Patents

Literature

633results about How to "Guaranteed carrying capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

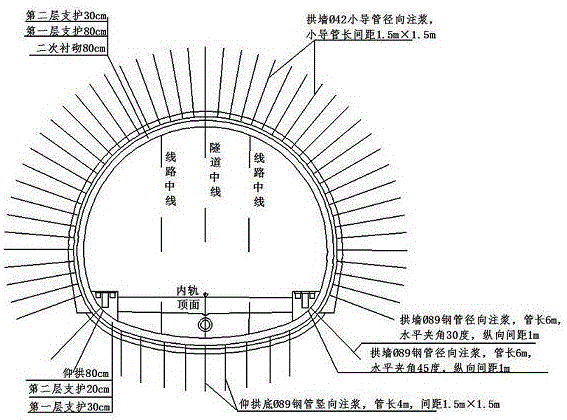

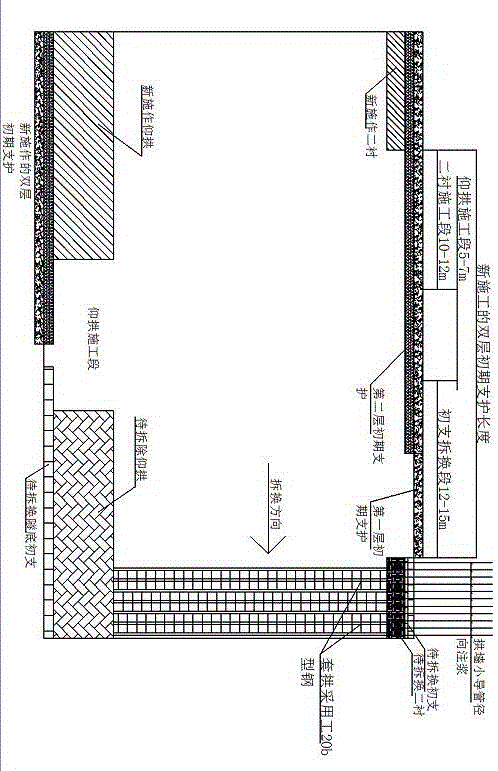

Construction method for soft rock deformation tunnel lining support dismantling-replacing arch

InactiveCN105781571AGuaranteed carrying capacityGuaranteed integrityUnderground chambersTunnel liningEngineeringLarge deformation

The invention provides a construction method for a soft rock deformation tunnel lining support dismantling-replacing arch. One-time whole section integral dismantling and replacing of a lining support is achieved. The construction method has the advantages that before dismantling and replacing, a lining which loses bearing capacity is subjected to grouting reinforcement treatment first, then a temporary cover arch is additionally arranged outside for reinforcement, and afterwards, the lining support is dismantled step by step, so that potential safety hazards caused by dismantling or removing of a temporary platform frame are avoided, and some security risks are avoided effectively. According to the construction method, the construction difficult problem of soft rock large deformation occurs during construction of a tunnel in special and complex geology is solved. Through the created novel construction method, the construction difficult problem of second lining cracking deformation needing remediation due to weak surrounding rock large deformation is solved. Through the construction method, safe, fast and economic treatment and remediation of the lining support and arch replacing construction are achieved, and the tunnel structure stability and construction safety are ensured effectively.

Owner:CCCC SECOND HIGHWAY ENG CO LTD

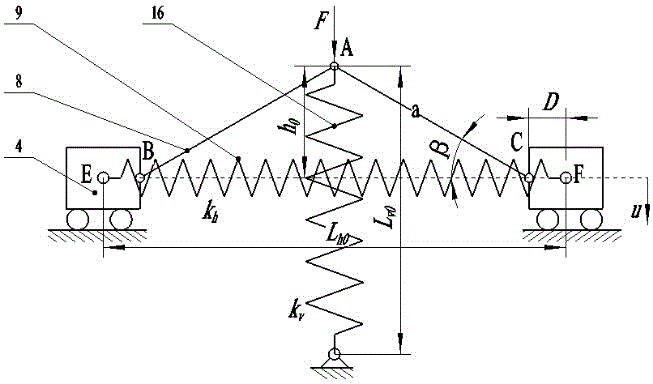

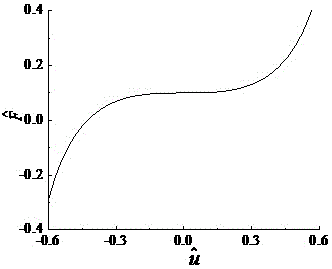

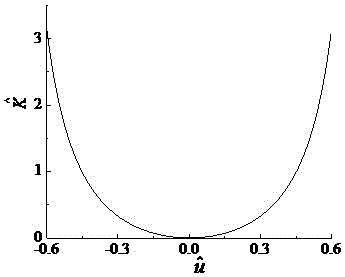

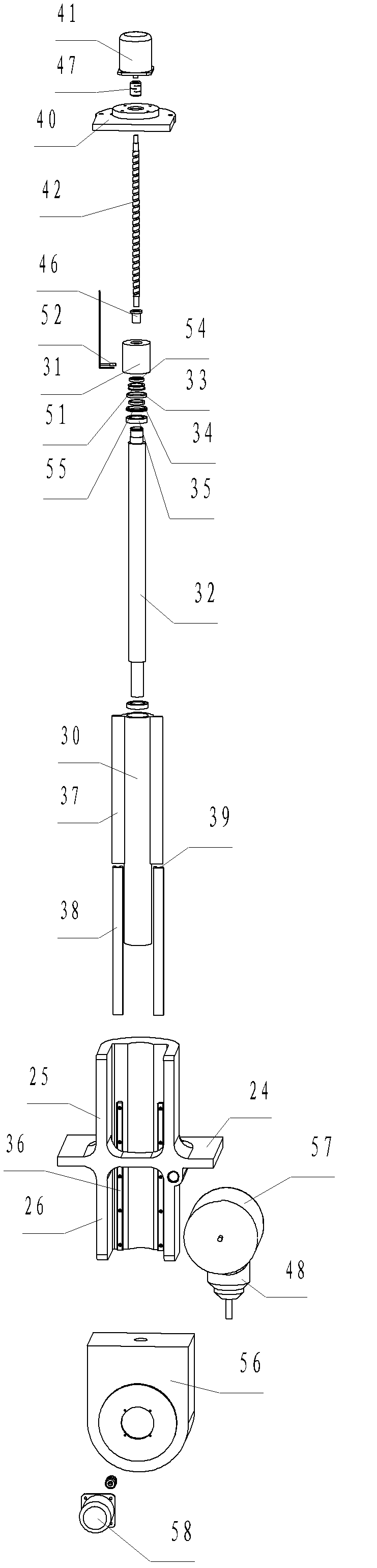

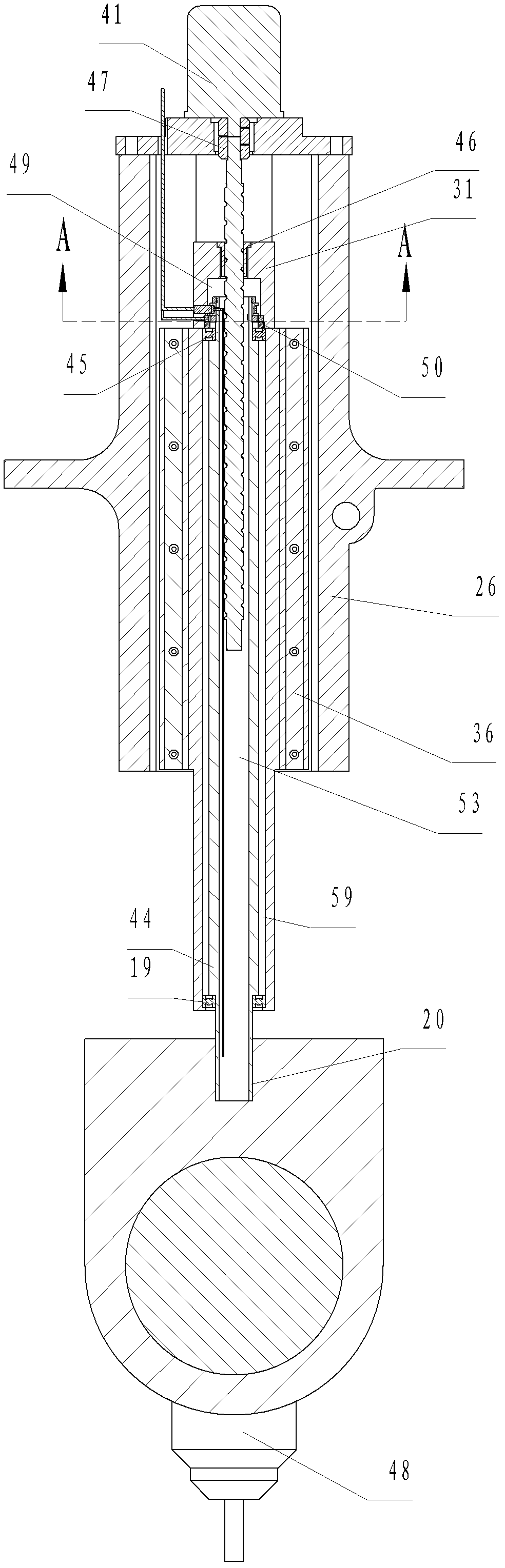

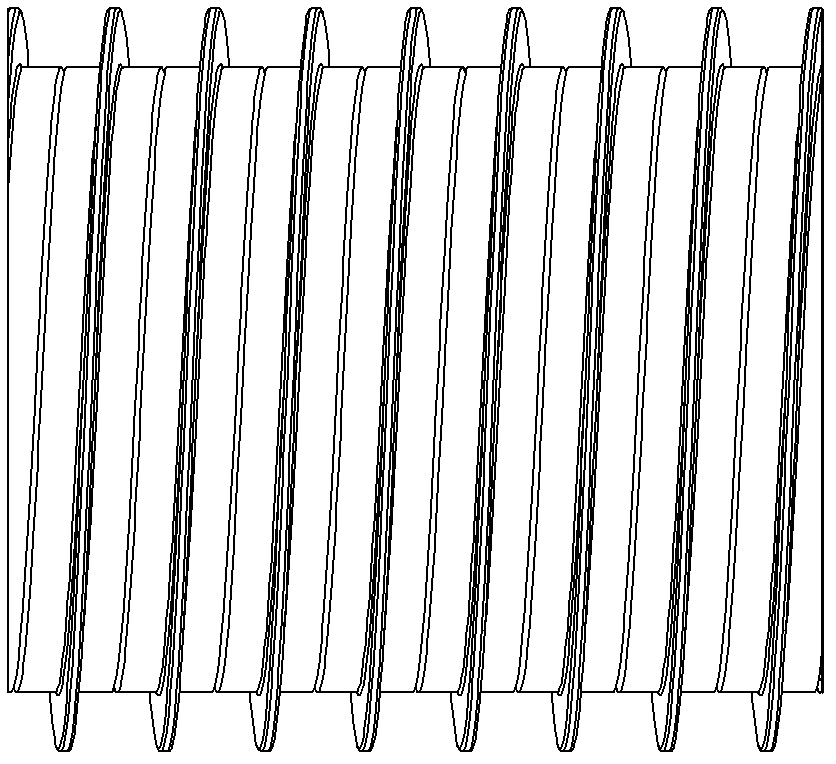

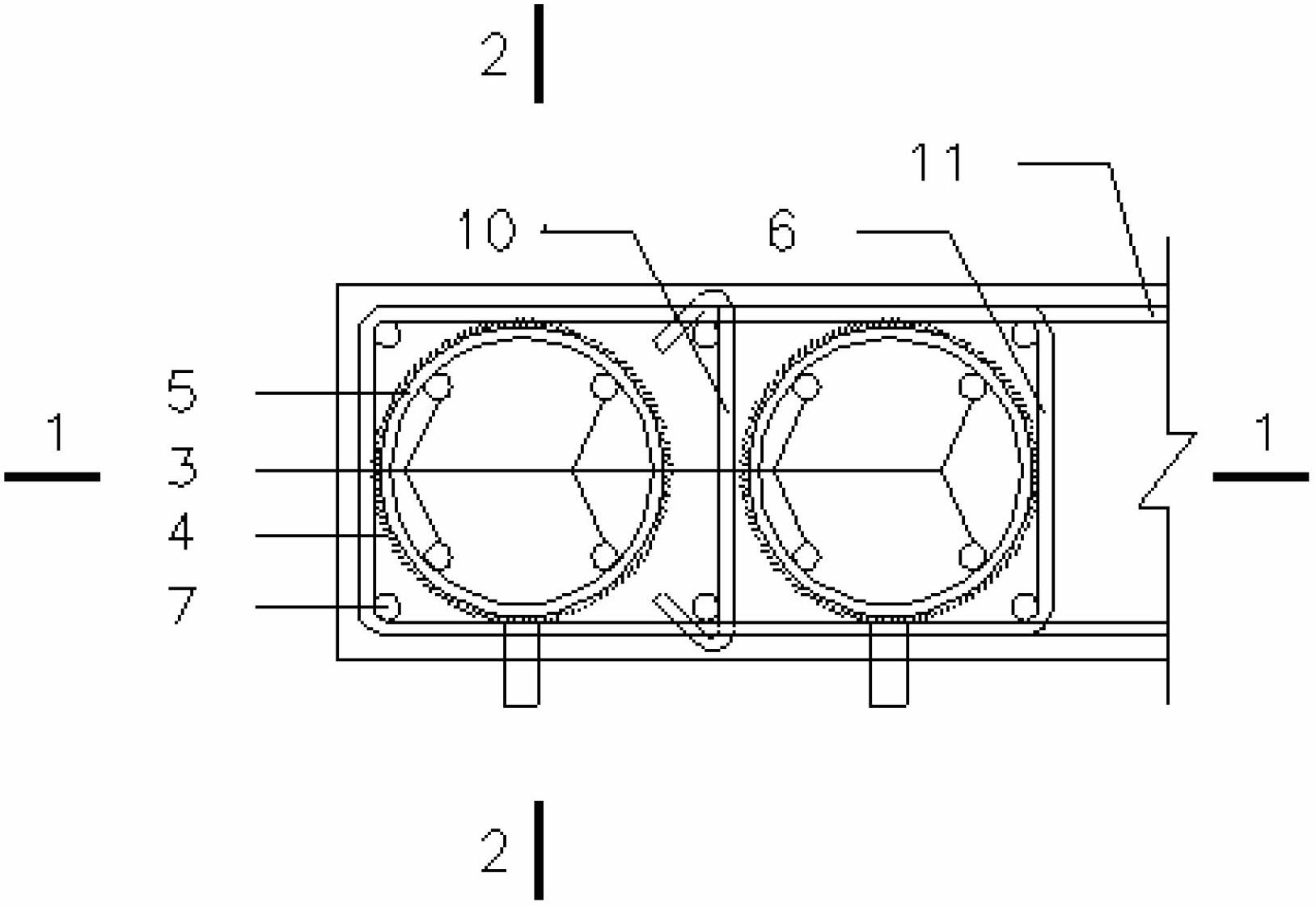

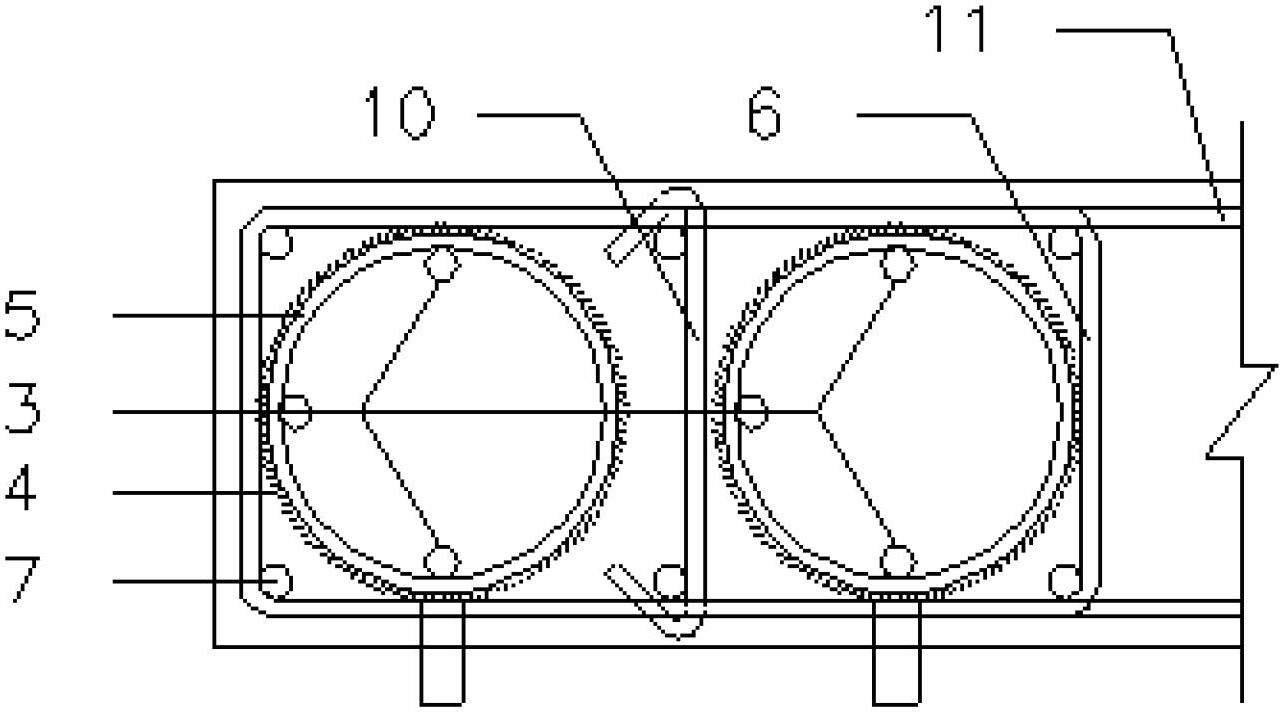

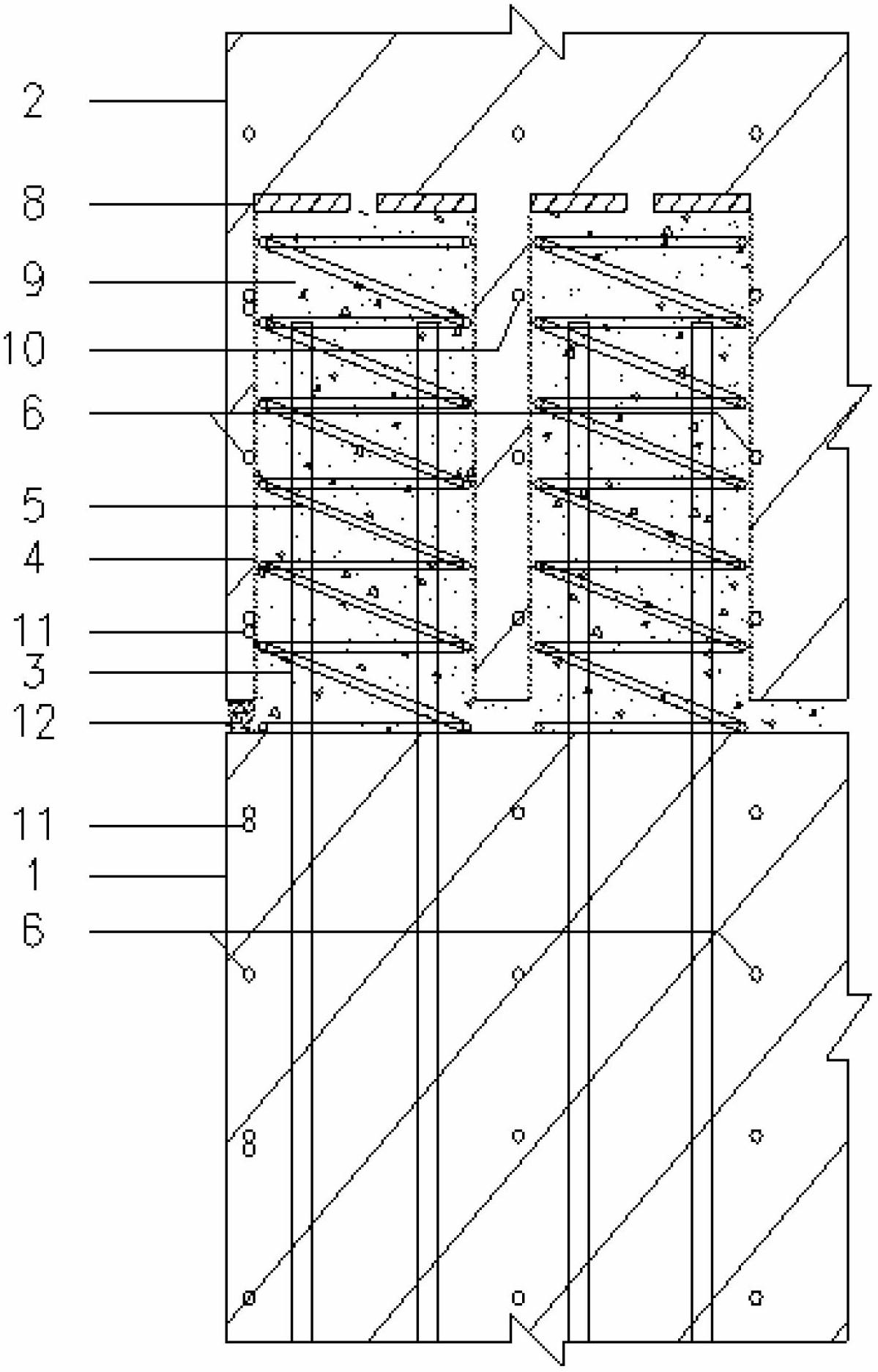

Extension type quasi-zero stiffness vibration isolator and implementation method thereof

InactiveCN106402267AAvoid the disadvantages of instabilityGuaranteed carrying capacityNon-rotating vibration suppressionShock absorbersAviationNegative stiffness

The invention relates to an extension type quasi-zero stiffness vibration isolator and an implementation method thereof. The vibration isolator is formed by a negative stiffness mechanism in parallel connection with a positive stiffness main spring, wherein the negative stiffness mechanism is composed of extension springs, connecting rods, slide blocks and guide rails; negative stiffness can be generated in the vertical direction, and in addition, the defect that compression springs lose stability can be avoided; and it can be guaranteed that the structure is in bilateral symmetry when fine adjustment is conducted in the horizontal direction. On the basis of the principle that positive stiffness and negative stiffness counteract each other, after the negative stiffness mechanism is in parallel connection with the positive stiffness spring, stiffness, at the equilibrium position, of the vibration isolator is close to zero, and inherent frequency is also close to zero, so that starting vibration isolation frequency is greatly reduced; the vibration isolation section is increased; and capability of isolating low frequency or ultralow frequency vibration is achieved. The vibration isolator is simple and compact in structure and convenient to assemble and debug and has certain engineering application value in the fields such as automobiles, precise instruments, sensitive equipment, precision machining and aerospace engineering.

Owner:FUZHOU UNIV

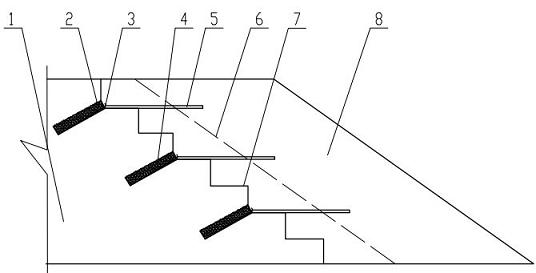

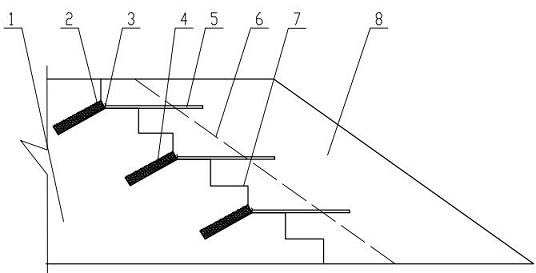

Anchored roadbed widening method

InactiveCN102619150AReduce shear deformationGuaranteed carrying capacityRoadwaysVertical planeEngineering

The invention discloses an anchored roadbed widening method, which belongs to the technical field of road construction. The anchored roadbed widening method comprises the following steps of: firstly performing slope cutting on an old roadbed slope, then excavating a step on the old roadbed slope from the ground, obliquely drilling an anchorage hole into an old roadbed at the joint of the vertical plane of the step and the horizontal plane, placing a steel bar into the anchorage hole, and casting the steel bar and the old roadbed into a whole by pouring cement grout; laying a new roadbed in layers, rolling, flatly laying a geogrid on the step of the old roadbed when the new roadbed is filled to be aligned with the step of the old roadbed provided with the anchorage drilled hole, connecting a transverse rib of the geogrid with an end hook which is bent upwards of the exposed part of the steel bar, tensing the geogrid, fixing with the lower layer of a soil body, and finally filling soil on the geogrid and rolling. According to the anchored roadbed widening method disclosed by the invention, an anchor rod technology is used for reinforcing the old roadbed slope, the geogrid and the old roadbed are connected into a whole, the geogrid can be prevented from sliding on the step of the old roadbed, the stability of the new roadbed and the old roadbed is improved, and non-uniform sedimentation can be effectively controlled.

Owner:SHIJIAZHUANG TIEDAO UNIV

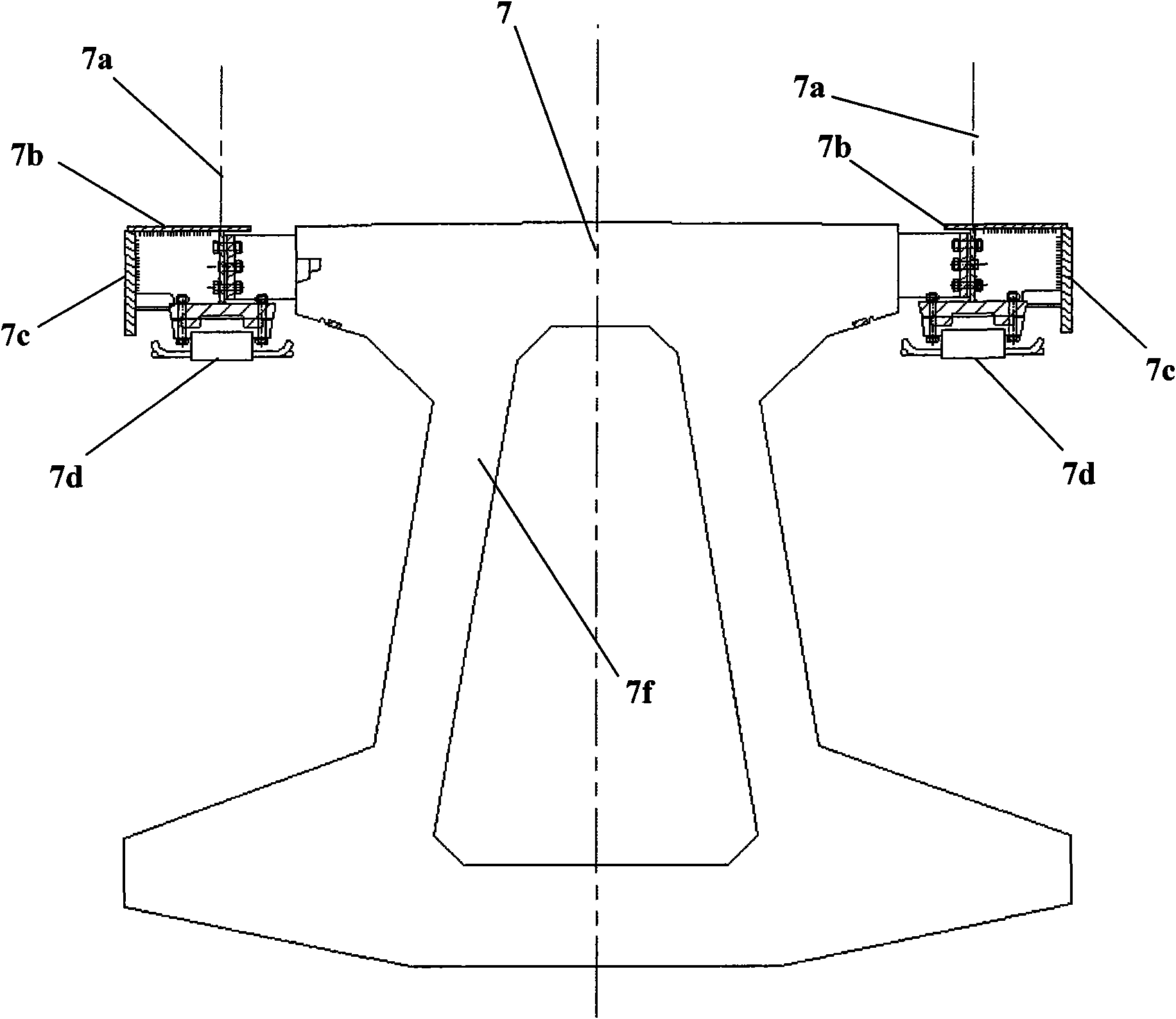

Travel structure of magnetic levitation type rail polling car

InactiveCN101624054AAchieving self-rescue abilityEfficient deliveryRailway inspection trolleysSliding/levitation railway systemsLow speedMotor drive

The invention provides a travel structure of a magnetic levitation type rail polling car, wherein the travel structure is fixedly arranged at the lower part of the bottom board of carriage of the rail polling car and comprises a plurality of floating frames which are sequentially arranged as well as a long stator linear motor traction device and an outer rotor motor driven supporting wheel device which are arranged on the floating frames; wherein the floating frames comprises a plurality of beam frames and corbel frames which are arranged at the two ends of the beam frame; the long stator linear motor traction device comprises a floating magnet module arranged on the corbel frame, a plurality of guiding magnet modules and a plurality of eddy braking magnet modules; the outer rotor motor driven supporting wheel device comprises a motor supporting wheel loading device which is arranged at the two ends of the beam frame and at the inner side of the corbel frame as well as an outer rotor motor supporting wheel arranged at the two ends of the bottom of the beam frame by the loading device. The invention can realize the compatible double traction pattern of long stator linear motor traction and outer rotor motor supporting wheel traction, so that the rail polling car can have the functions of high speed polling and low speed detection.

Owner:TONGJI UNIV

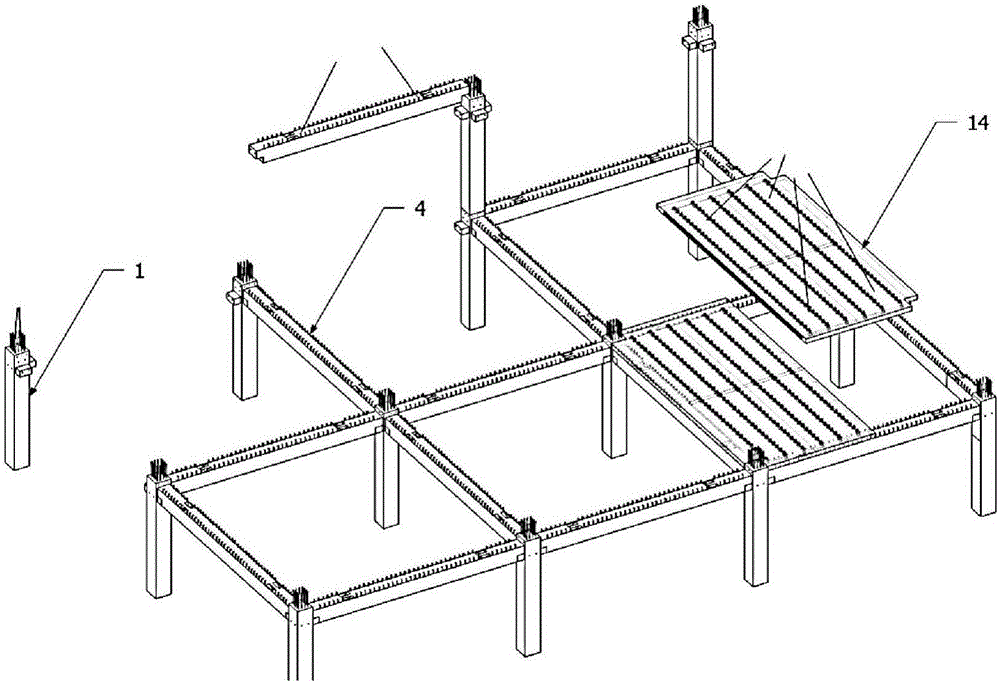

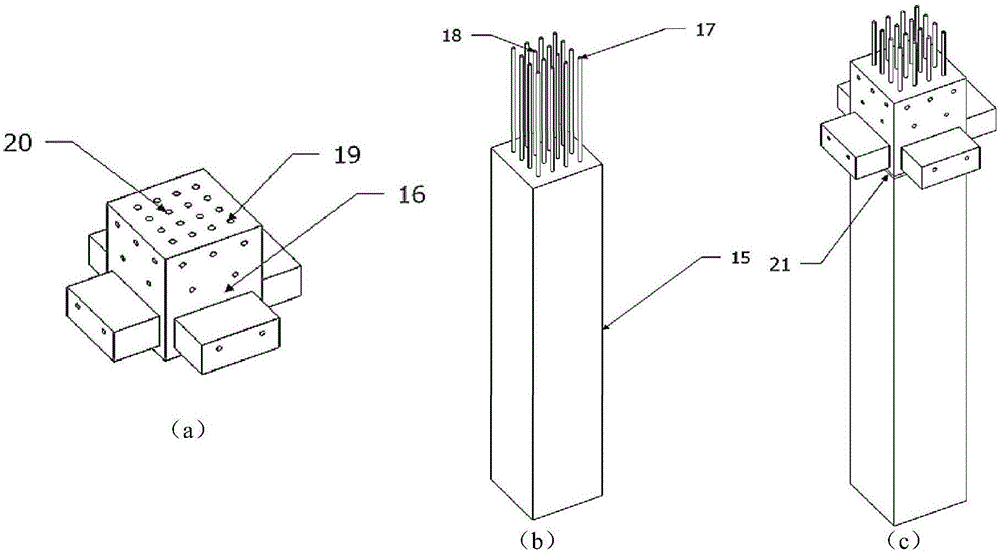

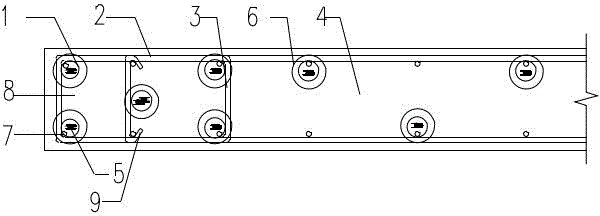

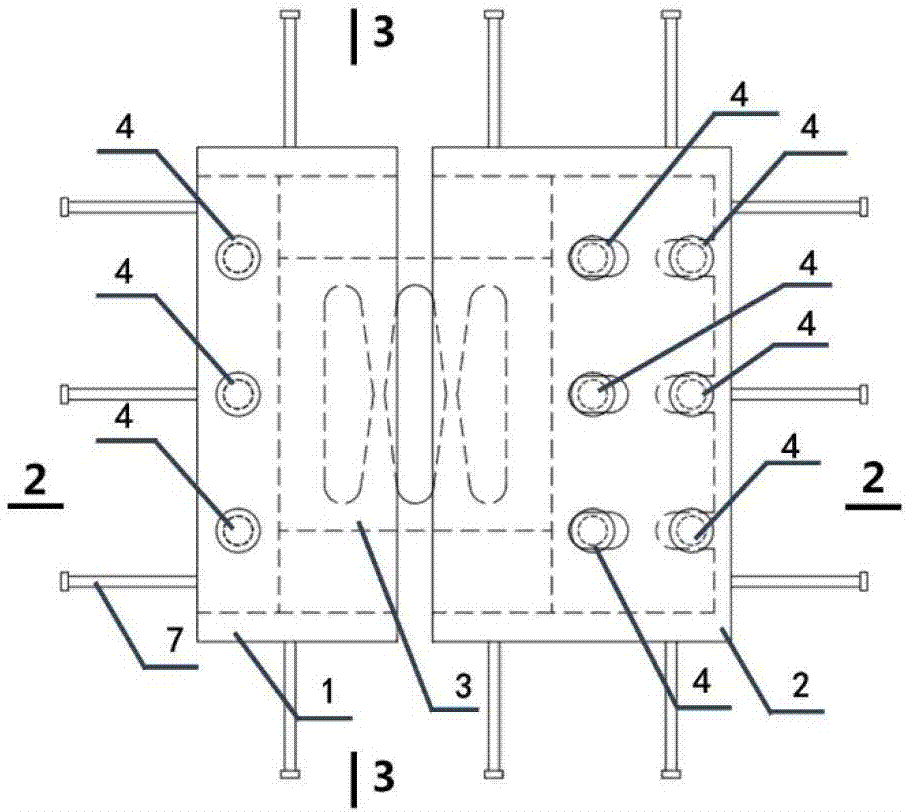

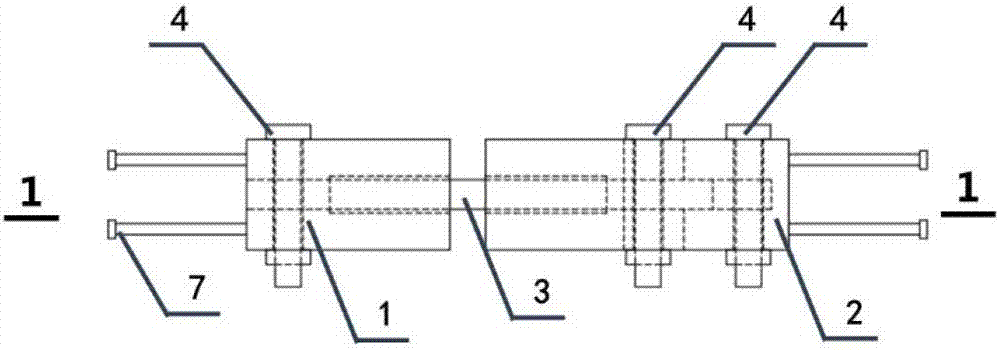

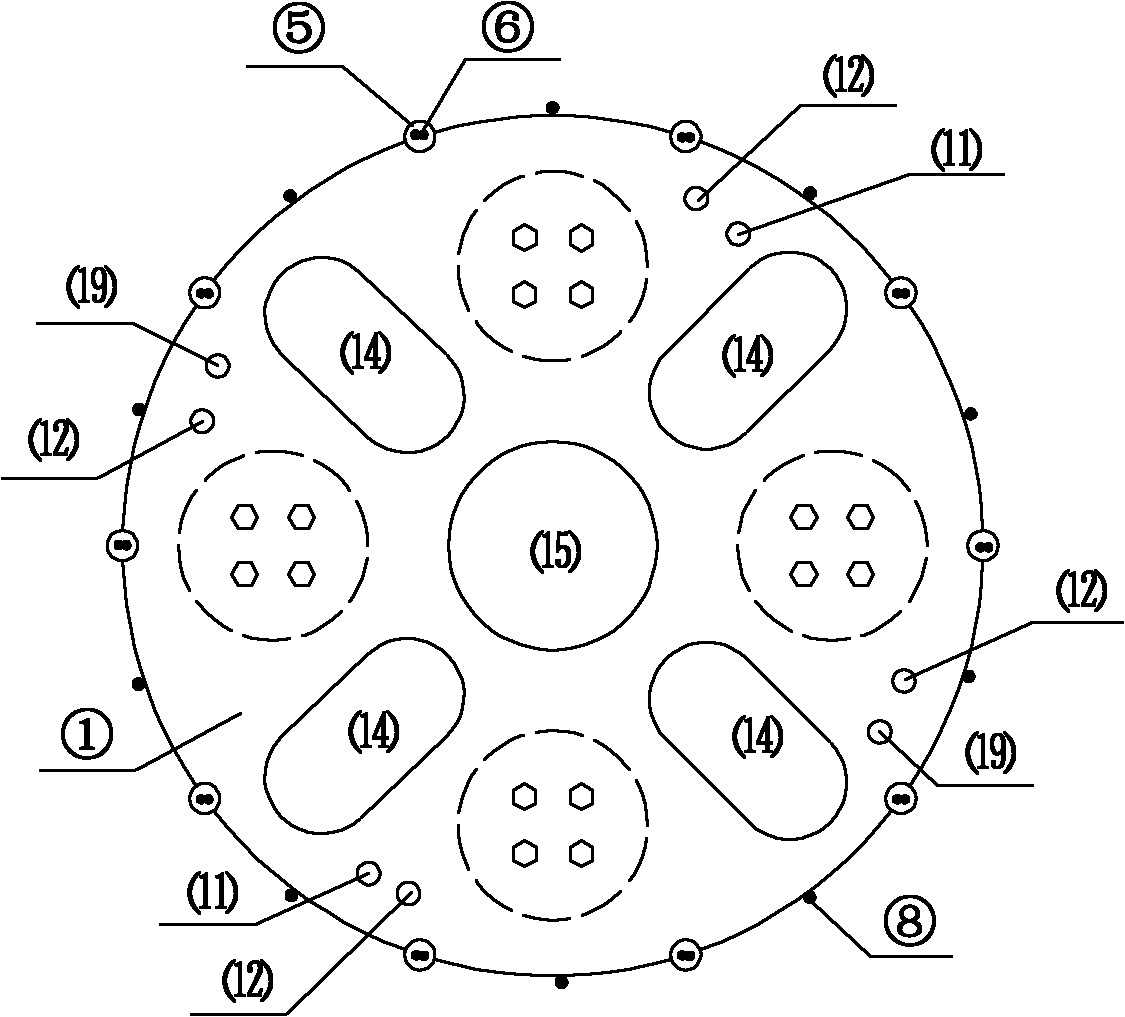

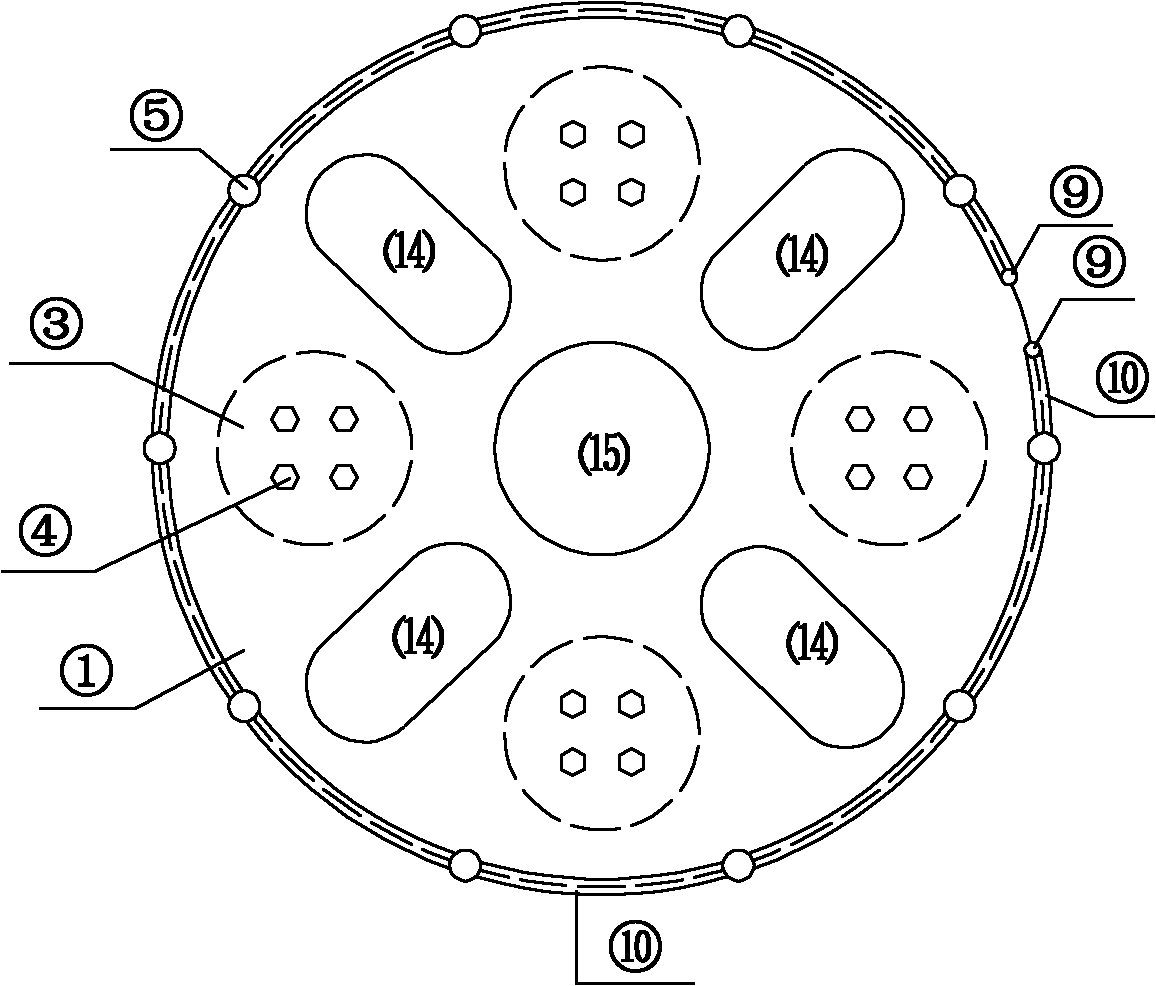

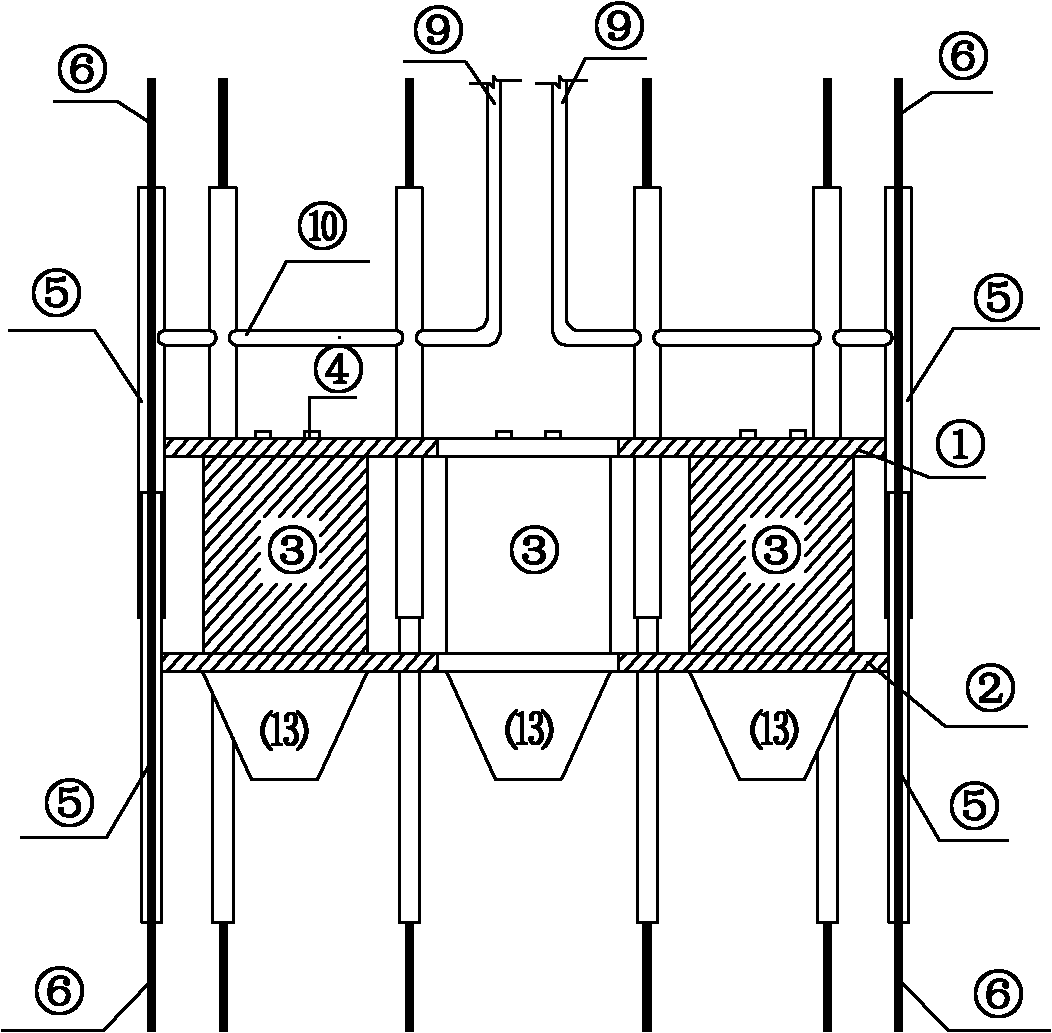

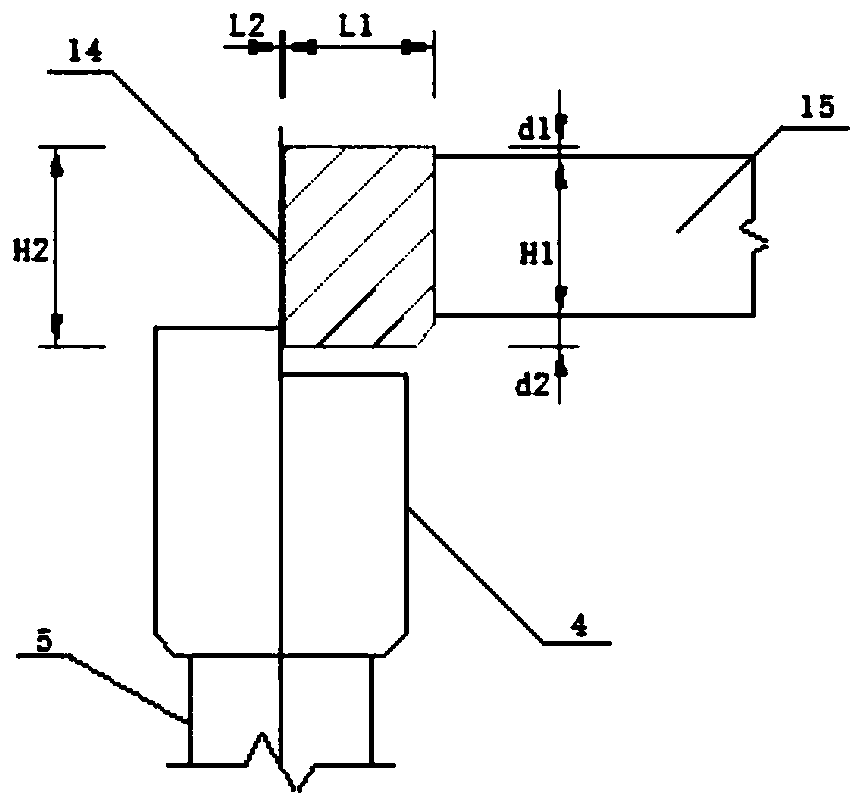

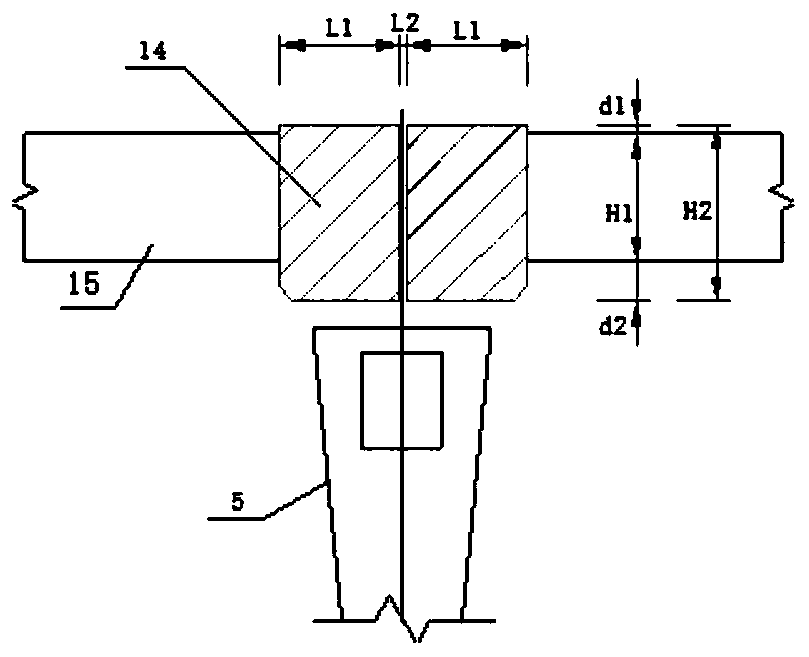

Assembly integral type concrete frame structure of dry-wet mixed connection of nodes and construction method

InactiveCN106677339AAchieving Plastic Hinge TransferShorten the construction time of flow waterBuilding material handlingConcrete beamsPre stress

The invention discloses an assembly integral type concrete frame structure of dry-wet mixed connection of nodes and a construction method. The assembly integral type concrete frame structure comprises pre-fabricated concrete pillars, pre-fabricated concrete beams, node local pre-stressed tendons, pre-fabricated concrete plates and rear-poured concrete combined interface layers; in an installation construction stage of a structural system, pre-fabricated components of the beams and the pillars adopt local pre-stress exerting and are connected in a dry mode, step-shaped rabbets at the ends of the pre-fabricated concrete beams are stored on side brackets of the pre-fabricated concrete pillars, and the pre-stressed tendons are inserted into vertical cross arc-shaped porous channels reserved in the beam ends and the node pillar sections of the pre-fabricated concrete pillars and are stretched; after dry-type connection between the pre-fabricated concrete beams and the pre-fabricated concrete pillars is completed, and the structural bearing capacity is achieved; in a using stage, after the pre-fabricated concrete plates or steel bearing plates, the pre-fabricated beams and steel rebars on the upper portions of the pre-fabricated plates are installed, the concrete combined interface layers are poured, and wet-type connection among the pre-fabricated concrete pillars, the pre-fabricated concrete beams and the pre-fabricated concrete plates is completed; and through dry-and-wet-type mixed connection of the nodes, the assembly integral type concrete frame structure is formed.

Owner:SOUTHEAST UNIV

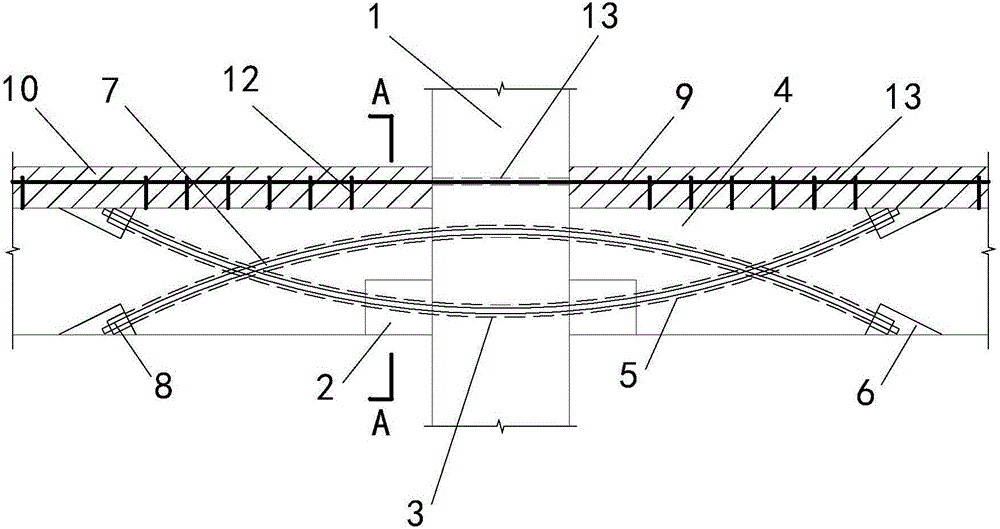

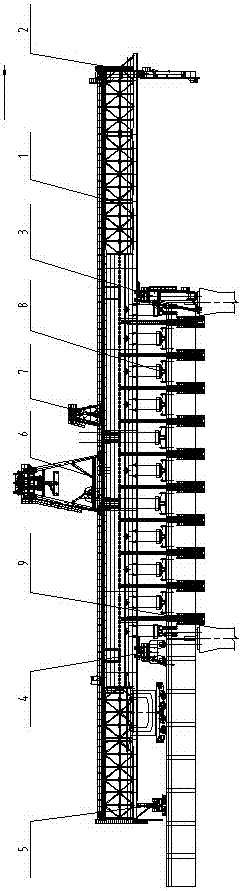

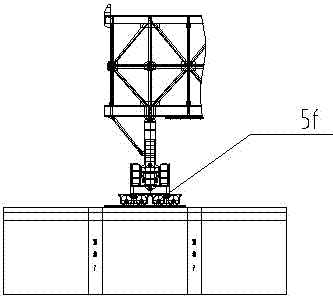

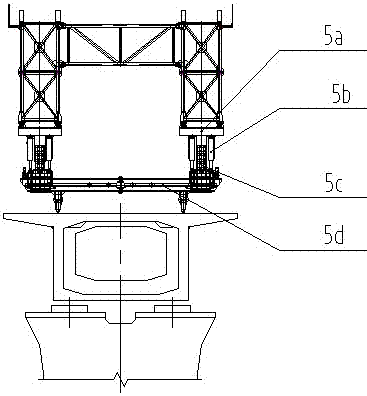

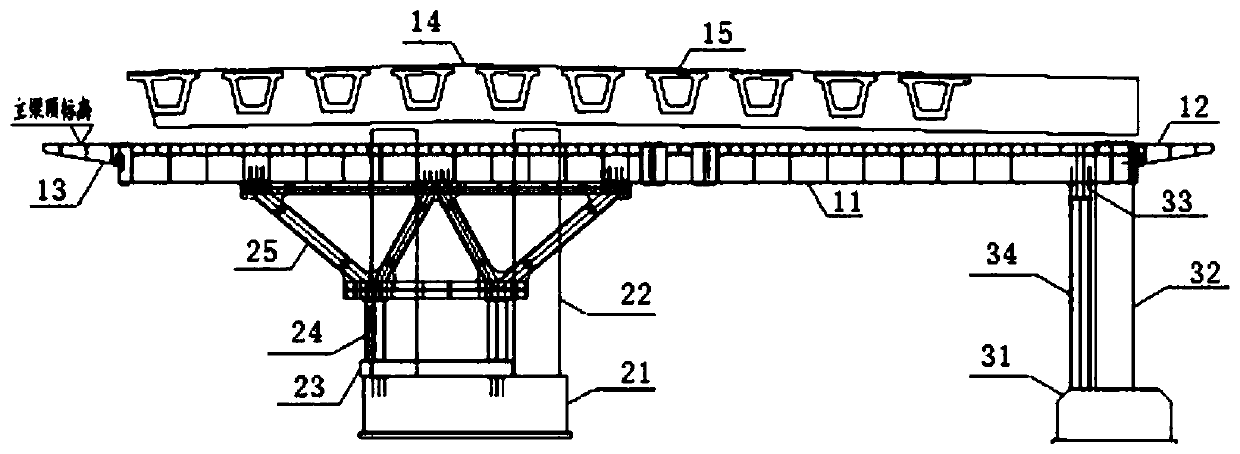

Bridge erecting machine for precast segmental beam span by span construction and construction method thereof

ActiveCN107059640ASmooth rotationNo need for staggered placementBridge erection/assemblyArchitectural engineeringHeavy load

The invention discloses a bridge erecting machine for precast segmental beam span by span construction and a construction method thereof. The bridge erecting machine for the precast segmental beam span by span construction comprises a main frame, a support leg system, a hanging system, a wet joint template system and an overhead travelling crane system. The support leg system comprises a number one support leg, a number two support leg, a number three support leg and a number four support leg, which sequentially arranged at the lower portion of the main frame from front to back, wherein the number one support leg and the number four support leg are located on two ends of the main frame as a auxiliary supporting support leg correspondingly, the number two support leg and the number three support leg are used as a heavy load supporting support leg, the hanging system is connected to the bottom of the main frame, the wet joint template system is connected to the outside of the main frame, the overhead travelling crane system is arranged on a longitudinal moving rail at the top of the main frame; and the construction method of the bridge erecting machine for precast segmental beam span by span construction comprises beam erecting process of the bridge erecting machine and bridge erecting machine through-hole process. The bridge erecting machine for the precast segmental beam span by span construction and the construction method thereof have the advantages that the construction demands of the precast segmental beam of high speed railway are met, the construction efficiency is high, and the construction is convenient and highly efficient.

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH

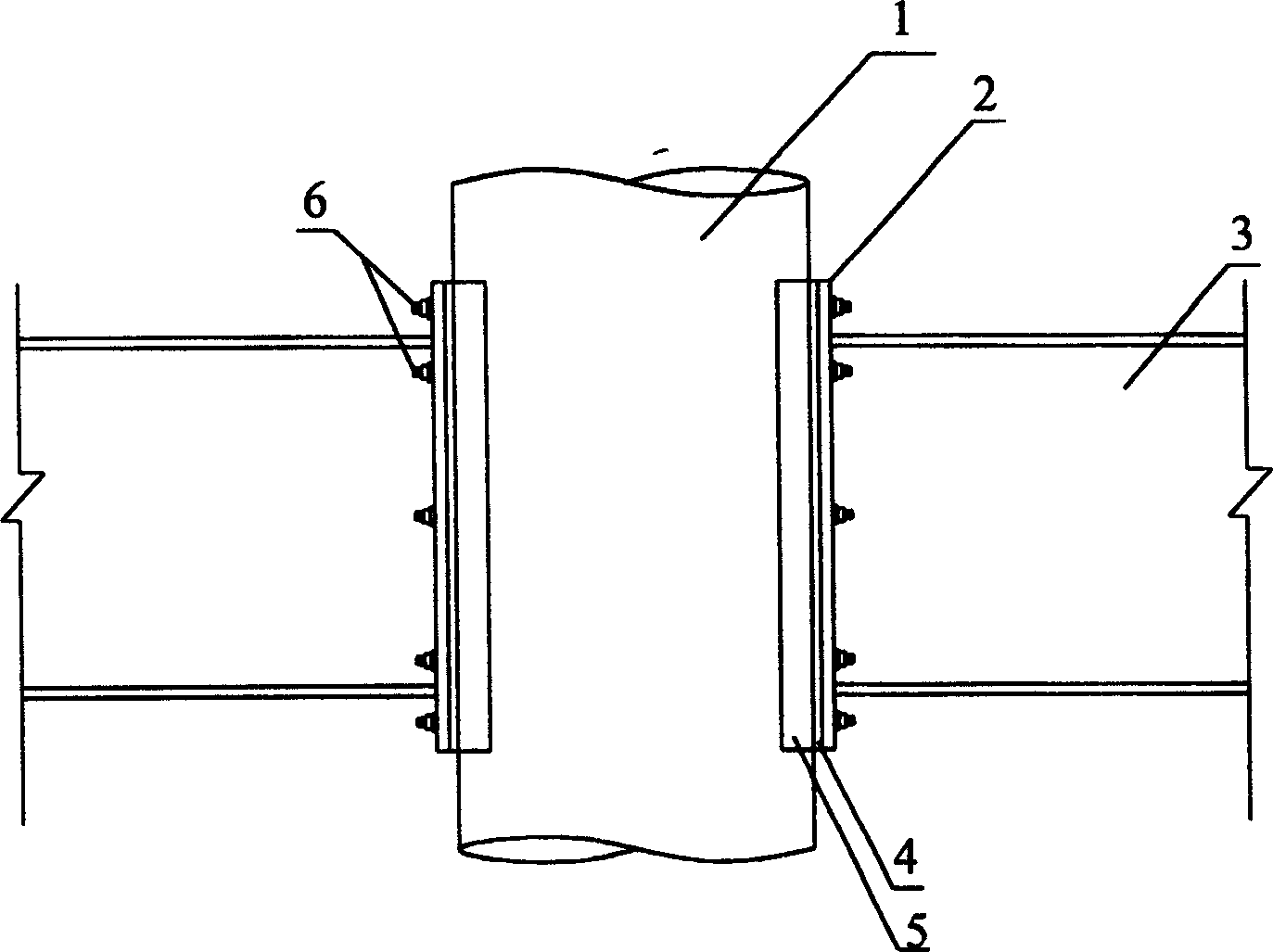

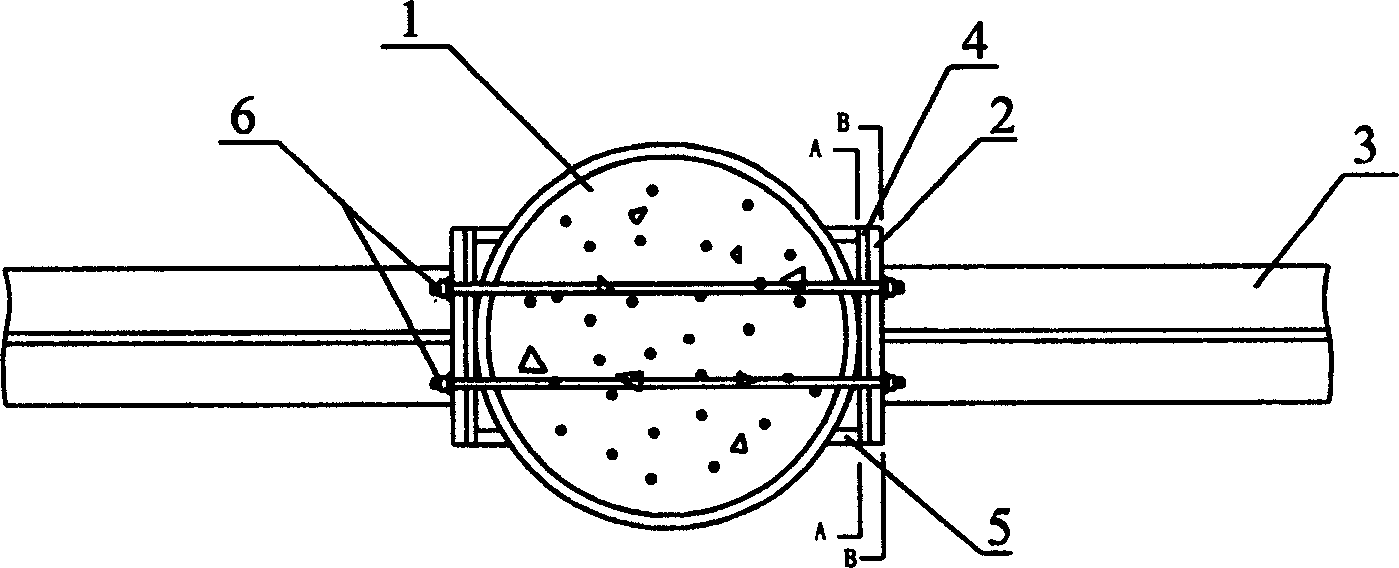

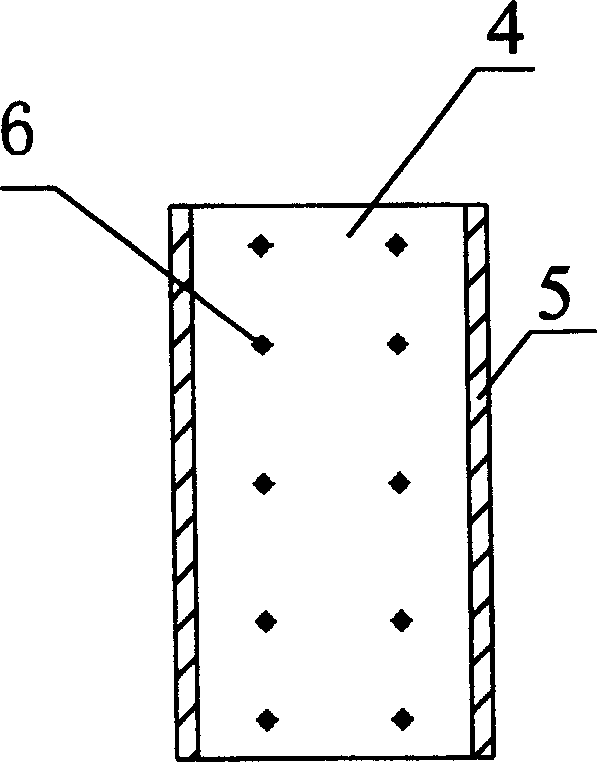

Round steel pipe concrete column joint for beam column connection and method for manufacturing the same

The invention discloses a kind to use in beam column the connection round steel pipe coagulation earth pyramid pitch point and its the manufacture method, it mainly included the round steel pipe coagulation earth pyramid and the steel girder which connected with this column, the round steel pipe coagulation earth pyramid and filled in in this round steel pipe including the round steel pipe the concrete, in carried with steel pipe coagulation earth pyramid connection steel girder Liang is equipped with an end board, this steel pipe coagulation earth pyramid with stated between the end board to be equipped with the belt rib level the steel plate, level the steel plate solidified on the round steel pipe, carried the board, level the steel plate as well as the round steel pipe through as soon as passed through core excels in the bold fastening in together. The invention cost inexpensive, mechanics performance good, design succinct convenient, the construction difficulty is small, also can avoid the scene welding, improves the connection quality and the construction benefit.

Owner:HUNAN UNIV

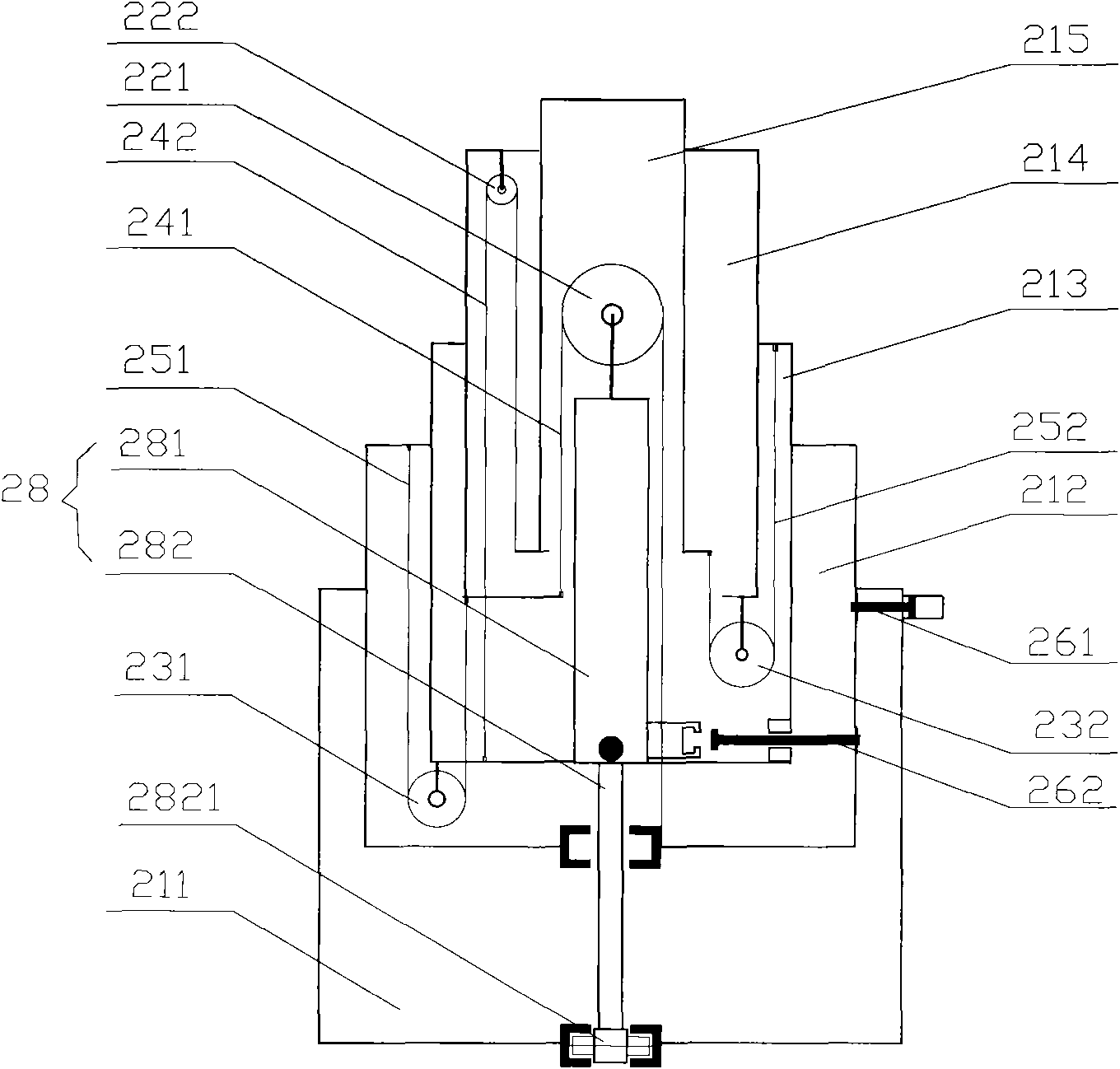

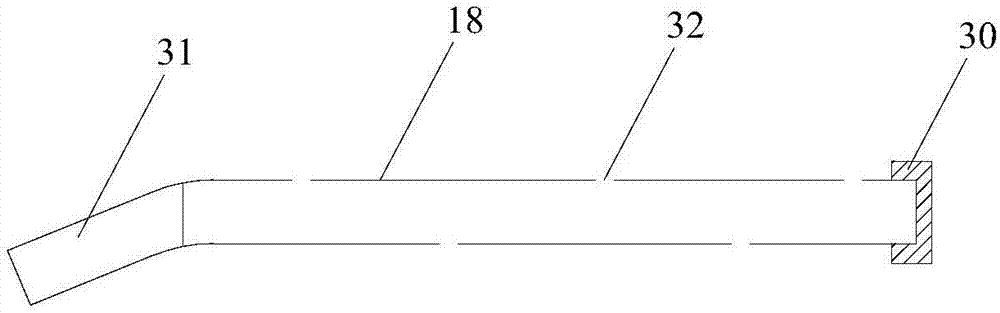

Automobile crane and device with multiple sections of telescopic jibs thereof

The invention discloses a device with multiple sections of telescopic jibs, comprising a fringe connection part and a bolt connection part; the fringe connection part comprises at least two sections of telescopic jibs located in the inside and connected with a travel cable through a turning wheel; the bolt connection part comprises at least one section of telescopic jib located at the outside and connected with a cylinder pin through a jib pin and a basic jib (211); a cylinder tube (281) of a telescopic cylinder (28) is connected with the outmost section of telescopic jib of the fringe connection part. Therefore, in the extending processing of the telescopic jibs, each section of telescopic jib of the fringe connection part extends synchronously, which increases the extending speed of the device with multiple sections of telescopic jibs as well as the working efficiency; at the same time, because the fringe connection part is connected with the bolt connection part by the jib pin (262), and the axial force between the telescopic jibs is transmitted through the jib pin, the stress condition of the telescopic cylinder (28) is improved, the size is reduced properly so as to reduce the cost. The invention further discloses an automobile crane comprising the device with multiple sections of telescopic jibs.

Owner:SANY AUTOMOBILE MFG CO LTD

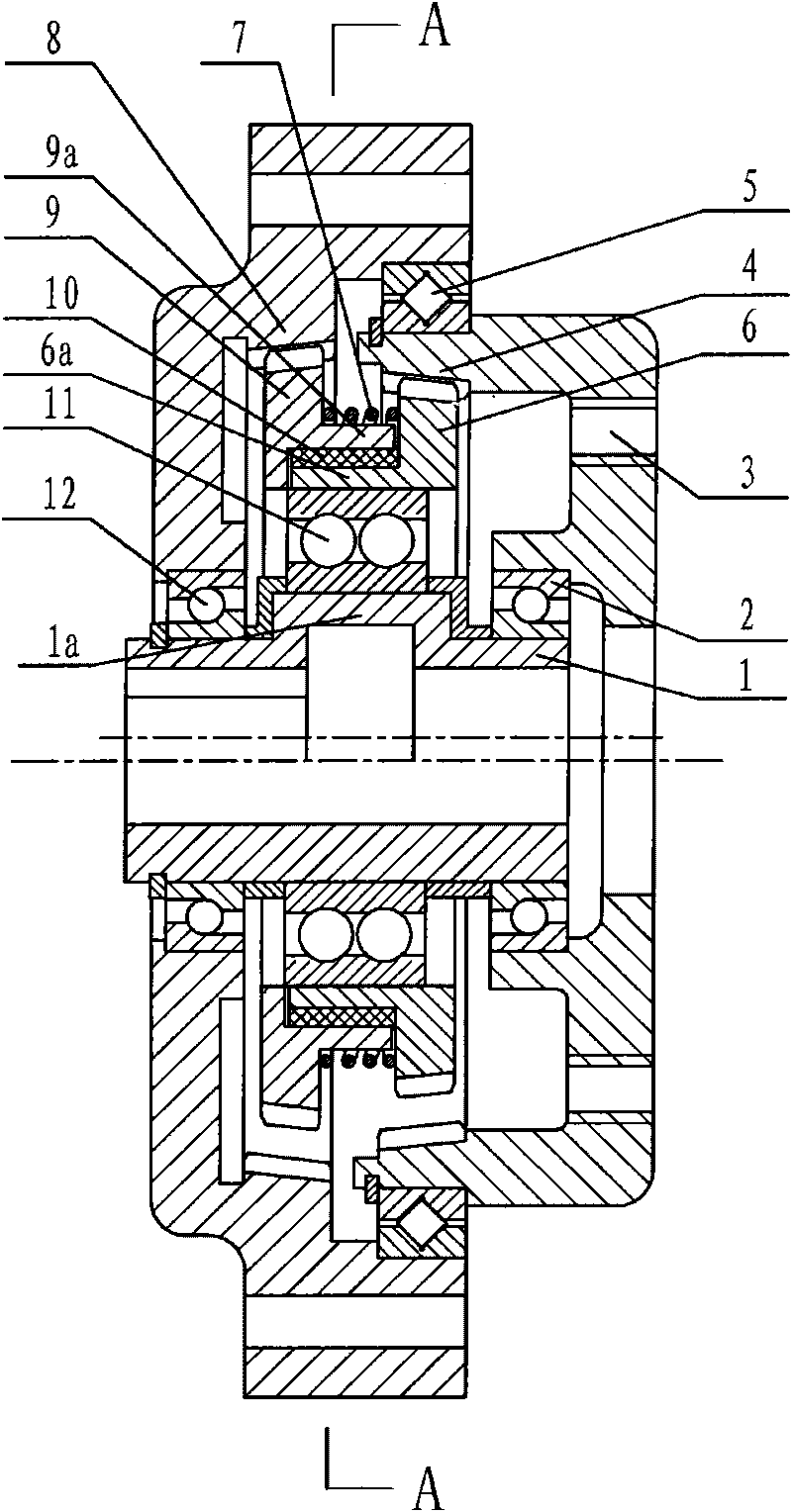

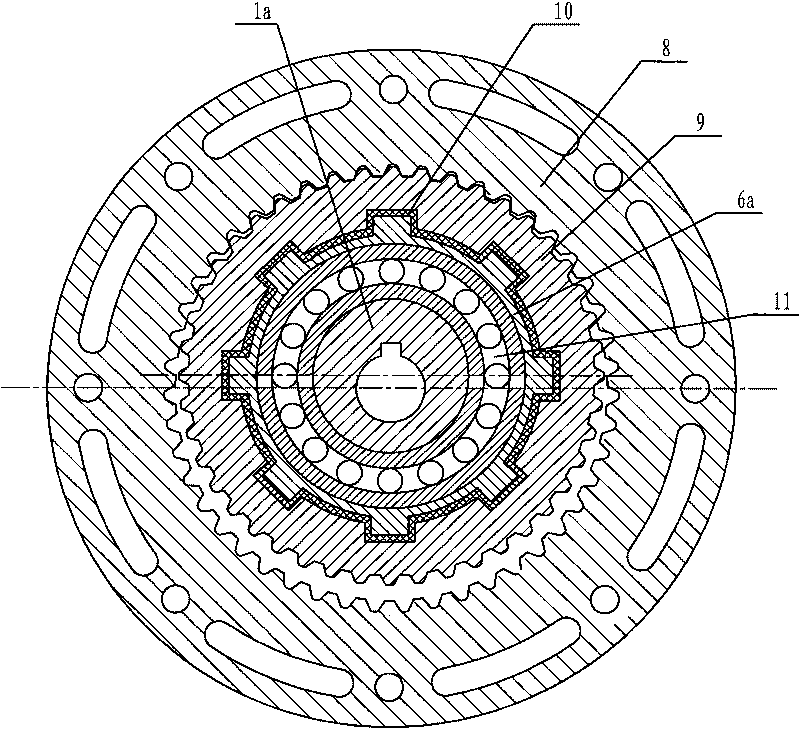

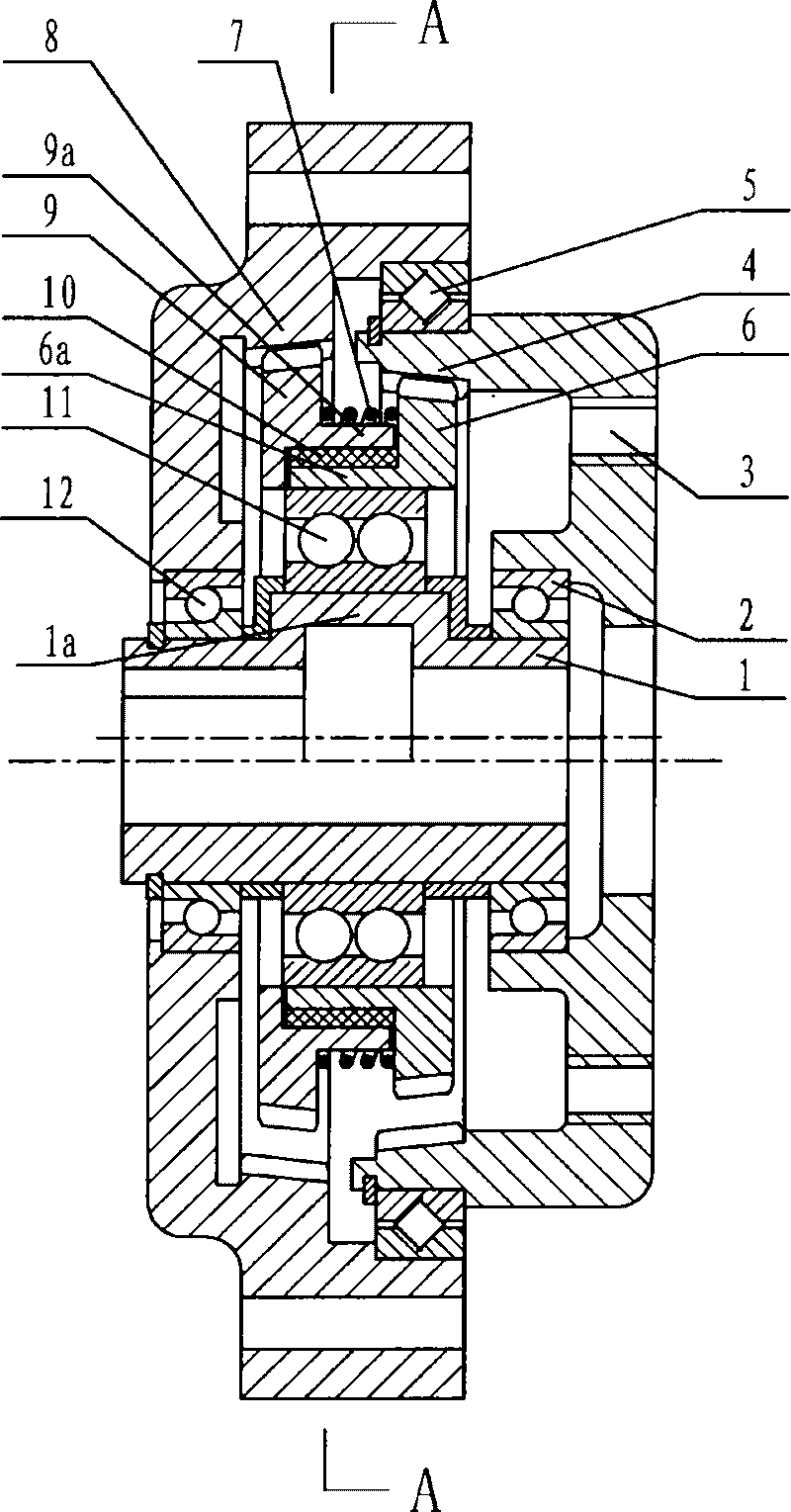

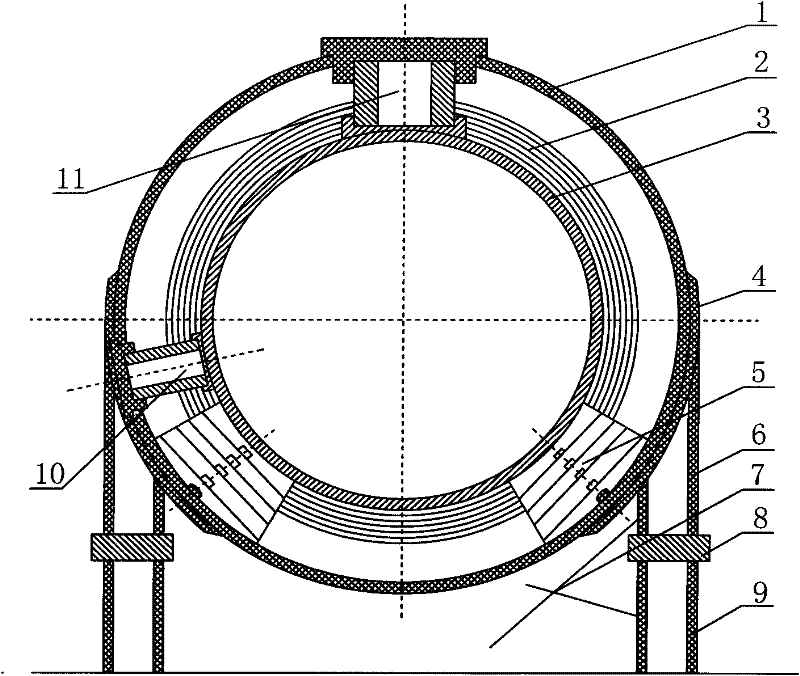

Magnetic bearing component and compressor

ActiveCN105650117AGuaranteed carrying capacityRealize the risk of damagePump componentsShaftsMagnetic bearingMachining

The invention relates to a magnetic bearing component and a compressor. The magnetic bearing component comprises a magnetic bearing, a fixing shell and a working clearance adjusting device. The magnetic bearing comprises a first iron core, a second iron core and a thrust disc, and the working clearance adjusting device is radially arranged between the radial inner periphery of the fixing shell and the thrust disc and axially arranged between the fixing shell and the second iron core. An axial end of the working clearance adjusting device is abutted against the second iron core, an avoidance gap is reserved between the fixing shell and the second iron core, and a distance between two axial ends of the working clearance adjusting device can be changed to realize adjustment of a working clearance of the magnetic bearing to make the working clearance accord with a design value. By the magnetic bearing component and the compressor, adjustment of the working clearance of the magnetic bearing can be realized conveniently on the premise that coil damage risks and machining errors in secondary machining of the magnetic bearing are effectively avoided.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Hydraulic vertically rotary airtight flood and preventive partition door in metro running

ActiveCN101666242AOvercome the disadvantage of being thickMeet strength requirementsGasproof doorsMining devicesMonitoring systemEngineering

An airtight flood and preventive partition door used for civil defense in metro running mainly comprises a door leaf, a door frame, a hinge, a hydraulic drive device, a manual and electric locking device, a manual gate valve, a manual and electric gate valve, a support locking device, a monitoring device and the like. A hydraulic drive system drives the door leaf to open and close. The manual andelectric locking device can open and close the locks manually and electrically. The gate valve is used for sealing a drainage ditch passing by the partition door. The support locking device is used for supporting and safely locking the door leaf. A monitoring system is used for monitoring the water level and state of each component and controlling action of each component. The partition door simultaneously satisfies the requirements of civil defense and flood standards, is suitable for the characteristics of the metro running structure, occupies little space, has low overall cost, is characterized in that all the components can be used manually and electrically, can be monitored remotely and opened and closed easily and quickly, and has higher application value.

Owner:4TH DESIGN & RES INST OF ENGINEER CENT STAFF PLA +1

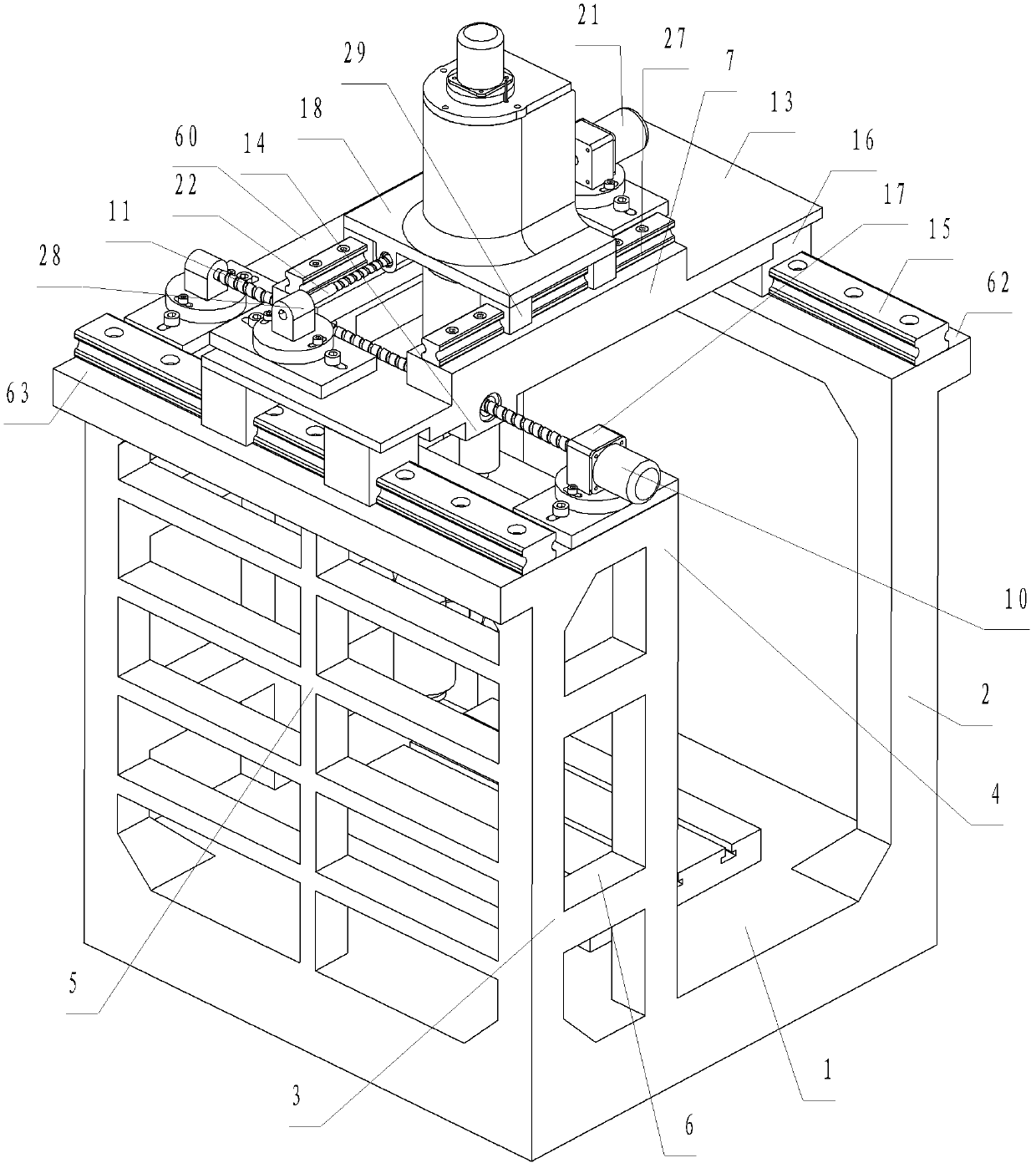

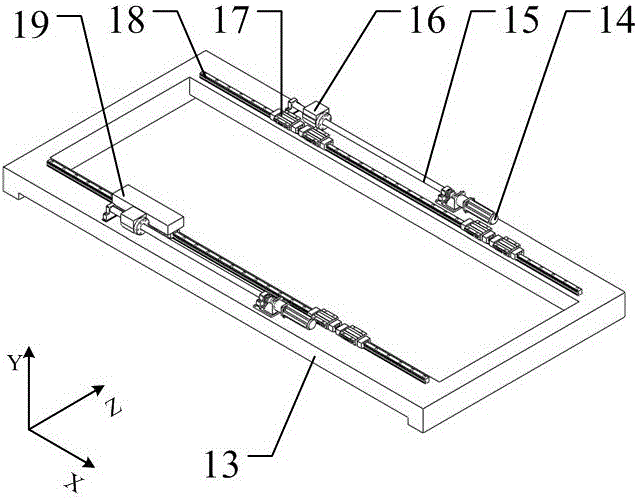

Numerical control equipment

InactiveCN102699768AGuaranteed shape and position accuracyAchieve rigid fixationFeeding apparatusLarge fixed membersNumerical controlEngineering

Numerical control equipment comprises a main frame and a workpiece clamping device. The main frame consists of a base, a first main support portion and a second main support portion, and the first main support portion and the second main support portion are arranged on two opposite sides of the base and are mounted with the base. The numerical control equipment is characterized in that the first main support portion and the second main support portion consist of separate first sides on the middle upper portions, a first driving device and a first driving device mounting portion, the first driving device drives an X-direction sliding seat to reciprocate, the first driving device mounting portion is connected with the first main support portion or the second support portion and is placed between an X-direction front guide rail and an X-direction rear guide rail, and the first driving device consists of an X-direction lead screw or a group of X-direction linear motors which drives the X-direction sliding seat to reciprocate and is parallel to the X-direction front guide rail and the X-direction rear guide rail. The X-direction lead screw penetrates through the X-direction sliding seat, and two ends of the X-direction lead screw are protruded out of a worktable and mounted on the first driving device mounting portion; or two ends of a stator of each X-direction linear motor are protruded out of the worktable and are fixed to the first driving device mounting portion. The numerical control equipment has the advantage that a workpiece is convenient to hoist.

Owner:杨东佐

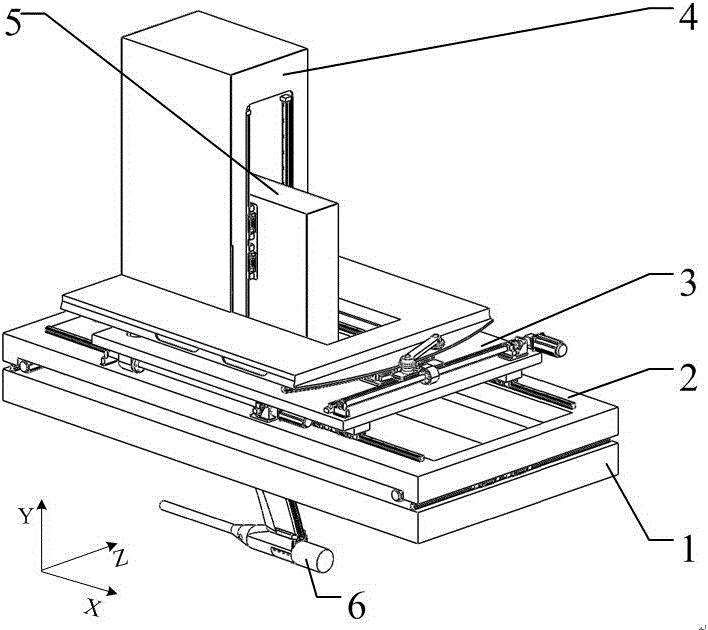

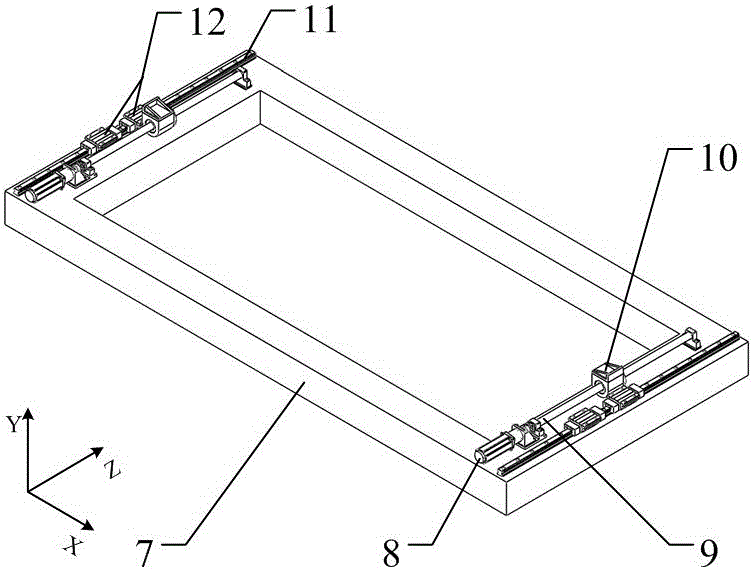

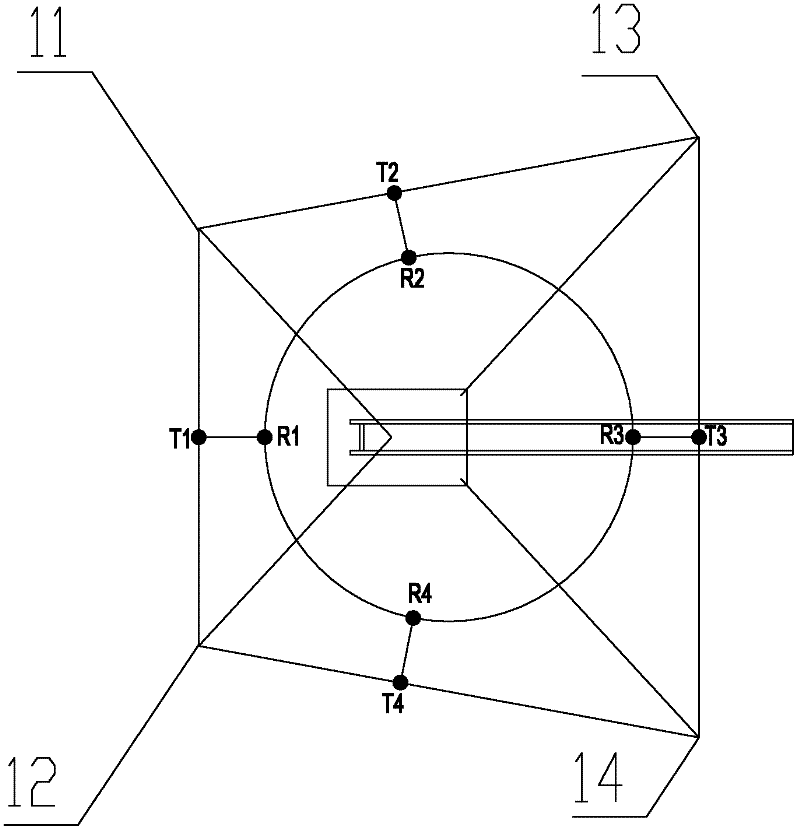

Space six-degrees-of-freedom mechanism used for hypersonic wind tunnel multi-body separation test

ActiveCN106124157ASmall degree of blockageGuaranteed independence movementAerodynamic testingThree degrees of freedomDrive motor

The invention provides a space six-degrees-of-freedom mechanism used for a hypersonic wind tunnel multi-body separation test. The mechanism comprises Z, X and Y three degrees of freedom straight-line motion mechanisms and [beta], [alpha] and [gamma] three degrees of freedom angular displacement motion mechanisms. The six-degrees-of-freedom are realized layer by layer and are connected step by step, and in terms of structure, embedment integration is achieved by a box stacking mode. A Z-direction mechanism, an X-direction mechanism and a [beta] mechanism are sequentially overlapped from bottom to top, and a Y-direction mechanism and a [alpha] mechanism are in embedded connection from outside to inside. A [gamma] mechanism is fixedly connected with the [alpha] mechanism through a bent blade, and is individually arranged in a wind tunnel flow field. Each of the Z-direction mechanism, the X-direction mechanism and the Y-direction mechanism adopts two driving assemblies in symmetric arrangement, so that the power and the size of a driving motor are effectively reduced, and the overall stability of the mechanism is improved. The [beta] mechanism and the [alpha] mechanism adopt line-to-arc mechanisms for implementation, so that overlapping of traditional three degrees of freedom rotation pairs is prevented, and the mechanism cantilever length is shortened. The structure is compact, the rigidity is good, andsix-degrees-of-freedom movement of high speed, high precision and high bearing capacity is achieved.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

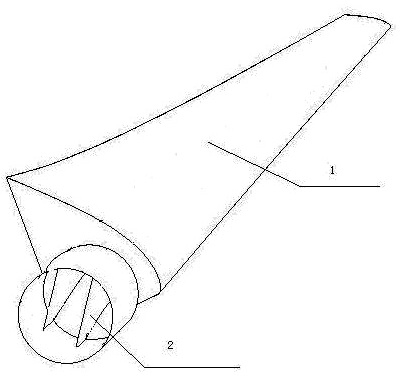

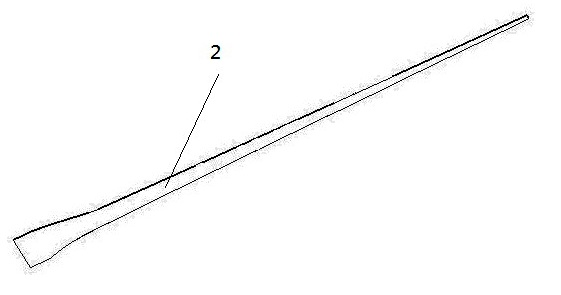

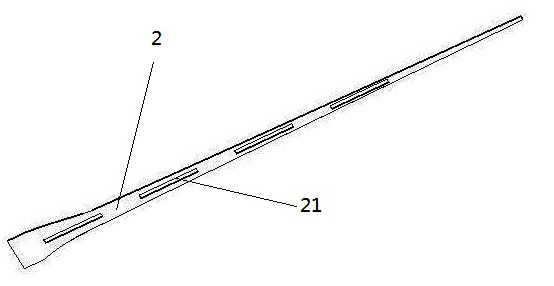

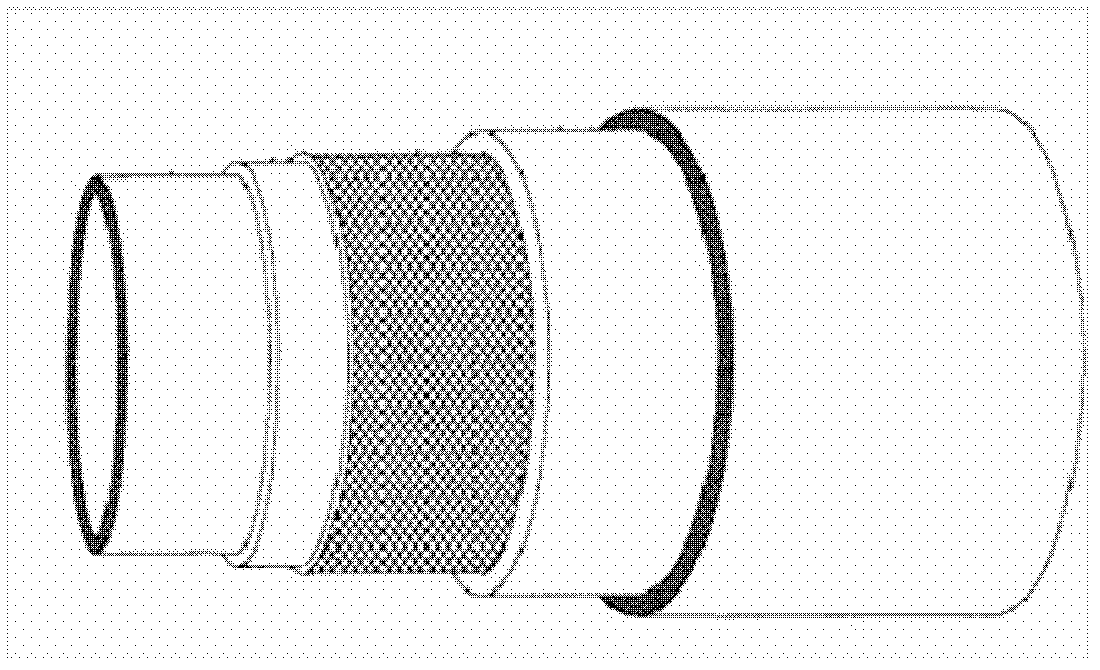

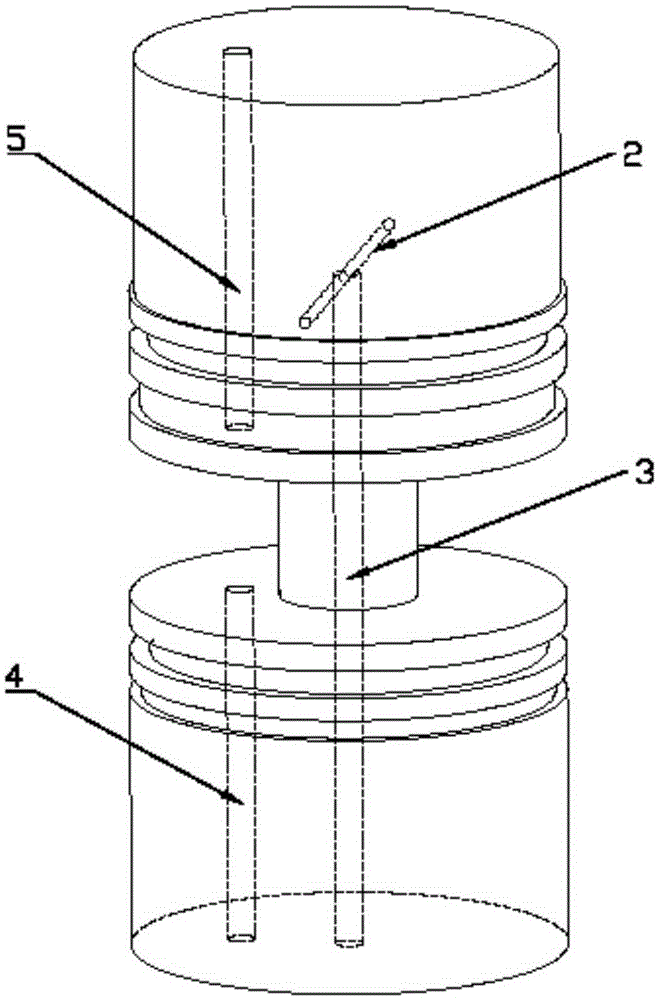

Wind machine blade and method for designing same

ActiveCN102141001AGuaranteed carrying capacityReduce weightMachines/enginesWind energy generationWinding machineTopology optimization

The invention discloses a method for designing a wind machine blade and the wind machine blade which is designed according to the method. The blade comprises a crossbeam (2) and skin (1); and the crossbeam (2) comprises at least one opening (21). The method comprises the following steps of: determining a pneumatic appearance parameter of the blade and a structure parameter of the crossbeam by theconventional method for designing the blade; forming openings on the substance crossbeam by a topological optimization method; primarily determining the design position, number and size of ribs, the material of skin and initial design thickness by optimization calculation; and checking intensity, rigidity and fatigue of the primarily designed blade structure, adjusting and optimizing according toa checking result to ensure that the blade has high structure performance. The openings are formed on the crossbeam, and reinforcement ribs are formed between the crossbeam and the skin, so that the weight of the blade is reduced when the intensity and rigidity of the blade structure are guaranteed, the cost of the blade is reduced, and the loading of the blade can be reduced conveniently.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Filter speed reducer

InactiveCN101725673AImprove carrying capacityImprove seismic performanceToothed gearingsLow speedEngineering

The invention discloses a filter speed reducer, which comprises an eccentric shaft, a split spine half-axle dual gear, a fixed gear, an output gear and a rubber alloy layer. The split spine half-axle dual gear, the fixed gear and the output gear are helical bevel gears which are organically meshed to form a backlash-free precise transmission pair and can adaptively compensate for abrasion of tooth surfaces; the rubber alloy layer adhered on the split spine half-axle dual gear can ensure that a transmission component filters fluctuation caused by the conversion of a low speed and high torque into a high speed and low torque of a motor, processing and mounting errors and the like through a controllable elastic distortion quantity in a designed transmission accuracy and bearing capacity range, effectively prevents generation of nonlinear coupled vibration of a transmission system caused by influences of extreme working conditions and special environments, and solves the problems of generation of jam even inflexible lock and the like of the transmission component. Thus, the filter speed reducer has the advantages of high precision, high reliability, long service life, high torque, low energy consumption, small volume and the like, and can be widely applied to equipments in engineering fields, such as robots, space flights, ships and vehicles.

Owner:重庆奔腾科技发展有限公司

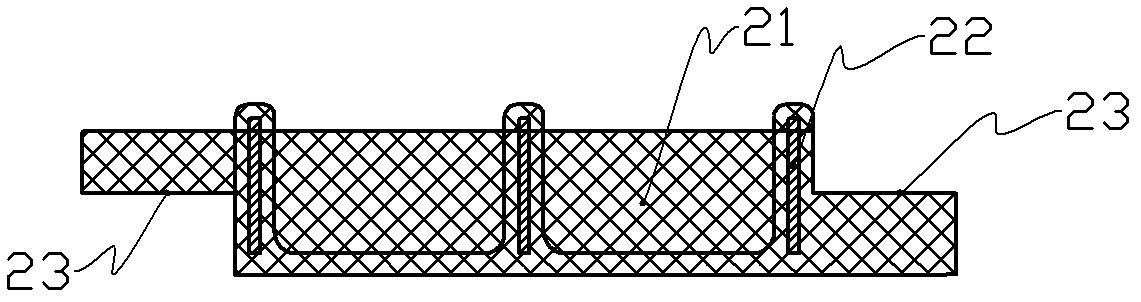

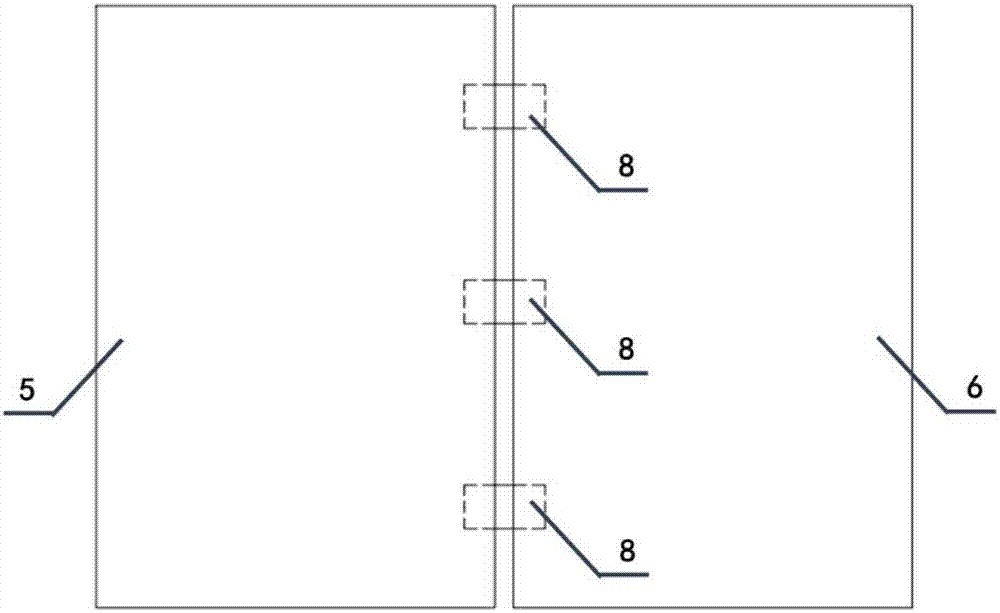

Reinforcing bar splicing connection component comprising thin-wall sleeves constrained by spiral bars

The invention relates to the technical field of building concrete member manufacturing, in particular to a reinforcing bar splicing connection component comprising thin-wall sleeves constrained by spiral bars. The reinforcing bar splicing connection component comprising the thin-wall sleeves constrained by the spiral bars is applicable to connection of reinforcing bars in concrete structures and particularly applicable to connection of vertical reinforcing bars in housing-industrialized assembly-type concrete shear wall components. Reliable connection of the concrete shear wall components is achieved through the thin-wall sleeves constrained by the spiral bars and reserved extending vertical connecting reinforcing bars and by pouring high-strength grouting materials into the thin-wall sleeves. Since horizontal bars, stirrups, tie bars, spiral stirrups and the thin-wall sleeves are designed for the shear wall components, and the high-strength grouting materials are poured into the thin-wall sleeves to achieve a stable constraint effect, the compression resistance and anti-deformation capability of the concrete shear wall components is obviously improved, and the ductility performance of prefabricated concrete shear wall components is guaranteed; moreover, the lapping joint performance of the vertical steel bars can be further improved, and the shearing performance of an upper-layer shear wall and a lower-layer shear wall is well guaranteed by pouring high-strength grouting materials into a bed mortar layer.

Owner:SHENYANG JIANZHU UNIVERSITY

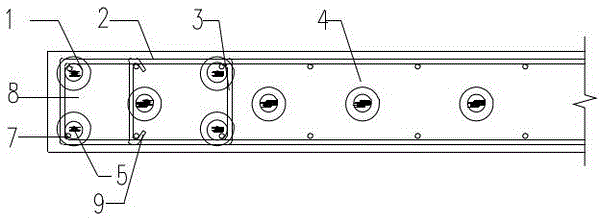

Two-dimensional code compiling method

InactiveCN103177281AImprove aestheticsAvoid influenceRecord carriers used with machinesData compressionTerra firma

The invention discloses a two-dimensional code compiling method. The two-dimensional code compiling method comprises the following steps of: on the basis of a self-adaptive code compiling extended black and white code compiling technology and a code compiling scheme applicable to different multimedia, introducing an interweaving technology into an error-correcting code compiling technology by using a data compression technology with an open structure during compression code compiling; and adopting an advanced morphologic image pre-processing technology based on multi-scale structural analysis. The two-dimensional code compiling method has the advantages that a two-dimensional code is superior to the conventional two-dimensional code standard in terms of information bearing capacity, robustness, safety, reliability and adaptability; and coding and decoding bottom-layer supporting software provides technical support for various types of application of the two-dimensional code to the field of the internet of things in an open interface mode, the market monopoly position of the conventional foreign two-dimensional code standard can be broken, the chaotic situation of the conventional domestic two-dimensional code application is changed, and a firm foundation is laid for the development of the internet-of-things industry.

Owner:江苏圆坤二维码研究院有限公司

Double composite plastic steel composite pipe and manufacture method thereof

InactiveCN102620066ASave raw materialsLow costRigid pipesTubular articlesInternal pressureMaterial consumption

The invention provides a double composite plastic steel composite pipe and a manufacture method thereof, discloses a method for manufacturing a liquid conveying pipeline with the advantages of high annular rigidity, low material consumption, capability of bearing internal pressure, favorable sanitary performance, long service life, and better comprehensive performance. The basic process comprises steps of: manufacturing a plastic steel strip, manufacturing a plastic steel winding pipe stock by using the plastic steel strip, compounding and winding a metal wire, extruding a hot melt adhesive and coating on an outer surface of the pipe stock and coating a fused plastic on the outer surface of the plastic steel winding pipe stock. Thus both the anti-corrosion performance of plastic and the rigidity of steel belts are utilized; due to the adoption of the embedded steel wire, the internal pressure bearing performance of a buried pipe can be guaranteed; due to the composite structure of the pipe, the consumption of plastic is reduced, and the performance-price ratio of the pipe is greatly improved; and the manufacture method can be used for manufacturing large caliber liquid conveying pipelines, so as to solve the problem that the manufacture of large caliber plastic pipes is difficult in China.

Owner:山东天迈管业有限公司

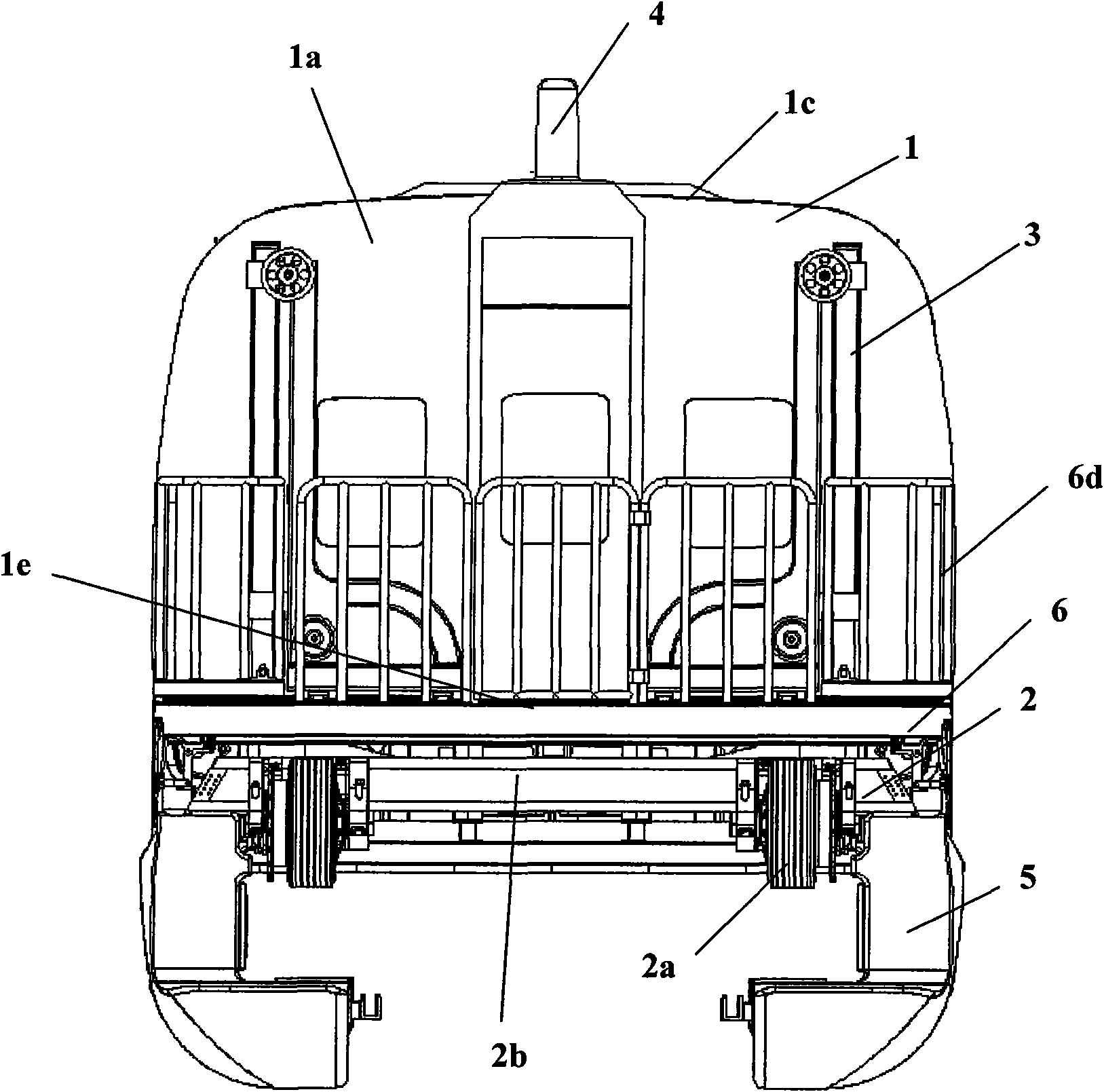

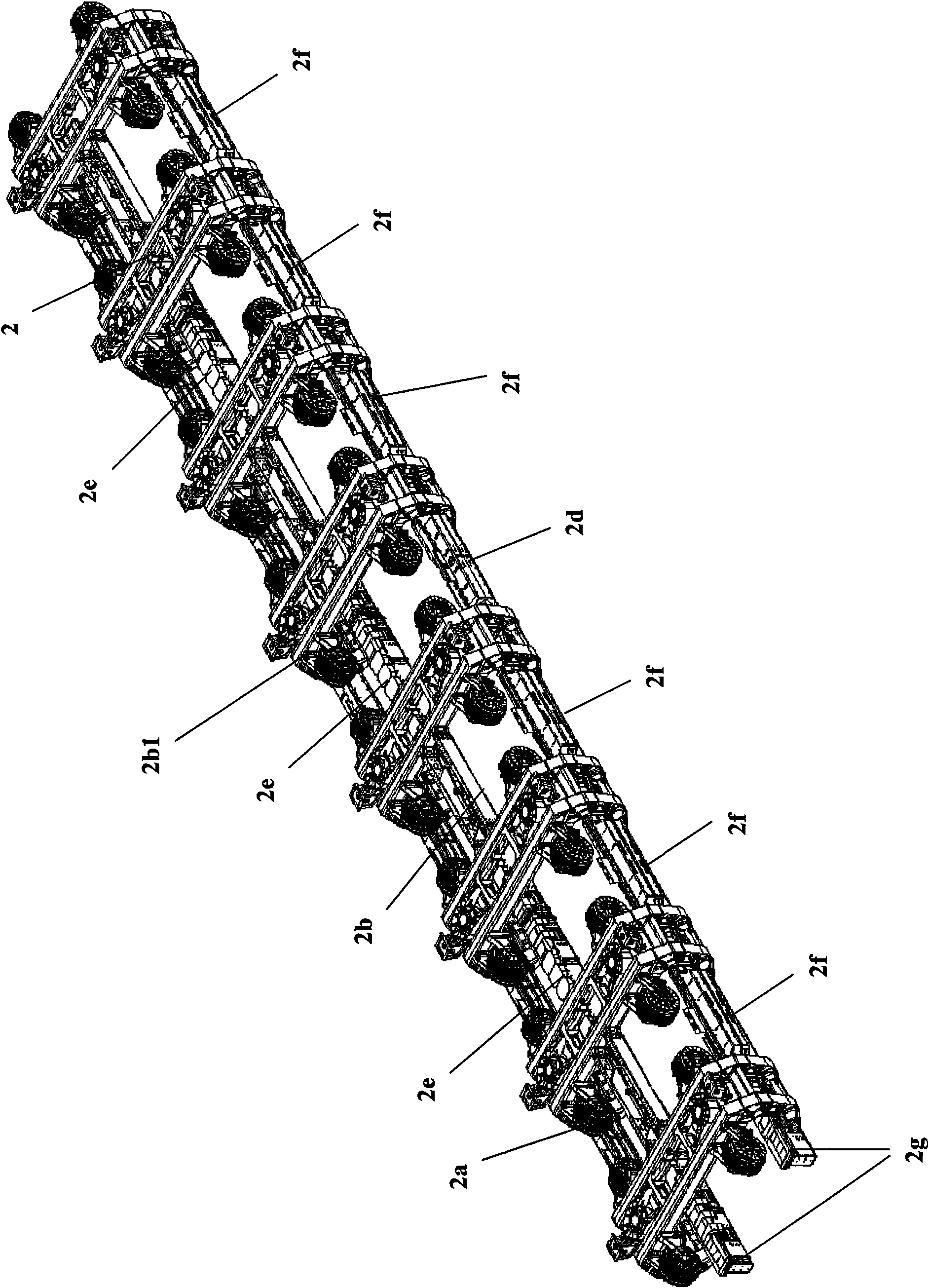

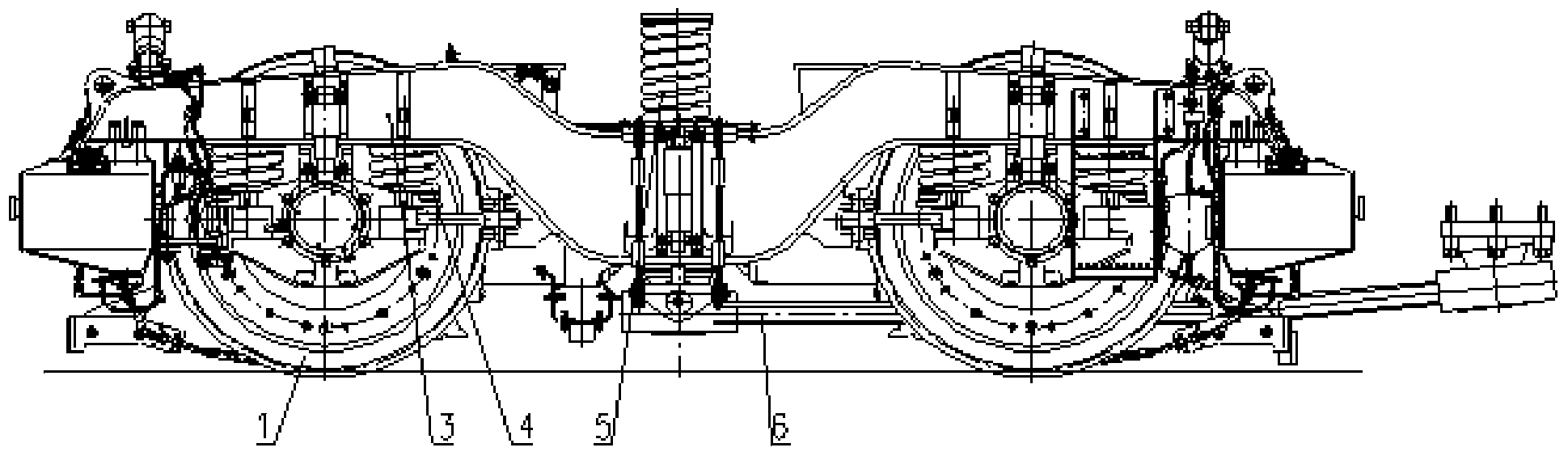

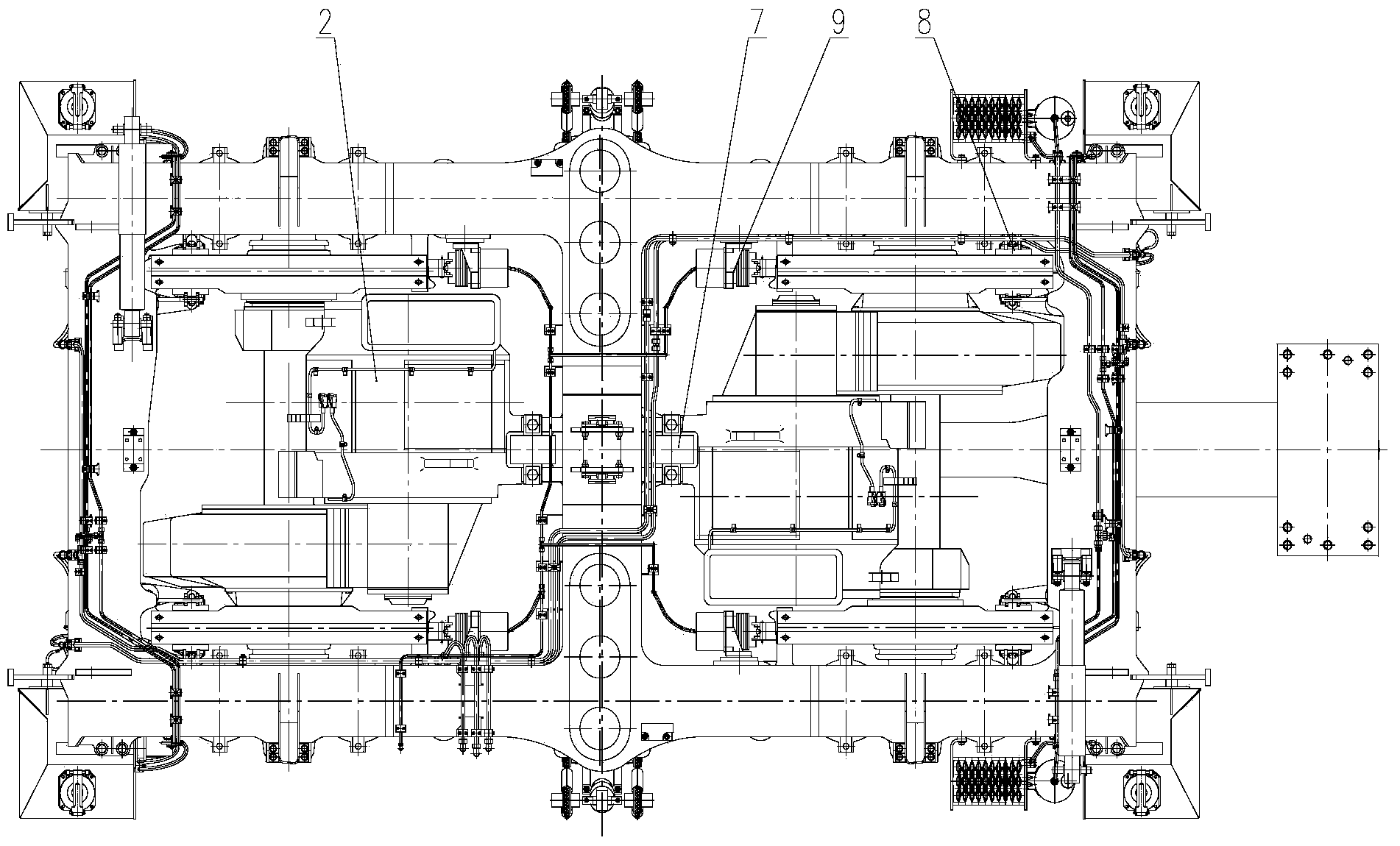

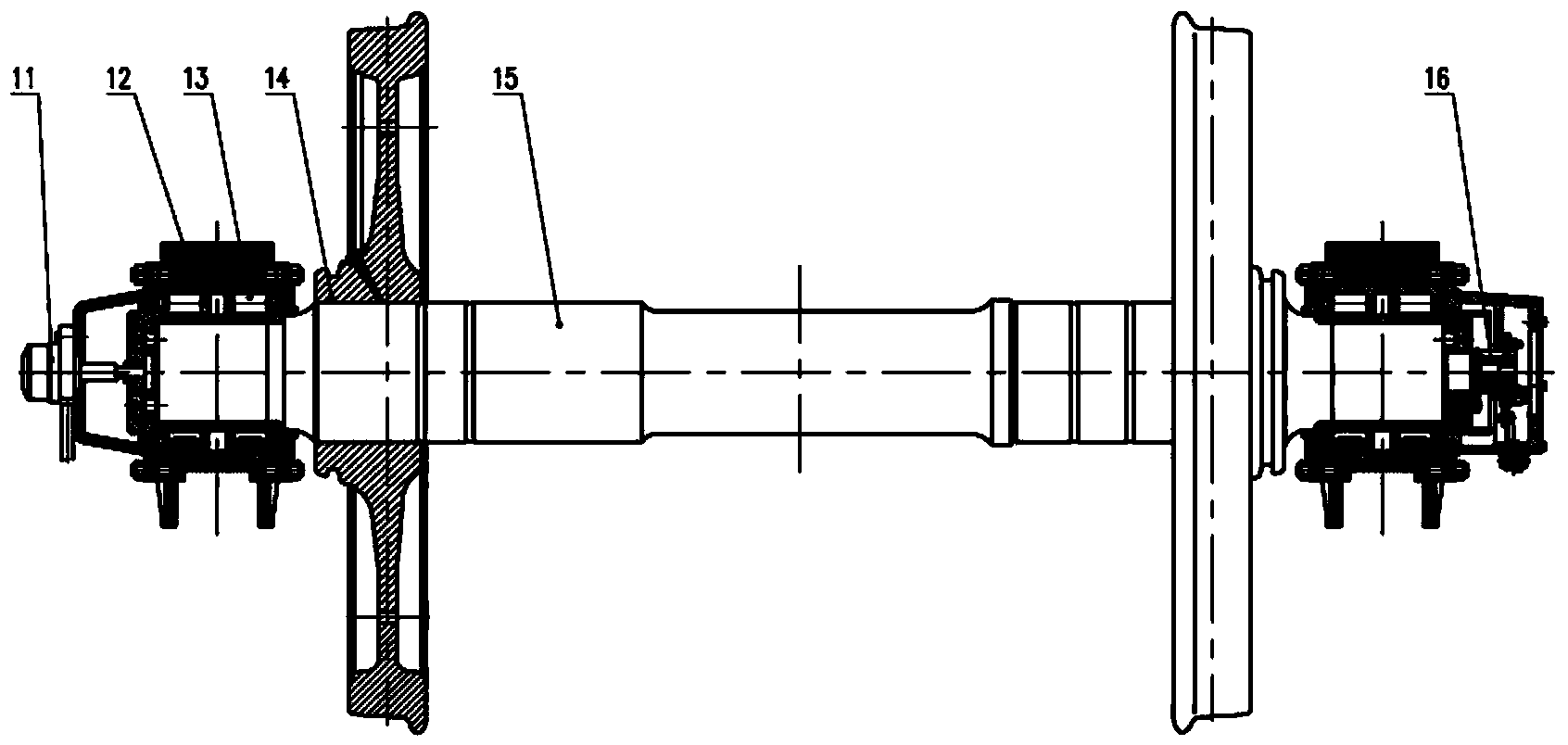

Two-axle bogie of electric locomotive with 30-ton axle weight

InactiveCN103625498AIncrease capacityOptimize lateral dynamicsAxle-boxes mountingBogieCarrying capacity

The invention discloses a two-axle bogie of an electric locomotive with the 30-ton axle weight. The two-axle bogie is of a two-axle structure and is mainly composed of two wheel set axle box assemblies, two driving units, a framework, four primary suspension devices, a secondary suspension device, a traction device, two motor suspension devices, two braking devices and four tread cleaning devices. According to the improved design of the bogie, the reasonable traction mode and the best suspension parameter configuration are adopted, the heavy-load locomotive can achieve the best adhesion utilization rate and have the good curve negotiating performance, the reliable requirement is met, the power capacity and the traction capacity of the locomotive are developed to the greatest extent, the comprehensive performance of the locomotive is optimized, the running safety, smoothness and comfort indexes are good, the two-axle bogie can be used for greatly improving the carrying capacity of a railway, a research and development platform for the bogie of the electric freight locomotive with the large axle weight, a relevant test system and a relevant standard system are built, and the technical gap for the electric locomotive with the large axle weight is filled in.

Owner:CHINA RAILWAYS CORPORATION +1

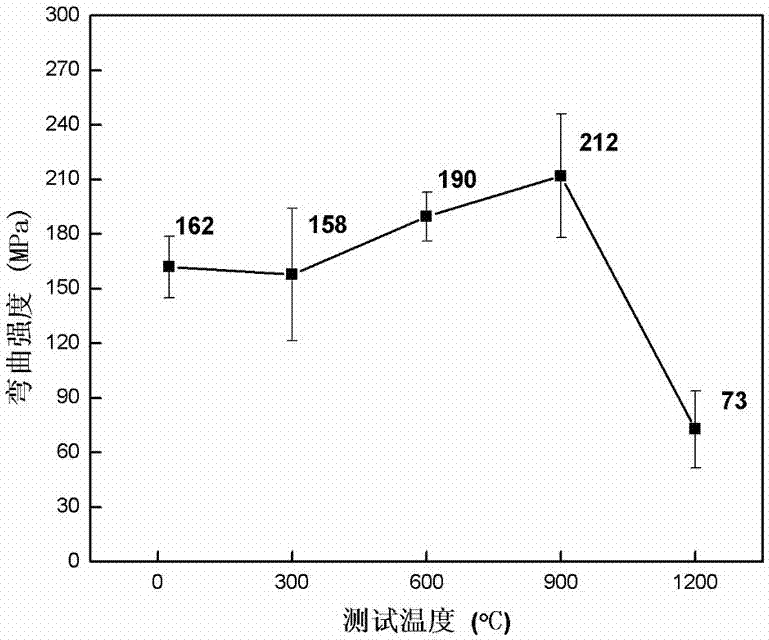

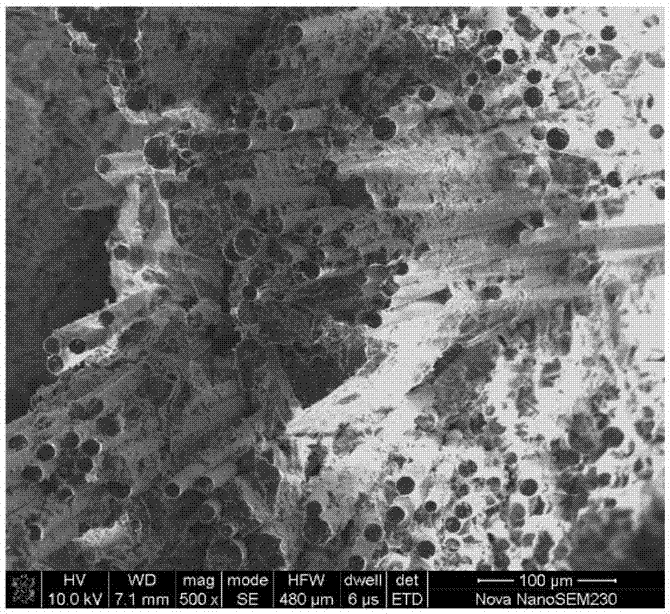

Silicon nitride fiber reinforced silicon dioxide ceramic based composite and preparation method and application thereof

ActiveCN107188591AHigh preparation temperatureLow dielectric constantRadiating element housingsFiberCarrying capacity

The invention discloses a silicon nitride fiber reinforced silicon dioxide ceramic based composite and a preparation method and application of the silicon nitride fiber reinforced silicon dioxide ceramic based composite. The silicon nitride fiber reinforced silicon dioxide ceramic based composite comprises an Si3N4 fiber prefabricate and an SiO2 ceramic base, and the SiO2 ceramic base is evenly put in holes of the Si3N4 fiber prefabricate. The preparation method comprises the following steps: (1) removing a binder from the Si3N4 fiber prefabricate in the vacuum or inertia atmosphere; (2) preparing an Si3N4 / SiO2 composite intermediate through the processes of impregnating in vacuum, drying a gel and sintering; and (3) decarbonizing thermally in the aerobic environment. The composite has the advantages of high temperature resistance, ablation resistance, scouring resistance, excellent oxidation resistance, strong carrying capacity and excellent dielectric property, and has an excellent application value in the field of high temperature wave transmitting material; and the preparation method is simple in process and relatively low in cost and is suitable for industrial production.

Owner:NAT UNIV OF DEFENSE TECH

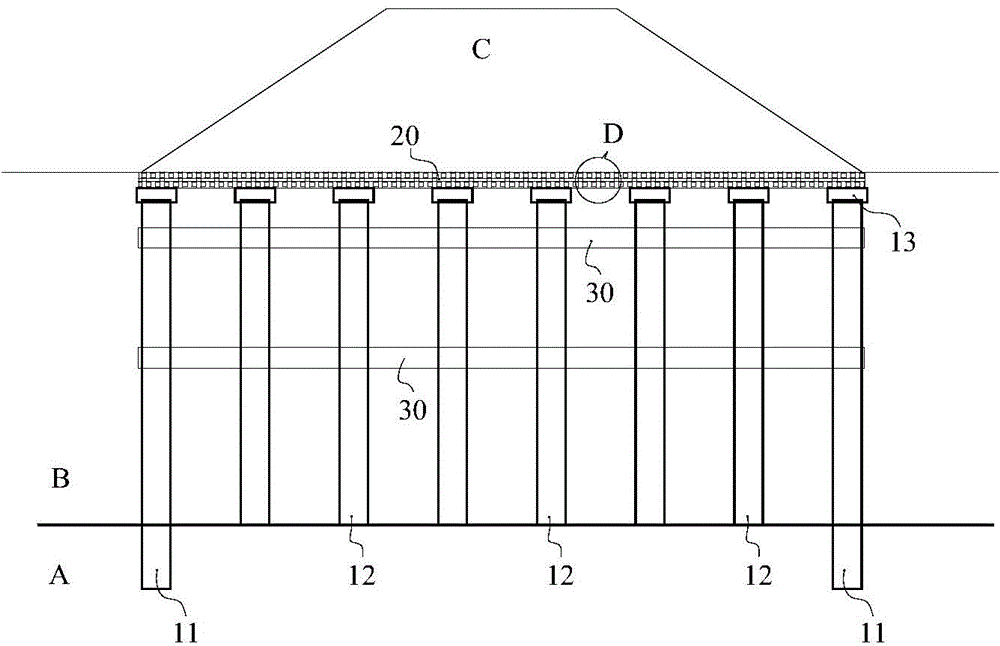

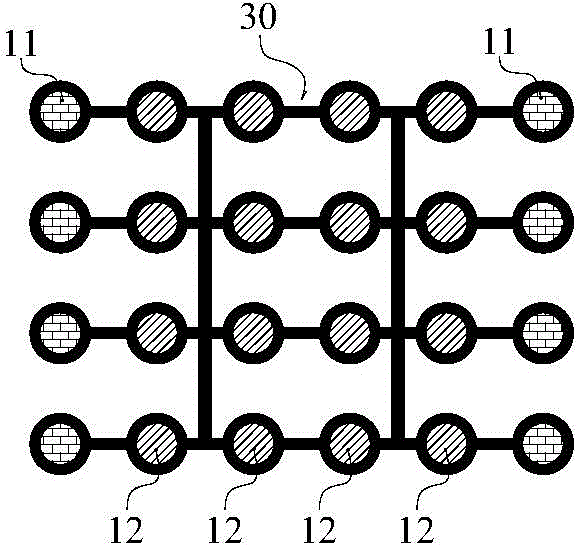

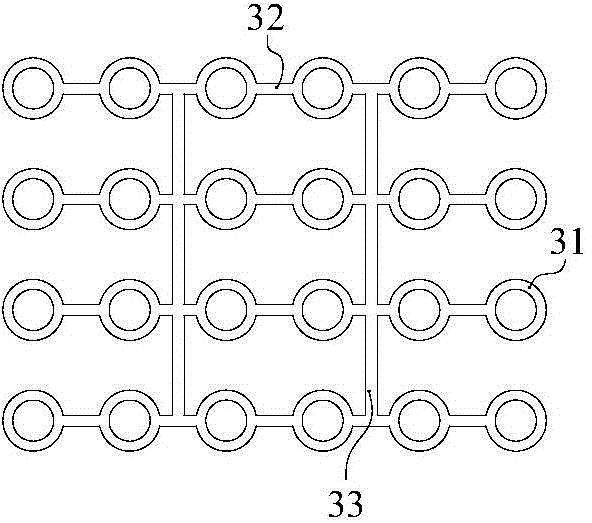

Soft soil foundation combined pile net structure

The invention discloses a soft soil foundation combined pile net structure, aims at effectively improving reinforcing effect and saving project investment and comprises cast-in-place piles, pressed piles, pile caps, guide fixing frame lattices and a cushion body. The cast-in-place piles are arranged around the boundary of a filling body at intervals, bottoms of the cast-in-place piles enter a bedrock layer below a soft soil layer by certain depth, the pressed piles are arranged in the soft soil layer within a range of the cast-in-place piles at intervals, bottoms of the pressed piles are pressed in the top surface of the bedrock layer, the pile caps are arranged at the tops of the cast-in-placed piles and the pressed piles and fixedly connected with the cast-in-placed piles and the pressed piles, the guide fixing frame lattices are positioned in the soft soil layer and transversely restrain the cast-in-place piles and the pressed piles, and the cushion body is laid between the tops of the piles caps and the undersurface of the filling body.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD +1

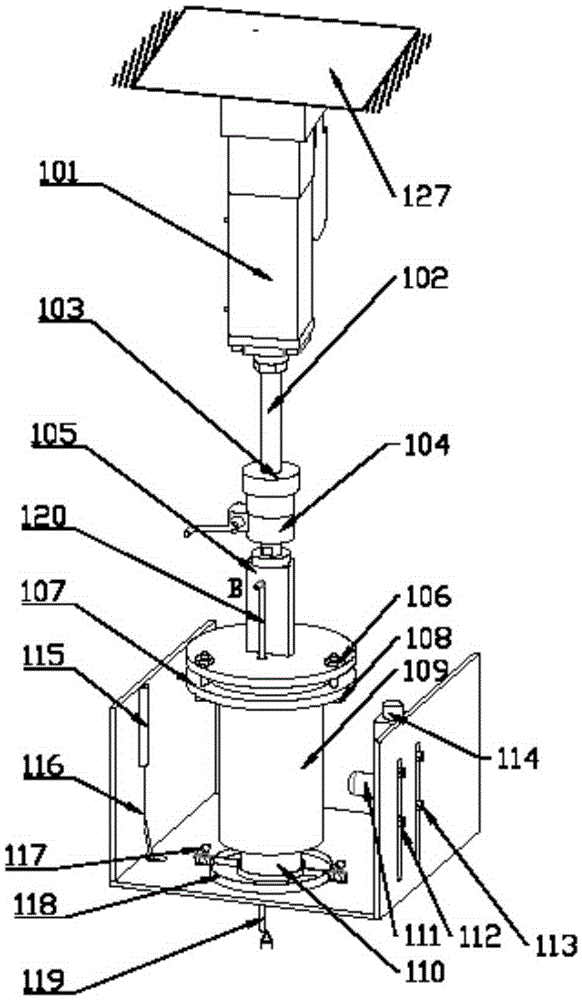

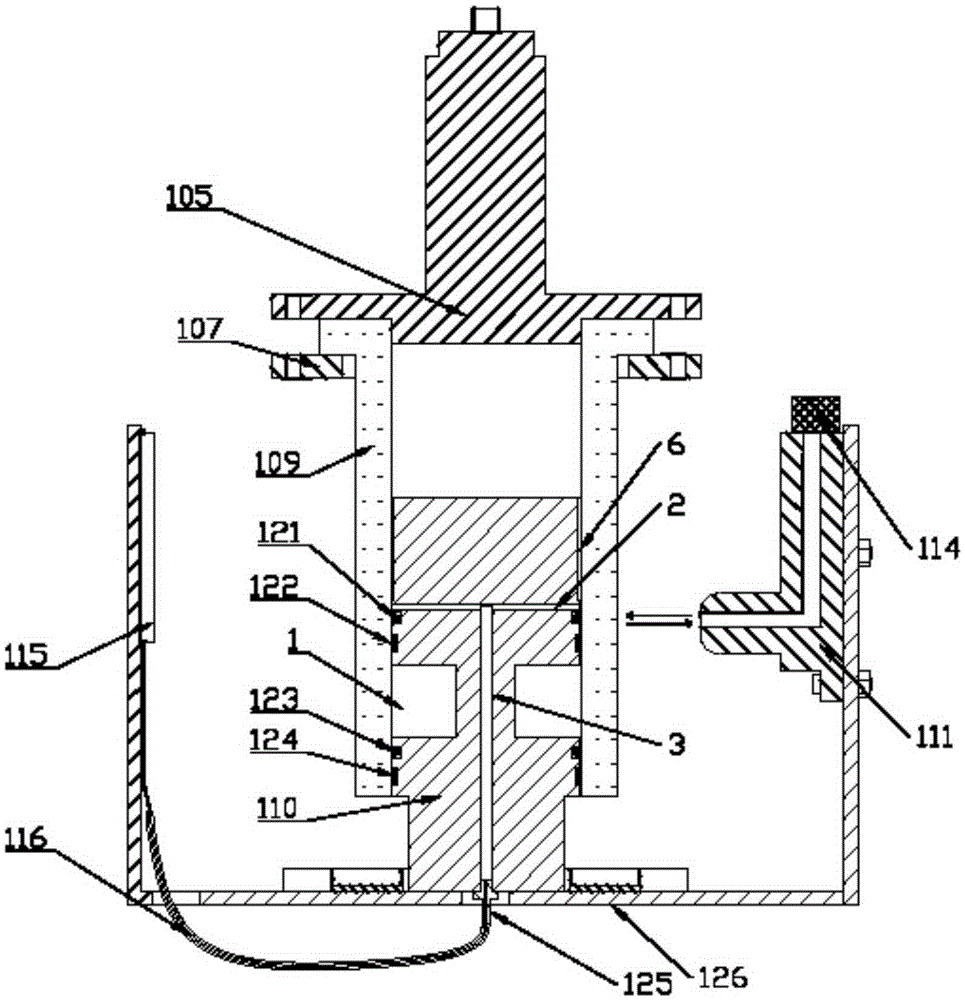

Closed oil film visualization device capable of measuring leakage of reciprocating sealing piston

ActiveCN105257618AStable liquid pressureAvoid destructionFluid-pressure actuator testingFluid-pressure actuator componentsLiquid heightLinear actuator

The invention discloses a closed oil film visualization device capable of measuring leakage of a reciprocating sealing piston. The device comprises a tabletop visualization mechanism and an oil supply system, wherein the tabletop visualization mechanism comprises a top plate, a base frame, a linear actuator, a pull pressure sensor, a piston and a transparent cylinder; lower leaked liquid detecting components are arranged around the bottom of the piston; an upper leaked liquid height detecting component and a microscope observation component are arranged on the side wall of the base frame; a vertical oil way and a horizontal oil way are arranged in the piston; the two ends of the horizontal oil way penetrate through the side wall of the piston; the vertical oil way is connected and communicated with the upper leaked liquid height detecting component; an annular groove is peripherally formed in the middle part of the piston to serve as an oil closed cavity to be connected to the oil supply system; and gaps are formed in the side surface of the piston and the inner wall of the transparent cylinder. The device solves the technical difficulties in a traditional device, supplies stable liquid pressure, guarantees the bearing capacity and the service life of a glass cylinder, and detects the sealing leakage quantity or the magnitude of pumping back quantity.

Owner:ZHEJIANG UNIV

Fabricated shear-wall energy-dissipation vibration-reduction horizontal connecting device and construction method thereof

ActiveCN107178163AGuaranteed durabilityAvoid Out-of-Plane WarpingWallsProtective buildings/sheltersCorrosionCarrying capacity

The invention belongs to the field of civil engineering, and relates to a fabricated shear-wall energy-dissipation vibration-reduction horizontal connecting device and a construction method thereof. A pre-embedded part and a connecting part of the fabricated shear-wall energy-dissipation vibration-reduction horizontal connecting device are both arranged in the wall body, changes of performances such as corrosion, erosion and aging can be avoided, the durability of the whole structure is ensured, plane outer warping of an energy-dissipation connecting device is avoided, and the better energy-dissipating capacity can be achieved. The energy-dissipation connecting part is placed in the wall body and coincides with the axis of a horizontal shaft of the section of the wall body, force balance of the wall body, rigidity in the plane and carrying capacity are ensured, and eccentric bending moment can not be generated. With the connecting mode, the efficiency of prefabricated shear-wall on-site assembling construction can be improved substantially, enough initial rigidity supplied to shear-wall to connect under the function of small vibration can be achieved, under the function of big vibration, earthquake energy can be dissipated, and vibration-reduction thoughts of structure and component ductility can be improved, and meanwhile, the whole effect of building beauty and space usage can not be influenced, steel products can be saved, and a certain economic benefit can be achieved.

Owner:DALIAN UNIV OF TECH

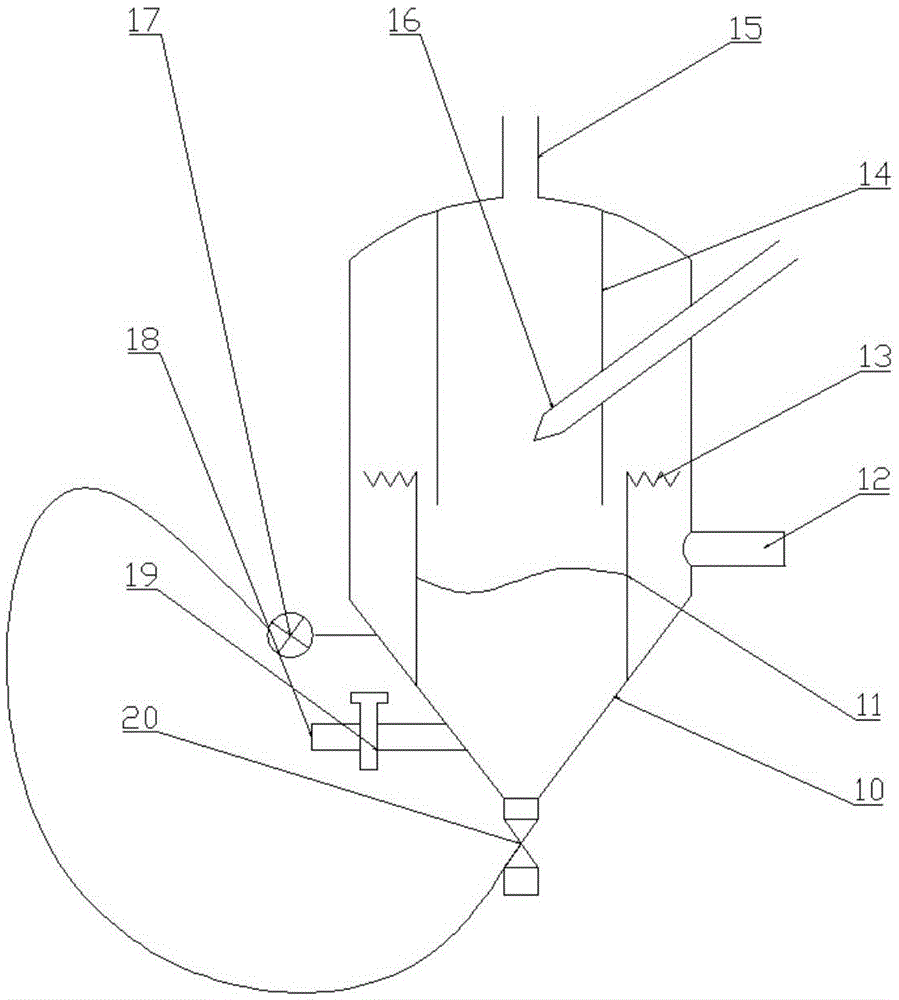

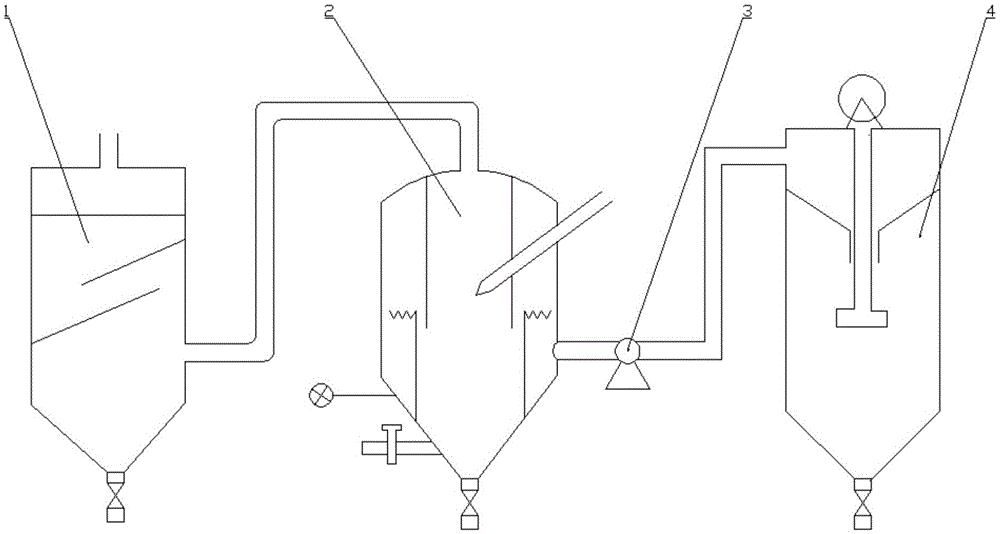

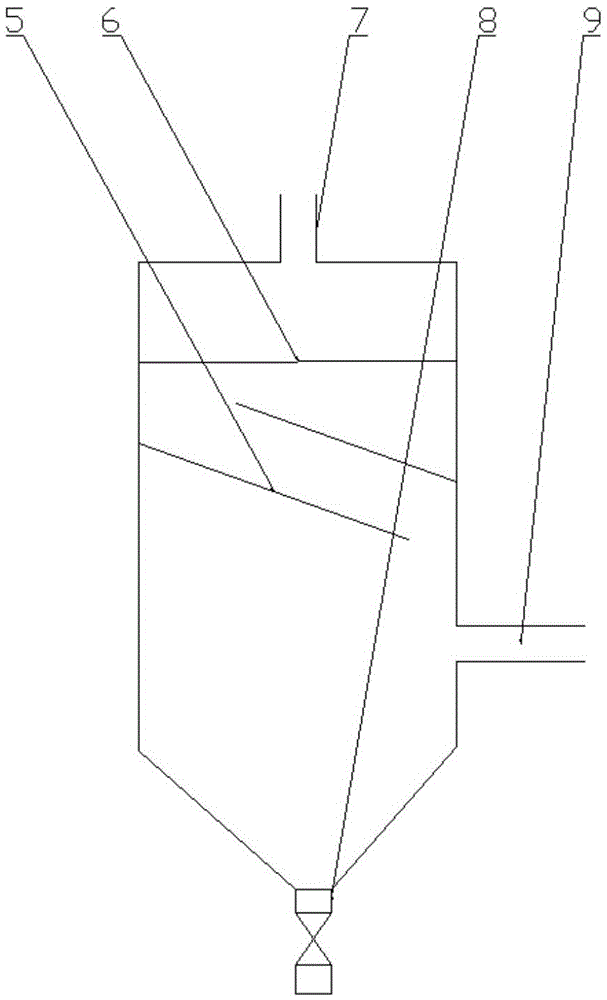

Gas, liquid and light-weight oil triphase separating device

ActiveCN105597378ASolving Multiphase Mixing ProblemsSmall pressure lossCombination devicesLiquid degasificationVapor–liquid separatorOil phase

The invention discloses a gas, liquid and light-weight oil triphase separating device which comprises a triphase separator, a gas-liquid separator, an oil-gas separator and an oil supply pump. The gas, liquid and light-weight oil triphase separating device realizes gas, liquid and light-weight oil triphase separation in steps by virtue of centrifugal force generated by whirl and the density difference between light-weight oil and water. The triphase separator is respectively connected with the gas-liquid separator and the oil supply pump by virtue of pipelines, and the oil supply pump is connected with the oil-gas separator by virtue of a pipeline; then gas enters into the gas-liquid separator, so that small liquid drops entrained in the gas are further separated out; and oil enters into the oil-gas separator, so that small gas bubbles entrained in an oil phase are separated out. The device is high in separation precision; according to actual measurement, more than 90% of gas and 90% of light-weight oil can be separated out, so that multi-phase mixing problem in the industries of oil extraction and gas production is solved.

Owner:XI AN JIAOTONG UNIV

Connecting structure for assembly type concrete shear wall edge member

InactiveCN102691365AImprove the anchoring effectGuaranteed carrying capacityWallsShock resistanceRebar

The invention discloses a connecting structure for an assembly type concrete shear wall edge member. vertical connecting reinforcing steel bar, which can be provided with an upset head, is reserved through a hole reserved in a large-diameter metal bellows, and is sleeved with a continuous spiral stirrup; then the vertical connecting reinforcing steel bar and the continuous spiral stirrup are commonly inserted into the large-diameter metal bellows; and fine aggregate concrete (or a grounding material) is poured into the metal bellows, so that the reliable connection of the edge member is realized. Due to reliable anchoring of the vertical connecting reinforcing steel bar, the optimization of the diameter, the quantity and the plane arrangement of the vertical connecting reinforcing steel bar, and the increase of the wet joint area on a splicing surface, full exertion of the bearing capacity of the shear wall is ensured; and multiple effective restrain for the subsequentlly-poured fine aggregate concrete (or the grouting material) is formed by the shear wall stirrup, a horizontal tie bar, the metal bellows and the continuous circular spiral stirrup, and thus the integral performance of the part is remarkably improved. According to the connecting method for the edge member, which is provided by the invention, the stress continuousness of the vertical steel reinforcing bar is ensured, the deformaility and the ductility performance of the vertical steel reinforcing bar are remarkably improved, and the shock resistance of the assembly type concrete shear wall is improved. Meanwhile, the method is simple in manufacturing process and facilitates the practice and application.

Owner:SOUTHEAST UNIV

Self counter force balance loading test method of engineering pile bearing capacity

The invention provides a method for ensuring the position of a load box and pile quality and effectively transmitting axial force, shearing force and bending moment in self counter force balance loading test of engineering pile bearing capacity. A built-in jack of the load box is connected with a top cover plate and a bottom cover plate through high strength bolts, without being affected for normal loading, and consequently the load box transmits certain bending moment. The periphery of the load box is provided with twisted steels that are mutually lapped together and protected by a telescopic pipe, and mudjacking and solid joints are conducted after test, so that a reinforcing cage achieves the effect of overall equivalent connection and bears great shearing force and bending moment. The load box and the reinforcing cage are connected by means of inside cutting, and the horizontal resistance of a pile is increased at the load box. The surrounding gap of the pile is mudjacked at the load box after test to keep the continuity and integrity of pile concrete and ensure the axial force transmission of the pile and the vertical bearing capacity. The bottom of the bottom cover plate of the load box is provided with a conical flow guide body in order to avoid mud and sediments remaining on the bottom of the bottom cover plate when the pile concrete passes through the load box in pouring and ensure the pile quality and test accuracy.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

Road bridge prefabricated small box girder type invisible cap beam temporary support system and construction method thereof

ActiveCN110747746AEasy to liftEasy to assemble and disassembleBridge structural detailsBridge erection/assemblySupporting systemArchitectural engineering

The invention discloses a road bridge prefabricated small box girder type invisible cap beam temporary support system and a construction method thereof. The support system comprises a main beam, a main pier supporting system and a side pier supporting system, wherein the main beam is arranged along the transverse side of a road bridge pier; the main pier supporting system is arranged on the transverse side of a main pier area and located below the main beam, the lower end of the main pier supporting system is fixed with a main pier bearing platform, and the upper end of the main pier supporting system is fixed with the main beam; and the side pier supporting system is arranged on the transverse side of a side pier area and located below the main beam, and the lower end of the side pier supporting system is fixed with a side pier bearing platform, and the upper end of the side pier supporting system is fixed with the main beam. Therefore, the support system only has a large cross-diameter support beam (main beam) between the transverse main pier area and the side pier area, and other support systems arranged in the vertical direction are not present, so that a vehicle operation space is provided, and disassembly and assembly of the prefabricated small box girder type invisible cap beam support system are convenient. In addition, the support system has the characteristics of highbearing capacity so as to meet the supporting requirements of the prefabricated small box girder type invisible cap beam.

Owner:NINGBO MUNICIPAL ENG CONSTR GROUP

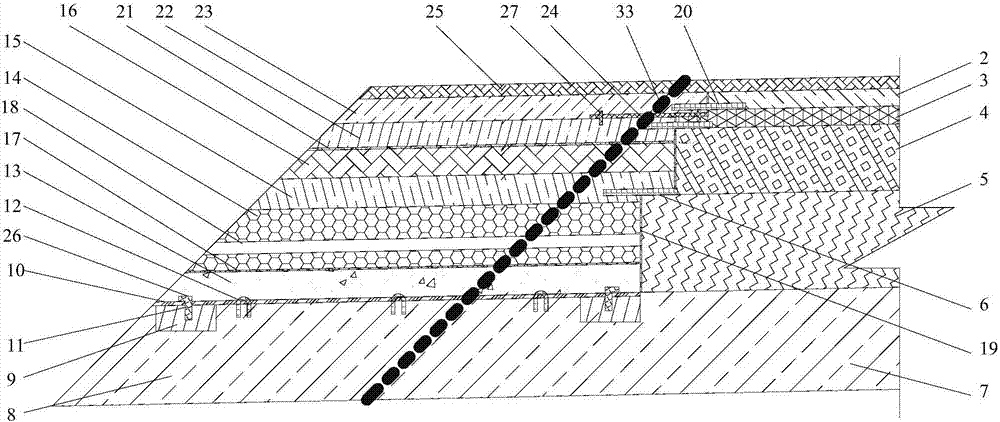

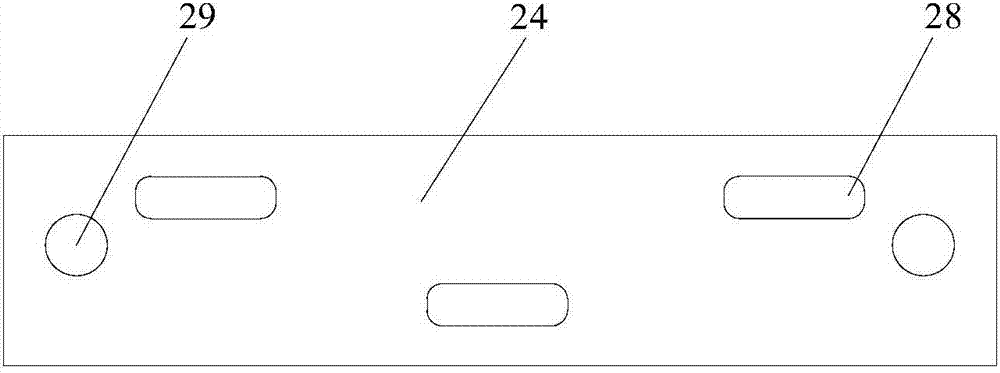

Flexible base layer asphalt pavement splicing and widening construction method

ActiveCN107227667AAvoid uneven deformationGuaranteed carrying capacityPaving reinforcementsIn situ pavingsGlass fiberRoad surface

The invention relates to a flexible base layer asphalt pavement splicing and widening construction method. The construction method is characterized in that old road pavement structure layers are milled and planed, and then connecting steps are arranged at the interfaces of the old road structure layers; then an old road splicing widening connecting joint and the road bed outer edge of a widening pavement are each provided with a road bed solidifying beam, and a steel bar mesh grid is laid on the top surface of each road bed solidifying beam; materials generated after the upper face layer of an old pavement structure and the other structure layers of the old pavement structure are milled are used for new road base layers; in construction, a glass fiber geogrid is laid on the top surface of a two-ash gravel recycling layer, a connecting grid and joint filling slurry are arranged at the connecting joint of a new pavement and an old pavement, and a crack partition plate is laid at a pavement splicing widening connecting joint on the top surface of a lower face layer; and finally, paving construction of pavement upper face layers of the new pavement and the old pavement are conducted simultaneously. The old road building materials can be recycled, the integrality of an asphalt pavement splicing widening structure can be improved, and the solidifying cost of the pavements in the later period can further be reduced.

Owner:SICHUAN JIAOTOU CONSTR ENG CO LTD

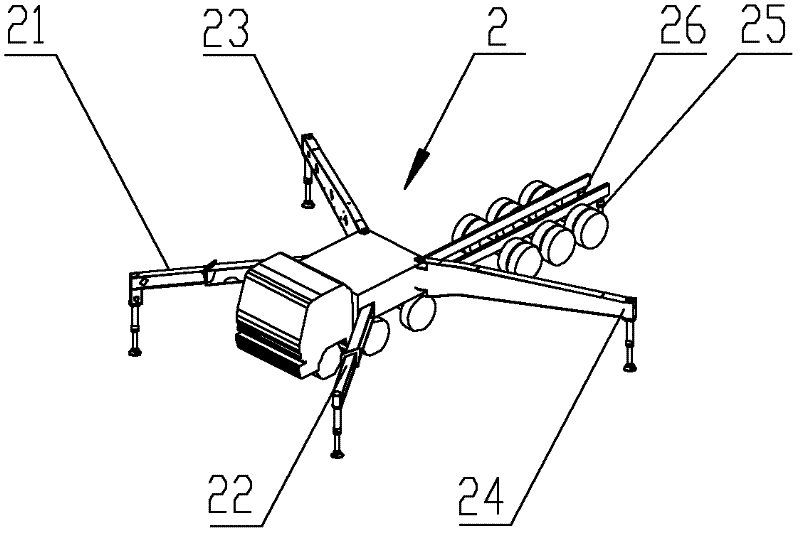

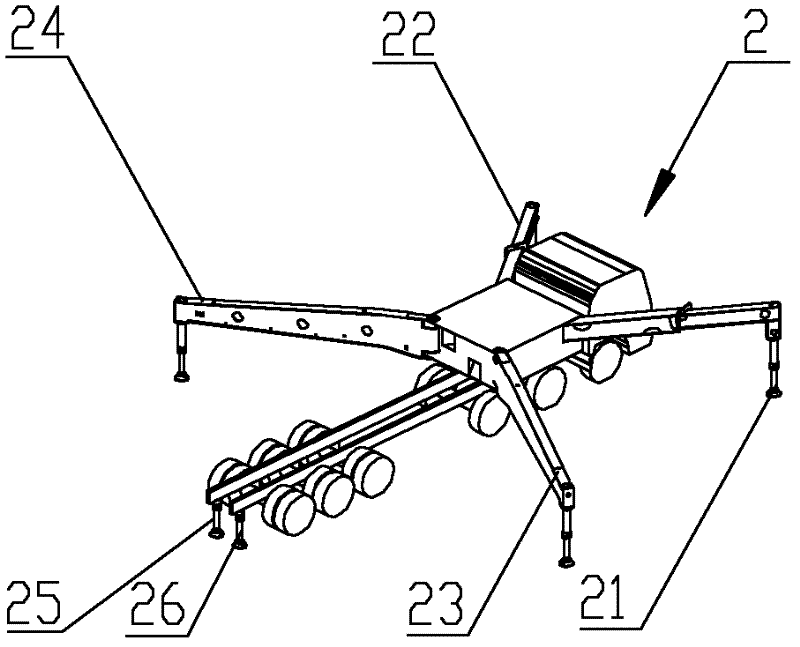

Supporting system and engineering machine with same

ActiveCN102582590AImproved rollover capabilityStable supportBase supporting structuresBraking devices for hoisting equipmentsSupporting systemGravity center

The invention discloses a supporting system of an engineering machine, which comprises a first supporting leg, a second supporting leg, a third supporting leg and a fourth supporting leg which are arranged on the engineering machine. Additional supporting legs are arranged between the third supporting leg and the fourth supporting leg, and the minimum distance from a ligature of a supporting point of the third supporting leg and a supporting point of the fourth supporting leg to the circumference of a gravity center circle of the engineering machine is shorter than the minimum distance from a ligature of supporting points of each two adjacent of the third supporting leg, the fourth supporting leg and the additional supporting legs to the circumference of the gravity center circle of the engineering machine. By the aid of the additional supporting legs, anti-tipping capacity and supporting capacity of a whole vehicle are improved, and when being shortened, the supporting legs do not need to occupy sites with large site and can keep stability as same as those in the prior art, so that the engineering machine with the supporting system can be operated in limited space and meet construction needs of the narrow sites, and the application range of the engineering machine is widened. The invention further discloses the engineering machine comprising the supporting system.

Owner:SANY AUTOMOBILE MFG CO LTD

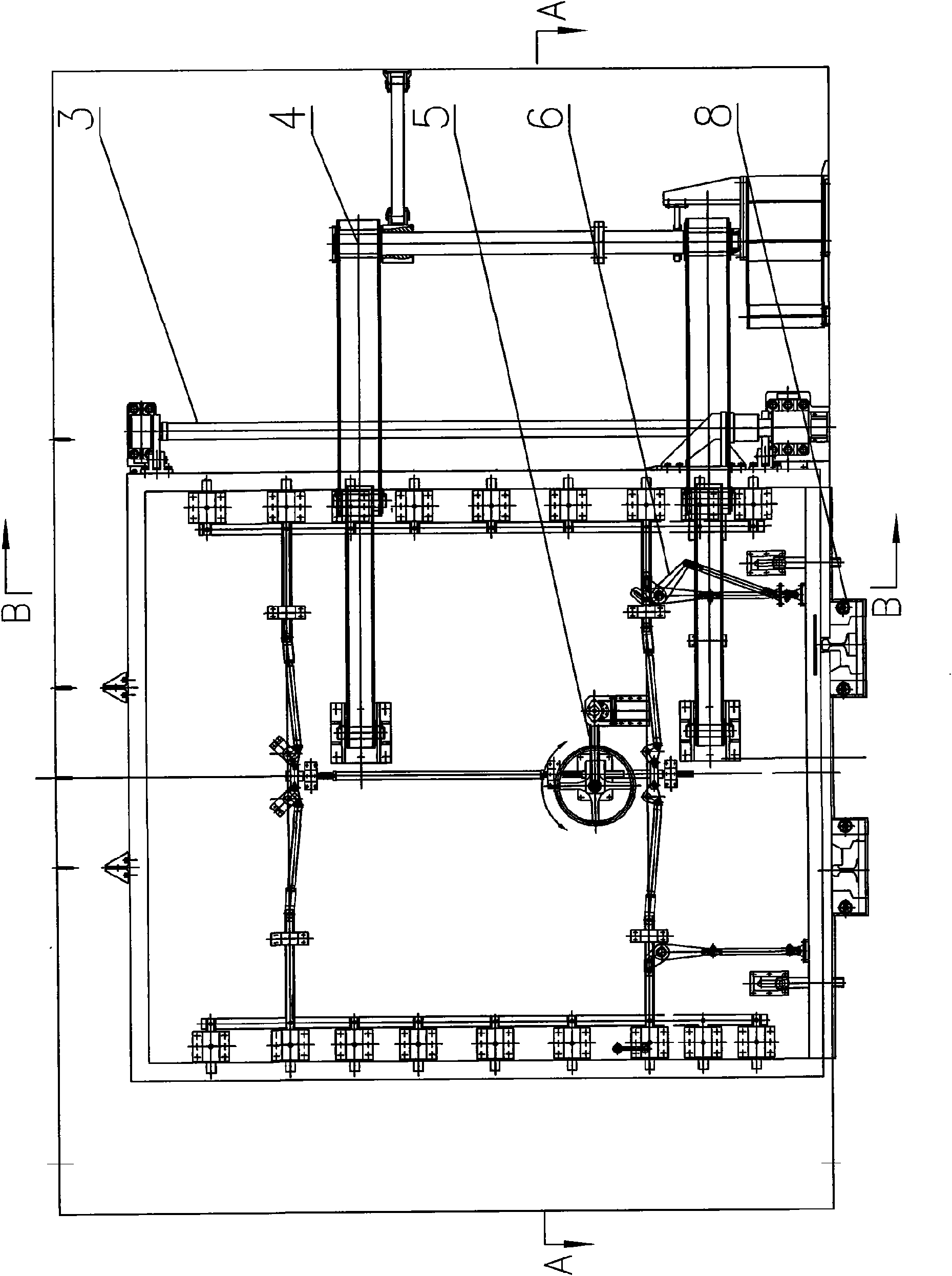

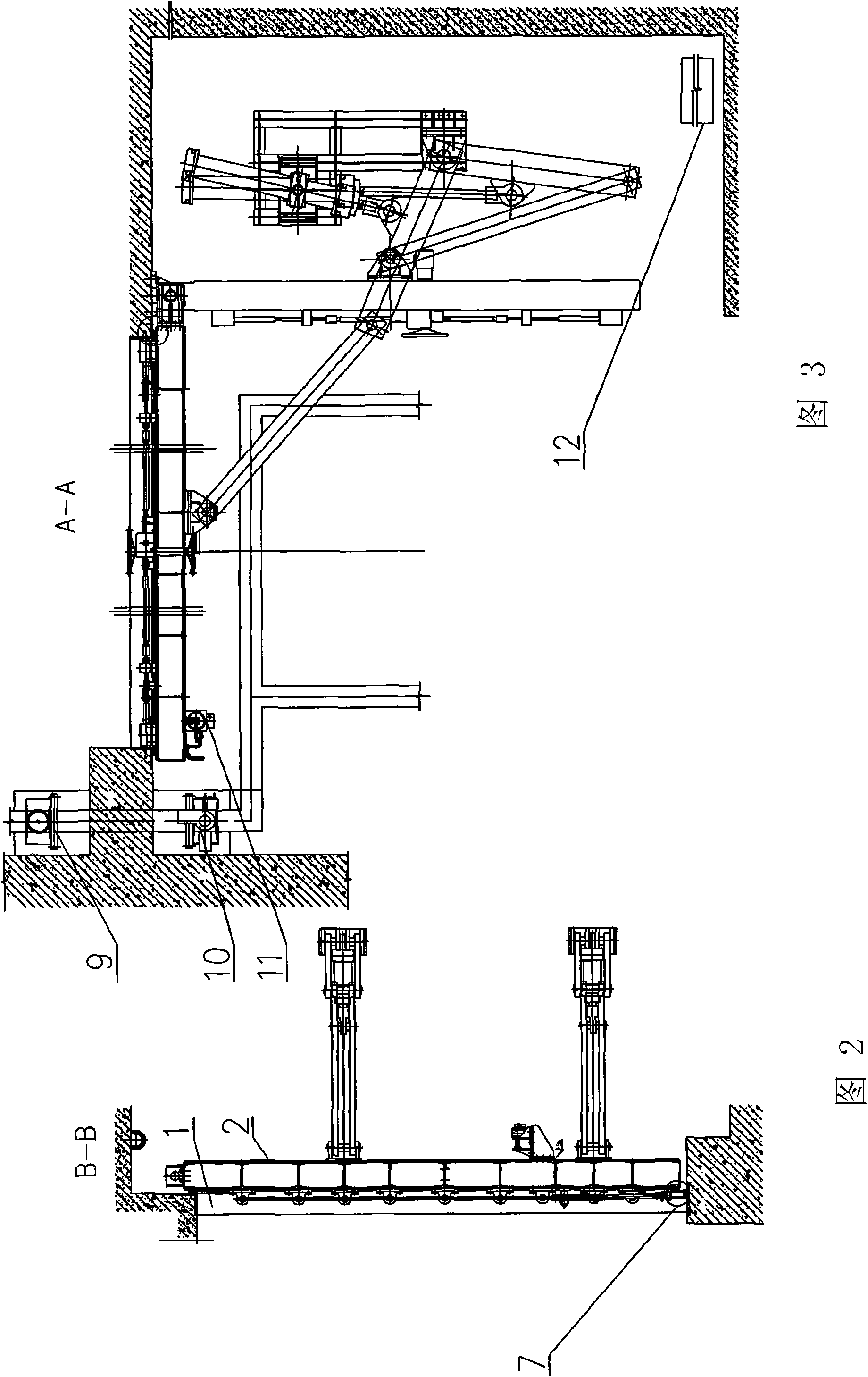

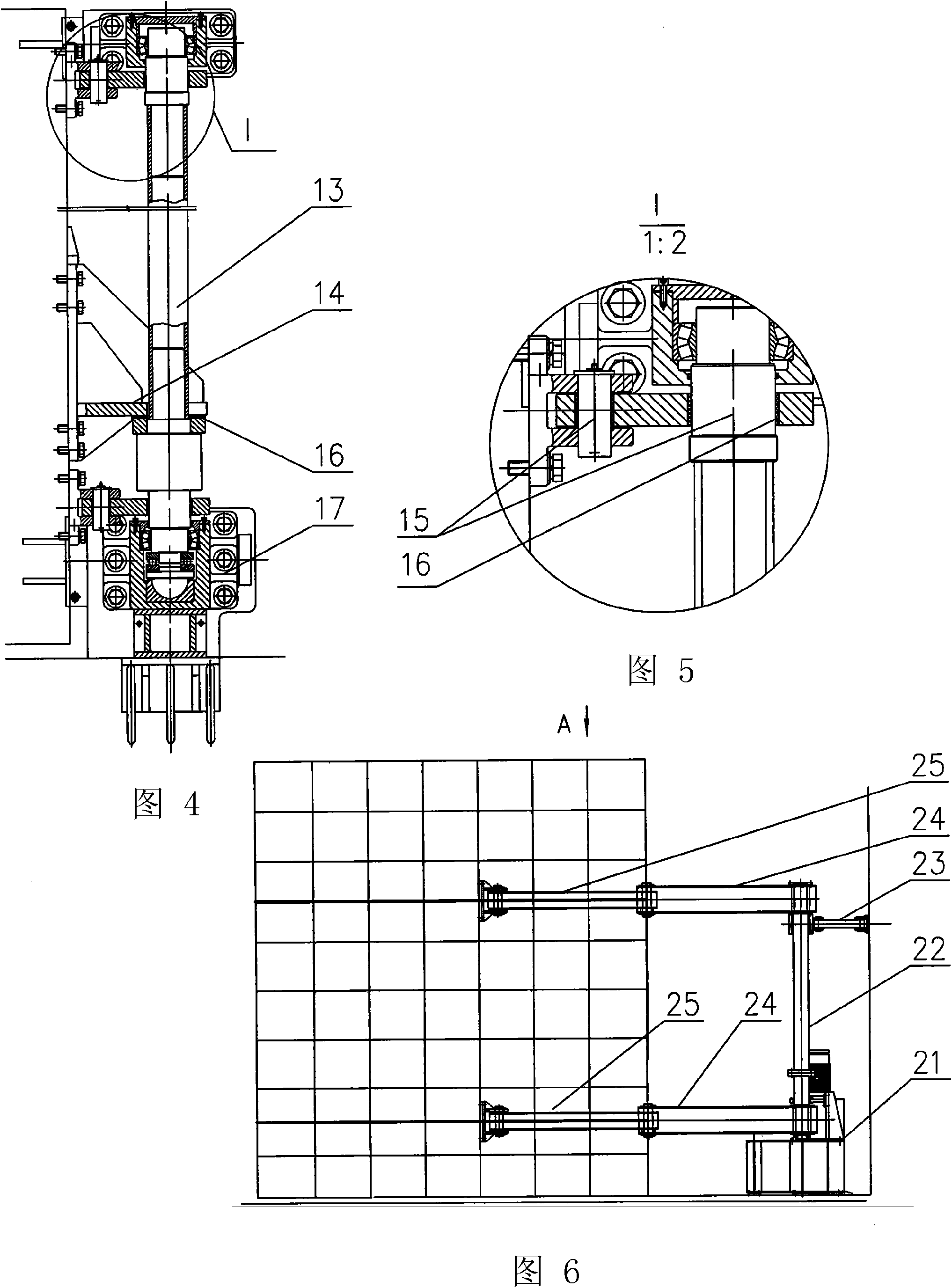

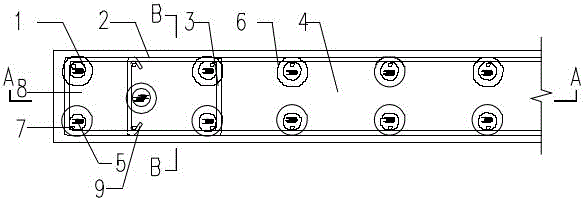

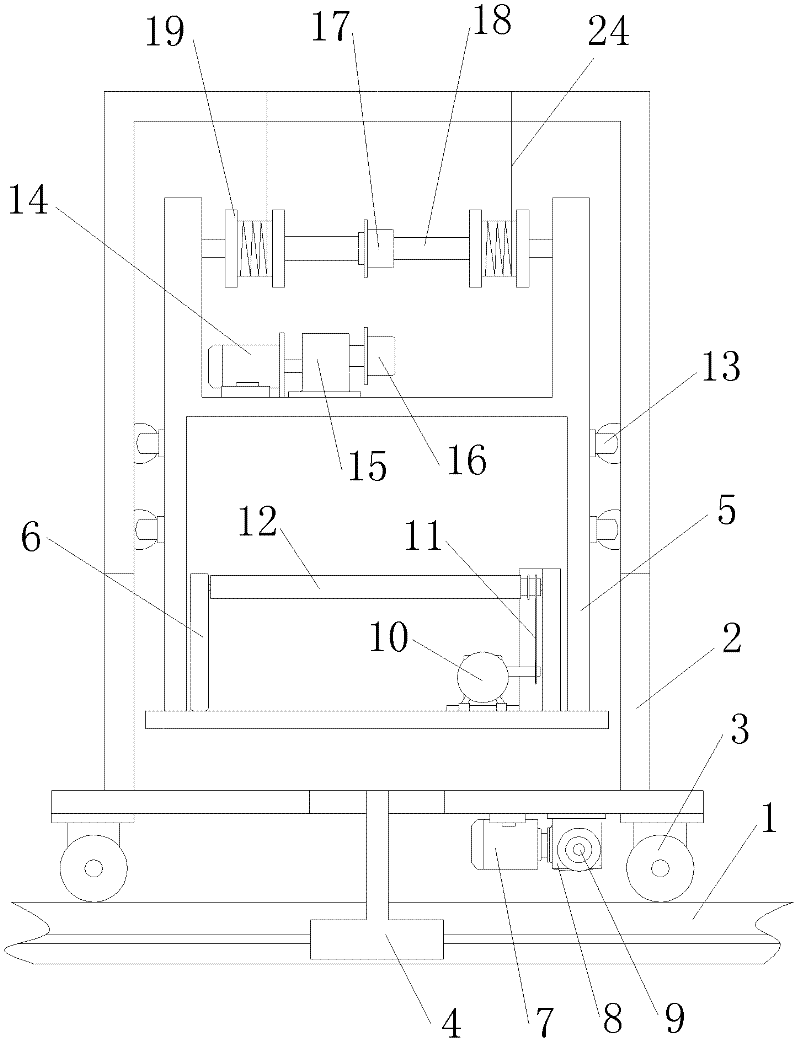

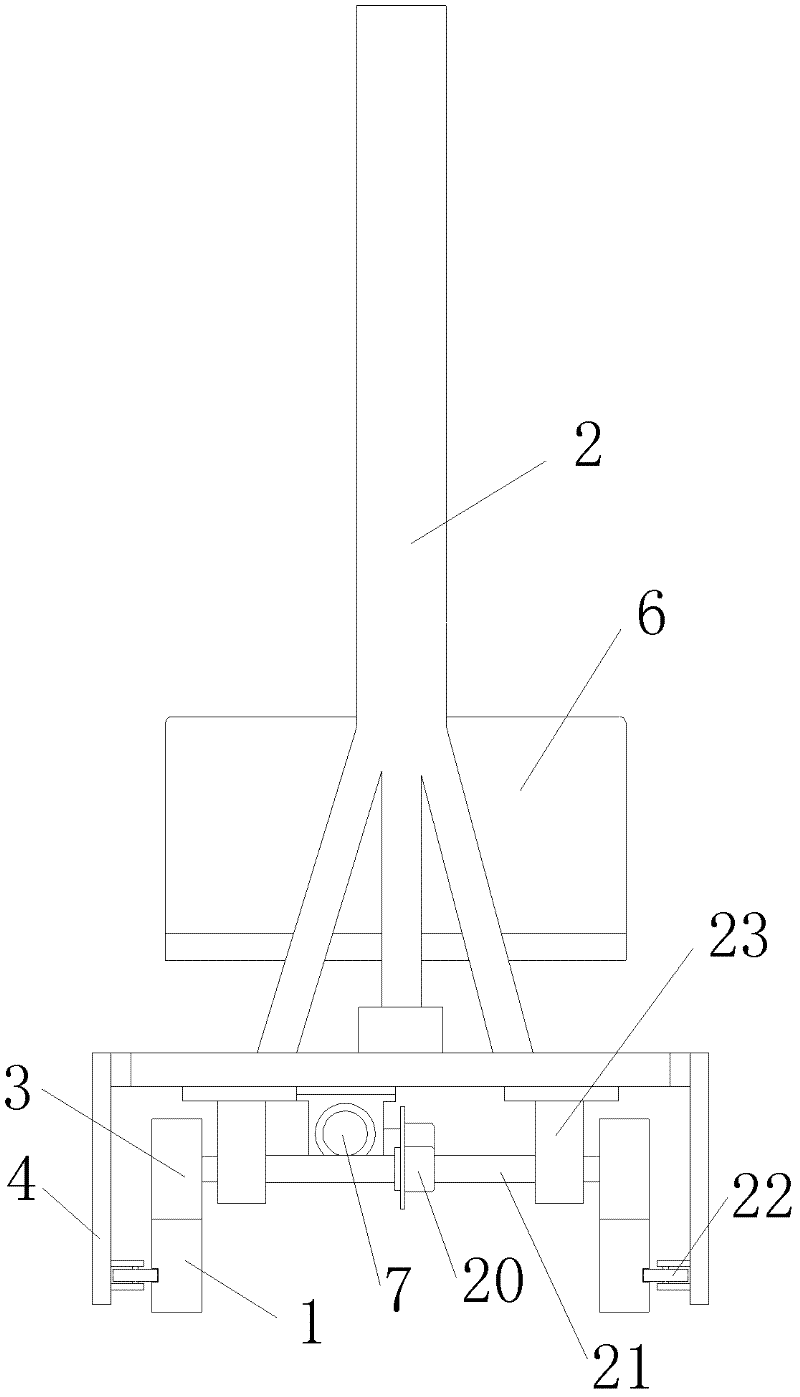

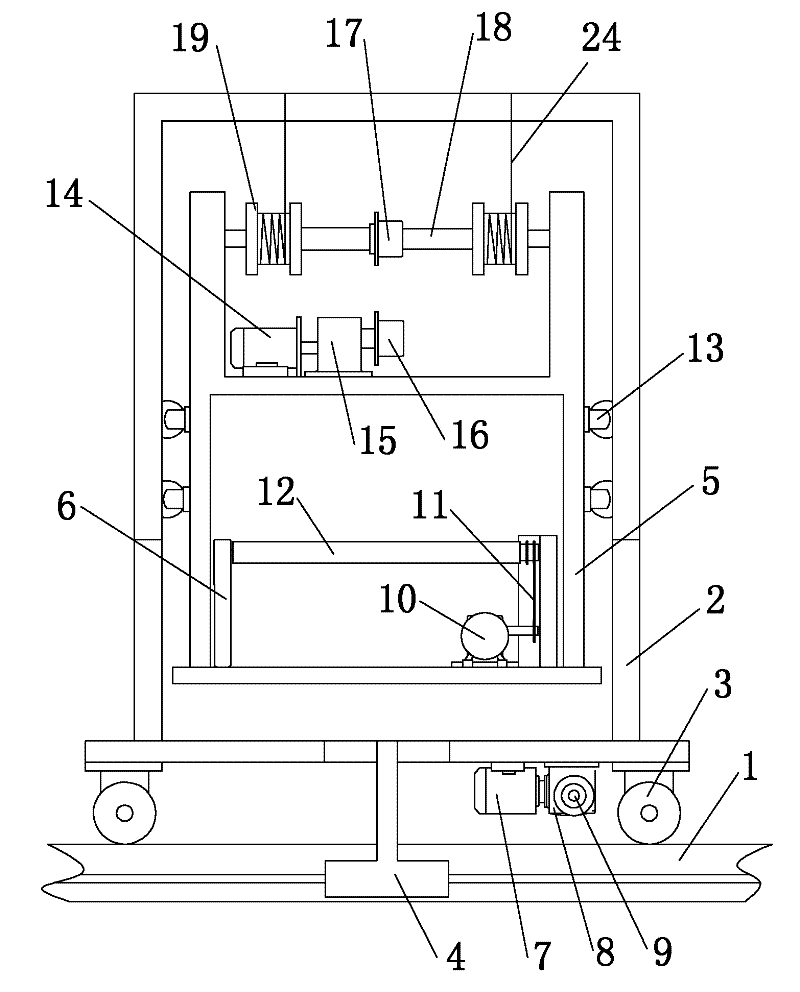

Gantry type lifting shuttle

InactiveCN102241313AGuaranteed carrying capacityImprove stabilityStorage devicesCarrying capacityMechanical engineering

The invention provides a gantry type lifting shuttle which comprises a gantry door frame, a traveling mechanism, a lifting mechanism and a conveying mechanism, wherein the traveling mechanism is arranged at the bottom of the gantry frame; the lifting mechanism is arranged in the gantry frame; the conveying mechanism is arranged at the bottom of the lifting mechanism; the walking mechanism comprises traveling wheels, traveling wheel axles and a traveling driving mechanism; the lifting mechanism comprises a lifting frame, a winding drum shaft, a winding drum and a lifting driving mechanism; and the conveying mechanism comprises a conveying bracket, a conveying roller and a conveying driving mechanism. Firstly, the conveying mechanism is arranged at the lowest point and goods are placed on the conveying roller of the conveying mechanism by using the lifting mechanism; the goods are transferred to a goods shelf to be placed by using the traveling mechanism; and the goods on the conveying roller are conveyed to the goods shelf by using the lifting mechanism. According to the gantry type lifting shuttle disclosed by the invention, a symmetrical gantry type structure is adopted to ensure the carrying capacity; and the gantry type lifting shuttle has high stability in the driving process and has the functions of automatically transporting and lifting the goods as well as automatically conveying the goods to the goods allocation after the goods are lifted to the goods allocation.

Owner:SHANDONG UNIV

High-vacuum multi-layer heat-insulating deep-cooling double-shell spherical storage tank

ActiveCN102305347AHighlight substantive featuresSignificant progressPressure vesselsCarrying capacityEngineering

The invention relates to a high-vacuum multi-layer heat-insulating deep-cooling double-shell spherical storage tank, which comprises an outer spherical tank and an inner spherical tank, wherein the inner spherical tank is placed in the outer spherical tank; the inner spherical tank is supported in the outer spherical tank through an upper fixed supporting member which is arranged on the upper part of the inner spherical tank and a lower fixed supporting member which is arranged on the lower part of the inner spherical tank; a laminated inner supporting member is arranged between the inner spherical tank and the outer spherical tank; a heat-insulating material is coated on an outer surface of the inner spherical tank; a reinforcing plate is arranged on the outer surface of the outer spherical tank; the reinforcing plate is welded with an upper supporting column through an equator tangential structure; the upper supporting column is fixedly connected with a lower supporting column through the heat-insulating material; and a pulling rod is connected between the upper supporting column and the lower supporting column. By adoption of a mixed spherical shell structure, the supporting columns are welded on the reinforcing plate on the outer surface of the outer spherical tank through the equator tangential structure, so the carrying capacity of the supporting columns is ensured; and a high-vacuum multi-layer heat-insulating cold-insulating structure is adopted between the inner spherical tank and the outer spherical tank, and the inner supporting member has a laminated supporting structure, so the problem of telescoping of the supporting member caused by temperature change is solved, and the light weight of the storage tank and volume maximization are realized.

Owner:CSSC SHENGHUI EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com