Patents

Literature

57results about How to "Controllable coefficient of thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

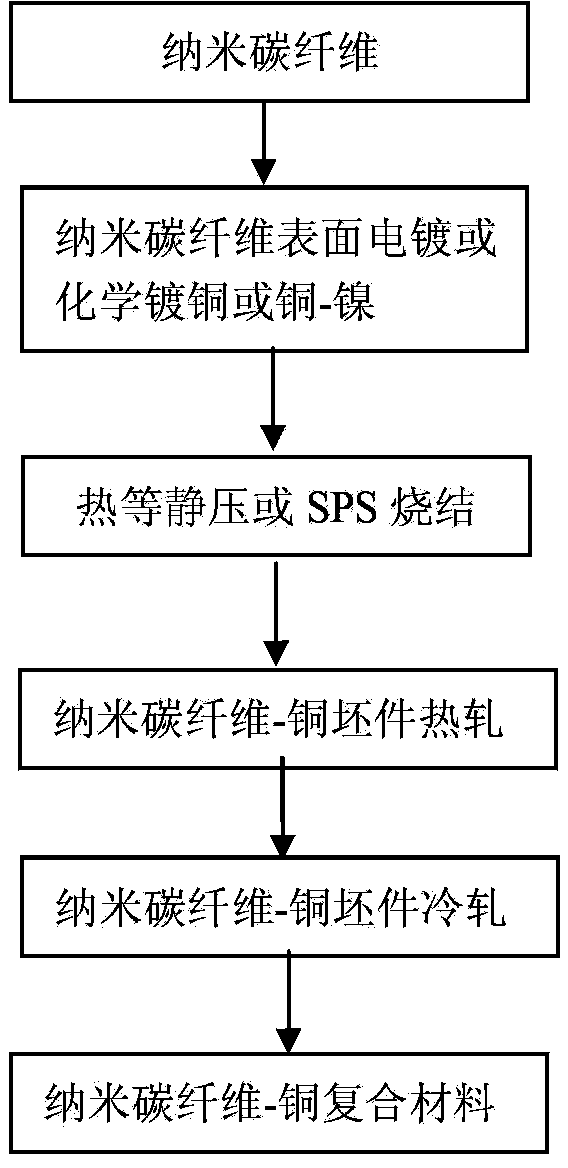

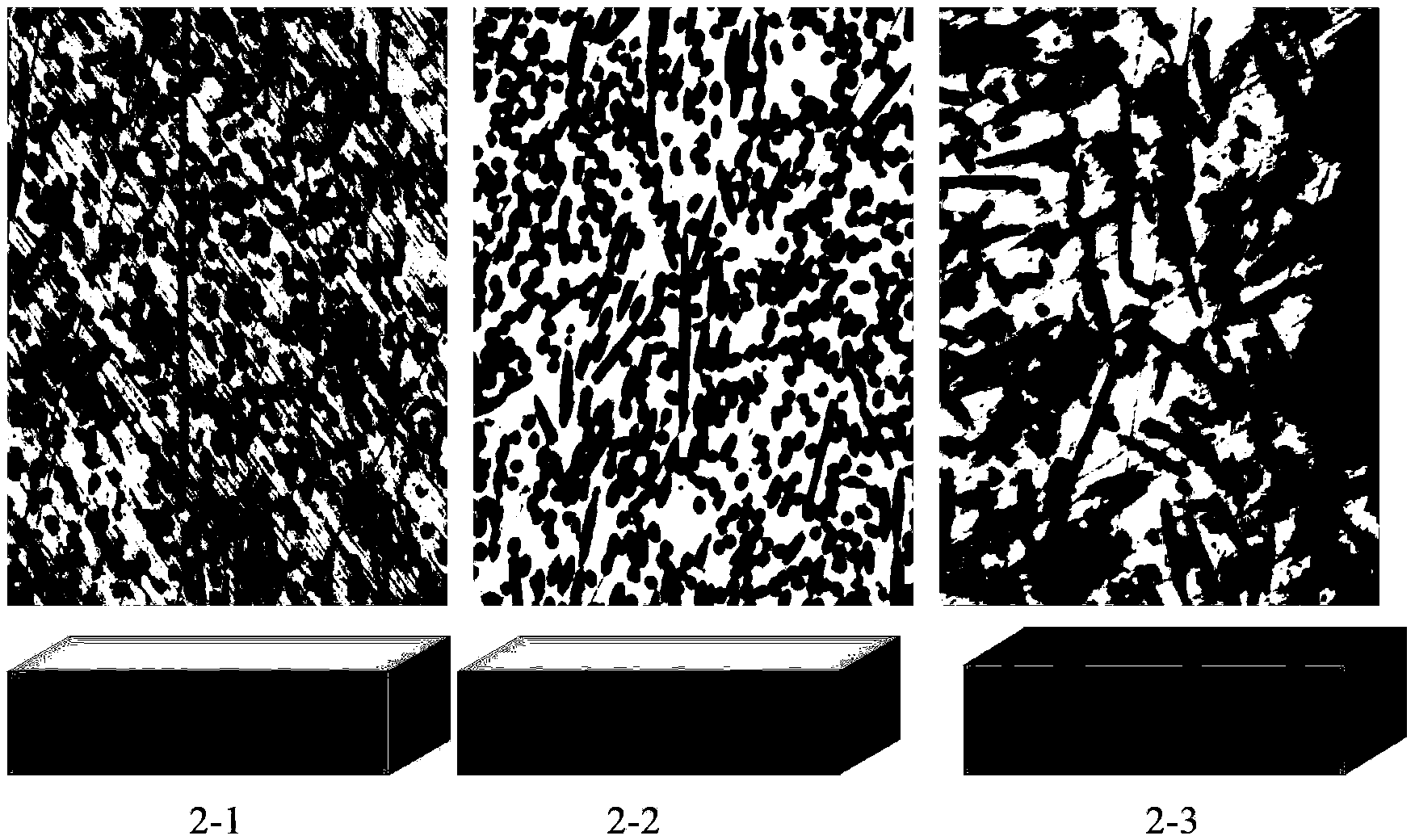

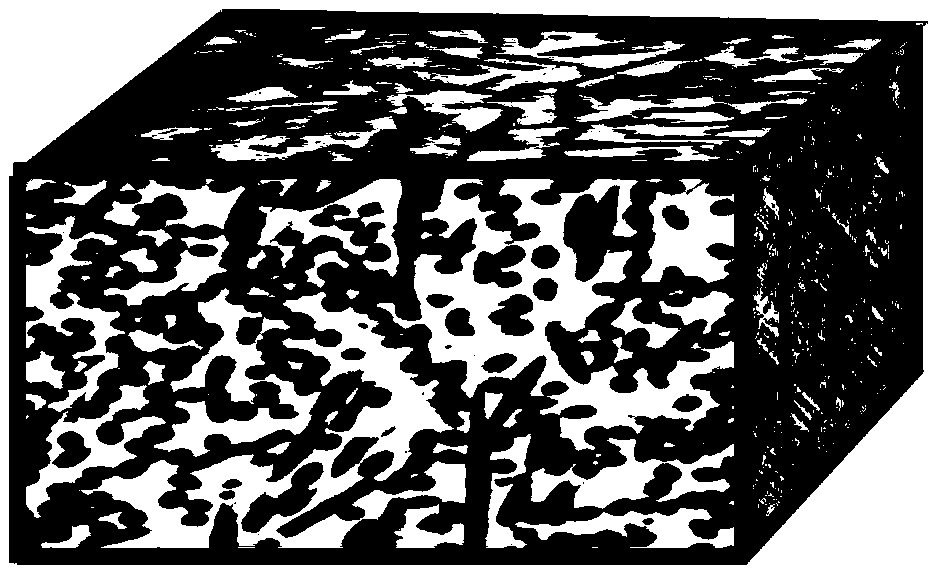

Preparation method of nanometer carbon fiber-copper composite material

The invention discloses a preparation method of a nanometer carbon fiber-copper composite material, which belongs to the technical field of preparation of electronic component composite materials. The method comprises the following steps: plating nanometer carbon fibers with a certain volume fraction of copper or copper-nickel alloy by chemical plating or electroplating, reducing the metalized nanometer carbon fibers in hydrogen, then preparing a nanometer carbon fiber-copper composite material blank by hot isostatic pressing or discharge plasma sintering, finally performing hot rolling cogging, and performing cold rolling to realize oriented arrangement of the nanometer carbon fibers, so as to prepare the nanometer carbon fiber-copper composite material. The prepared nanometer carbon fiber composite material has a density lower than that of copper, is adjustable in thermal expansion coefficient, is high in thermal conductivity in the parallel fiber direction, and is widely used in microelectronic packaging, laser diodes, IGBT and semiconductors, radiating fins, and cover plates.

Owner:GRIMAT ENG INST CO LTD

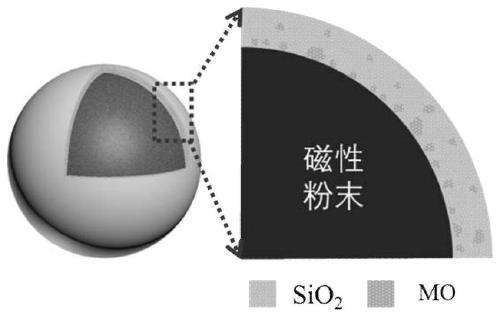

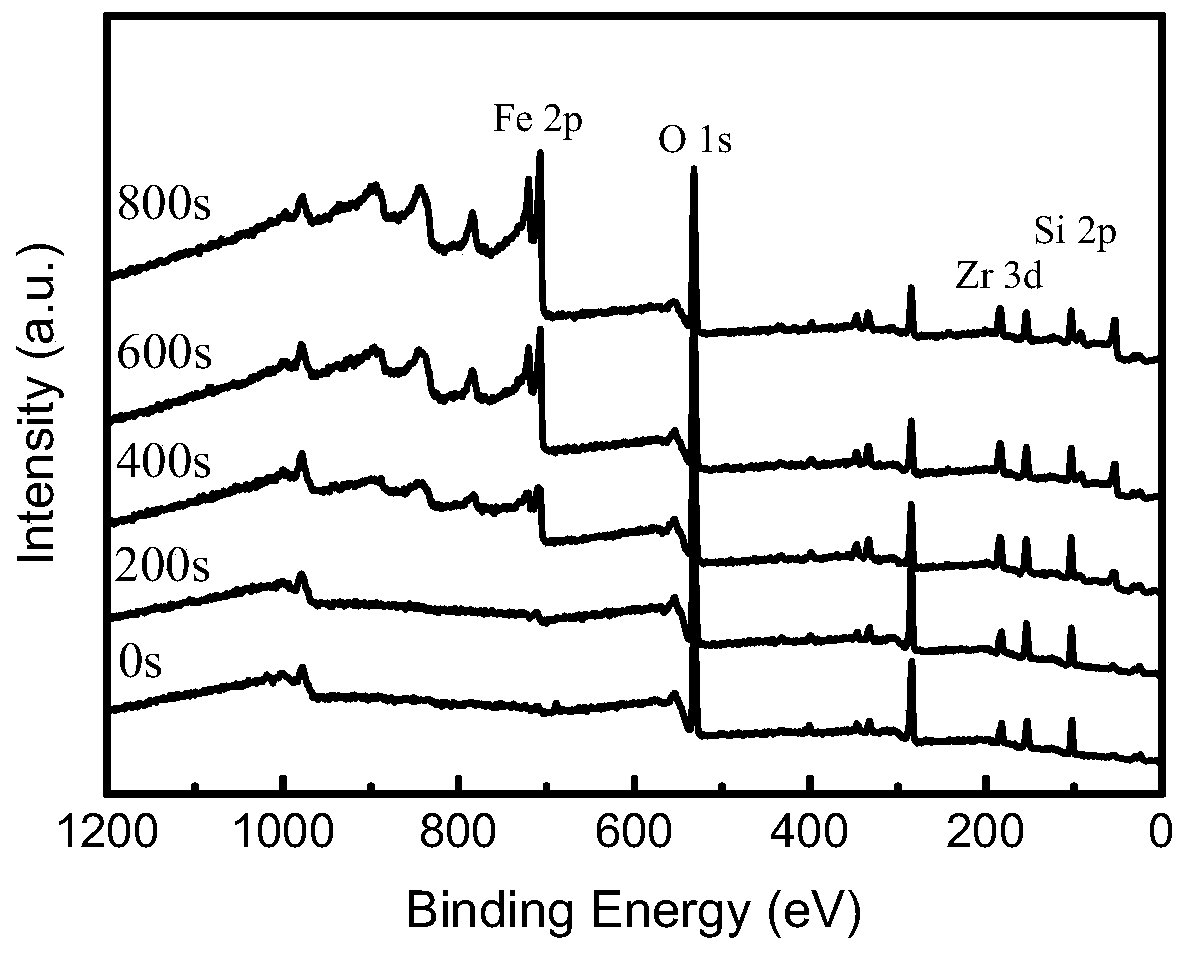

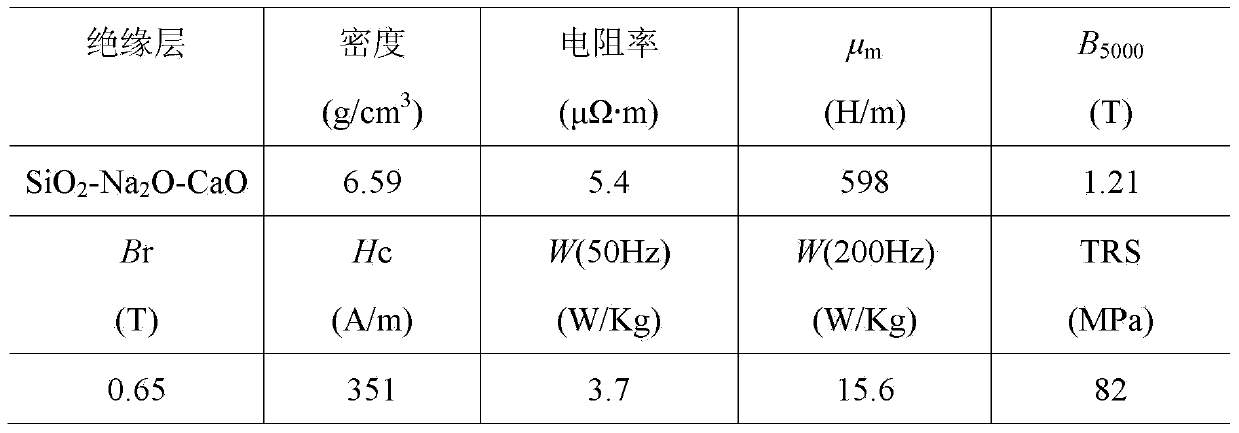

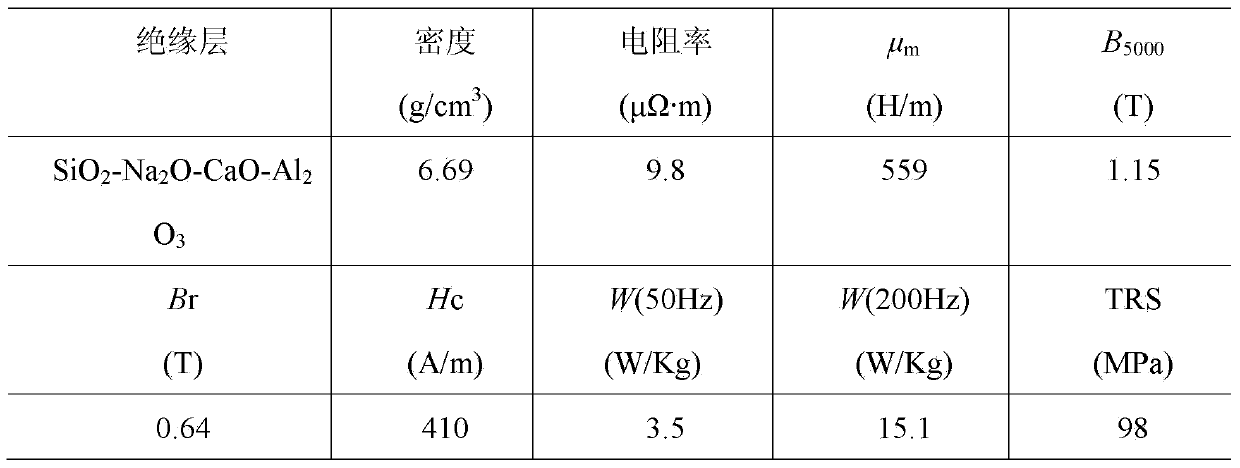

Magnetic powder surface gradient coating structure and coating method and soft magnetic composite

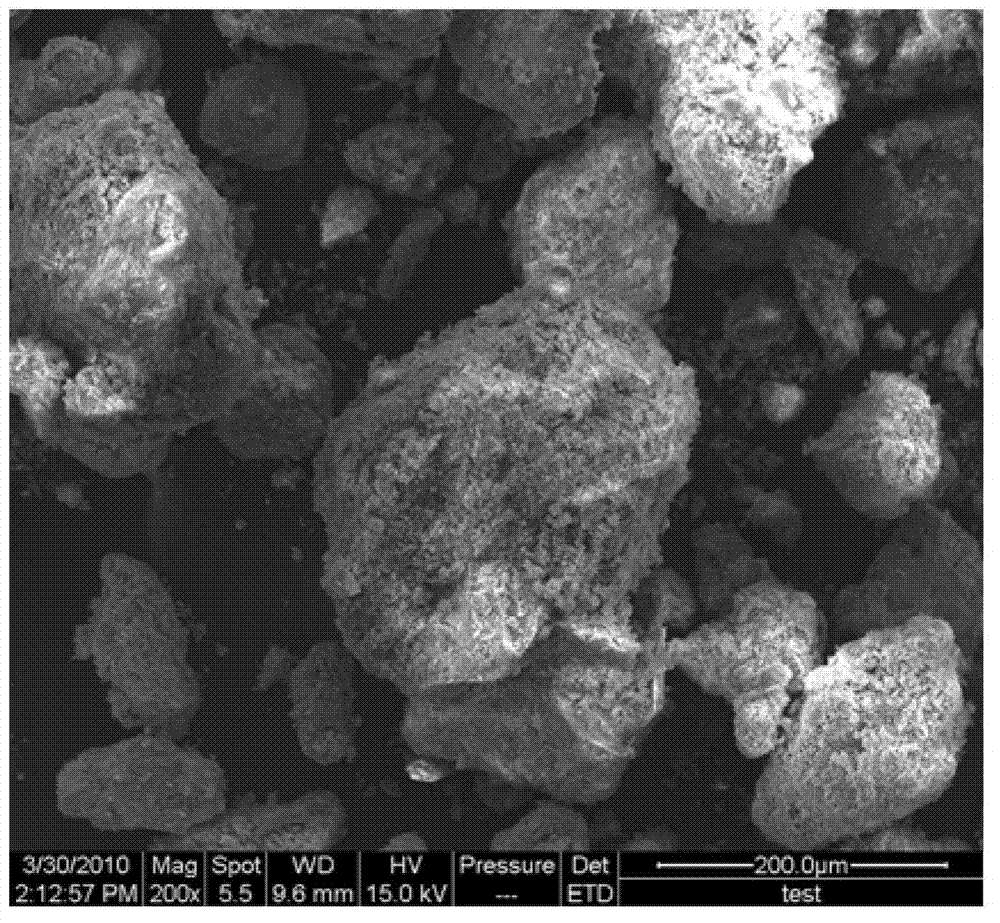

ActiveCN110405201ACoated evenlyCover tightlyTransportation and packagingMetal-working apparatusHigh resistivityThermal expansion

The invention relates to a magnetic powder surface gradient coating structure and coating method and a soft magnetic composite. The gradient coating structure is prepared from a coating layer which isformed on the surface of ferromagnetic powder by silicon dioxide and other coated components, and the contents of the silicon dioxide and other coated components in the coating layer are gradiently distributed. The coating method comprises the step of depositing the silicon dioxide and other coated components on the surface of the ferromagnetic powder in one step by adopting a chemical coprecipitation method, wherein the pH value of the system is adjusted in the deposition process. The soft magnetic composite is obtained by sectionally annealing the ferromagnetic powder with the coating layeron the surface after being pressed and formed. The coefficient of thermal expansion of the coating layer prepared by using the method can be controlled, the prepared soft magnetic composite has the advantages of low eddy current loss, high magnetic conductivity, high resistivity and high saturation magnetization, and the defects of low resistivity, mismatching of the coefficient of thermal expansion between coating layers and the like of the material in the prior art are overcome; in order to solve the problems of the reduction of the medium-high frequency magnetic conductivity, high eddy current loss, serious heating and the like of an existing magnetic powder core, a good method is provided.

Owner:CENT SOUTH UNIV

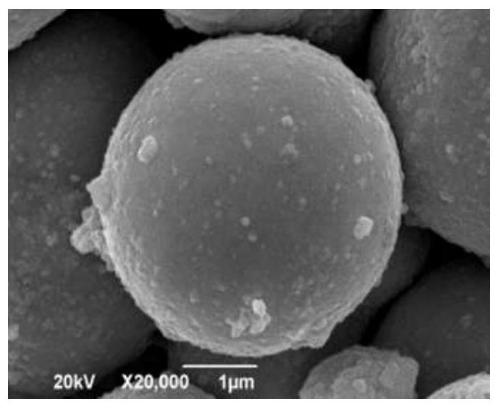

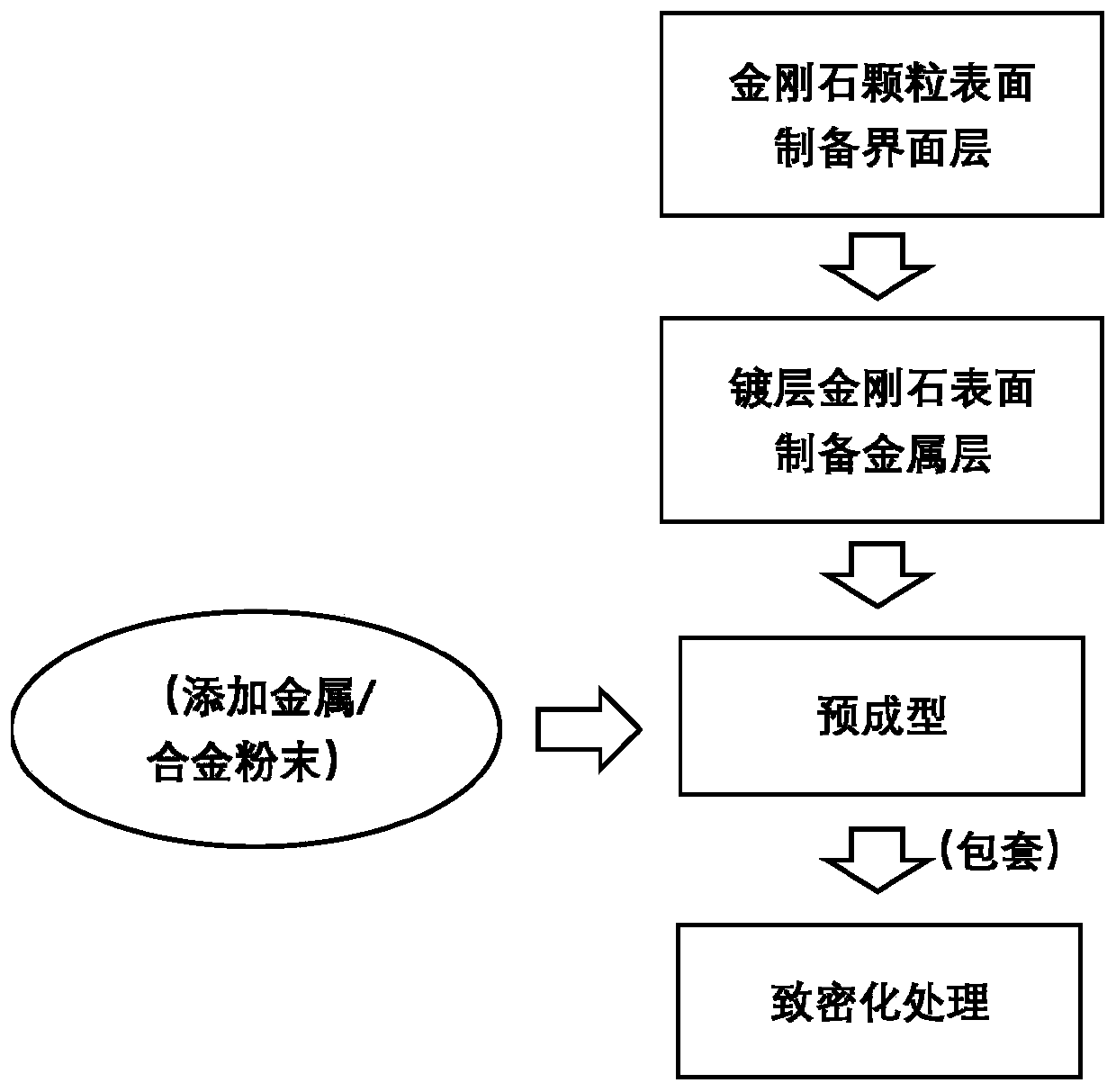

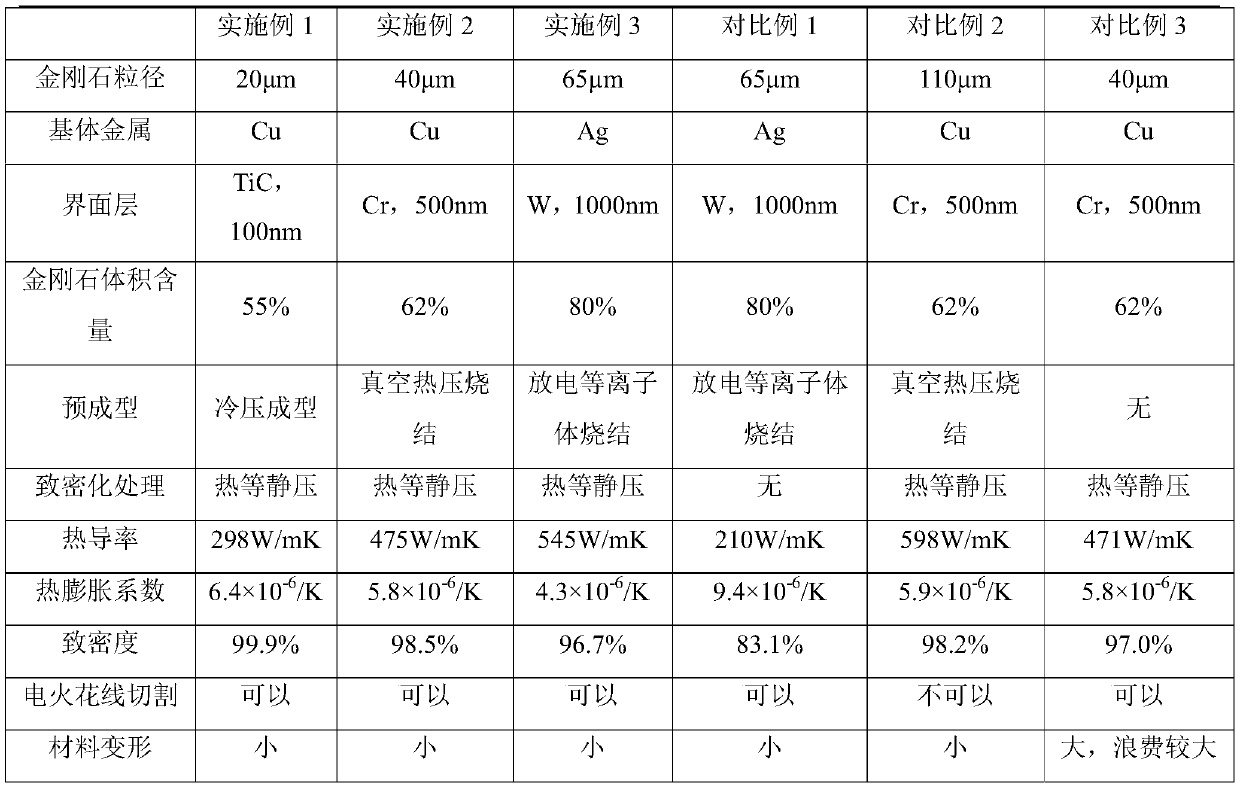

Diamond particle reinforced metal matrix composite material and preparation method and application thereof

InactiveCN111519076AEliminate uneven powder mixingHigh thermal conductivityTransportation and packagingMetal-working apparatusInterface layerThermal expansion

The invention discloses a diamond particle reinforced metal matrix composite material and a preparation method and application thereof. The preparation method comprises the steps of 1, preparing an interface layer; 2, preparing a metal layer; 3, premolding; and 4, carrying out densification treatment. According to the diamond particle reinforced metal matrix composite material and the preparationmethod and application thereof, the adopted sintering of a two-step solid-phase method combined with the premolding and densification treatment is characterized by complementing for each other, fostering strengths and circumventing weaknesses, so that the the characteristic that the solid-phase sintering method capable of preparing a material with smaller particle size is retained, the size of thematerial prepared in a single batch is larger, the thickness reaches the centimeter level or a higher level, the production efficiency is higher, and the cost is greatly reduced; the prepared material has higher thermal conductivity, adjustable thermal expansion coefficient and better uniformity and reliability, and can be directly cut for processing by an electric spark wire; and meanwhile, thepremolding before the densification treatment can solve the problem that a bag sintered by directly adopting hot isostatic pressing is deformed too much so as to result in too much waste of the material, and the material utilization rate is higher.

Owner:成都本征新材料技术有限公司

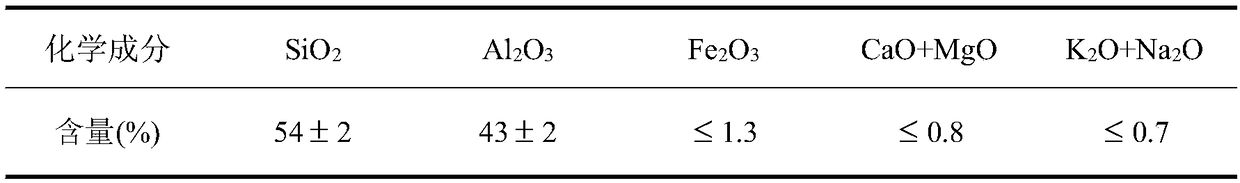

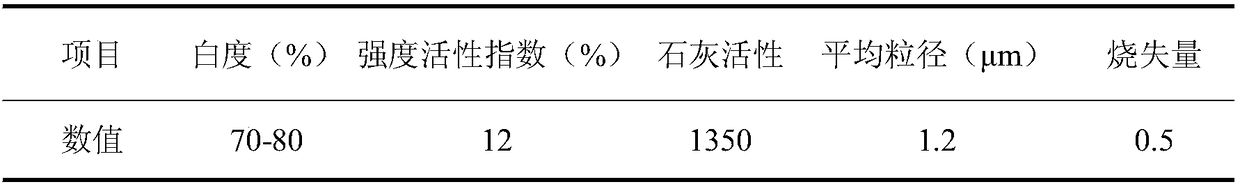

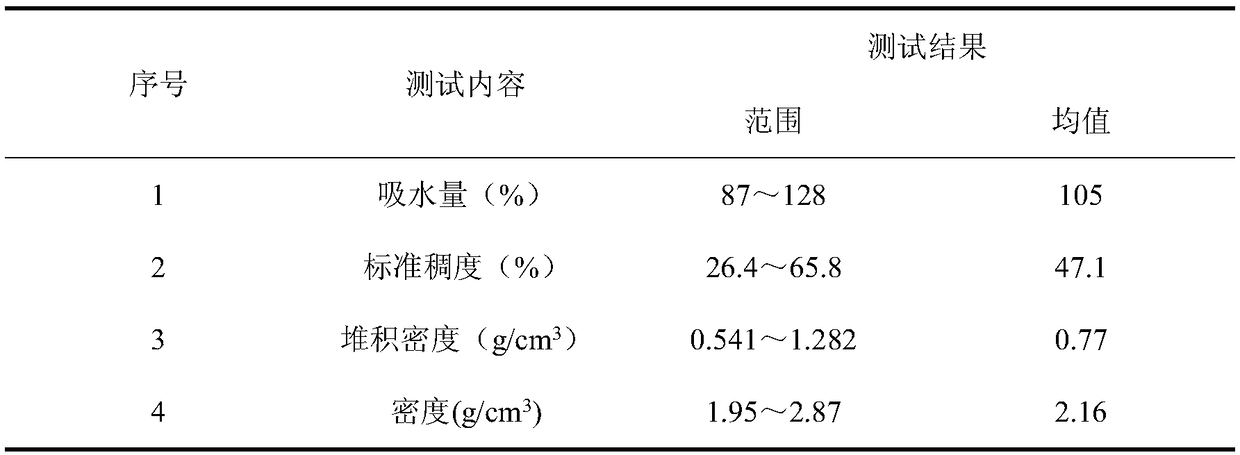

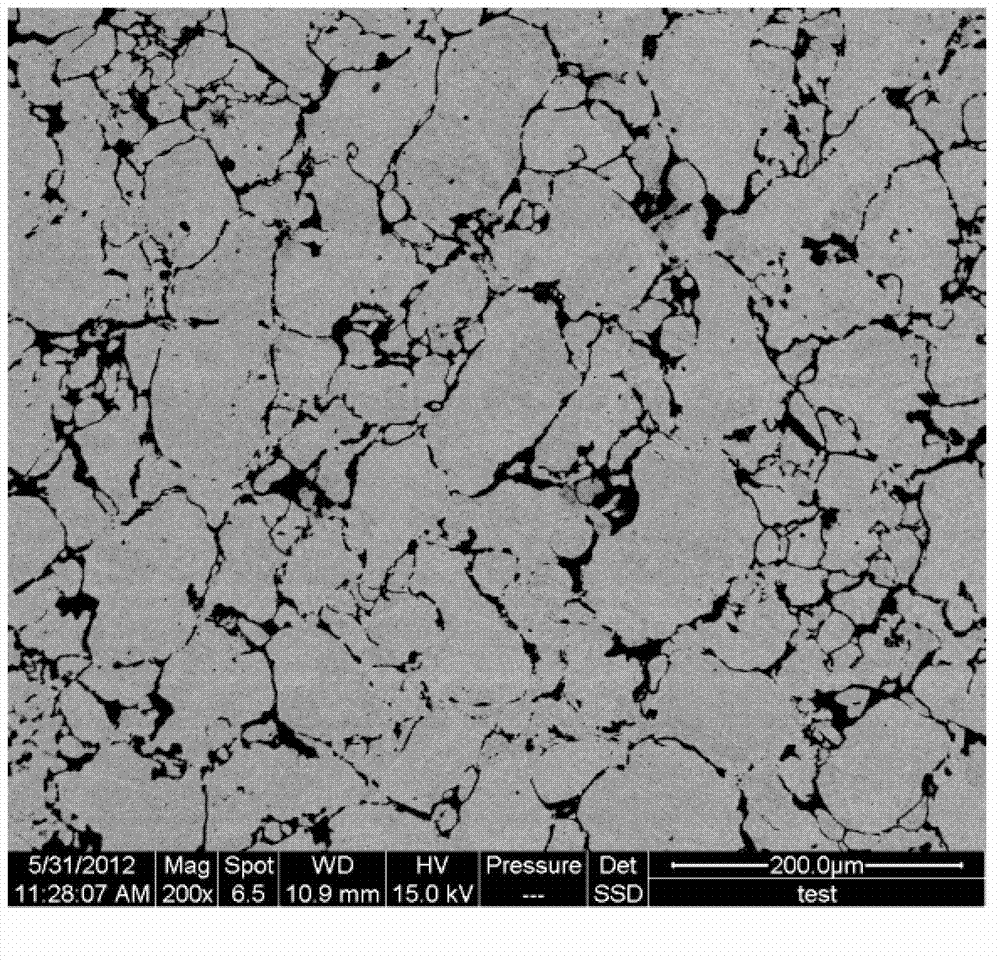

Nanometer SiO2 and PVA (polyvinyl alcohol) fiber reinforced geopolymer mortar

The invention discloses nanometer SiO2 and PVA (polyvinyl alcohol) fiber reinforced geopolymer mortar, and belongs to the field of inorganic polymeric materials. The nanometer SiO2 and PVA fiber reinforced geopolymer mortar comprises water, metakaolin, fly ash, quartz sand, alkali activators, PVA fibers, nanometer SiO2 and water reducing agents. The nanometer SiO2 and PVA fiber reinforced geopolymer mortar has the advantages of good mechanical property, excellent bonding characteristics and broad application prospect in the fields of buildings, roads and bridges, water conservation, military science and the like.

Owner:ZHENGZHOU UNIV

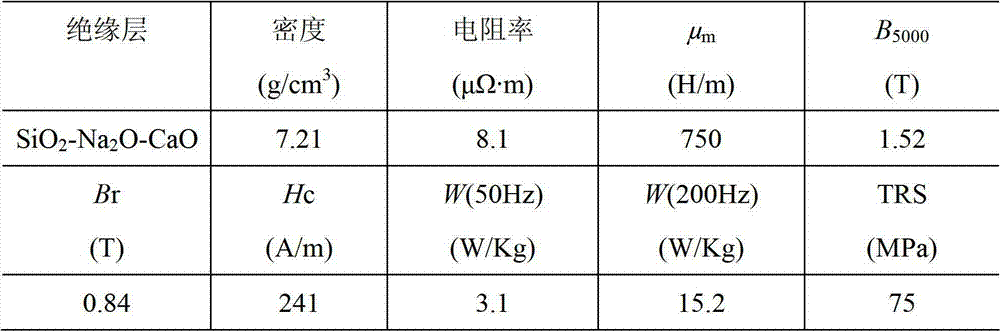

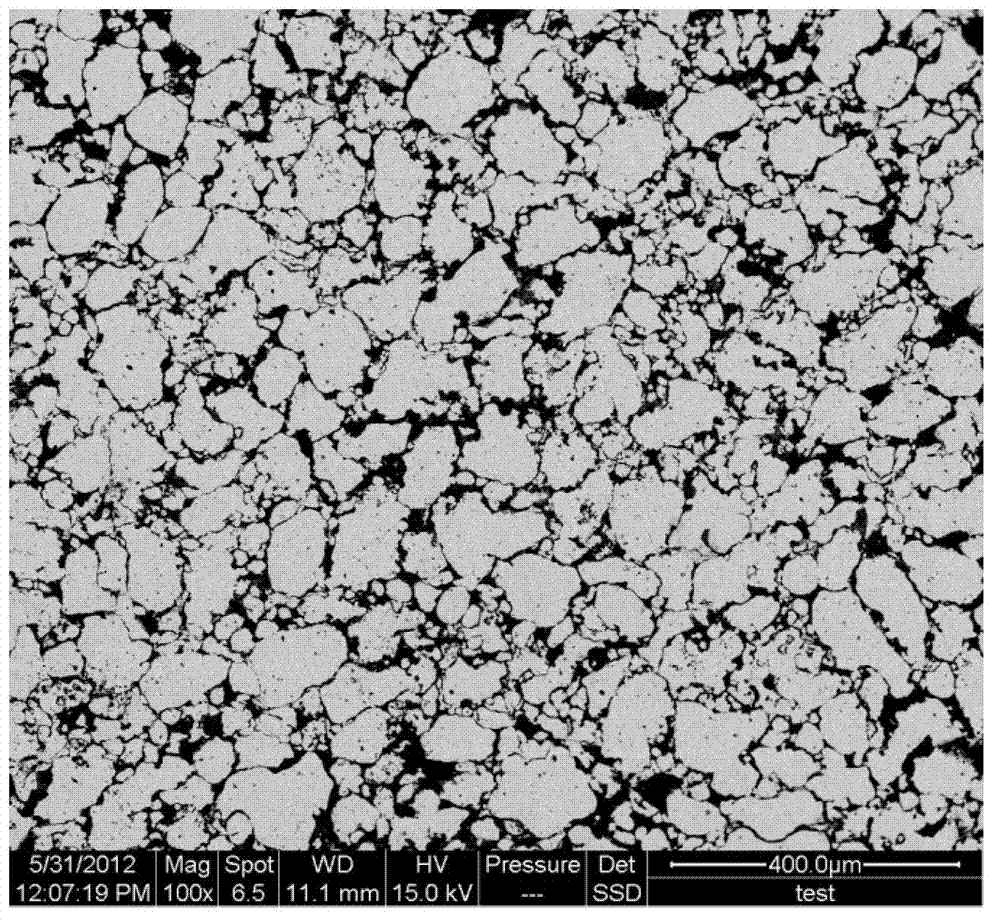

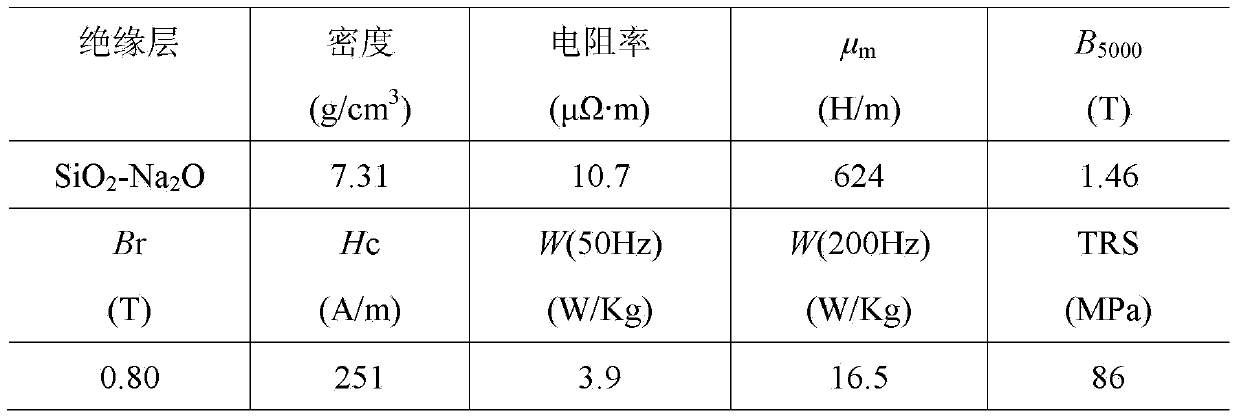

Soft magnetic composite material and preparation method thereof

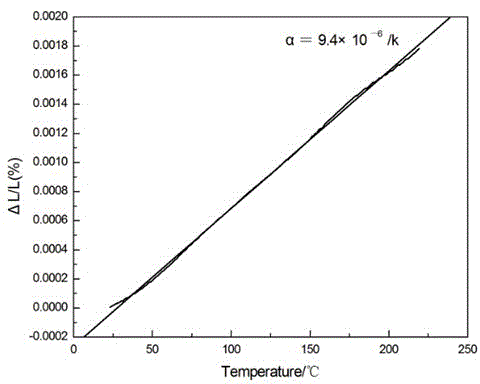

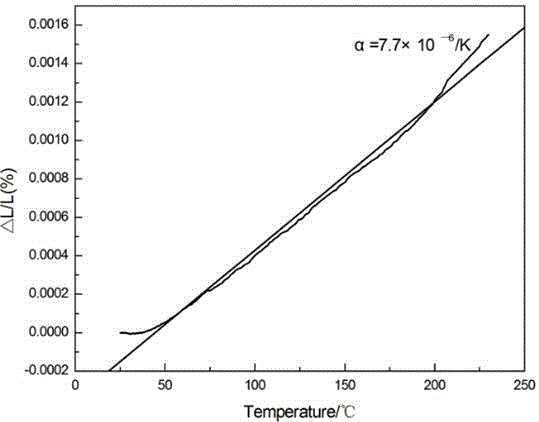

ActiveCN102789859AControllable coefficient of thermal expansionControllable change of thermal expansion coefficientInorganic material magnetismResonanceThermal expansion

The invention relates to a soft magnetic composite material and a preparation method thereof, relating to a soft magnetic material and the preparation method thereof, and aiming to solve the problem that the coefficients of thermal expansion of an inorganic insulating layer and magnetic powder greatly differs from each other and the coefficient of thermal expansion of the inorganic insulating layer can not be changed. The soft magnetic composite material consists of magnetic powder, a silicon dioxide layer coated by the magnetic powder and a glass layer coated outside the silicon dioxide layer. The preparation method comprises the following steps: firstly, pre-treating the magnetic powder; secondly, coating the silicon dioxide layer on the surface of the magnetic powder; thirdly, coating the glass layer outside the silicon dioxide layer; fourthly, preparing a blank material of the soft magnetic composite material; and fifthly, preparing the soft magnetic composite material. The soft magnetic composite material is applied to the fields of switch magnetic resistance, resonance inductance, anti-lock brake sensors, electromagnetic drive devices, brushless direct current motors, rotating machinery and low-frequency filters.

Owner:HARBIN INST OF TECH

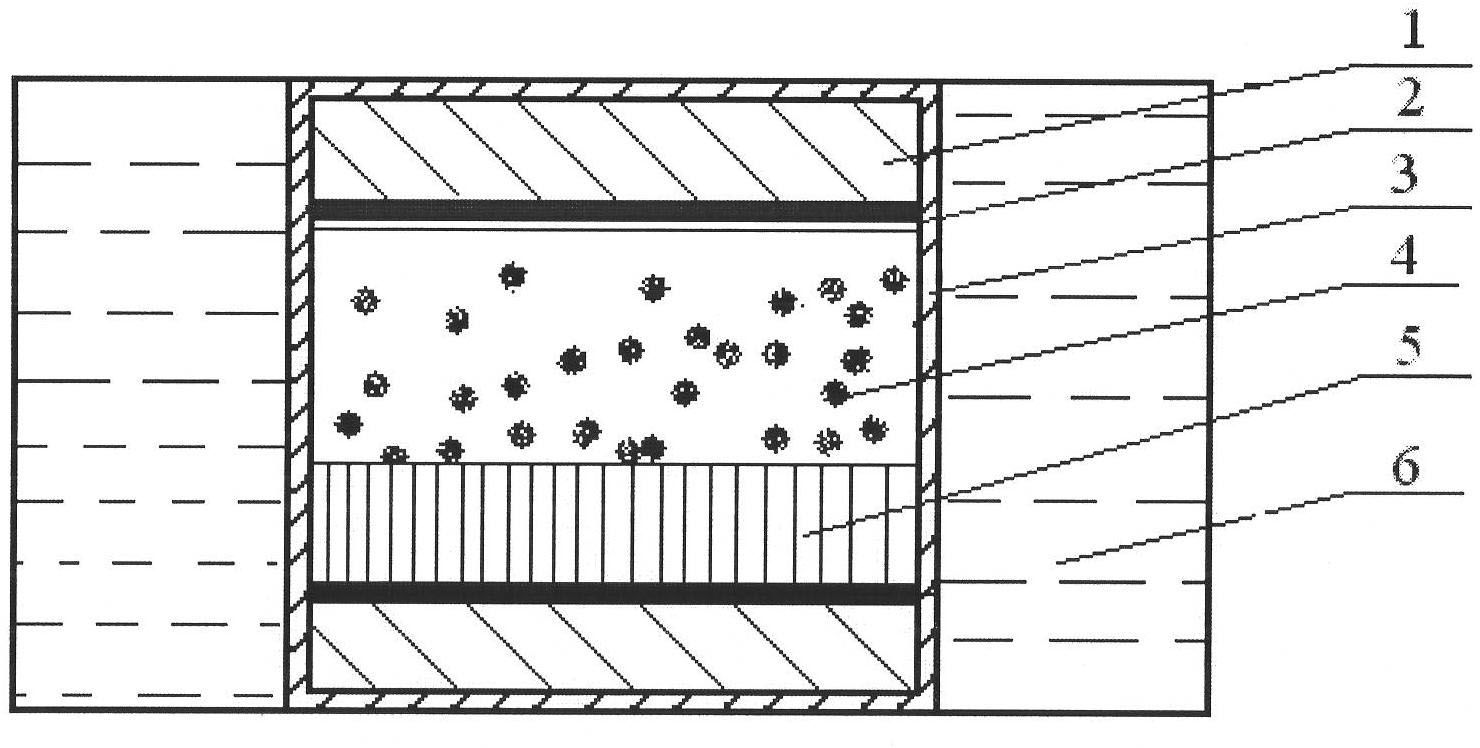

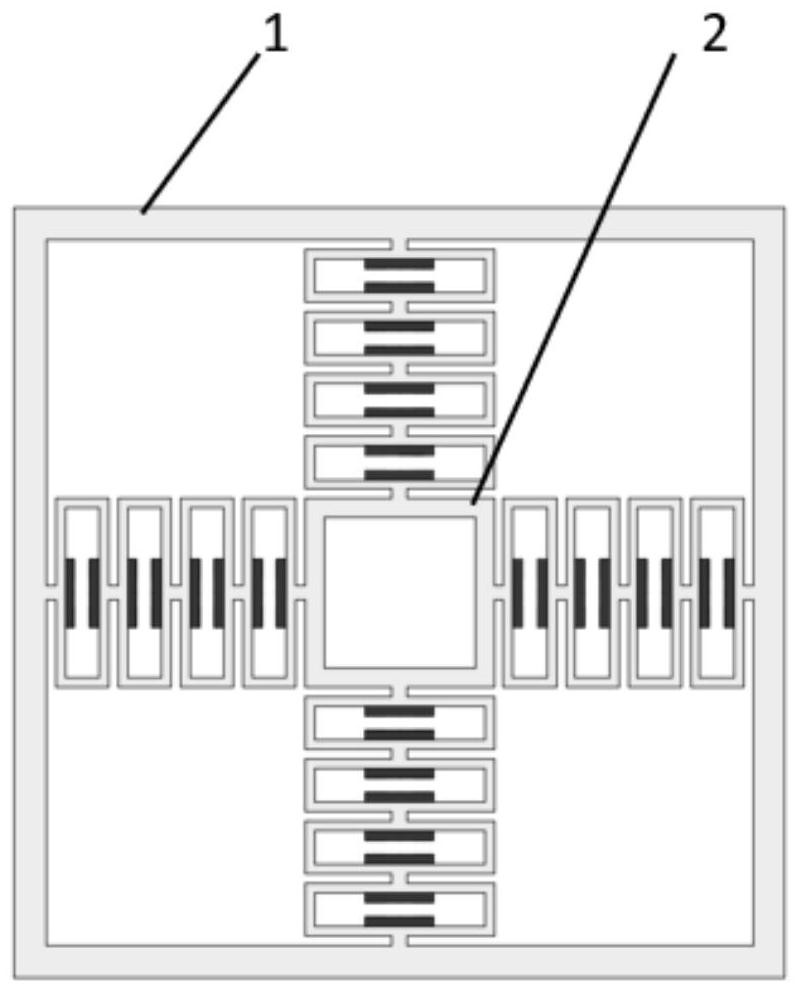

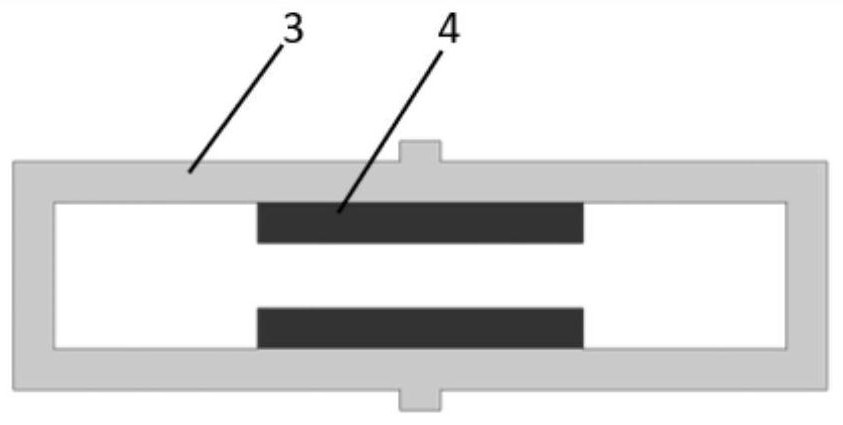

Preparation method of microchannel heat sink for high-heat flux heat dissipation

InactiveCN106571307AMiniaturizationImplement input and output functionsSemiconductor/solid-state device detailsSolid-state devicesSolderabilityMiniaturization

The invention relates to a preparation method of a microchannel heat sink for high-heat flux heat dissipation. The method includes the following steps that: a) materials are selected; b) a microchannel is made inside a plate; c) three-dimensional microchannel deformation-free modeling is performed; d ) and a metal frame, a ceramic frame, an outer lead, an IC device, a sensor and a heater are integrated on an active microchannel heat sink, so that system miniaturization can be realized, mechanical support and environmental protection are provided for a chip and an internal circuit, and an input and output function is realized for the chip and the internal circuit. The thermal expansion coefficient of the product is adjustable; and heat generated by devices or a system can be taken away from the heat sink through a high-thermal conductivity medium, the temperature of the surface of the heat sink can be decreased as much as possible and remain constant. The microchannel heat sink has the advantages of small size, large heat dissipation area, good solderability and high stability, and can meet the requirement of high-power density heat dissipation, and can be in sealed connection with other components or parts.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

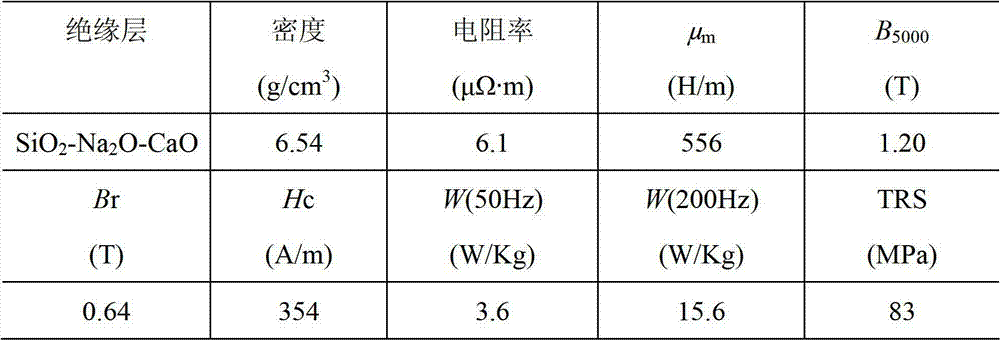

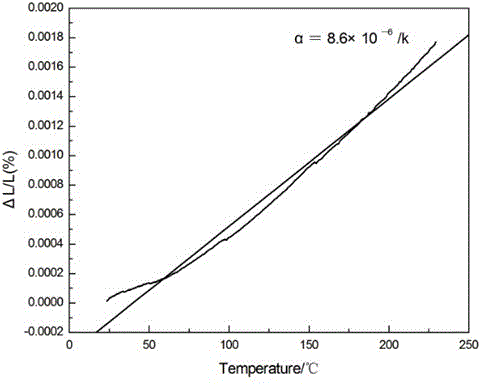

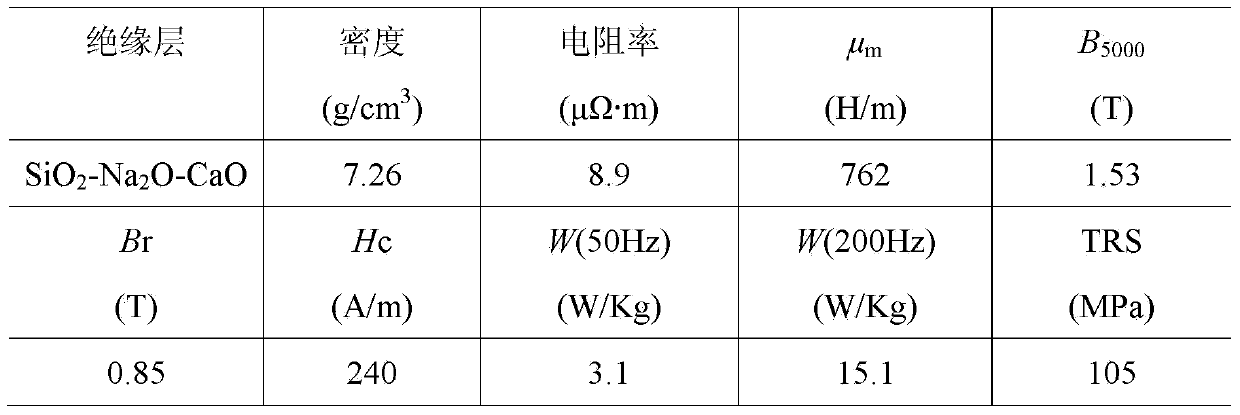

Soft magnetic composite material of collosol infiltrating glass powder coating layer and preparation method of soft magnetic composite material

ActiveCN102789861AControllable coefficient of thermal expansionControllable change of thermal expansion coefficientInorganic material magnetismThermal dilatationMechanical property

The invention relates to a soft magnetic composite material of a collosol infiltrating glass powder coating layer and a preparation method of the soft magnetic composite material, relating to a soft magnetic material and a preparation method thereof. In the invention, the problem that in the traditional soft magnetic composite material of an inorganic coating layer, excellent mechanical property of the soft magnetic composite material and excellent magnetic property of the soft magnetic composite material resulting from an annealing mean can not coexist, and the difference of coefficients of thermal expansion between an inorganic insulating layer and magnetic powder is greater is solved. The soft magnetic composite material of the collosol infiltrating glass powder coating layer consists of magnetic powder, a silicon dioxide layer coated by the magnetic powder, a glass powder layer coated outside the silicon dioxide layer and a glass collosol infiltrating layer. The preparation method comprises the following steps: firstly, pre-treating the magnetic powder; secondly, coating the silicon dioxide layer; thirdly, preparing the glass powder; fourthly, coating the glass powder layer; fifthly, preparing a blank material; sixthly, infiltrating the blank material with the glass collosol; and seventhly, annealing the blank material. The soft magnetic composite material of the collosol infiltrating glass powder coating layer and the preparation method are applied to the fields of switch magnetic resistance, resonance inductance, anti-lock brake sensors, electromagnetic driving devices and low-frequency filters.

Owner:HARBIN INST OF TECH

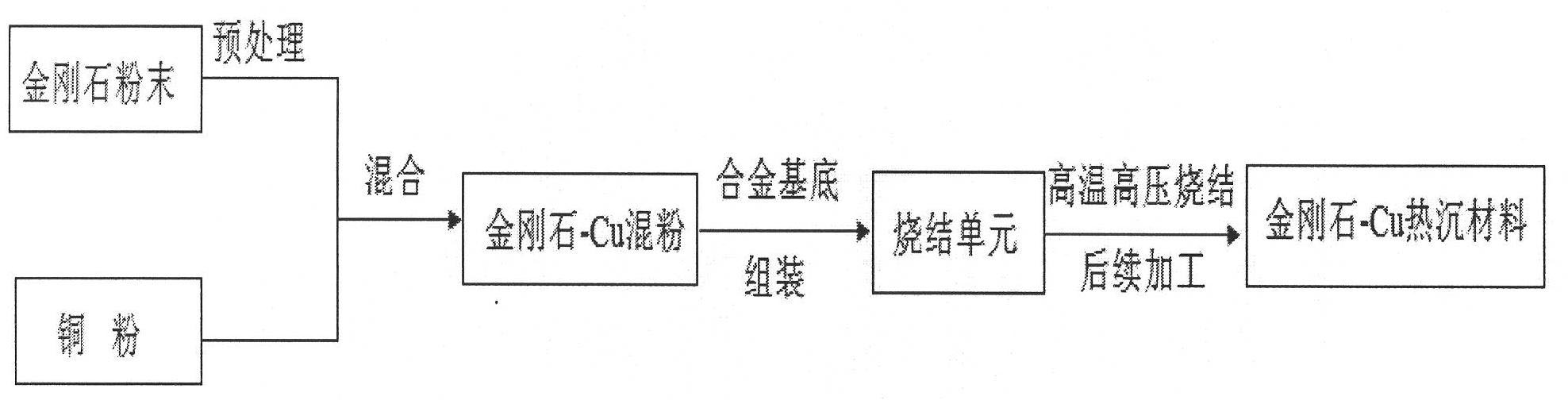

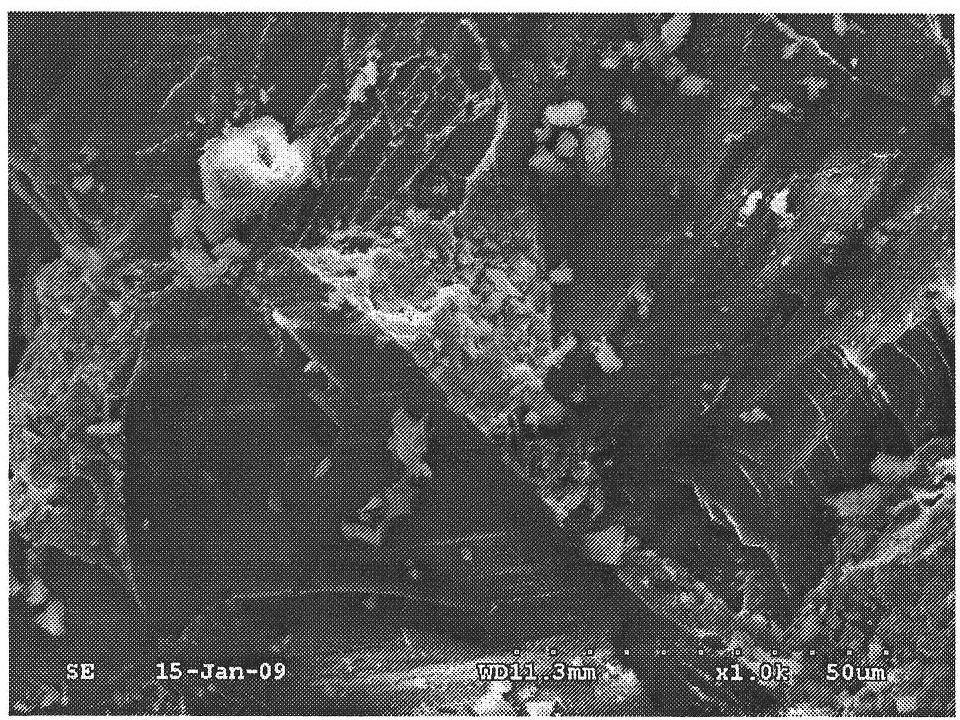

High heat conduction diamond heat sink material and preparation method thereof

InactiveCN102465213AHigh thermal conductivityControllable coefficient of thermal expansionThermal dilatationHeat resistance

The invention relates to a high heat conduction diamond heat sink material. The diamond heat sink material comprises, by mass, 0.1-1.5% of Co, and the balance diamond particles and Cu, wherein the content of the diamond particles in the balance diamond particles and Cu is 70-90% by volume. Raw material powder and a Co-containing alloy base which are assembled to form a sintering component undergo high-temperature high-pressure sintering after adjusting sintering parameters, The composite material which forms a diamond-diamond based strong metallurgy combination interface allows the influence of the heat resistance of a heterogeneous material interface to the heat conductivity to be reduced and the top thermal conductivity of the diamond-Cu heat sink material to be 639W.m<-1>.K<-1>. The diamond-Cu heat sink material prepared in the invention, which has the characteristics of high heat conductivity and adjustable heat expansion coefficient, allows the high heat conductivity to be satisfied and the heat expansion coupling with a substrate material to be improved through adjusting the volume fraction of a reinforced phase.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Silicon carbide and silicon particle reinforced aluminum-copper based composite material and preparation method thereof

Owner:有研金属复材技术有限公司

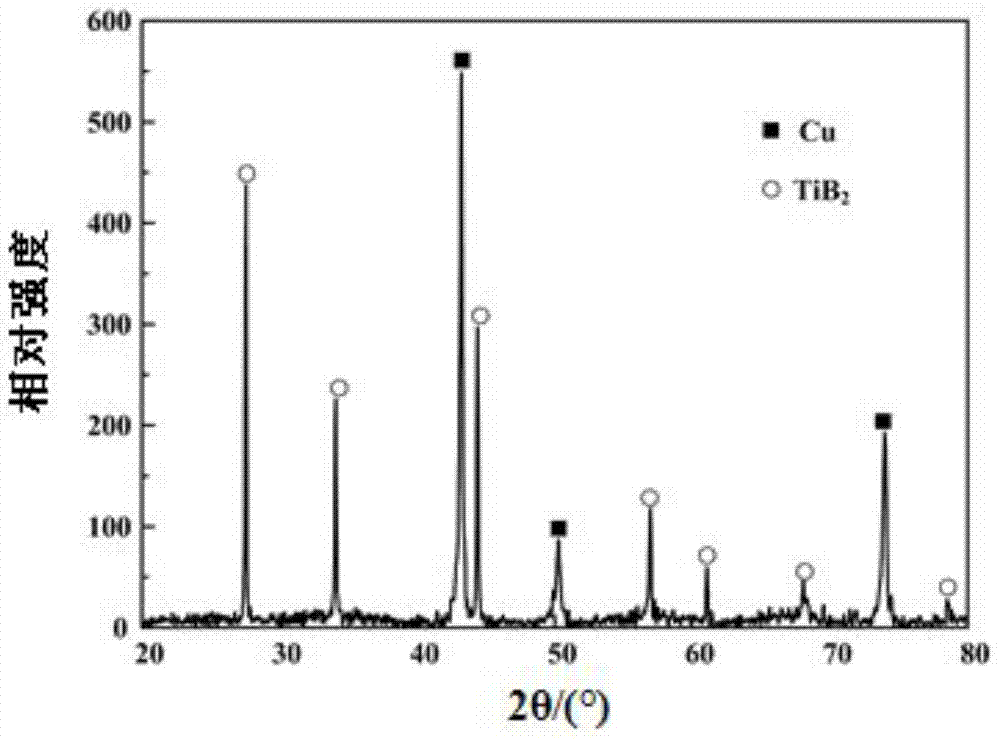

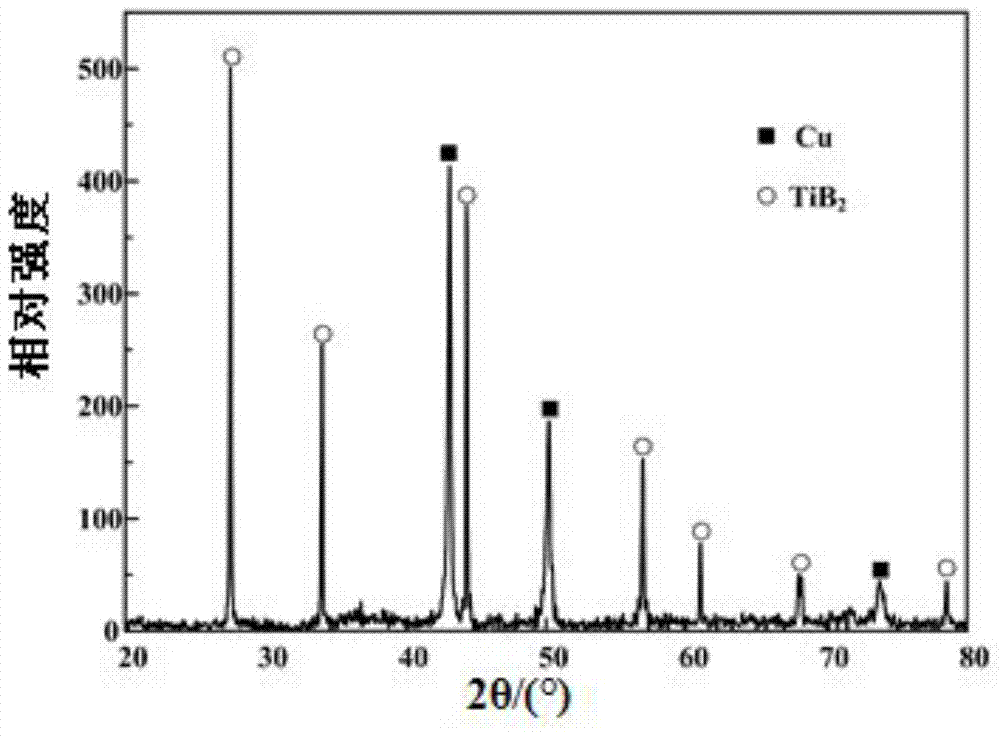

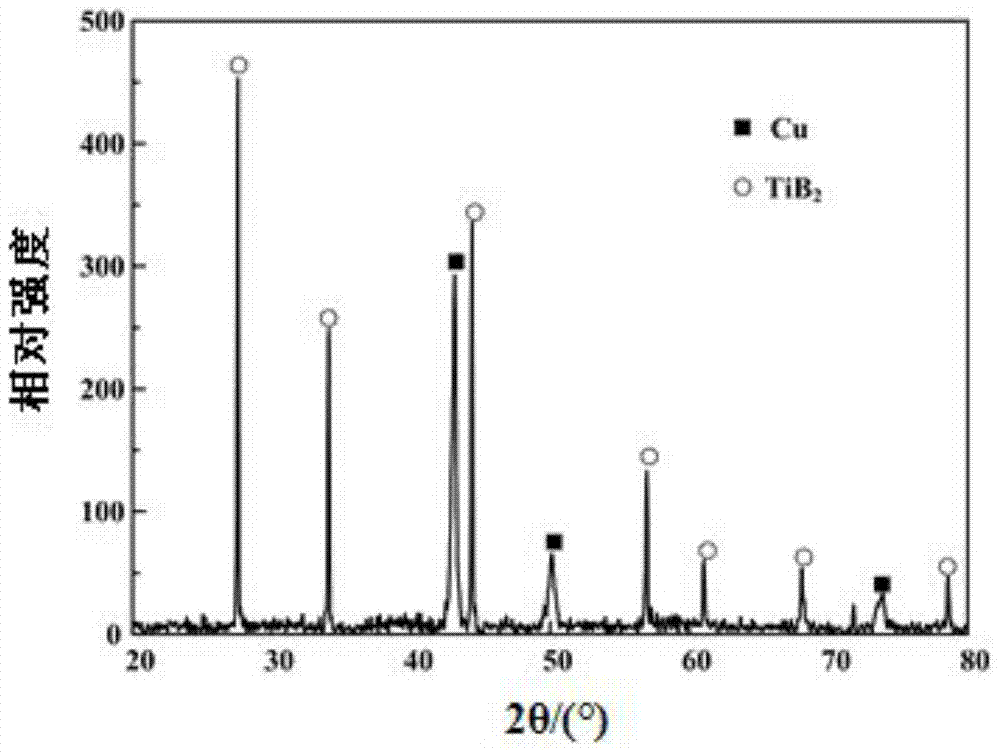

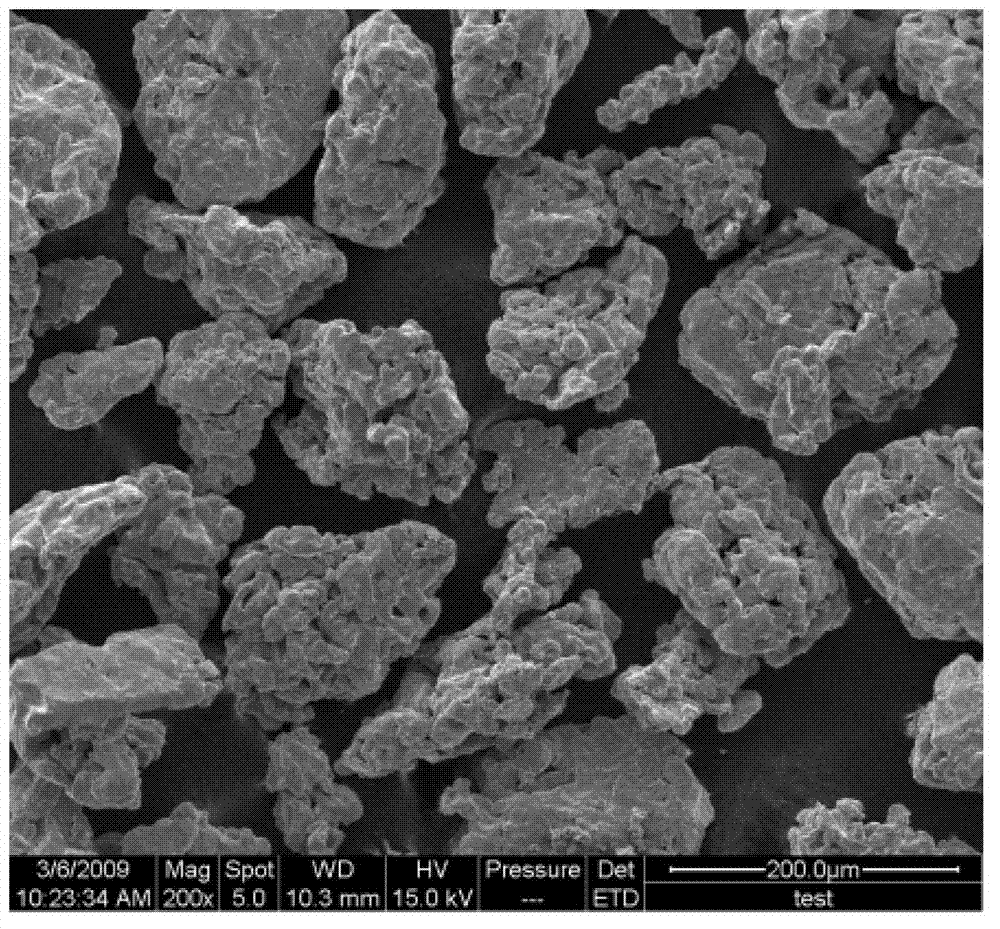

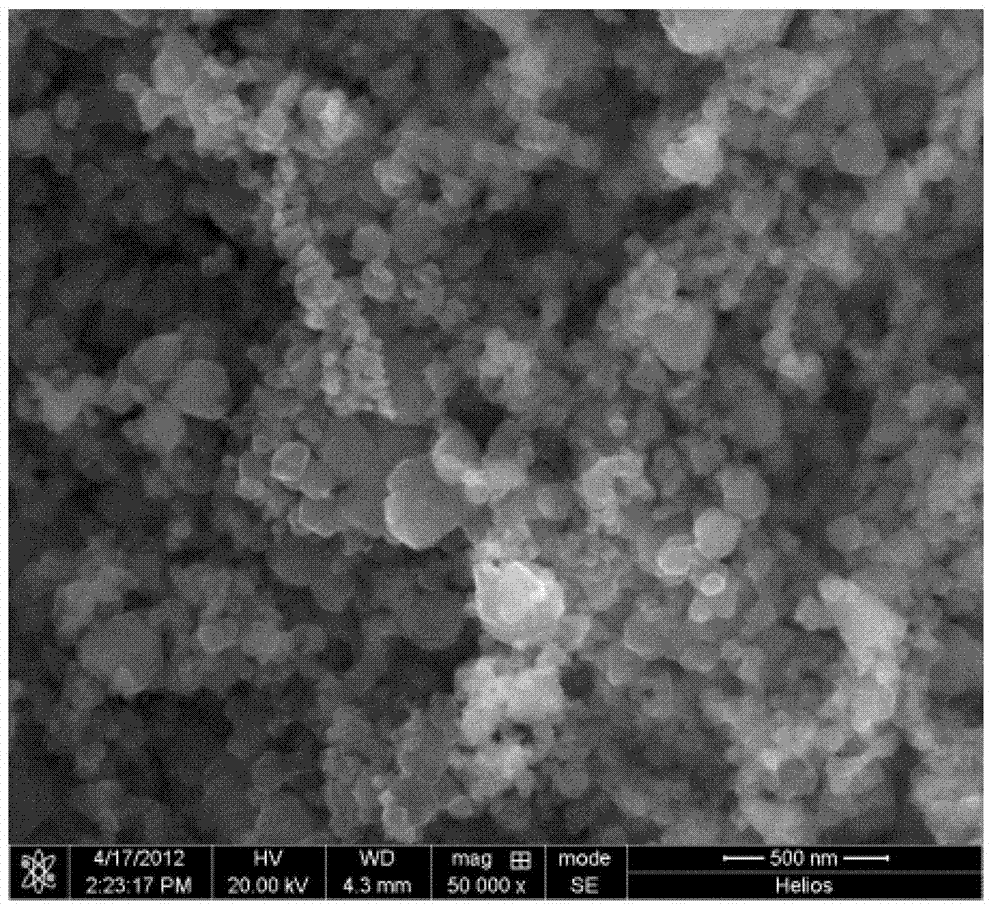

Thermal expansion coefficient adjustable Cu heat sink and preparation method thereof

InactiveCN104498766AImprove reliabilityExtended service lifeLaser detailsSemiconductor lasersThermal expansionHeat sink

The invention discloses a thermal expansion coefficient adjustable Cu heat sink and a preparation method thereof, belonging to the technical field of semiconductor laser unit chip packaging, and solving the problems that the thermal expansion coefficient of a metal heat sink is high, the heat conductivity coefficients of most ceramic heat sinks are poor, and the ceramic heat sinks with low expansion and high heat conductivity properties are high in price and are difficult to process in the prior art. The heat sink consists of Cu being 20-80vol.% and ceramic particles being 20-80vol.%, wherein the ceramic particles are TiB2, TiC, ZrB2 or ZrC. The thermal expansion coefficient of the Cu heat sink can be adjustable in the range of 5.91*10<-6> / K to 13.44*10<-6> / K by adjusting the content of the ceramic particles, and further the thermal expansion coefficient of the Cu heat sink is matched with that of a semiconductor laser unit chip; the internal stress for welding is reduced; the reliability of the semiconductor laser unit is improved; the service life of the semiconductor laser unit is prolonged; the thermal expansion coefficient adjustable Cu heat sink and the preparation method thereof are applicable to heat dissipation and packaging of semiconductor laser unit chips.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

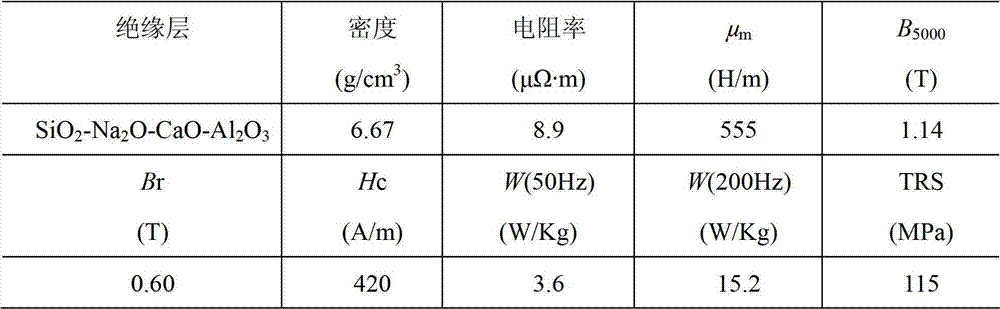

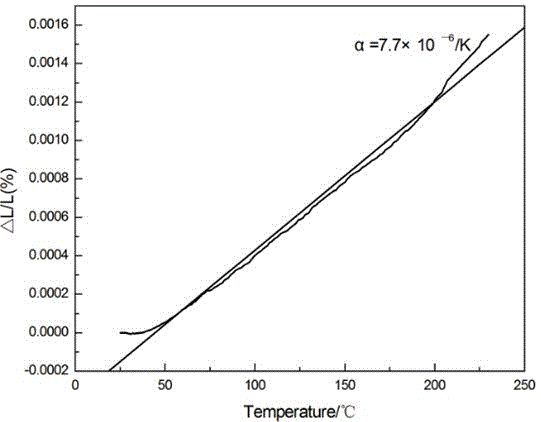

Soft magnetic composite material taking glass powder as coating layer and preparation method of soft magnetic composite material

ActiveCN102789863AImprove magnetic propertiesEliminate internal stressInorganic material magnetismMagnetic powderMechanical properties of carbon nanotubes

The invention relates to a soft magnetic composite material taking glass powder as a coating layer and a preparation method of the soft magnetic composite material, relating to the soft magnetic material and the preparation method thereof. In the invention, the problem that in the traditional soft magnetic composite material of an inorganic coating layer, excellent mechanical property of the soft magnetic composite material and excellent magnetic property of the soft magnetic composite material resulting from an annealing mean can not coexist, and the difference of coefficients of thermal expansion between an inorganic insulating layer and magnetic powder is greater is solved. The soft magnetic composite material taking the glass powder as the coating layer consists of the magnetic powder, a silicon dioxide layer coated by the magnetic powder and a glass powder layer coated outside the silicon dioxide layer. The preparation method comprises the following steps: firstly, pre-treating the magnetic powder; secondly, coating the silicon dioxide layer on the surface of the magnetic powder; thirdly, coating the glass powder layer outside the silicon dioxide layer; fourthly, preparing a blank material; and fifthly, annealing the blank material. The soft magnetic composite material taking the glass powder as the coating layer and the preparation method of the soft magnetic composite material are applied to the fields of switch magnetic resistance, resonance inductance, anti-lock brake sensors, electromagnetic driving devices, brushless direct current motors, rotating machinery and low-frequency filters.

Owner:HARBIN INST OF TECH

SiC/Al2(WO4)3/Al composite material with adjustable thermal expansion

ActiveCN104694775AControllable coefficient of thermal expansionSimple processThermal dilatationElectronic packages

The invention belongs to the technical field of composite materials, and specifically relates to a SiC / Al2(WO4)3 / Al composite material with an adjustable thermal expansion. Al is used as a matrix; a low thermal expansion material SiC is used as a reinforcement; meanwhile, a certain amount of Al2(WO4)3 powder is added in for achieving a reduction of the thermal expansion coefficient. Al2(WO4)3 is a negative thermal expansion material that is able to resist a high temperature and is stable in property. On one aspect, Al2(WO4)3 is added in for reducing the thermal expansion coefficient of the original SiC / Al composite material; on the other aspect, Al2(WO4)3 is added in for reducing the content of the highly hard abrasive SiC and increasing the subsequent processing performance of the composite material. The SiC / Al2(WO4)3 / Al composite material with the adjustable thermal expansion is prepared by a powder metallurgy technology. The thermal expansion coefficient of the SiC / Al2(WO4)3 / Al composite material is significantly lower than that of the SiC / Al composite material. Accordingly, the requirement to the thermal expansion coefficient of electronic packaging materials is met better.

Owner:江苏时代华宜电子科技有限公司 +1

Near-zero expansion lattice structure

ActiveCN112407334ANear zero expansion is goodEfficient use ofGeometric CADCosmonautic vehiclesManufacturing technologyHeat stability

The invention relates to a near-zero expansion lattice structure, and belongs to the field of aerospace. The invention aims to solve the problem that a spacecraft is easy to fail in the extreme environment service process, and provides a near-zero expansion lattice structure. According to the structure, common materials of a spacecraft can be selected, the structure has the near-zero expansion characteristic through a certain design, the linear expansion coefficient of the structure can reach the order of magnitude of 1 * e-7 through simulation tests, the thermal stability is good, the selected test materials are titanium alloy and aluminum alloy and are common structural materials in the spacecraft, the function is stable and reliable, and replaceability is realized. In the aspect of machining, due to the fact that the complexity of the design structure is low, the structure can be machined and manufactured through the additive manufacturing technology or the machining technology, andthe practical applicability is high.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A kind of silicon carbide and silicon particle reinforced aluminum-copper matrix composite material and preparation method thereof

The invention relates to a silicon carbide and silicon particle reinforced aluminum-copper based composite material and a preparation method thereof, and belongs to the field of the particle reinforced metal based composite material. The composite material is composed of the components by the weight percentage: 15-25 wt.% of silicon carbide, 45-50 wt.% of silicon and 25-40wt.% of an aluminum-copper alloy; the silicon carbide and silicon particles as a reinforcement phase are uniformly distributed in the aluminum-copper alloy matrix, and the aluminum-copper alloy matrix forms a three-dimensional reticular structure. A powder metallurgy method is used for preparation. The obtained aluminum based composite material has uniform structure, is fully dense, has the comprehensive performance of light weight, low expansion, high modulus, high strength, resistance to space radiation environment, easy processing and the like, is suitable for use in space environments, and can be used as related component materials in the aviation and aerospace fields.

Owner:有研金属复材技术有限公司

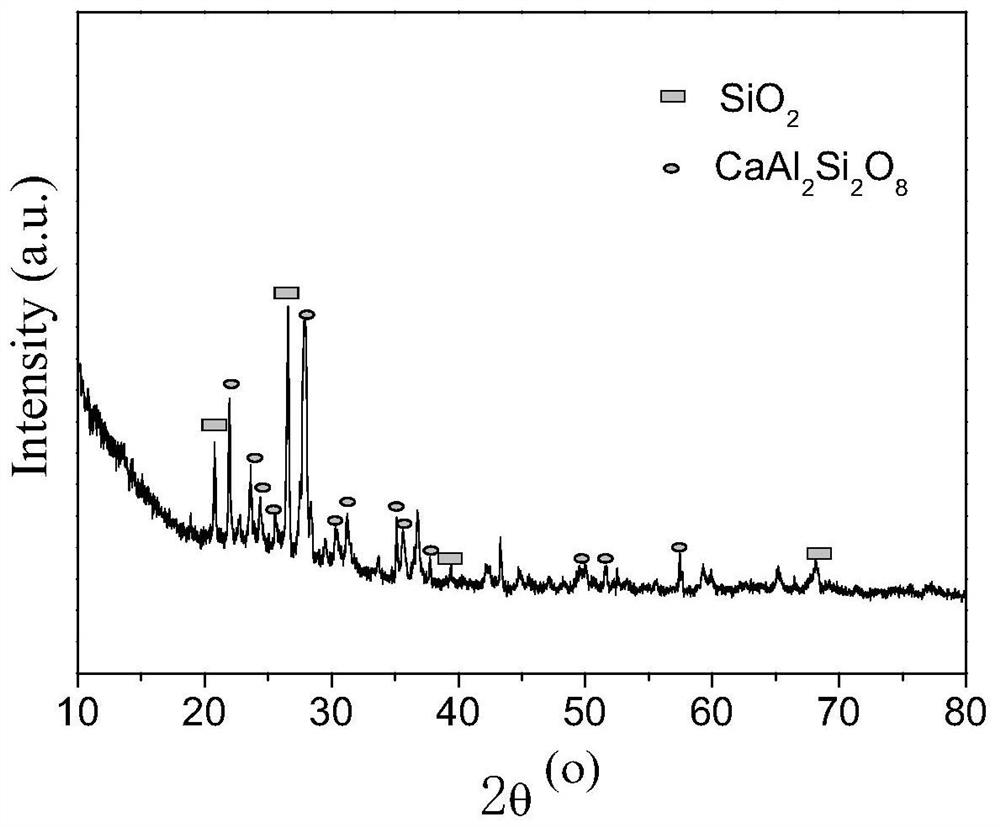

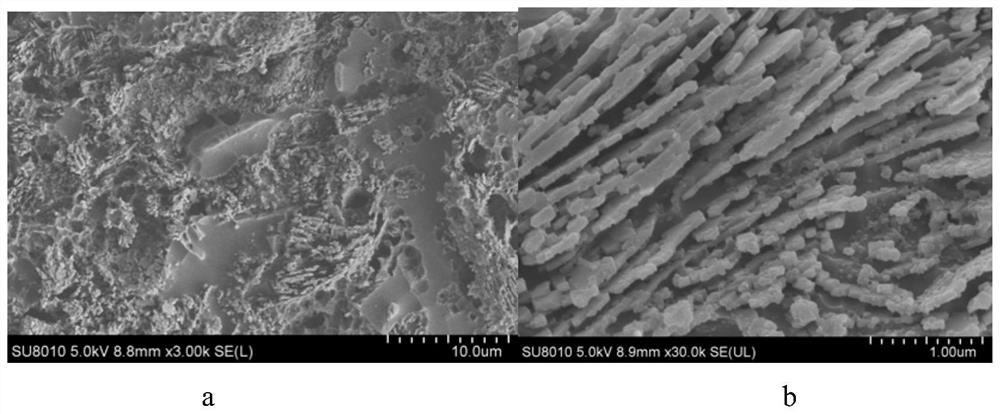

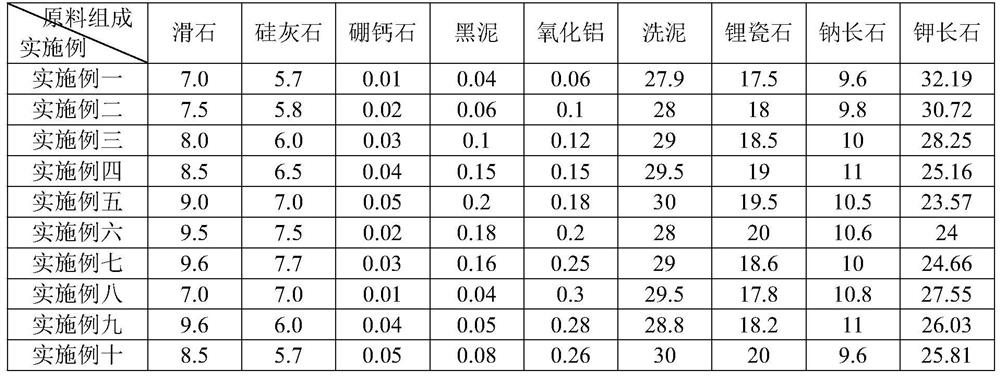

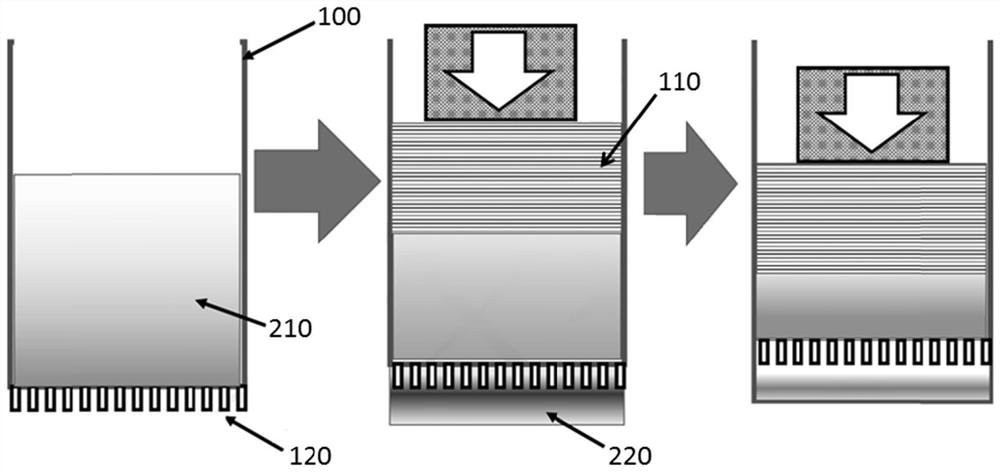

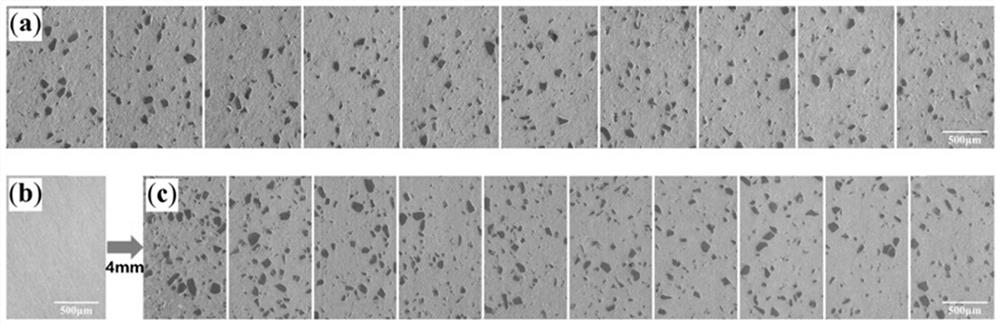

High-performance ceramic rock plate and preparation method thereof

The invention discloses a high-performance ceramic rock plate, which is prepared from the following raw materials in percentage by weight: 7.0 to 9.6 percent of talc, 5.7 to 7.7 percent of wollastonite, 0.01 to 0.05 percent of borocalcite, 0.04 to 0.2 percent of black mud, 0.06 to 0.3 percent of aluminum oxide, 27.9 to 30 percent of washing mud, 17.5 to 20 percent of lithium chinastone, 9.6 to 11 percent of albite and 24 to 32.19 percent of potassium feldspar. In addition, the invention further discloses a preparation method of the high-performance ceramic rock plate. Through formula design, a large number of layered anorthite crystals are separated out from a system, and the thermal expansion coefficient with a glass phase can be reduced by regulating and controlling the anorthite / quartz crystal phase proportion and increasing the anorthite content, so that internal stress formed in the cooling process is avoided, and the problems that a rock plate product is prone to cracking and edge breakage, high in splicing difficulty and the like are effectively solved; and the purpose of easy processing is achieved while good stability is achieved. The preparation method disclosed by the invention is based on a general traditional ceramic glaze and a ceramic production process, and has a promotion effect on technical progress and application development of the architectural ceramic industry.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Metal-based composite material as well as preparation method and application thereof

PendingCN114369750ASimple designImprove thermal deformationSemiconductor/solid-state device detailsSolid-state devicesThermal dilatationGradient material

The invention provides a metal-based composite material and a preparation method and application thereof. According to the metal-based composite material disclosed by the invention, the reinforcement particles are distributed in the metal matrix in a gradient manner, so that the metal-based composite material has excellent comprehensive performance, including relatively high heat conductivity coefficient, adjustable thermal expansion coefficient, relatively high hardness, relatively low density and good and long-term stable performance, and is an ideal heat dissipation packaging material. According to the metal-based composite material, in the metal-based composite material, the reinforcement particles are distributed in the metal matrix in a gradient mode, the gradient material can relieve the internal thermal stress of the material under the cyclic change of the high-temperature and low-temperature environment, and the failure of electronic components due to the thermal problem can be solved. For example, a silicon carbide aluminum-based composite material (SiCp / Al) with a high volume fraction ratio has excellent comprehensive performance, including relatively high heat conductivity coefficient, adjustable thermal expansion coefficient, relatively high hardness and relatively low density, and is an ideal material in the field of electronic packaging.

Owner:深圳市知行新材料科技有限公司

Method for preparing polyimide film

ActiveCN110272549AAdjust the coefficient of thermal expansionEffective adjustment of thermal expansion coefficientPolymer scienceMolecular materials

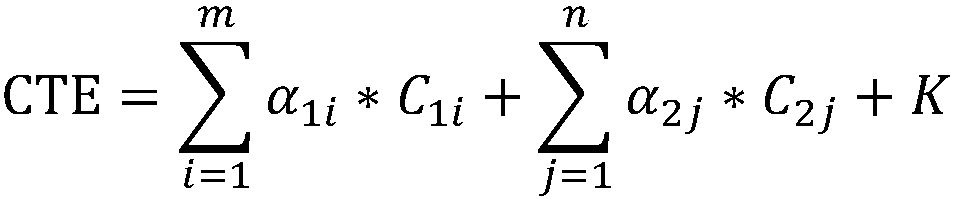

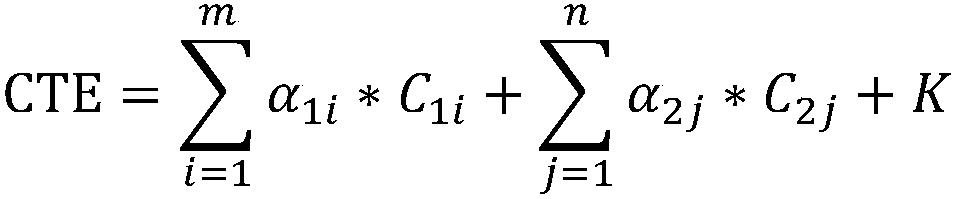

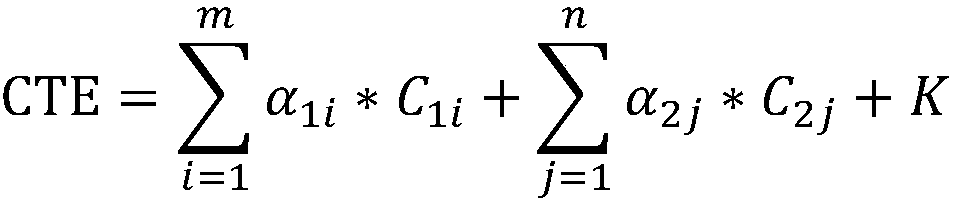

The invention relates to the field of high-molecular materials, and concretely relates to a method for preparing a polyimide film. The method comprises the following steps: (1) selecting at least one diamine monomer and at least one dianhydride monomer, and adjusting the molar ratio of the diamine monomer to the dianhydride monomer according to a calculating formula in order to obtain the moles of the diamine monomer and the dianhydride monomer when a target thermal expansion coefficient is achieved; and (2) reacting the selected diamine and dianhydride monomers in a solvent according to the above moles to obtain a polyamic acid solution, and performing film formation and imidization on the polyamic acid solution to obtain the polyimide film. The method of the invention adopts a structure containing a hydrogen bond, the dianhydride and diamine monomers are selected, and the ratio of the two monomers is adjusted to effectively adjust the thermal expansion coefficient of the polyimide film, so the obtained polyimide film has excellent mechanical performances and high-temperature application performances, and has the thermal expansion coefficient matching with an adhered substrate to avoid the deformation and curling of the polyimide film due to the difference in thermal expansion coefficients.

Owner:BEIJING UNIV OF CHEM TECH

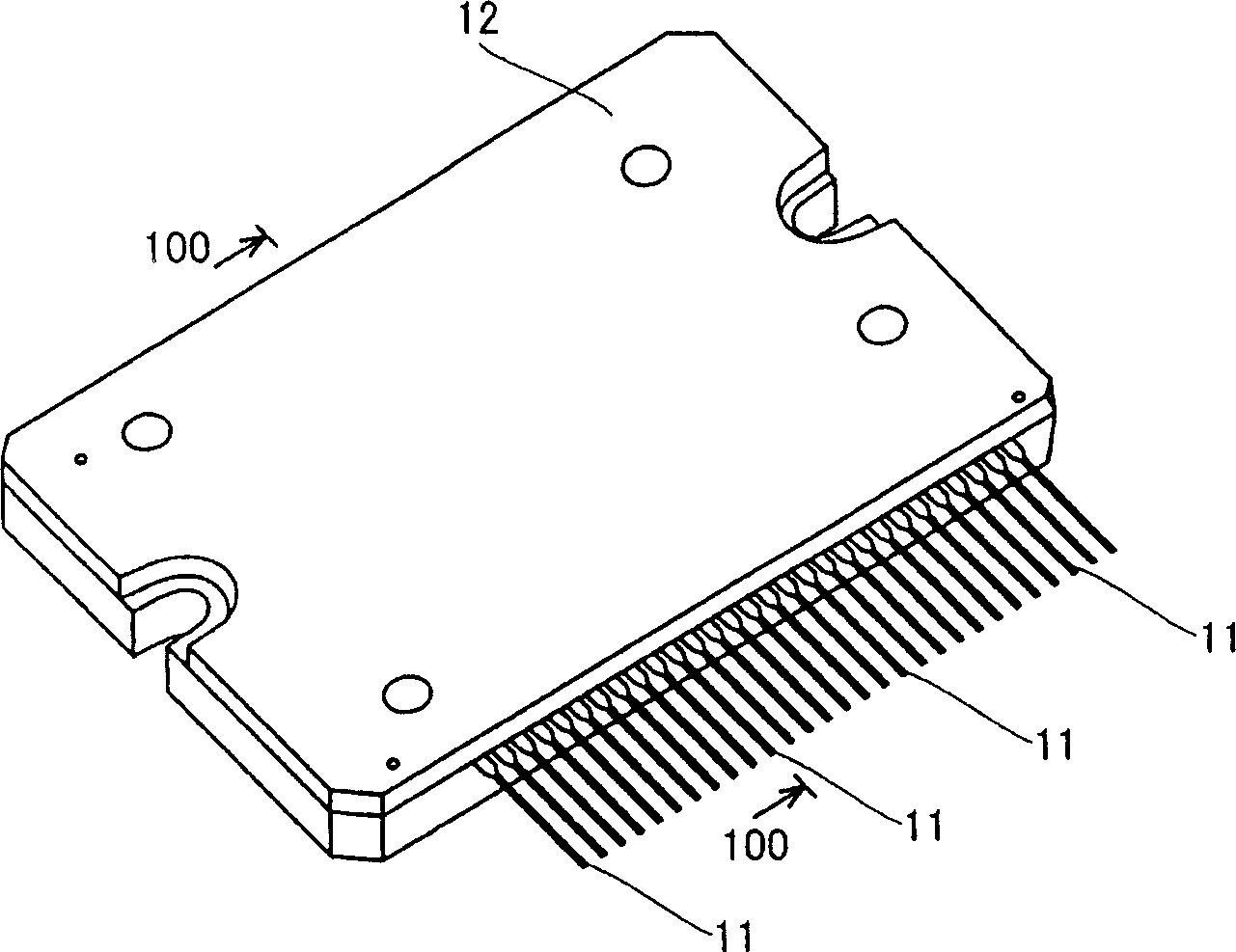

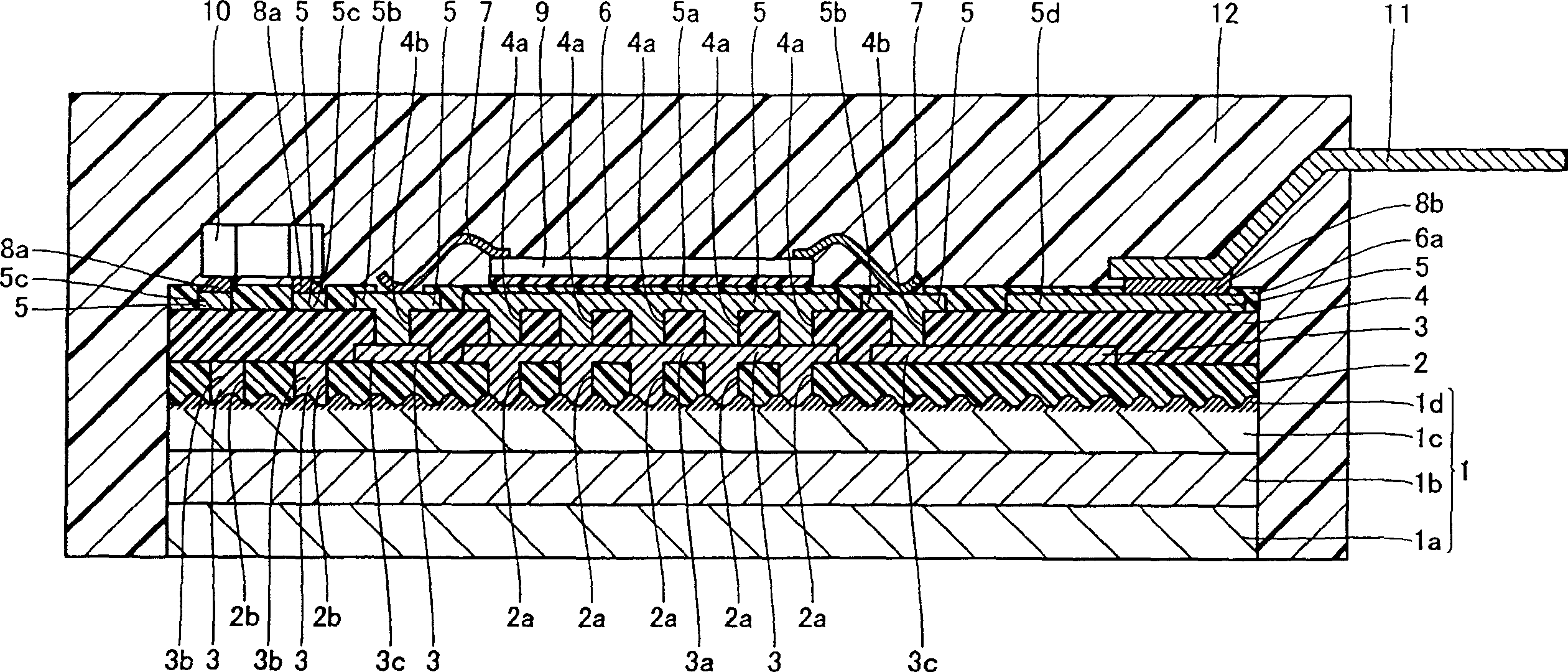

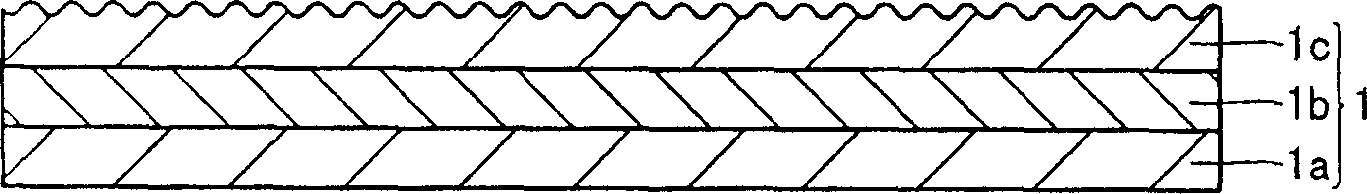

Circuit device

InactiveCN1702863AControllable coefficient of thermal expansionInhibition of peeling phenomenonInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsThermal expansionMaterials science

A circuit device that inhibits peeling of an insulating layer from a substrate. The circuit device includes: a substrate, which is mainly made of metal containing a first metal layer, a second metal layer, and a third metal layer, wherein the first metal layer has a first thermal expansion coefficient, and the second metal layer is formed on the first metal layer. On the metal layer and having a second thermal expansion coefficient, a third metal layer is formed on the second metal layer and has a third thermal expansion coefficient; an insulating layer formed on the substrate; a conductive layer formed on the insulating layer; circuit element , which is electrically connected to the conductive layer.

Owner:SANYO ELECTRIC CO LTD

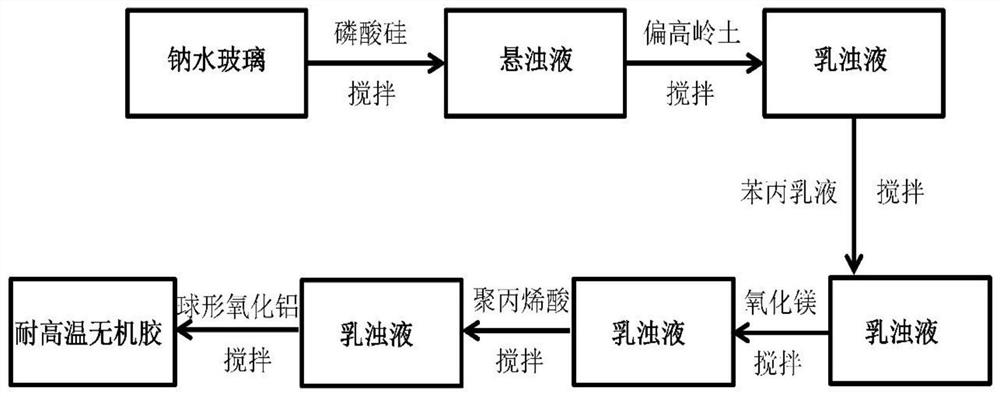

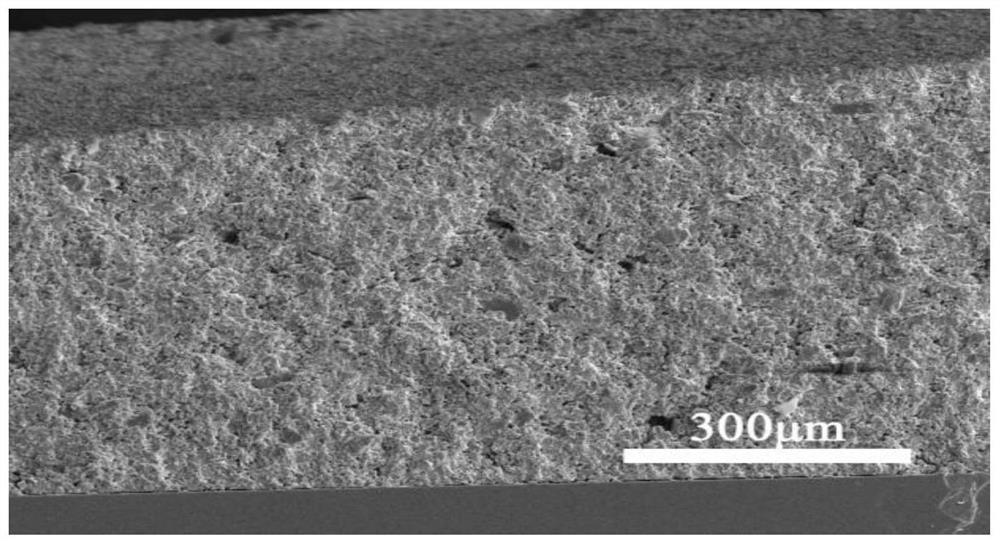

High-temperature-resistant inorganic adhesive and preparation method thereof

ActiveCN113121193ALow curing temperatureShorten the timeSemiconductor/solid-state device detailsSolid-state devicesAdhesivePhosphate

The invention discloses a high-temperature-resistant inorganic adhesive and a preparation method thereof. The high-temperature-resistant inorganic adhesive contains sodium water glass, meta-kaolin, silicon phosphate, styrene-acrylic emulsion, magnesium oxide, polyacrylic acid and spherical aluminum oxide. The high-temperature-resistant inorganic adhesive provided by the invention has the advantages of low curing temperature, safety and environmental protection, can tolerate the high temperature of 300 DEG C or above for a long time, can have good adhesive property with ceramics in the range of normal temperature to 300 DEG C, has good water resistance and acid and alkali resistance, has a compact cured body structure, and can isolate air and moisture permeation.

Owner:武汉利之达科技股份有限公司

Tough and invisible bullet-proof glass

InactiveCN104527162AImprove impact performanceGood dimensional stabilitySynthetic resin layered productsGlass/slag layered productsGlass fiberPolyethylene terephthalate glycol

The invention discloses a piece of tough and invisible bullet-proof glass which comprises a bearing layer, a bullet-proof layer and an outer protecting layer which are adhered from inside to outside in sequence, wherein a layer of liquid crystal dimming membrane is added between the bullet-proof layer and the outer protecting layer; the bullet-proof layer is made of polyethylene glycol terephthalate layer; the outer protecting layer is a glass fiber layer; the thickness of the bullet-proof glass is within 3-8mm. The tough and invisible bullet-proof glass disclosed by the invention is very high in stability and high-strength high breakage toughness, and can be widely applied to bullet-proof transparent window of aircrafts and ground vehicles.

Owner:SUZHOU KUANWEN ELECTRONICS SCI & TECH

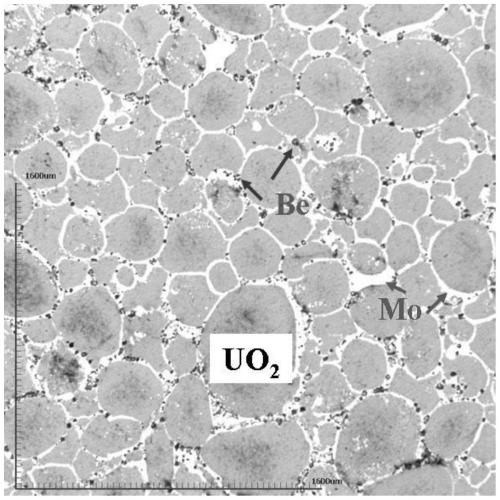

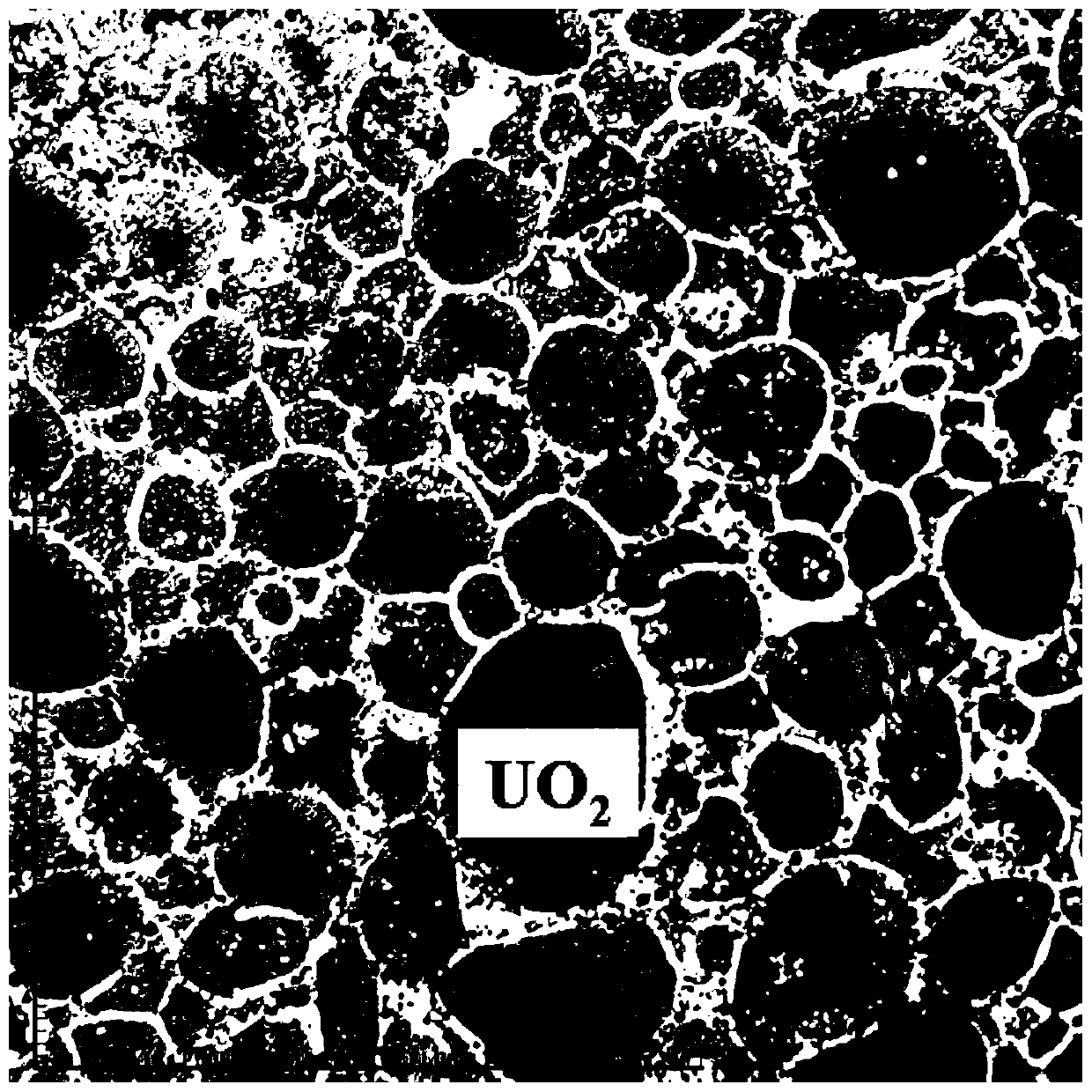

Uranium dioxide-based fuel pellet with adjustable thermal expansion coefficient and enhanced thermal conductivity, and preparation method thereof

ActiveCN111145926AImprove thermal conductivityStable serviceNuclear energy generationTransportation and packagingThermal dilatationUranium oxide

The invention discloses a uranium dioxide-based fuel pellet with an adjustable thermal expansion coefficient and enhanced thermal conductivity, and a preparation method thereof. According to the preparation method, metal beryllium (Be) with high thermal conductivity and high thermal expansion coefficient and metal molybdenum (Mo) with high thermal conductivity and a low thermal expansion coefficient are added into a uranium dioxide pellet matrix, the component ratio of Be / Mo is regulated and controlled, the densified fuel pellet is sintered at a high temperature, so that the thermal conductivity of the uranium dioxide fuel pellet is enhanced, the thermal expansion coefficient of the uranium dioxide pellet is adjusted, the residual thermal stress of the fuel pellet is reduced, and the service cycle of the fuel pellet is prolonged so as to meet the harsh reactor work design requirements of the cladding-pellet fuel element under the normal work condition and the accident work condition ofthe reactor, improve the safety and the economy of the existing commercial pressurized water reactor, effectively delay the closing time of the air gap between the cladding and the fuel pellet underthe accident condition and delay the mechanical interaction between the fuel and the cladding to substantially improve the safety margin of the reactor under the accident condition.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

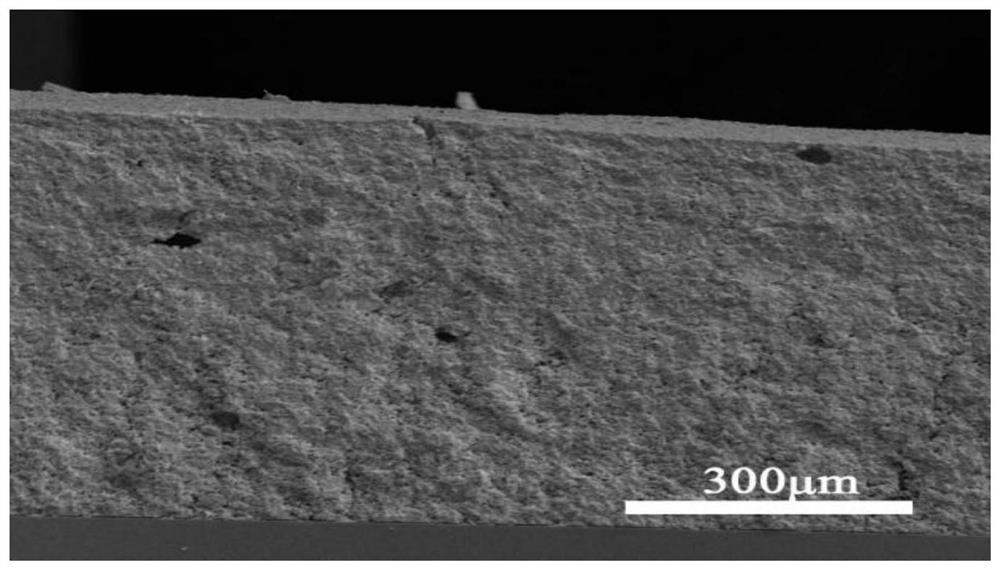

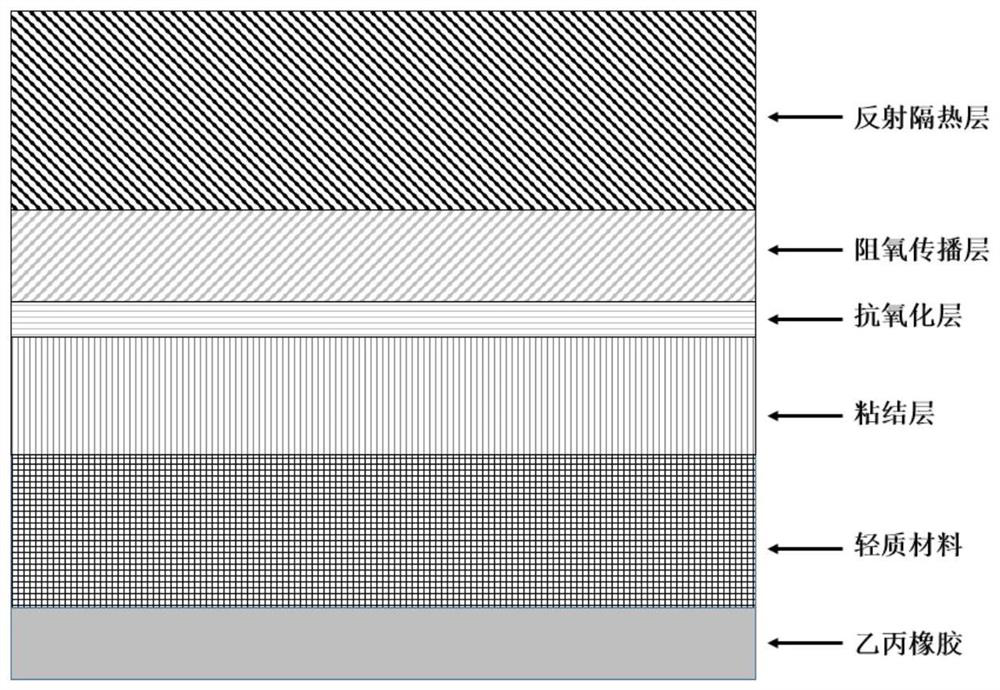

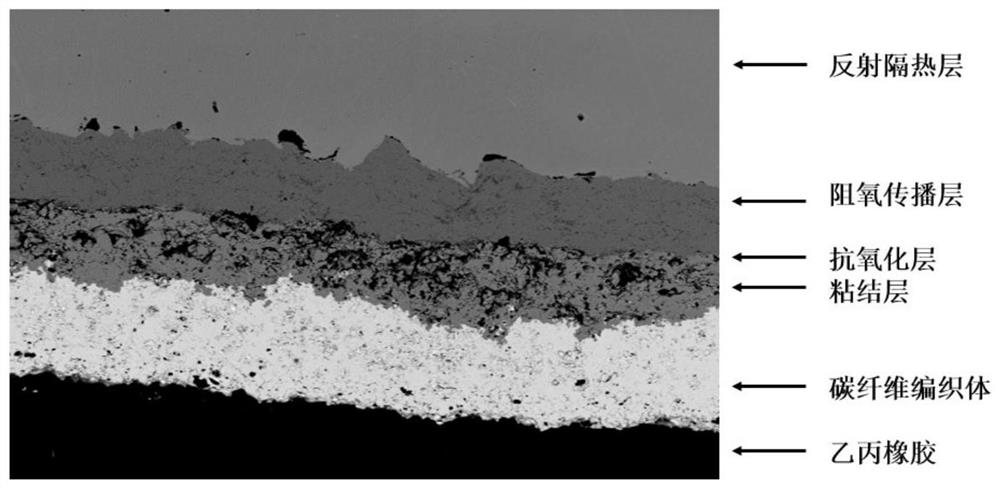

Fire disaster low-altitude flight rescue unmanned aerial vehicle fuselage light material surface coating and preparation method thereof

ActiveCN113981381AIncrease temperatureImprove antioxidant capacityMolten spray coatingVacuum evaporation coatingThermal dilatationThermal break

The invention discloses a fire disaster low-altitude flight rescue unmanned aerial vehicle fuselage light material surface coating and a preparation method thereof. The coating comprises a bonding layer, an anti-oxidation layer, an oxygen propagation prevention layer and a reflective thermal insulation layer. The preparation method comprises the following steps: selecting a material with a thermal expansion coefficient similar to that of a light material, and preparing a bonding layer on the surface of the light material; heating and oxidizing the bonding layer, so that a compact oxidation film is generated on the surface of the bonding layer to form an anti-oxidation layer; preparing an oxygen propagation prevention layer on the surface of the anti-oxidation layer by using a ceramic material; and preparing a reflective thermal insulation layer on the surface of the oxygen propagation prevention layer by using the ceramic material. According to the invention, the coating has a matched thermal expansion coefficient with a light fuselage material of the unmanned aerial vehicle, and the unmanned aerial vehicle fuselage has oxidation resistance by combining extremely low thermal conductivity, high reflectivity and extremely strong oxygen transmission resistance of each layer of material in the coating, so that the working temperature of the unmanned aerial vehicle is increased, and it is ensured that the unmanned aerial vehicle can be used in fire disaster rescue and can be used for a long time.

Owner:KUNMING UNIV OF SCI & TECH

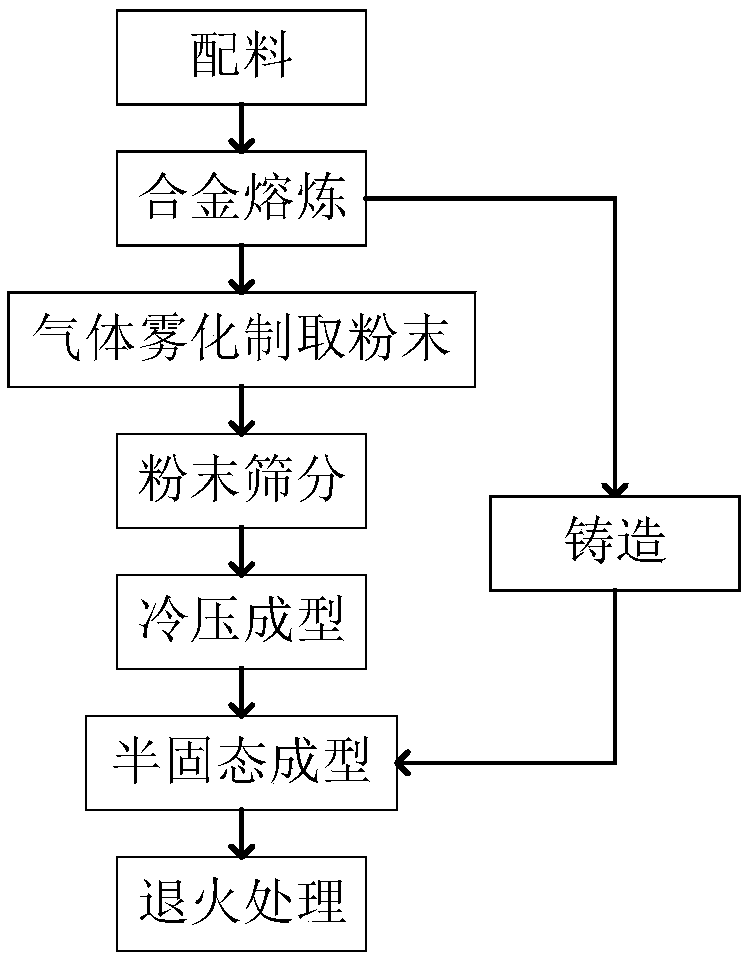

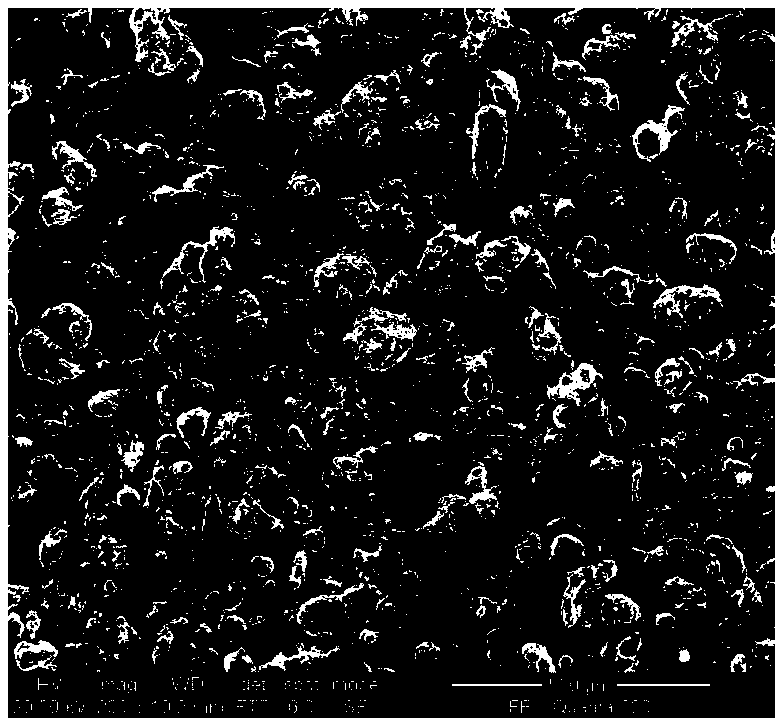

Preparation method of aluminum-silicon composite material for electronic packaging

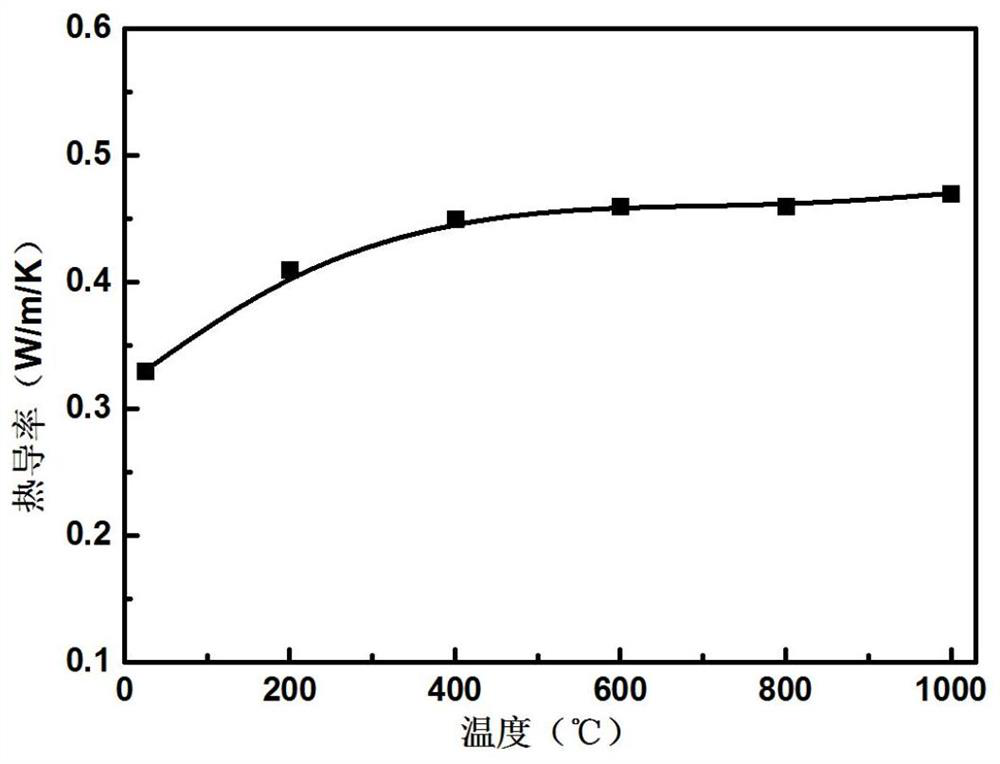

InactiveCN108866360AControllable coefficient of thermal expansionHigh thermal conductivitySilicon alloySemi solid

The invention discloses a preparation method of an aluminum-silicon composite material for electronic packaging. The preparation method is characterized by comprising the following steps of S1, preparing pure aluminum and pure silicon, and smelting aluminum-silicon alloy to obtain an aluminum-silicon alloy melt; S2, performing gas atomization powder preparation on the aluminum-silicon alloy melt,and sieving powder to obtain aluminum-silicon alloy powder; S3, performing cold briquetting on the aluminum-silicon alloy powder to obtain an aluminum-silicon alloy green compact; S4, performing semi-solid forming on the aluminum-silicon alloy green compact after cold pressing to obtain an aluminum-silicon composite material; and S5, performing annealing treatment on the aluminum-silicon compositematerial. The aluminum-silicon composite material for electronic packaging prepared by the method is fine in silicon phase size, is passivated in silicon phase corner angle, is uniformly distributedin an aluminum matrix and has good microstructure characteristics and comprehensive properties.

Owner:长沙博朗思达新材料科技有限公司

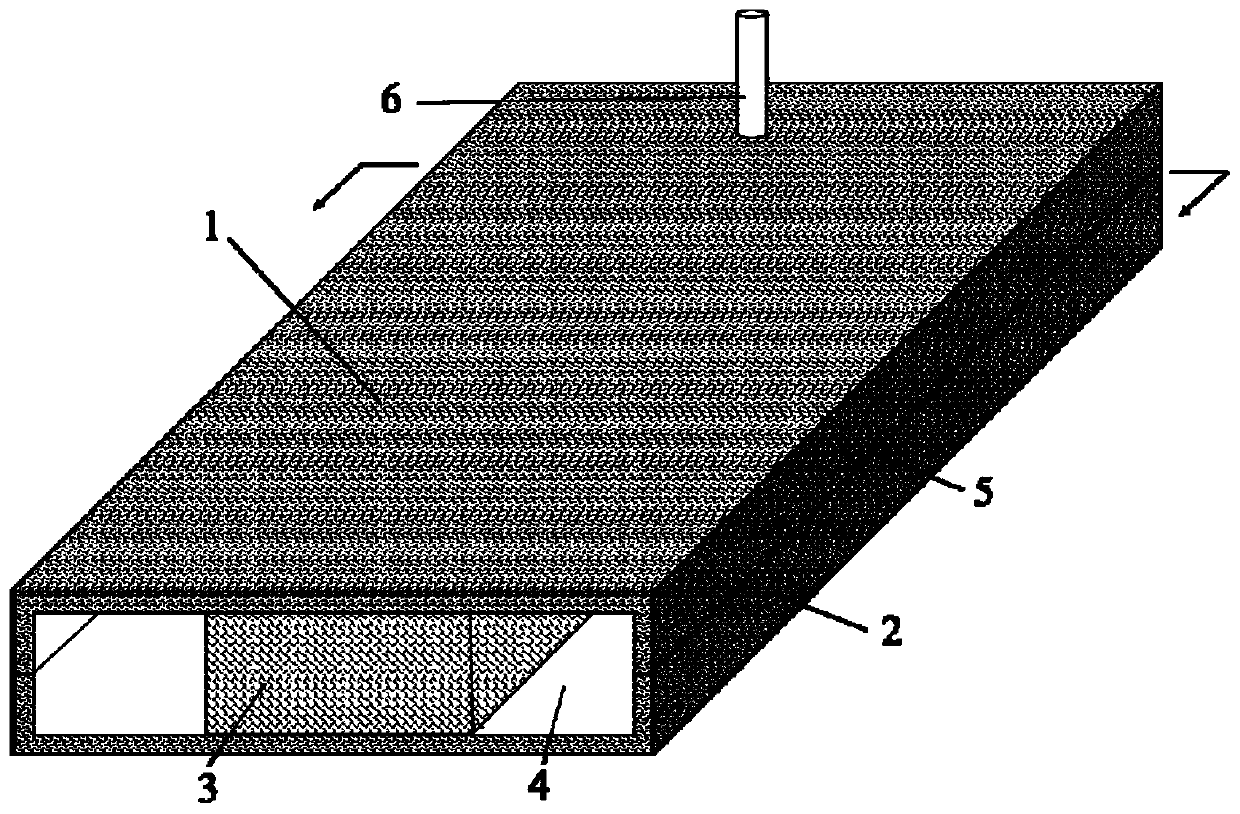

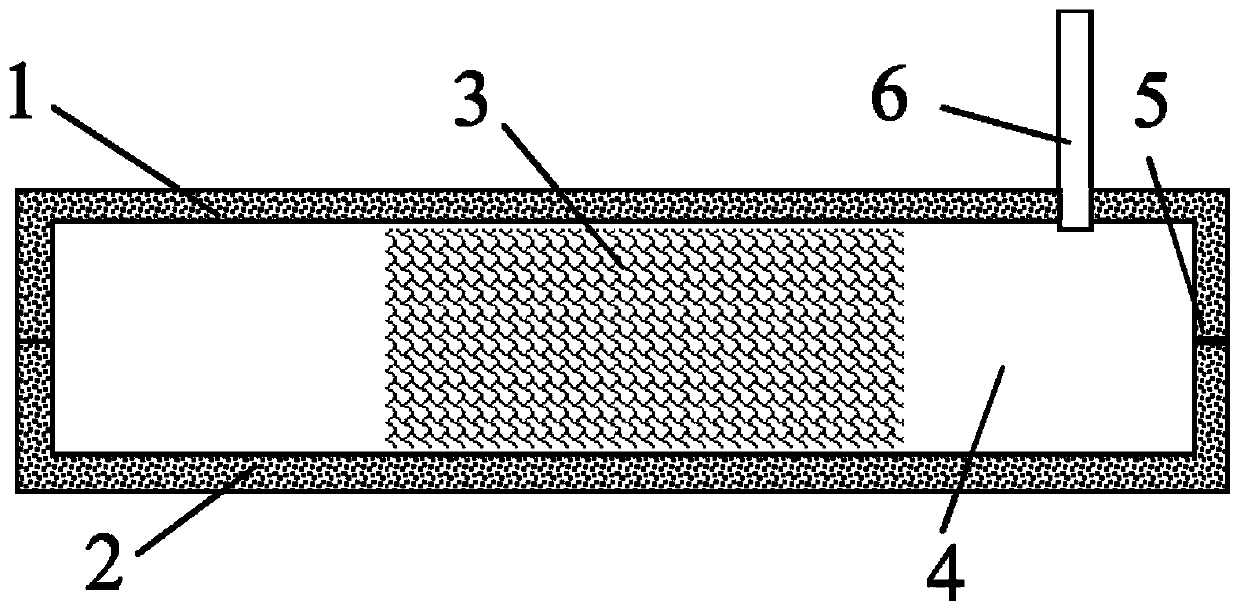

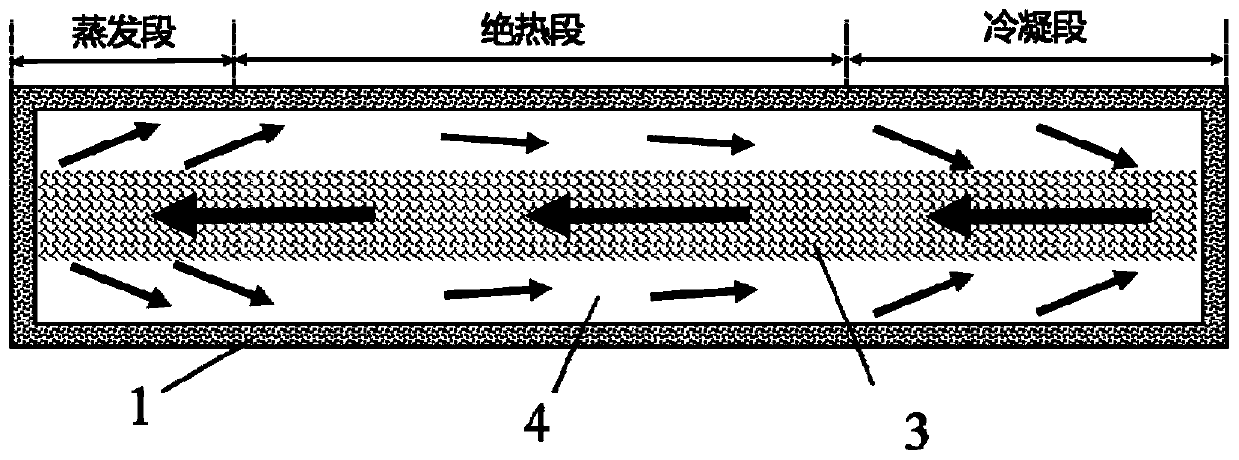

Metal-based composite material device based on gas-liquid phase change and preparation method of metal-based composite material device

ActiveCN110944493AHigh thermal conductivityReduce shell thicknessModifications using liquid coolingThermal dilatationPorous medium

The invention relates to a metal-based composite material device based on gas-liquid phase change and a preparation method thereof. The composite material device comprises a metal tube shell forming aclosed cavity, and a porous medium layer arranged in the middle of the metal tube shell and soaked with a liquid working medium, wherein the porous medium layer is arranged in the metal tube shell, the liquid filling port is arranged at one end outside the metal tube shell and connected with the porous medium layer, a heat source device can be arranged at the other end outside the metal tube shell, the liquid working medium can generate gas-liquid phase change after being heated, and the porous medium layer divides a closed cavity of the metal tube shell into two steam channels. Compared withthe prior art, the invention effectively solves the problem that the traditional single metal or ceramic heat dissipation material is difficult to consider the requirements of high thermal conductivity, controllable thermal expansion coefficient and high comprehensive mechanical properties at the same time, and provides a new direction for the development of high-power density devices.

Owner:SHANGHAI JIAO TONG UNIV

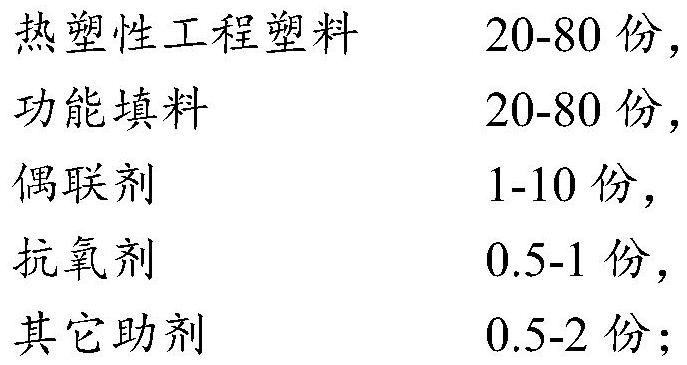

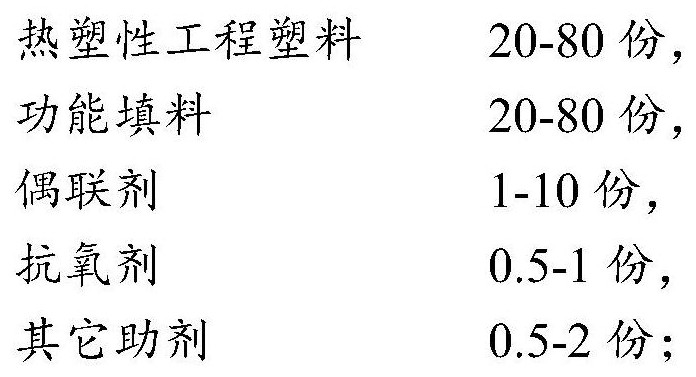

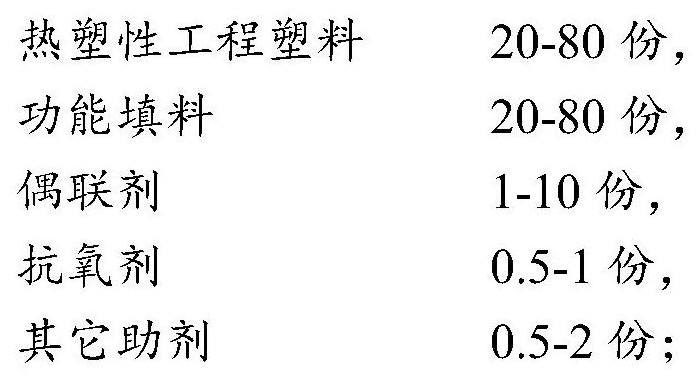

Thermoplastic composite material, preparation method thereof and high-precision plastic part

ActiveCN111849161AImprove heat resistanceSmall coefficient of thermal expansionThermal dilatationEngineering plastic

The embodiment of the invention provides a thermoplastic composite material taking engineering plastic as a matrix. The composite material is prepared from the following components in parts by weight:20-80 parts of thermoplastic engineering plastic, 20-80 parts of functional filler, 1-10 parts of coupling agent, 0.5-1 part of antioxidant and 0.5-2 parts of other auxiliaries, the functional filleris prepared from 0-80 parts of negative thermal expansion material and 0-80 parts of silicon dioxide microbeads, and the total weight part of the thermoplastic engineering plastic and the functionalfiller is 100 parts. The thermoplastic composite material has an extremely low linear thermal expansion coefficient, good heat resistance and high stability, can be used for preparing high-precision structural parts such as optical communication and 5G equipment, and improves the long-term operation precision of precision equipment products. The embodiment of the invention also provides a preparation method of the composite material and a high-precision plastic part.

Owner:HUAWEI TECH CO LTD

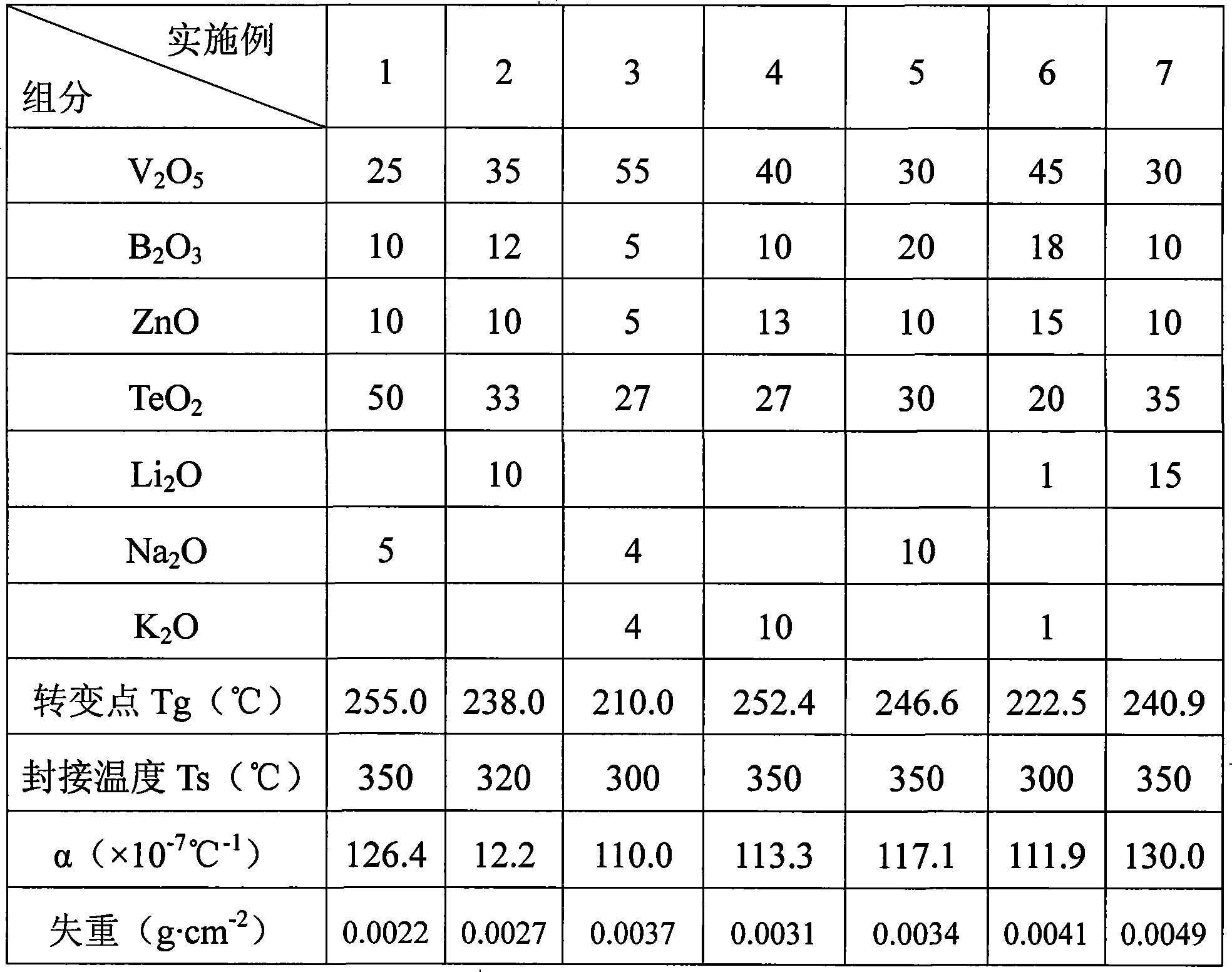

Vanadates leadless low-temperature sealing glass material and method for preparing same

The invention relates to a vanadate-system lead-free low temperature sealing glass material and a preparation method thereof. The components of the sealing glass material by mol percentage are as follows: 25 percent to 55 percent of V2O5, 5 percent to 20 percent of B2O3, 5 percent to15 percent of ZnO, 20 percent to 50 percent of TeO2 and 2 percent to 15 percent of an alkali metal oxide R2O. The preparation method of the invention comprises the steps that vanadium pentoxide, boric acid, zinc oxide, tellurium dioxide and alkali metal carbonate are adopted as raw materials; the weight percentages of the raw materials are calculated according to the mol percentage of each component of the sealing glass; the raw materials are then weighted and evenly mixed to be placed in a corundum crucible and fused under the temperature of 800 to 900 DEG C; molten glass is then cast for formation or ground into powder after being treated with water quenching and the powder is then filtered by a 200-meshsieve. The sealing glass material of the invention contains no toxic and harmful substances such as lead, cadmium, thallium, and the like, and has the advantages of low temperature for sealing, the minimum temperature reaching 300 DEG C, and good chemical stability, and is especially applicable to the sealing of electronic components.

Owner:CHINA JILIANG UNIV

Sol soaked glass wrapped layer soft magnetism composite material and preparation method thereof

ActiveCN102820115BControllable coefficient of thermal expansionControllable change of thermal expansion coefficientInorganic material magnetismThermal expansionSilicon dioxide

Owner:HARBIN INST OF TECH

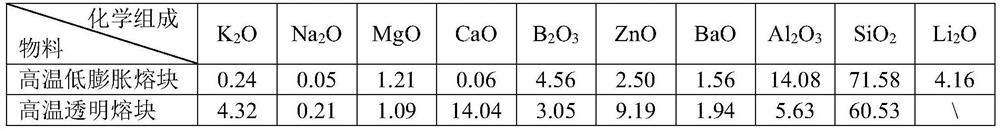

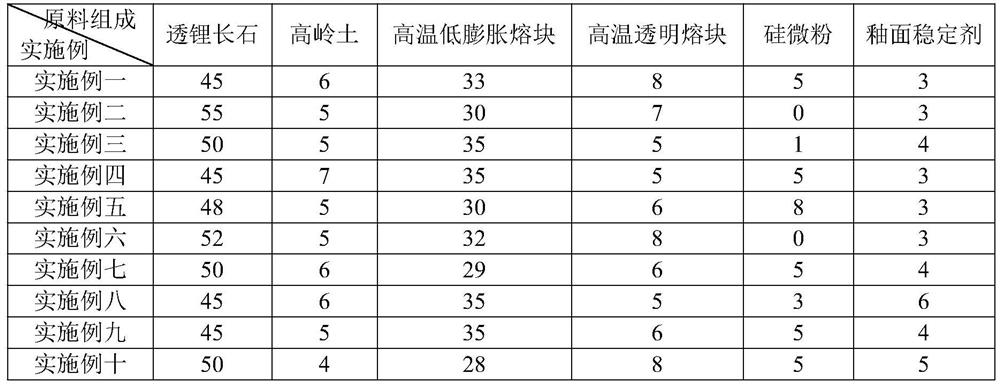

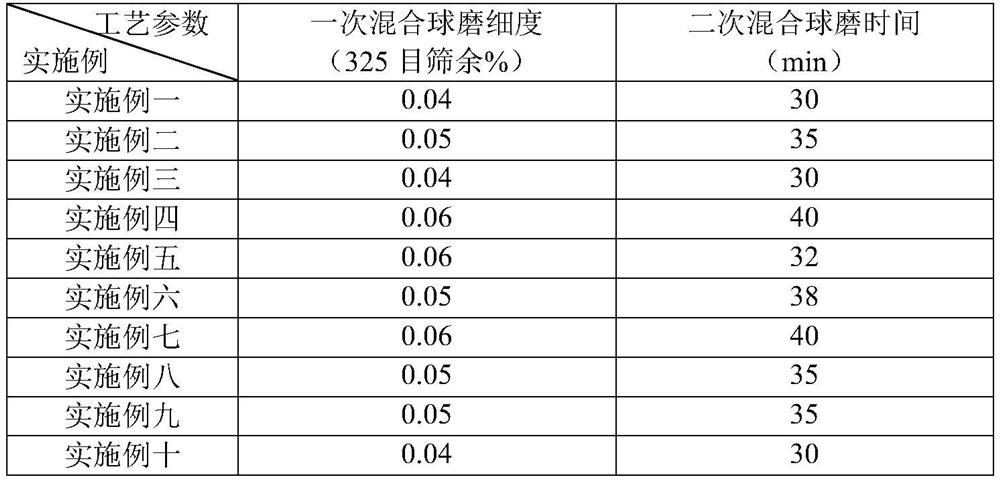

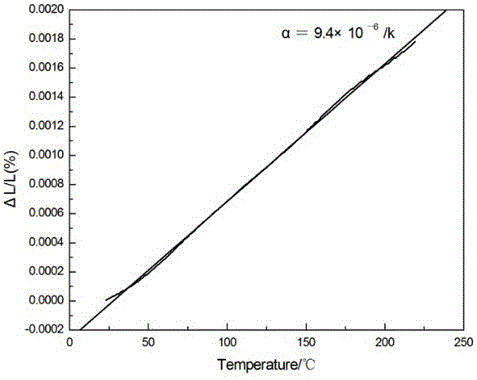

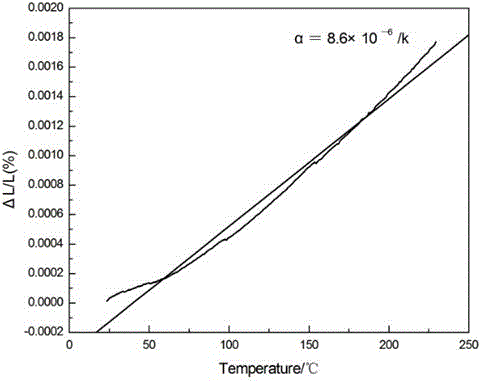

A kind of easy-to-clean milky white glaze suitable for low-expansion ceramics and its preparation method and application

The invention discloses an easy-to-clean milky white glaze suitable for low-expansion ceramics. The raw materials are composed of: petalite feldspar 45-55wt%, kaolin 4-7wt%, high-temperature low-expansion frit 25-35wt%, high-temperature transparent frit Block 5-15wt%, silicon micropowder 0-10wt%, glaze stabilizer 3-6wt%. In addition, the preparation method and application of the above-mentioned easy-to-clean milky white glaze suitable for low-expansion ceramics are also disclosed. The formula system of the invention has a relatively large melting temperature range under the condition of an oxidizing atmosphere, effectively solves defects such as holes in the glaze surface, and achieves the purpose of easy cleaning while having good stability. The preparation method of the present invention is based on the general daily-use ceramic glaze and the production process of daily-use ceramics. It is suitable for various low-expansion ceramic bodies, and especially provides prerequisites for low-expansion ceramic pots used in conjunction with electrical appliances. It can promote the technological progress and application development of the low expansion ceramic industry.

Owner:JINGDEZHEN CERAMIC UNIV

A sic/al with adjustable thermal expansion 2 (wo 4 ) 3 /al composites

ActiveCN104694775BControllable coefficient of thermal expansionSimple processElectronic packagingElectron

The invention belongs to the technical field of composite materials, and specifically relates to a SiC / Al2(WO4)3 / Al composite material with an adjustable thermal expansion. Al is used as a matrix; a low thermal expansion material SiC is used as a reinforcement; meanwhile, a certain amount of Al2(WO4)3 powder is added in for achieving a reduction of the thermal expansion coefficient. Al2(WO4)3 is a negative thermal expansion material that is able to resist a high temperature and is stable in property. On one aspect, Al2(WO4)3 is added in for reducing the thermal expansion coefficient of the original SiC / Al composite material; on the other aspect, Al2(WO4)3 is added in for reducing the content of the highly hard abrasive SiC and increasing the subsequent processing performance of the composite material. The SiC / Al2(WO4)3 / Al composite material with the adjustable thermal expansion is prepared by a powder metallurgy technology. The thermal expansion coefficient of the SiC / Al2(WO4)3 / Al composite material is significantly lower than that of the SiC / Al composite material. Accordingly, the requirement to the thermal expansion coefficient of electronic packaging materials is met better.

Owner:江苏时代华宜电子科技有限公司 +1

Soft magnetic composite with glass xerogel serving as coating layer and method for preparing soft magnetic composite

ActiveCN102789860BControllable coefficient of thermal expansionControllable change of thermal expansion coefficientInorganic material magnetismResonanceThermal expansion

The invention relates to a soft magnetic material and a method for preparing the same, in particular to a soft magnetic composite with glass xerogel serving as a coating layer and a method for preparing the soft magnetic composite. The soft magnetic composite with glass xerogel serving as the coating layer and the method for preparing the soft magnetic composite solve the problems that coefficients of thermal expansion of an inorganic insulating layer and magnetic powder are large in difference and the intrinsic coefficient of thermal expansion of the inorganic insulating layer is unchangeable. The soft magnetic composite with glass xerogel serving as the coating layer is composed of the magnetic powder, a silicon dioxide layer coating the magnetic powder and a glass xerogel layer coating the silicon dioxide layer. The preparation method includes: firstly, preprocessing the magnetic powder; secondly, coating the silicon dioxide layer on the surface of the magnetic powder; thirdly, preparing the glass xerogel; fourthly, coating the glass xerogel layer outside the silicon dioxide layer; fifthly, preparing blanks of the soft magnetic material; and sixthly, preparing the soft magnetic material. The soft magnetic composite with glass xerogel serving as the coating layer and the method for preparing the soft magnetic composite are applicable to the field of switch magnetic resistors, resonance inductors, anti-lock brake sensors, electromagnetic driving devices, brushless direct-current motors, rotary machinery and low-frequency filters.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com