Patents

Literature

4556results about How to "Add depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Systems and Methods for Synthesizing Images from Image Data Captured by an Array Camera Using Restricted Depth of Field Depth Maps in which Depth Estimation Precision Varies

ActiveUS20140267243A1Great depth estimation precisionHigh depth estimateImage enhancementImage analysisImaging processingViewpoints

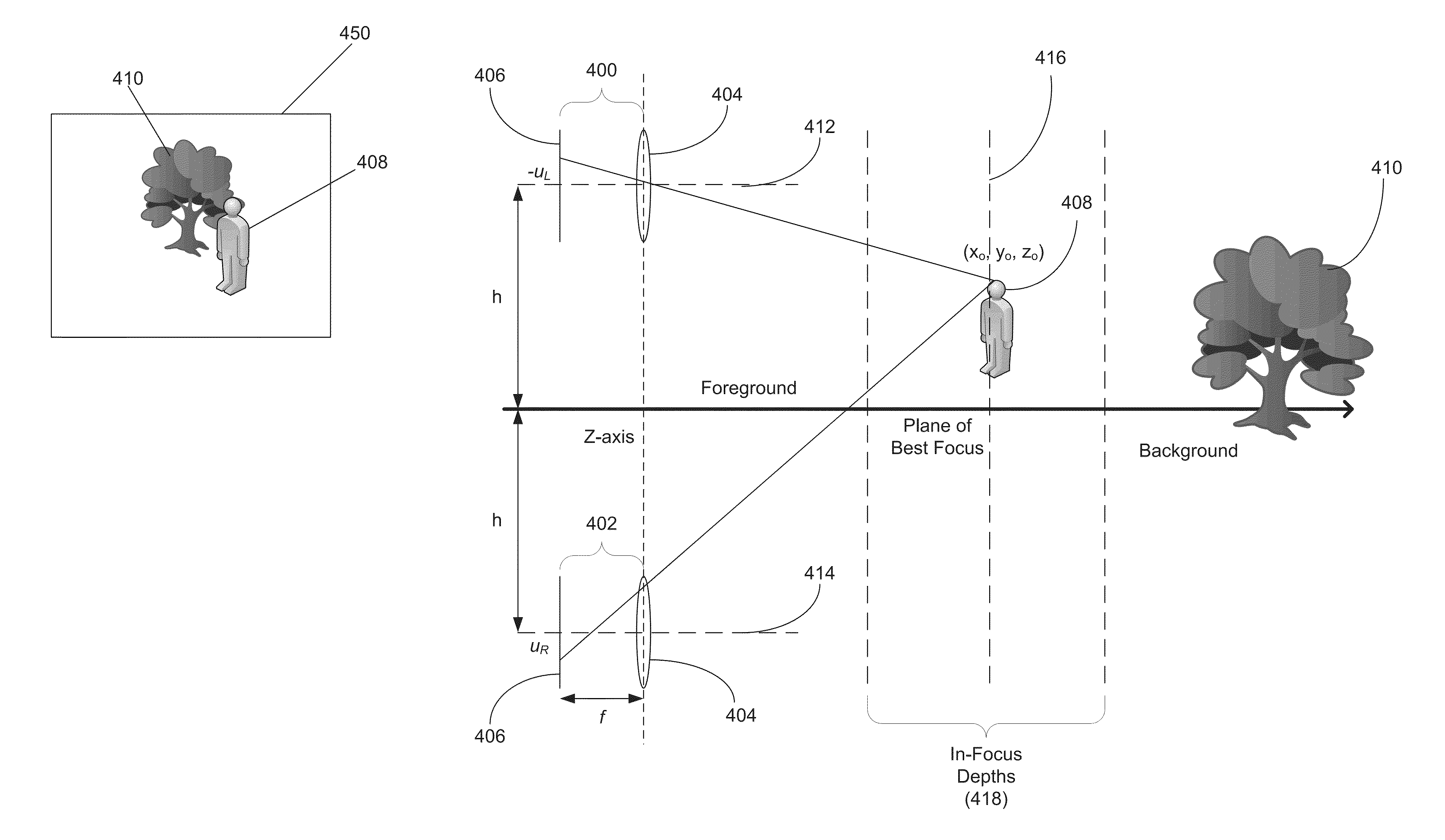

Systems and methods are described for generating restricted depth of field depth maps. In one embodiment, an image processing pipeline application configures a processor to: determine a desired focal plane distance and a range of distances corresponding to a restricted depth of field for an image rendered from a reference viewpoint; generate a restricted depth of field depth map from the reference viewpoint using the set of images captured from different viewpoints, where depth estimation precision is higher for pixels with depth estimates within the range of distances corresponding to the restricted depth of field and lower for pixels with depth estimates outside of the range of distances corresponding to the restricted depth of field; and render a restricted depth of field image from the reference viewpoint using the set of images captured from different viewpoints and the restricted depth of field depth map.

Owner:FOTONATION LTD

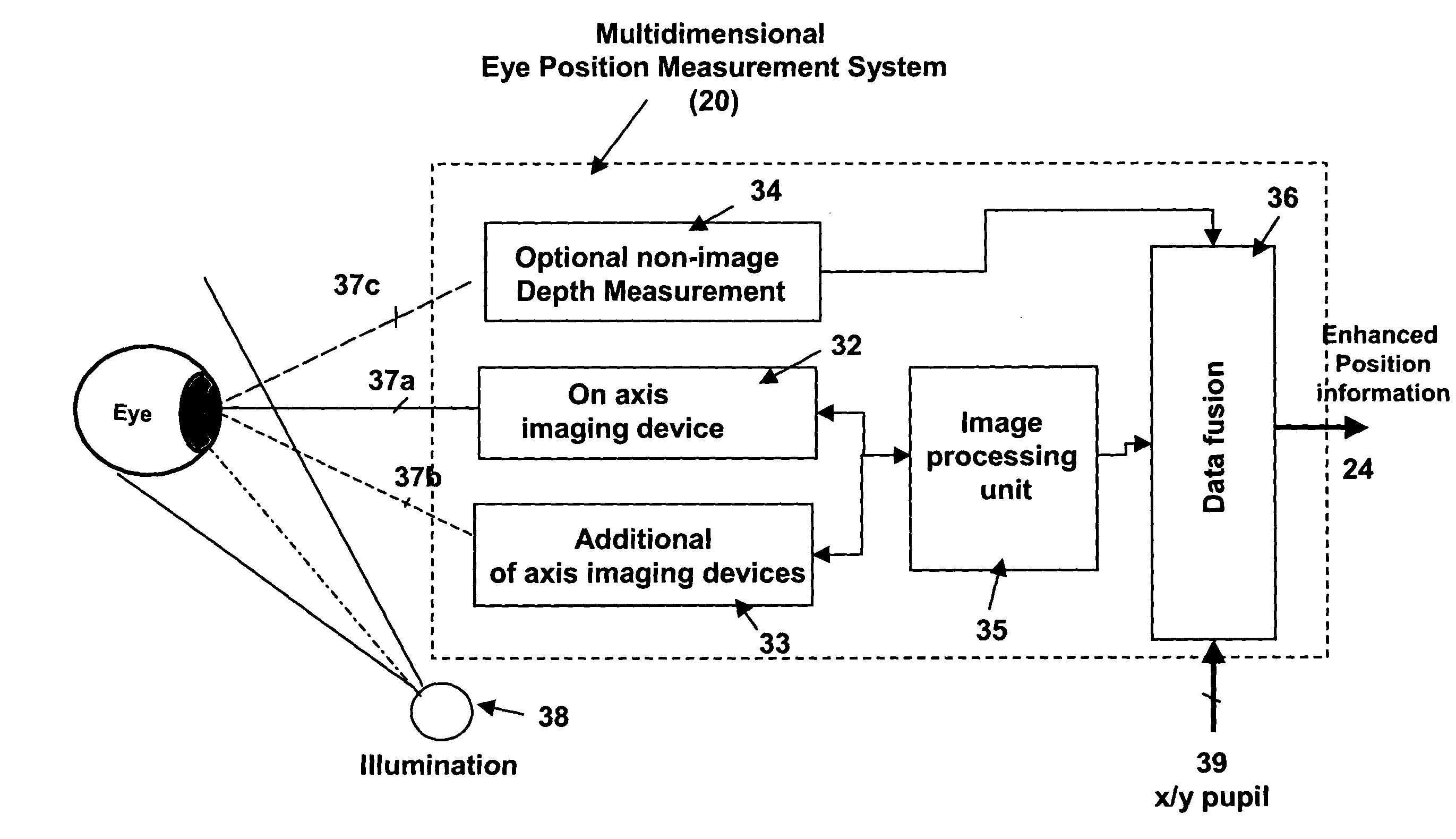

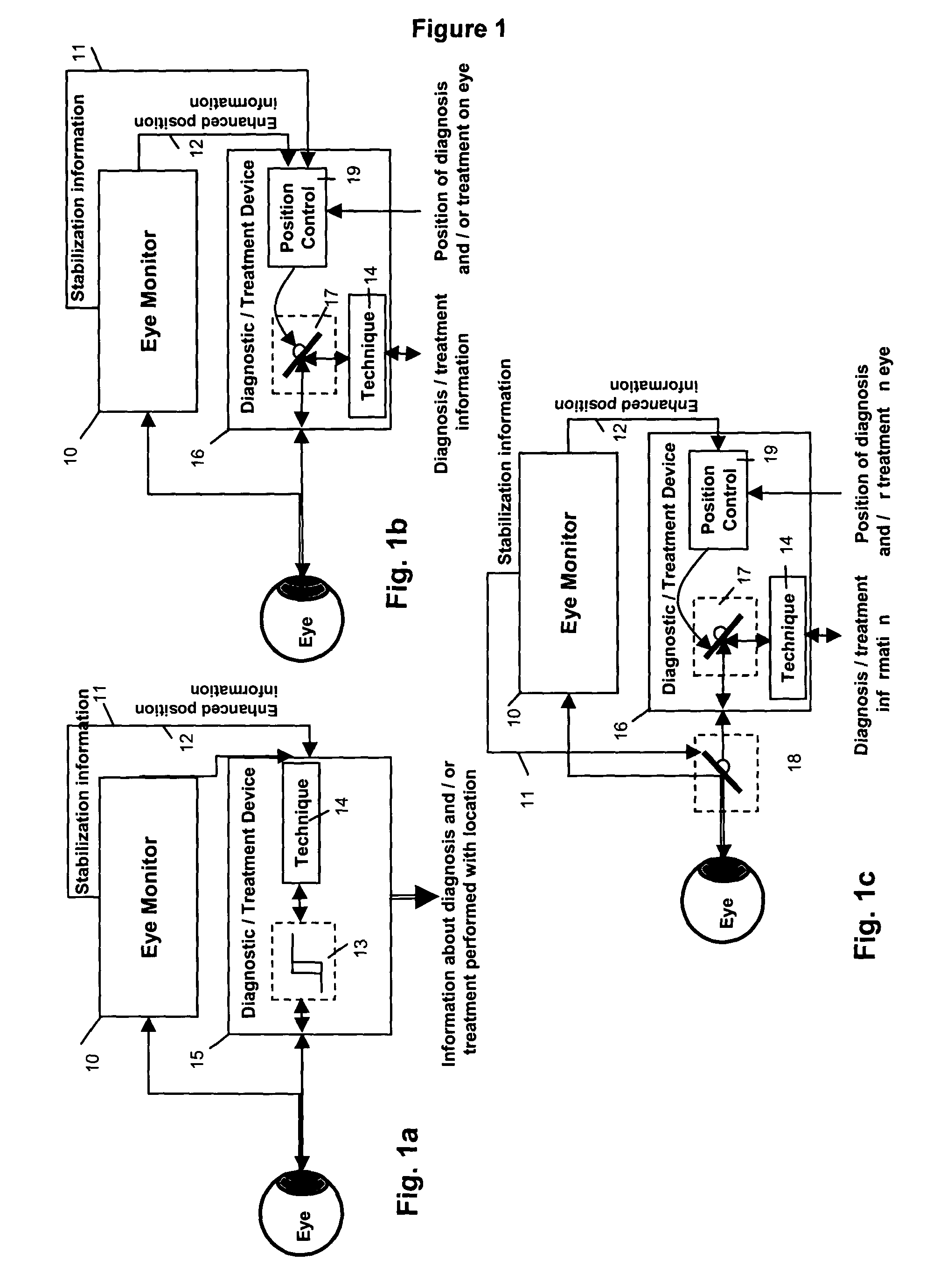

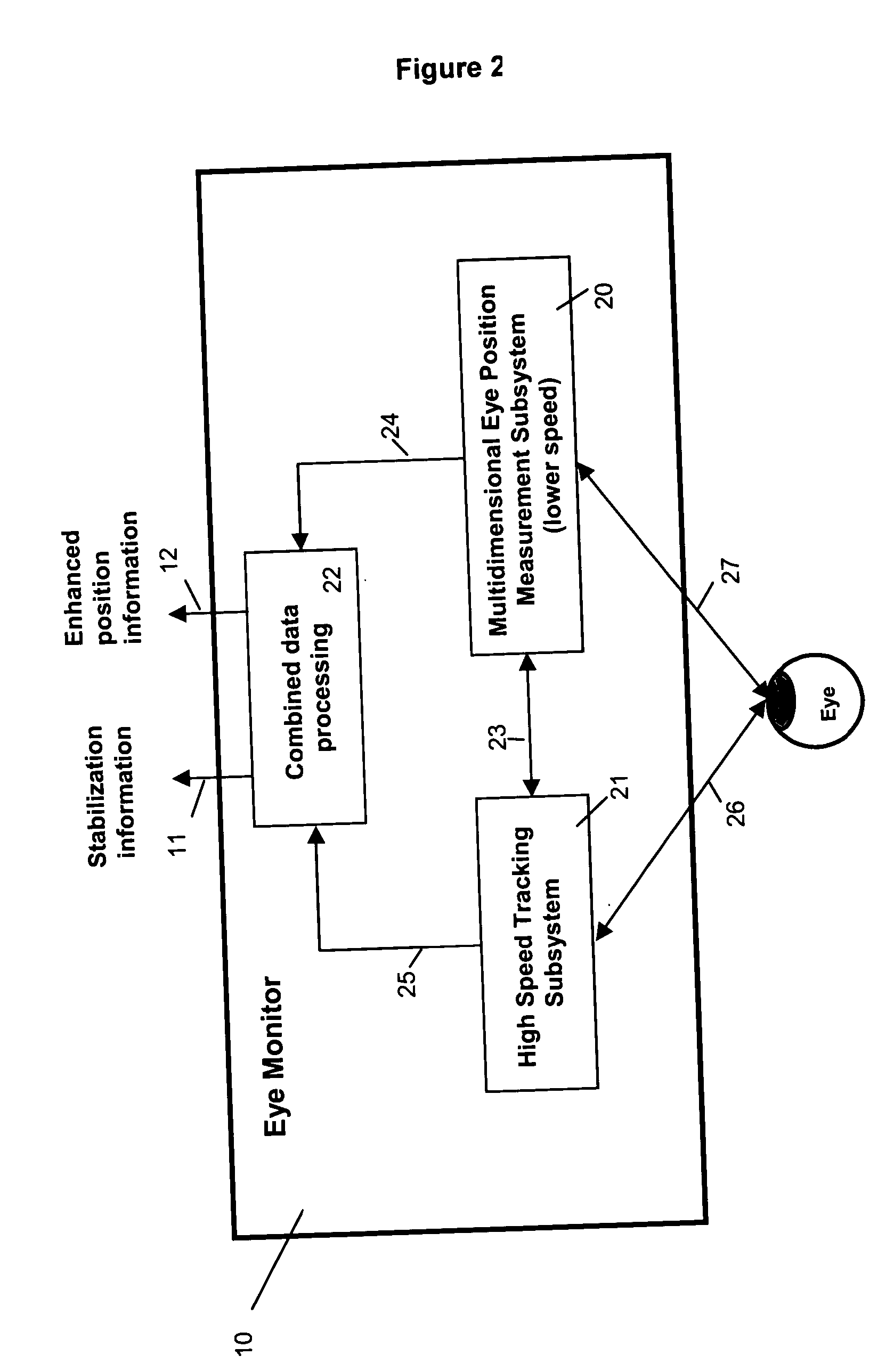

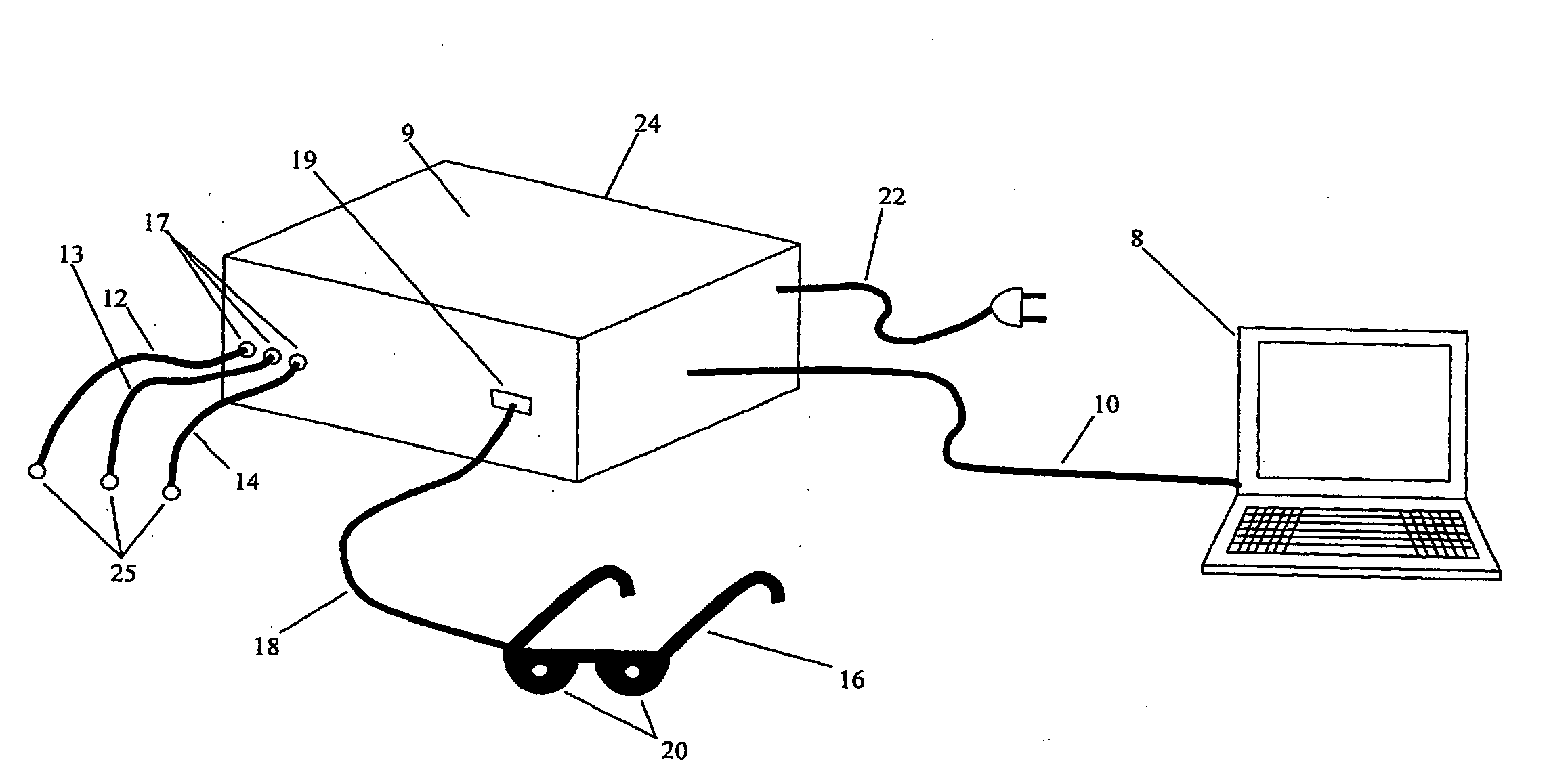

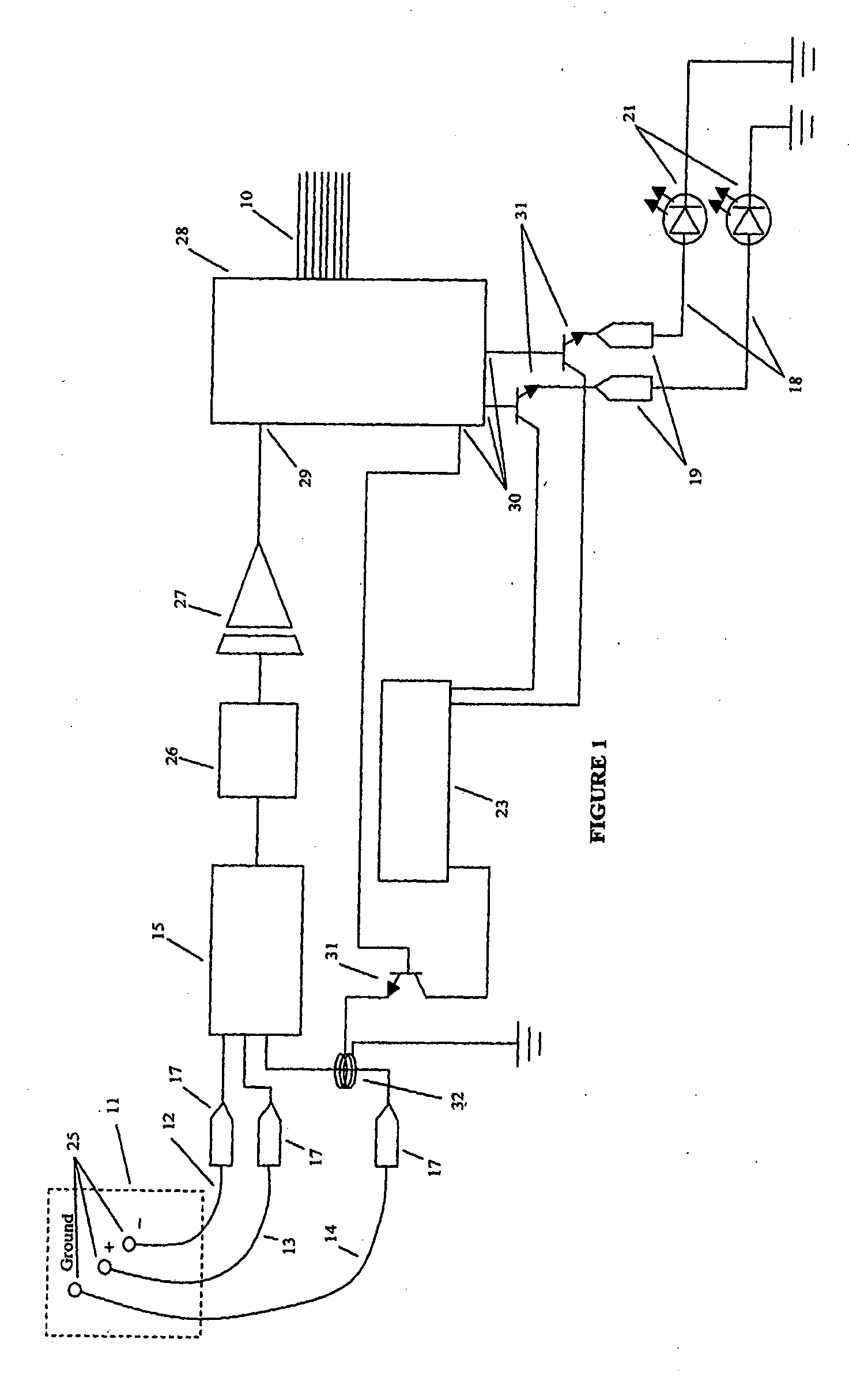

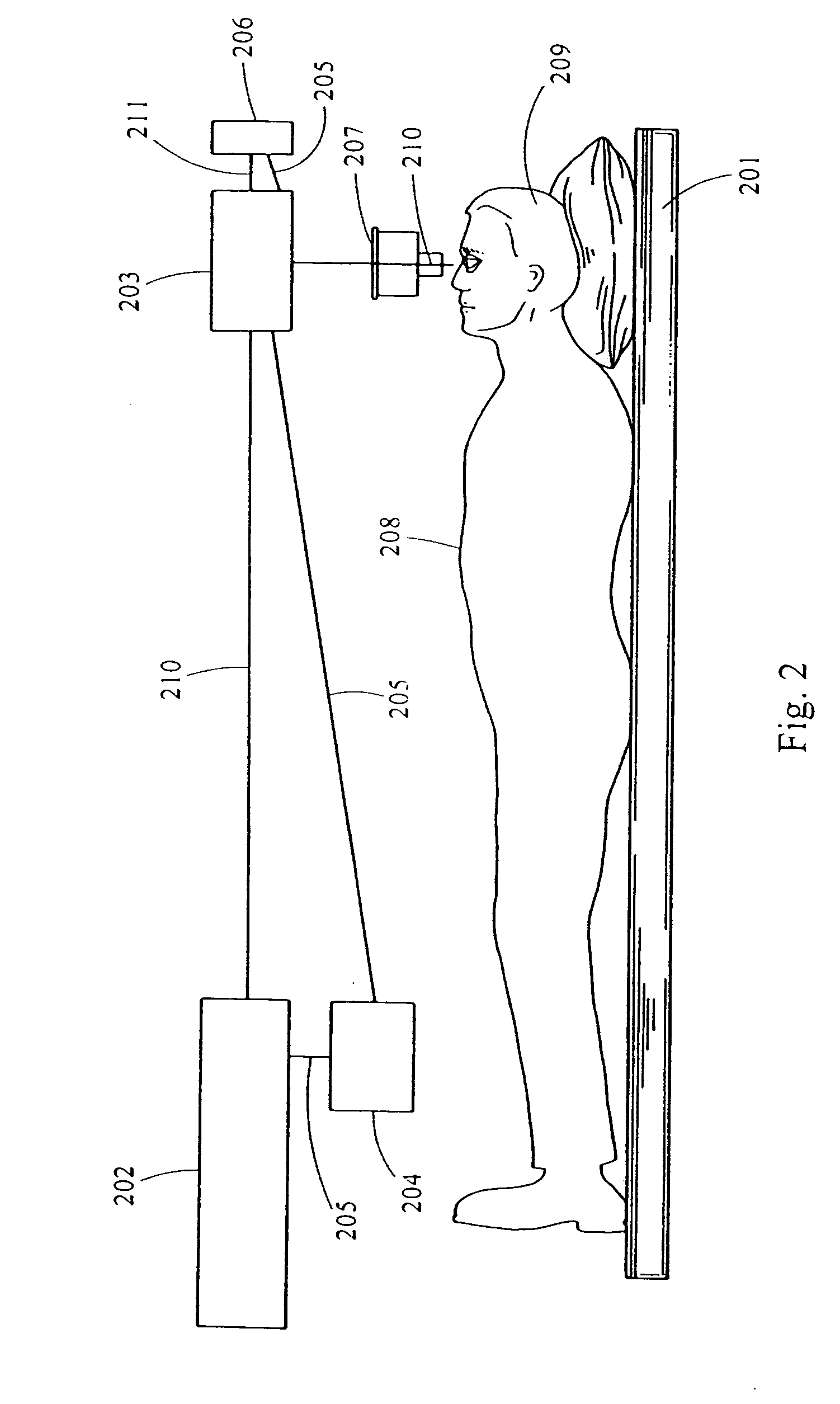

Multidimensional eye tracking and position measurement system for diagnosis and treatment of the eye

ActiveUS20050024586A1Improve spatial resolutionLess field of viewLaser surgeryCharacter and pattern recognitionMeasurement deviceSaccadic movements

The present invention relates to improved ophthalmic diagnostic measurement or treatment methods or devices, that make use of a combination of a high speed eye tracking device, measuring fast translation or saccadic motion of the eye, and an eye position measurement device, determining multiple dimensions of eye position or other components of eye, relative to an ophthalmic diagnostic or treatment instrument.

Owner:SENSOMOTORIC INSTR FUR INNOVATIVE SENSORIK MBH D B A SENSOMOTORIC INSTR

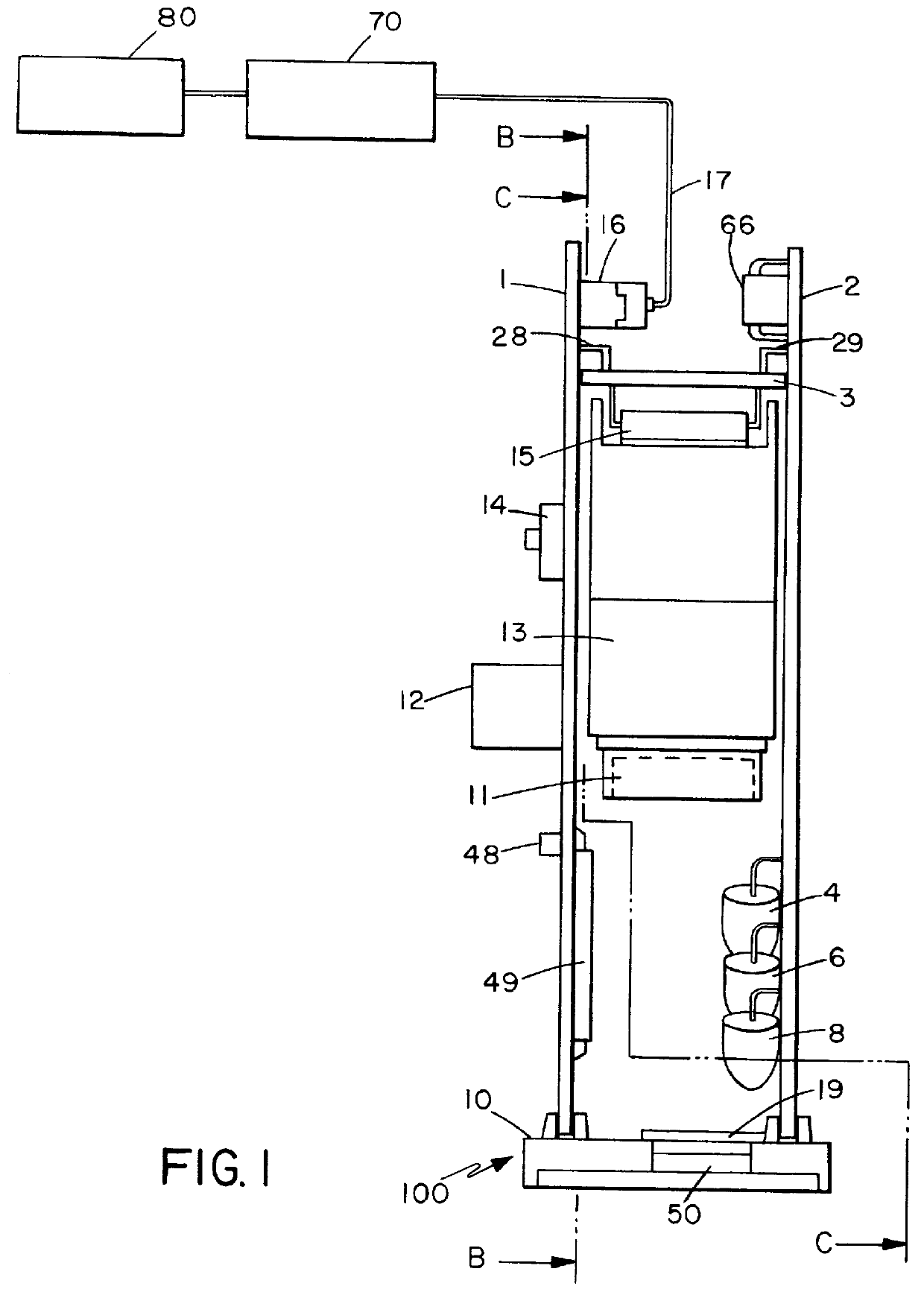

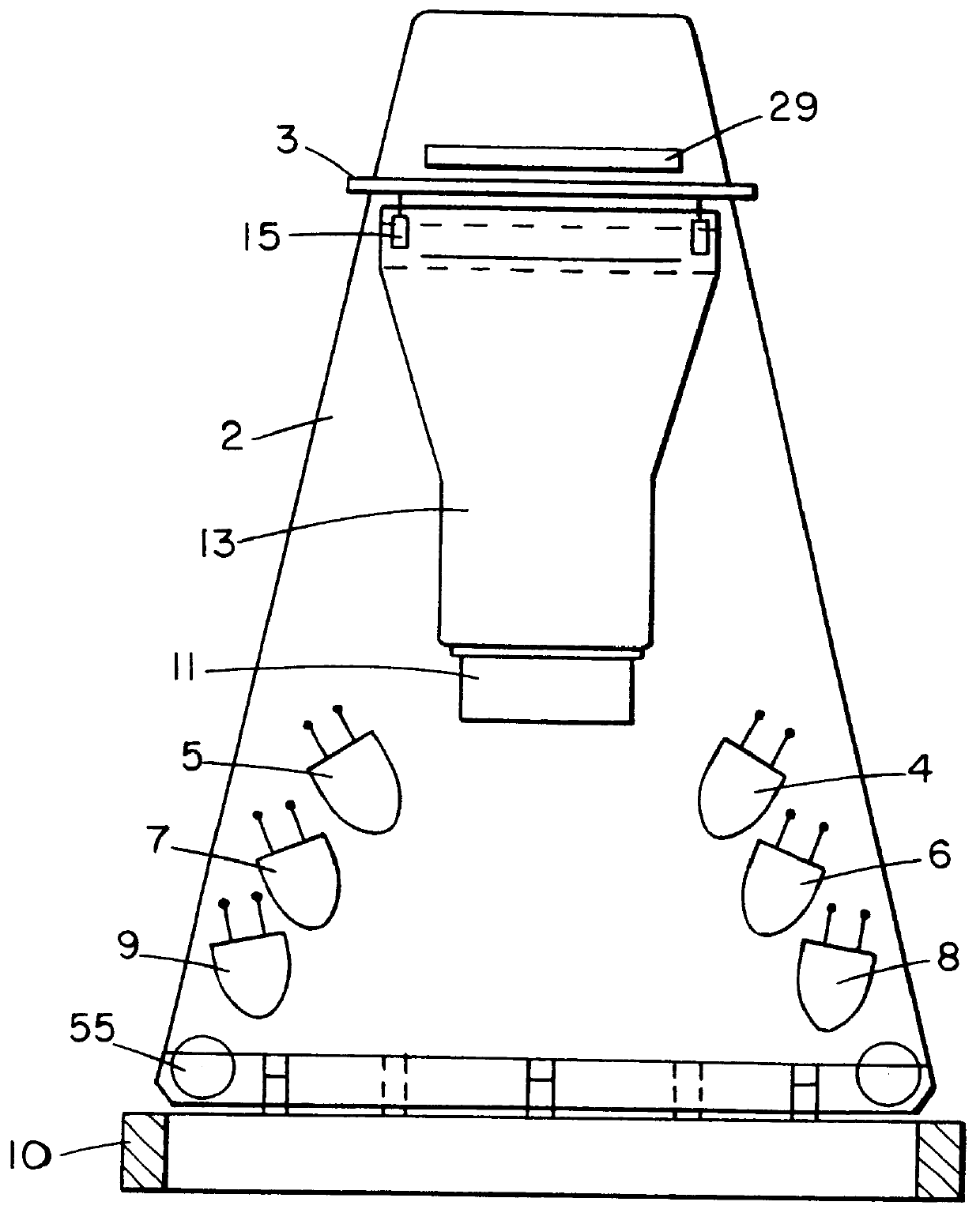

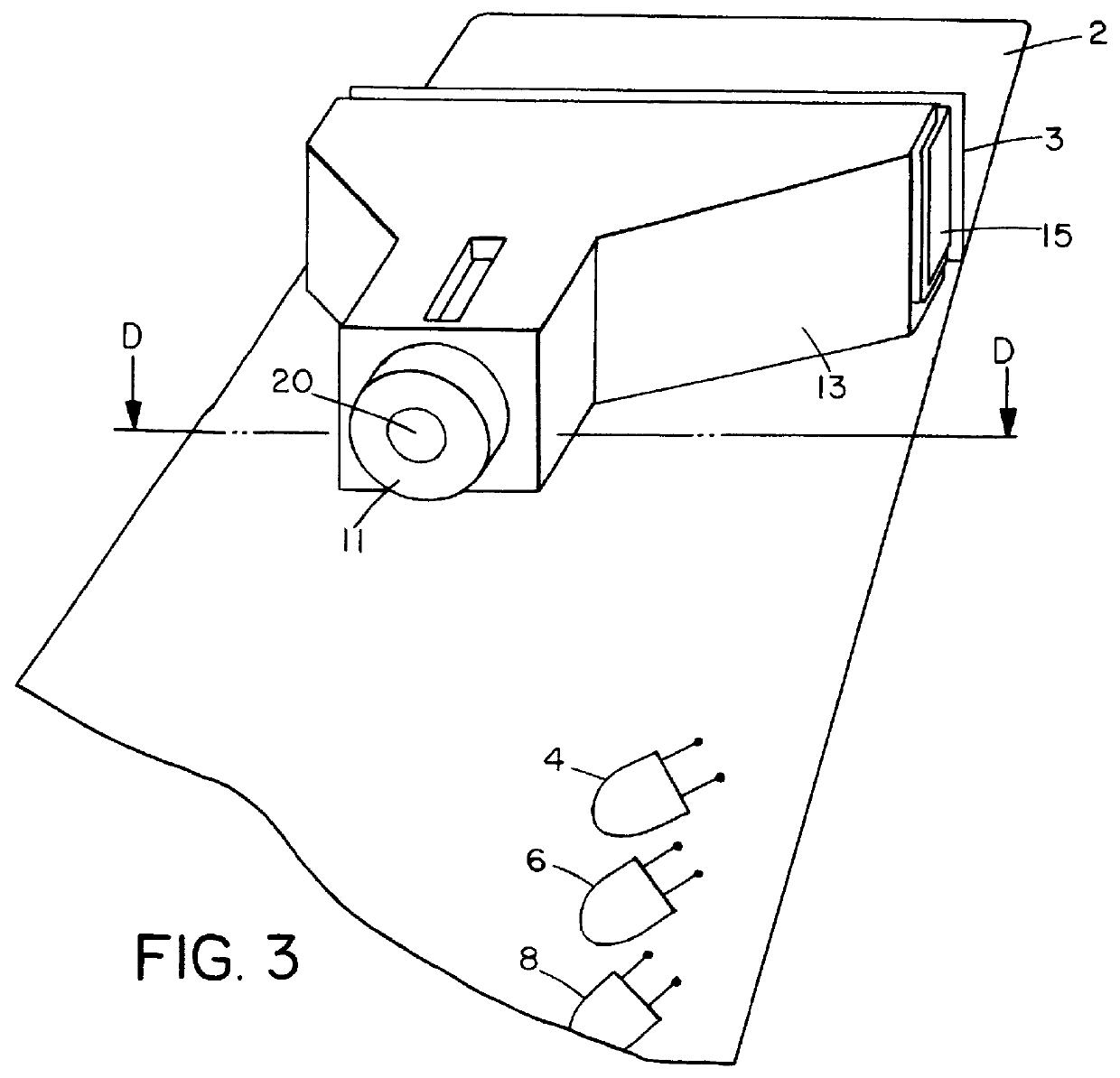

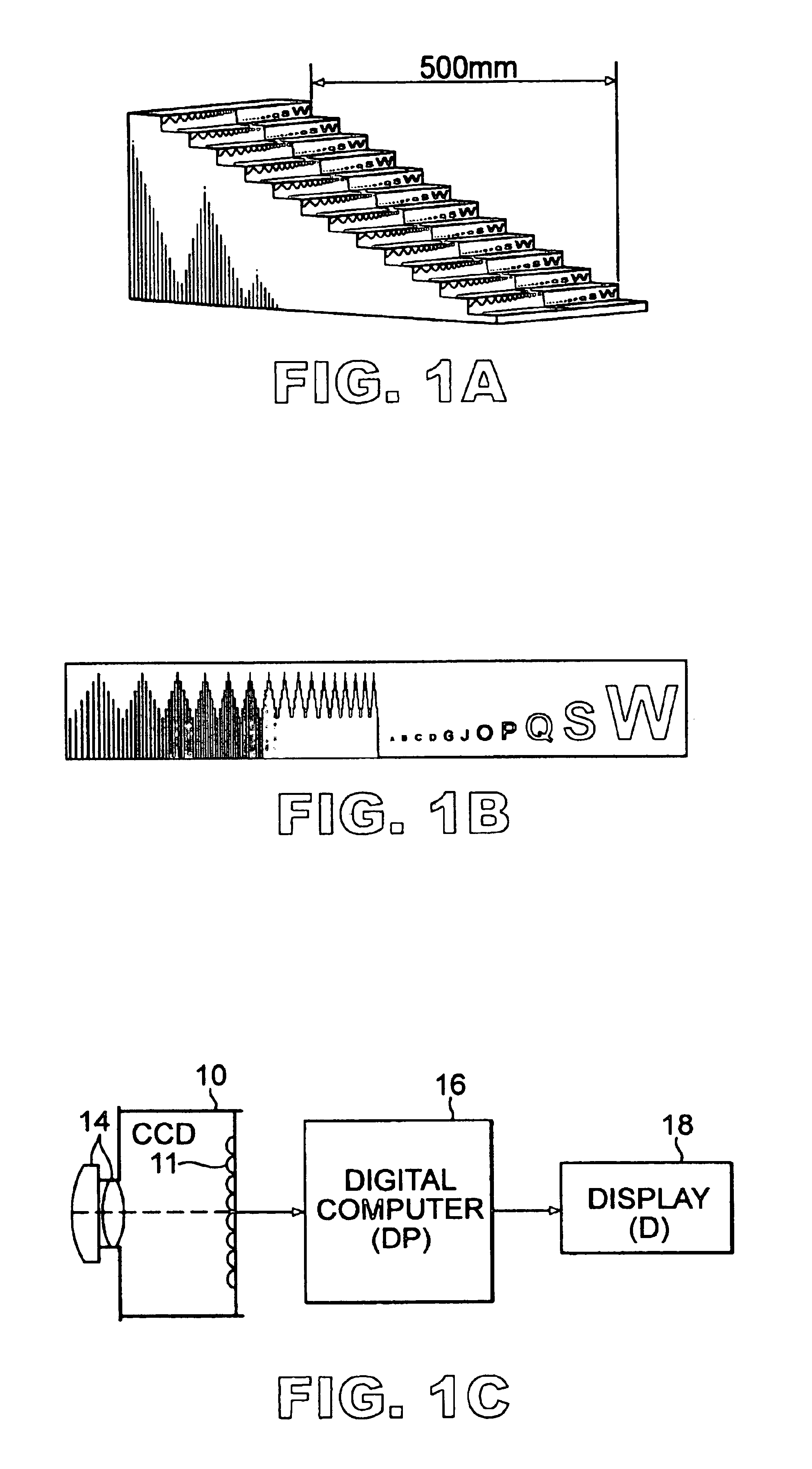

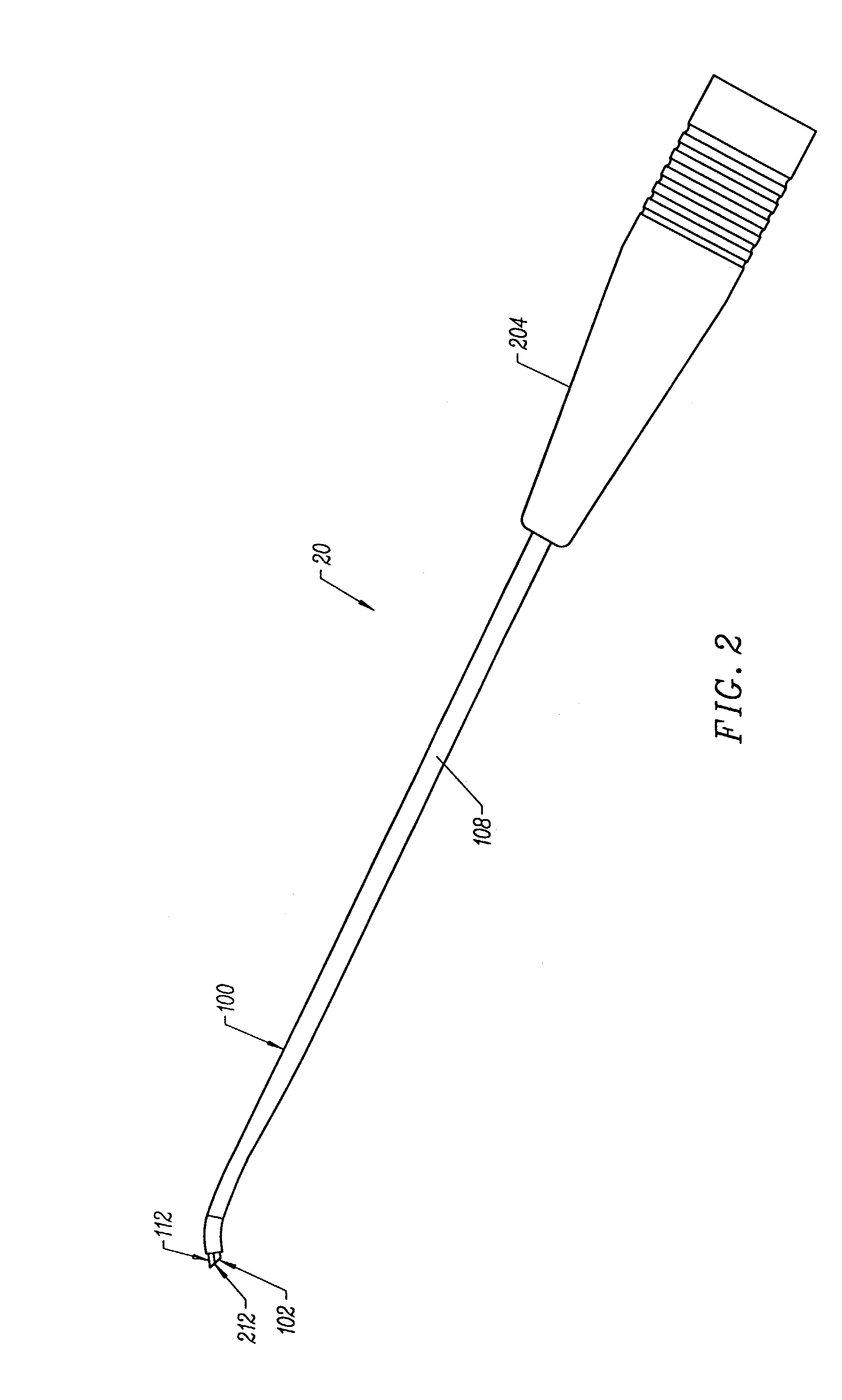

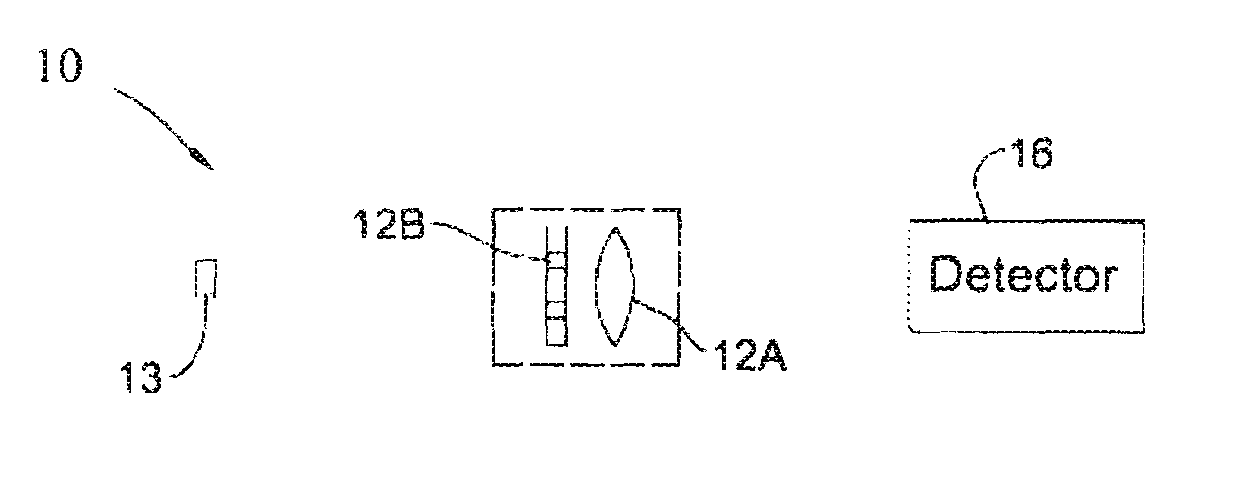

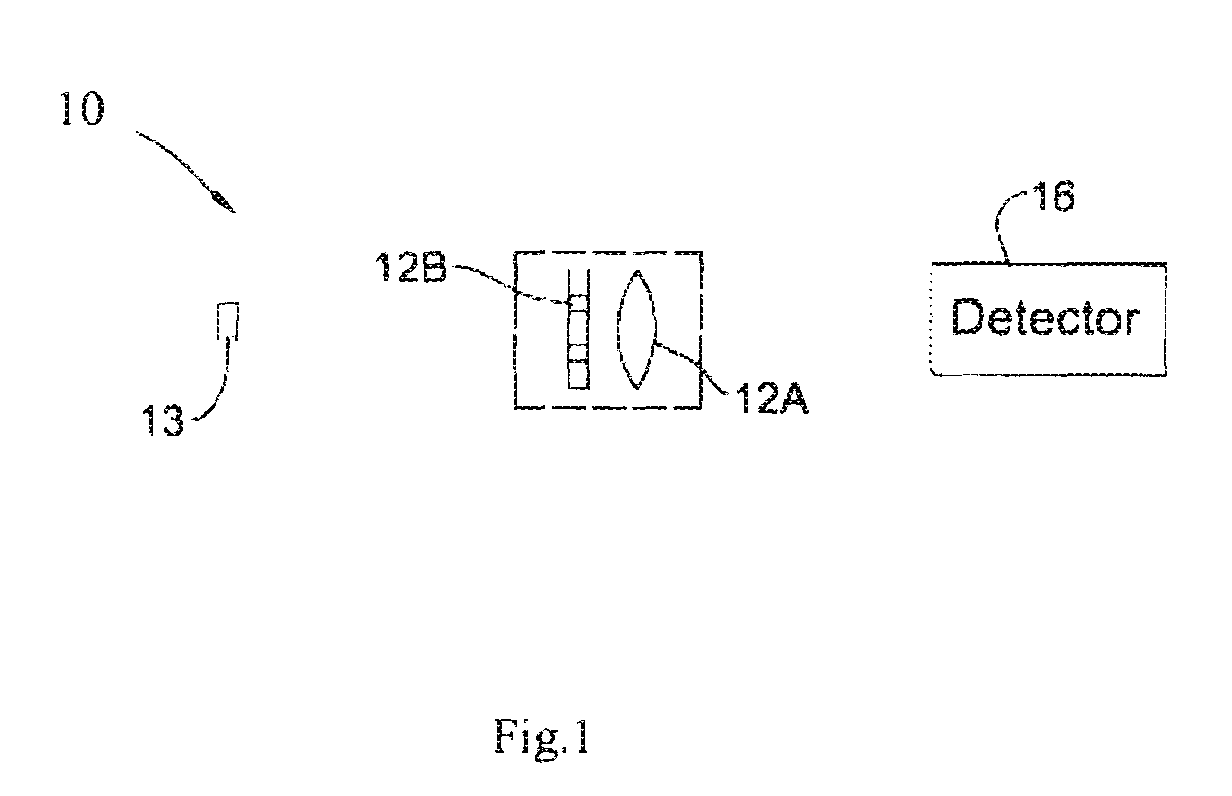

Optical scanning head

InactiveUSRE36528E1Add depthIncrease distanceVisual representatino by photographic printingPhotomechanical exposure apparatusOptical scannersBarcode

The [ornamental] design for a bar code Scanner using the Light Emitting Diode (LED), Optical Scanner assembly and Charge-Coupled Devices (CCD) capable of reading the barcode symbols at the variable distance, as shown and described. The optical passive elements for increasing the depth of field and method of fabricating the scanning head by mass-production techniques are also disclosed.

Owner:SYMBOL TECH INC

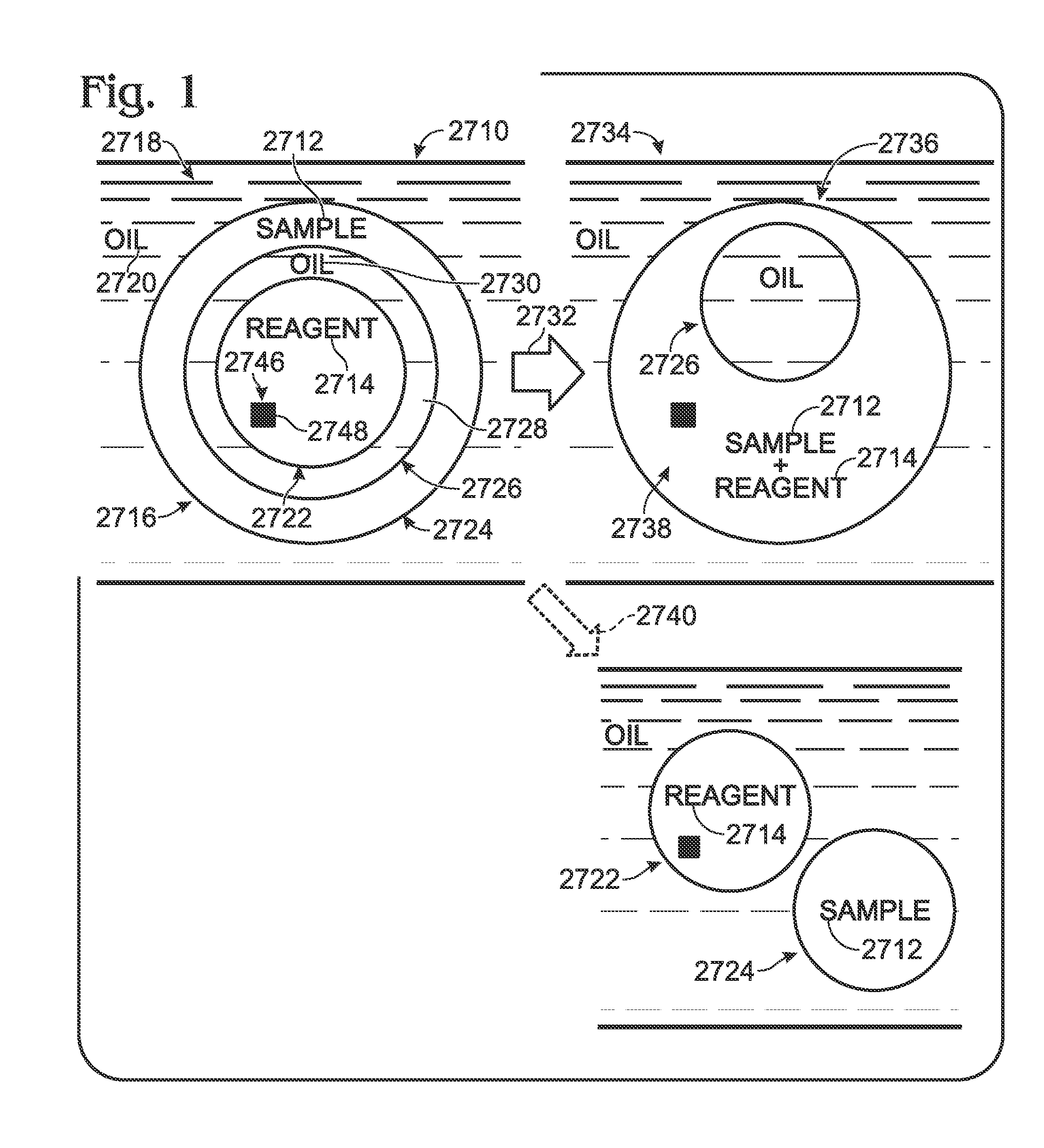

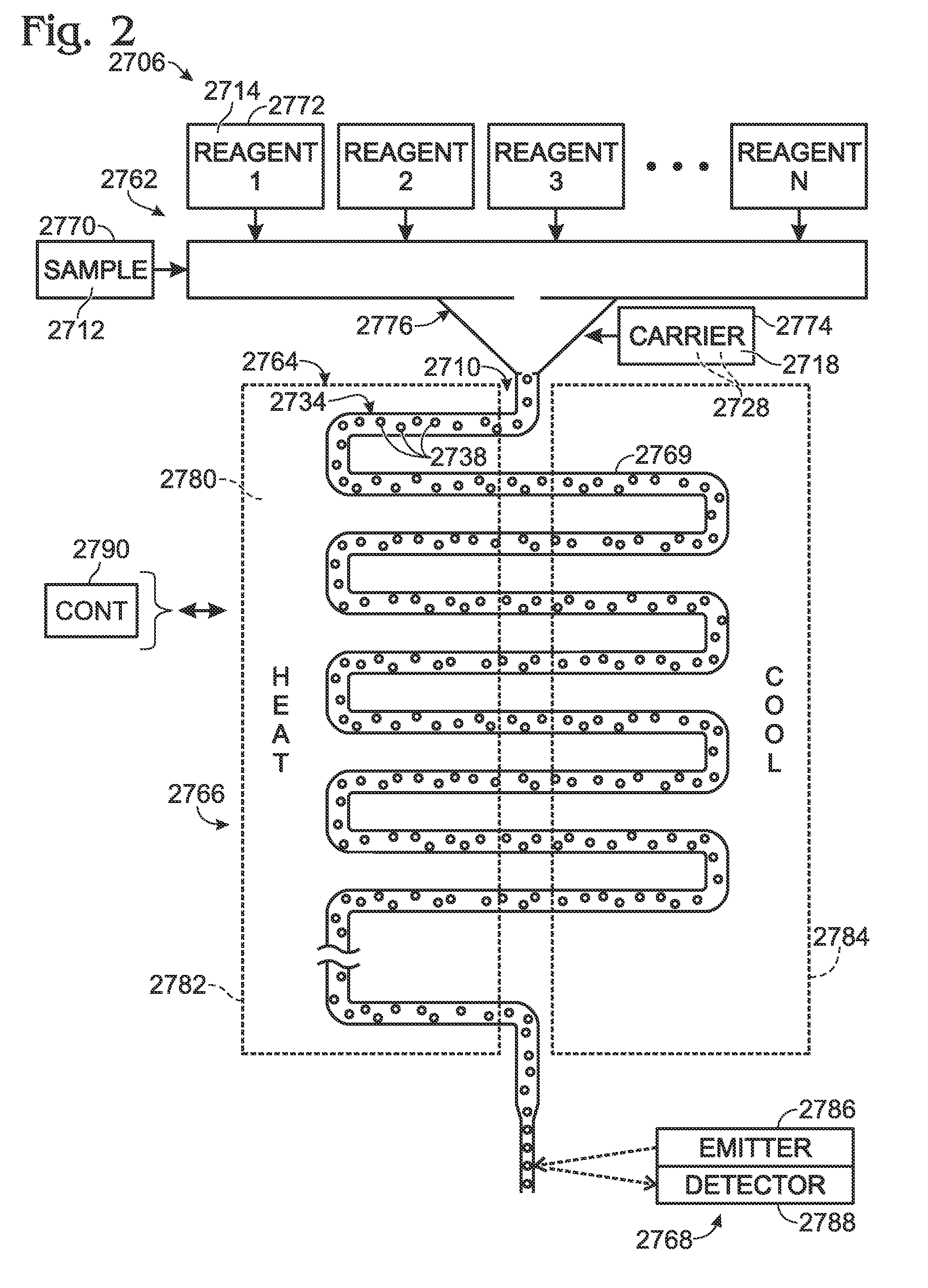

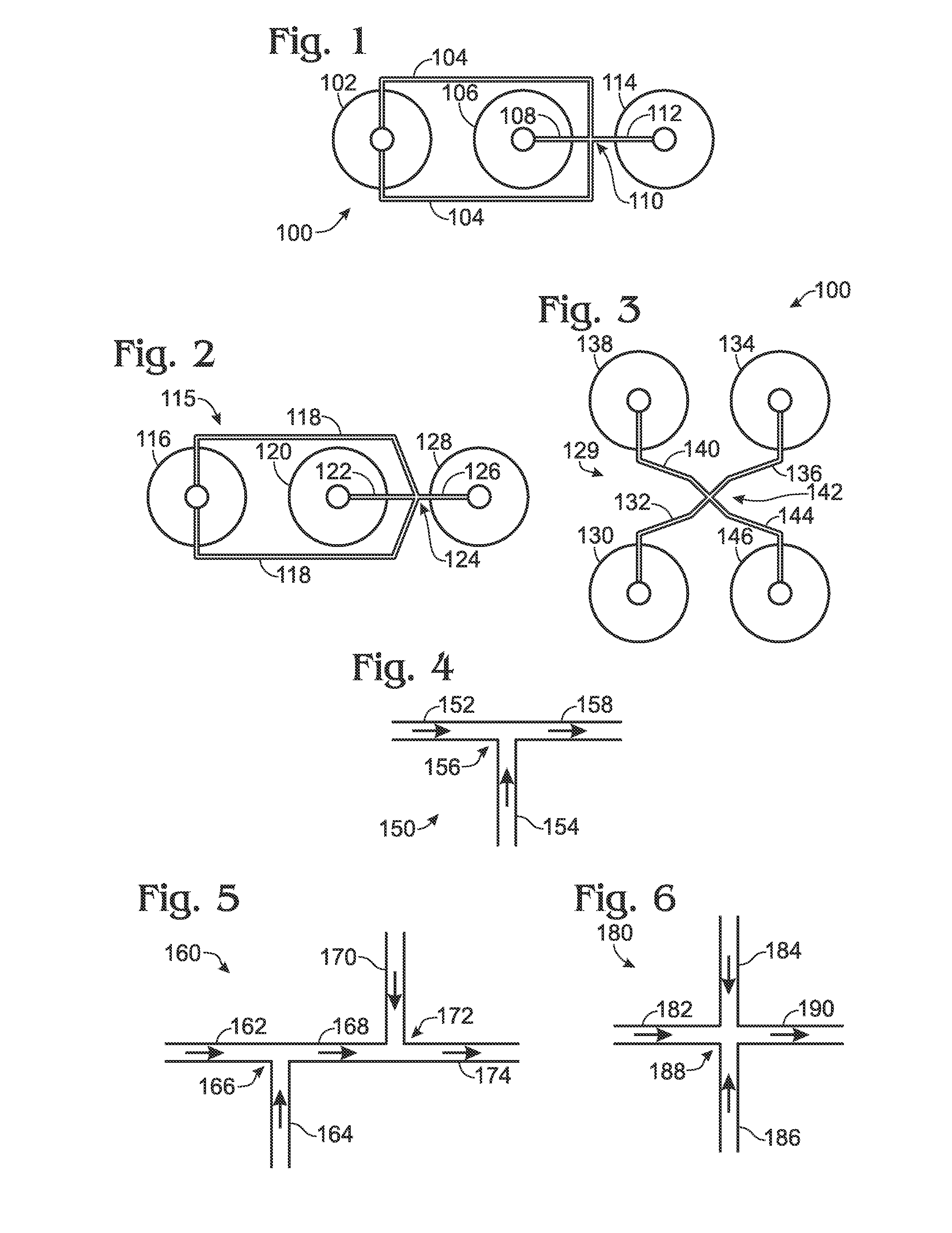

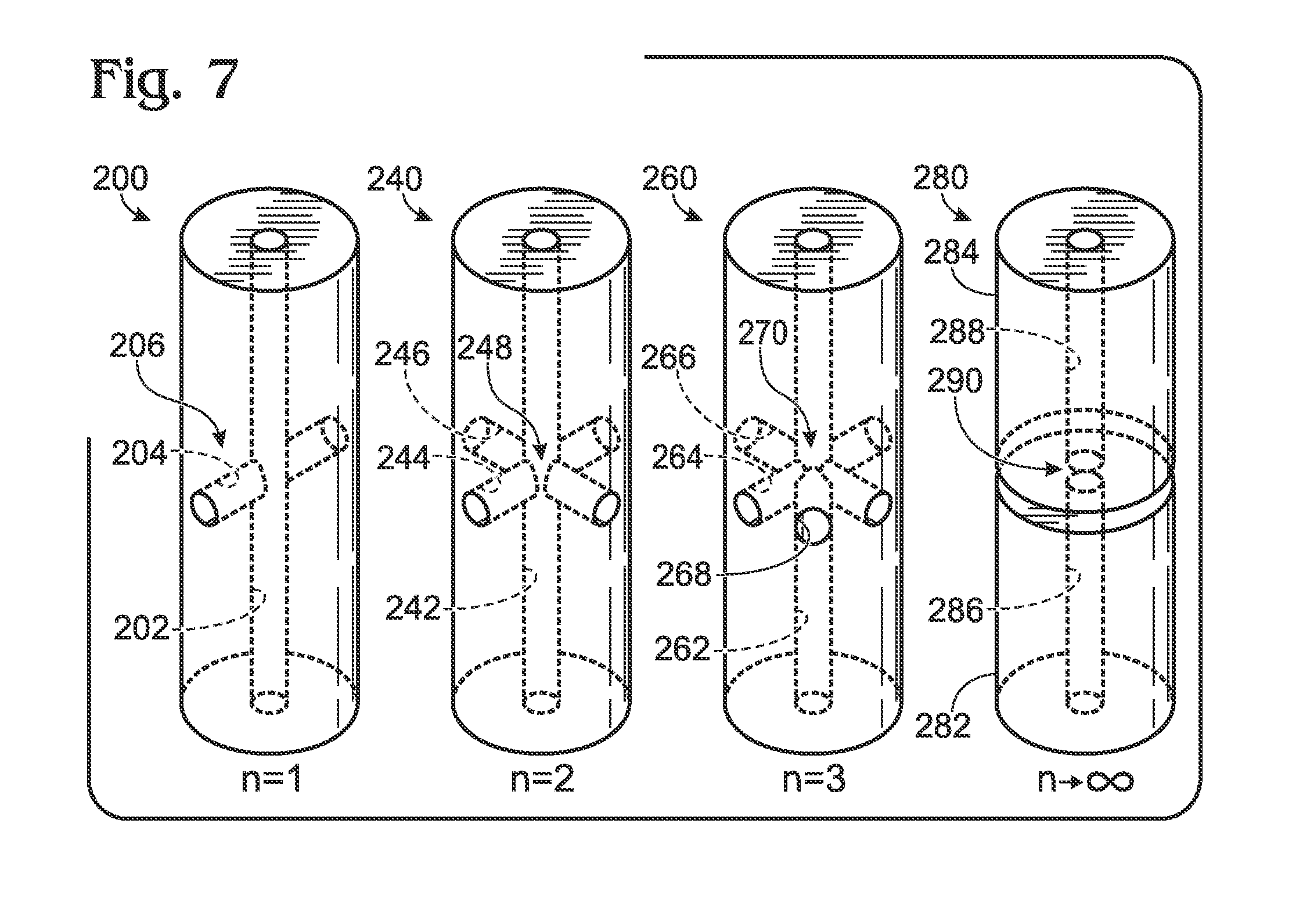

System for mixing fluids by coalescence of multiple emulsions

ActiveUS20110053798A1High-confidence resultLower the volumeSequential/parallel process reactionsHeating or cooling apparatusEmulsionChemistry

System, including methods, apparatus, compositions, and kits, for the mixing of small volumes of fluid by coalescence of multiple emulsions.

Owner:BIO RAD LAB INC

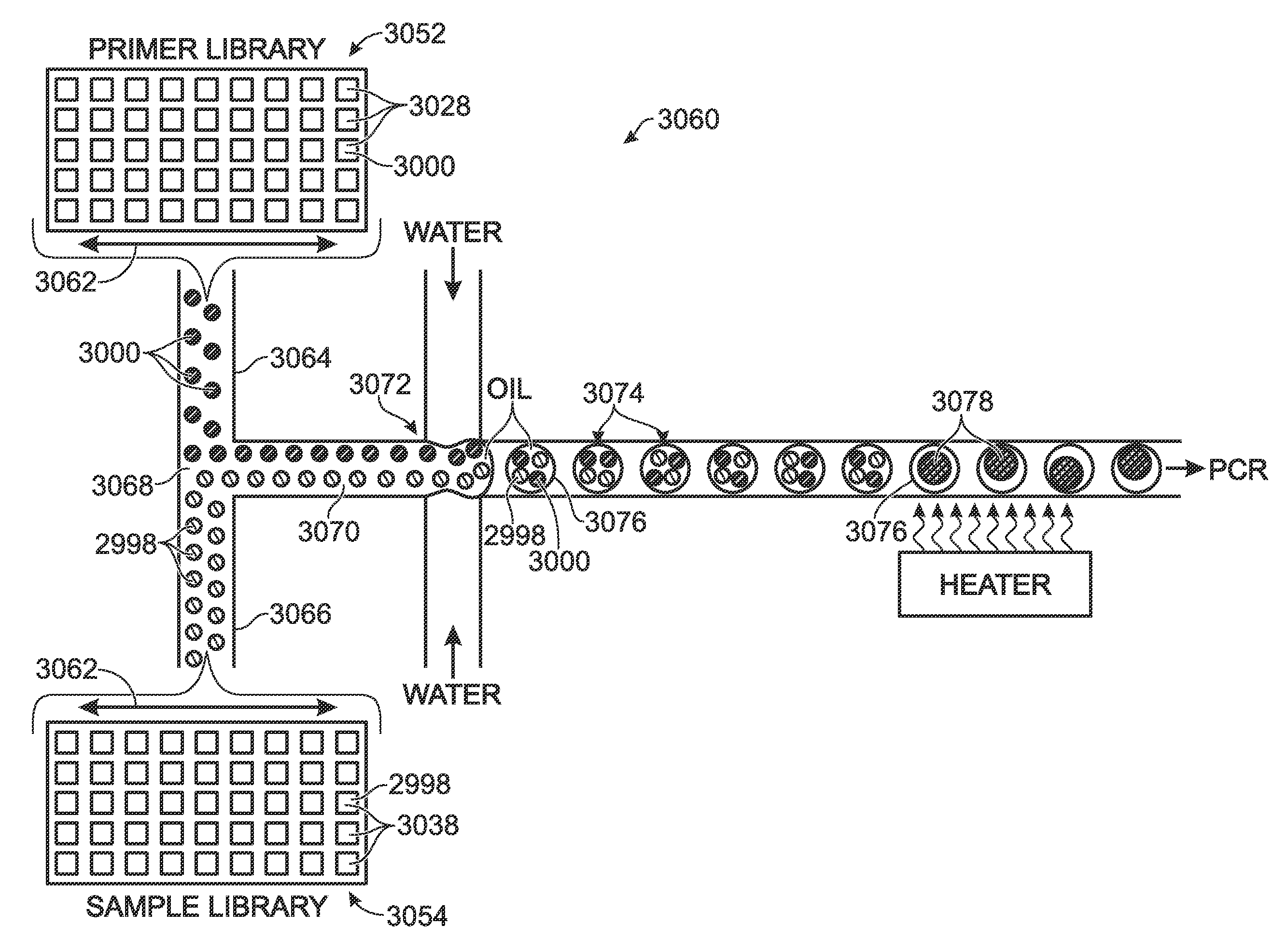

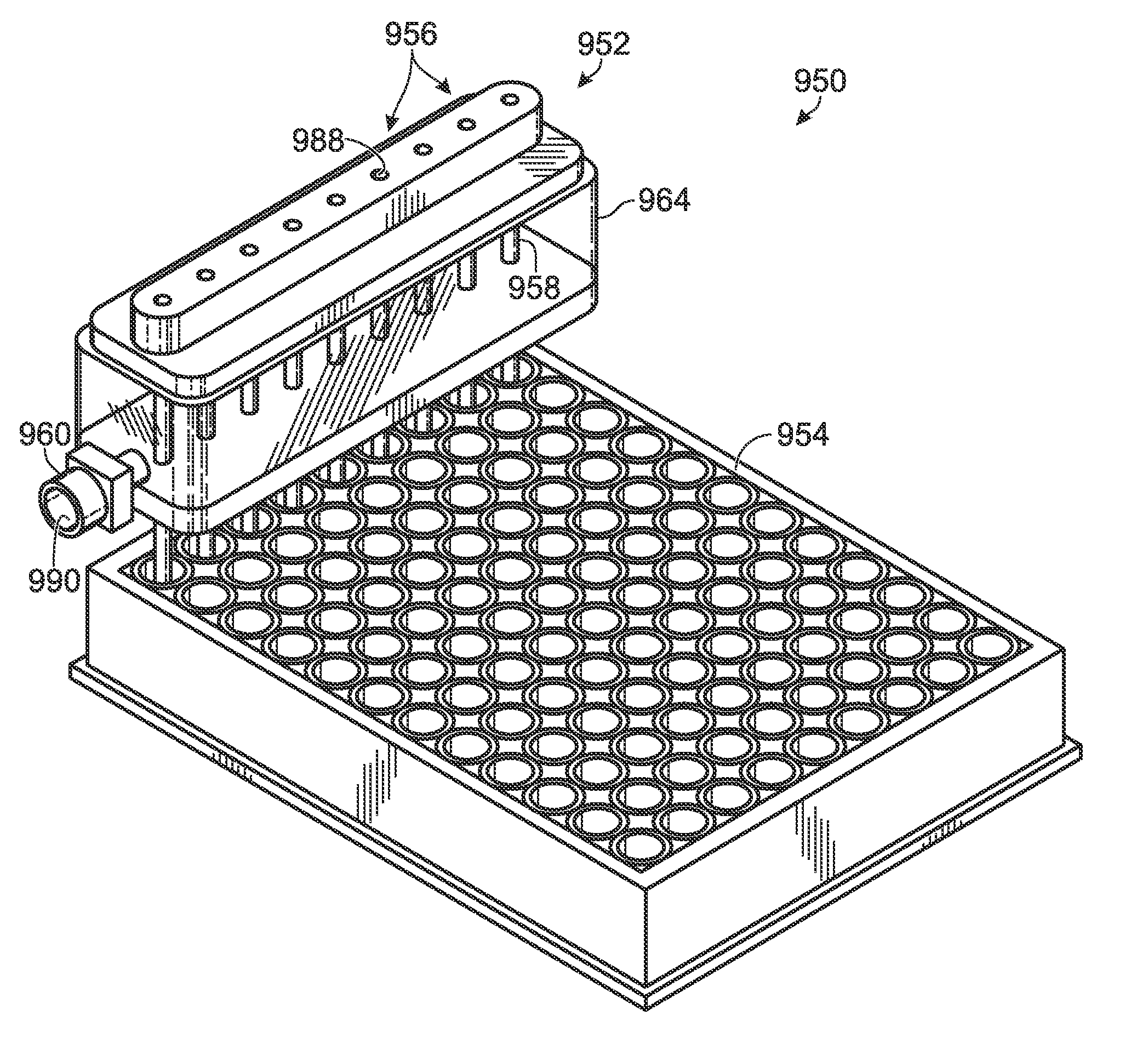

Droplet generation for droplet-based assays

ActiveUS20120190032A1High-confidence resultLower the volumeBioreactor/fermenter combinationsBiological substance pretreatmentsAssayEmulsion

A system, including method and apparatus, for generating droplets suitable for droplet-based assays. The disclosed systems may include either one-piece or multi-piece droplet generation components configured to form sample-containing droplets by merging aqueous, sample-containing fluid with a background emulsion fluid such as oil, to form an emulsion of sample-containing droplets suspended in the background fluid. In some cases, the disclosed systems may include channels or other suitable mechanisms configured to transport the sample-containing droplets to an outlet region, so that subsequent assay steps may be performed.

Owner:BIO RAD LAB INC

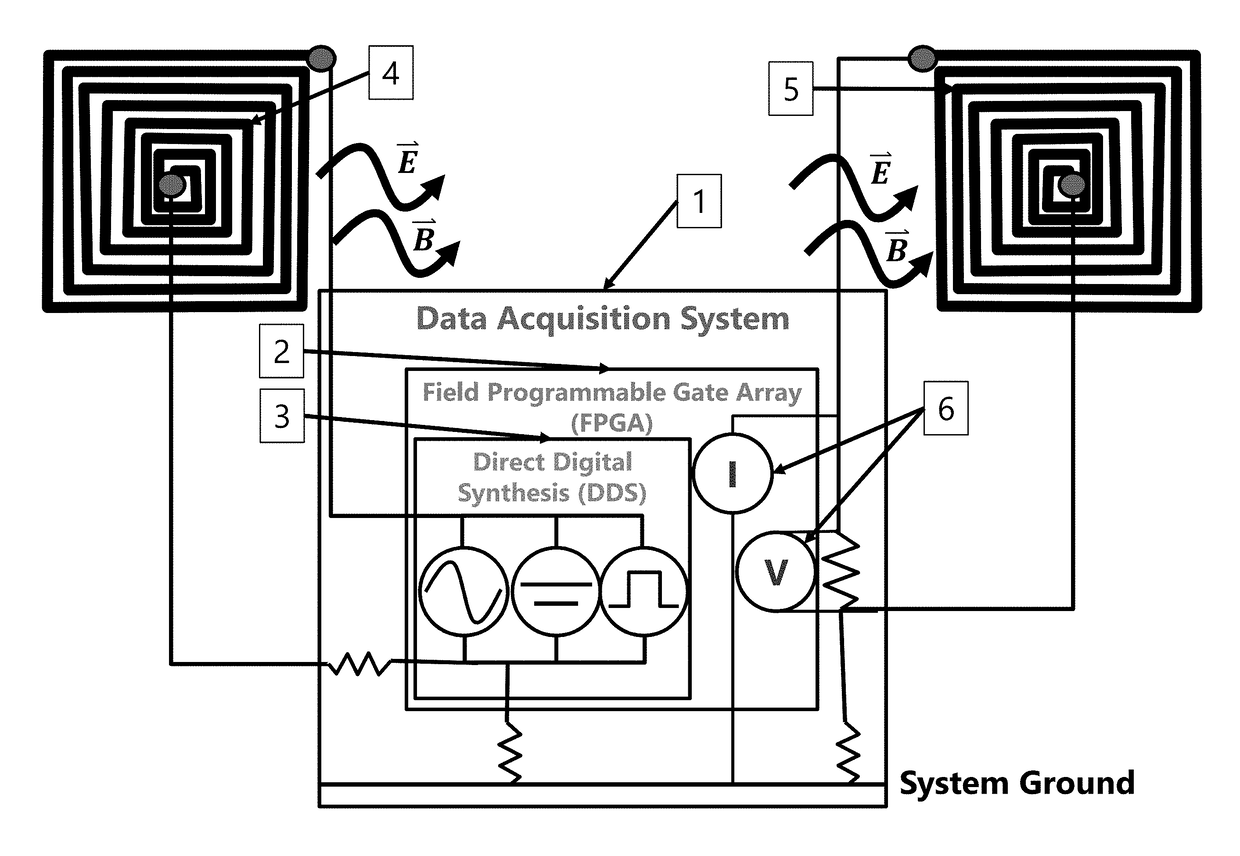

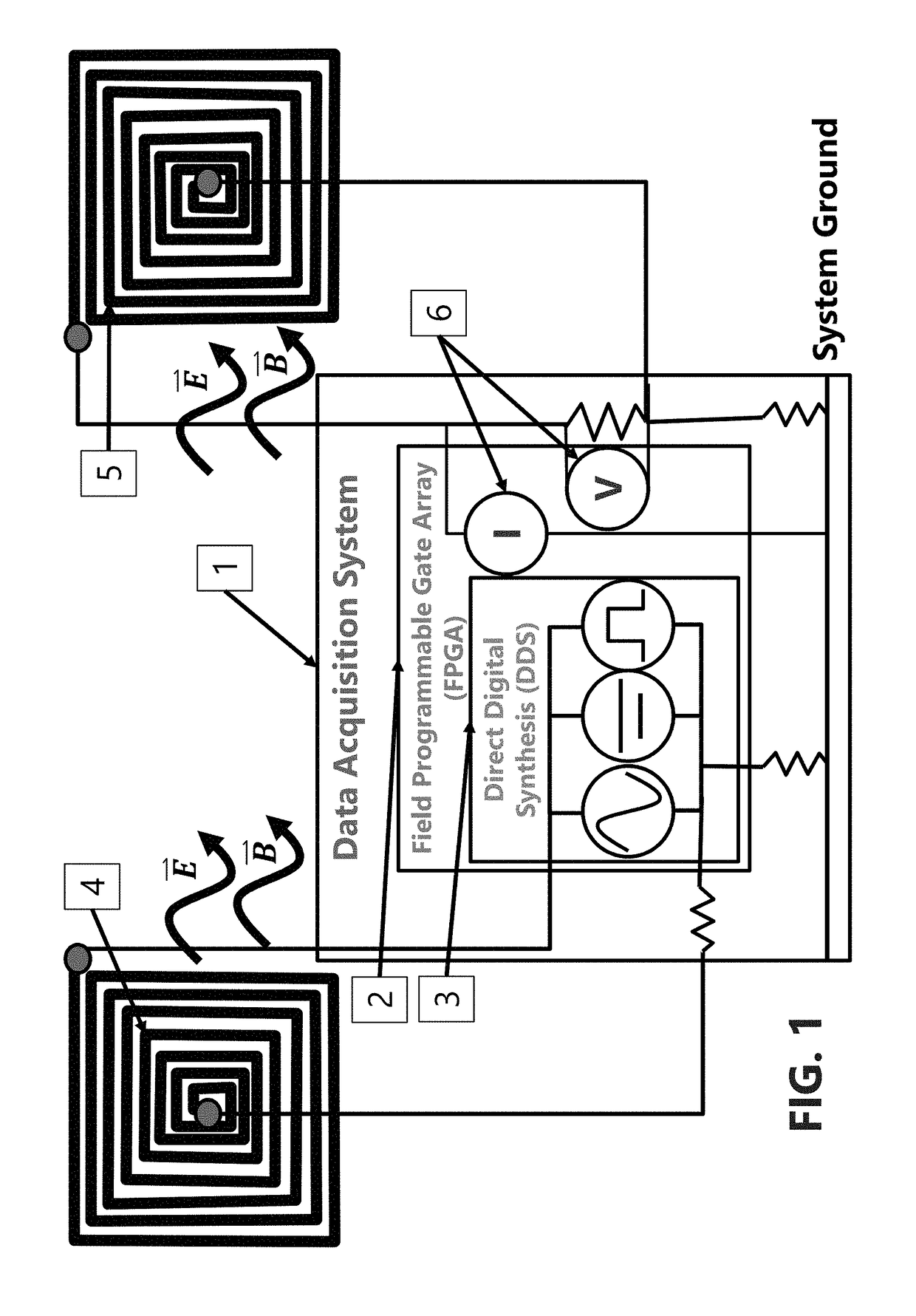

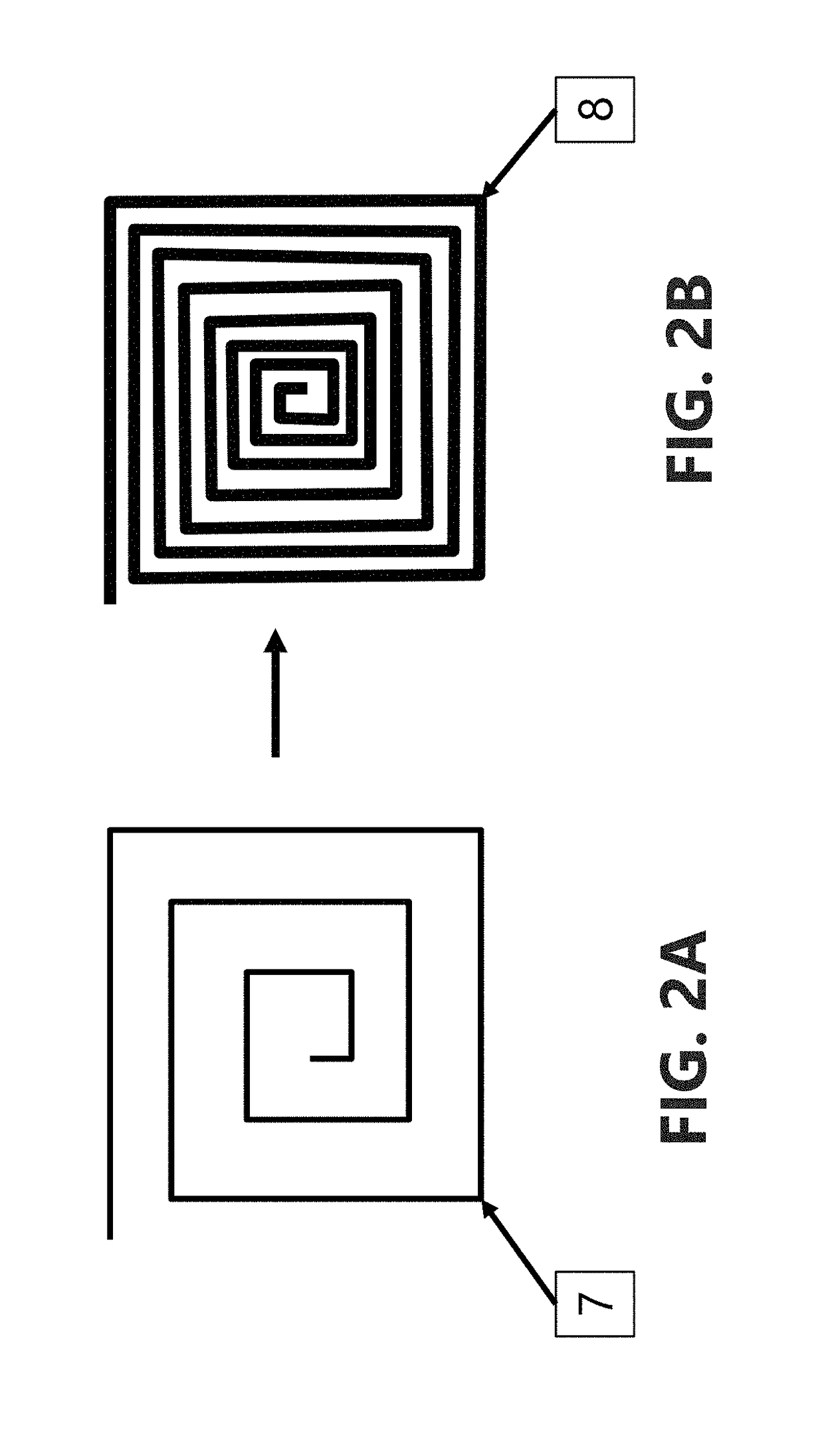

Electro-magneto volume tomography system and methodology for non-invasive volume tomography

InactiveUS20180325414A1Maximize surface areaMaximize number of turnReconstruction from projectionMaterial analysis by electric/magnetic meansCapacitanceImage resolution

A system and method capable of performing multiple types of non-invasive tomographic techniques. The system is capable, via electronic control, of detecting and imaging materials within a volume using electrical capacitance, displacement phase current, magnetic inductance, and magnetic pressure sensing. The system is also able to control the amplitude, phase, and frequency of individual electrode excitation to increase imaging resolution and phase detection. This allows many dimensions of non-invasive data to be captured without the need for multiple instruments or moving parts, at a high data capture rate.

Owner:TECH4IMAGING

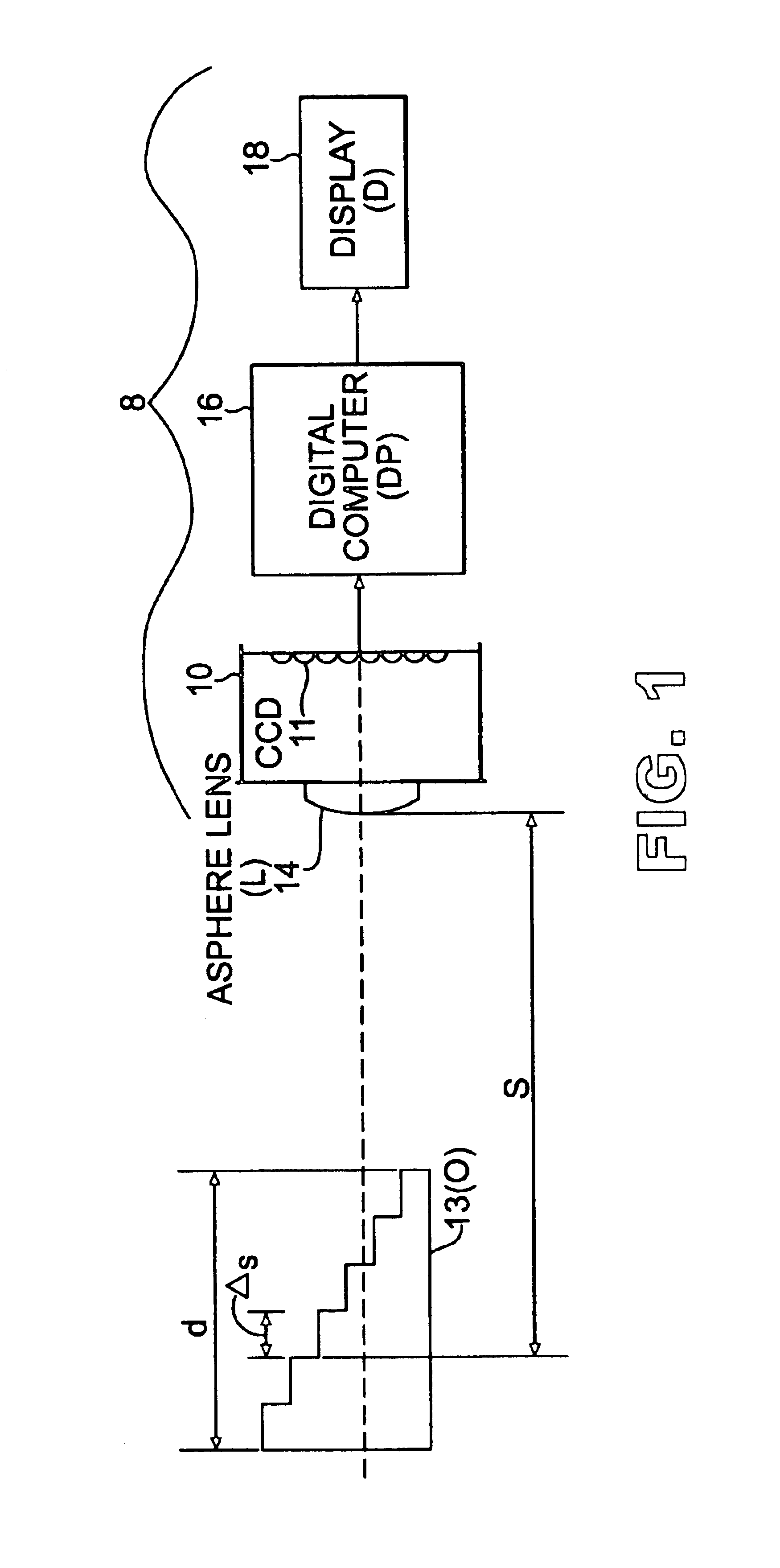

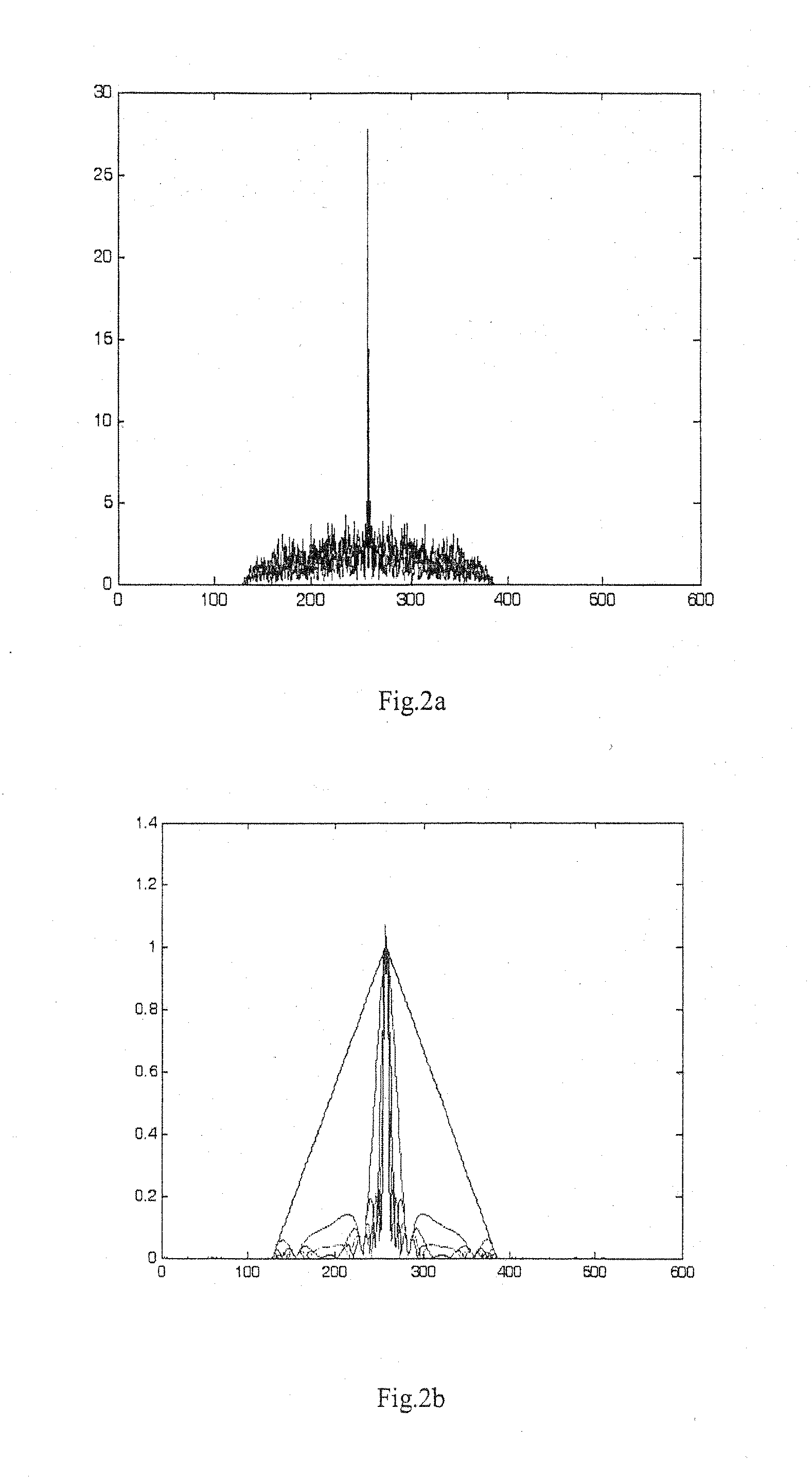

Imaging using a multifocal aspheric lens to obtain extended depth of field

InactiveUS6927922B2Add depthAvoid the needTelevision system detailsImage enhancementAspheric lensEdge enhancement

A system for imaging with a circularly symmetric multifocal aspheric lens is provided for obtaining an extended depth of field. The system includes a camera for capturing an image of at least one object through a circularly symmetric multifocal aspheric lens to provide a blurred image, and a computer system for processing the captured blurred image to provide a recovered image of the object having an extended depth of field. The recovered image may be outputted to a display or other peripheral device. Processing of the blurred image utilizes one of inverse filtering, convolution matrix (e.g., edge sharpening matrix), or maximum entropy. The computer system performing image processing may be in the camera or represent a computer system external to the camera which receives the blurred image. The extended depth of field is characterized by the object being in focus over a range of distances in the recovered image.

Owner:UNIVERSITY OF ROCHESTER

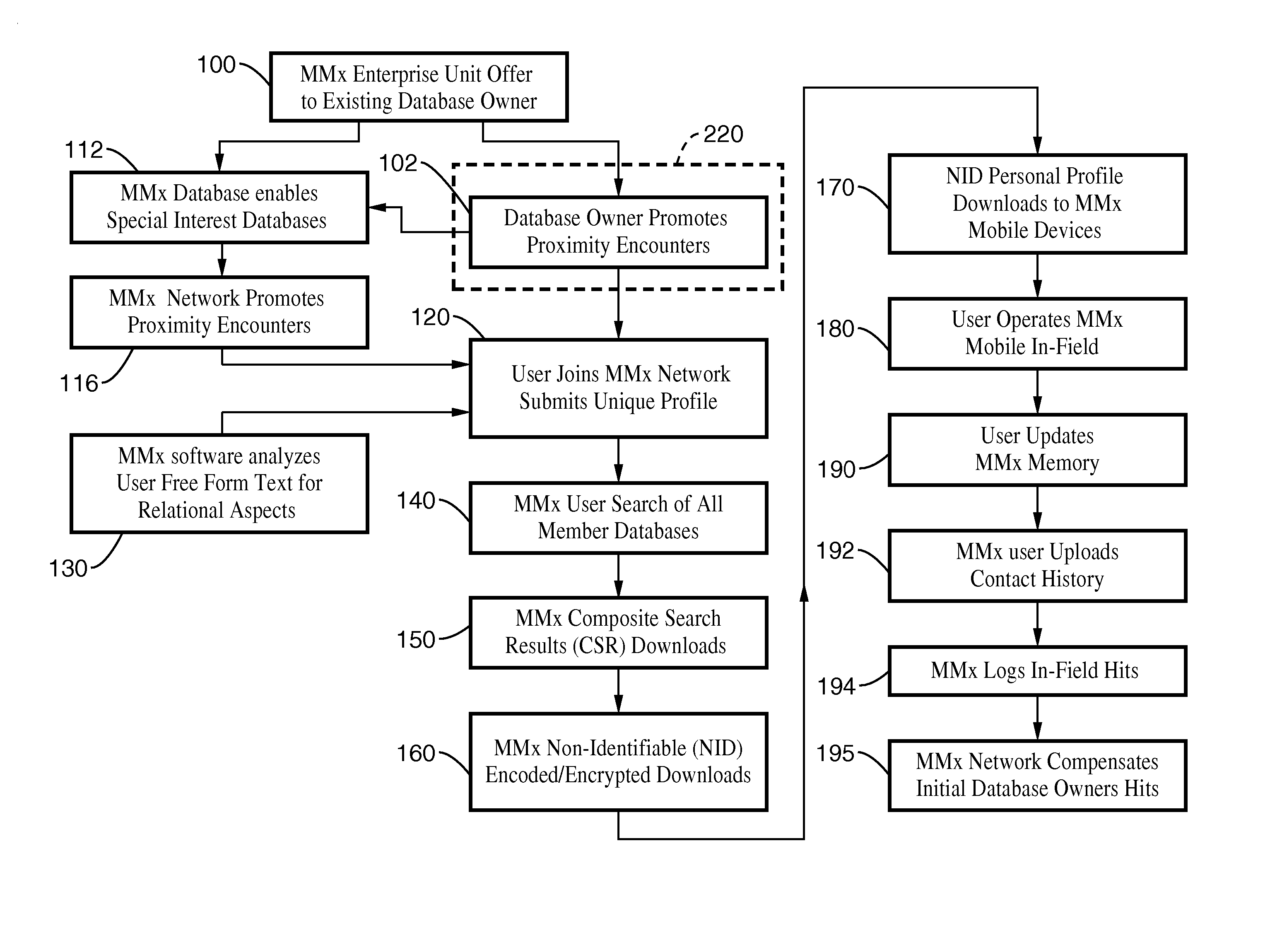

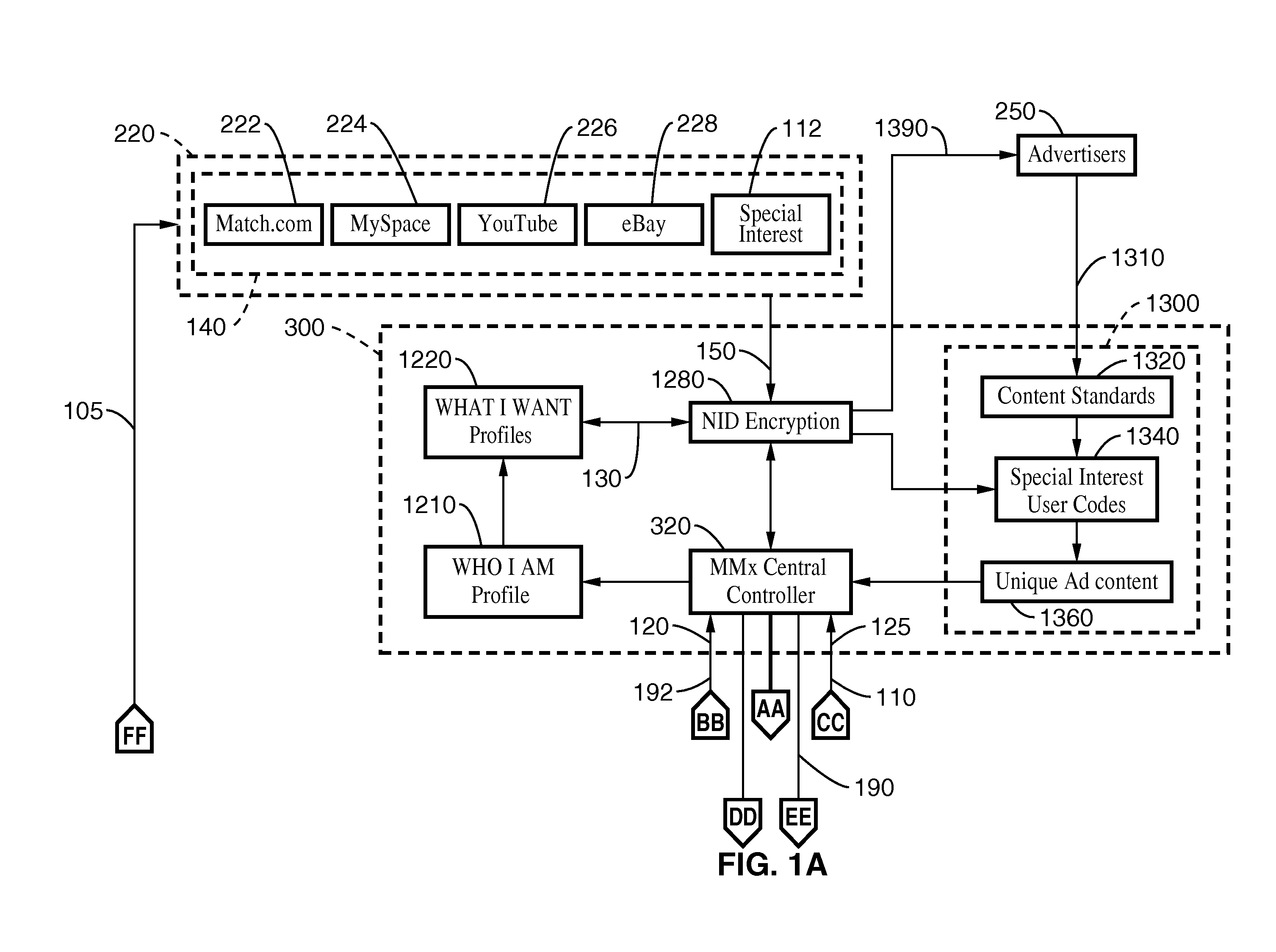

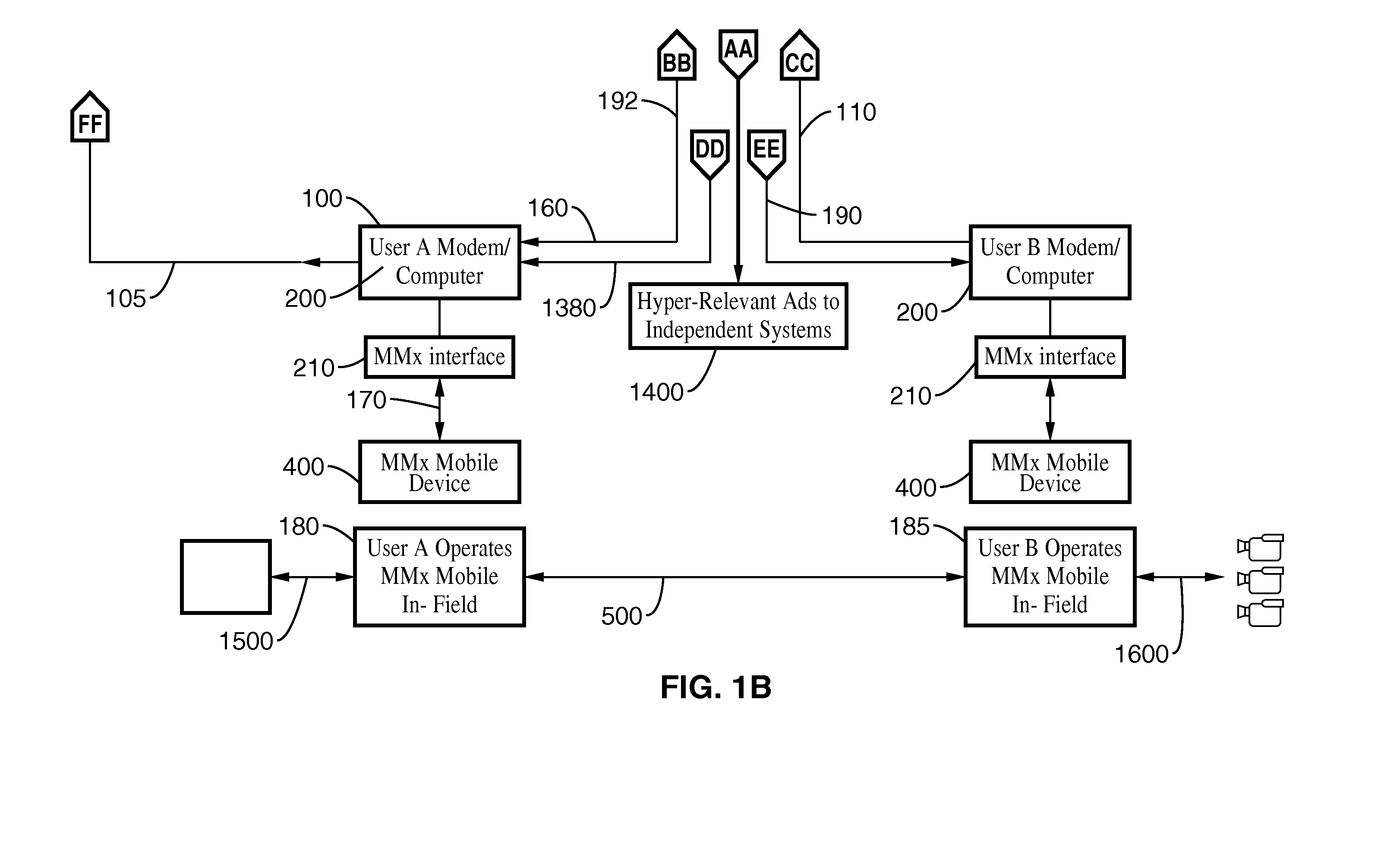

Method and apparatus for obtaining revenue from the distribution of hyper-relevant advertising through permissive mind reading, proximity encounters, and database aggregation

ActiveUS20070112762A1Add depthQuality improvementDigital data information retrievalMarketingPersonalizationUser code

A method and apparatus enabling the distribution of hyper-relevant advertising to consumers who have confirmed interests in specific content, products, and services is described. Users define “who they are” and “what they want” in a spontaneous, guided, voluntary disclosure of rich, candid, personal information conceived to attract individuals who seek or share common relationships, experiences, objectives, skills, knowledge, acquaintances, interests, needs, or desires for mutual gain. The information is converted into encrypted user codes; these codes are used to generate precisely controlled electronic encounters, the creation and delivery of highly personalized hyper-relevant advertising, and the gathering of amounts of research data through the ad hoc interaction of unique mobile devices.

Owner:VE

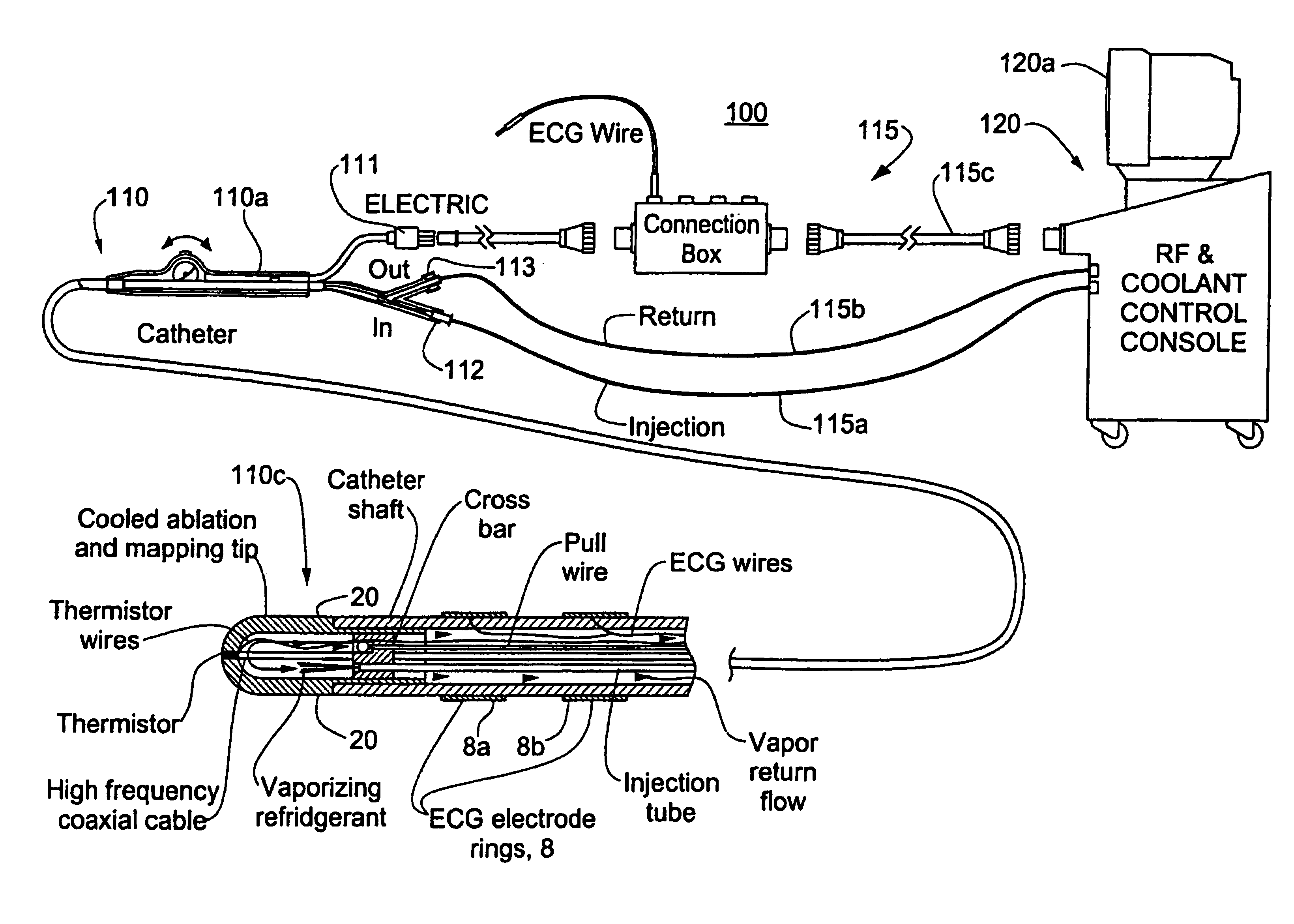

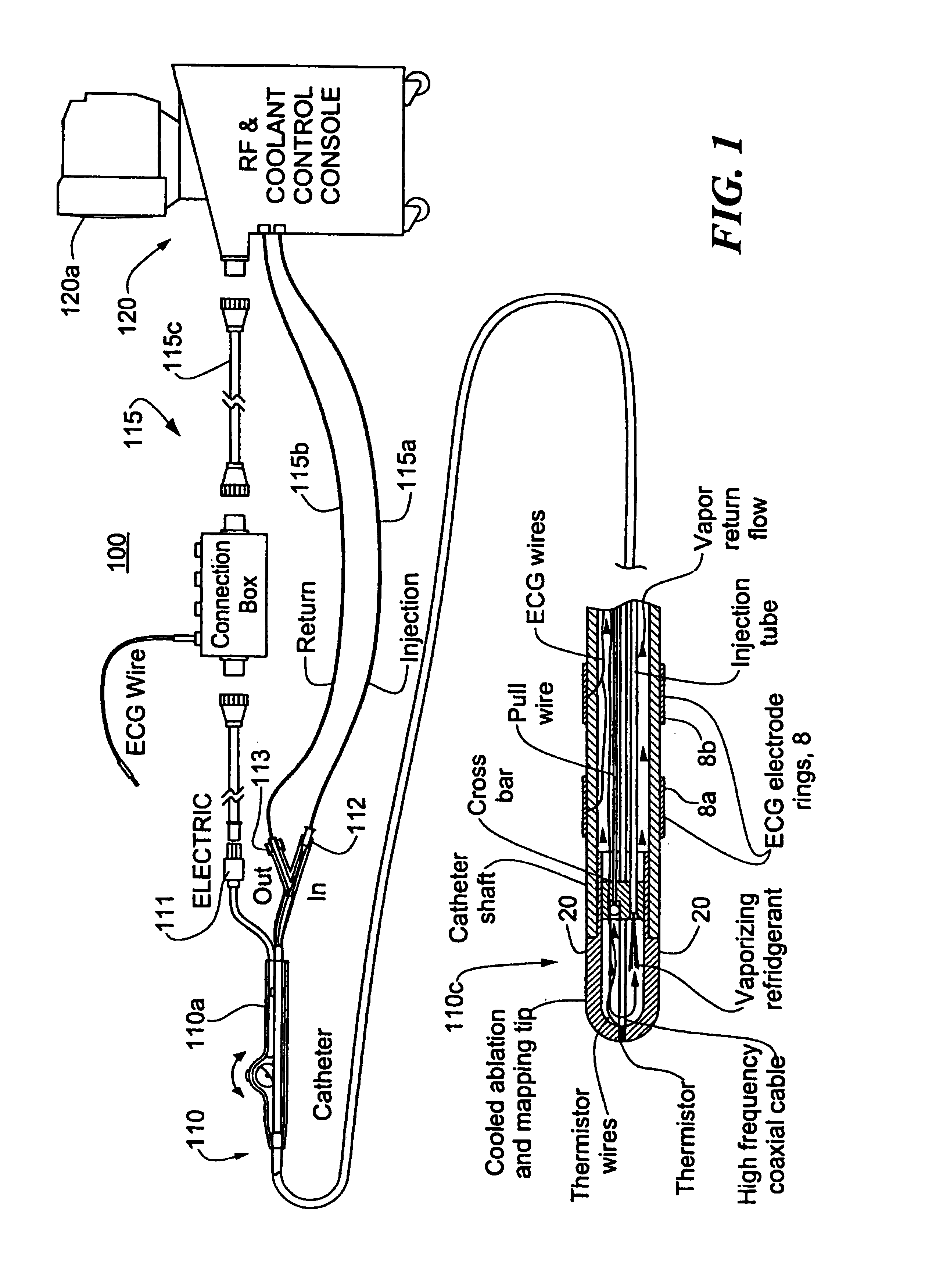

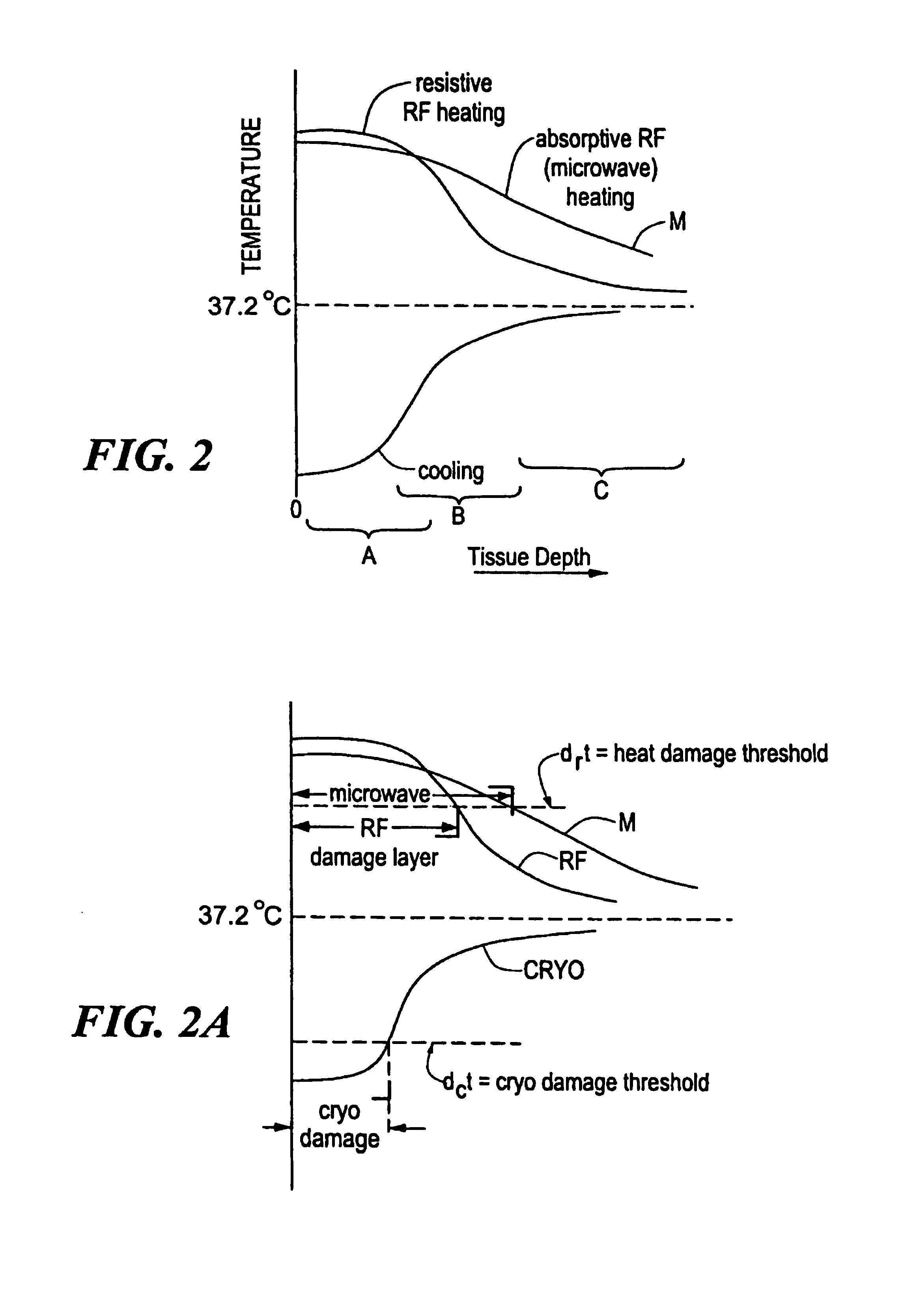

Catheter with cryogenic and heating ablation

InactiveUS7097641B1Improve versatilityEnhancing speed and placement lesionCatheterSurgical instruments for heatingTissue remodelingCelsius Degree

A catheter includes a cryoablation tip with an electrically-driven ablation assembly for heating tissue. The cryoablation tip may be implemented with a cooling chamber through which a controllably injected coolant circulates to lower the tip temperature, and having an RF electrode at its distal end. The RF electrode may be operated to warm cryogenically-cooled tissue, or the coolant may be controlled to conductively cool the tissue in coordination with an RF treatment regimen, allowing greater versatility of operation and enhancing the lesion size, speed or placement of multi-lesion treatment or single lesion re-treatment cycles. In one embodiment a microwave energy source operates at a frequency to extend beyond the thermal conduction depth, or to penetrate the cryogenic ice ball and be absorbed in tissue beyond an ice boundary, thus extending the depth and / or width of a single treatment locus. In another embodiment, the cooling and the application of RF energy are both controlled to position the ablation region away from the surface contacted by the electrode, for example to leave surface tissue unharmed while ablating at depth or to provide an ablation band of greater uniformity with increasing depth. The driver or RF energy source may supply microwave energy at a frequency effective to penetrate the ice ball which develops on a cryocatheter, and different frequencies may be selected for preferential absorption in a layer of defined thickness at depth in the nearby tissue. The catheter may operate between 70 and minus 70 degrees Celsius for different tissue applications, such as angioplasty, cardiac ablation and tissue remodeling, and may preset the temperature of the tip or adjacent tissue, and otherwise overlay or delay the two different profiles to tailor the shape or position where ablation occurs or to speed up a treatment cycle.

Owner:MEDTRONIC CRYOCATH LP

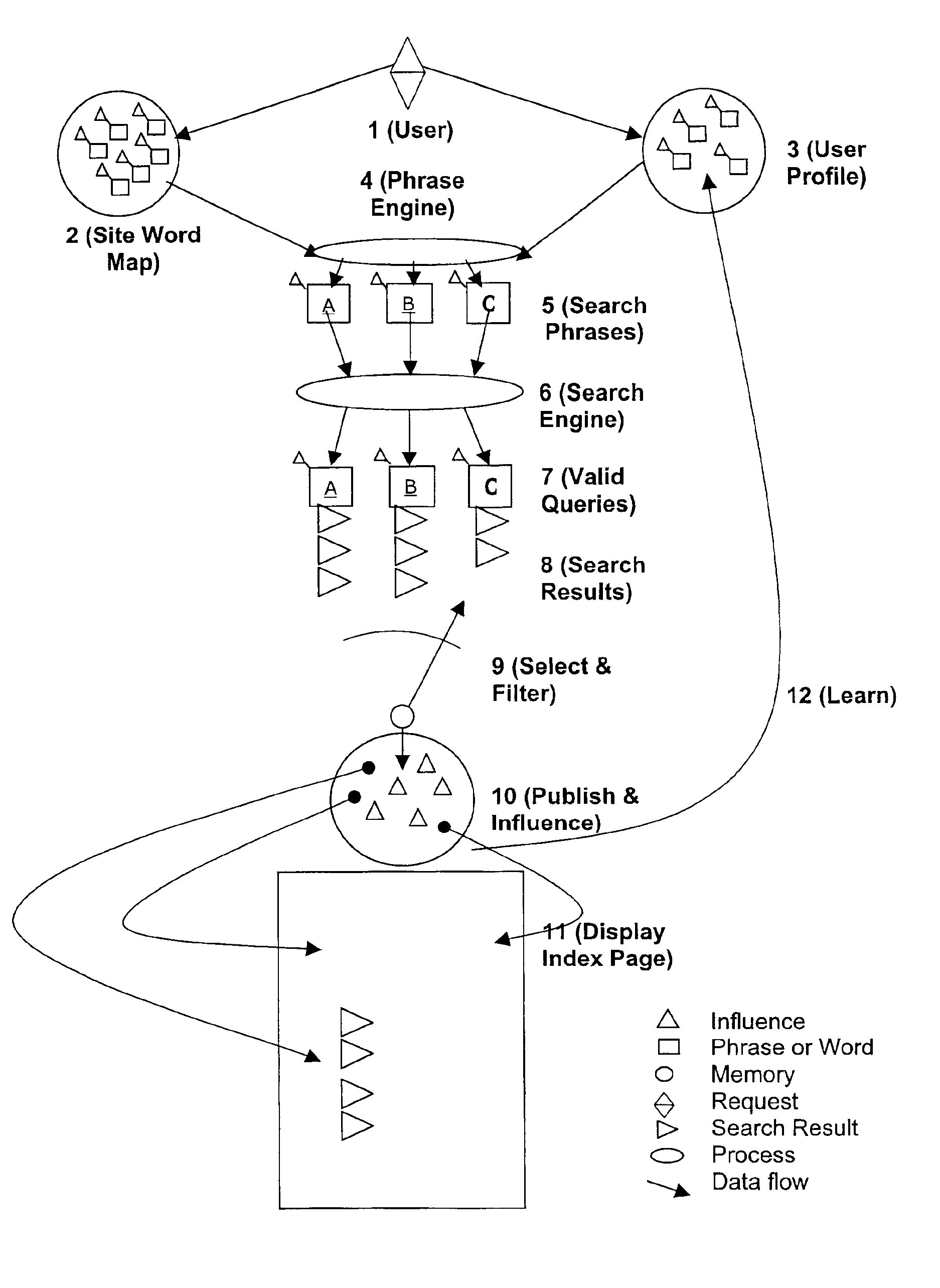

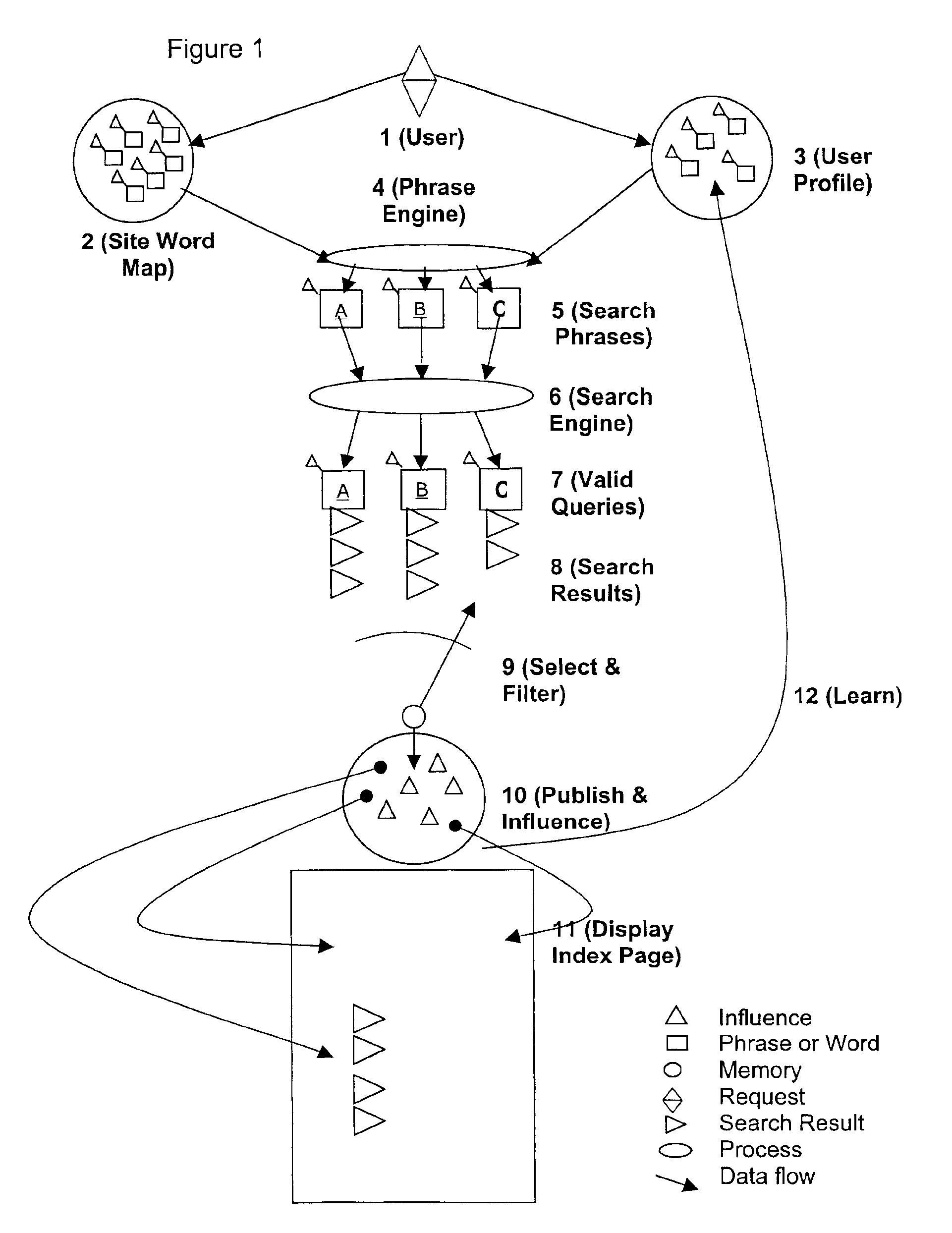

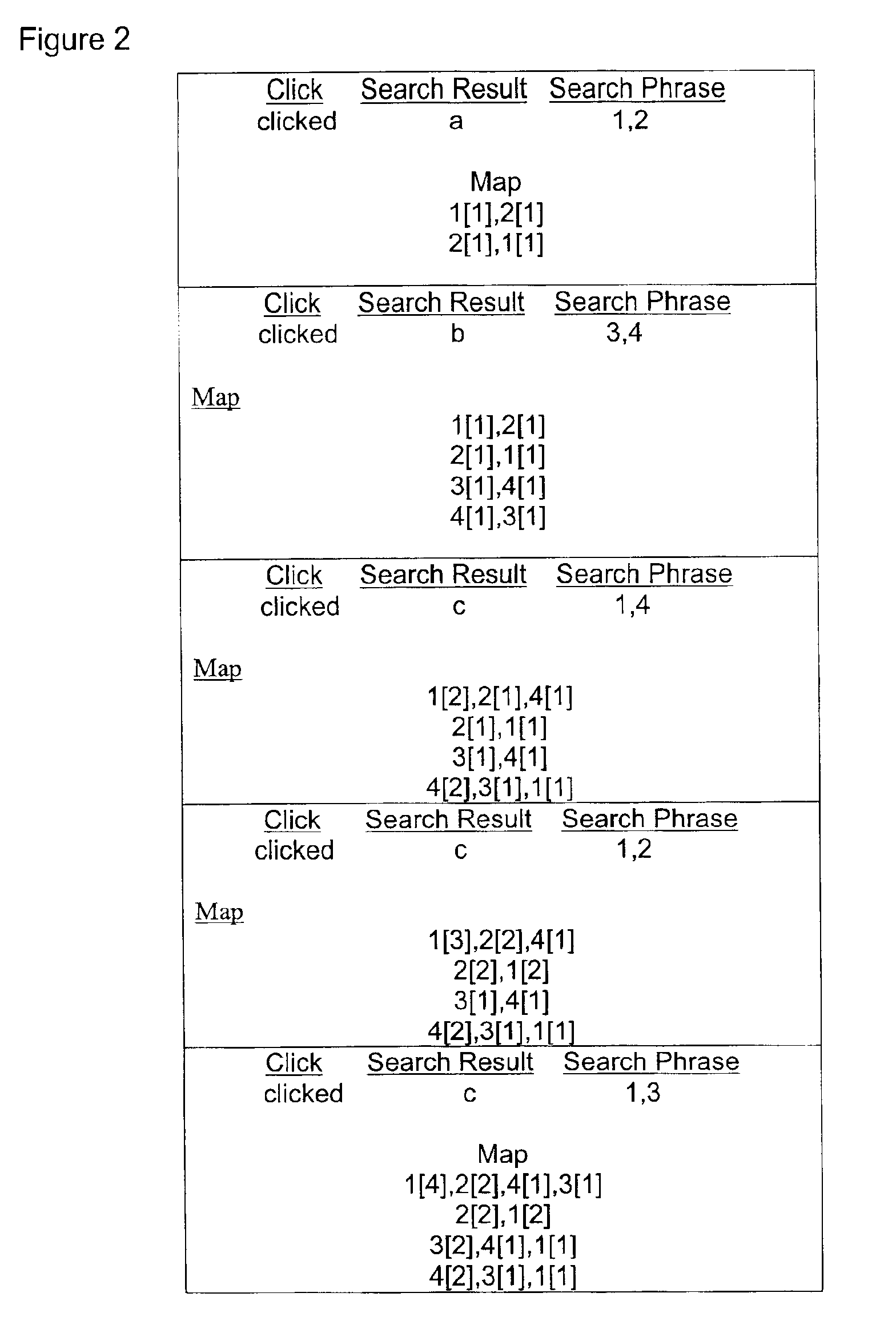

Dynamic personalization method of creating personalized user profiles for searching a database of information

InactiveUS6895406B2Enhanced couplingEnhance the imageData processing applicationsDigital data information retrievalWeb sitePersonalization

A method for creating a personal profile of a user for searching a database comprises the following steps: (a) words or words linked to graphical elements are presented as choices to a user in a display; (b) each word is associated with other keywords or default words; (c) if a profile of the user has previously been established, the profile is referenced for previous added keywords or associative words; (d) search phrases are made from selected keywords or associative words added to the profile; (e) the search phrases are sent as search queries to search for objects in the database; (f) the objects returned from the search are presented to the user as a new display of choices; (g) when a user selects an object, the words that were used to search for that object are added to the user's profile, or reinforced if already present; and the steps (d) to (g) above are repeated iteratively. The user profiling method is preferably employed with a standard browser while the user visits websites or portals on the Internet which are structured with site word maps to implement the keyword references. The user profile can then be used to identify the user's preferences for items of interest on websites visited by the user.

Owner:SEASEER R&D

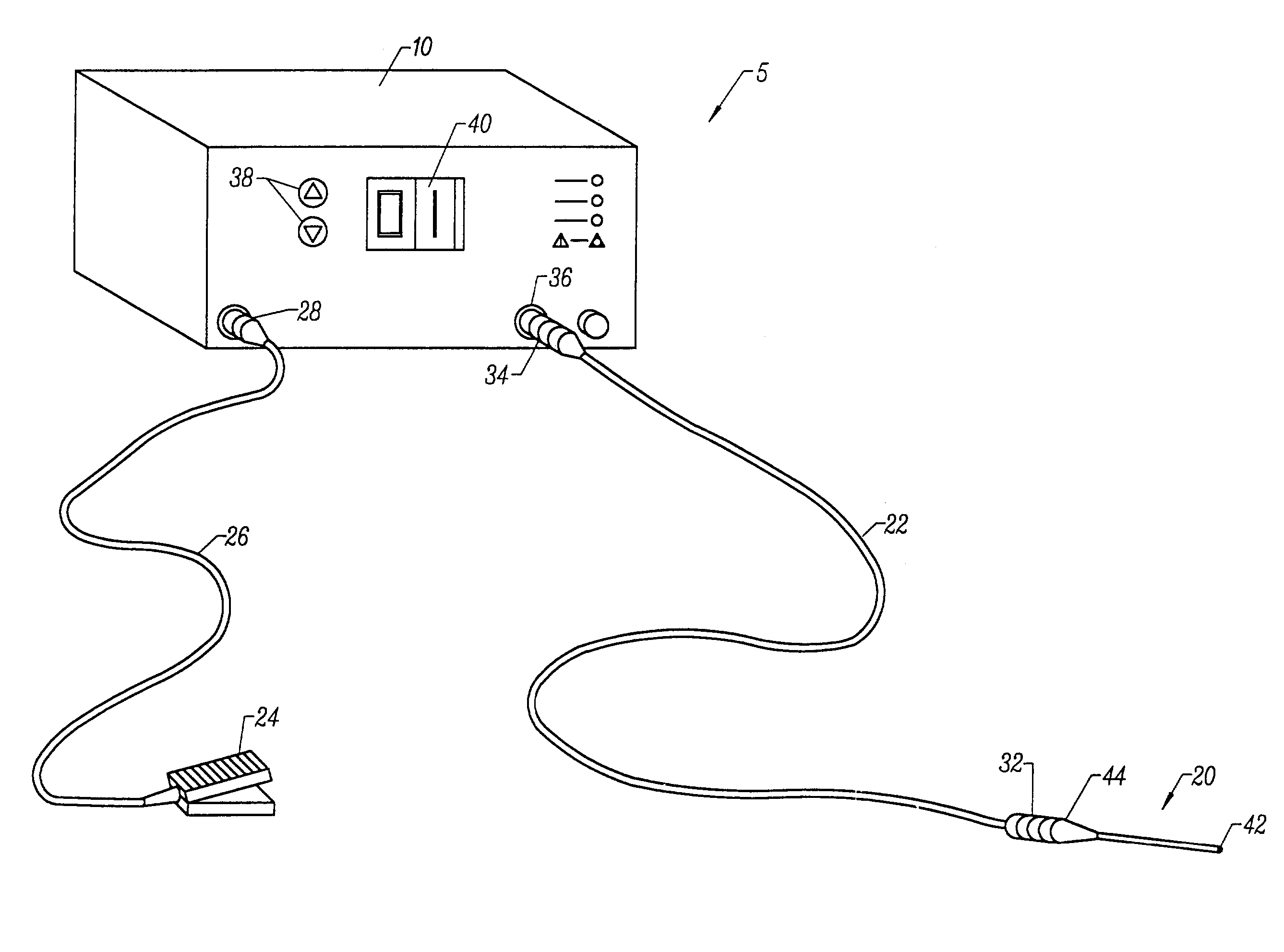

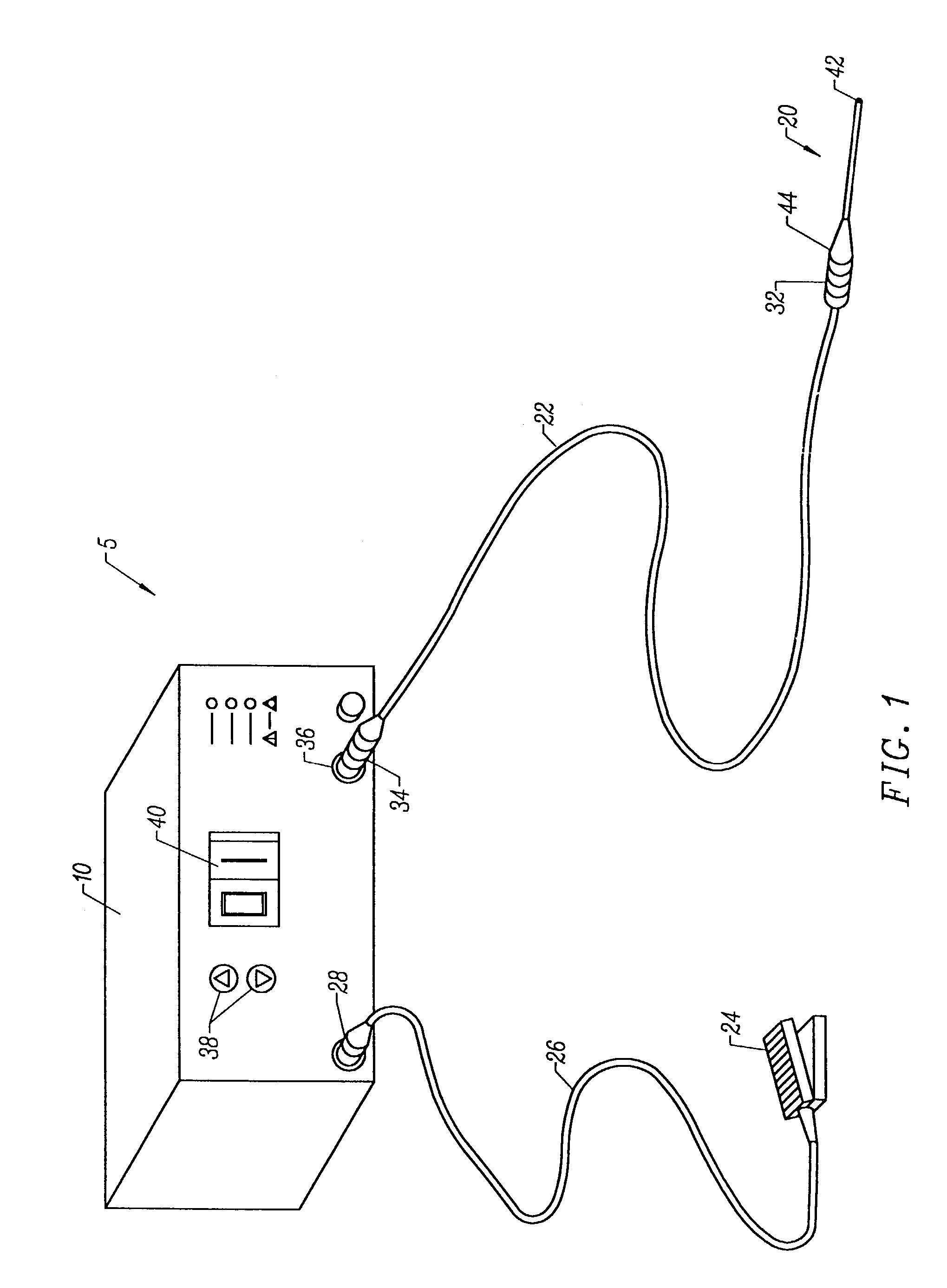

Systems and methods for electrosurgical tissue contraction

InactiveUS7094215B2Limiting thermal damage and dissociationSuppress thermal damageEye treatmentSurgical instruments for heatingSacroiliac jointSurgical department

Systems and methods are provided for performing electrosurgical interventions, such as selectively contracting soft collagen tissue and other body structures, while limiting thermal damage or molecular dissociation of such tissue and limiting the thermal damage to tissue adjacent to and underlying the treatment site. The systems and methods of the present invention are particularly useful for surgical procedures in electrically conducting environments, such as arthroscopic procedures in the joints, e.g., shoulder, knee, hip, hand, foot, elbow or the like. The present invention is also useful in relatively dry environments, such as treating and shaping the cornea, and dermatological procedures involving surface tissue contraction of tissue underlying the surface of the skin for tissue rejuvenation, wrinkle removal and the like.

Owner:ARTHROCARE

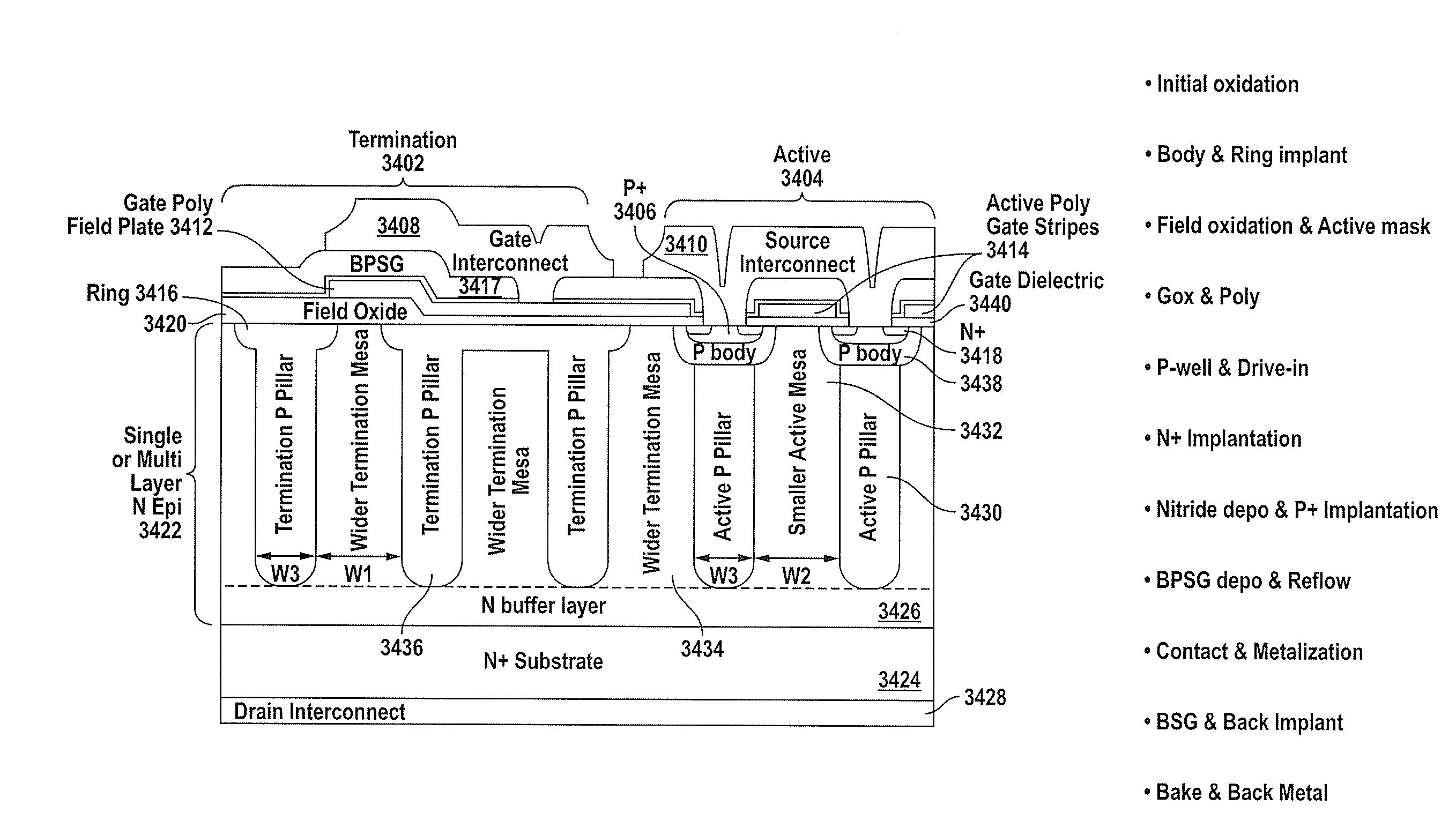

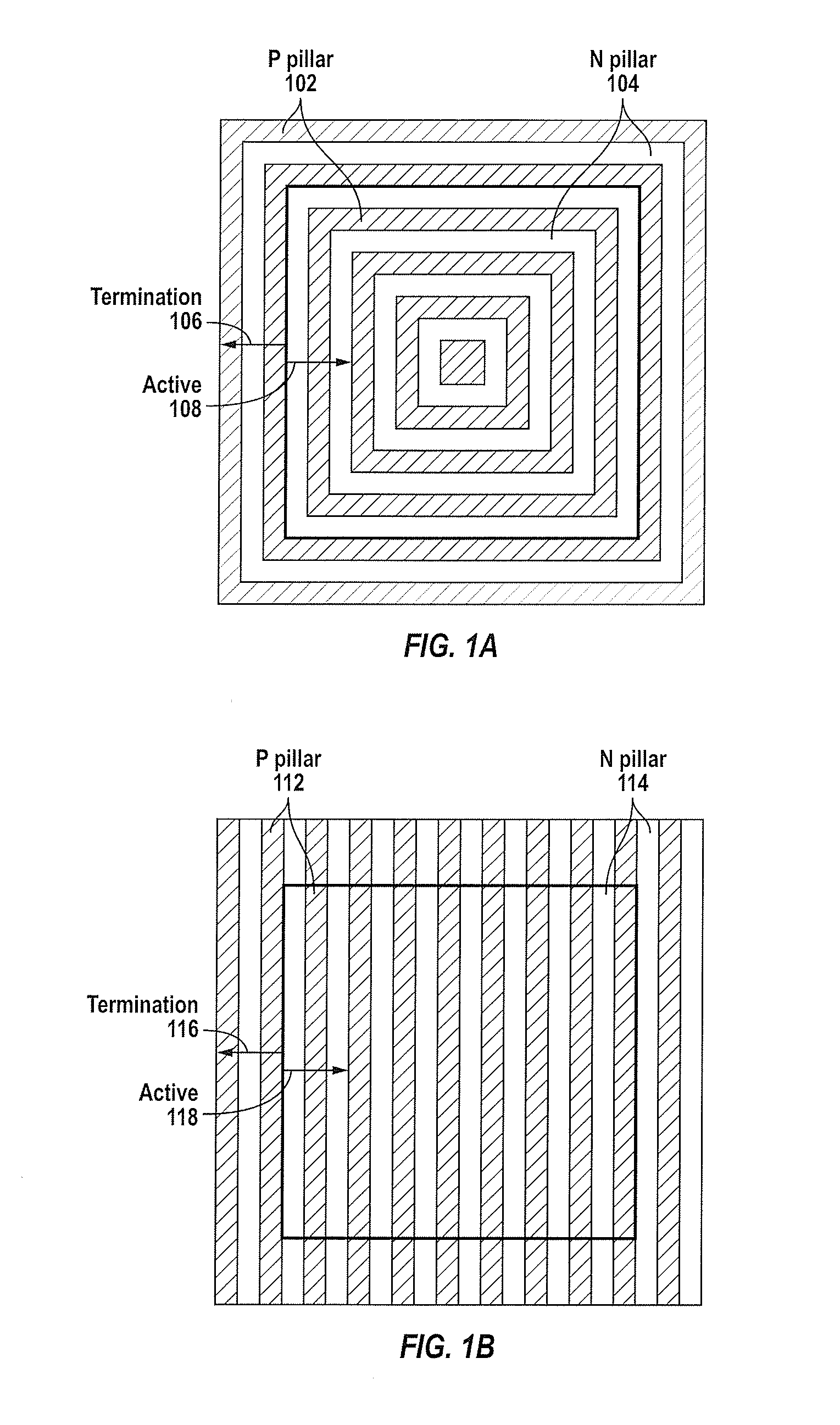

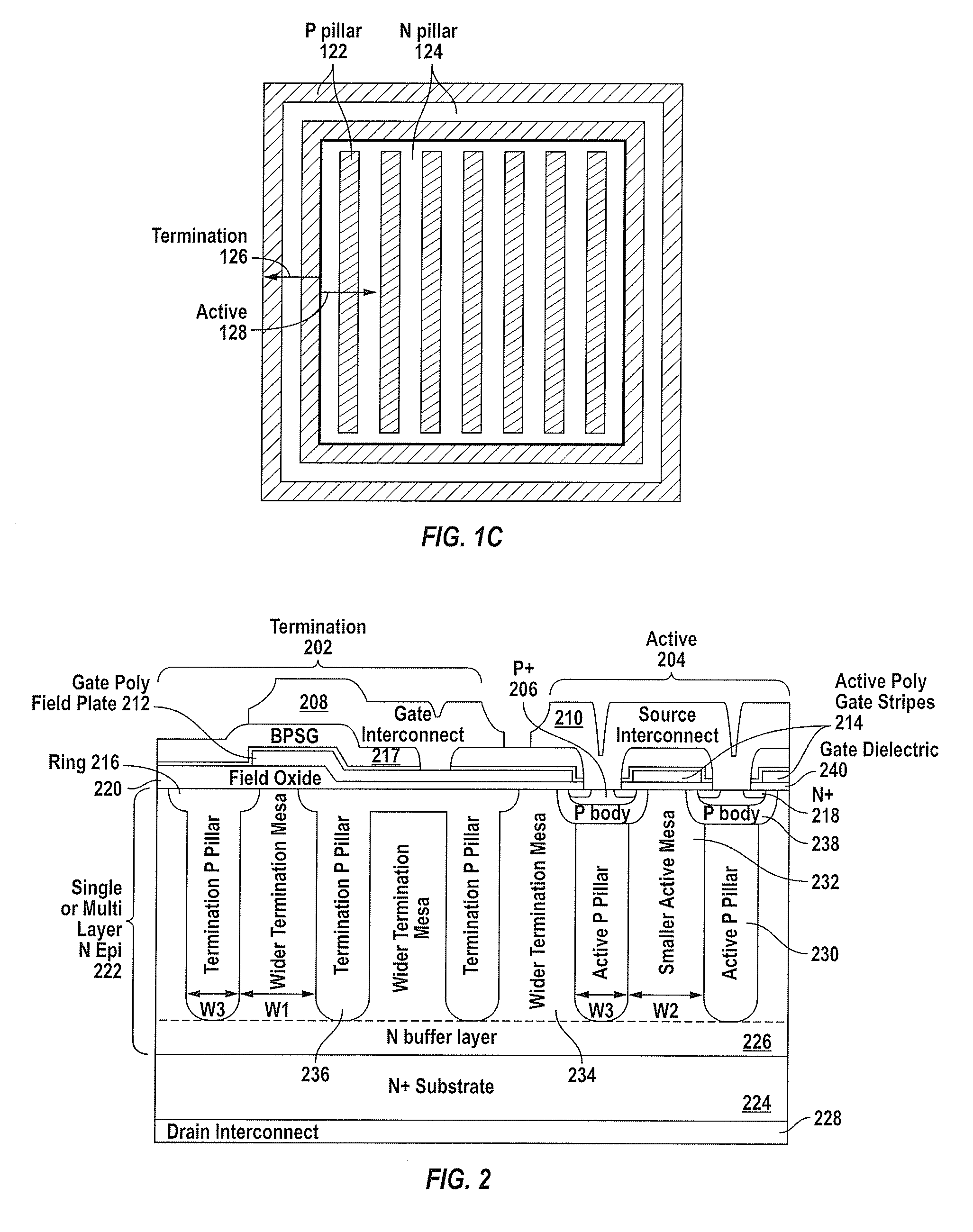

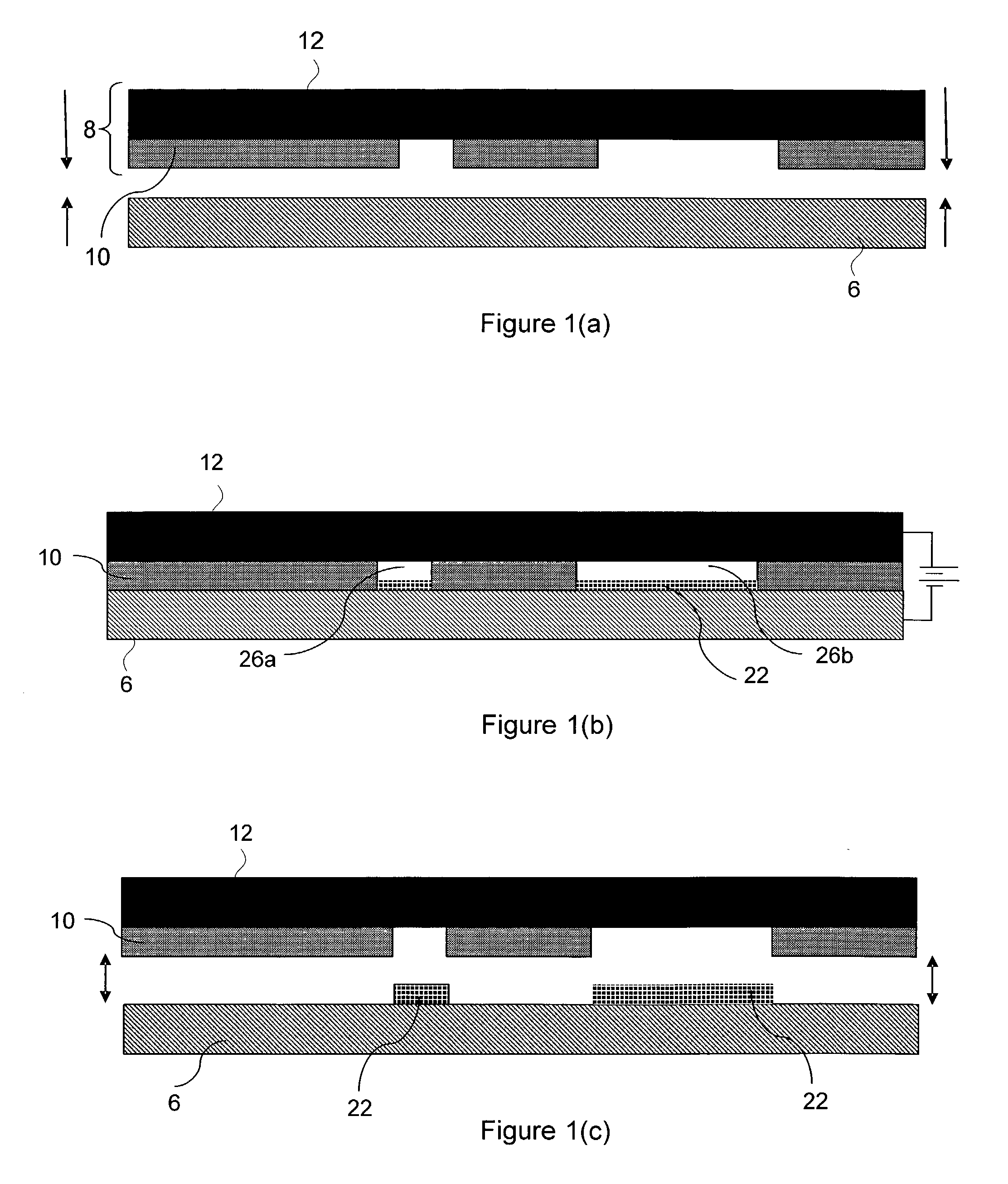

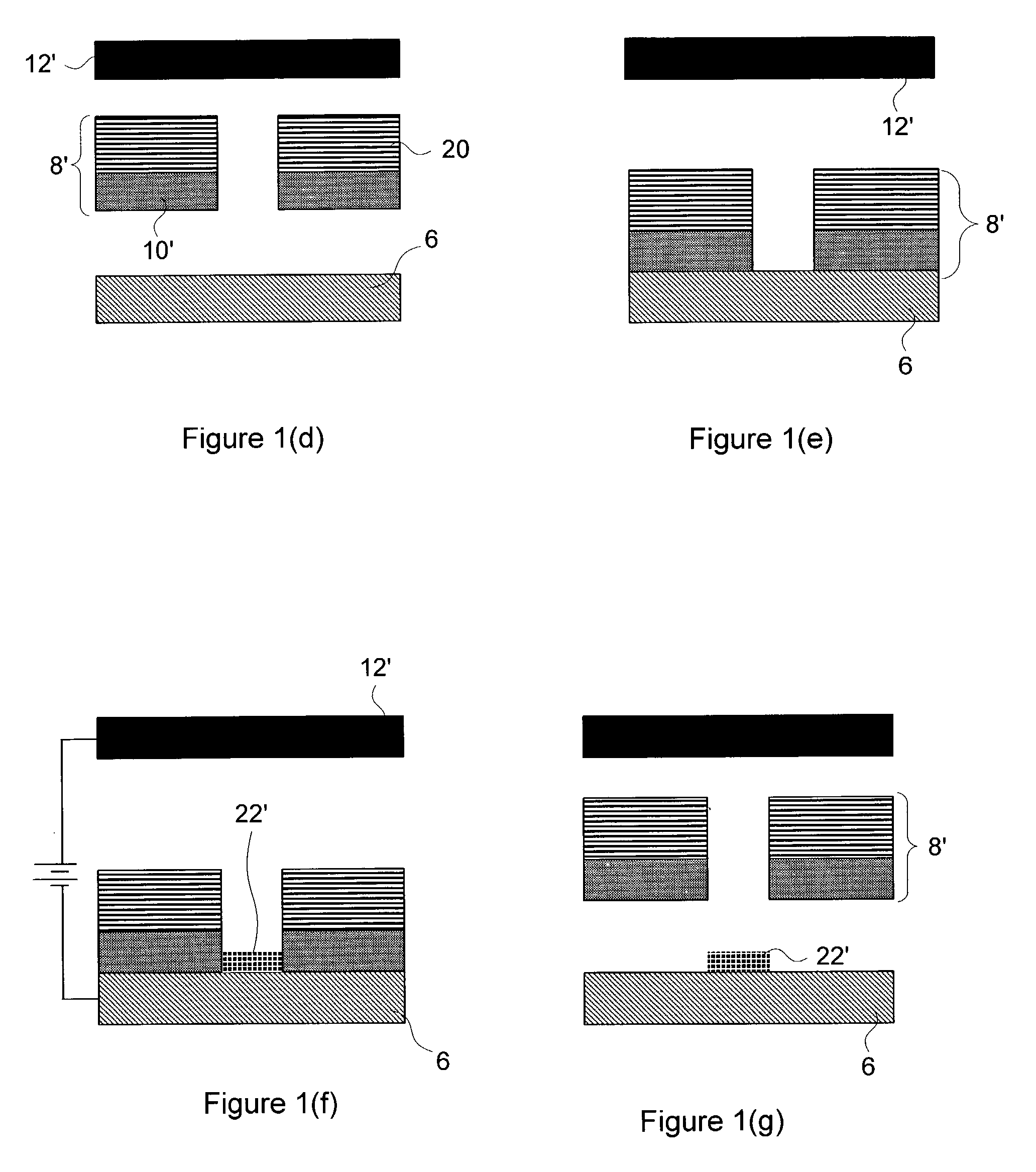

Superjunction Structures for Power Devices and Methods of Manufacture

ActiveUS20090079002A1Reduce leakageAdd depthTransistorSemiconductor/solid-state device detailsEngineeringBreakdown voltage

A power device includes an active region and a termination region surrounding the active region. A plurality of pillars of first and second conductivity type are alternately arranged in each of the active and termination regions. The pillars of first conductivity type in the active and termination regions have substantially the same width, and the pillars of second conductivity type in the active region have a smaller width than the pillars of second conductivity type in the termination region so that a charge balance condition in each of the active and termination regions results in a higher breakdown voltage in the termination region than in the active region.

Owner:SEMICON COMPONENTS IND LLC

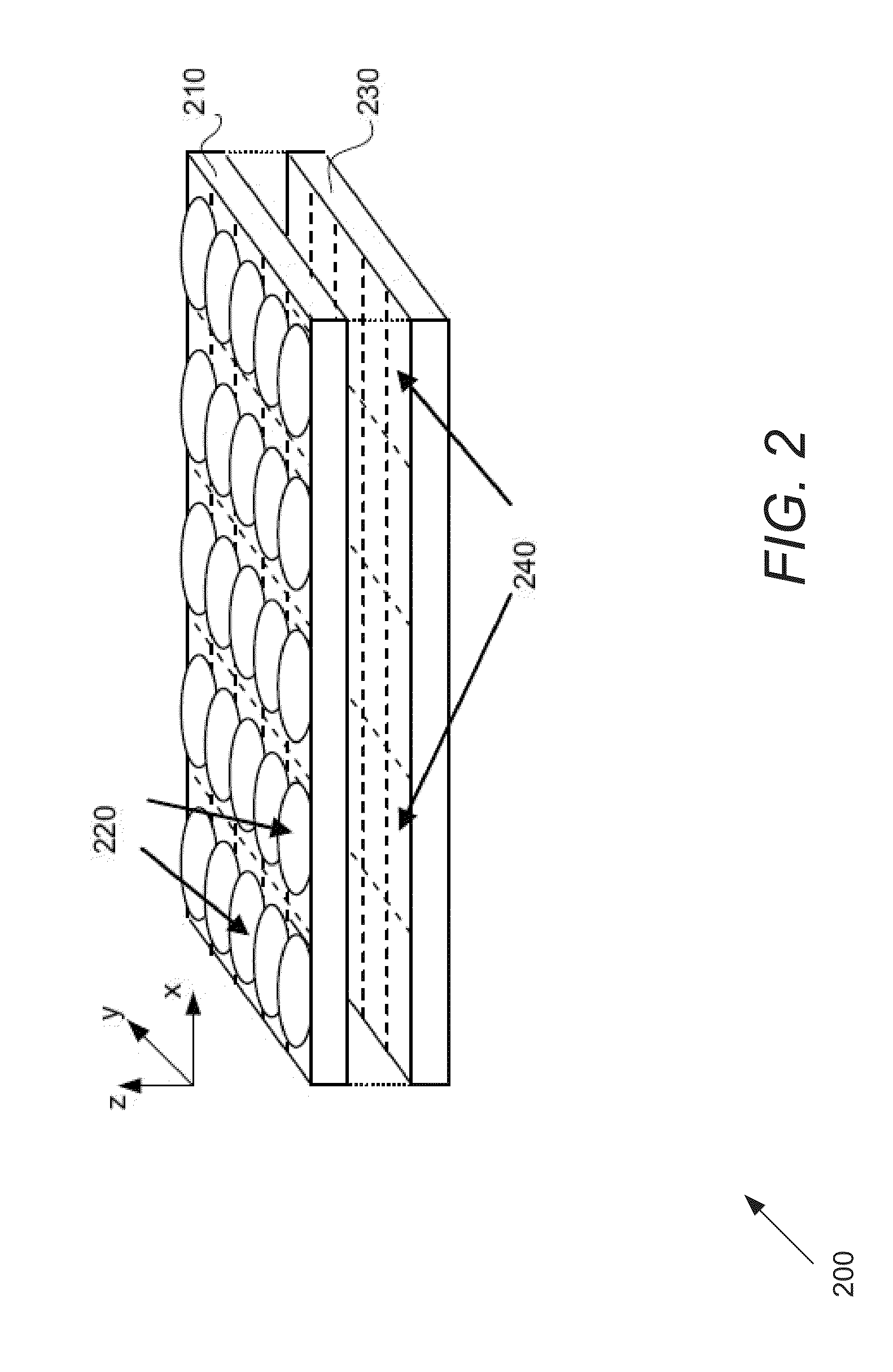

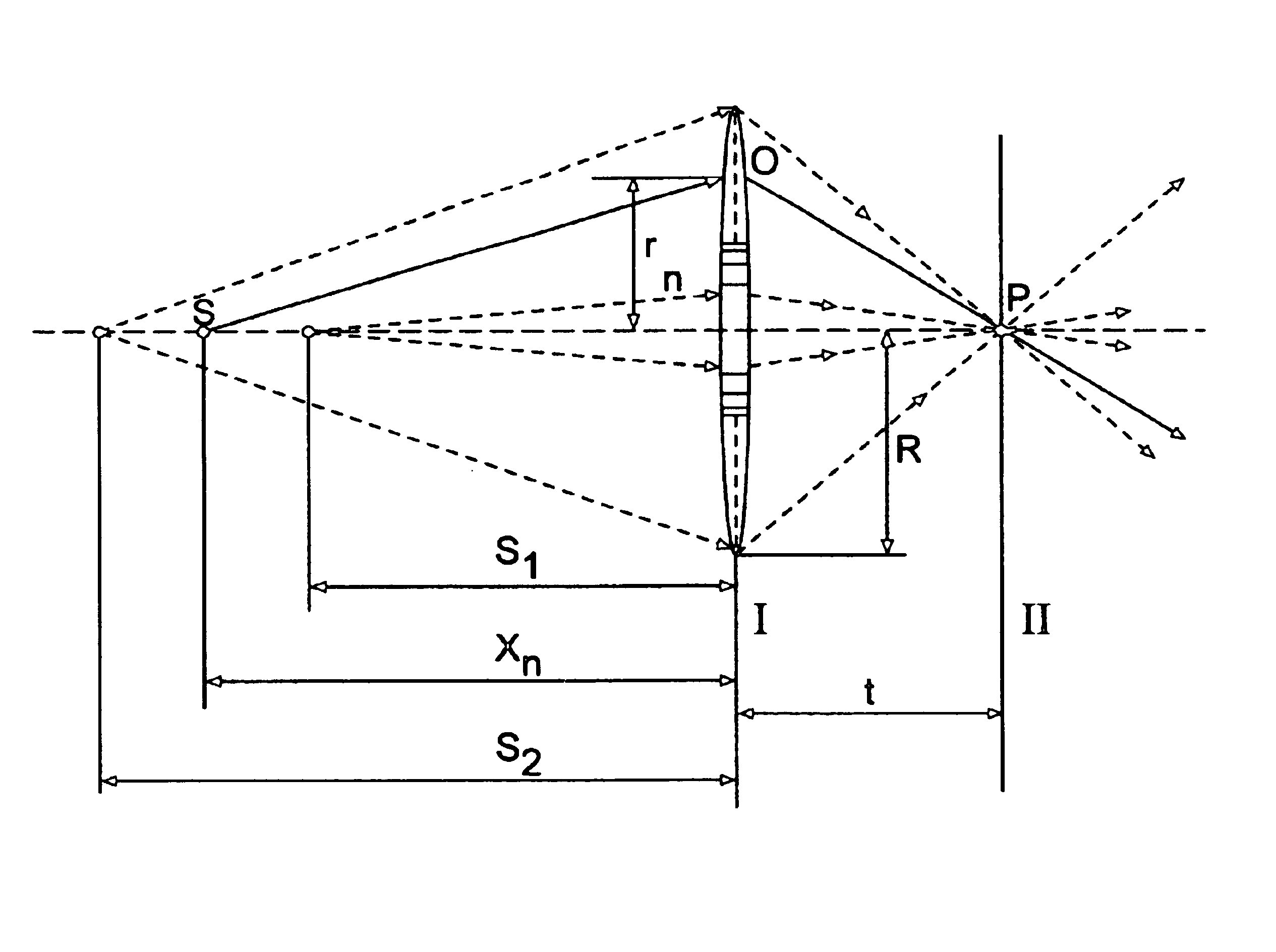

Imaging system and method for providing extended depth of focus, range extraction and super resolved imaging

InactiveUS7646549B2Improving geometrical resolutionIncrease depth of focusSemiconductor/solid-state device manufacturingDiffraction gratingsImaging lensField of view

An imaging system is presented for imaging objects within a field of view of the system. The imaging system comprises an imaging lens arrangement, a light detector unit at a certain distance from the imaging lens arrangement, and a control unit connectable to the output of the detection unit. The imaging lens arrangement comprises an imaging lens and an optical element located in the vicinity of the lens aperture, said optical element introducing aperture coding by an array of regions differently affecting a phase of light incident thereon which are randomly distributed within the lens aperture, thereby generating an axially-dependent randomized phase distribution in the Optical Transfer Function (OTF) of the imaging system resulting in an extended depth of focus of the imaging system. The control unit is configured to decode the sampled output of the detection unit by using the random aperture coding to thereby extract 3D information of the objects in the field of view of the light detector unit.

Owner:BRIEN HOLDEN VISION INST (AU)

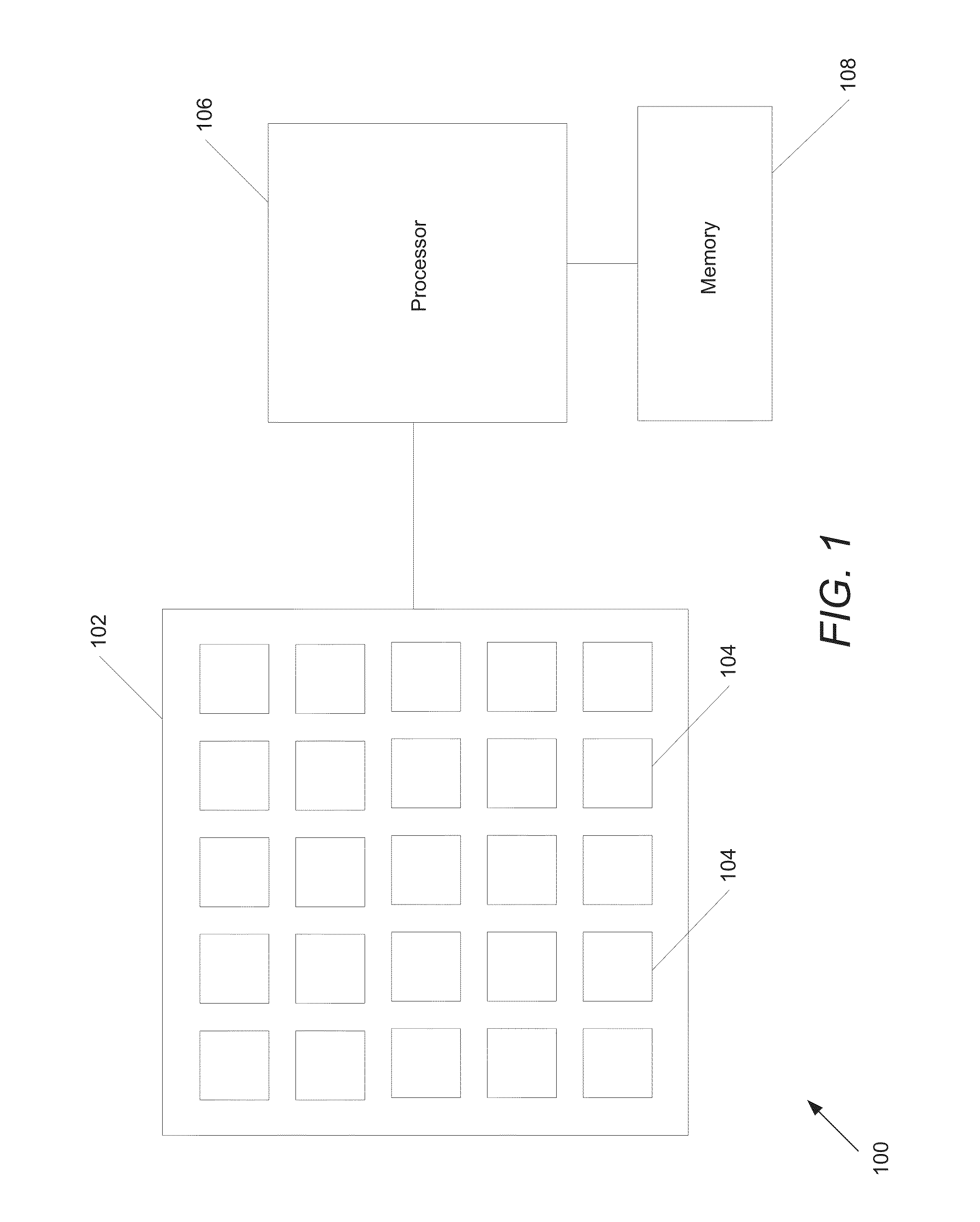

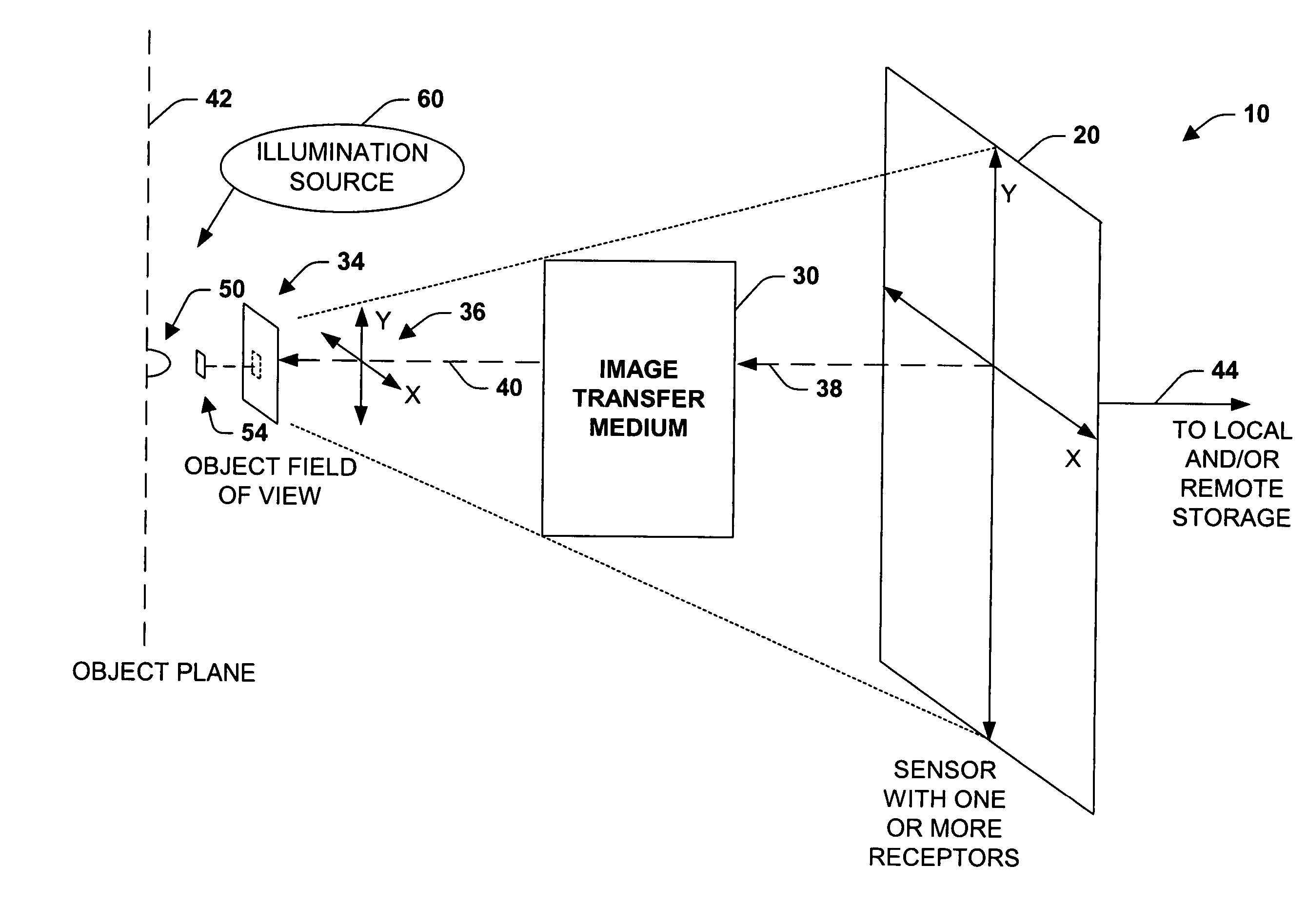

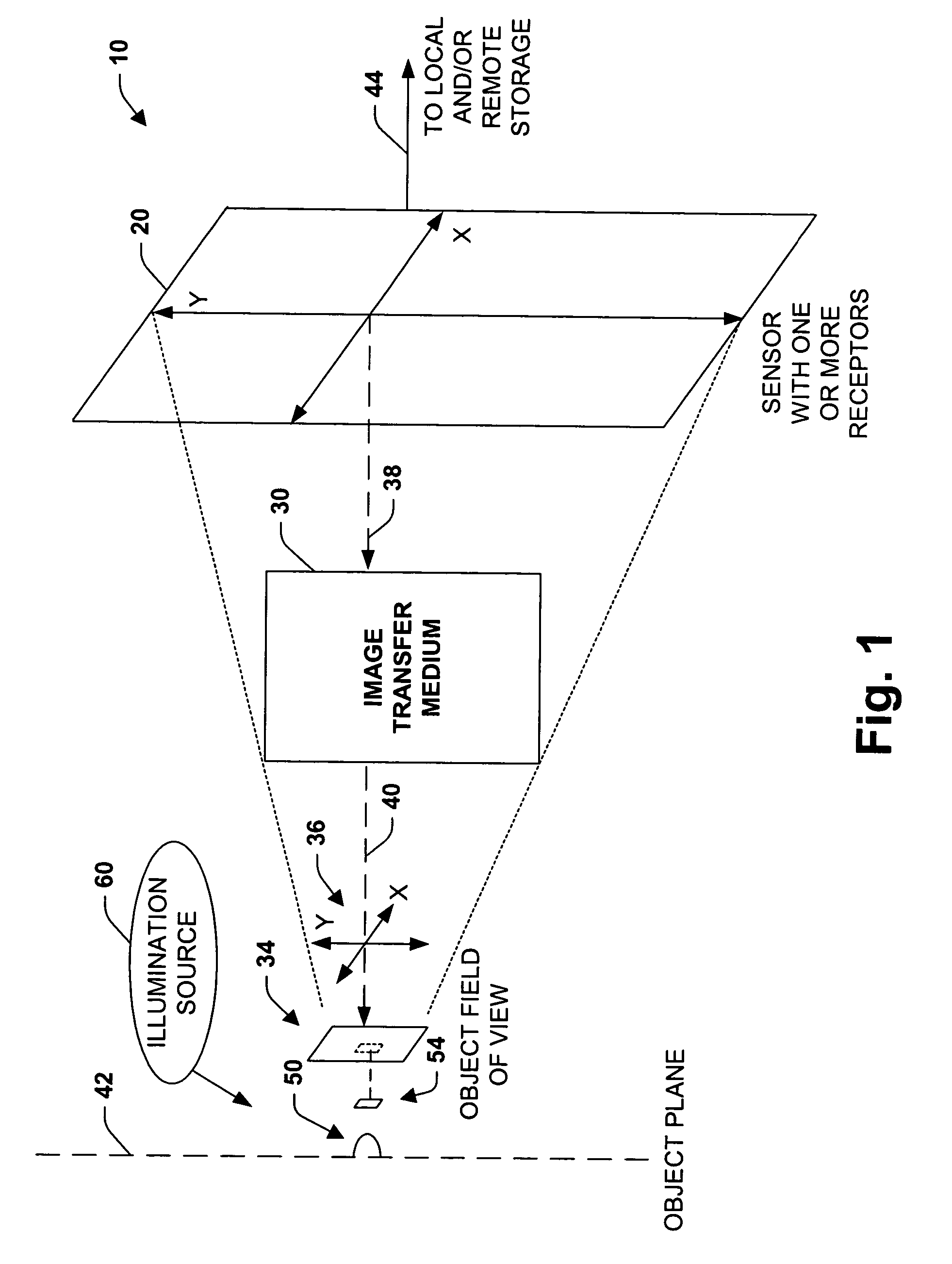

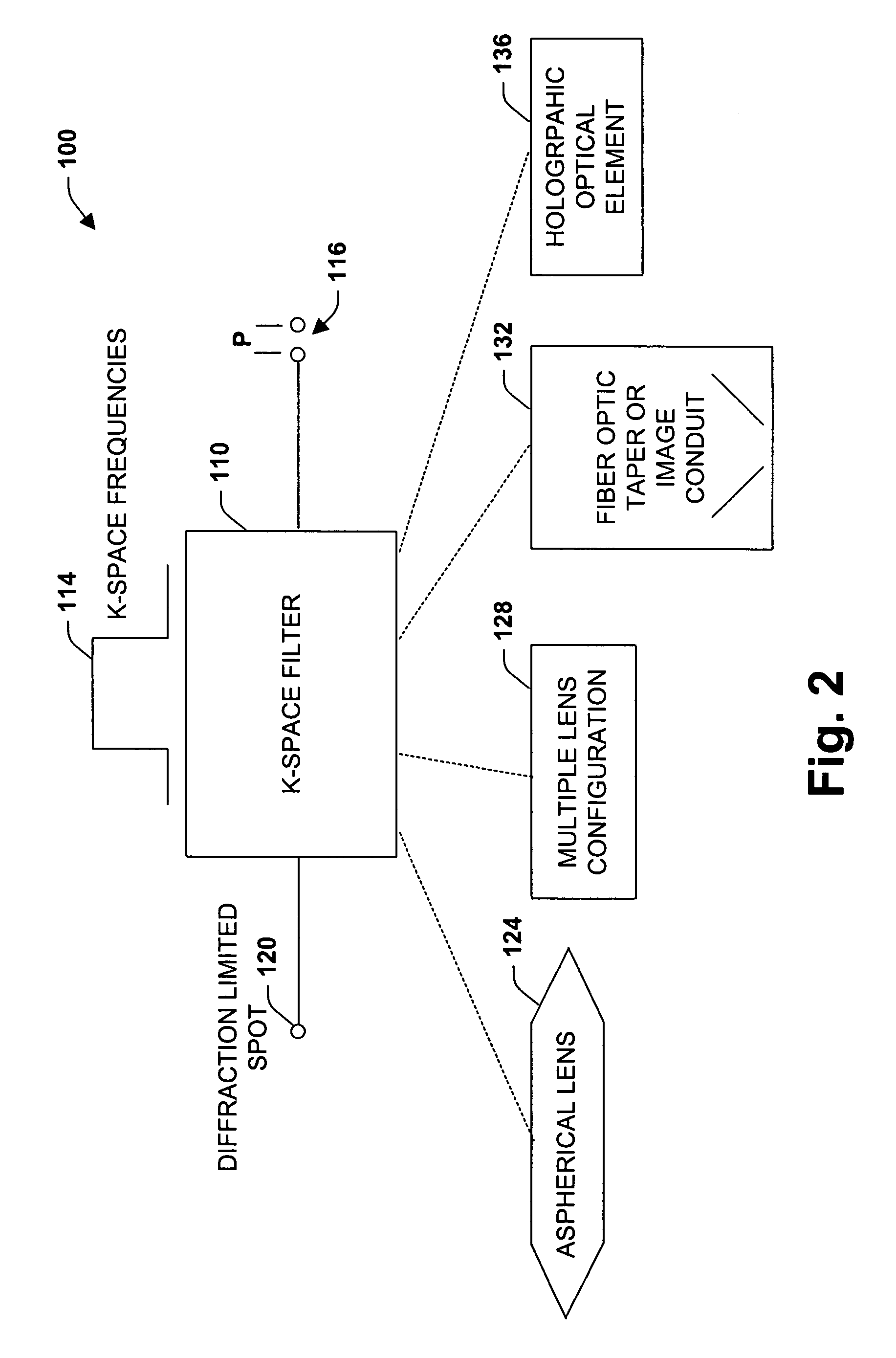

Imaging system and methodology

InactiveUS7151246B2Improve performanceEffectively scaledTelevision system detailsGeometric image transformationImage transferDisplay device

An imaging system, methodology, and various applications are provided to facilitate optical imaging performance. The system contains a sensor having one or more receptors and an image transfer medium to scale the sensor and receptors in accordance with resolvable characteristics of the medium, and as defined with certain ratios. A computer, memory, and / or display associated with the sensor provides storage and / or display of information relating to output from the receptors to produce and / or process an image, wherein a plurality of illumination sources can also be utilized in conjunction with the image transfer medium. The image transfer medium can be configured as a k-space filter that correlates projected receptor size to a diffraction-limited spot associated with the image transfer medium, wherein the projected receptor size can be unit-mapped within a certain ratio to the size of the diffraction-limited spot, both in the object plane.

Owner:HIMANSHU S AMIN +3

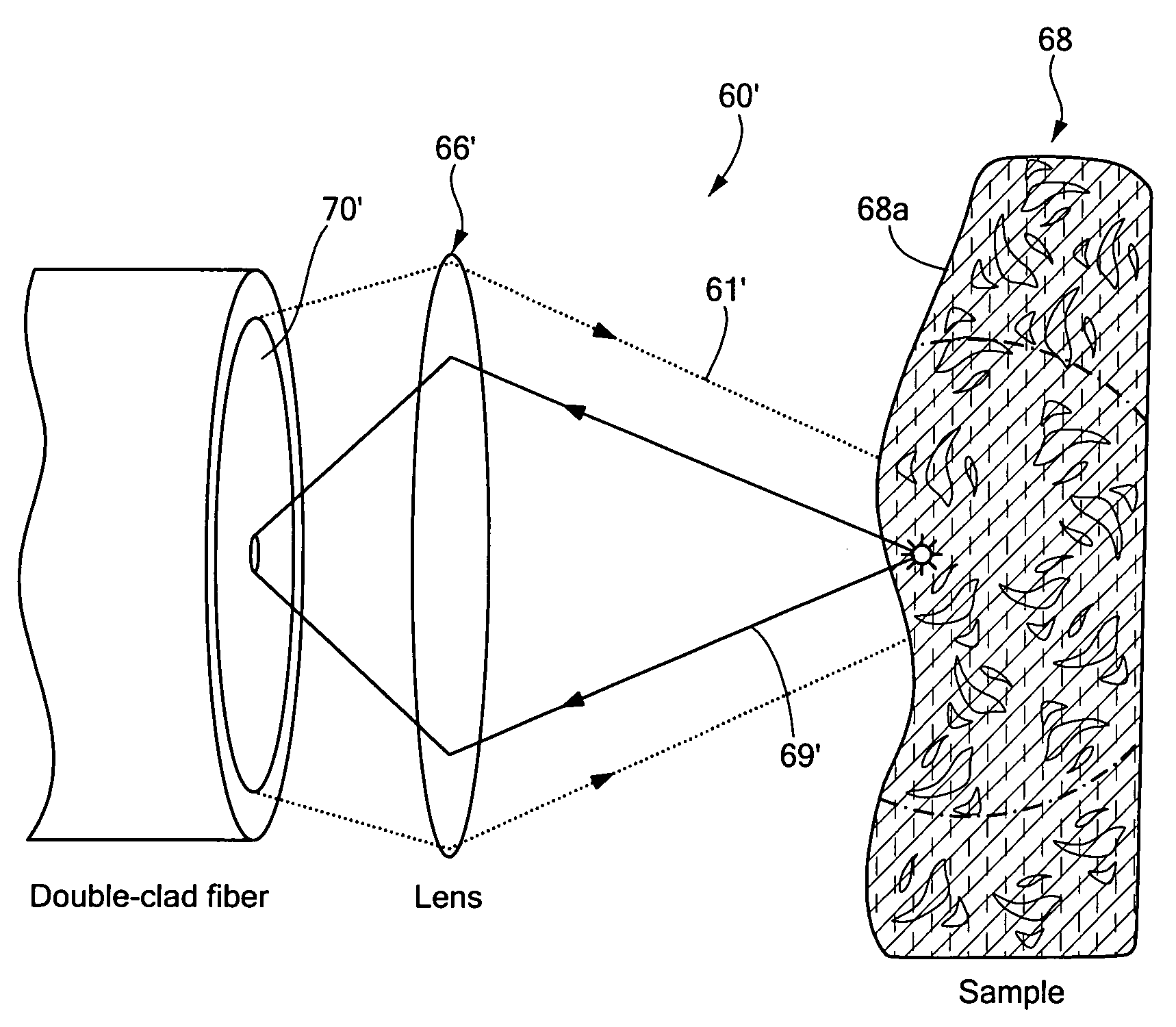

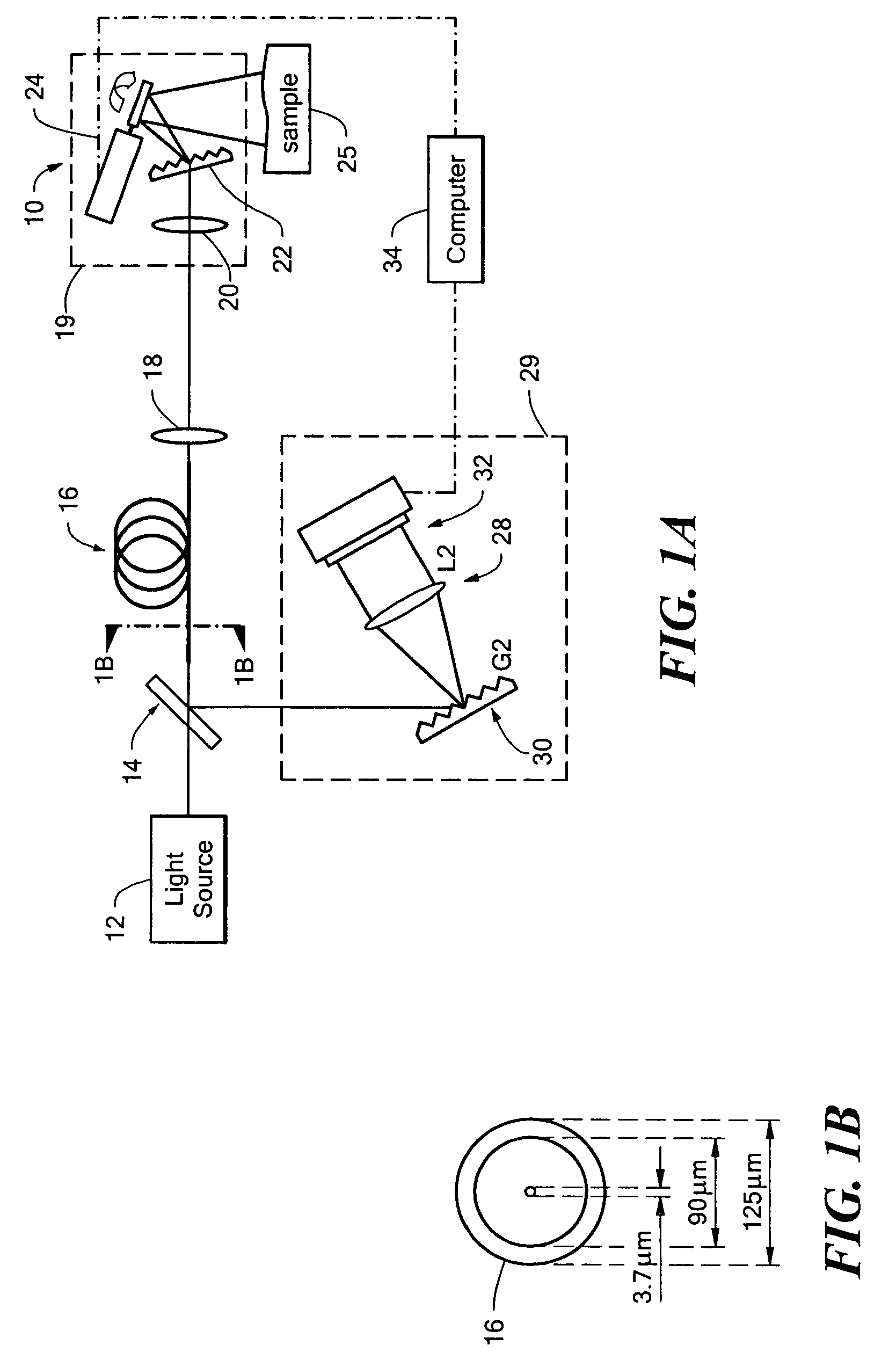

Imaging system and related techniques

ActiveUS7447408B2Reduces image speckleAdd depthRadiation pyrometrySpectrum investigationDouble-clad fiberComputer science

Owner:THE GENERAL HOSPITAL CORP

Damage-resistant glass articles and method

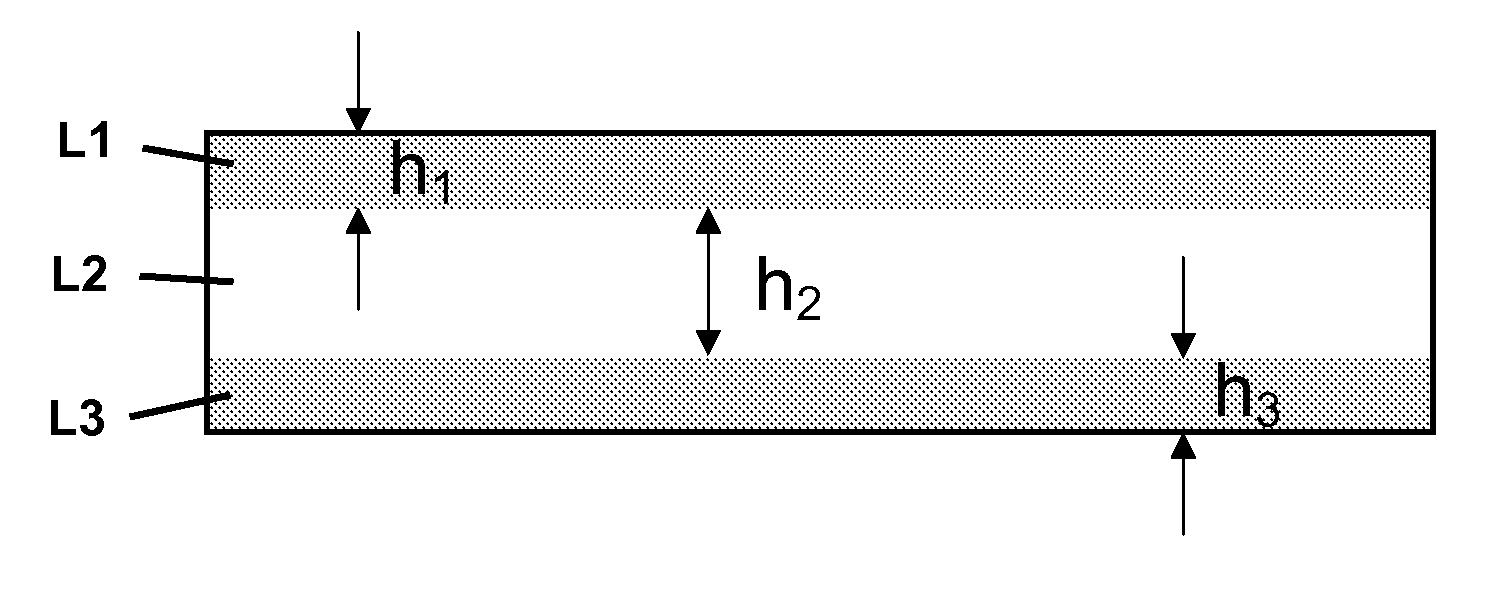

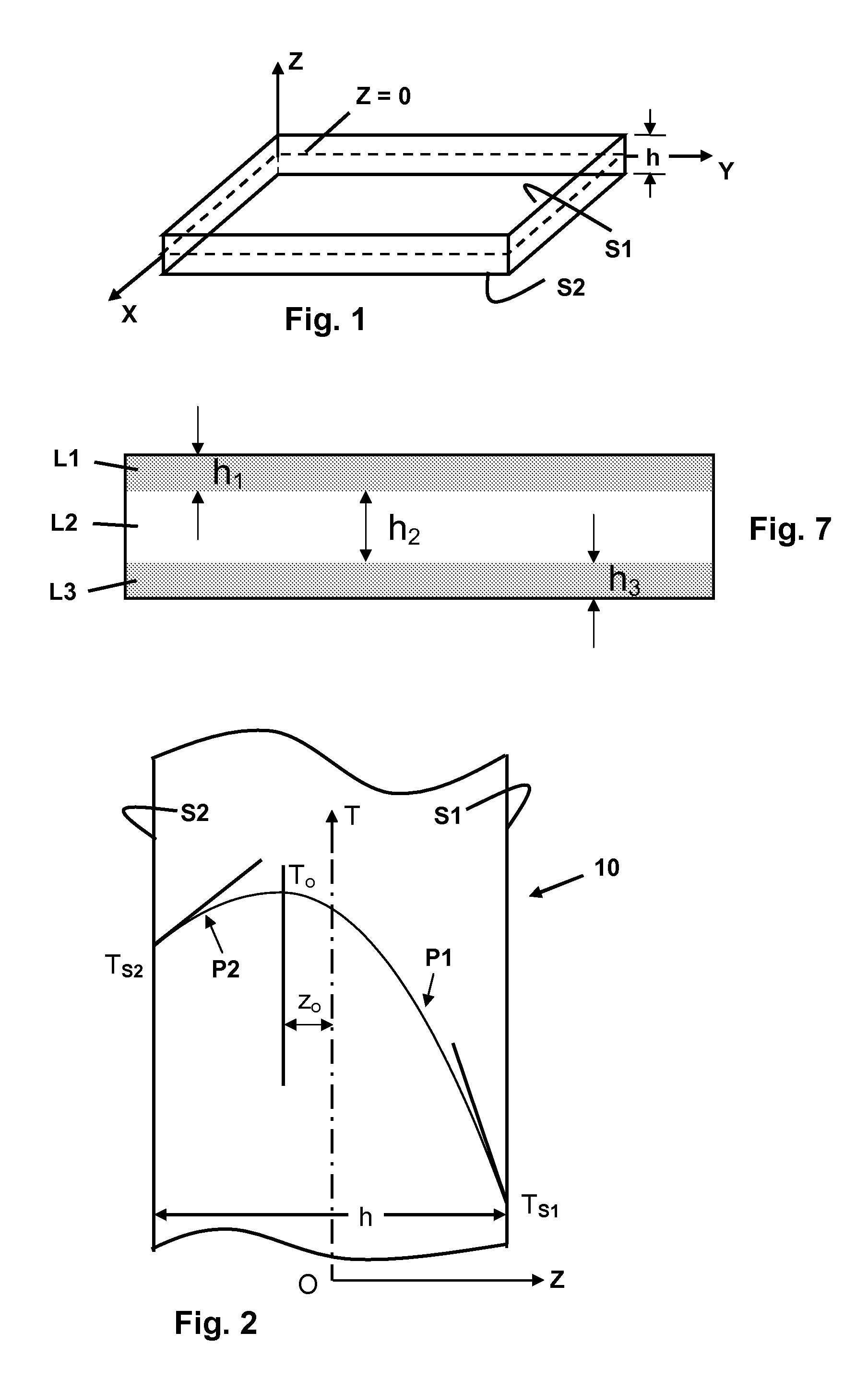

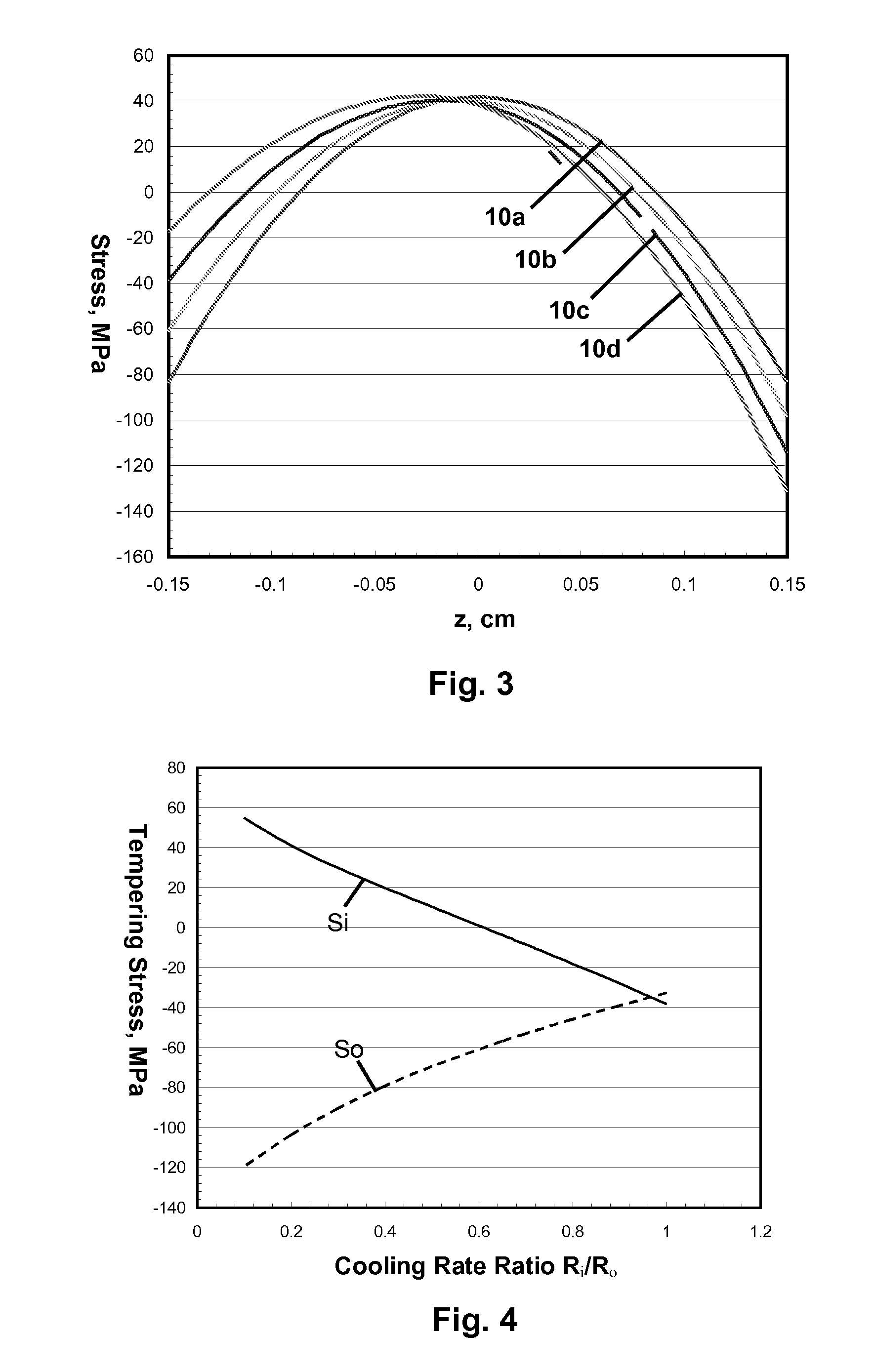

ActiveUS20110281093A1Effectively controlGood propertyLaminationLamination apparatusIon exchangeStress profile

A strengthened glass article has opposing first and second compressively stressed surface portions bound to a tensilely stressed core portion, with the first surface portion having a higher level of compressive surface stress than the second surface portion for improved resistance to surface damage, the compressively stressed surface portions being provided by lamination, ion-exchange, thermal tempering, or combinations thereof to control the stress profiles and limit the fracture energies of the articles.

Owner:CORNING INC

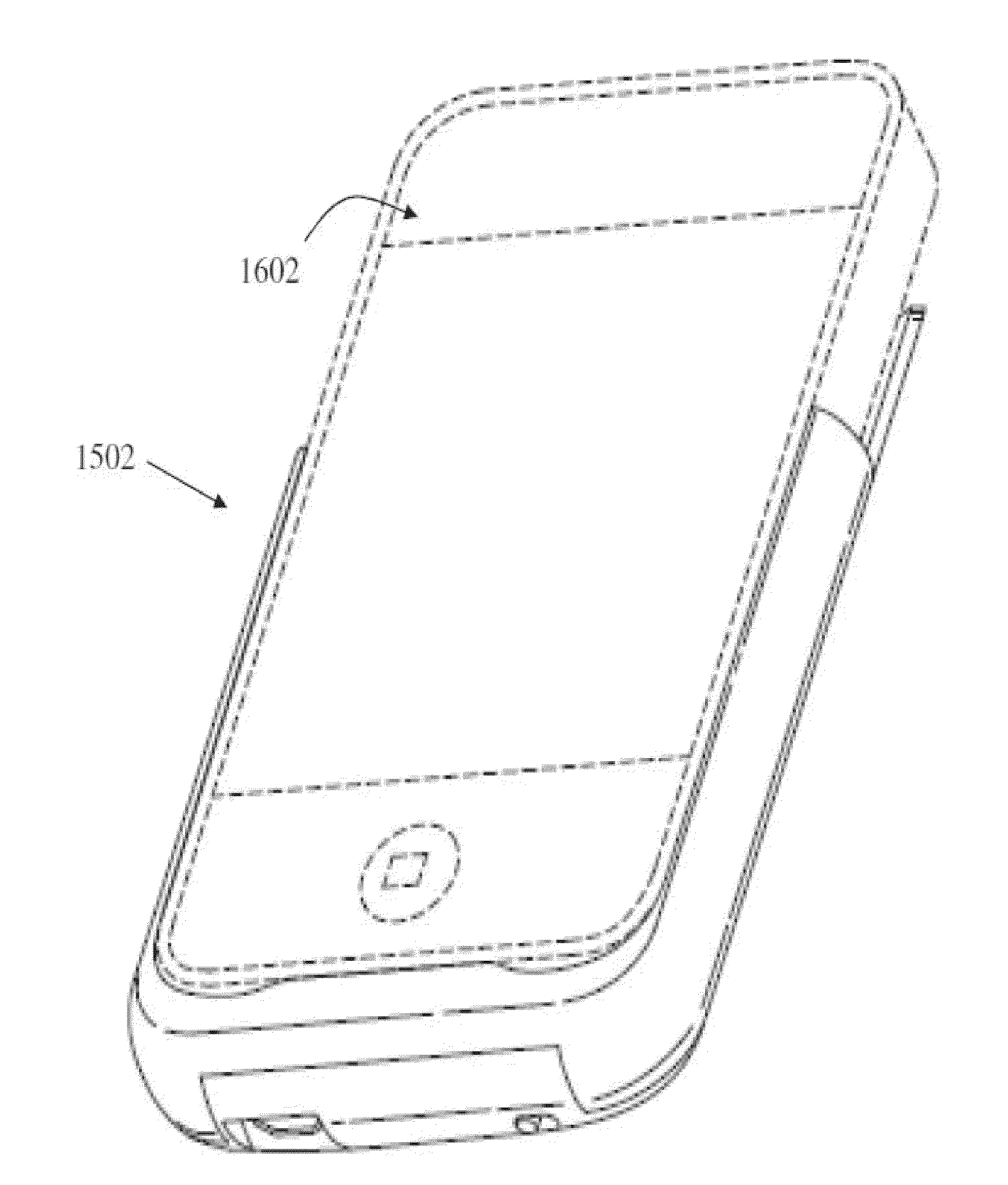

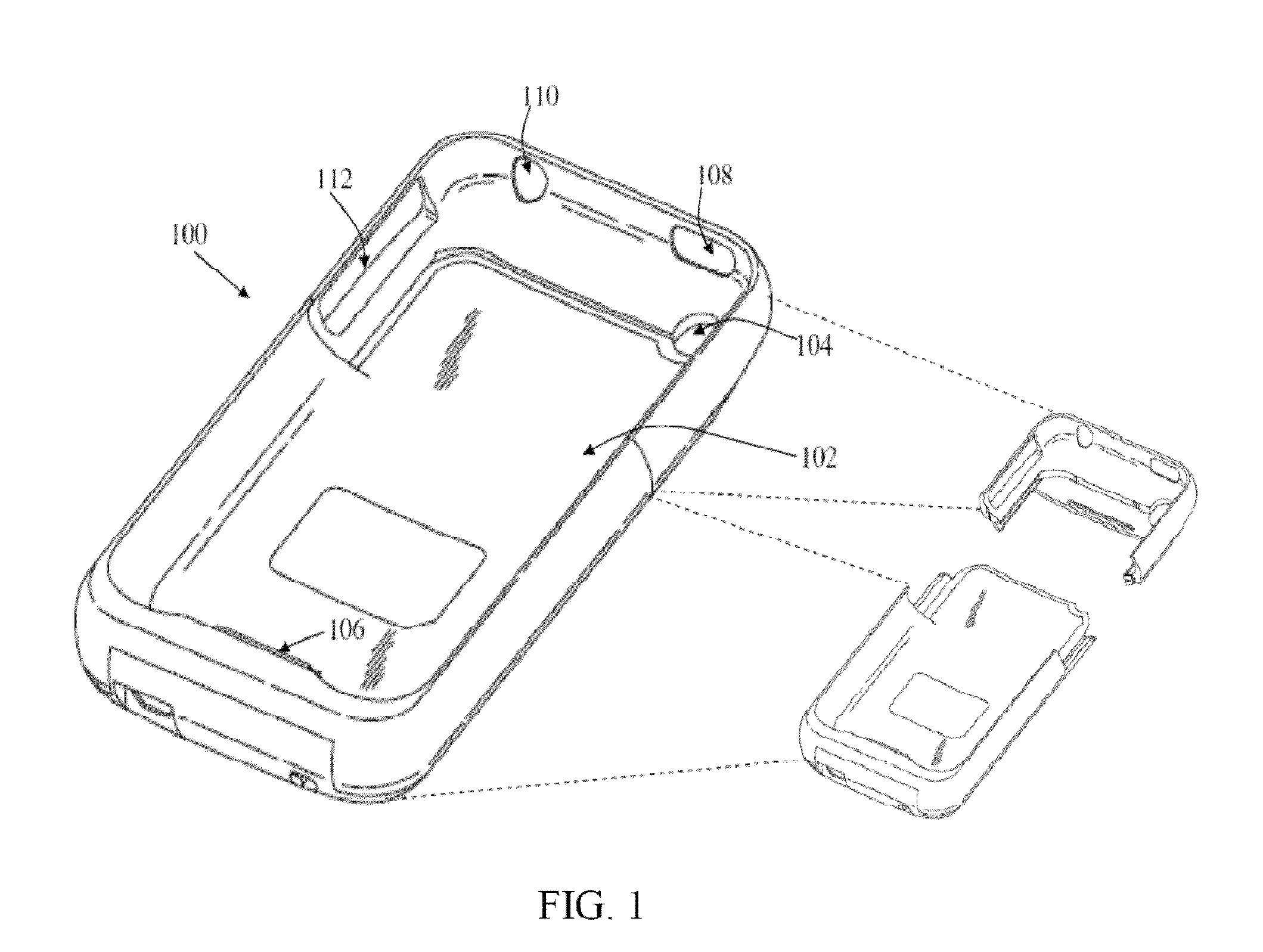

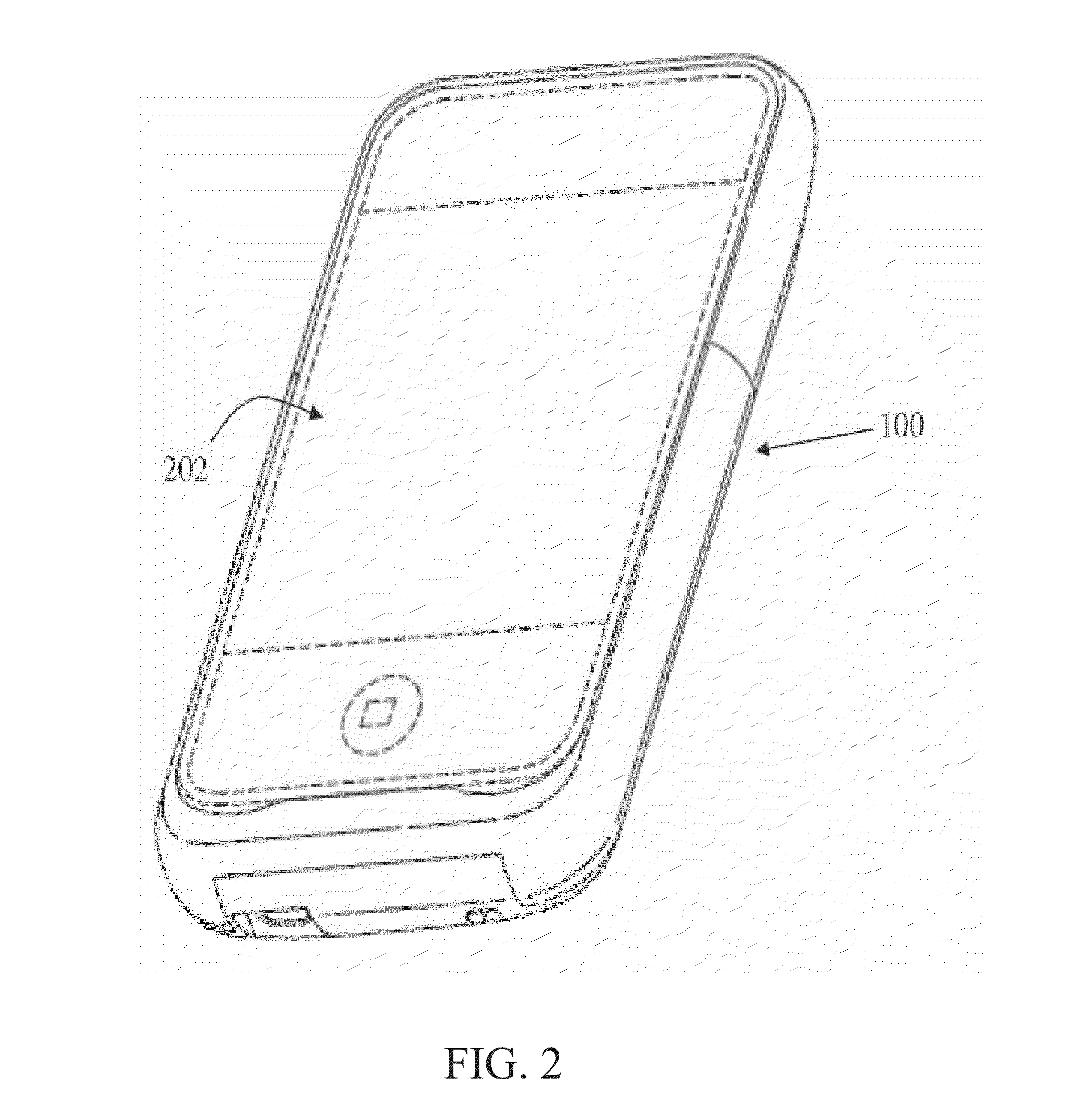

Wireless communication accessory for a mobile device

ActiveUS20140065948A1Improve rendering capabilitiesImprove functionalityCircuit monitoring/indicationRepeater circuitsMobile deviceElectric power

A mobile device peripheral that incorporates a repeater antenna inside of a protective case for a mobile device to extend the range of short-range communications while minimizing interference caused by the thickness or materials of the protective case. The repeater antenna can be capable of receiving a wireless signal from an antenna in the mobile device and transmitting the same signal or an amplified version of the same signal. The repeater antenna can be capable of receiving a wireless signal from an external antenna and transmitting the same signal or an amplified version of the same signal to the mobile device. The mobile device peripheral can also include a battery that provides additional power the mobile device. Without a repeater antenna, the materials and / or thickness of the additional battery and / or the case can partially or completely block a short-range, low-frequency, or low-power communication signal such as Near Field Communication (NFC).

Owner:MOPHIE

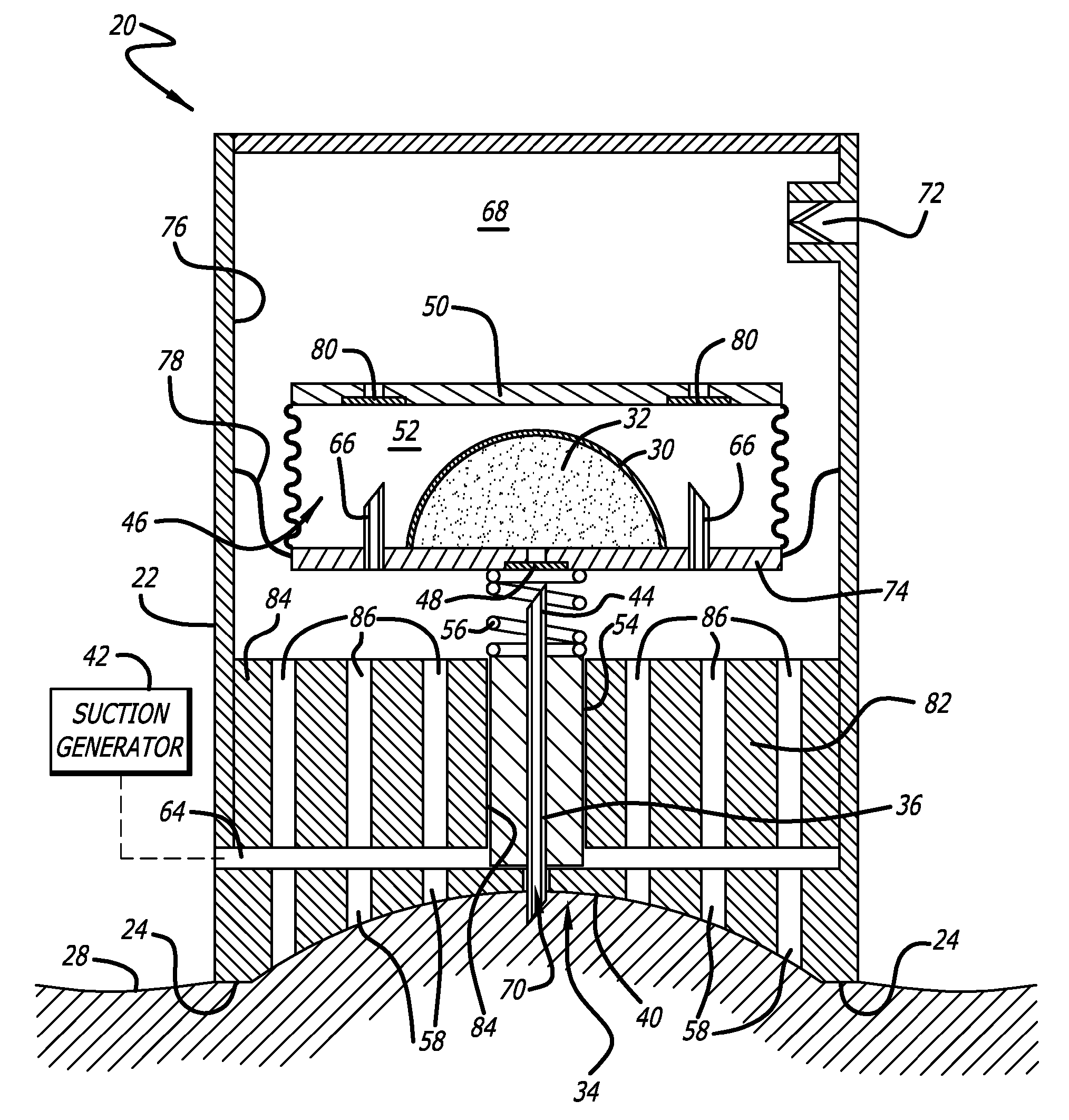

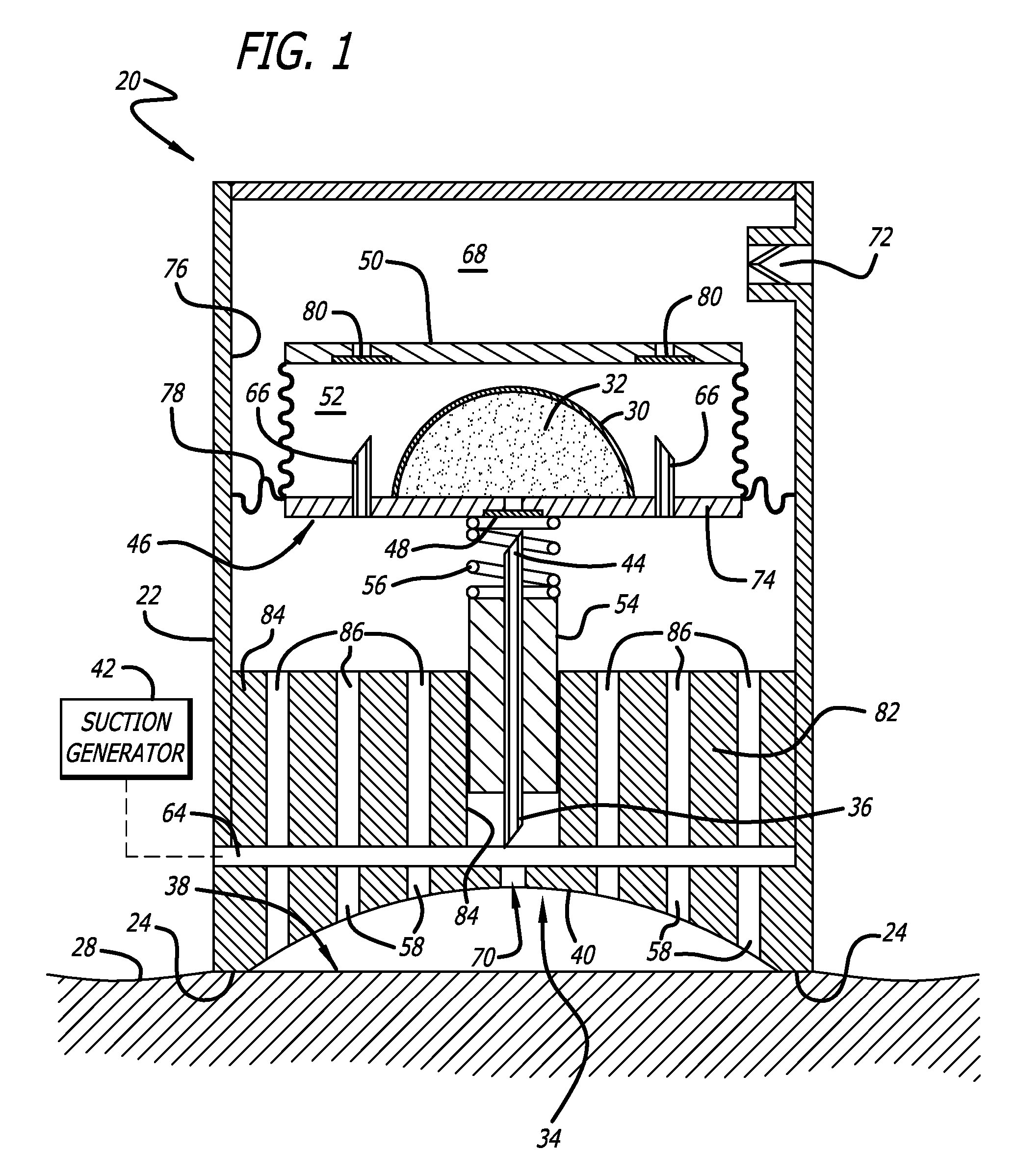

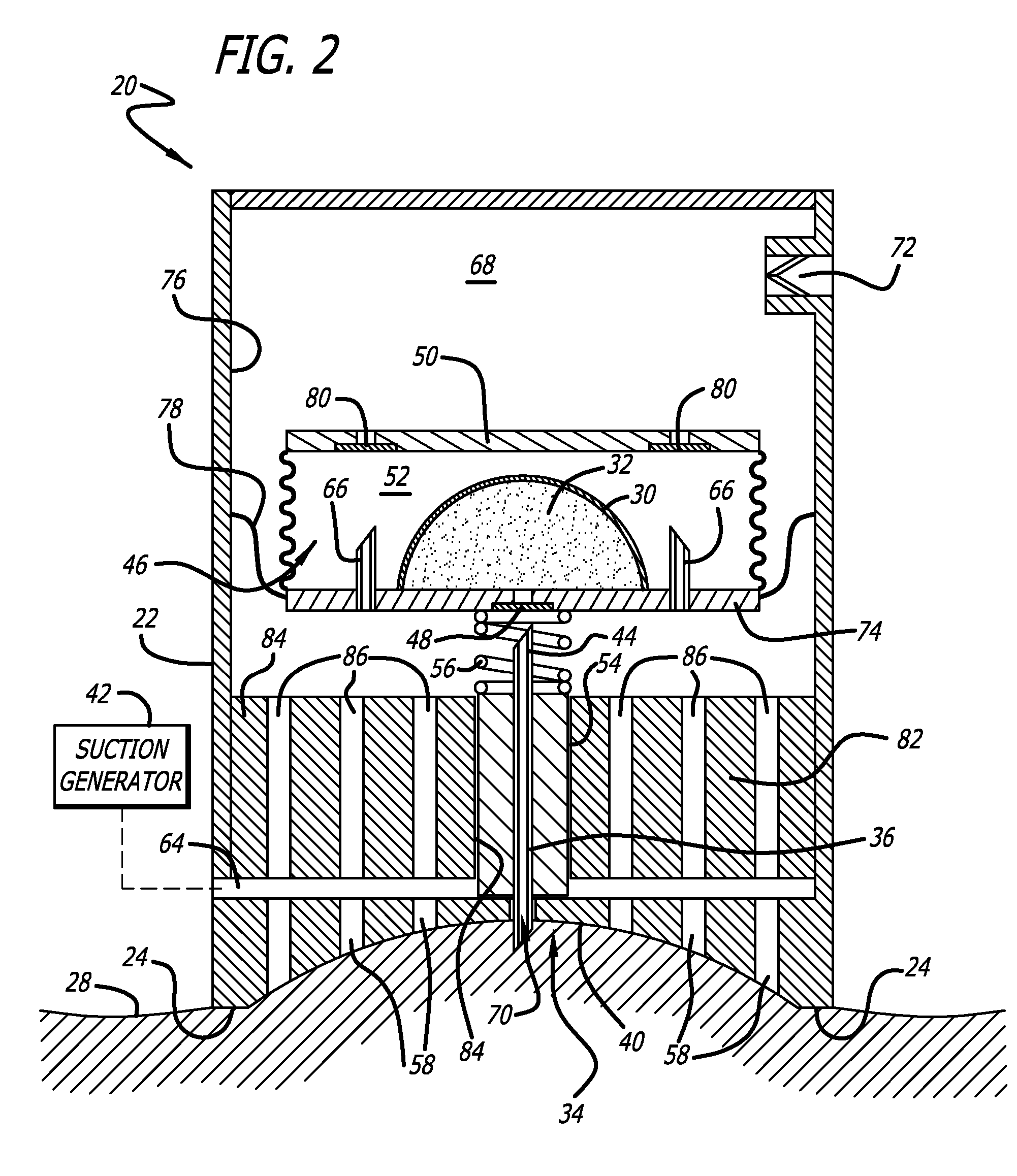

Cutaneous stabilization by vacuum for delivery of micro-needle array

InactiveUS20060264926A1Add depthImprove uniformityAmpoule syringesSurgical needlesMicro-needleSecondary layer

Owner:MEDICAL MICRODEVICES

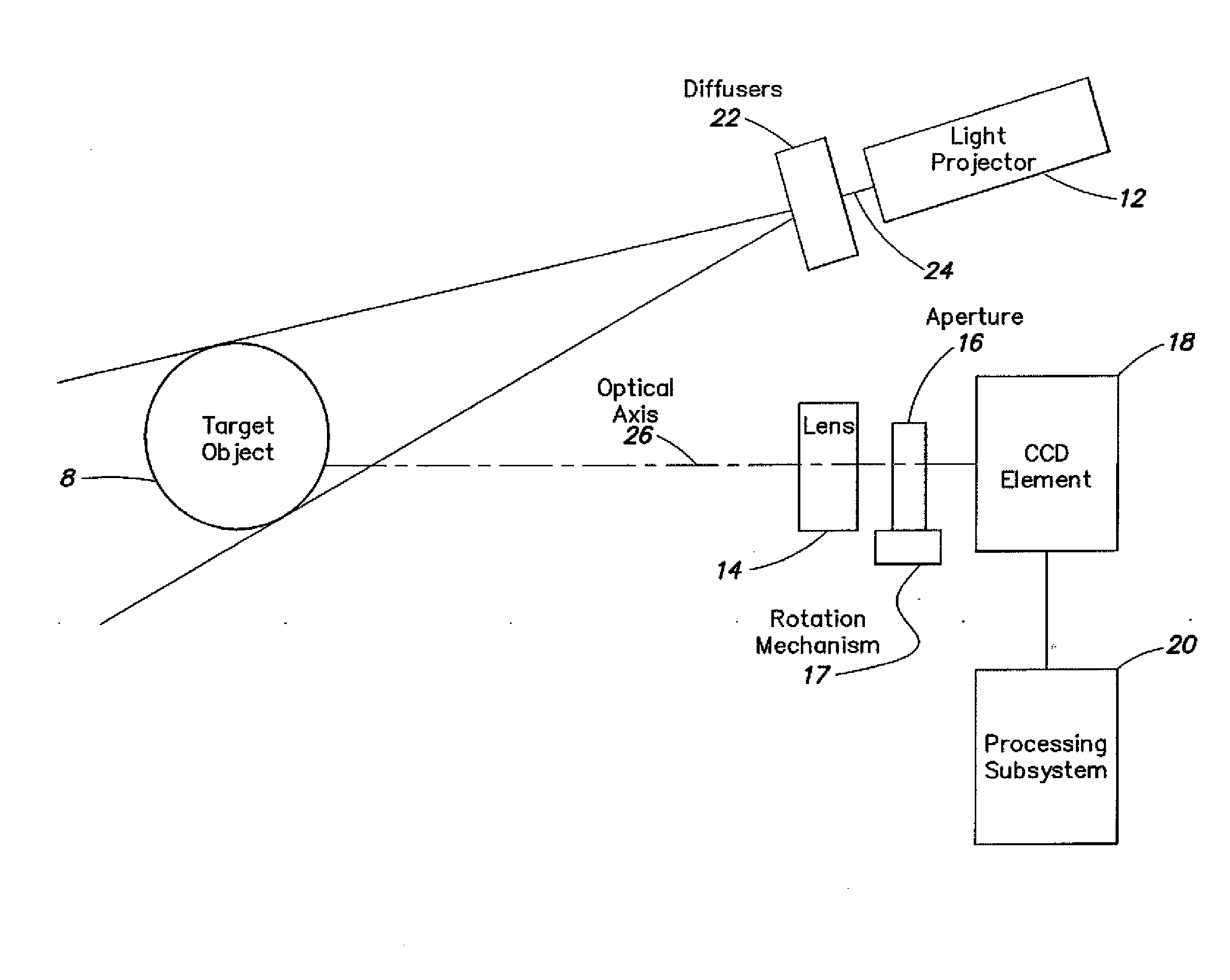

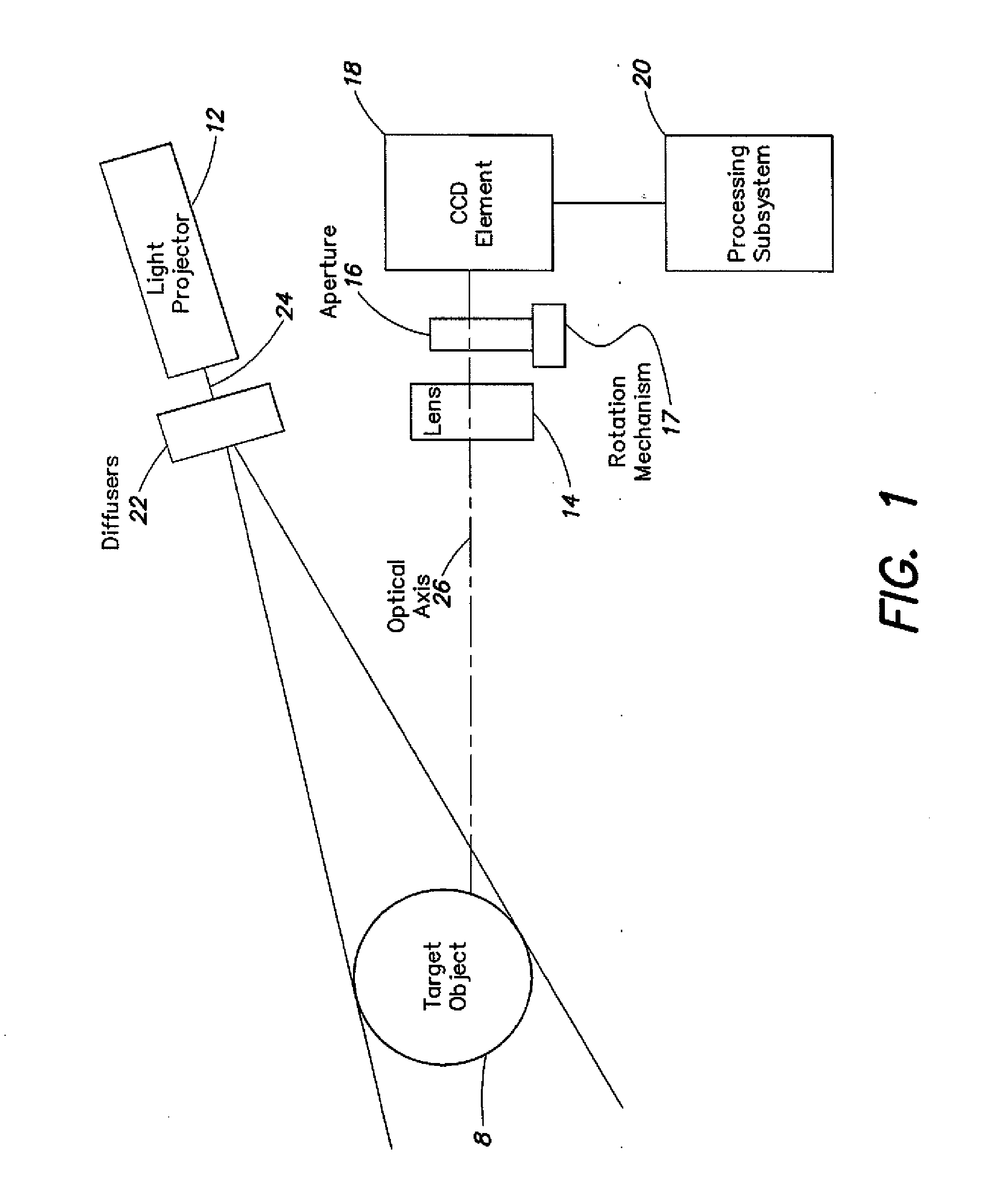

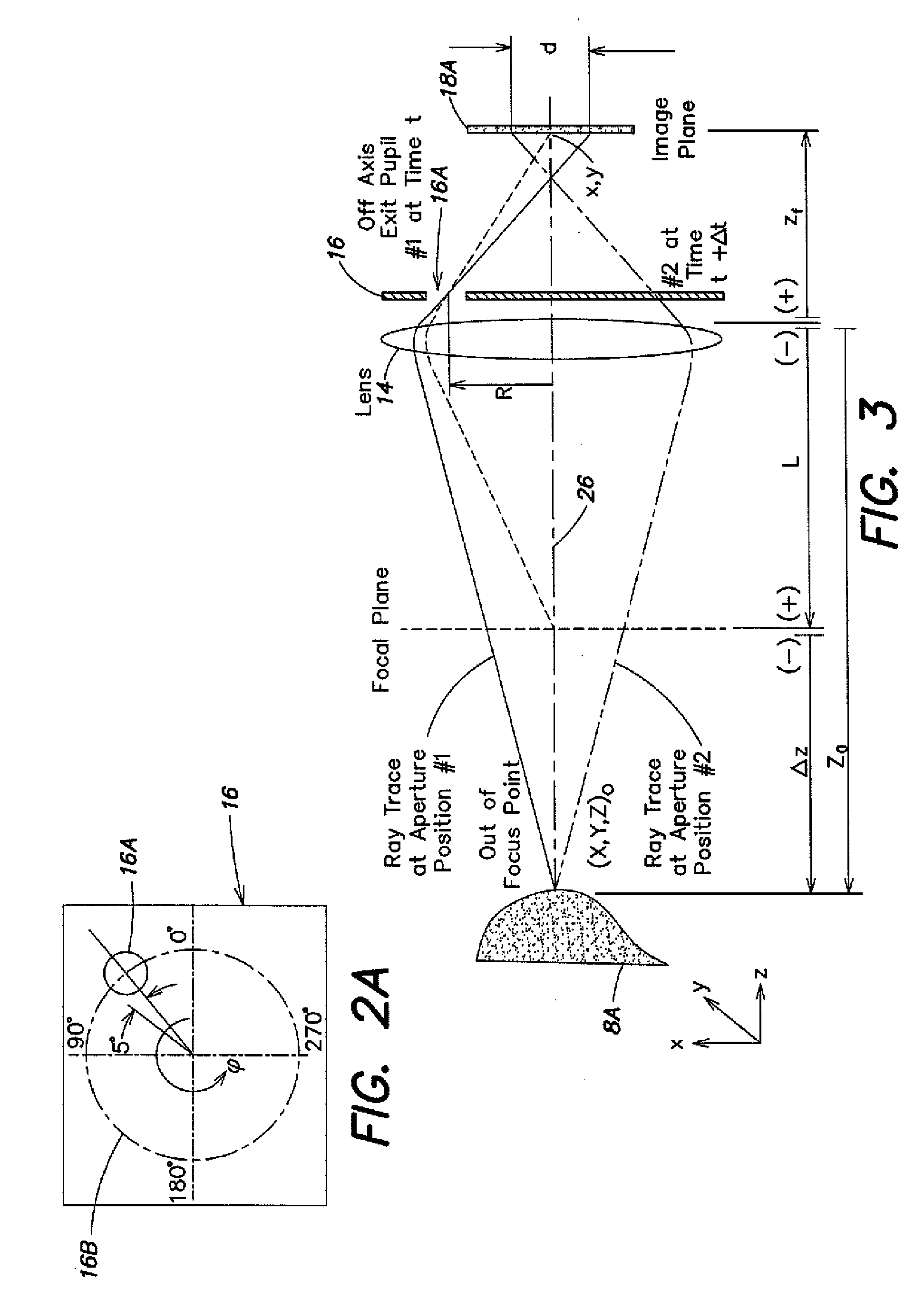

Method and system for high resolution, ultra fast 3-d imaging

InactiveUS20090016642A1Add depthHigh displacement accuracyTelevision system detailsImage analysisImage resolutionUltra fast

A high-speed three-dimensional imaging system includes a single lens camera subsystem with an active imaging element and CCD element, and a correlation processing subsystem. The active imaging element can be a rotating aperture which allows adjustable non-equilateral spacing between defocused images to achieve greater depth of field and higher sub-pixel displacement accuracy. A speckle pattern is projected onto an object and images of the resulting pattern are acquired from multiple angles. The images are locally cross-correlated using a sparse array image correlation technique and the surface is resolved by using relative camera position information to calculate the three-dimensional coordinates of each locally correlated region. Increased resolution and accuracy are provided by recursively correlating the images down to the level of individual points of light and using the Gaussian nature of the projected speckle pattern to determine subpixel displacement between images. Processing is done at very high-speeds by compressing the images before they are correlated. Correlation errors are eliminated during processing by a technique based on the multiplication of correlation table elements from one or more adjacent regions.

Owner:MASSACHUSETTS INST OF TECH

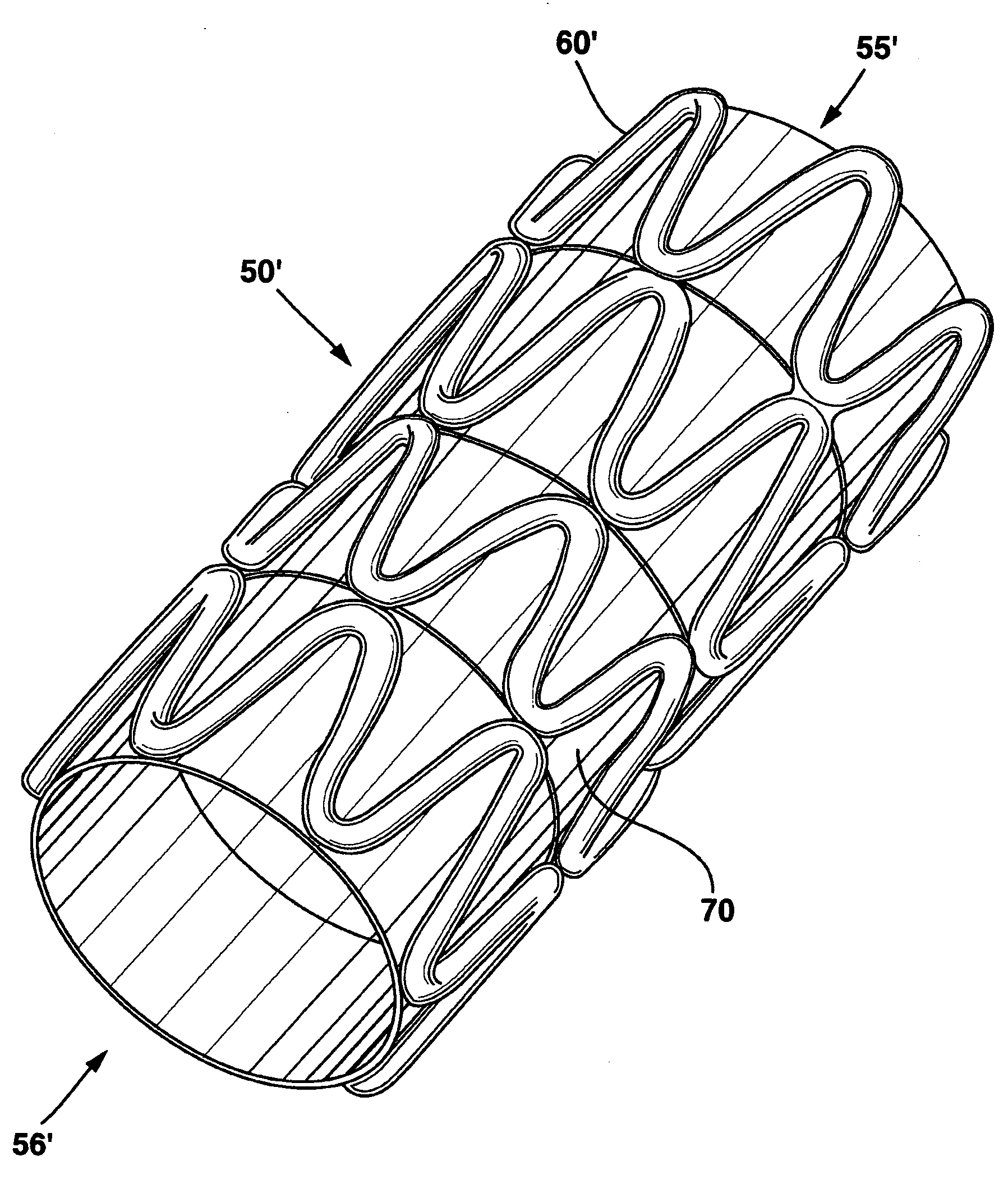

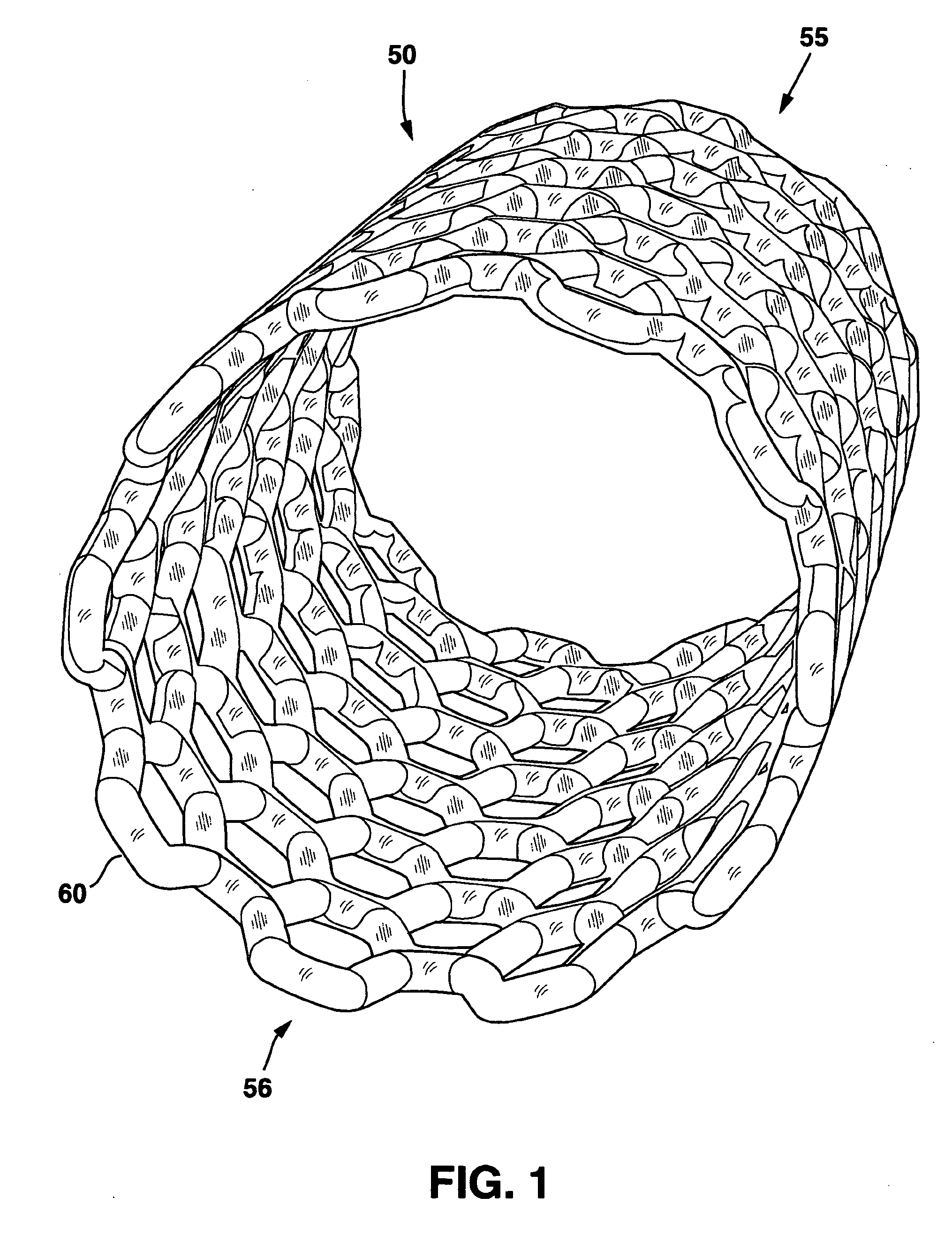

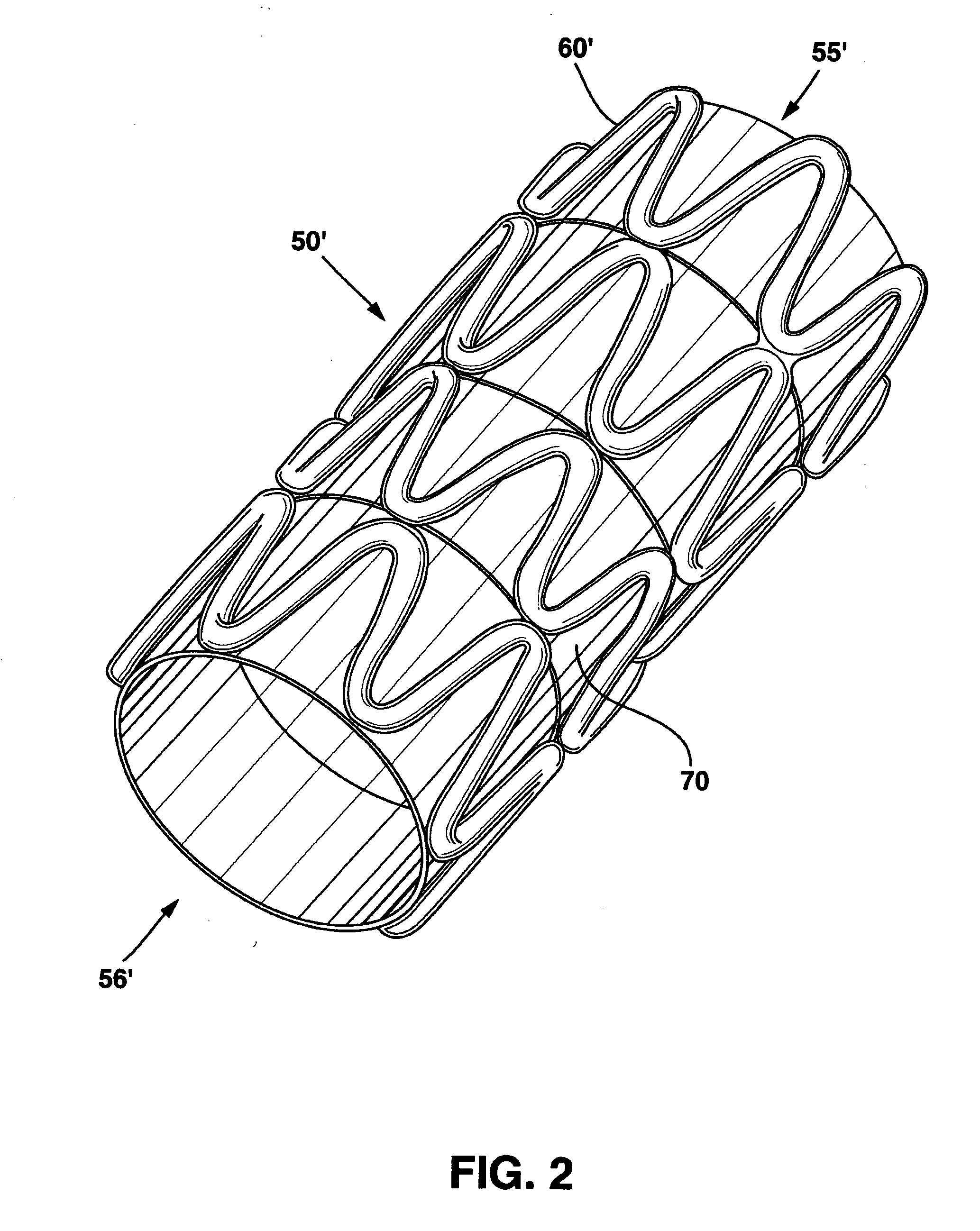

Modulated stents and methods of making the stents

InactiveUS20050055080A1Improve manufacturabilityLow costStentsBlood vesselsPresent methodTreatment field

Manufacturing methods are provided to build modulated medical devices and segments of the devices for applications in the field of intraluminal intervention, reconstruction, or therapy. The methods, comprise steps of metal injection molding and processes of modulation, improve the manufacturability of the devices and / or expand the design alternatives for the devices. The modulated medical devices and their segments, made from the present method inventions, enhance the versatility in intraluminal treatments.

Owner:MEDTRONIC INC

Vapor deposition method and apparatus

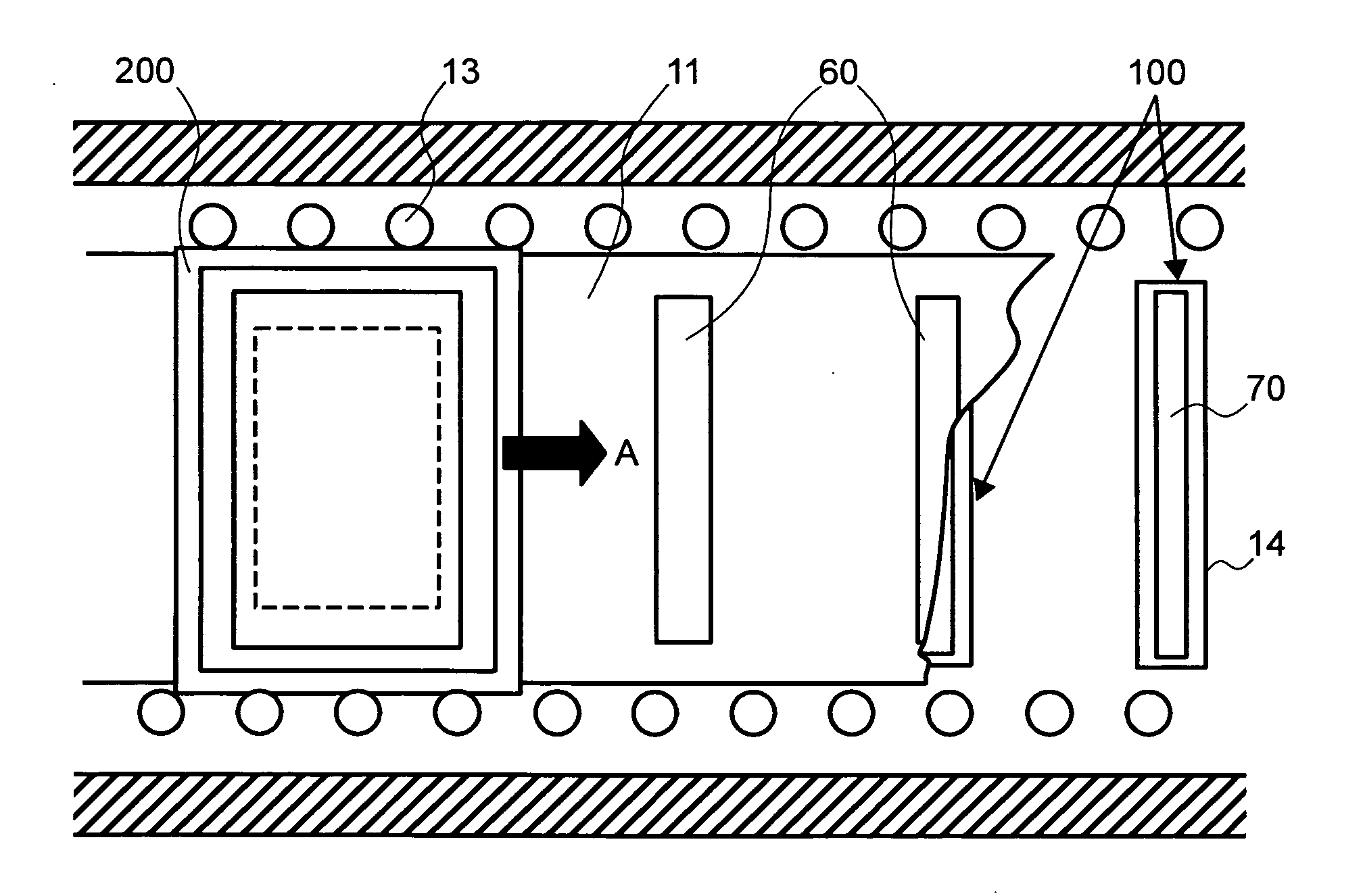

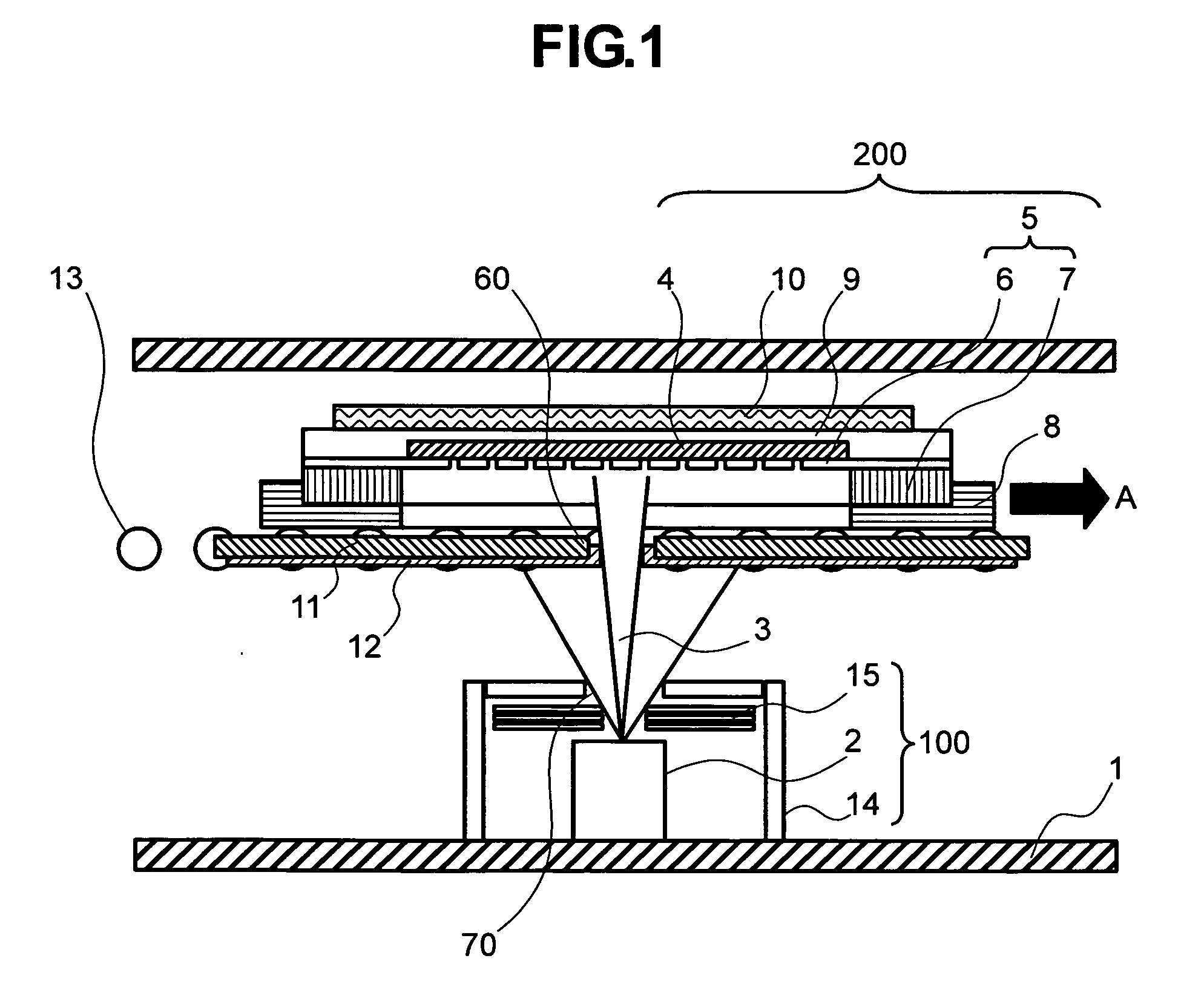

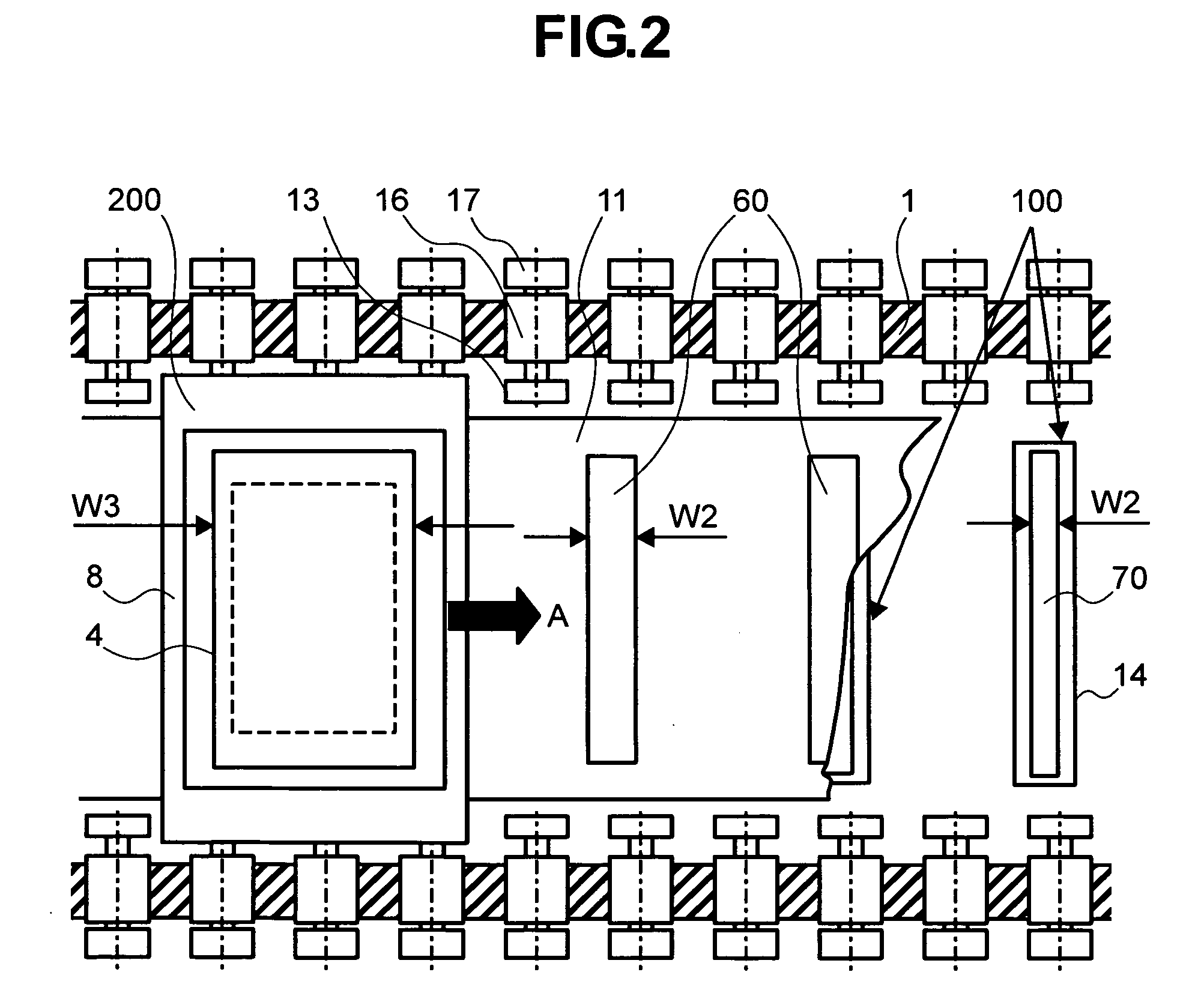

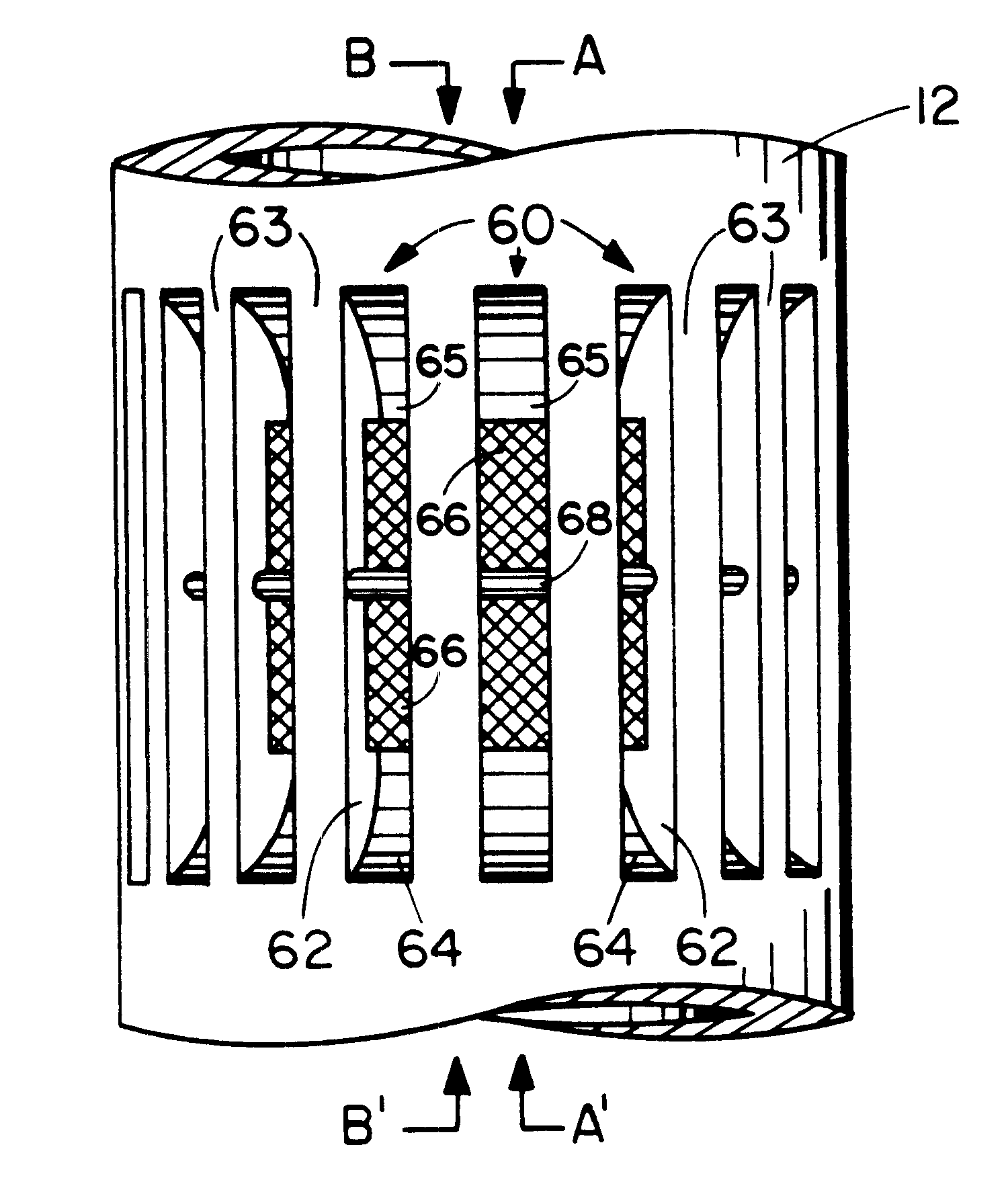

ActiveUS20090017192A1Improve cooling effectAvoid misalignmentVacuum evaporation coatingSolid-state devicesGas phaseEvaporation

Provided is a method for moving, in a vacuum chamber carrying therein a fixedly-provided evaporation source, a substrate toward the evaporation source together with a mask closely attached to the substrate surface, and onto the surface substrate, evaporating a material vaporized in the evaporation source through an aperture formed to the mask. In this method of the invention, means for moving the substrate toward the evaporation source is provided with cooling means not to come in contact with but to be in proximity to a surface of the mask on the evaporation source side, and a cooling plate formed with an aperture proximal to the evaporation source is disposed. With such a configuration, the steam of the material coming from the evaporation source is directed to the mask and the substrate through the aperture of the cooling plate. As such, the material film evaporated on the substrate surface shows a satisfactory distribution of film thickness, and any possible misalignment from desired positions of evaporation can be accordingly suppressed.

Owner:HITACHI DISPLAYS +1

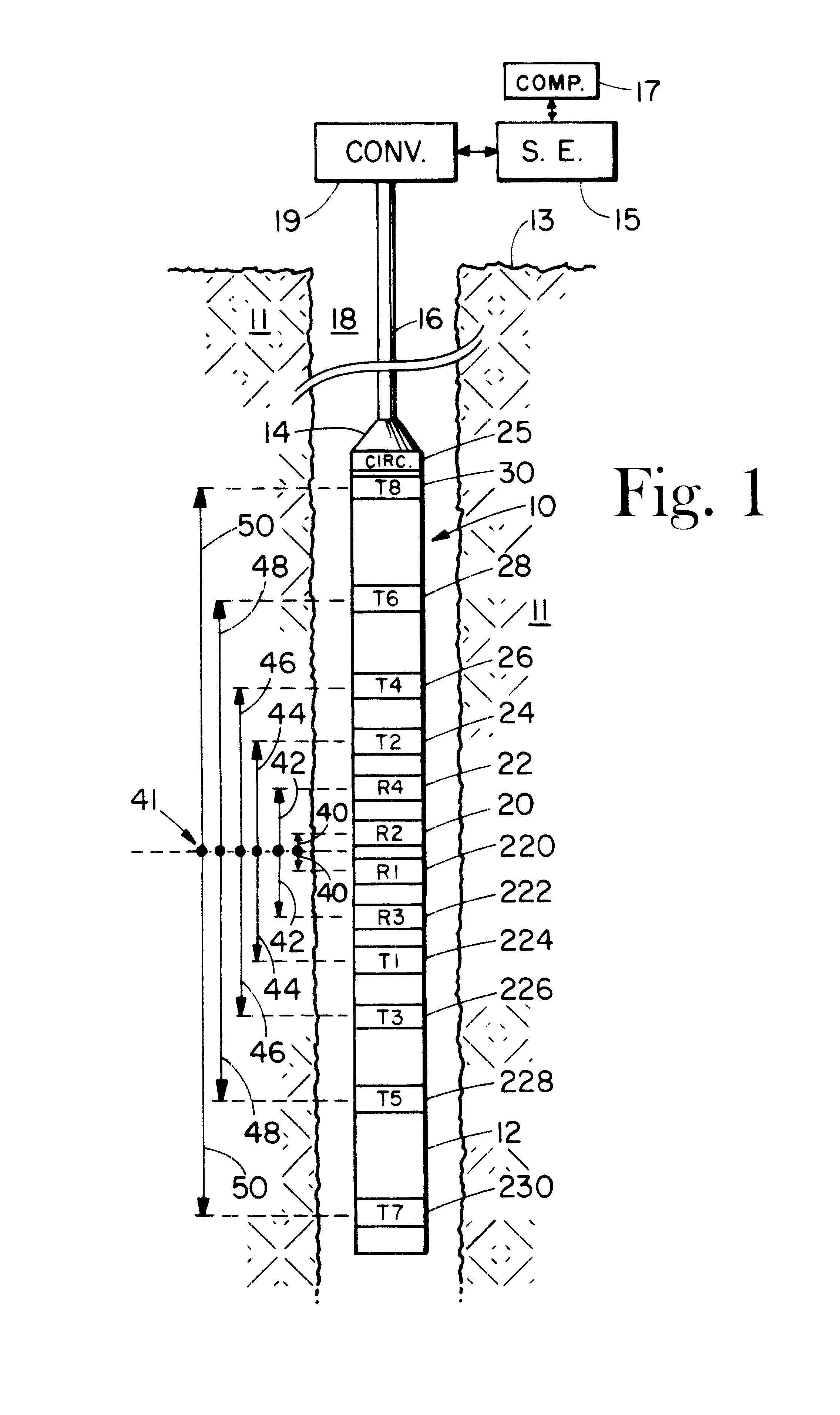

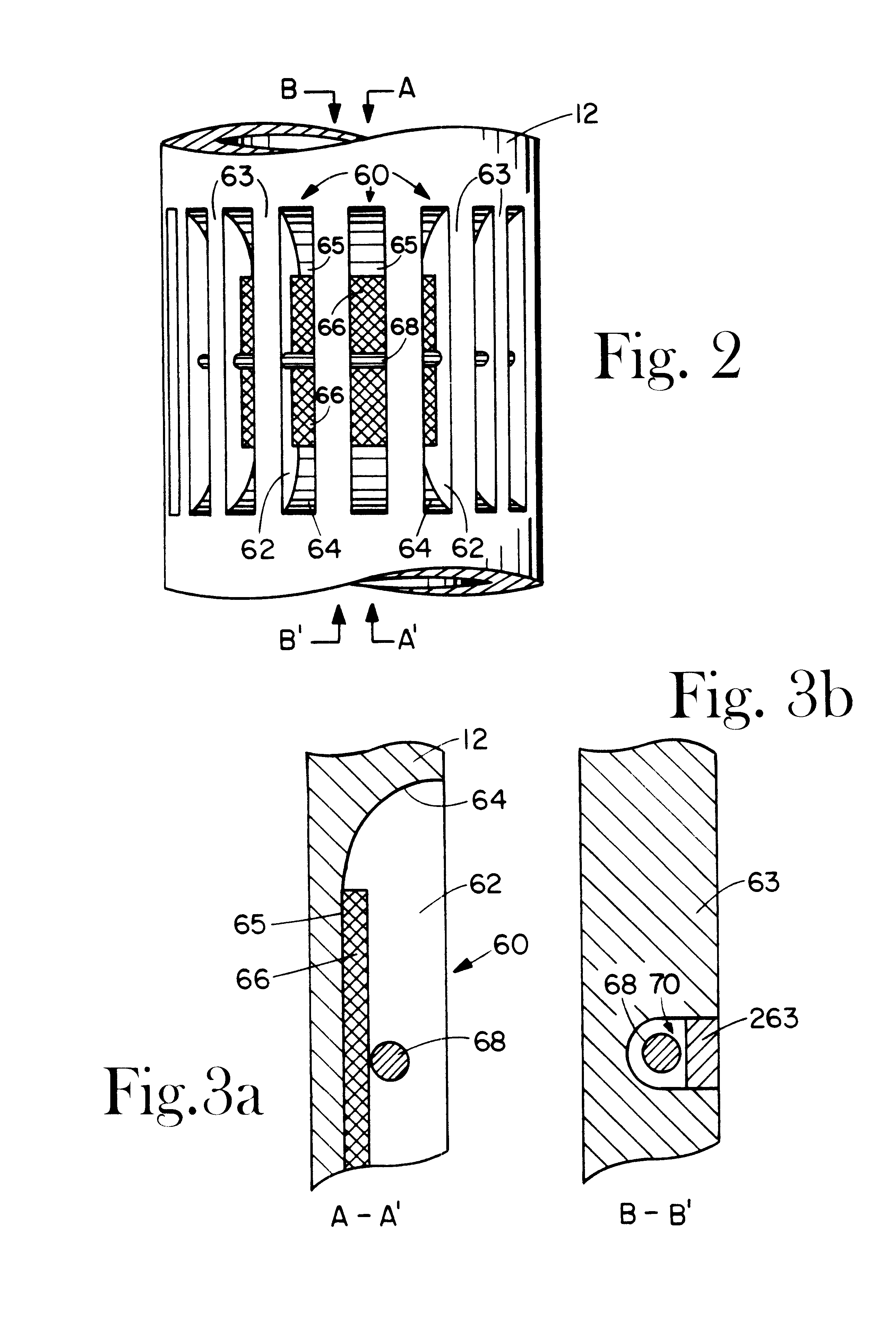

Well logging system for determining directional resistivity using multiple transmitter-receiver groups focused with magnetic reluctance material

InactiveUS6577129B1Improve antenna efficiencyHigh gainElectric/magnetic detection for well-loggingSubaqueous/subterranean adaptionWell loggingMagnetic reluctance

An electromagnetic wave propagation resistivity borehole logging system comprising multiple groups of electromagnetic transmitter-receiver arrays operating at three frequencies. The borehole logging tool component of the system employs eight transmitters and four receivers. The transmitters and receivers are disposed axially and symmetrically along the major axis of the tool to form four group pairs. Each group pair consists of a transmitter-receiver groups axially and symmetrically on opposing sides of a reference point on the tool. Each, transmitter-receiver group consists of one transmitter assembly and two receiver assemblies. Each transmitter-receiver group is operated at two of three operating frequencies which are 100 kHz, 400 kHz and 2 MHz. Some of the transmitter and receiver assemblies are fabricated to yield azimuthally focused resistivity measurements, and to yield vertical and horizontal resistivity in anisotropic dipping beds. The system can be embodied as a logging-while-drilling system or as a wireline logging system.

Owner:WEATHERFORD TECH HLDG LLC

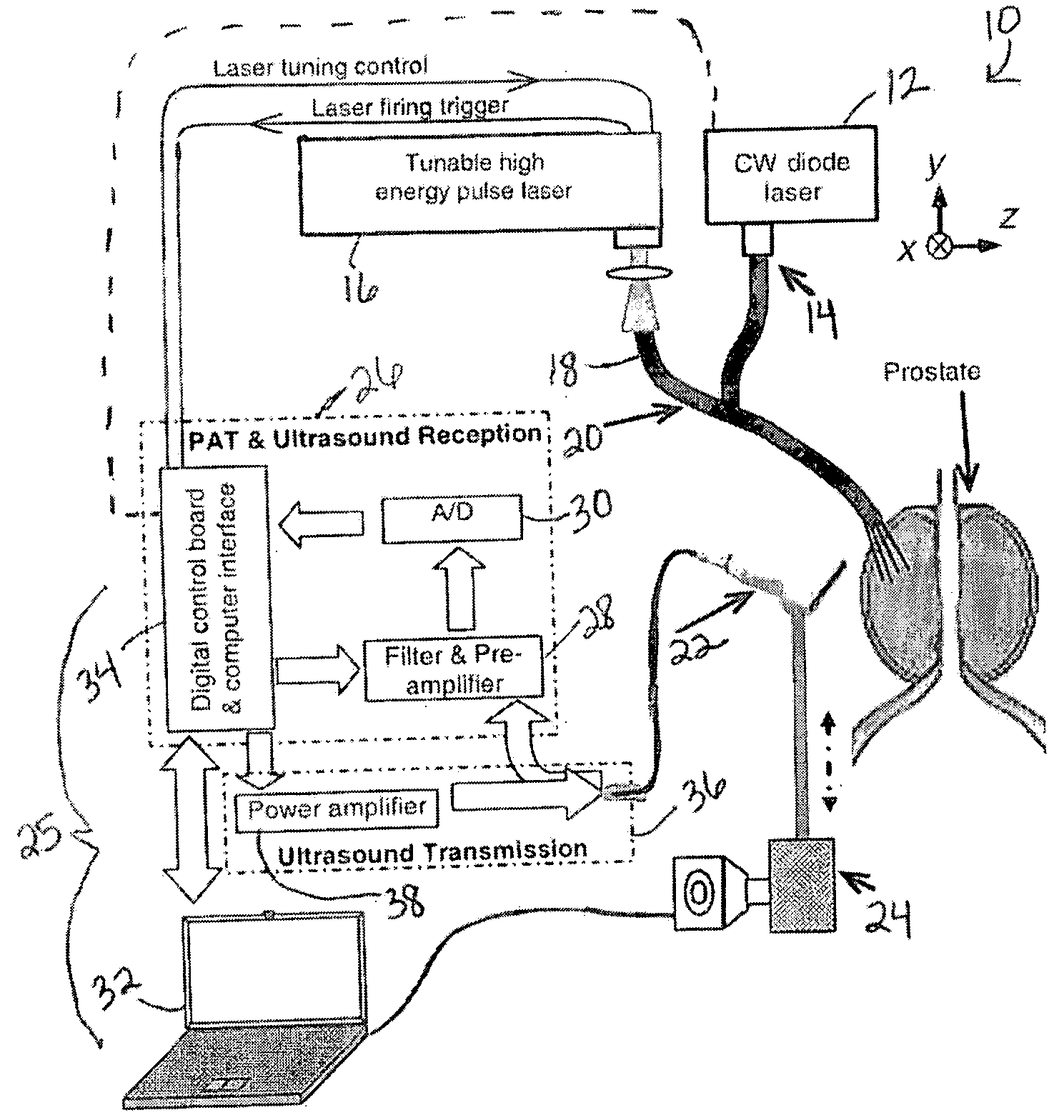

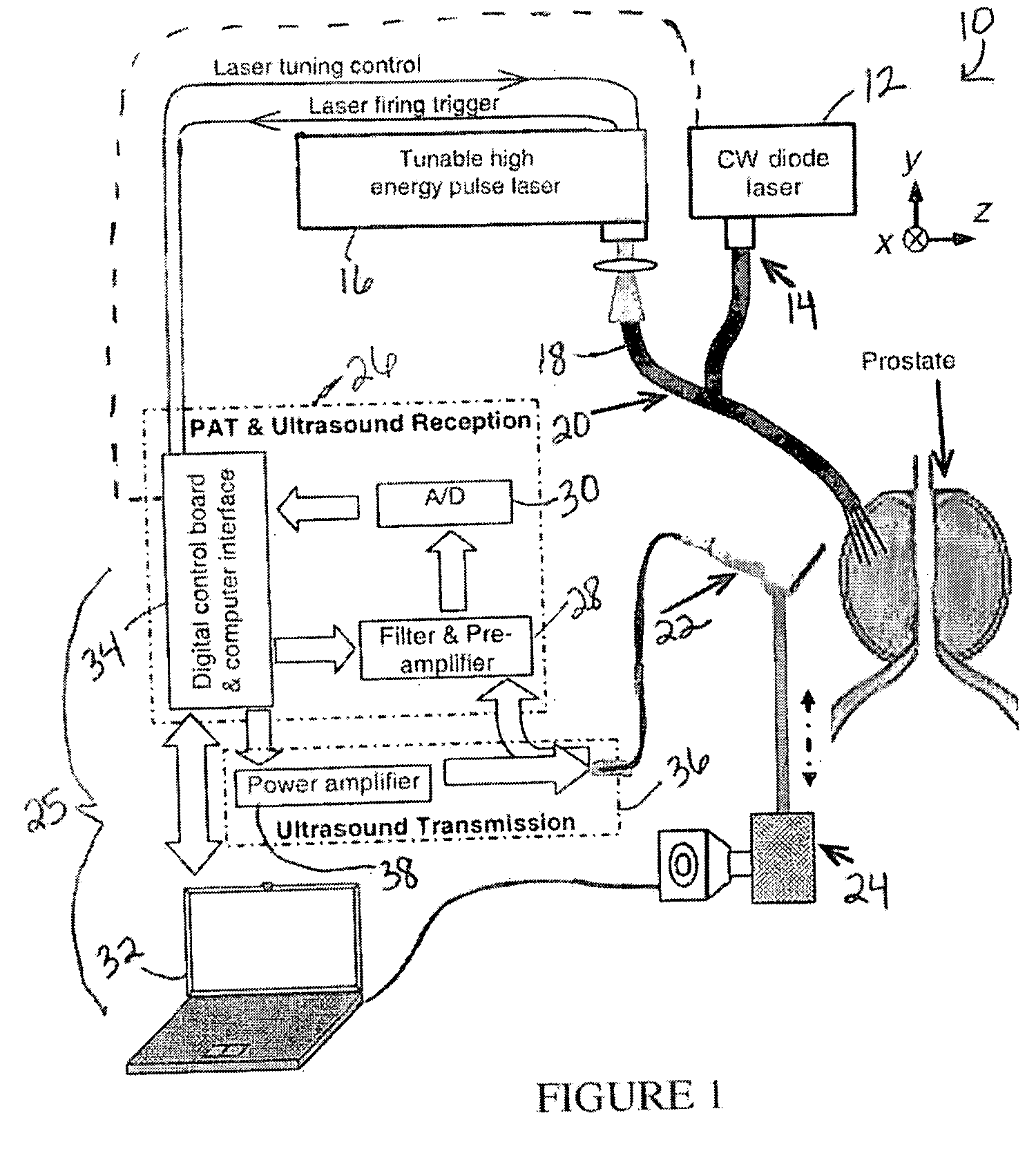

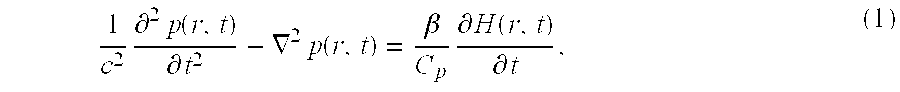

System and method for monitoring photodynamic therapy

InactiveUS20080221647A1High electromagnetic contrastHighly sensitive detection and monitoringSurgeryCharacter and pattern recognitionPhotodynamic therapyUltrasonic sensor

A system and method for monitoring photodynamic therapy of a target tissue, where the target tissue contains a photosensitizing substance, include a first light source configured to deliver light to the target tissue, the first light source having a wavelength capable of exciting the photosensitizing substance. An ultrasonic transducer receives photoacoustic signals generated due to optical absorption of light energy by the target tissue, and a control unit in communication with the ultrasonic transducer reconstructs photoacoustic tomographic images from the received photoacoustic signals to provide an indication of optical energy deposition due to the photosensitizing substance in the target tissue.

Owner:RGT UNIV OF MICHIGAN

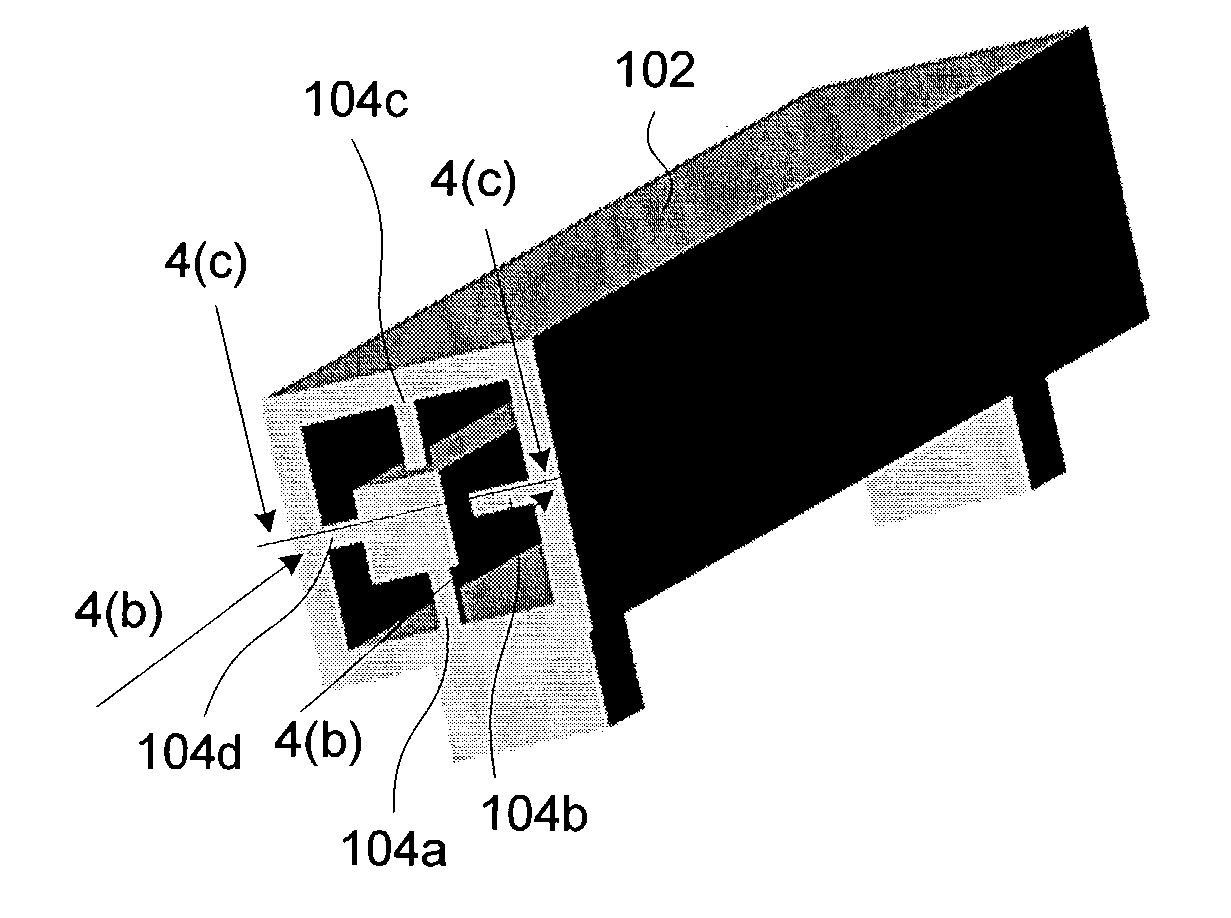

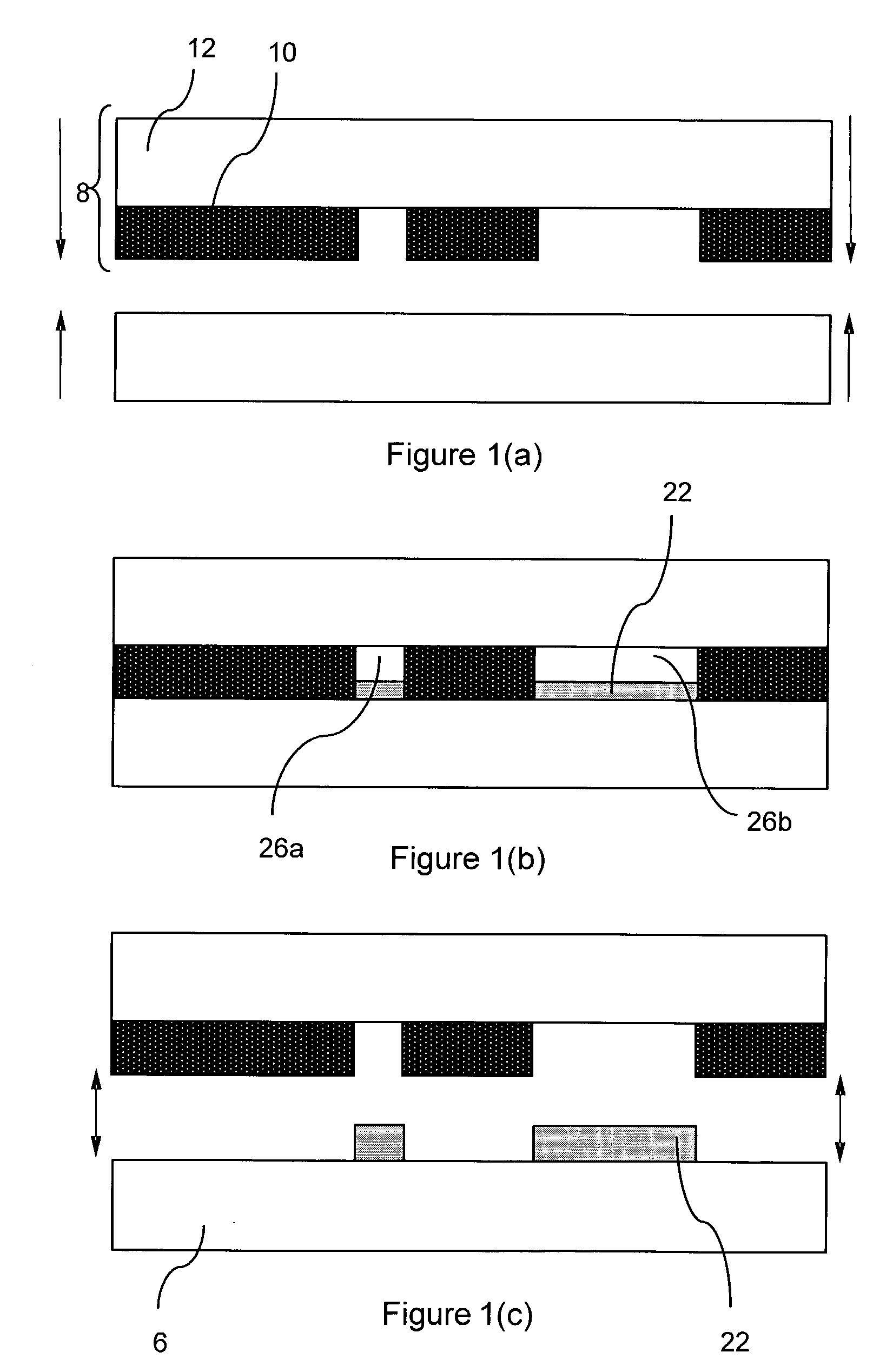

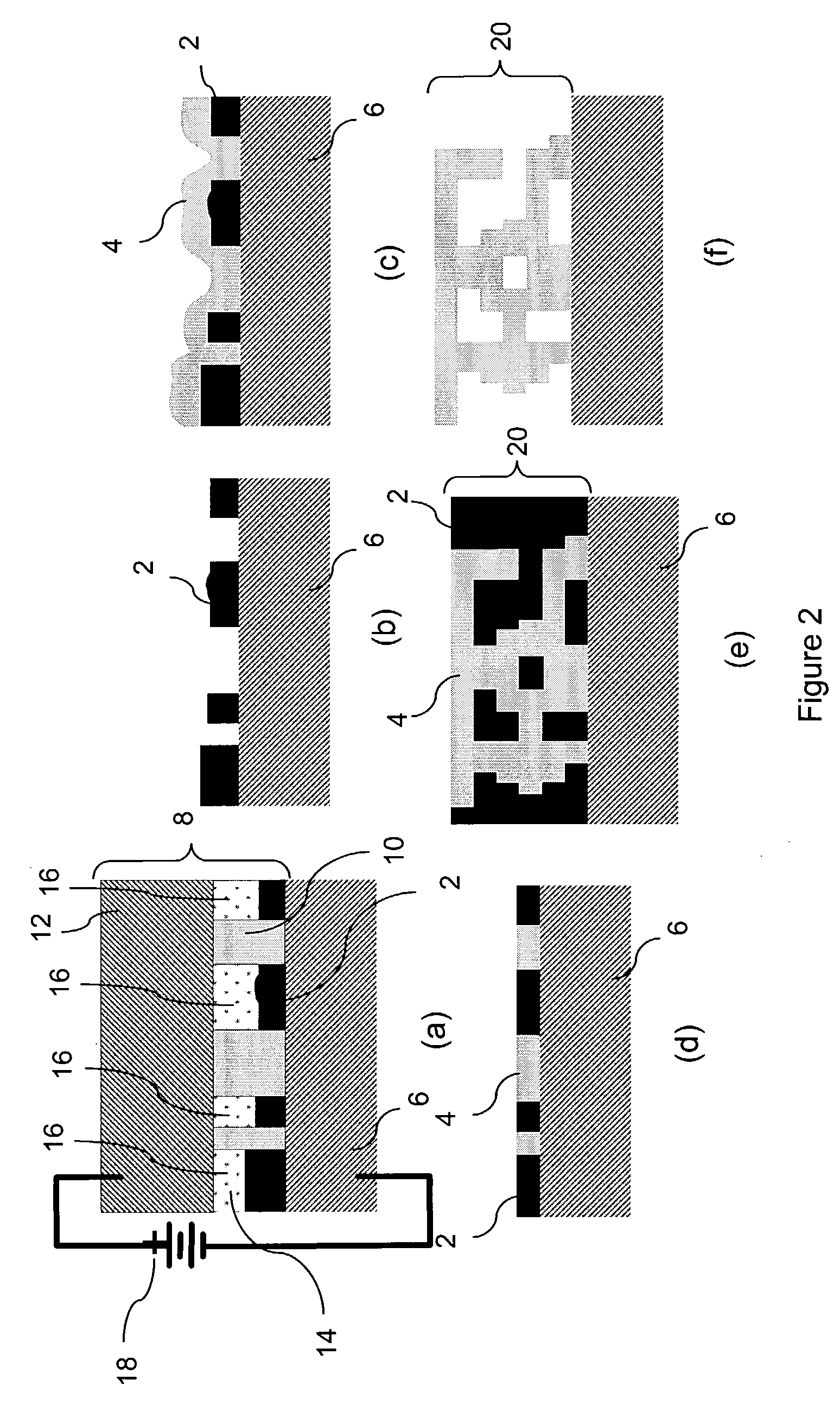

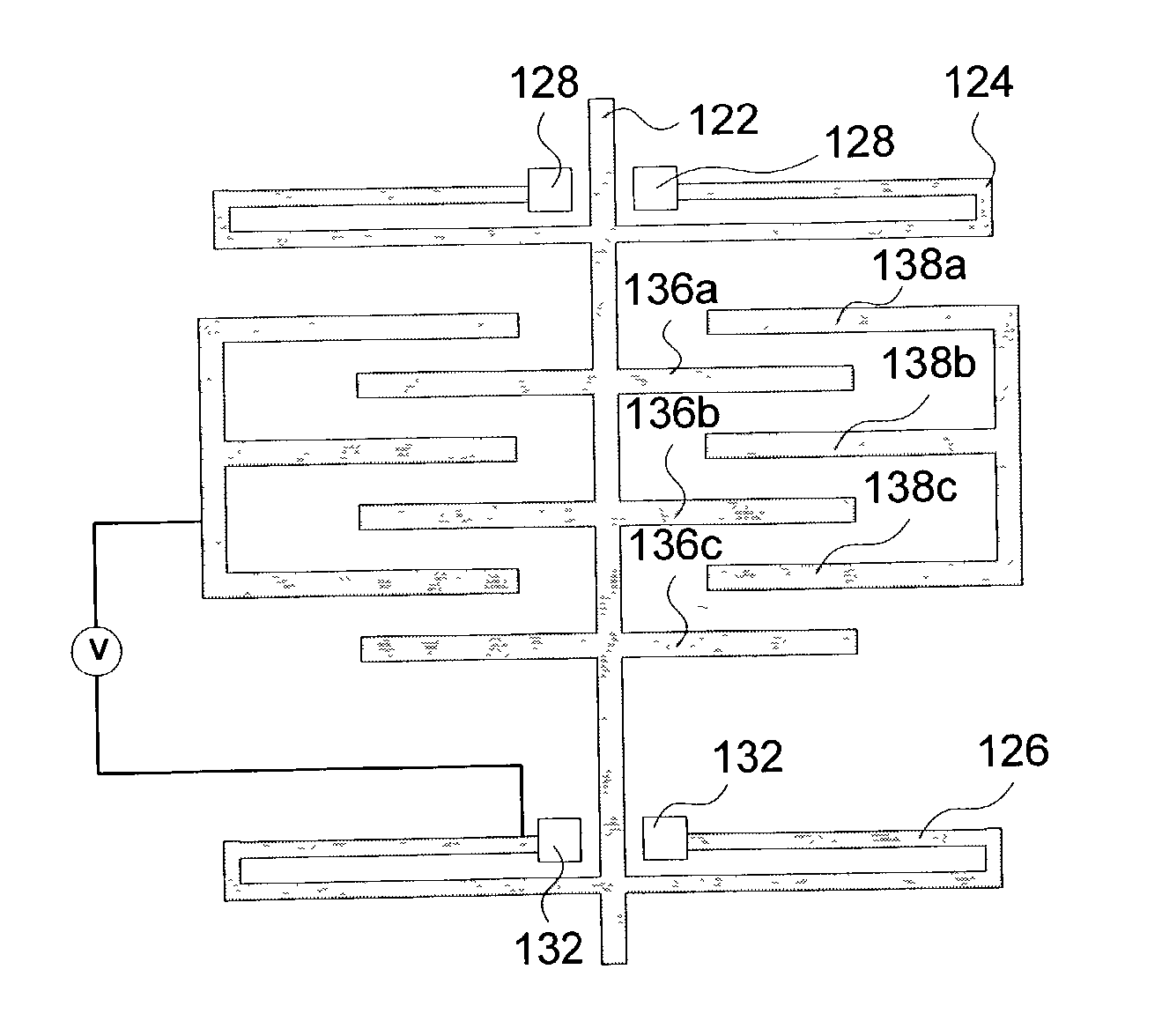

Miniature RF and microwave components and methods for fabricating such components

ActiveUS20030222738A1Add depthAcceleration measurement using interia forcesAdditive manufacturing apparatusElectricityInductor

RF and microwave radiation directing or controlling components are provided that may be monolithic, that may be formed from a plurality of electrodeposition operations and / or from a plurality of deposited layers of material, that may include switches, inductors, antennae, transmission lines, filters, and / or other active or passive components. Components may include non-radiation-entry and non-radiation-exit channels that are useful in separating sacrificial materials from structural materials. Preferred formation processes use electrochemical fabrication techniques (e.g. including selective depositions, bulk depositions, etching operations and planarization operations) and post-deposition processes (e.g. selective etching operations and / or back filling operations).

Owner:MEMGEN

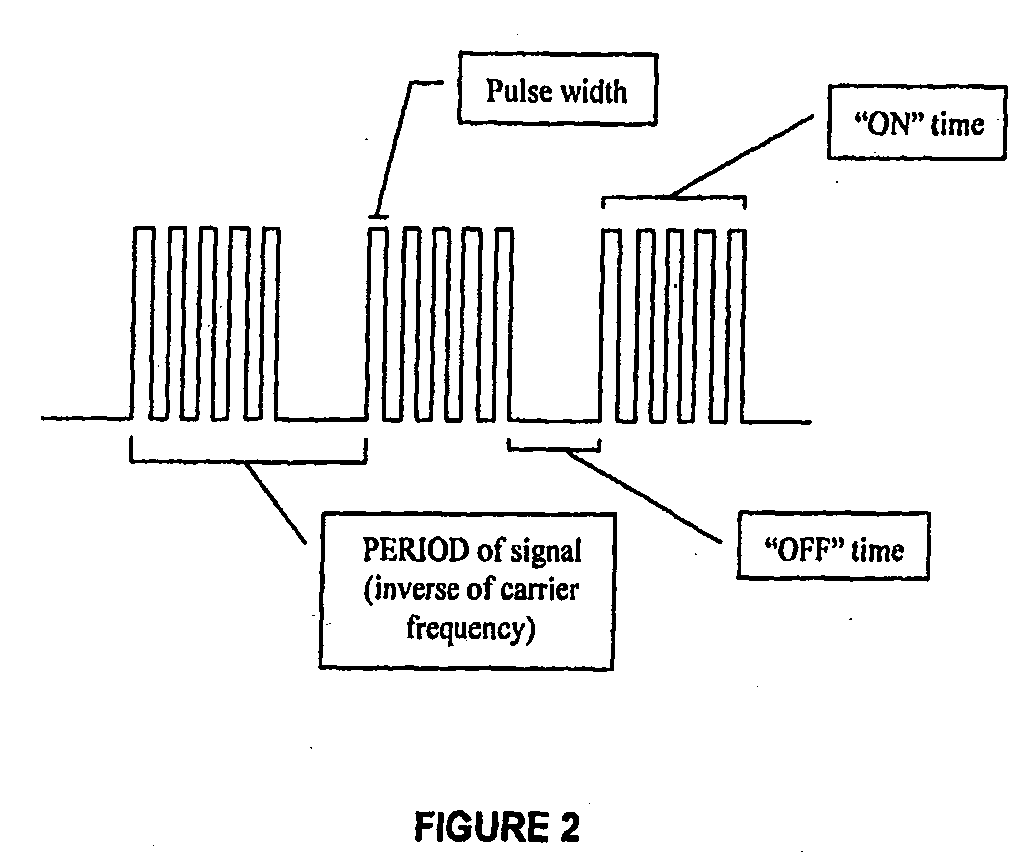

Methods and Apparatus for Electrical Stimulation of Tissues Using Signals that Minimize the Effects of Tissue Impedance

InactiveUS20090030476A1Optimization mechanismFunction increaseElectroencephalographyElectrotherapyElectricityMedicine

A tissue stimulation system that generates an electrical tissue stimulation signal configured to reduce tissue impedance and increase depth of signal penetration. The use of leads is dynamically controlled and altered between conducting biopotential voltages, conducting electrical tissue stimulation signals, and grounding, in response to a computational analysis of biopotential data acquired from a region of tissue to be stimulated.

Owner:HARGROVE JEFFREY B

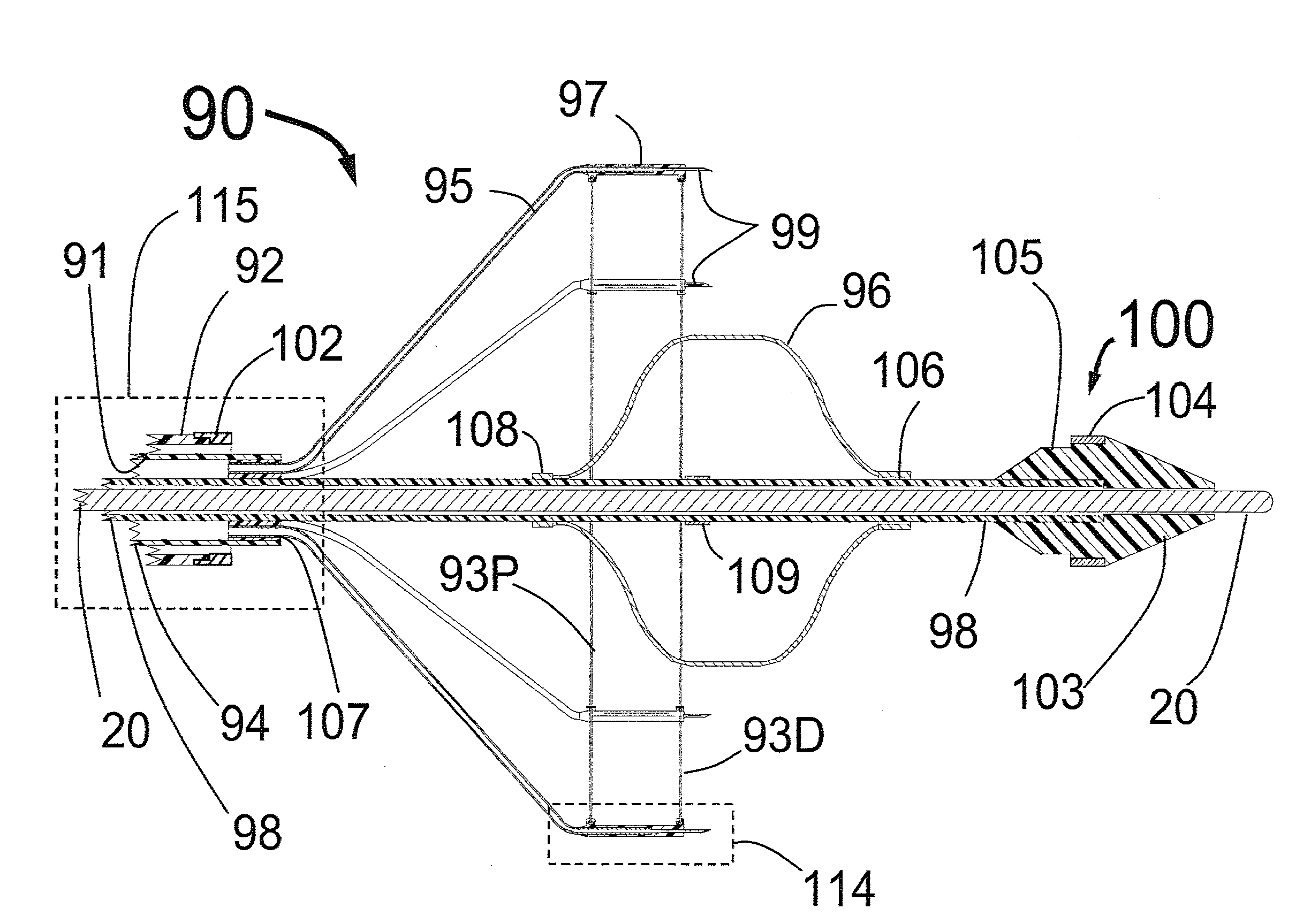

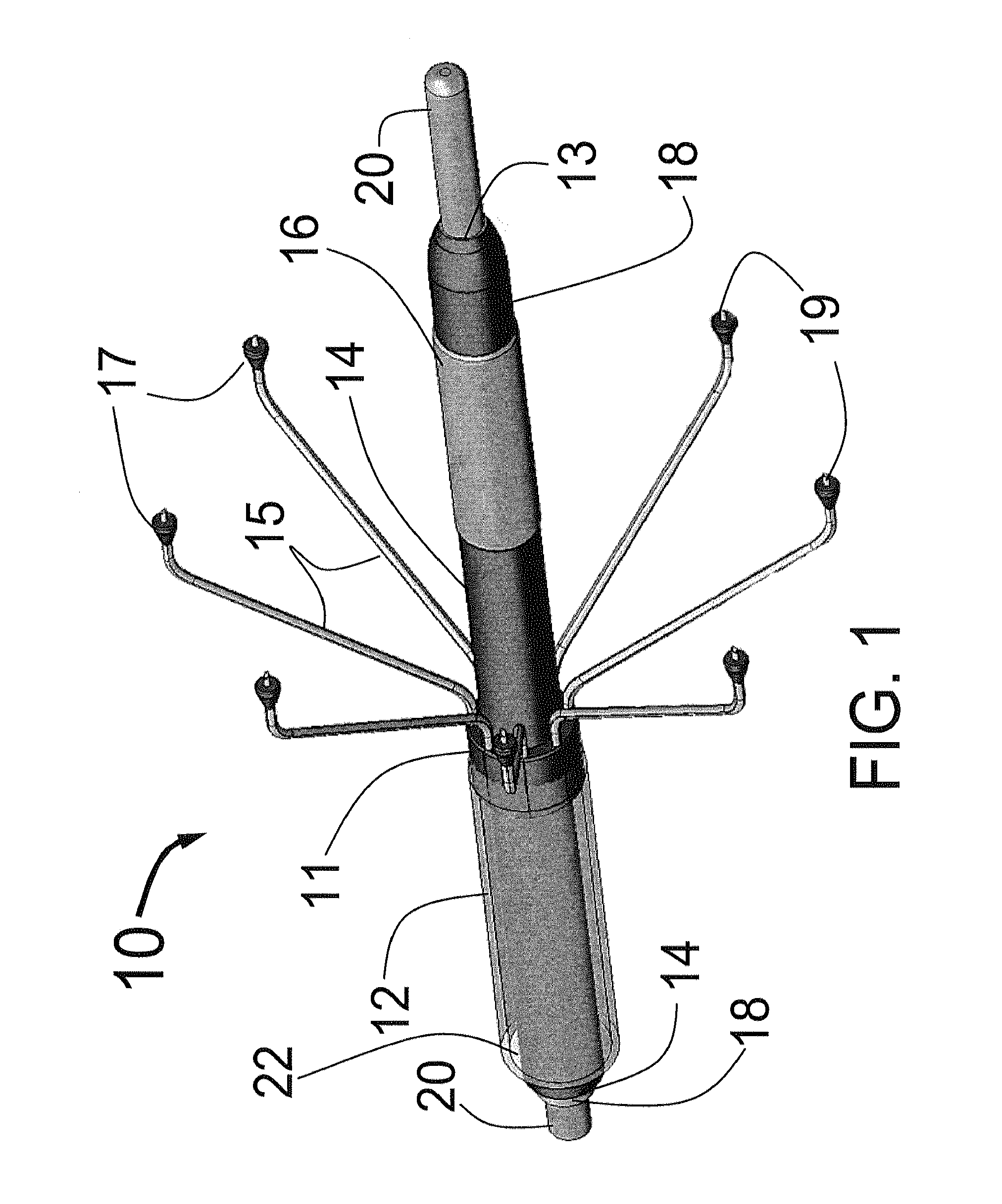

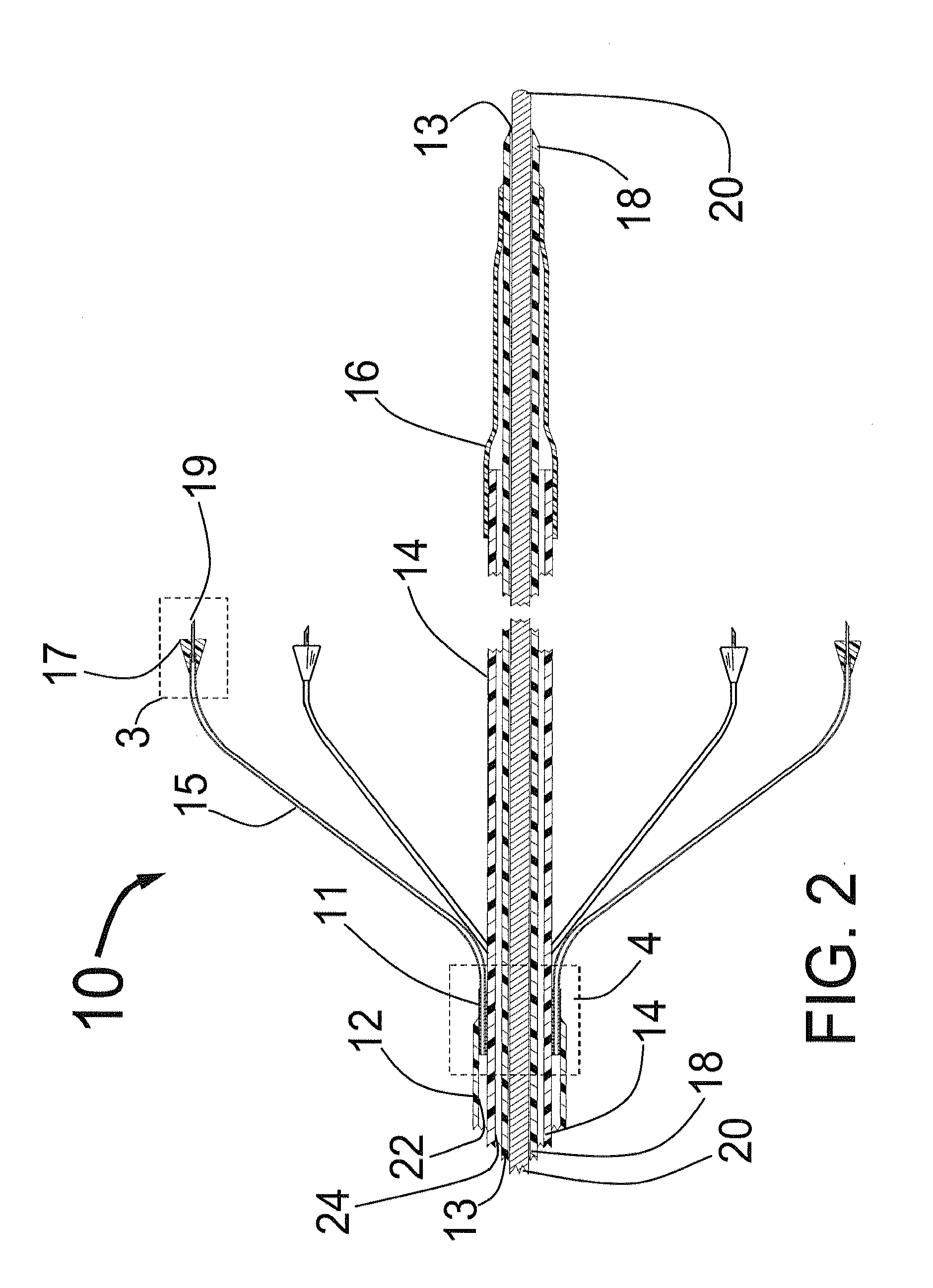

Expandable catheter system for peri-ostial injection and muscle and nerve fiber ablation

ActiveUS20120271277A1Improve control and treatmentTime efficient and safeElectrocardiographySurgical needlesCapital equipmentLeft atrium

At the present time, physicians often treat patients with atrial fibrillation (AF) using radiofrequency (RF) catheter systems to ablate conducting tissue in the wall of the Left Atrium of the heart around the ostium of the pulmonary veins. These systems are expensive and take time consuming to use. The present invention circular ablation system CAS includes a multiplicity of expandable needles that can be expanded around a central axis and positioned to inject a fluid like ethanol to ablate conductive tissue in a ring around the ostium of a pulmonary vein quickly and without the need for expensive capital equipment. The expansion of the needles is accomplished by self-expanding or balloon expandable structures. The invention includes centering means so that the needles will be situated in a pattern surrounding the outside of the ostium of a vein. Also included are members that limit the distance of penetration of the needles into the wall of the left atrium, or the aortic wall. The present invention also has an important application to ablate tissue around the ostium of one or both renal arteries, for the ablation of the sympathetic nerve fibers and / or other afferent or efferent nerves going to or from each kidney in order to treat hypertension.

Owner:ABLATIVE SOLUTIONS INC

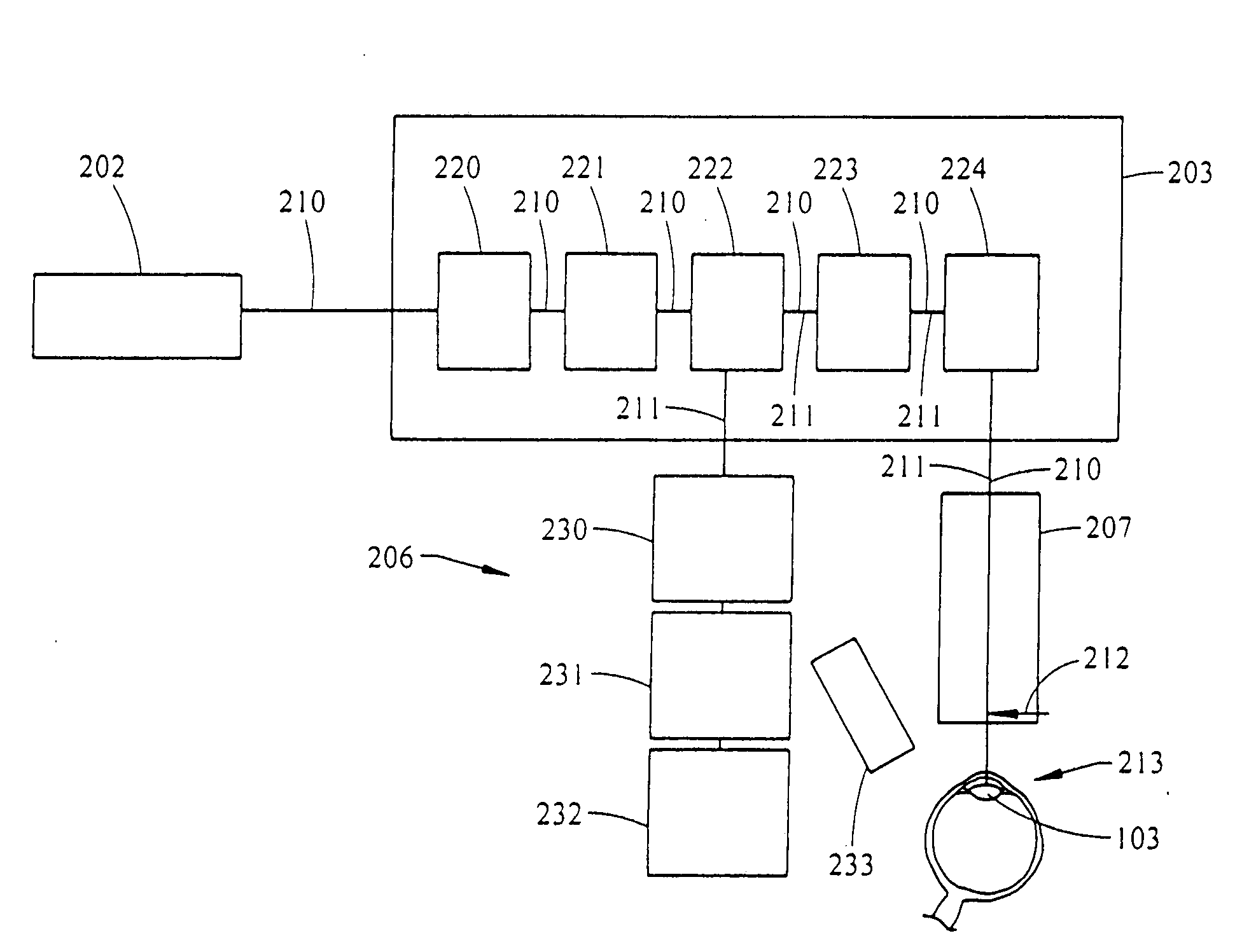

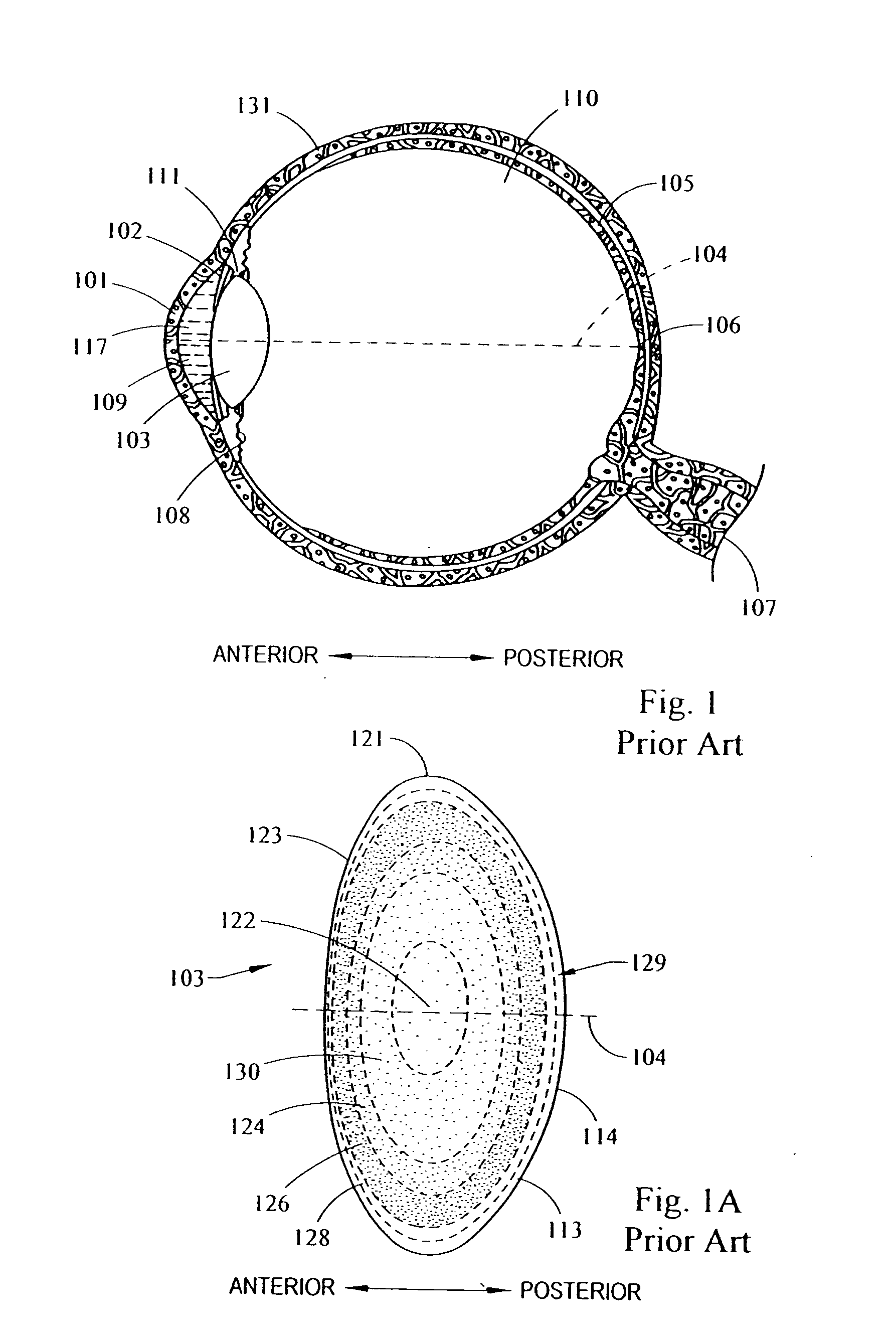

System and method for improving the accommodative amplitude and increasing the refractive power of the human lens with a laser

ActiveUS20100004643A1Add depthIncrease flexibilityLaser surgerySurgical instrument detailsRefractive errorDepth of field

A system and method for increasing the amplitude of accommodation and / or changing the refractive power of lens material of a natural crystalline lens is provided. Generally, there is provided methods and systems for delivering a laser beam to a lens of an eye in a plurality of patterns results in the increased accommodative amplitude and / or refractive power of the lens. There is further provided a system and method of treating presbyopia by increasing both the flexibility of the human lens and the depth of field of the eye.

Owner:LENSAR LLC

Complex microdevices and apparatus and methods for fabricating such devices

InactiveUS20030183008A1Add depthAcceleration measurement using interia forcesAdditive manufacturing apparatusAccelerometerEngineering

Owner:MEMGEN

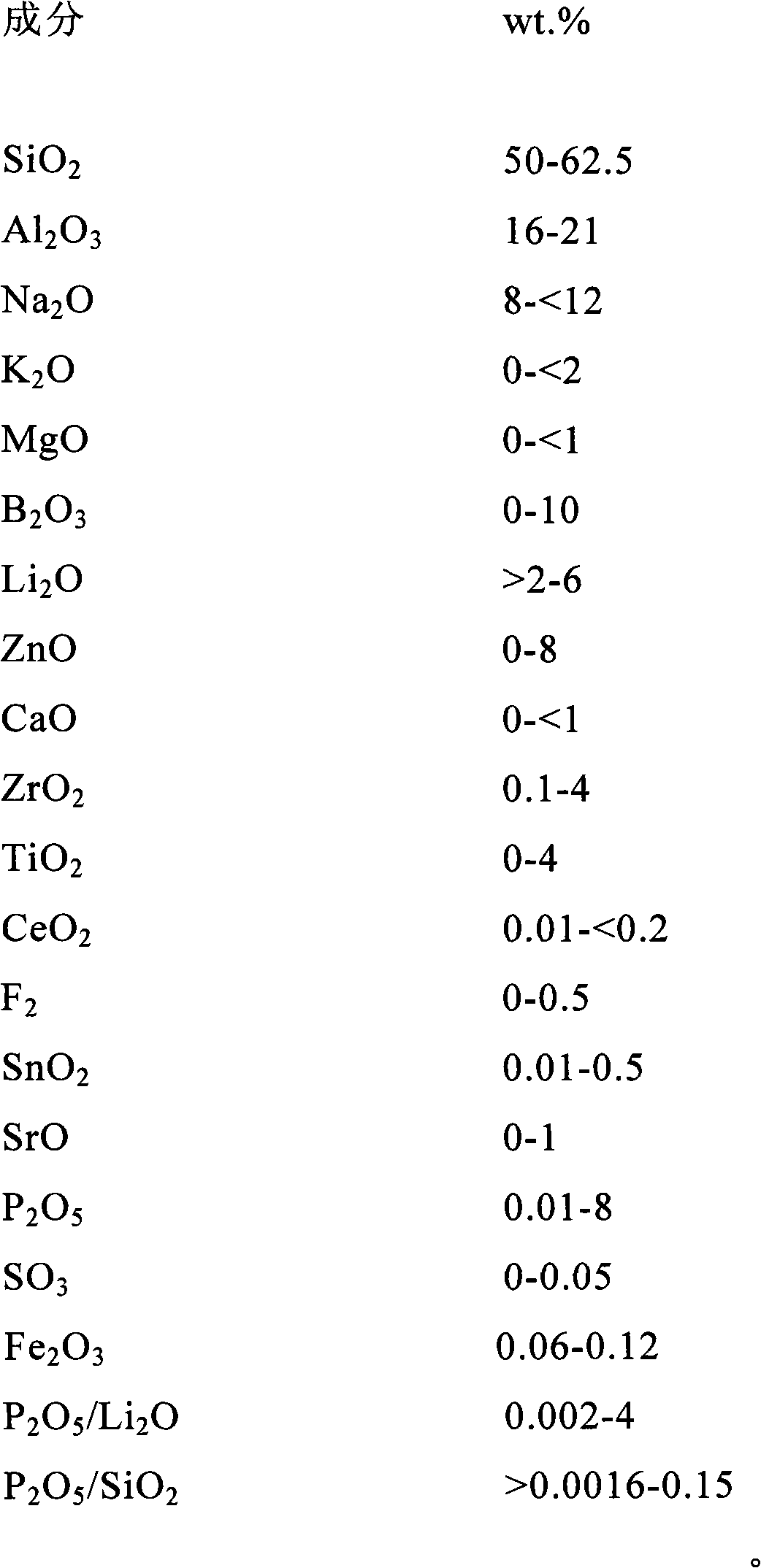

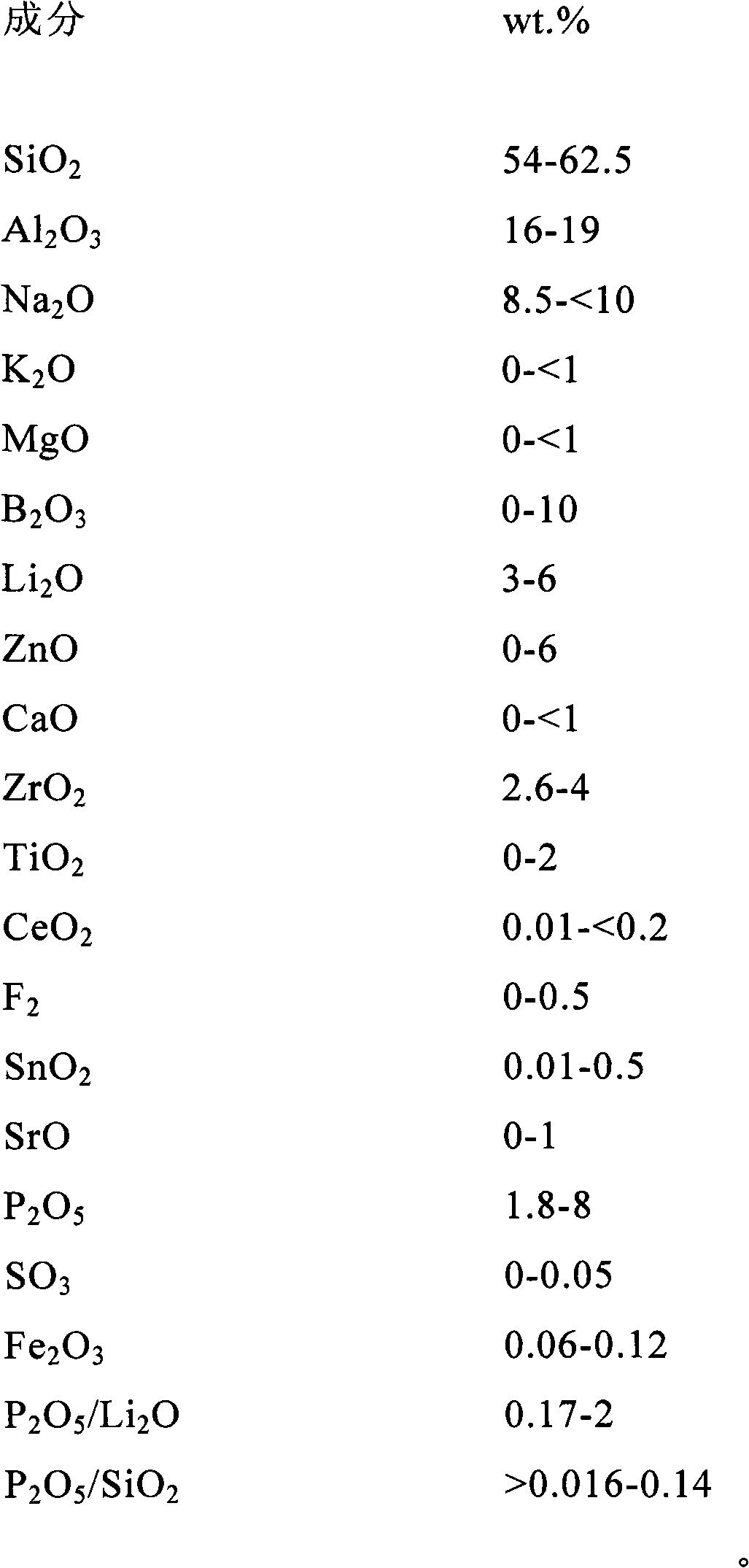

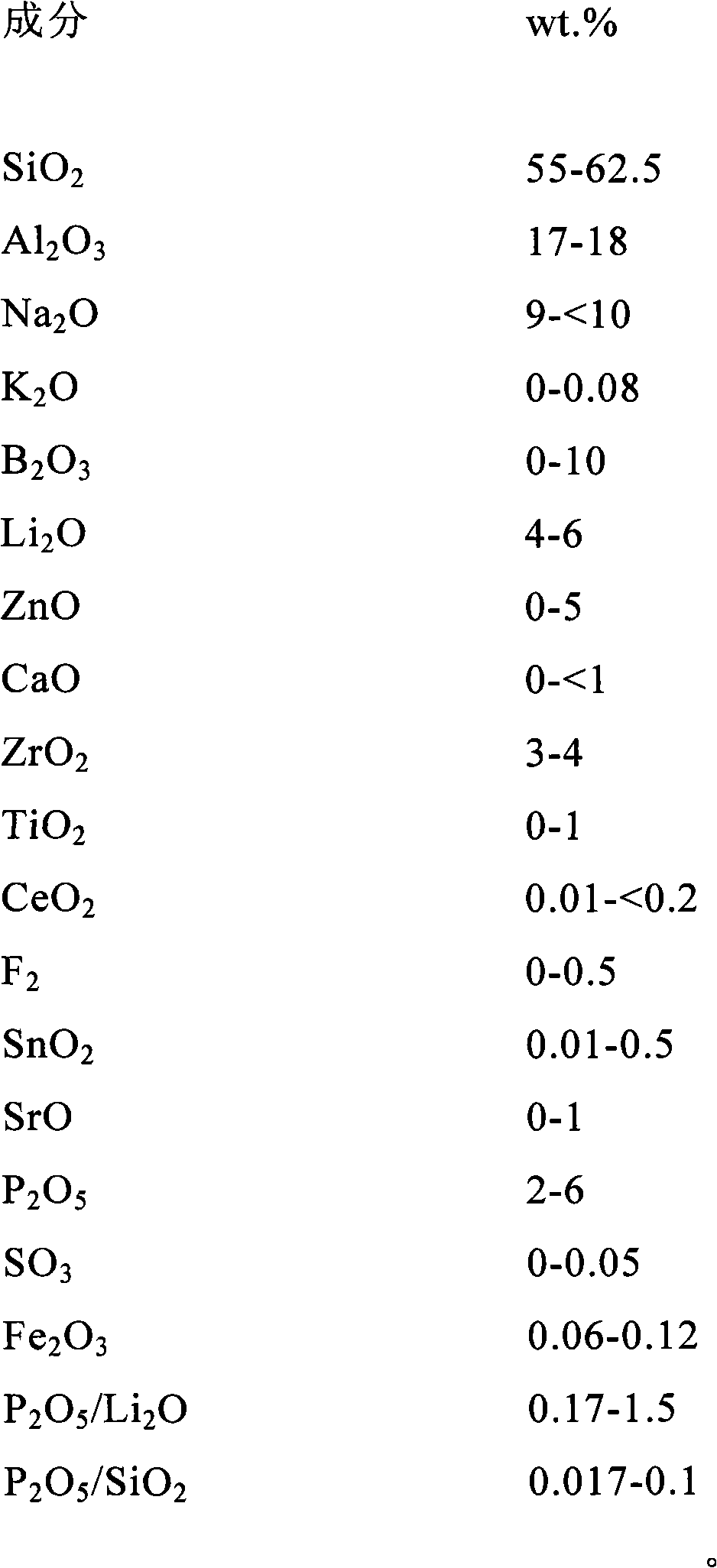

Aluminosilicate glass for chemical tempering and glass ceramics

The invention discloses aluminosilicate glass for chemical tempering and glass ceramics, and particularly discloses aluminosilicate glass which contains Li2O and P2O5 and can be chemically tempered. The glass of the invention can realize high ion exchange speed by the addition of 0.01-8 wt% of P2O5. The glass of the invention contains 2-6 wt% of Li2O, which can reduce the glass melting temperature and the glass-transition temperature. The glass of the invention has a low glass-transition temperature (Tg) of 480-590 DEG C, and the glass hardness is at least 600 Kg / mm2. After chemical tempering, the glass of the invention has a large surface stress layer depth (DoL) and a high surface crushing stress (CS). After tempering in pure KNO3, a potassium ion stress layer is formed, which has a DoL of at least 20 microns and a CS of at least 600 MPa. After tempering in a mixed salt of KNO3 and NaNO3 or two-step tempering in KNO3 and NaNO3, a potassium and sodium ion stress layers can be formed simultaneously, which have a DoL of at least 50 microns and a CS of at least 600 MPa. In addition, the aluminosilicate glass of the invention can be converted into glass ceramics through further heat treatment.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

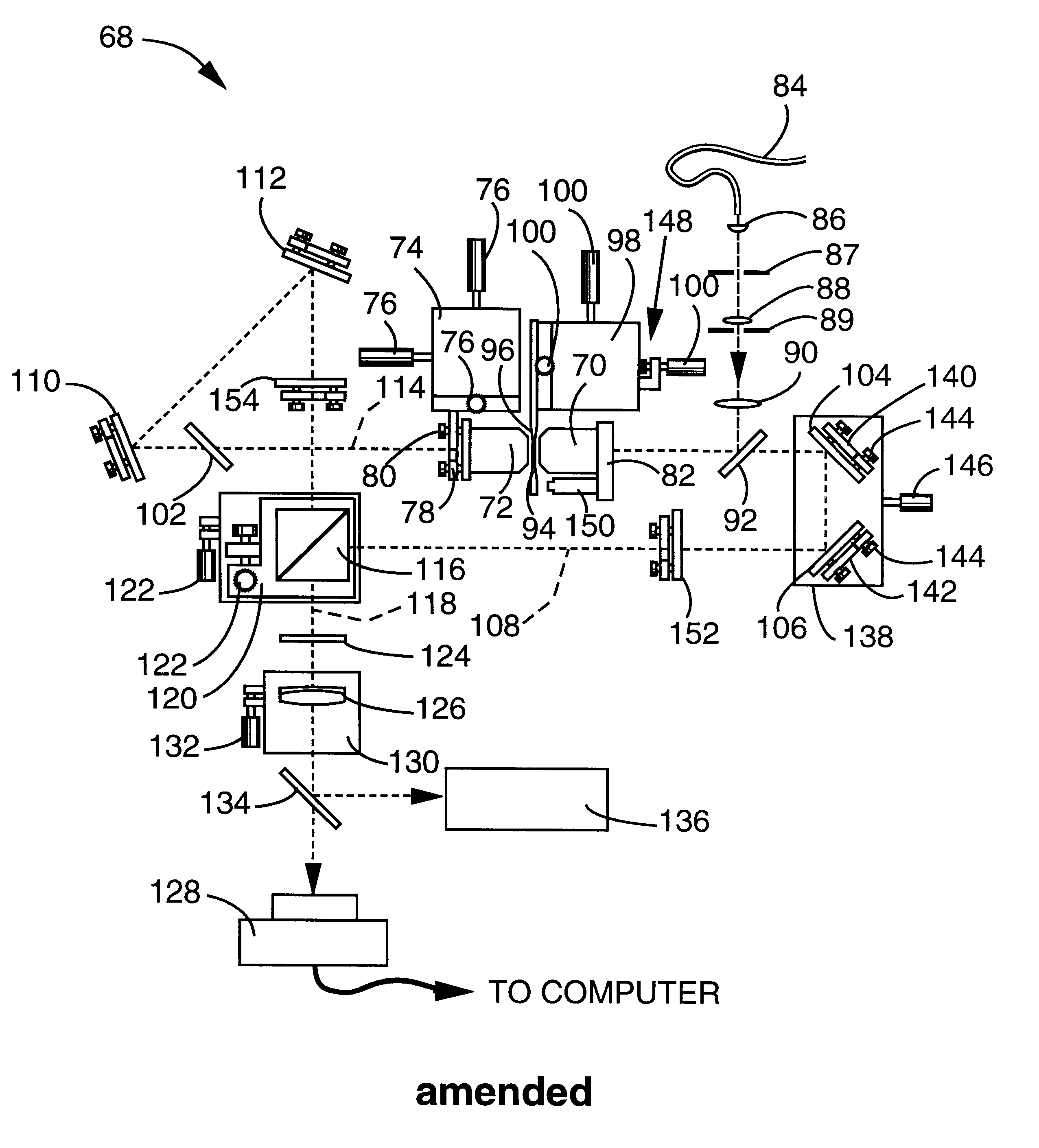

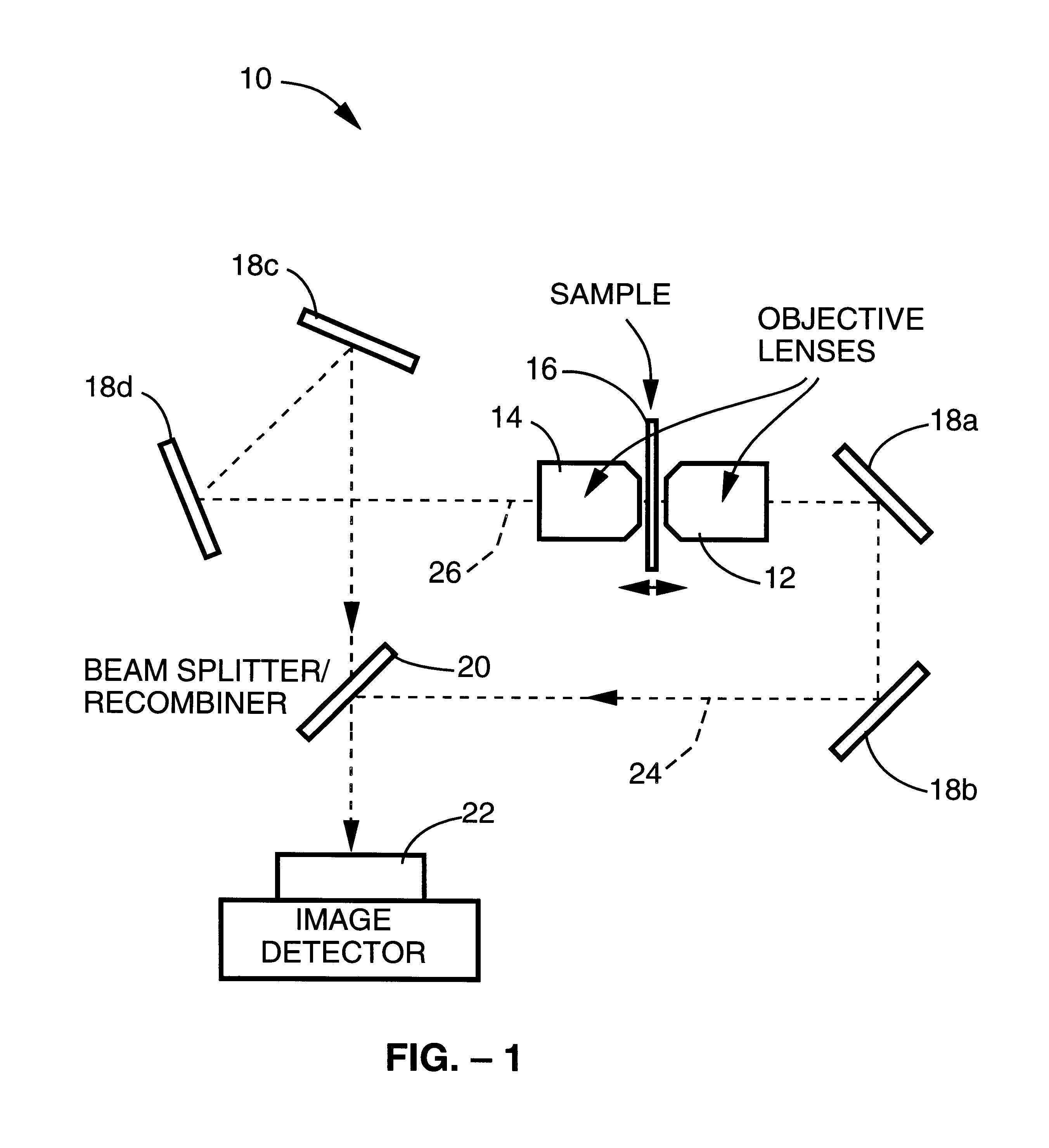

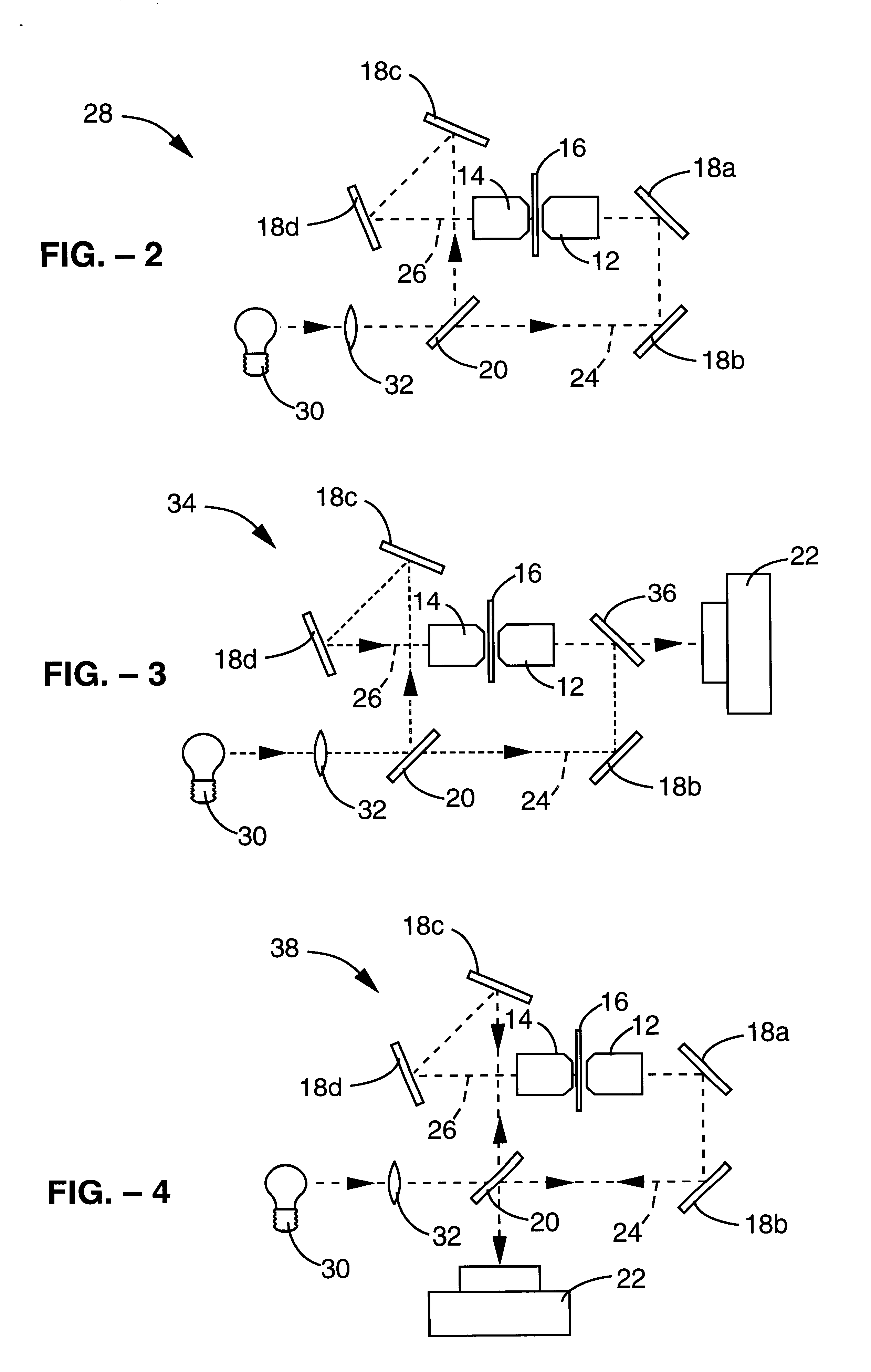

Method and apparatus for three-dimensional microscopy with enhanced resolution

InactiveUSRE38307E1Add depthImprove resolutionMicroscopesColor/spectral properties measurementsOphthalmologyImage resolution

A method and apparatus for three dimensional optical microscopy is disclosed which employs dual opposing objective lenses about a sample and extended incoherent illumination to provide enhanced depth or Z.Iadd.-.Iaddend.direction resolution. In a first embodiment, observed light from both objective lenses are brought into coincidence on an image detector and caused to interfere thereon by optical path length adjustment. In a second embodiment, illuminating light from an extended incoherent light source is detected to the sample through both objective lenses and caused to interfere with a section of the sample by adjusting optical path lengths. Observed light from one objective lens is then recorded. In a third embodiment, which combines the first two embodiments, illuminating light from an extended incoherent light source is directed to the sample through both objective lenses and caused to interfere within a section of the sample by adjusting optical path lengths. The observed light from both lenses is caused to interfere on the image detector by the same optical path length adjustment. .Iadd.In a fourth embodiment of the invention, further spatial structure is introduced into the illumination light. Computational processing is used to enhance lateral or XY resolution as well as depth or Z resolution..Iaddend.

Owner:RGT UNIV OF CALIFORNIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com