Connecting sleeve, prefabricated part comprising same as well as production method and connecting method thereof

A technology for prefabricated components and production methods, which is applied in basic structural engineering, reinforcement molding, sheet pile walls, etc., can solve the problems of high labor intensity, heavy end plates, complex processing procedures, etc., to improve production quality, reduce labor intensity, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

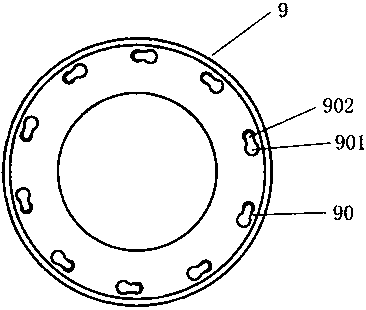

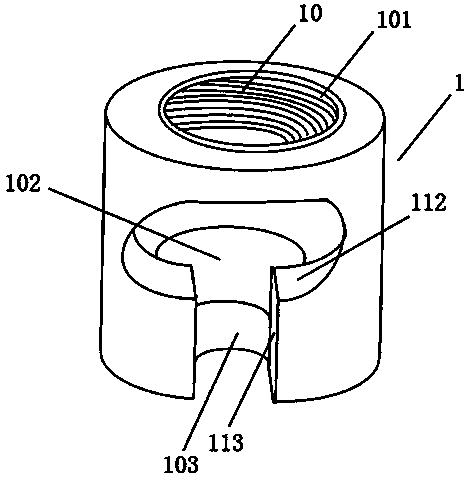

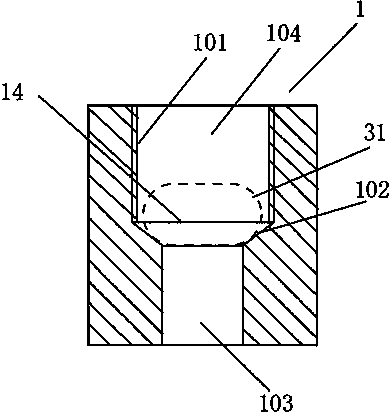

[0060] Such as Figure 2 to Figure 8 As shown, it is a schematic diagram of a preferred embodiment of the connecting sleeve 1 for prefabricated components of the present invention, which has the following structure: the overall shape of the connecting sleeve 1 is cylindrical, and the connecting sleeve 1 has a through hole in the axial direction 10. The through hole 10 includes at least two parts from top to bottom. The first part of the through hole 10 is provided with internal threads 101, that is, the inner wall is provided with threads; the second part of the through hole 10 is The generally tapered tapered hole 102 is used to accommodate the header 31 of the prestressed main rib 3 after the header treatment; in addition, the side wall of the connecting sleeve 1 is also provided with a hole extending into the through hole 10 Open slot 11, and, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com