Patents

Literature

2151 results about "Prestressed concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prestressed concrete is a form of concrete used in construction. It is substantially "prestressed" (compressed) during its fabrication, in a manner that strengthens it against tensile forces which will exist when in service.

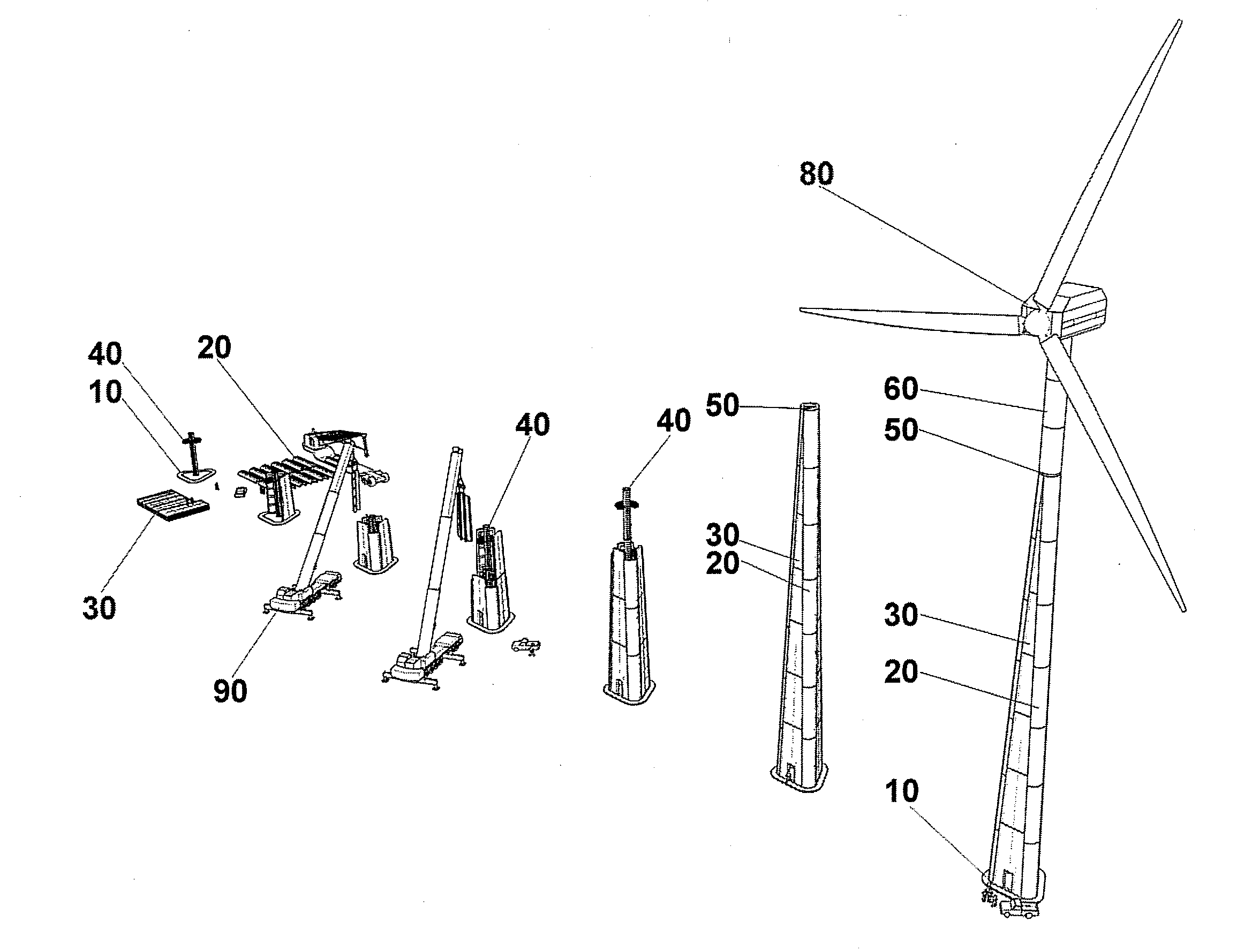

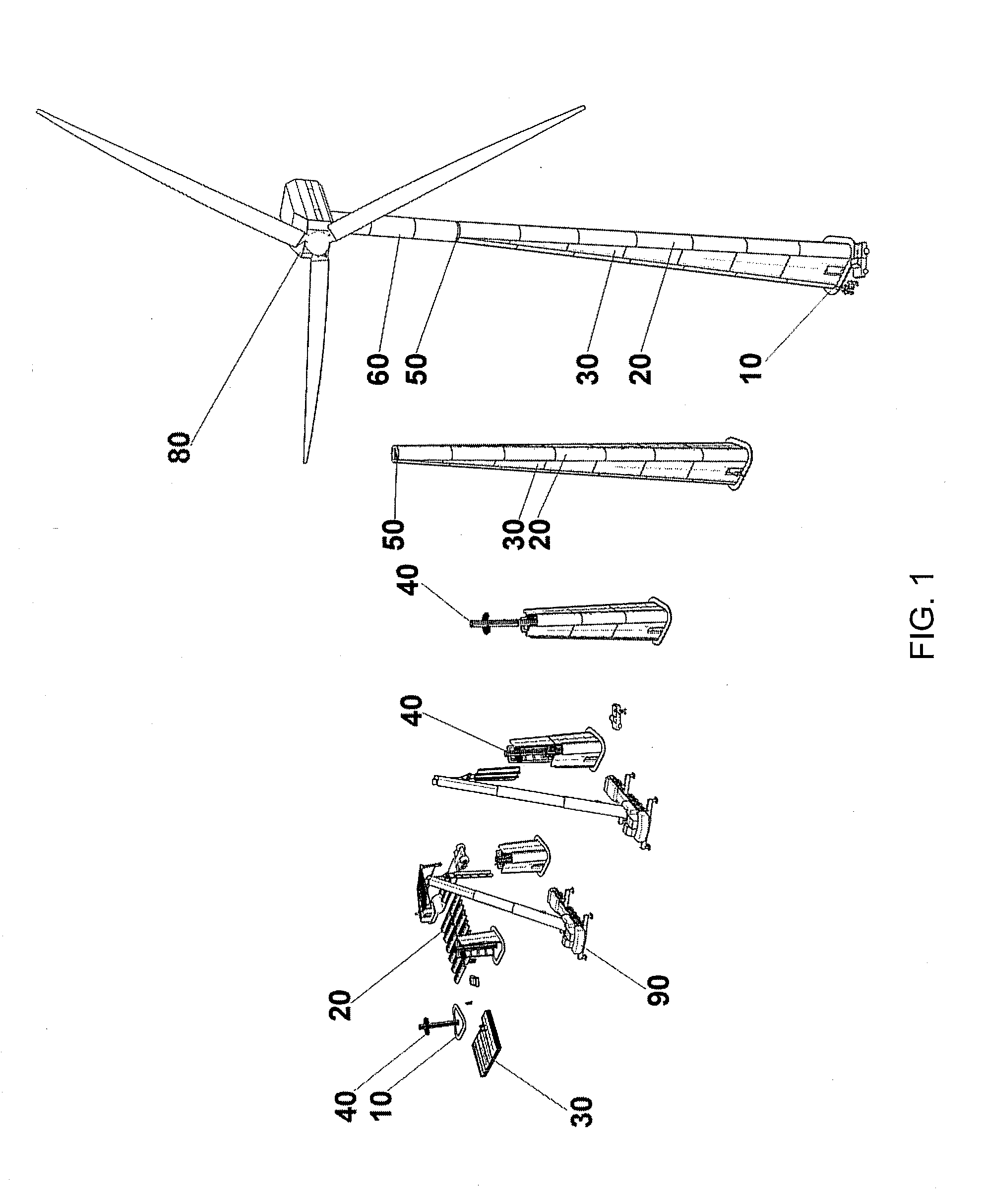

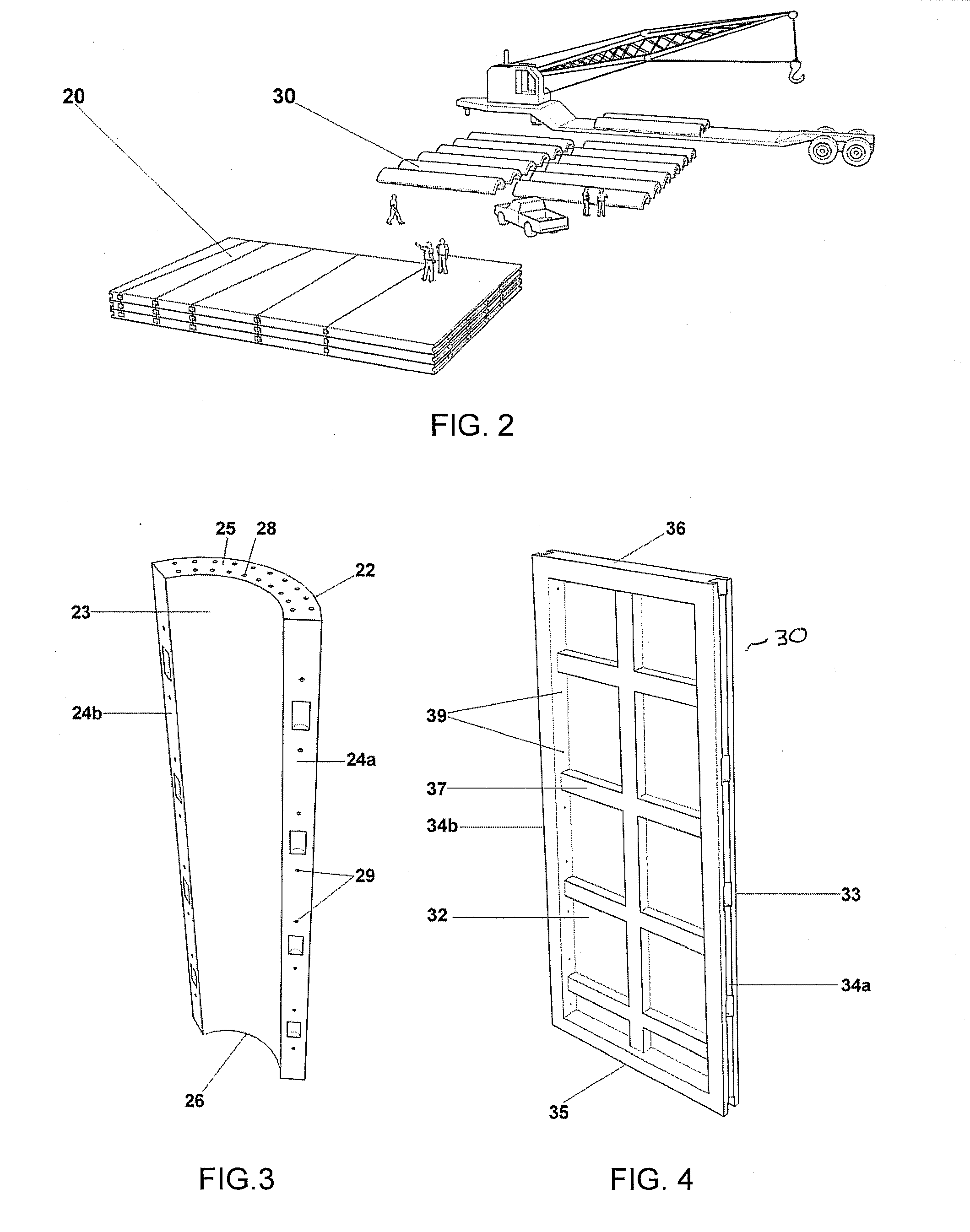

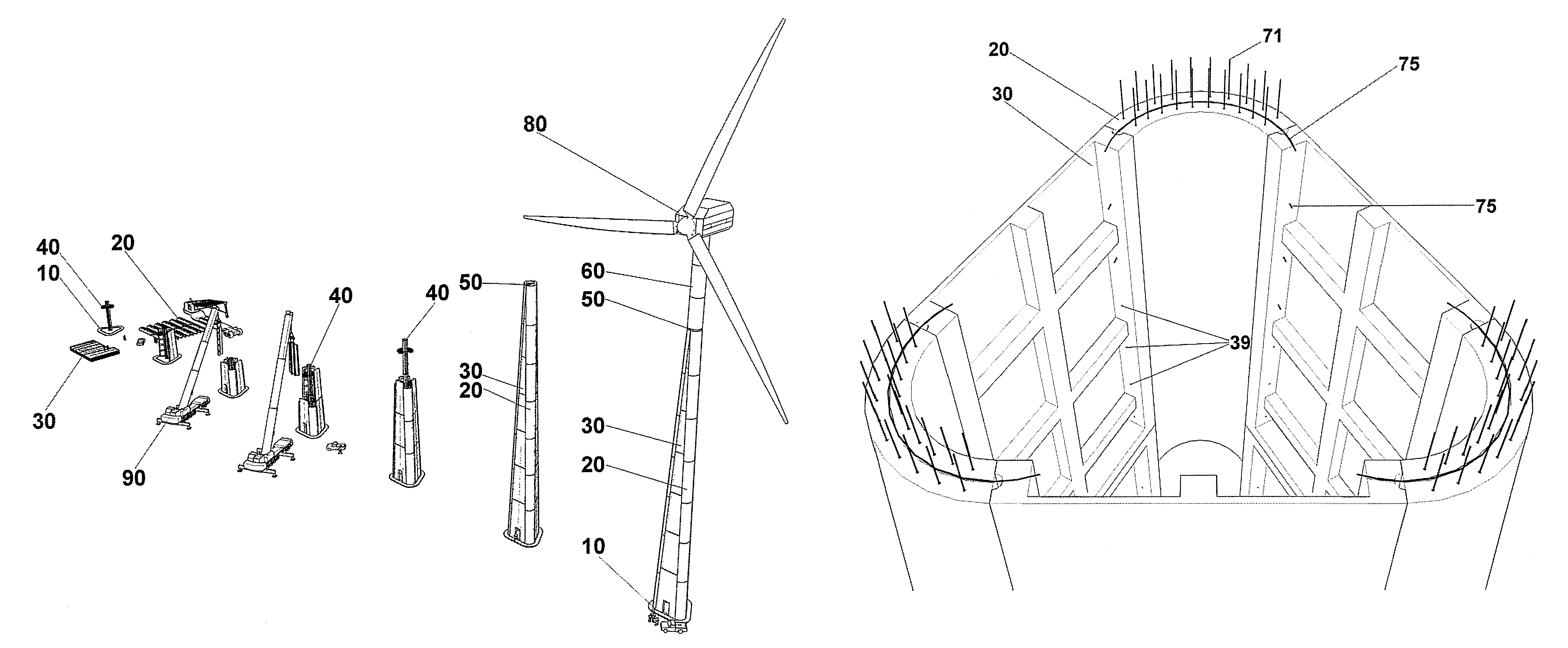

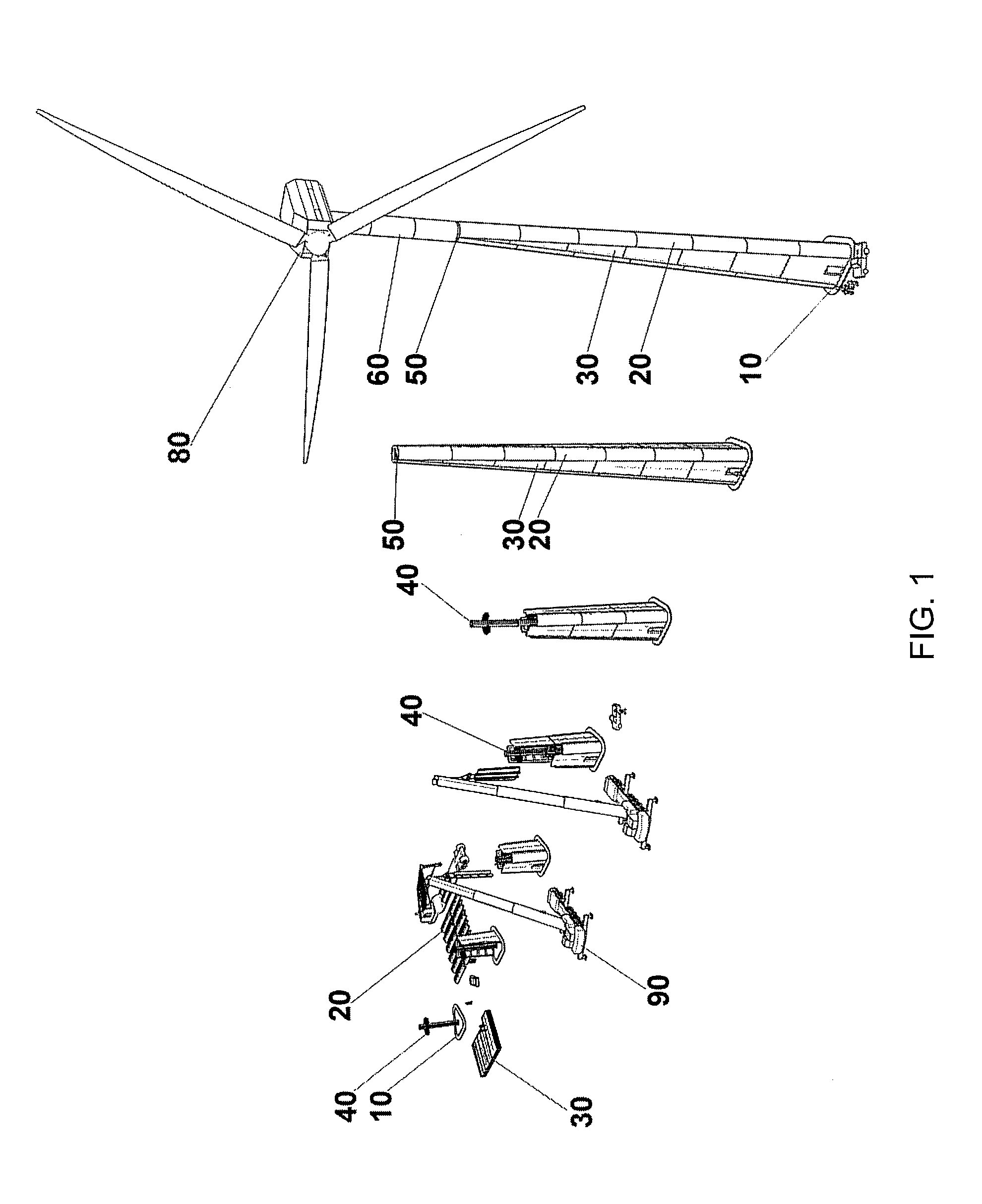

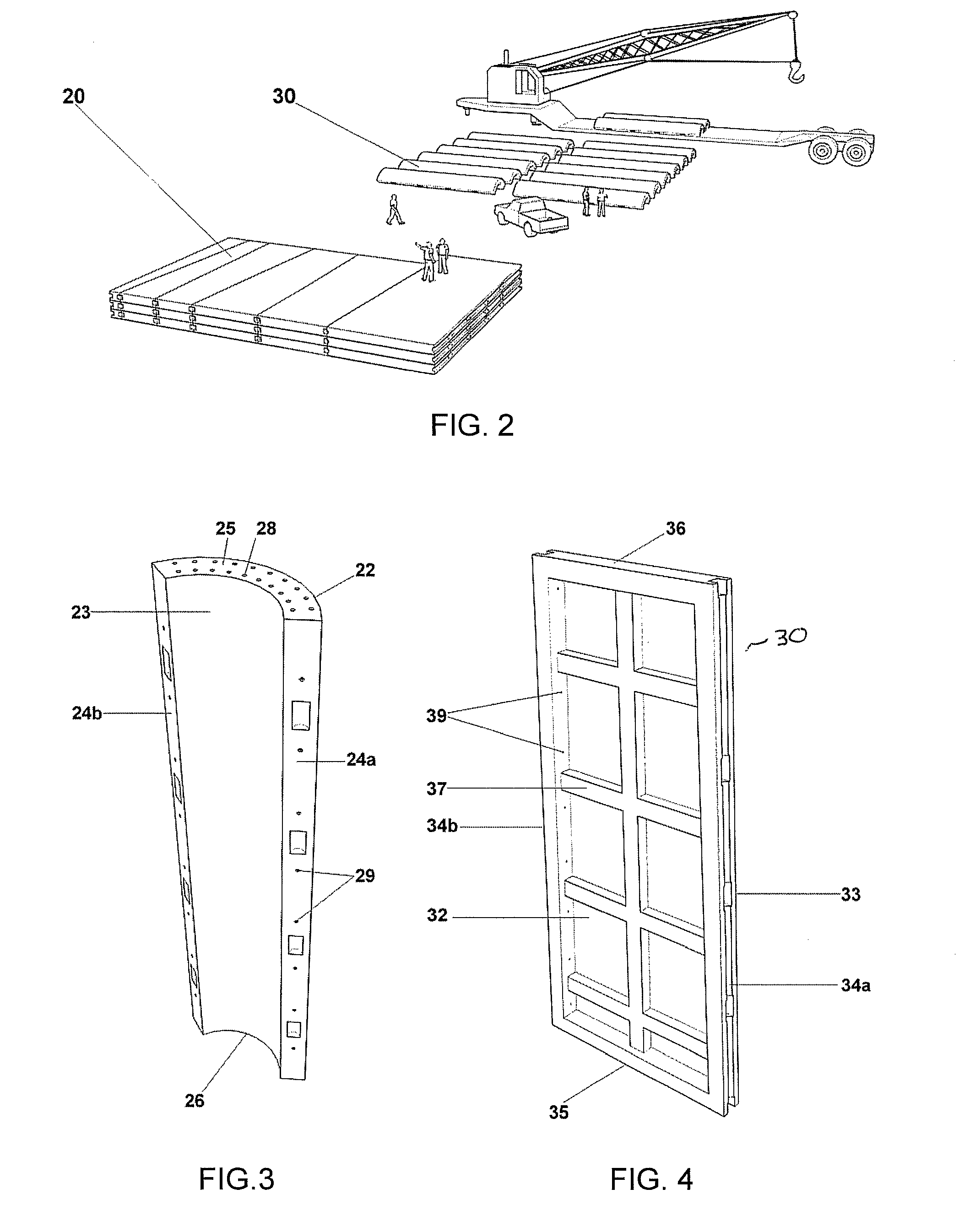

Pre-stressed concrete tower for wind power generators

InactiveUS20090031639A1Simplifying erectionSimplifying fabricationFinal product manufactureWind motor assemblyPre stressPre stressing

A pre-stressed segmented concrete tower for wind power generators is described, and a method for its fabrication, wherein in a pyramidal structure is formed by prefabricated segments, the structure comprising three rounded walls formed with circular segments, and three flat walls, formed with flat segments between the circular walls. One standard curved mold is used for the circular walls, and the flat walls are fabricated horizontally, over templates.

Owner:CORTINA INNOVATIONS DE C V

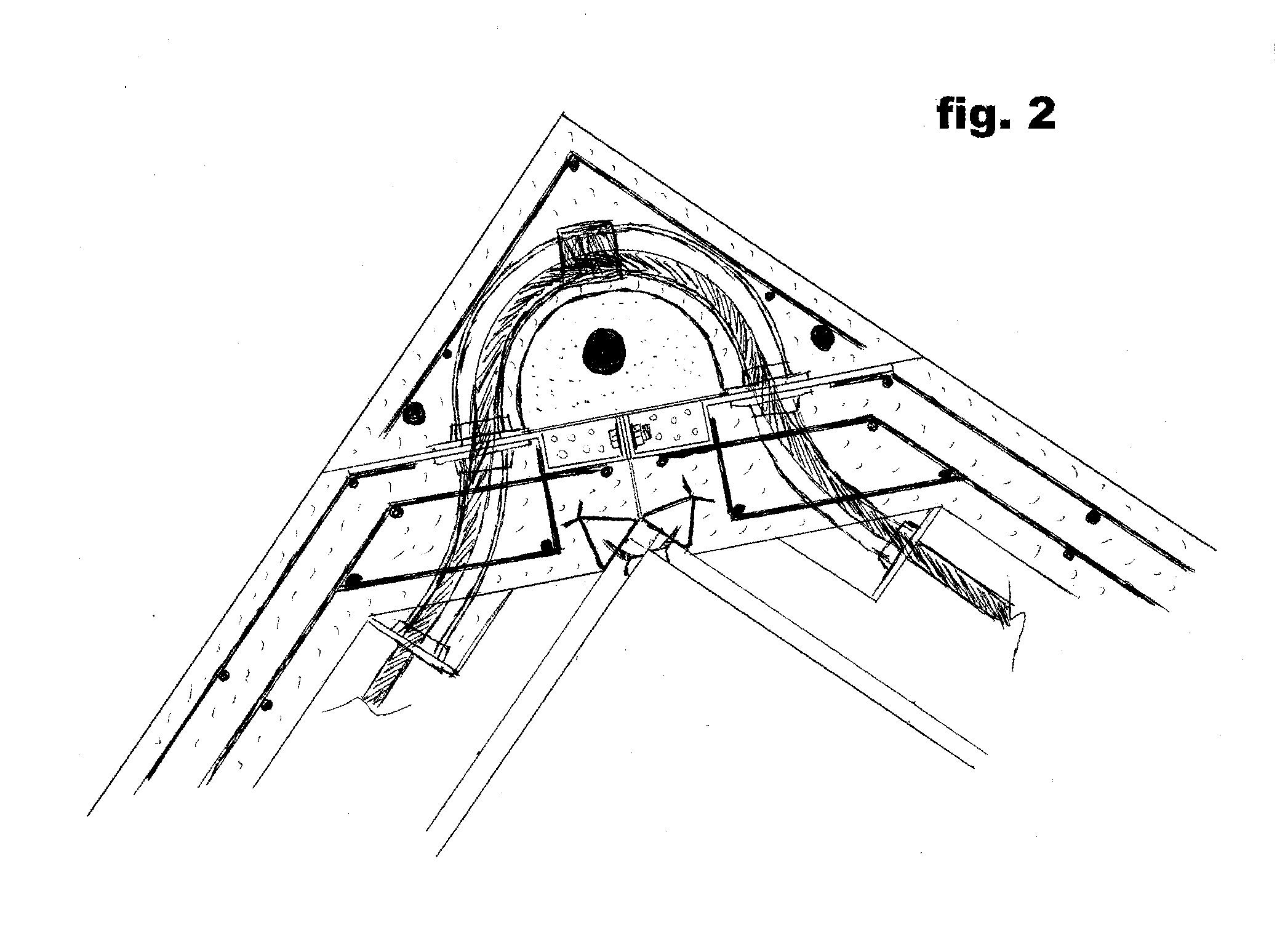

Pre-stressed concrete tower for wind power generators

InactiveUS7739843B2Simplifying erectionSimplifying fabricationFinal product manufactureWind motor assemblyPre stressPre stressing

A pre-stressed segmented concrete tower for wind power generators is described, and a method for its fabrication, wherein in a pyramidal structure is formed by prefabricated segments, the structure comprising three rounded walls formed with semi-circular segments, and three flat walls, formed with flat segments between the semi-circular walls. One standard curved mold is used for the semi-circular walls, and the flat walls are fabricated horizontally, over templates.

Owner:CORTINA INNOVATIONS DE C V

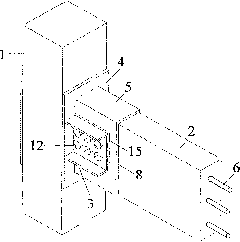

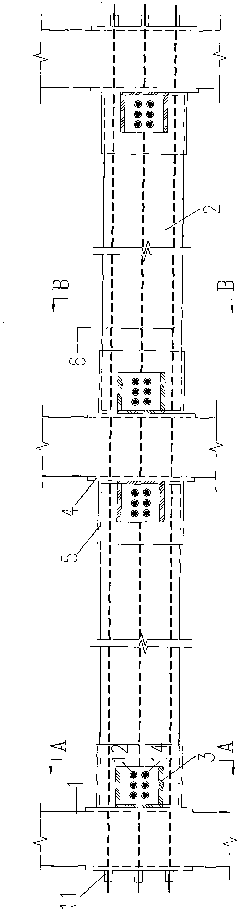

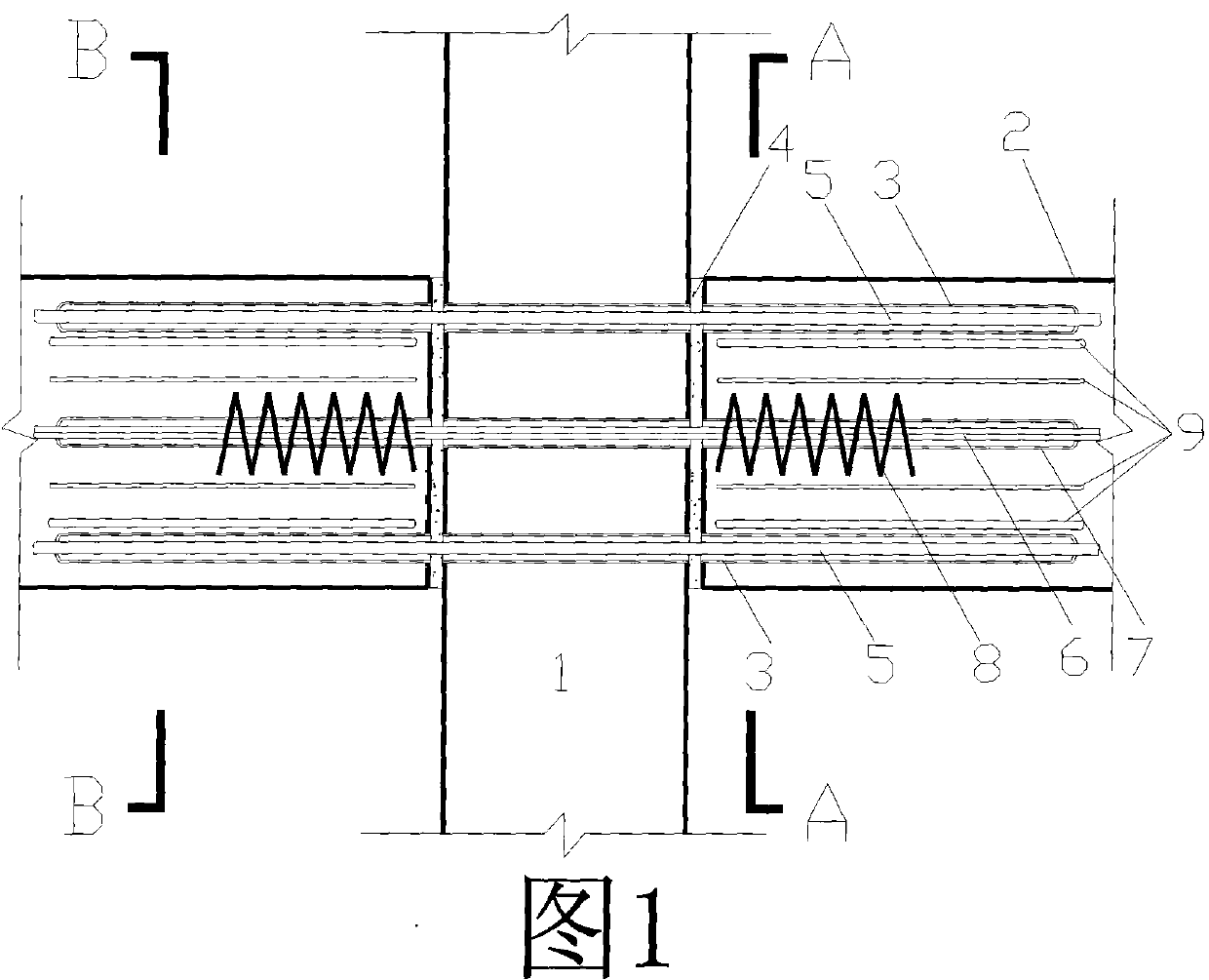

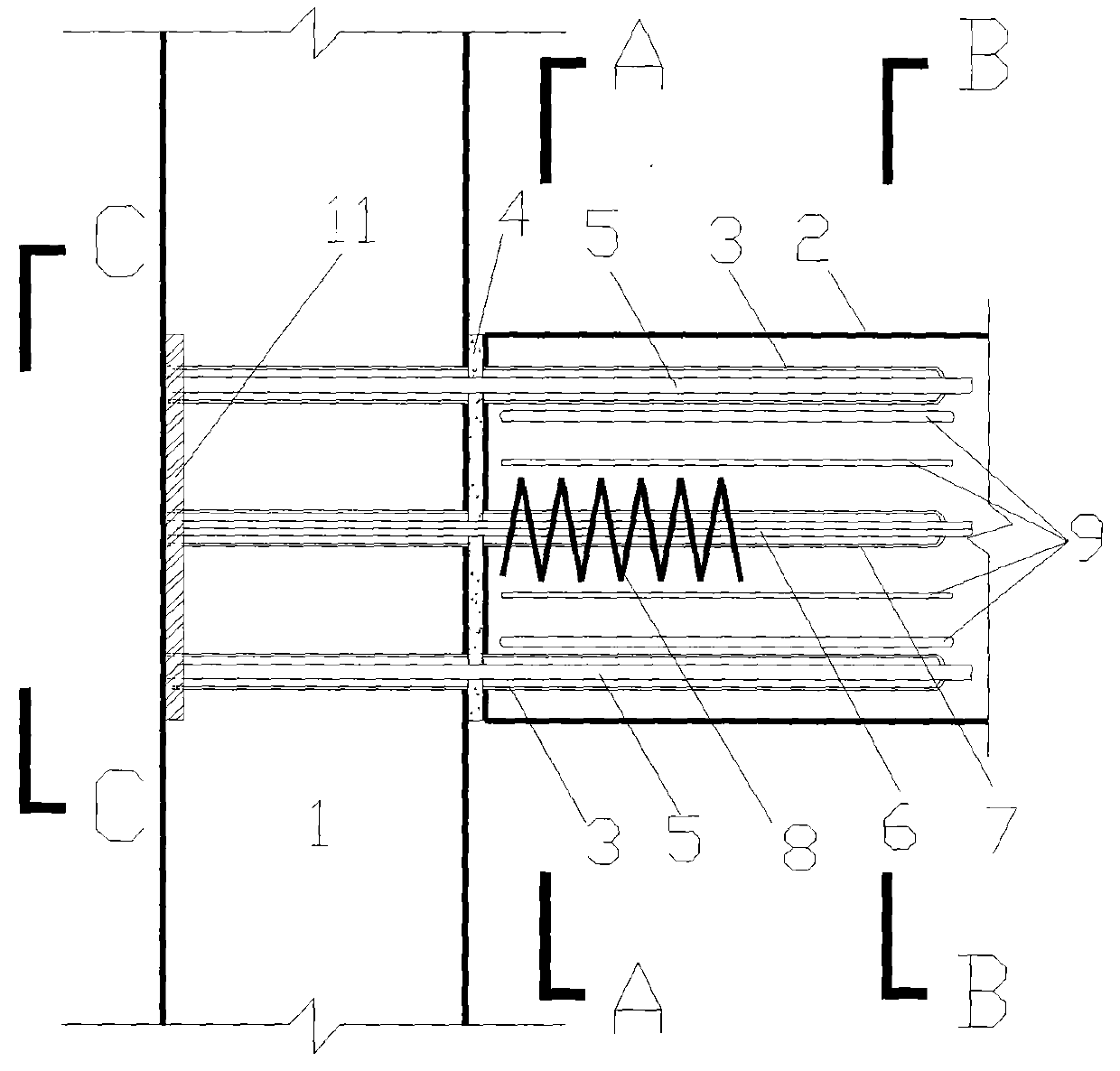

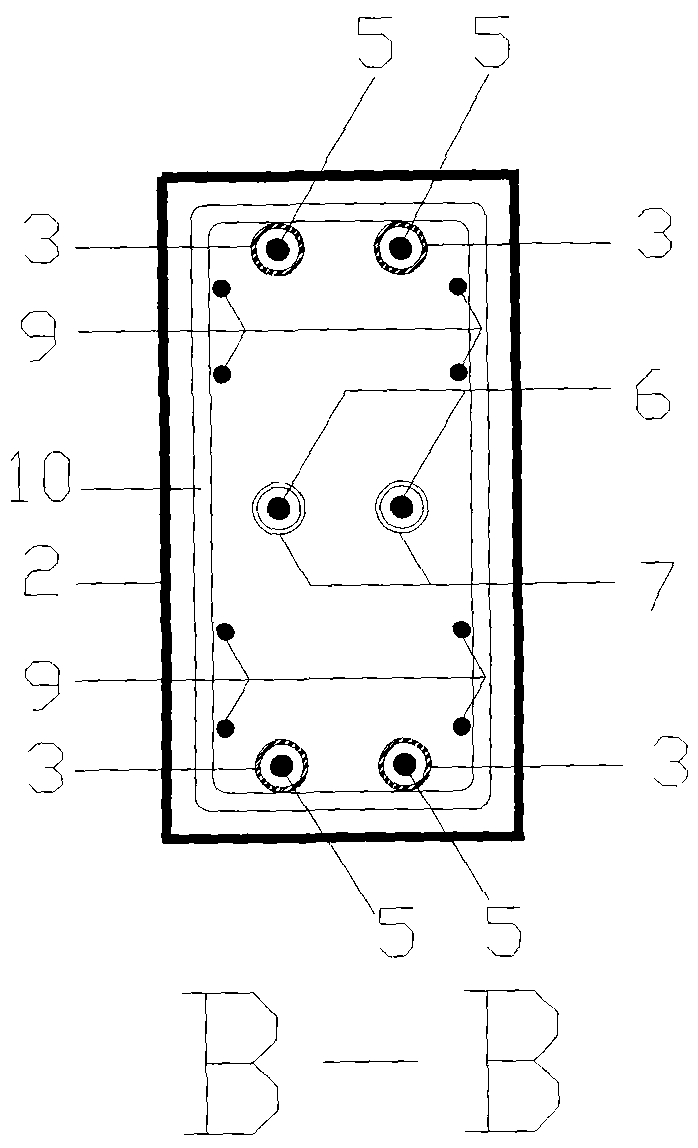

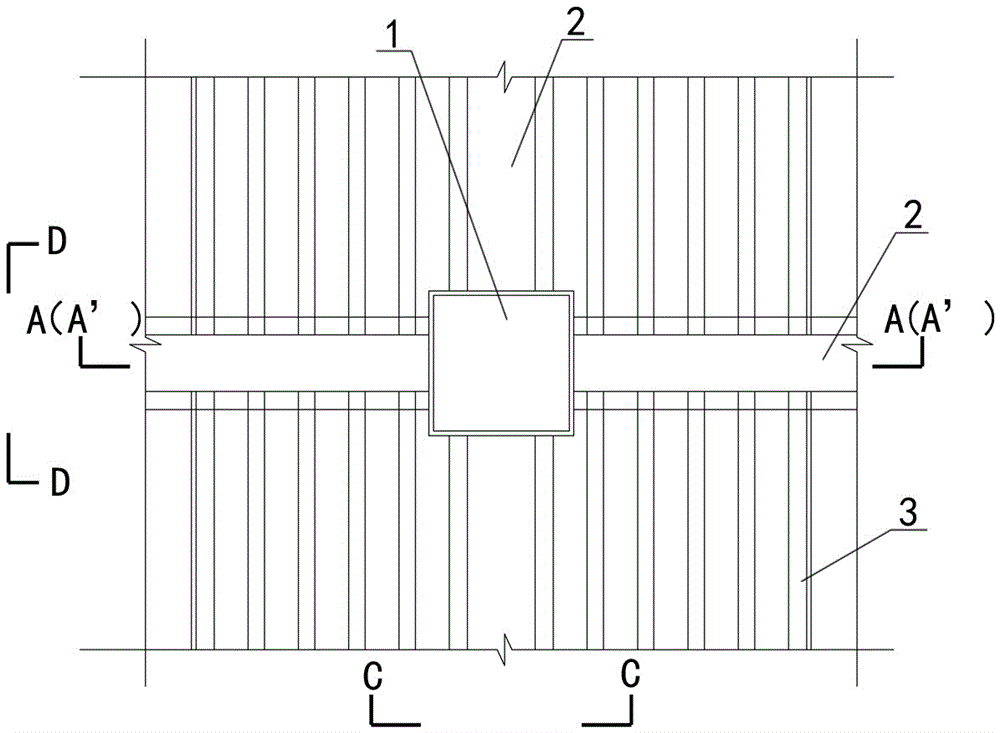

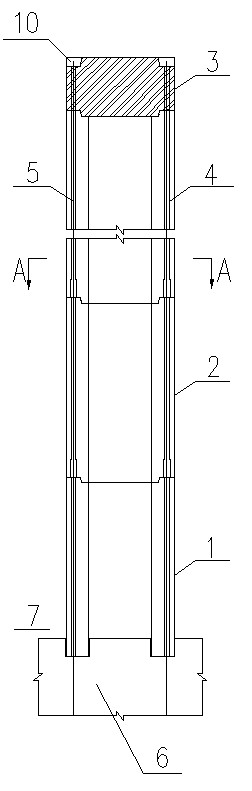

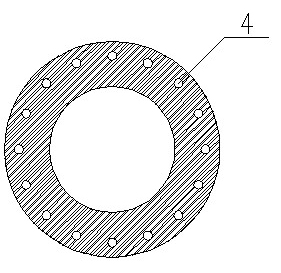

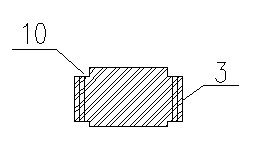

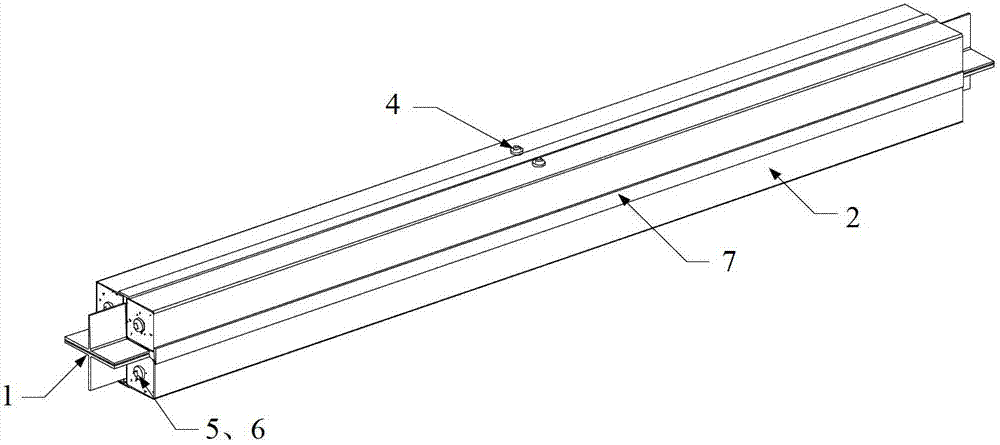

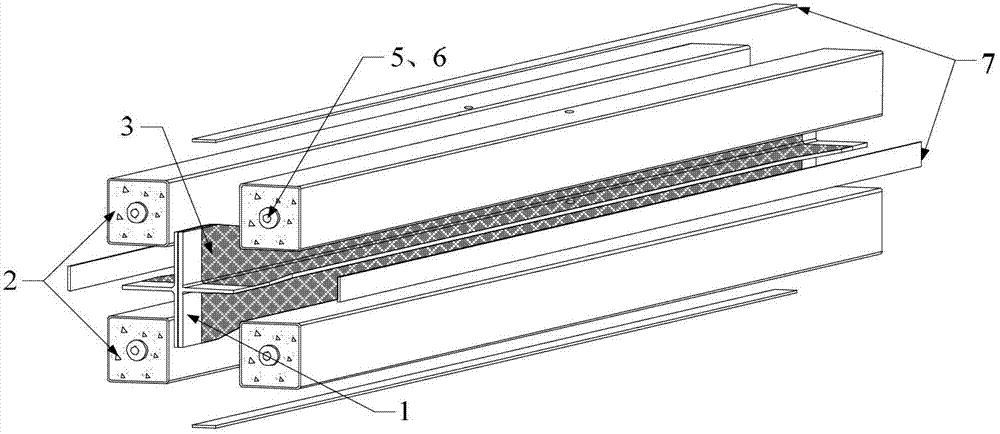

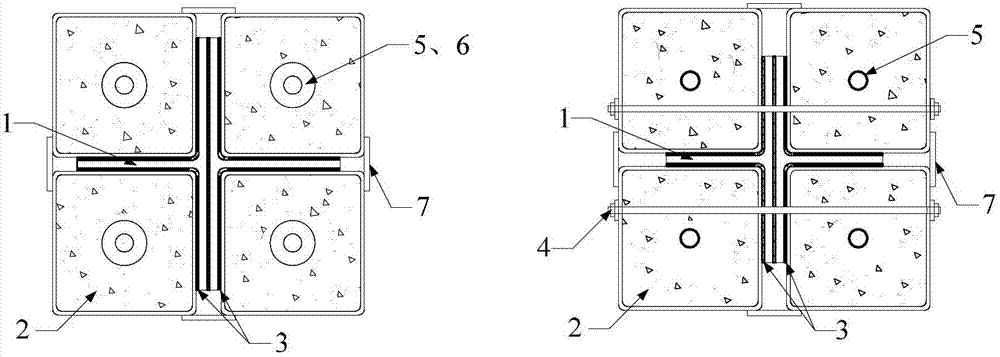

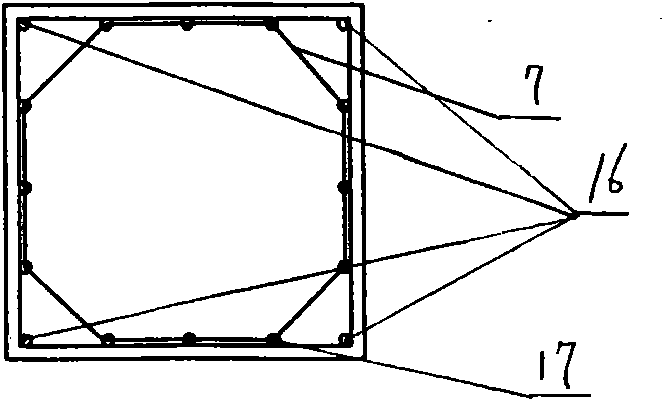

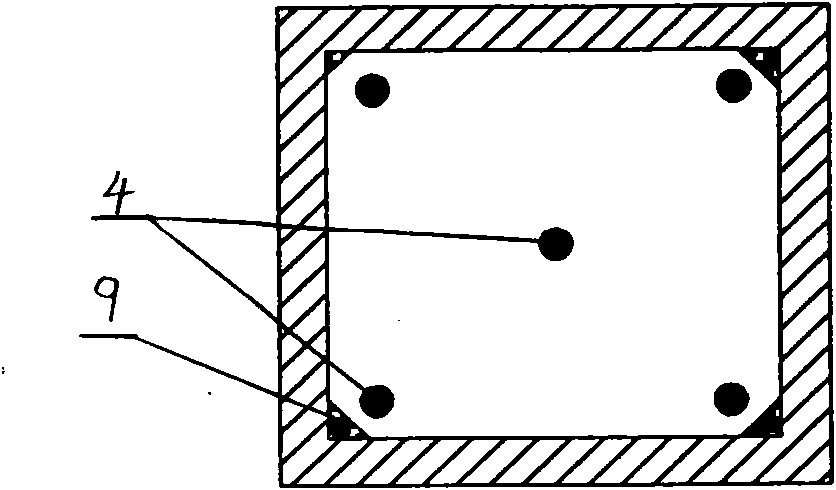

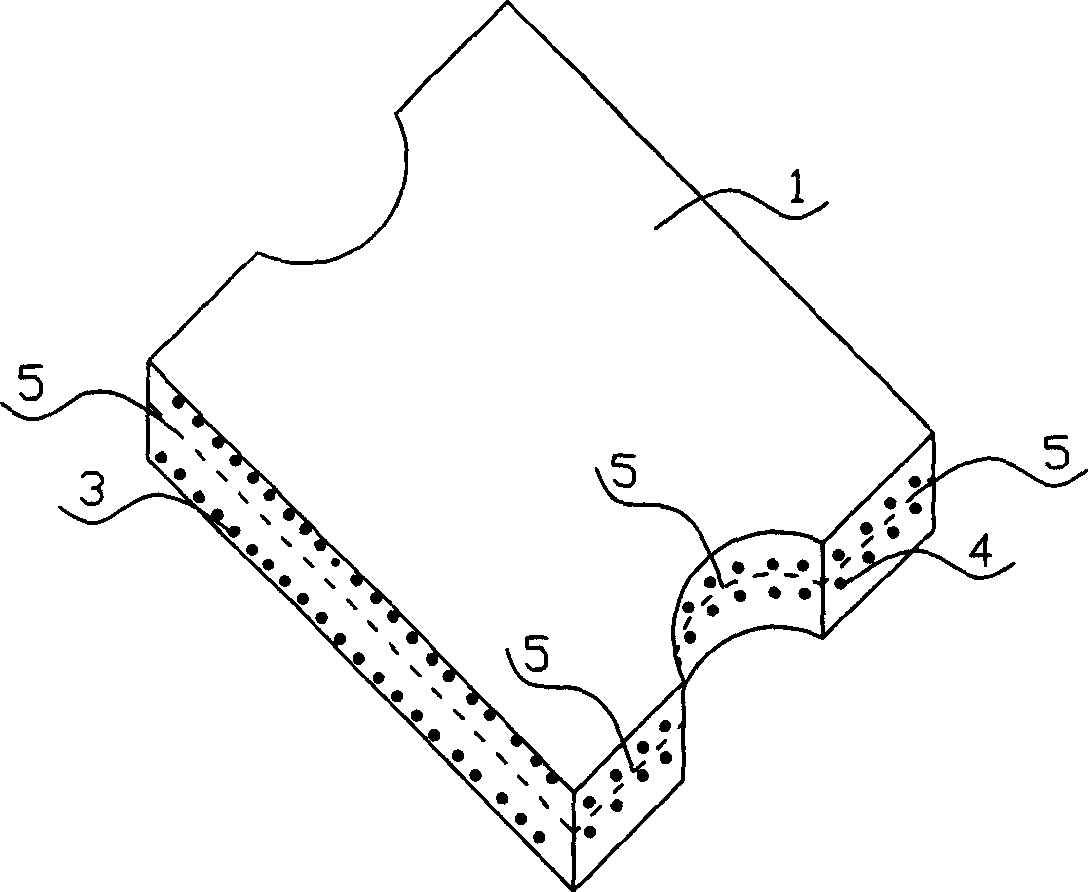

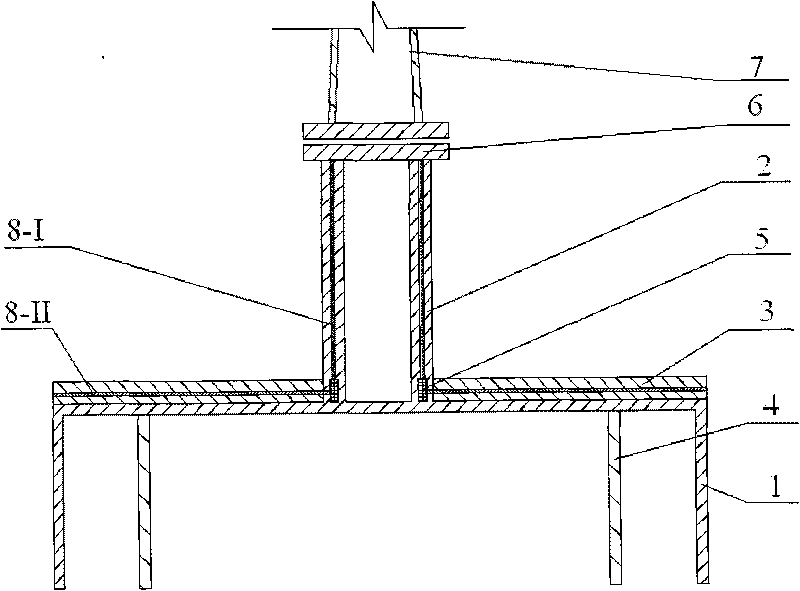

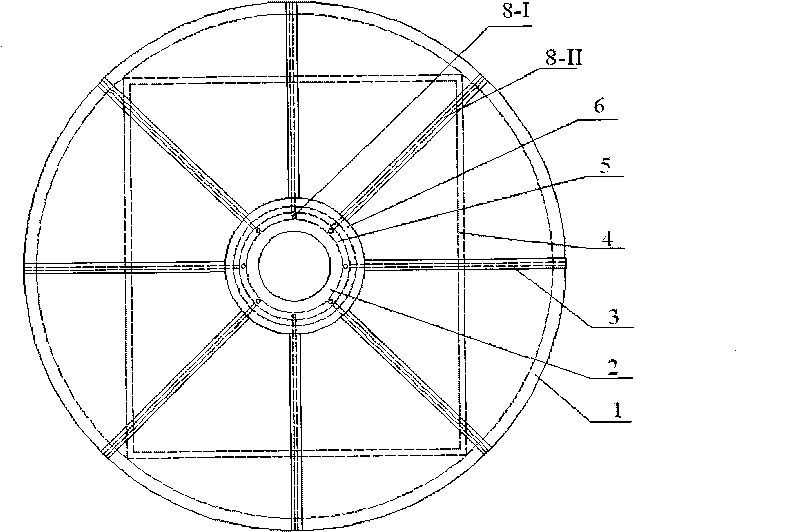

Node connection device for self-centering prestressed concrete frame

InactiveCN101798849ASolve local pressure problemsEliminate or reduce residual deformationShock proofingResidual deformationWhole body

The invention relates to a node connection device for a self-centering prestressed concrete frame. The node connection device is a device used for the connection between the beam and the column of a prefabricated reinforced concrete frame, and aims at improving energy consumption of a frame structure under seismic action and eliminating or reducing the residual deformation and damage of the frame structure. The connection device is characterized in that combined steel parts form an energy consuming device, two external friction steel plates (3) are arranged in the energy consuming device, are respectively and symmetrically arranged on the two sides of a column end reinforcing steel plate (4) and are connected with the column end reinforcing steel plate (4) into a whole body, two internal friction steel plates (8) are arranged between the two external friction steel plates (3), the upper end and the lower end of each internal friction steel plate (8) are respectively provided with a bean end reinforcing steel plate (5), friction discs (15) are respectively arranged between the two internal friction steel plates (8) and the two external friction steel plates (3), and friction-type high-strength bolts (12) penetrate through the external friction steel plates (3), the friction discs (15), the internal friction steel plates (8) and a prefabricated concrete beam (2) and connect all parts together.

Owner:SOUTHEAST UNIV

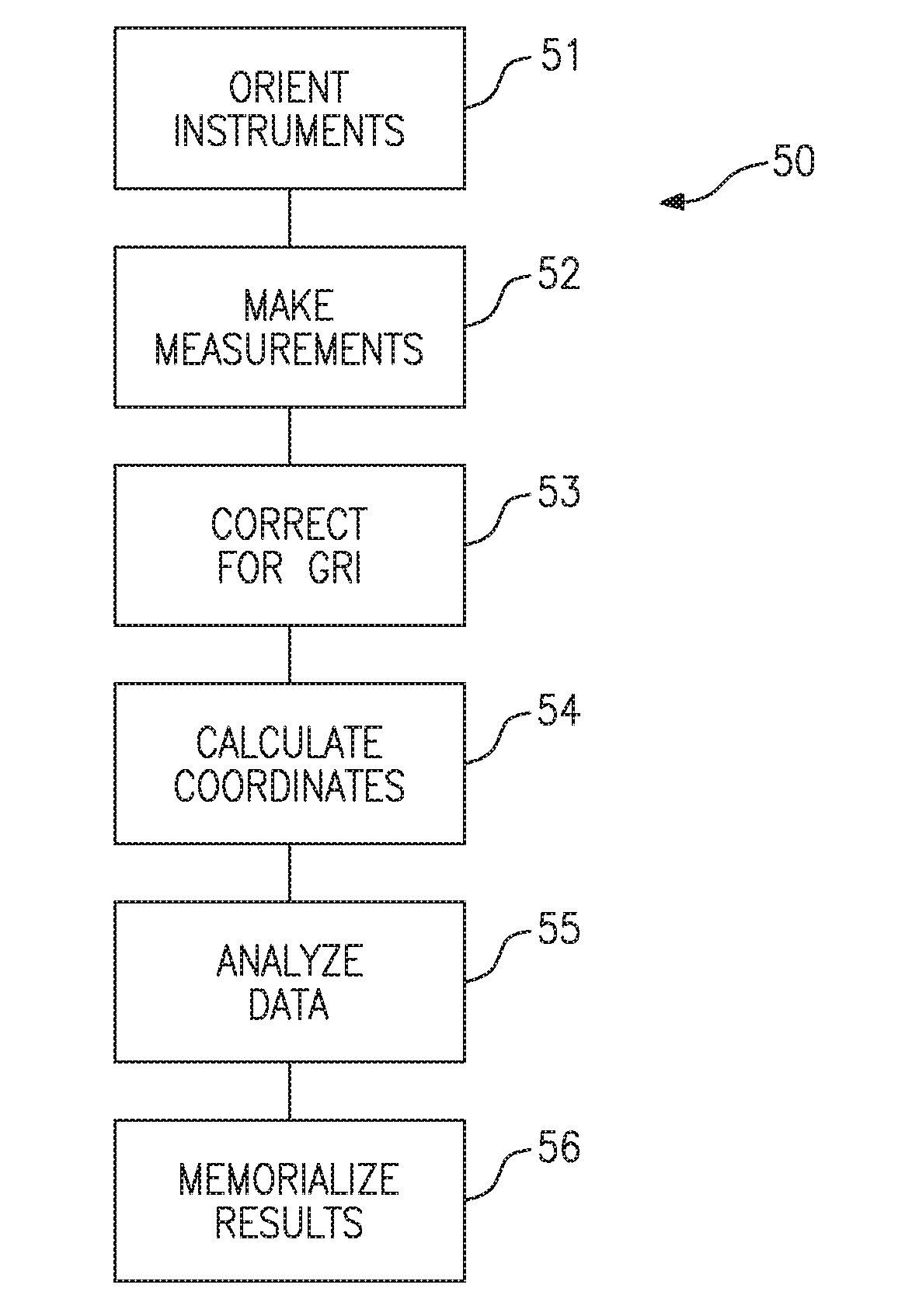

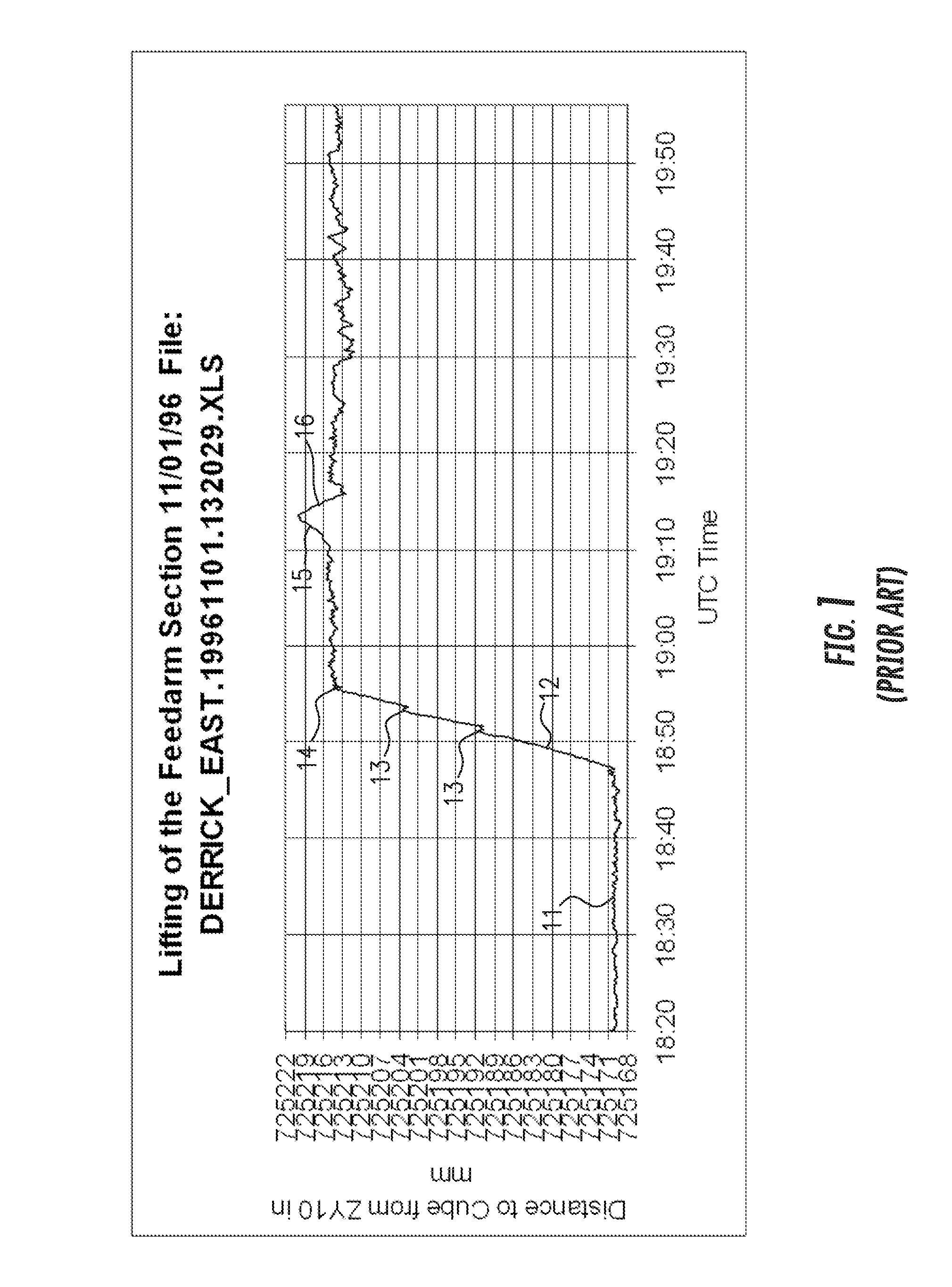

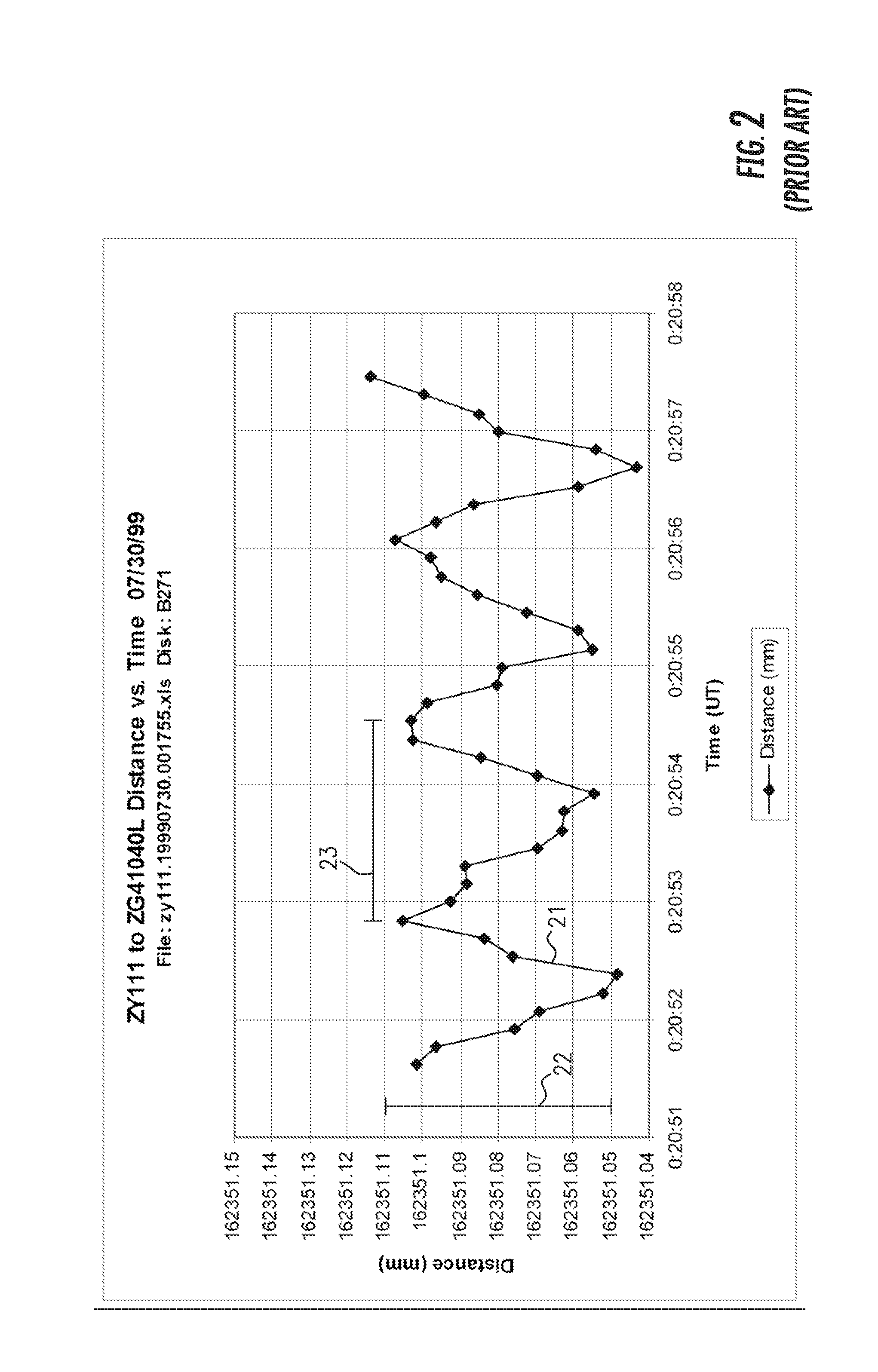

Methods for measuring and modeling the process of prestressing concrete during tensioning/detensioning based on electronic distance measurements

Methods are disclosed for nondestructive testing and measuring the structural health of prestressed concrete structures, such as slabs, columns, girders, bridges, towers, elevated storage tanks, silos, cooling towers, wind power generation towers, liquefied gas storage tanks, nuclear power containment buildings, and the like. Measurements are made as the structure undergoes tensioning and detensioning operations. By measuring actual movements of cardinal points on the structure, in an absolute three-dimensional coordinate system, and comparing the measurements to a model—as tension on a tendon is changed—a margin of safety is assured. High accuracy measurements are made by electronic distance measurement (EDM) instruments over hundreds of meters, which yield coordinates of cardinal points with an uncertainty of the order of one part per million. The methods are proposed as possible alternatives to prior failures of post-tensioned concrete, including the Las Lomas Bridge, the Kapiolani Interchange On-Ramp, Turkey Point Unit 3 Nuclear Power Plant, and Crystal River Unit 3 Nuclear Power Plant. An extensive review of the most closely related prior arts is included.

Owner:SOPHIE LIN TRUSTEE OF THE JOHN MICHAEL PAYNE FAMILY TRUST +1

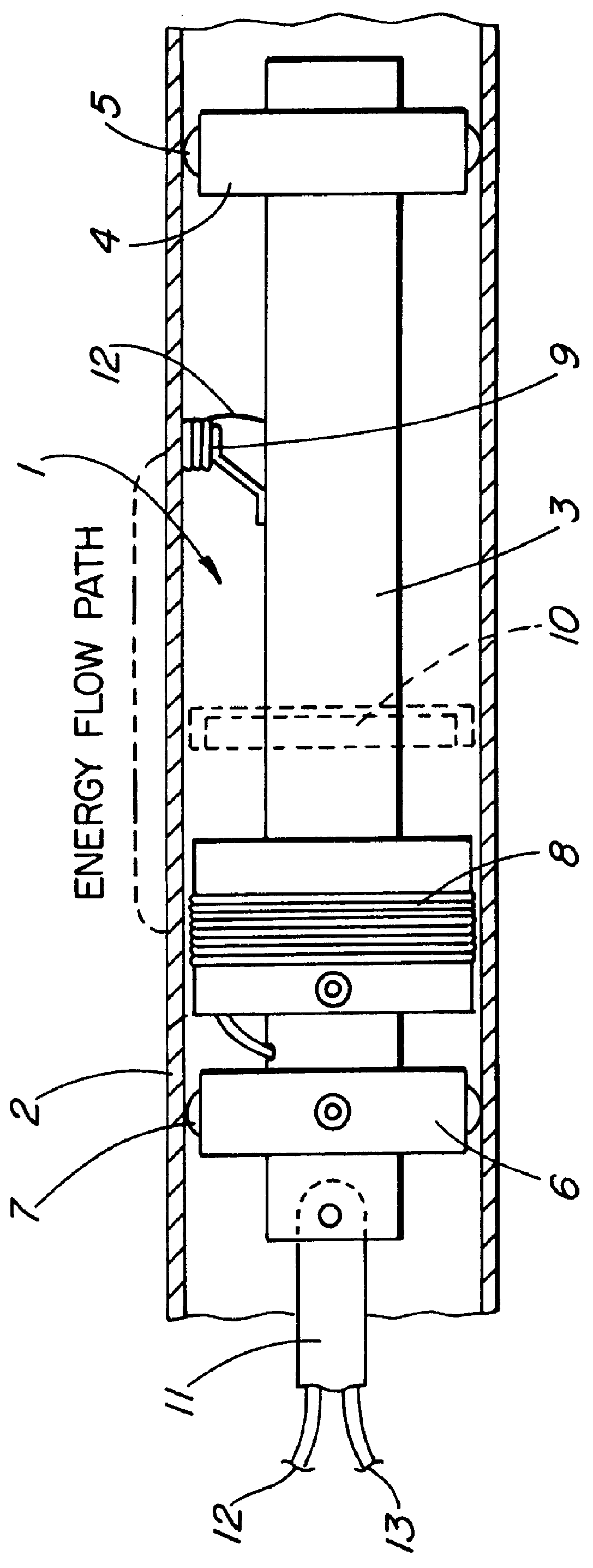

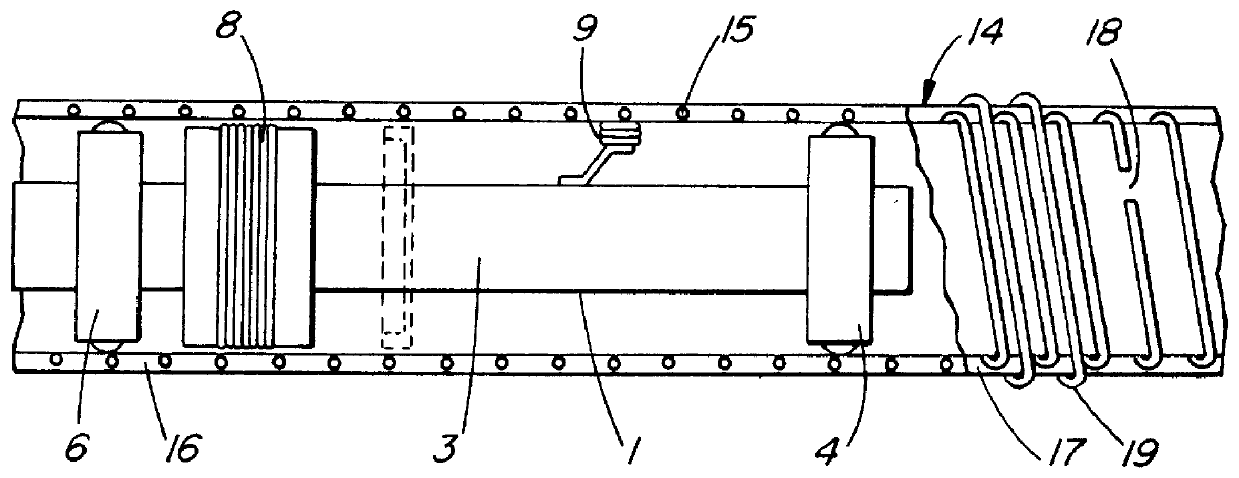

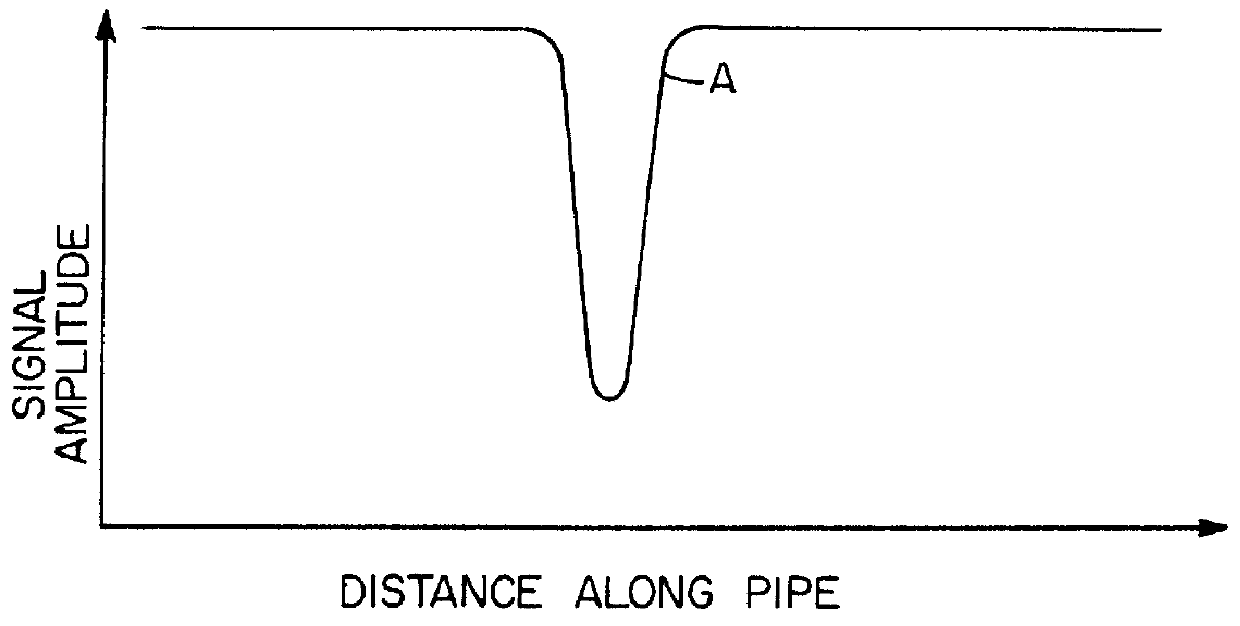

Electromagnetic method for non-destructive testing of prestressed concrete pipes for broken prestressing wires

InactiveUS6127823AImprove energy transferMagnetic property measurementsMaterial magnetic variablesNon destructivePre stress

A method for detecting breaks in a prestressed wire, rod or bar embedded in concrete surrounding a metal pipe is described. A remote field eddy current probe is traversed axially internally through the pipe so as to create an energy flow path externally of the pipe and a transformer coupling through the pipe, and generate a signal in a detector coil axially spaced from an exciter coil. As the exciter coil traverses the wire, rod or bar containing the break a signal change is generated, regardless of the radial position of the detector coil relative to the break.

Owner:THE PRESSURE PIPE INSPECTION COMPANY

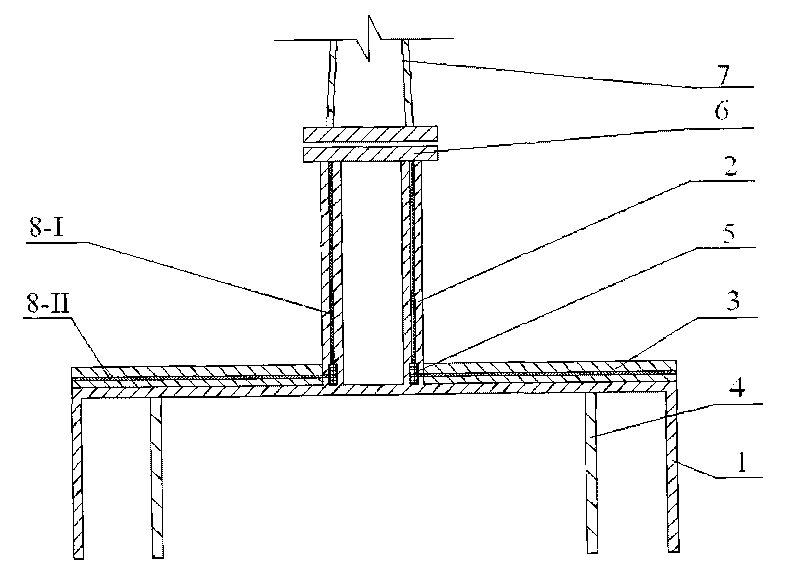

Beam and pile assembled node of precast and prestressed concrete structure

InactiveCN101029503AImprove seismic performanceAvoid damageBuilding reinforcementsResidual deformationPre stress

Owner:BEIJING UNIV OF TECH

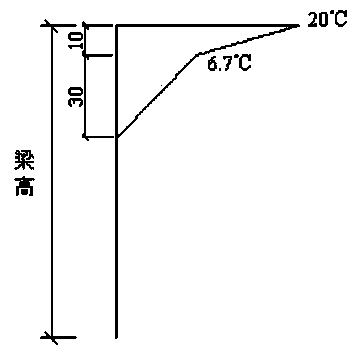

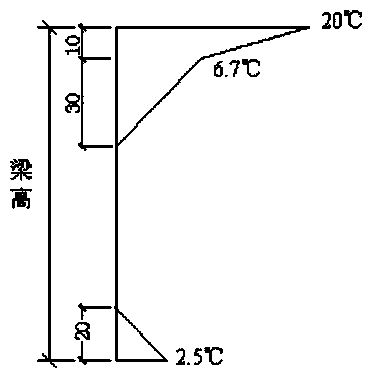

Finite element analysis method for temperature action on prestressed reinforced concrete continuous rigid frame bridge

ActiveCN104166792AAccelerated settlementEfficient solutionSpecial data processing applicationsStructural deformationElement analysis

The invention provides a finite element analysis method for the temperature action on a prestressed reinforced concrete continuous rigid frame bridge. The finite element analysis method is used for analyzing and calculating the stress and displacement distribution in the construction and finished bridge stage under different temperature gradient models, and provides references for designing and optimizing the prestressed reinforced concrete continuous rigid frame bridge. Through calculational analysis based on finite elements and the structural mechanics, the forward-calculation method is adopted for structural distortion and stress analysis according to the actual construction loading sequence of the bridge structure, so that the complex mechanics problem of box girder temperature self-stress, temperature secondary internal force in a prestressed reinforced concrete statically indeterminate structure and secondary stress of the temperature secondary internal force is solved easily, conveniently and efficiently, and the finite element analysis method has important practical value.

Owner:江苏中国科学院能源动力研究中心 +1

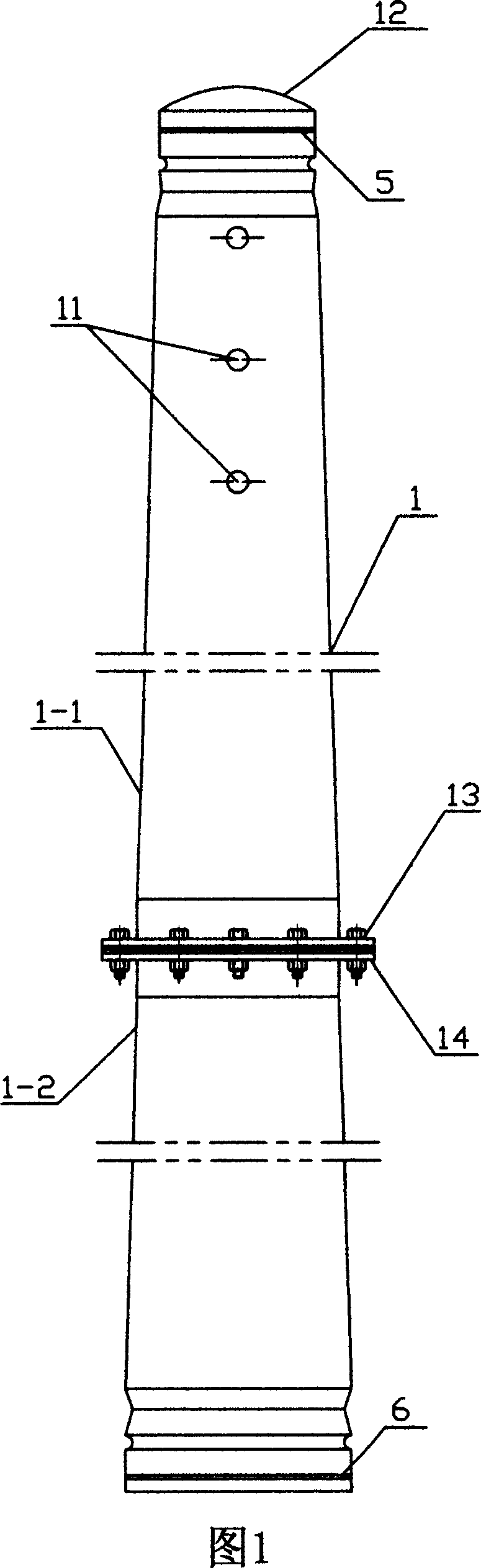

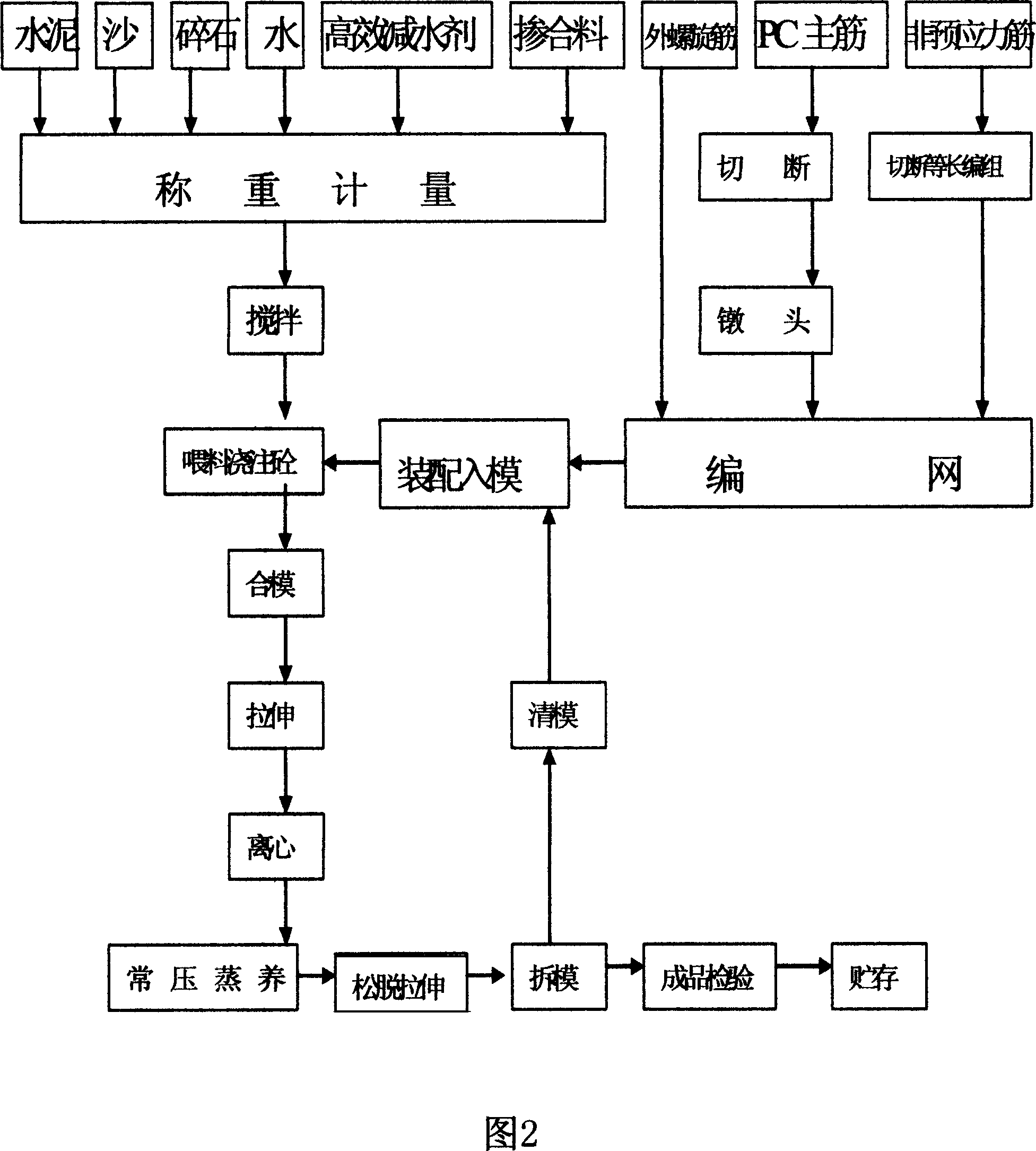

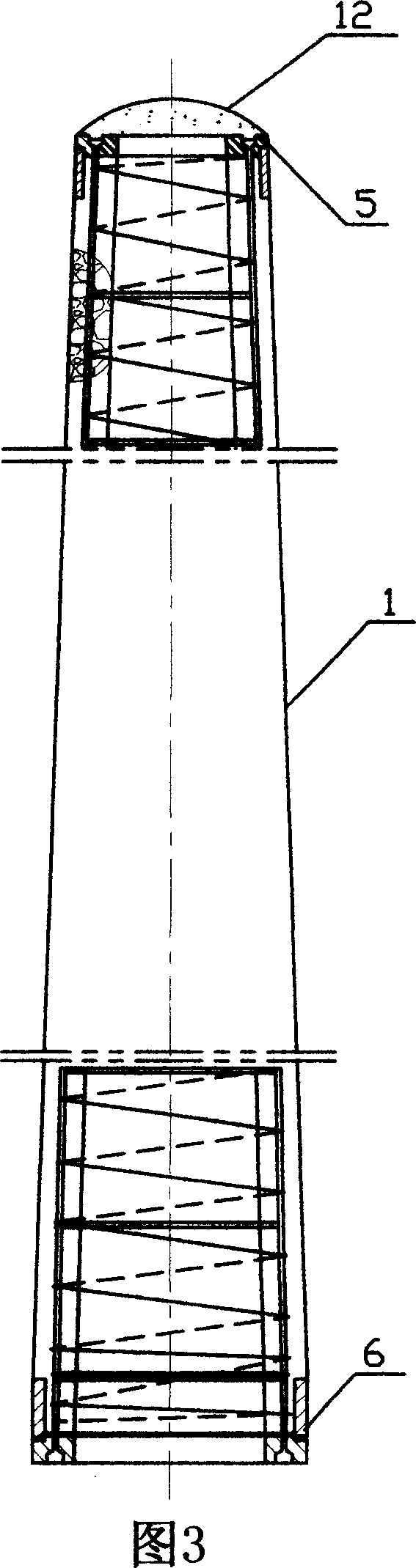

Prestressed concrete electrical pole and its production

InactiveCN101029540AImprove carrying capacityAvoid breakingCeramic shaping apparatusTowersReinforced concretePre stress

This invention is a prestressed concrete pole and its construction method. The pole is of a conicity at 1:75, with holes for cables. It can be a single pole or sectional fabricated. The pole is made by reinforce bar cage centrifugal casting. The reinforce bar cage is composed by vertical main bars and normal bars fixed on supporting and positioning loops, and binding outside by helix wire. Two end plates are installed to the pole ends to fix the mail bars. After installed the end plates and before centrifugal casting, pull the plates with 1000-1900KN power, and steaming the concrete to grade over C60, then loose the power. In case of sectional fabricated, the sections are connected to each other through bolts.

Owner:吕森金

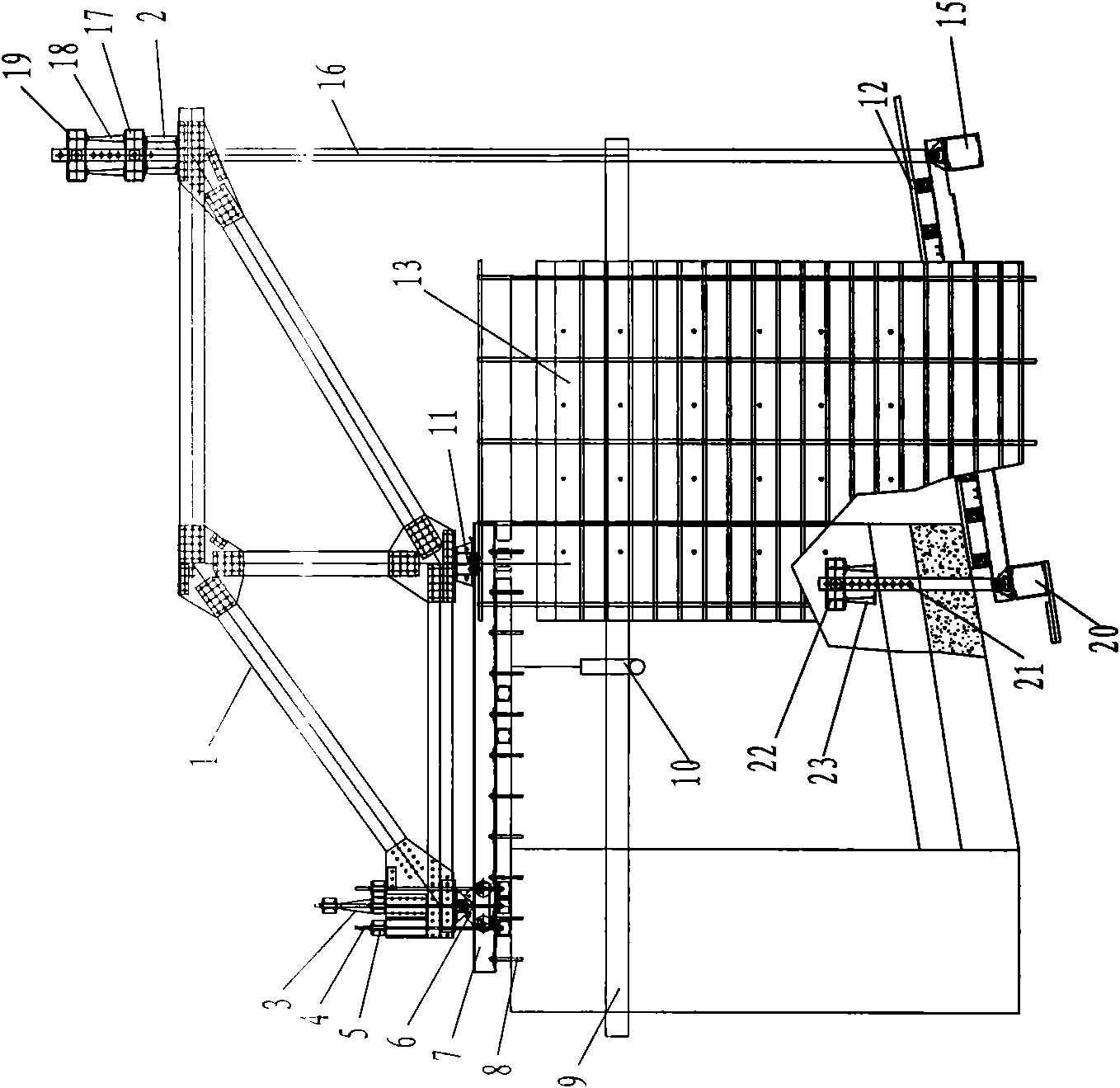

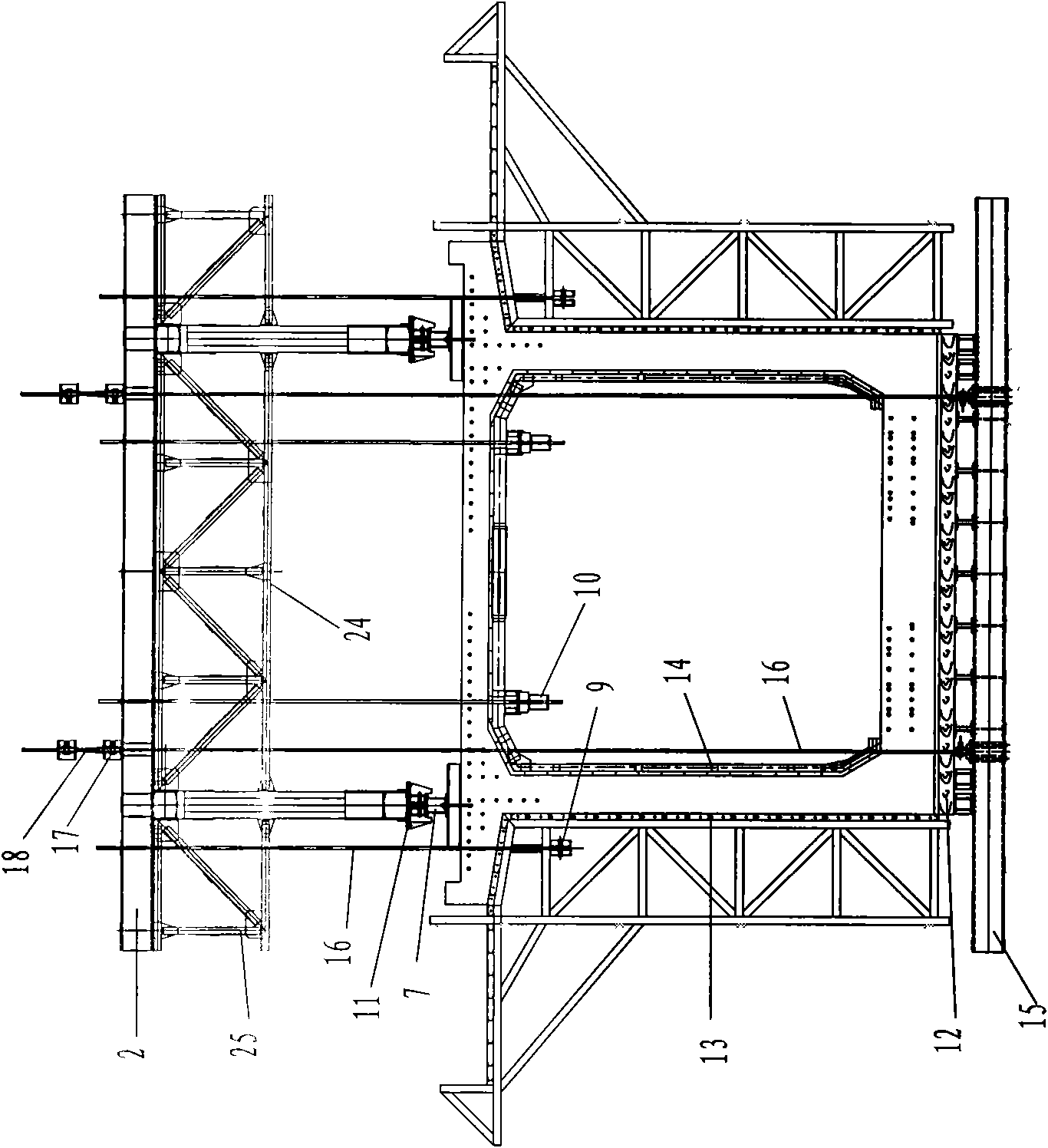

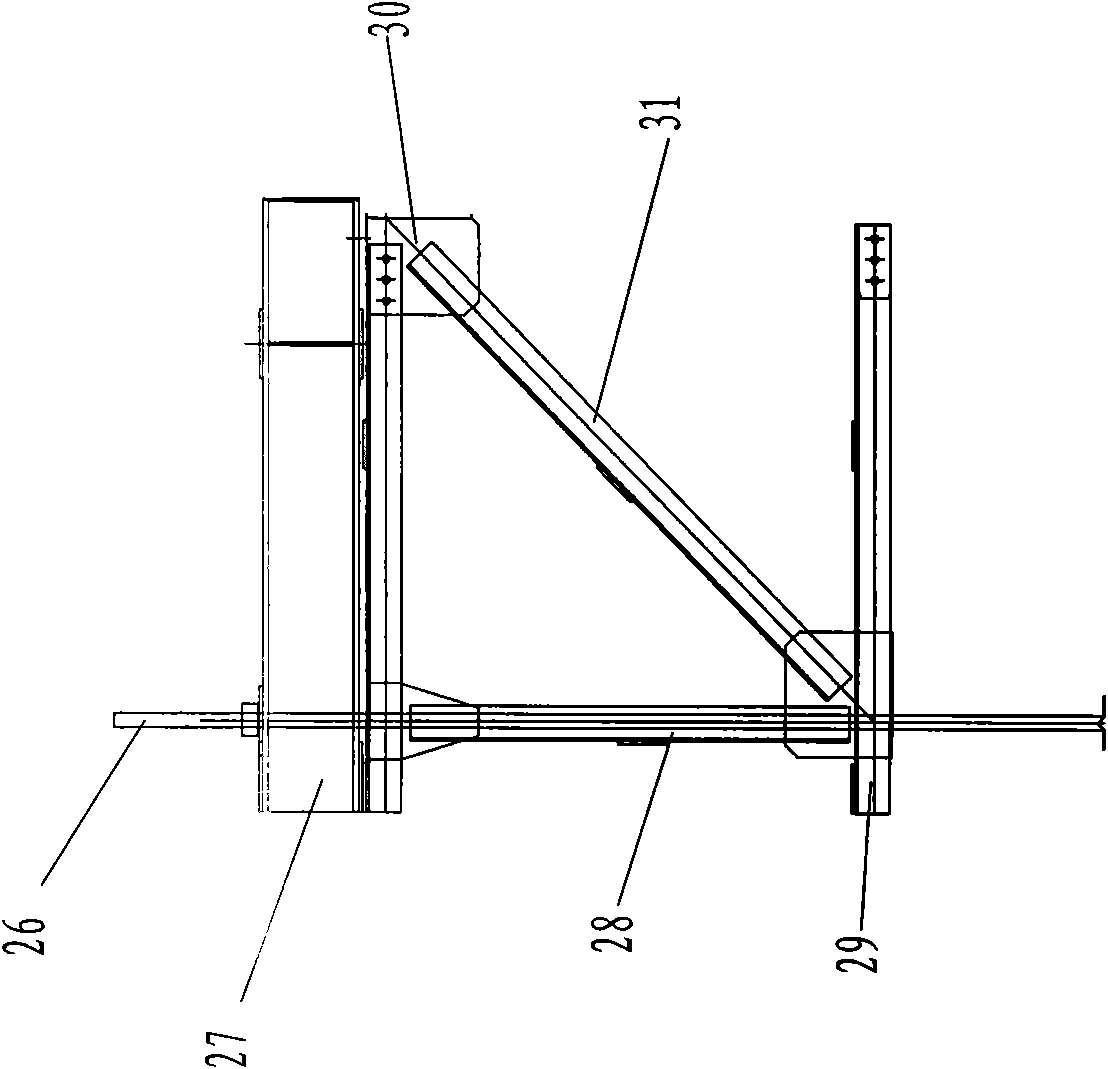

Receding construction method of cradle of continuous girder bridge made of prestressing concrete

The invention relates to a receding construction method of a cradle of a continuous girder bridge made of prestressing concrete, which is characterized in that the bridge surface of a bridge prefabricated by concrete is provided with a track and a door-shaped truss traveling device, and the width of a ceiling girder inside the door-shaped truss traveling device is wider than that of the bridge surface by 90cm-110cm; a front bottom cross beam and a rear bottom cross beam must extend to the outer side of an external mold by 45cm-55cm to form a main cradle truss, and an overhanging auxiliary door frame is additionally arranged outside the main cradle truss, after the construction of a closure segment of the bridge prefabricated by concrete is finished, and precise rolling deformed steel bars with the diameter of 32 outside a box girder positioned on the overhanging auxiliary door frame are connected with the rear bottom cross beam to disassemble a rear hanging strip; a bottom mold frame is separated from a beam body by utilizing a manual spiral type jack to loose the precise rolling deformed steel bars positioned on the door frame and the front bottom cross beam; a leading chain or a hoist are utilized to drive the main cradle truss so that the cradle recedes in a slideway to a first cast-in-situ segment; and a bottom mold and the external mold are fallen by the leading chain or the hoist to disassemble the main truss.

Owner:NO 1 ENG CO LTD OF CR11BG +1

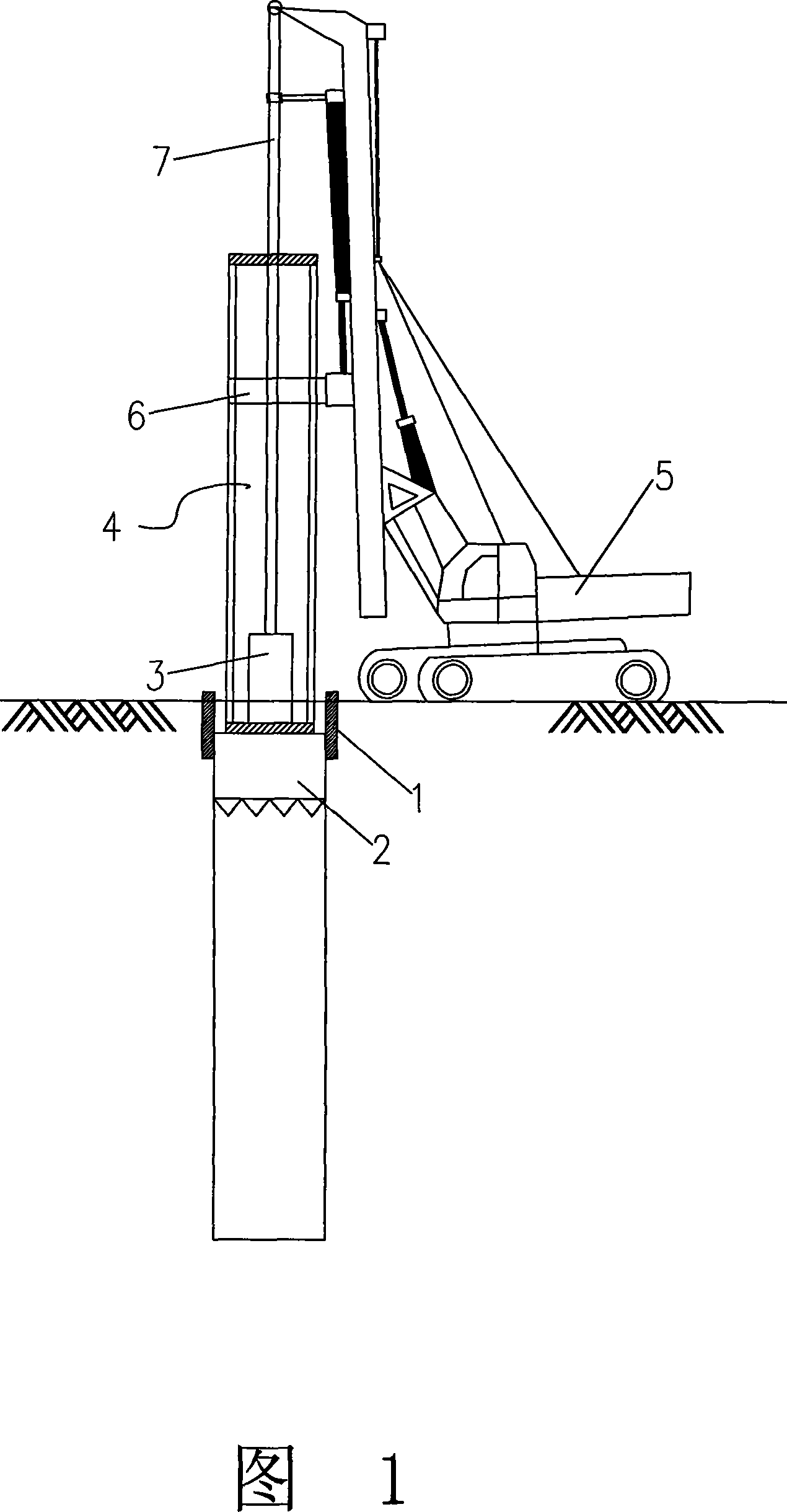

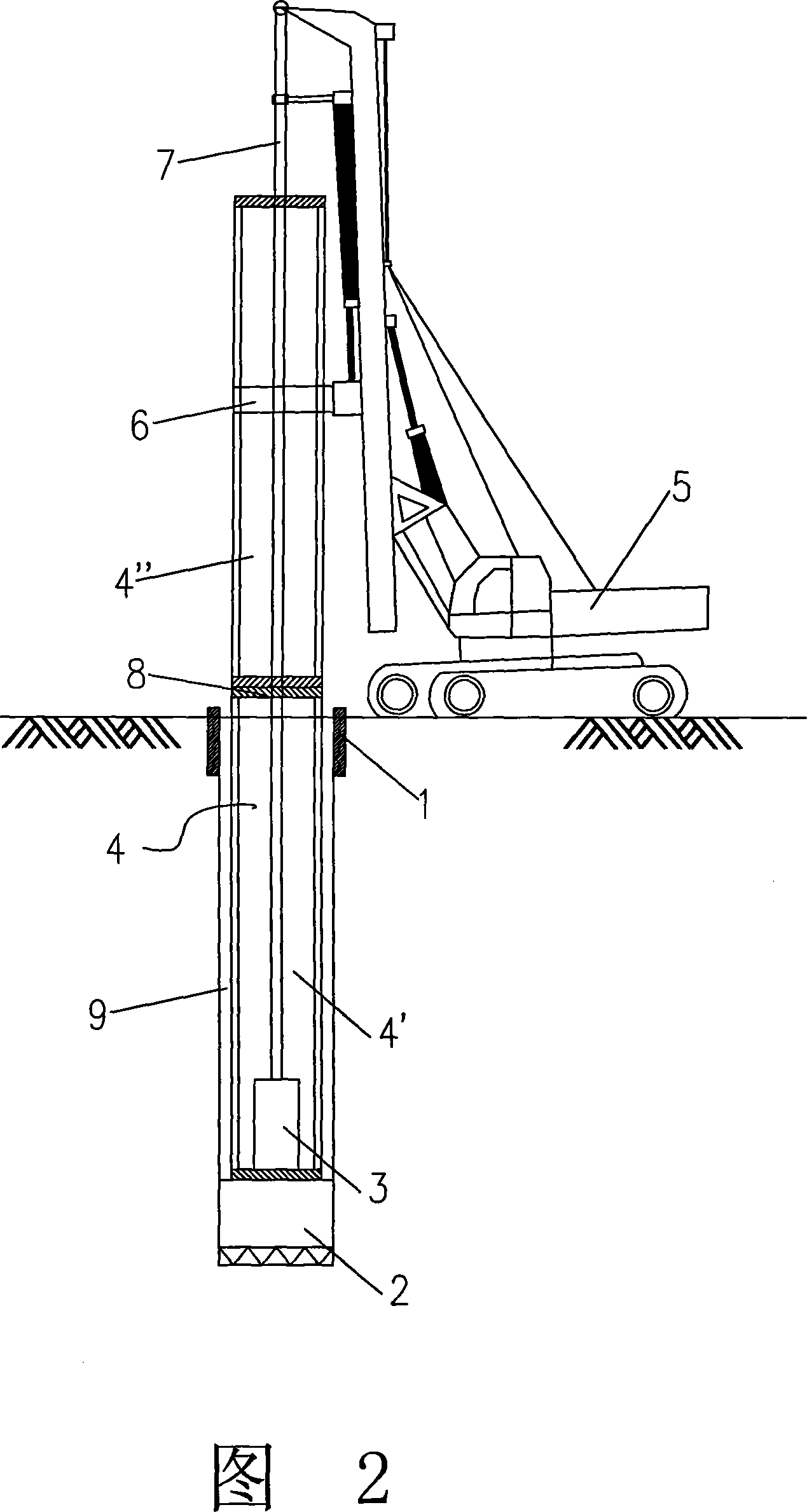

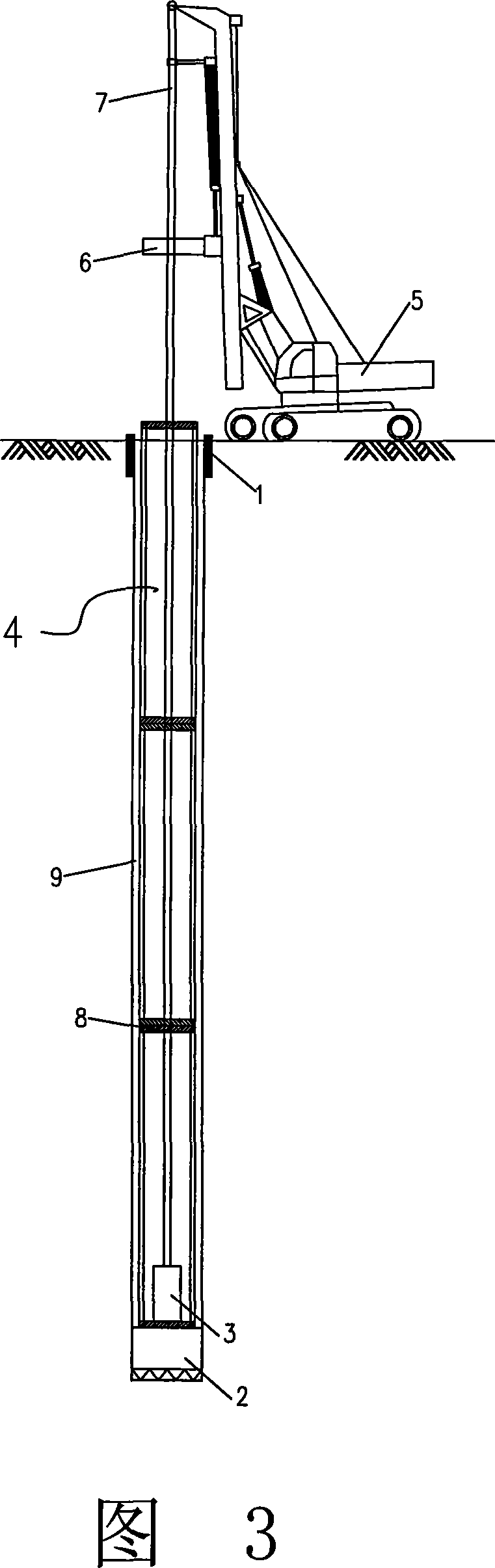

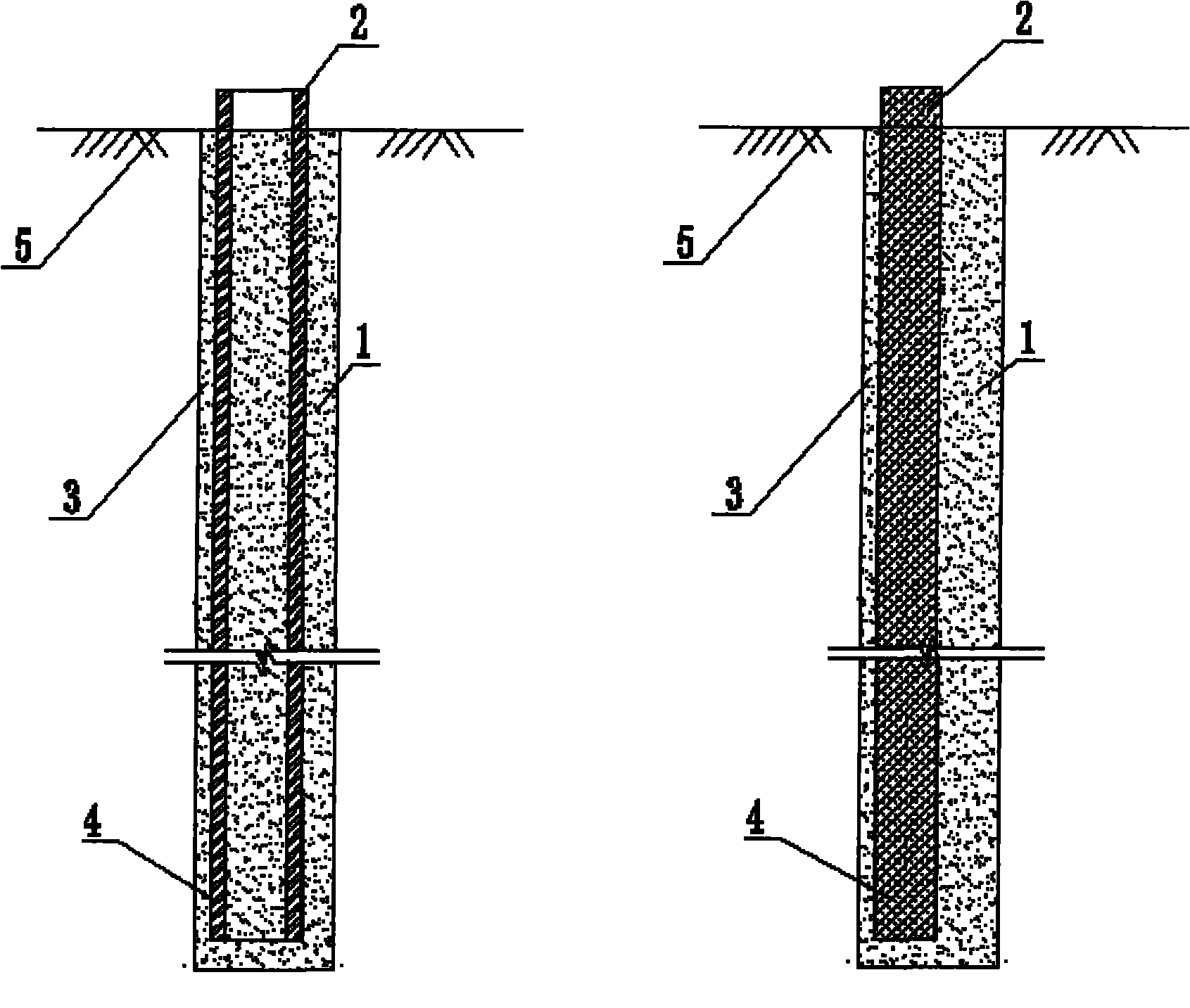

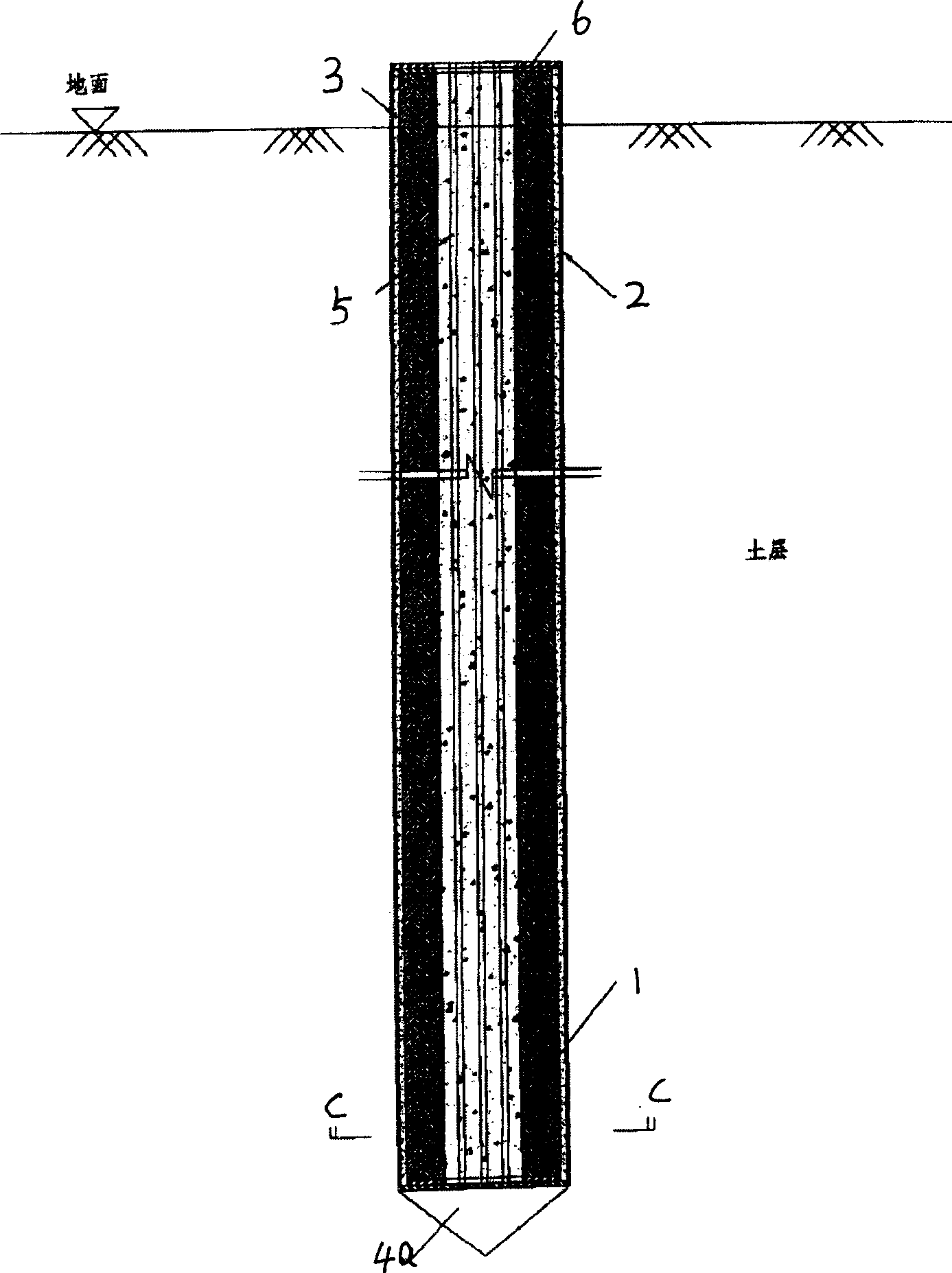

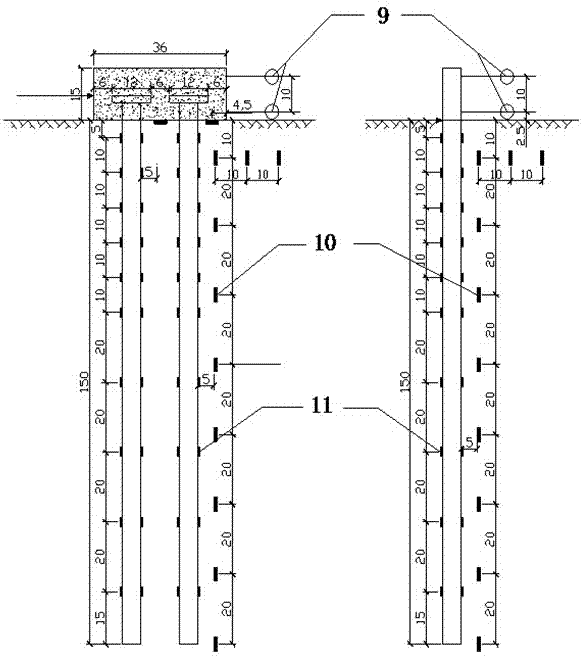

Construction method of drilling follow casting pile used for building or bridge foundation

A method for constructing pipe piles while drilling for building or bridge foundations. The construction steps are to cover high-strength prestressed concrete pipes or steel pipes with drill pipes on the ground first, and install impactors and reaming retractable drill bits at the front ends of the drill pipes. , Follow the pipe while drilling, follow the pipe retaining wall, drill to the design elevation, stop drilling, withdraw from the reaming to shrink the drill bit, use the mud pump to clean the mud and sediment, pour concrete into the pipe, and simultaneously inject pressure grout to the outside of the pipe wall , stop when concrete and grout reach the ground; the object of the invention is to propose a construction method with fast construction speed, reliable quality, less material consumption, high bearing capacity of piles, mechanized operation, and environmental protection. In the construction method of bored cast-in-place piles, the use of mud retaining walls pollutes the environment, the hole is easy to collapse during the drilling process, the quality of concrete pouring is unstable, and the prestressed pipe piles are easy to cause the soil to rise. The strength of the pile body constructed by the invention is high. , There is no sediment at the bottom of the pile, and the pile end is completely rock-socketed, which can reach more than 2 times the bearing capacity of the same diameter bored pile.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD +1

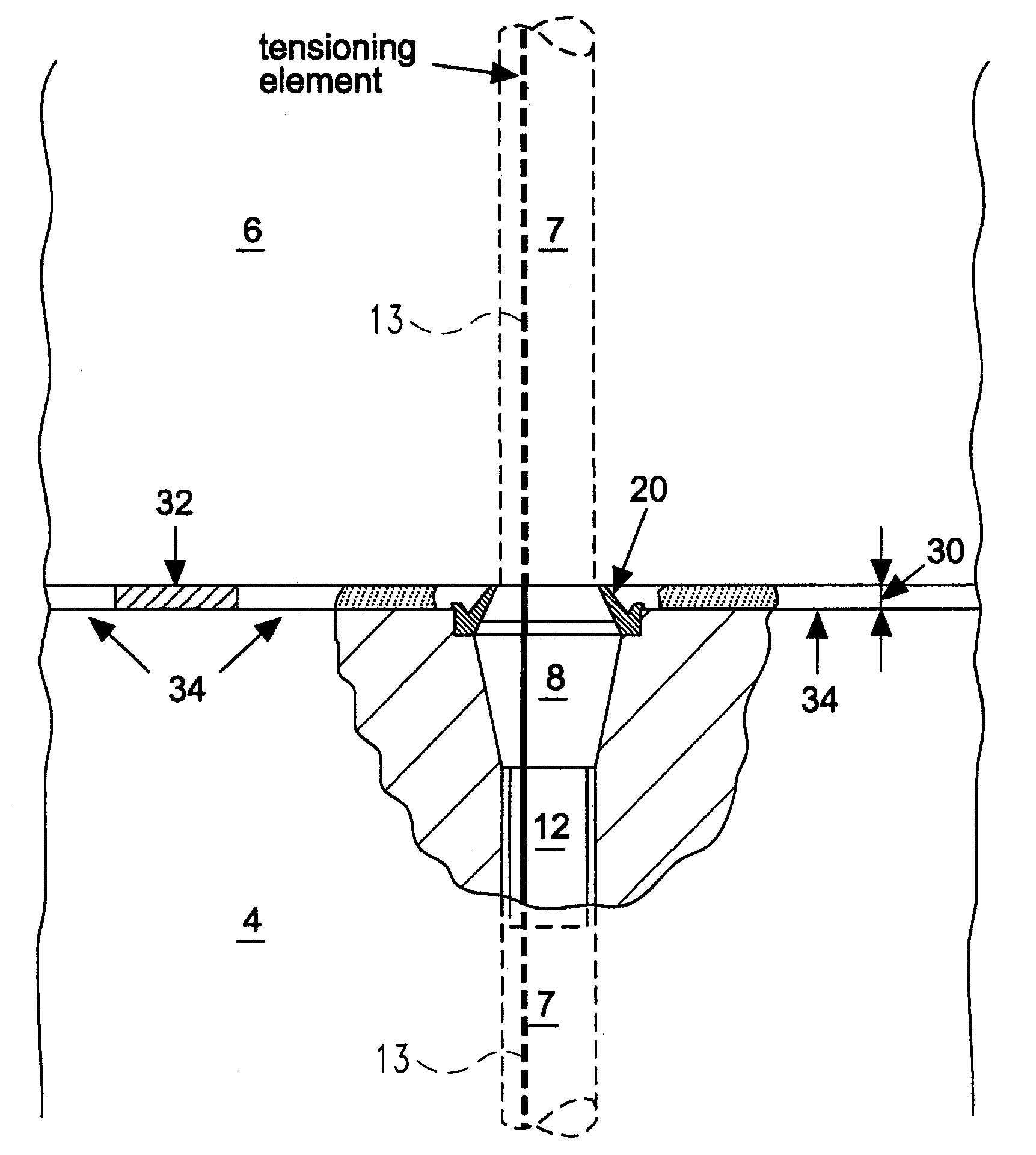

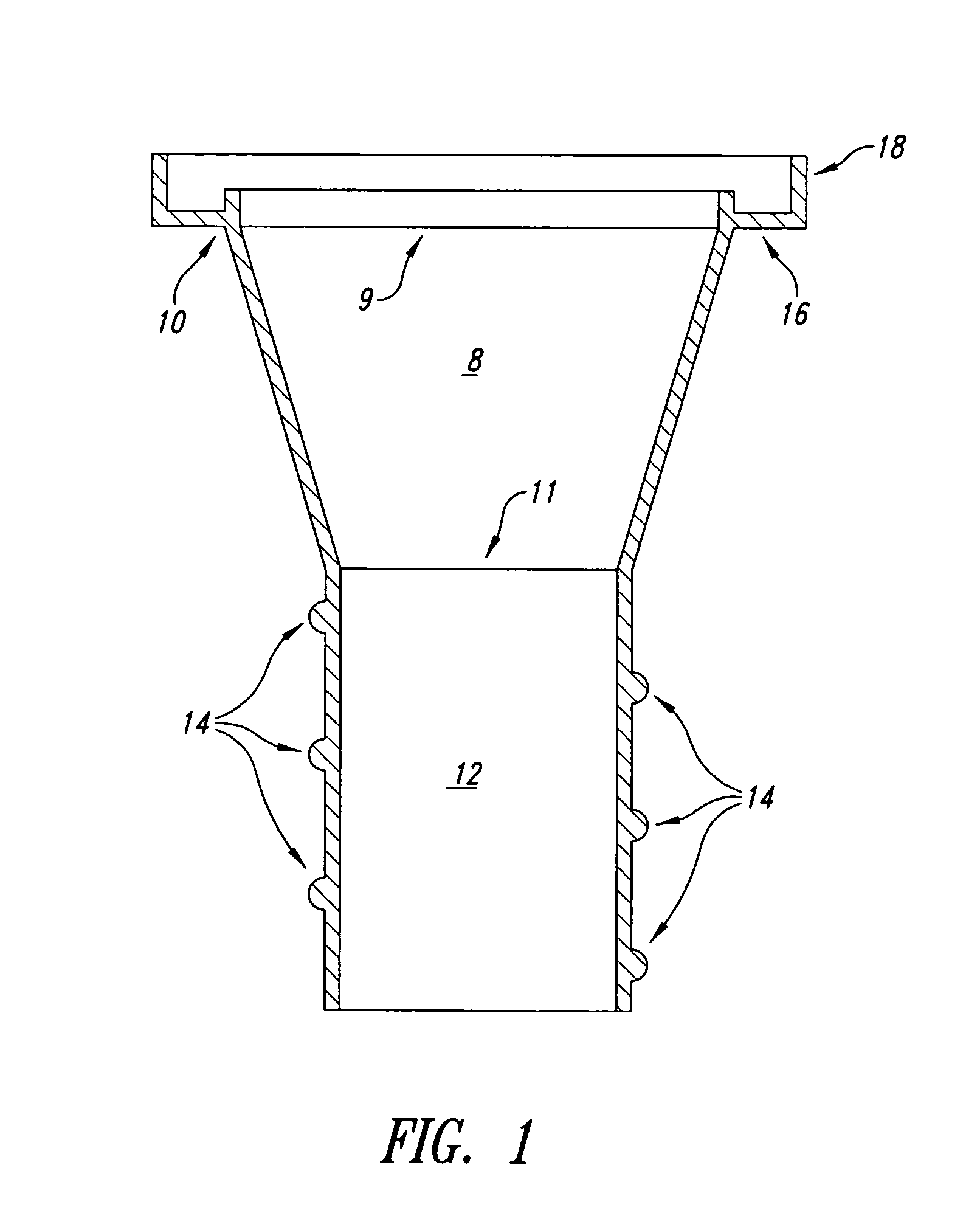

Tower made of prestressed concrete prefabricated assembly units

The invention concerns a method of erecting a pylon of prestressed concrete finished parts and an apparatus for advantageously carrying out the method. In order to at least reduce the problems present in the state of the art when erecting a pylon, there is provided a funnel-shaped apparatus 8 for guiding a tensioning wire, the smaller cross-section 11 thereof being substantially the same as that of the jacket tube 7. There is further provided a seal 20 for producing a pressure-tight transition between two mutually superposed segments 4, 6, wherein the height of the seal 20 substantially corresponds to the intended spacing of the segments. Also provided is a prestressed concrete finished part 4, 6 in which the apparatus 8 according to the invention is integrated. Finally there is provided a method in which epoxy resin is used as a composite joining material 34 between two segments.

Owner:WOBBEN ALOYS

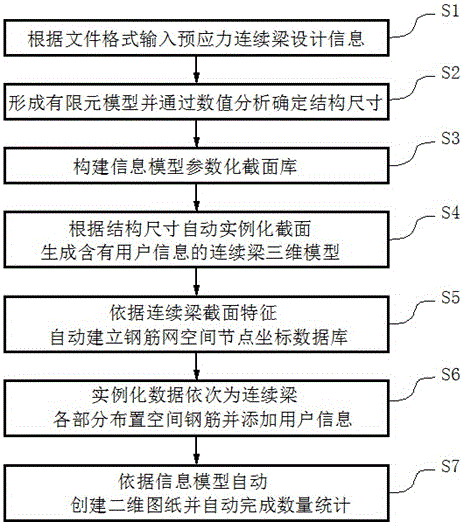

Pre-stressed continuous concrete beam design method based on BIM technology

ActiveCN106354968AAchieve integrationRealize automatic generationGeometric CADDesign optimisation/simulationElement modelContinuous beam

The invention discloses a pre-stressed continuous concrete beam design method based on the BIM technology. The pre-stressed continuous concrete beam design method includes the following steps that according to a file format, pre-stressed continuous beam design information is input; a finite element model is formed, and the structure size is analyzed and determined through the numerical value; an information-model parameterization cross section library is built; according to the structure size, a cross section is automatically instantiated to generate a continuous beam three-dimensional model containing user information; according to the characteristics of the cross section of the continuous beam, a reinforcing-steel-bar-net space node coordinate database is automatically built; instantiation data is sequentially comprises all parts of arrangement space reinforcing steel bars of the continuous beam, and user information is added; according to an information module, two-dimensional drawings are automatically established, quantity statistics is automatically completed. By means of the pre-stressed continuous concrete beam design method based on the BIM technology, rapid forming of universal data, the three-dimensional information model and the reinforcing-steel-bar drawings is achieved, and the pre-stressed continuous concrete beam design method has good popularization value and the good application value.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

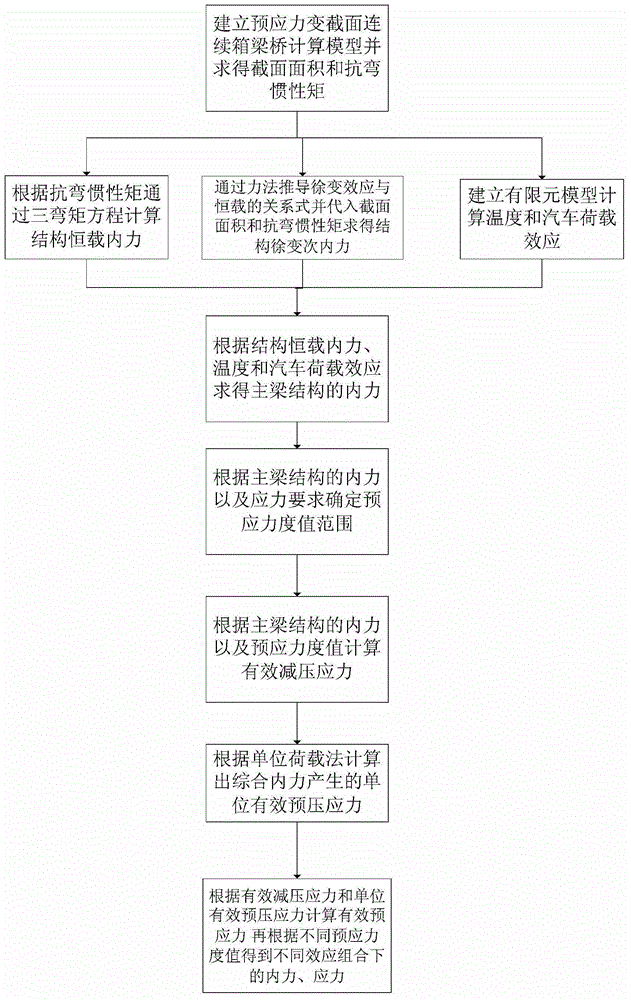

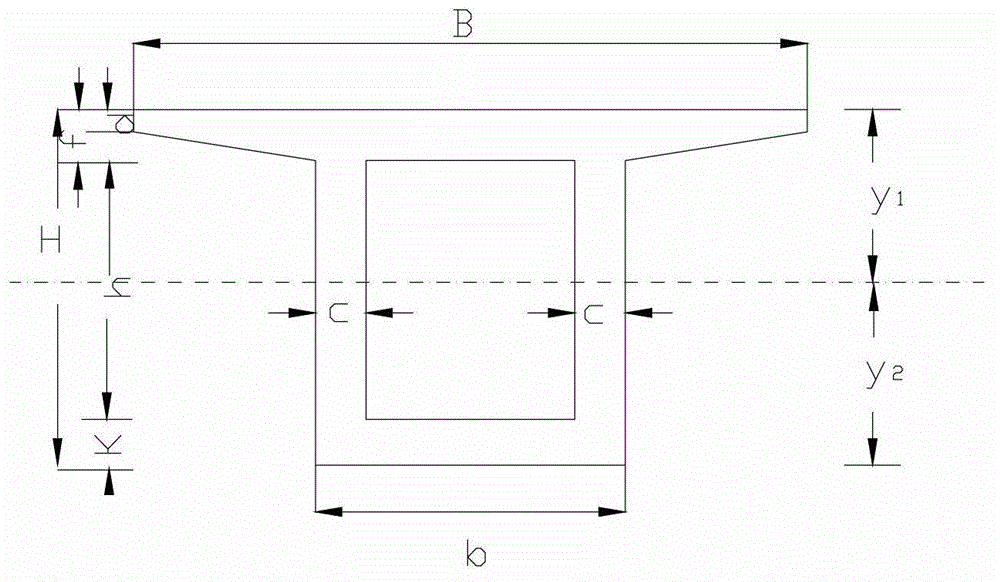

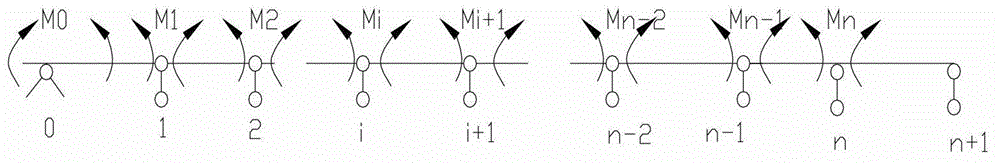

Design method for longitudinal pre-stressing tendons of variable-cross-section pre-stressed concrete continuous bridge

InactiveCN103065035ADevelop longitudinal prestressDevelopment of Analytical Computational MethodsSpecial data processing applicationsBridge materialsStress ratioPre stressing

The invention discloses a design method for longitudinal pre-stressing tendons of a variable-cross-section pre-stressed concrete continuous bridge. The optimization design method for the longitudinal pre-stressing tendons of the pre-stressed concrete continuous bridge is built based on the design principle of the pre-stressed degree and through combining an analytic method with a finite element method and compressively considering dead load and live load action effects. A three moment equation of the variable-cross-section pre-stressed concrete continuous box girder bridge is established to solve the internal force of the structure under the action of the self weight on the basis of the average bending moment method. A calculation formula of pre-stressed effective pre-pressure is built through a load equal effect method and a unit load method; a creep effect calculation formula is built through a force method; the temperature effect and the automobile load effect are calculated through the finite element method; and a variable-cross-section statically indeterminate structure pre-stressing tendon reinforcement calculation formula is obtained through combination of the stress ratio with the definition of the competitive pre-stressed degree.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

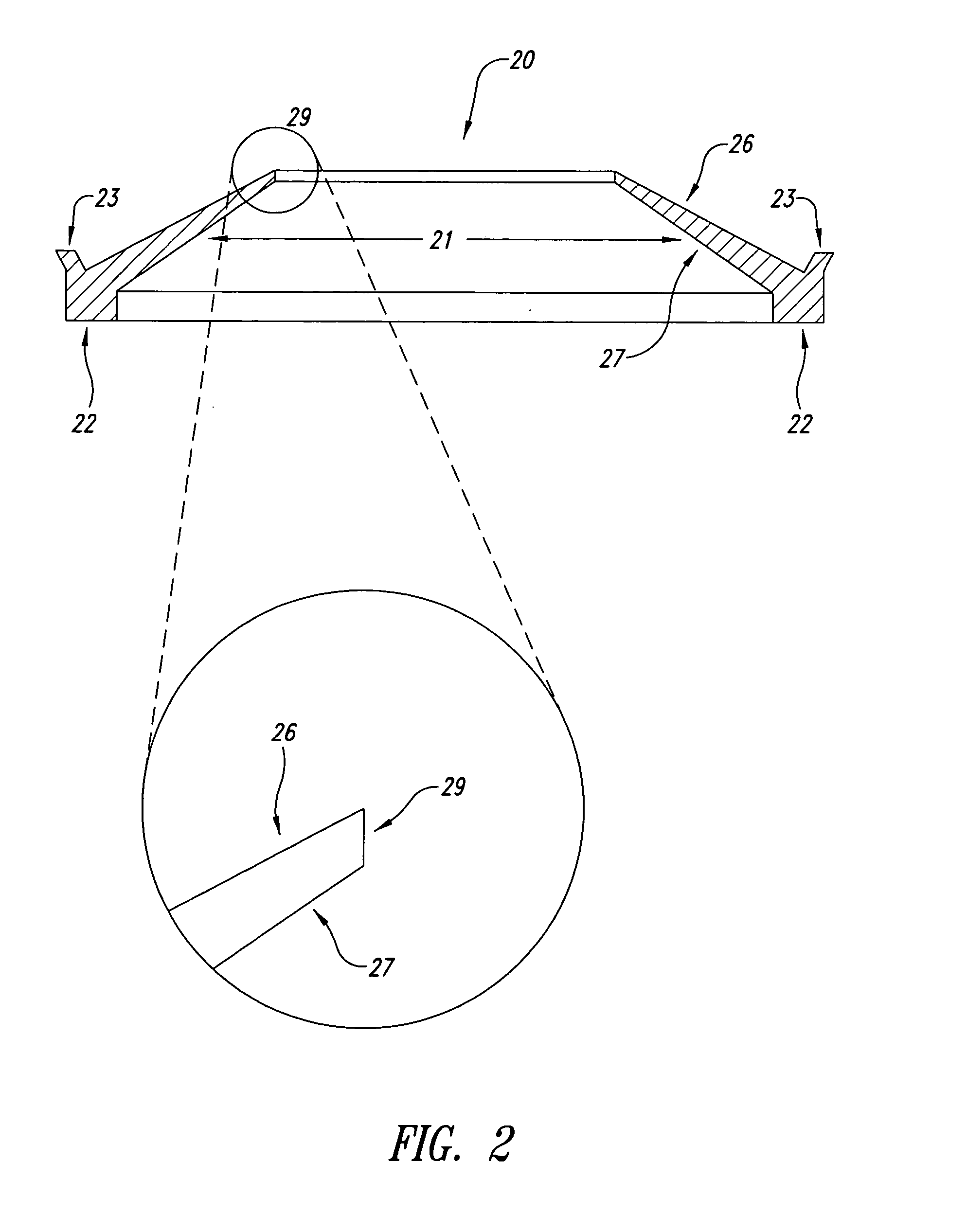

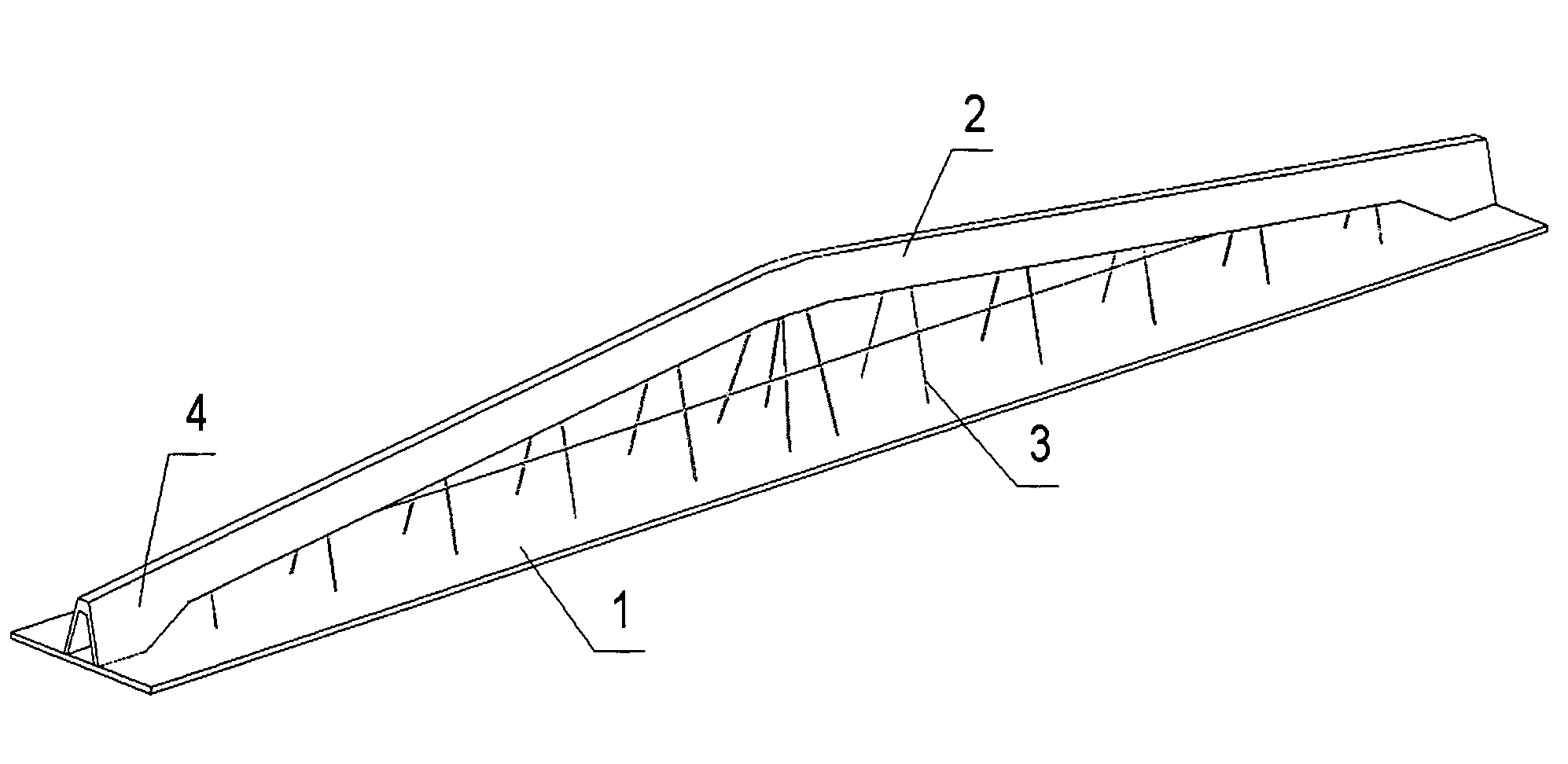

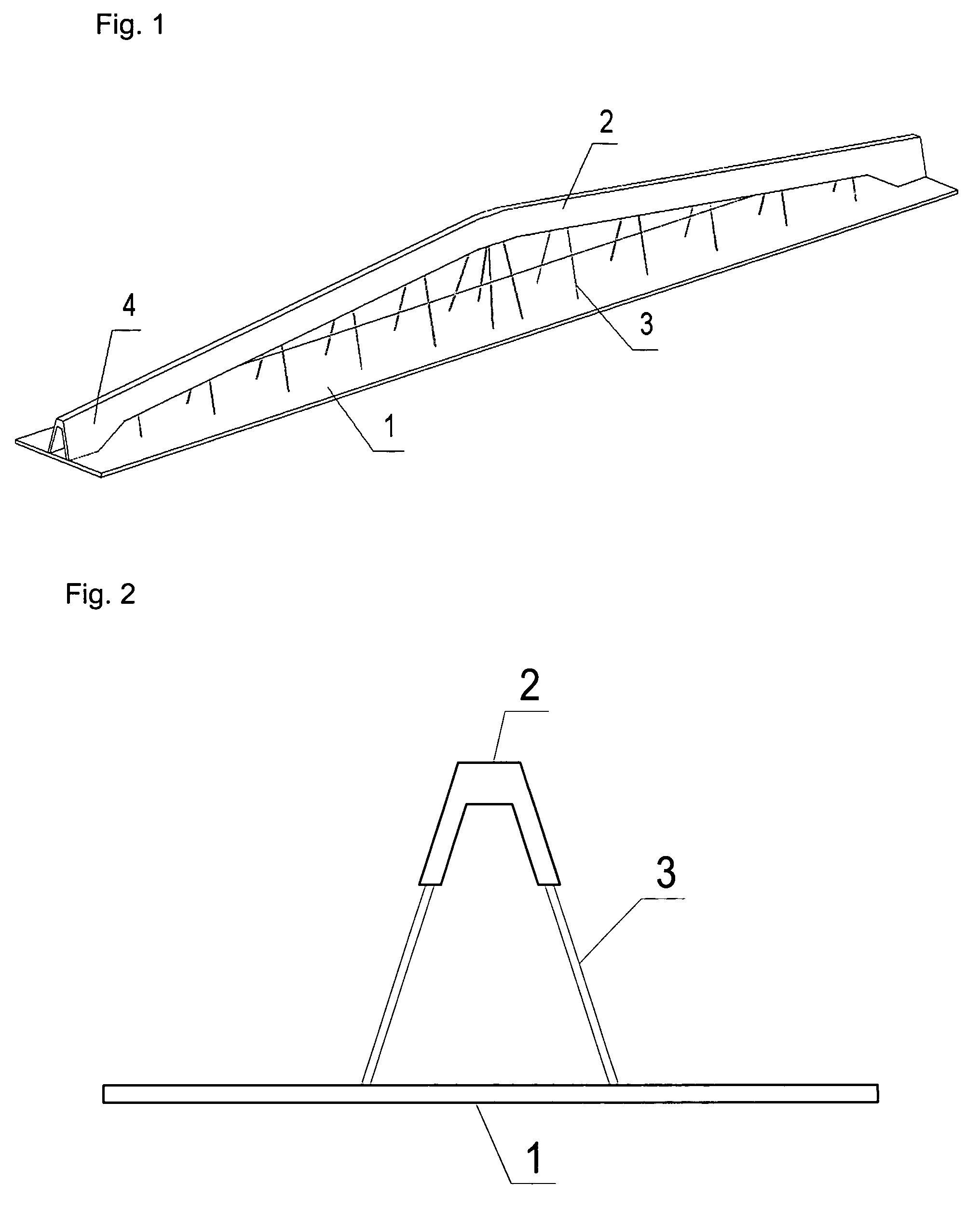

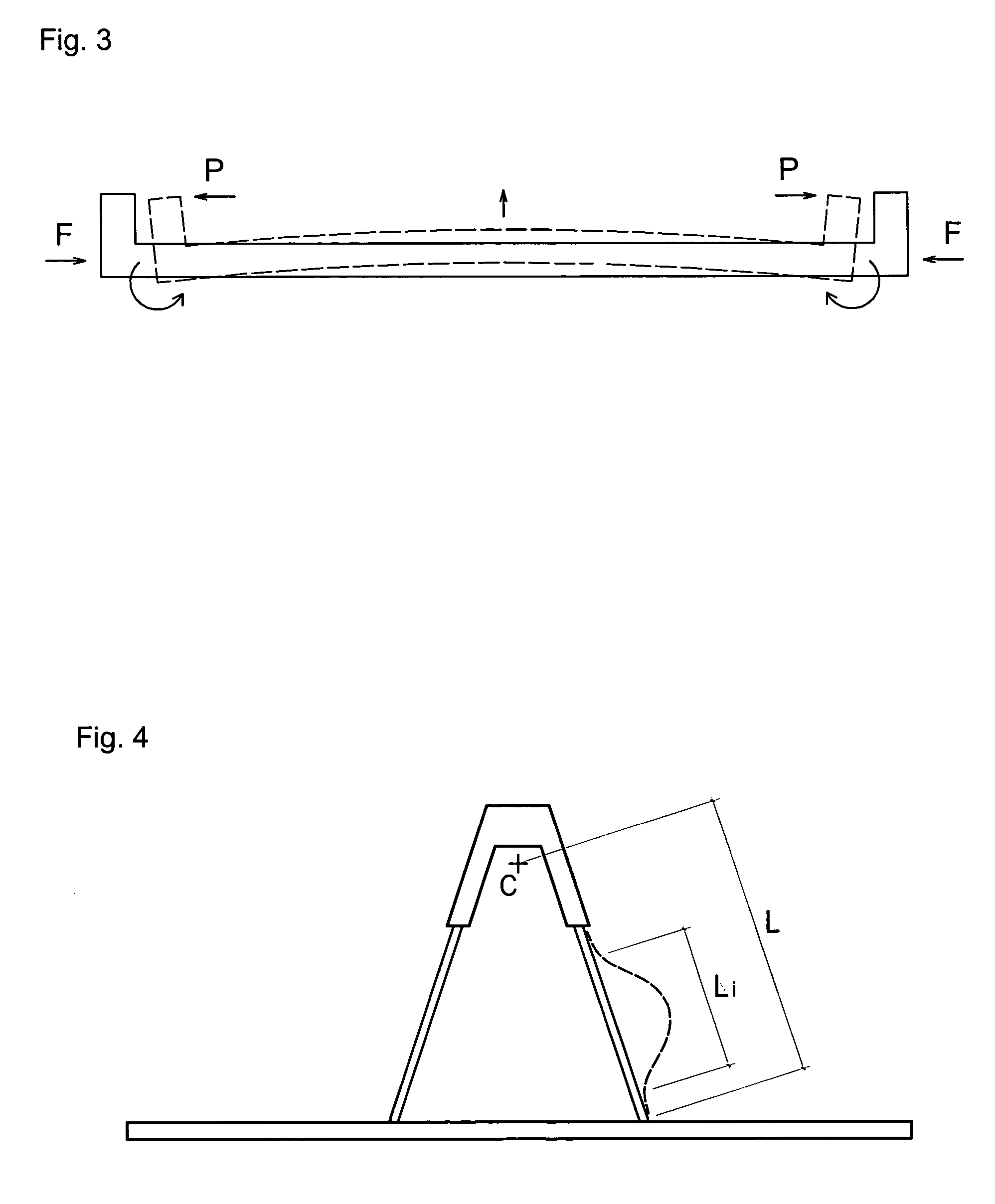

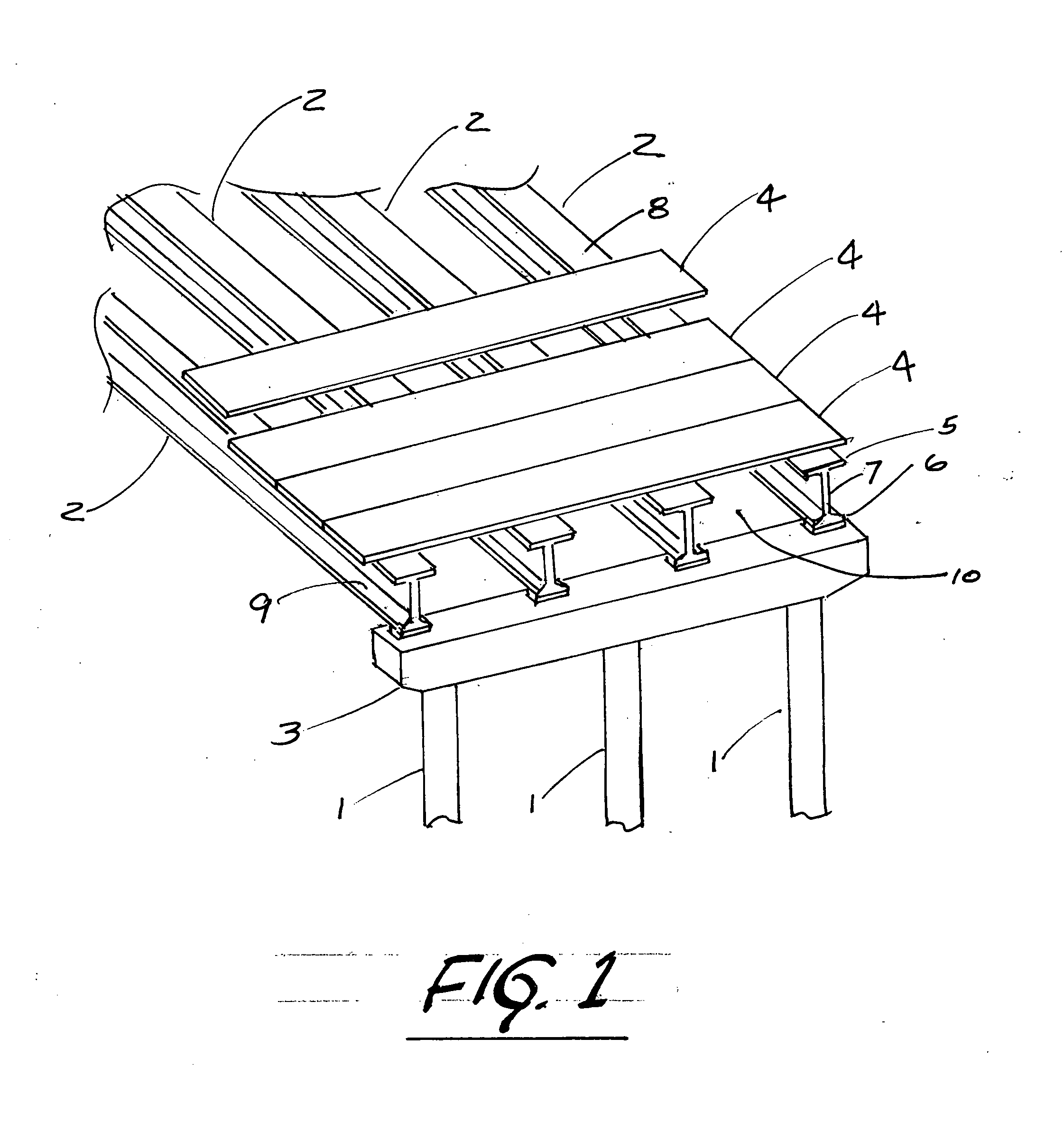

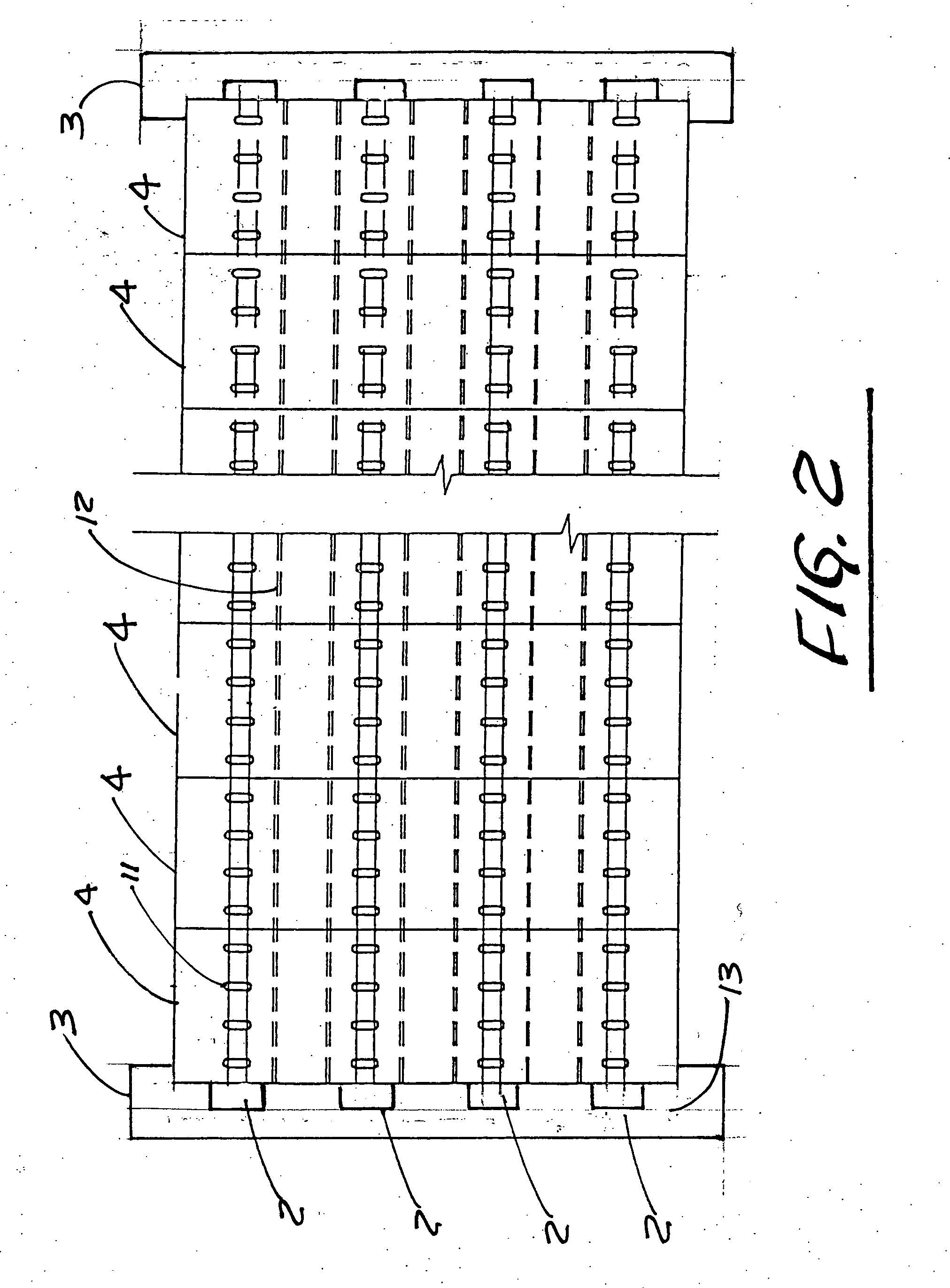

Indirectly prestressed, concrete, roof-ceiling construction with flat soffit

An indirectly prestressed concrete roof-ceiling construction is a prefabricated element for constructing large-span industrial buildings. The construction includes a distinctly wide and thin concrete soffit plate and an upper concrete girder of an inverse “V”-shaped cross section, interconnected by slender steel pipe-rods that are used to stabilize the upper girder against lateral buckling and to prevent the plate and the girder from getting closer or further away from each other. Prestressing of the soffit plate causes compression in the upper girder which passively (indirectly) pushes the ends of the construction, acting on some eccentricity over the center of gravity of the cross section, causing rotation of its ends, bending in that way the soffit plate upwards. There are two efficient methods of prestressing these constructions.

Owner:MARA INST D O O

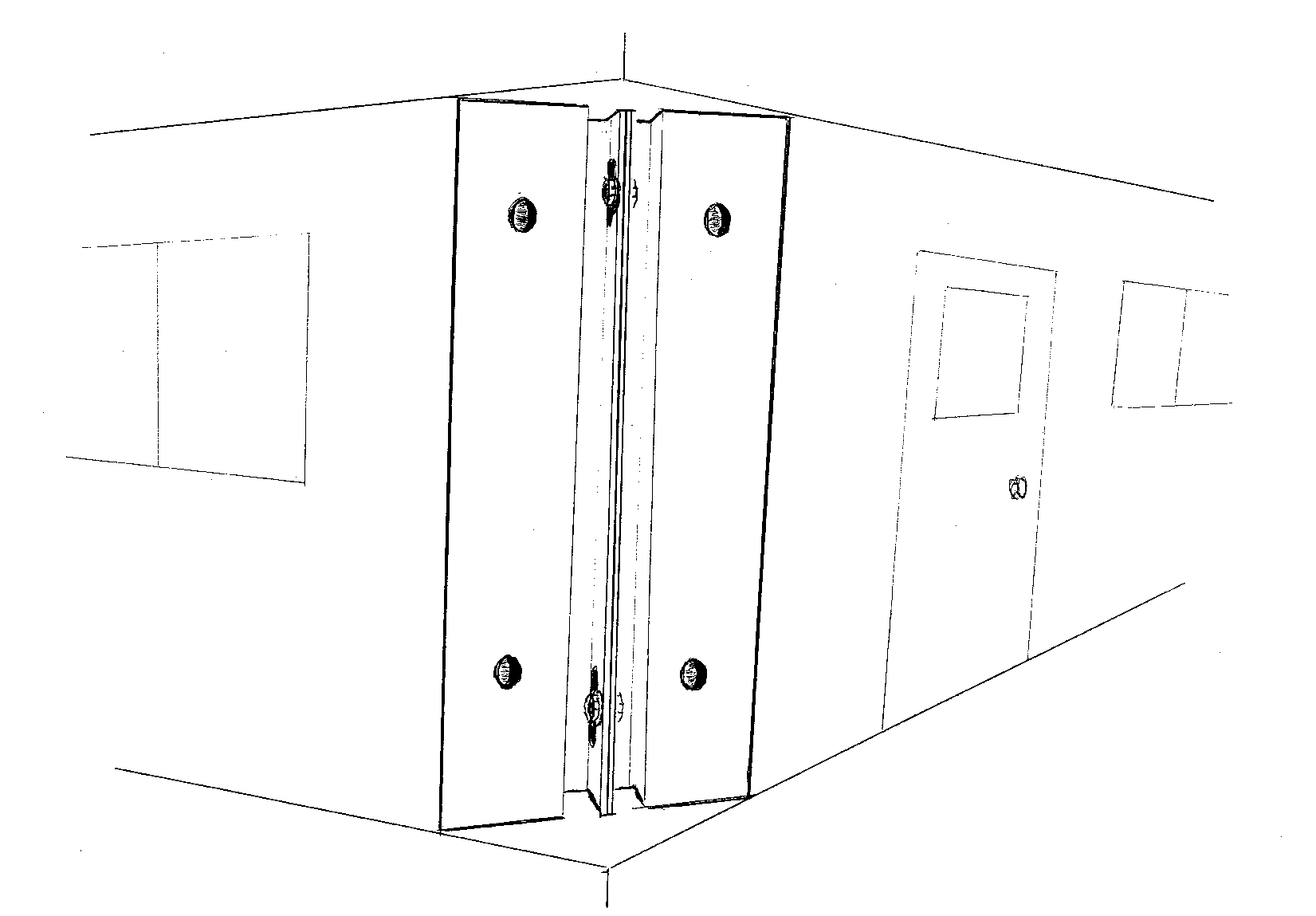

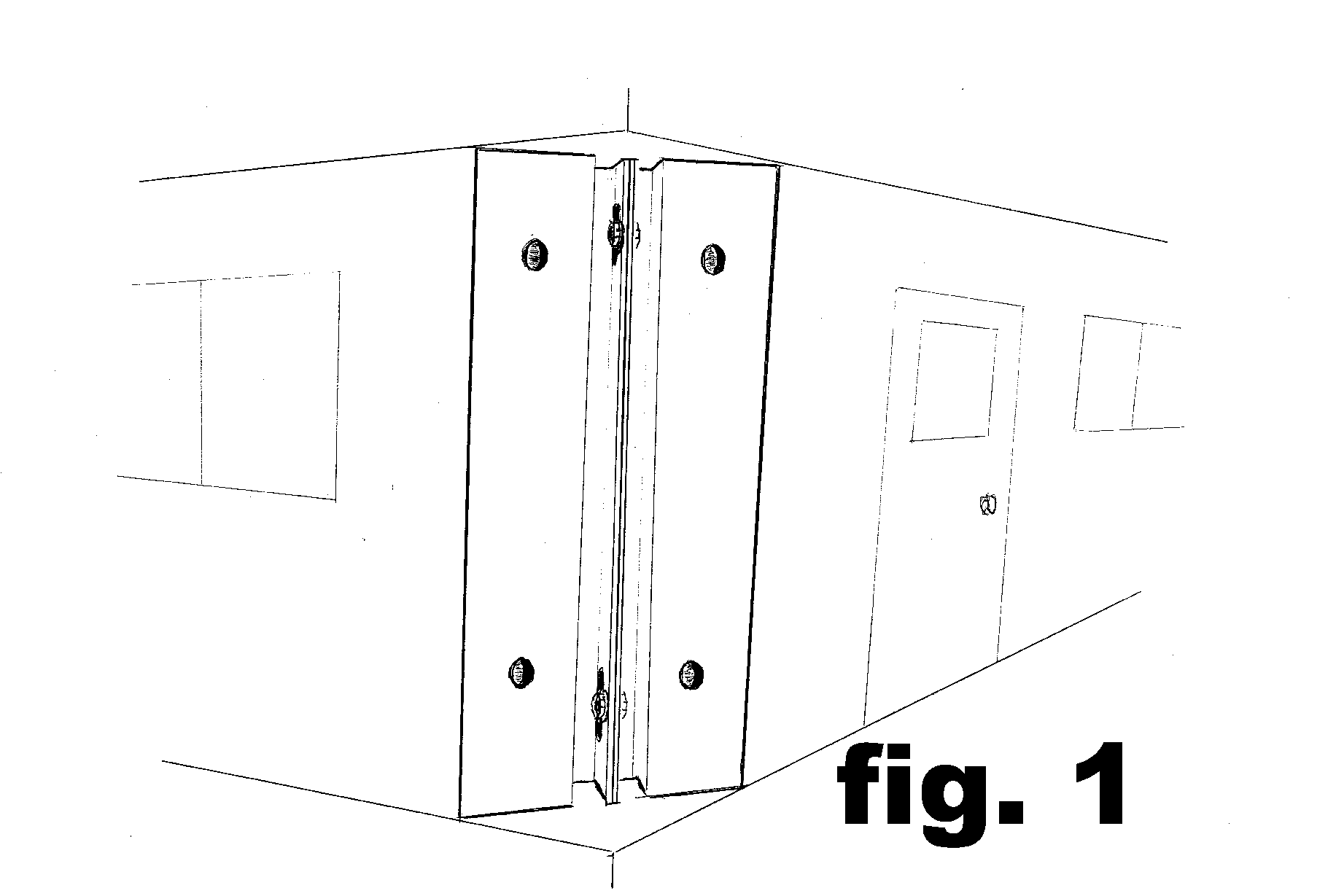

Connectors and Methods of Construction for a Precast Special Concrete Moment Resisting Shear Wall and Precast Special Concrete Moment Resisting Frame Building Panel System

InactiveUS20080098676A1Saving environment protectionThermally efficientMoulding surfacesBuilding roofsComposite constructionInternational Building Code

A precast concrete wall panel molding system for fabricating a wall shell and a plurality of ribs and beams. A precast concrete wall panel molding system with facilities for incorporating door and window frames. A ductile panel end connector for attaching panels one to another whether in parallel or angled as in inside or outside corners. A ductile panel end connector for attaching panels to columns. A wall anchor / shear plate with post-tensioning brace plate. A hybrid precast / cast-in-place special moment resisting shear wall / special moment resisting frame reinforced concrete building system for regions of potential seismic activity. A prescriptive method building system for composite structural building assemblies with conventional wood and light-gauge steel framing, structural steel, and other building code approved and tested building systems, building components, building panel systems, building roofing systems, modular and manufactured buildings, and building electrical, mechanical, and plumbing systems. A precast concrete wall panel system conforming to industry practices and standards as published by the Precast / Prestressed Concrete Institute, (PCI) in it's “PCI Design Handbook” (fifth edition, 1999), the American Concrete Institute “Building Code Requirements for Structural Concrete” (ACI 318-05), The “International Building Code 2006” and the “Uniform Building Code”.

Owner:HUTCHENS JOHN FRANCIS

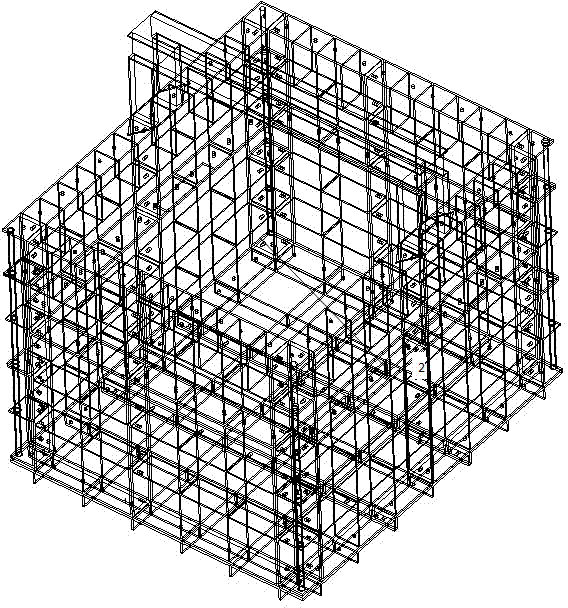

Column-through assembled prestressed concrete frame system and construction method thereof

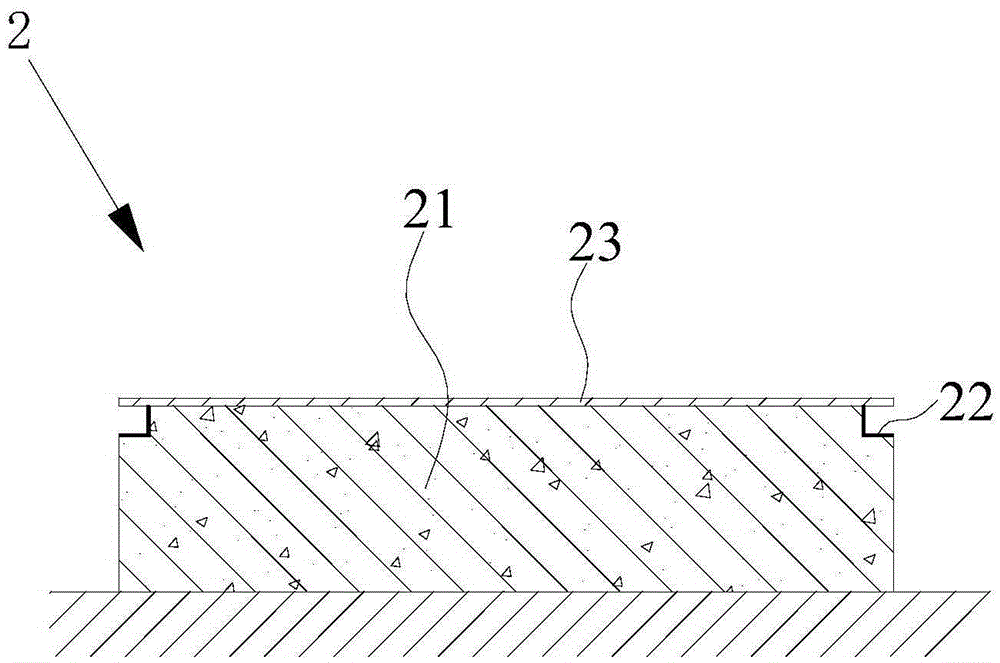

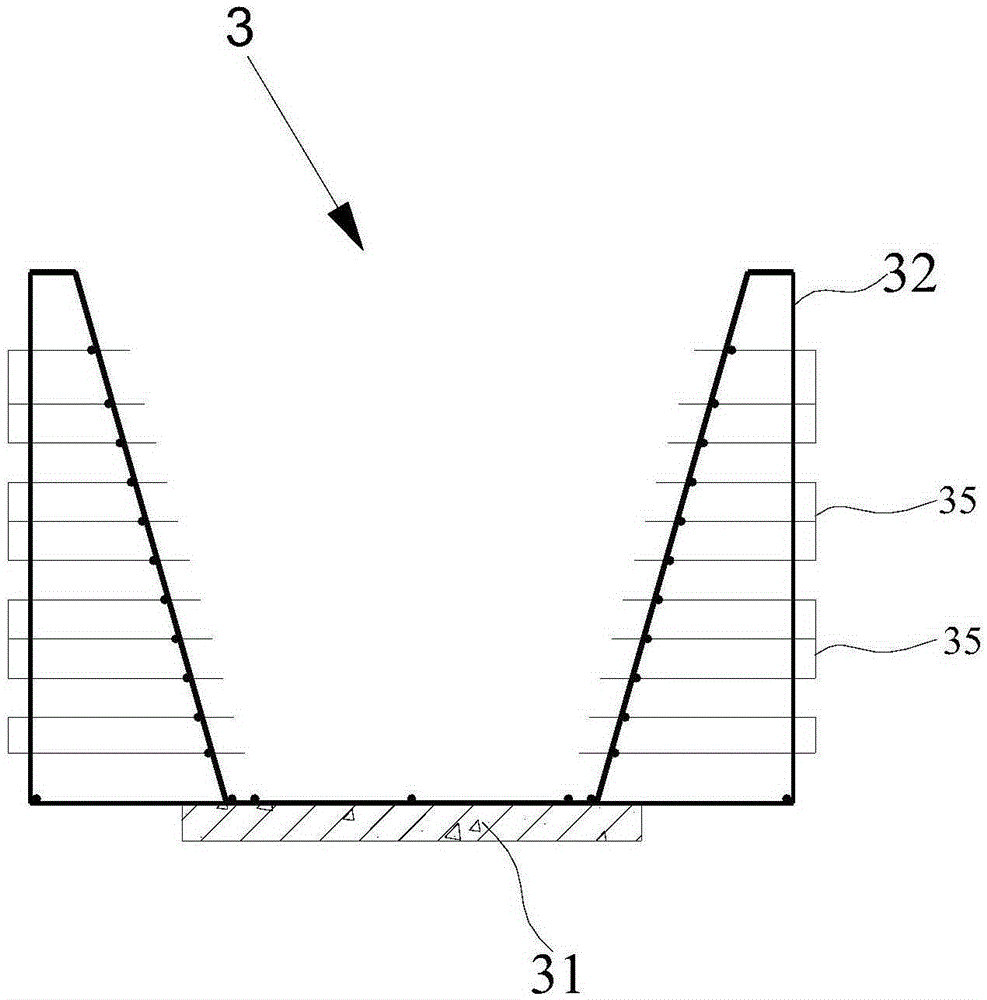

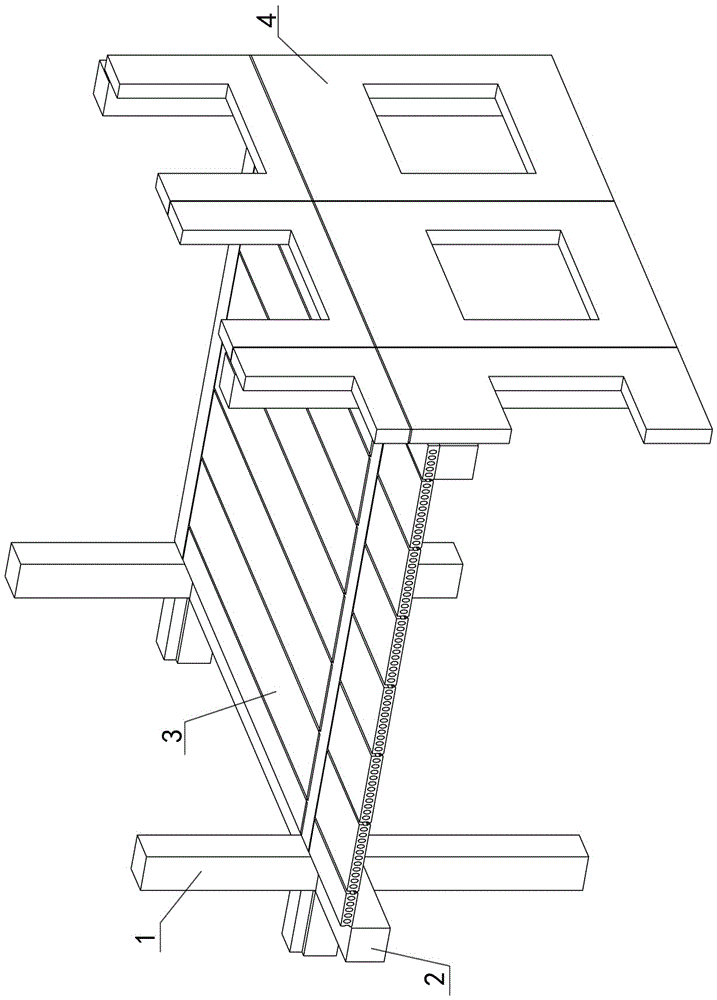

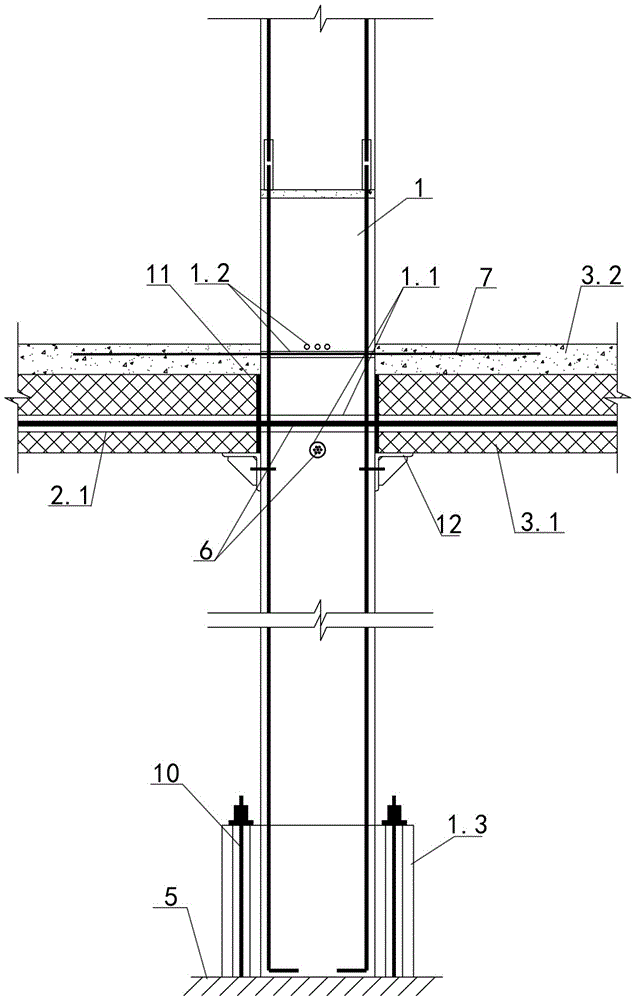

ActiveCN106499051AEfficient constructionImprove seismic performanceBuilding constructionsReinforced concrete columnFloor slab

The invention discloses a column-through assembled prestressed concrete frame system and a construction method thereof. The system comprises a foundation, a prefabricated reinforced concrete column, a prefabricated reinforced concrete beam, a superimposed floor slab and an external hung prefabricated wallboard, wherein a column prestressed duct is formed in the prefabricated reinforced concrete column; a beam prestressed duct is formed in the prefabricated reinforced concrete beam; post-tensioned unbonded prestressed tendons are penetrated into the beam prestressed duct and the column prestressed duct; energy-dissipation steel bars are anchored between the prefabricated reinforced concrete column and the superimposed floor slab. The structure provided by the invention has a good seismic performance; the lower part of a beam-column joint is subjected to unreinforced connection so that the structure is simple; the post-tensioned unbonded prestressed tendons and a replaceable column base energy dissipater are used so that the structure is less damaged and easy to be repaired in the earthquake; a construction manner of using the prefabricated superimposed floor slab and prestressed assembly makes site construction convenient and rapid and saves a lot of supports compared with a traditional prefabricated assembly structure; the column-through assembled prestressed concrete frame system provided by the invention is used in combination with lateral supports, shear walls and other lateral force resisting members, and is applicable to most high-rise public buildings.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

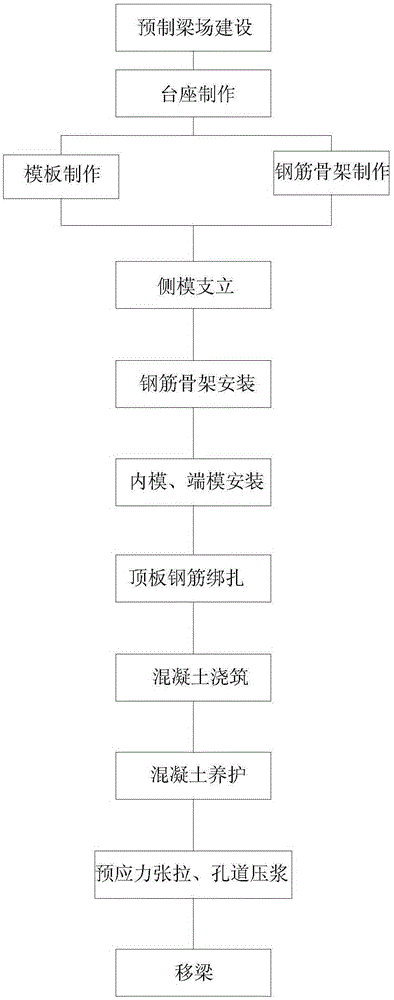

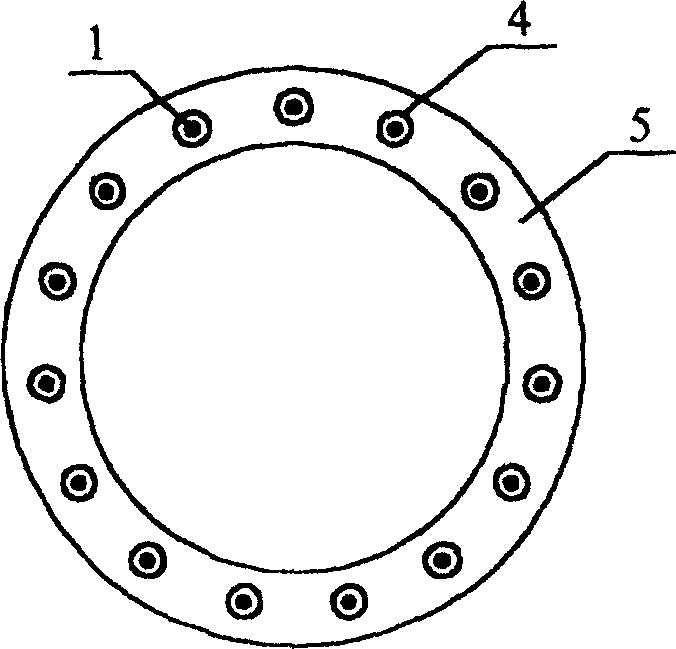

Precast assembly process of prestressed concrete cylindrical hollow pier

InactiveCN101831875AReduce usageSmall amount of workBridge structural detailsBridge erection/assemblyPre stressRebar

The invention relates to a precast assembly process of a prestressed concrete cylindrical hollow pier. The traditional process has the defects that construction period is longer, the cast-in-situ construction is greatly influenced by environment, and the construction quality can not be controlled easily. The precast assembly process of the prestressed concrete cylindrical hollow pier, which is provided by the invention, mainly comprises the following ten steps of: preparing a precast component, casting a bearing platform in situ, installing a transition section, installing a standard section, installing a pier top section, stretching a prestressed thick steel bar and anchoring at the part of a stretching and anchoring construction groove, grouting, casting concrete at the part of the prestressed stretching and anchoring construction groove at the upper end of the pier top section, protecting the anchoring end of the prestressed thick steel bar in a sealing way, and the like. The invention can save a large number of building materials, fully exert the action of high-strength materials and simultaneously shorten the construction period, is beneficial to quality control, and has high construction efficiency.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

Prestressed concrete constraining buckling-restrained brace

InactiveCN102817422AGive full play to the constraintsReduce section sizeShock proofingBuckling-restrained braceUltimate tensile strength

The invention discloses a prestressed concrete constraining buckling-restrained brace. The brace comprises a cross inner core member, concrete-filled square steel tube constraining members, a hard rubber plate, long bolt shank positioning parts and prestressed tendons, wherein four concrete-filled square steel tube constraining members are made of prestressed thin-wall steel tube concrete and attached to the cross inner core member closely to form a stressed whole; the cross inner core member is made of two pieces of low-intensity high-stretchability hot rolled section steel with a T-shaped cross section, and an inner surface and an outer surface are attached to the hard rubber plate; and a circular hole is arranged in the middle of the buckling-restrained brace, and the long bolt shank positioning parts penetrate through the circular hole and connect the cross inner core member, concrete-filled square steel tube constraining members and the hard rubber plate. The prestressed concrete constraining buckling-restrained brace has the advantages that the constraining effects of concrete can be implemented fully, the cross section size of the member is reduced, high efficiency and economy are achieved.

Owner:TSINGHUA UNIV

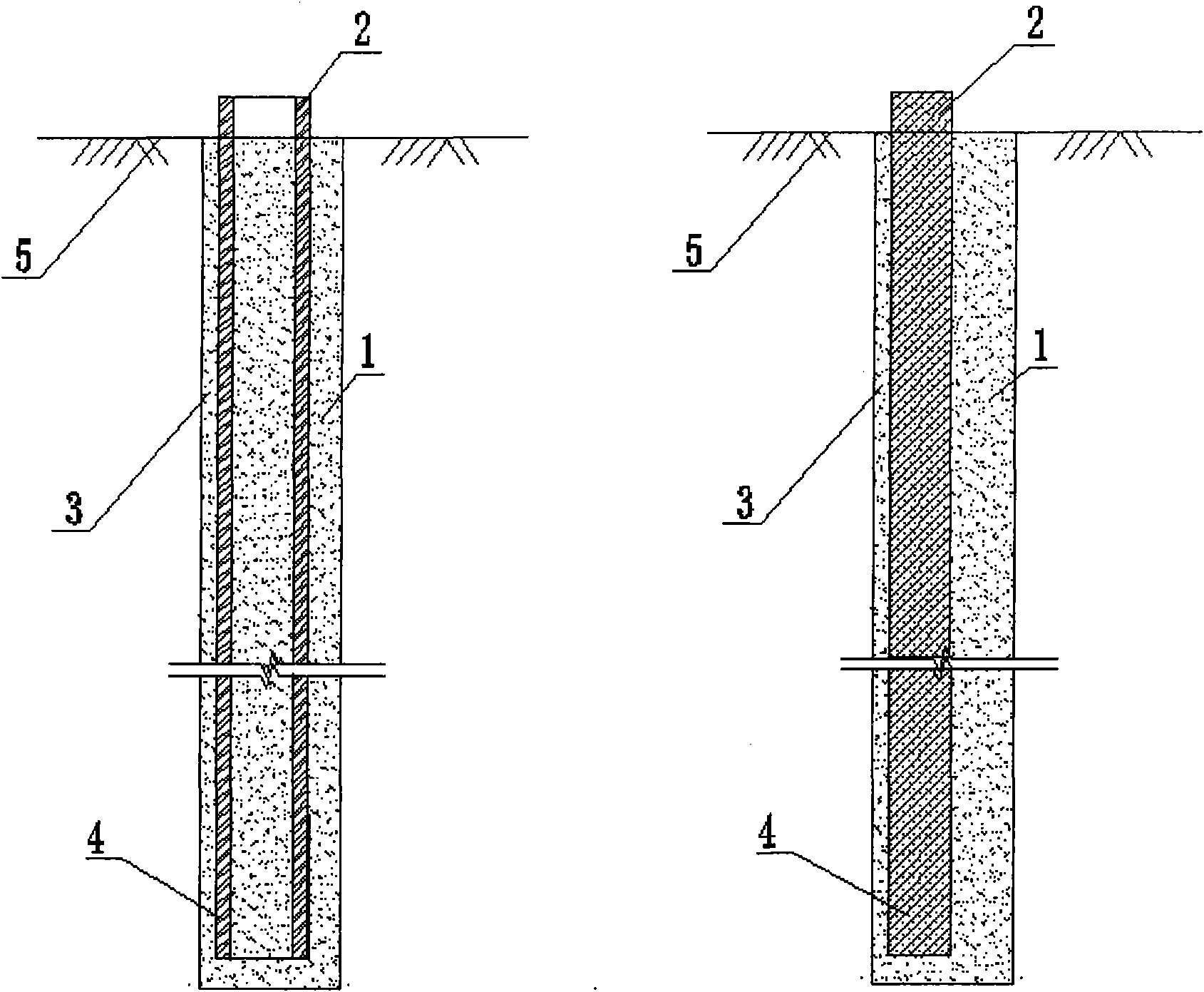

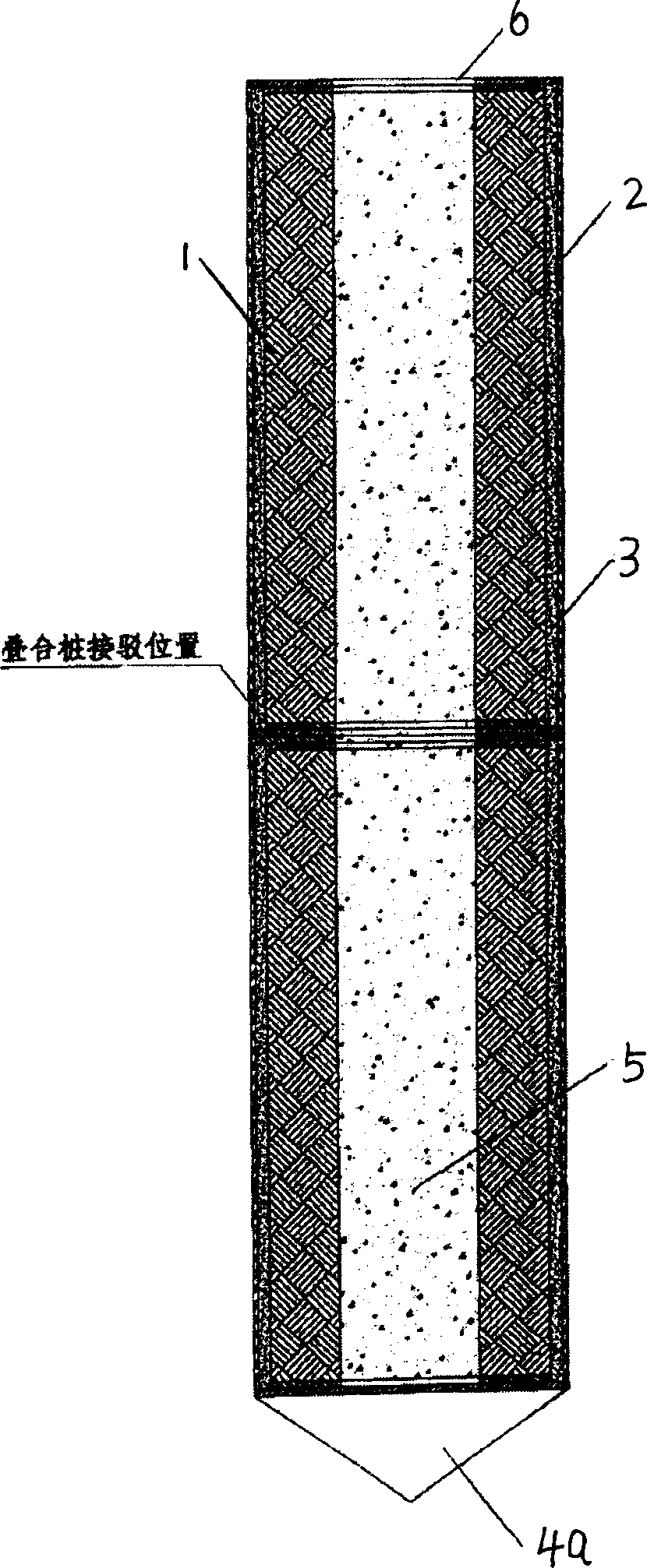

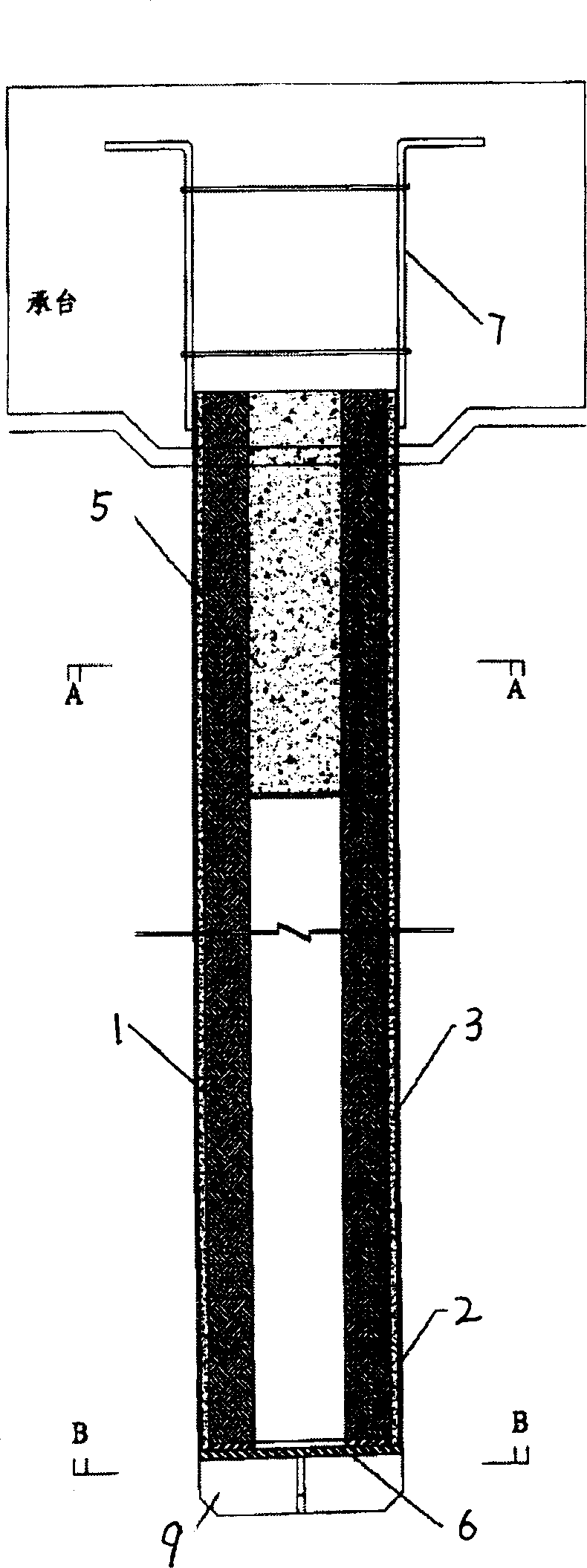

Cement-soil composite pile inserted into reinforced concrete core materials

InactiveCN101798810ATo overcome the problem that deep stirring can only stop water but not supportIncrease side frictionBulkheads/pilesReinforced concreteCement slurry

The invention relates to a cement-soil composite pile inserted into reinforced concrete core materials. The cement-soil composite pile is a novel composite pile which is formed by inserting a prestressed concrete tubular pile or a prestressed concrete square pile or a reinforced concrete member, serving as a core material, into a deeply-stirred cement-soil pile (which is formed by deeply stirring through a single-shaft, double-shaft or three-shaft stirring pile machine). The cement-soil composite pile consists of a cement-soil stirring pile and a high-strength core pile. The cement-soil composite pile is formed by the following steps of: stirring soil and cement slurry to form the cement-soil by using the single-shaft, double-shaft or three-shaft stirring pile machine; and then inserting one (or a plurality of) core material (such as the prestressed concrete tubular pile, the prestressed concrete square pile, the precast reinforced concrete member and the like) into the cement-soil by a vibration or self-weight method to obtain the composite pile body. The composite pile has higher bending strength, tensile strength and shear strength so as to meet different bearing requirements, and has the lateral bearing capacity 30 percent higher than that of the core pile and comprehensive cost 40 percent lower than that of a bored pile.

Owner:SHANGHAI STRONG FOUND ENG

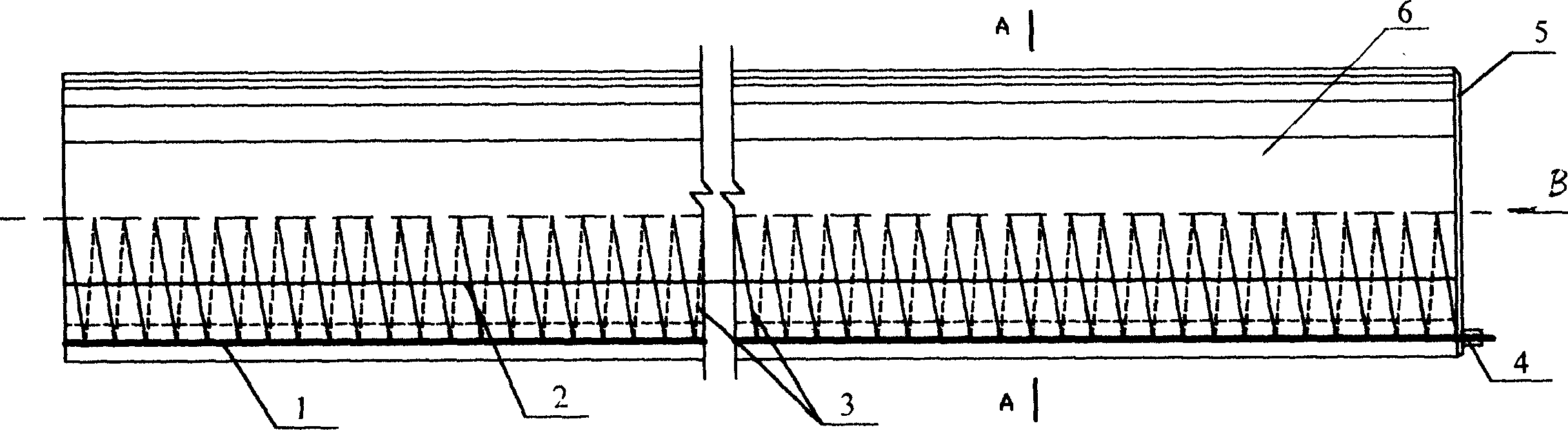

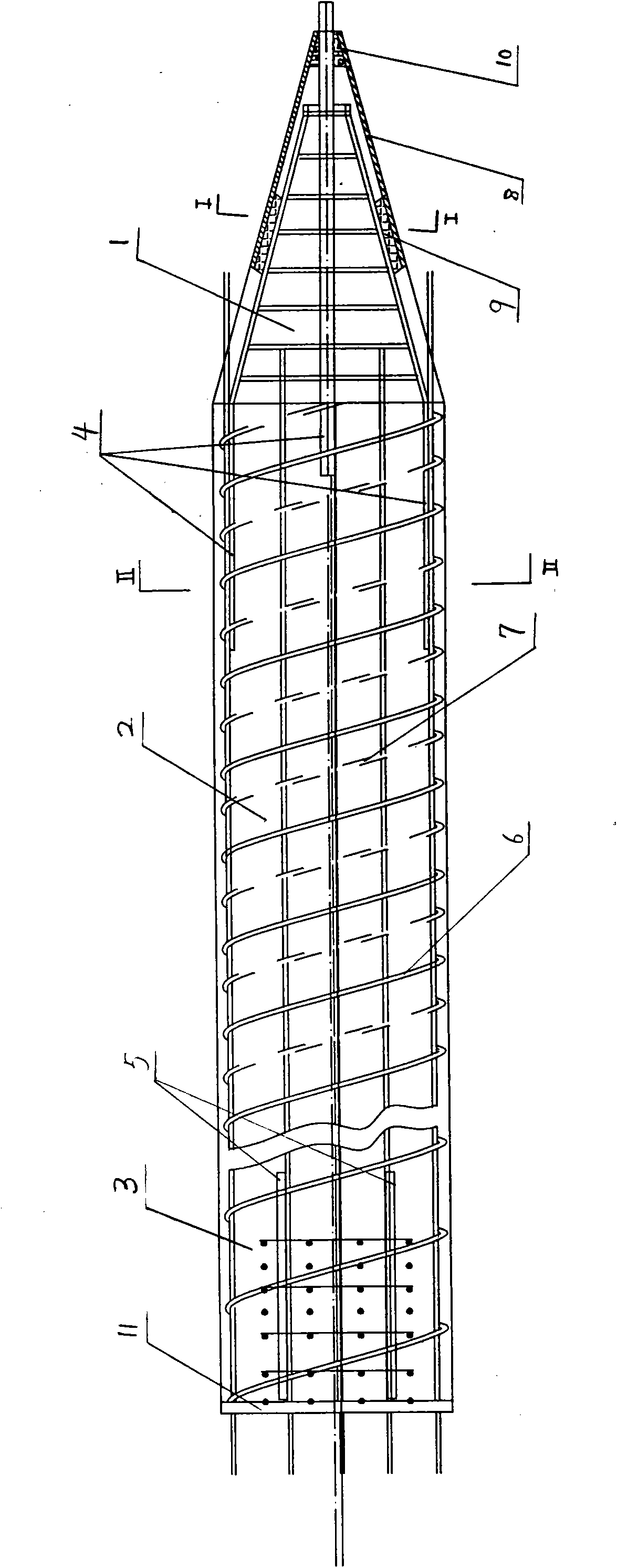

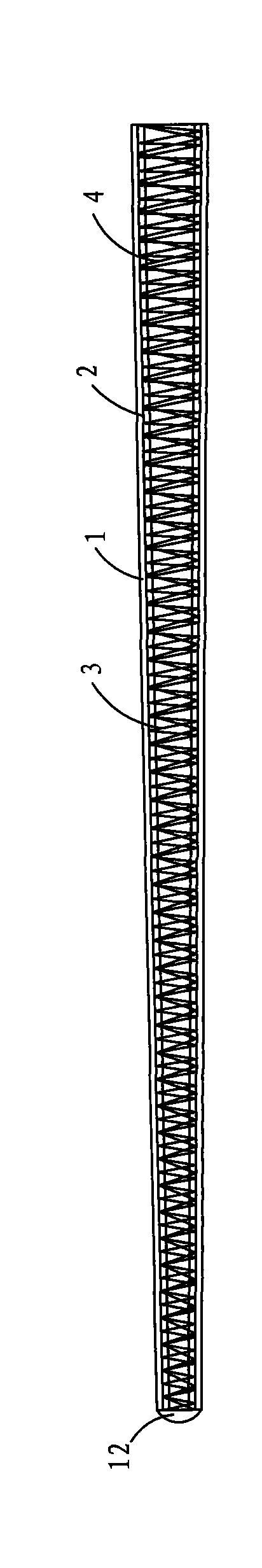

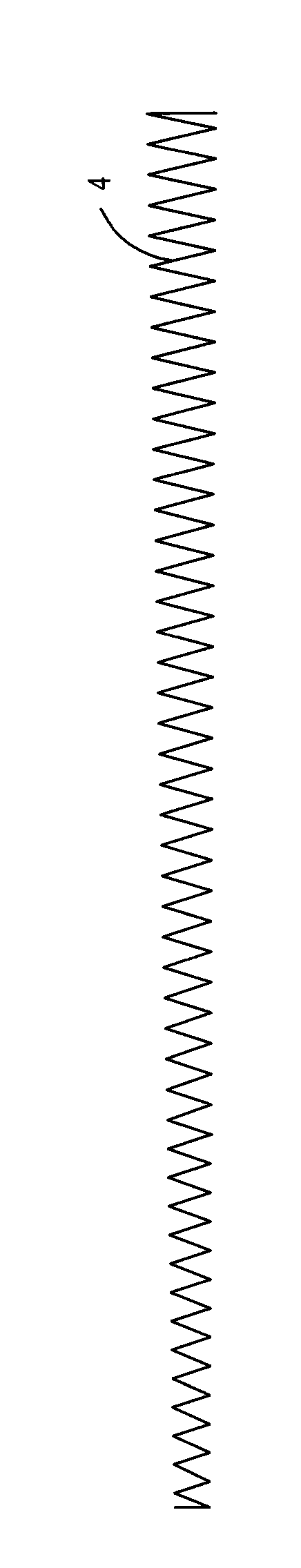

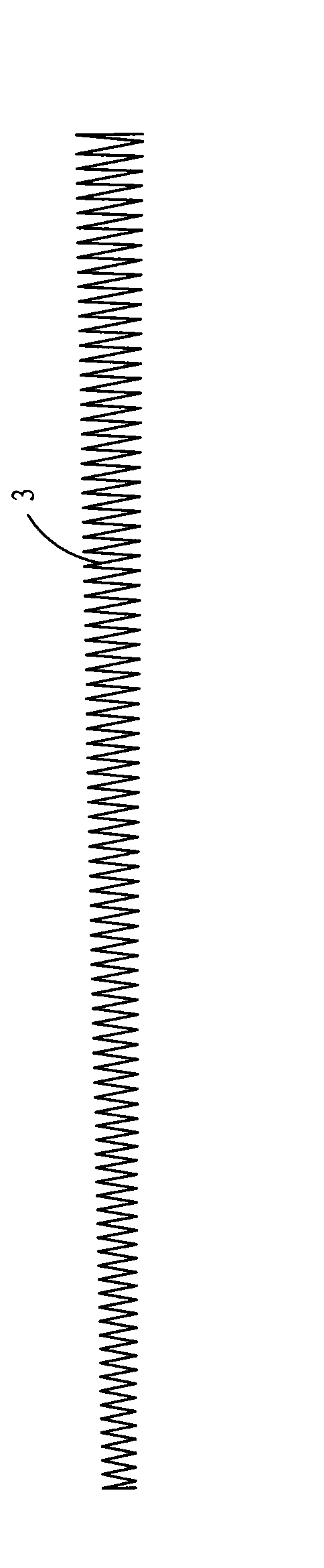

Prestressed concrete pipe pile with pretensioning type strands

Pretensioning steel strand wire concrete tubular pile consists of annular tubular concrete pile body and end plate. Inside the tubular concrete pile body there equips steel bar framework. The prestressing force main reinforcement in the steel bar framework is steel strand wire, whose end crosses the stretching hole at the end to produce anchor. The screwy reinforcement helically encircles to fix prestressing force main reinforcement and set-up reinforcement as a whole. Because the quality of steel strand wire material is steady, it can not only insure the quality of the high strength prestressing force concrete tubular pile, but also the pile is provided with the advantages of high material strength, strong prestressing force, high bending strength and good carrying capability.

Owner:王伟明

Prestressed concrete steel pipe congruent pile and its manufacture and construction method

InactiveCN1912254AReduce construction costsReduce steel consumptionBulkheads/pilesPre stressPrestressed concrete

A method for preparing prestressed concrete steel-tube polypile includes sleeving steel-tube with large diameter over prestressed concrete tubular pile, using end sealing component to connect the two together and injecting grout materials into gap between the two, erecting pile shoe at bottom of said pilypile for pile sinking.

Owner:胡柏英

Full prestressed concrete integrated root solid square pile with steel pile tip and manufacturing method thereof

InactiveCN101942832AFunctionalRealize industrial productionBulkheads/pilesPre stressIntegrated design

The invention discloses a full prestressed concrete integrated root solid square pile with a steel pile tip and a manufacturing method thereof, relating to the field of building material construction. The full prestressed concrete integrated root solid square pile with the steel pile tip comprises the pile tip, a pile body and a pile cap, wherein the pile body is formed by spirally winding a prestress main bar through a hooping; the hooping is strapped and connected with the main bar in the crossing position; the pile tip is inserted into the pile body through a pile tip anchor bar; the pile tip anchor bar is strapped and connected with the hooping in the crossing position; the pile cap is inserted into the pile body through a pile cap anchor bar; the pile cap anchor bar is strapped and connected with the hooping in the crossing position; and the integrated pouring of the full prestressed concrete integrated root solid square pile with the steel pile tip is realized by utilizing concrete. According to the full prestressed concrete integrated root solid square pile with a steel pile tip and the manufacturing method thereof, the integrated design, the integrated pouring and the one-step molding of the pile body, the pile cap and the pile tip are utilized; the pile tip is inserted into the pile body through the pile tip anchor bar; the industrial production of the square pile can be realized by utilizing the manufacturing method; the production industrialization of the square pile can be easily realized; and the manual work is saved.

Owner:德睿盛兴(大连)装配式建筑科技有限公司

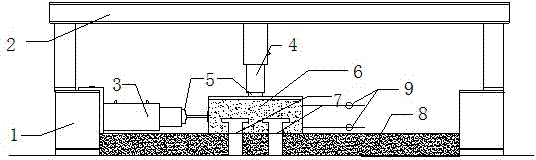

Prestressed concrete pipe pile horizontal bearing characteristic test model and test method

ActiveCN103882894ASimple and fast operationHighly adjustableFoundation testingMaterial strength using tensile/compressive forcesHorizontal forcePre stress

The invention discloses a prestressed concrete pipe pile horizontal bearing characteristic test model and a test method. The prestressed concrete pipe pile horizontal bearing characteristic test model comprises a model groove, a bearing table used for bearing a model pile is arranged in the model groove, and the upper end of the model pile is embedded into the bearing table. A vertical pneumatic loading system exerting vertical force on the bearing table and connected with a counter force frame is arranged above the model groove. The inner side of the model groove is provided with a horizontal pneumatic loading system exerting horizontal force on the bearing table and connected with the model groove. Monitoring devices are arranged on the bearing table, the model pile and the loading system. The invention provides a test device which can well meet the requirement for load conditions of a pile foundation load test, simulate the practical working conditions of the pile foundation more truly and detect the bearing characteristics of a single pipe pile and group pipe piles under the action of horizontal loads.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

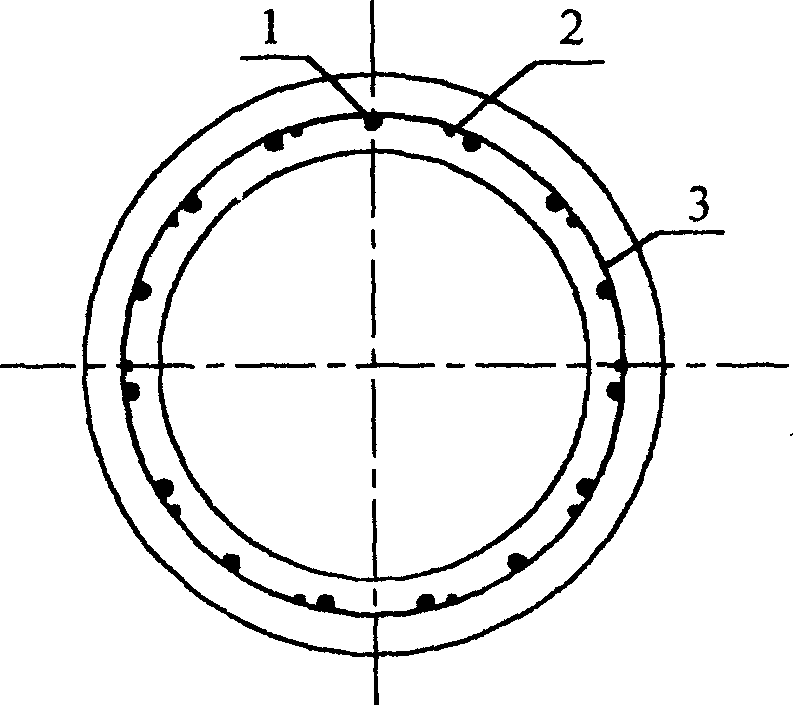

Annular prestressed concrete electric pole and production process thereof

InactiveCN101654963AHigh strengthUniform stressShaping reinforcementsTowersPre stressArchitectural engineering

The invention relates to an overhead line apparatus for power communication transmission, in particular to a concrete electric pole used for erecting a transmission line and a production process thereof. The electric pole comprises a concrete pole body and a steel reinforcement cage buried in the pole body. The concrete pole body is of a cone shape of which the conical degree of the concrete polebody is 1:75. The head of the concrete pole body is provided with an end cover. The steel reinforcement cage is formed by binding a plurality of main reinforcements, internally spiral reinforcements and externally spiral reinforcements which are equal in length. The main reinforcements are uniformly distributed in the annular side wall of the concrete pole body with the central line of the concrete pole body as an axis. The internally spiral reinforcements and externally spiral reinforcements are uniformly wound and distributed on the inner and outer sides of the main reinforcements with the central line of the concrete pole body as an axis as well. A concrete protective layer of the steel reinforcement cage in the concrete pole body is no less than 10mm.

Owner:陈子成

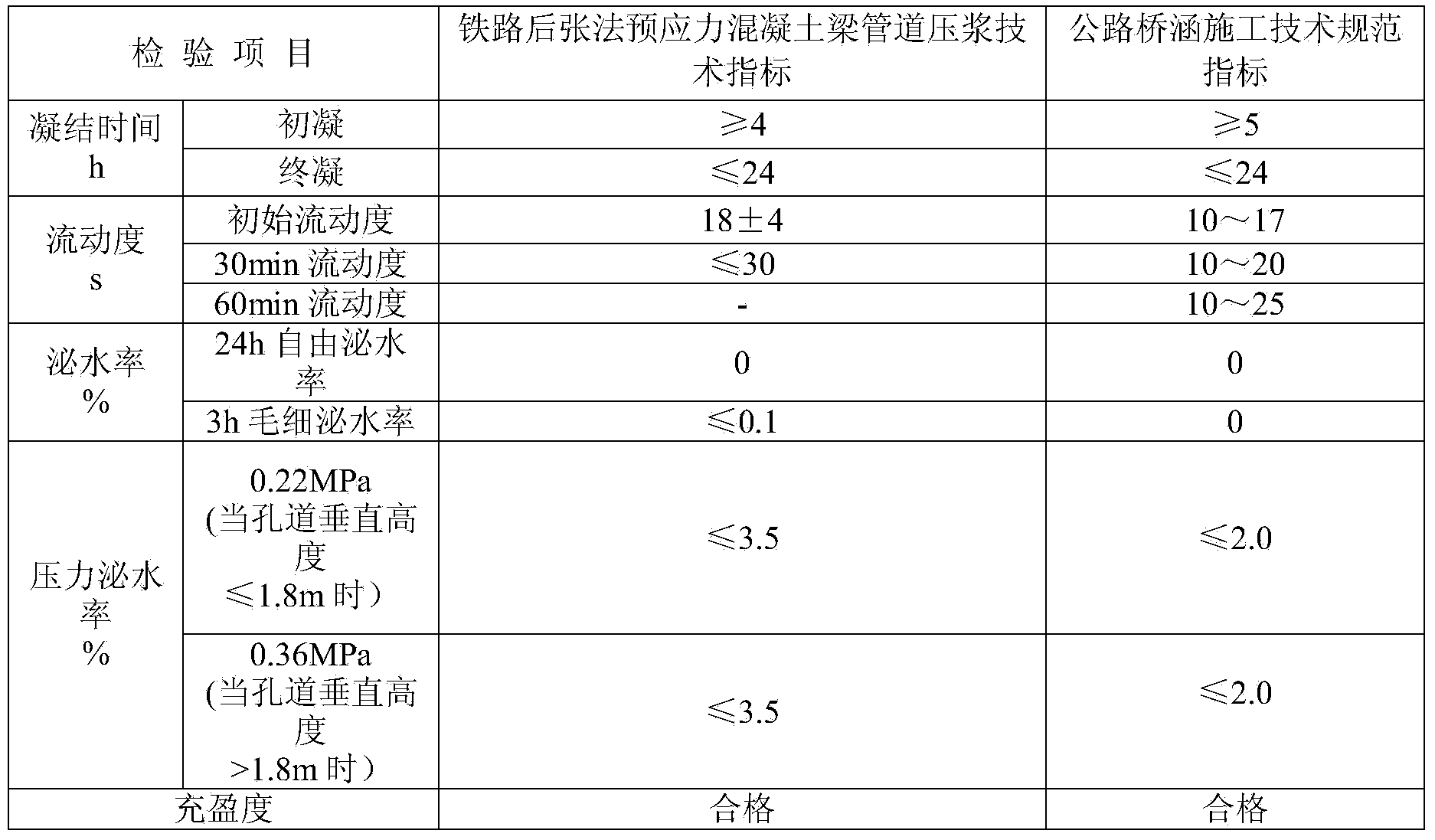

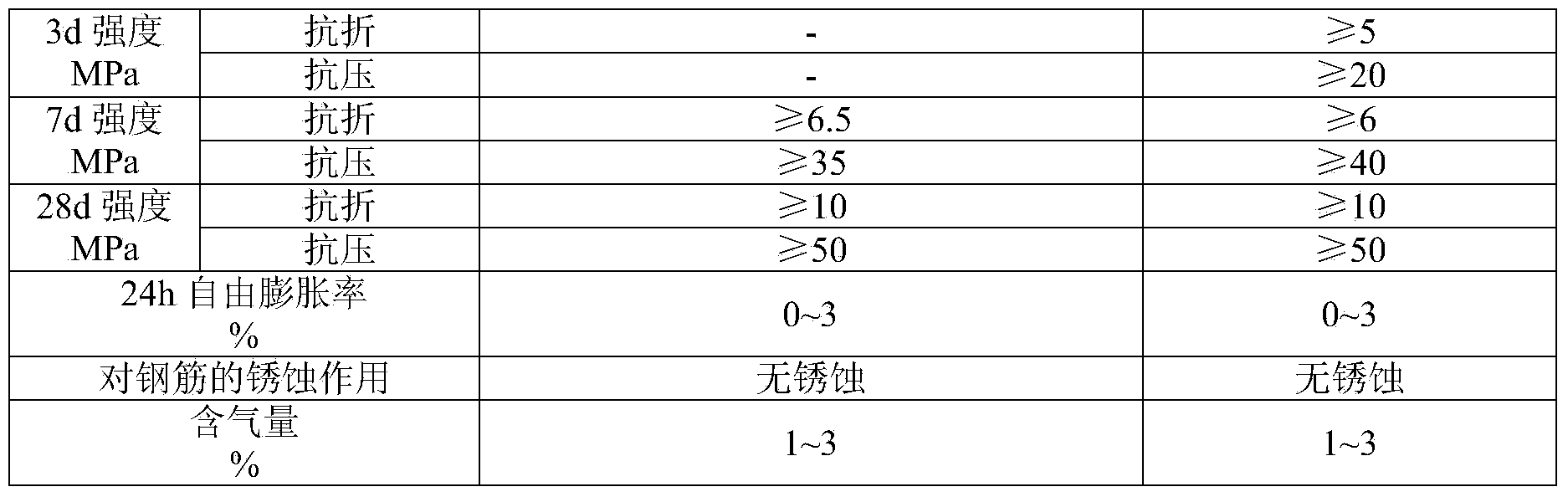

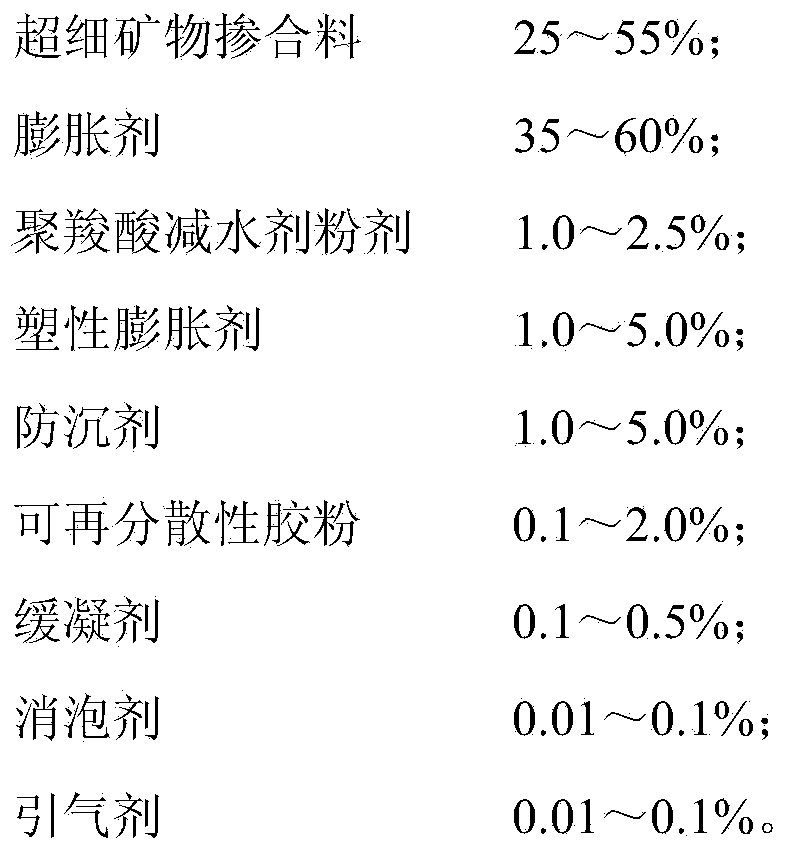

Upper-flow-regime micro-expanding post-tensioning prestressed porelike grouting agent and preparation method thereof

The invention provides an upper-flow-regime micro-expanding highway bridge post-tensioning porelike grouting agent and a preparation method of the upper-flow-regime micro-expanding highway bridge post-tensioning porelike grouting agent. The grouting agent comprises a superfine mineral admixture, an expanding agent, a polycarboxylate superplasticizer powder, a plastic expanding agent, an anti-settling agent, a redispersible rubber powder, a retarder, a defoamer and an air entraining agent, and the targets of low water-binder ratio (0.26-0.28), high fluidity (the initial fluidity is not more than 17s), zero bleeding (the free bleeding rate is 0% within 24 hours), early expanding (the free expanding rate is 0-2% within 3 hours) of a grouting material are achieved after the grouting agent is doped. A slurry layer is not layered or does not bleed, expands slightly, and is good in filling degree and volume stability at the low temperature, so that the quality reliability and durability of post-tensioning prestressed porelike grouting agent can be comprehensively improved. The post-tensioning prestressed concrete porelike grouting agent completely meets the requirements in the Technical Specifications for Construction of Highway Bridges and Culverts (JTG / TF50-2011).

Owner:武汉品泰新型建材有限公司

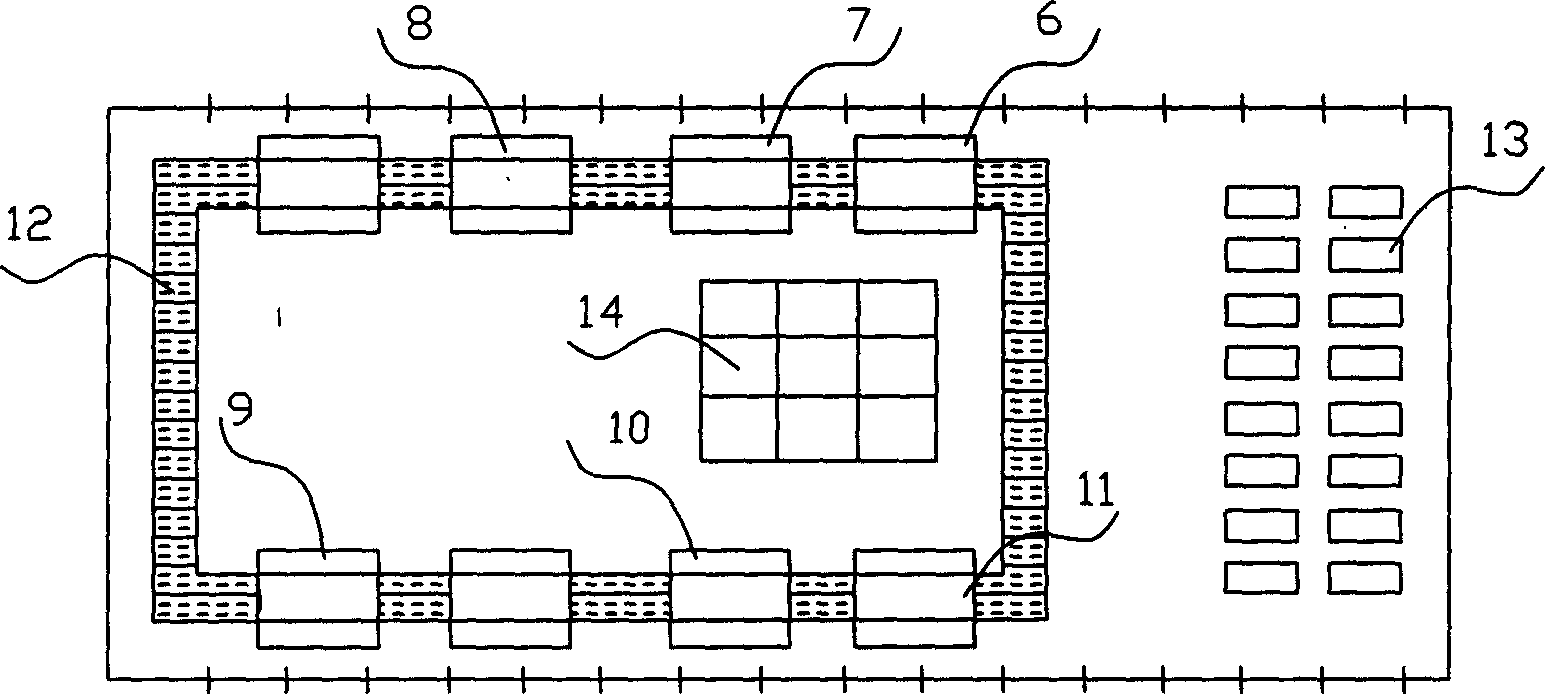

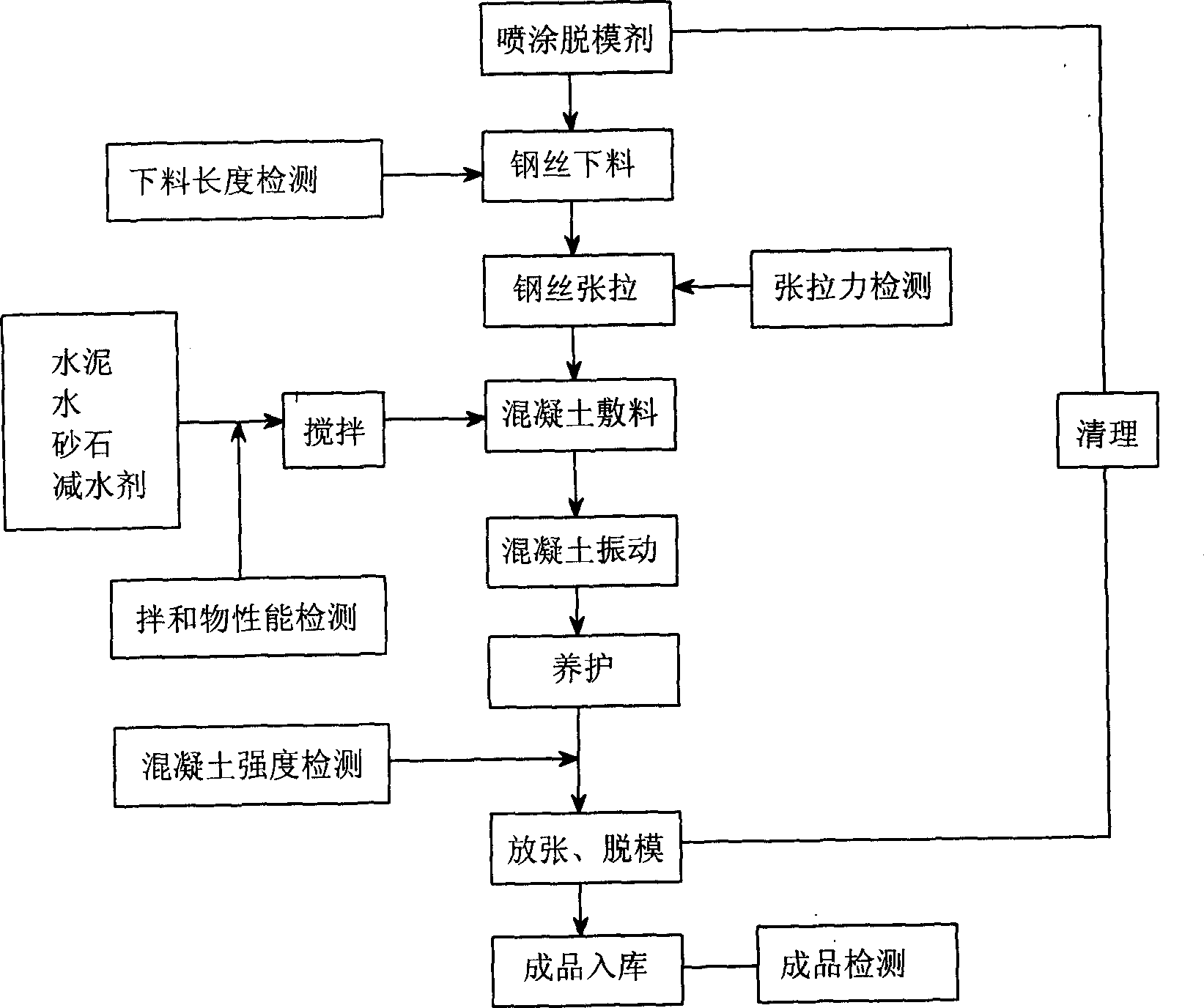

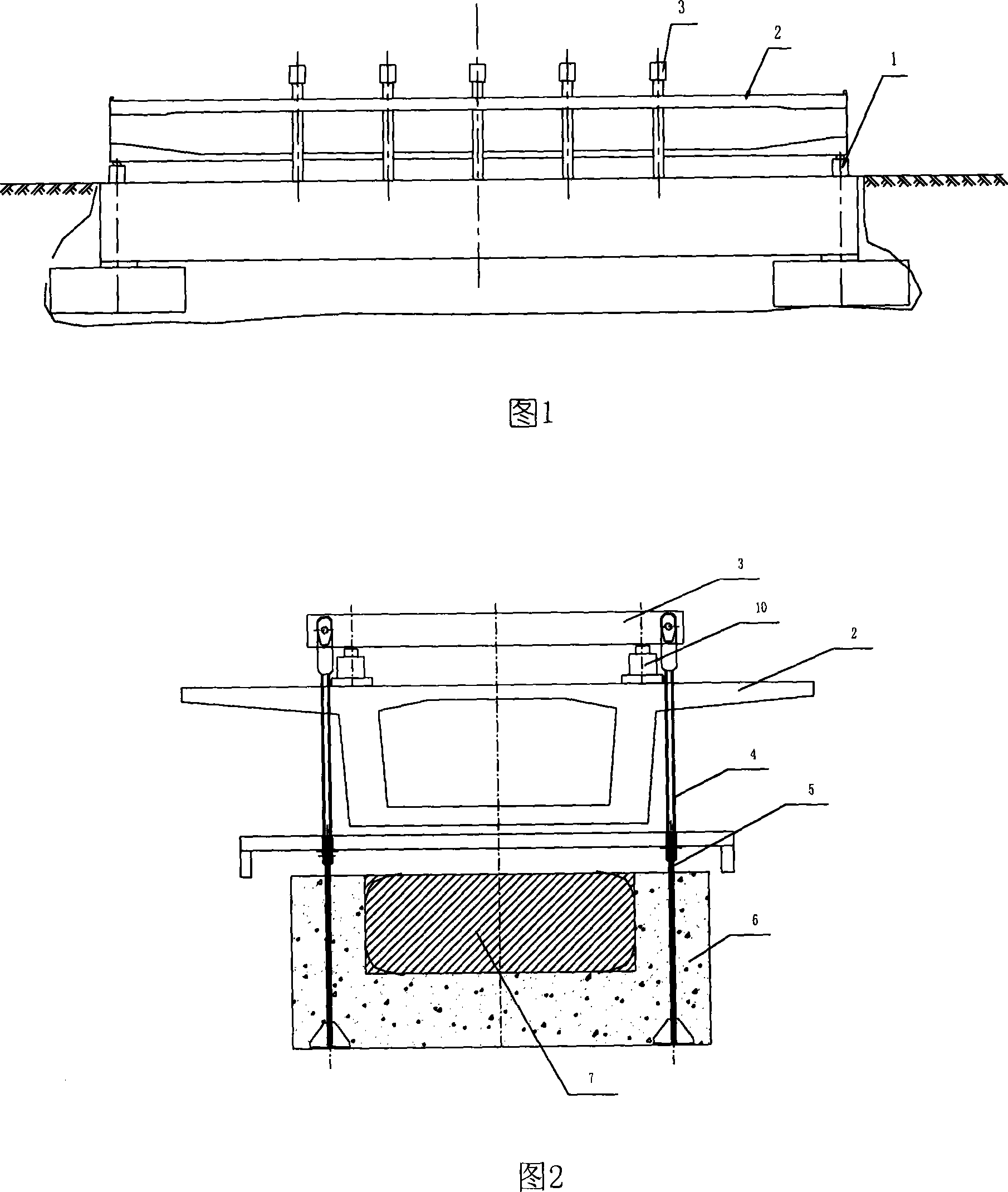

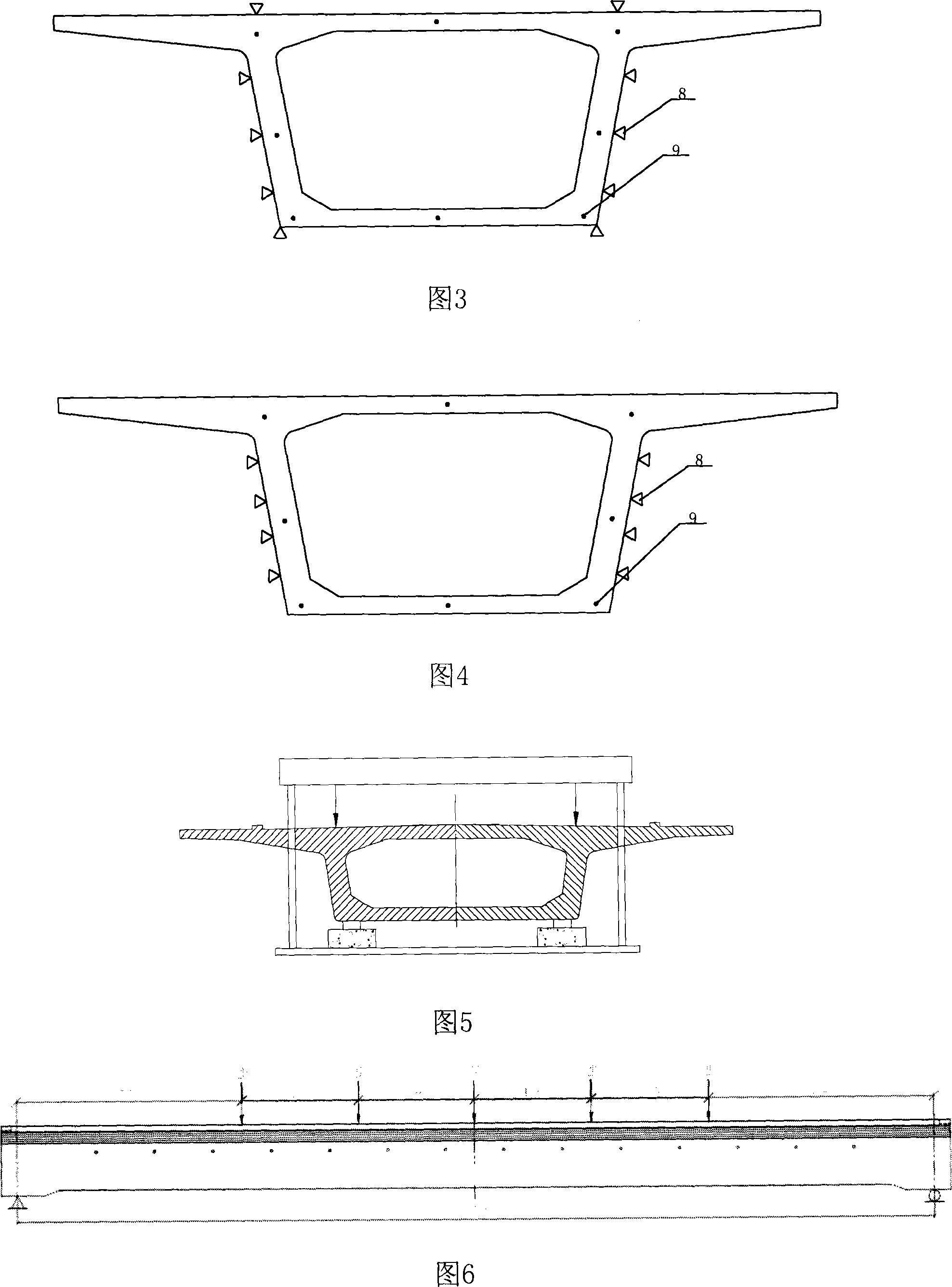

Bidirectional pretensioning method prestressed concrete railway board and assembly machine sets method production process

InactiveCN1865593AReduced creep warpageReduces the possibility of creep warpingBallastwayCeramic shaping plantsProduction linePre stress

The invention relates to a bidirectional pre-stress concrete track plate with significant electric property and lower producing cost, and relative production line. Wherein, the track plate is a cuboid, with several preset structures; there are at least two layers of steel wires inside the track plate along its length and width directions; the steel wires in said two directions do not contact each other; said pre-stress concrete track plate are tensioned along the length and width directions; the production method comprises: spraying demoulding agent, feeding material, tensioning, coating concrete, vibrating, maintaining, tensioning and demoulding. The invention can overcome the defects of present technique, with simple method, while it can be used to build high-speed railway.

Owner:欧阳炎

32m/900t prestressed concrete pretension box beam static loading test method

ActiveCN101101249AVerify crack resistanceAuthentication strengthFoundation testingMaterial strength using tensile/compressive forcesTest beamPre stress

The invention discloses a test procedure of 32m / 900t pre stress pre open box girder concrete box, it includes building testing counter, laying test beam body, fixing balance weight and setting test equipment, and doing load test of three circulation by ordering step by step, and dong crack test for the 32m / 900t pre open box girder effectively, splitting test and breaking test, dong experiment for the design of 32m pre open box girder, construct artwork, workmanship and the anti split and intensive properties of box girder.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Offshore wind power unit foundation adopting prestressed concrete cylindrical structure

The invention discloses an offshore wind power unit foundation using a prestressed concrete cylindrical structure, consisting of a cylindrical foundation, prestressed cross beams and a connecting stepped drum, wherein the cylindrical foundation is in a reinforced steel bar concrete cylindrical structure and internally provided with clapboards for separating a bin; the prestressed cross beams are arranged on a sealing coping of the cylindrical foundation and radially and evenly distributed; the connecting stepped drum is in a prestressed concrete cylindrical structure; the lower end of the connecting stepped drum, the reinforced steel bar concrete cylindrical foundation and the prestressed cross beams are poured into a whole; metal rings are arranged on the joint parts; and a flange plate is arranged at the upper end of the connecting stepped drum and fixedly connected with the stepped drum of an electric generating set. The invention has the advantages that: the offshore wind power unit foundation has simple structure, convenient construction, small construction quantity, low construction cost and favorable load-carrying capability, and can be prefabricated on land and reach the construction position by traction, towing and floating so as to reduce the transportation cost; and with the prestressed concrete structure, the invention can effectively improve the structural strength, reduce the dead weight of the foundation, save materials and improve the durability and the corrosion resistance of the structure.

Owner:JLANGSU DAODA OFFSHORE WIND CONSTR TECH

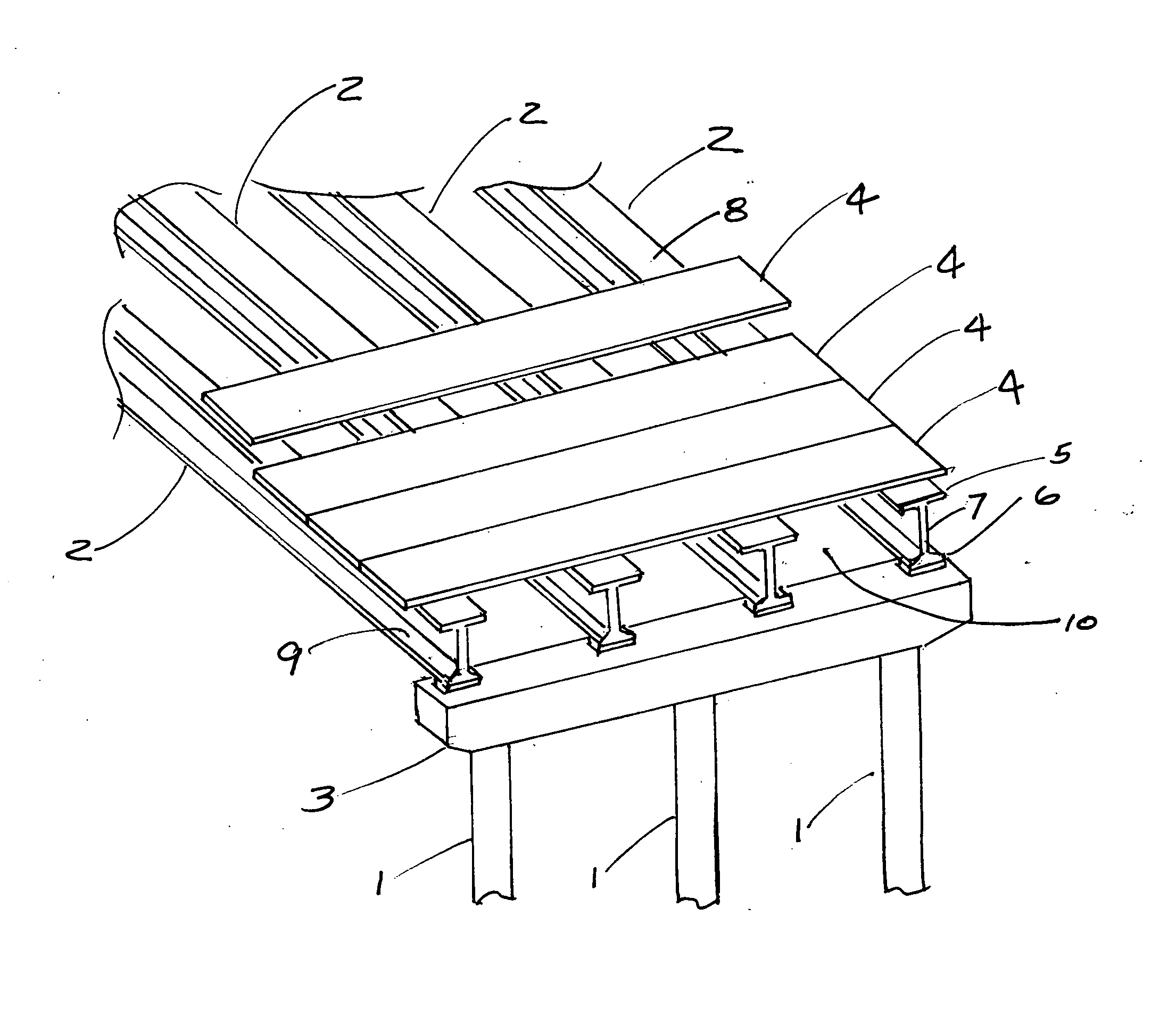

Bridge construction system and method

InactiveUS20060117504A1Expanded span capabilityOvercome problemsBridge structural detailsBridge erection/assemblyBogiePre stress

A system and method for construction of bridges and elevated roadways with pre-stressed concrete or steel bridge girders is provided including cast-in-place concrete deck slabs and partial and full depth pre-stressed pre-cast concrete deck slabs with post-tensioning conduits for post-tensioning a series of deck slabs. A plurality of bogies traveling on the lower flanges of the bridge girders are provided to place and level the deck slabs and to pre-load the bridge girders to eliminate camber before placement of the deck slabs on the bridge girders or to level, place, support and remove deck forms for a cast-in-place deck slab on the bridge girders. Also provided is a system for attachment of cast-in-place parapets.

Owner:RAPID PRECAST CONSTR SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com