Test device and test method capable of simulating water pressure in tunnel

A test device and pressure technology, used in measuring devices, machine/structural components testing, instruments, etc., can solve problems such as very high requirements for hole plugging, inability to continue testing, and damage to the construction environment, so as to ensure the construction and operation of the project. Safety, good economic and technical benefits, the effect of flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

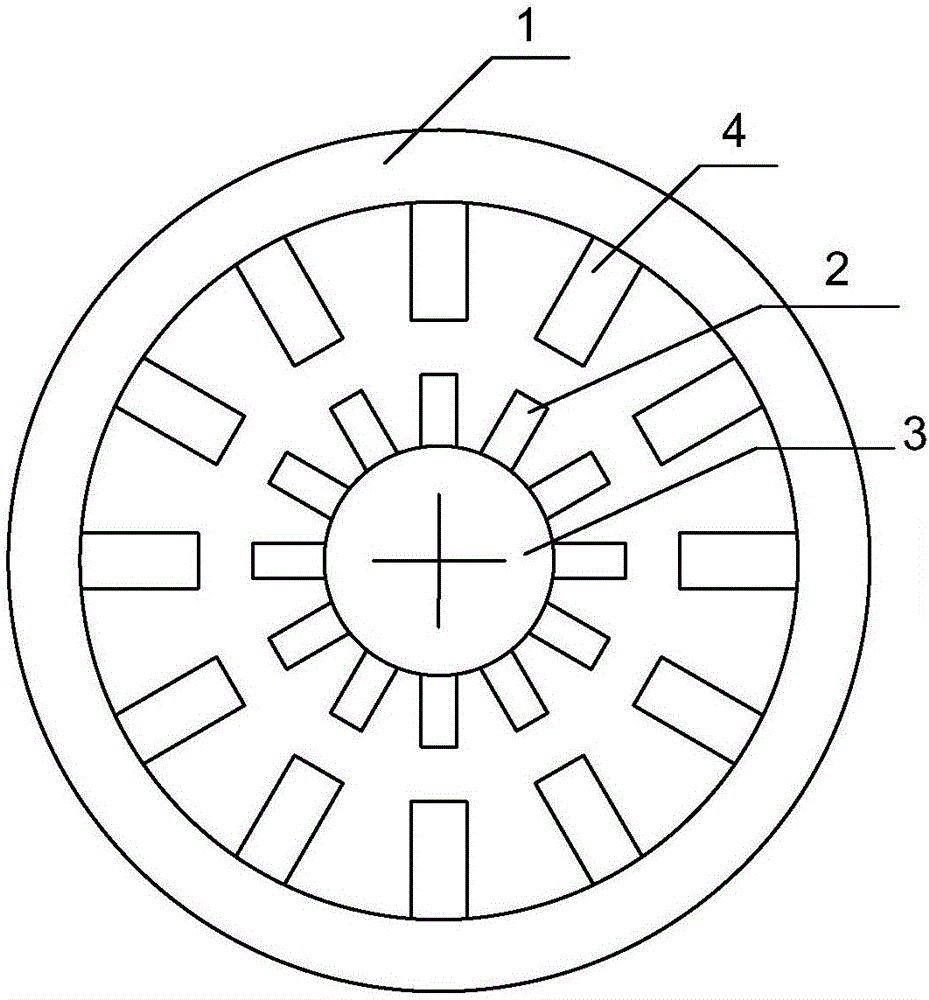

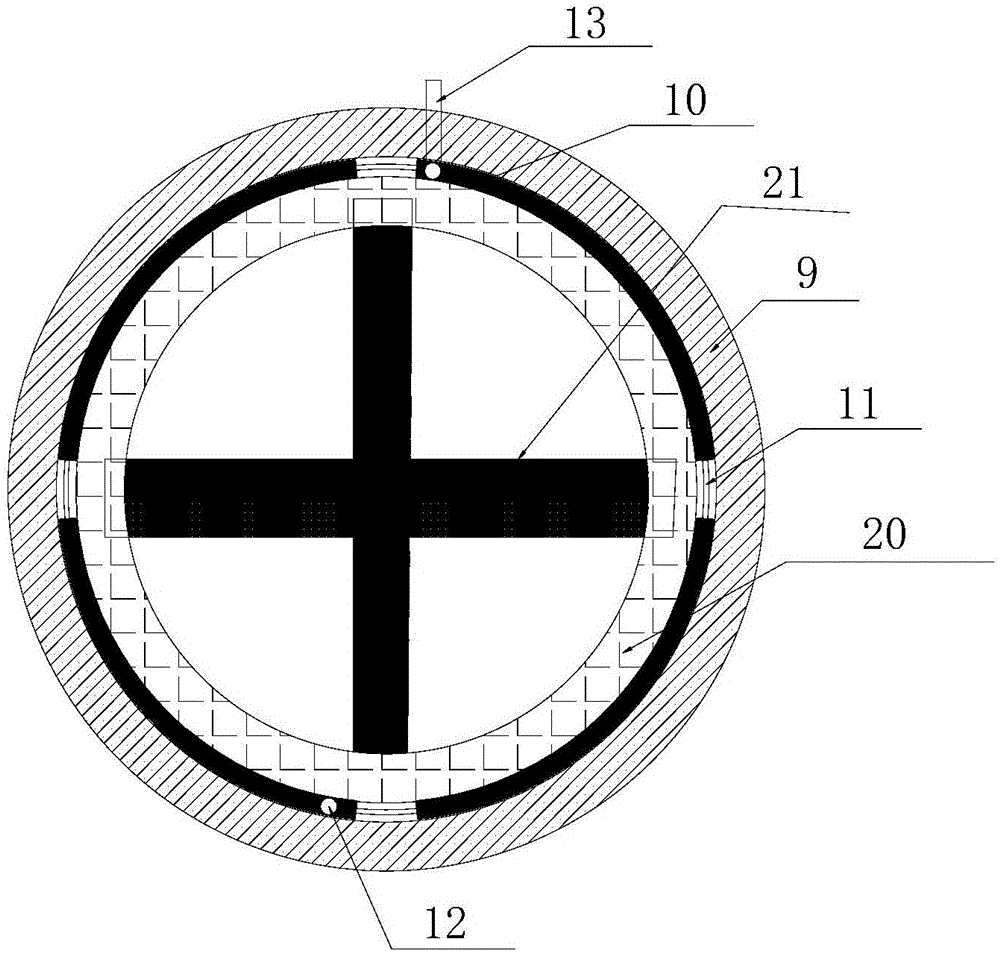

[0045] Such as Figure 3-7 As shown, the test device for simulating water pressure in a tunnel of the present invention includes a load loading mechanism, a monitoring system, and a reaction force mechanism;

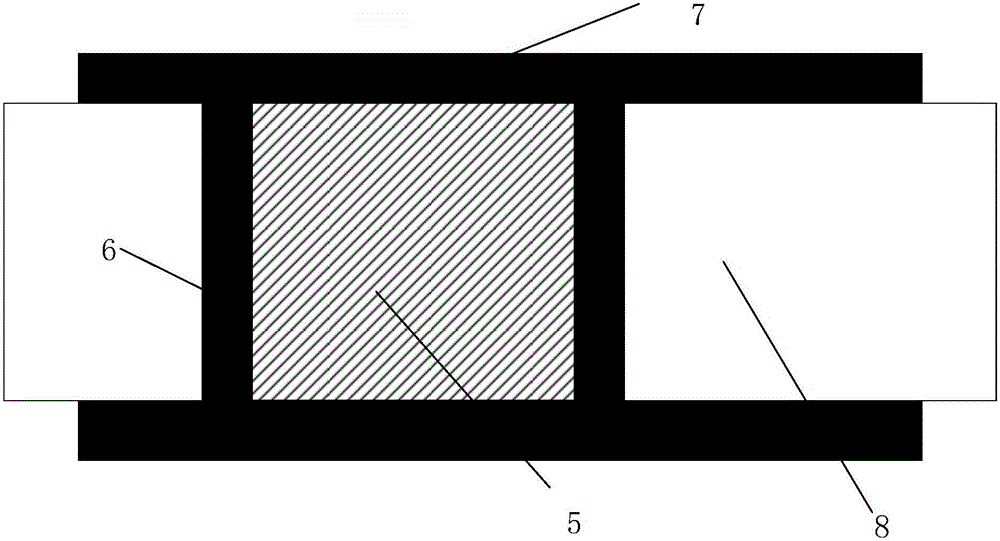

[0046] The load loading mechanism includes a plurality of flexible containers 10, connecting pipes 11, and liquid filling pumps 15. Connectors are provided at both ends of the flexible containers 10, and the two flexible containers are connected through the connecting pipes 11, and the two flexible containers are connected in pairs. After the pipes are connected, the outer side 16 of each flexible container 10 is arranged on the ring section of the lining 9, the flexible container near the lower end of the lining ring section is provided with a liquid injection pipe 12, and the flexible container near the upper end of the lining ring sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com