Patents

Literature

787 results about "Staged combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Staged combustion is a method for reducing nitrogen oxides (NOx) emissions from combustion. There are two methods - air staged supply and fuel staged supply. Applications include boilers and rocket engines.

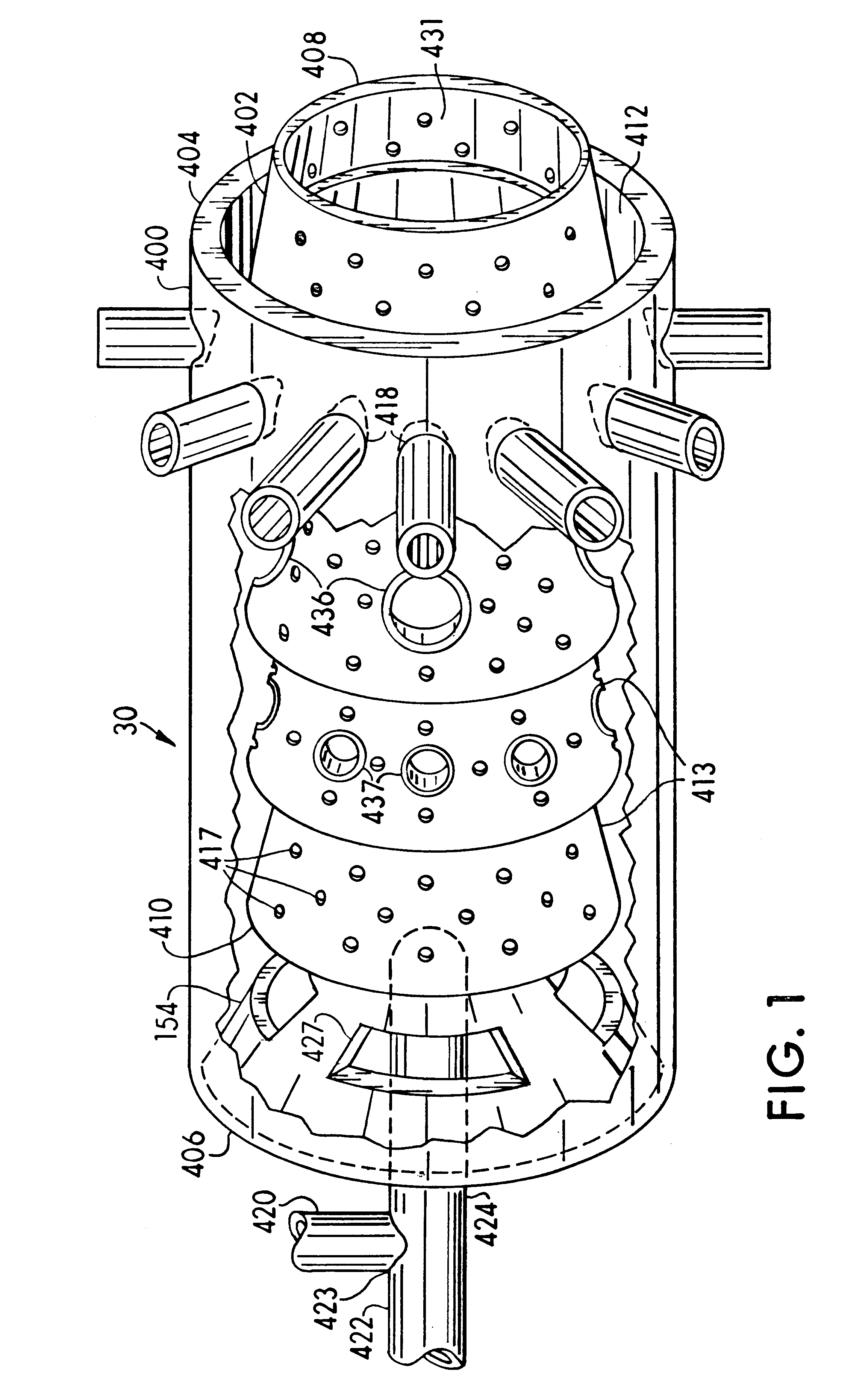

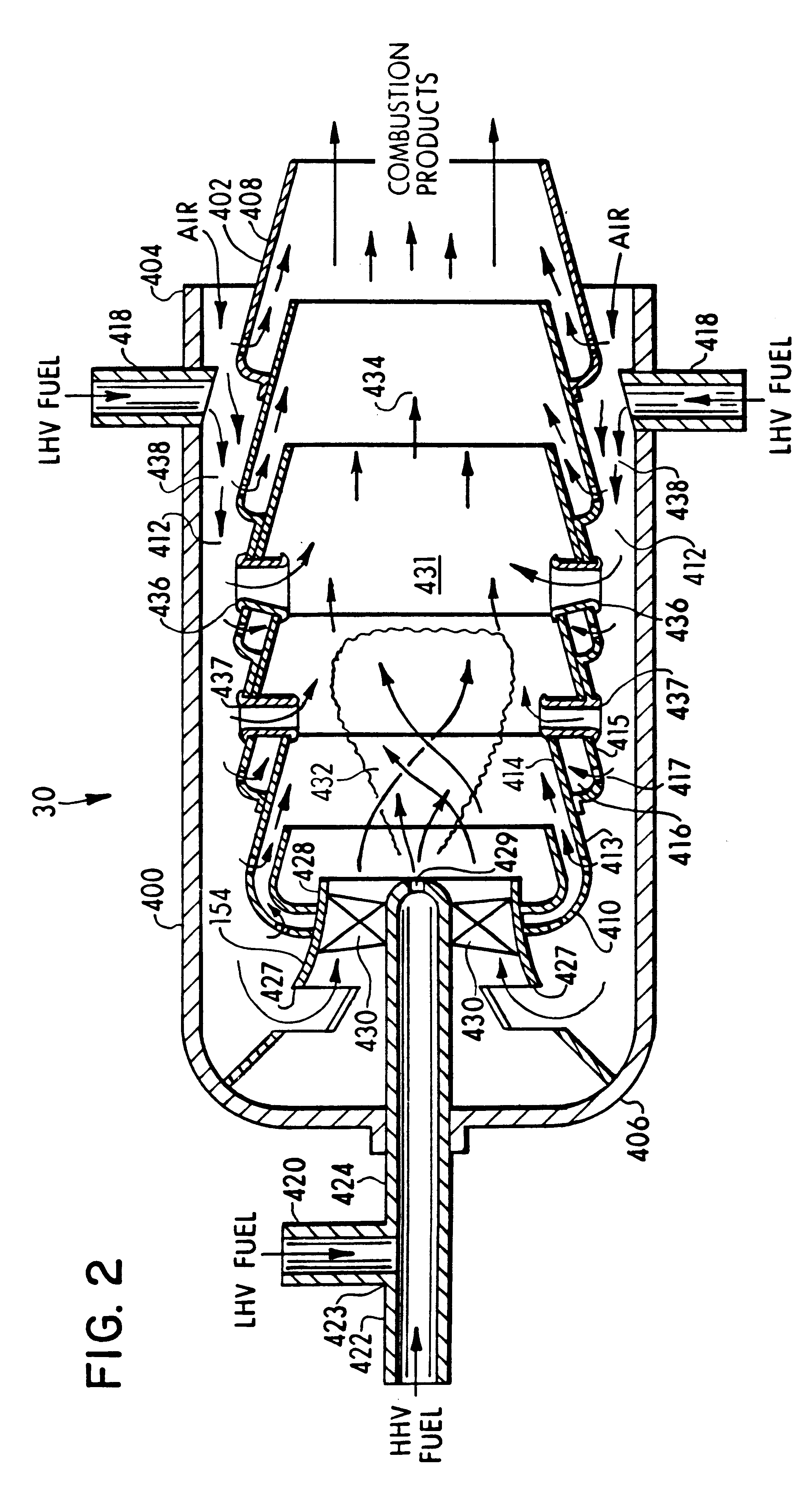

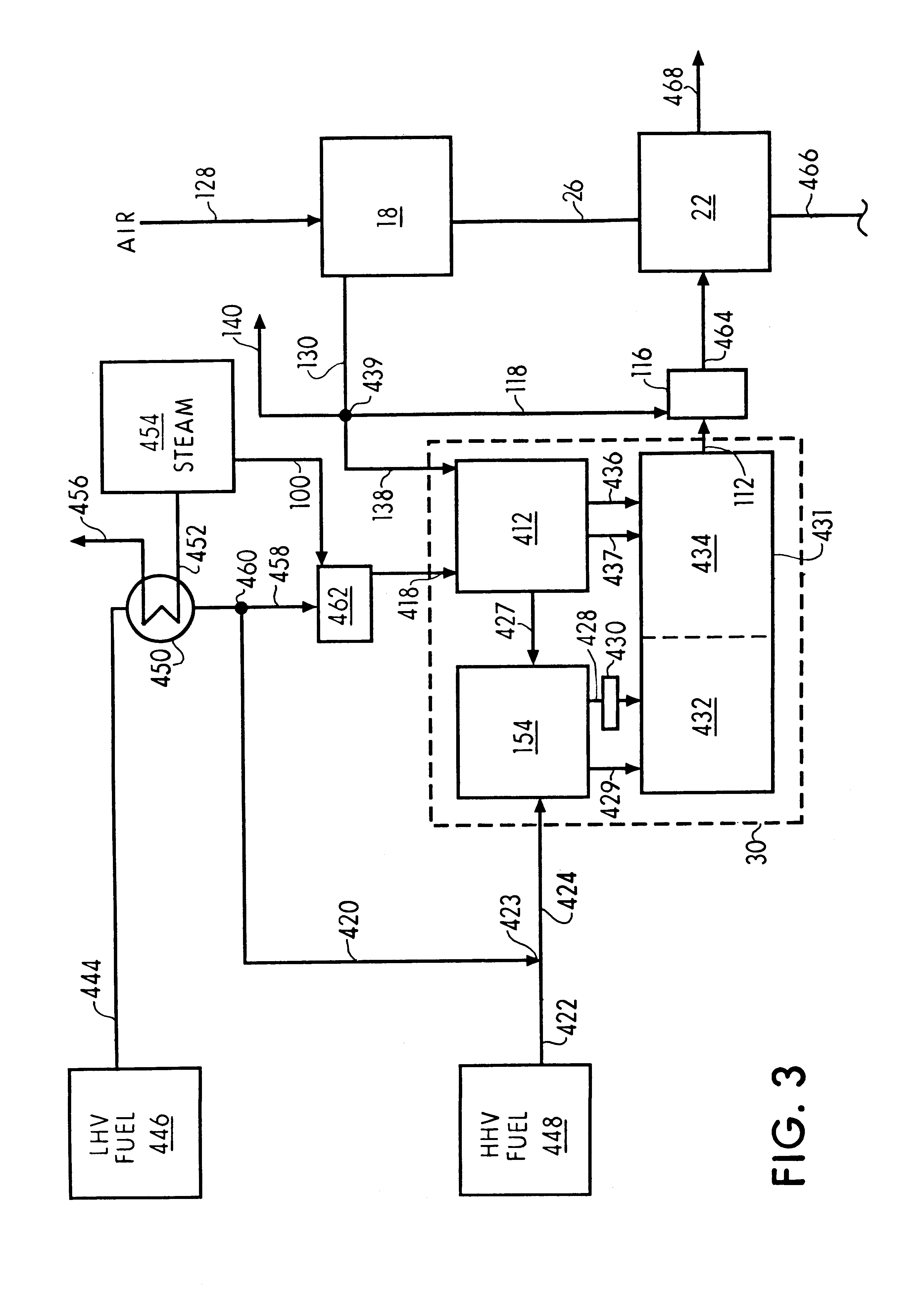

Staged combustion of a low heating value fuel gas for driving a gas turbine

A process is provided for combusting a low heating value fuel gas in a combustor to drive an associated gas turbine. A low heating value fuel gas feed is divided into a burner portion and a combustion chamber portion. The combustion chamber portion and a combustion air are conveyed into a mixing zone of the combustor to form an air / fuel mixture. The burner portion is conveyed into a flame zone of the combustor through a burner nozzle while a first portion of the air / fuel mixture is conveyed into the flame zone through a burner port adjacent to the burner nozzle. The burner portion and first portion of the air / fuel mixture are contacted in the flame zone to combust the portions and produce flame zone products. The flame zone products are conveyed into an oxidation zone of the combustor downstream of the flame zone while a second portion of the air / fuel mixture is also conveyed into the oxidation zone. The second portion is combusted in the oxidation zone in the presence of the flame zone products to produce combustion products. The combustion products are conveyed into the associated gas turbine and drive the gas turbine.

Owner:MARATHON OIL CO +1

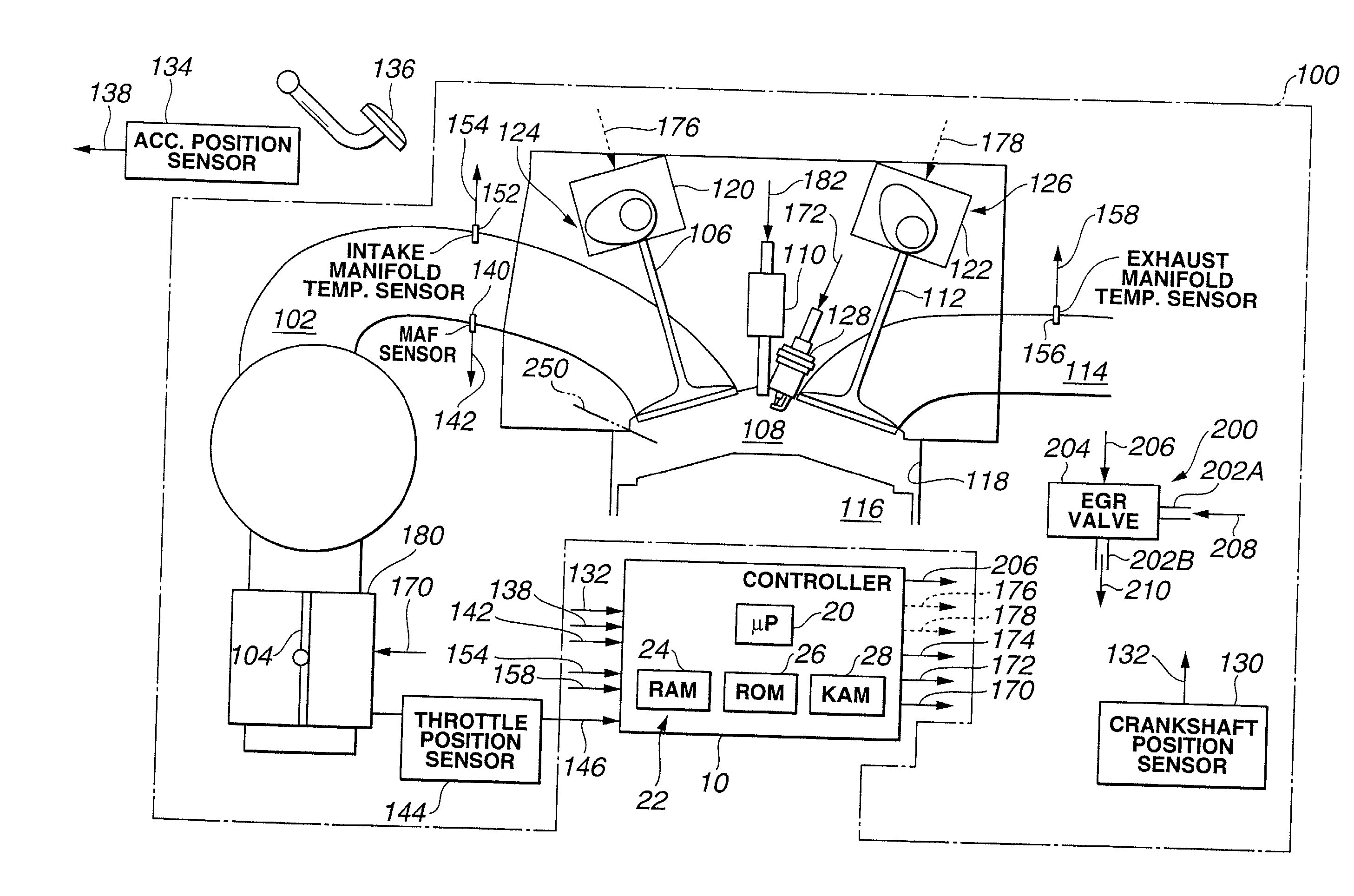

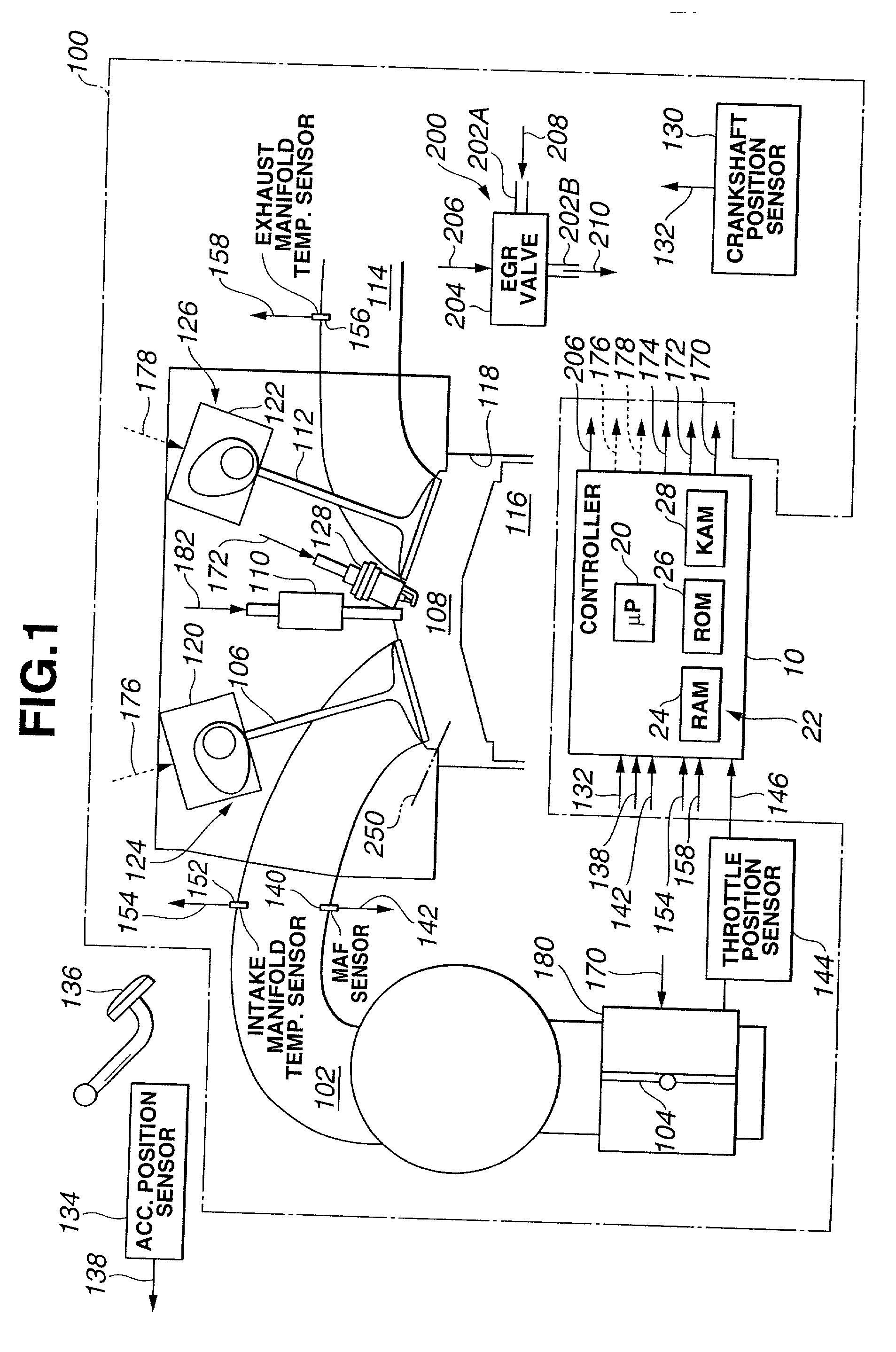

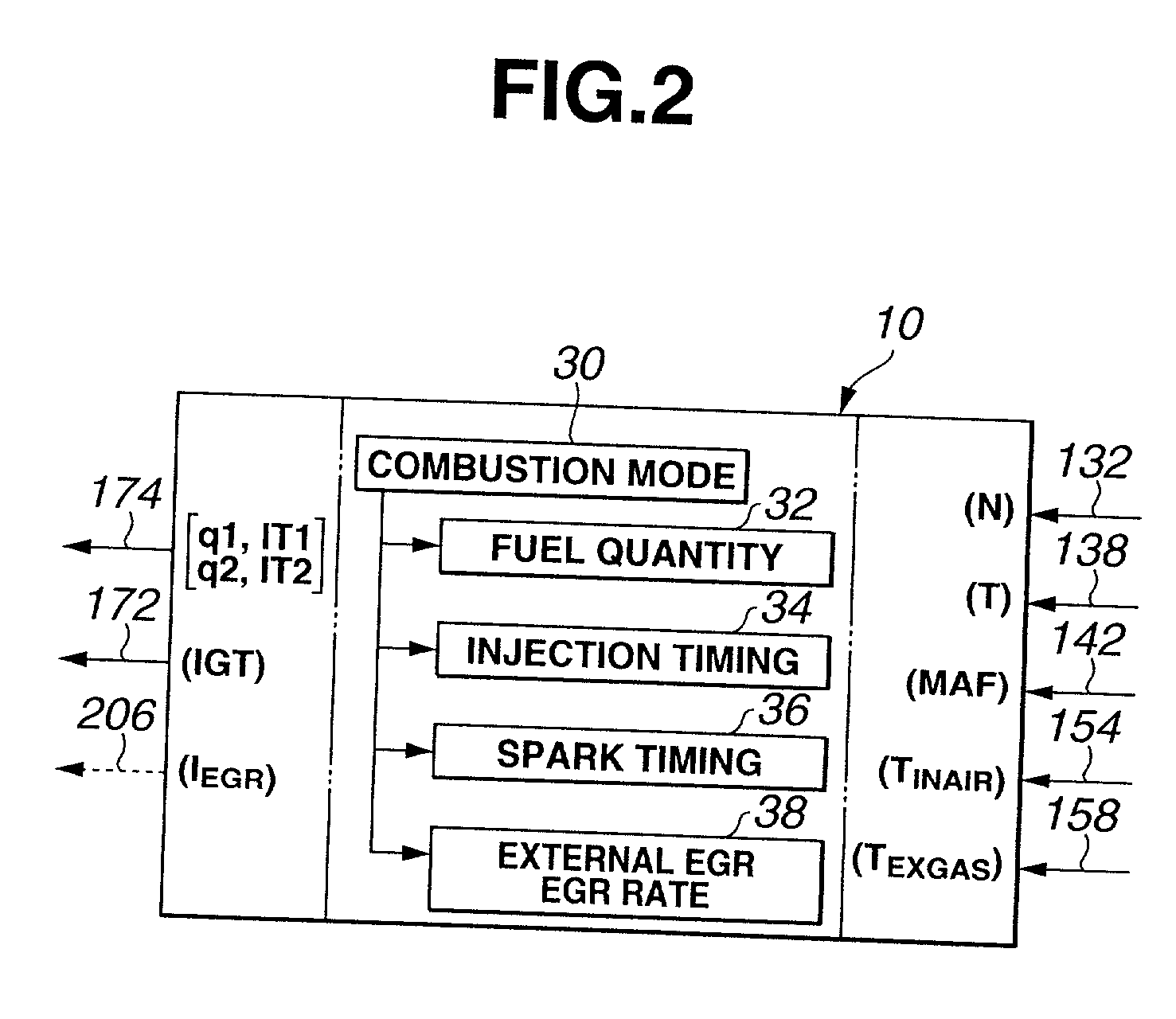

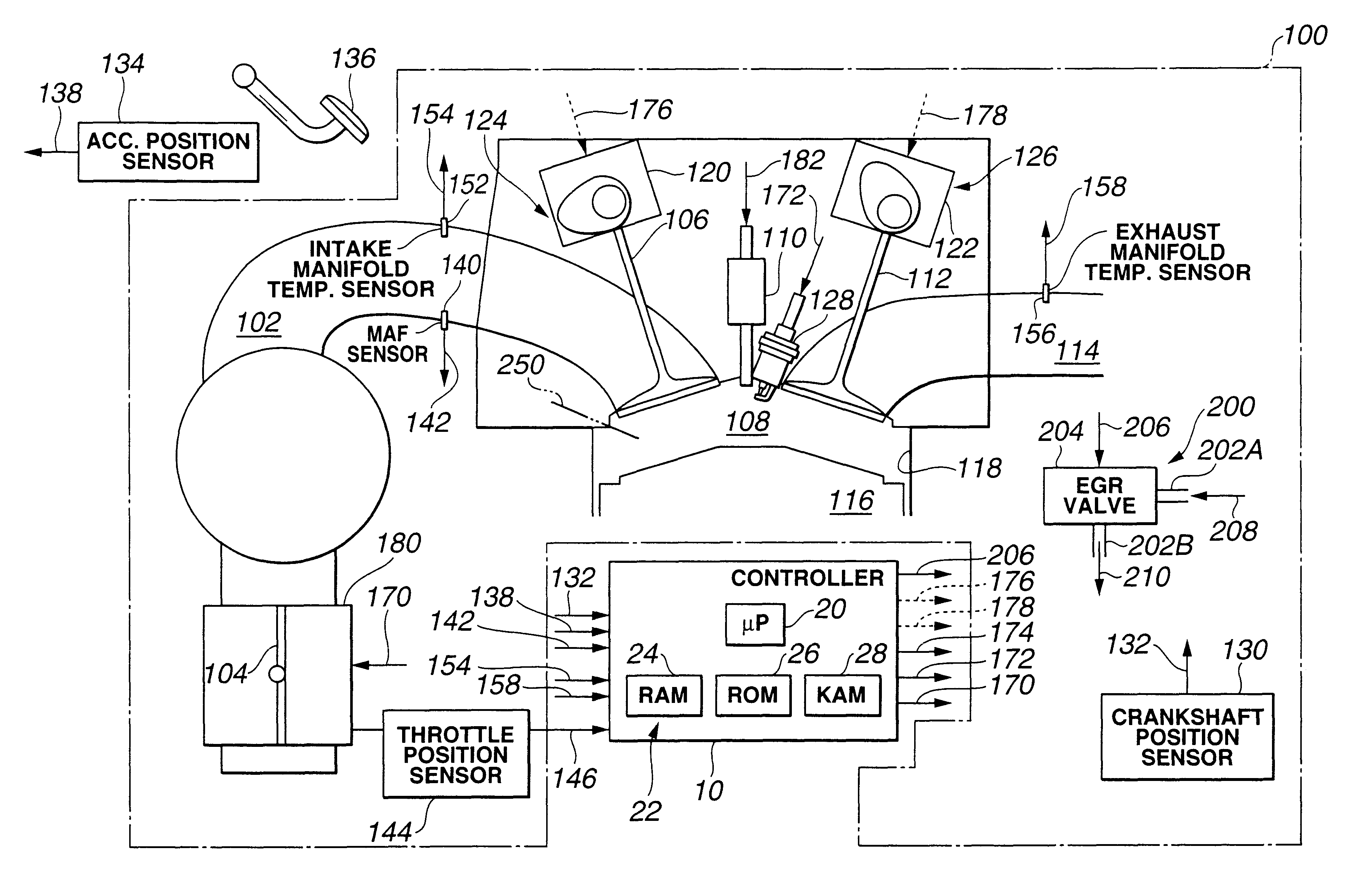

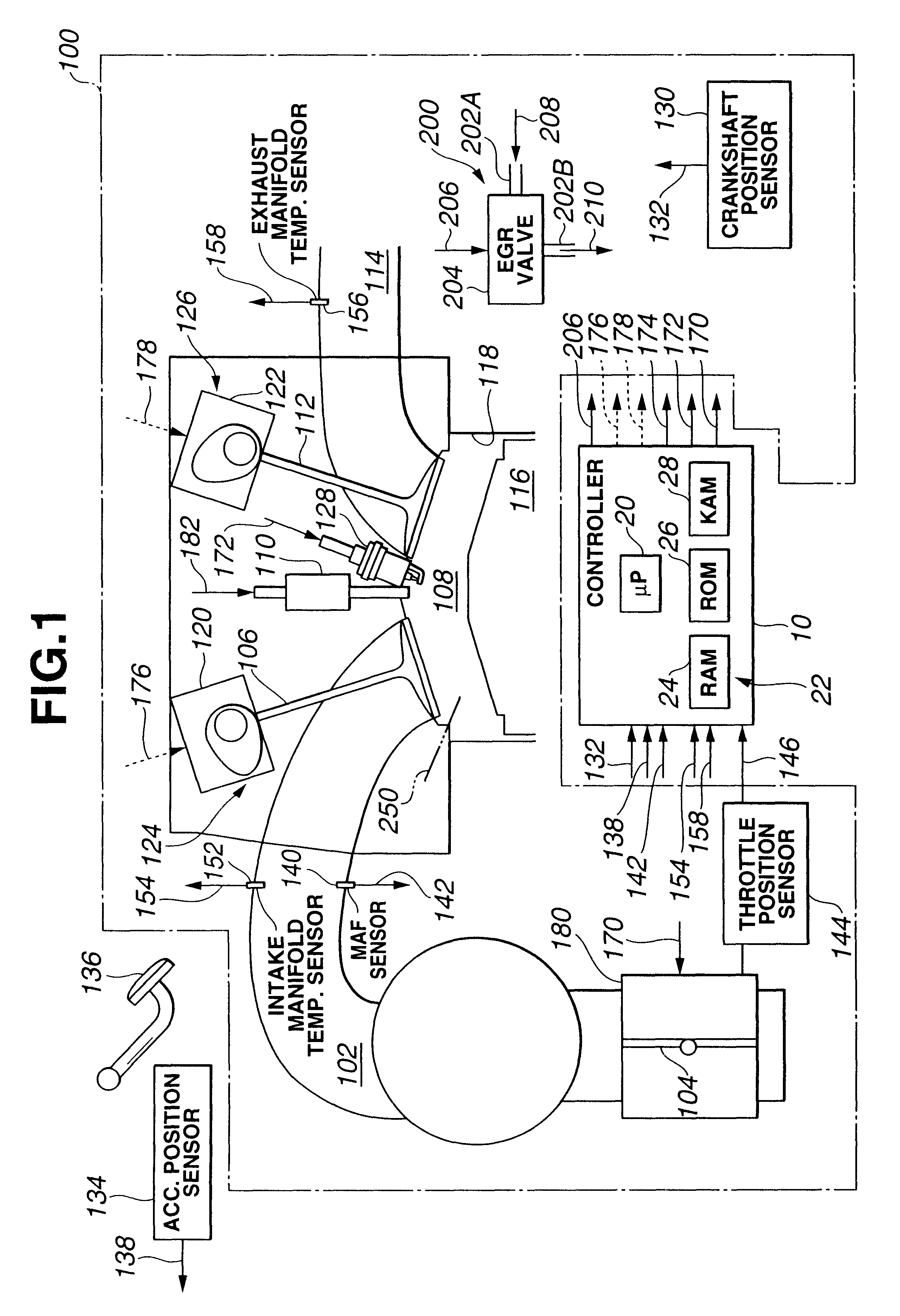

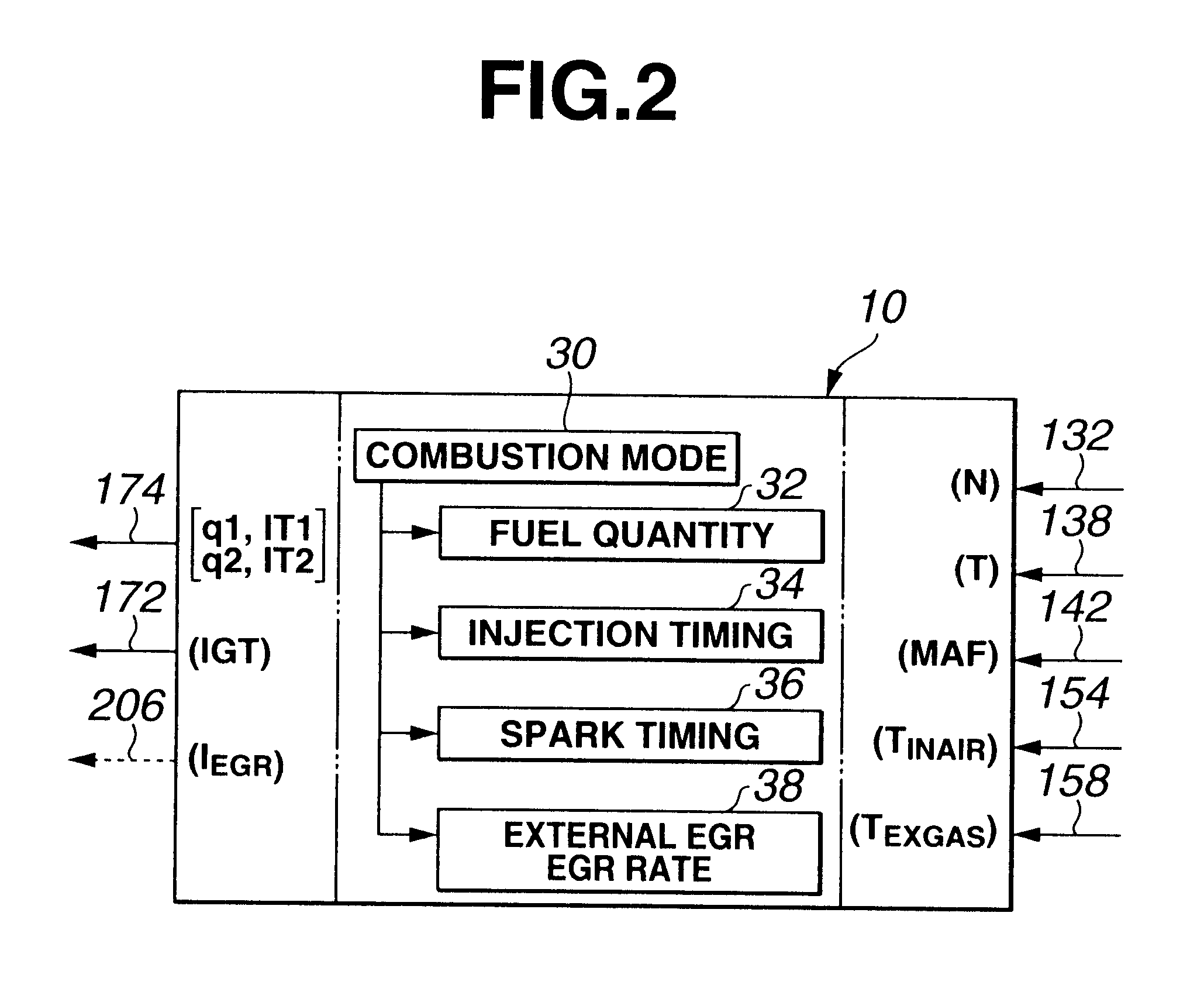

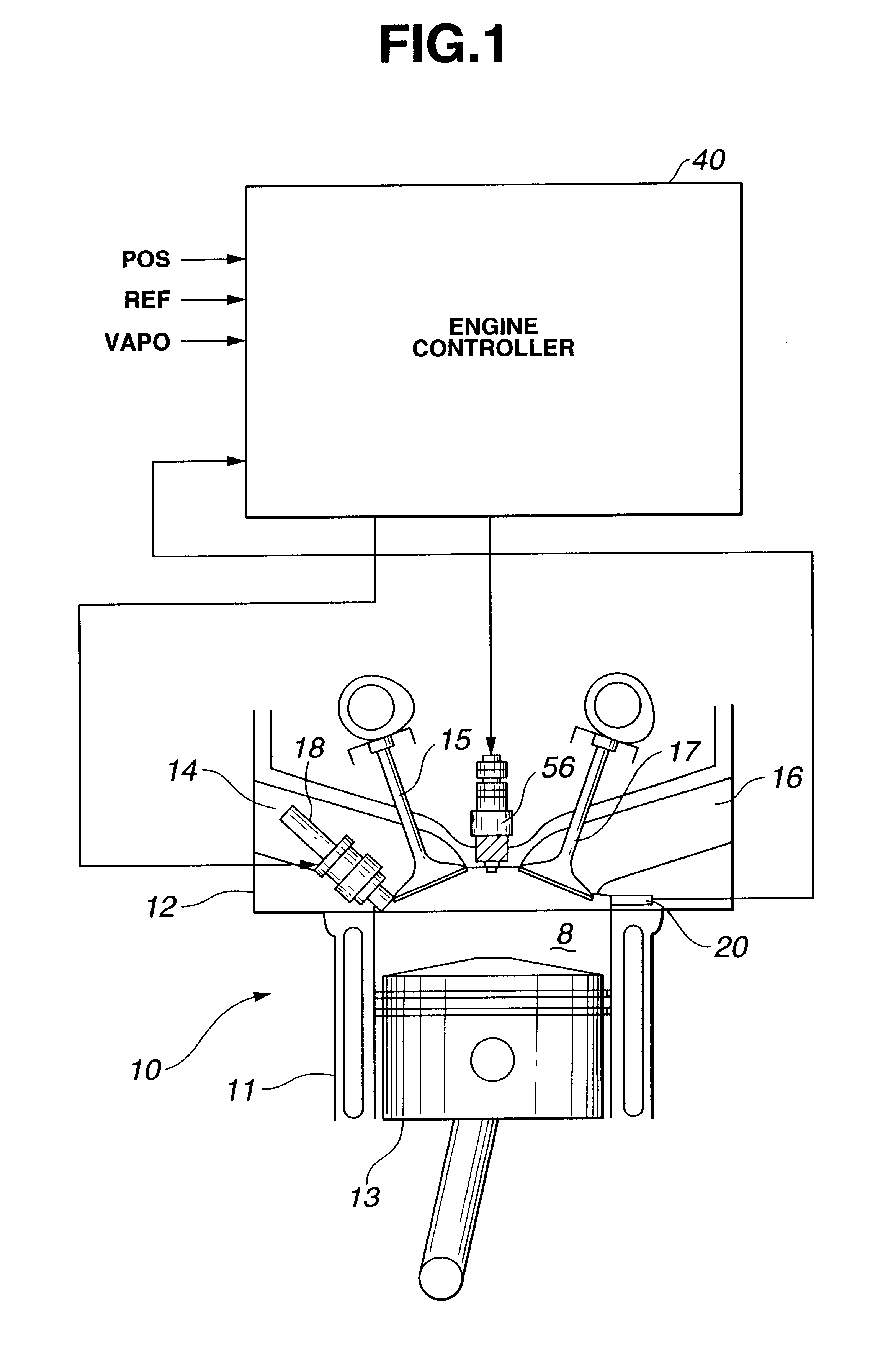

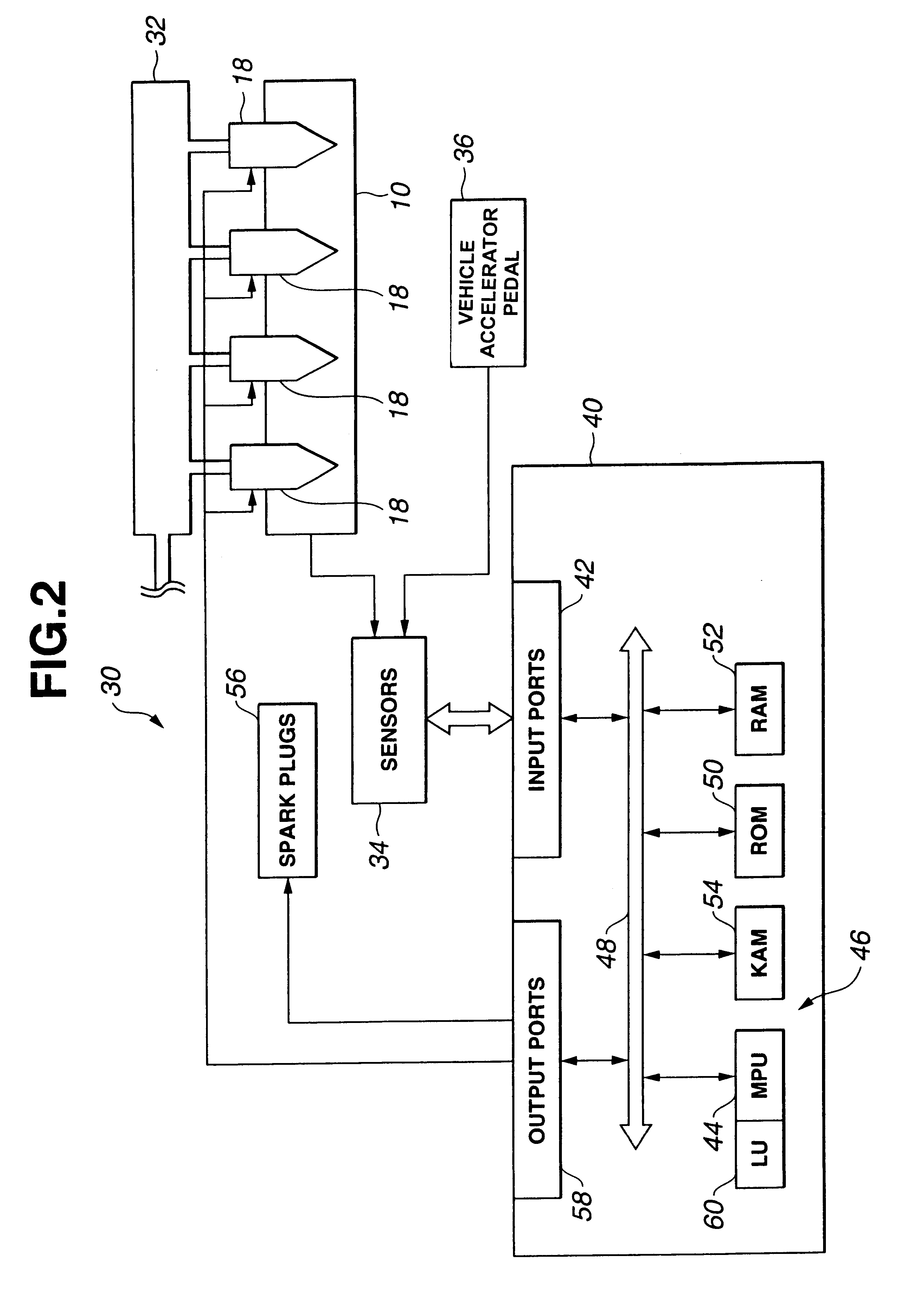

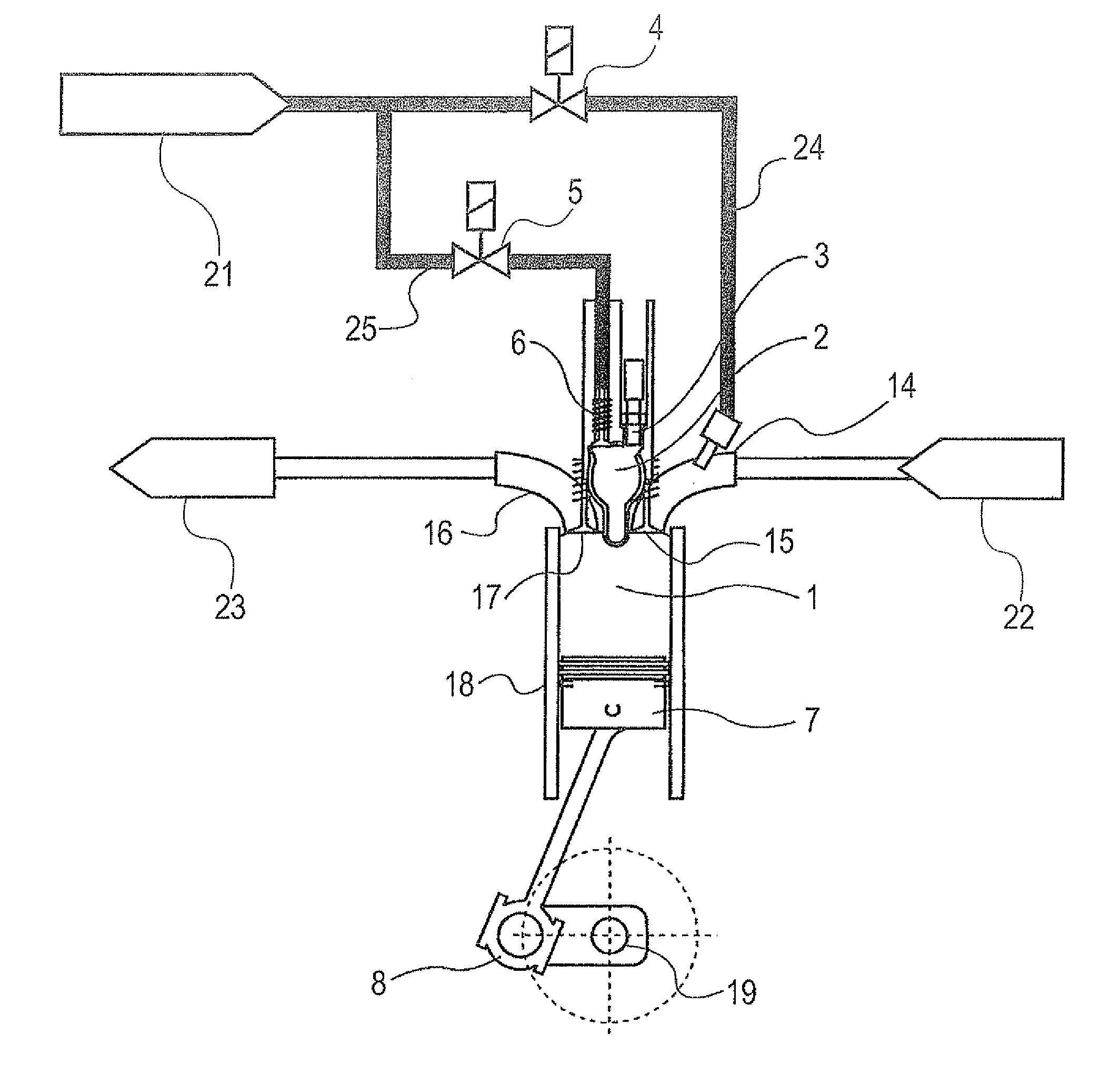

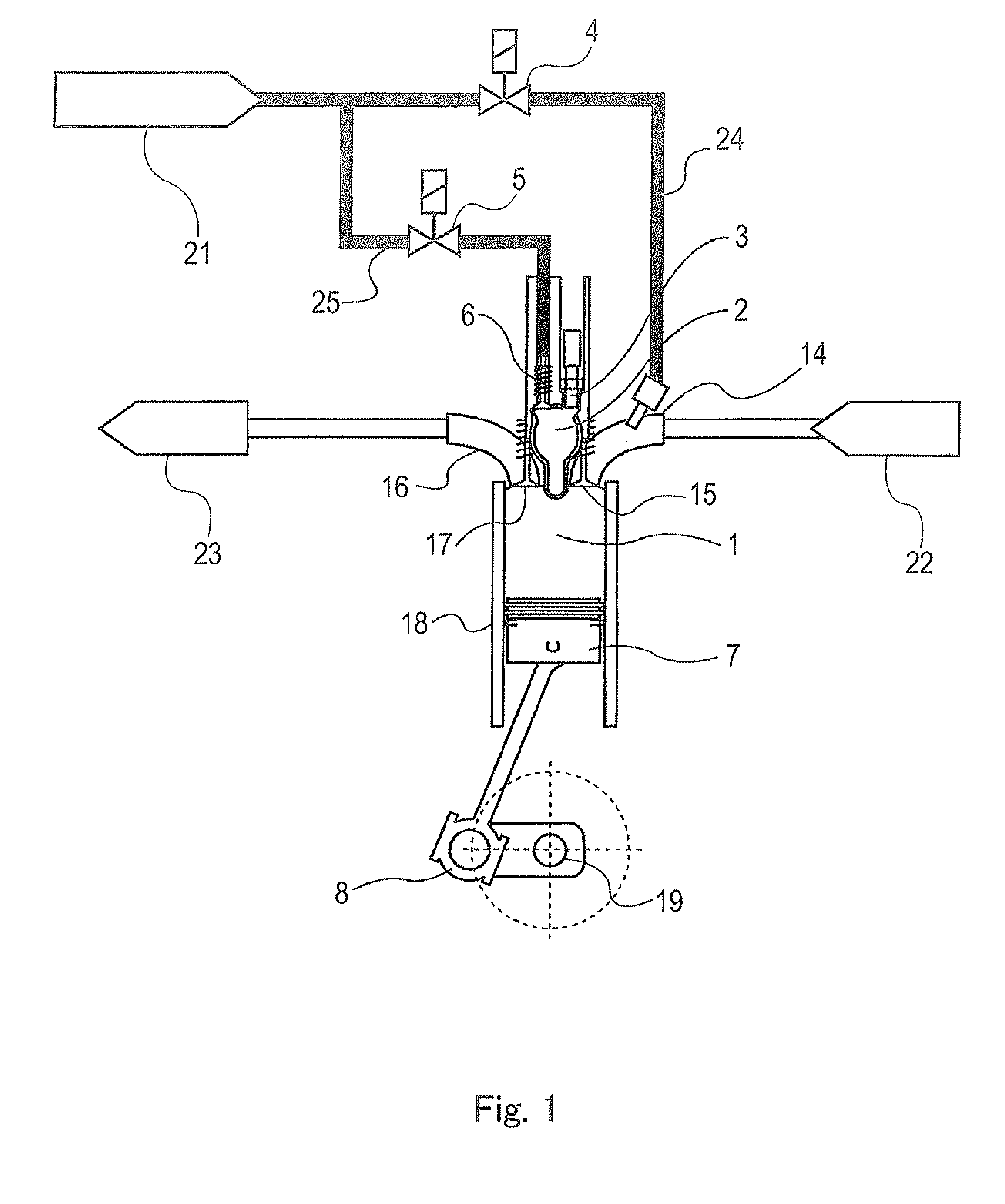

System and method for enhanced combustion control in an internal combustion engine

InactiveUS20020059914A1Electrical controlInternal combustion piston enginesExternal combustion engineStaged combustion

A system and method for enhanced combustion control in an internal combustion engine is disclosed. A fuel supply system has a fuel injector positioned to directly inject fuel into a combustion chamber, and it is capable of performing a split injection wherein a first fuel injection in each engine cycle precedes a second fuel injection that occurs during compression stroke in the same engine cycle. A spark plug produces a spark to ignite a first air / fuel mixture portion created due to the second fuel injection, initiating a first stage combustion. The first stage combustion raises temperature and pressure high enough to cause auto-ignition of a second air / fuel mixture portion surrounding the first air-fuel mixture portion, initiating a second stage combustion. An engine controller is programmed to perform control over initiation timing of the second stage combustion in response to at least one of the engine speed and load. This control is accomplished by varying at least one of a fuel injection timing of the first fuel injection, a fuel injection timing of the second fuel injection, spark timing, a proportion of fuel quantity of the second fuel injection to the total fuel injected in each engine cycle, and an EGR rate in response to at least one of engine speed and load.

Owner:NISSAN MOTOR CO LTD

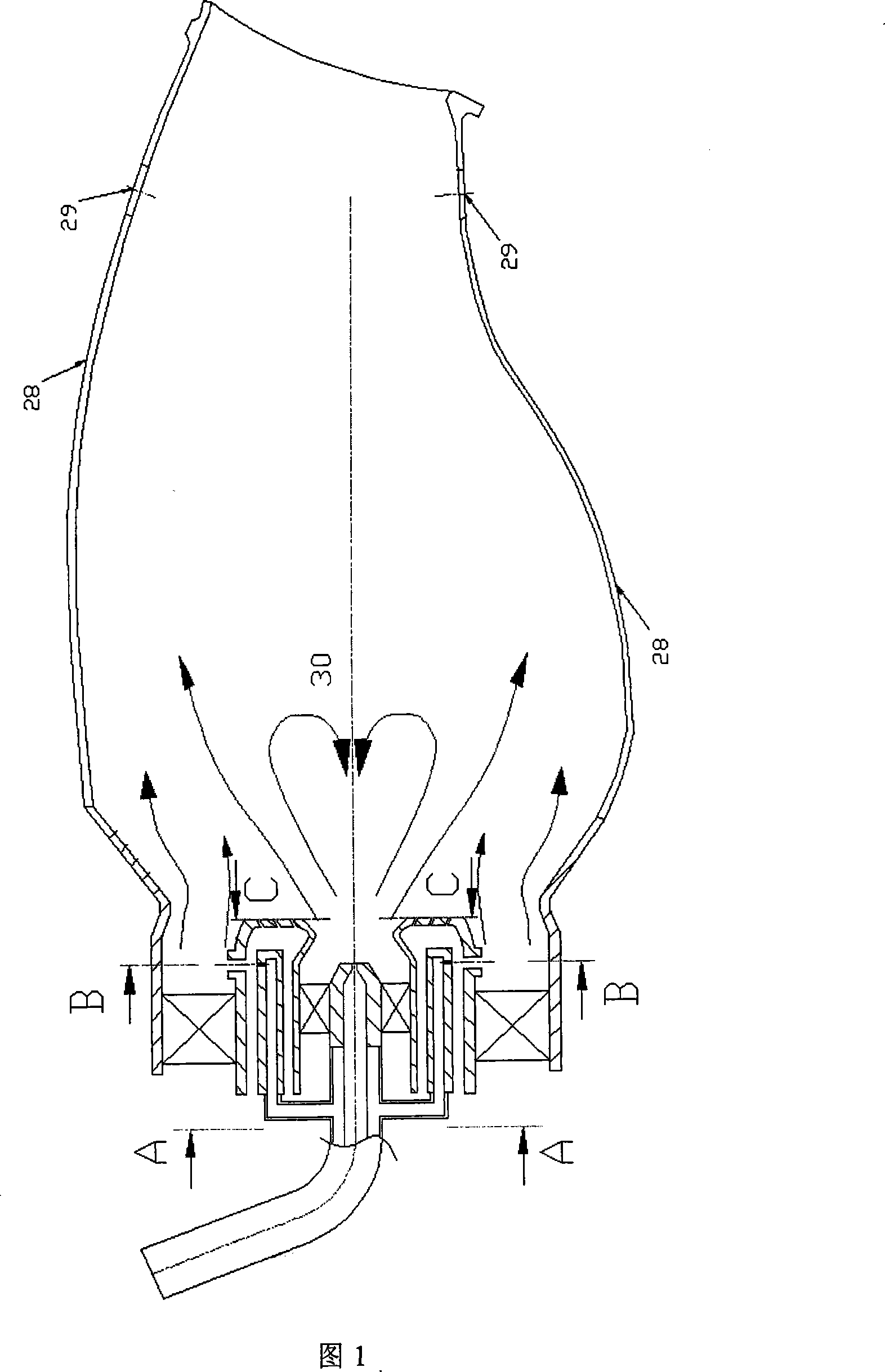

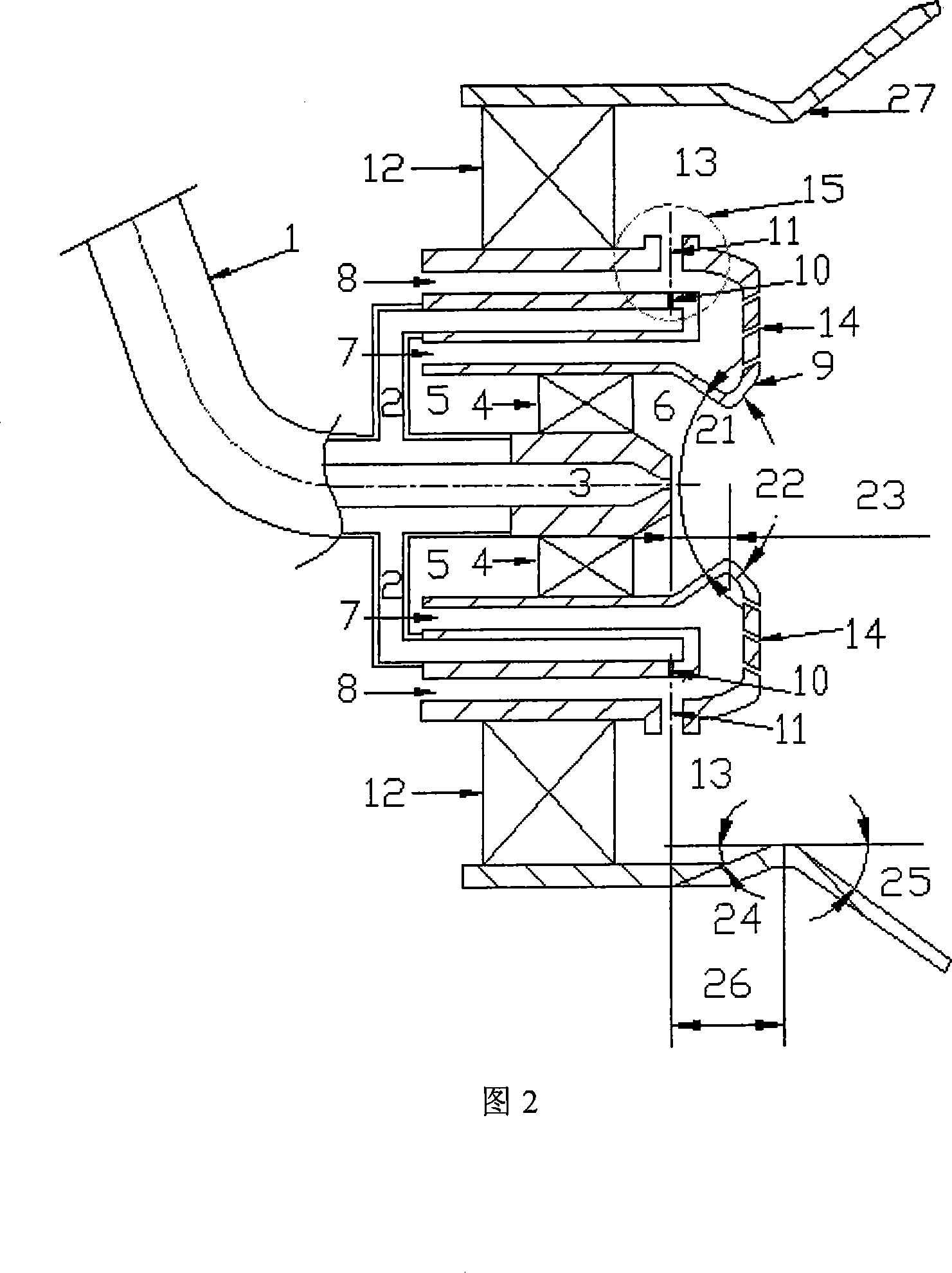

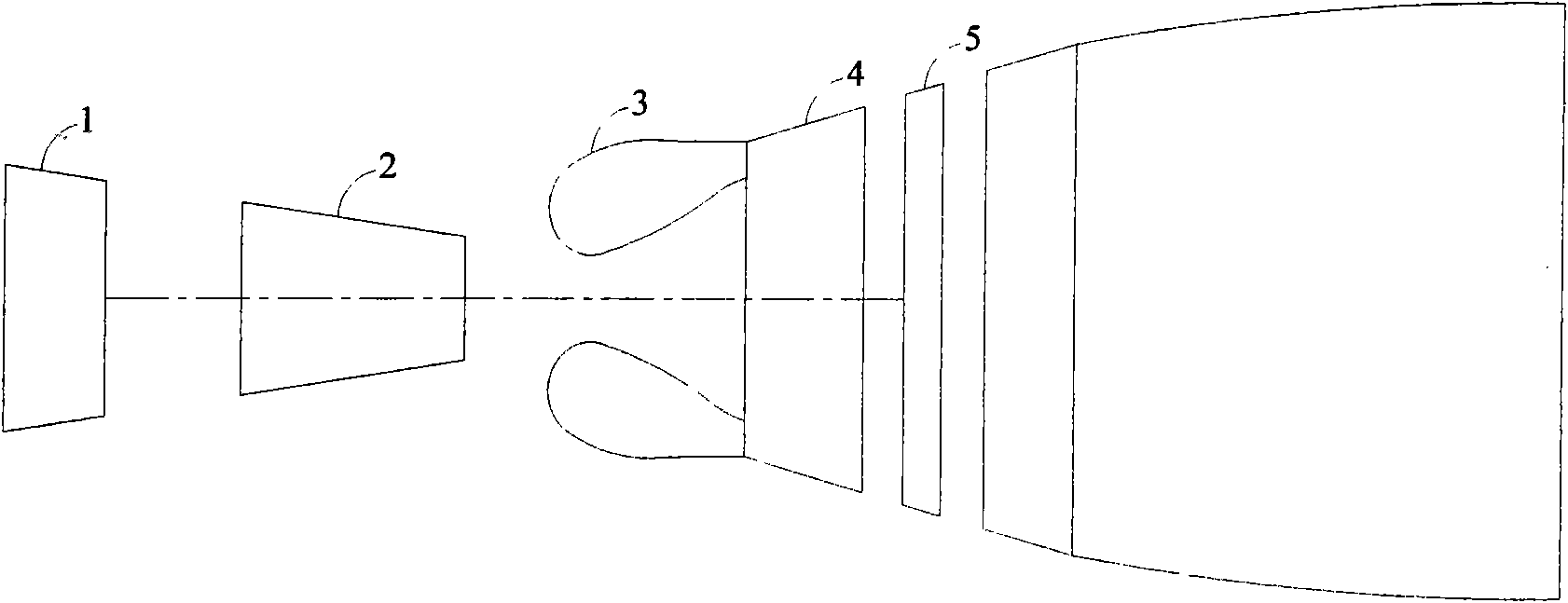

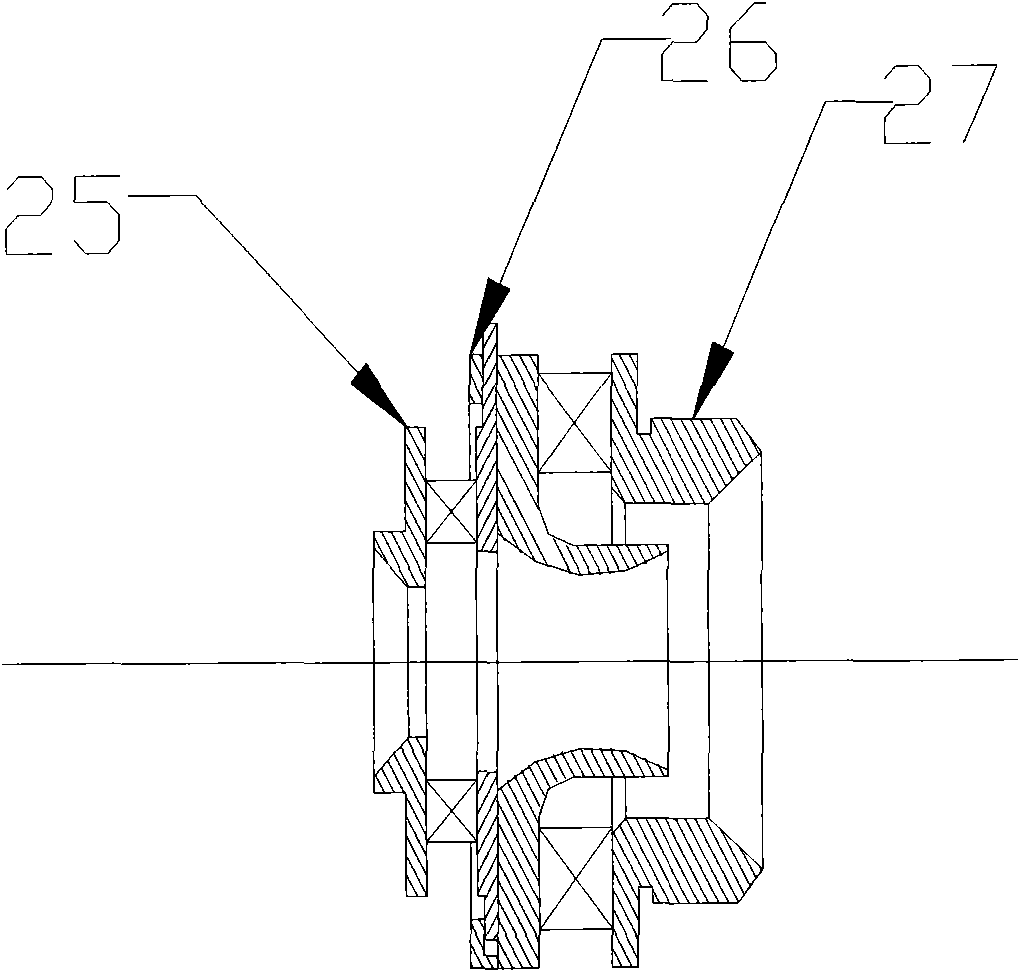

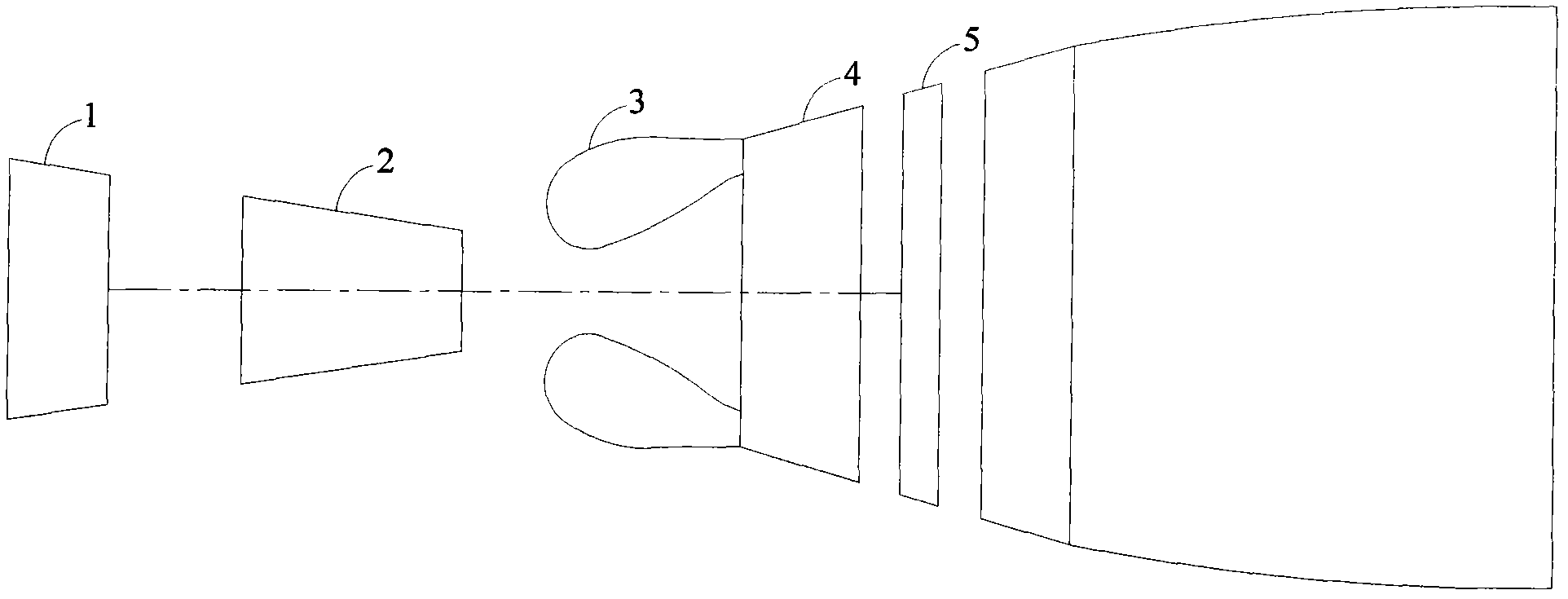

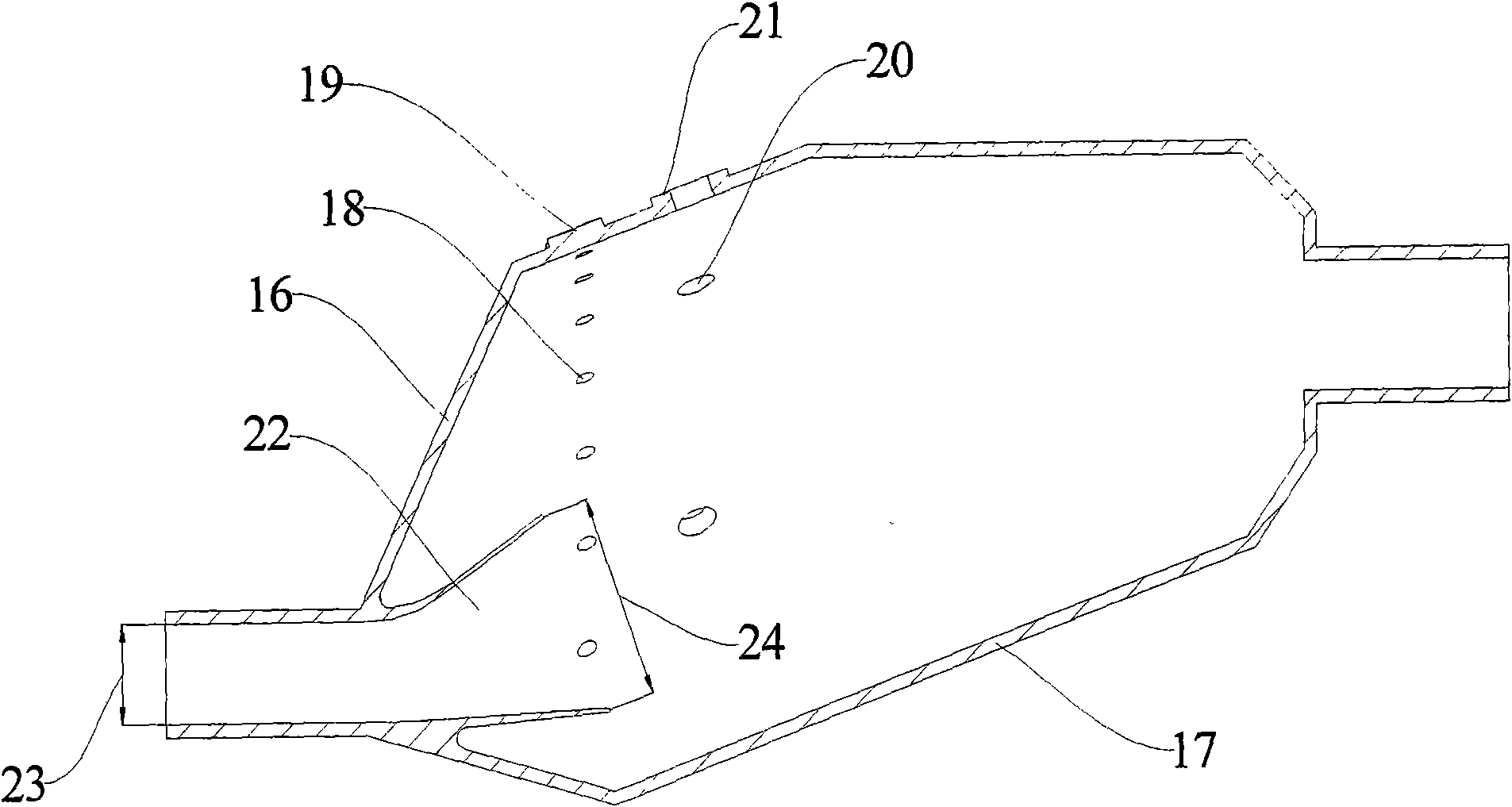

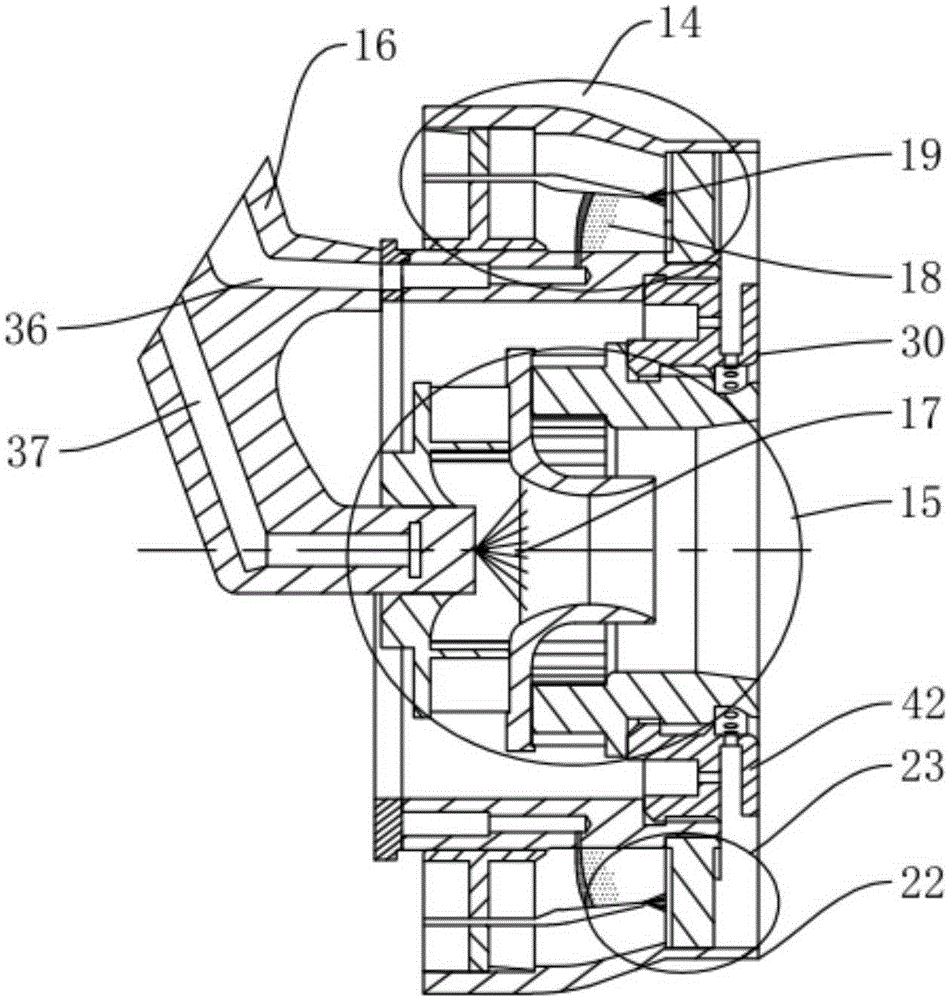

Aerial engine lean premixed preevaporated low contamination combustion chamber

An aero-engine lean-oil premixed pre-evaporation low-pollution combustor consists of a head and a flame tube, the combustion gas is all supplied from the head of the combustor, and the cooling gas and mixed gas enter from the flame tube; the head is The double-ring cavity structure is divided into two stages, the pre-combustion stage and the main combustion stage. The pre-combustion stage is included, and the main combustion stage surrounds the pre-combustion stage. The pre-combustion stage includes a centrifugal nozzle and a swirler surrounding the centrifugal nozzle. After being sprayed out from the centrifugal nozzle, the fuel is sheared and broken by the air swirl from the swirler, mixed in the mixing chamber area of the pre-combustion stage and then enters the combustion area Diffusion combustion is formed inside; the main combustion stage includes a direct air atomizing nozzle, a main swirler and a premixing ring chamber, the main swirler is located upstream of the nozzle, and the premixing ring chamber is located downstream of the nozzle, and the fuel goes first in the nozzle It is mixed and atomized with air, and then tangentially injected into the premixed ring cavity for premixed pre-evaporation, and enters the combustion area to form premixed combustion; in the downstream of the pre-combustion stage combustion and main combustion stage fuel outlets, contraction and expansion ports are used to prevent backflow fire and carbon buildup. The invention has a simple structure and can effectively reduce the pollution discharge of the aero-engine under the condition of ensuring the working state.

Owner:BEIHANG UNIV

System and method for enhanced combustion control in an internal combustion engine

InactiveUS6609493B2Electrical controlInternal combustion piston enginesExternal combustion engineEngineering

A fuel supply system has a fuel injector positioned to directly inject fuel into a combustion chamber, and it is capable of performing a split injection wherein a first fuel injection in each engine cycle precedes a second fuel injection that occurs during compression stroke in the same engine cycle. A spark plug produces a spark to ignite a first air / fuel mixture portion created due to the second fuel injection, initiating a first stage combustion. The first stage combustion raises temperature and pressure high enough to cause auto-ignition of a second air / fuel mixture portion surrounding the first air-fuel mixture portion, initiating a second stage combustion. This control is accomplished by varying at least one of a fuel injection timing of the first fuel injection, a fuel injection timing of the second fuel injection, spark timing, a proportion of fuel quantity of the second fuel injection to the total fuel injected in each engine cycle, and an EGR rate in response to at least one of engine speed and load.

Owner:NISSAN MOTOR CO LTD

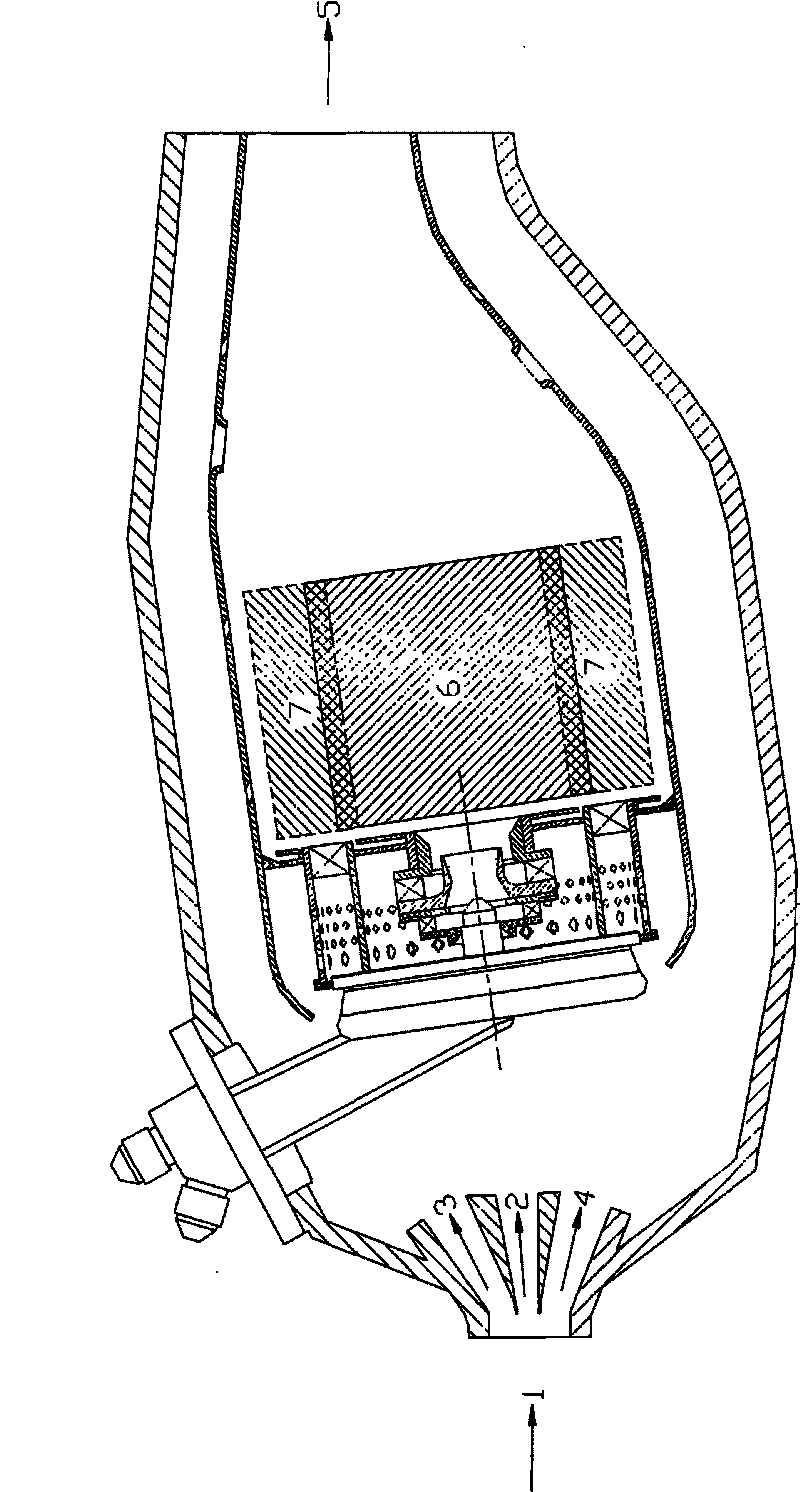

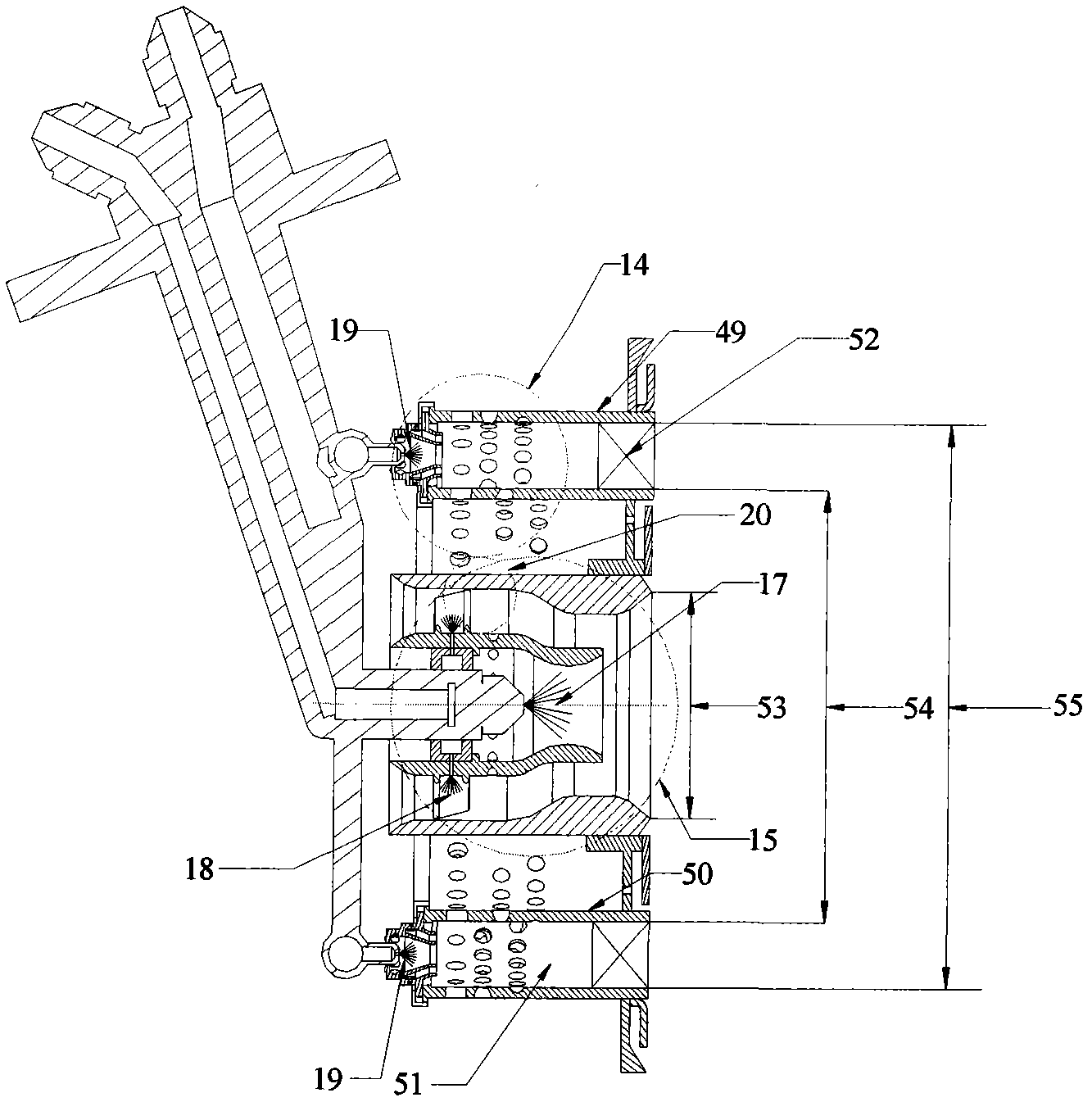

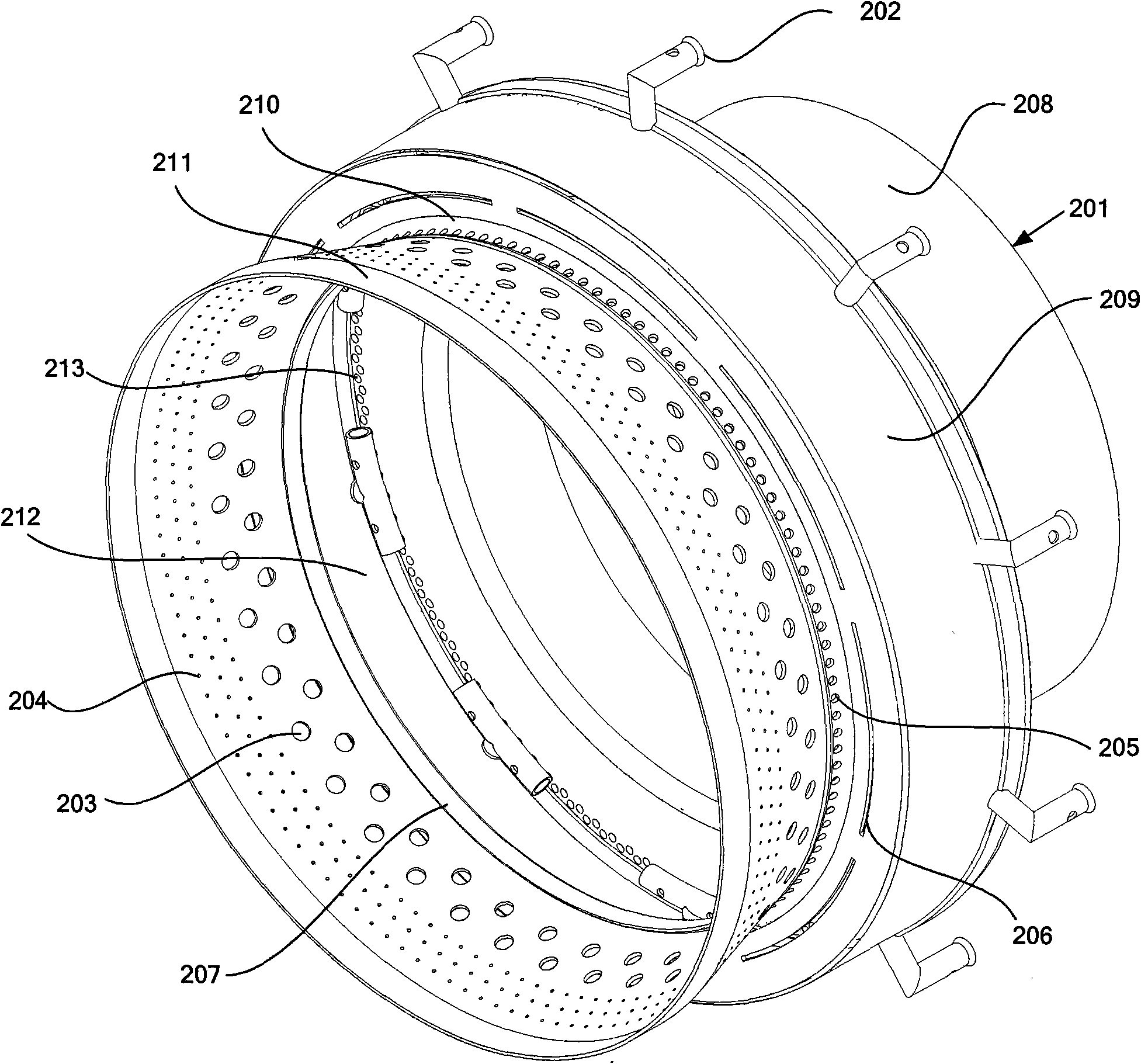

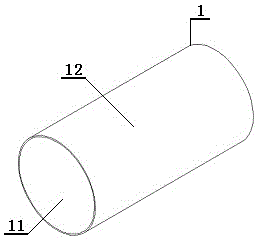

Low-pollution combustion chamber provided with premixing and pre-evaporating ring pipe

ActiveCN101788157AReduce pollutionFast evaporation blendingContinuous combustion chamberCombustion chamberCombustible gas

The invention relates to a low-pollution combustion chamber provided with a premixing and pre-evaporating ring pipe, which adopts a single-ring cavity structure and consists of a combustion chamber outer casing, a combustion chamber inner casing, an outer flame tube, an inner flame tube and a combustion chamber head part, wherein air used for combustion completely enters into the flame tubes from the combustion chamber head part; the scheme of fractional combustion can be adopted, and pre-combustion stage and a main-combustion stage are divided; the main-combustion stage comprises the premixing and pre-evaporating ring pipe, a main-combustion stage nozzle and a main-combustion stage swirler; fuel oil is evaporated and mixed inside the premixing and pre-evaporating ring pipe and then enters into the flame tubes after forming even mixed combustible gas, belonging to premixed combustion; a fuel nozzle is used for supplying the fuel oil for the pre-combustion stage and the main-combustion stage; the stable working range of the combustion chamber is mainly controlled by the pre-combustion stage, so that the stable combustion can be ensured to be carried out in the combustion chamber within wider working range, and a stable ignition source can be provided for the main-combustion stage; the pollution emission is mainly controlled by the main-combustion stage, and the equivalent weight ration of the premixed gas of the main-combustion stage can be controlled within the low-pollution combustion range, so that the pollution emission of the whole combustion chamber cam be ensured to be greatly reduced. The premixing and pre-evaporating structure has small size, simple structure and modularized characteristic, can reduce the pollution emission of the combustion chamber of an aircraft engine, and ensures good combustion stability.

Owner:BEIHANG UNIV

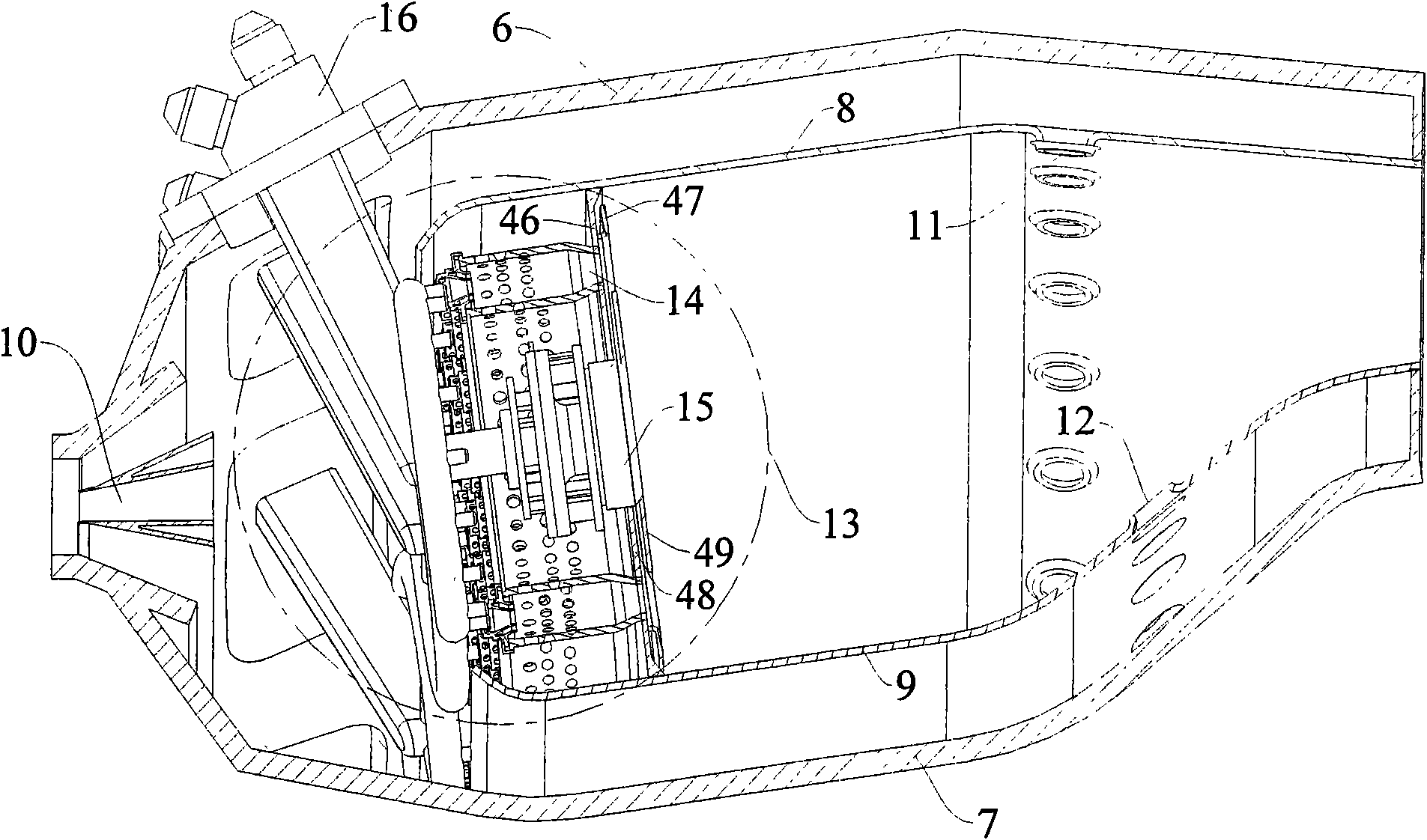

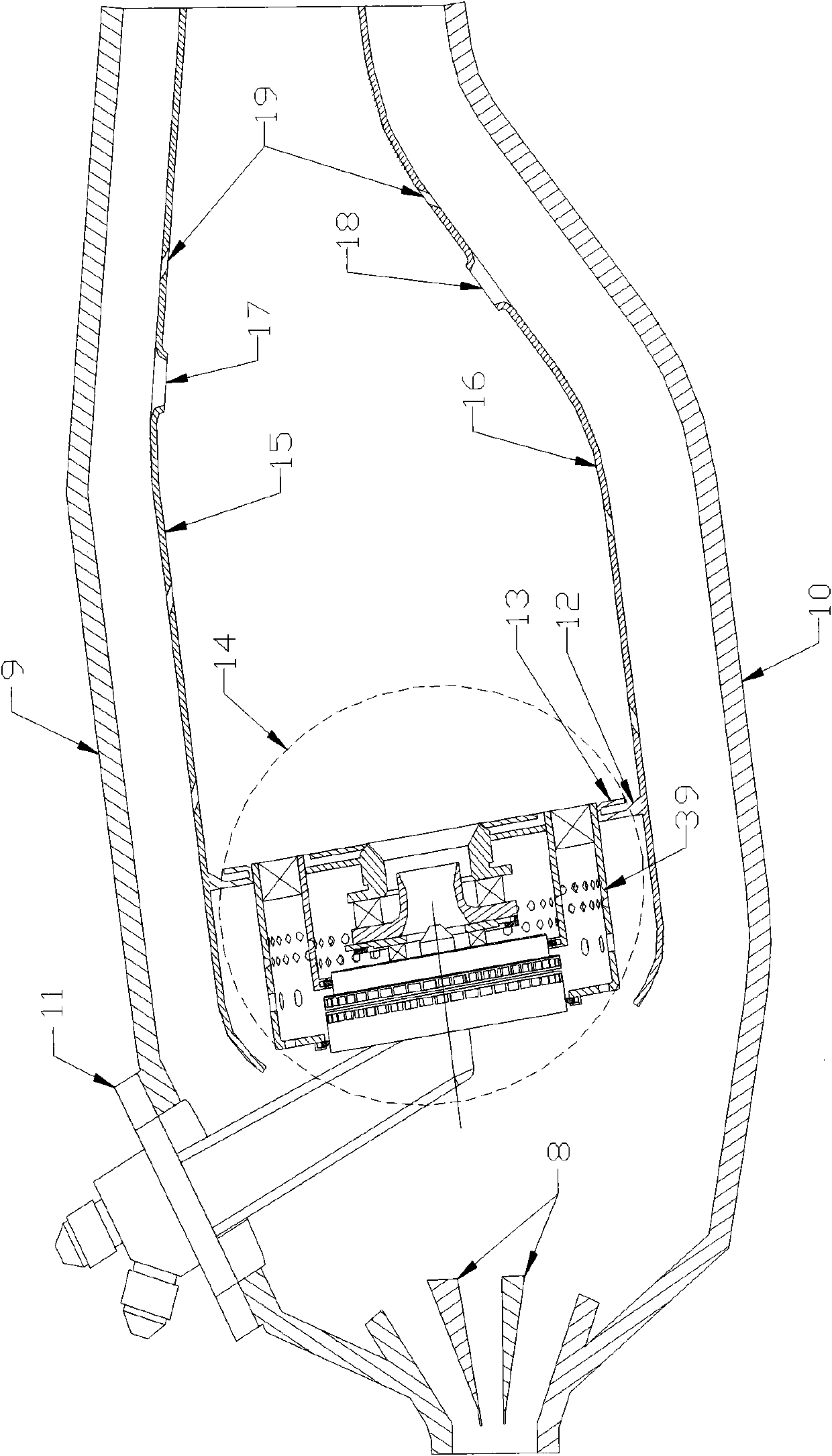

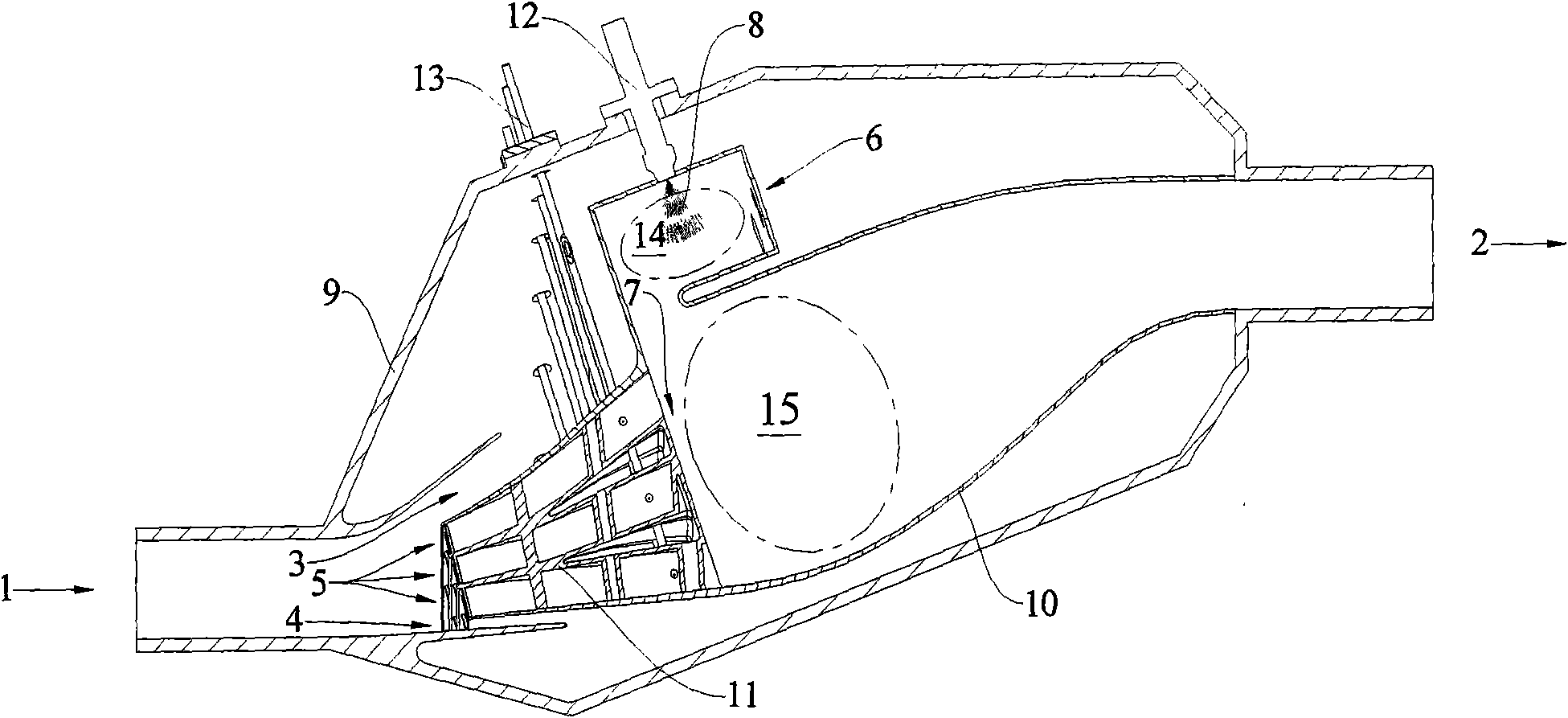

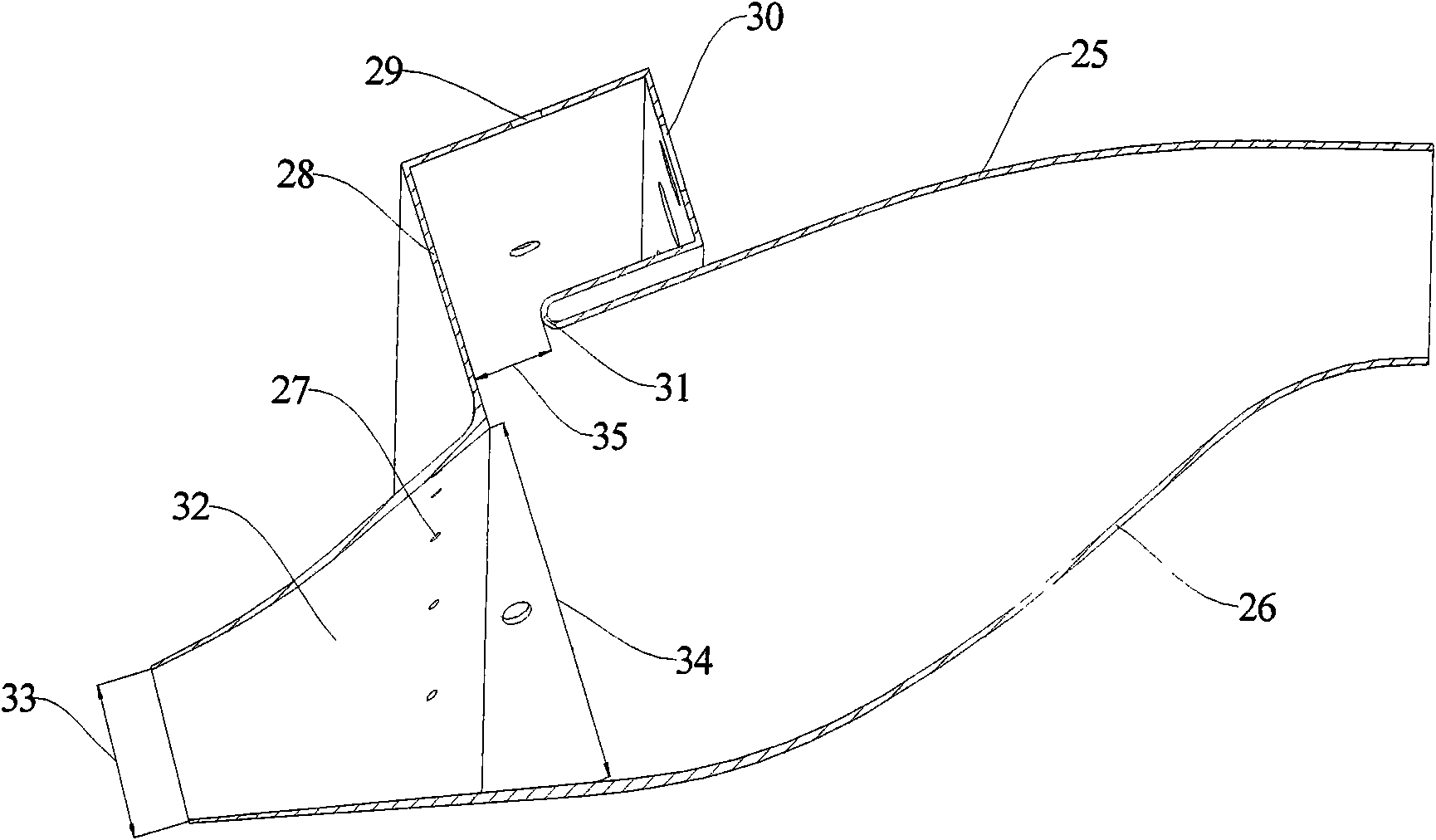

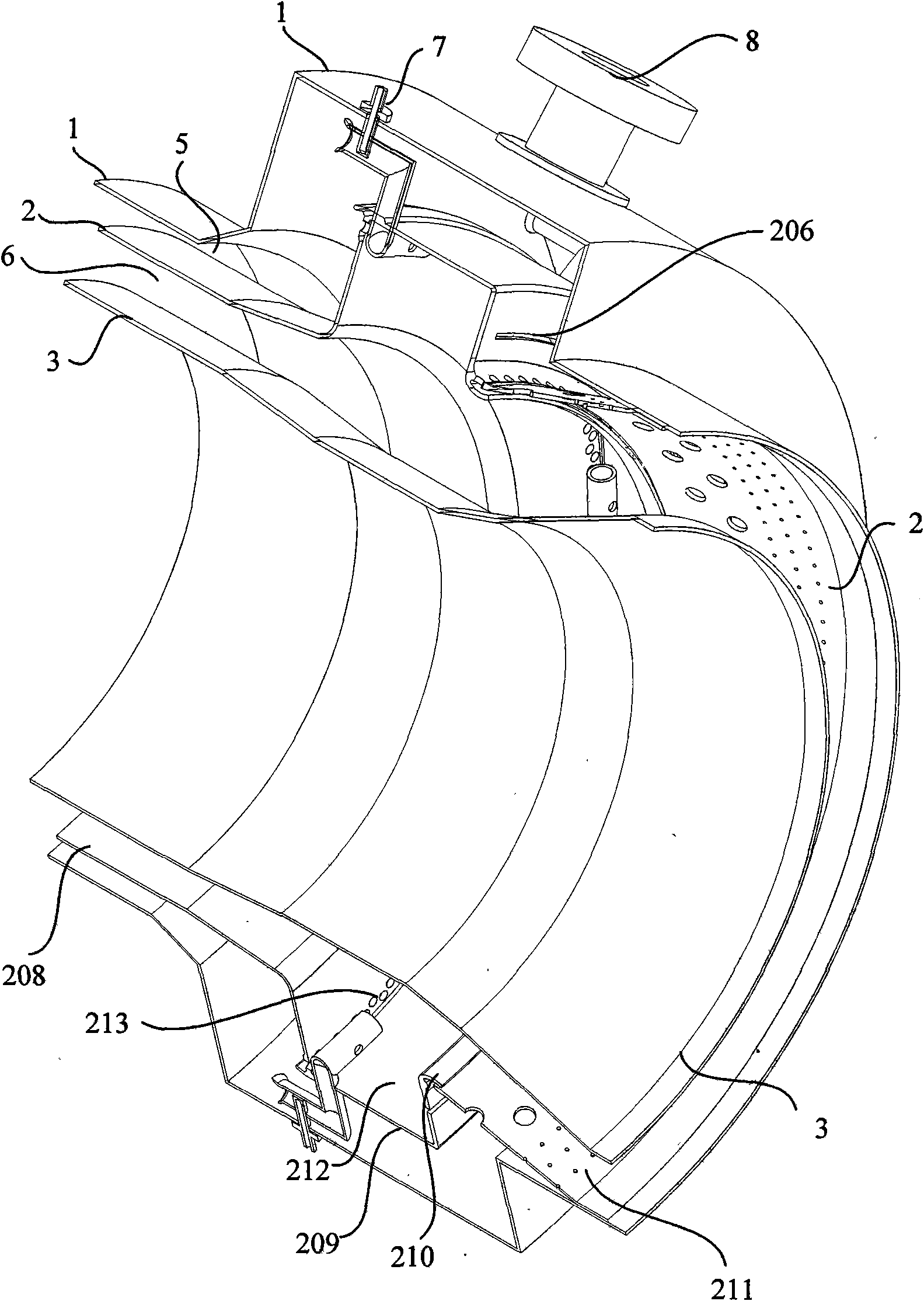

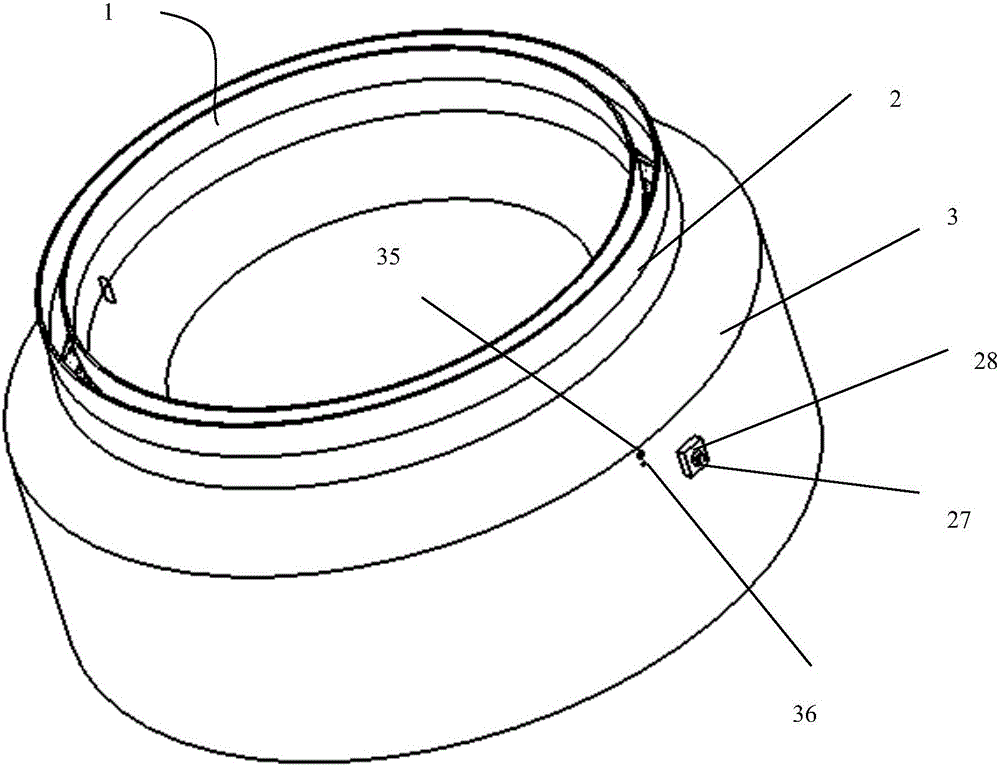

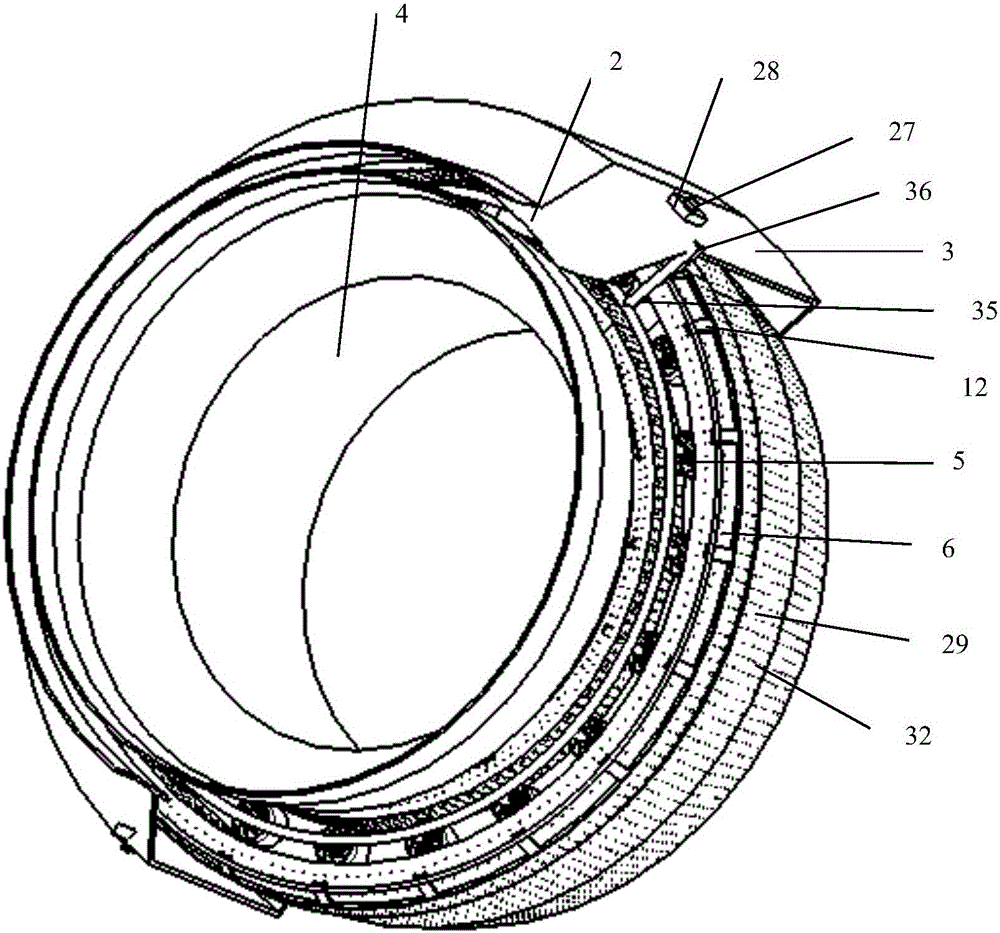

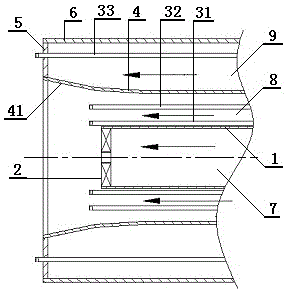

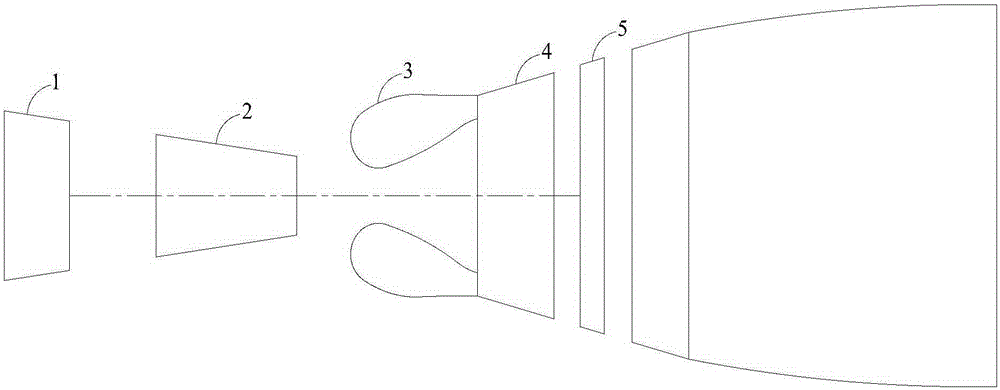

Premixing and pre-evaporating combustion chamber

ActiveCN101709884ASimple structureImprove efficacyContinuous combustion chamberDiffusion flameCombustion chamber

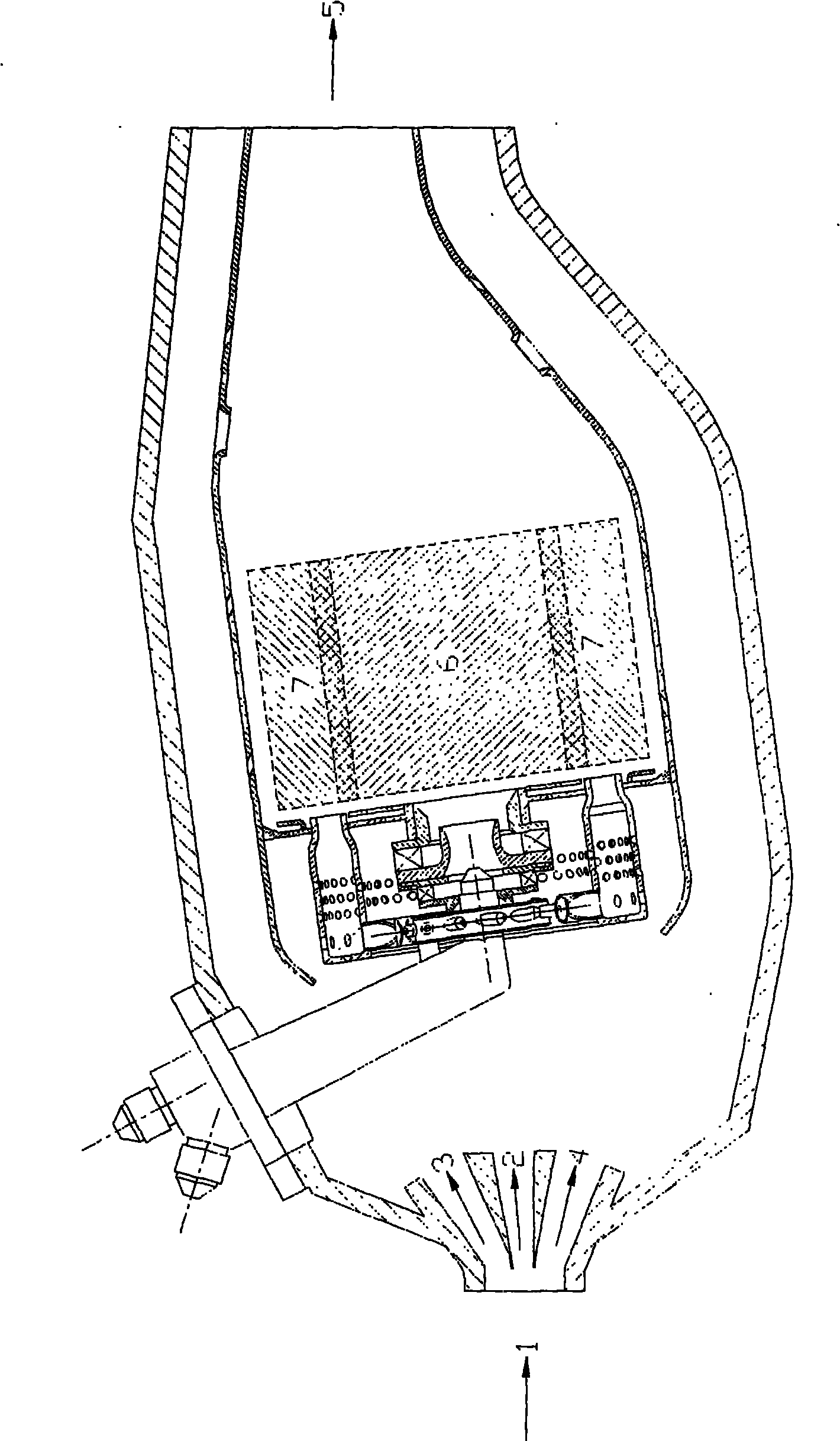

The invention discloses a premixing and pre-evaporating combustion chamber, which has a single annular chamber structure and adopts a conceptual design of fractional combustion. In the combustion chamber, the total combustion gas volume is supplied by a pre-combustion fraction and a main combustion fraction, the pre-combustion fraction adopts a swirl-flow stable diffusion flame combustion organization mode and the main combustion fraction adopts a premixing and pre-evaporating combustion organization mode. The combustion chamber mainly comprises a shunting diffuser, a combustion chamber outer casing, a combustion chamber inner casing, a fuel oil nozzle, the pre-combustion fraction, the main combustion fraction, a combustion liner outer wall and a combustion liner inner wall. The pre-combustion fraction stabilizes flame by using a low-speed refluxing zone generated by swirl air entering the combustion chamber from a pre-combustion fraction swirler; and after being sprayed out by a main combustion fraction nozzle, the fuel oil needed by the main combustion fraction first form an oil-gas mixed gas through atomization under the action of an air flow in a prefilming air ring in the main combustion fraction nozzle and then flows to the premixing and pre-evaporating fraction to be evaporated and further blended with the air, so a uniform oil-gas mixed gas jet flow is formed at the position of the outlet of the premixing and pre-evaporating fraction and enters the combustion liner to be ignited by flame in the pre-combustion fraction to combust. The combustion chamber is simple in structure and can effectively reduce pollutant discharge while ensuring an aeroengine works normally.

Owner:BEIHANG UNIV

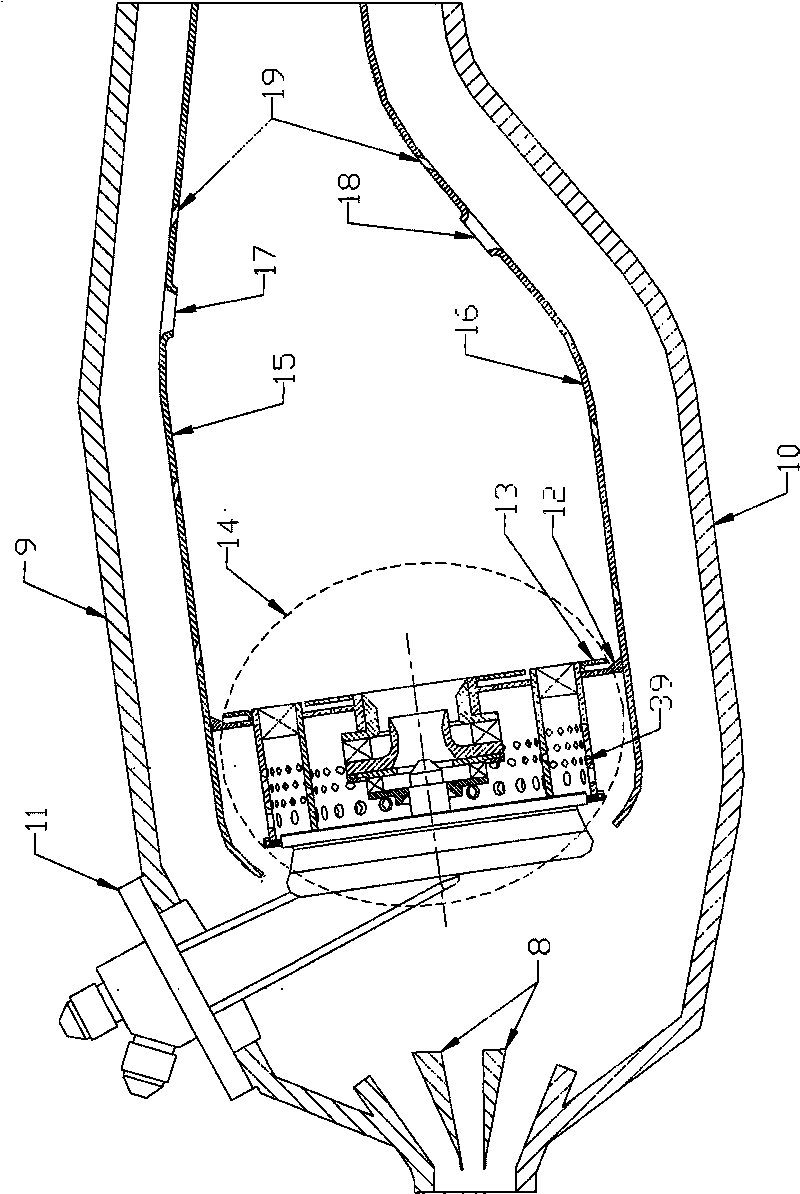

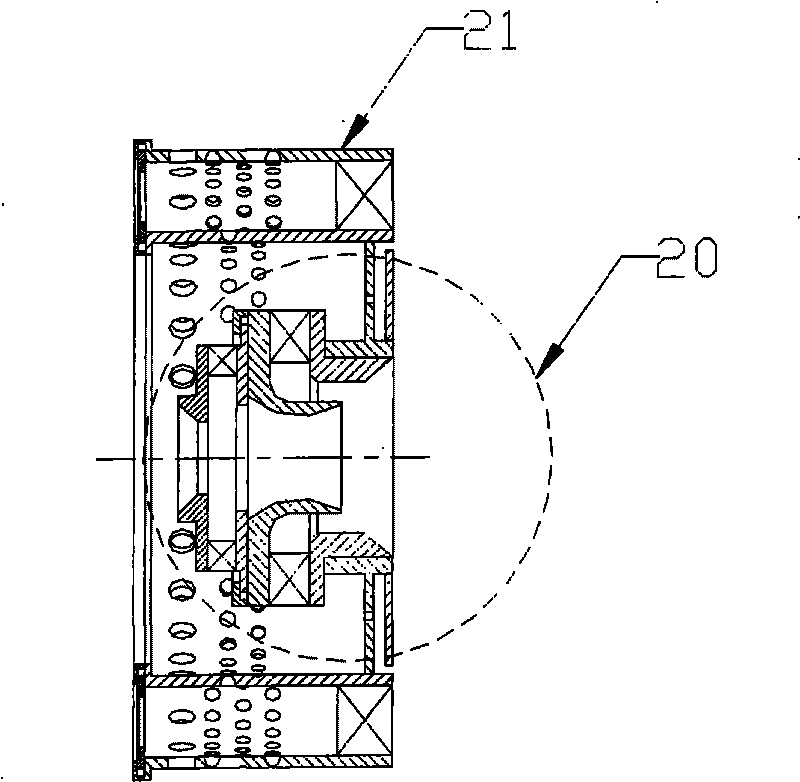

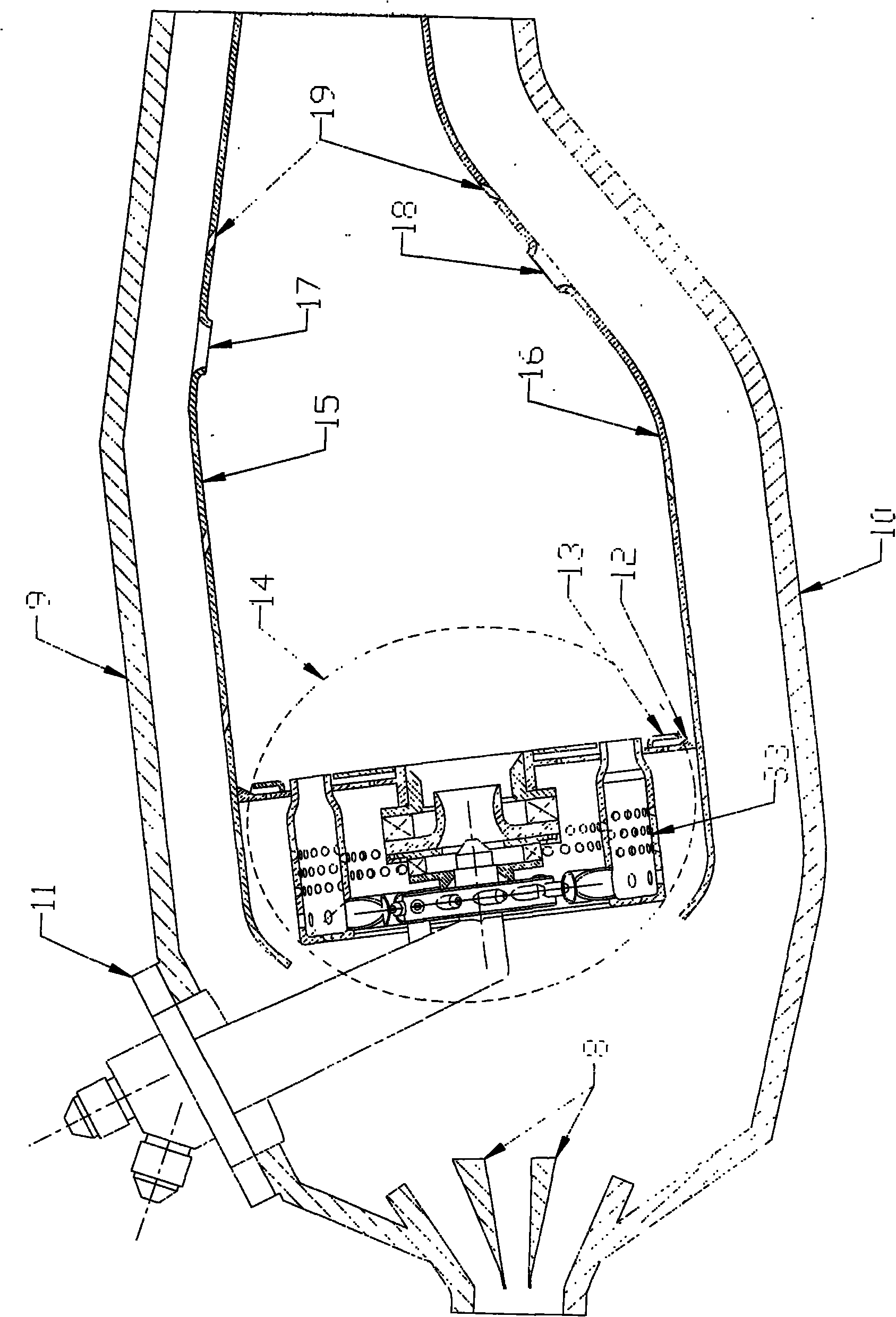

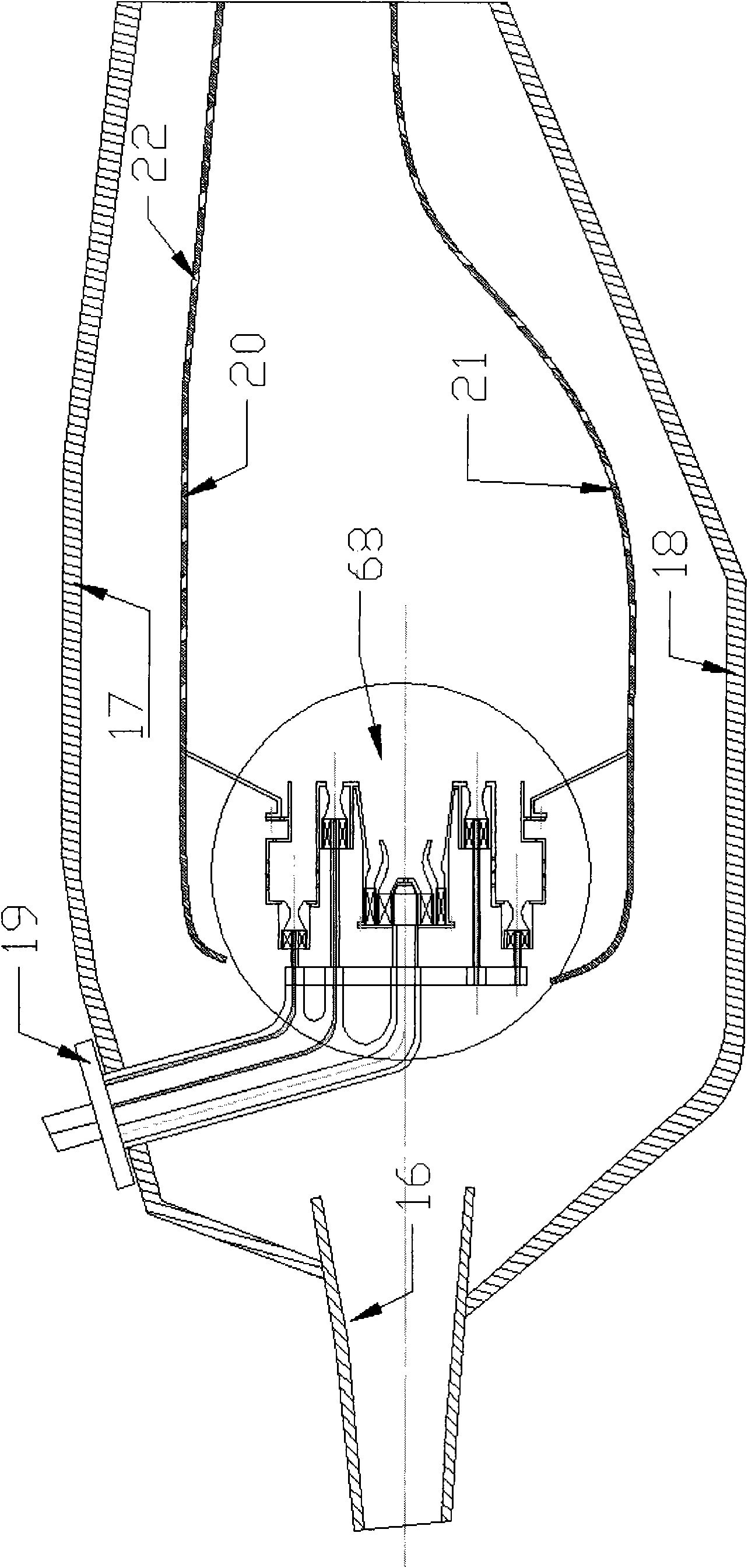

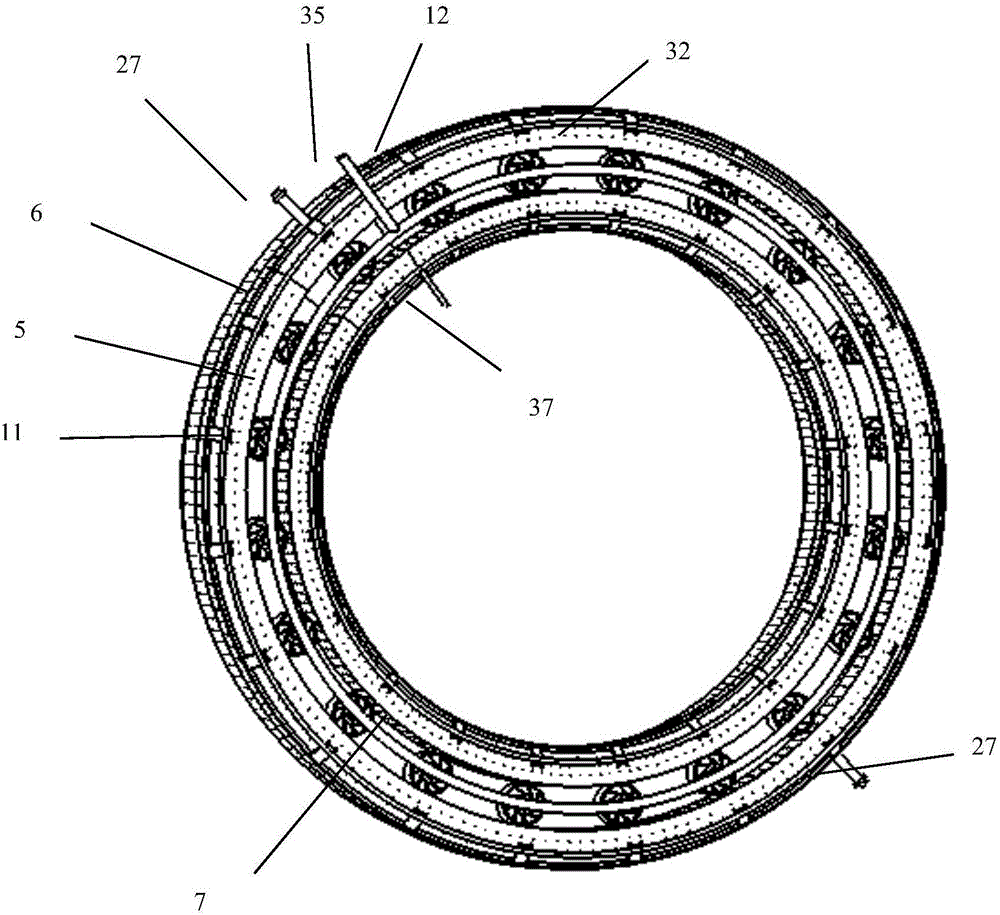

Main combustible stage tangential oil supply premix and pre-evaporation combustion chamber

The invention relates to a main combustion stage tangential oil supply premix and pre-evaporation combustion chamber. The combustion chamber is in a single-ring chamber structure and is designed by adopting the conceptual design of staging combustion, and all the used amount of gas for combustion is supplied by the precombustion stage and the main combustion stage. The combustion chamber mainly comprises a flow-dividing type diffuser, a combustion chamber outer case, a combustion chamber inner case, a fuel nozzle, the precombustion stage, the main combustion stage, a flame tube outer wall and a flame tube inner wall. The precombustion stage utilizes a low-speed flow returning zone generated by swirl air entering the combustion chamber by a precombustion stage swirler component; the fuel needed by the main combustion stage is ejected by the tangential main combustion stage nozzle, is atomized under the air flow effect generated by entering of atomized air of the main combustion stage nozzle into a pipe, then flows into a premix and pre-evaporation ring pipe for evaporation, and is further blended with air; and even oil-gas mixed gas formed at the outlet of the premix and pre-evaporation ring pipe enters a flame tube and combusts under the pilot combustion of the precombustion stage flame. The combustion chamber has simple structure, and can effectively reduce the discharge of pollution simultaneously while guaranteeing that an aeroengine is in normal working state.

Owner:BEIHANG UNIV

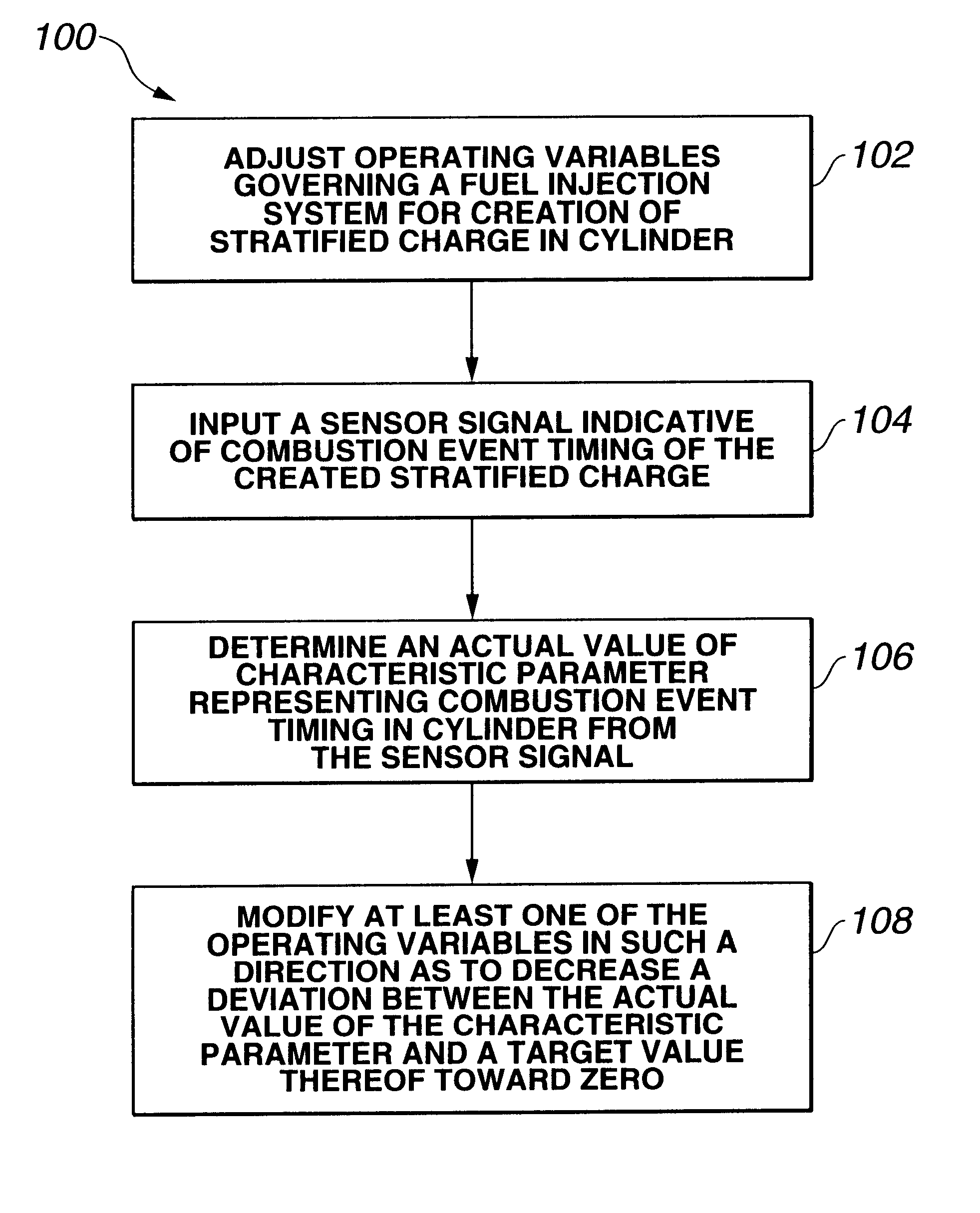

Feedback control for auto-ignition two-stage combustion of gasoline in engine cylinder

A split injection of gasoline produces stratified charge in at least one cylinder. A sensor measures cylinder pressure or knock and generates a sensor signal indicative of combustion event timing of stratified charge. From the sensor signal, a controller determines an actual value of a characteristic parameter representing combustion event timing in the cylinder. The controller modifies at least one of operating variables governing a split injection for the subsequent cycle in such a direction as to decrease a deviation between the actual value of the characteristic parameter and a target value thereof toward zero.

Owner:NISSAN MOTOR CO LTD

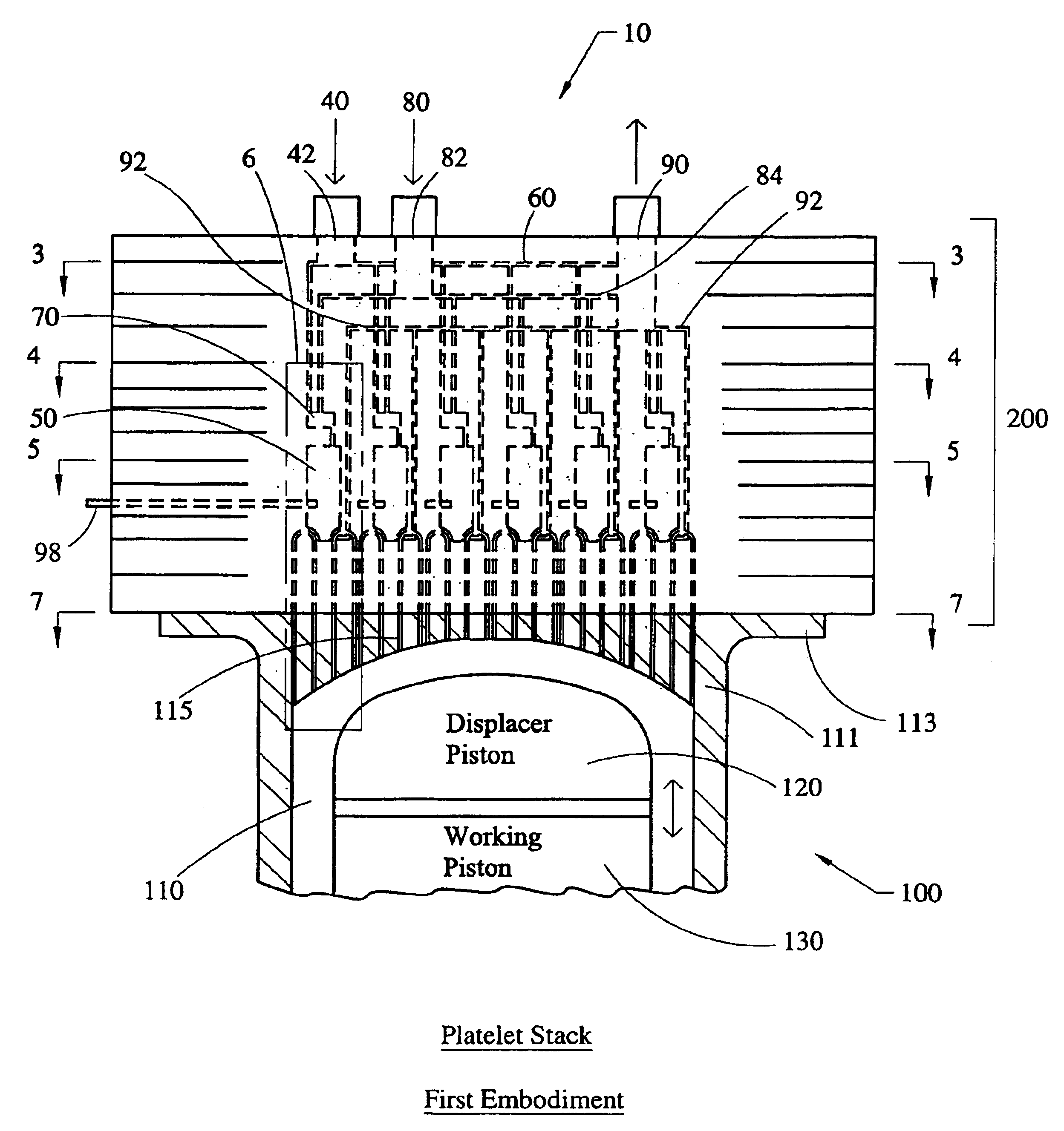

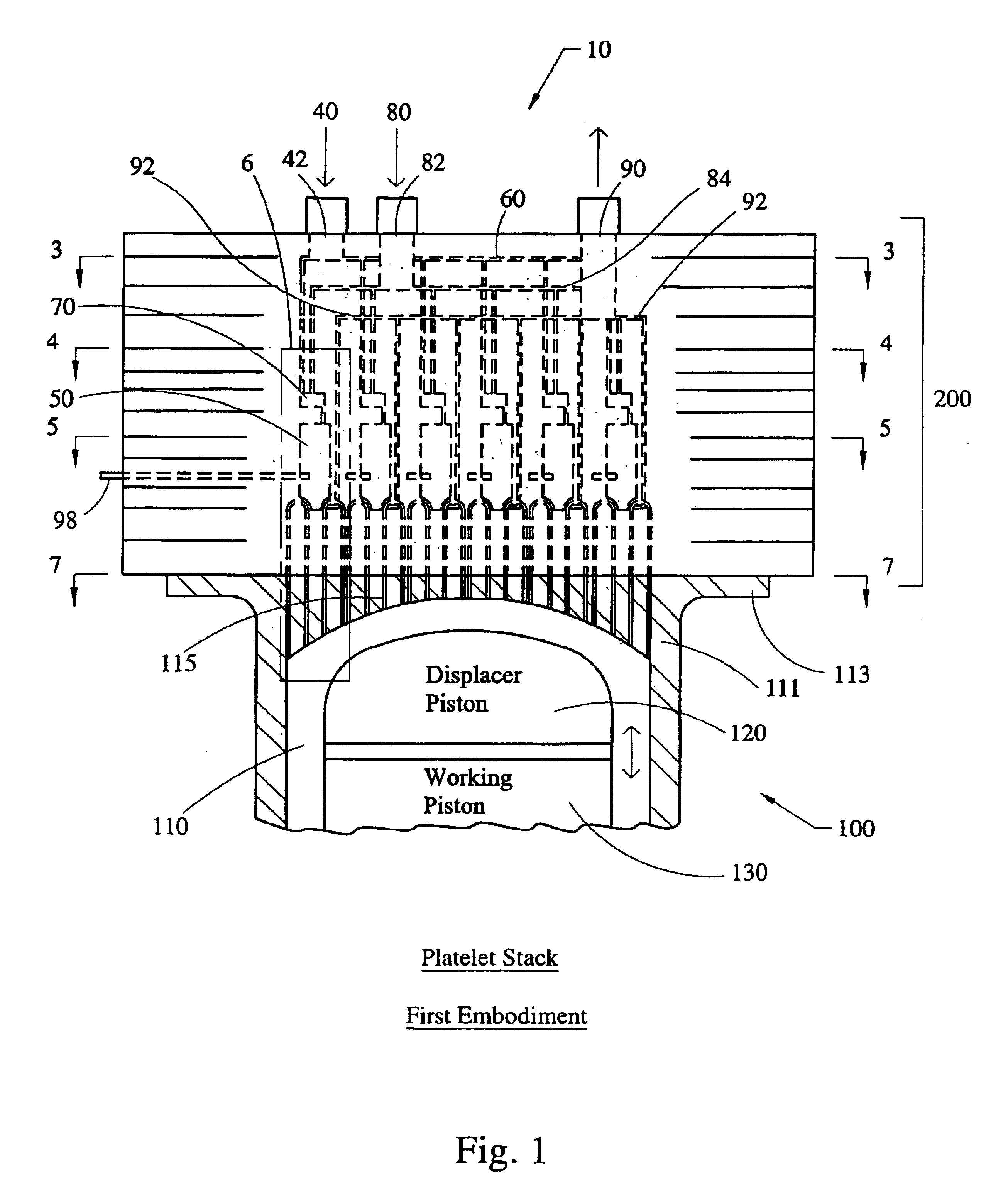

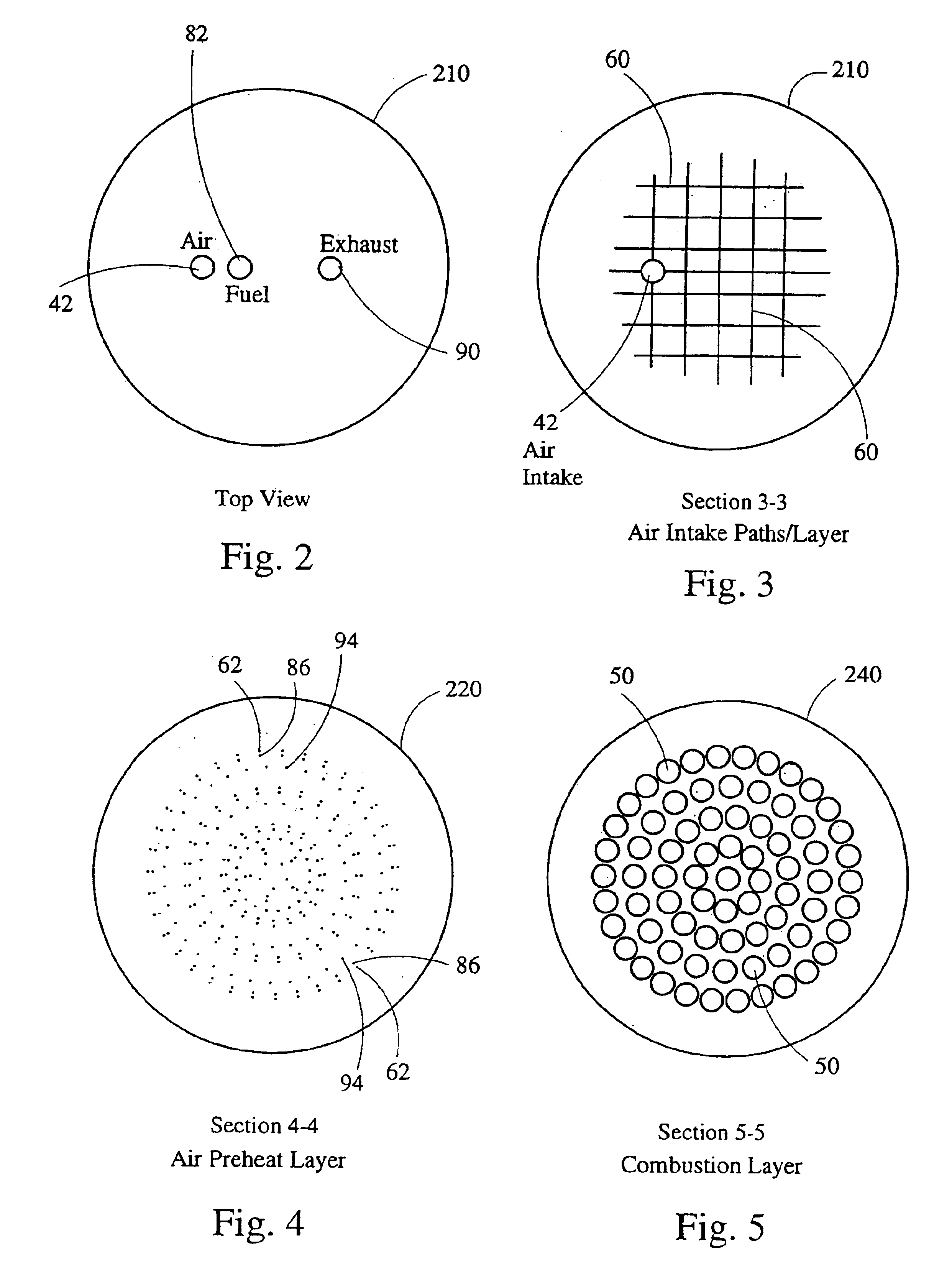

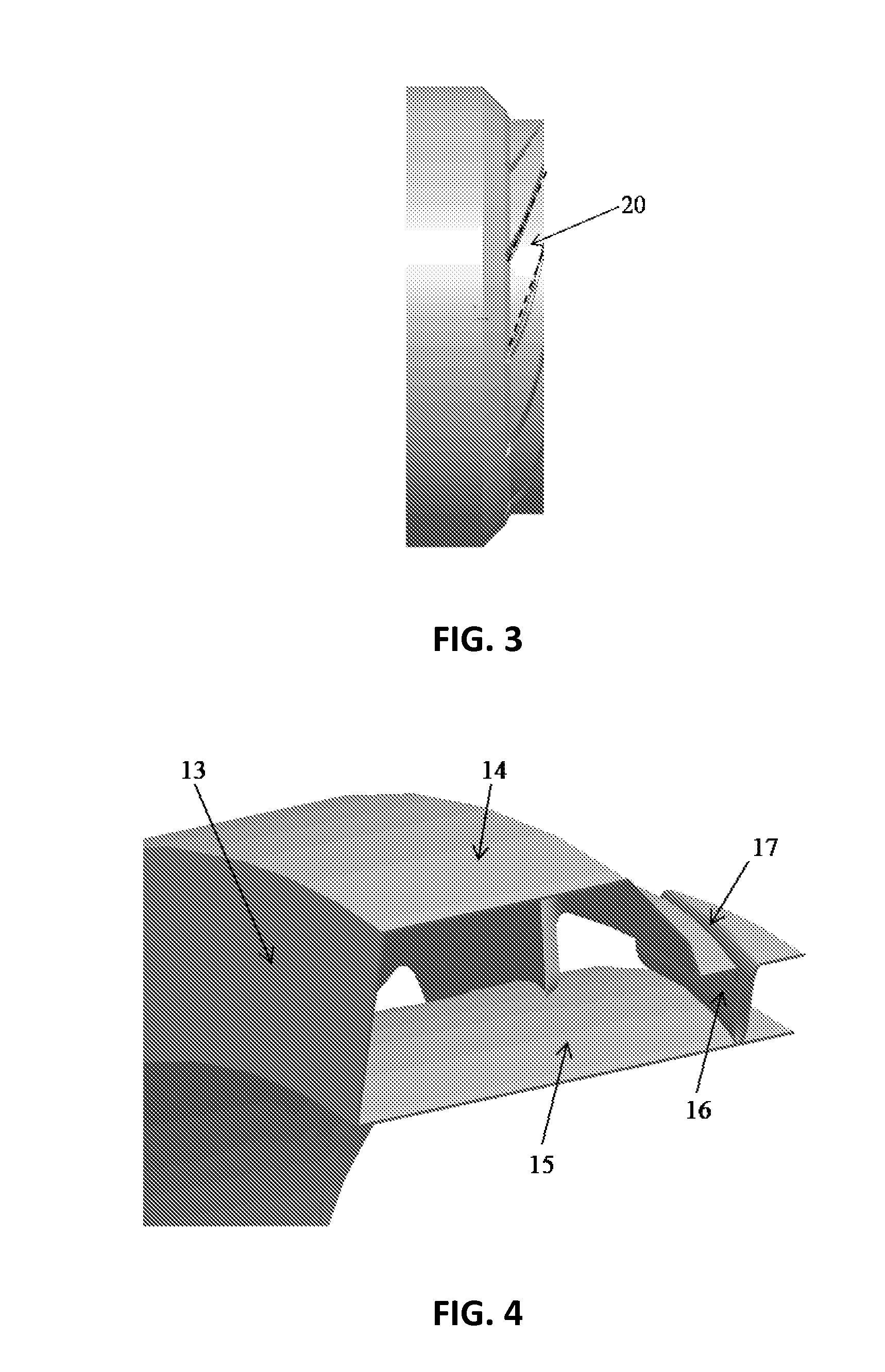

Stirling engine having platelet heat exchanging elements

InactiveUS6931848B2Guaranteed uptimeEfficient heat transferSolar heating energySolar heat devicesEngineeringStaged combustion

The present invention provides heat exchanging elements for use in Stirling engines. According to the present invention, the heat exchanging elements are made from muliple platelets that are stacked and joined together. The use of platelets to make heat exchanging elements permits Stirling engines to run more effiecient because the heat transfer and combustion processes are improved. In one embodiment, multi-stage combustion can be introduced with platlets, along with the flexibility to use different types of fuels. In another embodiment, a single component constructed from platelets can provide the heat transfer rquirements betweeen the combustion gas / working gas, working gas in the regenerator and the working gas / coolant fluid of a Stirling engine. In another embodiment, the platelet heat exchanging element can recieve solar energy to heat the Stirling engine's working gas. Also, this invention provides a heat exchanging method that allows for multiple fluids to flow in opposing or same direction.

Owner:DISENCO +1

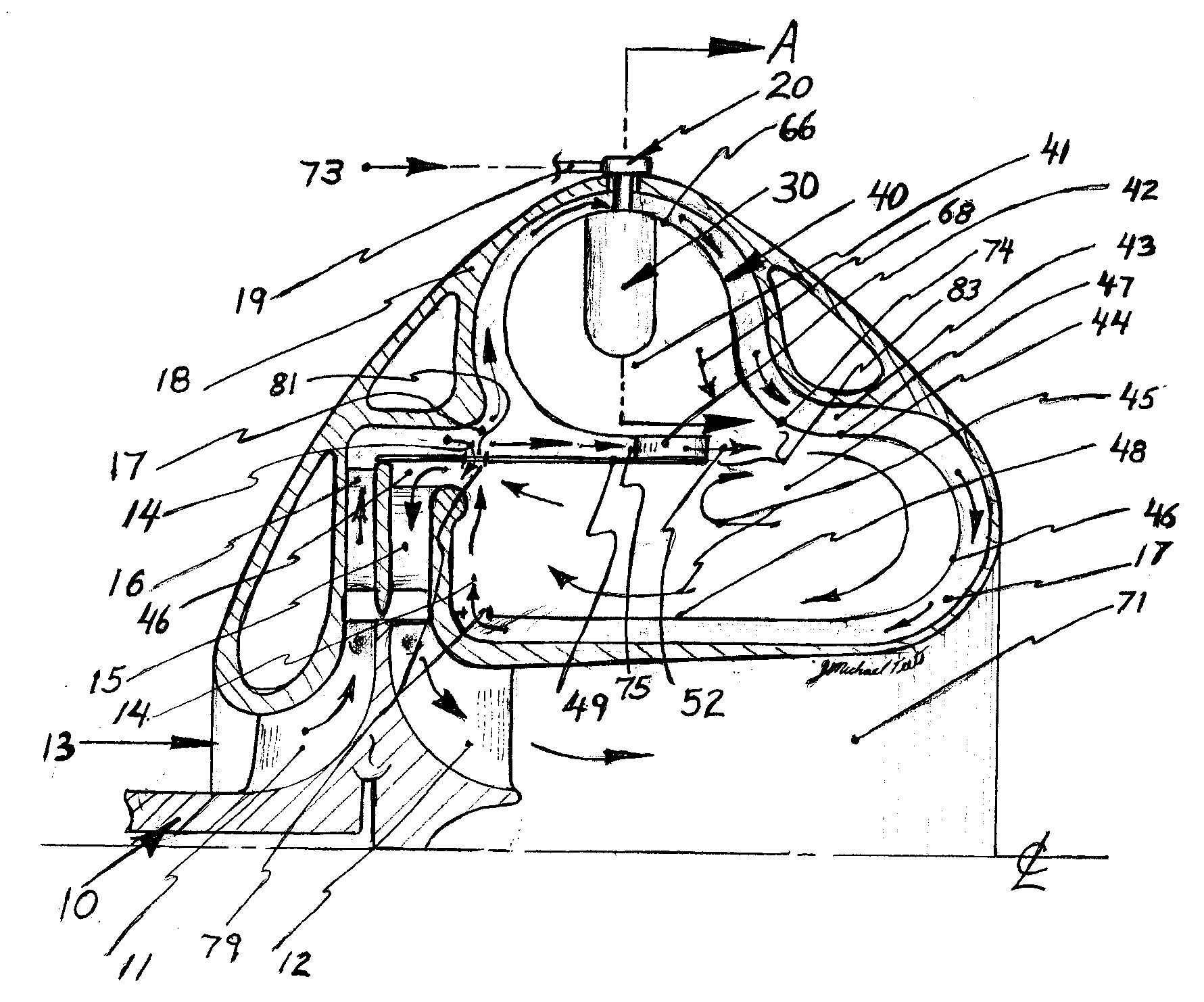

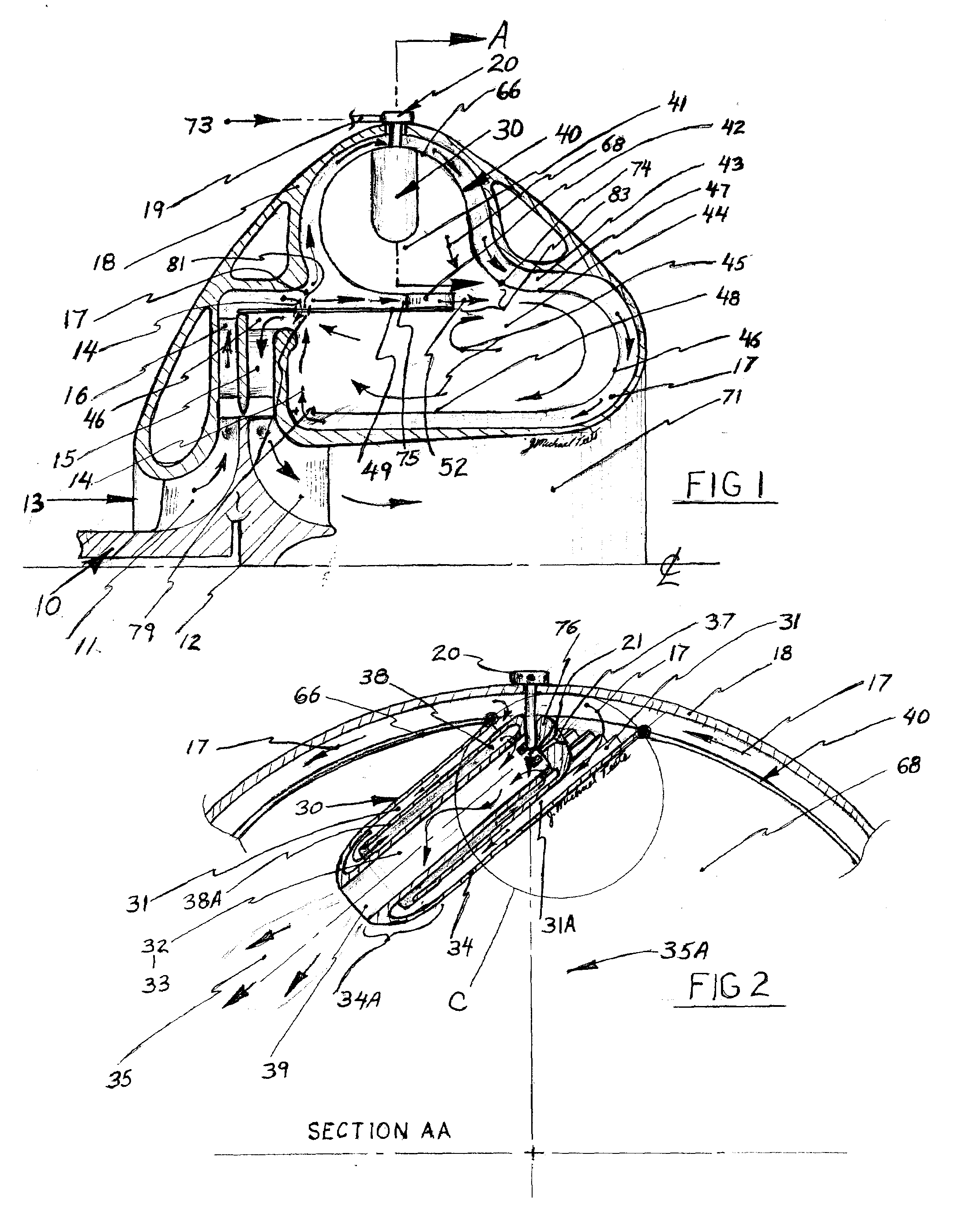

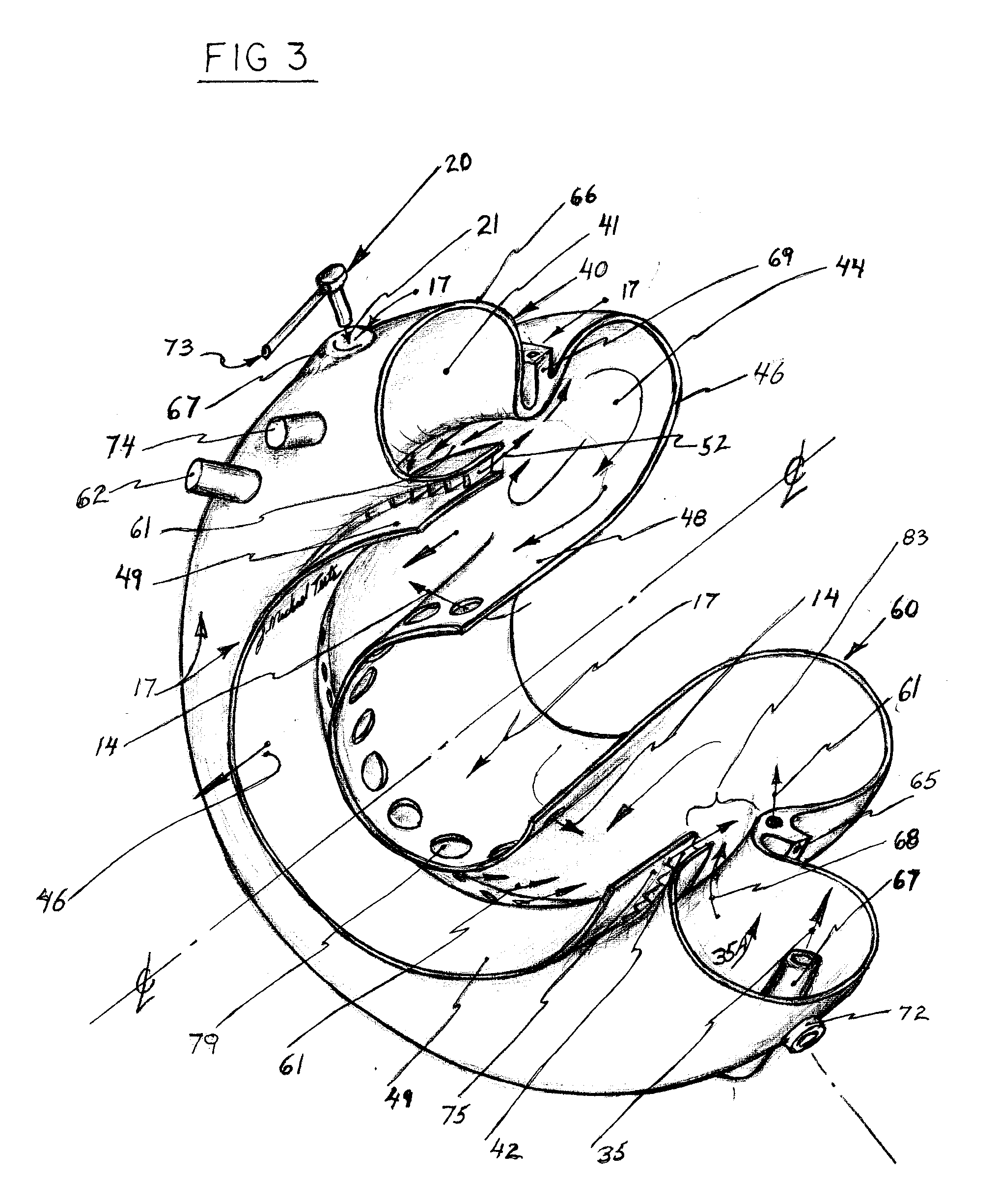

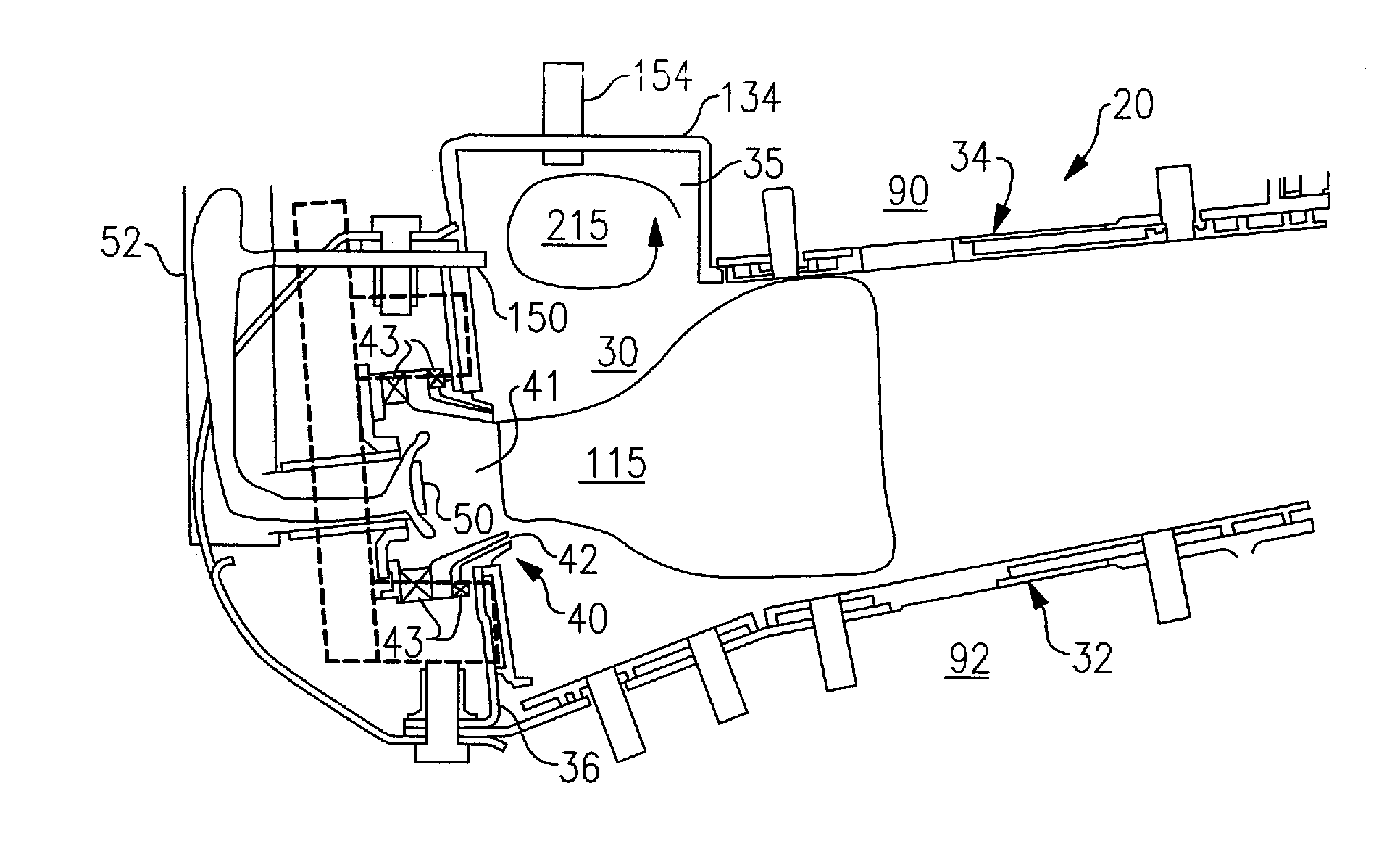

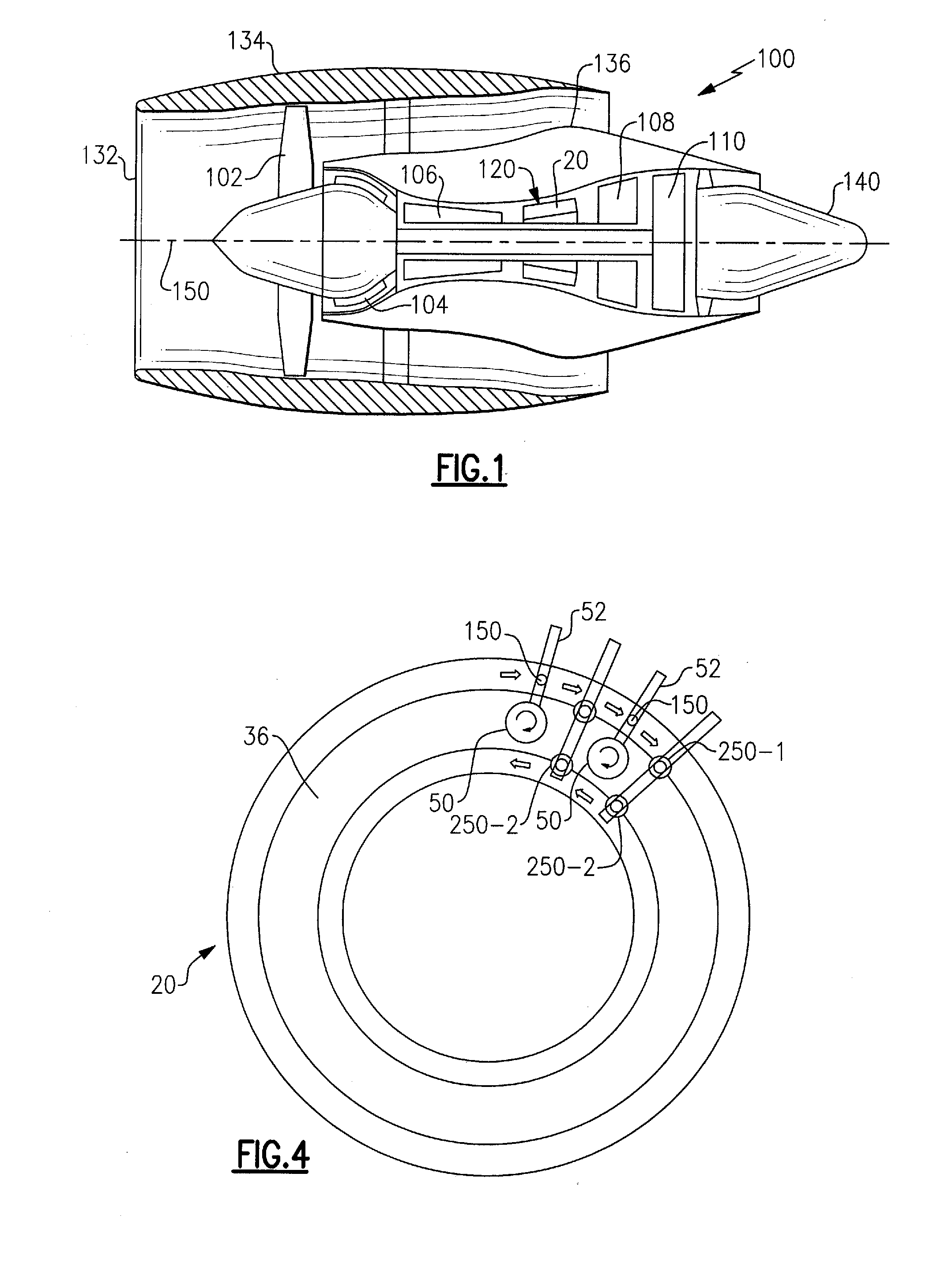

Radially staged RQL combustor with tangential fuel premixers

ActiveUS20080041059A1Emission reductionLow costContinuous combustion chamberGas turbine plantsCombustorVaporization

A double annular radially staged combustor having an axially reduced common internal flow transitioning area between outboard primary combustion zone and inboard secondary combustion zone. The primary zone geometry is generally a toroidal shell form with a radially inboard wall annular exiting thru flow area into the secondary fuel air premixing section. Fuel and Air premixing chambers are incorporated into the primary combustion zone with vaporization capability for liquid fuels. The secondary zone is of an annular shell form, generally inboard and adjacent to the primary zone, accepts the primary combustion gases and mixes with additional supplied air in a reduced annular flow area and then combusted in the secondary combustion zone. The secondary combustion zone exiting gas, flows into a dilution zone where further air is mixed and with continued flow downstream this heat energy is delivered to the turbine stage of a gas turbine engine.

Owner:TEETS JOSEPH MICHAEL MR

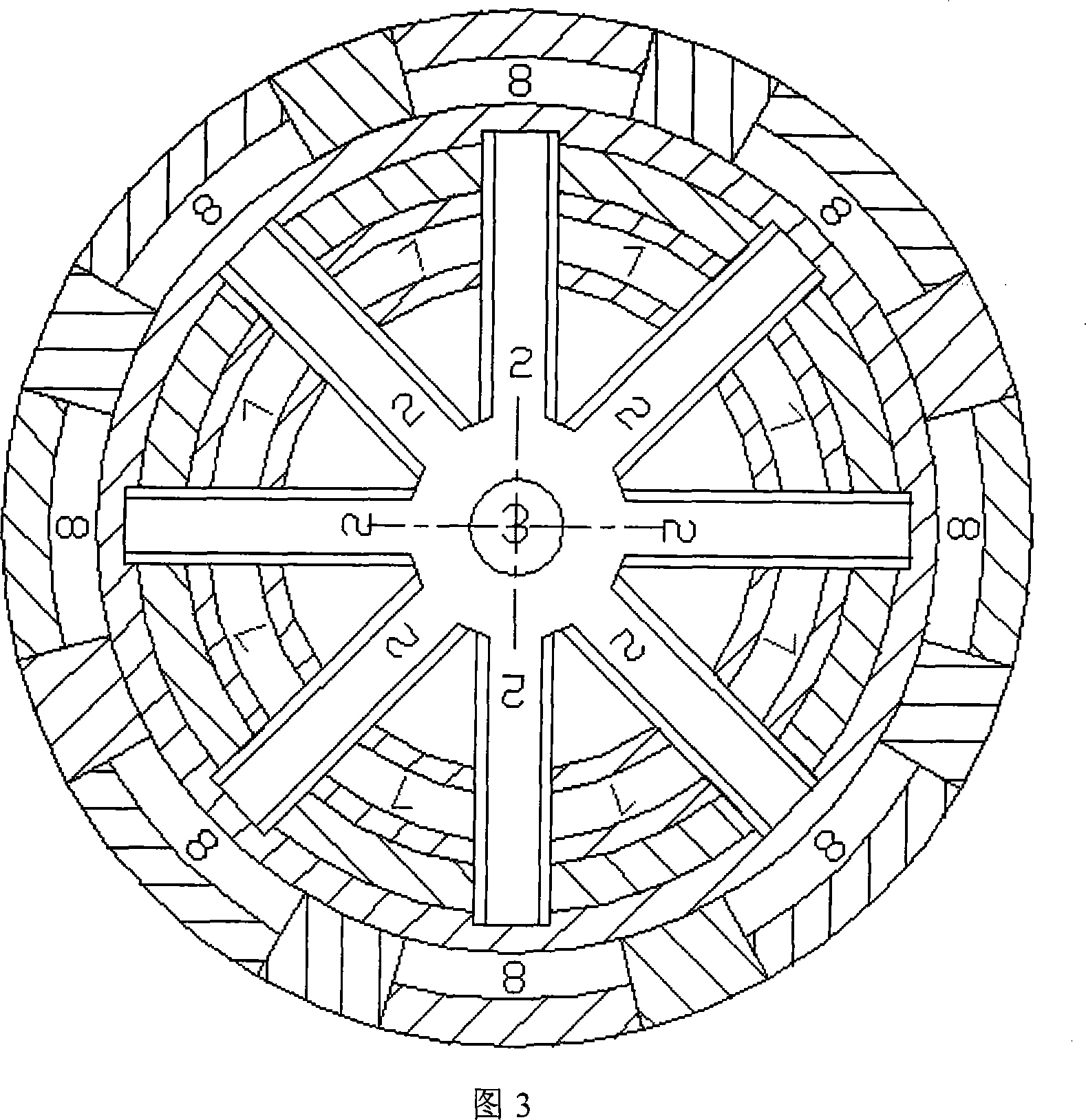

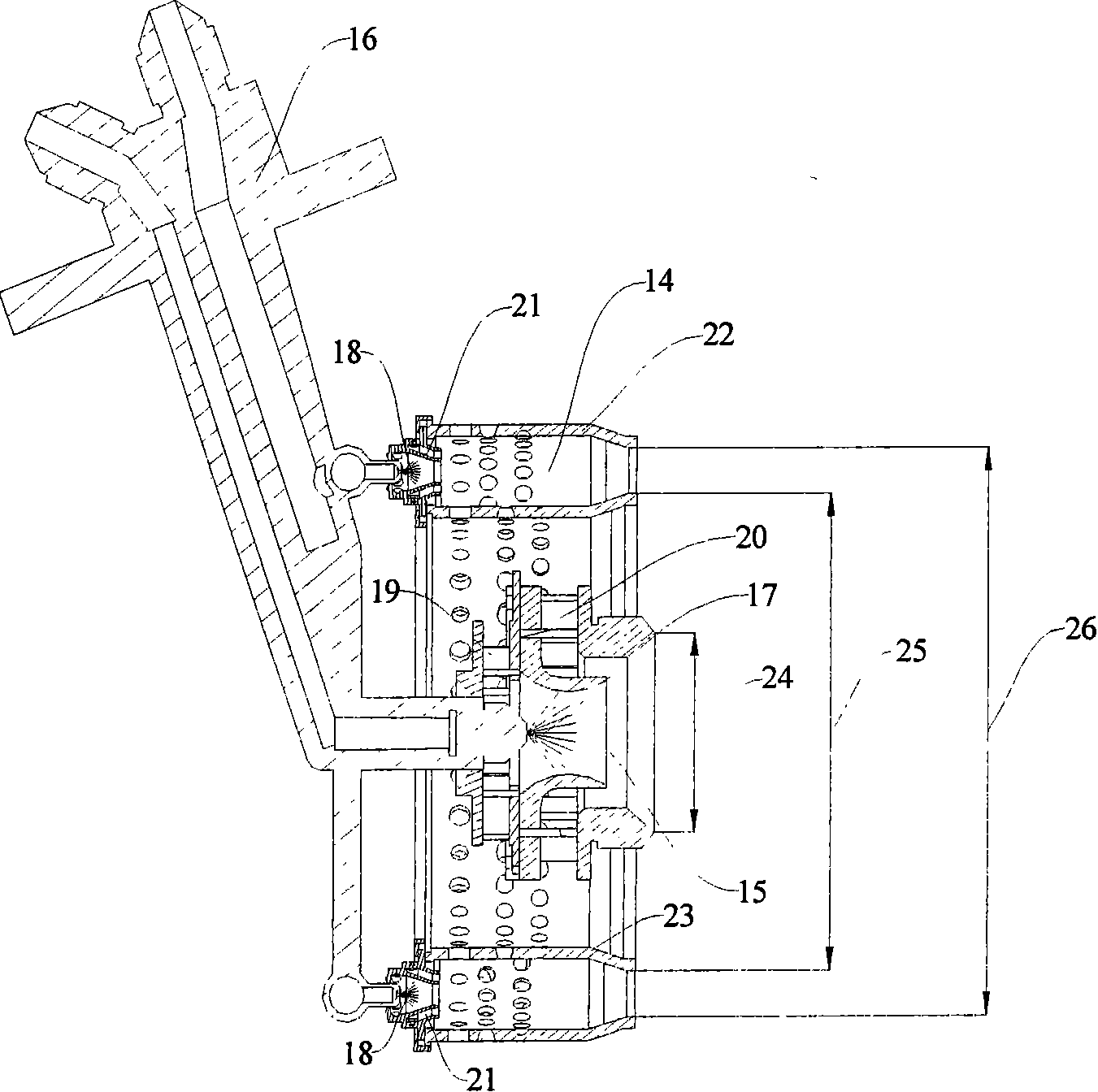

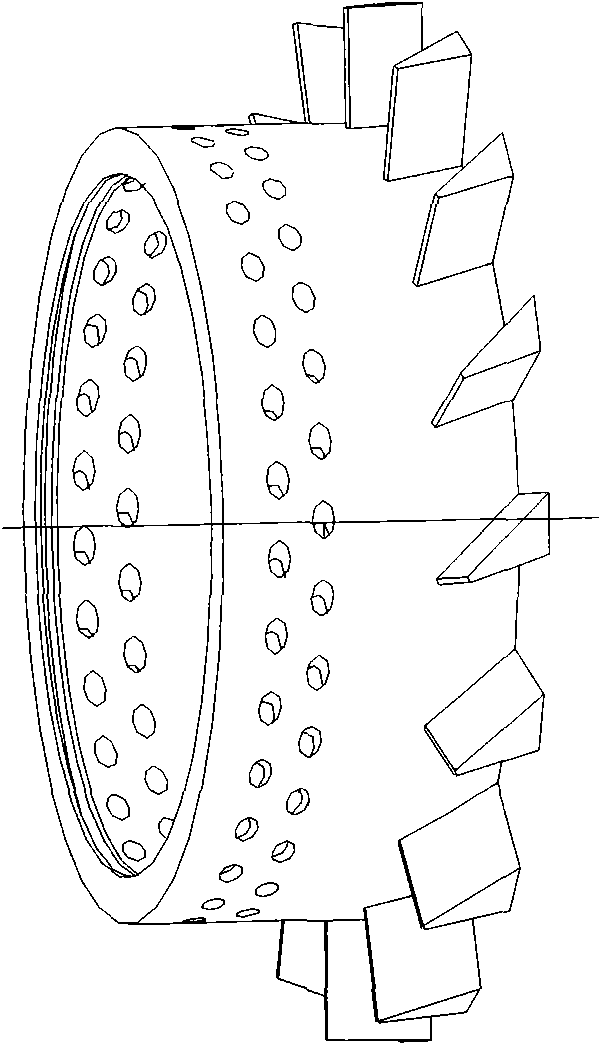

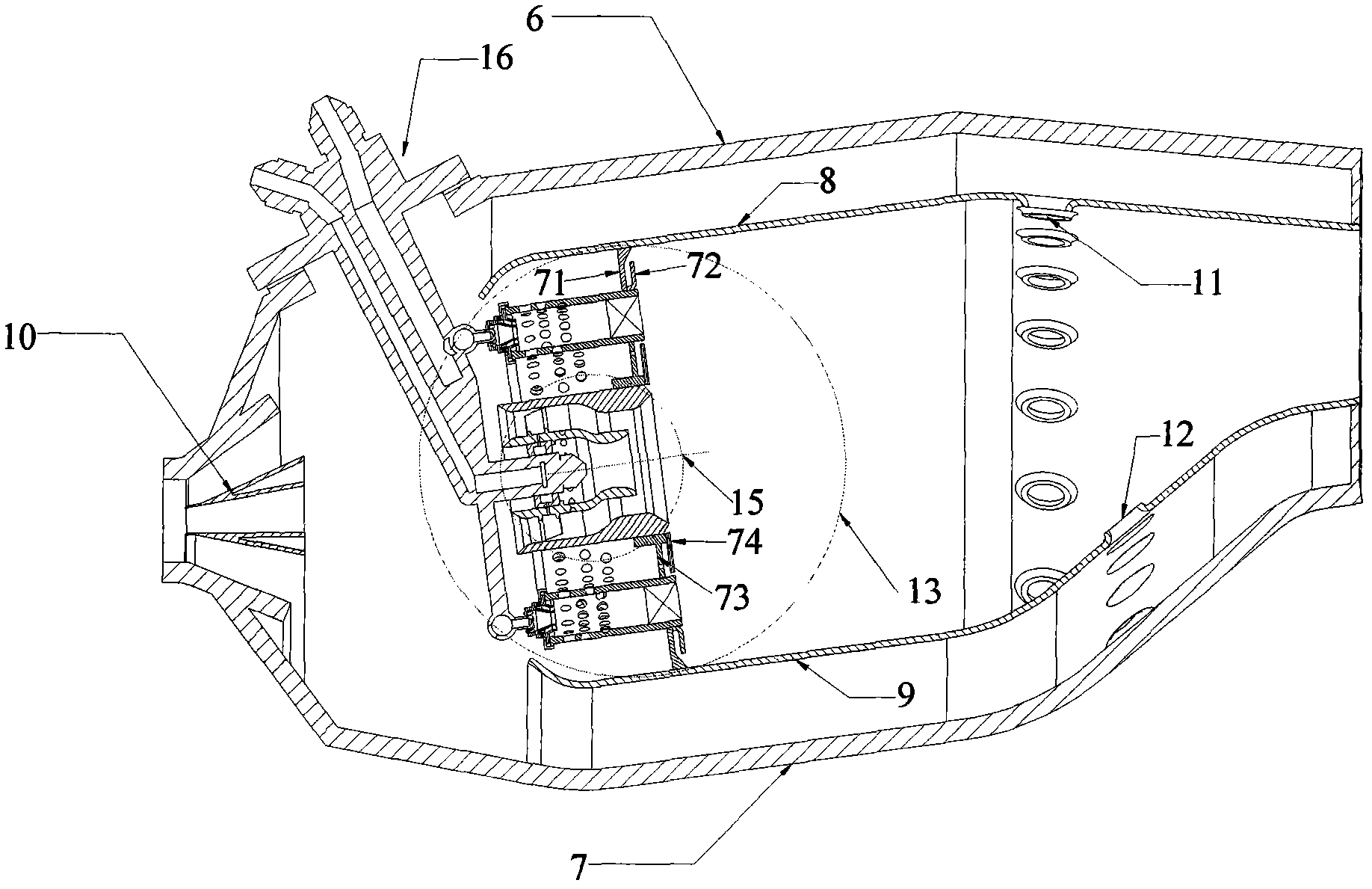

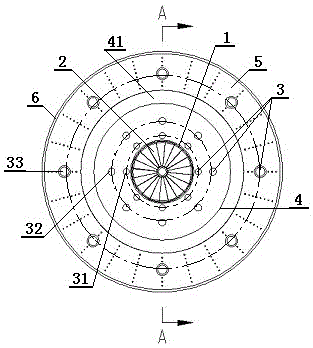

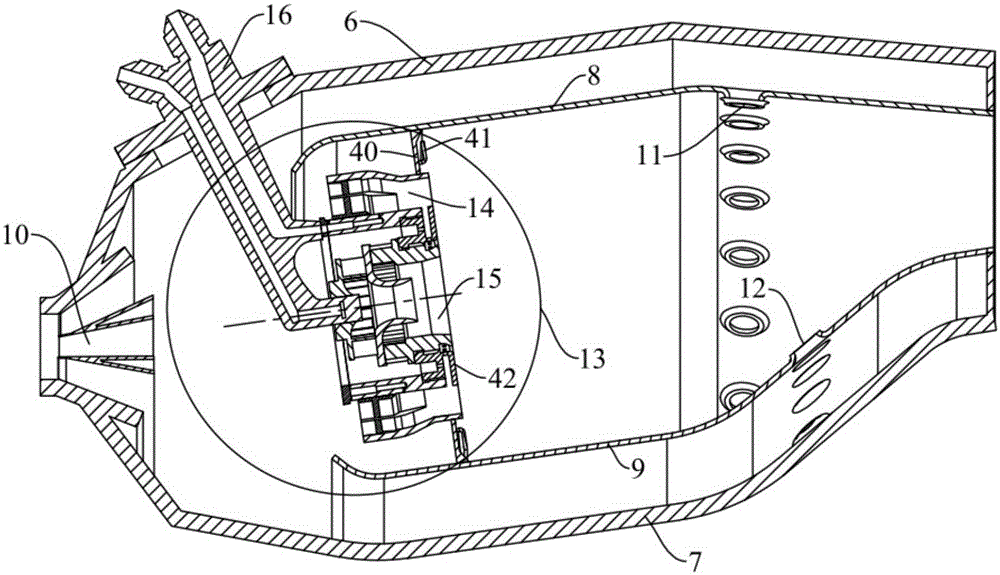

Circumferentially graded low-pollution combustion chamber with multiple middle spiral-flow flame stabilizing stages

InactiveCN102032598AImprove combustion stabilityIncrease the intermediate flame levelContinuous combustion chamberCombustion chamberLow speed

The invention discloses a circumferentially graded low-pollution combustion chamber with multiple middle spiral-flow flame stabilizing stages. The combustion chamber has a single annular cavity structure; a low-pollution combustion organization mode in which air grading is matched with fuel oil grading is adopted; all fuel gas is supplied by a duty stage, a middle stage and a main combustion stage; and fuel oil grading supply proportion is controlled accurately according to the operating condition of an engine and the requirement on stable low-pollution combustion. The duty stage has a combined structure in which two-stage axial spiral flow is matched with a venturi tube, and a formed low-speed reflux region can support stable combustion of the combustion chamber; the middle stage has a combined structure in which a plurality of single-stage axial spiral flow circumferentially and uniformly distributed on the same circumference in the same axial cross section are matched with the venturi tube, and a formed middle flame stabilizing stage combustion region is used for intensifying and stabilizing flame in the main combustion stage; and the main combustion stage has a combined structure in which a plurality of single-stage axial spiral flow circumferentially and uniformly distributed on the same circumference in the same axial cross section are matched with the venturi tube, so that an oil and gas mixed poor-oil premixing and pre-evaporation combustion mode is intensified and the emission of pollutants is further reduced greatly.

Owner:BEIHANG UNIV

Premix and pre-evaporation combustion chamber

InactiveCN101949551ASimple structureImprove efficacyContinuous combustion chamberAviationDiffusion flame

The invention discloses a tangential premix and pre-evaporation combustion chamber. The combustion chamber has a single-ring cavity structure; and through a design by adopting a concept of staged combustion, combustion gas is totally supplied by a pre-combustion stage and a main combustion stage, wherein the pre-combustion stage adopts a steady-rotational flow diffusion flame combustion organization mode; and the main combustion stage adopts a premix and pre-evaporation combustion organization mode. The combustion chamber mainly comprises a flow-dividing diffuser, an outer casing of the combustion chamber, an inner casing of the combustion chamber, a fuel nozzle, the pre-combustion stage, the main combustion stage, a flame tube outer wall and a flame tube inner wall, wherein the pre-combustion stage stabilizes the flame by a low-speed return area generated by rotational flow air entering the combustion chamber from a pre-combustion stage swirler assembly; and the fuel needed by the main combustion stage is ejected from a nozzle of the main combustion stage, is atomized to form oil-gas mixed gas under the airflow action of a prefilming air ring of the nozzle of the main combustion stage, flows into a premix and pre-evaporation section to be evaporated, is further doped with the air to form a uniform oil-gas mixed air jet at an opening of the premix and pre-evaporation section to enter the flame tube, and is combusted under the ignition of a pre-combustion stage flame. The tangential premix and pre-evaporation combustion chamber has the advantages of simple structure and capacities of guaranteeing the normal working state of an aircraft engine and effectively reducing pollution discharge simultaneously.

Owner:BEIHANG UNIV

Low-pollution combustion chamber with premixed and pre-evaporated precombustion part

ActiveCN102022753ADoes not affect work stabilityReduce pollutionContinuous combustion chamberCombustion chamberPollutant emissions

The invention relates to a low-pollution combustion chamber with a premixed and pre-evaporated precombustion part, which adopts a monocylic cavity structure and comprises a pressure diffuser, an outer receiver of a combustion chamber, an outer wall of a flame tube, an inner wall of the flame tube and a combustion chamber head, wherein all air for combustion enters the flame tube from the combustion chamber head, a grade combustion scheme is adopted and comprises a precombustion grade and a main combustion grade ; the main combustion grade adopts a premixed combustion mode, and the precombustion grade adopts a mode of combining diffusion combustion with stable rotational flow and rotational-flow premixed combustion; and the precombustion grade adopts the mode of combining the diffusion combustion and the premixed combustion, and pollutant discharge under a small working condition is reduced without influencing stable combustion. In the invention, the precombustion grade structure is simple, and the pollutant discharge is reduced under a small working condition without influencing the combustion stability so as to ensure that the pollution discharge of the whole landing and take-off (LTO) of an aircraft engine combustion chamber is further reduced.

Owner:BEIHANG UNIV

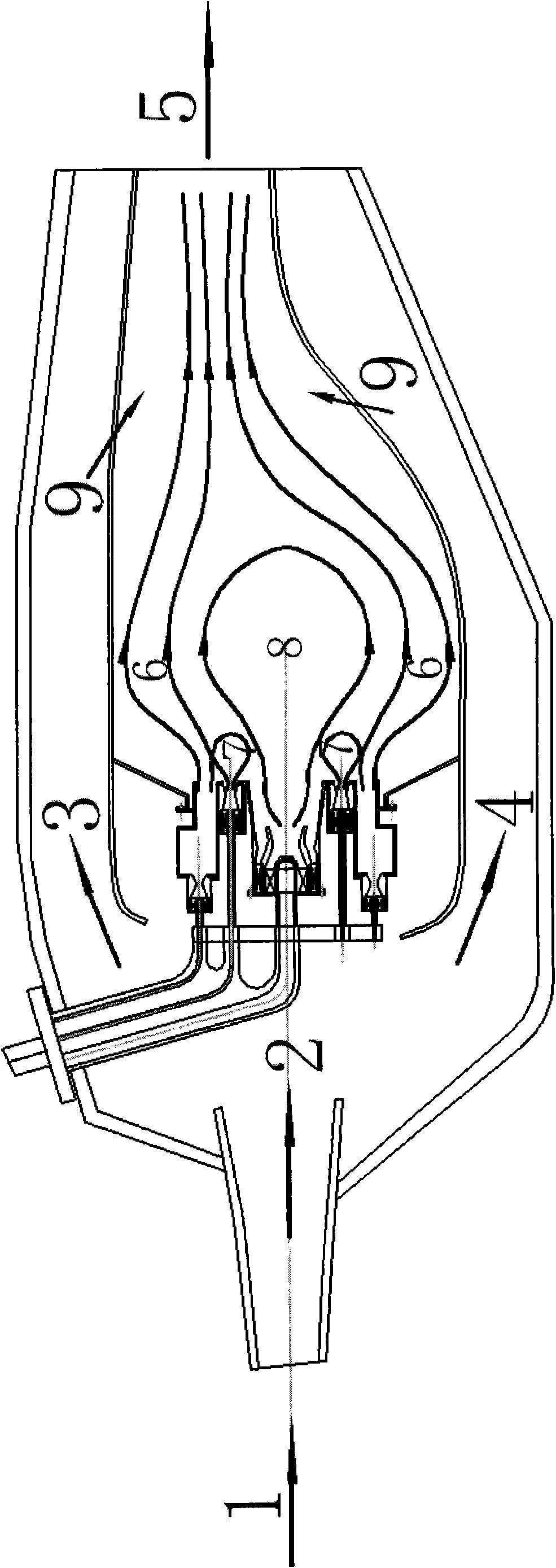

Integrated diffusion oriented combustion chamber

InactiveCN101650038AGuaranteed temperature distributionSimplified matching structureContinuous combustion chamberLow speedCombustion chamber

The invention relates to an integrated diffusion oriented combustion chamber which adopts a full ring combustion chamber structure. The integrated diffusion oriented combustion chamber mainly comprises a crankcase, a combustion liner and an oriented diffuser. The oriented diffuser realizes pneumatic and structural coupling, controls the tangential flow direction and carries out diffusion and speedreduction, and a local return low-speed zone is formed, thereby being good for flame linkage and tangential stable combustion; grading combustion is adopted, and a pre-combustion grade can be selected to work alone and work together with a main pre-combustion grade according to work conditions; the pre-combustion grade utilizes the trapped vortex combustion technology for stable work, goes into amain combustion zone to inflame a main combustion grade through a contraction outlet, and provides a stable ignition source for the main combustion grade; fuel of the main combustion grade is injected to a main combustion grade airflow in the oriented diffuser, atomization evaporation mixing with short distance is realized, and combustible mixture gas with uniform mixing is provided for the maincombustion zone. The invention allows tangential rotational flow of a gas compressor to directly go into the combustion chamber so as to realize tangential highly efficient and stable combustion; in addition, the discharge of pollutants is low, pre-rotation is provided for a turbine, the structure can be simplified, the weight is lightened, and the densification of a gas turbine is realized.

Owner:BEIHANG UNIV

Gas turbine combustor with staged combustion

ActiveUS20110185735A1Easy to optimizeExpand the scope of operationTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorStaged combustion

An annular combustor for a gas turbine engine is provided that facilitates staged combustion in a lean direct ignition (LDI) mode over an extended range of operating fuel air ratios. A method is also provided for operating a gas turbine engine over a power demand range that facilitates staged combustion in a lean direct ignition (LDI) mode over an extended range of operating fuel air ratios.

Owner:RAYTHEON TECH CORP

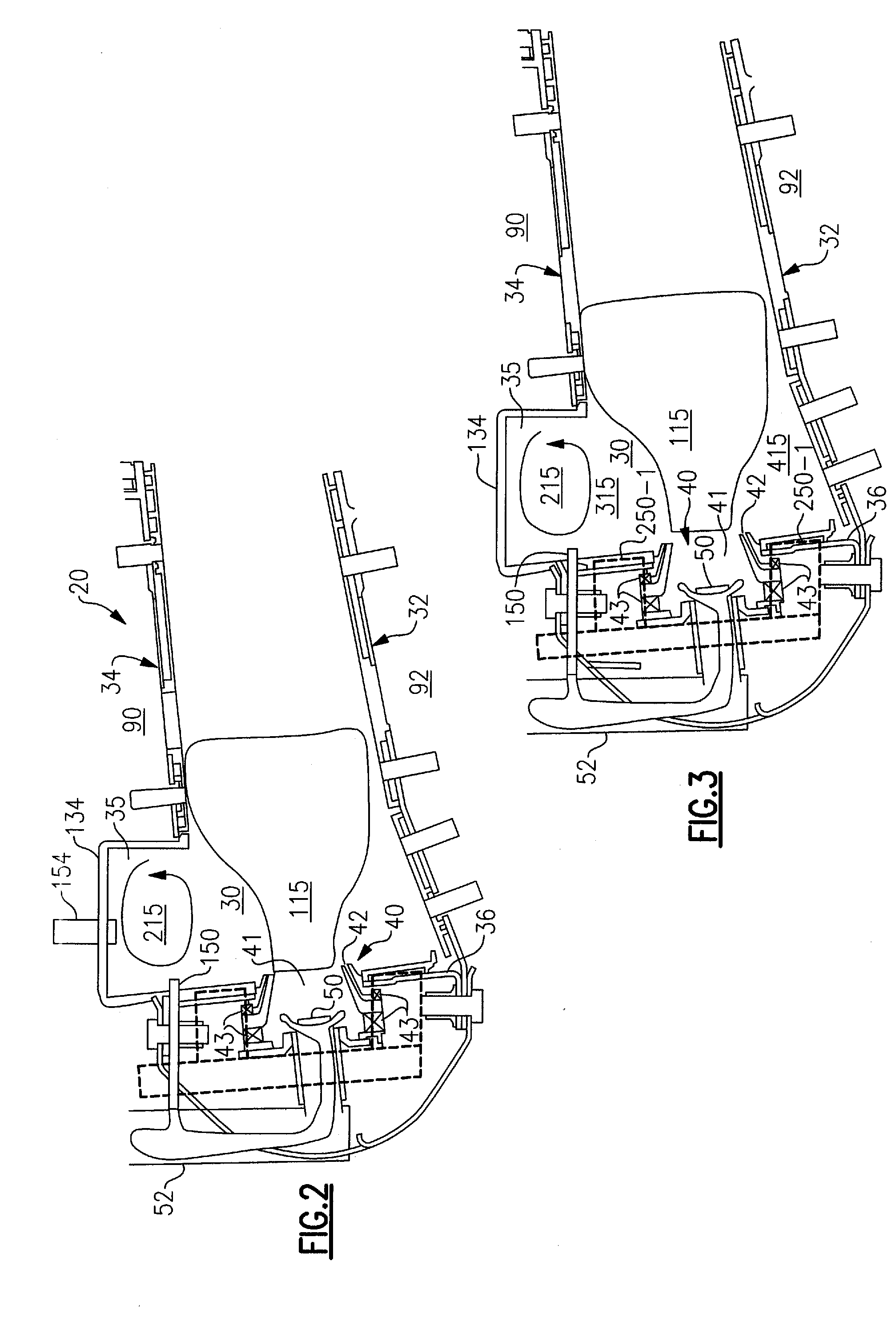

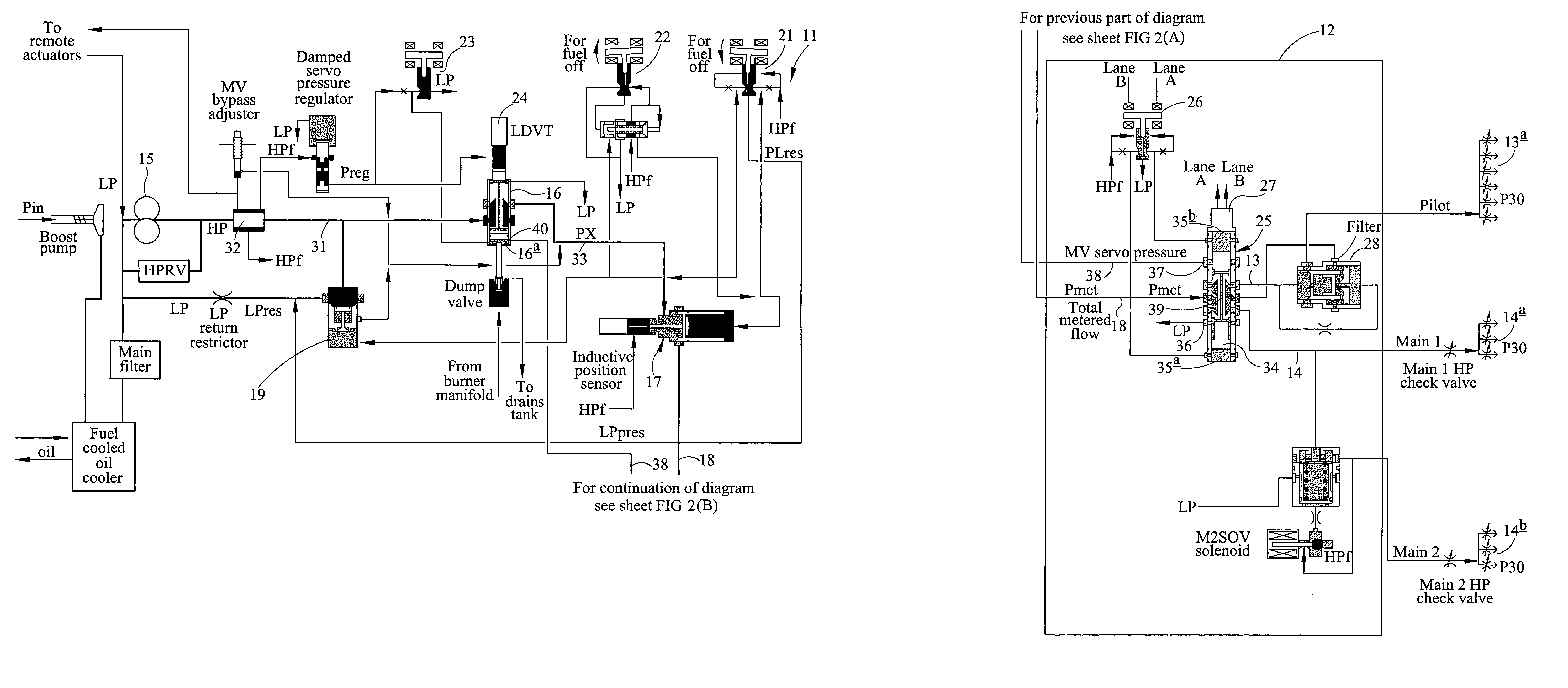

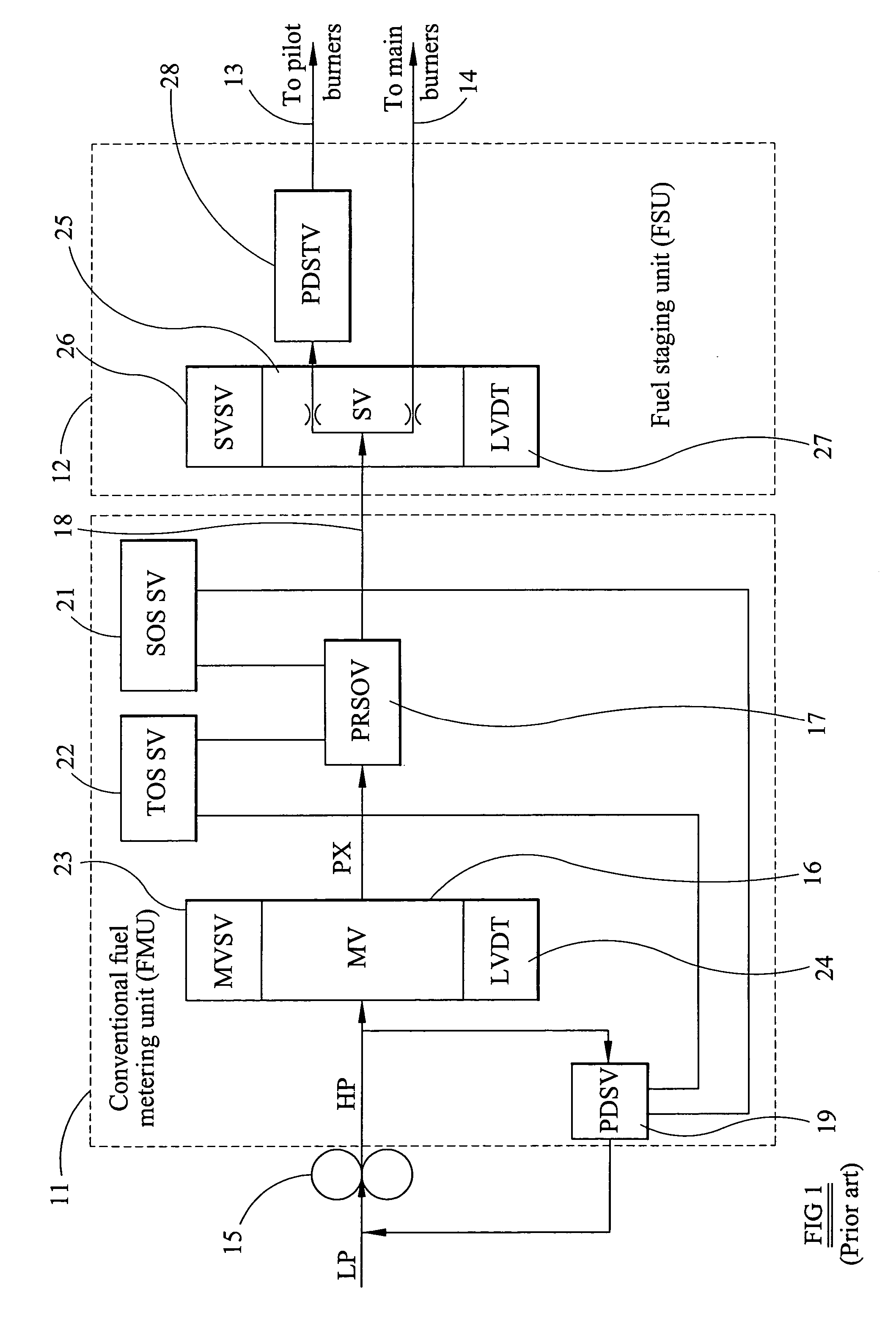

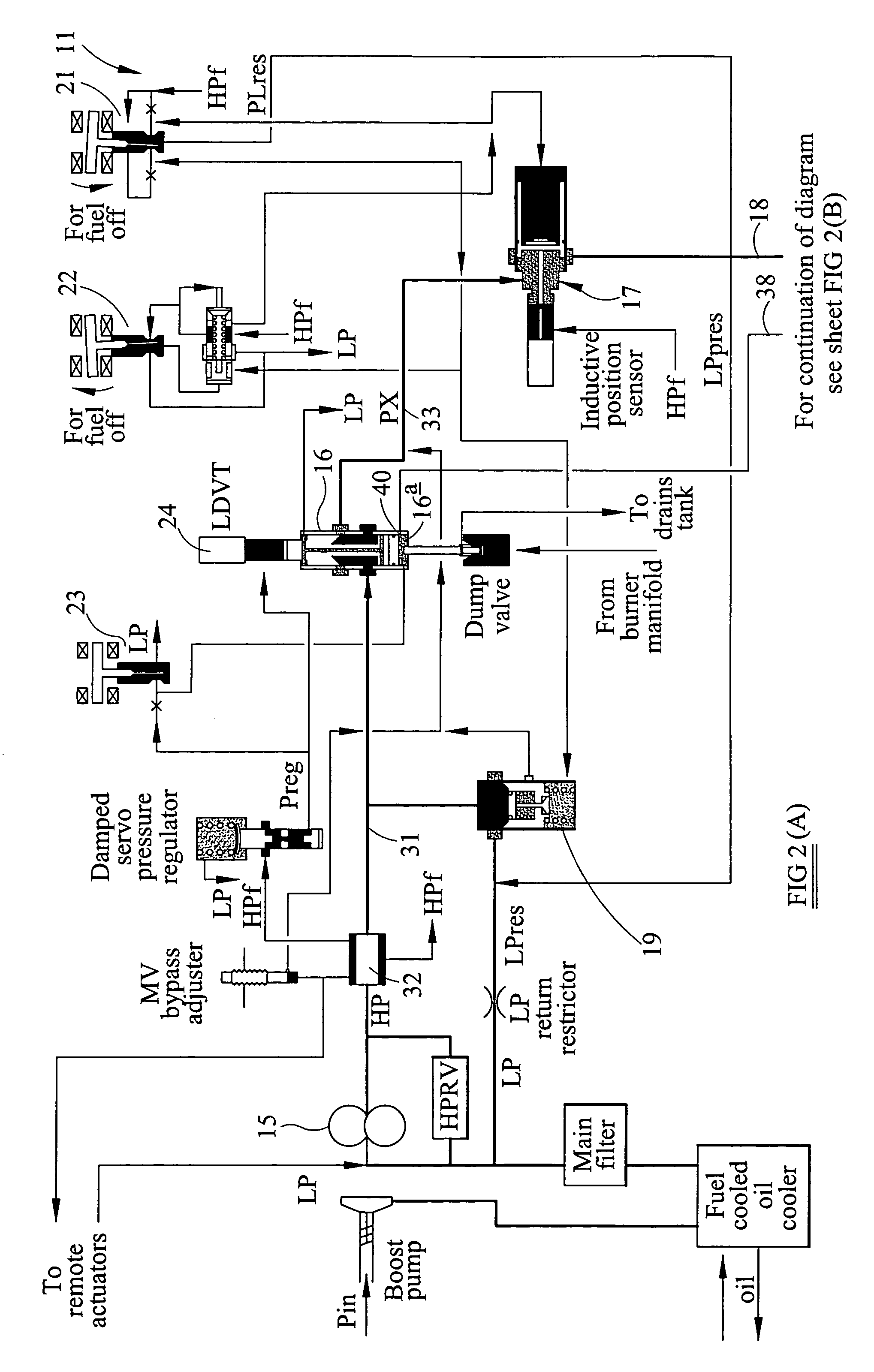

Fuel system

InactiveUS7137242B2Reduce the amount requiredFuel supply regulationLiquid fuel feeder/distributionCombustorControl system

A fuel control system for a staged combustion engine comprising, a fuel metering unit including a fuel metering valve having a fuel metering orifice the opening of which is varied to meter the flow of fuel through the metering valve in use, a fuel staging unit receiving fuel from the metering valve of the fuel metering unit and incorporating a staging valve for dividing the flow of fuel from the fuel metering unit to pilot burner and main burner output lines, a connection between a fuel pressure region of said fuel metering unit and a port of said staging valve, and, overthrust detection means causing said staging valve, in response to overthrust detection, to connect said port of said staging valve to low pressure, whereby to drain fuel under pressure from said pressure zone of said fuel metering unit to low pressure to limit or reduce the fuel supplied from the fuel metering unit to the fuel staging unit and thus to the engine in use.

Owner:GOODRICH CONTROL SYST LTD

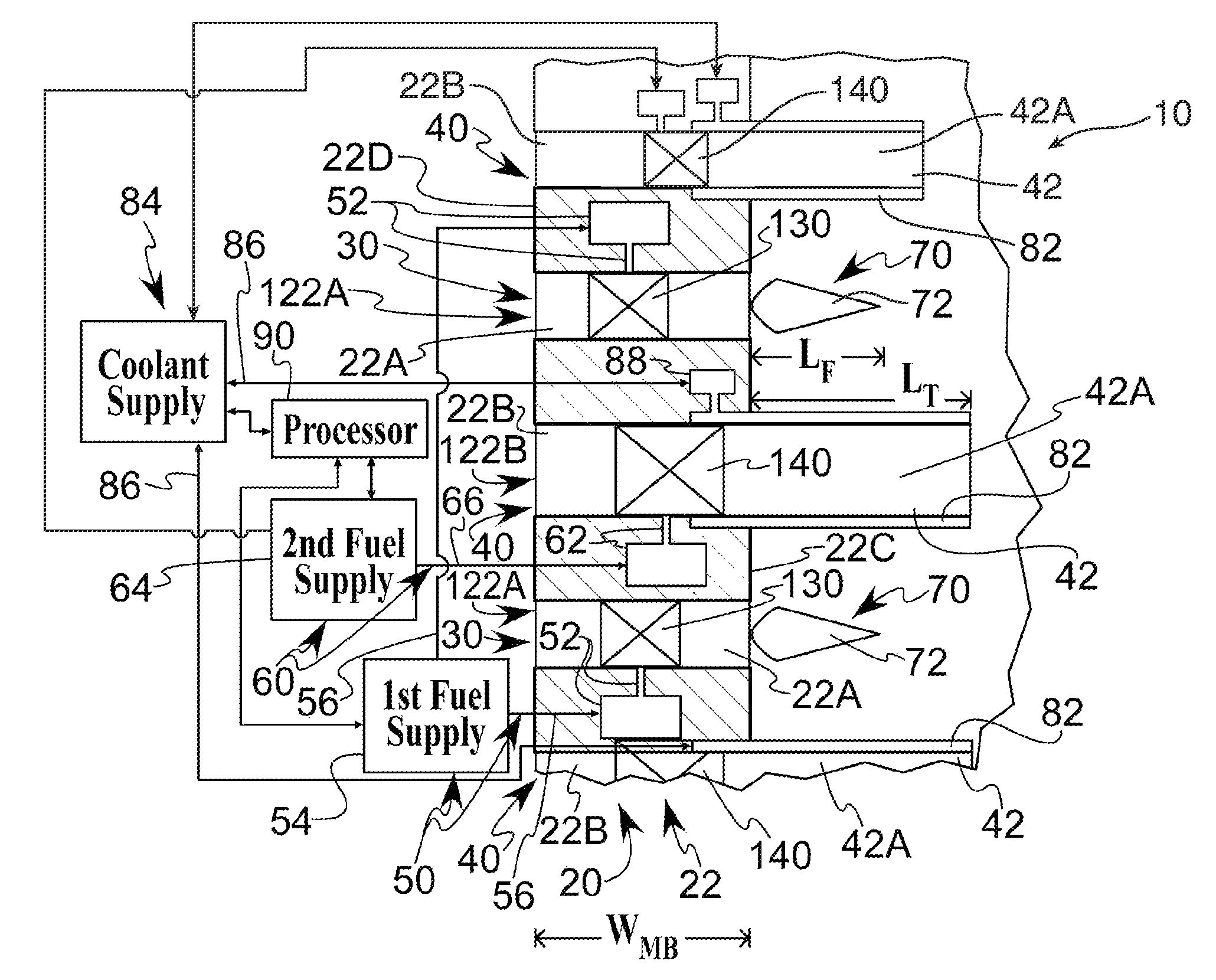

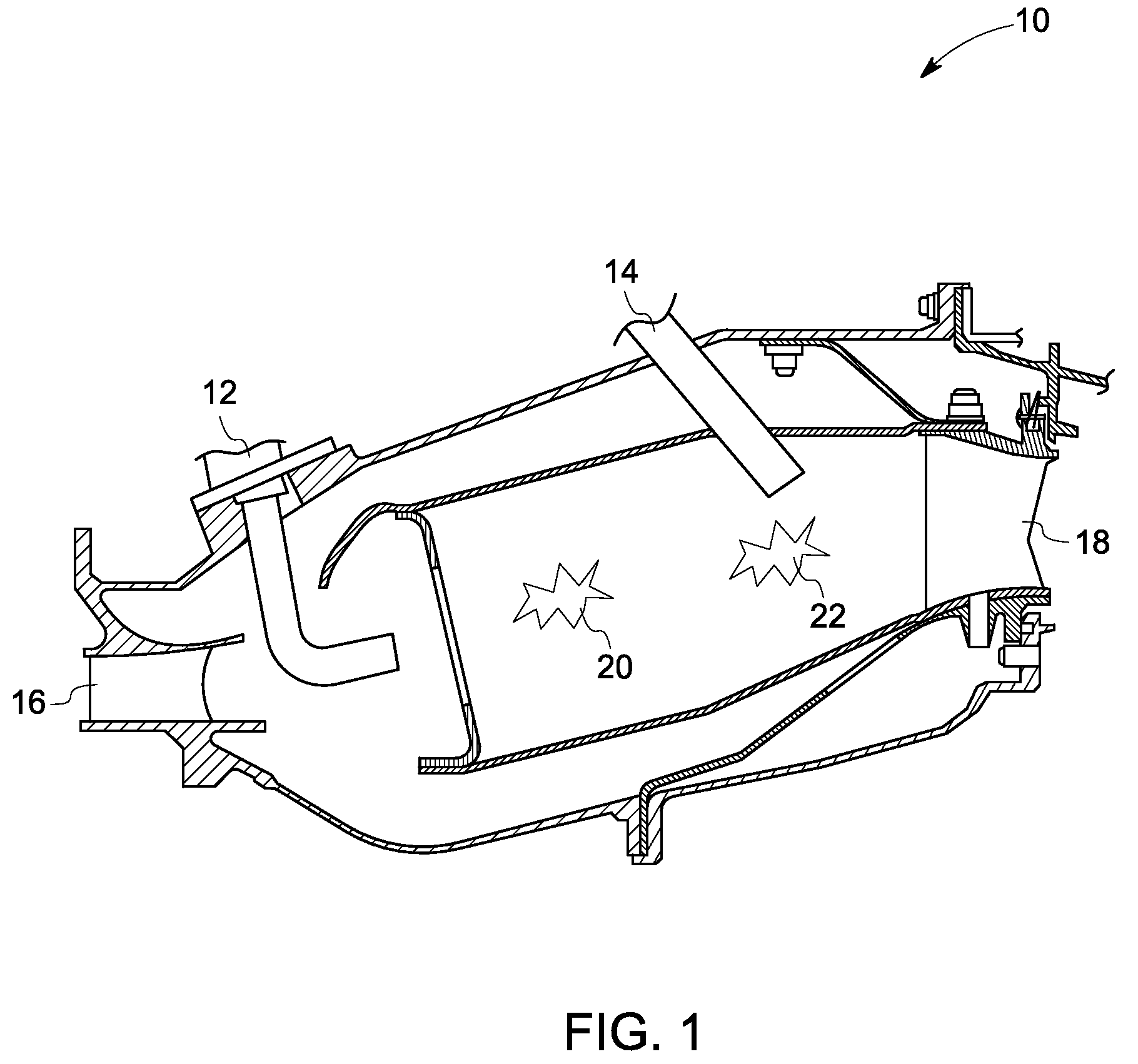

Gas turbine combustor having staged burners with dissimilar mixing passage geometries

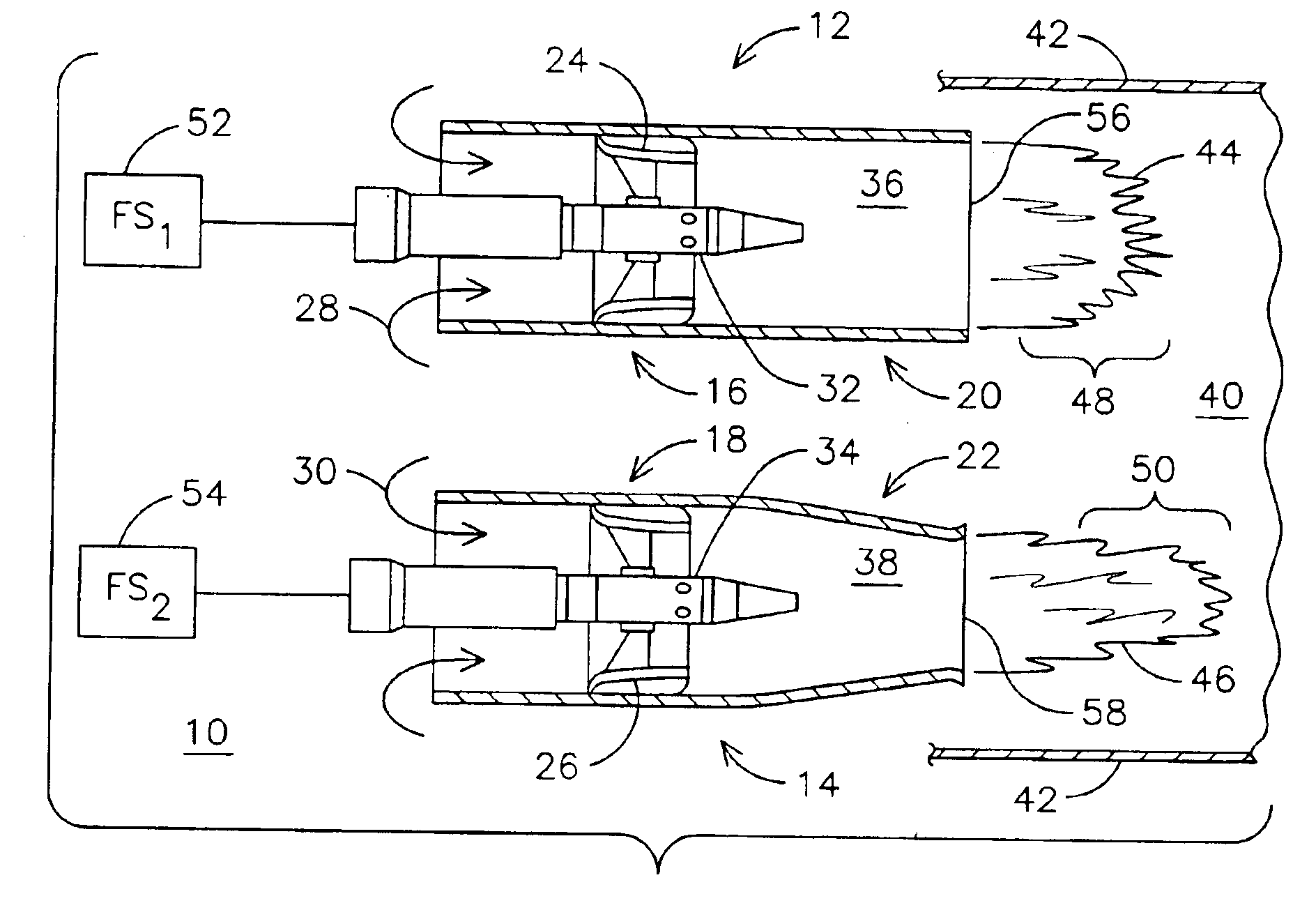

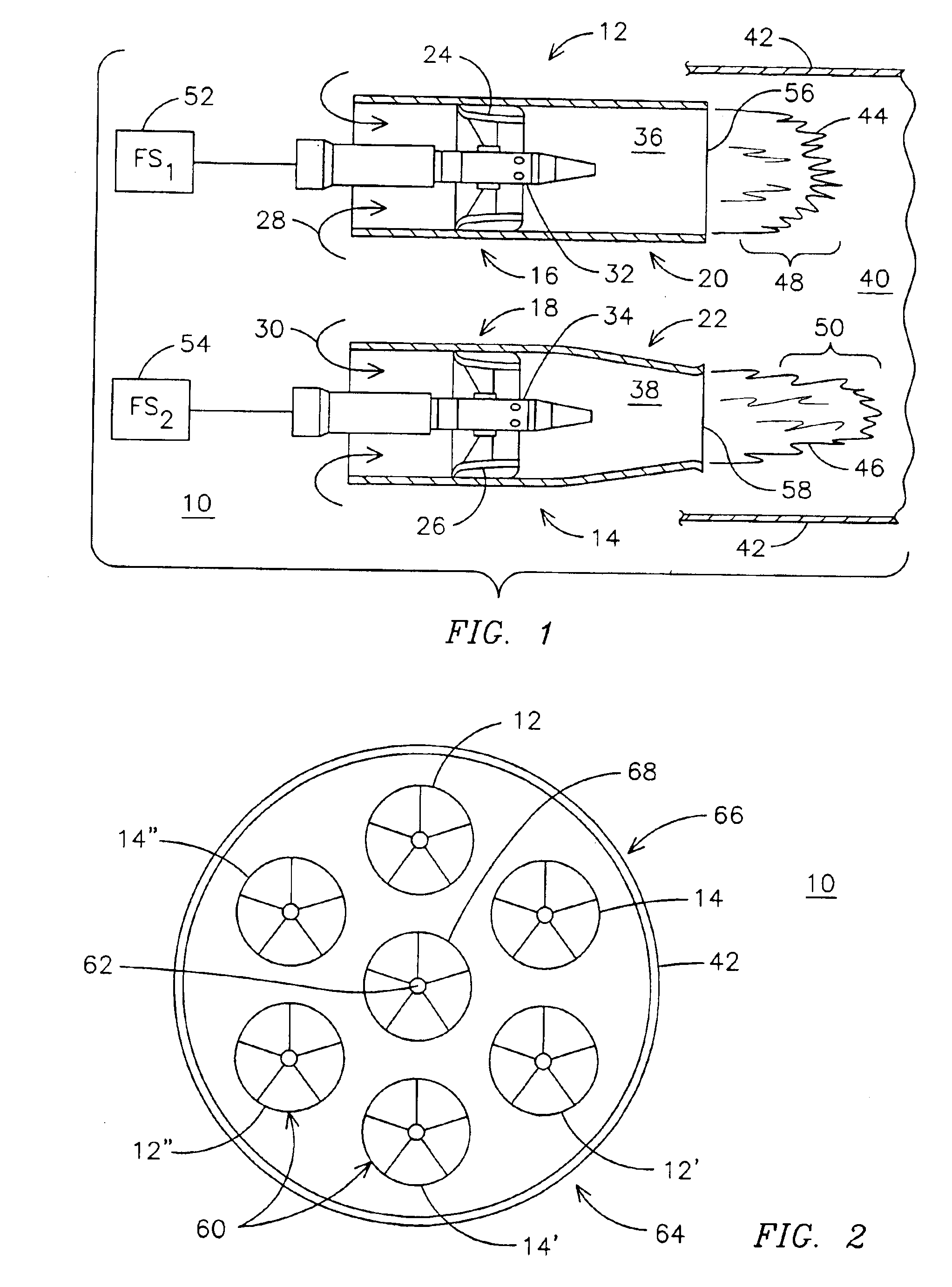

A gas turbine combustor (10) having a first grouping (64) of pre-mix burners (12, 12′, 12″) having mixing passages (36) that are geometrically different than the mixing passages (38) of a second grouping (66) of pre-mix burners (14, 14′, 14″). The aerodynamic differences created by these geometric differences provide a degree of control over combustion properties of the respective flames (44, 46) produced in a downstream combustion chamber (40) when the two groupings of burners are fueled by separate fuel stages (52, 54). The geometric difference between the fuel passages of the two groupings may be outlet diameter, slope of convergence of the passage diameter, or outlet contour. The fuel injection regions (16, 18) of all of the burners may be identical to reduce cost and inventory complexity. The burners may be arranged in a ring (60) with a center pre-mix burner (68) being identical to burners of either of the groupings.

Owner:SIEMENS ENERGY INC

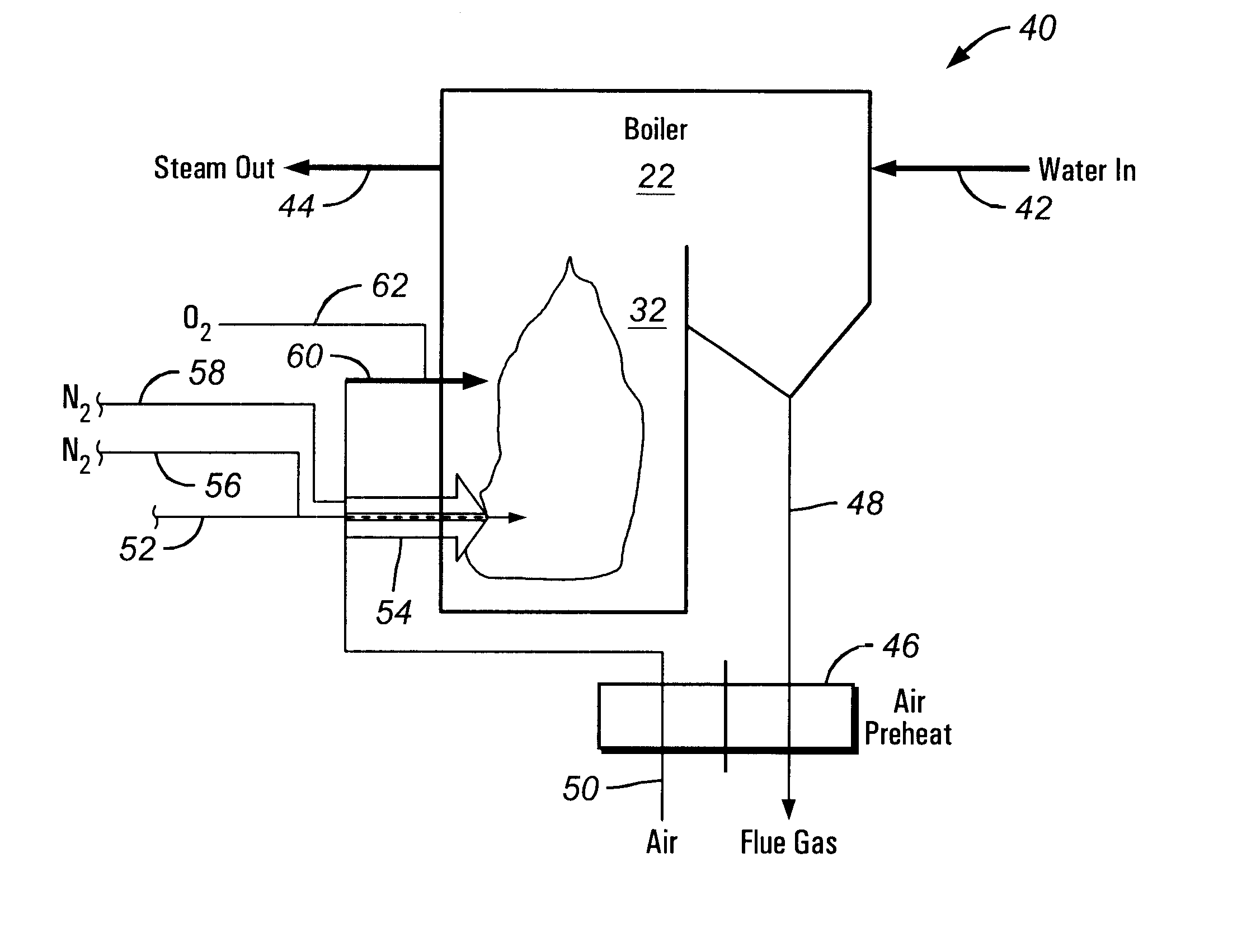

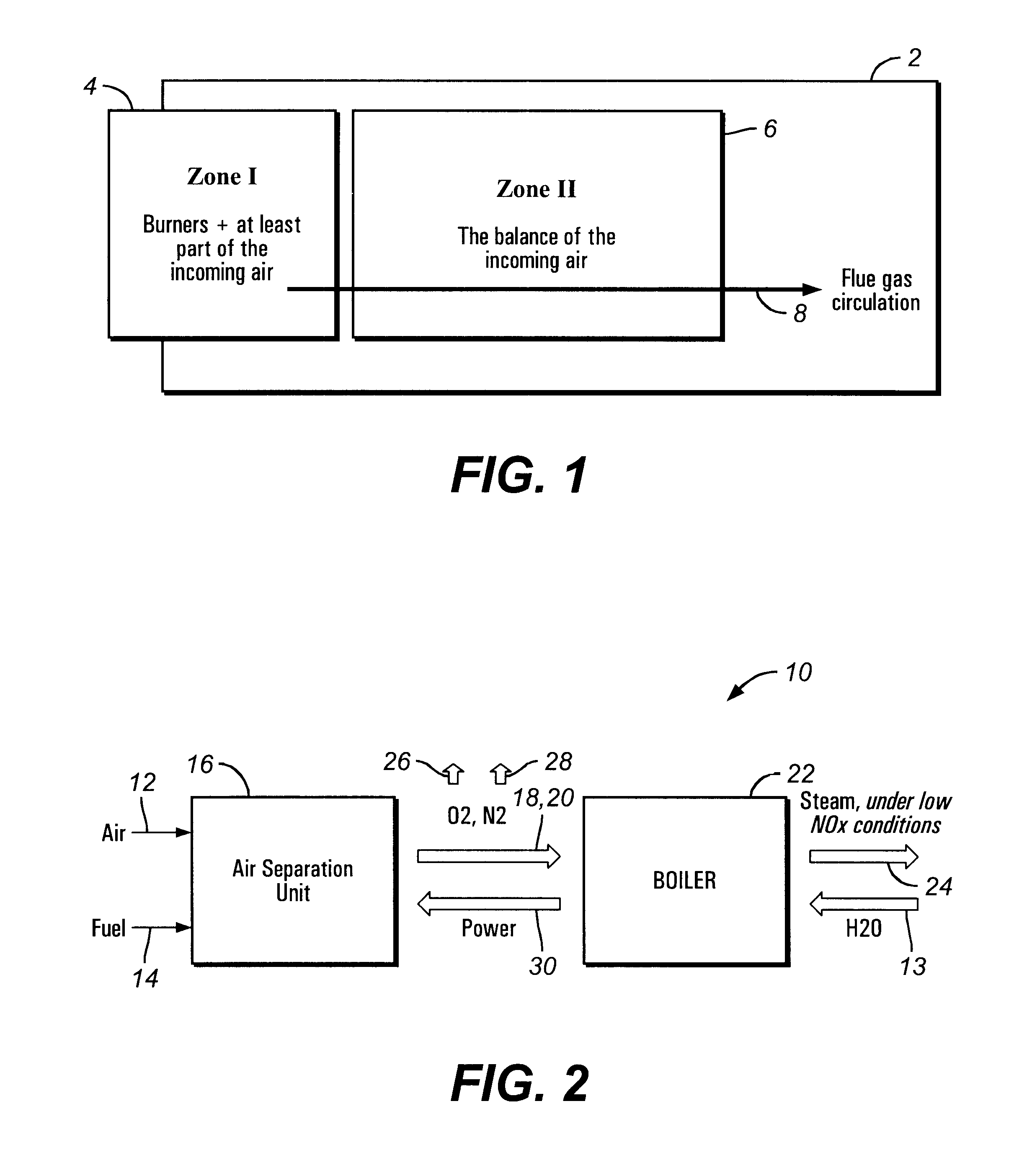

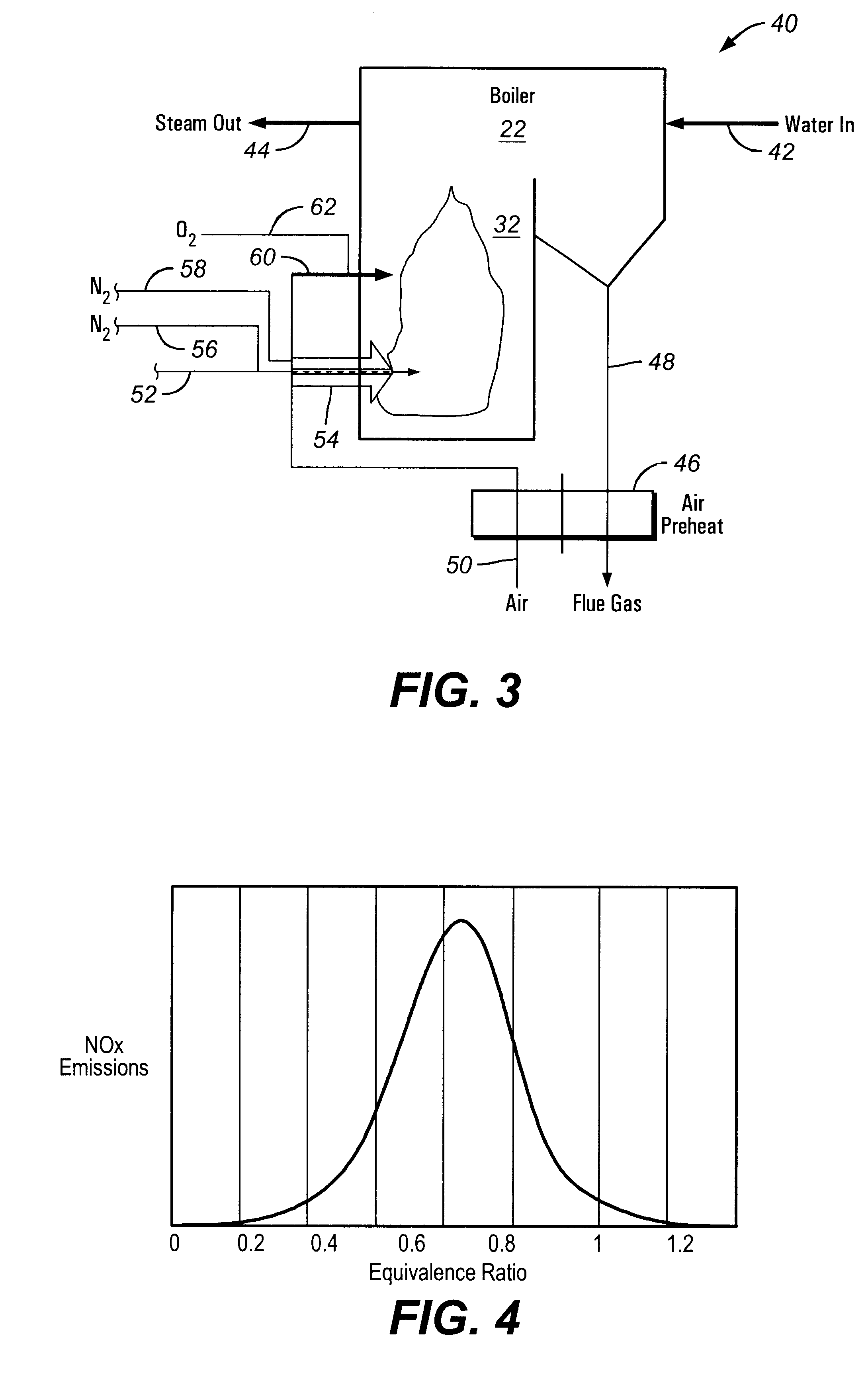

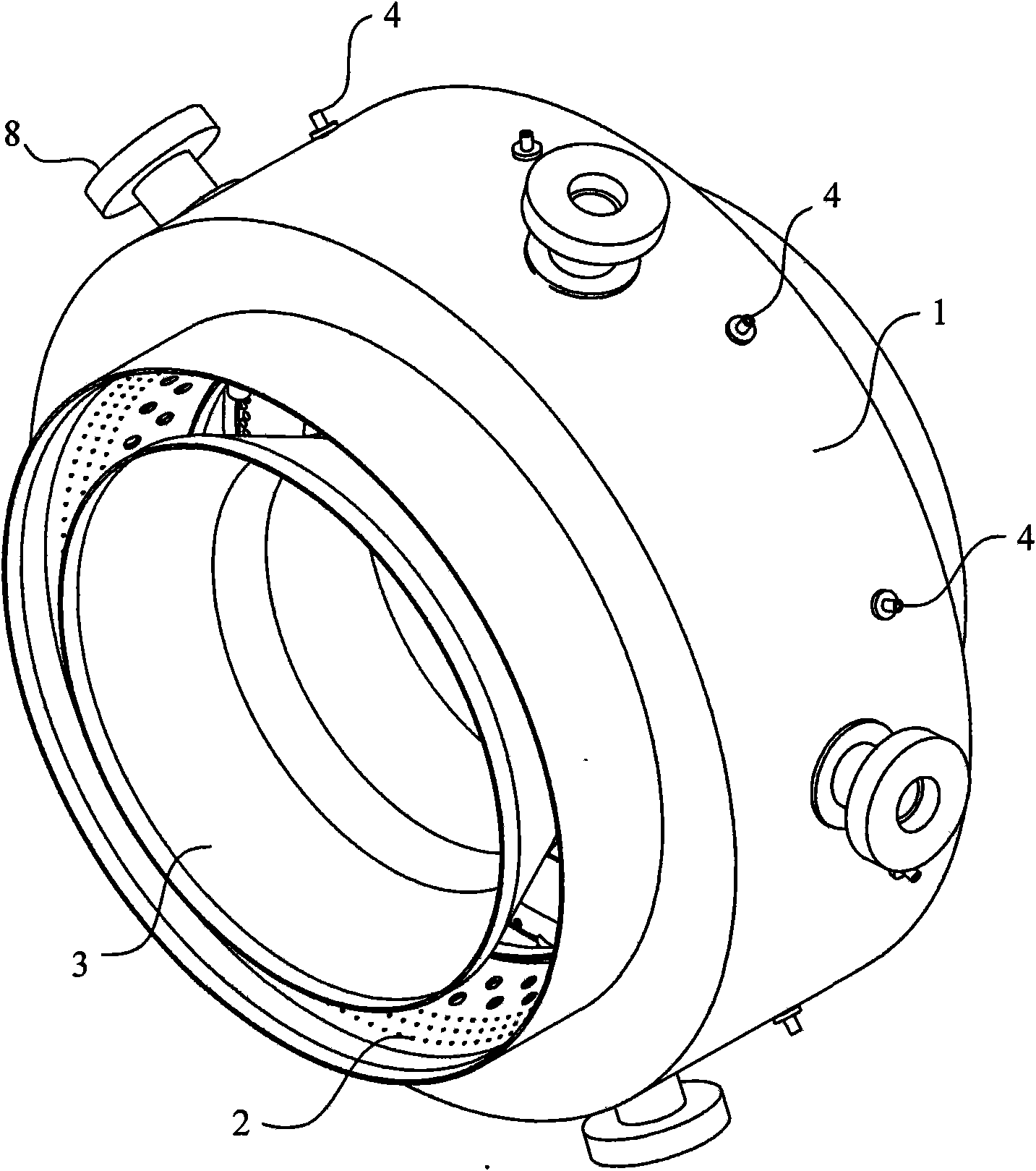

Combination air separation and steam-generation processes and plants therefore

InactiveUS6568185B1Low quality scoreIncreases adiabatic temperature of flameSolidificationLiquefactionNitrogenAir separation

This invention proposes innovative techniques of NOx reduction in boiler operation through an adaptation of staged combustion in combustion boilers. In preferred processes, air is fed into an air separation unit, and a nitrogen-enriched stream is combined with air to produce a nitrogen-enriched first stage air stream, and at least a portion of an oxygen-enriched stream is mixed with air to produce an oxygen-enriched second stage air stream. A reduction in NOx and increase in efficiency is promoted by the inventive processes and systems.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

Double-vortex combustion chamber

InactiveCN101566353AReduce weightImprove combustion efficiencyContinuous combustion chamberCombustion chamberEngineering

The invention discloses a double-vortex combustion chamber which adopts a full ring shaped flame tube structure and comprises a shell, an inner flame tube and an outer flame tube. The outer wall of the outer flame tube and the inner wall of the shell form a cooling cavity channel; the inner wall of the outer flame tube and the outer wall of the inner flame tube form a combustion channel; oil injection pipes and an igniting seat are arranged on the periphery of the shell; the outer flame tube is an integral forming part, the first section thereof is a diffusion section which adopts a constant pressure gradient design, and the second section thereof is provided with two rows of advancing air holes at the edge of the front wall of a recessed cavity, an evaporating pipe extends into the recessed cavity along the periphery direction of the recessed cavity and close to the inner side of the front wall of the recessed cavity, and the back wall of the recessed cavity is provided with a back air inlet duct at the half height; the third section is provided with an air film cooling air inlet port and an air film cooling air inlet baffle; and the fourth section is provided with a blending hole and a diffusion cooling hole. The double-vortex structure formed in the recessed cavity of the double-vortex combustion chamber improves the distribution of a fuel concentration field, realizes fractional combustion, increases the residence time of fuel combustion, reduces the pollutant discharge and ensures the outlet temperature to be more uniform.

Owner:BEIHANG UNIV

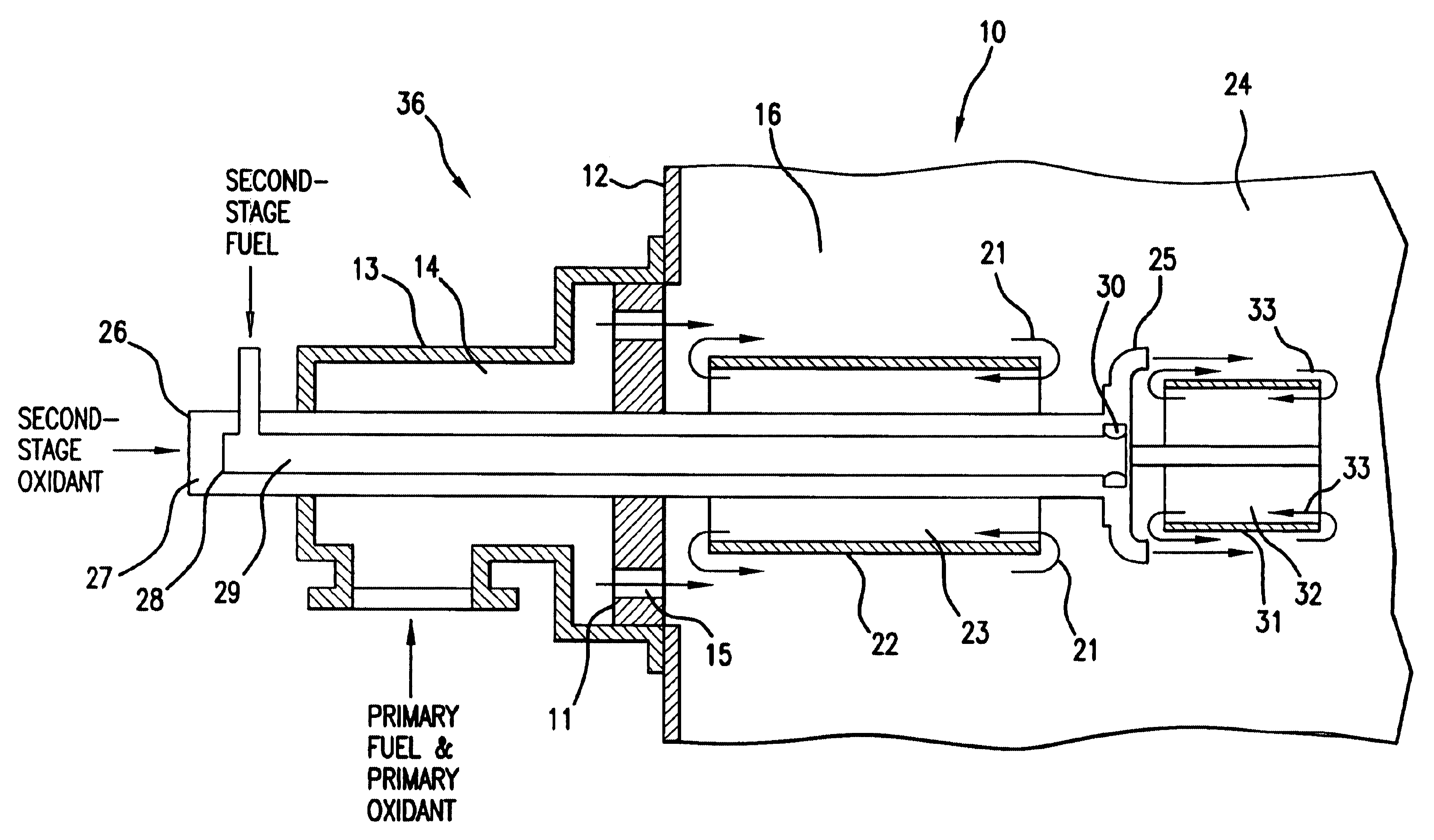

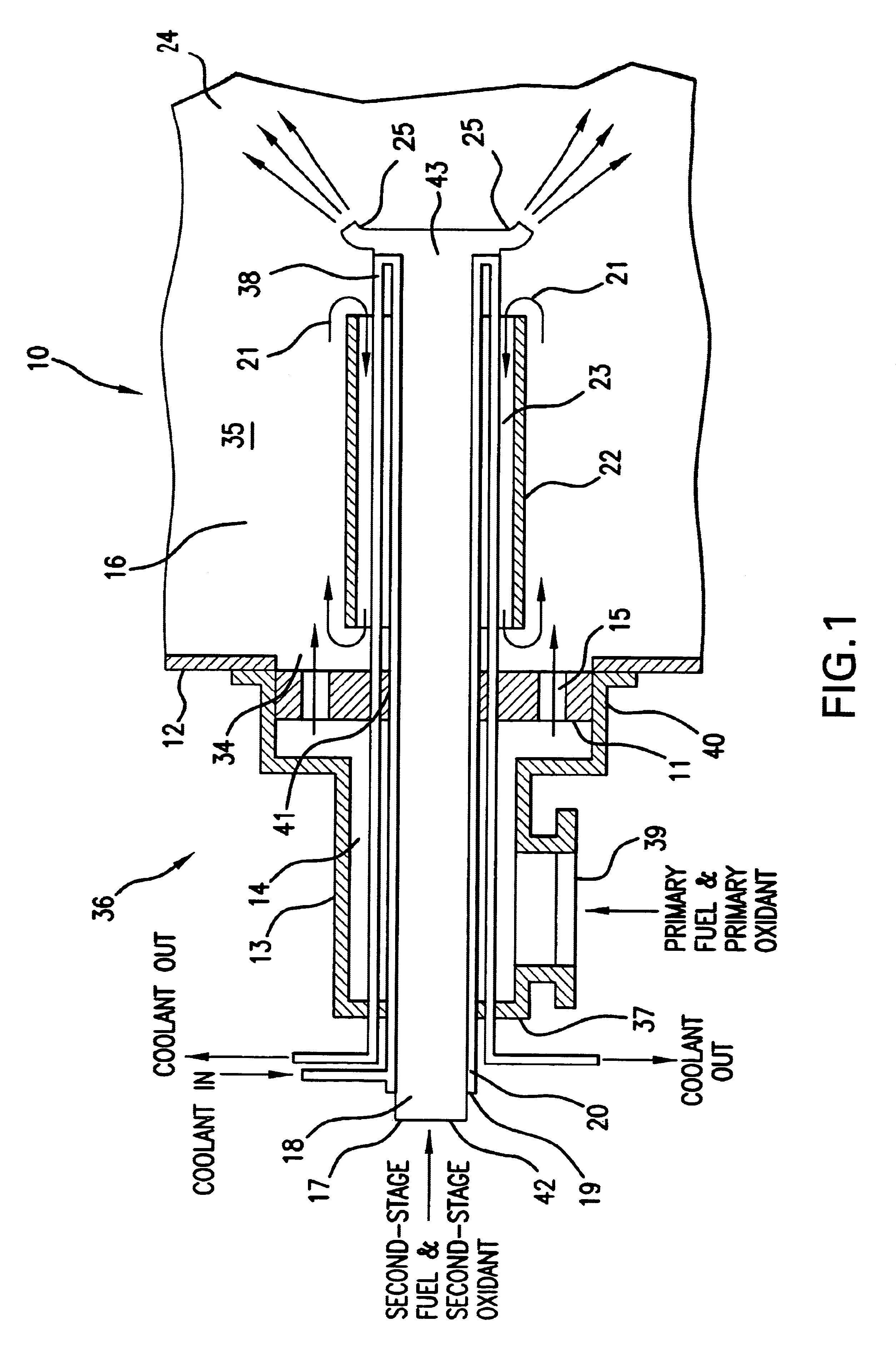

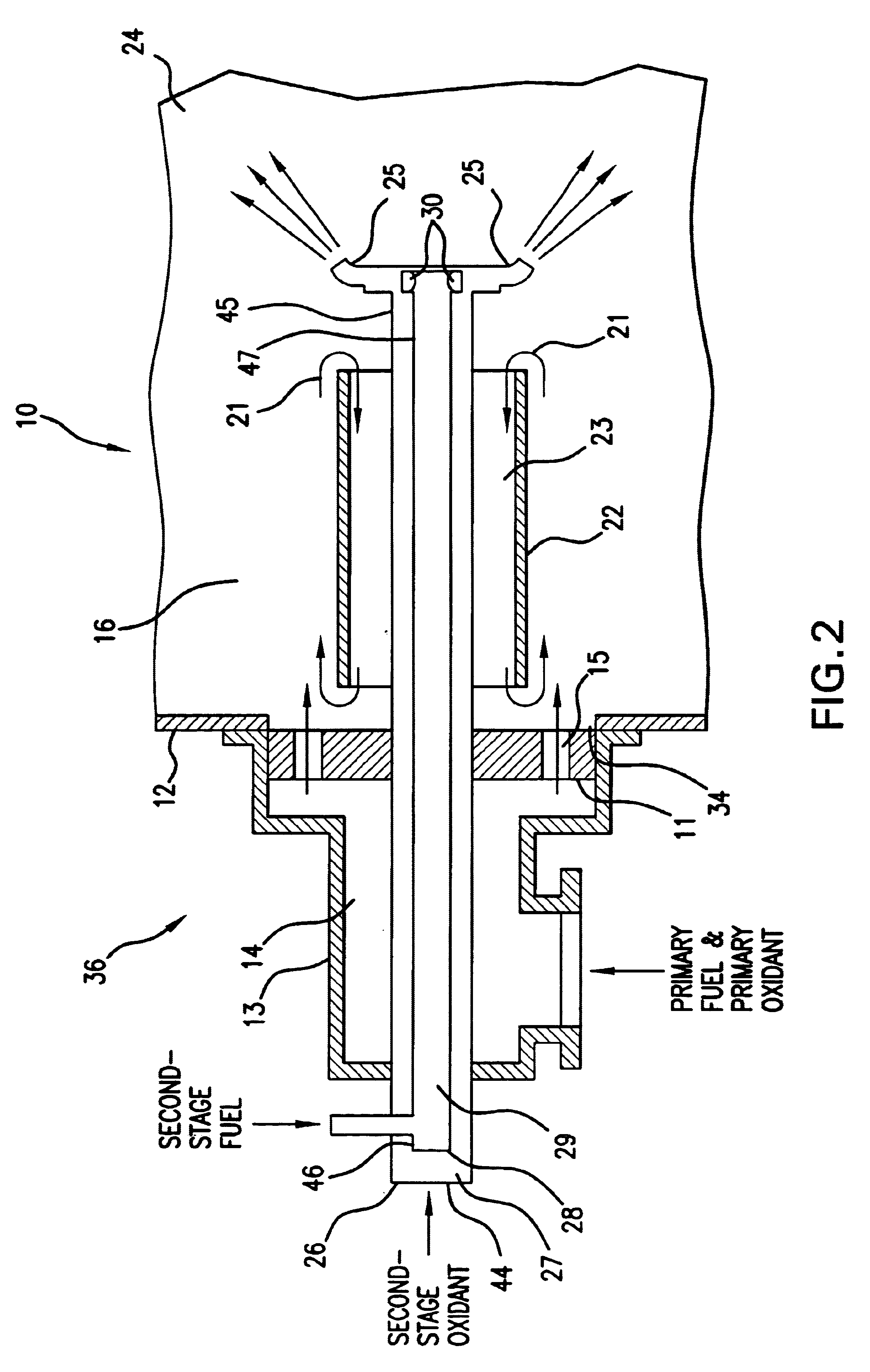

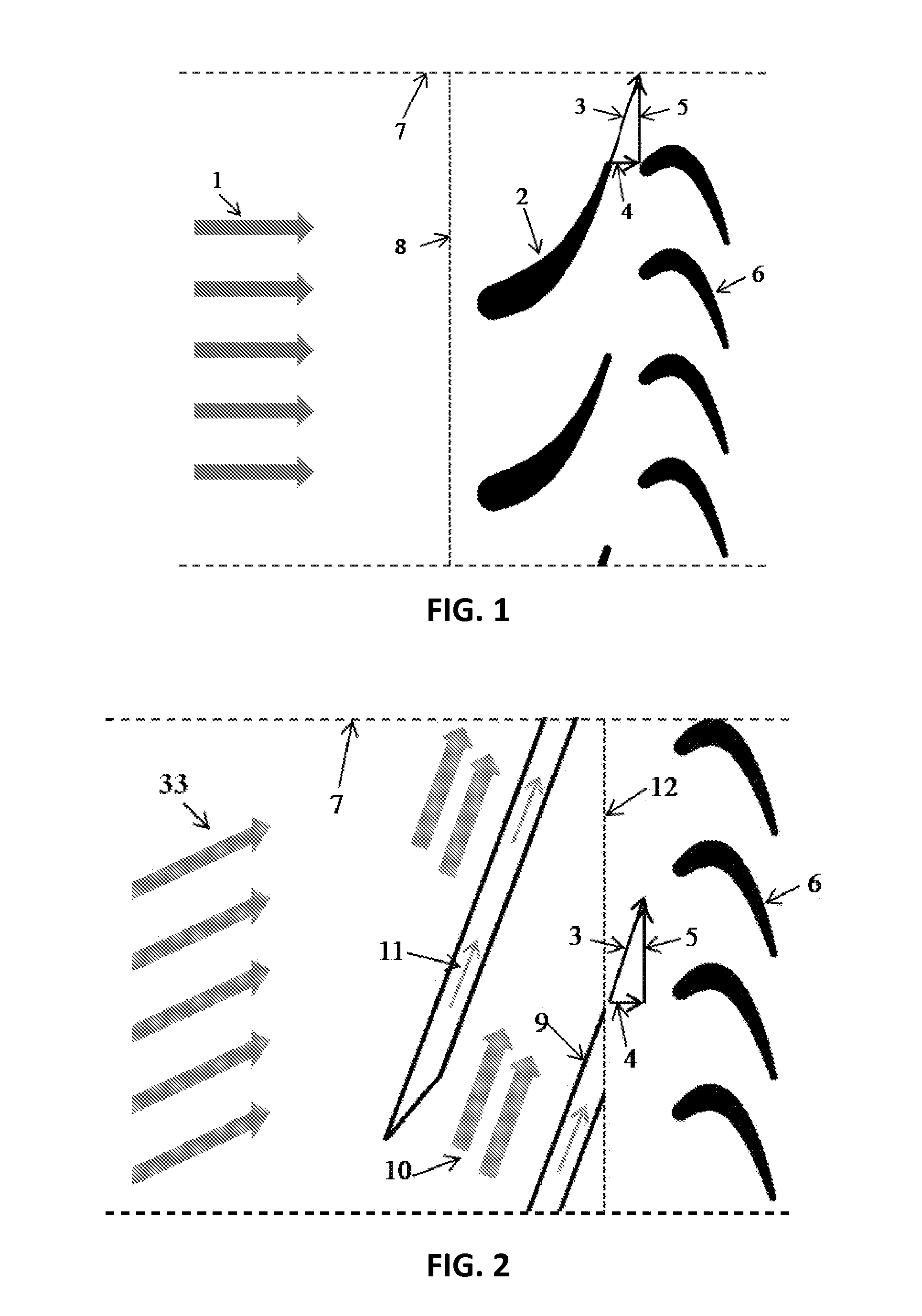

Method and apparatus for advanced staged combustion utilizing forced internal recirculation

InactiveUS6663380B2Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberEngineering

A method and apparatus for combustion of a fuel in which a first-stage fuel and a first-stage oxidant are introduced into a combustion chamber and ignited, forming a primary combustion zone. At least about 5% of the total heat output produced by combustion of the first-stage fuel and the first-stage oxidant is removed from the primary combustion zone, forming cooled first-stage combustion products. A portion of the cooled first-stage combustion products from a downstream region of the primary combustion zone is recirculated to an upstream region of primary combustion zone. A second-stage fuel is introduced into the combustion chamber downstream of the primary combustion zone and ignited, forming a secondary combustion zone. At least about 5% of the heat from the secondary combustion zone is removed. In accordance with one embodiment, a third-stage oxidant is introduced into the combustion chamber downstream of the secondary combustion zone, forming a tertiary combustion zone.

Owner:GAS TECH INST

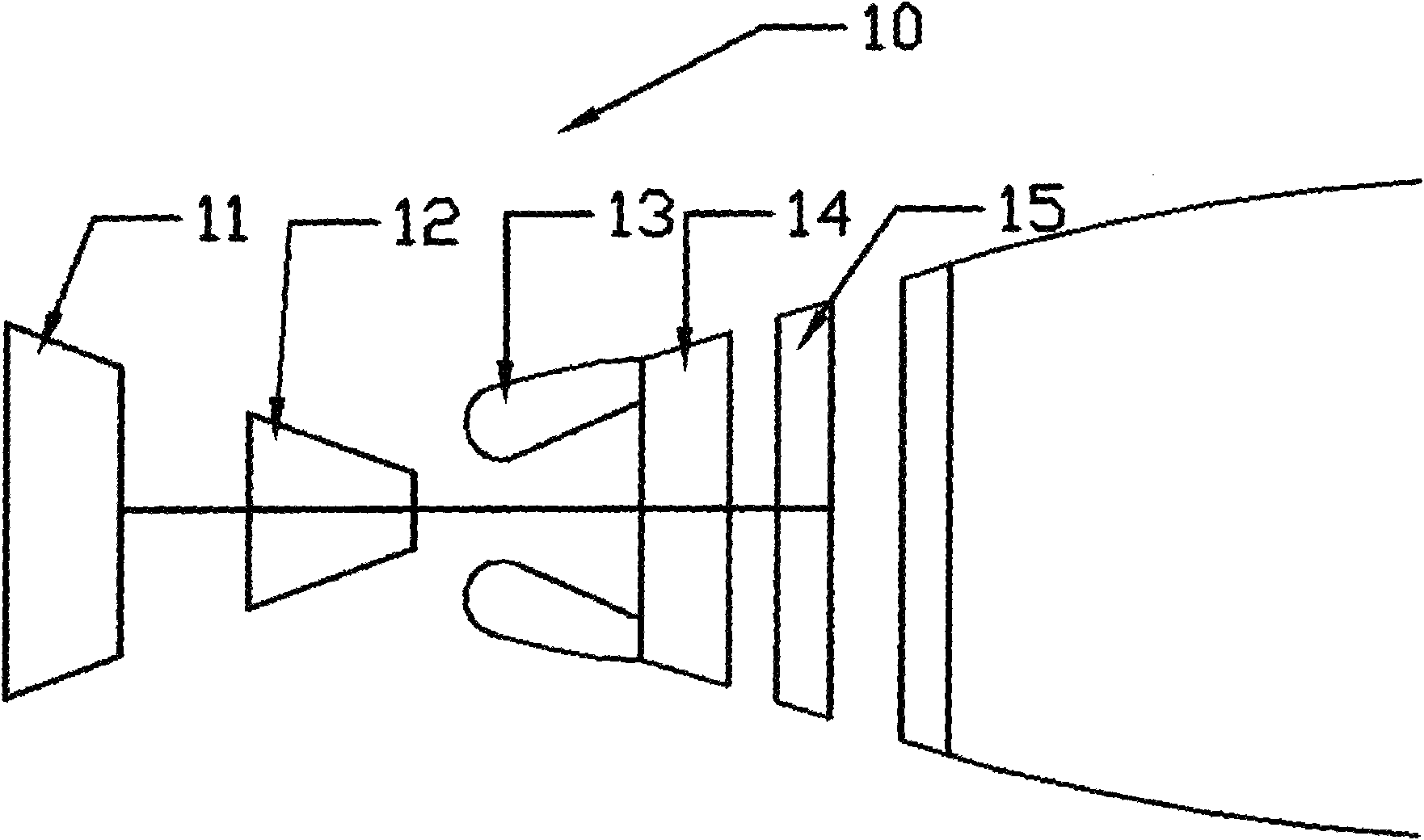

Axially staged combustion system for a gas turbine engine

Owner:SIEMENS ENERGY INC

Combination combustion chamber

ActiveCN105953265AEnhanced blendingImprove flame stabilityContinuous combustion chamberCycloneCombustion instability

The invention relates to a combination combustion chamber. A combustion chamber head part consists of a main combustion stage and a pre-combustion stage; the main combustion stage consists of a single-grade axial cyclone, a main combustion stage nozzle and a venturi pipe; and the pre-combustion stage consists of double concave cavities and a pre-combustion stage nozzle. The main combustion stage adopts a single-oil-way centrifugal nozzle, and enables fuel to reach needed concentration and particle size distribution through pressure atomization. The pre-combustion stage adopts an evaporation pipe type nozzle; and the fuel is sprayed to an evaporation pipe for primary atomization through a straight spraying nozzle, and performs secondary atomization and evaporation mixing in the evaporation pipe under an air shearing effect. The combination combustion chamber not only can achieve the purpose of reducing the pollutant discharge in a low-pollution combustion chamber, but also can solve the problems of small-state combustion instability and large-stage visible smoke in a high-temperature-rise combustion chamber so as to widen stable working range of the high-temperature-rise combustion chamber through classified combustion, in particular special structural design and arrangement mode of the pre-combustion stage and the main combustion stage.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Ultra-low-NOx gas burner

The invention relates to an ultra-low-NOx gas burner. The ultra-low-NOx gas burner comprises a central drum, a swirler, a gas gun group, a throat opening, a front panel and a shell; the swirler is arranged at a connector of the central drum, the throat opening and the shell are coaxially arranged on the periphery of the central drum, the gas gun group is composed of multiple inter gas guns, multiple middle gas guns and multiple outer gas guns, and the front panel is provided with opposite penetrating gas flow holes and outer gas gun nozzle containing holes; a central drum cavity is a center combustion-supporting air passage, an annular cavity between the central drum and the throat opening is a direct-current combustion-supporting air passage, and an annular cavity between the periphery of the throat opening and the shell is a cooling air passage; the inner gas guns and the middle gas guns are arranged in the direct-current combustion-supporting air passage, and the outer gas guns are arranged in the cooling air passage. In the working process, due to the fact that gas sprayed from the middle gas guns is transition gas, segmented configuration and staged combustion are achieved, sufficient combustion of the gas in the dispersed state can be achieved, the content of oxygen in a furnace hearth is effectively diluted, the emission amount of NOx is decreased to below 10 ppm, and CO is not generated.

Owner:SHANGHAI WISEBOND TECH

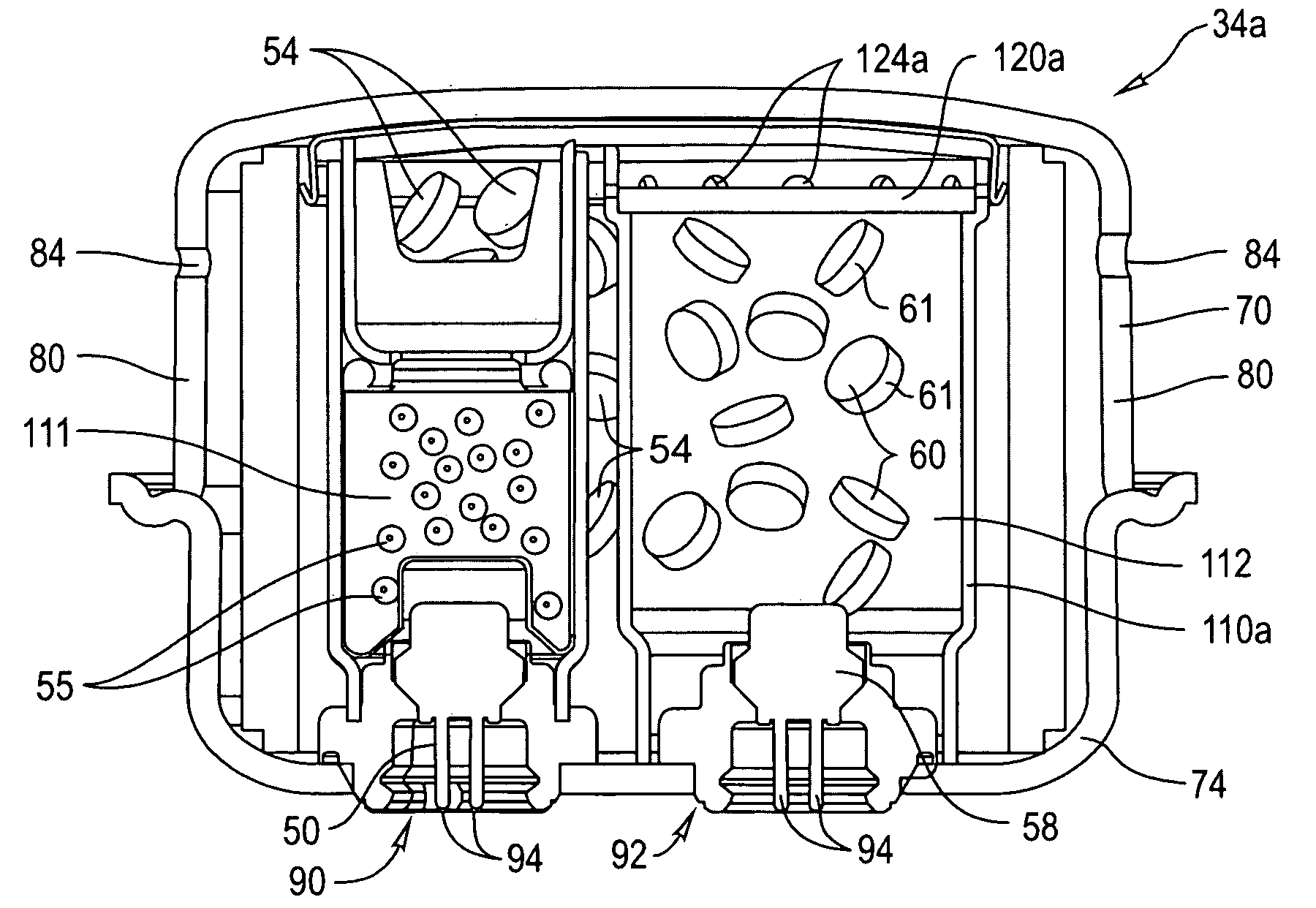

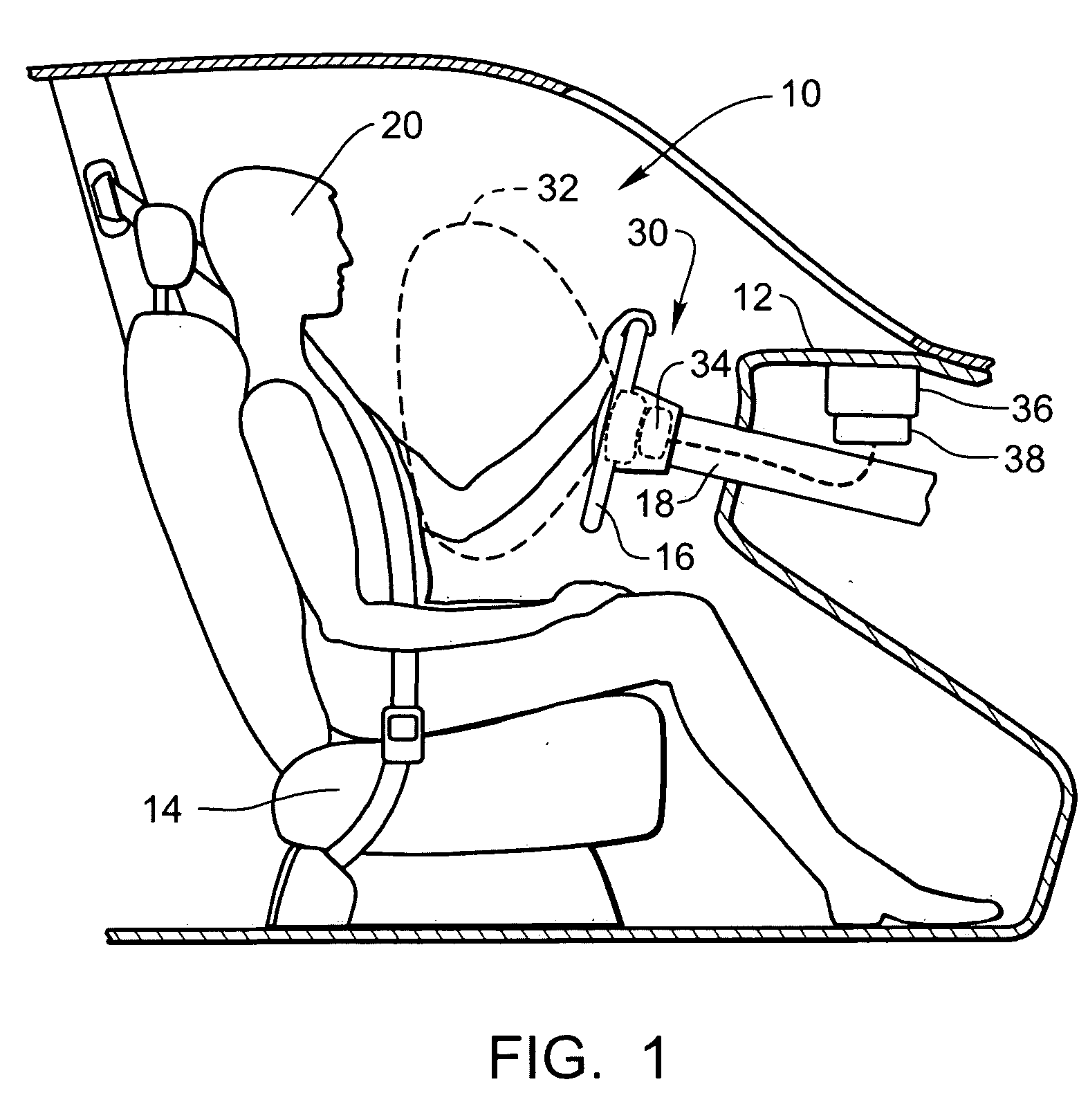

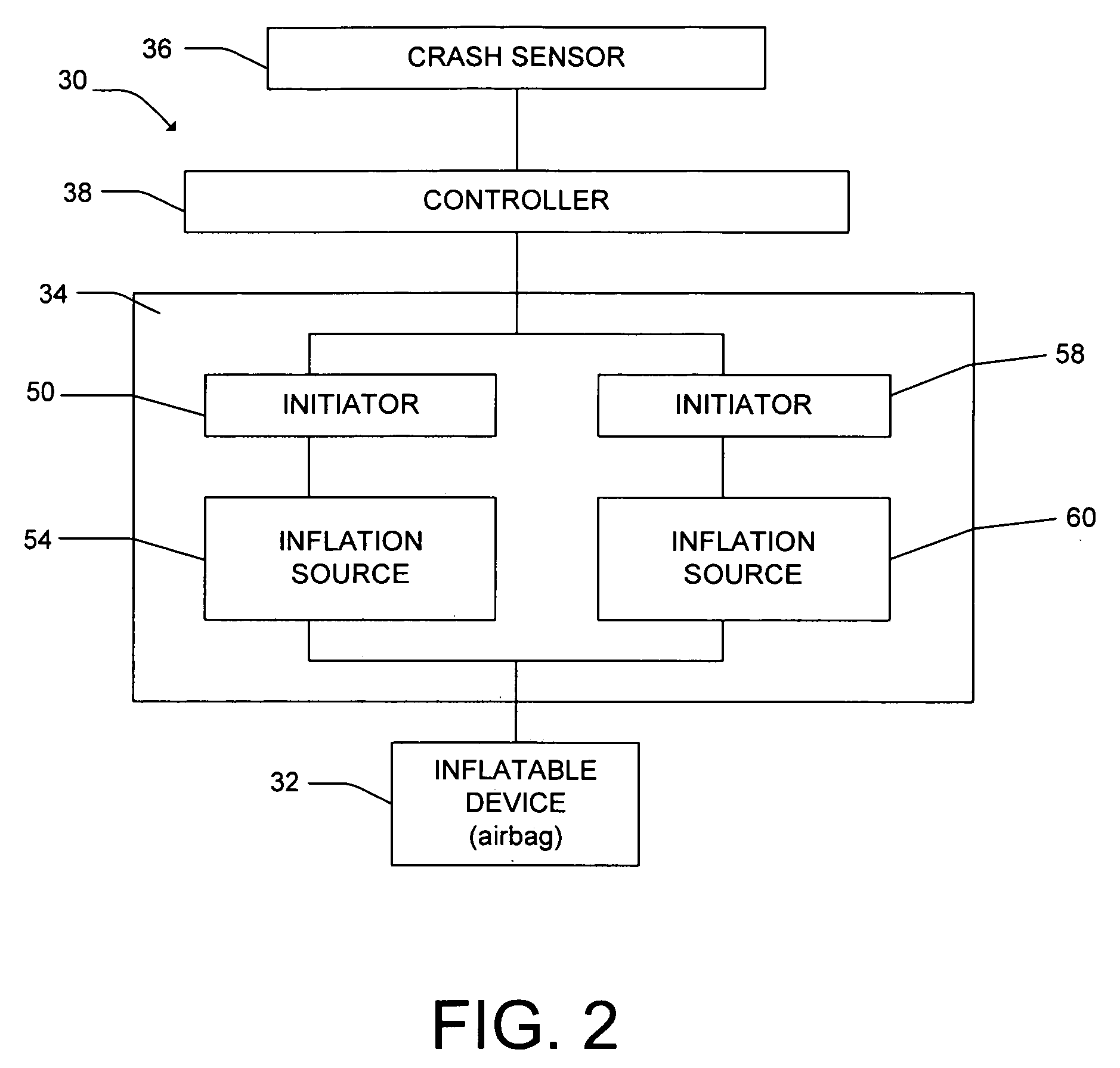

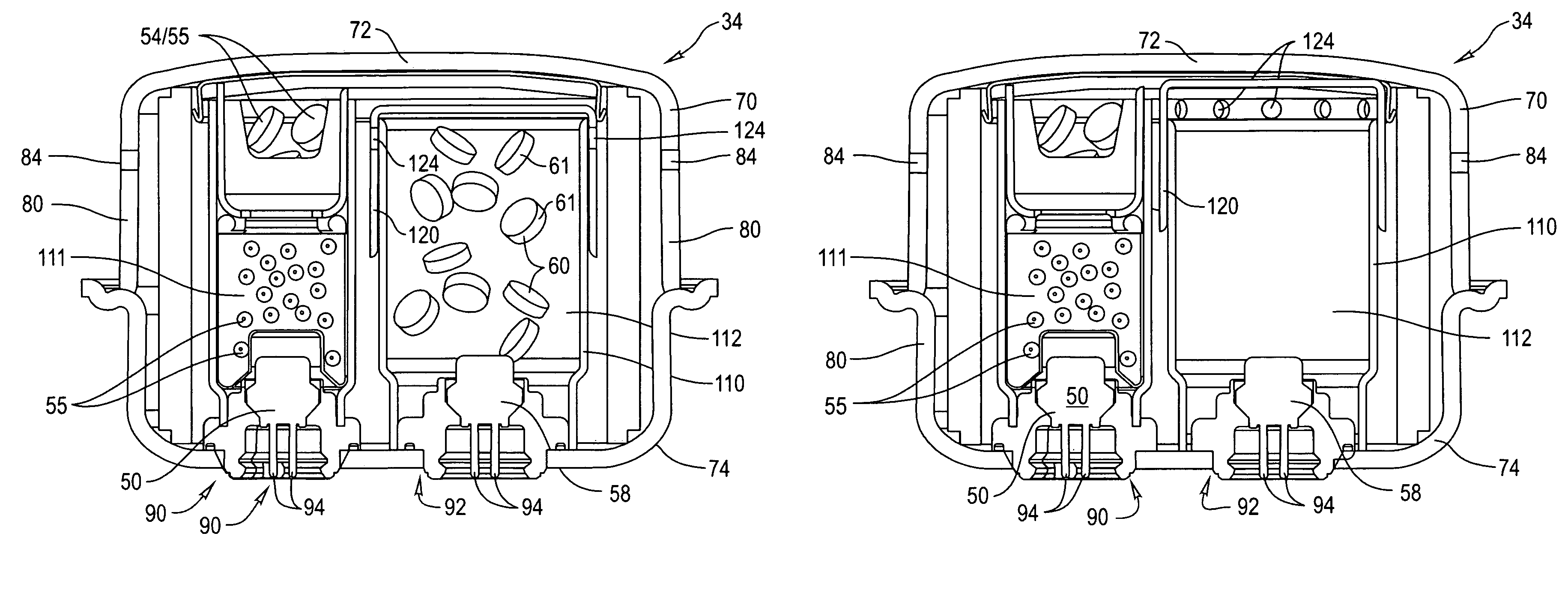

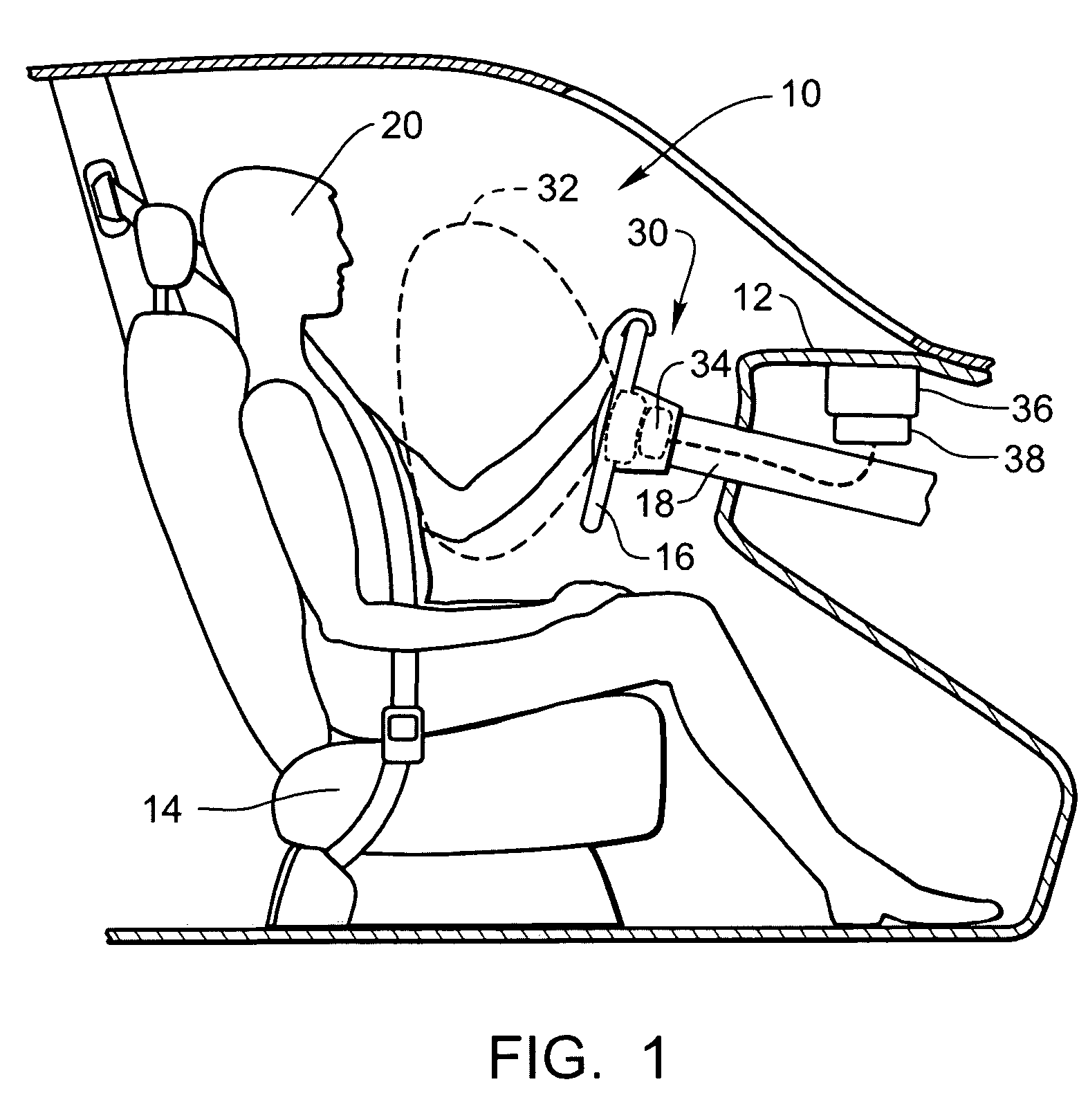

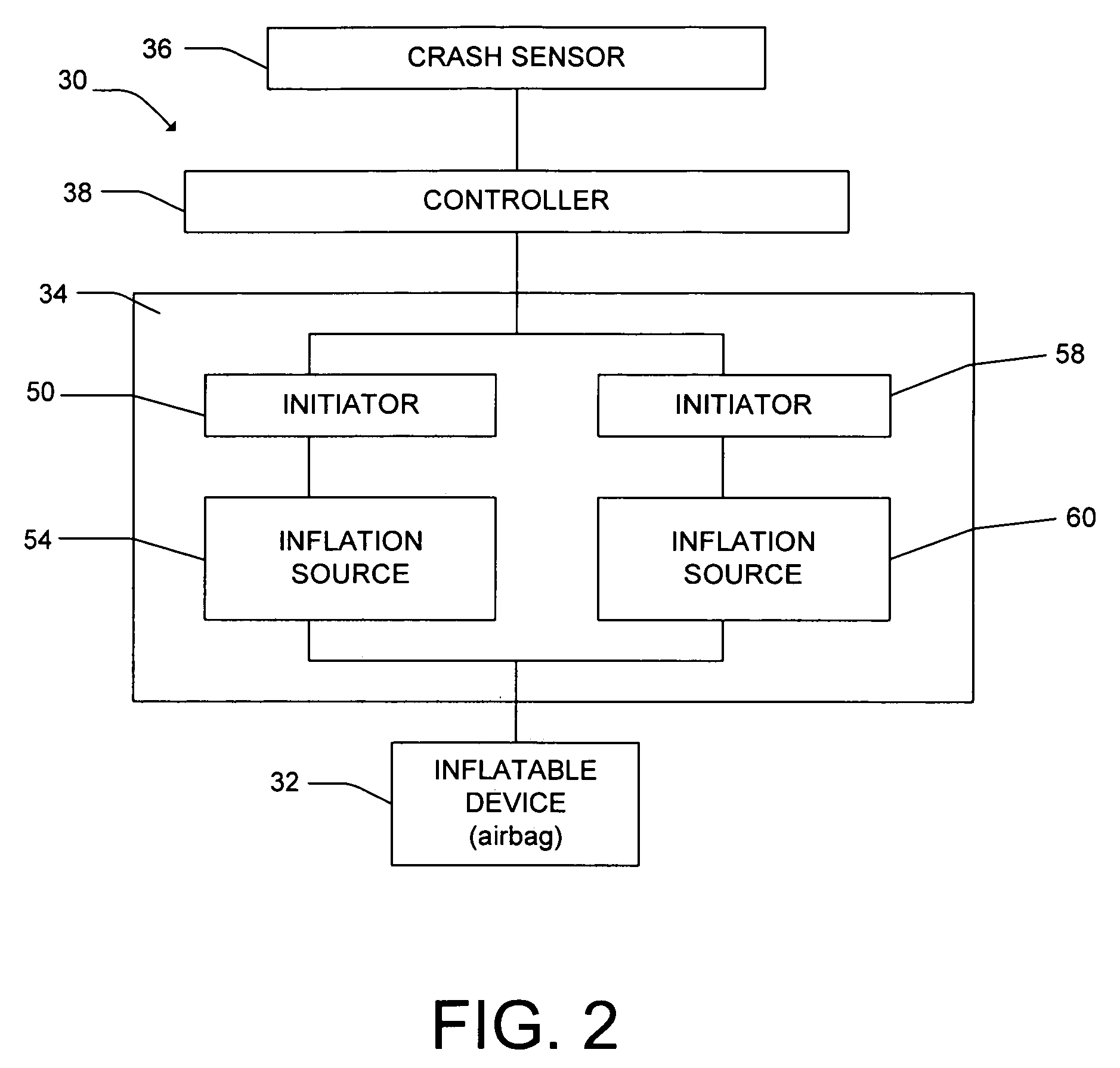

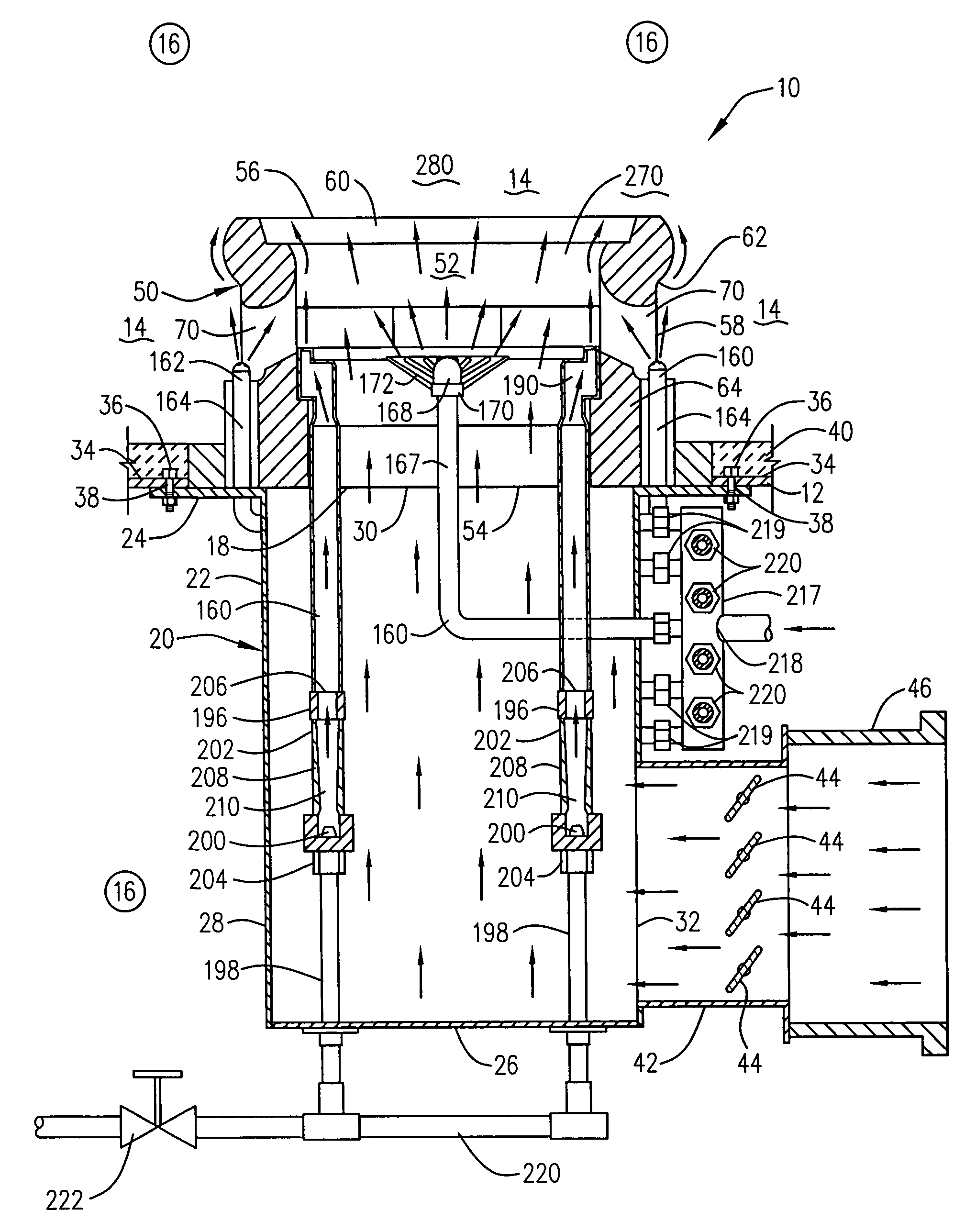

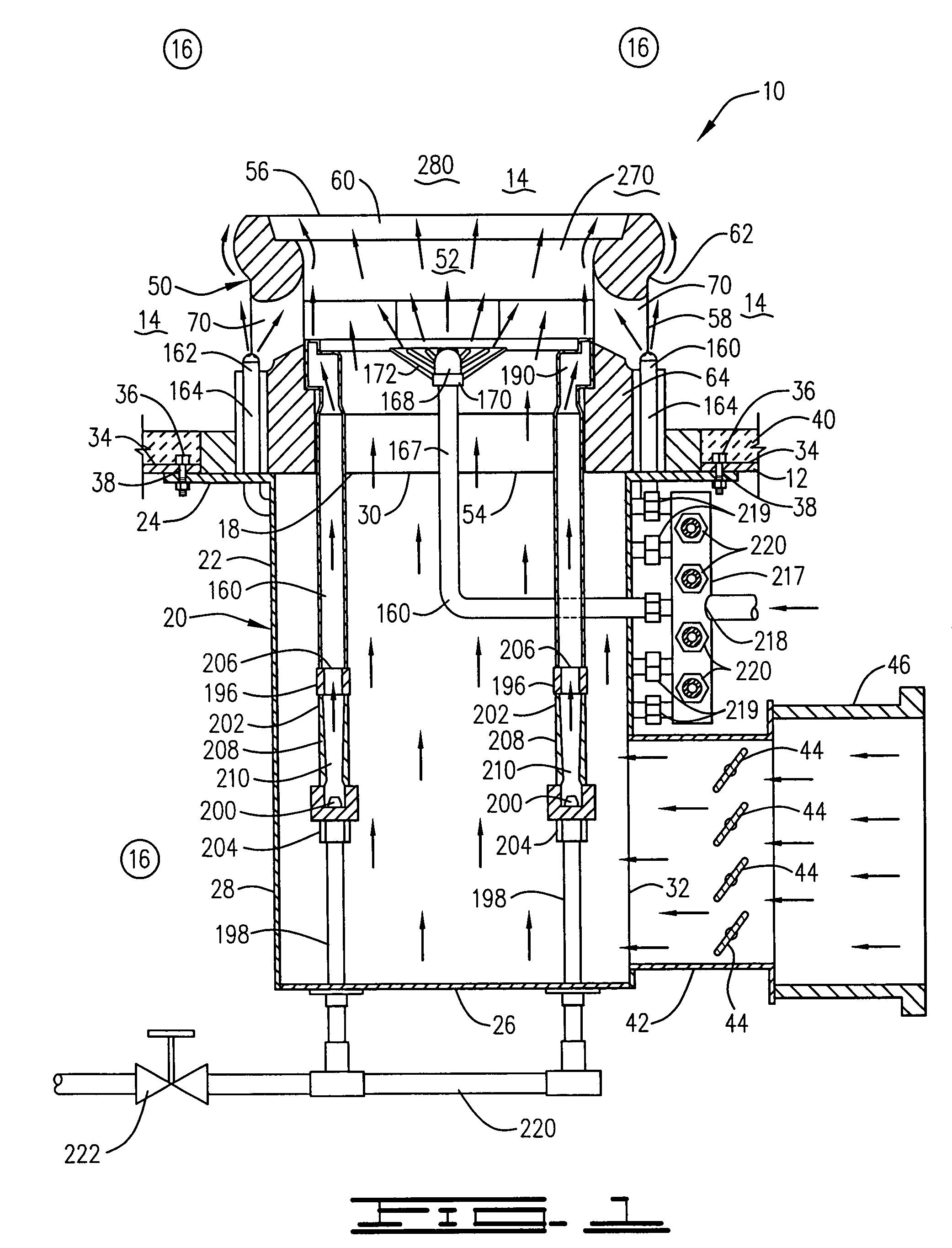

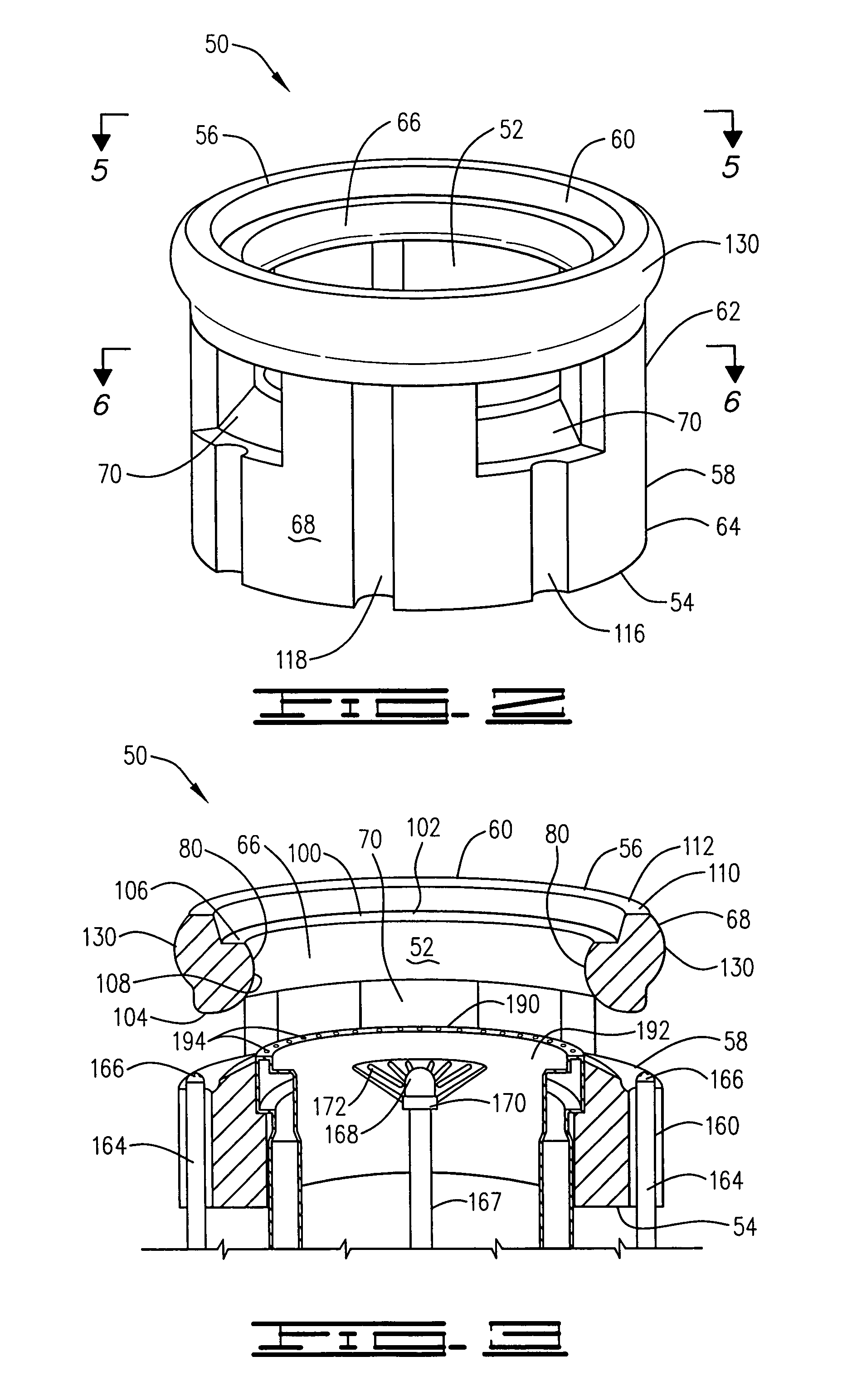

Inflator second stage combustion control

ActiveUS20070120349A1Avoid harmful effectsPedestrian/occupant safety arrangementDual stageEngineering

A new type of airbag inflator that may be used in an airbag system is disclosed. The inflator will generally include a housing and two initiators. Accordingly, the inflator is a “dual-stage” inflator. The two stages are disposed within the housing. The second initiator is disposed within a second stage generant cup. A cap is also used to engage the second stage cup. The cap maintains seated engagement with the second stage cup, even during deployment of the second stage. The second stage will also include one or more perforations, which constitute openings through which gas may flow. When the second initiator is in the unactuated state, these perforations will be isolated from the generant by the cap. Actuation of the second initiator unseals the one or more perforations but does not unseat the cap from the cup, due to constraints put in place to prevent such unseating.

Owner:AUTOLIV ASP INC

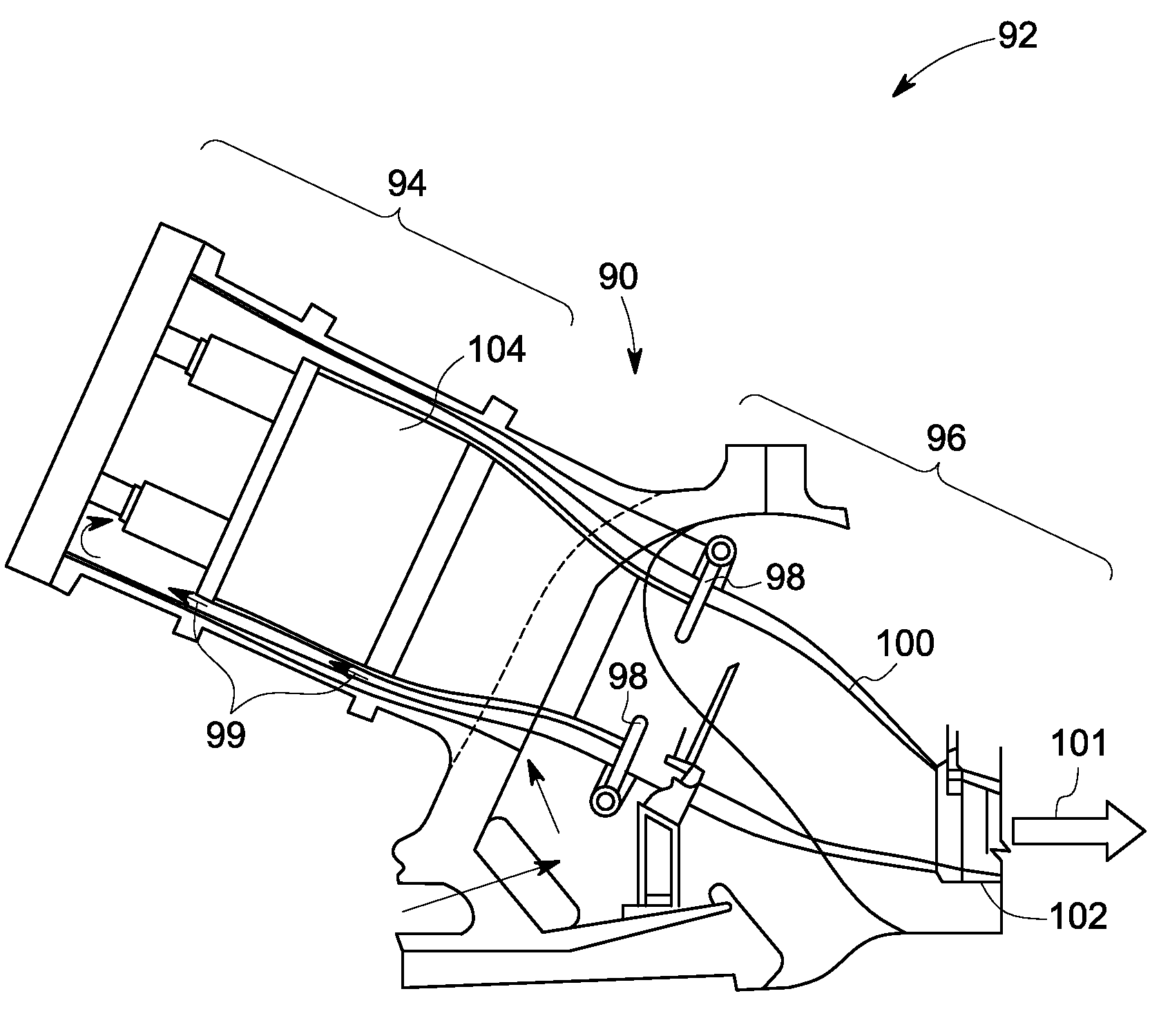

Tangential combustor with vaneless turbine for use on gas turbine engines

ActiveUS20110209482A1Shorten the lengthReduce manufacturing costContinuous combustion chamberGas turbine plantsTurbine bladeStaged combustion

A combustion device used in gas turbine engines includes an annular combustor that contains the combustion process of air and fuel and then guides the hot gas products to a first stage turbine subsection of a gas turbine engine. The annular combustor has an inner / outer shell having corrugated surfaces that extend radially outward and inward across an entire hot gas stream inside the annular combustor. The corrugations twist about the engine centerline in a longitudinal direction of travel of the engine. The resulting flow path accelerates and turns the hot gas stream to conditions suitable for introduction into the first stage turbine blades, which eliminate the need for first stage turbine vanes. The annular combustor is configured with a system of fuel and air inlet passages and nozzles that results in a staged combustion of premixed fuel and air.

Owner:TOQAN MAJED +3

Inflator second stage combustion control

Owner:AUTOLIV ASP INC

Coanda gas burner apparatus and methods

A gas burner apparatus for discharging a mixture of fuel gas, air and flue gas into a furnace space of a furnace wherein the mixture is burned and flue gas having a low content of nitrous oxides and carbon monoxide is formed is provided. The burner tile includes at least one gas circulation port extending though the wall of the tile. The interior surface of the wall of the tile includes a Coanda surface. Fuel gas and / or flue gas conducted through the gas circulation port follows the path of the Coanda surface which allows more flue gas to be introduced into the stream. The exterior surface of the wall of the tile also includes a Coanda surface for facilitating the creation of a staged combustion zone. Also provided are improved burner tiles, improved gas tips and methods of burning a mixture of air, fuel gas and flue gas in a furnace space.

Owner:JOHN ZINK CO LLC

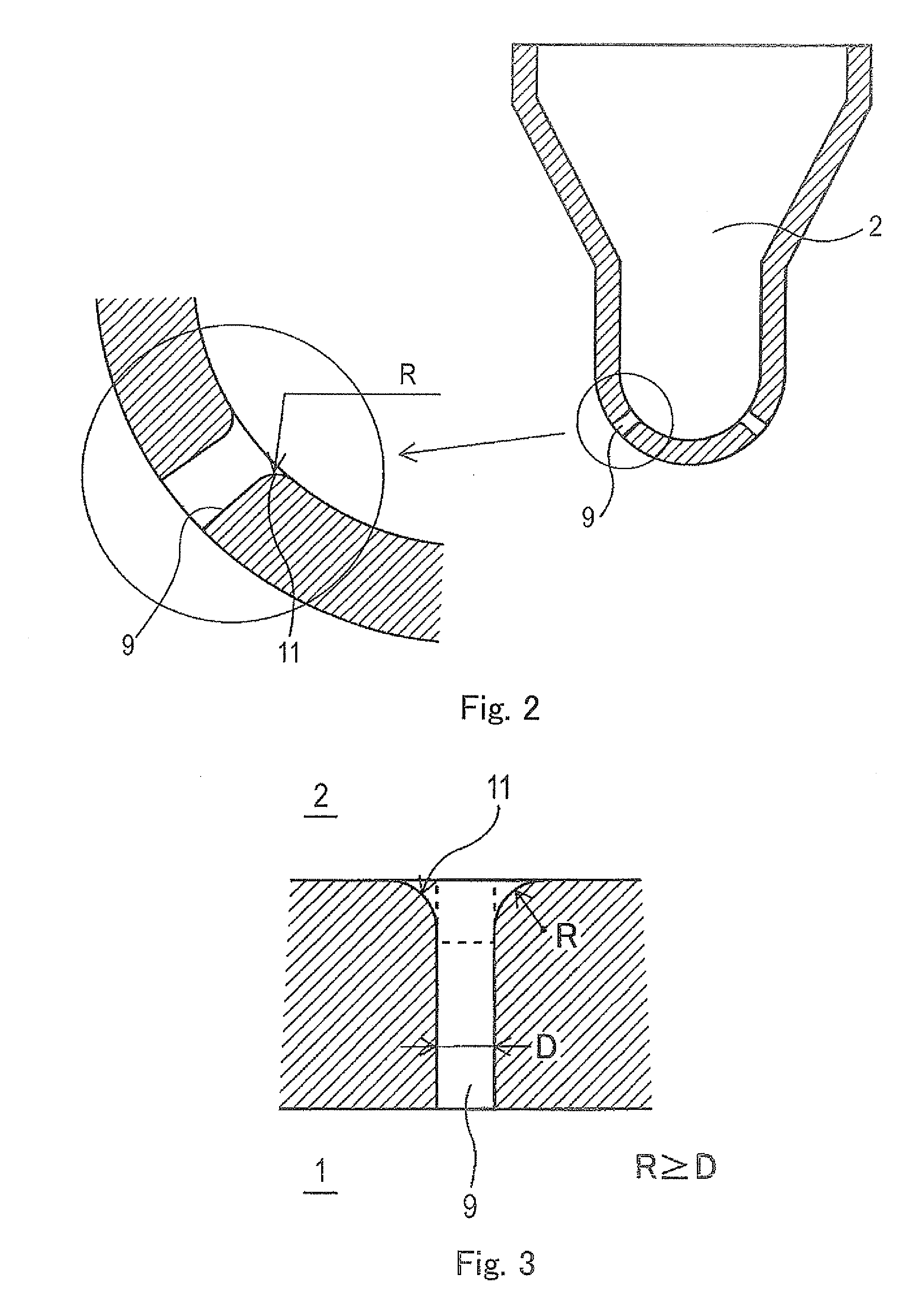

Divided-chamber gas engine

InactiveUS20130000598A1Avoid deformationAvoid performance degradationInternal combustion piston enginesCylinder headsCombustion chamberStaged combustion

A gas engine is configured to inject a combustion gas from an auxiliary combustion chamber through a plurality of nozzles, through which the auxiliary combustion chamber and a main combustion chamber are in communication with each other, so as to ignite a fuel in the main combustion chamber. An opening edge, at the auxiliary combustion chamber side, of each of the plurality of nozzles is formed to have a curved surface. This structure makes it possible to maintain stable combustion in the main combustion chamber while preventing degradation in combustion performance.

Owner:KAWASAKI HEAVY IND LTD

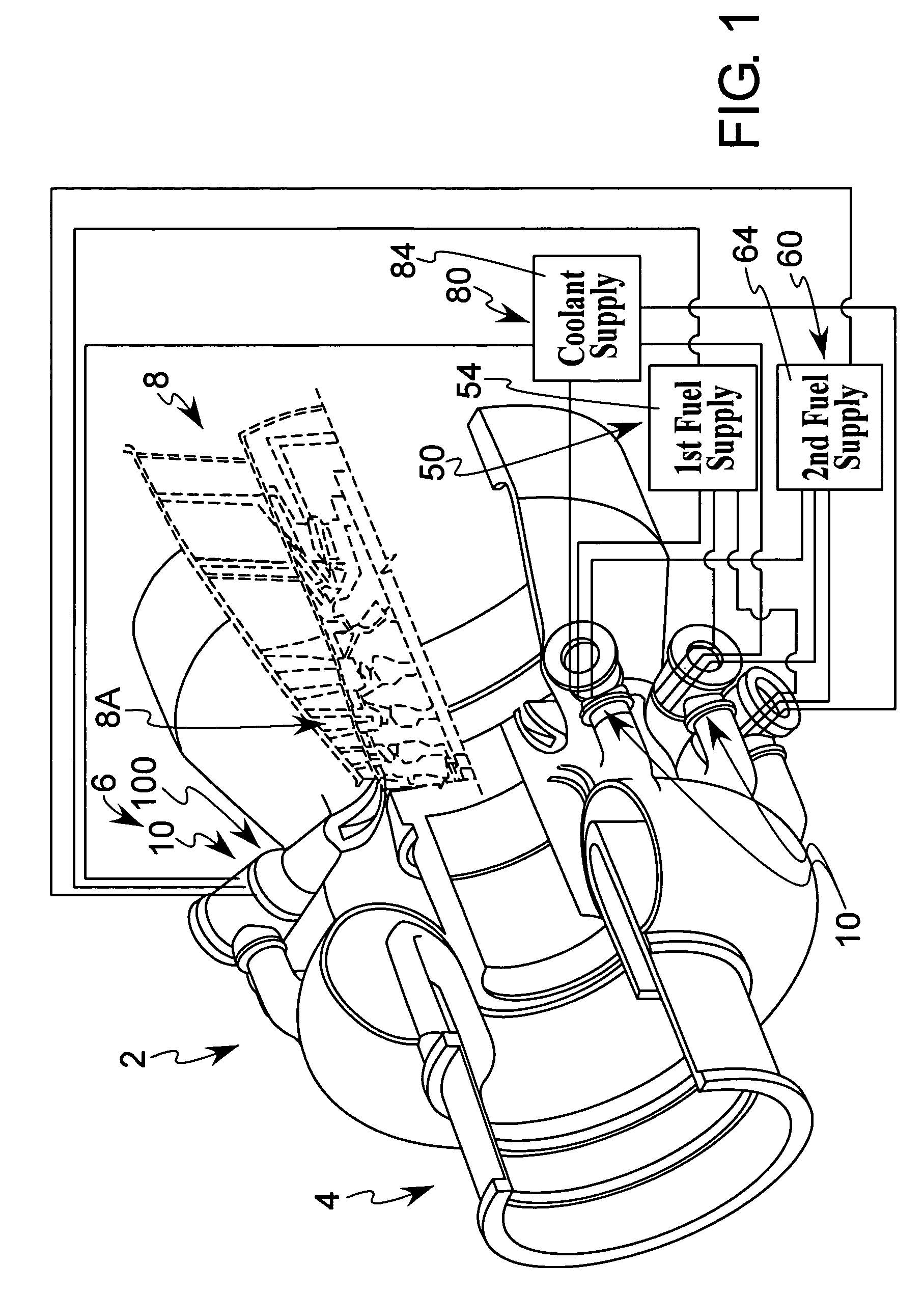

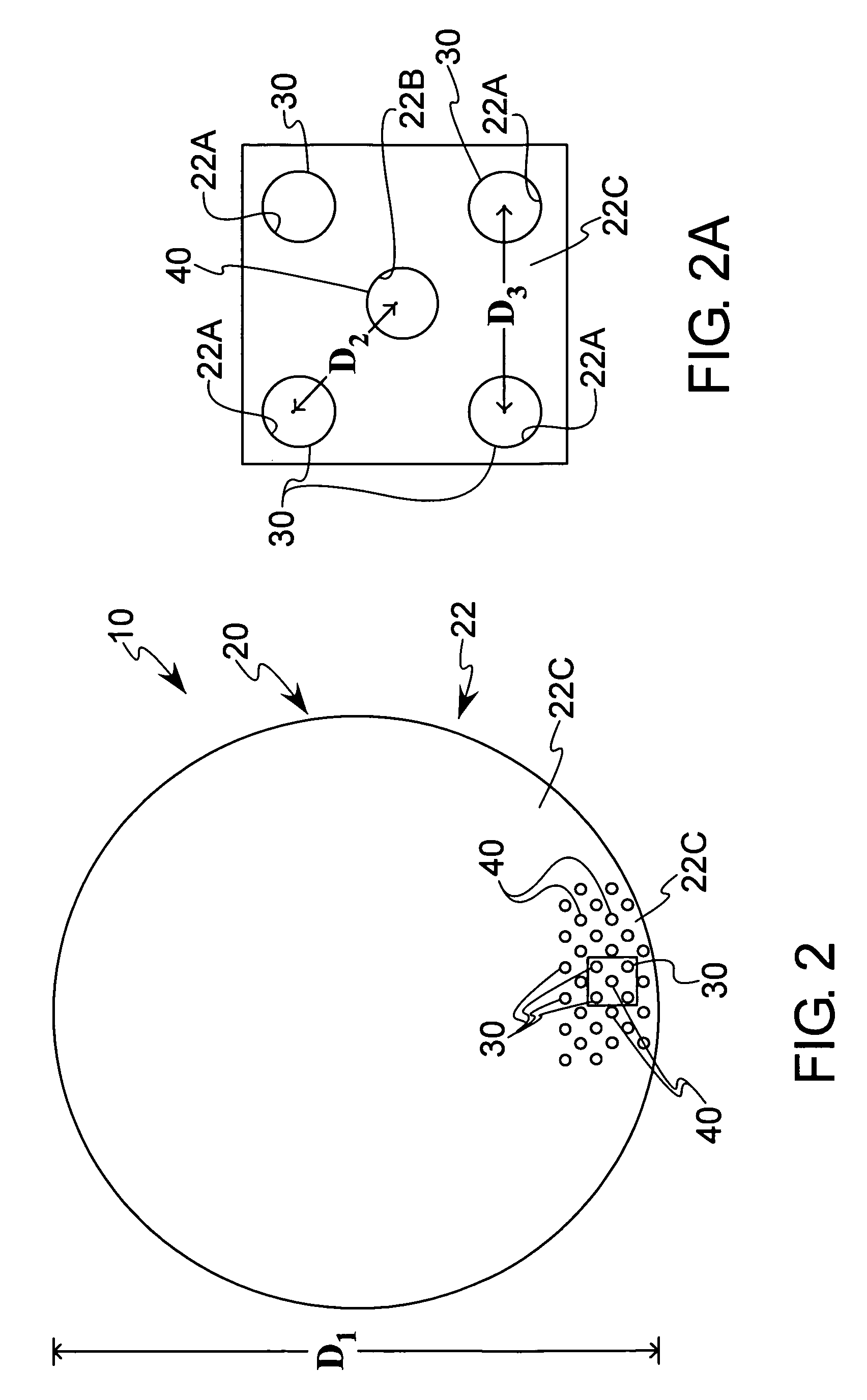

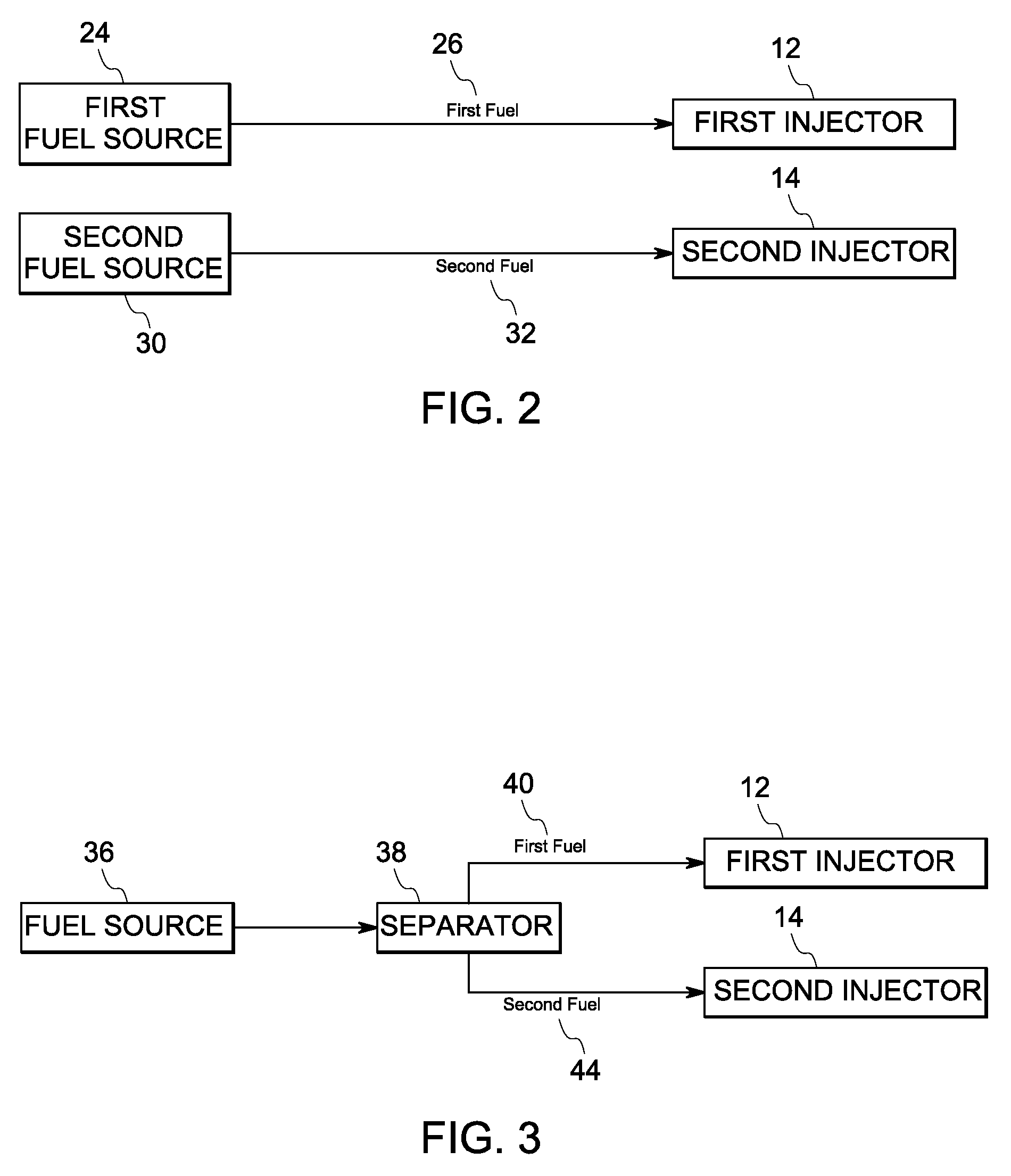

Staged combustion systems and methods

InactiveUS20100095649A1Reduce undesired emissionDesign moreContinuous combustion chamberGas turbine plantsCombustion systemHydrogen

Systems and methods for staged combustion are provided. One staged combustion system includes a first fuel source for supplying a first fuel having a first chemical composition, a first injector for injecting the first fuel, a second fuel source for supplying a second fuel having a second chemical composition such that a relative reactive concentration of one or more of hydrogen, carbon monoxide, a hydrocarbon, or a combination of two or more hydrocarbons, in the first chemical composition is different from that of the second chemical composition, and a second injector situated for injecting the second fuel downstream of the first injector.

Owner:GENERAL ELECTRIC CO

Low-pollution combustion chamber with main combustion stage adopting single-layer pre-film radial two-grade reverse rotational flow

InactiveCN105180215AImprove blending uniformityStrong shearContinuous combustion chamberAviationCyclone

The invention discloses a low-pollution combustion chamber with a main combustion stage adopting single-layer pre-film radial two-grade reverse rotational flow. The low-pollution combustion chamber adopts a single annular cavity structure, and comprises a diffuser, a combustion outdoor box, a combustion indoor box, a flame cylinder outer wall, a flame cylinder inner wall and a combustion chamber head part; the combustion chamber adopts a classification combustion scheme; the combustion head part is divided into a pre-combustion stage and the main combustion stage; the pre-combustion stage adopts a mode of combining rotational flow-stable diffusion combustion with rotational flow premixing combustion; the combustion mode reduces the pollutant discharge under small working conditions when not influencing stable combustion; and the main combustion stage adopts a premixing pre-evaporation combustion mode to be in favor of uniform combustion. The combustion chamber adopts a center classification structure; the pre-combustion stage is simple in structure; the main combustion grade adopts a two-grade reverse cyclone distributed in the radial direction; and two parts of reverse rotational flows shear an oil film, so that the atomization effect is greatly improved, the atomization of fuel of the main combustion stage and the mixing with air are enhanced, the premixing pre-evaporation of the fuel is reinforced, and the pollution discharge of whole landing and taking-off circulation of an aero-engine combustion chamber is further reduced.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com