Patents

Literature

2004 results about "Cylinder pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

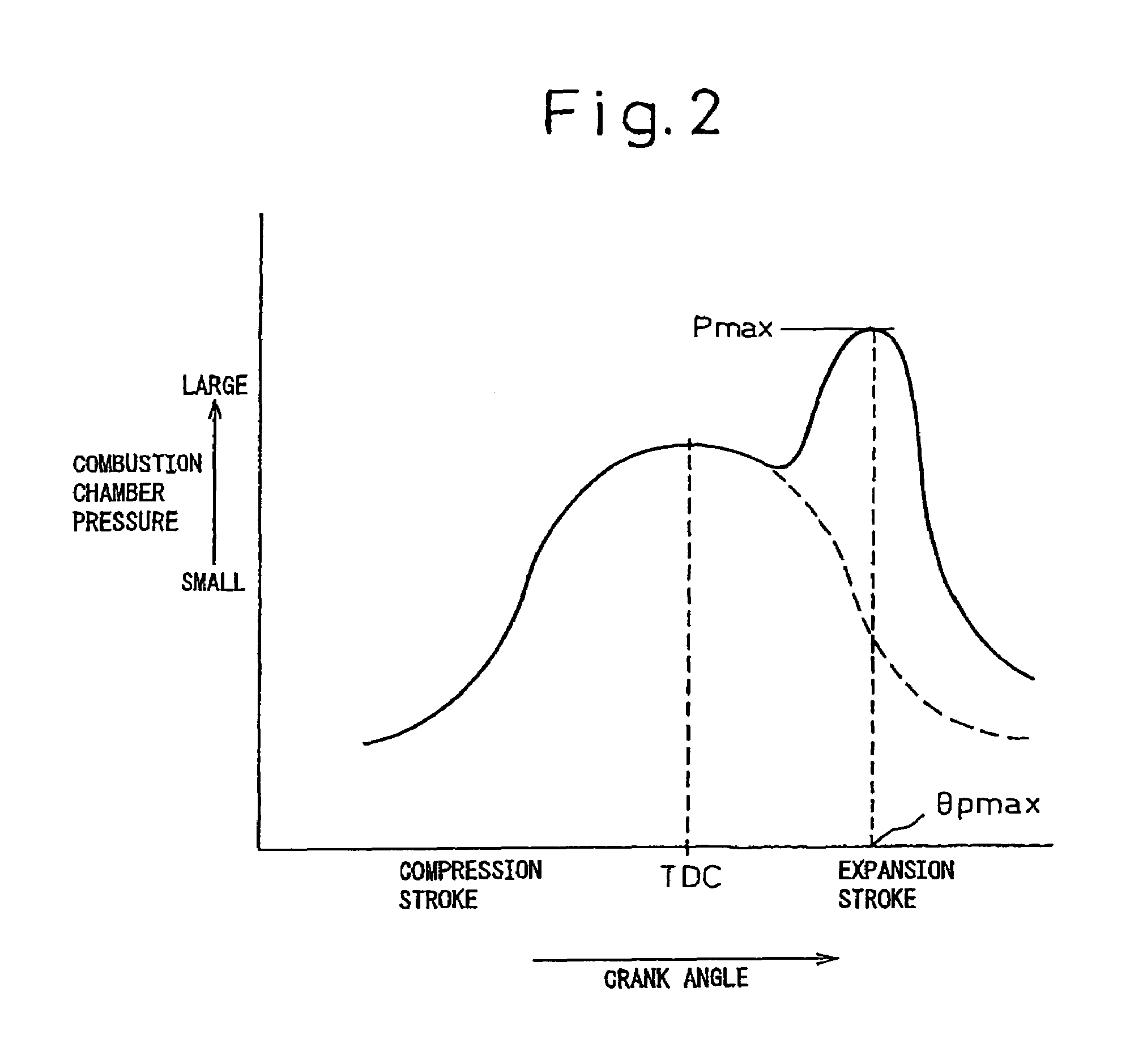

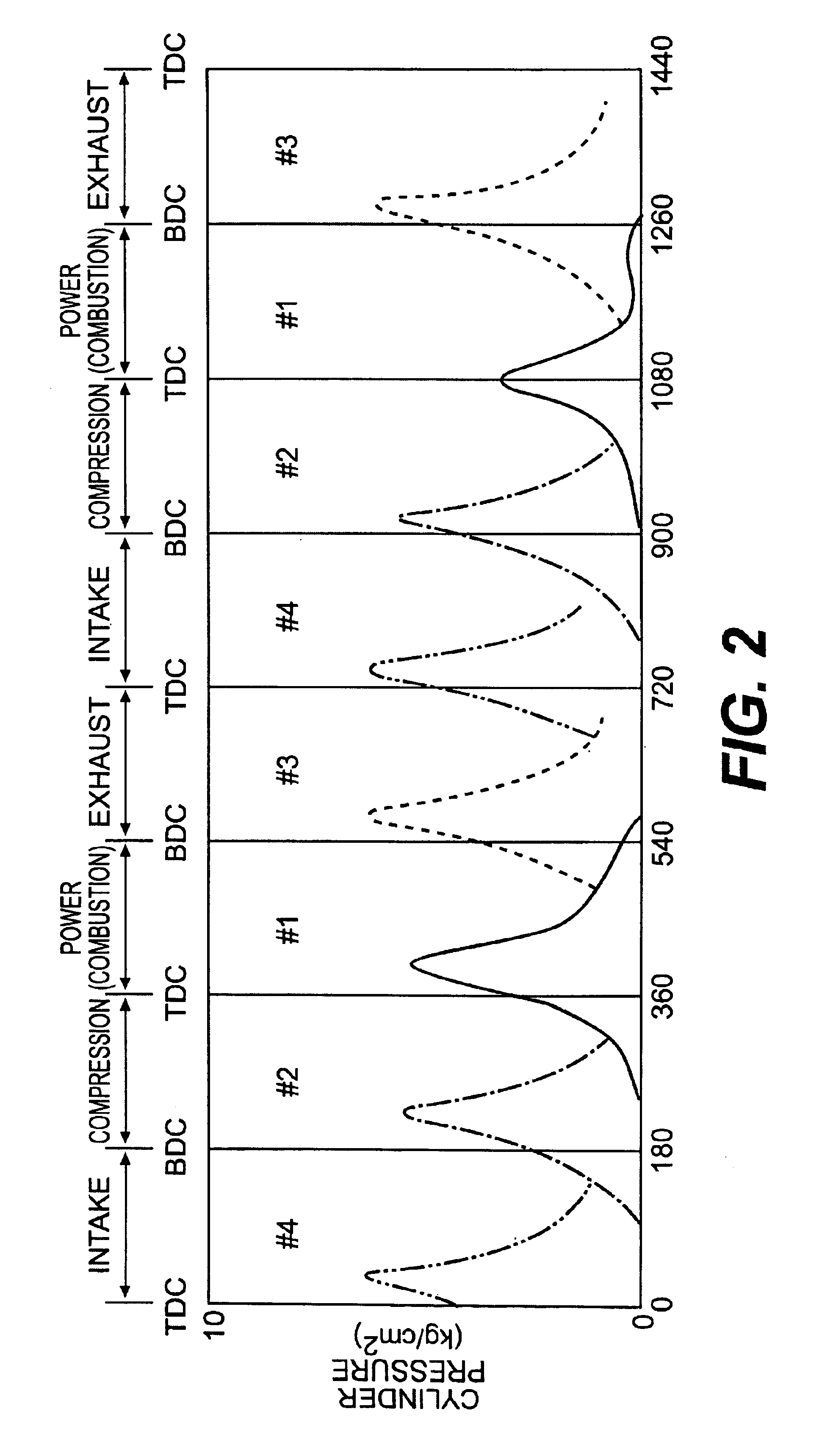

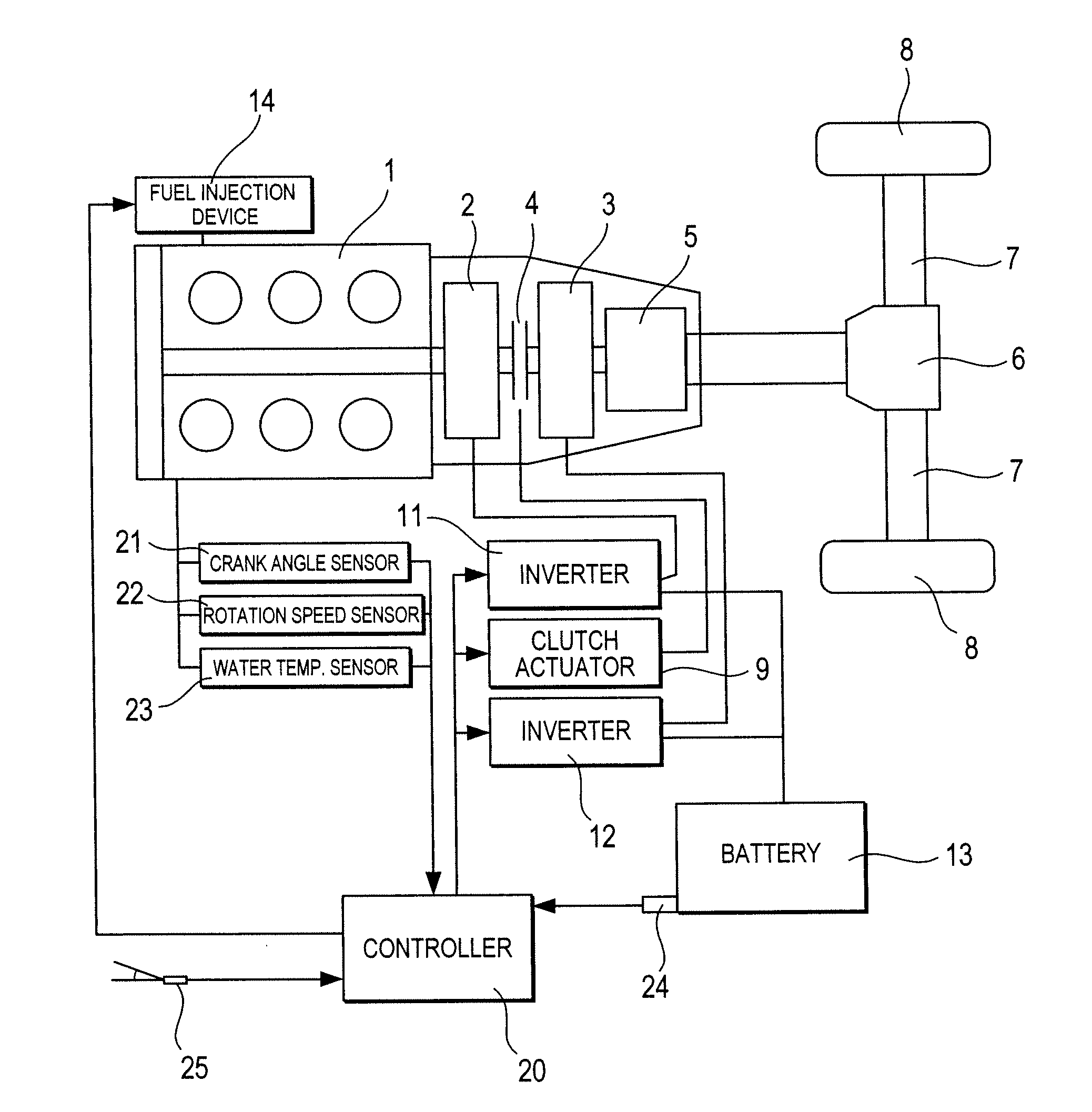

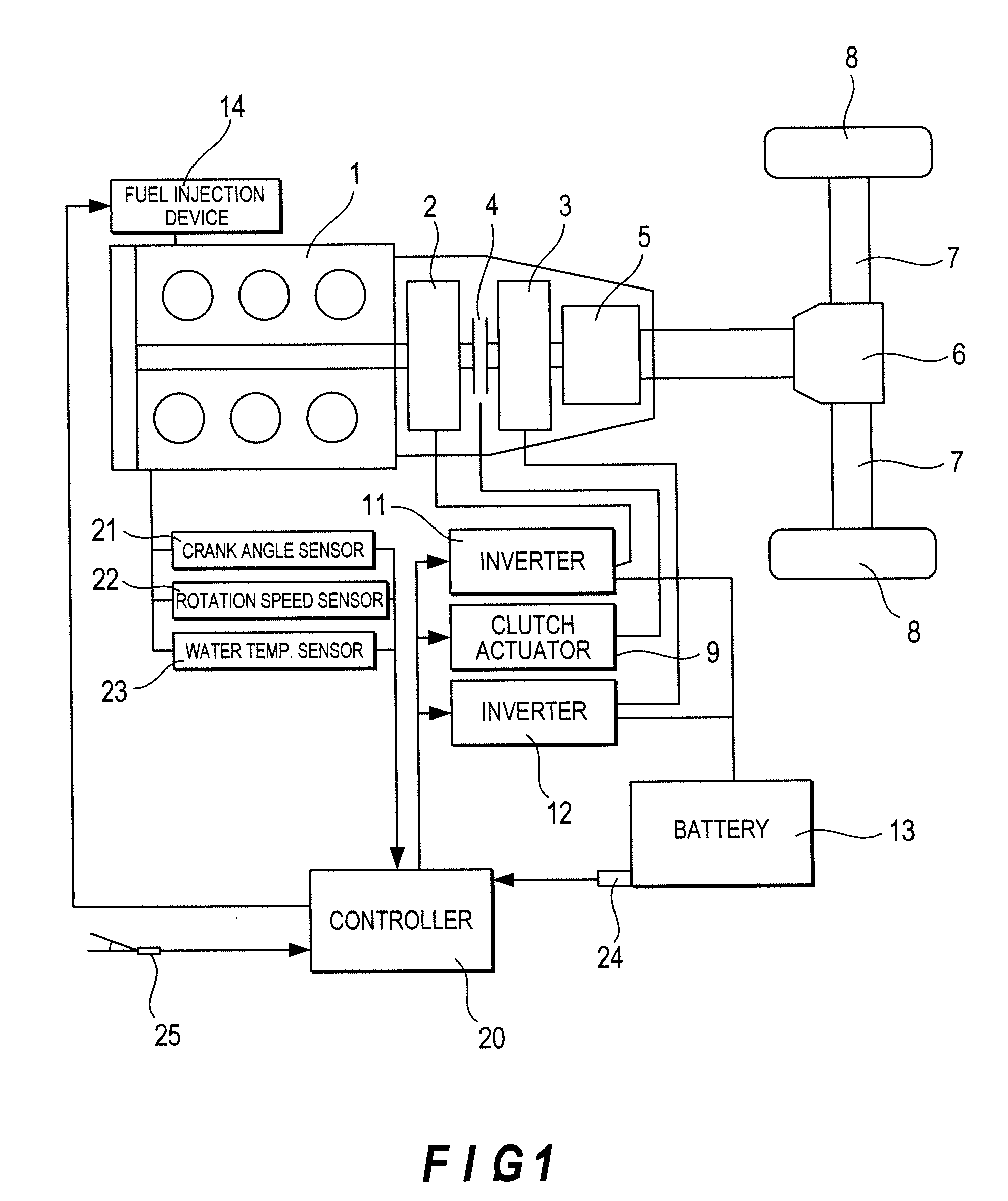

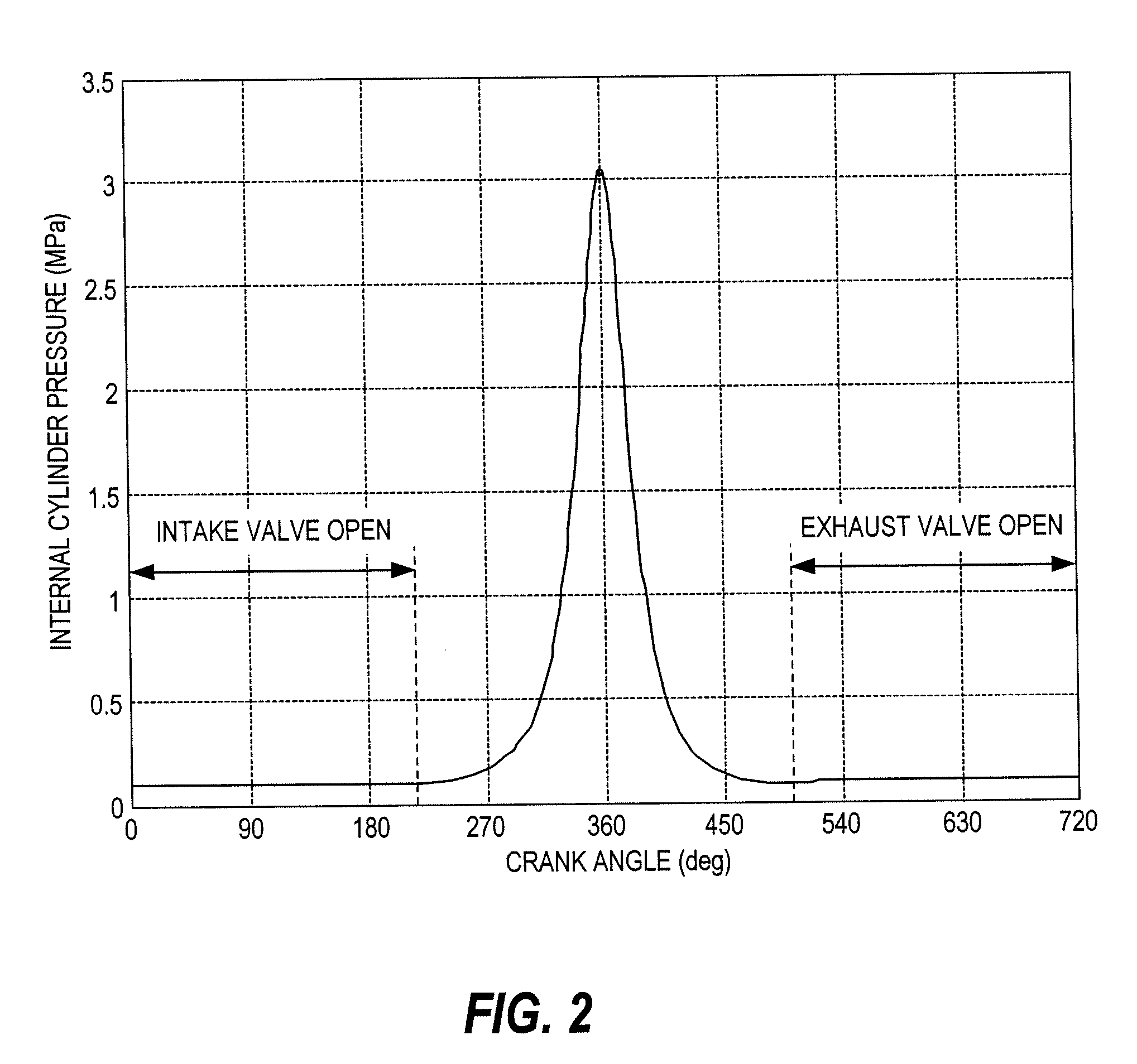

Cylinder Pressure is the pressure in the engine cylinder during the 4 strokes of engine operation (intake, compression, combustion and expansion, and exhaust). You could argue that pressure during expansion is the most important, because that is the cylinder pressure pushing on the piston to produce power.

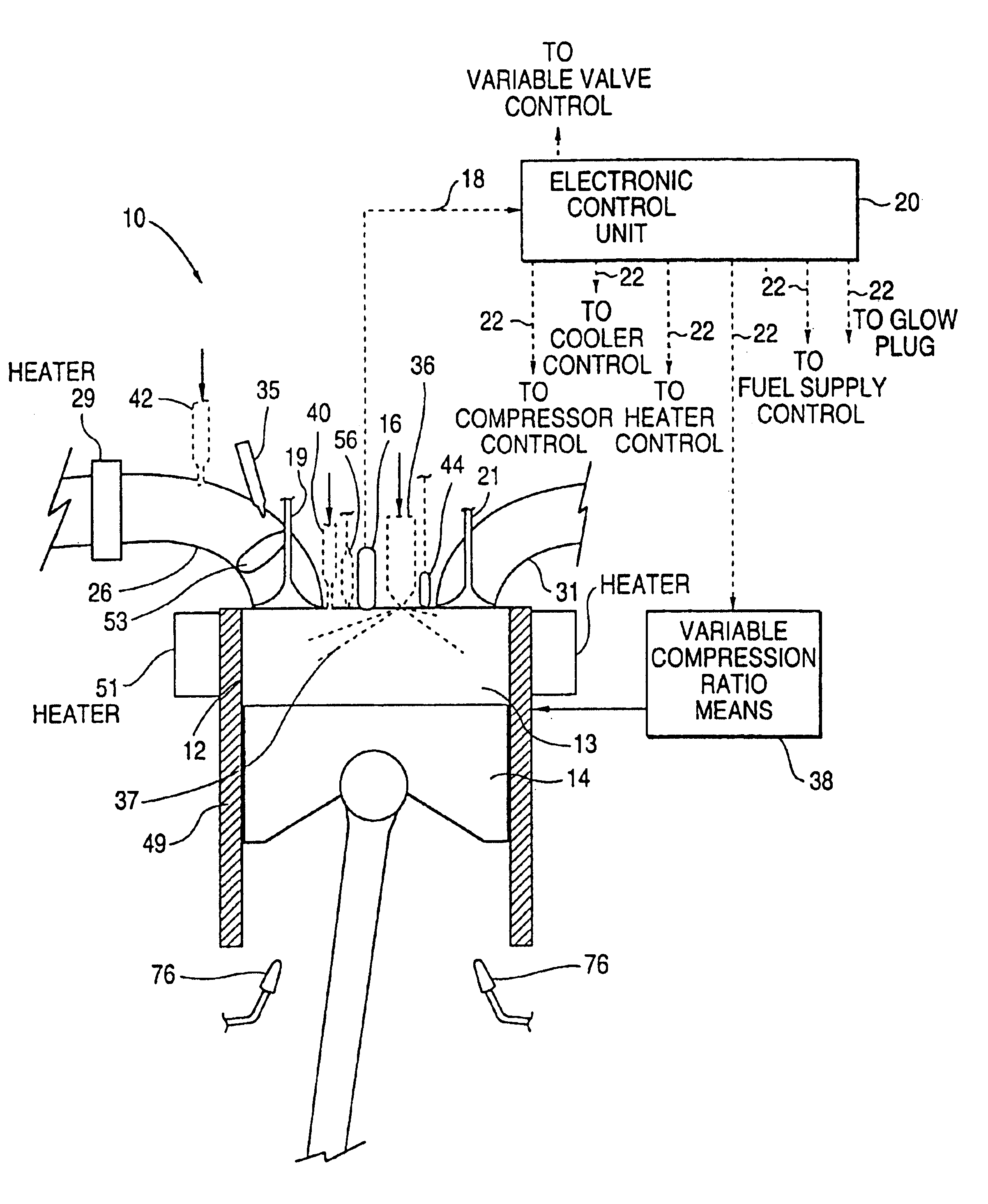

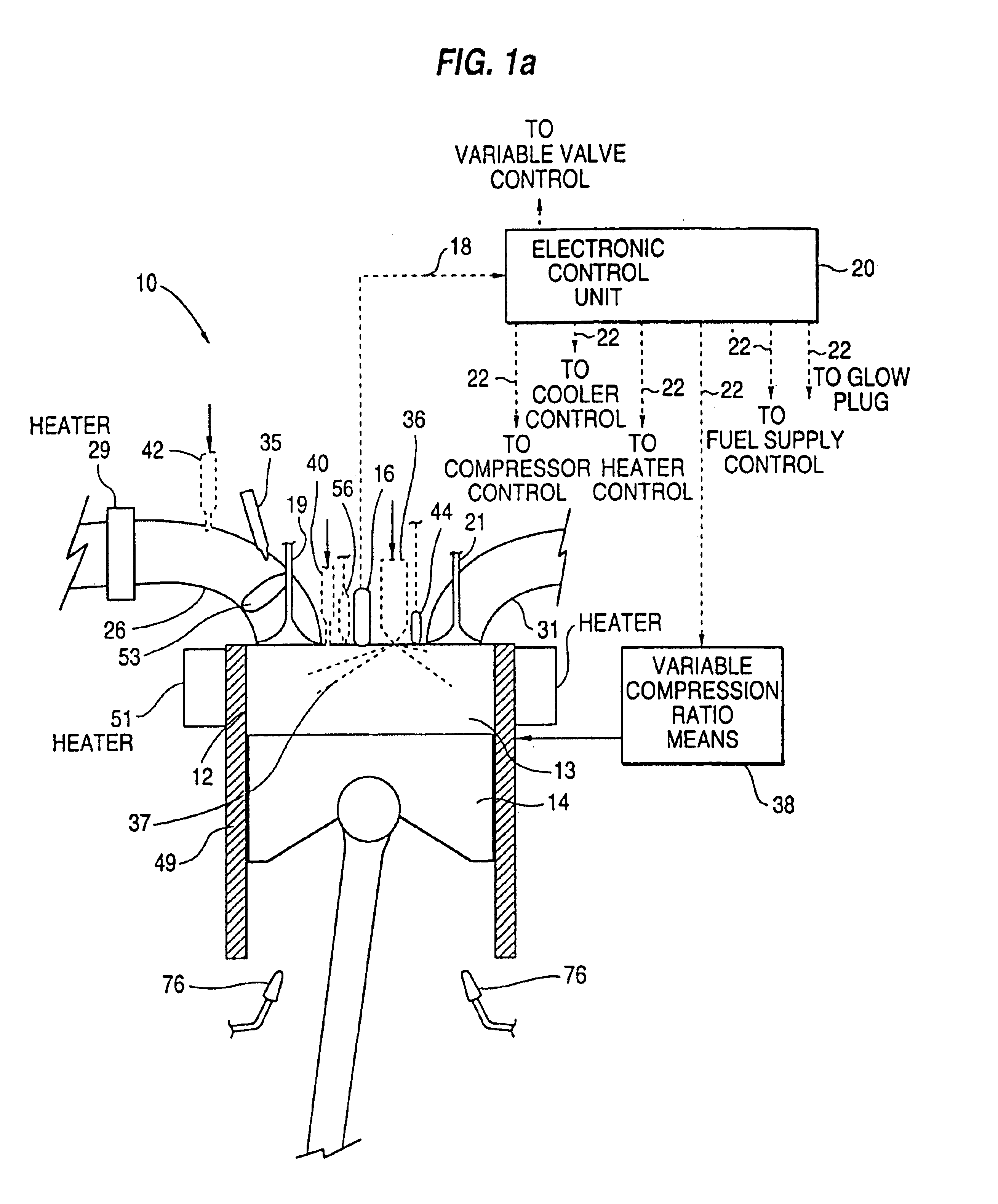

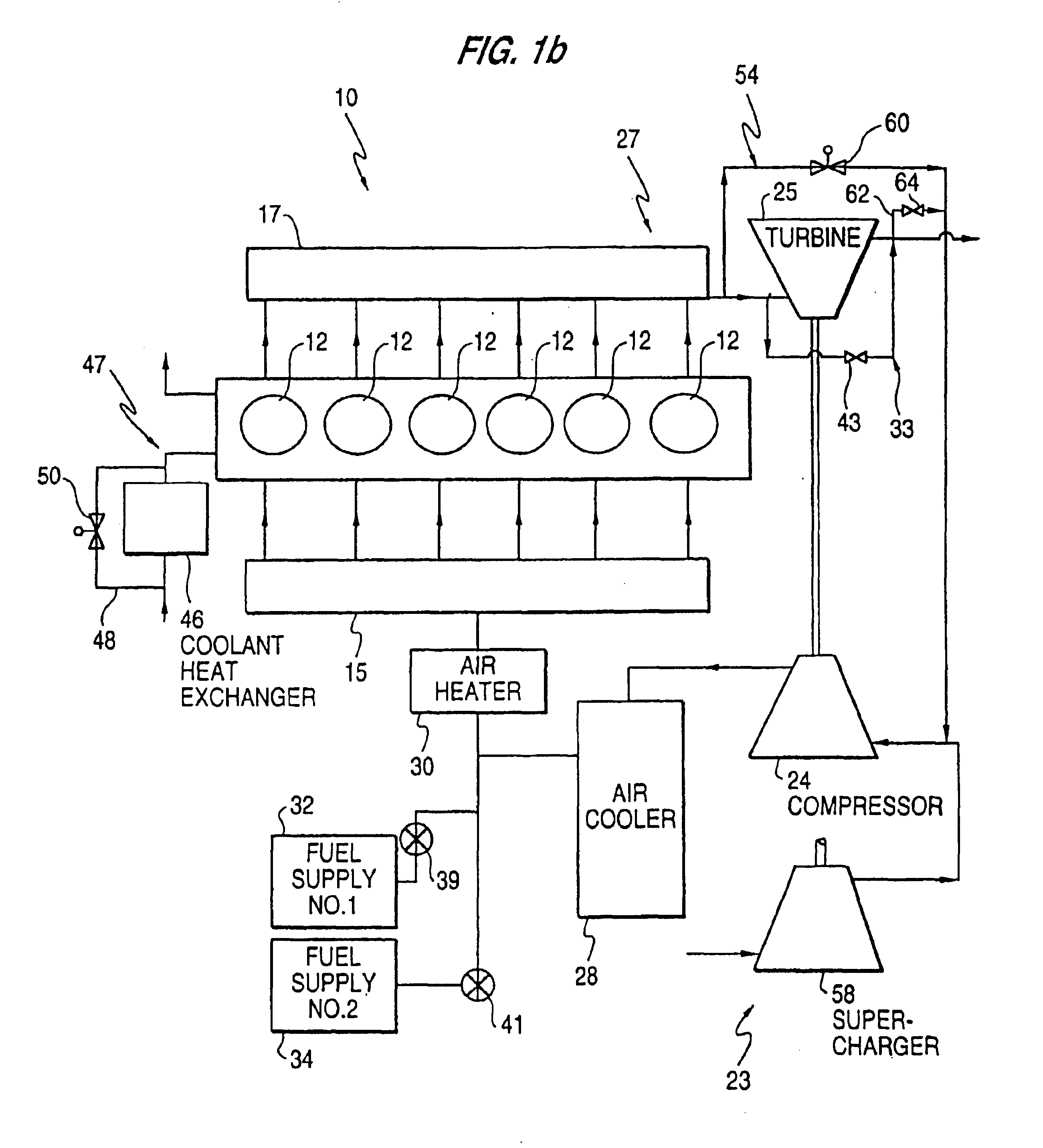

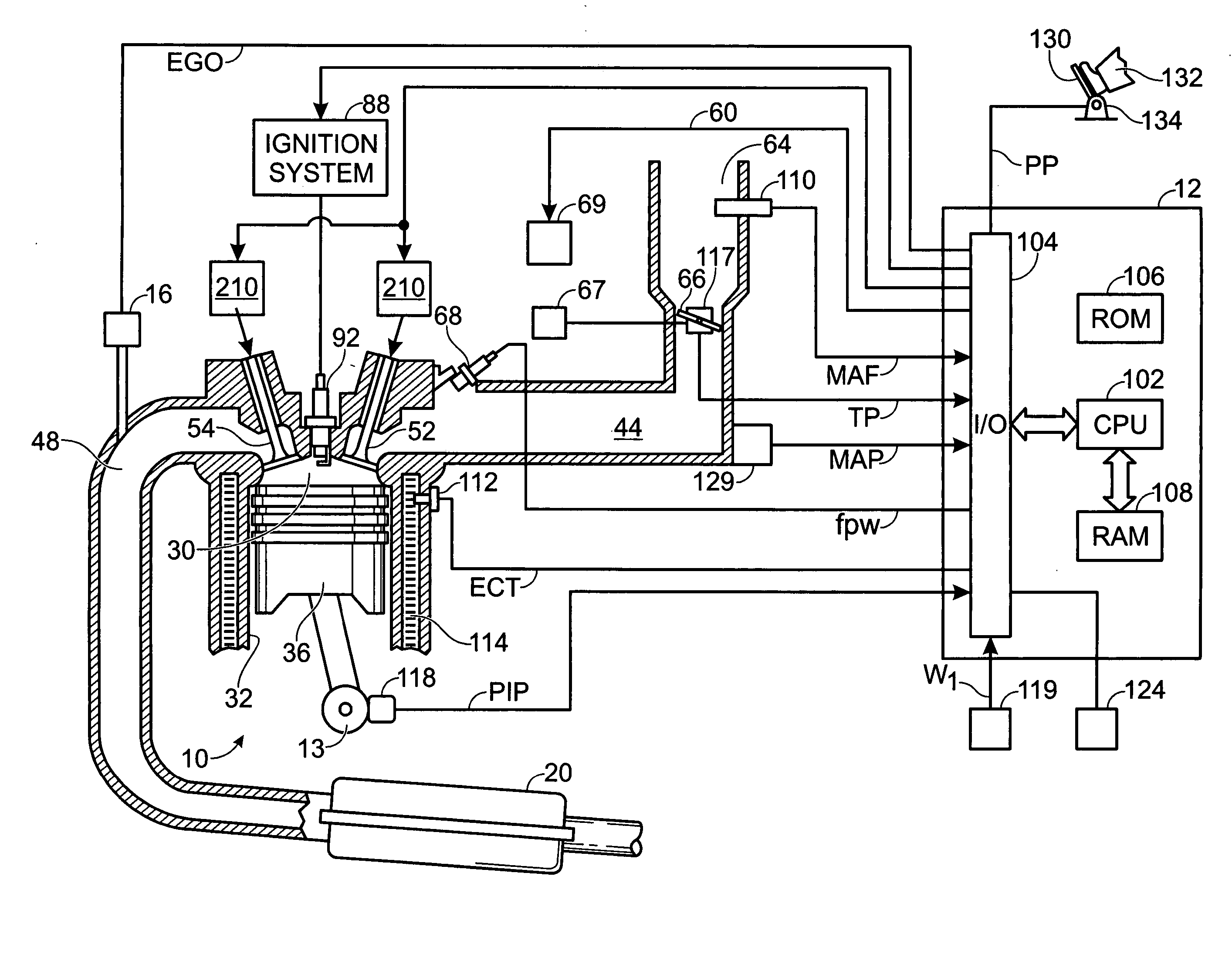

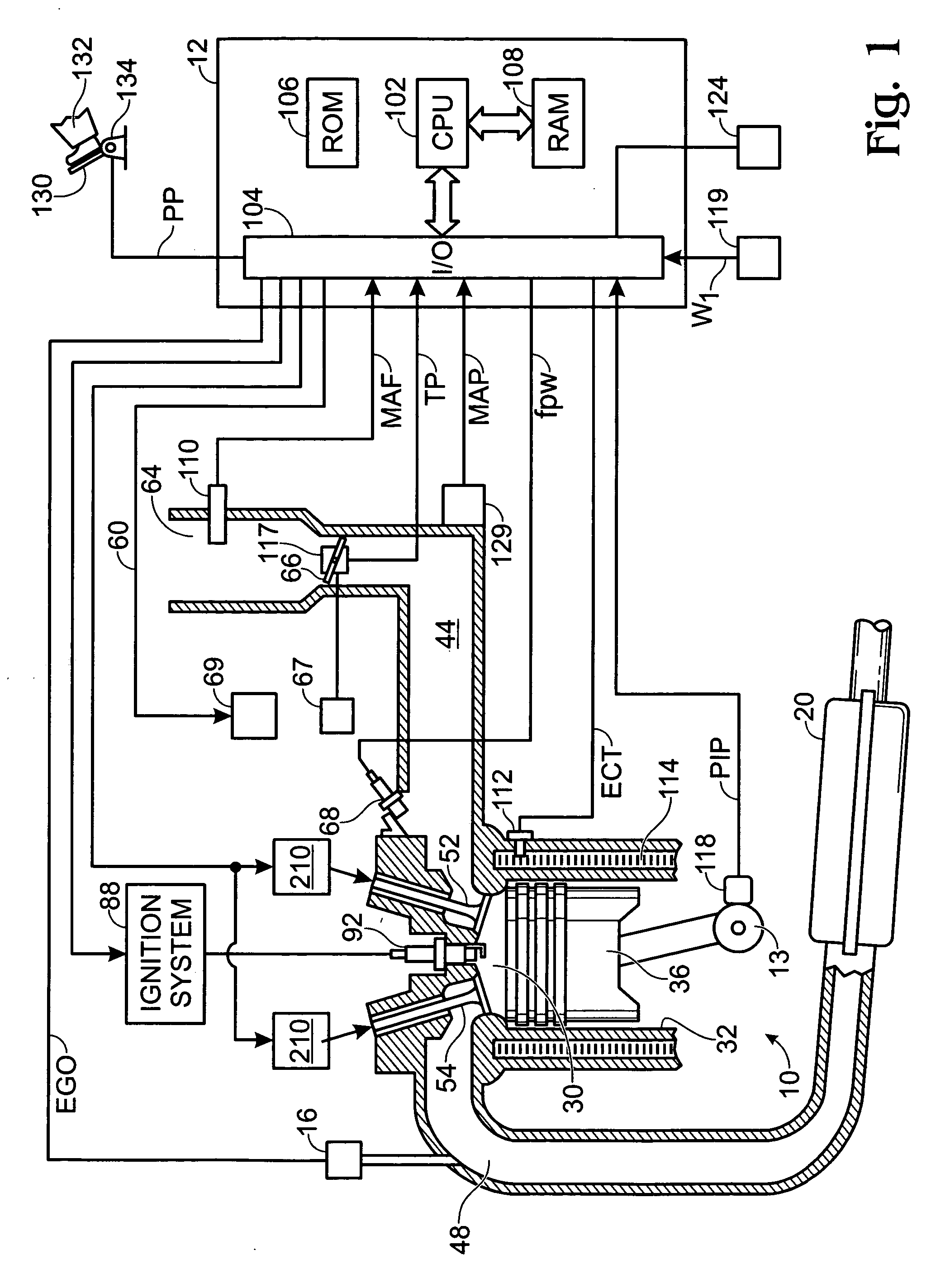

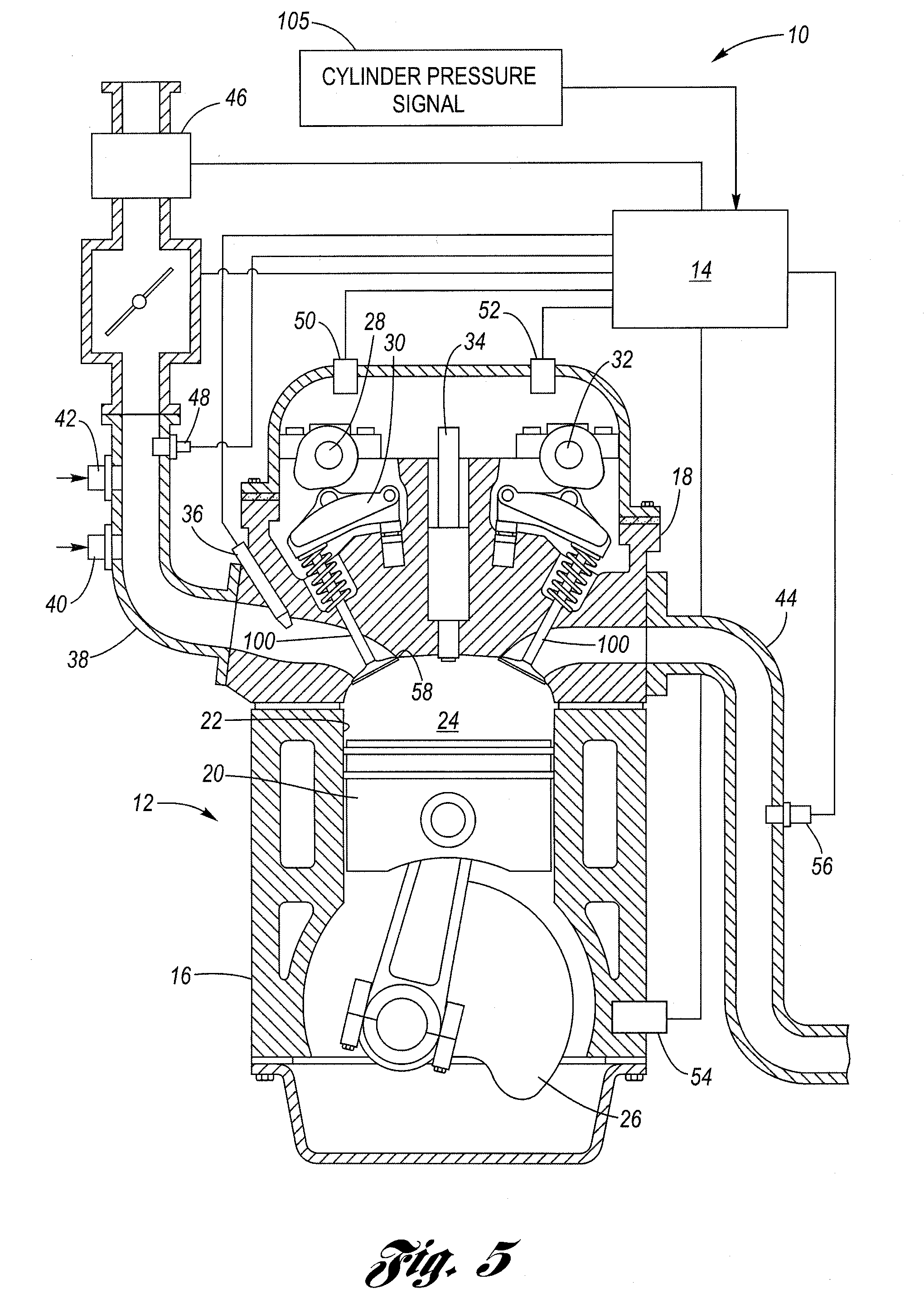

Premixed charge compression ignition engine with optimal combustion control

InactiveUS6915776B2Operate efficiently and effectivelyOvercome deficienciesElectrical controlNon-fuel substance addition to fuelCombustion noiseControl signal

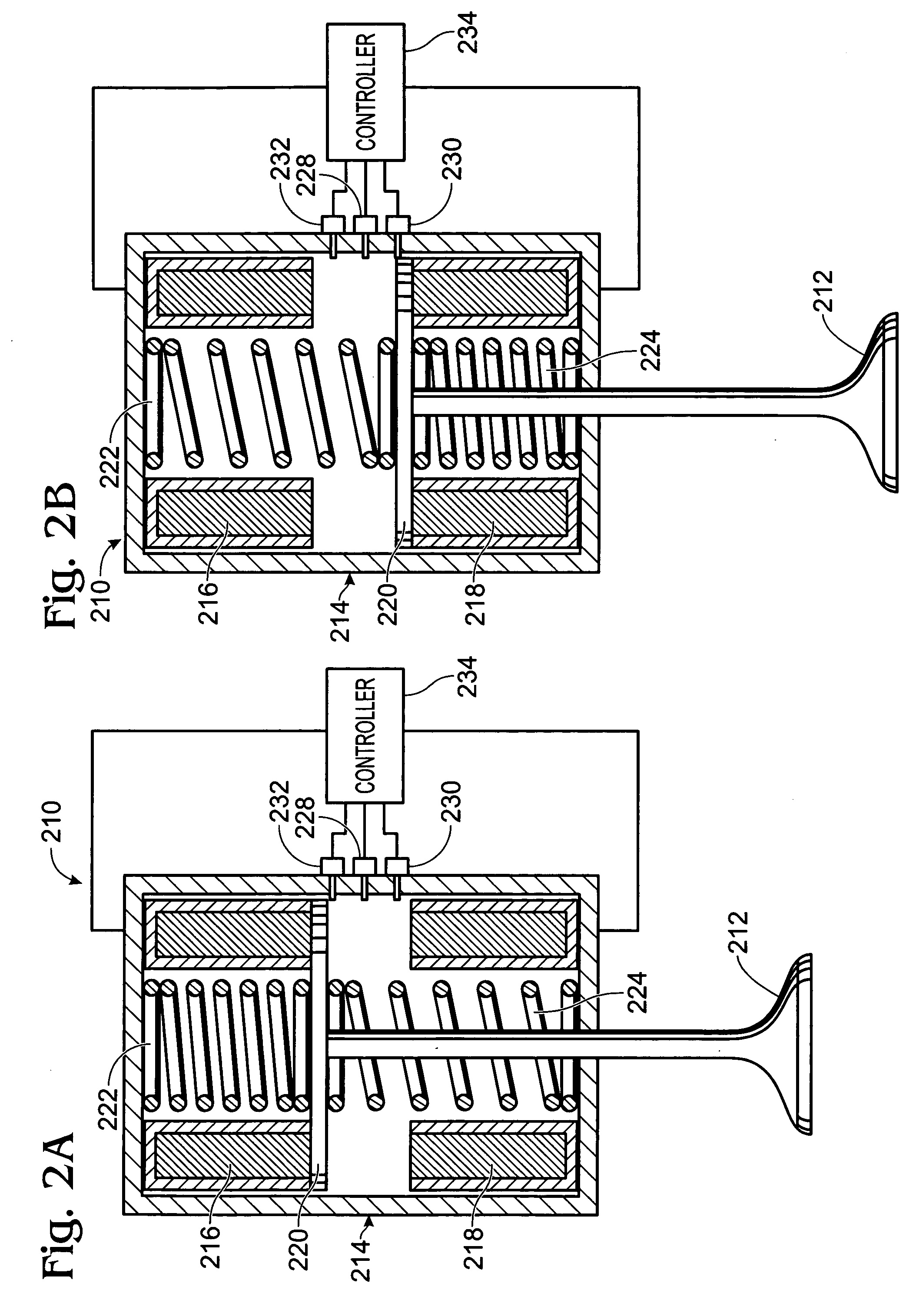

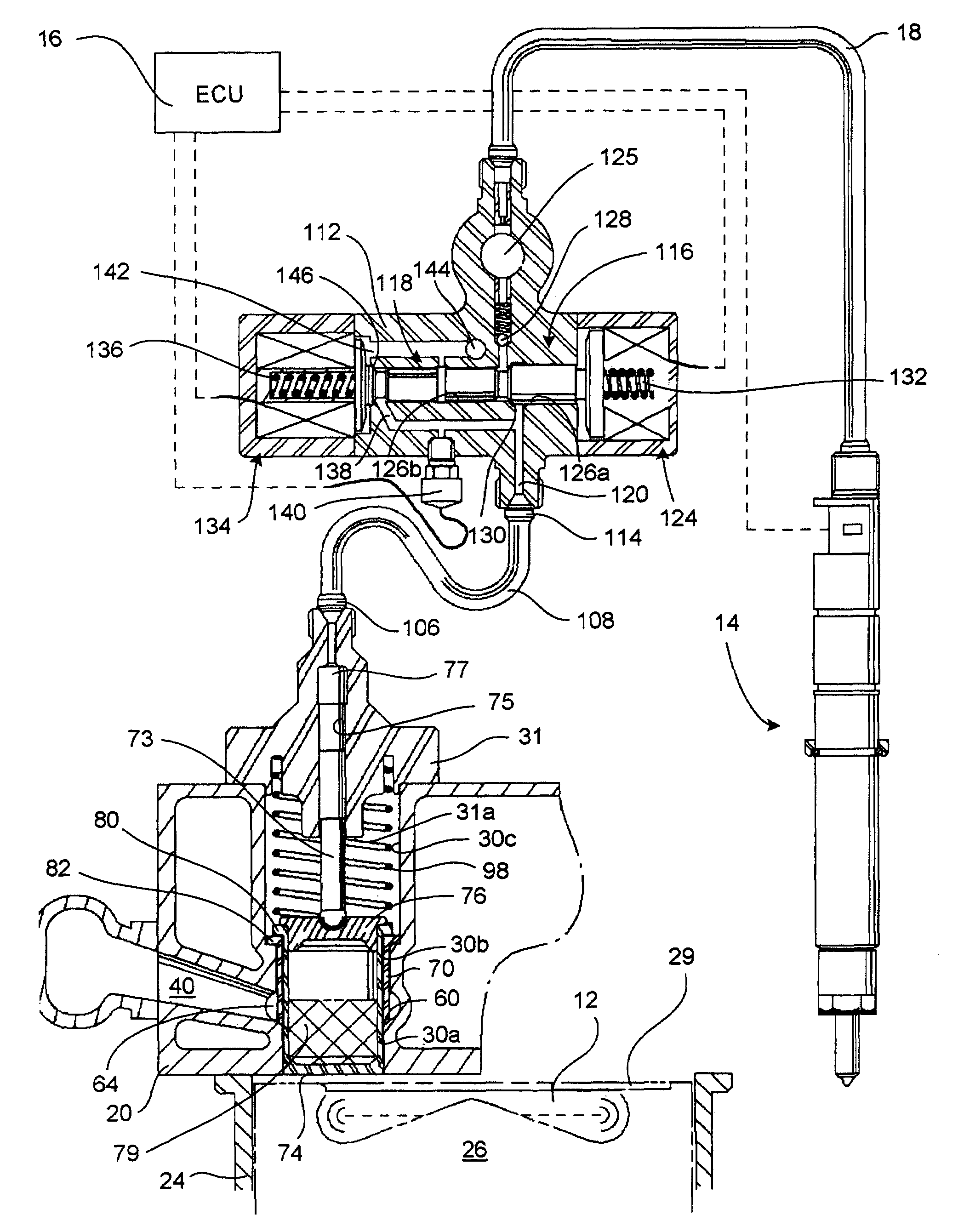

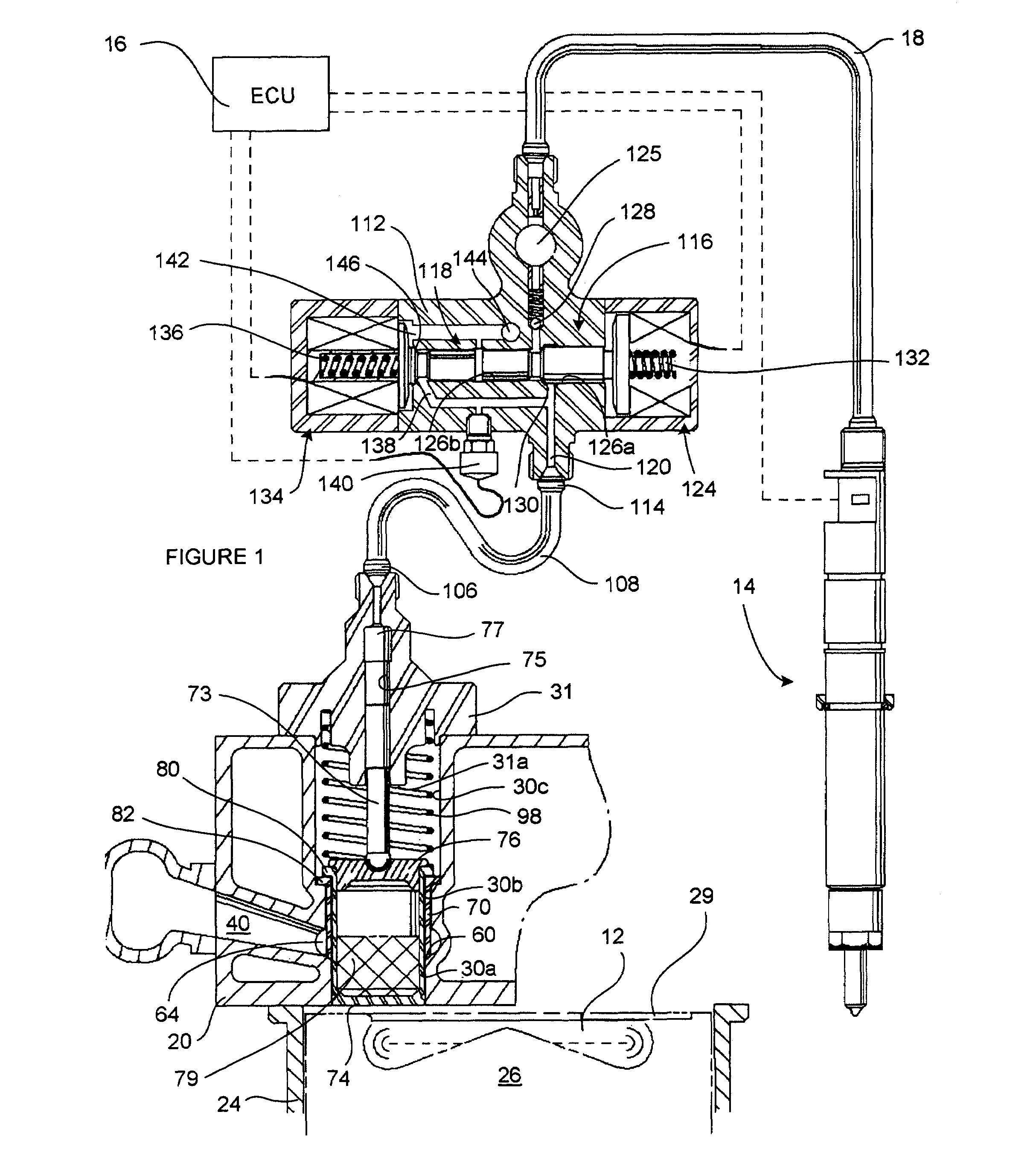

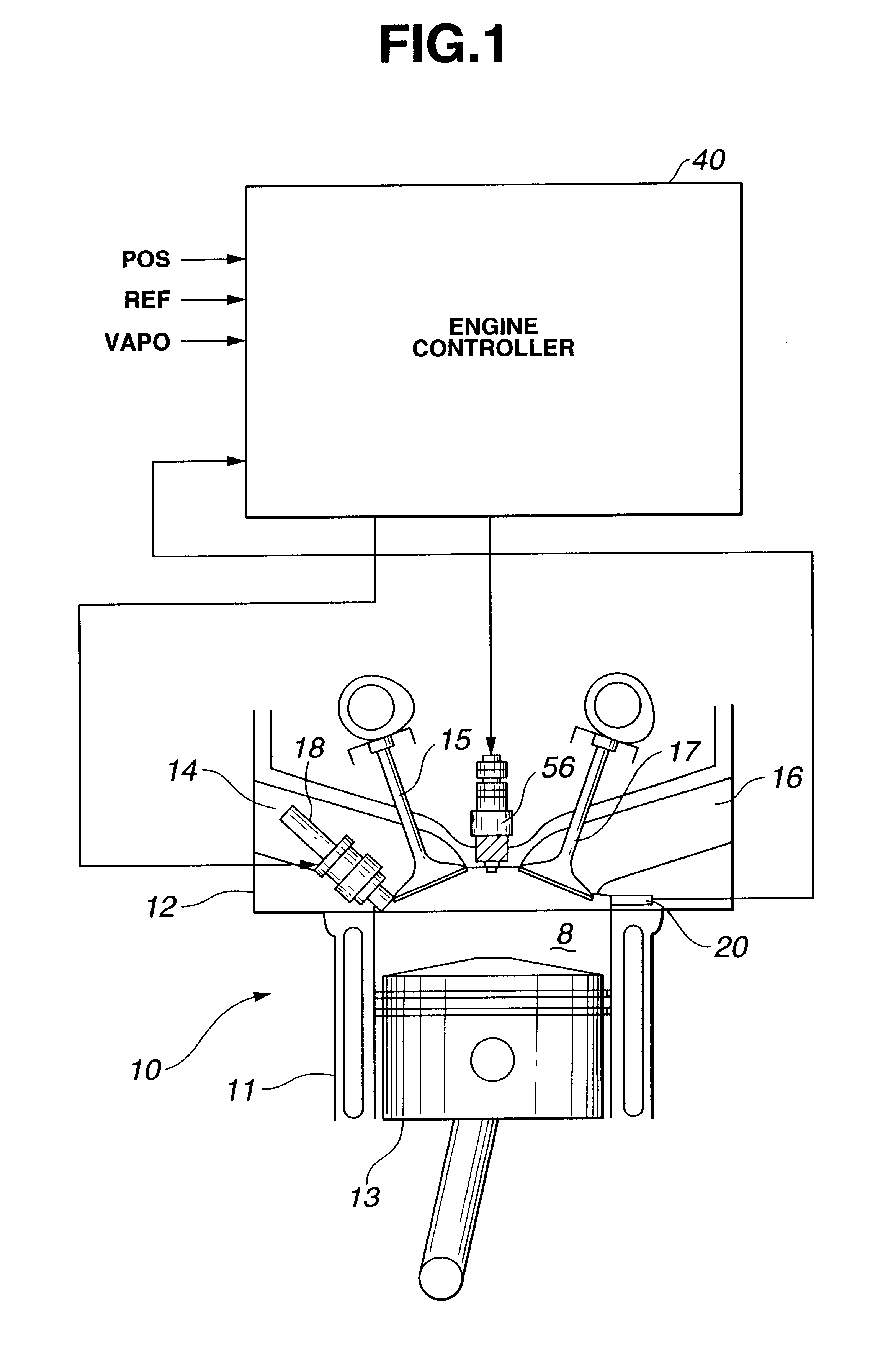

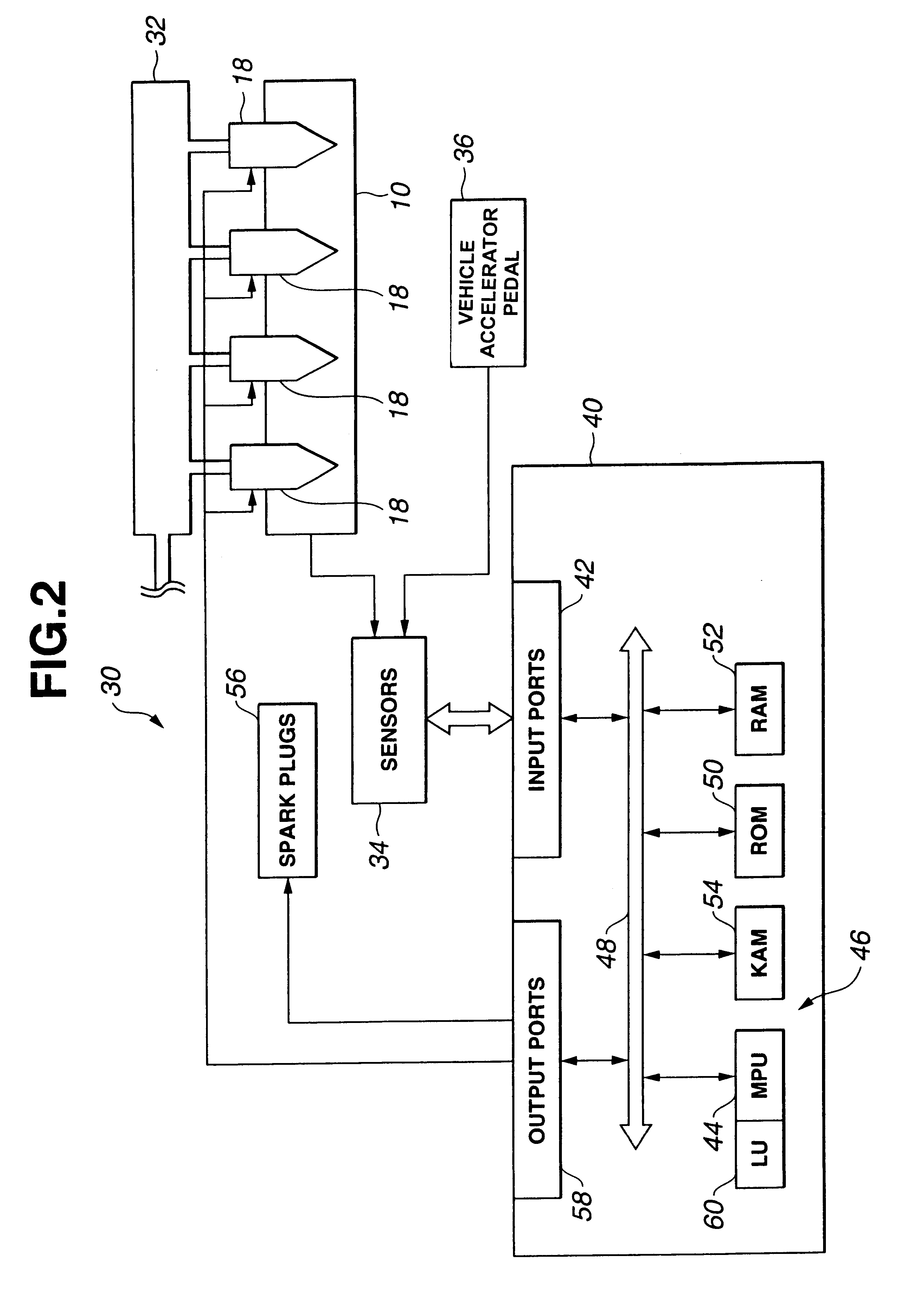

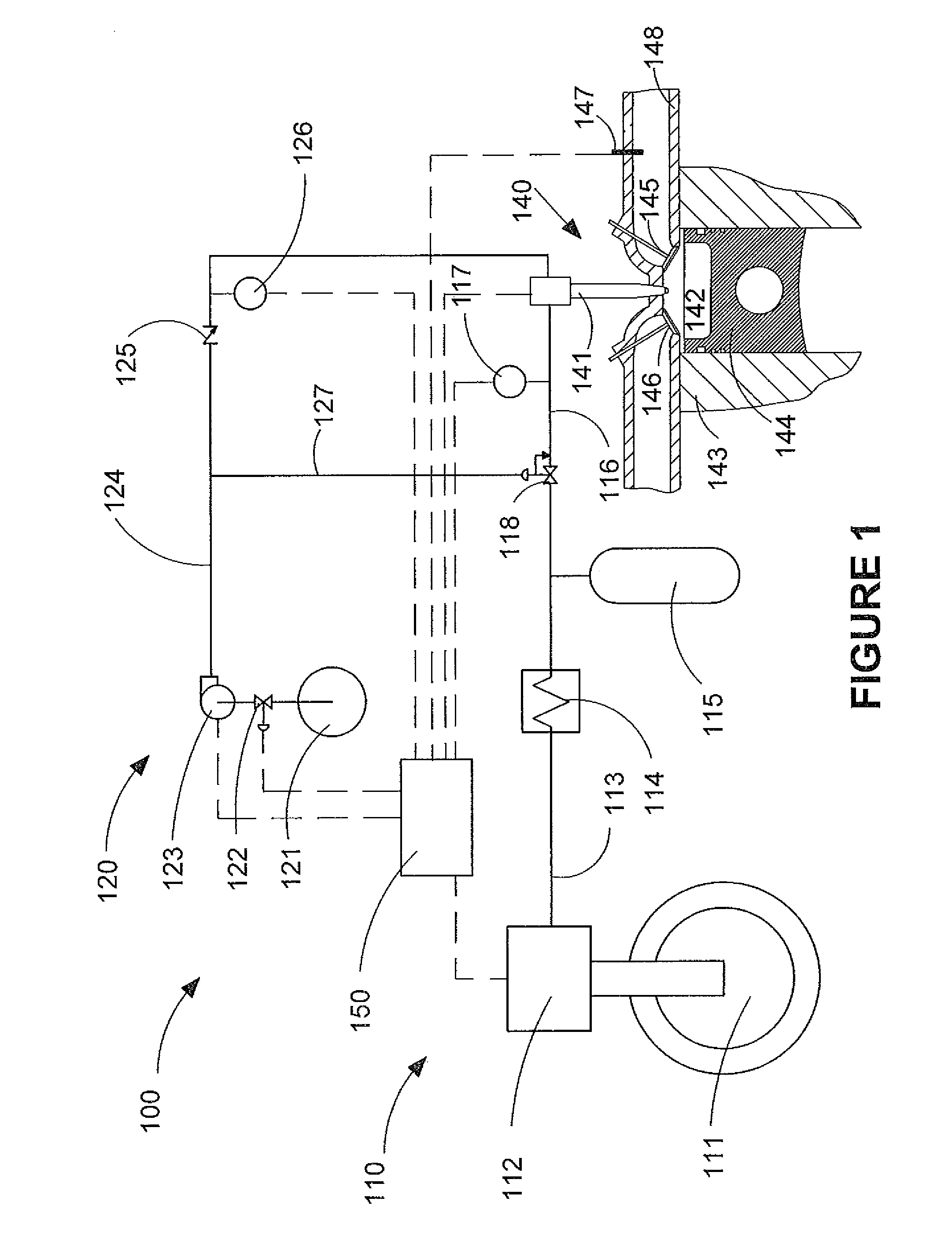

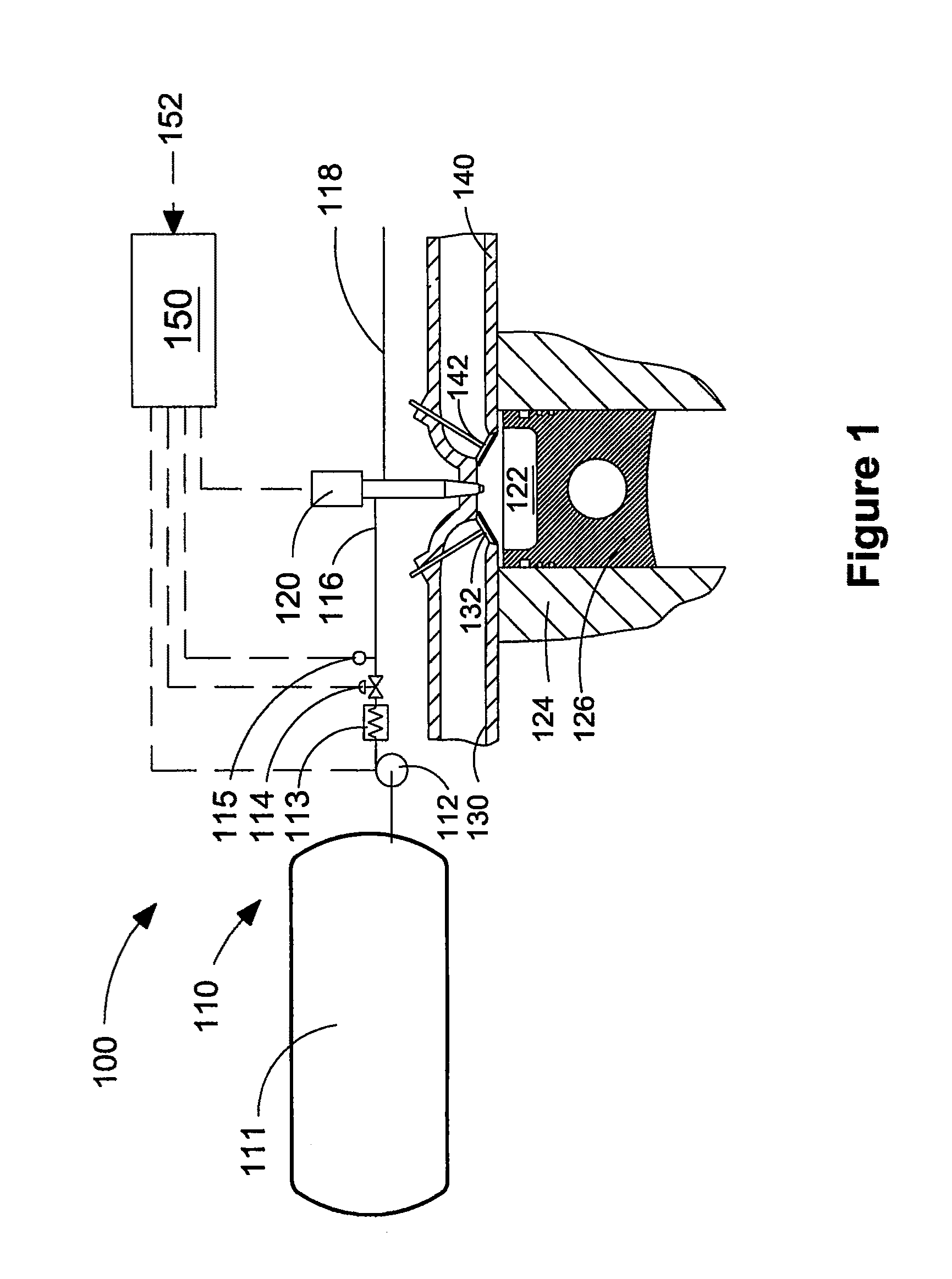

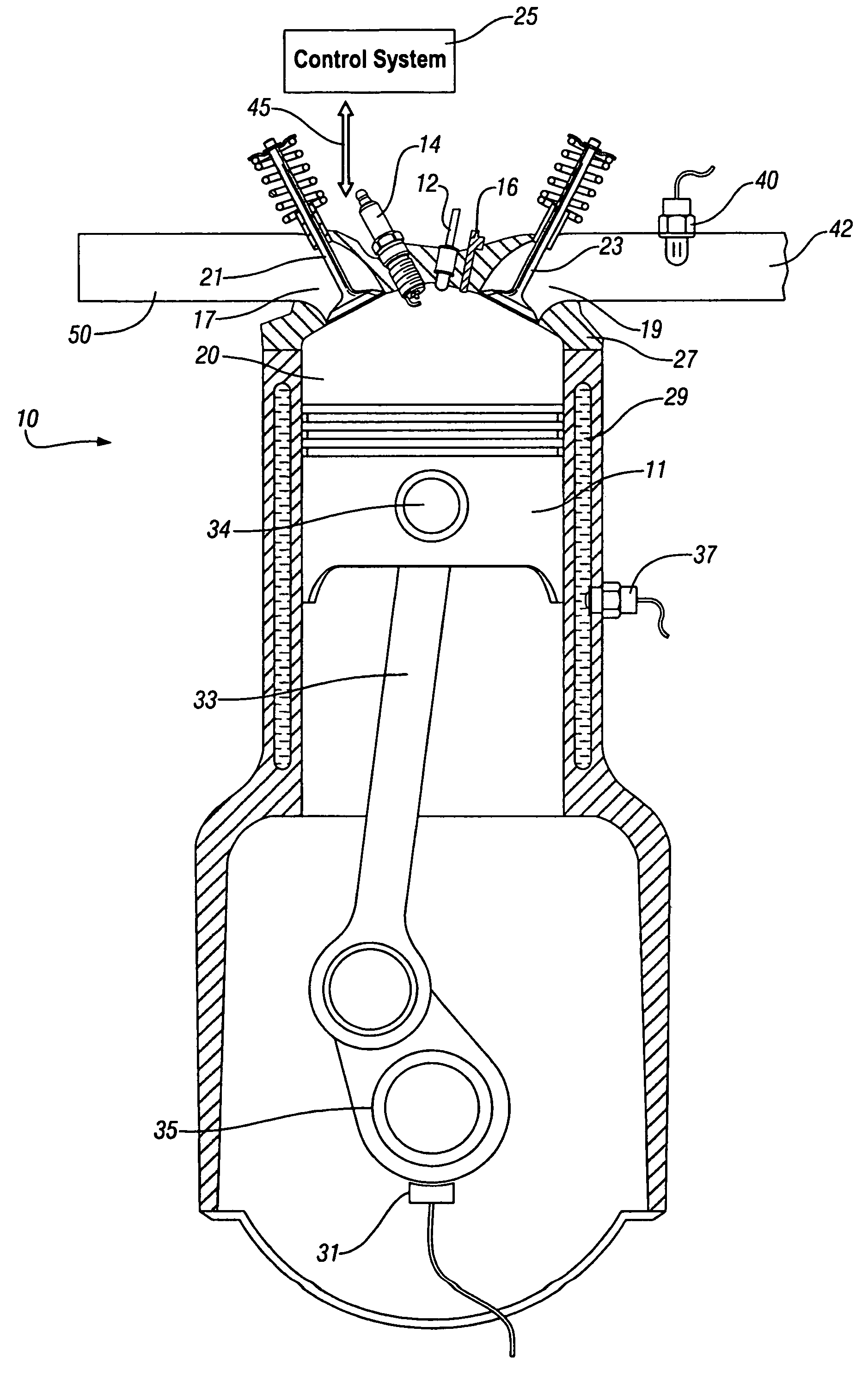

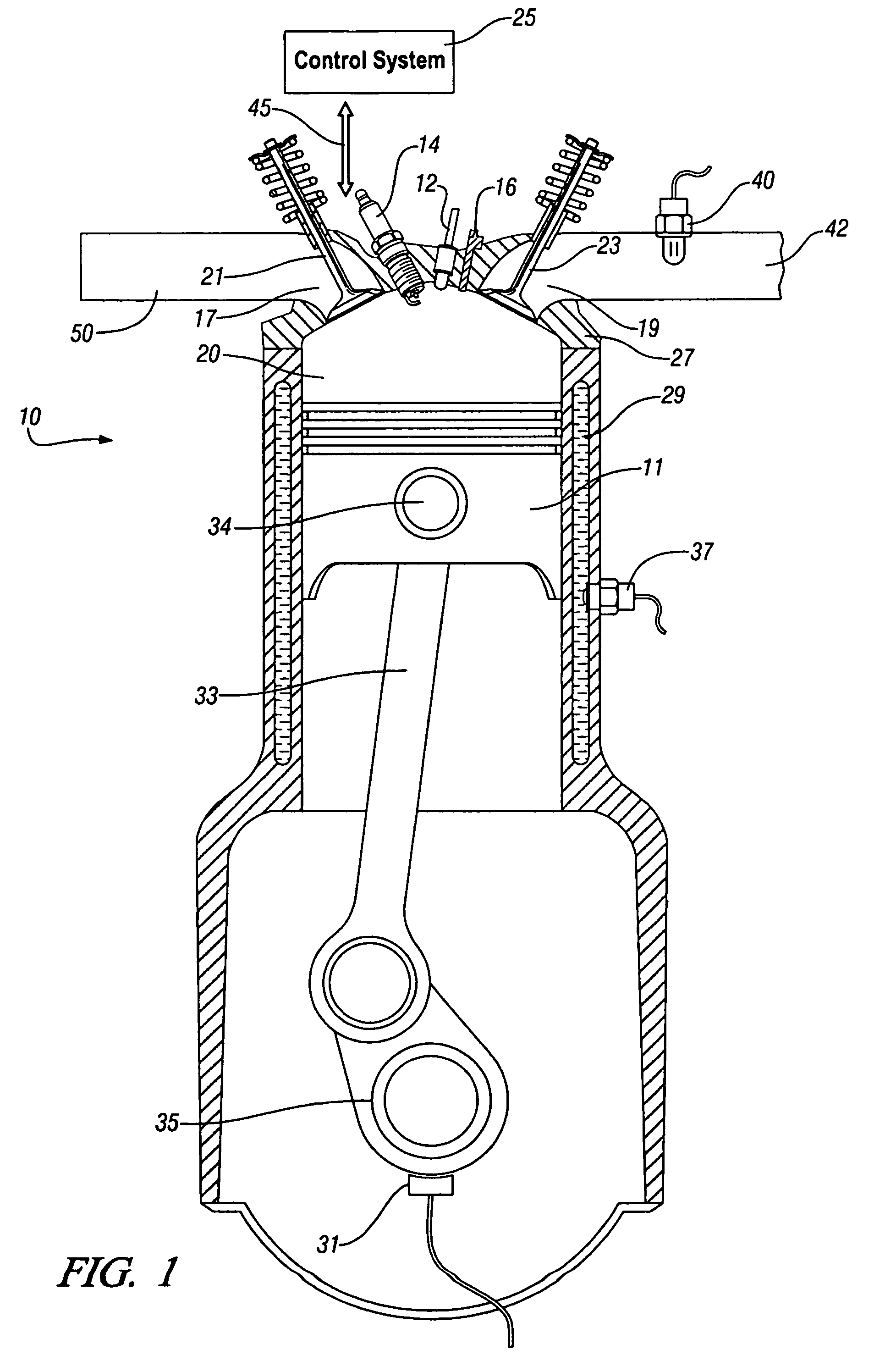

A premixed charge compression ignition engine, and a control system, is provided which effectively initiates combustion by compression ignition and maintains stable combustion while achieving extremely low nitrous oxide emissions, good overall efficiency and acceptable combustion noise and cylinder pressures. The present engine and control system effectively controls the combustion history, that is, the time at which combustion occurs, the rate of combustion, the duration of combustion and / or the completeness of combustion, by controlling the operation of certain control variables providing temperature control, pressure control, control of the mixture's autoignition properties and equivalence ratio control. The combustion control system provides active feedback control of the combustion event and includes a sensor, e.g. pressure sensor, for detecting an engine operating condition indicative of the combustion history, e.g. the start of combustion, and generating an associated engine operating condition signal. A processor receives the signal and generates control signals based on the engine operating condition signal for controlling various engine components to control the temperature, pressure, equivalence ratio and / or autoignition properties so as to variably control the combustion history of future combustion events to achieve stable, low emission combustion in each cylinder and combustion balancing between the cylinders.

Owner:CUMMINS INC

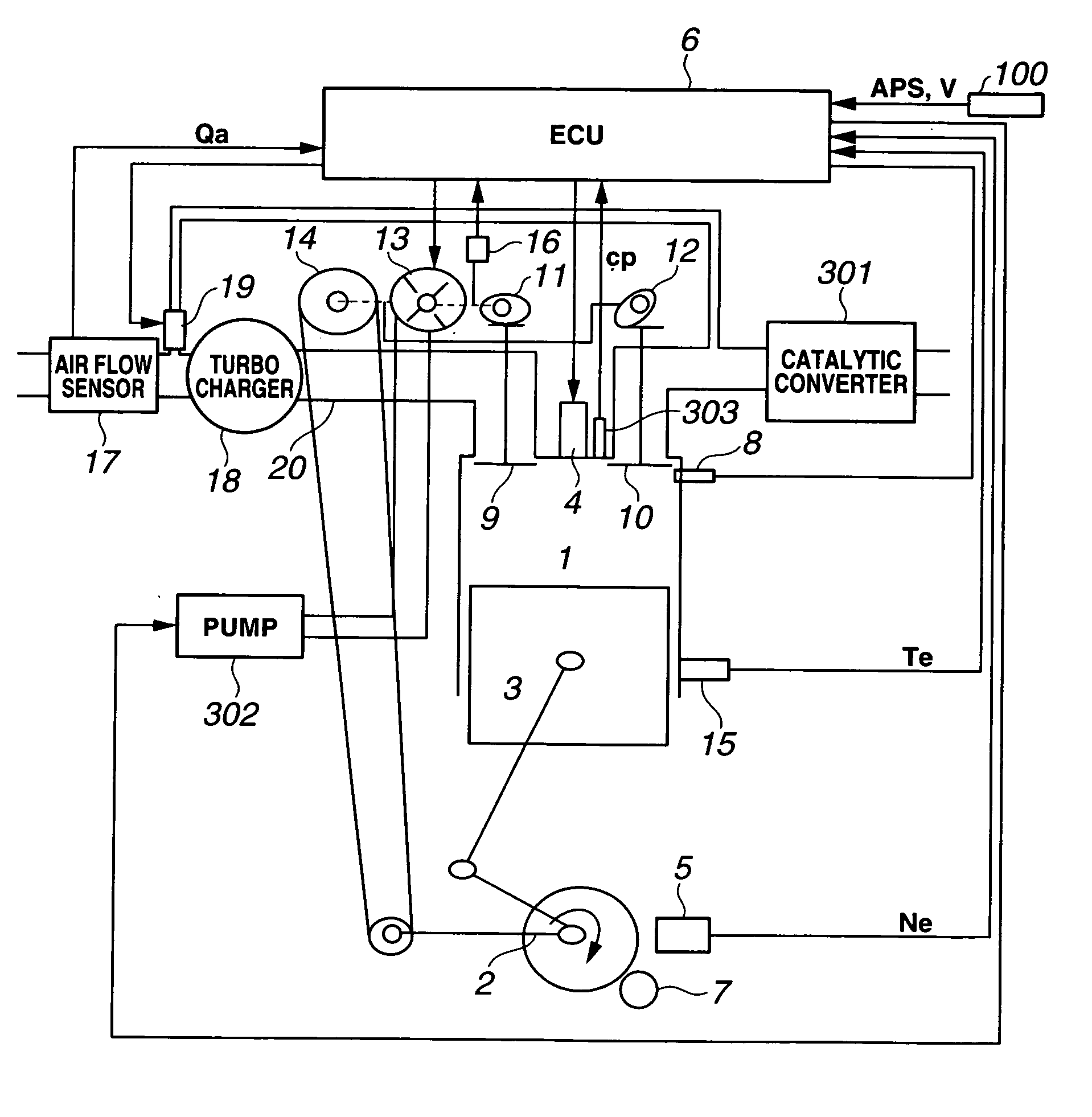

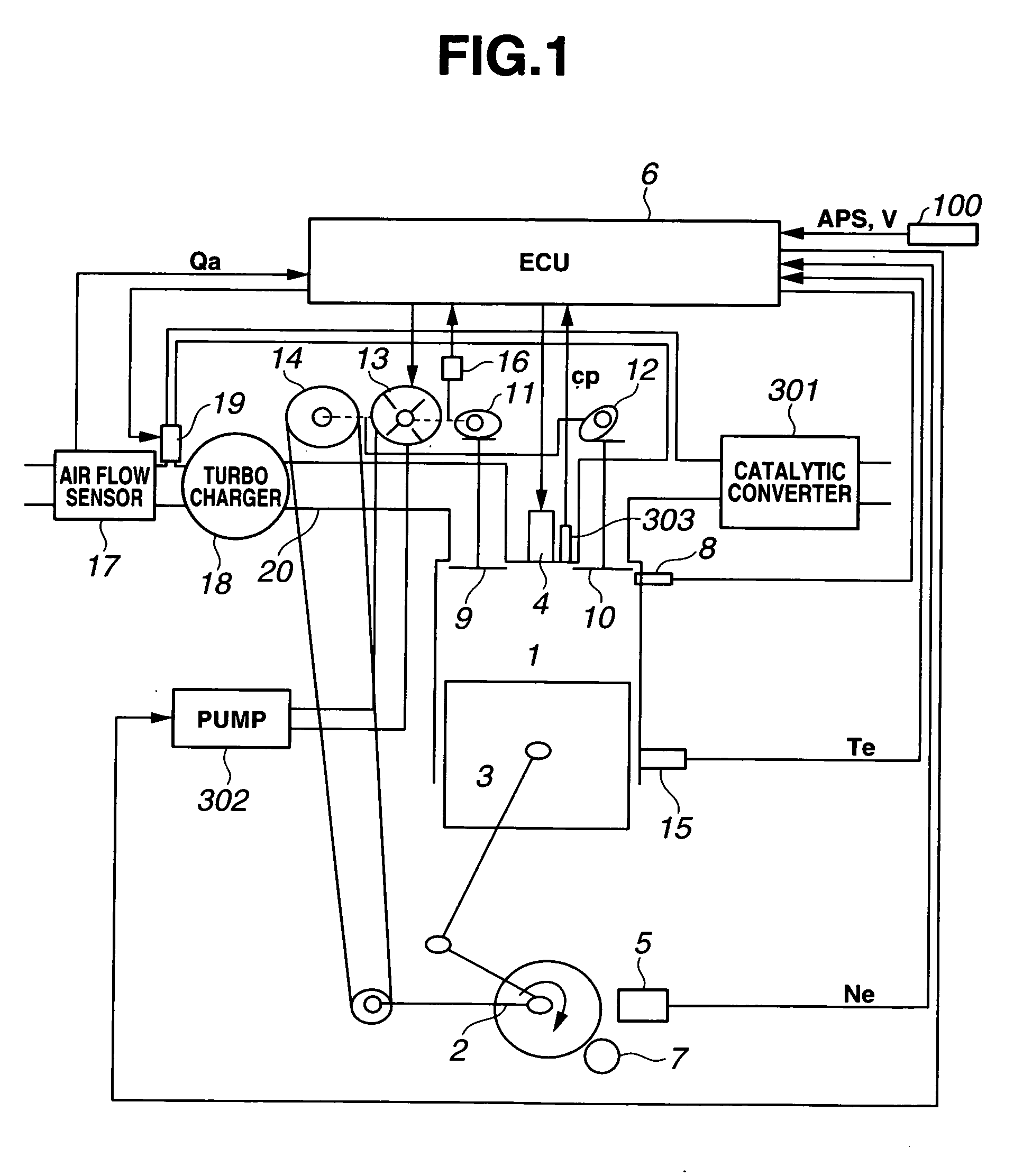

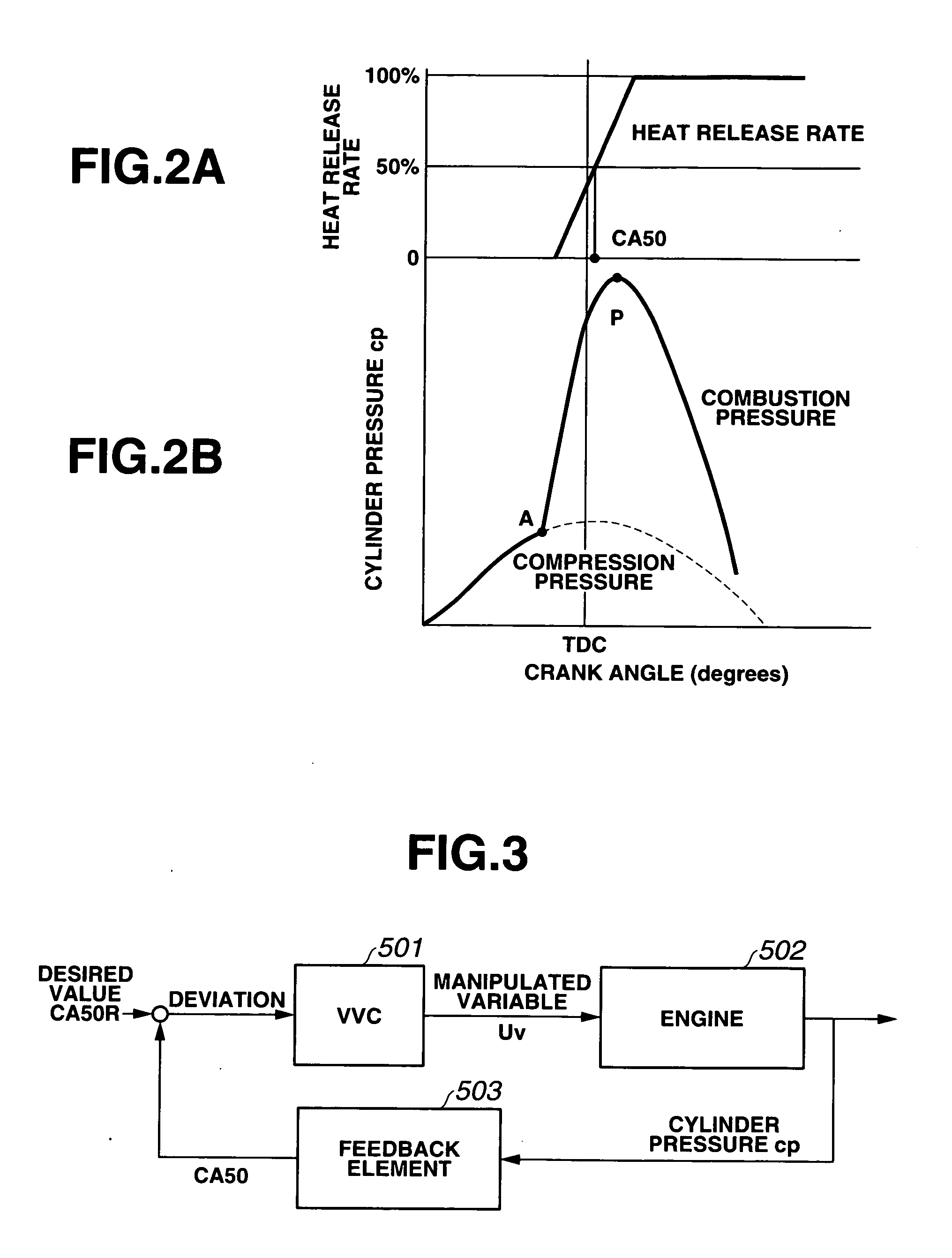

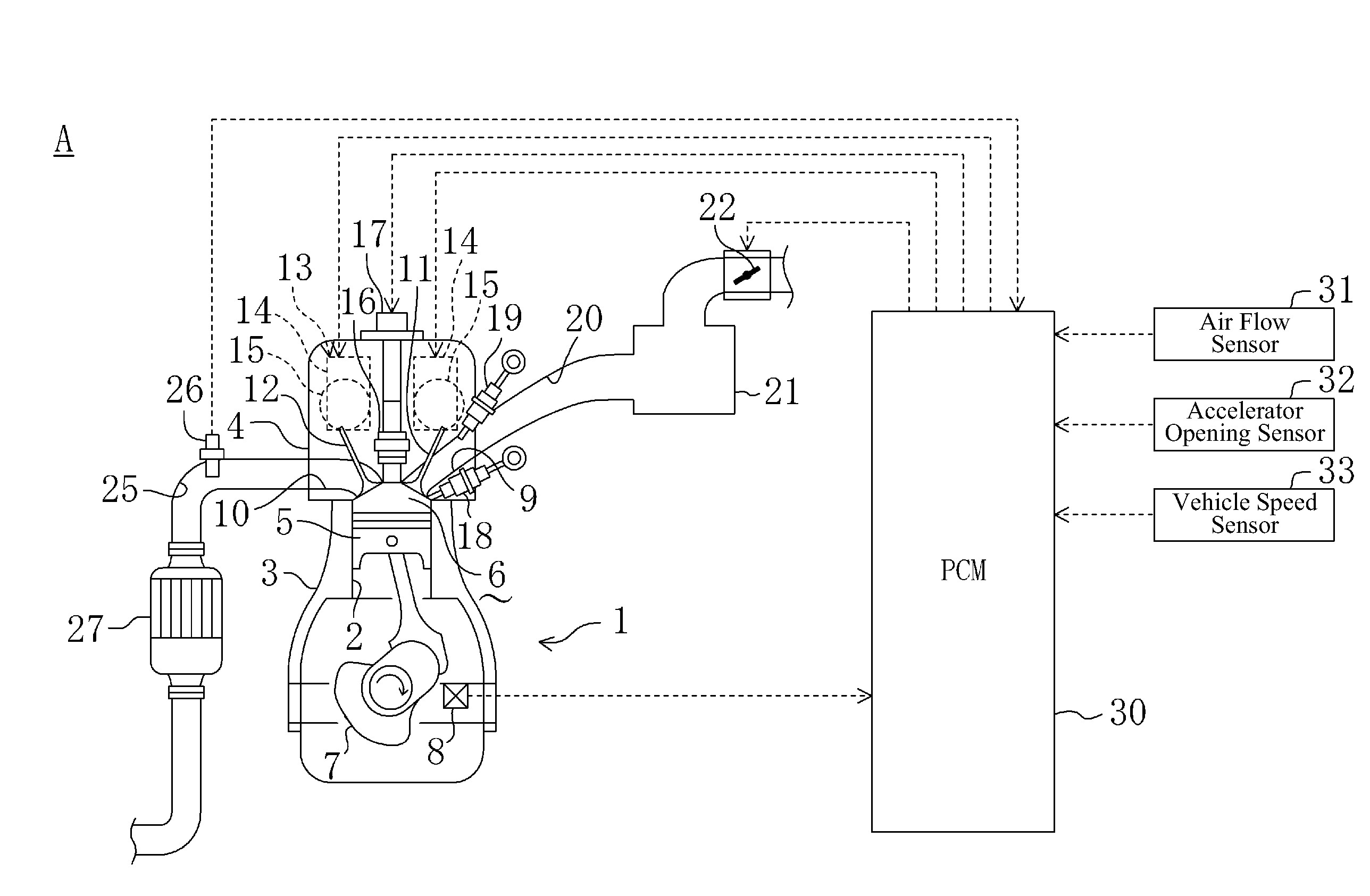

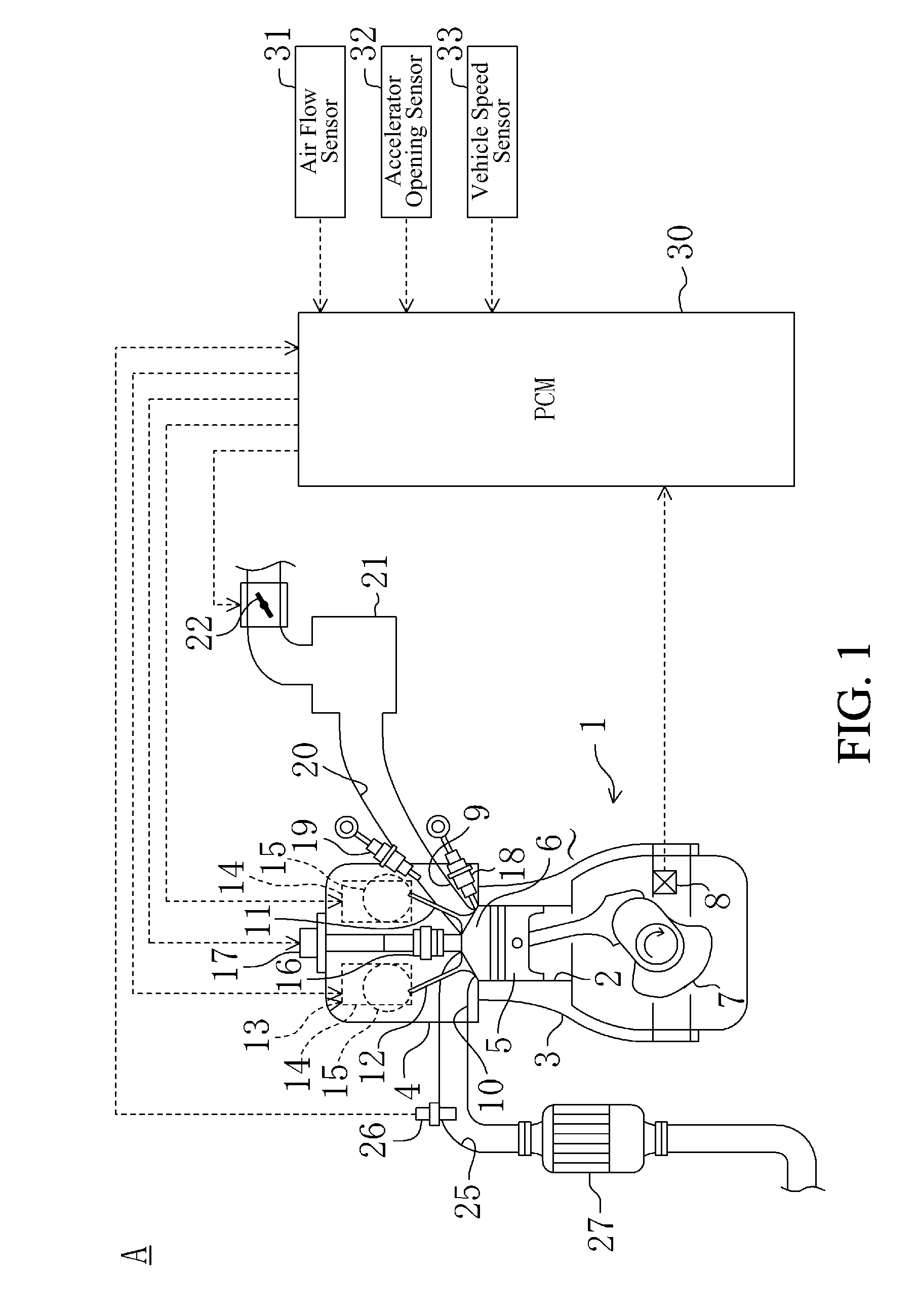

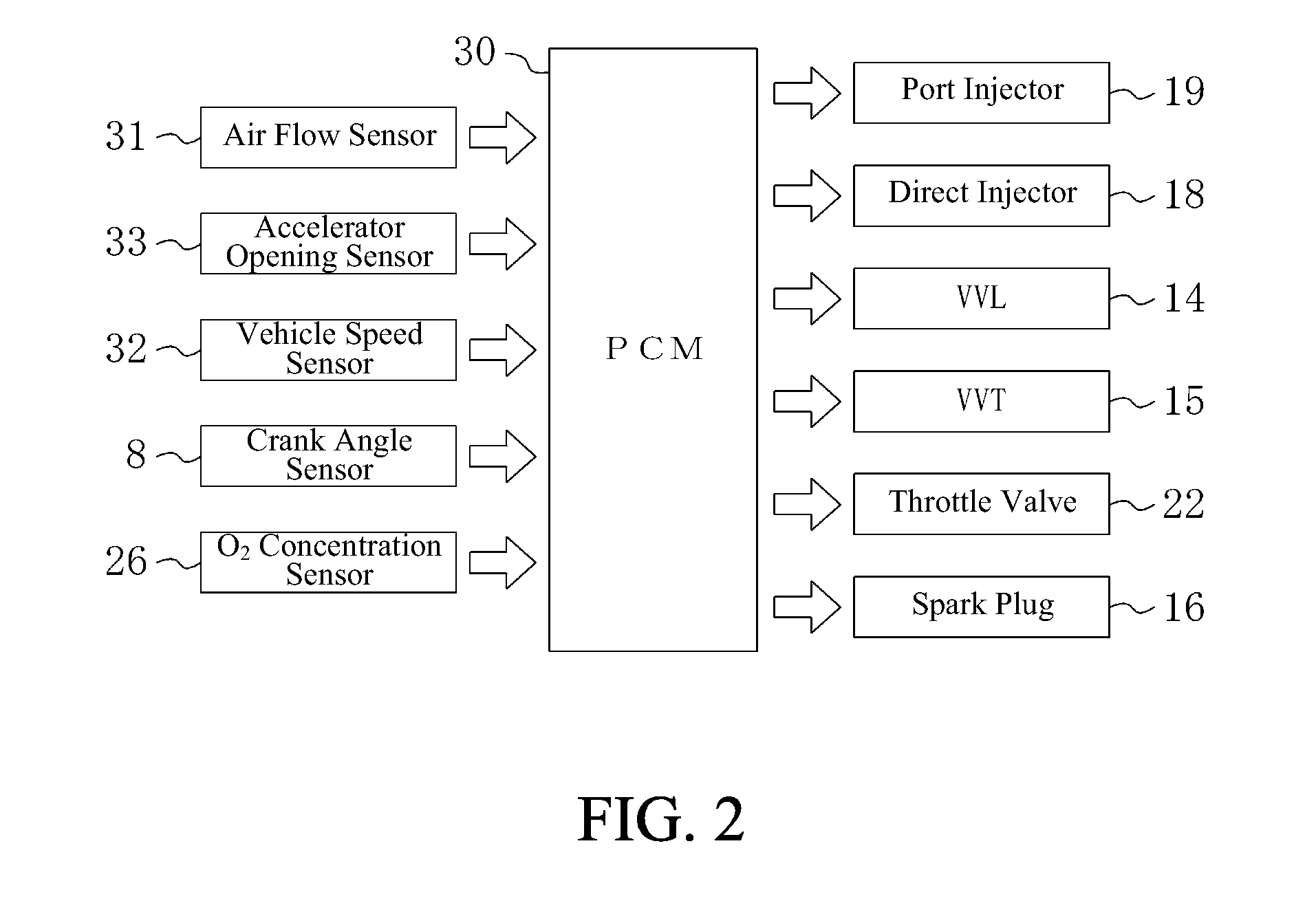

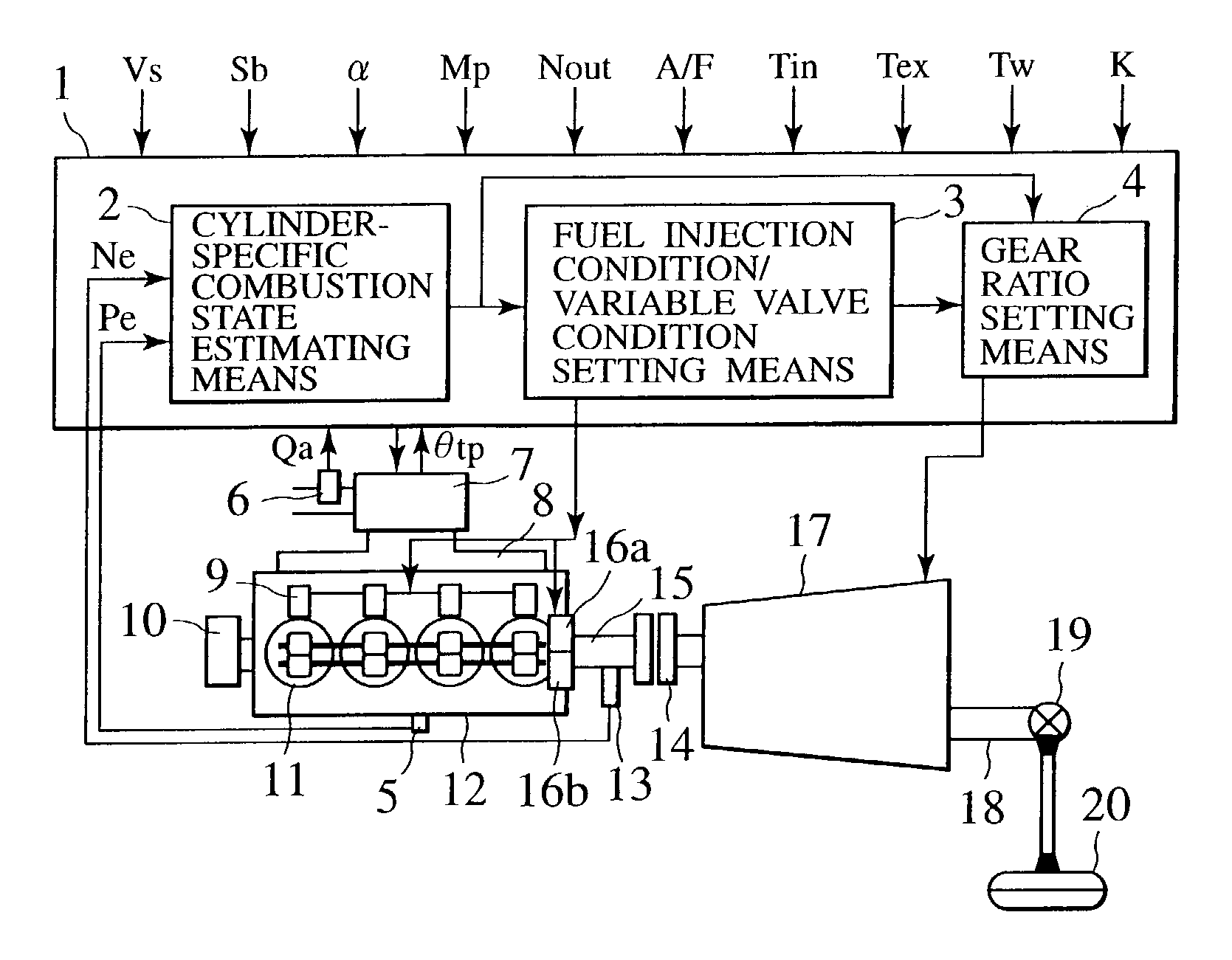

Control apparatus for controlling internal combustion engines

InactiveUS20070089697A1Minimize biasElectrical controlInternal combustion piston enginesControl systemInternal combustion engine

In a control apparatus for controlling a variable valve actuation system employed in an internal combustion engine, engine / vehicle sensors are provided to detect at least a cylinder pressure in an engine cylinder for monitoring a change of state in combustion, arising from fluctuations in states / characteristics of air-fuel mixture such as a change in fuel property. Also provided is a control system that controls the variable valve actuation system responsively to a manipulated variable modified based on the cylinder pressure reflecting the change of state in combustion by a model of combustion.

Owner:HITACHI LTD

Cylinder deactivation method to minimize drivetrain torsional disturbances

ActiveUS20050131618A1Reduce engine vibrationImprove fuel economyAnalogue computers for vehiclesElectrical controlDriver/operatorDrivetrain

Owner:FORD GLOBAL TECH LLC

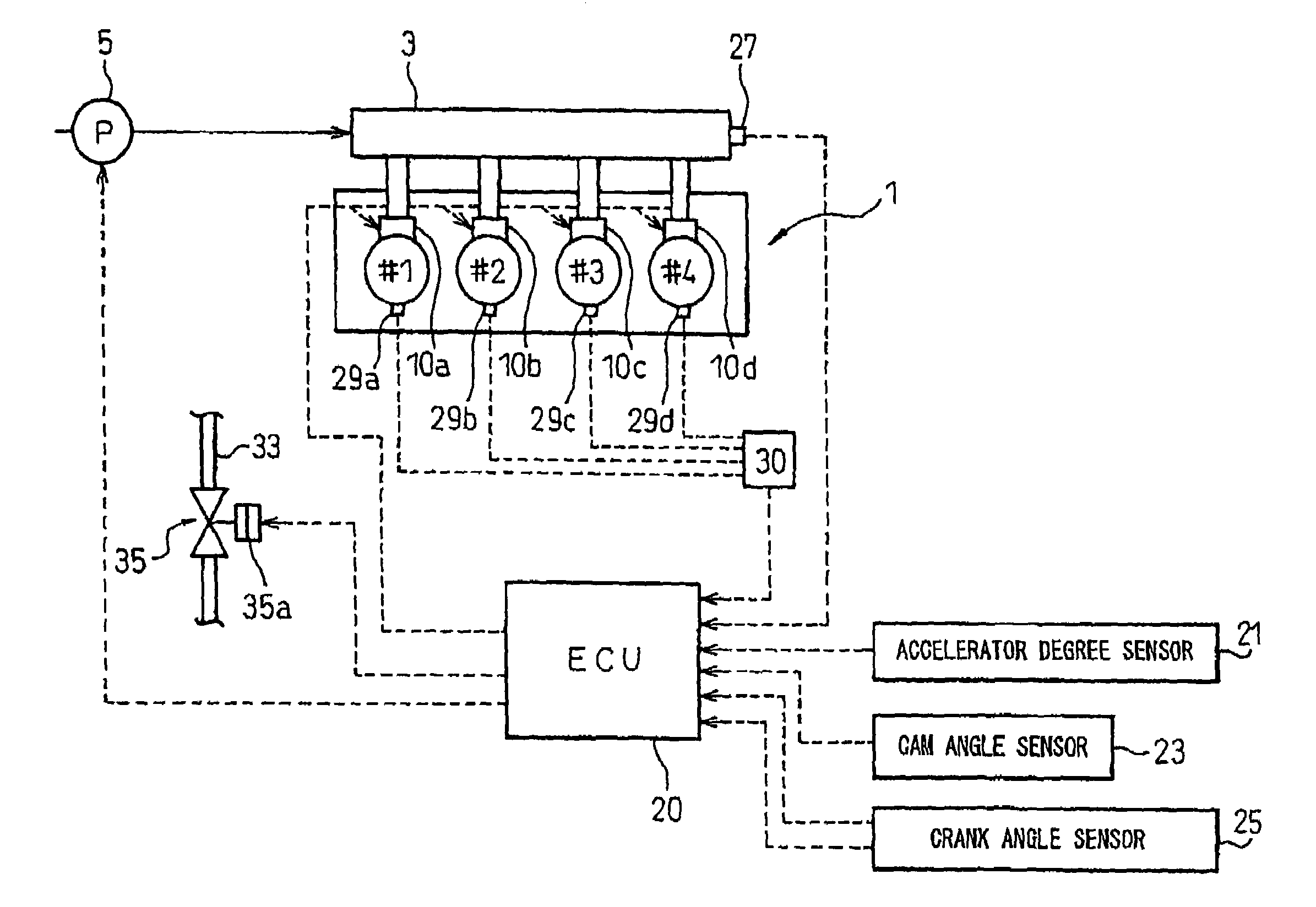

Control device of internal combustion engine

InactiveUS20050229903A1Good precision EGR controlEasy to controlElectrical controlNon-fuel substance addition to fuelCombustion chamberInternal combustion engine

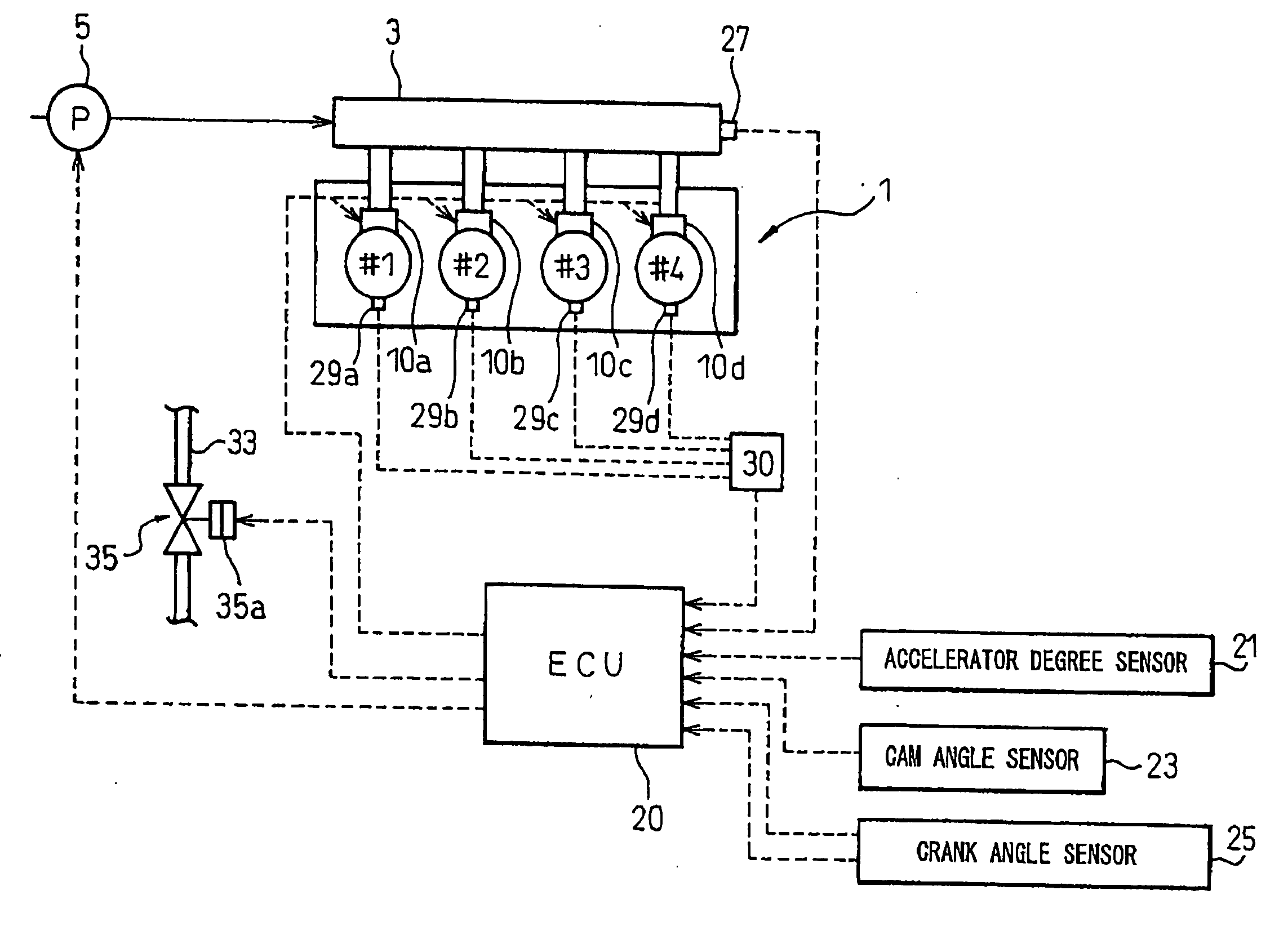

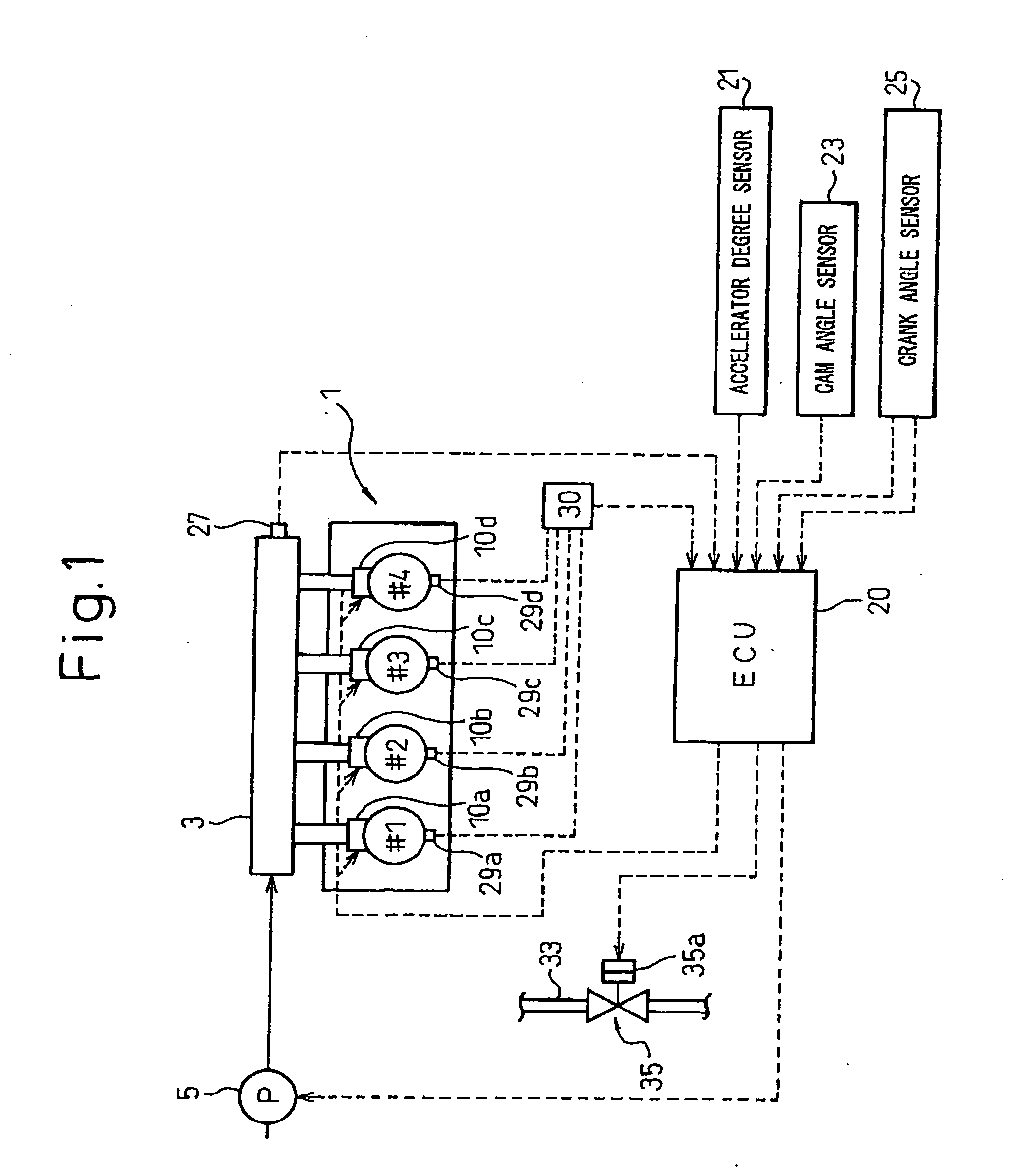

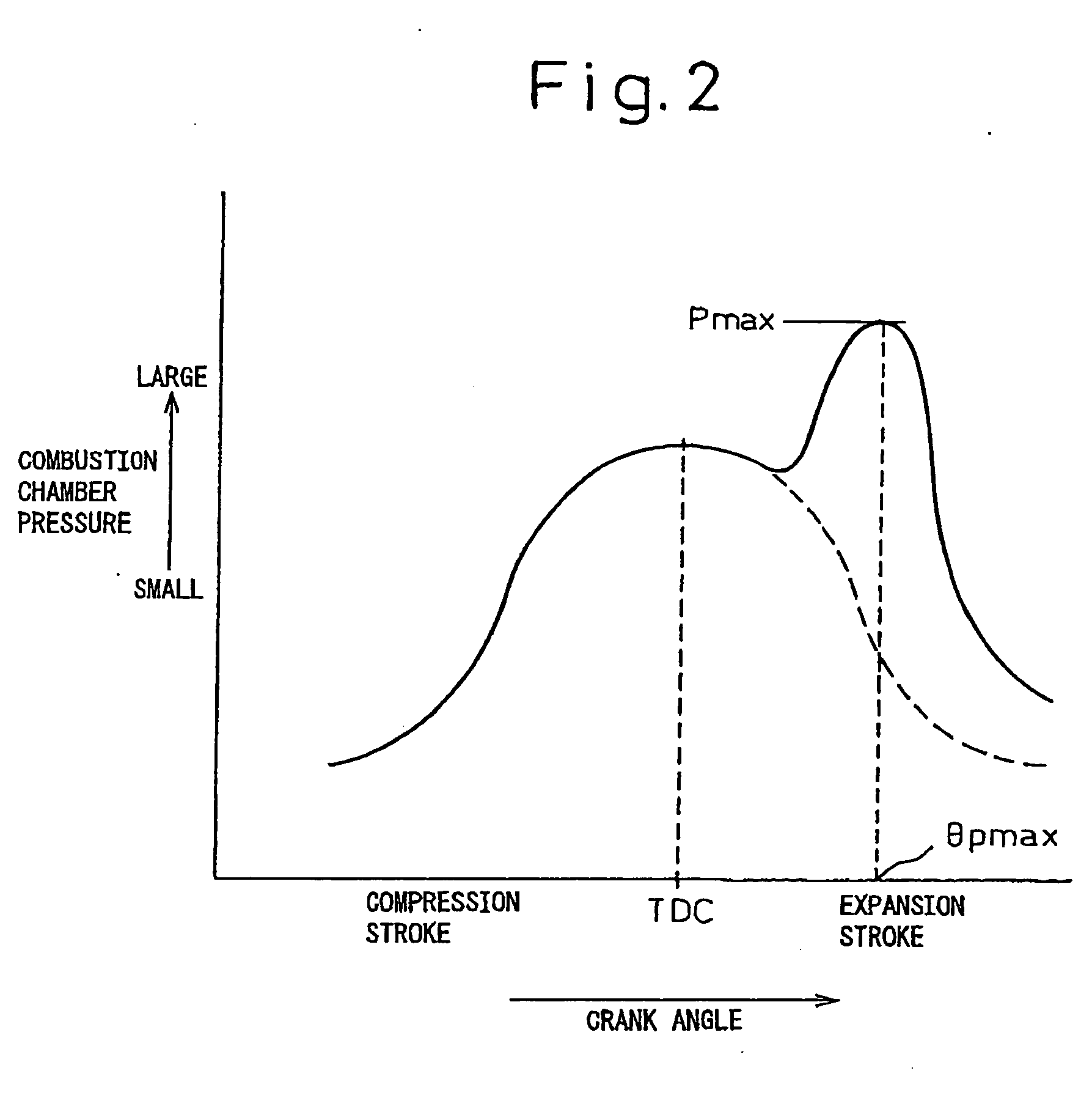

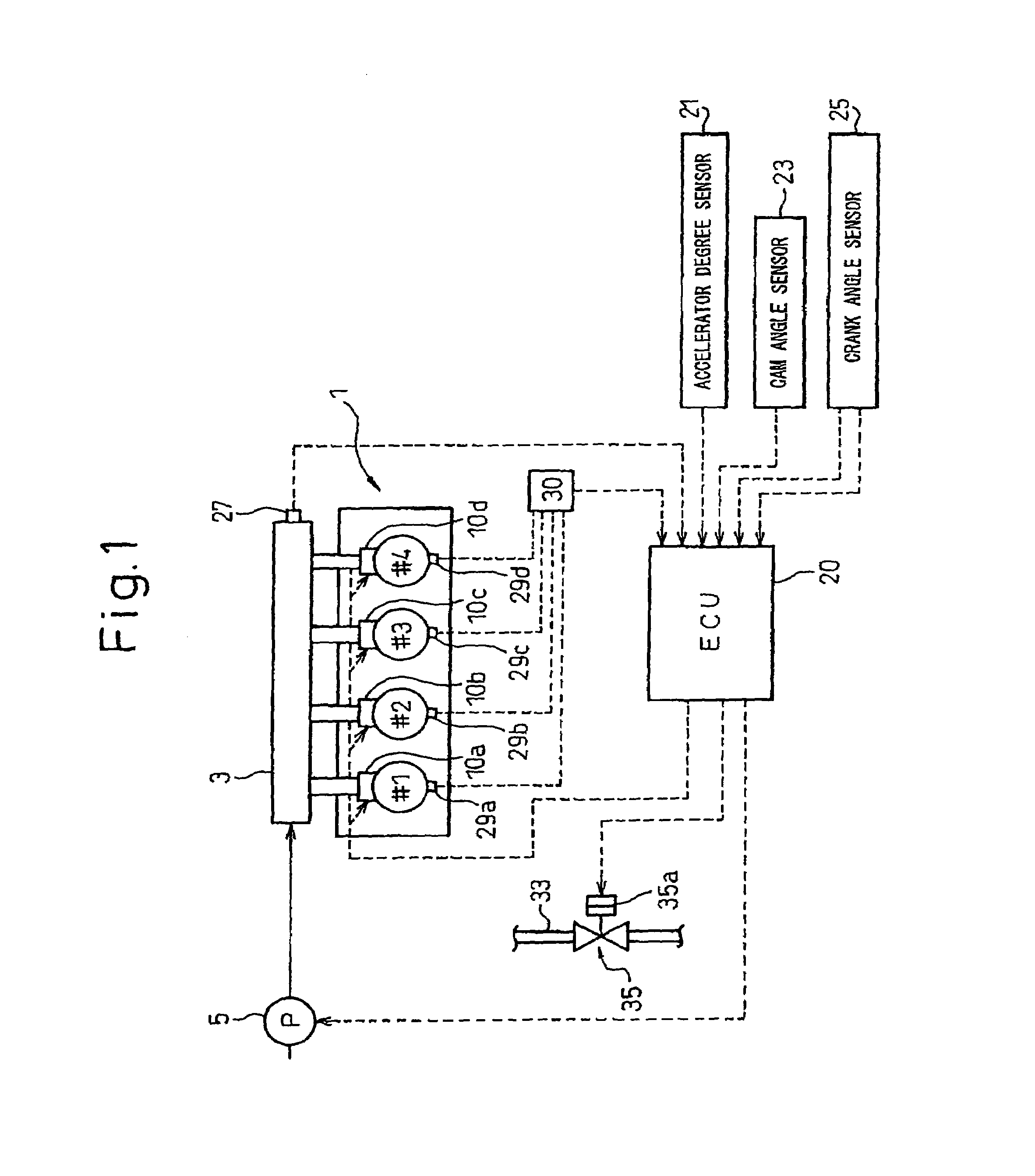

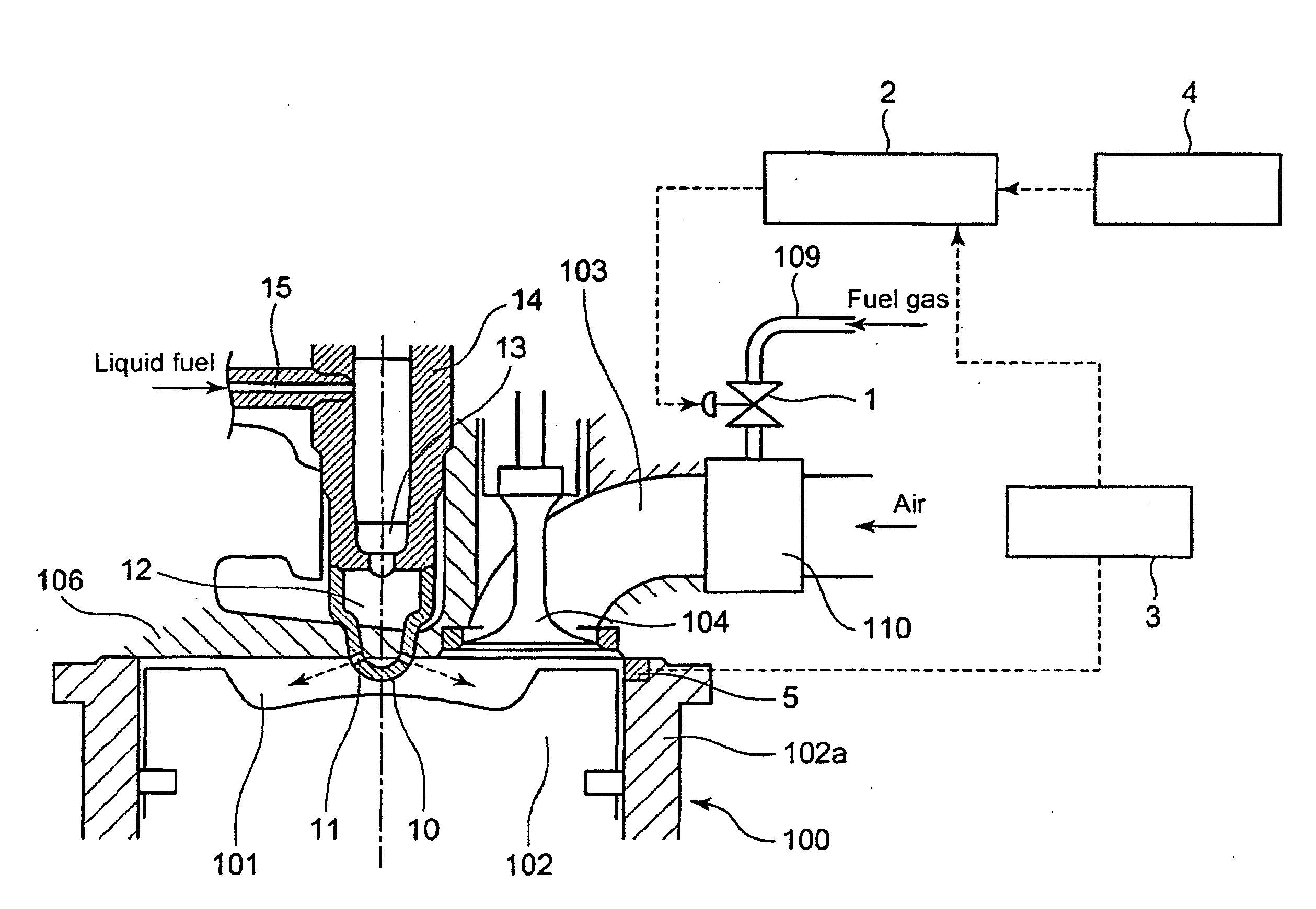

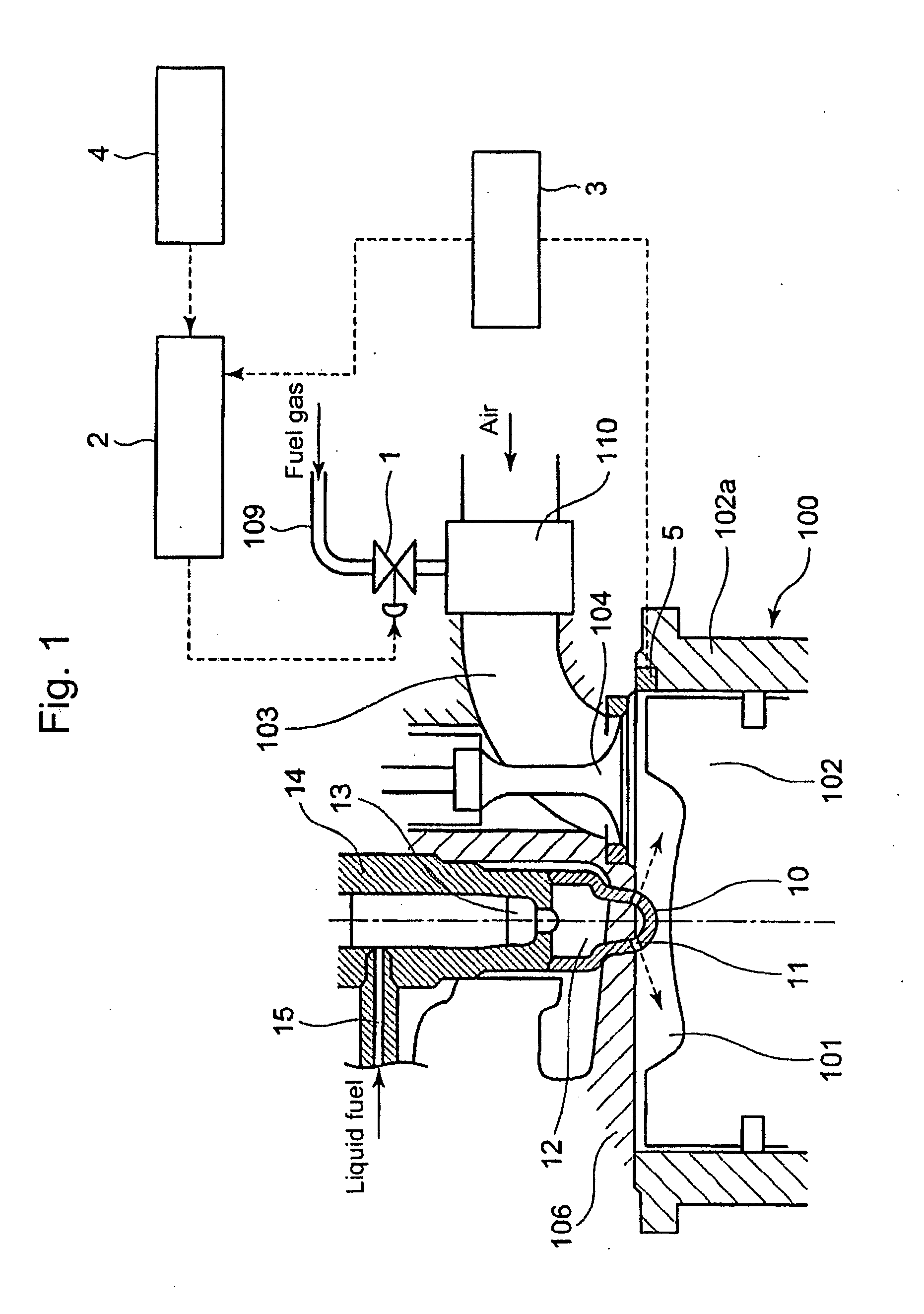

Cylinders of a diesel engine 1 are provided with cylinder pressure sensors 29a to 29d for detecting combustion chamber pressures. An electronic control unit (ECU) 20 of the engine selects optimum combustion parameters in accordance with a fuel injection mode of fuel injectors 10a to 10d of the engine and a combustion mode determined by the amount of EGR gas supplied from the EGR valve 35 from among a plurality of types of combustion parameters expressing the combustion state of the engine calculated based on the cylinder pressure sensor output and feedback controls the fuel injection amount and fuel injection timing so that the values of the combustion parameters match target values determined in accordance with the engine operating conditions. Due to this, the engine combustion state is controlled to the optimum state at all times regardless of the fuel injection mode or combustion mode.

Owner:TOYOTA JIDOSHA KK

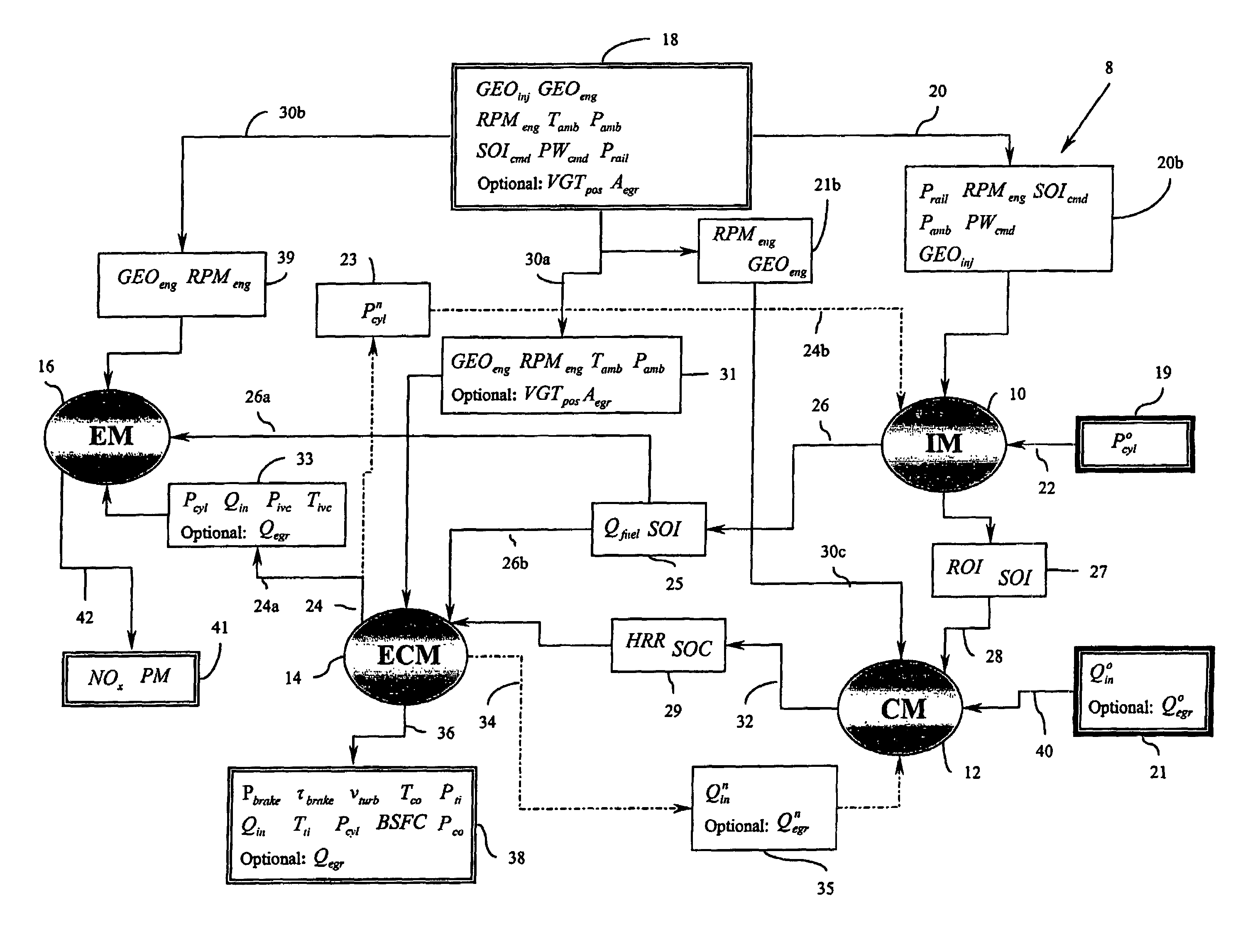

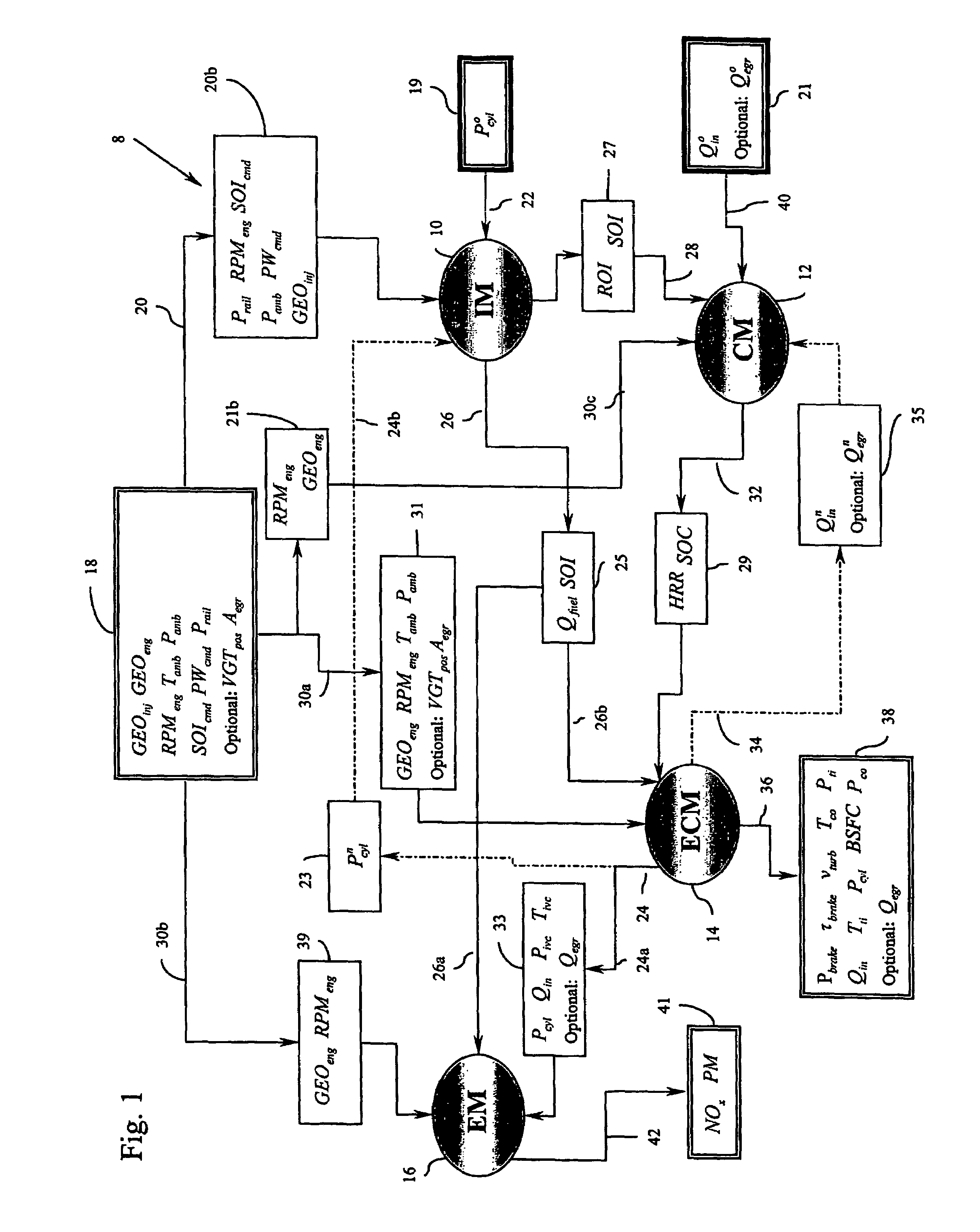

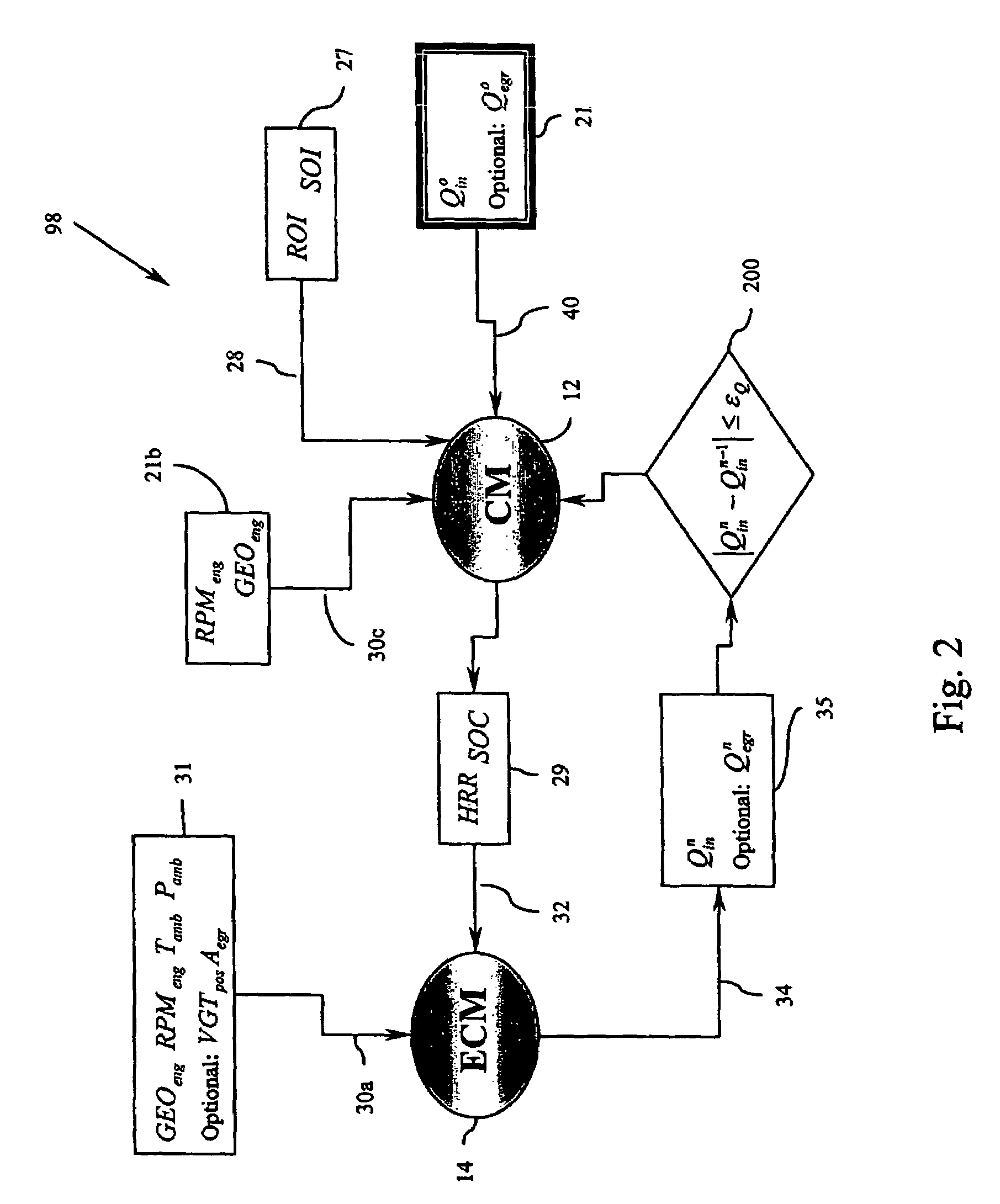

Method for controlling combustion in an internal combustion engine and predicting performance and emissions

InactiveUS7392129B2Electrical controlInternal combustion piston enginesBrake torqueBrake specific fuel consumption

Owner:WESTPORT POWER

Control system for internal combustion engine

InactiveUS6994077B2Easy to controlElectrical controlInternal combustion piston enginesCombustion chamberControl system

Cylinders of a diesel engine 1 are provided with cylinder pressure sensors 29a to 29d for detecting combustion chamber pressures. An electronic control unit (ECU) 20 of the engine selects optimum combustion parameters in accordance with a fuel injection mode of fuel injectors 10a to 10d of the engine and a combustion mode determined by the amount of EGR gas supplied from the EGR valve 35 from among a plurality of types of combustion parameters expressing the combustion state of the engine calculated based on the cylinder pressure sensor output and feedback controls the fuel injection amount and fuel injection timing so that the values of the combustion parameters match target values determined in accordance with the engine operating conditions. Due to this, the engine combustion state is controlled to the optimum state at all times regardless of the fuel injection mode or combustion mode.

Owner:TOYOTA JIDOSHA KK

Exhaust valve arrangement and a fuel system incorporating an exhaust valve arrangement

InactiveUS7533656B2Small diameterSecure attachmentMachines/enginesFuel injecting pumpsCombustion chamberExhaust valve

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

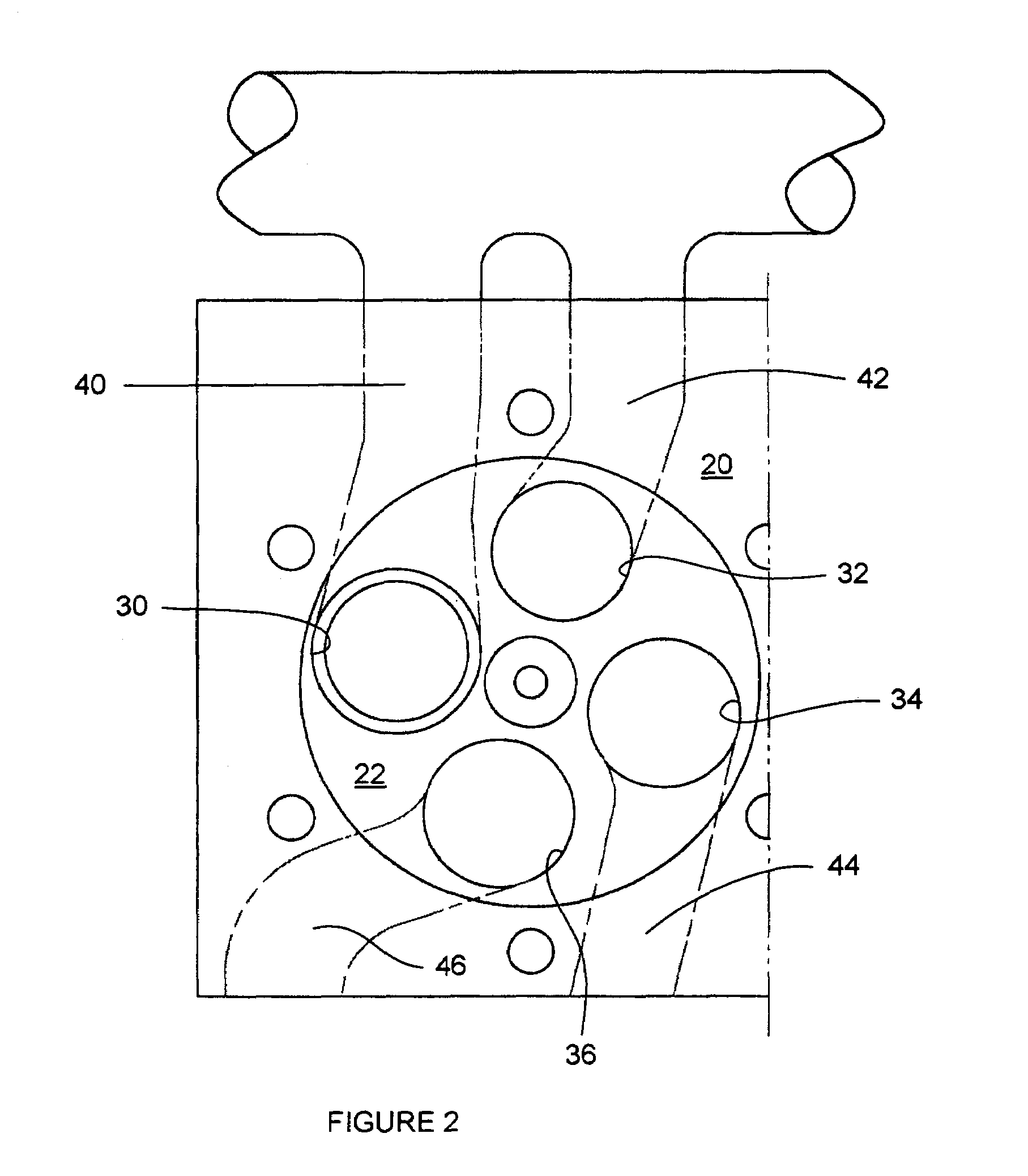

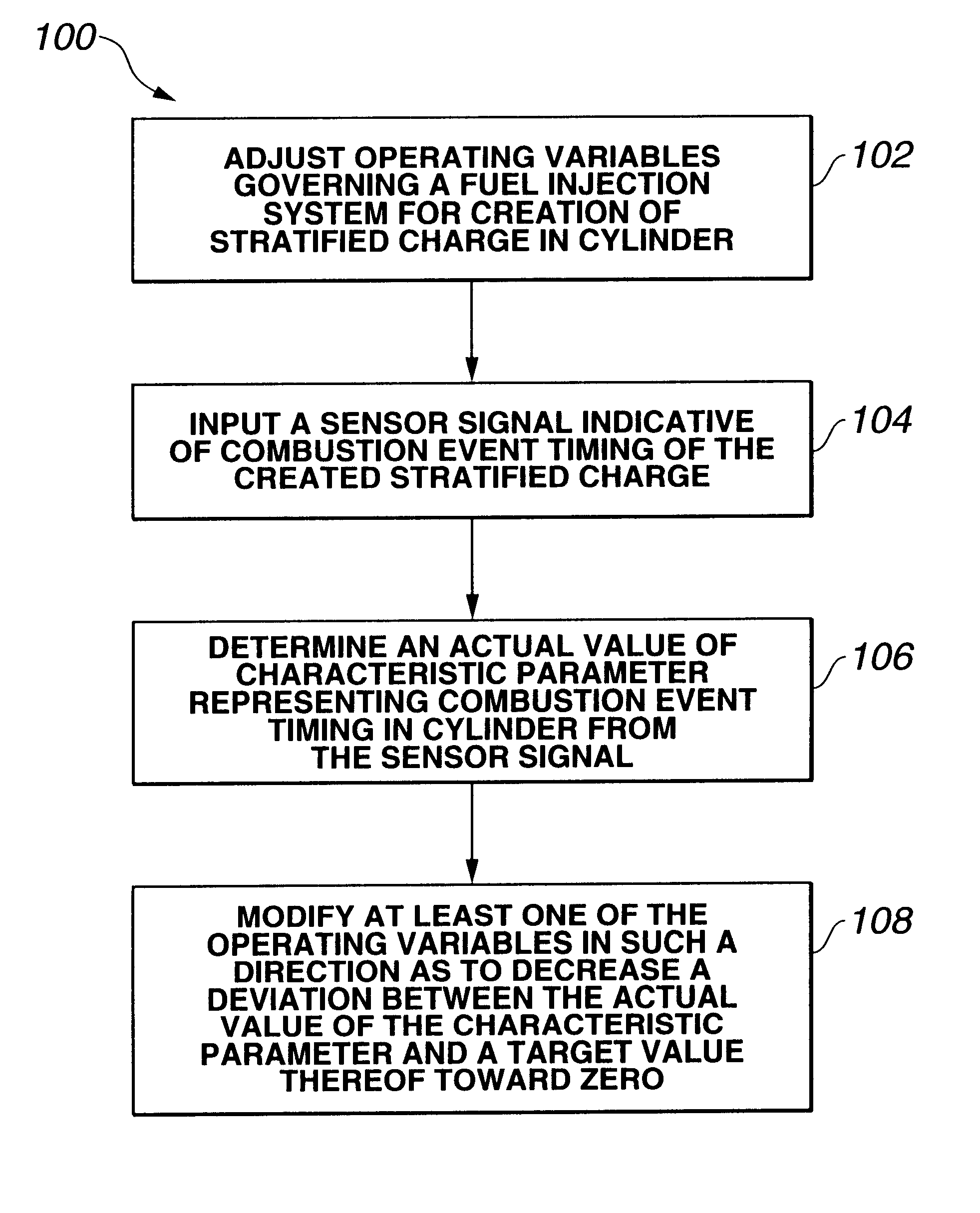

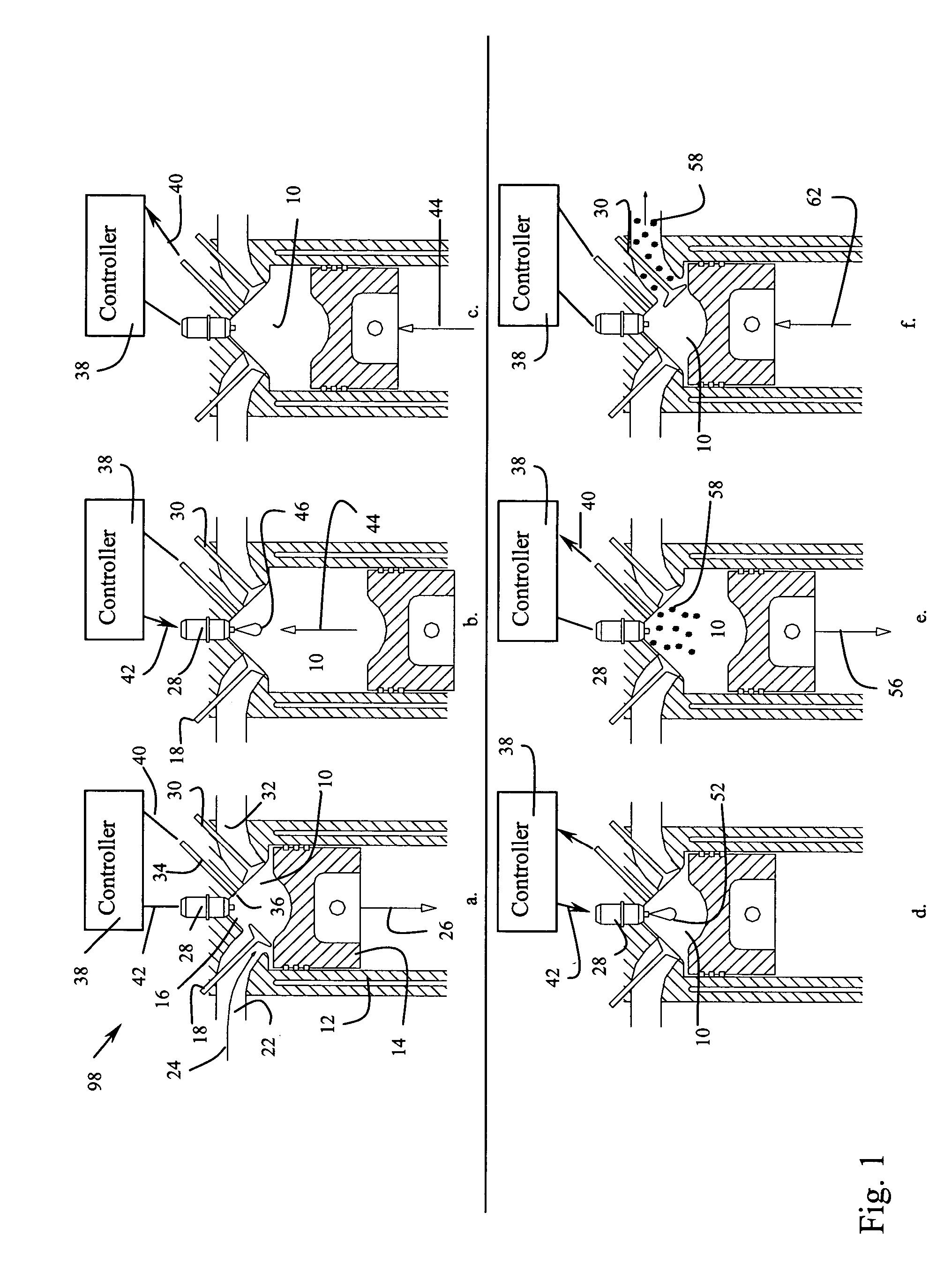

Feedback control for auto-ignition two-stage combustion of gasoline in engine cylinder

A split injection of gasoline produces stratified charge in at least one cylinder. A sensor measures cylinder pressure or knock and generates a sensor signal indicative of combustion event timing of stratified charge. From the sensor signal, a controller determines an actual value of a characteristic parameter representing combustion event timing in the cylinder. The controller modifies at least one of operating variables governing a split injection for the subsequent cycle in such a direction as to decrease a deviation between the actual value of the characteristic parameter and a target value thereof toward zero.

Owner:NISSAN MOTOR CO LTD

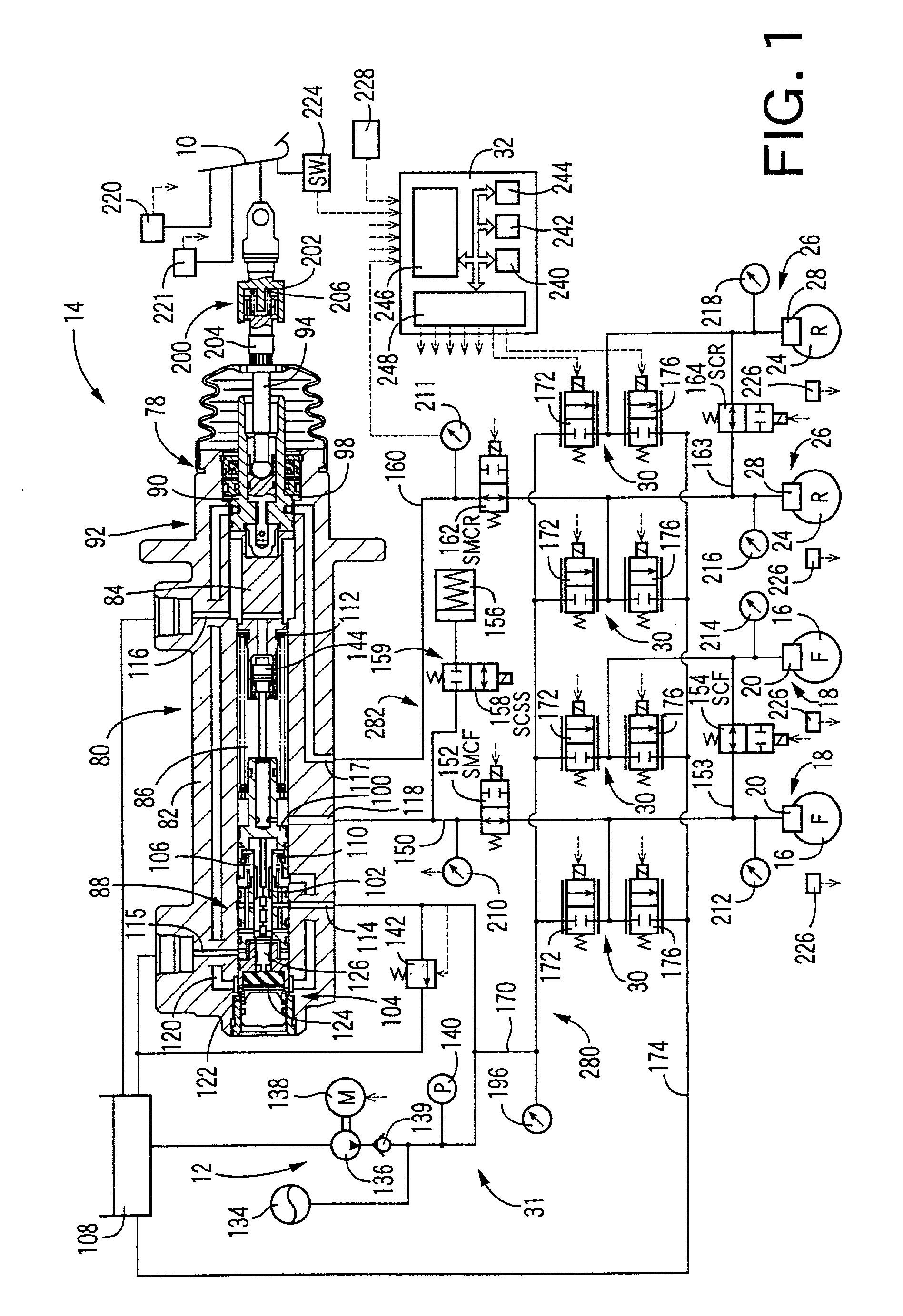

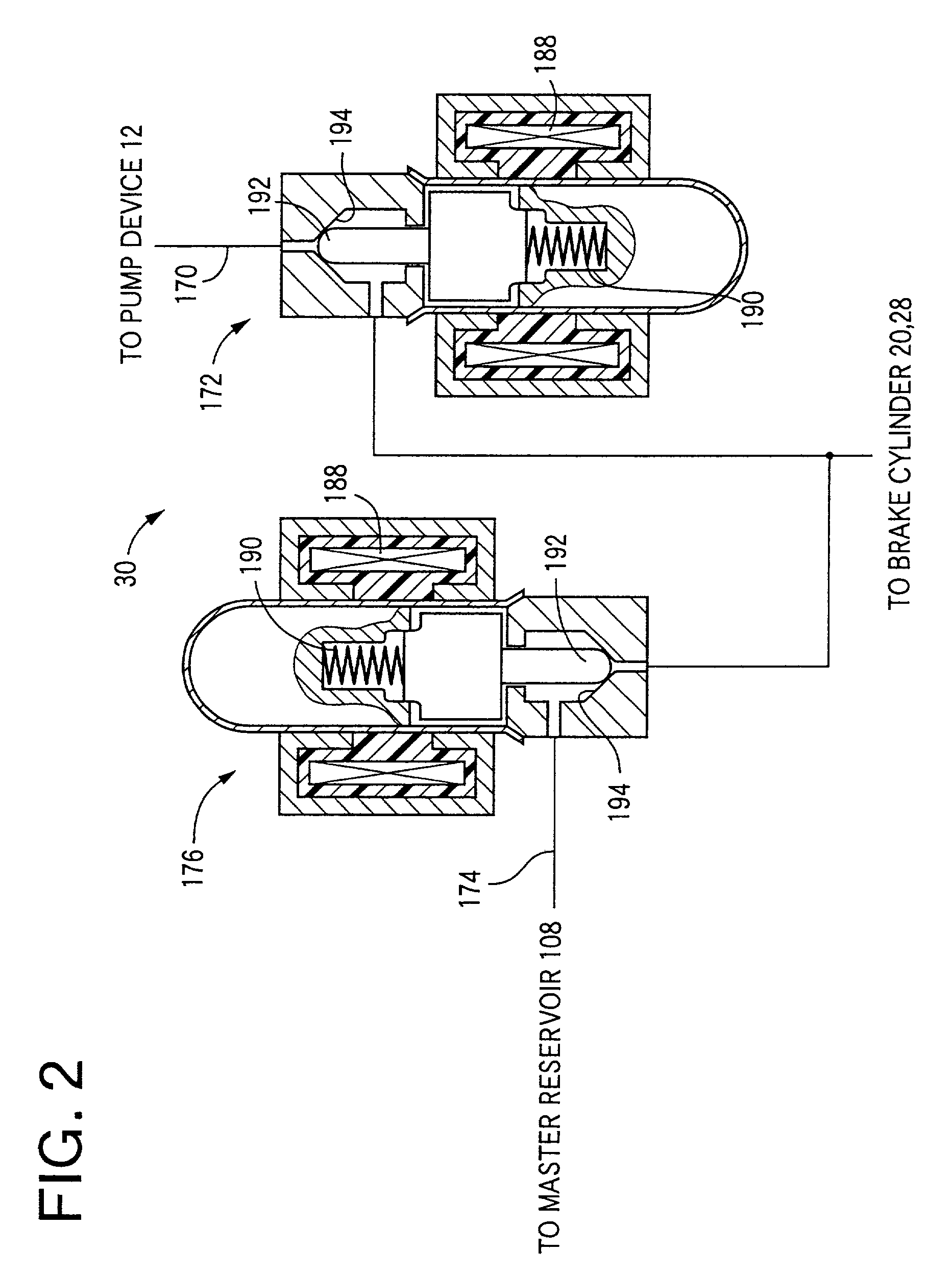

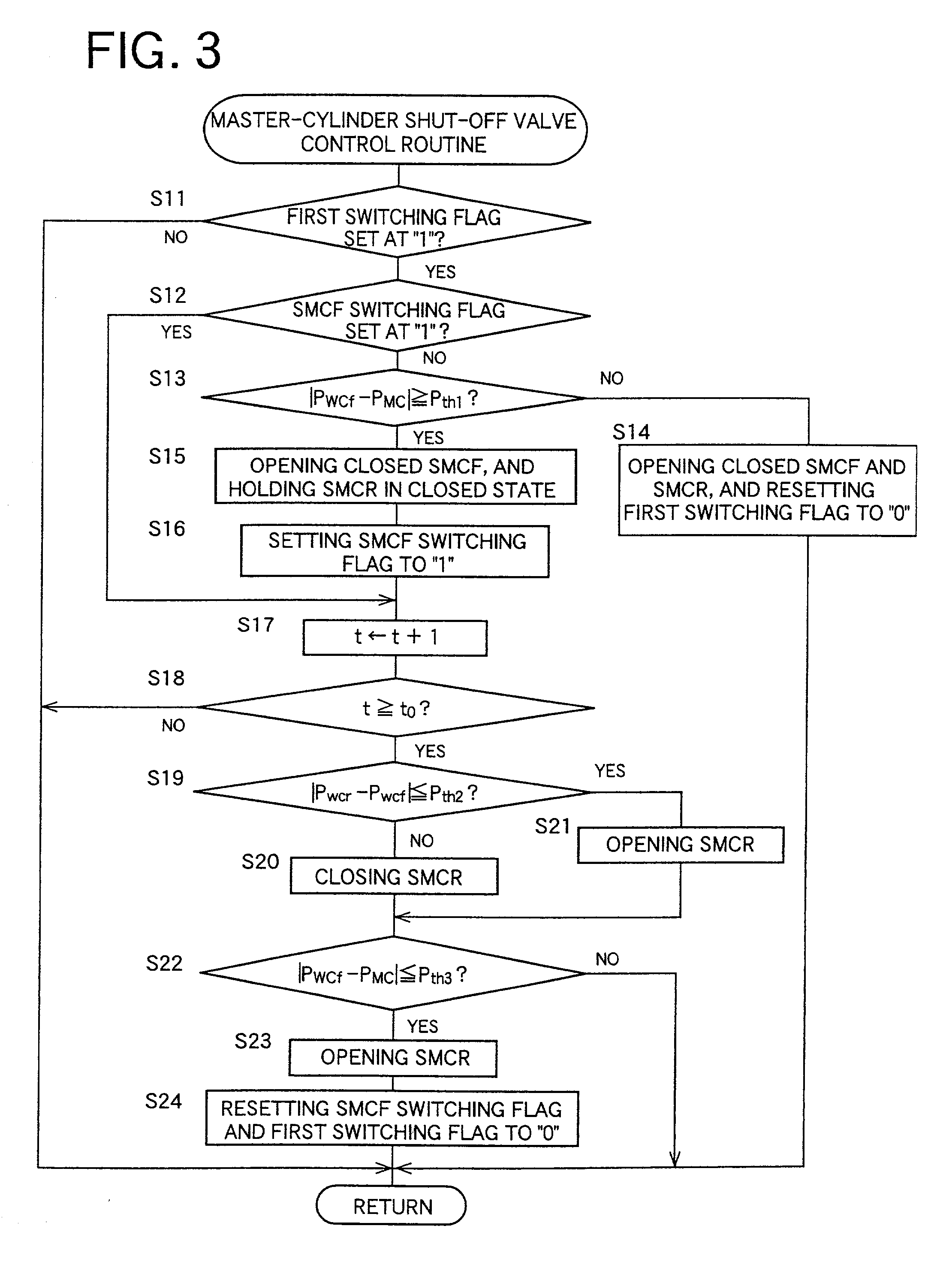

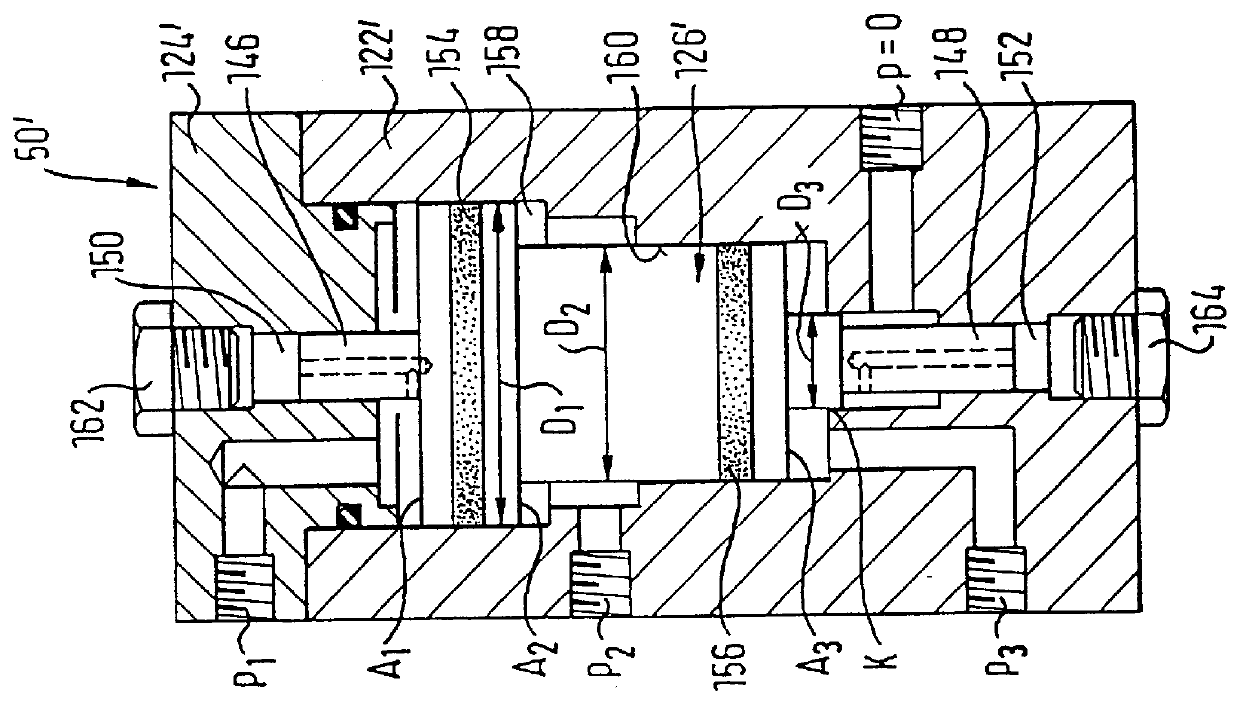

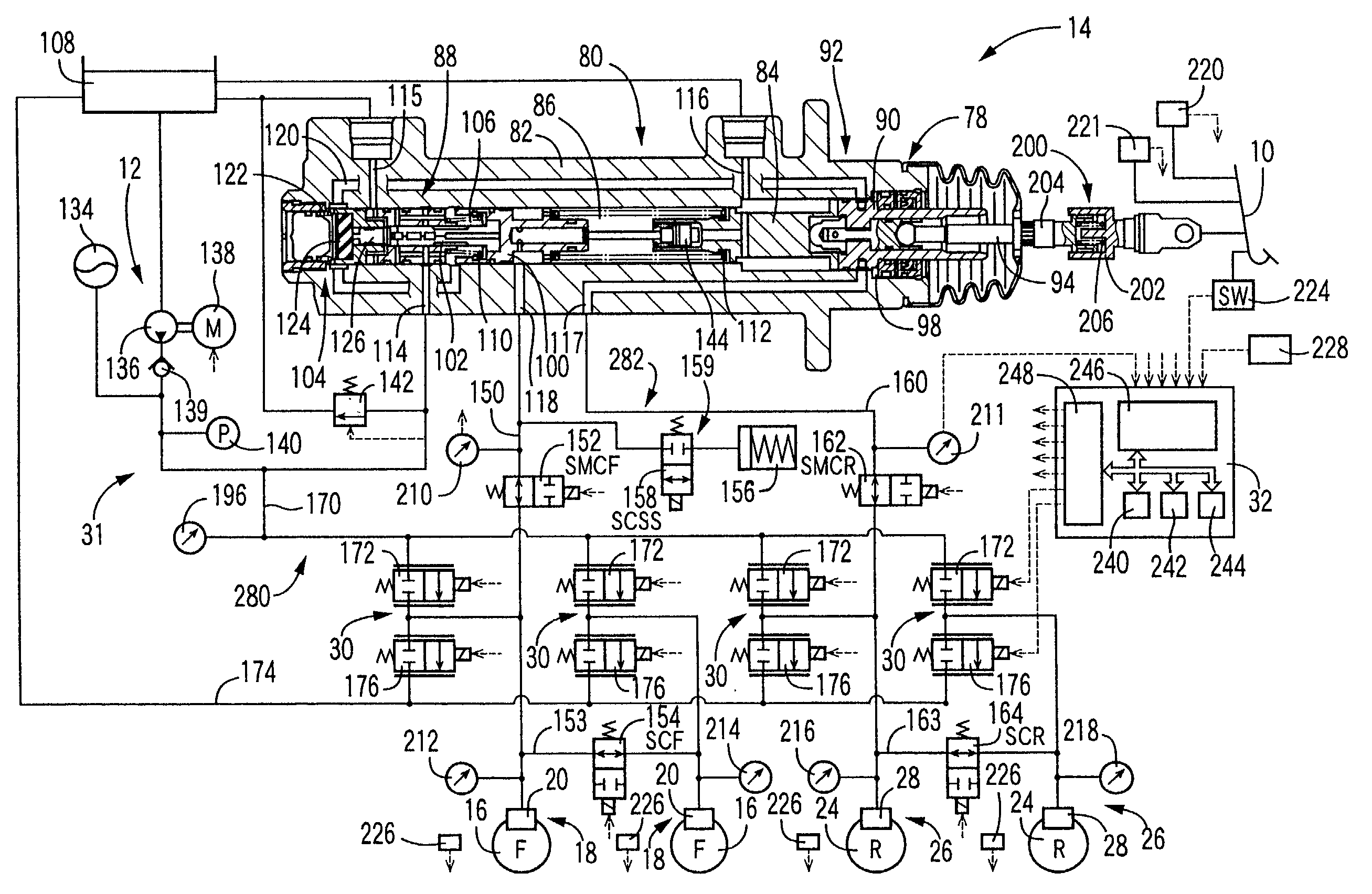

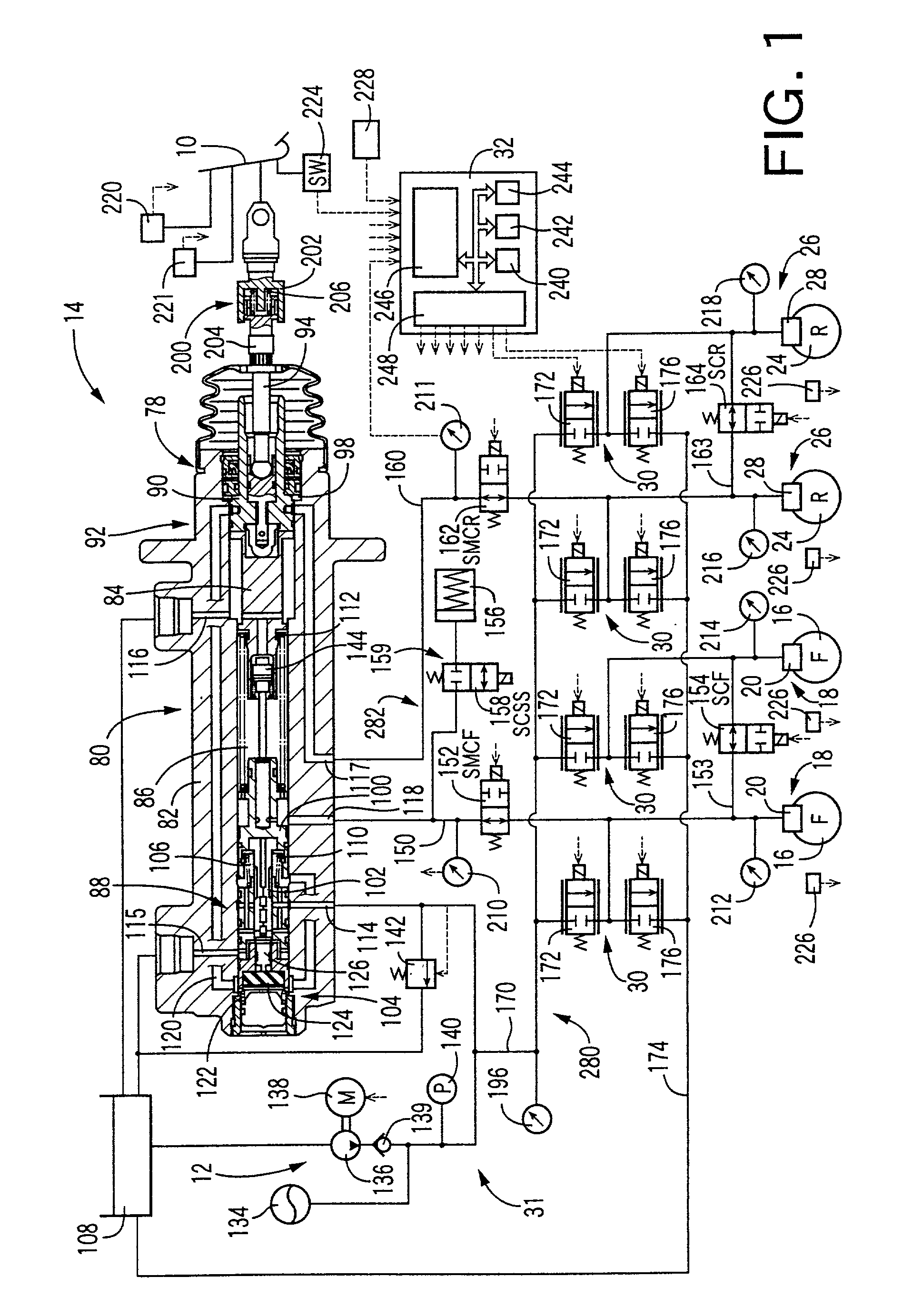

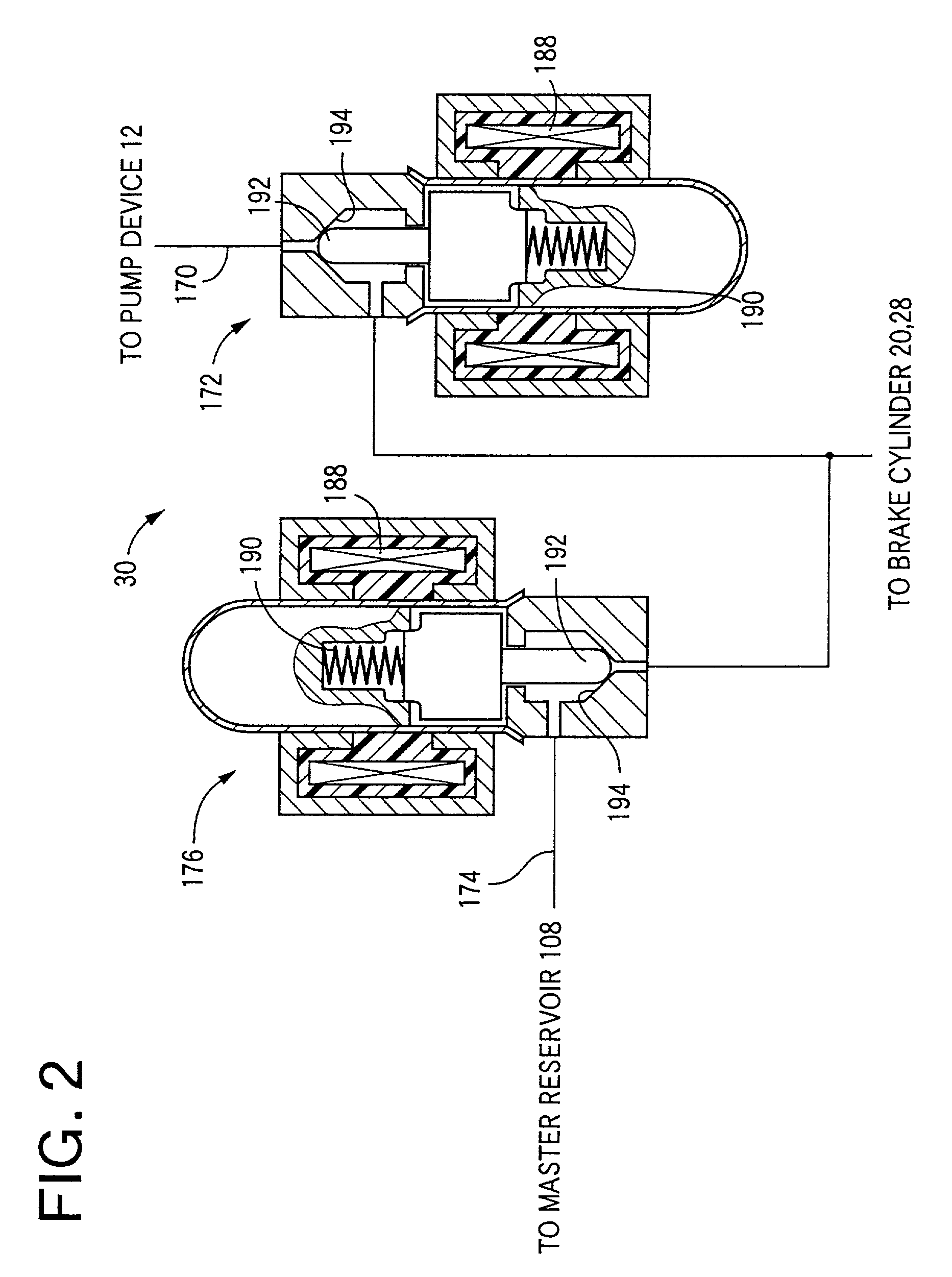

Braking pressure control apparatus capable of switching between two brake operating states using power-operated and manually operated pressure sources, respectively

InactiveUS20010006306A1Efficient workBraking action transmissionBrake control systemsPressure controlled ventilationBraking system

A braking pressure control apparatus including a first pressure source including a power-operated pressurizing device, a second pressure source operable by a manually operable brake operating member to pressurize a fluid to a pressure higher than a level corresponding to the operating force of the brake operating member, a switching device for selectively placing the braking system in a first state in which a brake cylinder is operated with the fluid pressurized by the first pressure source and a second state in which the brake cylinder is operated with the fluid pressurized by the second pressure source, and a change restricting device operable upon a switching between the first and second states, to restrict a change of the operating state of the brake operating member and a change of the brake cylinder pressure, which change take place due to the switching, or a switching control device for controlling the switching device on the basis of the running condition of a vehicle whose wheel is braked by the braking pressure.

Owner:TOYOTA JIDOSHA KK

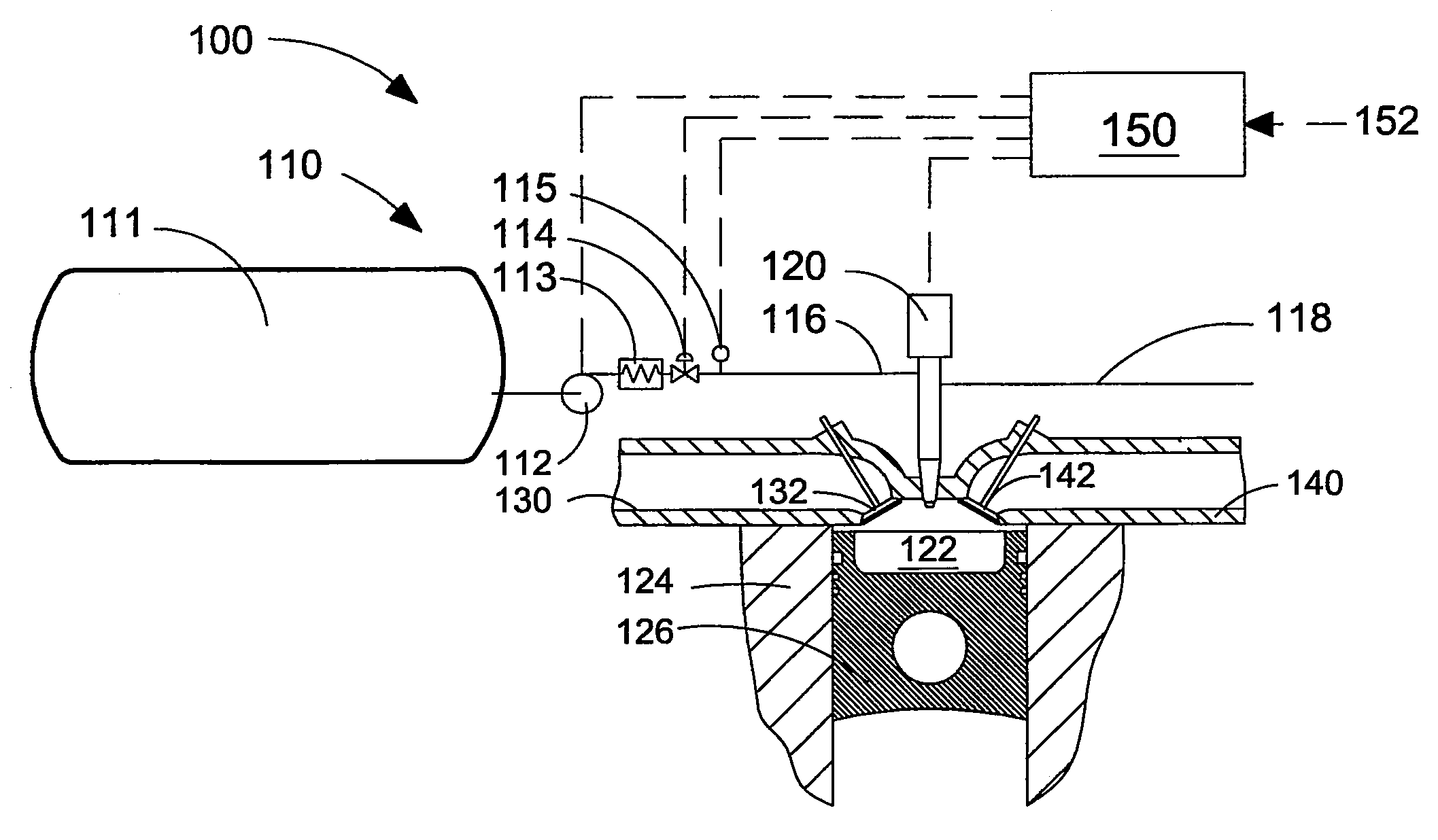

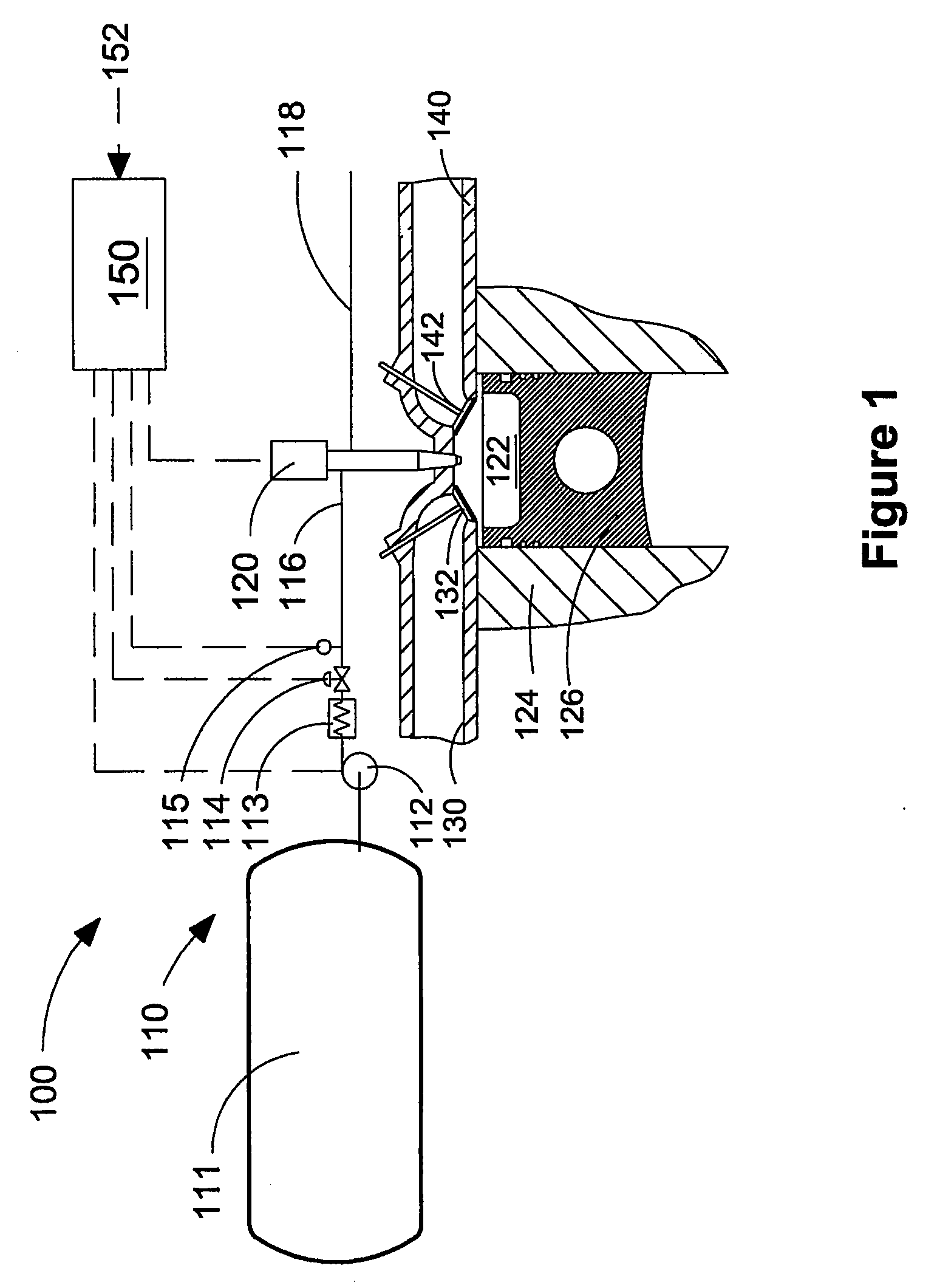

Method for determining fuel injection on-time in a gaseous-fuelled internal combustion engine

ActiveUS8095294B1Electrical controlInternal combustion piston enginesRail pressureExternal combustion engine

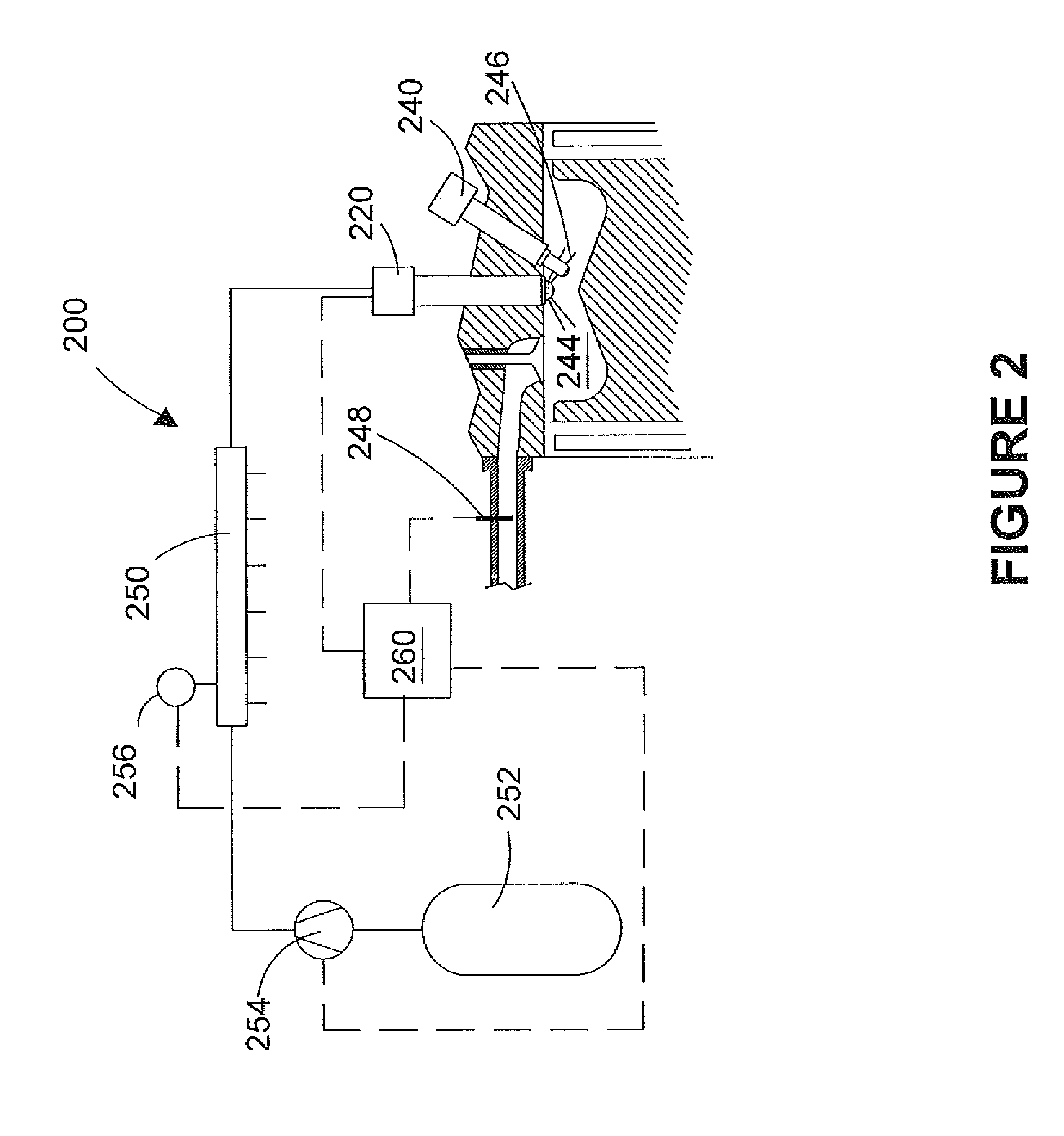

A method and apparatus determine the fuel injection on-time to accurately meter fuel injected directly into the combustion chamber of a gaseous fuelled internal combustion engine. The fuel injection on-time is determined by interpolating between values retrieved from two of a plurality of predetermined look-up tables, which each define fuel injection on-time as a function of gaseous fuel rail pressure and fuelling amount. Each table corresponds to a fixed value of a third parameter that correlates to in-cylinder pressure.

Owner:WESTPORT FUEL SYST CANADA INC

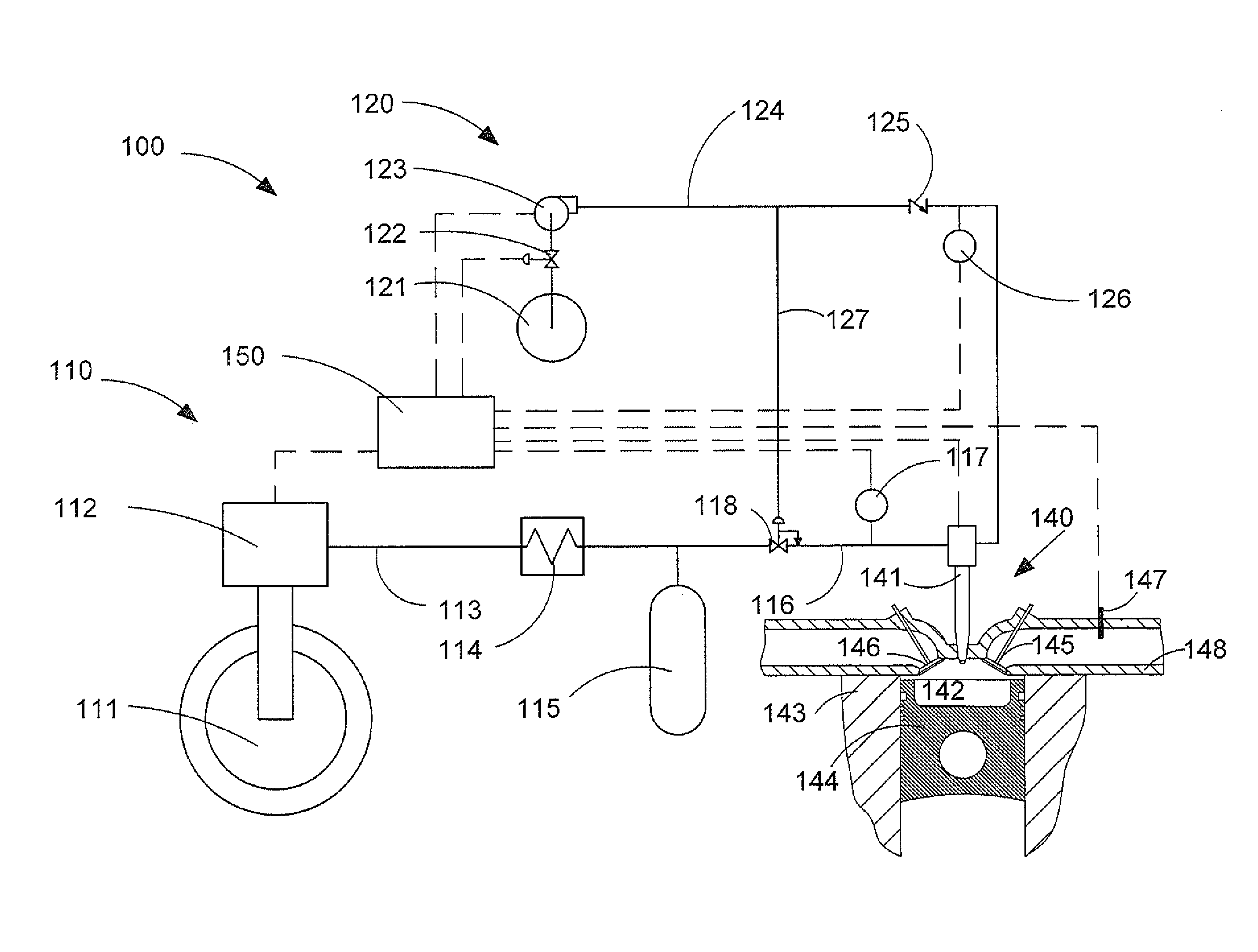

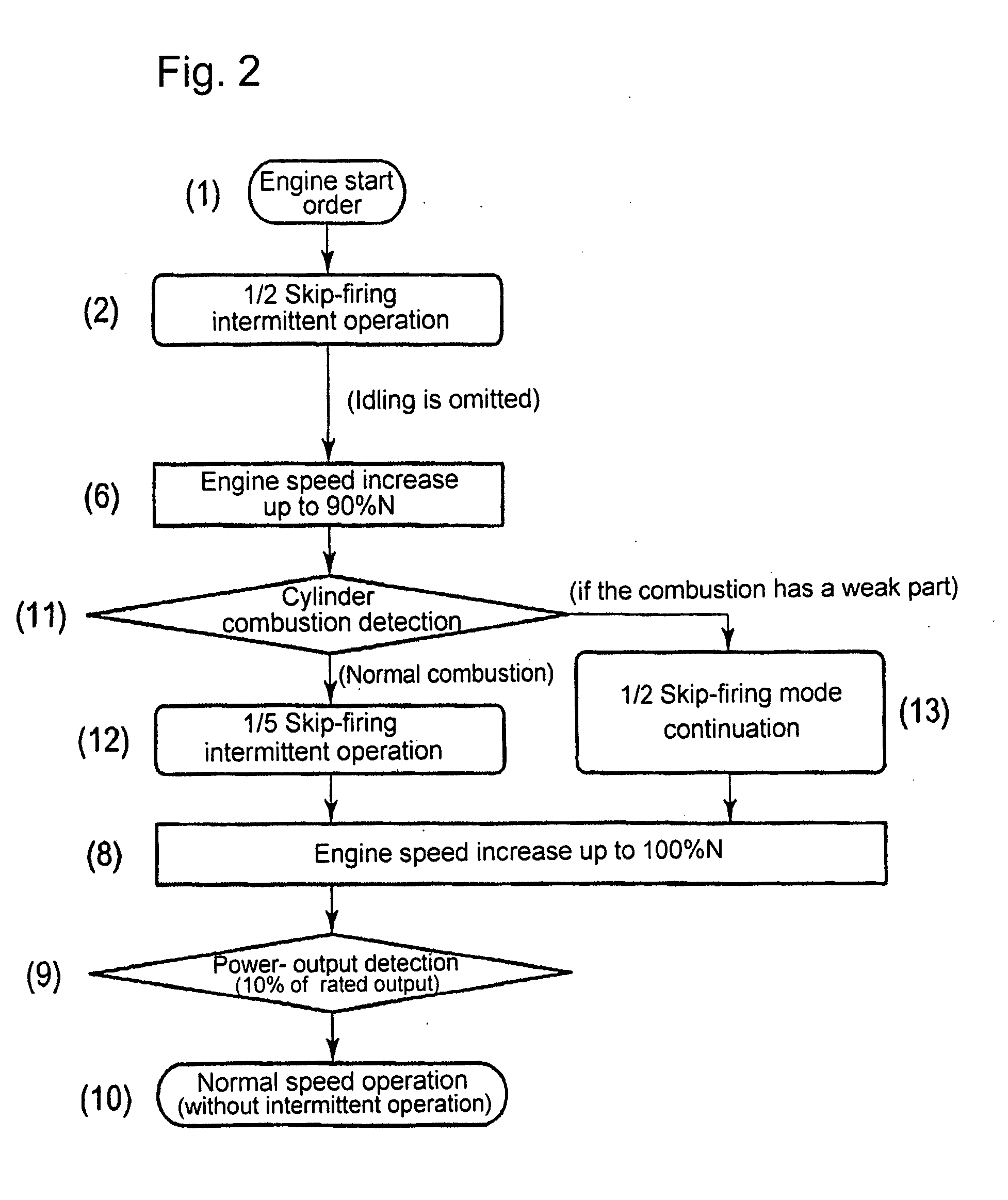

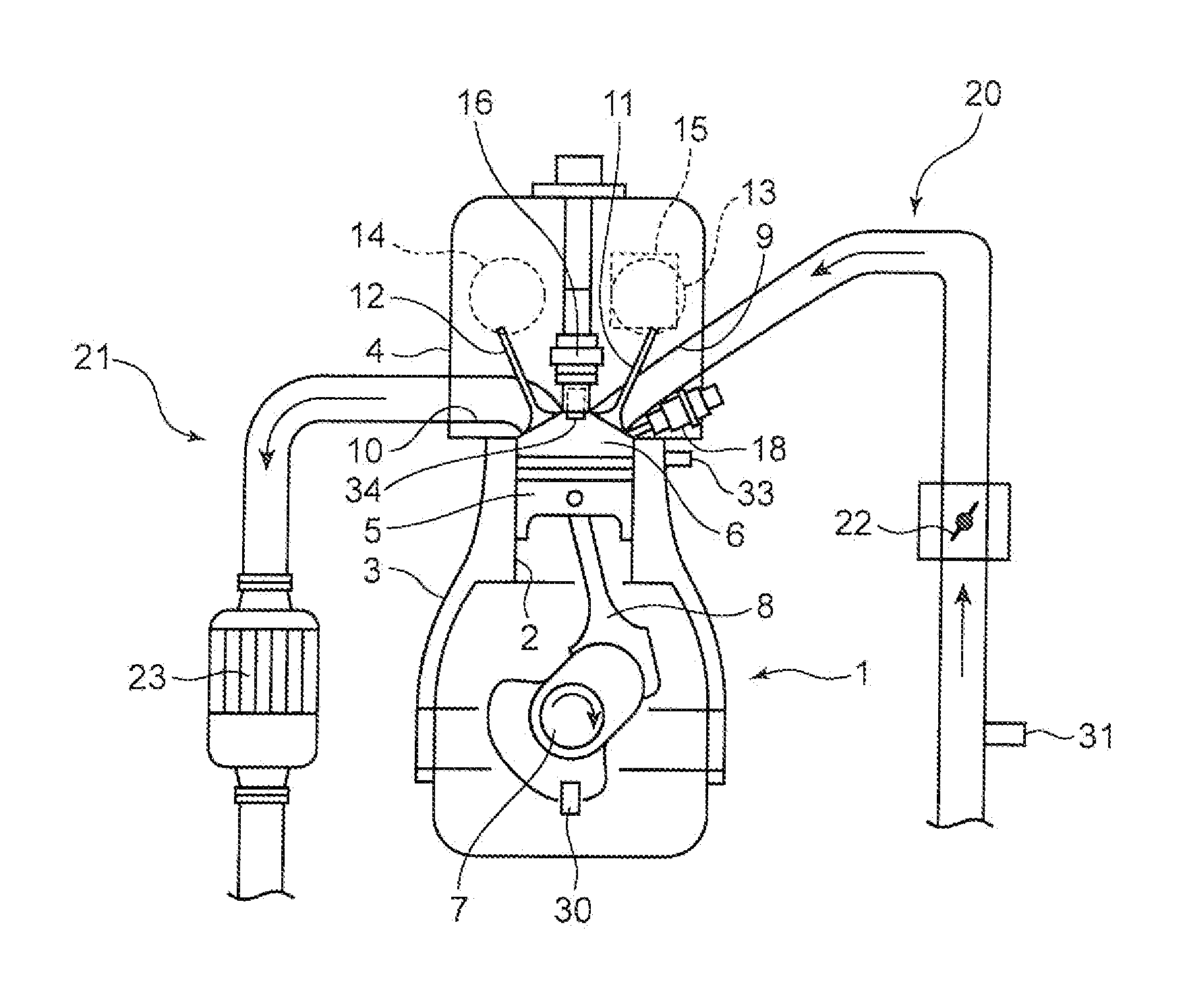

Micro-pilot injection ignition type gas engine

ActiveUS20100043744A1High precisionIdle timeValve arrangementsElectrical controlFuel supplyAir–fuel ratio

What is disclosed is a micro-pilot injection ignition type gas engine, whereby an air fuel ratio control in starting the engine is executed with enhanced precision, by means of introducing skip-firing intermittent operations which reflect the engine operation conditions, while an idling time span can be shortened or omitted.The engine includes: a gas valve that opens and closes a fuel-gas passage in front of each cylinder, so as to arbitrarily control the throat area as well as the opening-closing time span of the gas valve; an engine speed detecting unit to detect the engine speed; a combustion diagnosis unit to detect an engine combustion state through a cylinder pressure distribution along elapsed time, as to each cylinder; an opening-closing control unit as to the gas valve, so as to control the intermittent opening-closing of the gas valve according to the levels of the detected engine speed as well as the cylinder pressure distribution; whereby, in starting the engine, the intermittent opening-closing of the gas-valve enables at least one skip-firing mode that brings an enhanced fuel-supply pressure-pulsation with which a relatively large amount of fuel-gas is supplied per engine cycle with firing so that the air fuel-gas ratio of each cylinder reaches a prescribed target value.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

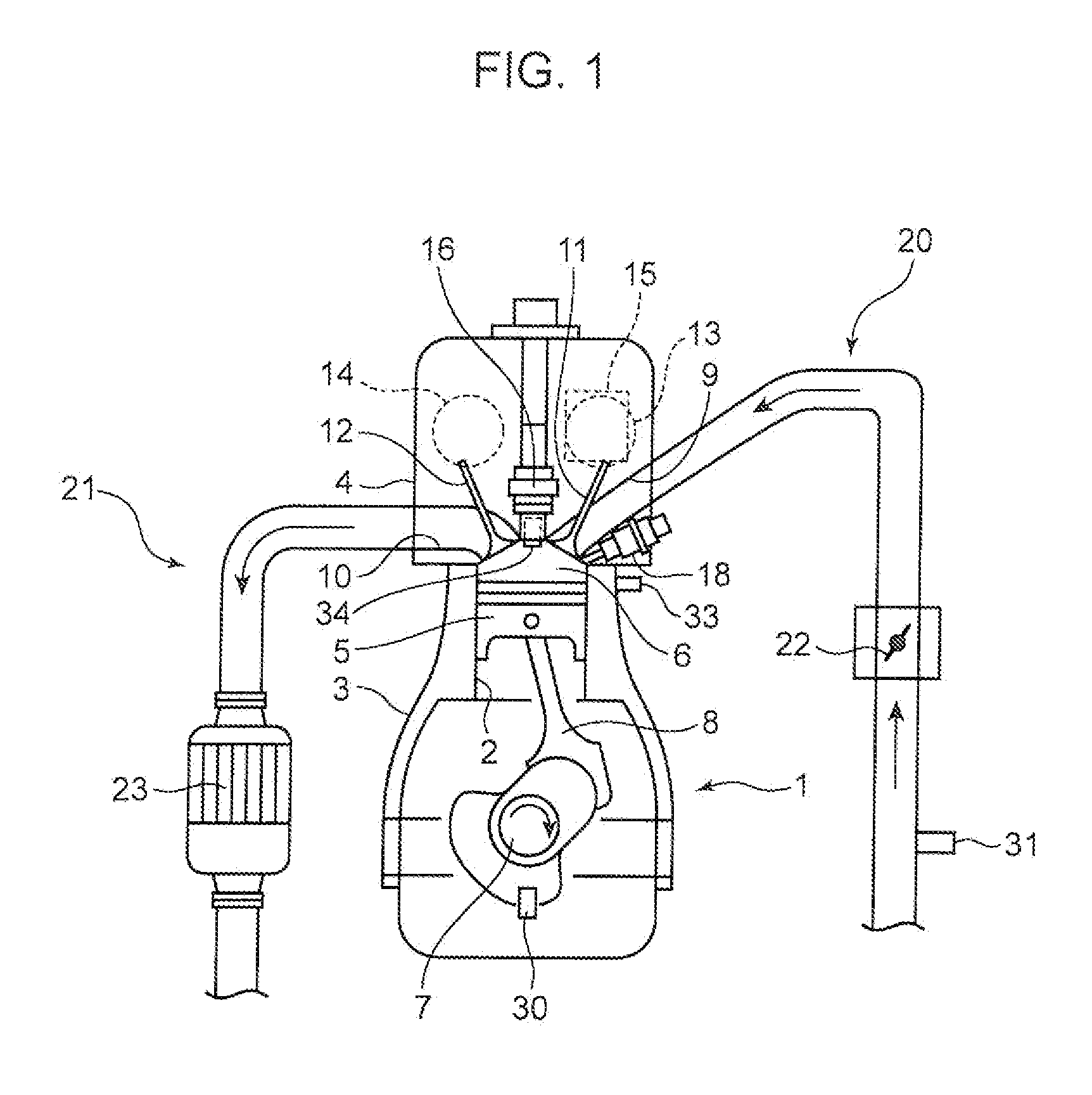

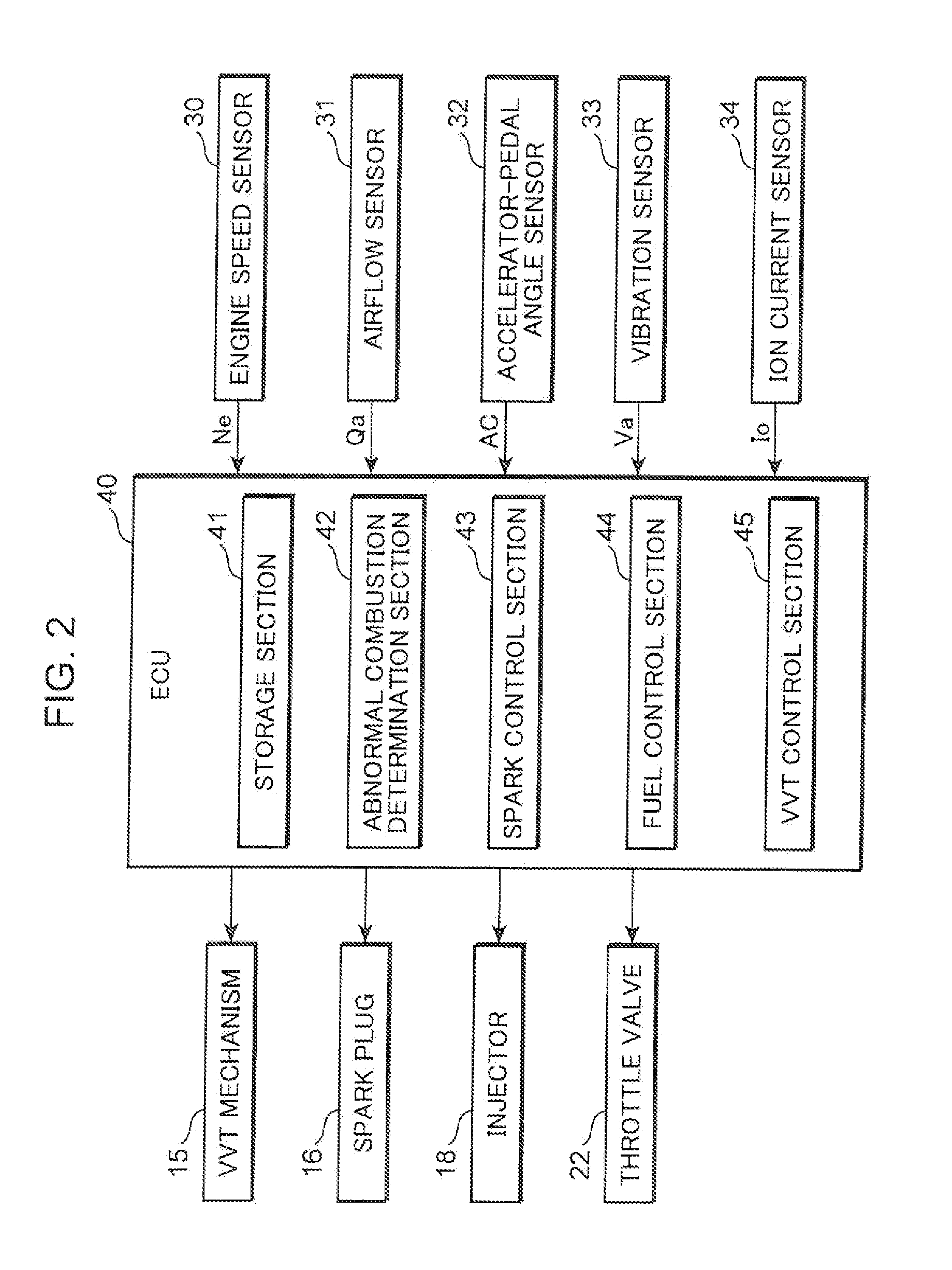

Abnormal combustion detection method for spark-ignition engine, and spark-ignition engine

ActiveUS20110246049A1Enough can be detectedInternal-combustion engine testingAnalogue computers for vehiclesTop dead centerEngineering

When a maximum value of vibration intensity (maximum vibration intensity) (Vmax) acquired from a vibration sensor (33) in a low engine speed / high engine load (operating region (R)) is equal to or greater than a given threshold value (X), a spark timing of a spark plug (16) is shifted from a point set in a normal state on a retard side with respect to a compression top dead center, farther toward the retard side. Then, when a maximum vibration intensity (Vmax2) acquired after the spark timing retard is greater than a maximum vibration intensity (Vmax1) acquired before the spark timing retard, it is determined that preignition occurs. This technique makes it possible to reliably detect preignition using the vibration sensor, while distinguishing the preignition from knocking. An in-cylinder pressure sensor for detecting an in-cylinder pressure of an engine may be used to determine the presence or absence of the preignition, in the same manner.

Owner:MAZDA MOTOR CORP

Method of operating an internal combustion engine

ActiveUS20080178836A1Overcome disadvantagesAccelerate emissionsValve arrangementsElectrical controlExternal combustion engineInternal combustion engine

A method of operating an internal combustion engine having a combustion chamber with a piston and a spark plug, comprising during a first mode, bringing the temperature of the combustion chamber to auto-ignition temperature by adjusting engine operating conditions and producing auto-ignition in said combustion chamber without requiring spark from said spark plug; and during a second mode, bringing the temperature of the combustion chamber close to auto-ignition temperature by adjusting engine operating conditions, forming a small cloud of stratified air-fuel mixture near said spark plug, igniting said fuel cloud by a spark form said spark plug, and then causing cylinder pressure to rise, thereby producing auto-ignition at other sites in said combustion chamber wherein said first mode is implemented in a first operating range and said second mode is implemented only in a second operating range where engine speed and load are lower than said first operating range.

Owner:MAZDA MOTOR CORP

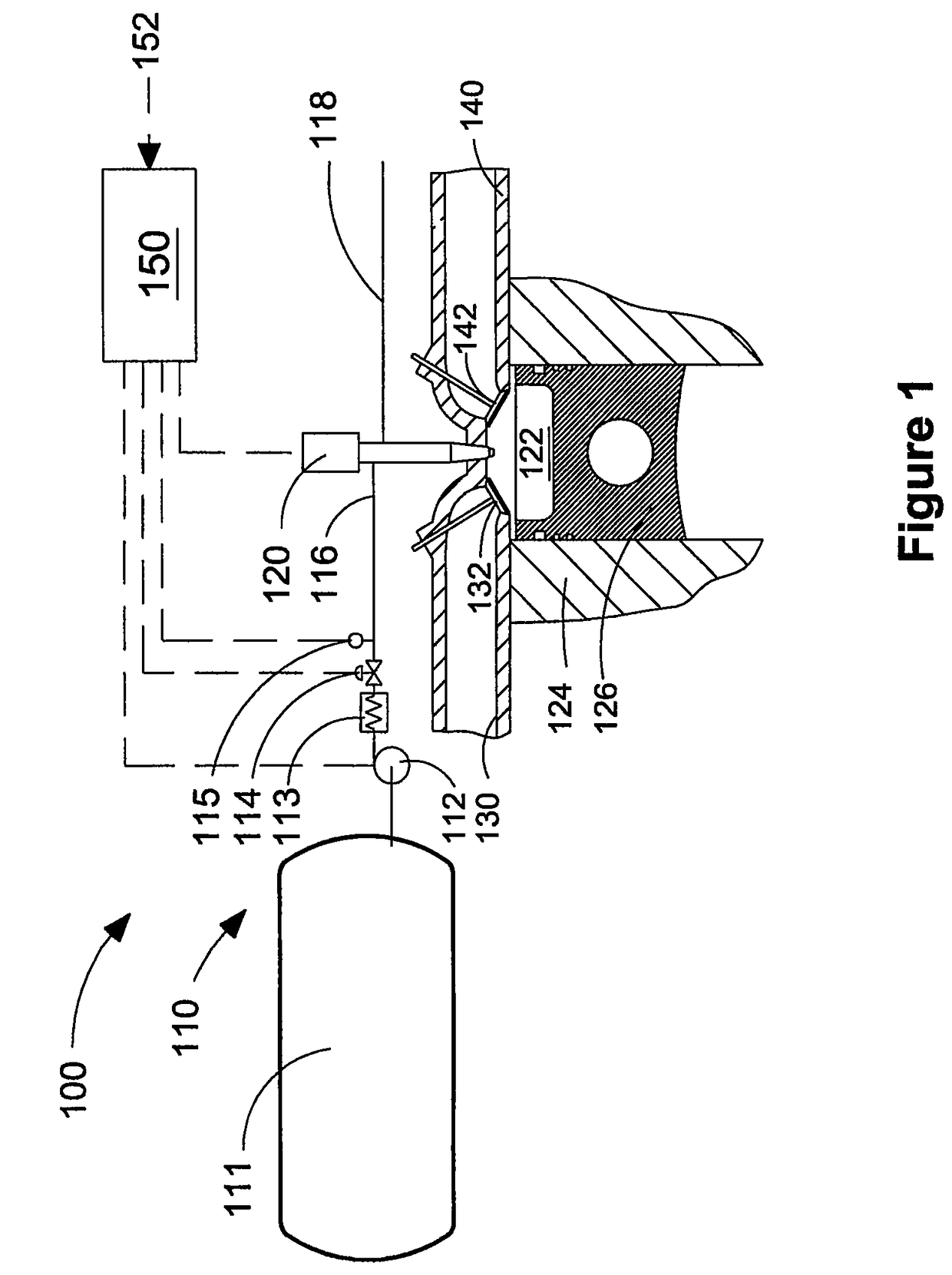

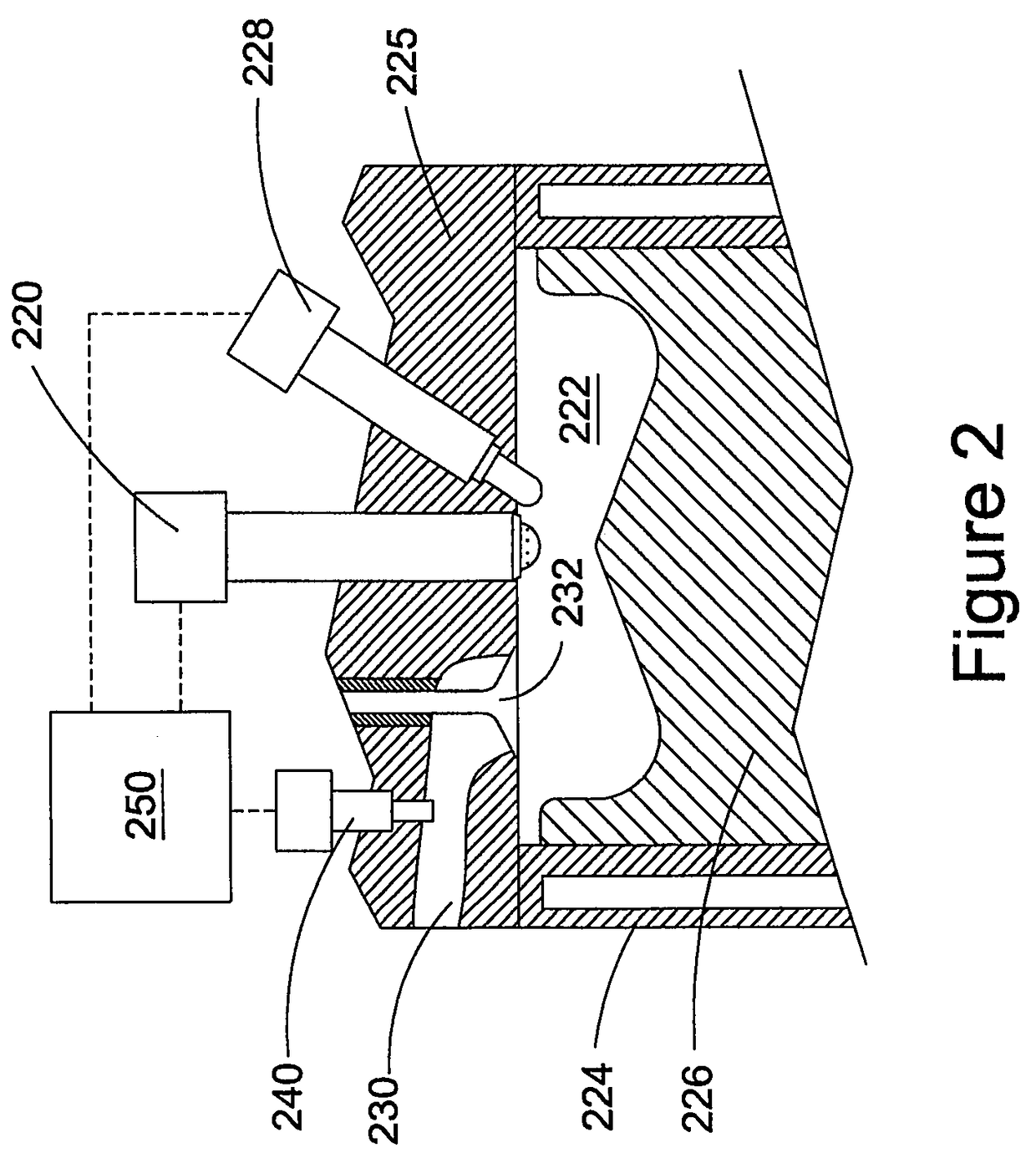

Method and apparatus of fuelling an internal combustion engine with hydrogen and methane

ActiveUS8091536B2Internal combustion piston enginesNon-fuel substance addition to fuelRail pressureElectronic controller

Owner:THE UNIV OF BRITISH COLUMBIA +1

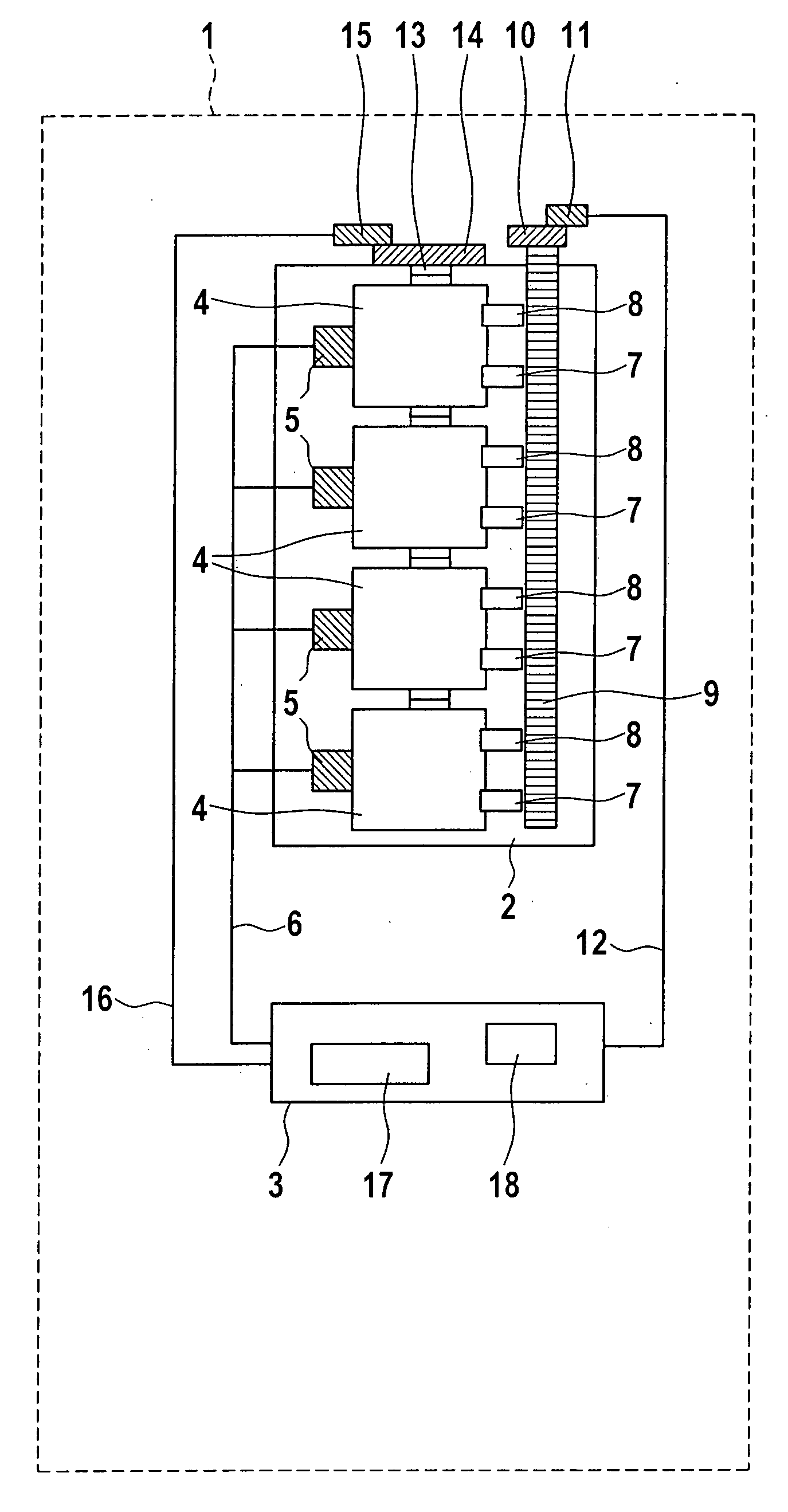

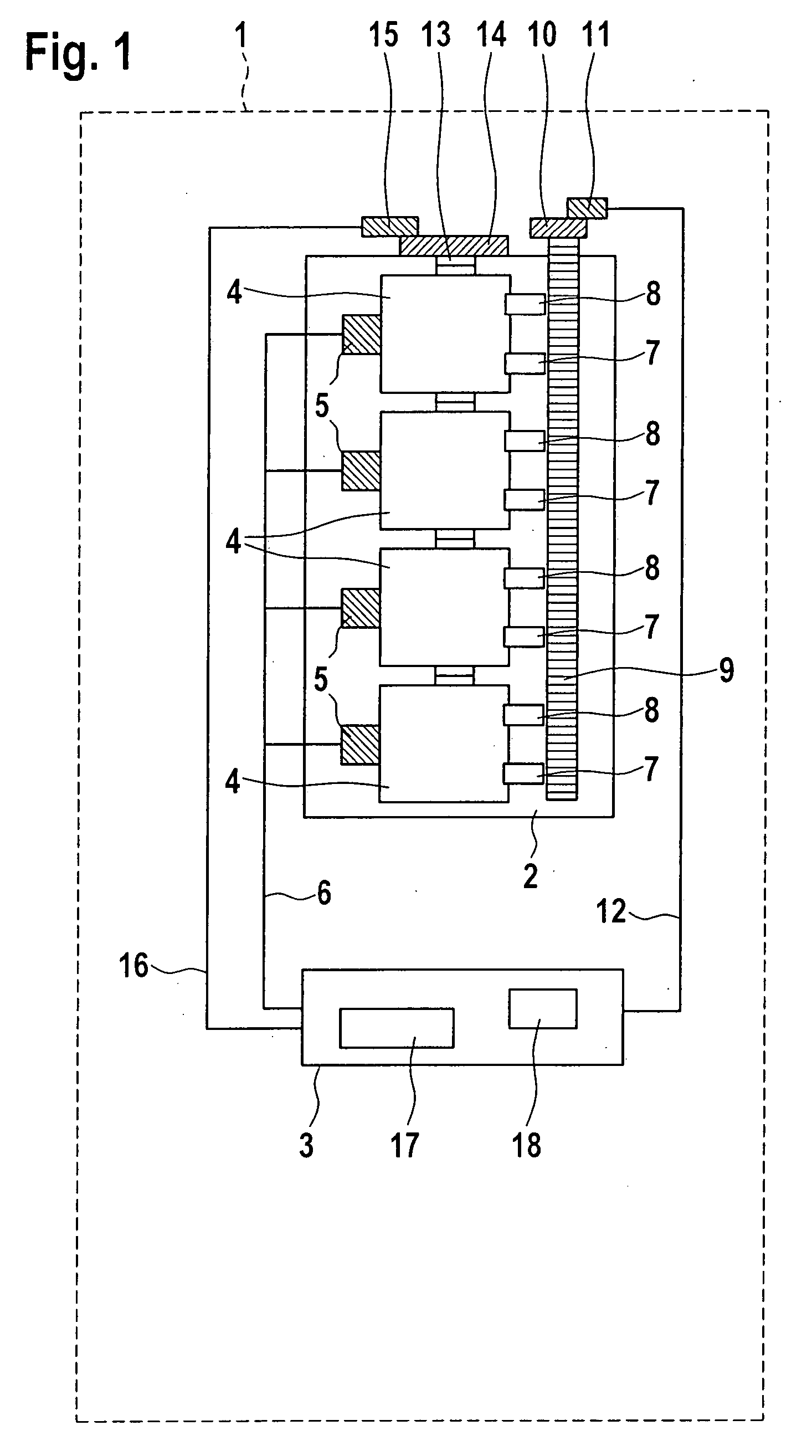

Shoe press unit

InactiveUS6036820ASimple wayControl is possibleNon-fibrous pulp additionNatural cellulose pulp/paperLine tubingEngineering

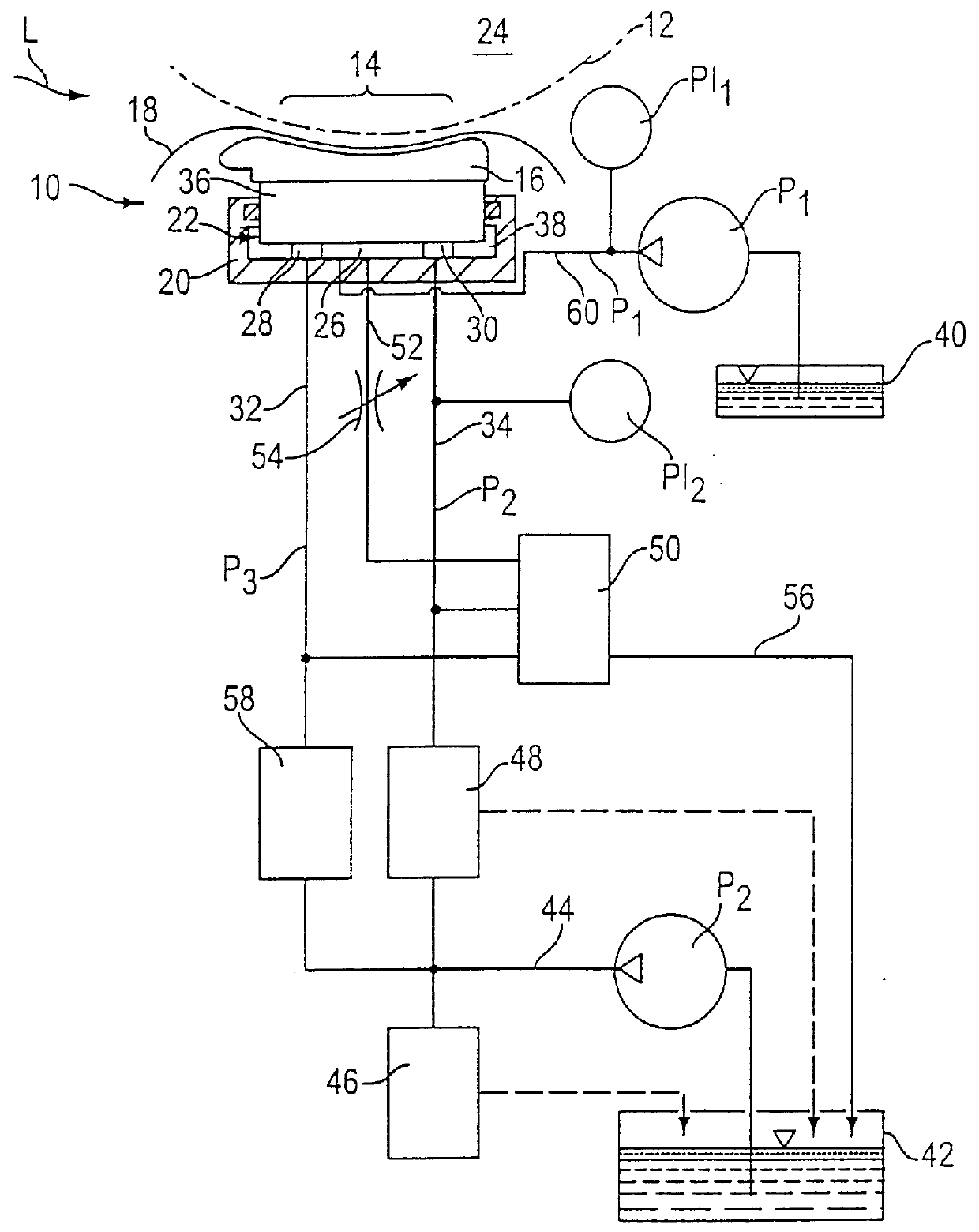

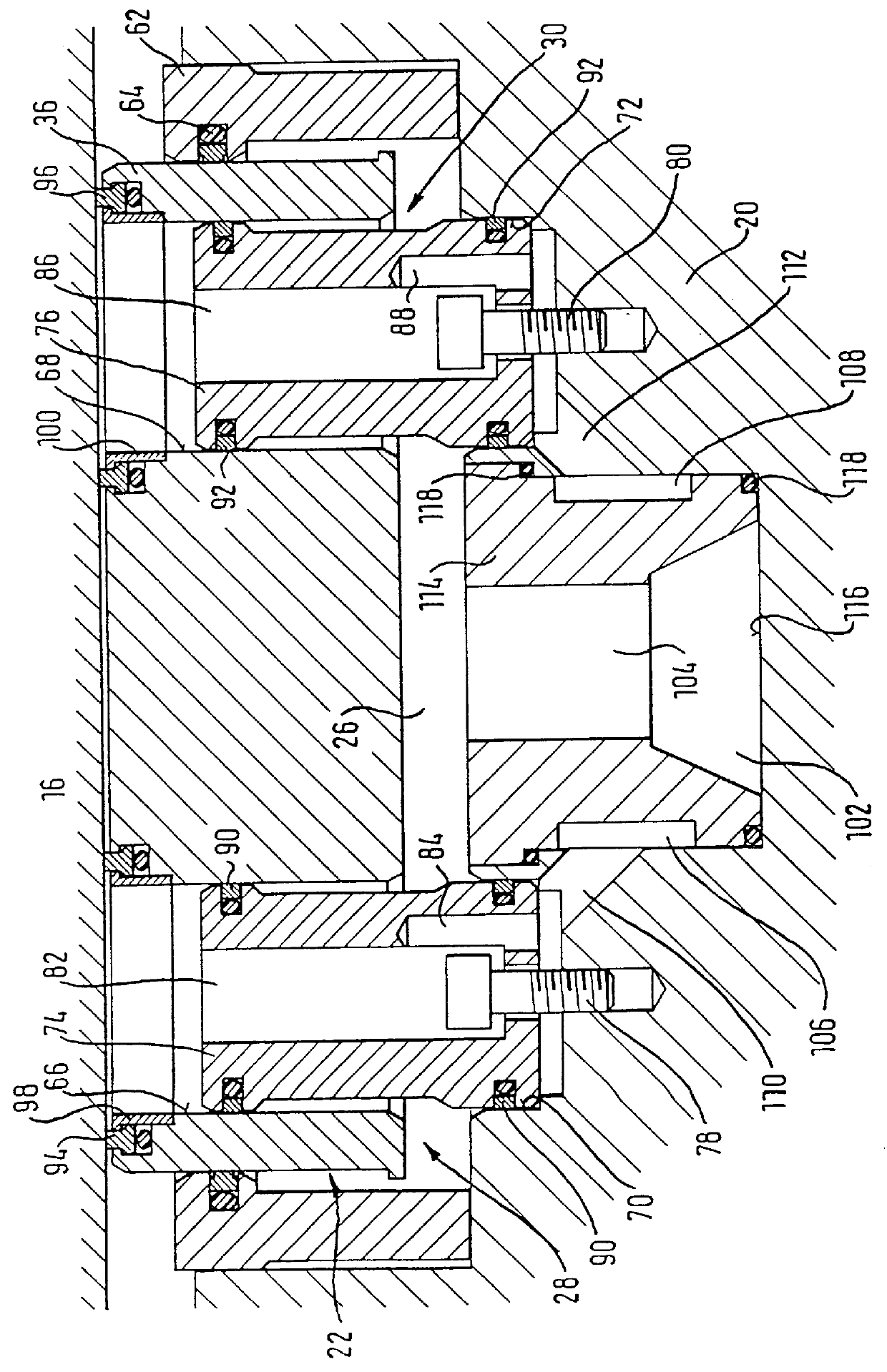

Shoe press unit and method for treatment of a fibrous pulp web. The shoe press unit includes at least one press shoe, an opposing surface, a flexible press belt guided over the press shoe, and at least one force element composed of a cylinder / piston unit supported on a carrier. The at least one force element presses the press belt against the opposing surface to form a press zone elongated in a web run direction, and the cylinder / piston unit include a pressure chamber having at least one pair of cylinder / piston subunits successively positioned in the web run direction. Pressure fluid lines are coupled to respective ones of the at least one pair of cylinder / piston subunits to separately supply pressure fluid to each cylinder / pressure subunit to impart a tilting moment long a tilt axis substantially perpendicular to the web run direction. The method includes supplying a pressure fluid to a first and second pressure fluid line from a common pressure fluid source at a source pressure, supplying pressure fluid through the first pressure fluid line at a first fluid pressure to a first subunit of the at least one pair of cylinder piston subunits, supplying pressure fluid through the second pressure fluid at a second fluid pressure to a second subunit of the at least one pair of cylinder piston subunits, and maintaining a sum of the first and second fluid pressures to be substantially equal to the source pressure.

Owner:VOITH SULZER PAPIERMASCHEN GMBH

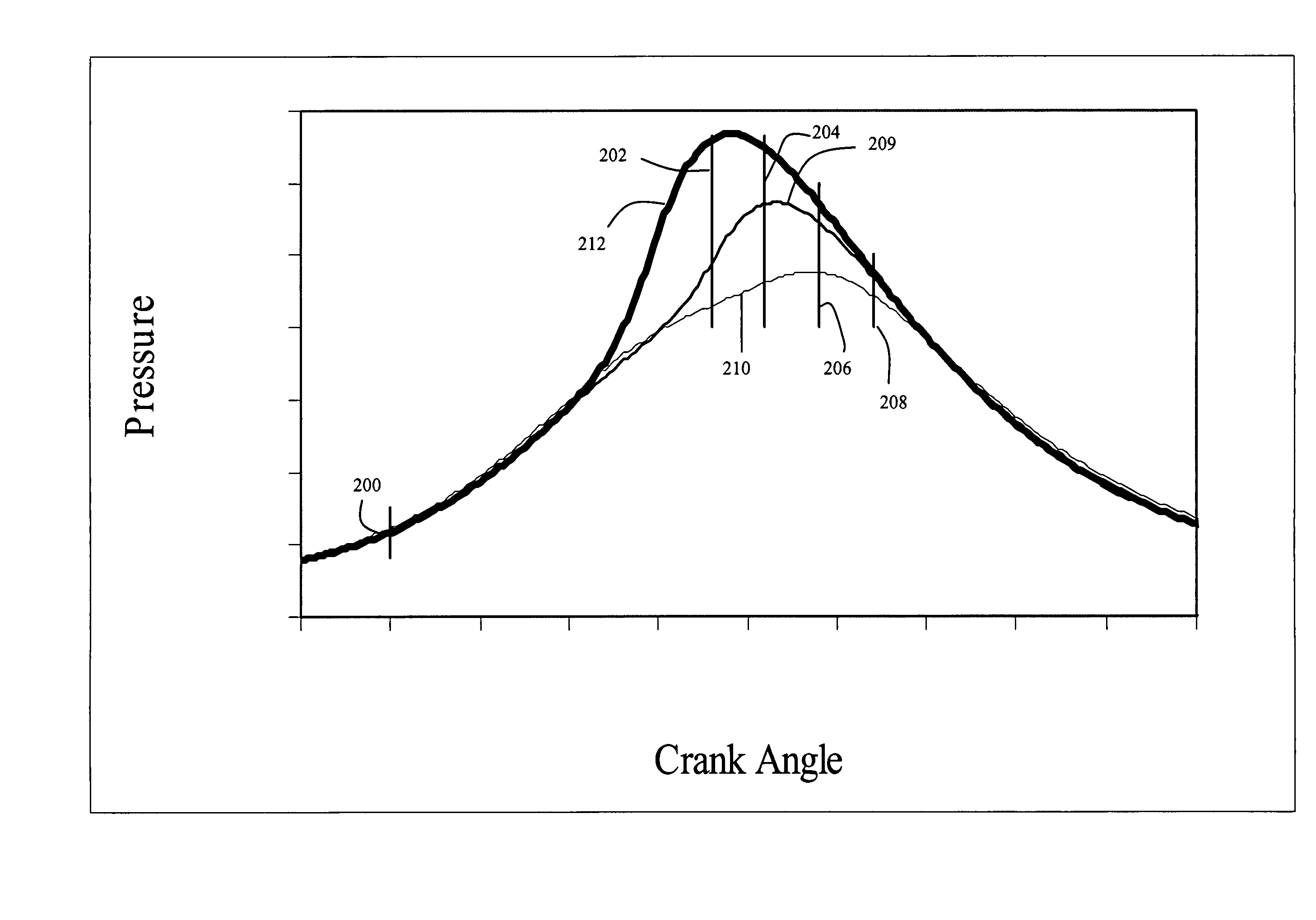

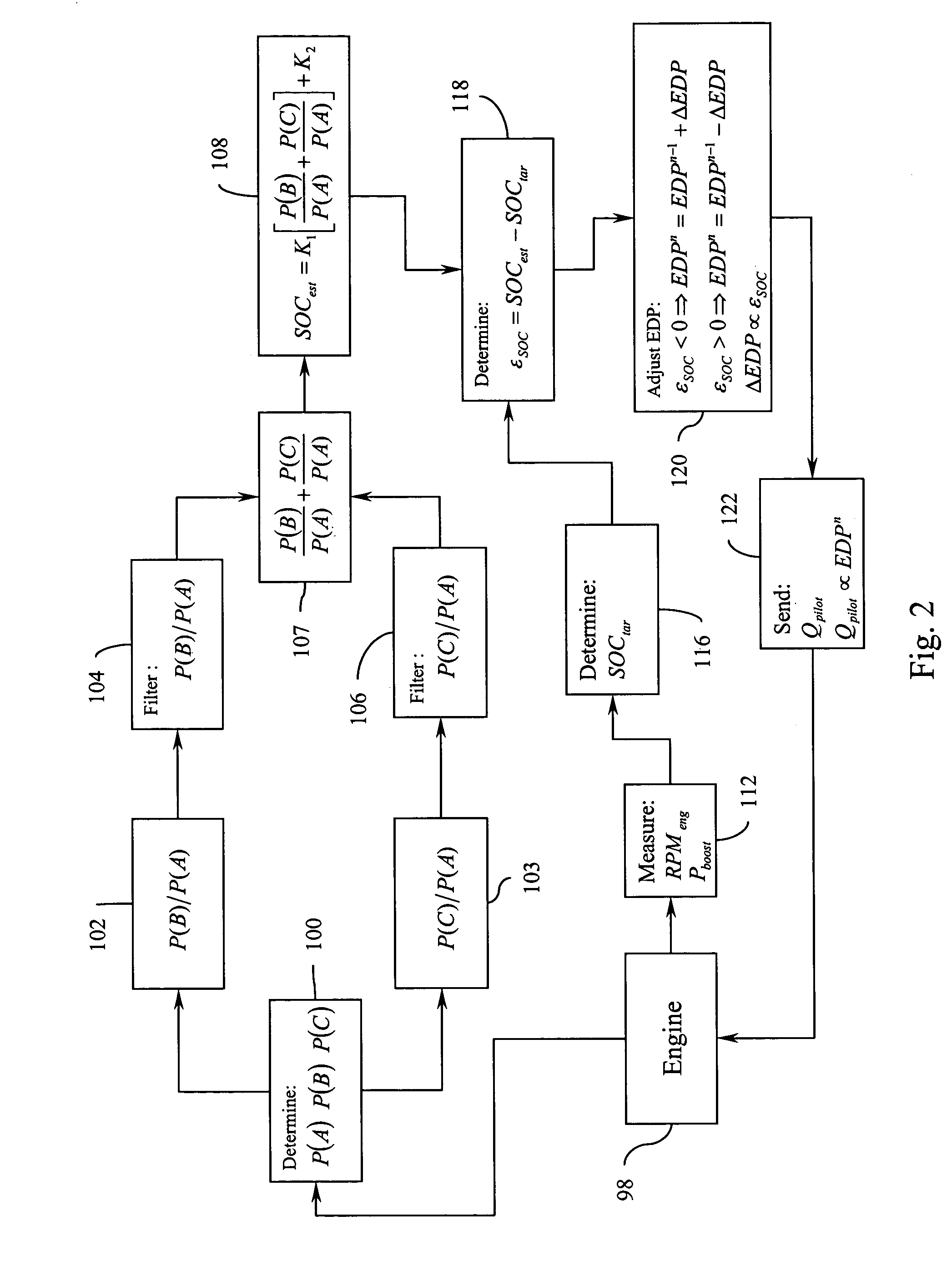

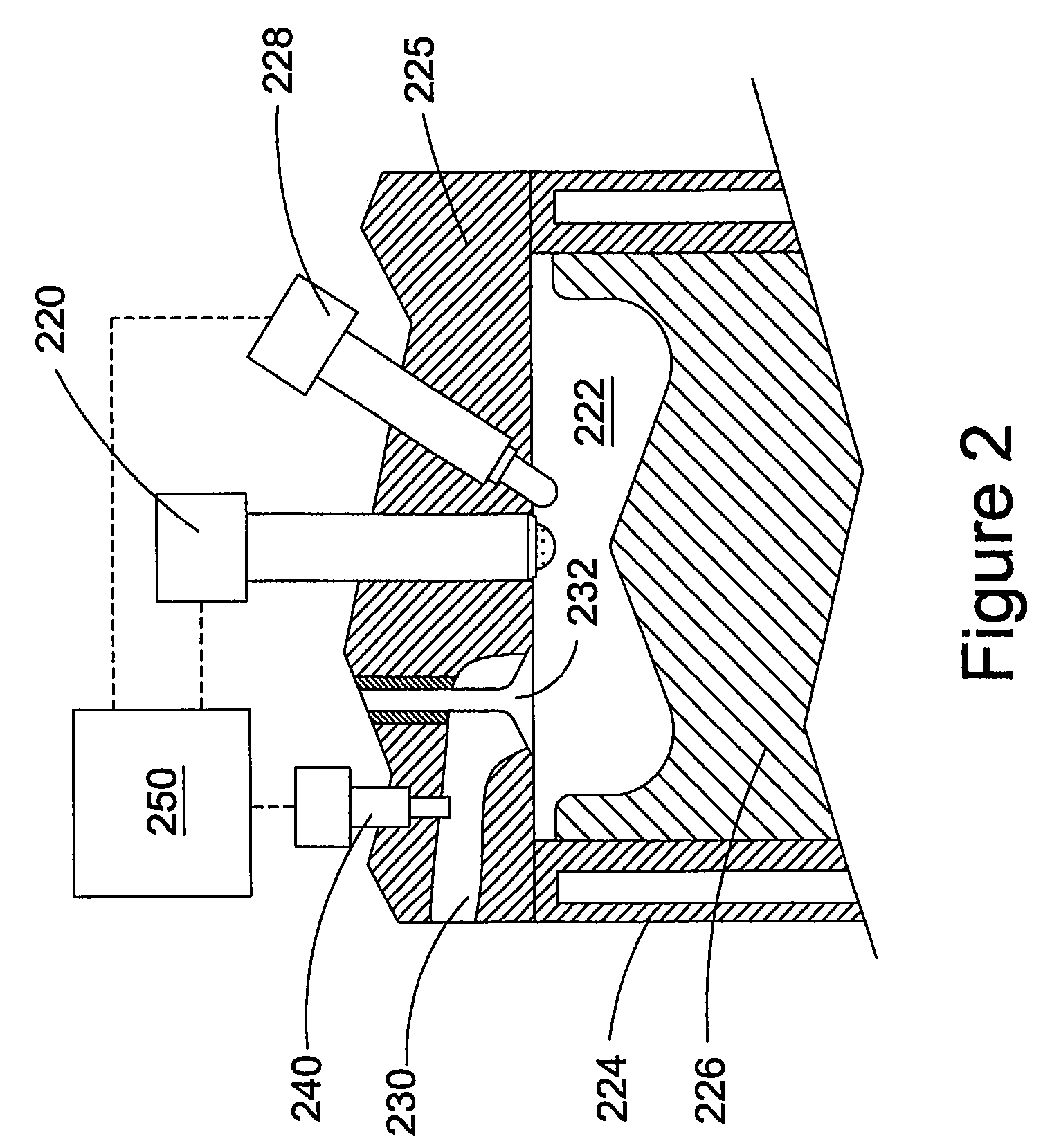

Method and apparatus for controlling an internal combustion engine using combustion chamber pressure sensing

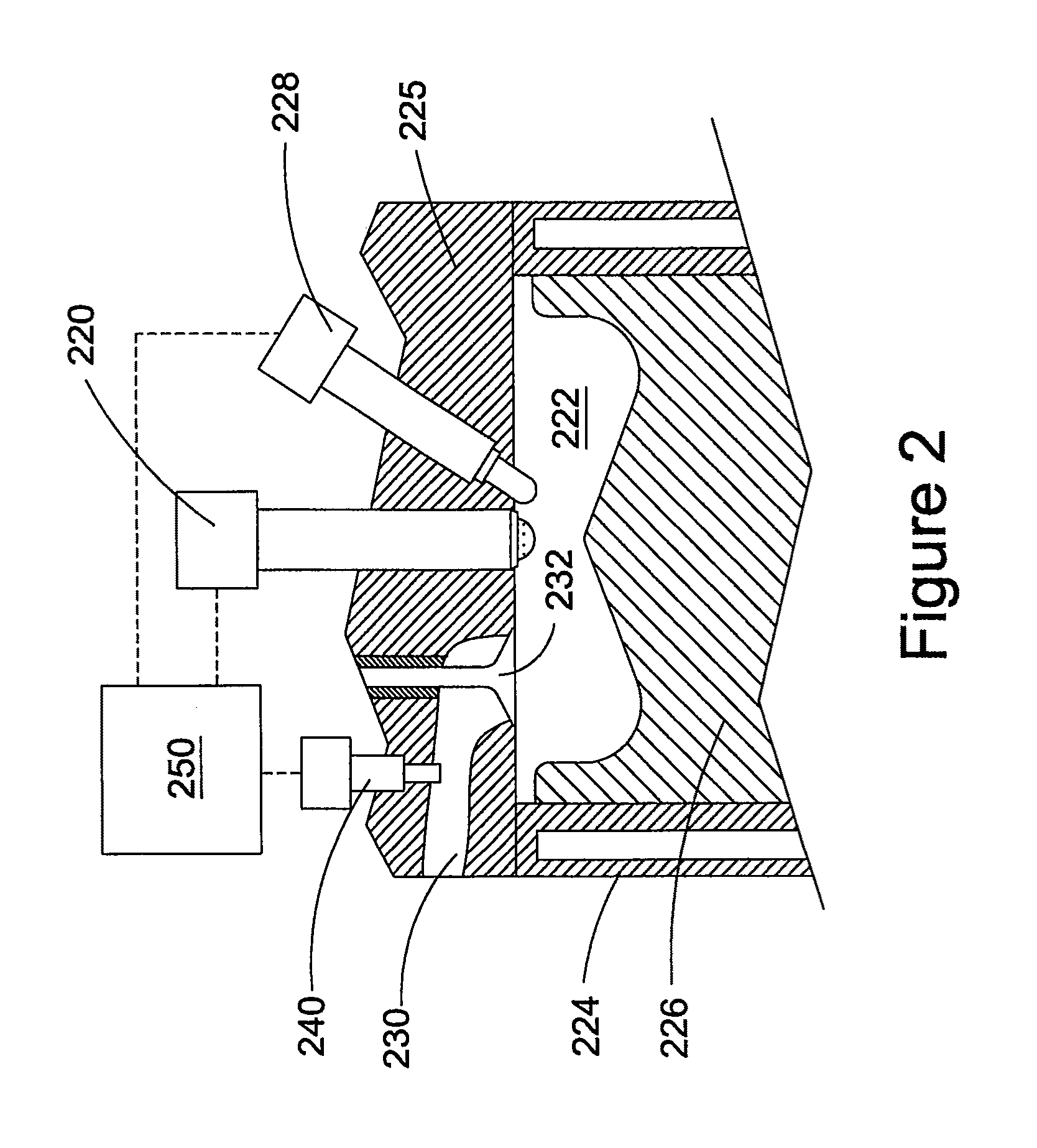

InactiveUS7000596B2Difficult to auto-igniteQuick changeElectrical controlInternal combustion piston enginesThermodynamicsCombustion chamber

The present method and apparatus employ a signal indicative of cylinder pressure within the combustion chamber of an internal combustion engine to control combustion phasing or start of combustion (SOC) in subsequent cycles of the engine where the engine is driven by combustion of both a fuel / air premixed charge and a directly injected quantity of fuel. A ratio of signals indicative of pre-combustion pressure and post-combustion pressure within a cycle are employed to estimate SOC and then, based on a predetermined target SOC, an ignition lever is employed to adjust subsequent SOC. A preferred ignition lever is, in a pilot fuel ignited engine, pilot fuel quantity.

Owner:WESTPORT POWER

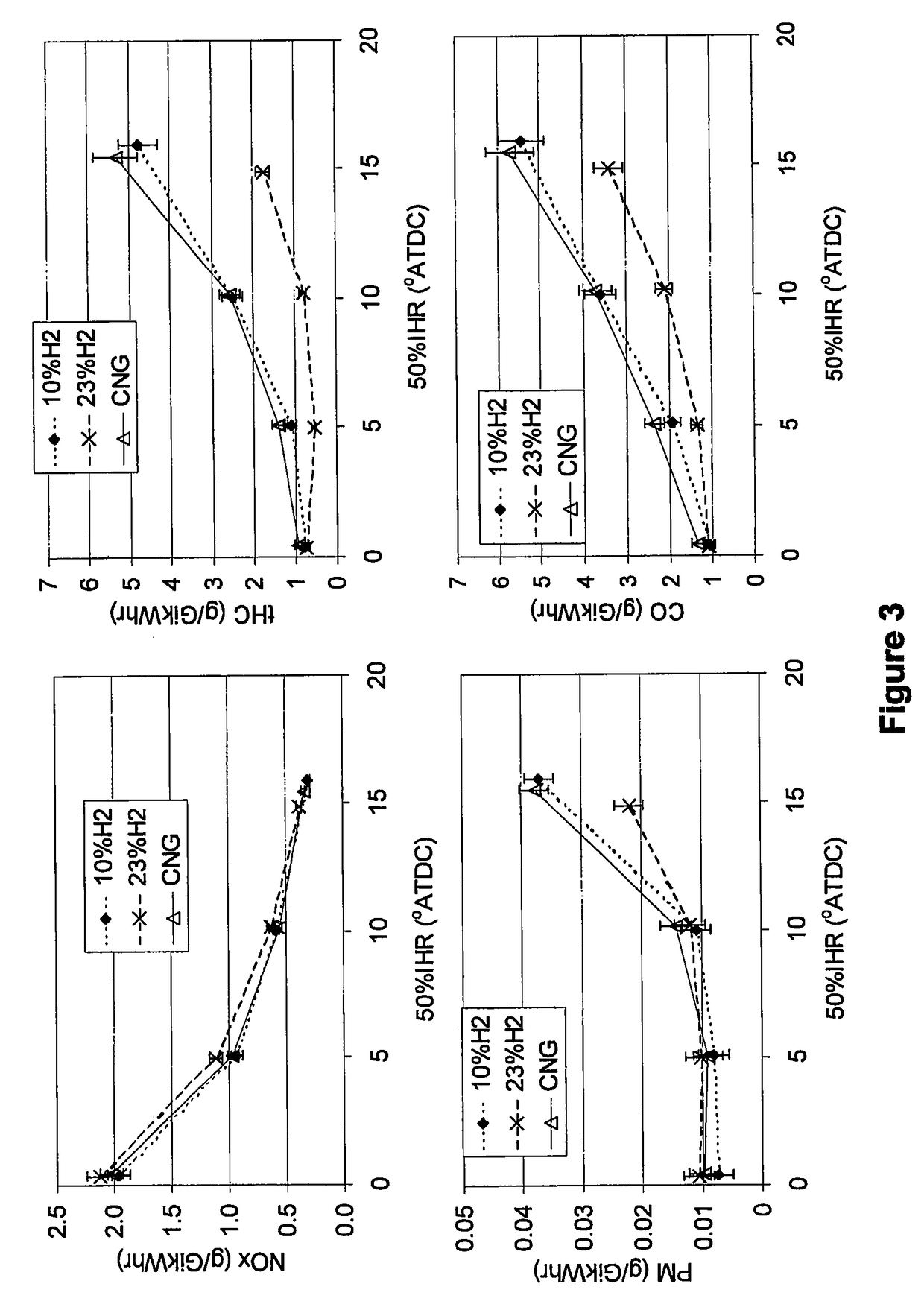

Method And Apparatus Of Fuelling An Internal Combustion Engine With Hydrogen And Methane

ActiveUS20090120385A1Internal combustion piston enginesNon-fuel substance addition to fuelRail pressureElectronic controller

A gaseous-fuelled internal combustion engine and a method of engine operation improve combustion stability and reducing emissions of NOx, PM, and unburned hydrocarbons. The method comprises fuelling an internal combustion engine with hydrogen and natural gas, which can be directly injected into the combustion chamber together or introduced separately. Of the total gaseous fuel delivered to the engine, at least 5% by volume at standard temperature and pressure is hydrogen. For at least one engine operating condition, the ratio of fuel rail pressure to peak in-cylinder pressure is at least 1.5:1. A fuel injection valve introduces the gaseous fuel mixture directly into the combustion chamber. Two separate fuel injection valves could also introduce the methane and hydrogen separately. An electronic controller controls timing for operating the fuel injection valve(s). The engine has a preferred compression ratio of at least 14:1.

Owner:THE UNIV OF BRITISH COLUMBIA +1

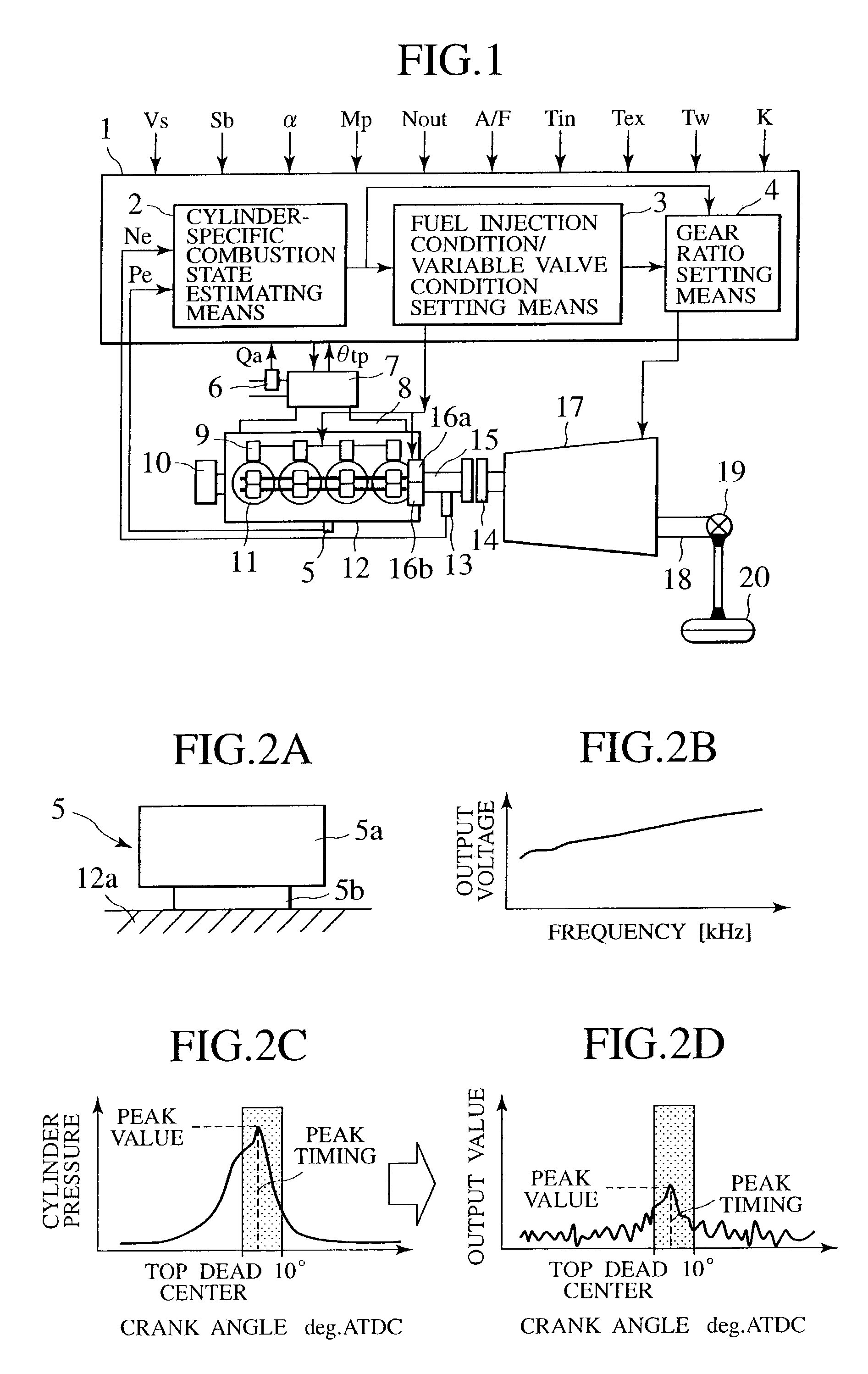

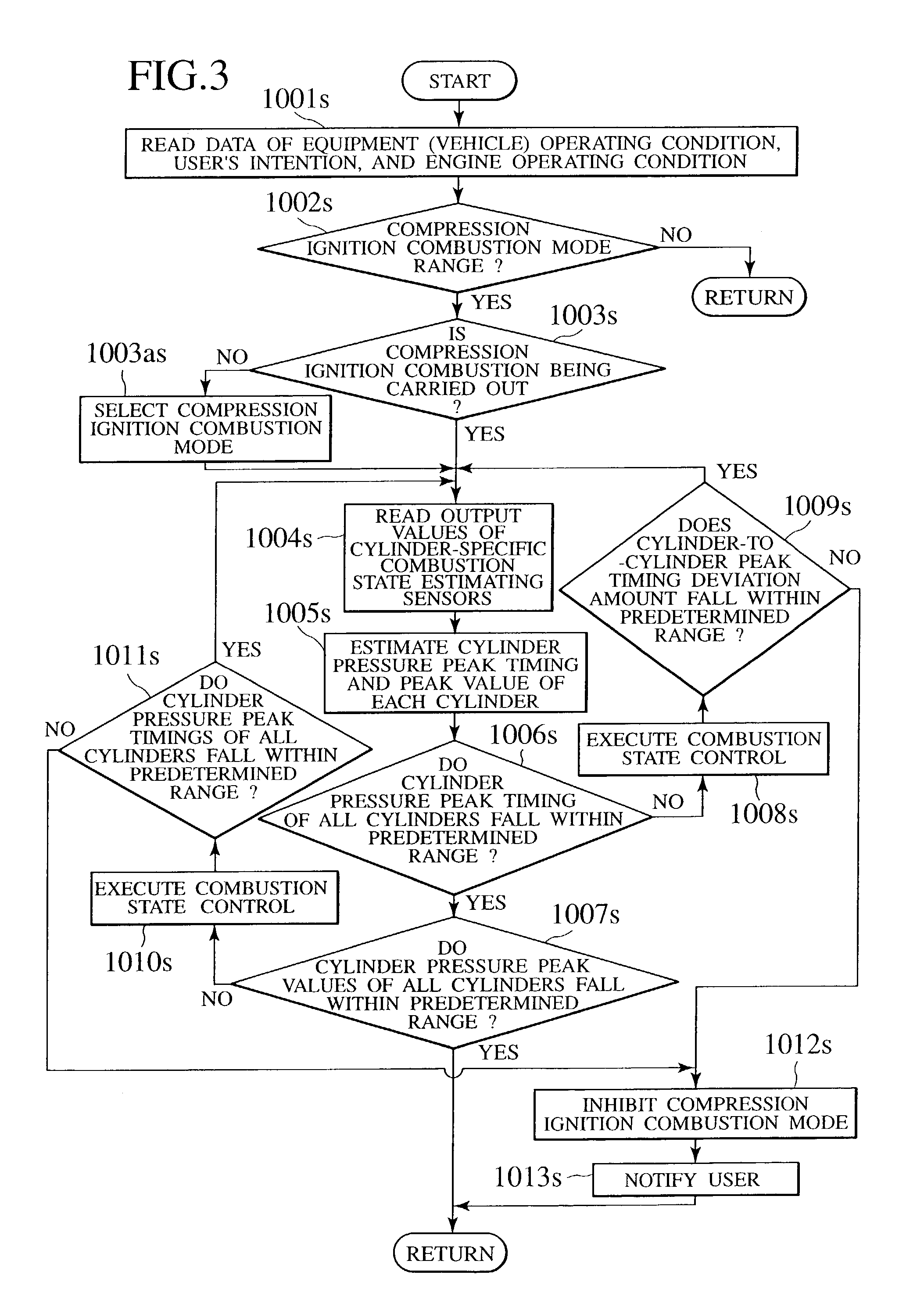

Control apparatus and control method for multi-cylinder engine

In a multi-cylinder engine having a compression ignition combustion mode, a vibration detecting sensor that is preferably mounted in a cylinder block or a cylinder head is used to detect a frequency and the detected frequency is appropriately analyzed to detect or estimate a cylinder pressure peak value and peak timing for each cylinder. An amount of internal EGR, a fuel injection condition, an engine speed and the like are then controlled so as to bring each of these parameters into an appropriate range thereof. The control apparatus suppresses variations in combustion states among different cylinders and different cycles arising from unit-to-unit variations or deterioration in the engine or part-to-part variations or deterioration in a component thereof.

Owner:HITACHI LTD

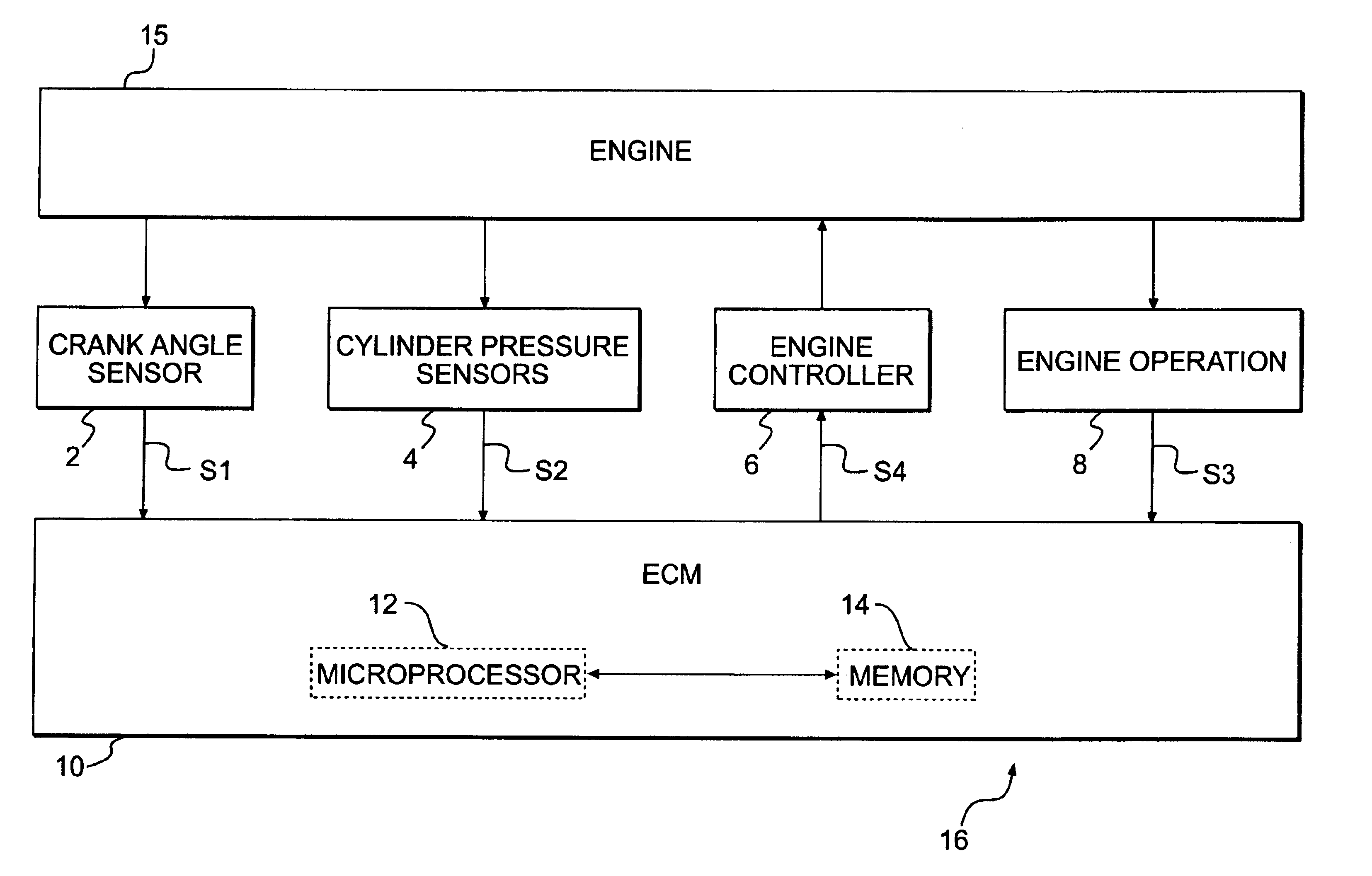

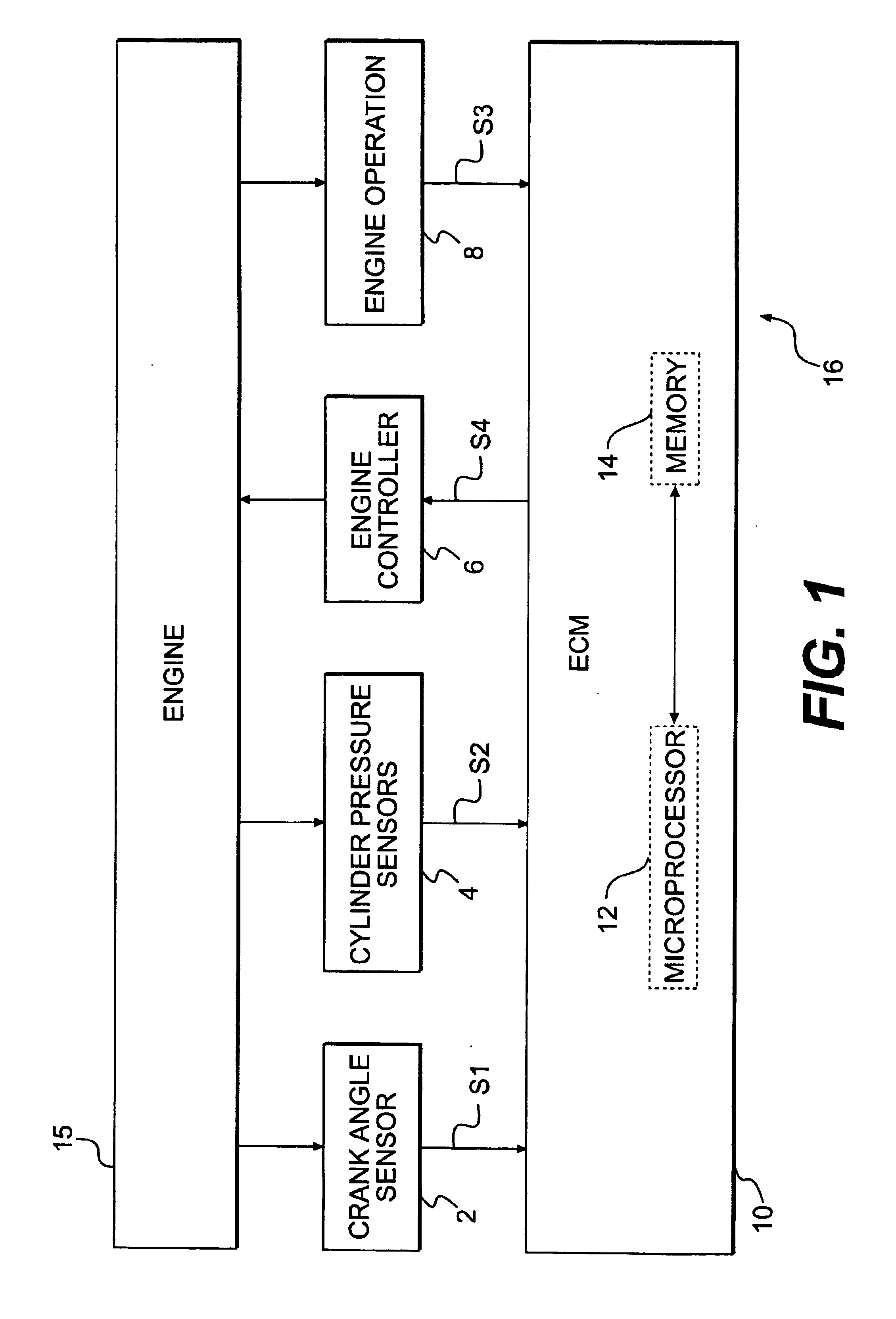

System and method for diagnosing and calibrating internal combustion engines

InactiveUS6935313B2Analogue computers for vehiclesElectrical controlCombustion chamberInternal combustion engine

A method, system, and machine-readable storage medium for determining a predetermined operating condition of an internal combustion engine are disclosed. In operation, the method, system and machine-readable storage medium measure a cylinder pressure in at least one combustion chamber at a predetermined point in a combustion cycle. Next, the method, system, and machine-readable storage medium determine at least a first value for an operating parameter of the engine using the measured cylinder pressure, determine a second value for the operating parameter of the engine using data received from at least one engine sensor, and then generate a predetermined signal if a difference between the first value and the second value has a predetermined relationship.

Owner:CATERPILLAR INC

Engine vibration suppression device and suppression method thereof

InactiveUS20070101965A1Reduce the ratioReduce torque variationHybrid vehiclesSpeed controllerControl theoryMotor–generator

A controller (20) estimates an internal cylinder pressure of an engine (1) on the basis of the operating conditions of the engine (1), torque variation in the engine (1) is calculated on the basis of the estimated internal cylinder pressure, and an opposite phase torque of the torque variation in the engine (1) is calculated as a torque correction amount. The controller (20) then calculates a torque command value for a motor generator (2) by adding the torque correction amount to a basic torque value for driving the motor generator (2) to rotate, and performs torque control such that the torque of the motor generator (2) equals the torque command value.

Owner:NISSAN MOTOR CO LTD

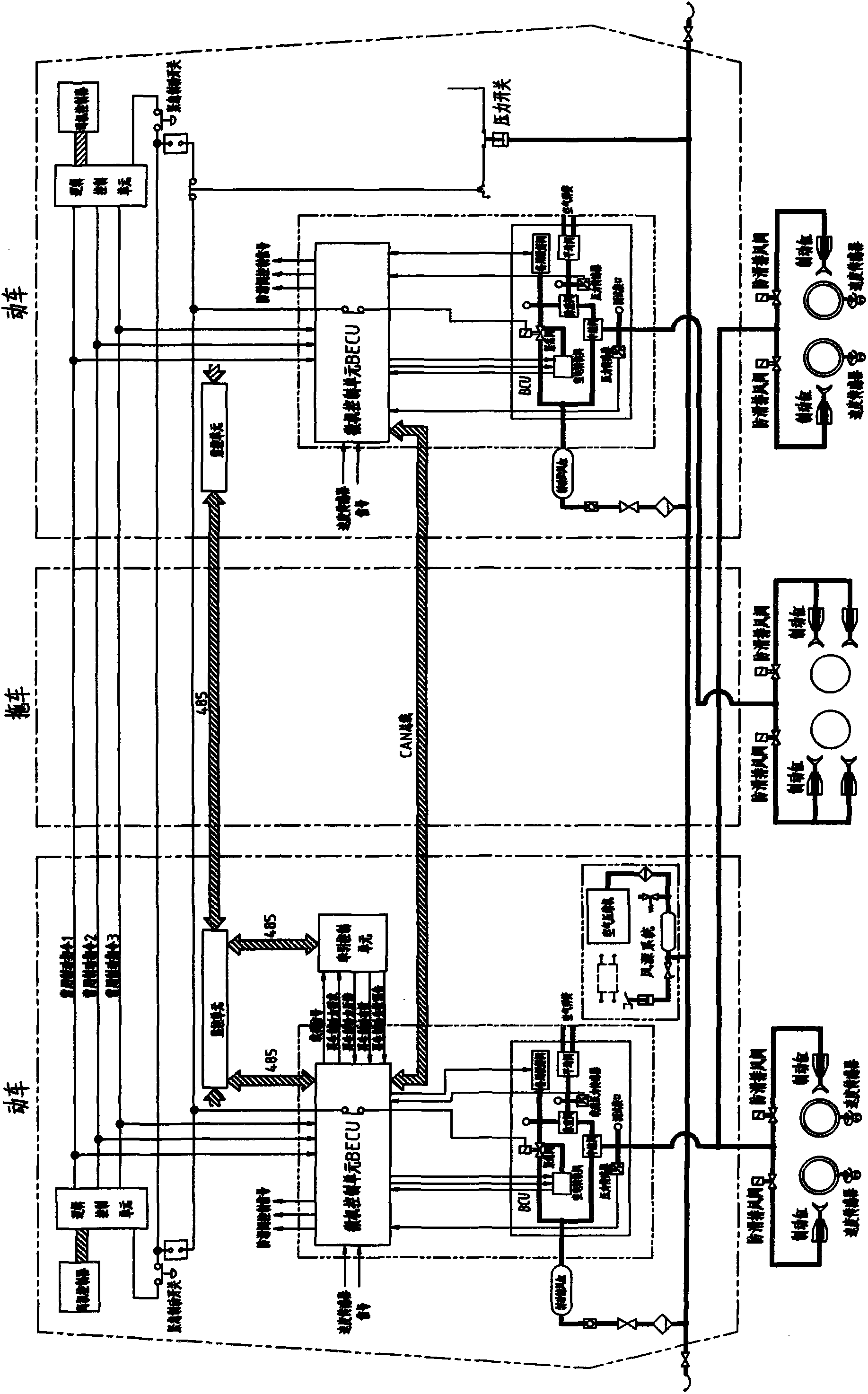

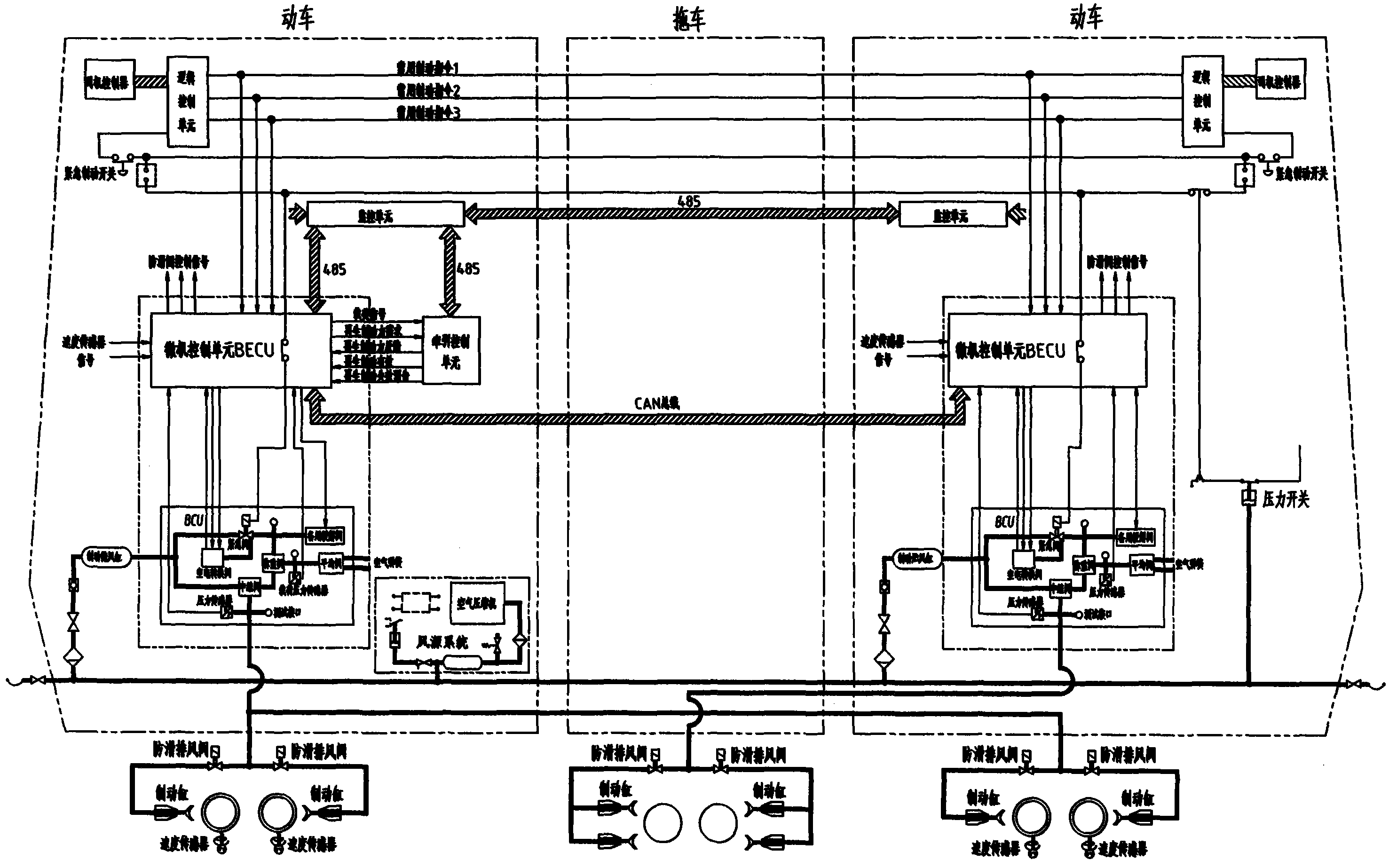

Urban tram braking system

ActiveCN102328646AImprove responsivenessStable controlAerodynamic brakesFluid braking transmissionExhaust valveDynamic braking

The invention relates to an urban tram braking system. The system comprises a braking instruction generation system, a braking control system and an anti-skid system, wherein the braking instruction generation system comprises a braking electronic control unit (BECU) and a braking control unit (BCU) and sends a braking instruction to the BECU; the BECU calculates required braking force according to the braking instruction and loading force detected by a loading pressure sensor and provides the braking force for a traction control unit; the traction control unit feeds a dynamic braking force signal back to the BECU; the BECU calculates air braking force which is needed to be supplemented and controls the BCU to generate braking cylinder pressure so as to realize braking control; the braking instruction generation system is provided with a driver controller, an emergency braking switch and a logic control unit connected with the emergency braking switch; the anti-skid system comprises a speed sensor arranged on a wheel axle and an anti-skid exhaust valve arranged on a braking cylinder pipe; the speed sensor detects a speed signal and transmits the speed signal to the BECU; and the BECU controls the action of the anti-skid exhaust valve according to the speed signal.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Braking pressure control apparatus capable of switching between two brake operating states using power-operated and manually operated pressure sources, respectively

InactiveUS6957870B2Reduce disadvantagesEfficient workBraking action transmissionBrake control systemsEngineeringBraking system

Owner:TOYOTA JIDOSHA KK

Method and apparatus of fuelling an internal combustion engine with hydrogen and methane

ActiveUS8469009B2Reduce the amount of solutionInternal combustion piston enginesNon-fuel substance addition to fuelElectronic controllerRail pressure

A gaseous-fuelled internal combustion engine and a method of engine operation improve combustion stability and reducing emissions of NOx, PM, and unburned hydrocarbons. The method comprises fuelling an internal combustion engine with hydrogen and natural gas, which can be directly injected into the combustion chamber together or introduced separately. Of the total gaseous fuel delivered to the engine, at least 5% by volume at standard temperature and pressure is hydrogen. For at least one engine operating condition, the ratio of fuel rail pressure to peak in-cylinder pressure is at least 1.5:1. A fuel injection valve introduces the gaseous fuel mixture directly into the combustion chamber. Two separate fuel injection valves could also introduce the methane and hydrogen separately. An electronic controller controls timing for operating the fuel injection valve(s). The engine has a preferred compression ratio of at least 14:1.

Owner:THE UNIV OF BRITISH COLUMBIA +1

Method for operating an internal combustion engine

InactiveUS20080059048A1Improved emergency driving functionEasy to testAnalogue computers for vehiclesElectrical controlEngineeringInternal combustion engine

To enable operation of an internal combustion engine even without the signals of a phase sensor while nonetheless enabling an emergency driving function in the case of a disturbance of a crankshaft signal acquired by a crankshaft sensor, a cylinder pressure is acquired using a cylinder pressure sensor and it is checked whether the cylinder pressure reaches a prespecifiable threshold value. When the threshold value is reached or exceeded, an angular position associated with the threshold value is inferred. The angular position is then made available for an operation of the internal combustion engine.

Owner:ROBERT BOSCH GMBH

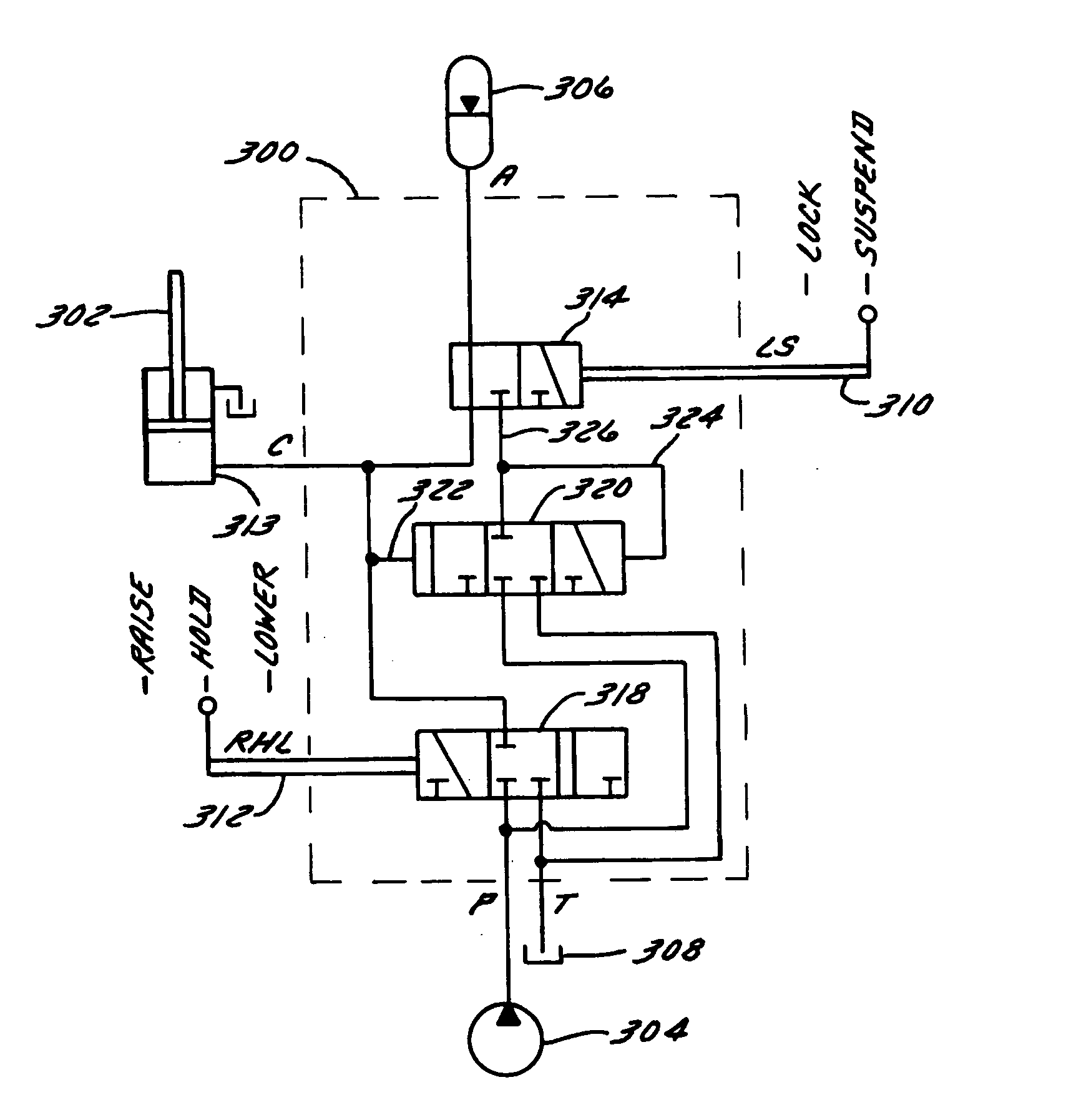

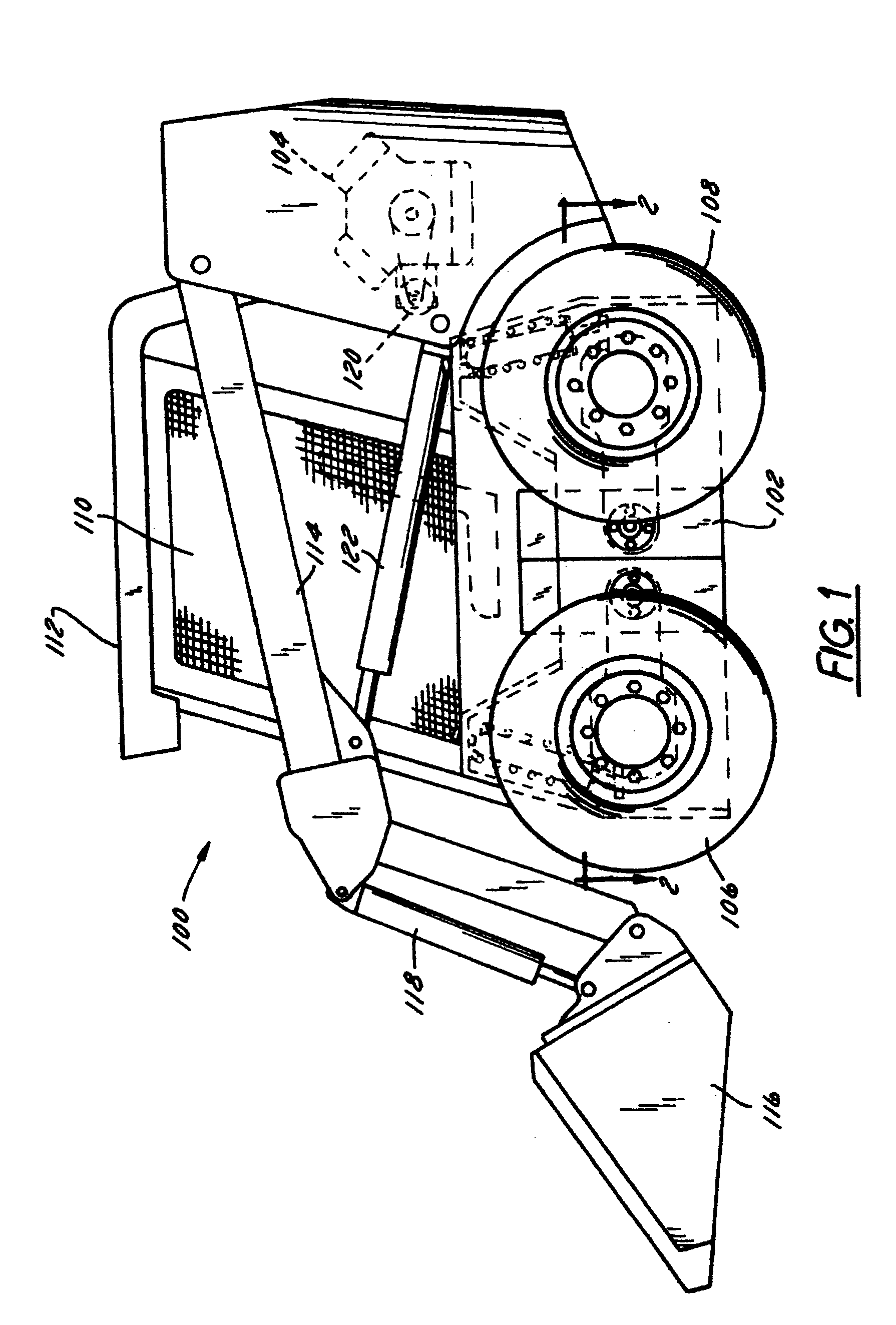

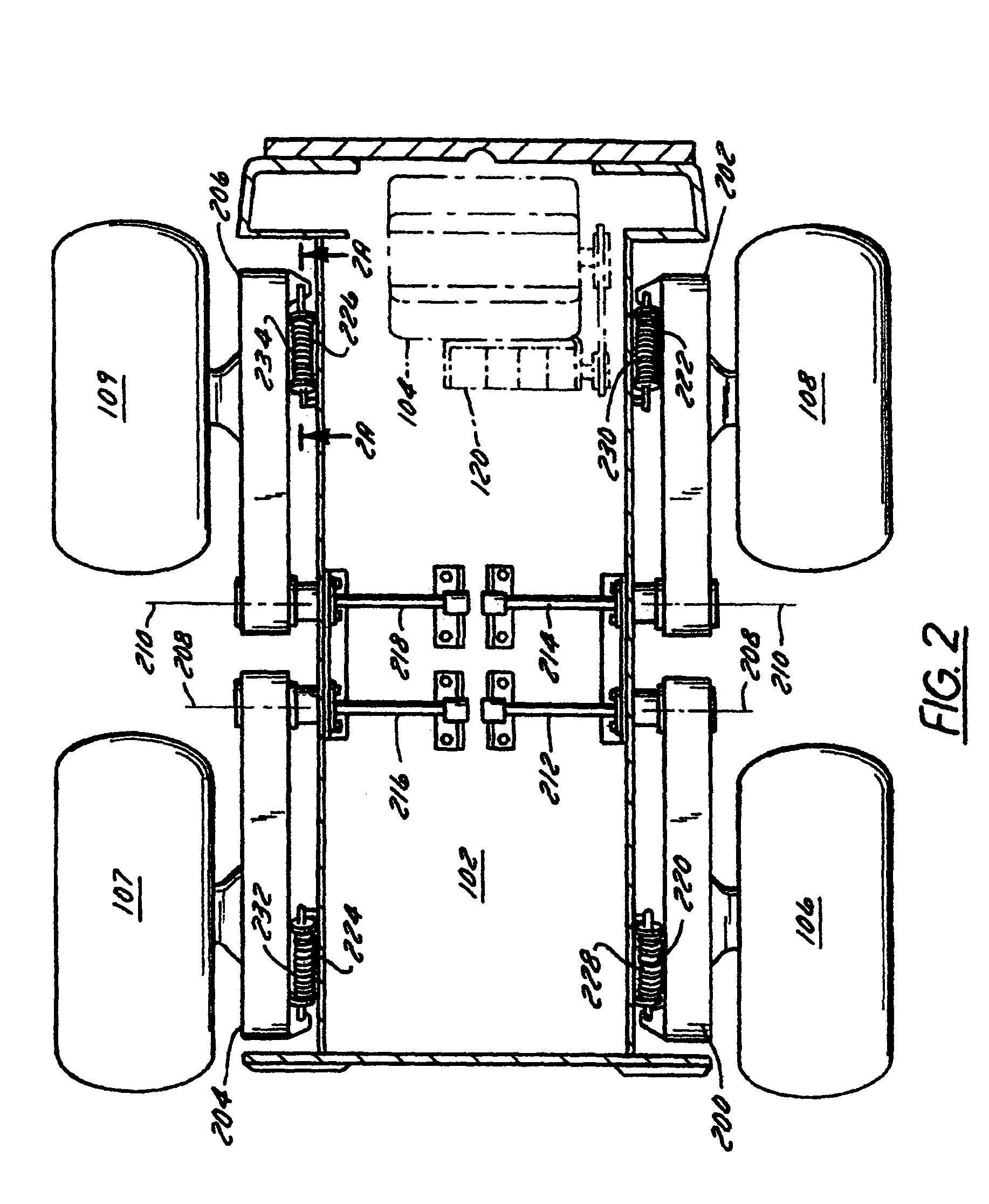

Locking anti-motion suspension

ActiveUS20050062239A1Effective lockingVehicle cleaning apparatusLoading/unloading vehicle arrangmentHydraulic cylinderControl arm

A skid steer vehicle has a suspension that includes a control arm pivotally coupled to the vehicle chassis that is supported by a hydraulic cylinder connected to an accumulator to provide springing. A hydraulic circuit coupled to the cylinder and accumulator permit the operator to raise and lower the chassis, to lock the suspension while the vehicle is loaded, and to automatically charge or discharge the accumulator to match the cylinder pressure during loading and unloading. In this manner, when the suspension is unlocked after loading, the vehicle chassis neither rises nor falls.

Owner:CNH IND AMERICA LLC +1

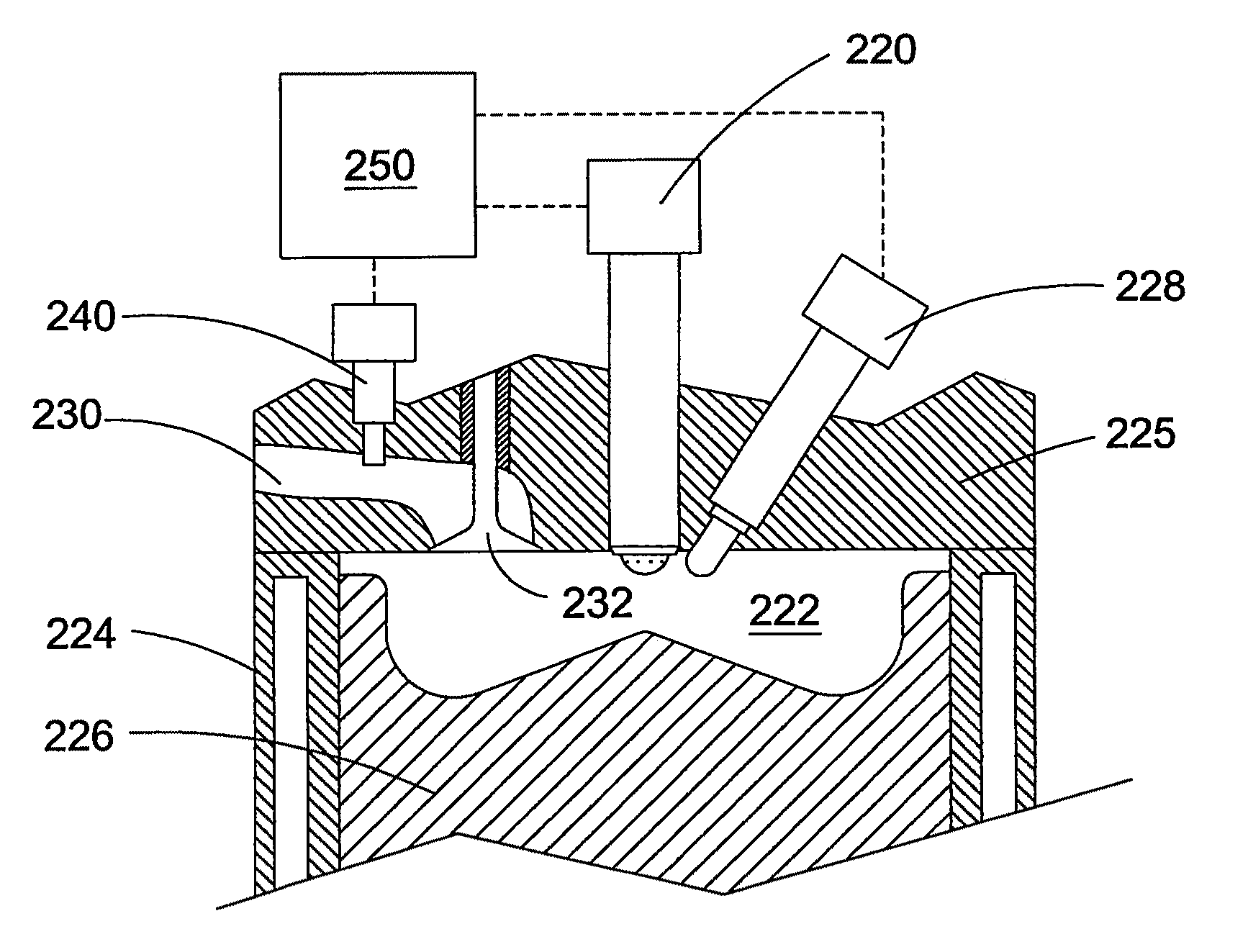

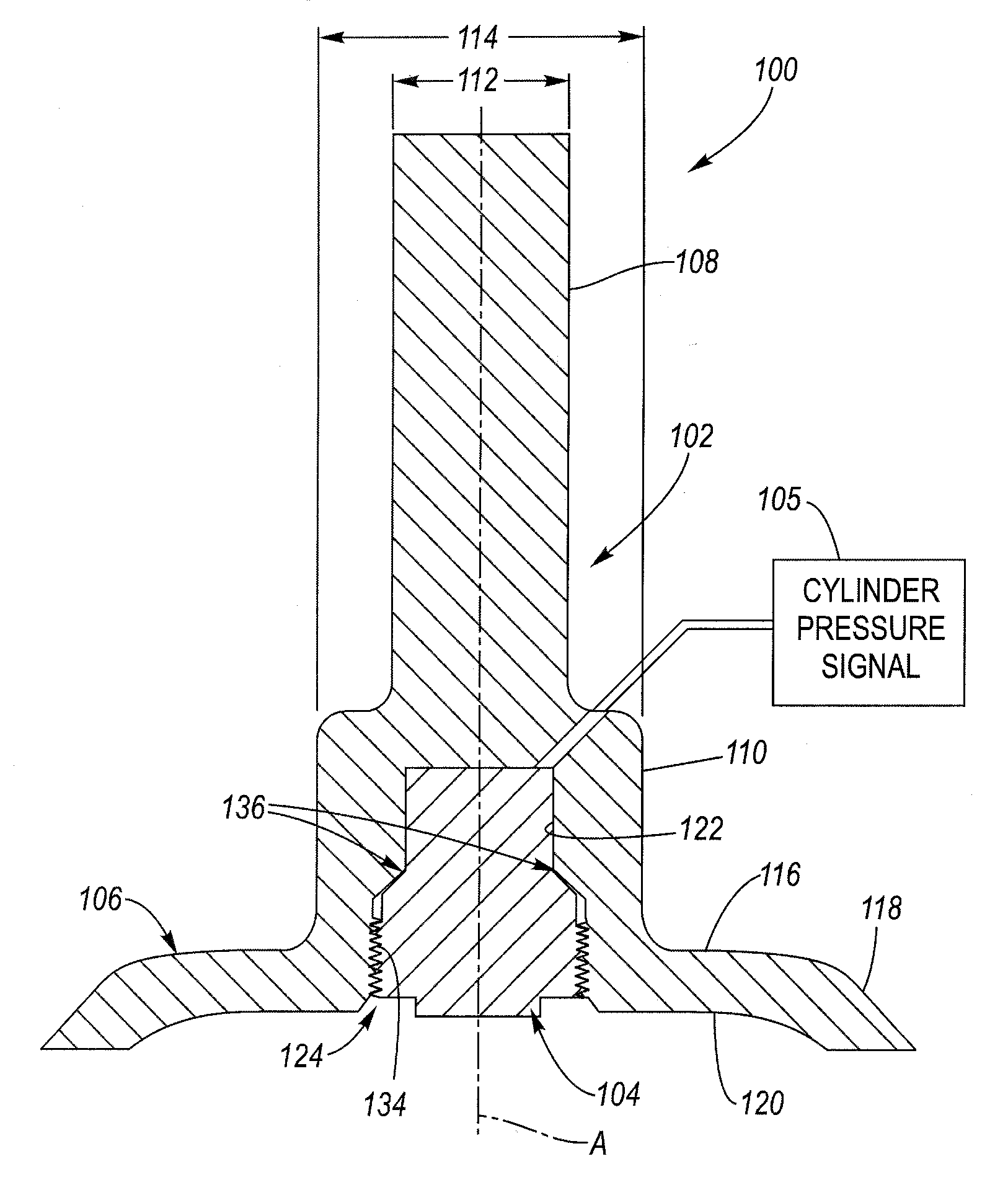

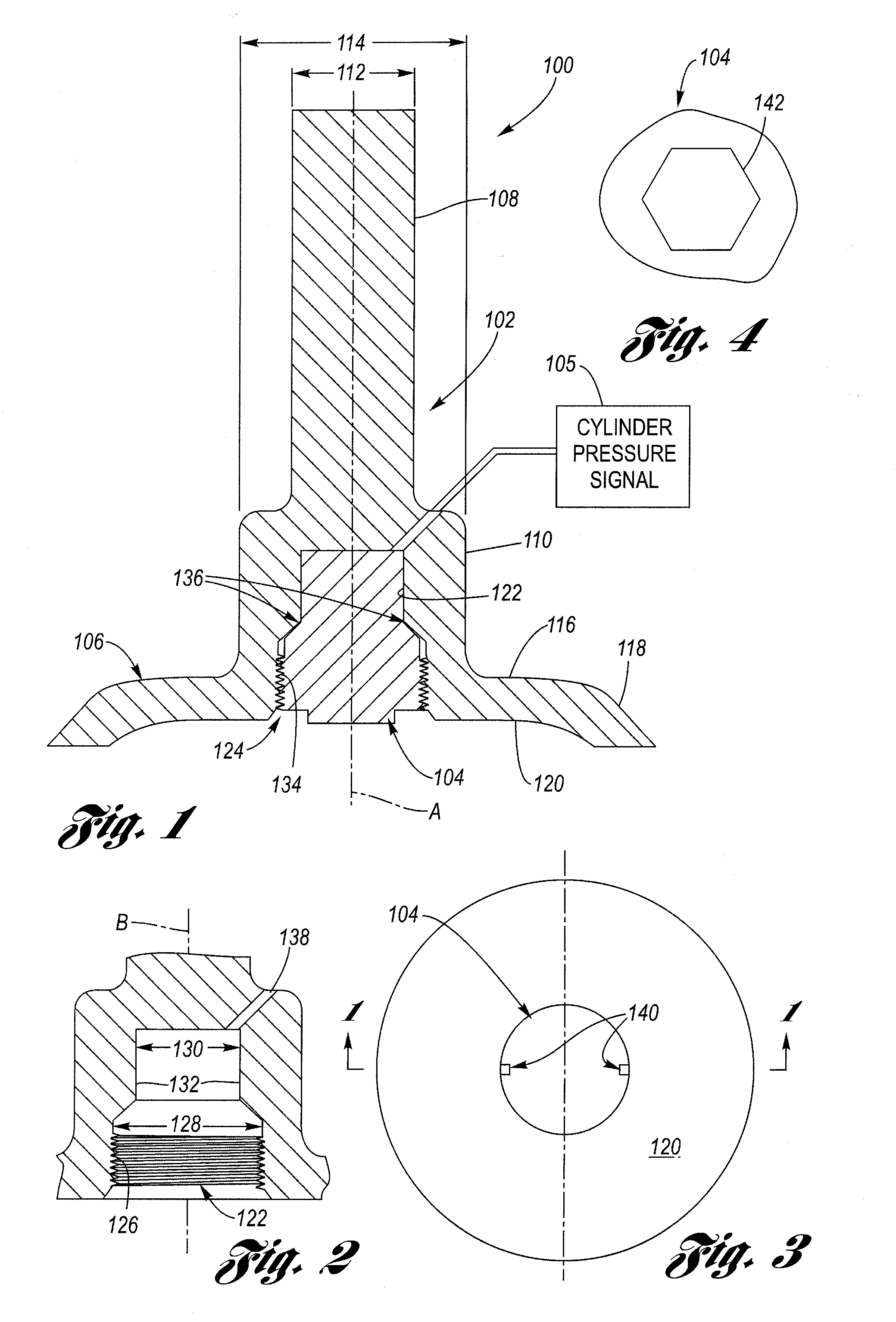

Cylinder pressure sensor system

InactiveUS20090090189A1Improve approachEliminate needFluid pressure measurement by electric/magnetic elementsRapid change measurementInlet valveEngineering

An engine intake valve has a threaded blind bore opening from its top surface facing the engine cylinder. A pressure sensor has a body portion whose exterior is threaded and is configured in size and shape to be completely received within and retained in the blind bore. The pressure sensor is configured to generate a pressure signal indicative of the cylinder pressure.

Owner:DELPHI TECH INC

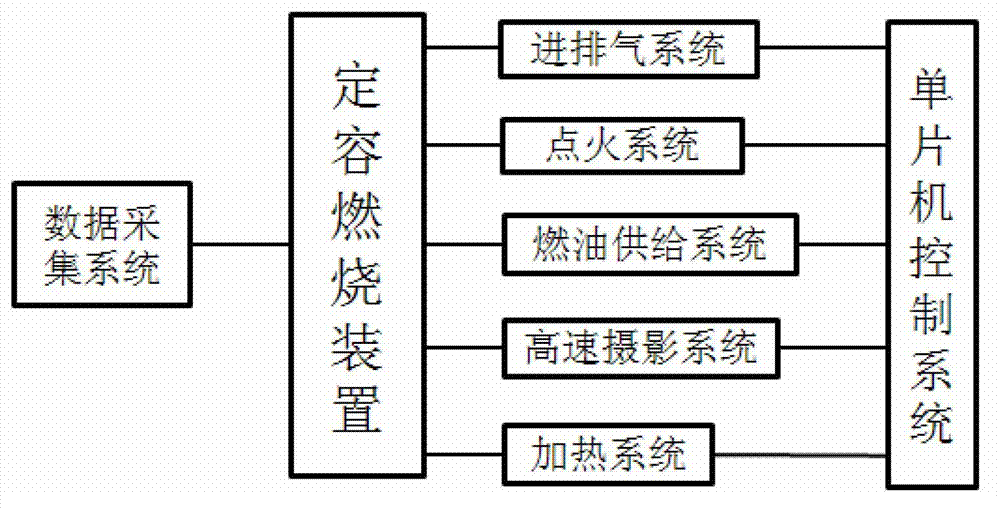

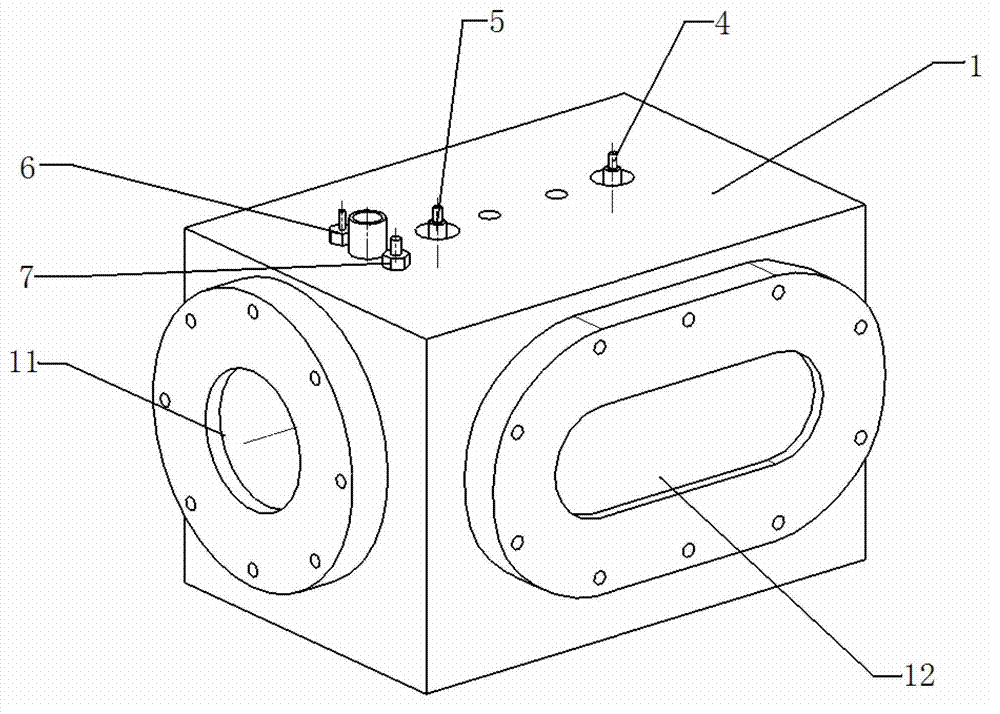

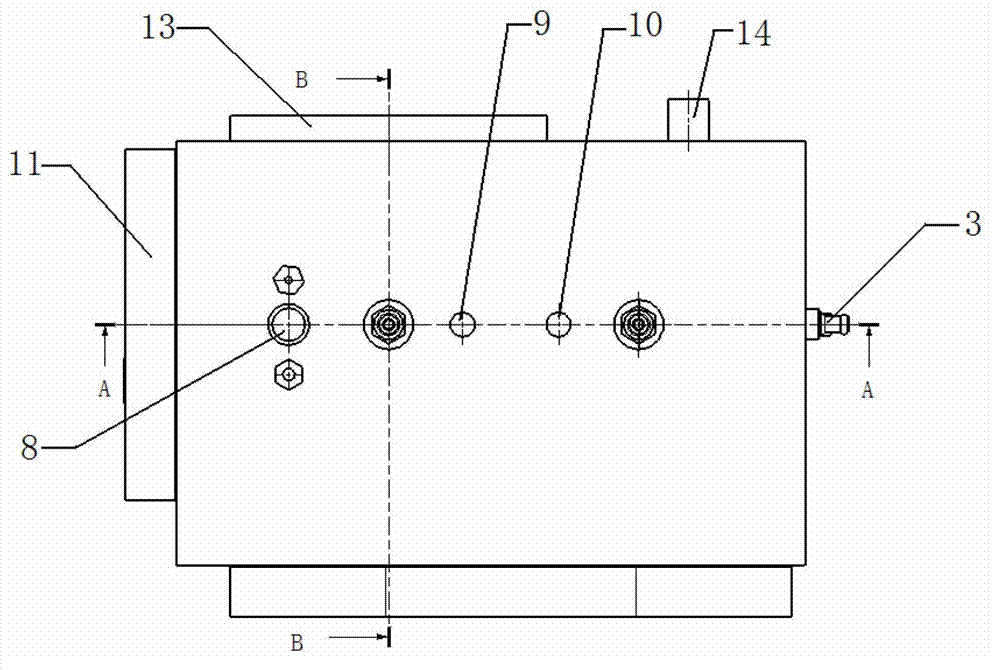

Constant-volume combustion bomb system for simulating self-combustion of gas at tail end of gasoline engine

ActiveCN103245511AExtend the mixing timeSimple structureInternal-combustion engine testingDetonationData acquisition

The invention discloses a constant-volume combustion bomb system for simulating self-combustion of gas at the tail end of a gasoline engine. The constant-volume combustion bomb system consists of a constant-volume combustion device, a fuel supply system, an ignition system, a high-speed photography system, a gas intake and exhaust system, a data acquisition system and a single-chip control system, wherein the constant-volume combustion device comprises a combustion bomb body with a cylindrical cavity; a main spark plug is mounted on the upper end surface of the combustion bomb body, at the end close to an oil injector, and an auxiliary spark plug is mounted close to the left end of the combustion bomb body; and the combustion bomb body is provided with a left window, a front window and a rear window and is further provided with the oil injector, a high-frequency response temperature sensor, a high-frequency response cylinder pressure sensor, a pressure transmitter mounting hole, a temperature transmitter mounting hole, an exhaust port and an intake channel. According to the invention, the main spark plug is adopted to simulate the normal flame ignition while the auxiliary spark plug is adopted to simulate self-combustion of gas at the tail end, so that self-combustion of gas at the tail end of the gasoline engine at all times can be simulated without the need of reaching high temperature and high pressure, and the constant-volume combustion bomb system is used for researching the influence of self-combustion of different tail-end gases to the cylinder internal pressure and detonation.

Owner:TIANJIN UNIV

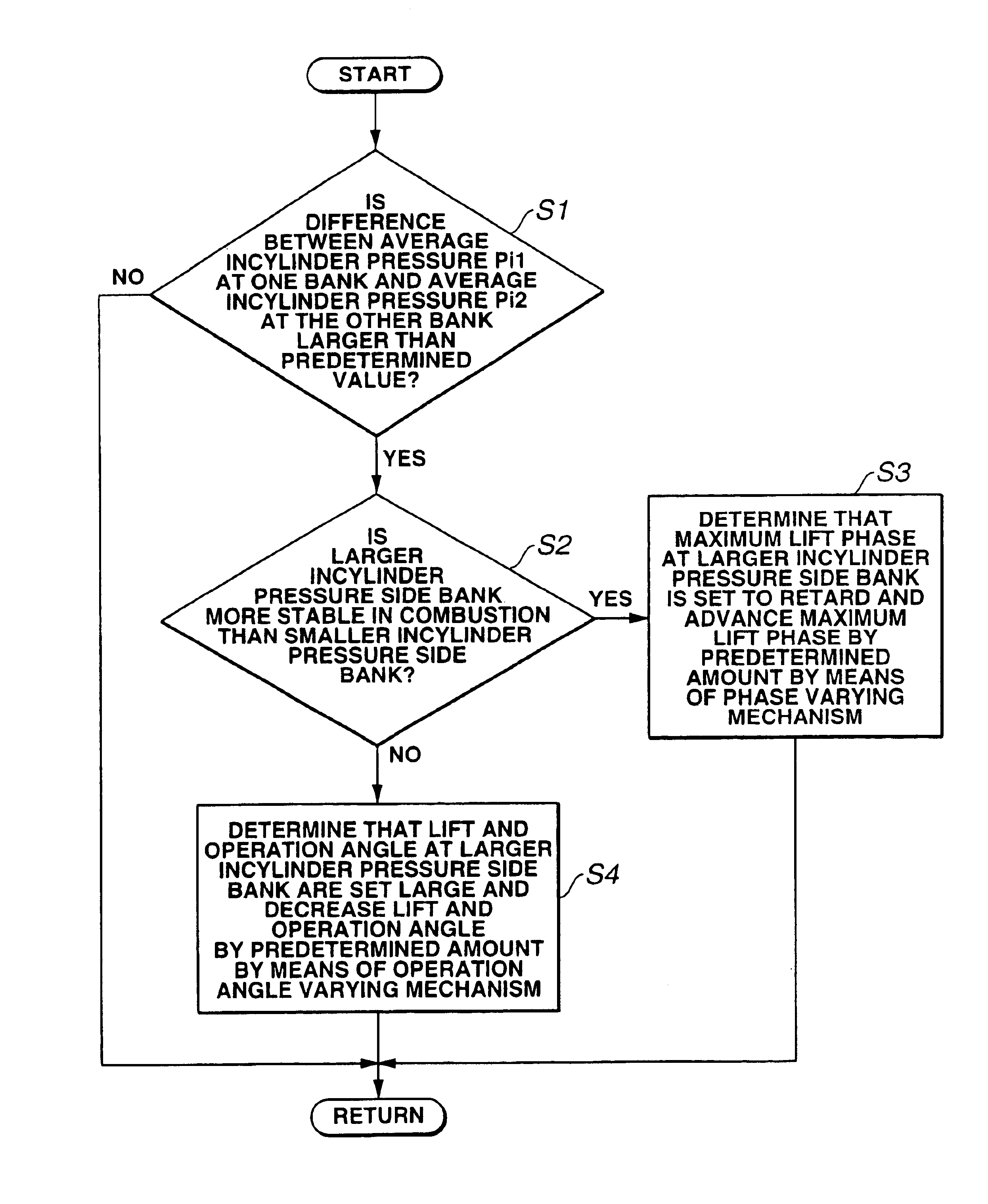

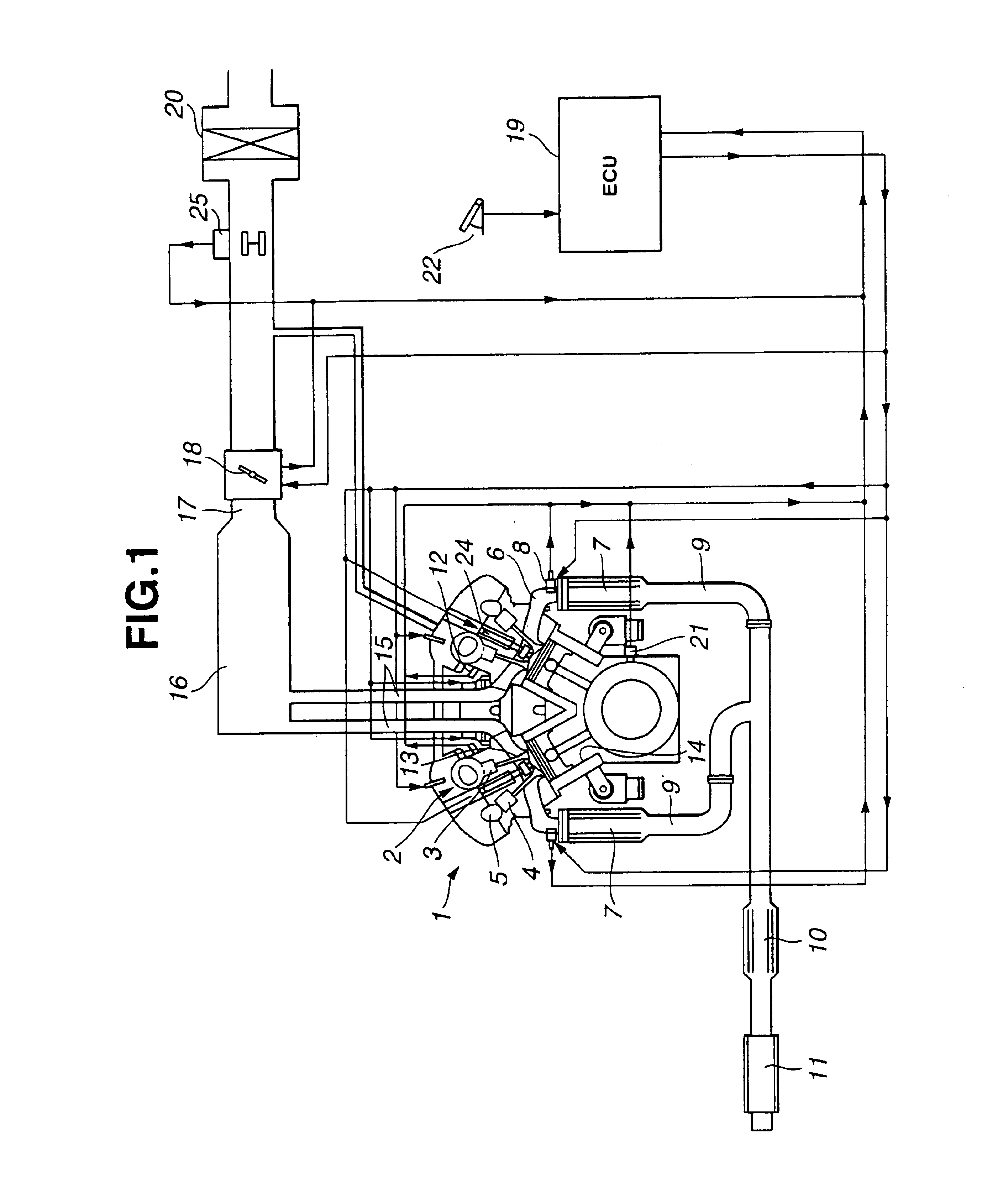

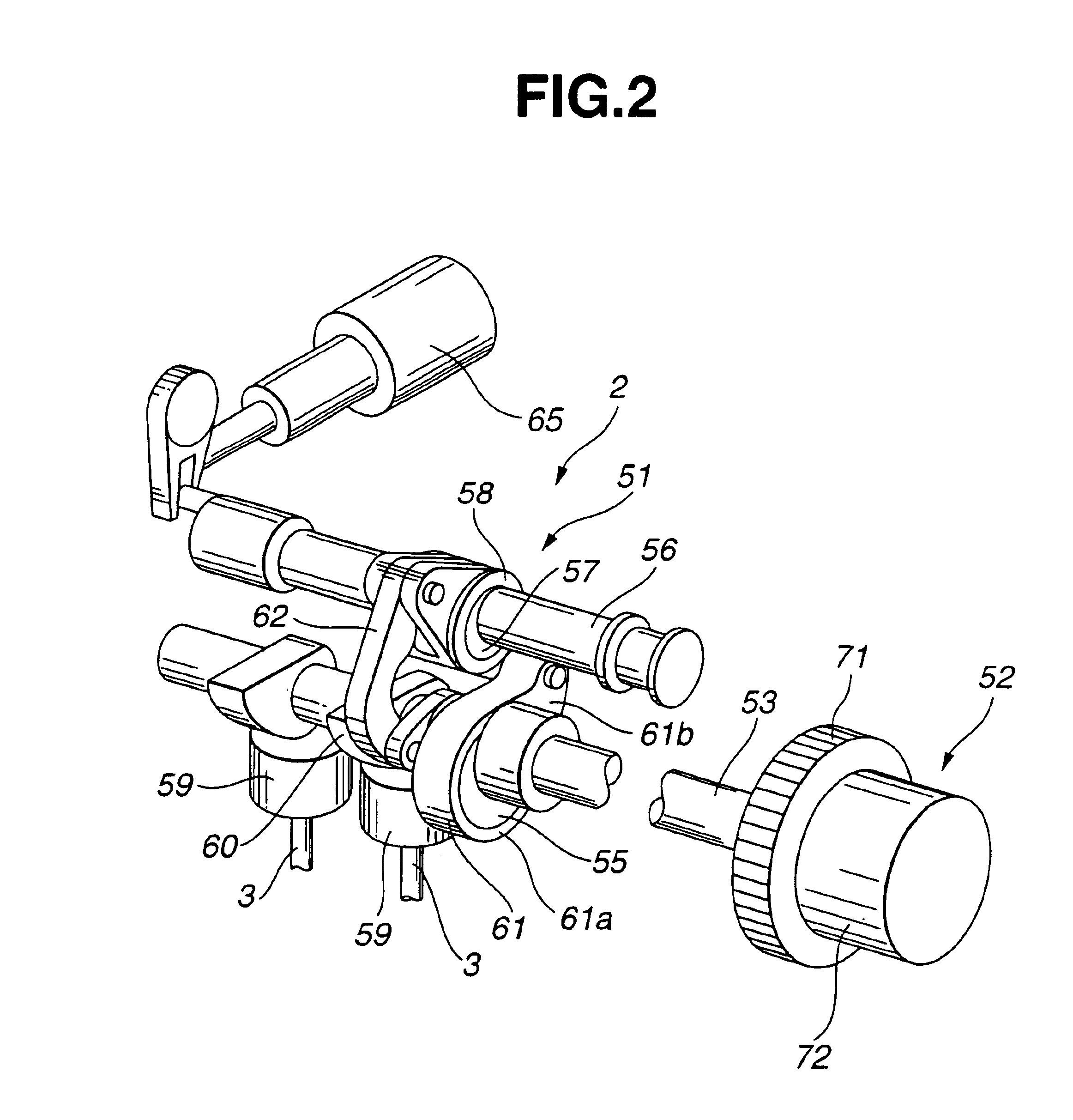

Control apparatus for internal combustion engine

InactiveUS6912995B2Effective absorptionSuppress in consumptionElectrical controlNon-fuel substance addition to fuelExternal combustion engineInlet valve

A control apparatus for an internal combustion engine having two cylinder groups and two variable valve control mechanisms provided to the respective cylinder groups, includes a detecting section that detects an incylinder pressure of each cylinder, a comparing section that makes a comparison between the two cylinder groups with respect to a combustion stability and a control section that varies valve lift characteristics of intake valves of one cylinder group which is larger in the average incylinder pressure than the other cylinder group in accordance with a result of comparison by the comparing section so as to make intake air quantities for the respective cylinder groups be equal to each other.

Owner:NISSAN MOTOR CO LTD

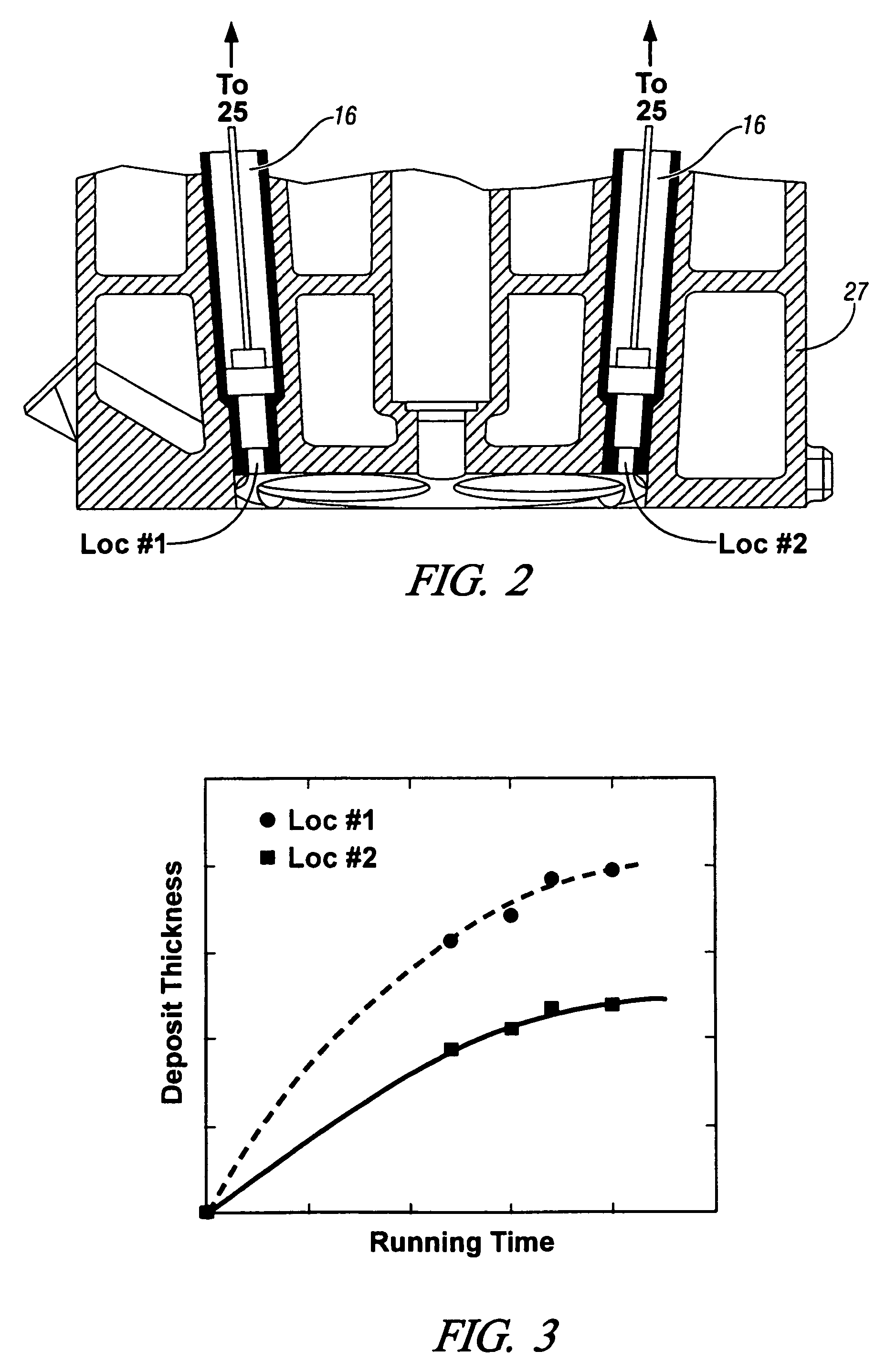

Method and apparatus to determine magnitude of combustion chamber deposits

Owner:MICHIGAN UNIVERISTY OF +1

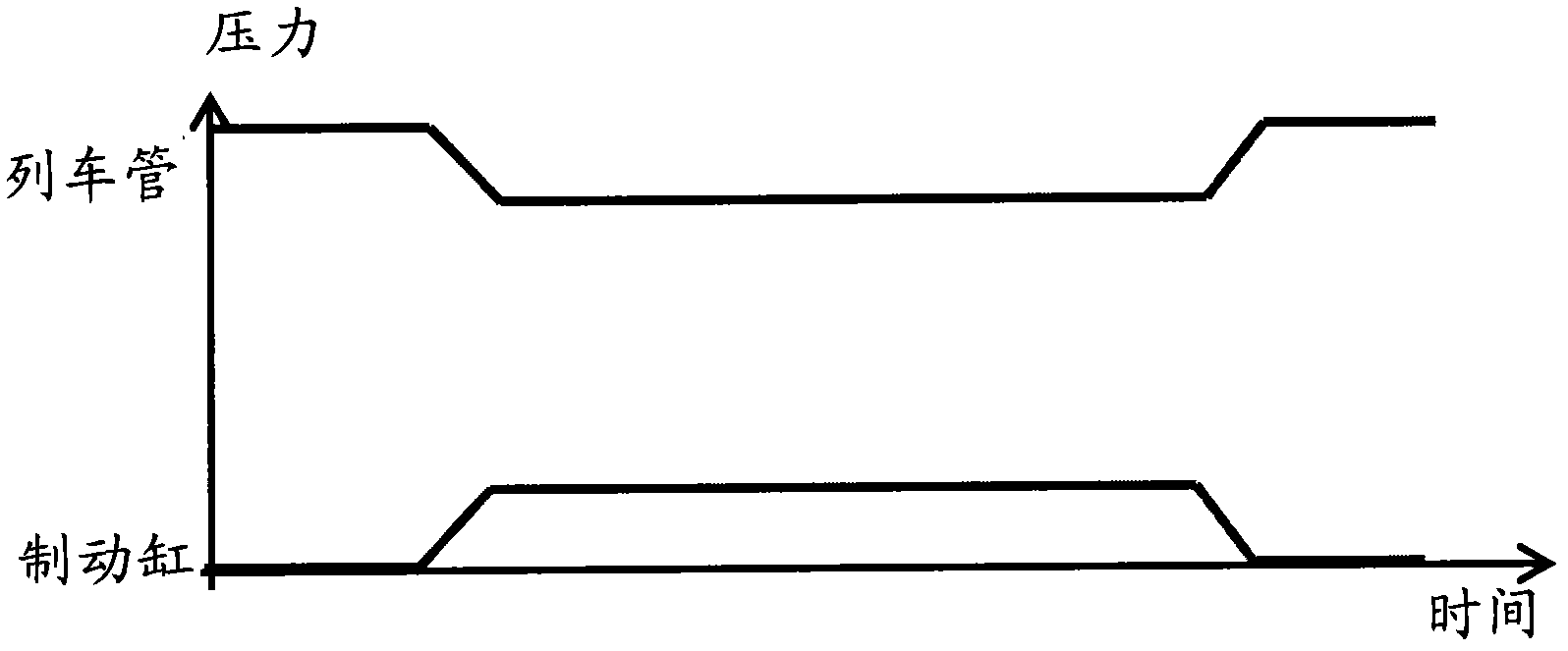

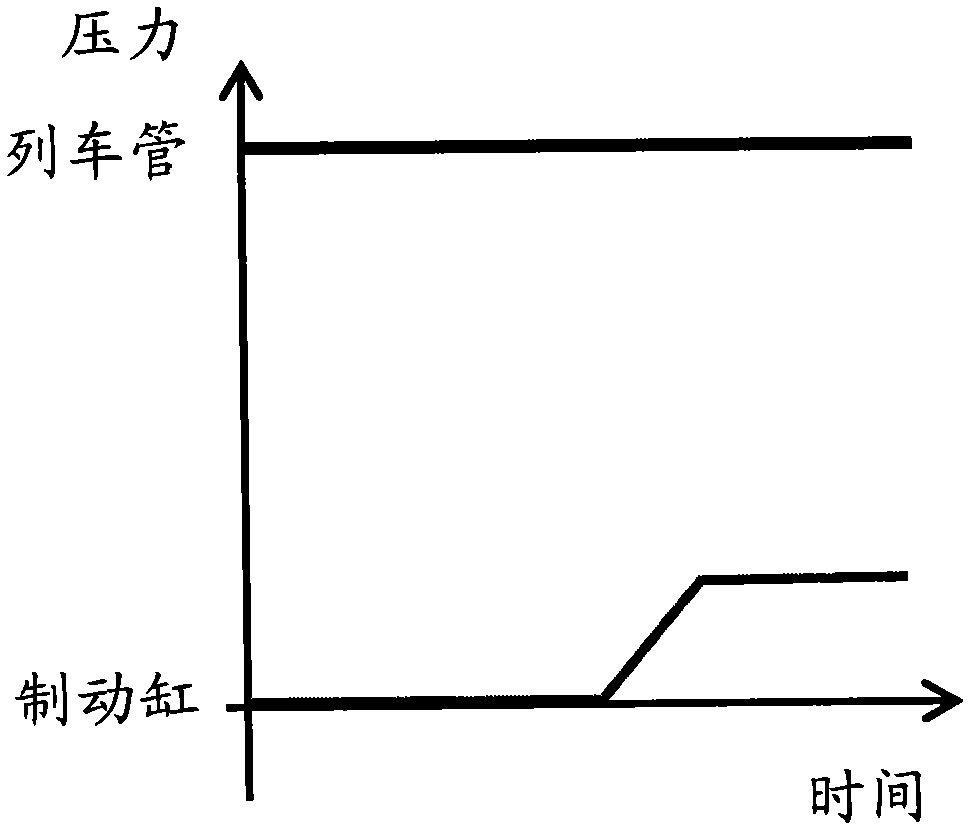

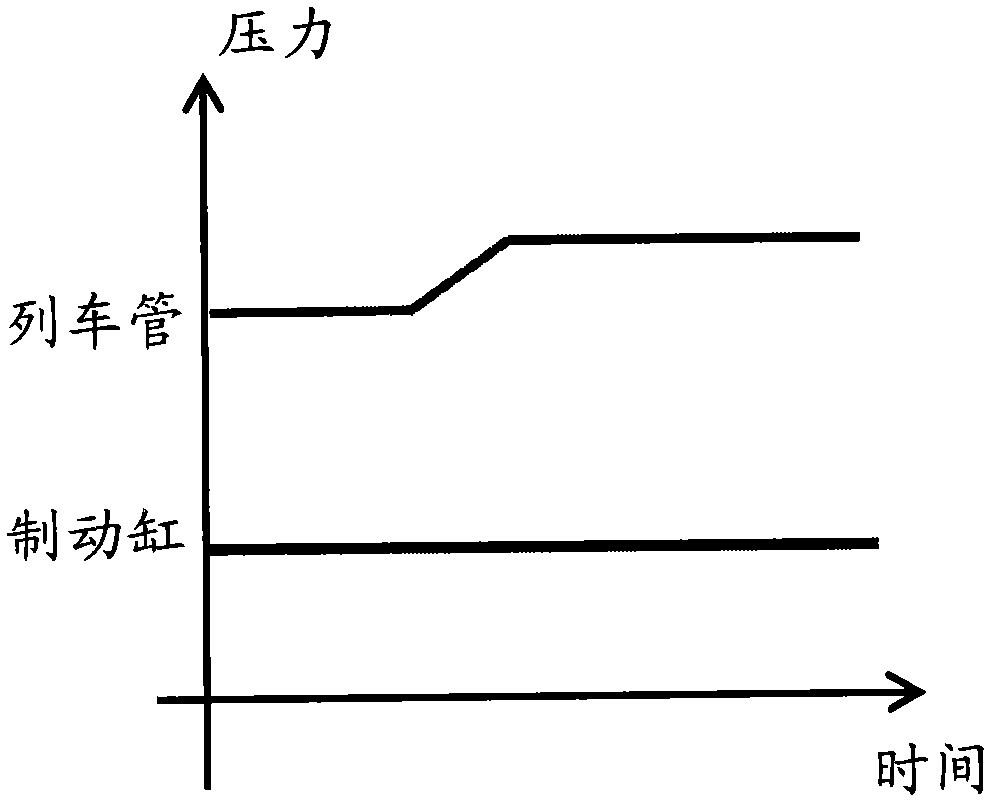

Detecting method and device for failure of automatic air brake system of train

ActiveCN102145689AGuaranteed operational safetyAvoid driving accidentsBrake safety systemsSystem failureBraking system

The invention relates to a detecting method for the failure of an automatic air brake system of a train, which comprises the following steps of: receiving and storing a train pipe pressure and a brake cylinder pressure transmitted by a sensor and acquired in a sampling period; obtaining first train pipe pressure and first brake cylinder pressure acquired in the sampling period as well as second train pipe pressure and second brake cylinder pressure acquired before a certain times of the sampling period; and judging whether the brake system is in failure according to the change of the first train pipe pressure relative to the second train pipe pressure and according to the change of the first brake cylinder pressure to the second brake cylinder pressure, wherein failure prompting information is output when the brake system is judged to be in failure. Correspondingly, the invention also relates to a detecting device for the failure of an automatic air brake system of a train, and monitoring and alarming equipment for the braking of the train. When the detecting method, the detecting device and the monitoring and alarming equipment are adopted, the online detection on the failure of the automatic air brake system of the train can be realized in real time, and the reliability and the accuracy of the detection result can reach a higher level.

Owner:LOCOMOTIVE & CAR RES INST OF CHINA ACAD OF RAILWAY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com