Annular prestressed concrete electric pole and production process thereof

A technology of concrete rods and concrete, applied in the direction of manufacturing tools, reinforced molding, ceramic molding machines, etc., can solve the problems of unfavorable transportation, loading and unloading and construction, complicated manufacturing process, high production cost, etc., and achieve simple structure, easy manufacturing, and weight reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

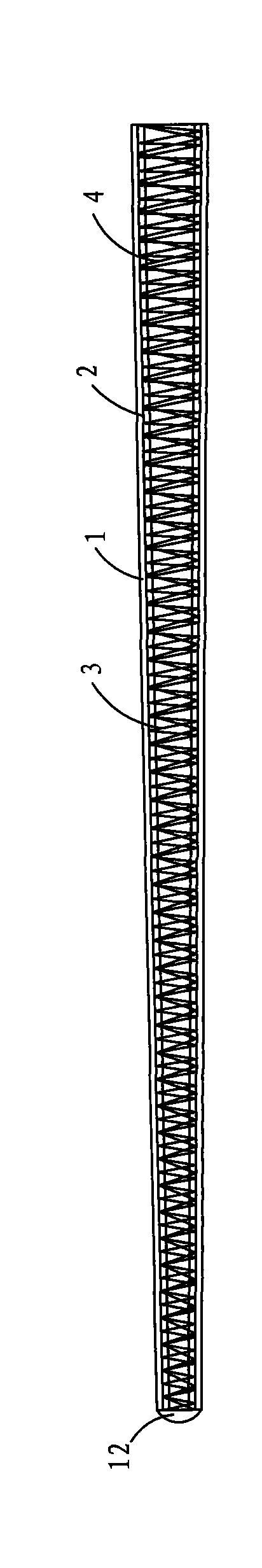

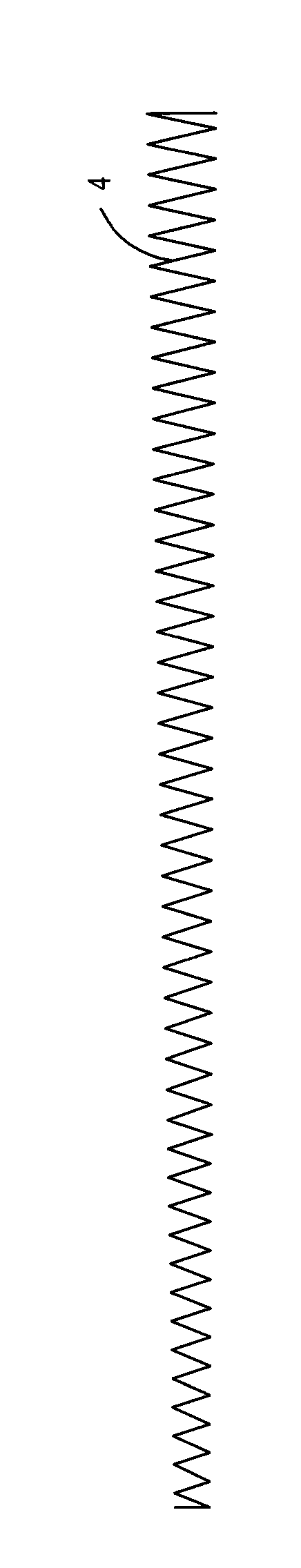

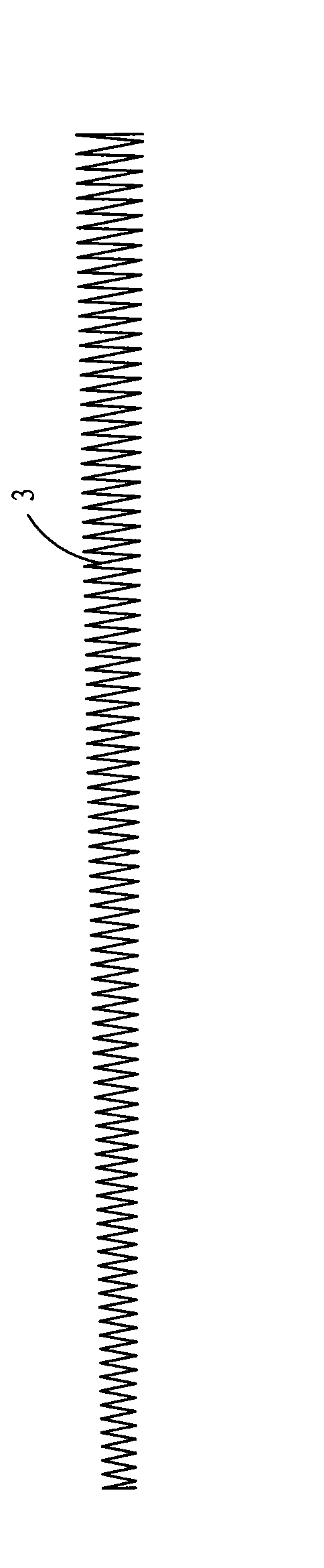

[0037] see figure 1 , is a schematic cross-sectional structure diagram of an embodiment of the annular prestressed concrete electric pole of the present invention, including a concrete pole body 1 and a reinforcement cage embedded in the pole body 1, the concrete pole body 1 is in the shape of a pyramid, and its taper is 1:75 , The head of the concrete rod body is provided with an end cover 12, and the steel cage is composed of 11 equal-length main bars 2, outer spiral bars 3 and inner spiral bars 4 bound together. The main reinforcement 2 is made of high-strength steel wire with a strength of 1570MPa and a diameter of 3.6mm; figure 2 As shown, the internal spiral rib 4 is made of high-strength steel wire with a strength of 1570MPa, a diameter of 2.0mm, and a pitch of 20cm; image 3 The outer spiral reinforcement shown is made of cold-drawn steel wire with a strength of 650MPa, a diameter of 2.0mm, and a pitch of 10cm.

[0038] like Figure 4 As shown, the 11 main ribs 2 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com