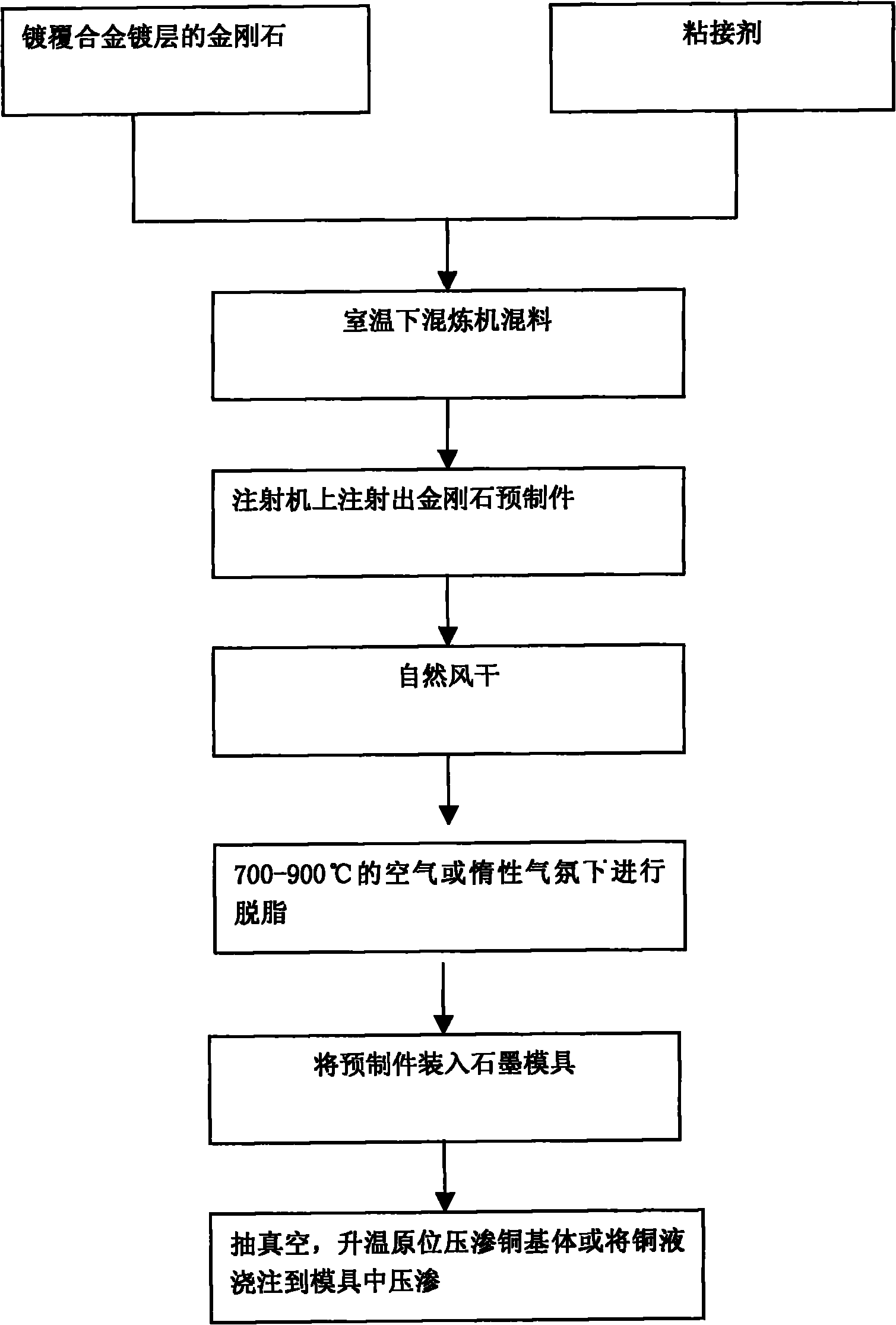

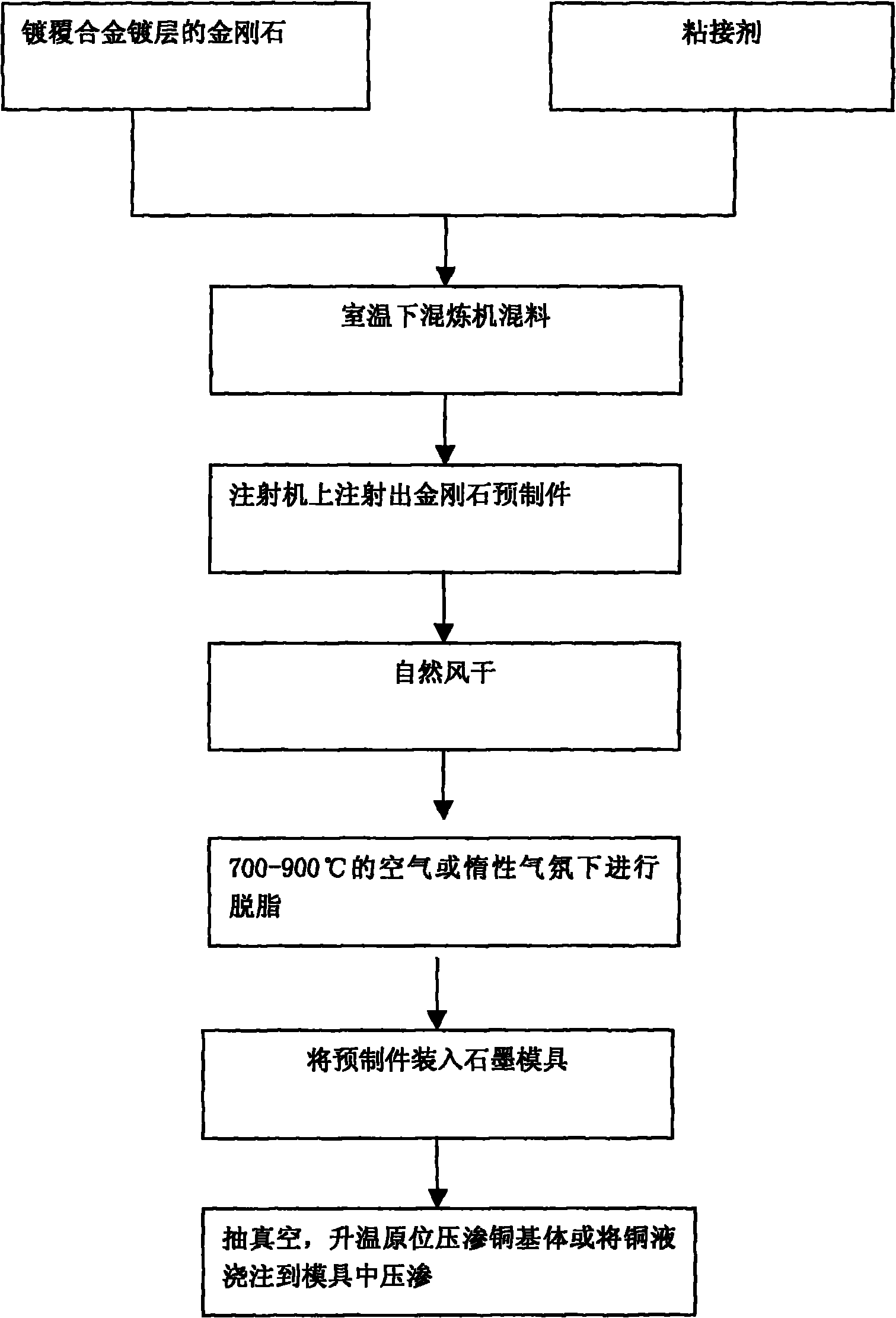

The invention relates to a high heat-conducting copper-based composite material and a preparation method thereof, belonging to the technical field of electronic packaging materials. The copper-based composite material consists of 50-80 percent by volume of electroplated diamond particles and 20-50 percent by volume of copper. The electroplated diamond particles and a caking agent are mixed according to the volume ratio of 1:1-4:1 and are produced into a diamond prefabricated part by using an injection forming process of the prefabricated part; and a copper matrix is directly placed on the diamond prefabricated part or is melt and poured on the diamond prefabricated part to be produced into the high heat-conducting copper-based composite material by using a pressure infiltration process. The copper-based composite material has higher heat conductivity ratio than that of an aluminum-based composite material; by plating the surface of diamond, the interface bonding of the matrix copper and the diamond can be improved and the interface heat resistance can be reduced; in addition, the material has low density and small thermal expansion coefficient and meets the requirement for light quality of packaging materials.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

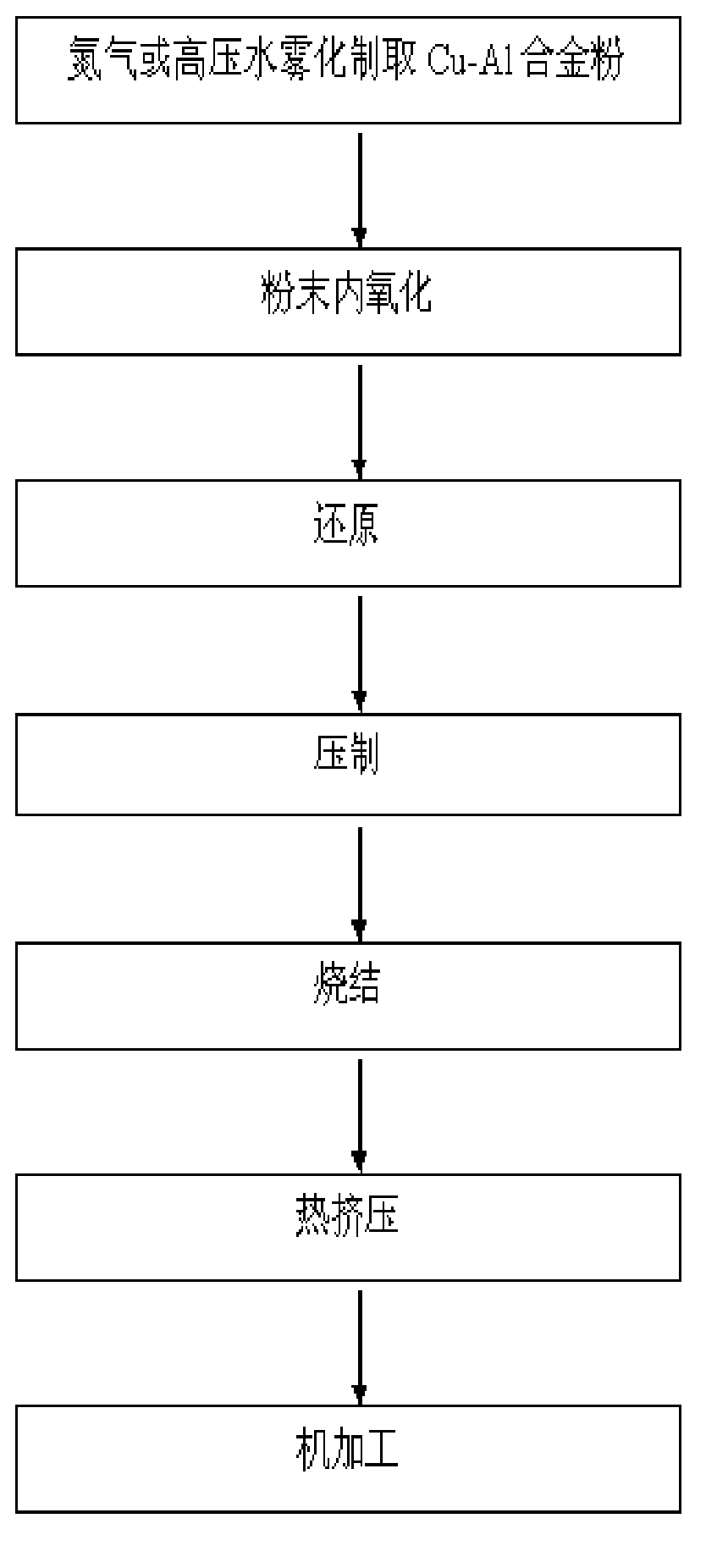

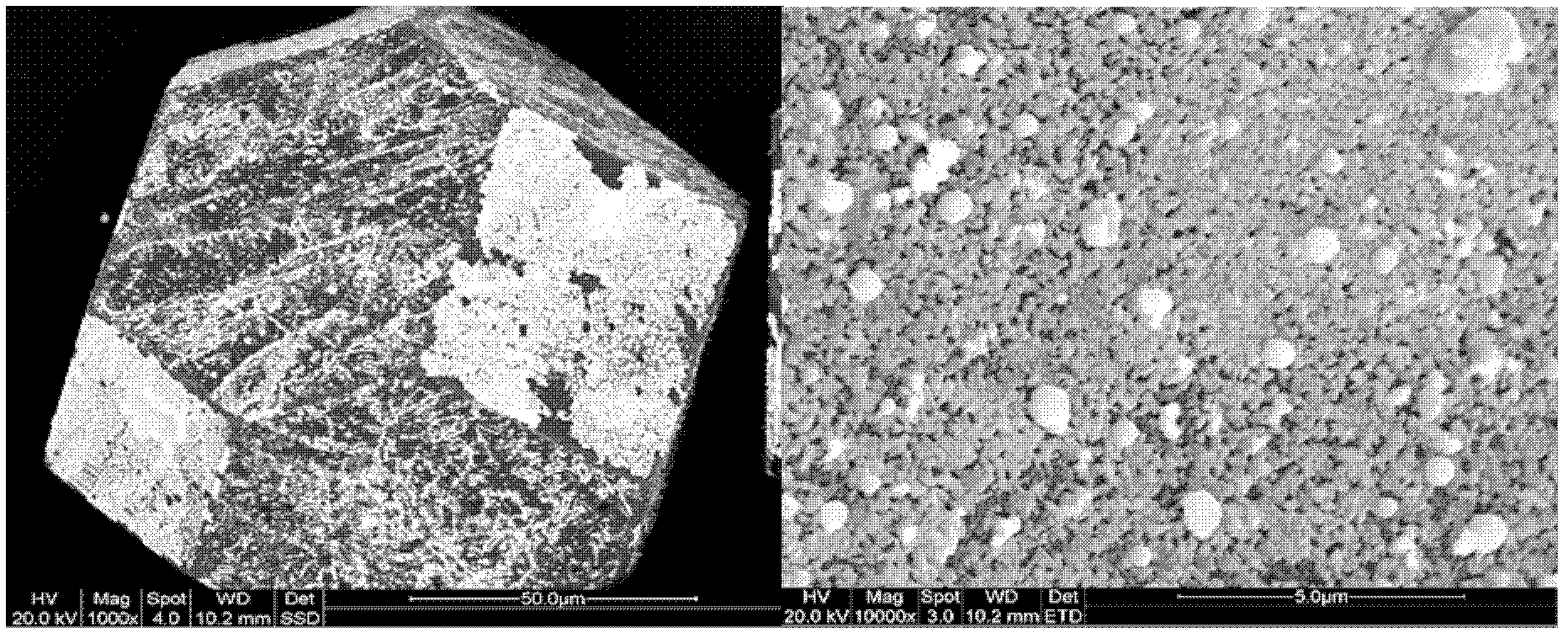

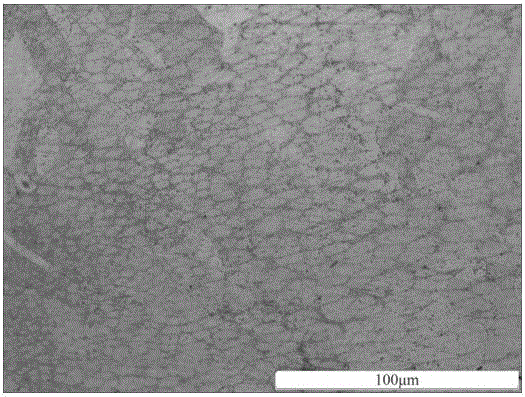

A process for preparing aluminum oxide dispersion strengthened copper with high strength and high conductivity

The invention provides a process for preparing aluminum oxide dispersion strengthened copper with high strength and high conductivity, wherein the Cu-Al alloy powder contains 0.1-0.6 wt% of Al and less than 0.5 wt% of impurity, and cuprous oxide is used as an oxidizing agent. The alloy is directly executed cold deformation after sintered and densification treatment, which avoids thermal deformation process in traditional preparation technique. The prepared aluminum oxide dispersion strengthened copper composite material has performances of high strength, high conductivity and excellent high temperature anti-softening, wherein the tensile strength is larger than 500N / mm, the electric conductivity is larger than 80% IACS, and the softening temperature is higher than 600 DEG C; and the tensile strength is larger than 400N / mm after annealing at 950 DEG C for 30min. The aluminum oxide dispersion strengthened copper is ideal material for making a lead frame of an integrate circuit, aerial extension of high speed electrified railroad, a resistance welding electrode, large thrust rocket engine inside lining, etc.

Owner:CENT SOUTH UNIV

Method of laser casting copper-based composites

InactiveUS6723278B1Additive manufacturing apparatusIncreasing energy efficiencyPowder mixtureMetal powder

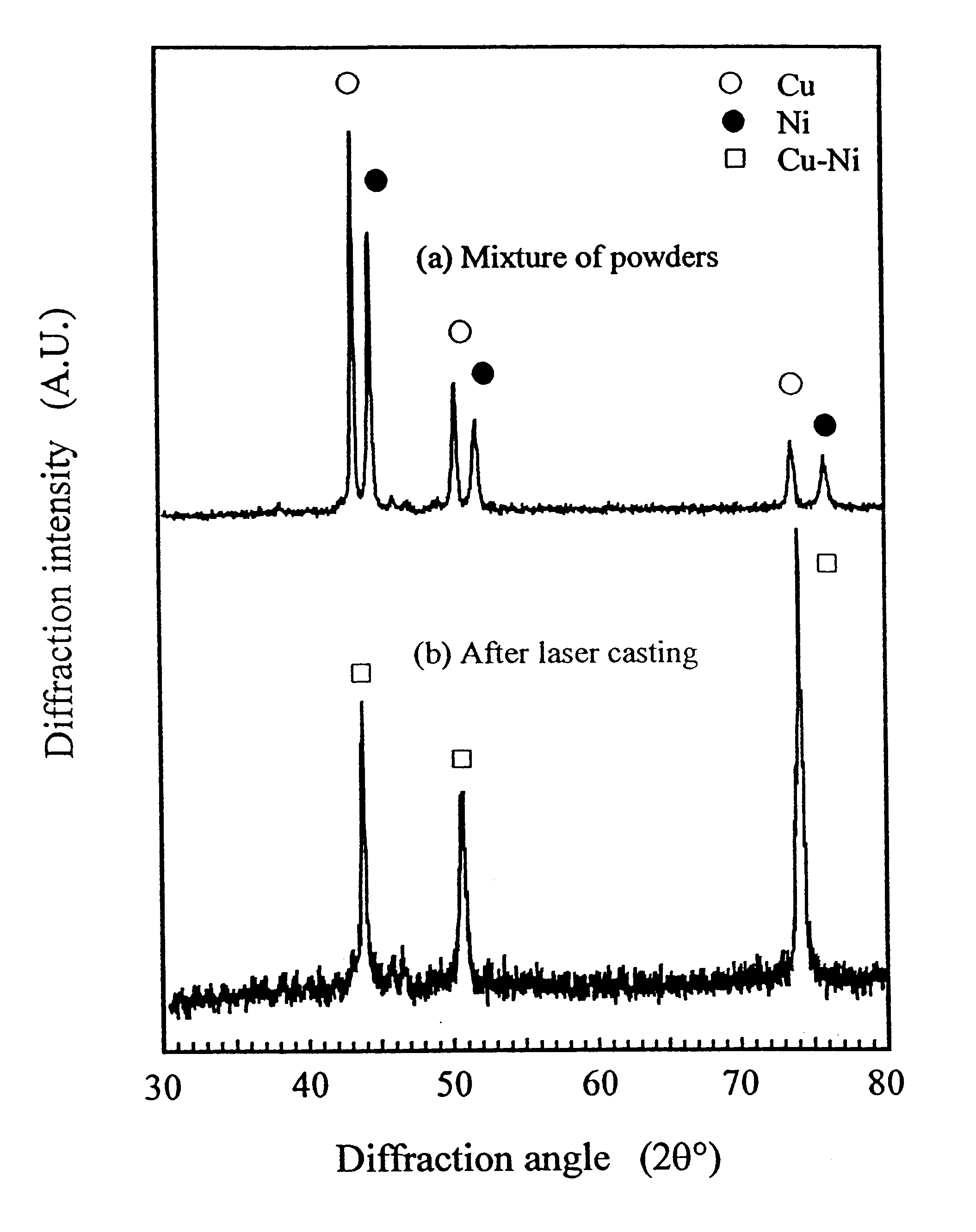

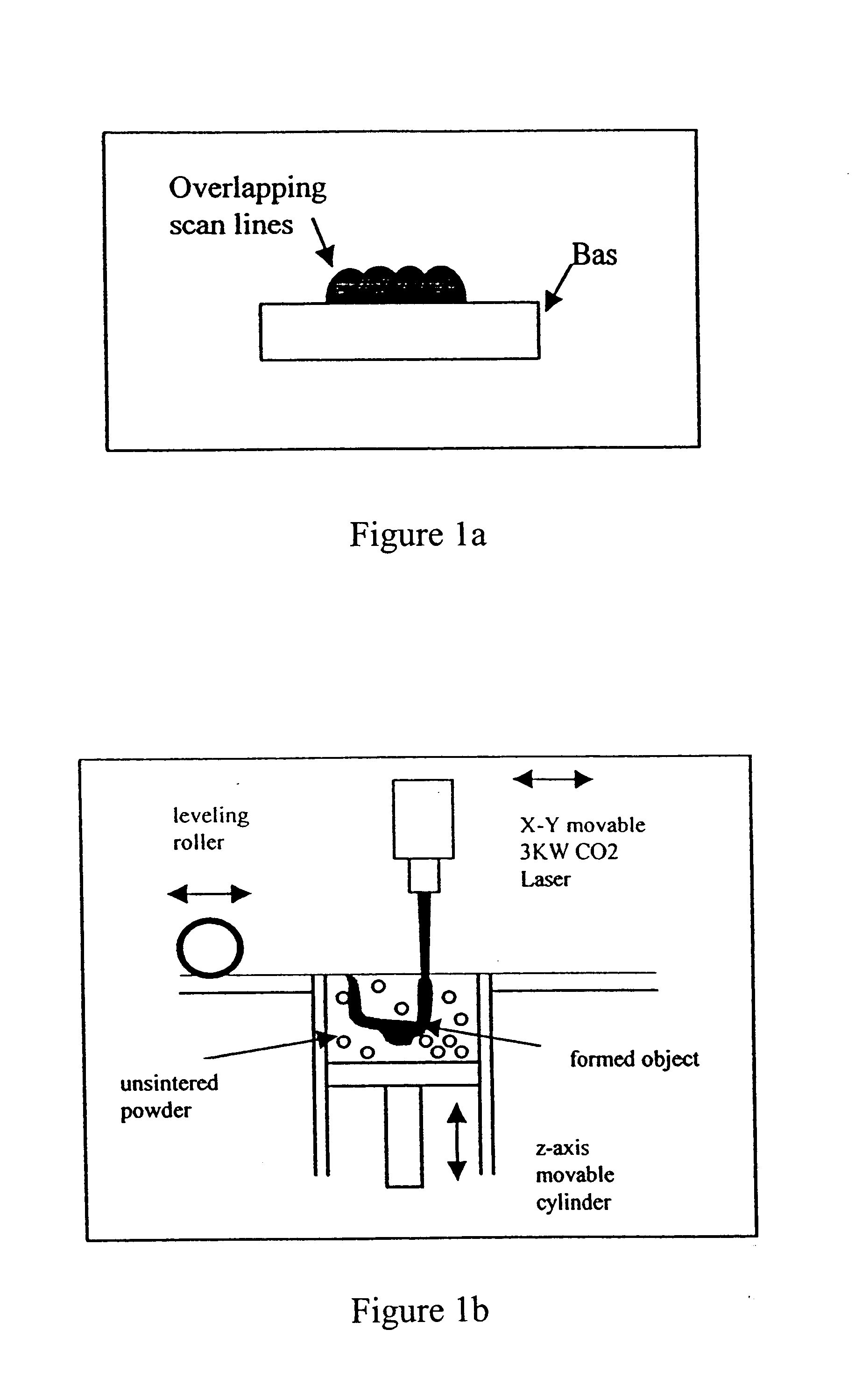

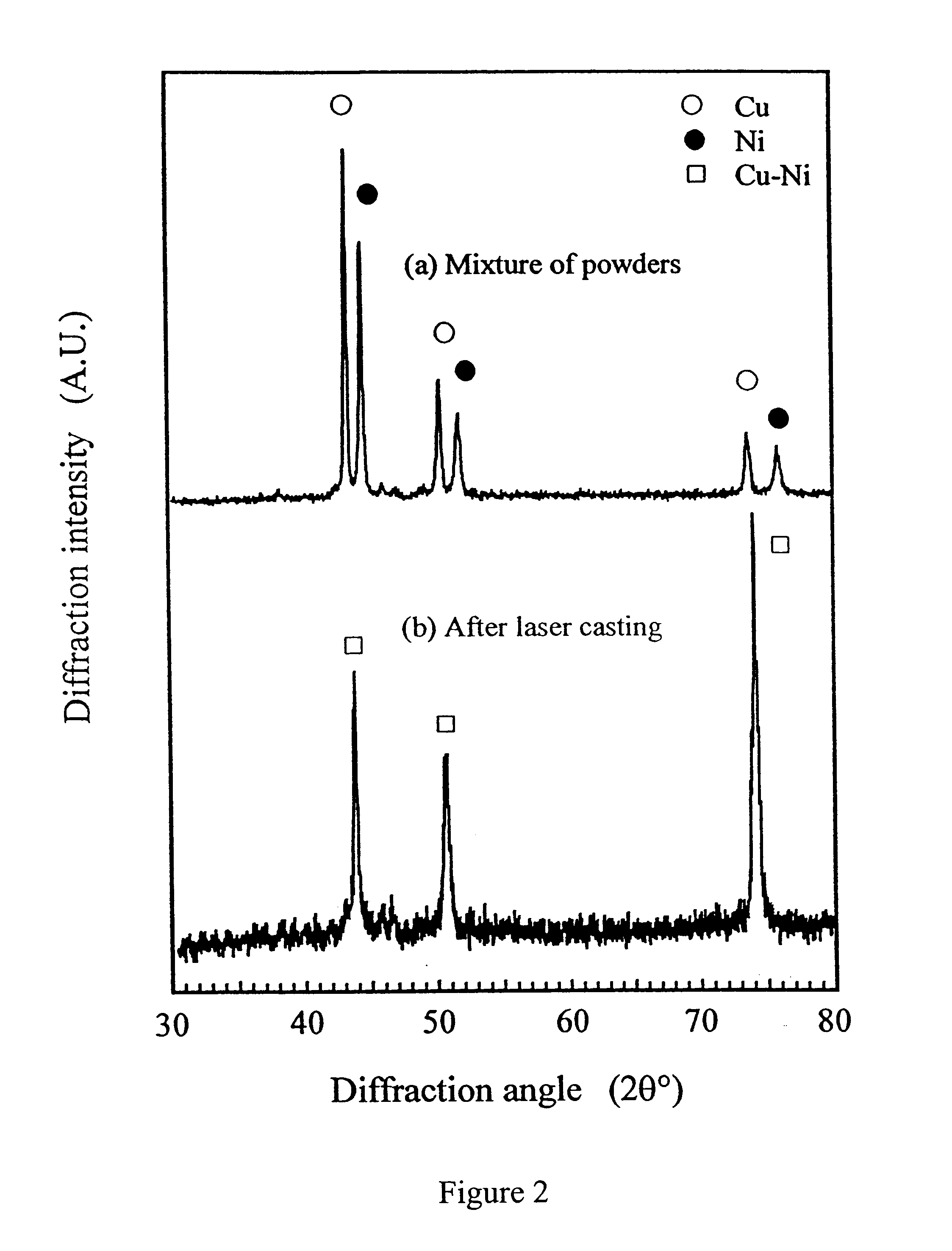

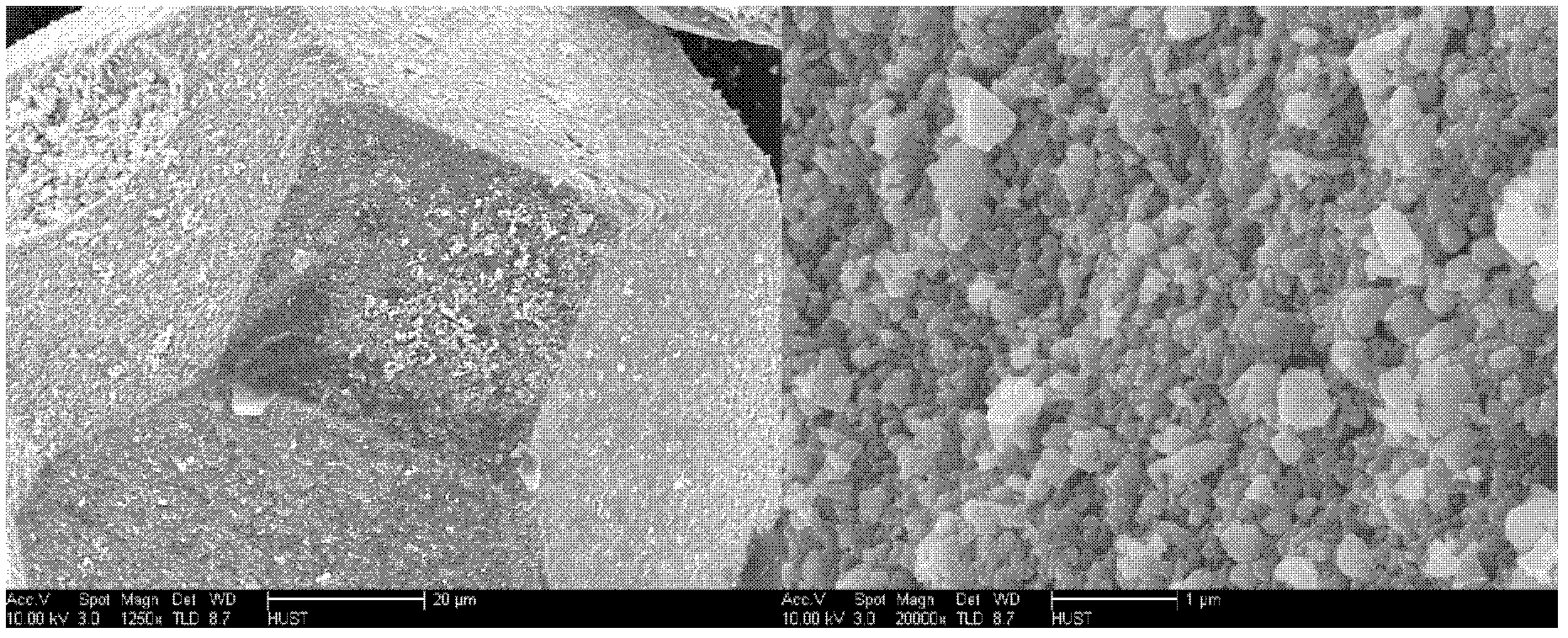

This invention presents the process of direct laser casting of copper alloys: Cu-X (where X=Ni, Fe, W;) and their composites Cu-Y and Cu-X-Y (Y=WC, TiC, Ti+C) from powders prepared using mechanical mixing and ball milling processes. Since the metallic powder is combined with a low melting point Cu metal, which has good thermal and electrical conductivity, the combination allows the powder mixture to be melted by CO2 laser and re-solidified into a part with good mechanical properties and conductivity. The laser casting process for the Cu-based in-situ formation and the material systems formed using the said method have been developed. The process can be used to fabricate complex three-dimensional objects by multi-layer overlapping and the material systems can be used to build rapid tooling due to the properties of good thermal conductivity and low wear rate.

Owner:SINGAPORE INST OF MFG TECH THE +1

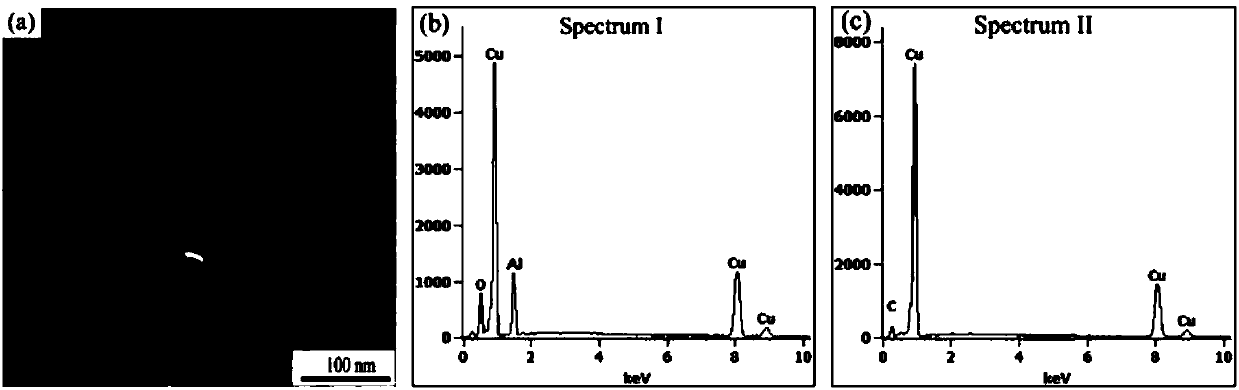

Method for preparing diamond-copper composite material by virtue of metallization of high-temperature blending surface

InactiveCN102383014AImprove wettabilityControllable coefficient of thermal expansionRoom temperatureCarbide

The invention belongs to a preparation technique of a copper-based composite material, and discloses a method for preparing a diamond-copper composite material by virtue of metallization of a surface. The method comprises the following steps of: mixing diamond micropowder with copper powder and powder formed by strong carbide elements, wherein the particle size of diamond is 80-300mu m, the content of the strong carbide elements is 1-10wt%, and the mass fraction of the copper powder is 20%-85%; blending the obtained mixed powder for 10-90 minutes at the temperature of 1050-1150 DEG C, and then cooling along with a furnace; sieving to select the powder with the particle size of 80-300 mu m; mixing the mixed powder with the copper powder again, wherein the mass fraction of the copper powderis 40%-95%; quickly heating the mixed powder material to 850-950 DEG C for sintering at the sintering pressure of 30-50MPa; and then, cooling the obtained product to a room temperature along with thefurnace to obtain the diamond-copper composite material. The method for preparing the diamond-copper composite material has the advantages that the operability of the metallization of the surface of the diamond is strong; the process is simple; the wetting property of a matrix and an enhancer in the prepared diamond-copper composite material is improved greatly; and as an electronic encapsulatingmaterial, the composite material has better comprehensive property, wherein the thermal conductivity is up to 672 W / m.K, the thermal expansion is lower than 7.6 mu m / m. DEG C, and the compactness reaches above 96%.

Owner:HUAZHONG UNIV OF SCI & TECH

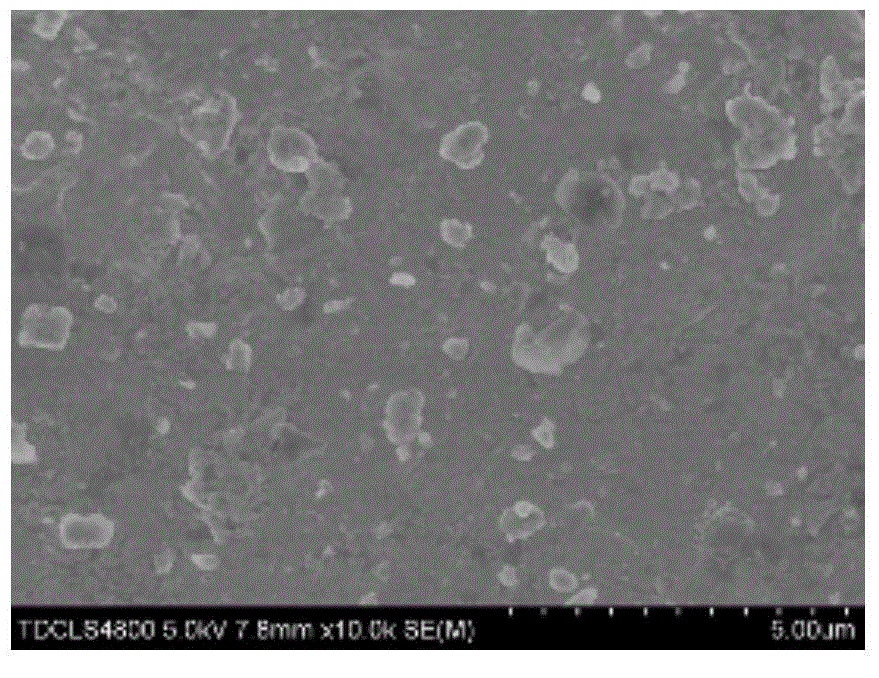

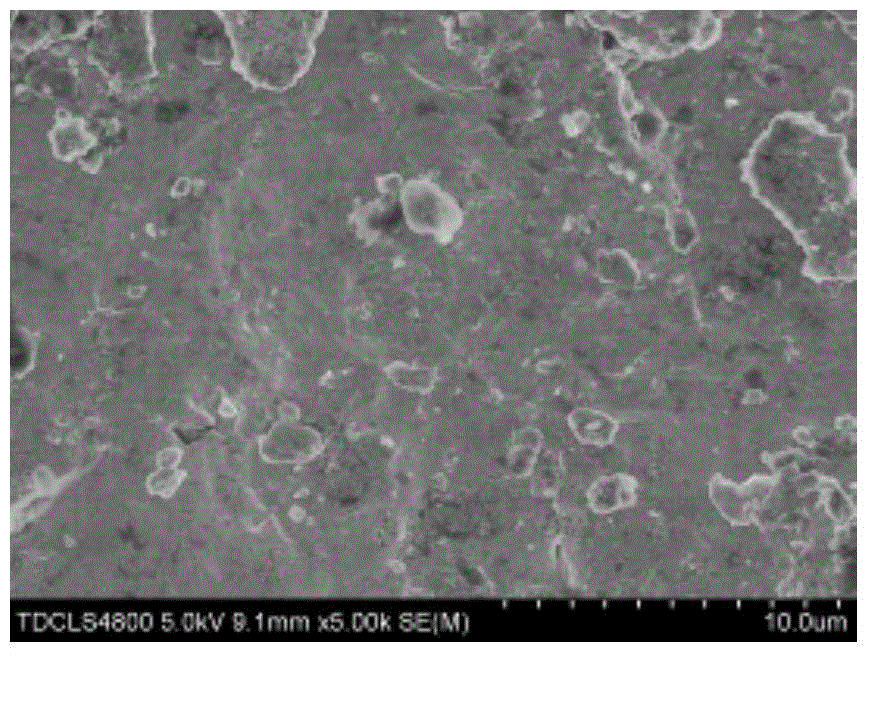

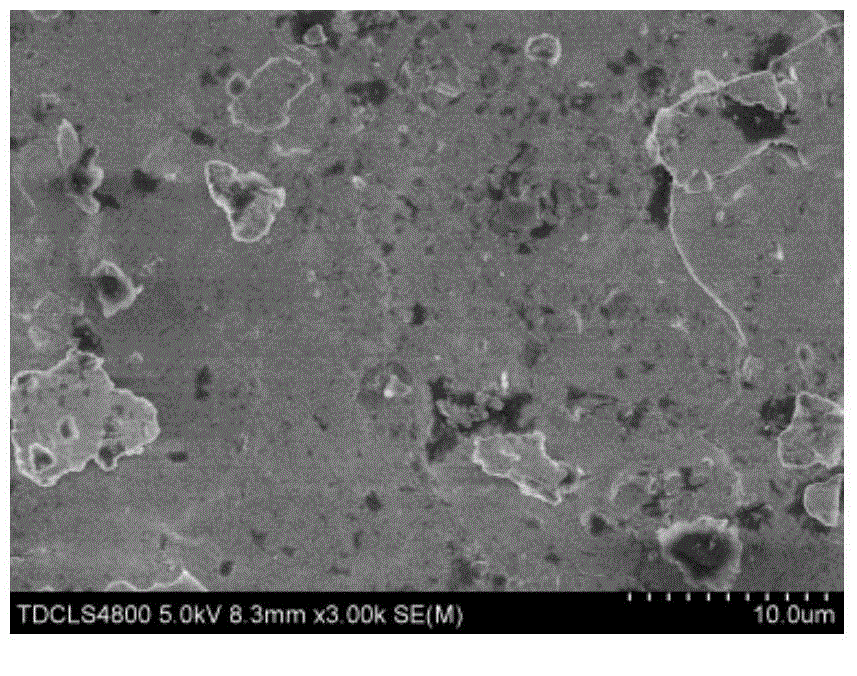

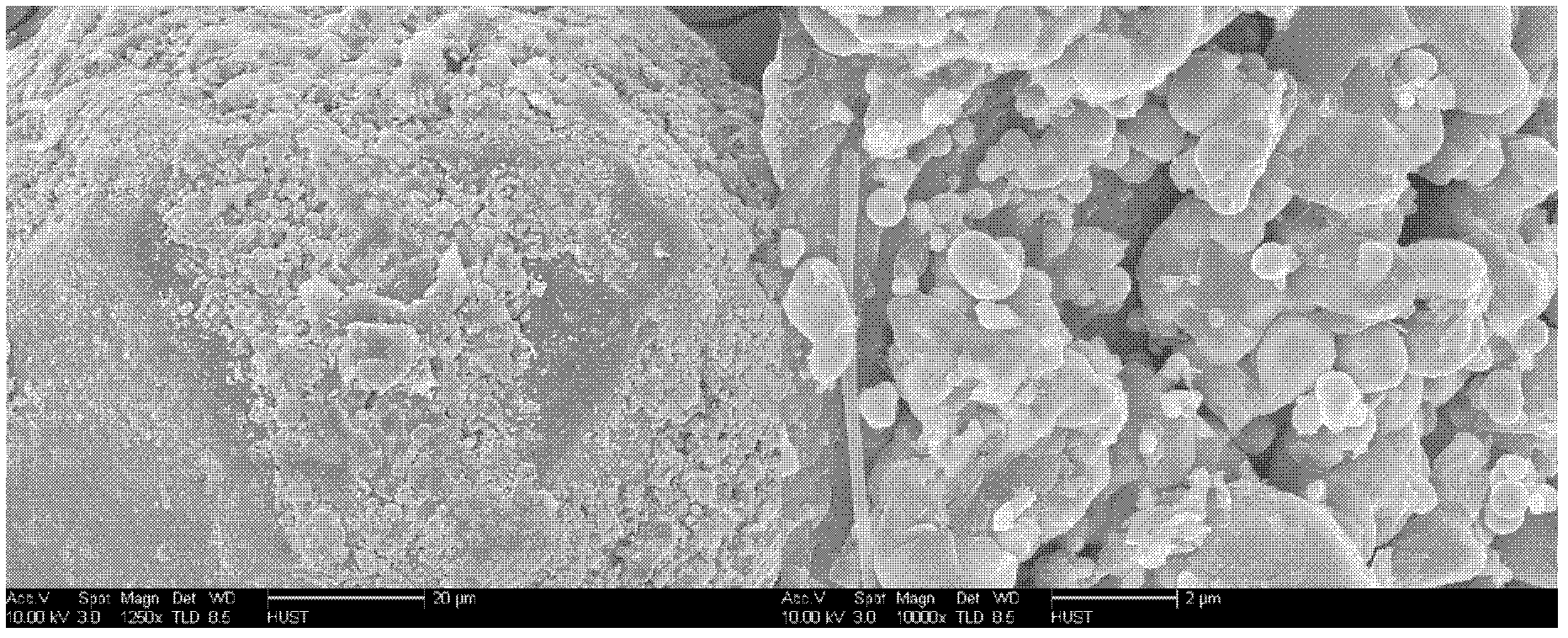

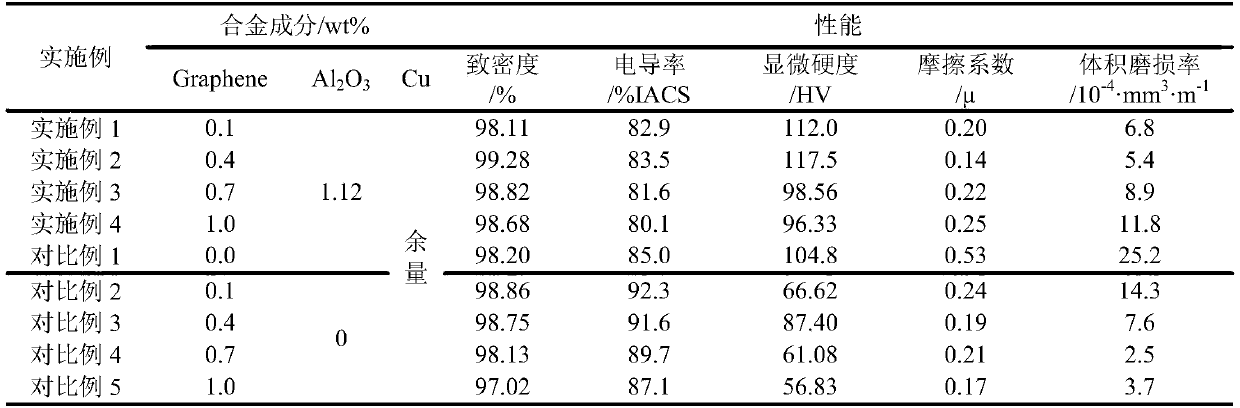

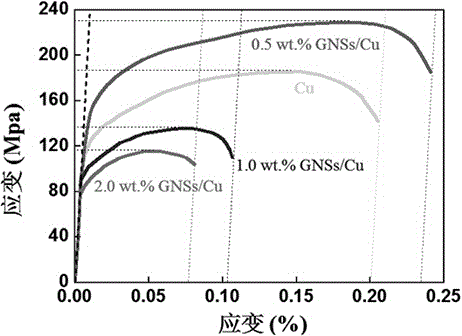

Graphene-aluminum oxide hybrid reinforced copper-based composite material and preparation method thereof

The invention discloses a graphene-aluminum oxide hybrid reinforced copper-based composite material. The composite material comprises 0.1-1.0 wt% of graphene, 1.0-1.2 wt% of Al2O3, and the balance copper. According to the copper-based composite material, the graphene and the aluminum oxide are adopted as complex-phase reinforcement bodies, zero-dimensional aluminum oxide particles can be effectively pinned through a special two-dimensional structure of a nano graphene sheet, a steric-hinerance effect is generated, accordingly, the agglomeration phenomenon of the particles is effectively reduced, and the particles are uniformly scattered; and the surface of the graphene is subjected to chemical nickel-plating and modification treatment, thus, the wettability and the interface bonding situation between the graphene / copper matrixes can be obviously improved, ideal interface bonding is achieved, accordingly, the synergistic effect between the graphene and the aluminum oxide particles is realized to the greatest extent, and the combination properties including strength, hardness, electrical conductivity, and friction and wear properties of the copper-based composite material are comprehensively improved.

Owner:ZOLTRIX MATERIAL GUANGZHOU

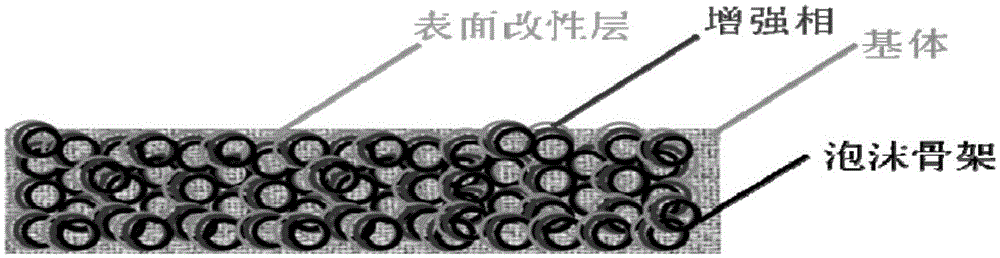

Foam graphene skeleton reinforced copper-base composite material and preparation method thereof

ActiveCN105603248AImprove thermal conductivityImprove conductivityChemical vapor deposition coatingThree-dimensional spaceCarbon nanotube

The invention discloses a foam graphene skeleton reinforced copper-base composite material and a preparation method thereof. The composite material consists of a foam substrate, a graphene reinforcing layer and a base material, wherein the foam substrate is foam metal, foam ceramic or foam carbon; the graphene reinforcing layer is a graphene film or combination of graphene and diamond and a carbon nanotube; and the base material comprises aluminum and an aluminum base alloy. In the composite material disclosed by the invention, since graphene and aluminum are continuously distributed in a three-dimensional space to form a network interpenetrating structure, remarkable influence on the thermal and electric properties of the material caused by the compound interface is weakened, the reinforcing phase can form a whole without reducing the good plasticity and toughness of the metal base in the composite material, and the heat conduction efficiency and electric conduction efficiency of the reinforcing body are maximized so that the thermal conductivity, electric conductivity and mechanical strength of the composite material are remarkably improved over traditional composite materials; and therefore, the foam graphene skeleton reinforced copper-base composite material is a novel multifunctional composite material with great potential.

Owner:CENT SOUTH UNIV

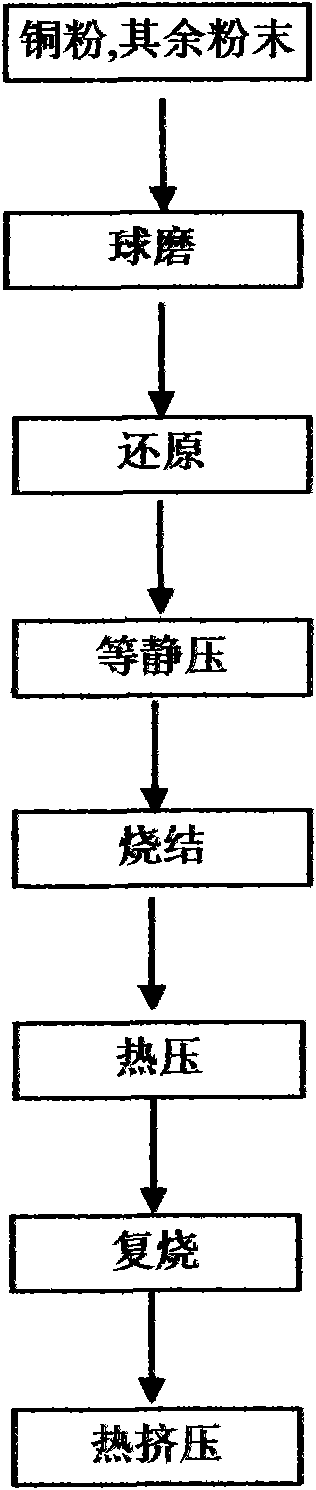

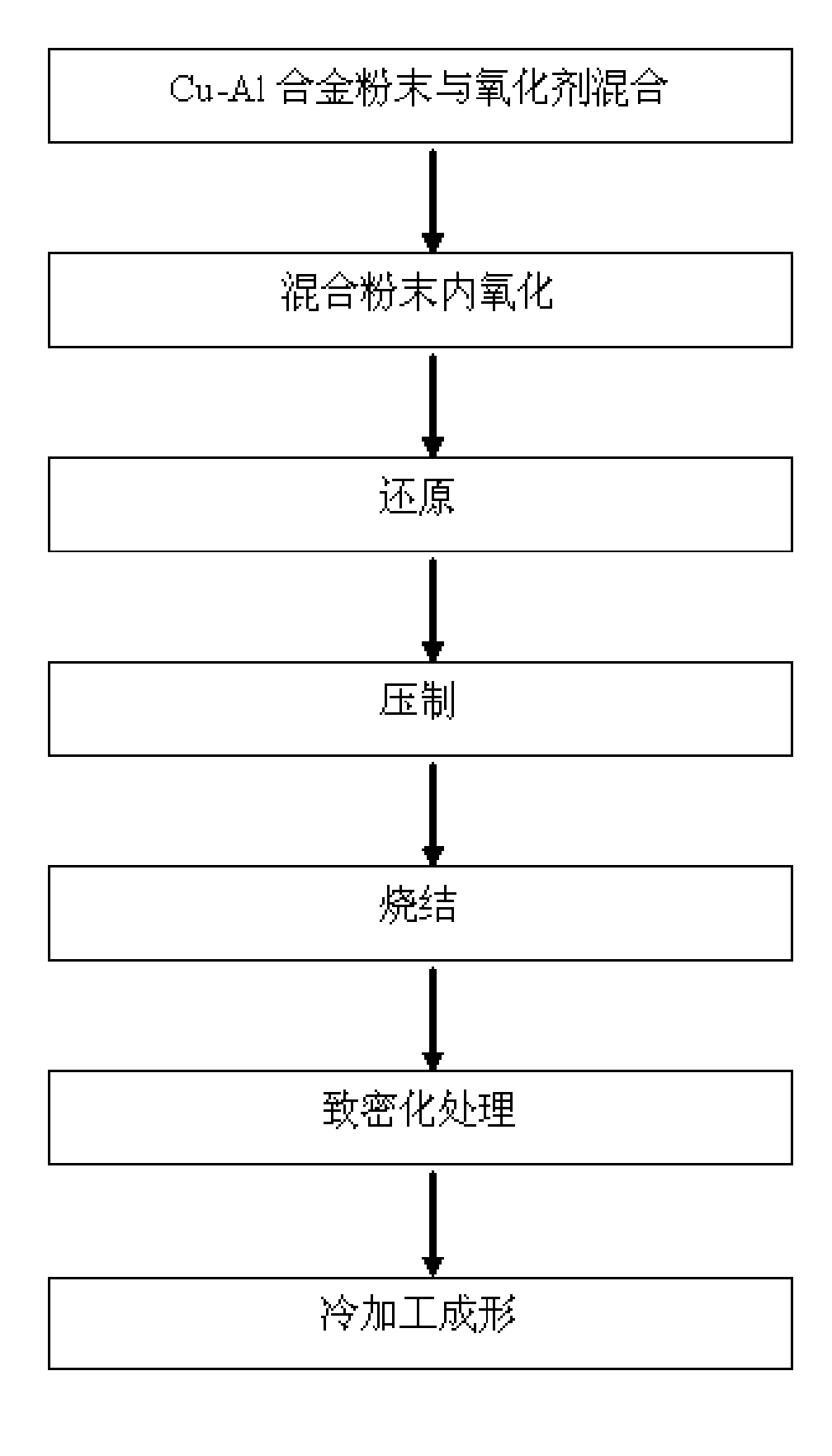

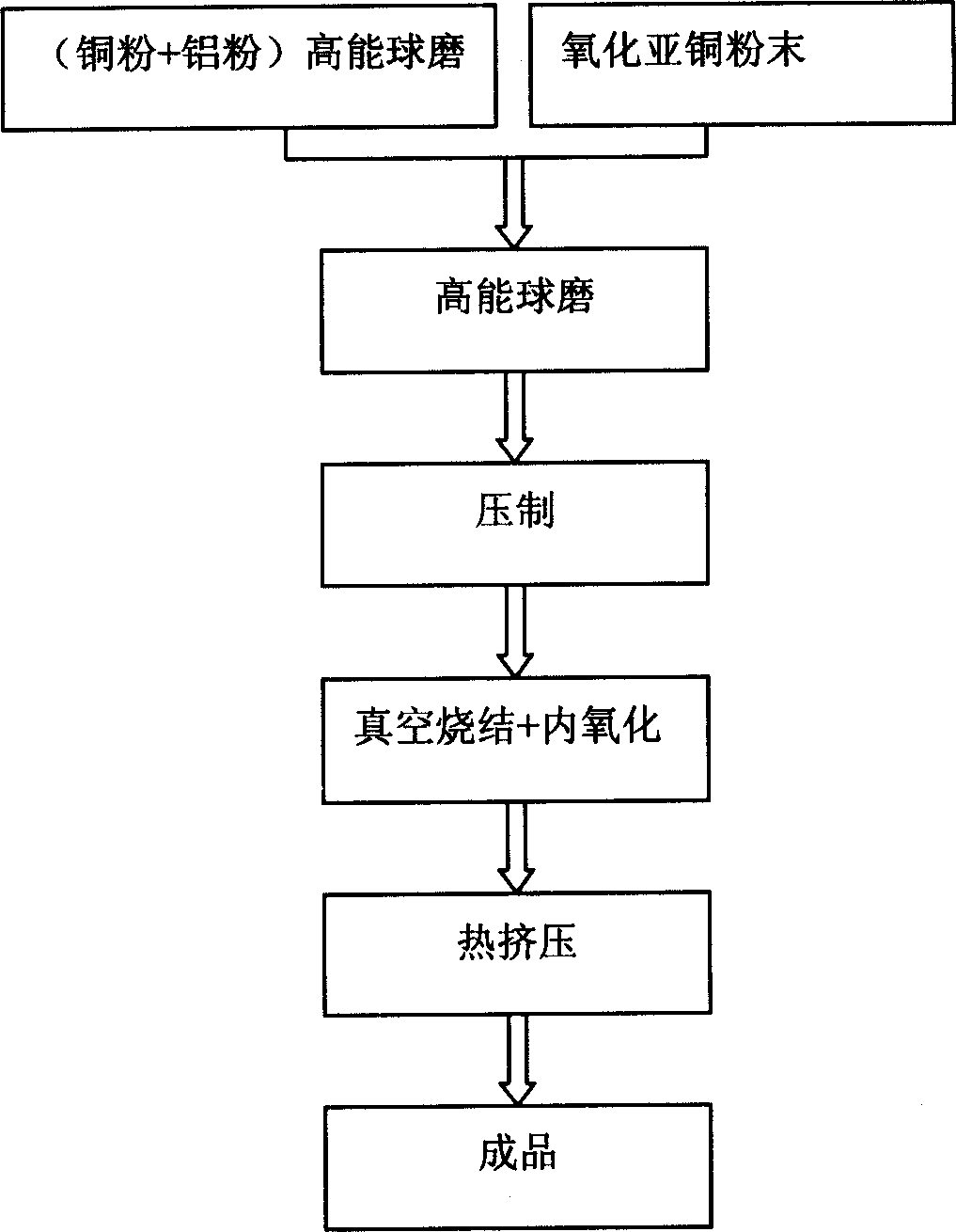

Method for preparing alumina dispersion-strenghtened copper-base composite material

The invention discloses a method to make alumina dispersion strengthening copper base composite material that includes the following steps: making copper-aluminum prealloying powder through high energy ball milling method, making the composite powder of copper plating powder and copper-aluminum prealloying powder through high energy ball milling method; cold press molding the powder, taking sintering and internal operation in vacuum furnace, after two times of hot extrusion, the material would be gained. The method has the advantages of simple technology, low cost, etc.

Owner:XIAN UNIV OF TECH

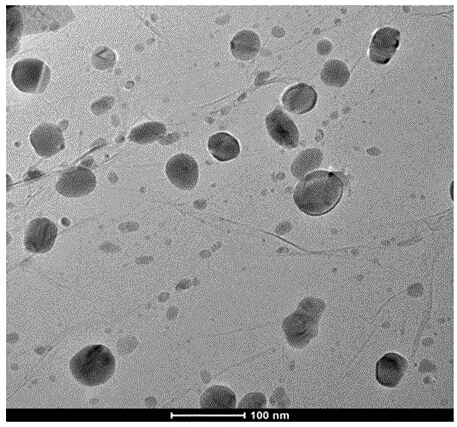

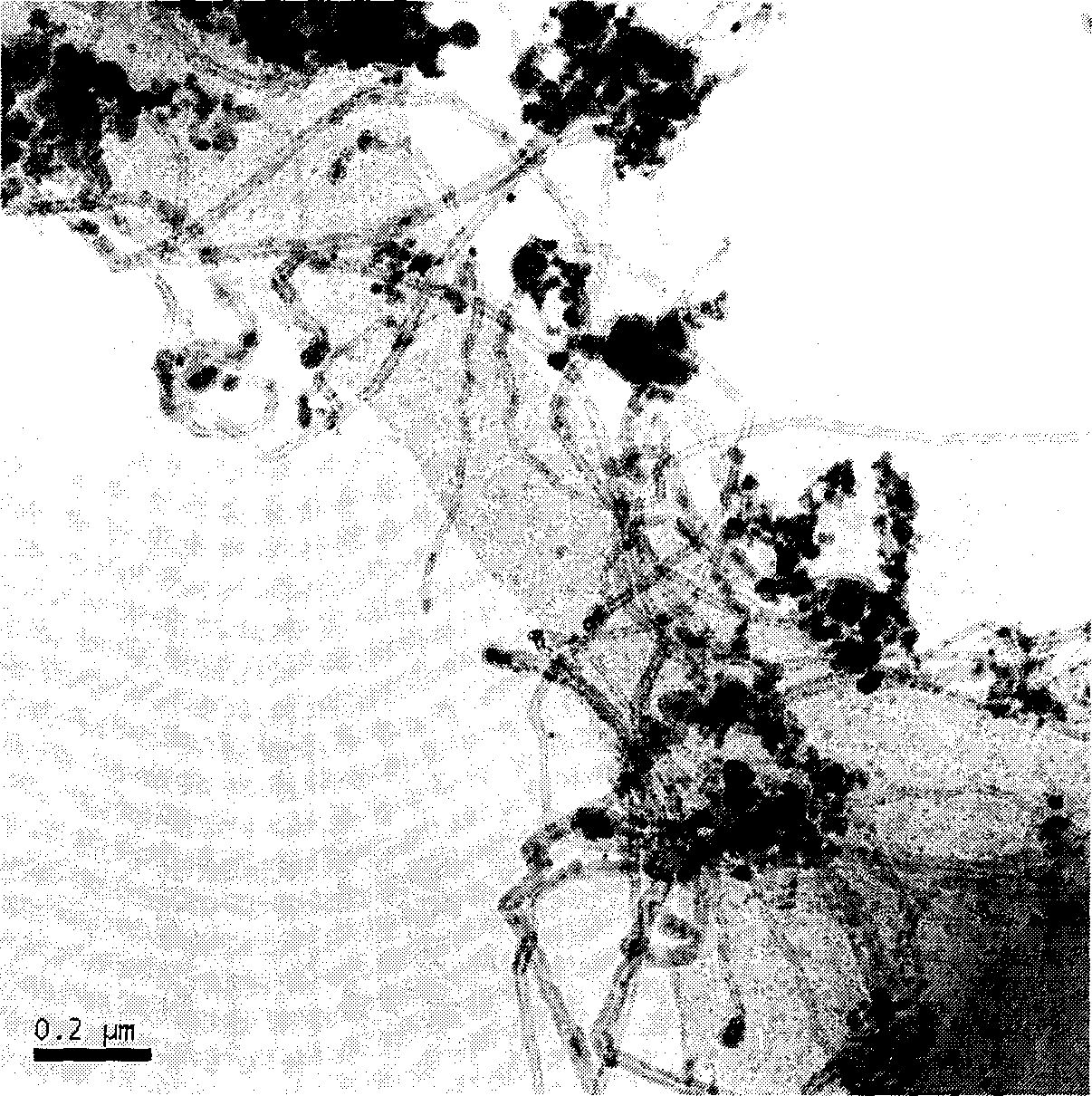

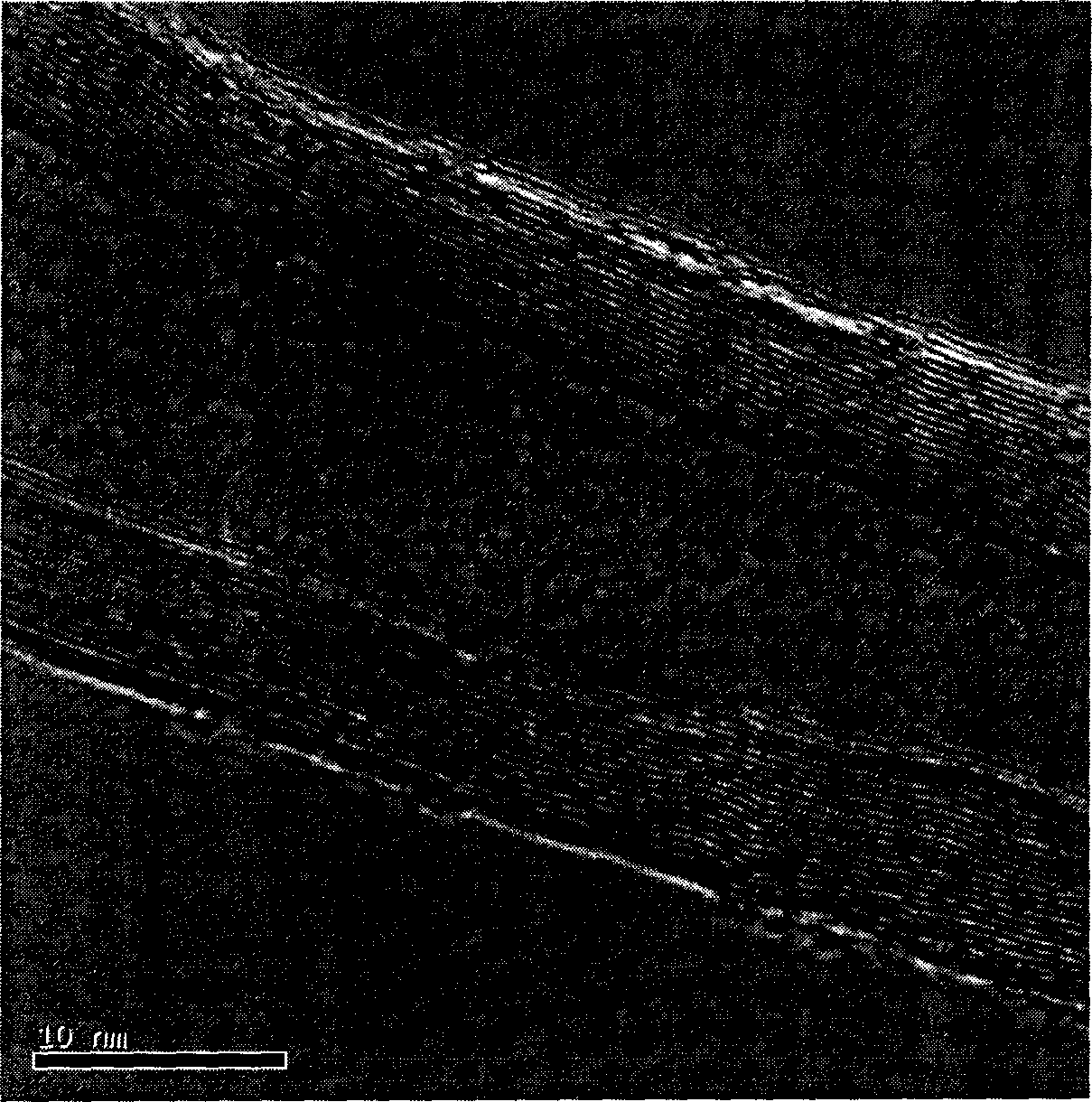

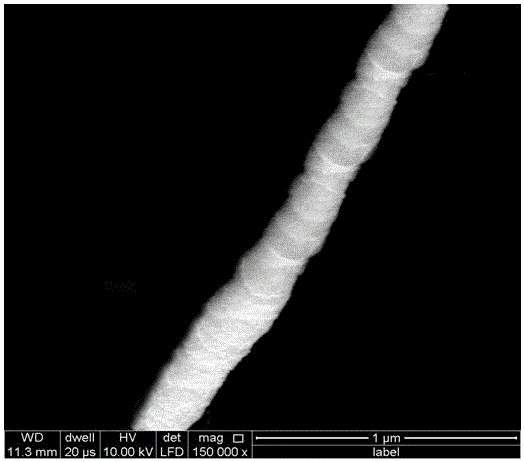

Vapor depositing in-situ reaction process for preparing carbon nanotube reinforced copper-base composite material

InactiveCN1888103ASolve the problem of fragmentationExcellent electrical performanceChemical vapor deposition coatingGas phaseCarbon nanotube

The present invention is preparation process of carbon nanotube reinforced copper-base composite material with high strength and high conductivity, and belongs to the field of copper-base composite material preparing technology. The preparation process includes the following steps: adding nickel nitrate hexahydrate, yttrium nitrate hexahydrate and ethanol soaked copper powder in certain weight proportion into distilled water to obtain nickel nitrate solution; dropping sodium hydroxide solution to the nickel nitrate solution to produce neutralizing reaction obtaining ternary Ni(OH)2 / Y(OH)3 / Cu colloid; washing, filtering, drying, grinding and calcining to obtain Ni / Y / Cu catalyst precursor; setting the precursor into reaction furnace, introducing H2 to reduce, and introducing N2 and reaction gas for catalytic cracking reaction to obtain composite carbon nanotube / Cu powder; initially pressing the composite powder, sintering and re-pressing to obtain carbon nanotube in-situ reinforced copper-base composite material.

Owner:TIANJIN UNIV

Carbon fiber reinforced copper-based composite material and preparation method thereof

The invention discloses a preparation method of a carbon fiber reinforced copper-based composite material. The preparation method comprises the following steps: I, weighing ingredients and carrying out ball-milling mixing for 3 hours, thereby obtaining a mixed material, and wrapping the surface of carbon fiber by a nickel layer, wherein the particle size of graphite powder is 50mu m, the graphite powder is subjected to chemical plating technical treatment, and a copper layer is plated on the surface of the graphite powder; II, pressing the mixed material prepared in the step I under the pressure of 700MPa, thereby obtaining a blank; III, performing secondary sintering on the blank prepared in the step II, thereby obtaining a sintered alloy block; and IV, performing thermal treatment on the alloy block treated in the step III, thereby obtaining the carbon fiber reinforced copper-based composite material. The carbon fiber reinforced copper-based composite material disclosed by the invention not only has excellent self-lubrication property, but also is particularly excellent in wearing resistance and mechanical property.

Owner:宁波新睦科技有限公司

Method for preparing graphene reinforced copper base composite material

The invention relates to a method for preparing a graphene reinforced copper base composite material, and aims to solve the problems of weak graphene dispersibility, high cost and complex process in a traditional method for preparing the graphene reinforced copper base composite material. The method uses oxide graphene as a reinforcing front body; the prepared oxide graphene and copper powder are ultrasonically mixed in ethanol solution; and the oxide graphene and the copper powder are uniformly dispersed by using a low-cost ball milling technology. Finally, the vacuum hot pressed sintering is adopted to prepare the graphene reinforced copper base composite material. The composite material, prepared by the method, has the advantages of good graphene dispersibility, simple and efficiency preparation method and easiness in realization of large-scale production.

Owner:HARBIN UNIV OF SCI & TECH

Method for producing diamond reinforced Cu-matrix compound material by surface metallization and chemical deposition

InactiveCN101279366AEasy to operateSimple processLiquid/solution decomposition chemical coatingThermal dilatationChemical plating

The invention relates to a method for preparing diamond enhanced copper-based composite material by surface metallization and chemical deposition, which pertains to the preparation technology of copper-based composite materials. The method comprises that: the chemical copper plating treatment is carried out after the pre-treatment of the surface of a diamond, then the chemical deposition method is used for in situ deposition of copper on the copper-plated diamond, and the diamond enhanced copper-based composite material is obtained by initial pressing, sintering and re-pressing treatment. The method has the advantages that: the metallization operation of the surface of the diamond is better, and the process is simple; the invasion of a matrix and an enhanced body in the prepared diamond enhanced copper-based composite material are greatly improved, the composite material is taken as the electronic packaging material, which has great comprehensive performance, wherein, the thermal conductivity is higher than 400W / m.k, the thermal expansion is lower than 7.9 Mum / m.DEG C, and the density can achieve more than 95 percent.

Owner:TIANJIN UNIV

High-strength and high-conductivity carbon nano tube strengthening copper-based composite material and preparing method thereof

The invention discloses a high-strength and high-conductivity carbon nano tube strengthening copper-based composite material and a preparing method thereof, and belongs to the technical field of composite materials and preparation of the composite materials. The preparation method includes the steps that, water bath ultrasonic agitation is carried out on 0.1% to 10% of a nickel / copper plating single wall carbon nano tube by volume fraction and 90% to 99.9% of pure copper powder or copper alloyed powder by volume fraction in absolute ethyl alcohol; cold pressing is carried out after vacuum drying is carried out to form a blank; preserving sintering, high temperature forging, repeated pressing, machining and cold extruding are carried out; and the high-strength and high-conductivity carbon nano tube strengthening copper-based composite material is obtained. The high-strength and high-conductivity carbon nano tube strengthening copper-based composite material has the beneficial effects that the single wall carbon nano tube in the composite material is evenly dispersed into a metallic matrix and is arranged in an orientation manner in the axial direction. The composite material has the excellent macroscopic combination property in the carbon nano tube orientation direction, has the mechanical property, the thermal conductivity and the electrical conductivity, can be widely applied to the field of preparing resistance spot welding electrodes, electric arch sliding plates, integrated circuit lead frames, relay supports and the like, and is particularly suitable for preparing spot welding electrode heads.

Owner:HUBEI UNIV OF TECH

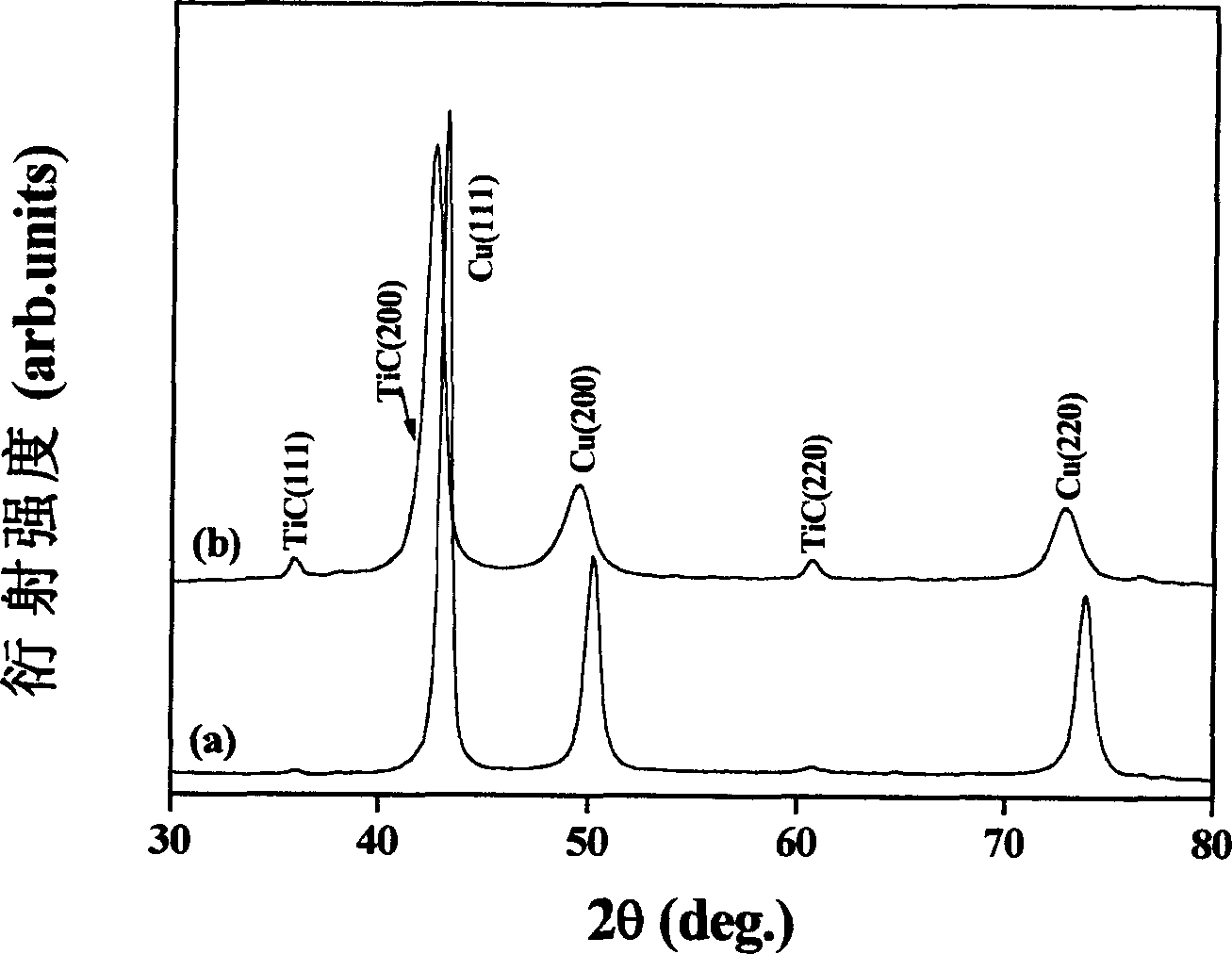

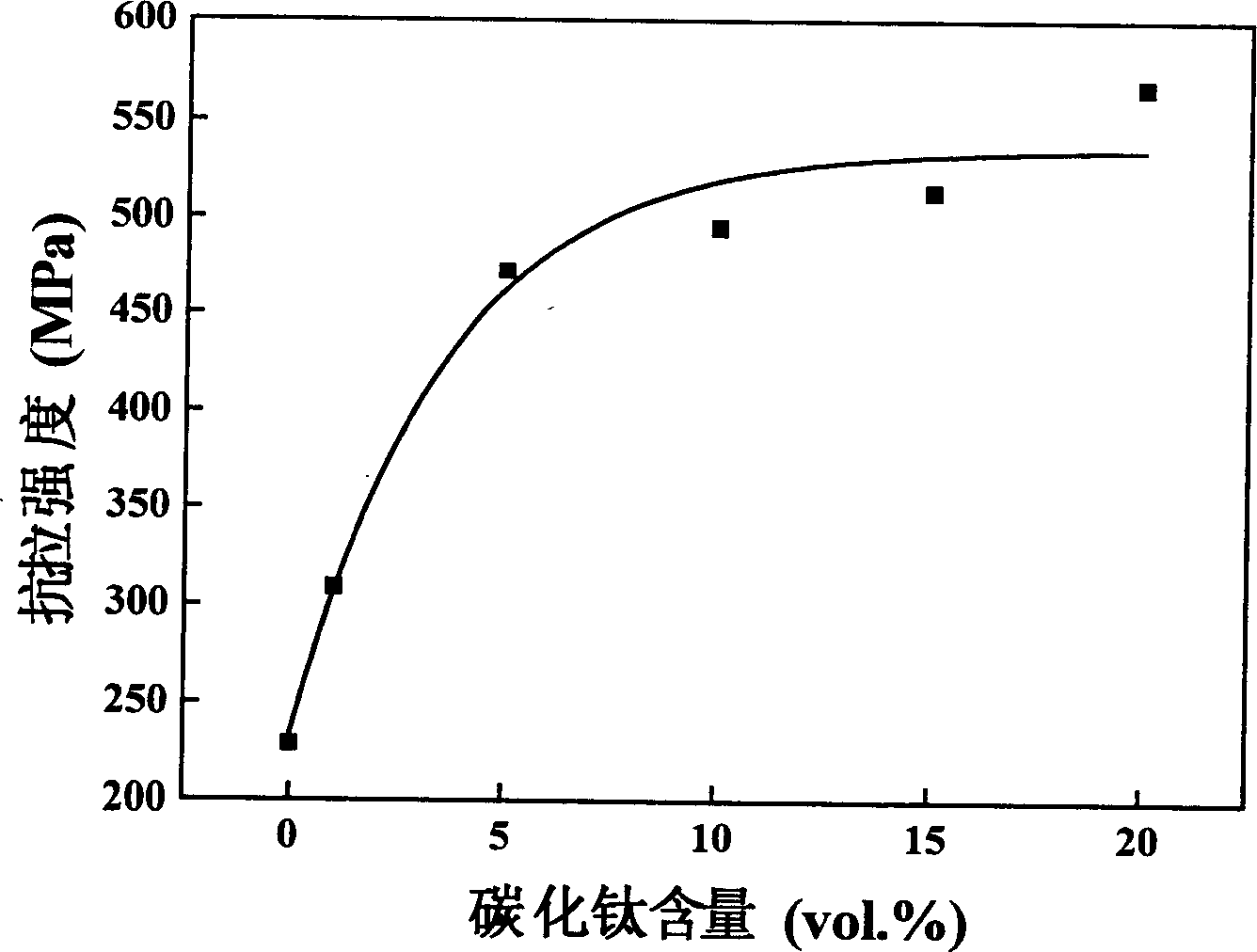

In-situ produced titanium carbide dispersion strengthening copper based composite material and method for preparing the same

The preparation method to decompose Ti2SnC dispersed in Cu-matrix and in-situ generate 1-20vol.% TiCx dispersion-strengthened Cu-base series composite material comprises: mixing Ti2SnC ultrafine powder with copper as given ratio to grind for 5-15h and then load into graphite mould; cold pressing on 5-15MPa; sintering in hot-pressing furnace with protective atmosphere for 0.5-3h on condition of 30-50MPa and 800-900Deg; finally, annealing at 950-1050Deg for 2-8h. This invention can prepare the composite with high hardness and strength with simple technique.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

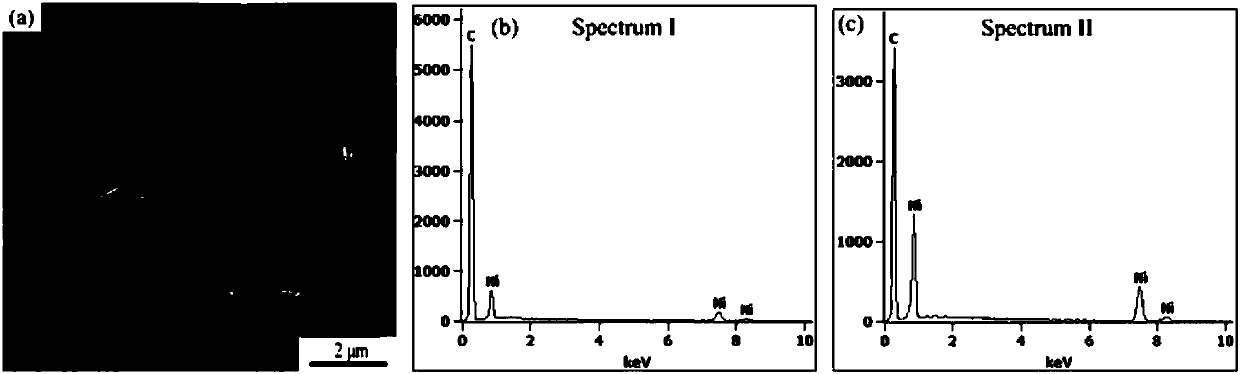

Carbon nanotube-metal composite enhanced copper-based composite material and preparation method thereof

The invention relates to a carbon nanotube-metal composite enhanced copper-based composite material and a preparation method thereof, and belongs to the field of preparation of composite materials. The preparation method comprises the following steps: preparing colloidal sol by using soluble salts containing metallic elements and copper ions and carbon nanotube as raw materials, carrying out spray granulation by using the colloidal sol through a spray dryer so as to obtain nanoscale mixed powder, calcining the mixed powder in an oxygen-free atmosphere so as to obtain black powder, reducing the black powder in a hydrogen atmosphere so as to obtain carbon nanotube-metallic element composite enhanced copper-based powder, carrying out isostatic press moulding on the mixed powder, and then sintering in the hydrogen atmosphere so as to obtain the carbon nanotube-metallic element composite enhanced copper-based composite material, wherein the content of a metallic element X in the composite material is 0.1-2wt%, and the content of the carbon nanotube in the composite material is 0.1-2wt%. The preparation method has the advantages that corresponding carbides can be formed, the problem of reinforcement agglomeration caused by poor interface bonding between reinforcement and a copper matrix is solved, and the copper-based composite material with excellent combination properties can be obtained.

Owner:NINGBO CPX ELECTRONICS TECH

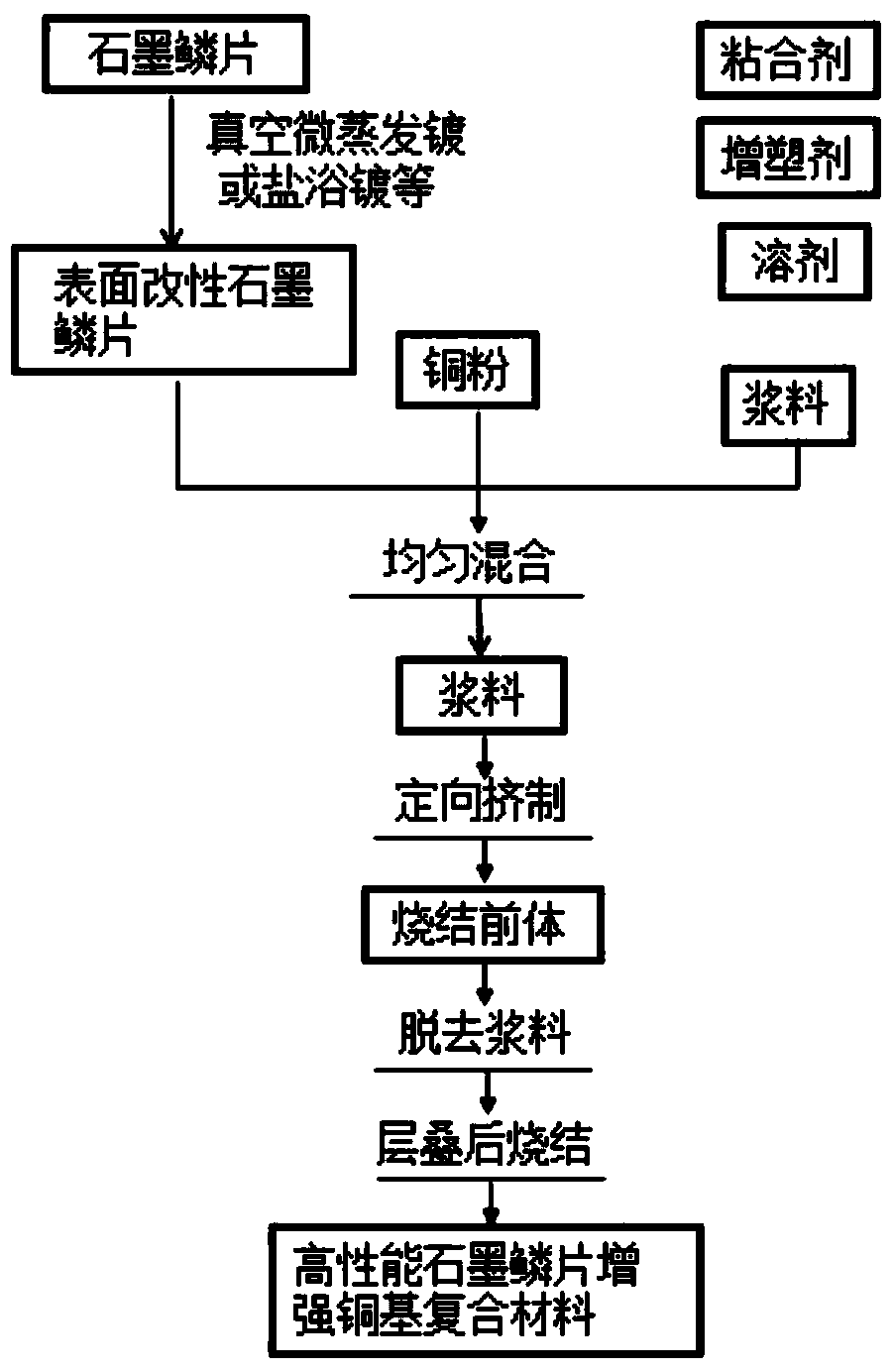

Ultrahigh heat conduction graphite flake/copper composite material and preparation method thereof

The invention discloses a high-heat conduction graphite flake referenced copper-based composite material and a preparation method thereof, belonging to the field of high-performance electronic packaging functional materials. The high-heat conduction graphite flake referenced copper-based composite material comprises a base material copper or copper alloy and a coated reinforcing phase high-heat conduction graphite flake, wherein the volume fraction of the coated graphite flake is 20-80 percent. The preparation method comprises the steps: firstly modifying the surface of the graphite flake, and coating a coating of metals of titanium, chromium, molybdenum, tungsten or relevant carbides on the surface of the graphite flake; then adding the surface modified graphite flake and the metal base body powder in a solvent containing a binding agent and a plasticizing agent, uniformly mixing to obtain a mixed slurry, placing the slurry in an extruding mould for performing directional extrusion, and then removing the binding agent to obtain a pre-sintered sheet; overlapping the sheets and then sintering to obtain the composite material. The composite material prepared by adopting the preparation method has the advantages that the flake reinforcing phase and the base body are well combined, and the flake is directionally arranged in the base body, thus ultrahigh heat conductivity, controllable coefficient of thermal expansion and better machinability are achieved.

Owner:UNIV OF SCI & TECH BEIJING

Preparing method of copper-base electric contact material enhanced by in-situ grown graphene

InactiveCN105483641AImprove mechanical propertiesExcellent thermalTransportation and packagingMetal-working apparatusMethane gasPlasma chemistry

The invention discloses a preparing method of a copper-base electric contact material enhanced by in-situ grown grapheme, relates to the preparing method of the copper-base electric contact material, solves the problems that a conventional silver-base electric contact composite material is high in cost and low in cost performance, and overcomes the defect that when a copper-base composite material with high performance replaces metal silver, grapheme is dispersed in copper nonuniformly. The method comprises the following steps: placing copper powder in a plasma enhanced chemical vapor deposition vacuum device, introducing hydrogen, insulating at a high temperature, introducing methane gas for deposition, stopping introducing methane gas after the deposition is finished, and finally cooling to be below the room temperature to obtain grapheme / copper composite powder.

Owner:HARBIN INST OF TECH

High wear resistant/friction reducing tin bronze base composite material

The present invention relates to one copper-base composite material comprising multiple wall carbon nanotube 0.2-4.5 wt%, TiB2 0.1-1.3 wt%, except Cu-Sn alloy containing Sn in 0.35-12.0 wt%. It has excellent wear resistance, low friction coifficient, relatively high compression and tensile strength, moderate hardness, excellent electric conductivity and heat conductivity. It may be used in productino transmission bush, current collecting slid board for electric train and electric contact material.

Owner:ZHEJIANG UNIV

Method for preparing (TiB2+TiC) dispersion-strengthened copper-based composite material by mechanical alloying

The invention discloses a method for preparing a (TiB2+TiC) dispersion-strengthened copper-based composite material by mechanical alloying. The method uses Cu powder, Ti powder and B4C powder with the particle size of less than 100 meshes and the purity of over 99 percent as raw materials and comprises the following steps: mixing the Ti powder and the B4C powder in a molar ratio 3 to 1 and performing high-energy ball milling on the mixed powder at room temperature for 2 to 20 hours; then adding a certain proportion of Cu powder into the mixed powder after the ball milling to ensure that the mass ratio of the Ti+B4C powder to the Cu powder is 1:99-20:80; performing high-energy ball milling on the new mixed powder added with the Cu powder at room temperature for 2 to 10 hours; performing cold-press molding on the mixed powder after the ball milling; and finally sintering pressed blanks in an argon protective atmosphere resistance furnace at the temperature of between 800 and 1,000 DEG C for 1 to 3 hours to obtain the TiB2+TiC dispersion-strengthened copper-based composite material with the average particle size of between 5 and 10 mu m. Through the simple high-energy ball-milling mechanical-alloying method adopted by the invention, the (TiB2+TiC) dispersion-strengthened copper-based composite material is prepared by synthesizing the pure Cu powder, Ti powder and B4C powder; and the method has the advantages of simple process, low production cost, high product yield, high product quality and the like.

Owner:KUNMING UNIV OF SCI & TECH

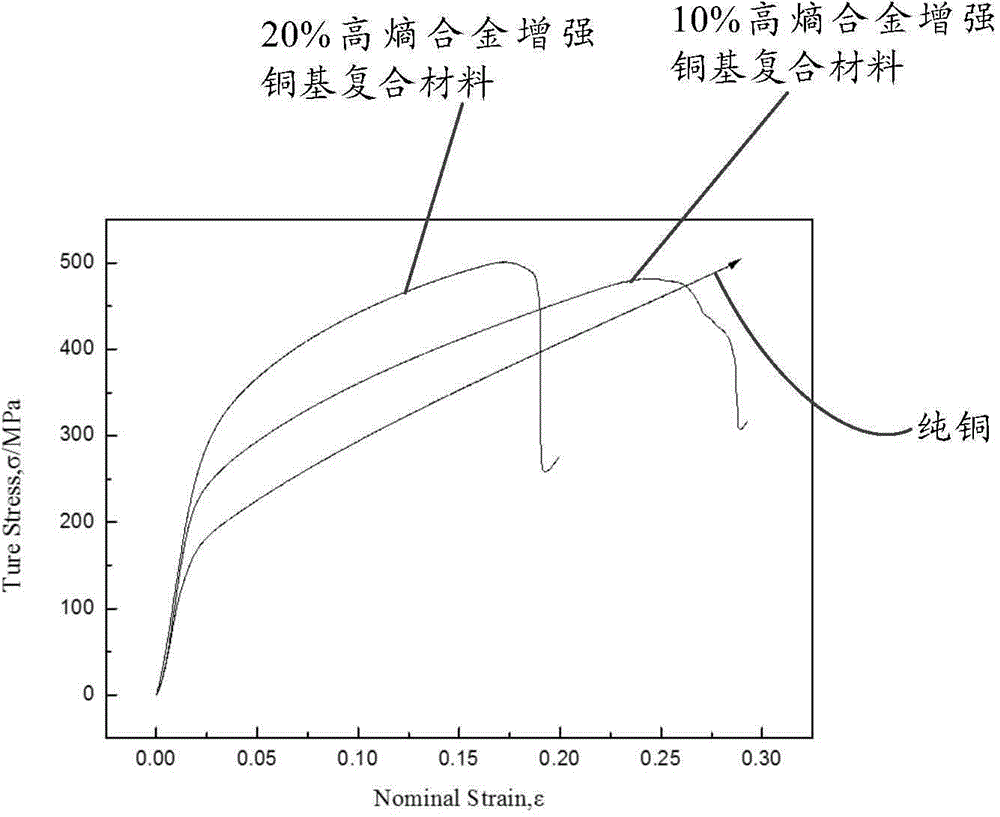

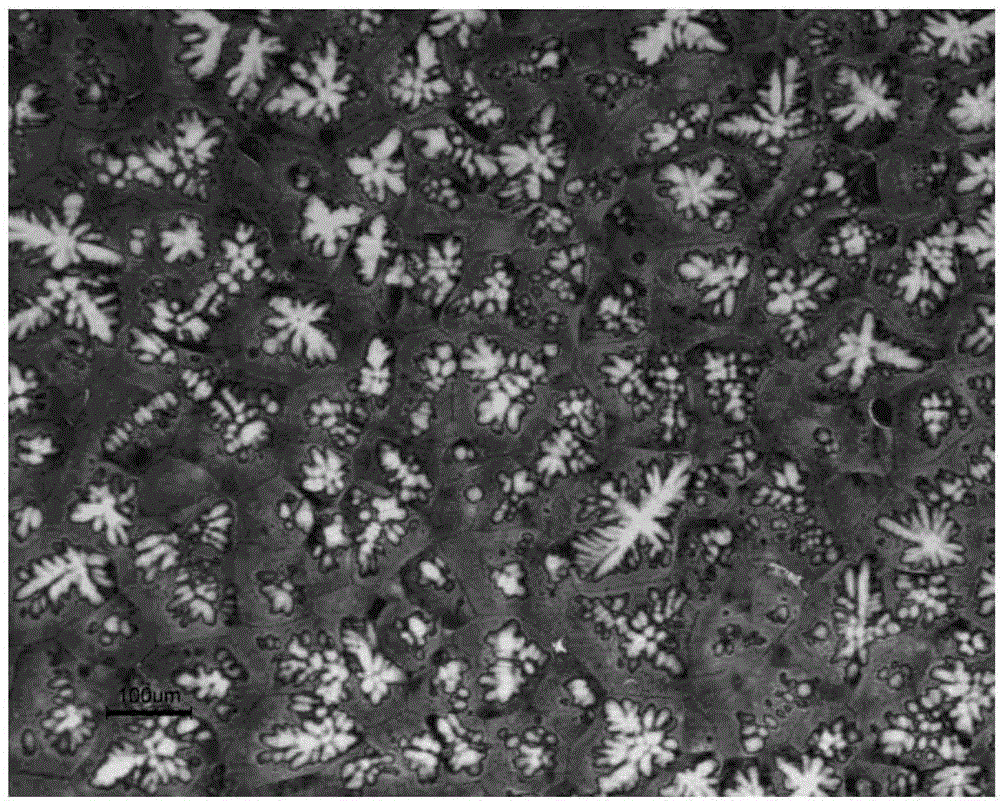

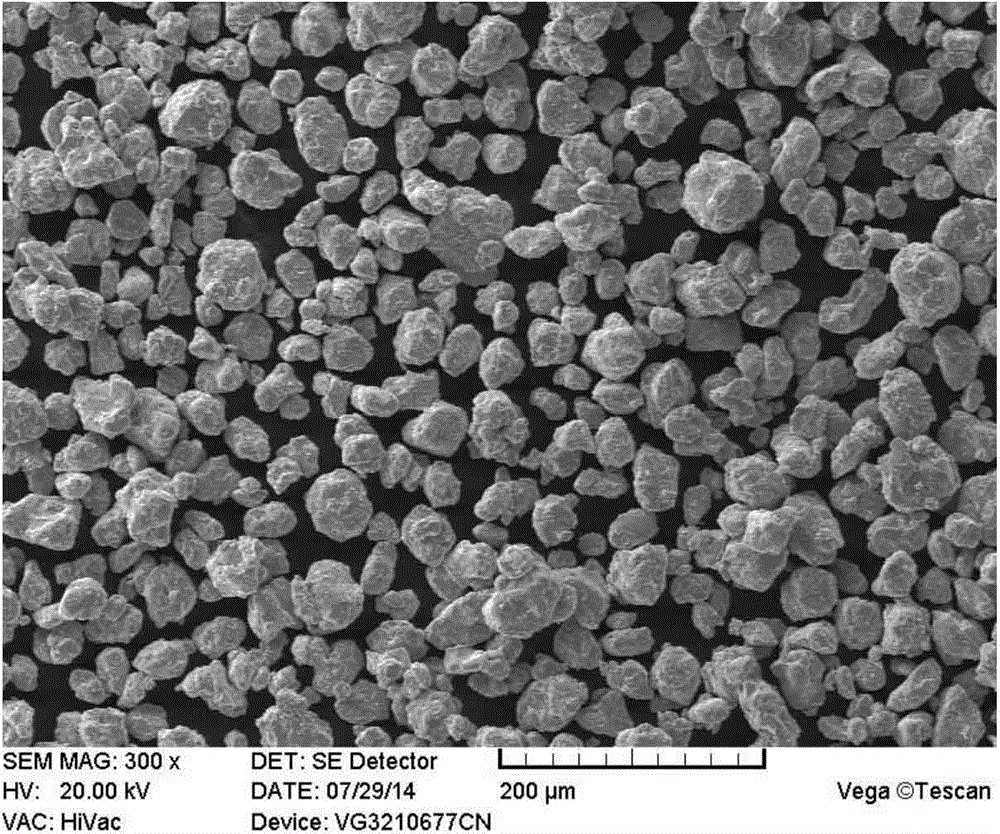

High-performance metal-matrix composite preparation method

The invention provides a high-performance metal-matrix composite preparation method. The method comprises steps: granular raw materials: Al, Fe, Cr, Co and Ni metal powder are acquired; under argon atmosphere protection, a high-entropy alloy powder body is prepared via a ball mill; a pure copper powder body and the high-entropy alloy powder body are weighed; the two are subjected to ball milling and mixing under the argon atmosphere protection, and composite powder is obtained; the composite powder is put in a cold pressing grinding tool, uniform pressurization is carried out, and after packing, a cold pressing green body is taken; the composite after cold pressing is put in a graphite grinding tool of an atmosphere protection sintering furnace, temperature rises to 800 DEG C, hot pressing is carried out and packing is carried out for one hour after temperature of the furnace is stable, and circulating nitrogen is provided during the whole process; and when the furnace is cooled to the room temperature, the copper-matrix composite is obtained. Compared with the prior art, by adopting the above preparation method, the high-entropy alloy and the metal matrix have good mutual dissolution and diffusion performance, the preparation process is simple, the high-entropy alloy has good hot stability, the composite has high density, the interface is good, and the mechanical performance is excellent.

Owner:XIAN TECHNOLOGICAL UNIV

Compact dispersion-strengthened copper-base composite material

The invention relates to a compact dispersion-strengthened copper-base composite material and a preparation method thereof. The compact dispersion-strengthened copper-base composite material is composed of a copper alloy base and Al2O3 particles which are uniformly dispersed in the copper alloy base. Composite metals are added into the copper-alumina master alloy, and a vacuum induction hot-pressing furnace or low-pressure isostatic sintering furnace is adopted for sintering to maximally eliminate the residual porosity and defects in the alloy, so that the sintered billet basically reaches the theoretical density. The prepared dispersion-strengthened copper product has the advantages of high electric conductivity, high softening temperature resistance and high compactness, and can achieve more than 99.5% of theoretical density.

Owner:YANTAI WANLONG VACUUM METALLURGY

Preparation method of high heat-conducting diamond/copper-based composite material

InactiveCN103981382AHigh thermal conductivityImprove interfaceSuperimposed coating processNon wettingChemical plating

The invention relates to a preparation method of a high heat-conducting diamond / copper-based composite material which consists of matrix copper, diamond powder and a molybdenum coating, wherein the volume fraction of molybdenum is 1-2%, the balance of diamond particles and copper. In diamond and copper, the volume fraction of the diamond powder is 15-50%. The preparation method provided by the invention can solve the problem that in methods of infiltration, powder metallurgy and the like, diamond powder and copper are non-wetting to lead to sintering densification. The preparation method comprises the following steps: I, plating molybdenum on the surfaces of the diamond particles by adopting a magnetron sputtering method to prepare molybdenum-coated diamond powder; II, plating copper on the surface of the molybdenum-coated diamond powder by a chemical plating method to prepare copper and molybdenum-coated diamond powder; III, mixing the composite powder obtained in step II and pure copper powder in a certain proportion by a mechanical mixing manner; and IV, hot pressing and sintering the mixed powder prepared in step III in vacuum to obtain the diamond / copper-based composite material. The material has a good interface bonding condition, high density and heat conductivity.

Owner:WUHAN UNIV OF TECH

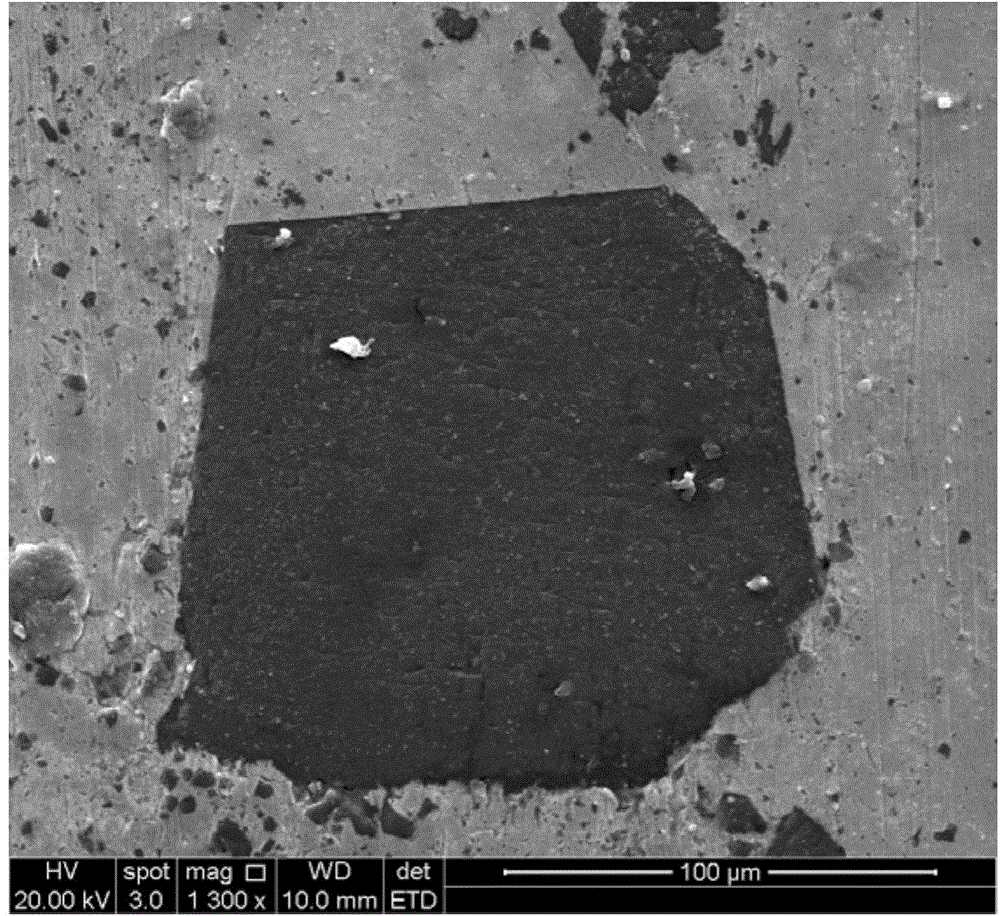

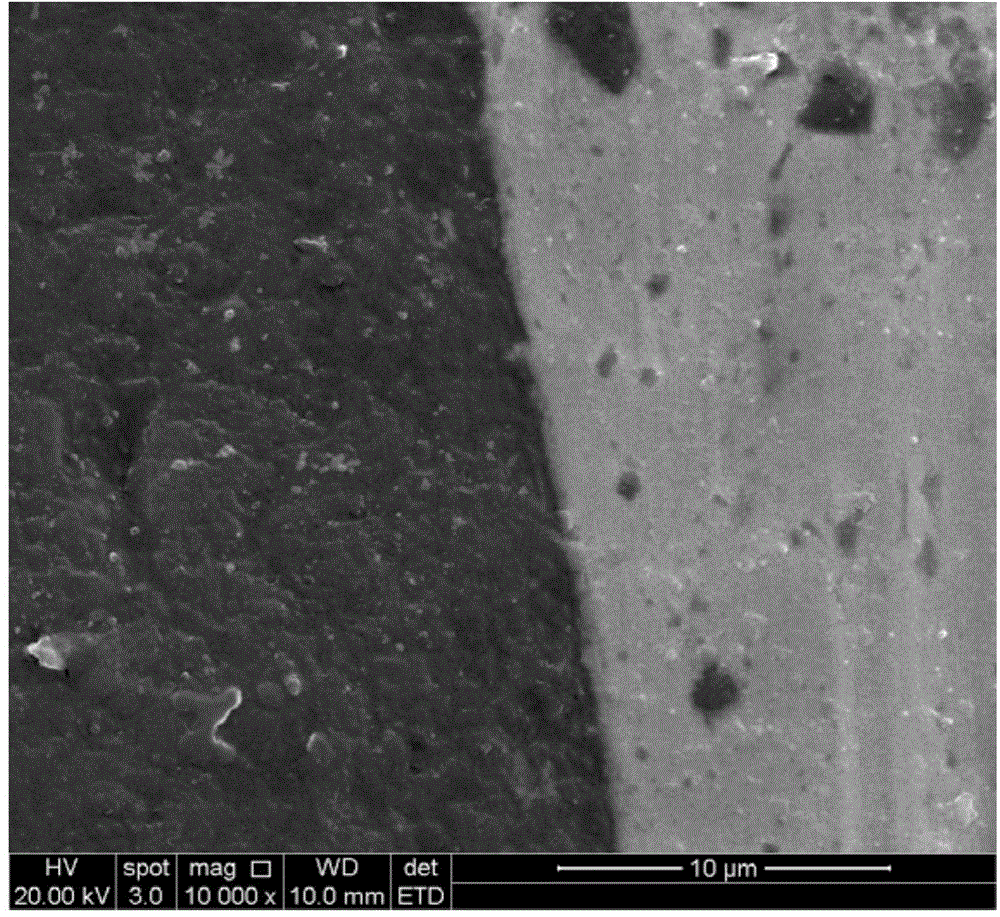

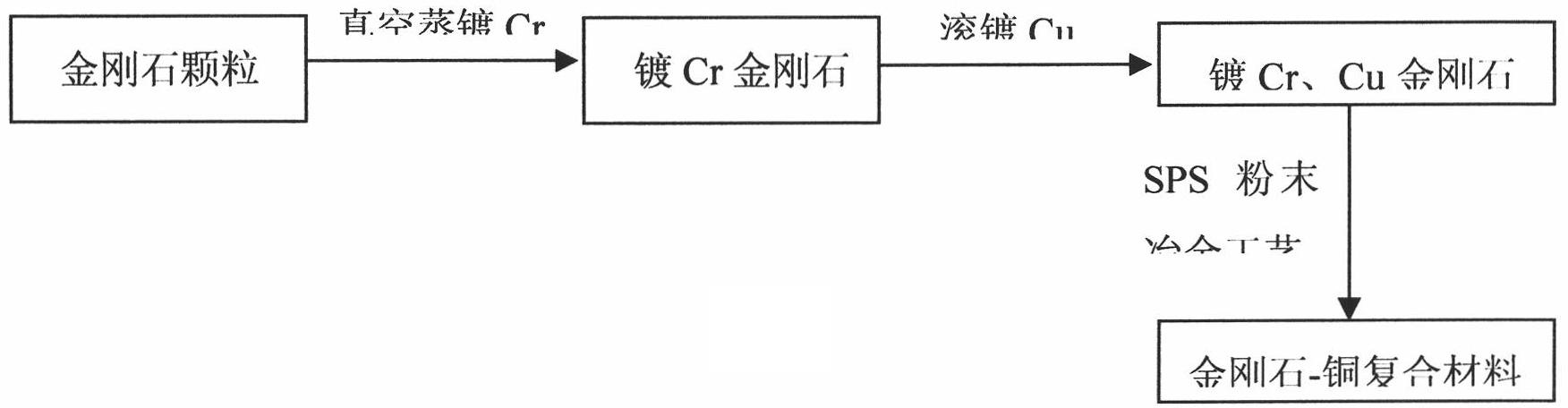

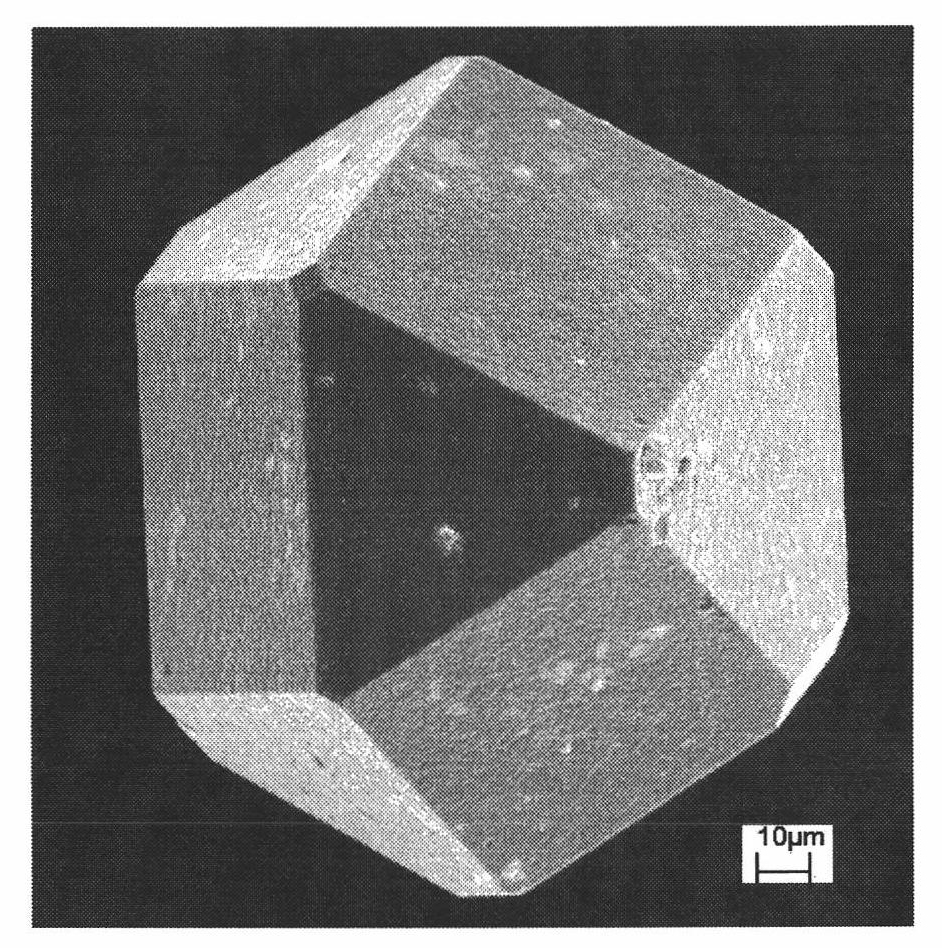

Method for preparing diamond enhanced copper based composite with high volume fraction

InactiveCN102071332AEvenly distributedImprove thermal conductivityInterfacial thermal resistanceVacuum evaporation

The invention relates to a diamond enhanced copper based composite and a preparation method thereof, belonging to the metal based composite field. In the composite of the invention, the volume ratio of diamond to copper is 40-70:60-30 and the particle size of diamond is 38-212mu m. The preparation method comprises the following steps: plating a 0.1-2mu m of Cr layer on the surface of diamond through vacuum evaporation after the surface pretreatment of diamond; placing the diamond plated with Cr in a barrel to perform copper element barrel plating and thickening, wherein the copper coating on the surface of diamond is 7-20mu m in thickness and the weight of the obtained diamond is increased by 100%-170%; and directly placing the obtained diamond in a spark plasma sintering (SPS) furnace to prepare the diamond-copper composite. The method of the invention directly uses the thicker copper coating on the surface of diamond as base material, thus avoiding the problem that diamond is not mixed uniformly with copper powder so as to cause the additional interfacial thermal resistance; and all kinds of composites with different diamond contents can be obtained by changing the increased weight of diamond, thus the maneuverability is high and the technology is simple. The composite has higher thermal conductivity and can be used in the fields such as electronic packaging.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com