Detecting method and device for failure of automatic air brake system of train

A technology for air braking and detecting trains, which is applied in the direction of braking safety systems, etc., and can solve problems such as the influence of modeling accuracy and the influence of device detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Image 6 It is a flow chart of an embodiment of the method for detecting the failure of the automatic air brake system of the train according to the present invention. see Image 6 , the method includes the following steps:

[0073] S101, receiving and storing the train pipe pressure and the brake cylinder pressure collected during the sampling period transmitted by the sensor.

[0074] In the present invention, two types of pressure sensors are installed in the train braking system, that is, the train pipe pressure sensor and the brake cylinder pressure sensor. The train pipe pressure sensor is installed on the pipeline between the cut-off plug and the distribution valve to collect the train pipe pressure. The brake cylinder pressure sensor is installed on the pipeline between the brake cylinder relief plug and the anti-skid exhaust valve to collect the pressure of the brake cylinder. The pressure of these two measuring points reflects the input and output characte...

Embodiment approach

[0082] Wherein, an implementation manner of judging whether the braking system is in a normal working state is as follows:

[0083] Calculate the decompression speed of the train pipe in the time interval from the time before a certain multiple of the sampling period to the time of the sampling period. For example, subtracting the pressure of the first train pipe from the pressure of the second train pipe and then dividing it by the time between collecting the pressures of the two train pipes, the decompression speed of the train pipe within the time interval can be obtained.

[0084] Comparing the decompression speed of the train tube with the set first decompression speed threshold;

[0085] When it is judged that the decompression speed is greater than the first decompression speed threshold, it is further judged whether the decompression speed is greater than the set second decompression speed threshold, if the decompression speed is greater than the second decompression s...

Embodiment 2

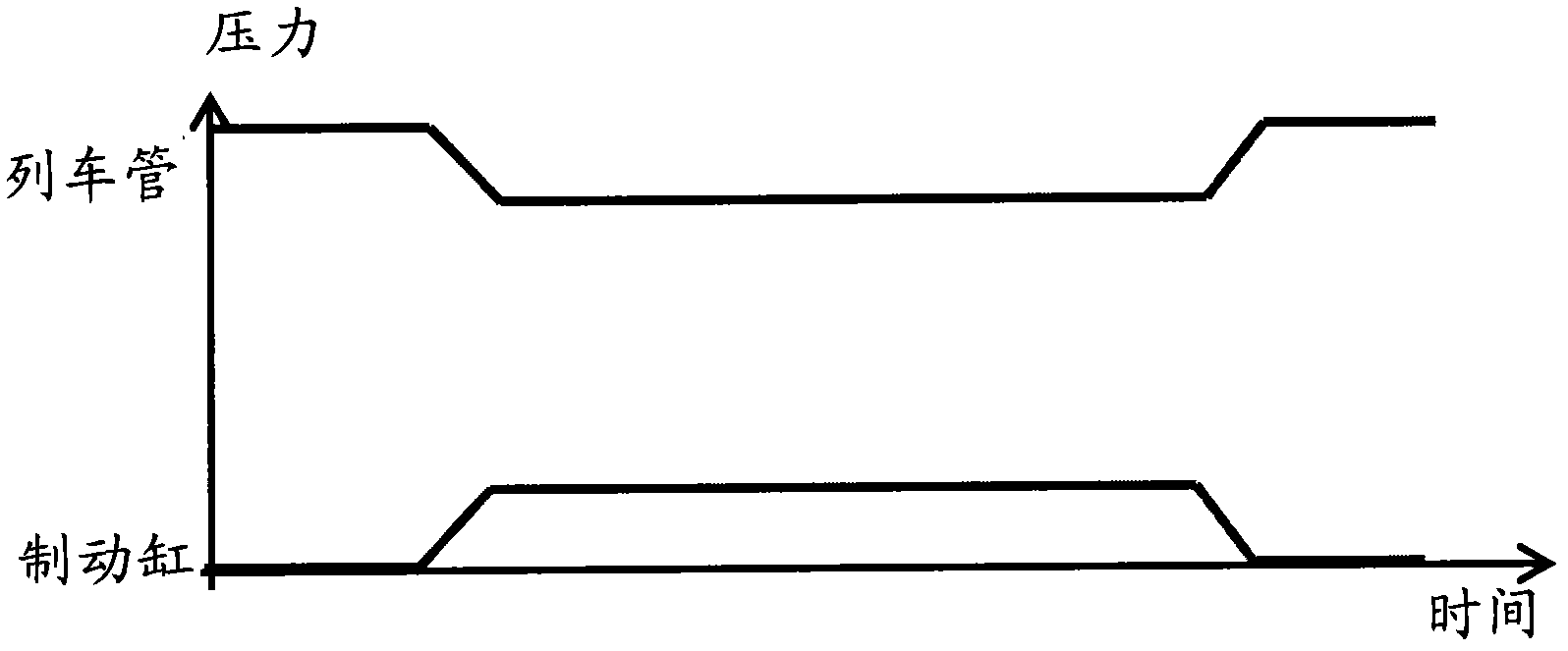

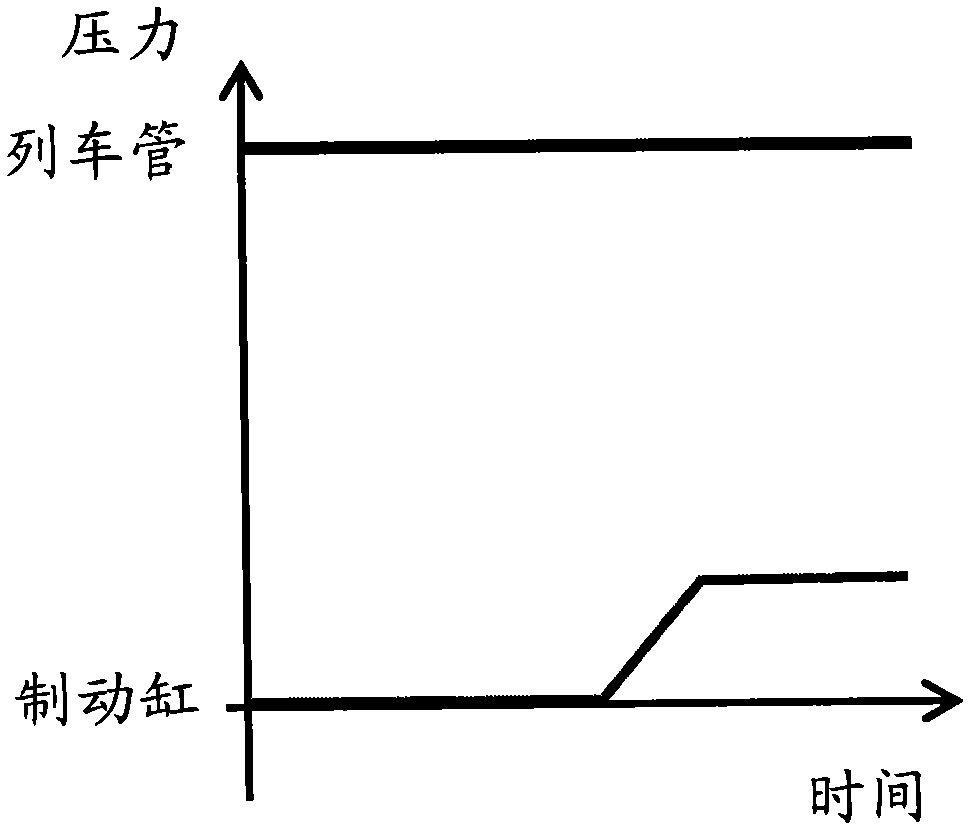

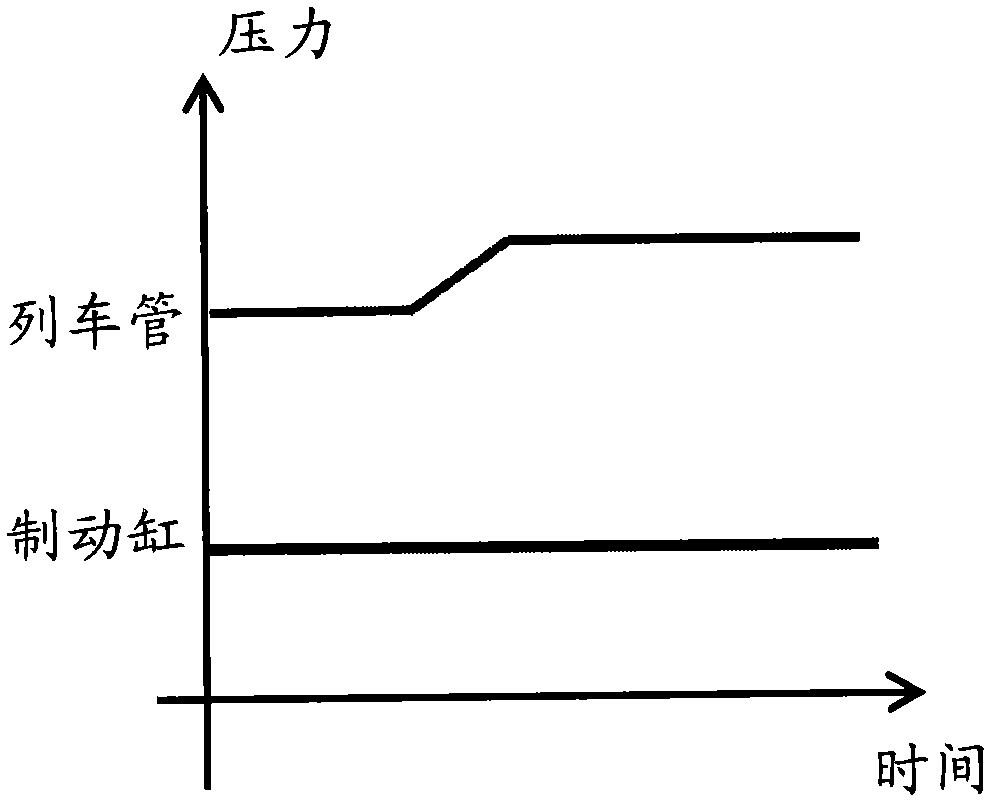

[0089] In the embodiment of the present invention, the inventor combines Figure 1 to Figure 5 Analysis of the characteristics of each fault further gives a table of fault detection conditions, see Table 1. When the train pipe pressure and brake cylinder pressure meet one of the following detection conditions, the brake system has a fault corresponding to the detection condition.

[0090] Table 1

[0091] fault name

Detection conditions

natural braking

r=0 and Pz=0 change to Pz>0

severe natural braking

∫PzVdt>M and Pz>50kPa during natural braking

natural relief

r>0 and Pz>0 change to Pz=0

No braking effect

r>0 and Pz=0

Poor relief

r>0 changes to r=0 while Pz>0

severe poor response

When the relief effect is poor, ∫PzVdt>M and Pz>50kPa

brake off

Pz=0 and r=600

[0092] Among them: M is the heat capacity of the brake disc (refer to the data provided by the brake disc manufacturer of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com