Patents

Literature

897results about "Shaping reinforcements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Concrete pile and preparation method thereof

InactiveCN102491702ASolve processing problemsHarm reductionSolid waste managementShaping reinforcementsSlagResource utilization

The invention discloses a concrete pile formed by concrete casting; the concrete comprises the components including cementing material, fine aggregate, crushed stones, water-reducing agent and water, wherein the fine aggregate is a mixture of sand and industrial waste slag, and the weight the industrial waste slag is 10 to 50% of that of the fine aggregate; the volume weight of the concrete is 2400 to 2600 kg / m<3>; the use amount of the cementing material is 300 to 600 kg / m<3>, the water-binder ratio is 0.2 to 0.4, and the sand percentage is 27 to 44%; and the weight of water-reducing agent is 10 to 50% of that of the cementing material. The invention further discloses a preparation method of the concrete pile. According to the invention, 10 to 50% of sand is replaced by industrial waste slag, moreover, the resource of the industrial waste slag is relatively ample, and the quality is relatively stable, so that under the premise of ensuring the quality of the concrete pile, through resource utilization of the waste material, not only the pollution problem is solved, but also great economic benefits and social benefits can be produced.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

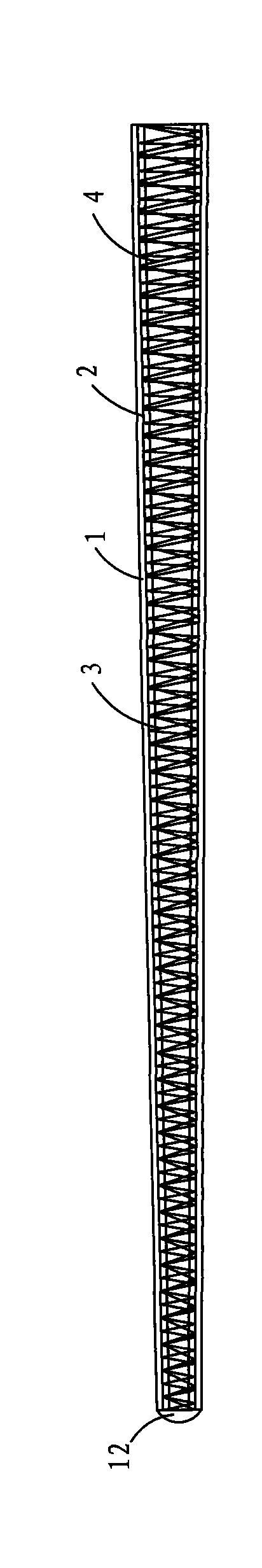

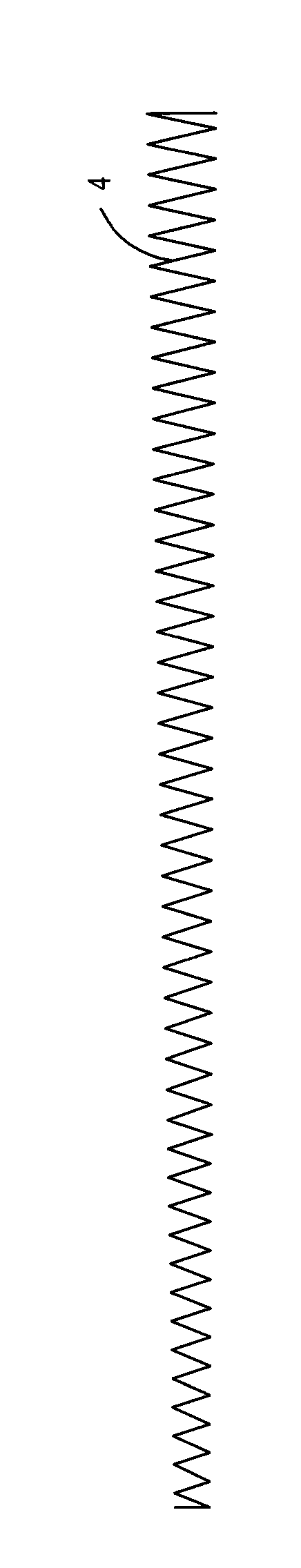

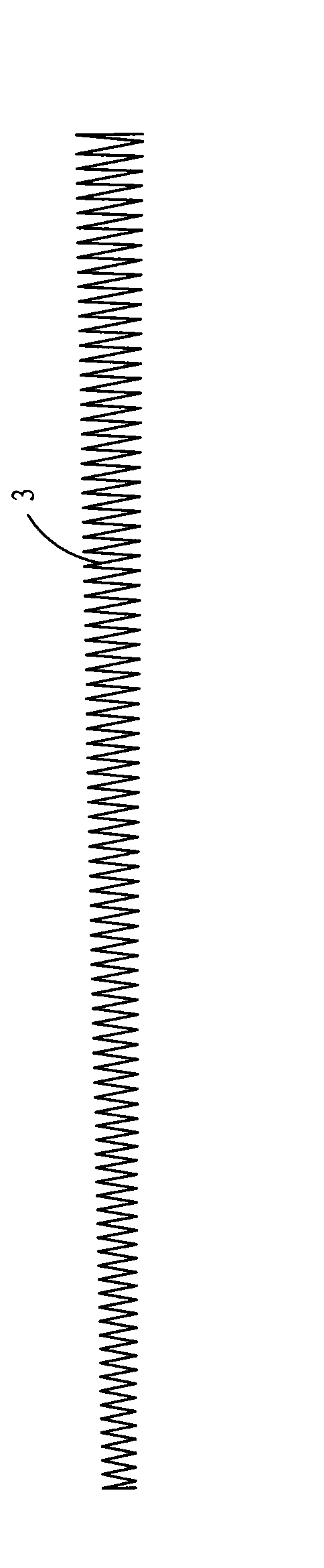

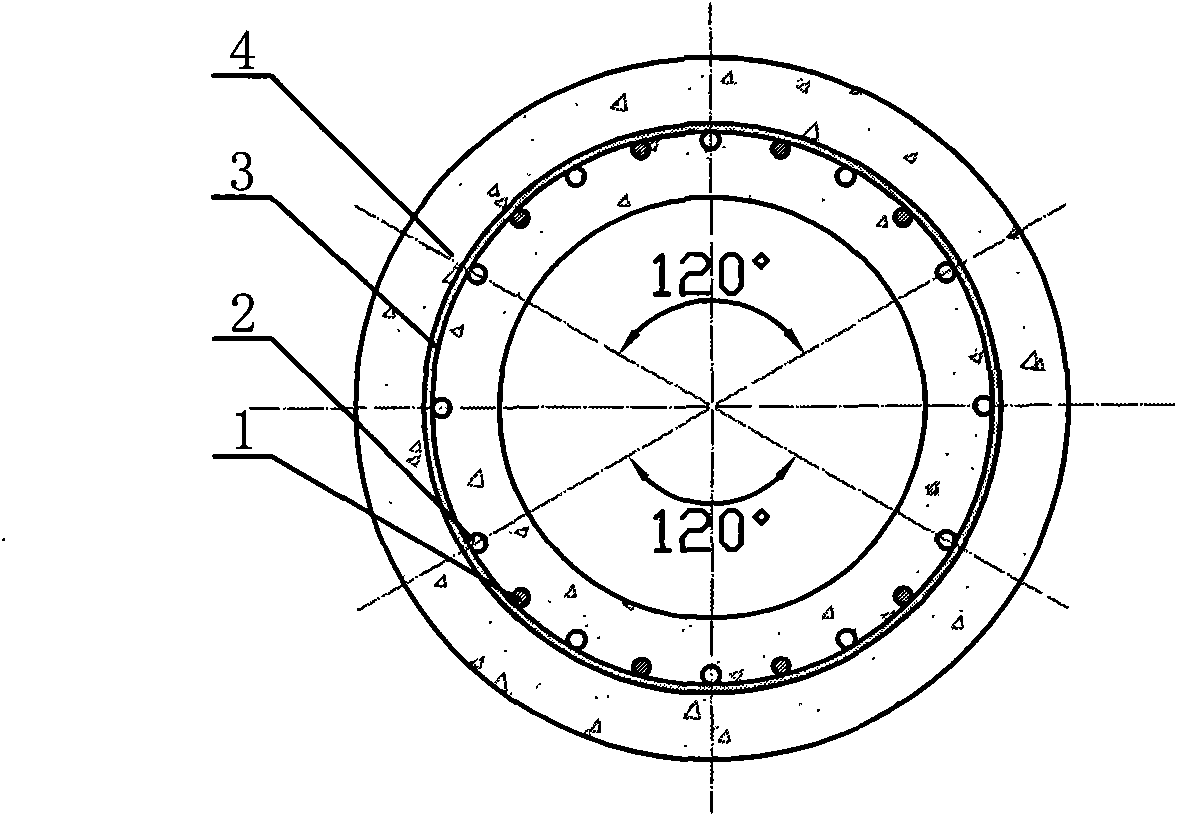

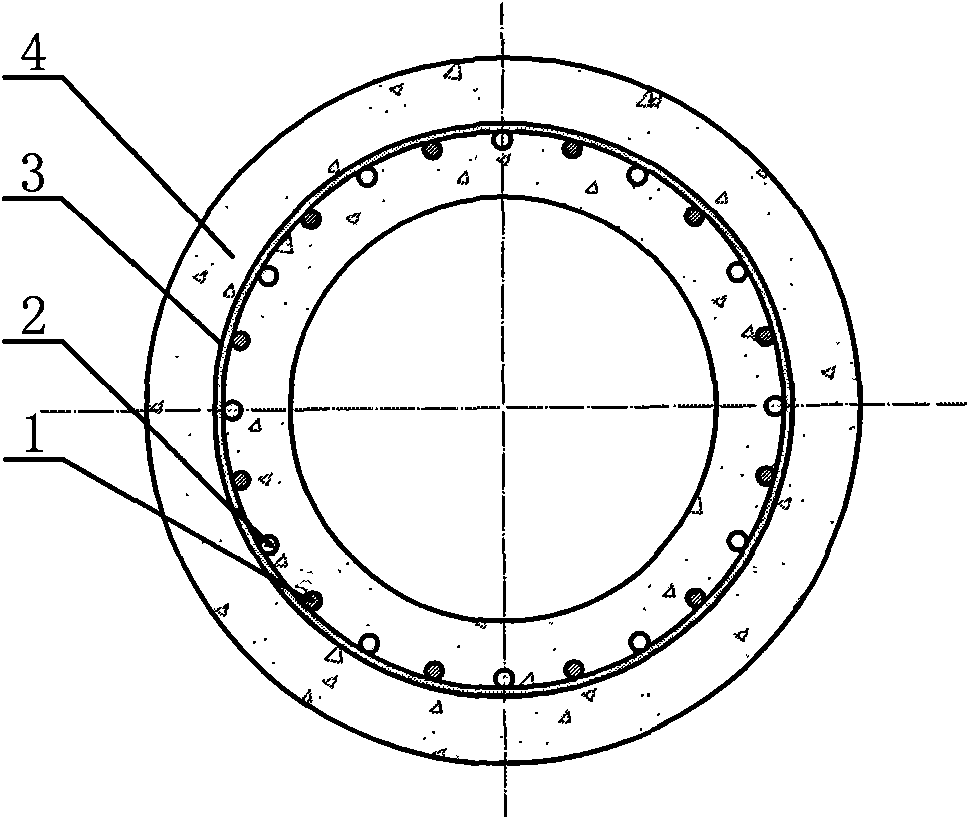

Annular prestressed concrete electric pole and production process thereof

InactiveCN101654963AHigh strengthUniform stressShaping reinforcementsTowersPre stressArchitectural engineering

The invention relates to an overhead line apparatus for power communication transmission, in particular to a concrete electric pole used for erecting a transmission line and a production process thereof. The electric pole comprises a concrete pole body and a steel reinforcement cage buried in the pole body. The concrete pole body is of a cone shape of which the conical degree of the concrete polebody is 1:75. The head of the concrete pole body is provided with an end cover. The steel reinforcement cage is formed by binding a plurality of main reinforcements, internally spiral reinforcements and externally spiral reinforcements which are equal in length. The main reinforcements are uniformly distributed in the annular side wall of the concrete pole body with the central line of the concrete pole body as an axis. The internally spiral reinforcements and externally spiral reinforcements are uniformly wound and distributed on the inner and outer sides of the main reinforcements with the central line of the concrete pole body as an axis as well. A concrete protective layer of the steel reinforcement cage in the concrete pole body is no less than 10mm.

Owner:陈子成

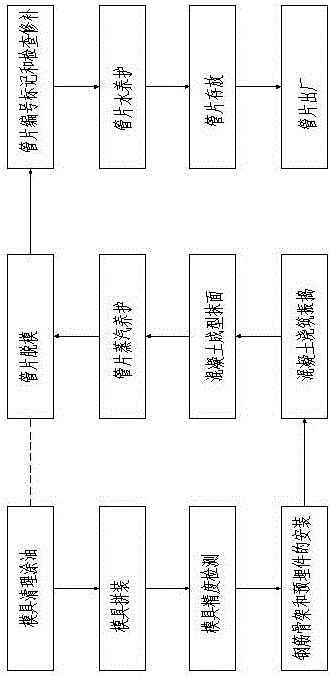

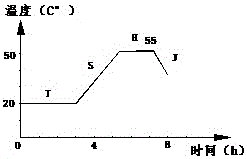

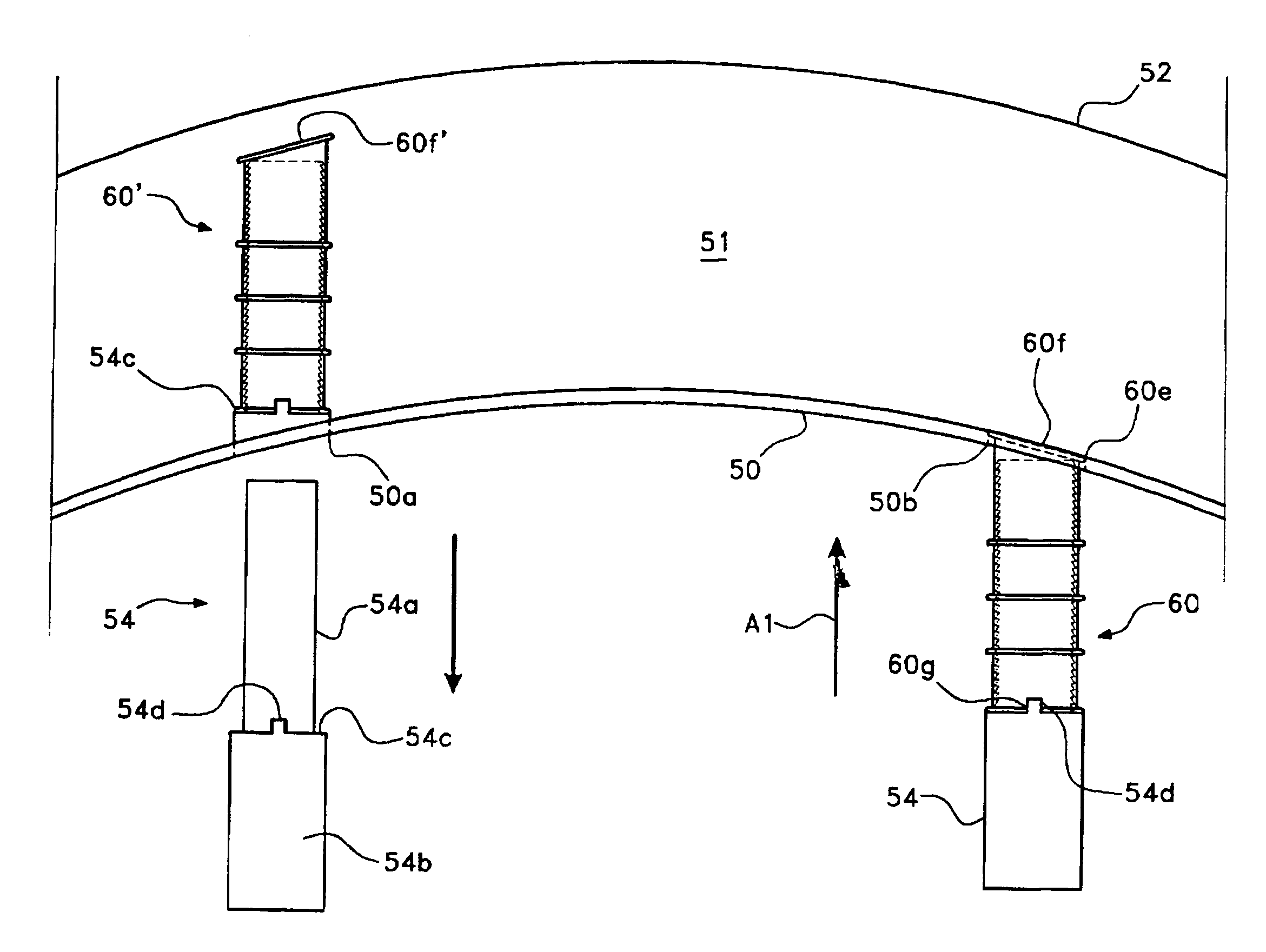

Production process for prefabricated reinforced concrete duct pieces

InactiveCN106584654AEasy to manage preciselySave construction timeShaping reinforcementsReinforced concreteRebar

The invention discloses a production process for prefabricated reinforced concrete duct pieces. The production process comprises the following steps of: a, clearing a mould and removing oil of the mould; b, assembling the mould; c, detecting precision of the mould; d, mounting a steel reinforcement framework and embedded parts; e, pouring and vibrating concrete, wherein vibrating time is controlled to be 4-10 minutes; f, molding and plastering concrete; g, carrying out steam curing on the duct pieces, resting for 3-4 hours and starting heating and steam-curing after vibrating is ended, wherein the duct piece steam-curing comprises four stages of a still resting stage T, a heating stage S, a constant-temperature stage H and a cooling stage J; h, de-molding the duct pieces; i, numbering and marking the duct pieces, and checking appearance to repair; j, carrying out water curing on the duct pieces; and k, storing the duct pieces. According to the production process disclosed by the invention, factory construction time can be saved, the whole construction period is effectively shortened, and factory construction cost is reduced; a fixed mould is on a designated position, and therefore, designated duct pieces with errors are favorably managed, and problem causes can be quickly determined; tunnel shield reinforced concrete duct pieces with high quality can be produced; and construction operation is normalized, programmed and standardized.

Owner:CHINA RAILWEY ENG SERVICE CO LTD

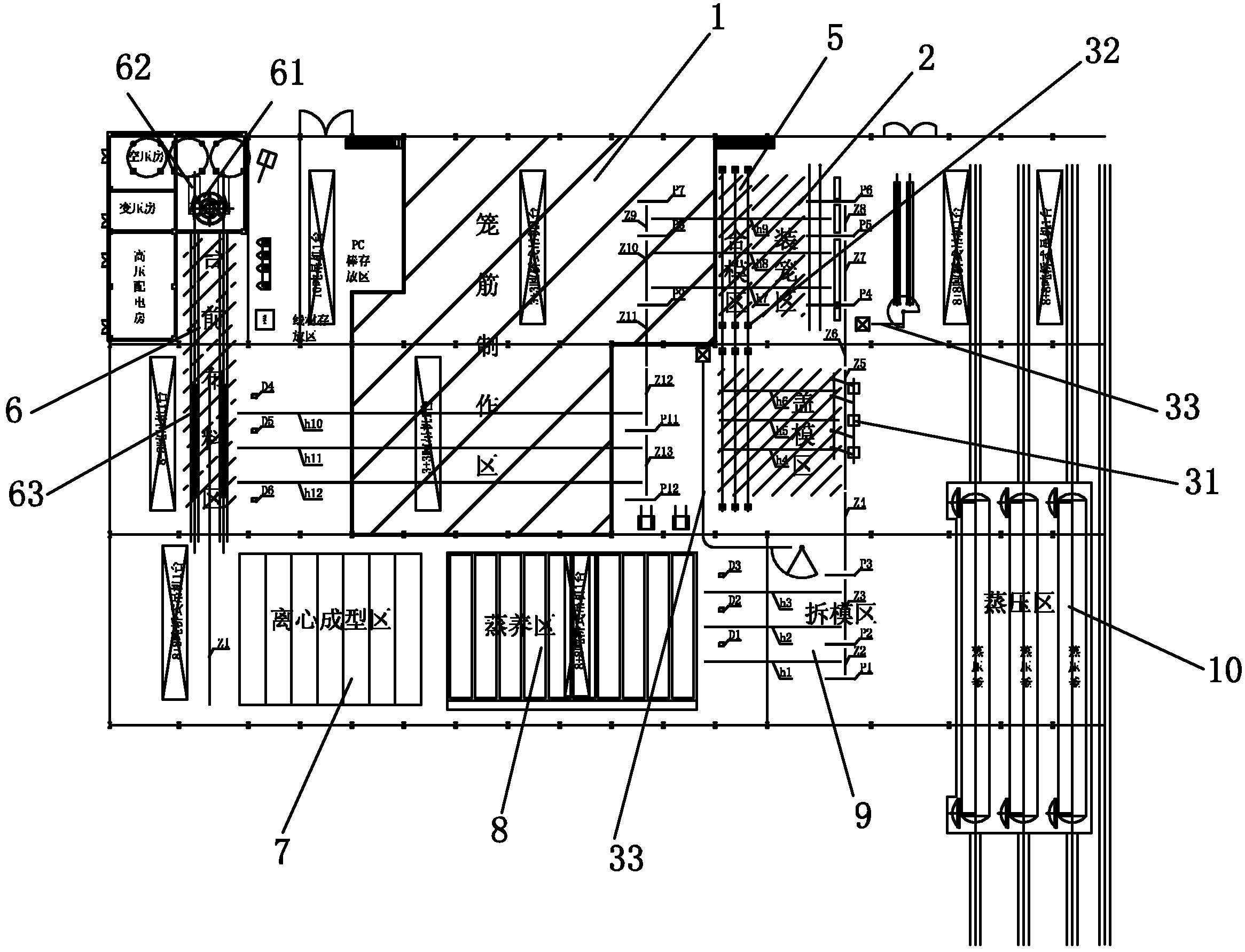

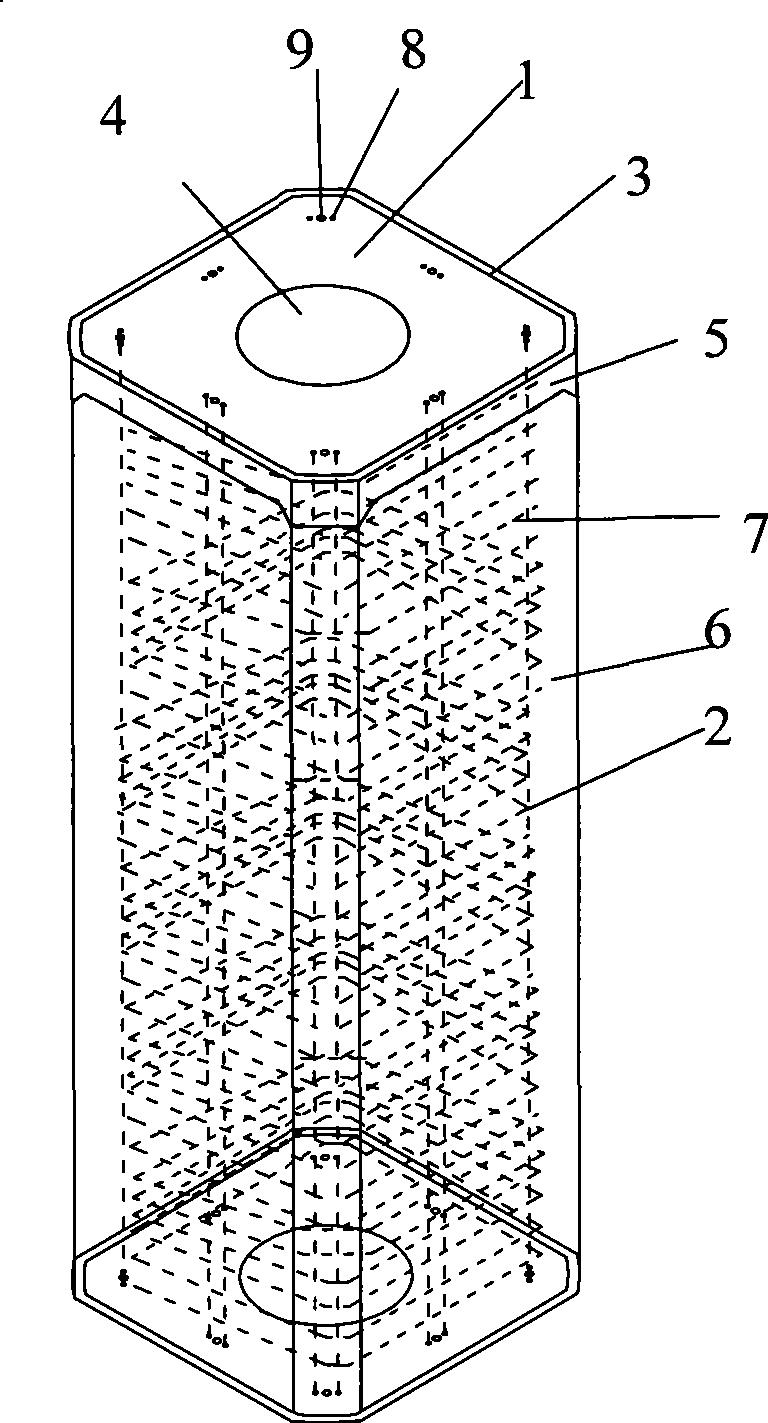

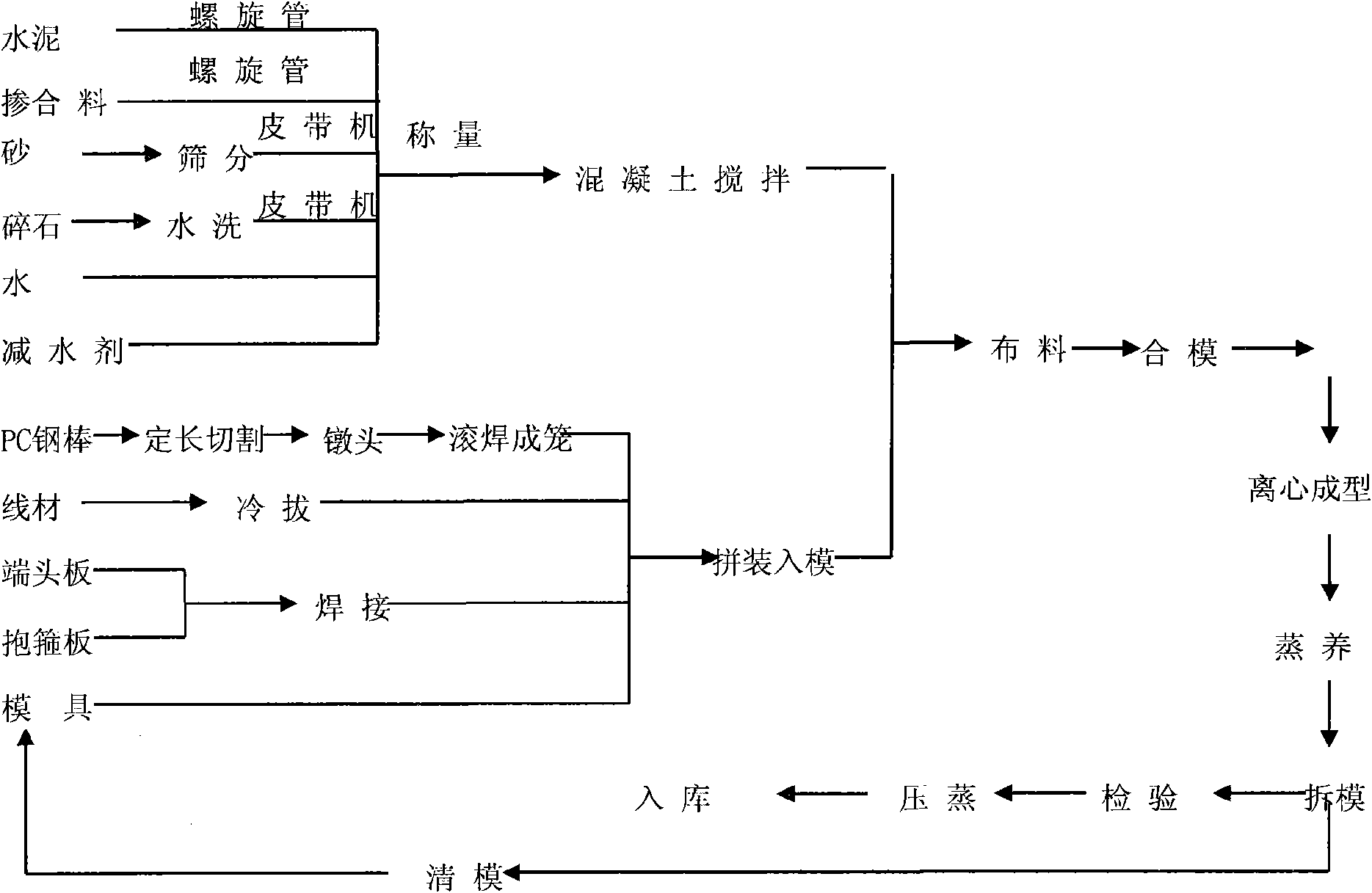

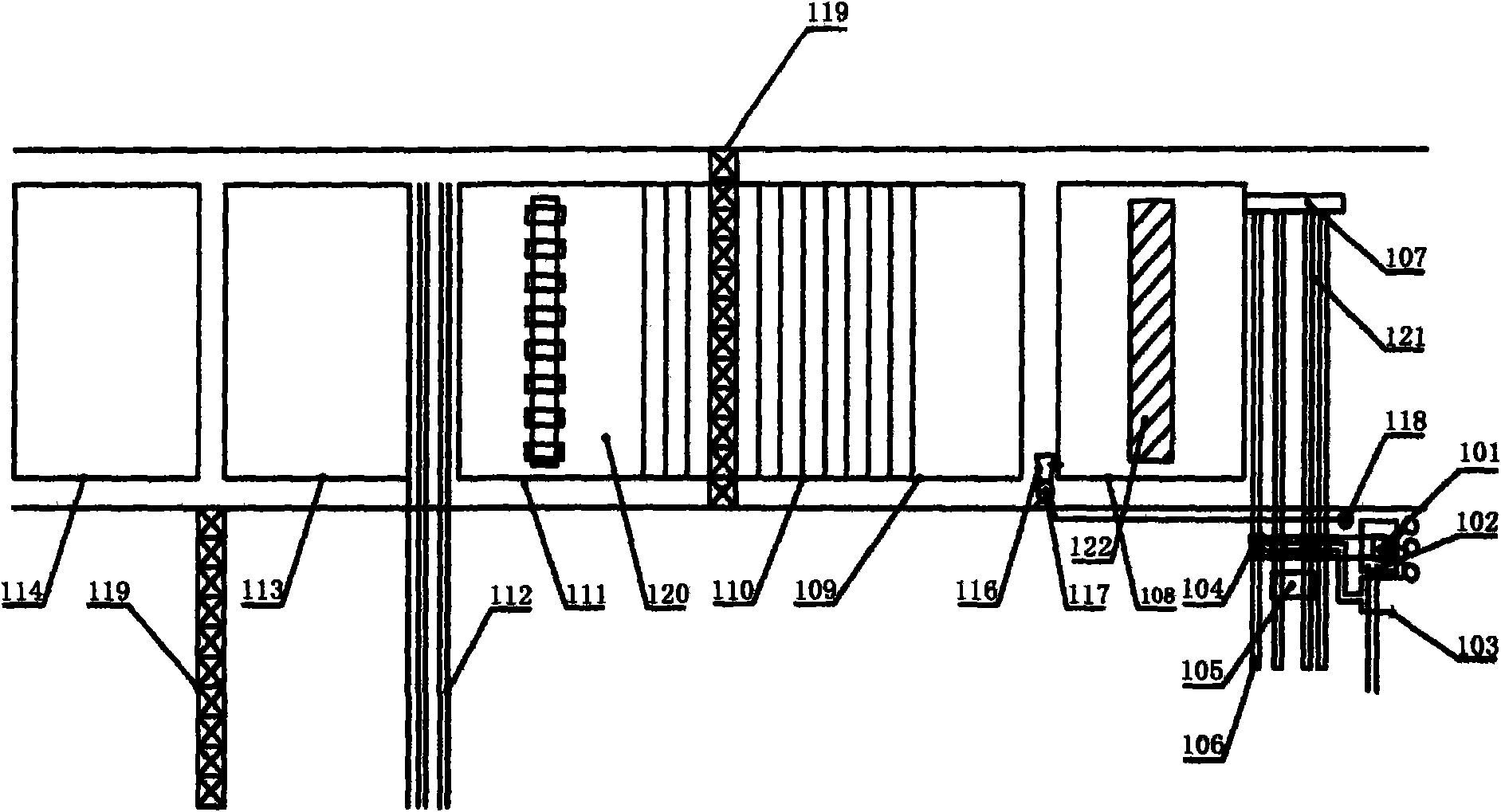

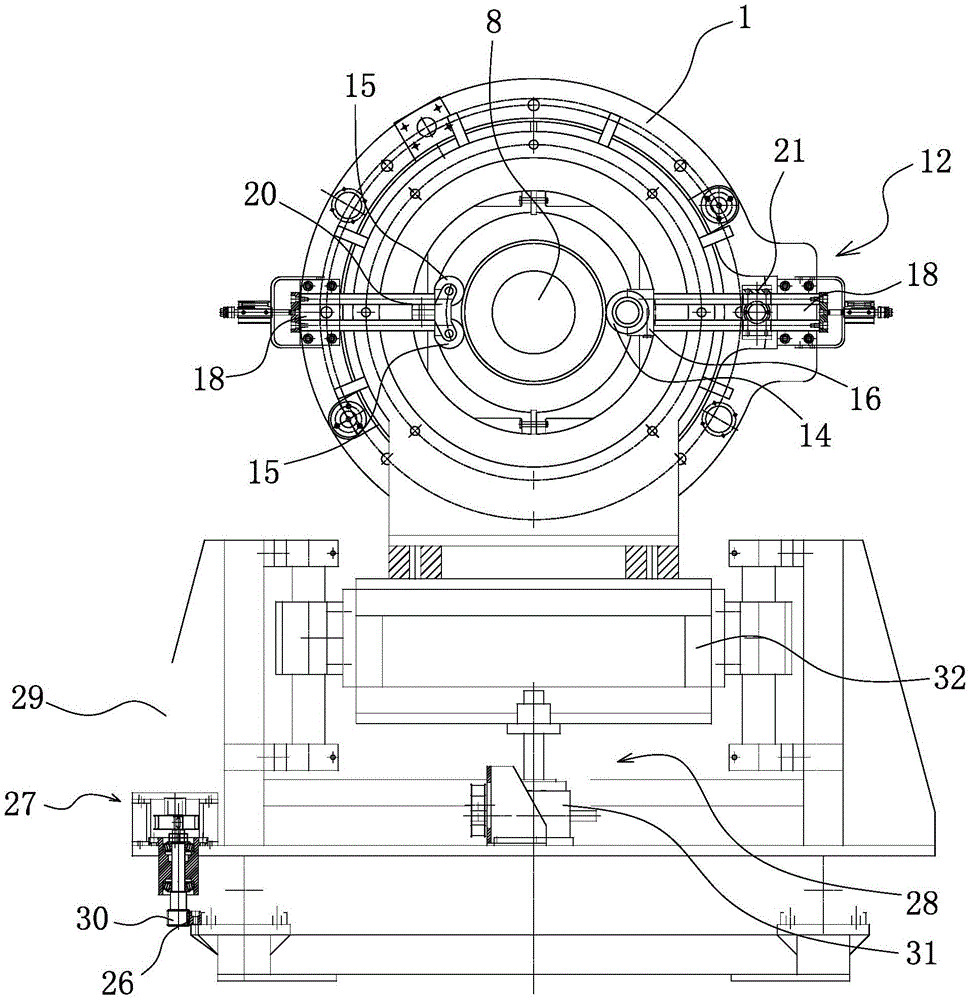

Pipe pile automatic production line

ActiveCN102275219AReduce end-face tilt problemsReduce weightCeramic shaping plantsShaping reinforcementsProduction lineEngineering

The invention discloses an automatic production line for a pipe pile. The automatic production line comprises a cage bar manufacturing area, a cage assembling area, a die covering area, a die assembly area, an area for distributing materials in front of a workbench, a centrifugal forming area, a steam curing area, a die removal area and a steam pressing area, wherein the cage assembling area is arranged on one side of the cage bar manufacturing area and is used for assembling manufactured cage bars to a bottom die; a pipe die conveying machine set is arranged between the cage bar manufacturing area and the cage assembling area; the die covering area is arranged on one side of the cage assembling area and is used for cleaning and conveying a cover die after the cover die is uncovered; the die assembly area is arranged between the cage assembling area and the cage bar manufacturing area and is used for performing the die assembly on the covered die; a pipe die conveying machine set is arranged between the die covering area and the die assembly area; the area for distributing the materials in front of the workbench is arranged on the other side of the cage bar manufacturing area and is used for distributing the materials for the die subjected to the die assembly; the centrifugal forming area is arranged on one side of the area for distributing the materials in front of the workbench; the steam curing area is arranged on one side of the centrifugal forming area; the die removal area is arranged on one side of the steam curing area, and is arranged on one side of the die covering area; and the steam pressing area is arranged on the other side of the die removal area.

Owner:JIANGSU TANGCHEN MACHINERY EQUIP MFG

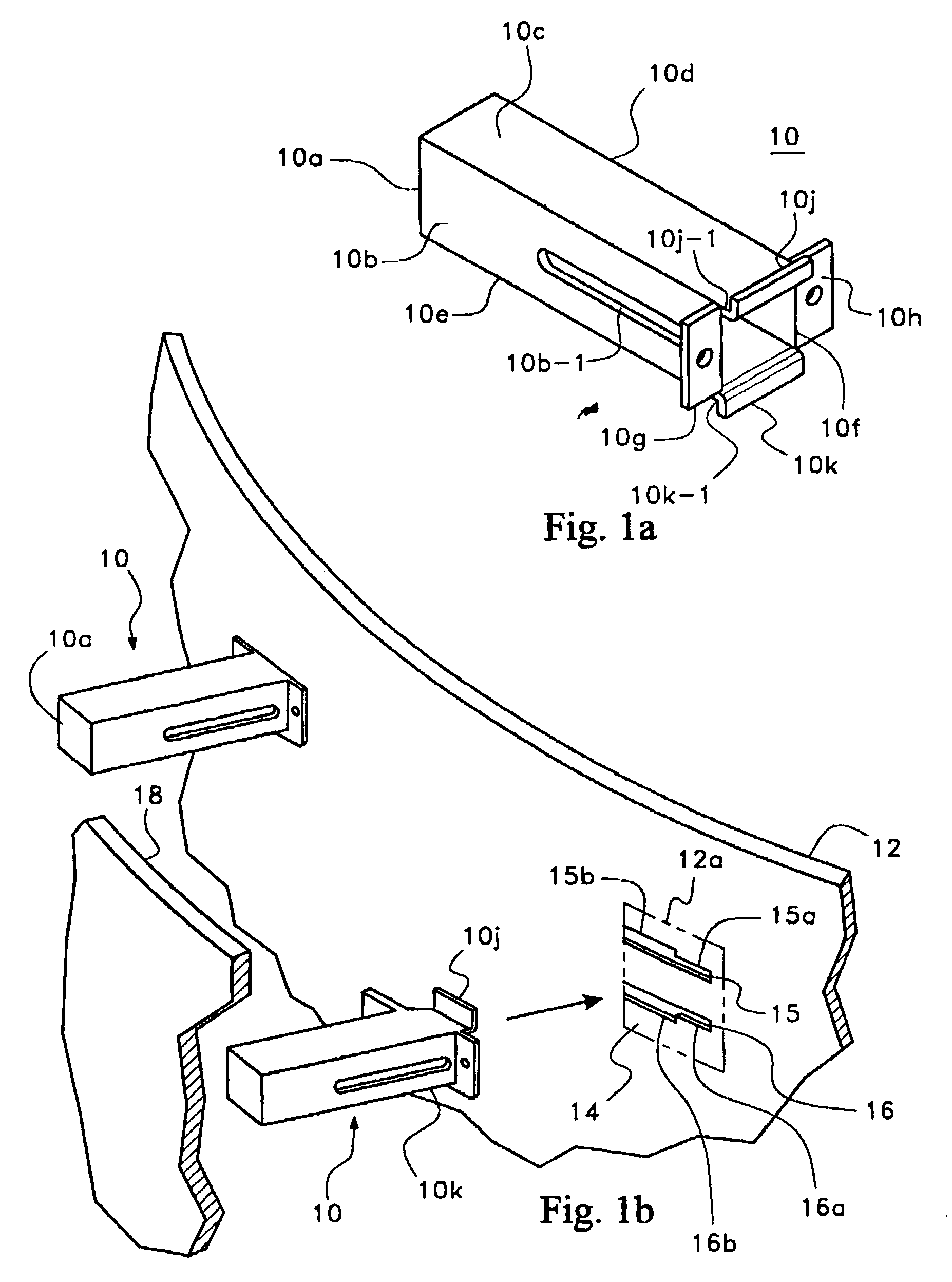

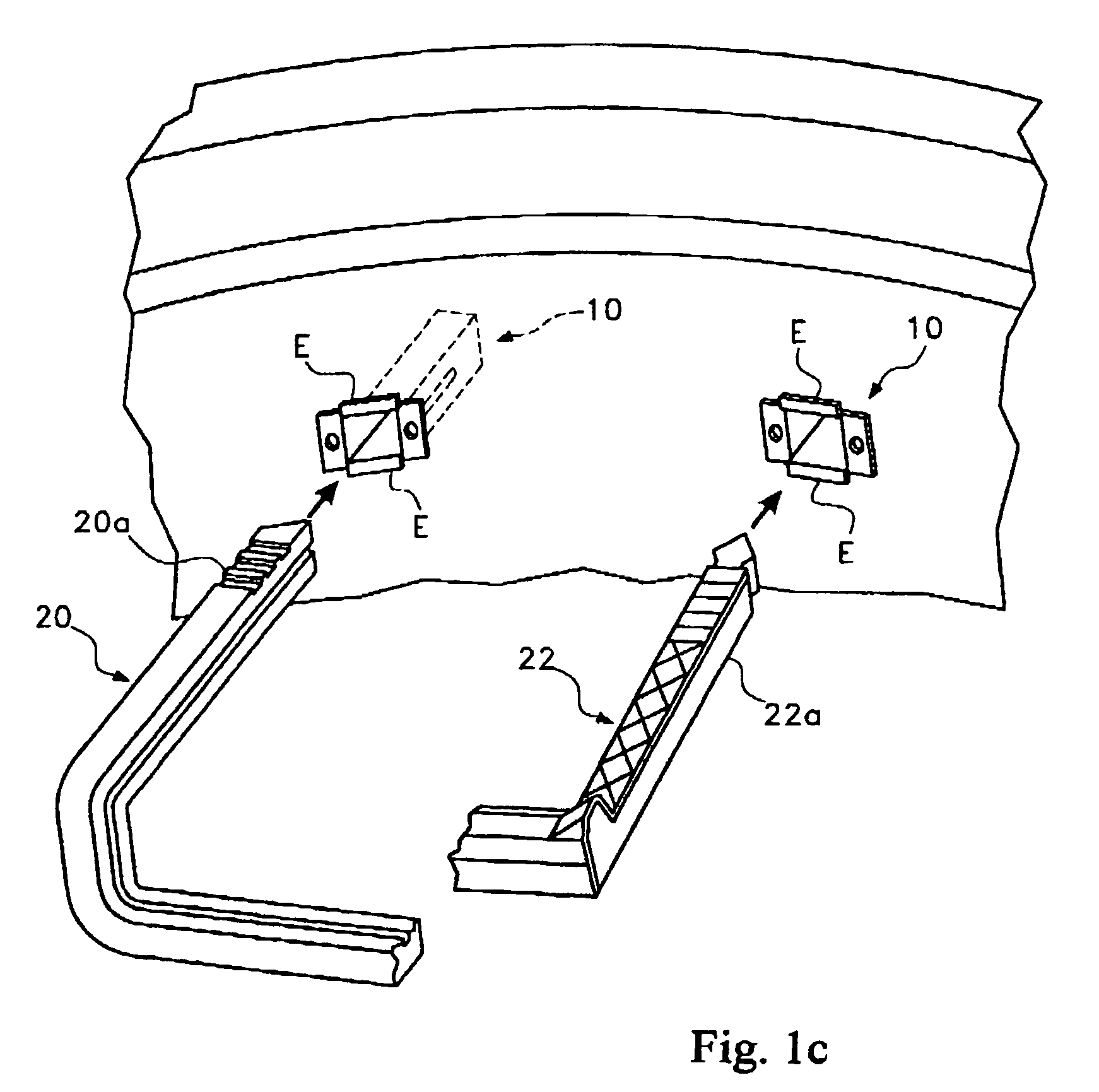

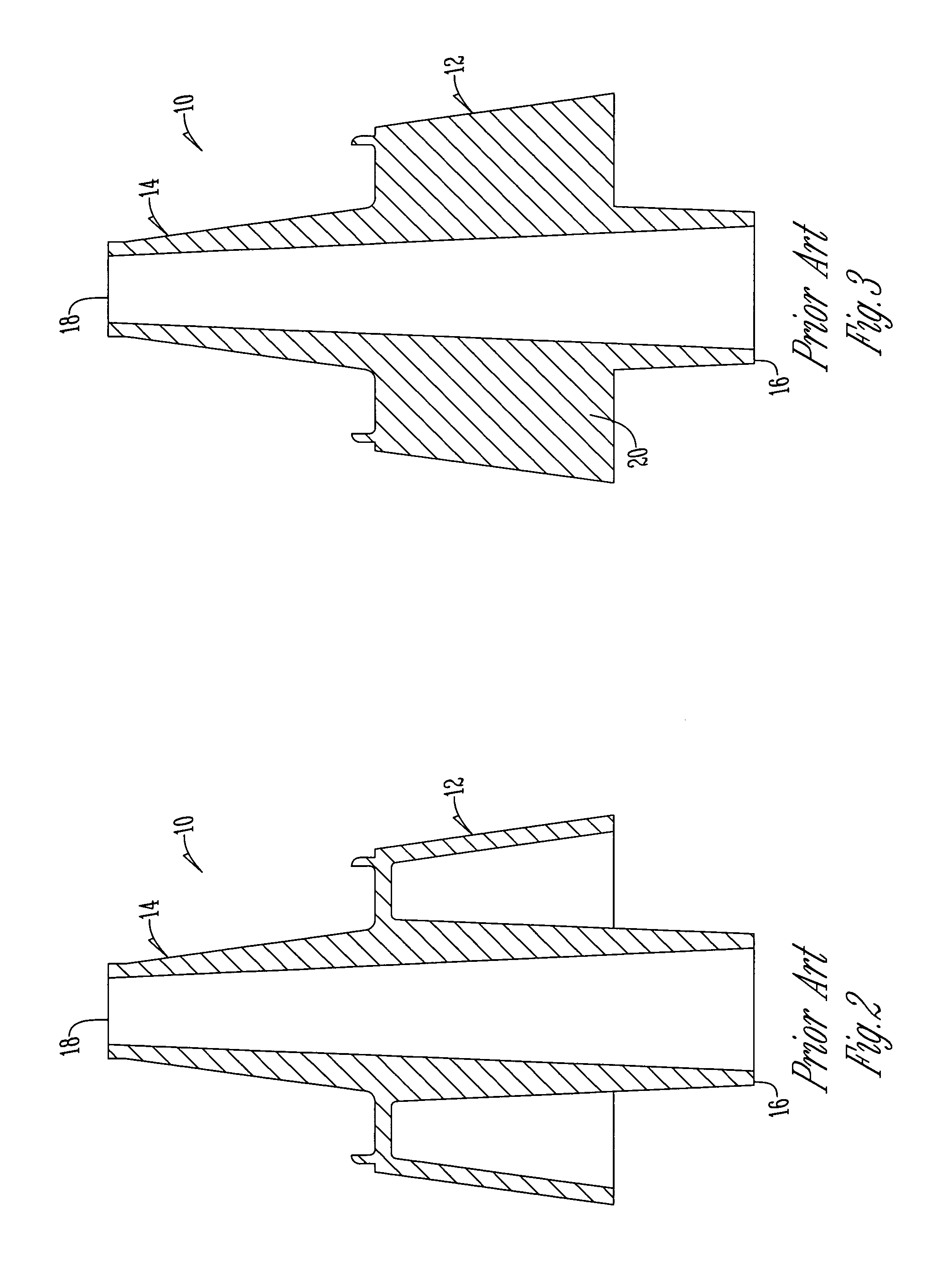

Manhole insert for manufacture of a cast member and to provide a step insert having increased structural and holding strength

InactiveUS7108101B1Prevent leakagePrecise alignmentNutsShaping reinforcementsUltimate tensile strengthHollow core

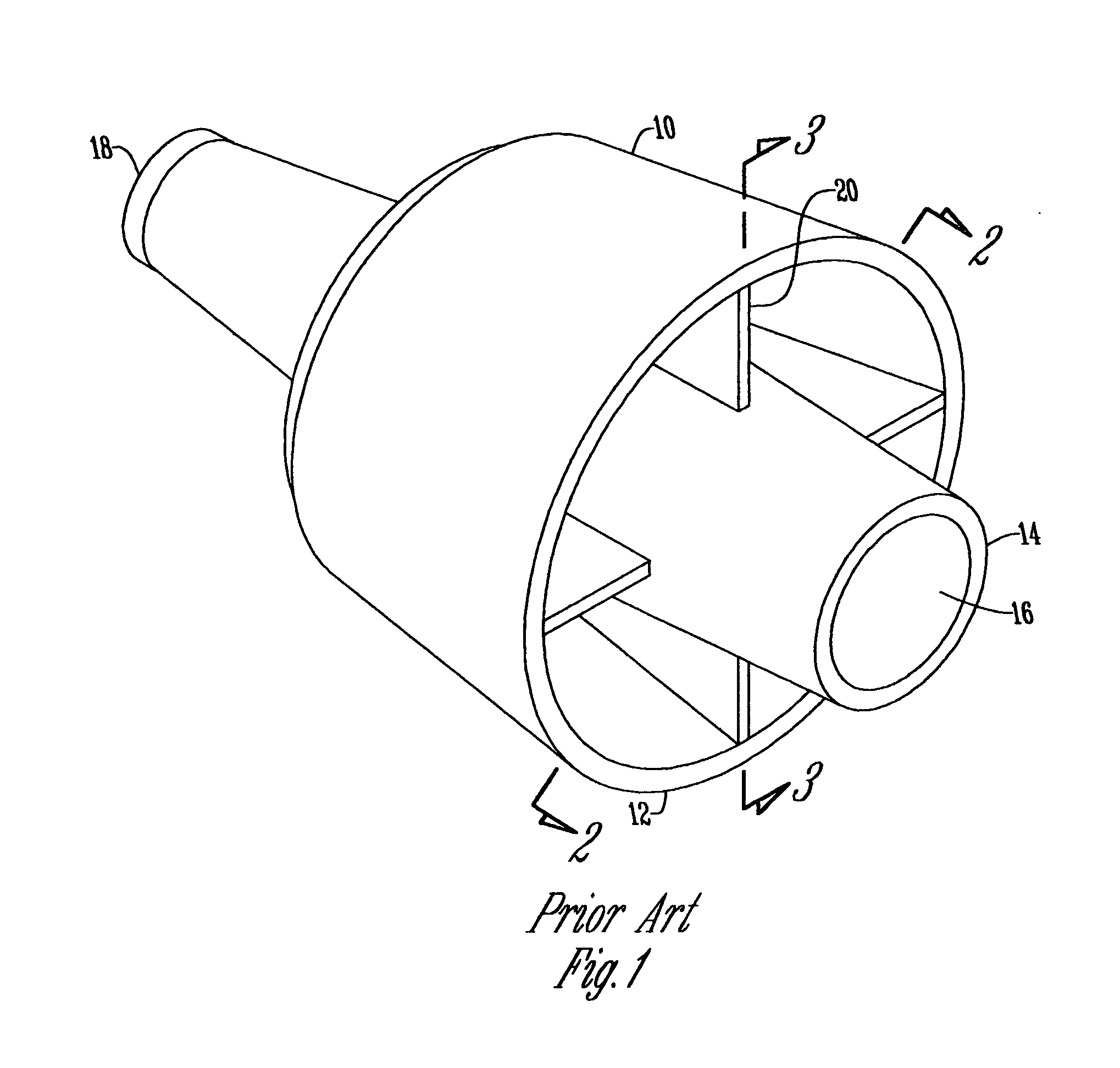

Method and apparatus for forming cast members. Steps are provided in the cast member by sliding mounting flanges of hollow plastic step inserts into slots provided in the inner mold shell. The cast material is then poured into the mold. Once the cast material has set, the cast member is withdrawn from the mold assembly. The step insert mounting flanges are broken away, leaving hollow step inserts into which manhole steps are force-fittingly mounted. The inserts are provided with integral cover tabs which cover larger slots provided to facilitate insertion of the step inserts, preventing leakage of the cast material into the mold assembly. Integral cover tabs are similarly provided on enforcement ring support members mounted in a similar fashion to insertion slots provided on one of the mold members to cover larger width slot portions to prevent seepage of cast material. Similar seals are provided by cylindrical-shaped inserts for use in wetcast and drycast fabrication methods.

Owner:POLY TEC PROD

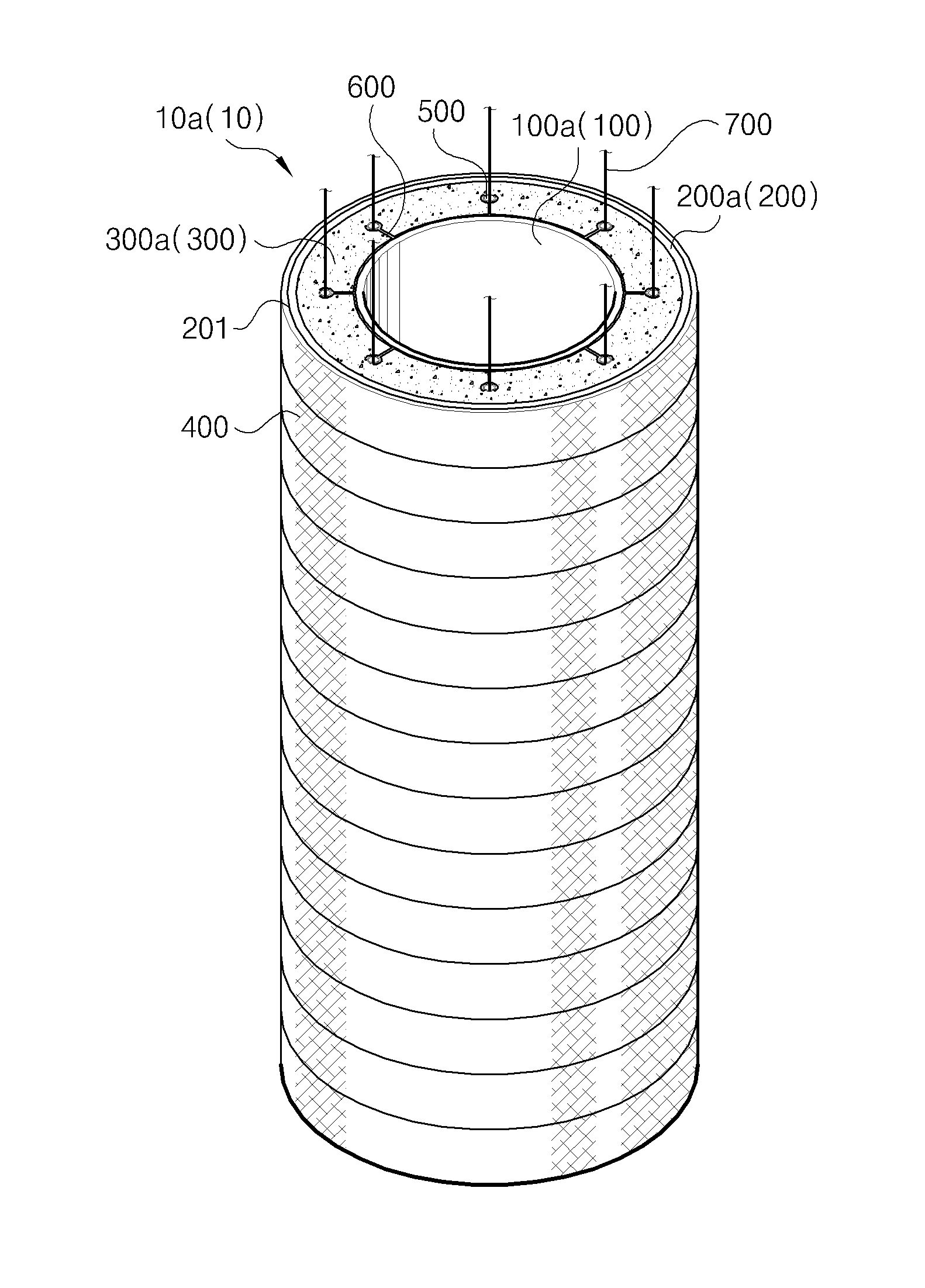

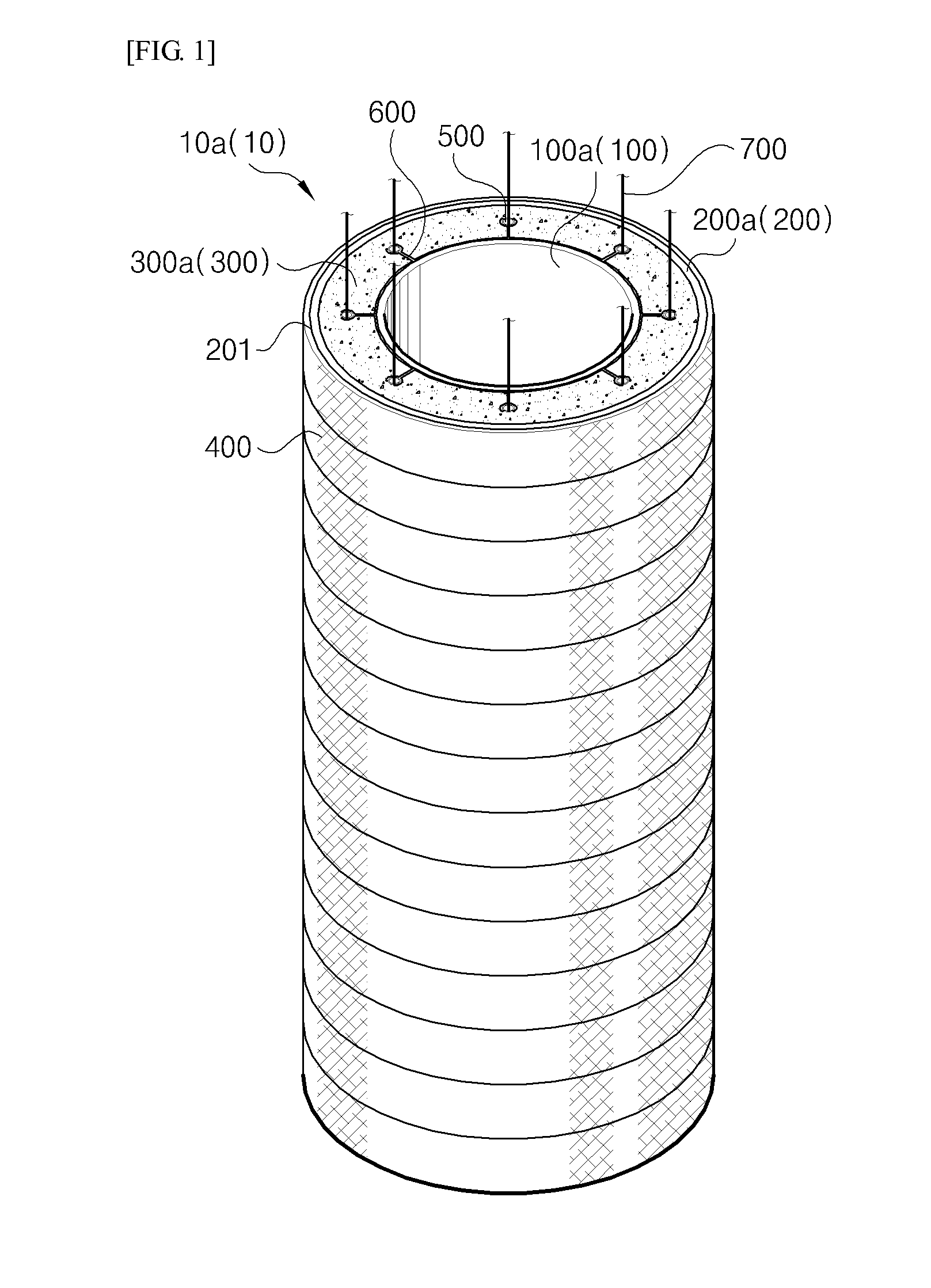

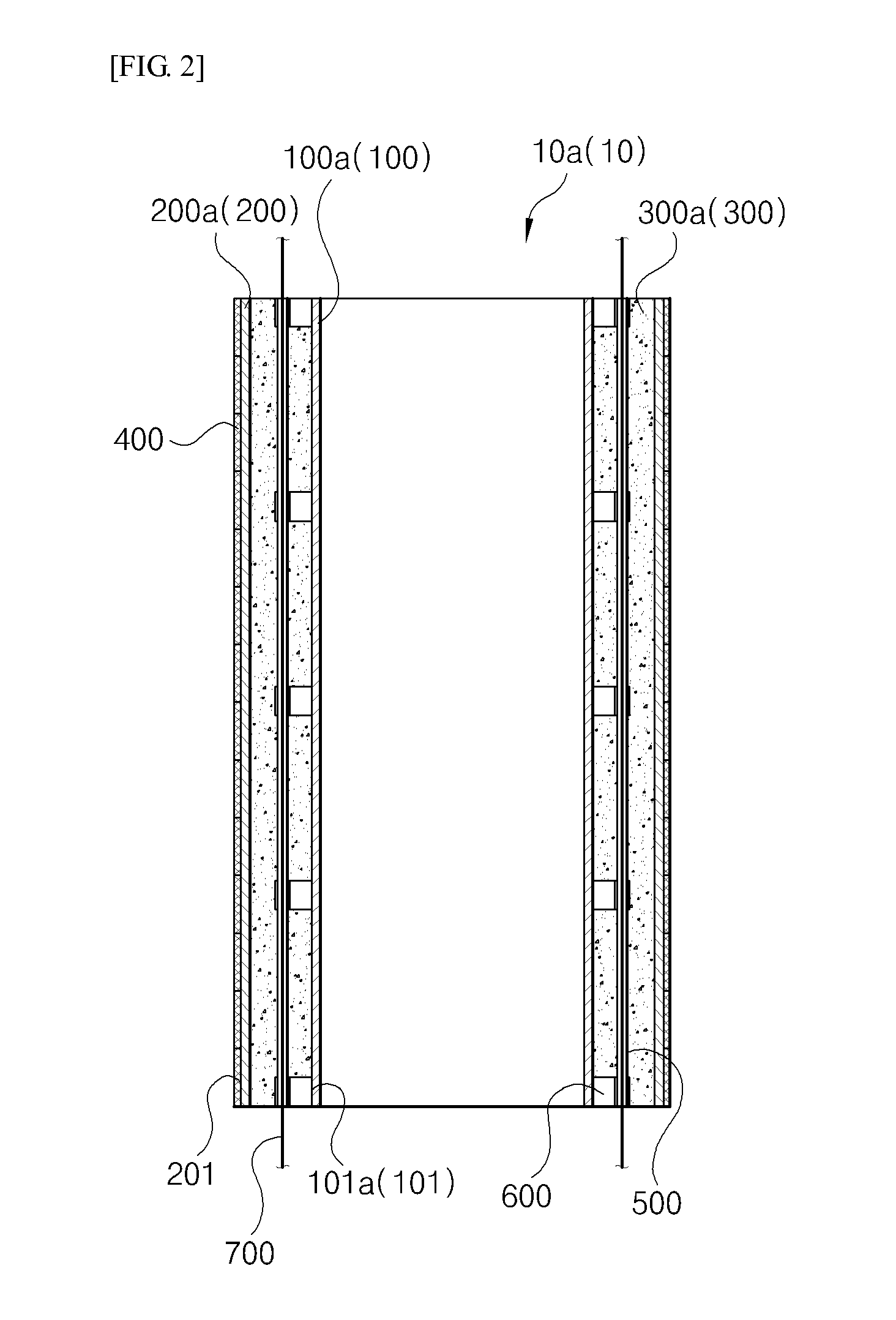

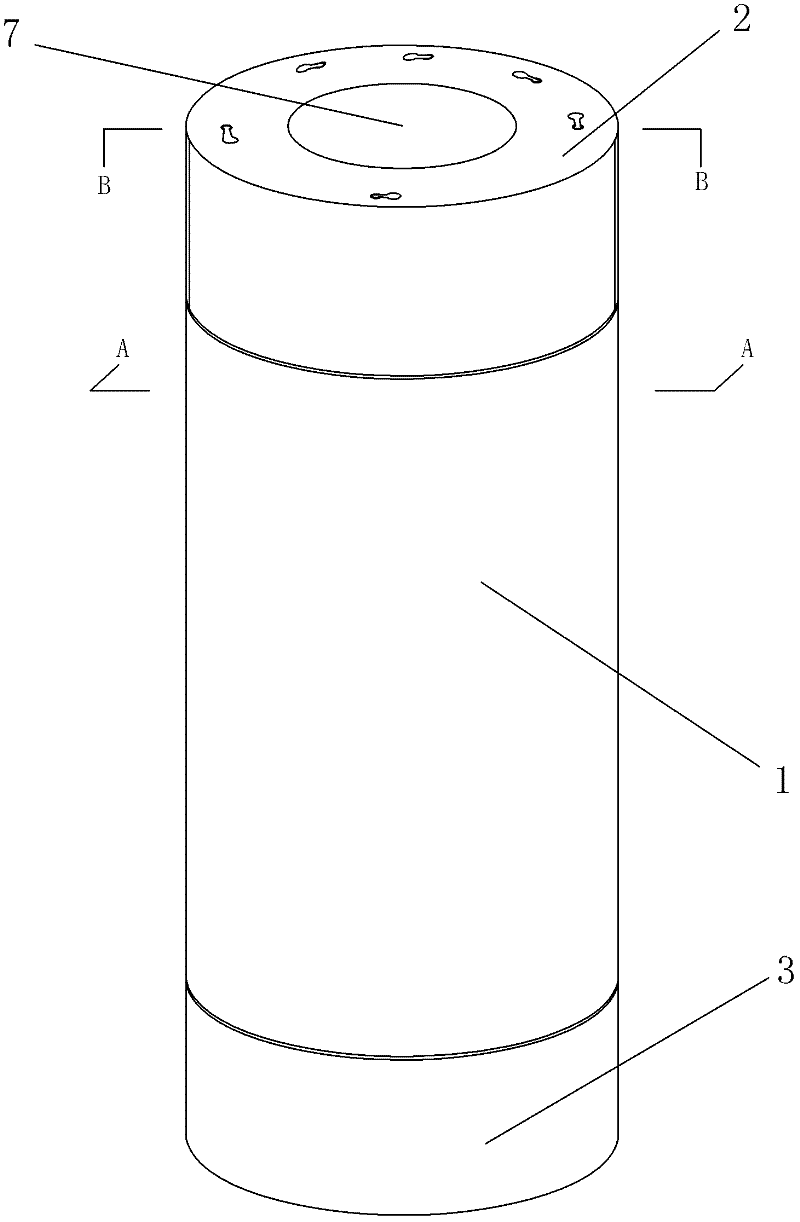

Hollow structure, and preparation method thereof

ActiveUS20150113913A1Improve structural performanceEasy to handleConstruction materialStrutsHollow coreMaterials science

Owner:AJOU UNIV IND ACADEMIC COOP FOUND

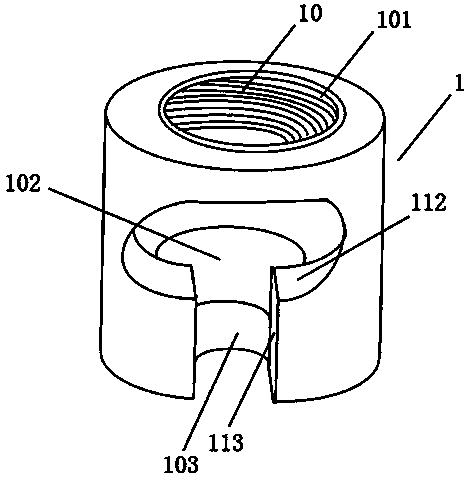

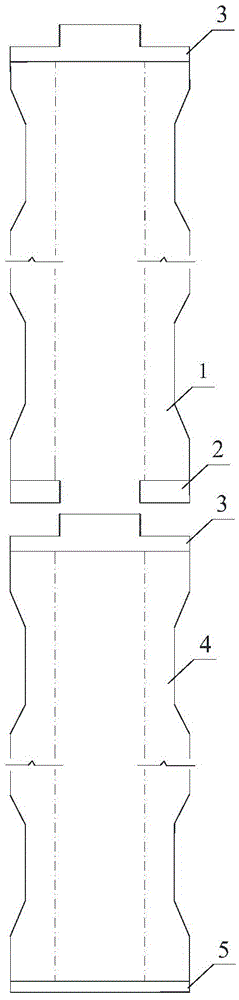

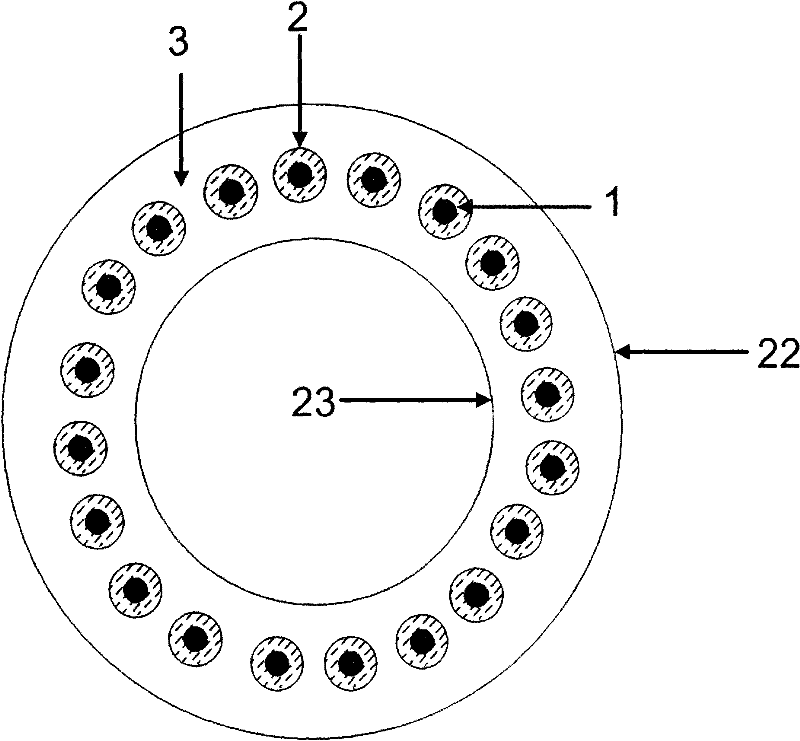

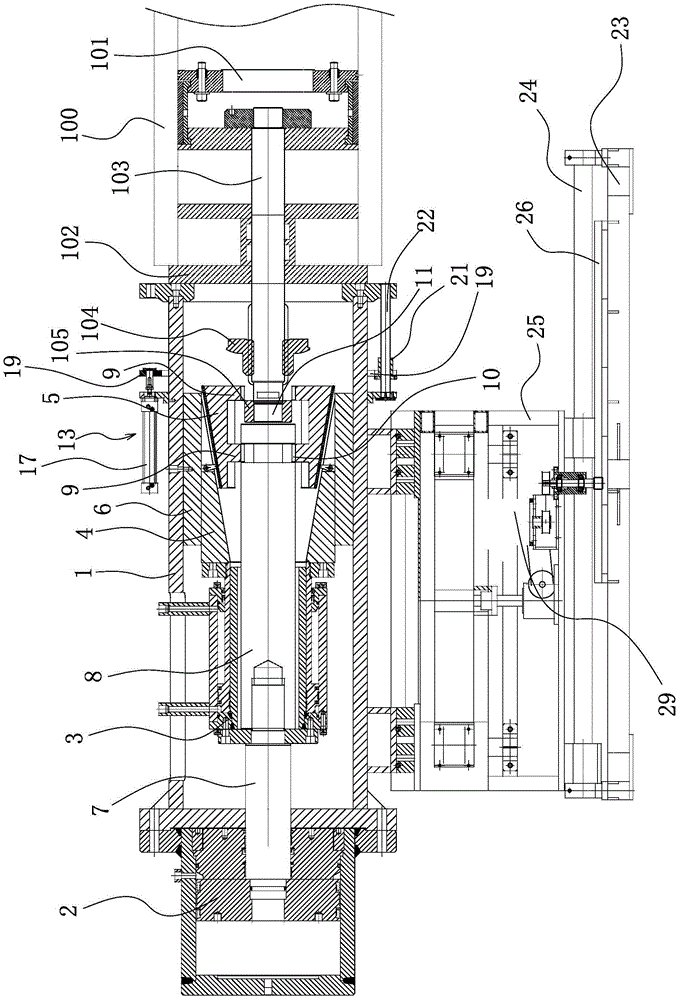

Connecting sleeve, prefabricated part comprising same as well as production method and connecting method thereof

ActiveCN103556624AReduce manufacturing costReduce labor intensityShaping reinforcementsBulkheads/pilesEngineering

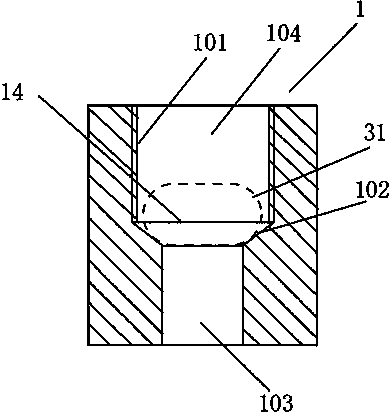

The invention provides a connecting sleeve used for a prefabricated part, the prefabricated part comprising the connecting sleeve as well as a production method and a connecting method of the prefabricated part. The connecting sleeve (1) is provided with a hole (10) along the axial direction; the outer wall of the connecting sleeve (1) is provided with external thread, or at least part of the hole (10) is provided with internal thread (101); the hole (10) also comprises a section of taper hole (102) with a cone shape, or is provided with a blocking table (105) arranged along the inner wall of the hole (10); the side wall of the connecting sleeve (1) is also provided with an open slot (11) extending into the hole (10); the open slot (11) passes through the lower end of the connecting sleeve (1) downwards. The connecting sleeve can greatly reduce the production cost of a precast pile, lightens the labor intensity of workers, increases the production efficiency and improves the product quality.

Owner:汤始建华建材(南通)有限公司

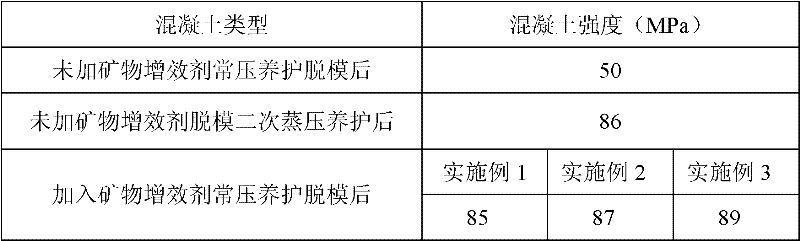

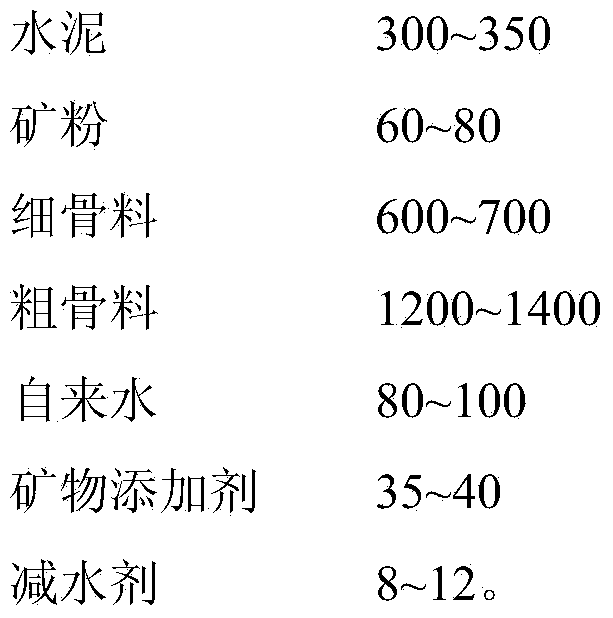

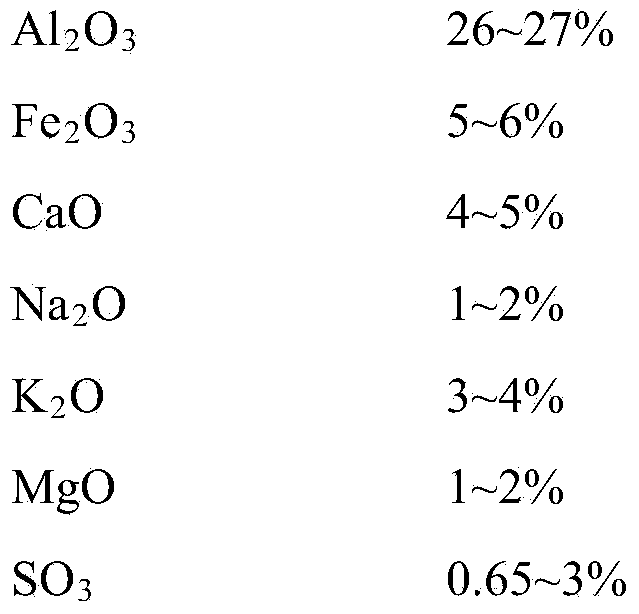

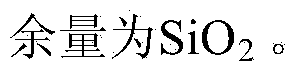

A kind of production method of concrete pile without autoclaving and pouring residual slurry

The invention discloses a production method of concrete piles free of autoclaving and pouring of residual slurry: first, sand, cementitious material, and mineral booster are put into a concrete mixer and stirred until uniform, and then water-reducing agents and the whole formula are put in successively. Add 75% of the water in the mixture, then stir until it is uniform, and finally put in gravel and the remaining 25% of the water and stir until it is even; put the pre-mixed concrete mixture in step A evenly into the mold with the steel cage skeleton installed In the middle, after the cloth is finished, mold closing and prestressed tensioning are carried out, and the tensioning force is about 70% of the total tensile strength of the prestressed steel bars; after the prestressed tensioning, the mold containing the concrete is subjected to centrifugal forming operations until the concrete Pile molding; after the centrifugation is completed, the mold equipped with concrete and steel skeleton cages is subjected to atmospheric pressure steam curing, and after atmospheric pressure steam curing, demoulding and cooling can be completed; the temperature of the atmospheric pressure steam curing is 75-95 ℃, curing time is 4-6 hours.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

Non-steam autoclaved high performance concrete tube pile using calcium silicate hydrate seed powder as exciting agent, and preparation method of non-steam autoclaved high performance concrete tube pile

InactiveCN105777006ALow costSimple preparation processShaping reinforcementsCalcium silicateHigh energy

The invention belongs to the technical field of building materials, and particularly relates to a non-steam autoclaved high performance concrete tube pile using calcium silicate hydrate seed powder as an exciting agent, and a preparation method of the non-steam autoclaved high performance concrete tube pile. The concrete tube pile is prepared from ordinary Portland cement, mineral additives, the calcium silicate hydrate seed powder, sand, stones, a water reducing agent and an antifoaming agent. According to the non-steam autoclaved high performance concrete tube pile and the preparation method thereof disclosed by the invention, the calcium silicate hydrate seed powder is used as the exciting agent, so that a nucleation potential barrier of cement hydration can be reduced, besides, preferential adsorption nucleation is performed on reactant ions, the cement hydration is promoted, the pozzolanic effect of the mineral additives can also be advanced, the early strength of the concrete is improved from many aspects, and the non-steam autoclaved purpose is realized. According to the non-steam autoclaved high performance concrete tube pile and the preparation method thereof disclosed by the invention, the defects of low early strength, complex production technology, high energy consumption and the like of a conventional high performance concrete tube pile can be overcome, the equipment purchase cost and the equipment maintenance cost can also be reduced, and good economic and social benefits can be achieved.

Owner:TONGJI UNIV

Fracture Toughness Of Medical Devices With A Stereocomplex Nucleating Agent

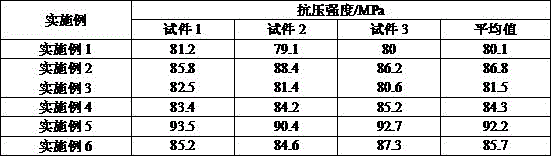

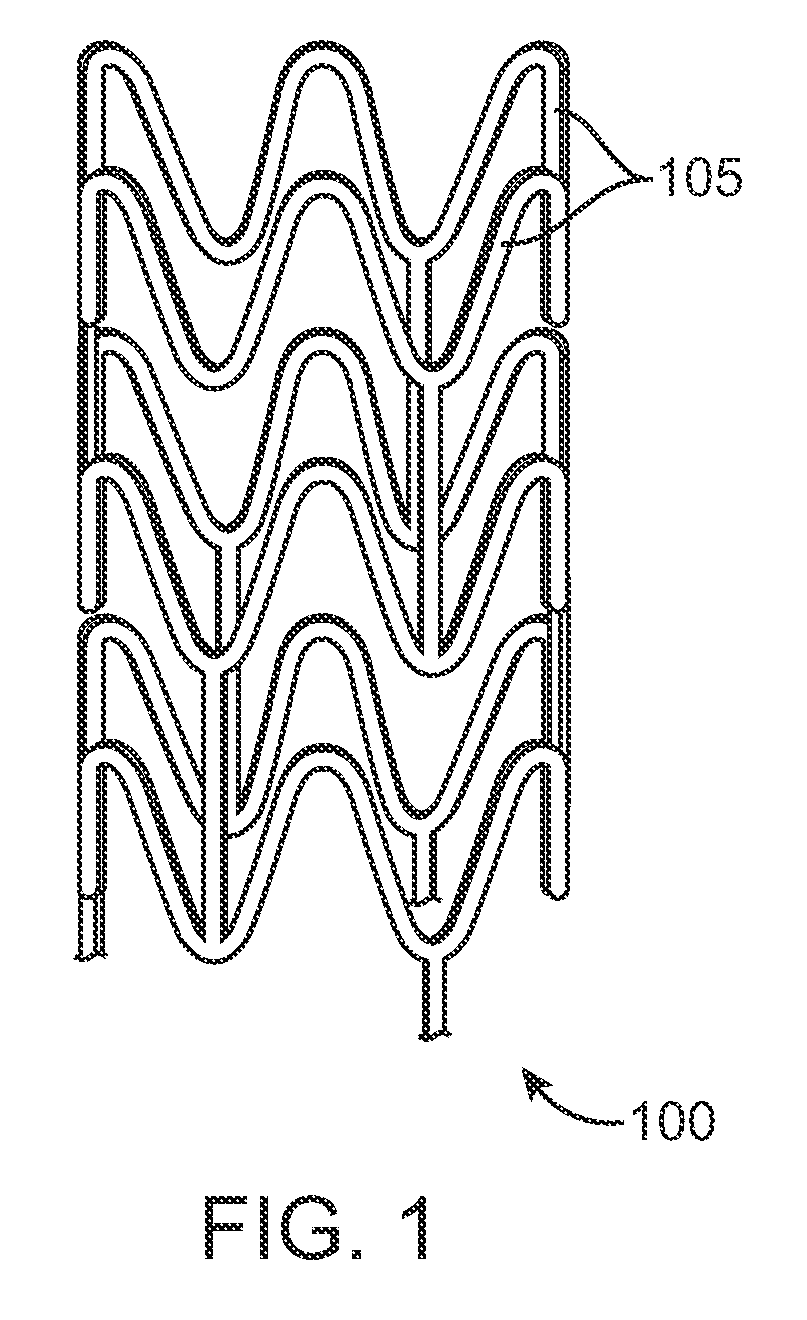

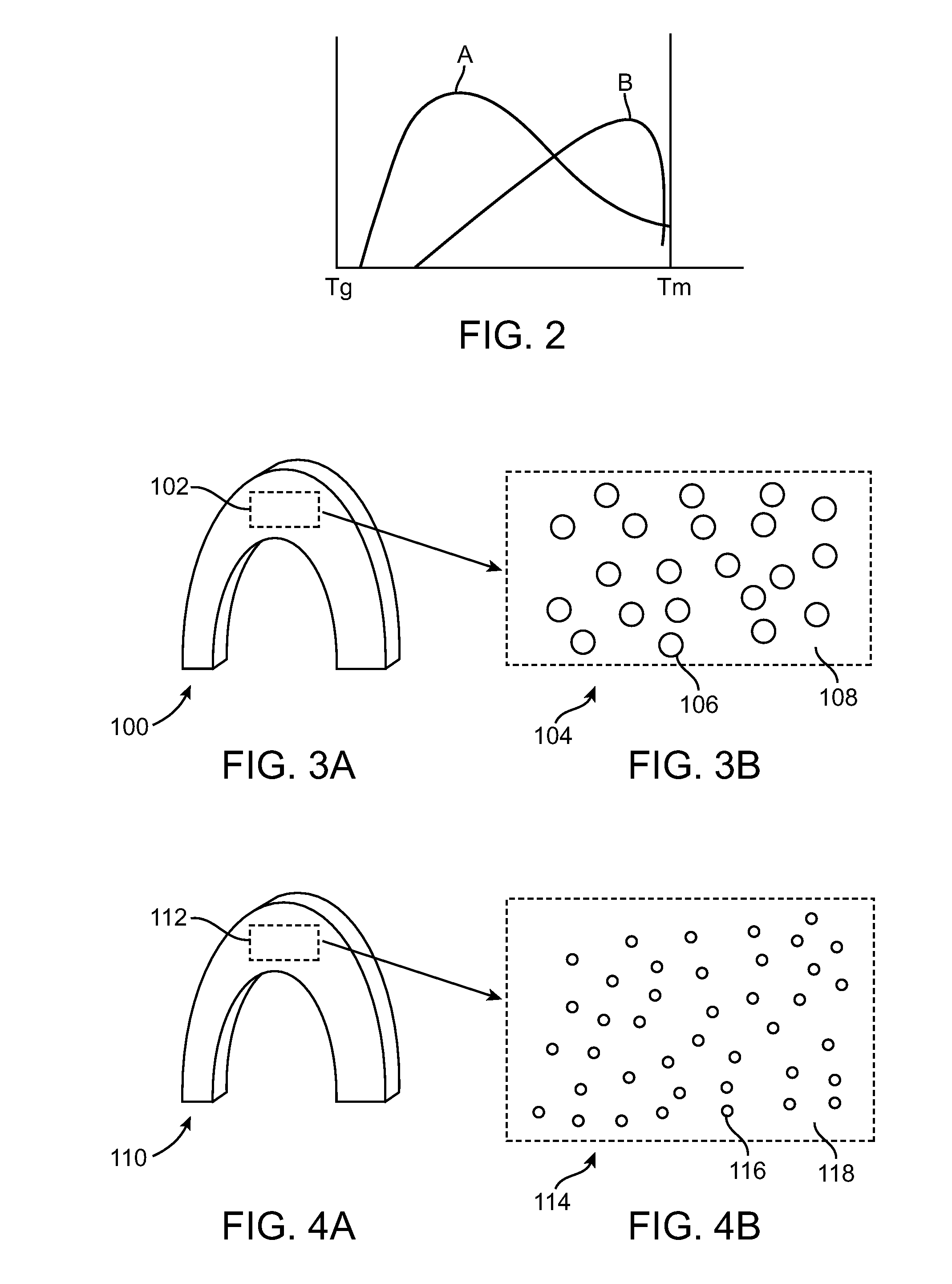

Methods of fabricating a polymeric implantable device from a PLLA / PDLA blend such as a stent with improved fracture toughness are disclosed. The blend is melt processed to allow formation of stereocomplex crystallites, which are nucleation sites for crystal growth. A polymer construct is formed from the melt processed blend and device is formed from the polymer construct. The stereocomplex crystallites result in an in increase in nucleation density and reduced crystal size, which increases fracture toughness of the formed device.

Owner:ABBOTT CARDIOVASCULAR

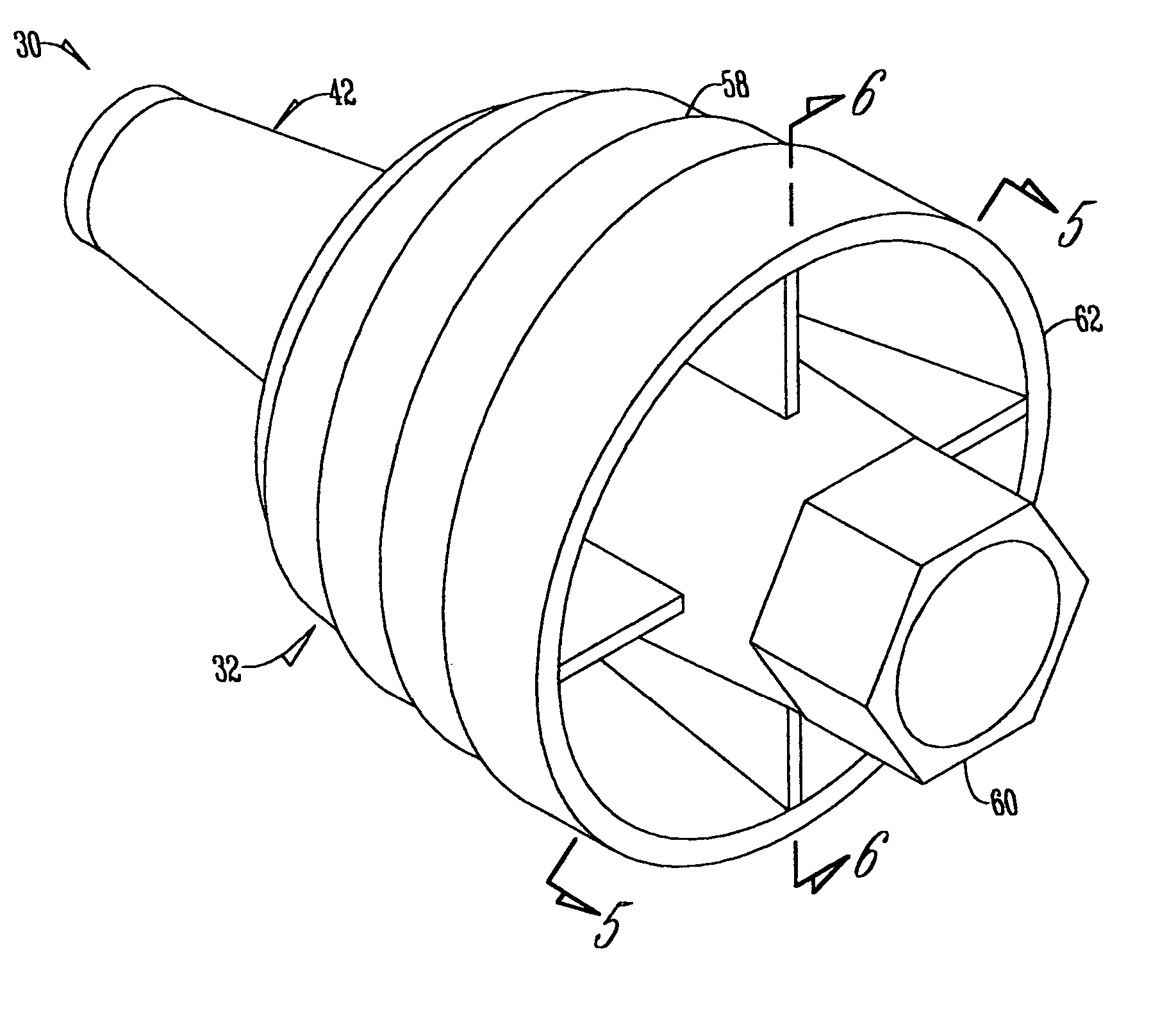

Pocket former

A pocket former includes an outer barrel having a first rim, a second rim and a frustoconical body portion extending from the first rim to the second rim. A center barrel is connected to the outer barrel and has a proximal lip adjacent the first rim of the outer barrel, a distal lip adjacent the second rim of the outer barrel, and a tubular body portion extending from the proximal lip to the distal lip, and extends beyond both the first rim and the second rim. An annular flange curves out and away from the second rim of the outer barrel. A spiral surface is located on the frustoconical body portion of the outer barrel. A nut surface is located on the tubular body portion of the center barrel adjacent the distal lip.

Owner:LOMONT MOLDING

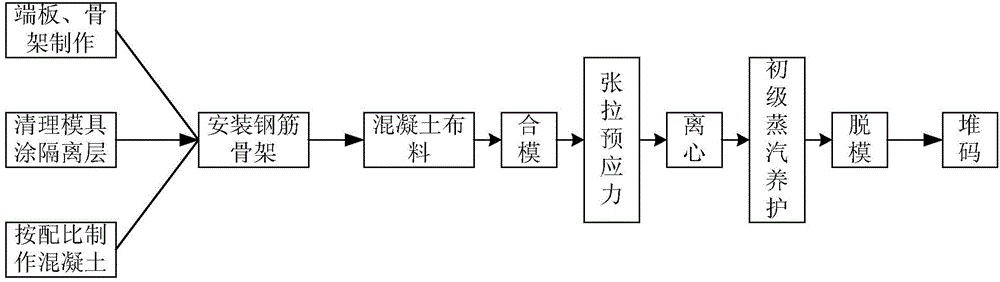

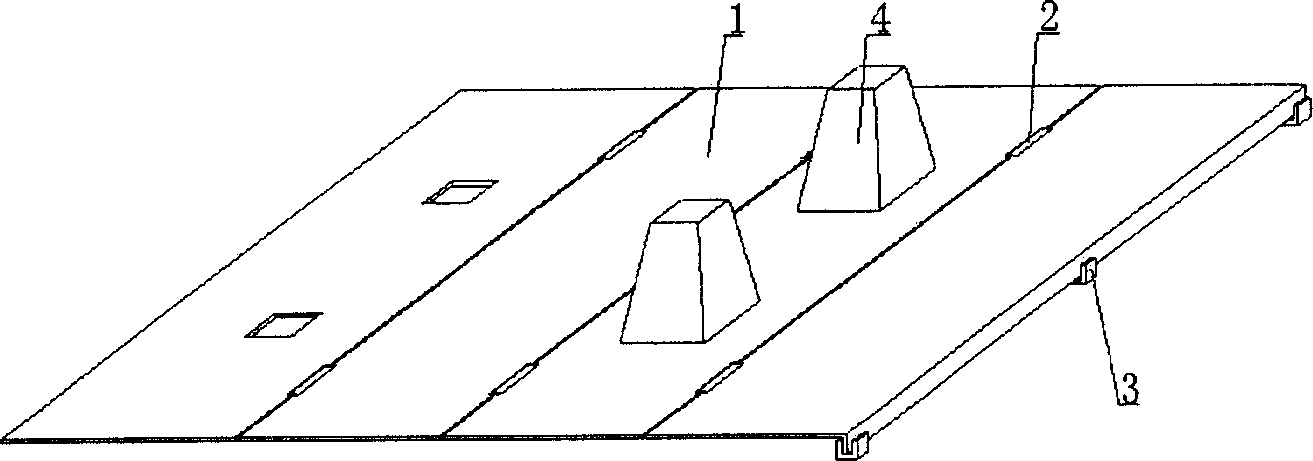

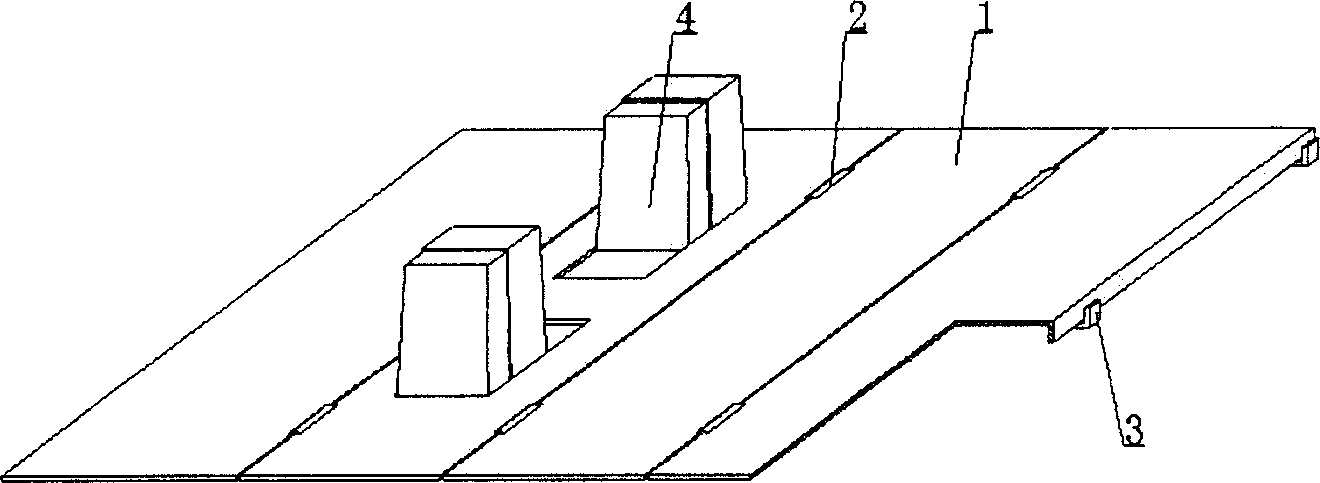

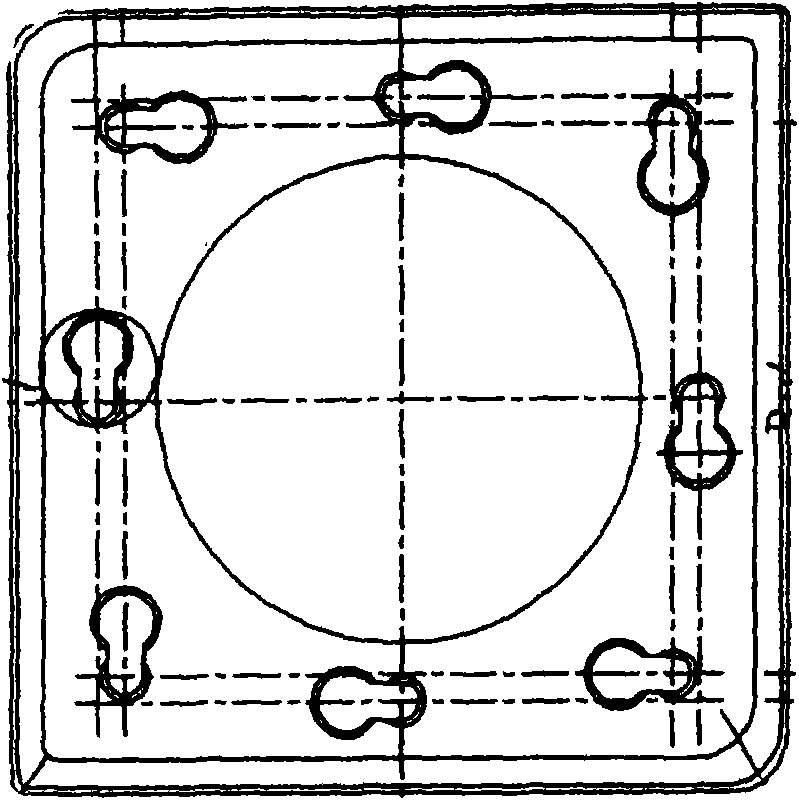

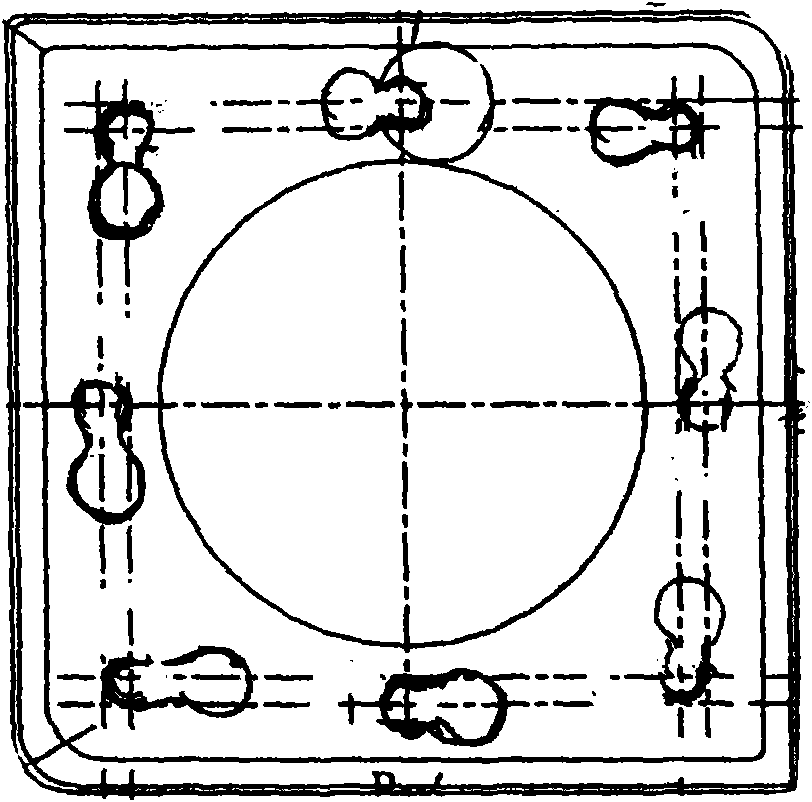

Manufacturing process of pre-tensioned prestressed centrifugal concrete square pile

The invention discloses a manufacturing process of a pre-tensioned prestressed centrifugal concrete square pile. The manufacturing process includes the steps of a, measuring and stirring concrete materials; b, manufacturing end plates of the centrifugal square pile; c, manufacturing a frame; d, mounting the reinforced frame; e, distributing concrete; f, closing a mold; g, performing prestress tensioning; h, performing centrifuging; I, performing primary steam curing; j, performing stripping; and k, directly lifting stripped centrifugal square piles, having concrete design strength level reaching C60, to a product yard for stacking, and delivering out of the factory after natural curing is complete and delivery strength is reached; subjecting the stripped centrifugal square piles, having the concrete design strength level reaching C80 and above, to high-temperature steam curing in a high-pressure autoclave, and directly delivering the piles subjected to the high-pressure curing. The manufacturing process has the advantages that the manufacturing process is simple, manufacturing time is short, fewer materials are used, energy consumption is low, and the manufactured centrifugal pile has high strength and good quality.

Owner:QINGDAO XINGHE BUILDING MATERIAL

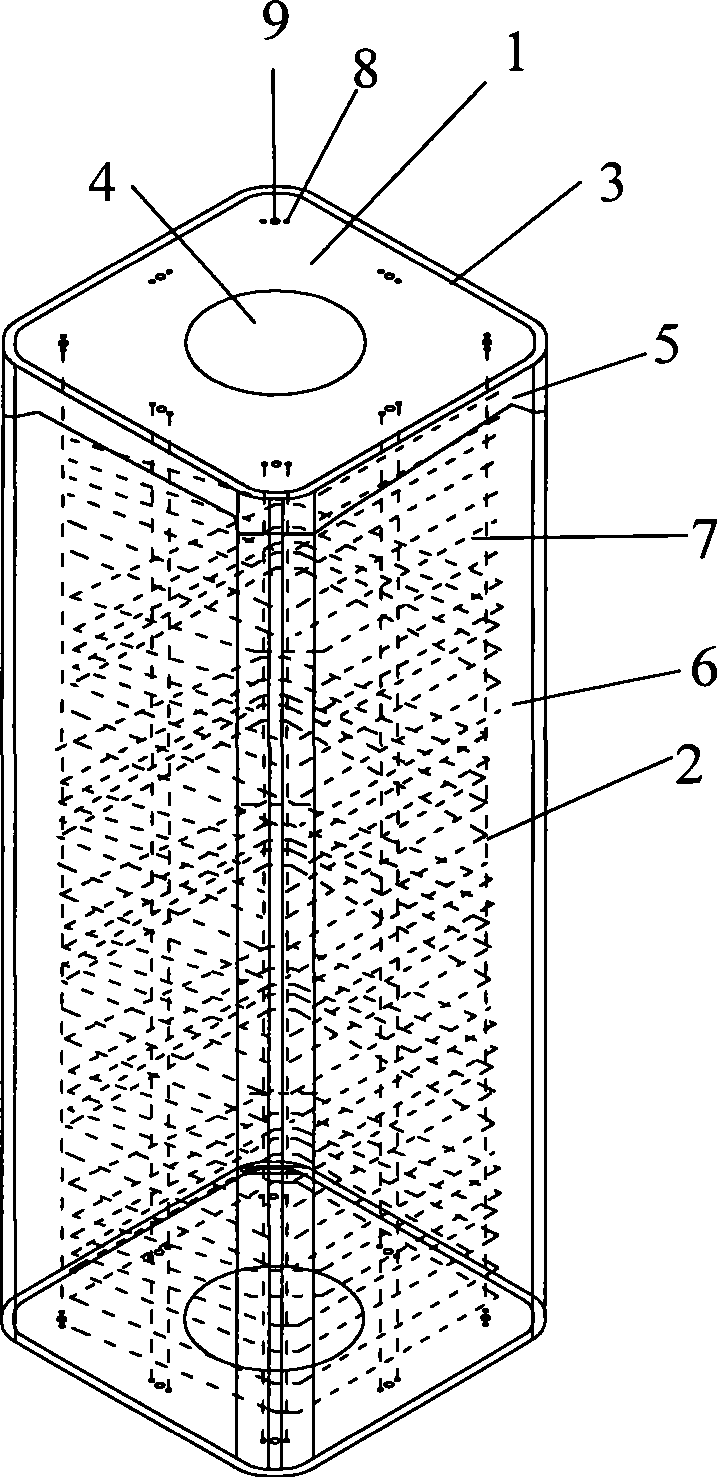

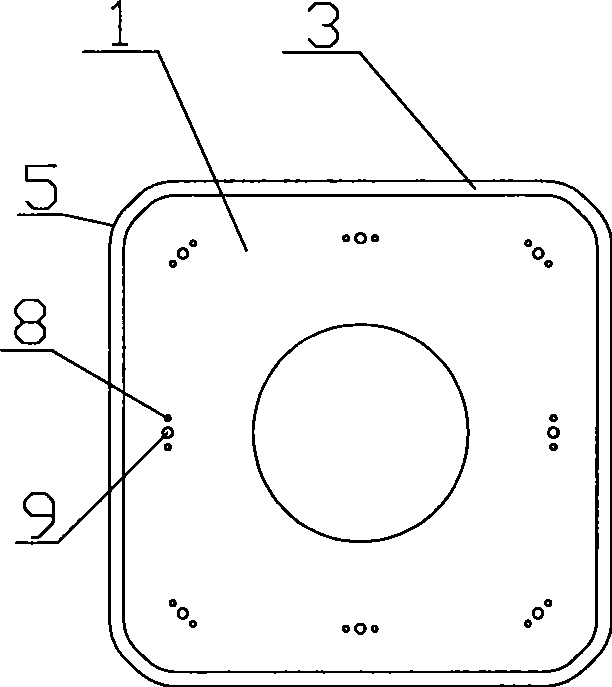

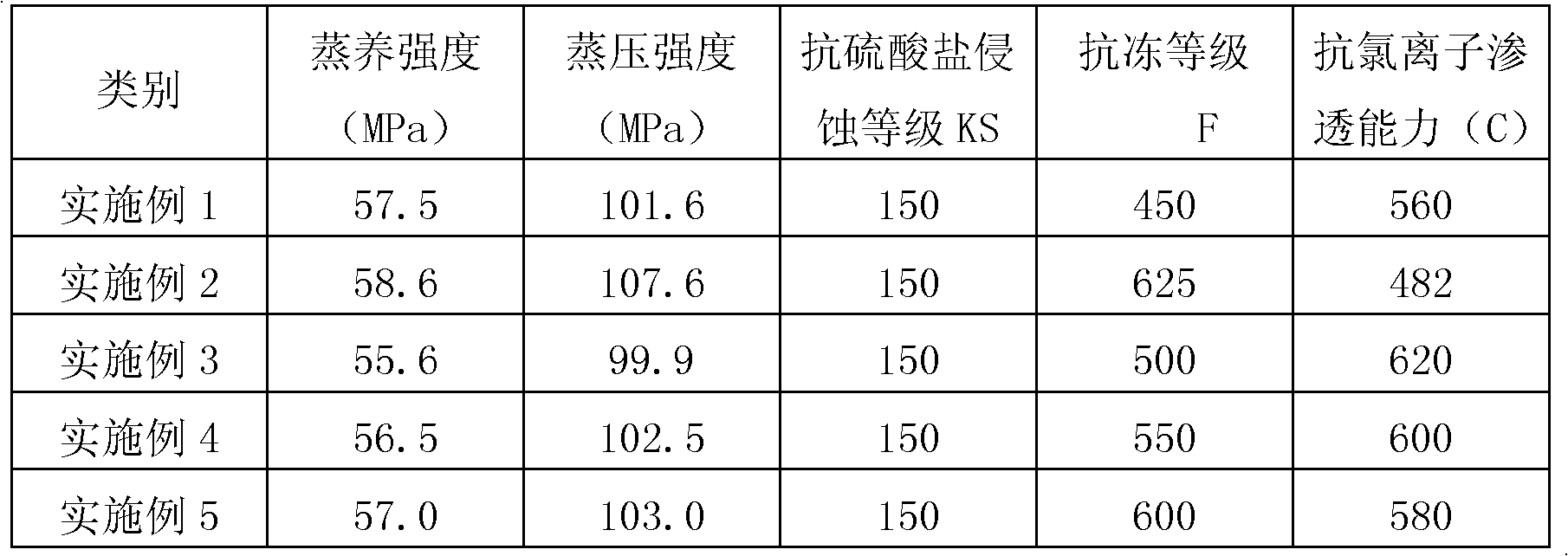

Preparation method for prestressed high-strength concrete pile

InactiveCN101544020AAvoid damageReduce stress concentrationShaping reinforcementsLubricant compositionHigh strength concreteStress concentration

The invention provides a prestressed high-strength concrete pile, belongs to the filed of building, and in particular relates to a driven fender pile applied to deep foundation pit engineering. The prestressed high-strength concrete pile comprises concrete, a reinforcing cage and an end plate, wherein the shape of the end plate is round-angle square; diameters of circular arc segments of round angles are equal and are 1.1 to 1.3 folds of the side length of the square, preferably 1.2 folds; central angles of the circular arc segments are 13 degrees to 17 degrees, and the length of a straight-line segment is 0.3 to 0.5 fold of the side length of the square; the grade of the concrete strength is higher than C40; and a main reinforcement of the reinforcing cage is arranged on a circle taking a centroid of the end plate as a center or on the square. The prestressed high-strength concrete pile greatly reduces the problem of stress concentration and the damage to a pile body in construction, and improves the bearing capacity of the pile body, horizontal bending resistance and shearing resistance performances, beat resistance capacity and pulling resistance performance.

Owner:SHANGHAI ZHONGJI PILE IND

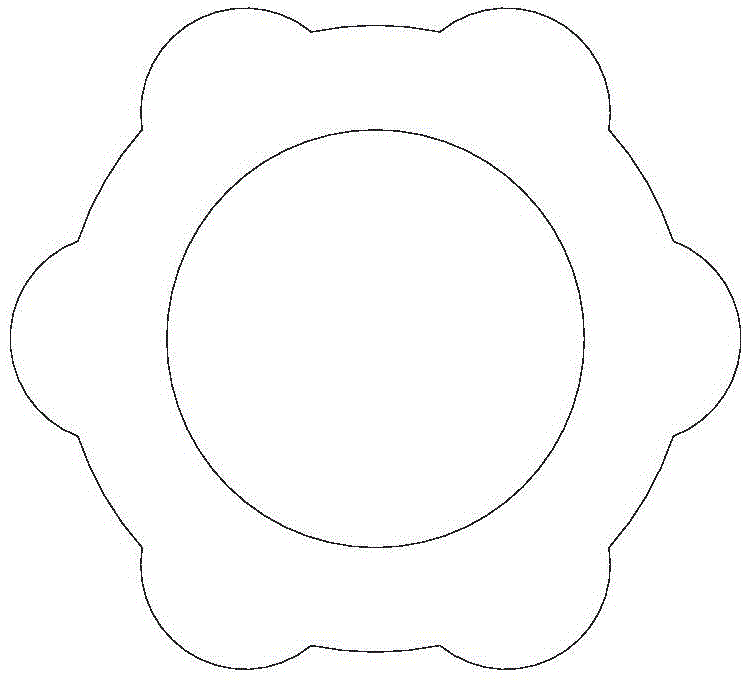

High-strength and high-durability pre-stressed concrete pile and production method thereof

InactiveCN102633472AHigh strengthImprove compactnessShaping reinforcementsHigh strength concretePre stress

The invention discloses a high-strength and high-durability pre-stressed concrete pile and a production method thereof. The high-strength and high-durability pre-stressed concrete pile provided by the invention is formed by casting pumped high-strength concrete. The pumped high-strength concrete comprises the following components: a binding material, fine aggregate, coarse aggregate, a polycarboxylate high-property water reducing agent and water. The pre-stressed concrete pile provided by the invention has higher strength and anti-corrosive and durable properties.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

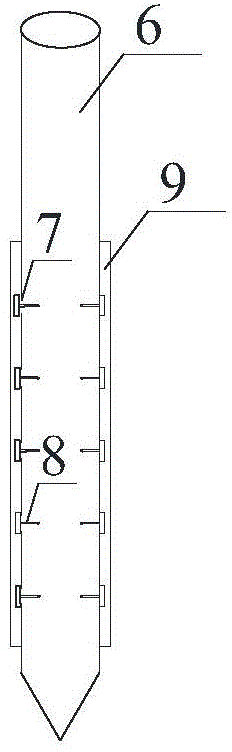

Ribbed prestressed pipe pile, and manufacturing method and drilling-planting construction process thereof

ActiveCN103603349AImprove ultimate carrying capacityReduce construction hazardsShaping reinforcementsBulkheads/pilesPre stressGrout

The invention discloses a ribbed prestressed pipe pile, and a manufacturing method and a drilling-planting construction process thereof. The ribbed prestressed pipe pile comprises an upper ribbed prestressed pipe pile and a plurality of lower ribbed prestressed pipe piles. The upper and lower ends of each lower ribbed prestressed pipe pile are provided with an external thread end plate and a closed end plate. Two ends of the upper ribbed prestressed pipe pile are provided with an external thread end plate and an internal thread end plate. According to the drilling-planting construction process, gravels are placed at the bottom of the pile and around the pile, grout is injected to the bottom of the pile and around the pile, and accordingly, limit bearing capacity of the single pile can be improved significantly and piles are saved. In addition, an injection pipe can be recycled after grout injection, so that fewer injection pipes are needed.

Owner:SHANDONG UNIV

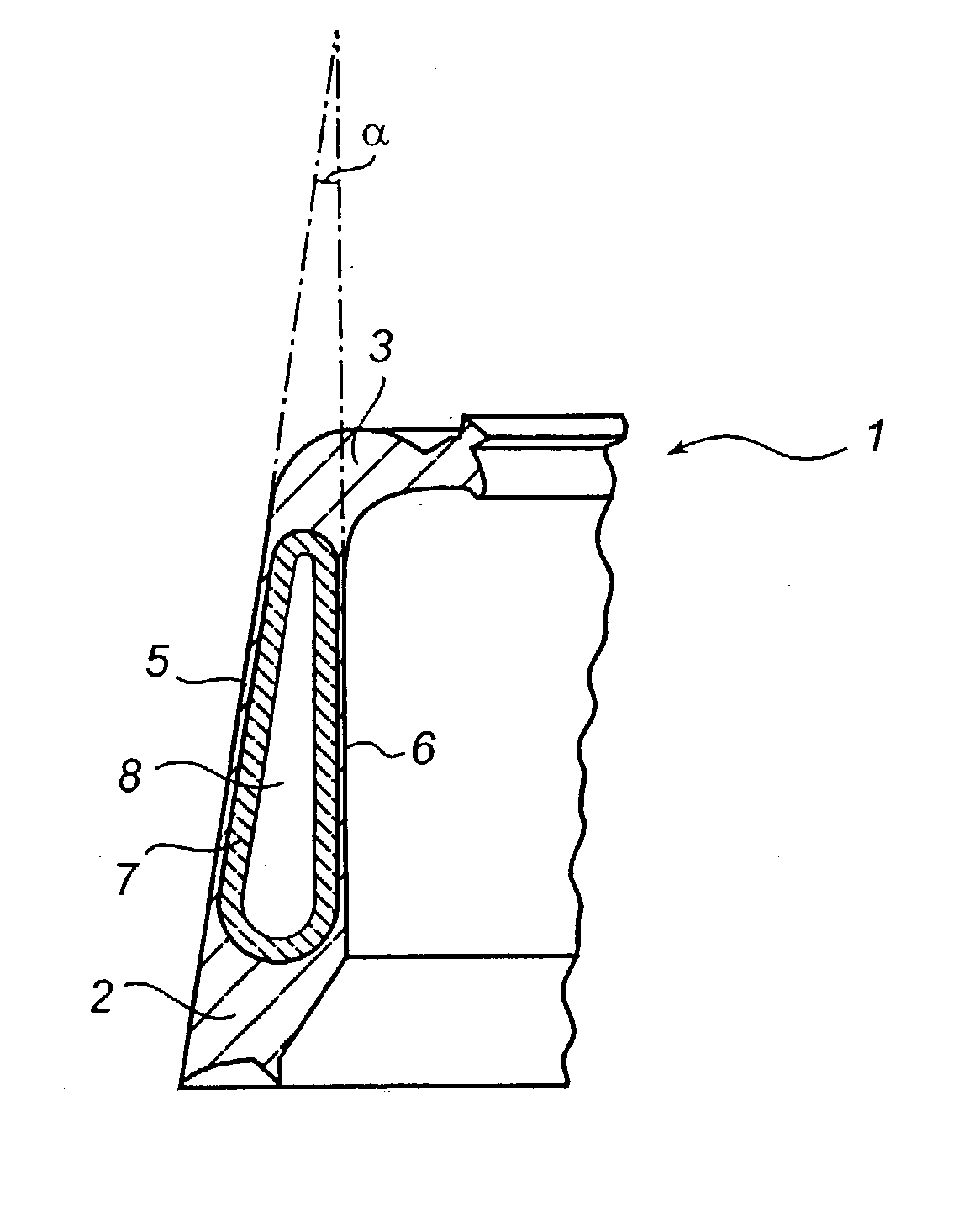

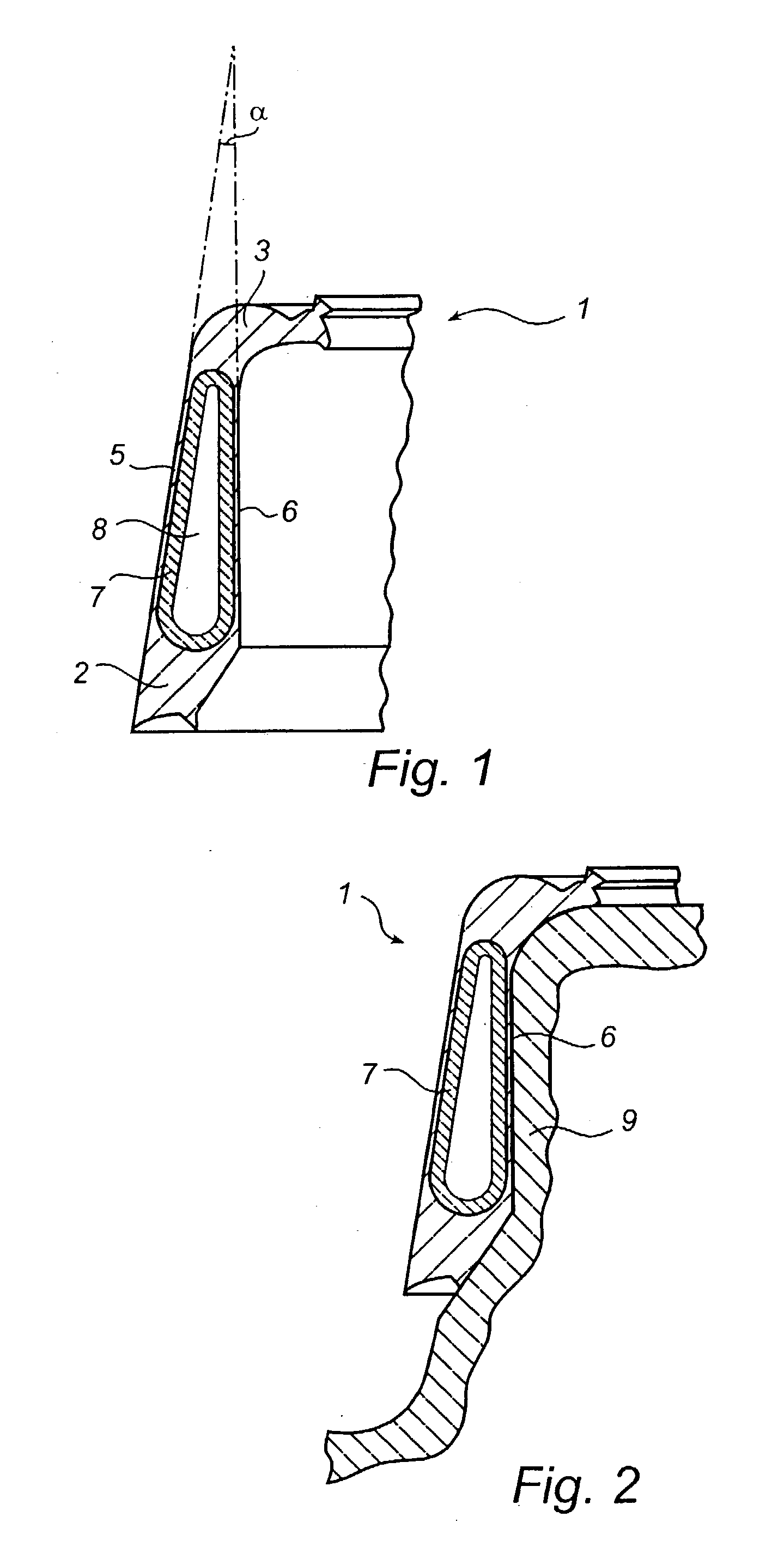

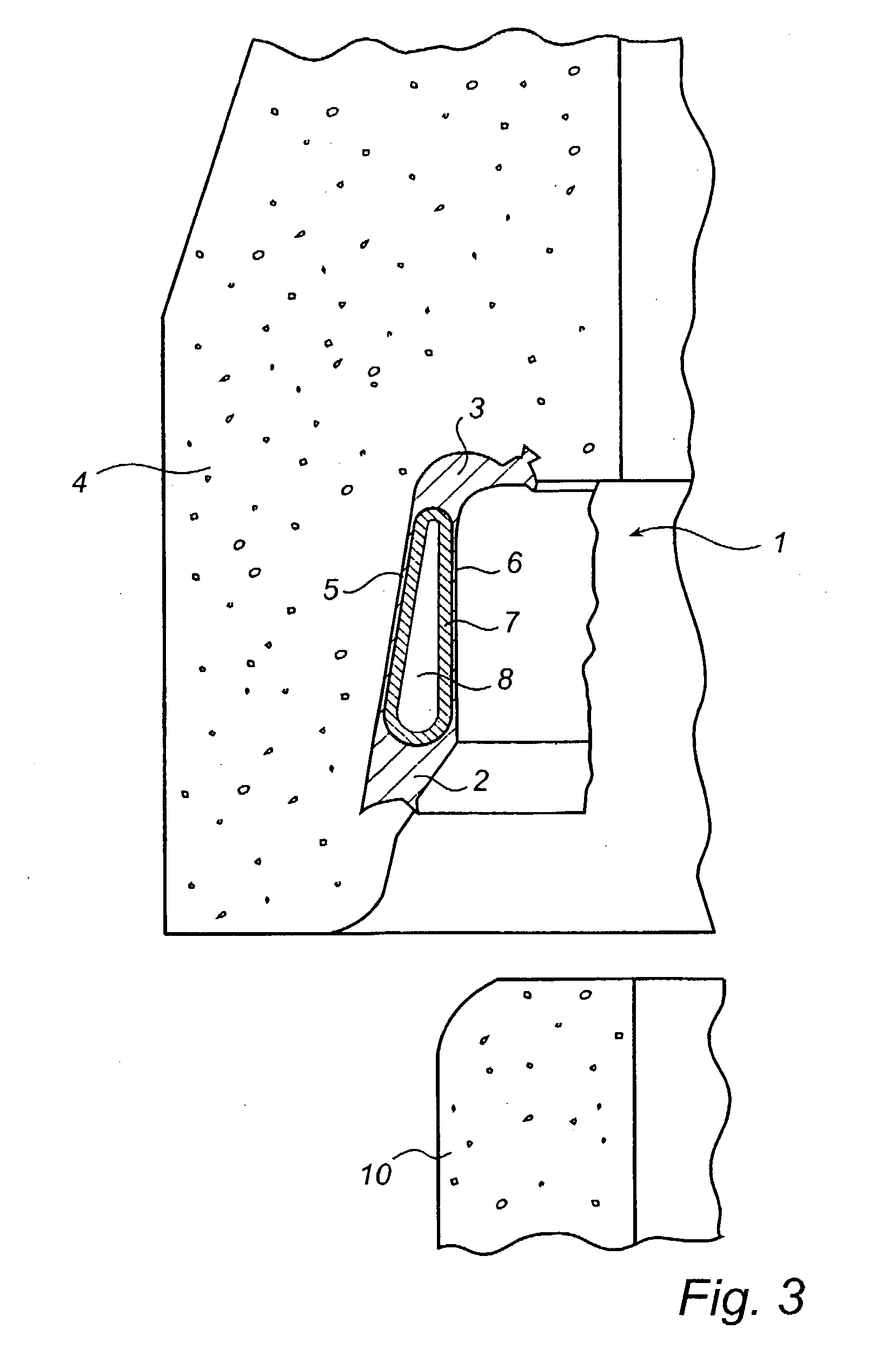

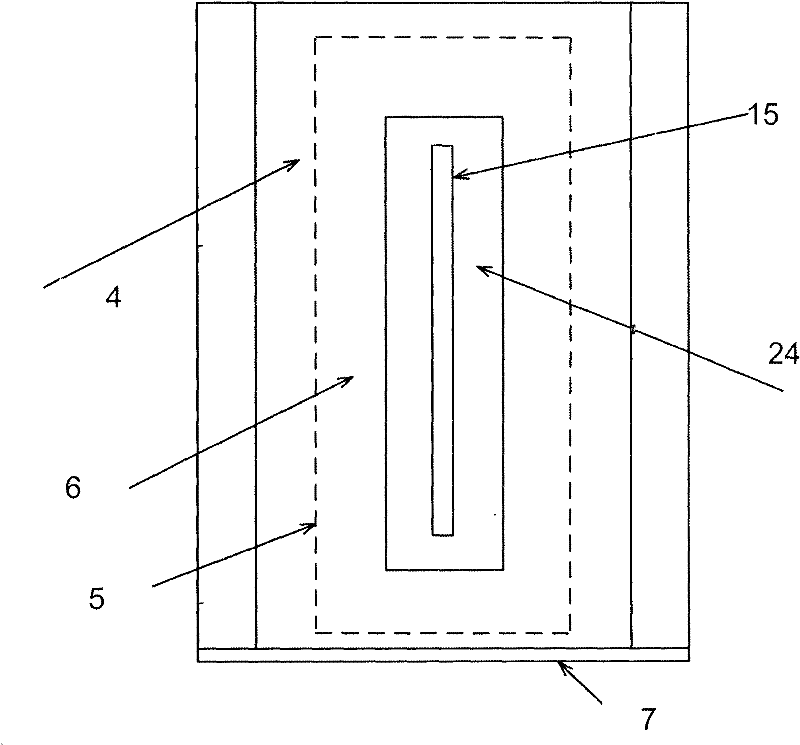

Sealing ring for connecting two especially insertable concrete components

InactiveUS20030107189A1Great wall thicknessReduce radial thicknessSleeve/socket jointsEngine sealsRubber materialEngineering

A scaling ring (1) for sealing an annular gap between a concrete pipe socket and a concrete pipe spigot end is adapted to be mounted on a mould ring intended for casting of a concrete pipe comprising a socket so as to be fixed in the socket by said casting. The scaling ring is made in one piece by means of co-extrusion of a soft rubber material and a hard rubber material. The soft rubber material has a hardness of 30-40 IRHD and forms a radially inner sealing layer (6), which is intended to abut against the mould ring during said casting and to abut sealingly against the spigot end during use of the sealing ring (1). The hard rubber material forms a second layer (7) located radially outside the radially inner sealing layer.

Owner:ASTRAZENECA AB

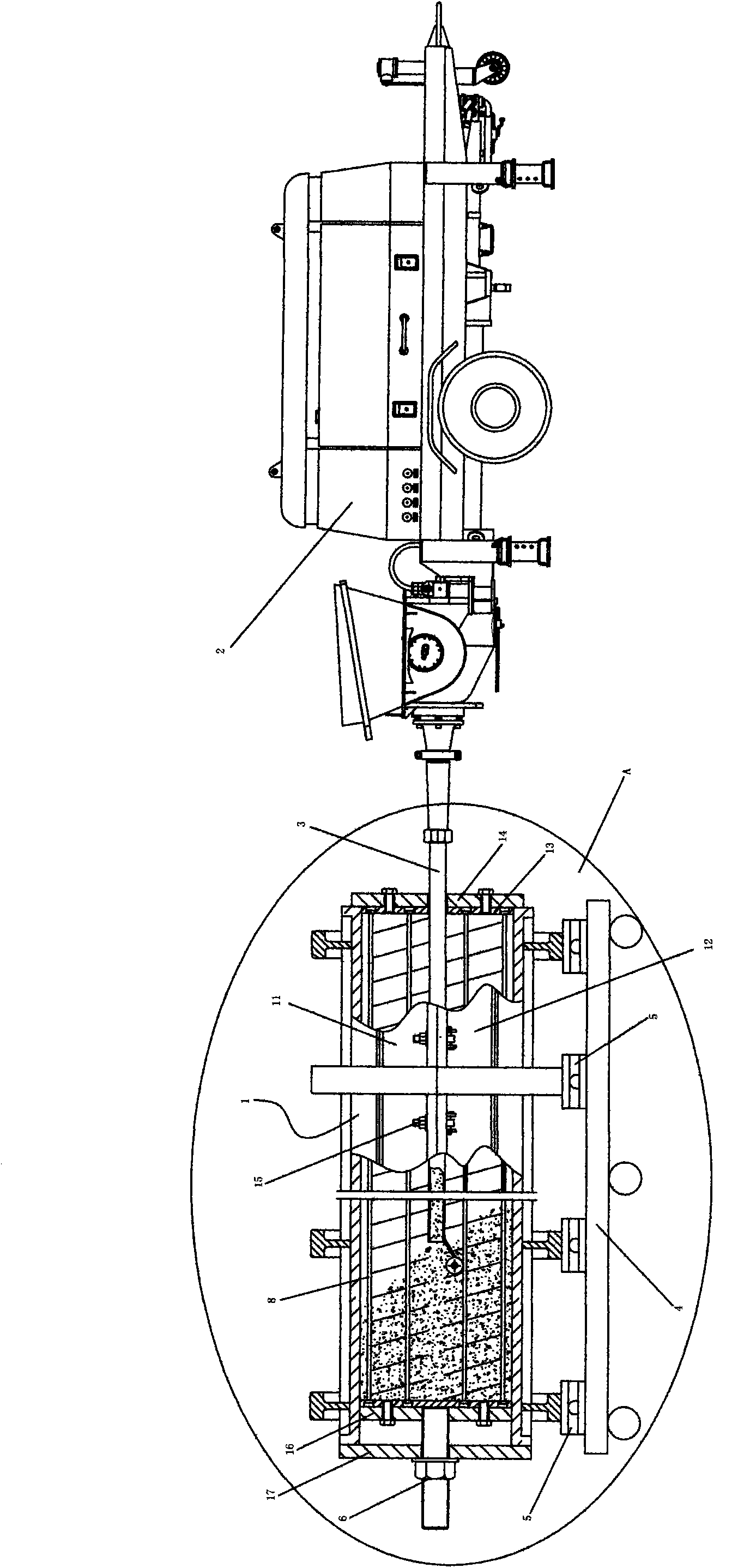

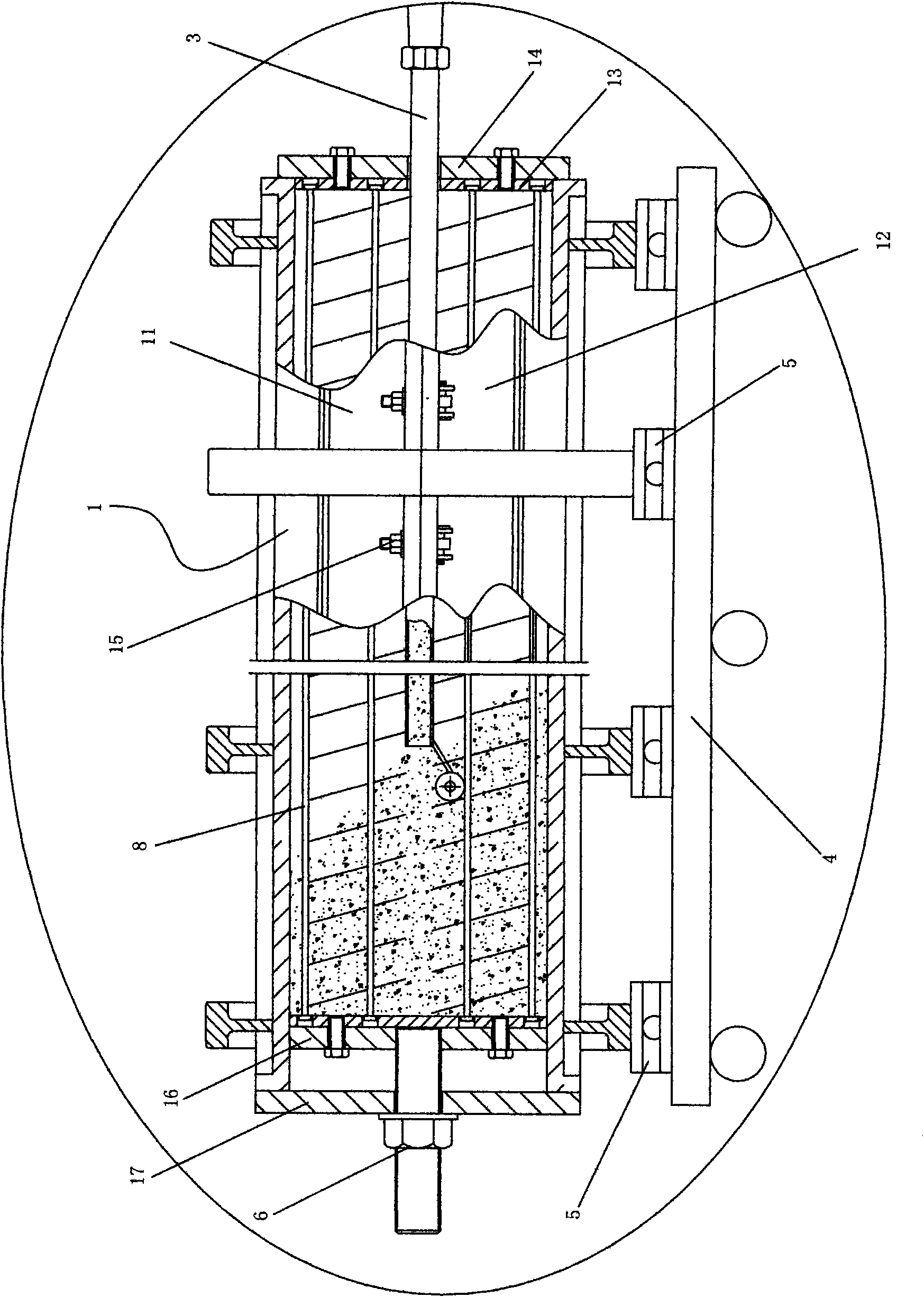

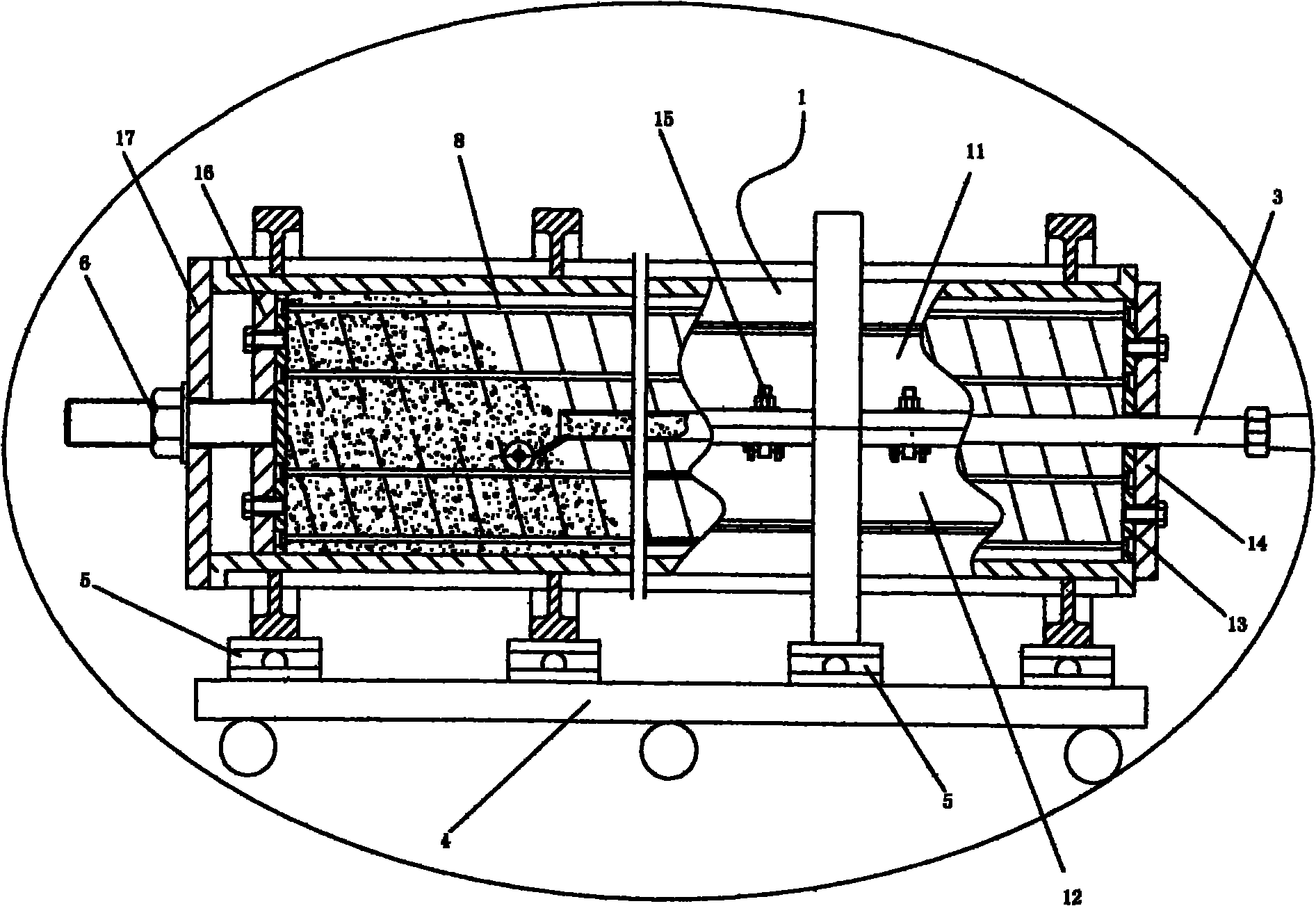

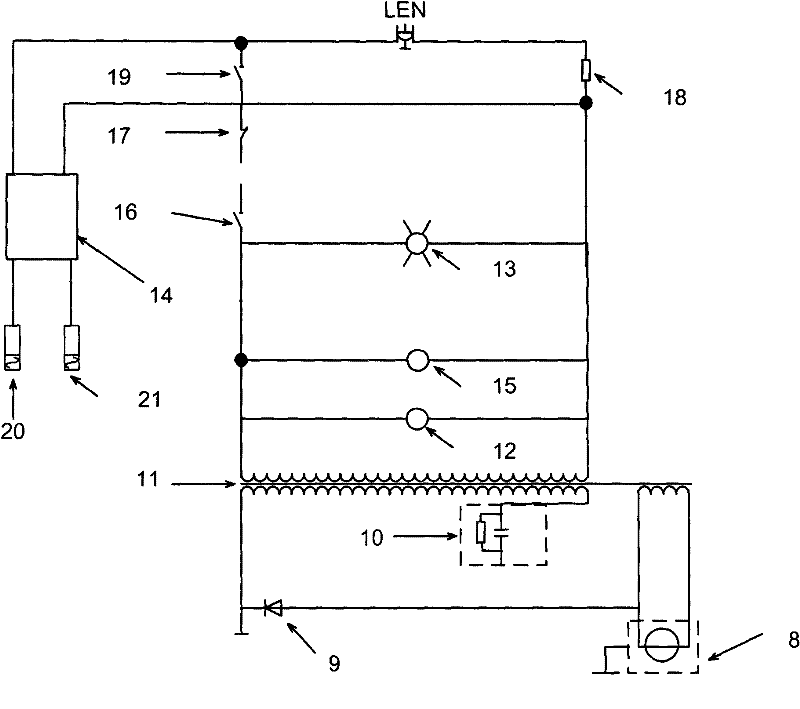

Equipment for producing concrete pipe pile and method for producing concrete pipe pile by using equipment

ActiveCN102029646AReduce wasteReduce labor intensityShaping reinforcementsPre stressElectric control

The invention discloses equipment for producing a concrete pipe pile and a method for producing the concrete pipe pile by using the equipment. The equipment is characterized by comprising a pipe pile mold and a conveyor for filling concrete in the mold, wherein a discharging port of the conveyor is provided with a feeding steel pipe capable of extending into the pipe pile mold; the pipe pile mold is arranged on a material distributing flat wagon which is provided with an electronic metering scale; the pipe pile mold is loaded on the electronic metering scale; and the equipment further comprises an electric control device which can control the movement speed of the material distributing flat wagon according to the value change condition of the electronic metering scale in the process of casting concrete. The invention provides the equipment which is simple in structure, can realize closed concrete casting and is applicable to producing pretensioning prestressed concrete pipe piles for the purpose of overcoming the defects in the prior art. Another purpose of the invention is to provide a method for producing the concrete pipe pile by using the equipment.

Owner:JIANGSU TANGCHEN MACHINERY EQUIP MFG

Die in use for molding component of concrete filled double thin wall

InactiveCN1727152AReduce manufacturing costMould separation apparatusMouldsUltimate tensile strengthThin walled

Owner:邱则有

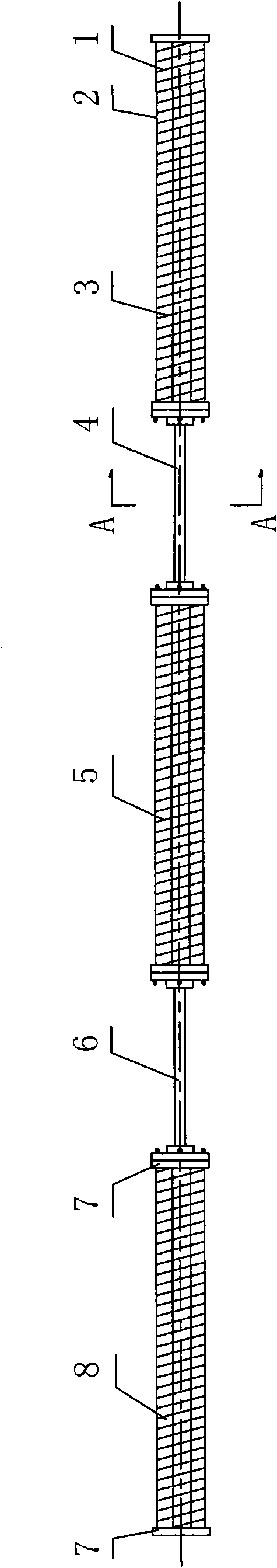

Production process of short tubular piles

ActiveCN101642932AImprove efficiencyReduce manufacturing costShaping reinforcementsHigh strength concretePre stress

The invention relates to a production process of prestressed high-strength concrete tubular piles. The production process of short tubular piles is characterized by comprising the following steps: 1,preparing high-performance concrete; 2, manufacturing a steel reinforcement cage with pile heads: firstly welding the steel reinforcement cage with the length of 1-3 meters through steel reinforcements, then respectively welding collar plates at both end parts of the steel reinforcement cage, and welding end plates on the collar plates to obtain the steel reinforcement cage with the pile heads andthe length of 1-3 meters; 3, connecting the steel reinforcement cage with the pile heads and the length of 1-3 meters into a whole by adopting a connecting device to obtain the conjoined steel reinforcement cage with the pile heads; 4, putting the conjoined steel reinforcement cage with the pile heads into a mould; 5, distributing materials; 6. then carrying out longitudinal tension; 6, putting the tensioned pile mould with the materials on a centrifuge for centrifugal forming; 7, putting the centrifugalized pile mould with the materials into a steam maintenance pool for steam maintenance; and 8, stripping after steam maintenance; then removing the connecting device; and obtaining a multisection tubular pile with the length of 1-3 meters. The production process has the characteristics ofhigh efficiency and low production cost.

Owner:湖北天利建筑技术有限责任公司 +1

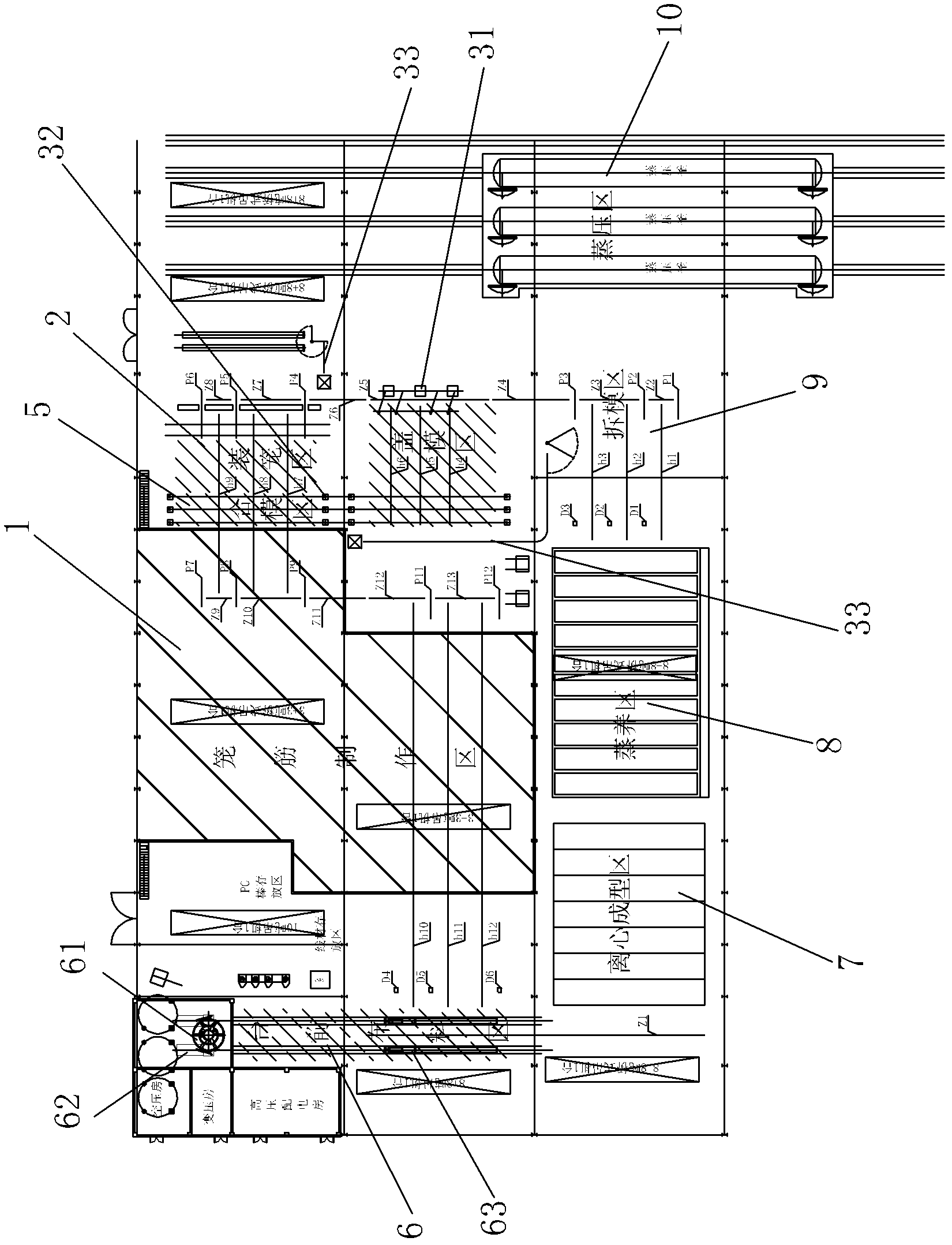

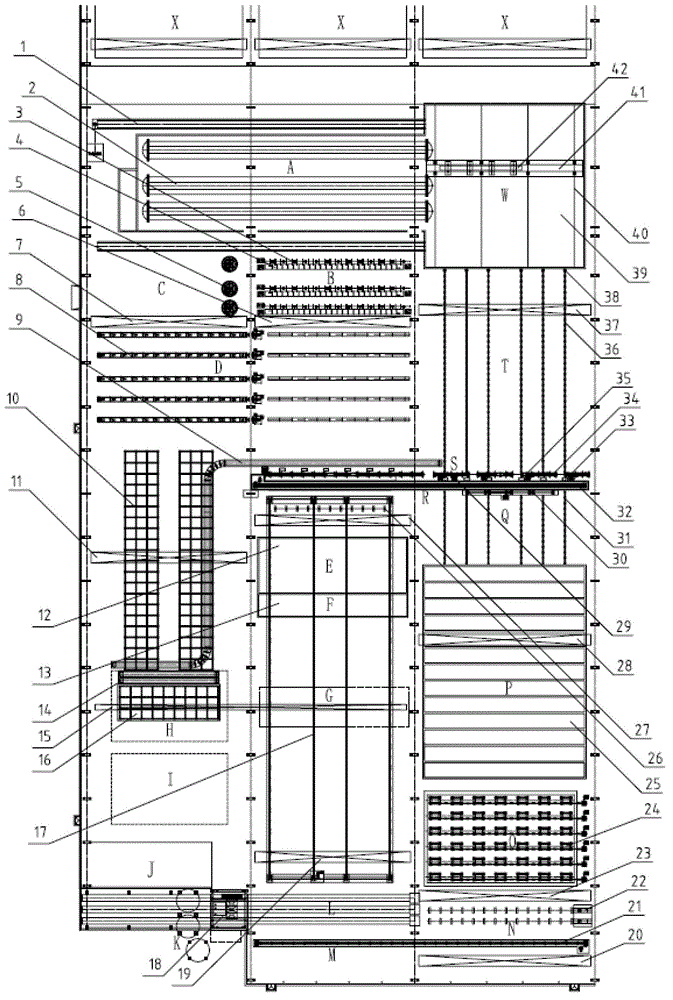

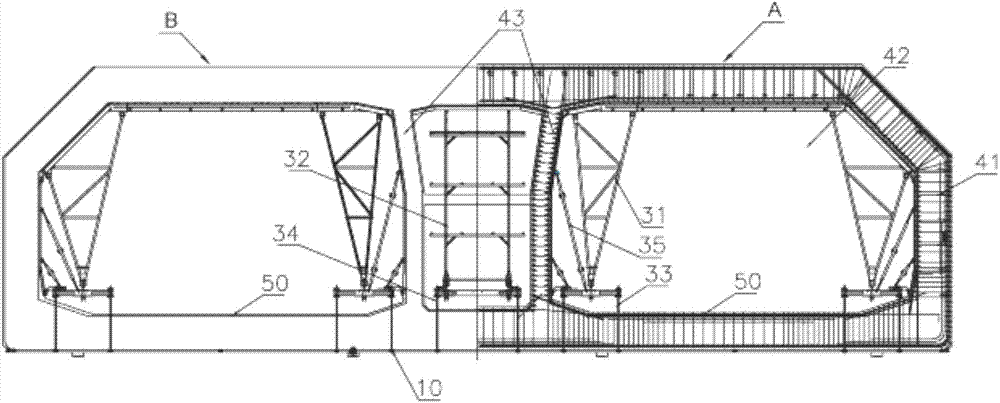

PHC (prestressed concrete pipe pile) pile streamline conveying production line

ActiveCN102744779AEasy to moveReduce incidenceCeramic shaping plantsShaping reinforcementsProduct inspectionProduction line

The invention belongs to a production process of a PHC pile and relates to a PHC pile streamline conveying production line. The production line is characterized by comprising a whole production workshop formed by a left area, a middle area and a right area, wherein from the front part to the back part of the workshop, the left area is sequentially provided with a blending floor, an end plate processing area, a steel reinforcement cage, an end plate assembling area and a steel reinforcement cage roll welding area, the middle area is sequentially provided with a concrete spreading area, a cage loading area, an oil spraying pool, a die-cleaning pool, a die-detaching area, and a steel rod precisely cutting and heading area, and the right area is sequentially provided with a tensioning area, a centrifugal molding area, a steaming area, a pipe pile expanding area, a product inspection and code-spraying identifier area, a to-be-high pressure steamed semi-finished pipe pile storing area and a high pressure kettle-entering transition carriage pit. The production line has the beneficial effects that plane circular arrangement is adopted, and the occurrence rate of accidents is reduced due to the adoption of a stereo lifting technical mode that the upper surface and the lower surface are mutually moved; and due to the adoption of a slope platform and a slope rail, the pipe pile is moved, the distance of carriage movement is greatly shortened, and the energy consumption is reduced.

Owner:TIANJIN PORT & CHANNEL PILE IND

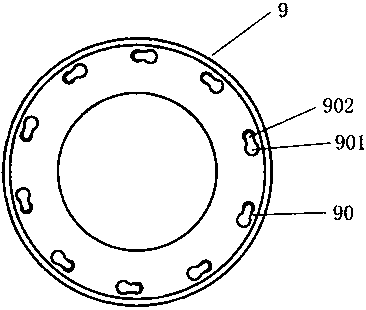

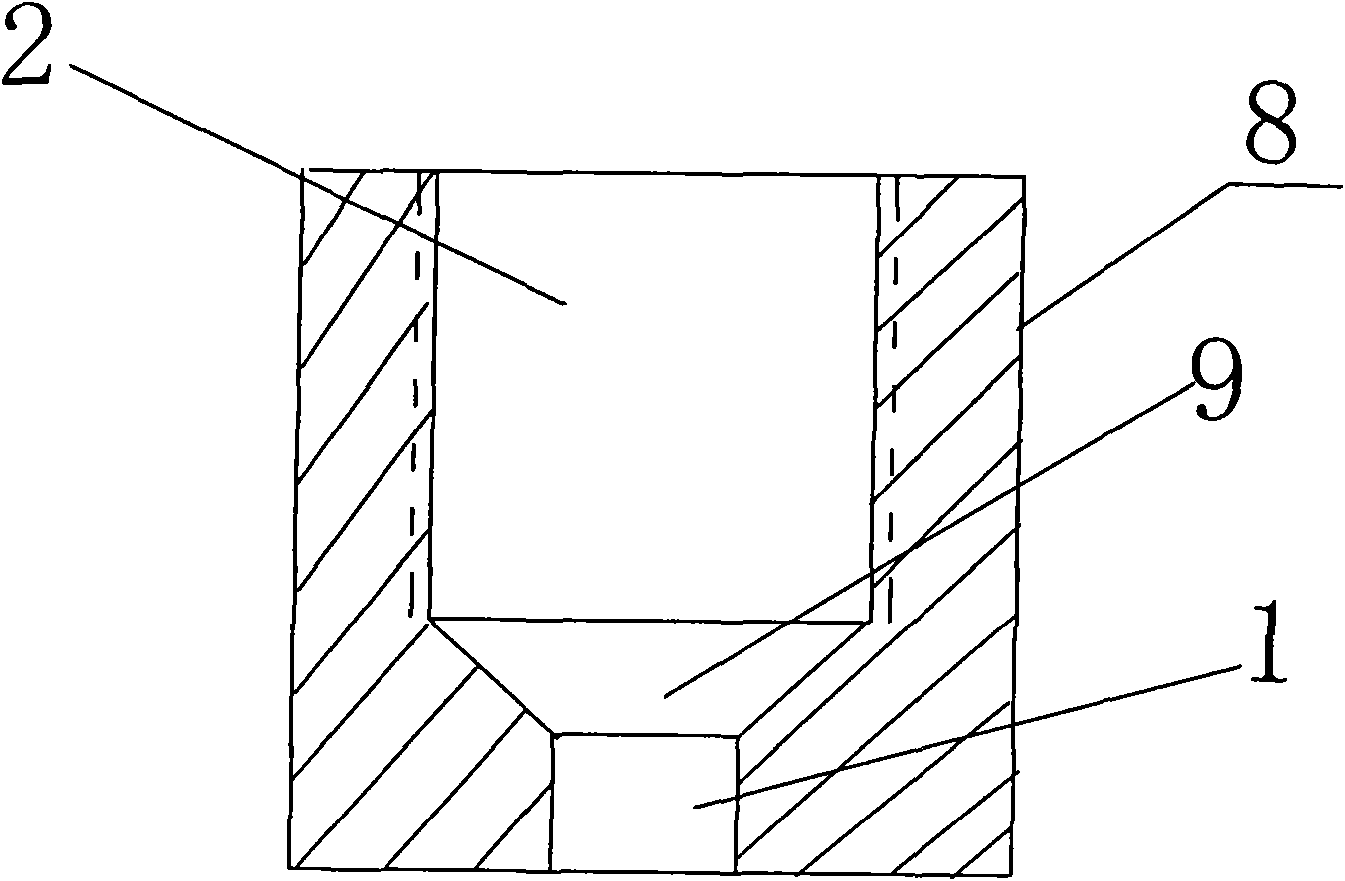

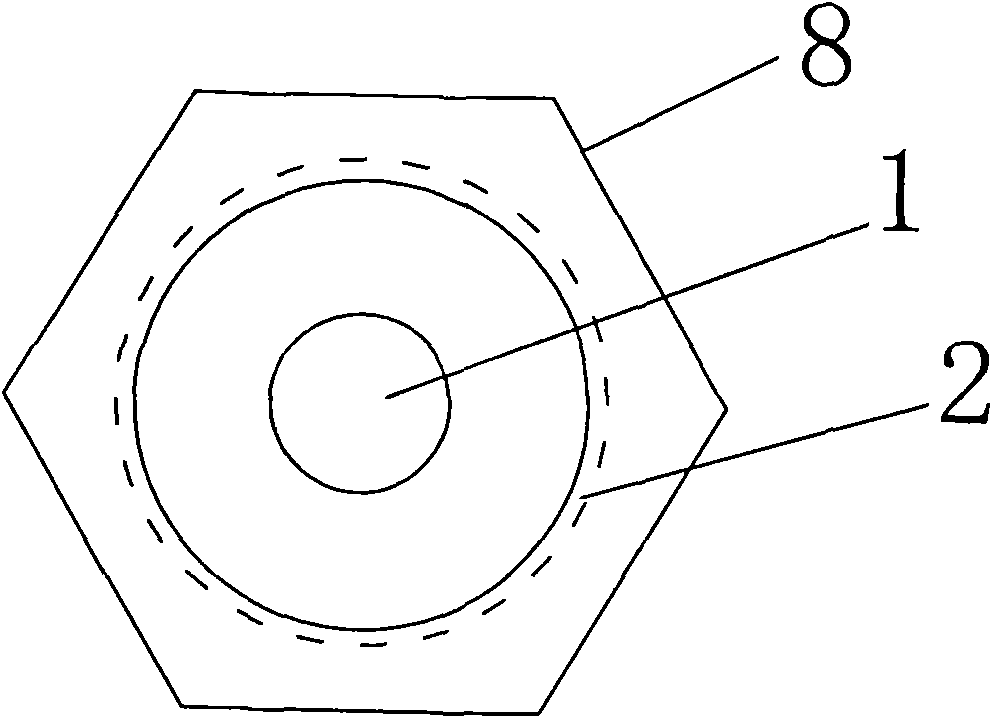

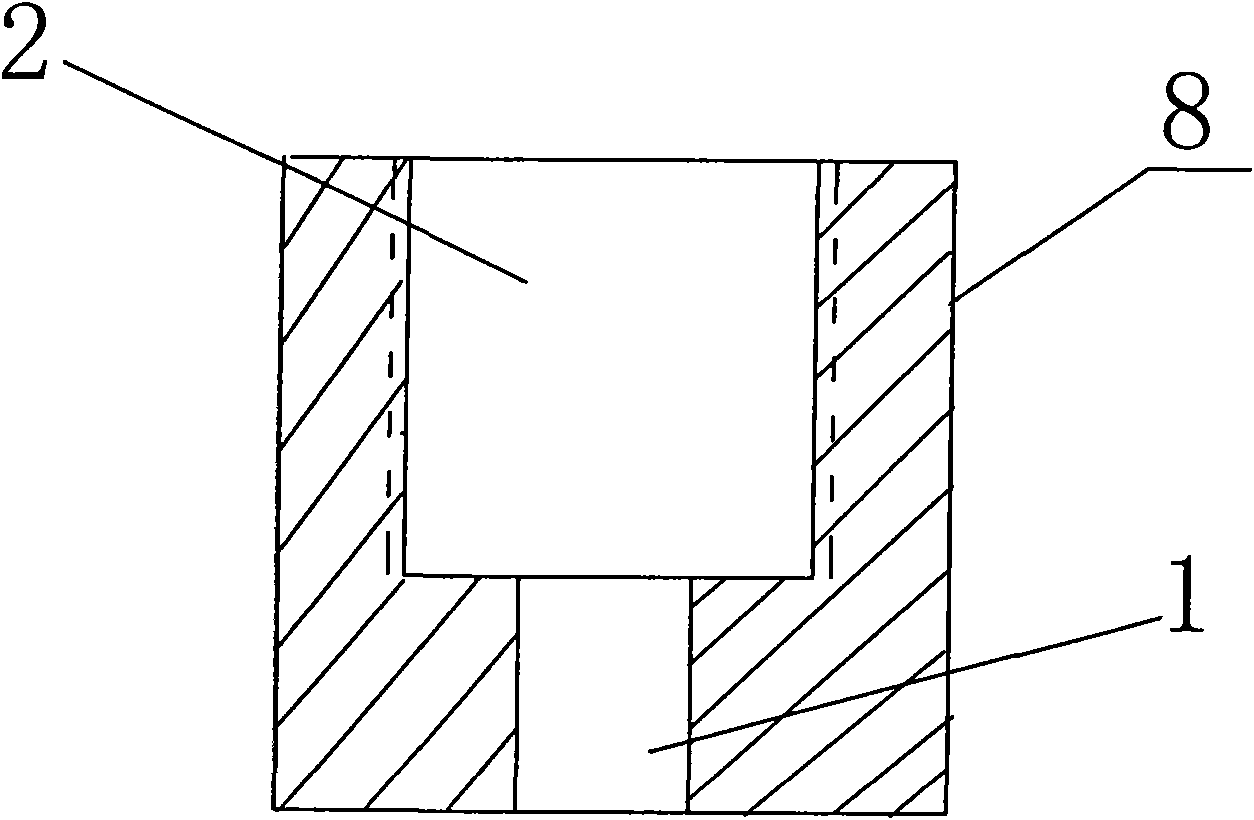

Pretensioning prestressed concrete pile, stretch-draw anchoring piece thereof and method for manufacturing stretch-draw anchoring piece

InactiveCN101614013AEasy to operateAvoid leaningShaping reinforcementsBulkheads/pilesPore diameterBiomedical engineering

The invention discloses a stretch-draw anchoring piece for a pretensioning prestressed concrete pile, a pile body structure thereof and a method for manufacturing the stretch-draw anchoring piece. The stretch-draw anchoring piece is the key of the invention. The stretch-draw anchoring piece comprises a body (8), wherein the body (8) is provided with screw pores (2) mutually running through, a tendon settling pore (1) and a transitional pore (9) for connecting the screw pores (2) and the tendon settling pore (1); the pore diameter of the tendon settling pore (1) is matched with the diameter of a prestressed main tendon; the pore diameter of each screw pore (2) is larger than that of the tendon settling pore (1); and the tendon settling pore (1) is a cylindrical pore or a polygon prism pore. The stretch-draw anchoring piece has the advantages of simple structure and convenient manufacture, and can greatly reduce the manufacturing cost and the cost of raw materials.

Owner:盐城市同力新型建材有限公司

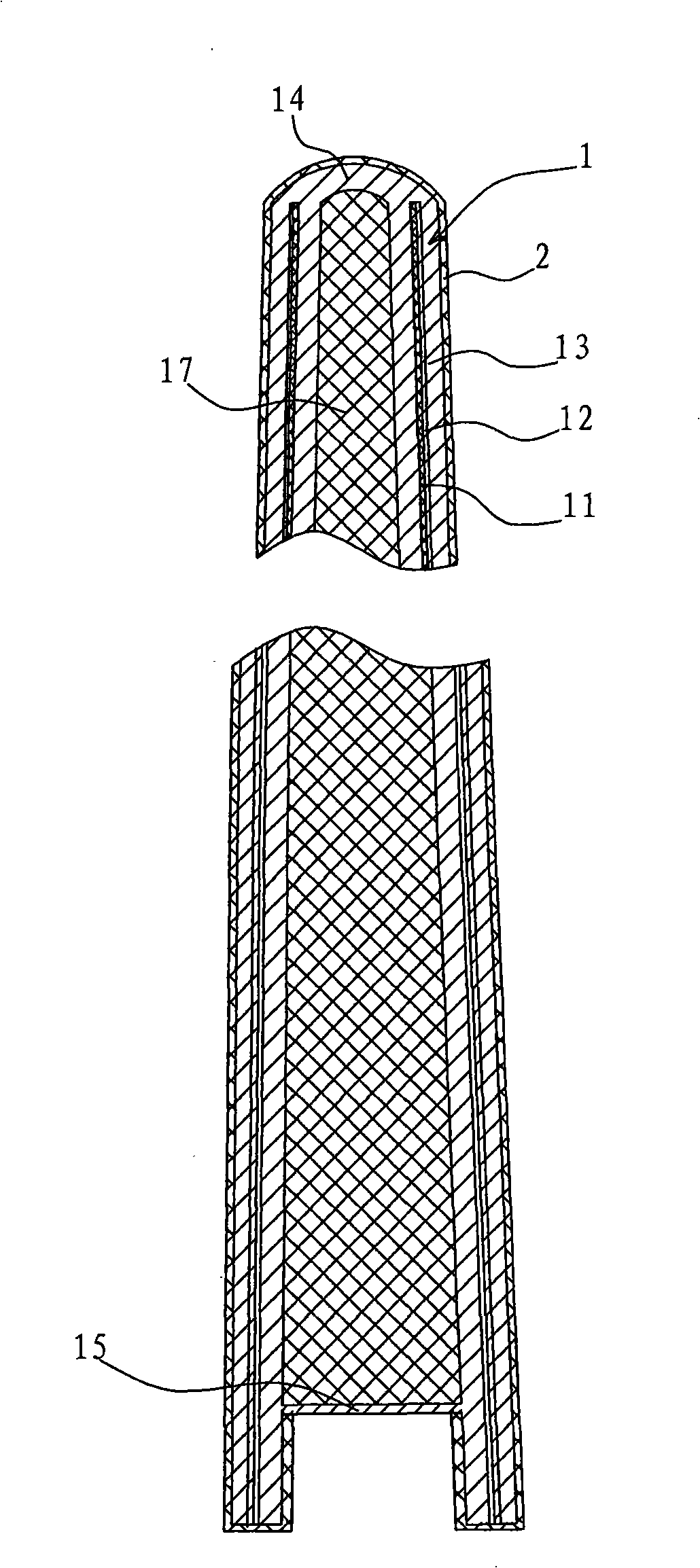

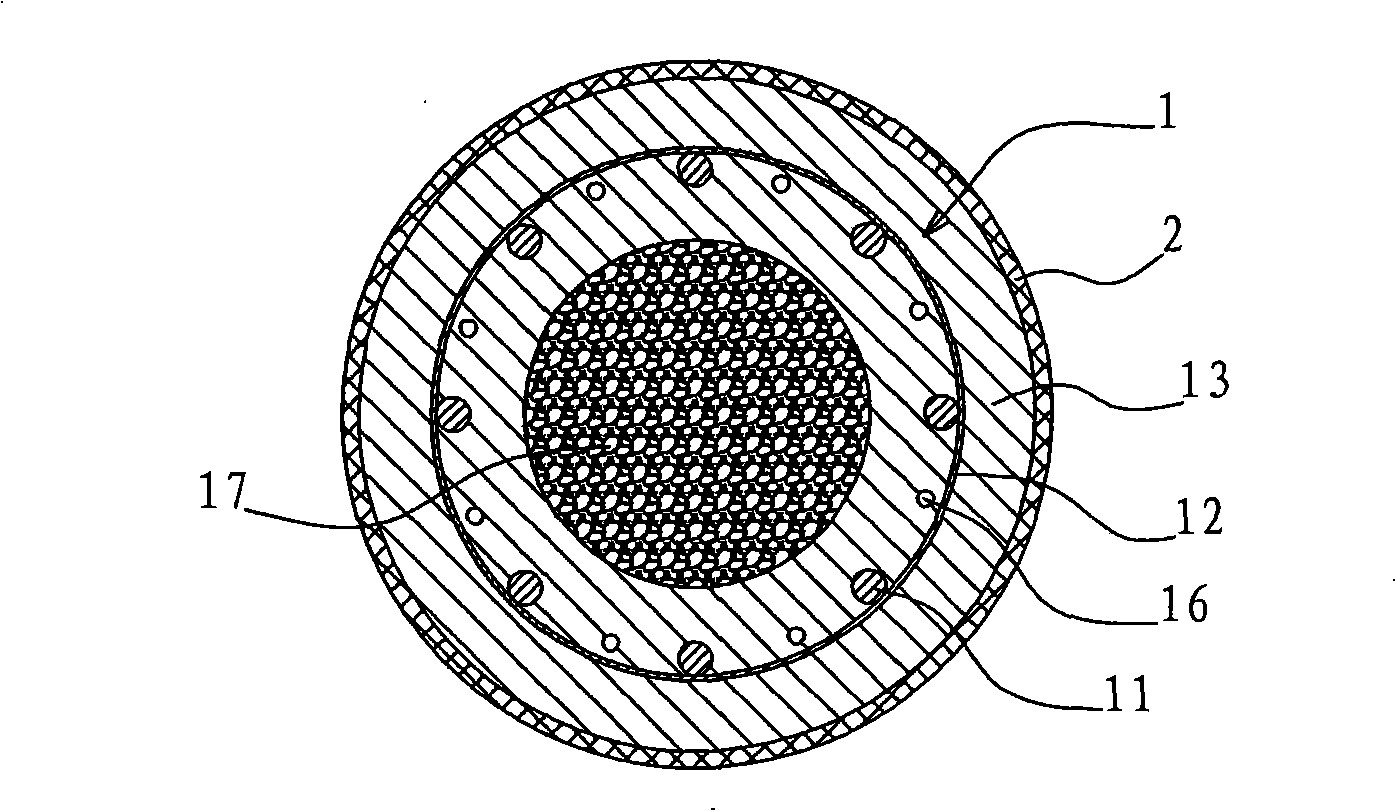

Insulated standard and processing technique thereof

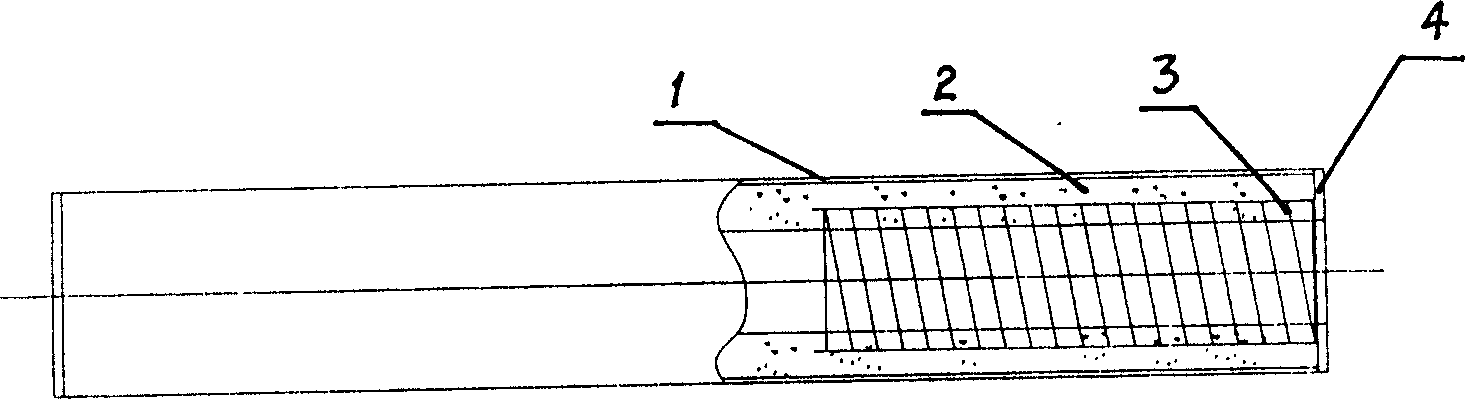

ActiveCN101294455AImprove insulation performanceEliminate leakage hazardsShaping reinforcementsTowersMesh gridEngineering

An insulated telegraph pole comprises a main layer (1) and a surface coat (2) coating the main layer (1). The insulated telegraph pole is characterized in that the surface coat (2) is a functional waterproof layer formed by combining organic substance with inorganic substance; the main layer comprises a plurality of insulated fiberglass-reinforced plastic main reinforcements (11), at least one layer of insulated grid glass fiber cloth (12) entwined with the main reinforcements (11) and fiber reinforced cement (13) for wrapping the main reinforcements (11) and the insulated grid glass fiber cloth (12). The top end and the lower end of the main layer (1) are sealed, and coated with functional waterproof layers formed by combining the organic substance and the inorganic substance. The insulated telegraph pole has excellent insulating property, high strength and long performance life.

Owner:CHANGSHU FENGFAN POWER EQUIP

Centrifugal tubular pile with concrete of thin-wall steel pipe and production thereof

InactiveCN1746434AEasy to operateImprove bindingShaping reinforcementsBulkheads/pilesReinforced concreteHigh pressure

A preparing progress of armoured concrete prefabricated member, thin-wall pipe centrifugal armoured concrete pipe pile is disclosed. It contains steal pipe and steel plate on ends of the pipe. Armoured concrete in the pipe and steal frame in inner layer. Steps of the progress contain form of steal frame, irrigating, centrifugating, evaporate protection and steam protection at high pressure and temperature.

Owner:SHANGHAI MCCZO ENG TECH +1

Production method of non-residual slurry non-autoclaved prestressed concrete pipe pile

ActiveCN103434020AReduce pollutionReduce energy consumptionShaping reinforcementsLow speedPre stress

The invention relates to a production method of a non-residual slurry non-autoclaved prestressed concrete pipe pile. The production method comprises the following steps: (1) sequentially adding fine aggregate, coarse aggregate, cement, mineral powder, a mineral additive, water and a water reducing agent into a reaction kettle, and evenly stirring to obtain a concrete mixture; (2) prestressed tensioning the concrete mixture after material distribution and die assembling; (3) centrifuging the concrete mixture after prestressed tensioning, and sequentially carrying out low speed, low medium speed, medium speed and high speed centrifugation steps in centrifugation without producing residual slurry in the centrifugation process; (4) placing the centrifuged concrete mixture into a steam maintenance pool for steam maintenance. According to the production method, after multiple experiments, through contrastive analysis, the nanoscale mineral additive is added, and by matching with the compound high-performance water reducing agent and adjusting existing pipe pile centrifugation and steam maintenance steps, the non-residual slurry centrifugation and one-time demoulding strength of C80 are realized, so that the working procedures of pouring residual slurry and steam maintenance are eliminated, and the environmental pollution and energy consumption of enterprises are greatly reduced.

Owner:TIANJIN YONGSHENG XINHE PILE

Novel highly-efficiency, energy-saving and environmentally-friendly method and system for manufacturing centrifugal concrete pile

InactiveCN101890756AQuality is not affectedSimple preparation processMouldsShaping reinforcementsCentrifugationNational standard

The invention discloses a novel highly-efficiency, energy-saving and environmentally-friendly method and a novel highly-efficiency, energy-saving and environmentally-friendly device for manufacturing a centrifugal concrete pile. The production process comprises the following: a step 1, processing a pile-shaped end plate according to national standards and requirements of a picture set; a step 2, producing two branched piles or square piles by using one die; a step 3, manufacturing two end plates with bolt holes at positions symmetrical to bolt holes in the picture set; and a step 4, cutting a part of each of four angles of a connection plate of a square pile hoop and the end plates. The method and device have the advantages that: slurry is not leaked during centrifugation; and the quality of the concrete pipe is not affected. Moreover, compared with the prior art, the method and the system have the advantages of simple pile manufacturing process, low cost, environment protection and waste recycling.

Owner:NINGBO YIZHONG CONCRETE PILE +2

A kind of production method of high-strength concrete prefabricated piles mixed with fiber-reinforced plastic bars

ActiveCN102259386AImprove performanceImprove the bending capacityShaping reinforcementsHigh strength concreteFiber

The invention discloses a production method of a high-strength concrete precast pile doped with a fiber enhanced plastic tendon. The method comprises the following steps: A. circularly arranging a plurality of prestressed reinforcements, welding spiral tendons on the outer sides of the plurality of prestressed reinforcements to cause the plurality of prestressed reinforcements to form a prestressed reinforcement skeleton cage, and arranging fiber enhanced plastic tendons in the prestressed reinforcement skeleton cage to form a compound skeleton cage; B. hoisting the compound skeleton cage into the lower die body of a cleaned die, and respectively installing end joint plates connected with an anchor ear plate onto two ends of the compound skeleton cage; C. conveying the pre-stirred concrete material to the die body by a concrete stirrer; D. horizontally putting the die in step C, and carrying out prestressed stretching on the compound skeleton cage; E. carrying out centrifugal shaping on the stretched die on a centrifugal machine, and completely pouring residual slurry on the inner wall after shaping; and F. hoisting the above die into a steam curing pool for steam curing, and removing the die after steam curing to obtain the pile.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

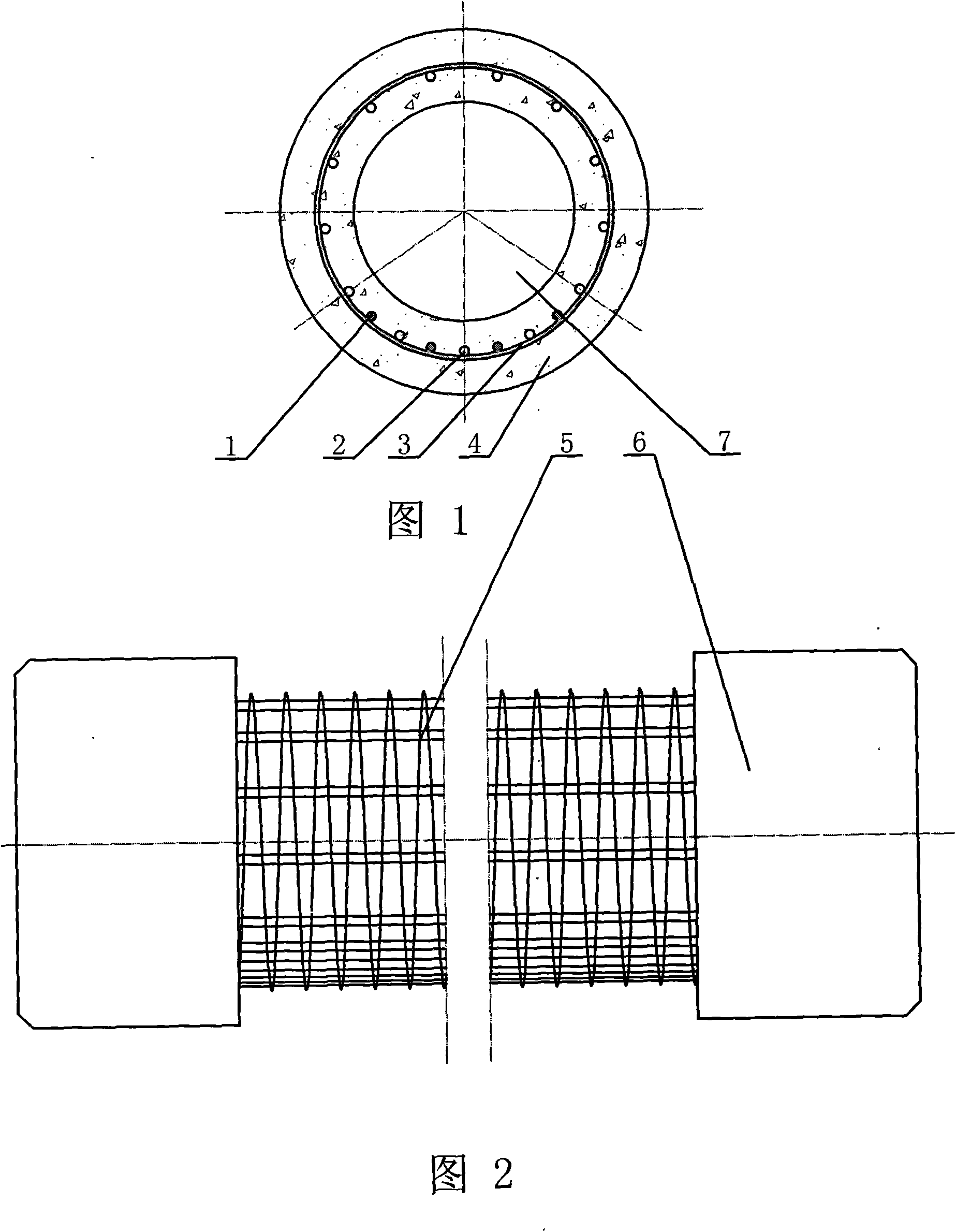

Horizontal force supporting pile and production process thereof

InactiveCN101570969AImprove performanceGood value for moneyShaping reinforcementsBulkheads/pilesHorizontal forcePre stress

The invention discloses a horizontal force supporting pile and a production process thereof. The horizontal force supporting pile comprises concrete, a reinforcement cage and end boards fixed on two ends of the reinforcement cage, wherein the reinforcement cage consists of prestressed reinforcement, helical reinforcement and nonprestressed reinforcement; the prestressed reinforcement can be made of PC steel bars with high tensile strength; the nonprestressed reinforcement is arranged on the helical reinforcement in a tensile zone of a tubular pile, and is vertically bound on the helical reinforcement, and does not participate prestressed tension after the tubular pile is in die closing, thereby changing the defects that the prior tubular pile has poor anti-bending strength, brittle fracture and poor ductility, the tubular pile spreads fast after fracture, and the reinforcement in the tensile zone quickly yields and contracts until fracture, nearly the same of ultimate bending moment and cracking bending moment, and the like. The horizontal force supporting pile and the production process improve the whole performance of the tubular pile, and have the advantages of simple process, low cost, high cost performance, wide application range and the like.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

Activated powder concrete pole with high strength and high conductivity and making method thereof

ActiveCN102251702AHigh strengthImprove conductivityShaping reinforcementsTowersRebarPolymer solution

Owner:江西饶电科技股份有限公司

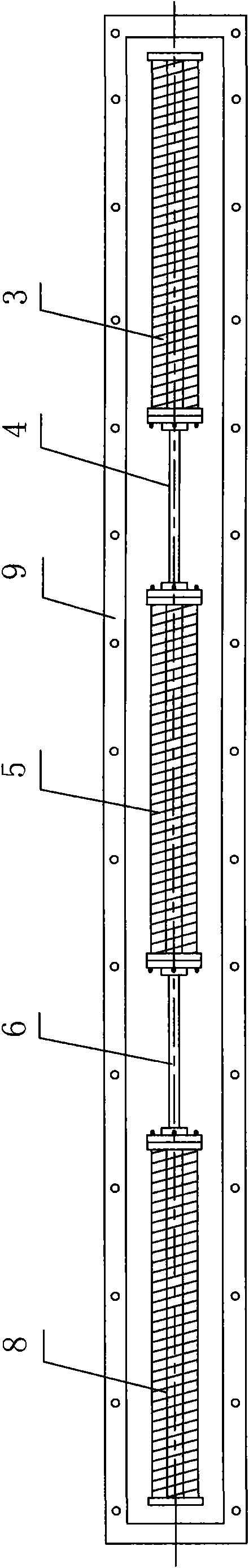

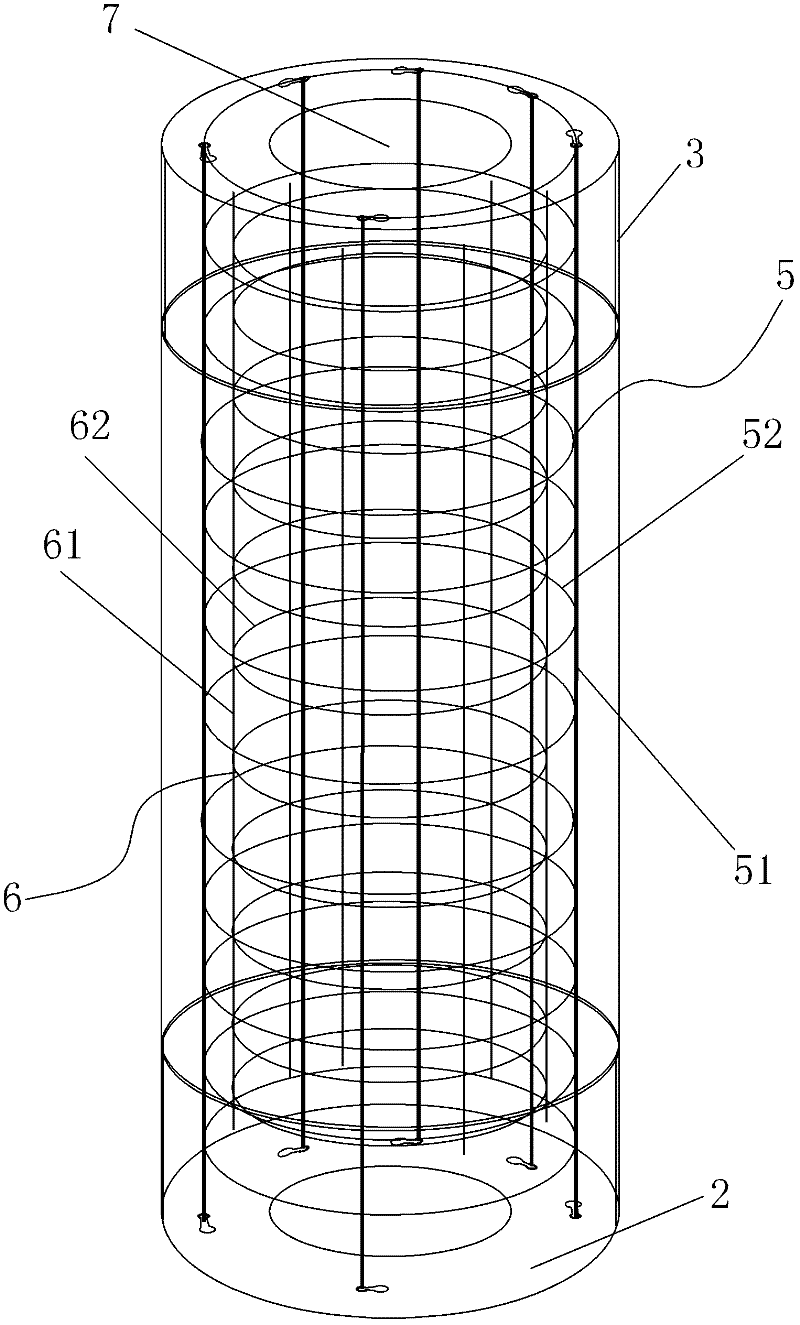

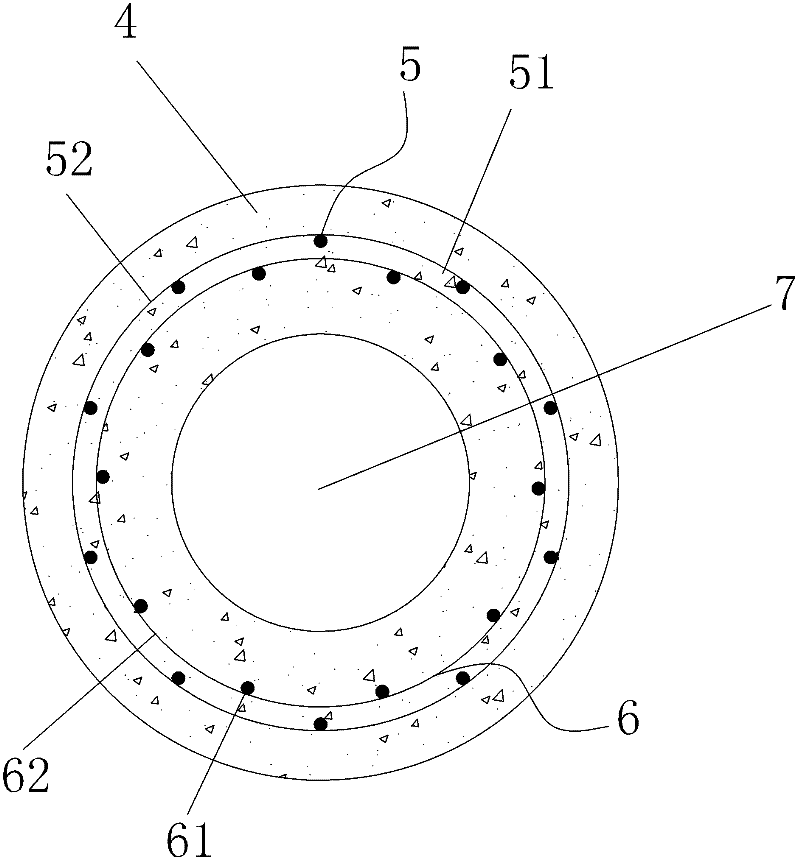

Prestress tensioning mechanism for steel reinforcement cage

ActiveCN105563636AHigh degree of automationFit closelyShaping reinforcementsRebarReciprocating motion

The invention belongs to the technical field of buildings, and relates to a prestress tensioning mechanism for a steel reinforcement cage. The prestress tensioning mechanism comprises a stander, wherein a tensioning oil cylinder is fixed on the stander; a connecting shaft oil cylinder which is in sliding connection with the stander is arranged in the stander; the power output shaft of the tensioning oil cylinder is fixedly connected with the connecting shaft oil cylinder, and the power output shaft of the connecting shaft oil cylinder is connected with a taper sleeve which is provided with a conical inner cavity and in sliding connection with the inner wall of the stander; the taper sleeve can do reciprocating motion along the inner wall of the stander under the action of the power output shaft of the connecting shaft oil cylinder and is hinged with a plurality of catching blocks which are uniformly arranged along the circumferential direction of the taper sleeve and are in sliding connection with the taper sleeve. The prestress tensioning mechanism can automatically realize connection with a tensioning screw rod and tension the steel reinforcement cage; after the steel reinforcement cage is tensioned, the prestress tensioning mechanism can automatically lock and tension large nuts and is high in automation degree.

Owner:周兆弟 +7

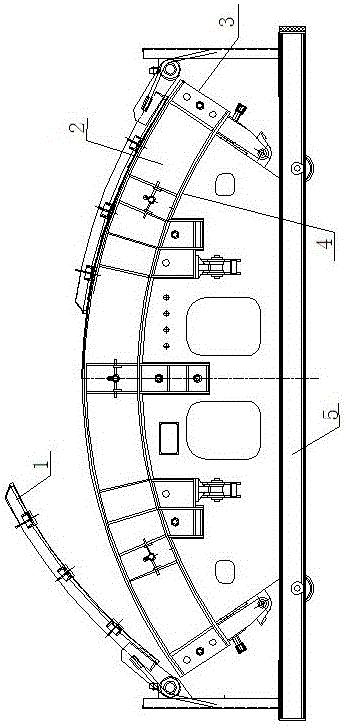

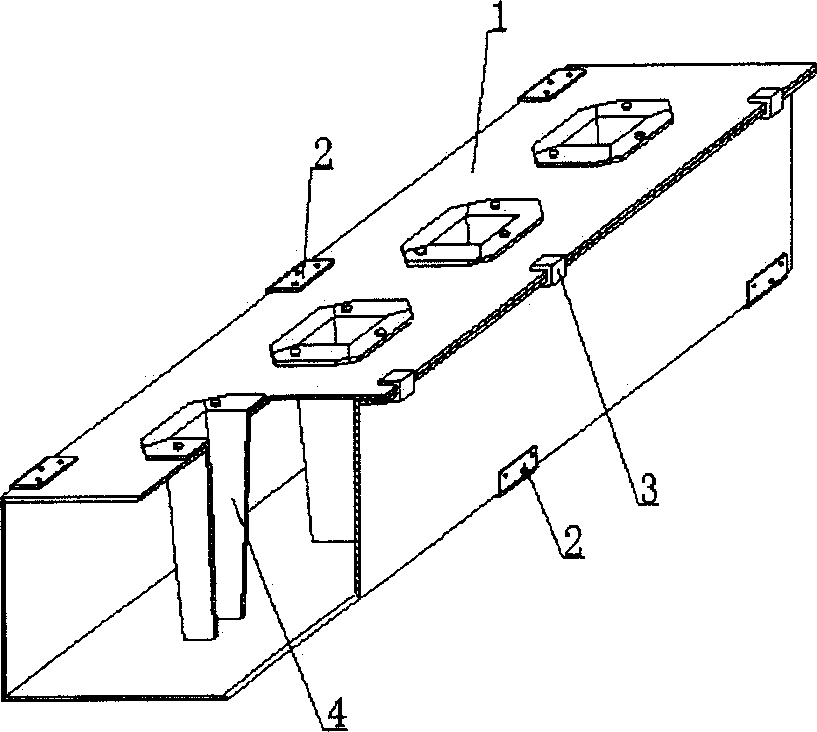

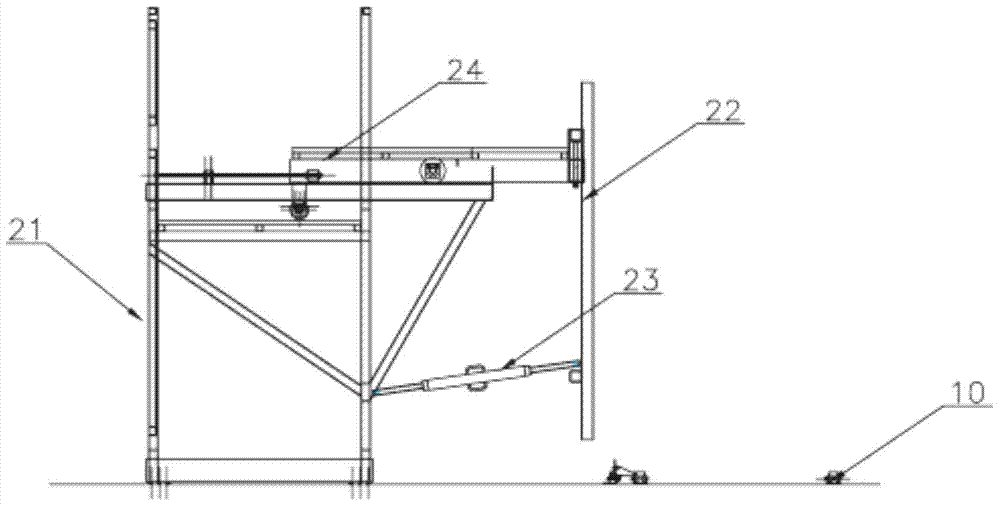

Movable reinforcement cage binding jig

InactiveCN103696440AImprove ergonomicsHigh precisionArtificial islandsShaping reinforcementsEngineeringRebar

The invention relates to the field of immersed tube tunnels, in particular to a movable reinforcement cage binding jig, which comprises a plurality of sliding tracks, an outer jig and an inner jig, wherein the sliding tracks are arranged in parallel, the outer jig is fixed out of a reinforcement cage, the inner jig is arranged in the reinforcement cage and is positioned on the sliding tracks, and the inner jig can move along the sliding tracks. The inner jig and the reinforcement cage of the movable reinforcement cage binding jig are arranged on the sliding tracks and can be removed and conveniently moved, the movable reinforcement cage binding jig is suitable for factory large-sized prefabricated parts, and a movable jig structure which can be quickly installed and removed is adopted, so that the work efficiency and the precision of binding the reinforcement cage are improved.

Owner:CCCC SECOND HARBOR ENG +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com