Patents

Literature

998 results about "Glass melting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Melting is the process where a solid becomes a liquid (ex. ice melts to water) which is more or less abrupt.You see glass doesn't actually melt persay. Rather it goes through a glass phase transition. Meaning that when it comes to glass "melting"it's a more gradual process.

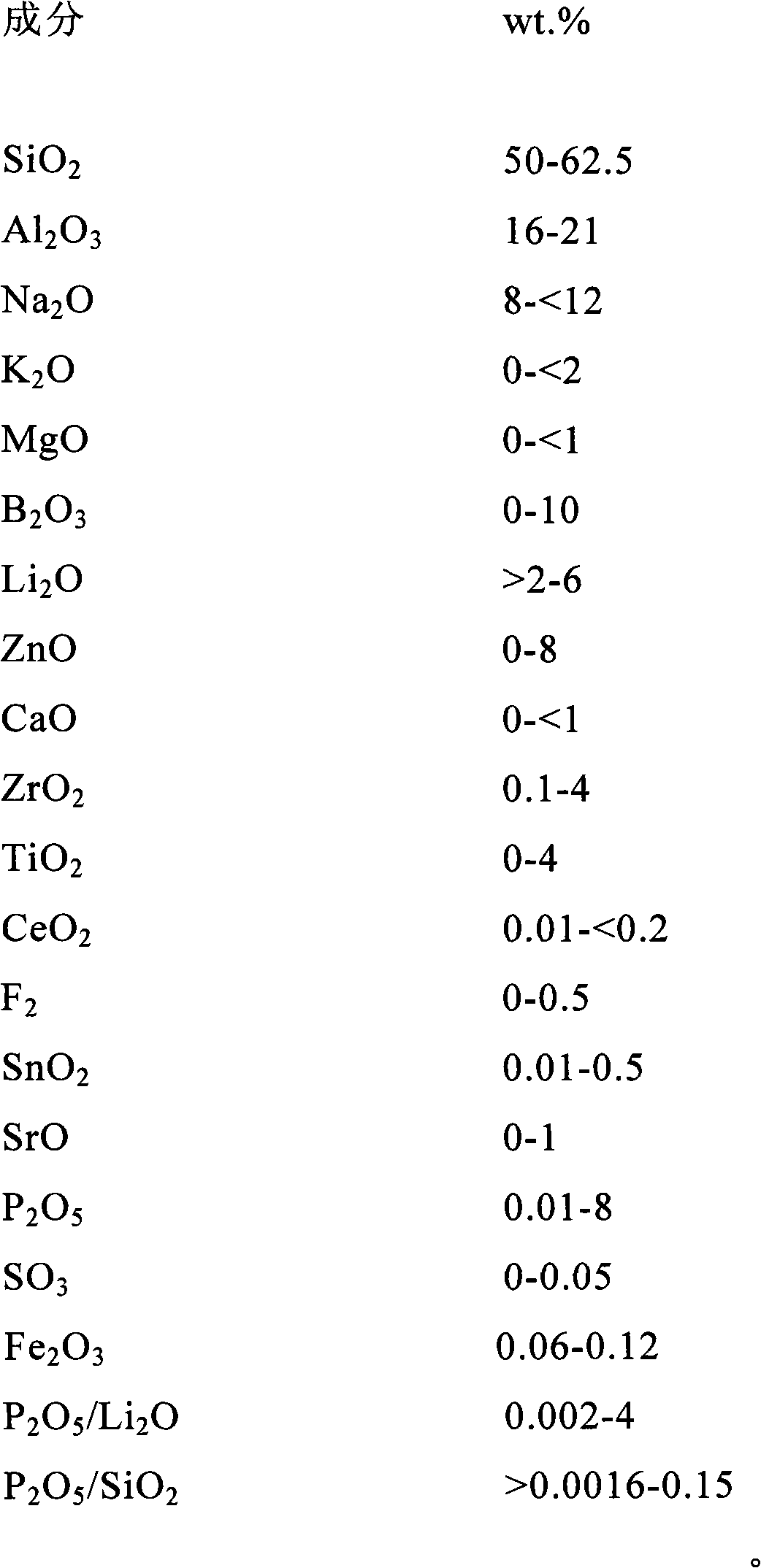

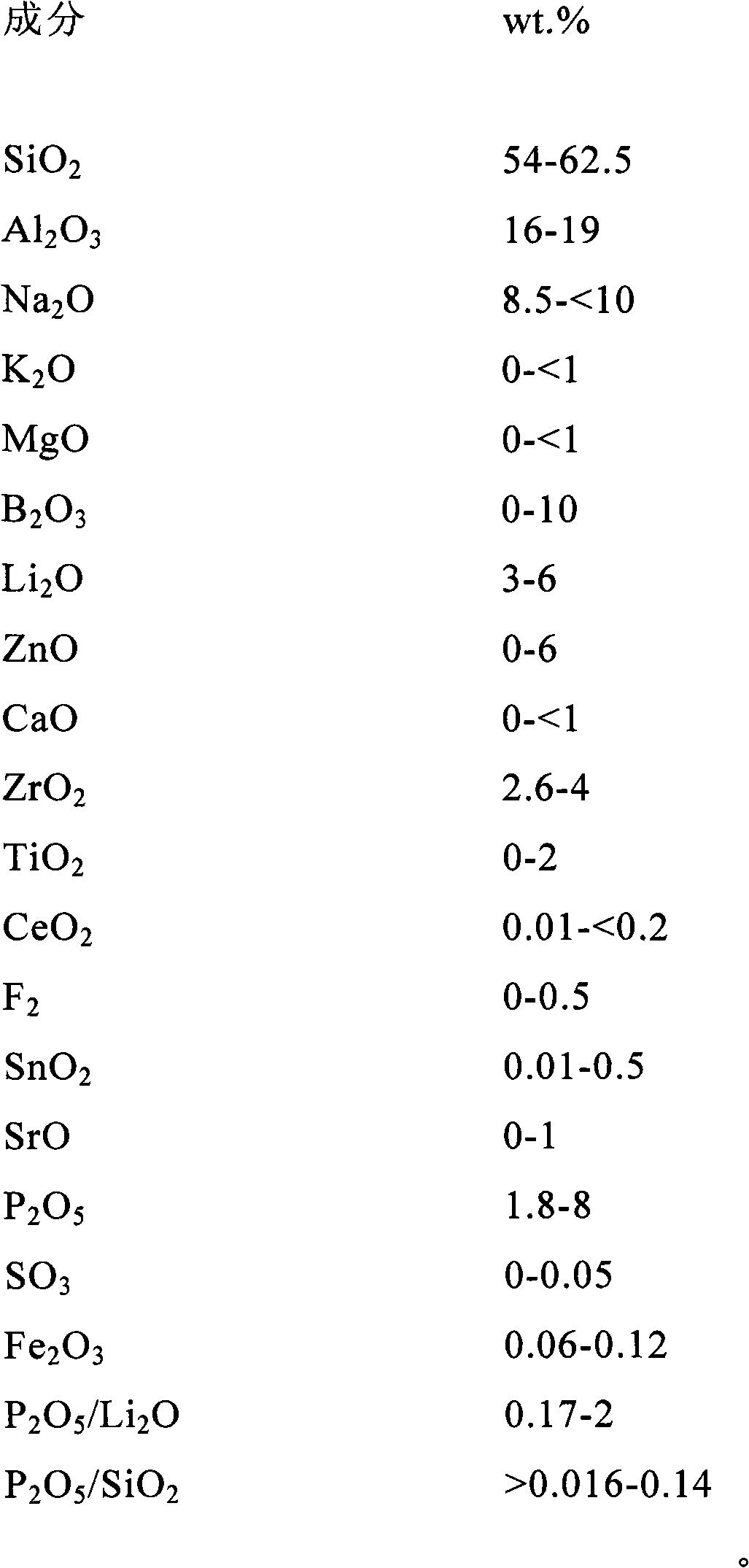

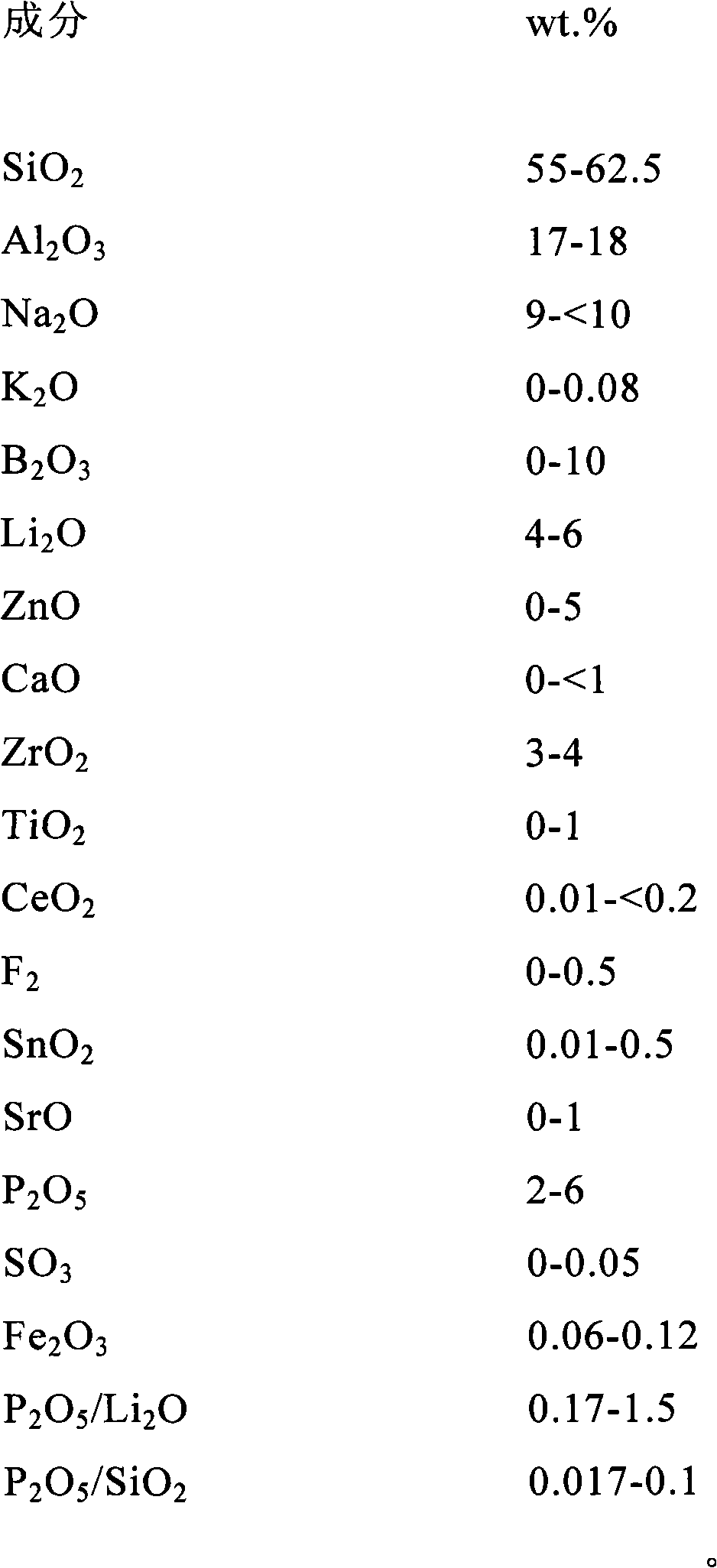

Aluminosilicate glass for chemical tempering and glass ceramics

The invention discloses aluminosilicate glass for chemical tempering and glass ceramics, and particularly discloses aluminosilicate glass which contains Li2O and P2O5 and can be chemically tempered. The glass of the invention can realize high ion exchange speed by the addition of 0.01-8 wt% of P2O5. The glass of the invention contains 2-6 wt% of Li2O, which can reduce the glass melting temperature and the glass-transition temperature. The glass of the invention has a low glass-transition temperature (Tg) of 480-590 DEG C, and the glass hardness is at least 600 Kg / mm2. After chemical tempering, the glass of the invention has a large surface stress layer depth (DoL) and a high surface crushing stress (CS). After tempering in pure KNO3, a potassium ion stress layer is formed, which has a DoL of at least 20 microns and a CS of at least 600 MPa. After tempering in a mixed salt of KNO3 and NaNO3 or two-step tempering in KNO3 and NaNO3, a potassium and sodium ion stress layers can be formed simultaneously, which have a DoL of at least 50 microns and a CS of at least 600 MPa. In addition, the aluminosilicate glass of the invention can be converted into glass ceramics through further heat treatment.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

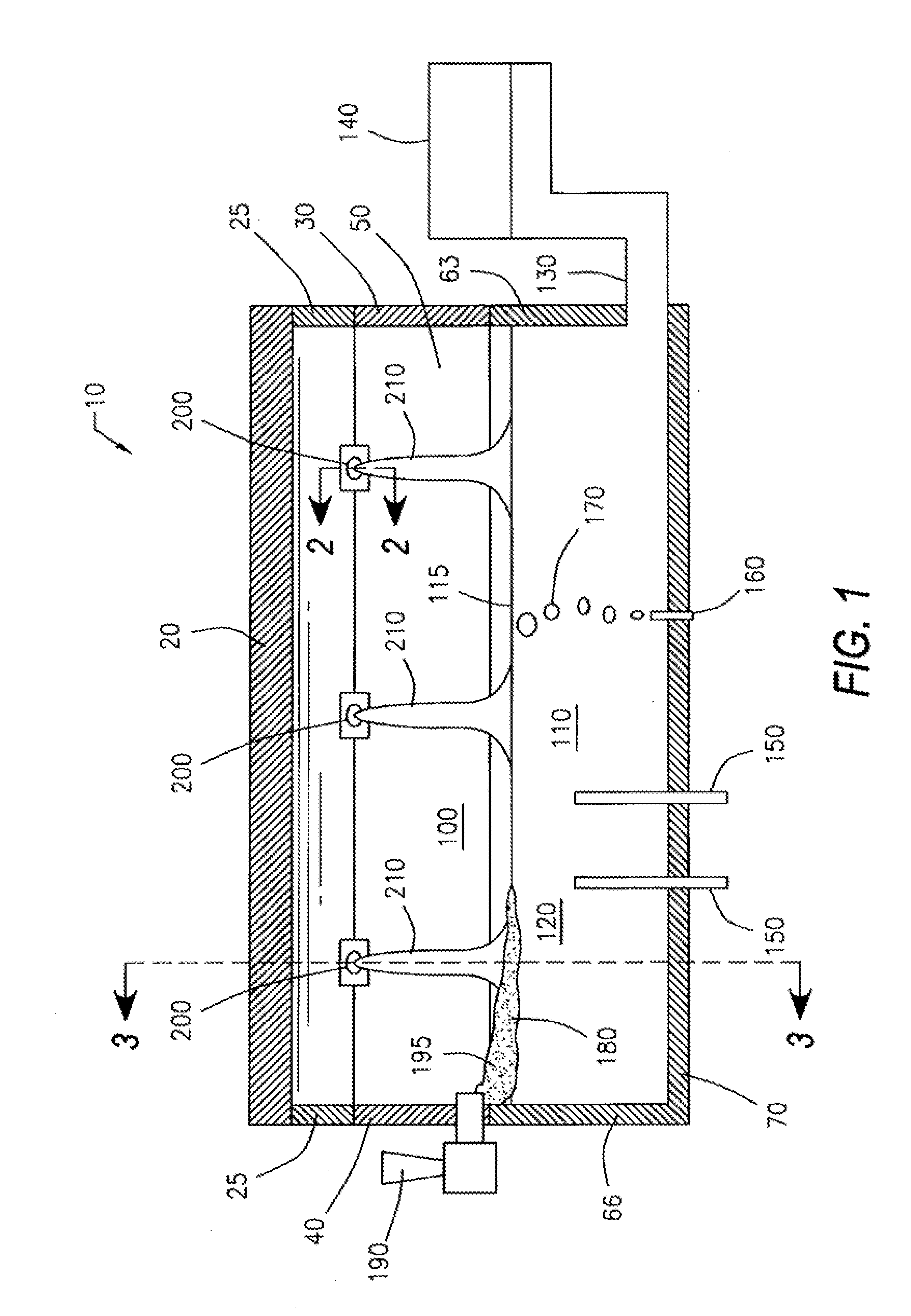

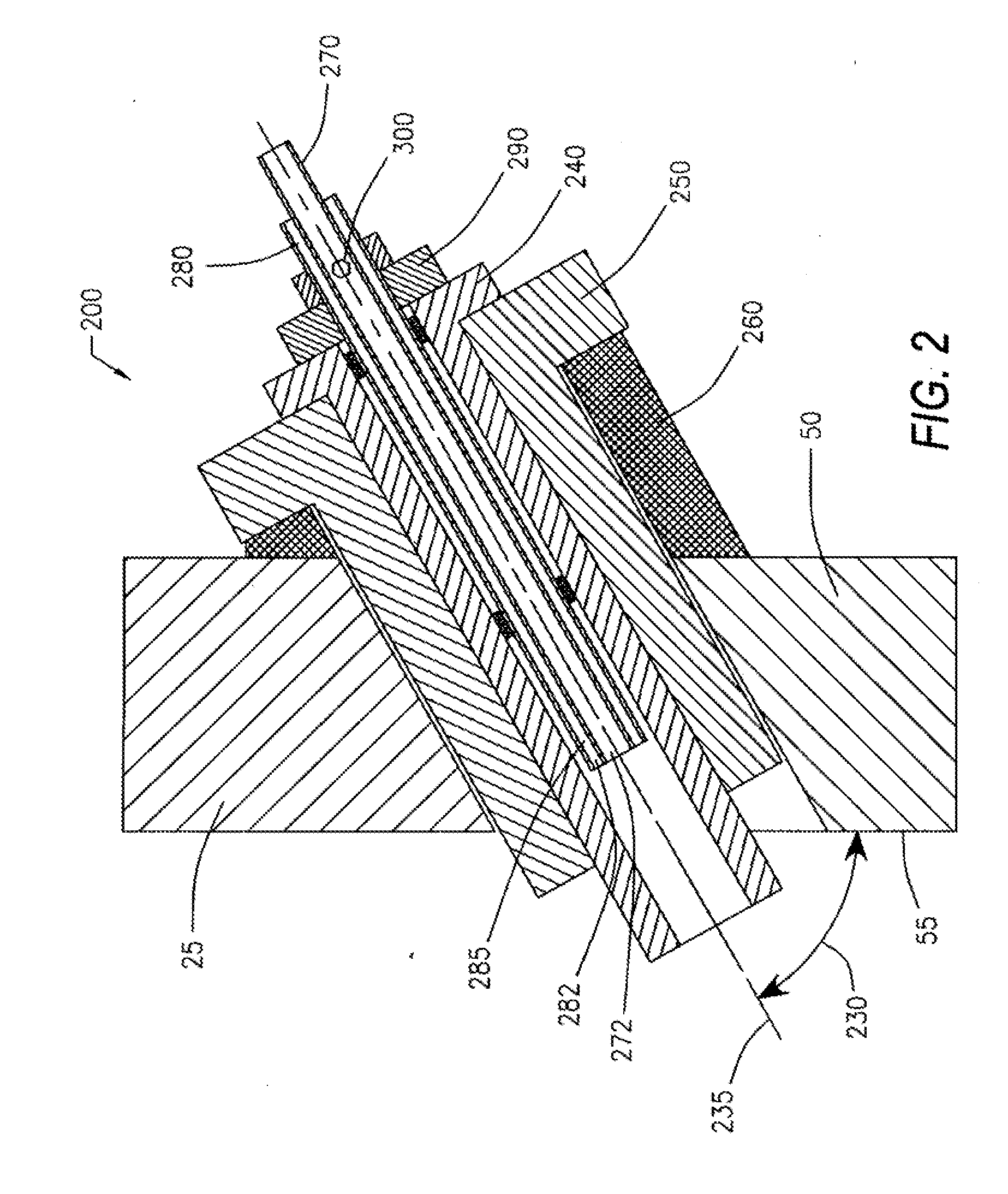

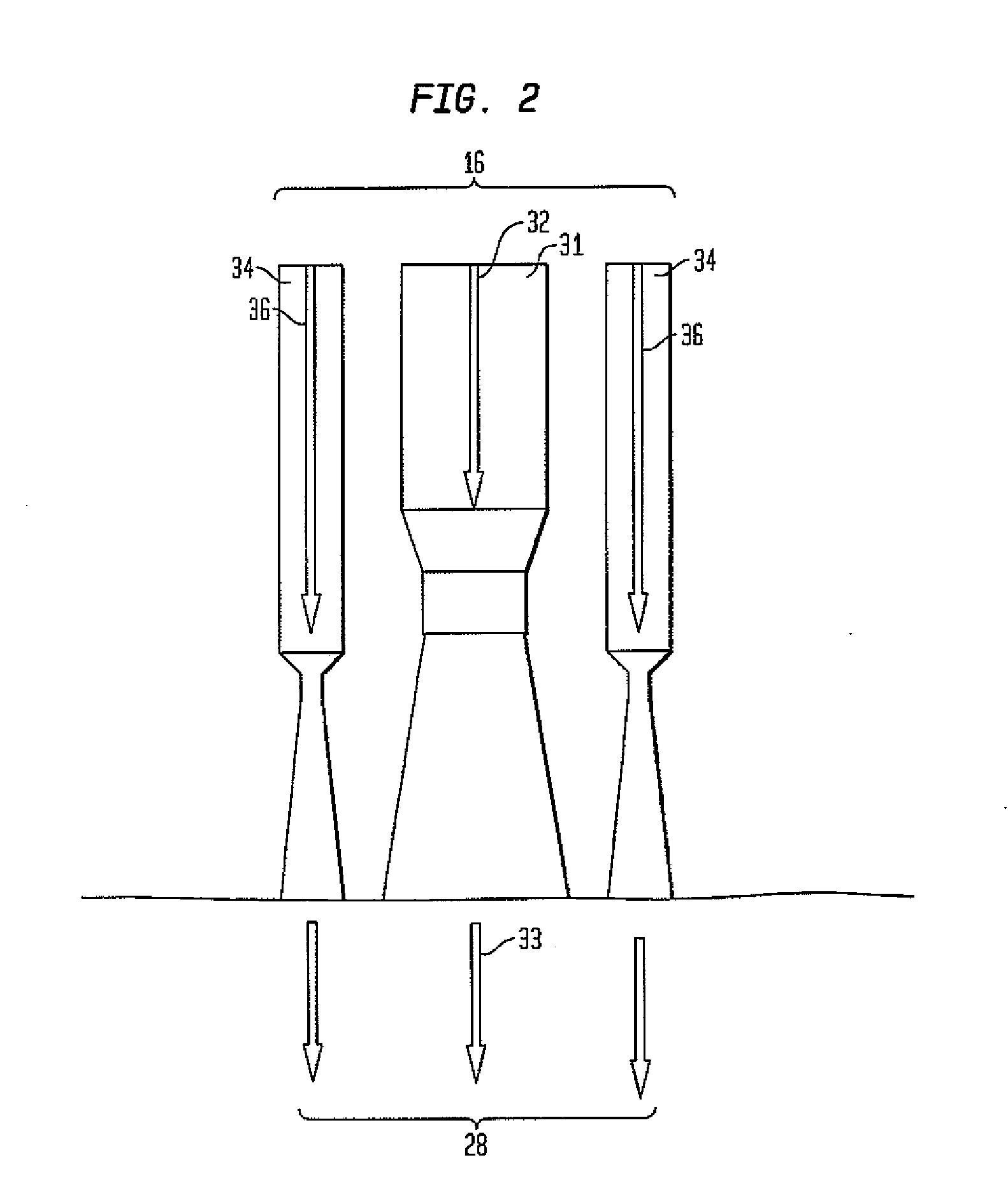

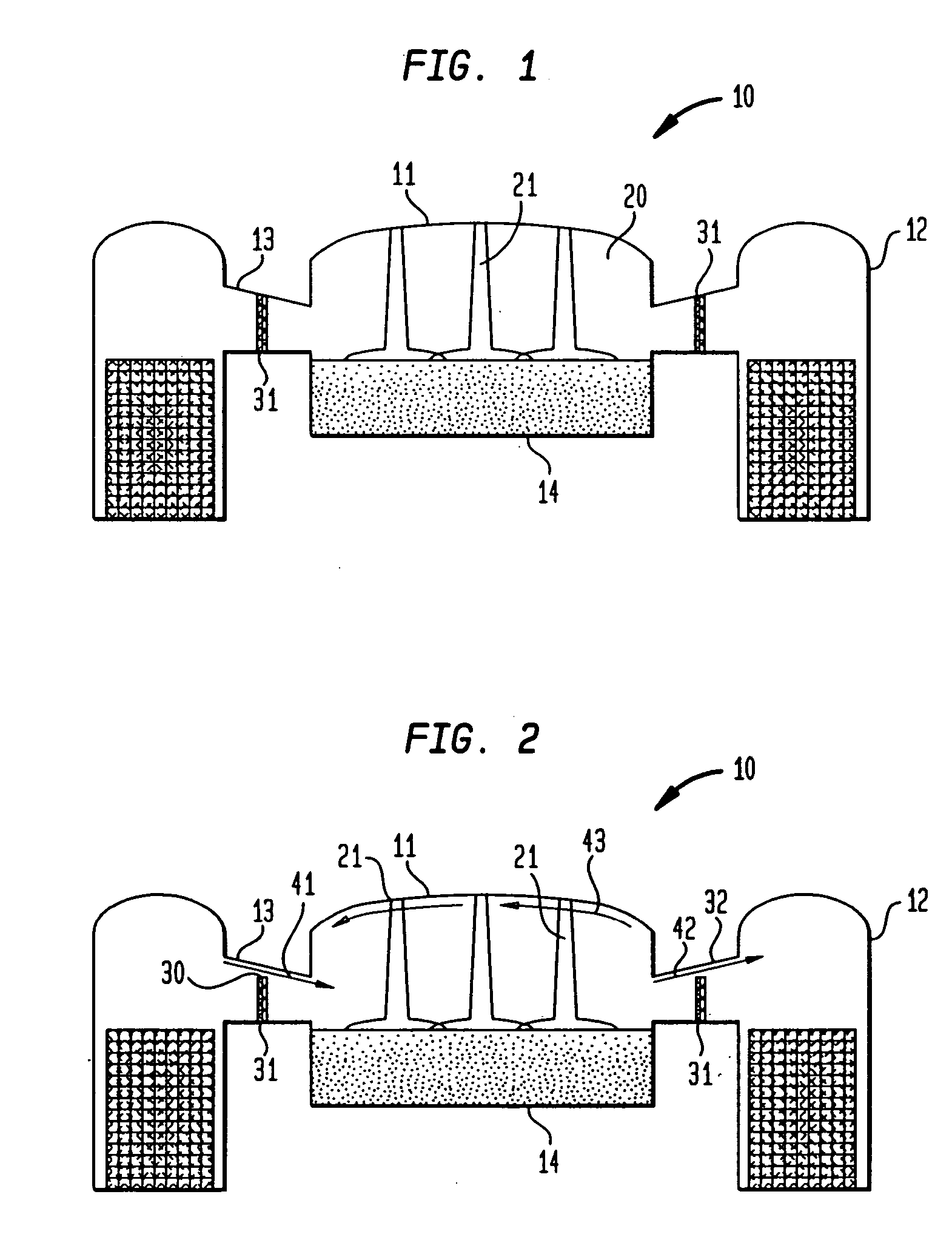

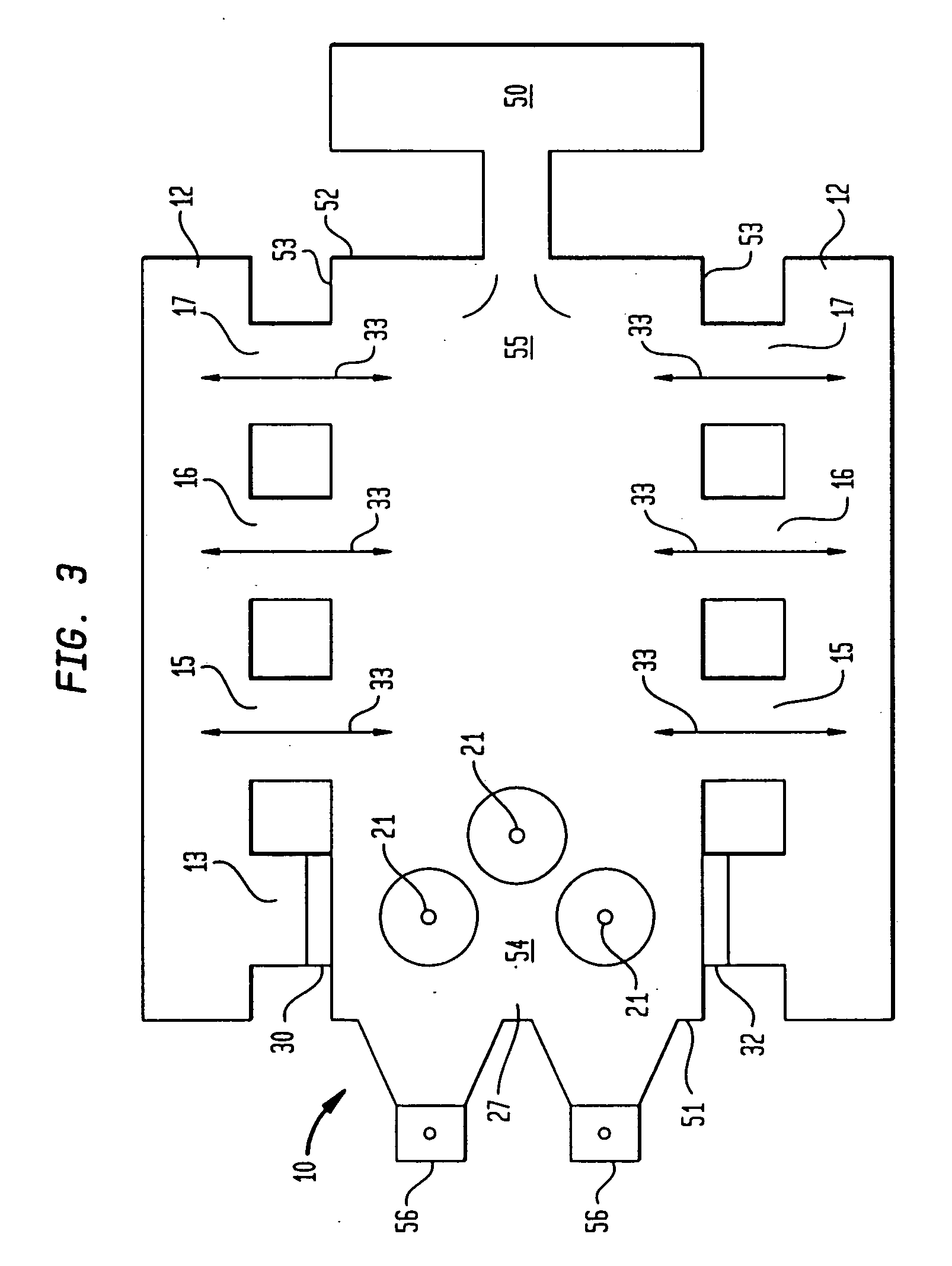

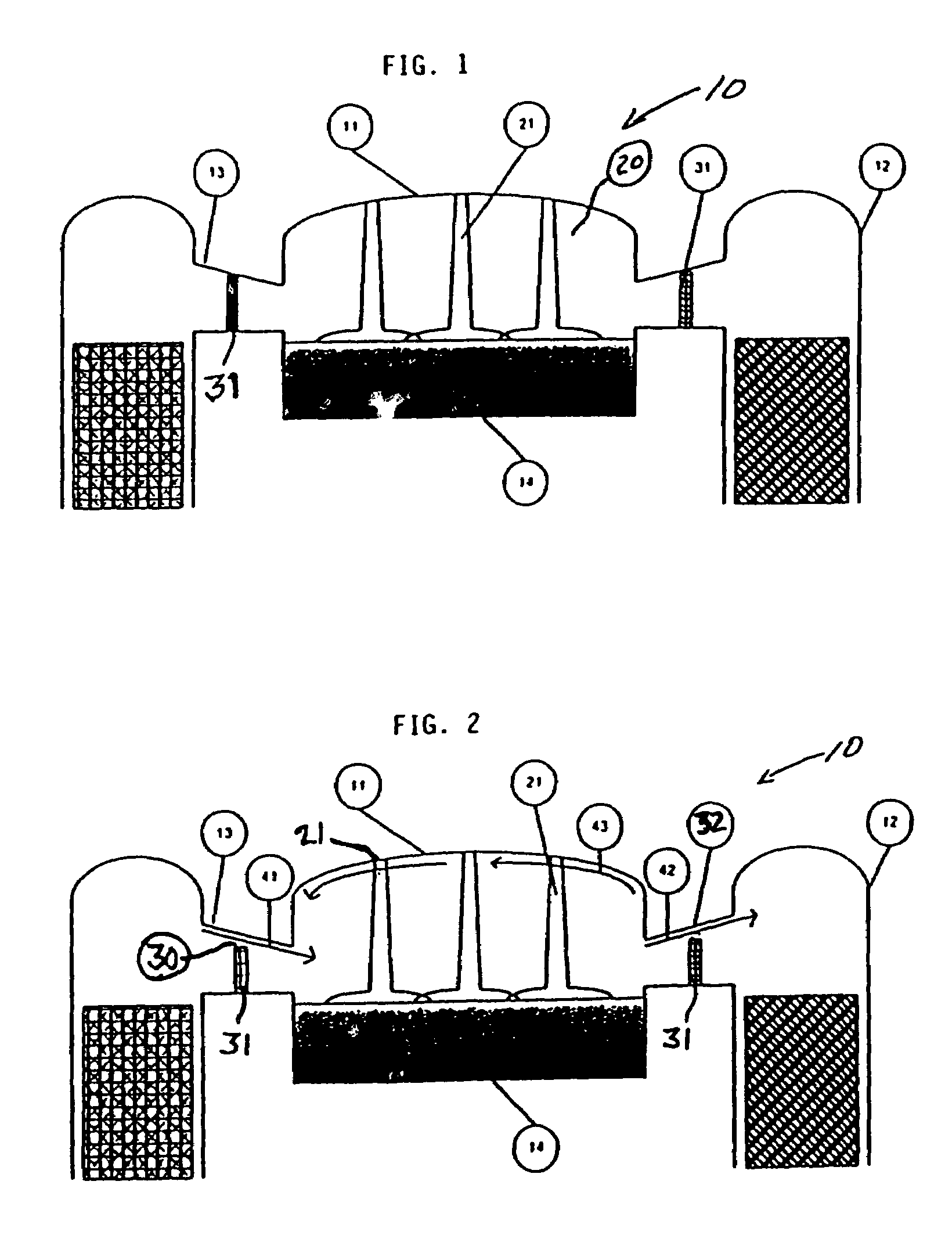

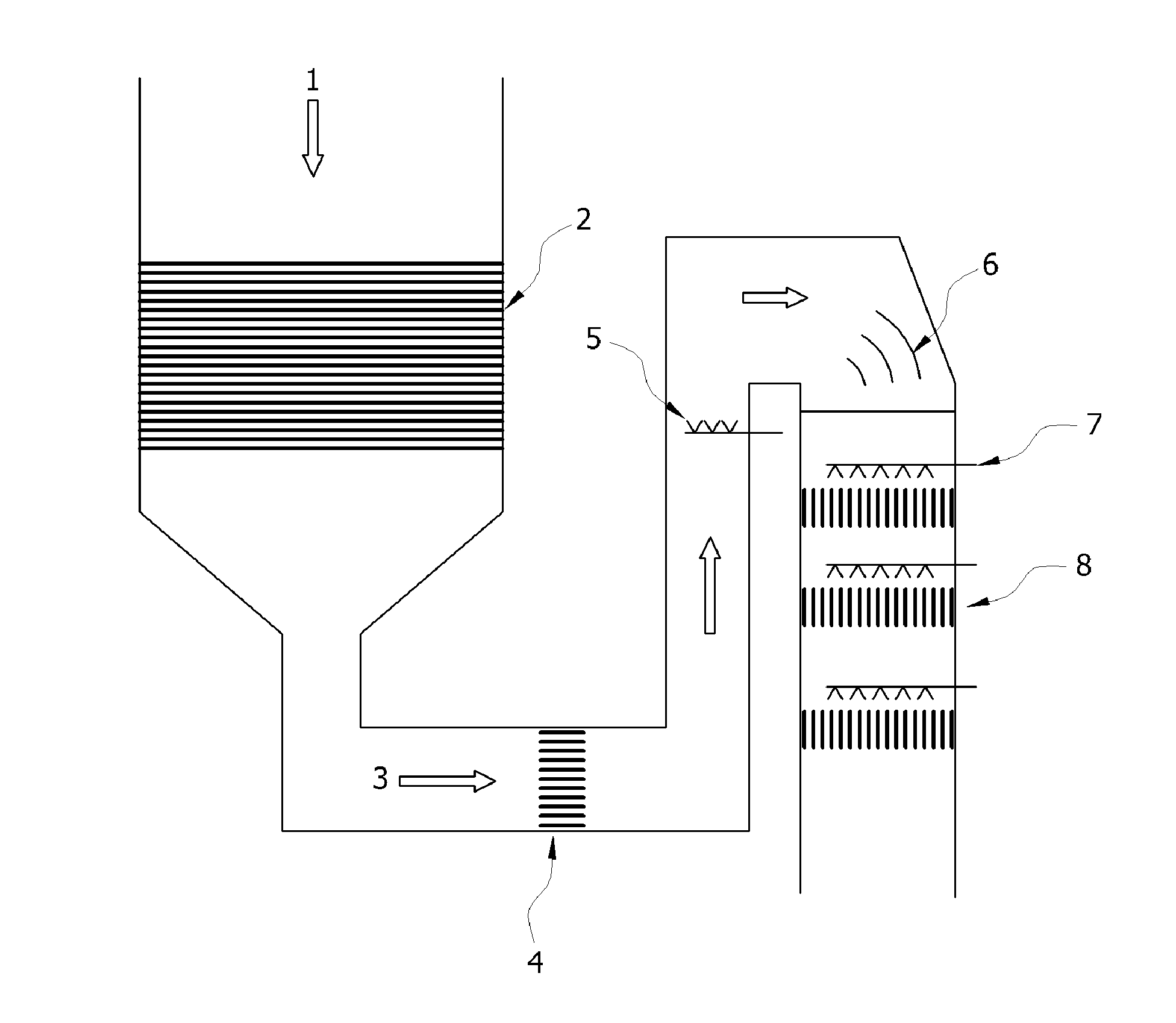

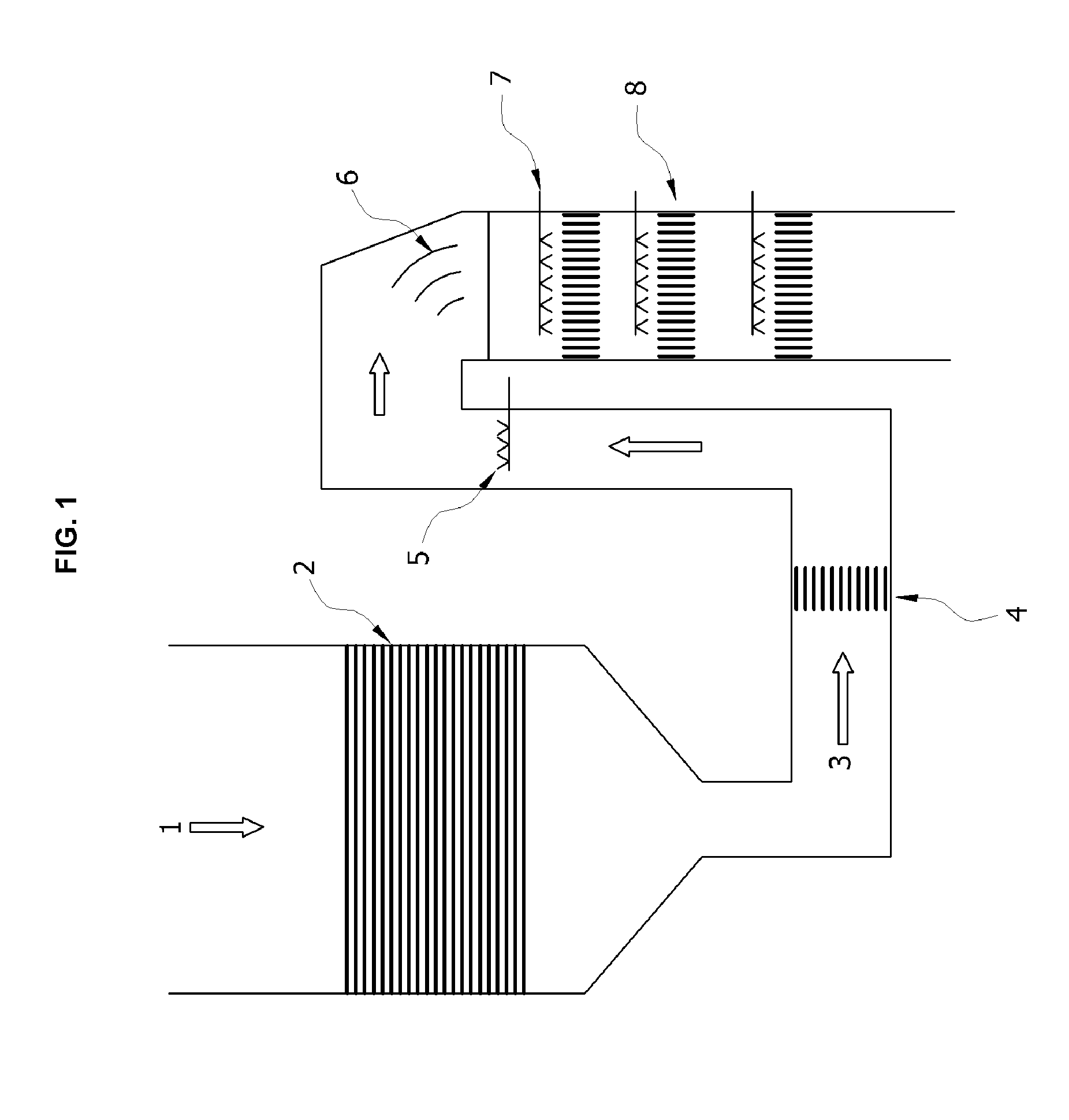

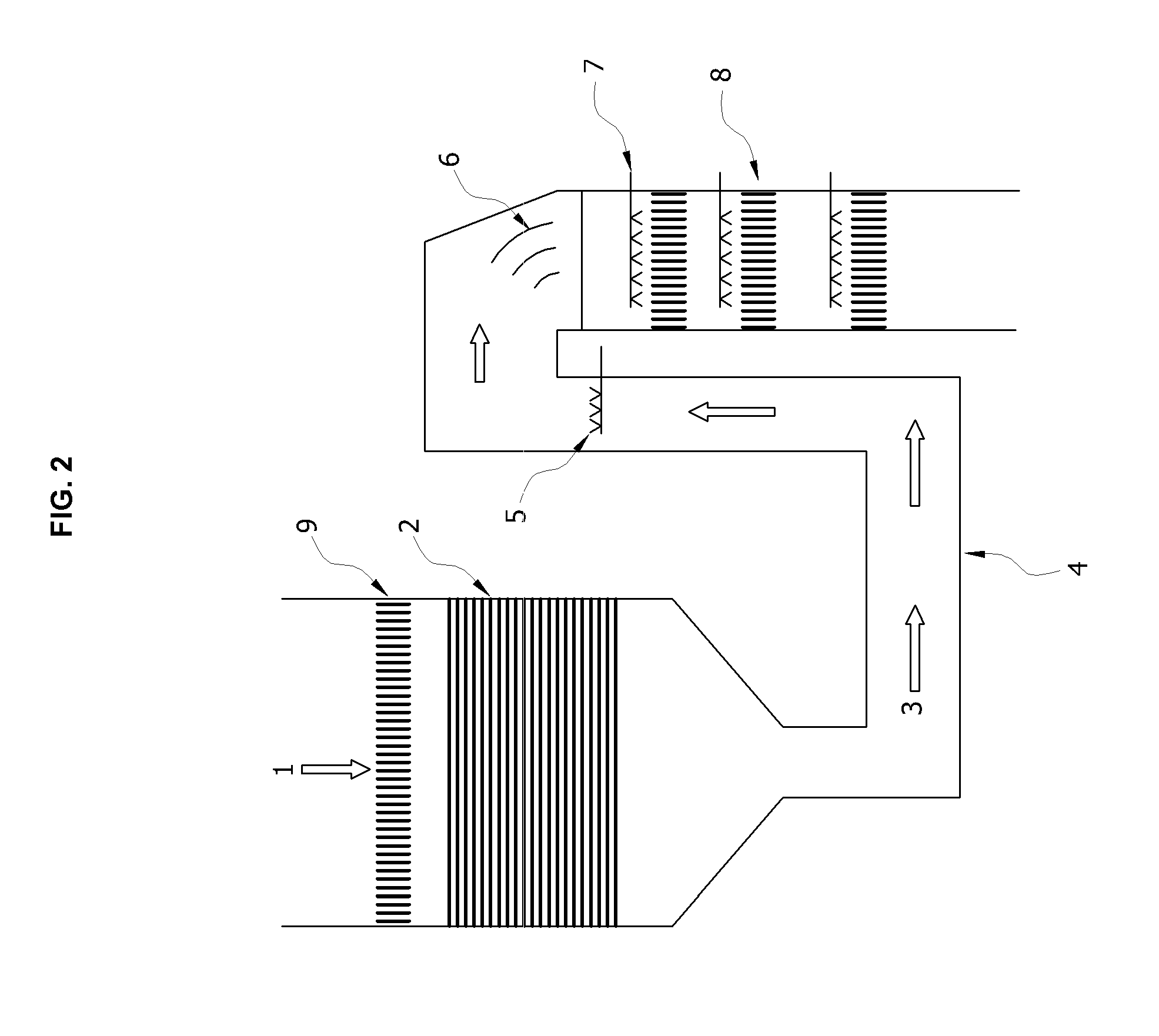

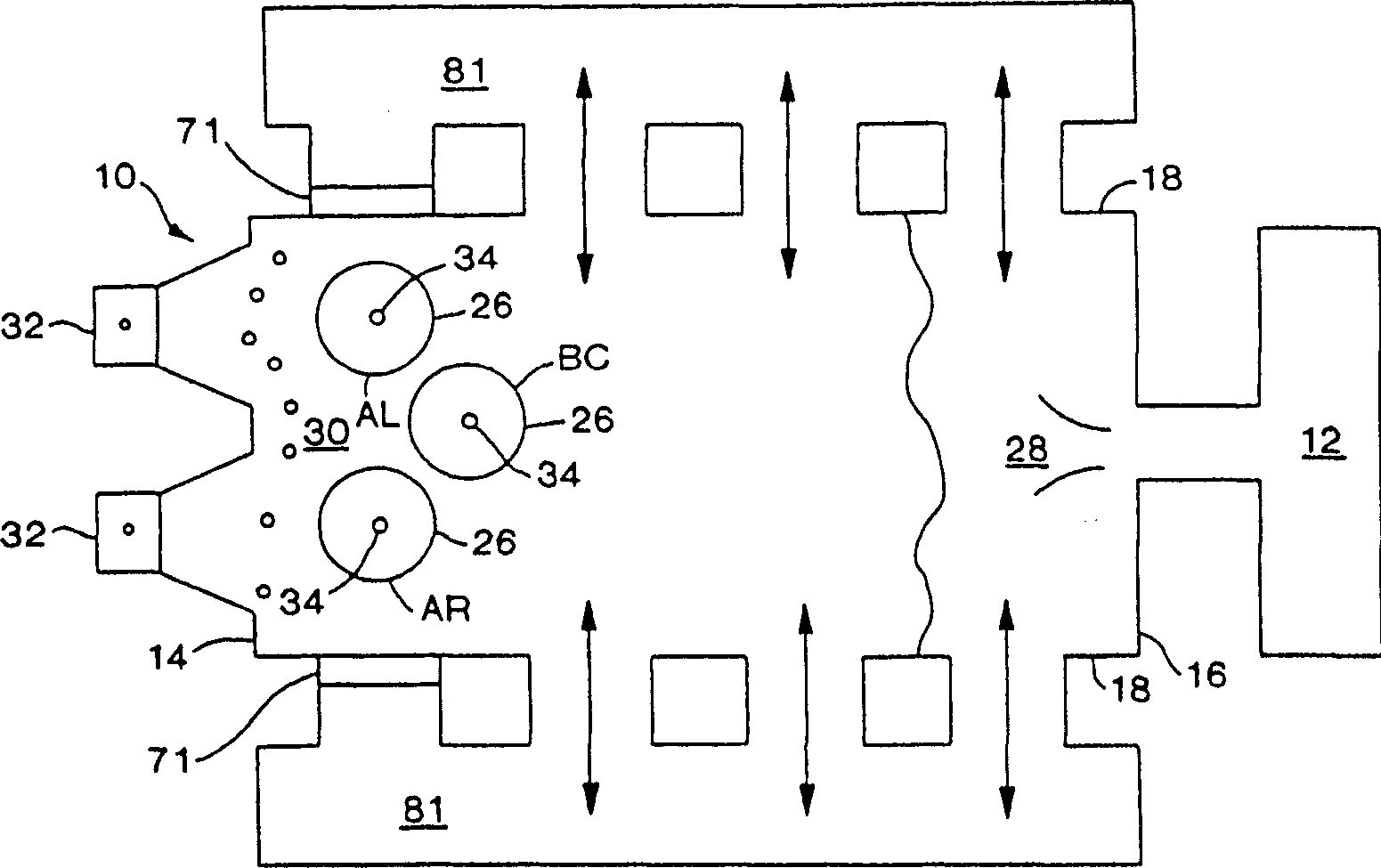

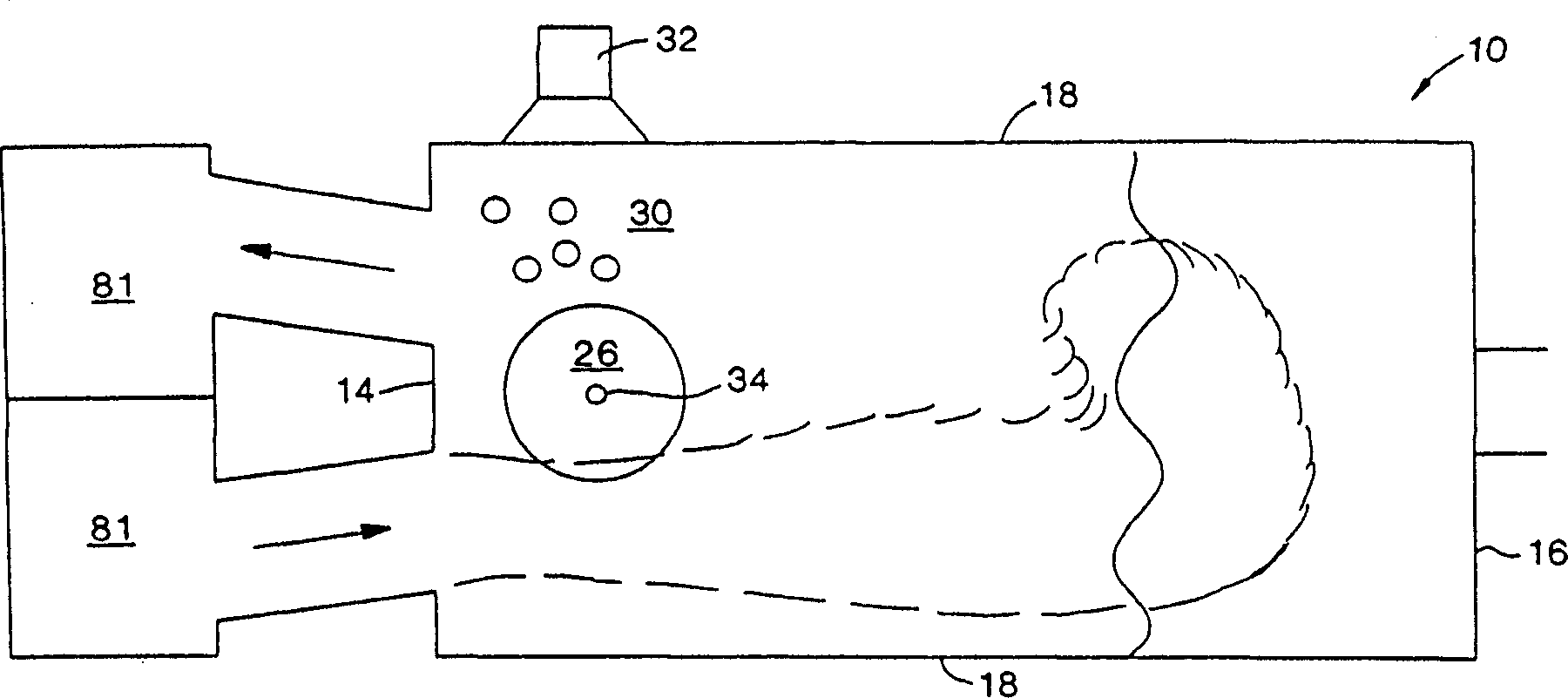

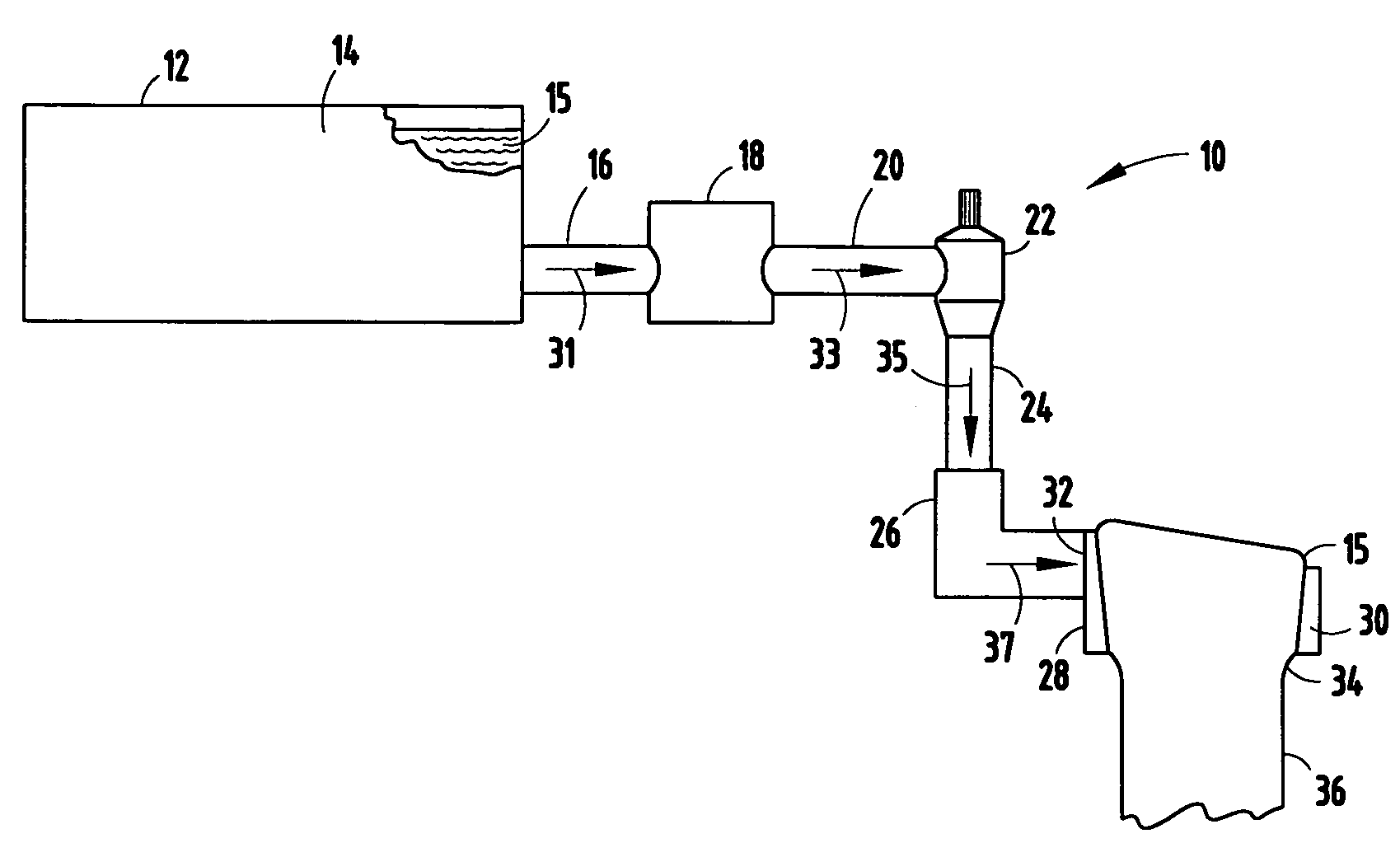

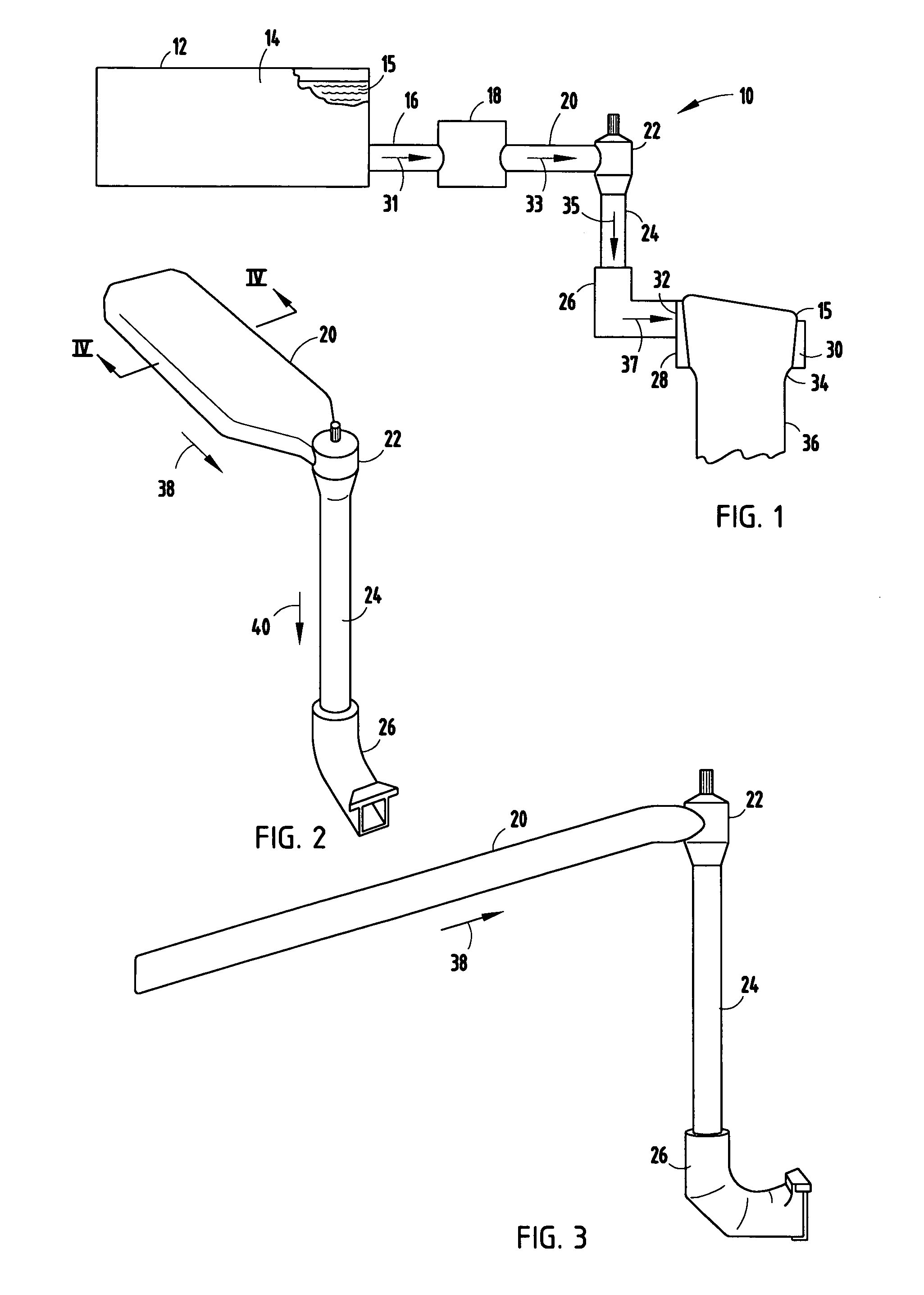

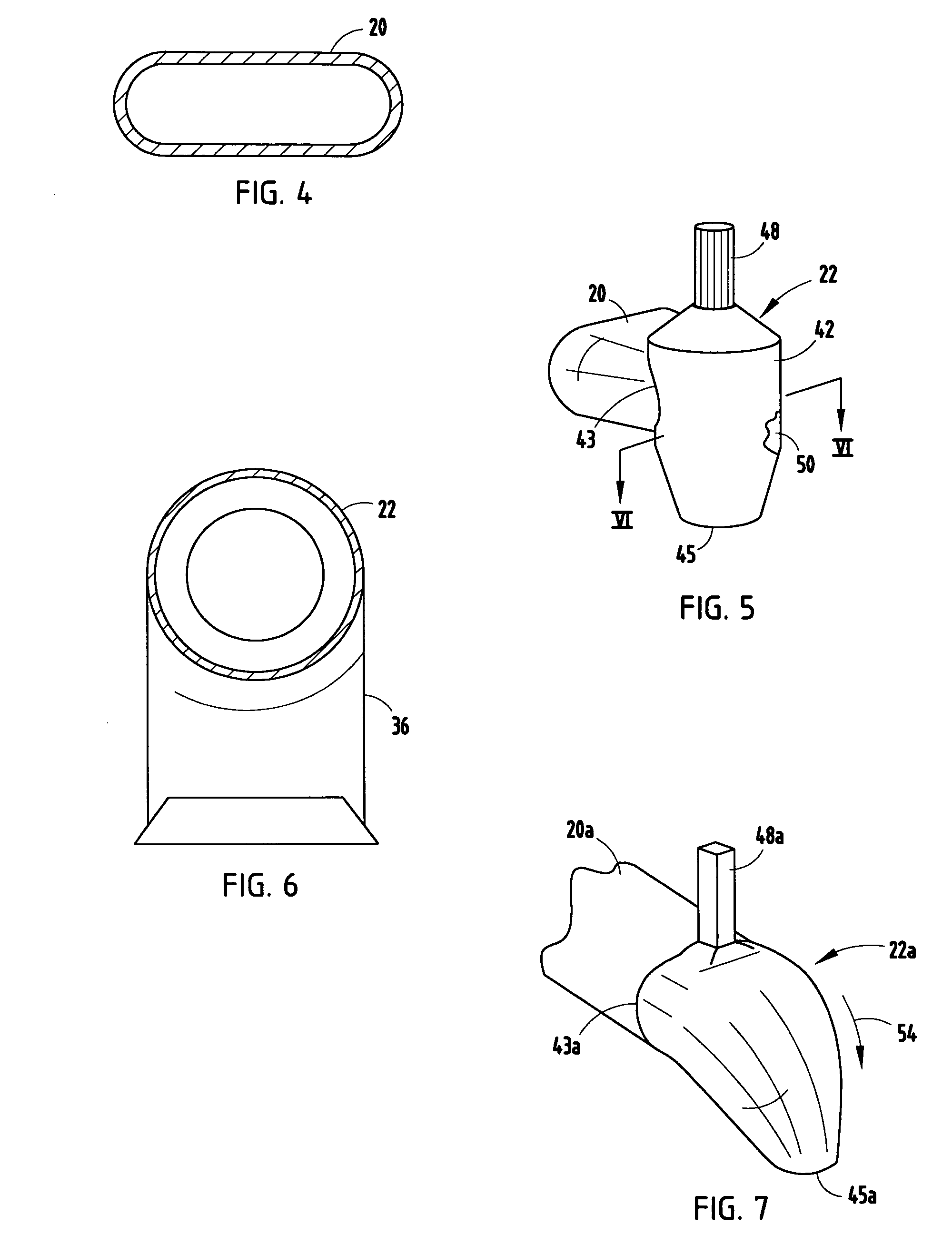

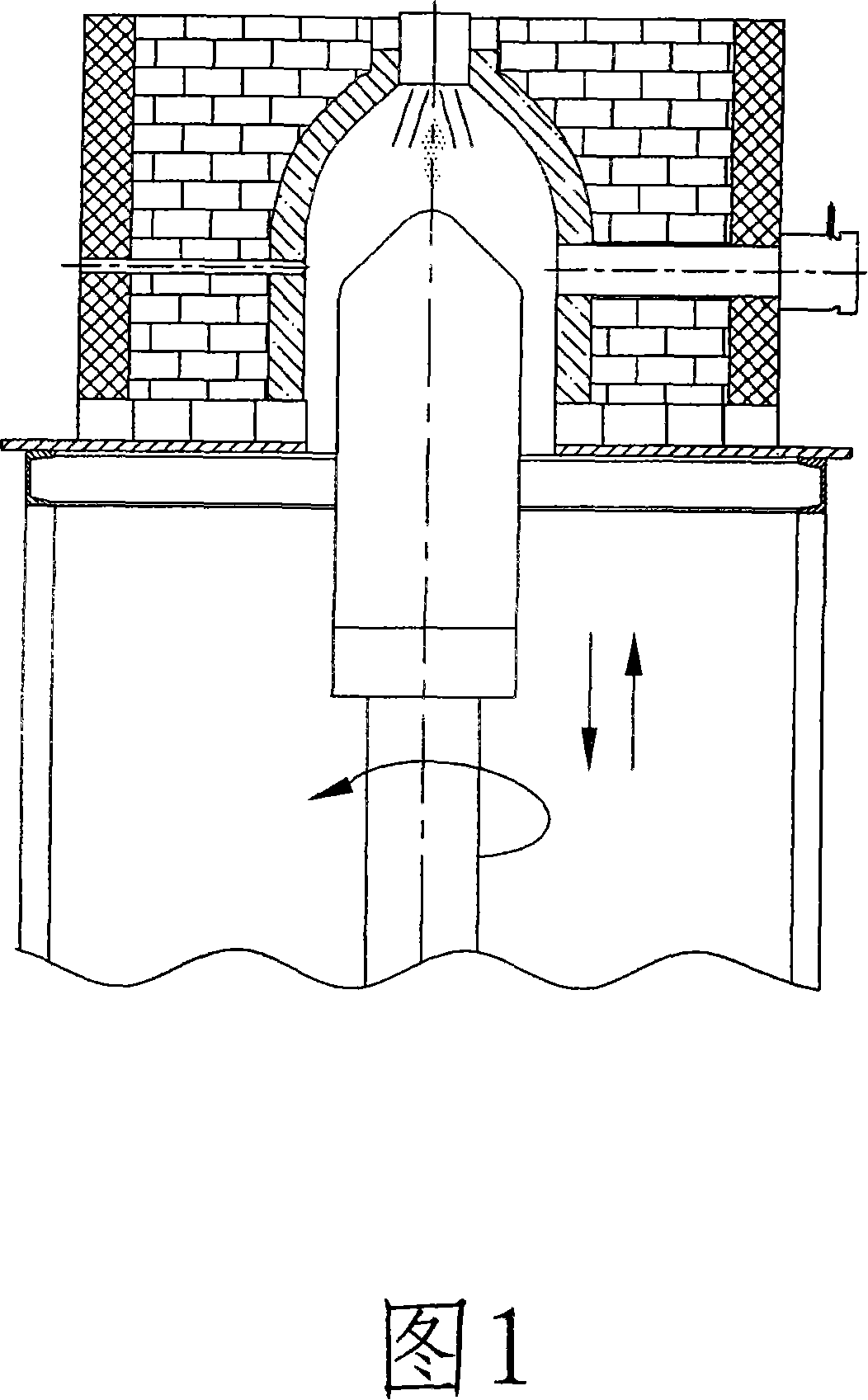

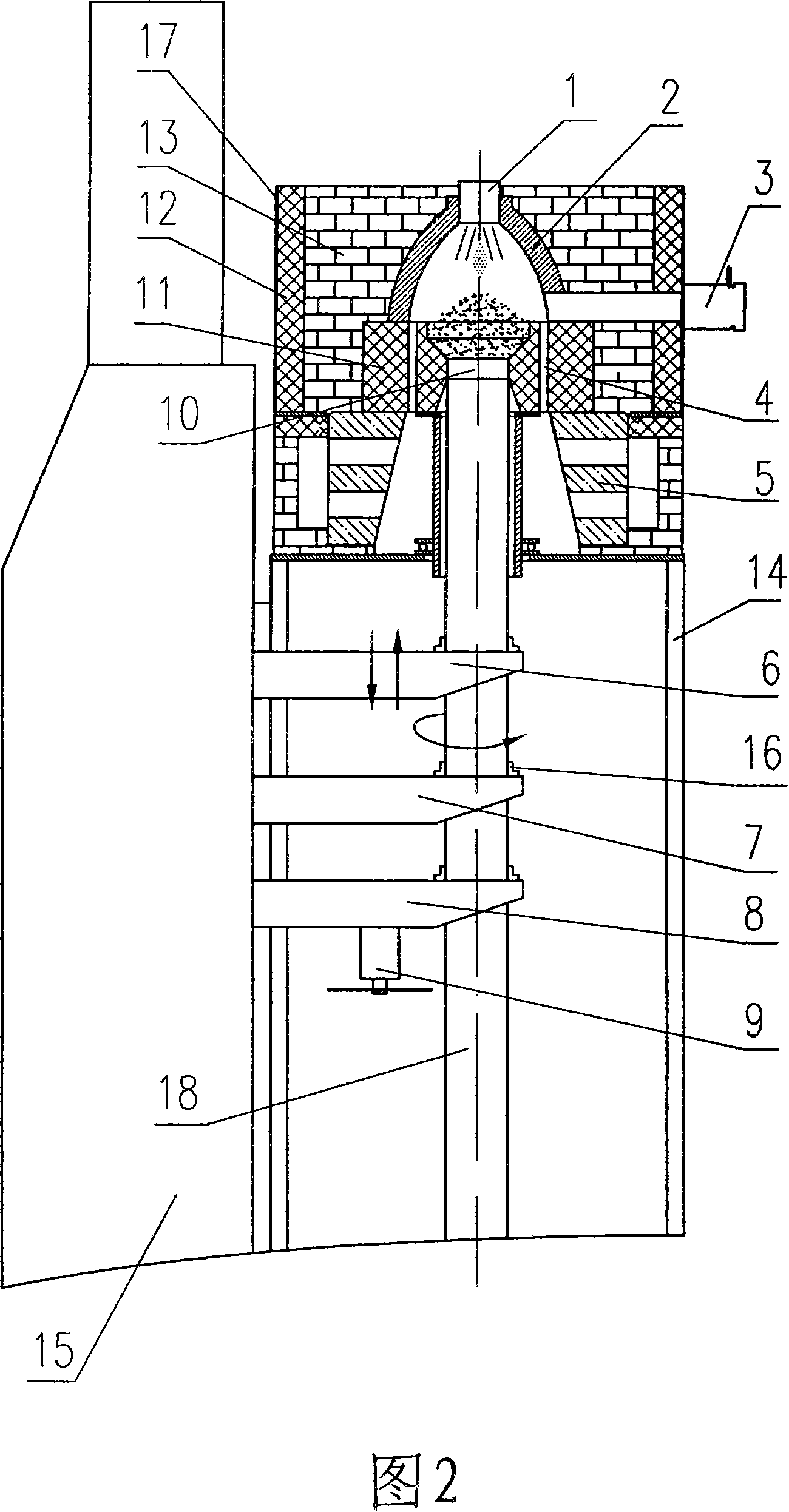

Downward Firing Oxygen-Fuel Burners for Glass Melting Furnaces

InactiveUS20100300153A1Maximize convective transferMaximize radiant heat transferCharging furnaceGlass furnace apparatusCombustorEngineering

This invention relates to a glass melting furnace with downward firing oxygen-fuel burners placed in the breast walls of the combustion space and adjacent to the skew block. The downward firing oxygen-fuel burner may be placed at an angle so that the oxygen-fuel flame from the downward firing oxygen-fuel burner impinges on the upper surface of the glass bath. The placement and angle of the downward firing oxygen-fuel burner may maximize the amount of heat transferred to the batch cover or the molten glass, ensure the formation of high quality glass products, and protect the integrity of the downward firing oxygen-fuel burners and the glass melting furnace.

Owner:ZHANG ZHIFA +1

Burner injection system for glass melting

A burner for melting glass forming batch material includes a burner assembly constructed and arranged with a first passage for providing a fuel stream and a second passage for providing an oxidant stream, the first and second streams coacting to produce a supersonic combustion jet flame penetrable into glass melt. A method for melting glass forming batch material is also provided and includes providing a fuel stream; providing an oxidant stream; mixing the fuel and oxidant streams with sufficient force for providing a supersonic combustion jet flame; directing the supersonic combustion jet flame to contact the glass forming batch material; and penetrating the glass forming batch material to a select depth with the supersonic combustion jet flame.

Owner:LINDE AG

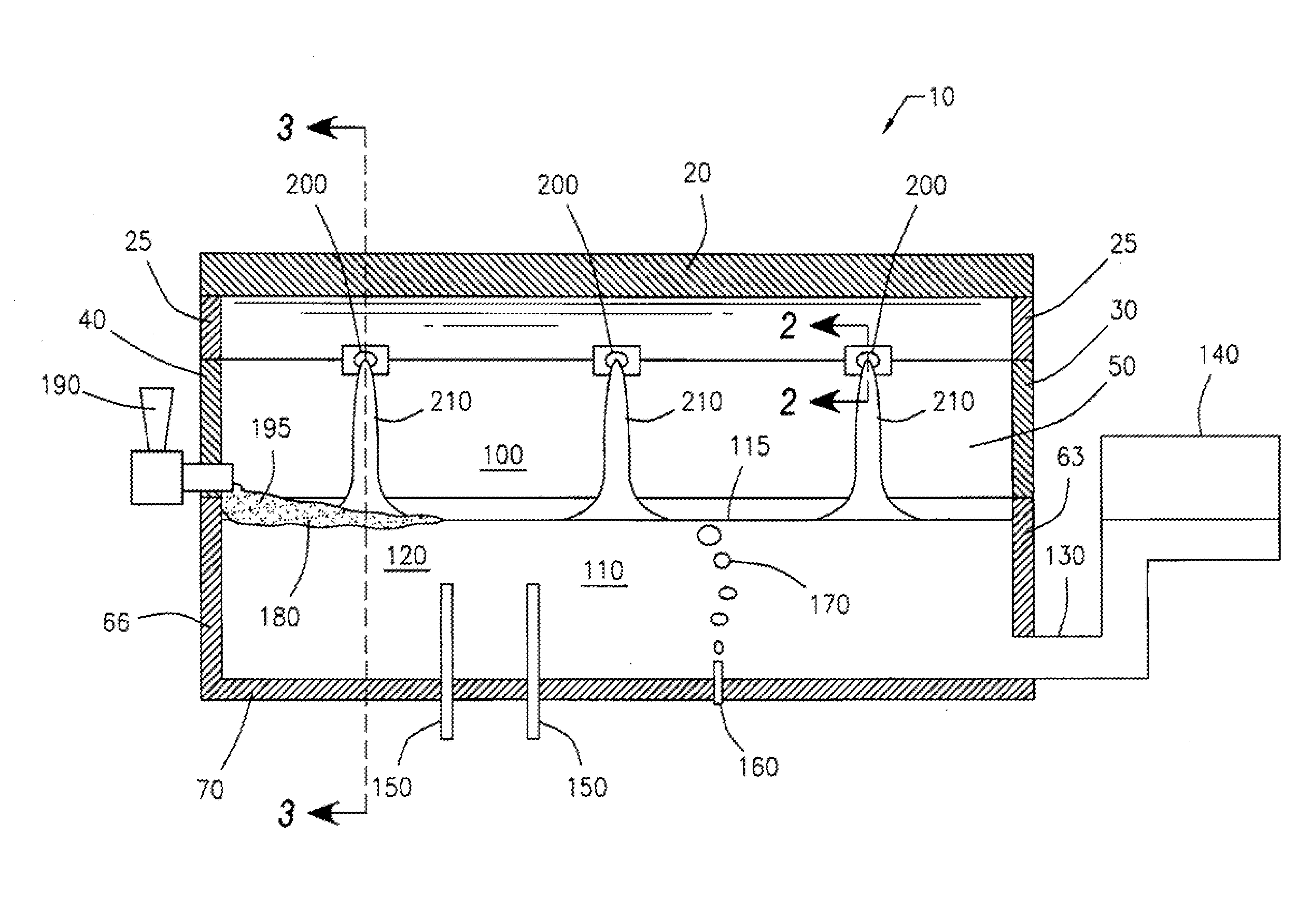

Glass melting process and apparatus with reduced emissions and refractory corrosion

A glassmelting apparatus which reduces alkali corrosion comprising: a glassmelting furnace having a plurality of walls, a crown, a charge end, a batch melting area and a fining area; at least two low momentum oxy-fuel burners located in at least one of the walls of the glassmelting furnace, each burner having at least one gas exit port, the lowest point of each gas exit port of each burner having a vertical position that is raised to a height of about 18 inches to about 36 inches above the surface of the glass; each oxy-fuel burner generating a flame along a path directed towards an opposite vertical wall of the glassmelting furnace; and said interior intersection of said walls and said crown of said glassmelting furnace being located at a height of between about 5.5 feet and 9 feet above the glassmelt surface.

Owner:PRAXAIR TECH INC

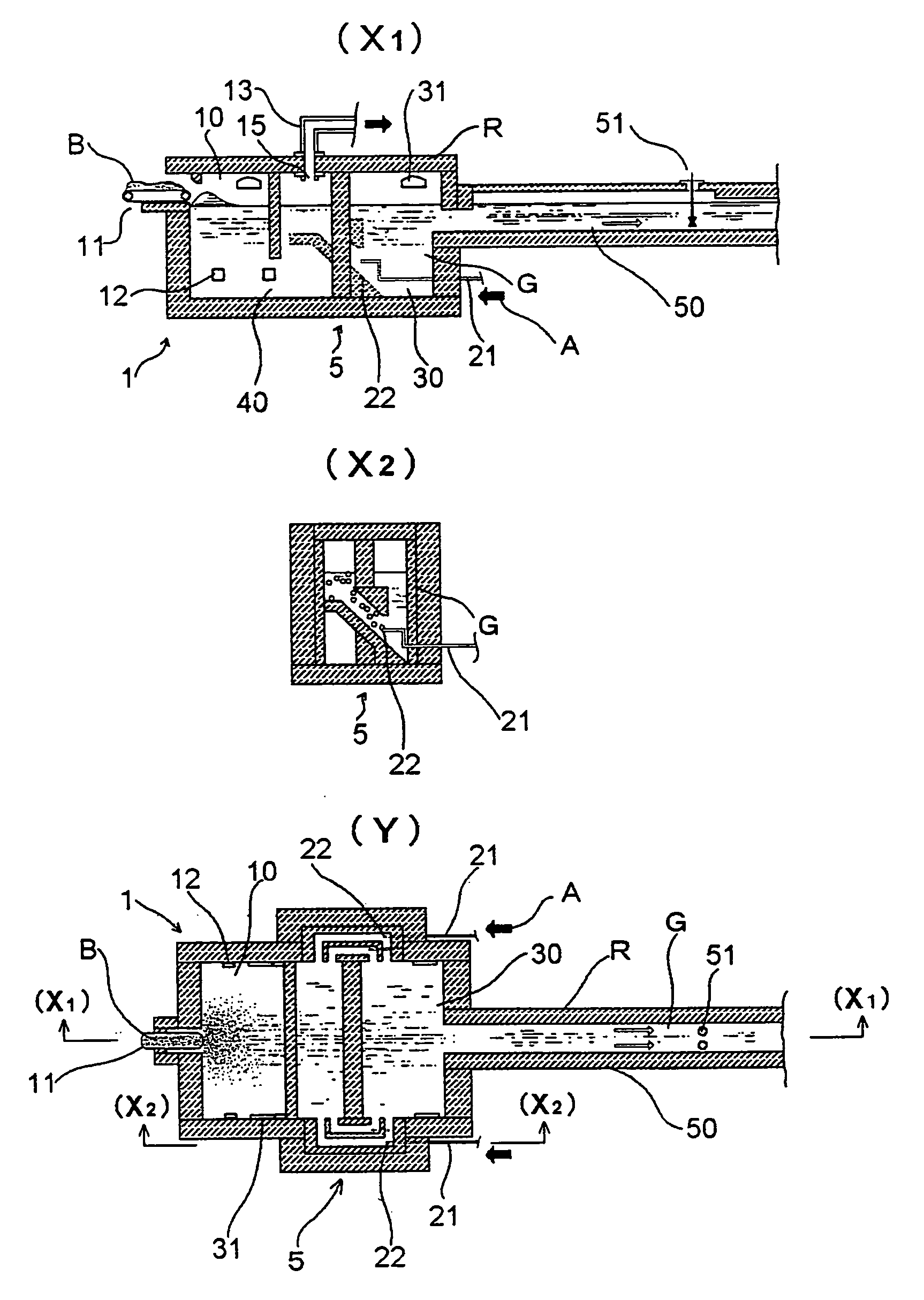

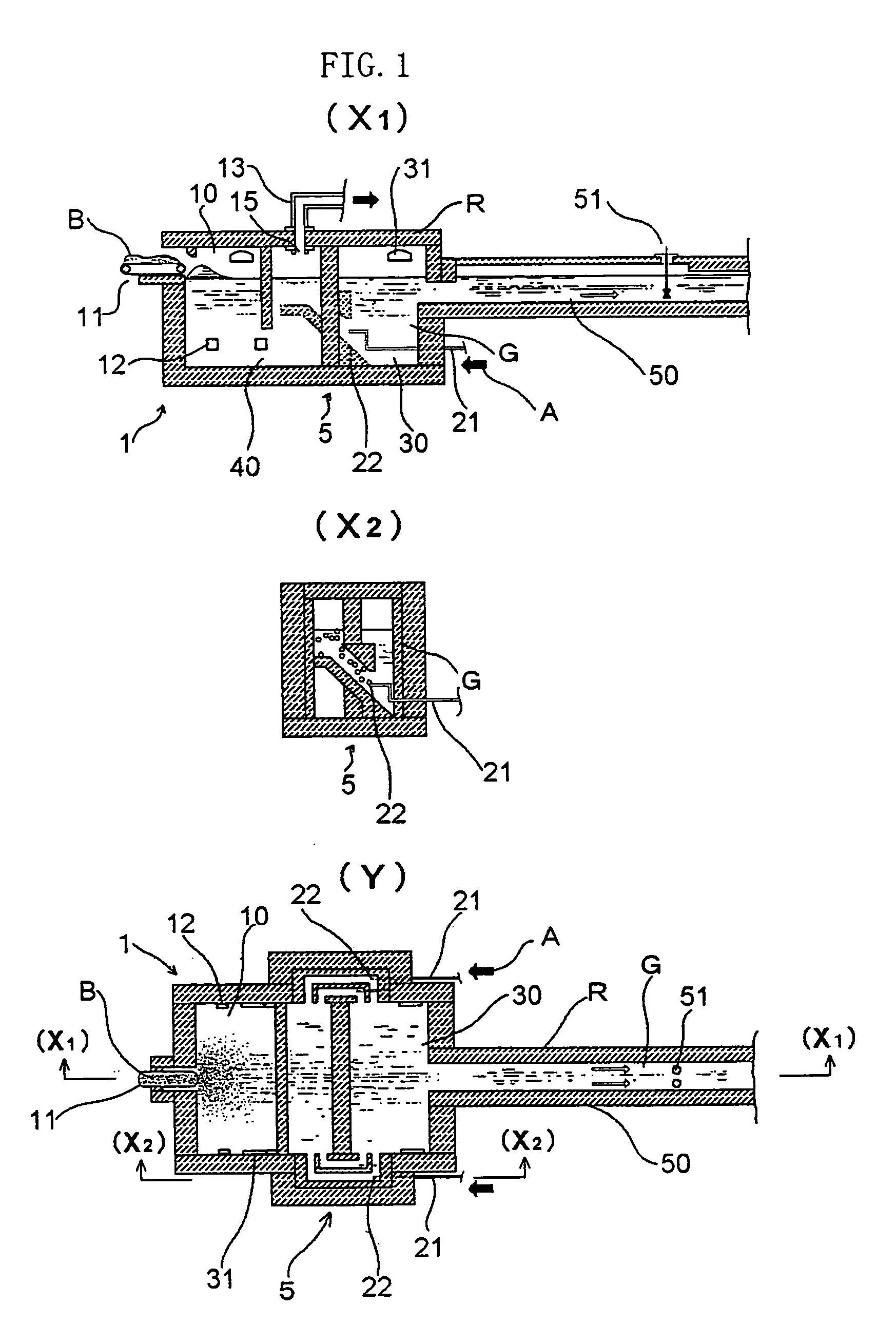

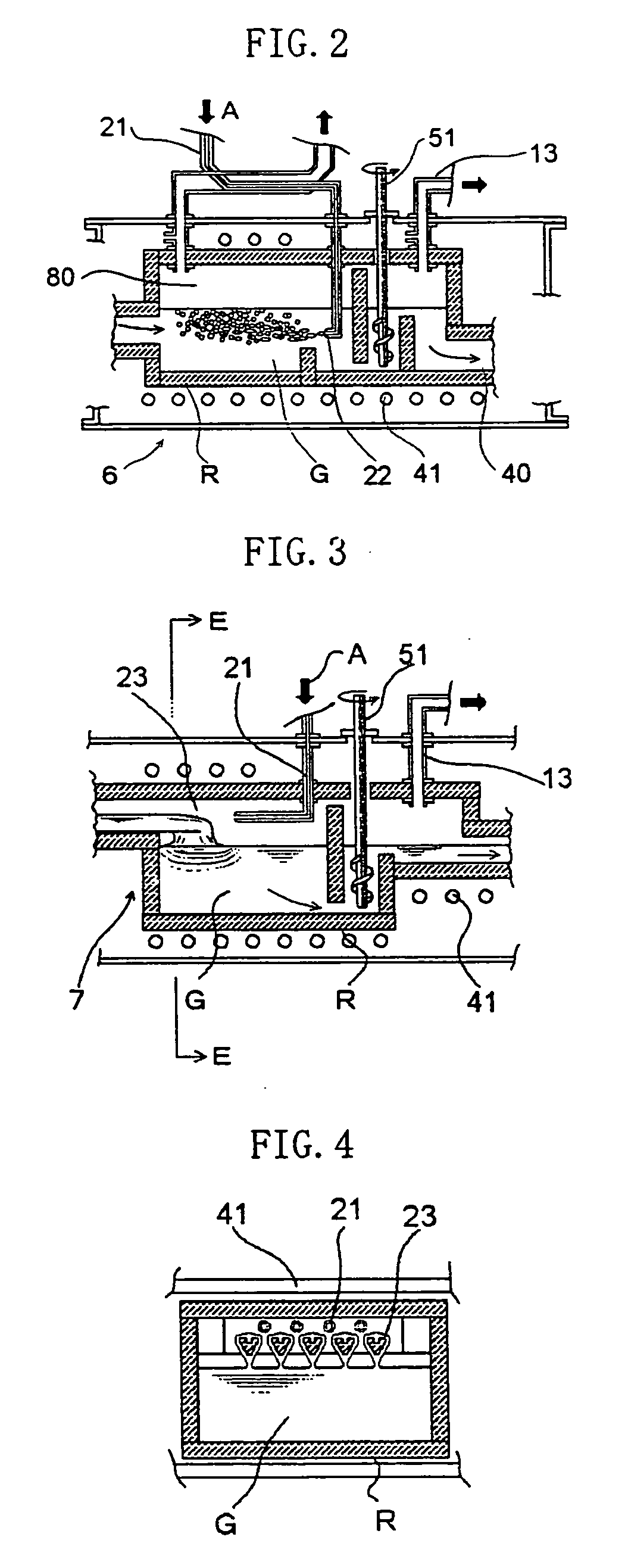

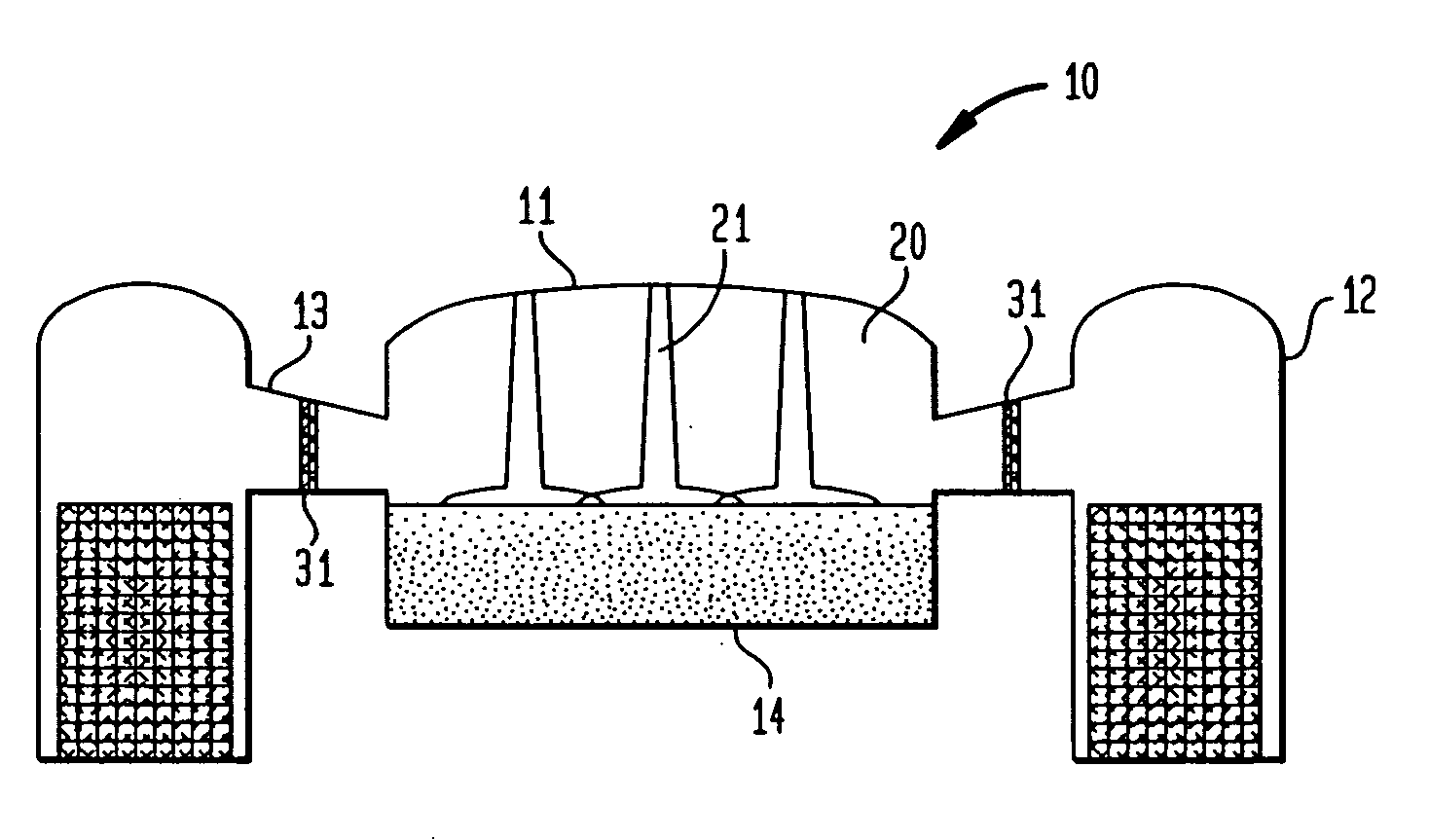

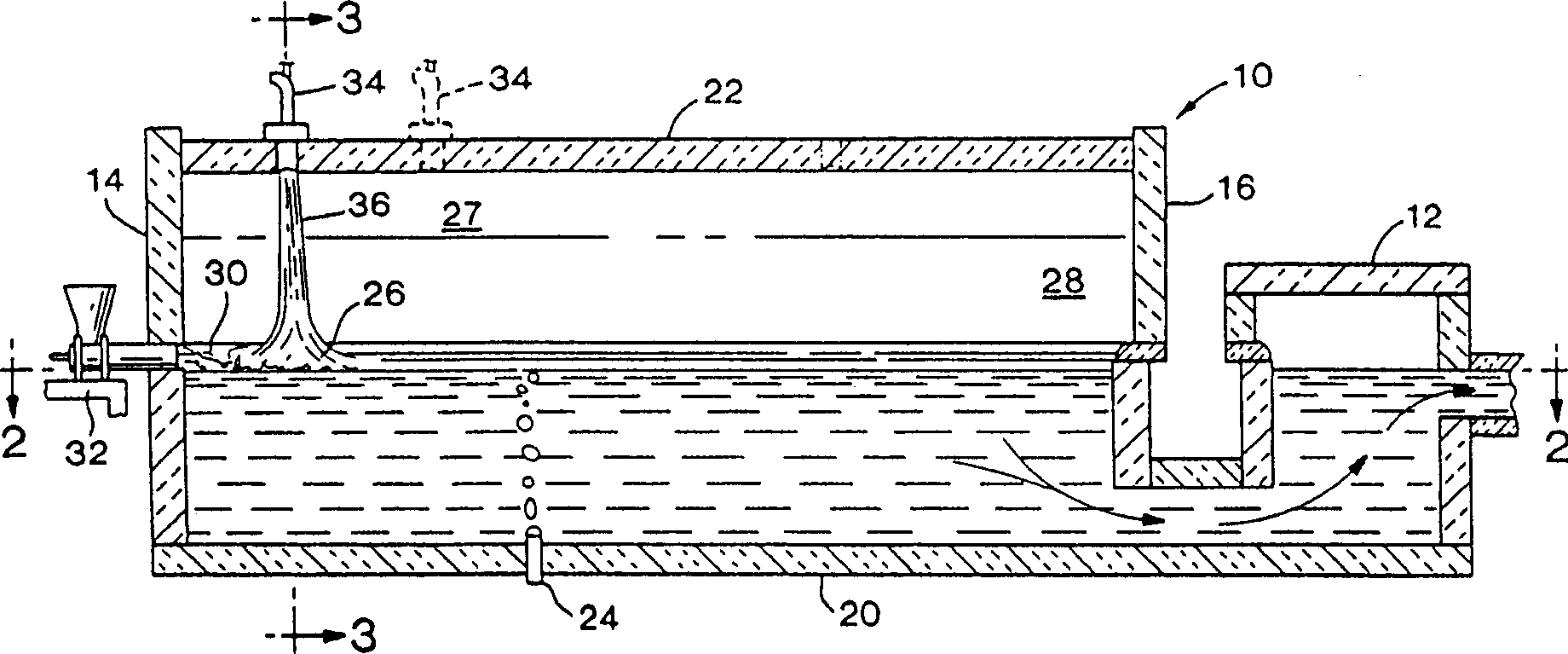

Glass melting gurnace and method for producing glass

InactiveUS20060101859A1Precise maintenanceReduce the environmentGlass furnace apparatusGlass pressing apparatusMelting tankNoble gas

A charged glass raw material B is melted in a melting tank 10 by heating with a burner 31 and by heating with electrodes 12, to form molten glass G. Then, the molten glass G flows into a tank additionally provided as a noble gas dissolving tank 20 through a throat 40. The noble gas dissolving tank 20 is provided with a noble gas dissolving device 53, and the noble gas dissolving device 53 is provided with sixteen noble gas inlets 22 for introducing a helium or neon gas supplied to a hearth through heat resistant gas introduction tubes 21 into the noble gas dissolving tank 20. Bubbles of a helium gas A having a purity of 99% are blown out from the noble gas inlets 22 in volumes such that the bubbles have an average diameter of 80 mm or less in the molten glass G.

Owner:NIPPON ELECTRIC GLASS CO LTD

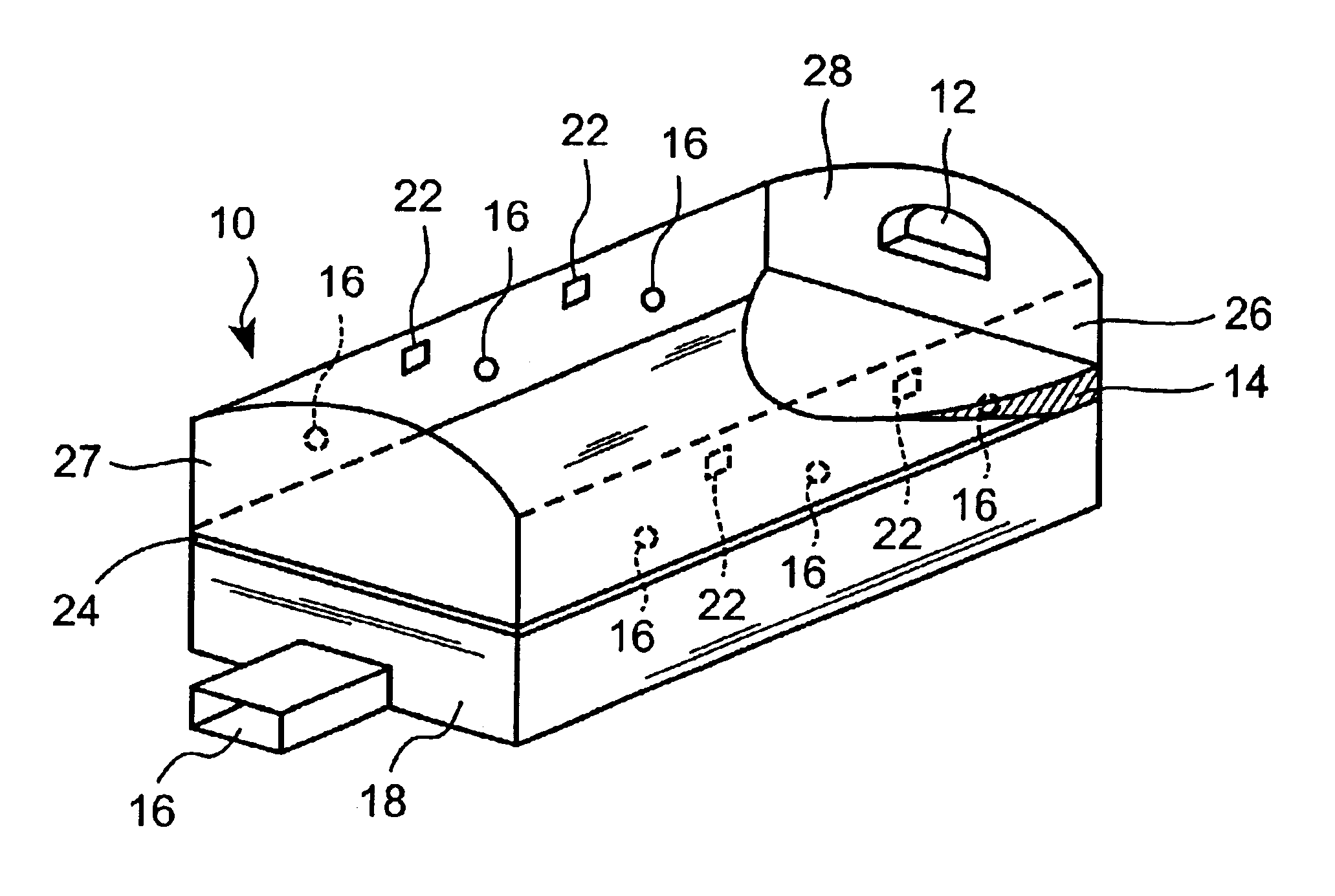

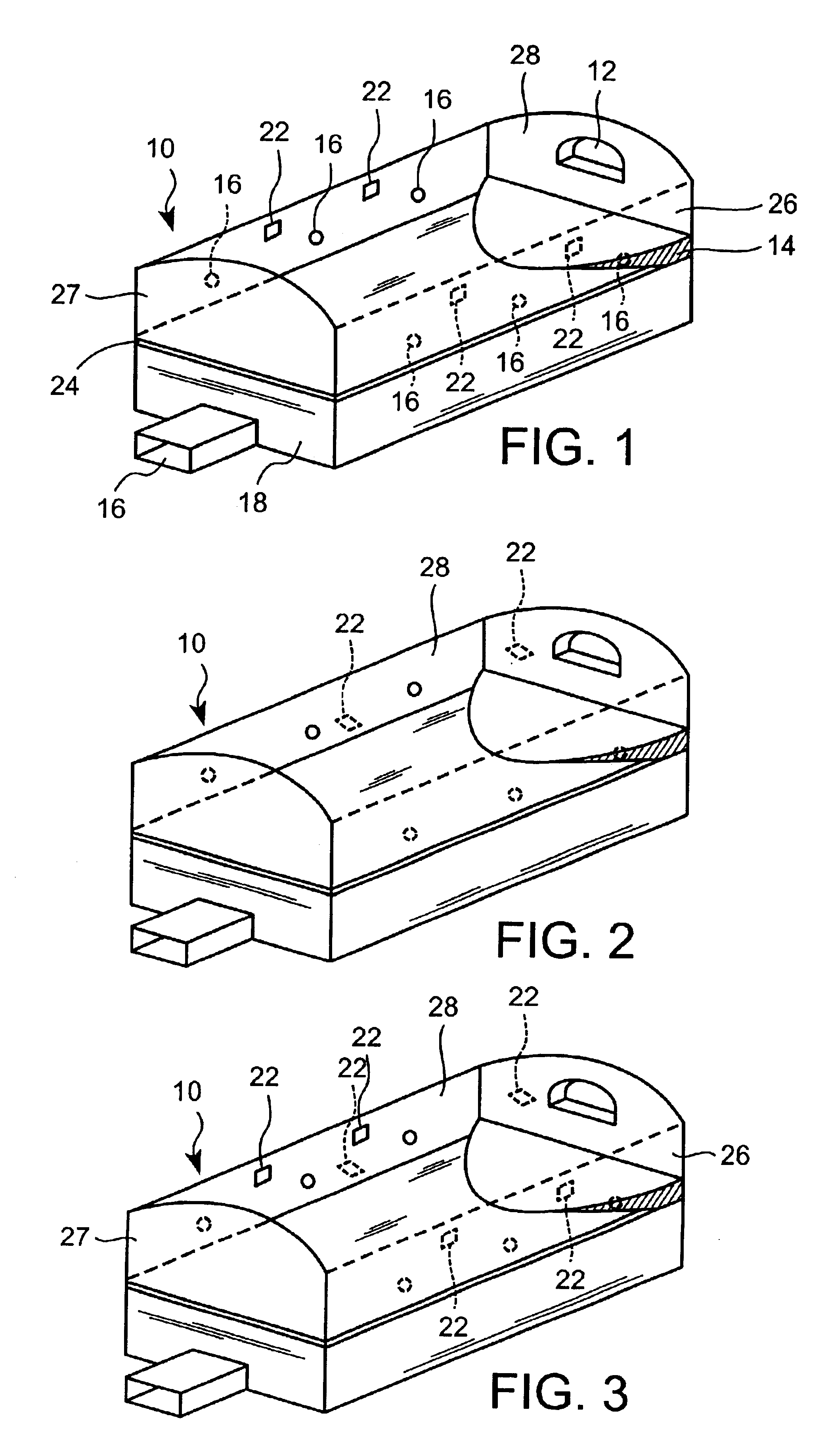

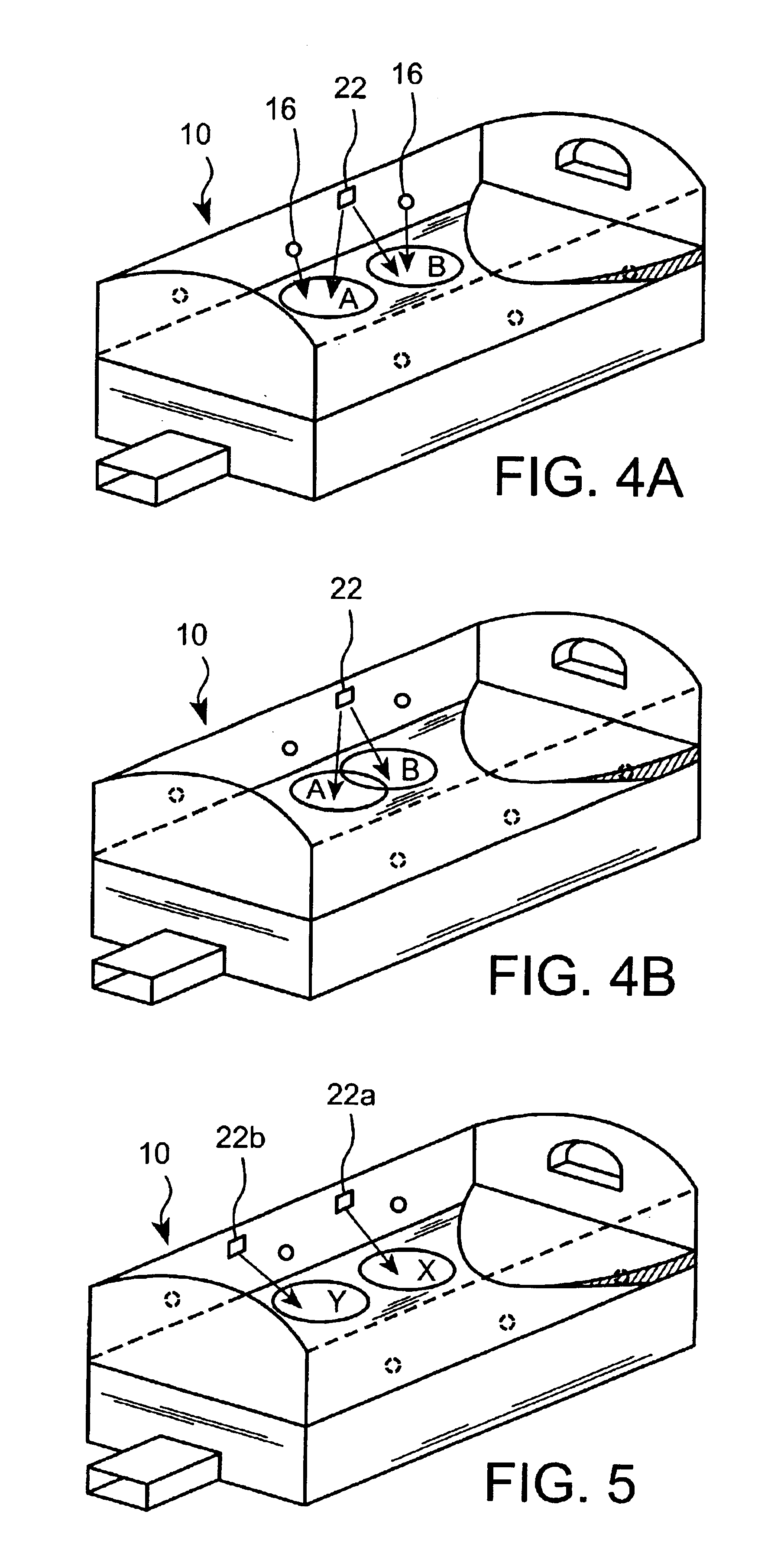

Gas injection for glass melting furnace to reduce refractory degradation

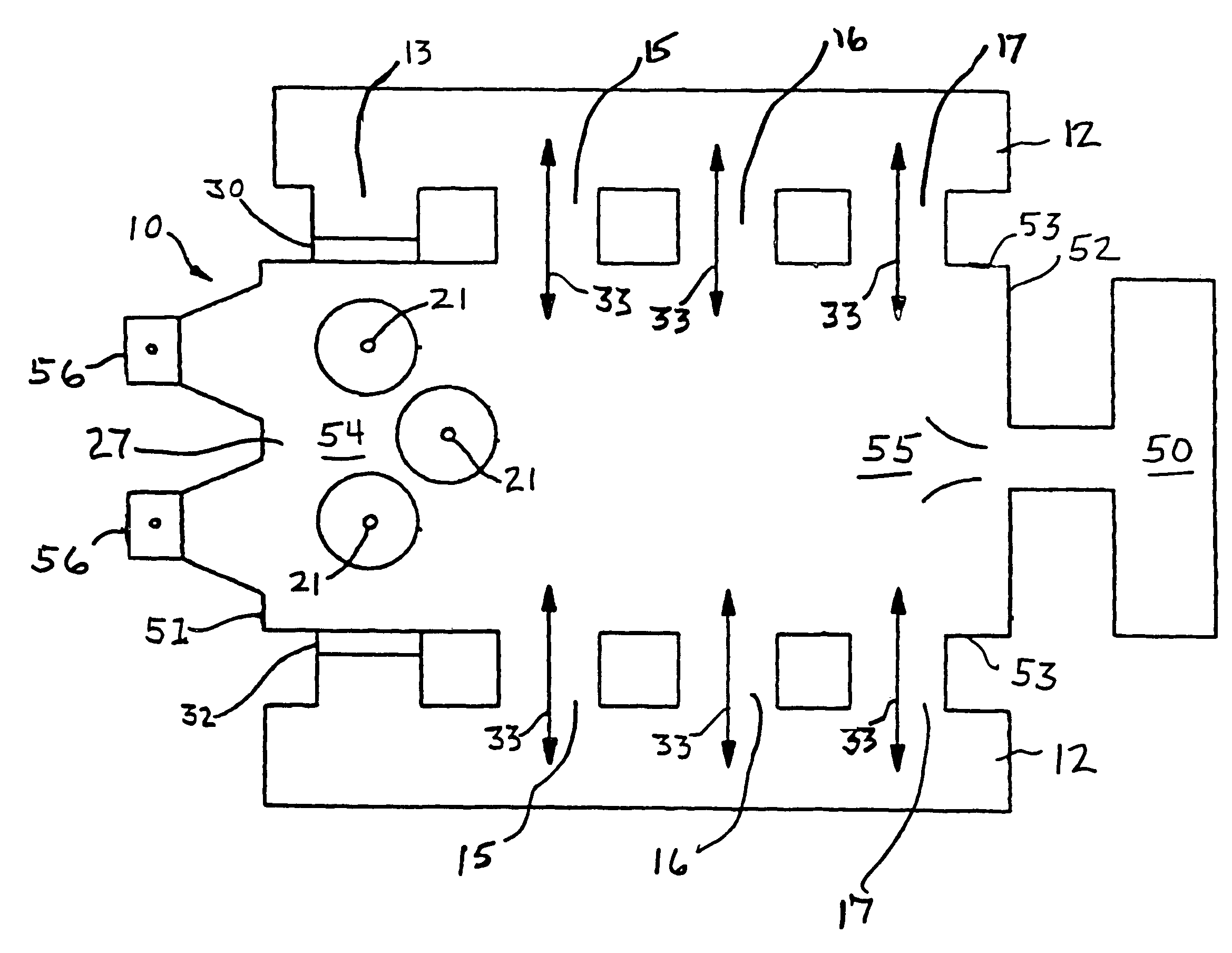

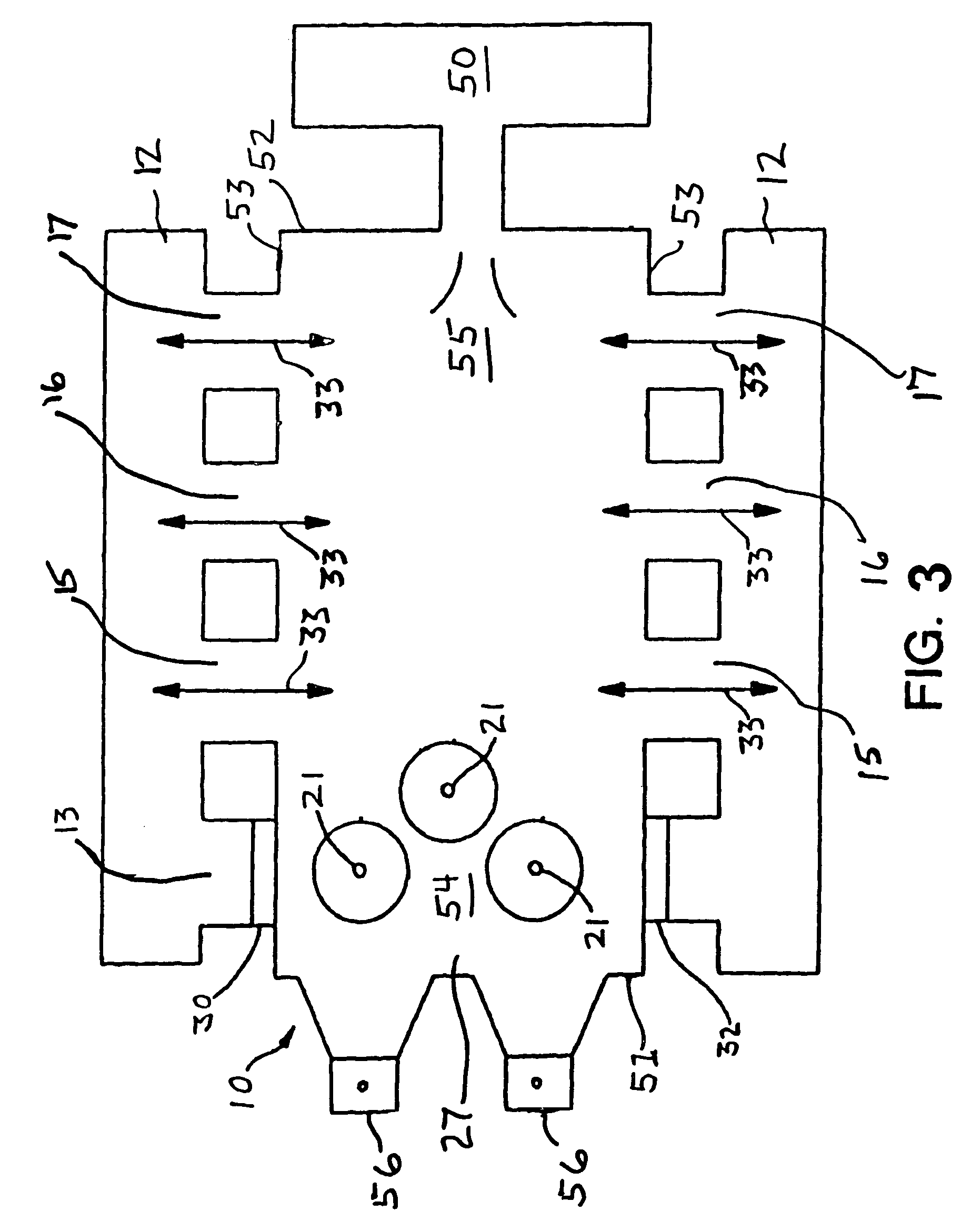

InactiveUS20070119213A1Reduce adverse effectsReduce corrosionGlass transportation apparatusSolid fuel combustionGlass furnaceRefractory

A glass melting furnace has a gas inlet positioned proximate to a charging section oxy-fuel combustion region to introduce gas into the region and to at least partially displace gas having a partial pressure of alkali vapor from the region, and optionally a gas outlet is adapted to provide an exit for a volume of furnace atmosphere. A method for reducing alkali vapor corrosion of glass furnace refractory structures includes providing a gas inlet proximate to the oxy-fuel combustion region; introducing a volume of gas from the inlet into the region, displacing a volume of gas having a partial pressure of alkali vapor from the region; and, optionally providing a gas outlet adapted to provide an exit for a volume of furnace atmosphere.

Owner:LINDE LLC

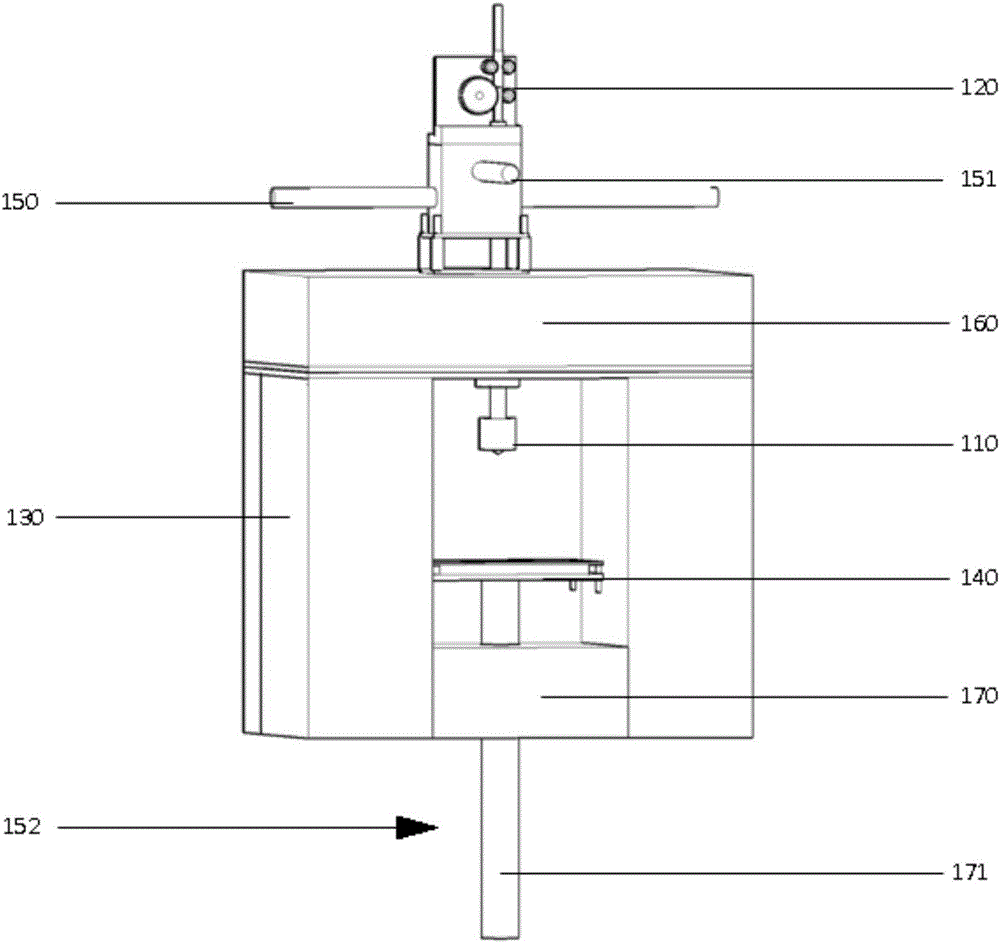

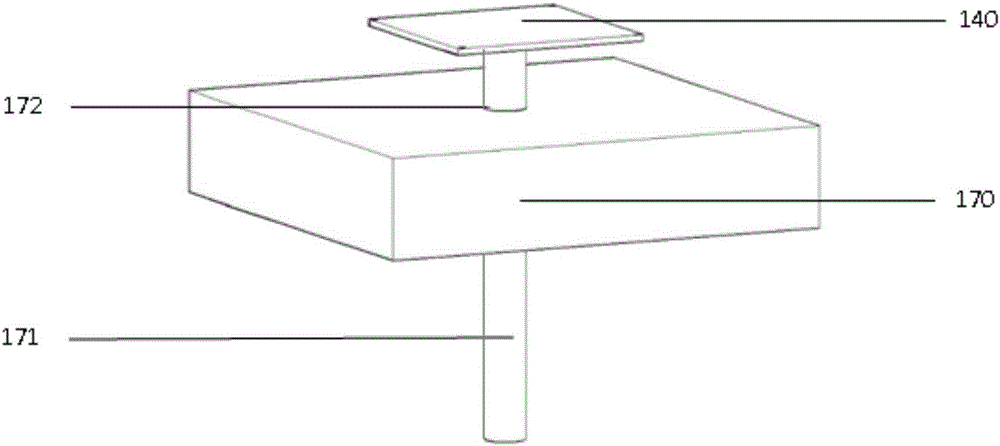

Glass-melting extrusion 3D (three-dimensional) printing device

ActiveCN106045283AHeat insulationFlexible movementAdditive manufacturing apparatusGlass shaping apparatusButt jointThermal insulation

The invention discloses a glass-melting extrusion 3D (three-dimensional) printing device, comprising a feeding mechanism, a printing nozzle component and a printing platform, and further comprising a forming room, a mobile thermal insulation plate, a translational mechanism and a lifting mechanism, wherein the printing nozzle component comprises a guiding pipe, a nozzle and a heating module; the guiding pipe is butt-jointed with the feeding mechanism; the nozzle is connected with the guiding pipe; the internal temperature of the forming room is controllable, and an opening port is formed in the top face of the forming room; the mobile thermal insulation plate is used for sealing the opening port, and the nozzle penetrates through the mobile thermal insulation plate and extends into the forming room; the translational mechanism is provided with the feeding mechanism, the printing nozzle component and the mobile thermal insulation plate; a lifting end of the lifting mechanism extends into the forming room through the bottom part of the forming room, and the printing platform is arranged on the lifting mechanism. The printing device disclosed by the invention has the advantages that a separate forming room is taken as a forming space, so that the situation that the service lives of electronic devices and moving components are not shortened due to high temperature influence in the forming room can be guaranteed; meanwhile the mobile thermal insulation plate is arranged for sealing the forming room, so that the heat of the forming room is further insulated and the flexible movement of the printing nozzle component is guaranteed at the same time.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Knife scraping method glass passivation process for silicon current rectifier

InactiveCN101038892AAchieve protectionReduce dependenceSemiconductor/solid-state device manufacturingSolventBottle

The invention provides a knife scraping glass passivating process for silicon rectifier which includes: (1) employing mixed acid to erode a diffusion chip which has been photoetched thereby forming PN junction and to remove photoresist; (2) compounding ethyl cellulose and thinner in ratio into solution and then filling the same and glass powder into an eggplant-shaped bottle to stir for making glass plasma; (3) equably coating the glass plasma on the surface of the silicon chip which has been etched with groove, and then removing the redundant glass plasma on electrode face by scraper; (4) pre-firing the coated silicon chip in a furnace for 20 min, 585 DEG C.; (5) taking out the fired silicon chip and erasing the redundant glass powder; (6) glass-melting the erased silicon chip in a furnace for 20 min, 820 DEG C.; (7) executing the procedures of coating, prefiring, erasing, melting for the glass-melted silicon chip once again; (8) plating nickel and gold on the passivated glass and then scribing the same thereby completing the chip of the silicon rectifier. The process can be easily operated, and has less equipment dependence, and is easy for application, and can reduce production cost and operation time.

Owner:TIANJIN ZHONGHUAN SEMICON CO LTD

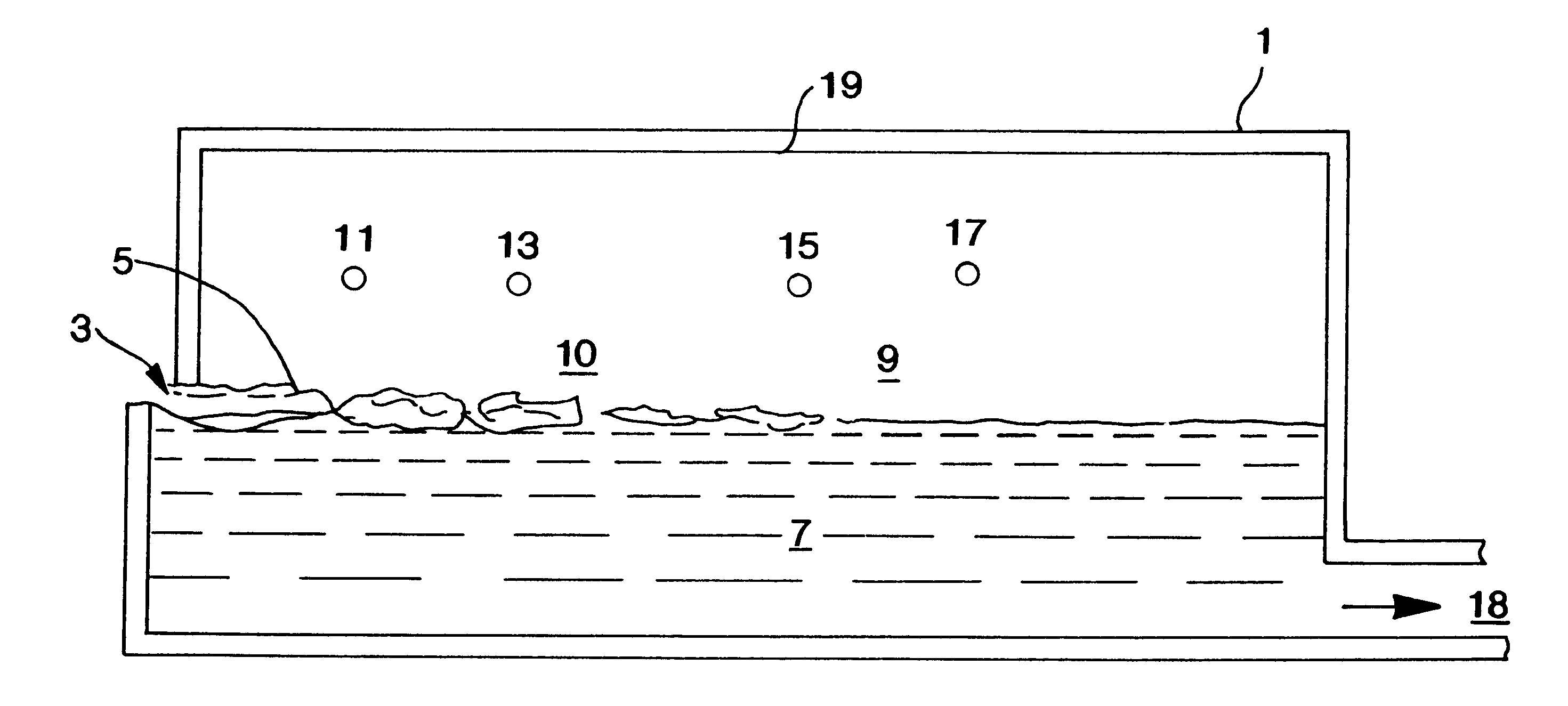

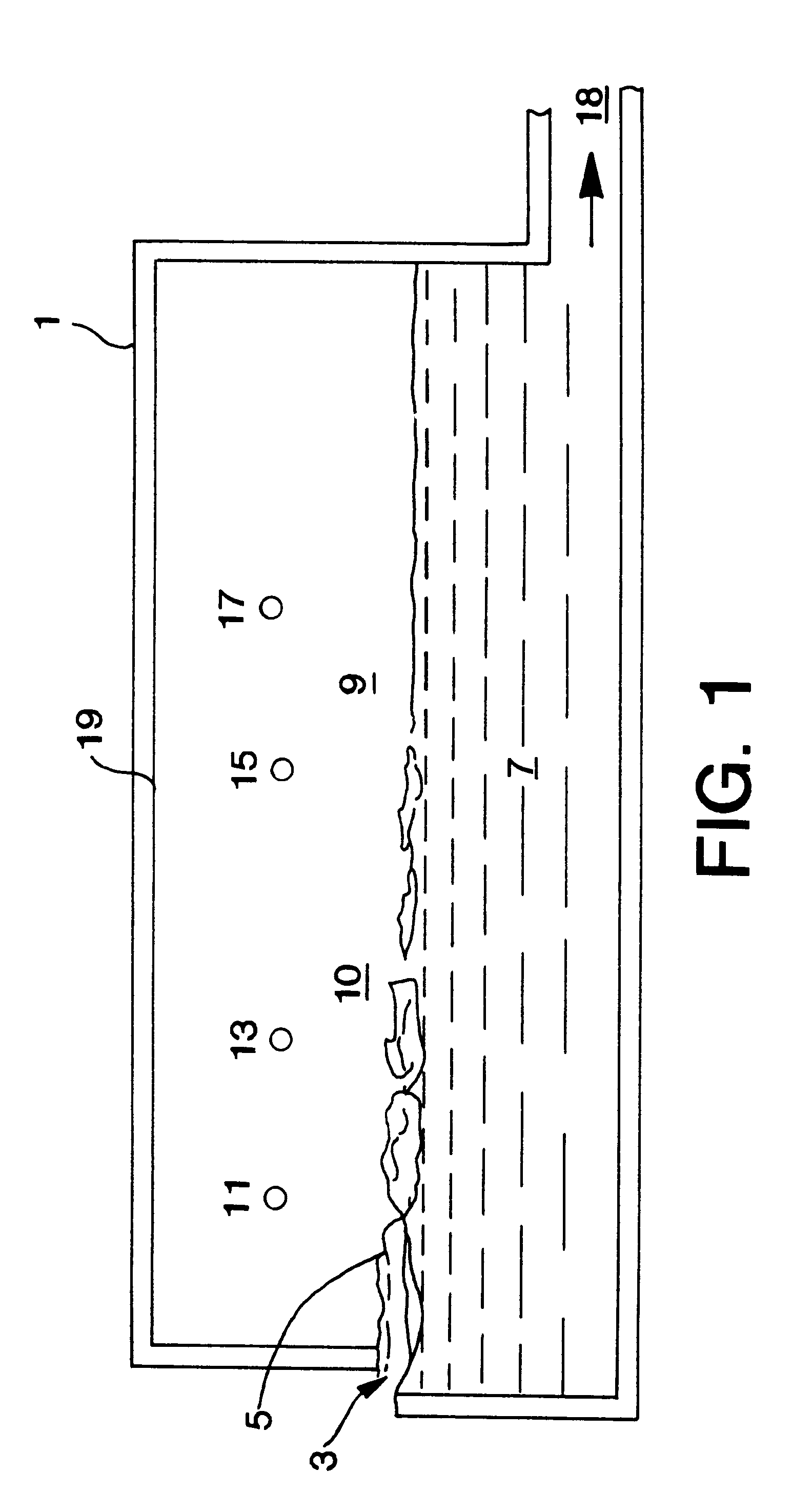

Gas injection for glass melting furnace to reduce refractory degradation

InactiveUS7168269B2Reducing alkali vapor corrosionReduce adverse effectsIndirect carbon-dioxide mitigationGaseous fuel burnerGlass furnaceRefractory

A glass melting furnace has a gas inlet positioned proximate to a charging section oxy-fuel combustion region to introduce gas into the region and to at least partially displace gas having a partial pressure of alkali vapor from the region, and optionally a gas outlet is adapted to provide an exit for a volume of furnace atmosphere. A method for reducing alkali vapor corrosion of glass furnace refractory structures includes providing a gas inlet proximate to the oxy-fuel combustion region; introducing a volume of gas from the inlet into the region, displacing a volume of gas having a partial pressure of alkali vapor from the region; and, optionally providing a gas outlet adapted to provide an exit for a volume of furnace atmosphere.

Owner:BOC GRP INC

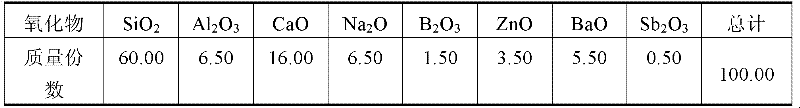

Method for producing glass beads used for curing high-level nuclear wastes

InactiveCN101857355AGood anti-devitrification performanceLow viscosityGlass shaping apparatusRotary furnaceRaw material

The invention provides a method for producing glass beads used for curing high-level nuclear wastes. The method comprises the following steps of: uniformly mixing raw materials, melting the raw materials into glass solution by using an all-electric glass melting furnace at the temperature of between 1,300 and 14,000 DEG C, clarifying and homogenizing the glass solution for 5 to 8 hours, cooling the glass solution to obtain glass block green bodies, and preparing glass blocks by specifications of finished products from the obtained glass block green bodies; uniformly mixing each 100 parts of the obtained glass blocks with 10 to 25 parts of charcoal powder and 1 to 3 parts of carbon black, and throwing a mixture into a glass bead electrothermal rotary furnace, of which the running speed is 20 to 30 revolution per minute, at a speed of 0.7 to 1.0 kilogram per minute at the temperature of between 850 and 940 DEG C through the glass bead electrothermal revolving furnace, and rolling the mixture to form a ball-shaped mixture; and finally annealing and cooling the ball-shaped mixture to obtain the glass beads used for curing the nuclear wastes. The glass beads used for curing the high-level nuclear wastes produced by the method has ideal high-temperature viscosity, high mechanical strength and high anti-crystallization performance.

Owner:天台精工西力玻璃珠有限公司

SYSTEM USING SELECTIVE CATALYTIC REDUCTION FOR IMPROVING LOW-TEMPERATURE De-NOx EFFICIENCY AND REDUCING YELLOW PLUME

ActiveUS20140010748A1Increase amount of catalystEfficient removalGas treatmentNitrogen compoundsNitrogen oxidesNitrogen

The present disclosure relates to a method for removing nitrogen oxides (NOx) more effectively at 300° C. or below in boilers, gas turbines, incinerators, diesel engines, glass melting furnaces, etc. by selective catalytic reduction (SCR).To this end, an oxidation catalyst is mounted in front of a NOx-reducing device based on selective catalytic reduction and the NOx composition, i.e. the ratio of NO:NO2, in the exhaust gas is adjusted to about 1:1, such that de-NOx catalytic reaction is carried out under optimized fast SCR condition and de-NOx efficiency at low temperature can be maximized.

Owner:GSCO

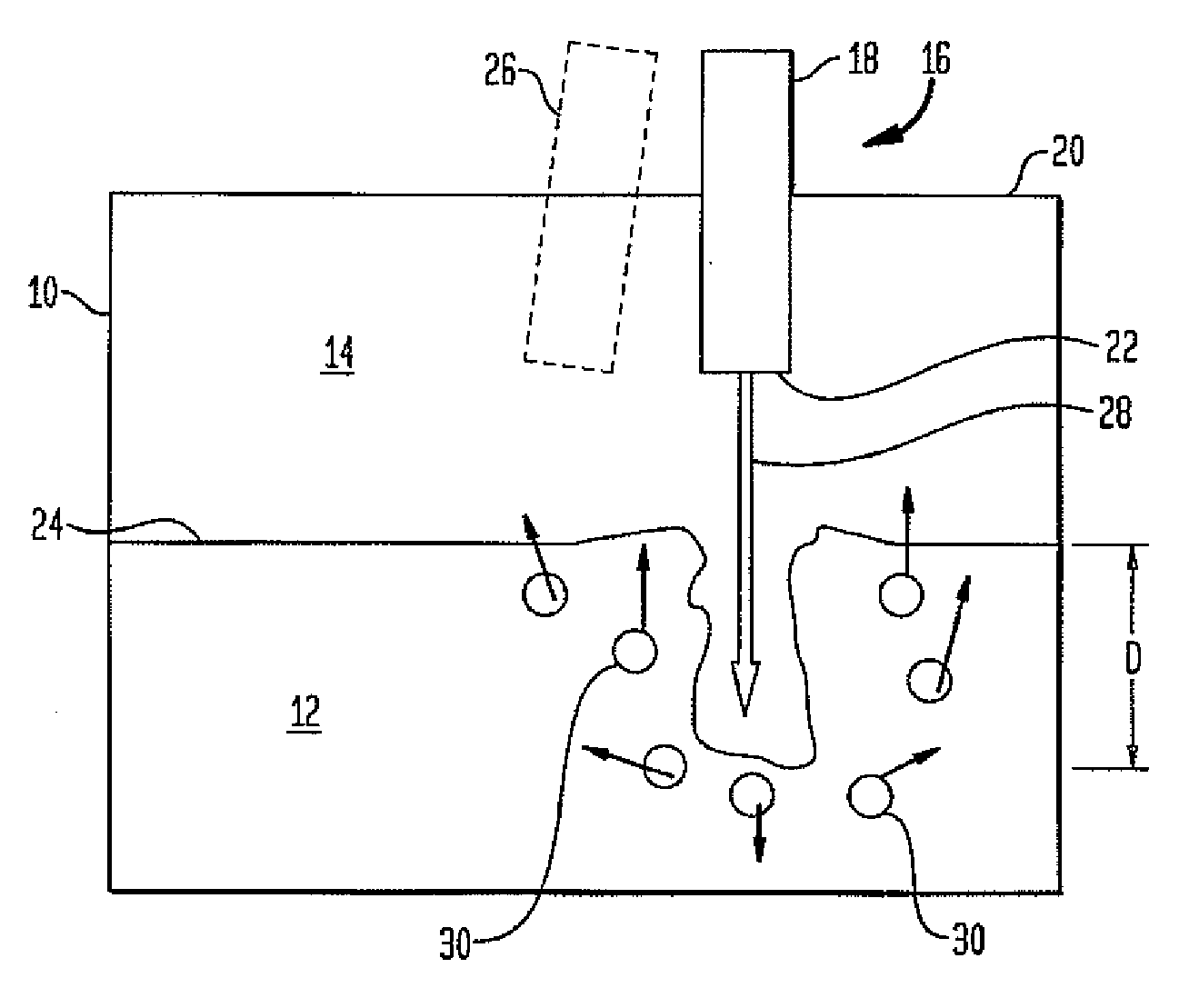

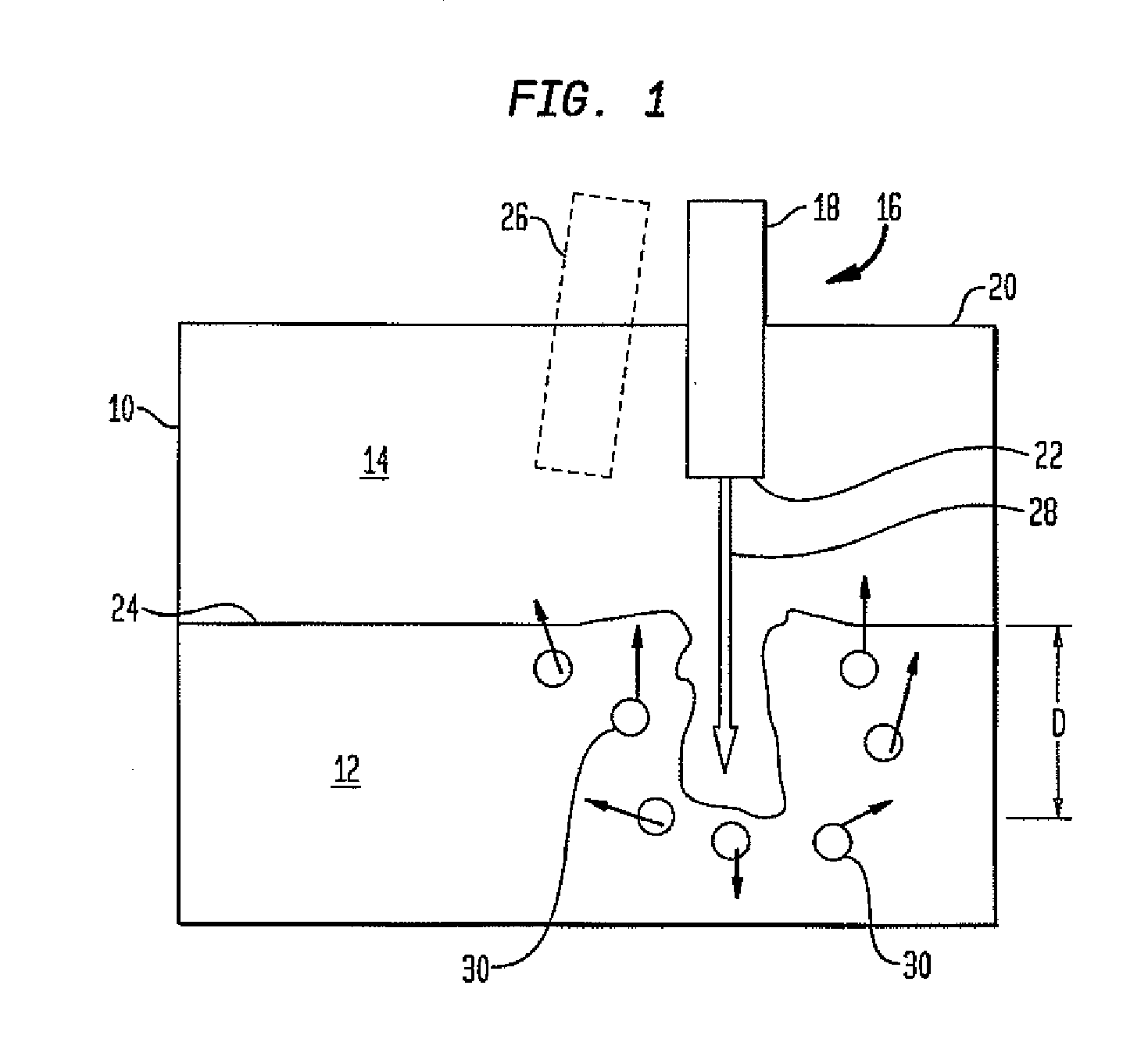

Method and system for reducing a foam in a glass melting furnace

Provided is a method for reducing or removing a foam present in a glass melting furnace, including providing an ultrasonic energy emitted from at least one ultrasonic energy source to a foam present above the surface of a molten material in a glass melting furnace. The ultrasonic energy is effective to reduce or remove at least a part of the foam. Also provided is a system for reducing or removing a foam present in a glass melting furnace.

Owner:JOHNS MANVILLE INT INC

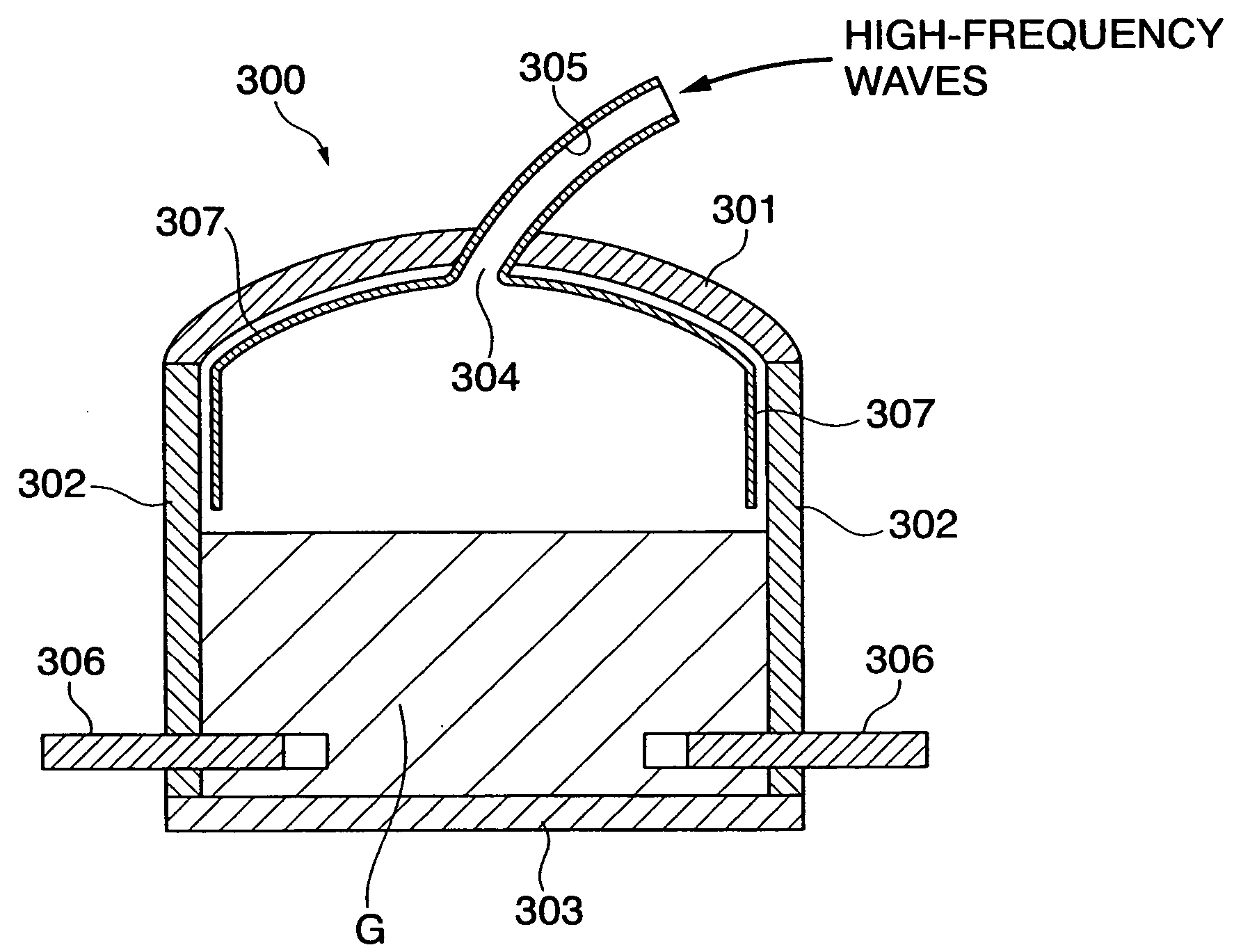

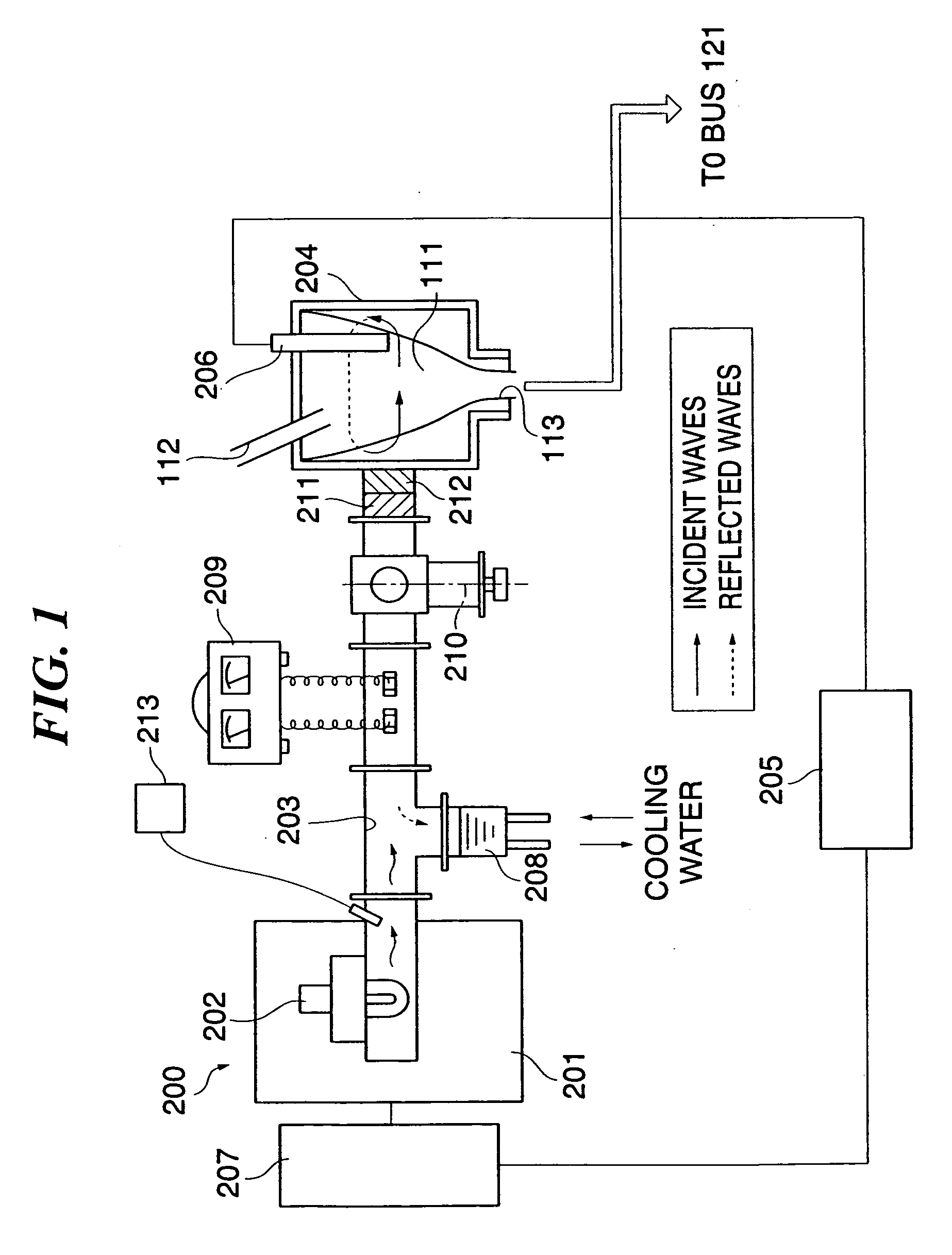

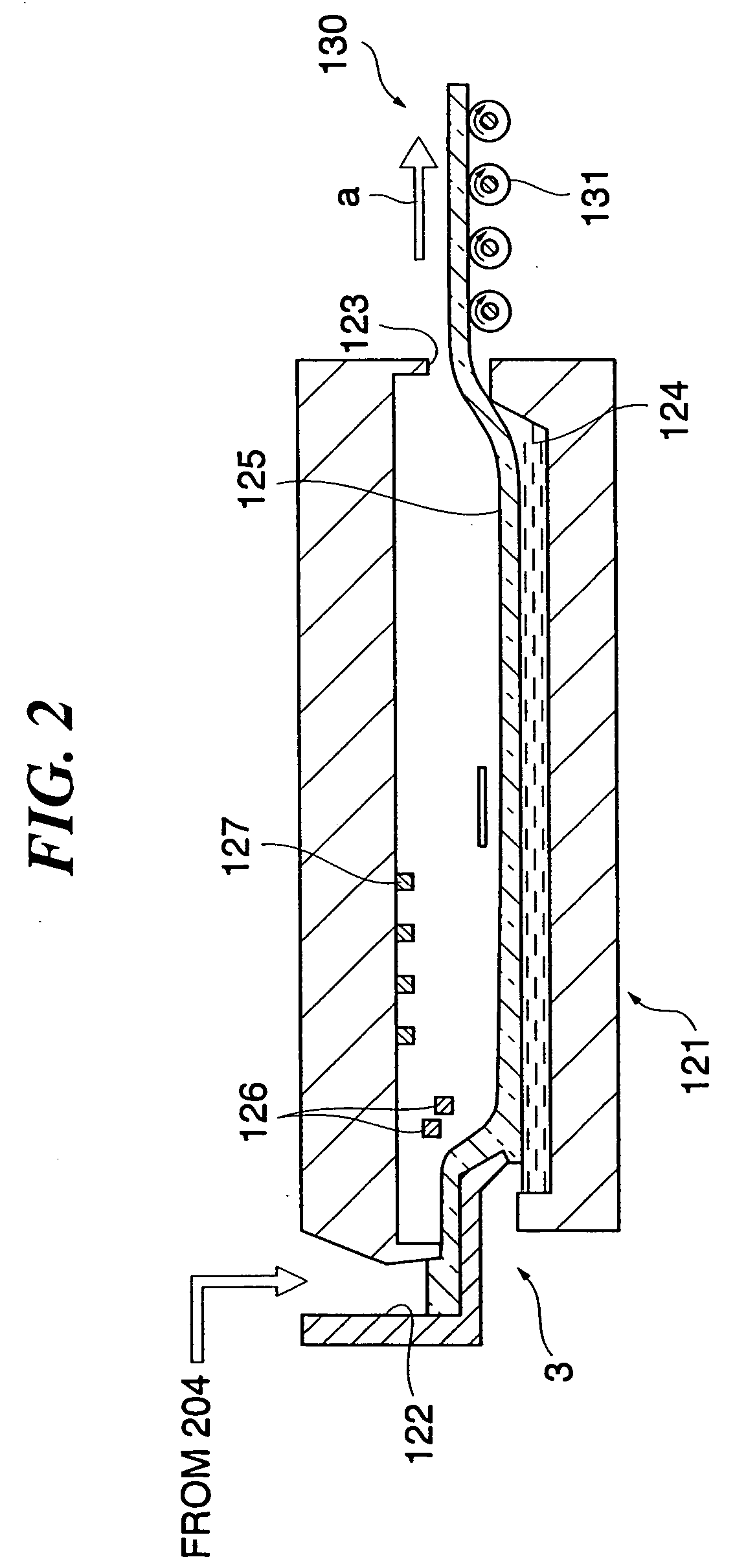

Glass melting apparatus and glass melting method

There are provided a glass melting apparatus and a glass melting method which are capable of uniformly melting glass materials and shortening or dispensing with a fining process. The glass melting apparatus 200 is comprised of an oscillator 201 having a gyrotron 202 disposed therein for emitting high-frequency waves of 28 GHz, a circular waveguide 203 for transmitting the millimeter waves from the oscillator 201, an applicator 204 having a ceramic furnace 111 disposed therein, and a CPU 205 controlling a thermocouple 206 for measuring the temperature of molten glass within the furnace 111 and a power supply panel 207 for supplying electric power to the oscillator 201. The furnace 111 has an upper part thereof formed with a batch inlet port 112 through which a mixture of glass materials (hereinafter referred to as “the batch”) is charged, and a lower part thereof formed with an outlet end 113 through which the batch melted uniformly by dielectric heating within the furnace 111 is dropped into a bus 121.

Owner:NIPPON SHEET GLASS CO LTD

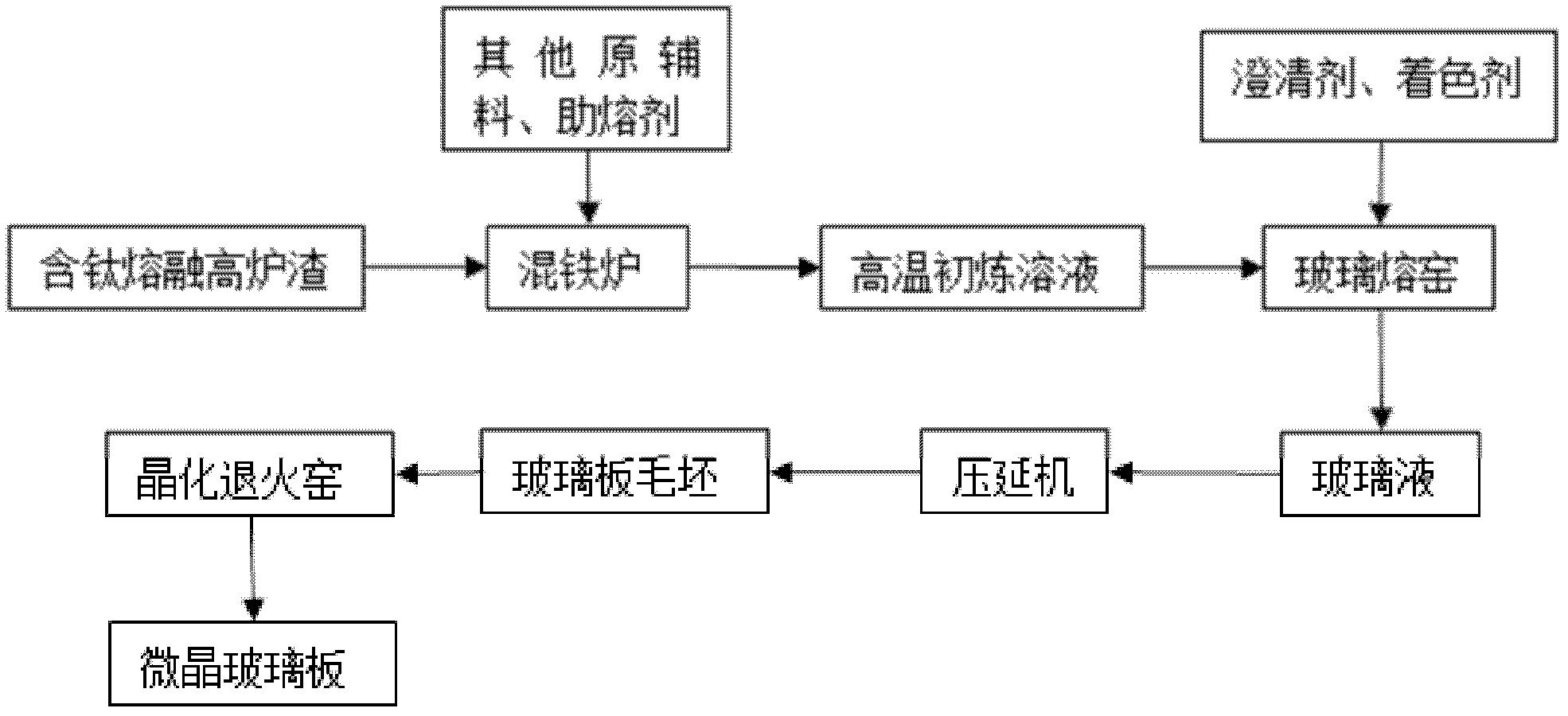

Method for manufacturing glass ceramic by titanium-containing melting blast furnace slag

The invention discloses a method for manufacturing glass ceramic by titanium-containing melting blast furnace slag. The method comprises the following steps of: directly feeding titanium-containing high-temperature melting blast furnace slag flowed out of a blast furnace into a metal mixer, mixing the slag with other auxiliary raw materials and a fluxing agent, feeding high-temperature initial-refining solution into a glass melting furnace and also adding a clarifying agent and a coloring agent, refining in the glass melting furnace to form the smelted glass with uniform elements, uniform temperature and good flowability, feeding the smelted glass into a calendar to form red and hot glass blanks by pressing, and feeding the pressed glass blanks into a crystallization annealing kiln to carry out thermal treatment to manufacture the glass ceramic which takes diopside as a main crystalline phase. Compared with the prior art, the method for manufacturing the glass ceramic by the titanium-containing melting blast furnace slag has the advantages that the blast furnace slag with high titanium content is taken as the raw material for preparing the glass ceramic, thus the effectively utilization rate of the blast furnace slag with the high titanium content is improved, the discharge of the blast furnace slag with the high titanium content is further reduced, and the recovery of an industrial solid waste resource is also realized when the environment is improved.

Owner:达州市海蓝冶金设备制造有限公司

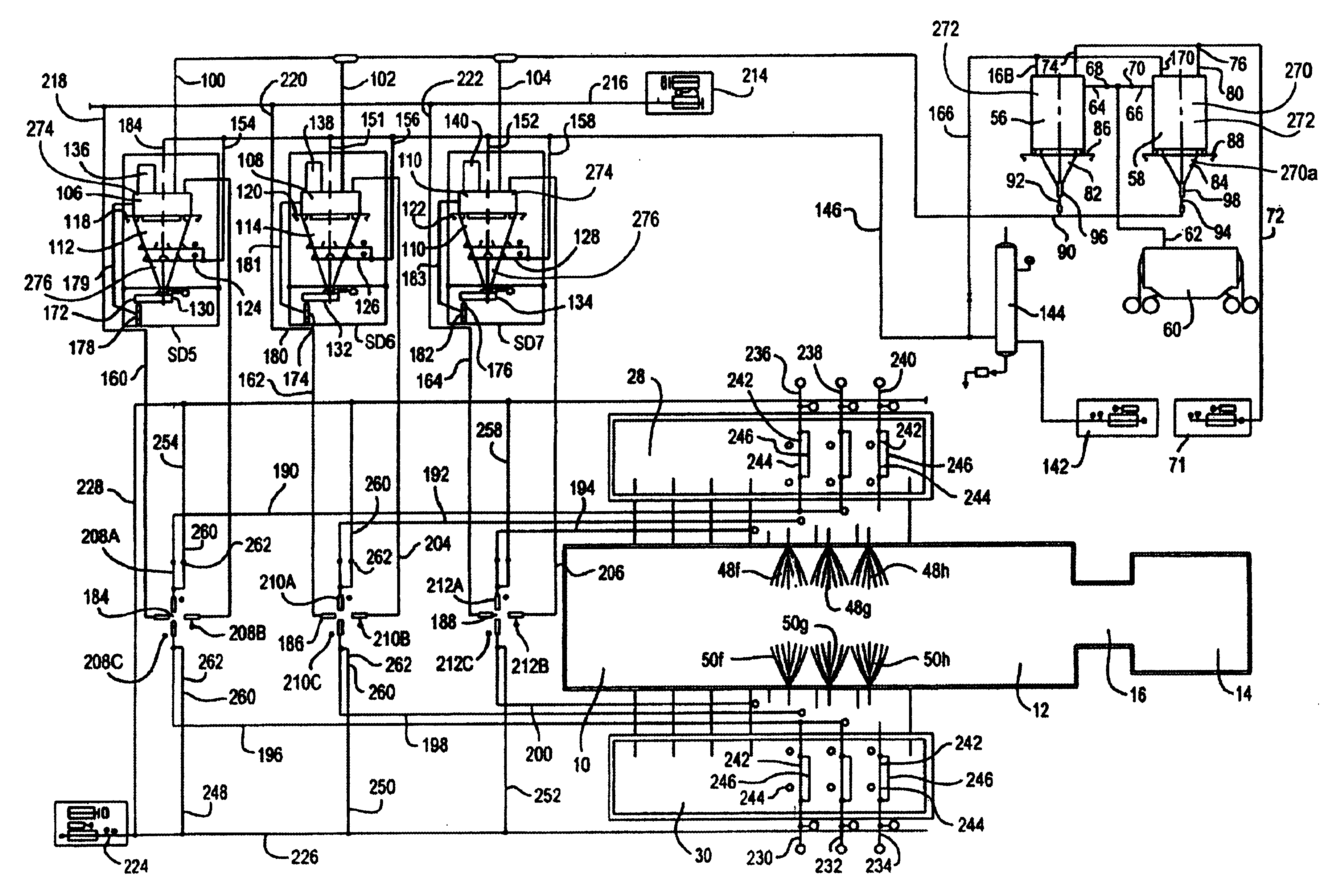

Control system for controlling the feeding and burning of a pulverized fuel in a glass melting furnace

Owner:VITRO GLOBAL

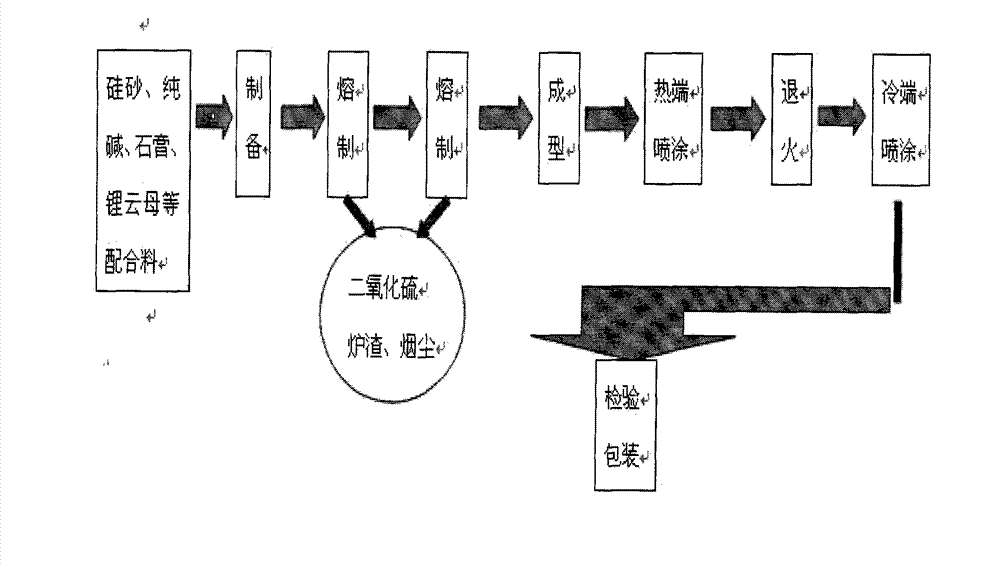

Method for producing calendaring type glass-ceramic decorative board by phosphorous slag

The invention discloses a method for producing calendared glass-ceramic decorative board by phosphorous slag, comprising the following steps of: step 1: preparing, namely, taking phosphorous slag, arenaceous quartz, calcined soda, alumina, zinc oxide, magnesia, barium carbonate and colorant according to a formulation; step 2: compounding, namely, mixing the materials uniformly to be used later; step 3: sintering glass melting liquid; step 4: pressing the glass melting liquid as a rough plate body of the glass-ceramic decorative board; step 5: annealing and cooling to prepare the rough plate of glass-ceramic decorative board; and step 6: grinding, polishing and cutting the rough plate, thus preparing the finished product. The glass-ceramic decorative board produced by the method has the advantages of excellent physical and mechanical property, uniform and fine quality, durable luster of the plate, pollution resistance, color-adjusting, no-pore, no radioelement pollution and the like. The method has mature process, simple operation and easy control, can effectively reduce the pollution of the phosphorous slag and yellow phosphorus tail gas to the environment, and takes the yellow phosphorus slag as raw material and the tail gas as the heat energy raw material to produce the calendared glass-ceramic decorative board. The method complies with the requirements of emission reduction, energy-saving, environment-protection, health and safety requested by National Environment Protection Commission and National Development and Reform Commission, is beneficial for improving the environment, provides high-class and safe decorative material for the building and has excellent social environment.

Owner:岑春华

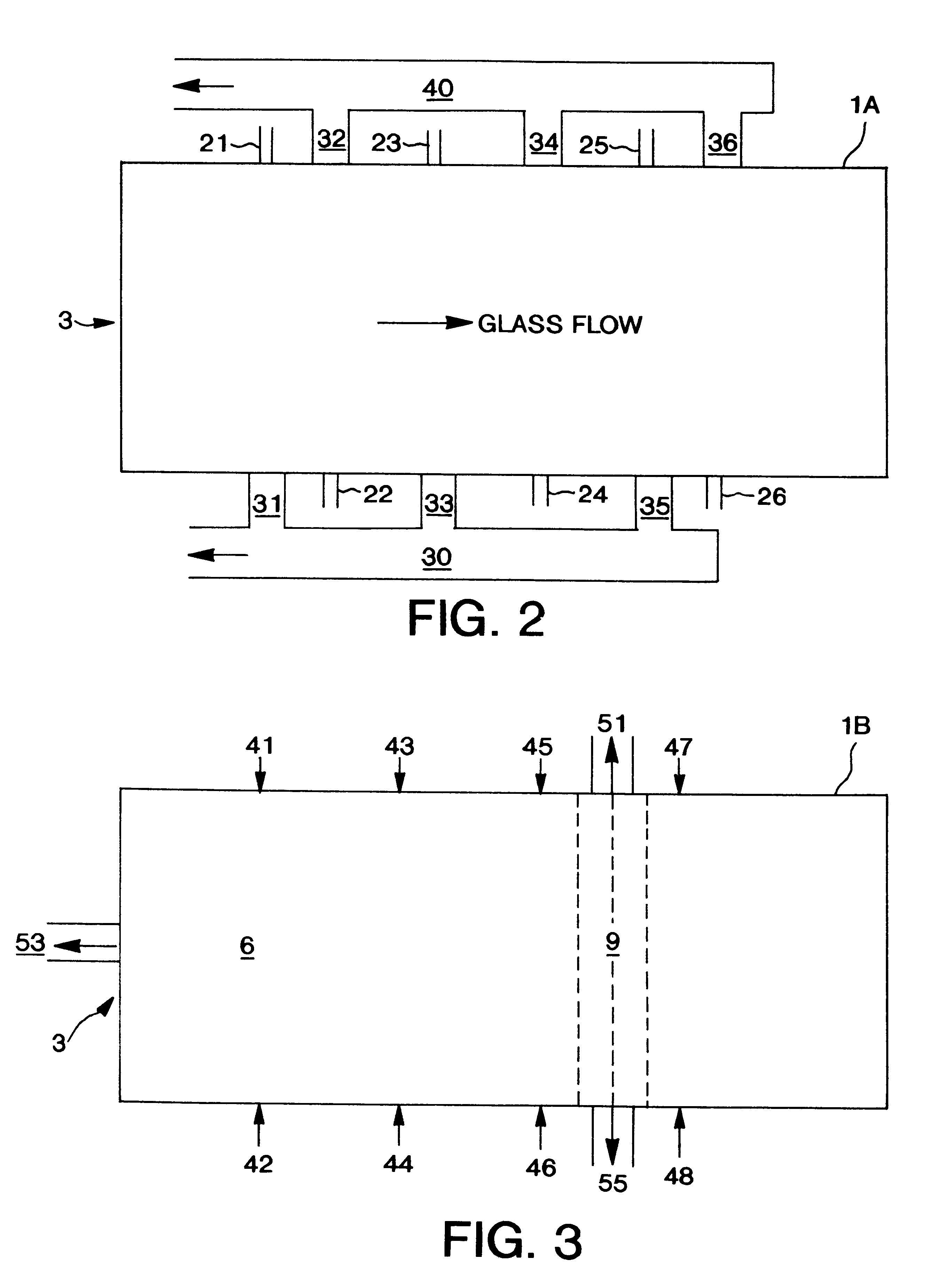

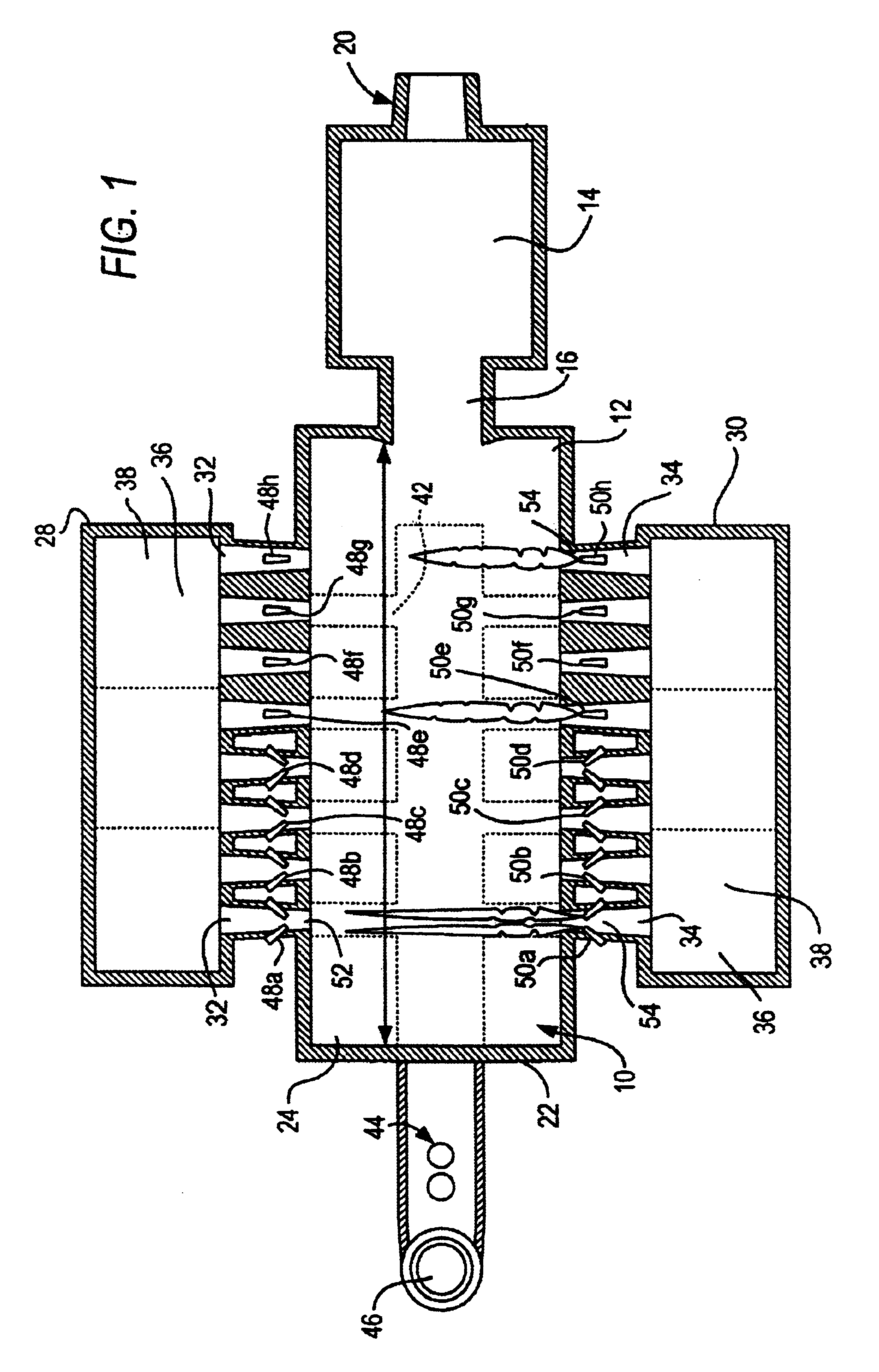

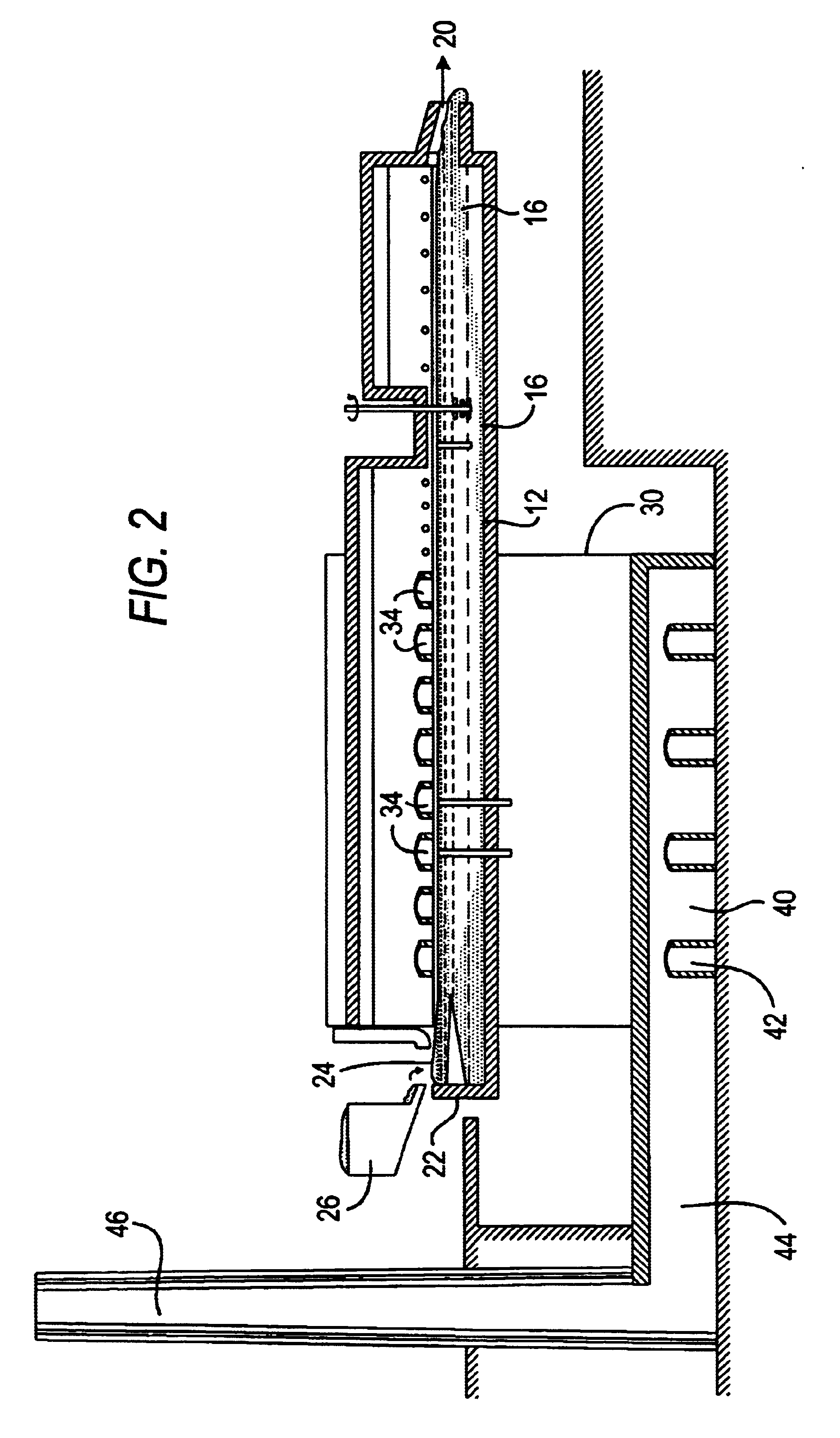

Method for heating glass melting furnace with sectional combustion oxygen fuel burner mounted on the top

InactiveCN1374261AMaintainance of heating chambersIndirect carbon-dioxide mitigationEngineeringLiquid fuel

An industrial glass furnace optionally housing a recuperator, regenerator, electrical heating, or other means for providing heat to the glass batch, having at least one staged combustion oxy-fuel burner in the top of the furnace providing heat to melt the glass batch by providing a flow of fuel to the oxy-fuel burner; providing a flow of gaseous oxidizer associated with the oxy-fuel burner; injecting the fuel and oxidizer into the furnace; and burning the fuel to cause At least a portion of the combustion is achieved in the vicinity of the glass-forming material such that convective and radiative heat transfer to the glass-forming material is enhanced without significantly disturbing the glass-forming material. In one embodiment, the oxy-fuel burner is adapted to inject liquid fuel. In another embodiment, the oxy-fuel burner is adapted for staged combustion of fuel and includes at least one external oxidizer injector and two internal fuel injectors, the innermost fuel injector being adapted for high velocity fuel injection, and the innermost fuel injector Another fuel injector between the injector and the external oxidizer injector is suitable for low speed fuel injection.

Owner:BOC GRP INC

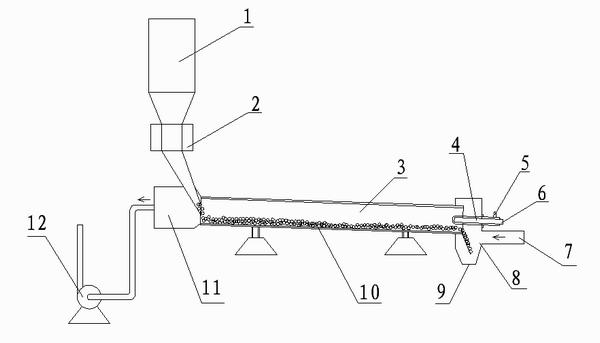

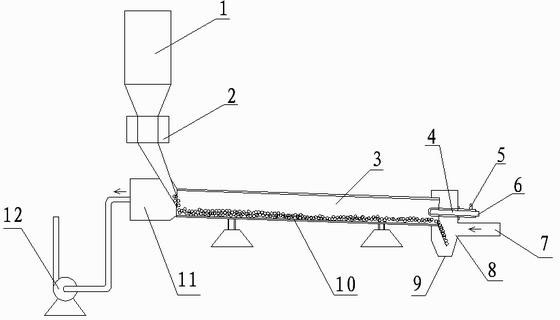

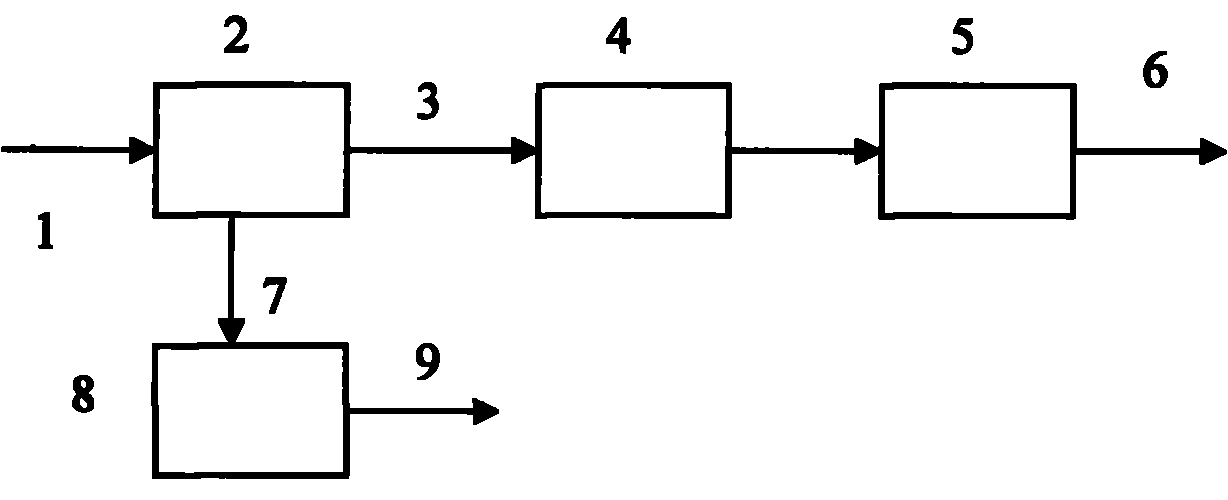

Presintering treatment process of glass batch and device thereof

ActiveCN102320715ADon't worry about flyingShorten clarificationCharging furnaceGlass productionGlass meltingHeating furnace

The invention discloses a presintering treatment process of a glass batch and a device thereof, and the process is performed according to the following steps: (1) adding 0.5 wt%-3 wt% of binders and 6 wt%-8 wt% of water into a glass batch, well mixing, pressing into spherical particle materials with a diameter of 3-25 mm; (2) adding the spherical particle materials into a rotary heating furnace, preheating at 1020-1250 DEG C for 0.5-2 hours, adding the sintered densified spherical particle materials into a glass melting furnace from the rotary heating furnace. According to the invention, the decomposition of carbonates in the glass batch is performed outside the glass melting furnace, which greatly reduces the gas content in the glass batch, effectively increases the heat transfer, shortens the time for glass clarification and homogenization, that is, increases the single-line yield and reduces the energy consumption without the enlargement of the glass melting furnace area; the invention can realize the increase of the melting amount by 20%-30% without the enlargement of a current melting furnace scale.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

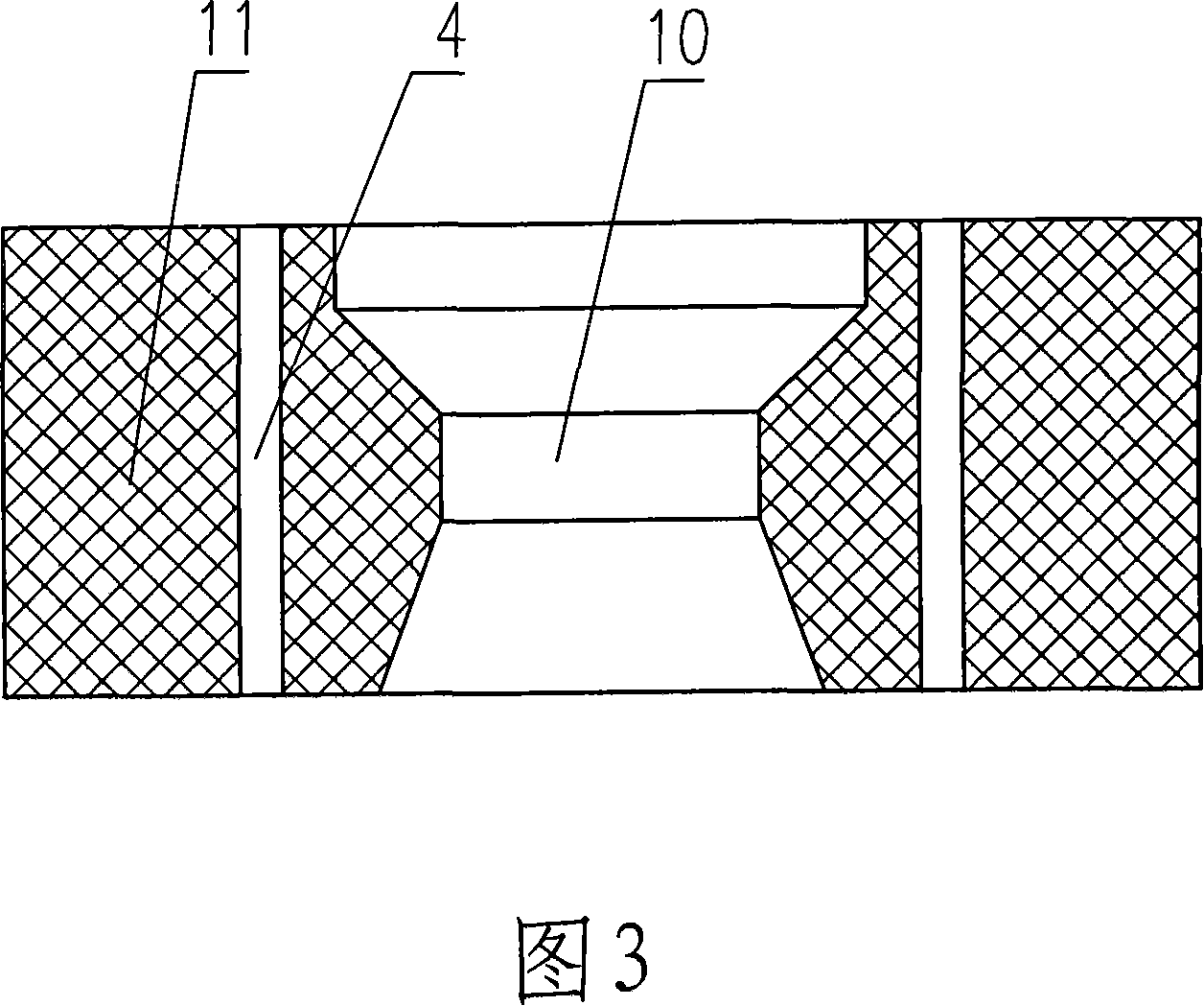

Reduced size bowl for display glass melting and delivery

InactiveUS20080034798A1Eliminate stagnationReduce formationForehearthsGlass furnace apparatusFlat glassReduced size

The present invention provides an improved apparatus for forming sheet glass, wherein the apparatus includes a reservoir from which to provide molten glass, an inlet plate in fluid communication with the reservoir to receive the molten glass from the reservoir in a flow direction, the inlet pipe having a cross-sectional area orthogonal to the fluid direction, and a trough in fluid communication with the inlet pipe to receive the molten glass and that is operably coupled to a wedge-shaped sheet forming structure to form the molten glass into a glass sheet. The improvement comprises a bowl that provides fluid communication between the inlet pipe and the trough, the bowl having a cross-sectional area orthogonal to a fluid direction at the molten through the bowl that is equal to or less than the cross-sectional area of the inlet pipe, thereby preventing stagnation of the molten glass within the bowl. Another embodiment of the present invention is a method that utilizes the inventive apparatus to form glass sheet.

Owner:CORNING INC

Fabrication method of beer bottle

The invention relates to a beer bottle and a fabrication method thereof. The beer bottle is fabricated by taking desulfurization gypsum of a thermal power plant as a raw material. According to the beer bottle and the fabrication method, a by-product, namely the desulfurization gypsum, for flue gas desulfurization of the thermal power plant serves as a clarifying agent to substitute fluorite and anhydrous sodium sulphate, so that the cost is lowered effectively, corrosion to fire-resisting materials is reduced, the service life of a kiln is prolonged, emission of fluoride is decreased, and pollution to an atmosphere is reduced. The desulfurization gypsum of the thermal power plant substitutes partial toxic raw materials, including fluoride such as the fluorite, so that the glass melting and clarification capacity can be improved, the glass component structure can be changed, the melting temperature and melt viscosity can be reduced, the thermal expansion coefficient can be reduced, the glass transparency can be enhanced, the thermal shock resistance and acid resistance of a product can be improved, and the glass strength can be improved; in addition, the corrosion of the clarifying agent such as the fluorite to the kiln is eliminated, volatilization of fluoride is reduced, atmosphere pollution is avoided, and an environment is protected.

Owner:青岛崂玻玻璃制品有限公司

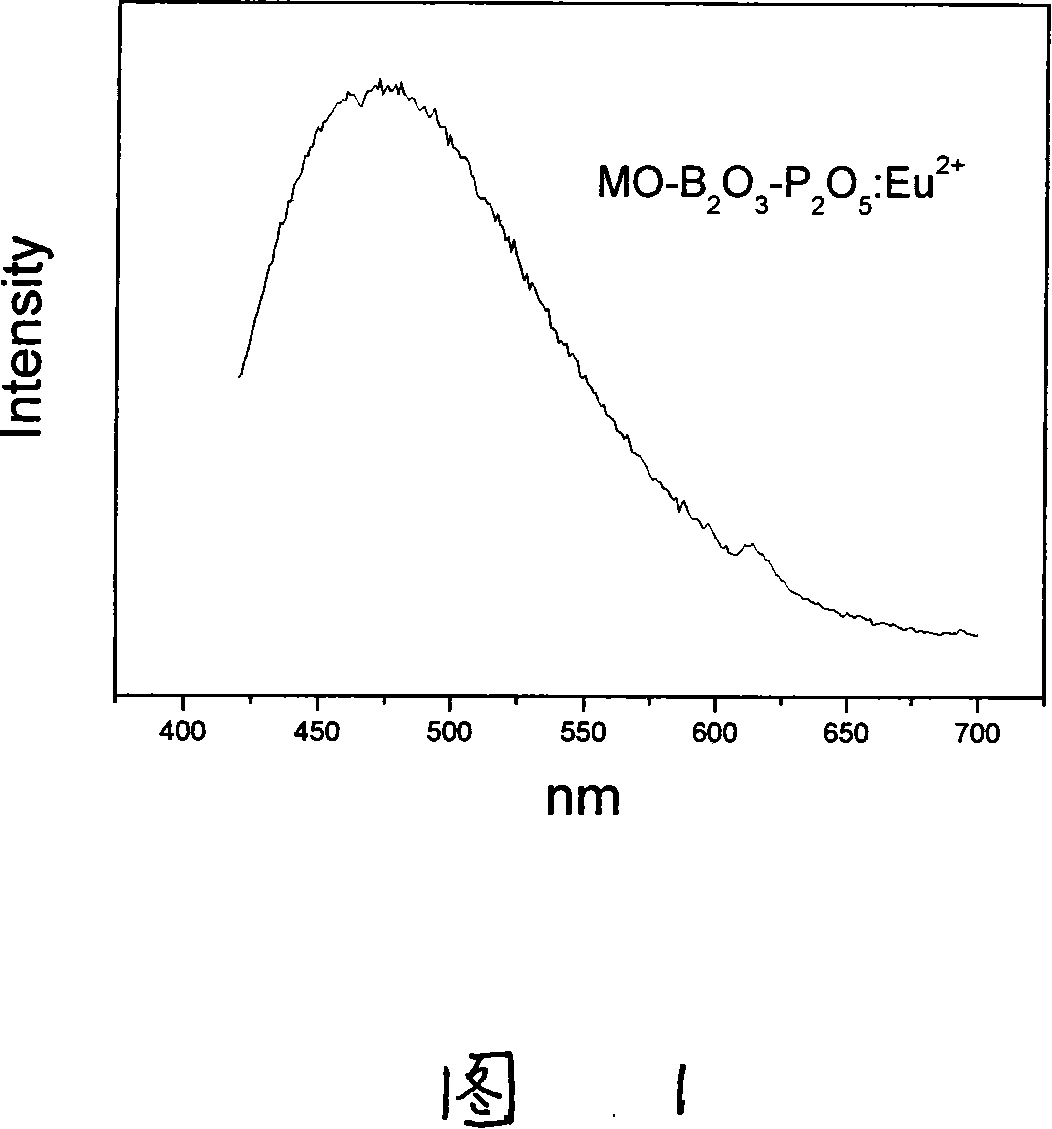

White light radiation glass for rare earth ion europium activating lamp and preparation method thereof

InactiveCN101104547AIncrease the doping concentrationImprove luminous brightnessHigh concentrationAlkaline earth metal

The present invention discloses a rare earth ions europium activated lamp-use glass which emits white light, as well as the related preparation method. The chemical composition of the glass is aMO-bB2O3-cP2O5:dEuO, wherein, the aMO-bB2O3-cP2O5 is glass matrix; Eu2+ is luminescence ion; M is one of or more of alkaline earth metal ions Ca, Ba and Sr; a, b, c, d are the correspondingly composed mole percentage coefficient. The preparation method is that alkaline earth metal carbonate, boron oxide, alkaline-earth metal hydrogen phosphate salt and europium oxide are measured according to the composition and proportion of the glass and are fully grinded and uniformly mixed; the mixture will then be fused at 1100 to 1500 DEG C under the reducing condition or in the air for 1 to 5 hours; the glass melting liquid is molded and annealed to get the final product. The invention can directly prepare Eu2+ under weak oxidation atmosphere conditions in the air by changing the glass matrix composition, and make the single rare earth ion Eu2 + directly mix into the glass to get the glass that emits white light. The invention has the advantages of high concentration of the rare earth ions and high brightness, which omits the past bepowdering technology, simplifies the technology process and reduces the production costs.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

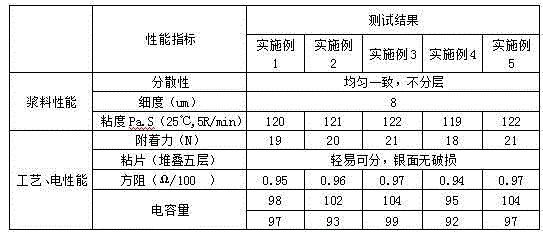

Silver paste for ceramic capacitor and preparation method thereof

InactiveCN104637571AExcellent electrical performanceReduce production processFixed capacitor electrodesNon-conductive material with dispersed conductive materialSilver pasteOrganic solvent

The invention provides a silver paste for a ceramic capacitor and a preparation method thereof. The silver paste contains the following ingredients in percentage by mass: 50-57% of silver conductive powder, 0.2-3% of inorganic additive, 40-44% of organic carrier and 2-5% of organic auxiliaries, wherein the organic carrier is a mixed system of an organic solvent and a macromolecular thickener, and the organic auxiliaries comprise a dispersing agent, a thixotropic agent and a leveling agent. According to the silver paste for the ceramic capacitor and the preparation method thereof, adhesive power between an electrode layer and a substrate is provided in a manner of replacing glass melting and curing with chemical bonding, a glass powder preparation process is avoided, the process is simple, good adhesive power with ceramic capacitor substrates of most current types can be formed, and thus, the adaptability is extensive.

Owner:HEFEI SHENGDA ELECTRONIC TECH IND CO LTD

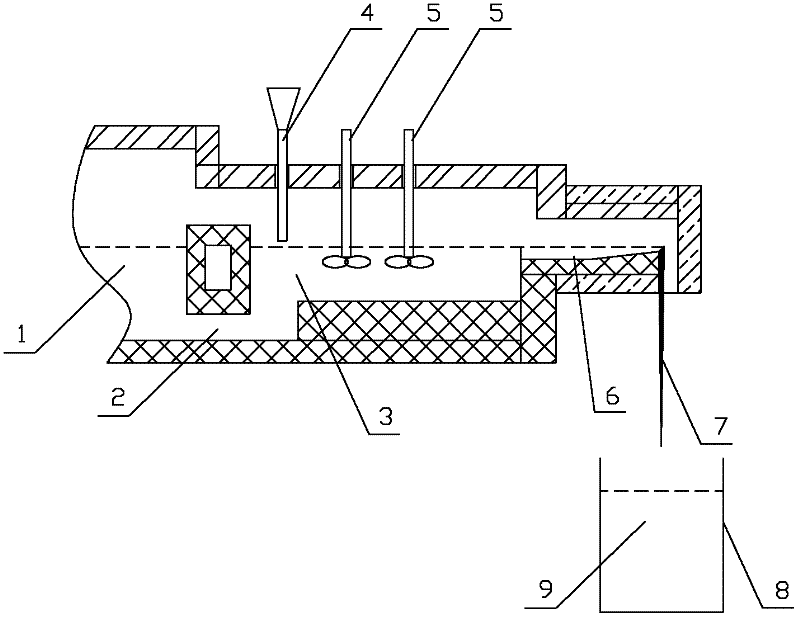

Device and technique for continuously melting transparent quartz glass ingot by gas refining

ActiveCN101148311AUniform appearanceImprove inner qualityGlass furnace apparatusGlass forming apparatusMelting tankBrick

The present invention is continuous transparent quartz glass ingot melting apparatus and process, and belongs to the field of quartz glass melting technology. The melting apparatus consists of one hydrogen burner, one smelting furnace with one melting bath and one forming port, one ring smoke flue, one furnace seat and one drawing machine. The continuous melting process includes the steps of setup, preheating, feeding material, drawing ingot and cutting ingot. The present invention can produce ingot of circular or non-circular cross section, and has high heat efficiency and high quartz glass ingot quality.

Owner:潜江菲利华石英玻璃材料有限公司

Fused silica ceramic material containing ytterbium oxide and preparation method thereof

The invention relates to a fused silica ceramic material containing ytterbium oxide and a preparation method thereof, belonging to the field of high-temperature structural ceramic materials. The ceramic material is prepared from the following materials by weight percentage: 97% to 99% of fine fused silica powder and 1% to 3% of fine ytterbium oxide powder. The preparation method comprises the following steps: dry-mixing the fine fused silica powder and the fine ytterbium oxide powder; wet-mixing the mixture by adding polyvinyl alcohol solution as binding agent; further sieving, stirring and ageing the mixture to obtain the perform body for molding the green body; molding the green body by a hydraulic press with the molding pressure being higher than or equal to 50MPa; drying and sintering the green body at 1,200 to 1,400 DEG C; and standing for 1 to 3 hours to obtain the fused silica ceramic material containing ytterbium oxide. The invention provides a novel high-temperature structural material for glass melting, ferrous and non-ferrous metallurgy, electronics, military missiles, spacecraft and other fields in China and has wide application prospect and great significance in strengthening the national defense.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

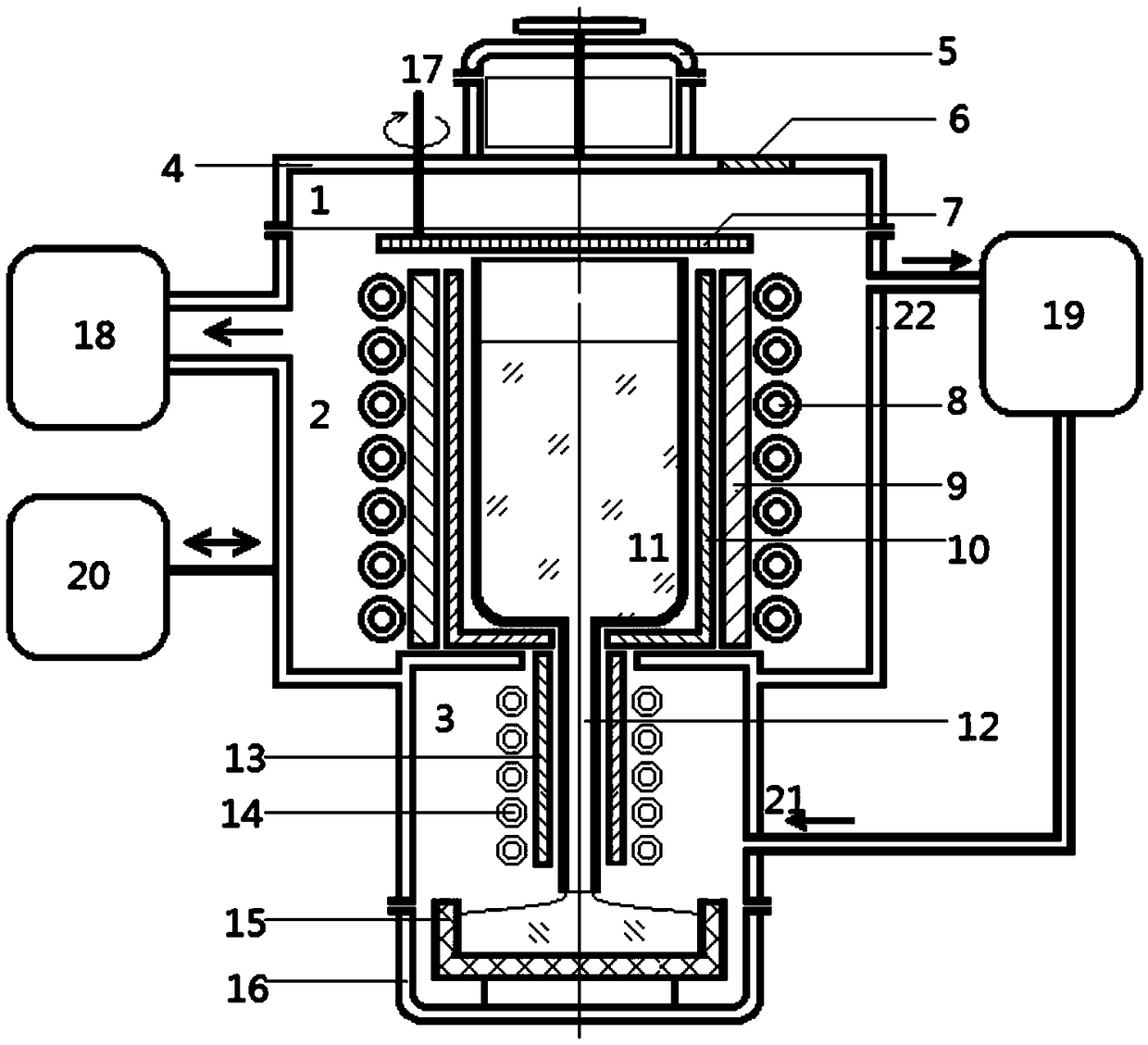

Pressure control glass melting device and method

ActiveCN108726850ARealize vacuum negative pressureEnsure consistencyGlass furnace apparatusGlass shaping apparatusPositive pressurePollution

The invention relates to a pressure control glass melting device and a pressure control glass melting method. The pressure control glass melting device comprises a closed furnace body; the furnace body comprises a charging part, a melting part and a discharging part sequentially from top to bottom, wherein the melting part is heated by an induction heating mode. The furnace body adopts a sealing structure, the melting pressure in the furnace can be controlled to 10<-3> to 0.3 MPa, vacuum negative pressure and gas positive pressure can be realized conveniently, or oxidation, reduction and inertatmosphere can be formed through gases with different properties; the consistency of the pressure and atmosphere in the furnace is guaranteed and influenced by impurities such as external air and water is avoided; meanwhile, component control in the melting process of the raw materials of the glass is facilitated, consistency of composition and performance of the glass is benefited and batch application of products is facilitated. A water-cooled metal furnace body avoids dust pollution, the temperature of the furnace wall is close to room temperature, and pollution to the glass caused by erosion of the oxidation and reduction atmospheres is effectively avoided.

Owner:CHINA BUILDING MATERIALS ACAD

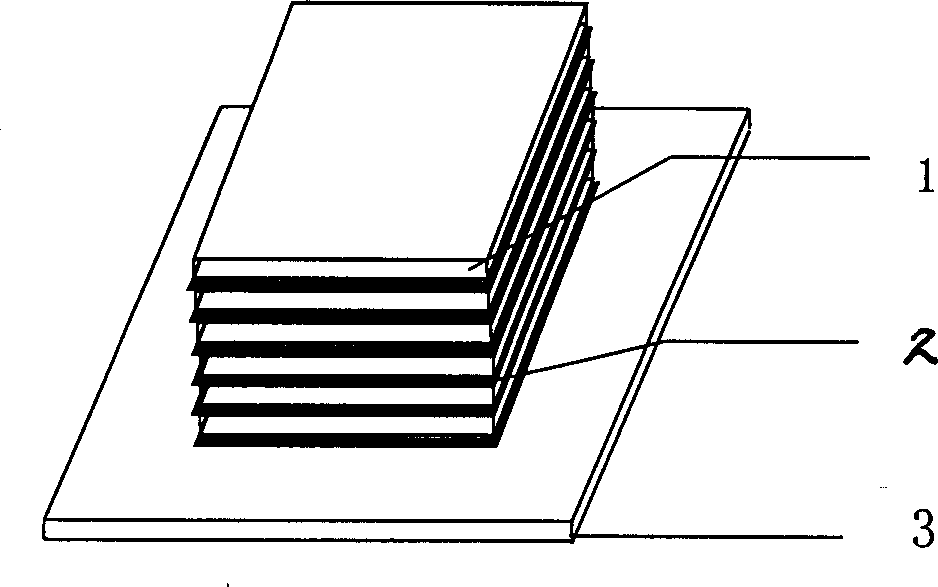

Production method of devitrified glass plate

A production method of nucleated glass sheet material includes the following steps: firstly, uniformly mixing raw materials according to a certain proportion, heating to 1400-1550 deg.C in a glass melting kiln, making the molten glass into thin glass sheet, superimposing glass sheets together to make crystallization at 900-1200 deg.C, crystallization period is 5-20 hr., taking out from the kiln and making the nucleated glass sheet respectively undergo the procedures of finishing and polishing so as to obtain the ultrathin product. This invented method can be used for producing ultrathin nucleated glass decorative sheet, and can be used for producing nucleated glass sheet material with higher thickness. Its production efficiency is high and cost is low, and its product is high in compact density and good in high levelness.

Owner:北京盛康宁科技开发有限公司

Low boron and fluorine glass formula

The invention relates to a glass formulation, in particular to a low-boron low-fluorine glass formulation. In the prior E glass formulation, more boron and fluorine are contained, and the boron and the fluorine are easily volatile in the glass melting process, thereby causing the emission of waste gas to obvious increase, not only increasing production cost and but also easily causing the secondary pollution of solid waste. The invention provides the low-boron low-fluorine glass formulation, which is characterized in that the formulation comprises the following components in weight percentage: 54 to 60 percent of SiO2, 20 to 28 percent of CaO, 12 to 18 percent of Al2O3, 0 to 5 percent of B2O3, 2 to 6 percent of MgO, 0 to 0.4 percent of F, 0 to 0.8 percent of K2O and Na2O, 0.1 to 1 percent of TiO2, 0.1 to 0.5 percent of Fe2O3, 0 to 0.6 percent of SO3, and less than 1 percent of impurities. The glass fiber produced by the glass formulation has low boron and low fluorine and good performances.

Owner:JUSHI GRP CO

Novel chromium slag innocent treatment method

The invention discloses a novel chromium slag innocent treatment method. In the method, quartz sand and an alkaline medicament are taken as melting agents, and chromium slag, the quartz sand and the alkaline medicament are uniformly mixed in a weight ratio of 25-45:35-75:5-22; the mixture is added into an electric glass melting furnace and is fully melted at a high temperature of between 1,350 and 1,500 DEG C to form molten glass; and the molten glass is subjected to water quenching by cold water, and cooled at room temperature to form glass slag. Through high-temperature electric melting treatment, hexavalent chromium in the chromium slag is reduced into trivalent chromium and is cured and stabilized after entering glass lattices, and the chromium slag is converted into glass state inert waste, and the leaching concentration of heavy metals is far lower than a standard limit value in Identification Standard for Hazardous Wastes-Identification for Extraction Procedure Toxicity (GB5085.3-2007) of the nation.

Owner:刘阳生 +1

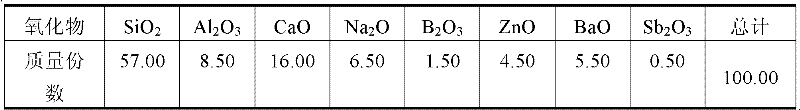

Colorizing method of building decoration microcrystalline glass produced by sintering method

The invention provides a colorizing method of building decoration microcrystalline glass produced by a sintering method. The colorizing method comprises the steps of: preparing glass basic composition materials, adding the glass basic composition materials to a horseshoe flame glass melting furnace for melting, and controlling melting temperature at 1520-1570 DEG C and the temperature of the melting furnace working part at 1360-1420 DEG C; uniformly adding a colorizing agent or an inorganic high-temperature pigment to the molten glass at the front end of the working part through a feeding port at the front end of the working part, arranging a stirring device at the middle of the working part behind the feeding port of the melting furnace, and forming uniform colored glass melt under the combined action of the temperature, molten glass flow and the stirring device; introducing the colored glass melt into a water quenching tank through a supplying channel connected with the working part of the horseshoe flame glass melting furnace, so as to obtain color-uniform glass granules with granularity of 1-6 mm; and carrying out subsequent processing according to a microcrystalline glass preparation process by the sintering method to obtain the product. The prepared glass granules have uniform color, and effectively avoid the problems of color transition material, energy consumption and the like generated by changing glass materials of different colors.

Owner:WUHAN UNIV OF TECH

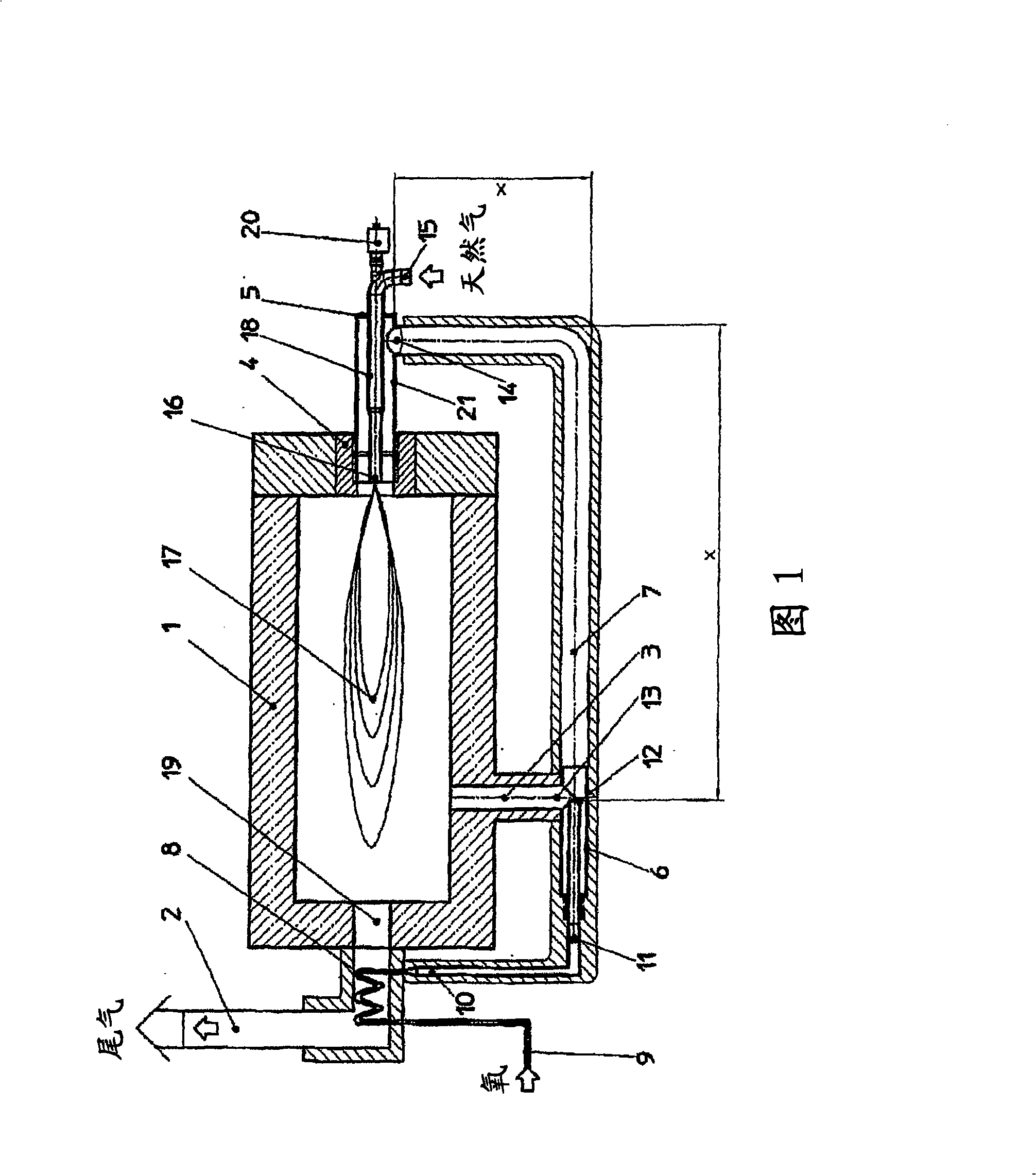

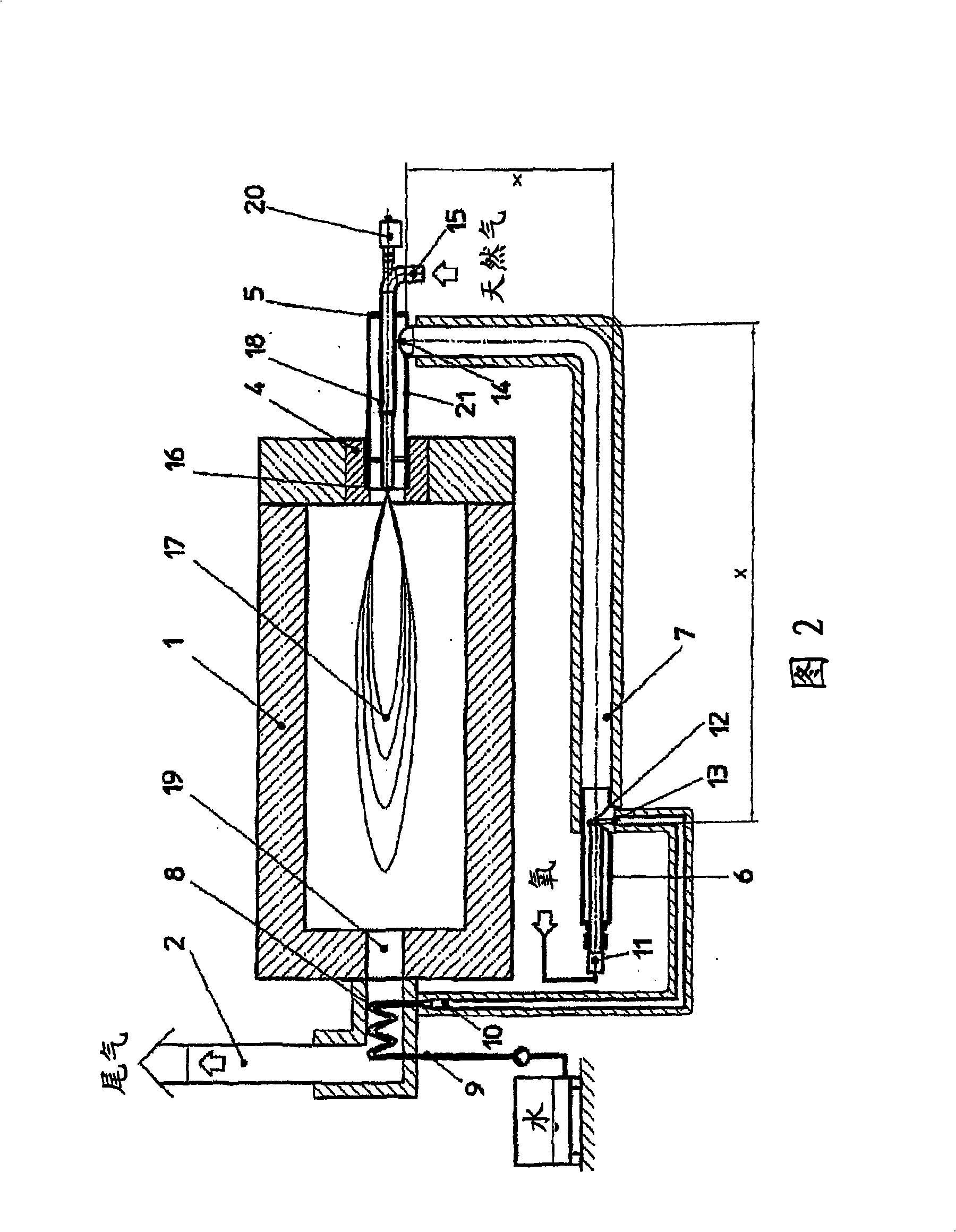

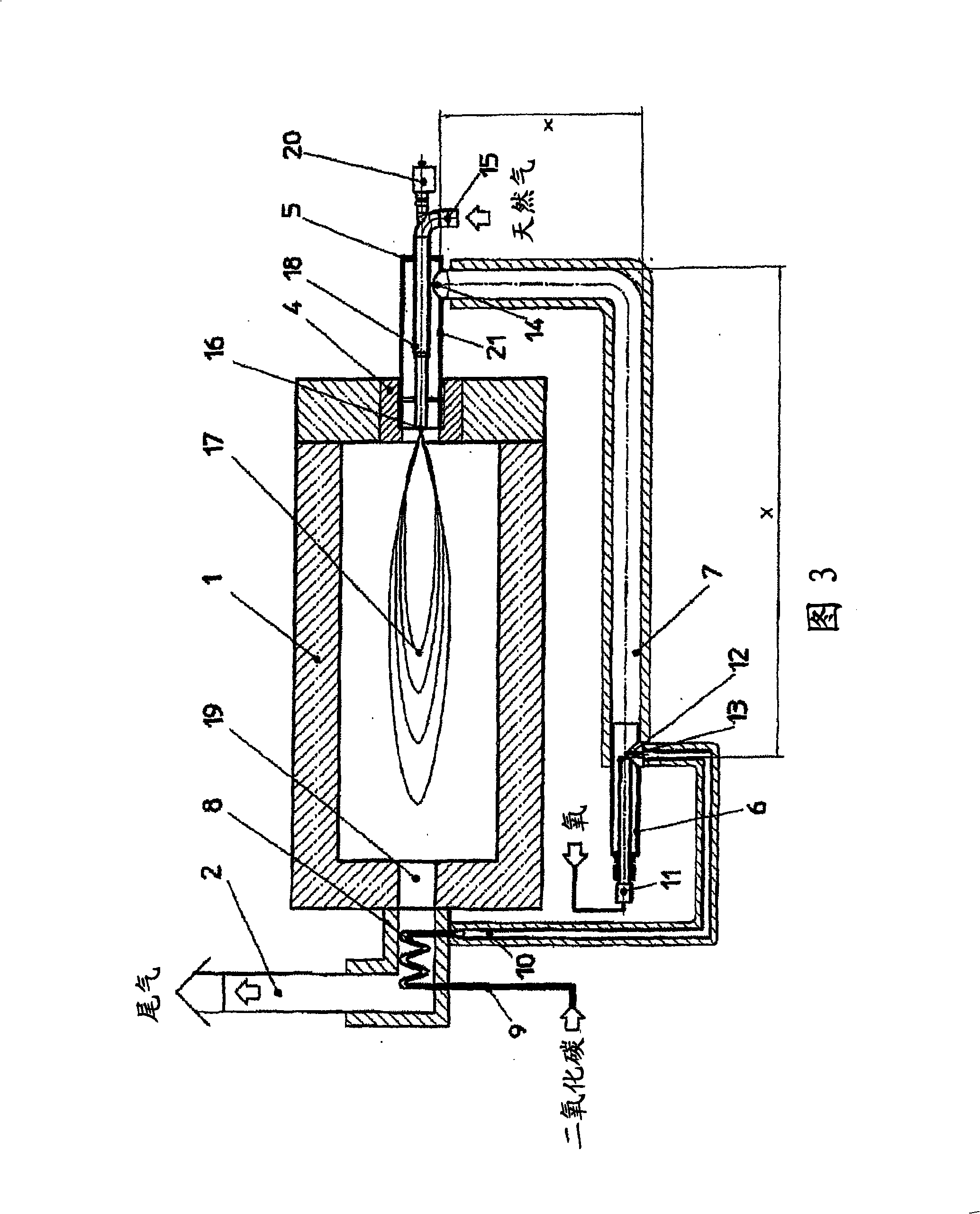

Low-nitrogen oxide combustion technique and device

InactiveCN101297157AIncrease heatPromote combustionBurnersGlass furnace apparatusCombustorLow nitrogen

The invention relates to a process and an apparatus for low-NOx combustion with at least one burner (5) using fuel and oxidizing agent and / or furnace off-gases and / or carbon dioxide and / or steam. The low-NOx combustion according to the invention can be used in conventional melting and holding furnaces, in particular in aluminium holding furnaces or rotary drum furnaces and glass-melting furnaces,with the potential for considerable economies to be made.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com