Aluminosilicate glass for chemical tempering and glass ceramics

A kind of aluminosilicate glass, chemical tempering technology, applied in the field of aluminosilicate glass containing Li2O and P2O5, glass ceramics, can not meet the requirements of 3D molding, can not meet the high DoL, not suitable for melting and forming Equipment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

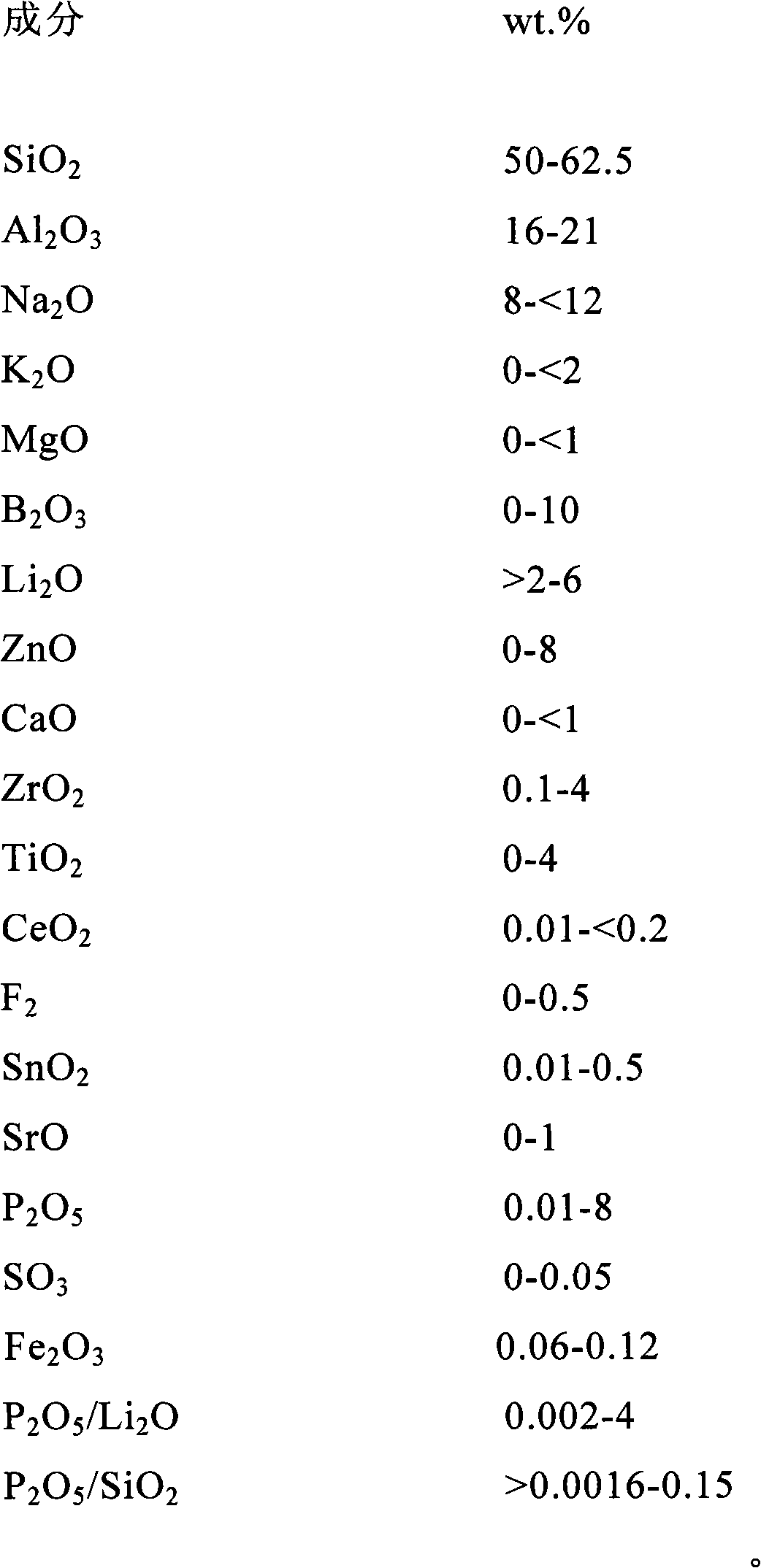

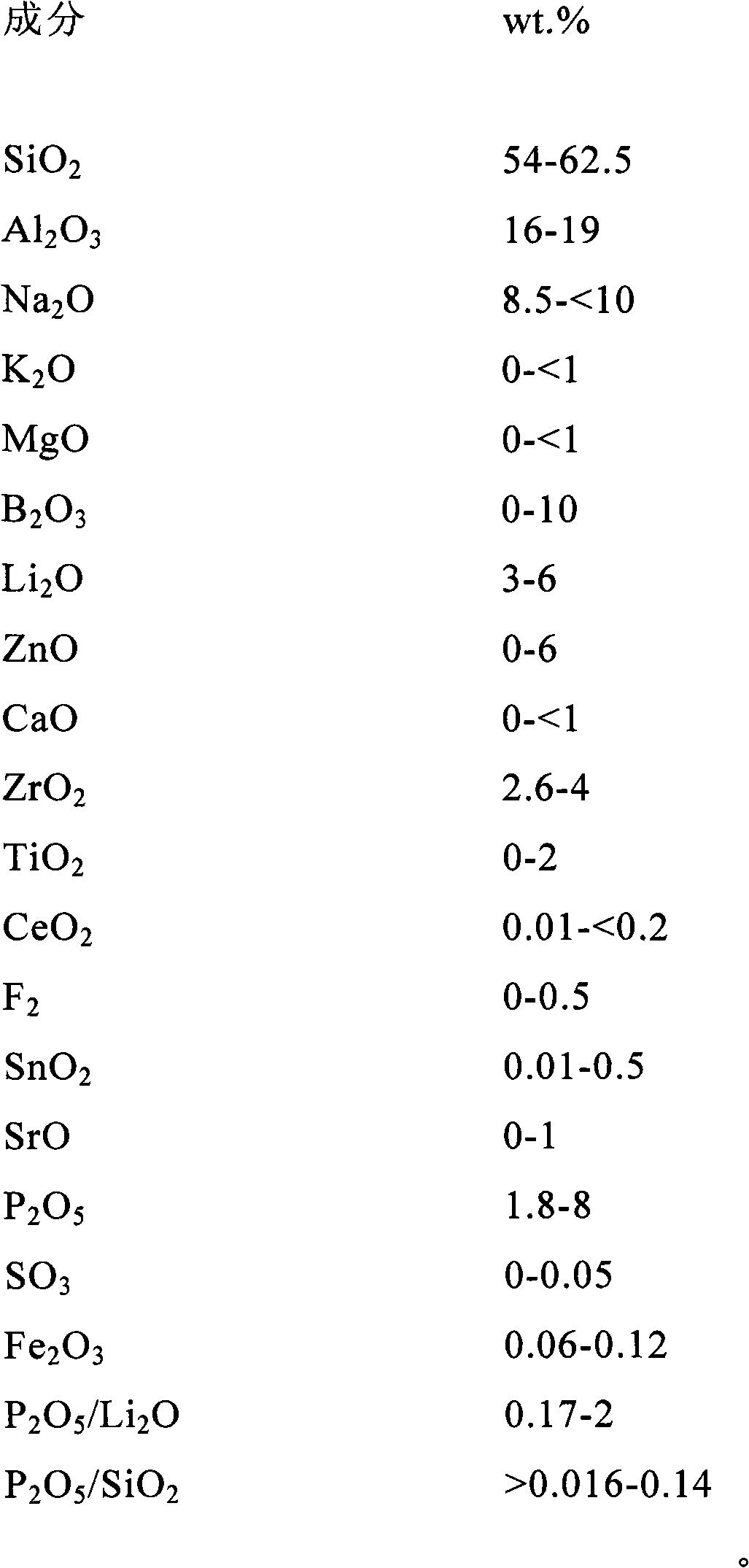

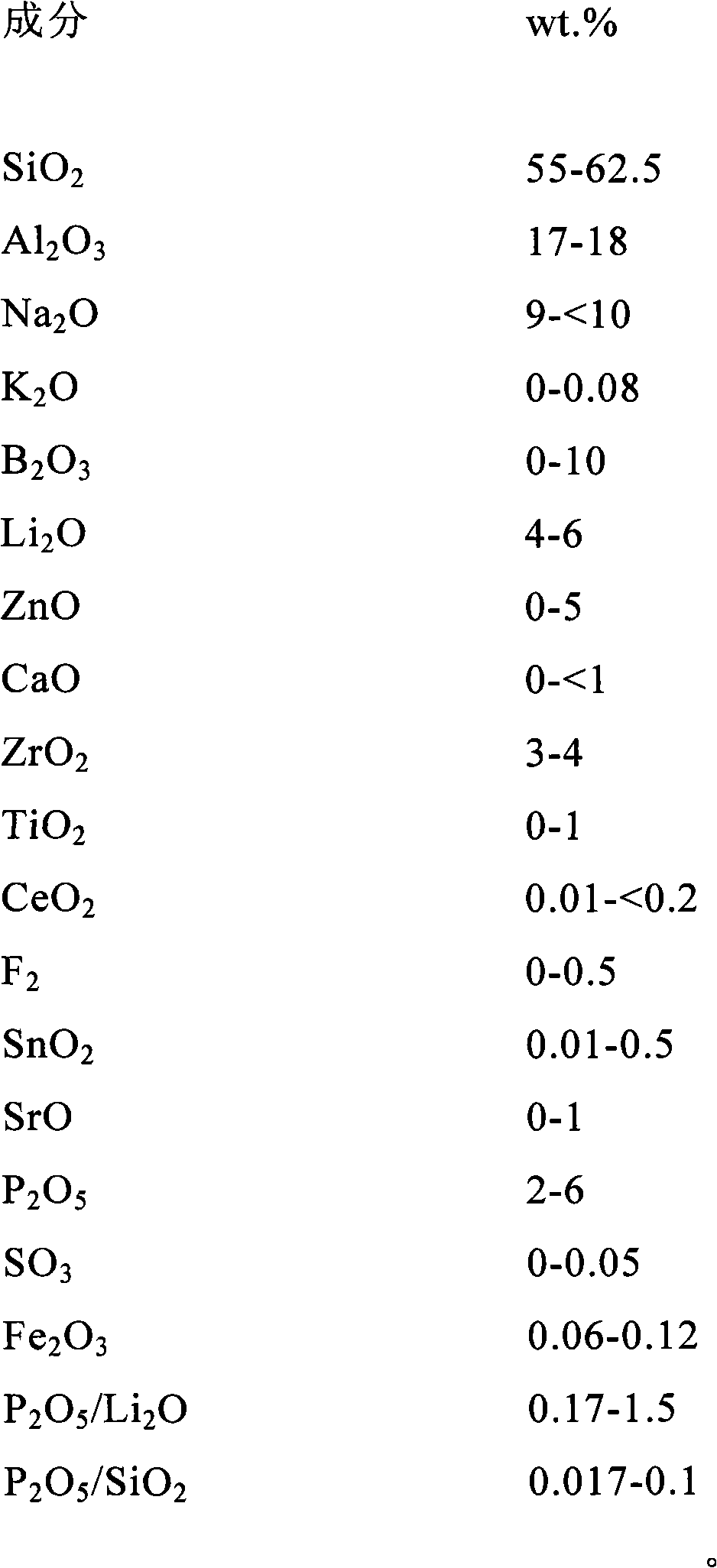

[0170] Table 1 lists examples within preferred compositional ranges. The glass of the embodiment of the present invention and comparative example is prepared according to the following steps: raw material oxide, hydroxide, carbonate and nitrate etc. (all purchased from Sinopharm Group Chemical Reagent Co., Ltd., Suzhou, chemical grade), after weighing and After mixing, the mixture was placed in a platinum crucible. It is then placed in an electric furnace, melted at 1550-1600°C, cast in a stainless steel mold preheated to 400°C, and cooled slowly for the next step of processing.

[0171] The transition temperature T of the glass in this experiment g , Yield point AT (refers to the deformation point temperature on the thermal expansion curve) and thermal expansion coefficient CTE, measured on a relaxation thermal dilatometer (relaxation DIL402PC). After the glass sample is made into a strip sample of about 50mm, the temperature is raised from room temperature at a rate of 5°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com