Patents

Literature

3761results about "Paper/cardboard articles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

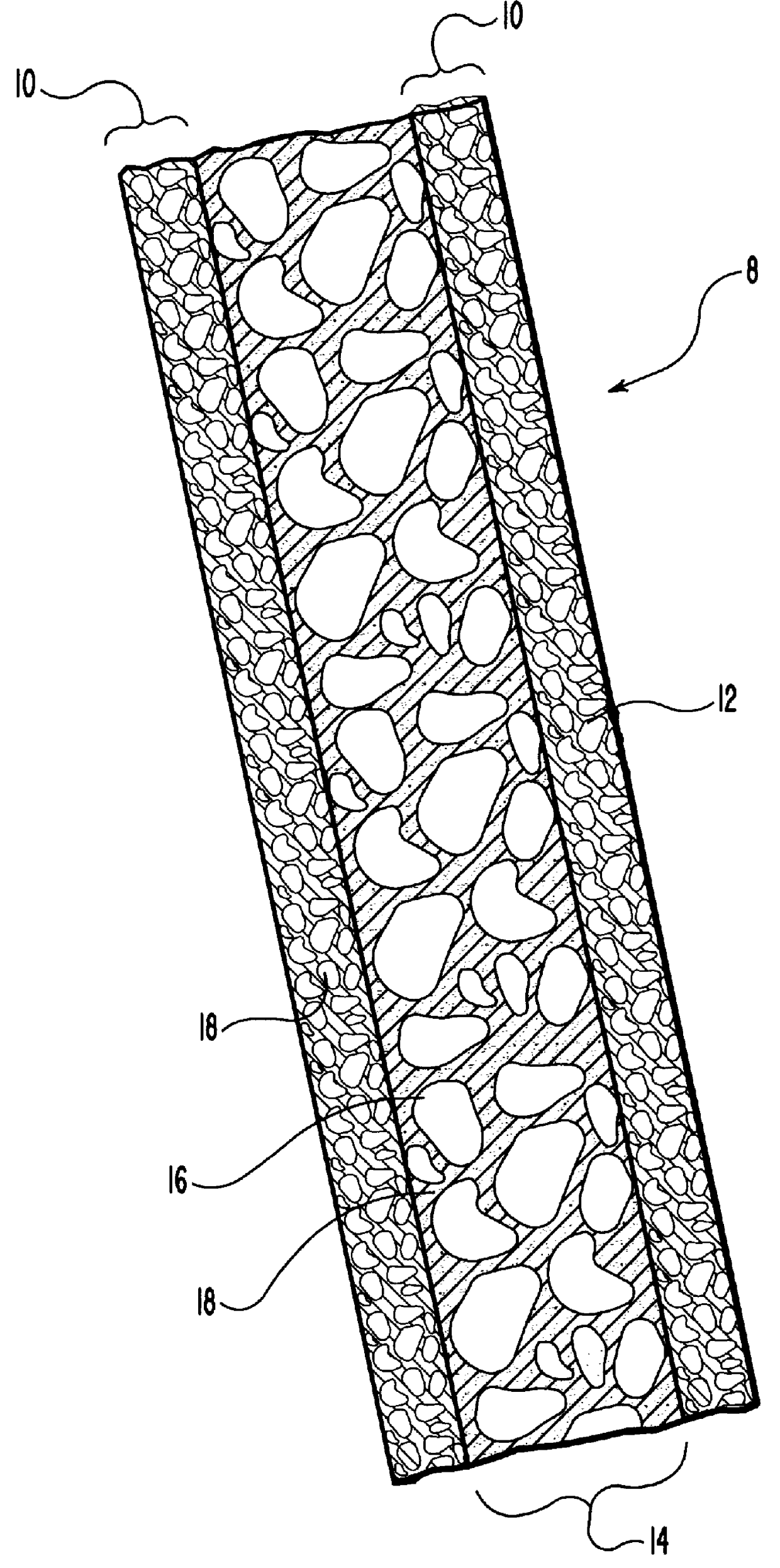

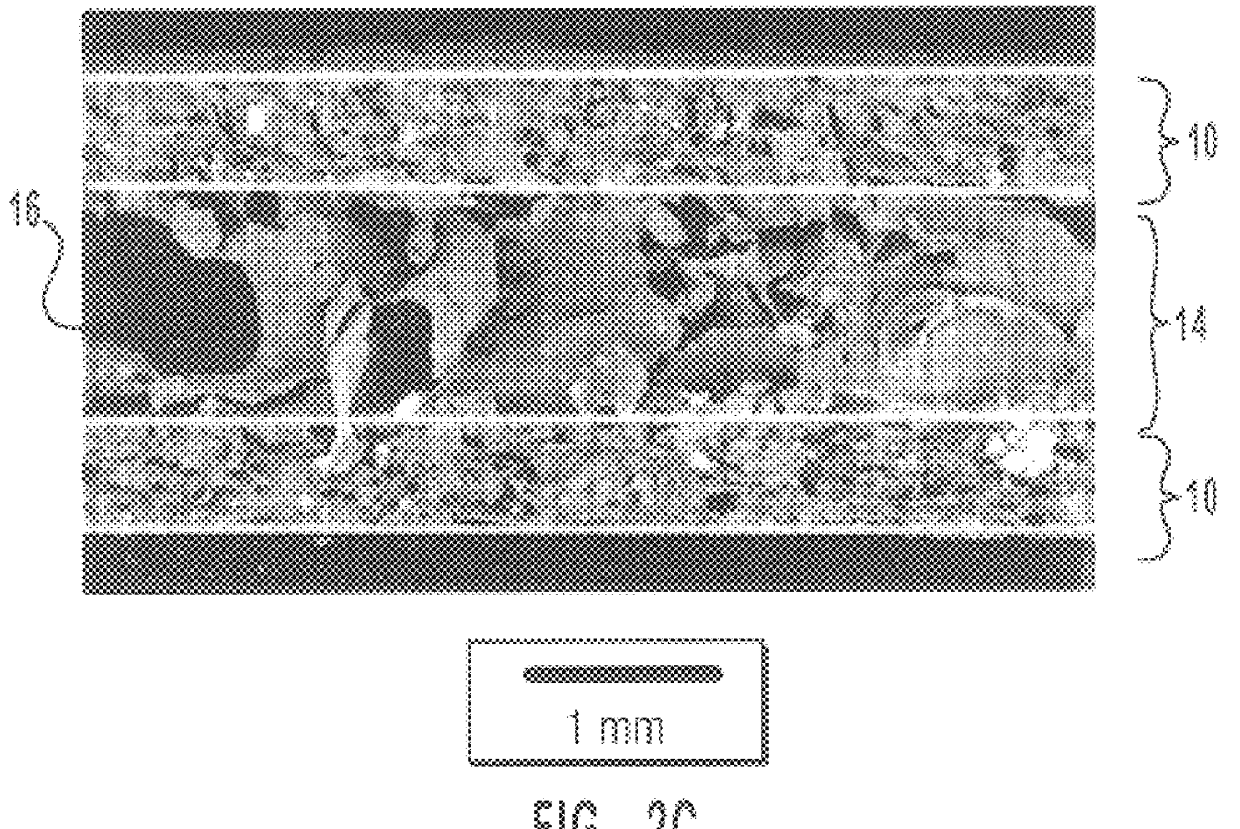

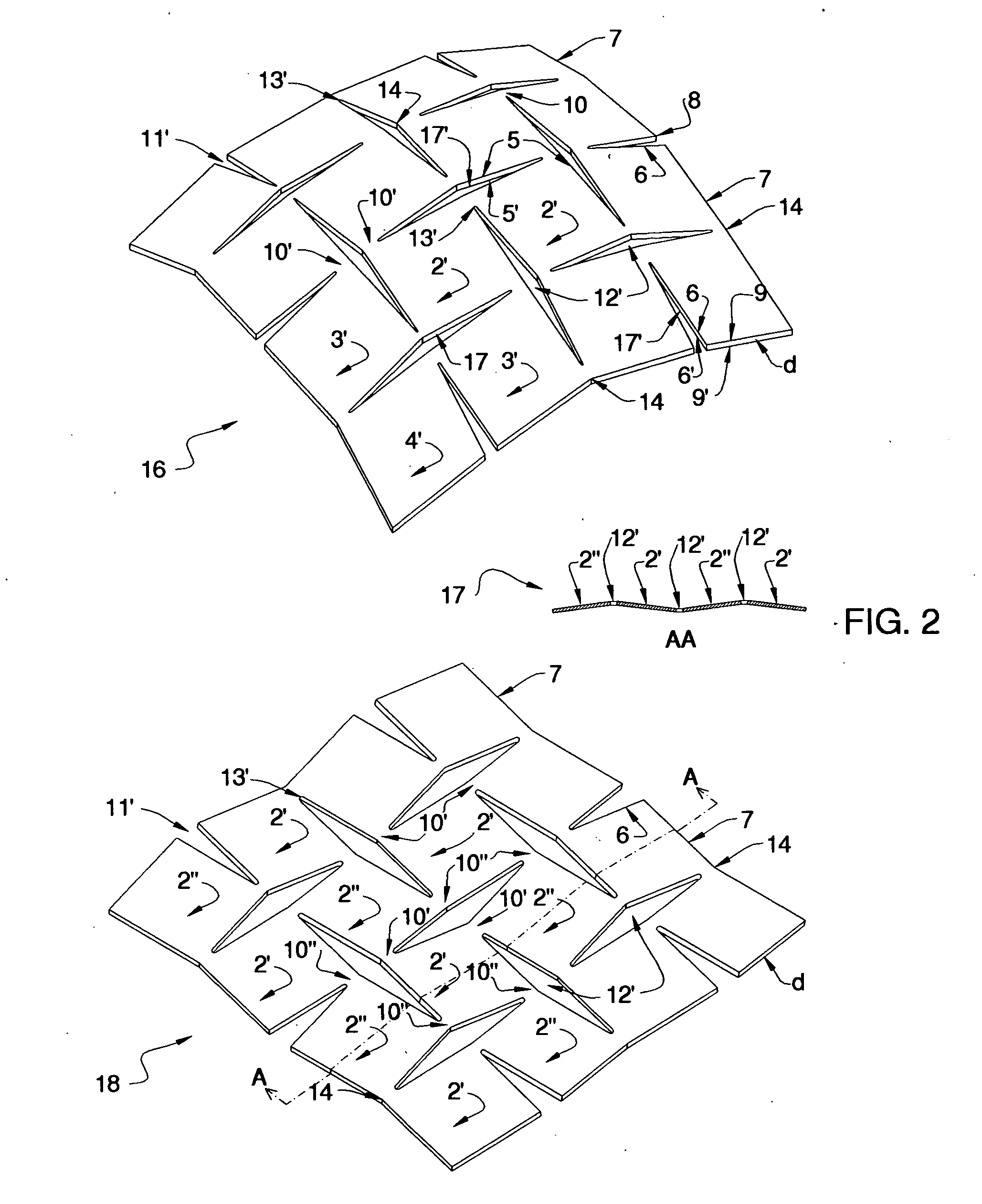

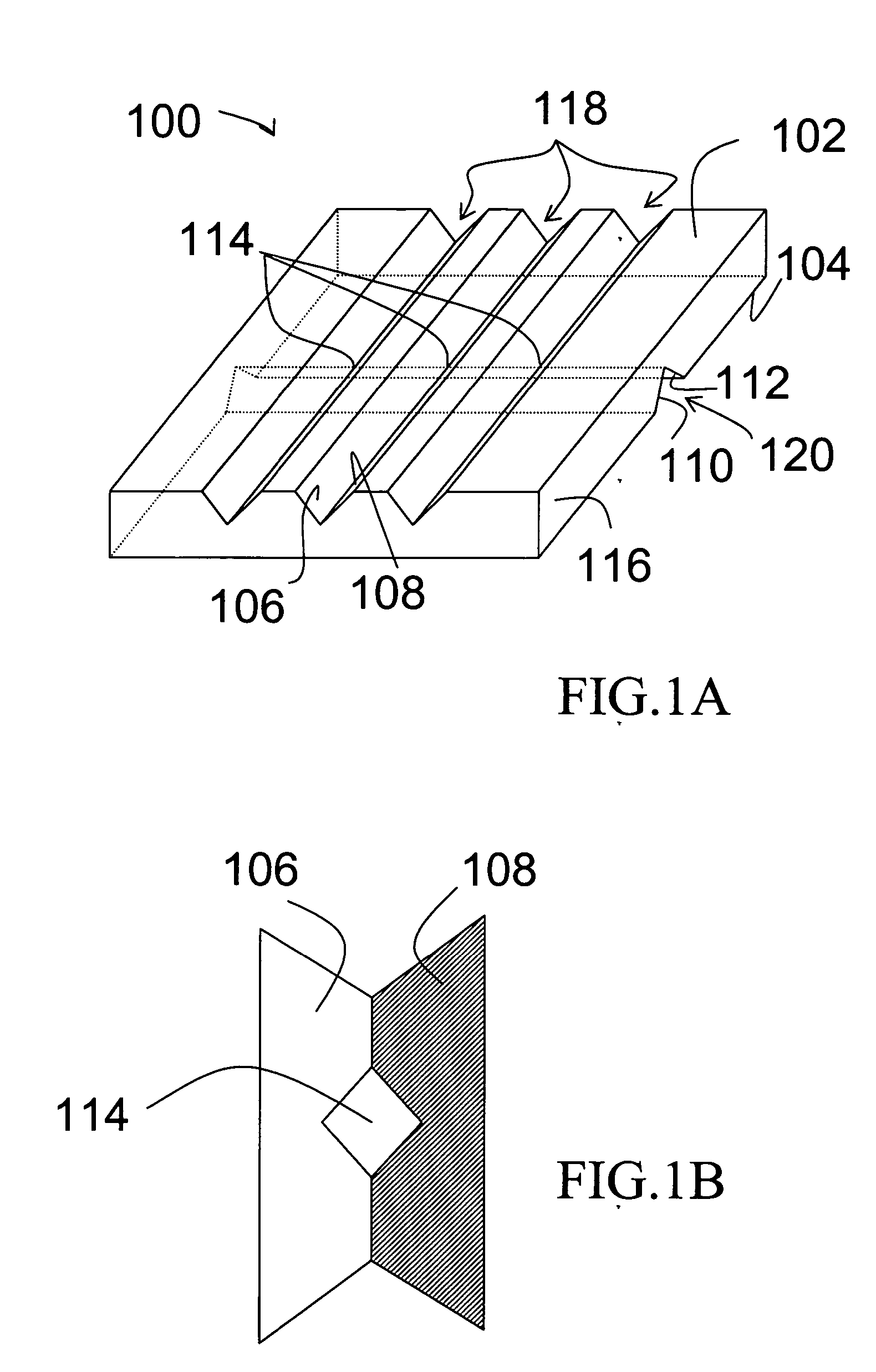

Three dimensionally periodic structural assemblies on nanometer and longer scales

InactiveUS6261469B1Low melting pointEasily de-infiltrateSilicaPaper/cardboard articlesChromatographic separationThermoelectric materials

This invention relates to processes for the assembly of three-dimensional structures having periodicities on the scale of optical wavelengths, and at both smaller and larger dimensions, as well as compositions and applications therefore. Invention embodiments involve the self assembly of three-dimensionally periodic arrays of spherical particles, the processing of these arrays so that both infiltration and extraction processes can occur, one or more infiltration steps for these periodic arrays, and, in some instances, extraction steps. The product articles are three-dimensionally periodic on a scale where conventional processing methods cannot be used. Articles and materials made by these processes are useful as thermoelectrics and thermionics, electrochromic display elements, low dielectric constant electronic substrate materials, electron emitters (particularly for displays), piezoelectric sensors and actuators, electrostrictive actuators, piezochromic rubbers, gas storage materials, chromatographic separation materials, catalyst support materials, photonic bandgap materials for optical circuitry, and opalescent colorants for the ultraviolet, visible, and infrared regions.

Owner:ALLIEDSIGNAL INC

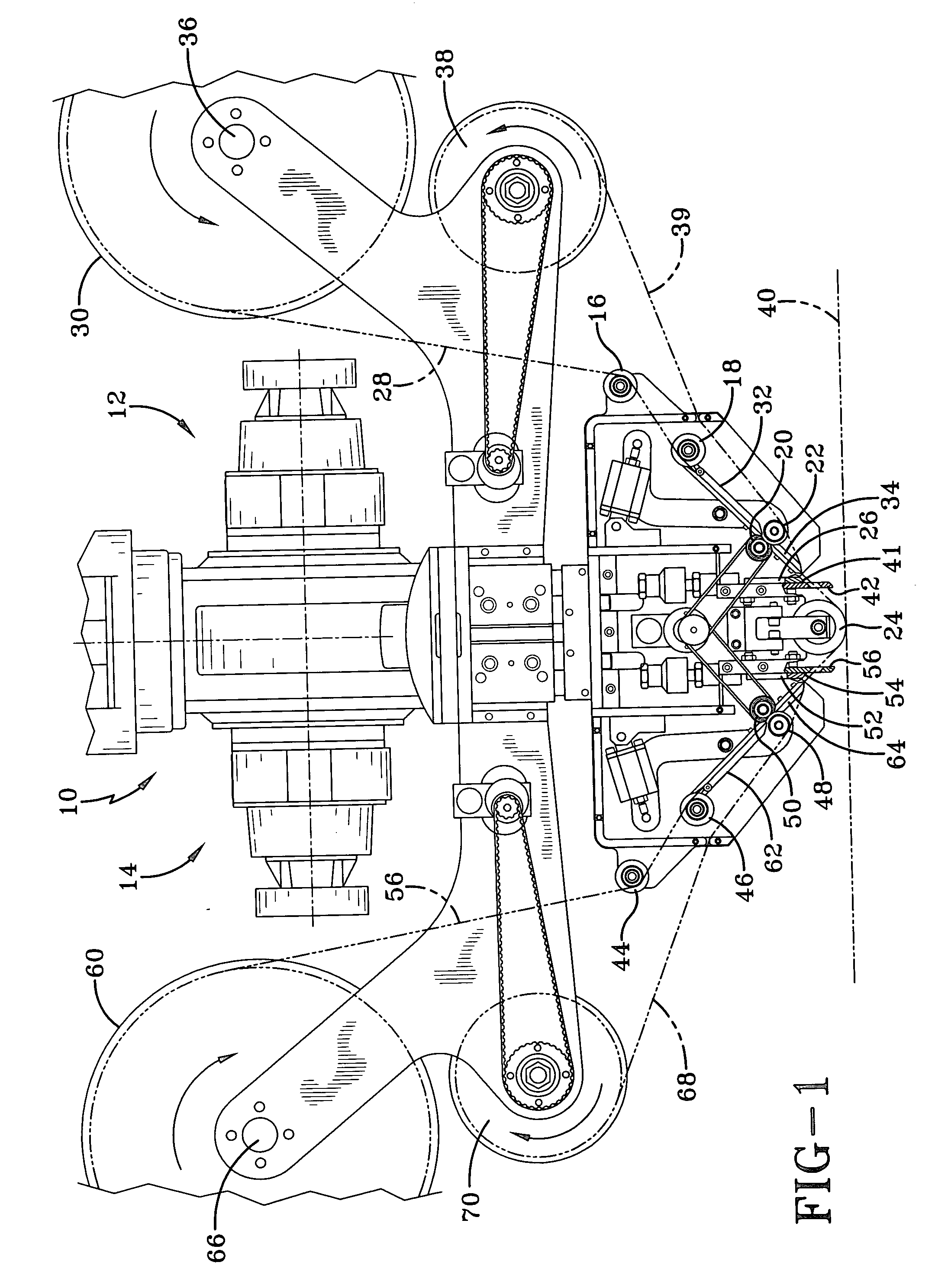

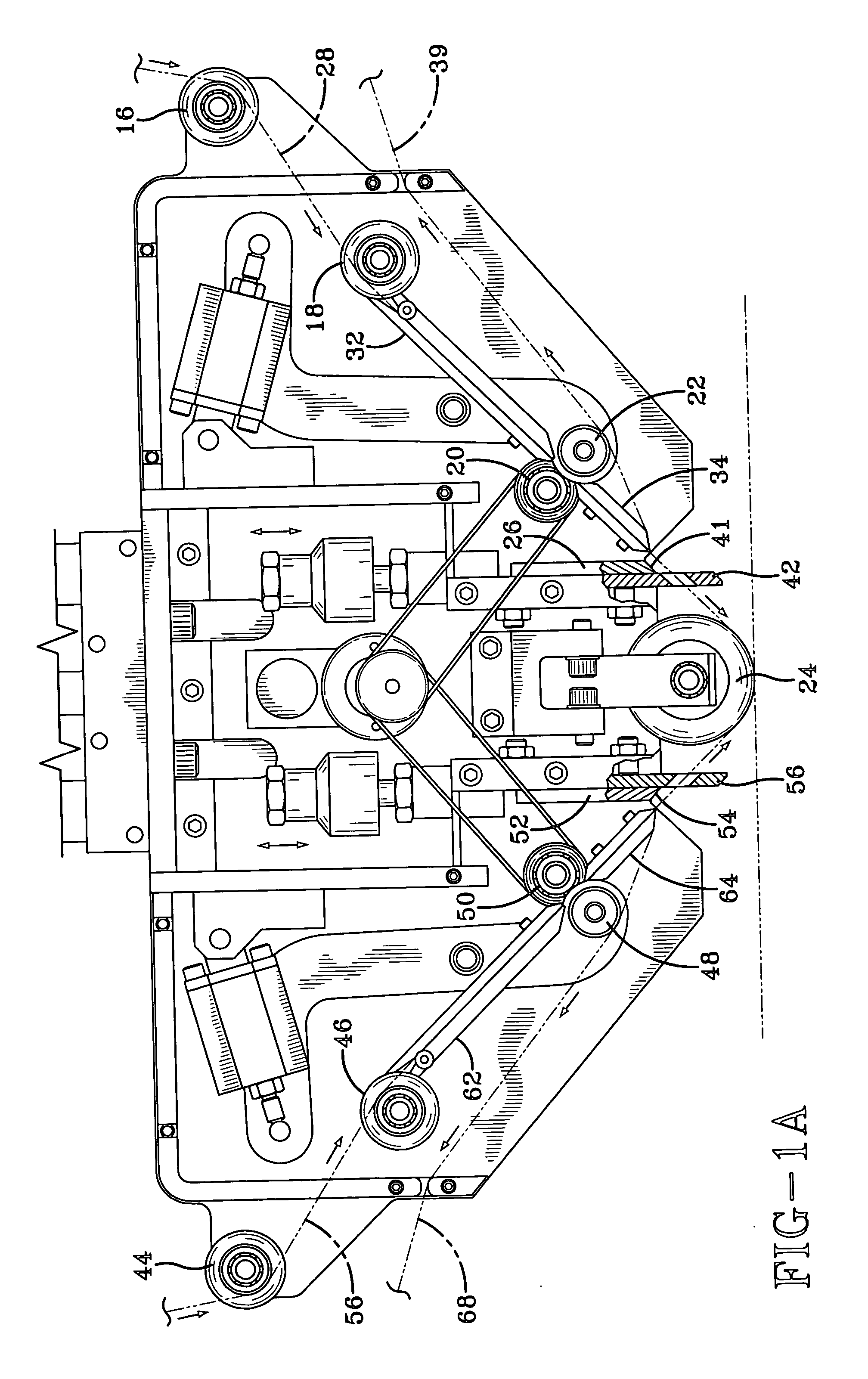

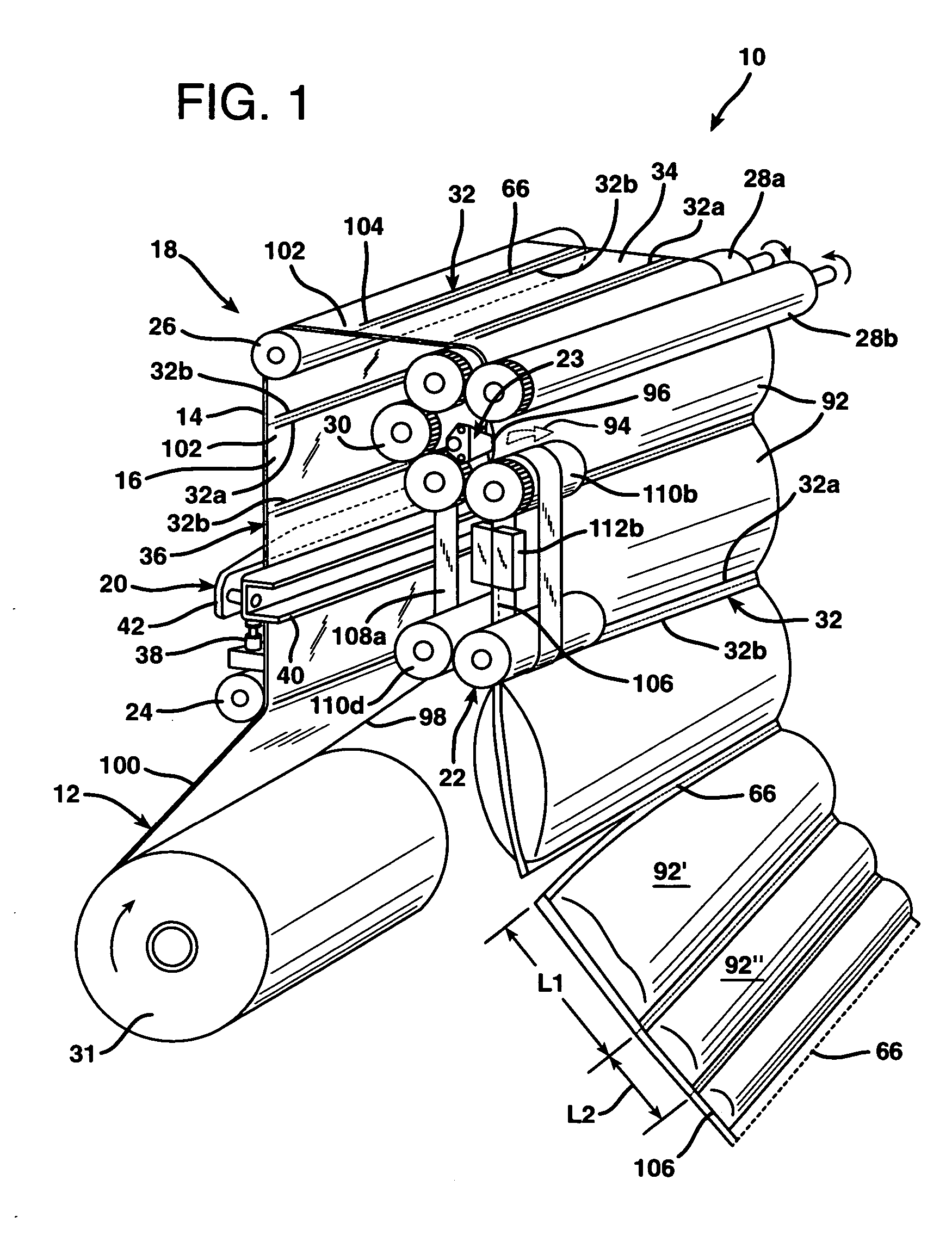

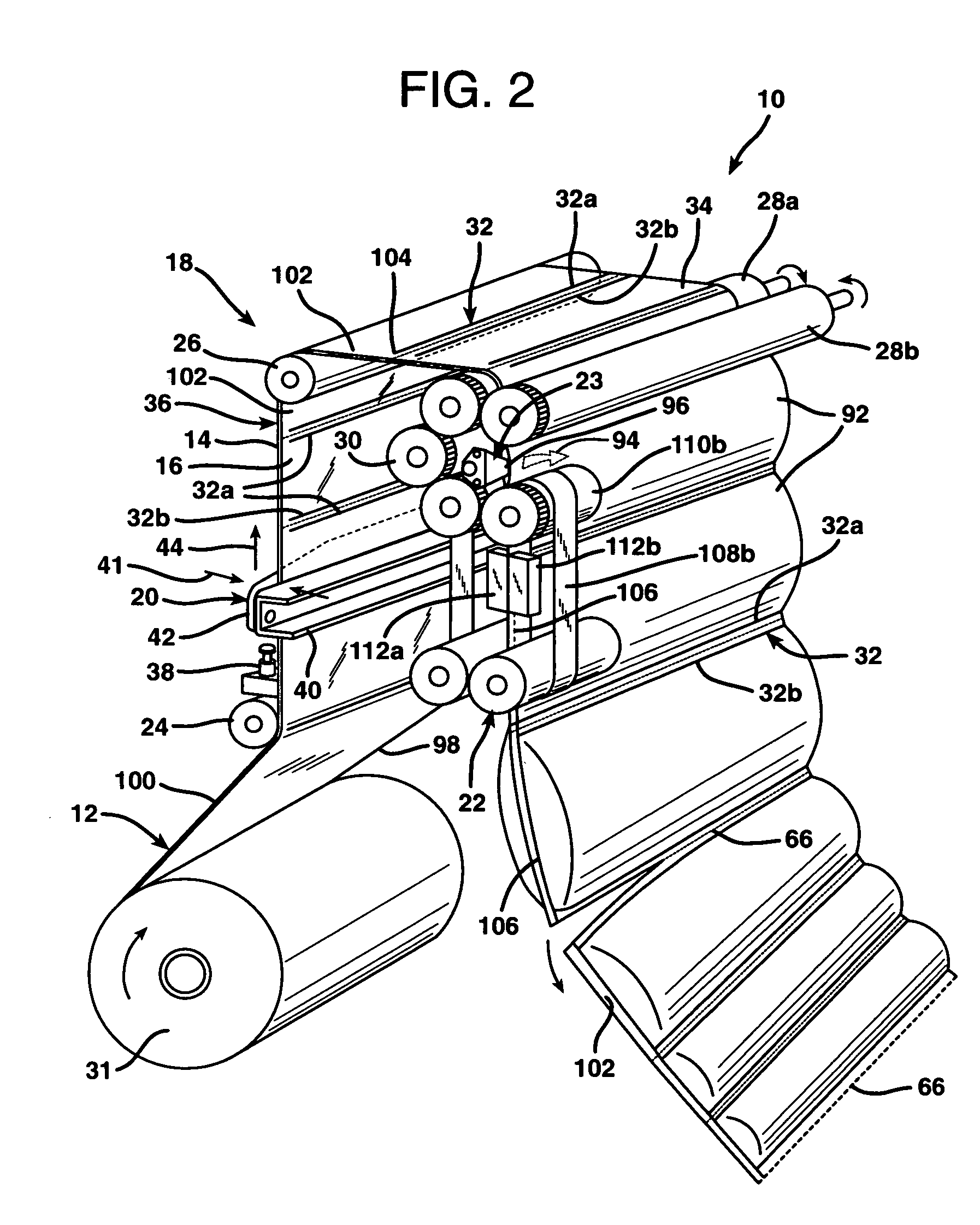

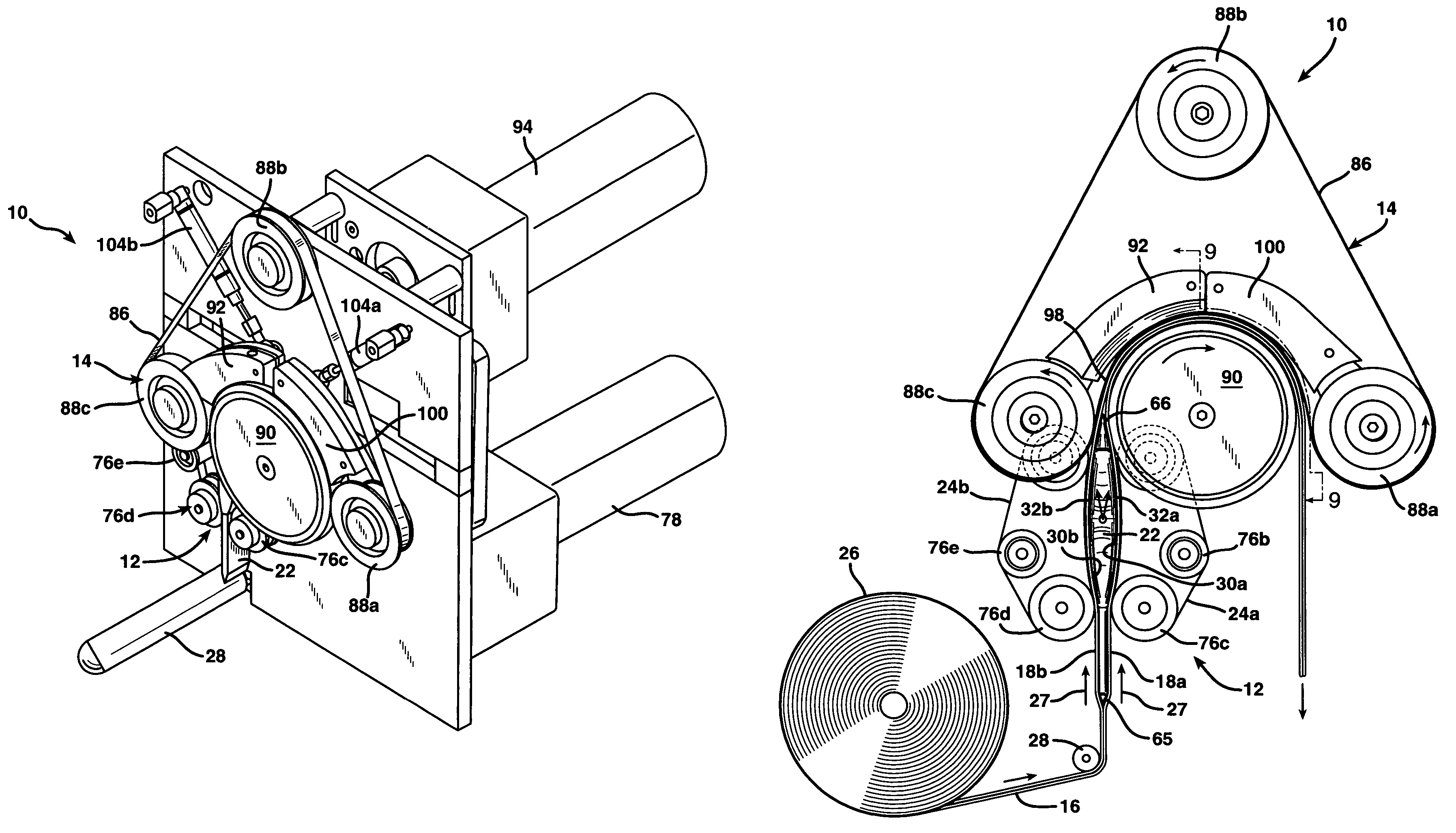

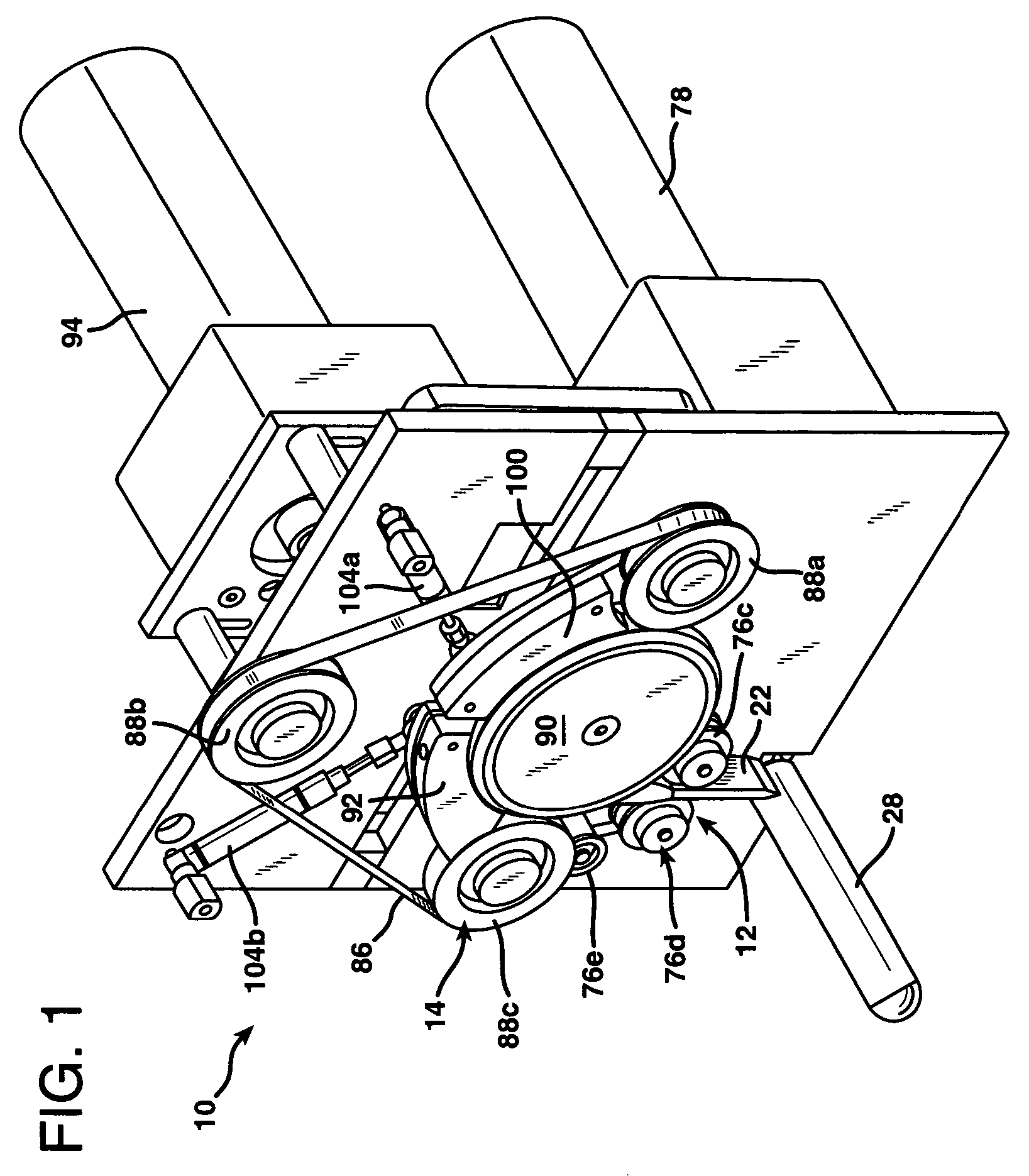

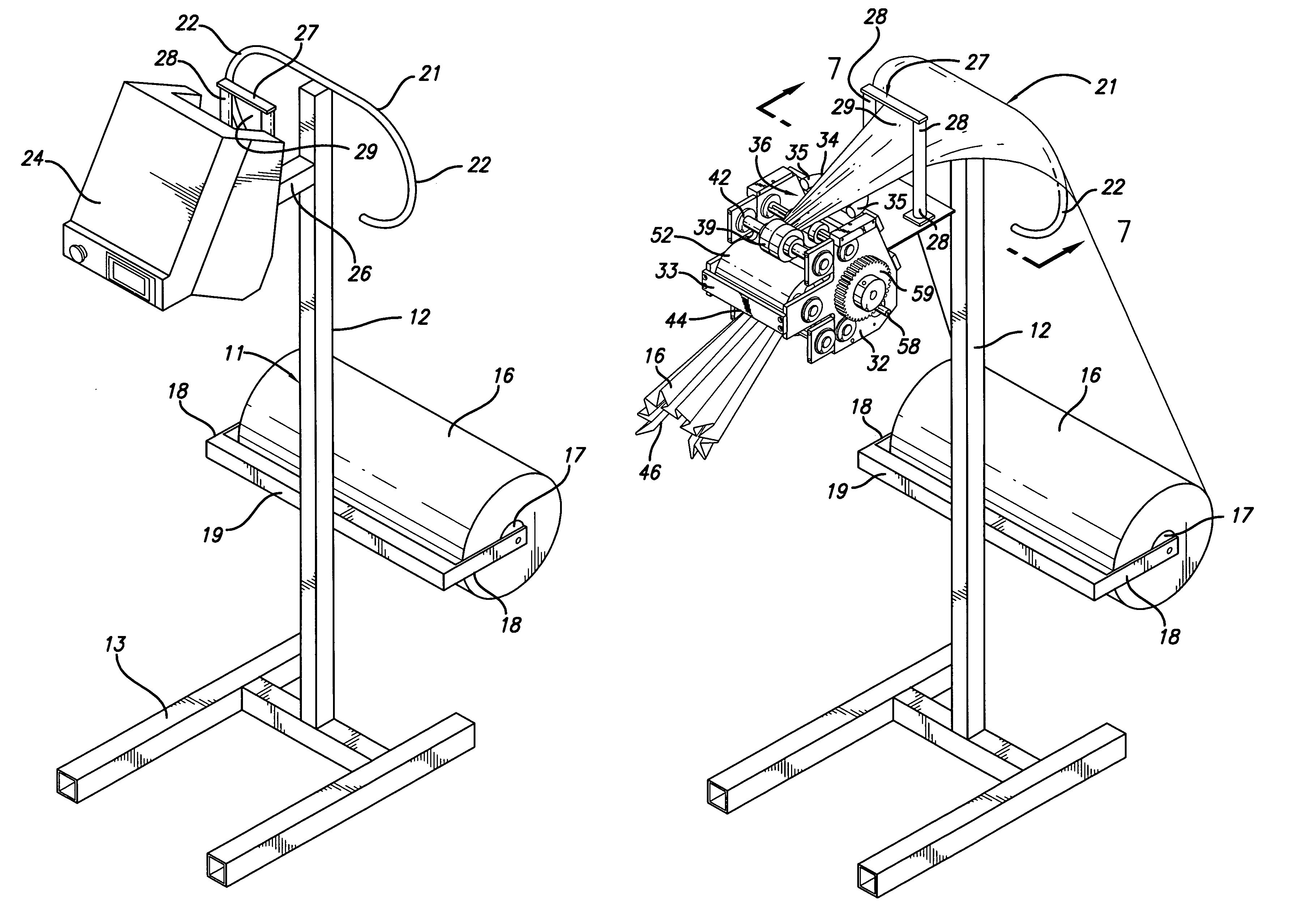

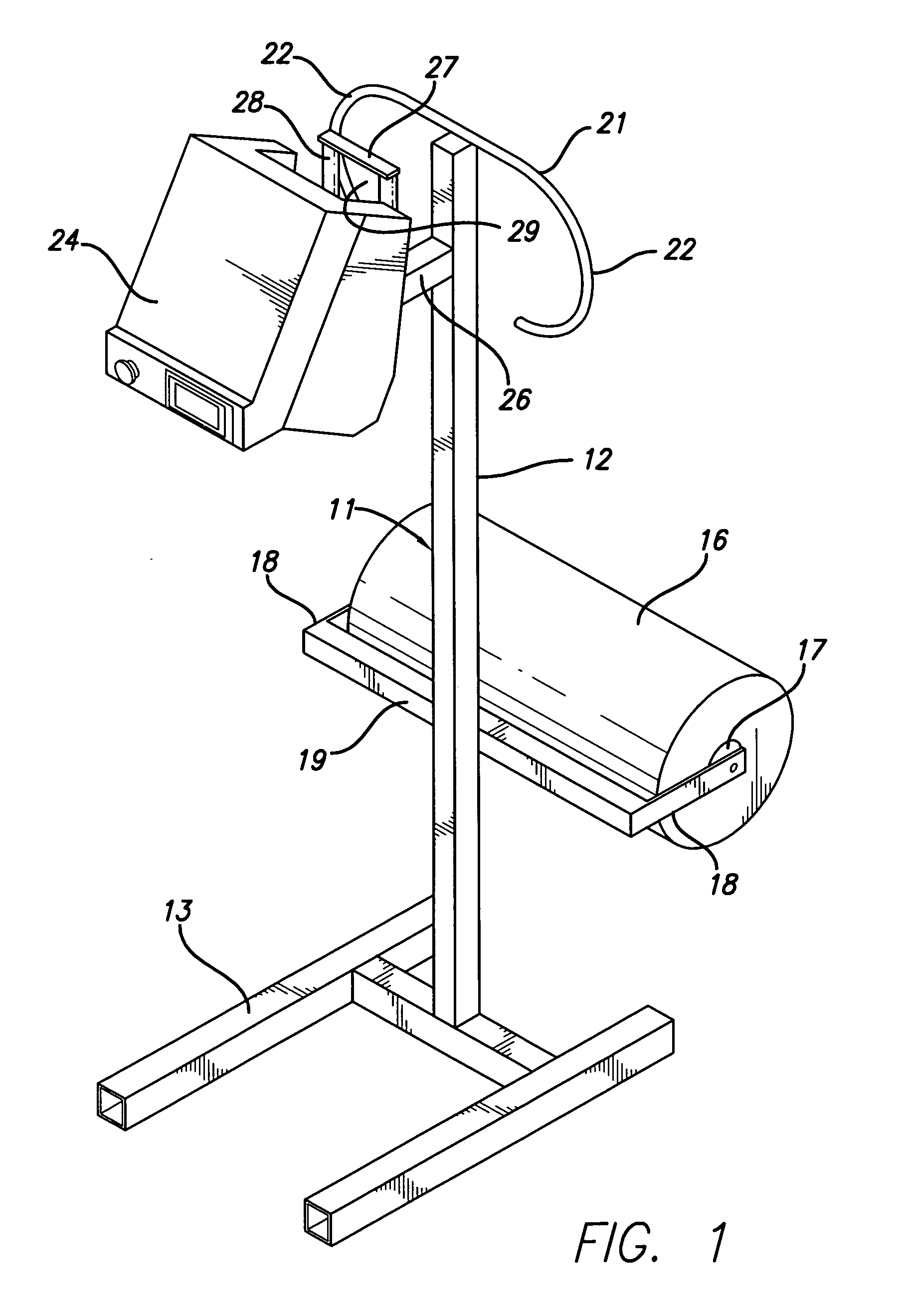

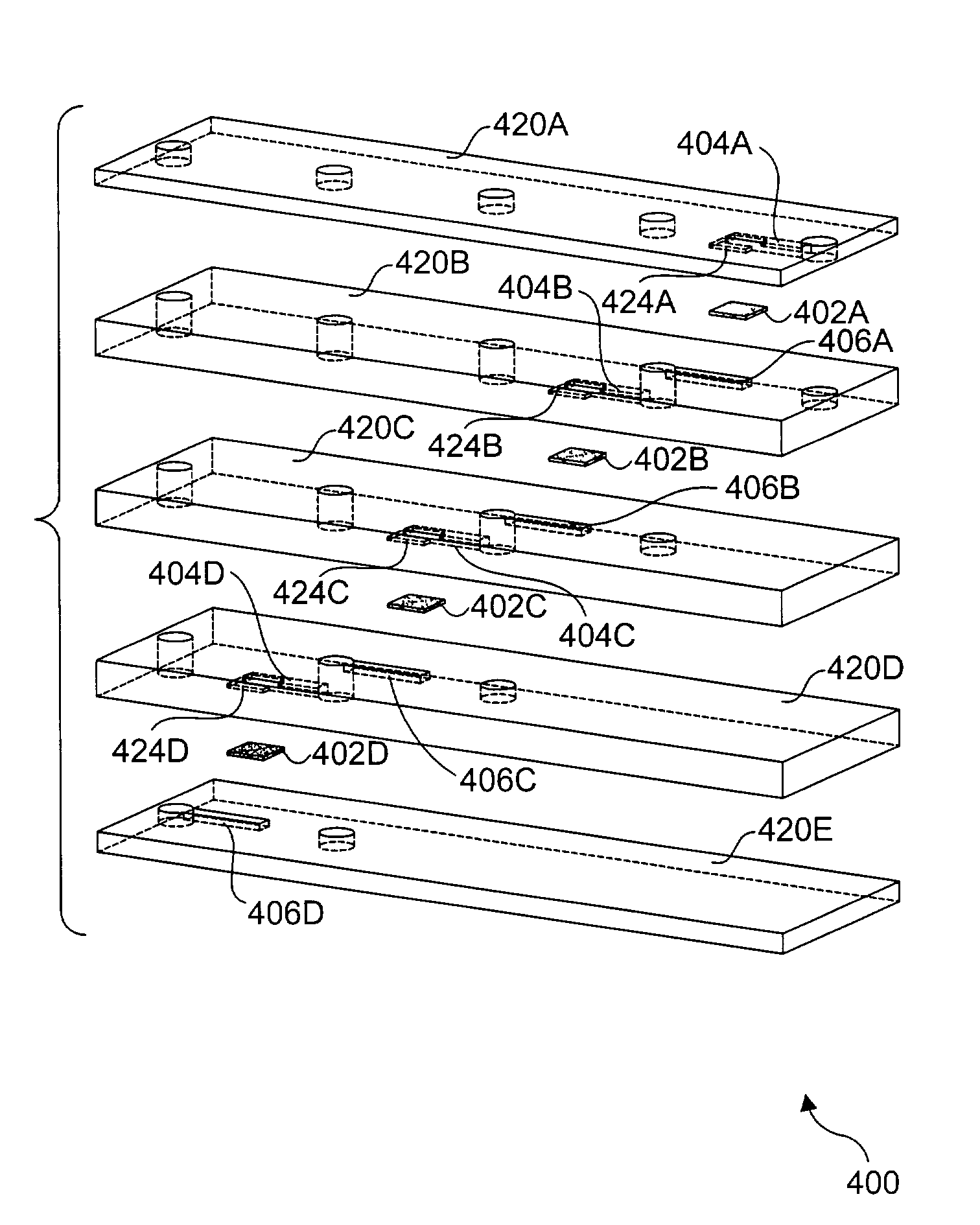

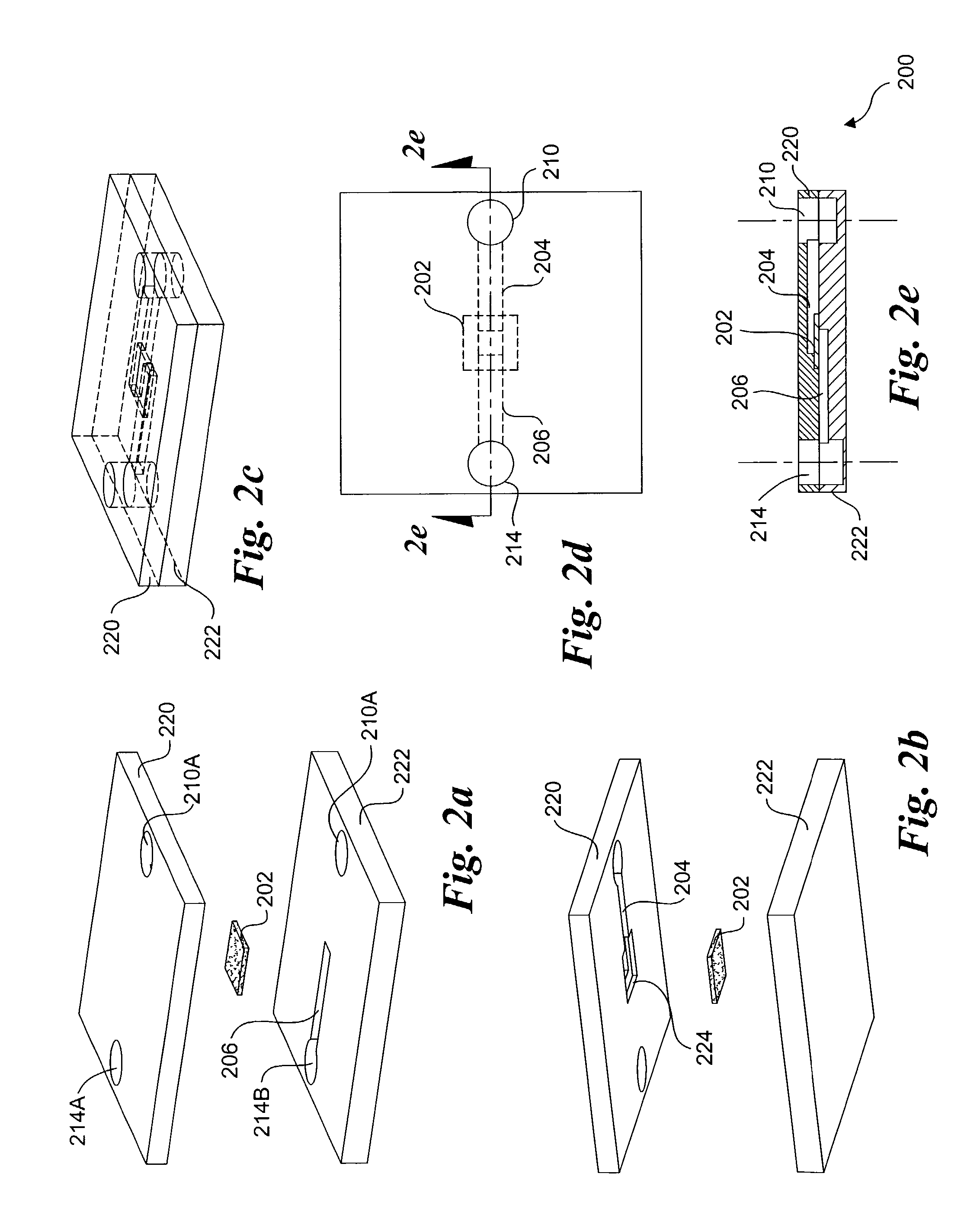

Multiple tape laying apparatus and method

ActiveUS20050061422A1Satisfactory depositionAvoid stickingLamination ancillary operationsPaper/cardboard articlesFiberMultiple layer

A fully automated method and apparatus is disclosed to laminate various structural articles with multiple layers of a resin impregnated fiber tape. The fiber tape is deposited with a tape laying member moving alternately in different travel directions. The tape laying member removes all backing layers from the tape being employed, then deposits the unbacked tape on the surface of the structural article and finally severs the end of the tape being deposited. An automated cut and restart procedure is employed in the present apparatus to increase throughput.

Owner:TRELLEBORG SEALING SOLUTIONS GERMANY

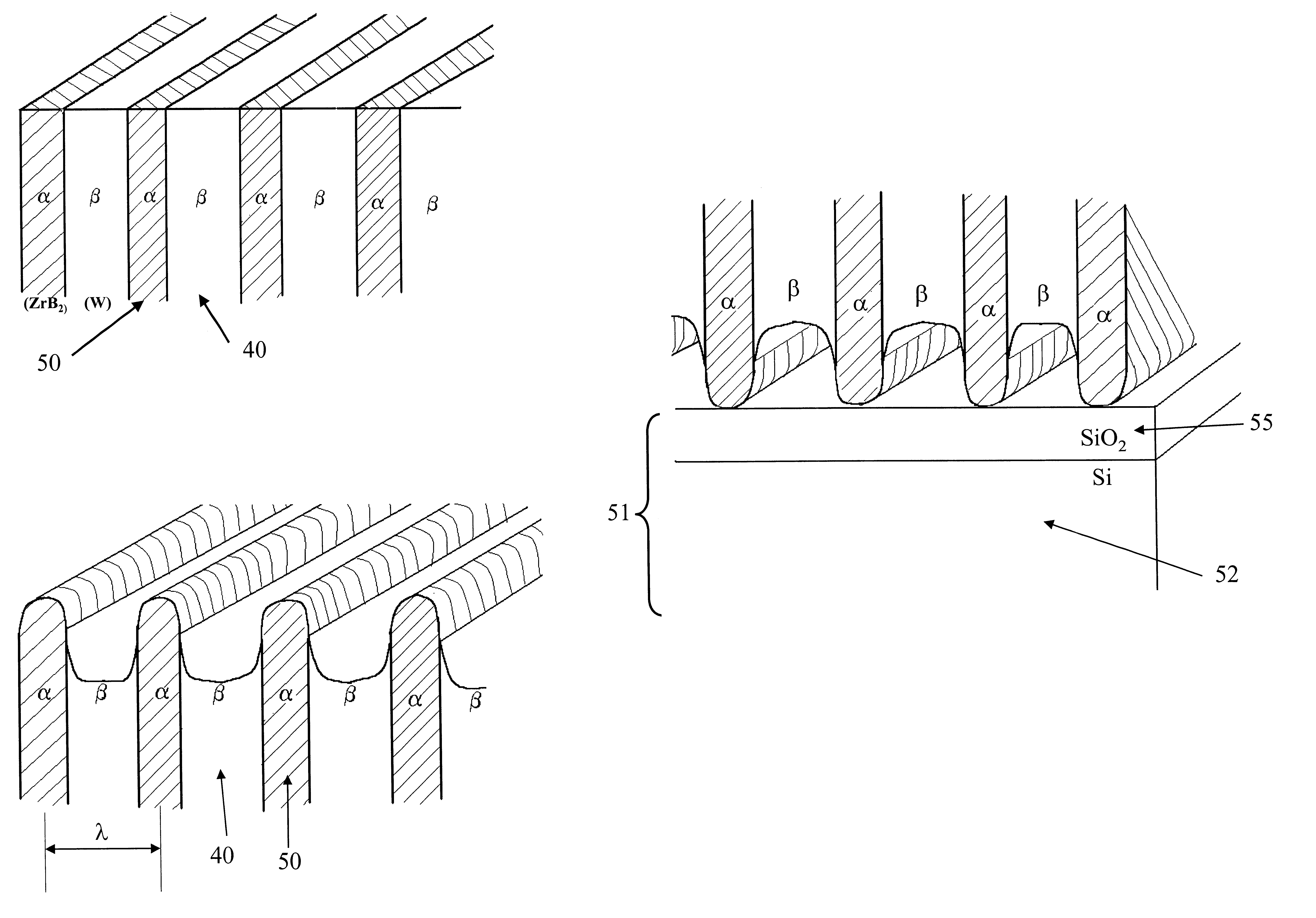

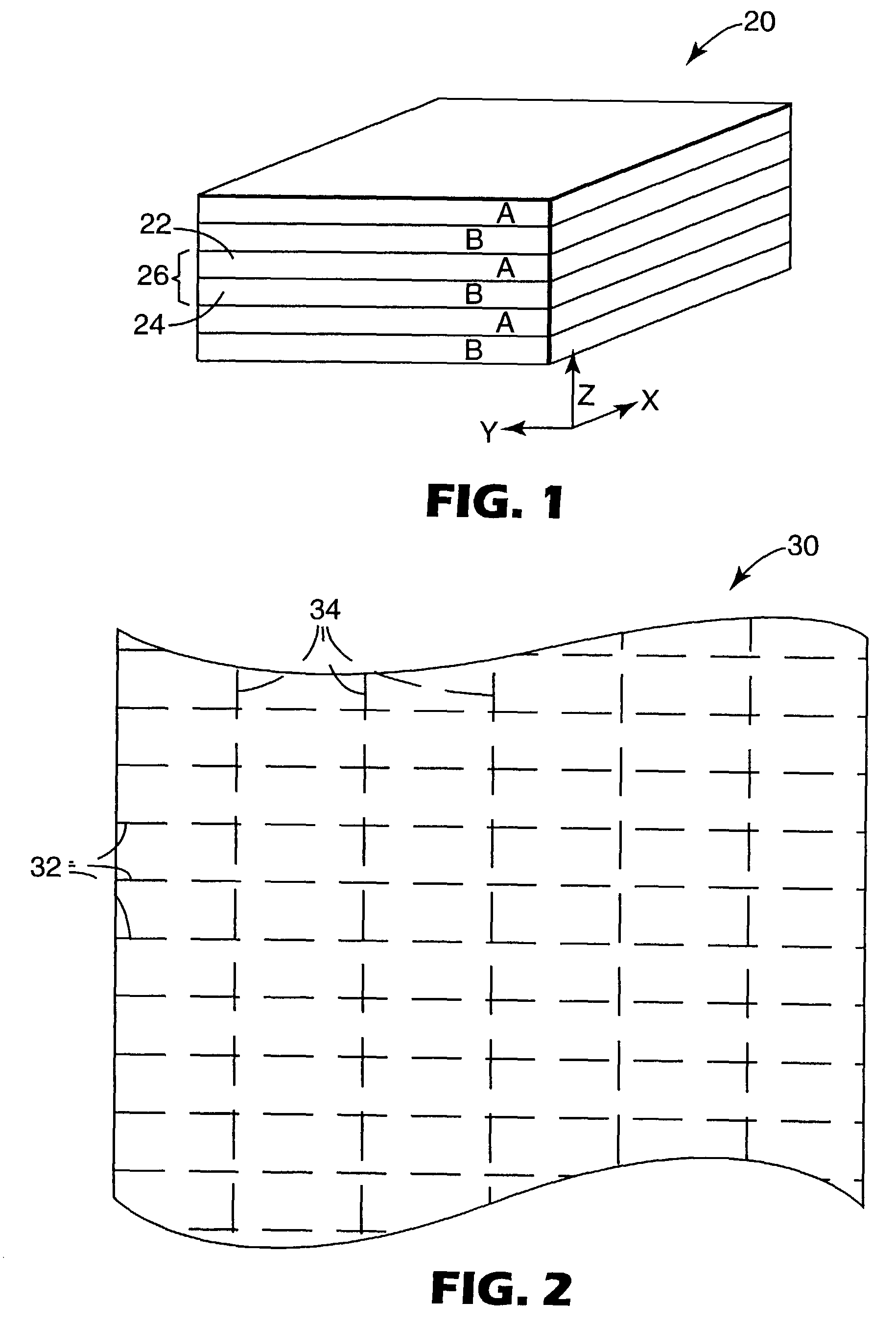

Method for making a nano-stamp and for forming, with the stamp, nano-size elements on a substrate

The stamping process and a method of fabrication of nano-stamps with characteristic dimensions below 1 nm and up to 100 nm intended for usage in making patterns of characteristic dimensions the same as those of the nano-stamp on surface of a substrate is provided. In the process a very hard stamp is fabricated by first depositing alternating layers of two materials, one of which has very high hardness, on some sacrificial substrate via PVD, CVD or any other deposition procedure that produces alternating layers of selected thickness, from sub 1 nm to above 100 nm. The layered film is then polished to an atomically smooth finish perpendicular to the plane of the layers and etched to produce dips in the softer layers. These steps produce a grid of parallel elevations and valleys on the etched surface, which now can be used as a stamp to stamp out patterns on a substrate of lower hardness than the hardness of the elevated layers. If the substrate is stamped twice with a turning of the stamp 90 degrees between first and second stampings, a square pattern of elevations or hills and valleys is formed, which can be used for magnetic memory storage by subsequently sputtering magnetic material on the tops of the elevations or hills.

Owner:VIGIL THOMAS R +1

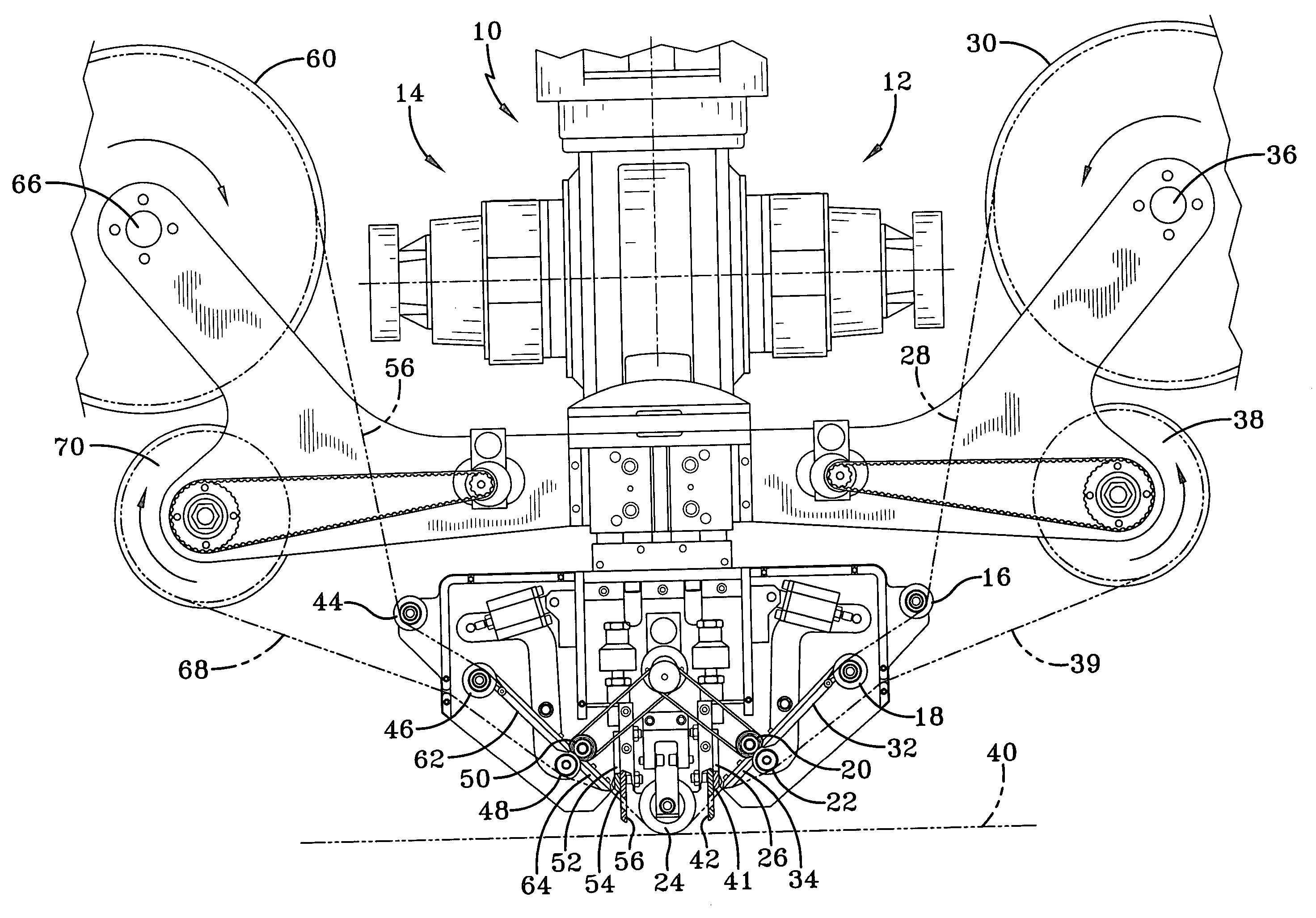

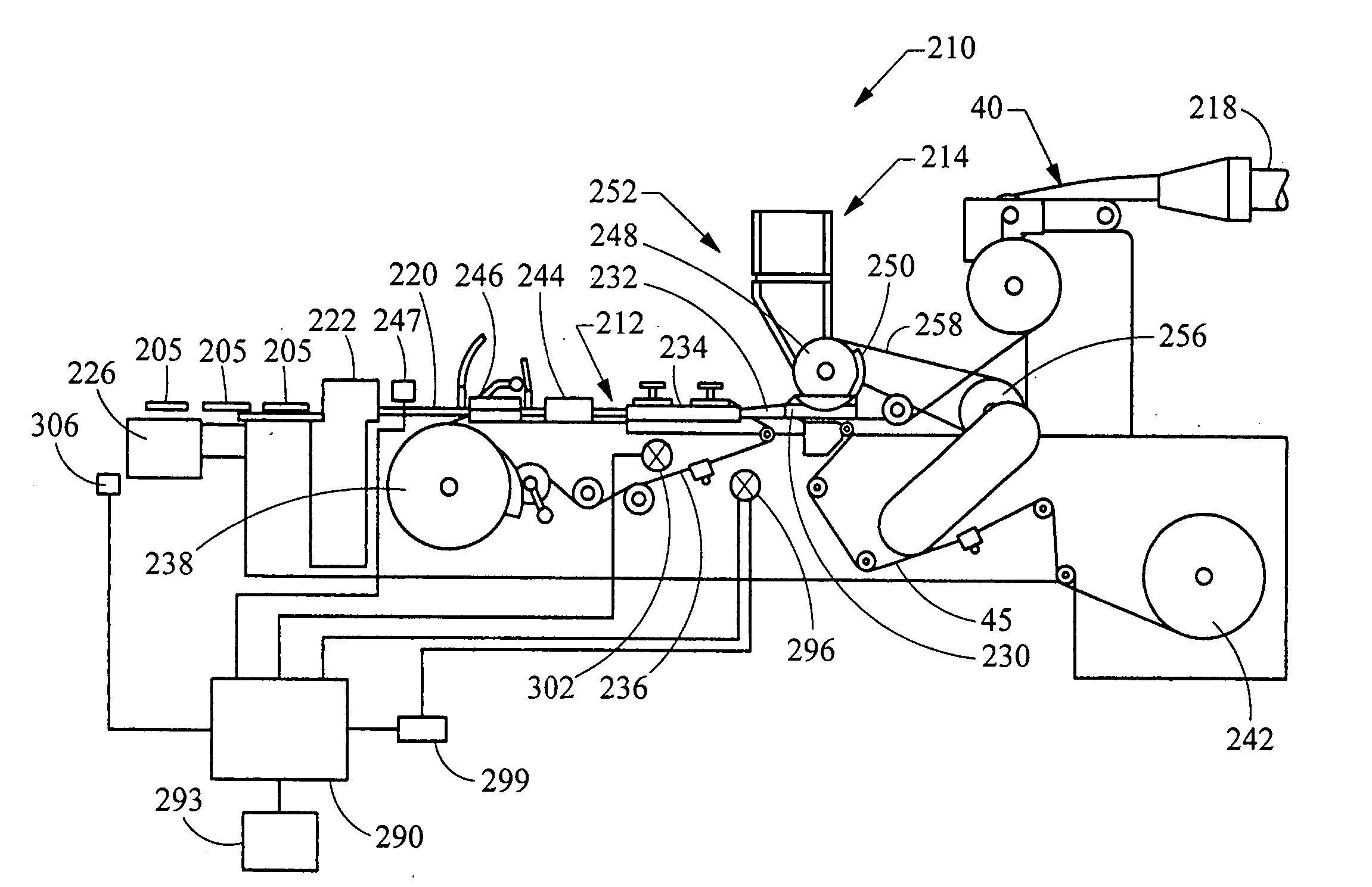

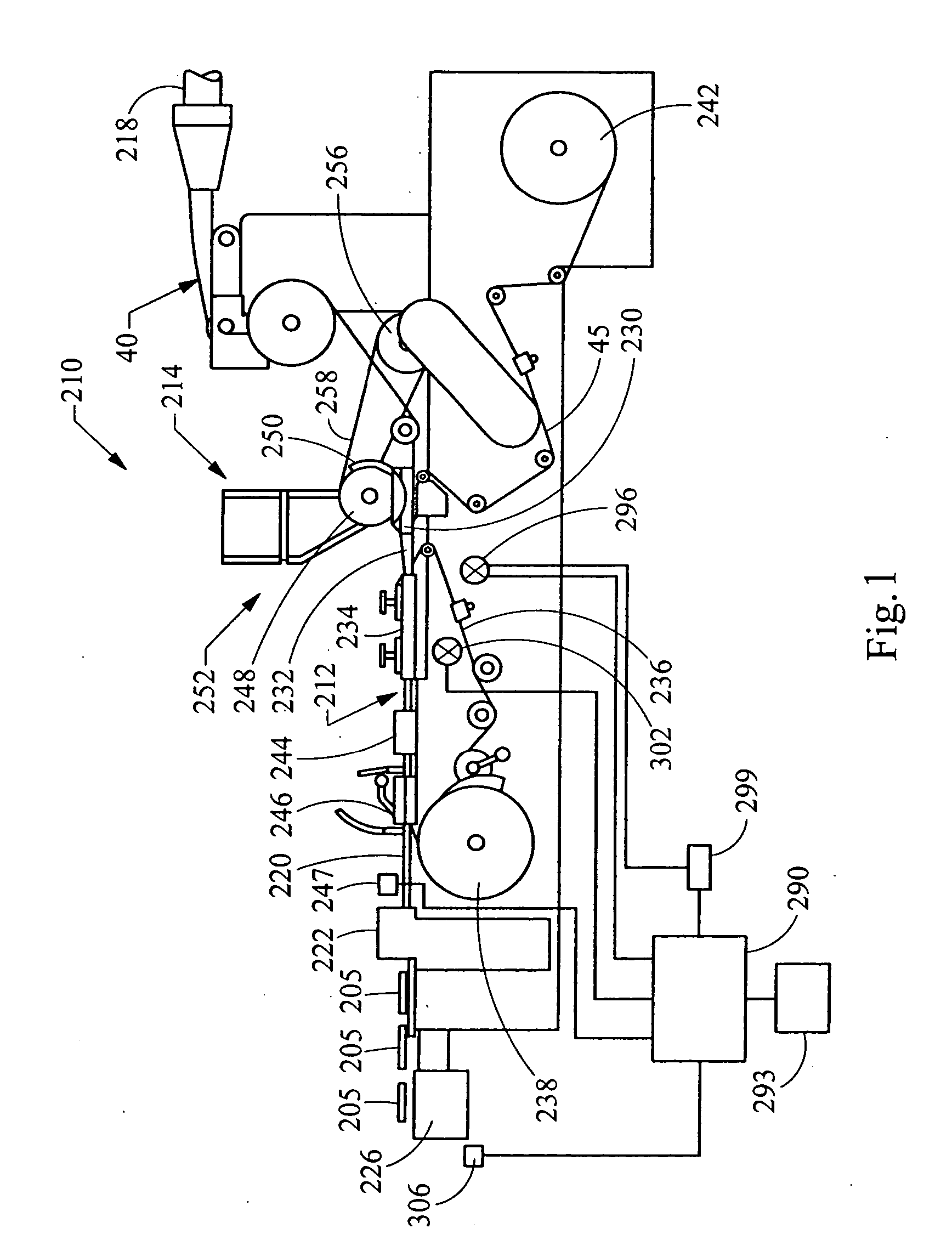

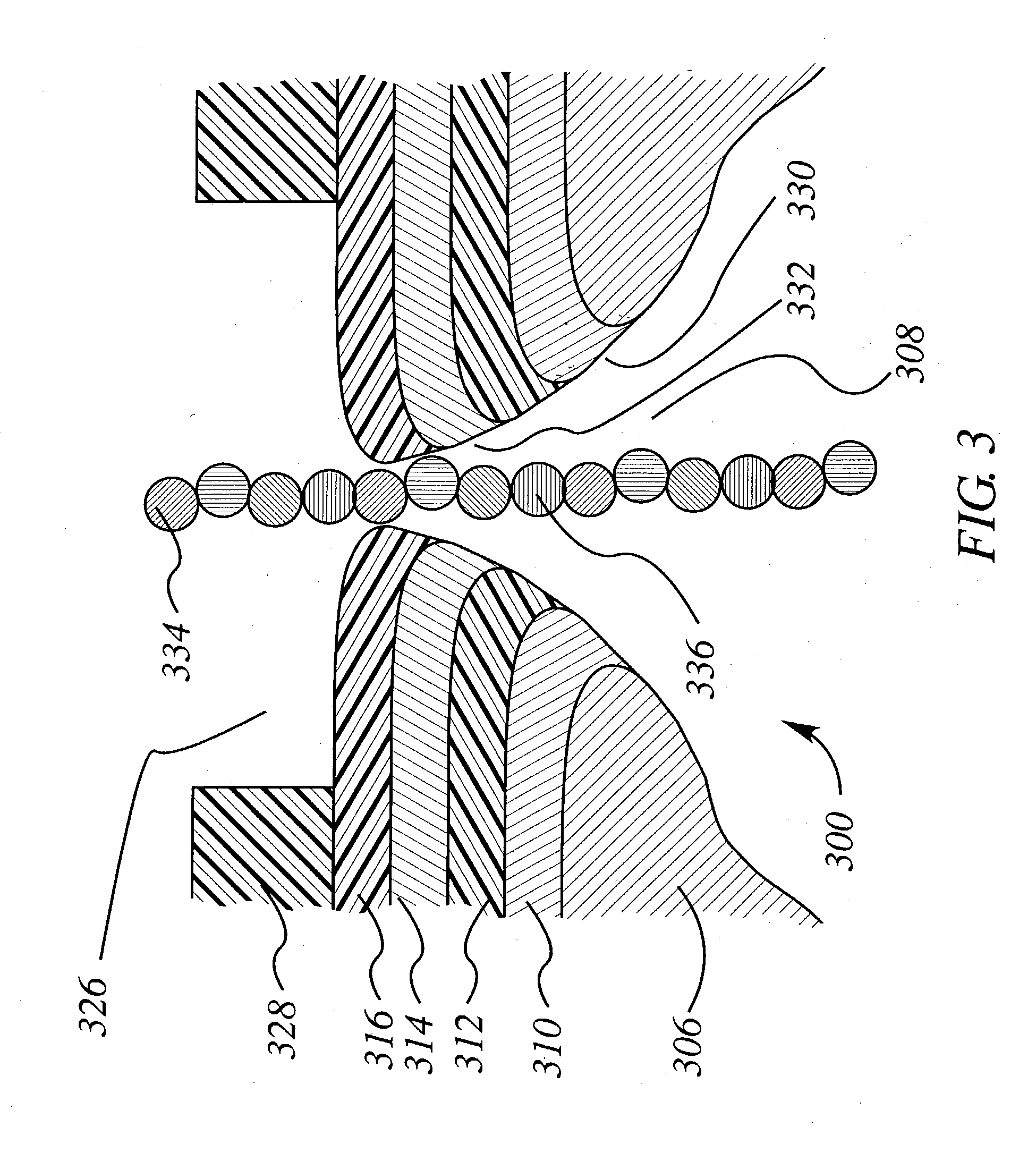

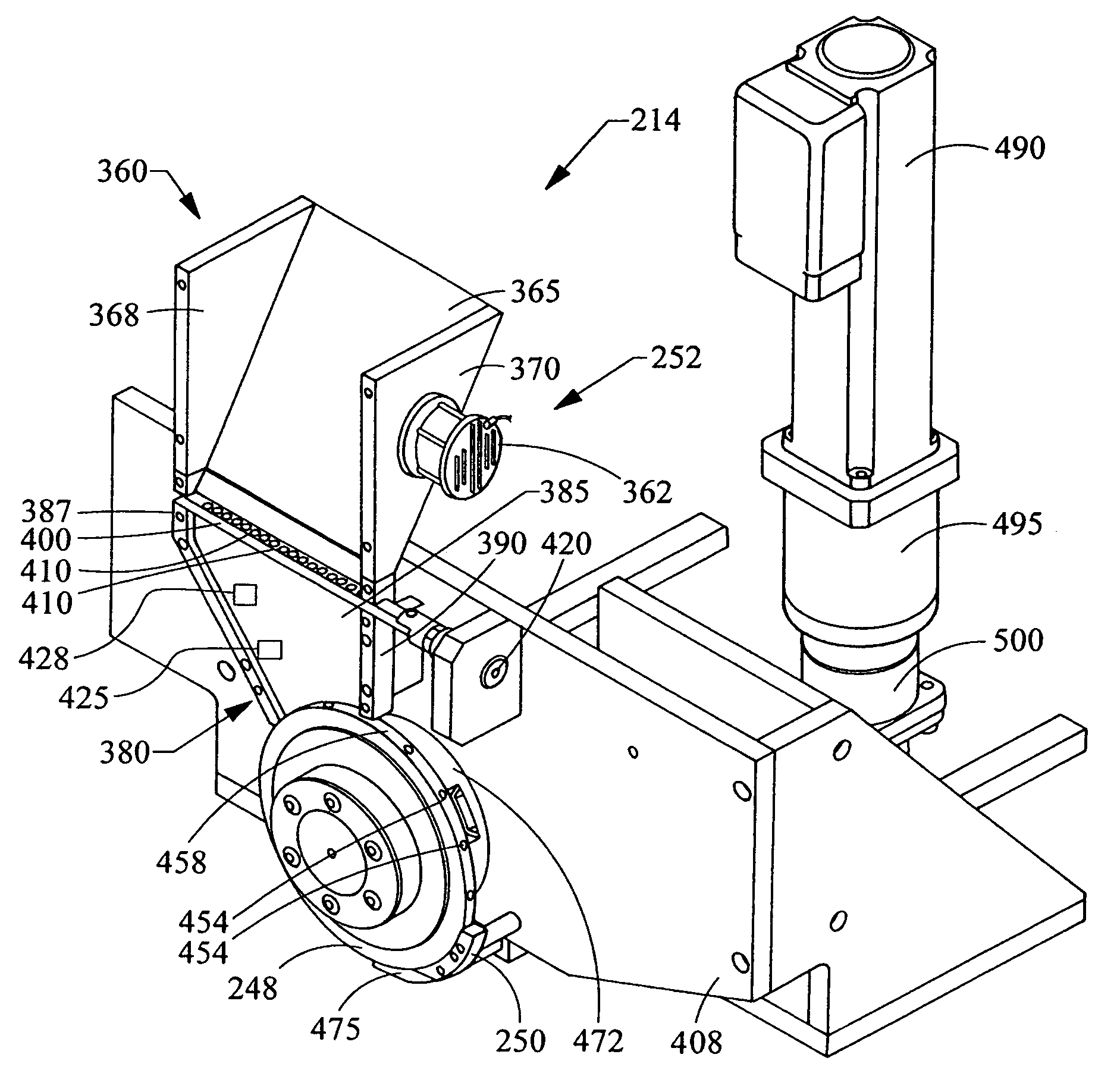

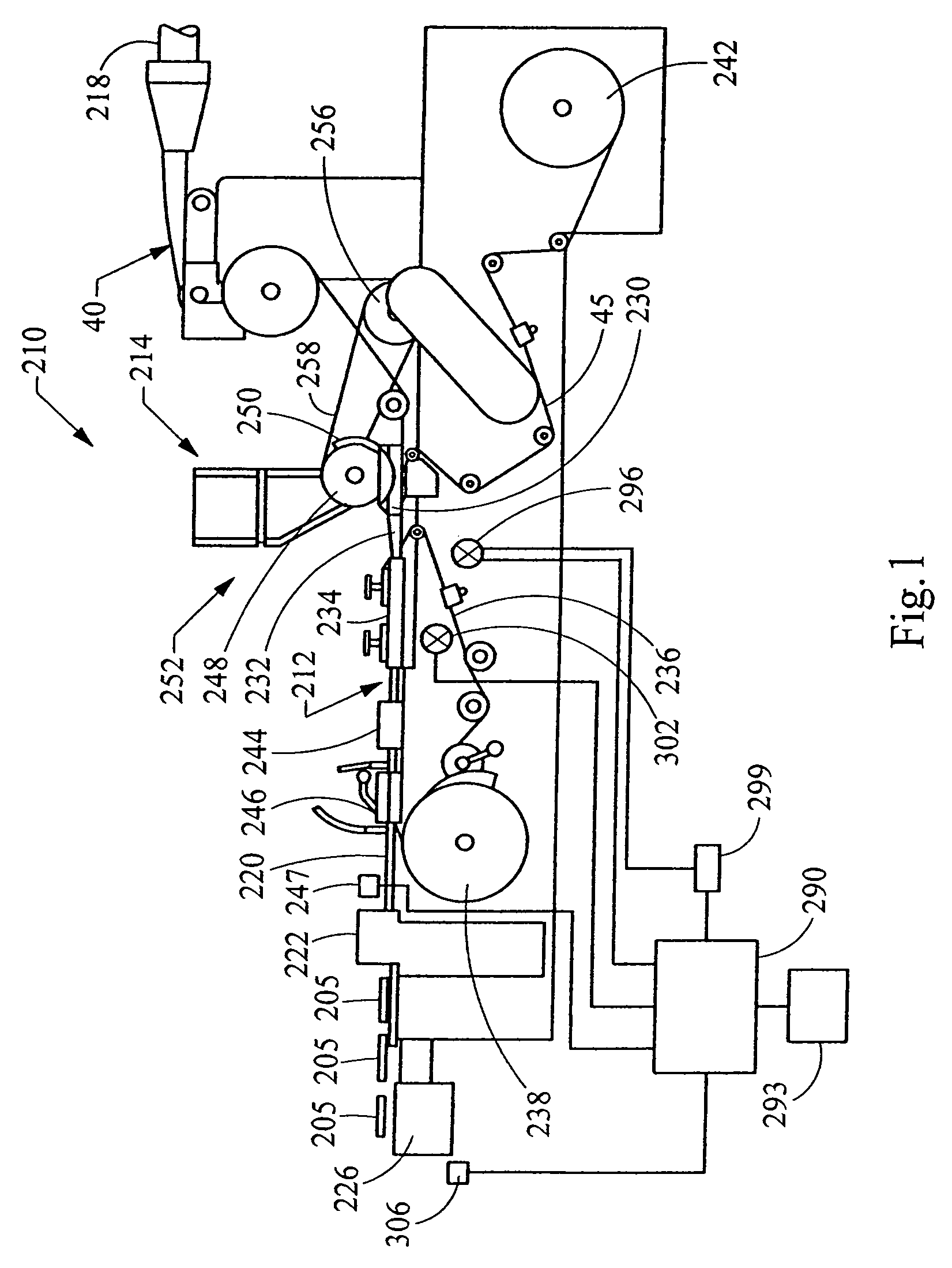

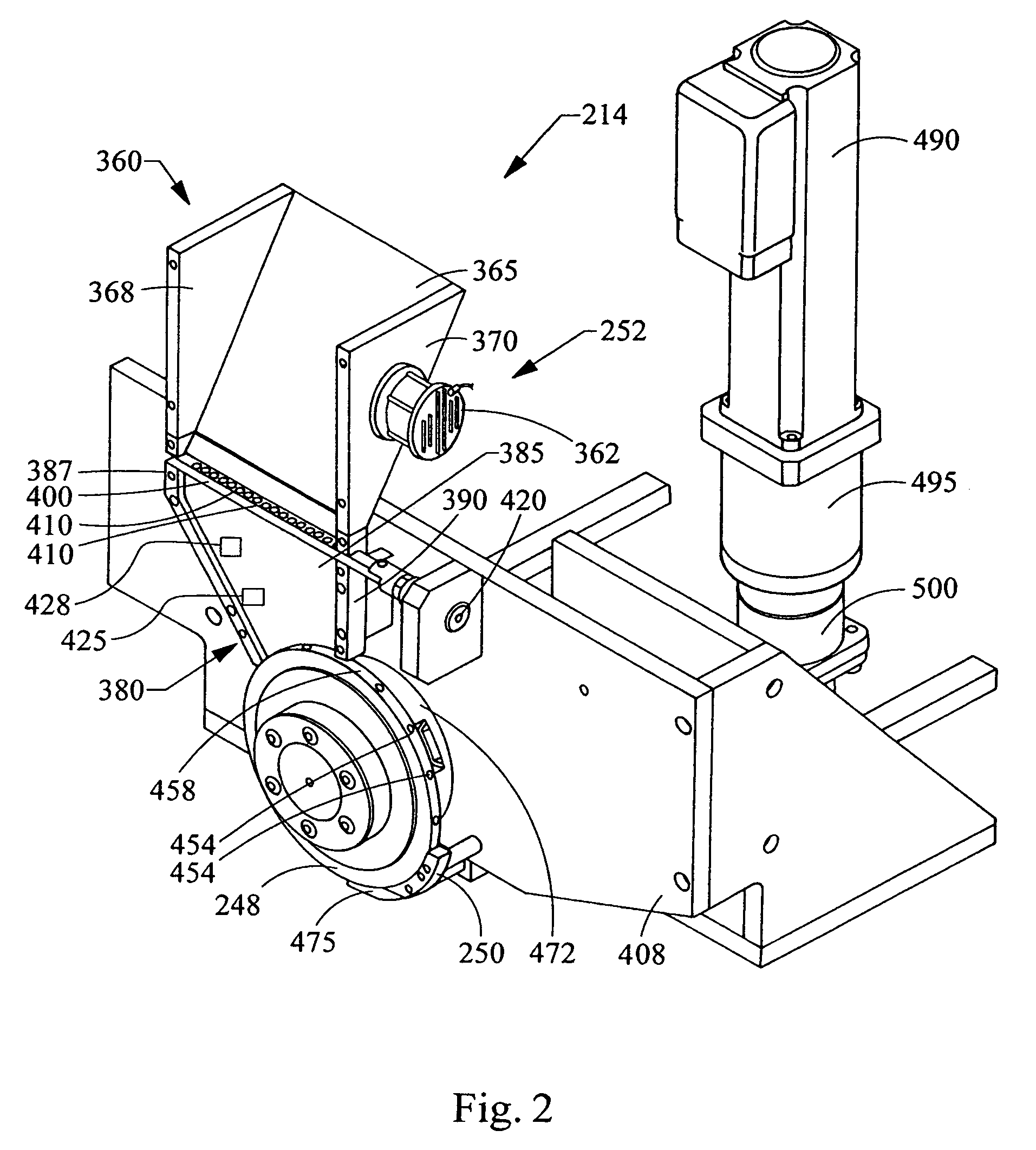

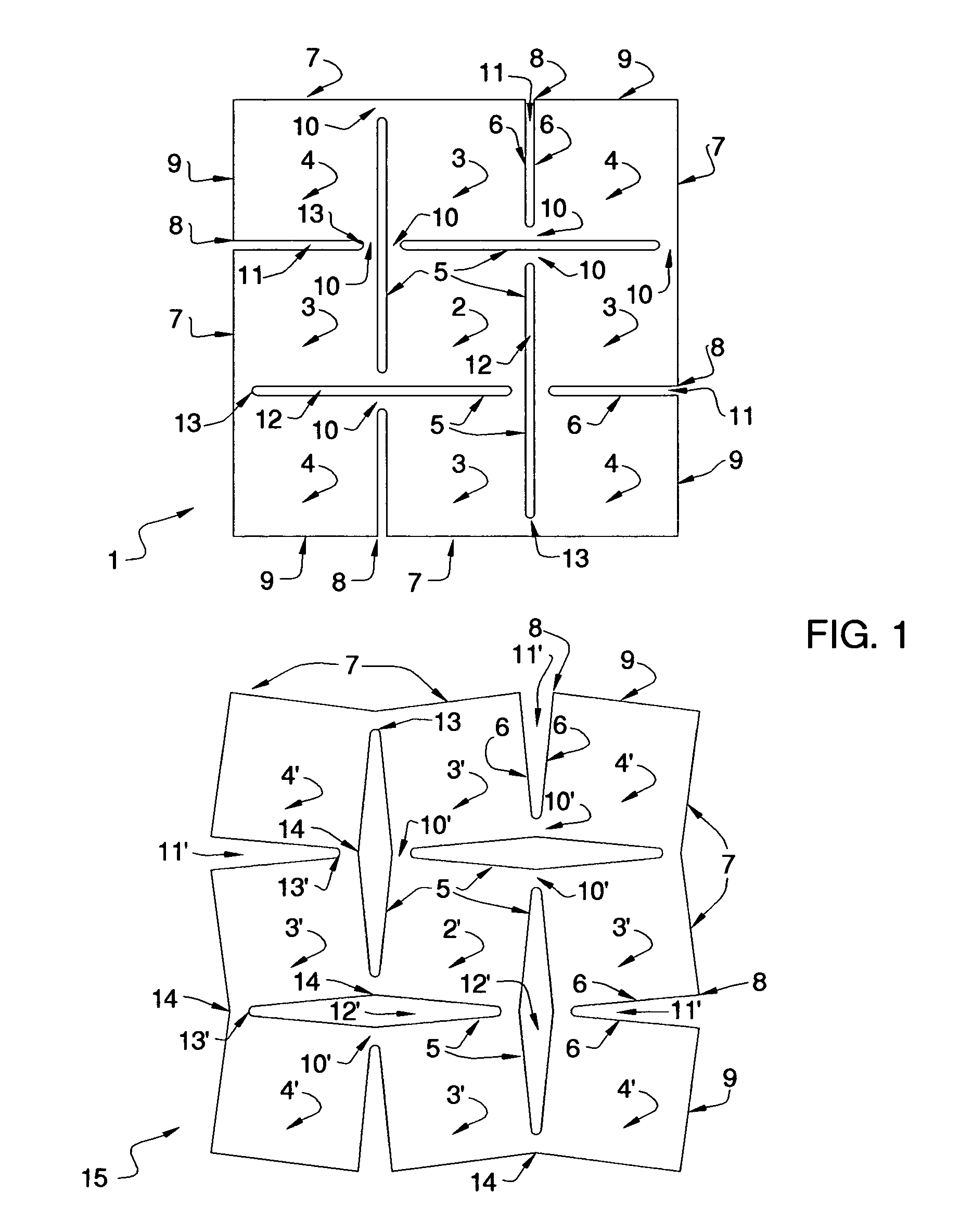

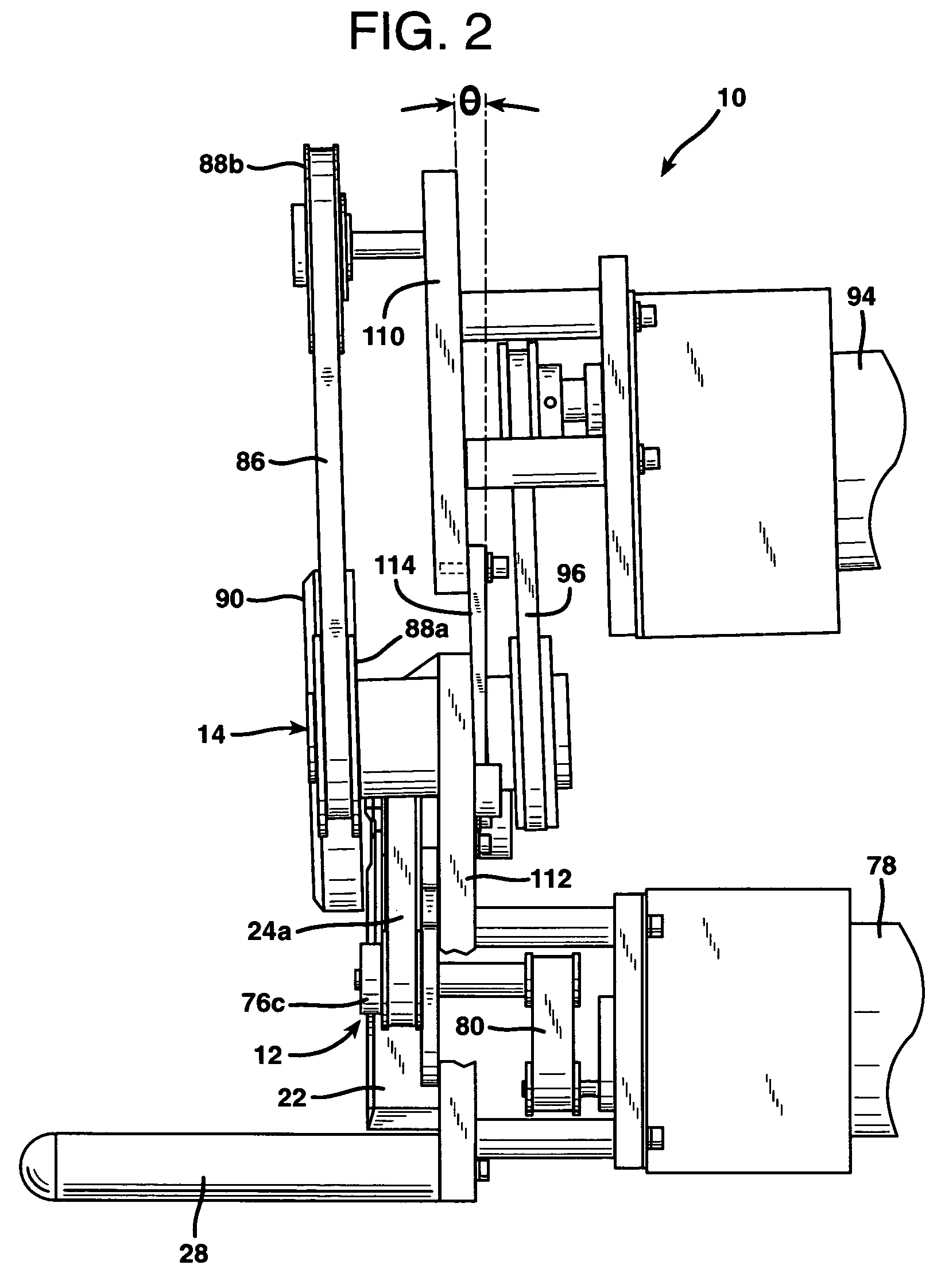

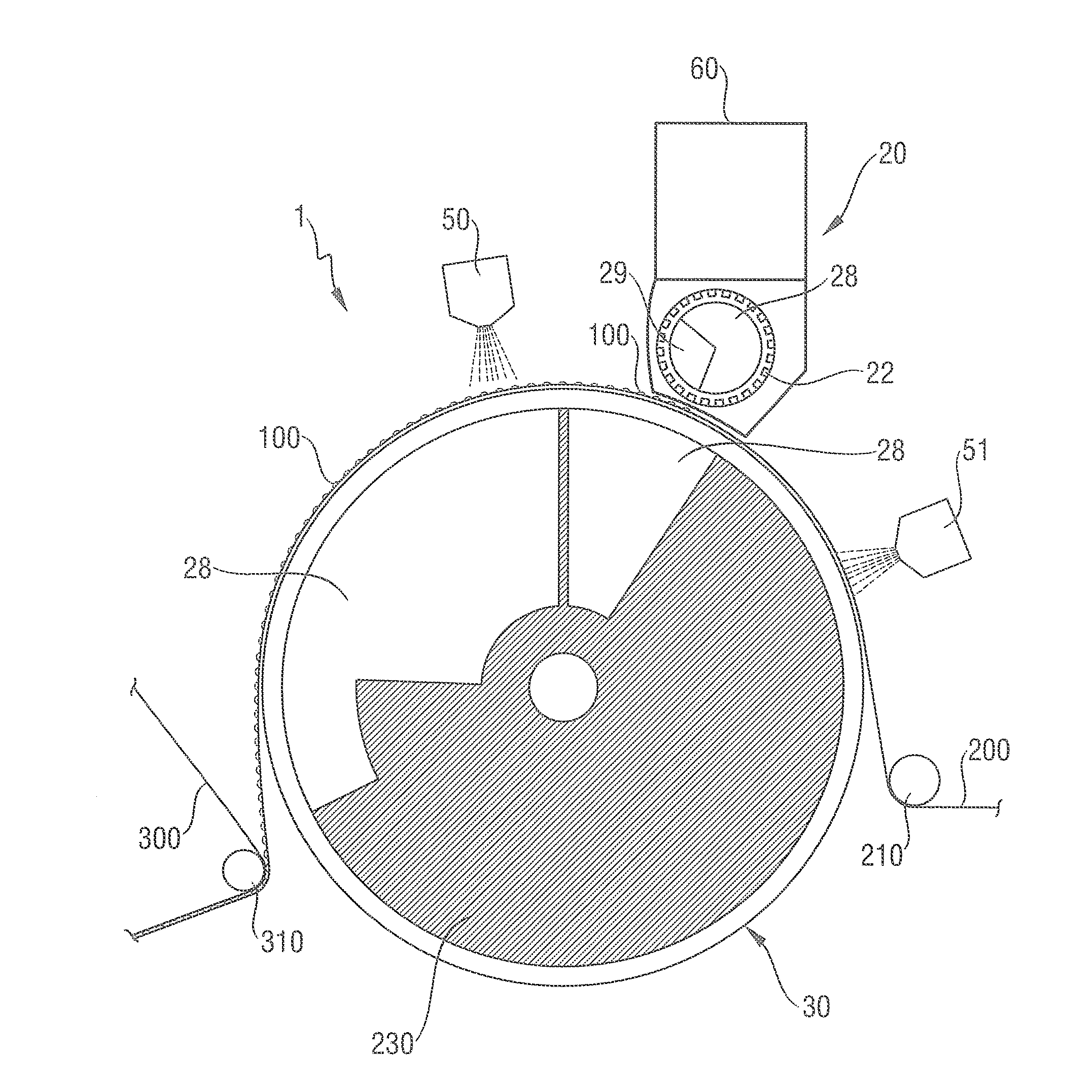

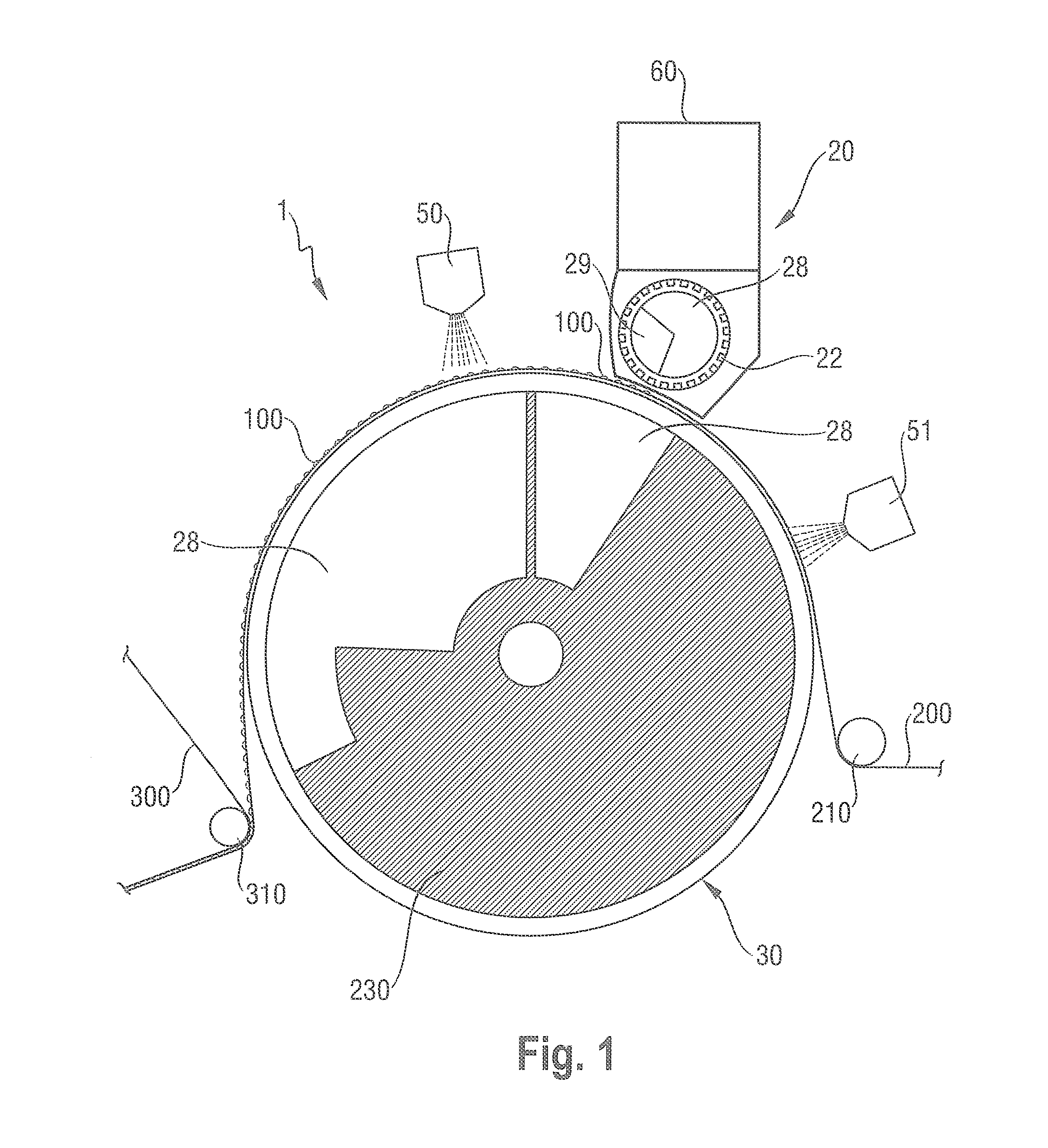

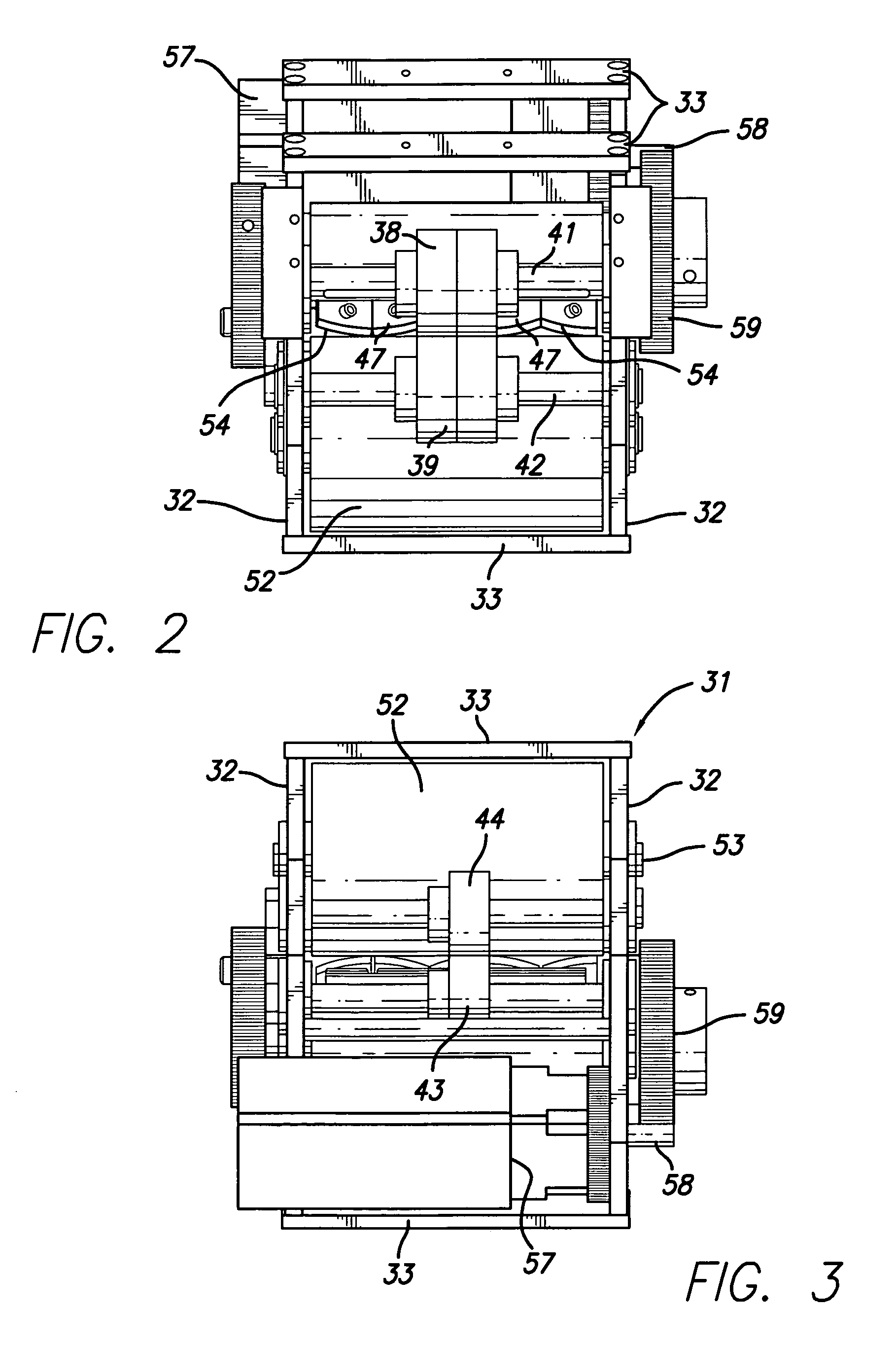

Equipment for insertion of objects into smoking articles

ActiveUS20070068540A1Sufficient shapeSufficient sizeMechanical working/deformationPaper/cardboard articlesEngineeringSpace object

Apparatus incorporating a filter tow processing unit adapted to supply filter tow to a continuous rod forming unit includes an object insertion unit that positions objects within the filter tow to manufacture a filter rod containing objects positioned at predetermined intervals. The apparatus also includes an upper hopper that acts as a reservoir for a plurality of objects, and provides for supply of objects to a lower hopper. The lower hopper is shaped so that objects are stacked therein. The bottom of the lower hopper is shaped so as to cooperate with a portion of upper region of a rotating wheel. The peripheral face of the rotating wheel incorporates a plurality of spaced pockets, each pocket being of sufficient shape and size to accommodate one object. Objects within the lower hopper are aligned in a single line along a portion of the peripheral face in the upper region of the rotating wheel. Each object then is positioned at predetermined intervals within a continuous supply of filter material. Then, the filter material is formed into a continuous rod having individual objects positioned at predetermined spaced intervals within that rod. The continuous rod then is subdivided at predetermined intervals so as to form a plurality of filter rods (e.g., four-up filter rods containing four spaced objects).

Owner:R J REYNOLDS TOBACCO COMPANY

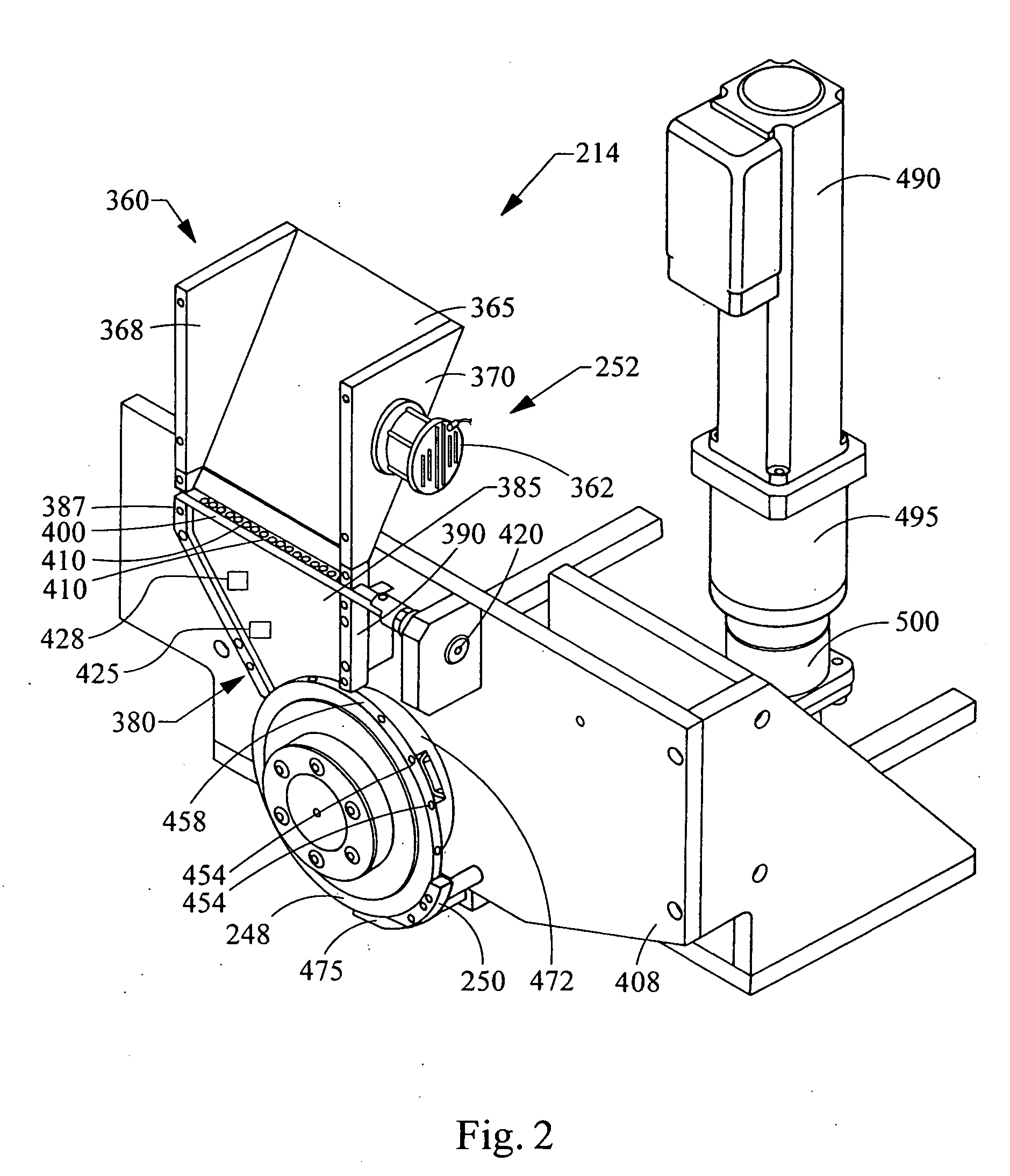

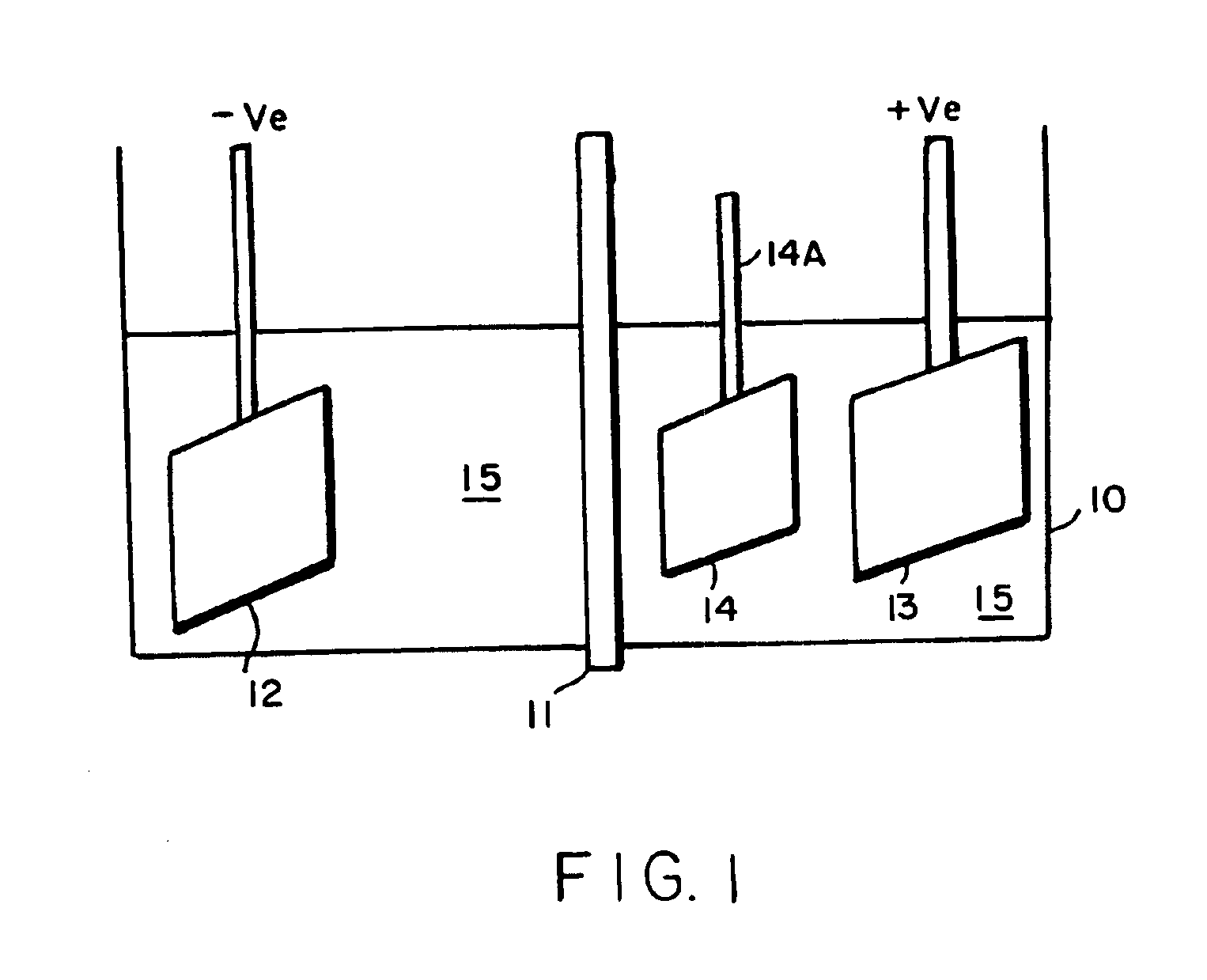

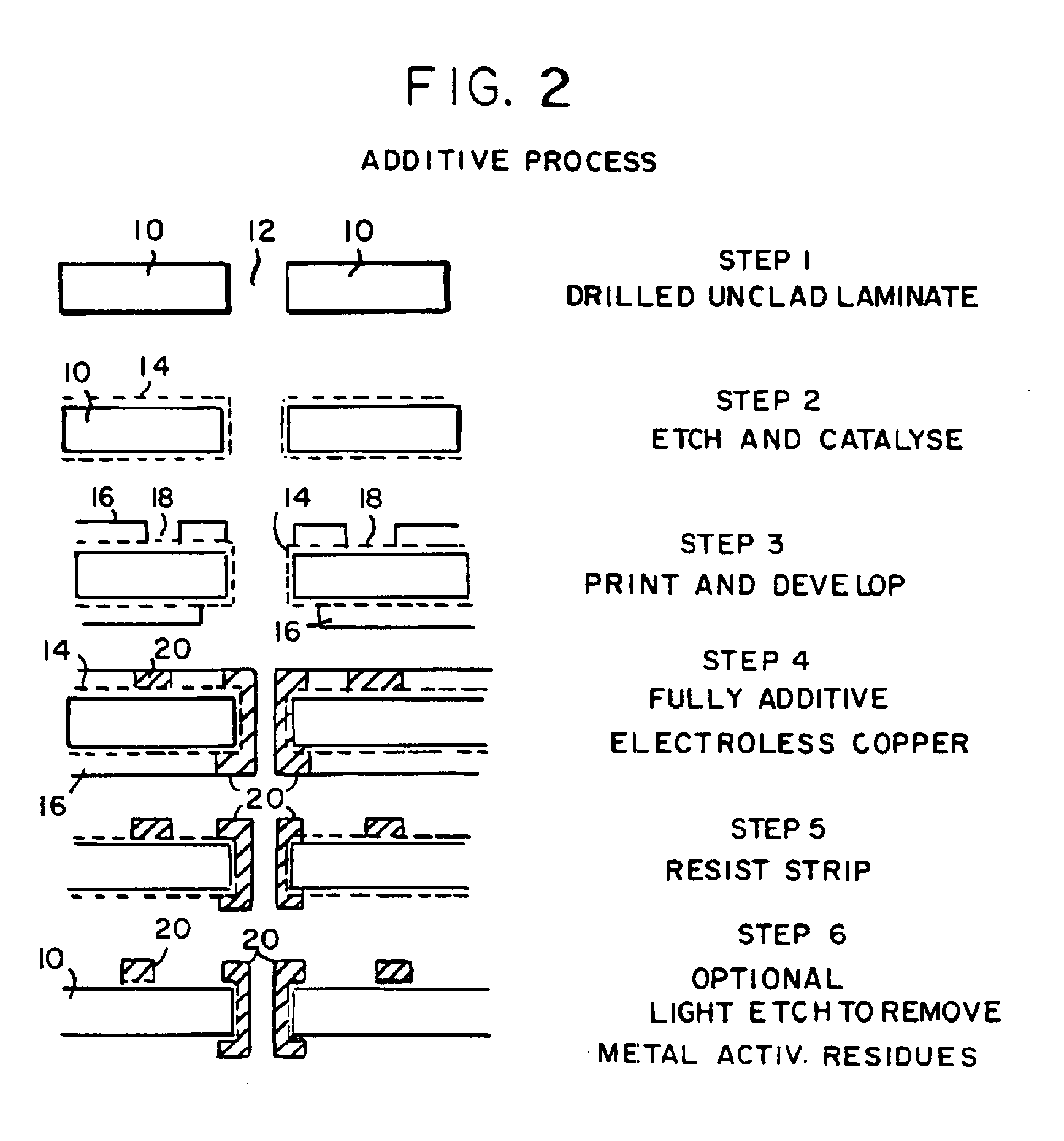

Electroless plating processes

InactiveUS6861097B1Reducing problem encounteredSimple methodPaper/cardboard articlesDecorative surface effectsPolymeric surfaceOxidation state

The invention includes processes for combined polymer surface treatment and metal deposition. Processes of the invention include forming an aqueous solution containing a metal activator, such as an oxidized species of silver, cobalt, ruthenium, cerium, iron, manganese, nickel, rhodium, or vanadium. The activator can be suitably oxidized to a higher oxidation state electrochemically. Exposing a part to be plated (such as an organic resin, e.g. a printed circuit board substrate) to the solution enables reactive hydroxyl species (e.g. hydroxyl radicals) to be generated and to texture the polymer surface. Such texturing facilitates good plated metal adhesion. As part of this contacting process sufficient time is allowed for both surface texturing to take place and for the oxidized metal activator to adsorb onto said part. The part is then contacted with a reducing agent capable of reducing the metal activator to a lower ionic form, or a lower oxidation state. That reduction can result in the formation of metallic catalytic material over the surface of the part. The reduced metal activator can then function to catalyze the electroless deposition of metal such as copper from solution by contacting the part with the plating solution.

Owner:SHIPLEY CO LLC

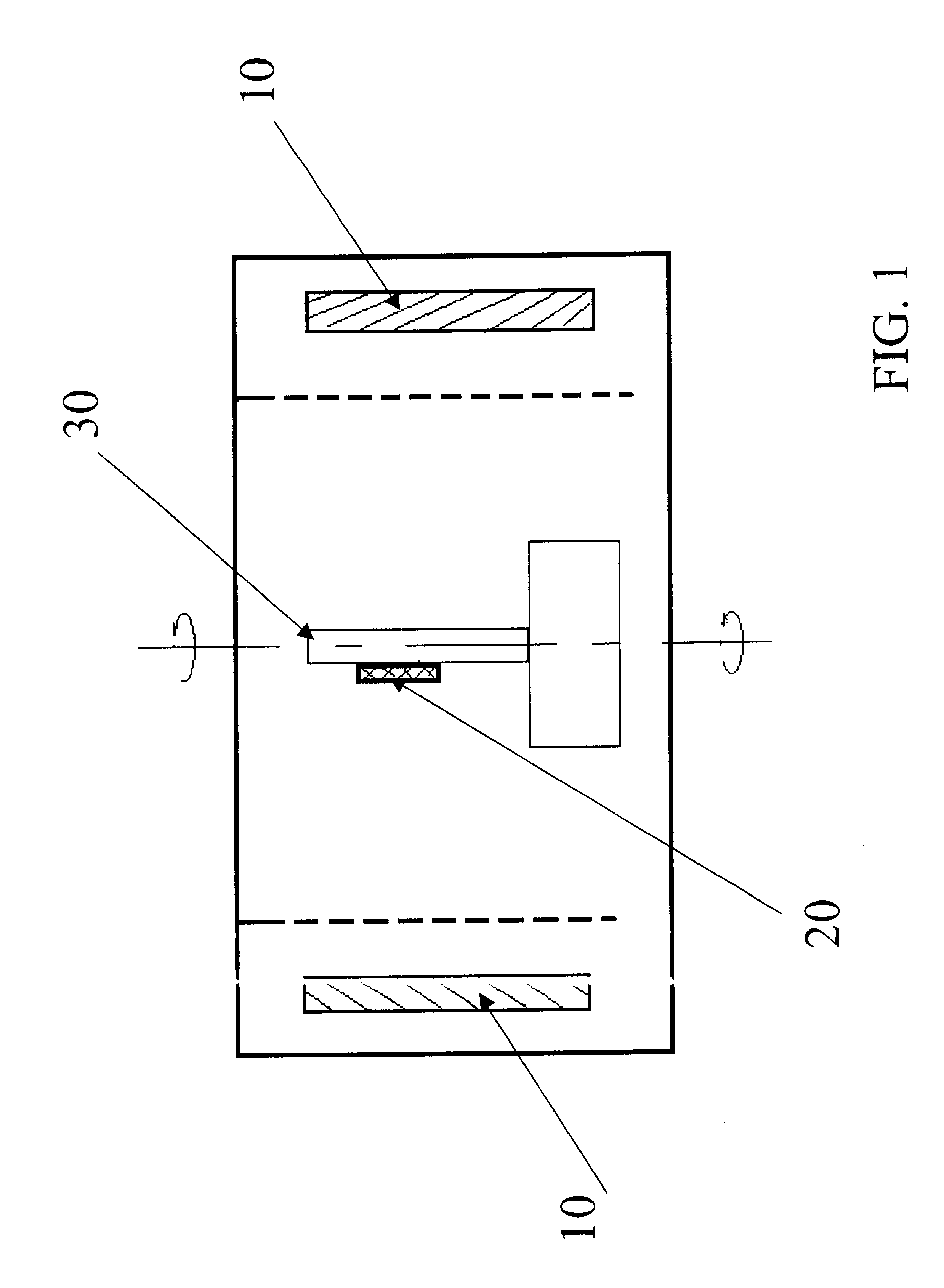

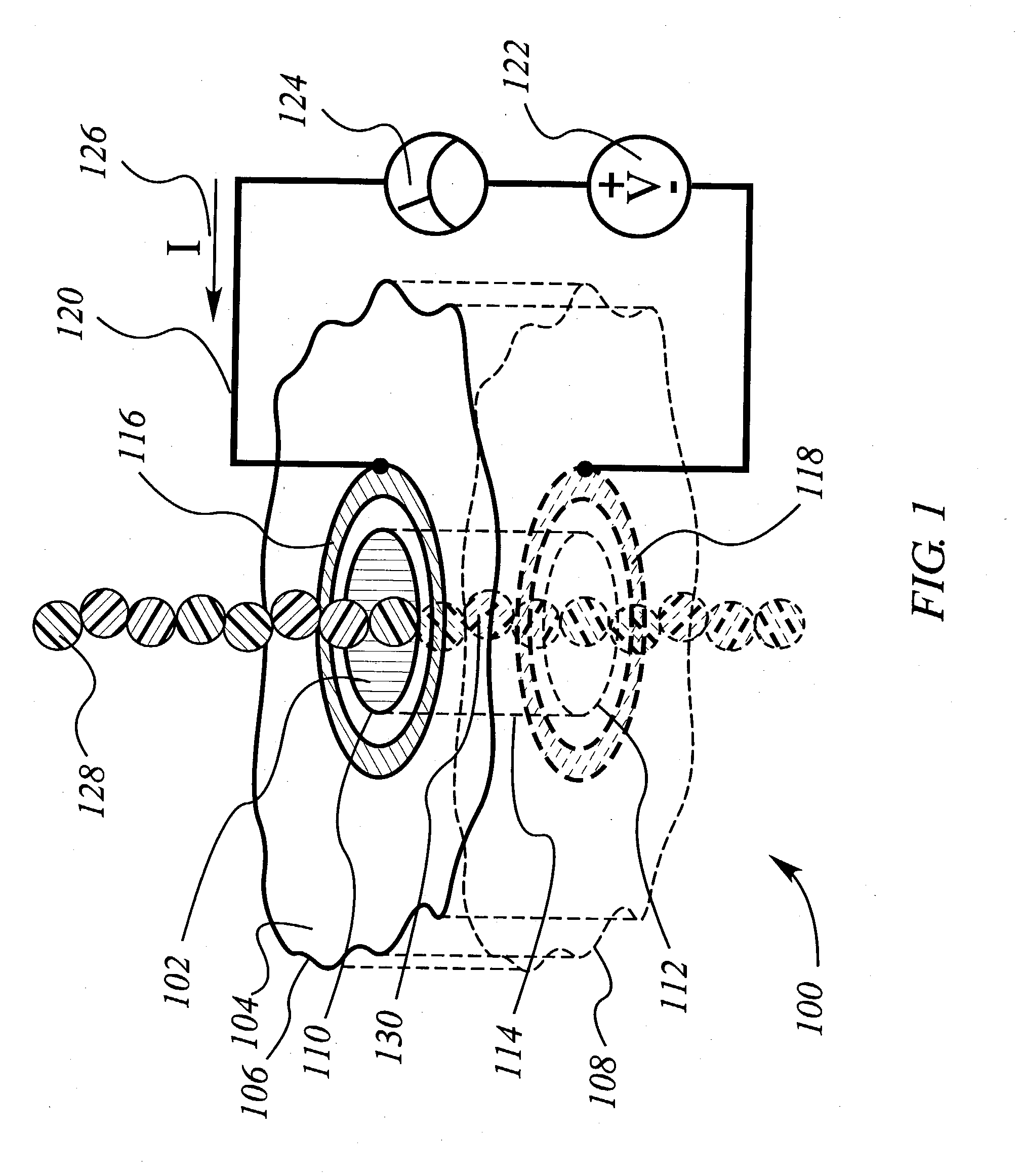

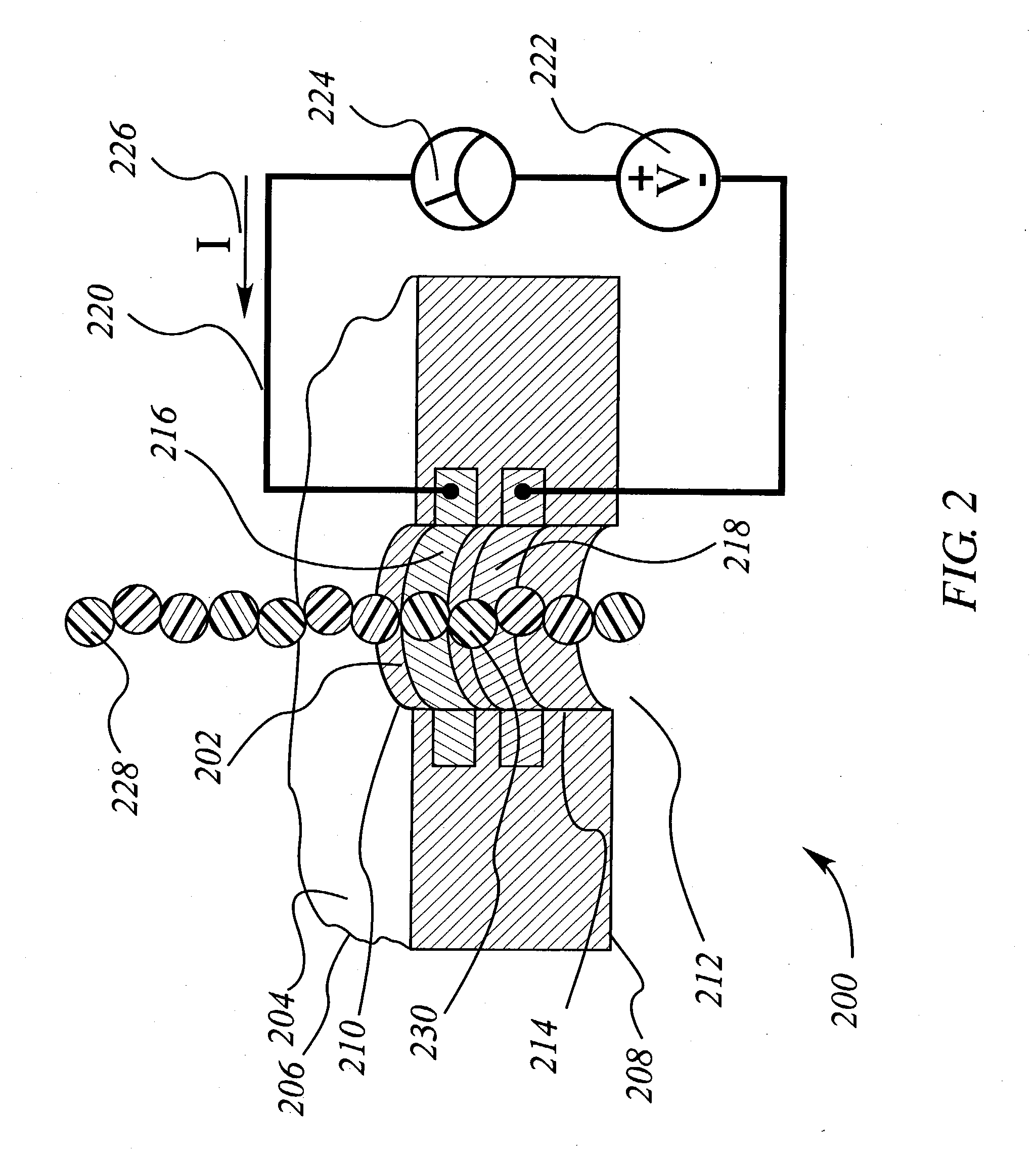

Nanopore with resonant tunneling electrodes

InactiveUS20070138132A1Paper/cardboard articlesDecorative surface effectsPotential differenceBiopolymer

The present invention provides an apparatus and method for making an apparatus for sensing and / or characterizing a biopolymer translocating a nanopore. The apparatus of the present invention provides a first electrode, a first insulator, a second electrode, a optional insulator, a voltage source for applying a time varying potential difference between the electrodes, and a means of measuring the resulting current between the two electrodes. A method for making the apparatus is also disclosed.

Owner:AGILENT TECH INC

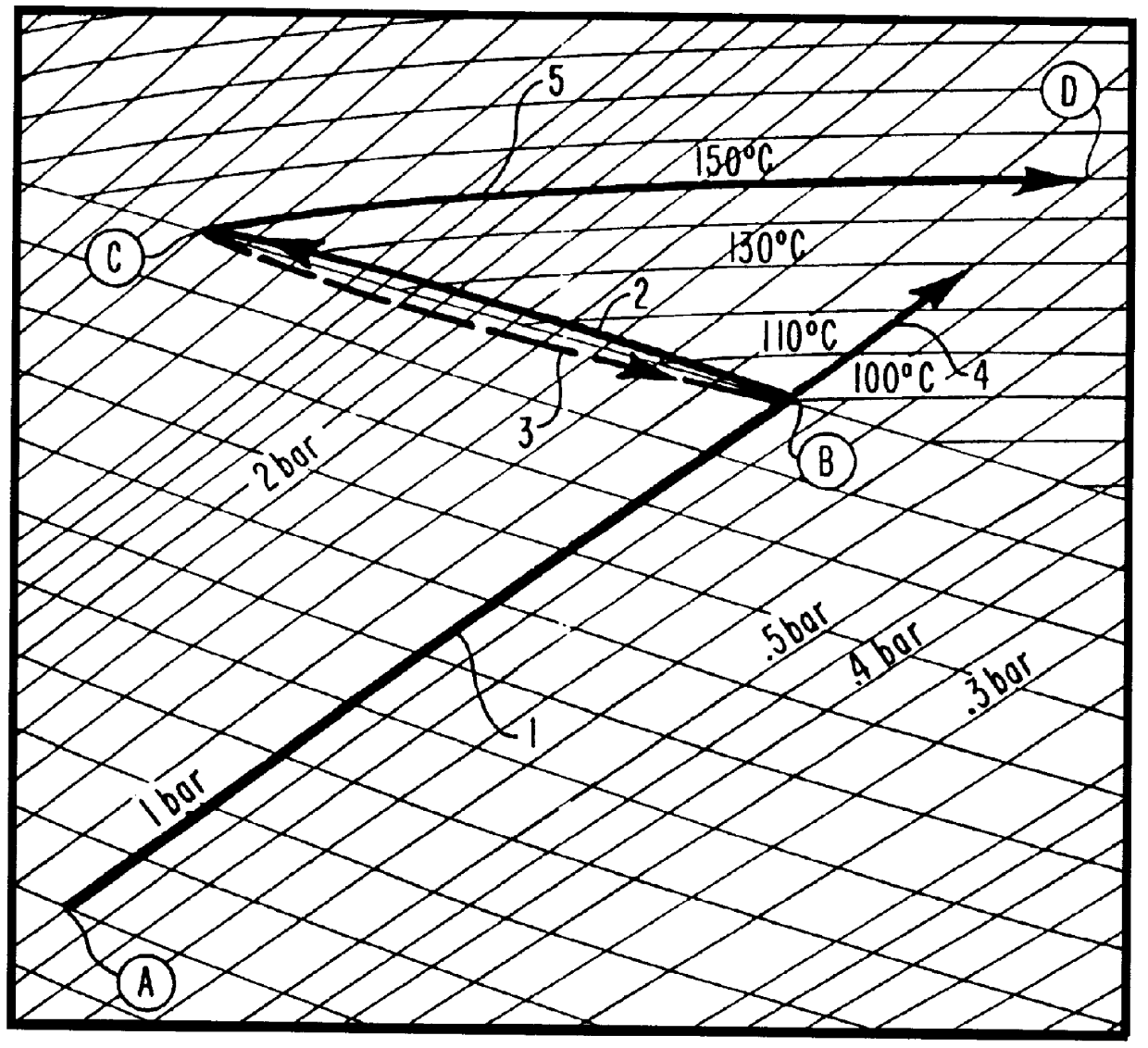

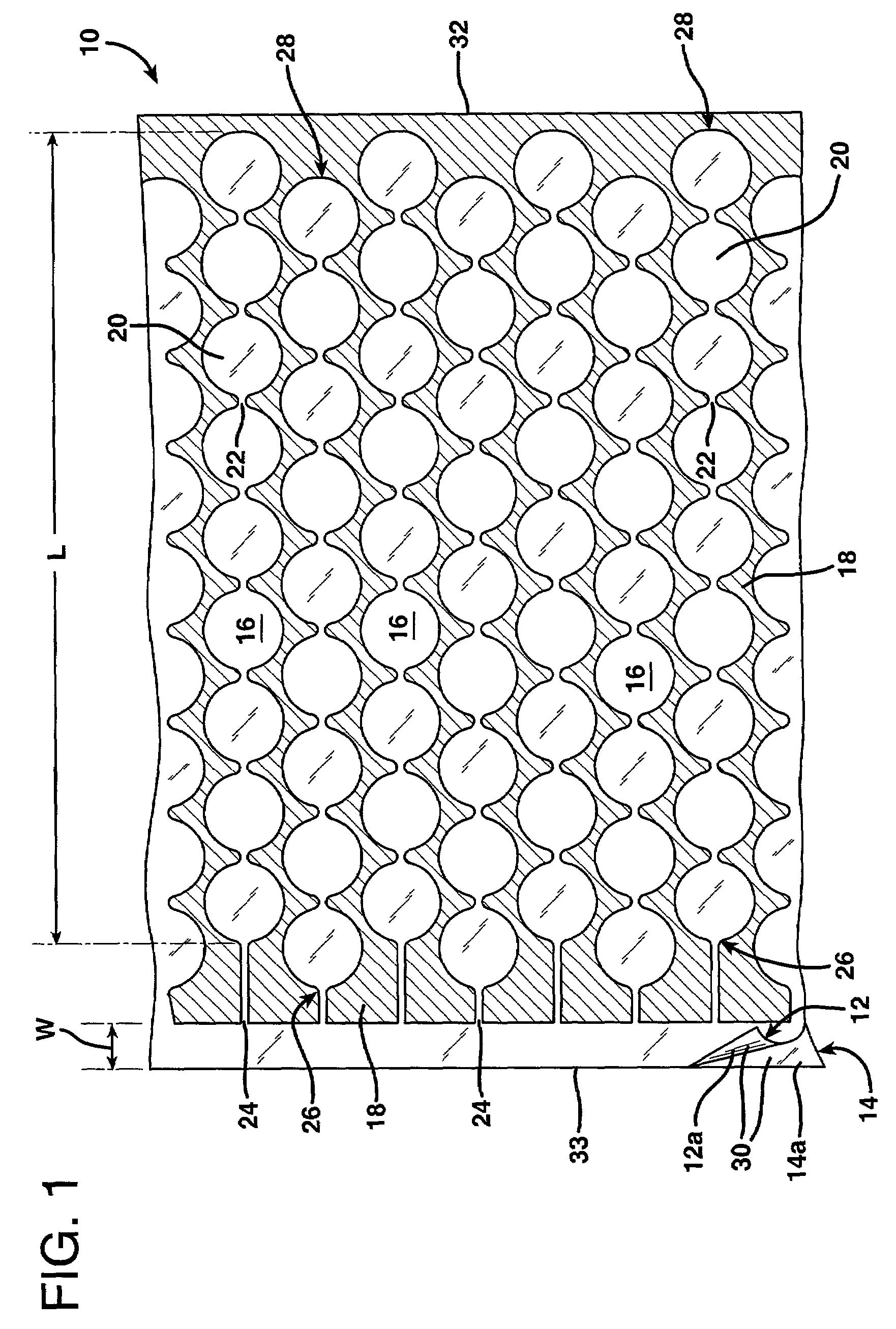

Molded starch-bound containers and other articles having natural and/or synthetic polymer coatings

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a particle packed, highly inorganically filled, cellular matrix are disclosed. Suitable inorganically filled mixtures are prepared by mixing together a starch-based binder, a solvent, inorganic aggregates, and optimal admixtures, e.g., fibers, mold-releasing agents, rheology-modifying agents, plasticizers, coating materials, and dispersants, in the correct proportions to form an article which has the desired performance criteria. The inorganically filled mixtures have a predetermined viscosity and are heated between molds at an elevated temperature and pressure to produce form-stable articles having a desired shape and a selectively controlled cellular, structure matrix. The molded articles may be placed in a high humidity chamber to obtain the necessary flexibility for their intended use. The articles may be manufactured to have properties substantially similar to articles presently made from conventional materials like paper, paperboard, polystyrene, plastic, or other organic materials. They have especial utility in the mass-production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

Equipment for insertion of objects into smoking articles

ActiveUS7479098B2Sufficient shapeSufficient sizeMechanical working/deformationPaper/cardboard articlesSpace objectEngineering

Apparatus incorporating a filter tow processing unit adapted to supply filter tow to a continuous rod forming unit includes an object insertion unit that positions objects within the filter tow to manufacture a filter rod containing objects positioned at predetermined intervals. The apparatus also includes an upper hopper that acts as a reservoir for a plurality of objects, and provides for supply of objects to a lower hopper. The lower hopper is shaped so that objects are stacked therein. The bottom of the lower hopper is shaped so as to cooperate with a portion of upper region of a rotating wheel. The peripheral face of the rotating wheel incorporates a plurality of spaced pockets, each pocket being of sufficient shape and size to accommodate one object. Objects within the lower hopper are aligned in a single line along a portion of the peripheral face in the upper region of the rotating wheel. Each object then is positioned at predetermined intervals within a continuous supply of filter material. Then, the filter material is formed into a continuous rod having individual objects positioned at predetermined spaced intervals within that rod. The continuous rod then is subdivided at predetermined intervals so as to form a plurality of filter rods (e.g., four-up filter rods containing four spaced objects).

Owner:R J REYNOLDS TOBACCO COMPANY

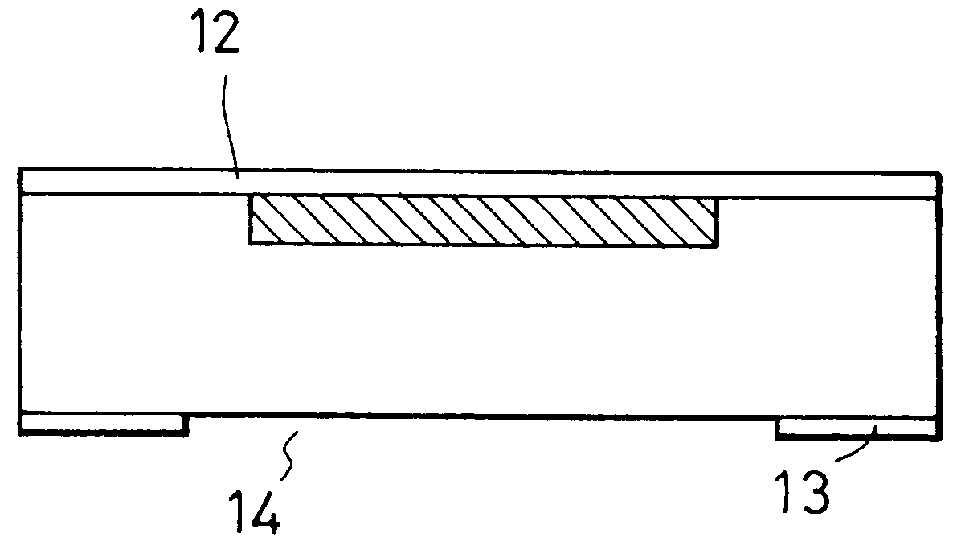

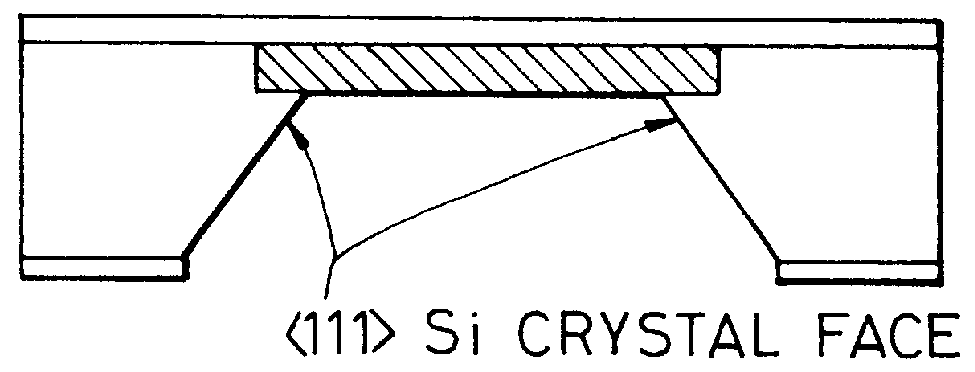

Method of producing a through-hole, silicon substrate having a through-hole, device using such a substrate, method of producing an ink-jet print head, and ink-jet print head

The invention provides a method of producing a through-hole, a substrate used to produce a through-hole, a substrate having a through-hole, and a device using such a through-hole or a substrate having such a through-hole, which are characterized in that: a through-hole can be produced only by etching a silicon substrate from its back side; the opening length d can be precisely controlled to a desired value regardless of the variations in the silicon wafer thickness, and the orientation flat angle, and also regardless of the type of a silicon crystal orientation-dependent anisotropic etchant employed; high productivity, high production reproducibility, and ease of production can be achieved; a high-liberality can be achieved in the shape of the opening end even if temperature treatment is performed at a high temperature for a long time; and a high-precision through-hole can be produced regardless of the shape of a device formed on the surface of a substrate.

Owner:CANON KK

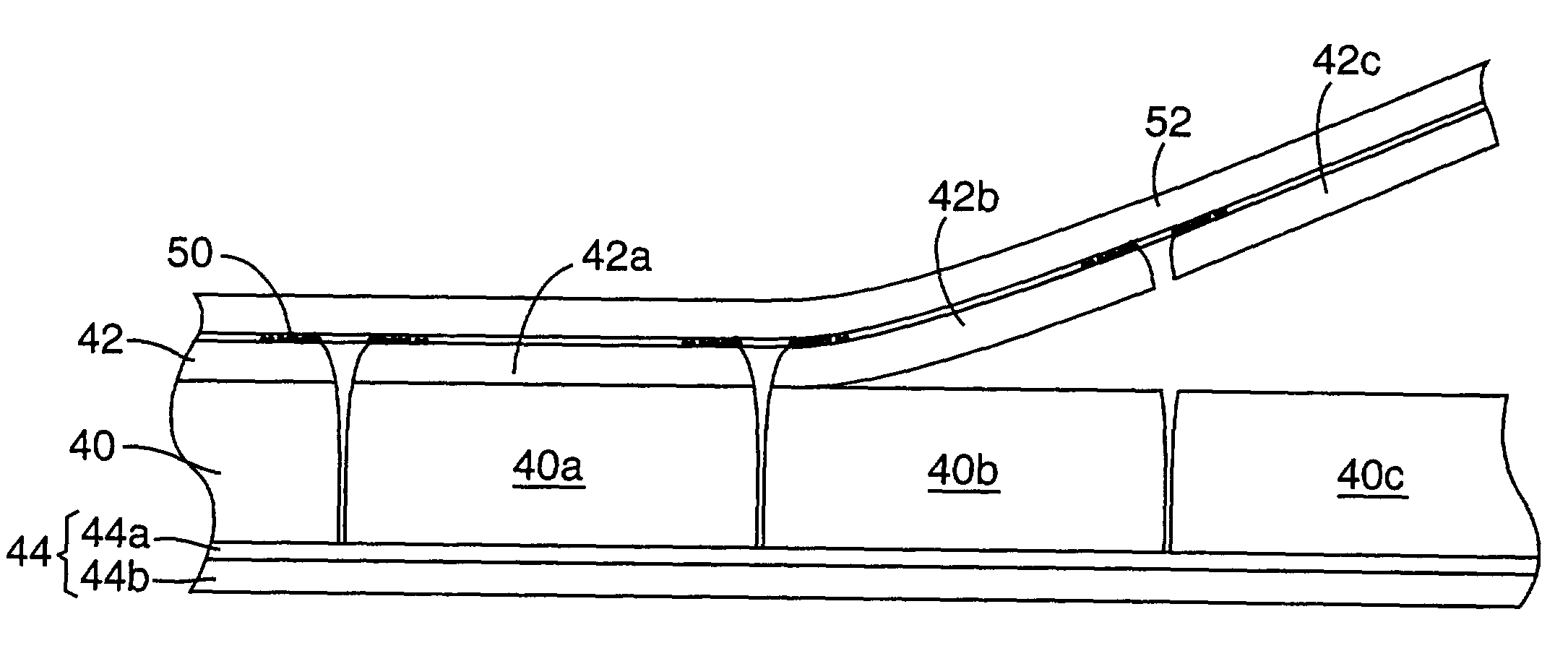

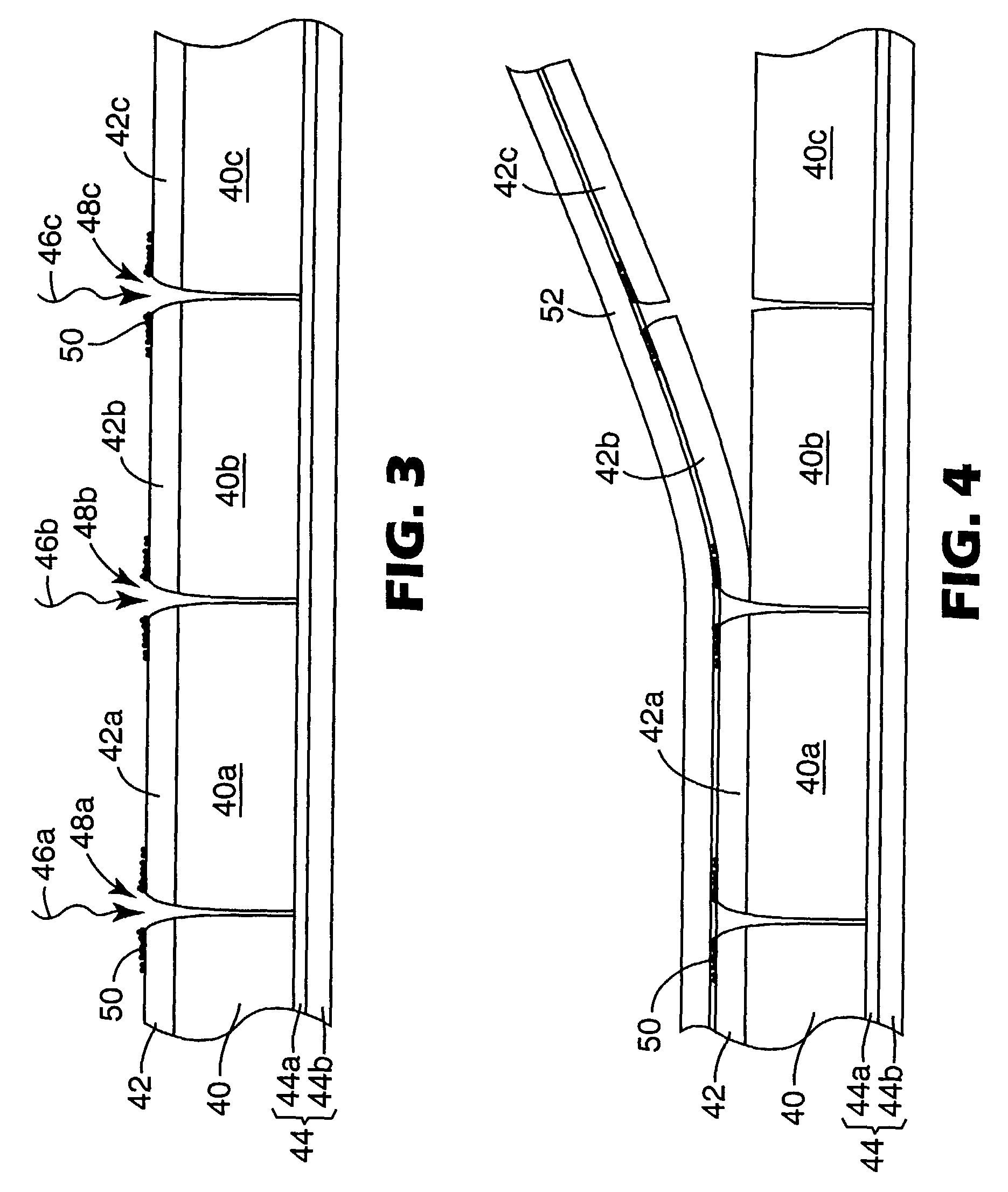

Method for subdividing multilayer optical film cleanly and rapidly

InactiveUS6991695B2Reduce electrostatic attractionPaper/cardboard articlesOptical articlesPolymerLaser

Owner:3M INNOVATIVE PROPERTIES CO

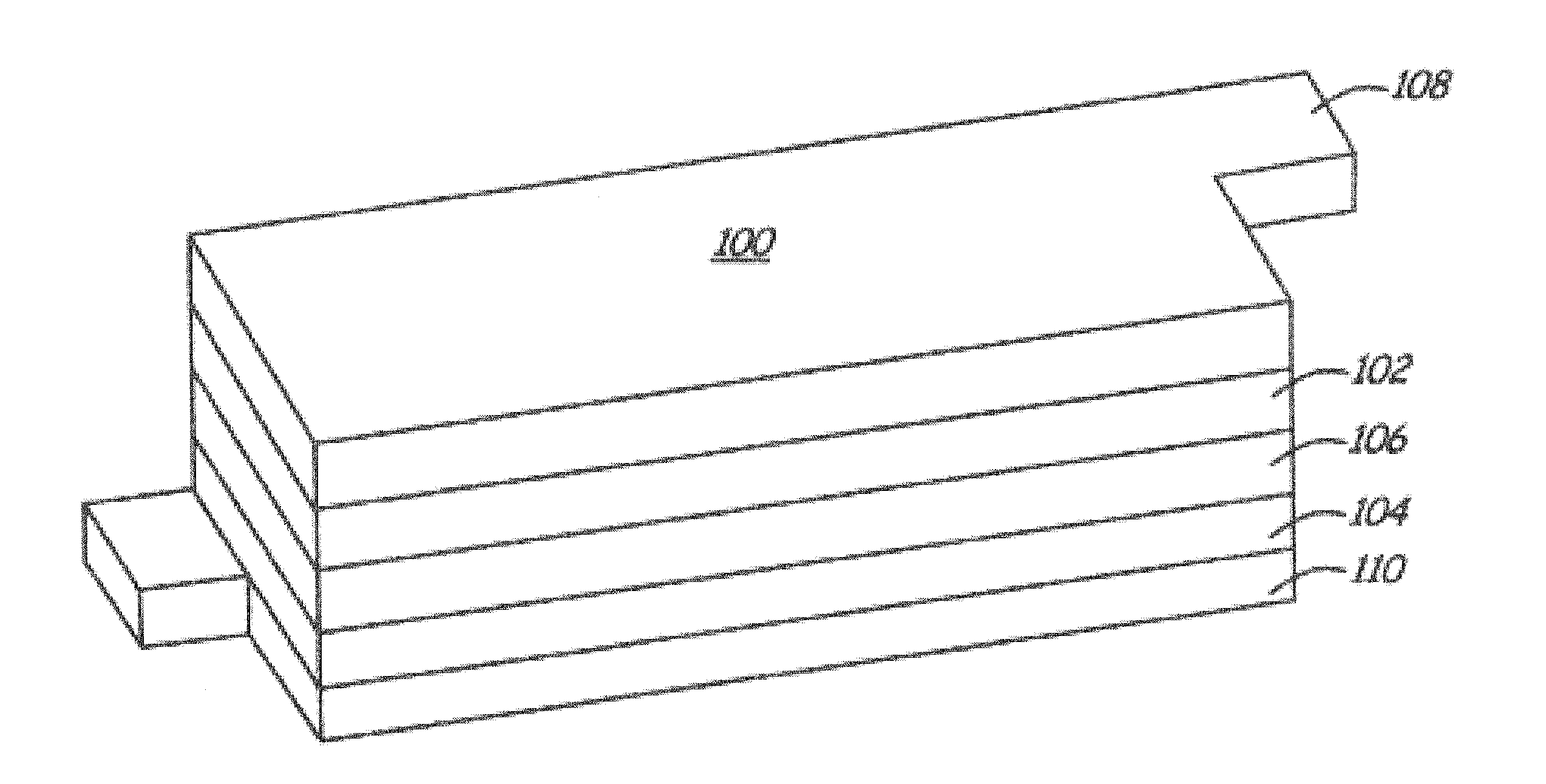

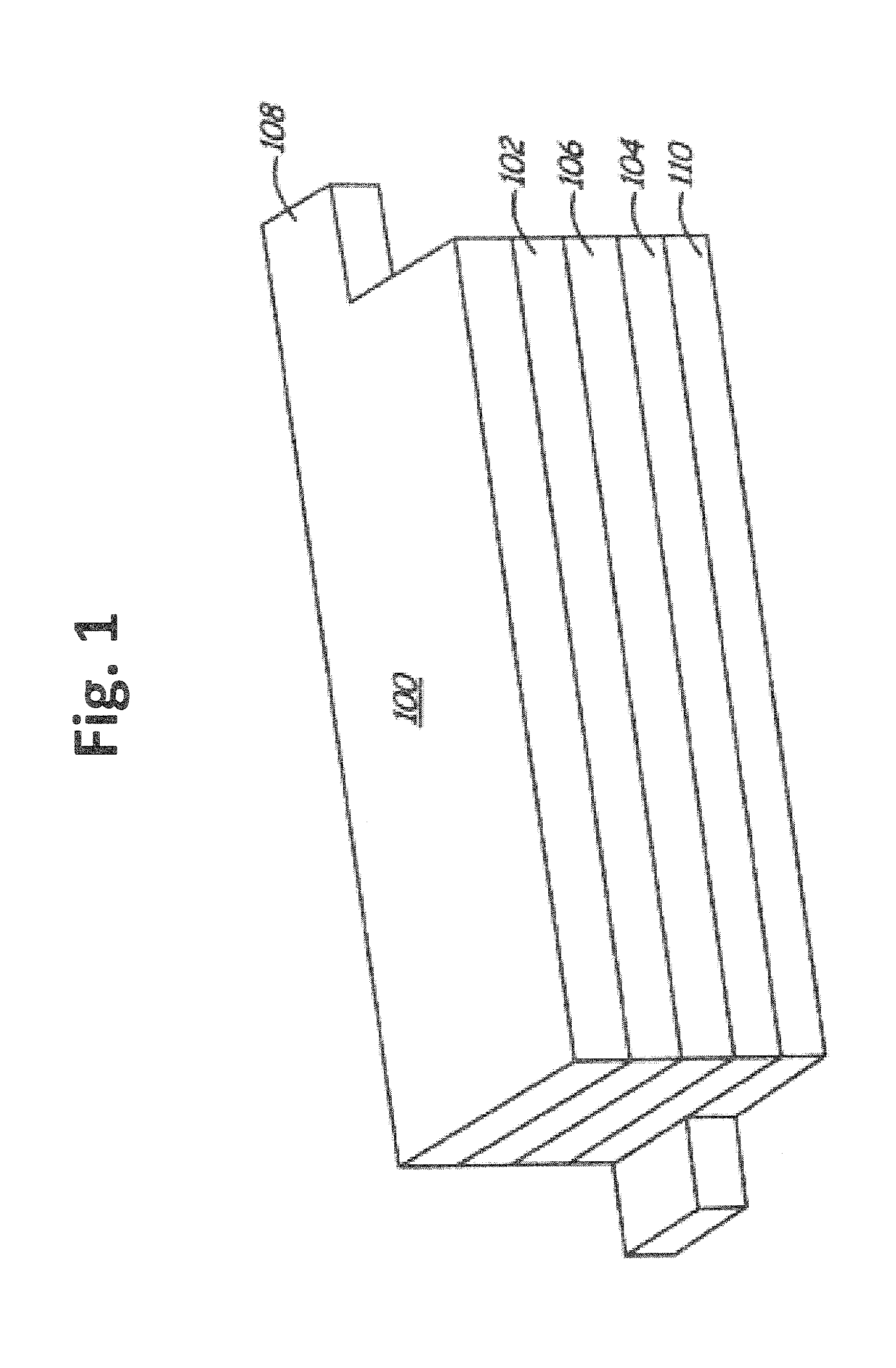

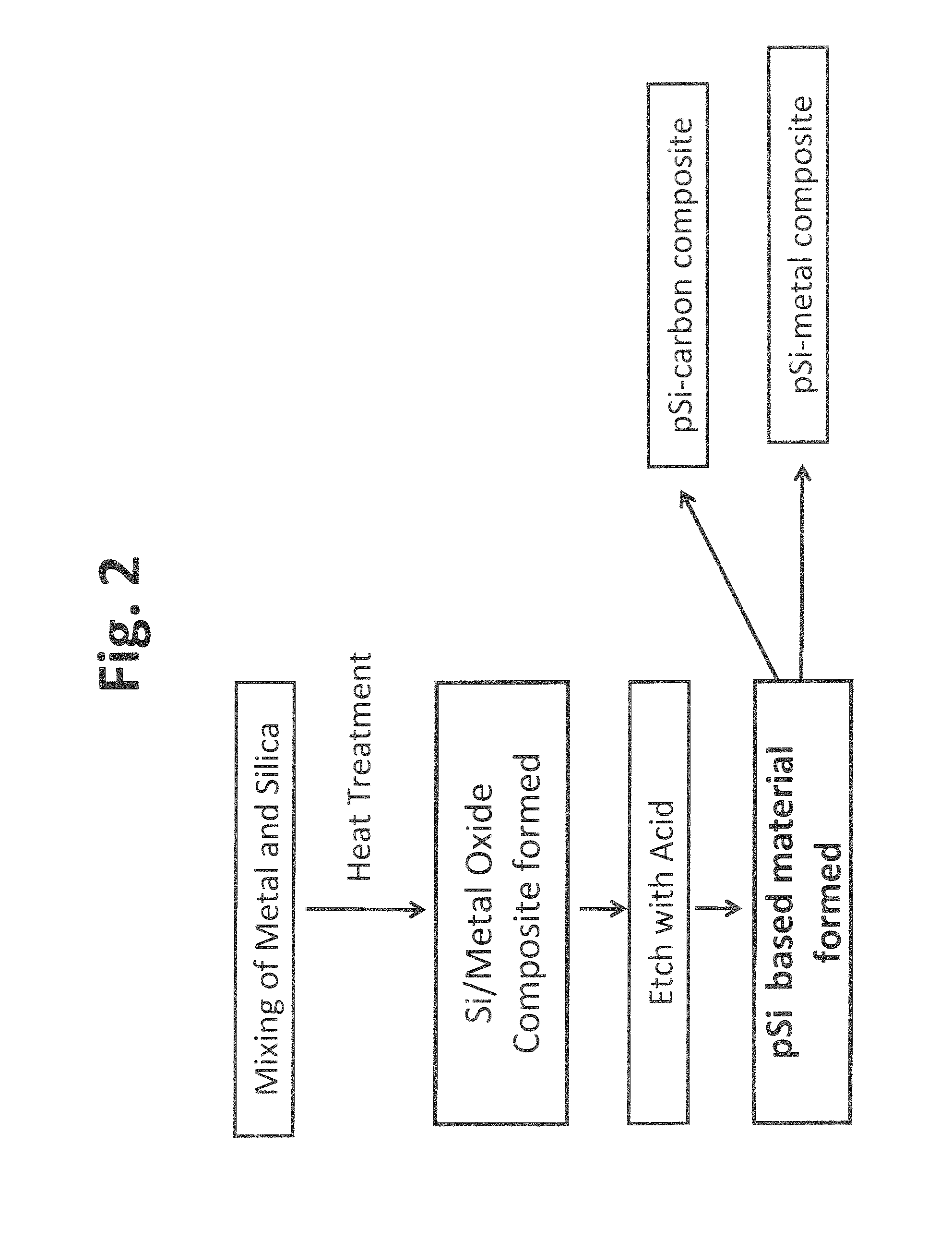

Porous silicon based anode material formed using metal reduction

A porous silicon based material comprising porous crystalline elemental silicon formed by reducing silicon dioxide with a reducing metal in a heating process followed by acid etching is used to construct negative electrode used in lithium ion batteries. Gradual temperature heating ramp(s) with optional temperature steps can be used to perform the heating process. The porous silicon formed has a high surface area from about 10 m2 / g to about 200 m2 / g and is substantially free of carbon. The negative electrode formed can have a discharge specific capacity of at least 1800 mAh / g at rate of C / 3 discharged from 1.5V to 0.005V against lithium with in some embodiments loading levels ranging from about 1.4 mg / cm2 to about 3.5 mg / cm2. In some embodiments, the porous silicon can be coated with a carbon coating or blended with carbon nanofibers or other conductive carbon material.

Owner:IONBLOX INC

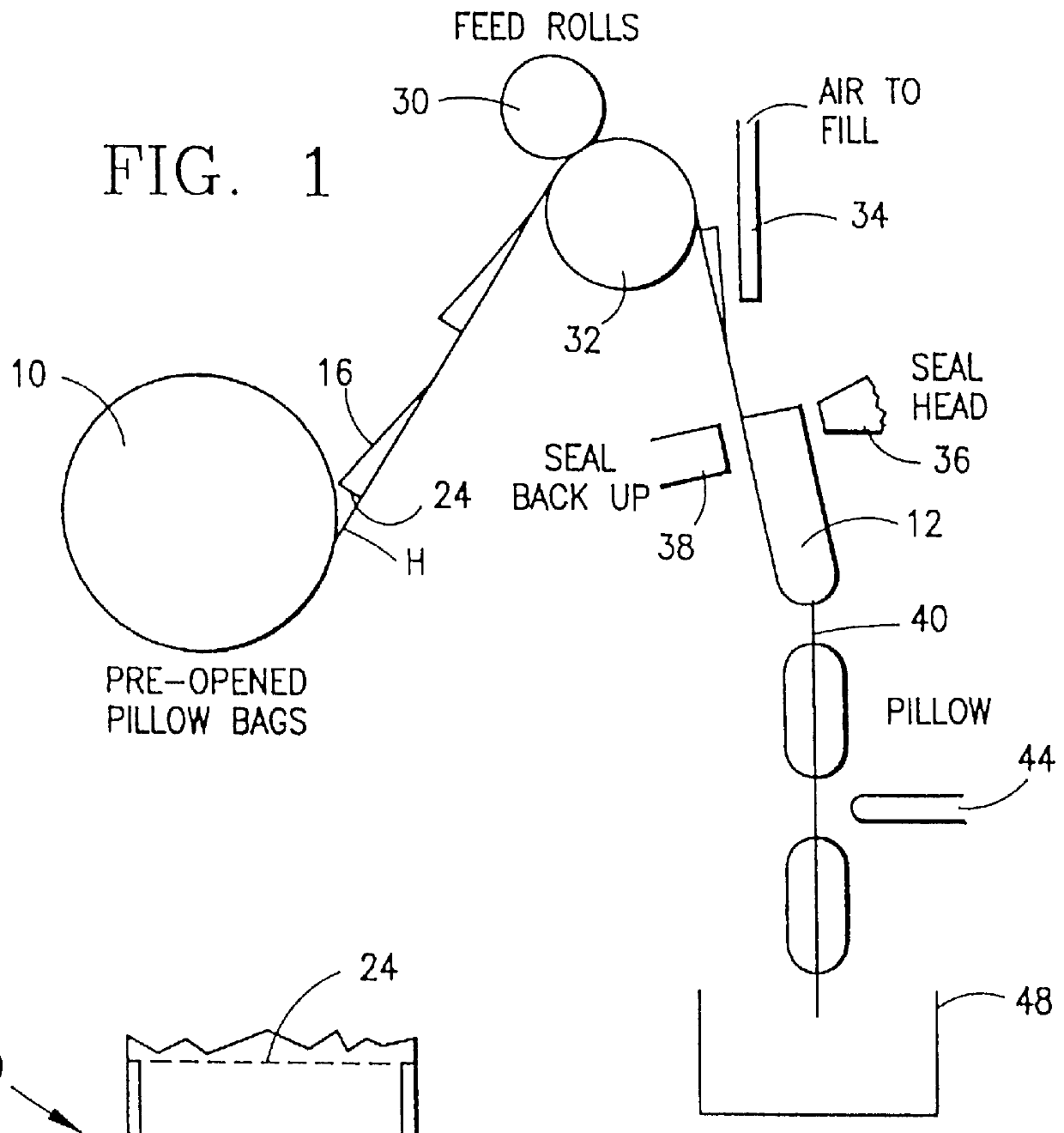

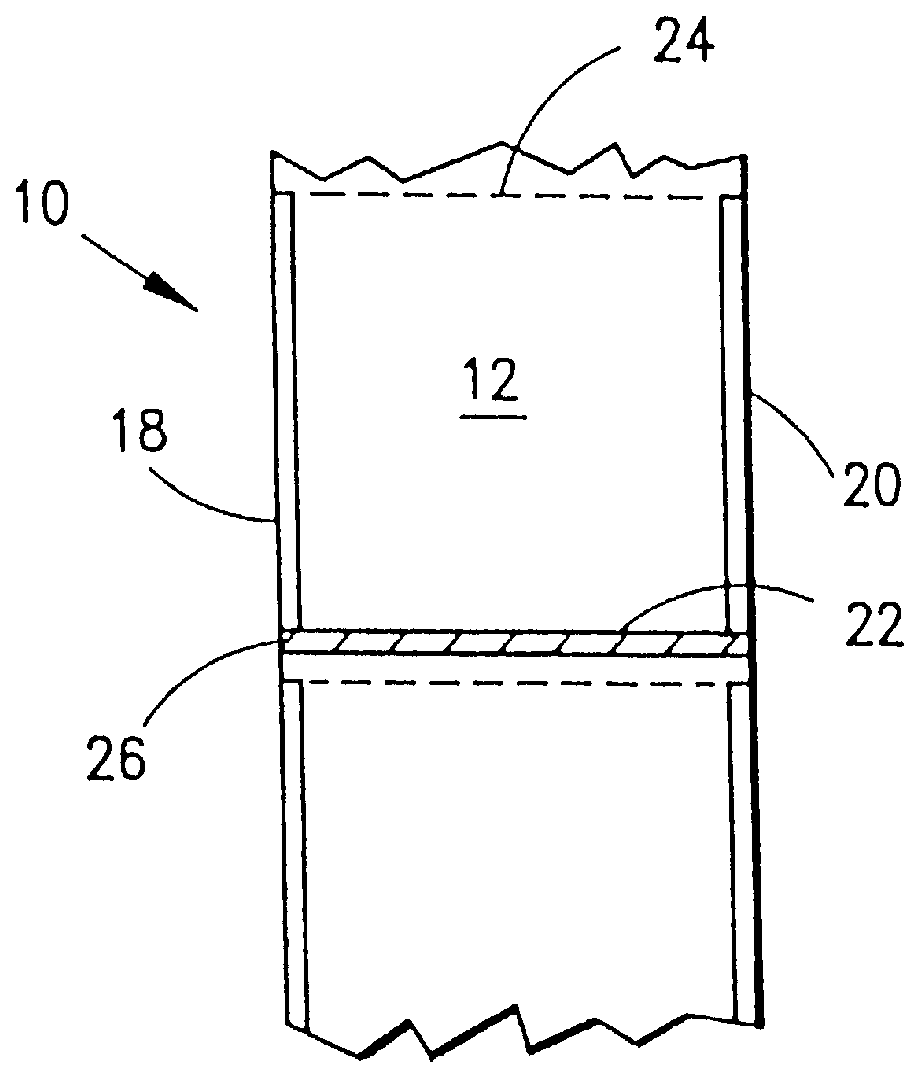

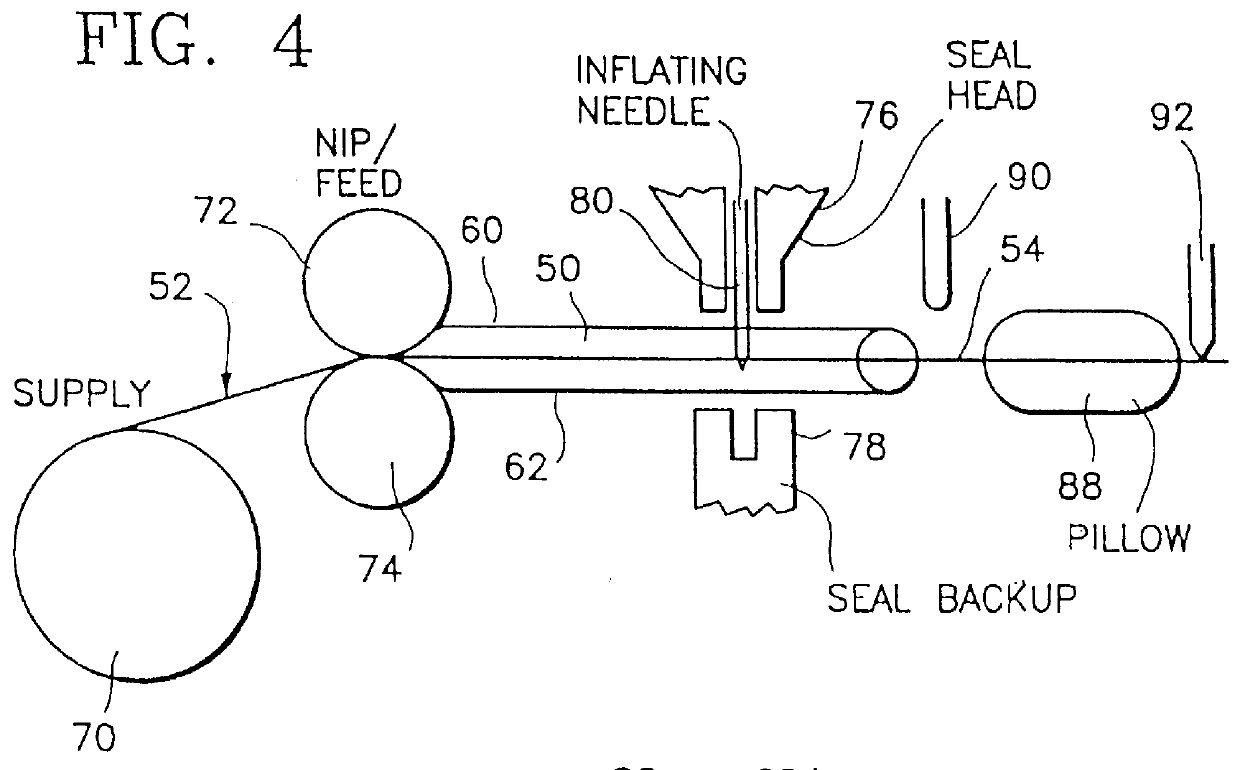

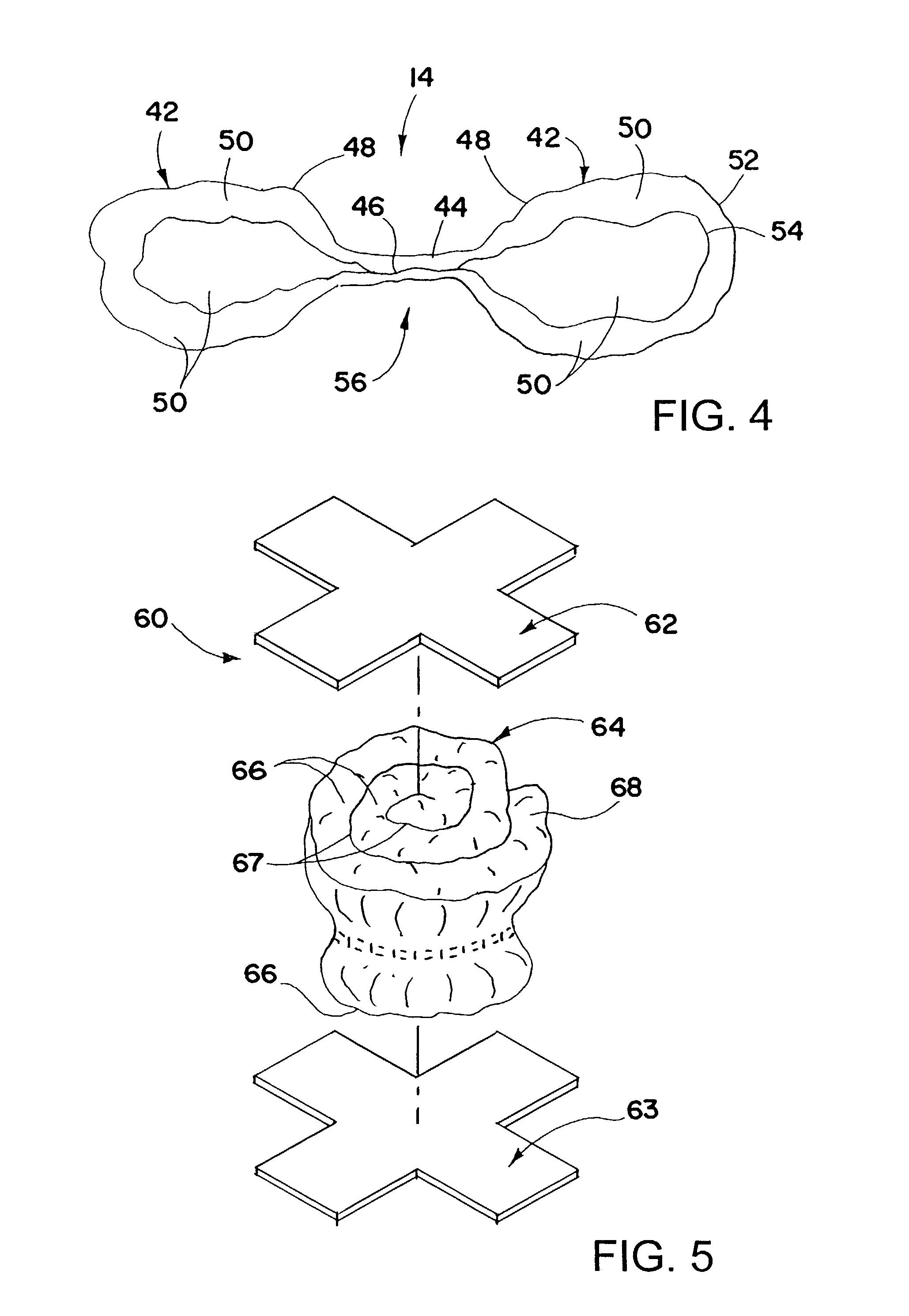

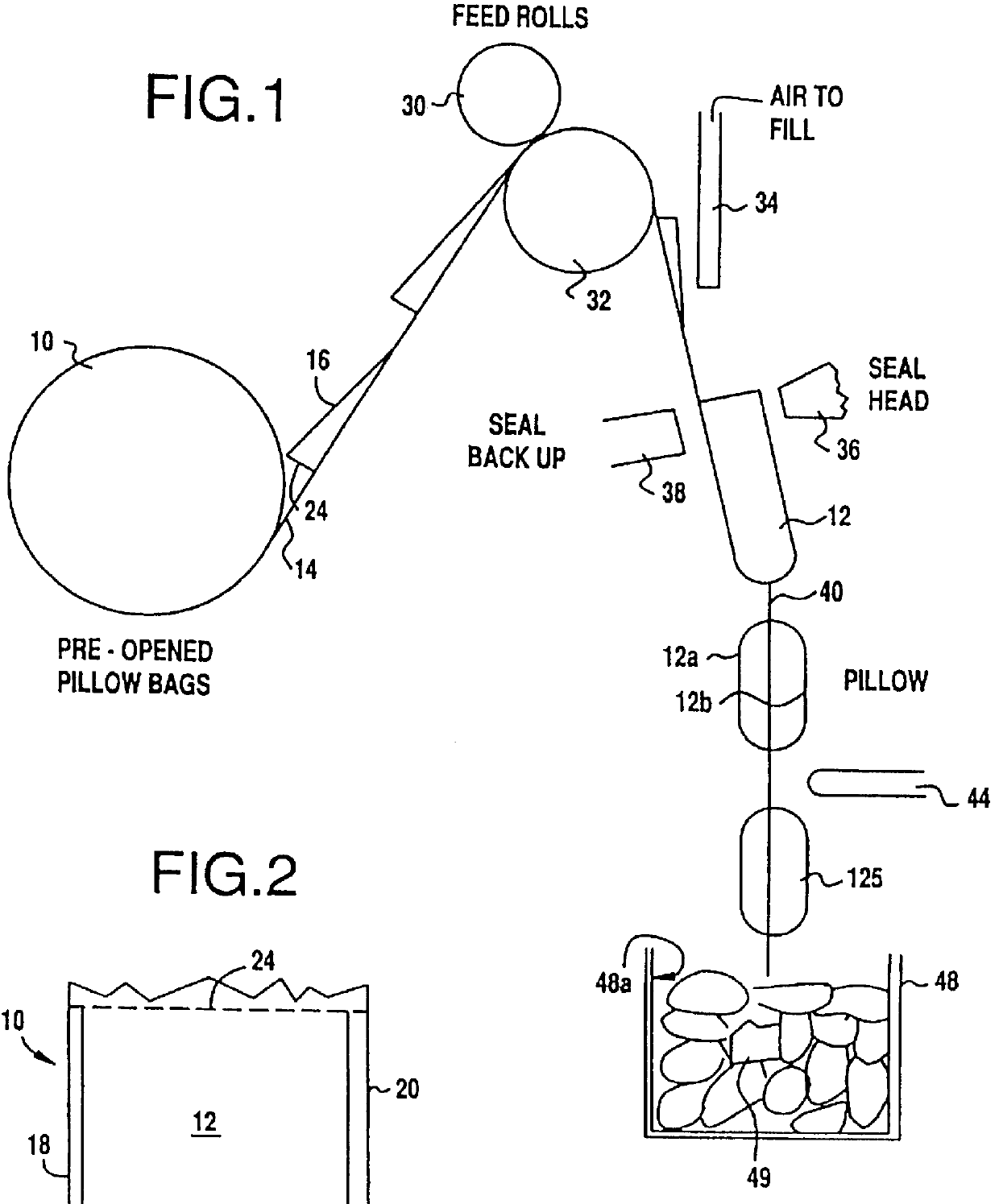

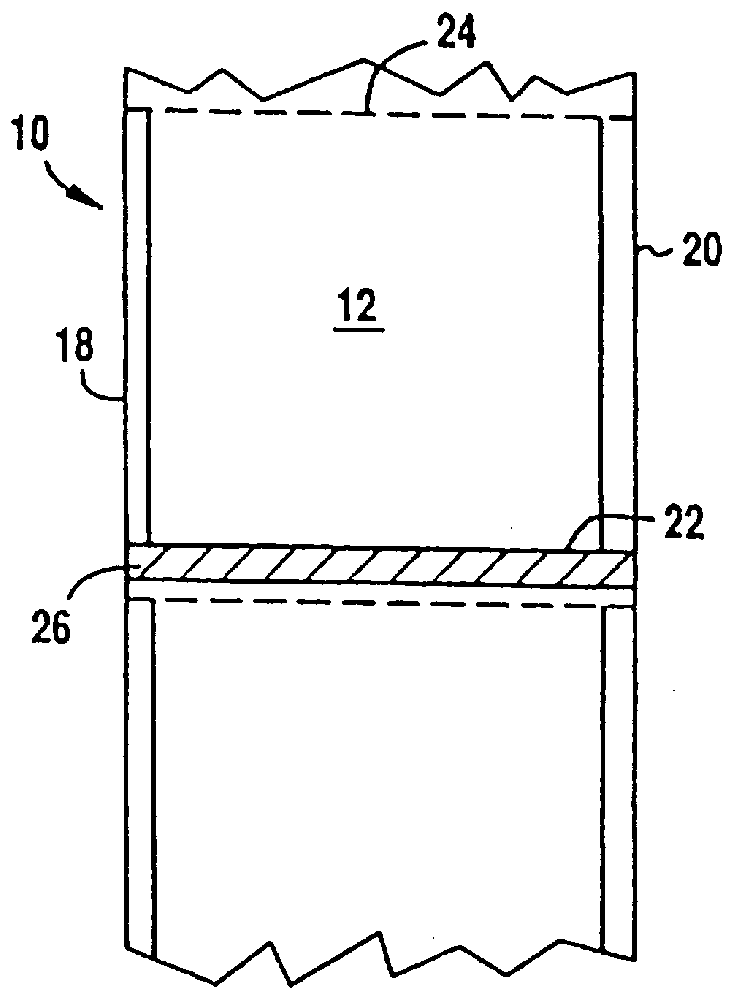

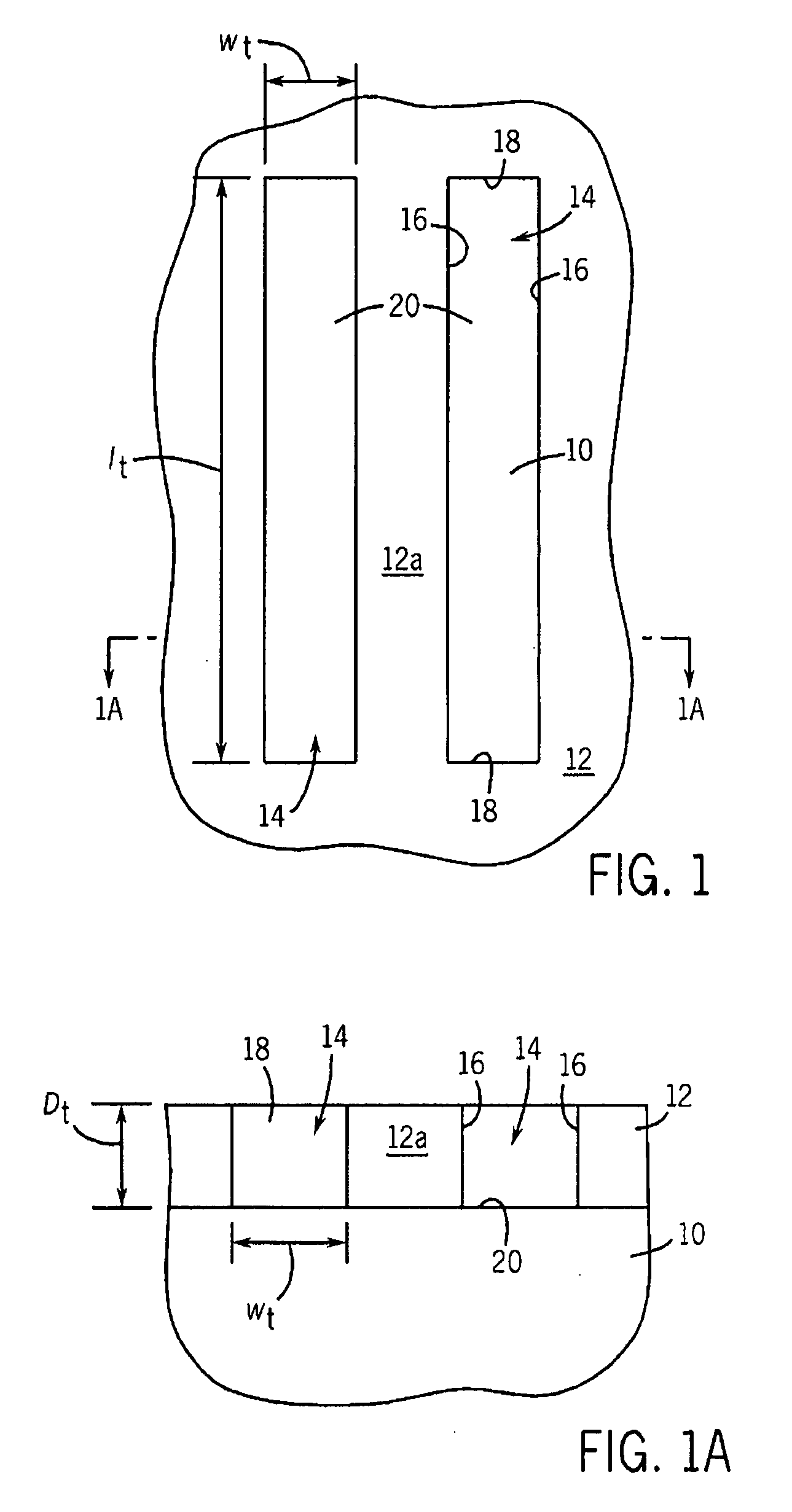

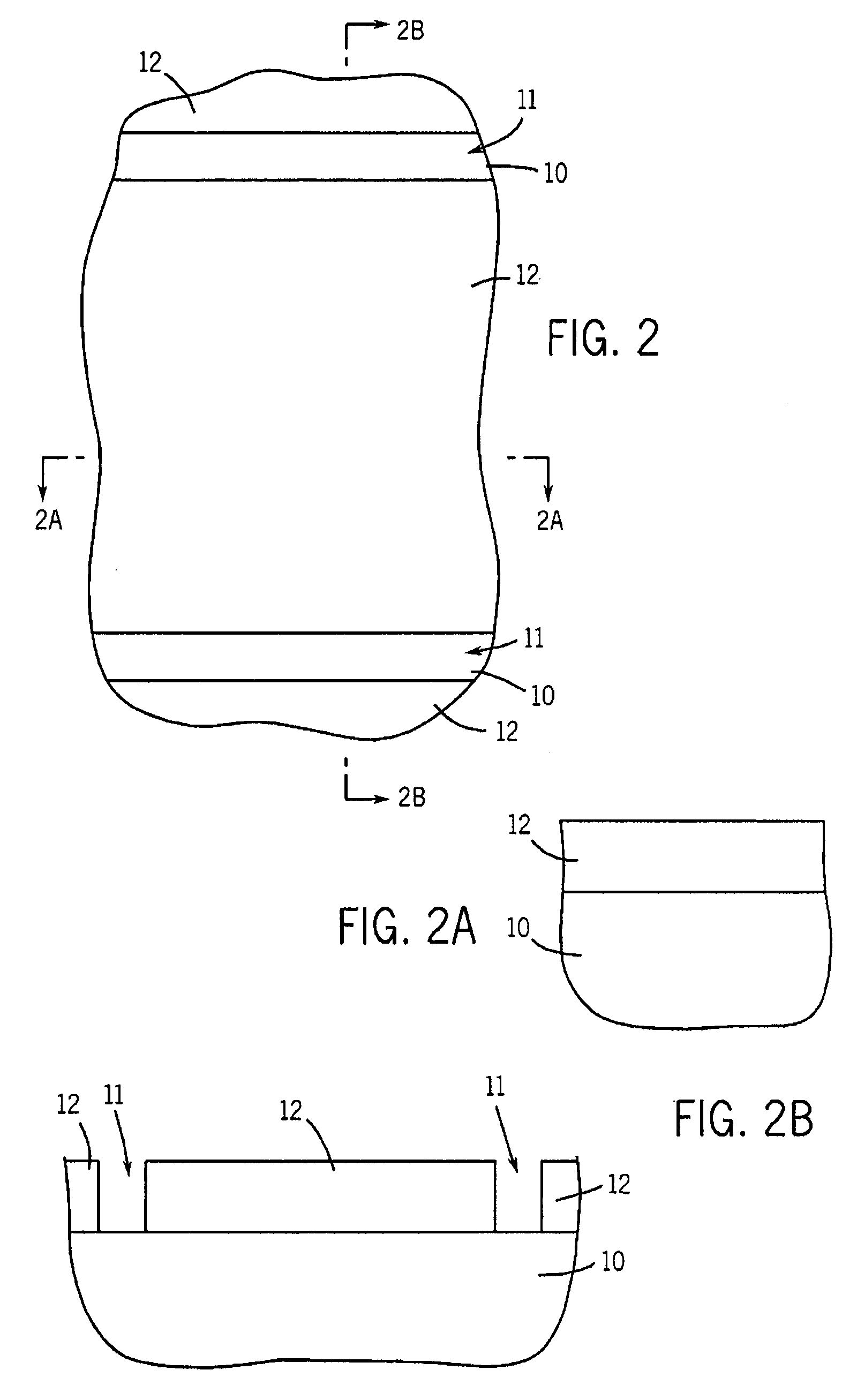

Method for producing inflated dunnage

InactiveUSRE36501E1Easy disposalEasy to reusePreventing unwanted cargo movementLabelling non-rigid containersDunnageCarton

A method for producing inflated dunnage on the site of use, comprising providing, in rolled form, a plurality of preformed plastic bags, each of the bags comprising two plastic sheets in facing relationship and sealed along three edges with one edge remaining open. Air is blown toward each of the open edges in sequence, causing each bag to inflate, and the fourth edge of each inflated bag is sealed, the bag being empty except for the air. At least one sealed inflated bag is separated from the roll and placed in a carton to serve as dunnage. In an alternate embodiment, the stock material is provided in a continuous tubular form, and an air inflation needle is used to puncture a surface of the tube for inflation purposes.

Owner:AUTOMATED PACKAGING SYST

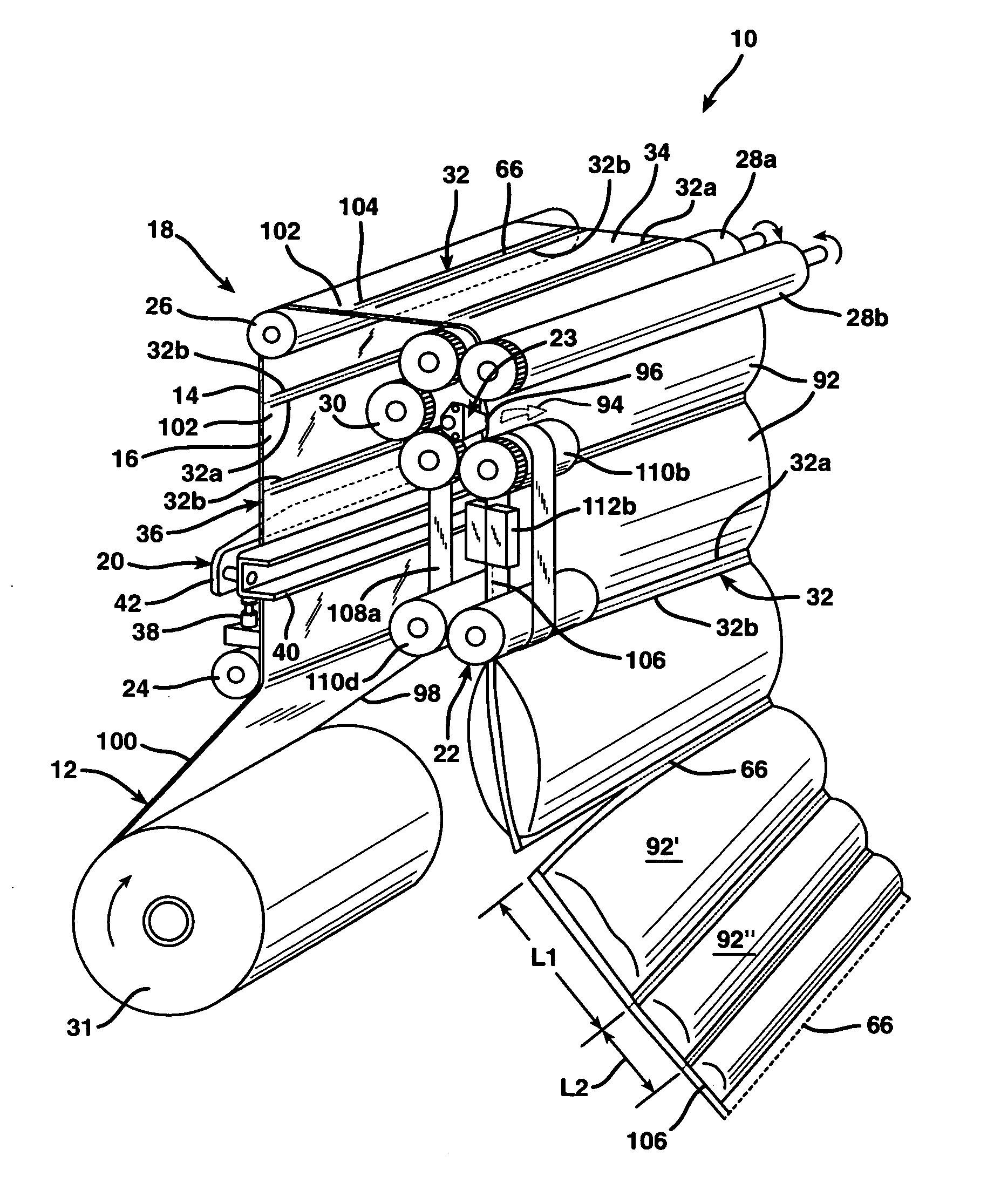

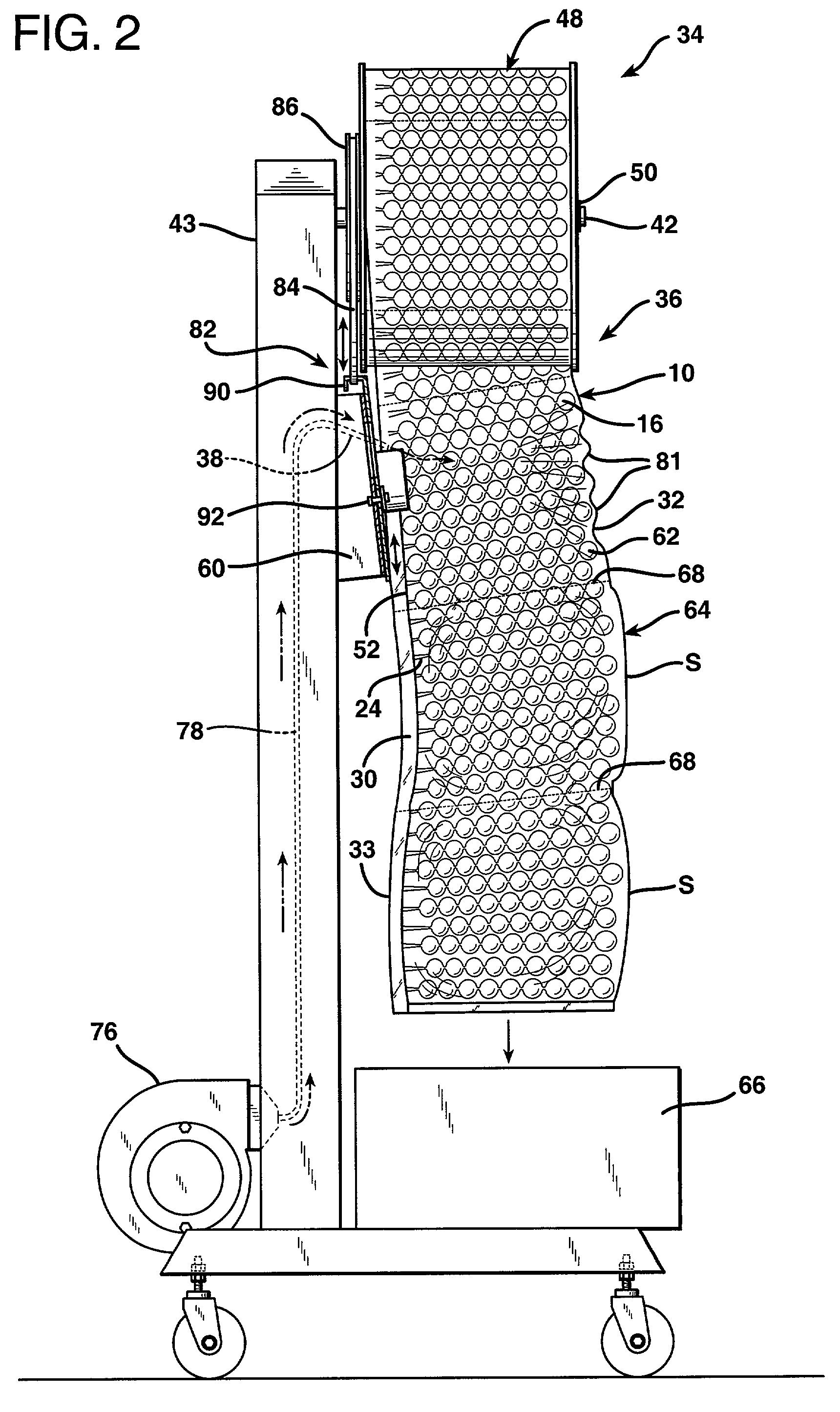

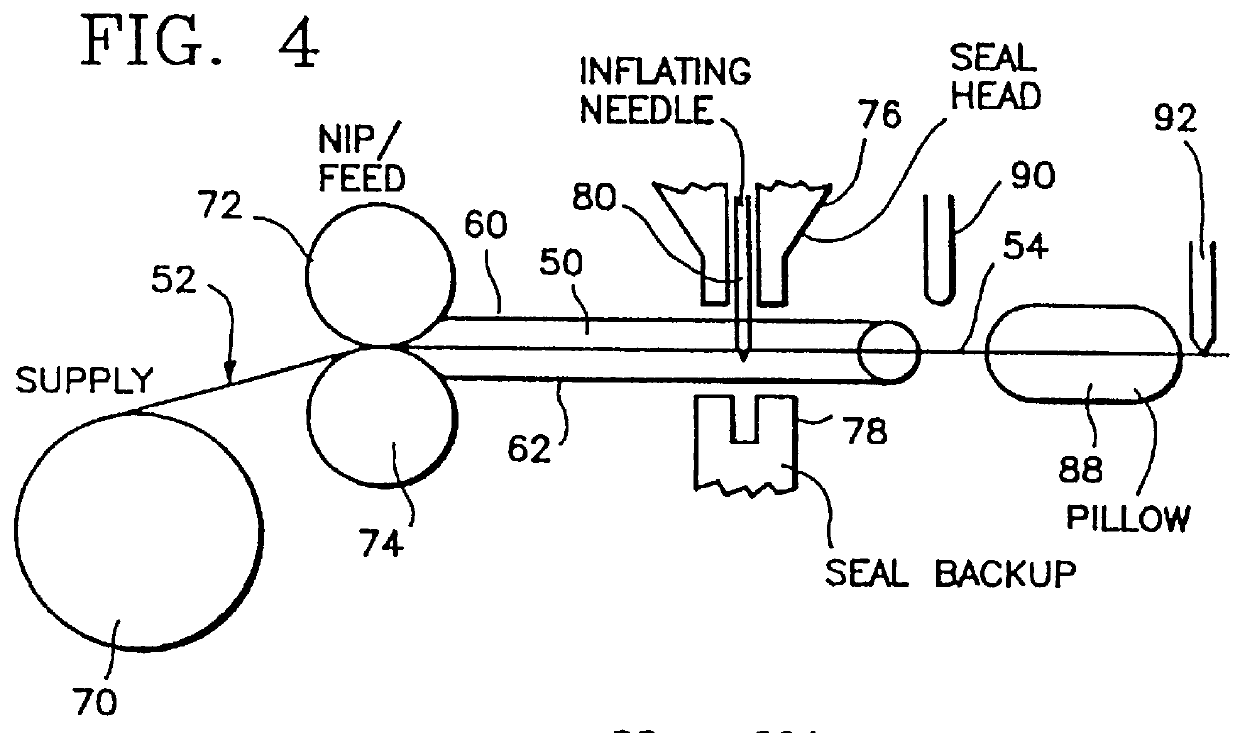

Apparatus and method for forming inflated containers

ActiveUS20060090421A1No sacrifice in production speedImprove sealingCapsPaper/cardboard articlesThin membraneEngineering

An apparatus for forming inflated containers from a film web having two juxtaposed film plies includes: a. a mechanism that conveys the film web along a path of travel; b. a first sealing device for producing one or more seals that bond the film plies together to form a container having at least one opening; c. an inflation assembly for inflating the container by directing a stream of gas into the opening thereof; and d. a second sealing device for sealing closed the opening of the inflated container.

Owner:SEALED AIR U S

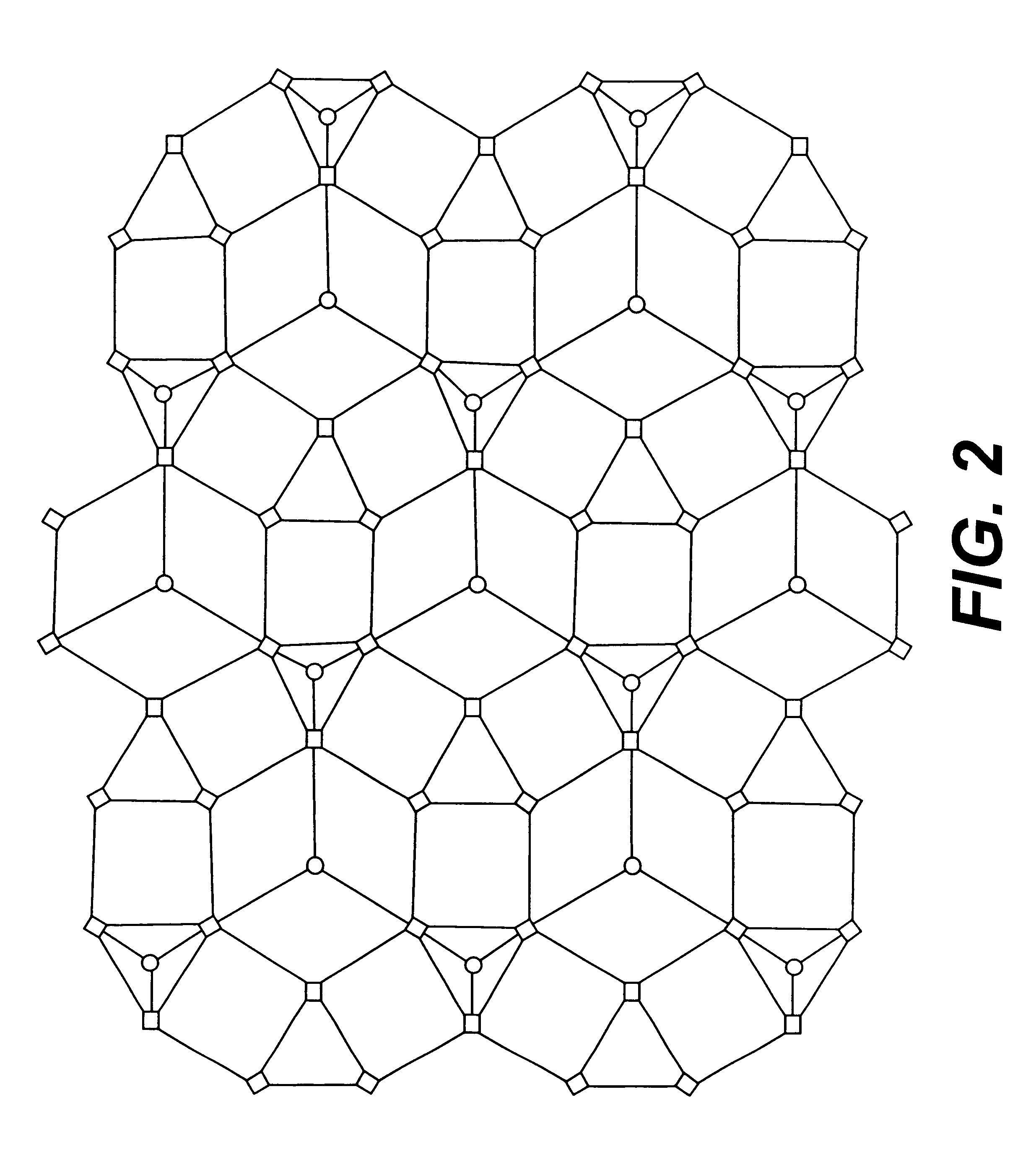

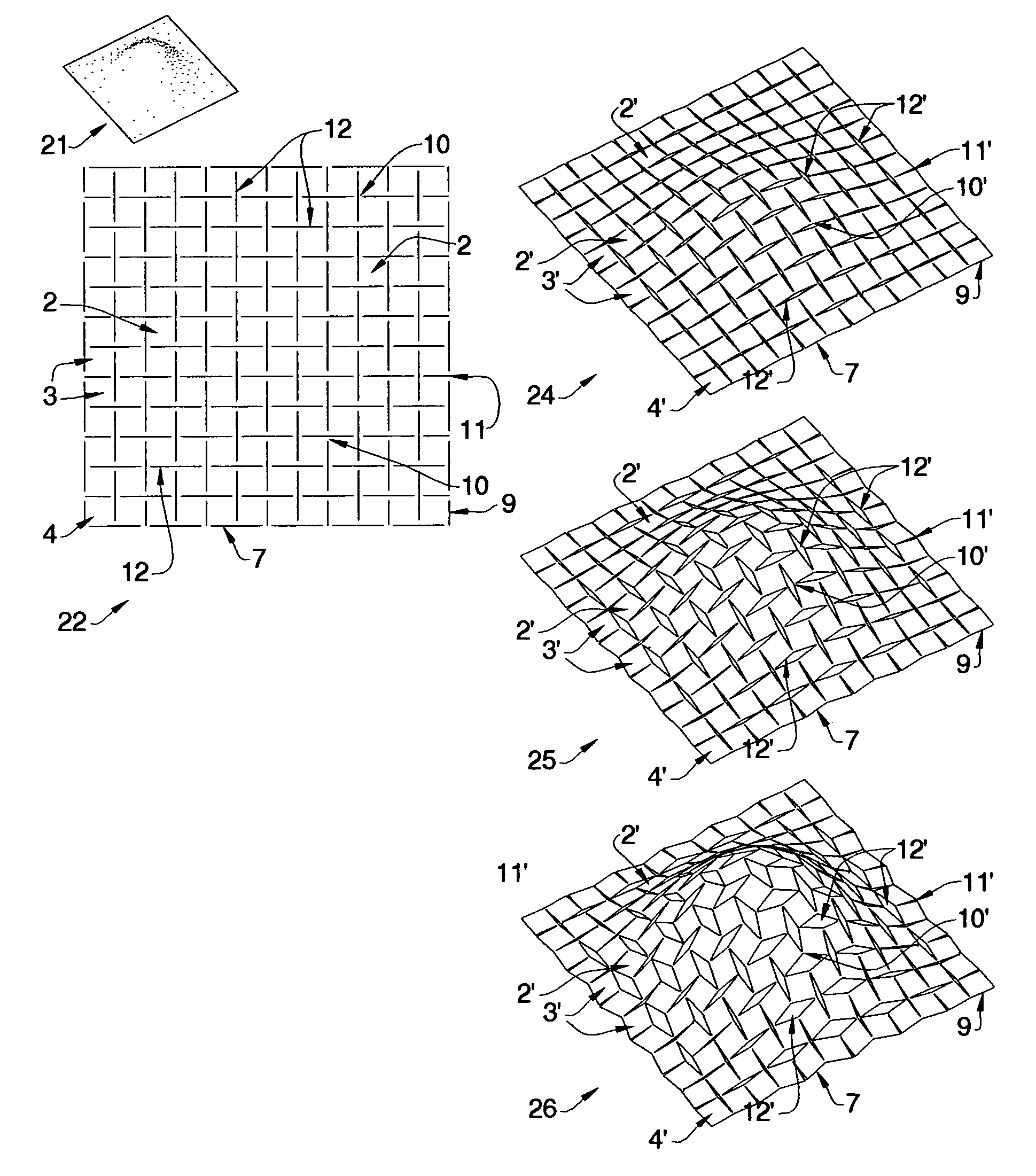

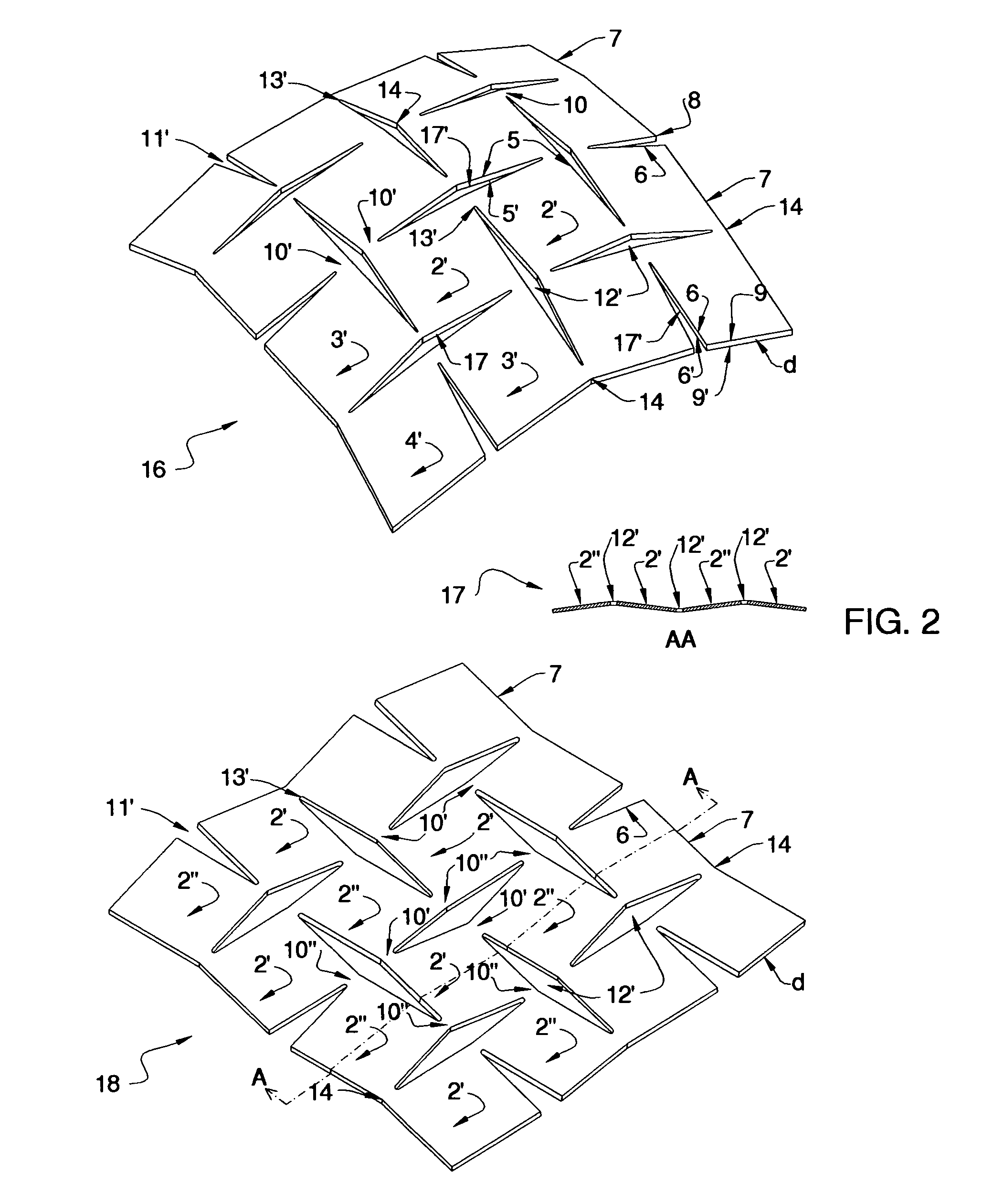

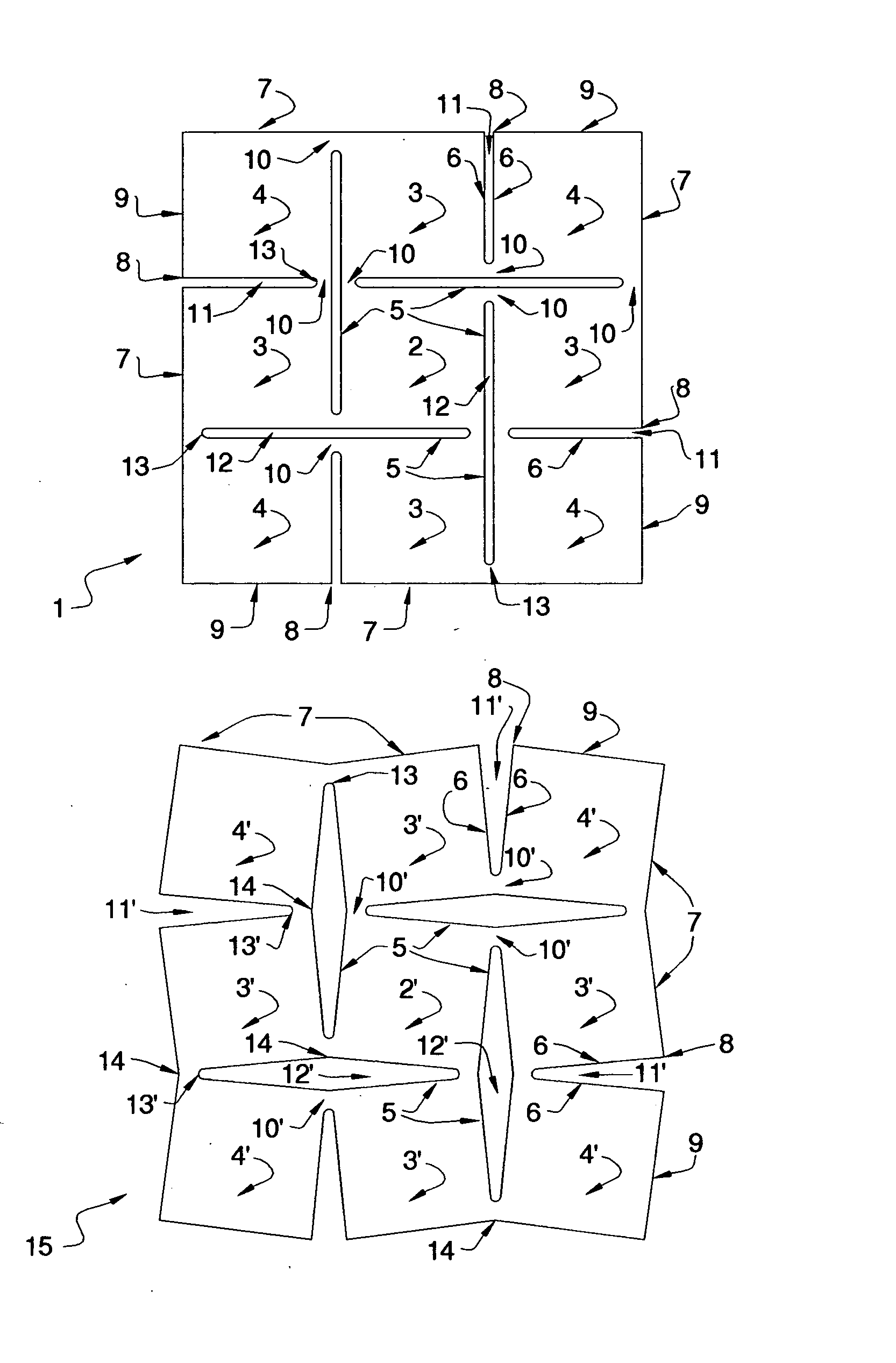

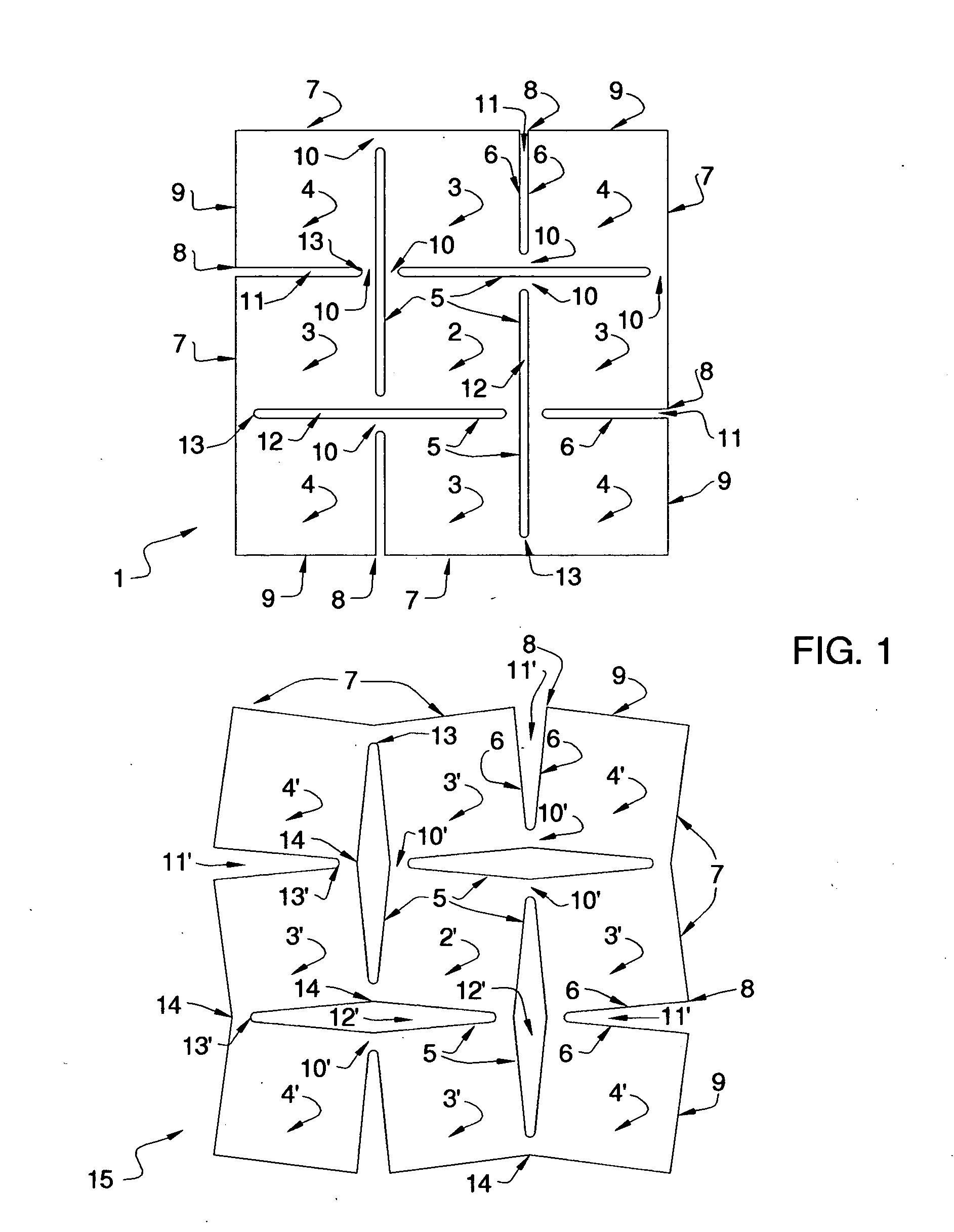

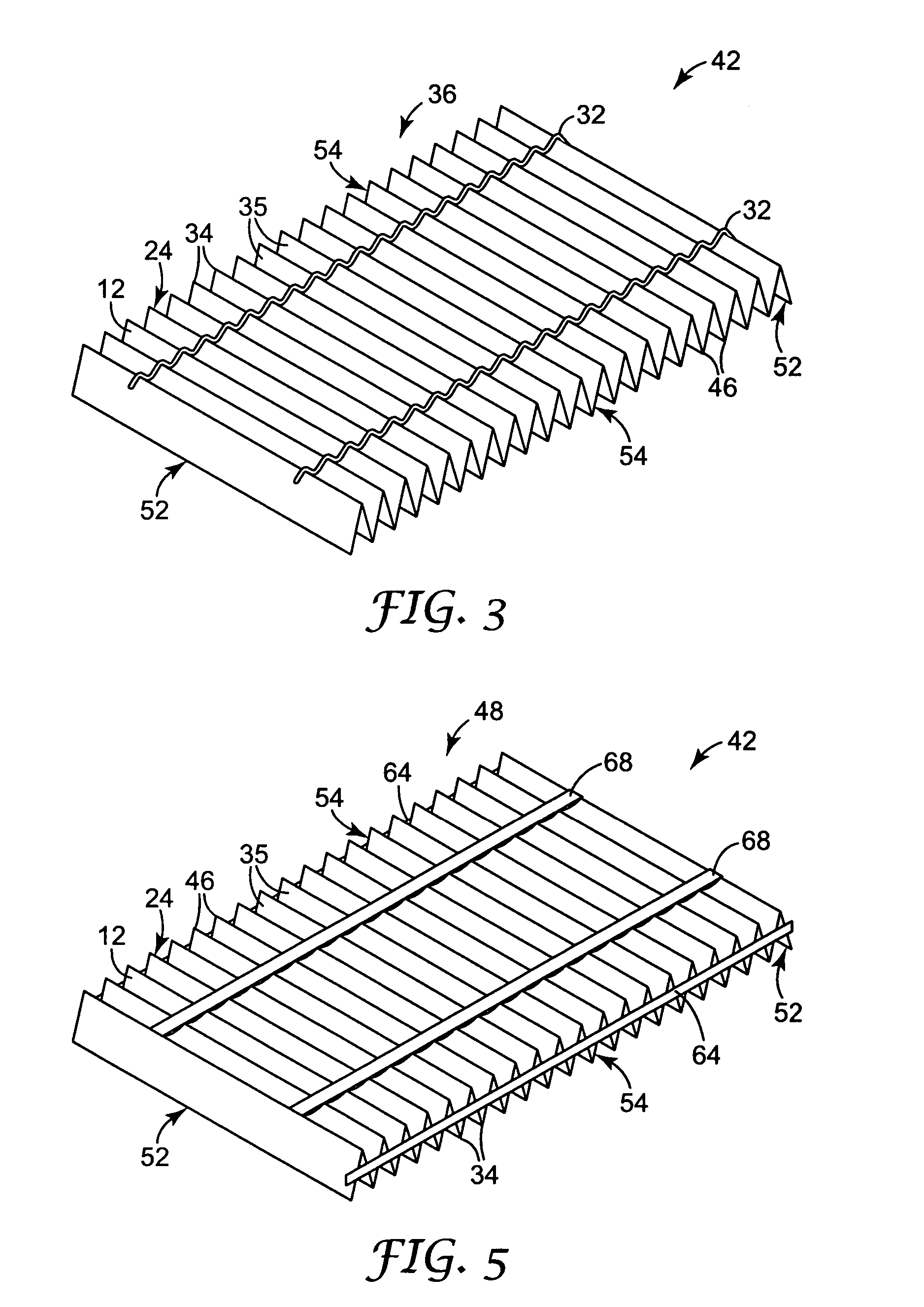

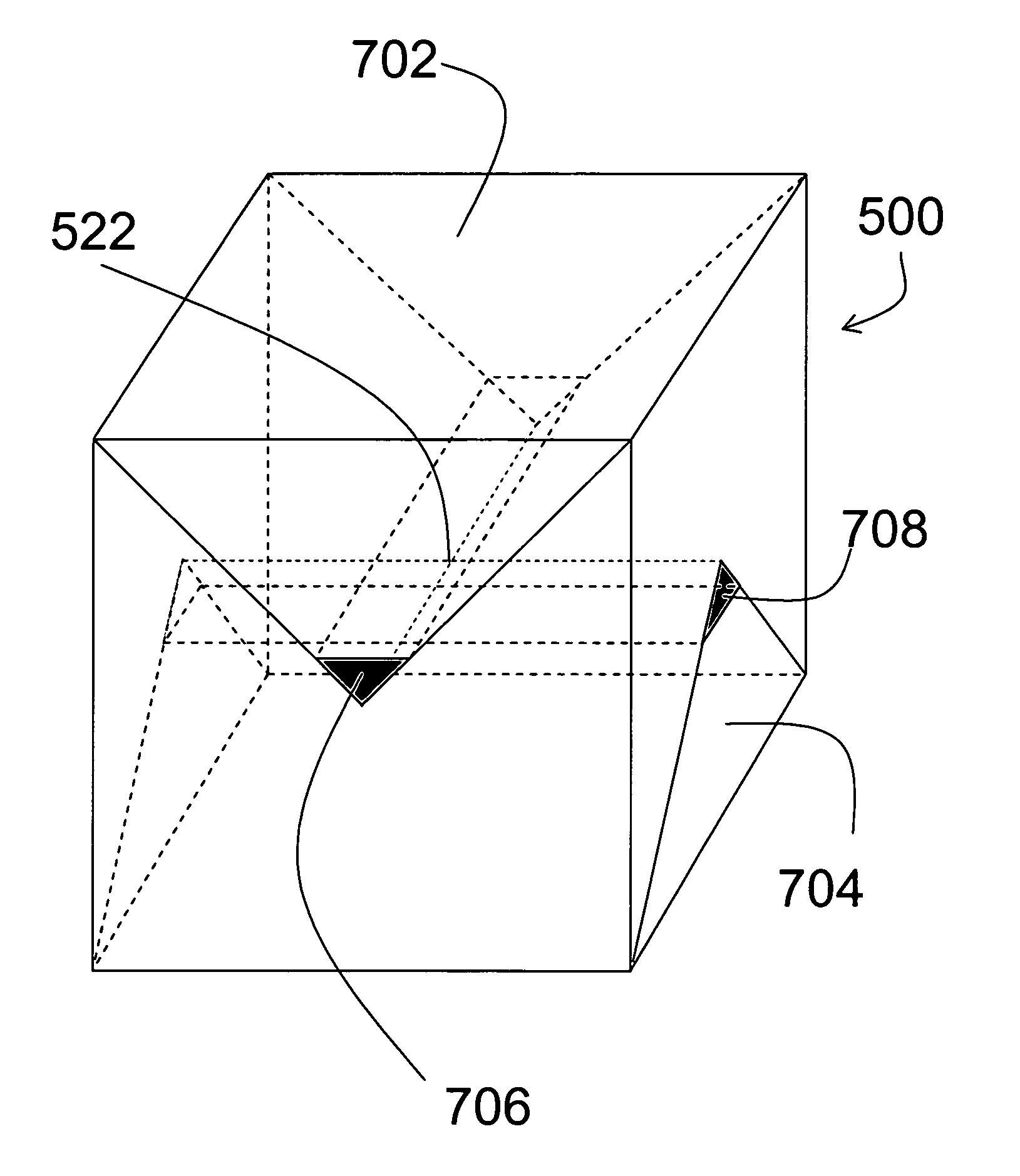

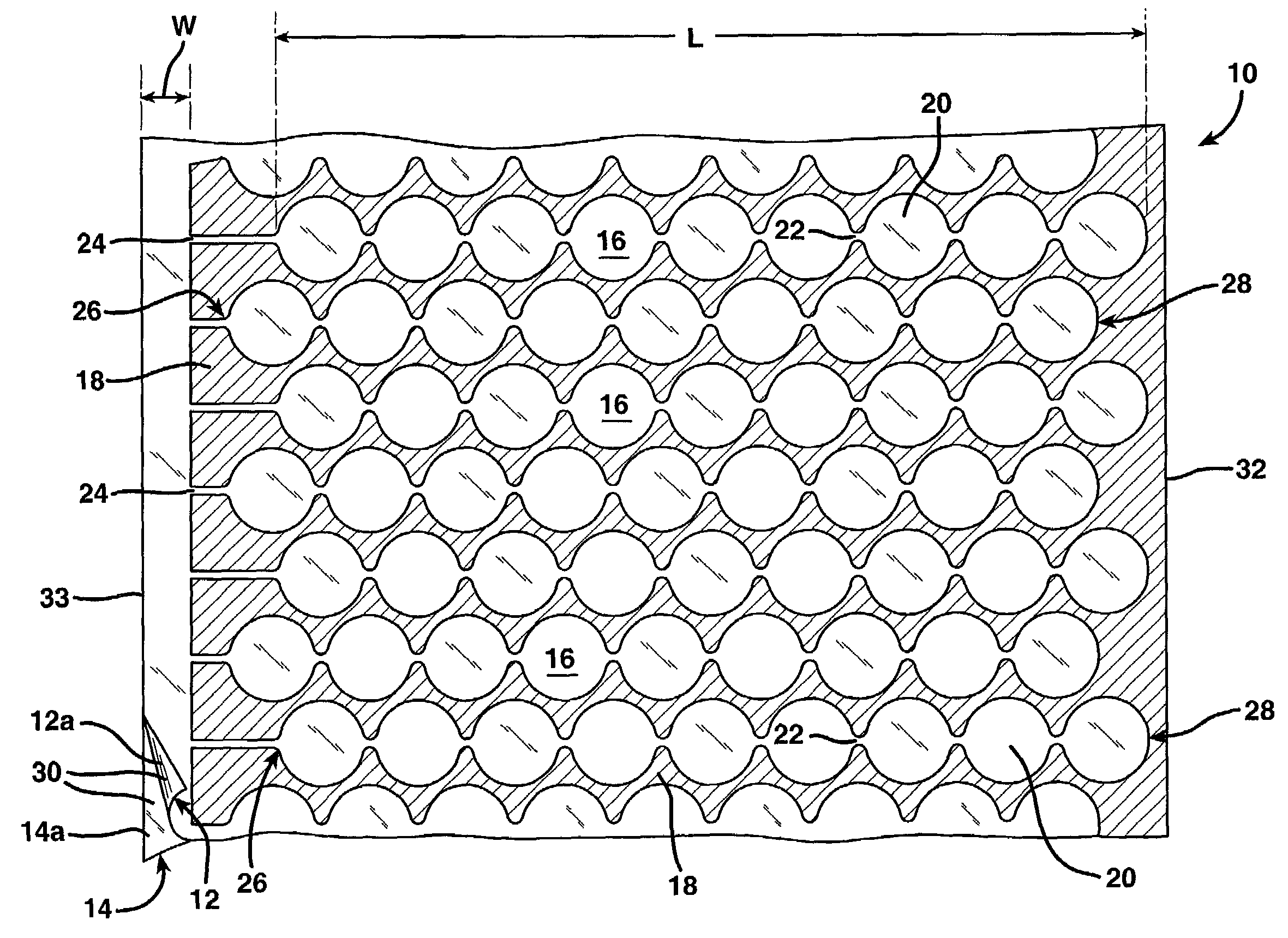

Multi-directional and variably expanded sheet material surfaces

ActiveUS8084117B2Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingMulti directional

Owner:LALVANI HARESH

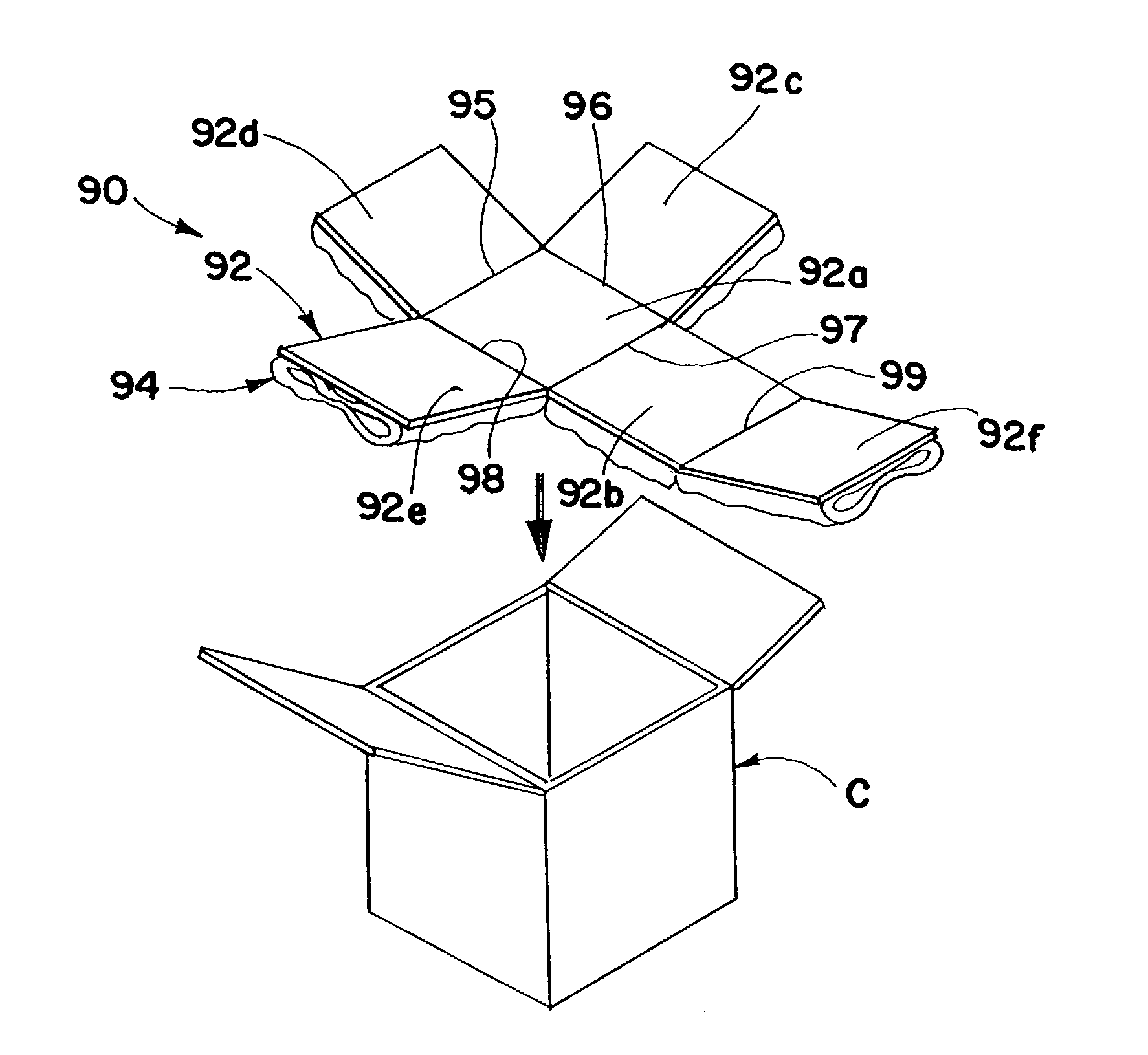

Packing product and apparatus and method for manufacturing same

ActiveUS7452316B2Wide range of resiliencySpreading capabilityBoxes/cartons making machineryPaper-makingDunnageEngineering

A packing product and apparatus and method for manufacturing same are disclosed. The packing product includes at least one face sheet and at least one crumpled sheet pad attached to the face sheet. A package and method of packaging an article are also disclosed, the package including a container, one or more crumpled sheet pads positioned in the container, one or more face sheets positioned adjacent to the crumpled sheet pads, and an article positioned in the container in at least partial abutting relation to the one or more face sheets. The one or more face sheets may have portions that are folded to envelop the article. Also, the face sheet may include an opening having a pattern corresponding to a shape of the article. A pad producing apparatus includes a dunnage supply machine for supplying a strip of dunnage, a folding device for forming a fold line in and transverse to the strip of dunnage, and a capture chute for guiding and accumulating the folded strip of dunnage so that a first layer downstream of the fold line overlaps a second layer upstream of the fold line, thereby forming an accordion-like pad.

Owner:RANPAK CORP

Multi-directional and variably expanded sheet material surfaces

ActiveUS20070122590A1Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingNanoscopic scale

Expandable surfaces made from sheet materials with slits distributed on the surface of sheet material where the surfaces expand by application of force along or / and across the surface of sheet material. The unexpanded surfaces are flat sheets, or closed surfaces like cylinders, spheres, tubes, or custom-designed organic shapes marked with pre-formed or post-formed slit designs. The expanded surfaces can be single units or modules which can be attached to one another through various means. The sheet materials range from hard surfaces like metals, to softer materials like papers and plastics, or pliable materials like fabrics, rubbers, synthetic surfaces or bio-surfaces. The slits are arranged in patterns ranging from periodic, non-periodic to irregular designs. The slits can be straight, bent, curved or irregularly shaped with even or uneven spacing. Slitting can be achieved by digital cutting or punching devices like laser-cutting, water-jet cutting, digital punching, automated dies, etc. or pre-formed when casting the sheet material. Force can be applied manually with tools or through the use of machines and special set-ups. Applications range from architectural surfaces, walls, ceilings, panel systems, structures and sculpture. On a smaller scale, applications include containers, packaging material, fabrics and human wear. On micro- to nano-scale, applications range from expandable surfaces for gauzes, band-aids, stent designs, skin grafts, semi-permeable membranes and micro-filters for various industries including purification of fluids and chemical substances.

Owner:LALVANI HARESH

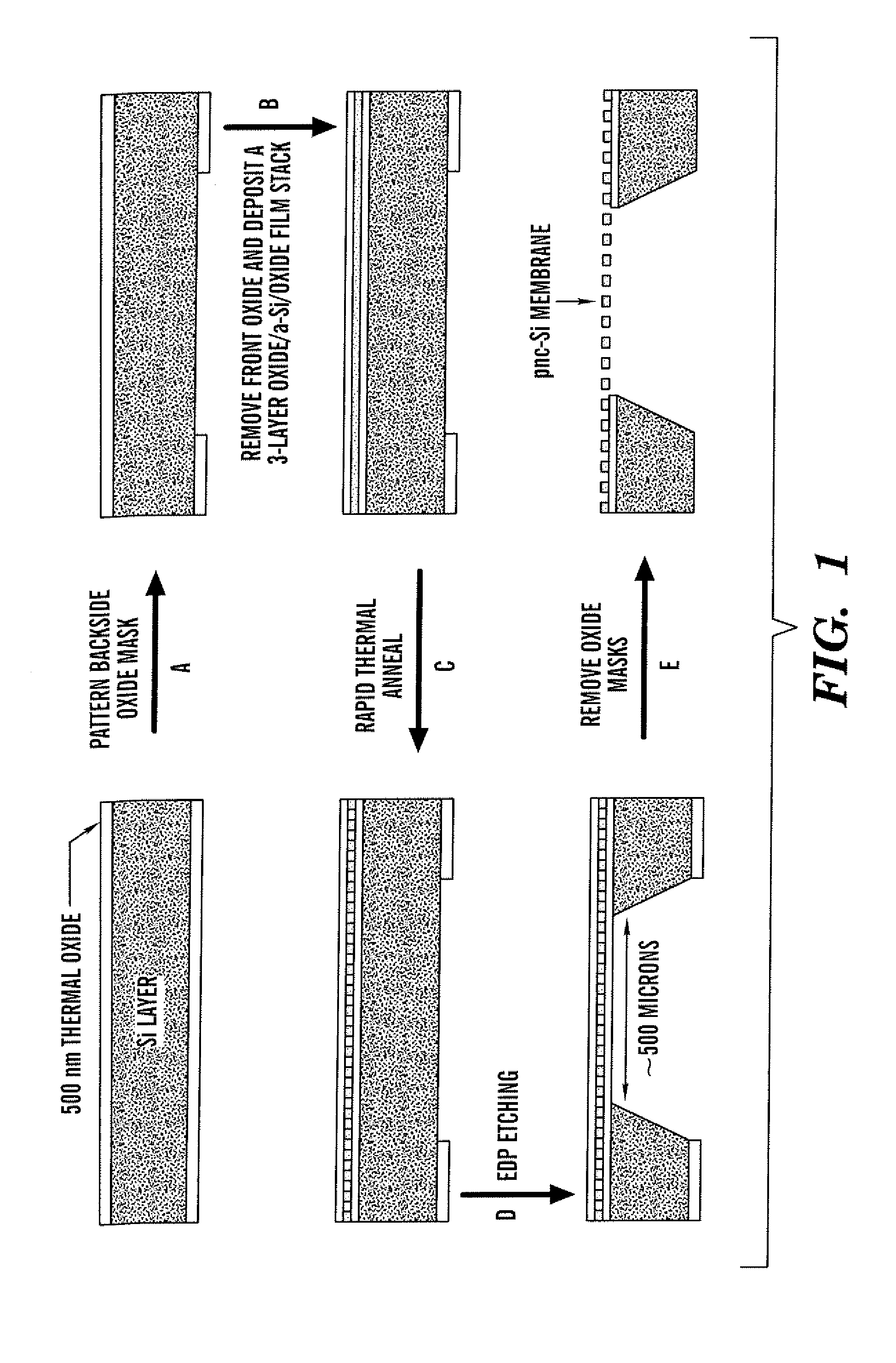

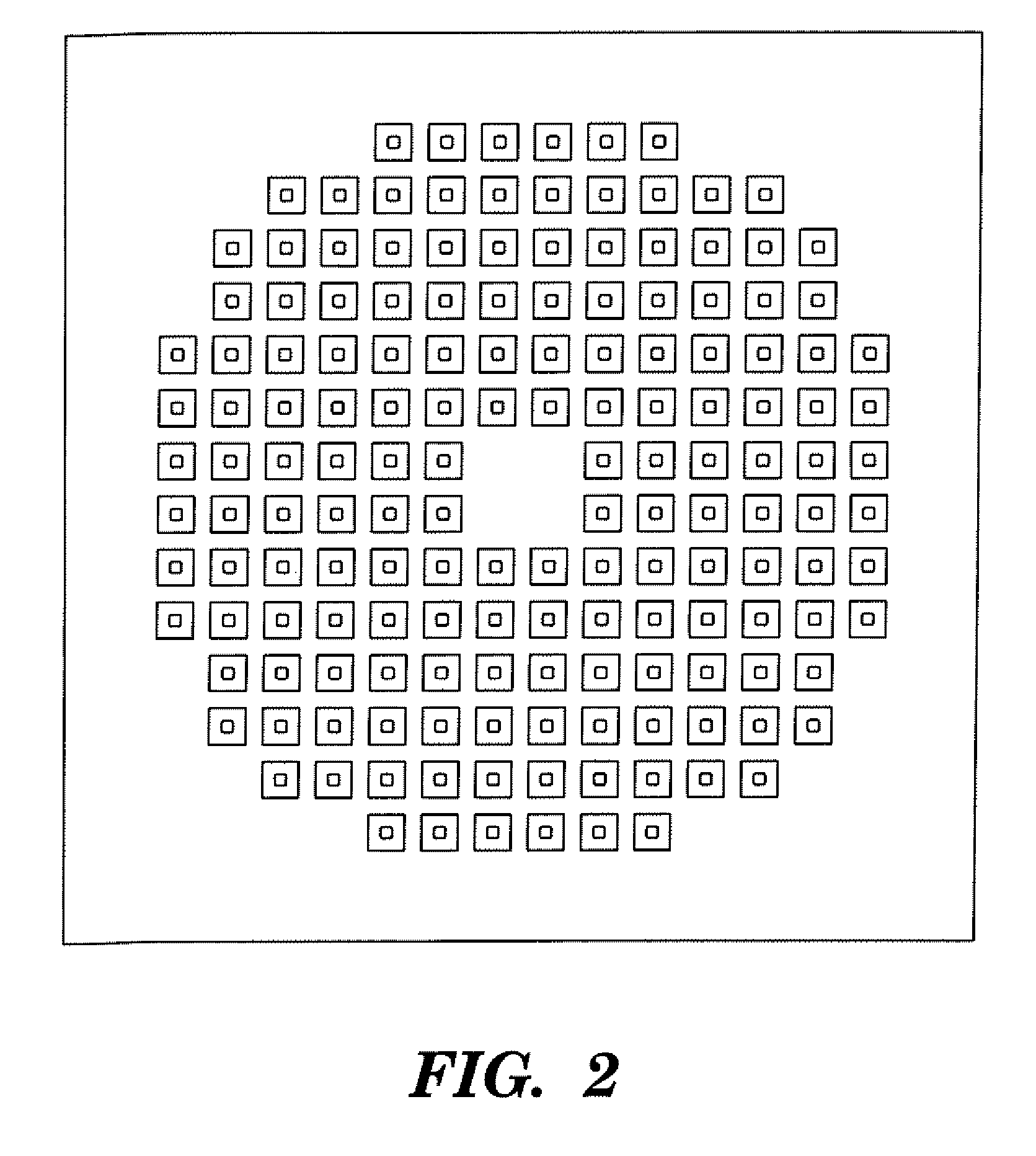

Ultrathin porous nanoscale membranes, methods of making, and uses thereof

ActiveUS20060278580A1Flat surfaceNot time-consumePaper/cardboard articlesCell electrodesFuel cellsSemiconductor materials

A process for forming a porous nanoscale membrane is described. The process involves applying a nanoscale film to one side of a substrate, where the nanoscale film includes a semiconductor material; masking an opposite side of the substrate; etching the substrate, beginning from the masked opposite side of the substrate and continuing until a passage is formed through the substrate, thereby exposing the film on both sides thereof to form a membrane; and then simultaneously forming a plurality of randomly spaced pores in the membrane. The resulting porous nanoscale membranes, characterized by substantially smooth surfaces, high pore densities, and high aspect ratio dimensions, can be used in filtration devices, microfluidic devices, fuel cell membranes, and as electron microscopy substrates.

Owner:UNIVERSITY OF ROCHESTER

Inflation device for forming inflated containers

Owner:SEALED AIR U S

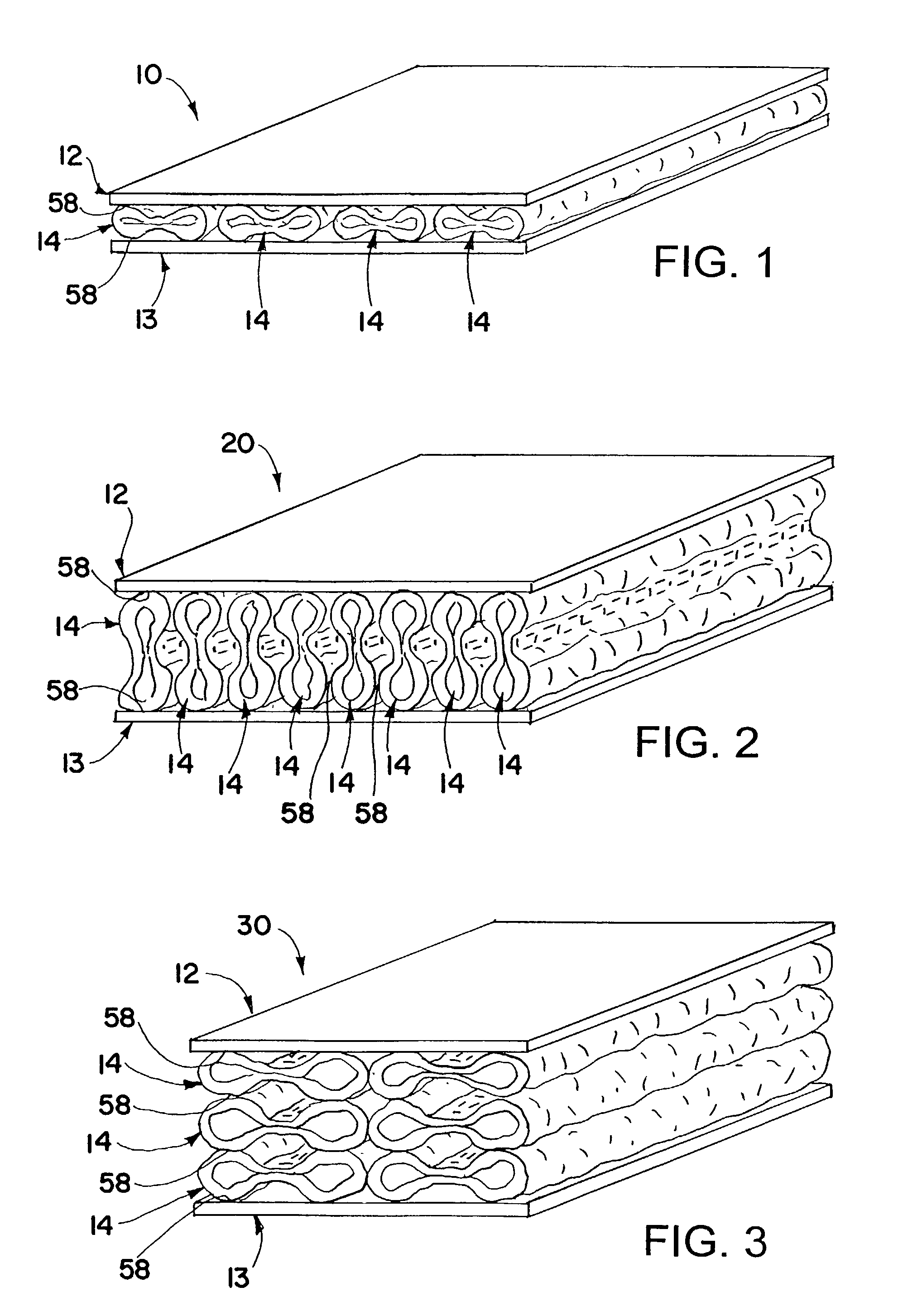

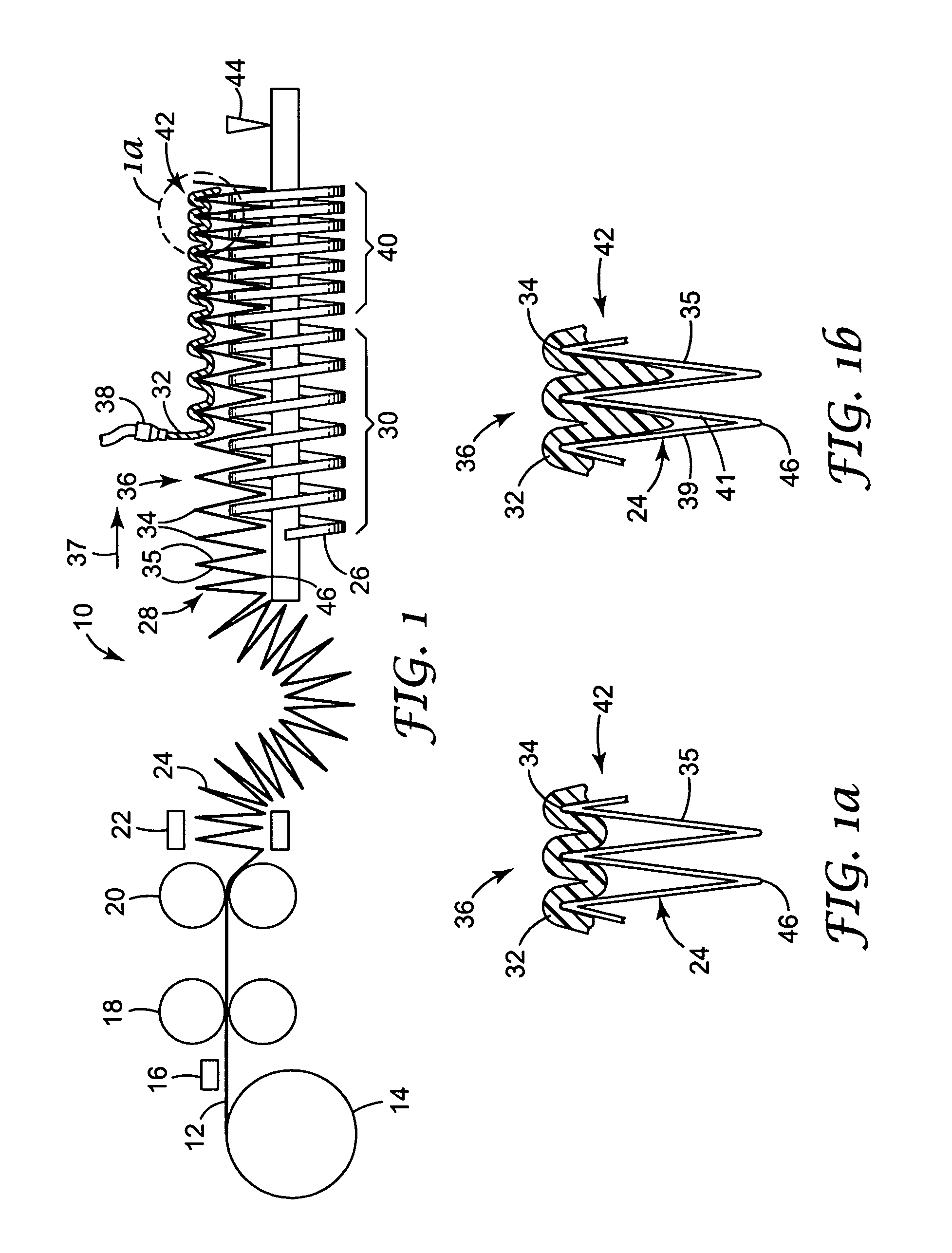

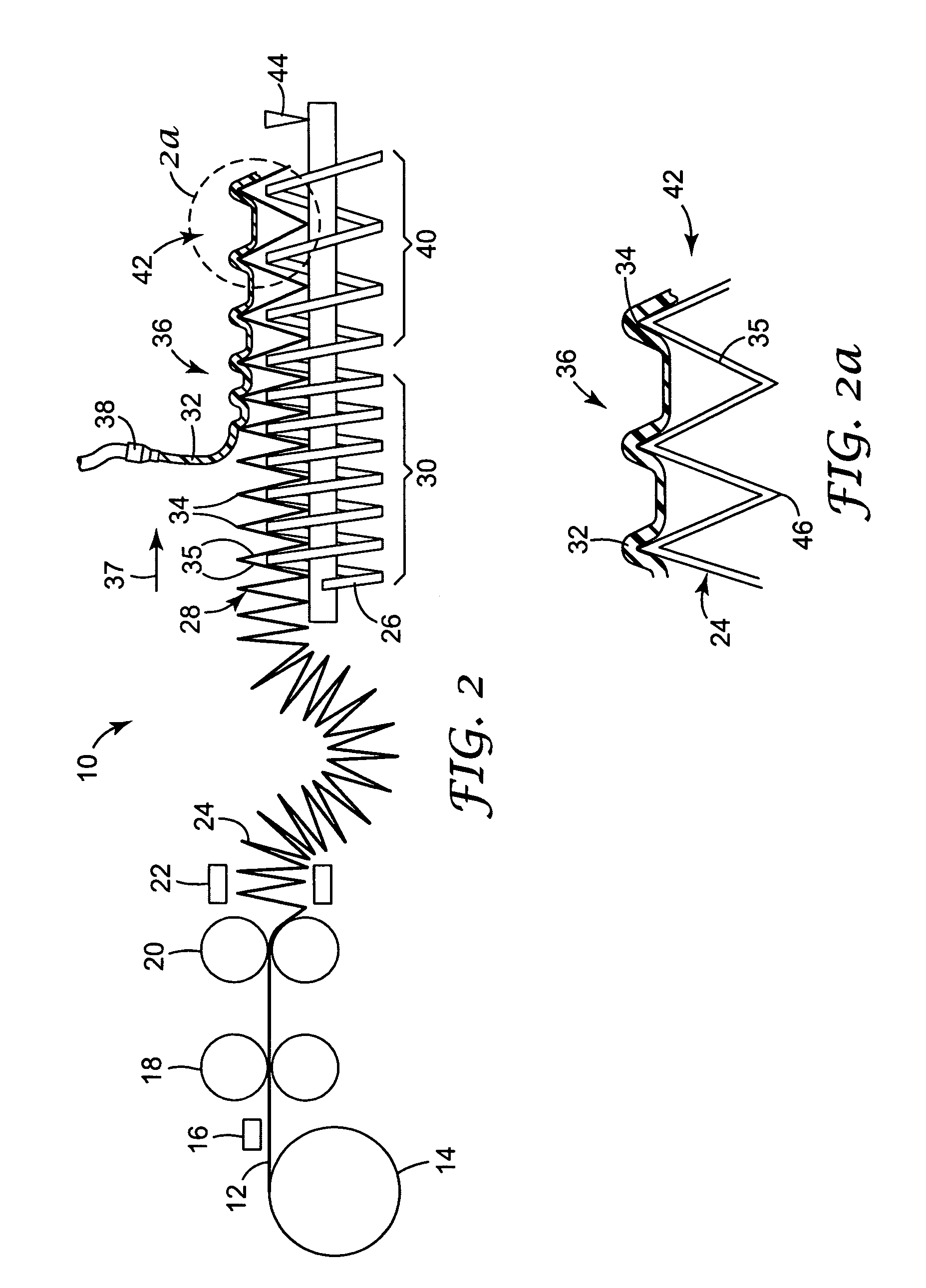

Method of forming self-supporting pleated filter media

The method of forming pleated filter media includes providing a generally planar web of filter material, folding the web to form a pleated web having a plurality of fold lines, arranging the plurality of pleats in a first spaced configuration defined by a first distance between adjacent pleat tips, applying a continuous strand of adhesive to the web, and adjusting the arrangement of the plurality of pleats into a second spaced configuration defined by a second distance between adjacent pleat tips. The web has a front face and a rear face. Each fold line is intermediate oppositely sloping first and second wall surfaces. The plurality of fold lines form a plurality of pleats having a first plurality of pleat tips and a second plurality of pleat valleys. The second distance is different from the first distance.

Owner:3M INNOVATIVE PROPERTIES CO

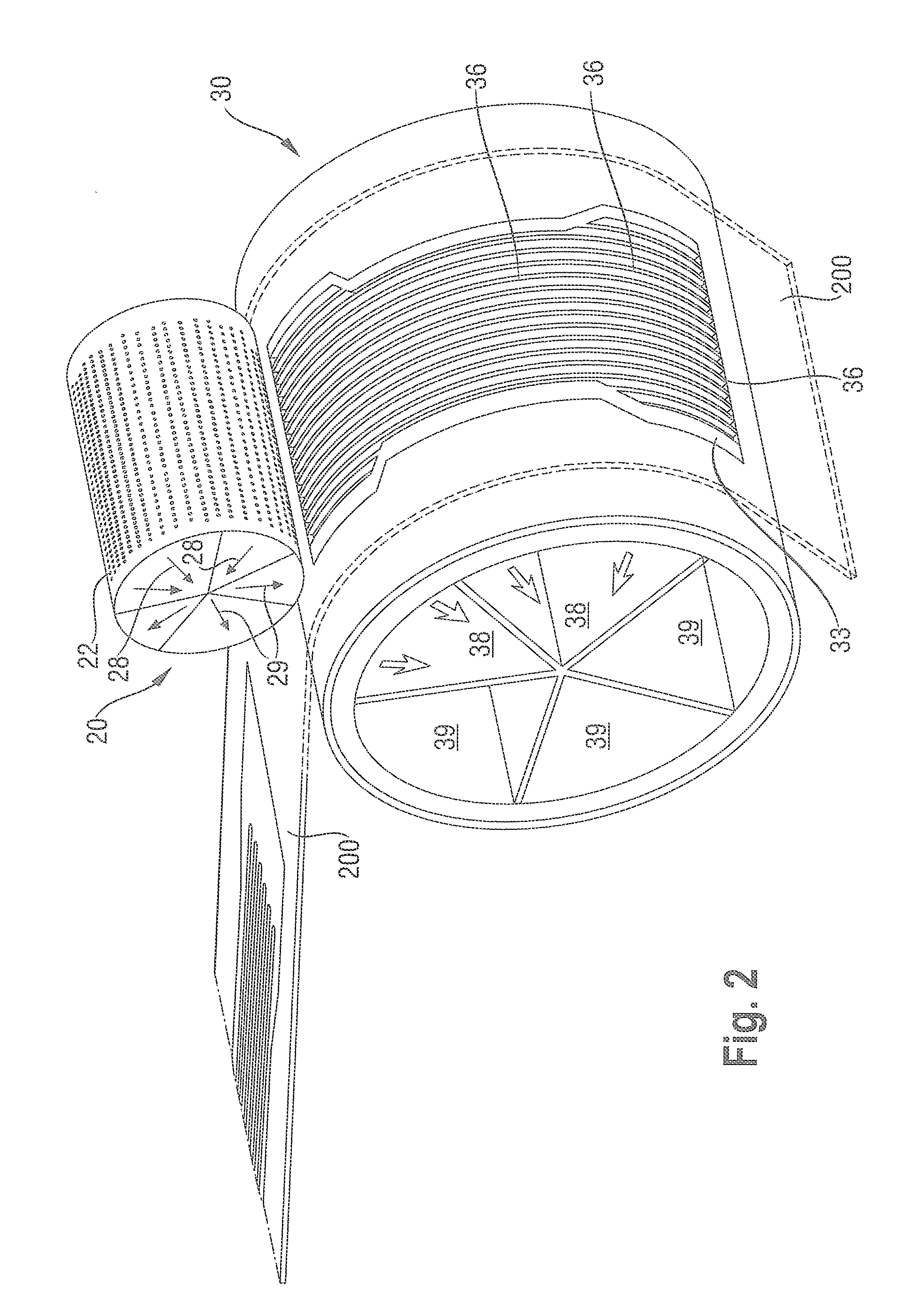

Method and Apparatus for Making Absorbent Structures with Absorbent Material

ActiveUS20120316046A1Boxes/cartons making machineryPaper/cardboard articlesAbsorbent materialMechanical engineering

A method and apparatus for making specific absorbent structures with an absorbent layer with absorbent material with therein substantially longitudinally extending strips that are free of absorbent material, using or having thereto a moving endless surface with receptacle(s) with specific longitudinally extending rods; and specific absorbent structures obtained therewith, suitable for absorbent articles, such as diapers and sanitary napkins.

Owner:THE PROCTER & GAMBLE COMPANY

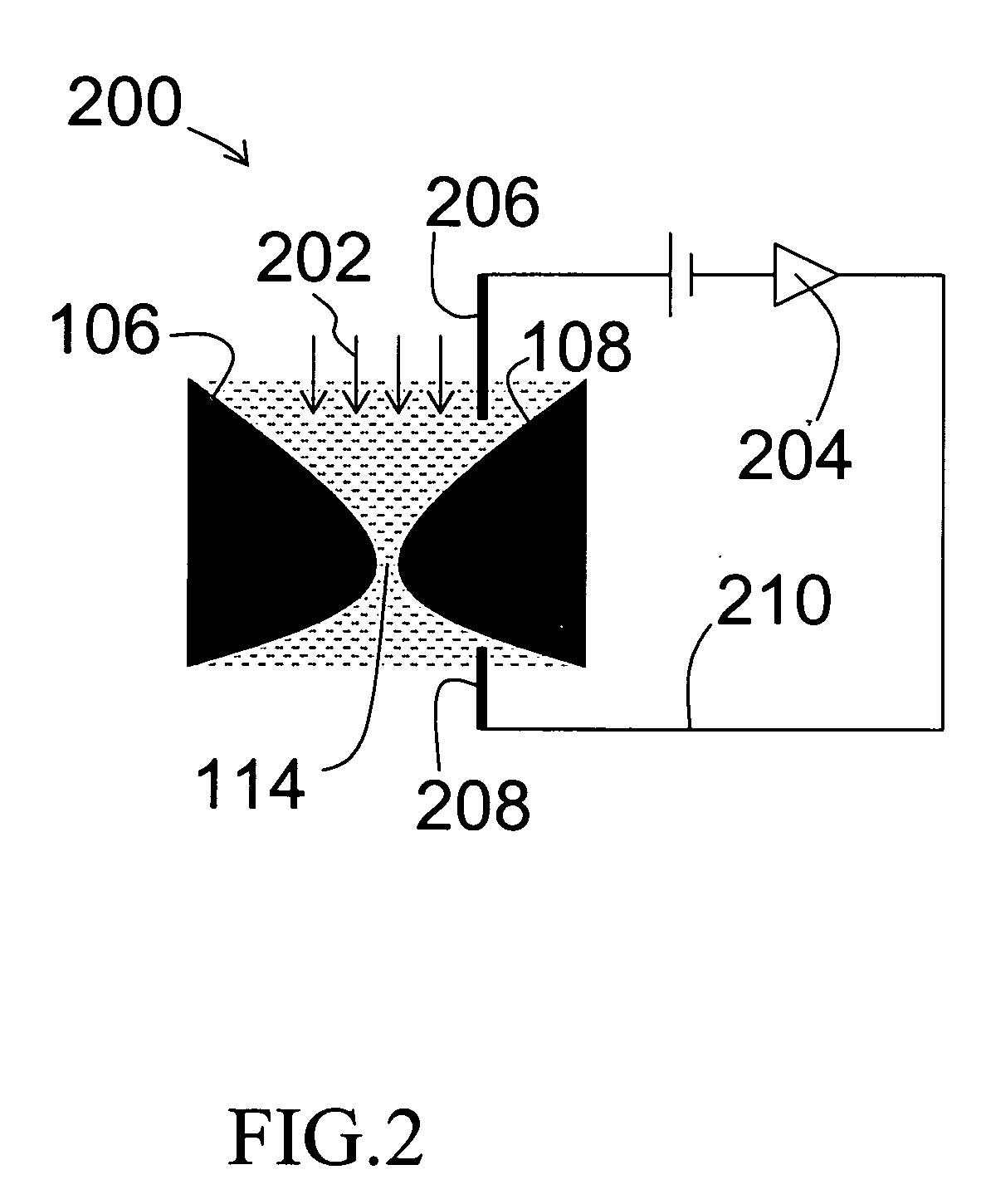

Addressable nanopores and micropores including methods for making and using same

ActiveUS20050127035A1Reduce the overall diameterEasy to controlBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringNanopore

Featured are devices and systems embodying one or more electrically-addressable-solid-state nanopores useful for sensing and / or characterizing single macromolecules as well as sequencing DNA or RNA. In one aspect of the present invention, there is featured a linear or 2-D electrically-addressable array of nanopores, where the nanopores are located at points of intersections between V-shaped grooves formed in an upper surface of the insulating member and a V-shaped groove formed in a lower surface of the insulating member. In another aspect of the present invention the solid-state nanopore of the present invention the width and / or length of the nanopore is defined or established by sharp edges of cleaved crystals that are maintained in fixed relation during the formation of the insulating member including the nanopore.

Owner:BROWN UNIVERSITY +1

Machine and method for making paper dunnage

InactiveUS6910997B1Mechanical working/deformationPaper/cardboard articlesDunnagePulp and paper industry

Dunnage making machine and method in which a web of paper is drawn across a forming bar with curved end sections to roll the edge portions of the paper, then drawn through a first throat section to urge the rolled edge portions toward each other and cause them to gather, and thereafter through a second throat section of lesser dimension than the first to gather the central portion of the paper and further gather the edge portions. The gathered paper is then pressed with a roller to crumple it, following which the crumpled paper is perforated along a serrated tear line.

Owner:PREGIS INNOVATIVE PACKAGING

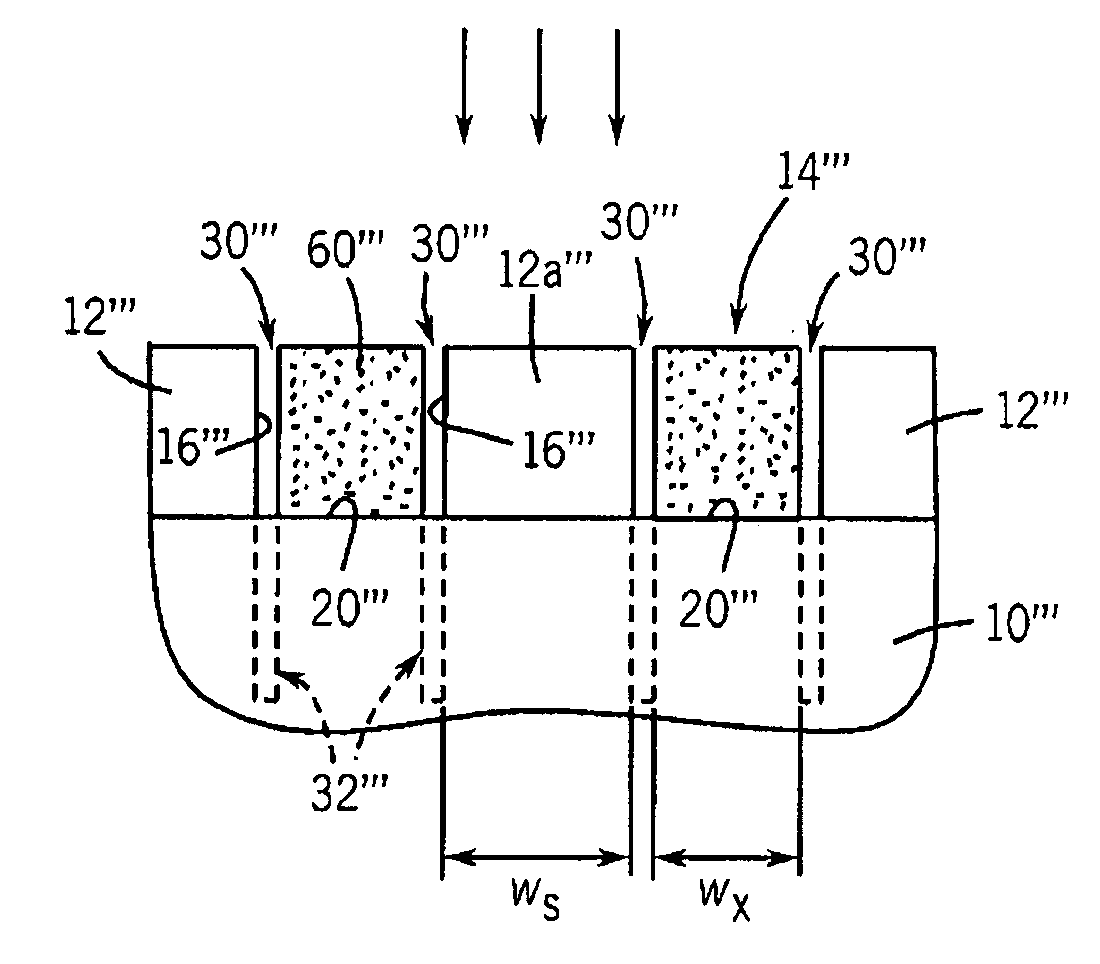

Apparatus and method for forming inflated chambers

An inflatable web, and method and apparatus for inflating the web, which generally includes two sheets having inner surfaces sealed to each other in a pattern defining a series of inflatable chambers of predetermined length, each of the chambers having at least one change in width over their length; an inflation port located at a proximal end of each chamber, the inflation ports being formed by intermittent seals between the sheets; and longitudinal flanges formed by a portion of each of the sheets that extend beyond the inflation ports and intermittent seals.

Owner:SEALED AIR U S

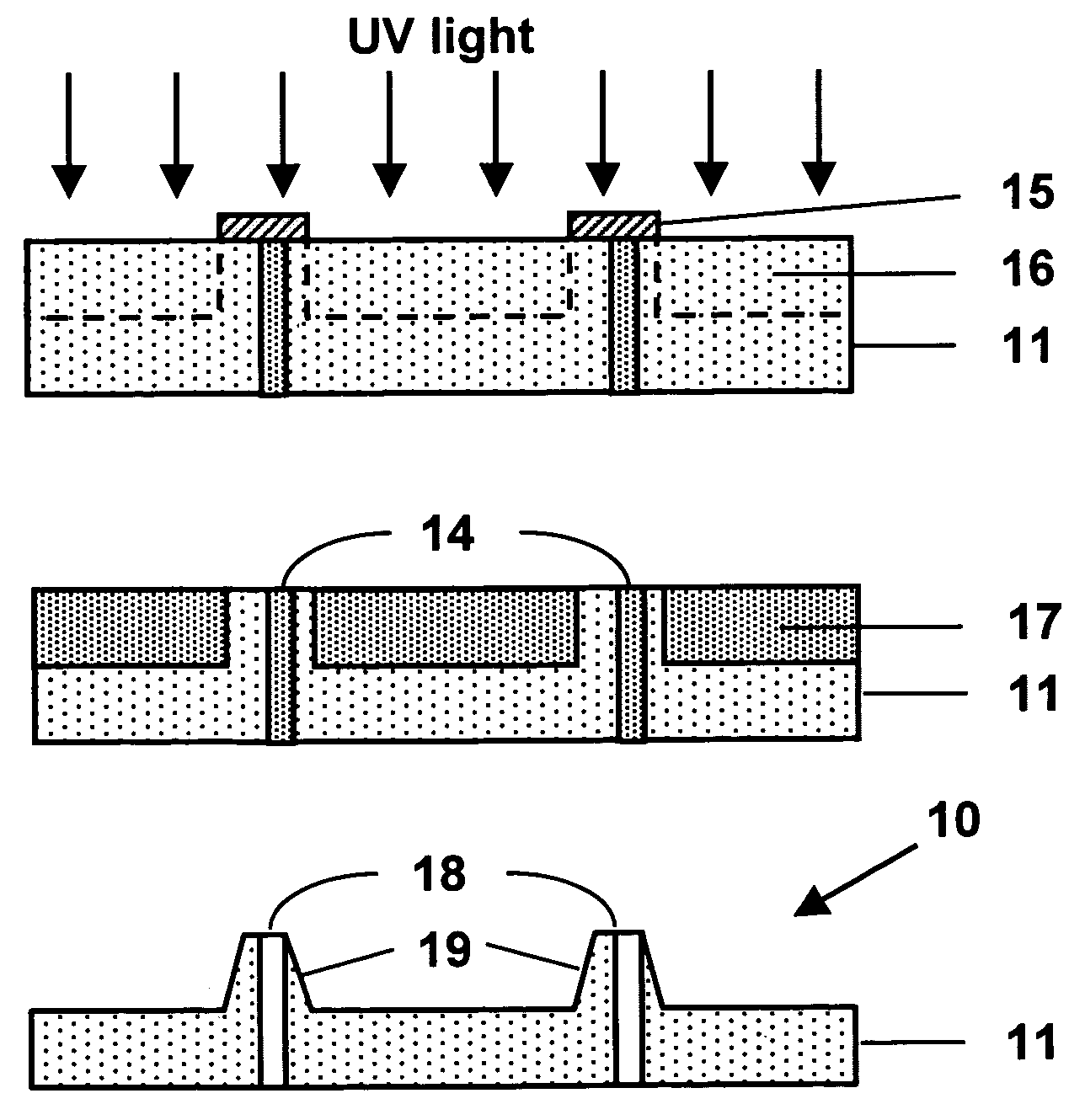

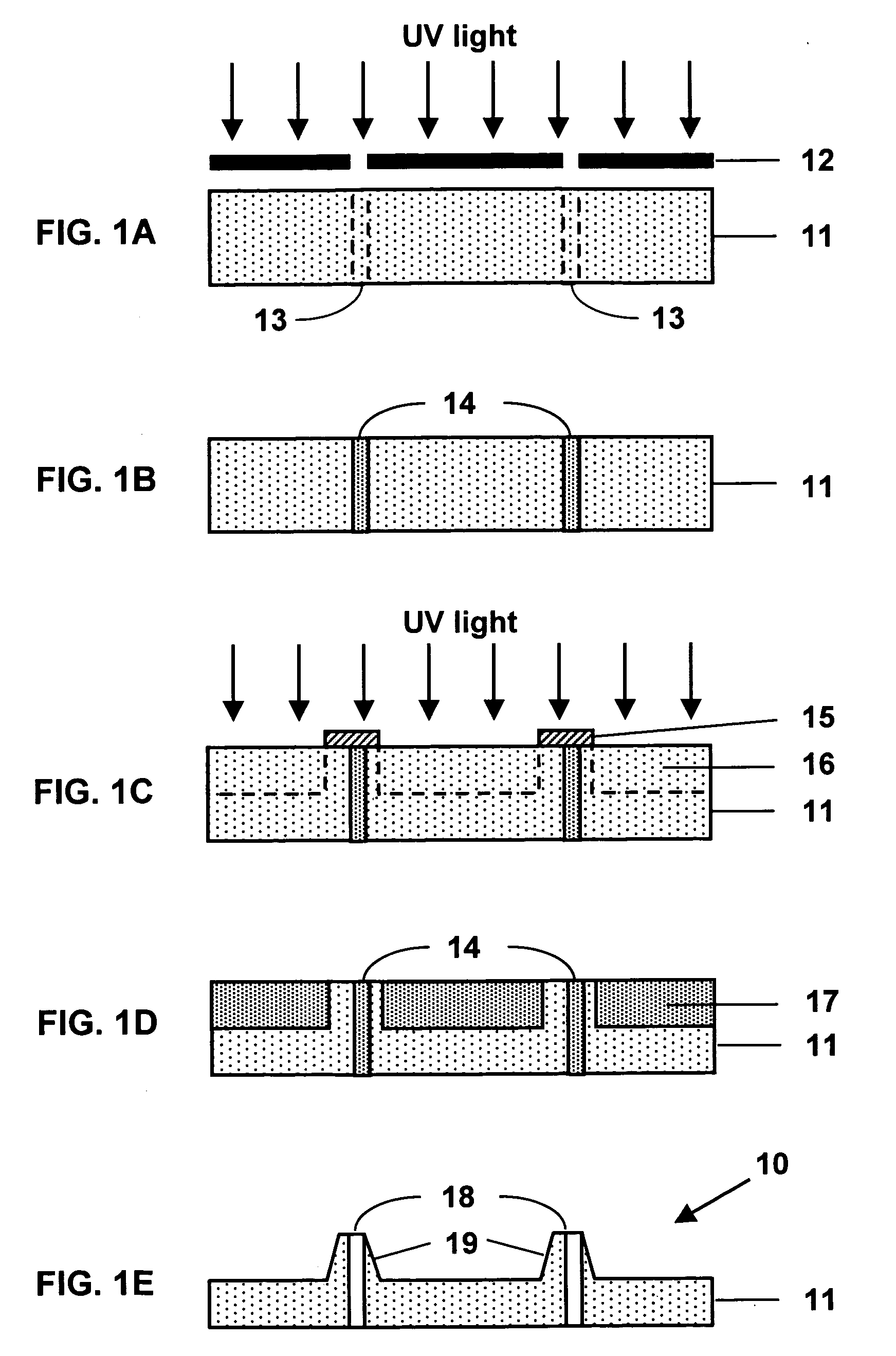

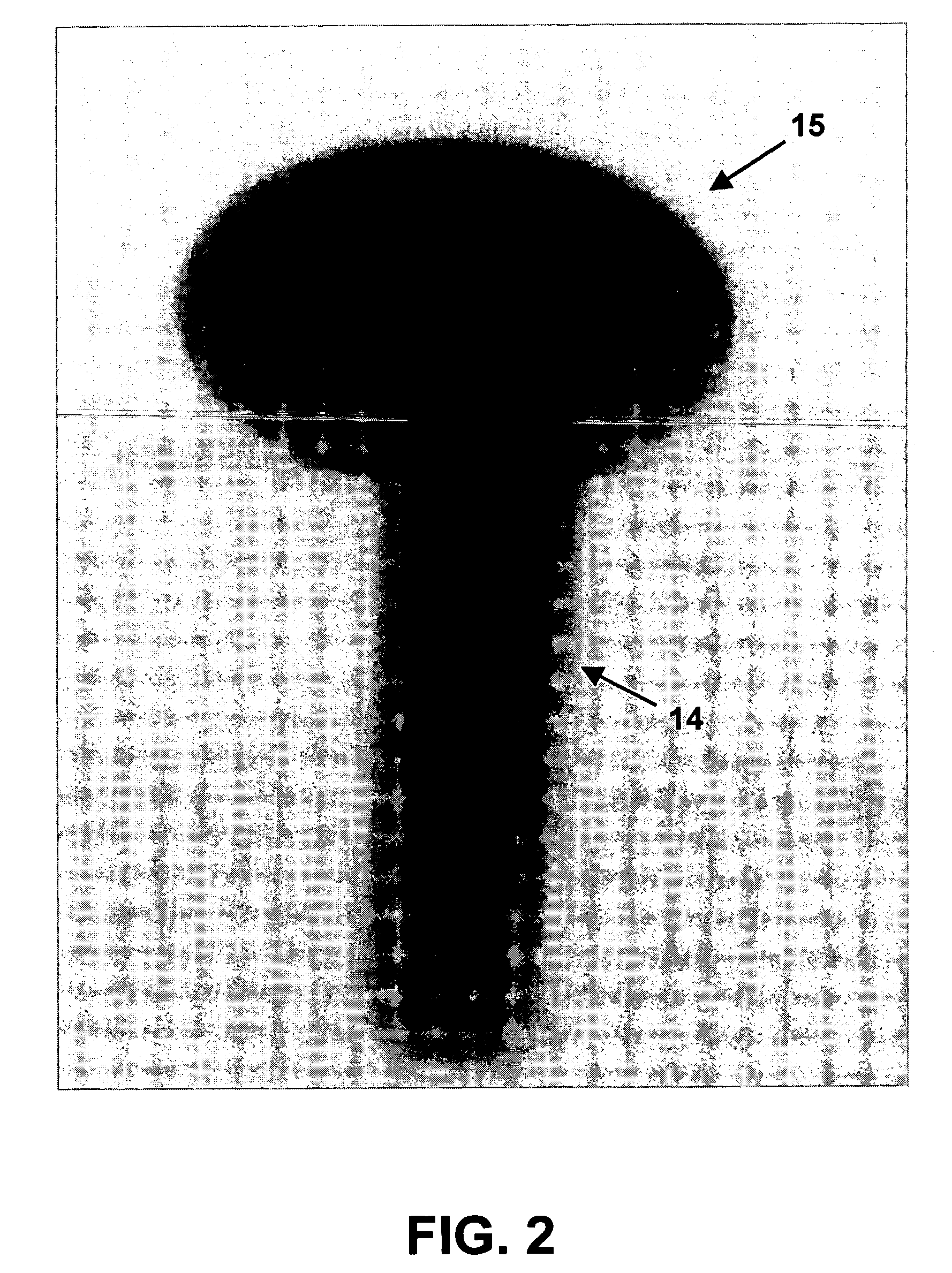

Method to fabricate hollow microneedle arrays

InactiveUS7132054B1Easy process developmentEquipment is cheapPaper/cardboard articlesDecorative surface effectsMetalMaterials science

An inexpensive and rapid method for fabricating arrays of hollow microneedles uses a photoetchable glass. Furthermore, the glass hollow microneedle array can be used to form a negative mold for replicating microneedles in biocompatible polymers or metals. These microneedle arrays can be used to extract fluids from plants or animals. Glucose transport through these hollow microneedles arrays has been found to be orders of magnitude more rapid than natural diffusion.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

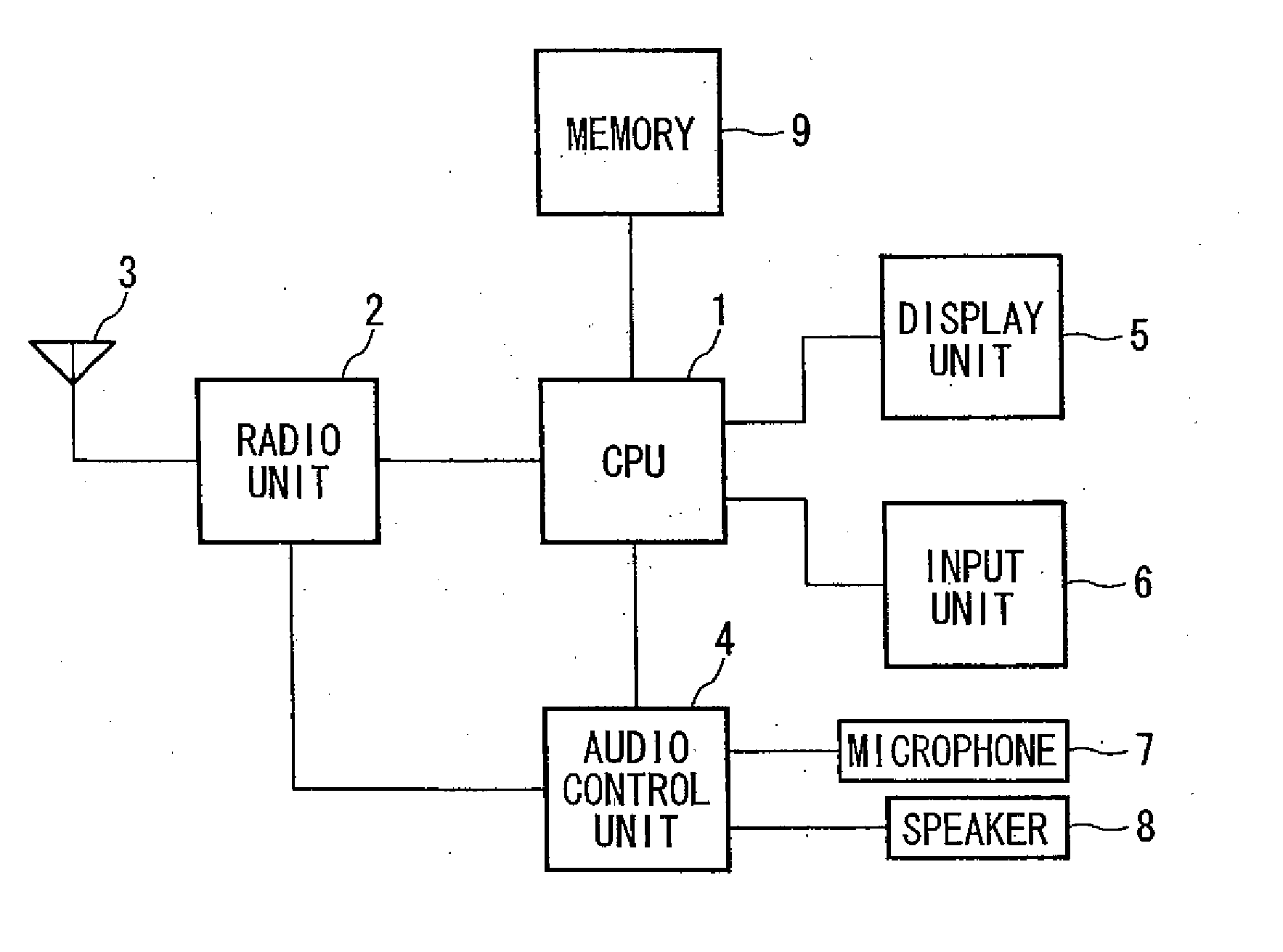

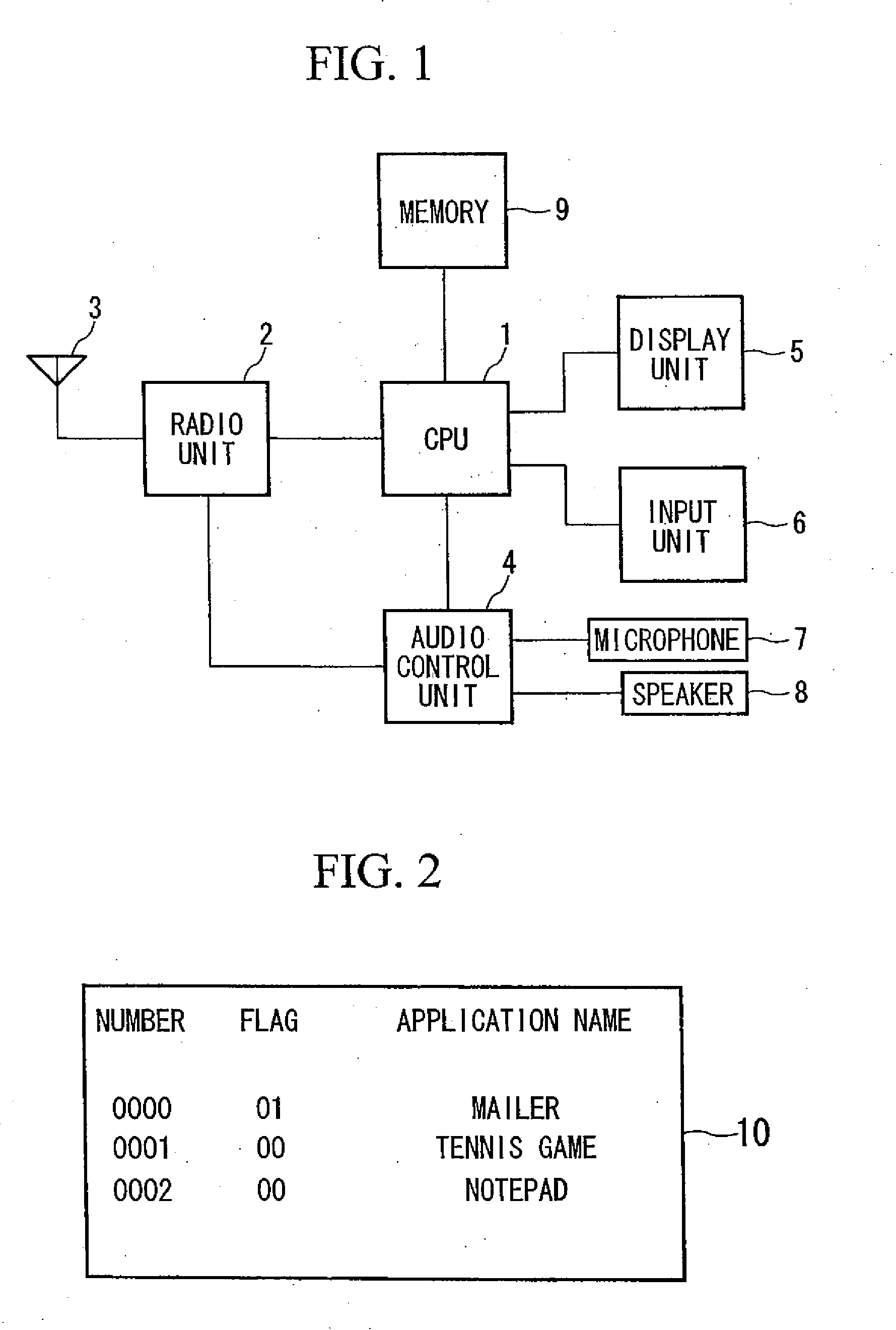

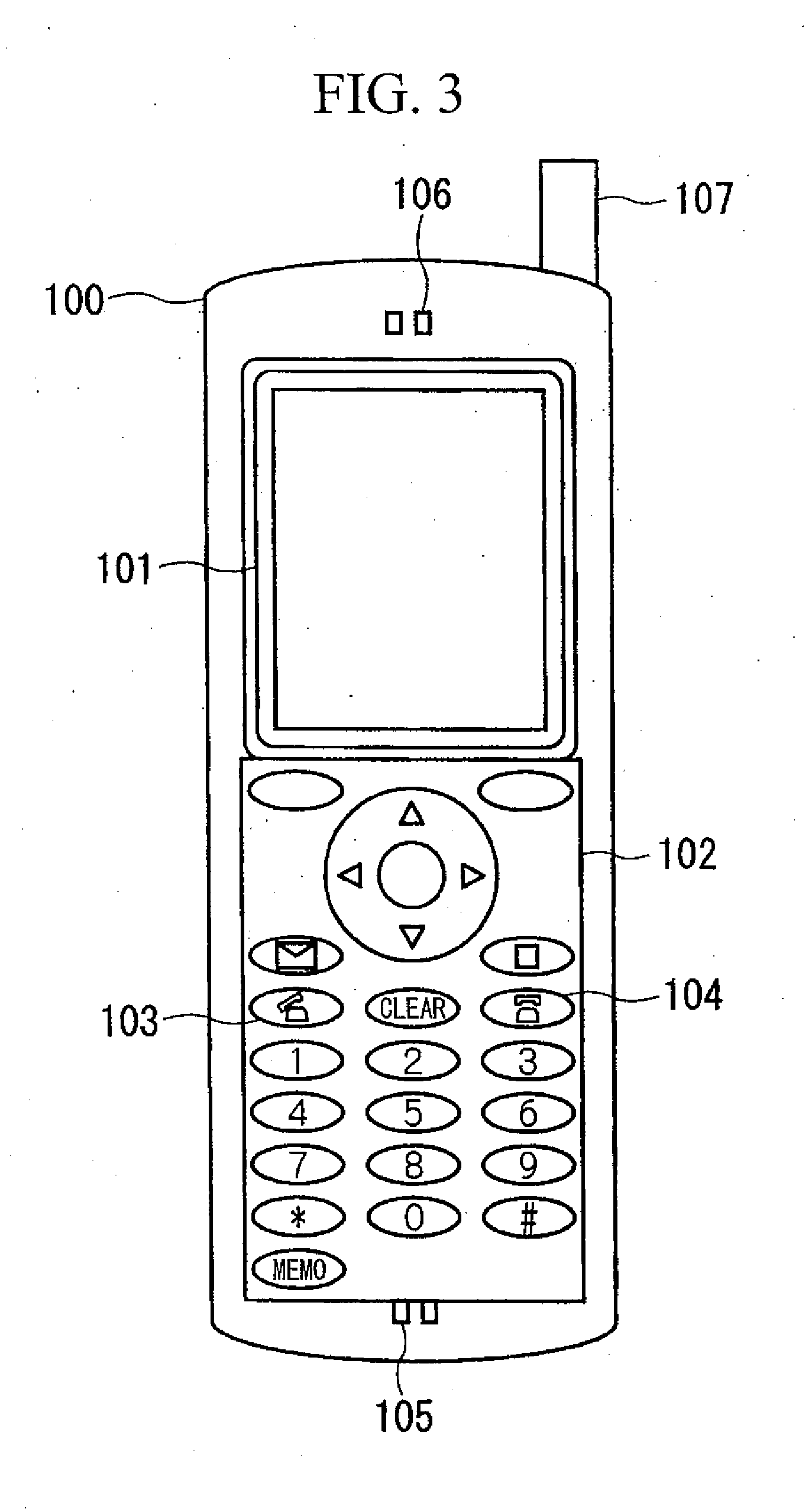

Mobile Terminal, Method for Controlling Mobile Telephone Terminal, and Mobile Telephone Terminal

InactiveUS20070225022A1Reduce processing loadIncrease speedStampsDollsTelephone terminalMultiple applications

Owner:KYOCERA CORP

Inflated dunnage and method for its production

InactiveUSRE36759E1Reduce slippageEasy to prevent slippingPreventing unwanted cargo movementLabelling non-rigid containersDunnageCarton

A method for producing inflated dunnage on the site of use, comprising providing, in web form, a plurality of preformed plastic bags, each of the bags comprising two plastic sheets in facing relationship and sealed along three edges with one edge remaining open. Air is blown toward each of the open edges in sequence, causing each bag to inflate, and the open edge of each inflated bag is sealed, the bag being empty except for the air. A plurality of sealed inflated bags is separated from the web and placed in a carton to serve as dunnage. The bags have a slip resistant outer surface which causes the bags to interlock in the carton and better protect object therein from shock.

Owner:AUTOMATED PACKAGING SYST

Sub-10 nm line features via rapid graphoepitaxial self-assembly of amphiphilic monolayers

Owner:MICRON TECH INC

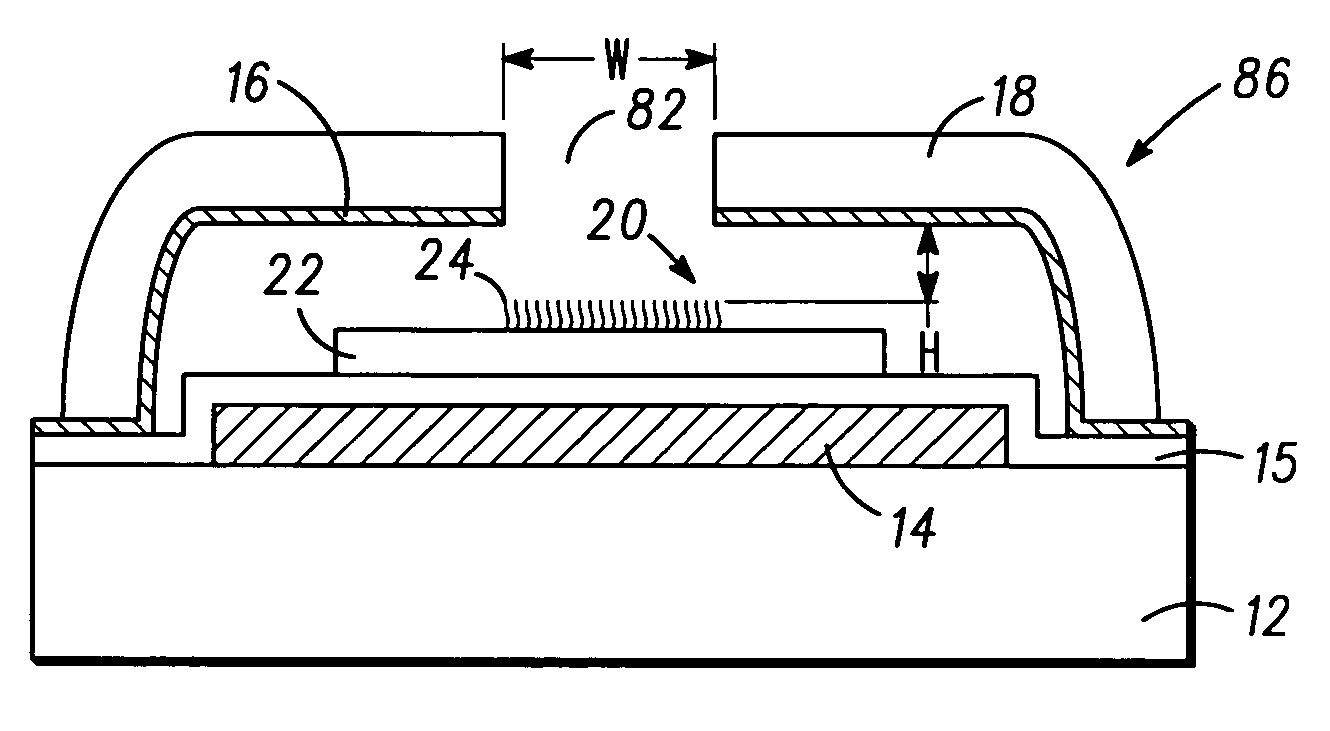

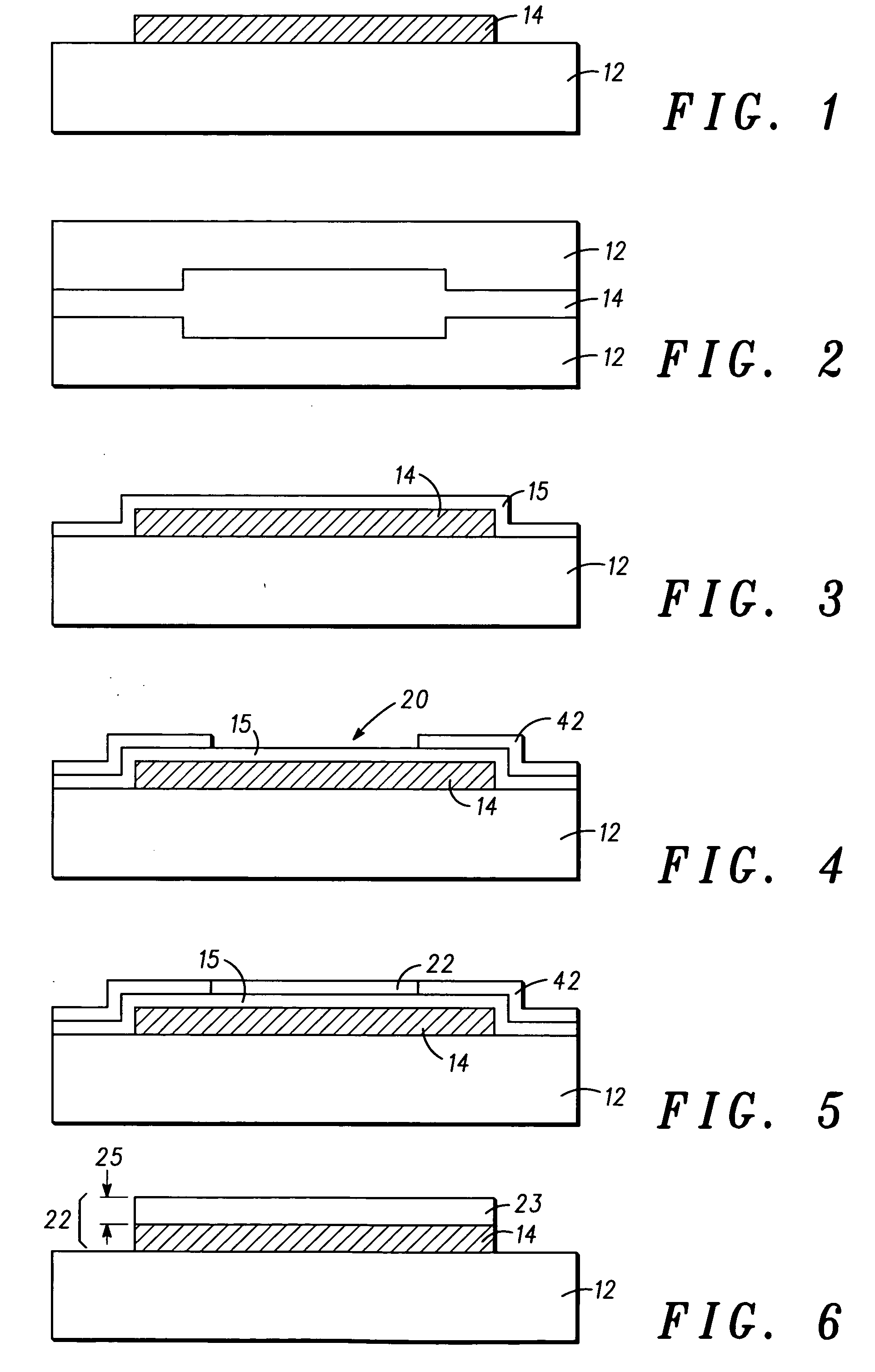

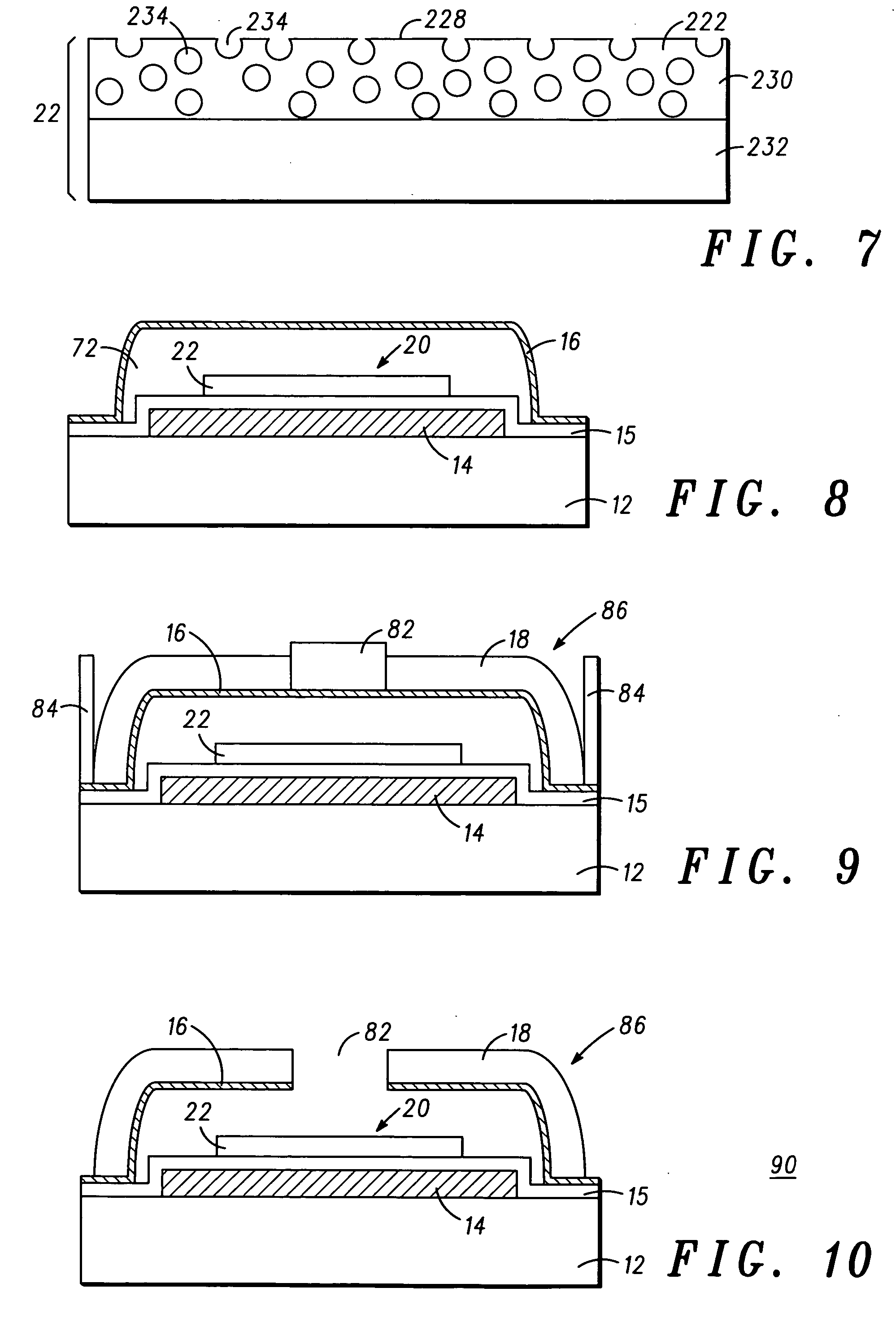

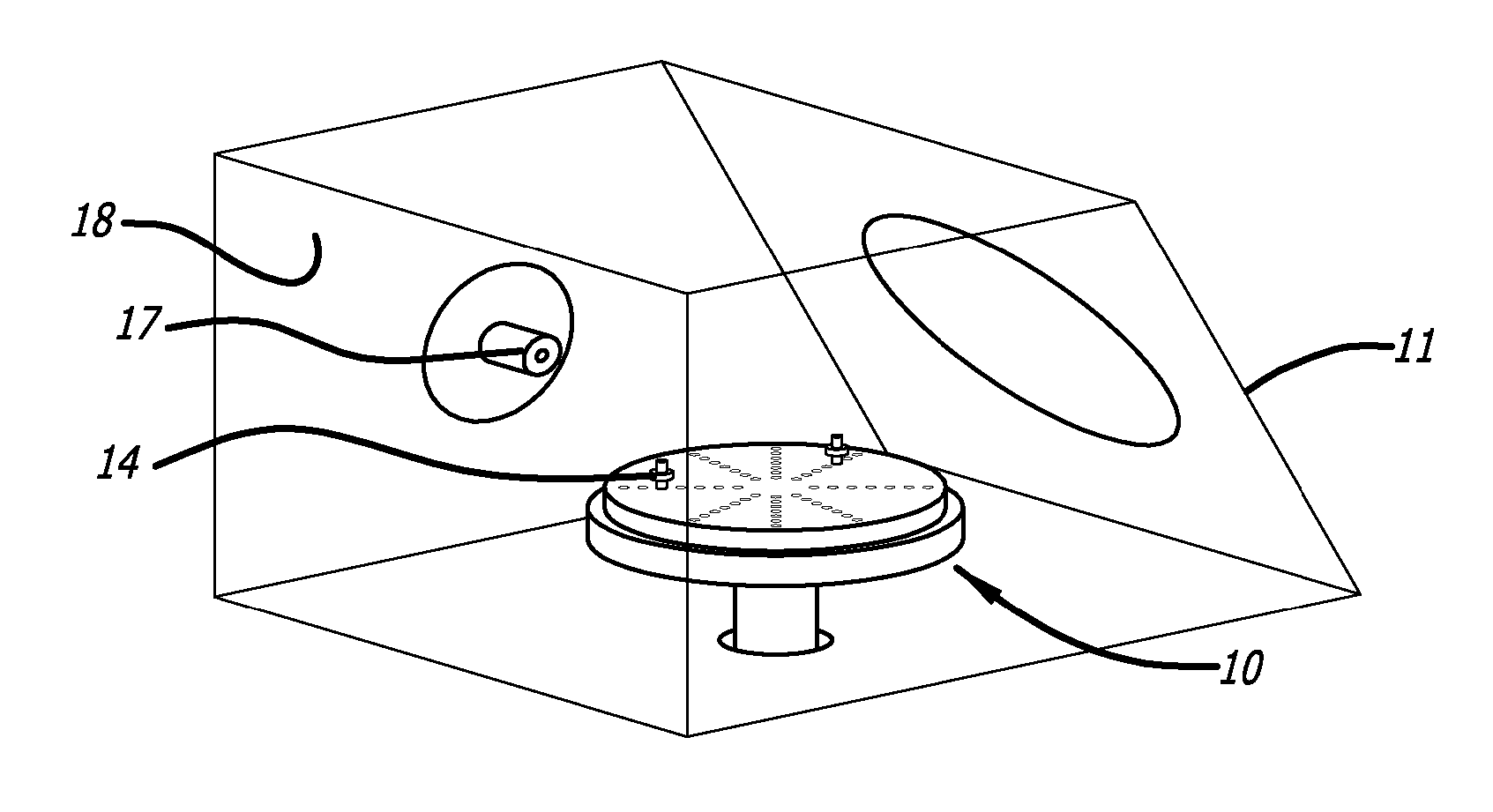

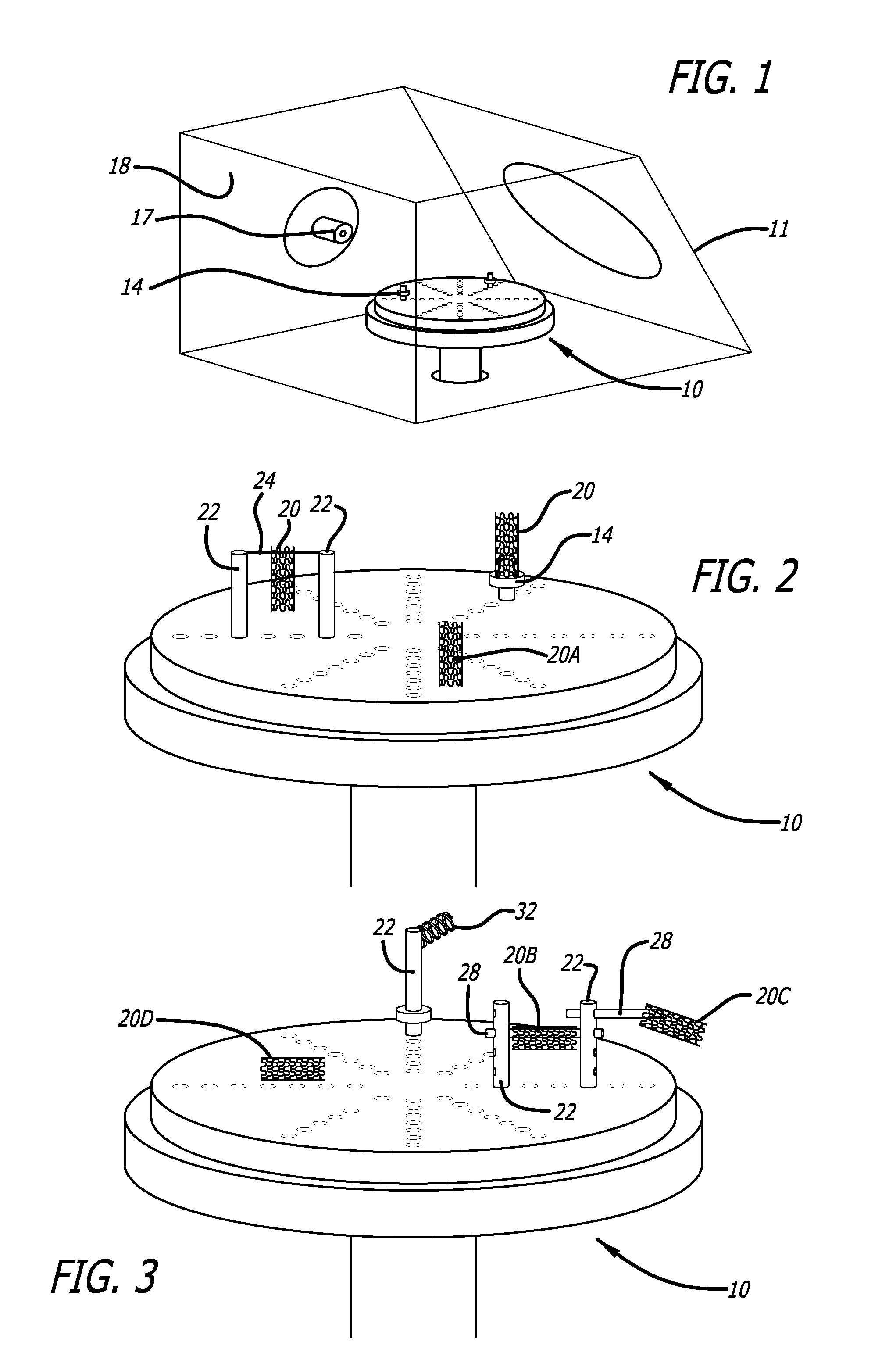

Field emission display and methods of forming a field emission display

A field emission device and method of forming a field emission device are provided in accordance with the present invention. The field emission device is comprised of a substrate (12) having a deformation temperature that is less than about six hundred and fifty degrees Celsius and a nano-supported catalyst (22) formed on the substrate (12) that has active catalytic particles that are less than about five hundred nanometers. The field emission device is also comprised of a nanotube (24) that is catalytically formed in situ on the nano-supported catalyst (22), which has a diameter that is less than about twenty nanometers.

Owner:MOTOROLA SOLUTIONS INC

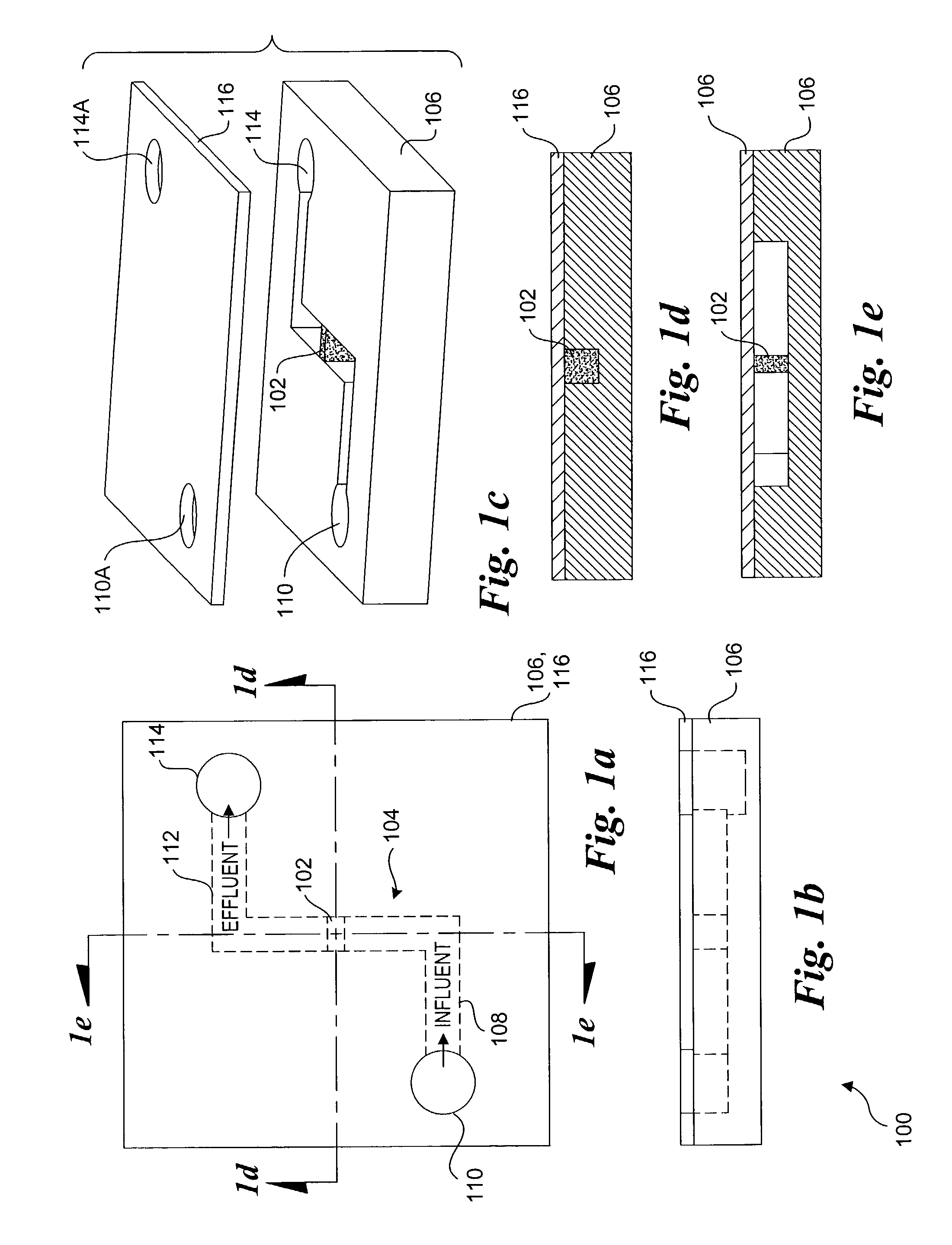

Microfluidic devices with porous membranes for molecular sieving, metering, and separations

Microfluidic devices with porous membranes for molecular sieving, metering, and separation of analyte fluids. In one aspect, a microfluidic device includes a substrate having input and output microfluidic channel sections separated by a porous membrane formed integral to the substrate. In another aspect, the porous membrane may comprise a thin membrane that is sandwiched between upper and lower substrate members. The microfluidic device may include one or a plurality of porous membranes. In one embodiment, a plurality of porous membranes having increasingly smaller pores are disposed along portions of a microfluidic channel. In another embodiment, a cascading series of upper and lower channels are employed, wherein each upper / lower channel interface is separated by a respective porous membrane. In another aspect, a porous membrane is rotatably coupled to a substrate within a microfluidic channel via a MEMS actuator to enable the porous membrane to be positioned in filtering and pass-through positions.

Owner:INTEL CORP

Medical devices having textured surfaces

ActiveUS20070225785A1Reduce atmospheric pressureDental implantsElectrotherapyGas phaseMedical device

Disclosed are medical devices having textured surfaces and related methods for texturing. Methods of surface texturing using gas-phase plasma provide medical devices with myriad complex surface morphologies.

Owner:MEDTRONIC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com