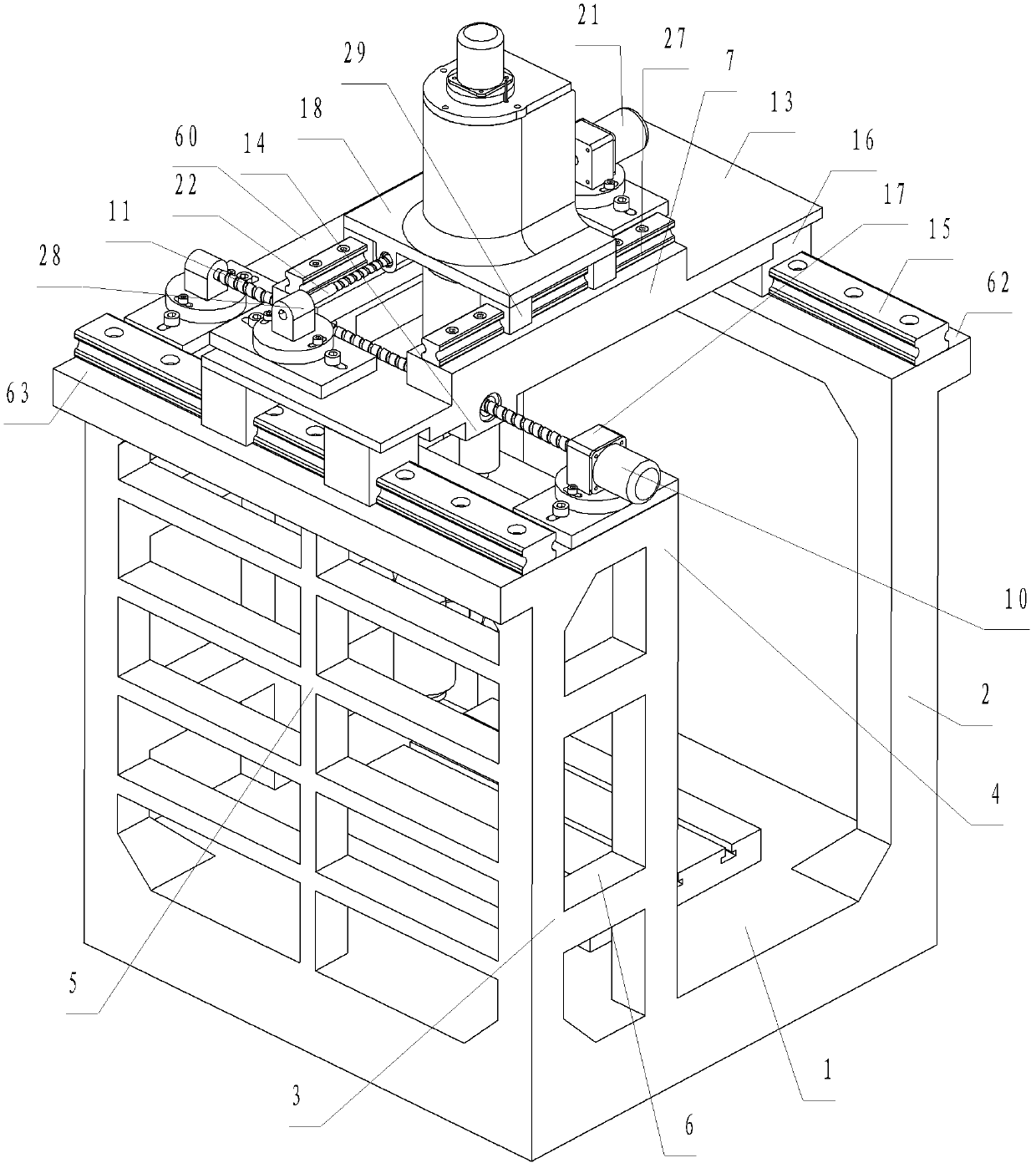

Numerical control equipment

A numerical control equipment and combined technology, applied in metal processing equipment, large fixed members, driving devices, etc., can solve the problems of affecting accuracy, poor movement, inaccurate positioning, etc., and achieve the effect of improving the overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0096] Such as Figure 5 to Figure 7 As shown, the difference from Embodiment 1 is that the Y-slider 70 includes a Y-slider base plate 71, and the upper convex portion 72 protrudes vertically upward from the Y-slider base plate 71, and vertically extends from the Y-slider base plate 71. The lower convex part 73 is convexly provided. A fixing plane 74 is provided on the outer surfaces of the upper protrusion 72 and the lower protrusion 73 , and a side protrusion 75 is provided on the fixing plane 74 . The outer periphery of the bottom plate 71 of the Y-direction sliding seat is square, and an upper convex portion 72 and a lower convex portion 73 protrude from the periphery. A round hole 78 and a square hole 79 are provided in the Y-direction sliding seat 70 through the upper convex part 72, the Y-direction sliding seat bottom plate 71, and the lower convex part 73. The round hole 78 is placed in the center of the square hole 79, and the round hole 78 The diameter is greater t...

Embodiment 3

[0099] Such as Figure 8 As shown, the difference from Embodiment 2 is that the Y-slider 120 includes a Y-slider bottom plate 121, a circular tube-shaped upper guide sleeve 122 protruding vertically upward from the Y-slider bottom plate 121, and a Y-slider bottom plate 121 protrudes vertically downwards to the circular tube-shaped lower guide sleeve 123, the outer periphery of the Y-slide base plate 121 is a square, and the periphery protrudes from the circular tube-shaped upper guide sleeve 122 and the circular tube-shaped lower guide sleeve 123.

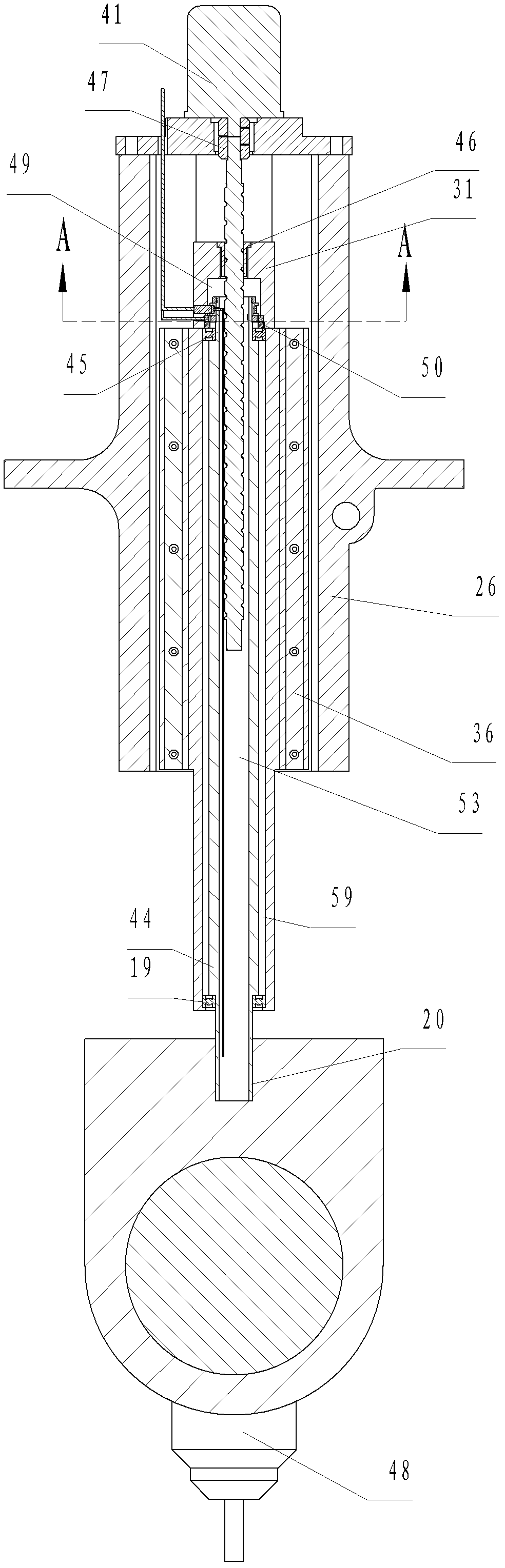

[0100]The spindle device comprises a cylindrical Z guide rod 126 that can move up and down, an end cover 127, a rotating shaft 128 that is installed in the Z guide rod 126 and can only rotate relative to the Z guide rod 126, a bearing 132, a bearing 131, an externally threaded nut 134, and a drive The rotating shaft 128 rotates the first rotor 129 and the first stator 130 , the internally threaded nut 135 , the Z-direction driving ...

Embodiment 4

[0102] Such as Figure 9 As shown, the difference from Embodiment 1 is that the X forward guide rail and the X backward guide rail are sliding guide rails, including a cylindrical X guide shaft 200, an X guide shaft support 201, and an X guide guide sleeve sliding seat 202. The shaft support 201 is provided with an arc surface 204 that cooperates with the X guide shaft 200. The X guide shaft 200 is installed on the X guide shaft support 201 and fits with the arc surface 204 on the X guide shaft support 201. The X guide shaft support 201 is fixed on the X-direction rail support part 205, and the X-direction rail sleeve slide seat 202 is fixed on the bottom of the side protrusions 207 on the front and rear sides of the X-direction slide seat 206. The X-guiding guide sleeve sliding seat 202 cooperates with the X-guiding shaft 200 and the X-guiding shaft bracket 201 installed together.

[0103] Y guide rail to the left and Y guide rail to the right are sliding guide rails, includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com