Preparation method for intelligent color changing window

A color-changing window and intelligent technology, applied in the field of materials, can solve problems such as unsuitable for large-scale production, uneven thickness of deposited film, poor thermal radiation resistance, etc., to increase the application range and commercial market prospects, fast color change ability, long, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A preparation method for an intelligent color-changing window, comprising the following steps:

[0059] (1) Substrate preparation: tempered glass substrate is used, that is, large pieces of glass are cut, shaped, edged and tempered, and prefabricated into the size and shape required for the specific application of architectural glass or vehicle window glass. The specific process can use glass industry or solar cell industry standard methods. Optical inspection is performed on the cleaned substrates to remove substrates with obvious surface defects, which can effectively improve the production yield and reduce the average production cost of products.

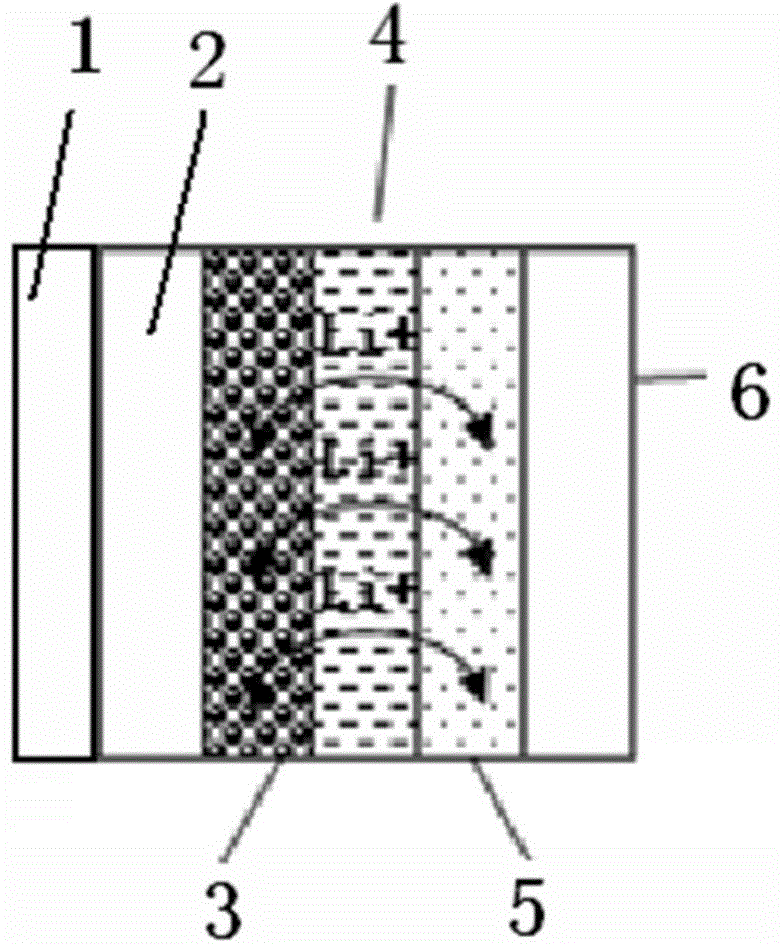

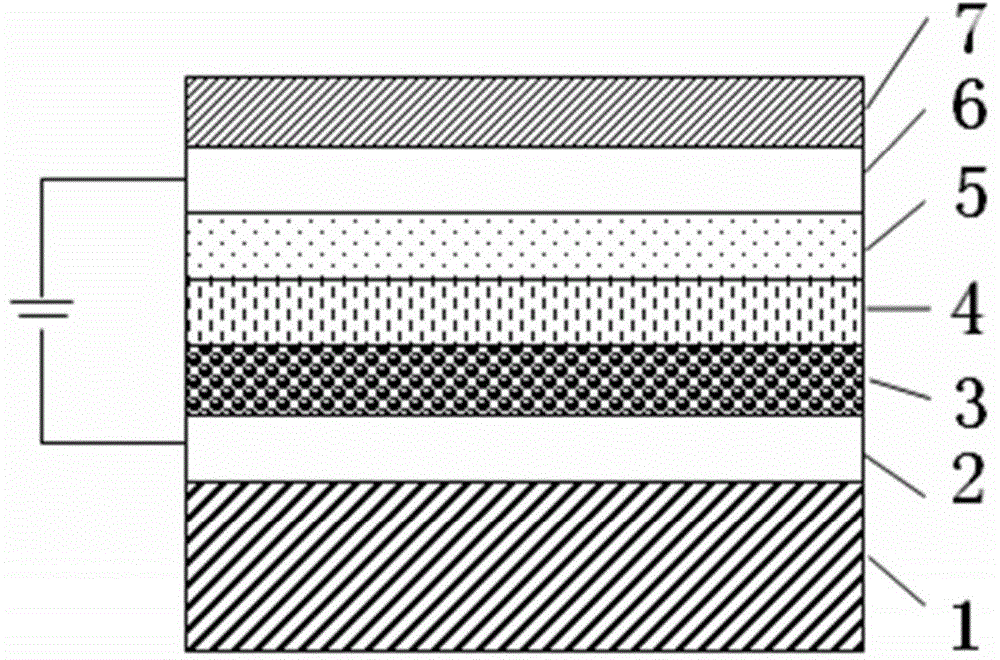

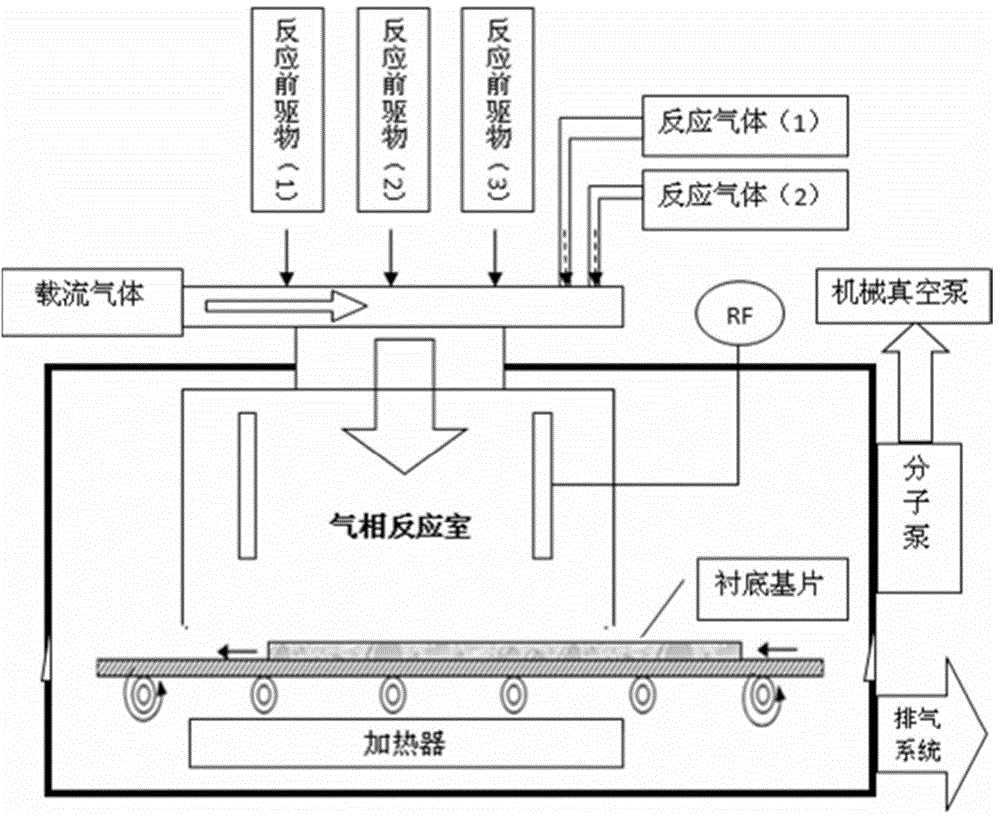

[0060] (2) The chemical vapor deposition method is used to grow conductive materials on the substrate 1 to form the first conductive layer 2; the chemical vapor deposition methods are all used such as image 3 The chemical vapor deposition reaction apparatus shown is implemented.

[0061] The present invention adopts the...

Embodiment 2

[0099] A preparation method for an intelligent color-changing window, comprising the following steps:

[0100] (1) Substrate preparation: Use common glass substrates to cut, shape and edge large pieces of glass. Optical inspection is performed on the cleaned substrates to remove substrates with obvious surface defects, which can effectively improve the production yield and reduce the average production cost of products.

[0101] (2) The conductive material is grown on the substrate 1 by chemical vapor deposition to form the first conductive layer 2; all chemical vapor deposition methods are implemented by chemical vapor deposition reaction devices.

[0102] The present invention adopts the chemical vapor deposition method to grow the first conductive layer 2, and the chemical vapor deposition device adopts the existing device. Using the reaction precursor F 3 CCOOH was used as the source of dopant F, and the reaction precursor Sn(C 3 h 7 ) Cl 3 As the Sn source, the react...

Embodiment 3

[0140] A preparation method for an intelligent color-changing window, comprising the following steps:

[0141] (1) Substrate preparation: Use plastic substrates, non-glass substrates, flexible substrates such as plastics, and perform pretreatments such as cutting, forming, and edging. The pretreated substrate is cleaned, for example, by mechanical scrubbing and / or ultrasonic cleaning to remove surface impurities such as organic imprints and inorganic particles on the surface of the substrate material. Check the cleaned substrates and remove the substrates with obvious surface defects, so as to effectively improve the production yield and reduce the average production cost of products.

[0142] (2) The conductive material is grown on the substrate 1 by chemical vapor deposition to form the first conductive layer 2; all chemical vapor deposition methods are implemented by chemical vapor deposition reaction devices.

[0143] The present invention adopts the chemical vapor deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com