Patents

Literature

14720results about How to "Reduce processing difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

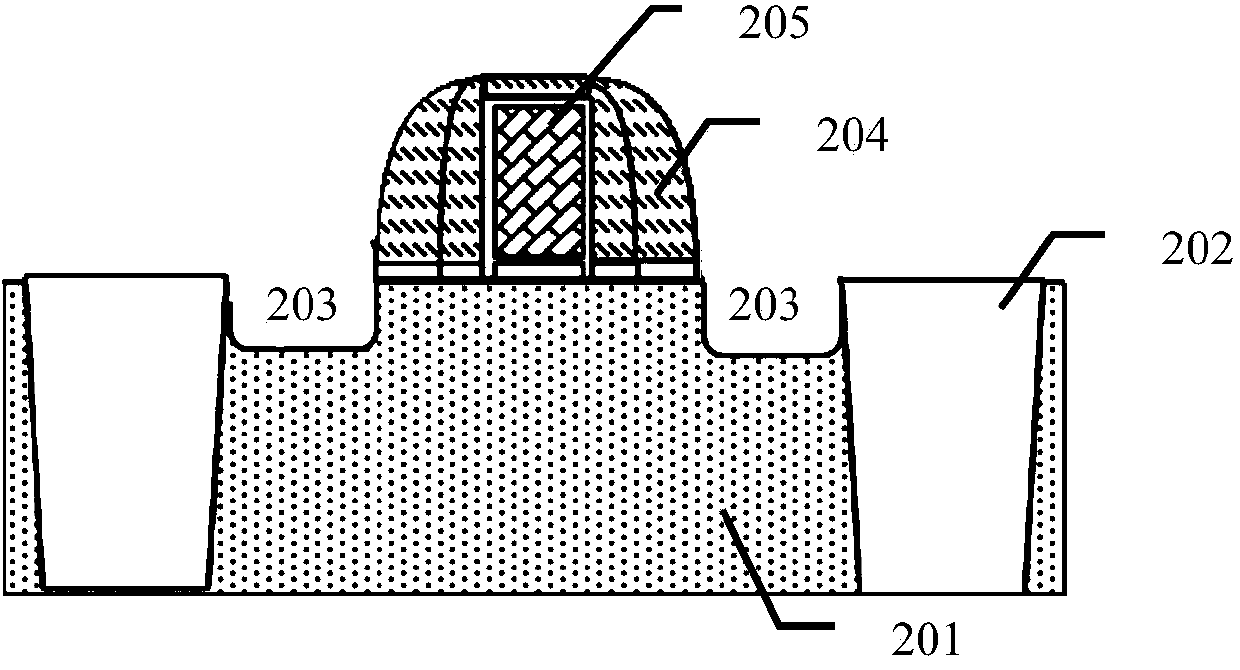

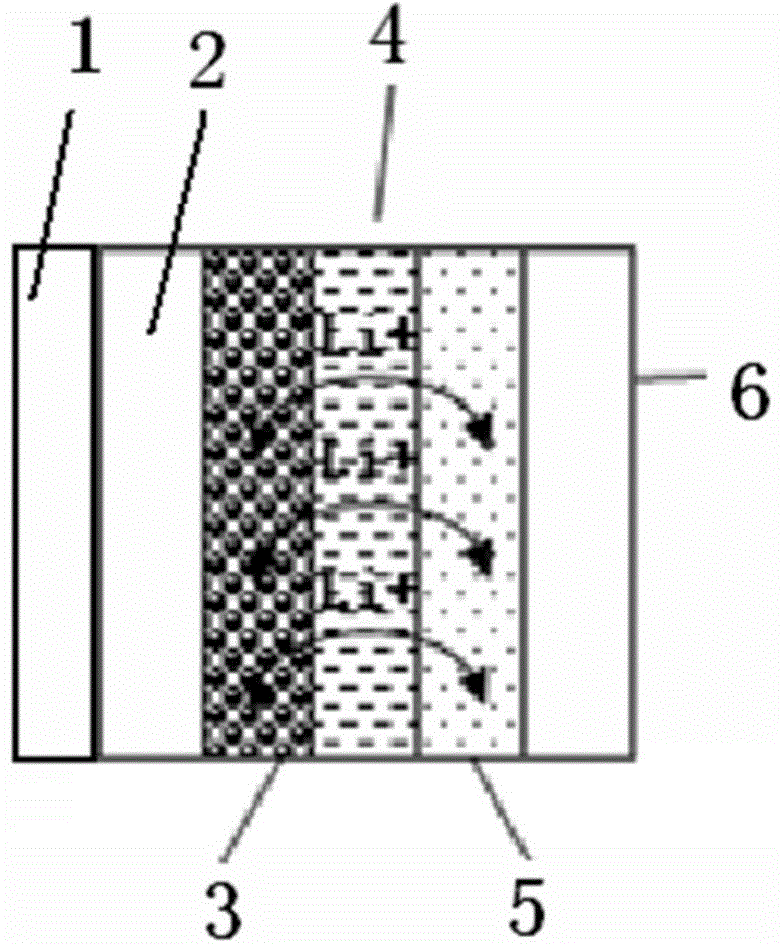

SiGe (silicon germanium) source and drain area manufacturing method

ActiveCN104201108AReduce thicknessAvoid stress relaxationSemiconductor/solid-state device manufacturingSemiconductor devicesHigh concentrationEngineering

The invention discloses a SiGe (silicon germanium) source and drain area manufacturing method. A multi-layer structure which comprises alternately stacked buffer layers and main body layers is formed by a method that the SiGe epitaxial growth of the buffer layer and the main body layers is alternated repeatedly and accordingly the thickness of every high Ge concentration of SiGe main body layer is effectively reduced and shared into every layer of main body layer and accordingly the stress relaxation due to the fact that thickness of every main body layer exceeds the critical thickness is avoided; the Ge content of every layer of SiGe main body layer is further improved to enable the stress of the SiGe source leakage on a channel to be increased; an SiGe process window is enlarged due to the repeated epitaxy and accordingly the process stability is enhanced and accordingly the device performance is improved; the stress can be effectively improved without increase of the process difficulty and accordingly the process is stable and controllable and the cost is low.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

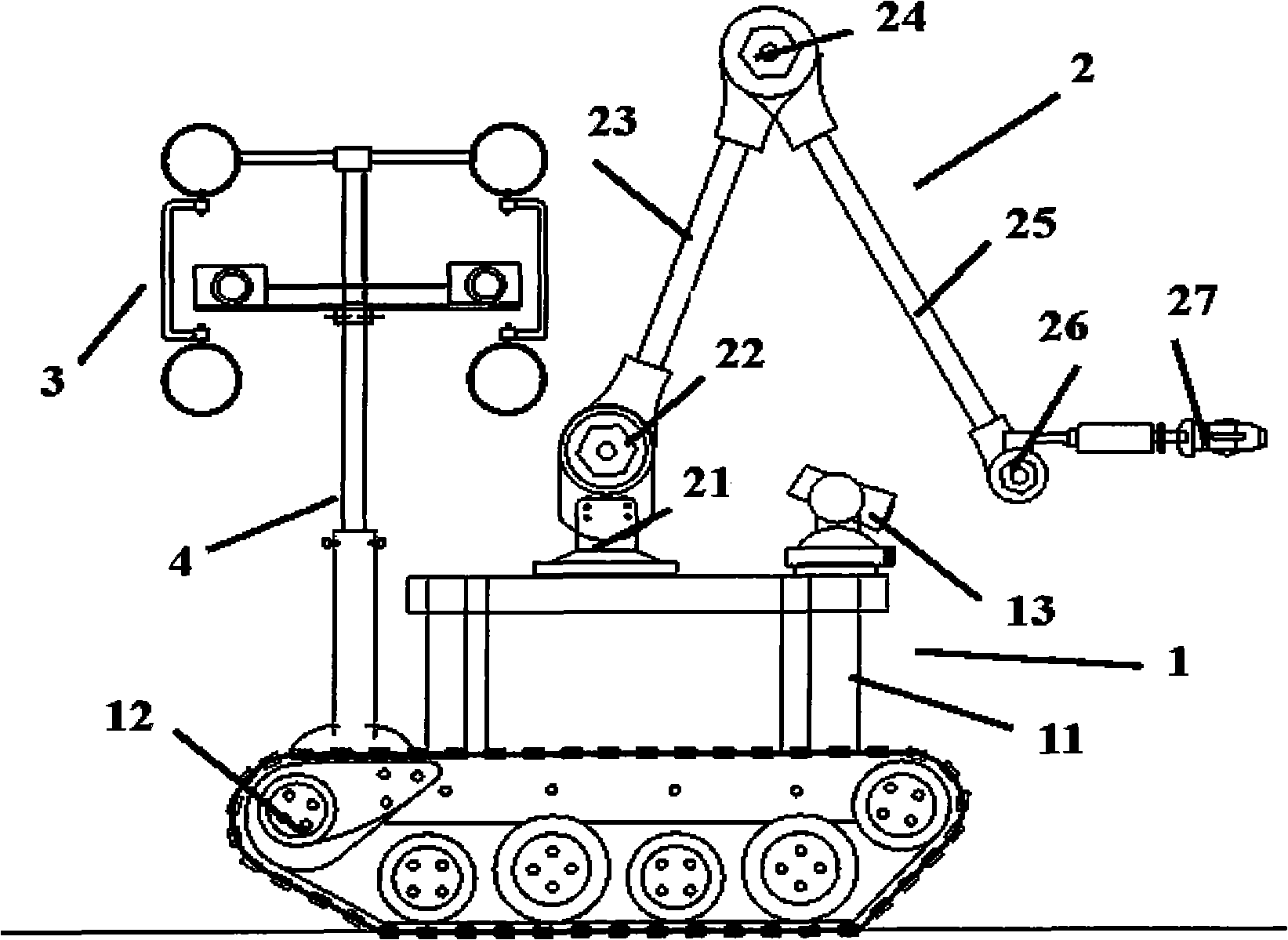

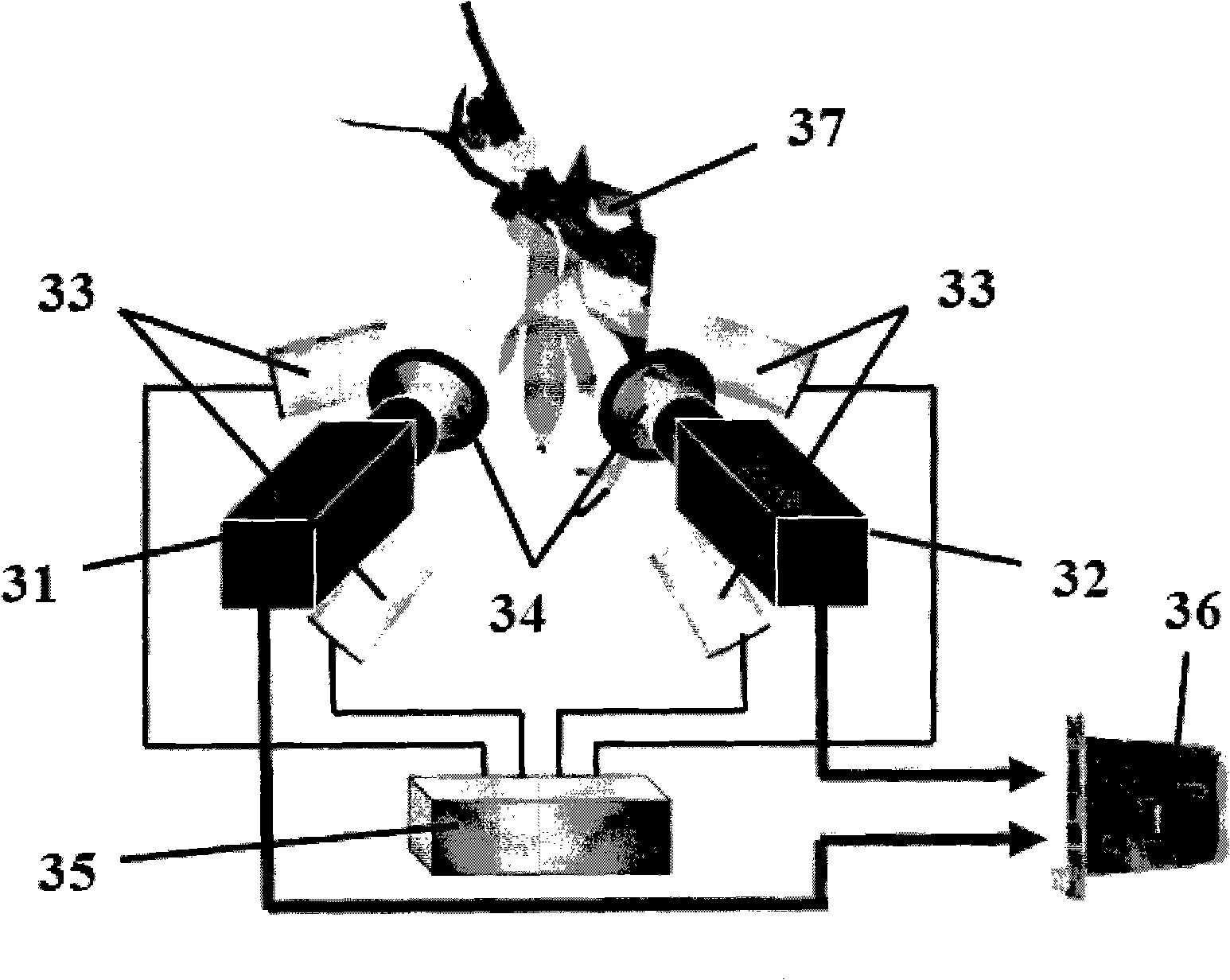

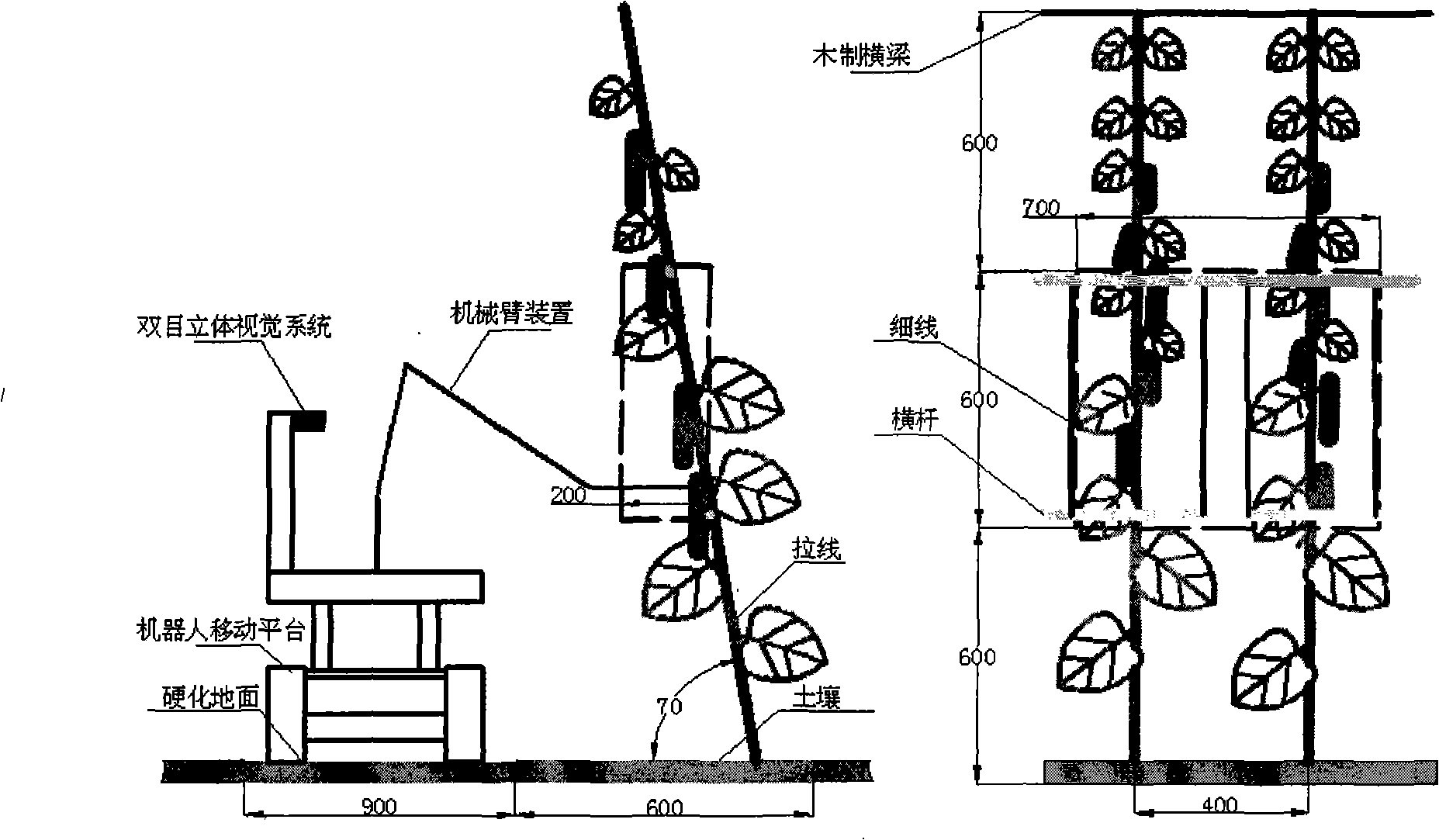

Cucumber picking robot system and picking method in greenhouse

The invention discloses a cucumber picking robot system in a greenhouse environment. The robot system comprises a binocular stereo vision system, a mechanical arm device and a robot mobile platform; the binocular stereo vision system is used for acquiring cucumber images, processing the images in real time and acquiring the position information of the acquired targets; the mechanical arm device is used for capturing and separating the acquired targets according to the position information of the acquired targets; and the robot mobile platform is used for independently moving in the greenhouse environment; wherein, the binocular stereo vision system comprises two black and white cameras, a dual-channel vision real-time processor, a lighting device and an optical filtering device; the mechanical arm device comprises an actuator, a motion control card and a joint actuator; and the robot mobile platform comprises a running mechanism, a motor actuator, a tripod head camera, a processor and a motion controller. The invention also discloses a cucumber picking method in the greenhouse environment. The method of combining machine vision and agricultural machinery is adopted to construct the cucumber picking robot system which is suitable for the greenhouse environment, thus realizing automatic robot navigation and automatic cucumber reaping, and reducing the human labor intensity.

Owner:SUZHOU AGRIBOT AUTOMATION TECH

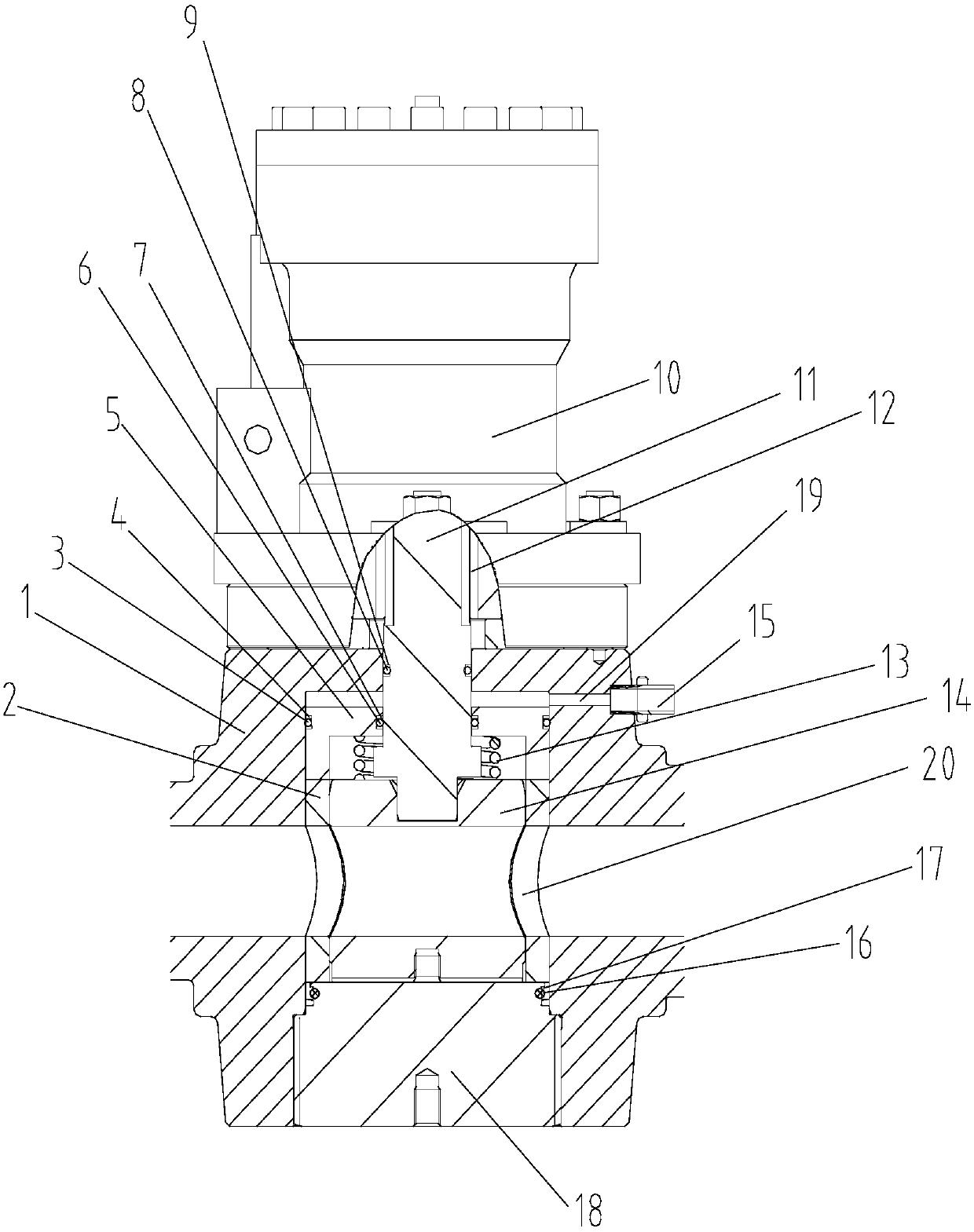

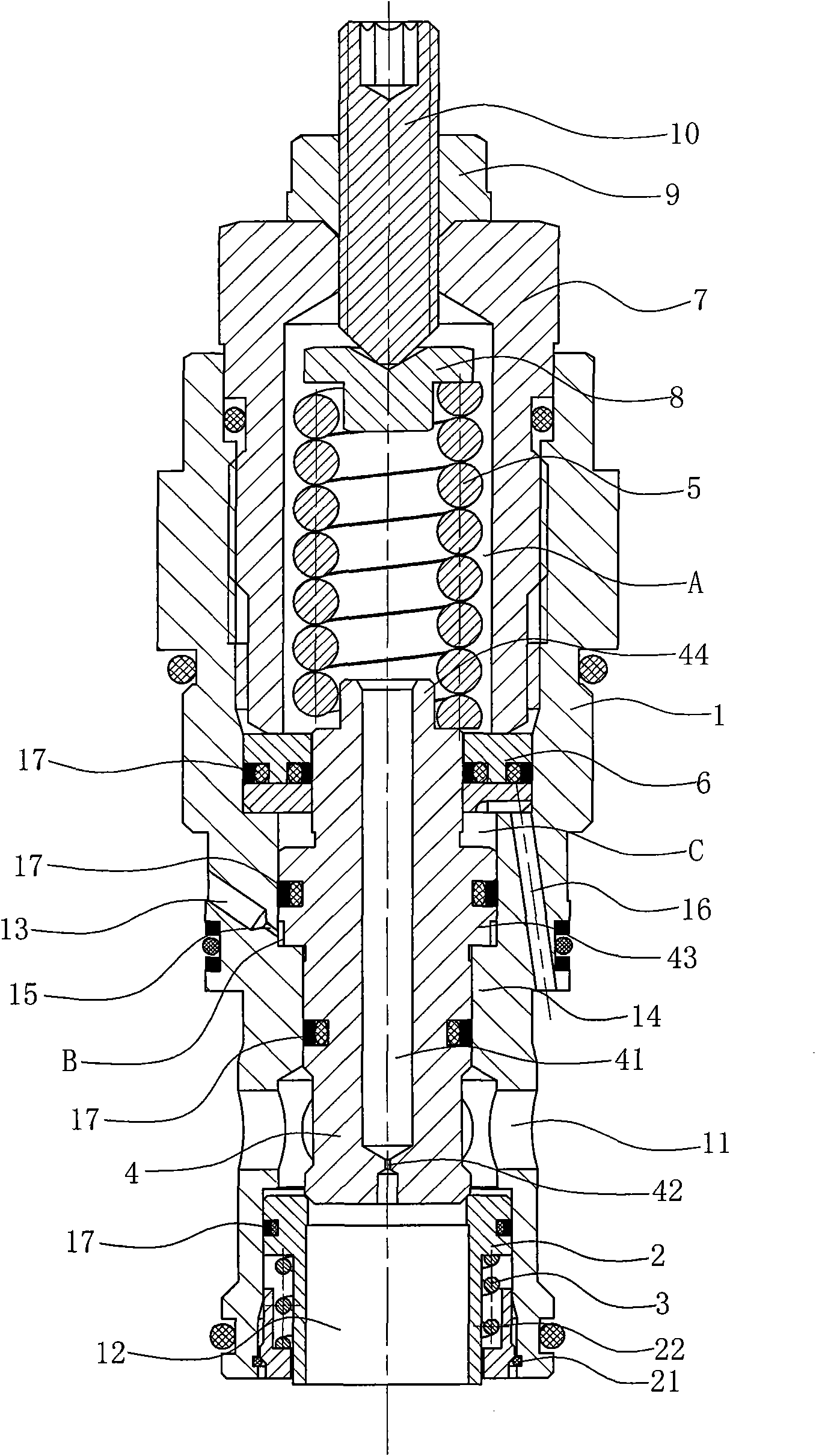

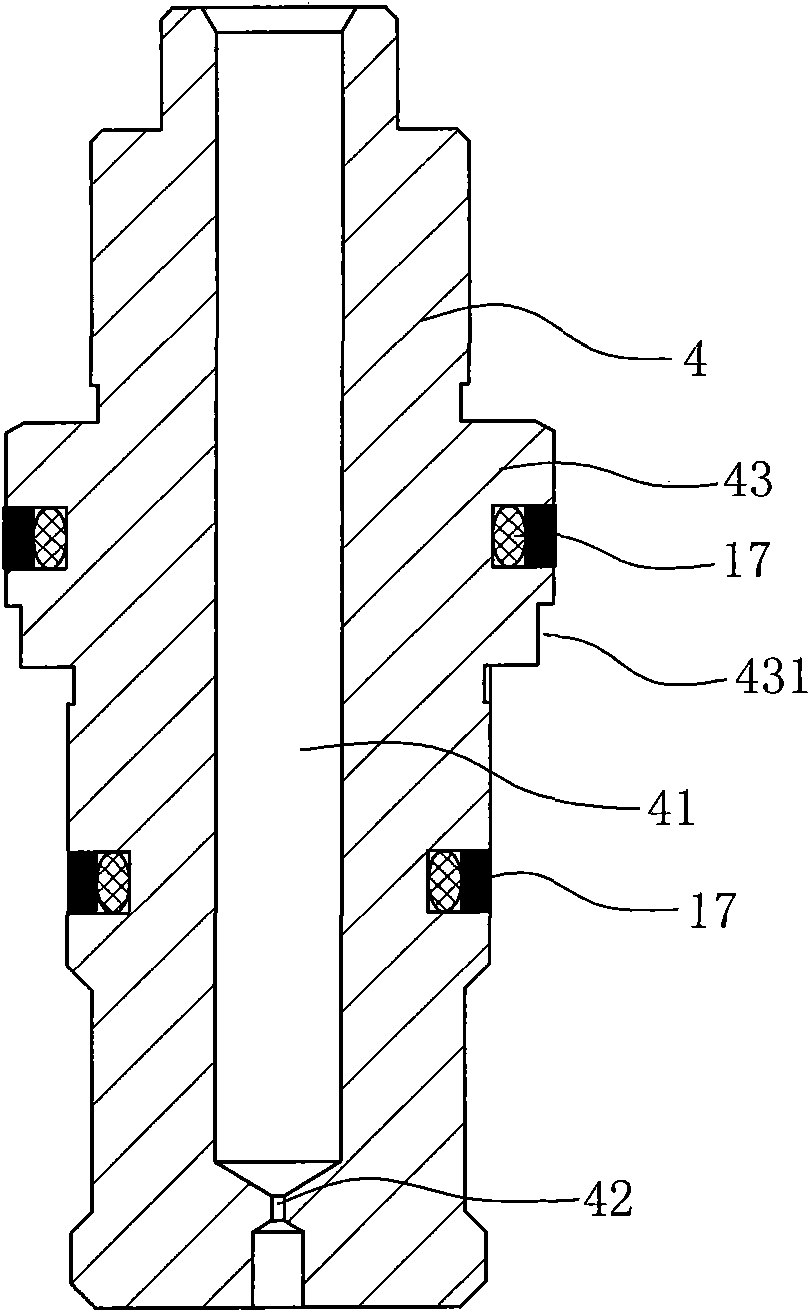

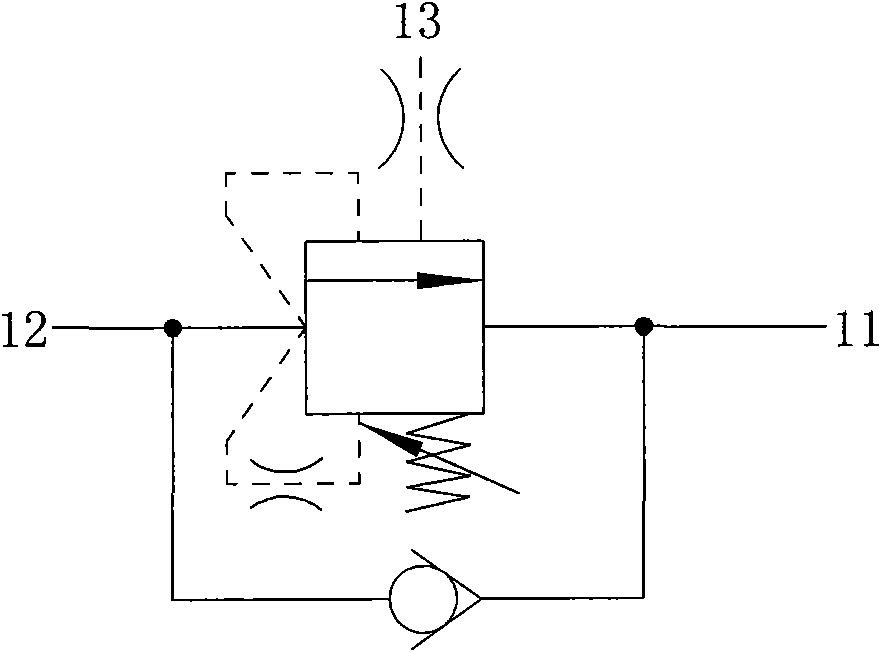

Anti-sand-accumulation plug valve

ActiveCN108036071AClearance adjustableGap noSpindle sealingsPlug valvesEngineeringMechanical engineering

The invention relates to the technical field of oil-gas field construction operation equipment, in particular to an anti-sand-accumulation plug valve which comprises a valve body, a valve cover and aplug rod arranged in the valve body. The valve body is connected with the valve cover; the lower end part of the plug rod is connected with a plug; a driver is arranged on the upper end part of the valve body and is connected with the valve body; the driver transmits a torque to the plug rod through a flat key; a sealing rubber core is arranged on the outer part of the plug; a piston is arranged on the upper part of the sealing rubber core; an annular seal cavity is formed among the plug, the plug rod and the piston; a spring is arranged in the seal cavity; the piston, the plug rod, the sealing rubber core and the plug are located in an inner core of the valve body; the inner core of the valve body communicates with an oil passage; and the oil passage is filled with hydraulic oil for driving the piston to move up and down. According to the anti-sand-accumulation plug valve provided by the invention, a gap between the sealing rubber core and the plug can be adjusted, and no gap exists among the plug, the sealing rubber core and the valve body during a pressure-bearing and fluid conveying process, so that sand is prevented from being accumulated.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

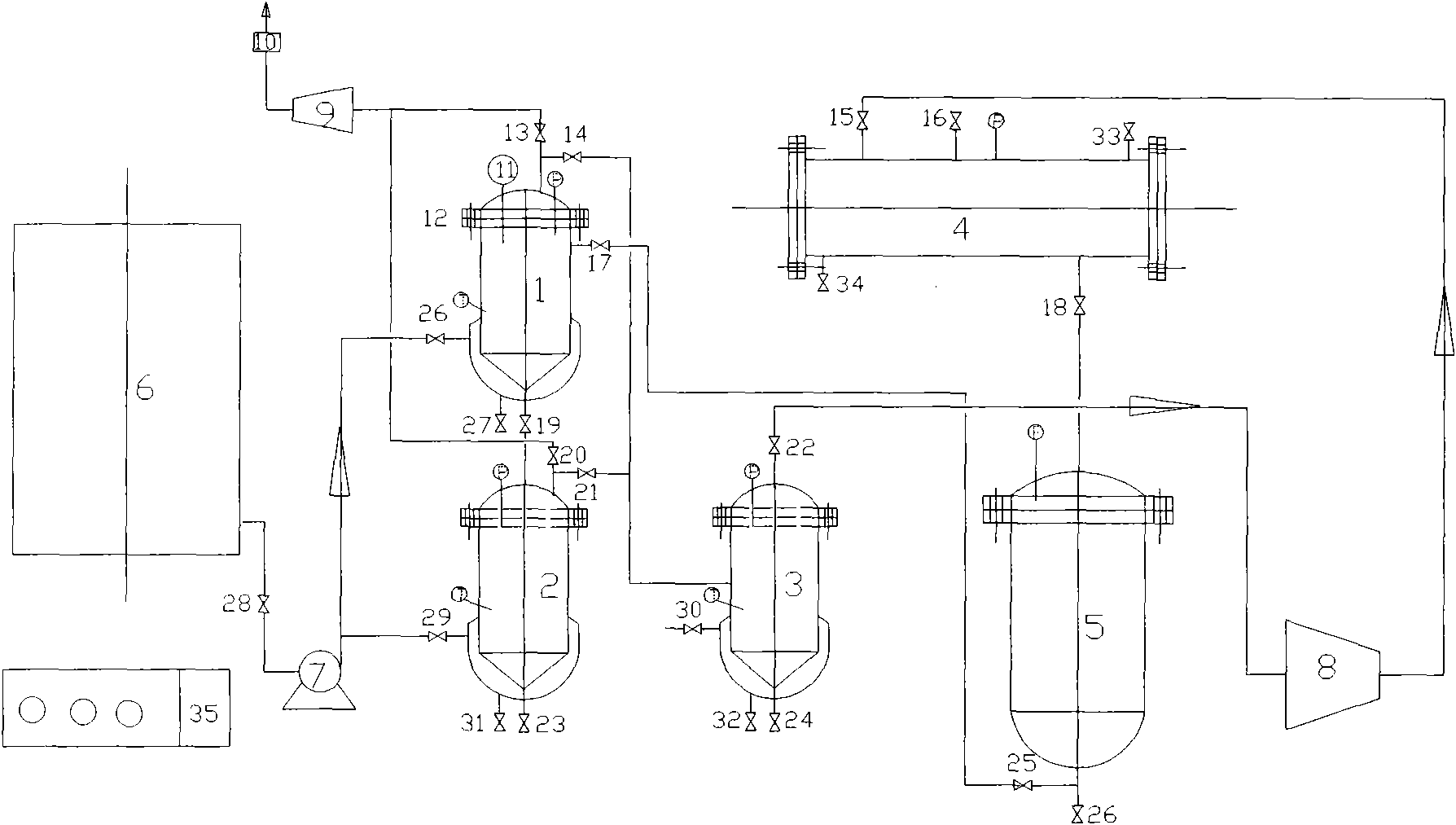

Subcritical liquid extraction device and subcritical liquid extraction method of active ingredients of natural products

InactiveCN101642632AHigh degree of automationReduce process difficultySolid solvent extractionSolventPressure feedback

The invention provides a subcritical liquid extraction device and a subcritical liquid extraction method of active ingredients of natural products, relating to a device and a method for extracting active ingredients of natural products. The device comprises a control system part and a leaching system part, wherein the leaching system part comprises an extraction tank 1, an evaporating tank 2, a buffer tank 3, a condenser 4, a solvent tank 5, an ultrasound generating device 11, a vacuum pump 9, a fire arrester 10, a compressor 8, a hot water pump 7 and a hot water box 6; the control system partcomprises a leaching temperature controller, a leaching time controller, a leaching frequency controller, a material dissolving ratio controller, an exsolution temperature regulation controller, an exsolution pressure feedback controller, an electric appliance controller of the device and an excess-temperature excess-pressure leaking alarm. The method can select different subcritical extraction media according to different extraction products, combines a subcritical liquid extraction technology and an ultrasonic extraction technology to increase extraction rate and reduce extraction time andis a new high-efficiency low-consumption environment-friendly technology for extracting active ingredients of natural products.

Owner:HENAN YALINJIE BIOLOGICAL TECH

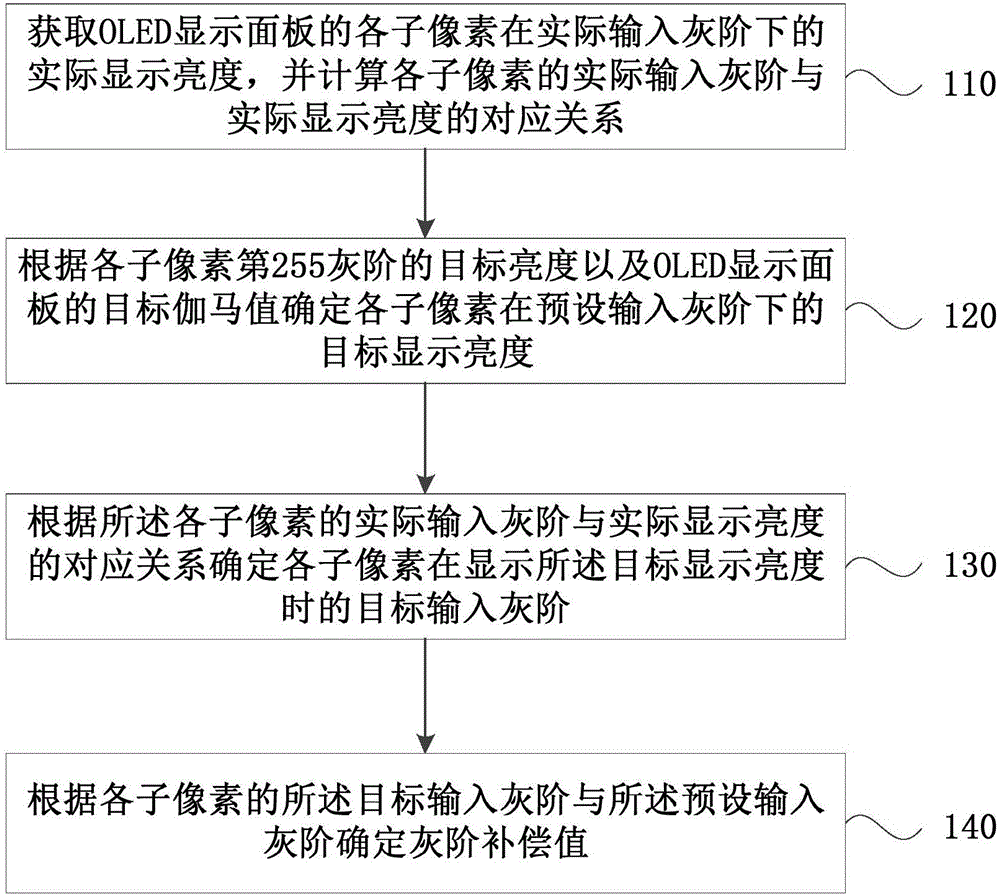

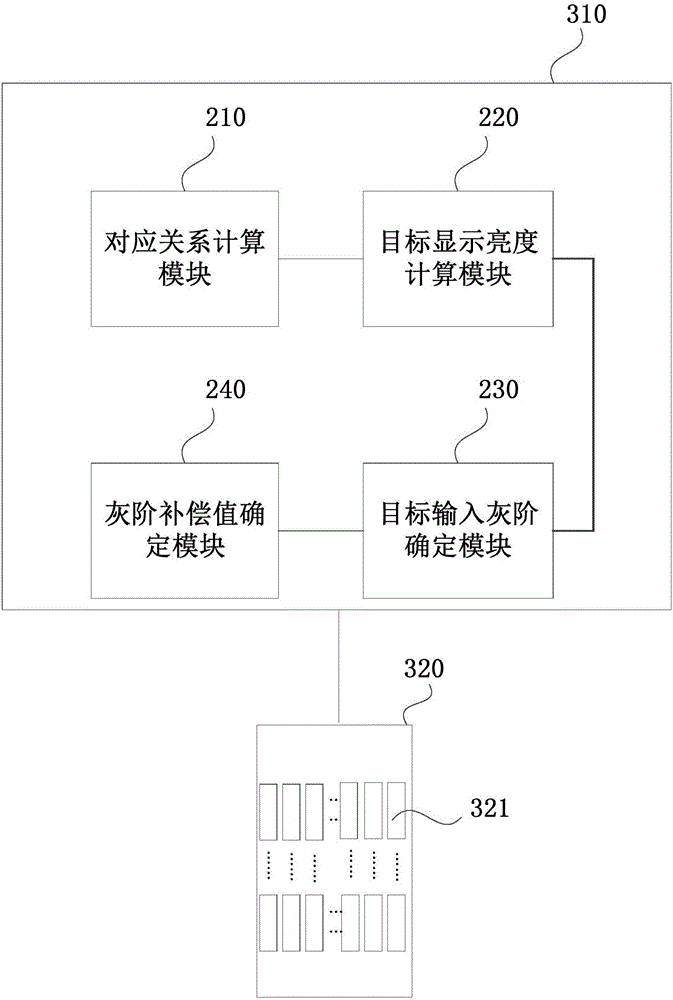

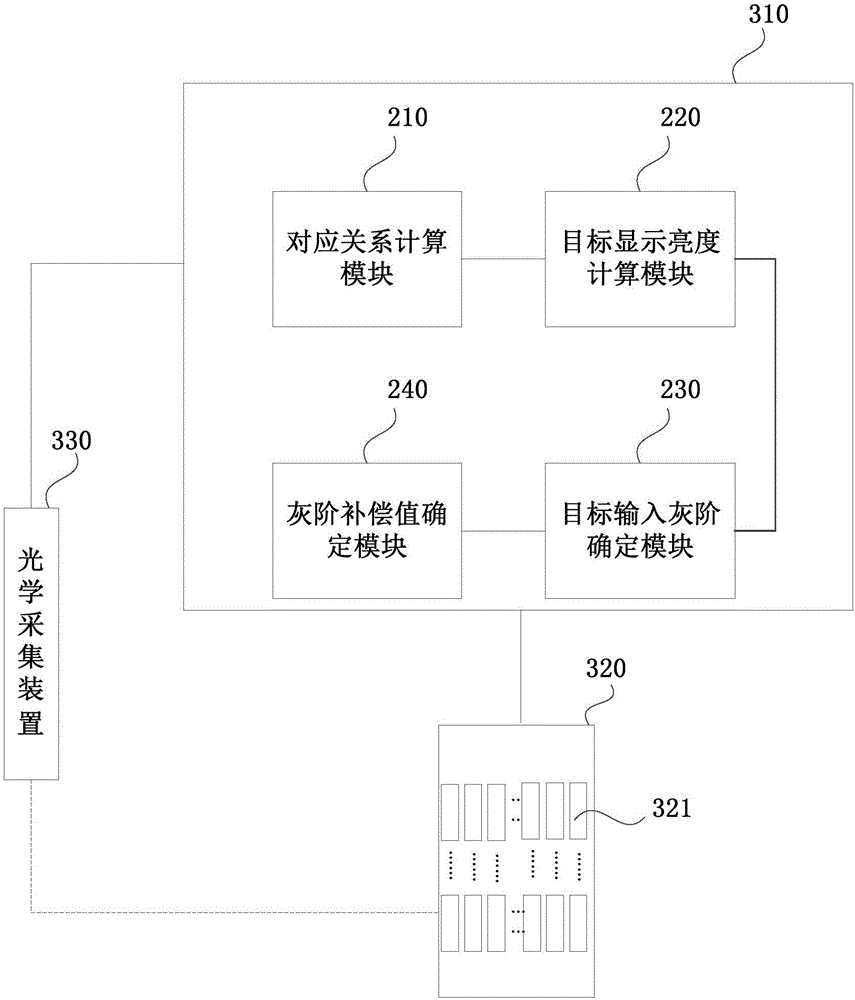

Grayscale compensation method and system of OLED display panel

ActiveCN106782307AImprove uneven lightingImprove brightness adjustment accuracyStatic indicating devicesSimulationLightness

An embodiment of the invention discloses a grayscale compensation method and system of an OLED display panel. The method includes: acquiring the actual display brightness of each subpixel of the OLED display panel under an actual input grayscale, and calculating the corresponding relationship between the actual input grayscale of each subpixel and the actual display brightness of each subpixel; determining the target display brightness of each subpixel under a preset input grayscale according to the target brightness of each subpixel under the 255th grayscale and the target gamma value of the OLED display panel; determining the target input grayscale of each subpixel when each subpixel displays the target display brightness according to the corresponding relationship between the actual input grayscale of each subpixel and the actual display brightness of each subpixel; determining a grayscale compensation value according to the target input grayscale of each subpixel and the preset input grayscale. By the grayscale compensation method, light-emitting unevenness among the subpixels of the OLED display panel is improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

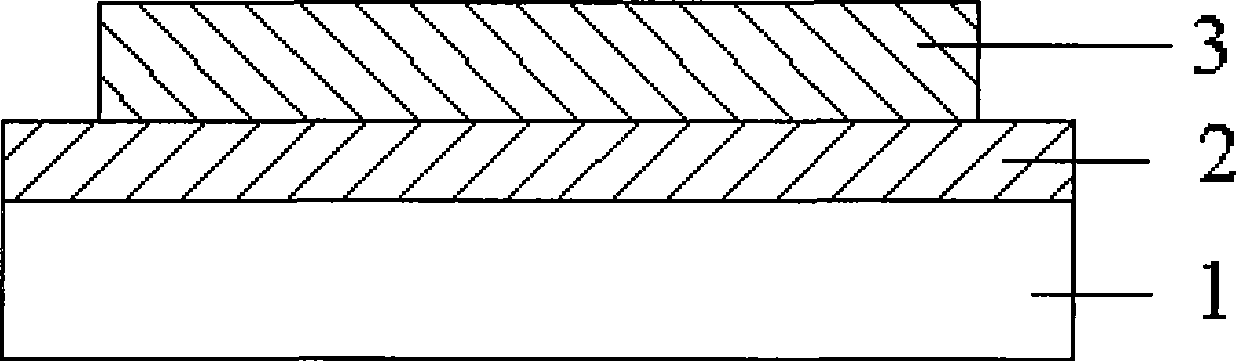

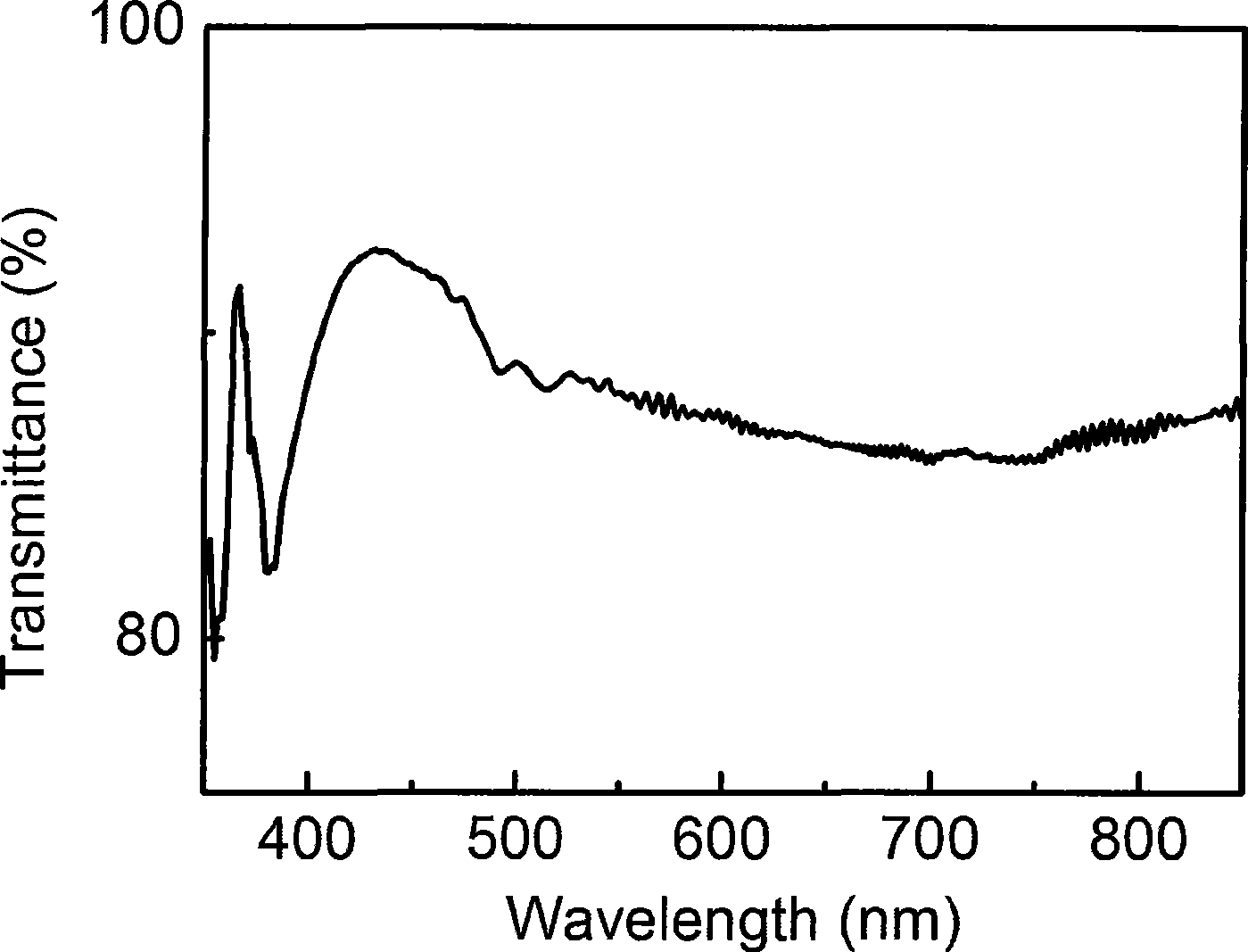

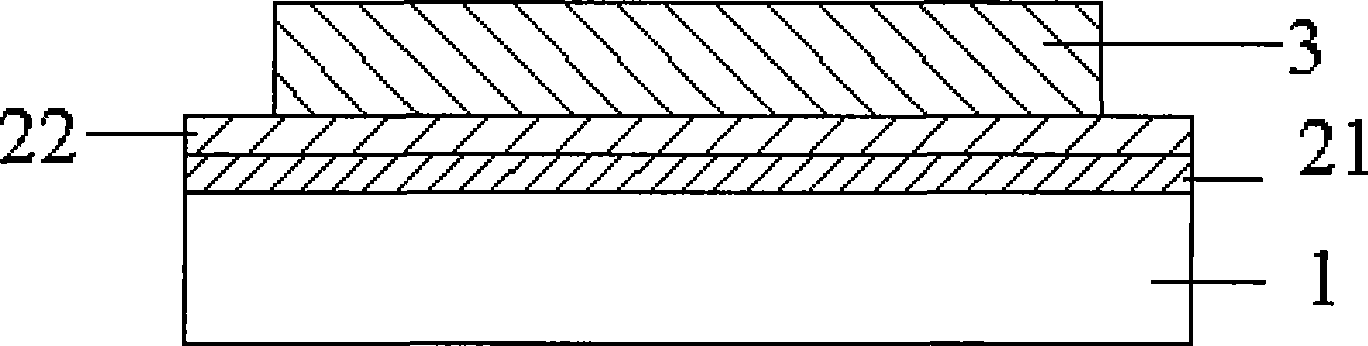

Substrate for flexible organic optoelectronic device and preparation method thereof

InactiveCN101465409AImprove flatnessImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingUV curingAdhesive

The invention discloses a flexible substrate used for optoelectronic devices and comprises a flexible substrate; the invention is characterized in that a bonding layer and a conductive thin film are arranged on the surface of the flexible substrate; the conductive thin film is deposited on the surface of the bonding layer; and the material of the bonding layer is an adhesive with a double-curing system comprising UV curing-thermal curing or UV curing-microwave curing or UV curing-anaerobic curing or UV curing-electron beam curing. The substrate solves the problem of poor adhesion between the deposited conductive thin film and the substrate due to low surface energy of the flexible substrate and improves the barrier properties of the substrate on water and oxygen, and also achieves good smoothing effect on the surface of the substrate; besides, the preparation method is simple and effective, which can significantly reduce the substrate production cost and process difficulty and increase the substrate yield rate in the etching process.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

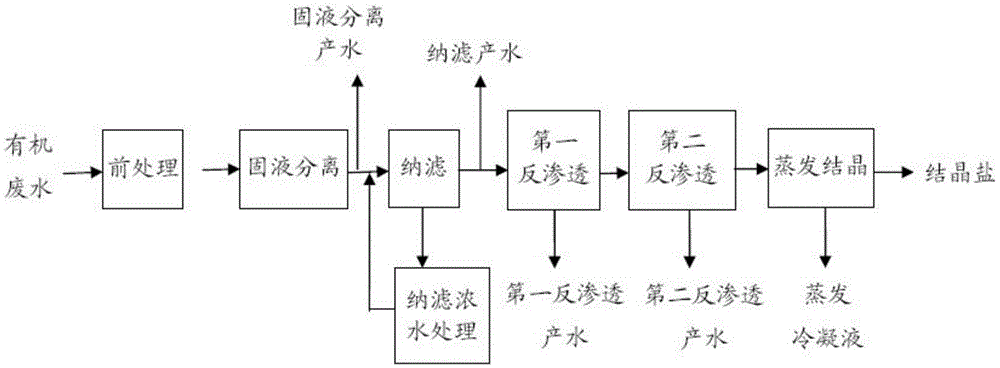

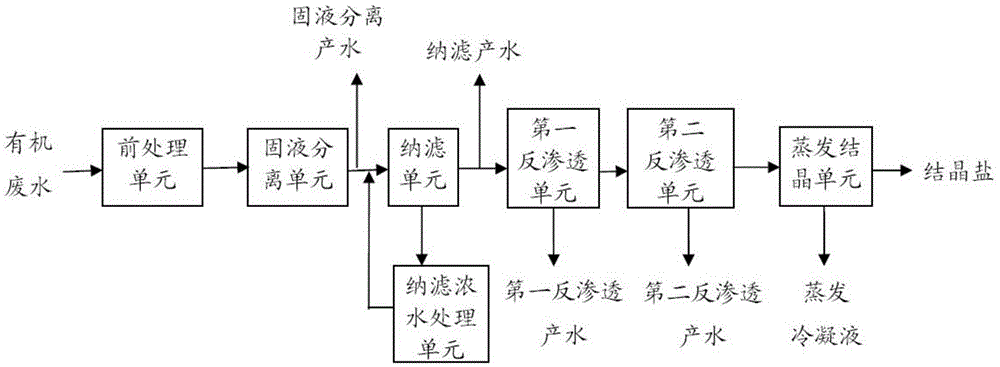

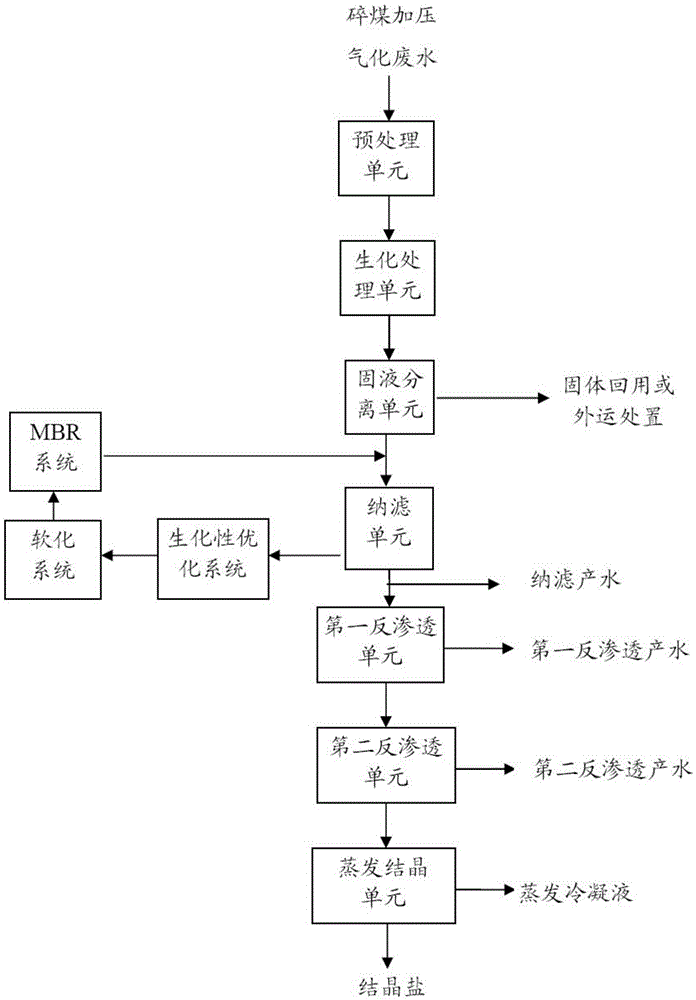

Processing method for reducing and recycling organic waste water and processing system

InactiveCN105540967AReduce foulingReduce the risk of contaminationFatty/oily/floating substances removal devicesWater contaminantsReverse osmosisWastewater

The invention provides a processing method for reducing and recycling organic waste water. The method comprises steps: (1) pre-treating waste water to obtain pre-treated out-water; (2) treating the out-water obtained from the step (1) through solid-liquid separation; (3) nano-filtering the out-water obtained from step (2); (4) treating nano-filtered concentrated water obtained from the step (3) to obtain out-water subjected concentrated water nano-filtering, returning to the step (3) for mixing the out-water subjected to concentrated water nano-filtering with the out-water subjected to solid-liquid separation, and performing nano-filtering; (5) performing first reverse osmosis treatment on out-water obtained from the step (3) through nano-filtering; (6) performing second reverse osmosis treatment on concentrated water obtained from the step (5) through first reverse osmosis treatment; and (7) evaporating and crystallizing a concentrated liquid obtained from the step (6) through second reverse osmosis treatment in order to obtain crystallized salt and evaporated concentrated water. The invention further provides a processing system of the method. Through the method and system, waste water is truly reduced and recycled.

Owner:DATANG INT CHEM TECH RESINST

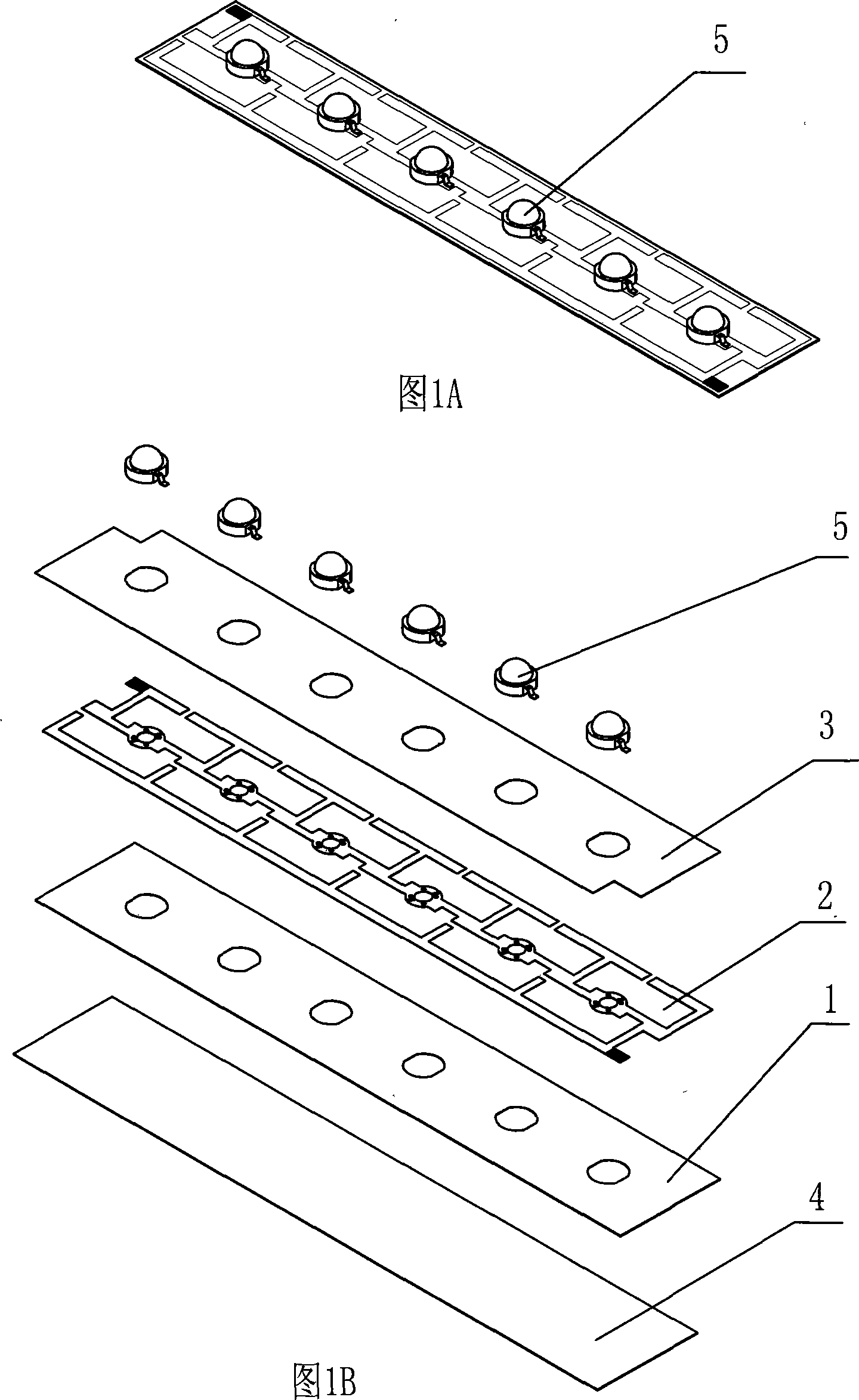

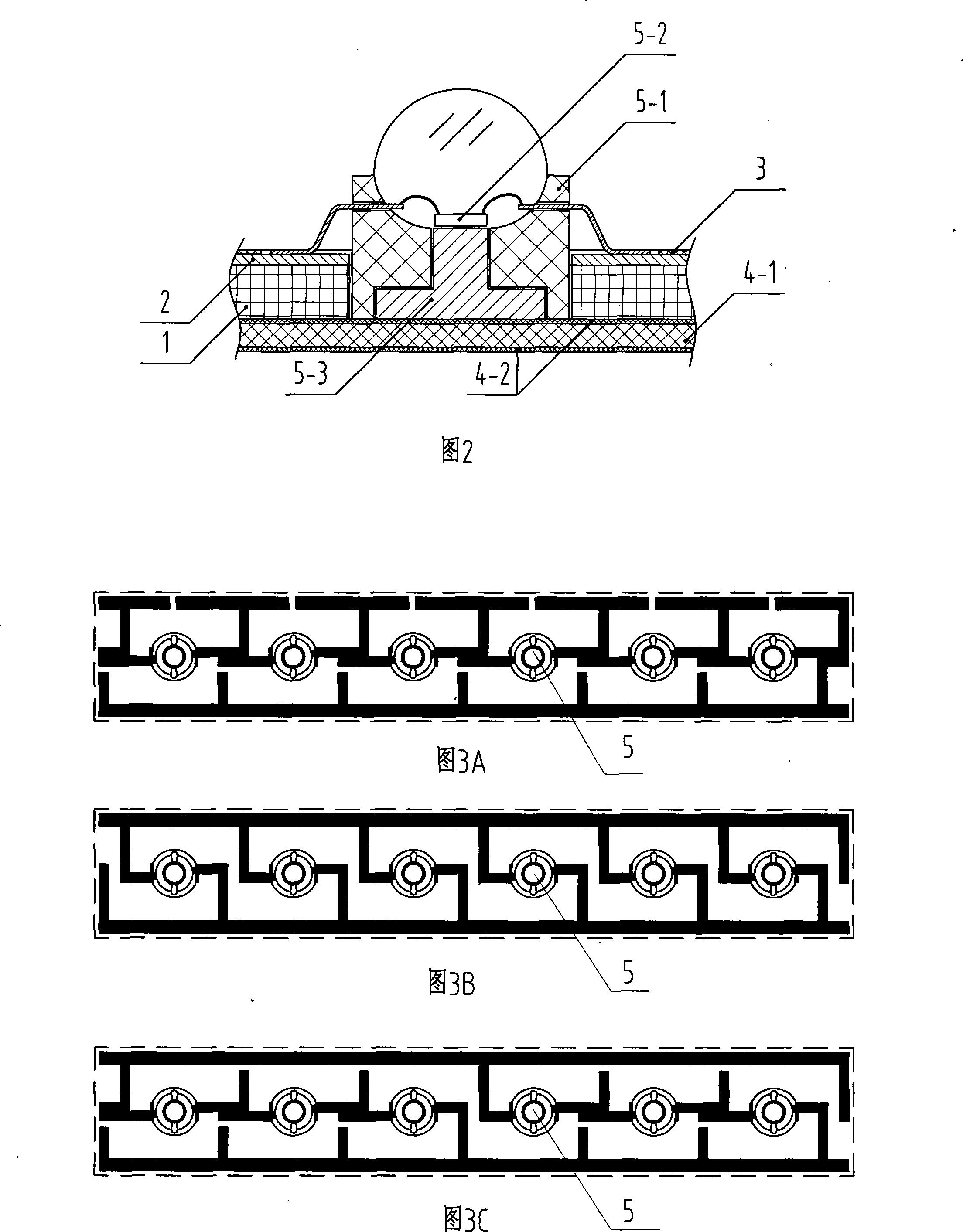

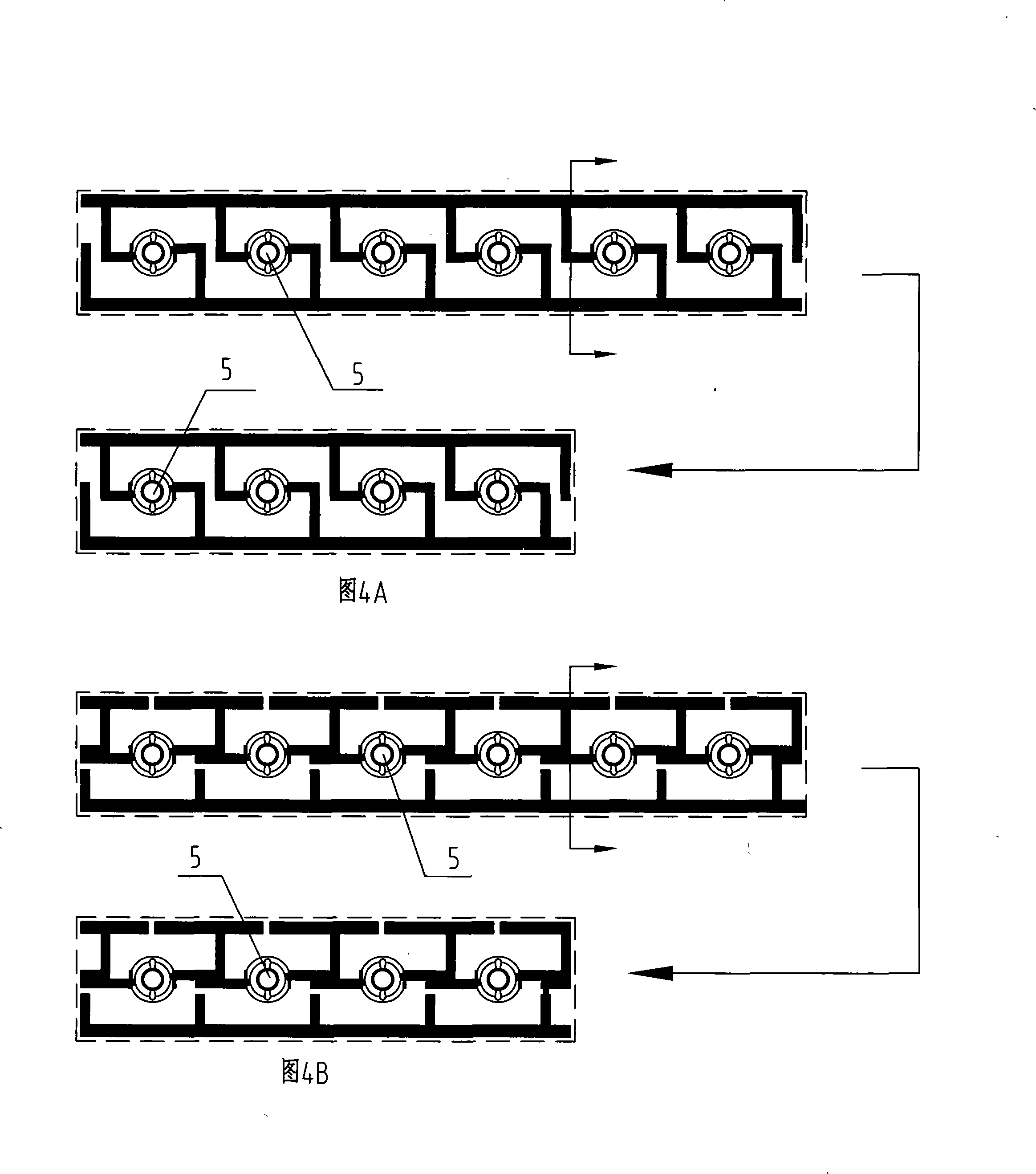

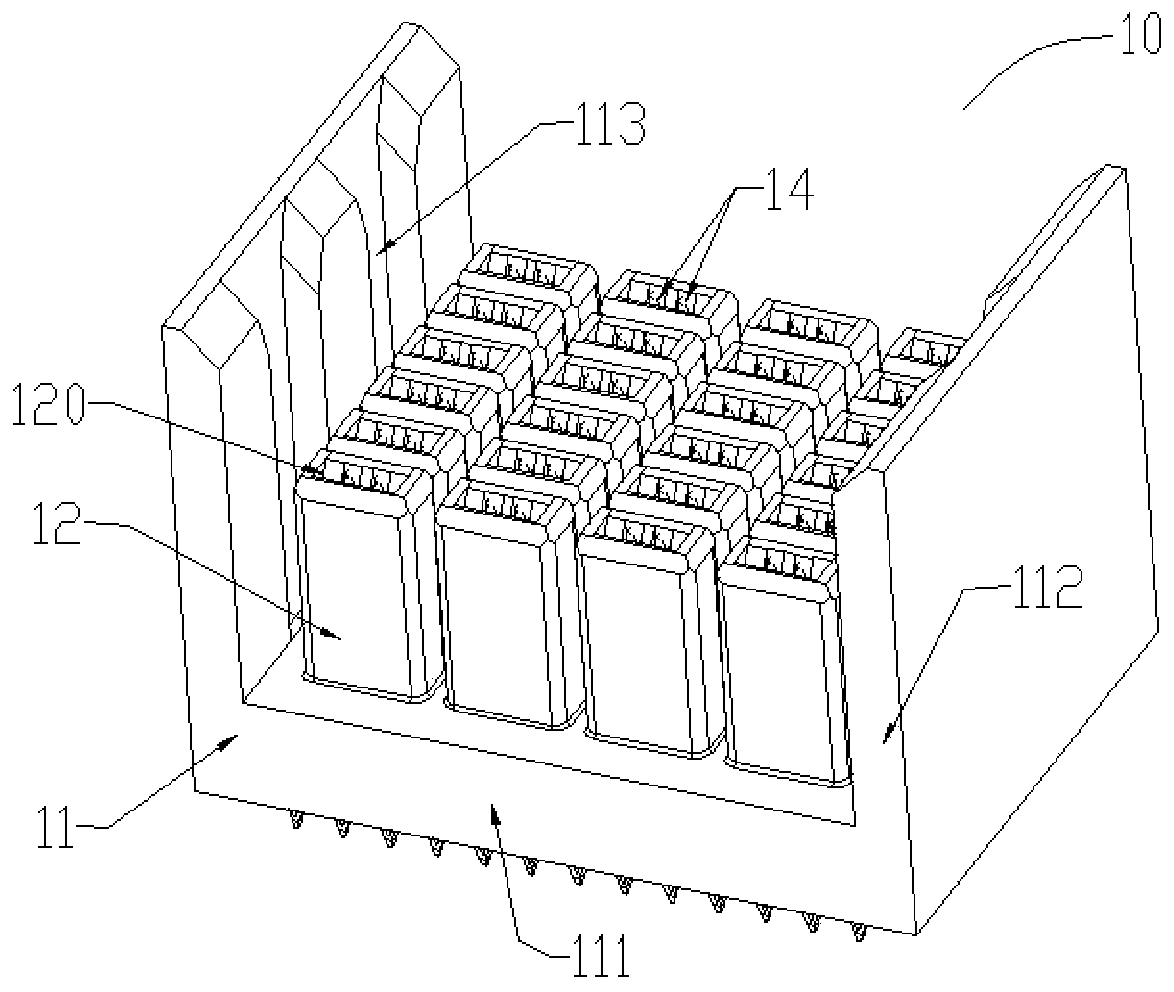

Flexible circuit board of LED illumination array

InactiveCN101198216ANovel, reasonable and compact structureEasy to producePrinted circuit detailsElectric circuit arrangementsFlexible circuitsHeat conducting

The invention discloses a flexible circuit board convenient for efficient heat dissipation and mainly used in a high-power LED illumination array, belonging to the semiconductor illumination technical field. The flexible circuit board of an LED illumination array is characterized in that: the circuit board is provided with a flexible substrate, a connection circuit, an insulating film-covered layer, a heat-conducting rubber pad and an LED light source; the connection circuit is arranged on the surface of the flexible substrate; the surfaces of the flexible substrate and the connection circuit are covered with the insulating film-covered layer to form a circuit board module; the LED light source is packaged inside the circuit board module in an array mode; the bottom surface of the flexible substrate is adhered to the surface of the heat-conducting rubber pad. Therefore, the entire flexible circuit board module has certain elasticity and flexibility and can adapt to bending, twisting and crimp deformation of certain strength; moreover, the invention can also be arranged on non-flat surfaces not more than a certain curvature such as a cylindrical surface or a spherical surface. The invention has wider application scope, better heat dissipation performance, less production cost, convenient installation and substantially increased production efficiency.

Owner:史杰

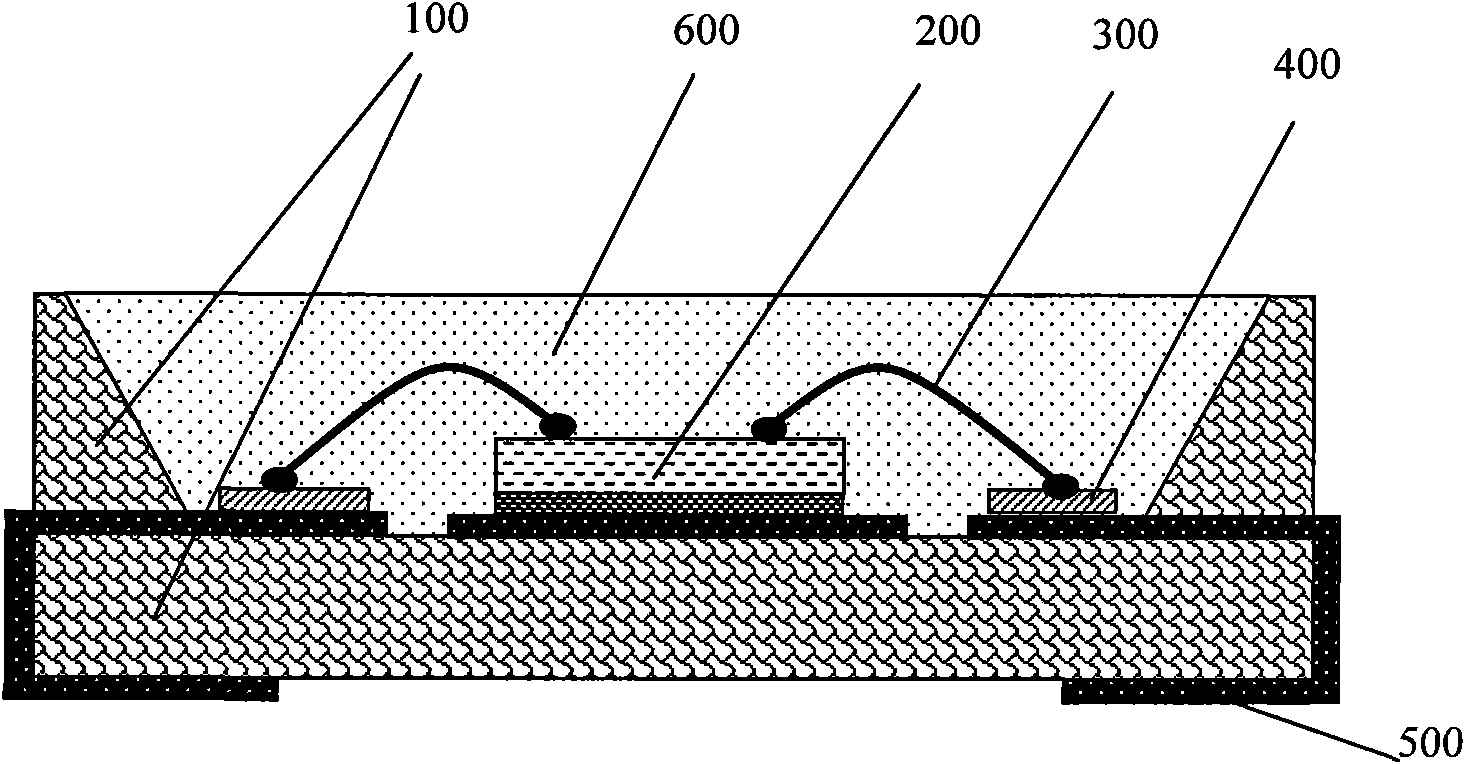

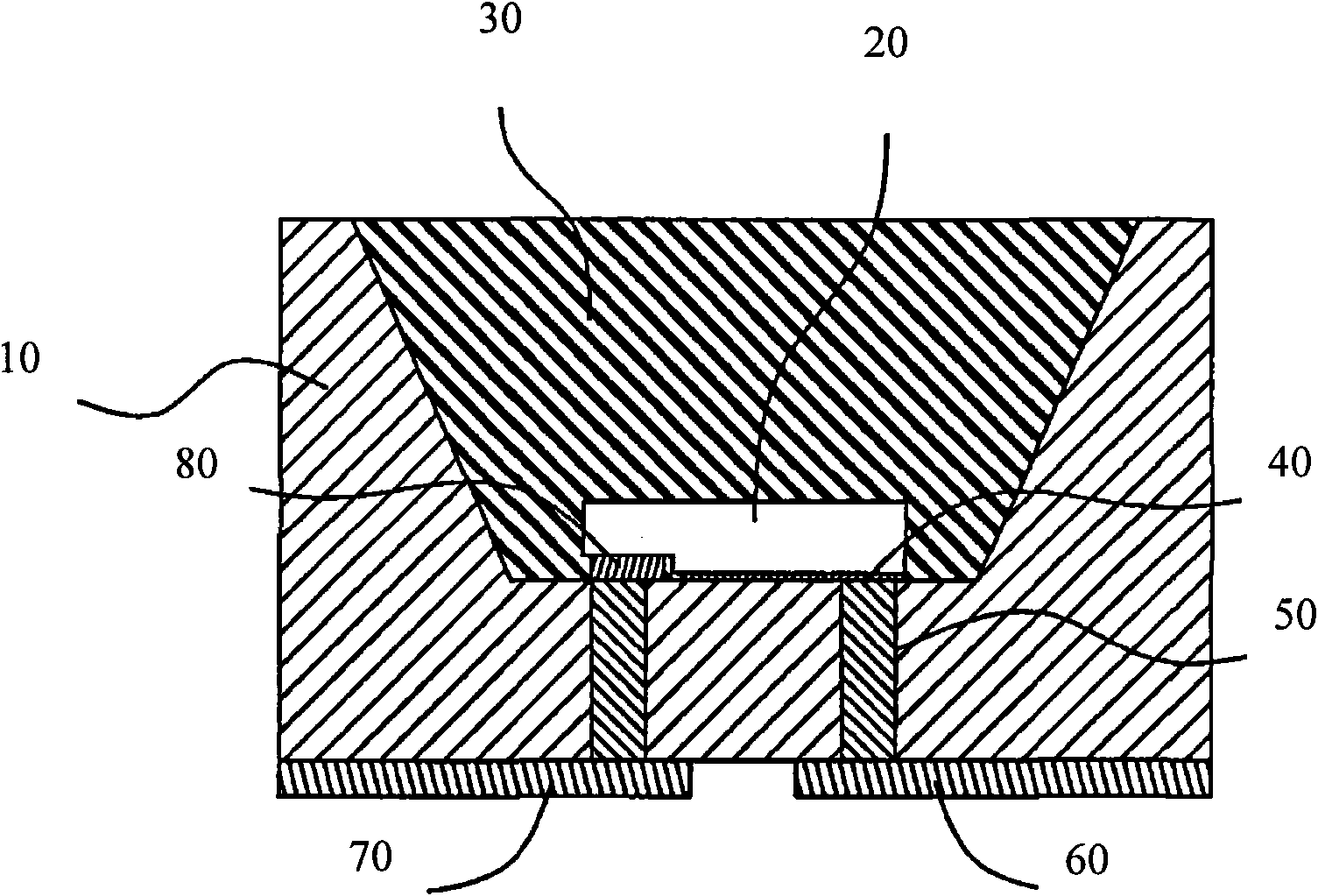

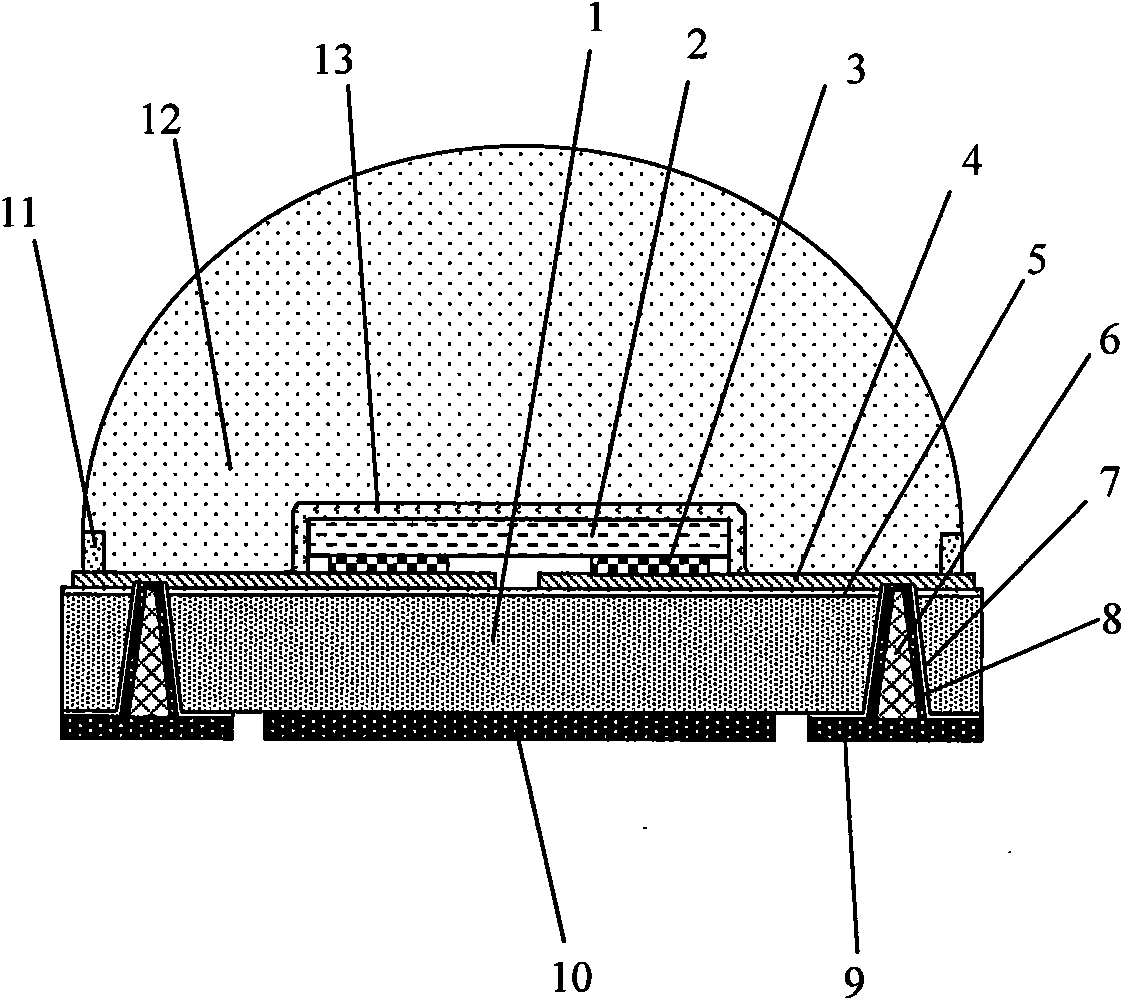

LED (Light Emitting Diode) surface patch type encapsulating structure based on silicon base plate and encapsulating method thereof

InactiveCN101997074AImprove cooling effectReduce volumeSolid-state devicesSemiconductor devicesInsulation layerHeat conducting

The invention relates to an LED (Light Emitting Diode) surface patch type encapsulating structure based on a silicon base plate, which comprises the silicon base plate, an LED chip, a circular ring convex wall and a lens, wherein the upper surface of the silicon base plate is a plane structure, an oxidation layer is covered on the upper surface of the silicon base plate, a metal electrode layer is arranged on the upper surface of the oxidation layer, the upper surface of the metal electrode layer is provided with metal convex points, a through hole penetrating through the silicon base plate is arranged below the metal electrode layer, an insulation layer covers the inner wall of the through hole and the partial lower surface of the silicon base plate, a metal connecting layer covers the surface of the insulation layer in the through hole, two electric conducting metal welding discs are respectively arranged at the lower surface of the silicon base plate and are insulated from the silicon base plate, a heat conducting metal welding disc is arranged at the lower surface of the silicon base plate, the LED chip is inversely arranged on the silicon base plate, and the LED chip and the metal electrode layer in the LED chip are isolated from the outside through the circular ring convex wall and the lens. The encapsulating structure has the advantages of good heat radiation effect and small size, also has high reliability because of no gold thread encapsulation, realizes the wafer level mass production encapsulation and hereby reduces the encapsulation cost.

Owner:APT ELECTRONICS

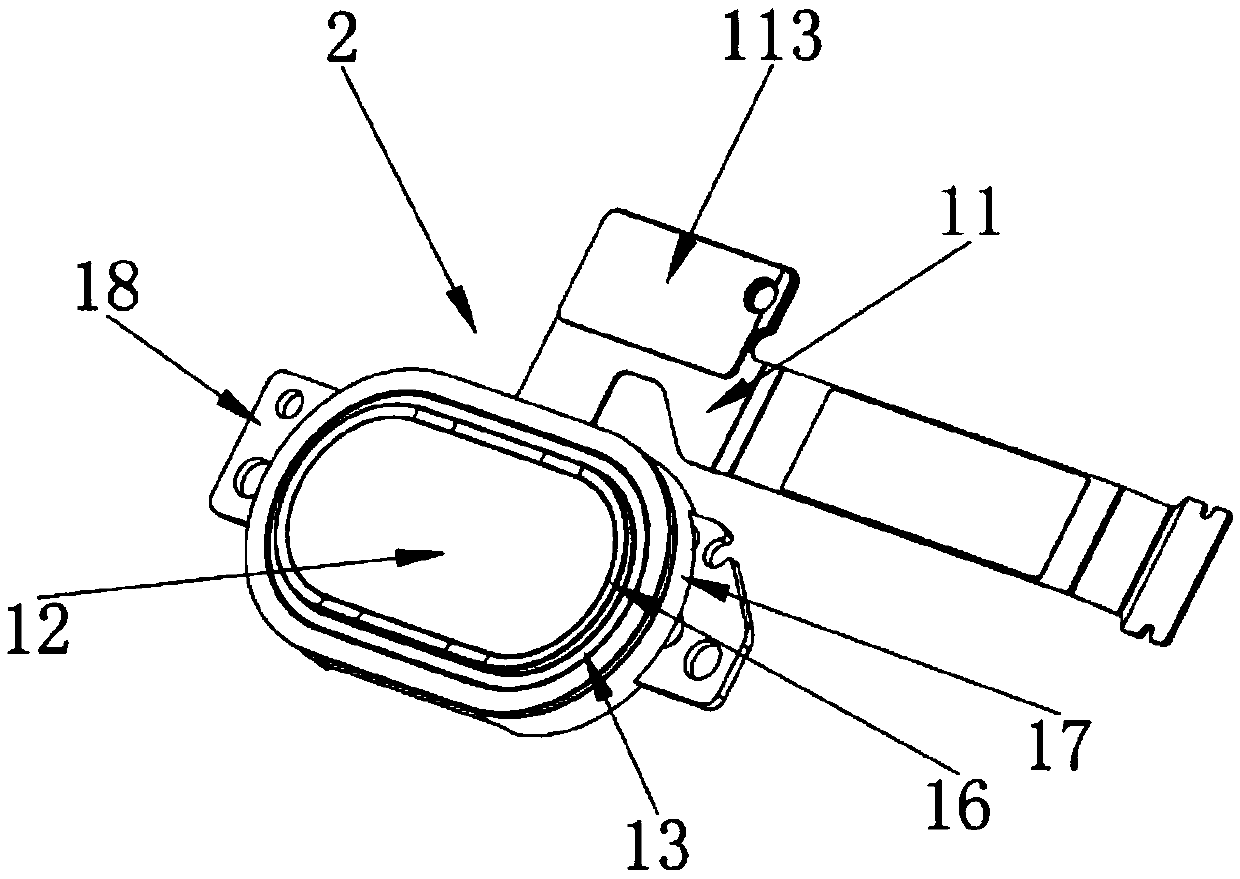

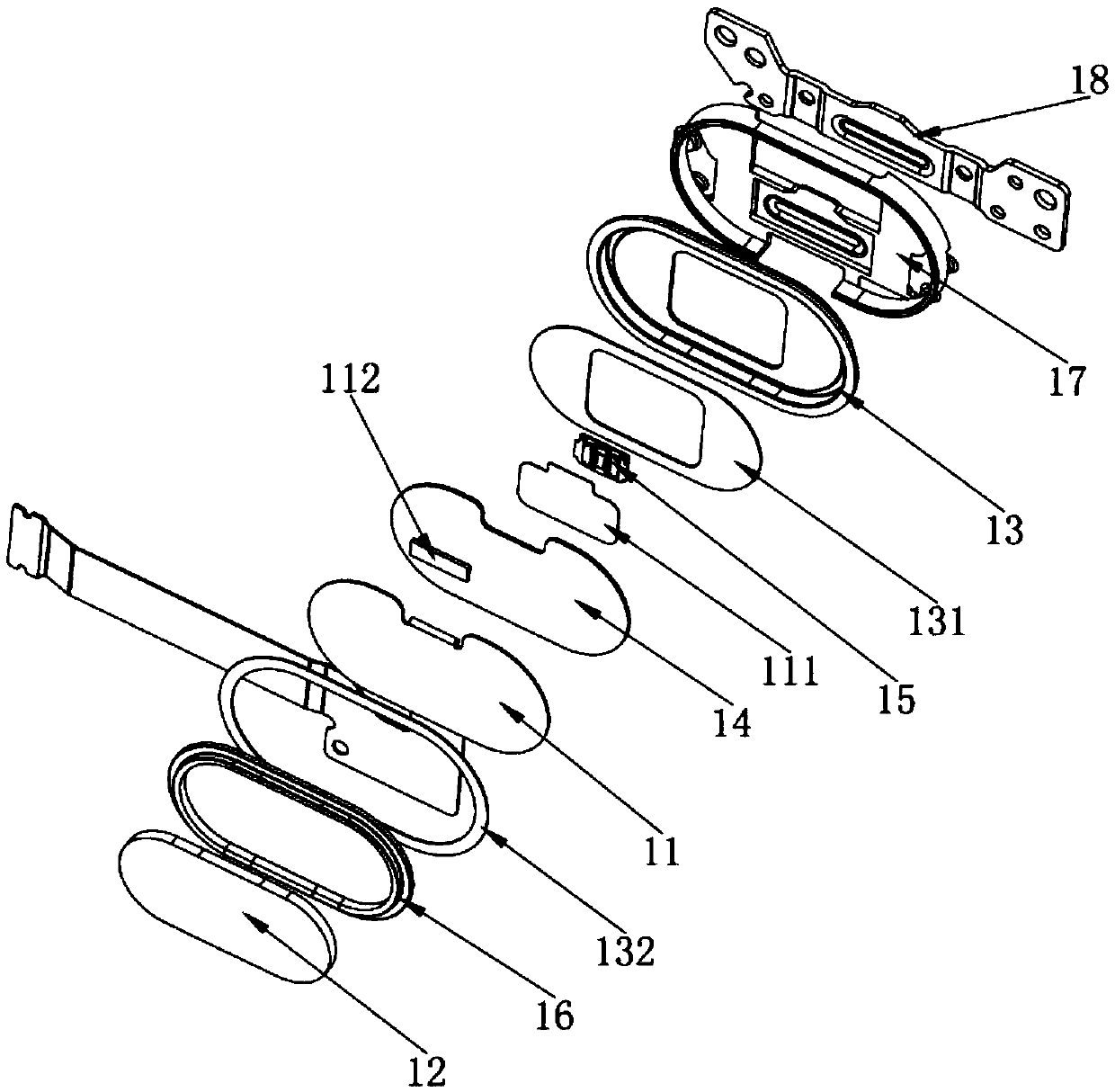

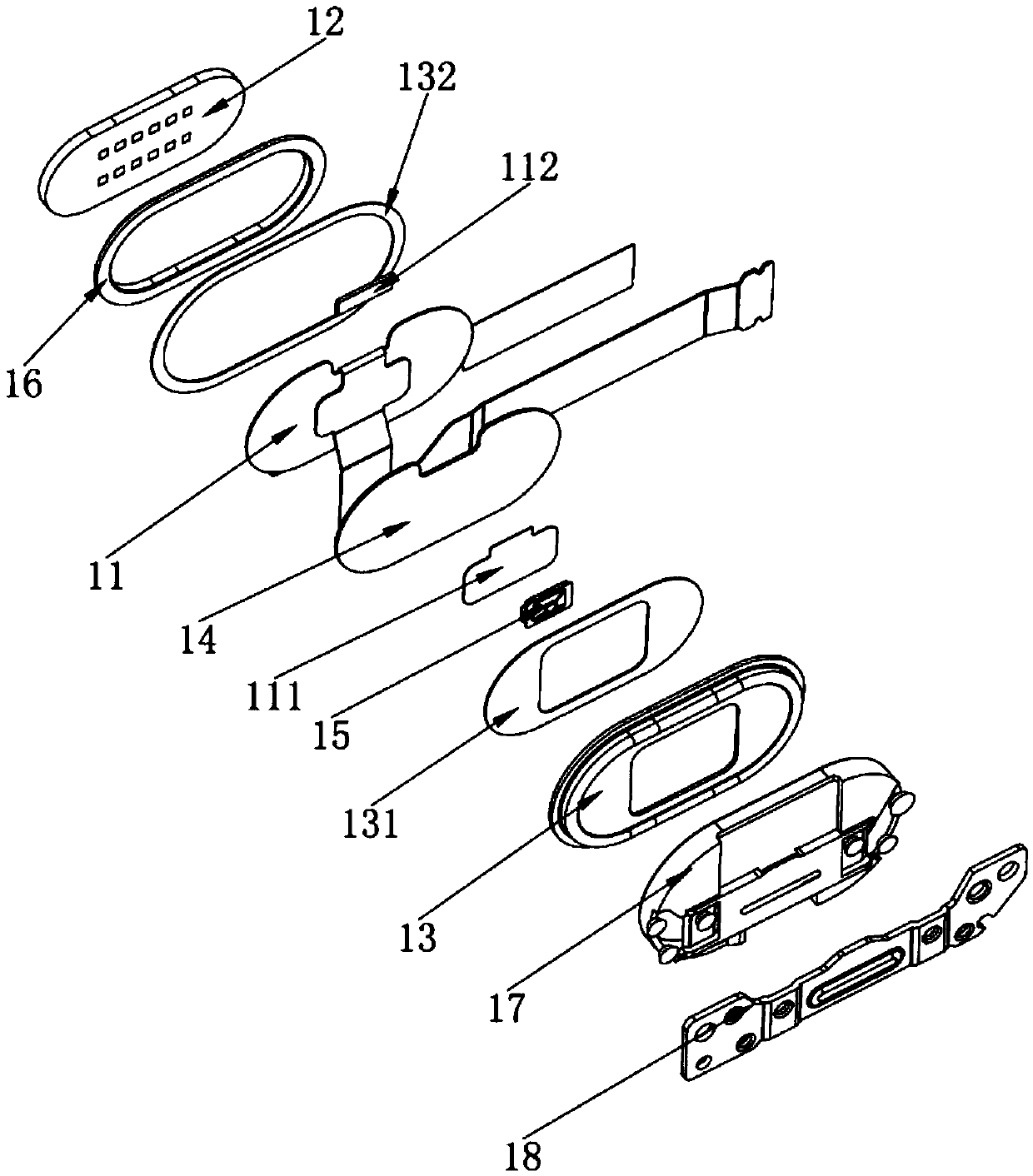

Fingerprint module and terminal

ActiveCN105373778AImprove pressing feelReduce processing difficultyPrint image acquisitionFlexible circuitsComputer module

The invention relates to the terminal manufacturing field and particularly relates to a fingerprint module and a terminal. The fingerprint module comprises a silica gel supporting member, a first supporting face of the silica gel supporting member is provided with a first reinforcing board, the first reinforcing board is provided with a first flexible circuit board electrically connected with the fingerprint module, the first flexible circuit board is provided with a fingerprint sensor module electrically connected with the first flexible circuit board, the first flexible circuit board is provided with a fingerprint identification processing chip, and a second supporting face of the silica gel supporting member is provided with a switch. According to the fingerprint module, a silica gel structure which has a complex structure and is used for completely wrapping the fingerprint module is not required, processing difficulty of silica gel parts is reduced, parts are reduced, the structure is simplified, assembly is easy, the yield is improved, the switch can be directly positioned on the assembled terminal, so no deviation occurs, and thereby pressing feeling of the fingerprint module can be improved.

Owner:MEIZU TECH CO LTD

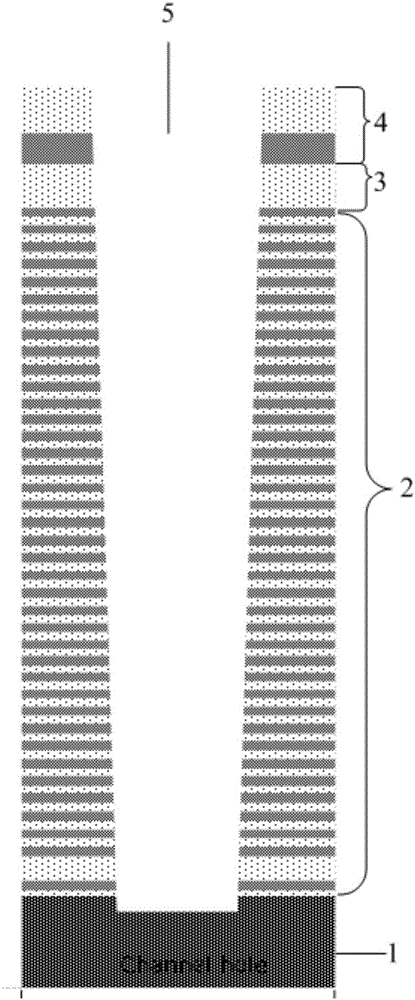

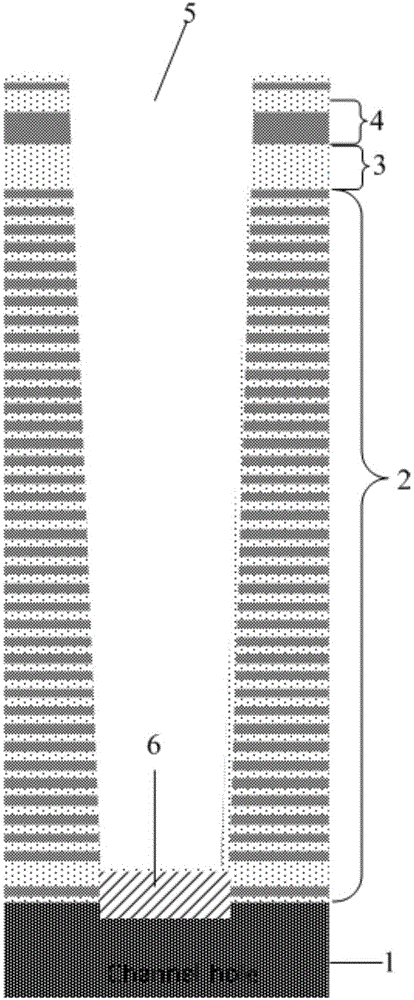

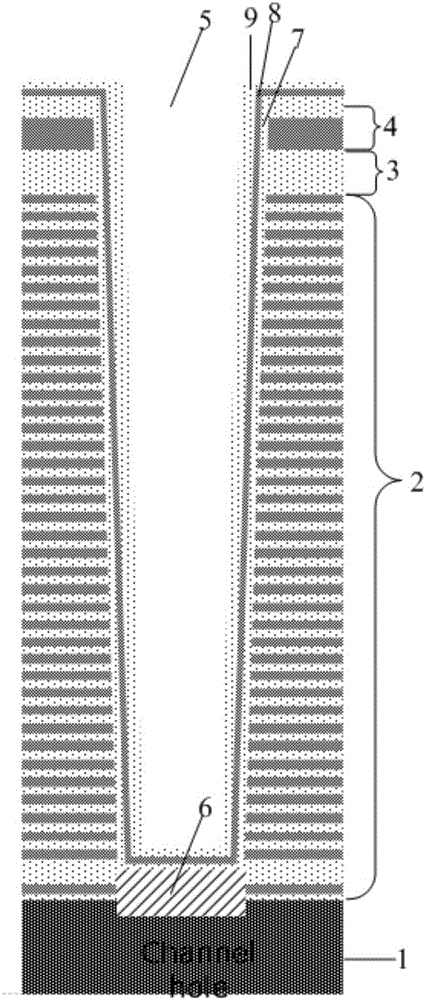

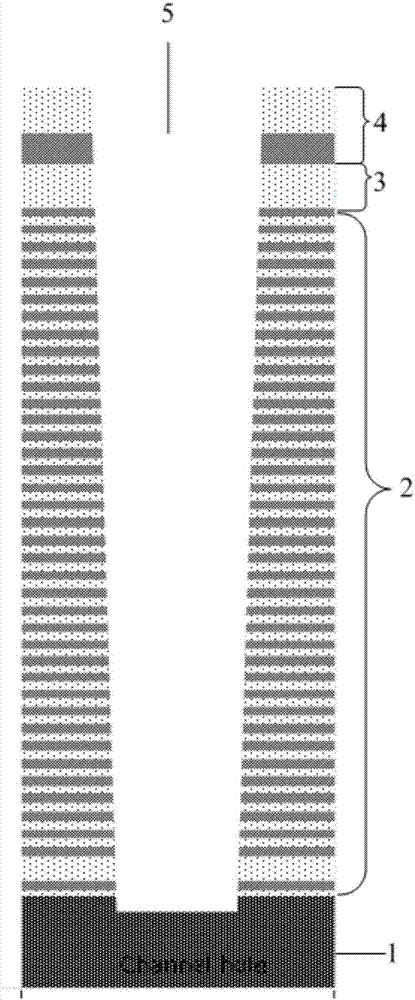

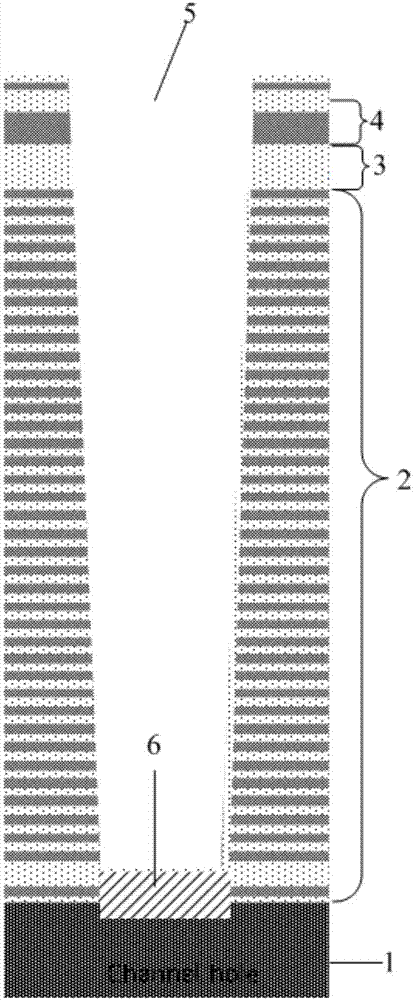

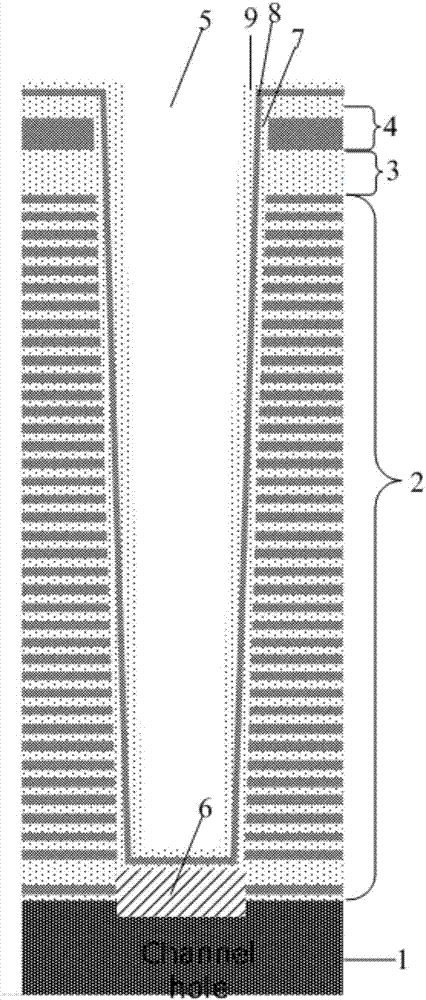

Three-dimensional memory and formation method of channel pore structure thereof

ActiveCN106653684AReduce the difficulty of manufacturing processLow manufacturing process costSemiconductor/solid-state device manufacturingGeomorphologyWidth ratio

The embodiment of the invention discloses a three-dimensional memory and a formation method of a channel pore structure thereof. According to the method, the channel pore structure in the three-dimensional memory is formed through a twice through-hole formation technology of a first through hole and a second through hole, so that the process difficulty and cost of the channel pore structure are greatly reduced, the problems of high process difficulty and high cost caused by ultrahigh through hole depth-to-width ratio under the same caliber are solved, and meanwhile the manufacturing process difficulty and cost of the three-dimensional memory are also reduced.

Owner:YANGTZE MEMORY TECH CO LTD

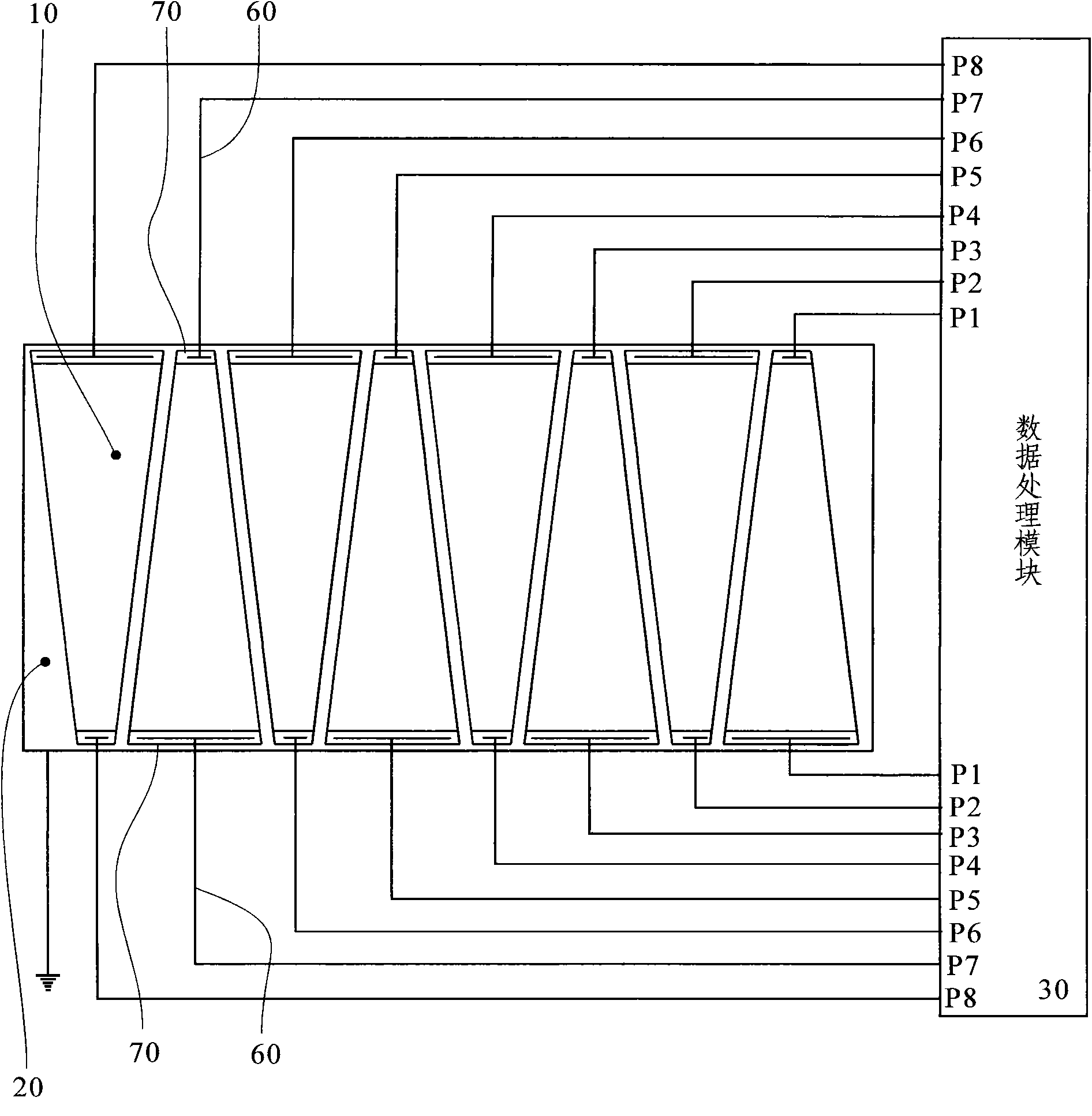

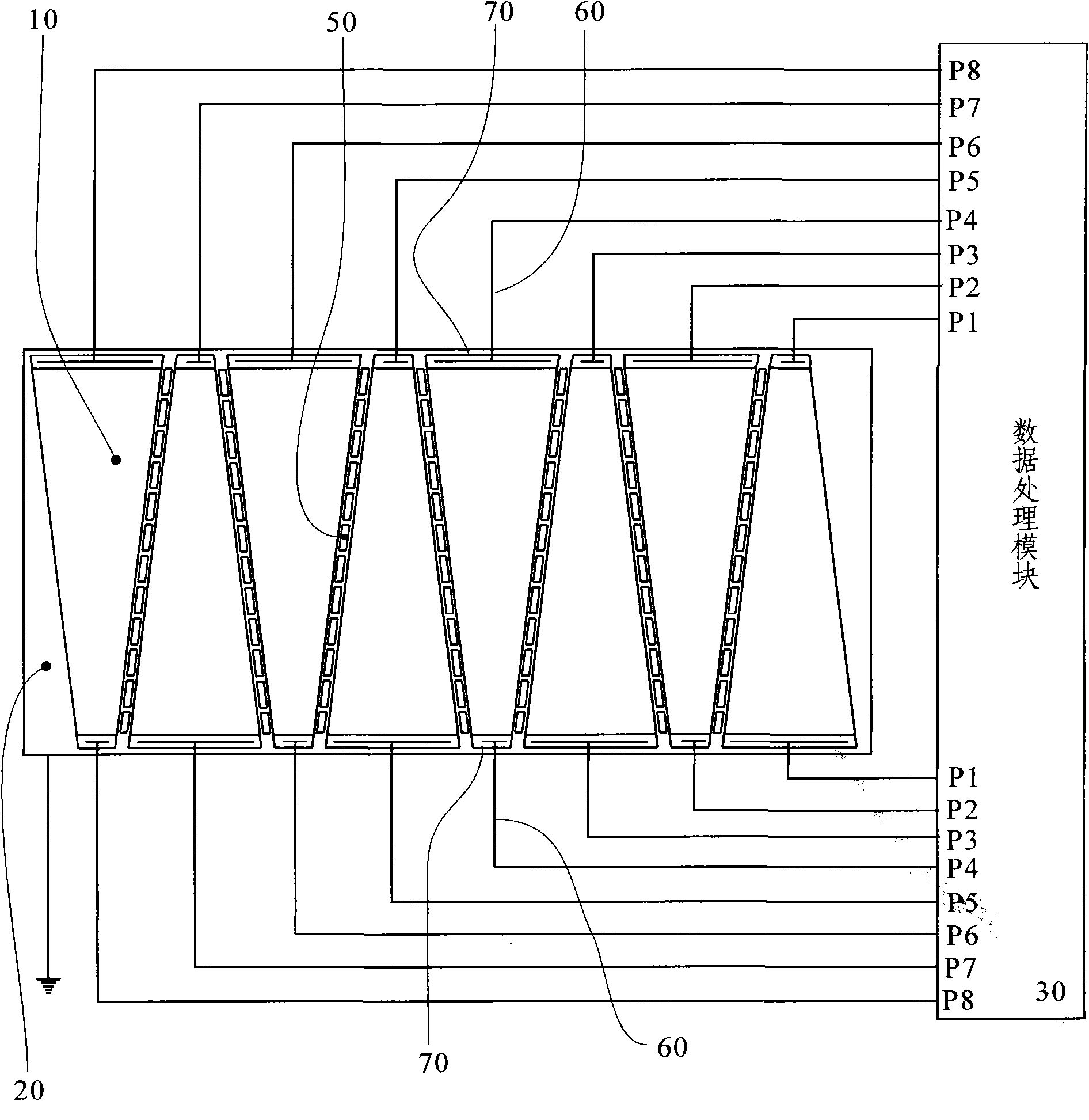

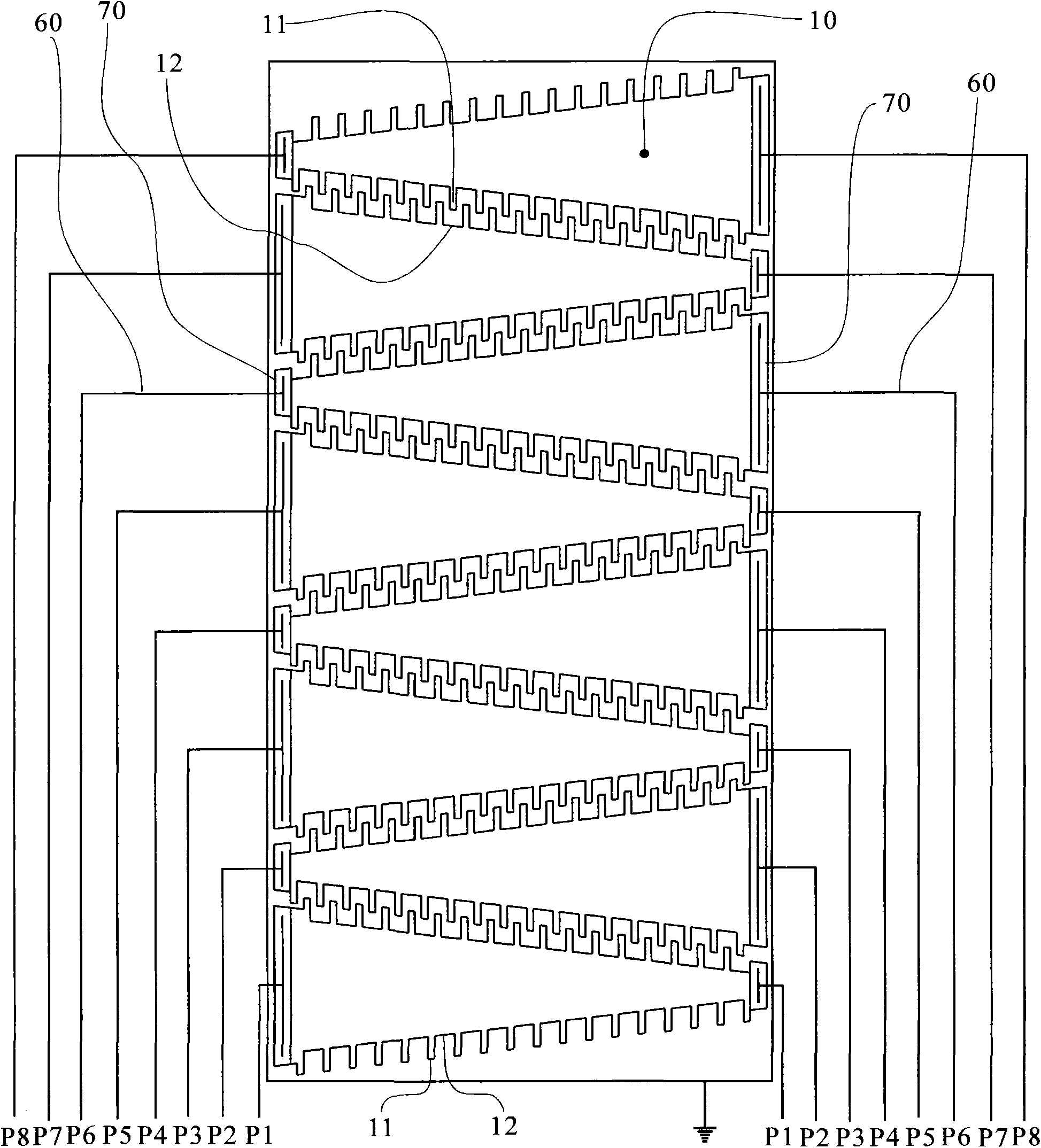

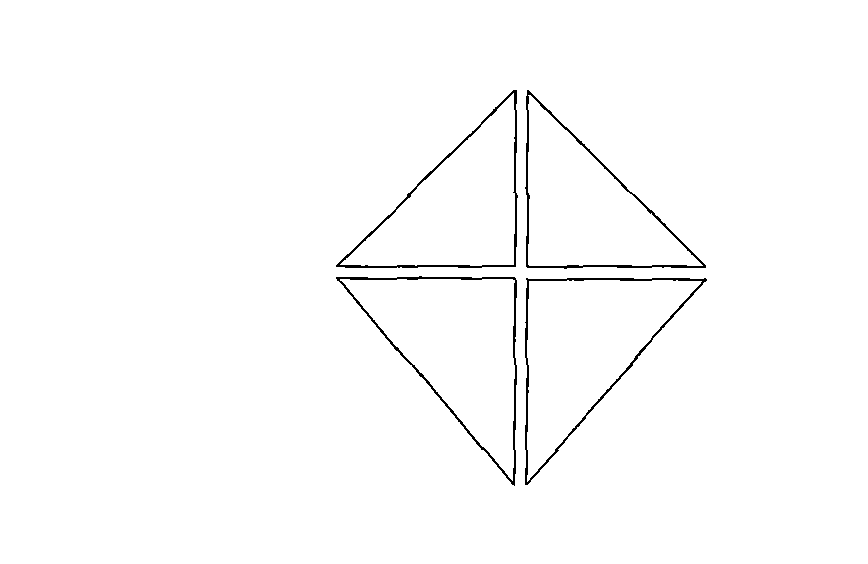

Self-capacitance touch screen with one-dimensional electrodes and coordinate data processing method thereof

InactiveCN101923419ALow costPrecise positioningInput/output processes for data processingCapacitanceTouchscreen

The invention discloses a self-capacitance touch screen with one-dimensional electrodes and a coordinate data processing method thereof. The self-capacitance touch screen comprises trapezoidal electrodes, wherein any two adjacent trapezoidal electrodes are arranged in the way that the upper base of one trapezoidal electrode and the lower base of the other trapezoidal electrode are positioned in one straight line and the lower base of the first trapezoidal electrode and the upper base of the other trapezoidal electrode are positioned in another straight line, so that all the trapezoidal electrodes are arranged in a touch plane of the touch screen in an engagement way. The self-capacitance touch screen is only provided with the electrodes in one dimension, a touch position can be accurately positioned from two dimensions, an intersecting part does not exist between every two electrodes and an insulating material is not needed, so that the process difficulty is reduced and the cost is saved. The coordinate data processing method of the invention converts data detected by the one-dimensional electrodes into two-dimensional coordinate data and simplifies the data processing cost.

Owner:FOCALTECH SYST LTD

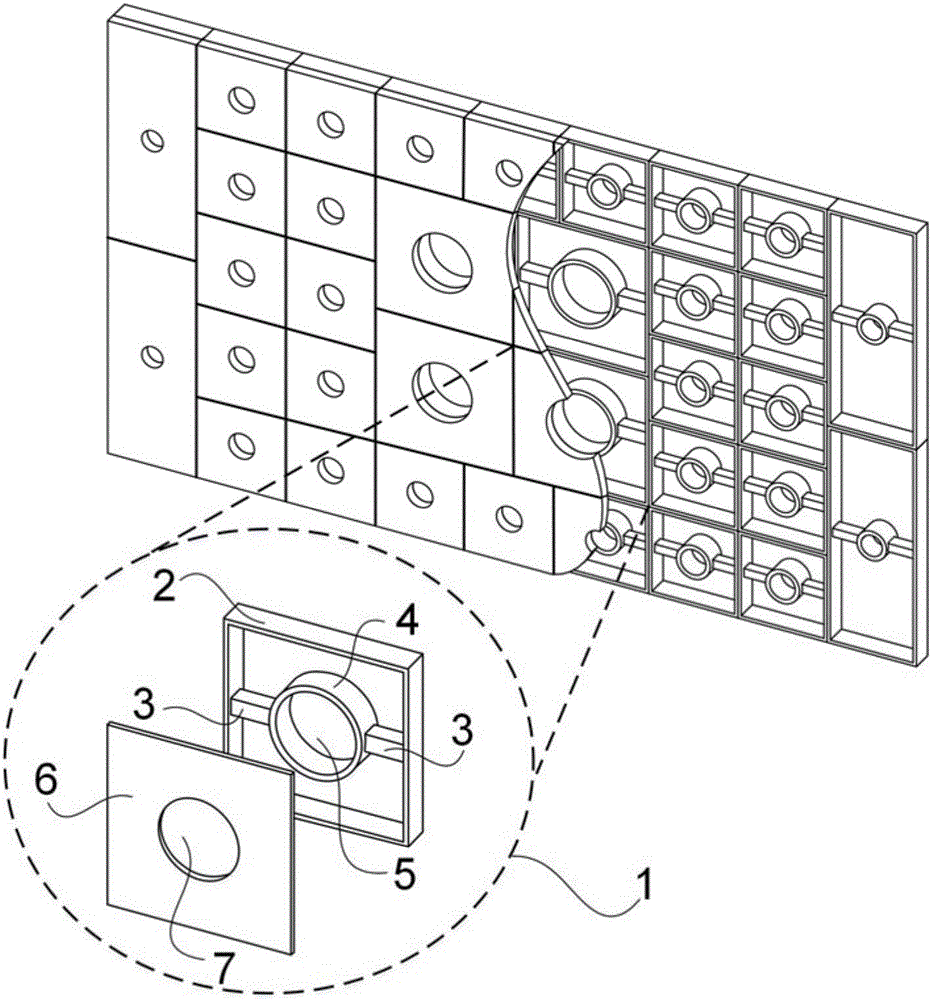

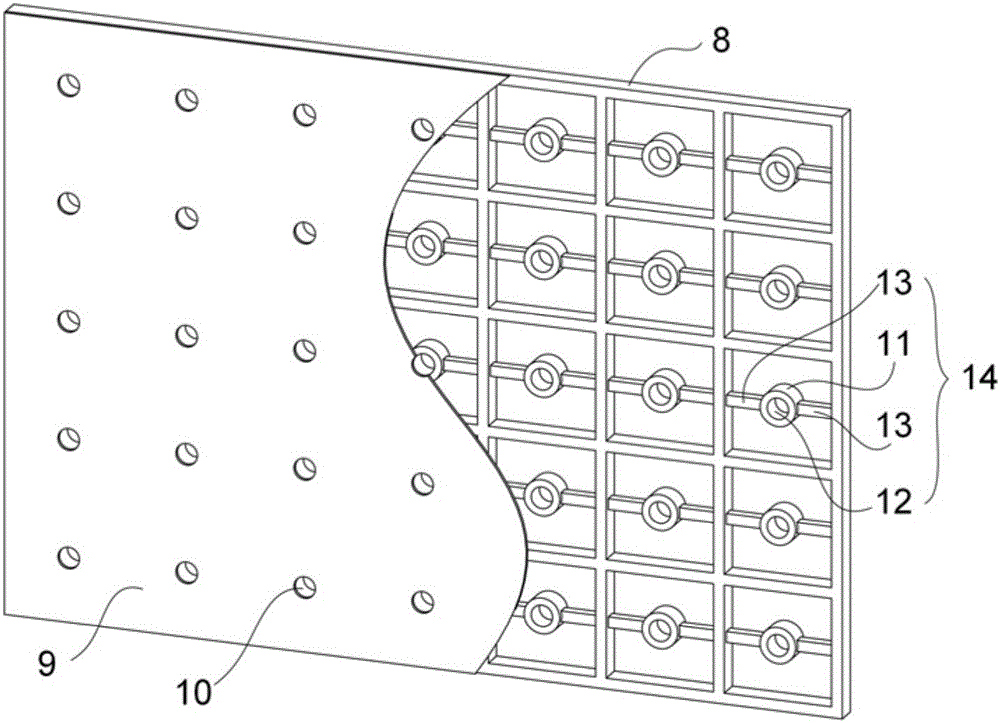

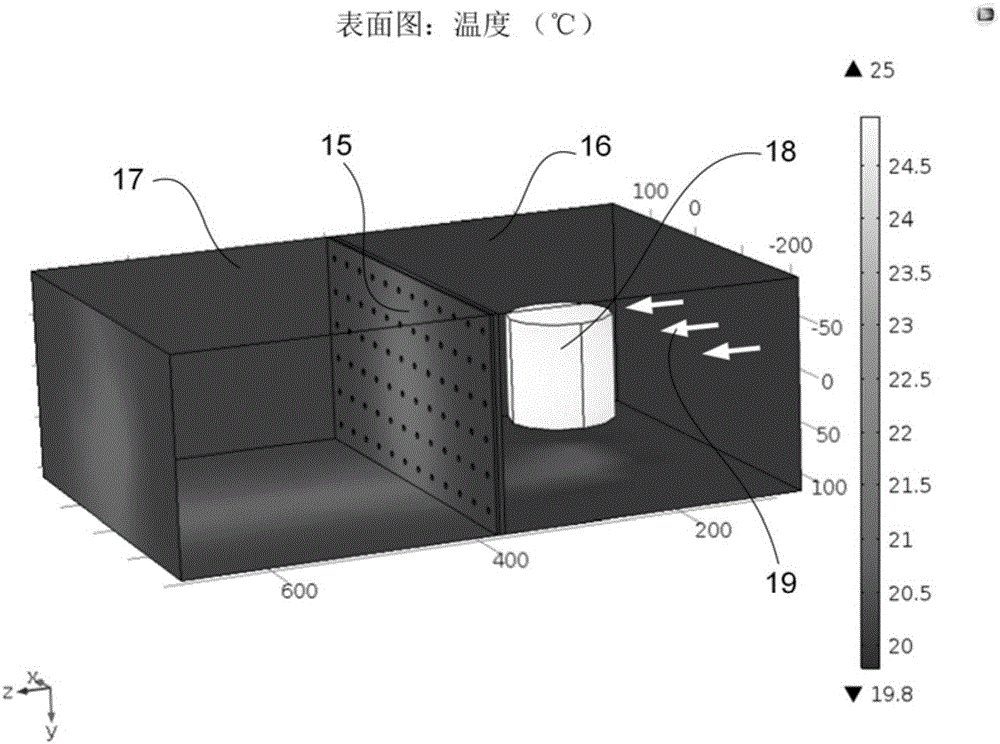

Sound-insulating, ventilating and heat transfer enhancing acoustic metamaterial unit, composite structure and preparation method

ActiveCN105845121AWorking frequency bandwidthImprove sound insulationStringed musical instrumentsSound producing devicesEngineeringComposite plate

The invention relates to a sound-insulating, ventilating and heat transfer enhancing acoustic metamaterial structural unit, which comprises a frame, wherein a restraining body is arranged inside the frame, and at least one of the upper and lower surfaces of the frame is coated with a thin film; and at least one hole is formed in the restraining body and the thin film. In addition, the invention provides an acoustic metamaterial composite plate and an acoustic metamaterial composite structure comprising the acoustic metamaterial structural unit, as well as a frequency modulation method and an assembly method. The acoustic metamaterial structural unit has sound insulation capability superior to that of an ordinary perforated plate or micro-perforated plate within a broadband, can ensure that sufficient heat flow, air flow or liquid flow can pass through smoothly, and increases heat diffusion rate of fluid media on both sides of holes and accelerates heat convection efficiency through unit localized vibration generated by the structure under excitation of acoustic waves. The acoustic metamaterial structural unit and the array composite structure have the advantages of simple assembly technology and stable working performance.

Owner:黄礼范

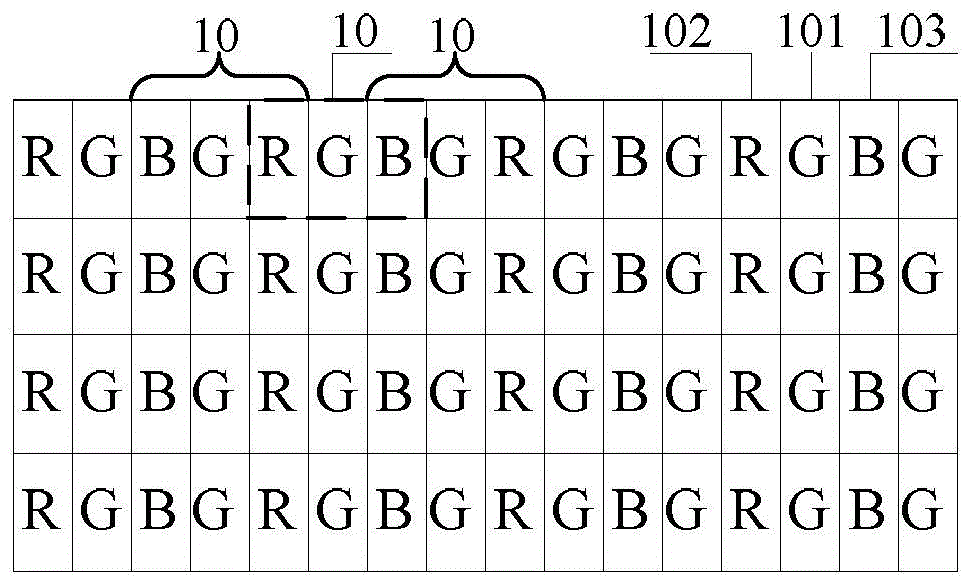

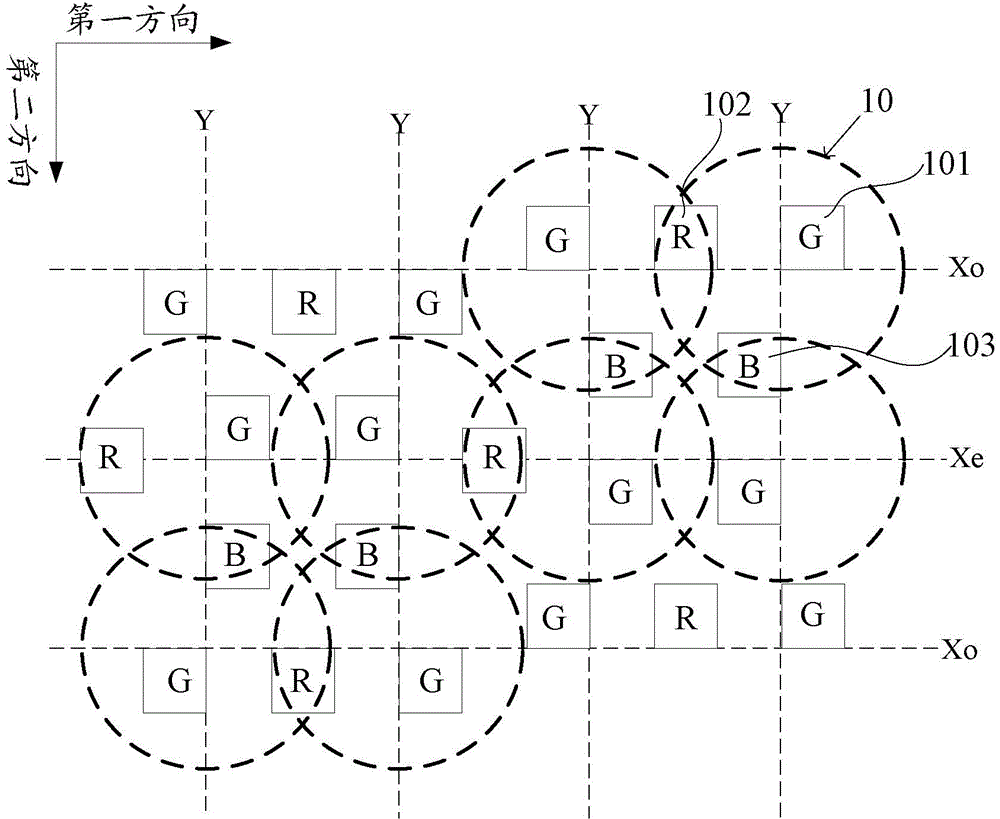

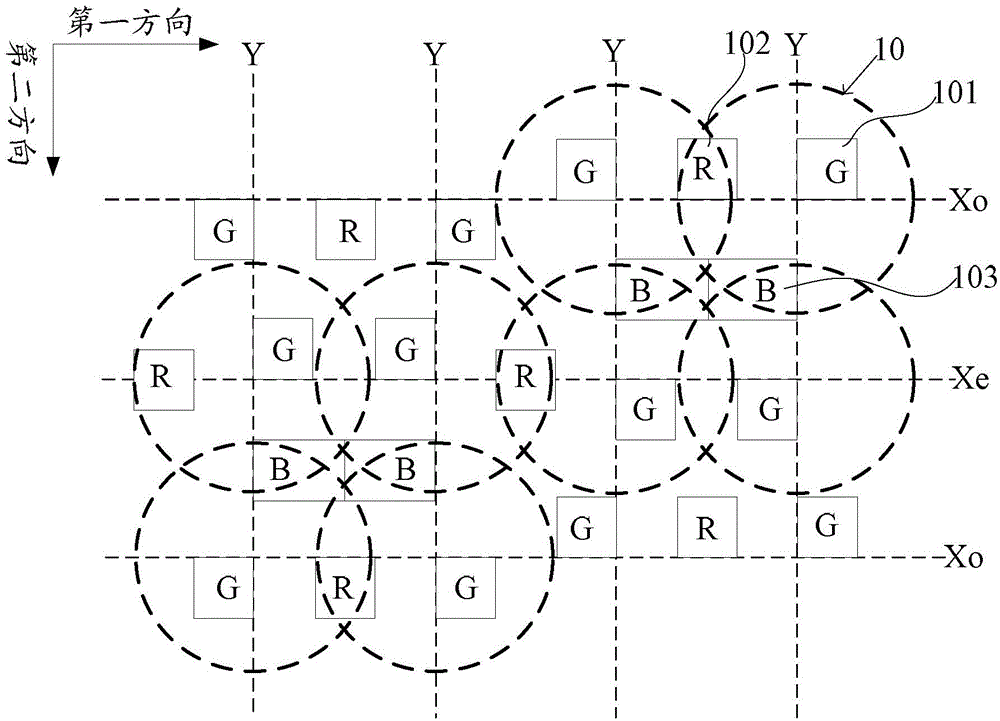

Pixel arraying structure, display panel and display device

ActiveCN104597655AReduce processing difficultyAvoid excessSolid-state devicesNon-linear opticsPixel densityDisplay device

The embodiment of the invention provides a pixel arraying structure, a display panel and a display device, and relates to the field of display technologies. Compared with the prior art, the technology difficulty in preparing the display device is reduced; the pixel arraying structure comprises a plurality of first sub-pixels, a plurality of second sub-pixels and a plurality of third sub-pixels; each pixel comprises a first sub-pixel; each second sub-pixel and each third sub-pixel are shared by at least two adjacent pixels respectively; the density of the sub-pixels is 1.5 times of that of the density of the pixels in the first direction of the pixel array; the density of the sub-pixels is 1.5 times of that of the density of the pixels in the second direction of the pixel array; the first direction and the second direction are different directions. The pixel arraying structure is used for high-resolution display devices.

Owner:BOE TECH GRP CO LTD

Plug-in type balance valve

InactiveCN101634317AReduce heat treatment requirementsReduce material requirementsServomotor componentsShoulder BladesThermal treatment

The invention relates to a plug-in type balance valve which comprises a valve body, a one-way valve core and a balance valve core, wherein a first oil opening, a second oil opening and a third oil opening are arranged on the valve body; the one-way valve core is arranged at the second oil opening and pushed by a first spring to maintain the trend of axial upward shift; the balance valve core is installed in the valve body and can be matched with a valve opening of the one-way valve core, and a second spring is arranged in a spring cavity of the valve body; the upper part in the balance valve core is provided with an axial passage and a first damping hole; the middle position of the balance valve core is provided with an axial convex shoulder; an annular notch is arranged on the periphery surface of the axial convex shoulder; the inner wall of the valve body is provided with an annular inner shoulder blade; an oil inlet cavity is formed among the annular notch, the inner wall of the valve body and the annular inner shoulder blade; and the third oil opening is communicated with the oil inlet cavity by a second damping hole on the side wall of the valve wall. The balance valve core and the one-way valve core are in an integral structure, and the structure is simple; the balance valve core and the one-way valve core are relatively independent on the relative position relationship, the assembly is convenient, and the requirements on heat treatment and materials of the balance valve core are lowered.

Owner:NINGBO HANSHANG HYDRAULIC

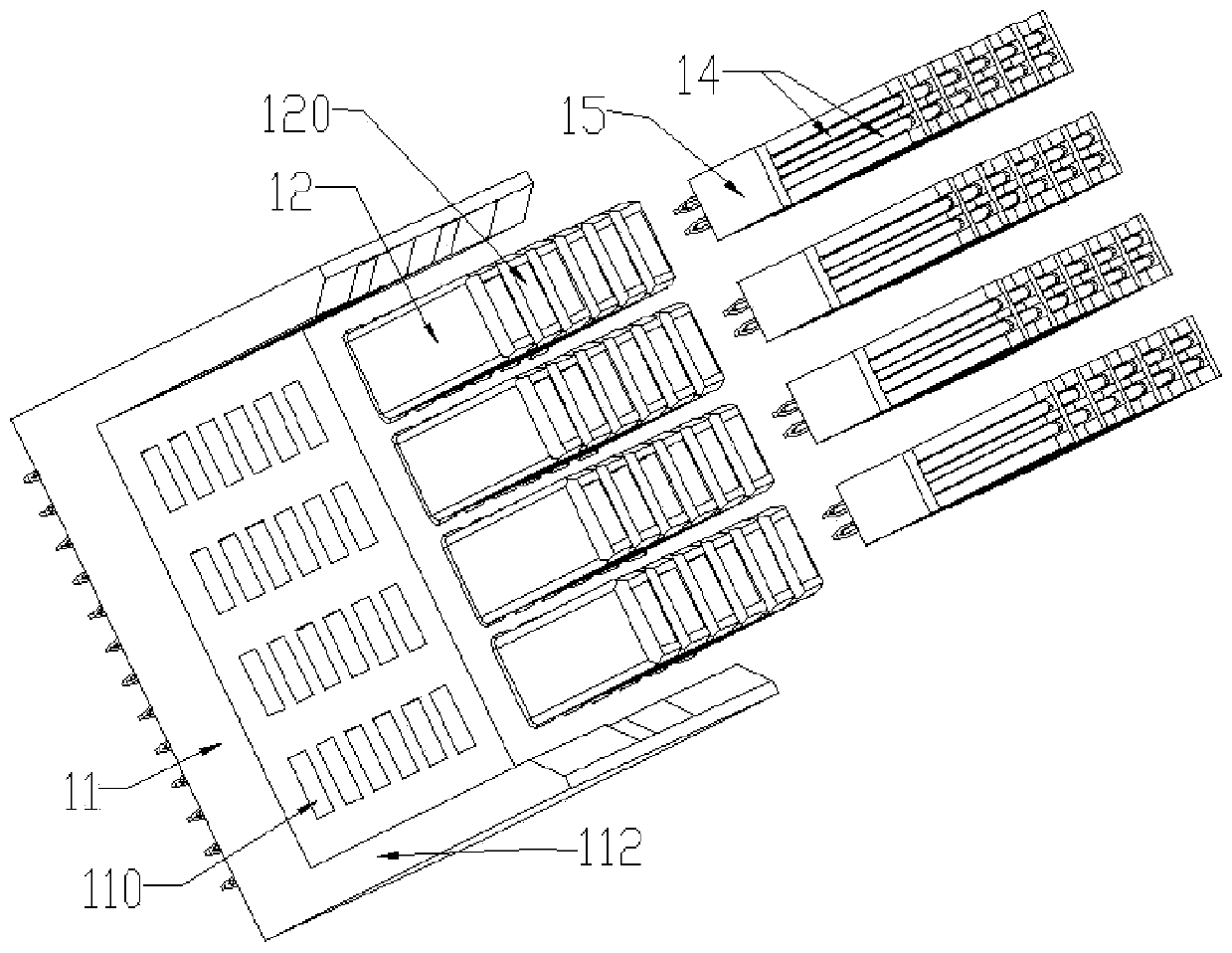

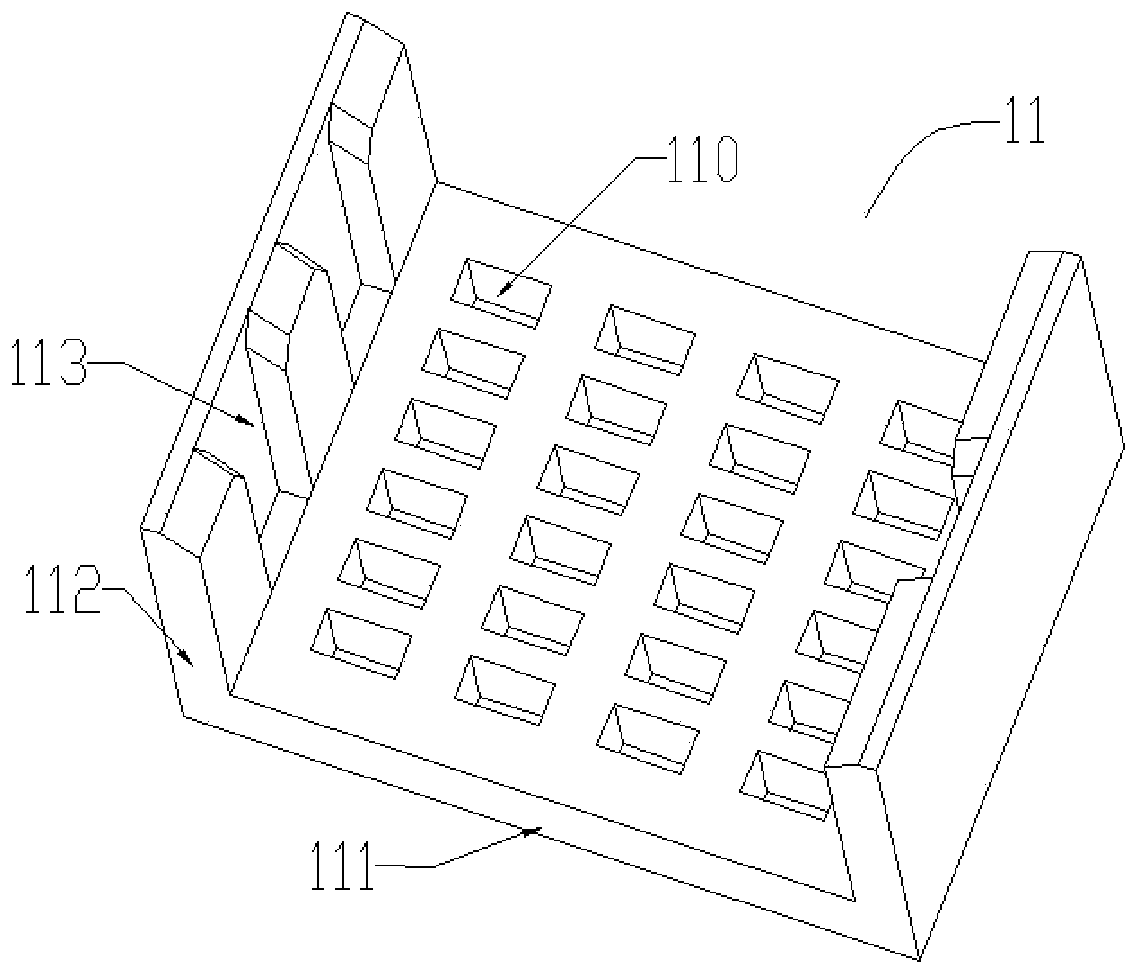

Male connector, female connector, connector assembly and communication equipment

ActiveCN110808499AEasy to processHigh mechanical strengthCoupling device detailsNetwork connectorsAnatomyElectrical connection

The present application provides a male connector, a female connector, a connector assembly and a communication equipment. The male connector comprises a male conductive base, wherein a plurality of first through holes are arranged on the male conductive base; a plurality of shielding sleeves which are fixed on the male conductive base and electrically connected with the male conductive base, theshielding sleeves have a sleeve structure, a front-back through shielding cavity is formed in the shielding sleeves, a plurality of the shielding sleeves are corresponding to a plurality of first through holes in a one-to-one way and the shielding cavity is communicated with the corresponding first through holes; and a plurality of male differential pairs, wherein a plurality of male differentialpairs are corresponding to a plurality of shielding sleeves in a one-to-one way, the male differential pairs are fixed in the shielding cavity by penetrating through the first through holes and the male differential pairs are electrically insulated from the male conductive base and the shielding sleeves. Compared with the connectors in the prior art, the connector has the advantages of convenientprocessing, high mechanical strength and good shielding effect.

Owner:HUAWEI MACHINERY

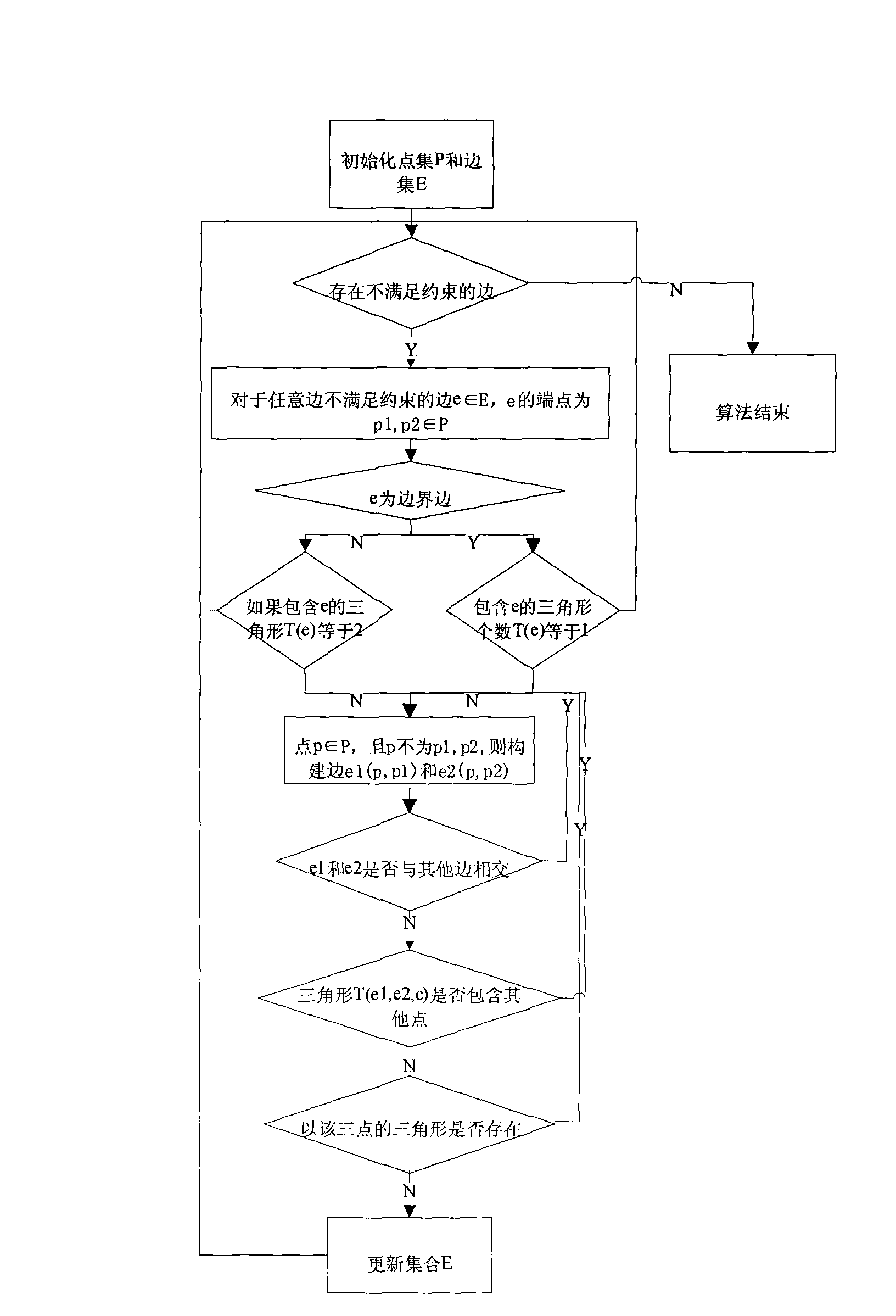

Block model building method for complex geological structure

InactiveCN101582173AEasy to buildSmall amount of calculationGeomodelling3D-image renderingGeometric consistencyTopological consistency

The invention discloses a block model building method for complex geological structure, and relates to the geological field of three-dimension modeling comprising the following steps: a, triangular meshing description is carried out on planes or fault planes; b, after step a, level intersection in block modeling for complex geological structure is converted into triangle intersection in space, whether the two triangles are intersected is judged, points of intersection are found from the two intersected triangles, and a line of intersection is obtained by connecting the points of intersection; c, geometric consistency and topological consistency are carried out on inside of each intersected triangle; d, after step c, enclosing block is extracted to obtain an interface formed by peripheral sides of the enclosing block, and is defined geological attribute to form three dimension model block. The method in the invention completely solves the problems of three dimension model input and blocking in complex geological regions, avoids using equations set with high solving difficulty and calculated amount, and is simple and practical.

Owner:BC P INC CHINA NAT PETROLEUM CORP

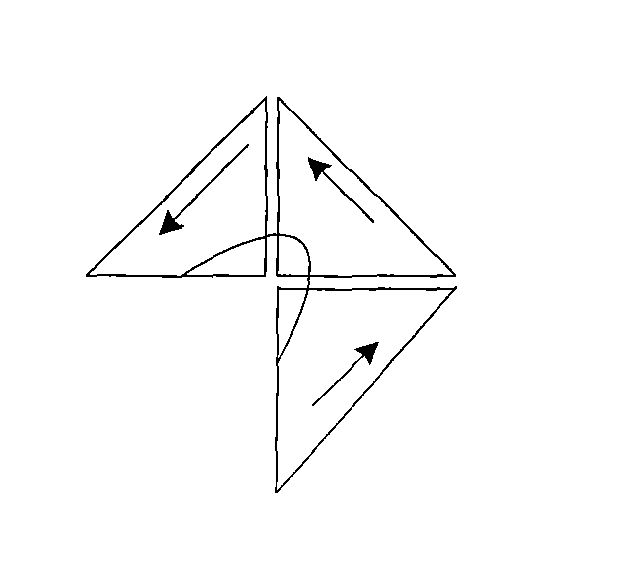

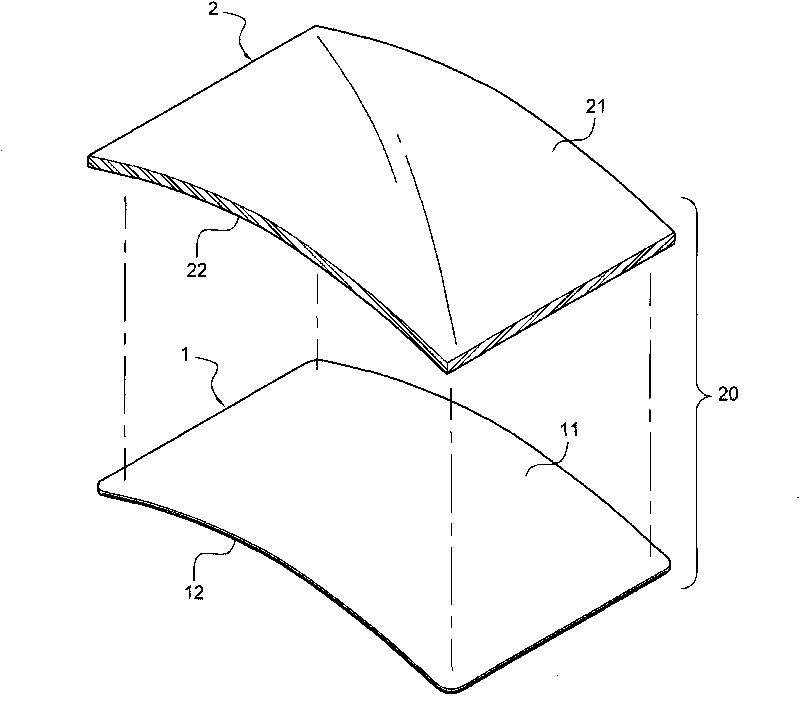

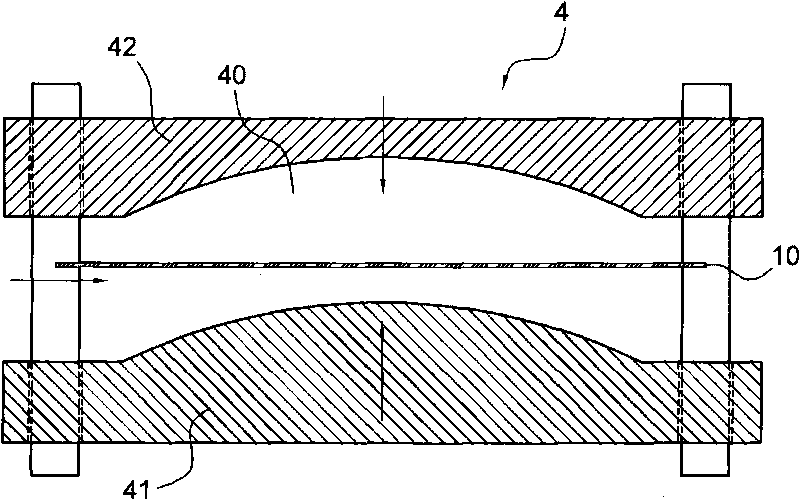

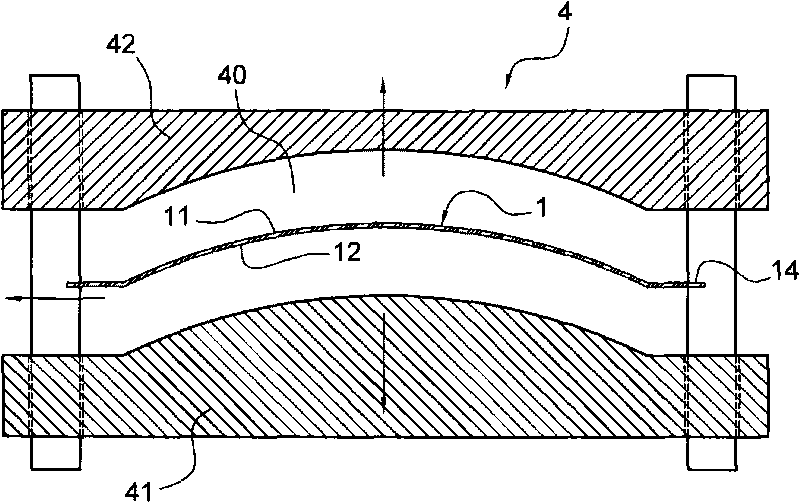

Manufacturing method and structure of camber-shaped capacitance type touch-control plate

ActiveCN101727249AControllable shapeReduce processing difficultyInput/output processes for data processingCompression moldingCapacitance

The invention provides a manufacturing method and a structure of a camber-shaped capacitance type touch-control plate. The manufacturing method comprises the following steps of: firstly providing a planar flexible circuit board with a capacitance type touch-control function; then compressing and molding the planar flexible circuit board into a camber-shaped flexible circuit board in a compression molding way; then providing a camber-shaped base plate, and coupling and attaching the outer camber of the camber-shaped flexible circuit board to the inner camber of the base plate, thus the camber-shaped capacitance type touch-control plate is assembled.

Owner:TPK ADVANCED SOLUTIONS

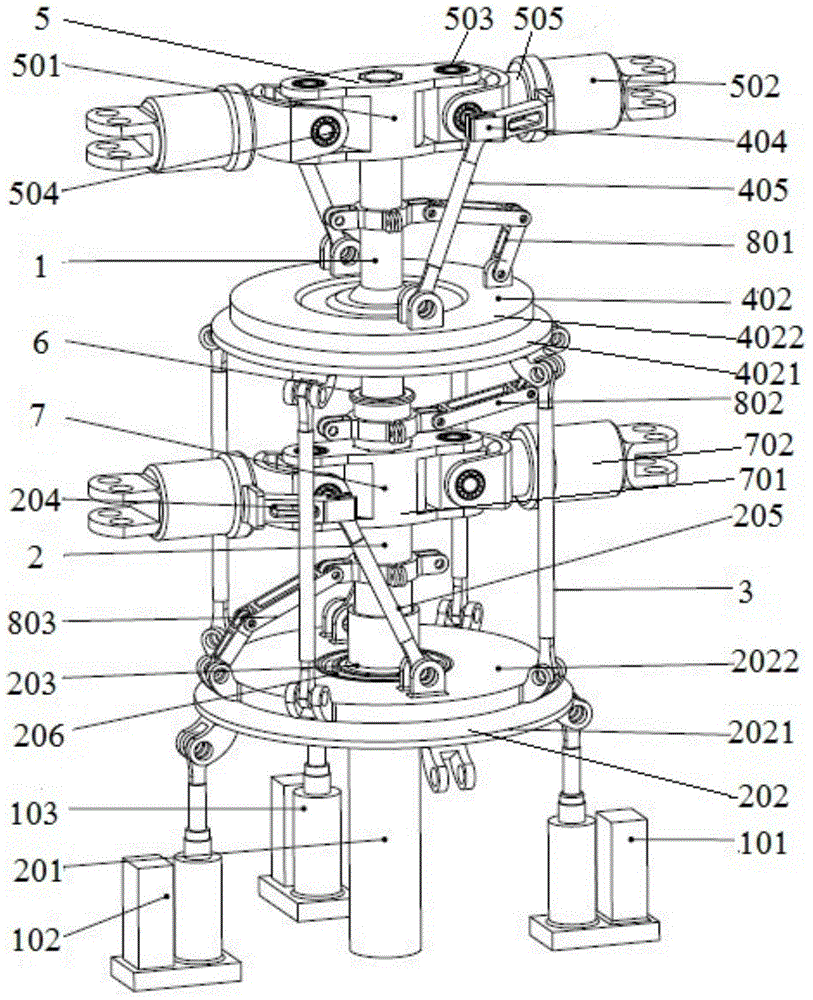

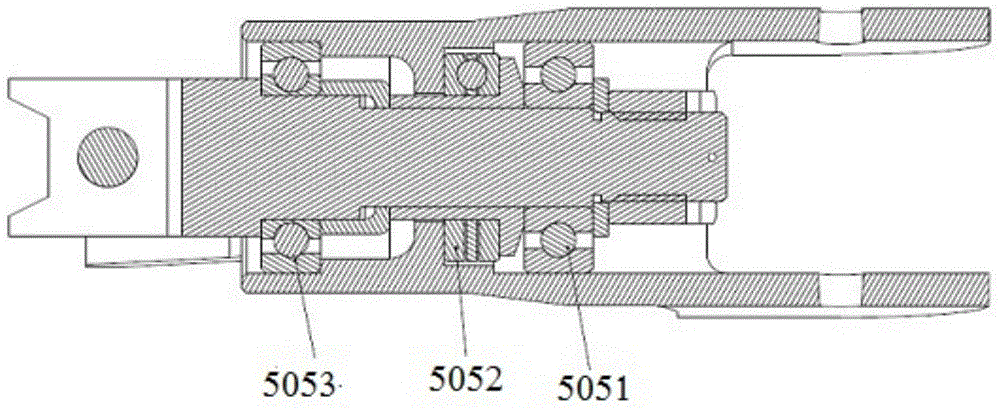

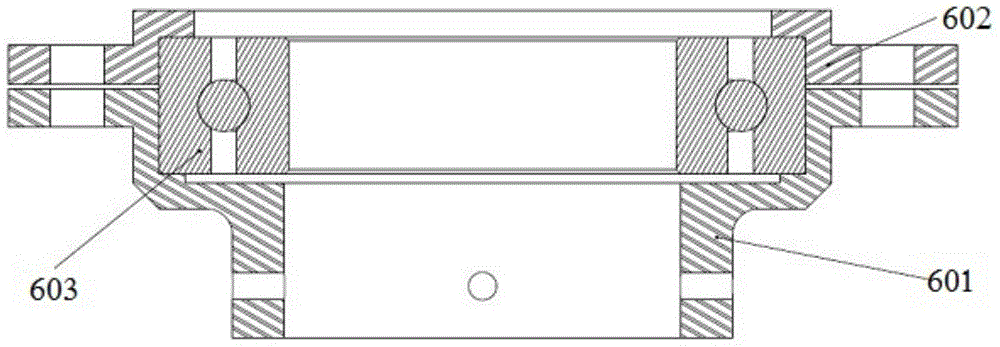

Simple rotor mechanism of coaxial dual-rotor helicopter test stand

InactiveCN104908976AAchieve collective controlRealization cycleStatic/dynamic balance measurementAircraft components testingControl systemPropeller

The invention relates to a simple rotor mechanism of a coaxial dual-rotor helicopter test stand. The rotor mechanism comprises an inner shaft, an outer shaft, an actuator group, a lower control system, an upper control system, an upper rotor propeller hub and a lower rotor propeller hub, wherein the upper rotor propeller hub comprises a first propeller hub seat, and a first paddle arm arranged on the first propeller hub seat in a full articulation manner; the lower rotor propeller hub comprises a second propeller hub seat and a second paddle arm arranged on the second propeller hub seat in a full articulation manner; the upper control system is connected with the first paddle arm; the lower control system is connected with the second paddle arm; the upper control system is connected with the lower control system via an intermediate draw bar; and the actuator group is connected with the lower control system to control synchronous motion of the first paddle arm and the second paddle arm. The mechanism can achieve collective pitch control and cyclic pitch change of coaxial dual rotors, and effectively achieves various dynamic tests of the helicopter such as upper and lower rotor aerodynamic characteristics of the coaxial dual rotors, dynamic stability of the rotors, and moving part loads of the rotors.

Owner:BEIHANG UNIV +1

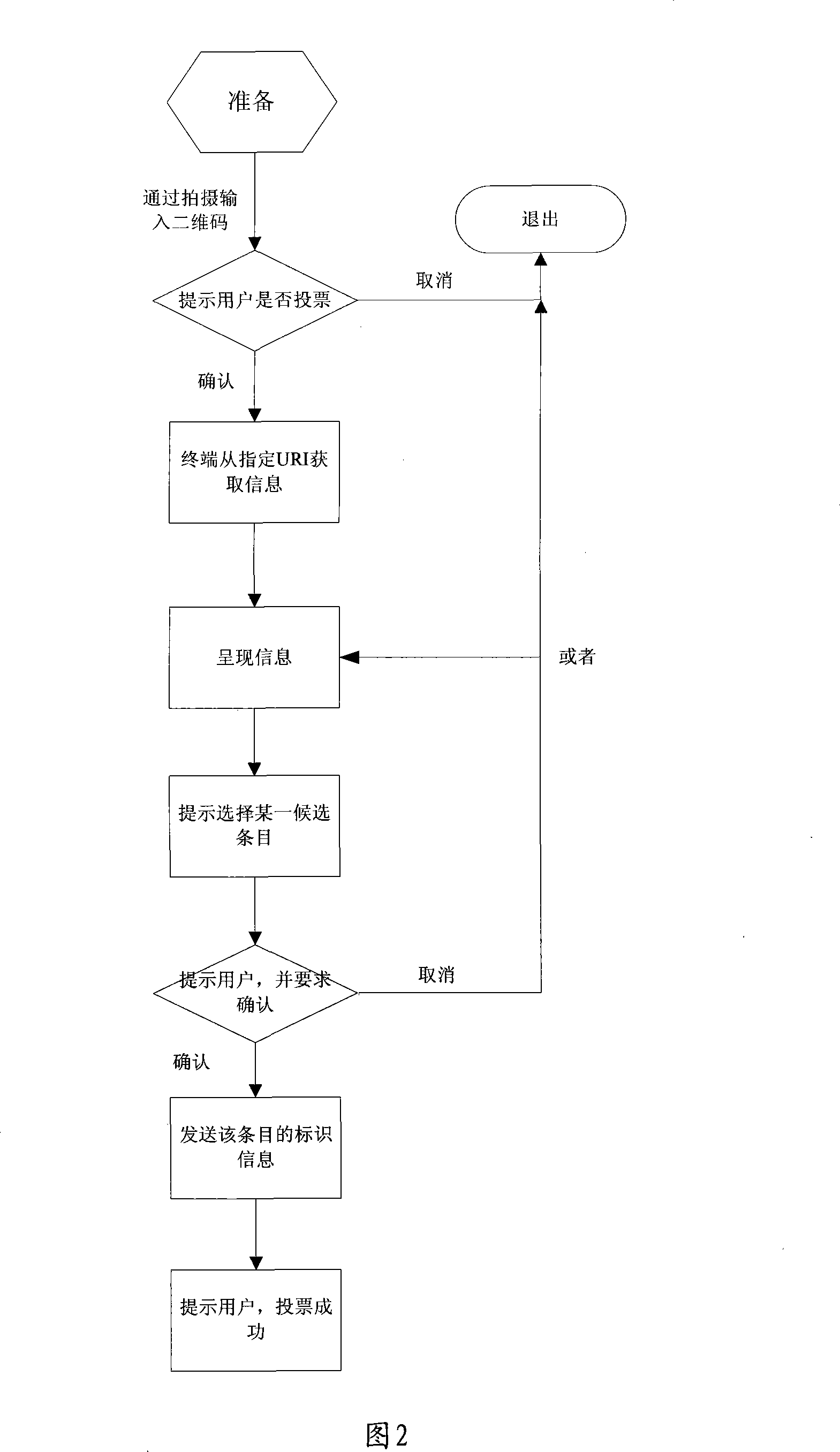

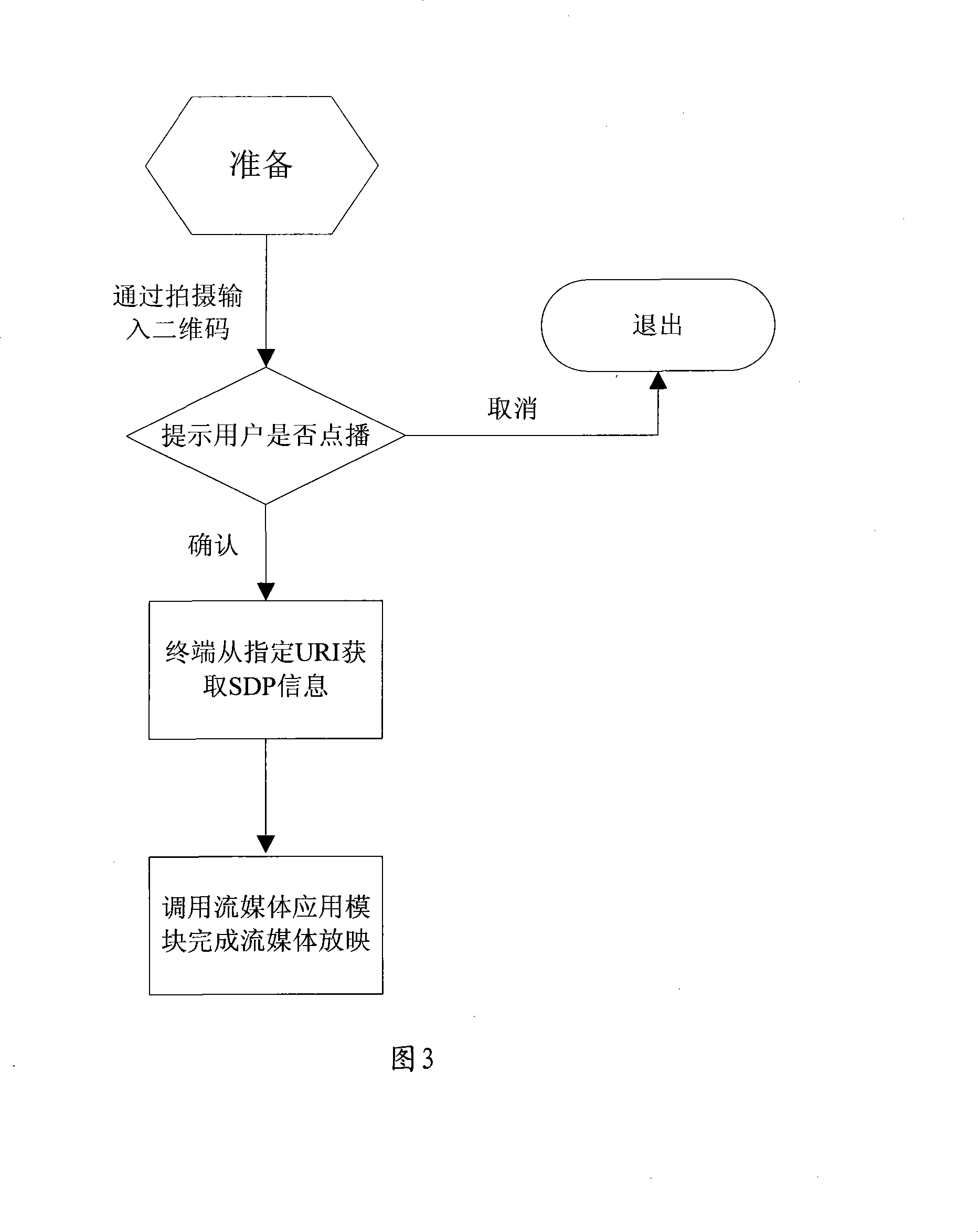

2D code application method and device

ActiveCN101187974AReduce processing difficultyReduce processing complexityDigital data information retrievalCo-operative working arrangementsSoftware engineeringData acquisition

The embodiment of the invention provides a method and a device for two-dimensional code application. The method essentially comprises the following procedures: a terminal acquires two-dimensional code data and conducts resolution of the two-dimensional data to obtain the sign operation flow in the two-dimensional data; the terminal uses a utility model program to execute the sign operation flow in the two-dimensional code data. The device essentially comprises a two-dimensional data acquisition module, a two-dimensional code data resolution module and an operation flow execution module. With the embodiment of the invention, the terminal executes vicinal utility according to execution sequence regulated in the two-dimensional code so as to provide the user with friendly business operation guidance, normalizing feedback information of the client side and reducing the processing difficulty and the complexity of the business platform.

Owner:HUAWEI DEVICE CO LTD

Three-dimensional memory and formation method for channel hole structure of three-dimensional memory

ActiveCN106920772AReduce the difficulty of manufacturing processLow manufacturing process costSolid-state devicesSemiconductor/solid-state device manufacturingWidth ratioEngineering

Embodiments of the invention disclose a three-dimensional memory and a formation method for a channel hole structure of the three-dimensional memory. By implementing two times of a through hole formation process of a first through hole and a second through hole, the channel hole structure in the three-dimensional memory is formed, so that the process difficulty and cost of the channel hole structure can be greatly lowered; the problem of high process difficulty and high cost caused by overhigh depth-to-width ratio of the through holes under the same caliber are solved; and meanwhile, the manufacturing process difficulty and cost of the three-dimensional memory are lowered.

Owner:YANGTZE MEMORY TECH CO LTD

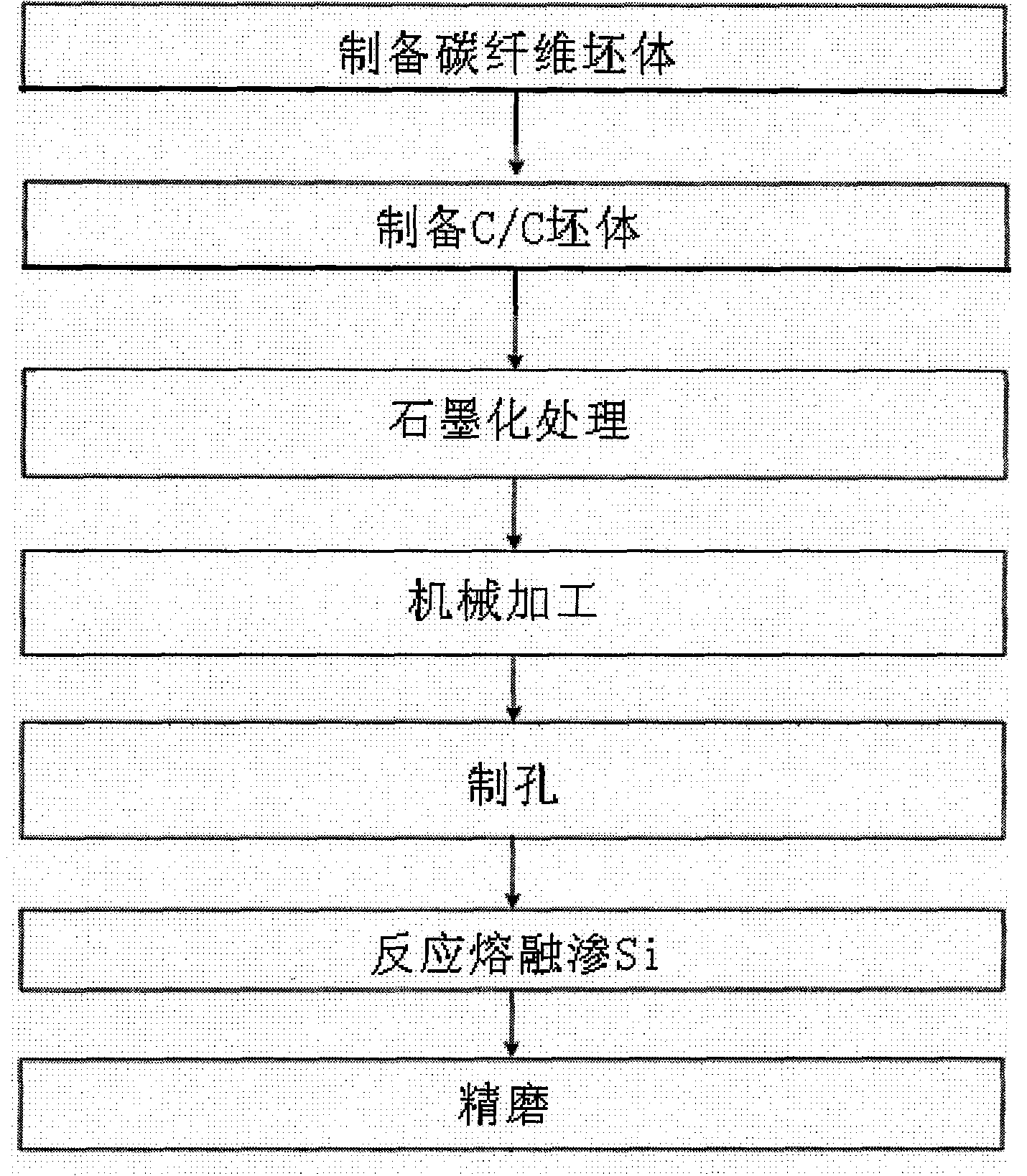

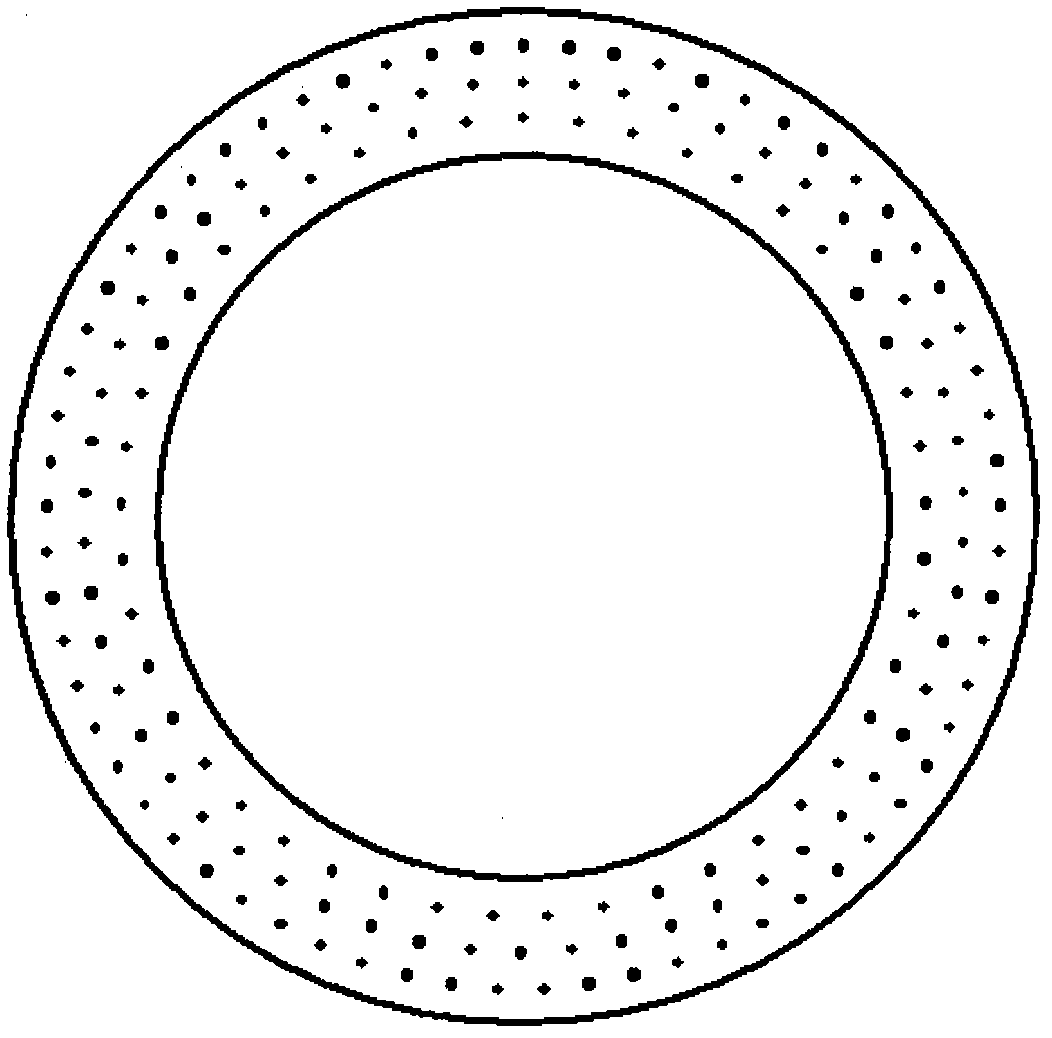

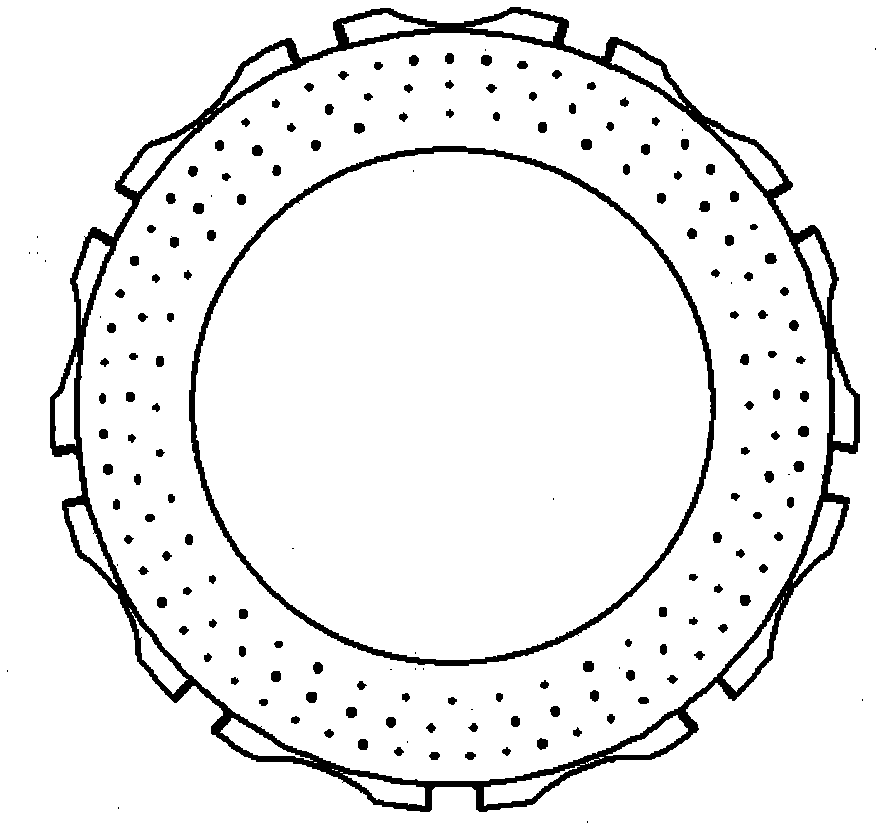

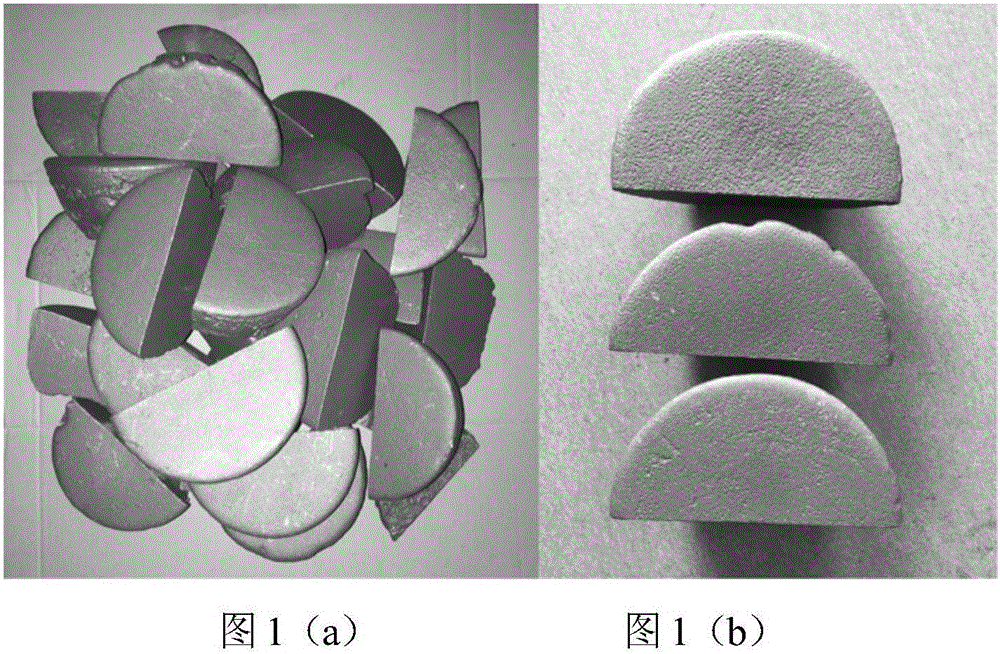

Method for manufacturing carbon ceramic brake disc

The invention relates to a method for manufacturing a carbon ceramic brake disc, which comprises the following steps of: preparing a carbon fiber blank body, performing natural gas chemical vapor immersion (CVI), graphitizing, machining, making holes, performing a melting reaction and grinding accurately to prepare a carbon ceramic composite brake disc, wherein in the hole making step, a plurality of through holes are distributed on a disc surface of the brake disc fully, and the center line of each through hole is perpendicular to the disc surface of the brake disc. In the method, the through holes distributed on the disc surface of the brake disc fully allows liquid state Si to permeate in the thickness direction of the brake disc uniformly and permeate on the whole friction surface uniformly in a melting Si permeating reaction and ensure the melting Si permeating reaction occurs at an area in the thickness direction intensively and influences the size of the thickness direction only without influencing the size at an area in the radial circumferencial direction basically, so that in the subsequent carbon ceramic machining, the thickness area is machined only. Therefore, the method has the characteristics that the Si permeating depth is desirable; the Si permeation is uniform; and products are easy to machine.

Owner:XIAN AVIATION BRAKE TECH

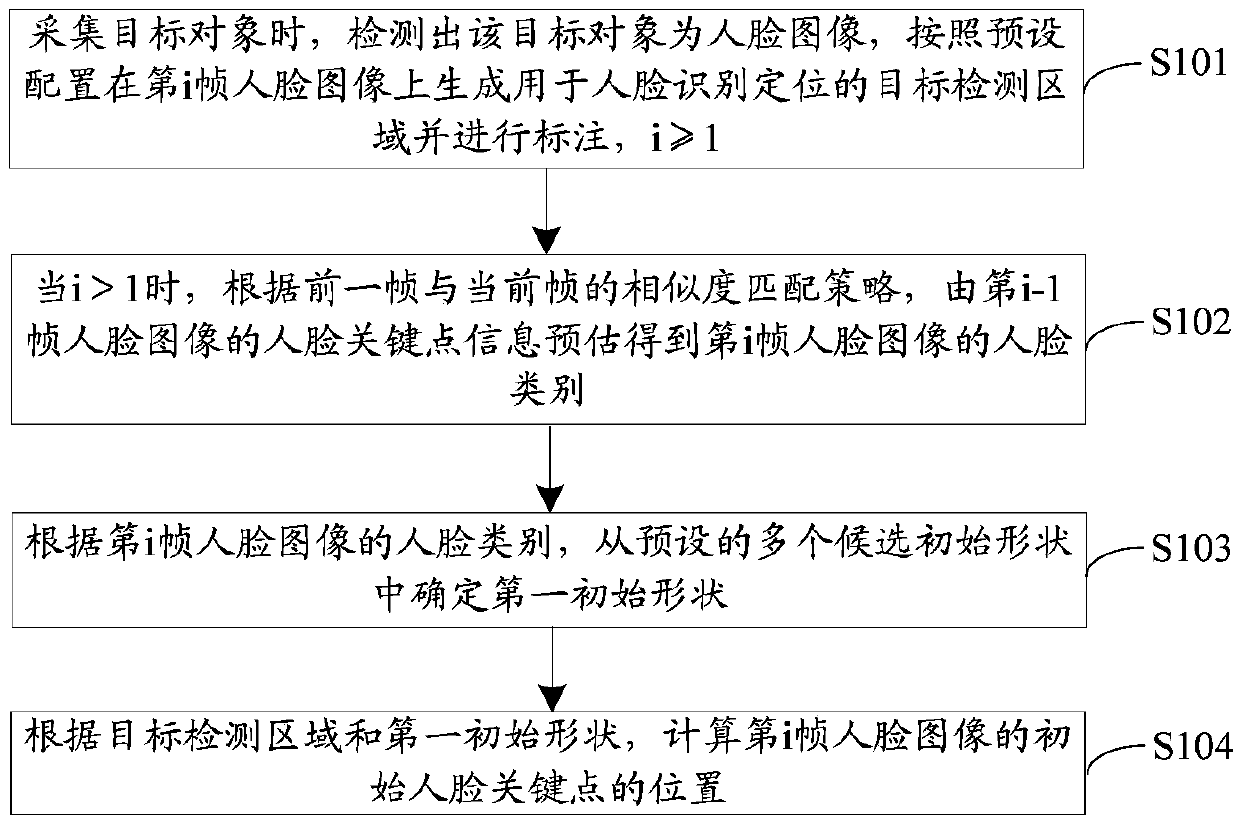

Key point positioning method and terminal

ActiveCN105512627AHigh precisionReduce processing difficultyCharacter and pattern recognitionComputer terminalFace perception

The embodiment of the invention discloses a key point positioning method and a terminal. The method comprises the steps of detecting a target object as a face image during the collecting process of the target object; generating a target detecting region on the face image of the i frame for human face recognition and location according to a preset configuration and annotating the target detecting region, wherein i is larger than or equal to 1; when i is larger than 1, estimating the key point information of a human face based on the face image of the i frame according to the similarity matching strategy between a previous frame and the current frame so as to obtain the category of the human face for the face image of the i frame; according to the category of the human face for the face image of the i frame, determining a first initial shape out of a plurality of preset candidate initial shapes; and calculating the position of an initial face key point in the face image of the i frame according to the target detecting region and the first initial shape.

Owner:TENCENT TECH (SHENZHEN) CO LTD

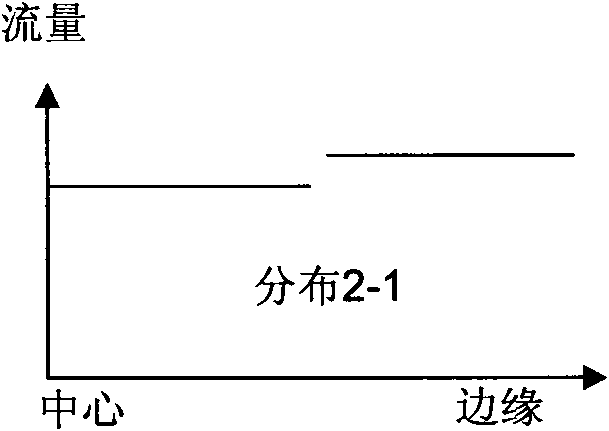

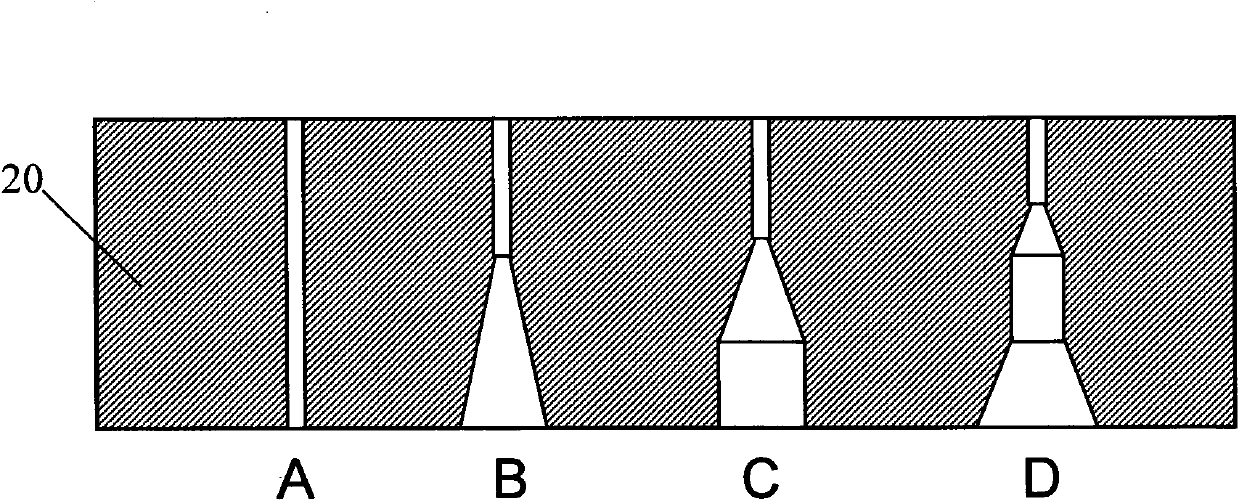

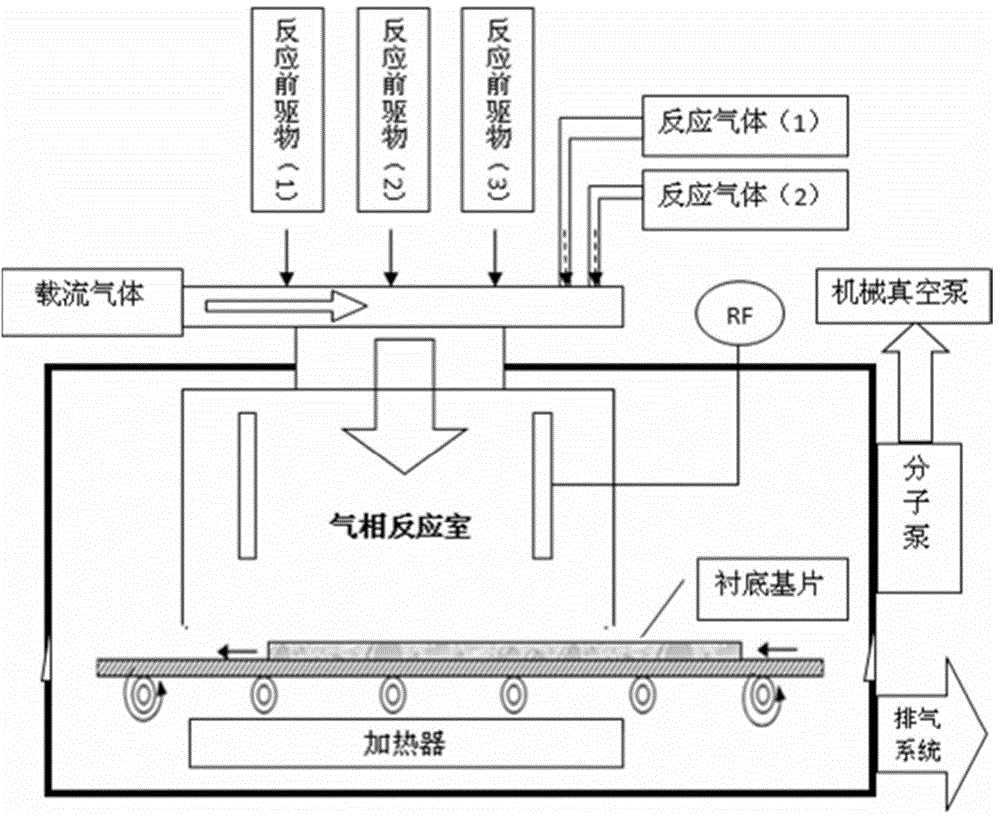

Device for controlling delivery and uniform distribution of reaction gases in MOCVD reaction chamber

ActiveCN101914761AReduce manufacturing costControl consumptionChemical vapor deposition coatingSystem capacityEngineering

The invention discloses a device for controlling the delivery and the uniform distribution of reaction gas in a MOCVD reaction chamber. By respectively controlling the flow of gas passages non-uniformly distributed radially on a front gas homogenizing plate and input passages at different positions, at least two reaction gases are respectively introduced into two paths which are radially and axially crossed on a spray header, and can be secondarily distributed by nozzles in different shapes, so the uniformly distributed boundary layer concentration, speed and temperature required are achieved on the surface of a rotary epitaxial wafer, the quality of massively produced epitaxial films and the finished product ratio of massively produced epitaxial wafers are improved, the consumption of expensive reaction gases can be effectively controlled and the epitaxial production cost is reduced. By properly increasing the distance between the surface of the spray header and the epitaxial wafer, deposits generated on the surface of the spray header and the nozzles in the epitaxial growth are reduced, the cleaning period is prolonged, and the production efficiency and system capacity are improved. The device also can reduce the processing difficulty and manufacturing cost of the nozzles of the spray header and cooling medium passages.

Owner:JIANGSU ZHONGSHENG SEMICON EQUIP

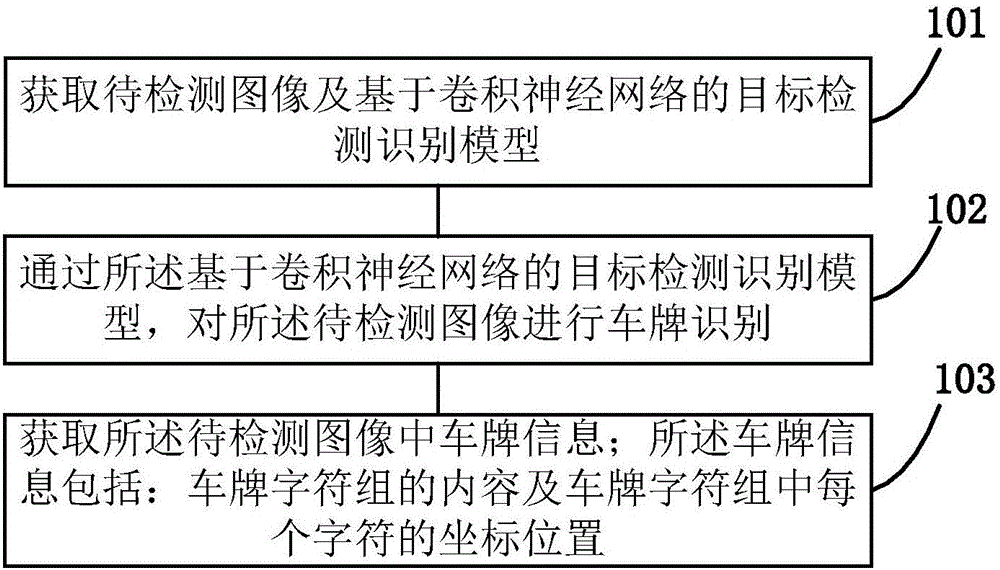

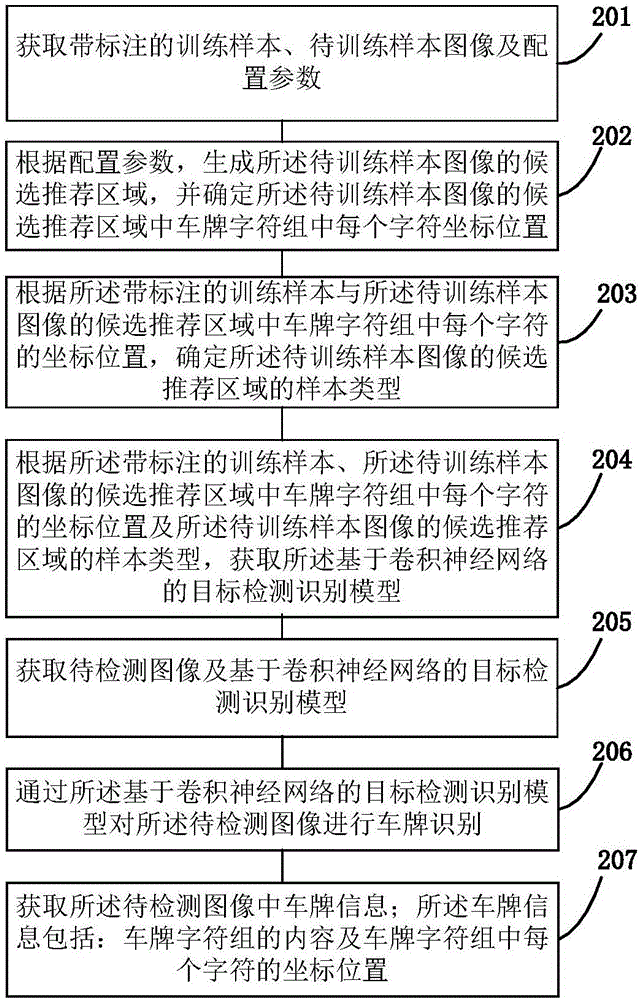

License plate recognition method, device and system

ActiveCN106407981AReduce processing difficultySolve problems that require complex post-processing algorithmsCharacter recognitionCharacter groupLicense

The invention discloses a license plate recognition method, device and system. The license plate recognition method comprises the steps that an image to be detected and the target detection recognition model based on a convolution neural network are acquired; license plate recognition is carried out on the image to be detected through the target detection recognition model based on the convolution neural network; and license plate information in the image to be detected is acquired, wherein the license plate information comprises the content of a license plate character group and the coordinate position of each character in the license plate character group. According to the technical scheme provided by the invention, the overall recognition of license plate characters is realized through the target detection recognition model based on the convolution neural network, which greatly reduces the processing difficulty of license plate recognition.

Owner:BEIJING WENAN INTELLIGENT TECH CO LTD

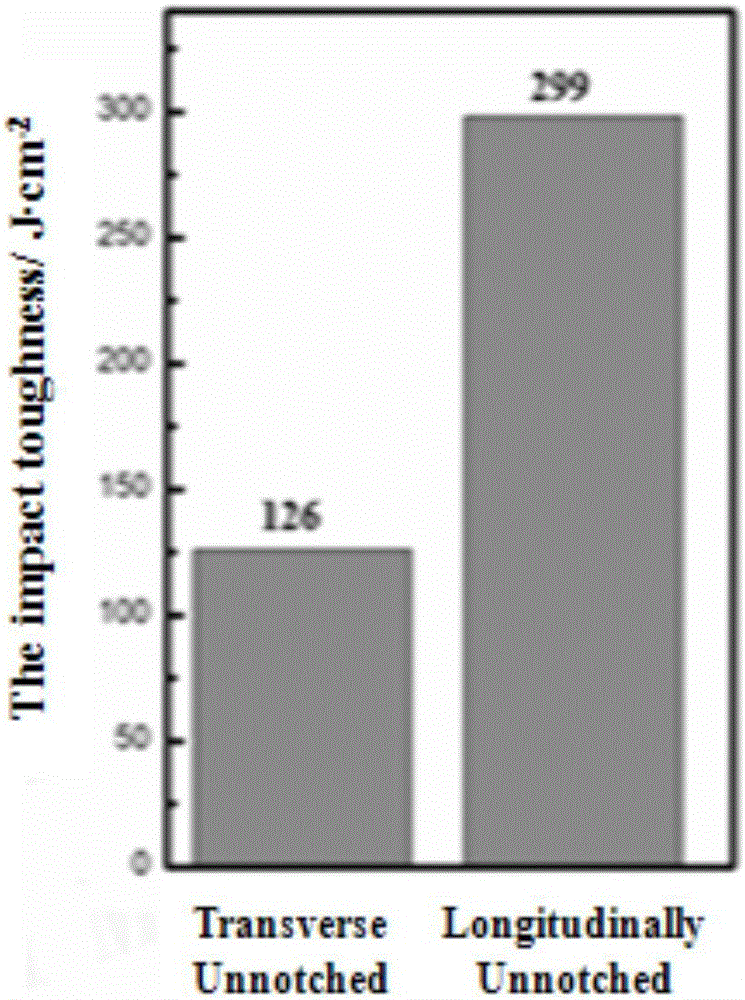

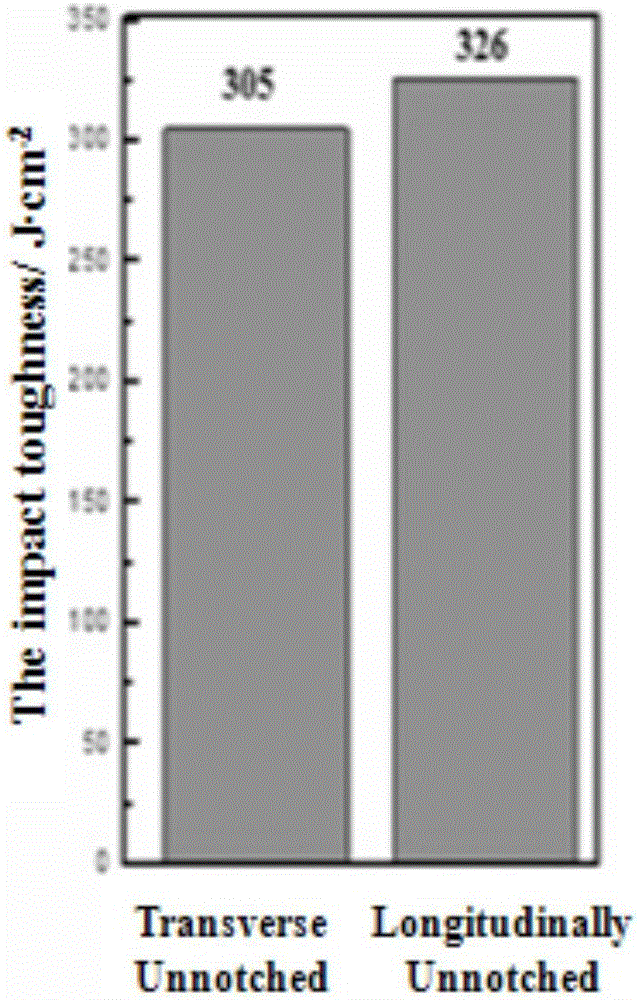

Method for adding rare earth metal into steel to improve performance

The invention relates to the field of manufacturing of high-quality metal materials, in particular to a method for adding rare earth metal into steel to improve the performance. In the smelting process of molten steel, the degree of purity of the molten steel and the degree of purity of the high-purity rare earth metal are strictly controlled; the high-purity rare earth metal is added into a steel ladle; the content of sulfur in the molten steel is below 200 ppm and the total oxygen content is below 40 ppm before the high-purity rare earth metal is added; and the total oxygen content of the added high-purity rare earth metal is below 200 ppm. The method is applicable to the processes such as a converter BOF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow, an electric arc furnace EAF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow and a converter BOF / intermediate frequency furnace GOR / AOD(-ladle refining LF)-continuous casting CC / mold casting MC flow, prepares high-quality carbon structural steel, low alloy steel, medium-high alloy steel, tool and mould steel, bearing steel, spring steel, stainless steel and electrical steel, and solves the bottleneck problems that due to a conventional rare earth adding process, the performance of rolled steel is not stable and a water gap is blocked in the production process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

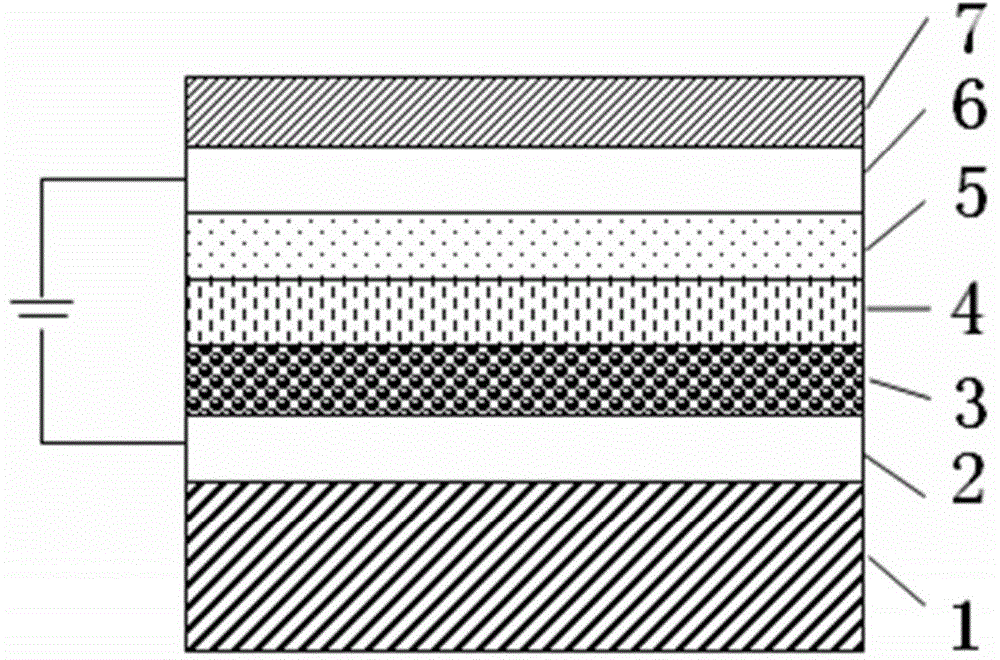

Preparation method for intelligent color changing window

InactiveCN104102060AReduce manufacturing costFast discolorationVacuum evaporation coatingSputtering coatingLithiumConductive materials

The invention provides a preparation method for an intelligent color changing window. The preparation method for the intelligent color changing window comprises the following steps: growing a conducting material on a substrate by adopting a chemical vapor deposition method to form a first conducting layer; growing transition metal oxides and a mixture thereof on the first conducting layer by adopting the chemical vapor deposition method to form an electrochromic layer; performing ion implantation on the electrochromic layer by adopting a two-electrode or three-electrode electrochemical method; growing oxides or inorganic solid state lithium salts on the electrochromic layer by adopting a method for performing lithiation on the electrochromic layer or the chemical vapor deposition method to form an ion conduction layer; growing the transition metal oxides and the mixture thereof on the ion conduction layer by adopting the chemical vapor deposition method to form an ion storage layer; growing the conducting material on the ion storage layer by the chemical vapor deposition method to form a second conducting layer; growing a protective layer on the second conducting layer to obtain the intelligent color changing window. The preparation method is low in production cost, and can prepare an electrochromic device on glass with a certain curved surface.

Owner:能源X控股有限公司

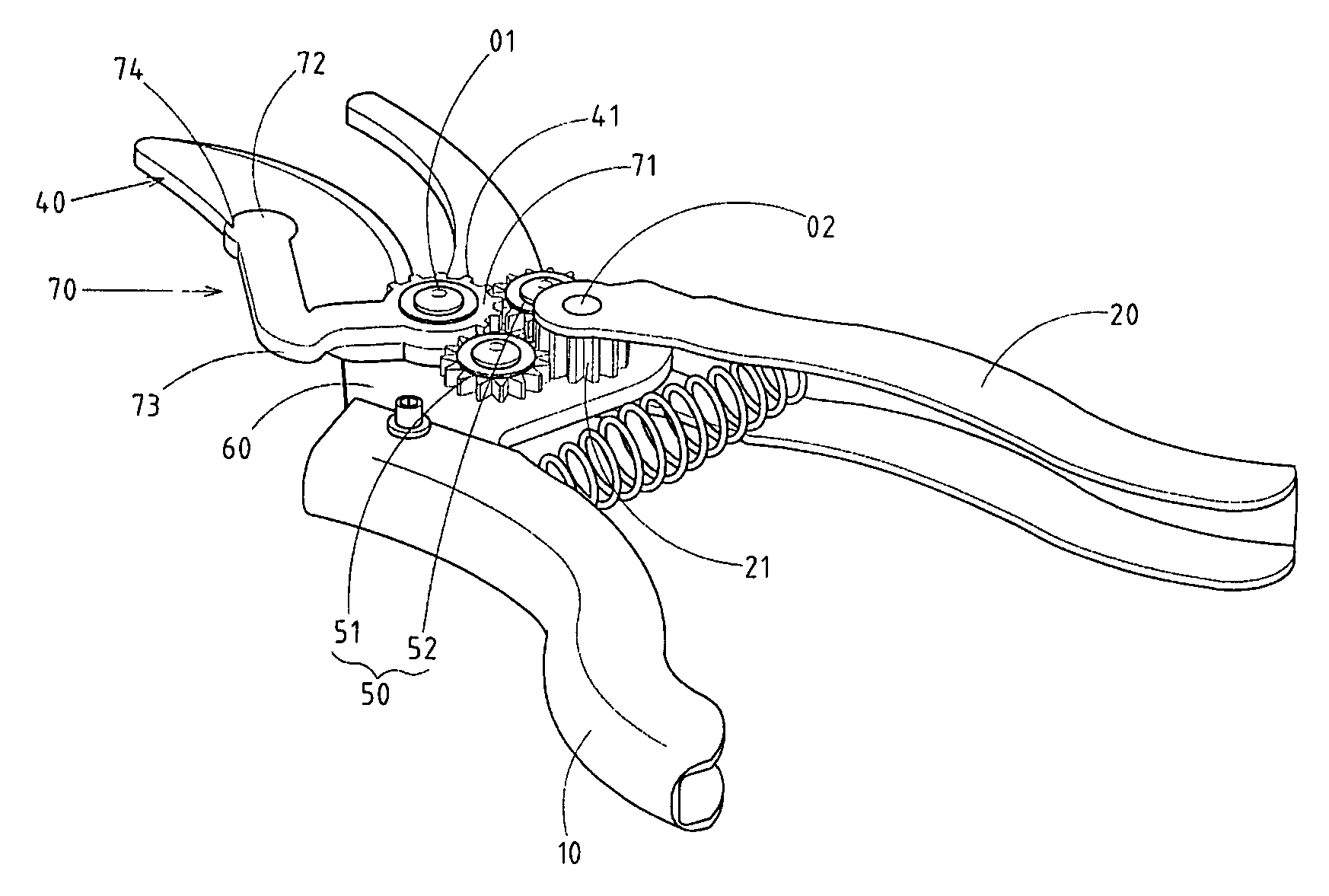

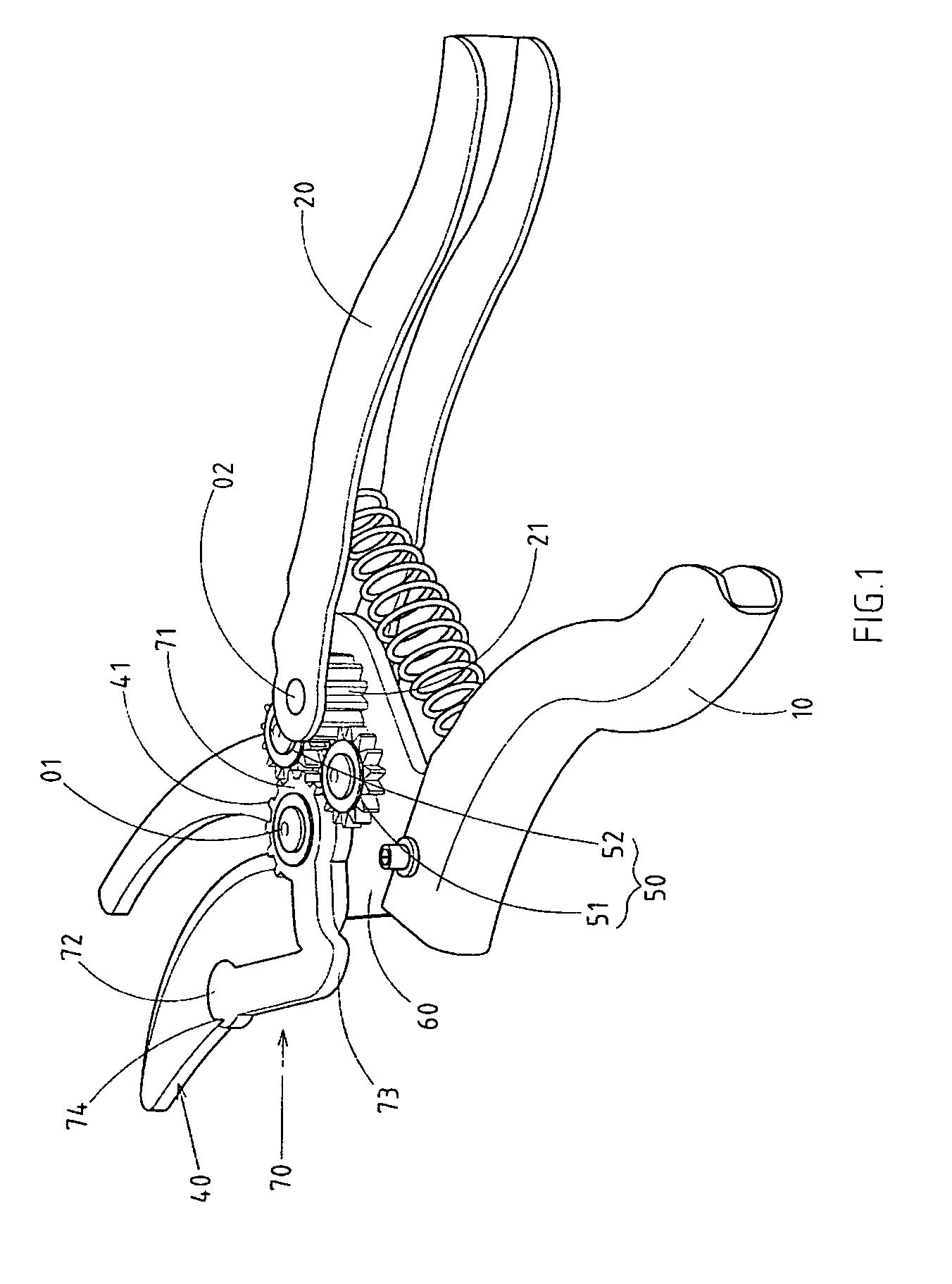

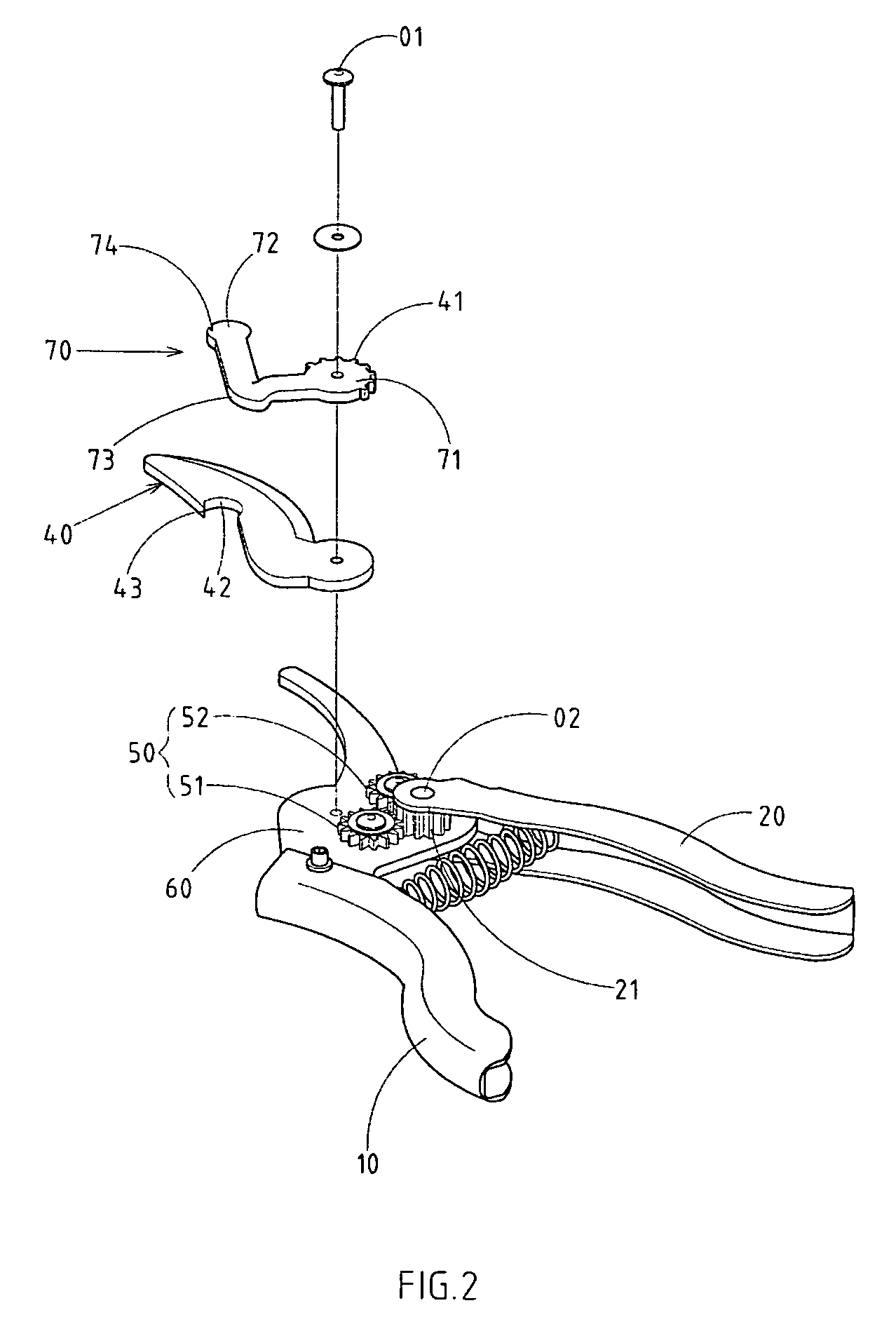

Gear-driven shears provided with a curved plate on a movable jaw

InactiveUS6935031B1Easy to useFlexible and intensiveSecateursMetal working apparatusGear driveGear wheel

Gear-driven shears include two grips, the fixed jaw, and the movable jaw and gear wheel module. The fixed jaw and the first grip are connected together at a joint of plate assembly module. The corresponding ends of movable jaw and the second grip are installed on the first pivot axle and second pivot axle of the plate assemble module. The characteristic of the invention is that one curved plate is installed additionally on one side of the movable jaw. Its first end is also installed on the first pivot axle of the plate assembly module sharing the same rotating point with the movable jaw. Meanwhile it is installed on the first edge of the curved plate together with the first tooth edge of the movable jaw. The second edge of the curved plate is equipped with wedge, which is locked in the notch on one side of the movable jaw. The middle section of curved plate is made into a curve.

Owner:HUNG CHUAN HSIAN INDS

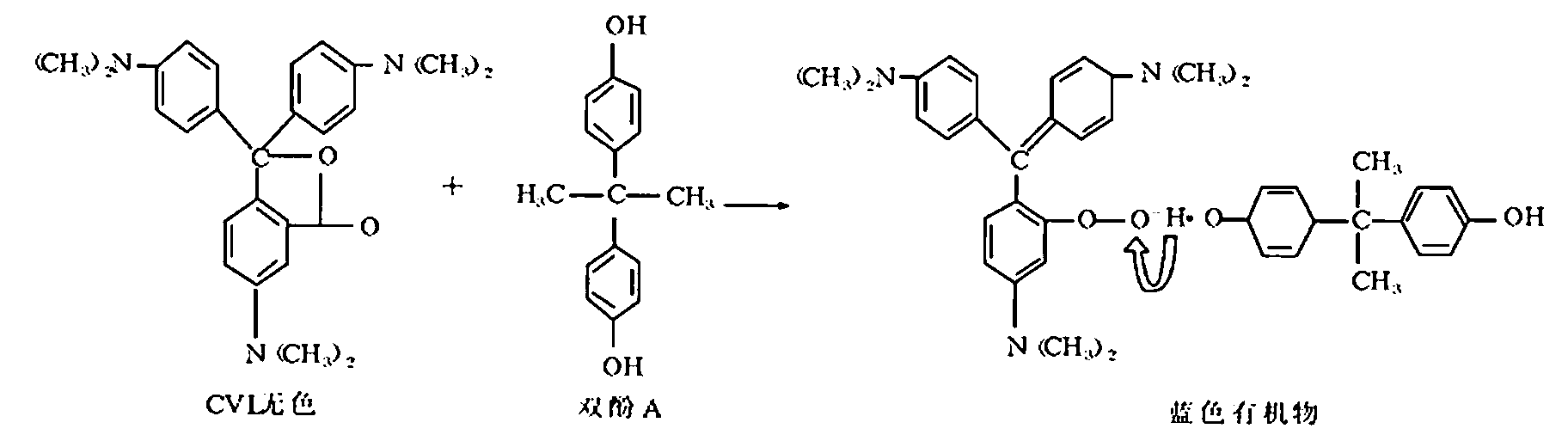

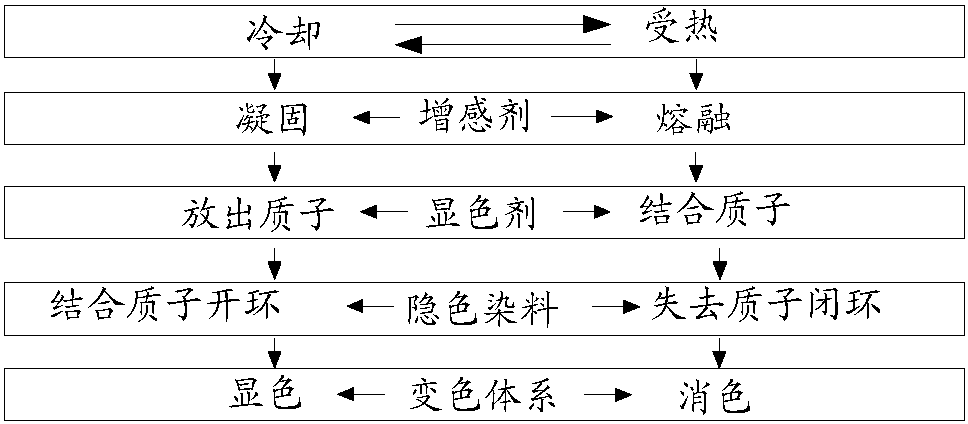

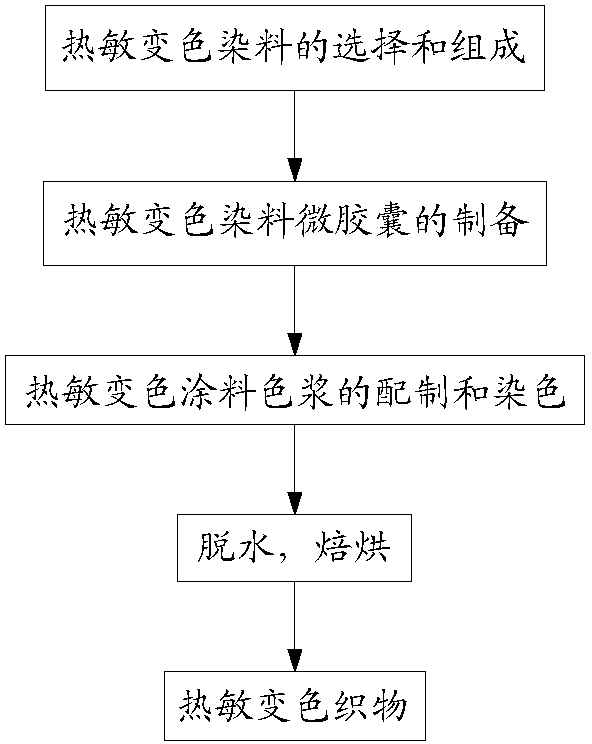

Temperature-sensitive color-changing paint dyeing technology of textile fabrics

InactiveCN103225212AObvious color differenceImprove qualityDyeing processMicroballoon preparationPolyesterFiber

Owner:FUJIAN ZHONGHE

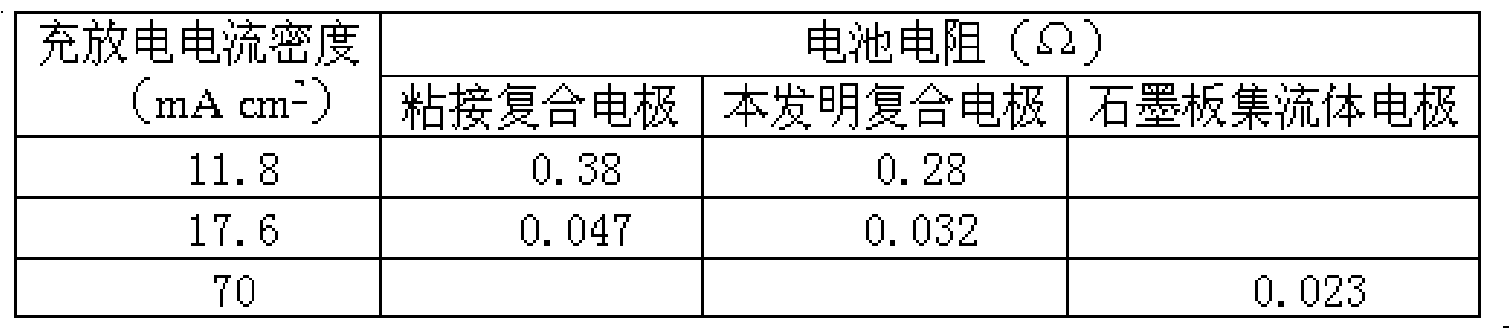

Combination electrode for all vanadium redox flow battery and preparation thereof

InactiveCN101335349AImprove mechanical propertiesImprove conductivityCell electrodesFiberVanadium redox battery

The invention relates to a composite electrode used in vanadium redox flow batteries and a preparation method thereof, pertaining to the vanadium battery manufacturing field. The composite electrode is prepared by adding three conductive fillers (conductive acetylene carbon black, conductive carbon fiber and graphite) into thermoplastic polymer to obtain a thermoplastic conductive plate which is compounded together with a graphite felt. Part of the conductive carbon fiber in the graphite felt is embedded into the surface of the conductive plate to form an interpenetrating conductive network and improve the conductivity of the whole product. Therefore, the composite electrode has excellent mechanical performance and conductivity (volume resistivity is less than or equal to 0.1omega question mark cm), integrates current collector and electrode into a whole, and effectively reduces surface resistance between the current collector and the electrode; meanwhile, during the process, no additional additive which can improve conductivity is used, thus ensuring relatively good conductivity and mechanical performance, and avoiding the falling of the additive which can improve conductivity into the electrolyte of a vanadium battery.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com