Curing forming tool and method for honeycomb sandwich structure

A honeycomb interlayer, curing and forming technology, applied in the direction of cardboard articles, etc., can solve the problems of increasing manufacturing cost and production cycle, tearing and crushing of composite skins, and achieving the effect of overcoming large differences in thermal expansion coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below in conjunction with accompanying drawing and specific example the present invention is described in further detail:

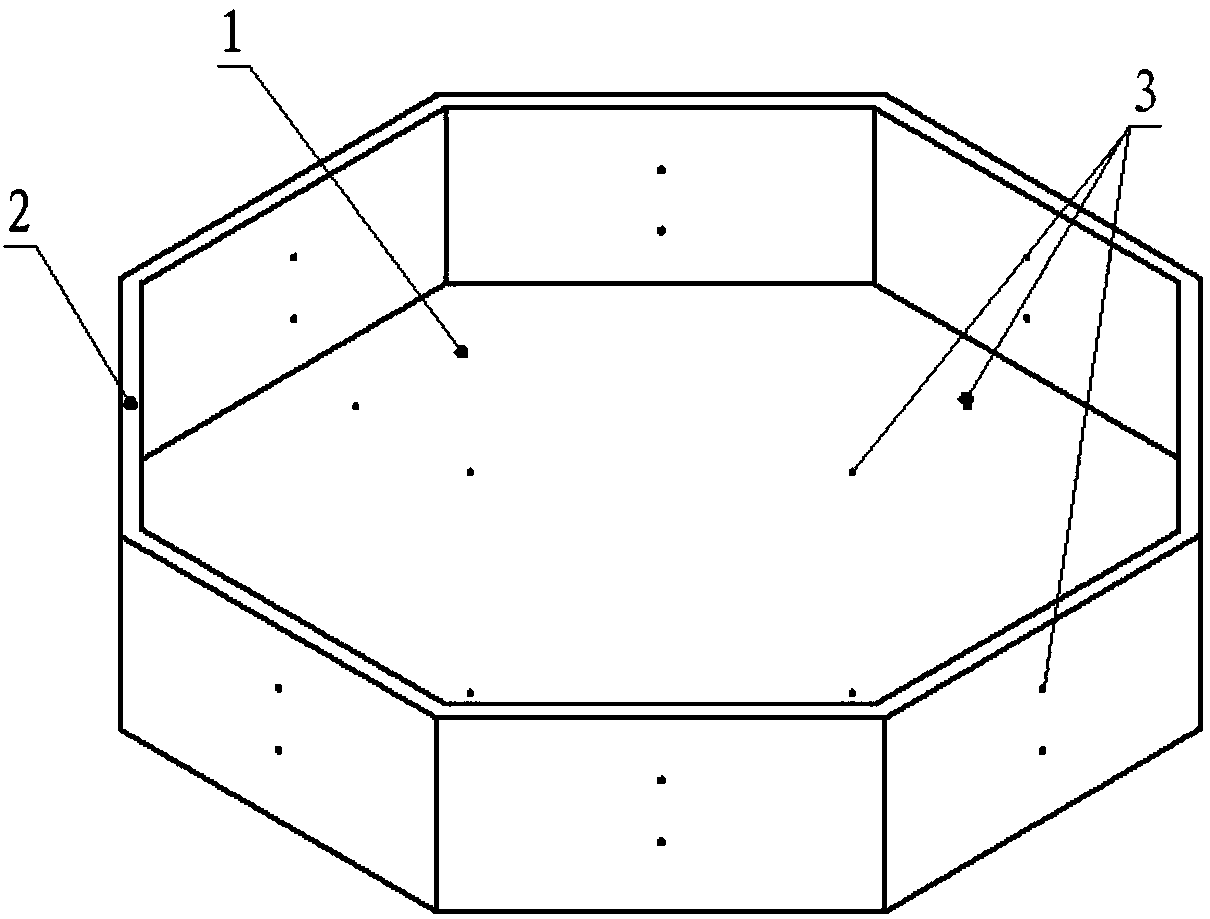

[0059] Such as figure 1 As shown, the octagonal box-shaped honeycomb sandwich structure served by the present invention includes a bottom surface 1, a side surface 2 and a functional interface 3, wherein the side surface 2 forms an octagonal structure on the bottom surface 1, and the functional interfaces 3 are all M5 screw holes.

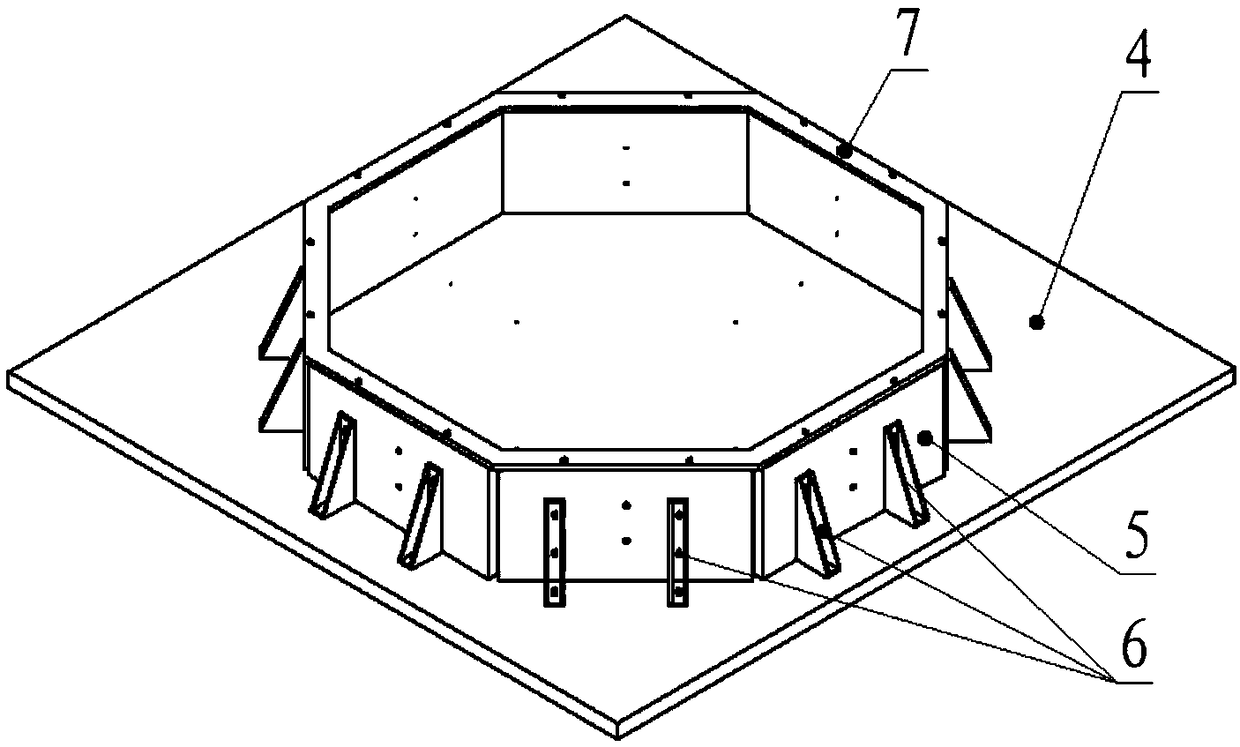

[0060] Such as figure 2 As shown, the main structure of the curing and forming tool includes a forming bottom plate 4 , a forming vertical plate 5 , vertical plate reinforcing ribs 6 and edge baffles 7 .

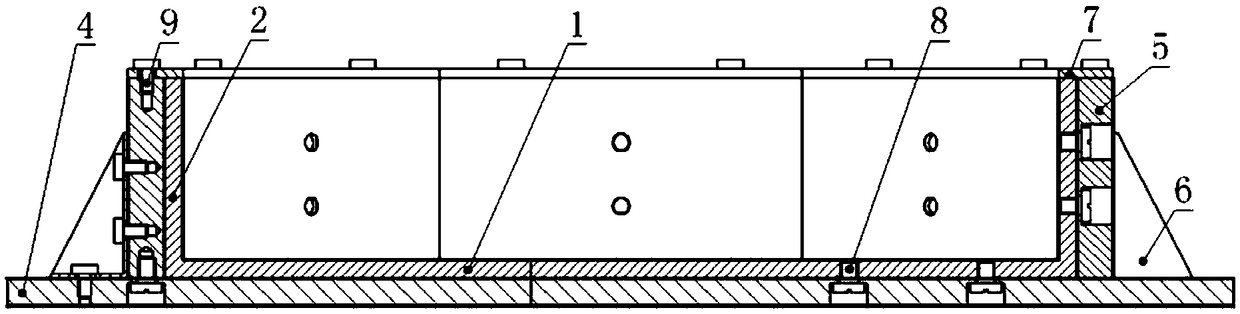

[0061] Such as image 3 As shown, the solidified forming tooling of the present invention and the octagonal box-shaped honeycomb sandwich structure to be formed are assembled as one through the positioning nail 8 and the standard part fastening nail 9, thereby synchronously realizing the formation of the octagonal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Large hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com