Microchannel heat radiator and manufacturing method thereof

A technology of micro-channels and heat sinks, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of limited quantity, high process cost, and reduced circuit density to meet grounding requirements, Reduce processing difficulty and smooth the upper and lower surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

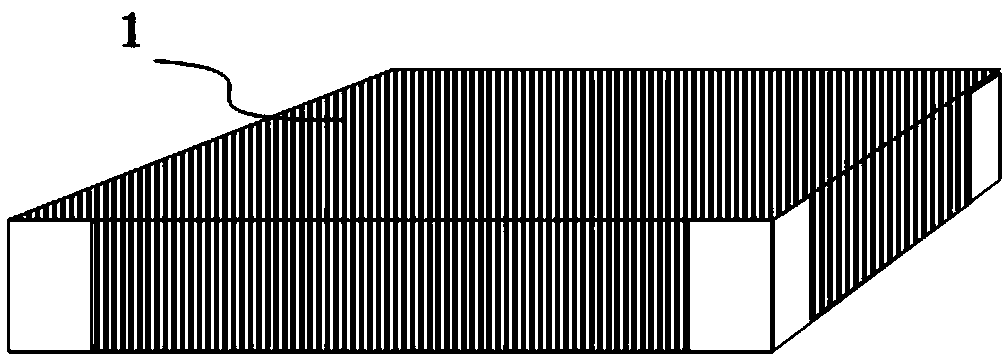

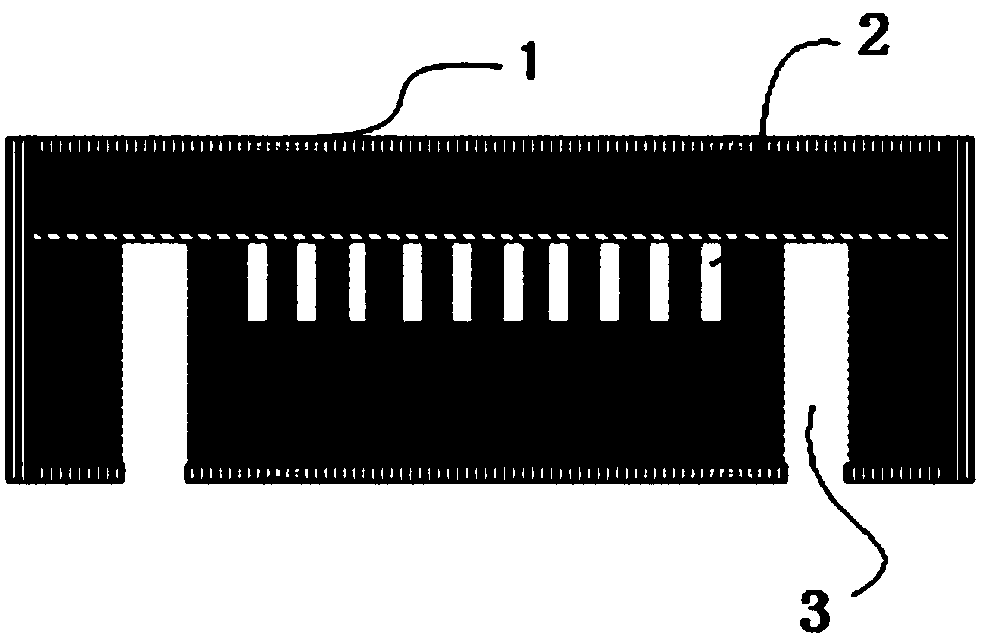

[0056] Such as Figure 1-10 Shown, a kind of micro-channel heat sink is provided with micro-channel (2), shunt network in it, and the surface is provided with liquid inlet and liquid outlet (3), and the outer surface of described micro-channel heat sink is provided with There is a metal layer (1).

[0057] In the above technical solution, by arranging the metal layer (1) on the surface of the micro-channel heat sink, it not only satisfies the grounding requirements of the high-frequency system well, but also avoids setting deep TSV holes on the micro-channel heat sink, reducing micro The processing difficulty and manufacturing cost of the runner heat sink ensure the integration density of the circuit and the reliability of the structure.

[0058] The micro-channel and shunt network can be in any shape, and the actual shape should be determined according to heat dissipation requirements. Exemplarily, the shape of the microchannel and the shunt network may be: serpentine, spir...

Embodiment

[0086] Such as Figure 1-10 As shown, a microchannel heat sink with a thickness of 400 μm:

[0087] The interior is provided with a micro-channel (2) and a distribution network, the micro-channel and the distribution network are serpentine, the width of the micro-channel (2) is 30 μm, and the depth is 250 μm; the lower surface is provided with a liquid inlet and an outlet The liquid inlet (3), the liquid inlet and the liquid outlet (3) are circular; the outer surface is provided with a metal layer (1), and the metal layer (1) is continuously distributed on the six micro-channel radiators. The surface is made of Au.

[0088] The manufacturing method is as follows:

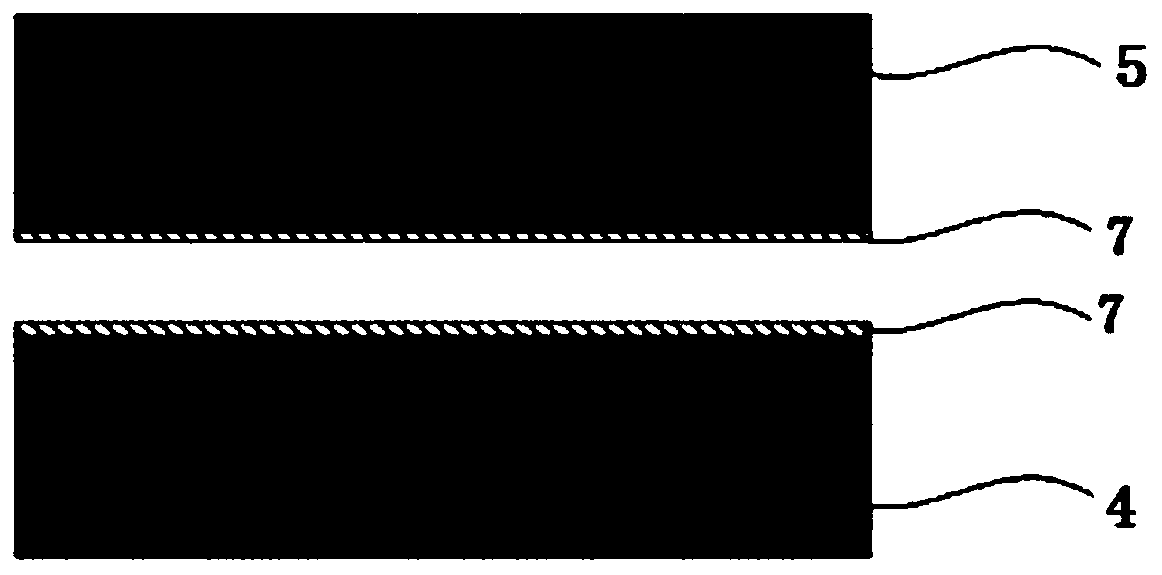

[0089] 1) Provide two smooth silicon wafers;

[0090] 2) if image 3 As shown, a layer of SiO was grown on the surface of silicon wafer A and the back of silicon wafer B respectively. 2 , and use chemical mechanical polishing technology to control its surface roughness below 1nm;

[0091] 3) if Figure 4 As s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com