Patents

Literature

171 results about "Microchannel heat sink" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

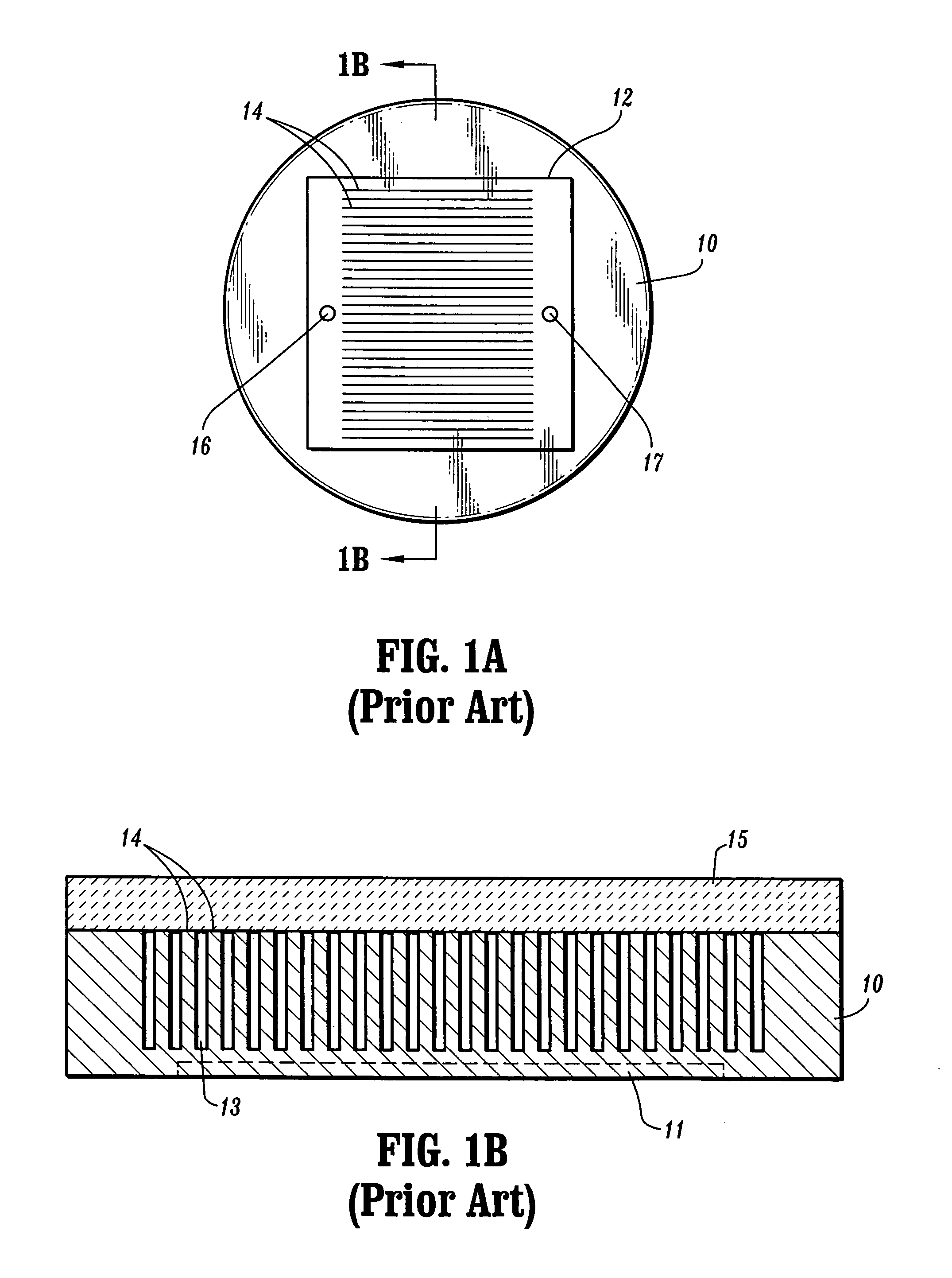

Apparatus and methods for microchannel cooling of semiconductor integrated circuit packages

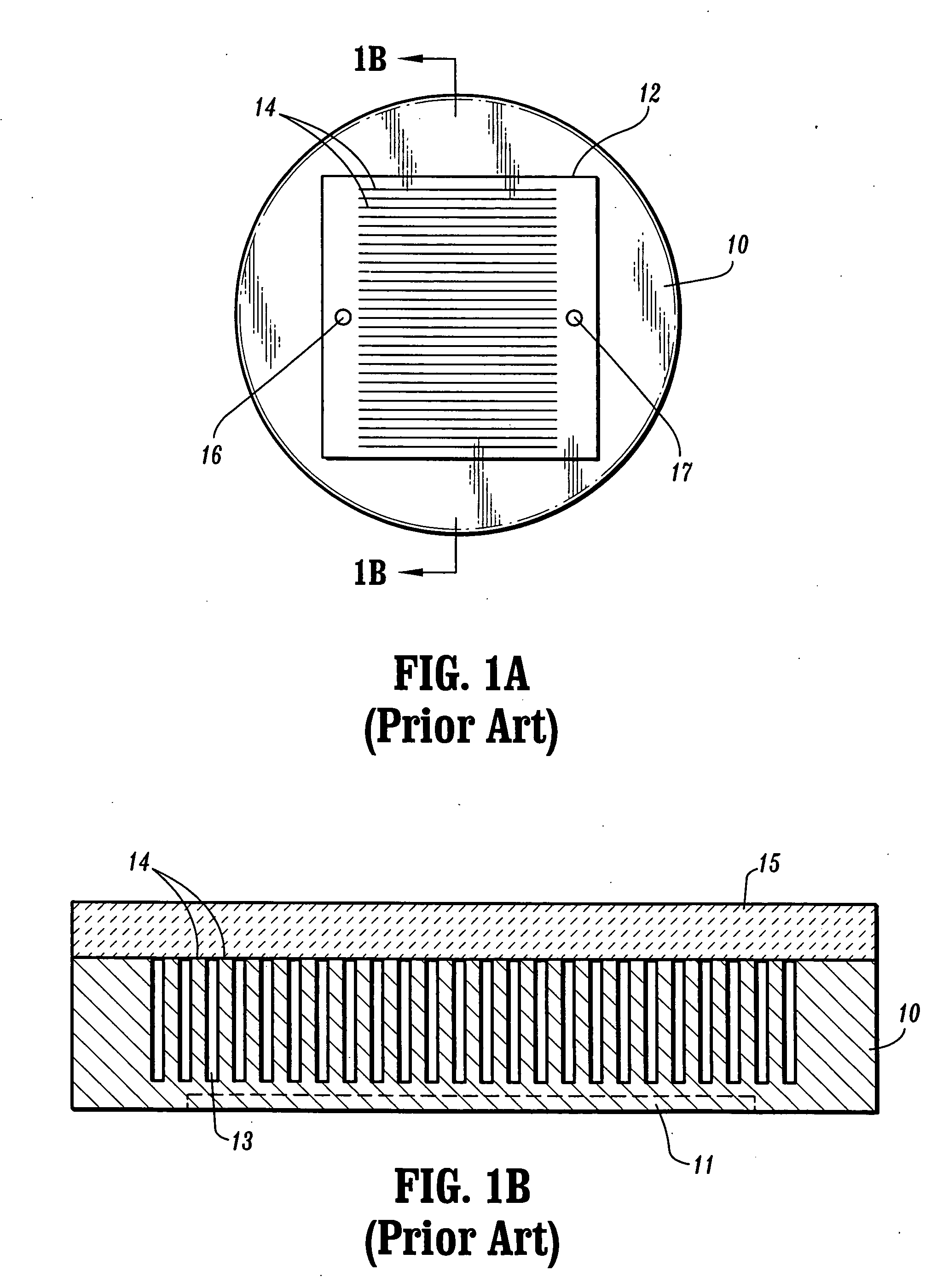

InactiveUS7190580B2Uniform flow and distributionEfficient and low operating pressure microchannel coolingSemiconductor/solid-state device detailsSolid-state devicesCoolant flowEngineering

Owner:INT BUSINESS MASCH CORP

Apparatus and methods for microchannel cooling of semiconductor integrated circuit packages

ActiveUS7139172B2Variable localized coolingImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesCoolant flowEngineering

Owner:GLOBALFOUNDRIES U S INC

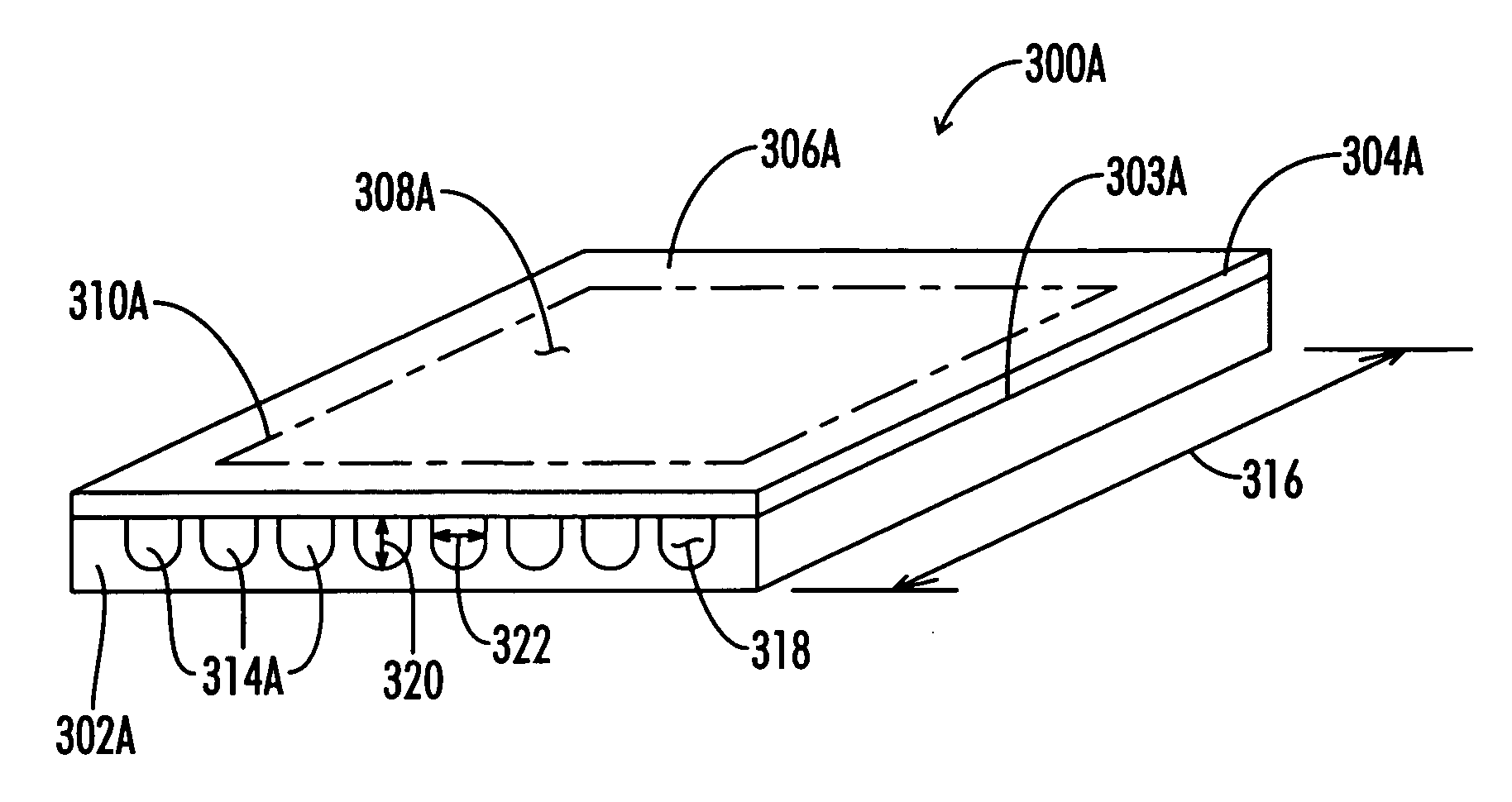

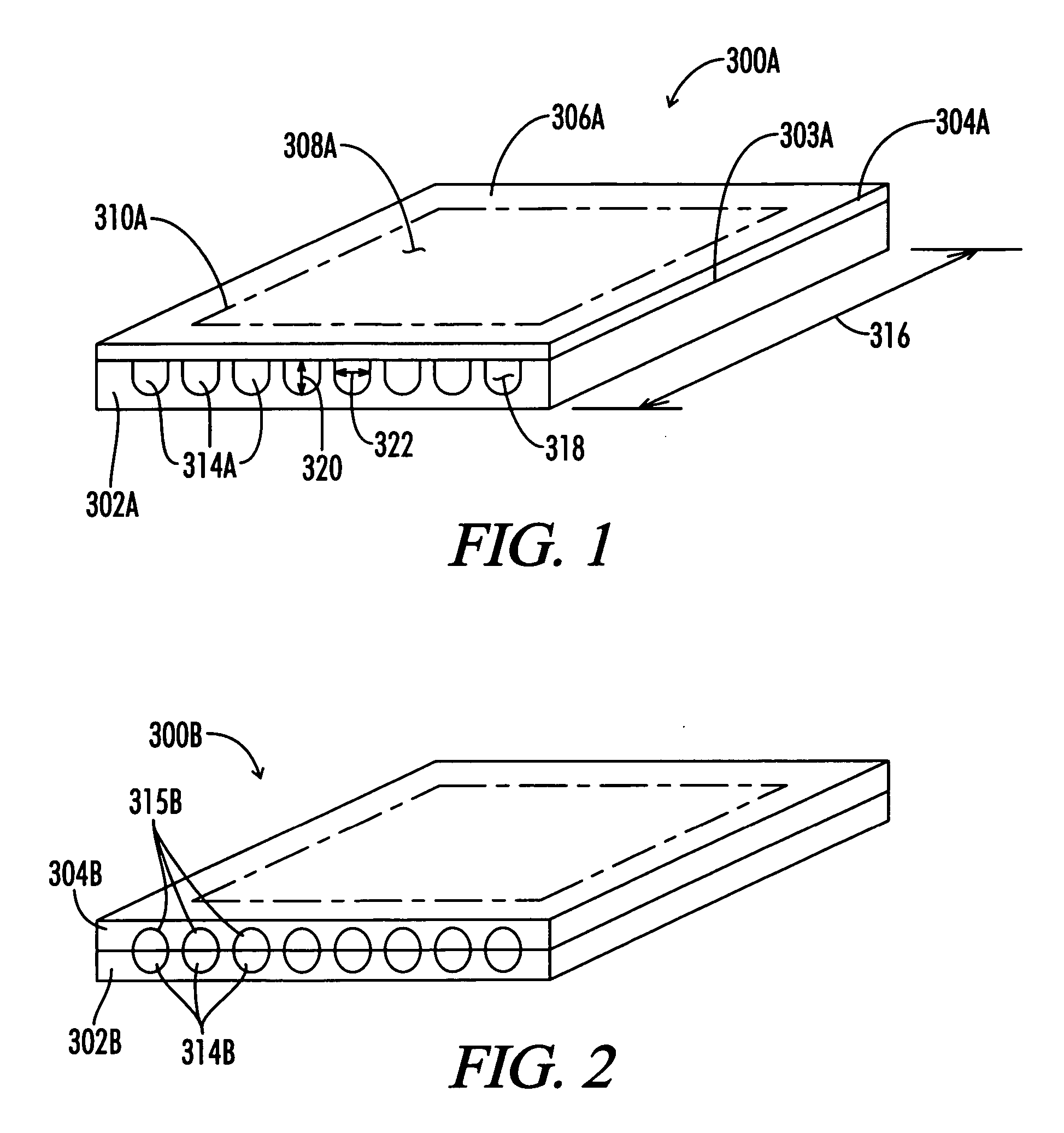

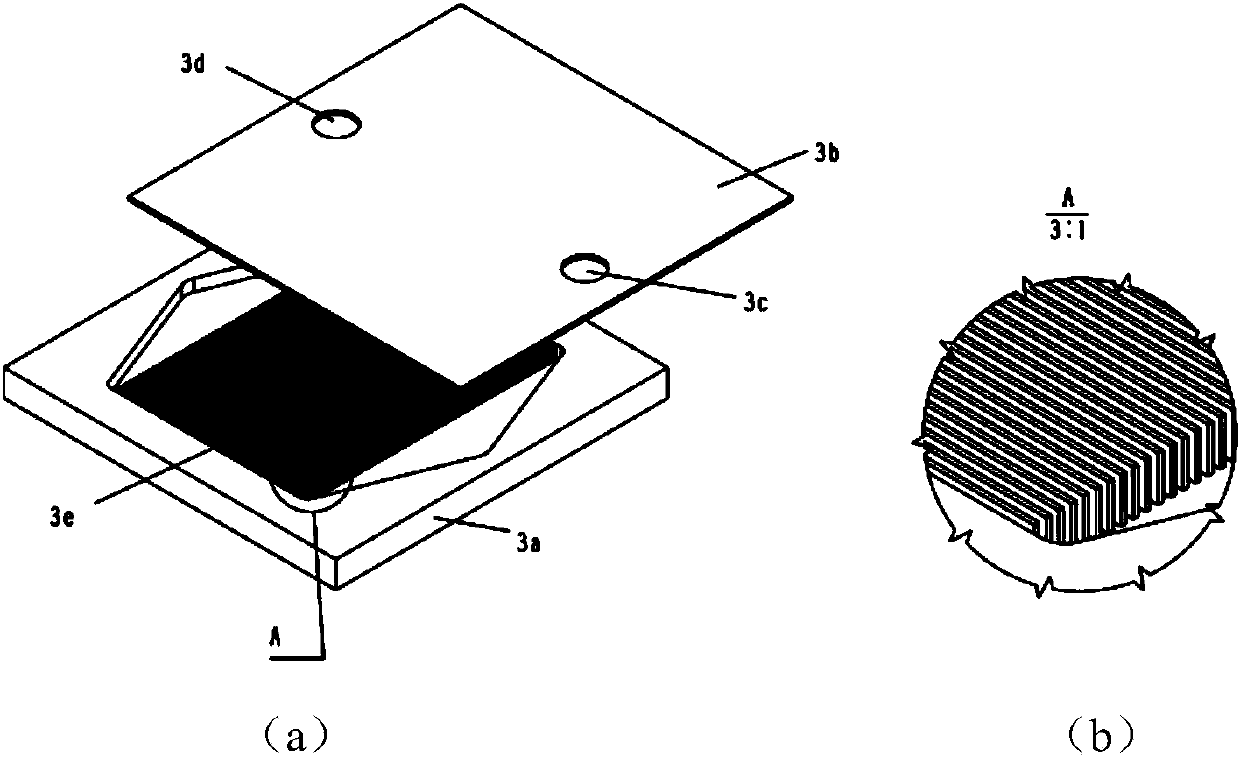

Microchannel heat sink manufactured from graphite materials

InactiveUS20070158050A1Improve thermal conductivityCost-effective manufacturingSemiconductor/solid-state device detailsSolid-state devicesEngineeringGraphite

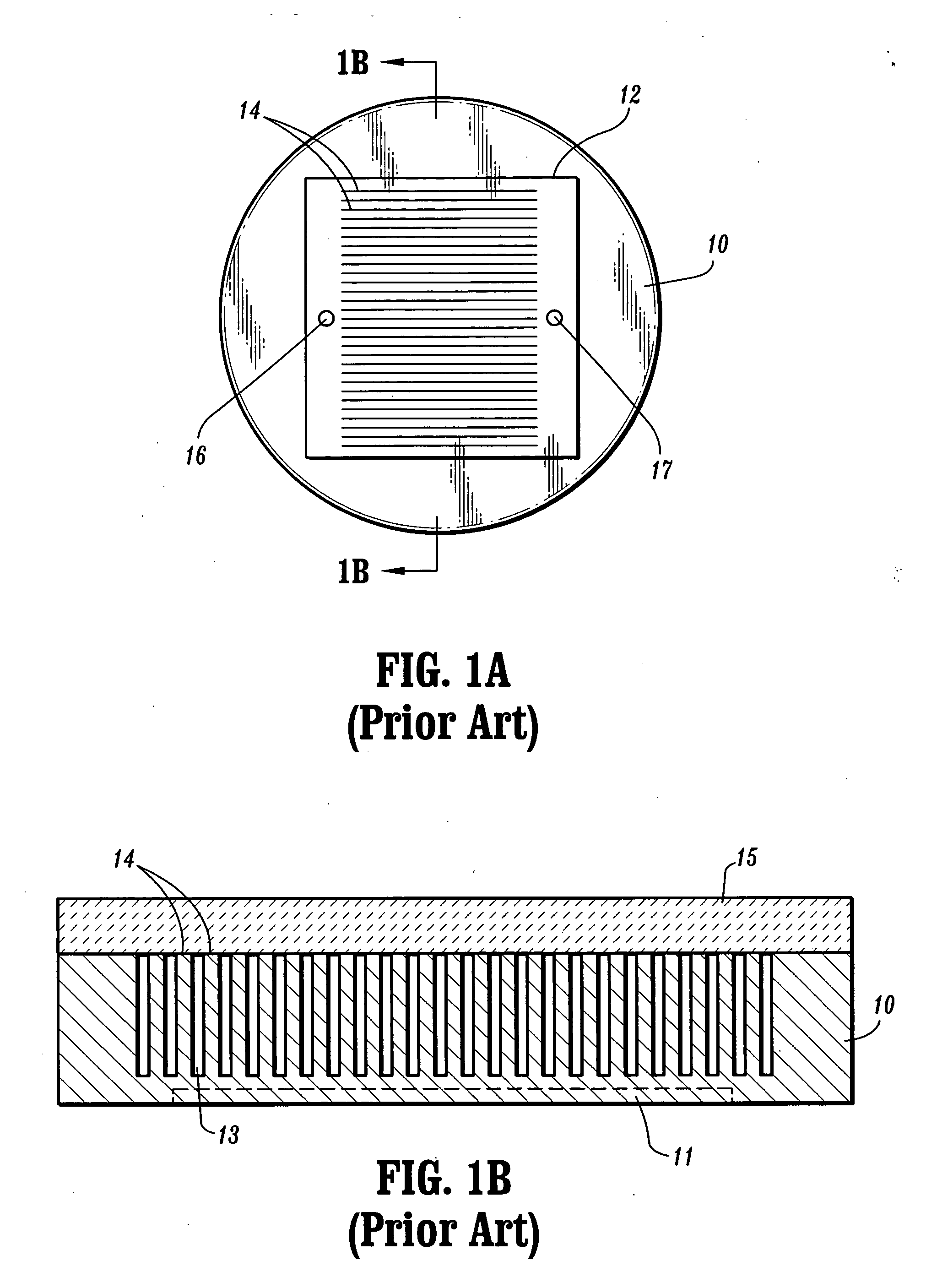

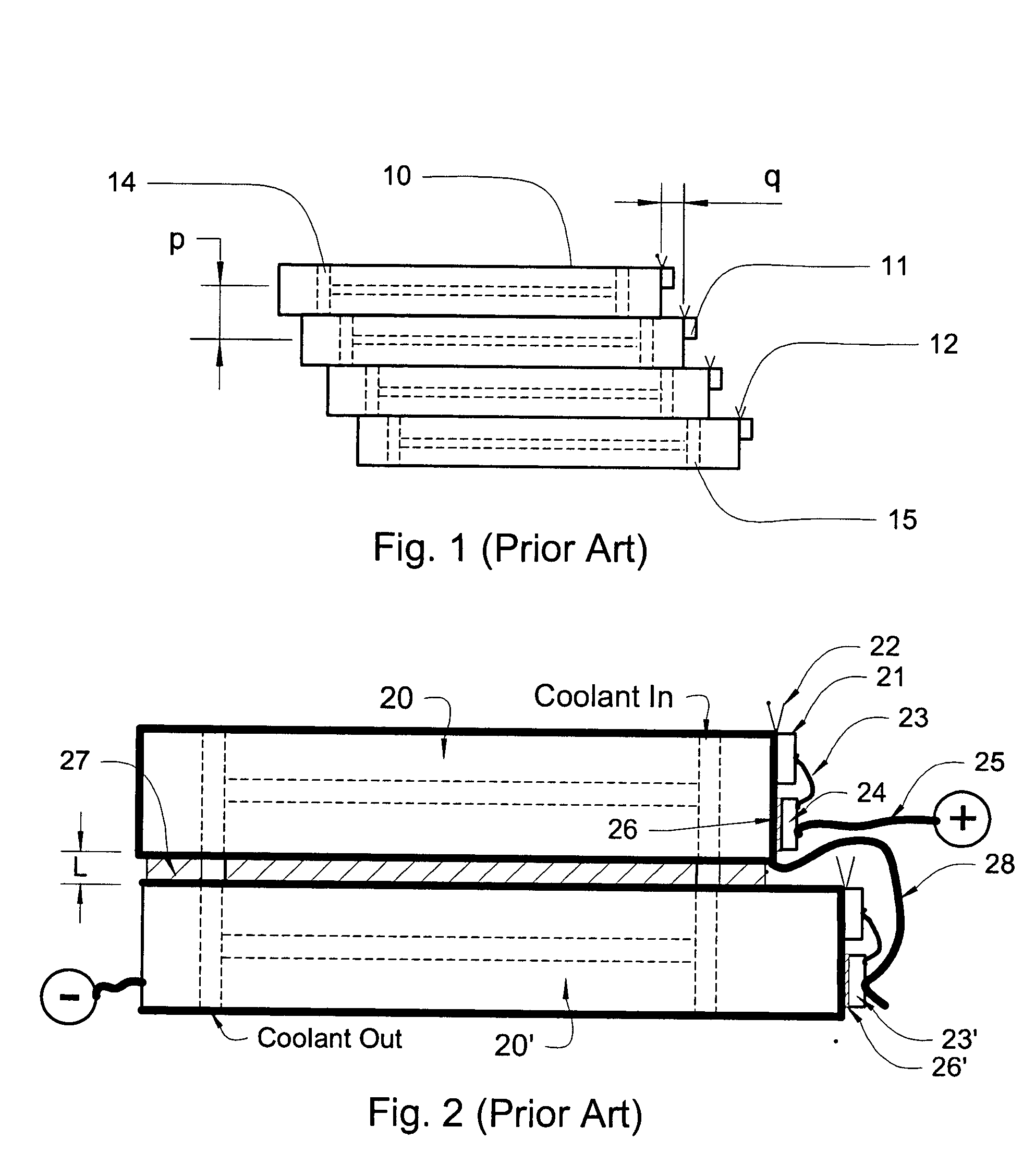

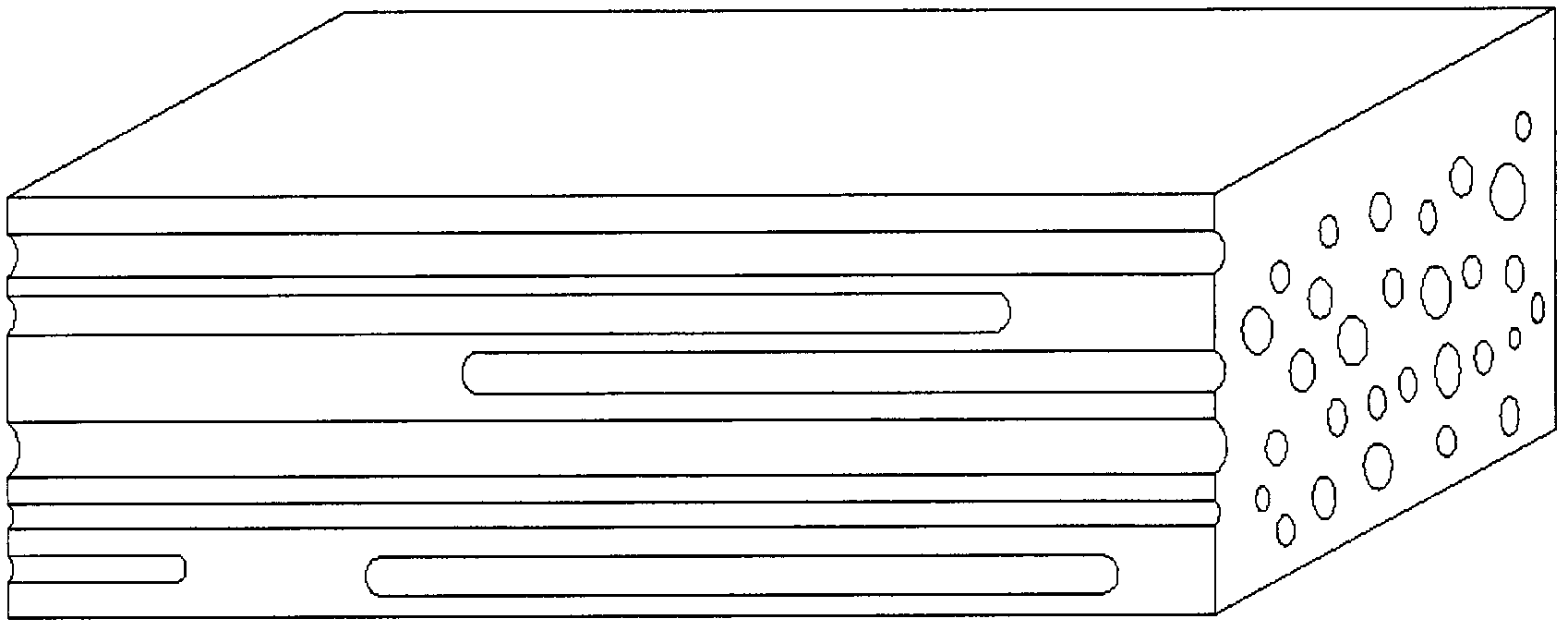

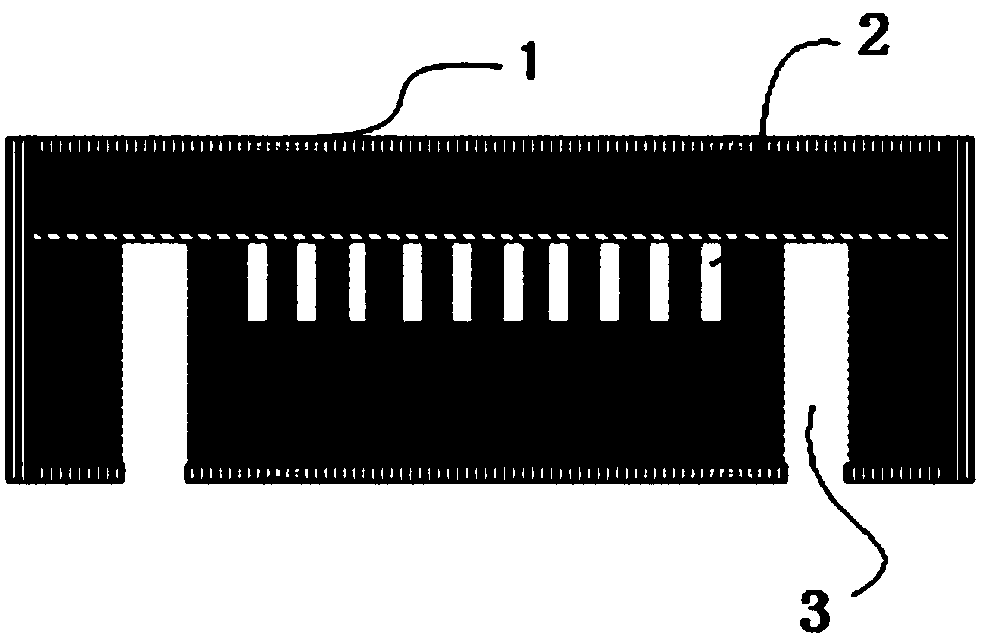

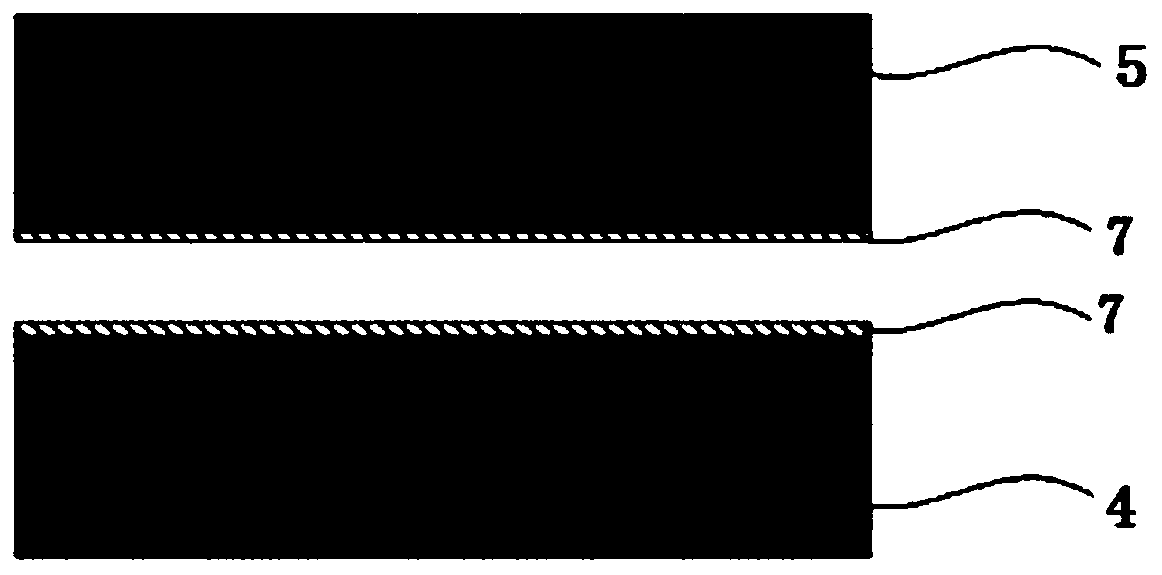

A microchannel heat sink is manufactured from graphite materials. A heat sink member has at least a first thermal contact surface for making thermal contact with an electronic device. The heat sink member is constructed of at least a first sheet of compressed particles of exfoliated graphite, the first sheet having two major surfaces. At least one of the major surfaces has a first plurality of microchannels formed therein for carrying coolant fluid. Said microchannels each have a length parallel to one of said major surfaces and have a cross section normal to said length. The cross-section has at least one dimension below about 1000 microns.

Owner:GRAFTECH INT HLDG INC

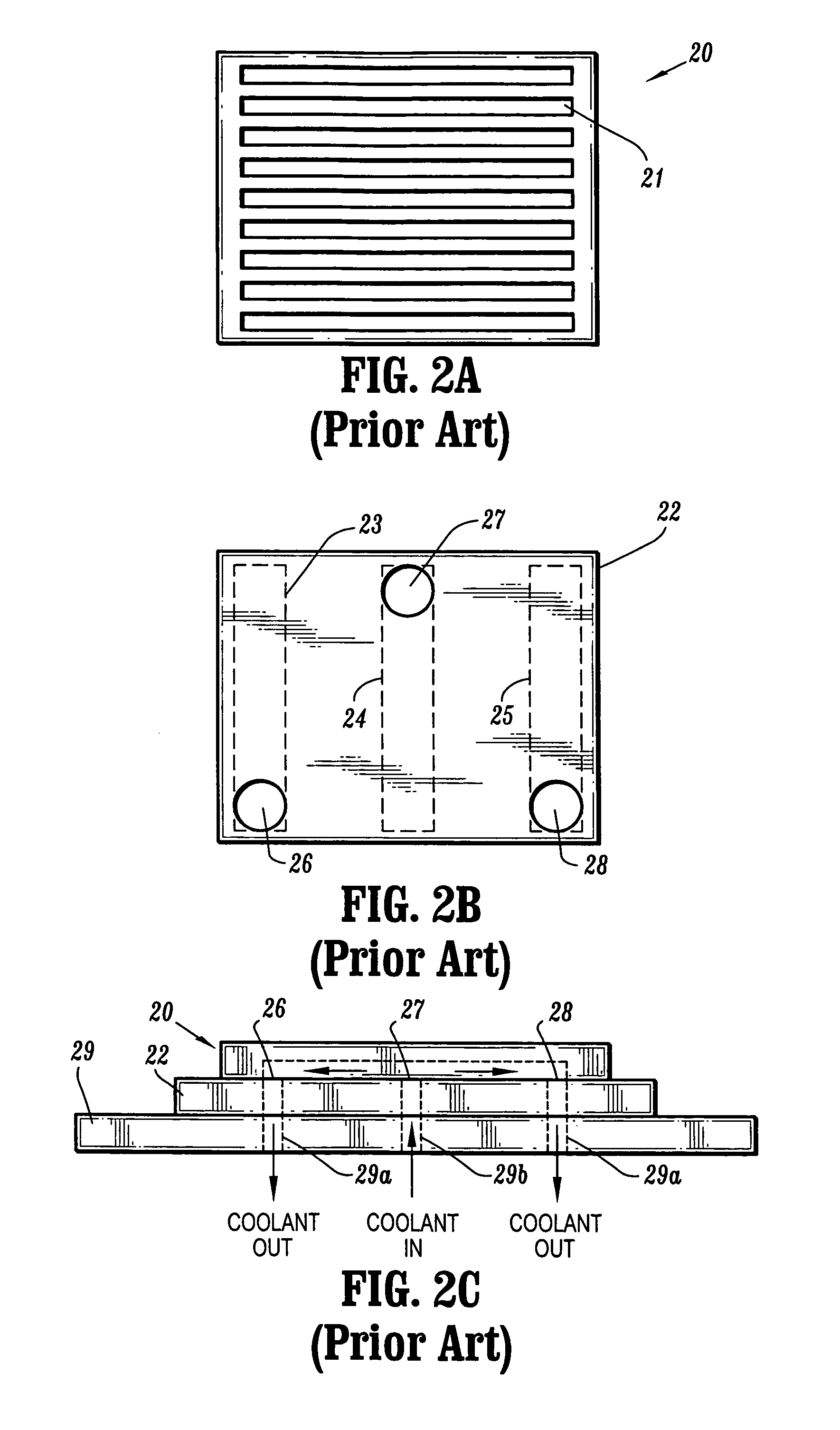

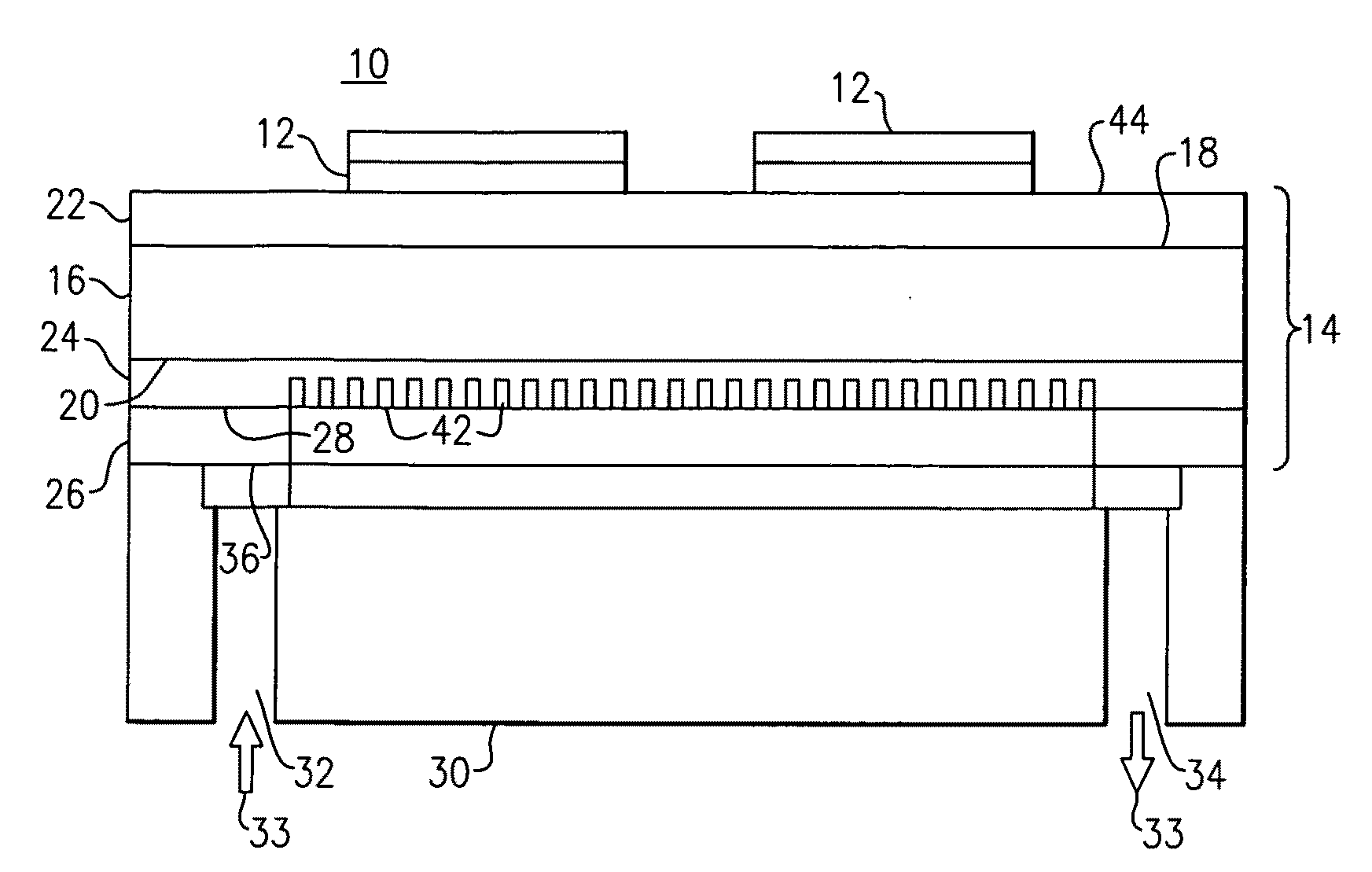

Apparatus and methods for microchannel cooling of semiconductor integrated circuit packages

ActiveUS20060002088A1Improve cooling effectVariable localized coolingSemiconductor/solid-state device detailsSolid-state devicesCoolant flowEngineering

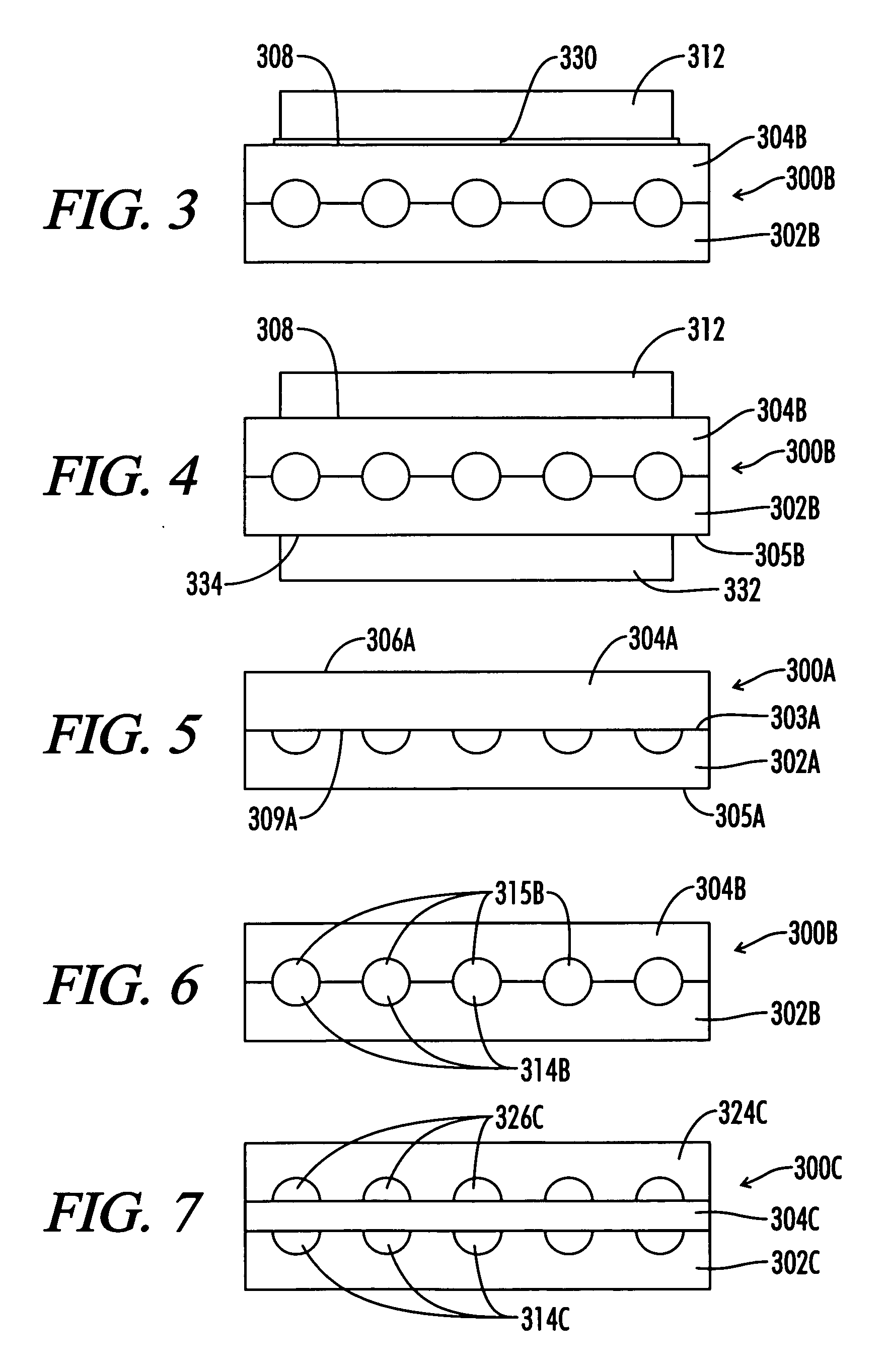

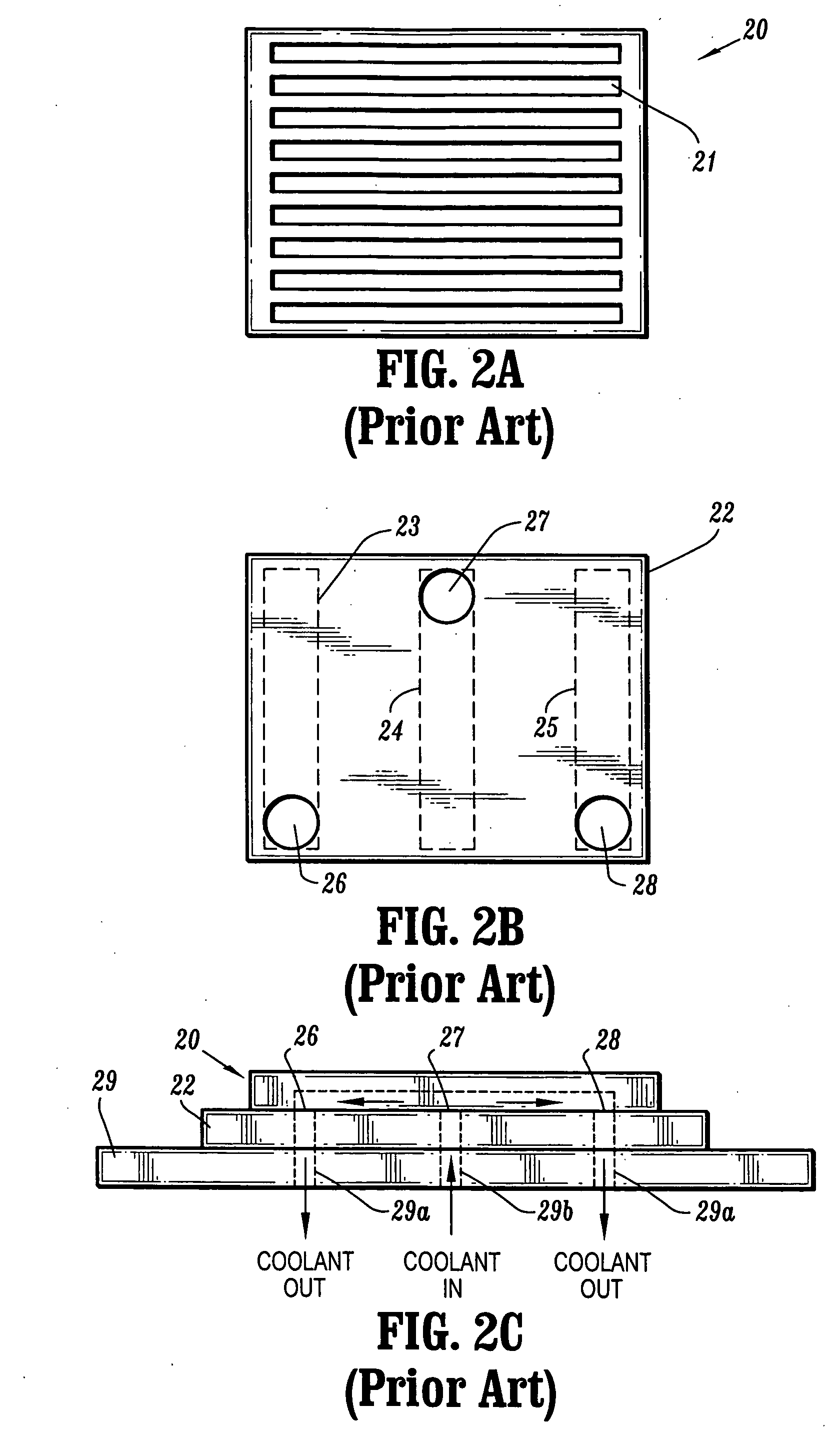

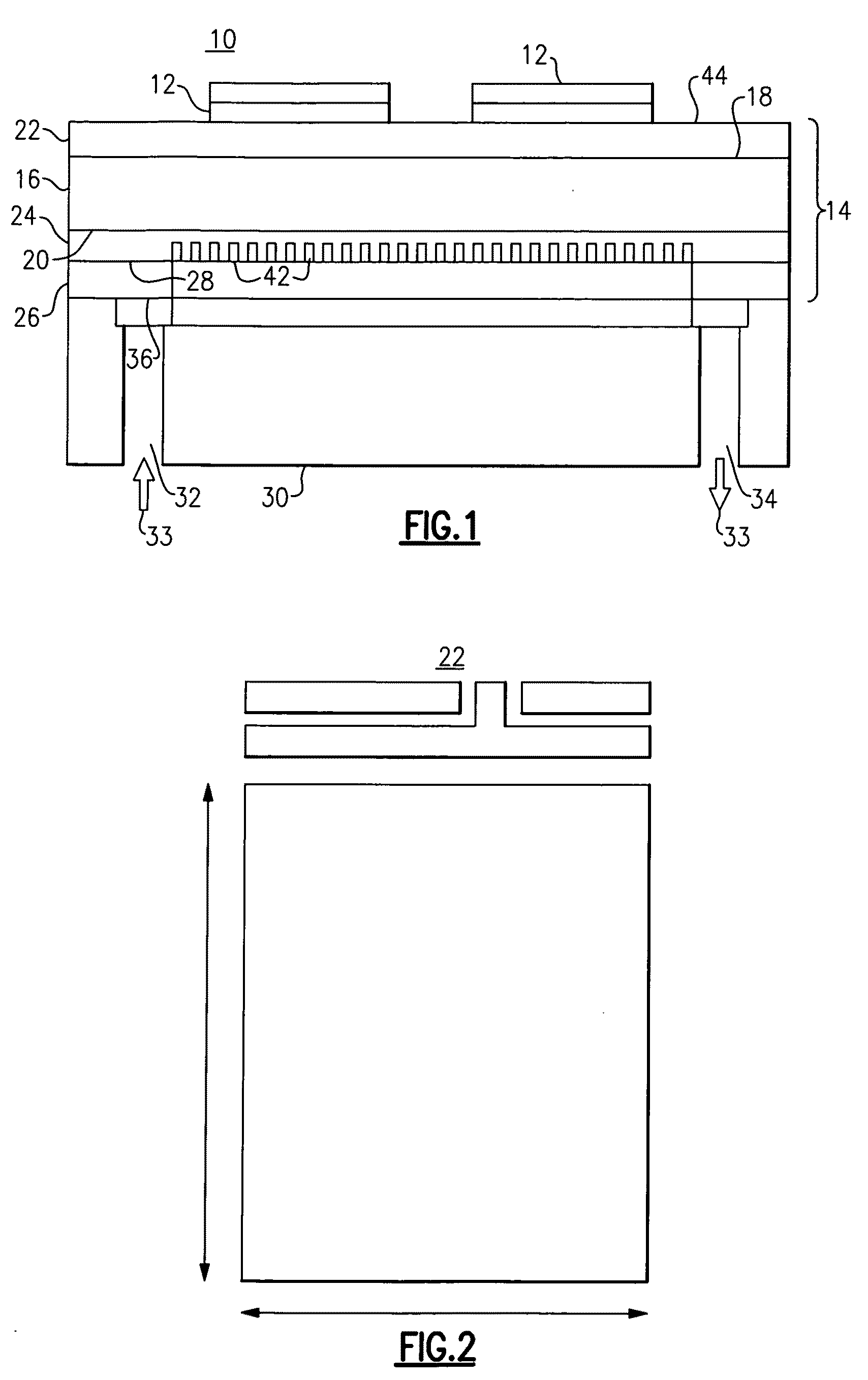

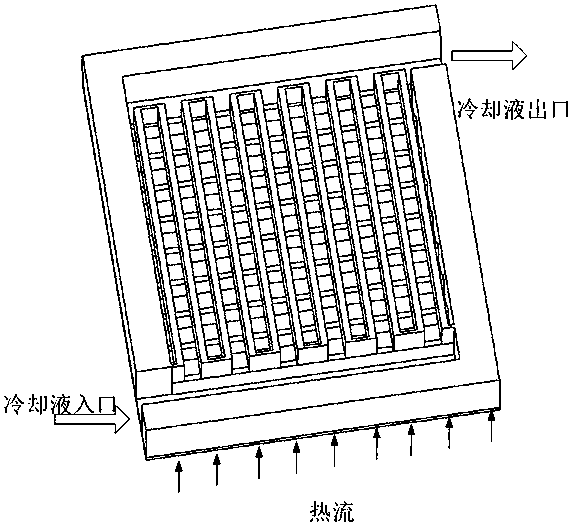

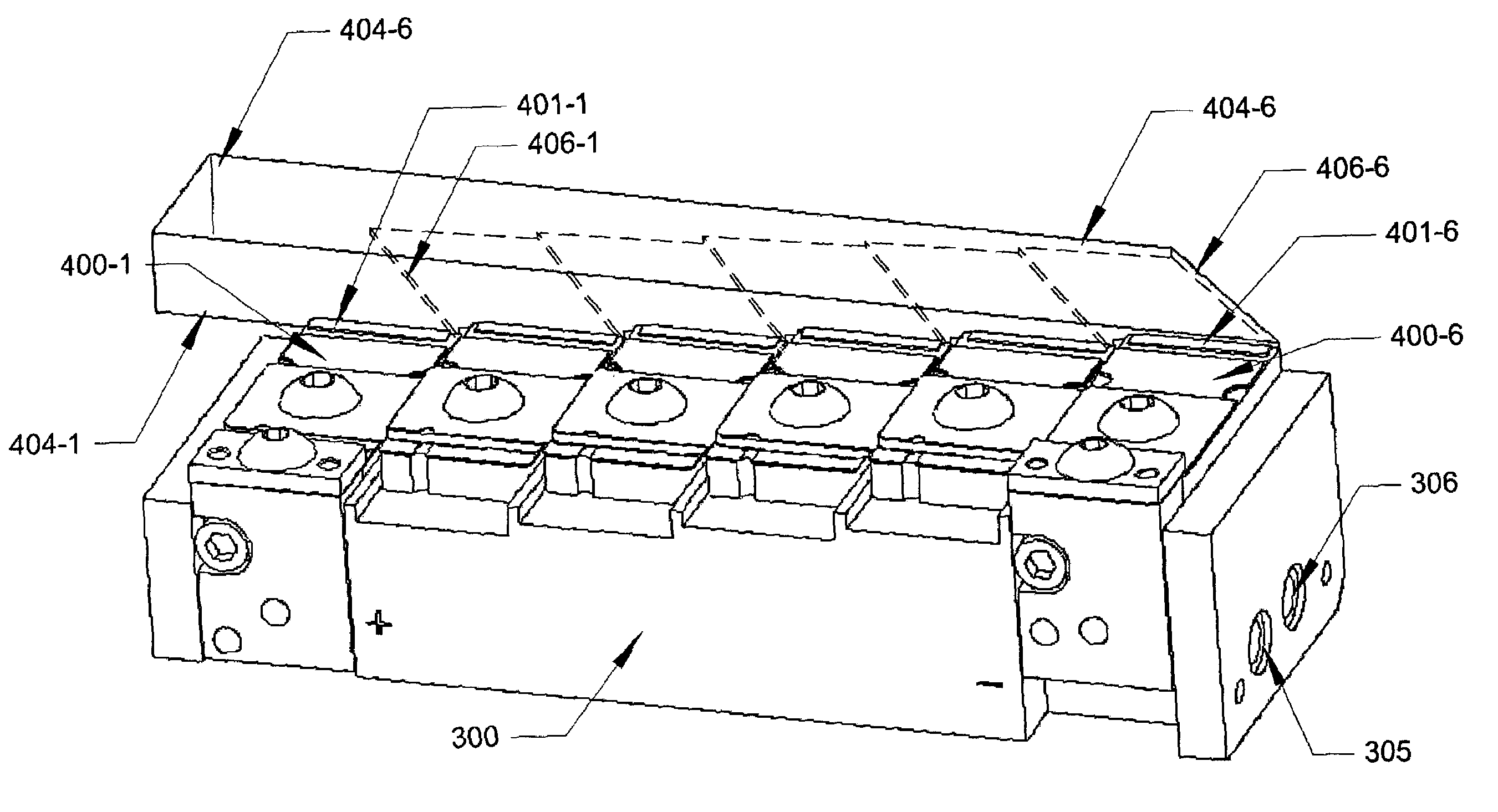

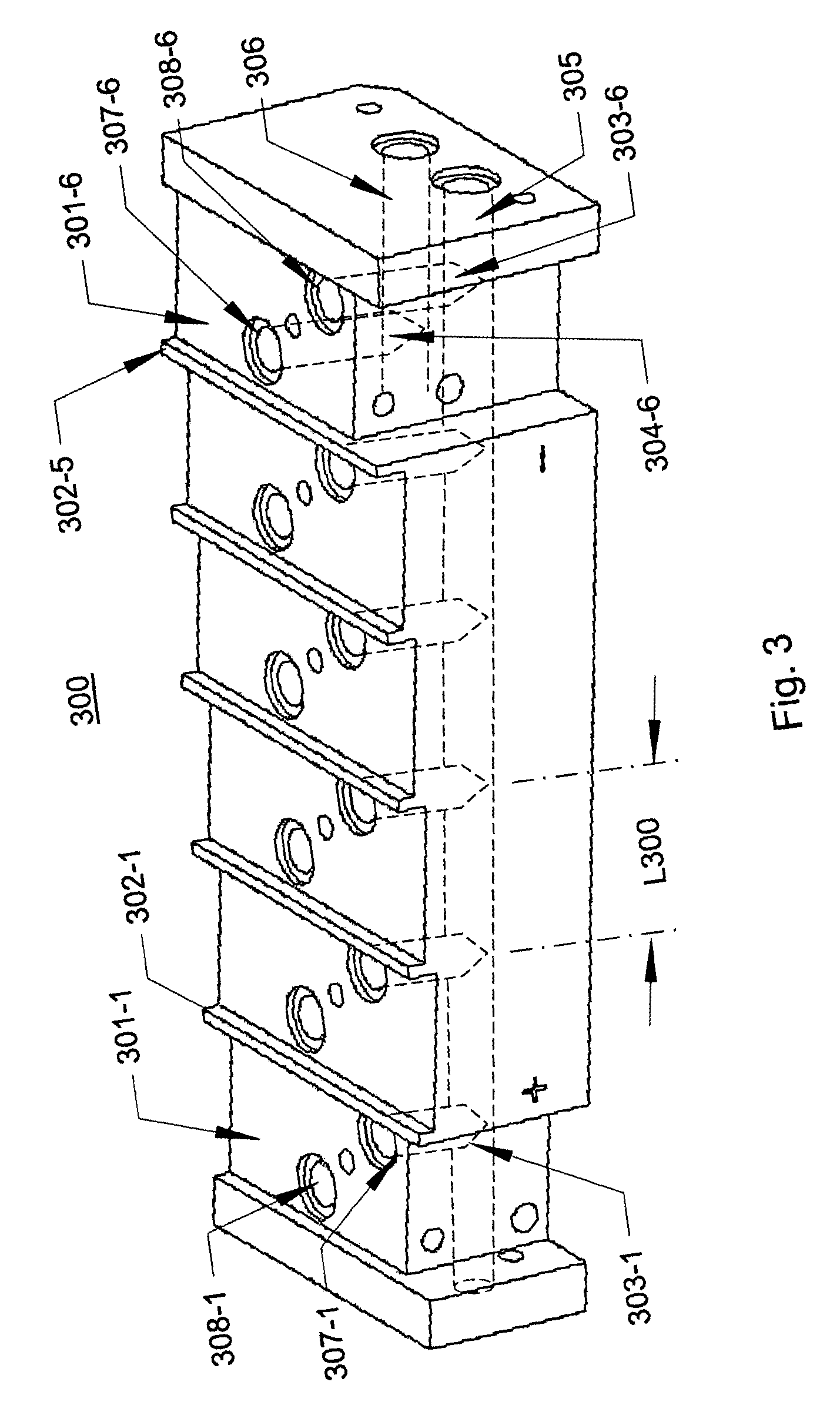

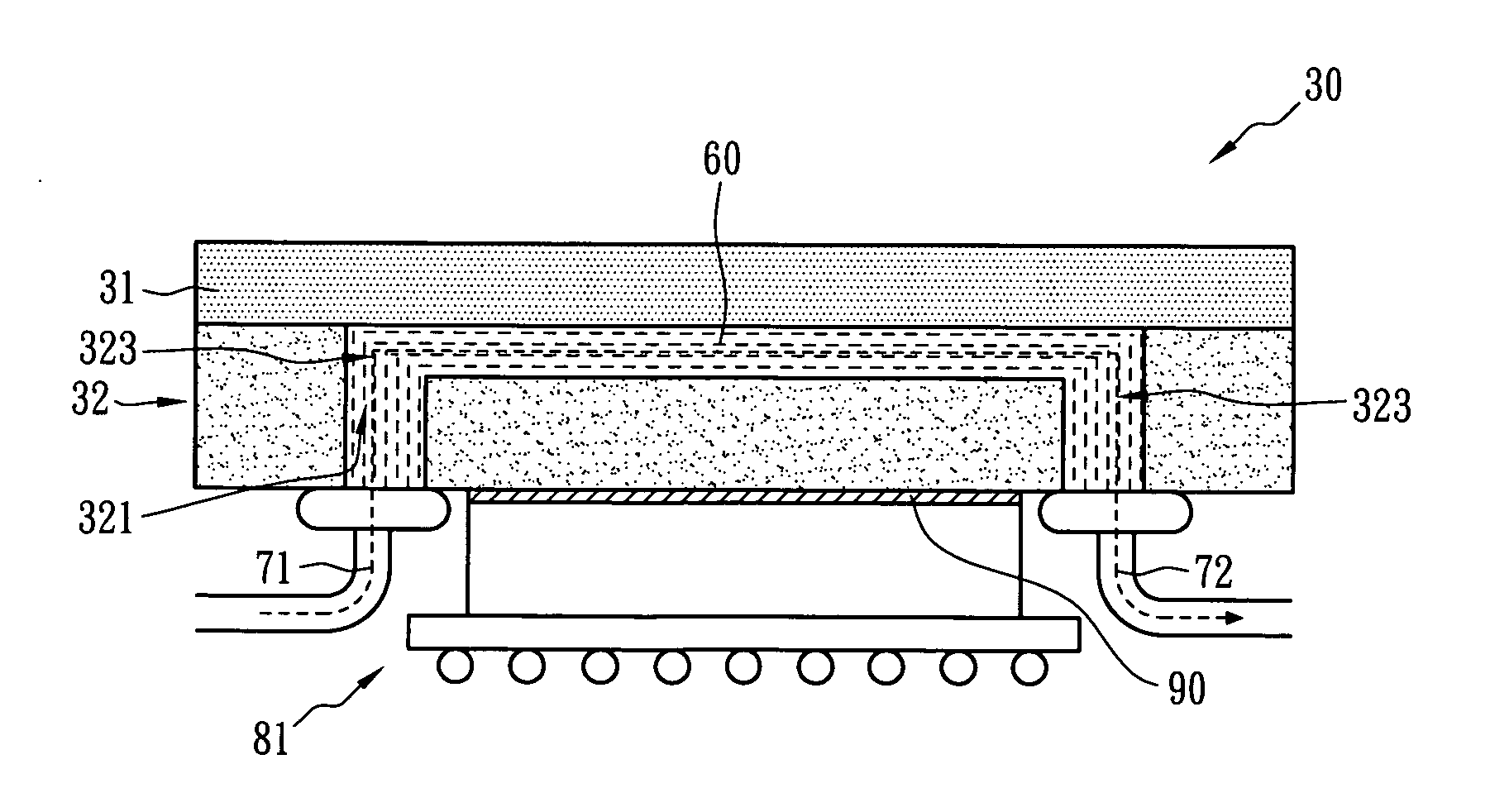

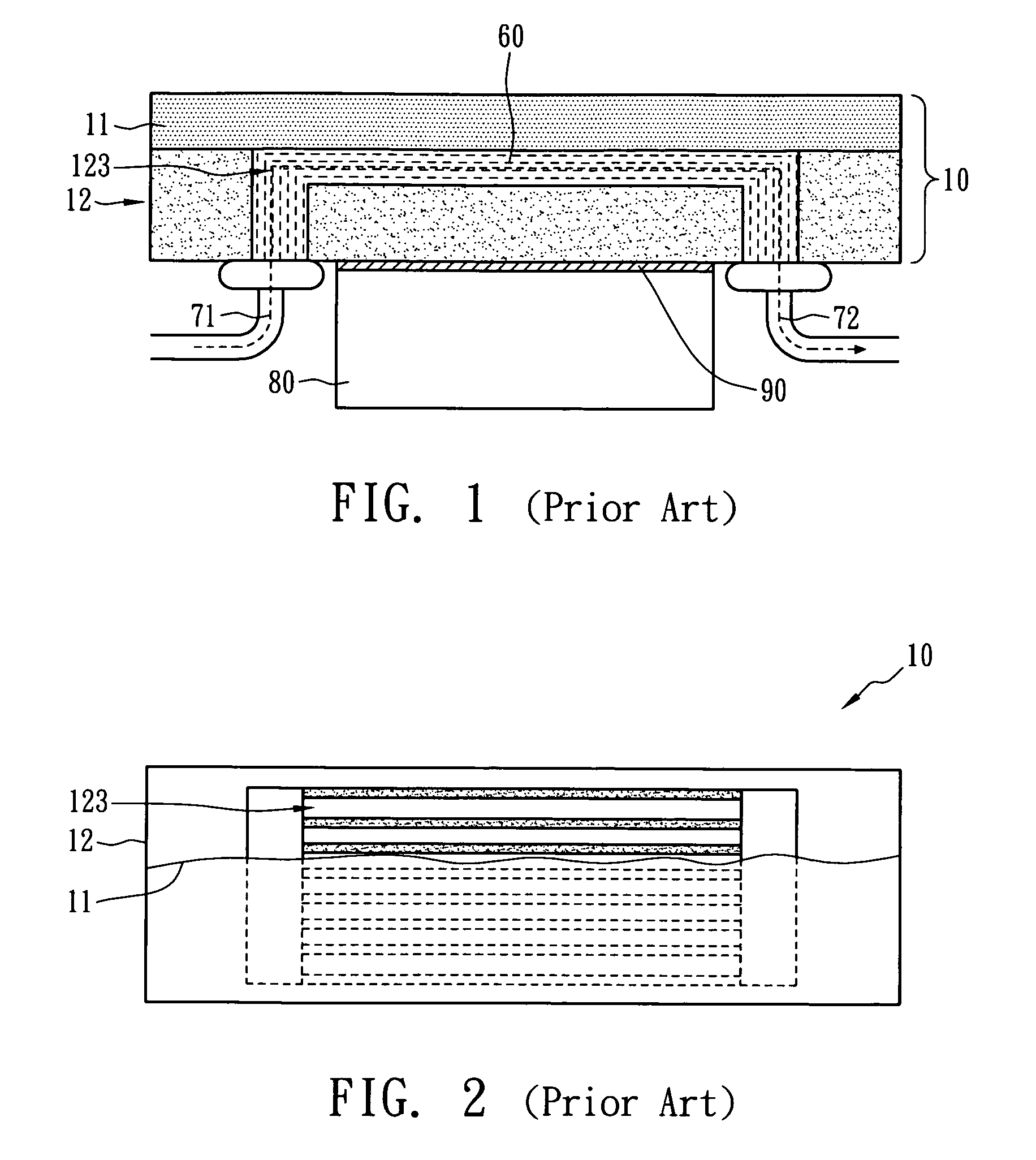

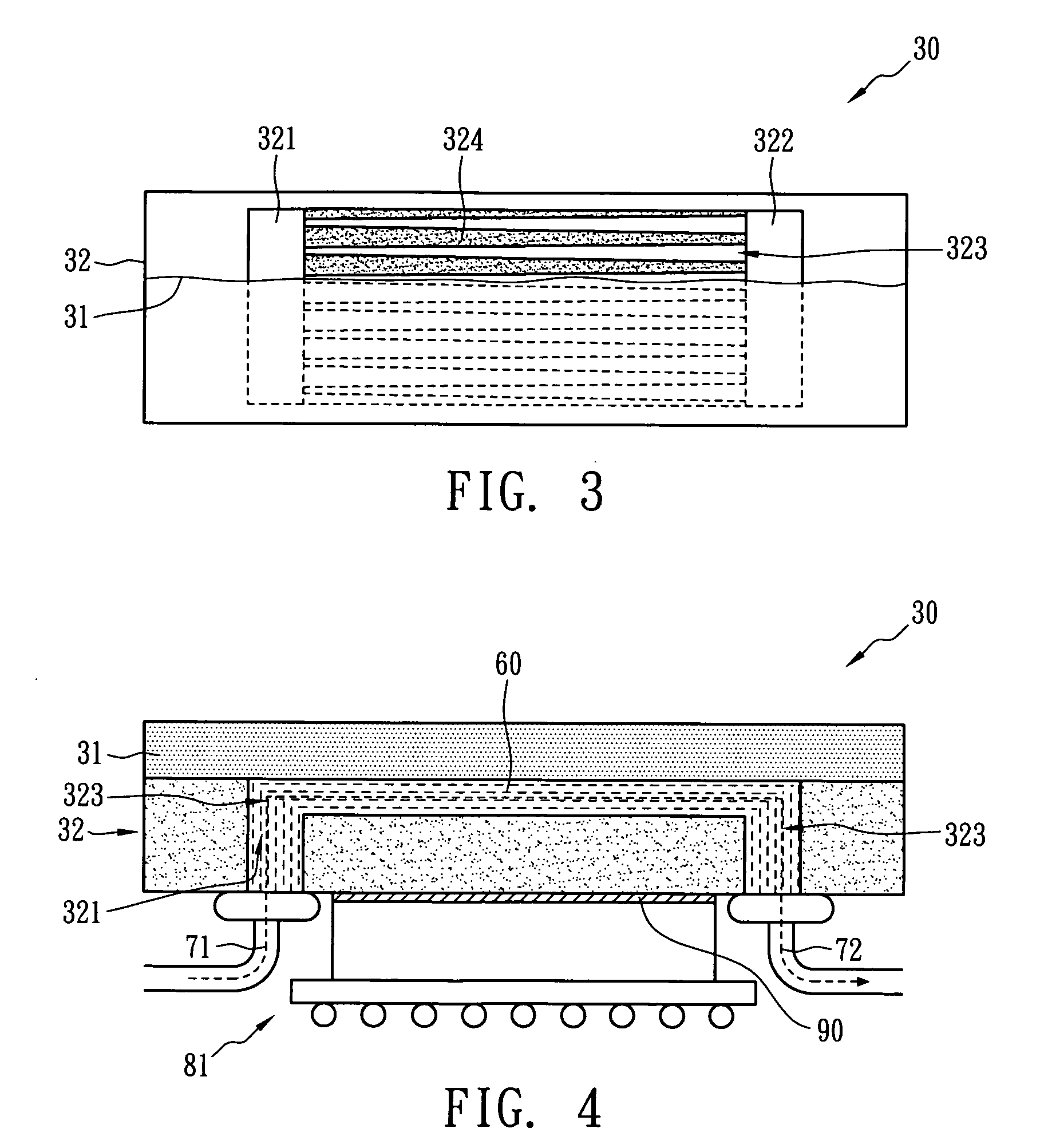

Apparatus and methods are provided for microchannel cooling of electronic devices such as IC chips, which enable efficient and low operating pressure microchannel cooling of high power density electronic devices having a non-uniform power density distribution, which are mounted face down on a package substrate. For example, integrated microchannel cooler devices (or microchannel heat sink devices) for cooling IC chips are designed to provide uniform flow and distribution of coolant fluid and minimize pressure drops along coolant flow paths, as well as provide variable localized cooling capabilities for high power density regions (or “hot spots”) of IC chips with higher than average power densities.

Owner:GLOBALFOUNDRIES US INC

Apparatus and methods for microchannel cooling of semiconductor integrated circuit packages

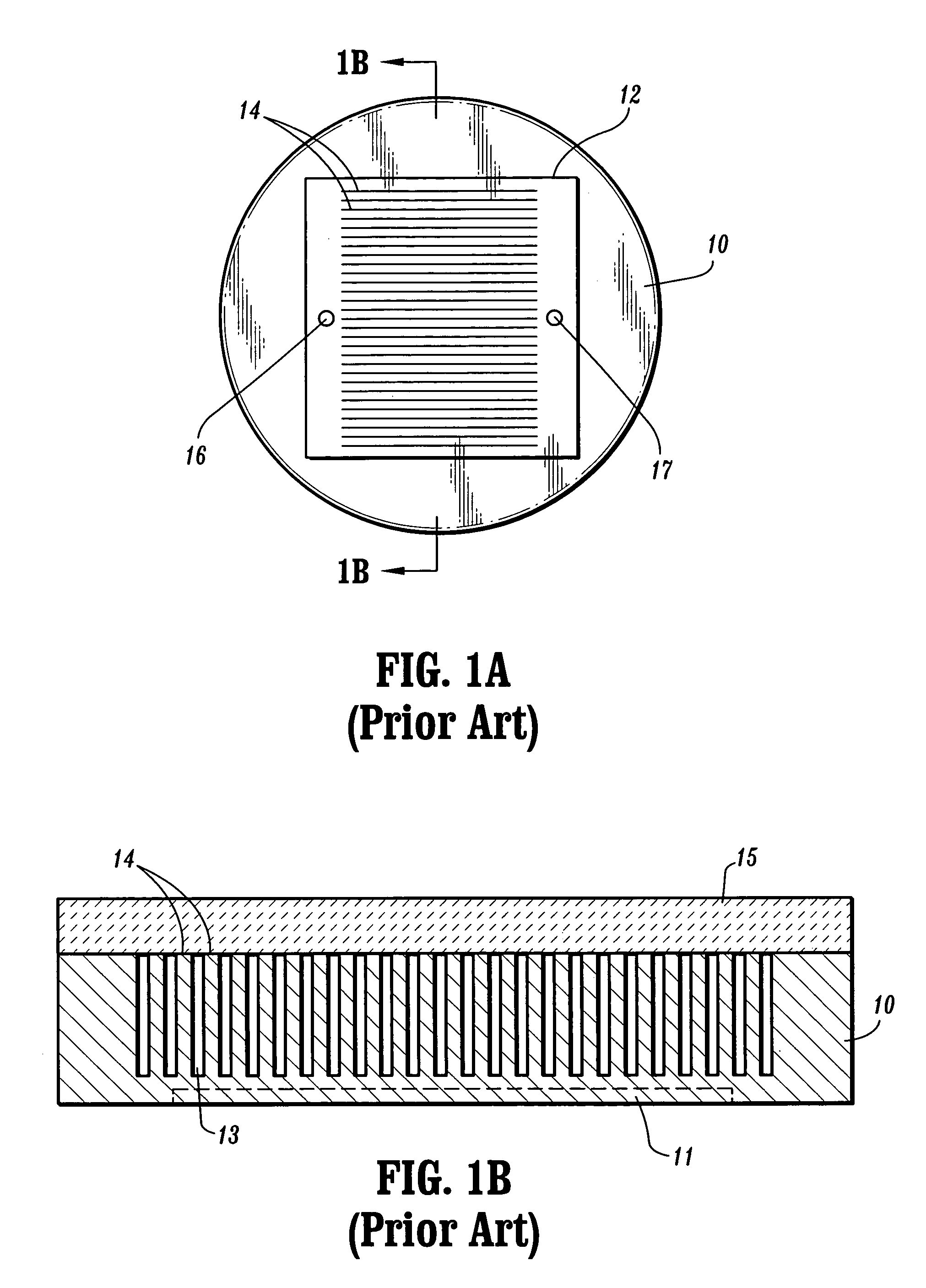

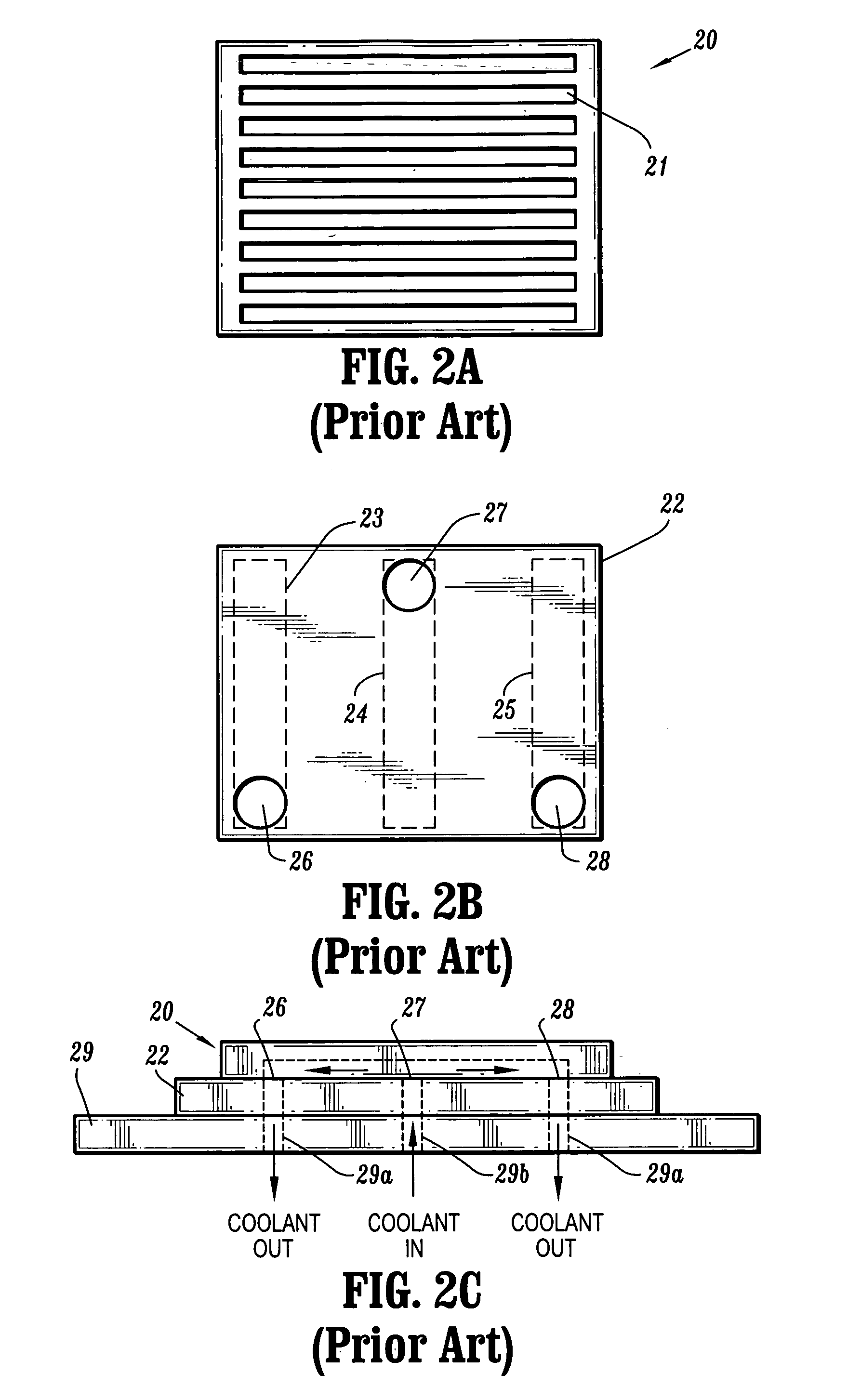

InactiveUS20060002087A1Uniform flowEvenly distributedSemiconductor/solid-state device detailsSolid-state devicesCoolant flowHigh power density

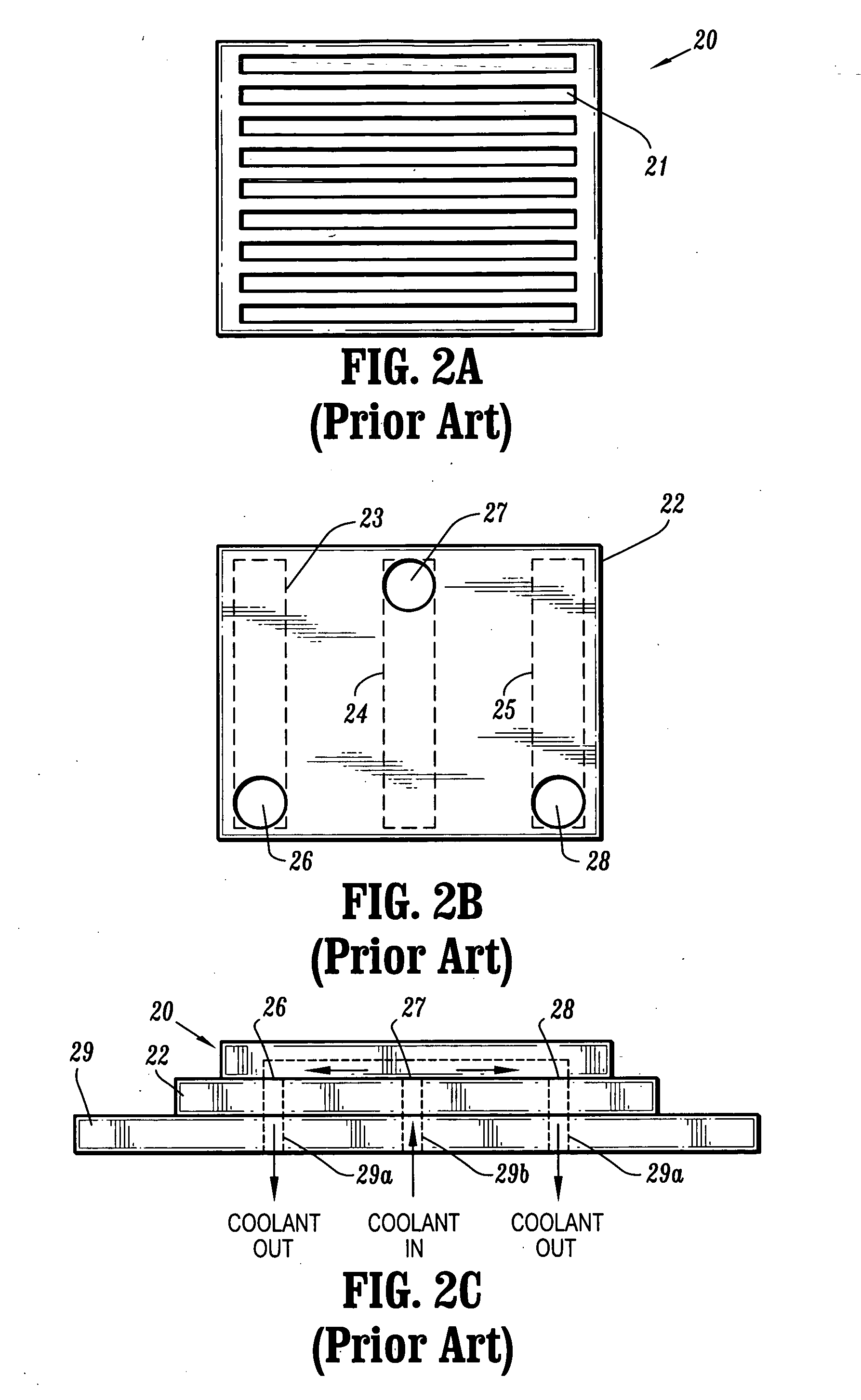

Apparatus and methods are provided for microchannel cooling of electronic devices such as IC chips, which enable efficient and low operating pressure microchannel cooling of high power density electronic devices. Apparatus for microchannel cooling include integrated microchannel heat sink devices and fluid distribution manifold structures that are designed to provide uniform flow and distribution of coolant fluid and minimize pressure drops along coolant flow paths.

Owner:IBM CORP

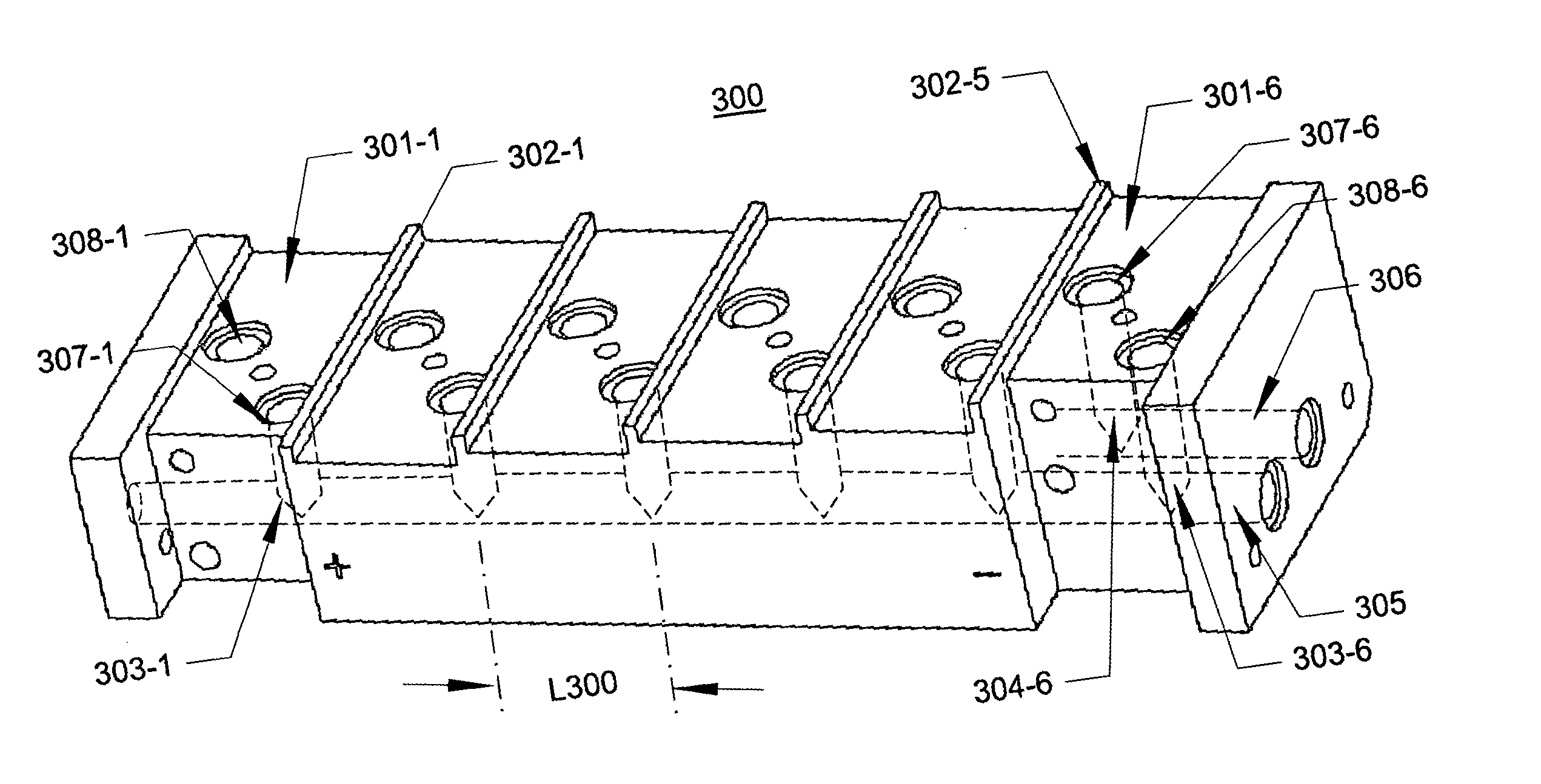

Stepped manifold array of microchannel heat sinks

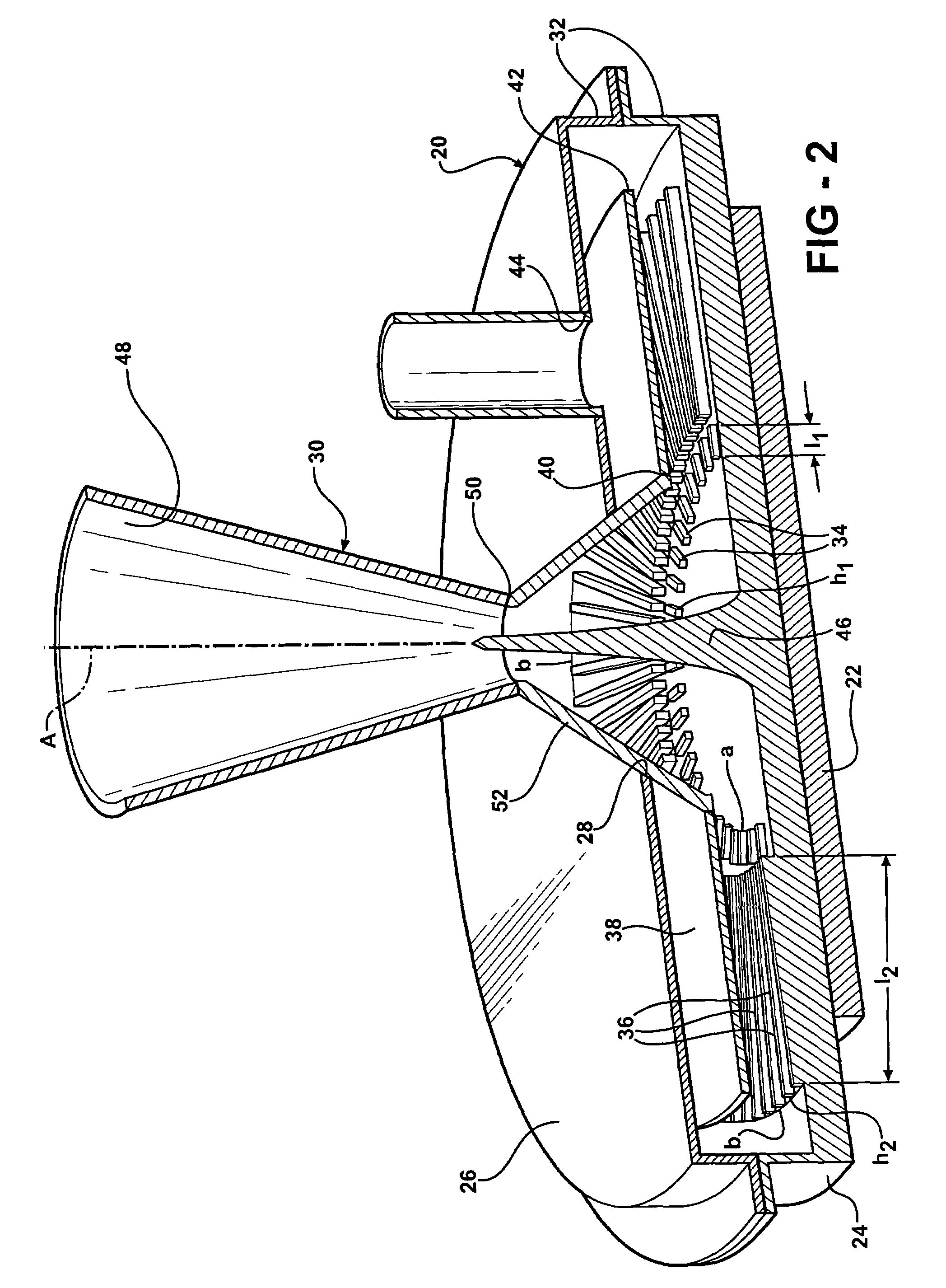

ActiveUS20050063433A1Reduce corrosionClosely spacedSemiconductor laser arrangementsLaser arrangementsEngineeringLaser beams

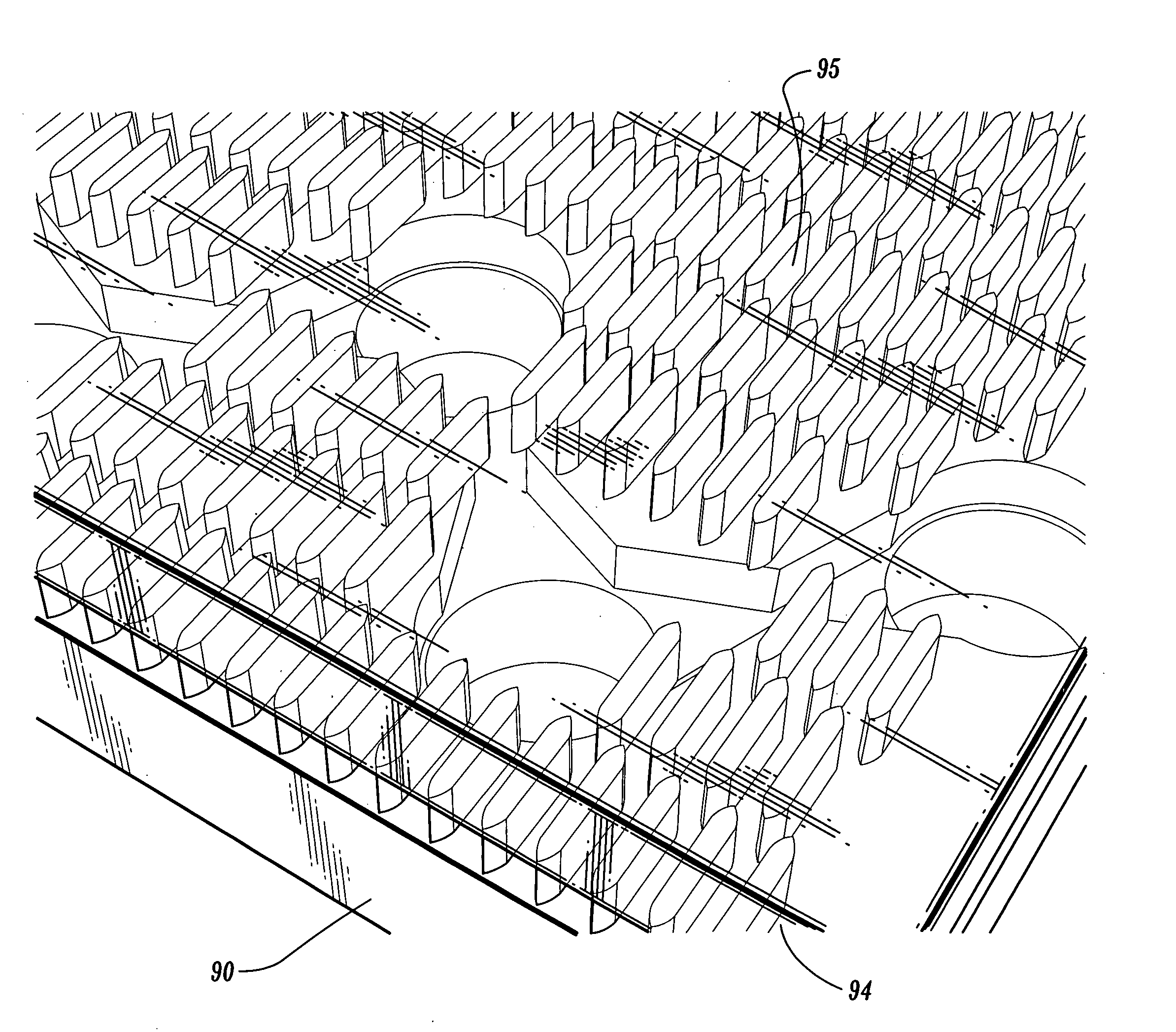

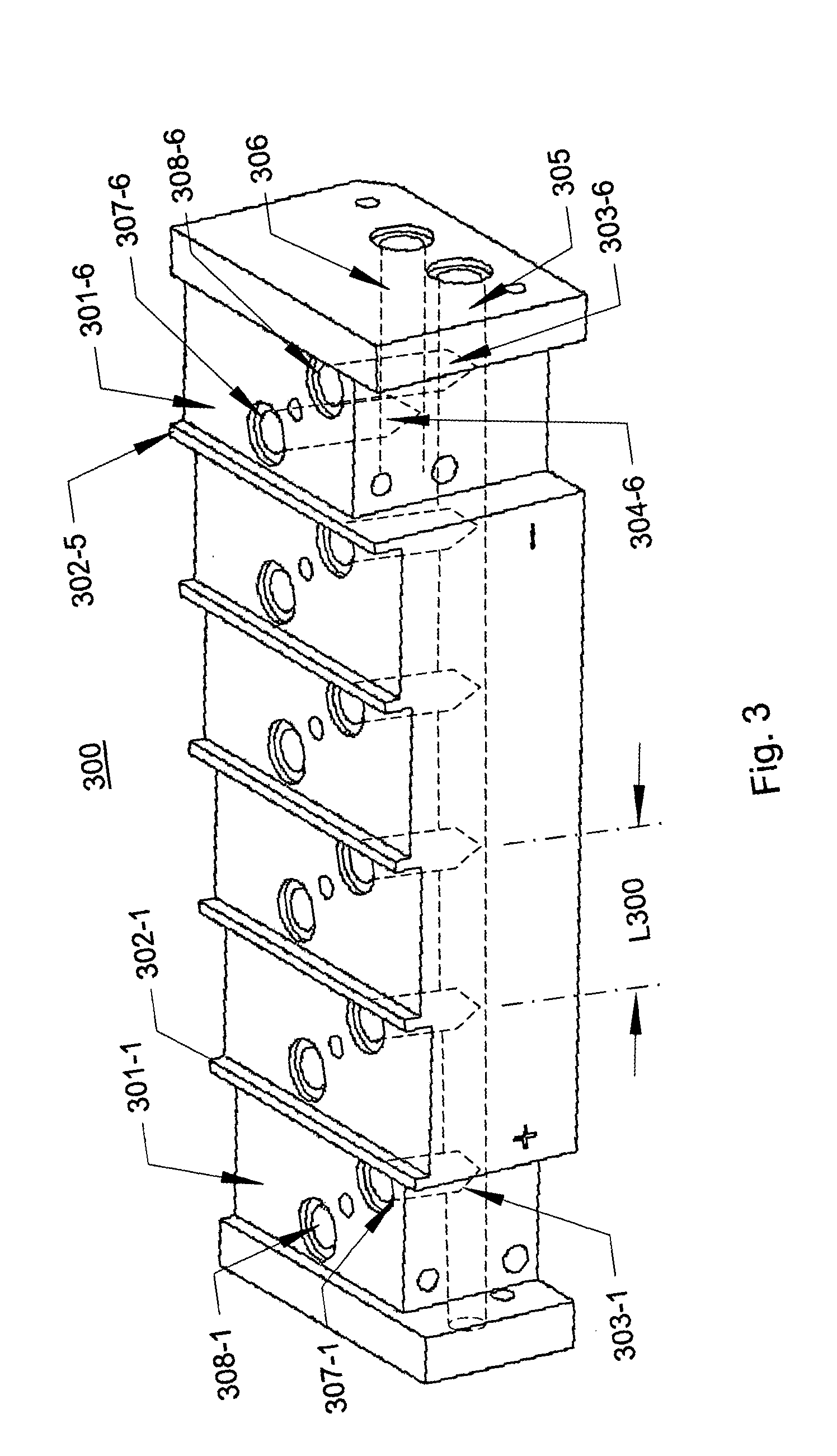

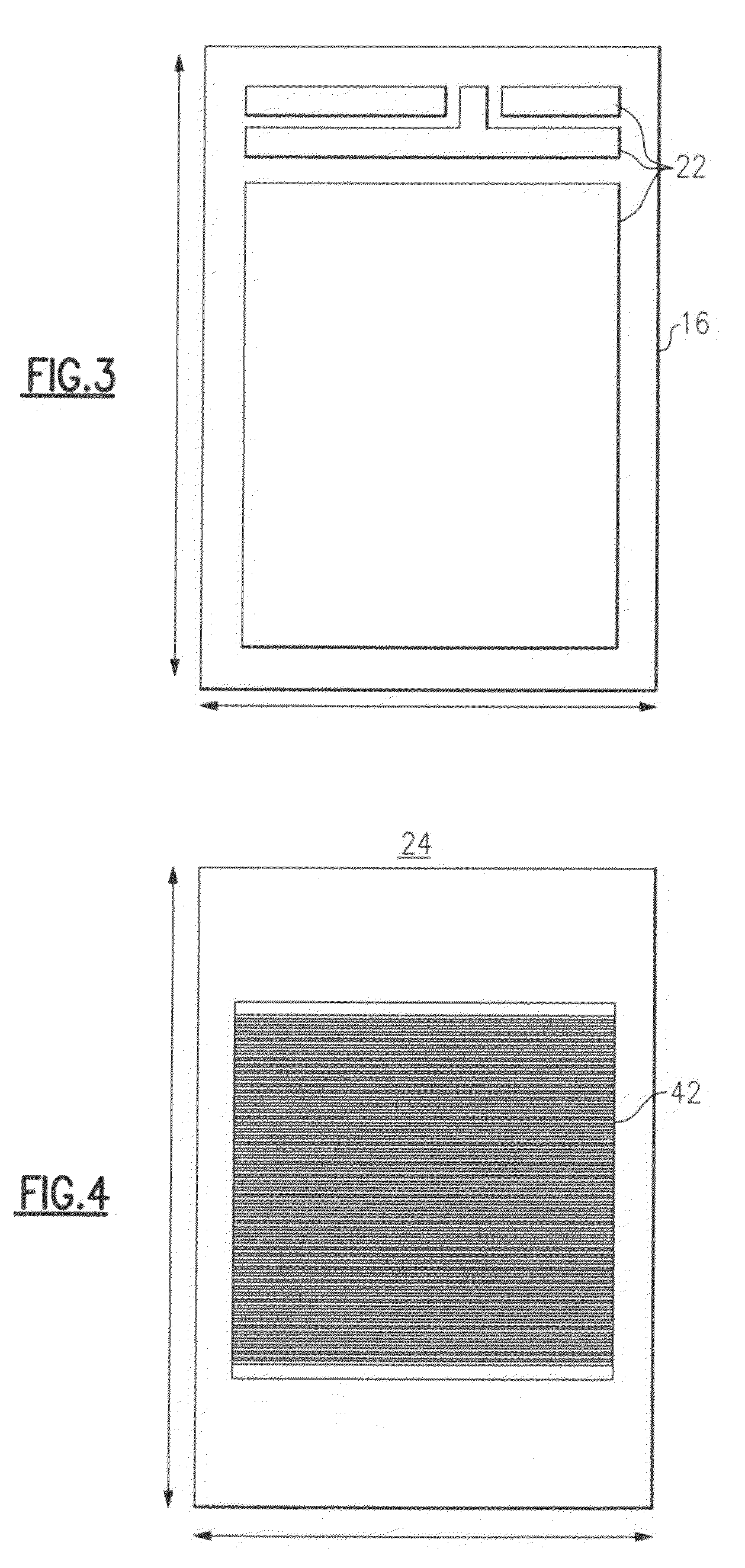

An assembly for providing a concentrated, vertically stacked array of laser beams from a horizontally offset array of electrically serially-connected metallic microchannel heat sinks each bearing a laser diode bar. The heat sinks are mounted on horizontally offset planes of the manifold which has coolant channels serving adjacent heat sinks that are separated from each to increase the electrical resistance of the fluid path between adjacent ones of said heat sinks. Stepped optical deflectors re-arrange the horizontally emitted laser beams into vertical stack.

Owner:II VI DELAWARE INC

Microchannel heat sink

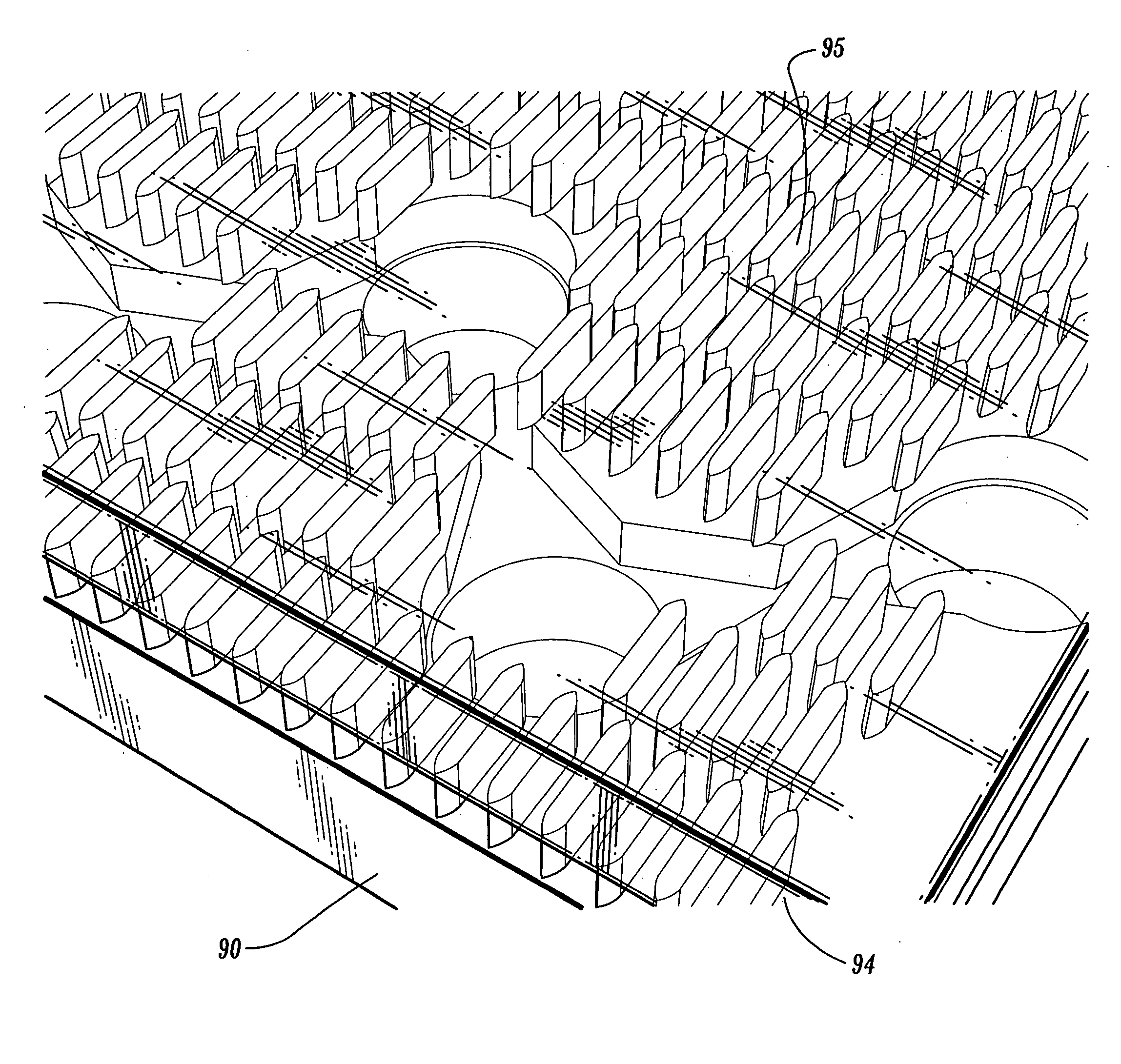

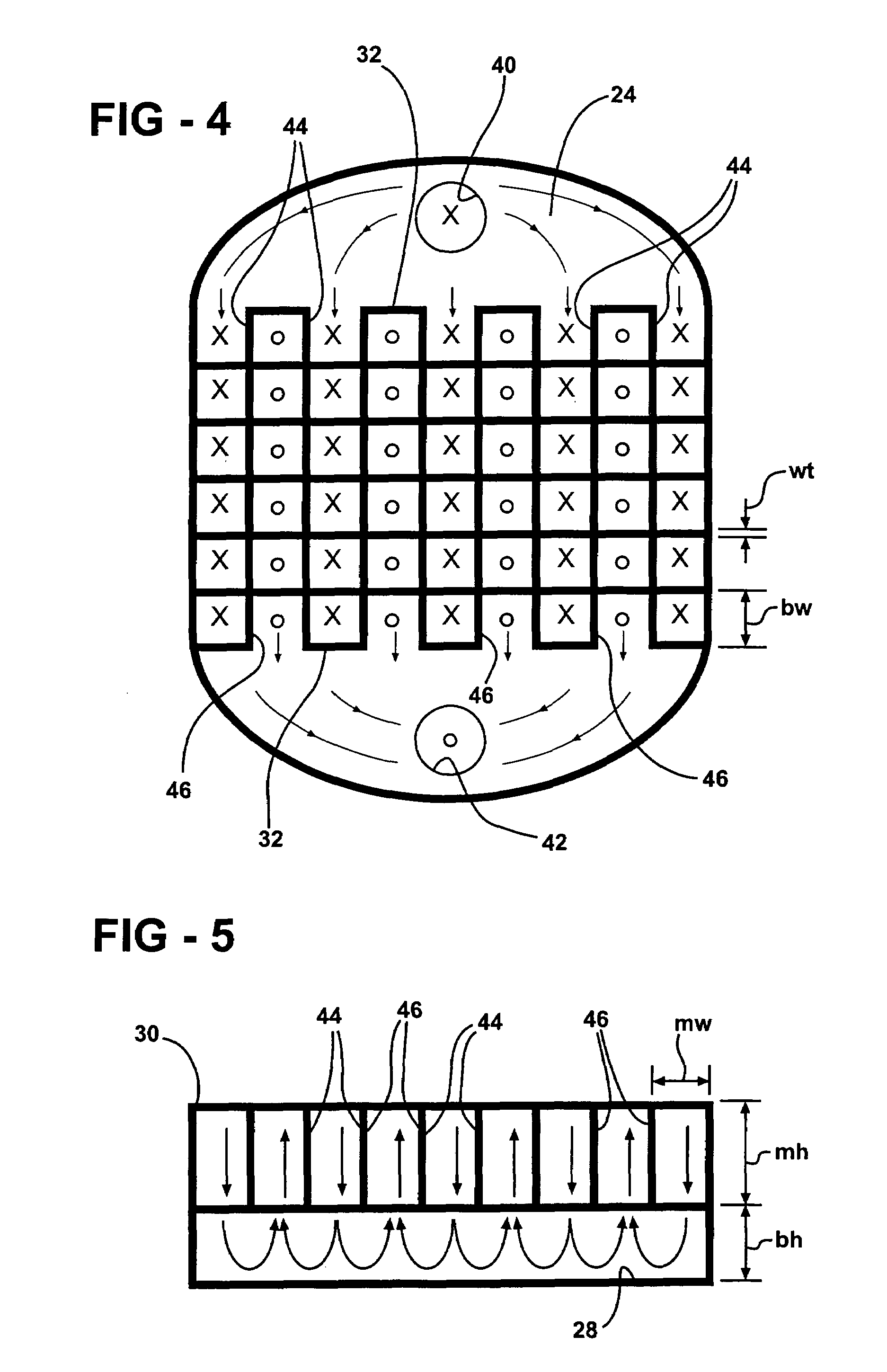

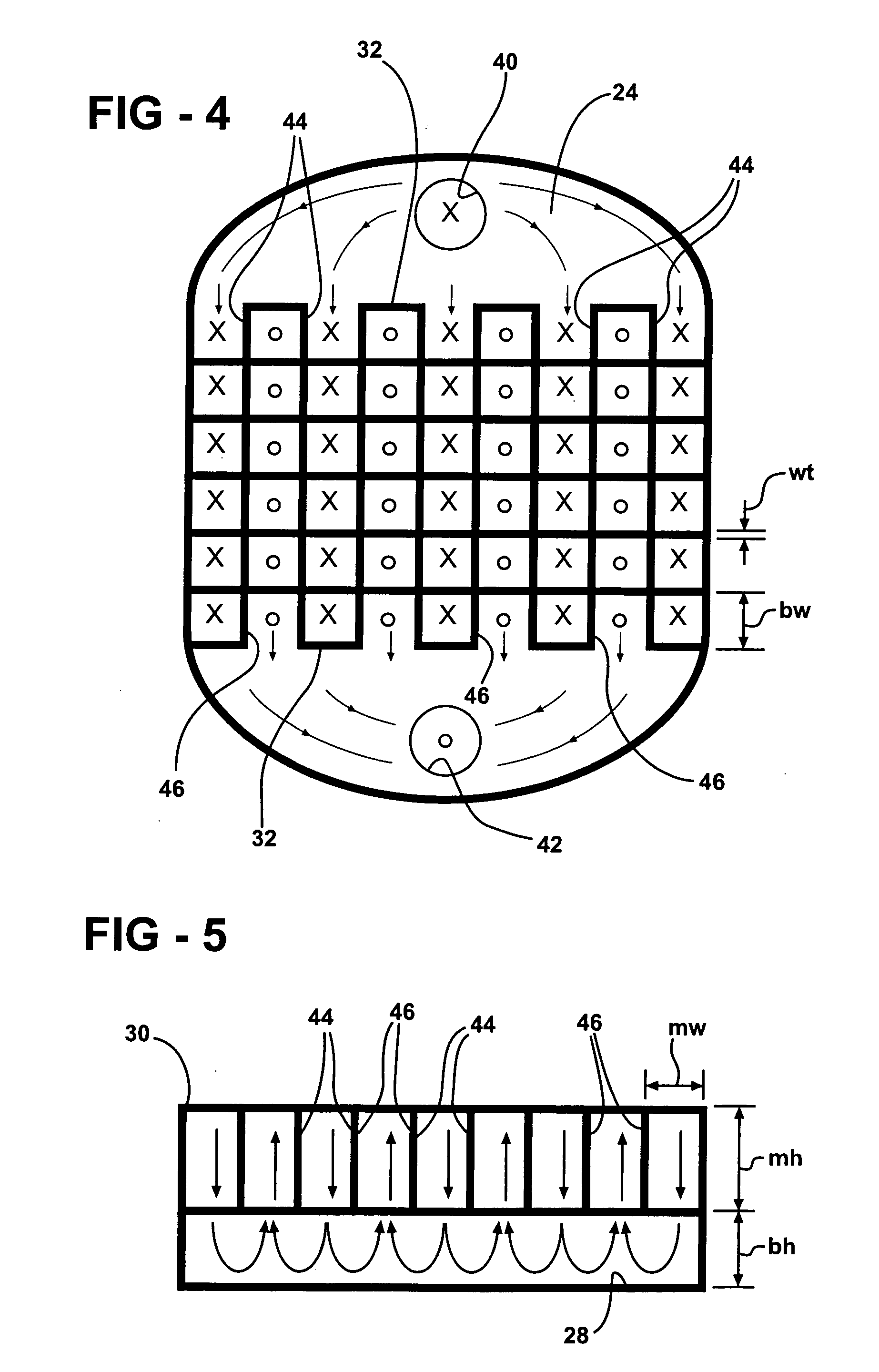

ActiveUS7331378B2Improve efficiencySemiconductor/solid-state device detailsSolid-state devicesInlet manifoldBiomedical engineering

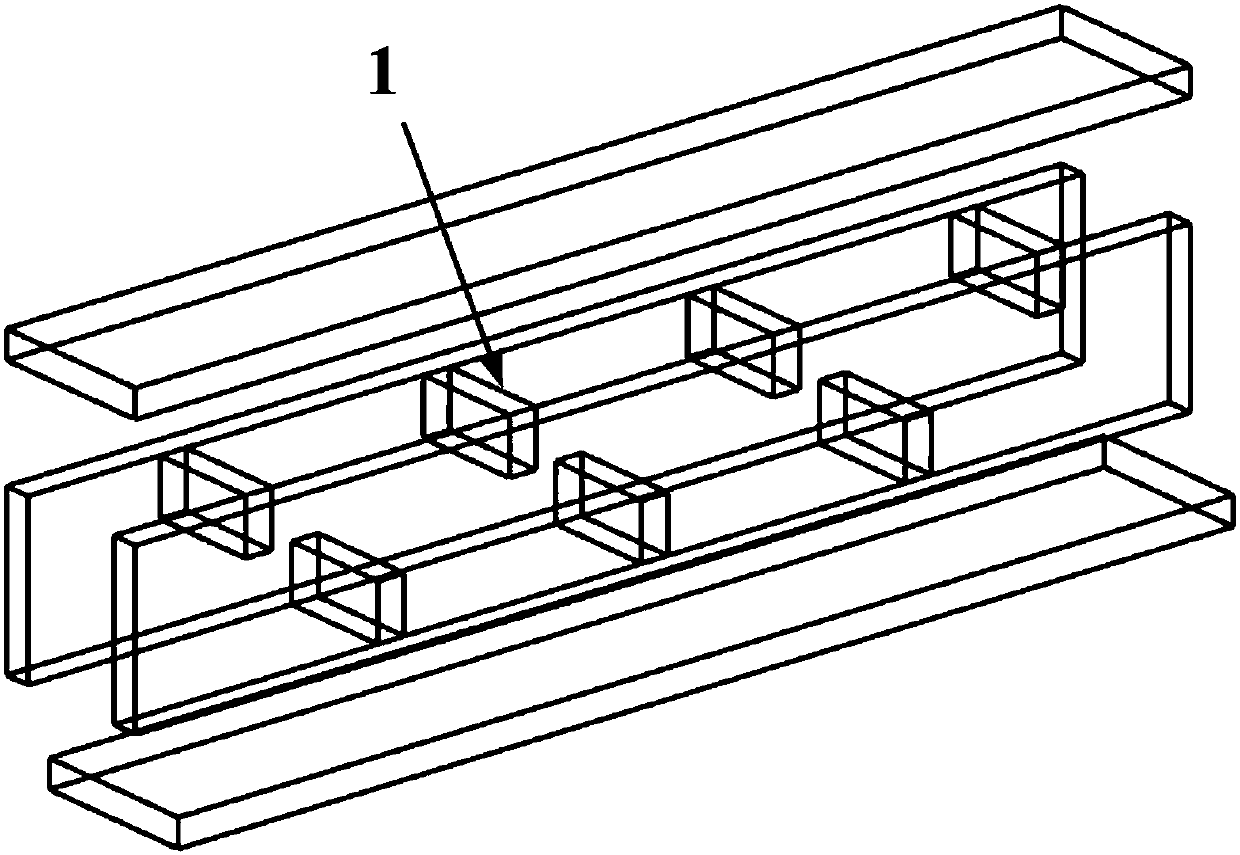

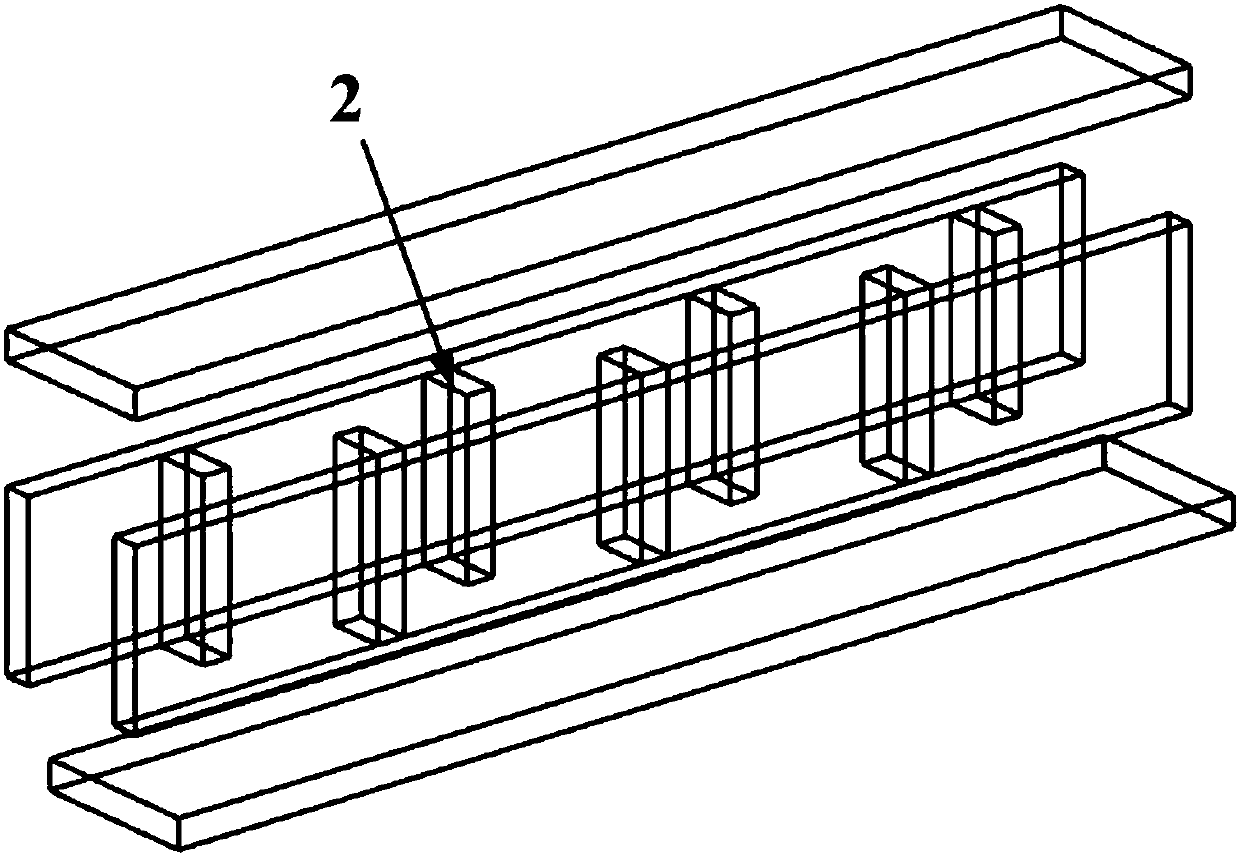

The invention provides a heat sink for flowing coolant into inlet manifold channels extending into a inlet edge of a manifold where the flow is forced downward into parallel and spaced micro-channels extending across the manifold channels and re-directing the coolant up into and out of outlet manifold channels extending into an outlet edge of the manifold and interleaved with the inlet manifold channels, and by maintaining a base-width of the micro-channels in the range of forty microns to one hundred microns, maintaining a base-height of the micro-channels in the range of two hundred microns to four hundred microns, maintaining a manifold-height through of the manifold channels in the range of one thousand microns to three thousand microns, and maintaining a manifold-width of the manifold channels in the range of three hundred and fifty microns to one thousand microns.

Owner:COOLIT SYSTEMS INC

Microchannel heat sink

ActiveUS20070163750A1Improve efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringBiomedical engineering

The invention provides a heat sink for flowing coolant into inlet manifold channels extending into a inlet edge of a manifold where the flow is forced downward into parallel and spaced micro-channels extending across the manifold channels and re-directing the coolant up into and out of outlet manifold channels extending into an outlet edge of the manifold and interleaved with the inlet manifold channels, and by maintaining a base-width of the micro-channels in the range of forty microns to one hundred microns, maintaining a base-height of the micro-channels in the range of two hundred microns to four hundred microns, maintaining a manifold-height through of the manifold channels in the range of one thousand microns to three thousand microns, and maintaining a manifold-width of the manifold channels in the range of three hundred and fifty microns to one thousand microns.

Owner:COOLIT SYSTEMS INC

Microchannel heat sink

ActiveUS7277284B2Increase heat removal rateIncrease heat transfer rateSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

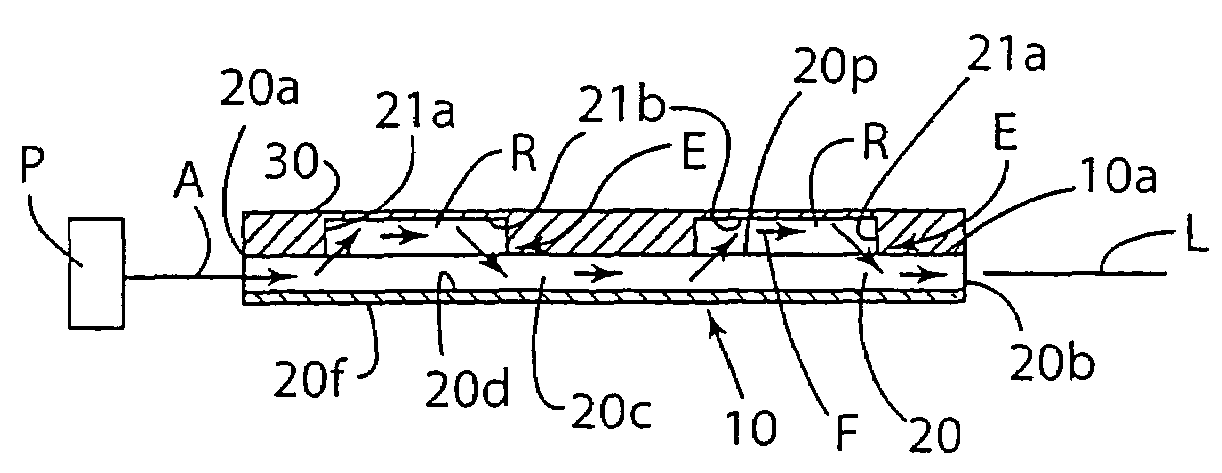

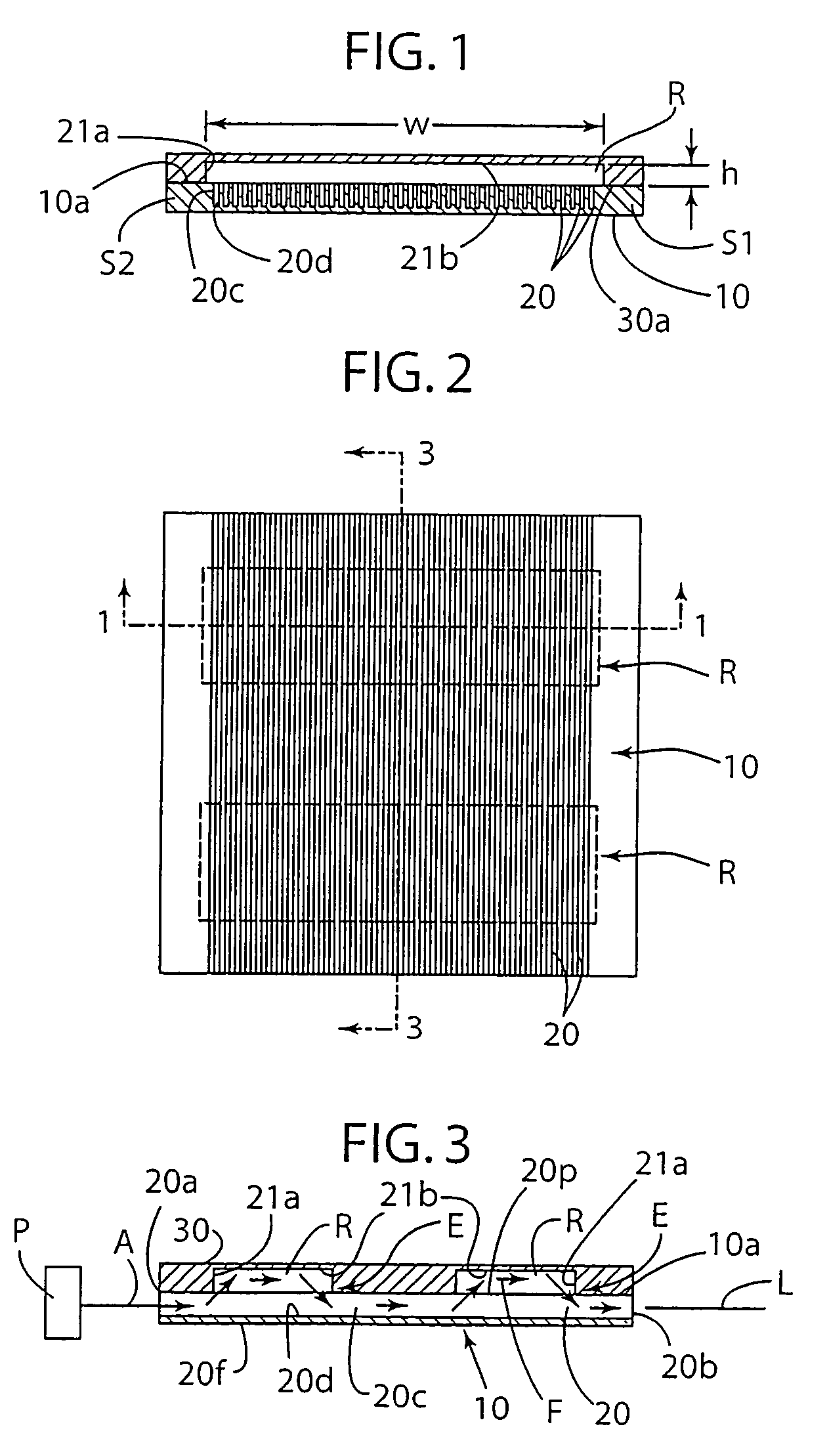

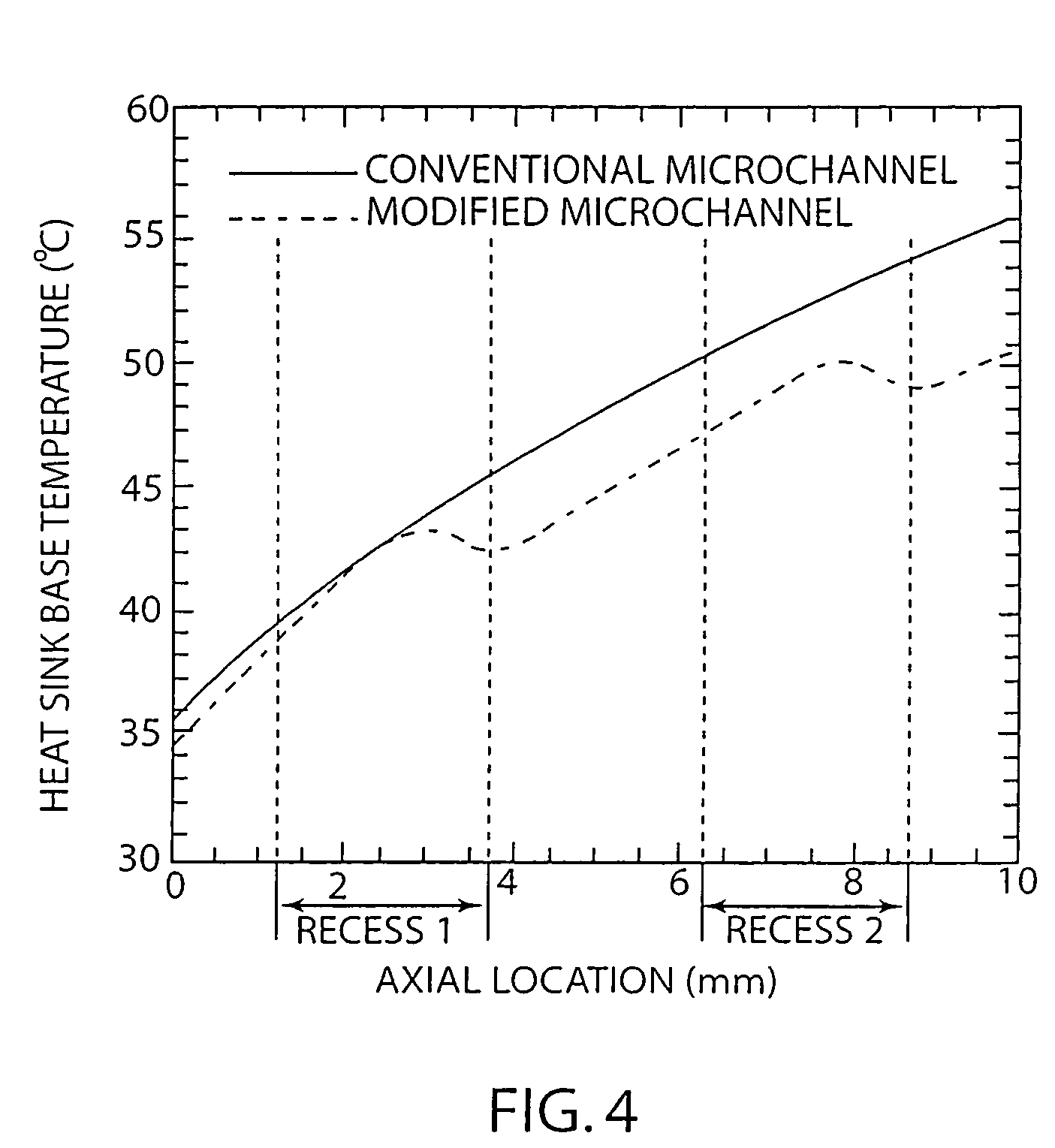

A microchannel heat sink as well as method includes one or more microchannels through which a working fluid flows to remove heat from a heat-generating component, such as a microelectronic chip, and one or more recesses disposed in a surface communicated to the one or more of the microchannel to enhance heat transfer rate of the microchannel heat sink. The recesses can be located in a surface of a cover that closes off the microchannels. The one or more recesses can be located at one or more local hot spot regions to enhance heat transfer rates at the local regions as well as overall heat removal rate of the heat sink.

Owner:PURDUE RES FOUND INC

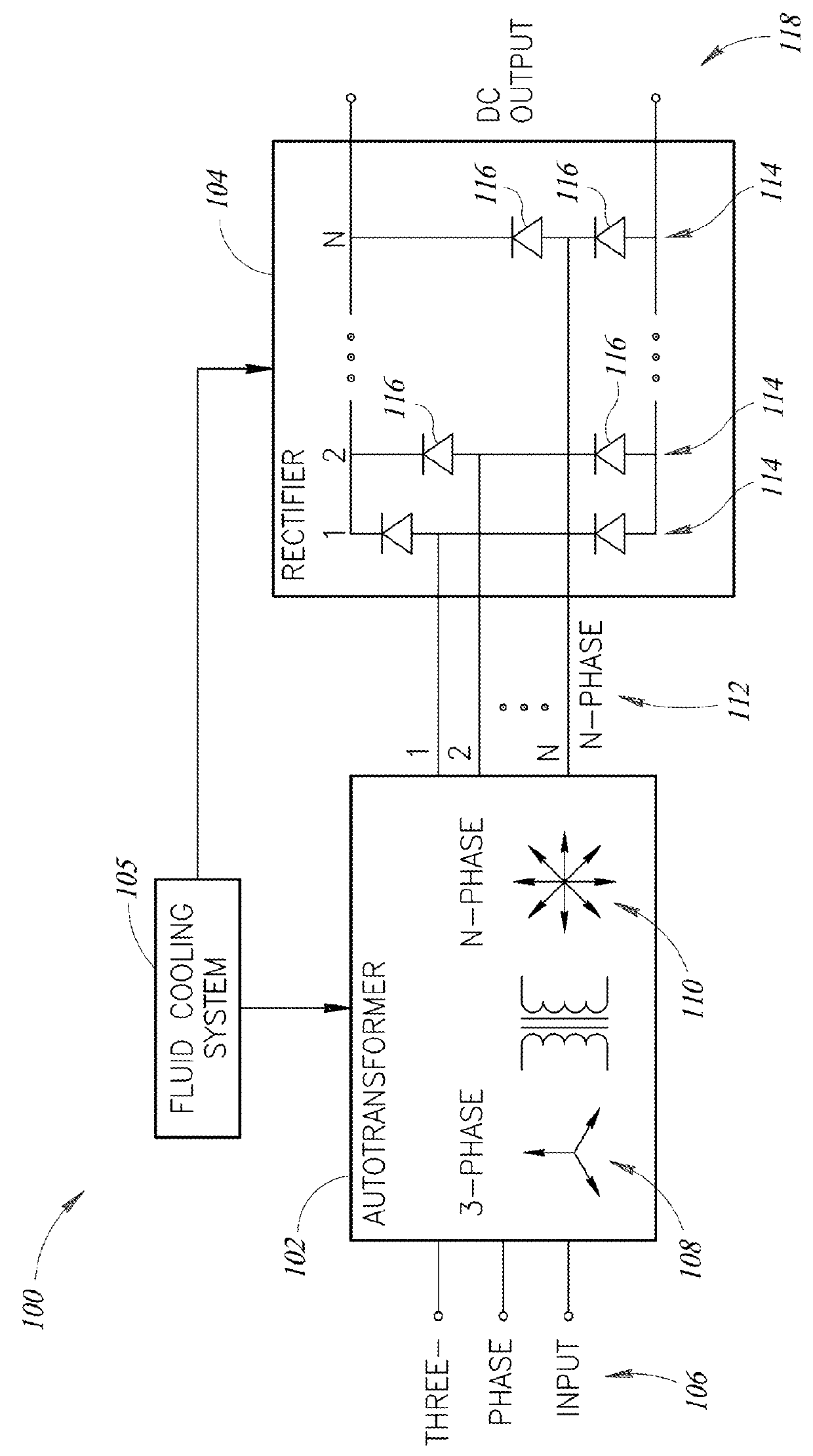

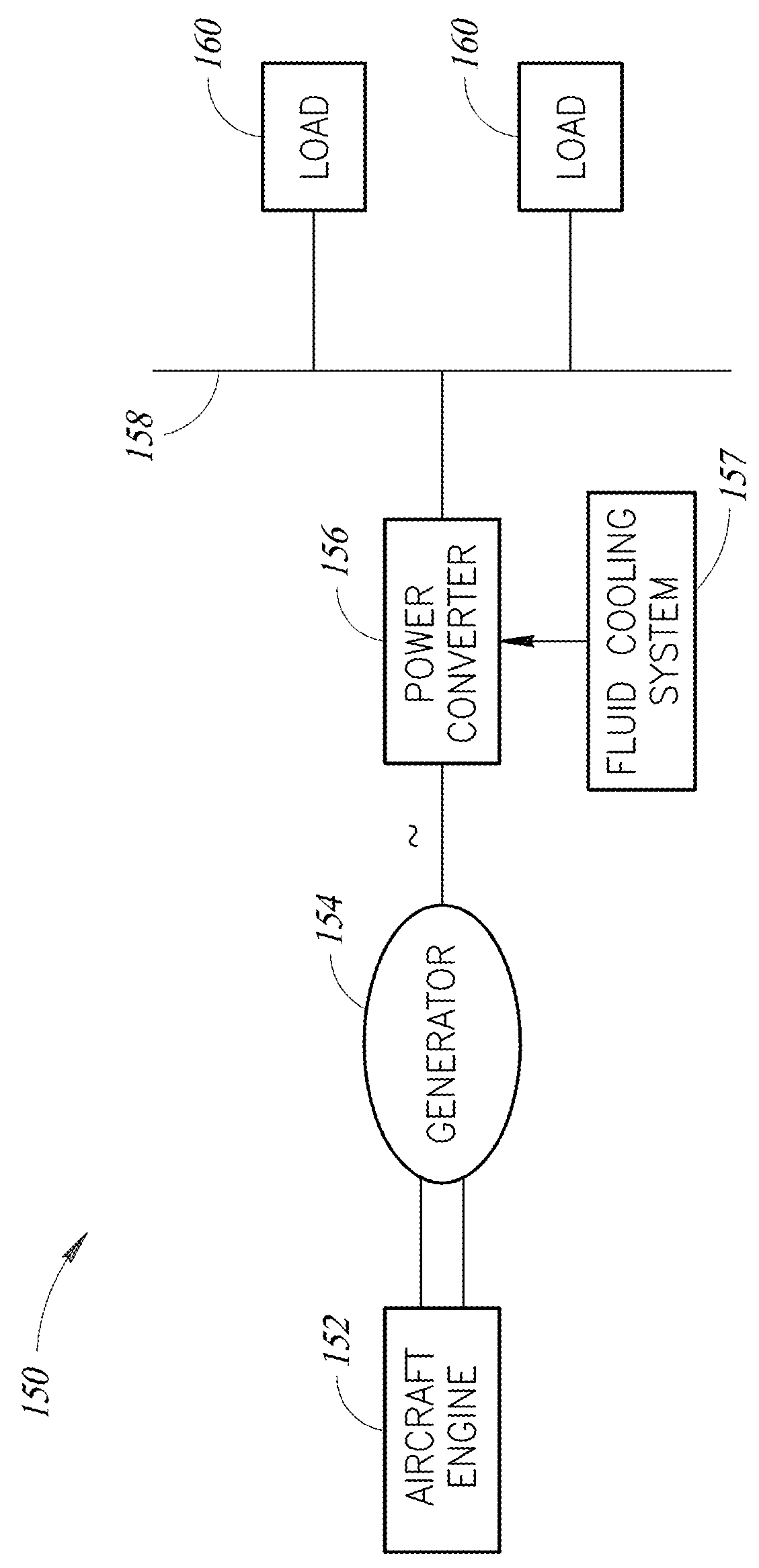

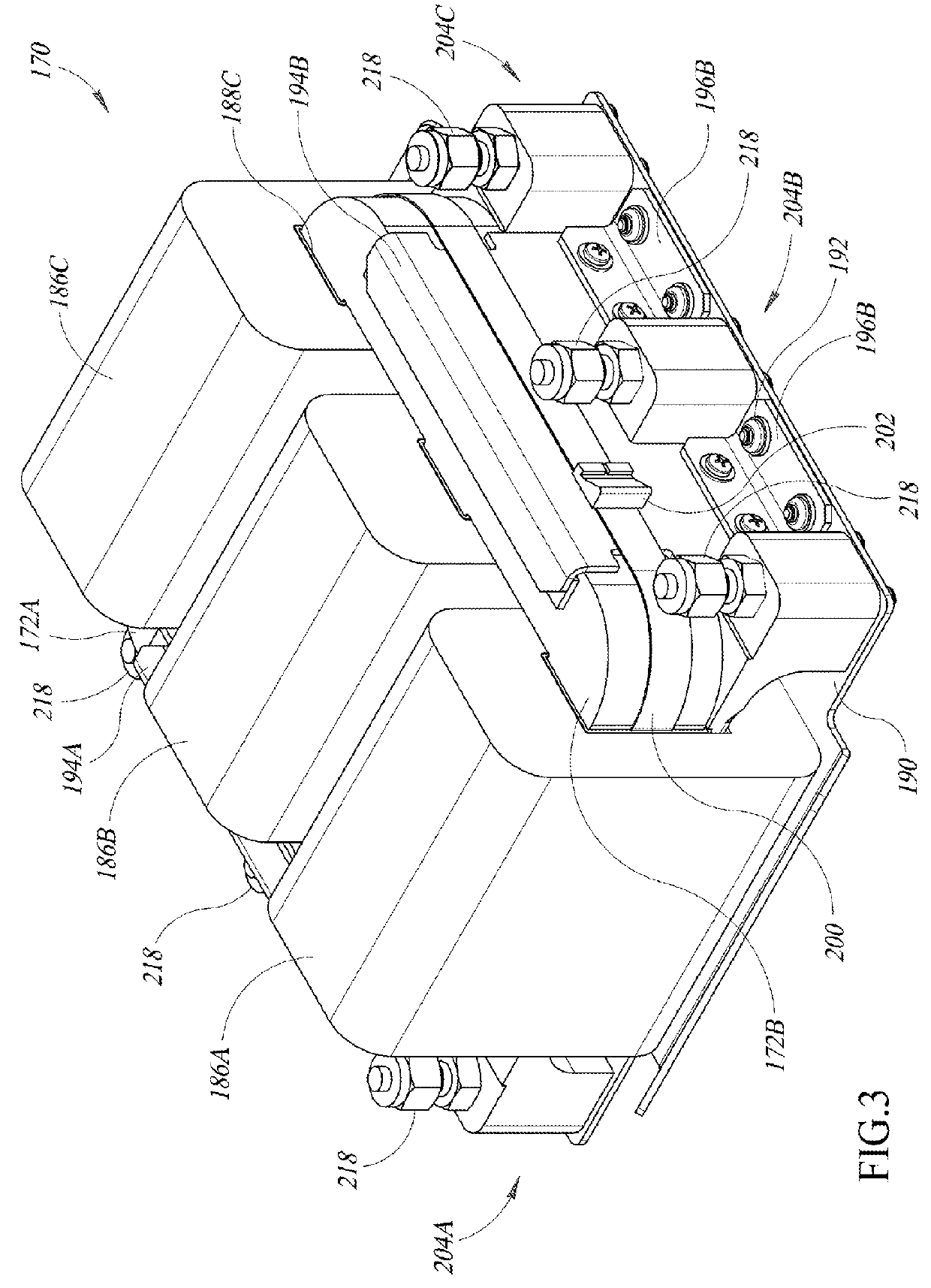

Transformer-based power converters with 3D printed microchannel heat sink

ActiveUS9230726B1Additive manufacturing apparatusTransformers/inductances coolingManufacturing technologyTransformer

Systems and methods that allow for weight and size reduction of electronics components, such as transformer rectifier units (TRUs) or autotransformer rectifier units (ATRUs), by providing a fluid cooling system is utilized to provide high heat dissipation for a transformer assembly of TRUs or ATRUs by providing a thermal interface at the windings of the transformer assembly, which are the hottest spots in such assemblies. The cooling system may include a fluid-cooled winding heat sink element or “finger,” which may be a thermally conductive bar (e.g., aluminum, copper) having microchannels therein positioned between the core and windings of a transformer or between turns of the windings of a transformer. Fluid passes through the microchannels of the heat sink element to provide direct cooling to the heat generating windings of the transformers. The heat sink element may be produced by an additive manufacturing technology.

Owner:CRANE ELECTRONICS INC

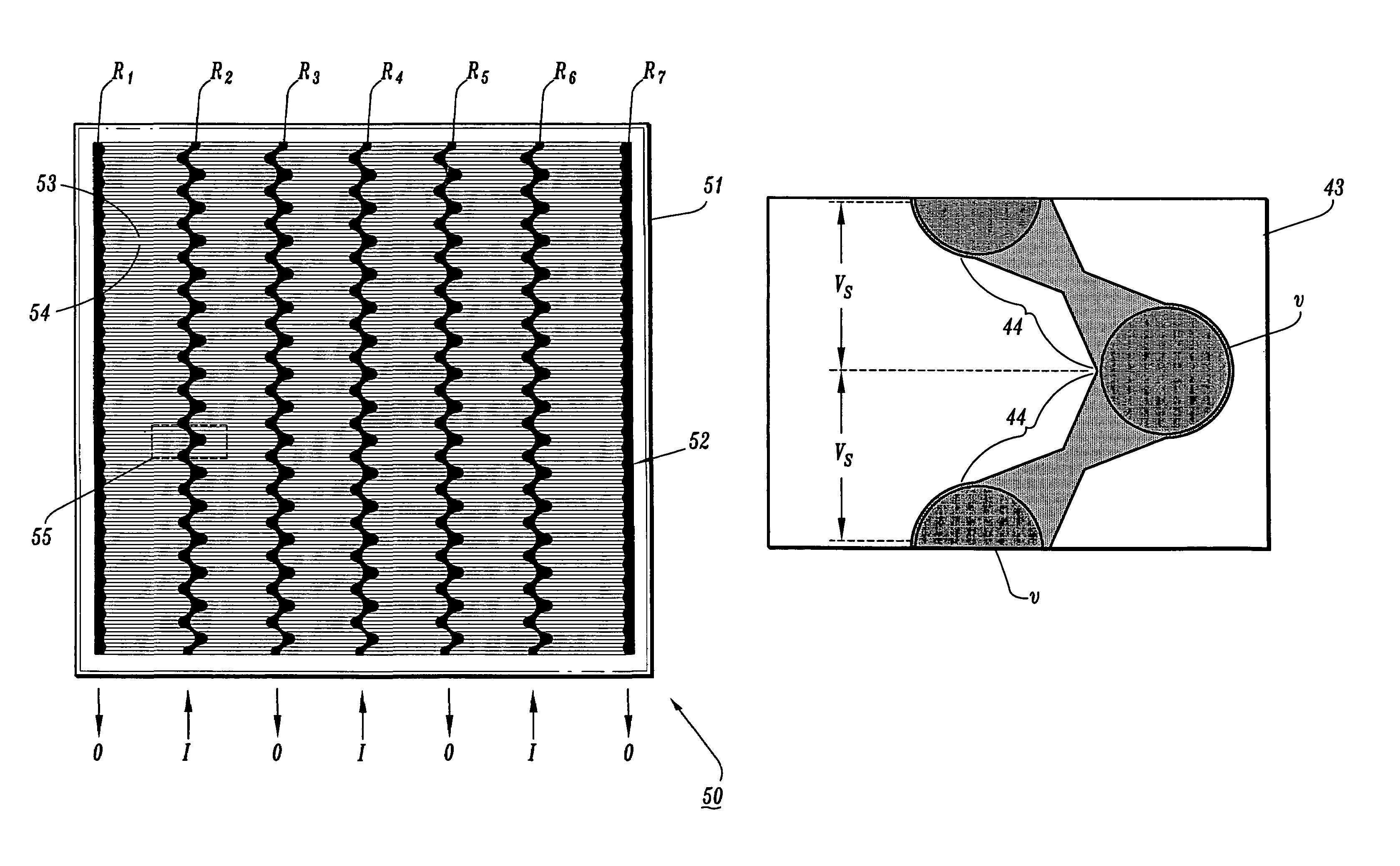

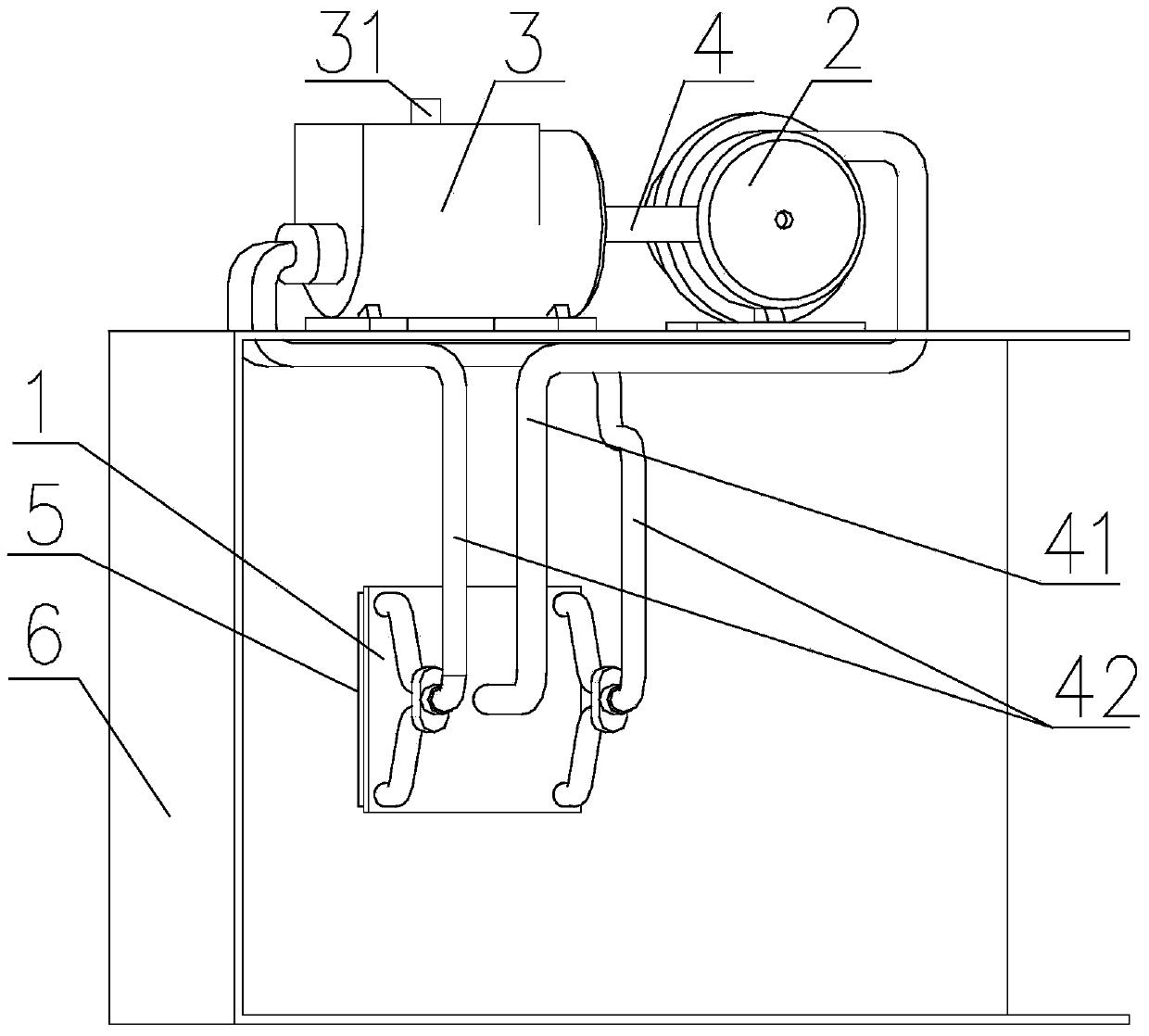

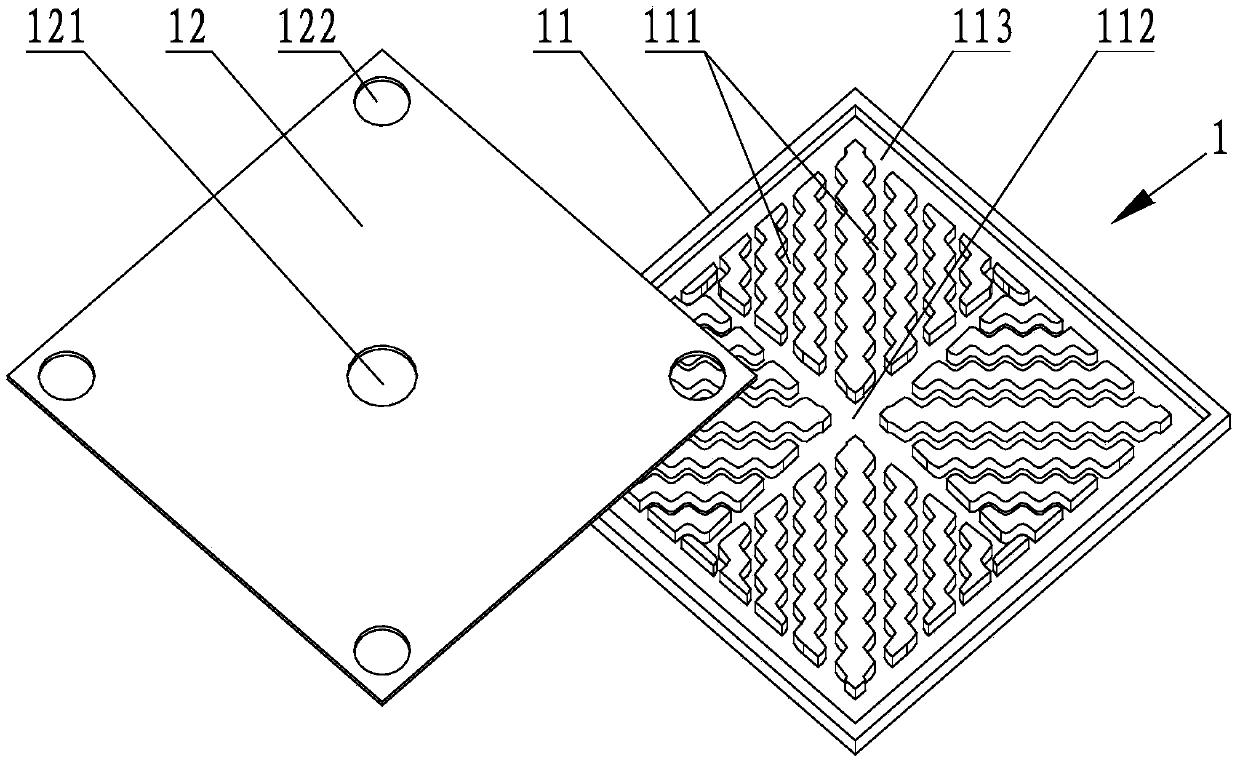

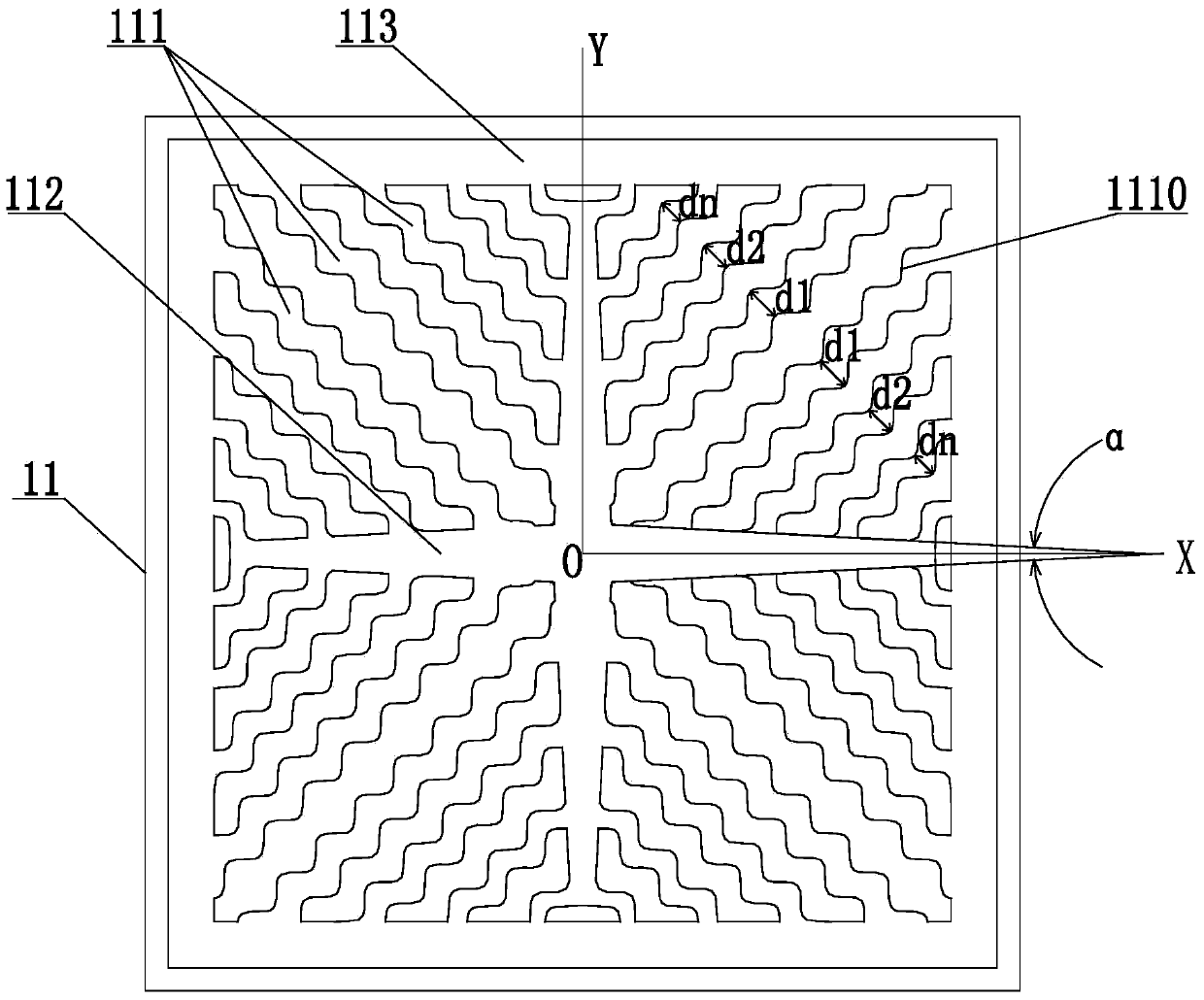

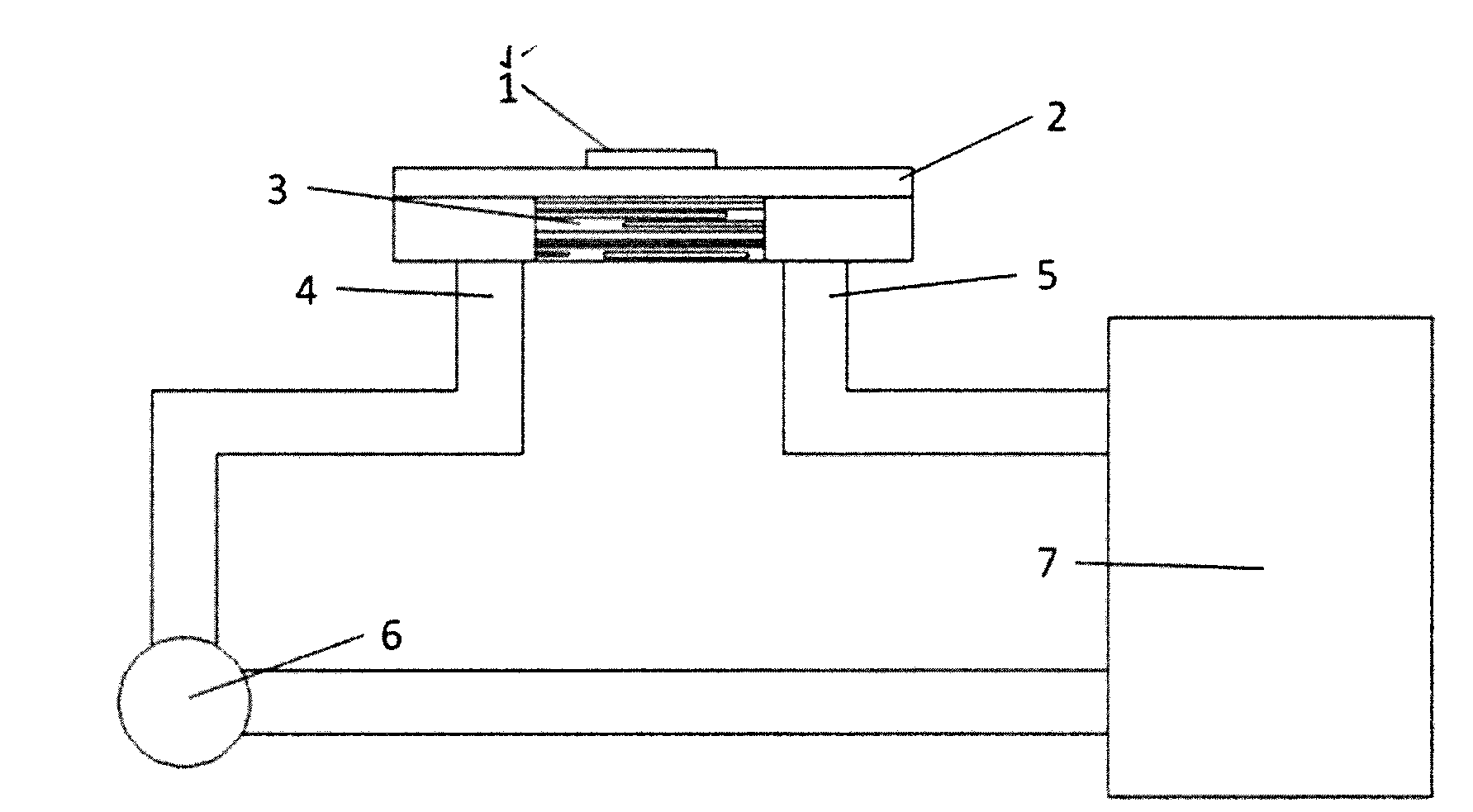

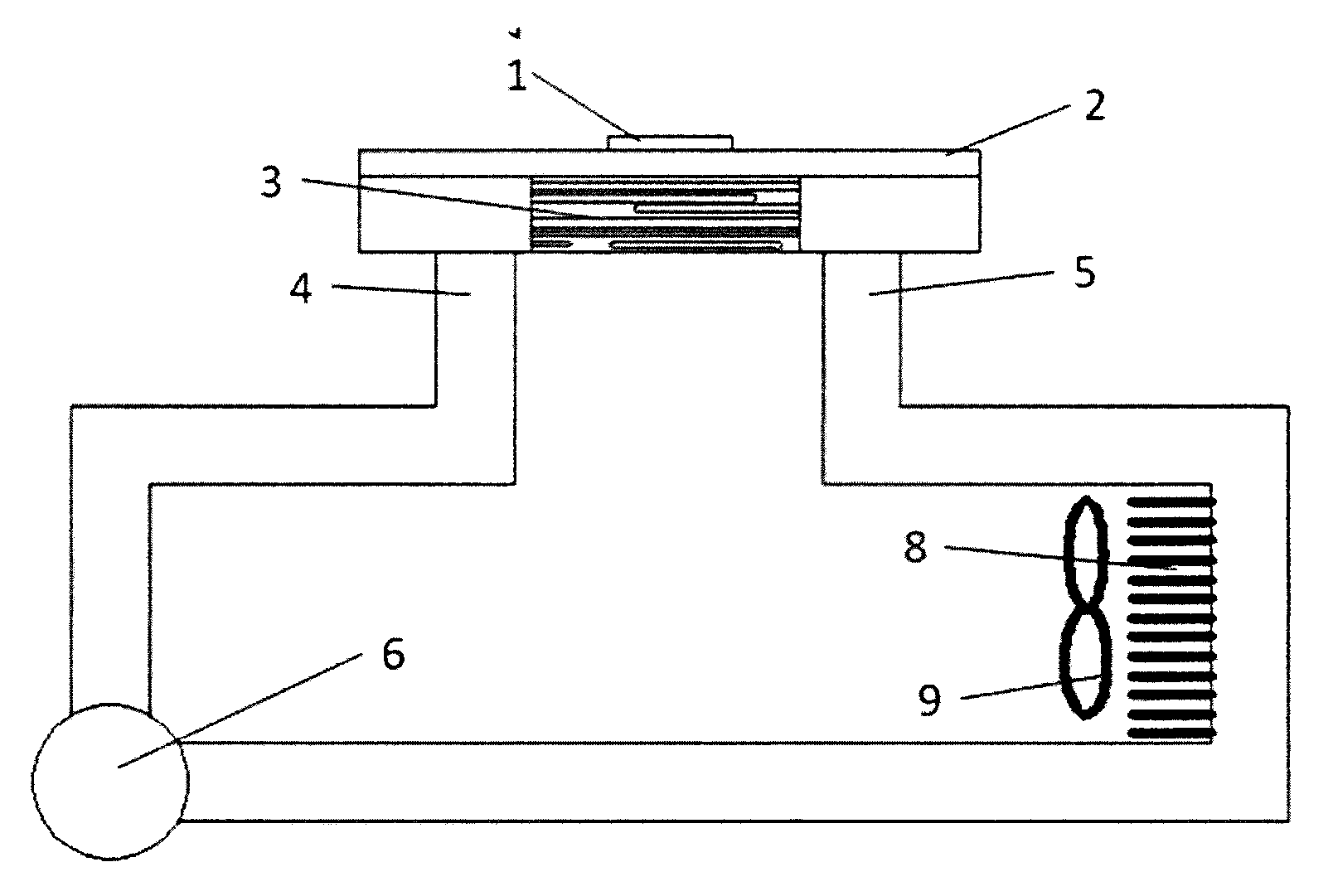

Enhanced heat dissipation device with pulsating flows and wavy-wall microchannels adopted

InactiveCN103996665AIncrease contact areaImprove uniformityDigital data processing detailsSemiconductor/solid-state device detailsAxis of symmetryEngineering

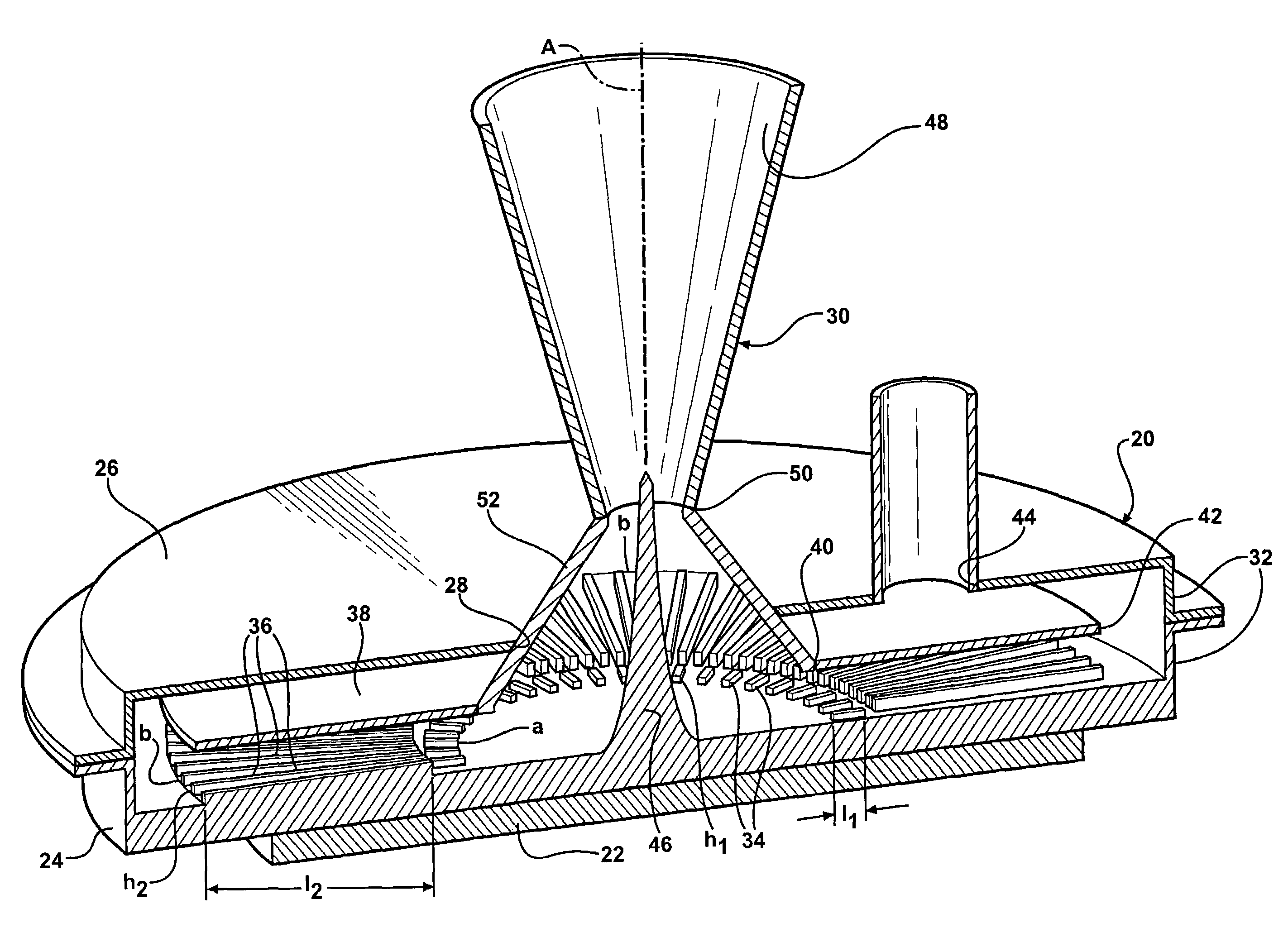

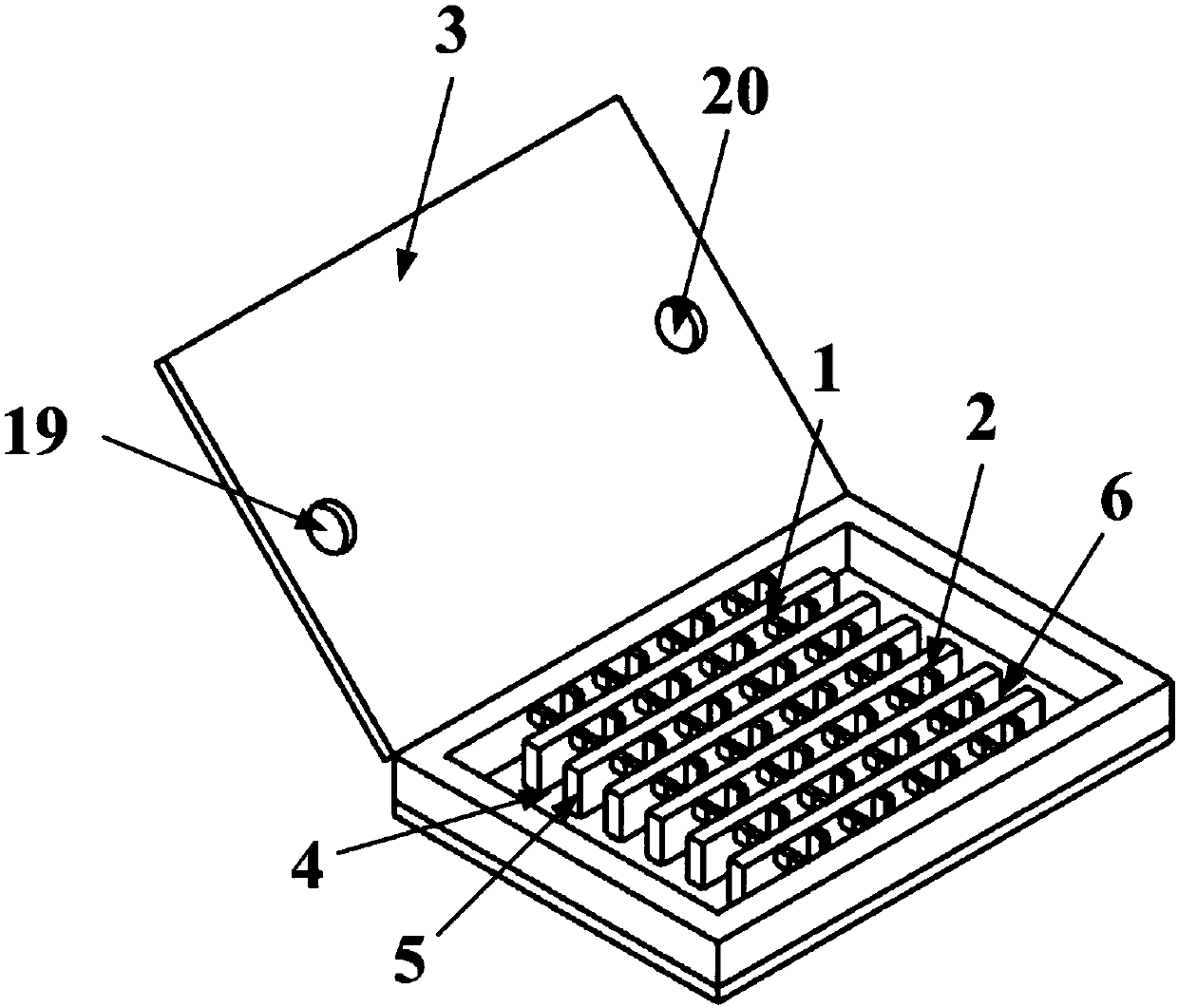

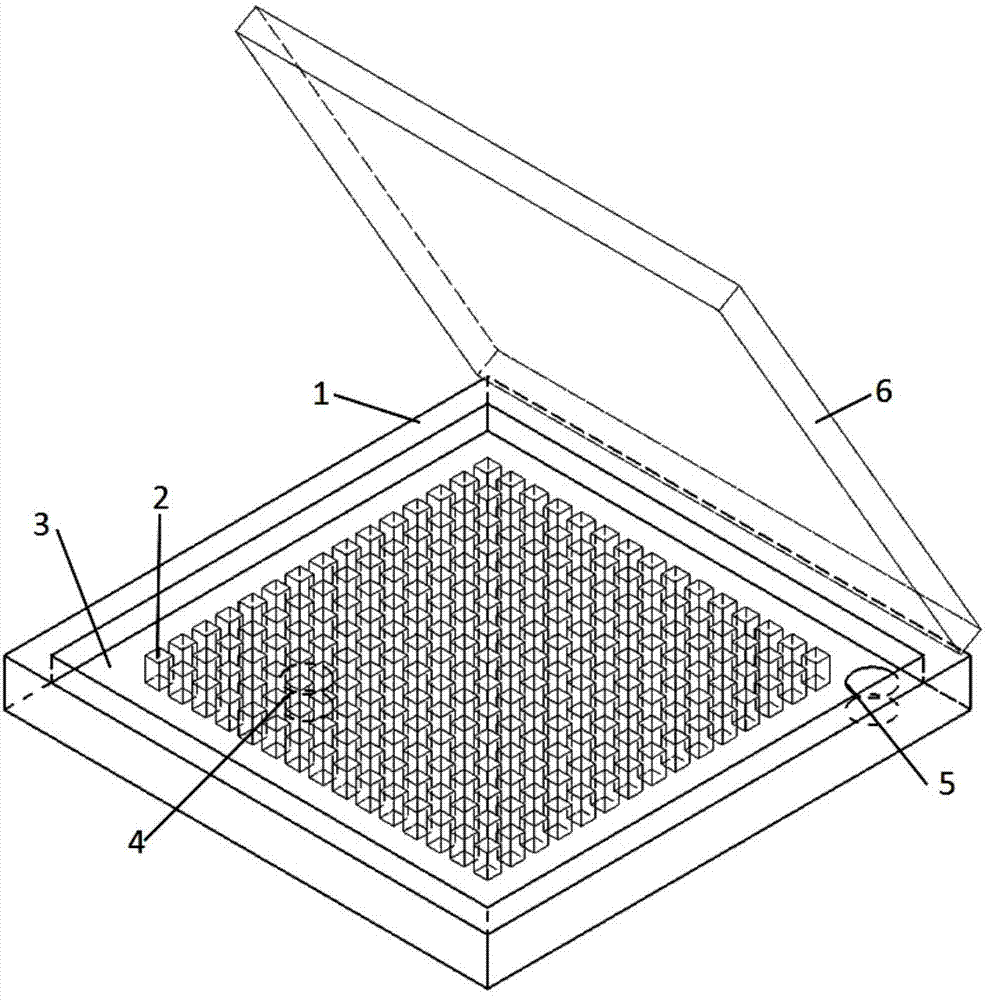

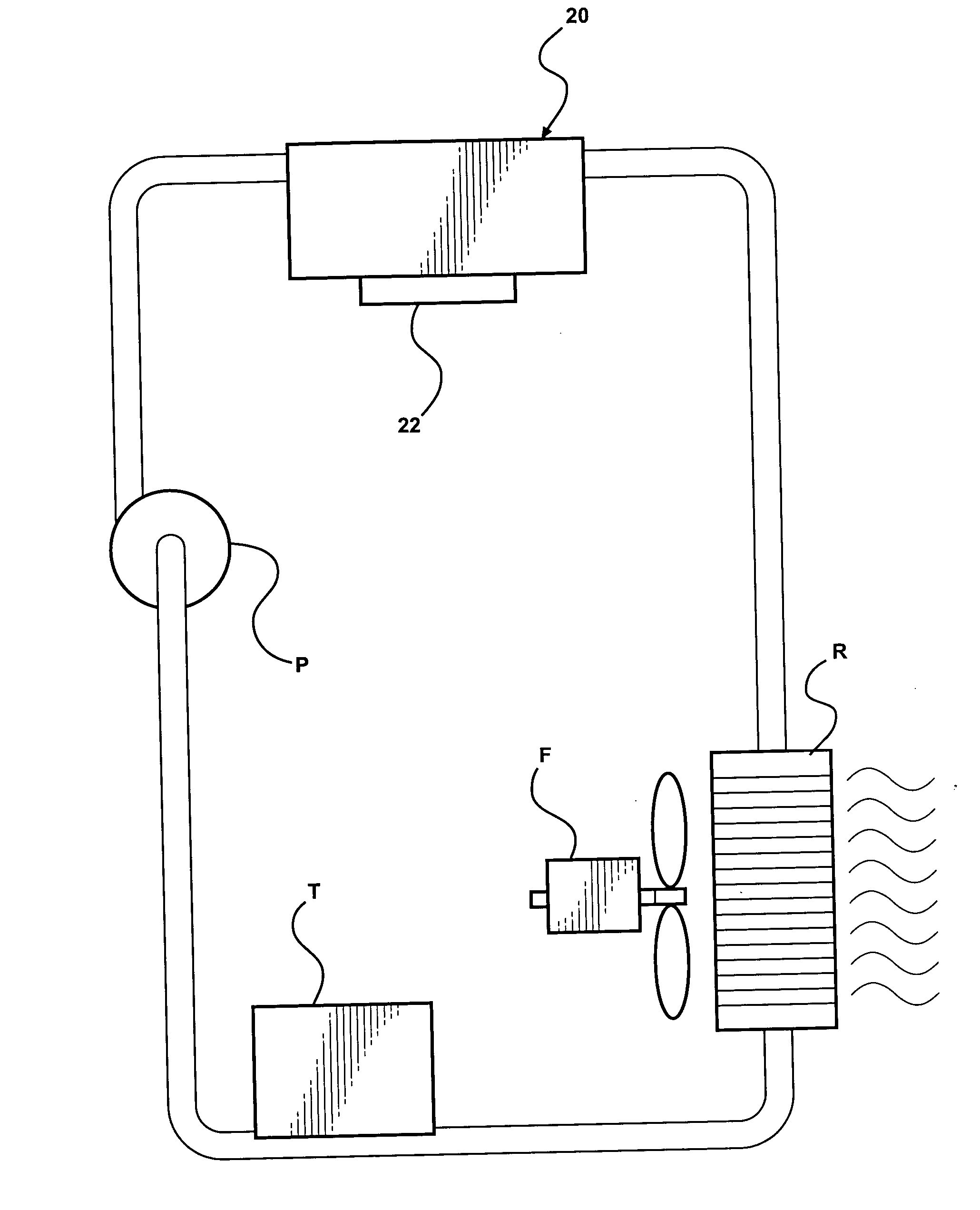

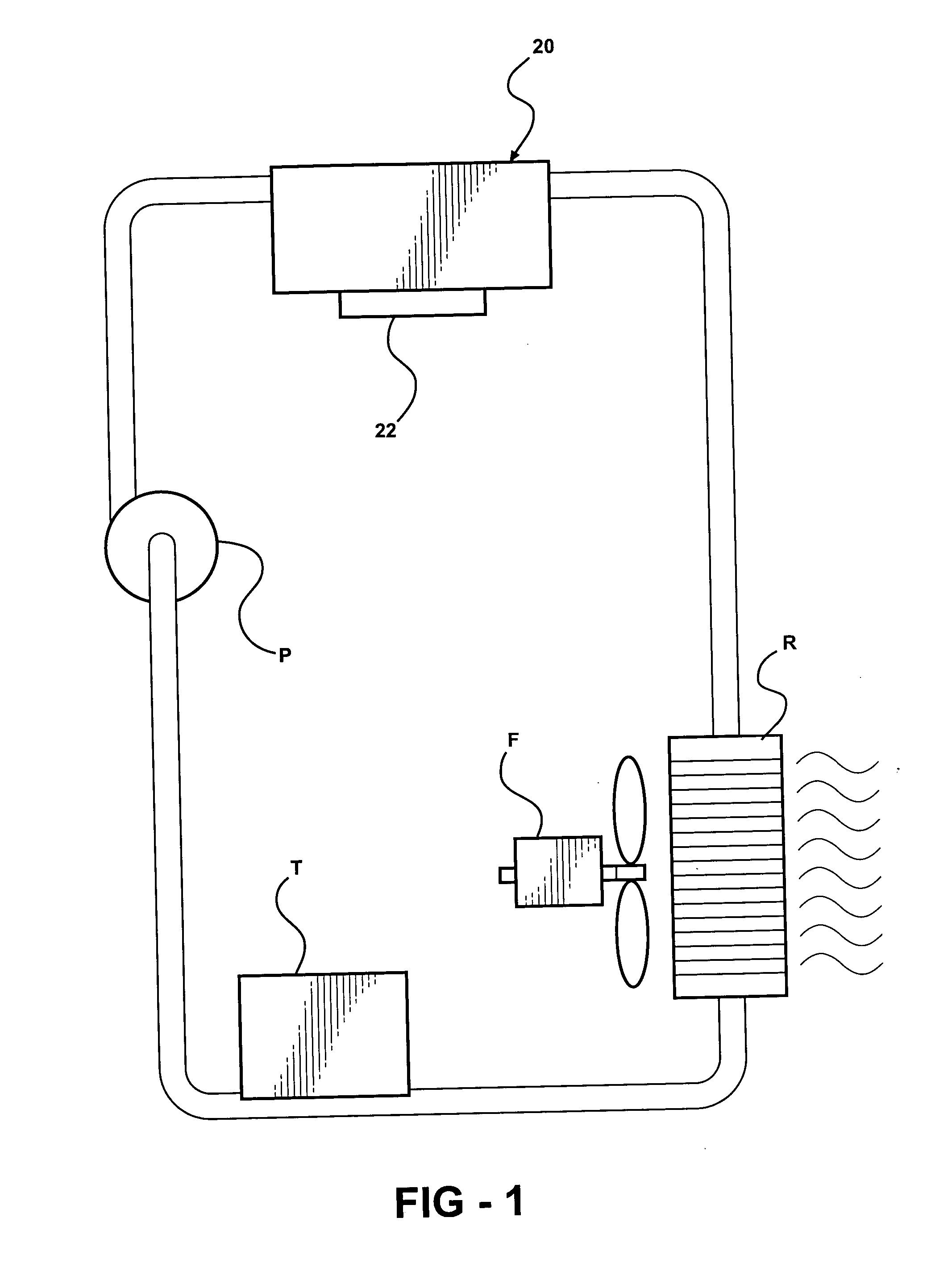

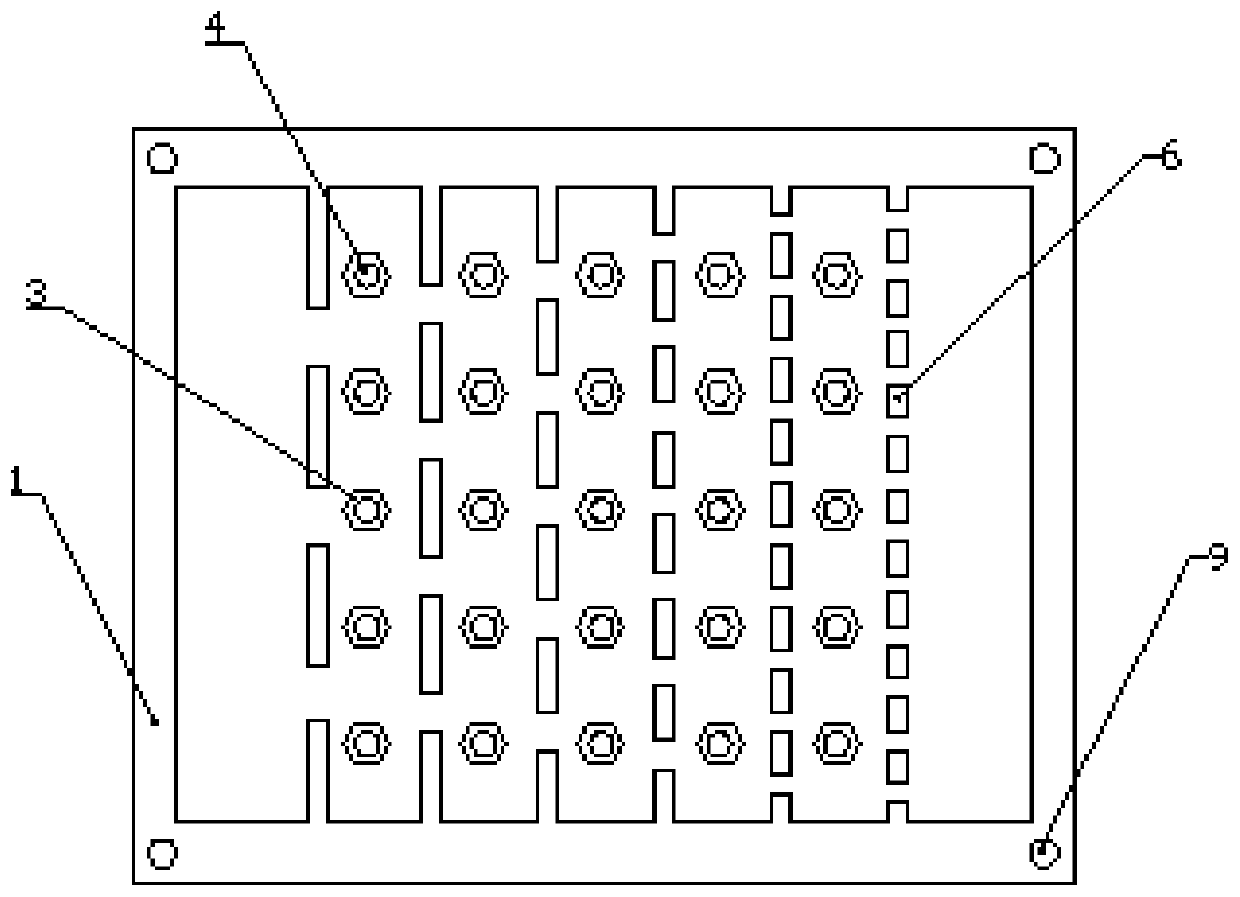

The invention relates to heat dissipation devices and discloses an enhanced heat dissipation device with pulsating flows and wavy-wall microchannels adopted. The device comprises a microchannel heat dissipation cold plate, a pulsating pump, a cooler, a liquid working medium injection pipeline and a liquid working medium return pipeline, wherein the liquid working medium injection pipeline and the liquid working medium return pipeline are used for connecting the microchannel heat dissipation cold plate, the pulsating pump and the cooler together, the microchannel heat dissipation cold plate is a rectangular thin plate and is composed of a microchannel heat sink and a microchannel heat sink cover plate, communicated liquid cavities are formed in the periphery of the microchannel heat sink, the part surrounded by the liquid cavities is divided into four equal parts by two perpendicular liquid division cavities located on the axis of symmetry of the rectangular thin plate, wavy-wall microchannels are distributed all over each equal part in the diagonal direction of the rectangular thin plate, four liquid working medium outlets are formed in the microchannel heat sink cover plate and connected with the liquid working medium return pipeline, and a liquid working medium inlet is formed in the microchannel heat sink cover plate and is connected with the liquid working medium injection pipeline. According to the device, the liquid working medium flowing path is fully optimized, and heat exchange efficiency is improved greatly.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Sound baffling cooling system for LED thermal management and associated methods

InactiveUS20120285667A1Compact form factorExtended service lifeSemiconductor/solid-state device detailsSolid-state devicesSound baffleEngineering

A cooling system for light emitting diodes (LEDs) is provided that may comprise acoustic baffle members, a micro-channel heatsink that includes fins adjacent to the LEDs, and a fluid flow generator adjacent to the micro-channel heatsink that directs a fluid in a flow direction. The fluid flow generator may include an input to receive the fluid and an exit to exhaust the fluid, which may contact a surface area of the fins. The sound emitted by the fluid flow generator may be substantially cancelled by the acoustic baffle members, which may reflect the sound to a source location as reflected sound waves defined by a substantially inverted phase.

Owner:LIGHTING SCI GROUP

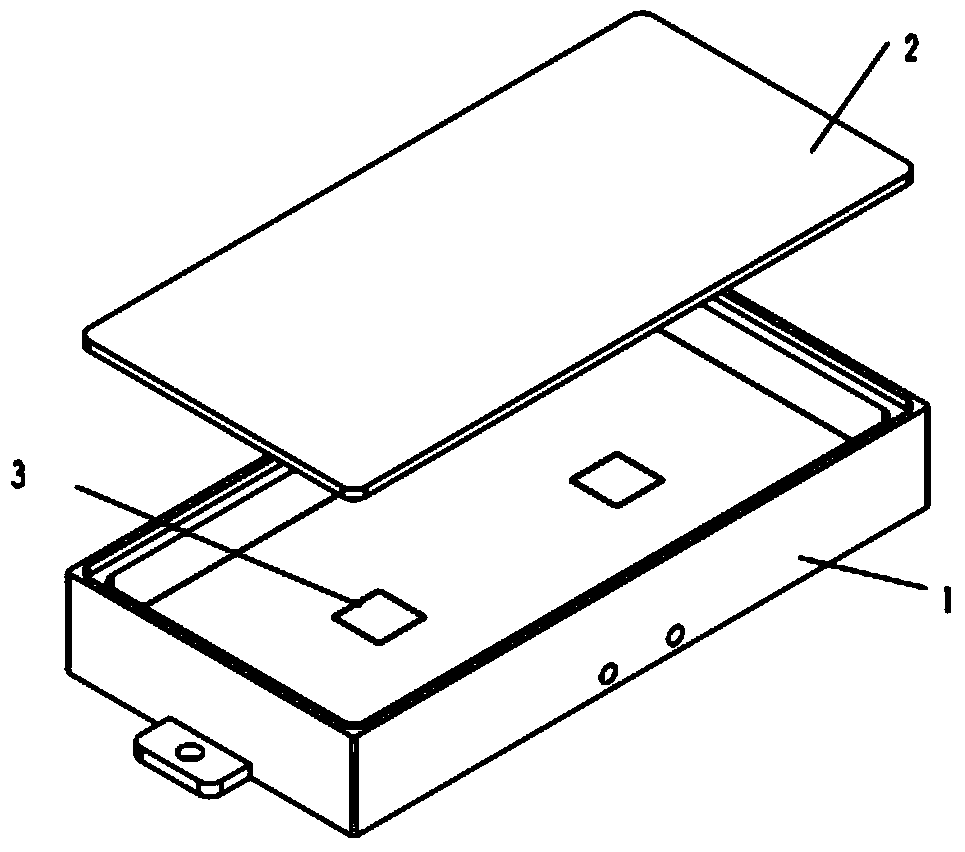

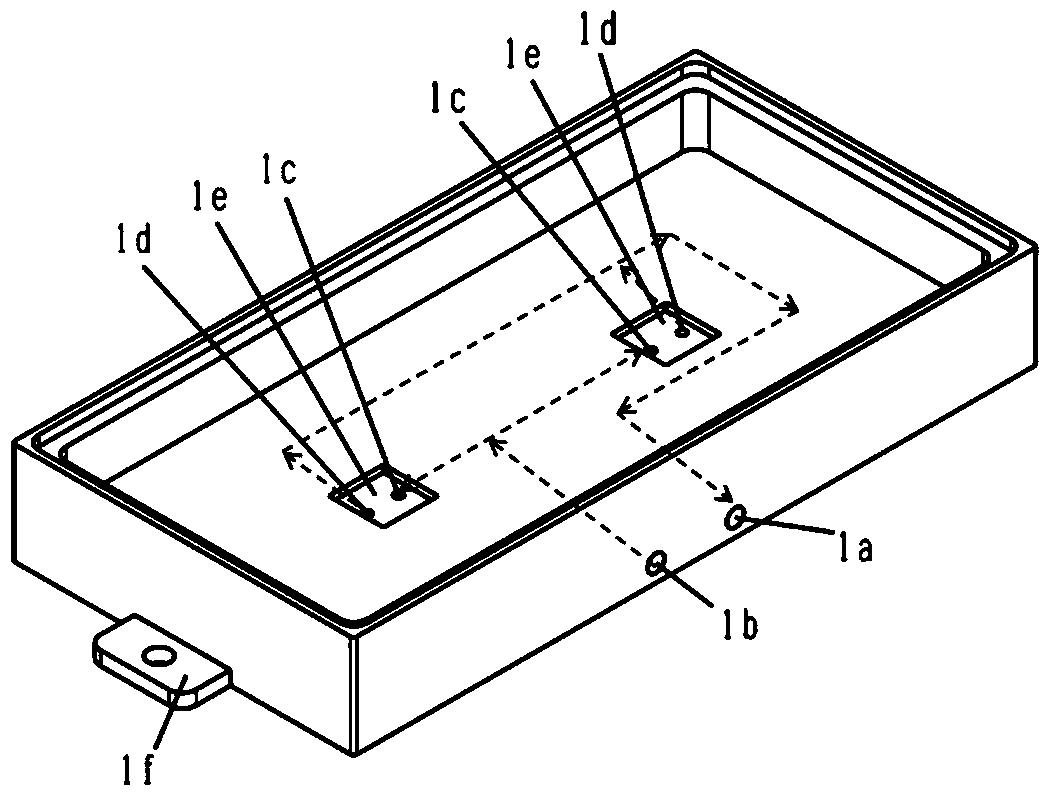

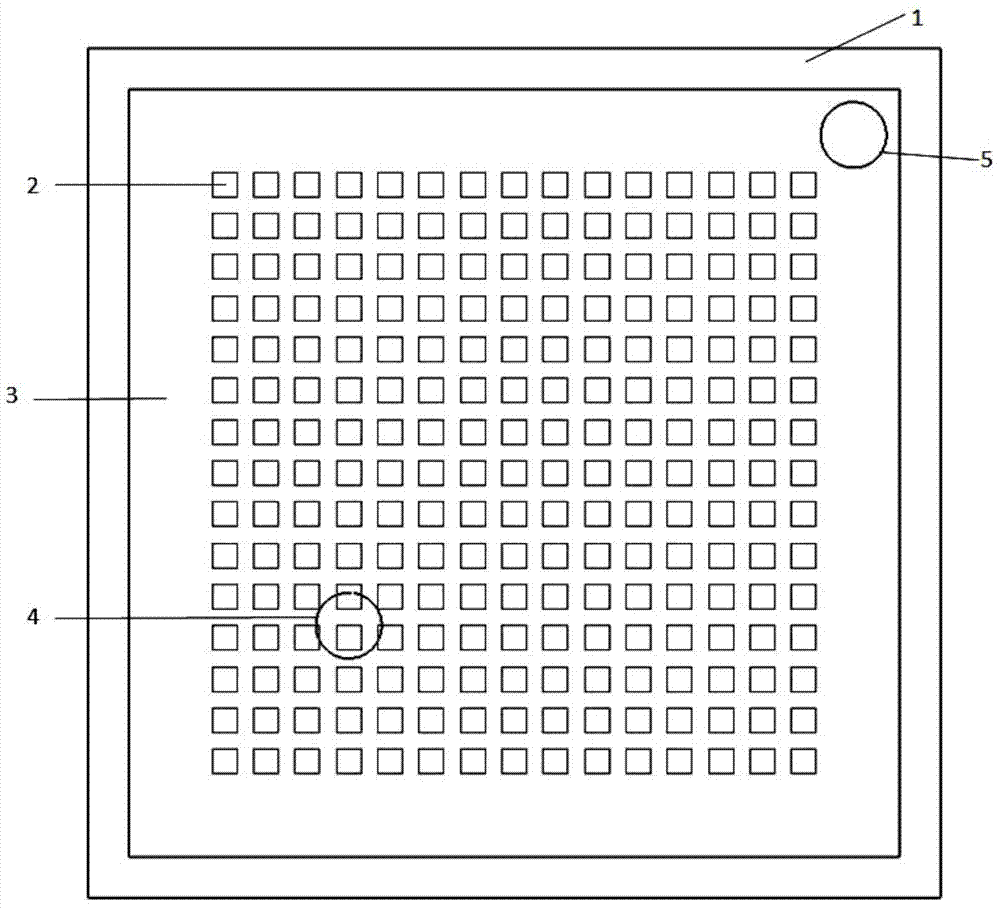

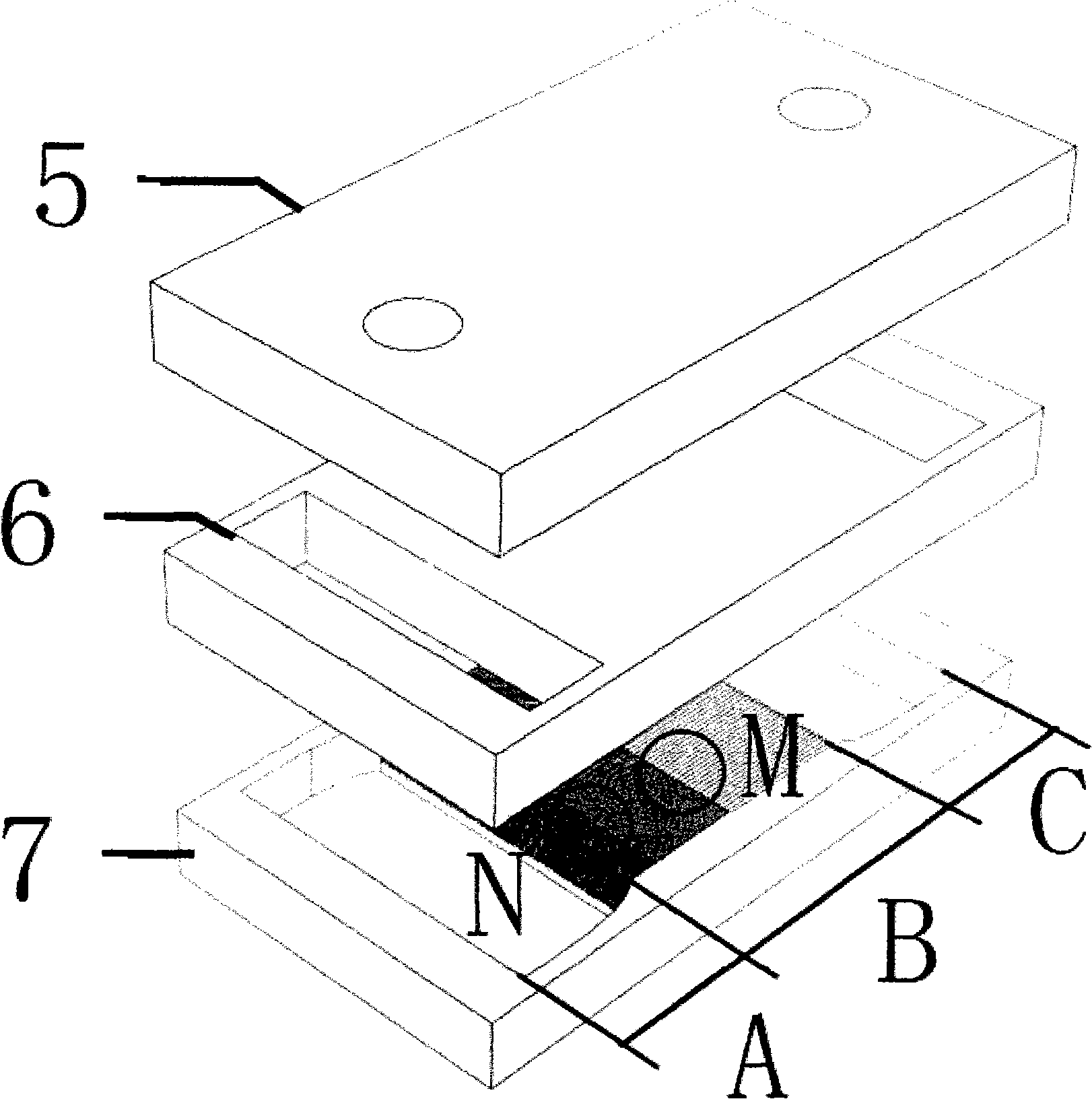

Integrated cooling device of silicon-based micro-channel radiator

InactiveCN104201158AReduce thermal resistanceGood expansion coefficient matchingSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic chip

The invention provides an integrated cooling device of a silicon-based micro-channel radiator, which is composed of a box body, a silicon-based micro-channel radiator and a cover plate. The box body is a cavity with an opening at the upper end; a flow channel is arranged inside the bottom plate of the box body; a unit cooling liquid inlet and outlet, and an externally connected opening of an internal electronic chip are arrange on the outer side face of the box body; multiple small grooves are formed in the bottom plate of the box body; the silicon-based micro-channel radiator is arranged in the small grooves; two openings are formed in the bottom of each small groove to realize communication between the cooling liquid inlet and outlet of the silicon-based micro-channel radiator and the flow channel at the bottom of the box body; the silicon-based micro-channel radiator is composed of a silicon bottom plate and a silicon cover plate; radiating fins are formed on the silicon bottom plate; both the thickness of the fins and the distance among the fins are less than 0.1 mm. Through such the integration way, the radiator can be arranged and expanded based on the number and positions of high heating flux density chips, the disadvantage that the silicon-based radiator cannot be enlarged is overcome, and strong universality is achieved.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Low cost anufacturing of micro-channel heatsink

ActiveUS20100157526A1Semiconductor/solid-state device detailsSolid-state devicesMetallurgyBonding process

A cooling device includes a ceramic substrate with a metal layer bonded to an outer planar surface. The cooling device also includes a channel layer bonded to an opposite side of the ceramic substrate and a manifold layer bonded to an outer surface of the channel layer. The substrate layers are bonded together using a high temperature process such as brazing to form a single substrate assembly. A plenum housing is bonded to the single substrate assembly via a low temperature bonding process such as adhesive bonding and is configured to provide extended manifold layer inlet and outlet ports.

Owner:GENERAL ELECTRIC CO

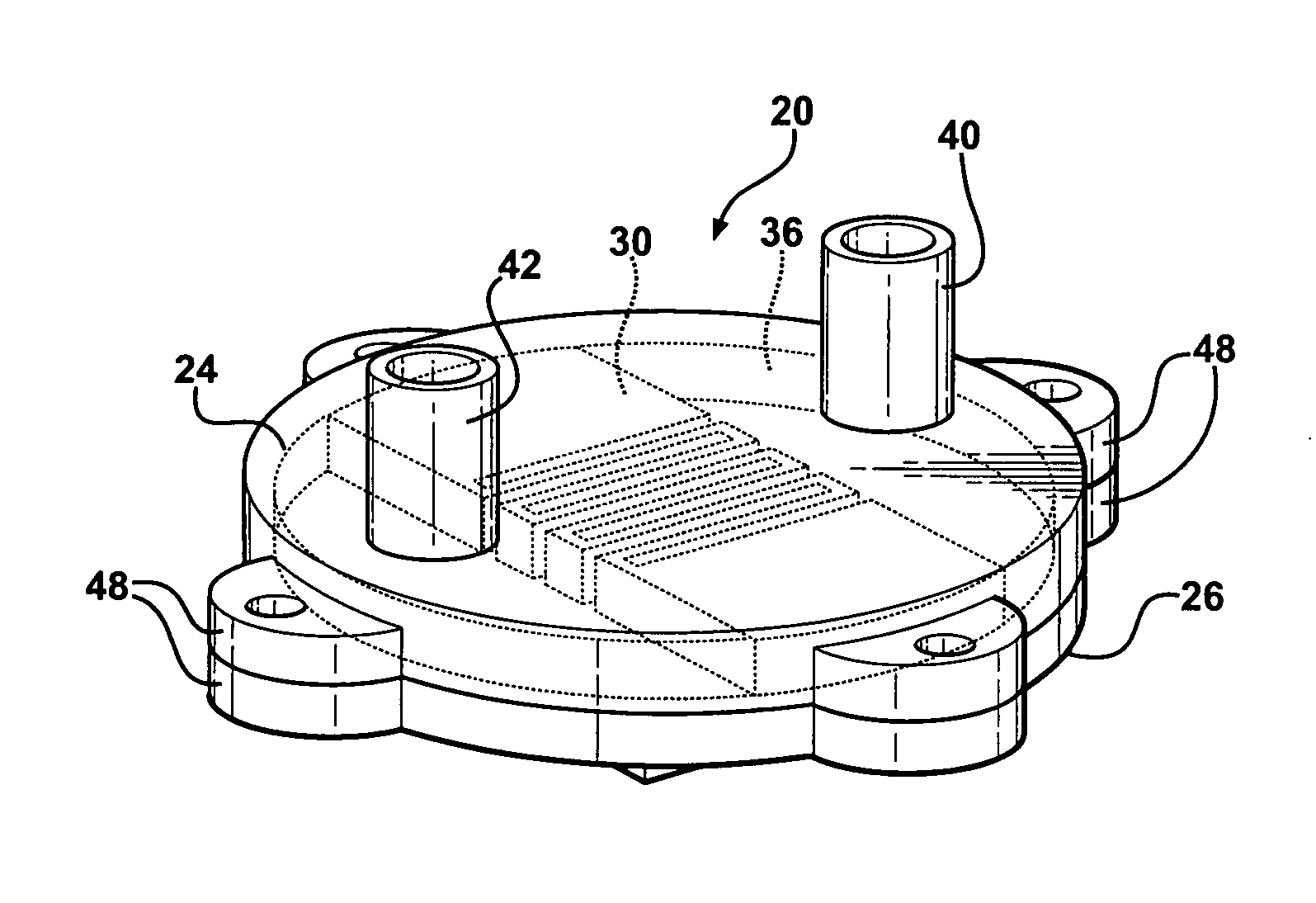

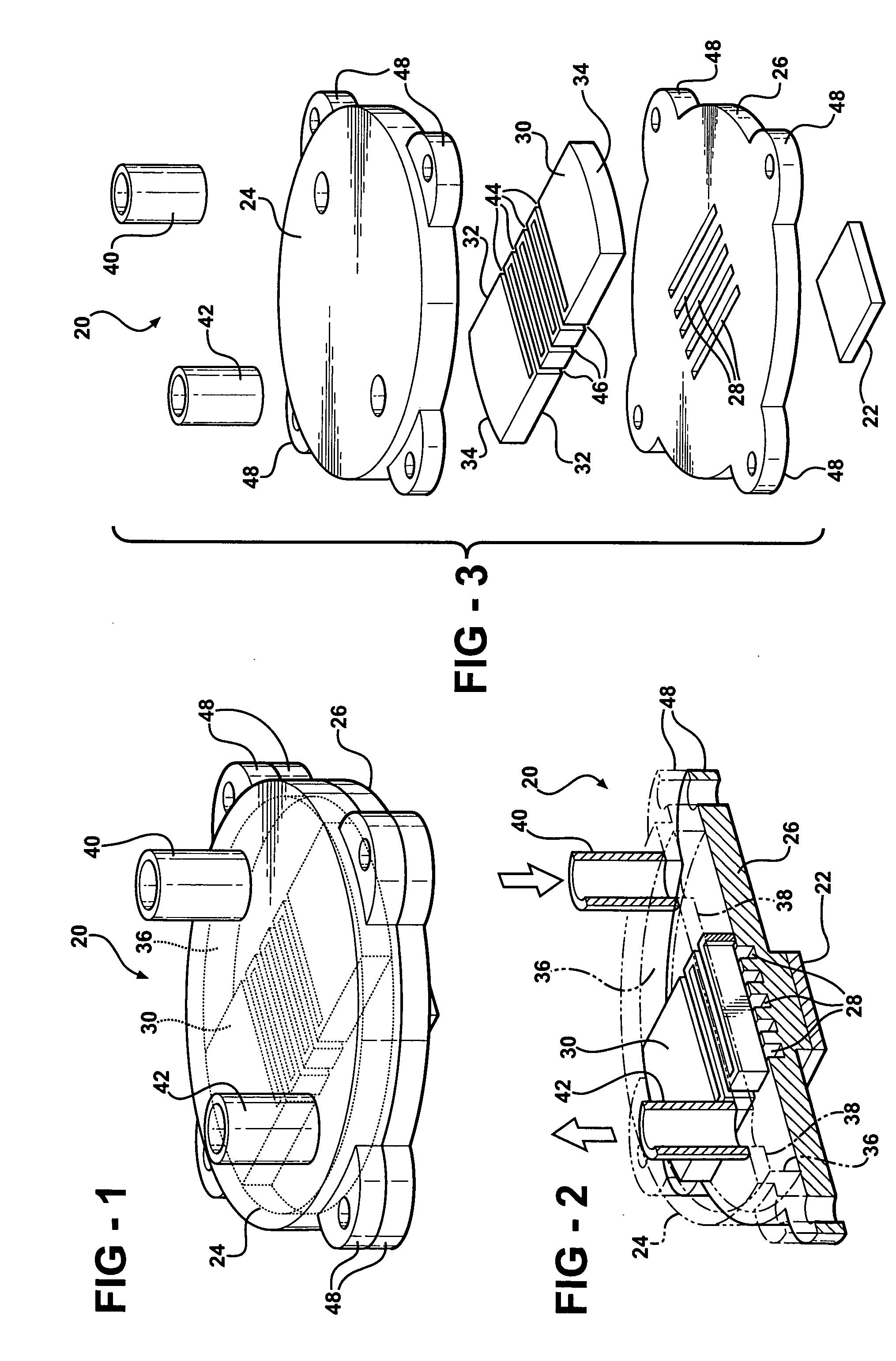

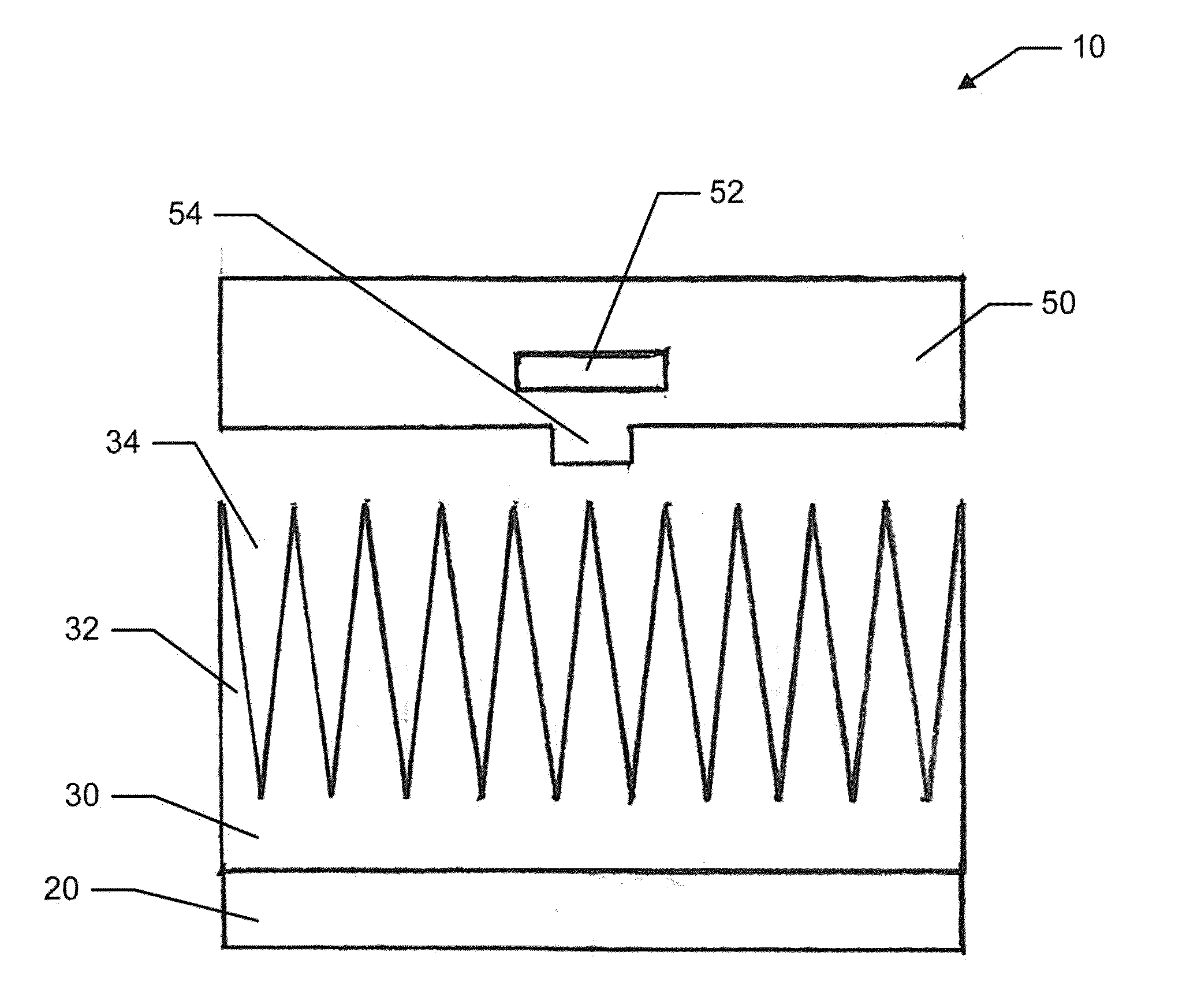

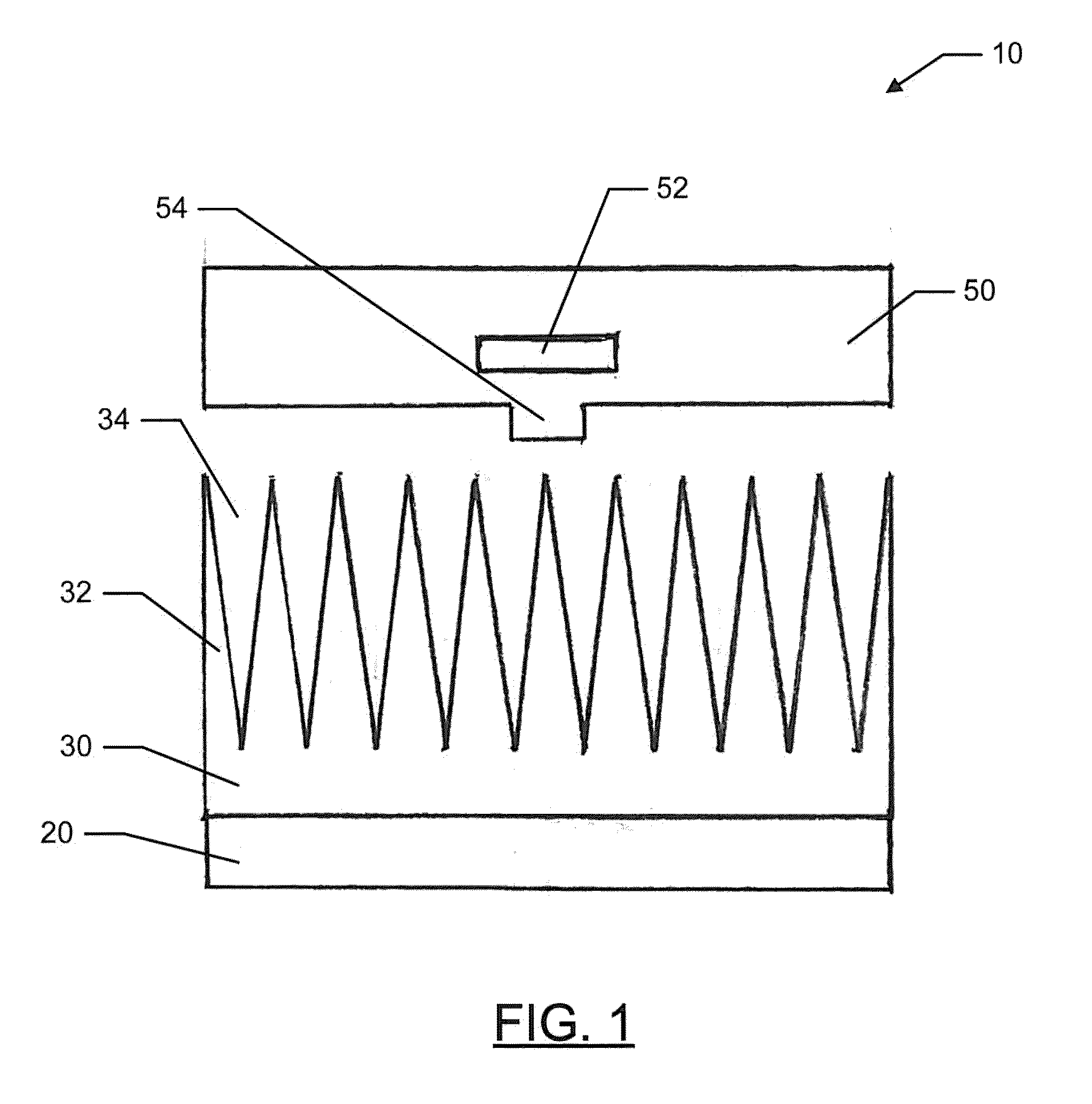

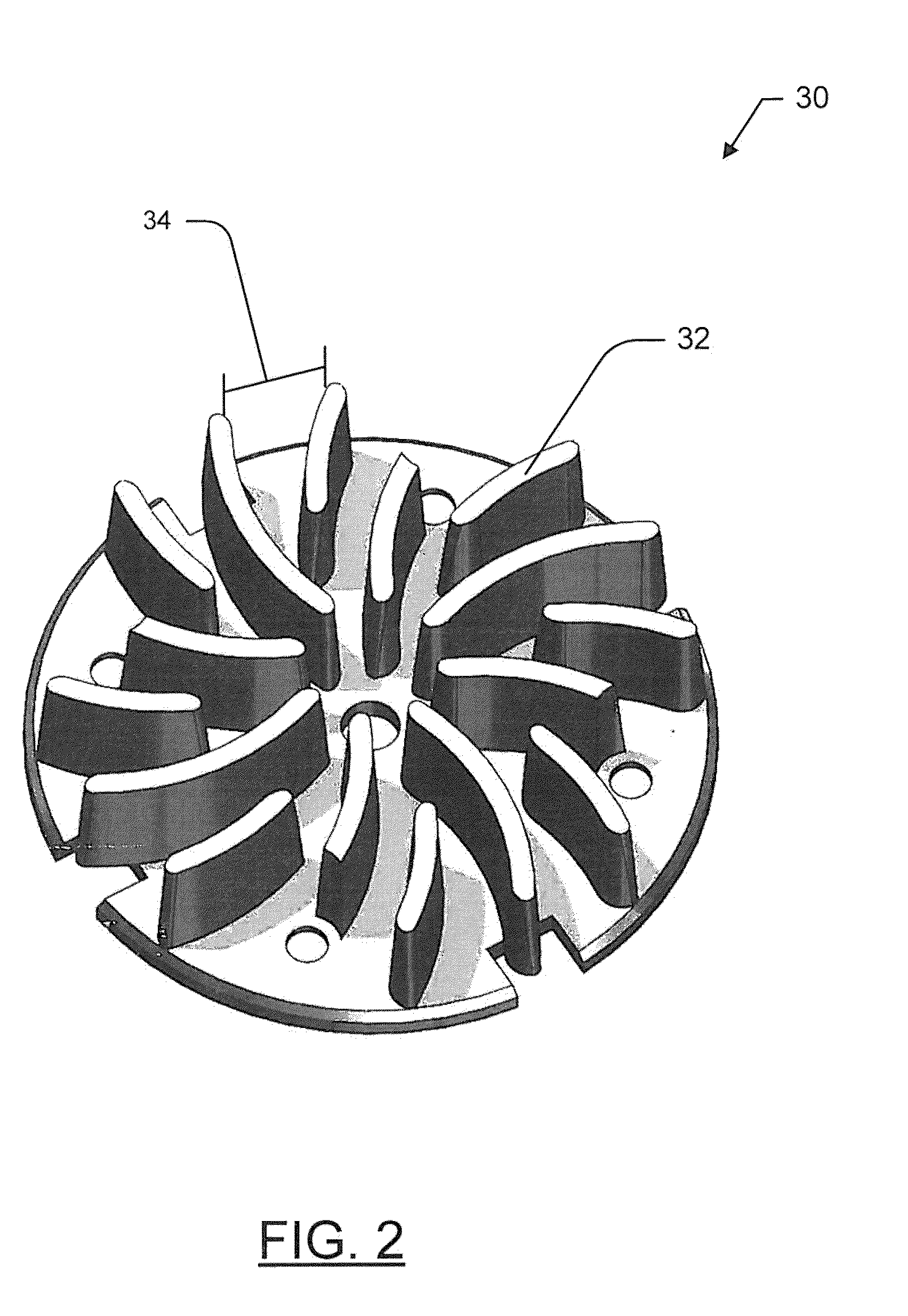

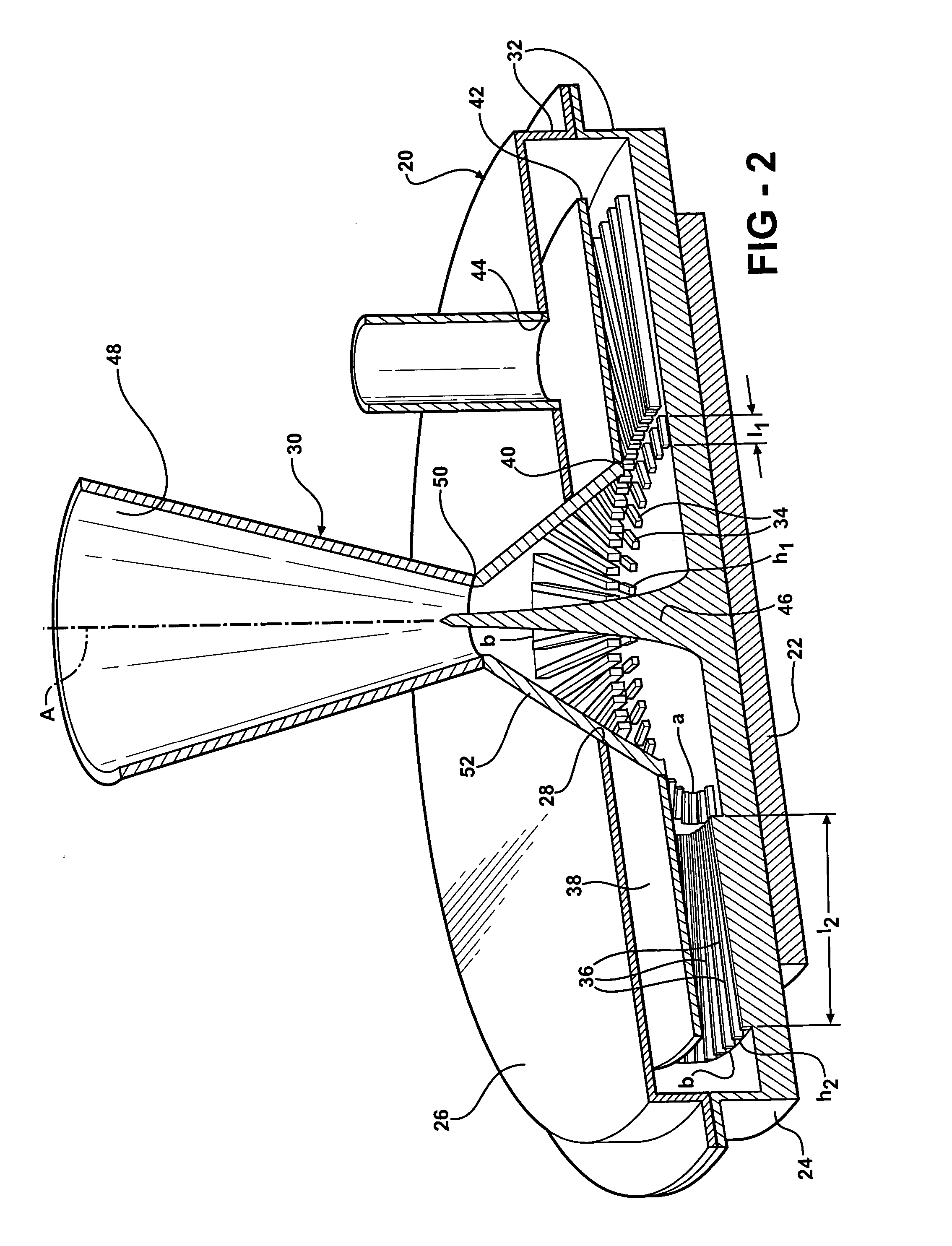

Radial flow micro-channel heat sink with impingement cooling

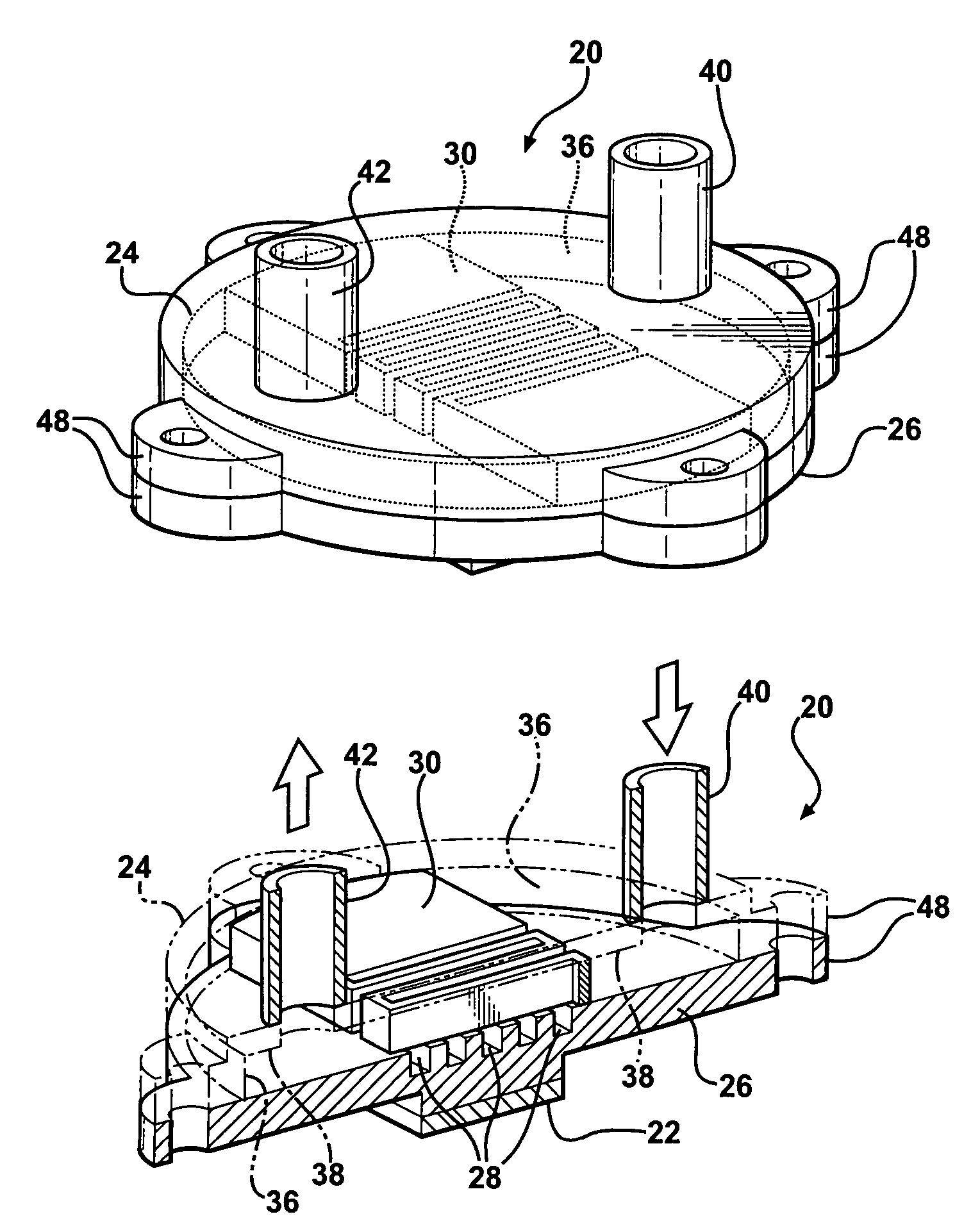

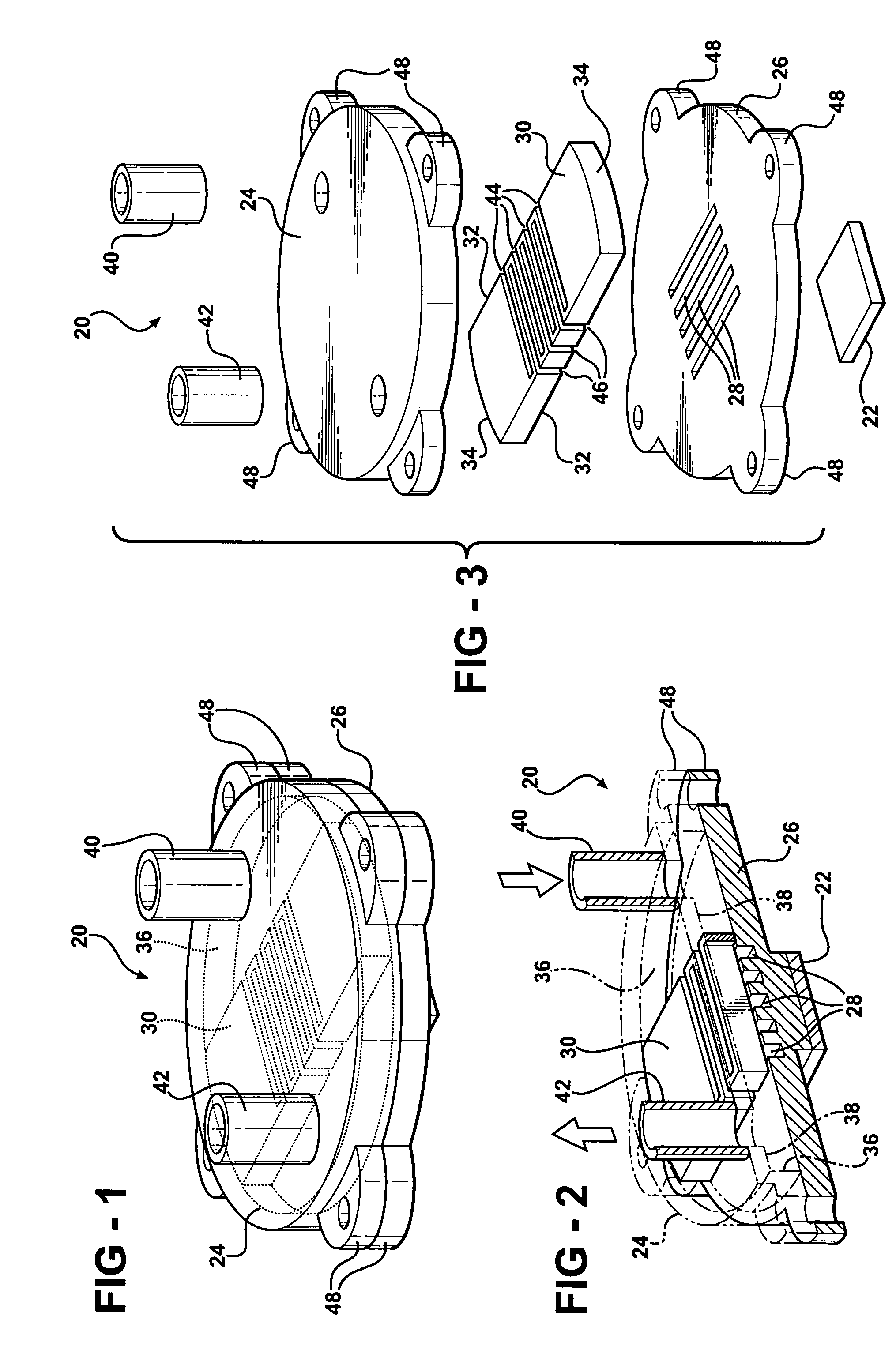

InactiveUS7331380B2Additional componentDomestic stoves or rangesSemiconductor/solid-state device detailsCoolant flowFlow diverter

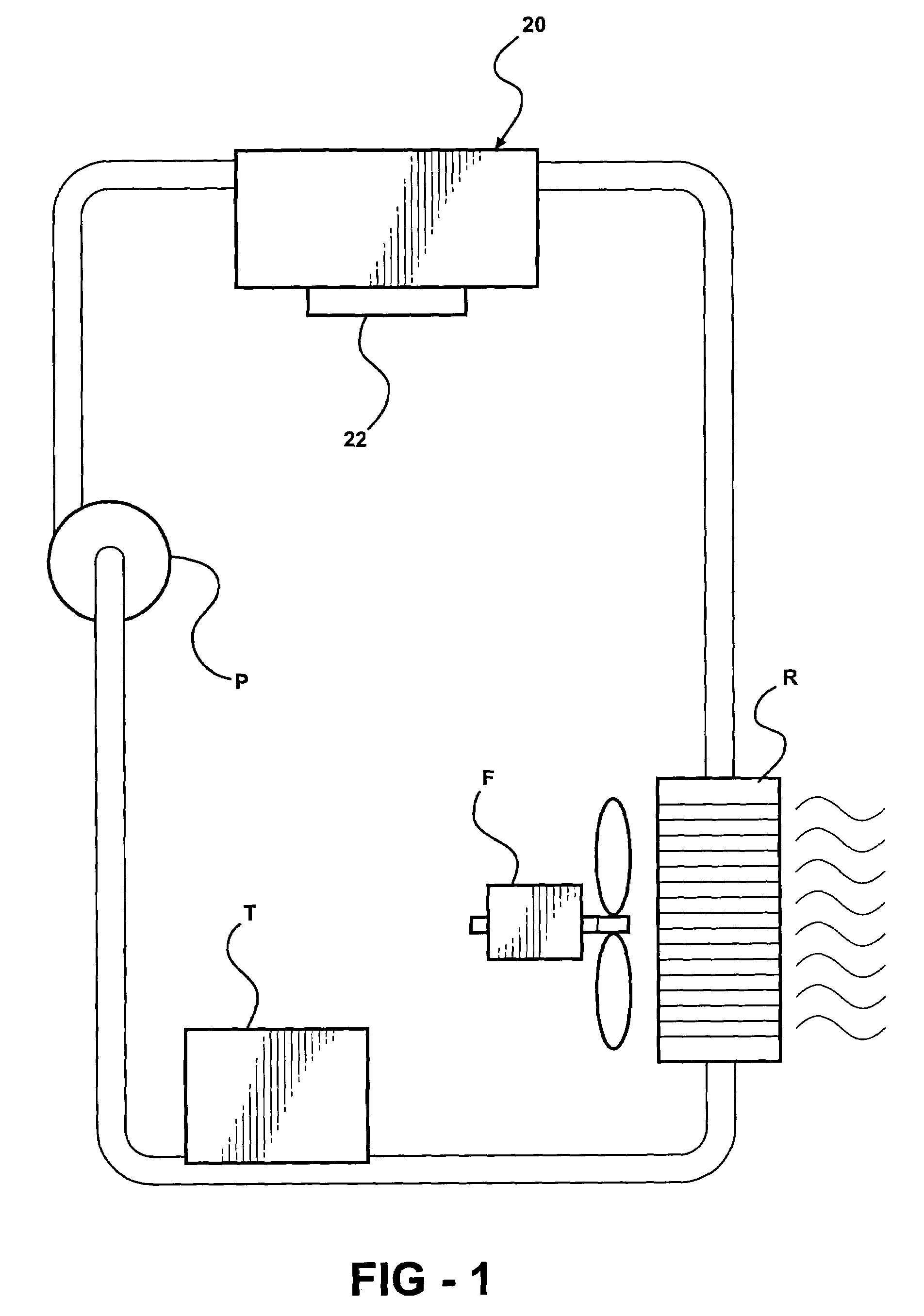

A heat sink removes heat from an electronic device and comprises a base, a lid. An inner ring of first fins extend radially outwardly first length from an inner circle and extend axially a first height from the top surface of the base, and an outer ring of second fins extend radially inwardly a second length from an outer periphery and extend axially a second height from the top surface of the base. A confining plate extends radially above the fins and is spaced below the bottom surface of the lid whereby coolant fluid flows from an inlet opening of the lid through the center opening of the confining plate and radially outwardly through the fins and upward around the outer edge of the confining plate and into the space above the confining plate to an outlet opening. A nozzle having a throat is disposed above the lid and extends below the lid to the confining plate. A flow diverter extends upwardly from the top surface of the base and into and through the throat of the nozzle.

Owner:COOLIT SYSTEMS INC

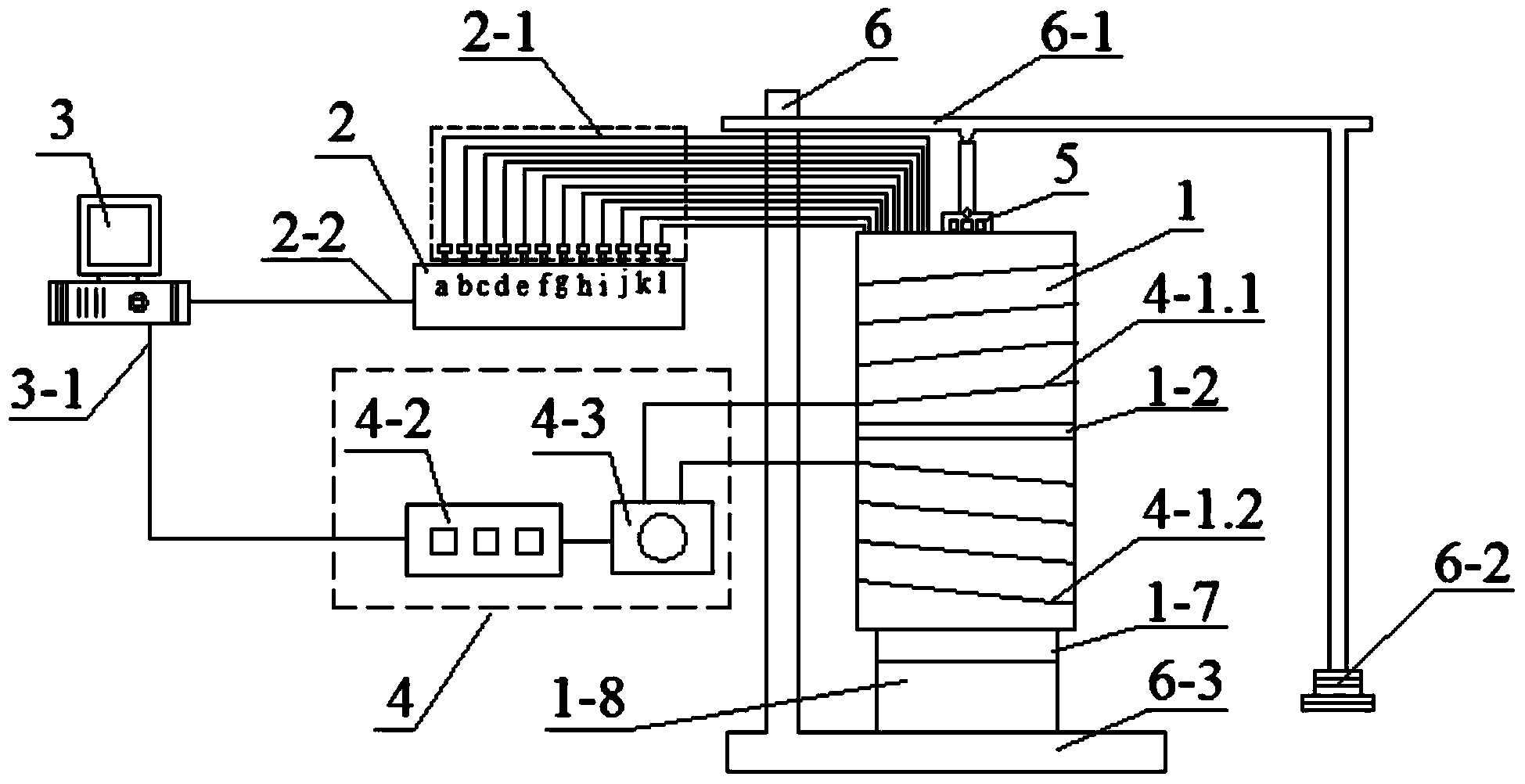

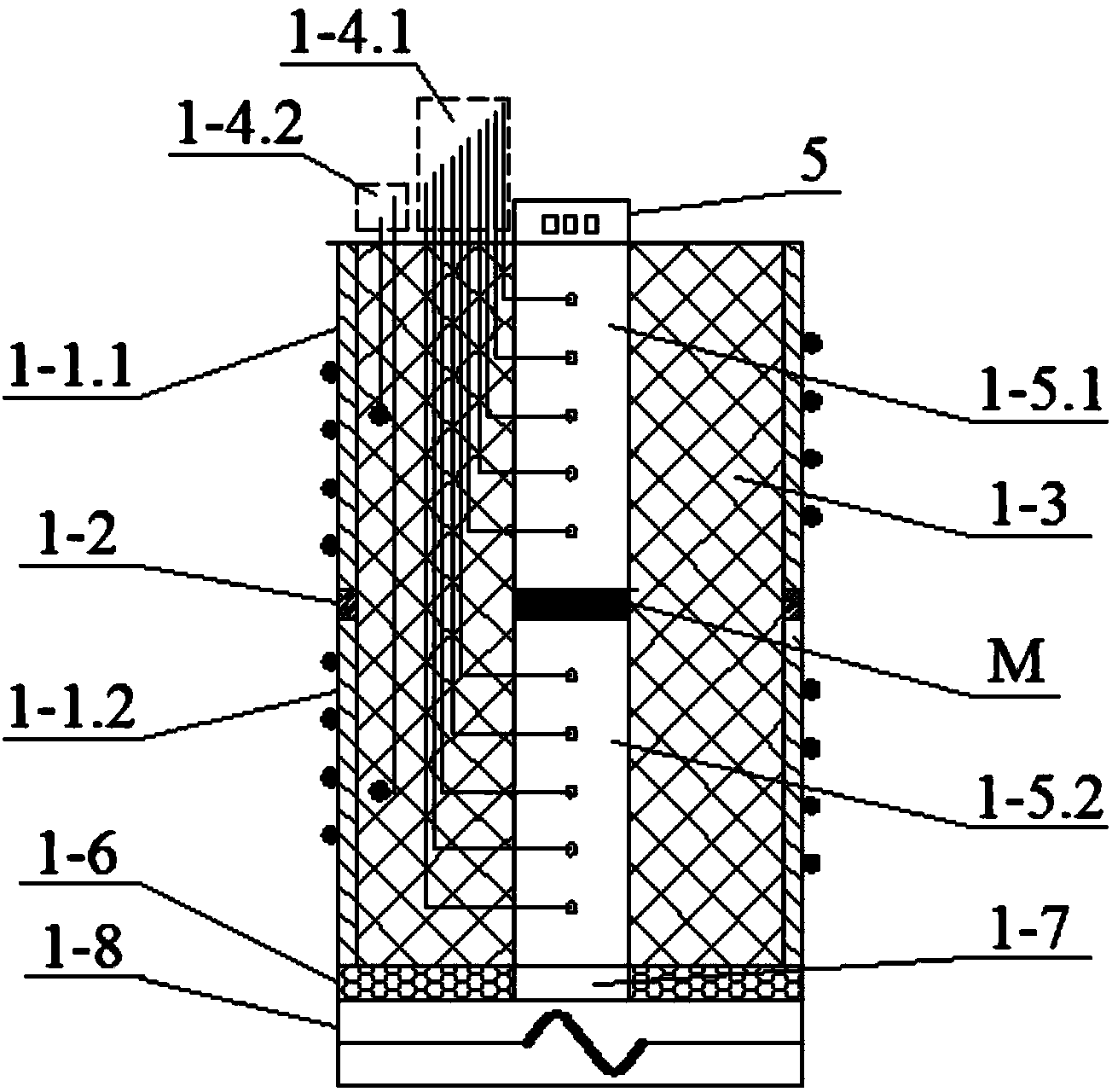

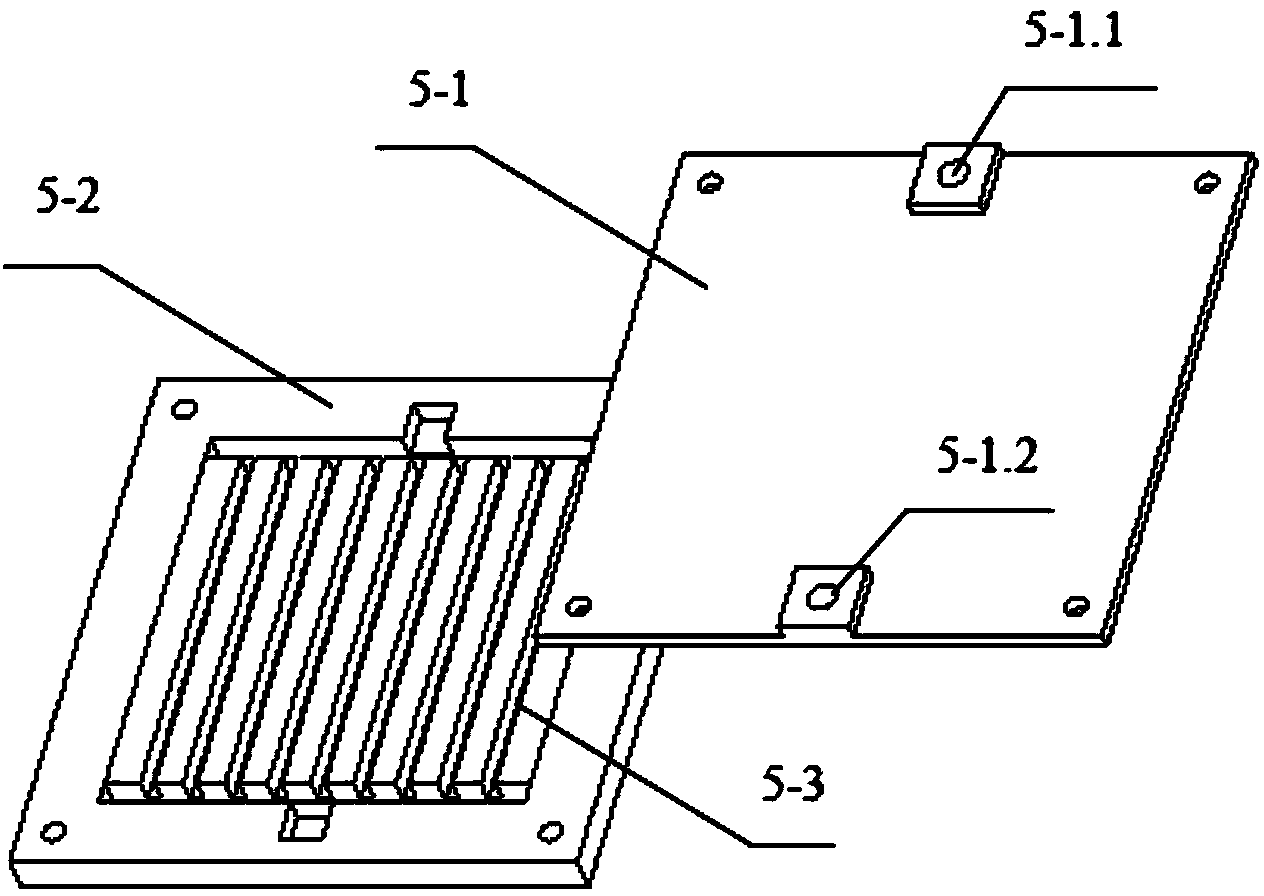

Steady-state method-based heat conductivity coefficient measurement device

InactiveCN104181195AAvoid lateral lossesStable deliveryMaterial heat developmentPhysical performance testingPhysical performance test

The invention discloses a steady-state method-based heat conductivity coefficient measurement device, and belongs to the technical field of physical performance tests of materials. The steady-state method-based heat conductivity coefficient measurement device comprises a main heater, an upper standard test piece, a lower standard test piece, a to-be-measured test piece holding cavity, a heat preservation layer, an upper shell, a lower shell, a heat insulation ring arranged between the upper shell and the lower shell, electric heating wires connected with a temperature compensation regulator, heating devices for thermocouple groups arranged in the upper standard test piece, the lower standard test piece and the heat preservation layer, a micro-channel cooling device, a temperature acquisition device, and a processing controller, and a pressurizing and fixing frame which consists of an upright post, a bottom plate, a lever and a weight, wherein the middle part of the lever is provided with a pressure rod. According to the steady-state method-based heat conductivity coefficient measurement device, an integrated heating device is used, meanwhile, the electric heating wires connected with the temperature compensation regulator are additionally arranged on the upper shell and the lower shell, and the main heater and the micro-channel cooling device are respectively arranged on the bottom and the top, so that the device has the characteristics that the measurement precision of a heat conductivity coefficient measurement is high, the consistency of repeated measurement and results is high, the stability is high, the measurement range is wide, the measurement can be performed under different heating conditions, and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

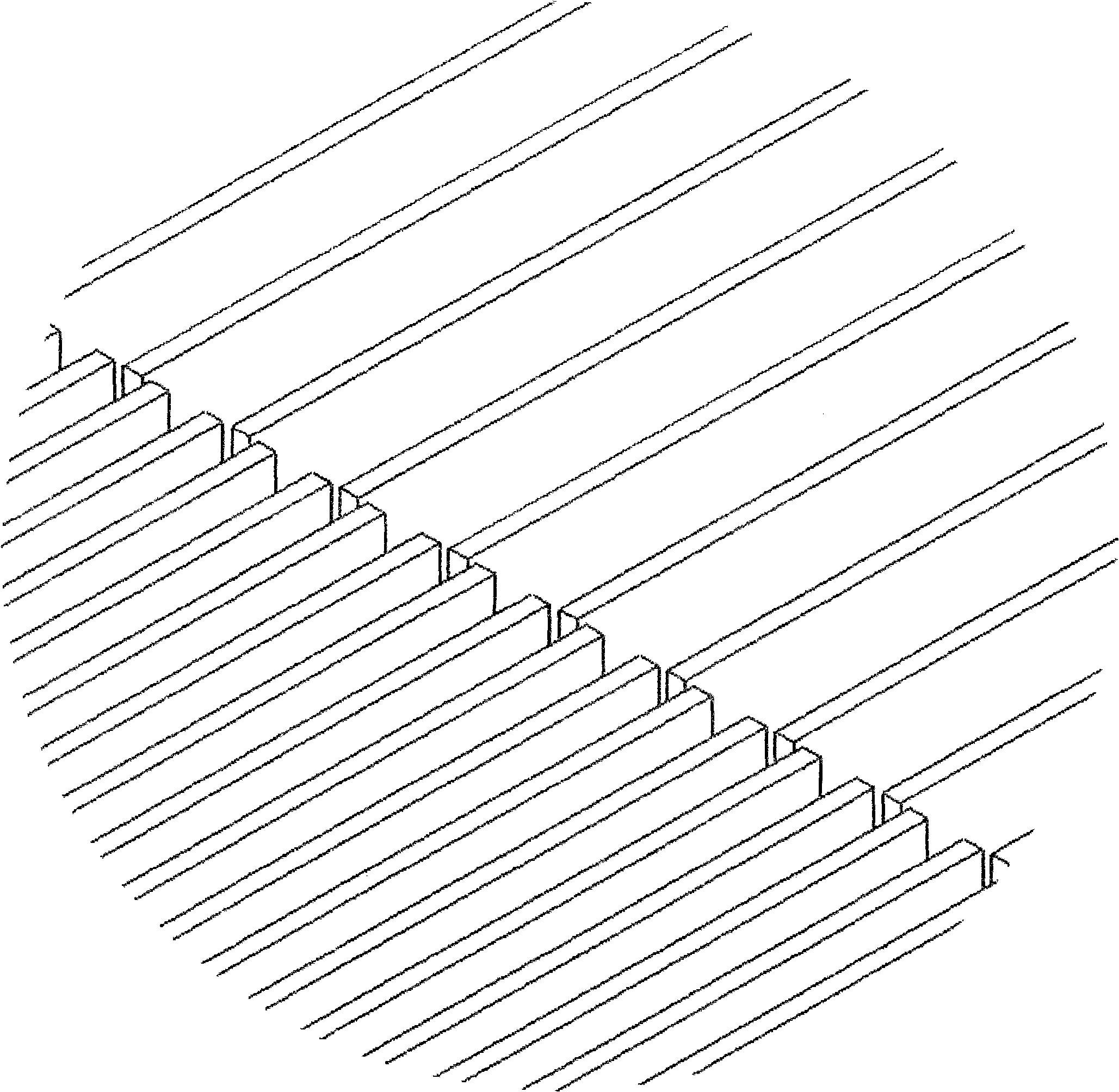

Micro-channel radiator with disturbed flow structures in horizontal and vertical directions

InactiveCN107731767AImprove cooling effectImprove temperature uniformitySemiconductor/solid-state device detailsSolid-state devicesStructural engineeringEngineering

The invention relates to a micro-channel radiator, belongs to the technical field of the radiator, and discloses a micro-channel radiator with disturbed flow structures in horizontal and vertical directions; the micro-channel radiator is characterized in that disturbed flow structures are arranged on three or four wall surfaces in the micro-channel radiator; the disturbed flow structure on the upper wall surface and the disturbed flow structure on the lower wall surface are arranged in a staggered manner to play a heat dissipation intensifying effect in the vertical direction; the disturbed flow structure on the left wall surface and the disturbed flow structure on the right wall surface are arranged in a staggered manner to play a heat dissipation intensifying effect in the horizontal direction; the disturbed flow structure on the upper wall surface and one of the disturbed flow structures on the left wall surface or the right wall surfaces can be mutually spliced on the same verticalsurface; and the disturbed flow structure on the lower wall surface and one of the disturbed flow structures on the left wall surface or the right wall surfaces can be mutually spliced on the same vertical surface. By virtue of the micro-channel radiator, the convection and heat transfer effects can be intensified synchronously in the horizontal and vertical directions, so that fluid temperatureuniformity and speed uniformity in the micro-channel can be improved, and the heat dissipation effect of the radiator can be intensified.

Owner:SHANGHAI UNIV OF ENG SCI

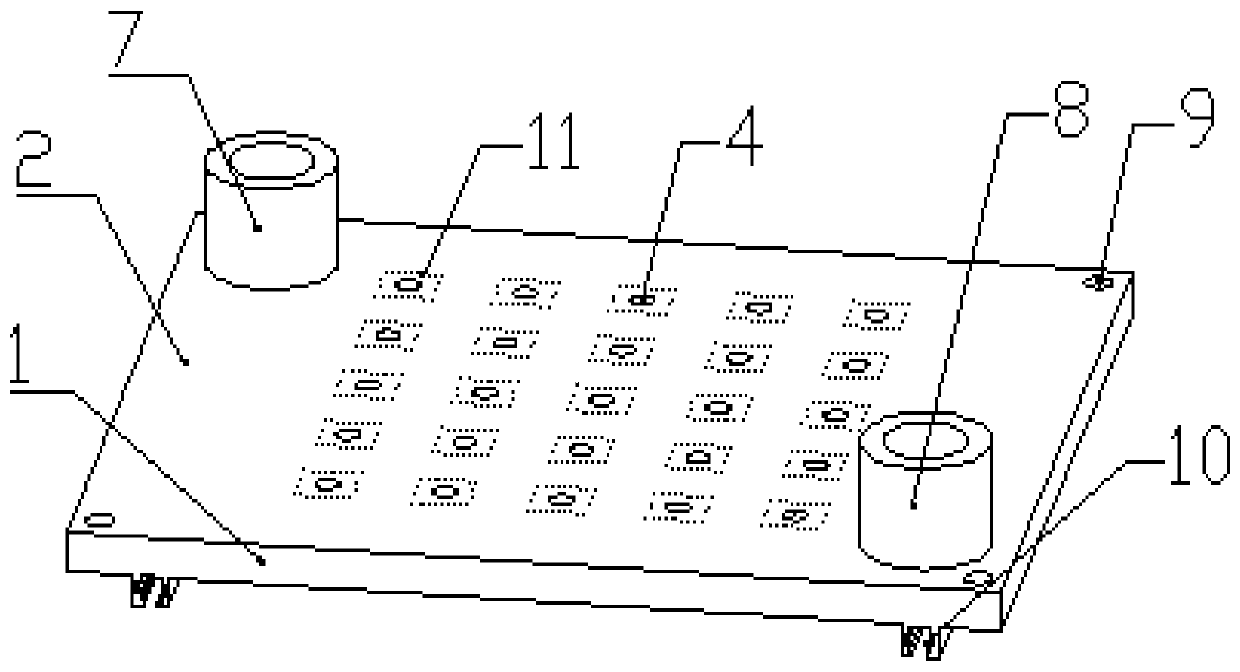

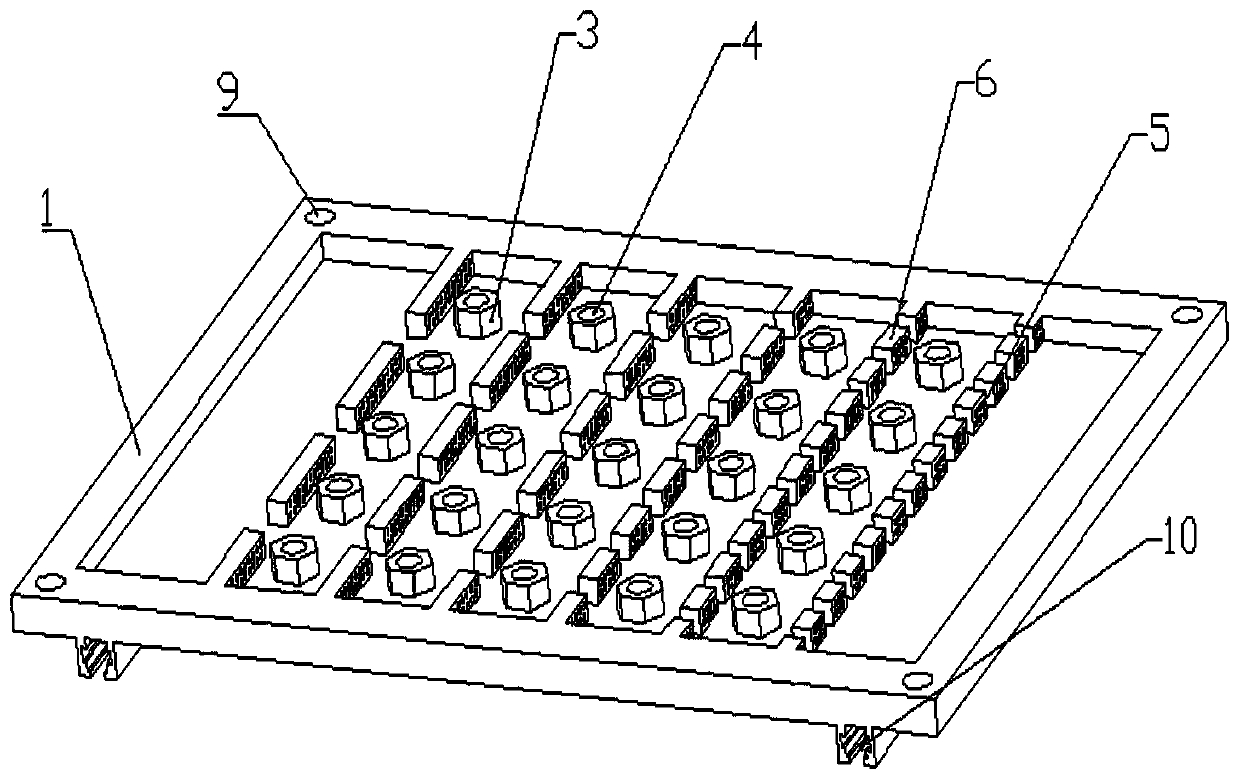

Micro-channel radiator for dissipating heat of power electronic device

ActiveCN103594430AUniform temperature distributionImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyMetallic materials

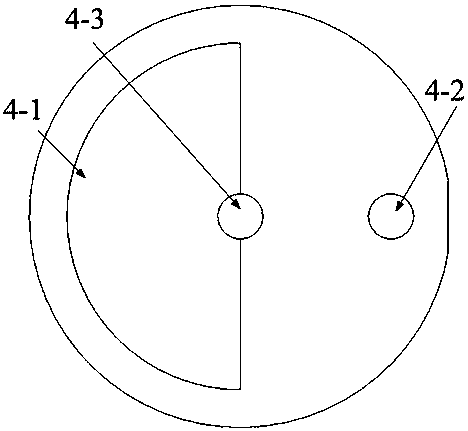

The invention provides a micro-channel radiator for dissipating heat of a power electronic device. The micro-channel radiator comprises an upper-layer cover board, a radiator outer wall, an internal flow channel structure, a heat dissipation working medium, a working medium inlet and a working medium outlet. The upper-layer cover board is connected a chip with heat to be dissipated, and the upper-layer cover board is in contact with the internal flow channel structure. Heat of the chip with heat to be dissipated is transmitted into the heat dissipation working medium through the upper-layer cover board and the internal flow channel structure and brought out through the heat dissipation working medium. The working medium outlet is formed in the inner side of the outer wall of the radiator. The working medium inlet is formed in the side, away from the position of the working medium outlet, of an eccentric position. According to the micro-channel radiator for dissipating heat of the power electronic device, the fresh heat dissipation working medium which has the lowest temperature is led into the radiator from the center area of a heat dissipation face which has the highest temperature, improvement of the heat exchange efficiency of the radiator is facilitated, the micro-channel radiator is constructed with selected metal materials with a high heat conduction rate, the heat dissipation efficiency is high, in addition, the manufacturing technology is mature, and the micro-channel radiator is easy to achieve.

Owner:SHANGHAI JIAO TONG UNIV

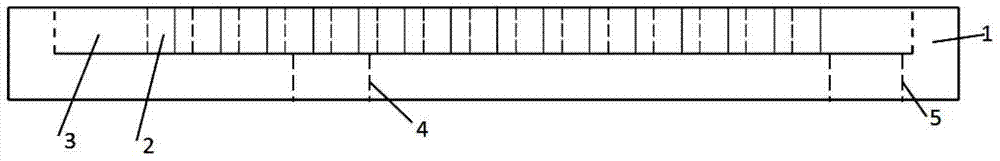

Lotus-type regular porous metal microchannel heat sink using liquid metal working medium

InactiveCN103188912ASimple preparation processEasy to processLaser detailsSemiconductor/solid-state device detailsManufacturing technologyLiquid metal

The invention discloses a lotus-type regular porous metal microchannel heat sink using a liquid metal working medium for an electronic component with high heating flux or a semiconductor laser, and belongs to a heat-dissipation device of a microelectronic device. The lotus-type regular porous metal microchannel heat sink solves the problems that inlet and outlet pressure drop is high, a structure is complicated, the processing is difficult, and the cost is high in the existing microchannel heat sink, and an excellent heat-dissipation effect can be obtained. The lotus-type regular porous metal microchannel heat sink is characterized in that a microchannel module 3, a micro pump 6 and a far-end heat-dissipation device 7 are connected by pipelines to form a closed circuit, wherein the core of the microchannel module is a porous material formed in a manner that cylindrical air holes obtained by a metal-gas eutectic directional solidification method are directionally arranged in a metal matrix, and the liquid working medium is low-melting-point liquid metal or an alloy. The lotus-type regular porous metal microchannel heat sink is simple in structure, simple and convenient in manufacturing technology, convenient to mount, small in inlet and outlet pressure drop, and high in heat-dissipation efficiency, and is suitable for the electronic component with the high heating flux or a laser diode arrayed heat-dissipation device.

Owner:TSINGHUA UNIV

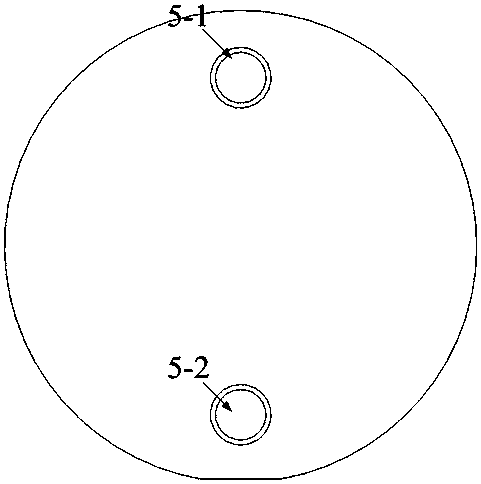

Flow-dividing annular micro-channel radiator

ActiveCN107658281AImprove heat transfer effectInhibit the effects of stagnationLaser detailsSemiconductor/solid-state device detailsEngineeringElectronic chip

The invention relates to a flow-dividing annular micro-channel radiator, which is mainly composed of a circular micro-rib plate, a circular flow dividing structure and a cover plate. The special flowdividing structure of the radiator is formed by annular micro-channels on the micro-rib plate and flow dividing channels on the flow dividing structure. The diameter of the circular flow dividing structure is less than that of the circular micro-rib plate, and an annular channel formed by the circular flow dividing structure and the circular micro-rib plate serve as a primary flow dividing channel, thereby effectively solving a problem of uneven primary flow dividing caused by a stagnation effect of a cooling working medium at the tail end of the flow dividing channel. Secondary flow dividingchannels are of a gradually shrinking structure, which can also weaken the influences of fluid stagnation inside the flow dividing channel and increase the uniformity of flow distribution between overflowing channels. The flow-dividing annular micro-channel radiator further improves the problem of nonuniform flow distribution on the basis of reserving advantages of the micro-channel flow dividingstructure, and has high heat exchange capacity and heat exchange limit. The flow-dividing annular micro-channel radiator is compact in structure and good in heat exchange capacity, and has excellent application prospects in the aspect of cooling for high heating equipment such as electronic chips, lasers and rectifiers.

Owner:SICHUAN UNIV

Complex heat pipe controller, and its manufacturing method and use

InactiveCN1743781AImprove reliabilityQuality improvementIndirect heat exchangersHeat exchange apparatusSingle substanceClosed loop

A complex heat pipe controller, making method and application consisting of the heat conductive controller and heating controller, which contains single substance or composite working medium, normal and / or closed cavity with changed and / or same section, the cavity can have only one closed loop, integral and / or auxiliary fins. Said invention also provides heat pipe heat column controller, complex heat pipe air cooling controller, complex heat pipe liquid cooling controller, complex heat pipe micro channel radiator, complex heat pipe fog jetting controller, complex heat pipe phase change material controller, and complex heat pipe controller with low cost, high reliability, high quality and long service life.

Owner:李建民

Stepped manifold array of microchannel heat sinks

ActiveUS7058101B2Reduce corrosionClosely spacedSemiconductor laser arrangementsLaser arrangementsEngineeringLaser beams

An assembly for providing a concentrated, vertically stacked array of laser beams from a horizontally offset array of electrically serially-connected metallic microchannel heat sinks each bearing a laser diode bar. The heat sinks are mounted on horizontally offset planes of the manifold which has coolant channels serving adjacent heat sinks that are separated from each to increase the electrical resistance of the fluid path between adjacent ones of said heat sinks. Stepped optical deflectors re-arrange the horizontally emitted laser beams into vertical stack.

Owner:II VI DELAWARE INC

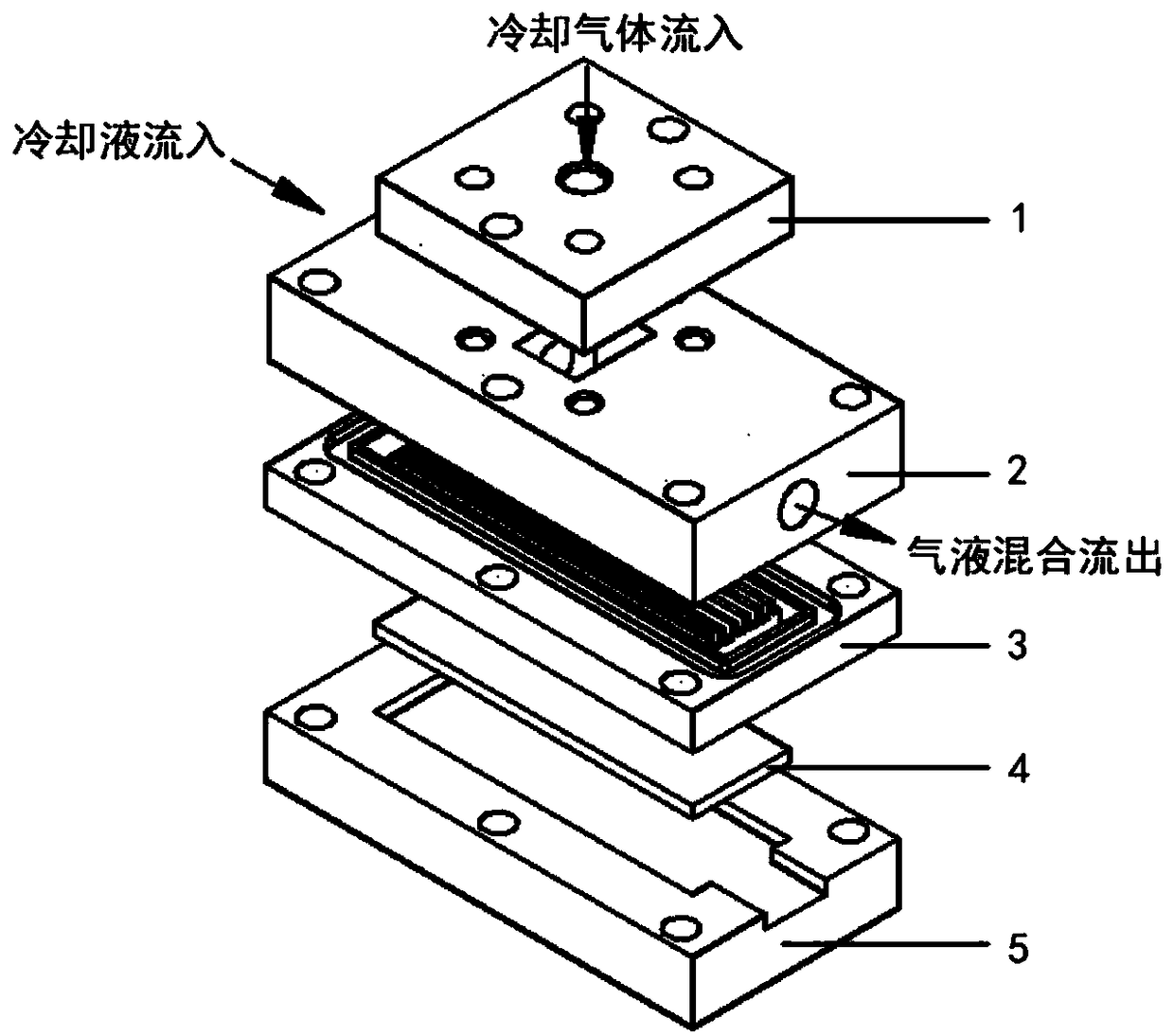

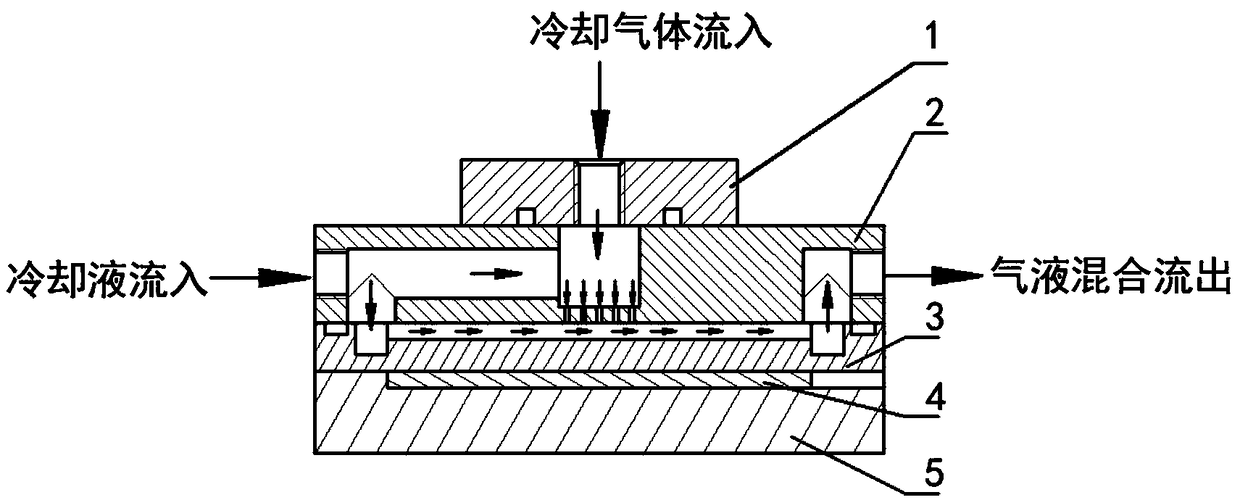

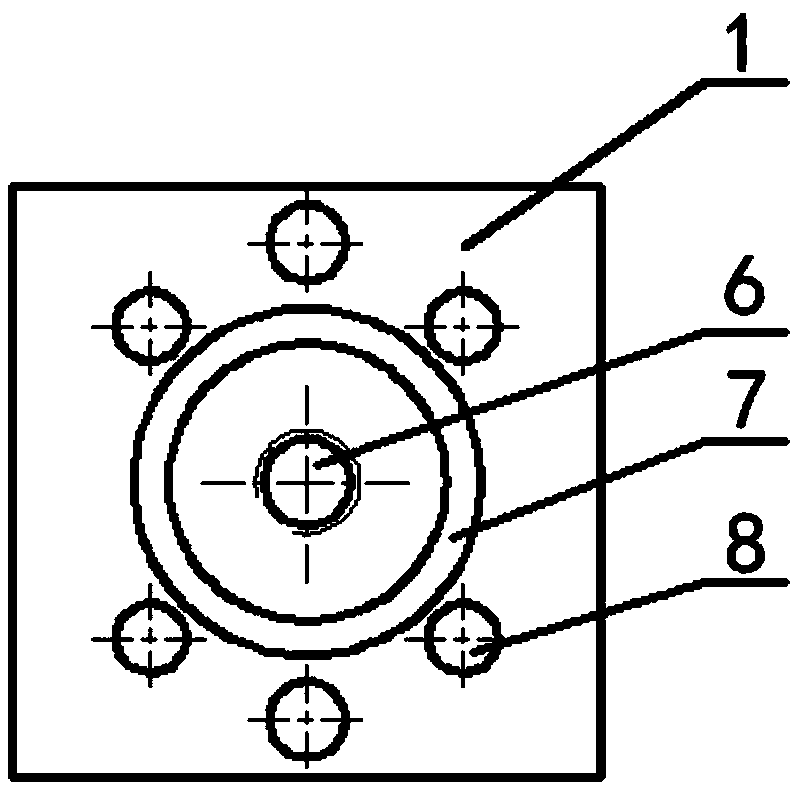

Gas-liquid two-phase mixed jet micro-channel heat sink

ActiveCN108712852AIncrease flow rateImprove heat transfer efficiencyCooling/ventilation/heating modificationsEnhanced heat transferInstability

The invention provides a gas-liquid two-phase mixed jet micro-channel heat sink. The heat sink comprises an upper cover plate, a gas-liquid mixed jet structure, a micro-channel plate, a heater and a base, wherein the gas-liquid two-phase mixed jet structure comprises a cooling liquid inlet, a cross-flow liquid inlet, a jet entry cavity, jet holes and a gas-liquid mixed flow outlet. Cooling liquidfirst flows in from the cooling liquid inlet, a part flows to the micro-channel plate through the cross-flow liquid inlet to form cross-flow liquid for heat exchange, and the other part flows to the jet entry cavity, mixes with gas flowing in from an inlet port, then is jet to the micro-channel plate through the jet holes for heat exchange, and is simultaneously mixed with the cooling liquid flowing from the cross-flow liquid inlet to micro-channels, so that the cooling liquid in the micro-channels is disordered, and finally flows out from the gas-liquid mixed flow outlet. The cross-flow liquid in the micro-channels is impacted by gas-liquid two-phase mixed jet to realize enhanced heat transfer and suppress micro-channel boiling instability. In addition, the heat sink also has the characteristics of compact structure, small size, simple manufacturing process and the like.

Owner:XIAMEN UNIV +1

Microchannel heat radiator and manufacturing method thereof

ActiveCN109411427AReduce processing difficultyReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesEngineeringHigh heat

The invention discloses a microchannel heat radiator. A microchannel and a shunting network are arranged in the microchannel heat radiator, a surface is provided with a liquid inlet and a liquid outlet, and an external surface of the microchannel is provided with a metal layer. According to the microchannel heat radiator provided by the invention, the surface of the microchannel heat radiator is provided with the metal layer, thus, a grounding requirement of a high-frequency system is satisfied well, arranging a deep TSV hole on the microchannel heat radiator is also avoided, processing difficulty and manufacturing cost of the microchannel heat radiator are reduced, and reliability of integration density of a circuit and reliability of a structure are guaranteed; with the metal layer, upper and lower surfaces of the microchannel heat radiator provided by the invention are flat and have no cavity, so, a plurality of high heat-flux density chips can be integrated on the surfaces of the microchannel heat radiator, and the circuits can be designed flexibly under the premise of guaranteeing heat dissipation performance of products.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Radial flow micro-channel heat sink with impingement cooling

InactiveUS20070039720A1Additional componentDomestic stoves or rangesSemiconductor/solid-state device detailsEngineeringFlow diverter

A heat sink removes heat from an electronic device and comprises a base, a lid. An inner ring of first fins extend radially outwardly first length from an inner circle and extend axially a first height from the top surface of the base, and an outer ring of second fins extend radially inwardly a second length from an outer periphery and extend axially a second height from the top surface of the base. A confining plate extends radially above the fins and is spaced below the bottom surface of the lid whereby coolant fluid flows from an inlet opening of the lid through the center opening of the confining plate and radially outwardly through the fins and upward around the outer edge of the confining plate and into the space above the confining plate to an outlet opening. A nozzle having a throat is disposed above the lid and extends below the lid to the confining plate. A flow diverter extends upwardly from the top surface of the base and into and through the throat of the nozzle.

Owner:COOLIT SYSTEMS INC

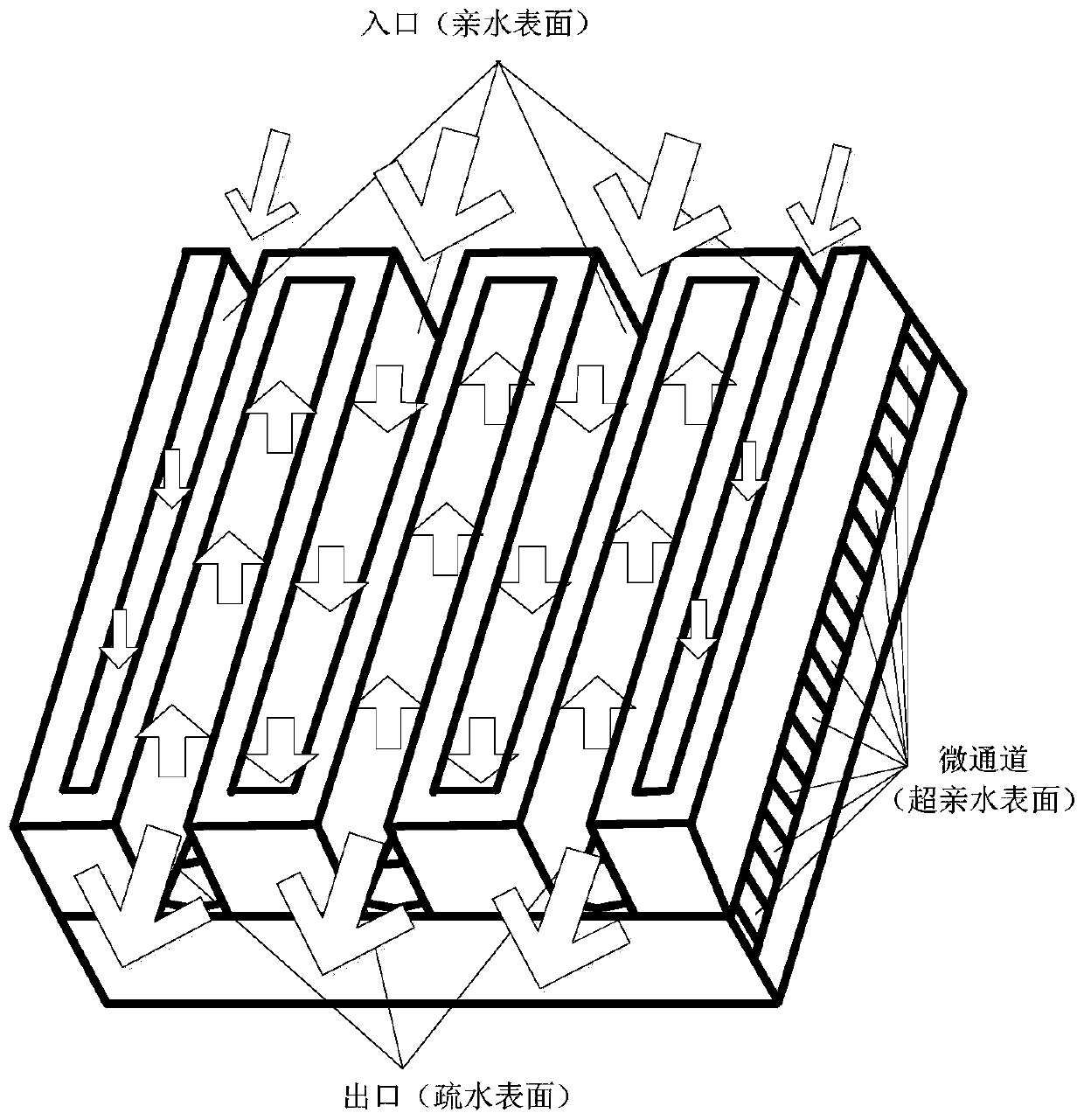

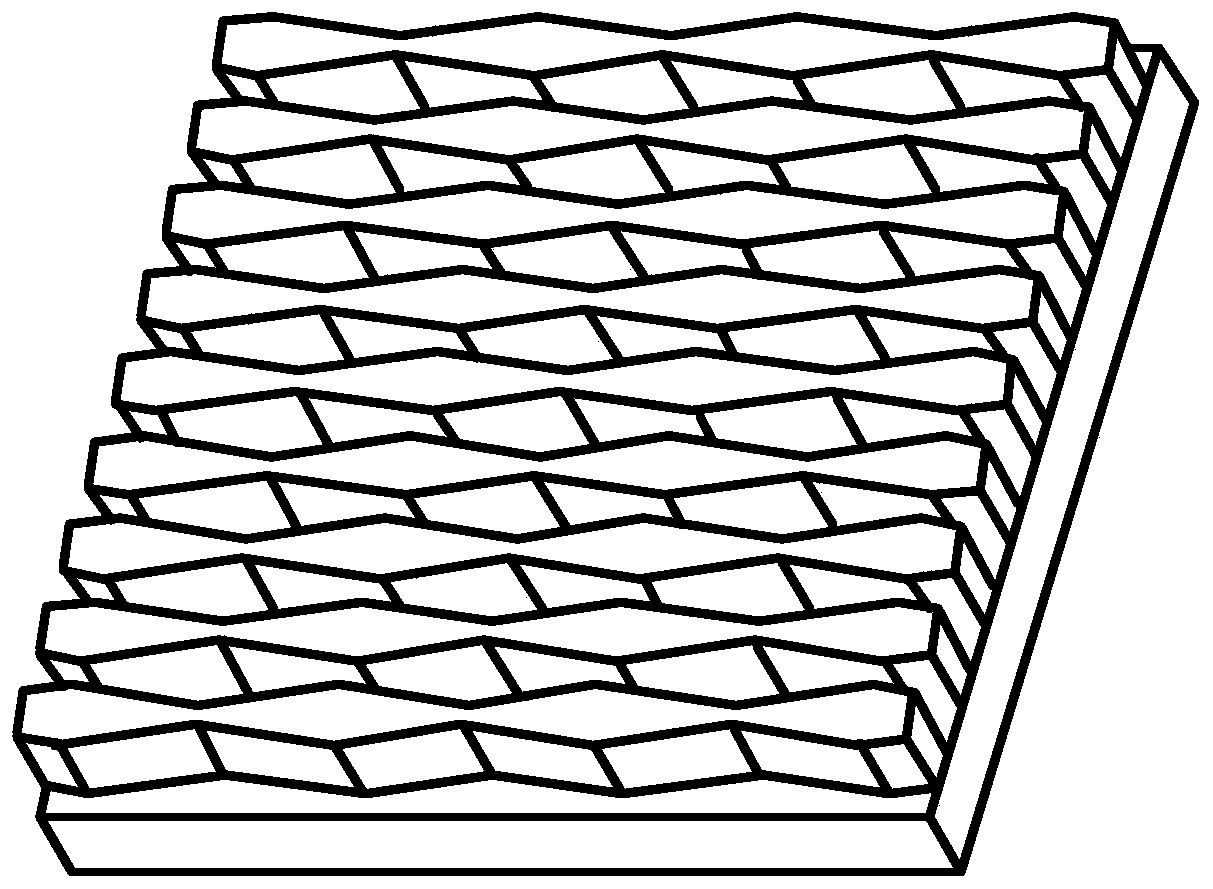

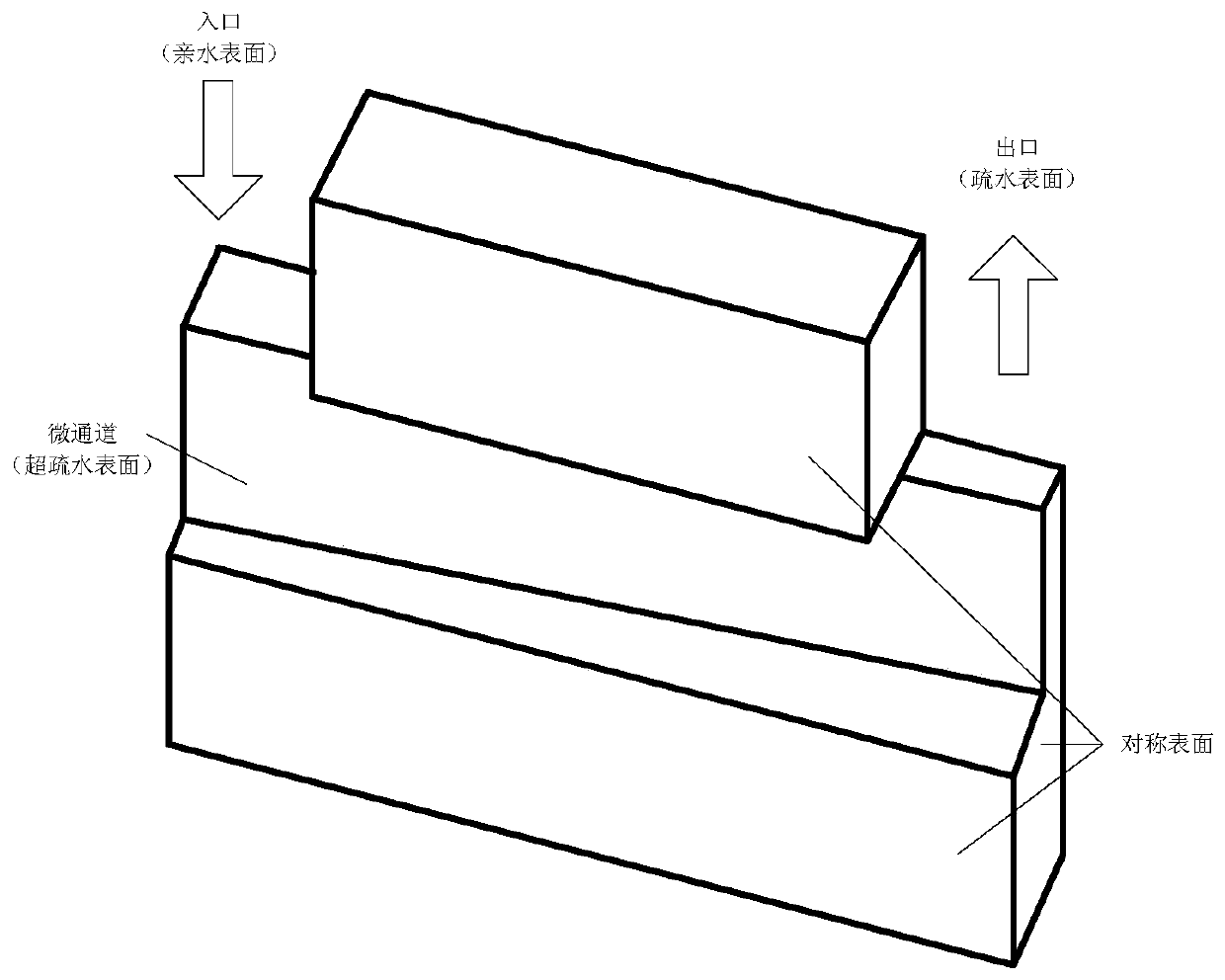

Low-resistance enhanced heat transfer structure based on nanometer super-wetting interface

ActiveCN110425914AShorten the length of the runnerReduce thicknessCoatingsModifications by conduction heat transferIsosceles trapezoidEnhanced heat transfer

The invention discloses a low-resistance enhanced heat transfer structure based on a nanometer super-wetting interface. The low-resistance enhanced heat transfer structure comprises a lower embedded microchannel layer and an upper manifold channel layer, wherein embedded microchannels are perpendicular to manifold channels; the lower embedded microchannel layer consists of a plurality of embeddedmicrochannel units; the cross section of each embedded microchannel of each unit is a rectangular divergent cross section along the flowing direction of a cooling working medium; the shape of each embedded microchannel of each unit is isosceles trapezoid; the upper manifold channel layer is composed of the S-shaped manifold channels; and two adjacent S-shaped manifold channels form inlets and outlets of the manifold channels. According to the low-resistance enhanced heat transfer structure, a microchannel radiator is constructed by utilizing a layered flow structure, the heat transfer characteristic and the resistance characteristic can be simultaneously improved by combining the microchannel radiator with the nano super-wetting interface and the divergent microchannel section, and the low-resistance enhanced heat exchange of the microchannel radiator is achieved under the condition of higher heat dissipation efficiency.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

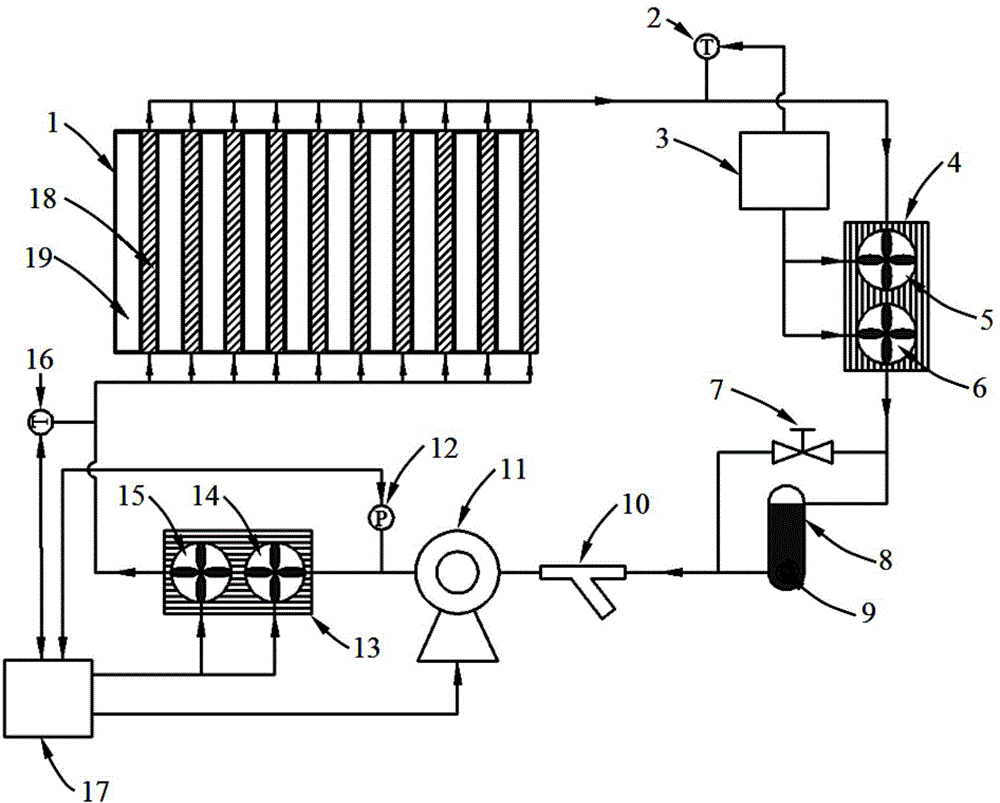

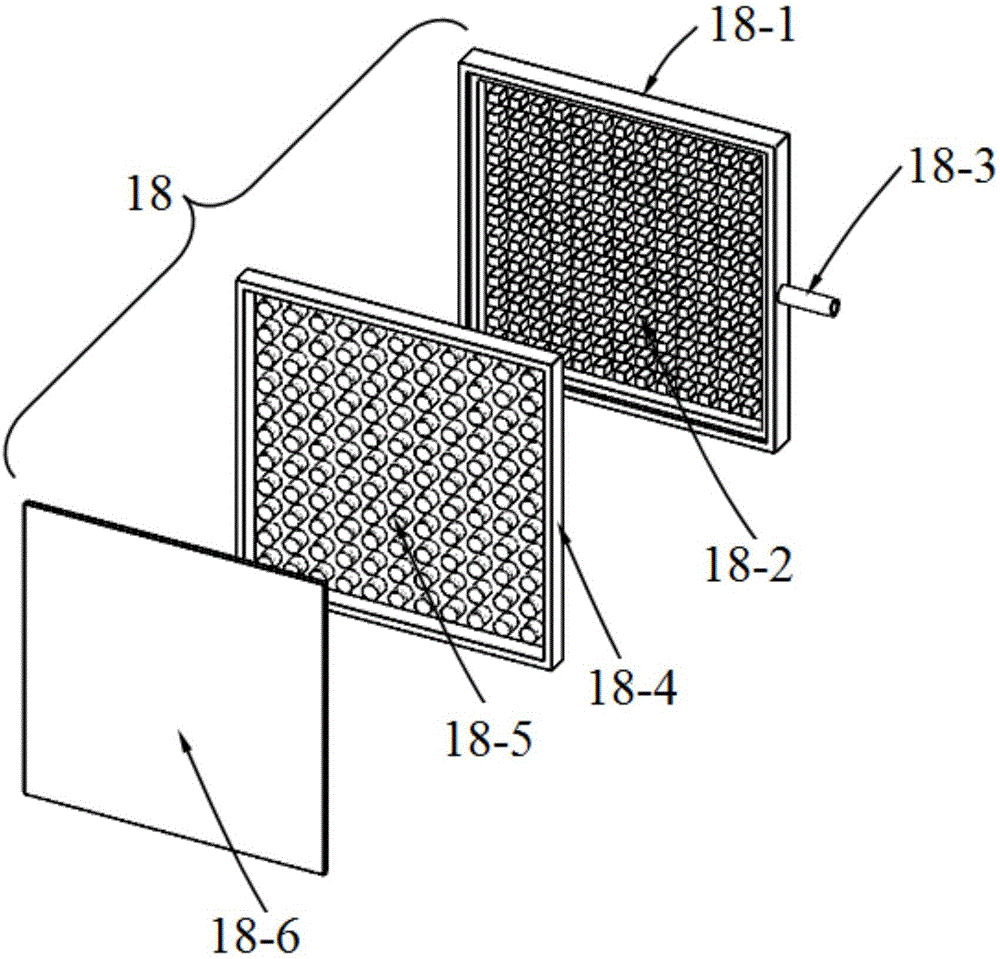

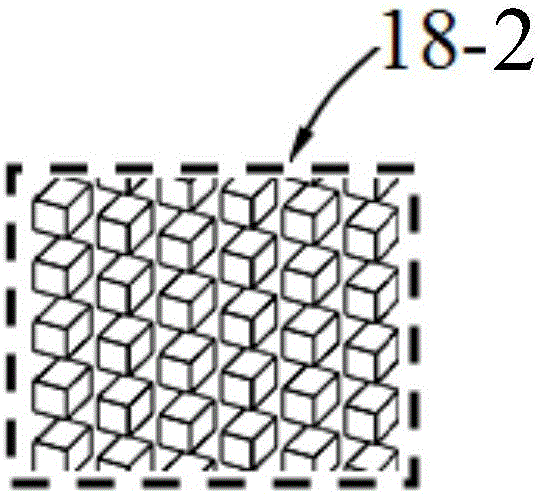

Thermal management system of proton exchange membrane fuel cell

ActiveCN106602105AImprove cooling efficiencyIncrease cooling areaFuel cell heat exchangeControl systemEvaporation

The invention discloses a thermal management system of a proton exchange membrane fuel cell. The thermal management system comprises heat dissipation devices, a fuel cell stack, a cooling liquid distribution pipe, a cooling liquid collection pip and a control system, wherein each heat dissipation device comprises a microchannel heat sink, an ultrathin uniform temperate plate evaporation cavity assembly and a sealing plate, the microchannel heat sink comprises a shell and a heat dissipation fin array, the ultrathin uniform temperate plate evaporation cavity assembly comprises a bottom plate and a capillary core, one end of the capillary core is in direct contact with a base part of the microchannel heat sink, an evaporation cavity is formed between the bottom plate and the base part, the ultrathin uniform temperate plate evaporation cavity assembly and the sealing plate are respectively connected with two ends of the microchannel heat sink, the fuel cell stack is formed by laminating and combining at least two single cells in a series mode, the heat dissipation device is correspondingly arranged at one side of each single cell, the single cells and the heat dissipation devices are arranged in a lamination way at intervals, and the control system is used for supplying a cooling liquid and controlling the cooling liquid to flow. By the thermal management system of the proton exchange membrane fuel cell, the fuel cell can be enabled to be in an appropriate temperature range during the operation process, and the temperature uniformity in the fuel cell can be ensured.

Owner:淳华氢能源科技(湖南)有限公司

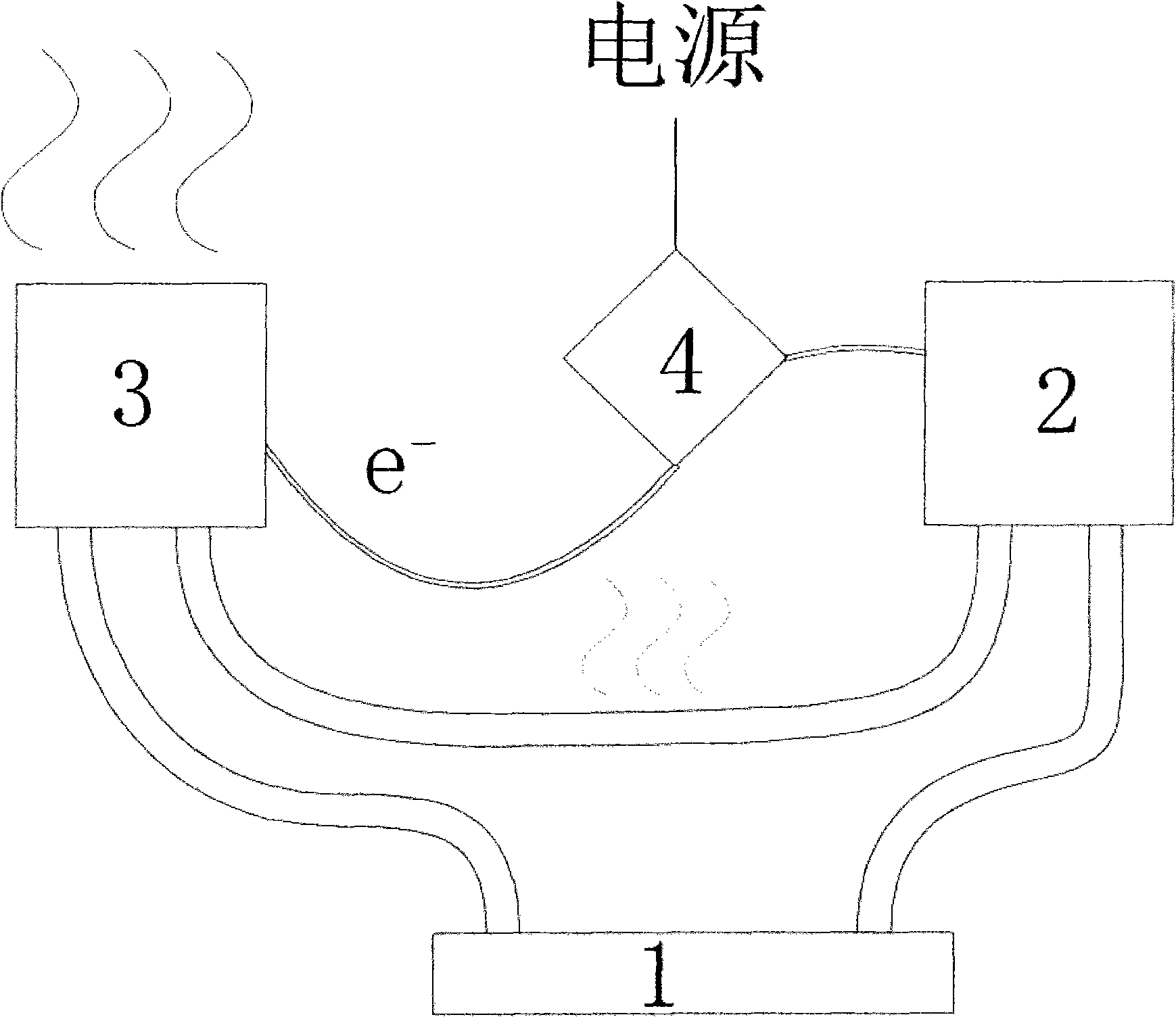

Radiating system

InactiveCN101778554AIncrease heat exchange intensityAdaptiveSemiconductor/solid-state device detailsSolid-state devicesHeat flowWorking fluid

The invention discloses a radiating system. The radiating system comprises a microchannel heat-sink system, a micropump device, a power supplying system and a power supply device, wherein the microchannel heat-sink system is used for contacting with a heating part to cool the heating part; the micropump device is connected with the pipeline of the radiating system to consume the electric power provided by the power supply device to provide a circulating power for working fluid in the radiating system; the power supplying system generates additional electric energy by using the afterheat of the working fluid to supply the micropump device; and the power supply device is provided with an additional power supply and a power supply merged by the power supplying system so as to merge the electric energy generated by the power supplying system into the additional power supply and supply power for the micropump device jointly through a series circuit. The radiating device of the radiating system has the advantages of high heat exchange intensity and adaptive characteristic and is applied to the heating parts with small size and high heat-flow density, such as electronic devices, laser devices and the like.

Owner:BEIJING JIAOTONG UNIV

3D printing integrated radiator and application thereof in phased-array antenna

InactiveCN110165355ALowered byHelp passIndividually energised antenna arraysDe-icing/drying-out arrangementsEngineeringTemperature difference

The invention relates to the field of heat dissipation, in particular to a micro-channel radiator, integrated manufacturing and an application of the micro-channel radiator in a control array antenna.The radiator is manufactured through 3D printing. Through a fluid channel which is distributed in a gradually changed manner and a liquid injection port and a liquid outlet which are respectively formed at the biggest end and the smallest end of the flow channel, cooling liquid uniformly passes through the whole fluid channel. When the radiator is in use, the highest temperature of the radiator is 298K, the lowest temperature of the radiator is 295K, and the temperature difference after heat dissipation is 3 DEG C. Compared with a pure runner structure, the radiator is stronger in heat dissipation capability and more uniform in temperature distribution after heat dissipation, and has the characteristics of good heat dissipation performance and temperature uniformity, one-time forming, noneed of using a nut sealing ring and the like for packaging.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

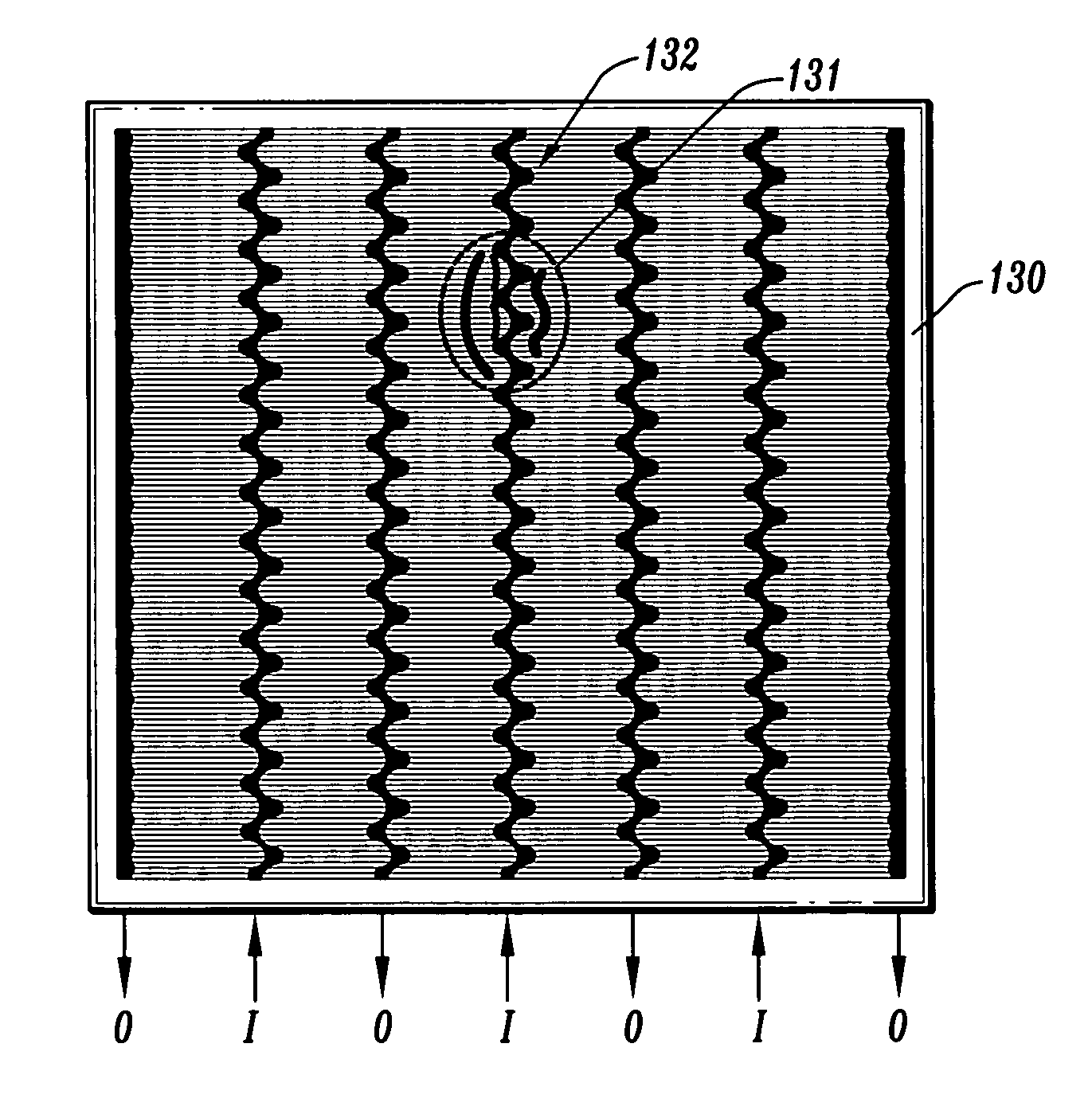

Micro-channel heat sink

InactiveUS20080308258A1Improve stabilityImprove heat transfer performanceSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

A micro-channel heat sink comprises an upper cover layer and a cooling layer. The cooling layer comprises at least one inlet fluid tank, a plurality of micro-channels, and at least one outlet fluid tank. The inlet fluid tank can store and deliver the working fluids, and the outlet fluid tank collects the heated working fluid flowing through the plurality of micro-channels. The plurality of micro-channels are disposed between the inlet fluid tank and the outlet fluid tank, wherein the cross sectional area of each of the micro-channels increases along the direction towards the outlet fluid tank.

Owner:NATIONAL TSING HUA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com