Patents

Literature

20347 results about "Bearing capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geotechnical engineering, bearing capacity is the capacity of soil to support the loads applied to the ground. The bearing capacity of soil is the maximum average contact pressure between the foundation and the soil which should not produce shear failure in the soil. Ultimate bearing capacity is the theoretical maximum pressure which can be supported without failure; allowable bearing capacity is the ultimate bearing capacity divided by a factor of safety. Sometimes, on soft soil sites, large settlements may occur under loaded foundations without actual shear failure occurring; in such cases, the allowable bearing capacity is based on the maximum allowable settlement.

Formula of wheel-rack solid lubrication additive for railway traffic

The invention discloses a prescription of a wheeltrack lubricant additive, which is characterized by strong bearing capacity, high temperature resistance and long effective time upon one time coating, thereby solving the defect that factigue crack expansion of the wheeltrack is accelerated by traditional grease for the generation of oil wedge effect. The prescription comprises 1 percent-30 percent of metal powder, 3 percent-50 percent of high temperature solid lubricant material and 5 percent-50 percent of fatty acid by weight. The strip solid materials can be produced in virtue of other accessories by the prescription.

Owner:张念

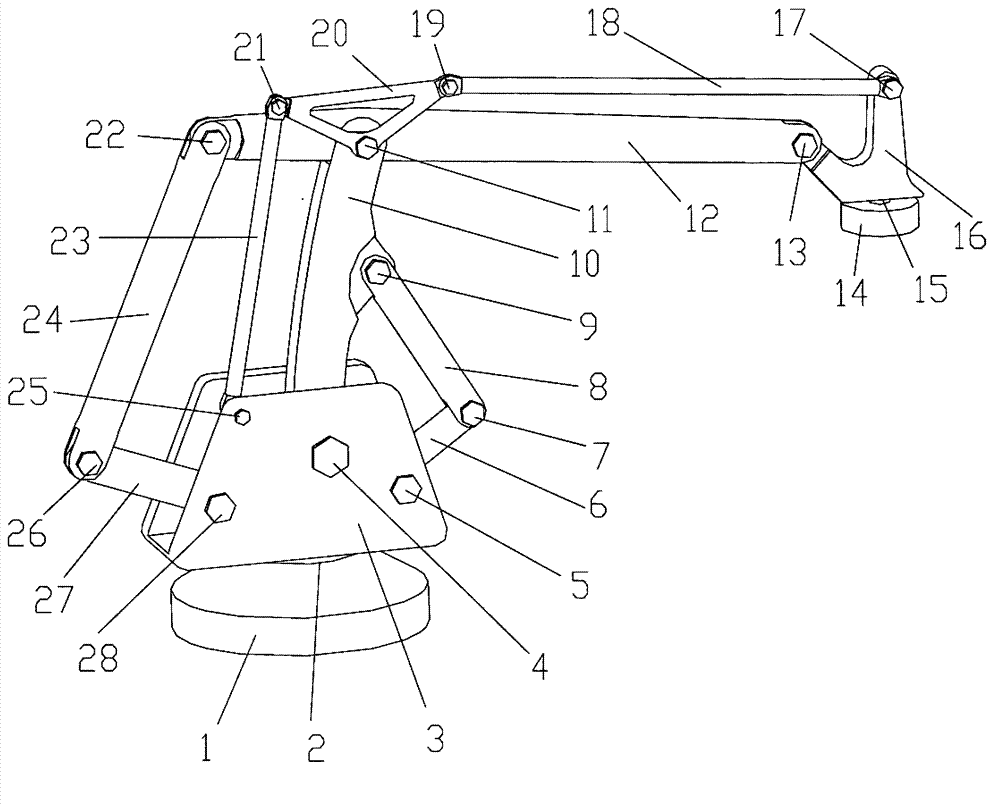

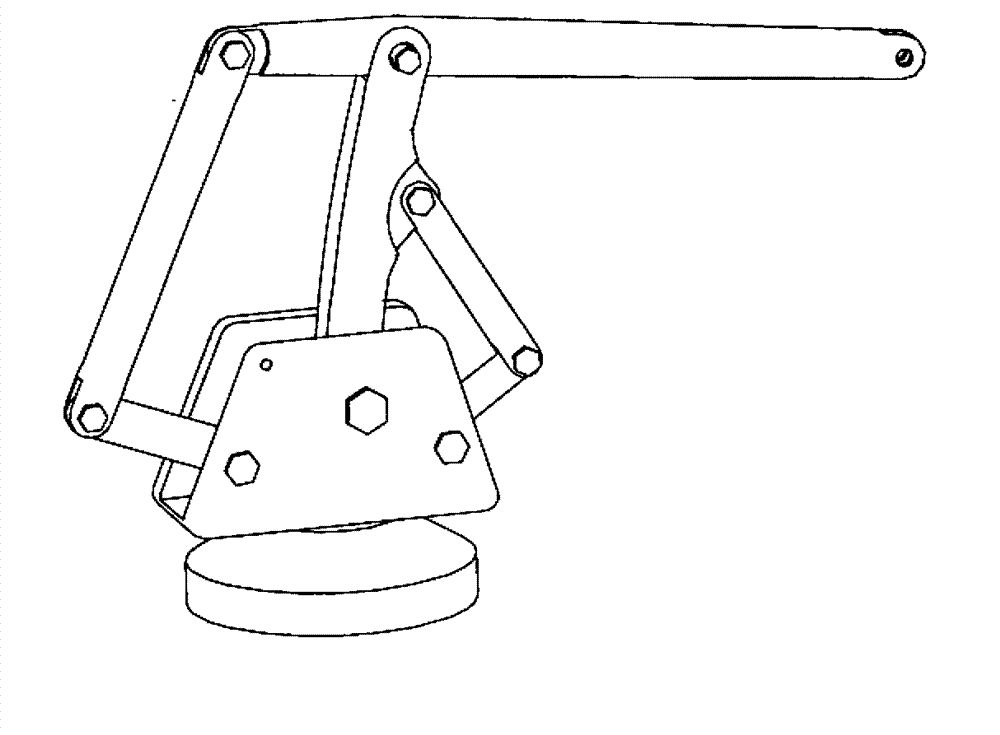

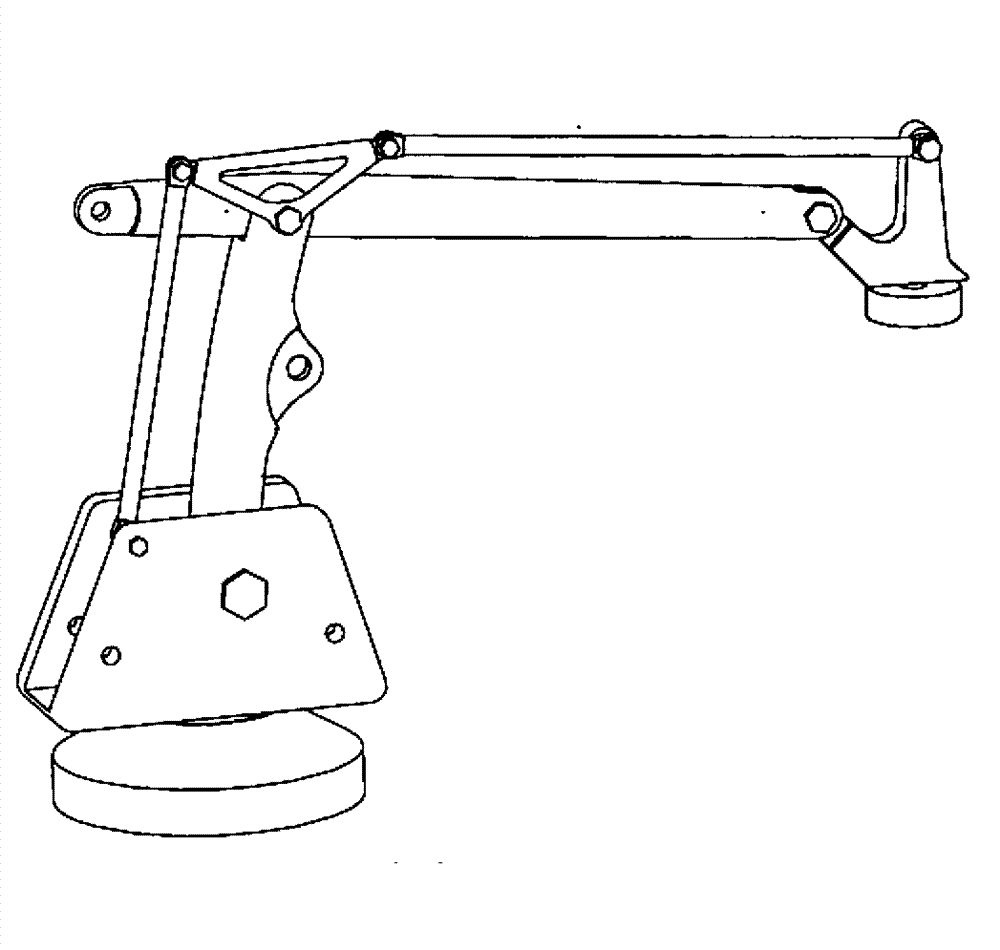

Multi-degree-of-freedom controllable mechanism type stacking robot

InactiveCN103029124AFlexible operationImprove flexibilityProgramme-controlled manipulatorGripping headsEngineeringMulti degree of freedom

The invention discloses a multi-degree-of-freedom controllable mechanism type stacking robot, which comprises a pedestal, a rotary rack, an arm lifting mechanism, an end effector translation retaining mechanism and a flange, wherein the rotary rack is connected to the pedestal through a rotary pair; the arm lifting mechanism comprises a large arm, a small arm, a first driving rod, a first connecting rod, a second driving rod and a second connecting rod; all the rods are connected through hinges; the end effector translation retaining mechanism comprises a parallelogram mechanism consisting of the large arm, a first auxiliary connecting rod, a triangular auxiliary rack and the rotary rack and a parallelogram mechanism consisting of the small arm, a second auxiliary connecting rod, a triangular auxiliary rack and an end effector translation retainer; all the rods are connected through hinges; the flange is connected to the end effector translation retainer through the rotary pair; and different end effectors can be arranged according to actual requirements. The multi-degree-of-freedom controllable mechanism type stacking robot has the advantages of simple structure, high bearing capacity, large working space, flexibility in operation, capabilities of driving through a servo motor for control, realizing intelligence and digital control and meeting handling and stacking requirements of high speed, heavy load, precision and the like and extremely broad application prospect.

Owner:GUANGXI UNIV

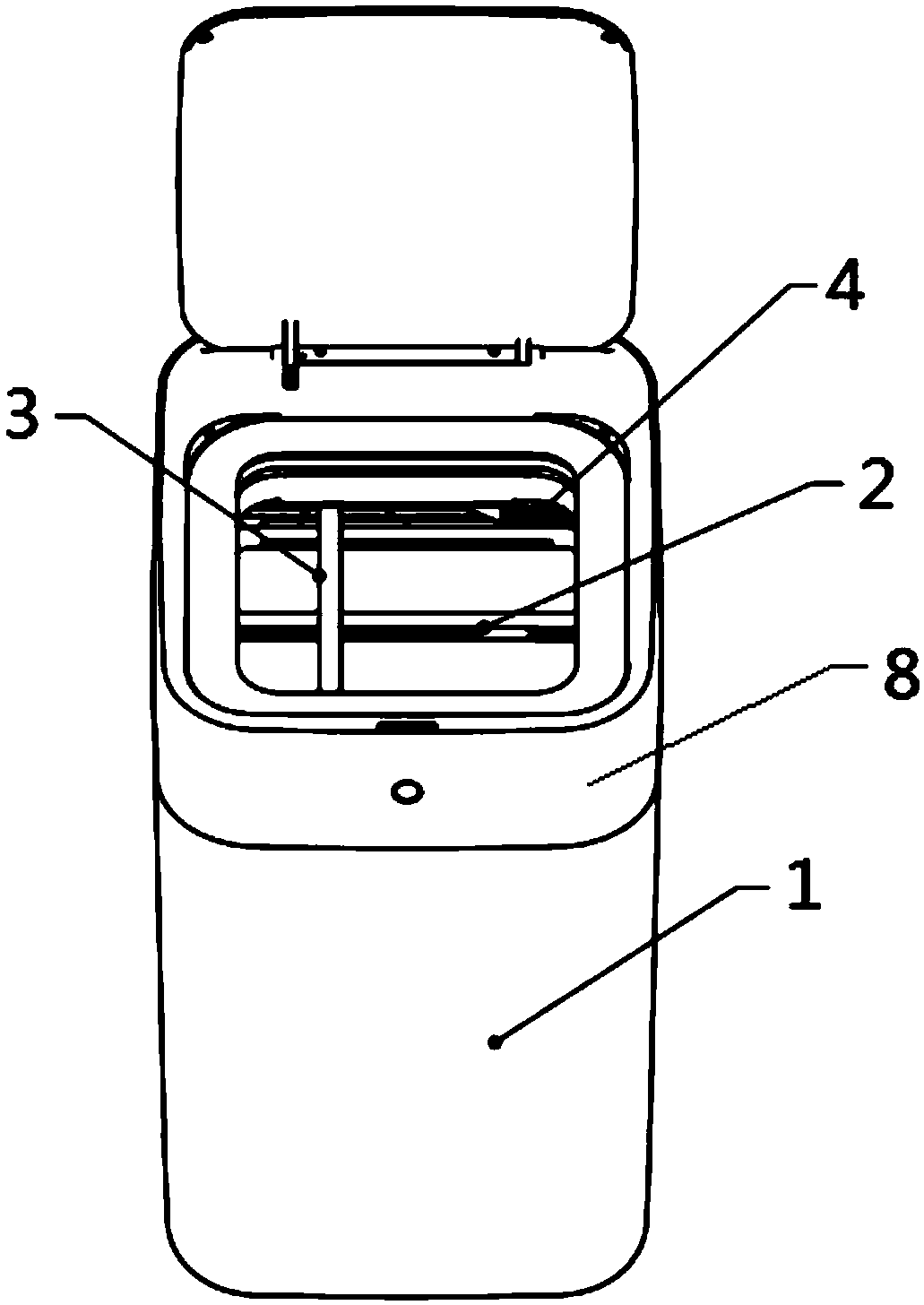

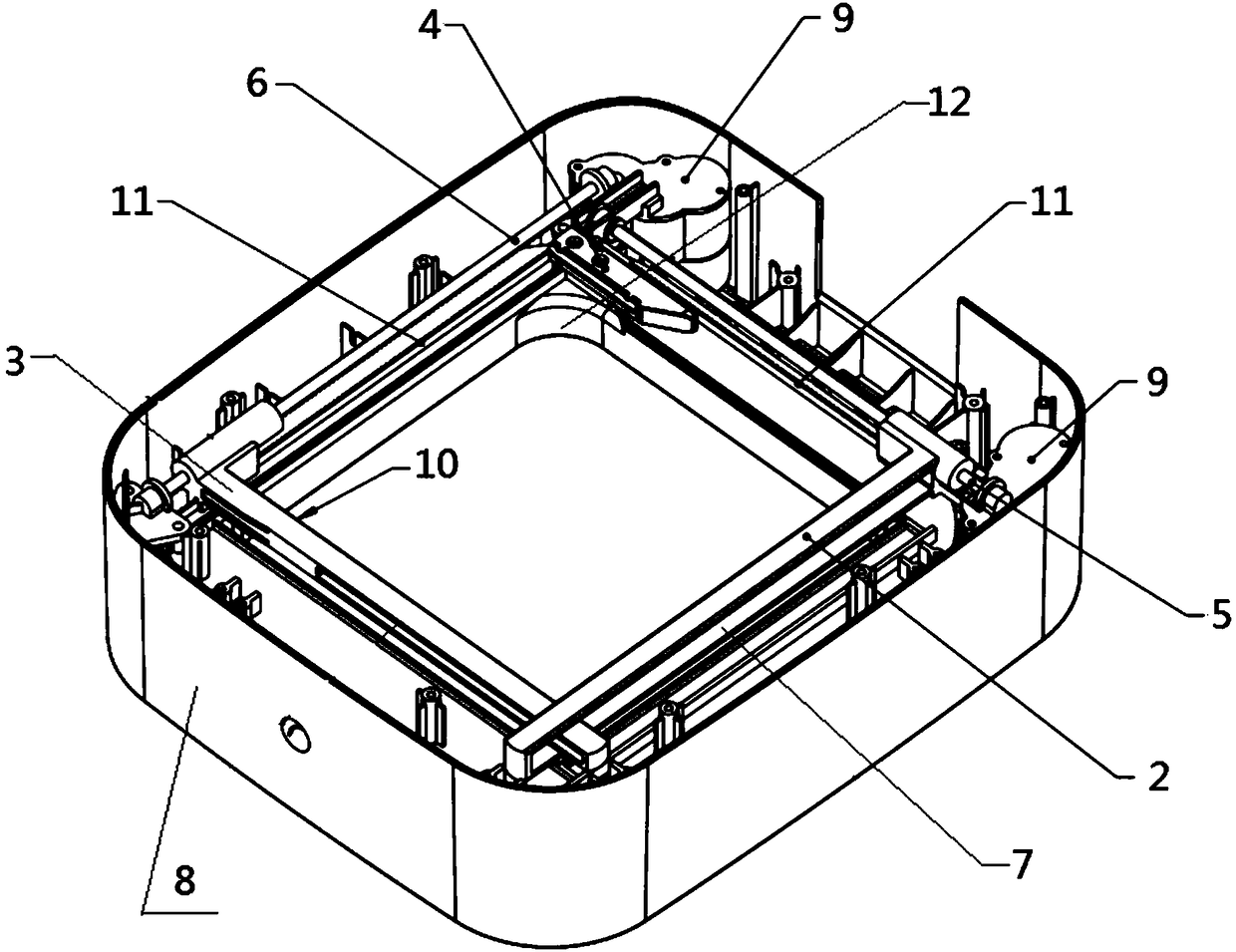

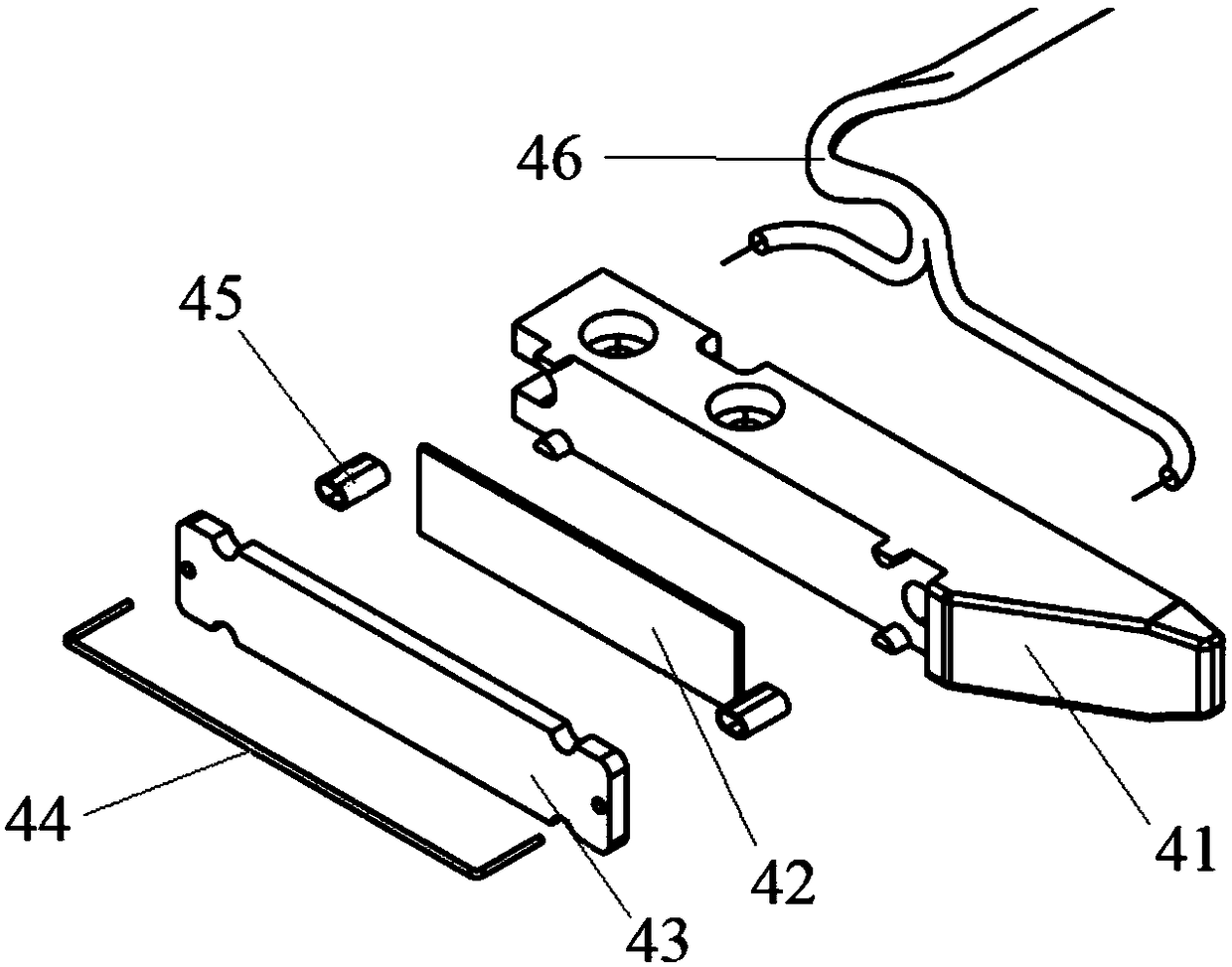

Garbage bag sealing mechanism and intelligent garbage can

PendingCN108584238ASolve the problems of poor sealing, weak sealing and weak bearing capacityRefuse receptaclesWrapper twisting/gatheringSemi automaticEngineering

The invention discloses a garbage bag sealing mechanism and an intelligent garbage can. The garbage bag sealing mechanism is arranged in a garbage can body. The top of the inner wall of the garbage can body is provided with a first fixing edge and a second fixing edge intersecting with the first fixing edge. The garbage bag sealing mechanism comprises a first pressing rod and a second pressing rod, wherein the first pressing rod can slide along the second fixing edge so as to gather an opening of the garbage bag to the first fixing edge, the second pressing rod can slide along the first fixingedge so as to gather the opening of the garbage bag to the second fixing edge, and the first pressing rod and the second pressing rod can gather the garbage bag to the intersection position of the first fixing edge and the second fixing edge. A hot melting device used for conducing hot melting and sealing on the garbage bag is arranged close to the intersection position. The garbage bag sealing mechanism further comprises drive devices driving the first pressing rod and the second pressing rod to move. By the adoption of the arrangement, the problems that an existing intelligent garbage can is not provided with an automatic sealing mechanism, or the existing intelligent garbage can can only seal the garbage bag in a semi-automatic manner and be poor in garbage bag sealing performance, opening seal is infirm, and the bearing capacity is poor are solved.

Owner:SHANGHAI TOWNEW INTELLIGENT TECH CO LTD

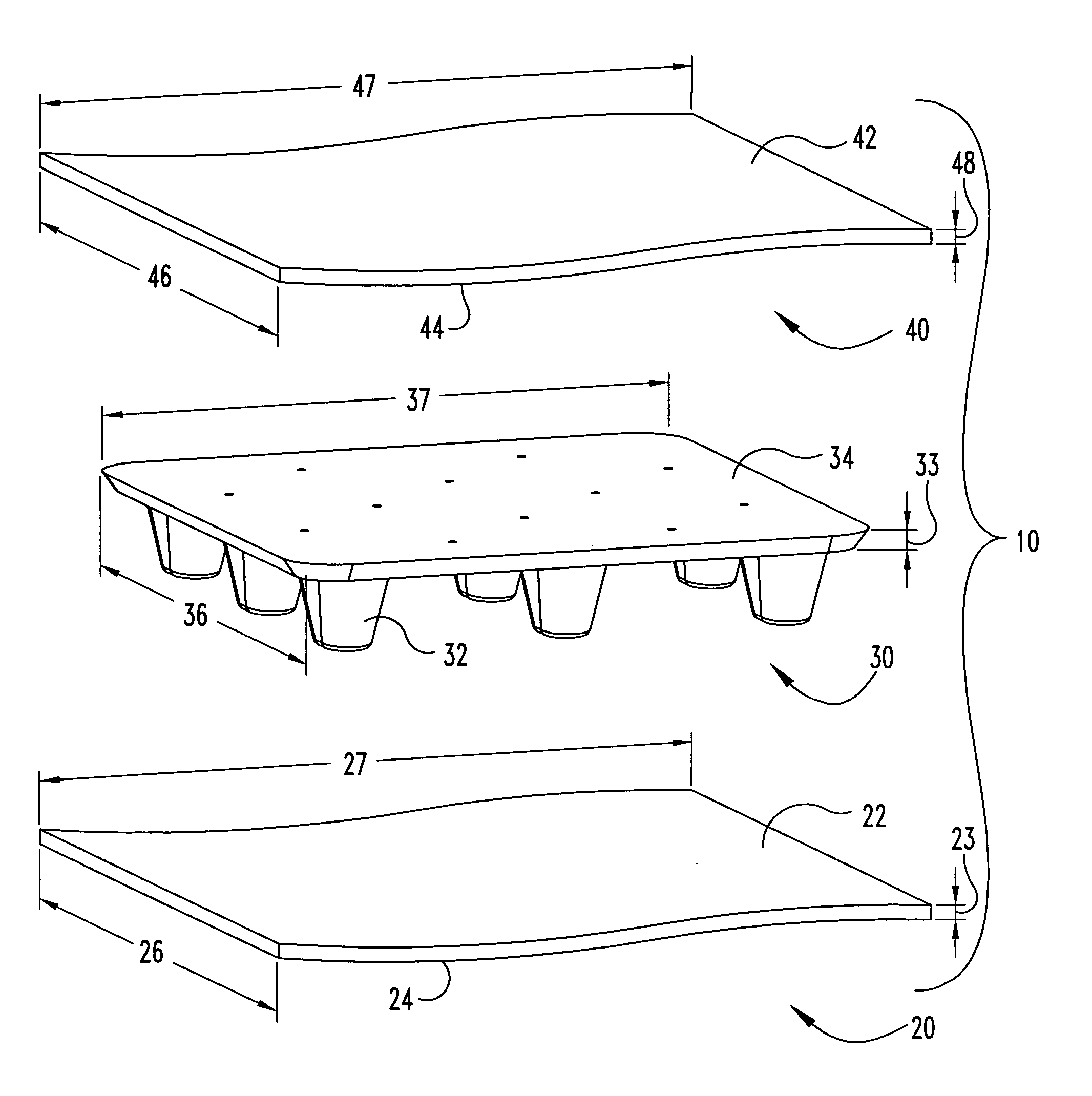

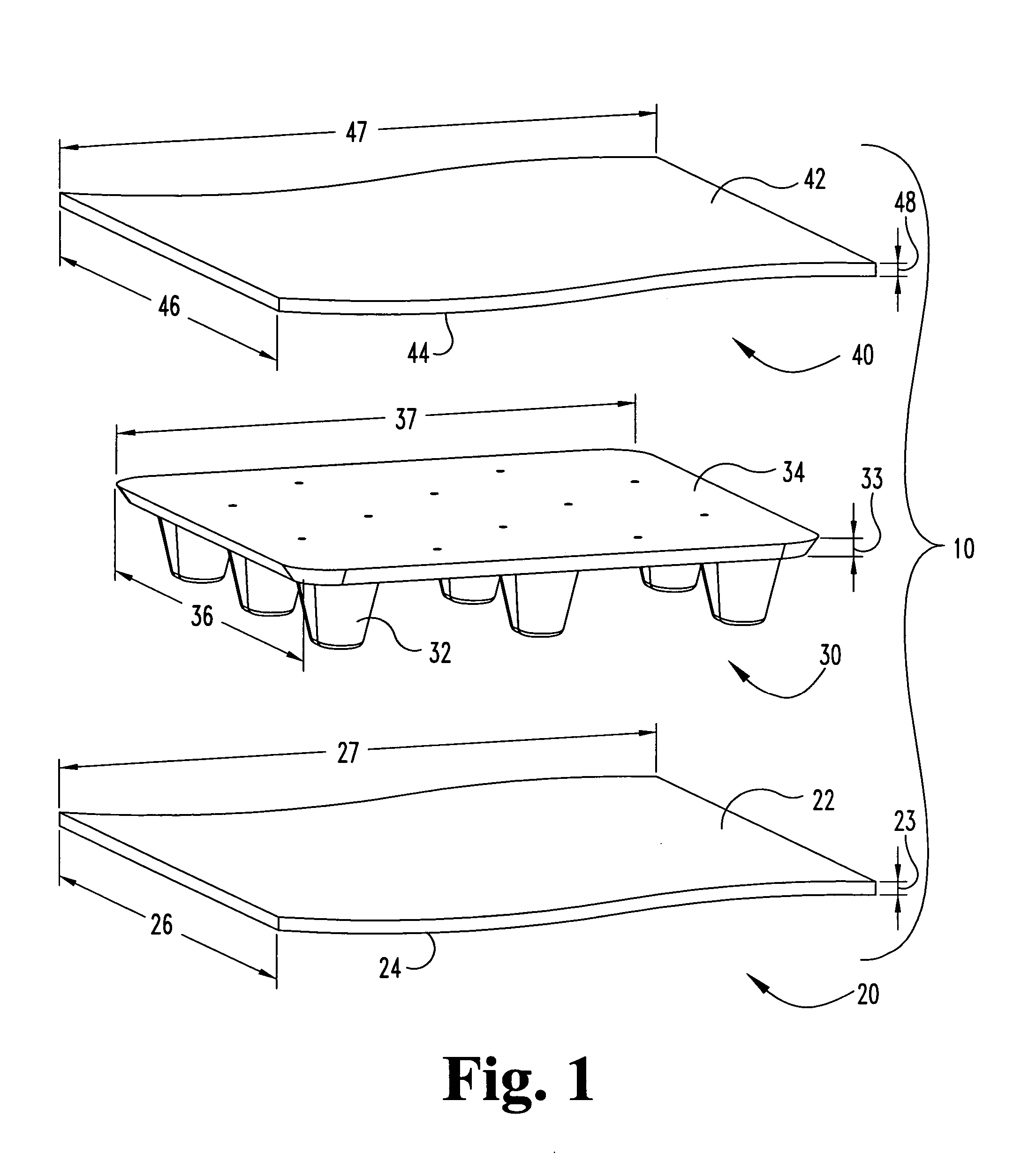

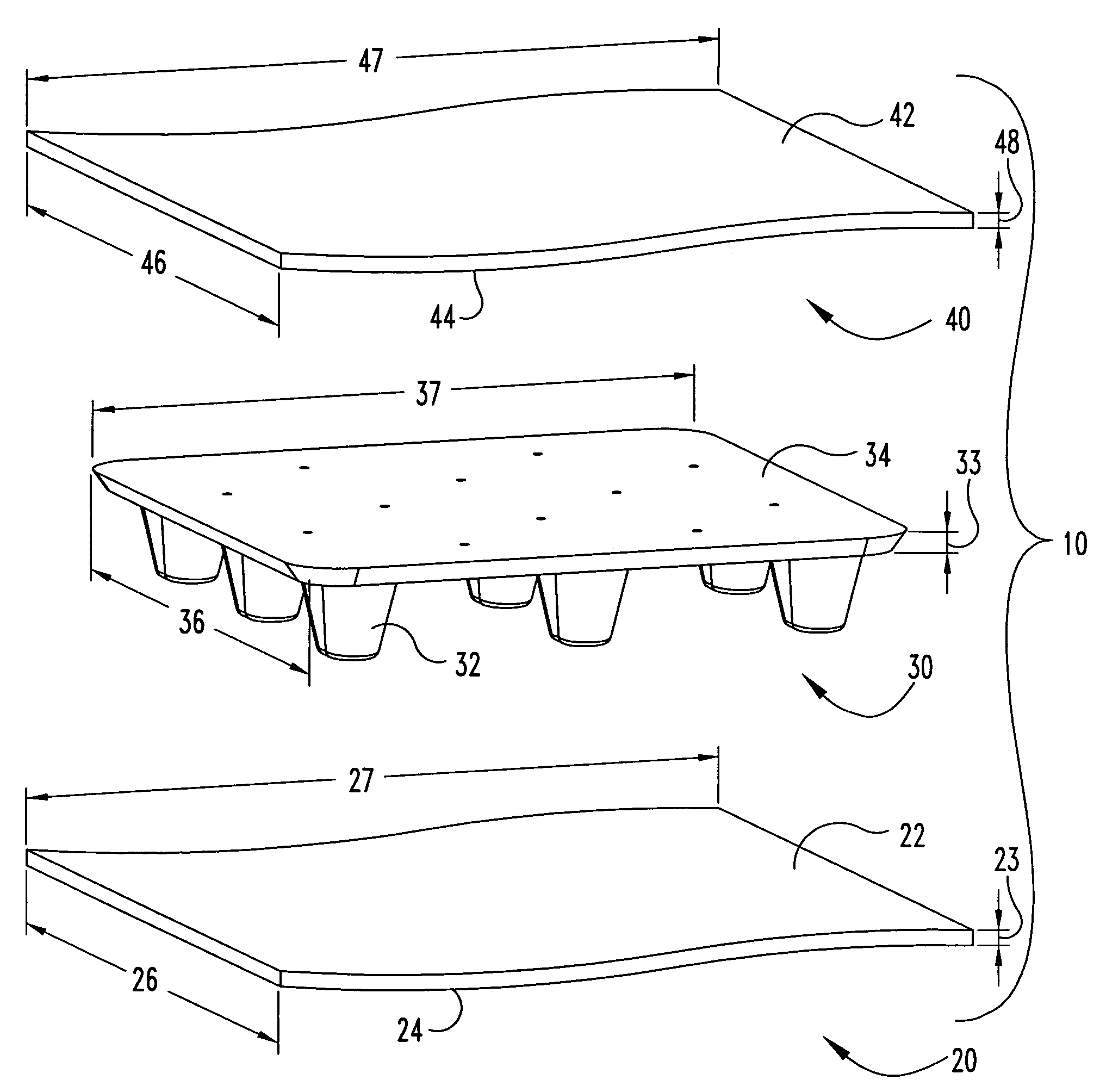

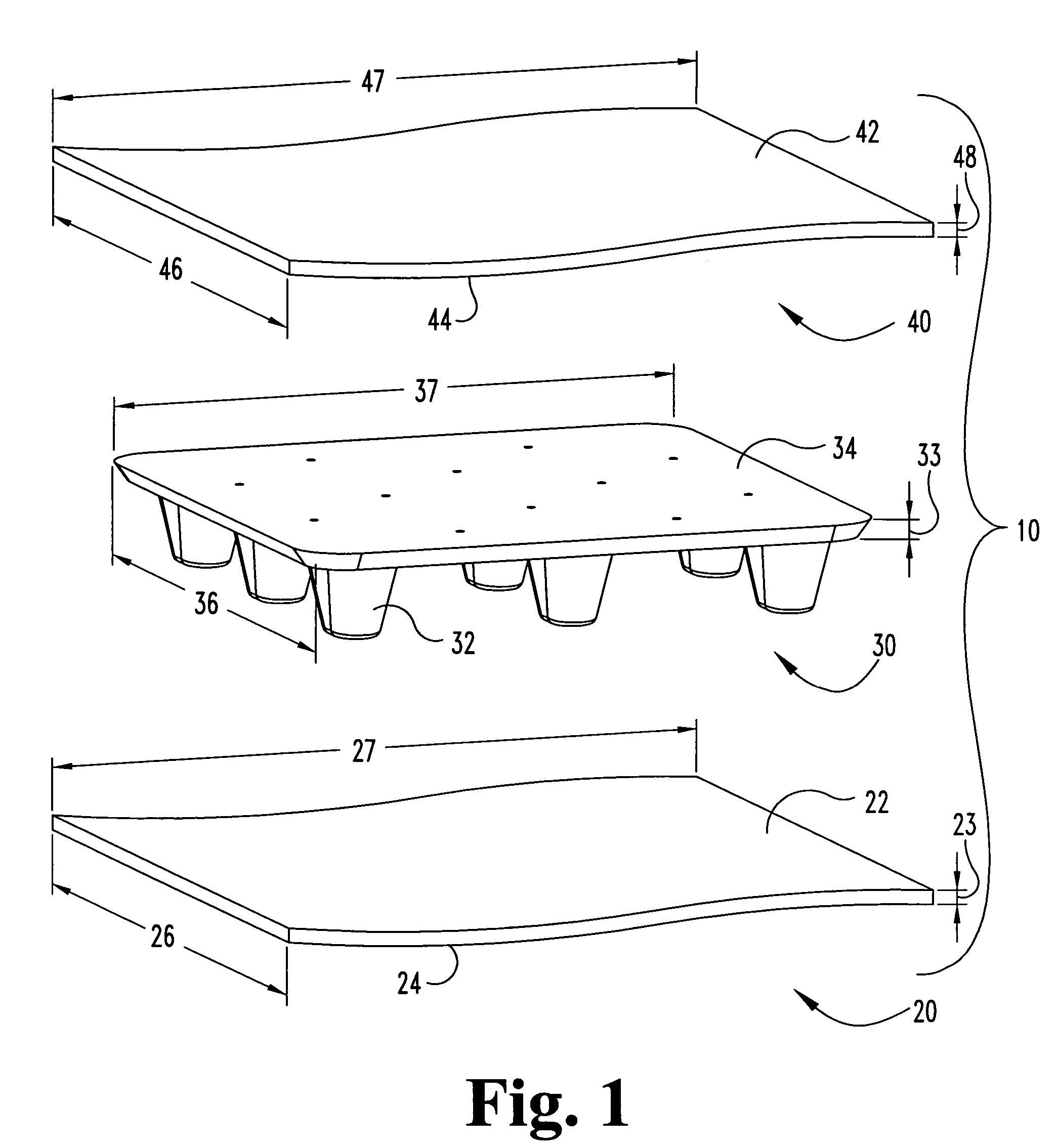

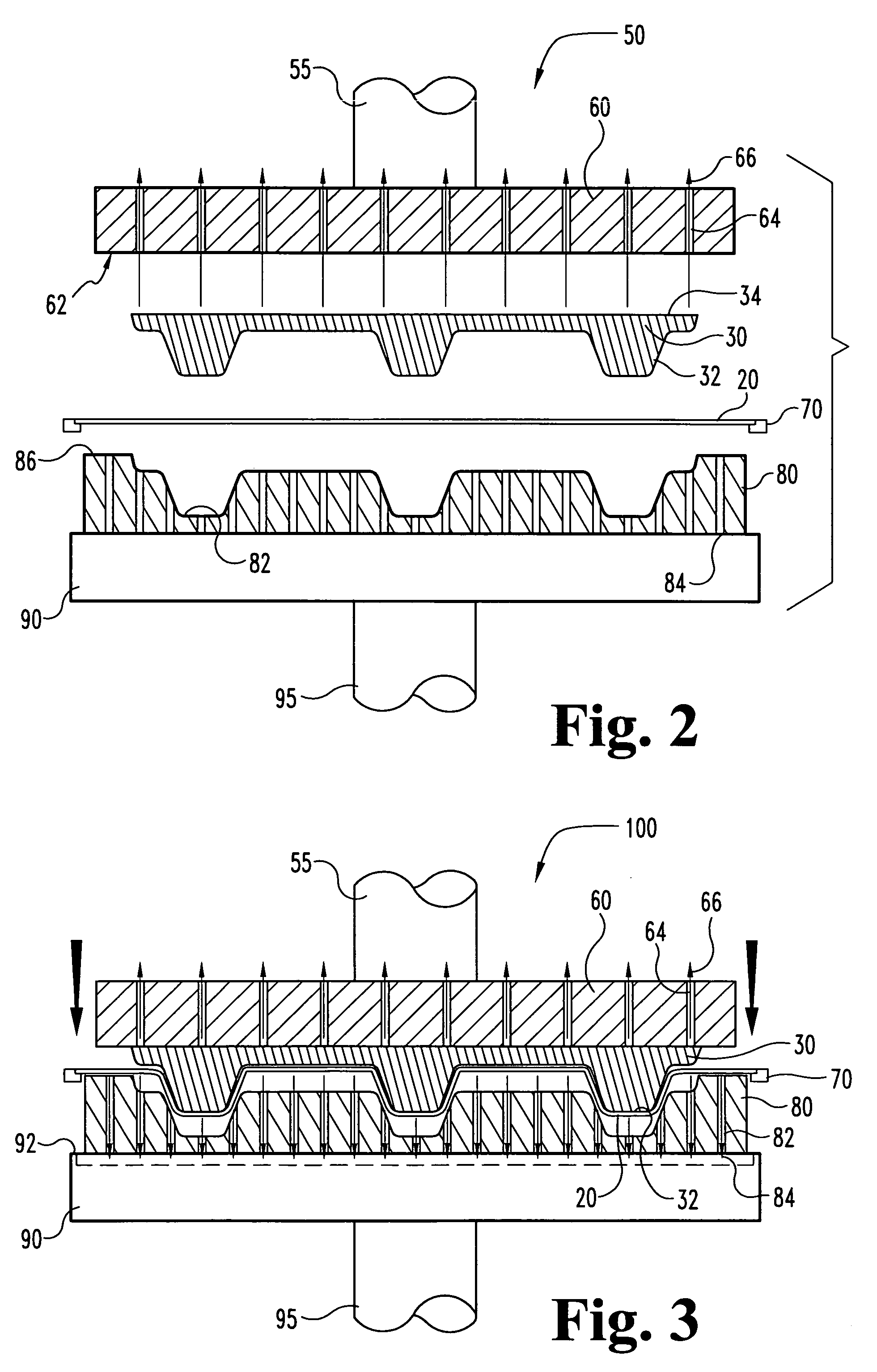

Method of molding load-bearing articles from compressible cores and heat malleable coverings

InactiveUS20050263044A1Strengthen and stabilizeStrengthen and stabilize articleDomestic articlesRigid containersThermoplasticEngineering

Load-bearing article are manufactured from shape defining compressible cores and thermoplastic shells. The manufacture of these articles requires specific methods and tools. Articles that can be manufactured using these methods include relatively lightweight pallets with high load-bearing capacity.

Owner:NOVO FOAM PRODS

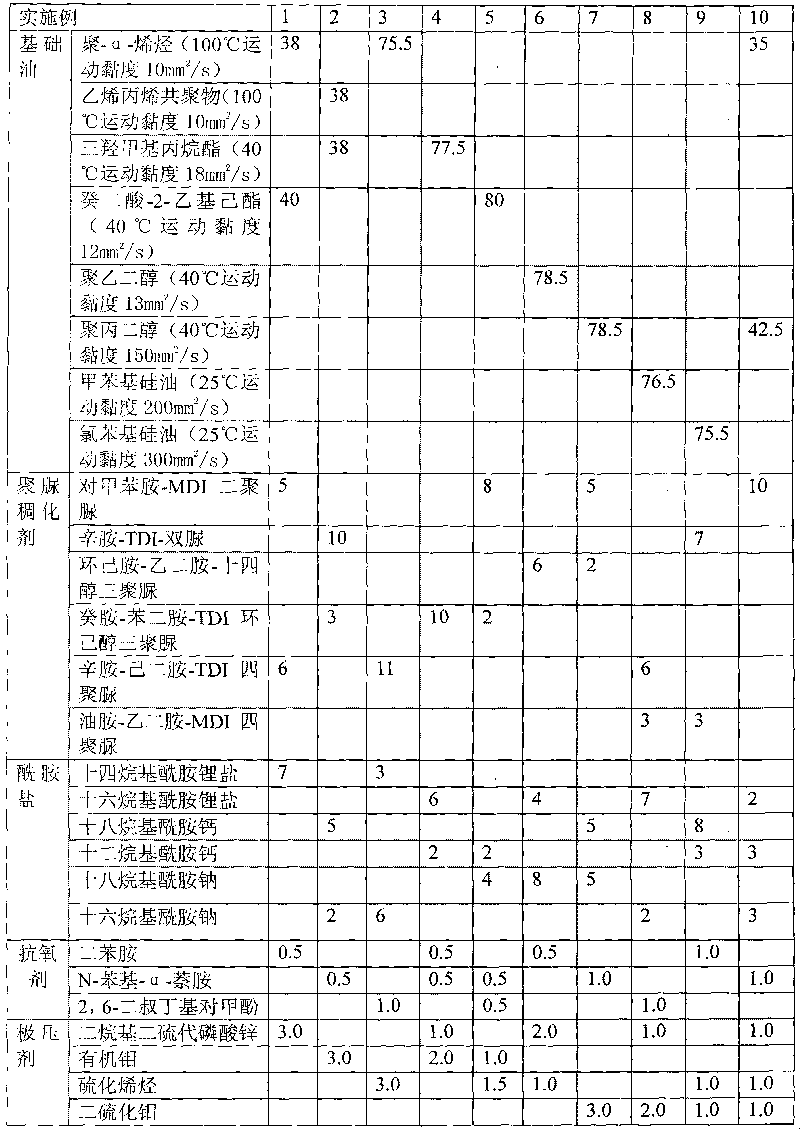

Synthetic high-temperature lubricating grease and production method thereof

InactiveCN101693851AGood colloidal stabilityGood shear stabilityThickenersAdditivesAntioxidantColloid

The invention discloses a synthetic high-temperature lubricating grease and a production method thereof. The synthetic high-temperature lubricating grease is produced by taking synthetic oil as base oil and mixing the base oil with thickening agents, an extreme-pressure additive, an antioxidant and an anticorrosive agent, wherein the weight ratios of all ingredients are as follows: 47-94% of base oil, 2-20% of polyurea thickening agent, 2-20% of acylamide thickening agent, 0.5-5.0% of antioxidant, 1.0-5.0% of extreme-pressure additive and 0.5-3.0% of anticorrosive agent. In the invention, the synthetic base oil, the polyurea thickening agent and the acylamide thickening agent all have excellent high-temperature performance, and the organic combination thereof leads the lubricating grease to obtain excellent high-temperature performance; the polyurea thickening agent endows the lubricating grease with good colloid stability, and the acylamide thickening agent endows the lubricating grease with excellent anti-shear stability, therefore, the organic combination of colloid stability and anti-shear stability leads the lubricating grease to have excellent high-temperature performance and good losing resistance, does not change to thin and avoids losing at high temperature. The extreme-pressure anti-wear additive endows the lubricating grease with excellent extreme-pressure anti-wear performance, and the bearing capacity is high.

Owner:CHINA PETROLEUM & CHEM CORP

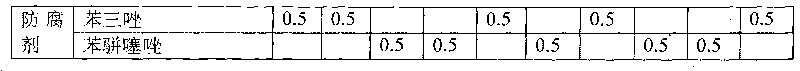

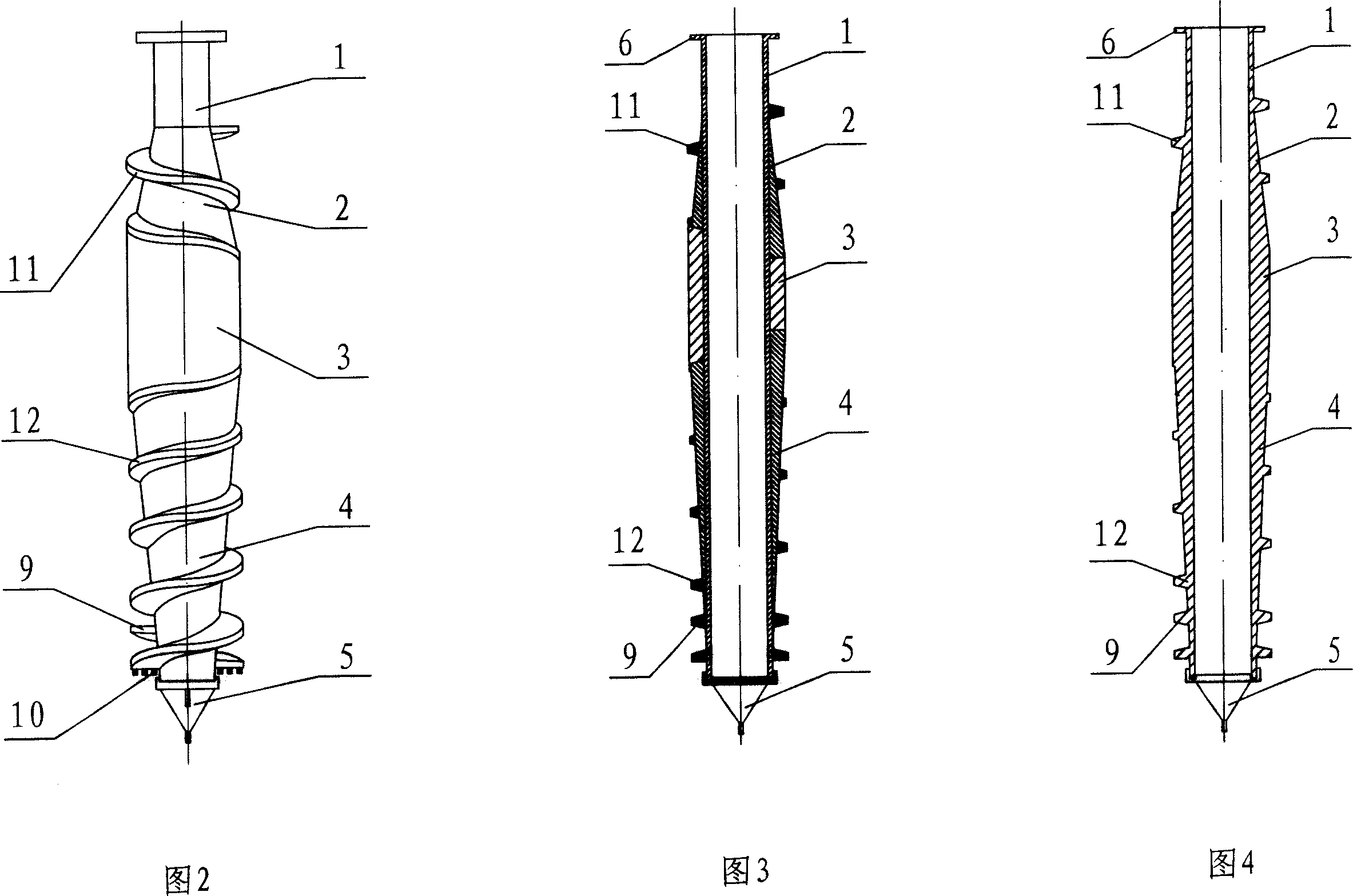

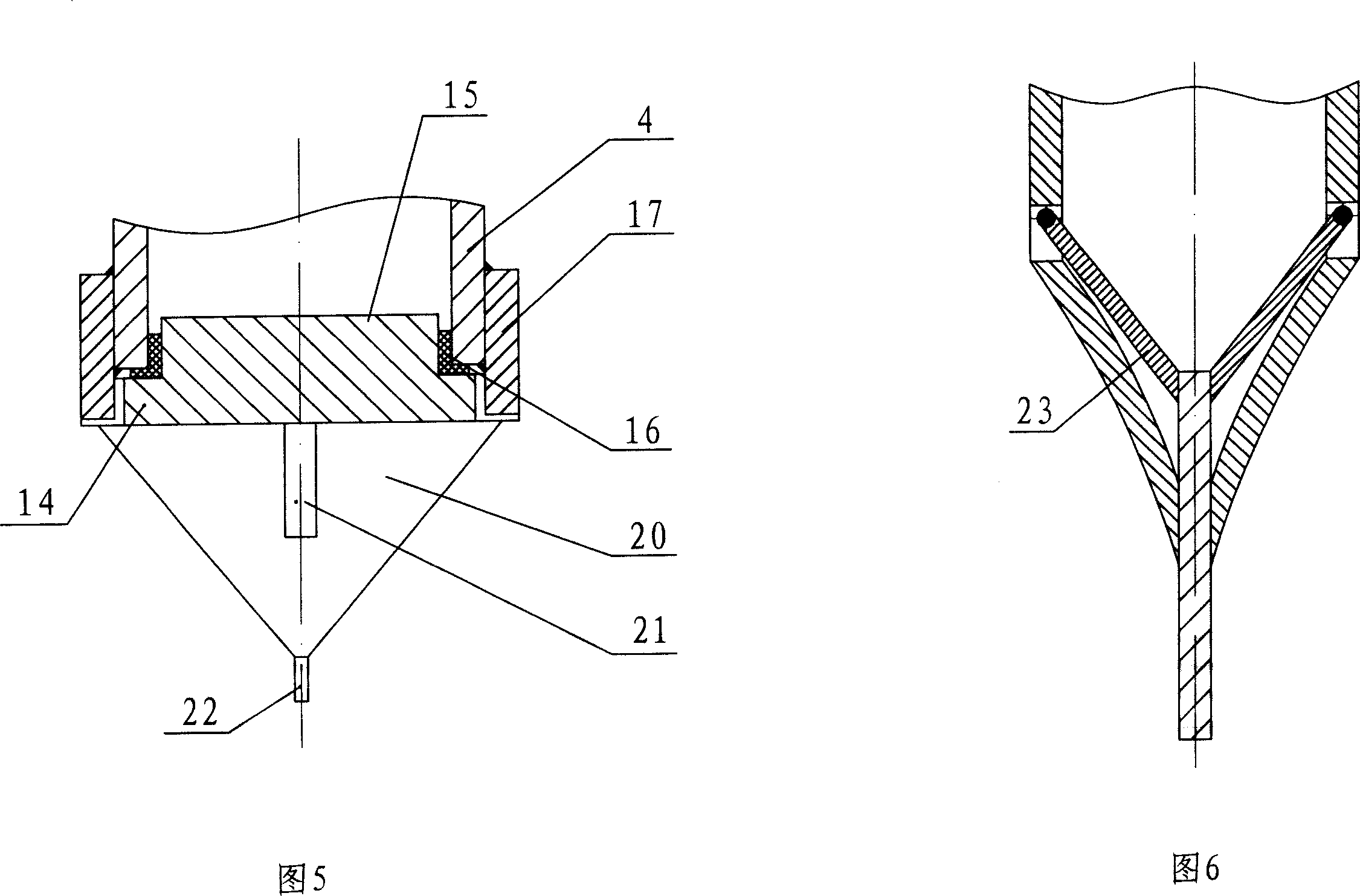

Bidirectional helix extruding-enlarging pile construction method and bidirectional helix closed extruding-enlarging aiguille

ActiveCN101012649AIncrease resistanceImprove bearing capacityDrill bitsBulkheads/pilesConcrete pumpEnergy consumption

The invention relates to a construction method for bidirectional spiral expand pile and the bidirectional spiral closed expand bit. The construction method comprises drilling and expanding bore by the bidirectional spiral closed expand bit; pushing soil, which is obtained in drilling and expanding bore downwards, into the side wall of pile bore; the bidirectional spiral closed expand bit rotating upwards to drill and expand the bore again; pushing soil, which is obtained in drilling, expanding and lifting upwards, into the side wall of pile bore; starting the concrete pump to press the pile material into the pile bore while the bit is lifted. The bidirectional spiral closed expand bit comprises a connecting bar. At the lower of the connecting bar spiral expand body, closed expand body and dynamic sealing expand body are assembled on the connecting bar in the same axial line in turn from the bottom to the top or they are machined on the connecting bar together. The invention is provided with high loading capacity, small sedimentation quantity, better quality, low cost and smaller energy consumption so on.

Owner:CHINA JINGYE ENG

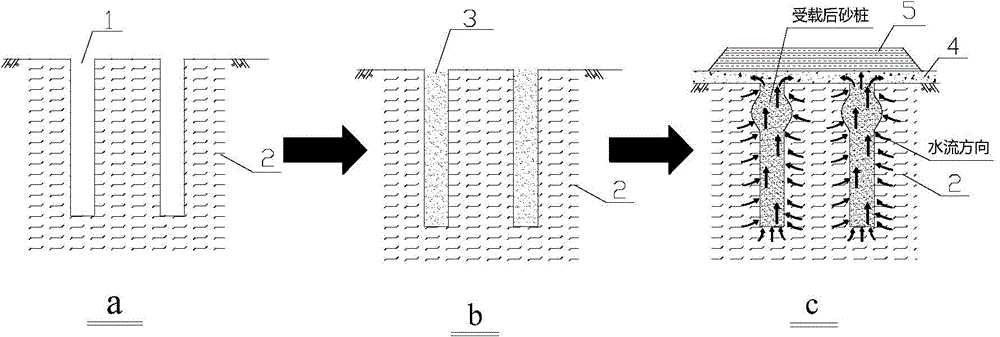

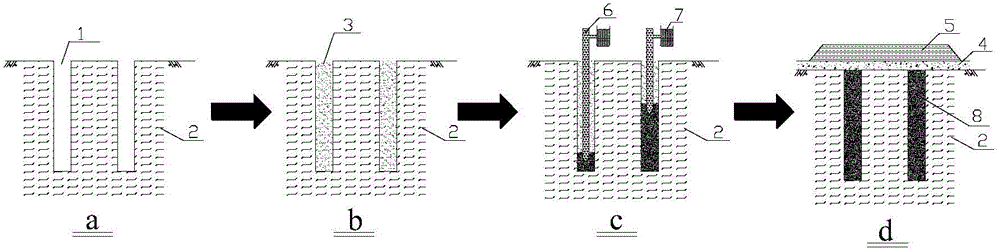

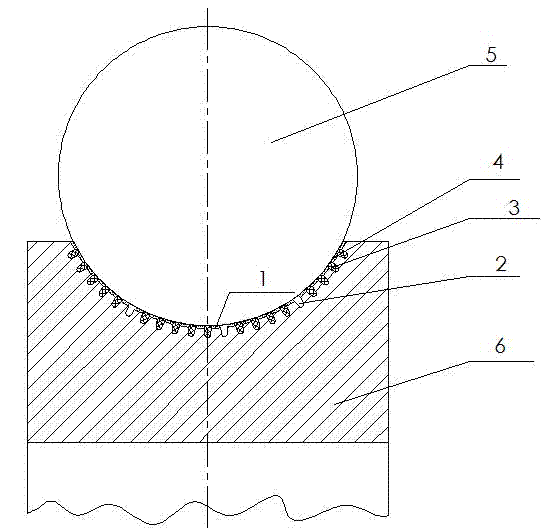

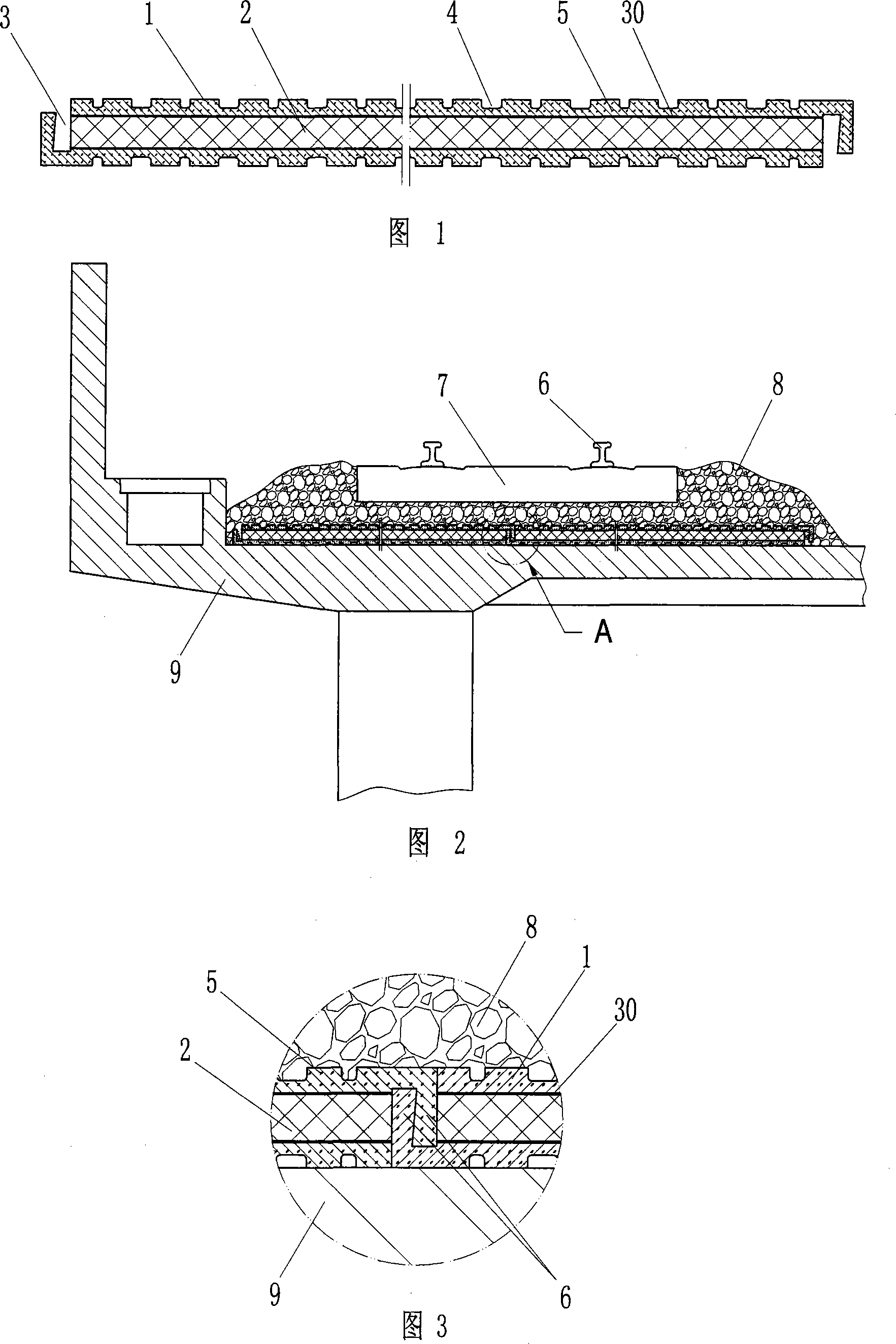

Method for soft soil foundation treatment through microorganism grouting sand drain

InactiveCN104631430AImprove vertical load carrying capacityPermeability changeOrganic fertilisersSoil conditioning compositionsSoil scienceSalt solution

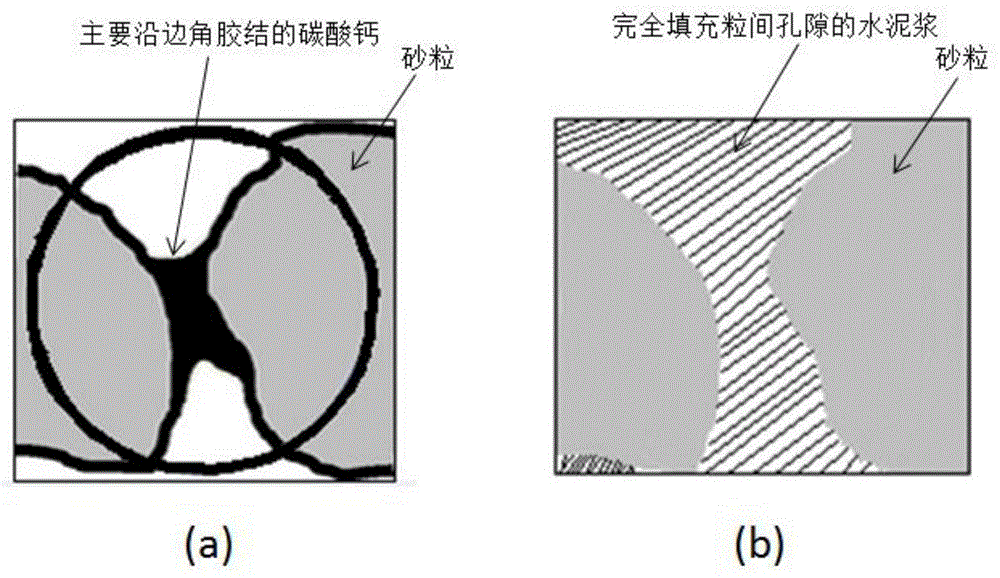

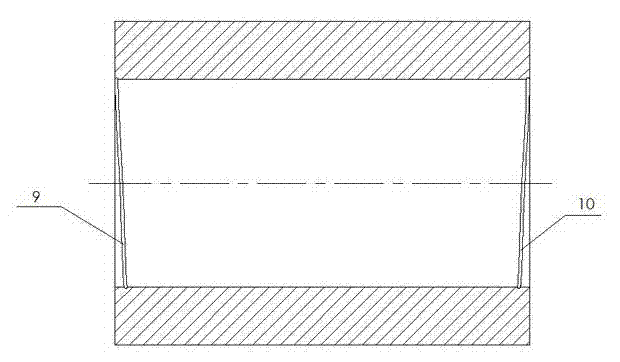

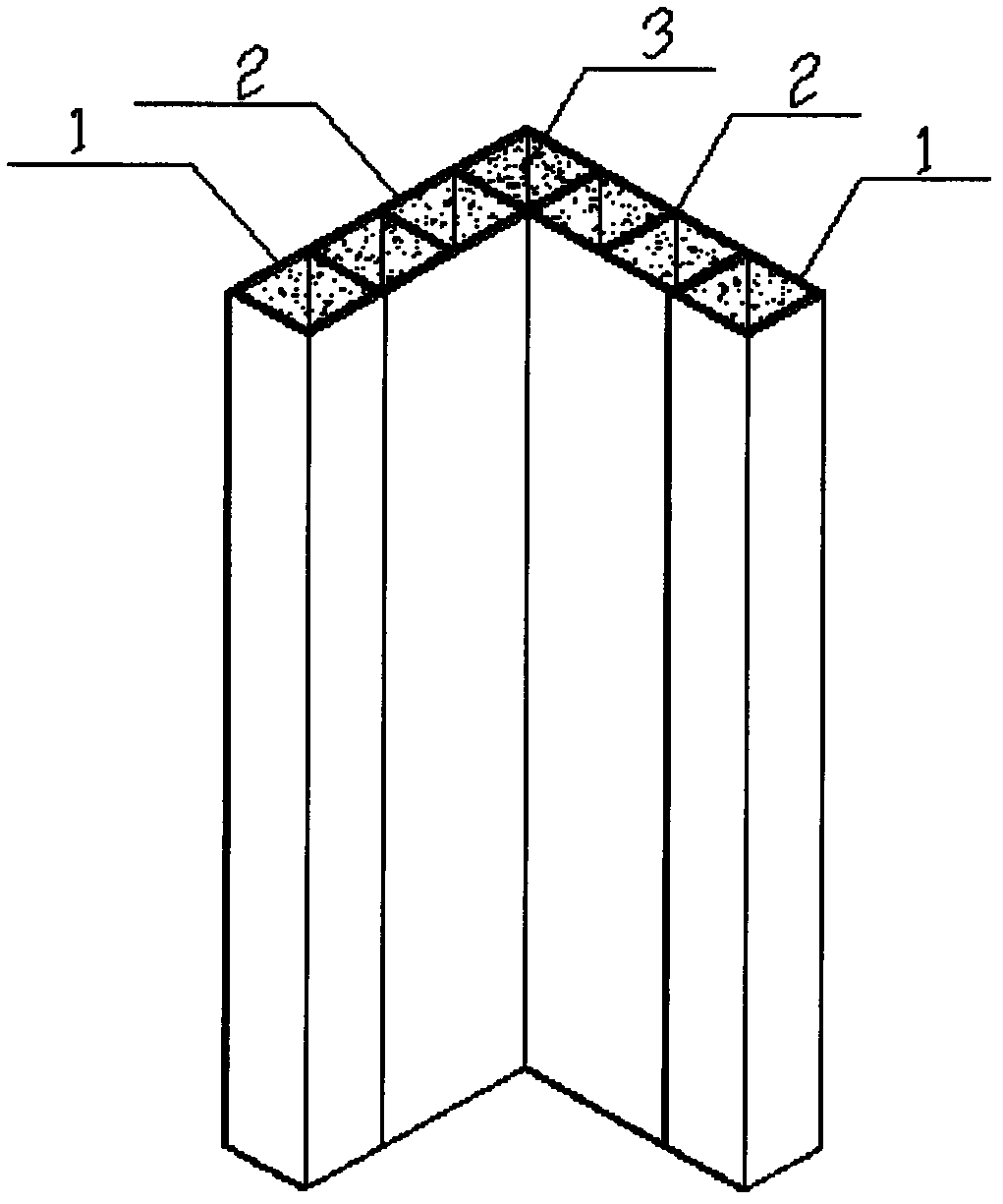

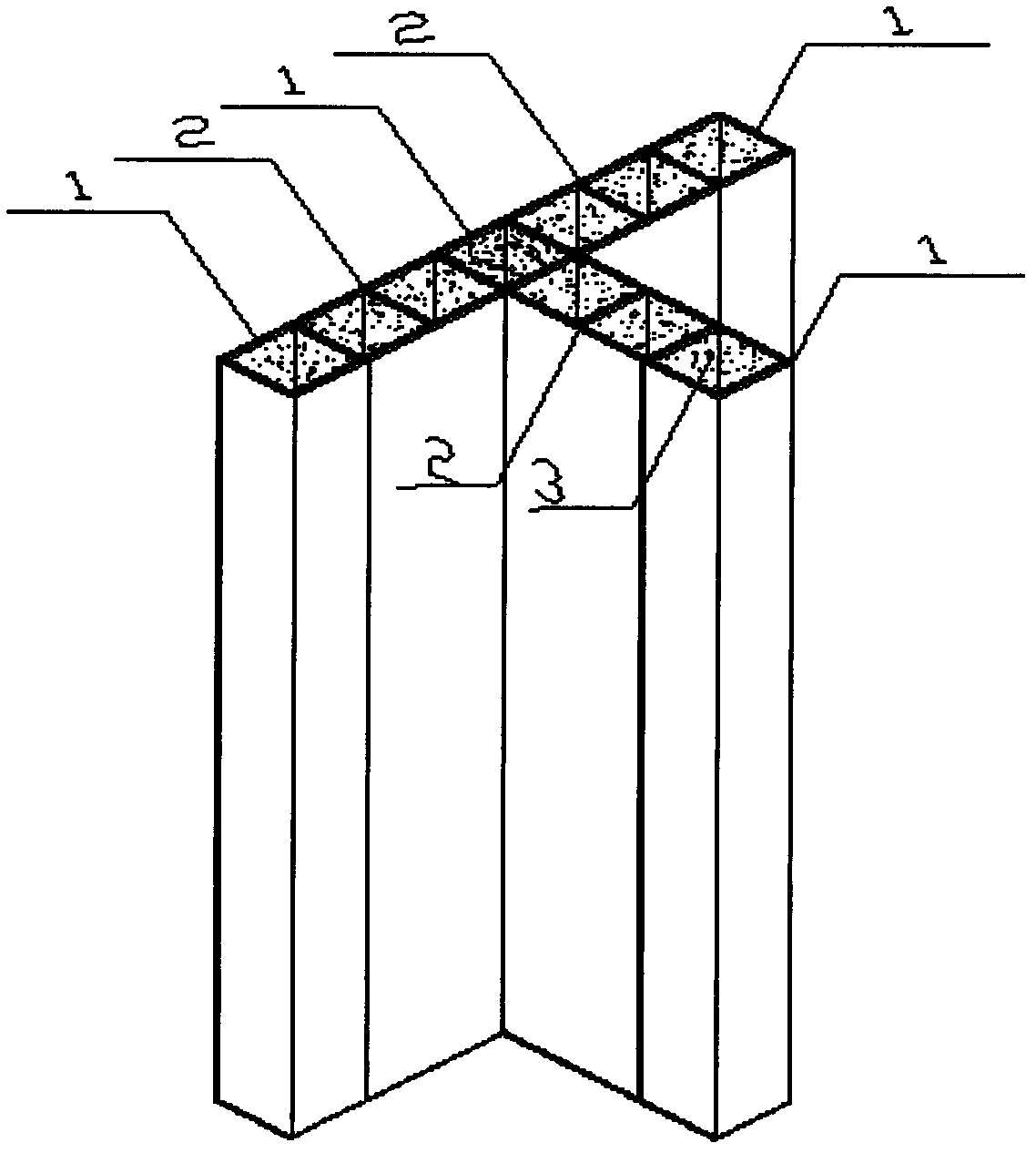

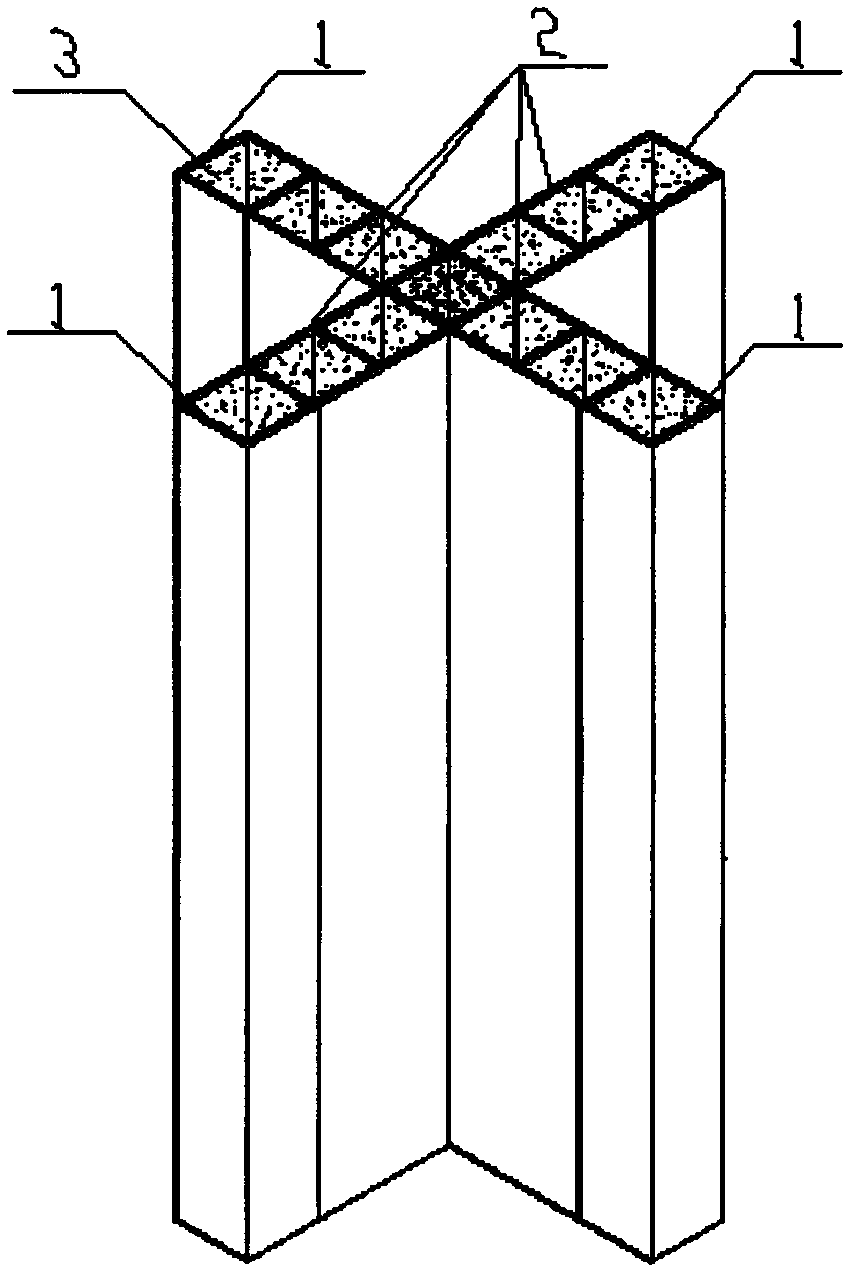

Disclosed is a method for soft soil foundation treatment through microorganism grouting sand drain. The method comprises the steps that a, a pile hole 1 is formed in a soft soil foundation to be treated, and sand is poured into the pile hole 1 to form a sand pile; b, a urease-producing microorganism solution 9 and a nutritive salt solution 10 are sequentially and evenly injected into the sand pile through a grouting tube 6, sand cementation is achieved through the microorganism induction calcium carbonate crystal technology, the concentration of the urease-producing microorganism solution 9 and the concentration of the nutritive salt solution 10 are controlled, sand in the pile body forms a specific cementation mode, and the good water permeable characteristic is ensured; c, after the microorganism grouting solidification sand pile is formed, a flexible water permeable sand cushion 4 is laid on the top of the foundation jointly formed by the sand oil and pile space soil 2, prepressing loads 5 are exerted on the top of the flexible water permeable sand cushion 4, pore water in the pile space soil 2 is made to be drained along a drainage channel formed by the sand pile and the sand cushion, the pile space soil is solidified, and the composite foundation with the high bearing capacity is formed jointly through the soft soil obtained after drainage and solidification are carried out on the microorganism grouting sand pile and the flexible water permeable sand cushion covering the soft soil.

Owner:NANJING FORESTRY UNIV

Perforated composites for joining of metallic and composite materials

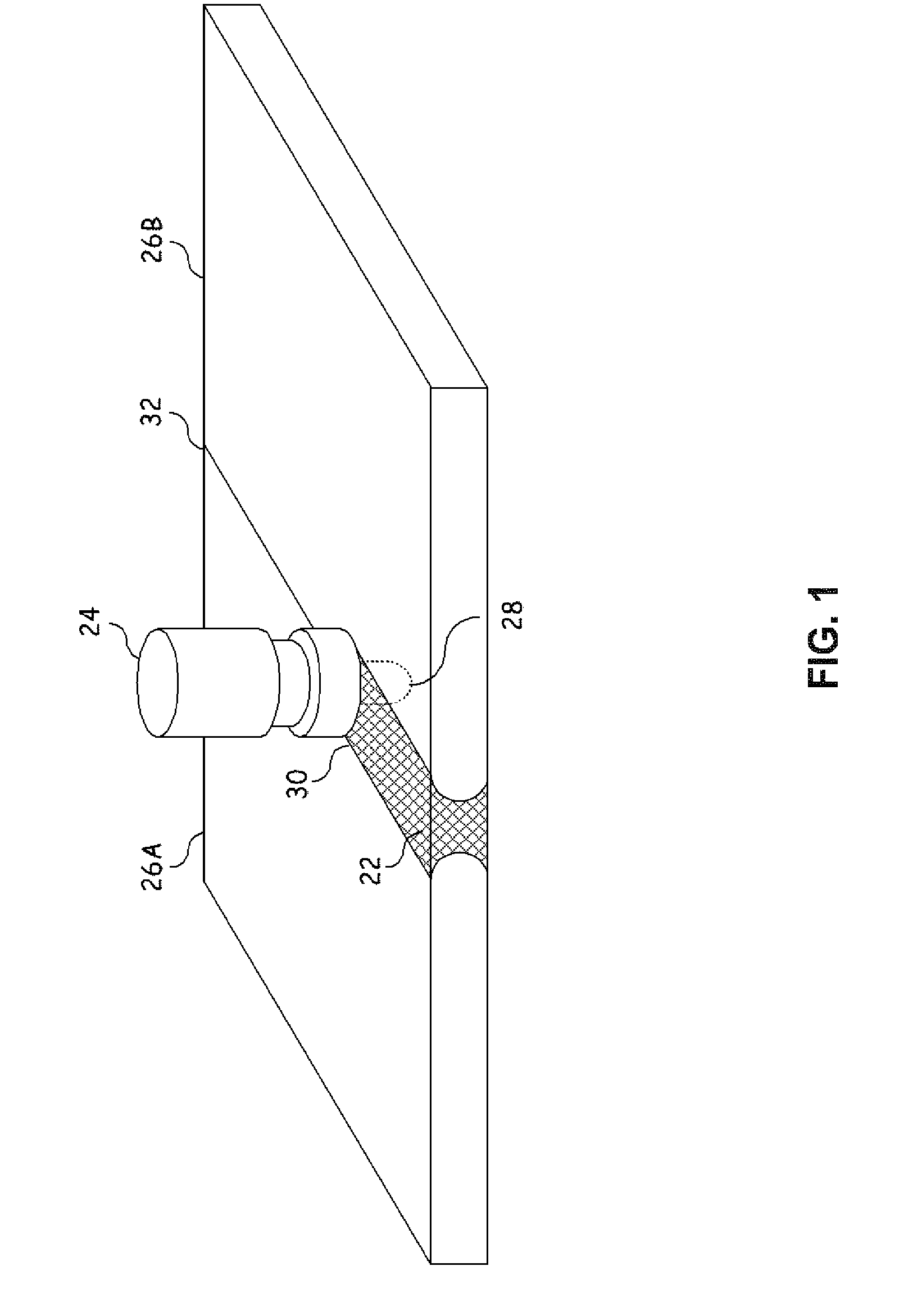

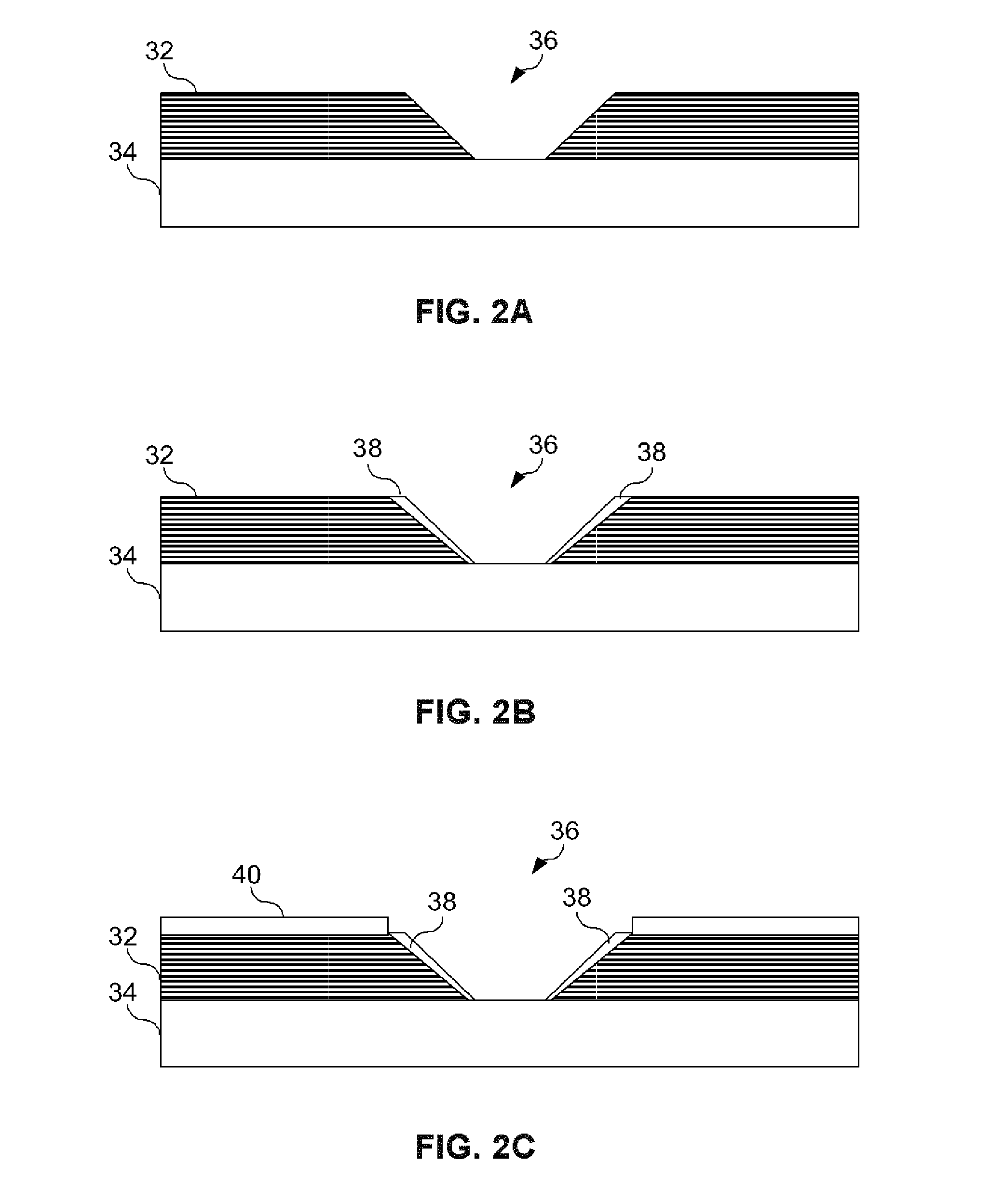

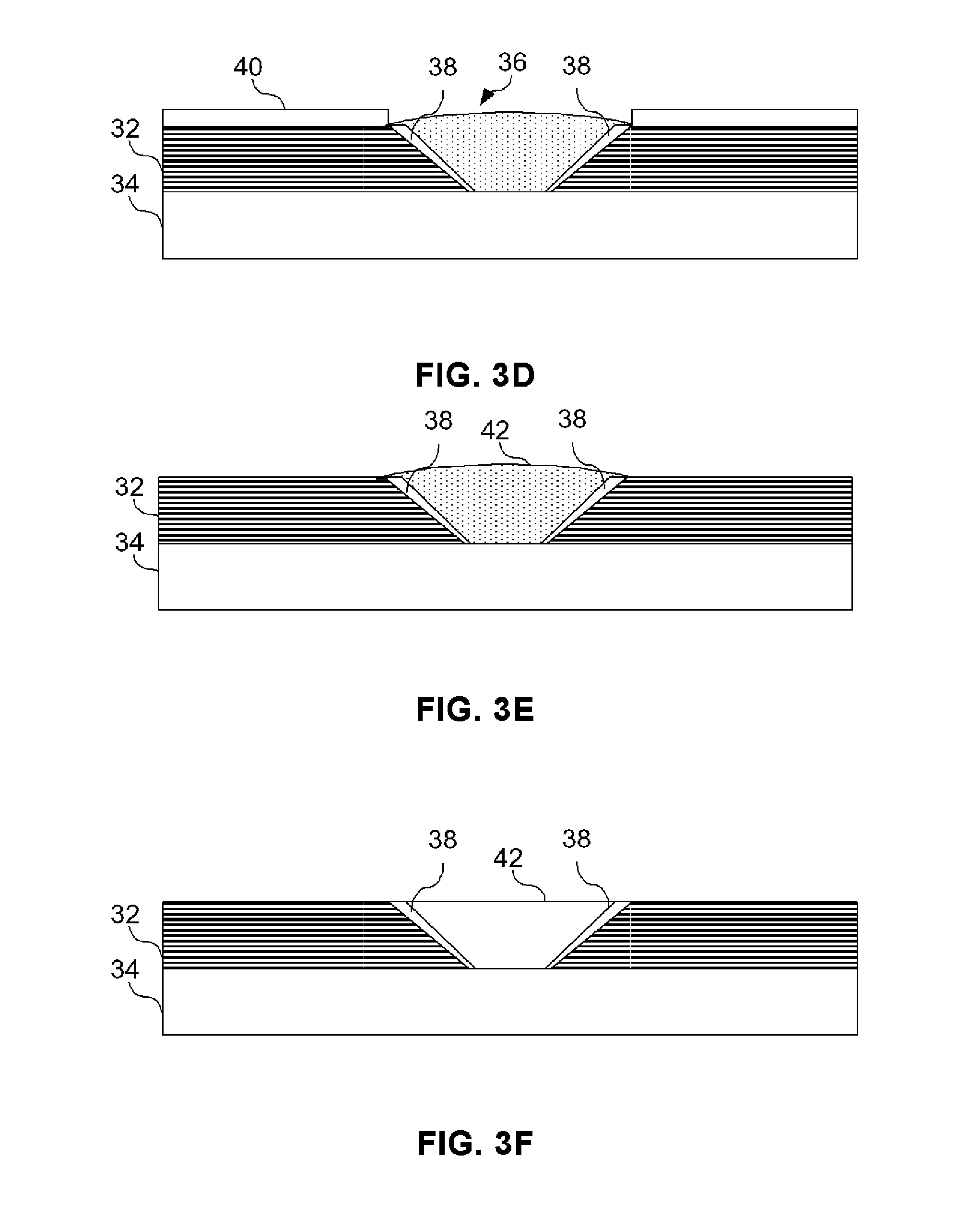

ActiveUS20070241164A1Improve carrying capacityCooking-vessel materialsPressure inorganic powder coatingCarrying capacityMetallic substrate

Embodiments in the present invention provide a system and method of joining structural members. This method involves aligning the first structural member to a metallic substrate when the first structural member has at least one tapered hole or cavity. A metallic or other like material suitable to cold spraying technology is deposited into the tapered cavity to form a shaped or tapered fastener bonded to the metallic substrate. The shape of the fastener secures the first structural member to the metallic substrate. Additionally, a protective insert may be placed within the shaped or tapered cavity to protect the first structural member during hoe cold spraying deposition when the first structural member is a composite material or other like material susceptible to erosion during the cold spraying technique. After the material has been deposited using cold spray techniques this material may be further solidified and bonded to the metallic substrate using a technique such as friction stir welding in order to increase the load carrying capacity of the in-situ shaped fastener.

Owner:LOCKHEED MARTIN CORP

Linear actuator

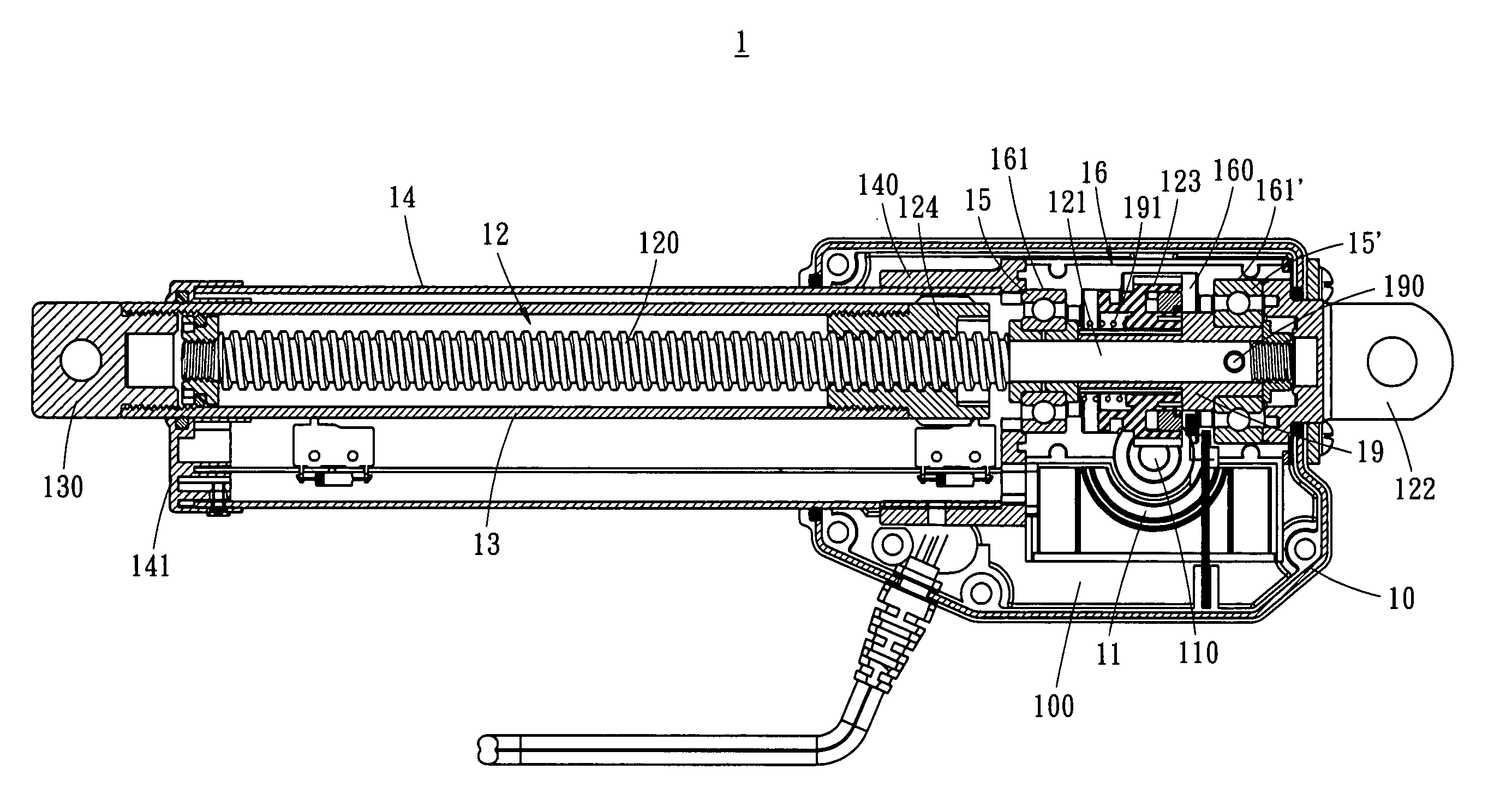

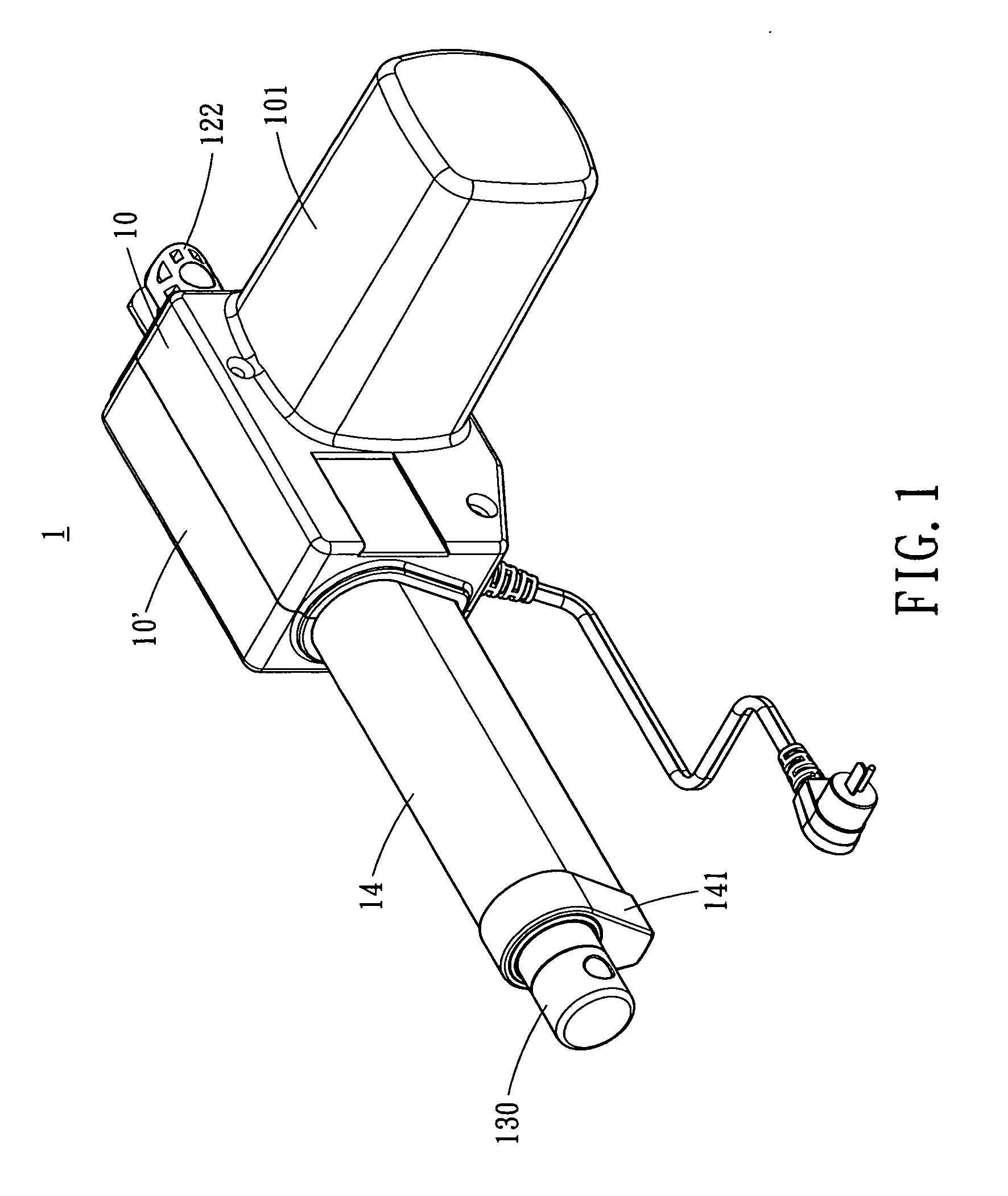

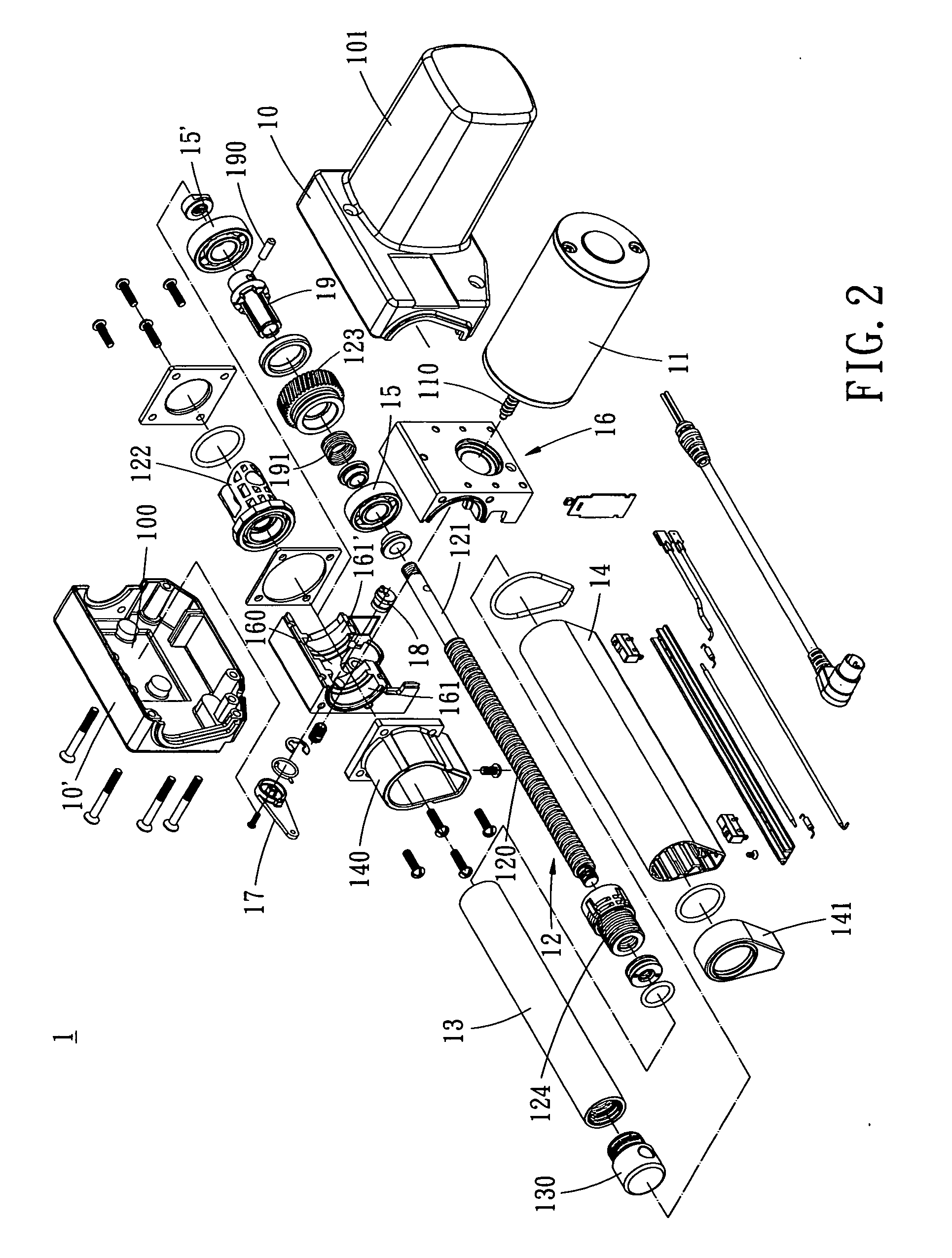

InactiveUS20050160846A1Smooth startIncrease load capacityToothed gearingsMechanical energy handlingBall bearingControl theory

A linear actuator has two half-shells, a motor housing, a motor installed in the motor housing, a guiding screw driven by the motor, a screw nut engaged with the guiding screw, an interior tube encircling the guiding screw and connected with the screw nut at one end thereof, a moveable exterior tube telescoping the interior tube therein, at least two ball bearings subject to radial and axial load, and fitting seat installed in the half-shells. The fitting seat has to bearing seats for mounting the ball bearings, such that the load capacity of the linear actuator is increased, while the application safety is enhanced.

Owner:JAEGER INDAL

High efficient plugging agent for well drilling

InactiveCN102127403AWide coverage of pluggingImprove pressure bearing capacityDrilling compositionWell drillingLost circulation

The invention relates to a plugging agent during well drilling in oil and gas field, and particularly to a high efficient plugging agent for severe lost circulation. The components are, by weight: 18-25% of walnut shell powder, 8-10% of sawdust, 8-10% of cottonseeds, 10-15% of hull powder, 20-30% of active plugging agents, and 15-25% of elastic rubber granules, and the raw materials are mixed uniformly to obtain a high efficient plugging agent for well drilling. According to the invention, the fibrous plugging agent with granules is formed by mixing natural plant inert materials, a synergistic agent, and a reinforcing agent with a certain preparation ratio. The plugging agent of the invention has the advantages of wide covering area for leak stopping, high pressure bearing capacity, good plugging effect, high success rate for disposable leak stopping, simple on-site preparation process, and reliable and safe construction, which can achieve the purposes of reducing loss of lost circulation and saving comprehensive cost. The high efficient plugging agent of the invention is applicable to leak stopping operations under various lost circulation conditions with good leak stopping effect and high success rate, and is superior to other types of plugging agents.

Owner:浙江仁智股份有限公司

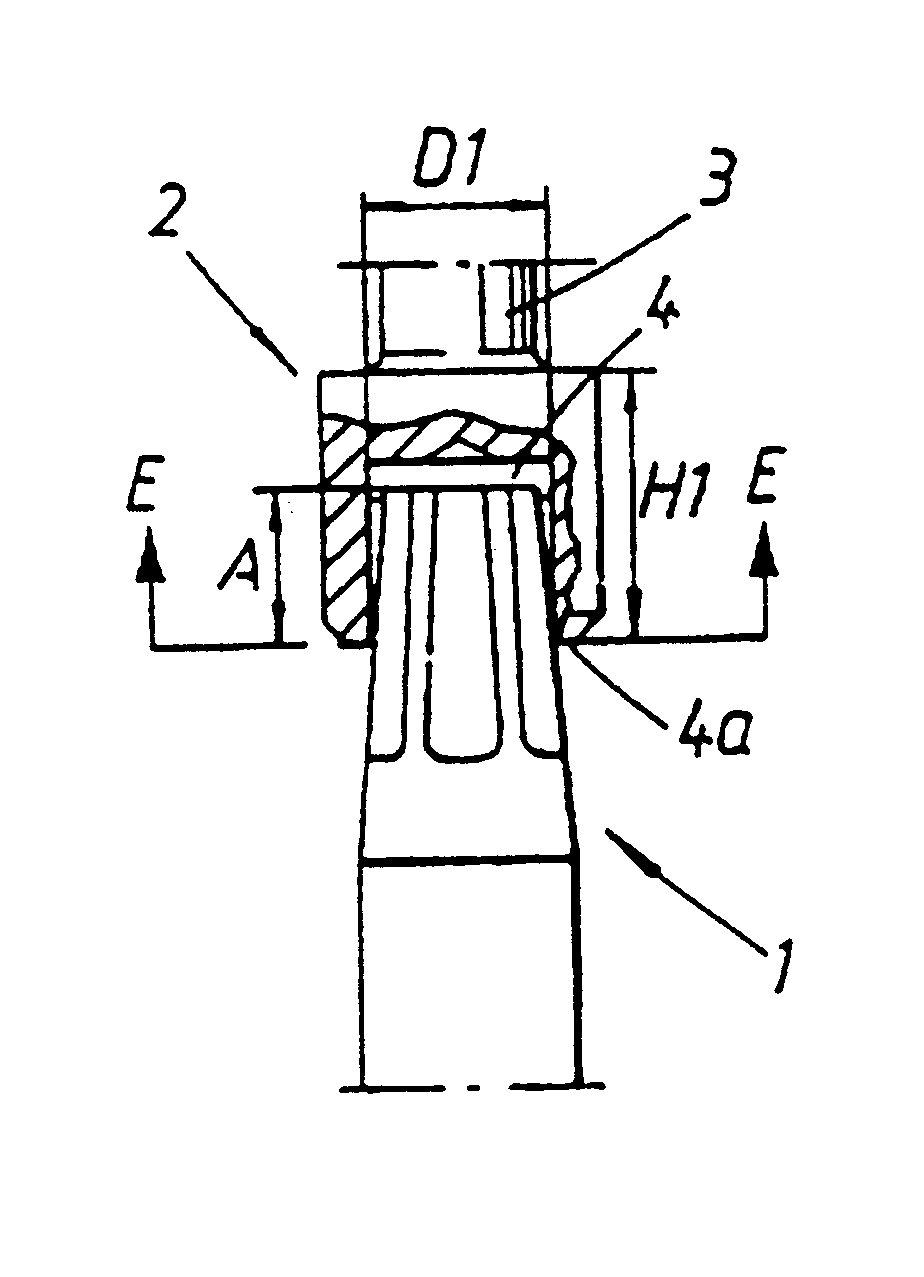

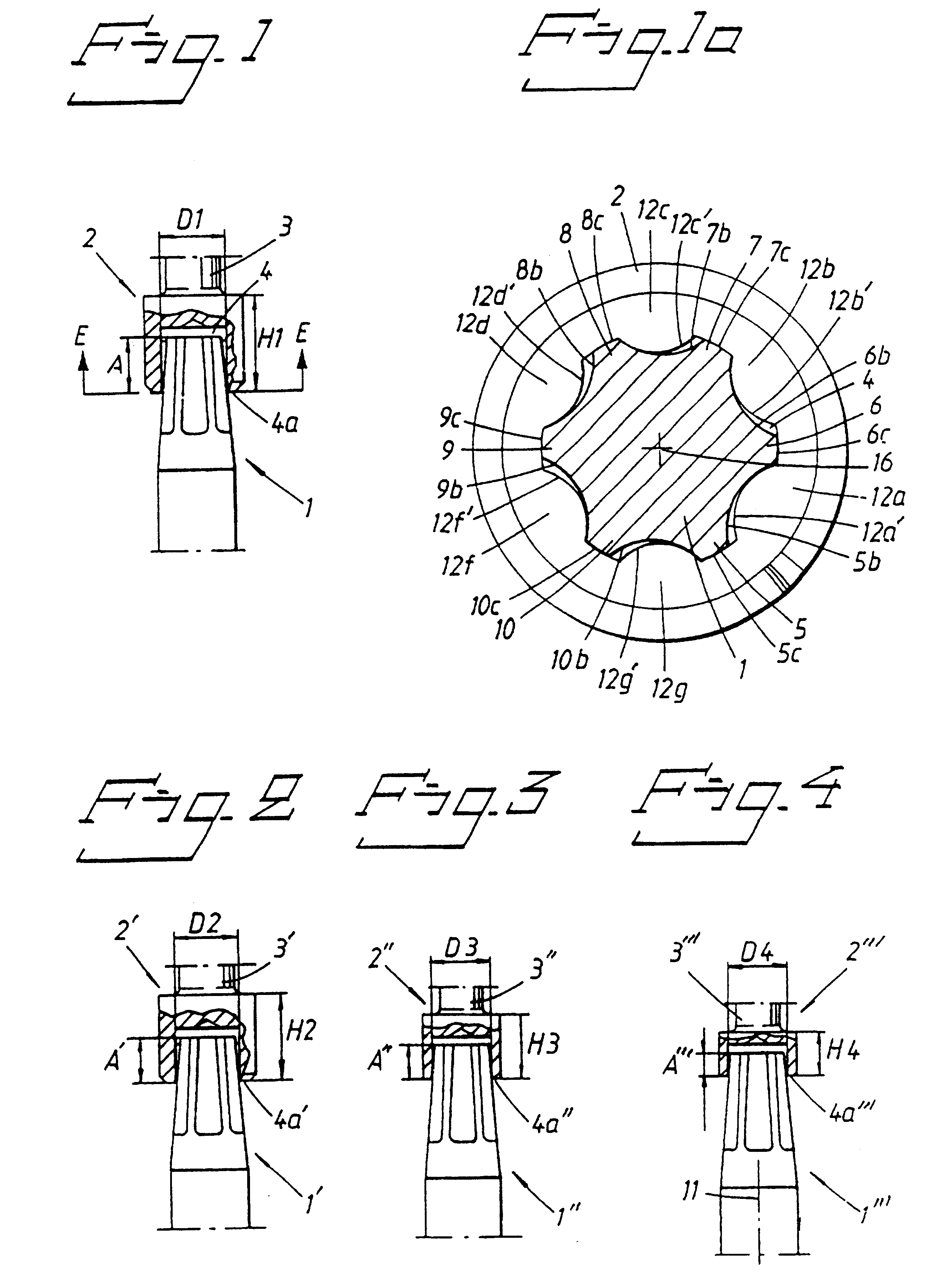

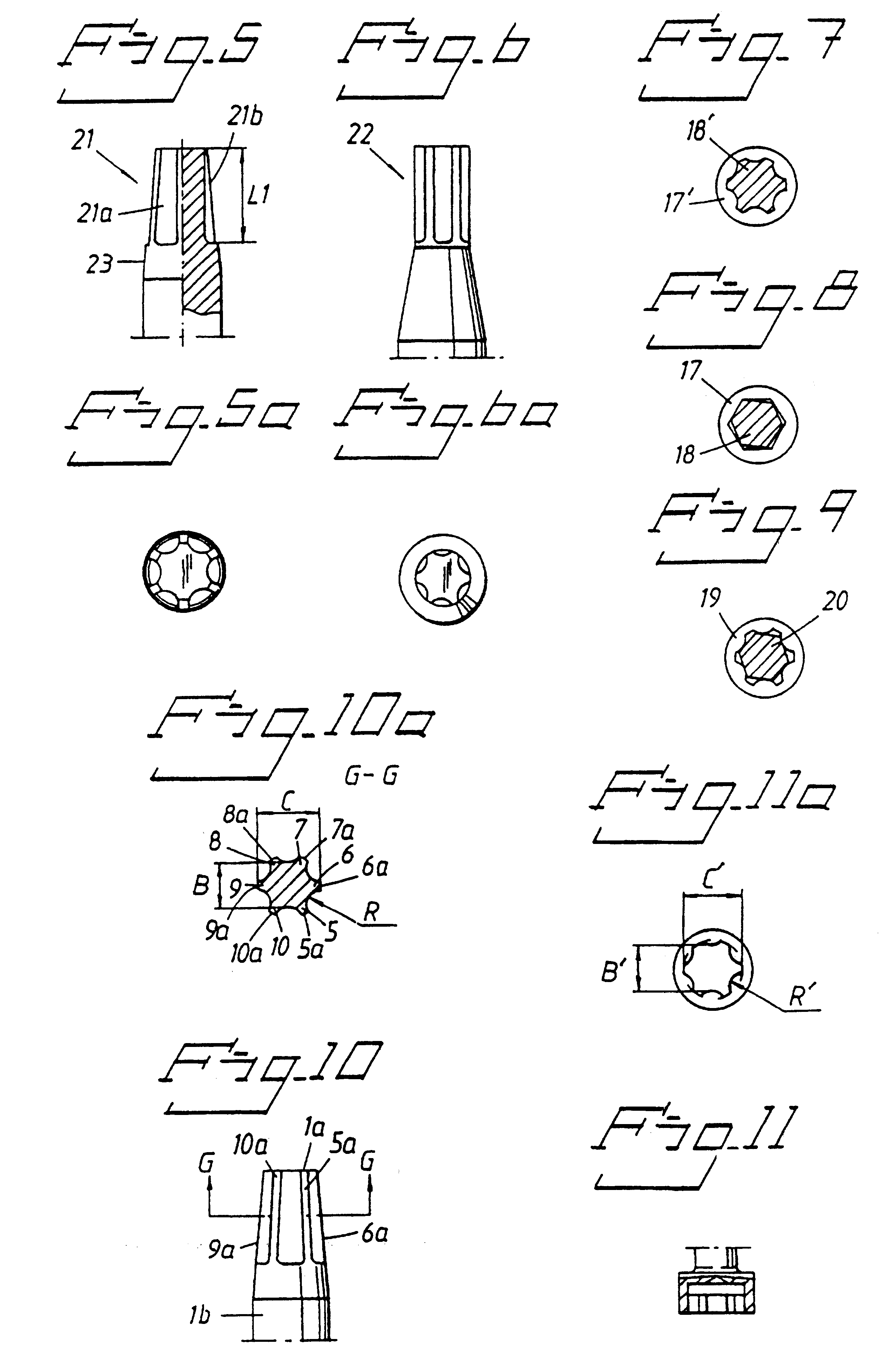

Arrangement for use in a system with a range of dental screws, and the range of dental screws

A system which provides a range of dental screws. The same screw tightener is used to tighten different screws, of different constructions. Each screw is provided with an internal recess which operates with the screw tightener. The recess has elements extending inward toward the center axis of the screw which cooperate with the screw tightener. Bearing capacity is provided by a wedging action between the screw tightener and recess, and a driving function occurs through actually extending elements within the recesses.

Owner:NOBEL BIOCARE SERVICES AG

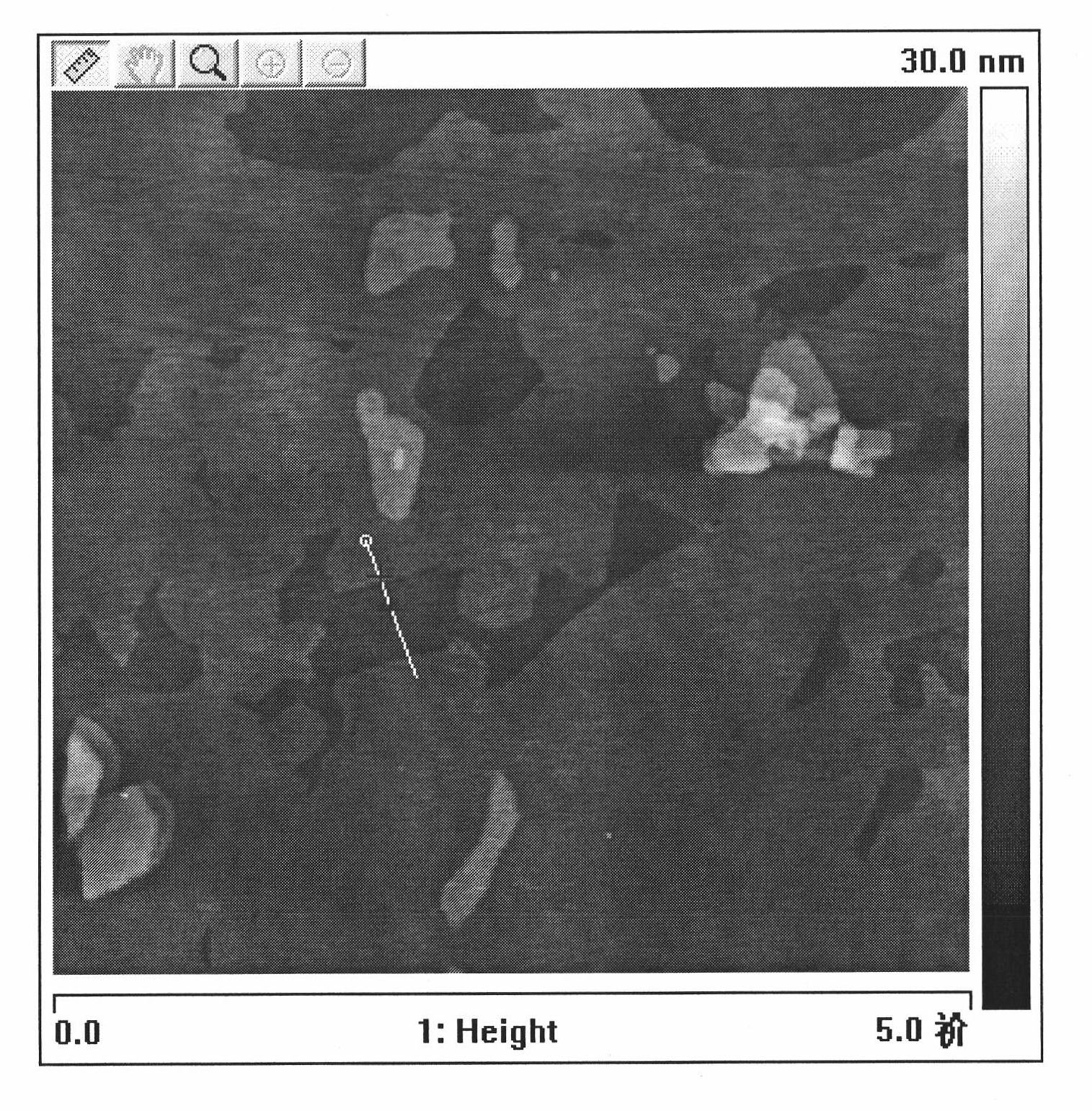

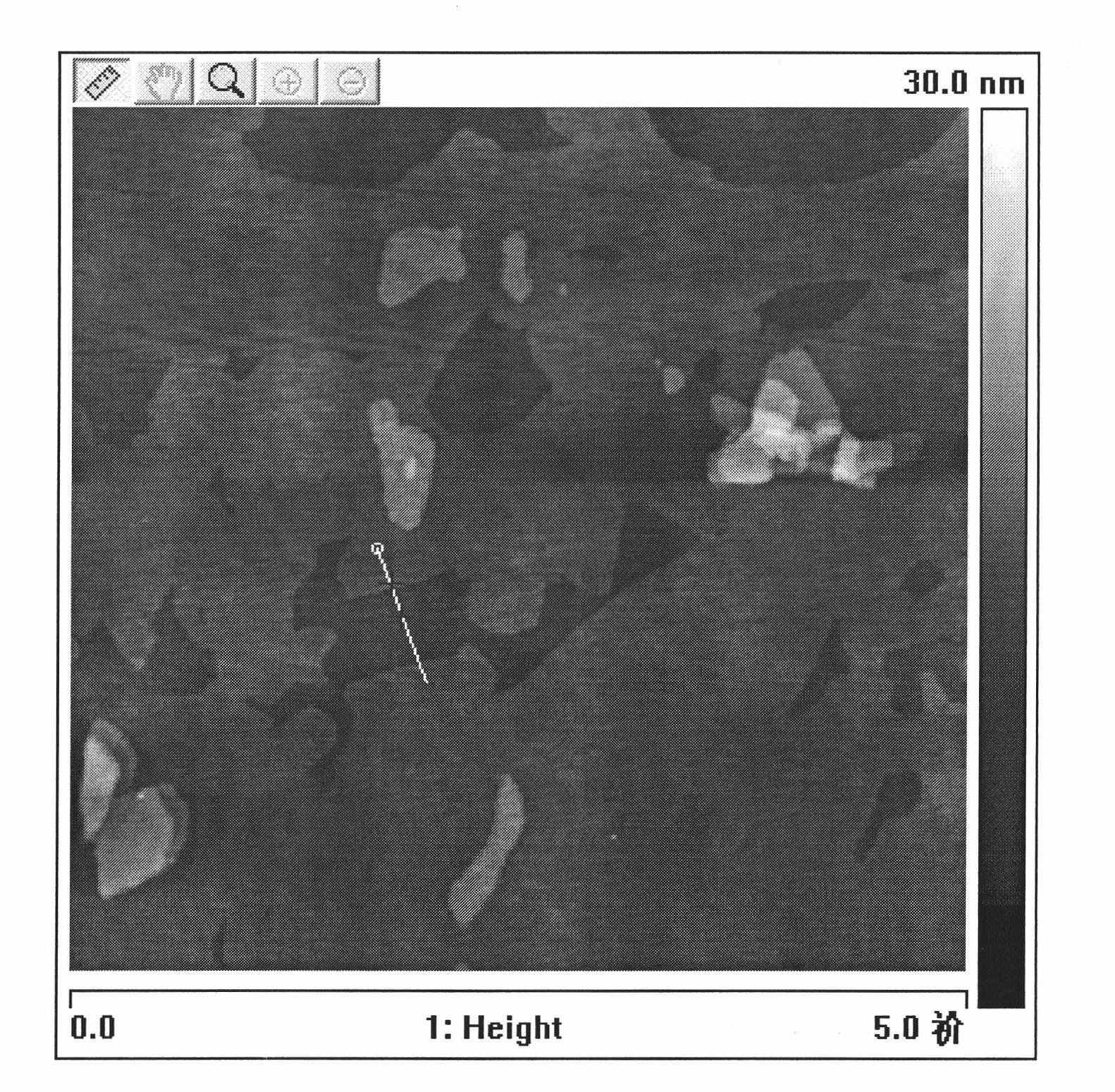

Lubricating oil additive based on single-layer or more-layer graphene

The invention relates to a lubricating oil additive based on single-layer or more-layer graphene, belonging to new high-tech materials and application field thereof and being mainly used for improving the property of lubricating oil. The lubricating oil additive is characterized in that single-layer or more-layer graphene and a dispersing agent are added into base oil, the content of the single-layer or more-layer graphene in the base oil is 0.0001-10 percent by mass, and the content of the dispersing agent in the lubricating oil is 0.001-2 percent by mass. The graphene has high specific surface area and thickness of 0.34-10 nanometers, is shaped as a sheet, is combined with the dispersing agent after being subjected to surface modification, and has excellent stability and dispersity in the base oil without easily precipitating like other additives. Under same filling amount, compared with the sheet graphite and the traditional graphite, more graphene can be absorbed on the secondary surface of the friction, the lubricating and anti-wear property of the base oil is improved, and the bearing capacity is enhanced.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

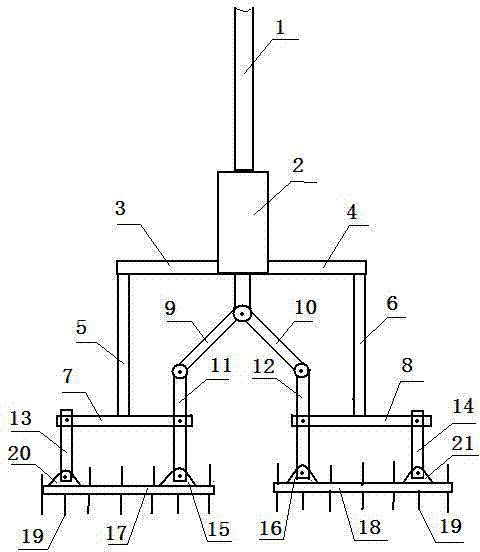

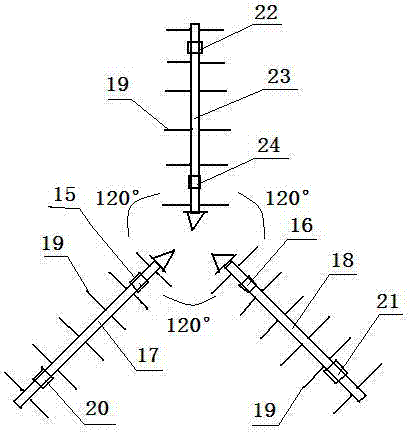

Y-shaped agitating pile drilling machine

The invention relates to a Y-shaped agitating pile drilling machine for reinforcing a soft land. A retracting oil jack drives three groups of agitating assemblies to move through a transmission rod A, a transmission rod B and a transmission rod C; a 120-degree angle is formed on a space by the three groups of the agitating assemblies; the section of a pile body formed by the Y-shaped agitating pile drilling machine is Y-shaped; the pile body of a Y-shaped agitating pile with the same volume is the pile body of the agitating pile, which has a circular section; and the bearing capability is greatly improved.

Owner:日照阳光电力设计有限公司 +2

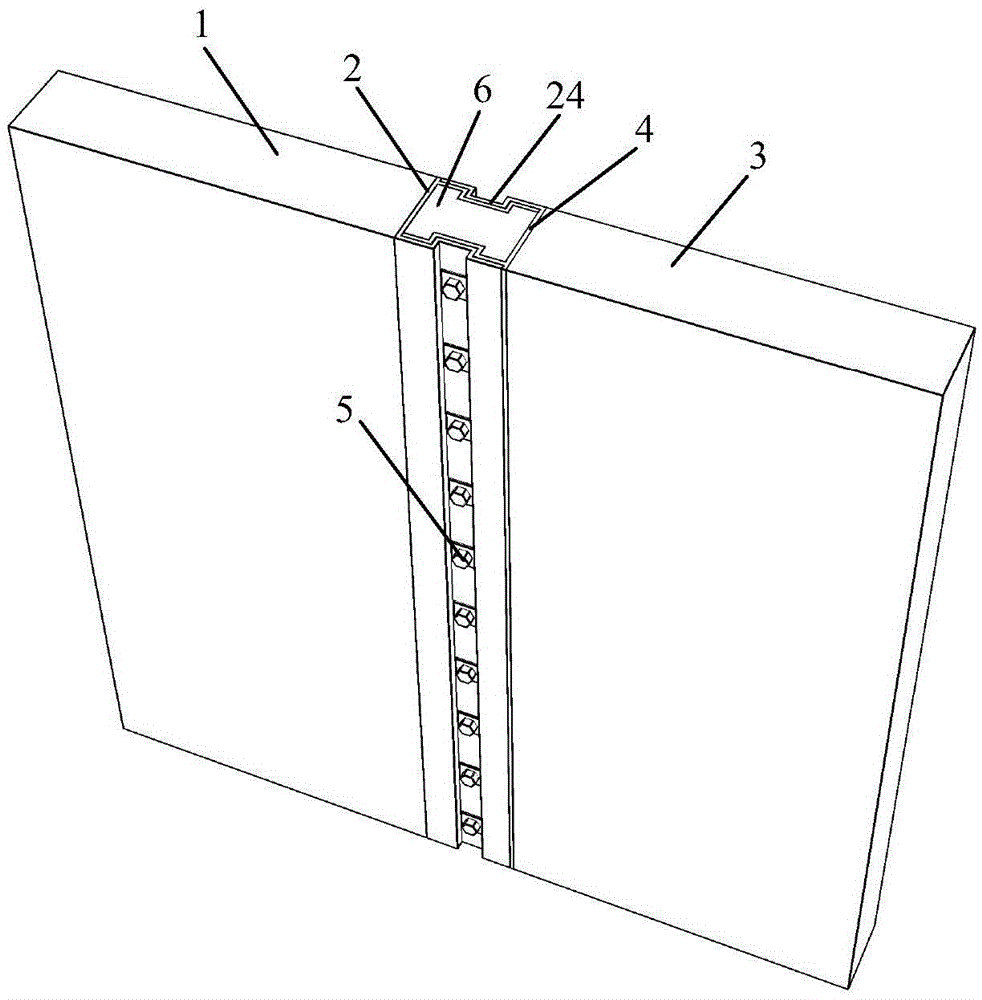

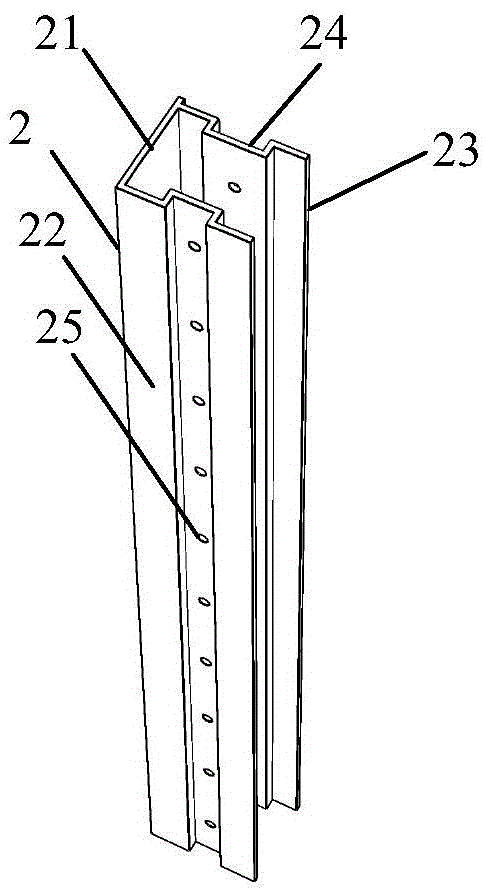

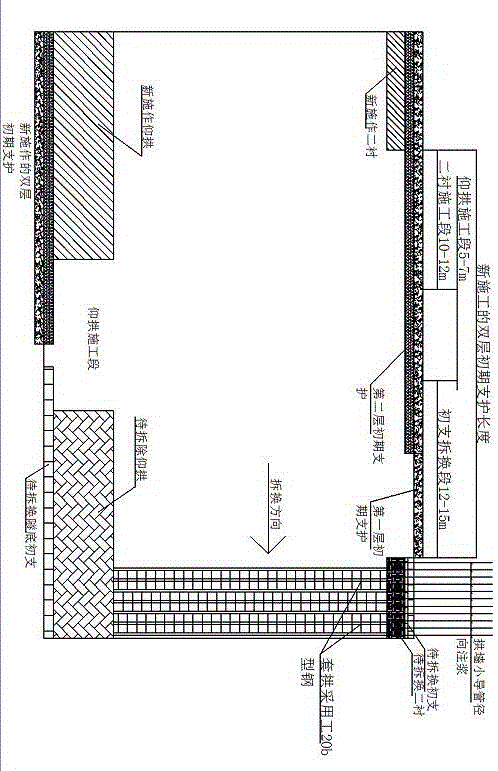

Prefabricated assembly type shear wall vertical slit connecting structure and construction method thereof

The present invention provides a prefabricated assembly type shear wall vertical slit connecting structure which comprises a left side shear wall, left side pre-embedded profile steel, a right side shear wall, right side pre-embedded profile steel, and a plurality of split bolts. The left side pre-embedded profile steel and the right side pre-embedded profile steel are disposed between the left side shear wall and the right side shear wall and have the same structure. The left side pre-embedded profile steel comprises a side plate, a front side plate and a rear side plate, the front side plate and the rear side plate are disposed at front and rear positions of the side plate, each of the front side plate and the rear side plate is inwardly provided with a groove, and the grooves are provided with a plurality of bolt holes. The split bolts are disposed in the bolt holes to lock and fix the left side pre-embedded profile steel and the right side pre-embedded profile steel. The present invention also provides a construction method of the prefabricated assembly type shear wall vertical slit connecting structure. The connecting structure is high in bearing capacity, high in stiffness, good in seismic ductility, excellent in integrity, convenient in construction and good in construction quality, and concrete is effectively restrained.

Owner:FUJIAN UNIV OF TECH

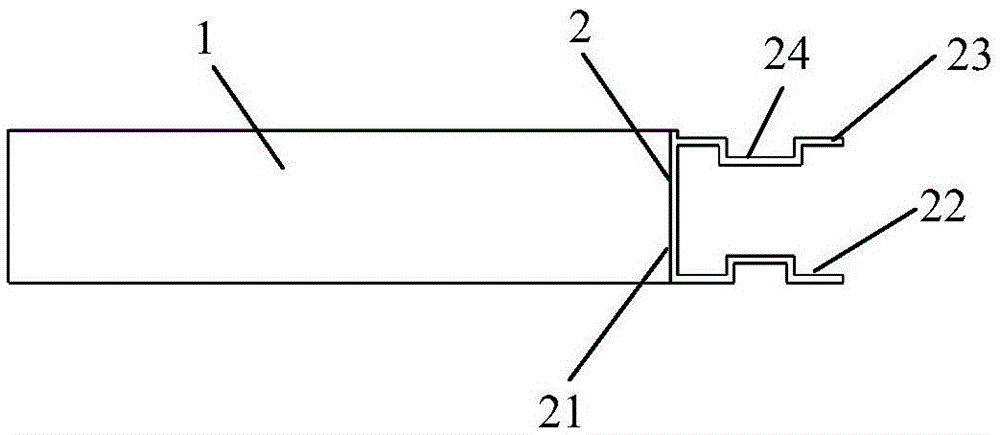

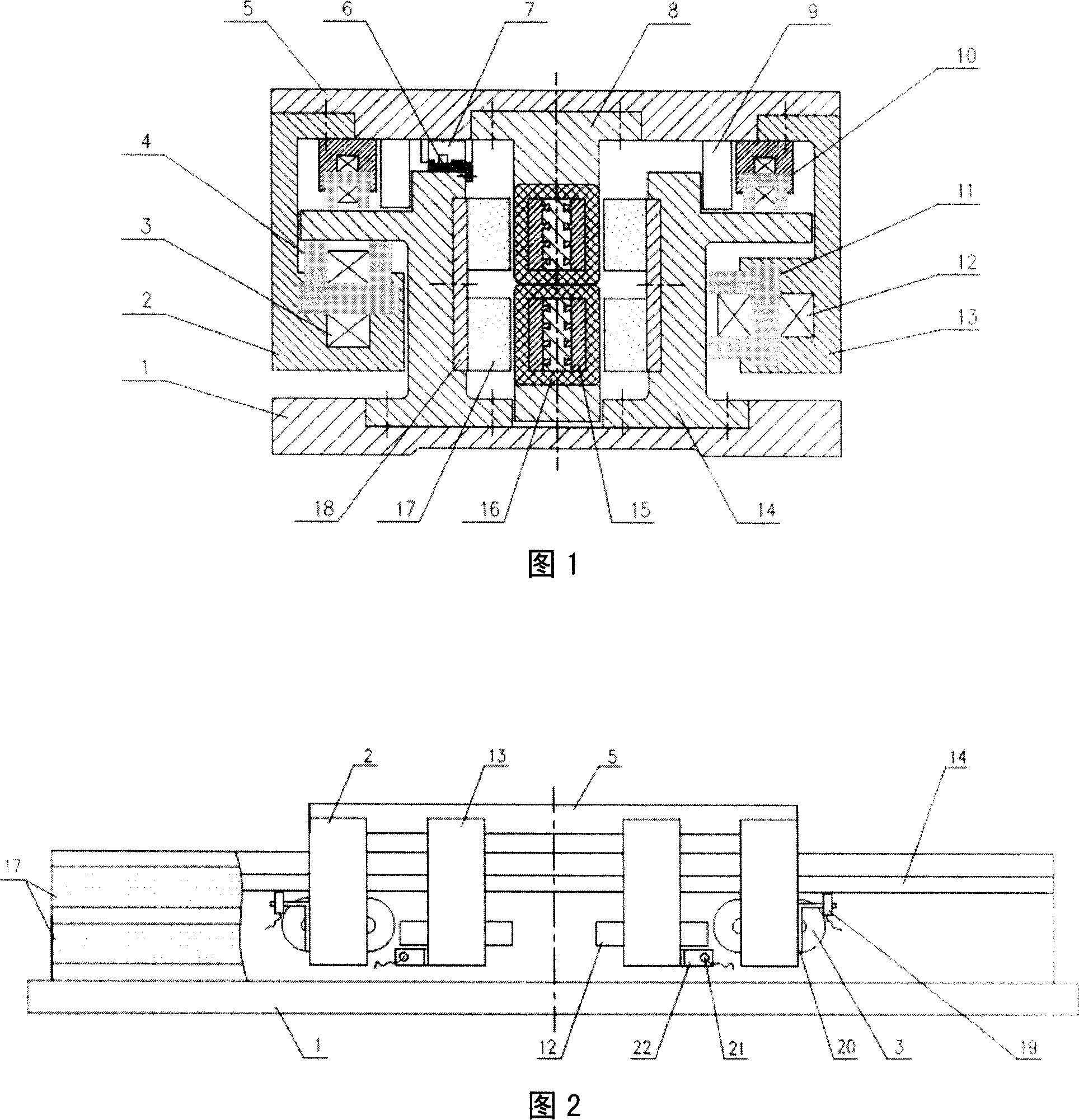

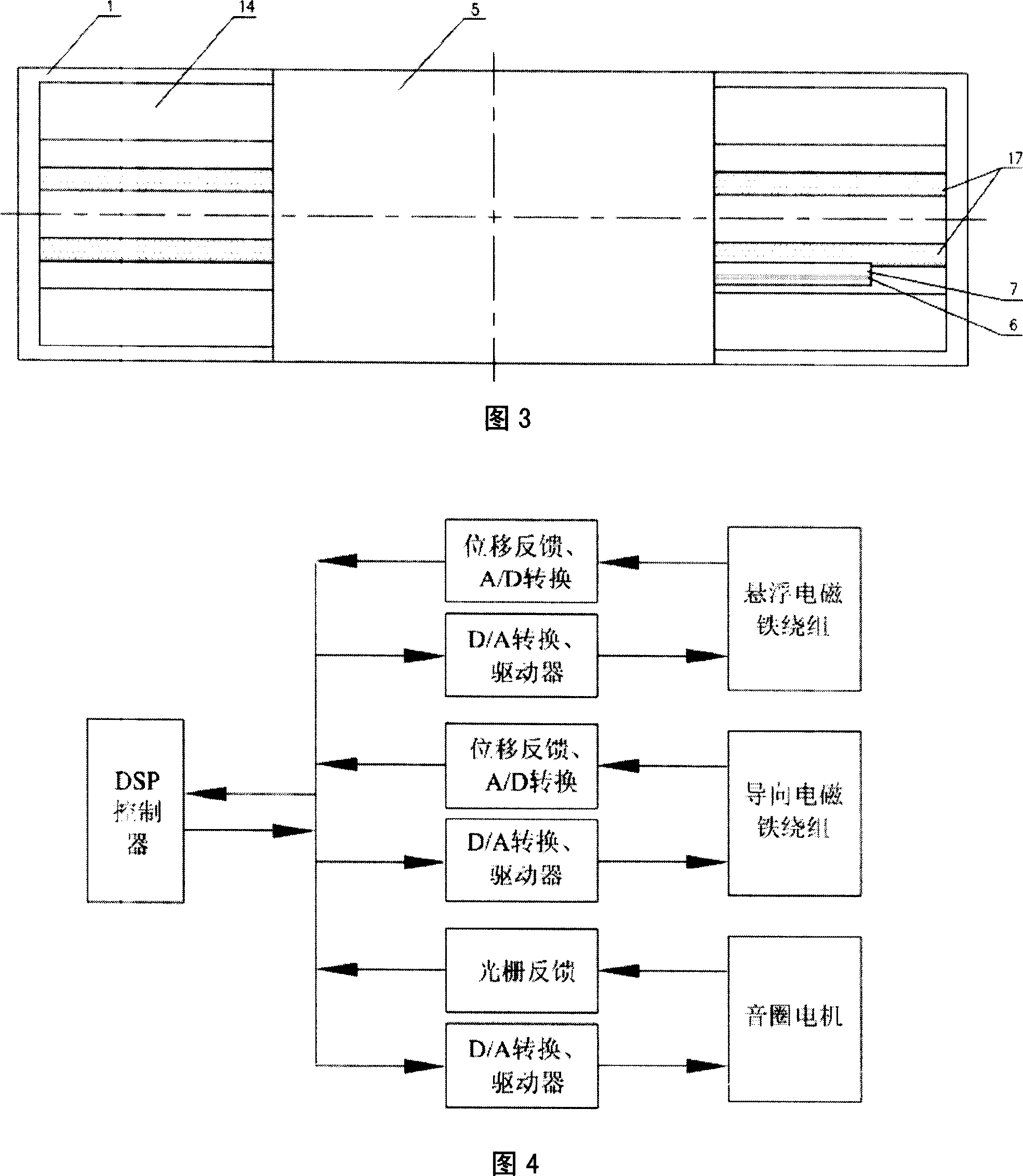

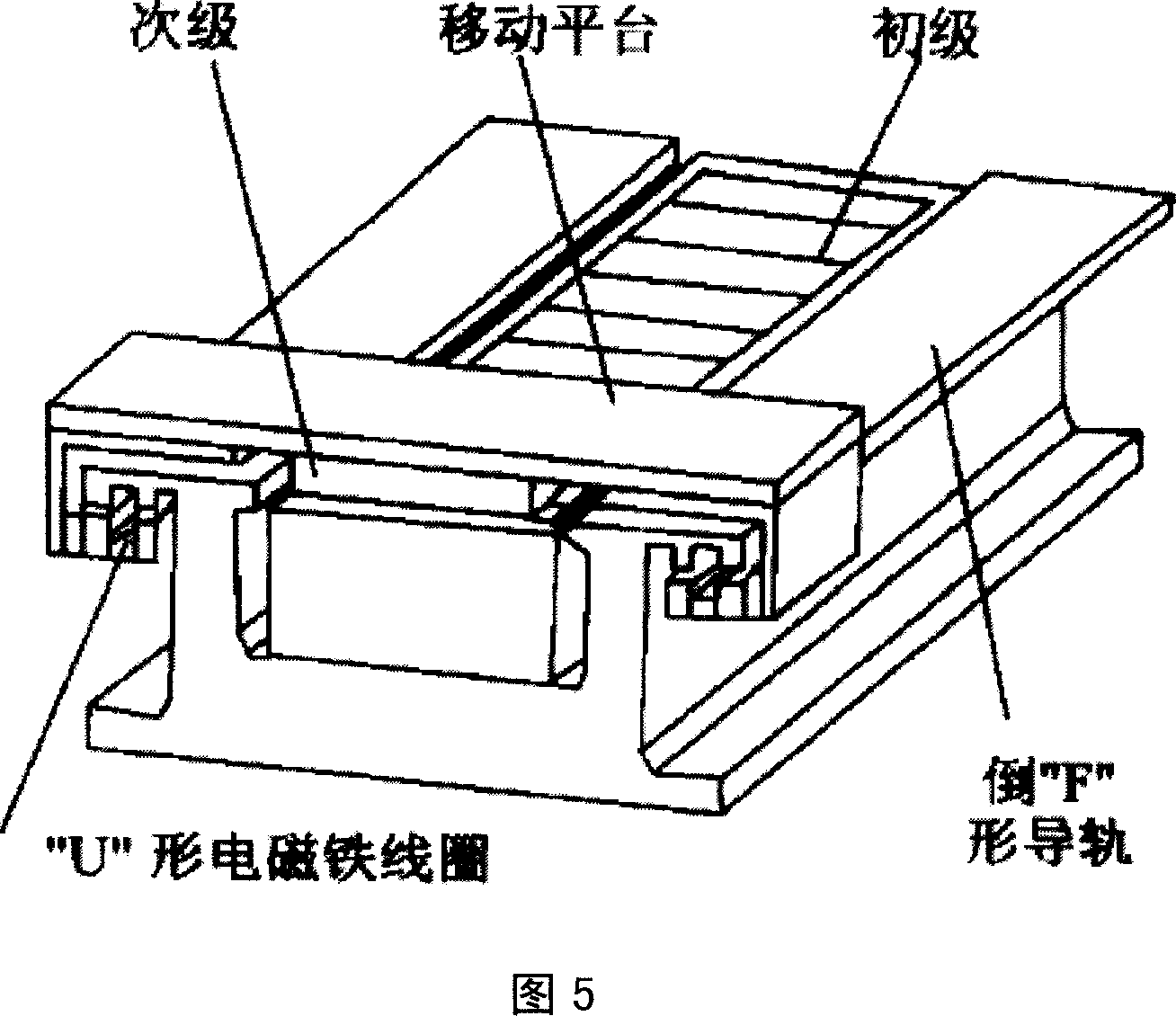

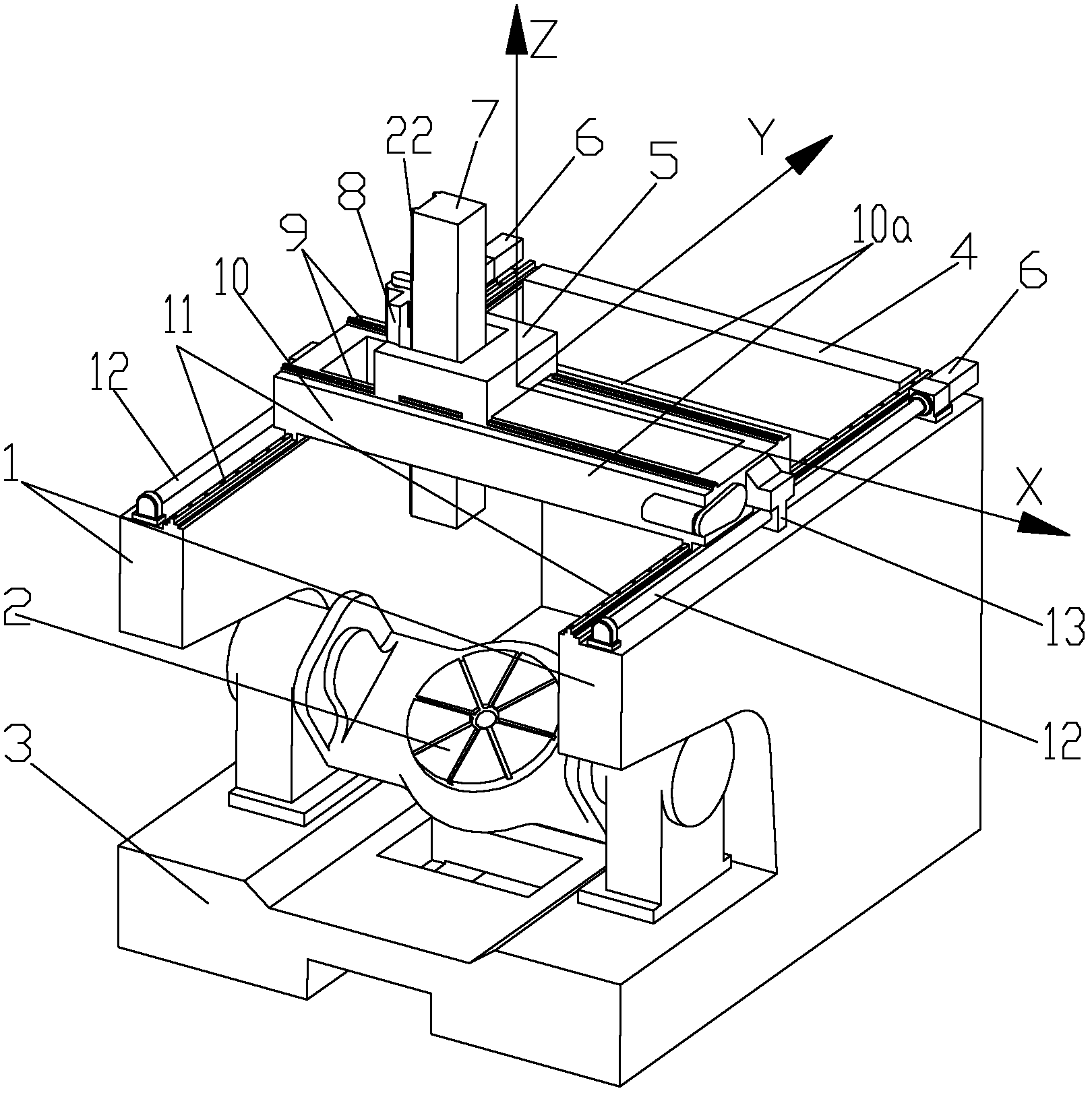

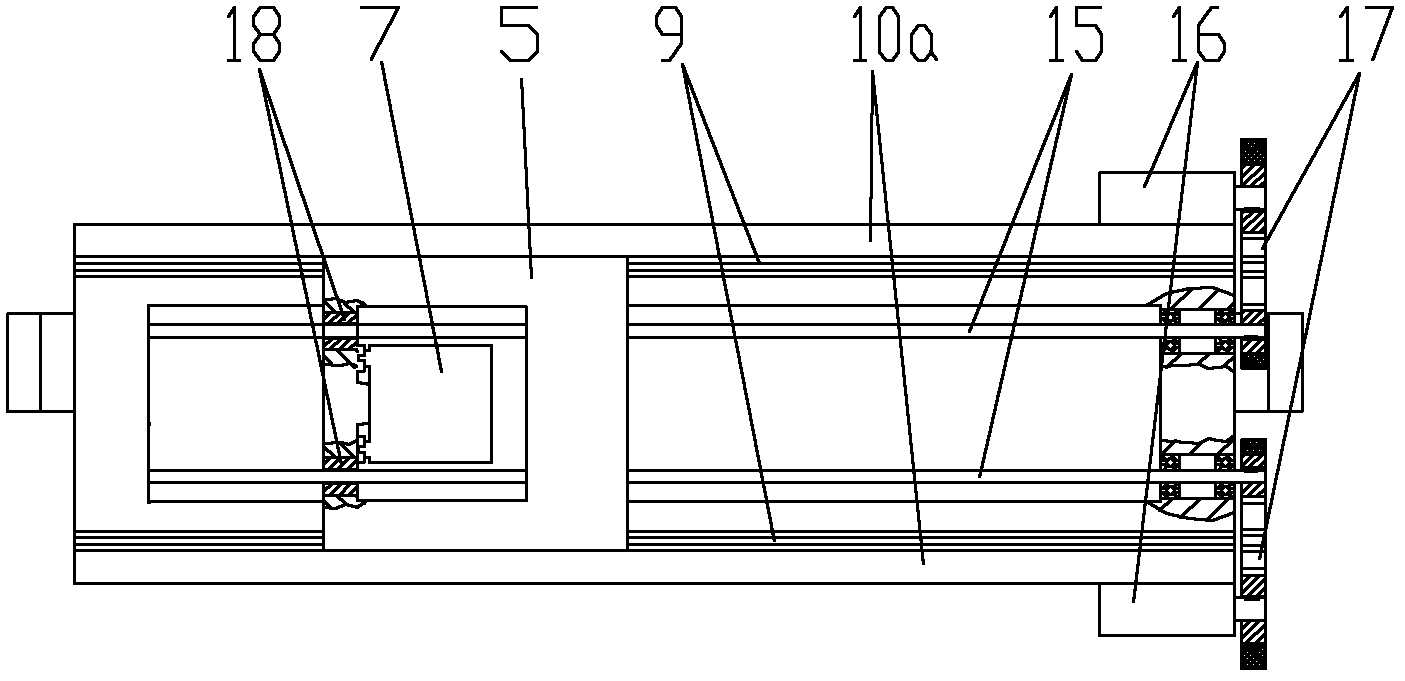

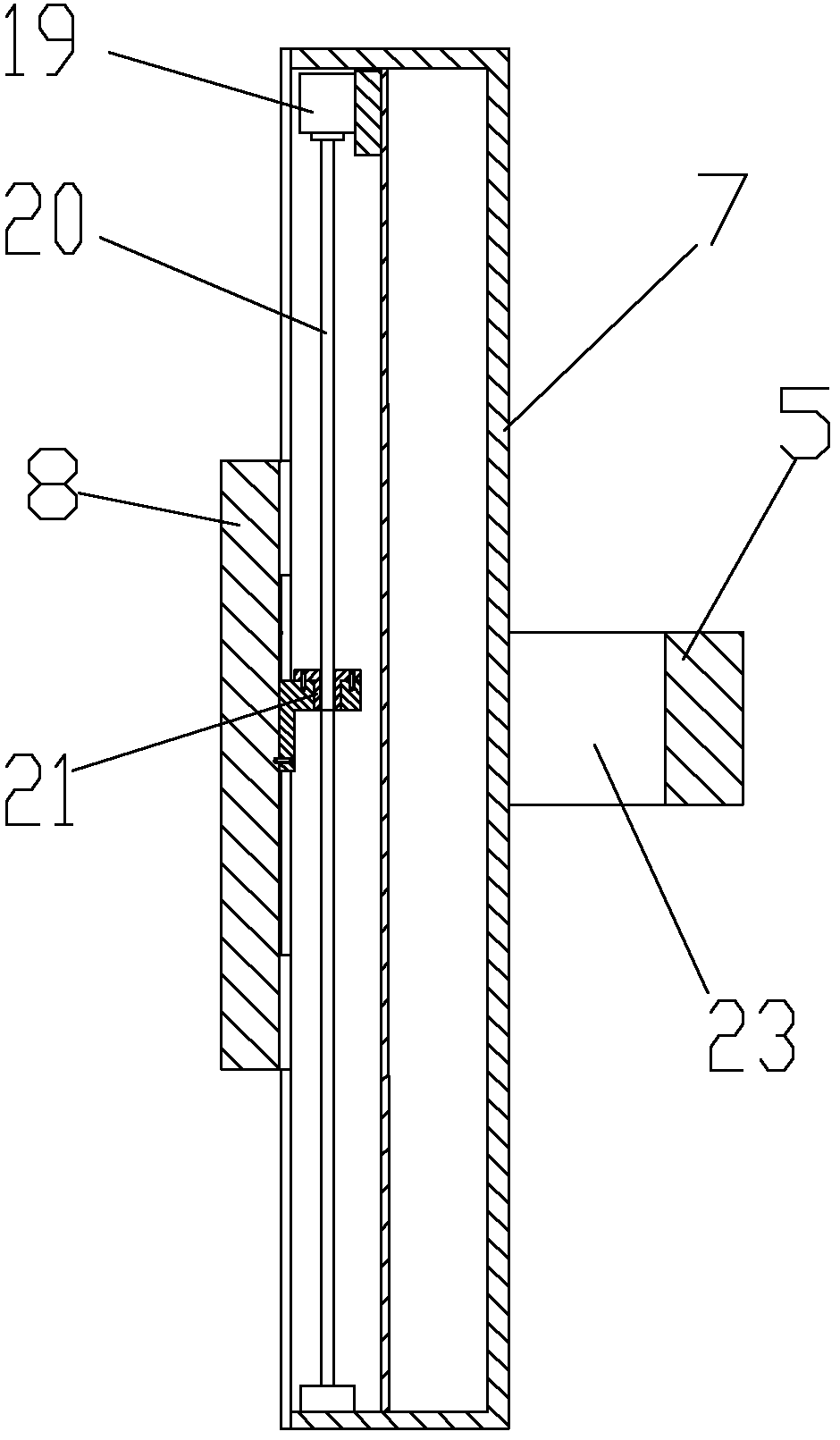

Numerical-control machine tool magnetic suspension linear feeding system

InactiveCN101024270AImprove carrying capacityEasy to driveFeeding apparatusControl using feedbackNumerical controlGrating

The invention relates to new type numerically controlled machine tool magnetic suspension feeding system. It includes engine base, two guide rails, linear motor stator part, four pairs of differential action suspension electromagnets, two pairs guide electromagnets, linear motor mover part, optical grating measuring system, and support device. The control system of the invention adopts clearance control system between DSP main controller suspension electromagnet, guide electromagnet, and the guide rail, and linear motor servo control system. Thus the invention can eliminate platen no touch support and guide, remove frictional wear, increase feed speed and positioning accuracy, supply enough bearing capacity and thrust, can be used in practical processing.

Owner:DALIAN JIAOTONG UNIVERSITY

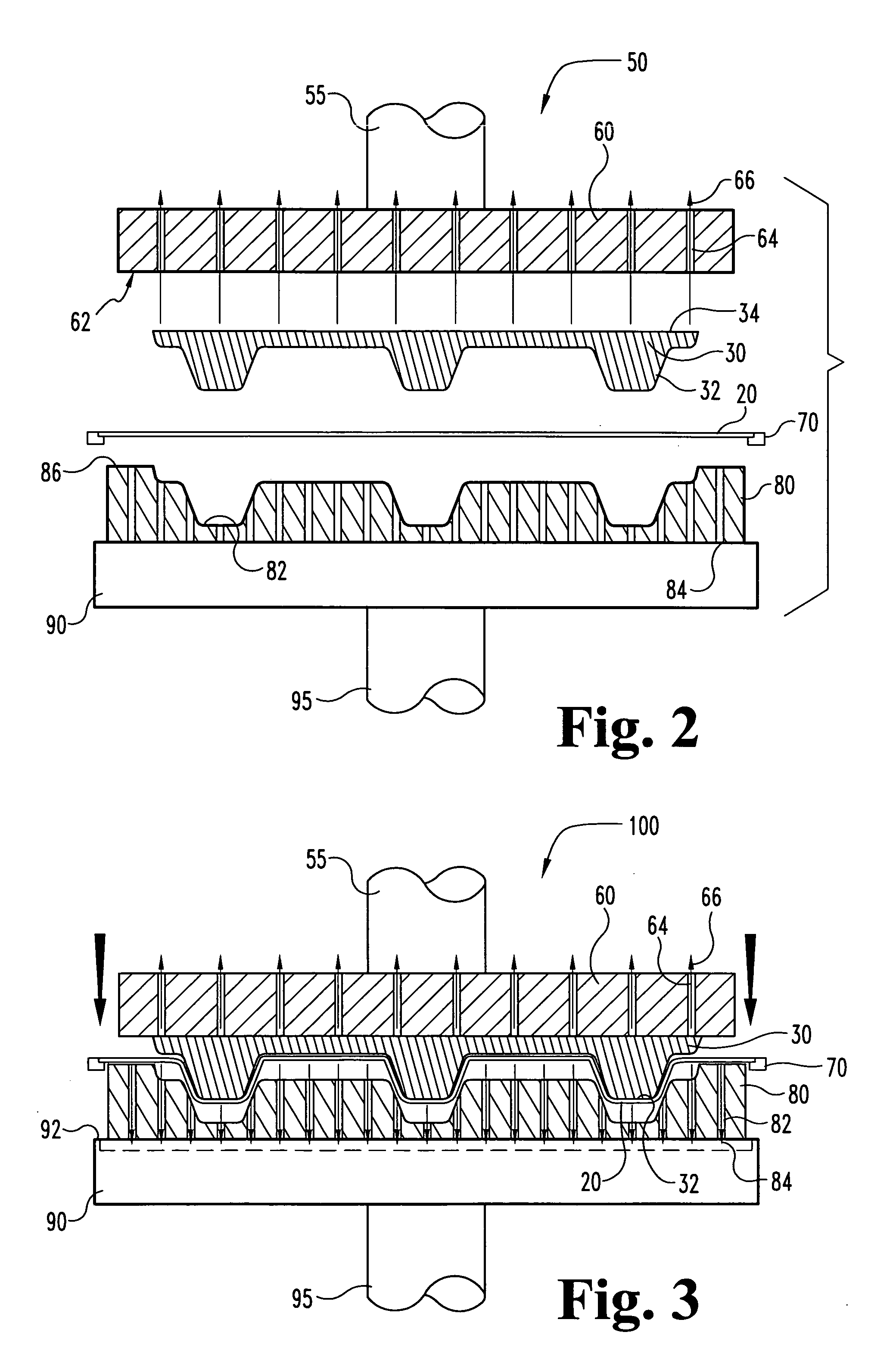

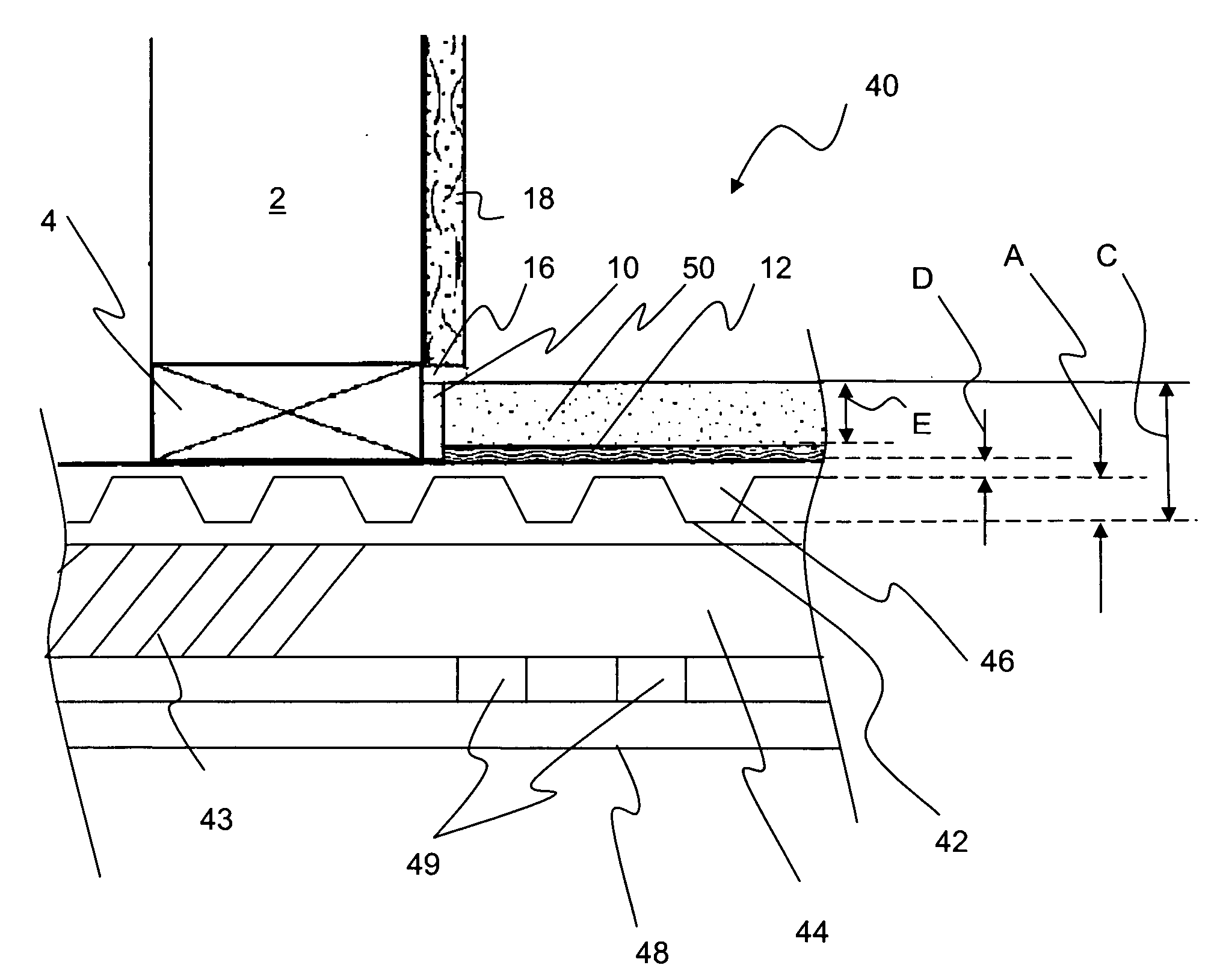

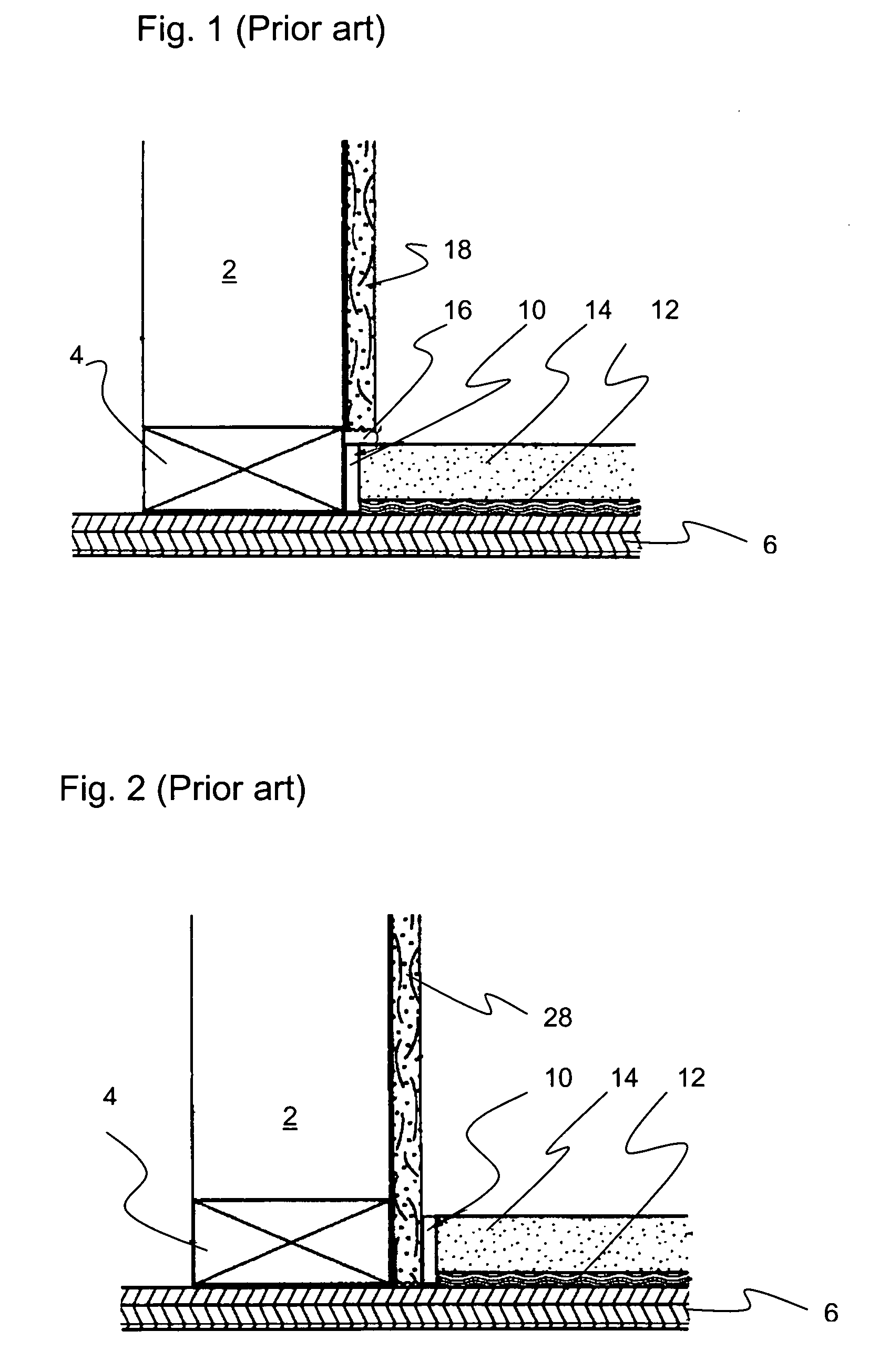

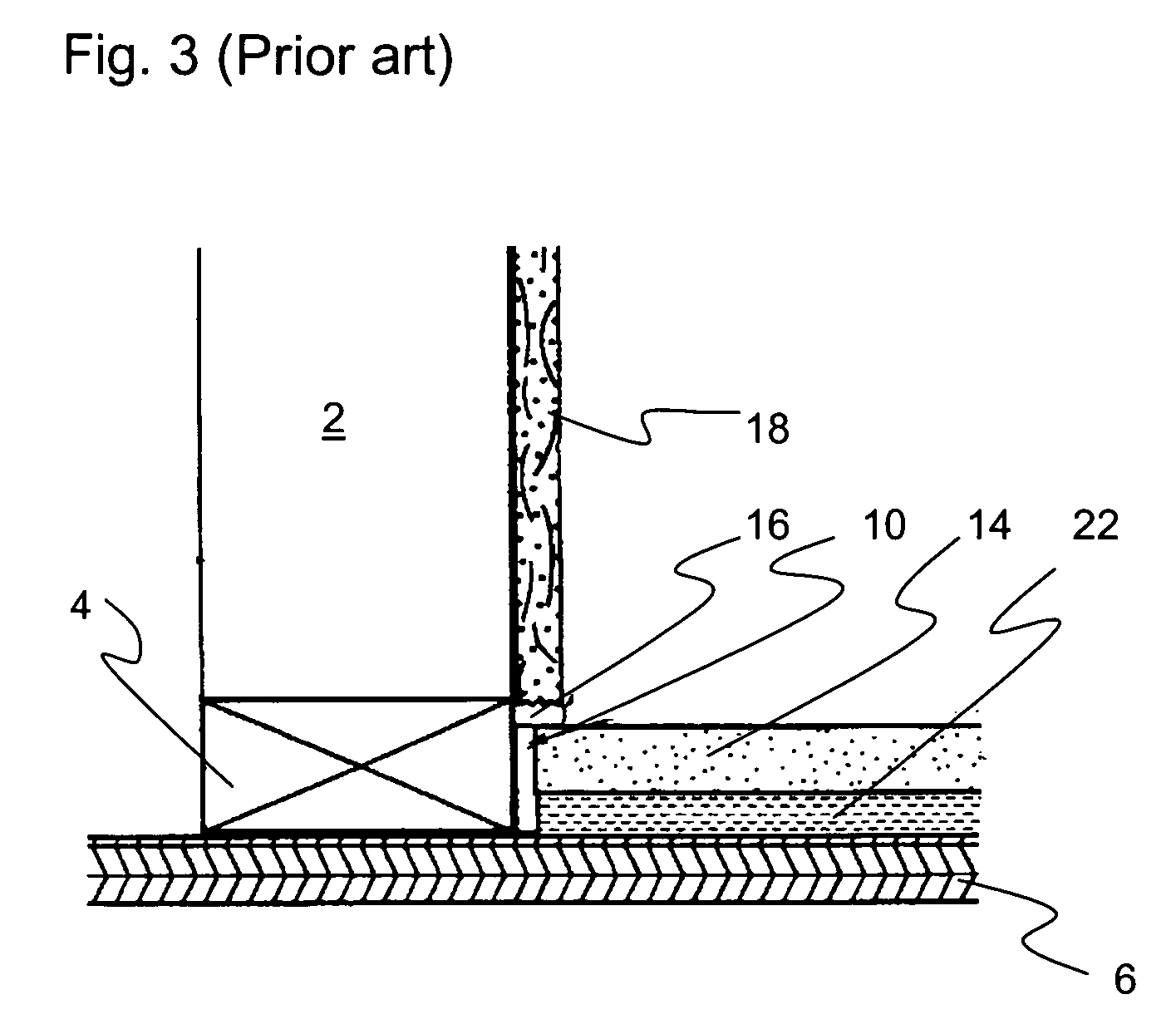

Corrugated steel deck system including acoustic features

ActiveUS20070000198A1Solve the slow construction speedReduce laborCeilingsCovering/liningsCarrying capacityEngineering

The present invention relates to a sound rated floor system for inhibiting sound transmission between floors. The system includes a corrugated steel deck; a first layer of cementitious material or board or sheet applied over the corrugated steel deck; a sound insulation mat or board applied over the first layer; a second layer of cementitious material applied over the sound insulation mat or board. The floor system has an IIC rating of at least 25 and the corrugated steel deck provides at least 50 percent of the ultimate load carrying capacity under static and impact loading of the floor system with a floor deflection of at most 1 / 360 of the floor span.

Owner:UNITED STATES GYPSUM CO

Method of molding load-bearing articles from compressible cores and heat malleable coverings

Load-bearing articles are manufactured from shape defining compressible cores and thermoplastic shells. The manufacture of these articles requires specific methods and tools. Articles that can be manufactured using these methods include relatively lightweight pallets with high load-bearing capacity.

Owner:NOVO FOAM PRODS

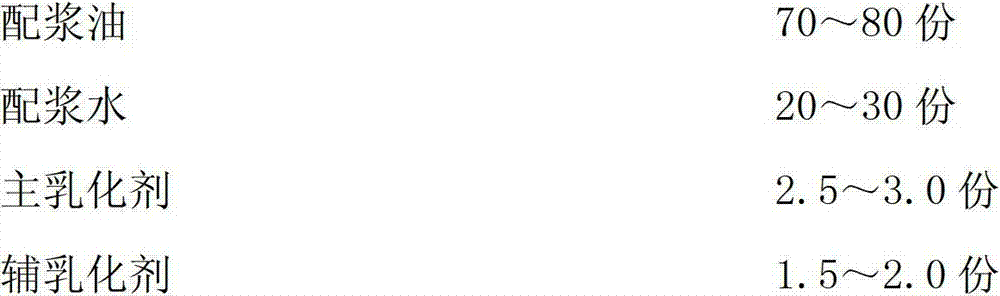

High-efficiency plugging oil-base drilling fluid and preparation method thereof

ActiveCN103045210AEffective blockingPrevent penetrationDrilling compositionAlkalinityDifferential pressure

The invention discloses a high-efficiency plugging oil-base drilling fluid and a preparation method thereof. The drilling fluid is prepared from the following raw materials in parts by mass: 70-80 parts of slurrying oil, 20-30 parts of slurrying water, 2.5-3.0 parts of main emulsifier, 1.5-2.0 parts of auxiliary emulsifier, 2.0-2.5 parts of wetting agent, 2.0-2.5 parts of flow pattern regulator, 2.5-3.0 parts of fluid loss agent, 1.5-2.0 parts of alkalinity regulator, 0.5-0.8 part of extracting agent and 7-9 parts of plugging material. A weighting material is added so that the density of the drilling fluid reaches 1.45-1.56 g / cm<3>. By utilizing the well-drilling positive differential pressure, the high-efficiency plugging oil-base drilling fluid quickly implements bridging, filling and filming to plug the formation fractures on the well wall surface and near the well wall, effectively prevents the drilling fluid and filtrate thereof from permeating into microfractures, enhances the bearing capacity of the formation, has favorable plugging effect, and is beneficial to the stability of the well wall.

Owner:CHINA PETROLEUM & CHEM CORP +1

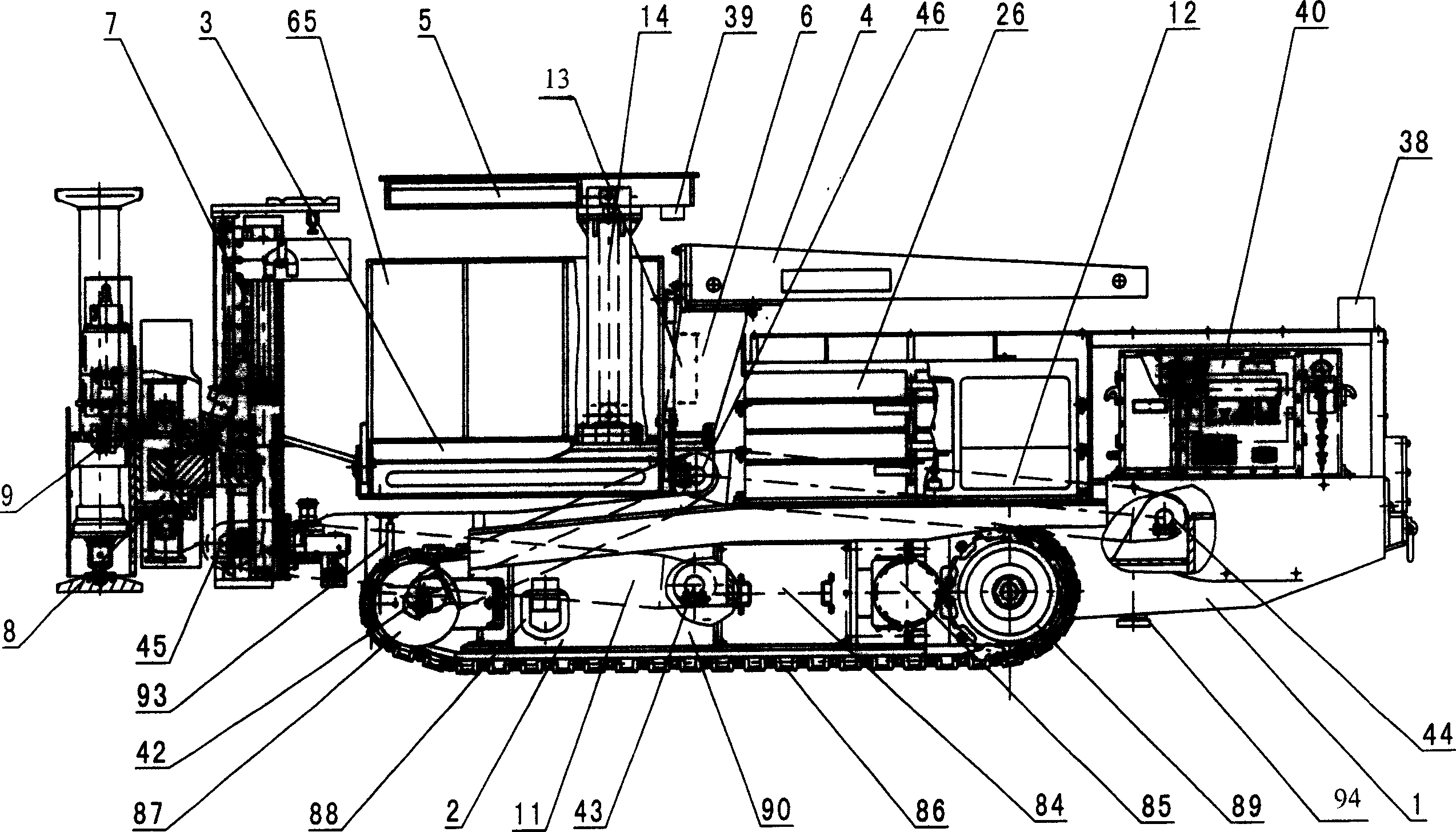

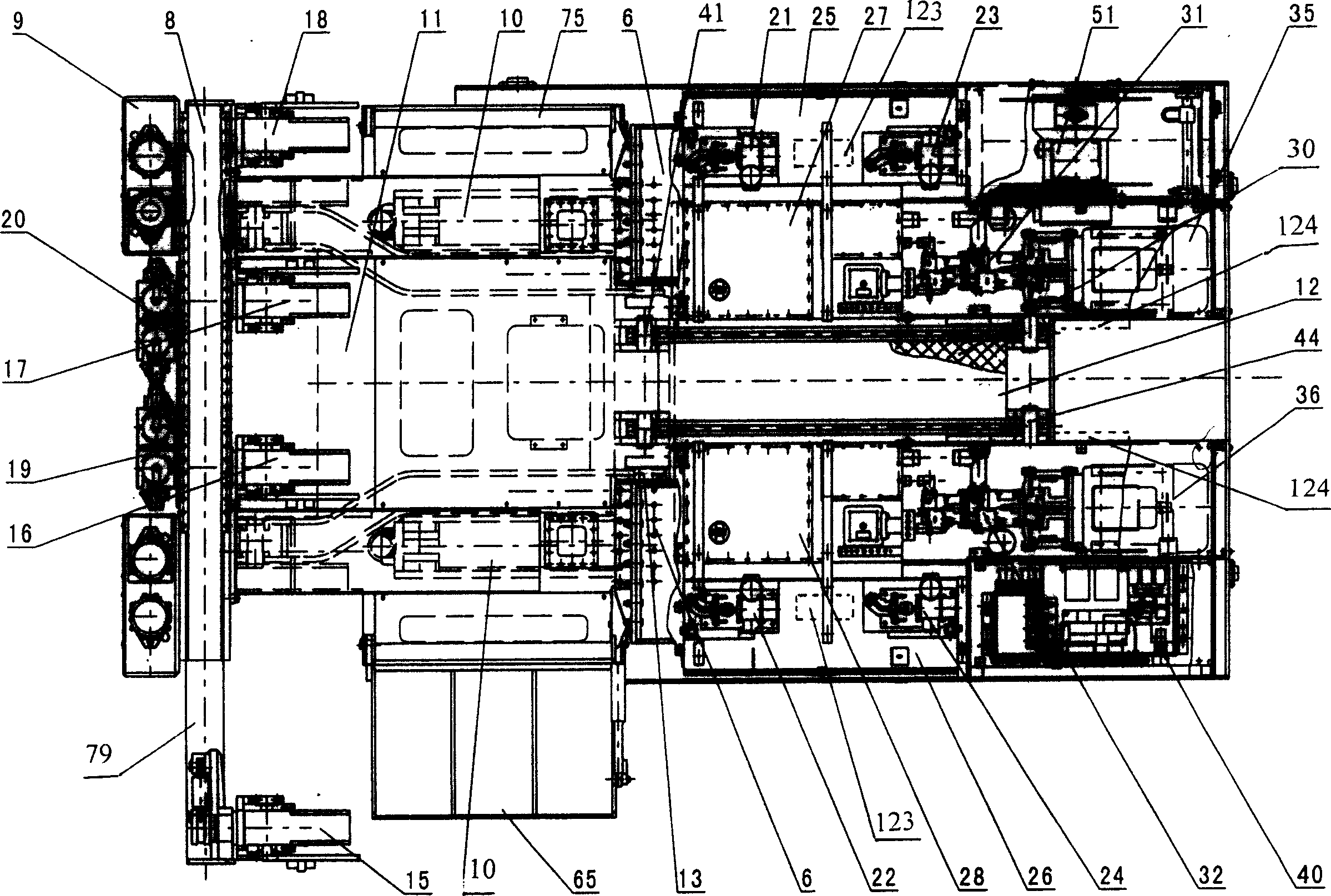

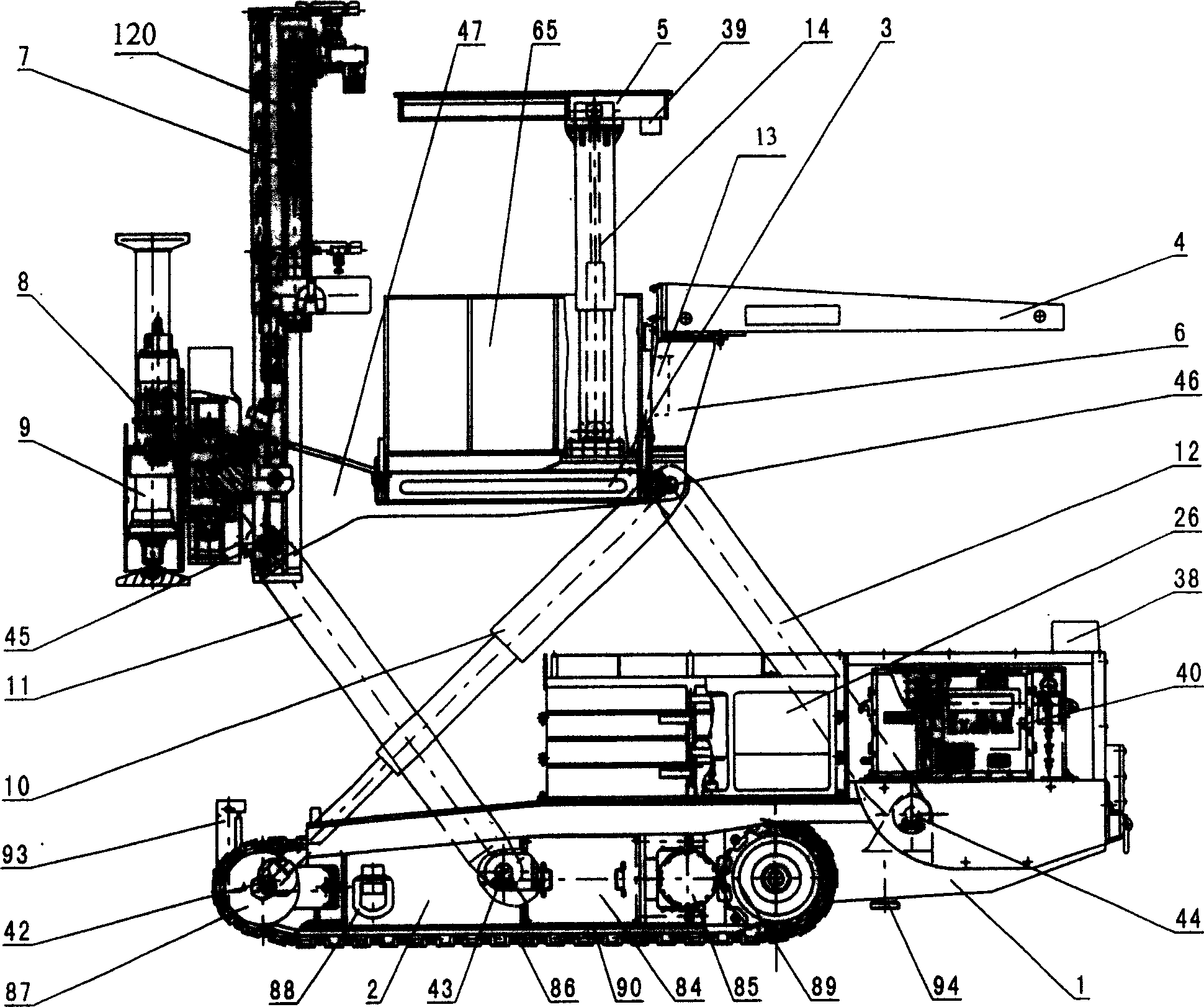

Crawler-type walking rockbolt drilling carriages

ActiveCN1584292AThe mechanical relationship is reasonableMechanizationAnchoring boltsDrilling machines and methodsElectric controlRock bolt

The present invention relates to a crawler running roof-bolting jumbo for coal extraction in the pit. It mainly includes machine seat, working table, running mechanism, lifting mechanism, hydraulic mechanism, dust-removing mechanism, cable-rolling mechanism, drilling cramp component, slideway component, support component and electric control box, said whole machine adopts hydraulic transmission, automatic dust-removing, automatic cable-rolling and crawler running modes, and utilizes the hydraulic oil cylinder to control parallelogram lifting movement and can make moving, lifting and multi-arm roof-bolt drilling works in the excavating tunnel. Said invention is reasonable in structure, large in load-bearing capacity, reliable and high in working efficiency.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP

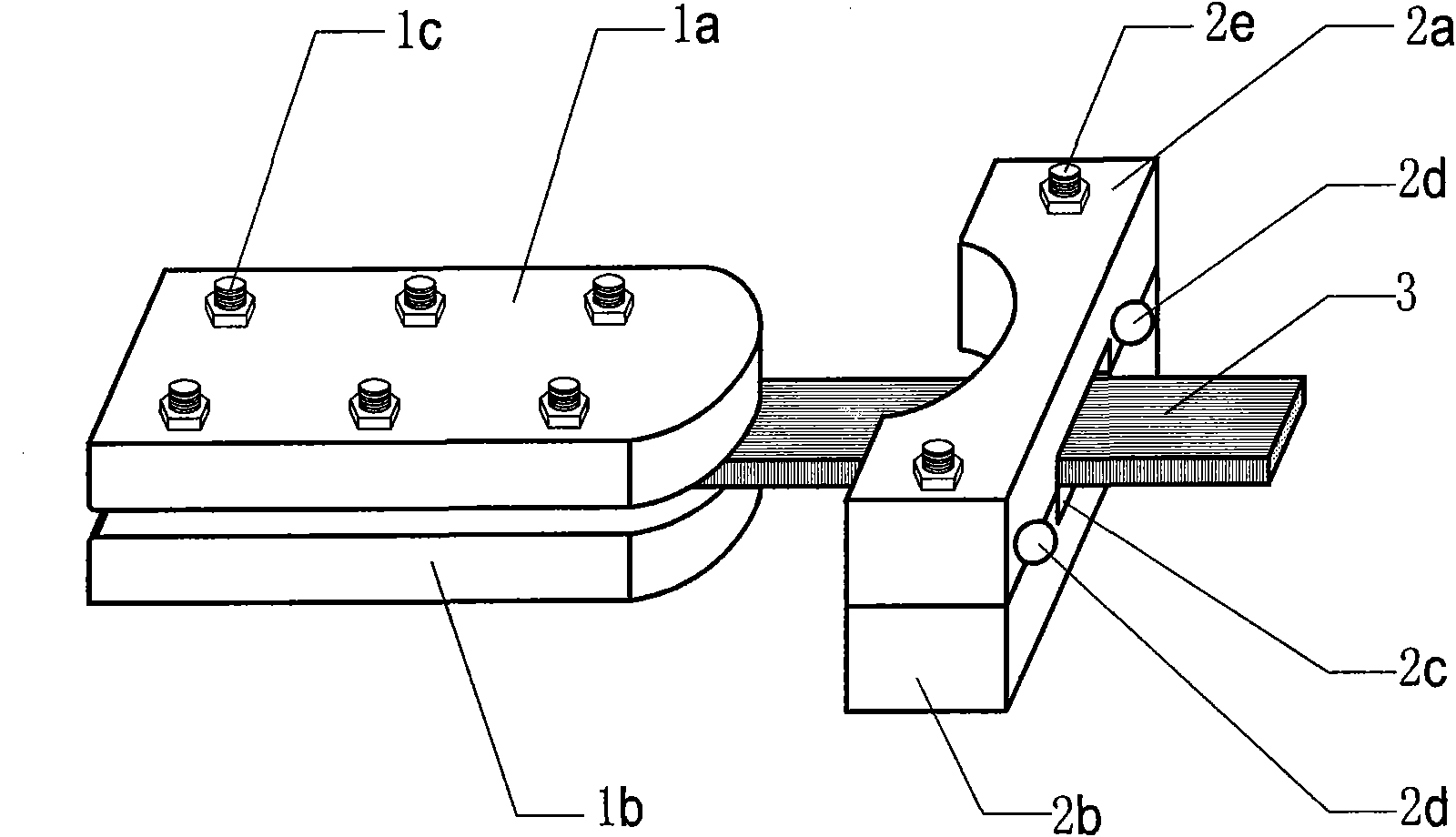

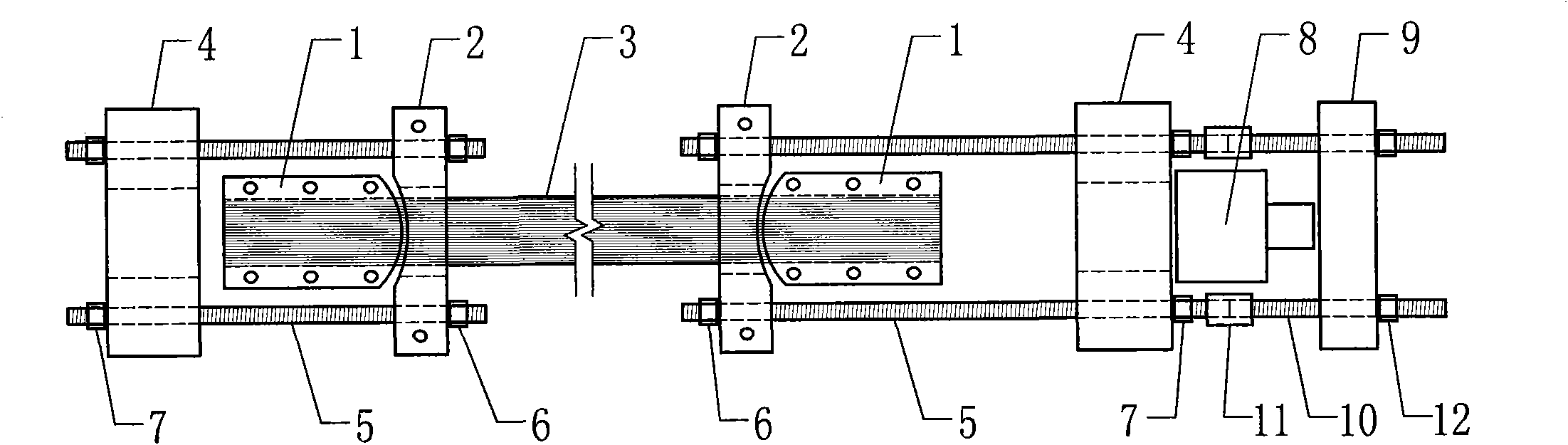

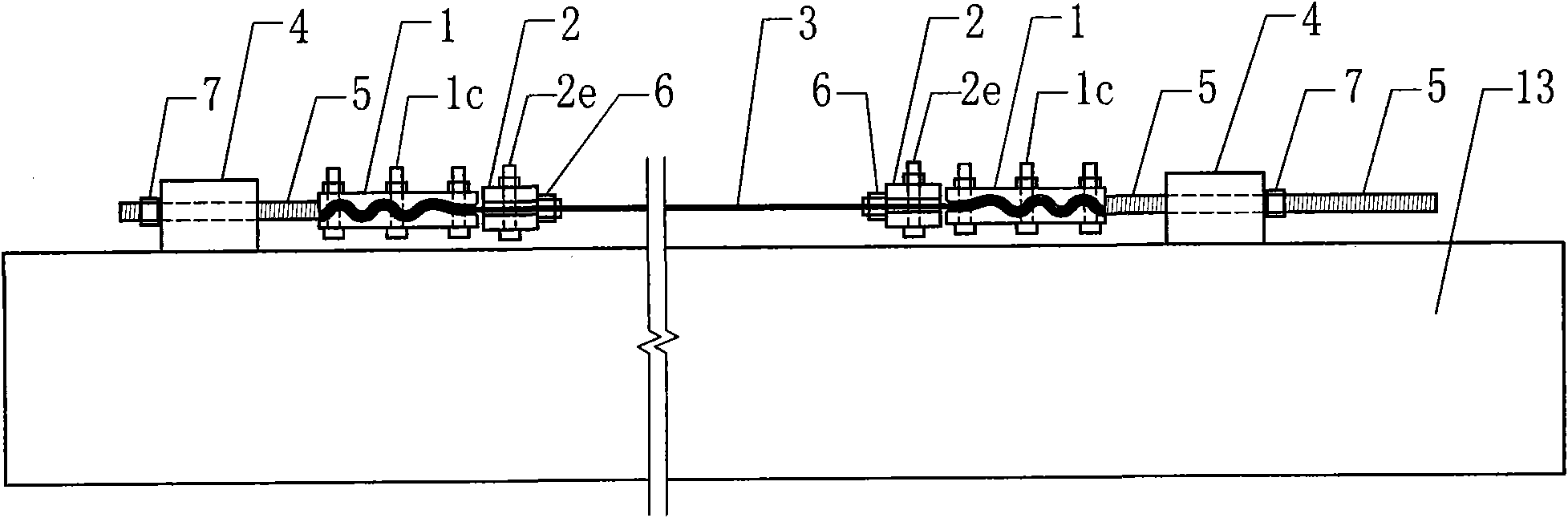

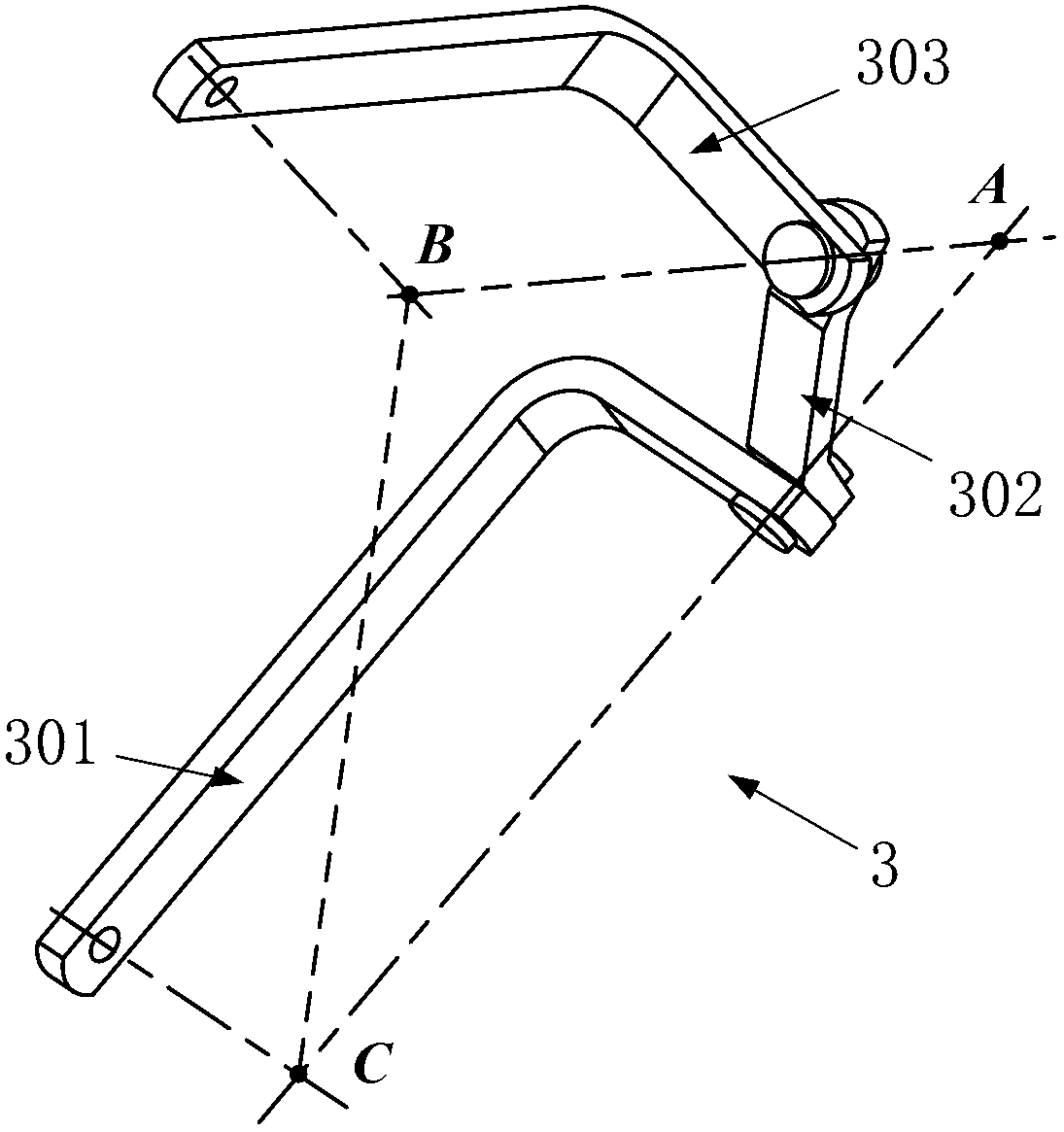

Articulated anchor and prestress tensioning method of high strength fibre composite sheet

ActiveCN101851985AGuaranteed automatic adjustmentGuaranteed uniformityBuilding reinforcementsBuilding material handlingFiberConcrete beams

An articulated anchor and a prestress tensioning method of high strength fibre composite sheet relate to an anchor holder used to perform prestress tensioning to the high strength fibre composite material of the enhancement or reinforcement engineering structure and a method thereof. The articulated anchor of the invention comprises an anchor head and a compression and locking device, and the articulated anchor is characterized in that the anchor head contains a raised head anchor and a concave block. The method of the invention is that the articulated anchor is used to clamp and anchor the two ends of FRP sheet, a jack is used to apply a tension on the concave block and the concave block pushes the raised head anchor to perform prestress tensioning to FRP sheet. The articulated anchor of the invention has simple structure, convenient installation and low cost; and the method of the invention is simple, intuitive and practical, and can ensure the tensioning uniformity of FRP sheet, made full use of the intensity of FRP sheet and effectively increase the bearing capacity of the engineering structure. The articulated anchor of the invention can be widely used to enhance or reinforce the large engineering structures such as bridges or buildings and especially to perform external prestressing reinforcement to longspan concrete beams, longspan concrete slabs and the like.

Owner:卓清

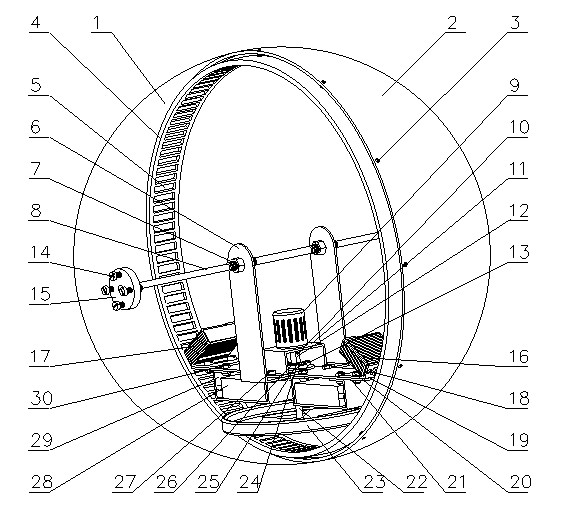

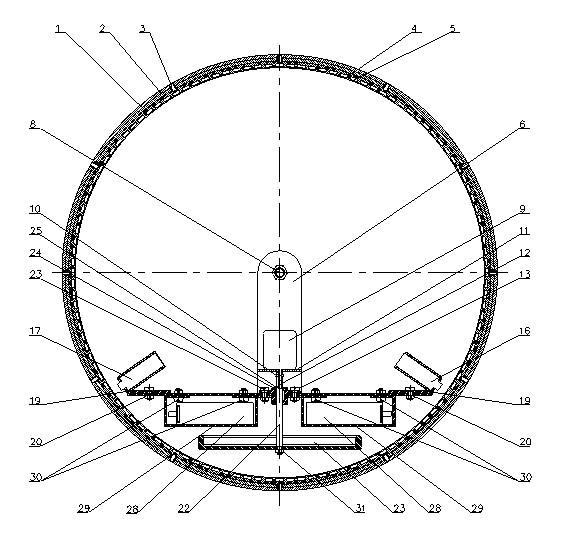

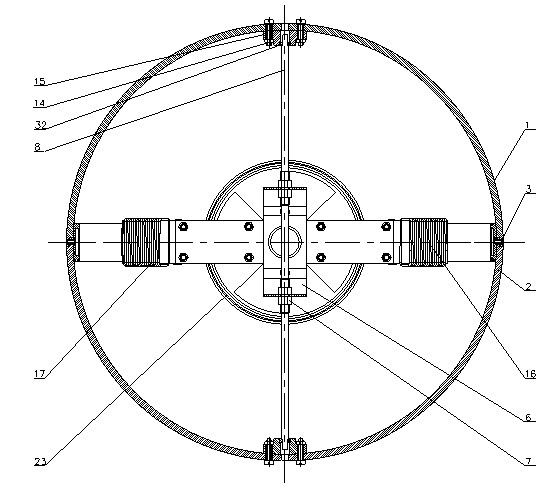

Electromagnetically-driven spherical robot

InactiveCN102060060AImprove internal space utilizationImprove carrying capacityVehiclesInterior spaceEngineering

The invention discloses an electromagnetically-driven spherical robot. The electromagnetically-driven spherical robot is characterized in that the spherical robot comprises a spherical case, and magnets uniformly and annularly arranged at the vertical middle positions on the inner wall of the spherical case, wherein adjacent magnets have opposite pole directions; a main shaft is transversely arranged in the spherical case in a rotary manner, and is fixedly connected with a bracket; at least one group of electromagnetic coils are disposed on the bracket; and each electromagnetic coil group includes two pairs of electromagnetic coils arranged symmetrically relative to the main shaft. The magnetic core of the electromagnetic coils can be controlled to attract and repel the magnets on the inner wall of the spherical case by controlling the polarity of the two electromagnetic coils to change alternately, so that the bracket can be driven to rotate around the main shaft; therefore, the spherical robot can move forwards and backwards based on the electromagnetic stepping principle. Compared with the conventional spherical robot, the electromagnetically-driven spherical robot has the advantages of simple and reliable structure, stable and flexible movement, and high controllability. Meanwhile, the driving manner of the spherical robot is simplified greatly in comparison with the existing spherical robot, thereby improving the utilization rate of the inner space of the spherical robot. Spherical robots with different dimensions can be manufactured according to different purposes, thereby enhancing the bearing capacity of the spherical robot, and facilitating the generation of serial products.

Owner:TAISHAN UNIV

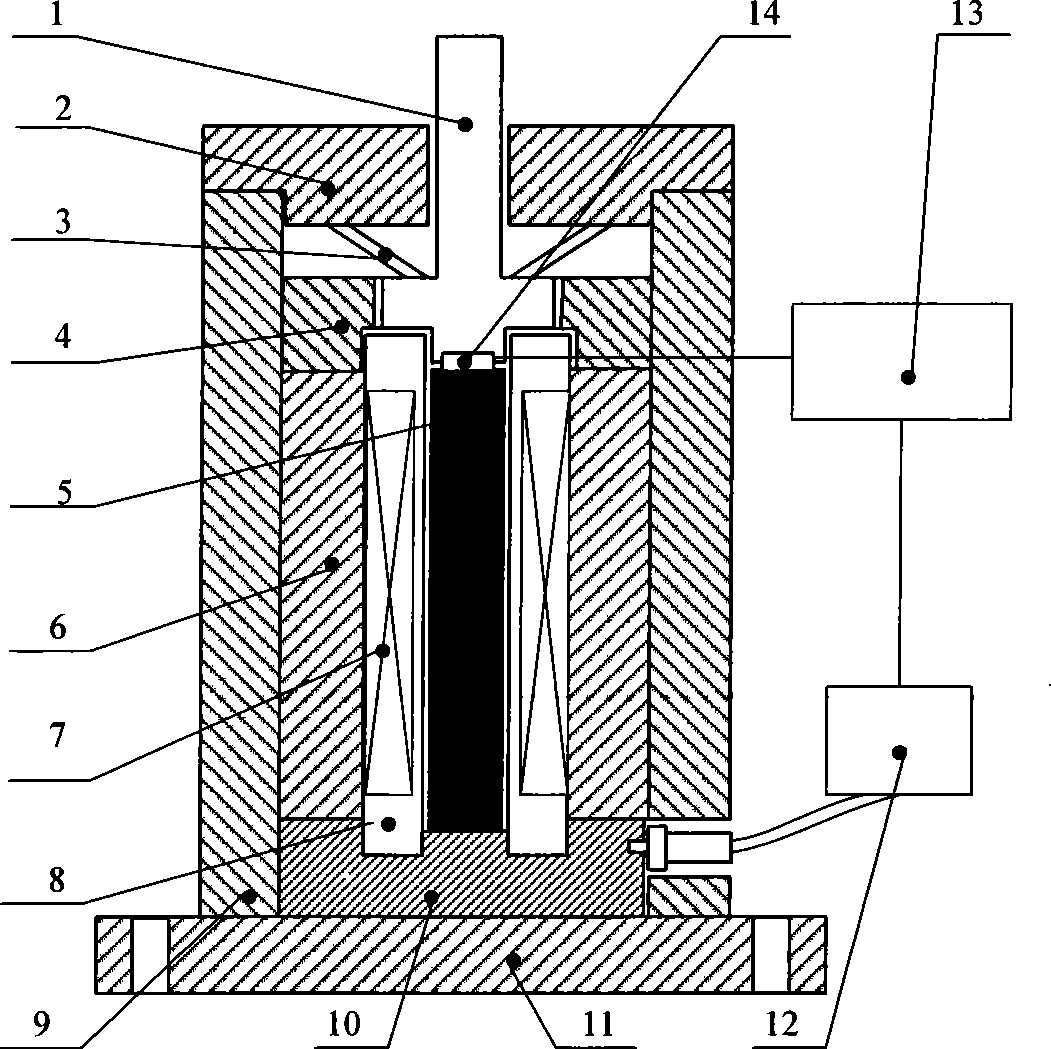

Method for self-lubricating treatment of laser micro-texture of bearing

InactiveCN102226459AImprove complex working conditionsGuaranteed carrying capacityBearing componentsLaser beam welding apparatusGraphiteOptoelectronics

The invention discloses a method for self-lubricating treatment of laser micro-texture of bearings. The invention comprises the following steps: firstly performing laser micro-processing technology of micro recessed cavities or micro grooves on a bearing surface, and then performing molding and bonding technology by a self-lubricating composite material on the bearing surface; the self-lubricating composite material comprises the following components by mass: 10-15% of polyimide (PI); 8-13% of graphite powder; 40-50% of polytetrafluoroethylene; 25-29% of MoS2; 0-5% of additives. By the self-lubricating treatment of laser micro-texture of a bearing, the invention guarantees the bearing capacity and the fitting accuracy of the bearing, realizes an optimized distribution of the lubricant on the bearing working surface, and improves comprehensive performance of antifriction and wear resistance of the bearing under complicated working conditions.

Owner:JIANGSU UNIV

Steel tube-I beam combination steel tube concrete special-shaped columns and manufacture method thereof

InactiveCN102587577AOvercome deficienciesOvercoming the lack of restraint abilityStrutsBuilding material handlingSheet steelShock resistance

The invention relates to steel tube-I-beam combination steel tube concrete special-shaped columns, which comprises steel tubes, I-beams and concrete poured inside the special-shaped columns. The steel tubes and the I-beams are welded together to compose the special-shaped columns with different sections. The whole sections are separated through the steel tubes and the I-beams, then the concrete is filled in separation spaces of the steel tubes and the I-beams, the steel tubes can be made by welding or rolling, and the I-beams can be made by welding or rolling. The steel tube-I-beam combination steel tube concrete special-shaped columns have the advantages that inside corner steel tube walls and I-beam flange steel plates are communicated with each other so as to overcome the defect that force delivery of inside corner portions of other steel tube concrete special-shaped columns is unclear, and whole working capacity of steel tube concrete special-shaped columns is improved. The steel tubes are placed at the edges and at corner portions of the sections so as to improve restrain capacity of the special-shaped columns. The steel tubes and the I-beams separate the concrete of the special-shaped columns, width-to-thickness ratio of the steel plates is reduced, bearing capacity and shock-resistance are improved, production and assembly of the special-shaped columns are modularized, and simultaneously construction speed is fast.

Owner:TIANJIN UNIV

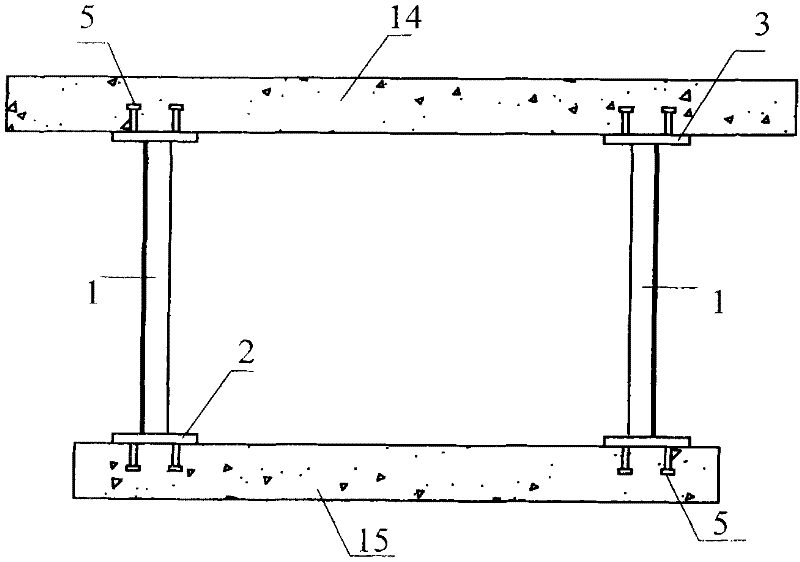

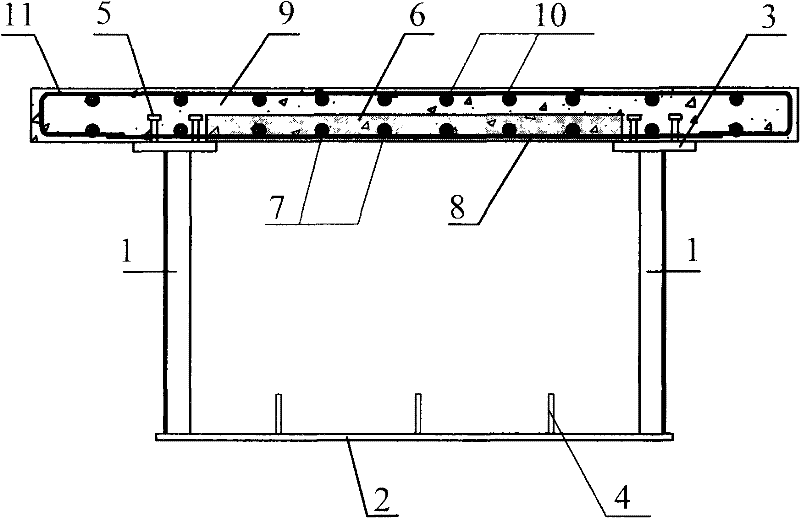

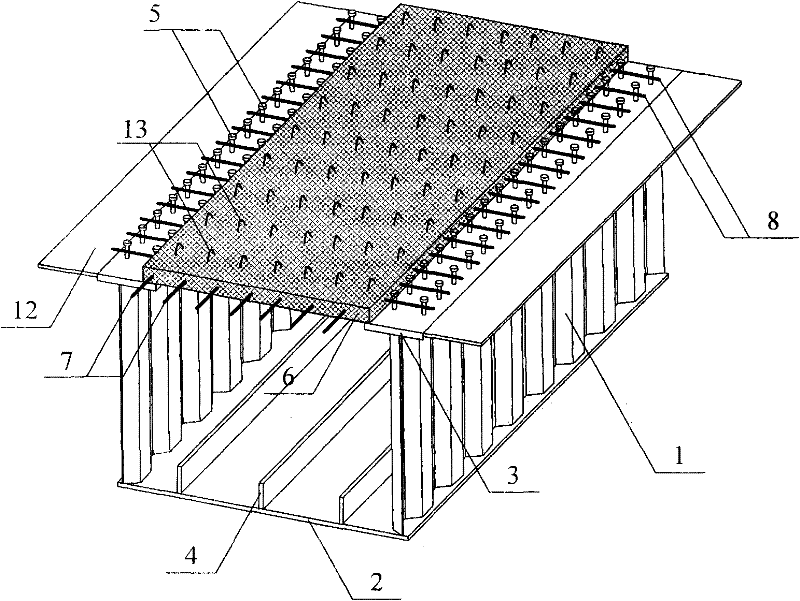

Steel-concrete composite beam adopting corrugated steel web and construction method thereof

The invention discloses a steel-concrete composite beam adopting a corrugated steel web, which relates to a corrugated steel web composite beam capable of being applicable to highway bridges and railway bridges. The beam comprises a top flange concrete composite plate, a corrugated steel web plate, a top flange steel plate, a box beam bottom plate and male pin connecting pieces, wherein the top flange comprises a precast concrete slab and a cast-in-place concrete layer; and the top flange concrete composite plate is connected with the top flange steel plate into a whole through the male pin connecting pieces welded on the top flange steel plate. By adopting the structure, the problems that the site workload and the construction difficulty for casting a bottom flange concrete slab of a traditional corrugated steel web composite beam are large, the construction quality is difficult to guarantee and the like are overcome on the premise that the quantity of steel is hardly increased, meanwhile, the tensile property of the steel plate is fully played, the bearing capacity, the rigidity and the cracking resistance of the structure are improved, and the durability of the structure is improved, therefore, the corrugated steel web composite beam has the advantages of simple structure, reasonable stress, quick and convenient construction, and good technical and economic benefits.

Owner:TSINGHUA UNIV

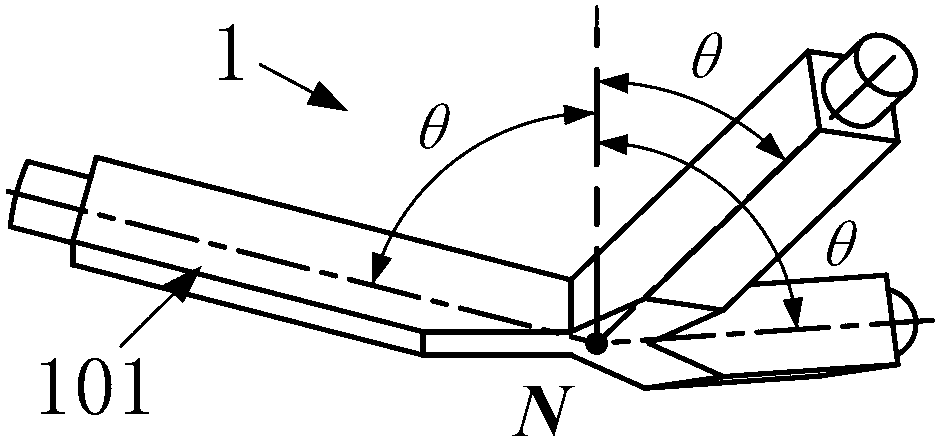

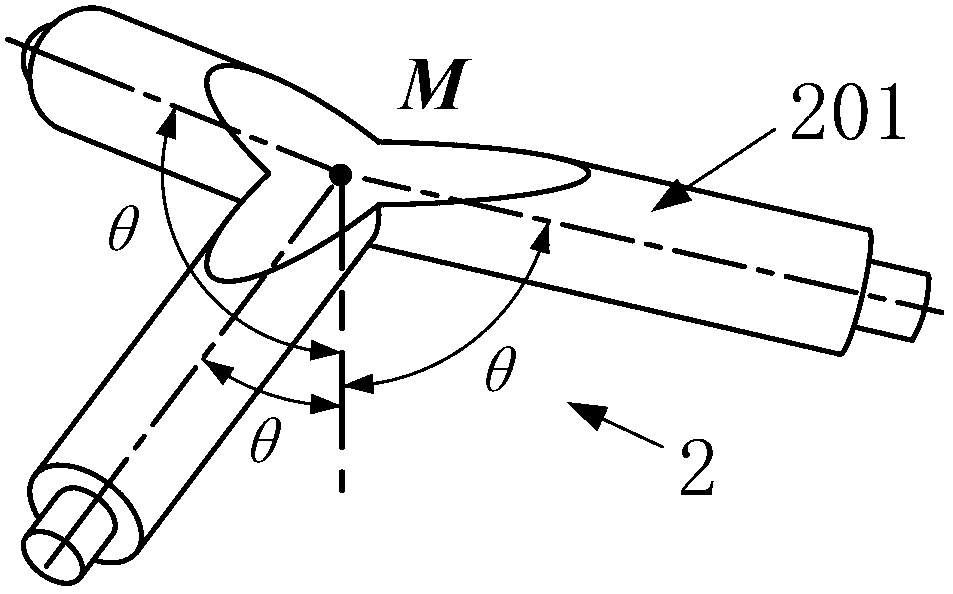

Two-freedom-degree parallel-connection rotation mechanism with spherical surface pure-rolling property

InactiveCN103217986AIncrease stiffnessImprove carrying capacityPosition/direction controlEngineeringKinematic chain

The invention discloses a two-freedom-degree parallel-connection rotation mechanism with a spherical surface pure-rolling property. The mechanism comprises a fixed base, a motion platform and branch kinematic chains, wherein the branch kinematic chains further includes two different types of branch kinematic chains, different numbers and types of branch kinematic chains, fixed bases and motion platforms can form twelve types of two-freedom-degree parallel-connection rotation mechanisms with the spherical surface pure-rolling property, each mechanism can achieve that the motion platform carries out two-freedom-degree equal-diameter spherical surface pure-rolling rotation around the fixed base, and the relative positions of all the branch kinematic chains of each parallel-connection mechanism can be asymmetrically arranged according to specific using requirements. The two-freedom-degree parallel-connection rotation mechanism with the spherical surface pure-rolling property has the advantages of being large in rigidity, strong in bearing capacity and multiple in structure type, each structure can achieve the two-freedom-degree equal-diameter spherical surface pure-rolling rotation, only rotation pairs are contained in the mechanism, the two-freedom-degree parallel-connection rotation mechanism is simple in structure and easy to manufacture, and accessories such as sensors can be installed conveniently.

Owner:BEIHANG UNIV

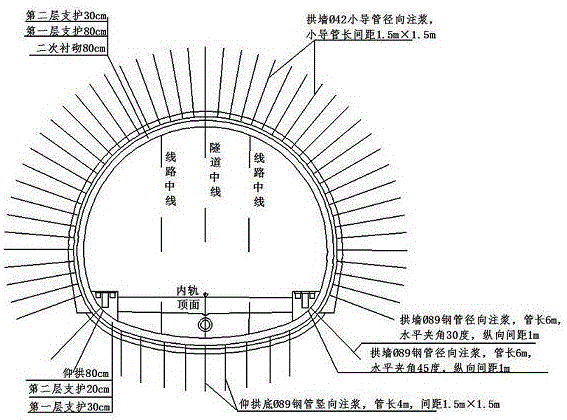

Construction method for soft rock deformation tunnel lining support dismantling-replacing arch

InactiveCN105781571AGuaranteed carrying capacityGuaranteed integrityUnderground chambersTunnel liningEngineeringLarge deformation

The invention provides a construction method for a soft rock deformation tunnel lining support dismantling-replacing arch. One-time whole section integral dismantling and replacing of a lining support is achieved. The construction method has the advantages that before dismantling and replacing, a lining which loses bearing capacity is subjected to grouting reinforcement treatment first, then a temporary cover arch is additionally arranged outside for reinforcement, and afterwards, the lining support is dismantled step by step, so that potential safety hazards caused by dismantling or removing of a temporary platform frame are avoided, and some security risks are avoided effectively. According to the construction method, the construction difficult problem of soft rock large deformation occurs during construction of a tunnel in special and complex geology is solved. Through the created novel construction method, the construction difficult problem of second lining cracking deformation needing remediation due to weak surrounding rock large deformation is solved. Through the construction method, safe, fast and economic treatment and remediation of the lining support and arch replacing construction are achieved, and the tunnel structure stability and construction safety are ensured effectively.

Owner:CCCC SECOND HIGHWAY ENG CO LTD

Small high-speed five-axis linkage machine tool

InactiveCN102632422AGuaranteed stabilitySmall sizeMachine tool componentsFeeding apparatusBridge typeEngineering

The invention discloses a small high-speed five-axis linkage machine tool, which comprises a foundation structure, a spindle box component and a cradle type worktable. The spindle box component is supported on the foundation structure, and a crossbeam with a frame-shaped structure is arranged on two upright columns to form a bridge-type portal structure. The torque bearing capacity of the crossbeam is improved, the small high-speed five-axis linkage machine tool has all advantages of a five-axis linkage machine tool in the prior art, and carries identical machining reacting force, the volume of a structural part is reduced, and the weight of the structural part is greatly lightened; a spindle box is positioned between two transverse rods of the frame-shaped crossbeam, overturning moment is eliminated, and the stability of the machine tool can be guaranteed; in addition, sizes of various components are greatly reduced on the premise of identical machining capacity, and the stroke of the machine tool can be large in the design; and by the aid of the structure, the machining precision is greatly improved, the machining range is greatly expanded, better dynamic characteristics and higher feeding speed and higher cutting speed can be realized, cutting and machining time is greatly shortened, better surface machining quality is obtained, and machining efficiency is enhanced.

Owner:CHONGQING UNIV

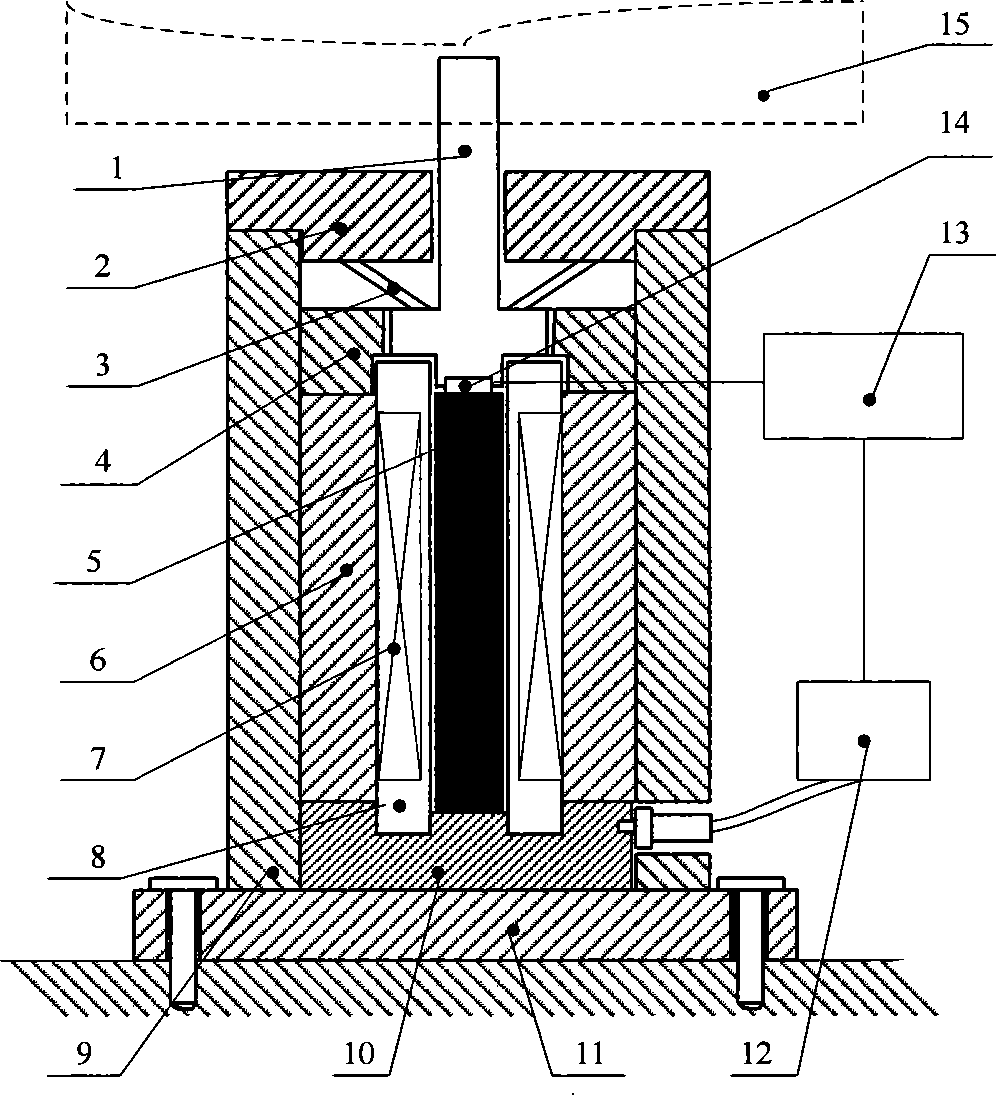

Magnetic rheology elastic body active-passive integrated damper based on extrusion type applied force

InactiveCN101251164AImprove control effectImprove carrying capacityNon-rotating vibration suppressionSolid based dampersMagnetic currentVibration control

The invention relates to a magnetorheological elastomer active and passive integrated damper based on an extrusion type stress, which belongs to the structure vibration isolation and control field, wherein a magnetorheological elastomer is arranged in a magnetic conductive sleeve; the upside of the magnetorheological elastomer is connected with a joint lever; the lower part of the magnetorheological elastomer is fixedly connected with a lower positioning plate; a groove is arranged on an outer circumferential surface of the magnetic conductive sleeve positioned in a permanent magnet, embedded with a coil winding and positioned and fixed by an upper positioning plate and the lower positioning plate; the permanent magnet, the upper positioning plate, the lower positioning plate and the lower part of the joint lever are arranged in an outer magnet isolating cylinder; the upside of the outer magnet isolating cylinder is provided with an upper end closure; the upper part of the joint lever extends out from a pylome of the upper end closure and is connected with a controlled object; a pretightening spring is sleeved on the joint lever; the bottom of the outer magnet isolating cylinder is provided with a lower end closure; a sensor is fixed on the joint lever and connected with a power amplifier through a control unit module; the power amplifier is connected with the coil winding through cables. The magnetorheological elastomer active and passive integrated damper has large bearing capacity, a simple structure and can be automatically suitable for active and passive vibration control and has wide application range.

Owner:SHANGHAI JIAO TONG UNIV

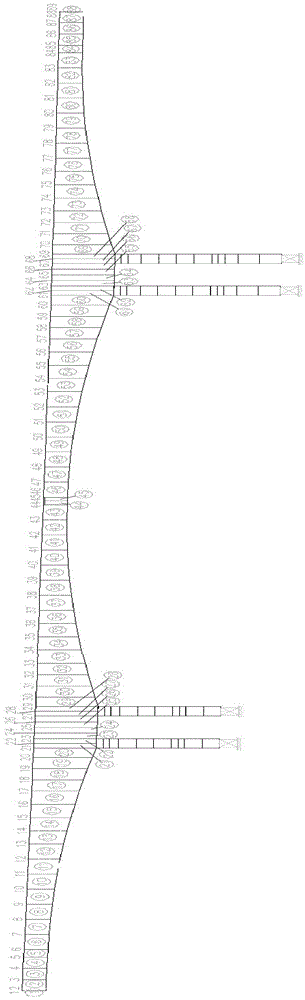

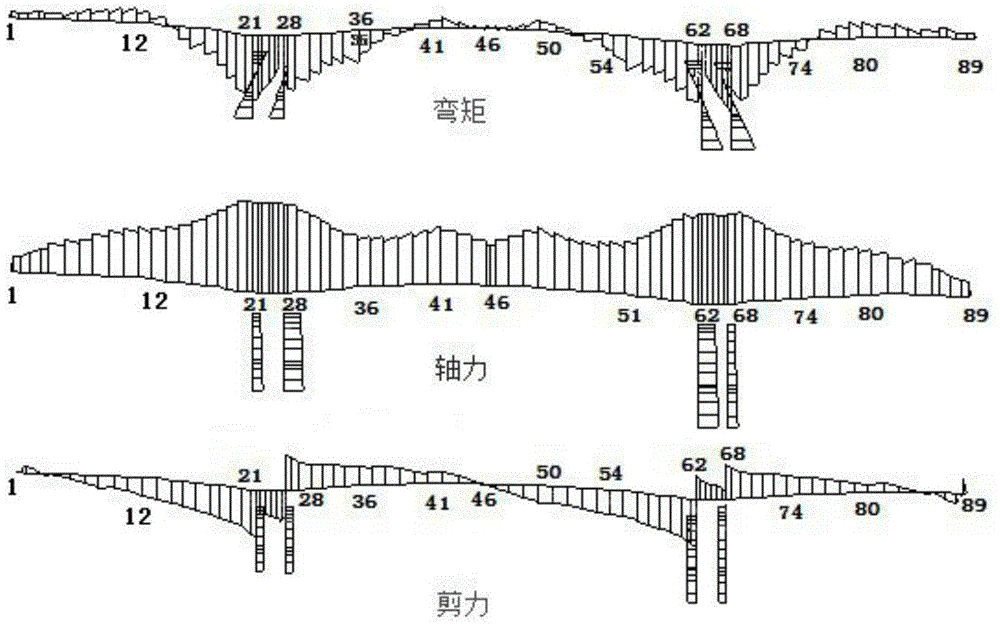

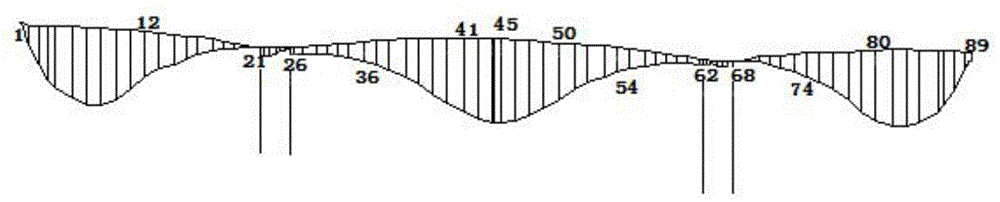

Bridge field static load test evaluation method

ActiveCN104933285AEffective and comprehensive assessmentImprove securitySpecial data processing applicationsElement modelEvaluation Interval

The present invention relates to a bridge field static load test evaluation method, which is mainly a method for evaluating the bearing capacity and adaptation performance of a bridge by means of a field static load test. The method comprises the following steps: (1) determining specific content and method for collecting relevant data for early stage preparation work; (2) establishing a reasonable and accurate bridge structure finite element model according to the collected data; (3) calculating and analyzing a result according to an endogenous force and a stress of the bridge under dead and live loads, and determining theoretical force bearing safety and live load force bearing characteristics; (4) in combination with a traditional key section of the bridge, determining a bridge test section and completing static load test solution designing; (5) performing the field static test for the bridge and processing the test data; (6) studying an evaluation interval corresponding to a preset test evaluation indicator; and (7) making a reasonable and comprehensive assessment on the structural performance of the bridge. The evaluation method and indicator according to the present invention can more effectively indicate the practical bearing capacity and applicability of the bridge in a refined manner, and improving the reasonability and accuracy of the evaluation result.

Owner:SOUTHWEST JIAOTONG UNIV

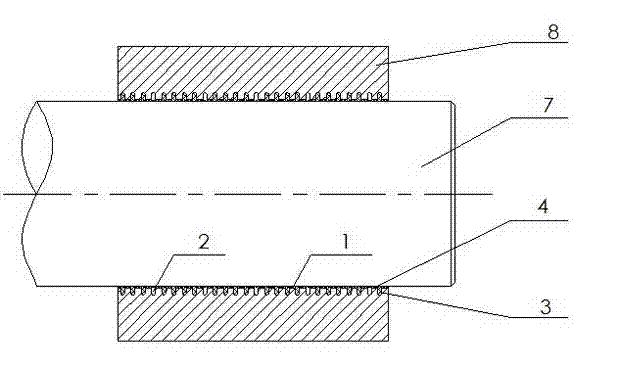

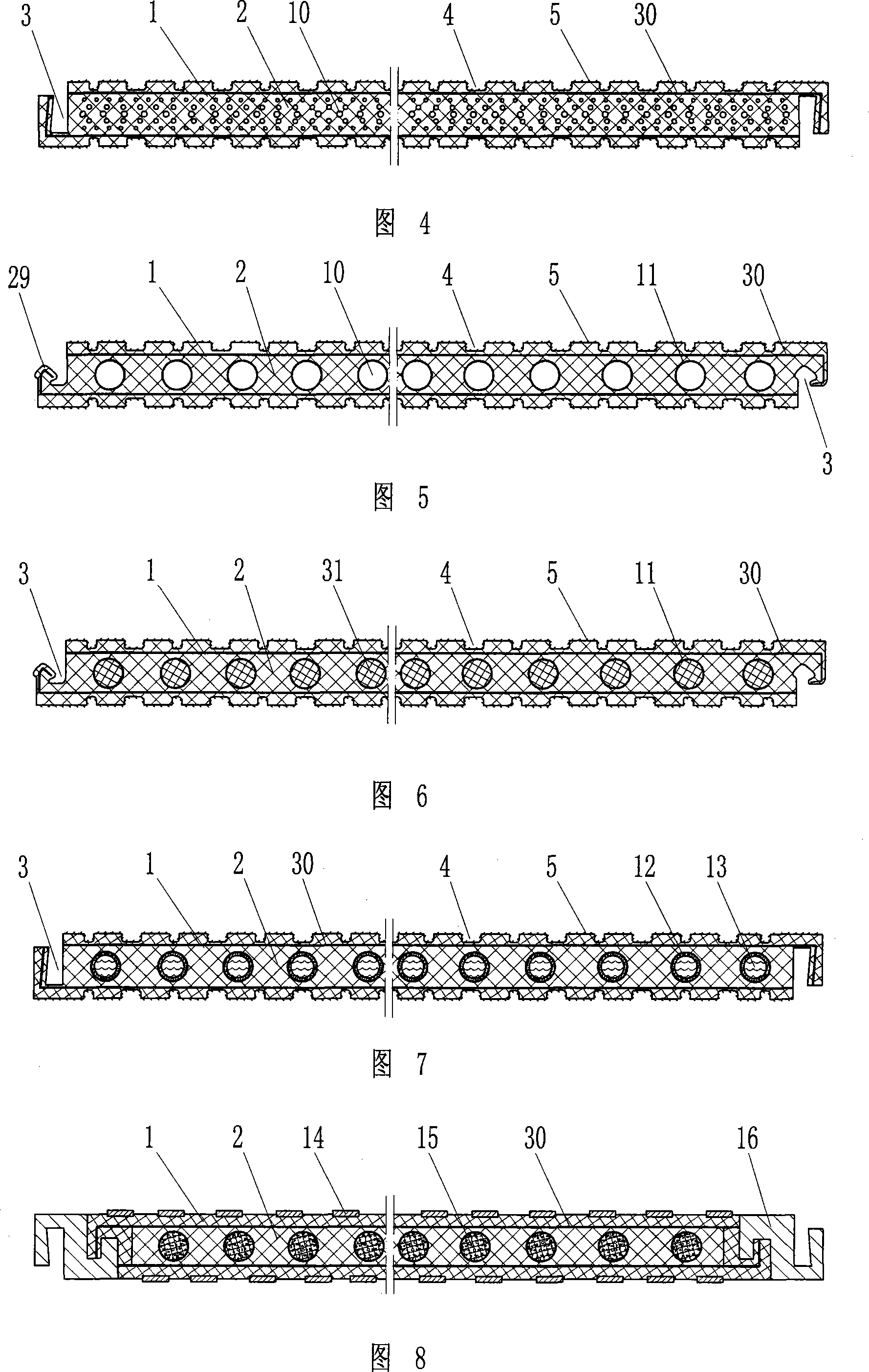

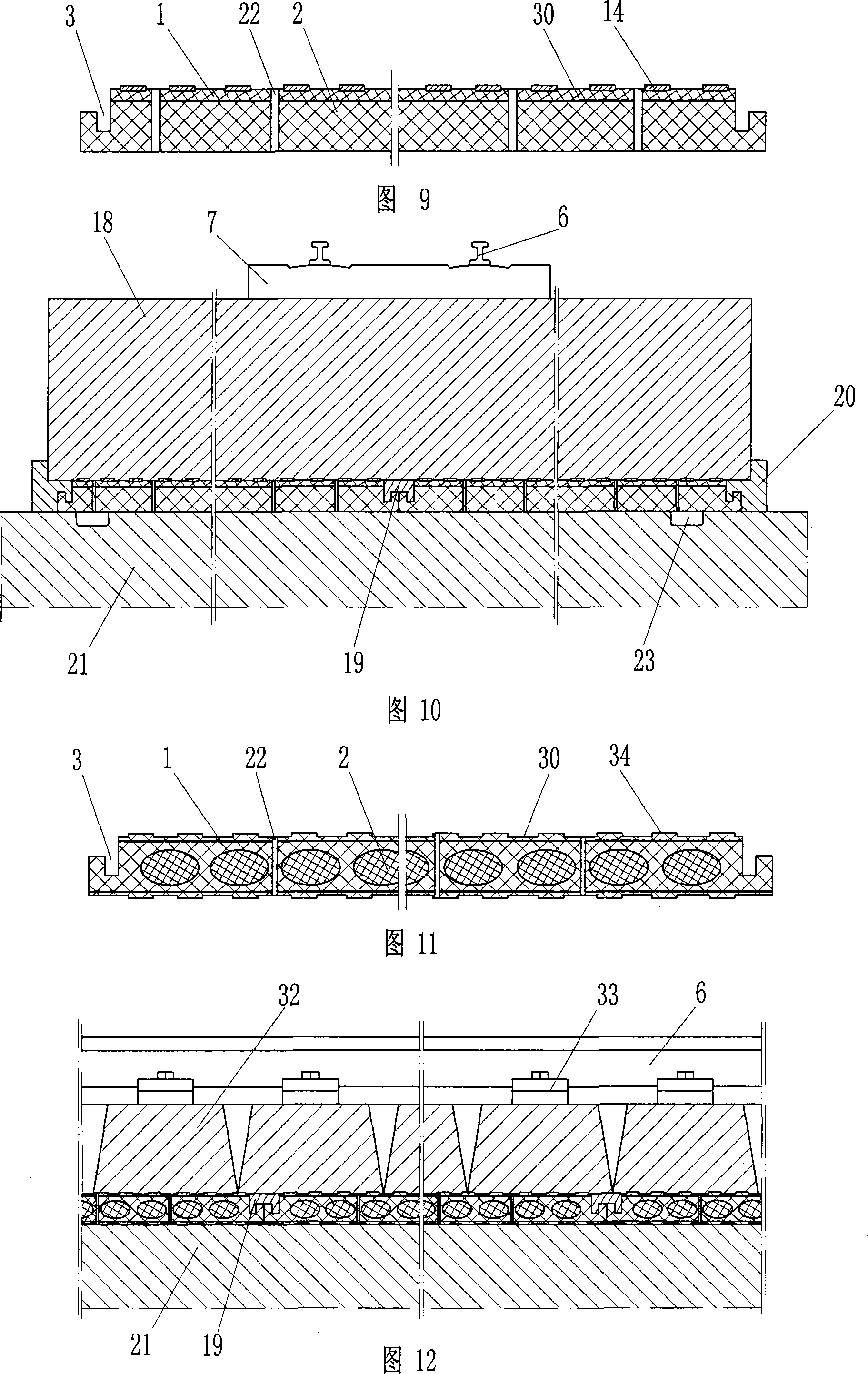

Elastic bearing plate

InactiveCN101135132AIncrease elasticityImprove damping performanceBallastwayRail fastenersElastomerEngineering

The present invention relates to railway ballast bed accessory, and is especially one kind of elastic bearing plate for use under ballast bed of railway. The elastic bearing plate includes antiwear elastic layers(s) and one buffering elastic body below or inside the antiwear elastic layers(s). The buffering elastic body has relatively lower area rigidity or elastic modulus. The elastic bearing plate has high elasticity, high bearing capacity, high durability, long service life, excellent buffering effect, and capacity of lowering vibration and noise greatly. It may be applied widely under ballast bed of railway for buffering and damping.

Owner:QINGDAO CREATE ENVIRONMENT CONTROL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com