Patents

Literature

259 results about "Dunnage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the technical sense treated here, dunnage is inexpensive or waste material used to load and secure cargo during transportation; more loosely, it refers to miscellaneous baggage, brought along during travel. The term can also refer to low-priority cargo used to fill out transport capacity which would otherwise ship underweight.

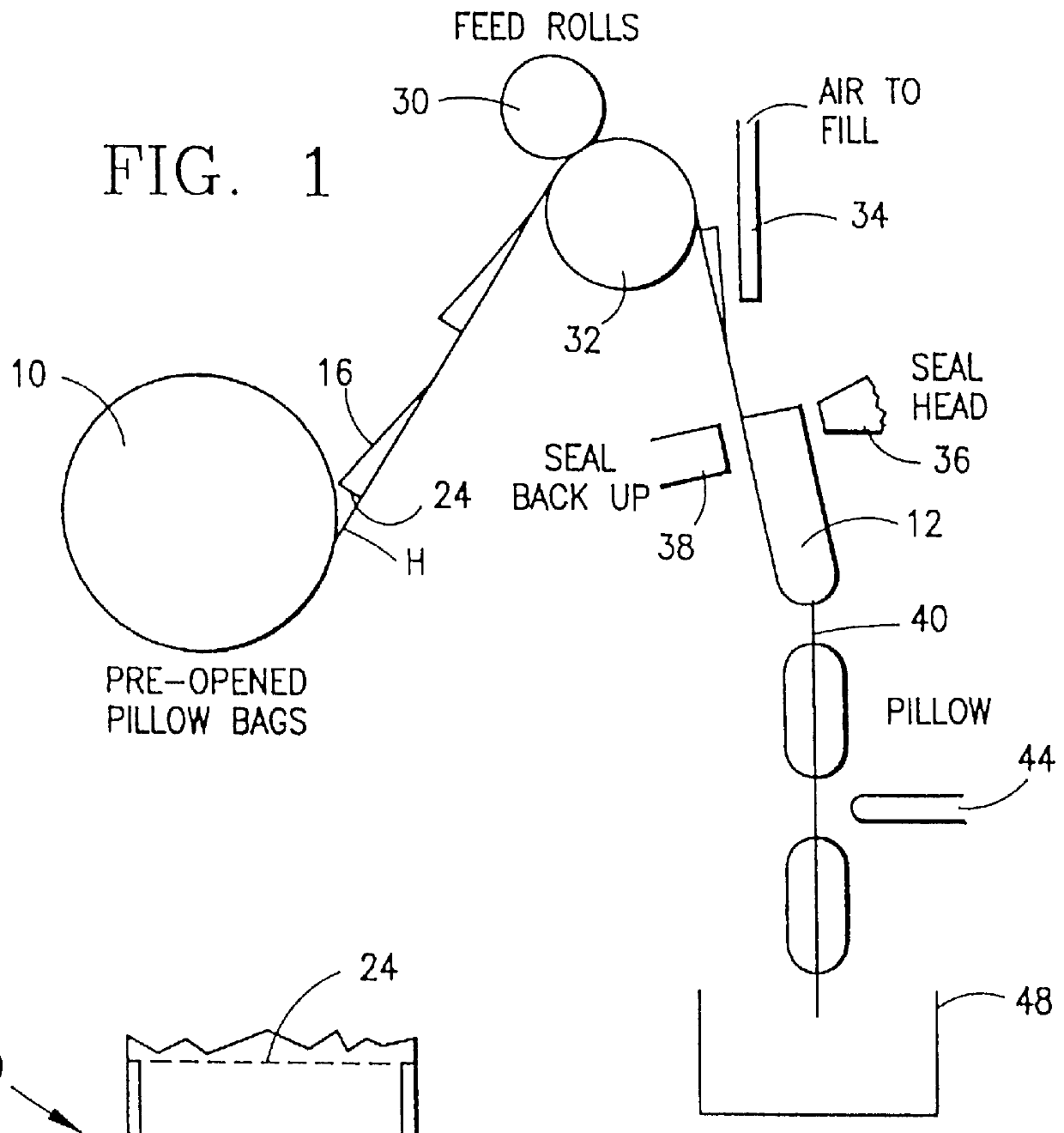

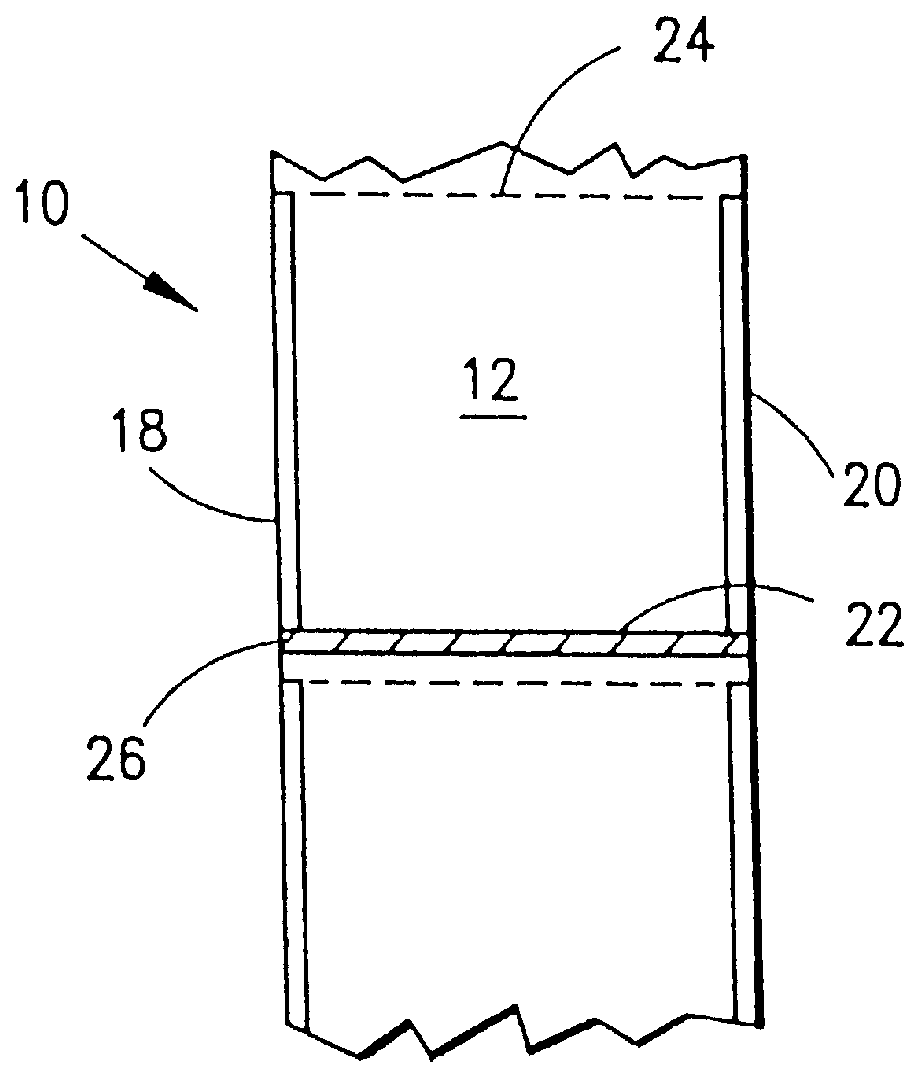

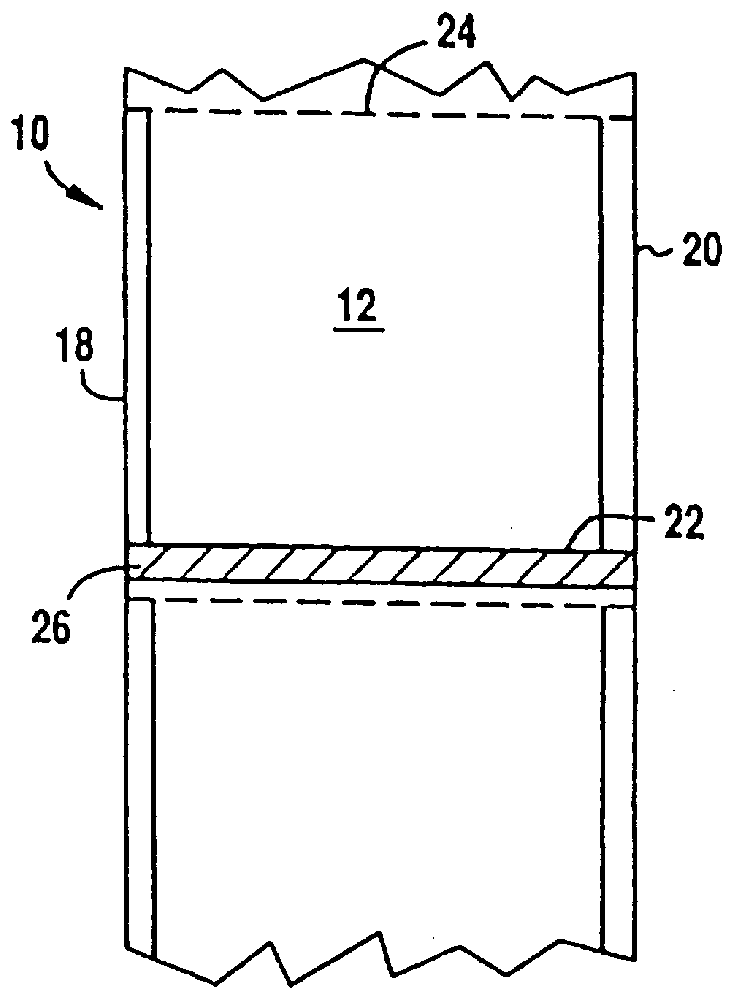

Method for producing inflated dunnage

InactiveUSRE36501E1Easy disposalEasy to reusePreventing unwanted cargo movementLabelling non-rigid containersDunnageCarton

A method for producing inflated dunnage on the site of use, comprising providing, in rolled form, a plurality of preformed plastic bags, each of the bags comprising two plastic sheets in facing relationship and sealed along three edges with one edge remaining open. Air is blown toward each of the open edges in sequence, causing each bag to inflate, and the fourth edge of each inflated bag is sealed, the bag being empty except for the air. At least one sealed inflated bag is separated from the roll and placed in a carton to serve as dunnage. In an alternate embodiment, the stock material is provided in a continuous tubular form, and an air inflation needle is used to puncture a surface of the tube for inflation purposes.

Owner:AUTOMATED PACKAGING SYST

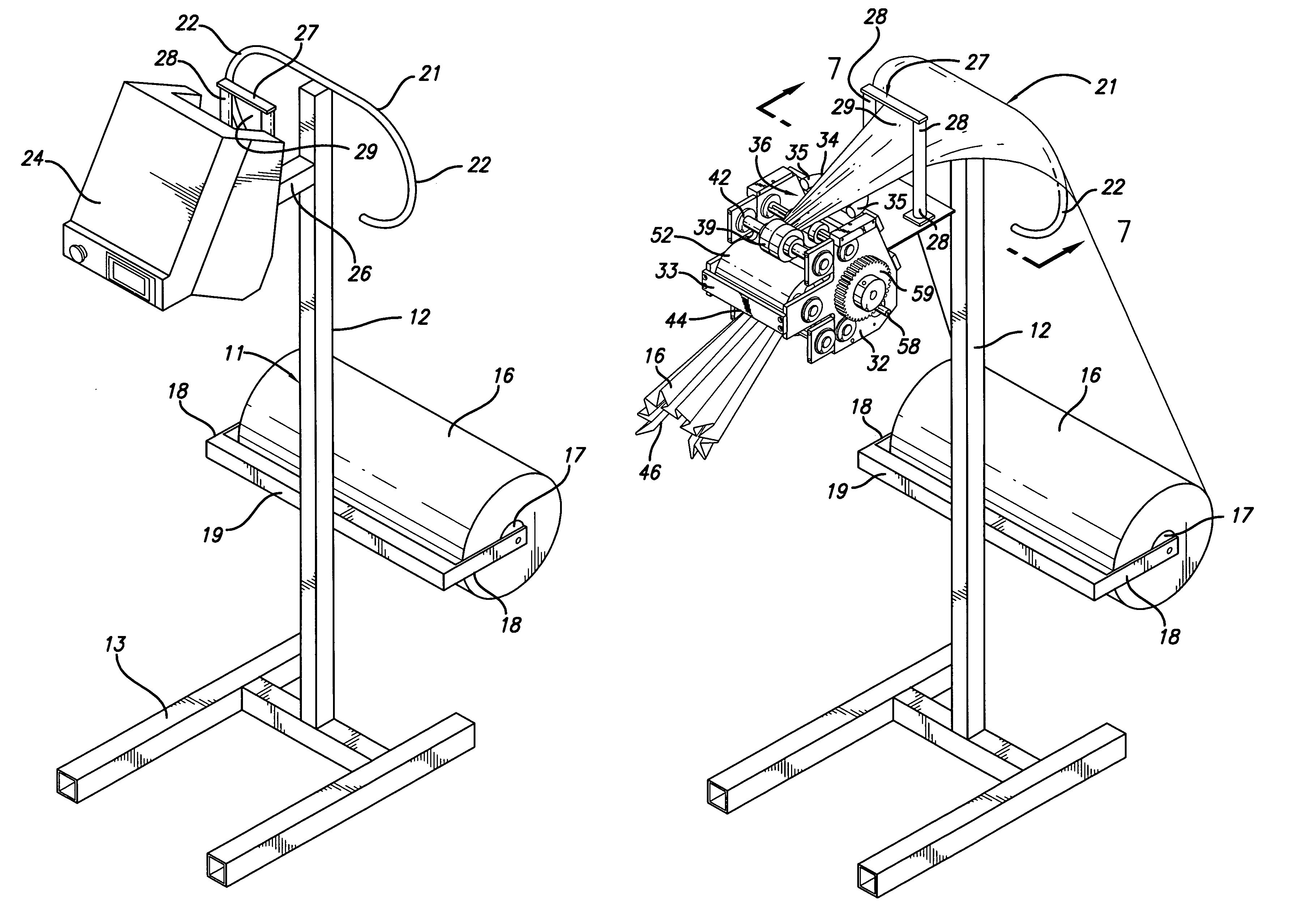

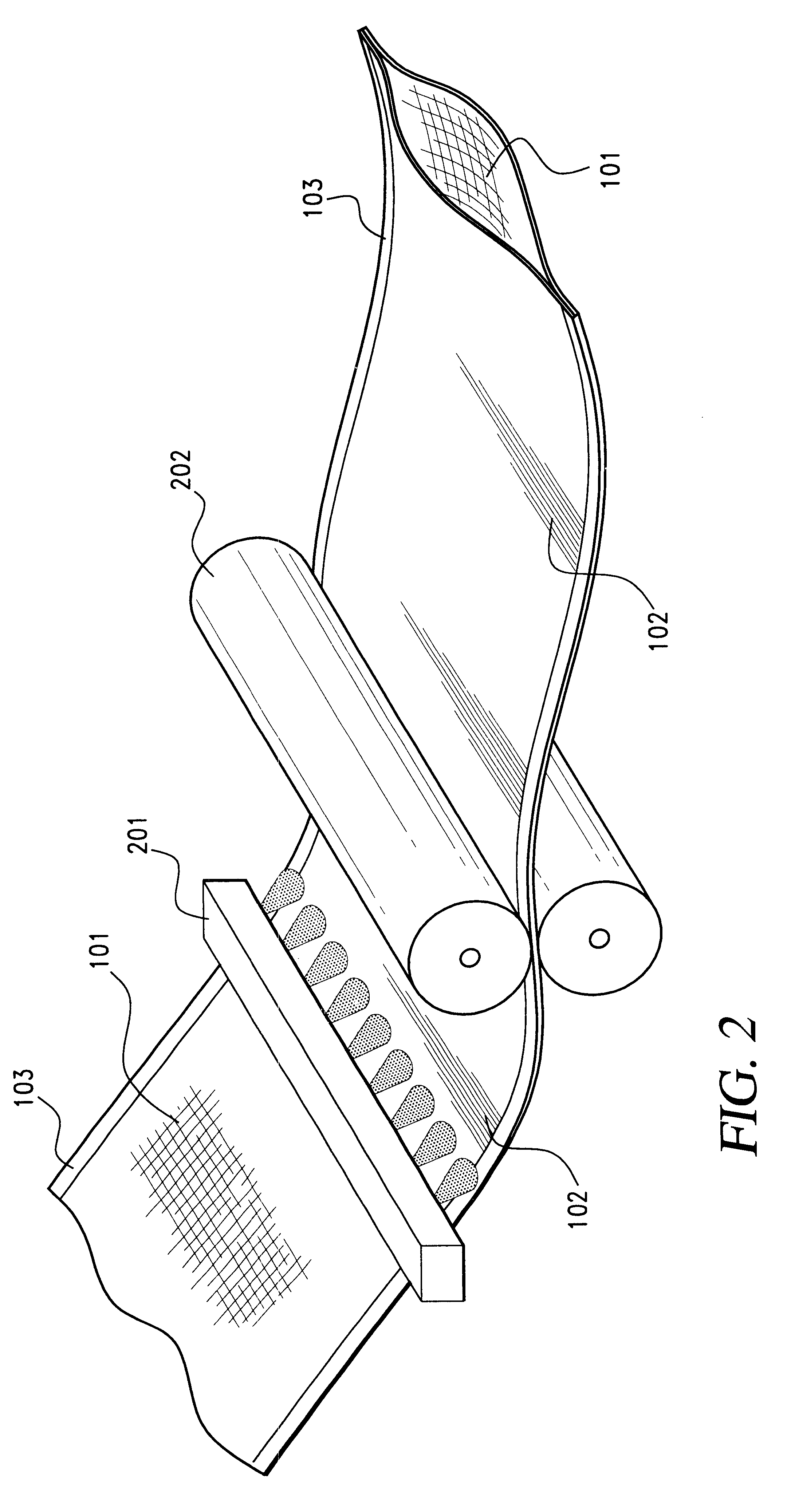

Machine and method for making paper dunnage

InactiveUS6910997B1Mechanical working/deformationPaper/cardboard articlesDunnagePulp and paper industry

Dunnage making machine and method in which a web of paper is drawn across a forming bar with curved end sections to roll the edge portions of the paper, then drawn through a first throat section to urge the rolled edge portions toward each other and cause them to gather, and thereafter through a second throat section of lesser dimension than the first to gather the central portion of the paper and further gather the edge portions. The gathered paper is then pressed with a roller to crumple it, following which the crumpled paper is perforated along a serrated tear line.

Owner:PREGIS INNOVATIVE PACKAGING

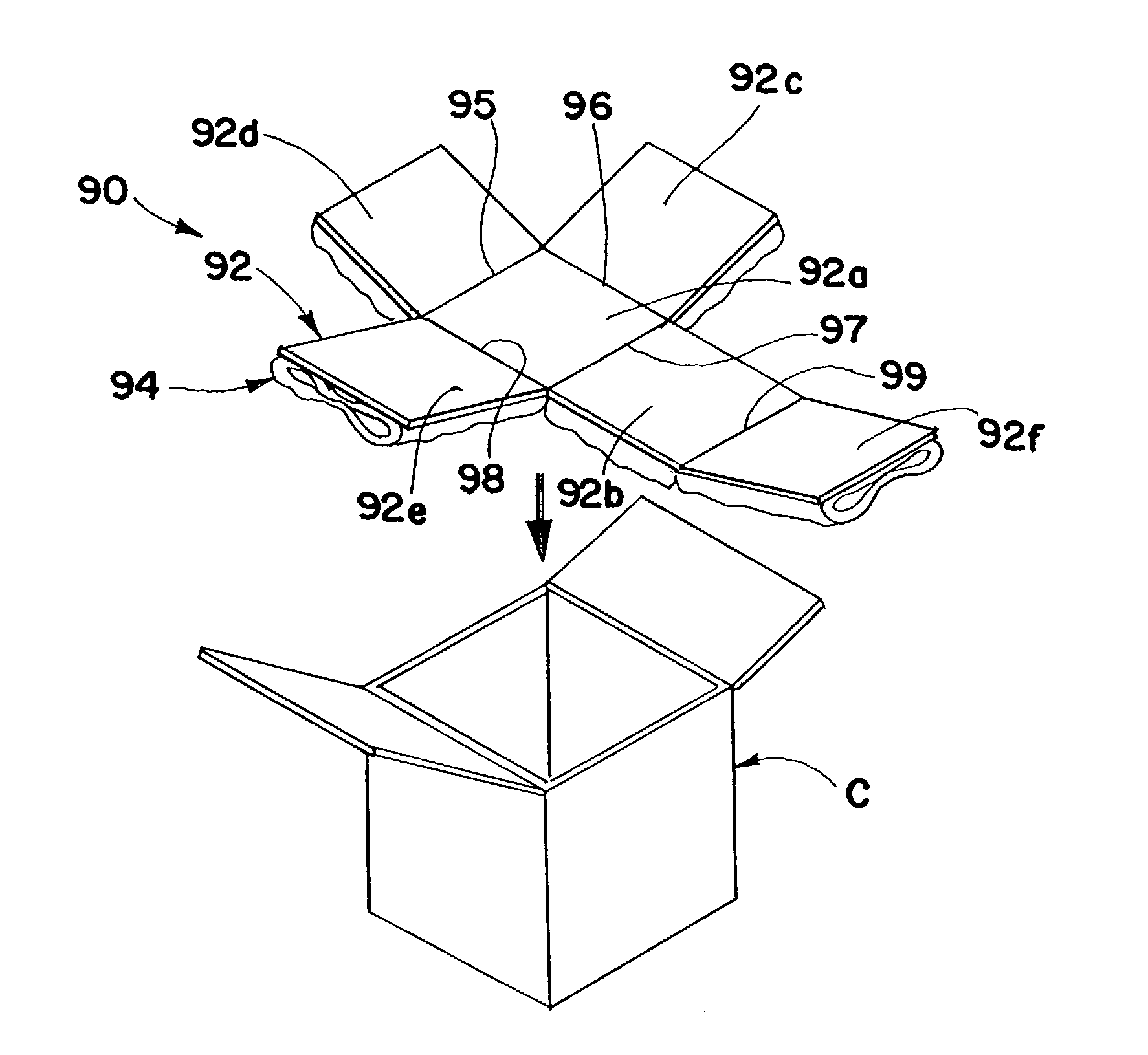

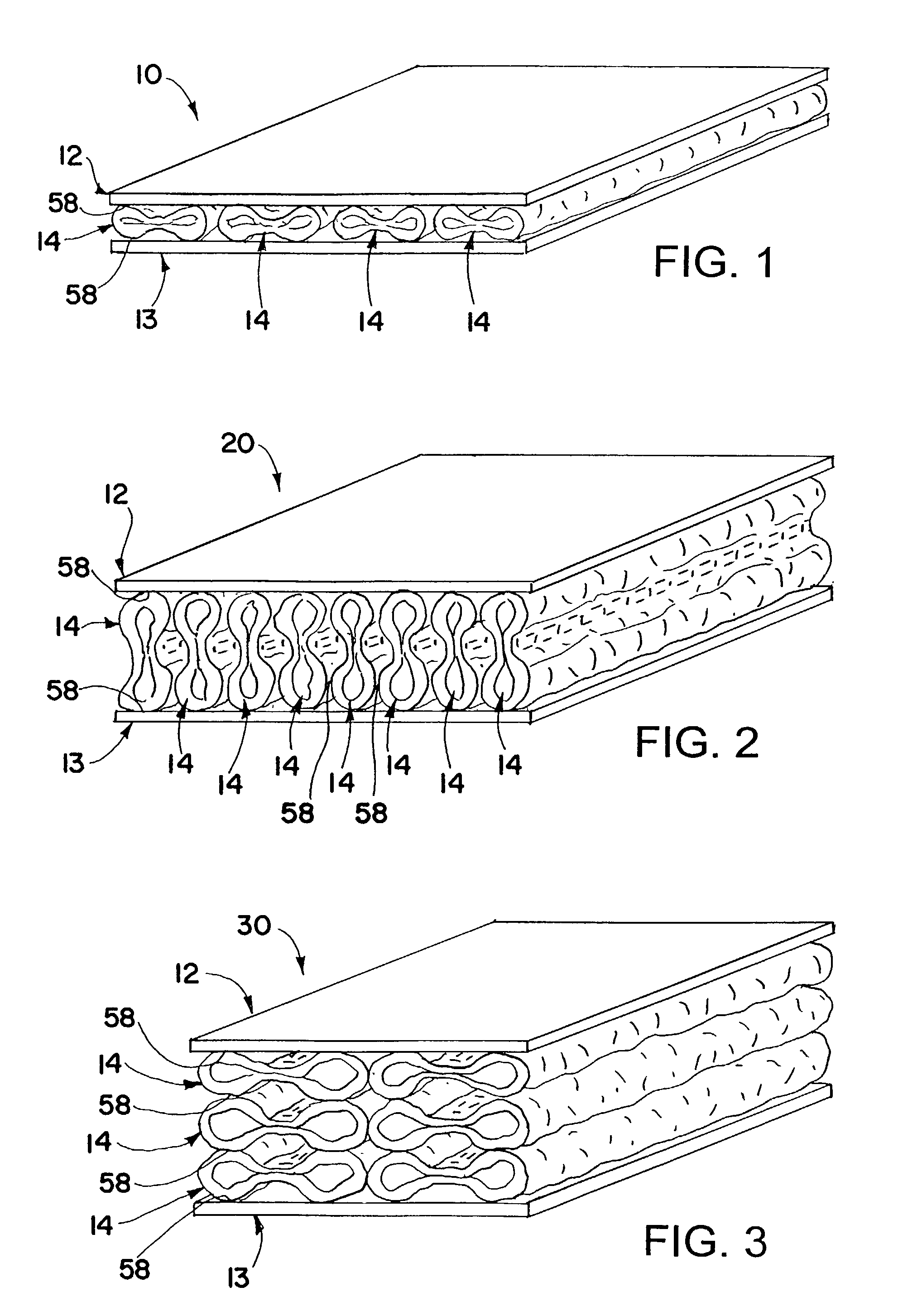

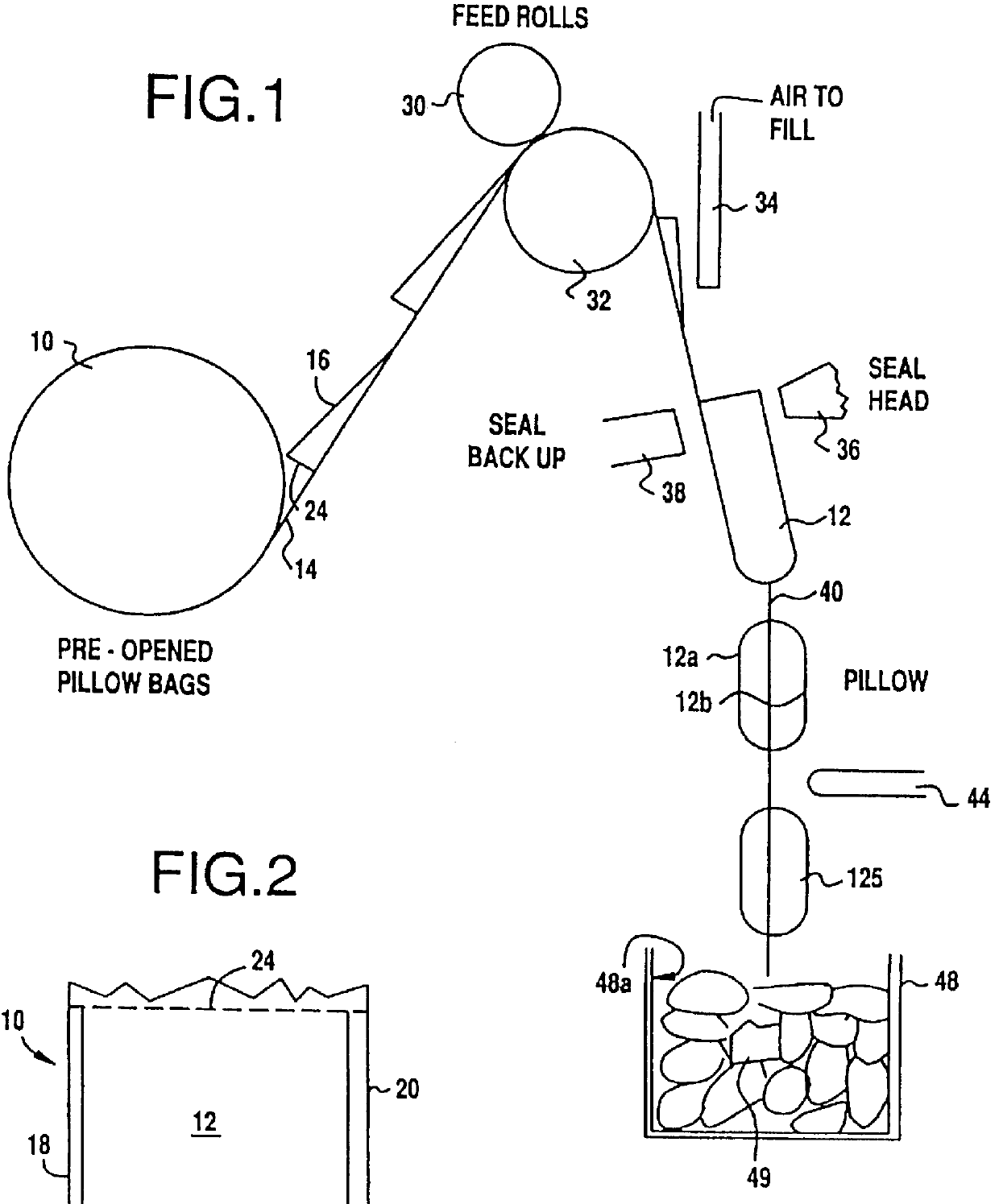

Packing product and apparatus and method for manufacturing same

ActiveUS7452316B2Wide range of resiliencySpreading capabilityBoxes/cartons making machineryPaper-makingDunnageEngineering

A packing product and apparatus and method for manufacturing same are disclosed. The packing product includes at least one face sheet and at least one crumpled sheet pad attached to the face sheet. A package and method of packaging an article are also disclosed, the package including a container, one or more crumpled sheet pads positioned in the container, one or more face sheets positioned adjacent to the crumpled sheet pads, and an article positioned in the container in at least partial abutting relation to the one or more face sheets. The one or more face sheets may have portions that are folded to envelop the article. Also, the face sheet may include an opening having a pattern corresponding to a shape of the article. A pad producing apparatus includes a dunnage supply machine for supplying a strip of dunnage, a folding device for forming a fold line in and transverse to the strip of dunnage, and a capture chute for guiding and accumulating the folded strip of dunnage so that a first layer downstream of the fold line overlaps a second layer upstream of the fold line, thereby forming an accordion-like pad.

Owner:RANPAK CORP

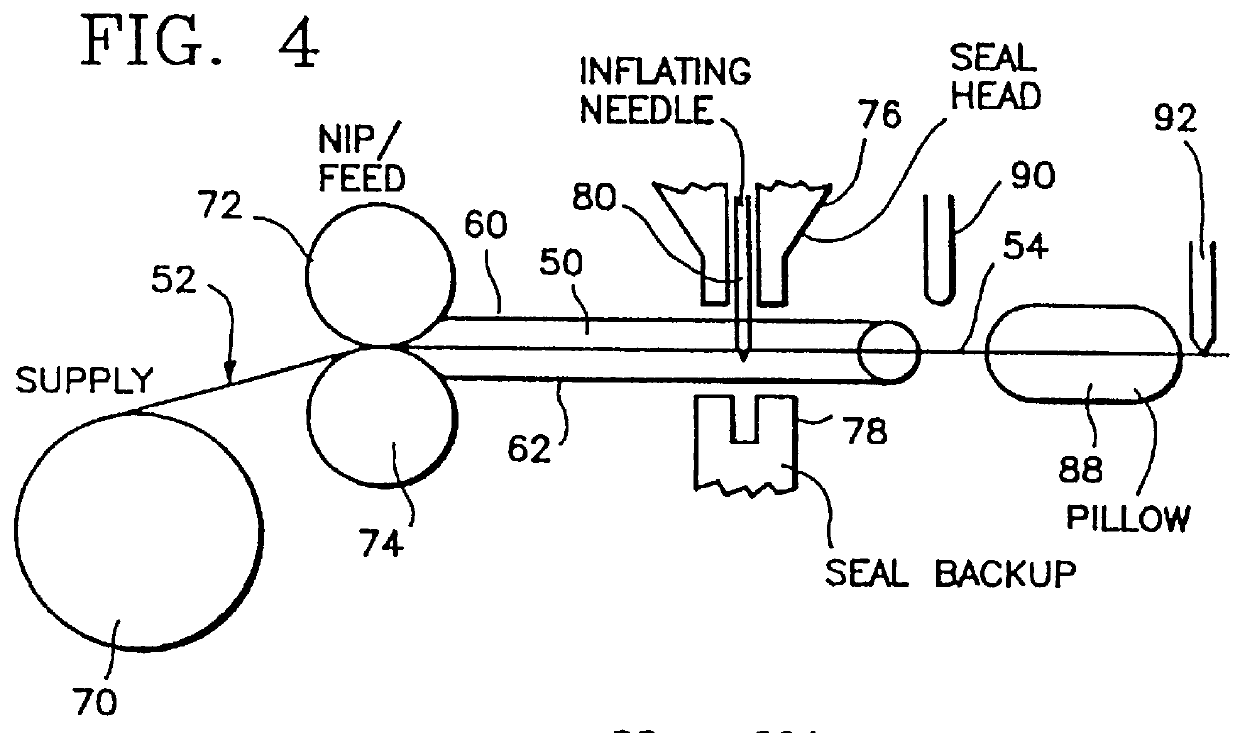

Inflated dunnage and method for its production

InactiveUSRE36759E1Reduce slippageEasy to prevent slippingPreventing unwanted cargo movementLabelling non-rigid containersDunnageCarton

A method for producing inflated dunnage on the site of use, comprising providing, in web form, a plurality of preformed plastic bags, each of the bags comprising two plastic sheets in facing relationship and sealed along three edges with one edge remaining open. Air is blown toward each of the open edges in sequence, causing each bag to inflate, and the open edge of each inflated bag is sealed, the bag being empty except for the air. A plurality of sealed inflated bags is separated from the web and placed in a carton to serve as dunnage. The bags have a slip resistant outer surface which causes the bags to interlock in the carton and better protect object therein from shock.

Owner:AUTOMATED PACKAGING SYST

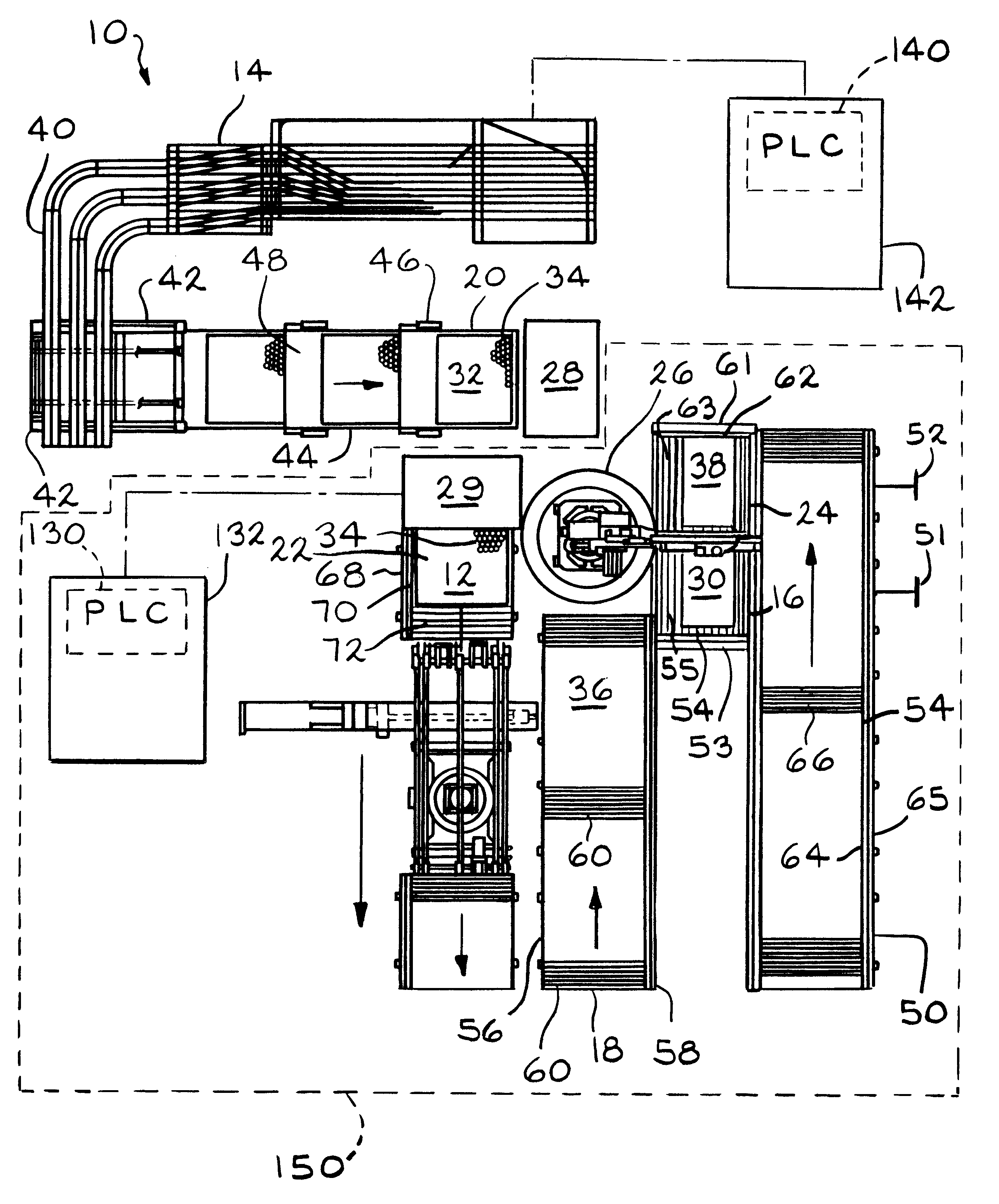

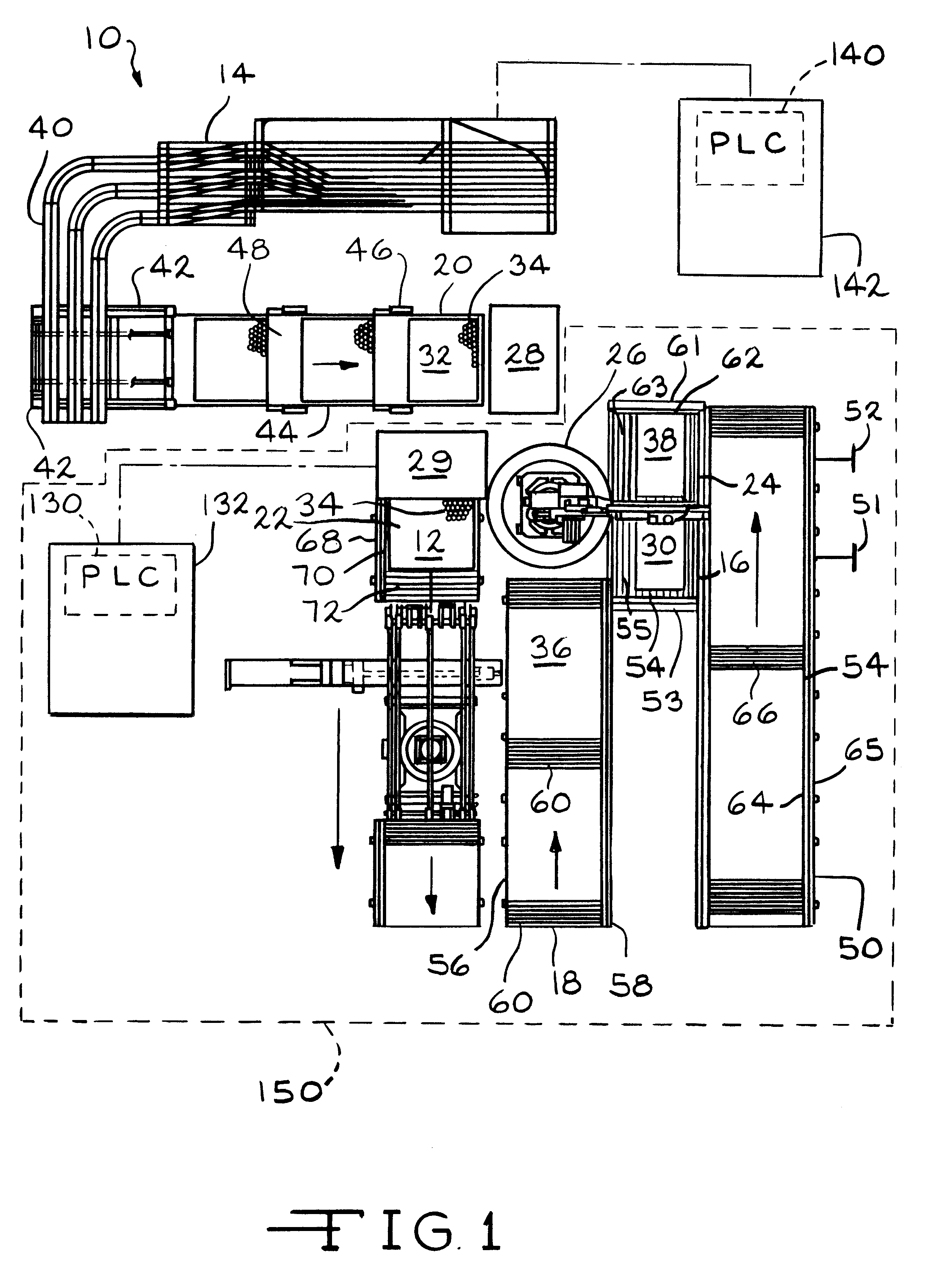

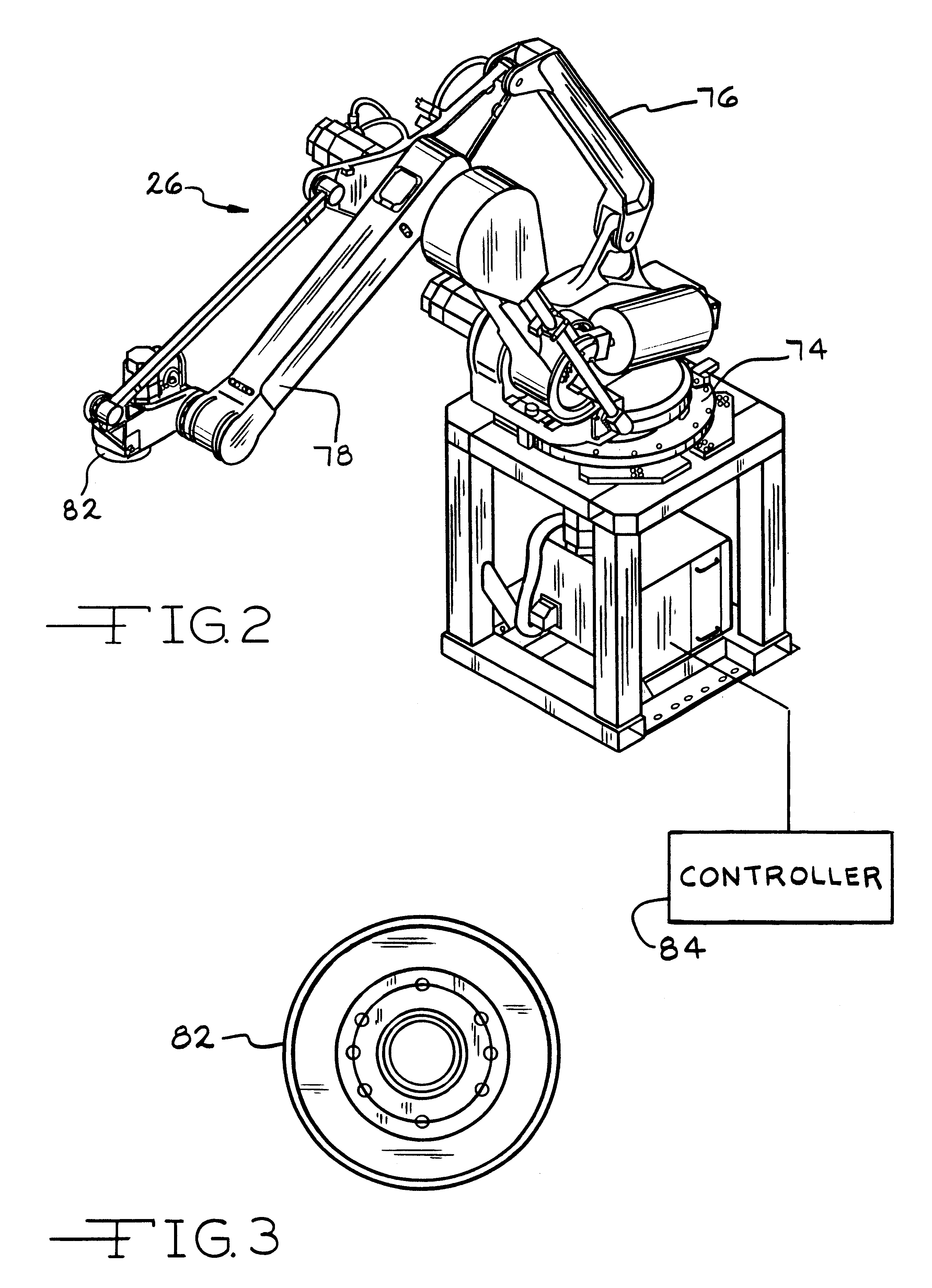

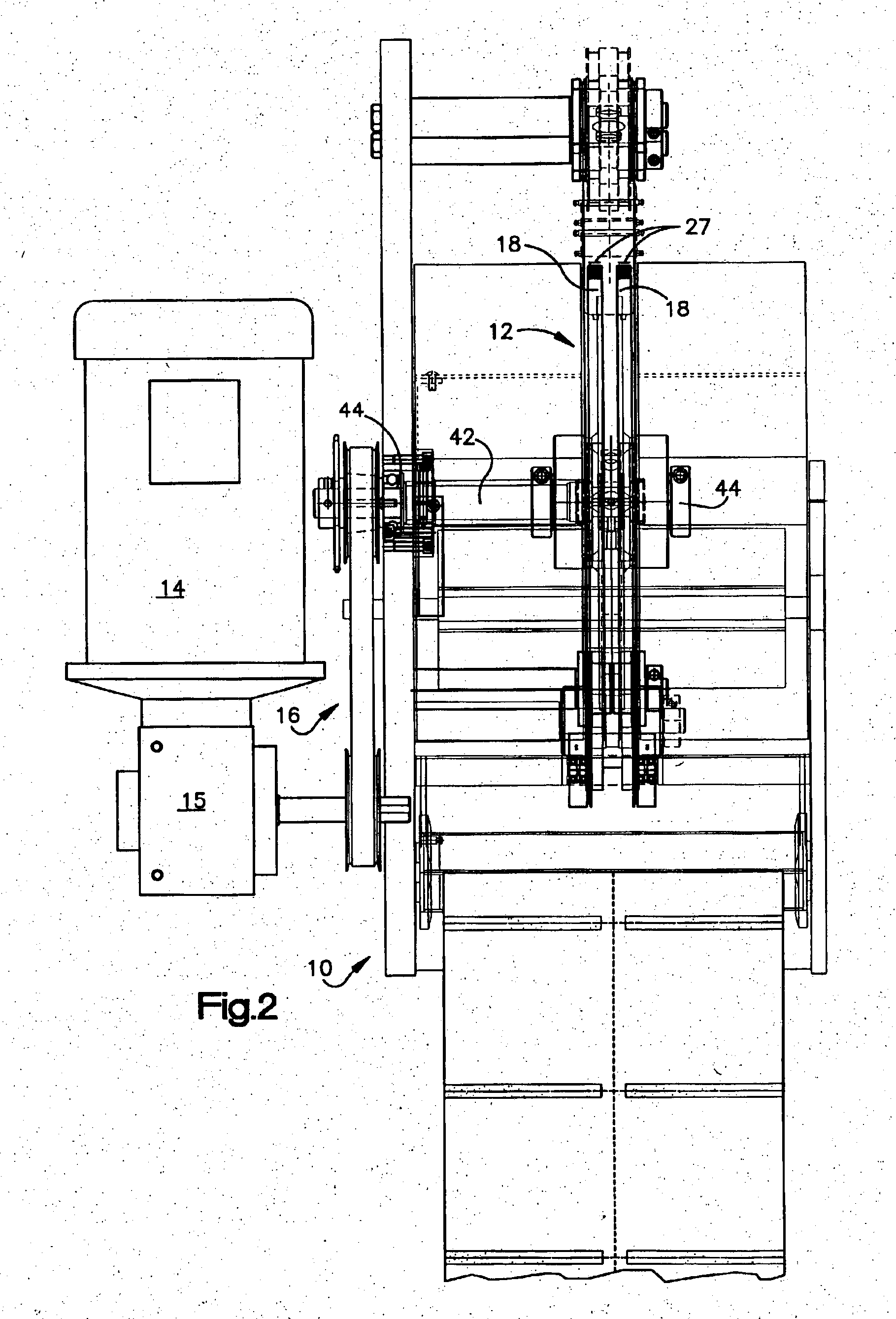

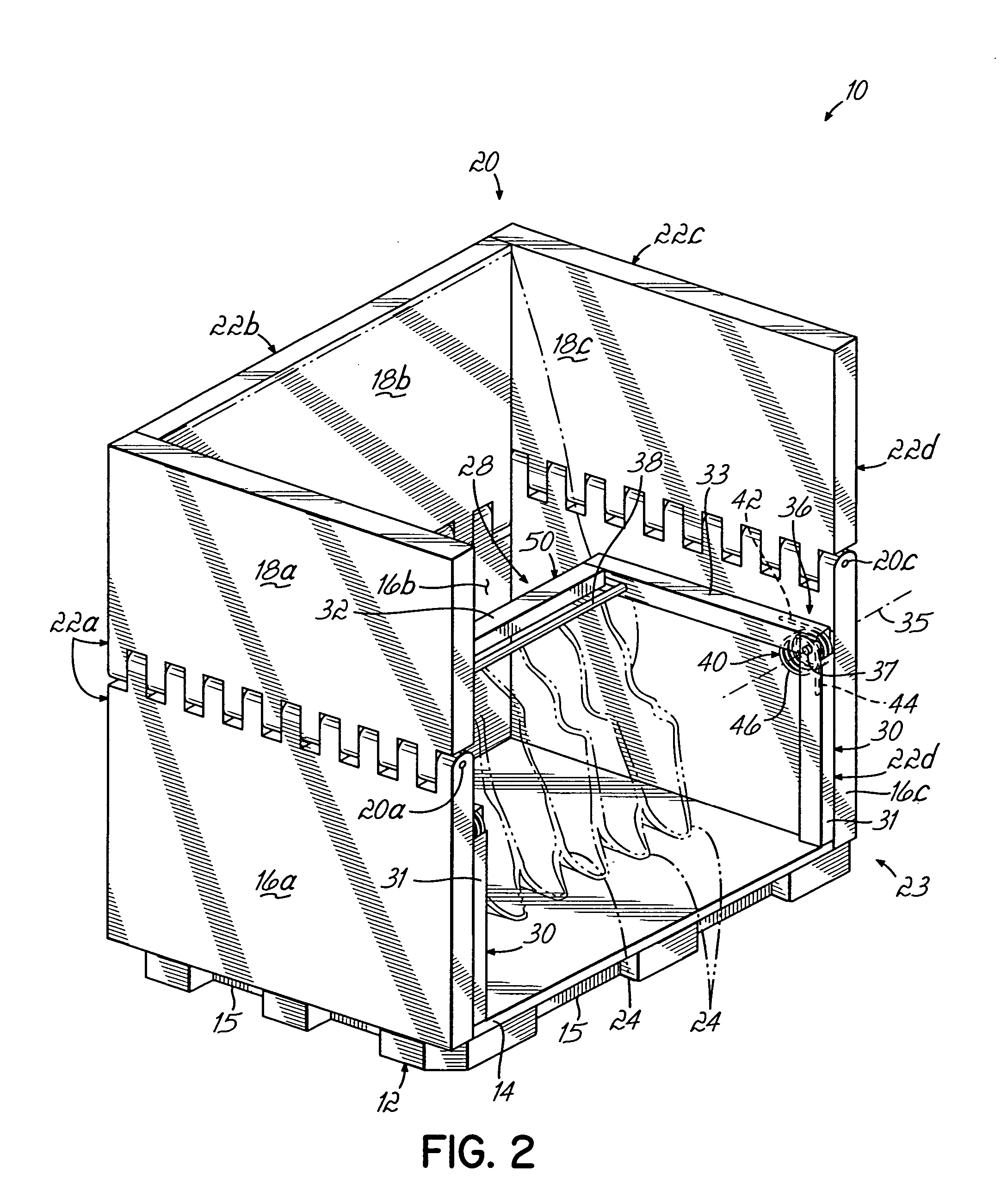

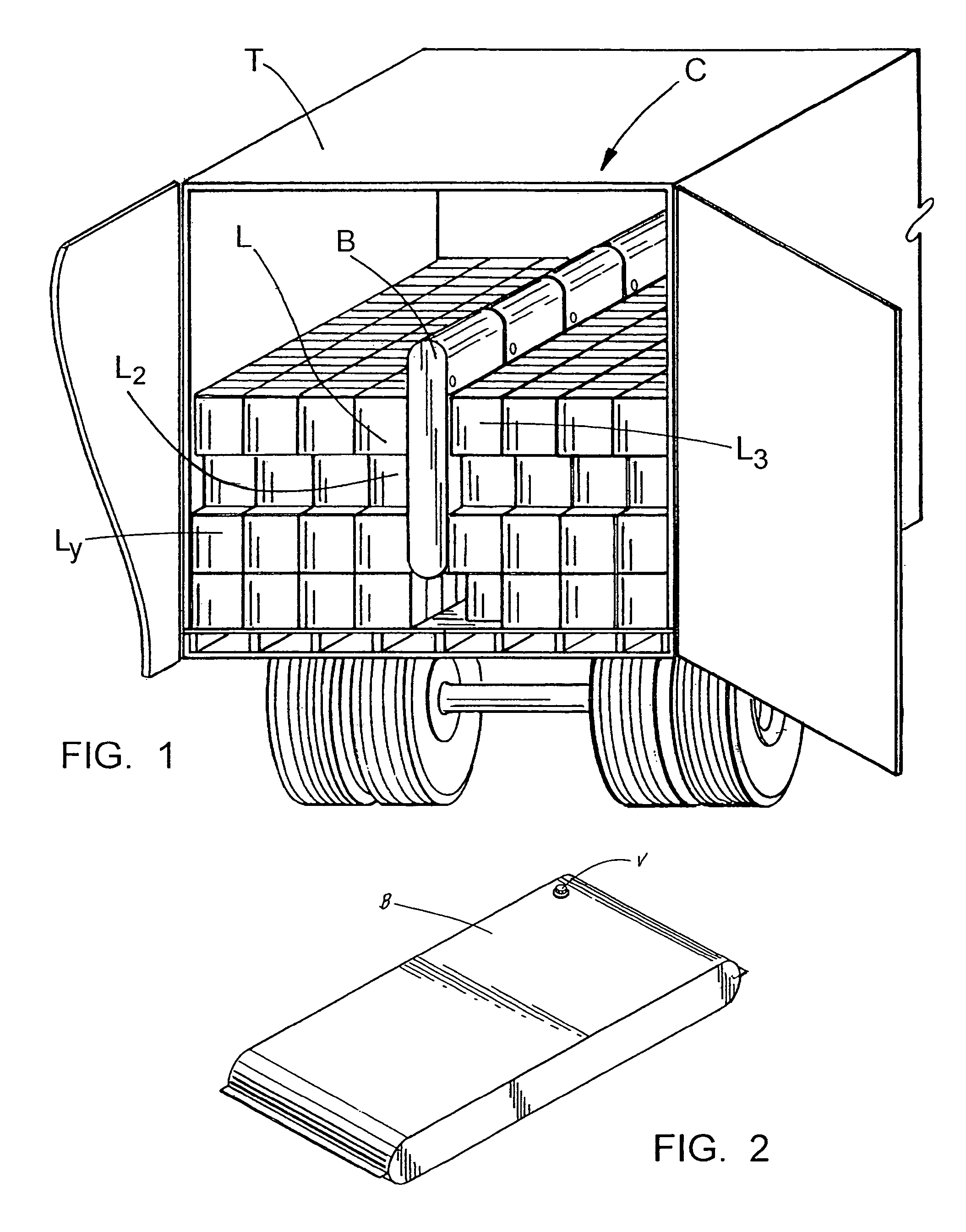

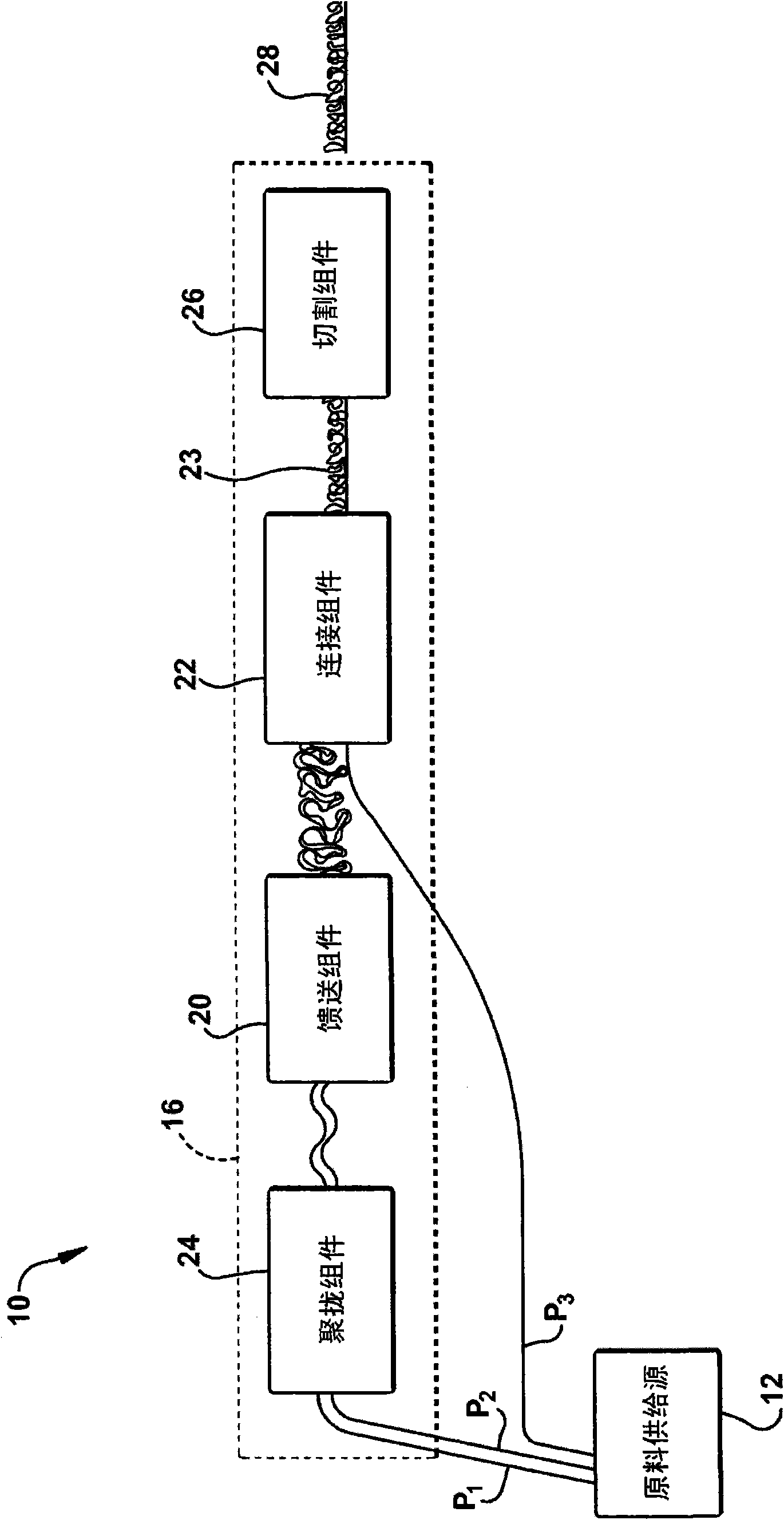

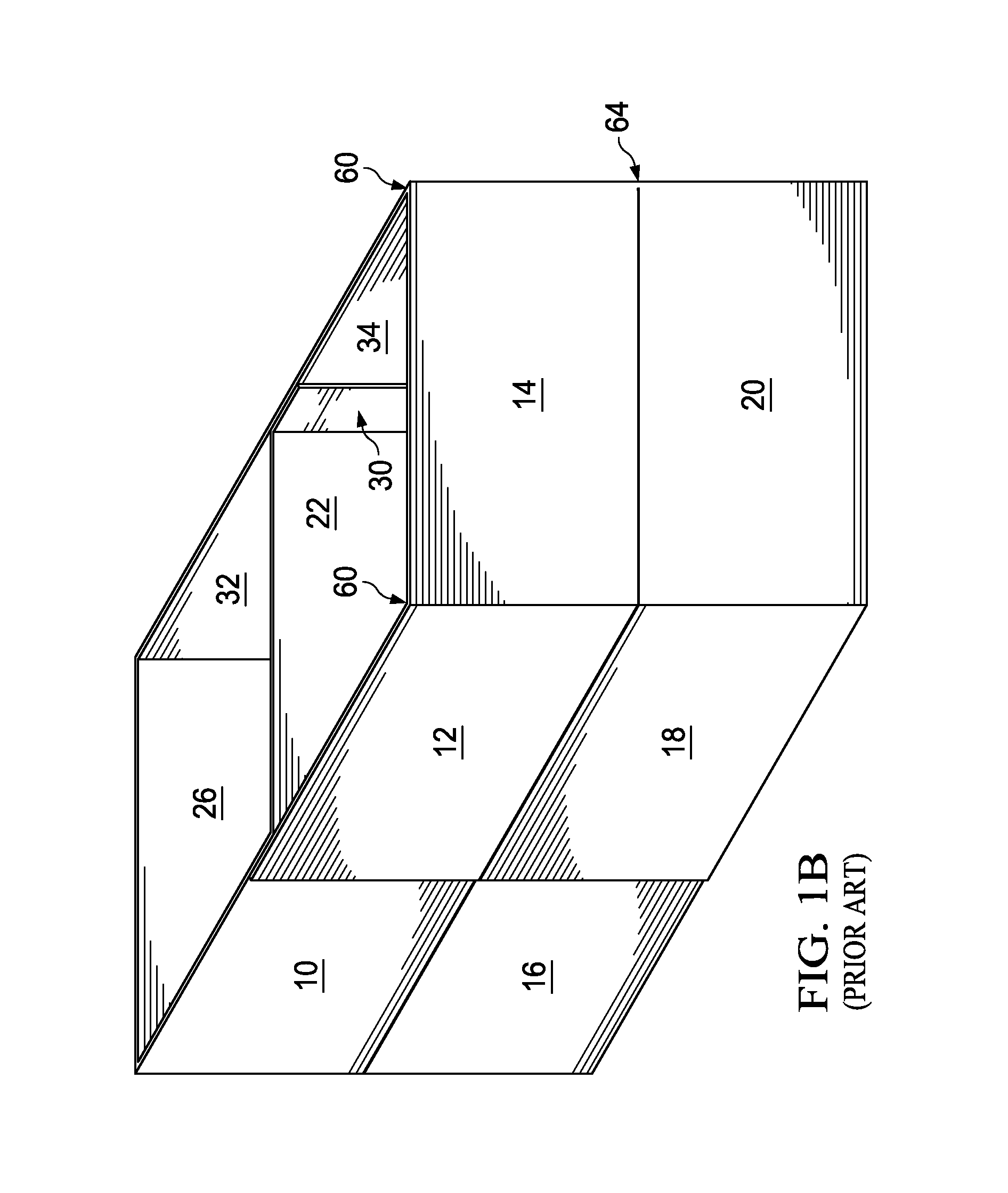

Bulk palletizer system

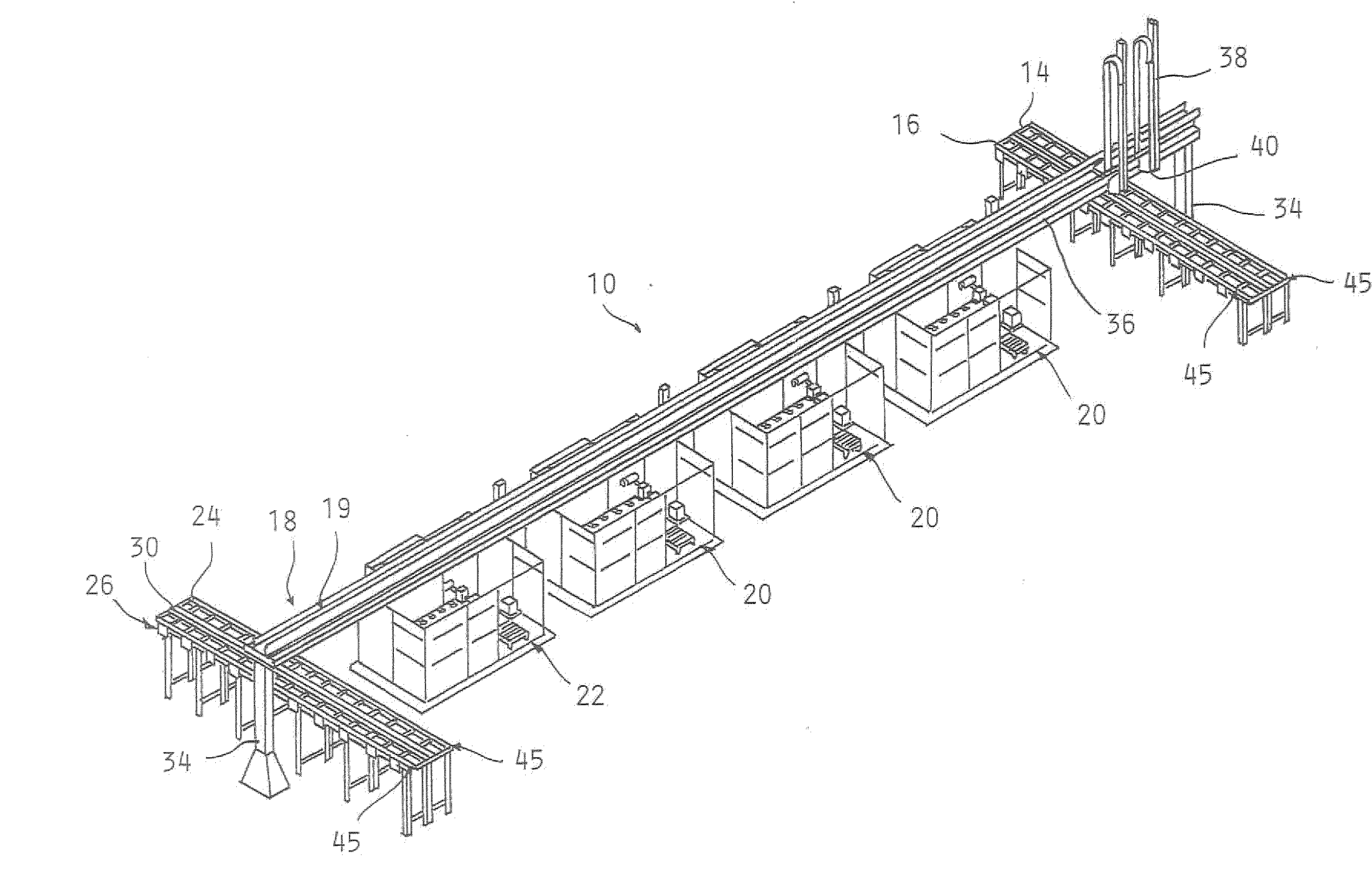

This machine is a cell for bulk palletizing a load such as the packaging of containers (bottles). The machine comprises a tier building system, a bulk load and dunnage supply systems. The cell also includes a programmable robot with cantilevered arm including an effector for transferring pallets, tiers of bulk product, tier sheets and top frames to the load build area. The effector includes an inverted drawer, suction means, pallet gripper means and top frame grippers for doing the transferring.

Owner:KAUFMAN ENGINEERED SYST

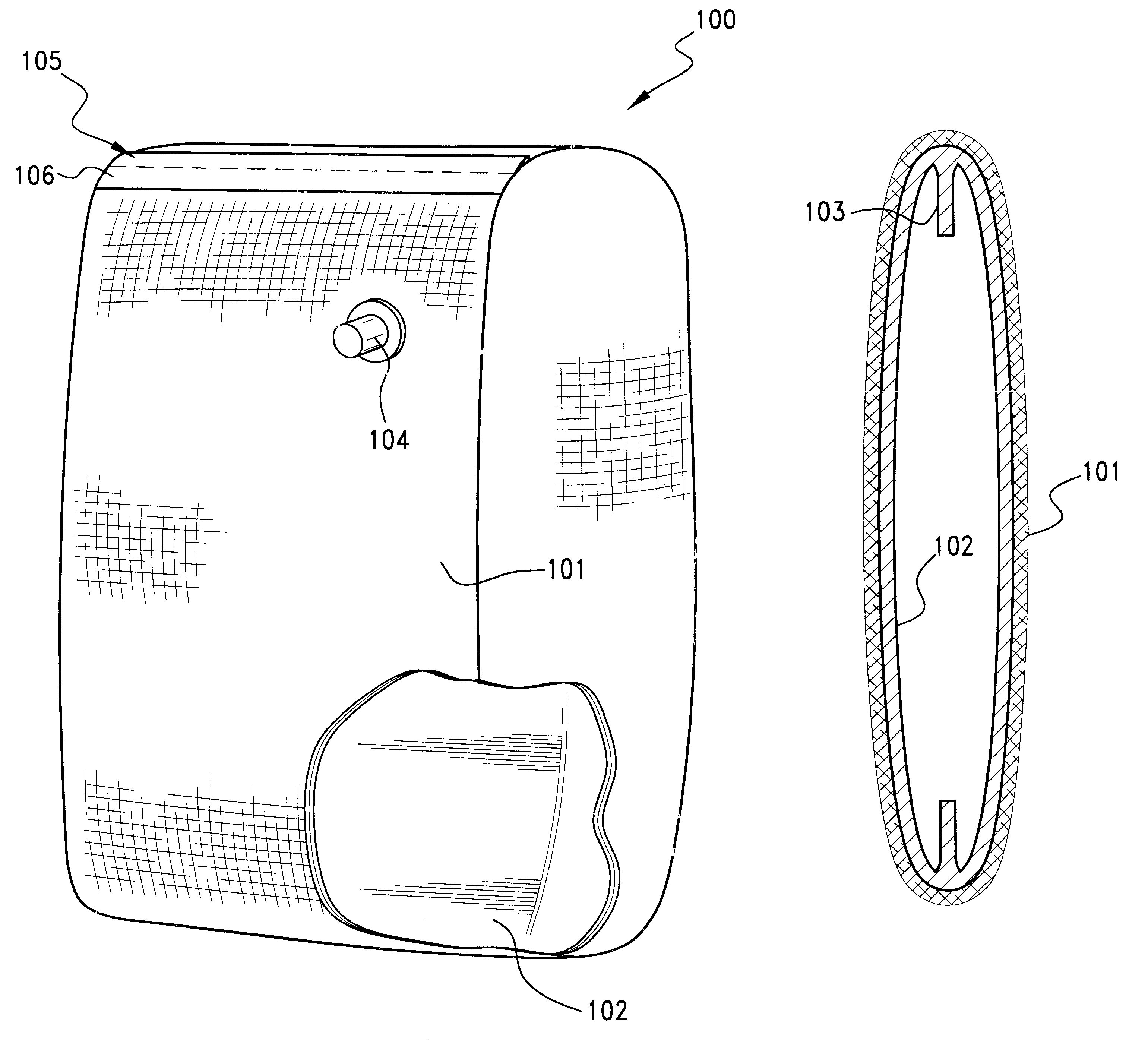

Method of making dunnage bags

InactiveUS6435787B1Abrasion resistanceReduce manufacturing costLoad securingCargo supporting/securing componentsDunnageAdhesive

A method of manufacturing an inflatable dunnage bag having a wall construction of two integrally fused layers of thermoplastic polymer, the outer layer of which is a sleeve of strips of woven polymer, the inner of layer of which is a continuous layer of gas impervious polymer. The ends of the sleeve are sealed against the escape of gas. The wall of the bag has a valve for the admittance of gas to the interior of the bag. The bag is formed by deposition of a continuous molten layer of gas impervious polymer to a sleeve of strips of woven polymer, installing a valve for admittance of gas into the wall of the sleeve and forming a gas tight seal at the ends of the sleeve. Deposition of the continuous layer of gas impervious polymer may be a two-step process wherein a molten layer of gas impervious polymer is deposited to one exterior side of the flattened sleeve, then to the other exterior side of the flattened sleeve and the sleeve turned "inside-out". The ends of the bag are sealed, may be folded, the folds secured to the exterior of the bag by adhesive and a binding strip. The dunnage so manufactured is strong, lightweight, scuff resistant, moisture resistant, reusable or easily recyclable.

Owner:JOHN DAVID M

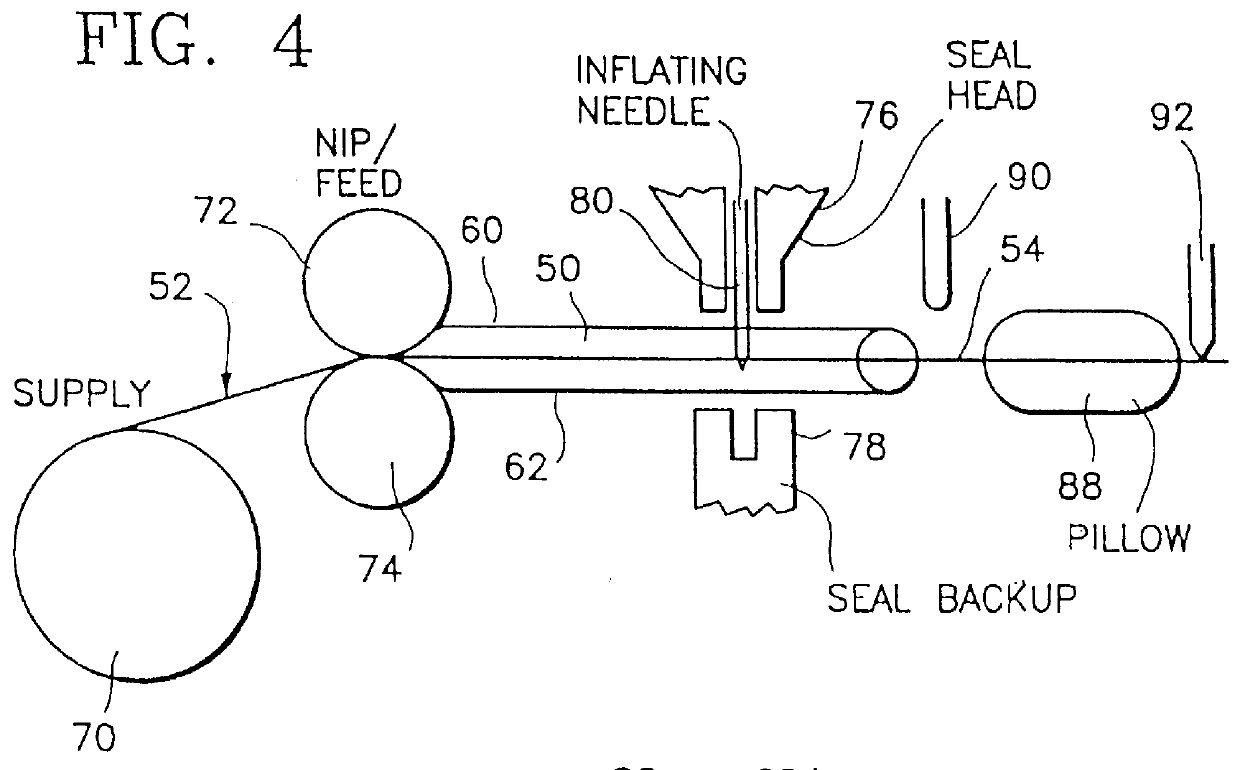

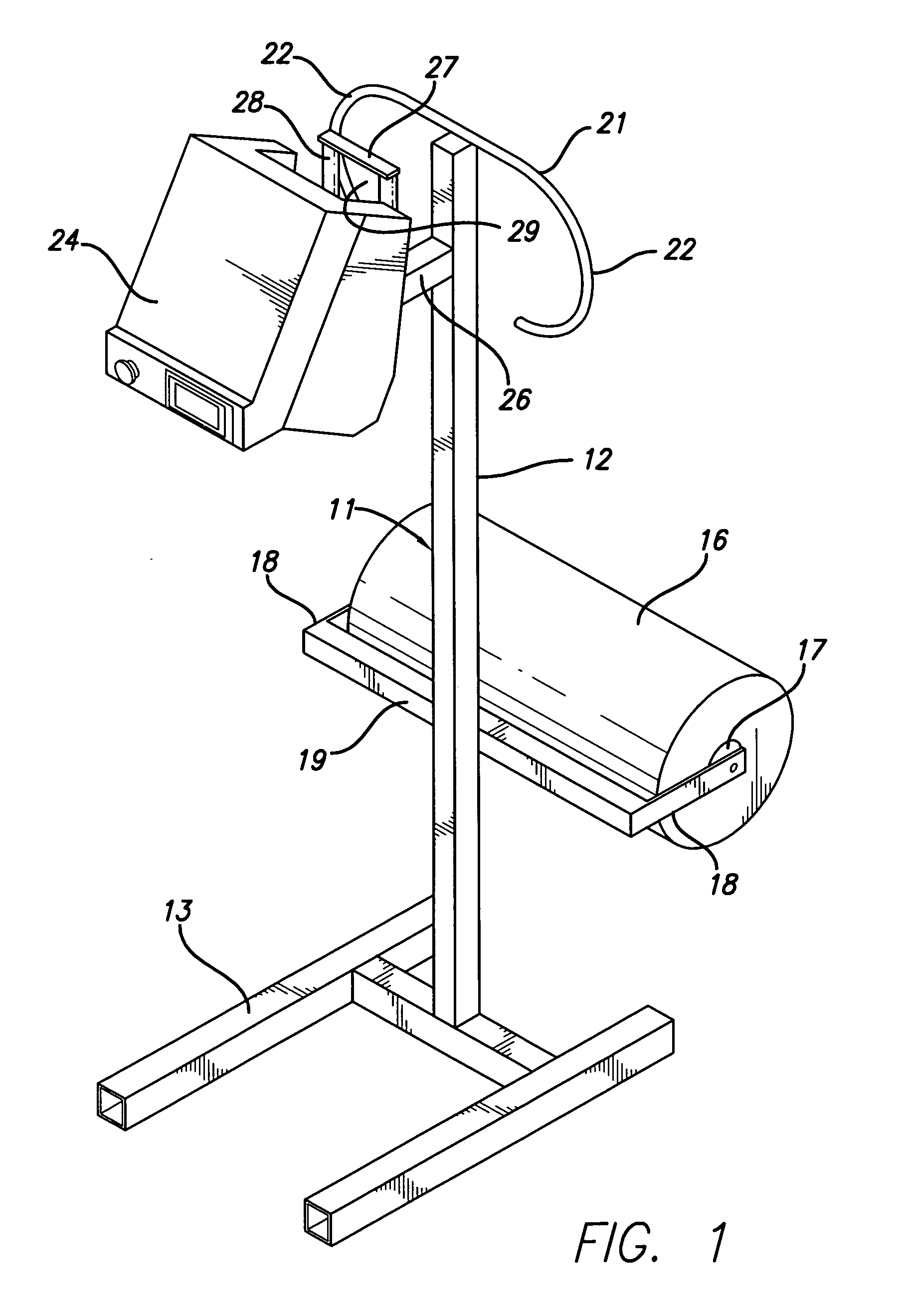

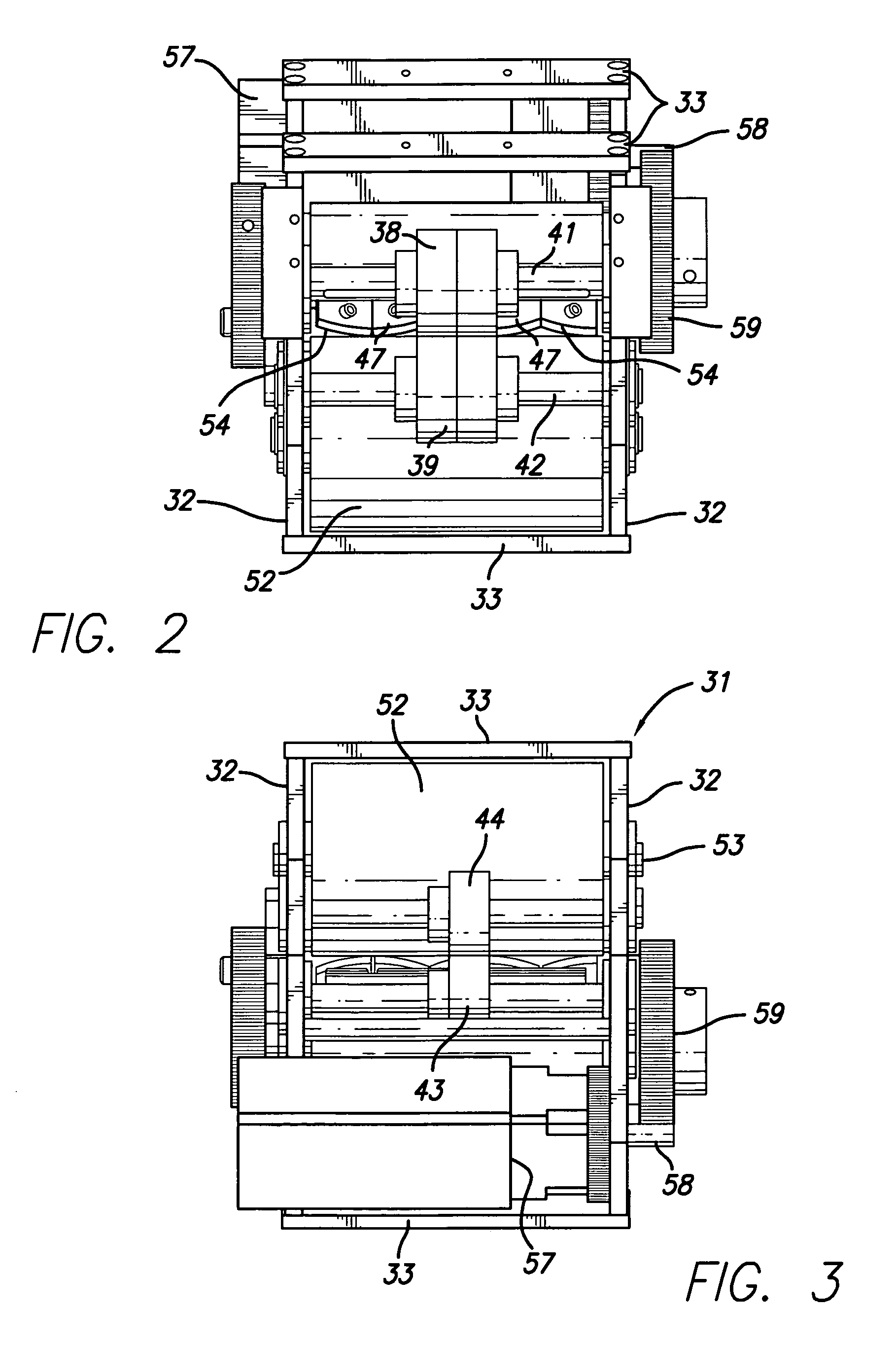

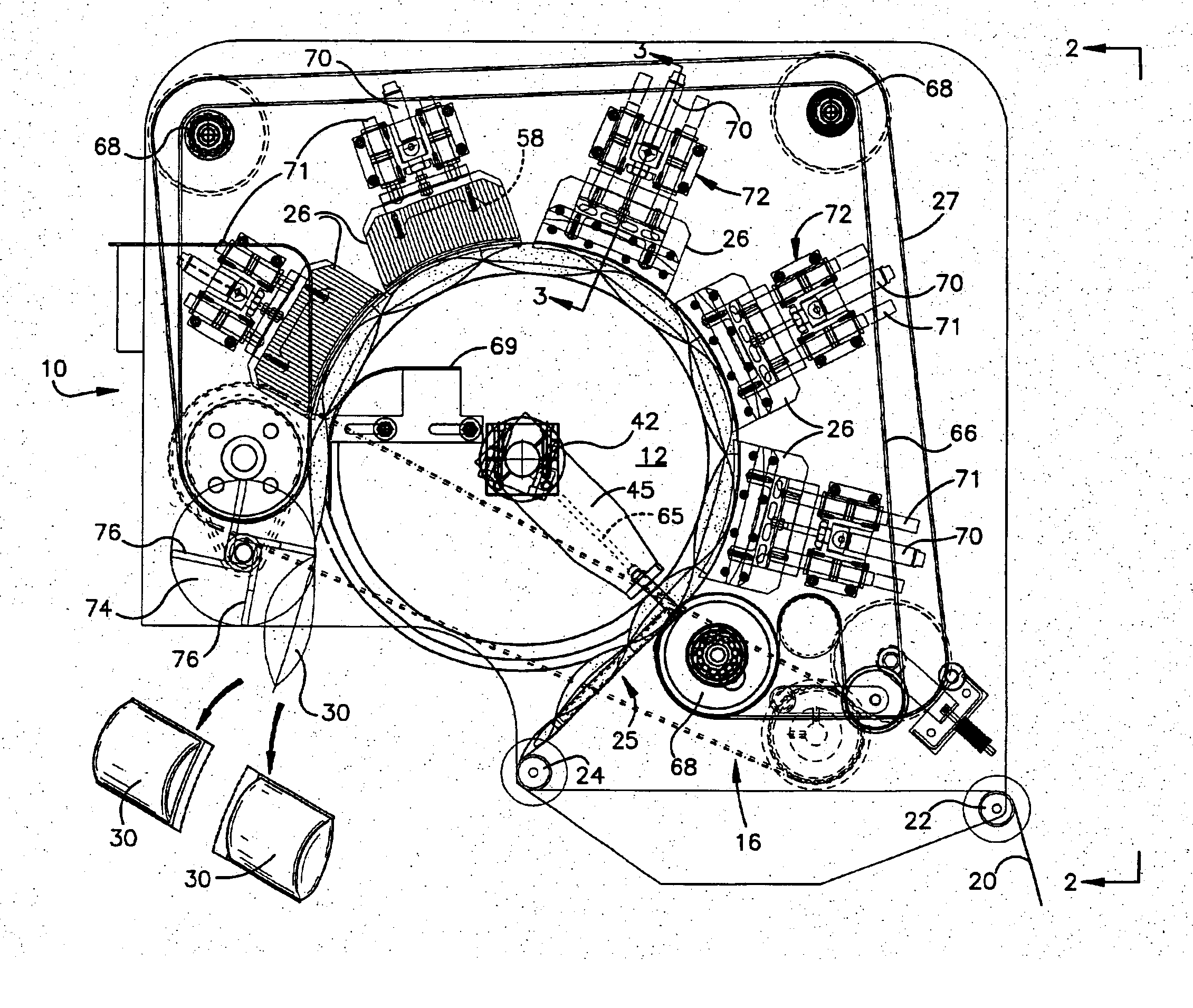

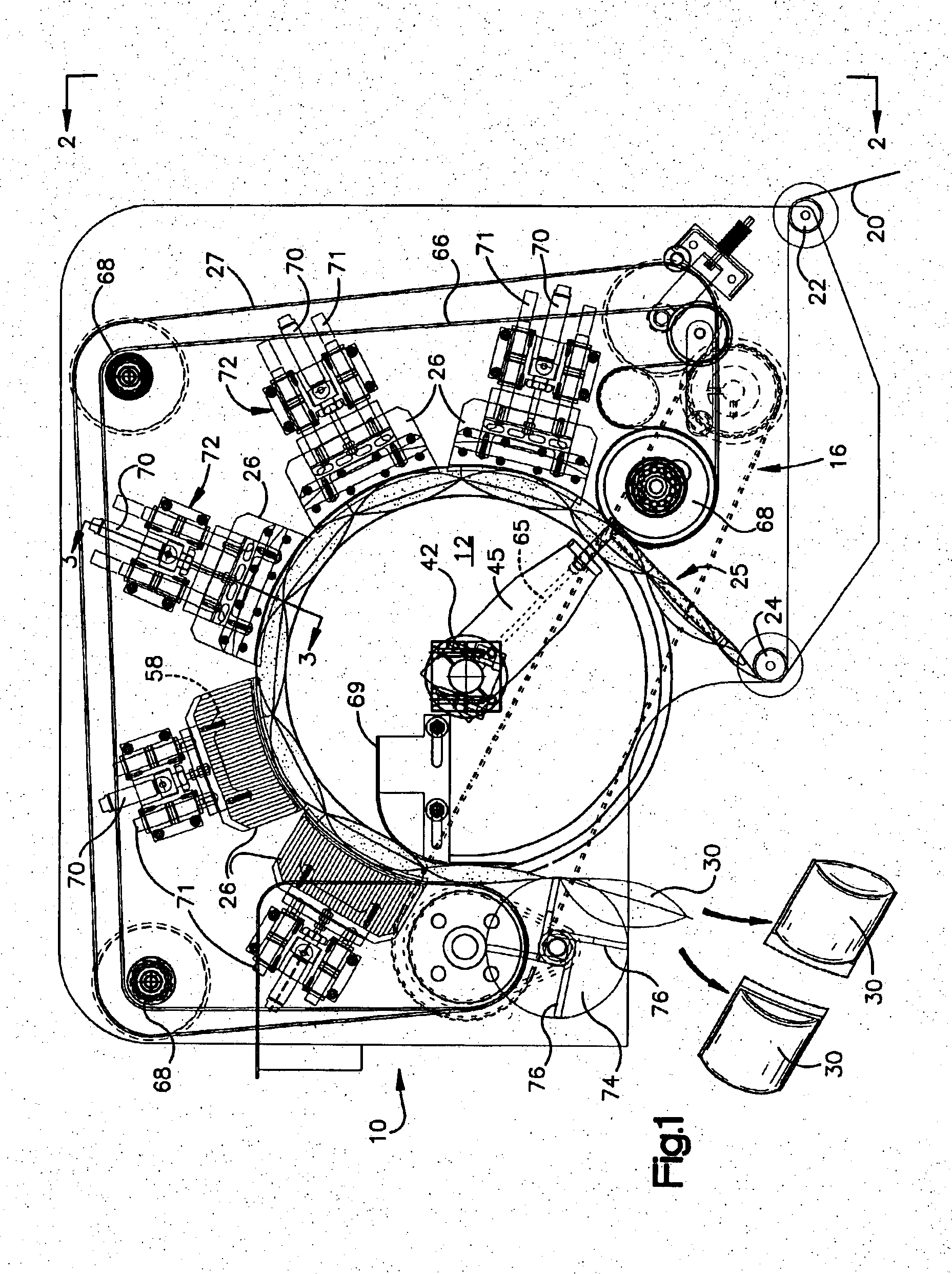

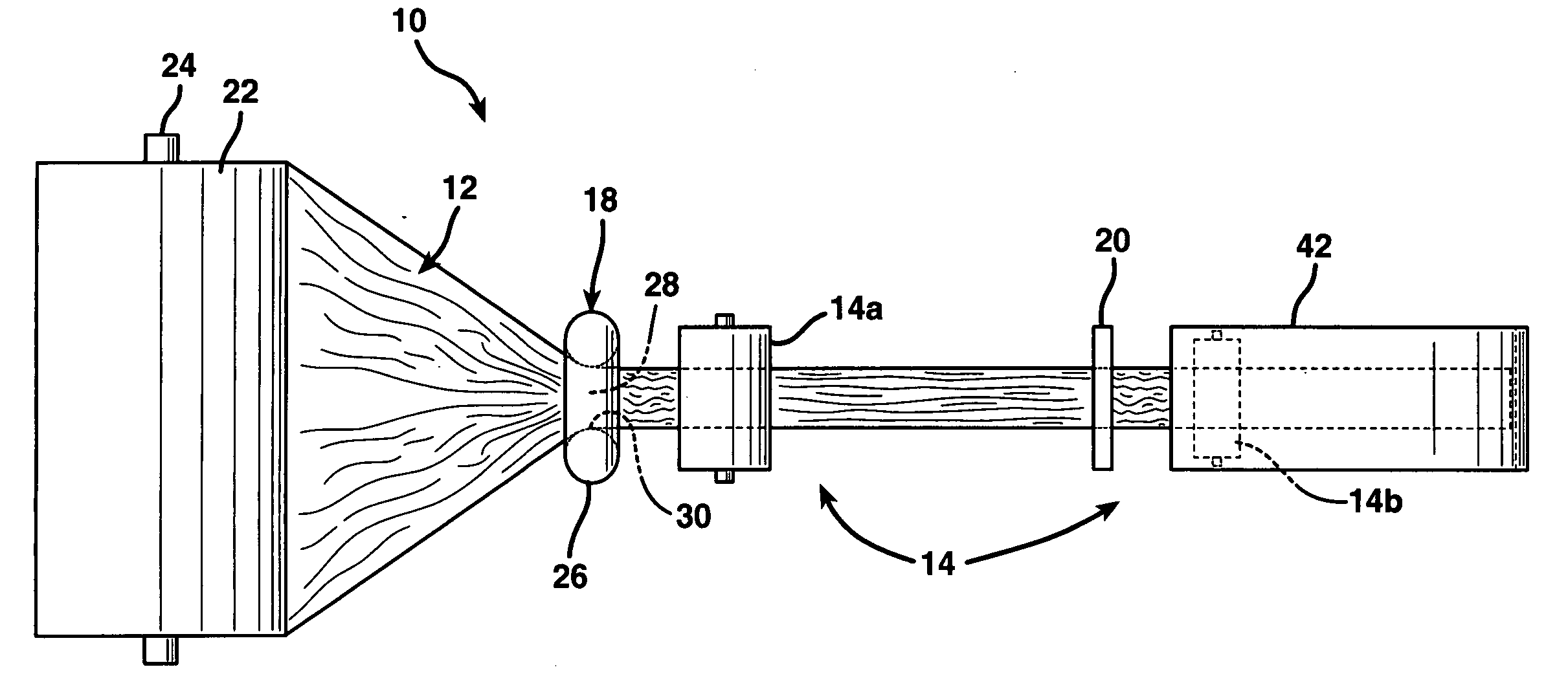

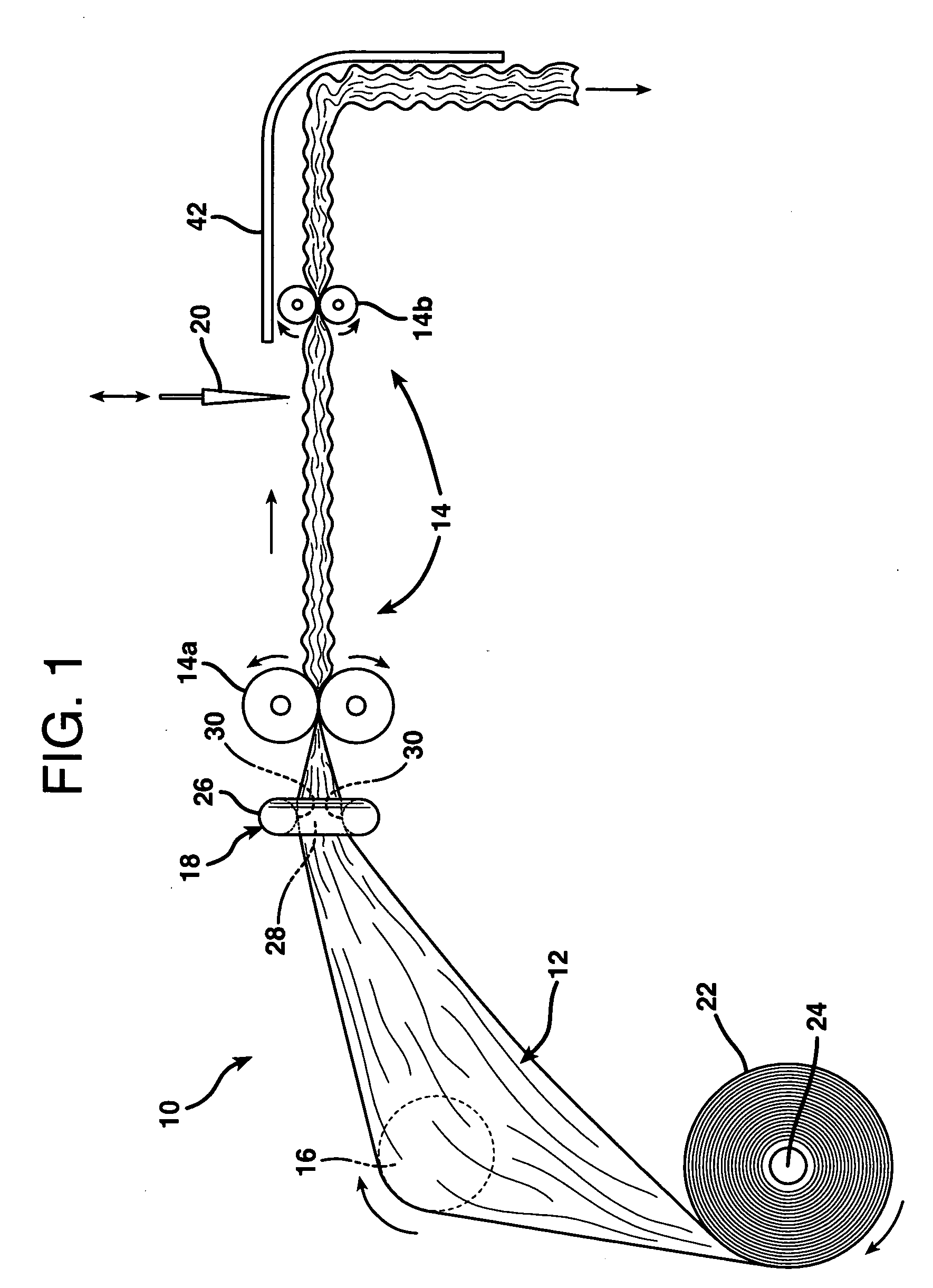

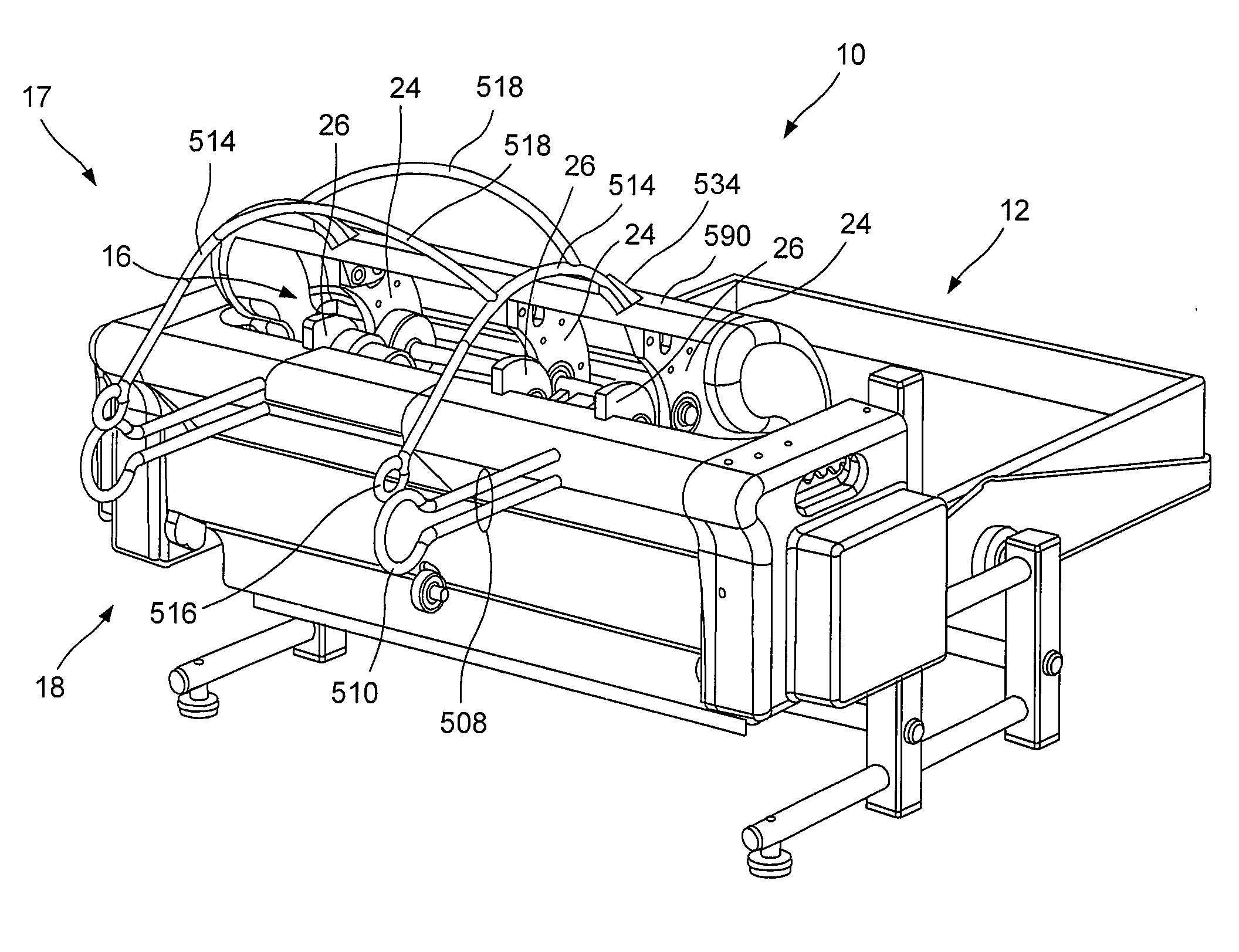

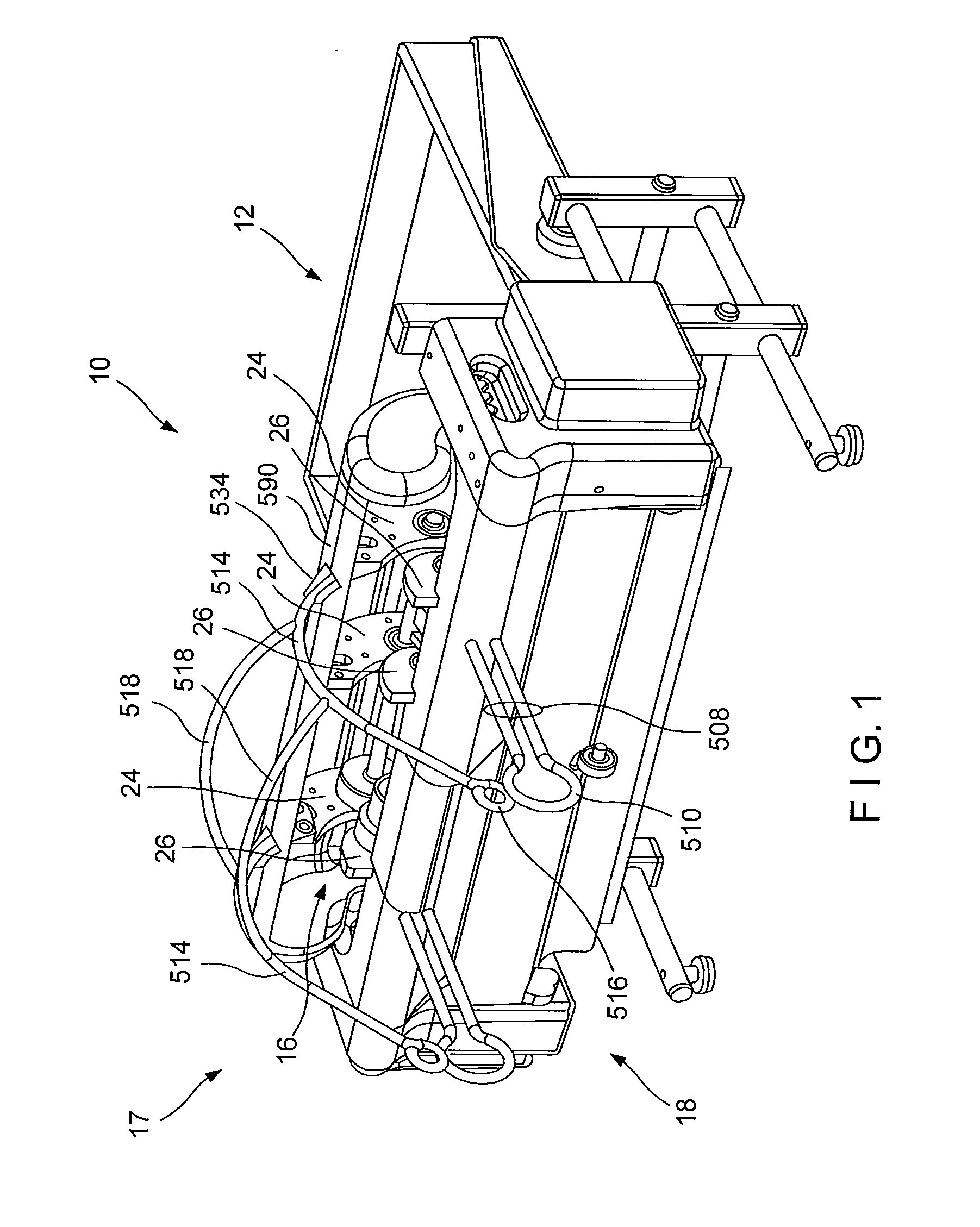

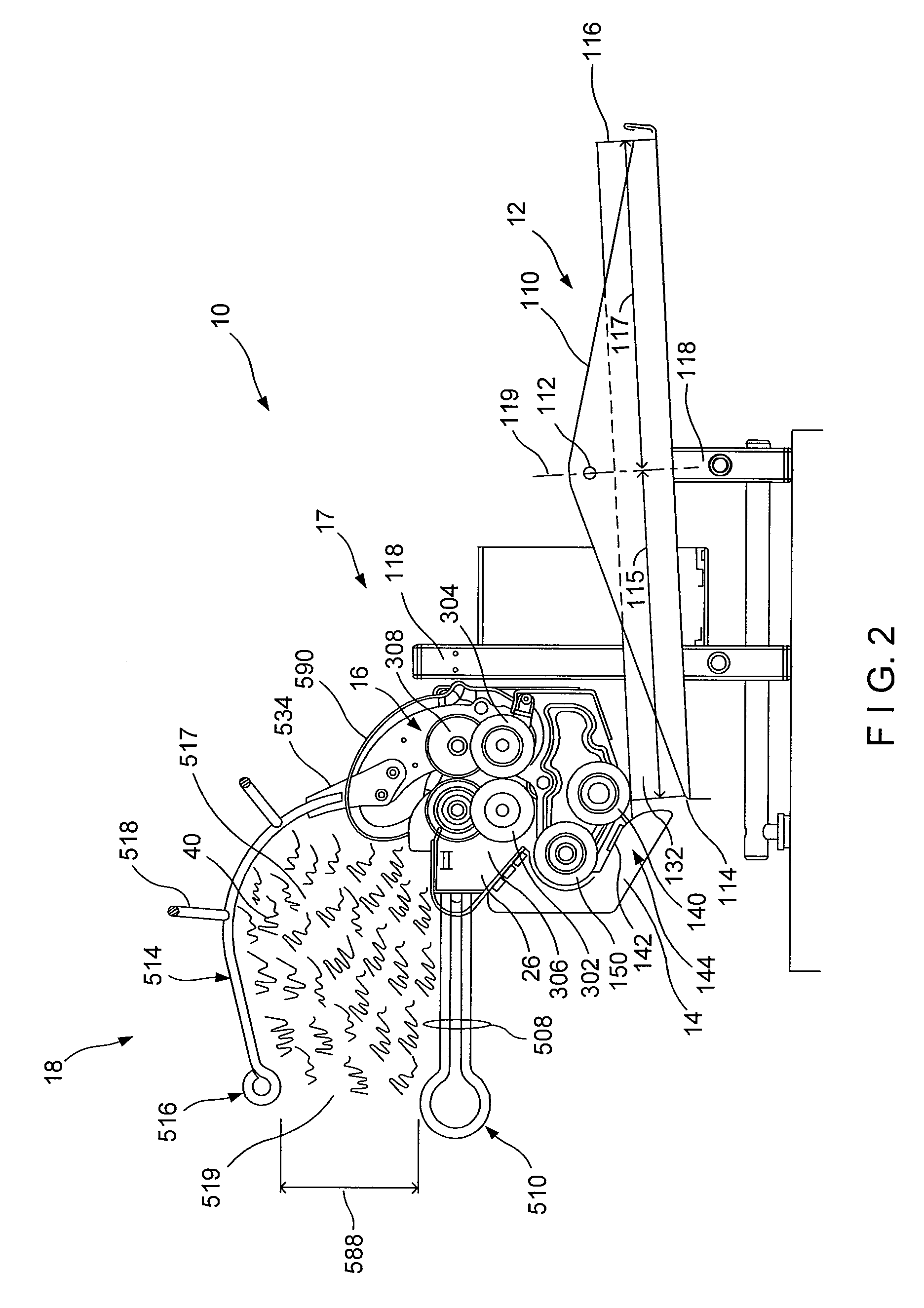

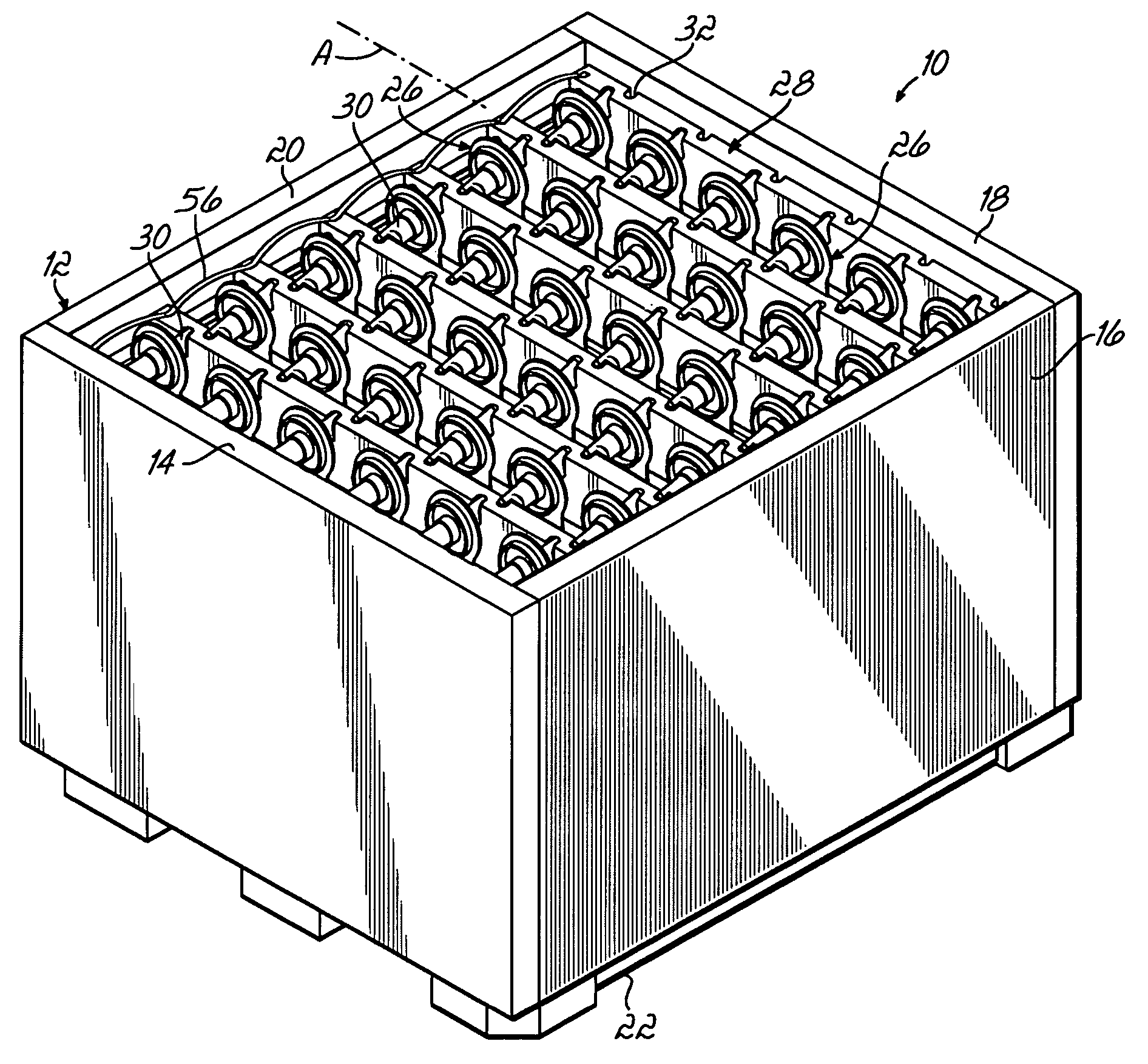

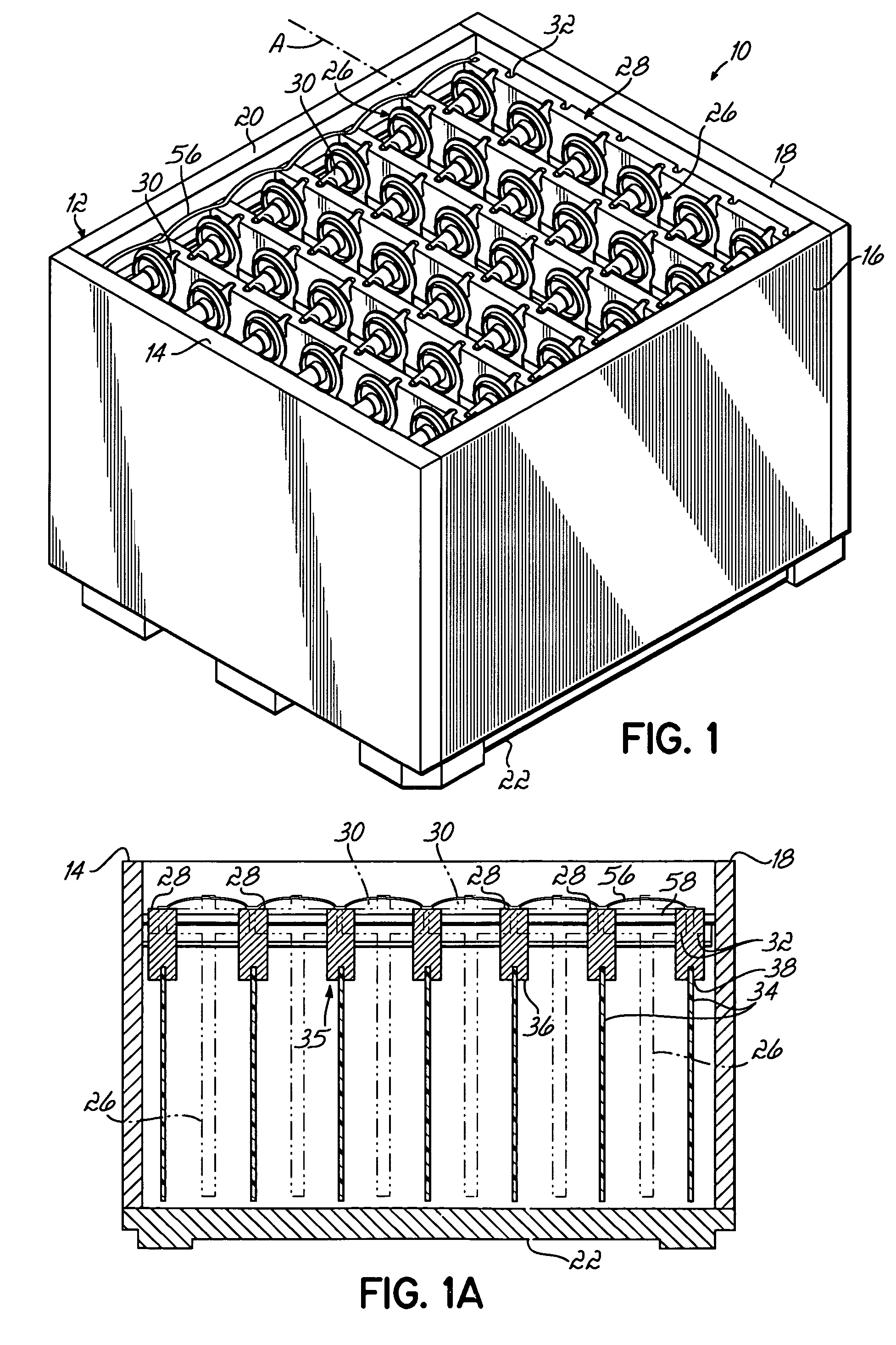

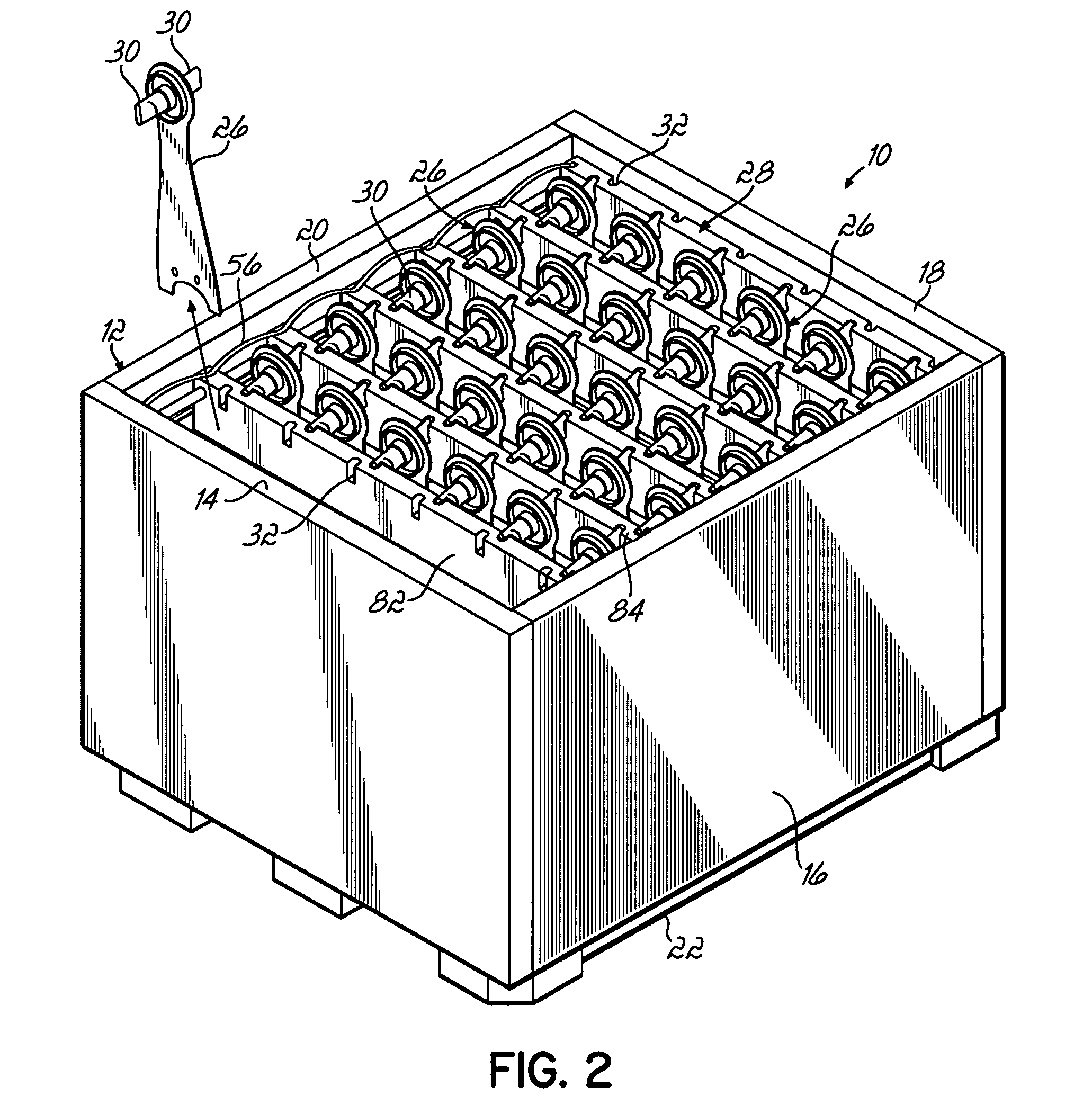

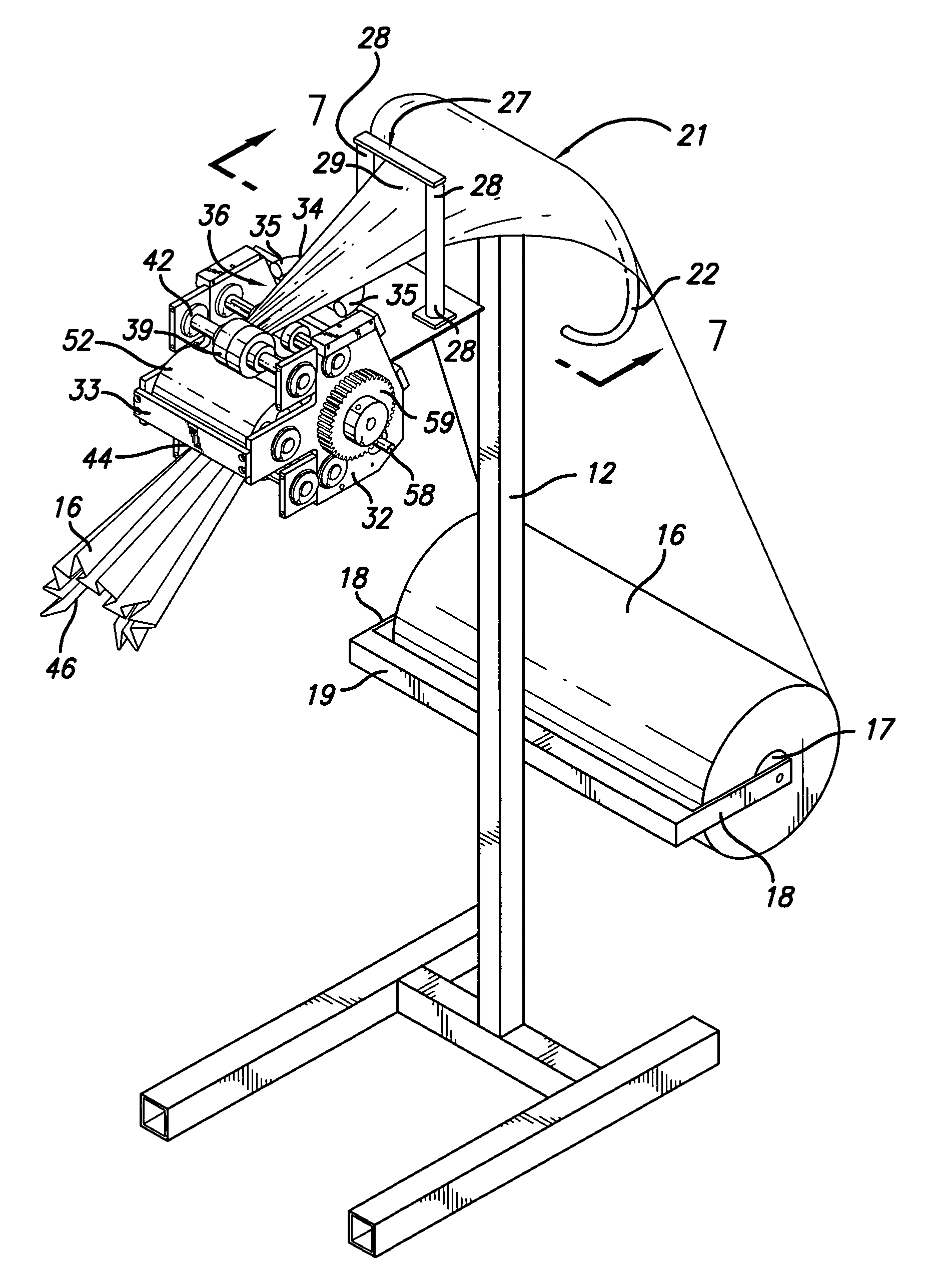

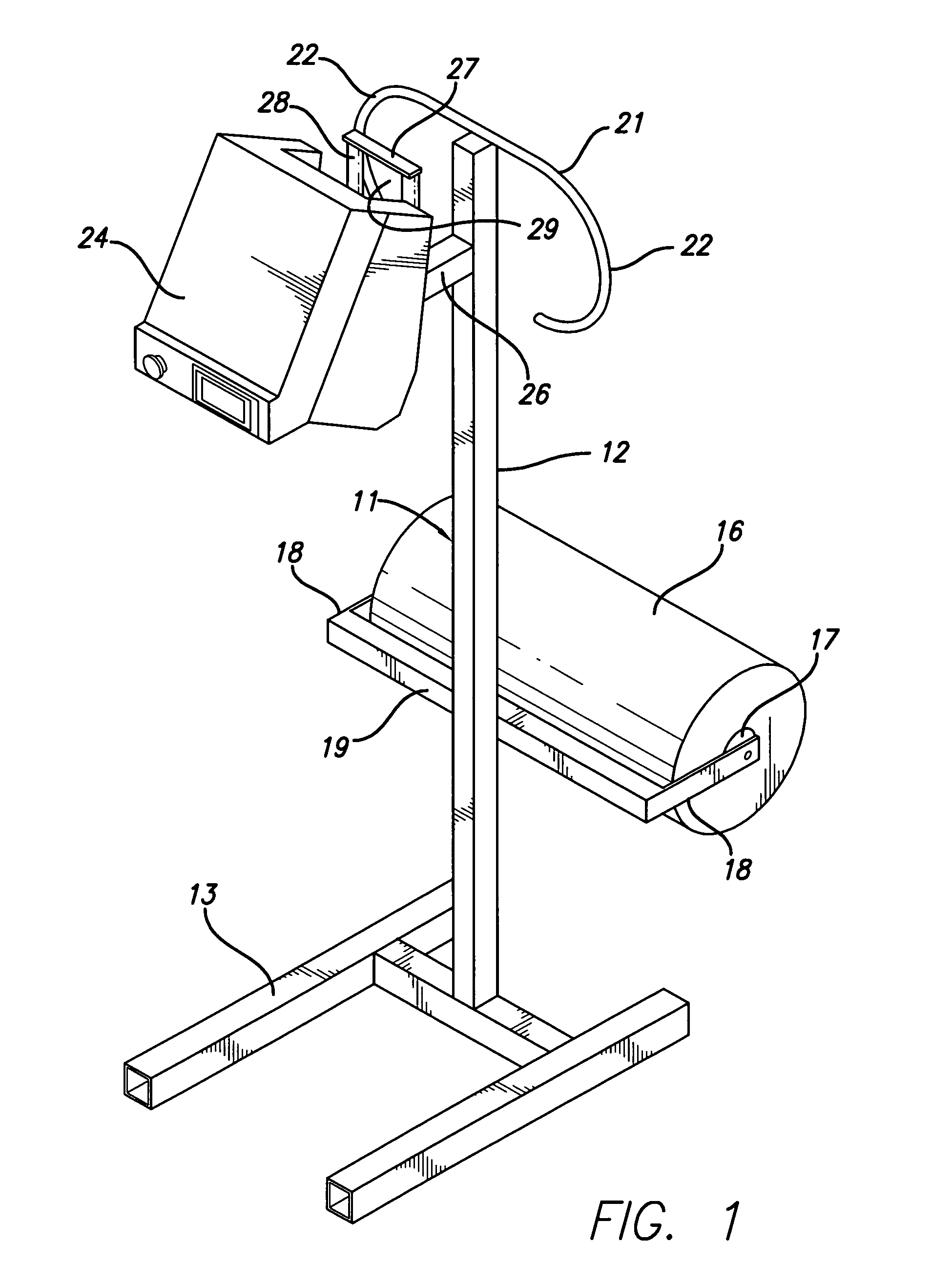

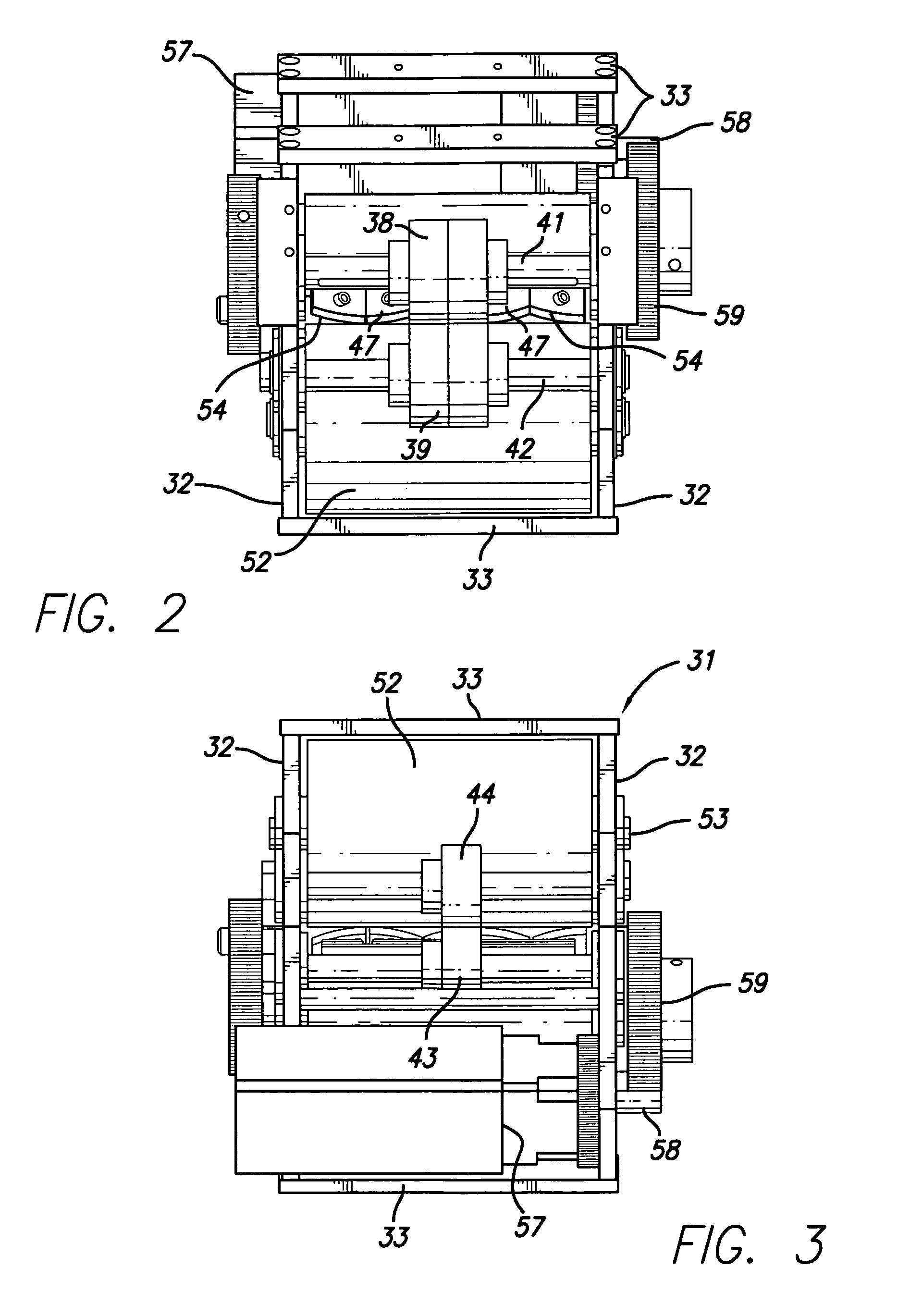

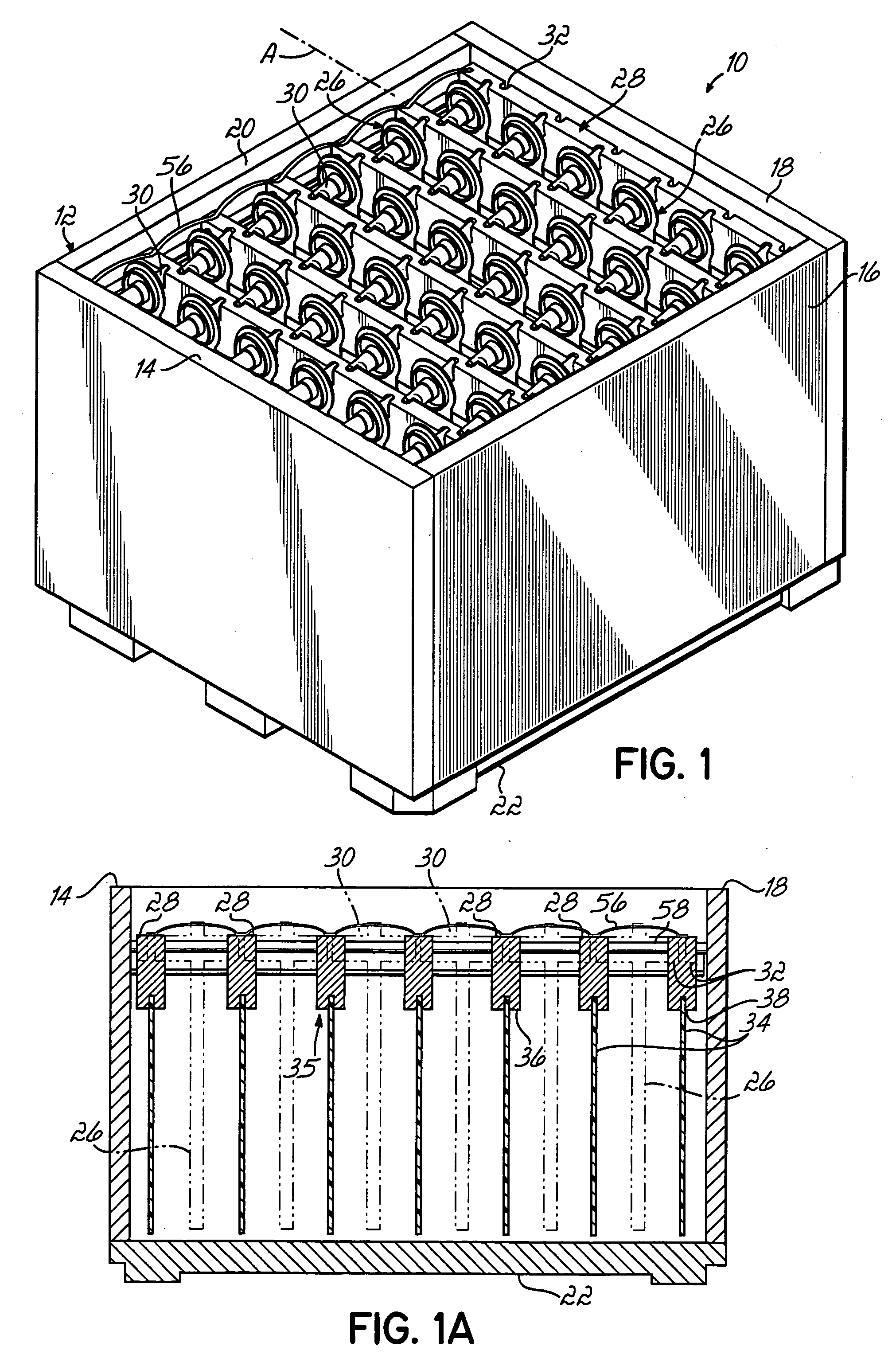

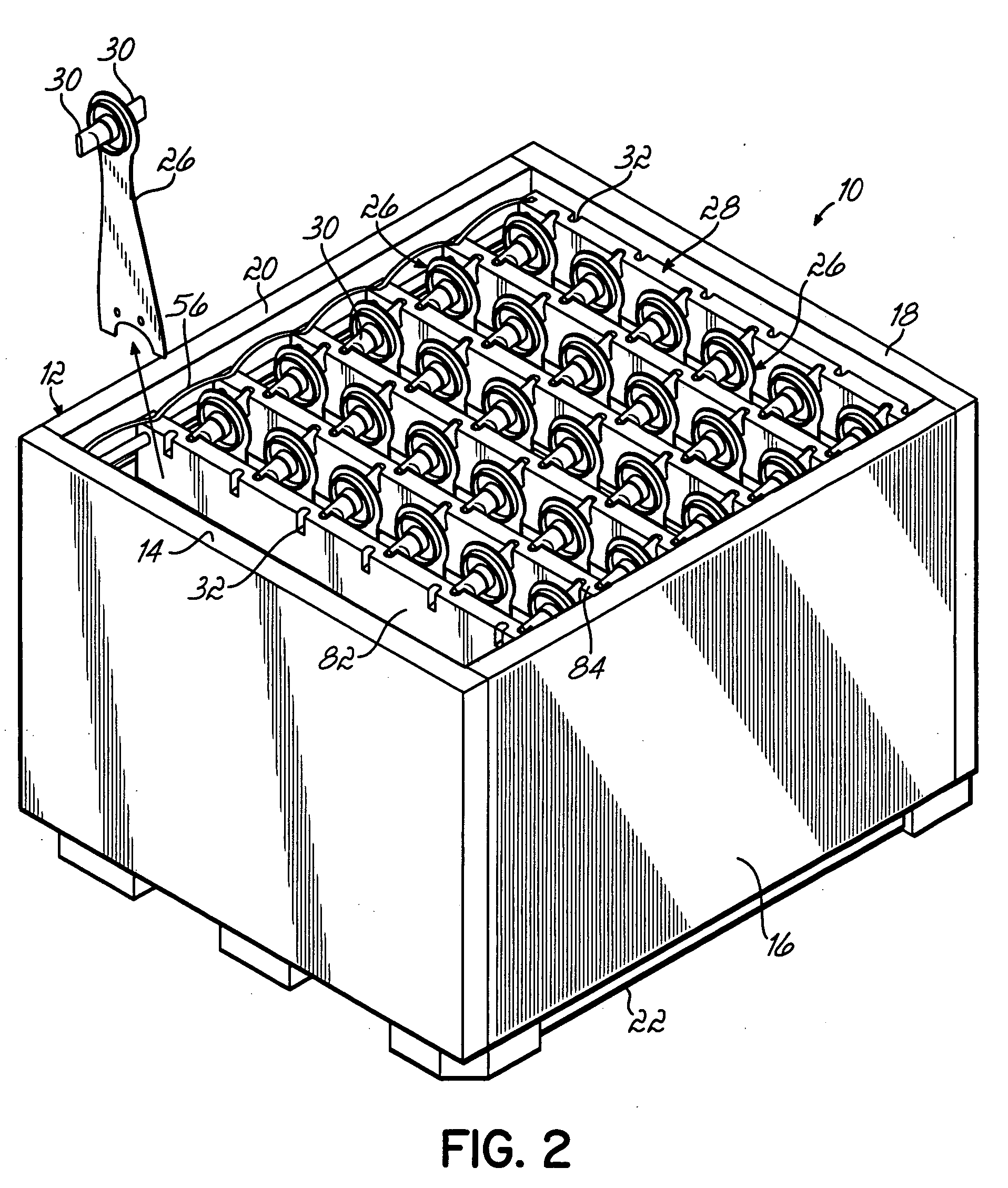

Fluid filled unit formation machine and process

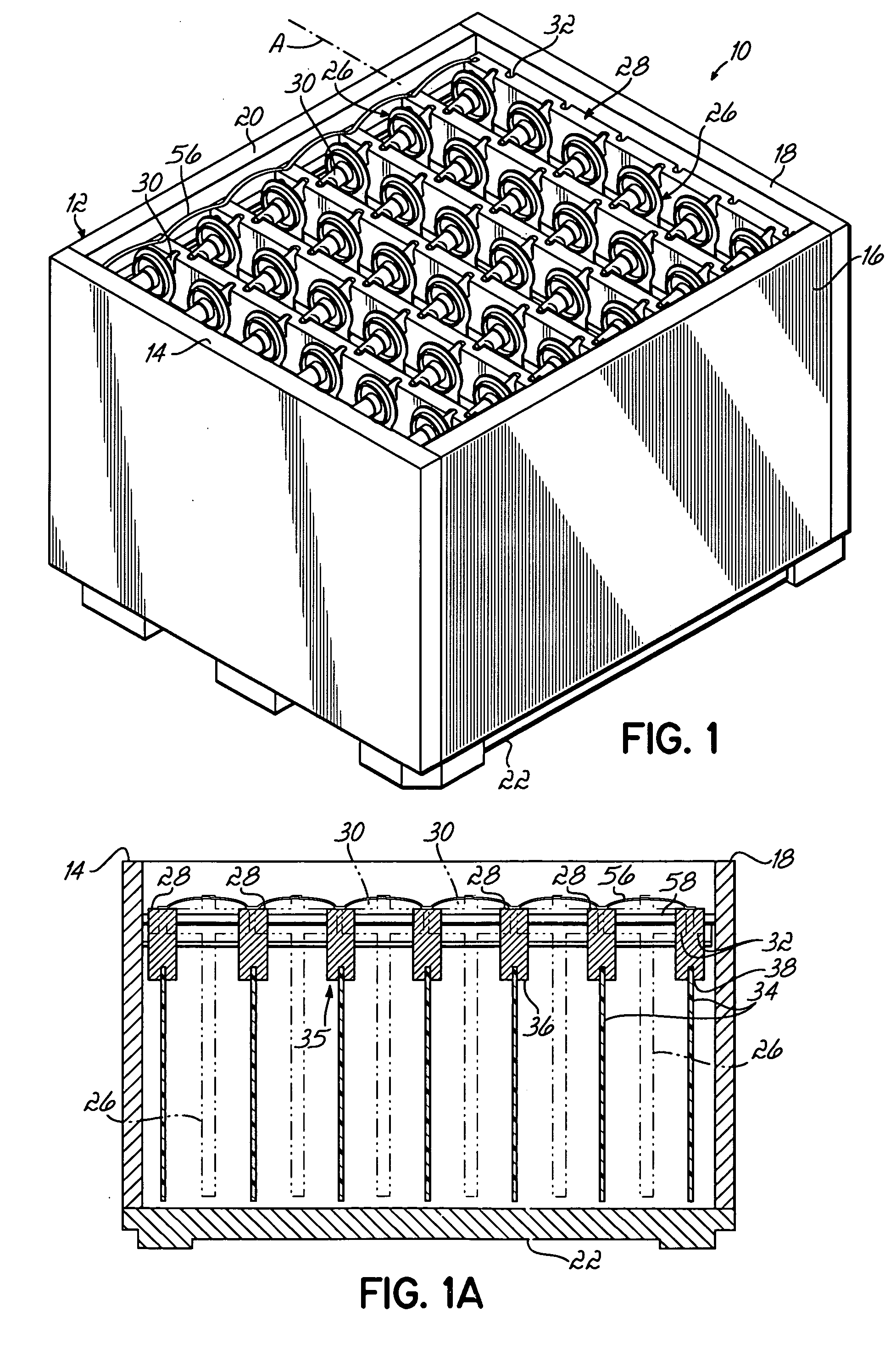

A machine for the manufacture of inflated plastic dunnage and other fluid filled units is disclosed. In a disclosed and pictured dunnage embodiment, the machine includes a hollow shaft rotatably mounted on a frame. In the preferred embodiment the shaft is solid. With either embodiment a drive is operably connected to the shaft for causing the shaft to rotate about its axis and a drum mounted on the shaft to rotate with the shaft. The drum is in the form of a pair of closely spaced discs having perimetral, cylindrically contoured sealing surfaces for support and, in cooperation with driven metal belts, transport of a web being formed into dunnage units. Sets of heating and cooling shoes having spaced arcuate surfaces are complementally positioned adjacent the drum surfaces with the cooling shoes downstream from the heating shoes in the direction of dunnage formation rotation. A nozzle is mounted generally tangentially of the drum at a location midway between the discs. Each of the cooling shoes includes an air expansion chamber communicating through a shoe inlet when in use with a supply of air under pressure. In the hollow shaft embodiment one cooling shoe chamber has an outlet in communication with the nozzle via the shaft.

Owner:AUTOMATED PACKAGING SYST

Machine and method for converting a web of material into dunnage

A machine and method for converting a web of material into dunnage, the machine comprising a mechanism for conveying the web through the machine, a first web-shaping device for crumpling the web, a second web-shaping device for further crumpling the web, and a severing mechanism to sever the web into discrete lengths.

Owner:SEALED AIR U S

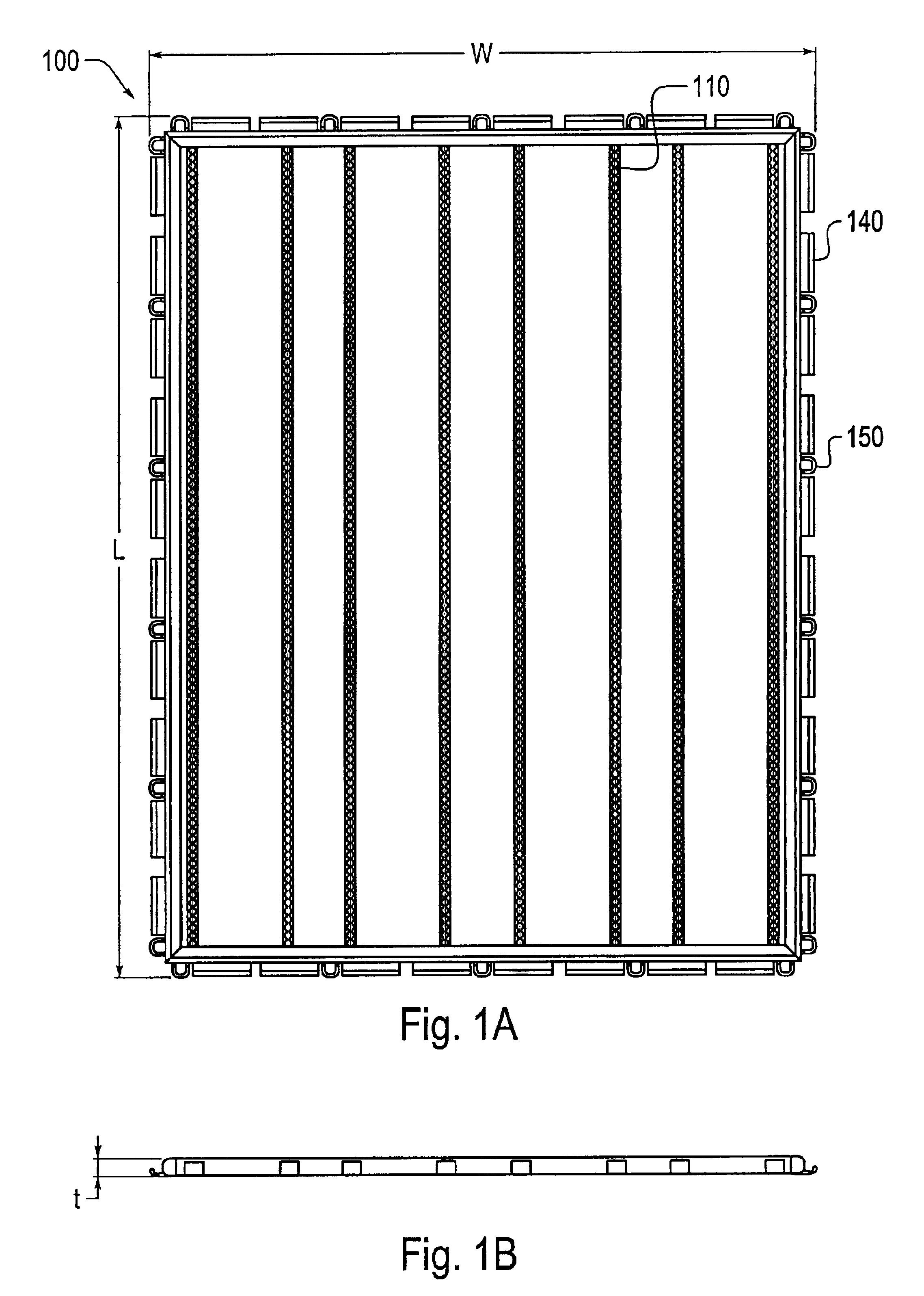

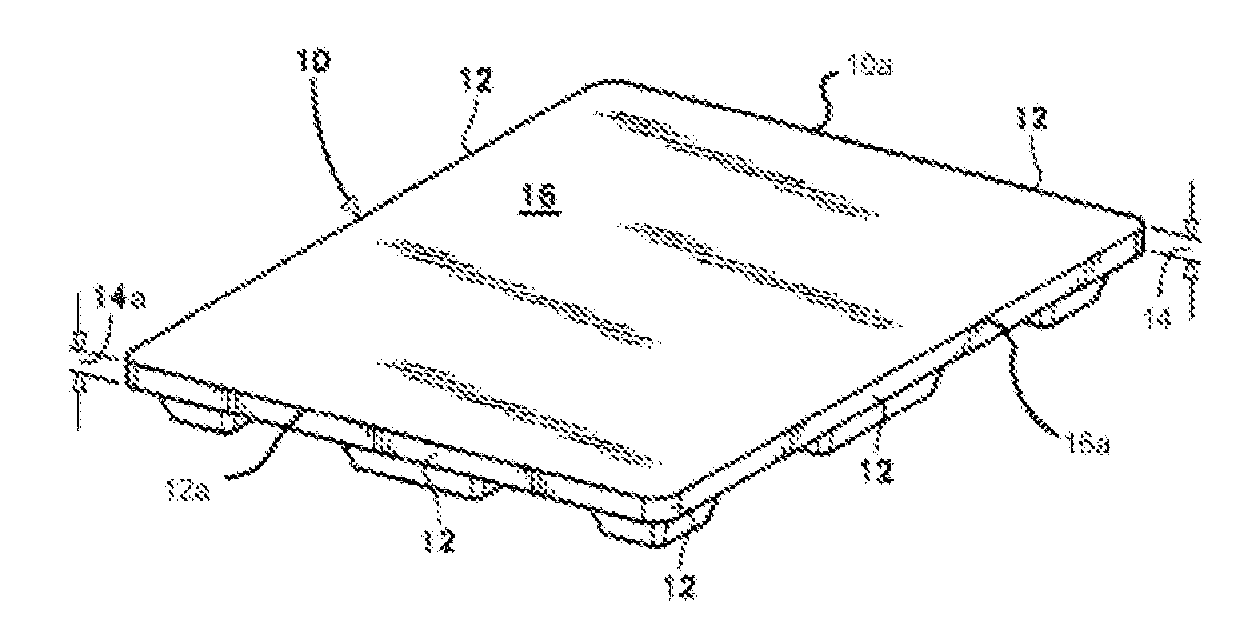

Dunnage platform

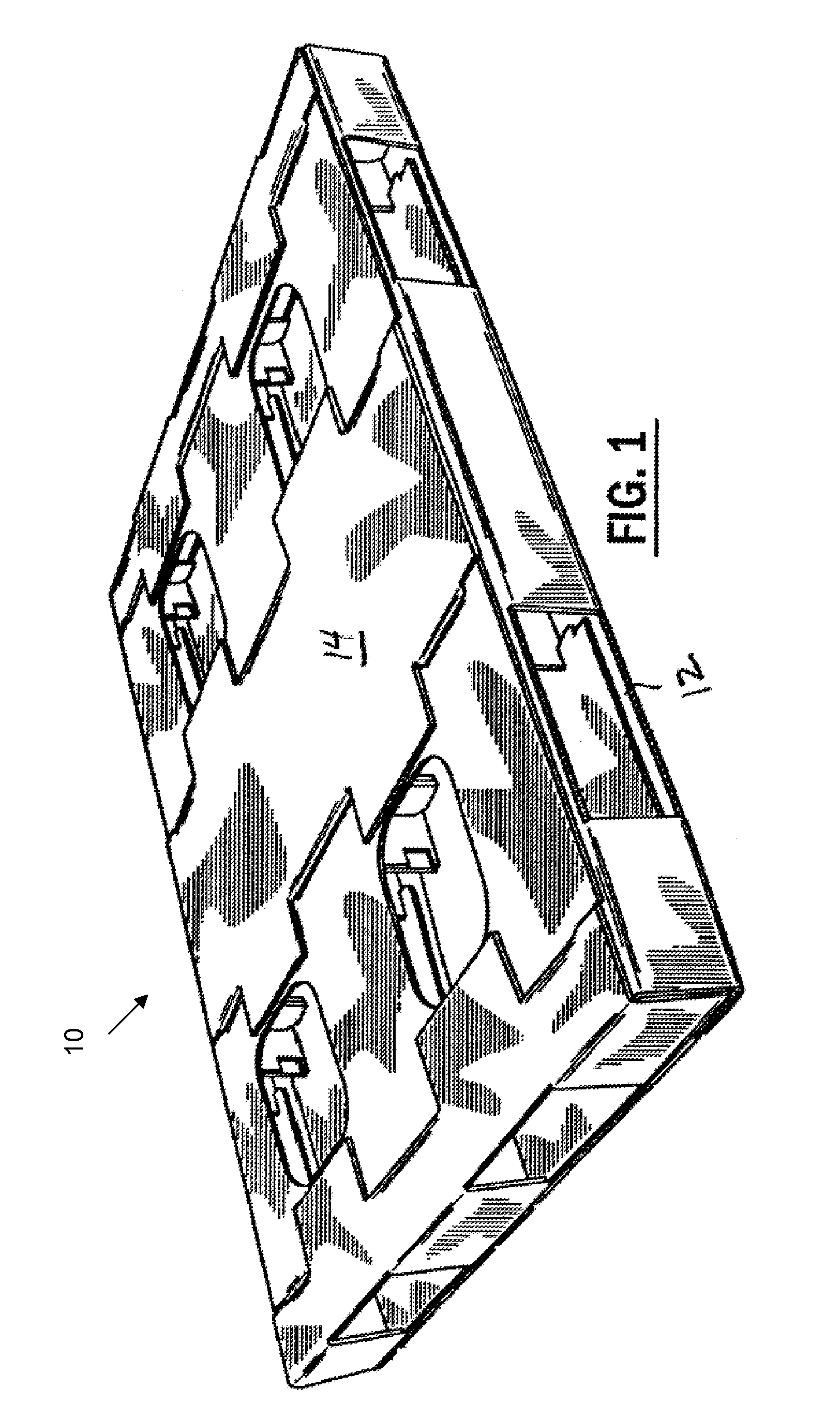

InactiveUS7128797B2Easy to moveAdhesive processesMechanical working/deformationDunnageChemical combination

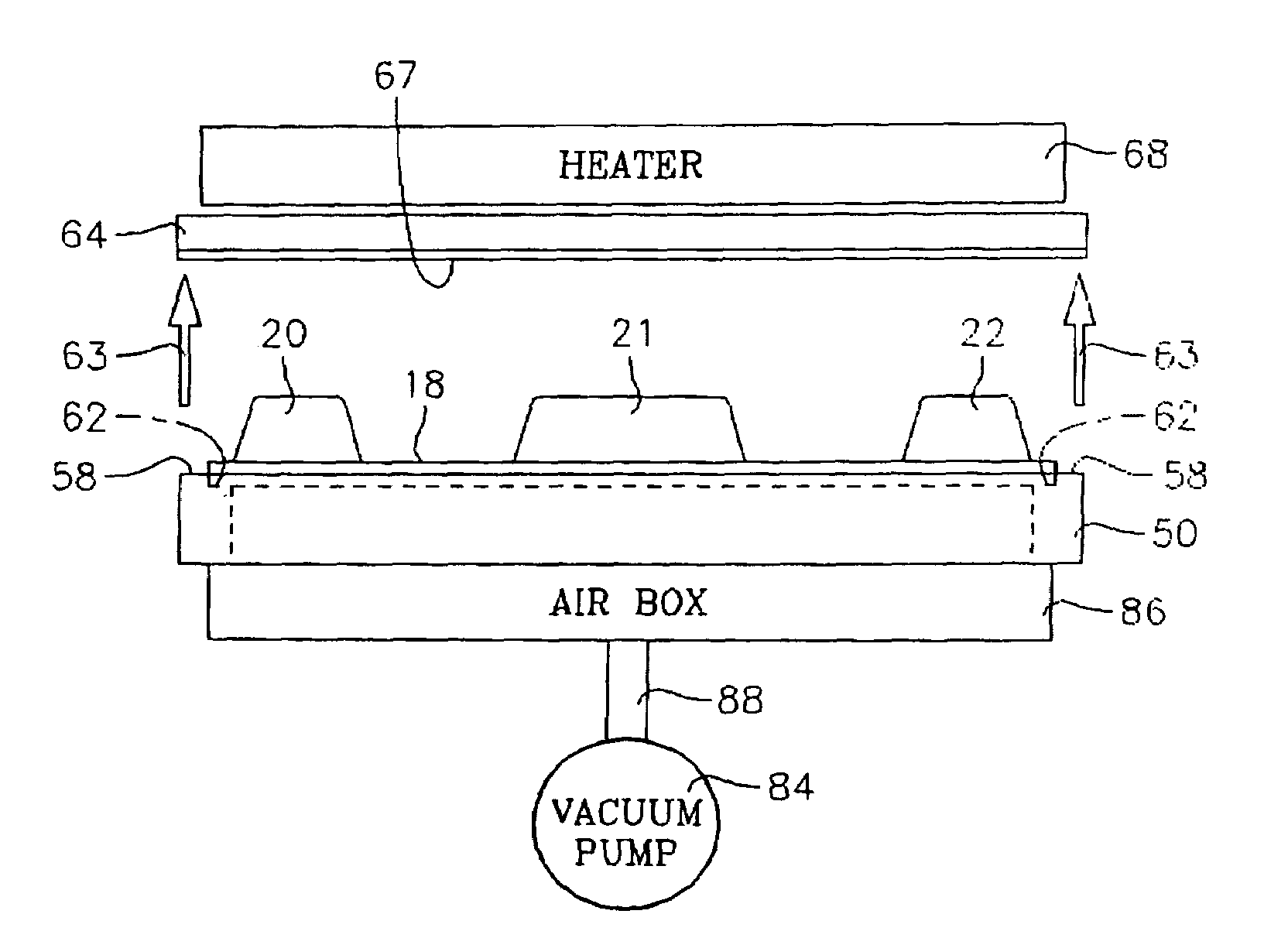

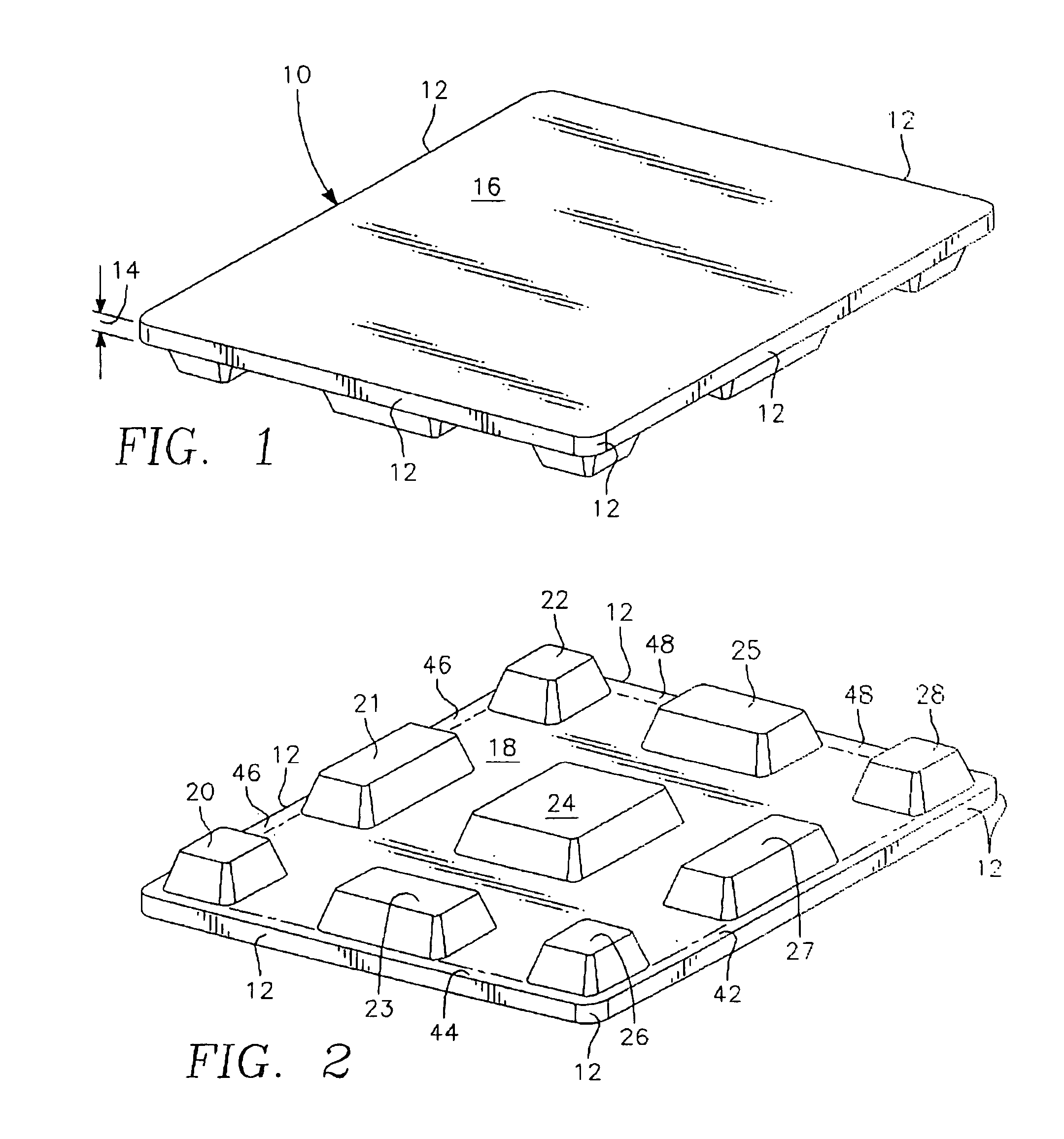

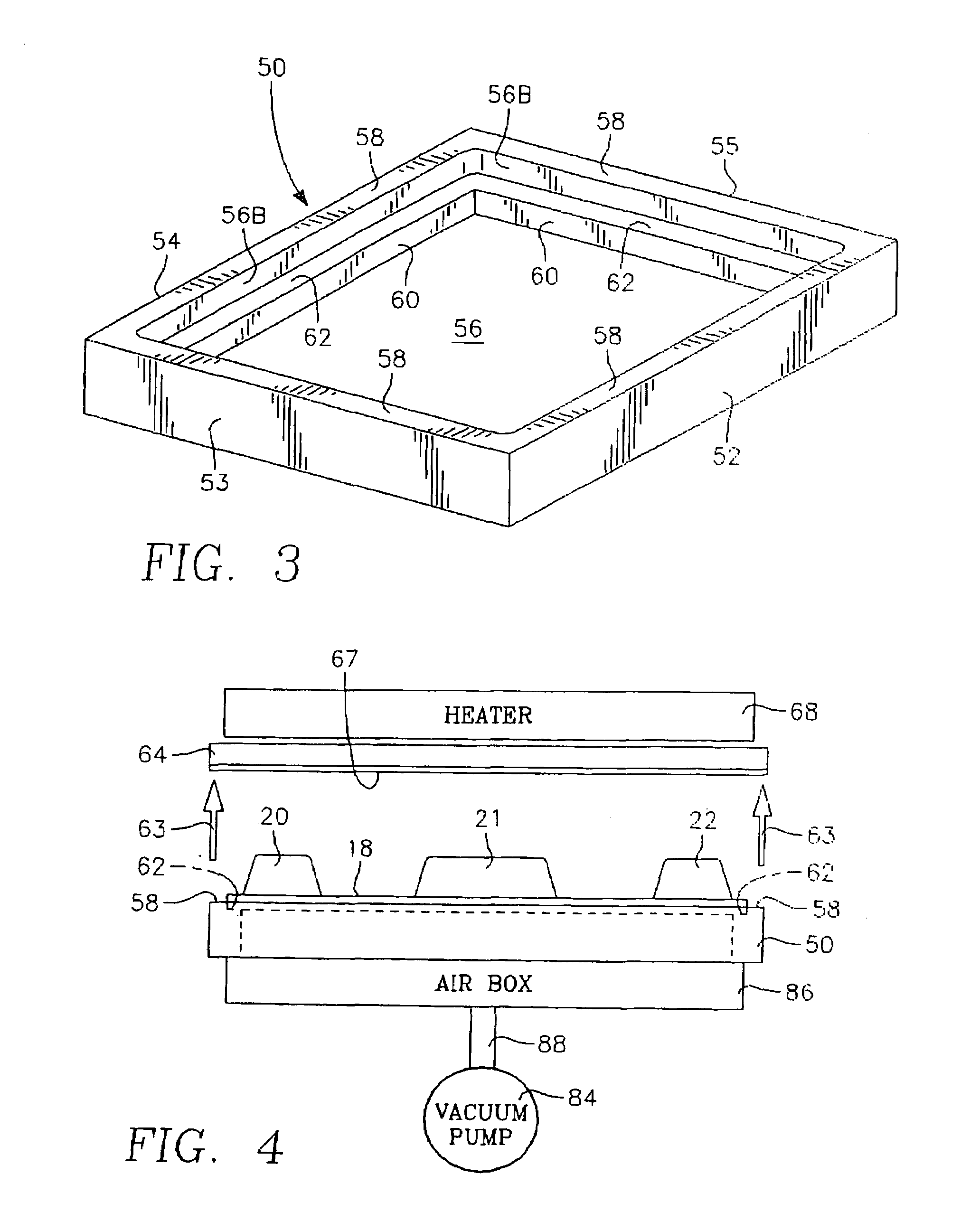

A dunnage platform is in the general shape of a rectangular slab with legs extending form one side. The dunnage platform is made from an expanded polystyrene core. A chemical combination process is used to chemically combine portion of the core proximal to its surface with high impact polystyrene. In a first of two parts of the combination process, the core is placed in a forming mold with one of its two sides and two thirds of its thickness extending therefrom. A heated sheet of high impact polystyrene is brought into contact with the portion of the core extending from the mold. In a similar manner, the other of the two sides of the core is made to extend from the forming mold for contact with a heated sheet of high impact polystyrene.

Owner:AIRDEX CORP

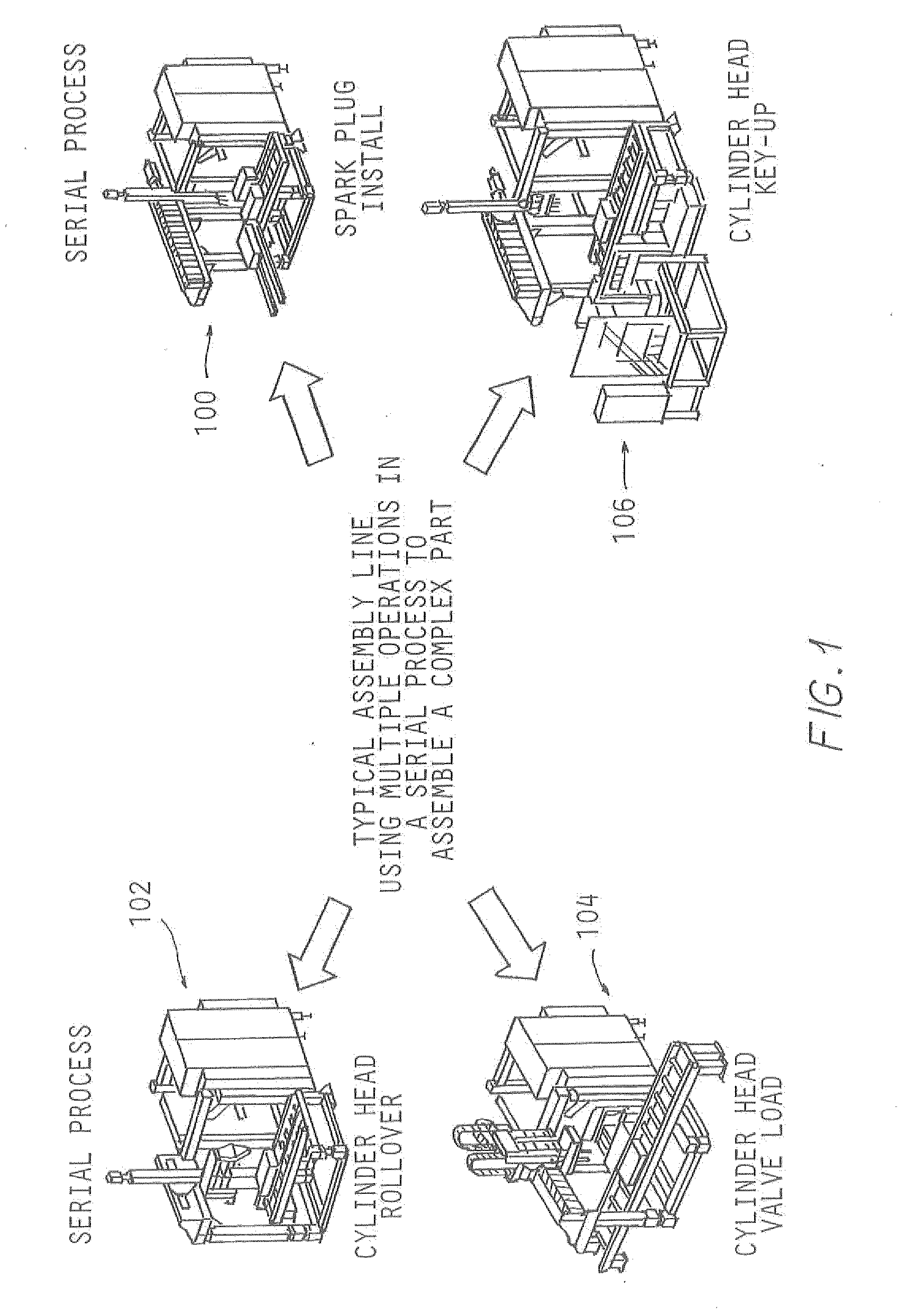

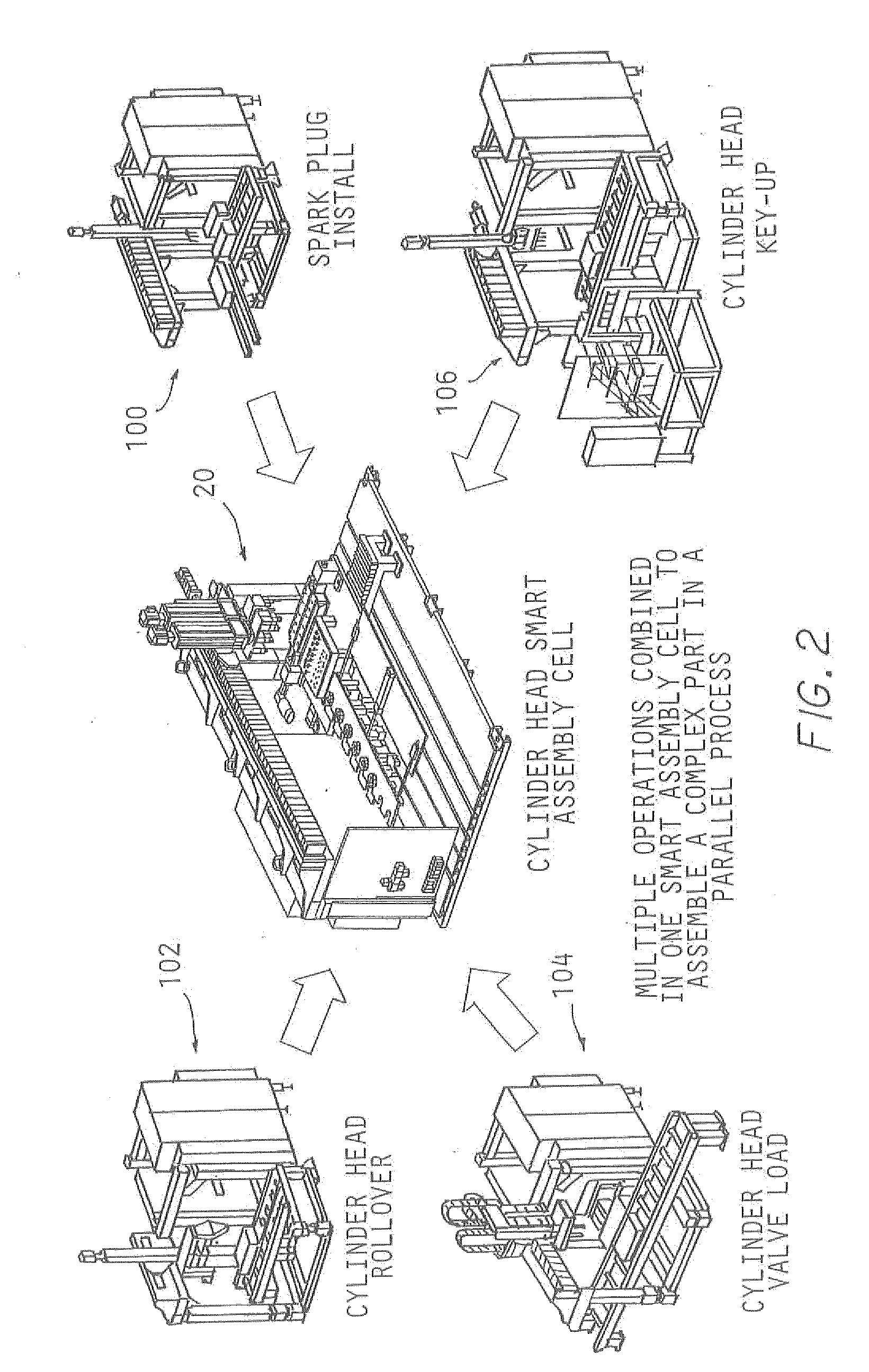

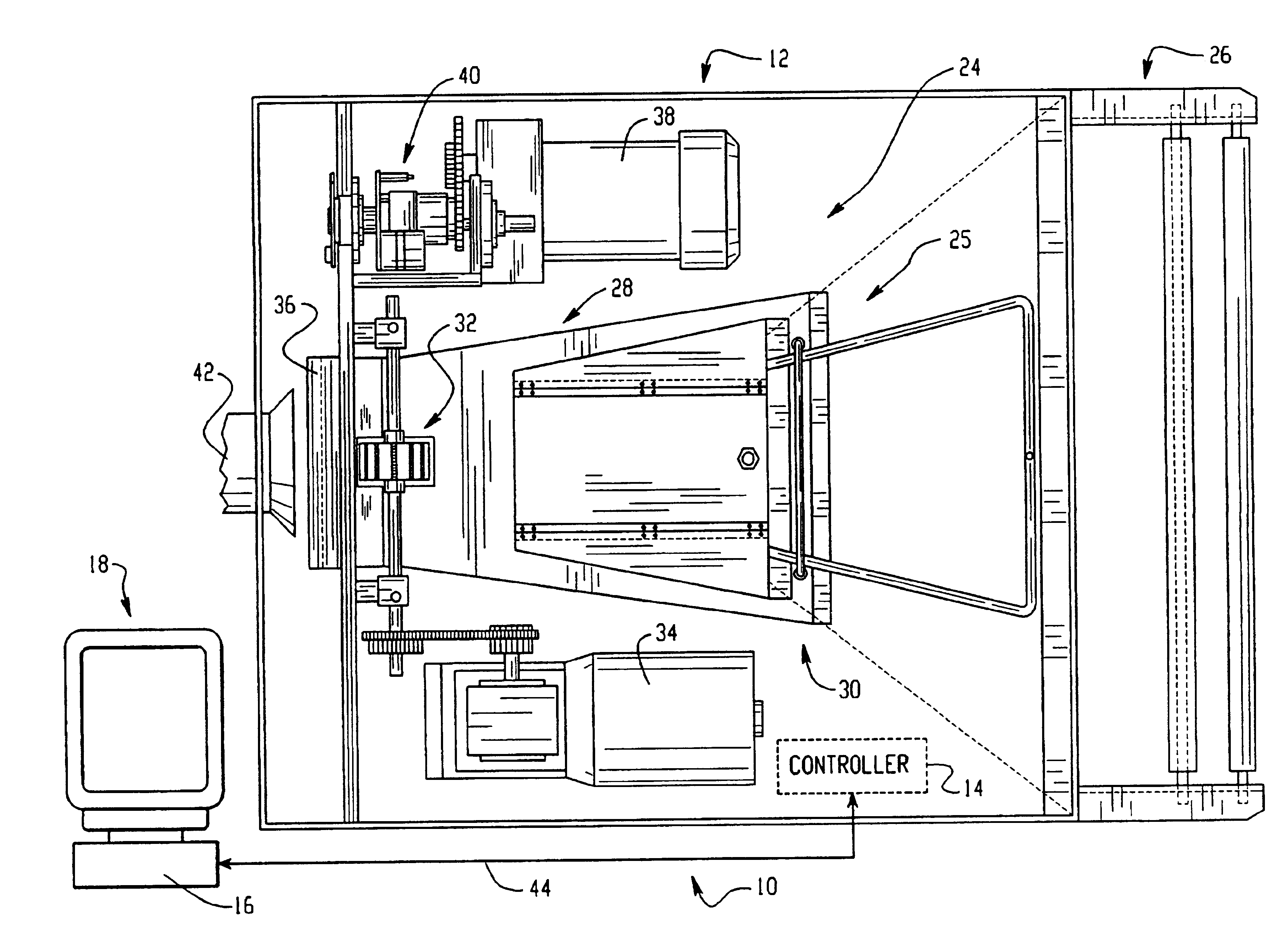

Method and apparatus forassembling a complex product ina parrallel process system

A method and apparatus for assembling a complex product in a parallel process system wherein a collection of components are provided for assembling the complex product. The present invention involves transferring the collection of the components to one of a plurality of similar computerized assembly cells through the use of a transport system. The collection of components is automatically assembled into the complex product through the use of the computerized assembly cells. The complex product is then transferred from one of the assembly cells to a computerized test cell, where the complex product is tested to ensure for the proper dimensioning and functioning of the complex product. The complex product is then transferred from the test cell via the transport system to either a part reject area or conveyor, if the complex product is defective, or to an automatic dunnage load or part return system, if the complex product is not defective.

Owner:COMAU LLC

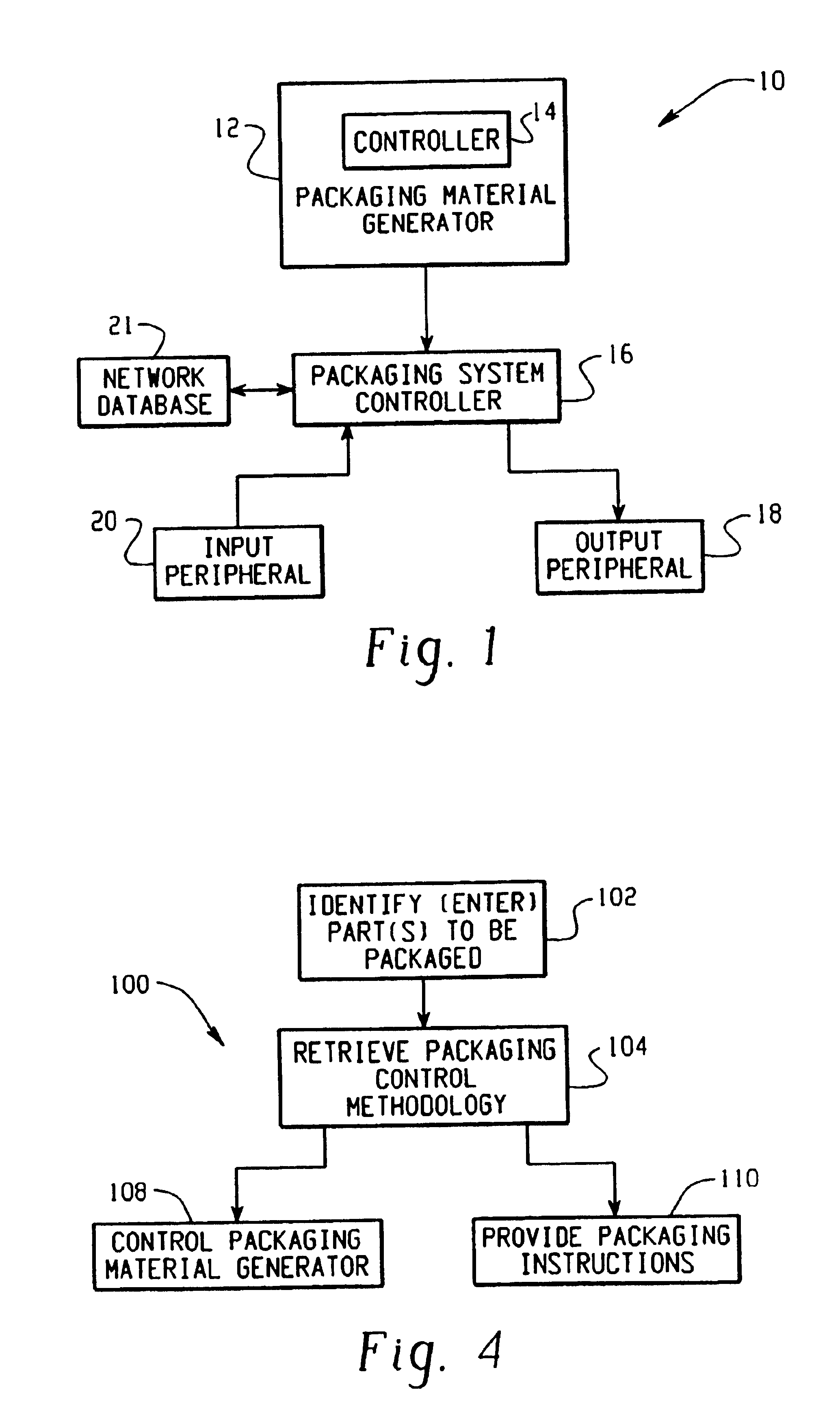

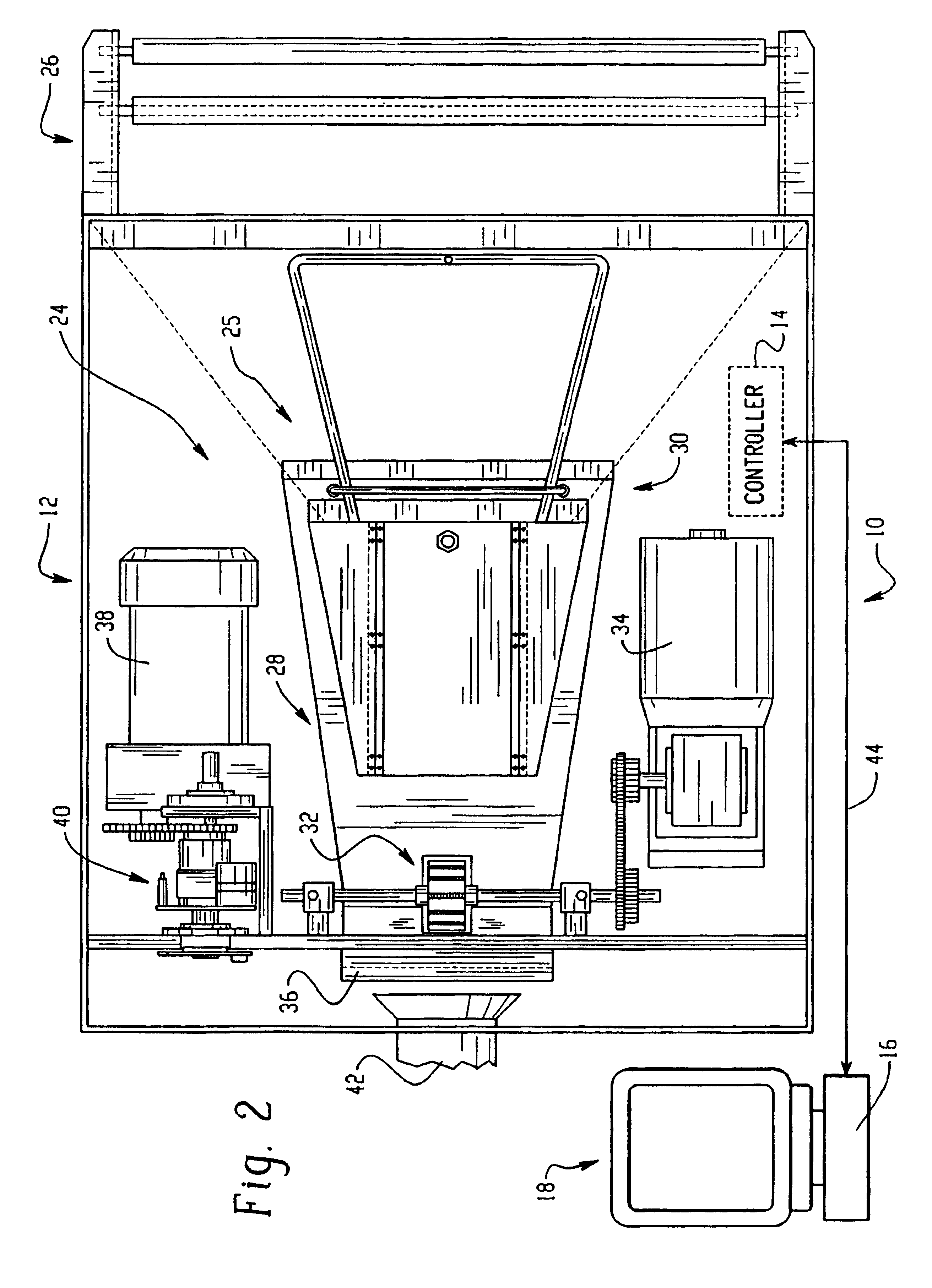

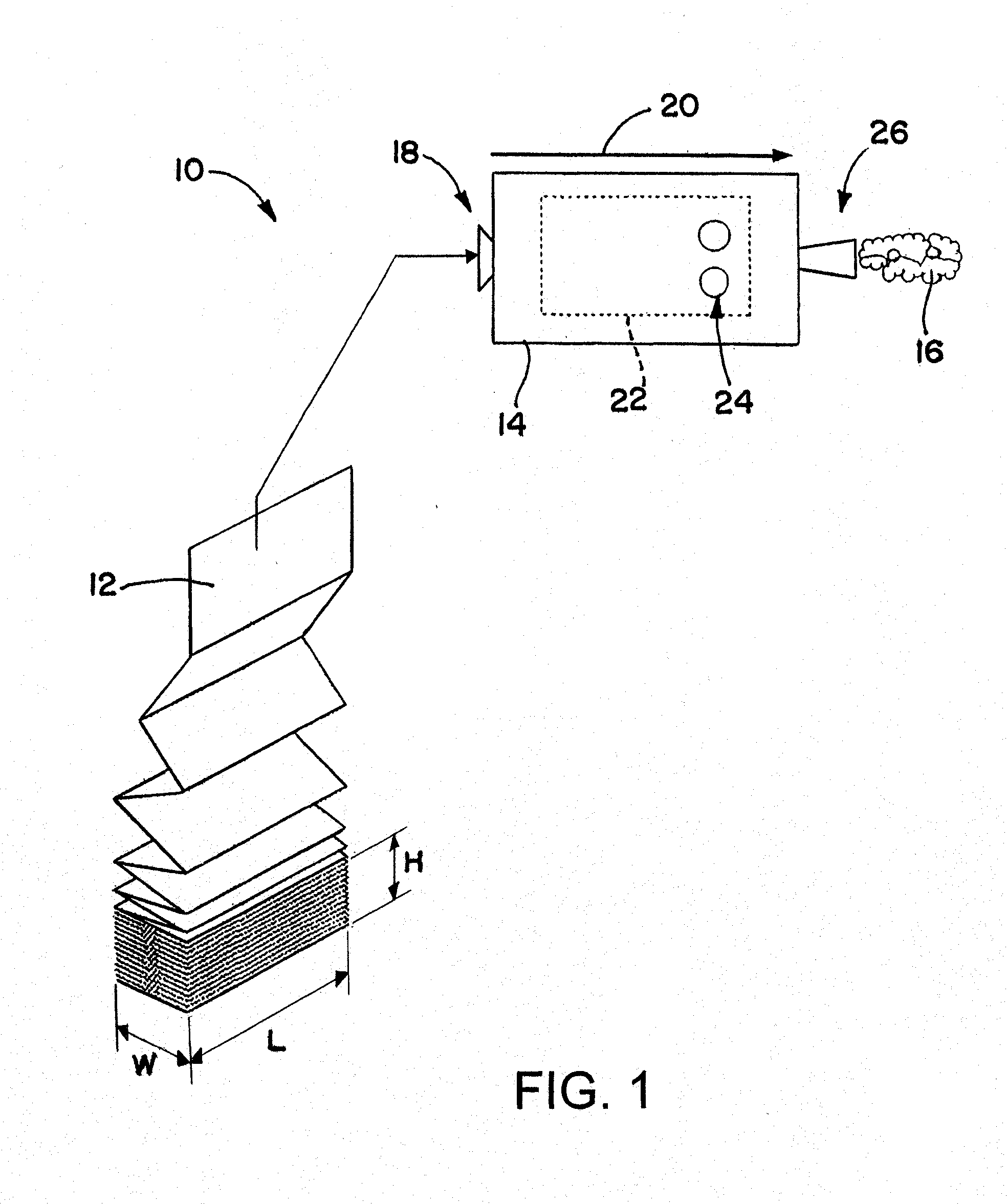

Cushioning conversion system and method

InactiveUS6877297B2Efficient and effective of partMaintained effectively and efficientlyPaper/cardboard articlesOral administration deviceCushioningDunnage

A packaging system includes a cushioning conversion machine for converting stock material into relatively low density cushioning material or dunnage and a packaging system controller. The packaging system controller provides packaging instructions related to a part or parts to be packaged and instructs the cushioning conversion machine to produce the cushioning material. In one aspect of the present invention the packaging system controller provides packaging instructions by retrieving a predetermined set of packaging instructions associated with a particular part. In another aspect of the present invention the packaging system controller provides packaging instructions by determining an optimized packaging methodology using one or more characteristics of the part or parts to be packaged. The packaging system also provides for automated inventory control and productivity monitoring.

Owner:RANPAK CORP

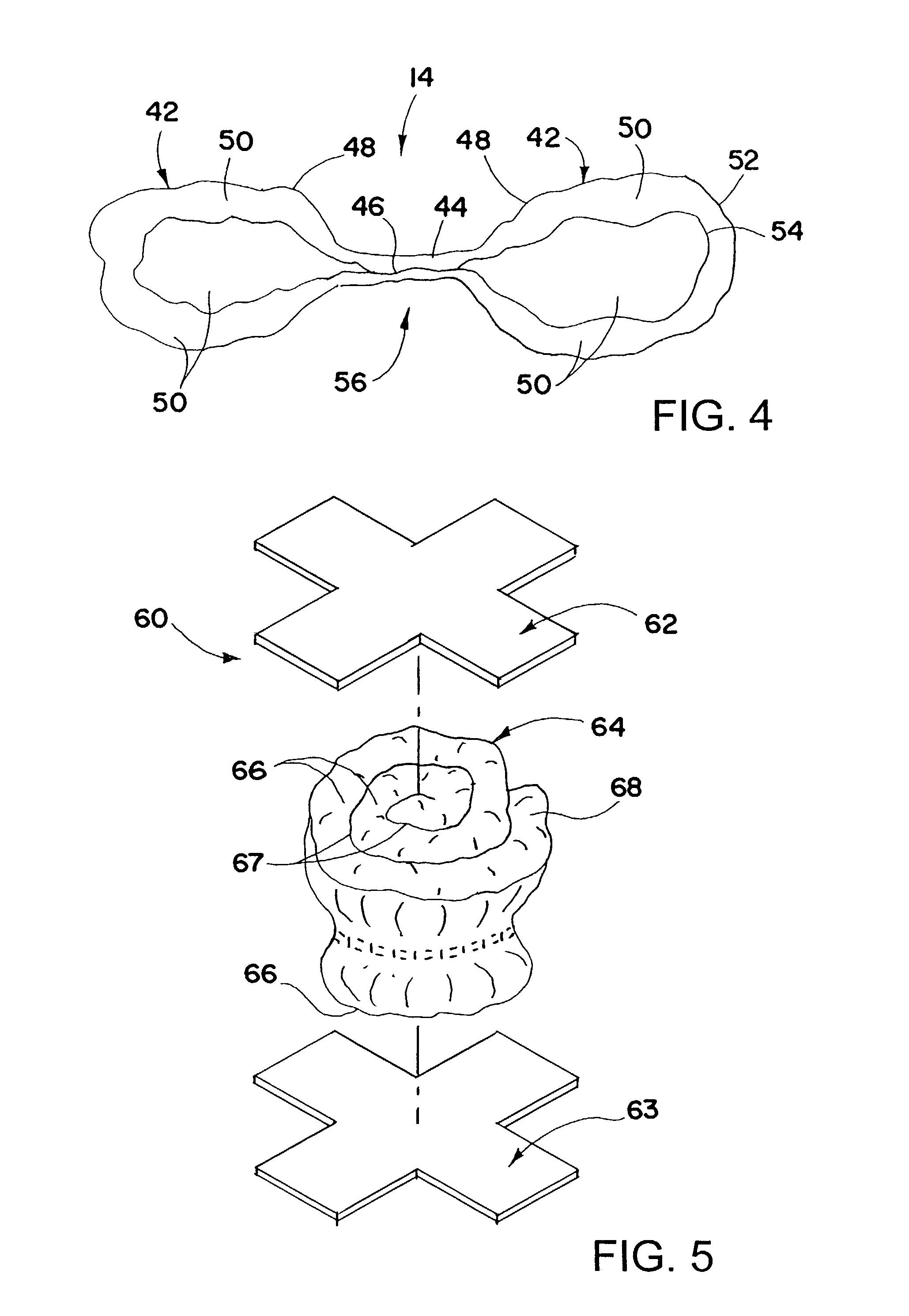

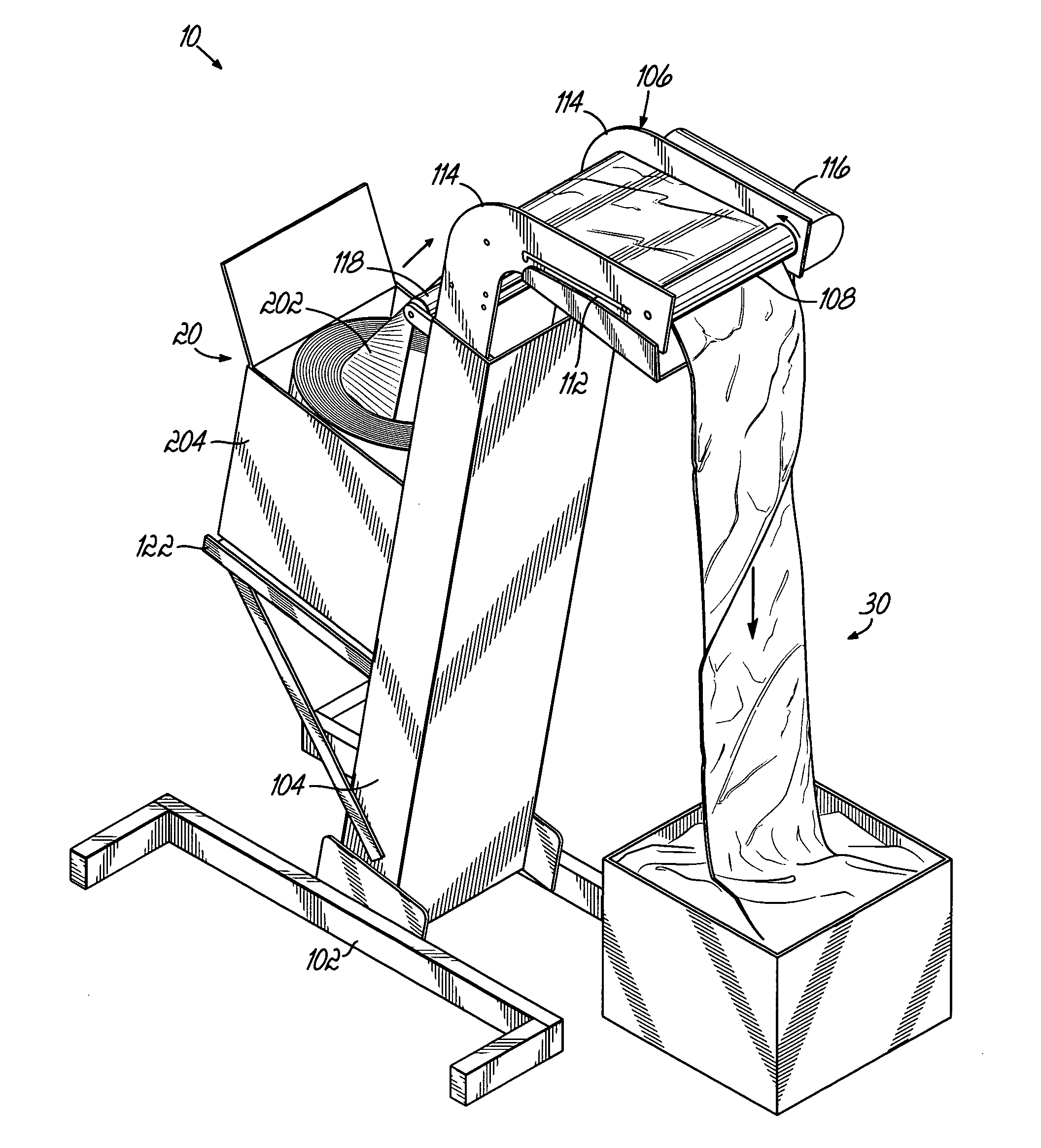

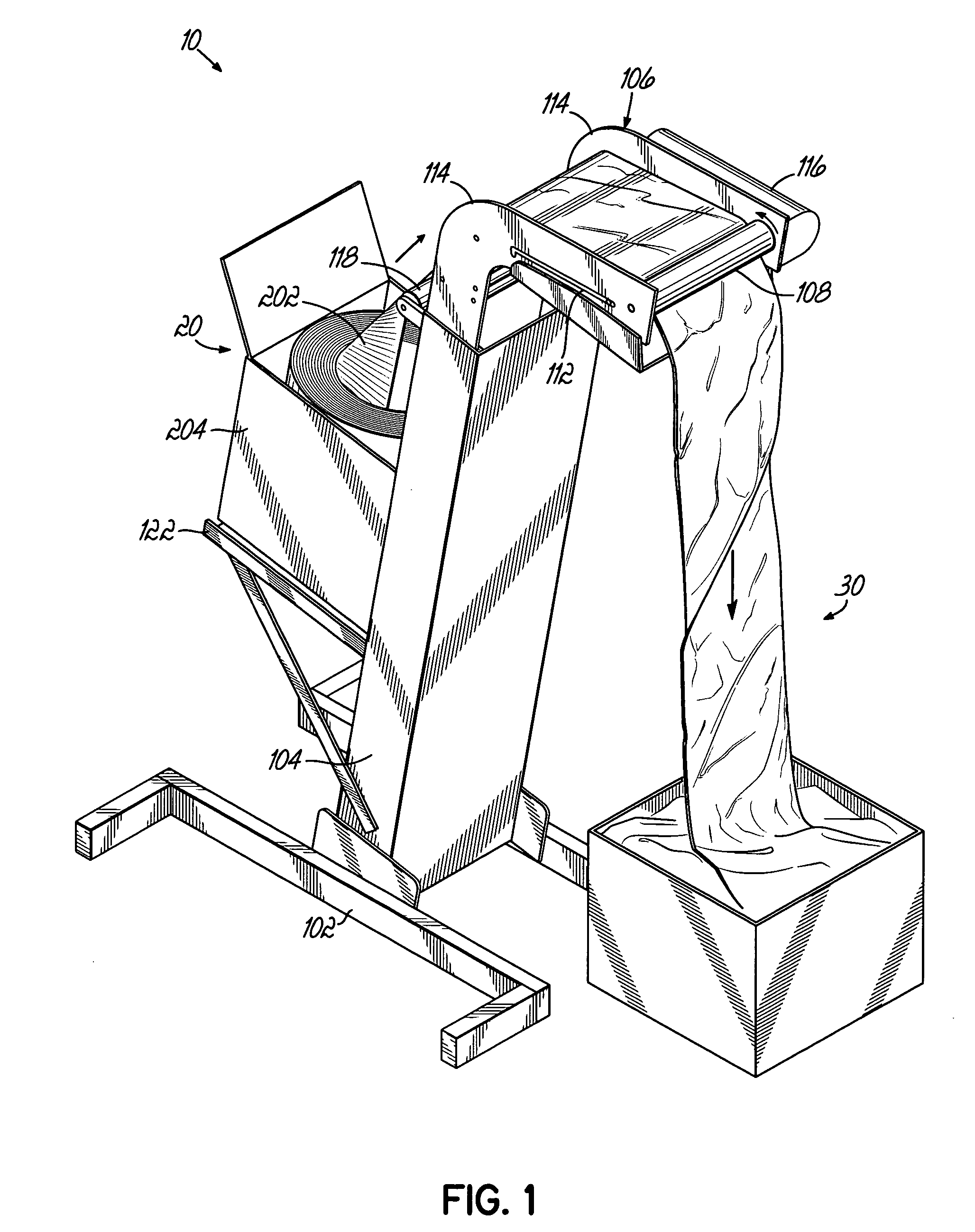

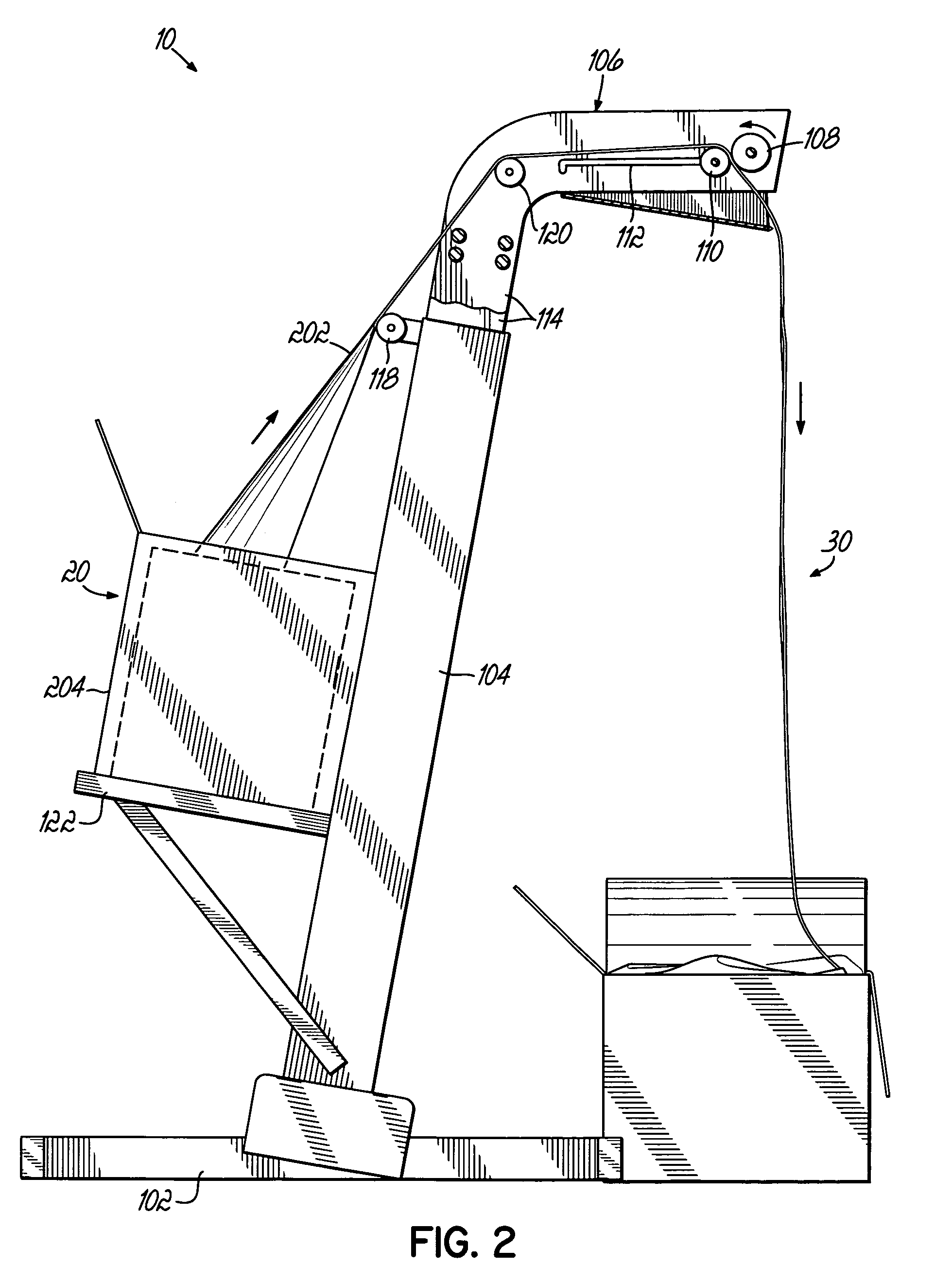

Cushioning product, machine and method

InactiveUS20080076653A1Tear is causedEliminate requirementsPaper/cardboard articlesContainer making machineryCushioningCardboard

A method of producing cushioning dunnage comprises the steps of providing a cushioning dunnage producing machine, providing a roll of paper sheet material, the roll of paper sheet material having a first end at a radially innermost location and a second end at a radially outermost location, feeding the first end of the paper sheet material into the cushioning dunnage producing machine, and producing cushioning dunnage with the cushioning dunnage producing machine. A cushioning product comprises an elongated sheet of paper having a longitudinal axis, the sheet of paper twisted about the longitudinal axis into a helix, the twisted sheet of paper crumpled along the longitudinal axis. A combination comprises a cushioning dunnage producing machine having a crumpler, a roll of paper sheet material having a first end at a radially innermost location and a second end at a radially outermost location, the first end fed into the cushioning dunnage producing machine, the crumpler drawing the paper sheet from the roll and crumpling the paper sheet into cushioning dunnage.

Owner:STOROPACK INC

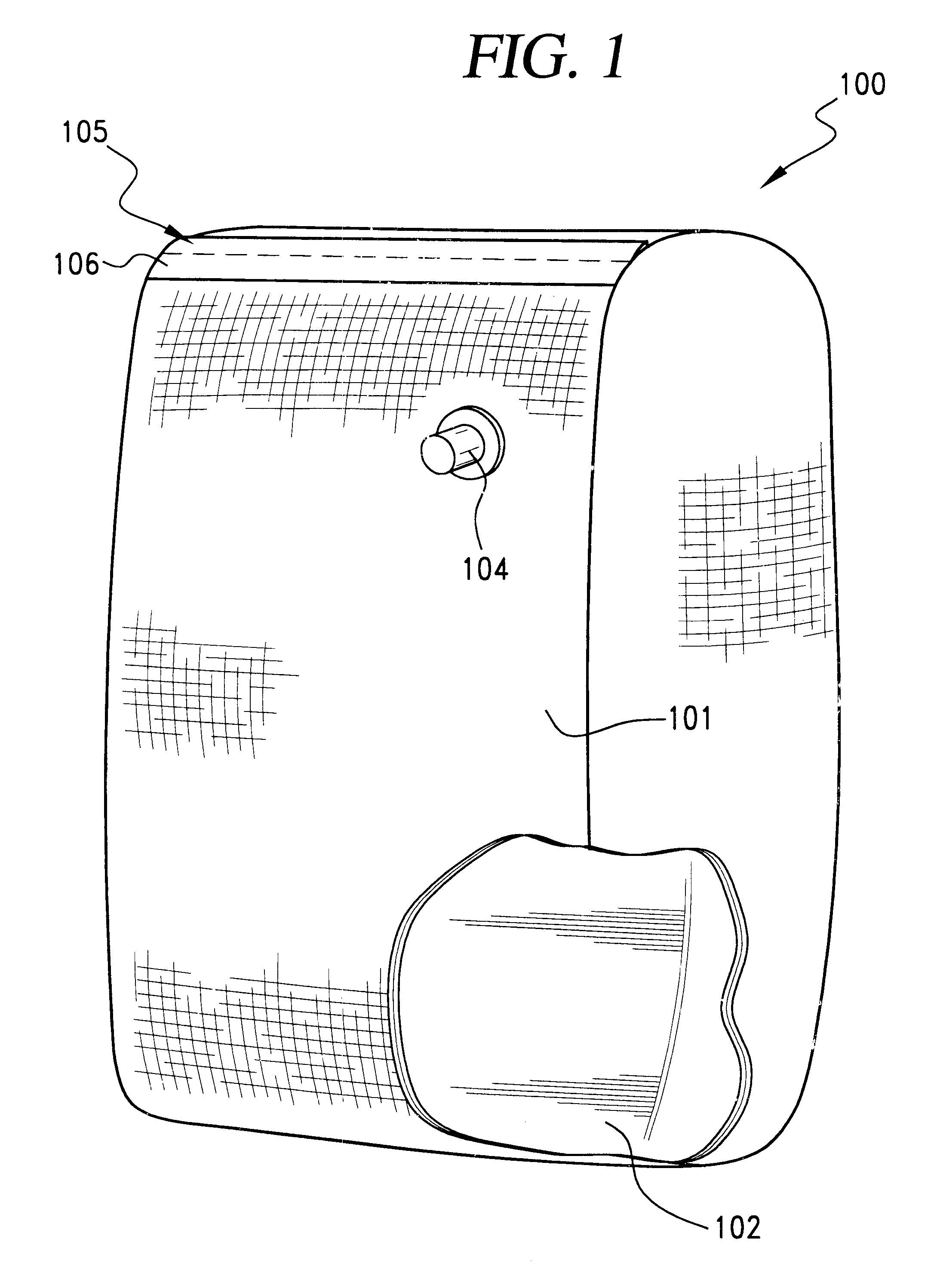

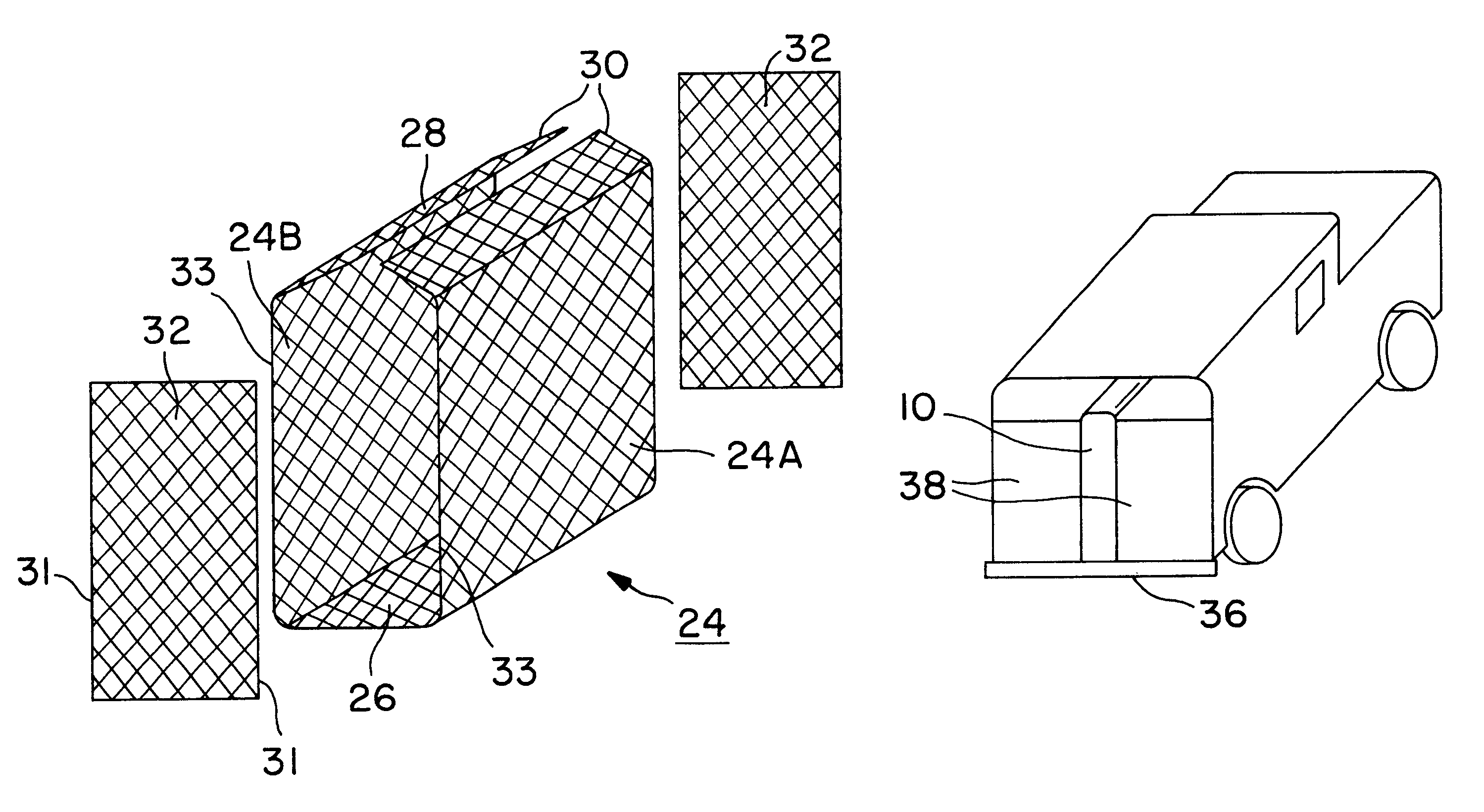

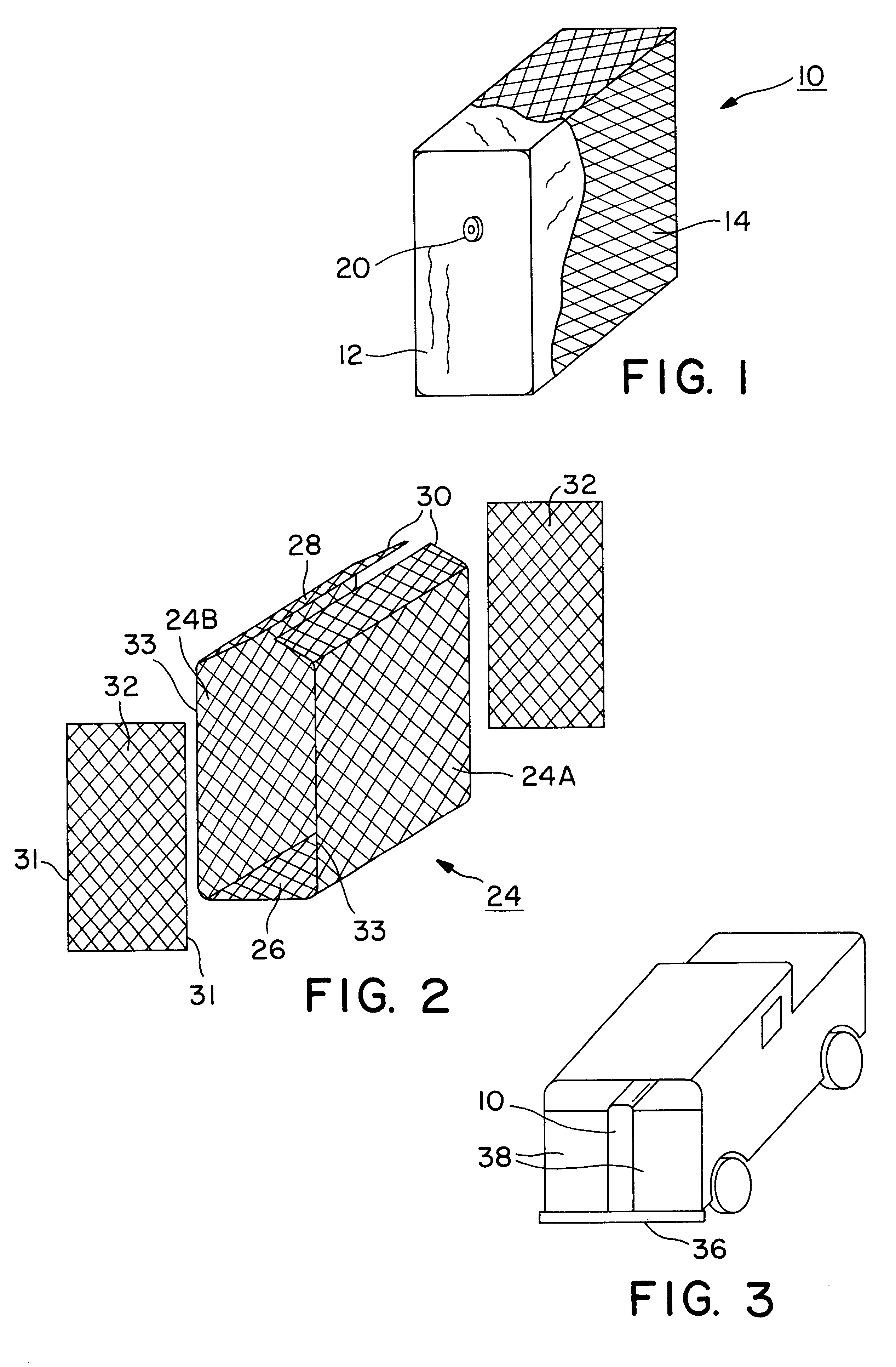

Dunnage bag having a mesh ply

A principal advantage of this composite bag compared to the bags disclosed in the present art using solid ply is improved combination of strength and flexibility. A composite dunnage bag being an elastic inner bag enclosed in a mesh outer bag. The bag replaces the system of state of the art bags plus filler panels which are currently used when the space between pallets is greater than 12 inches. The combination mesh and plastic is sufficiently strong and flexible to permit the bag to apply an 80% footprint against the cargo walls.

Owner:ILLINOIS TOOL WORKS INC

Crumpling mechanism for creating dunnage

A dunnage crumpling apparatus is provided having first and second entry-side crumpling members and first and second exit-side crumpling members. The first and second entry-side crumpling members define an entry therebetween. The first and second exit-side crumpling members define an exit therebetween that is disposed along the longitudinal path downstream of the entry. A crumpling zone being defined between the entry and exit. The first entry-side crumpling member is configured for moving at an first rate and is associated with the second entry-side crumpling member for moving sheet material through the entry in a first direction along a longitudinal path at an entry rate. The first exit-side crumpling member is configured for moving at an second rate and is associated with the second exit-side crumpling member for moving the sheet material through the exit in the first direction along the path at a exit rate that is slower than the entry rate to crumple the sheet material for producing dunnage. The entry and exit-side crumpling members are displaced laterally along the path with respect to each other to cause shearing of the sheet within the crumpling zone.

Owner:PREGIS INNOVATIVE PACKAGING

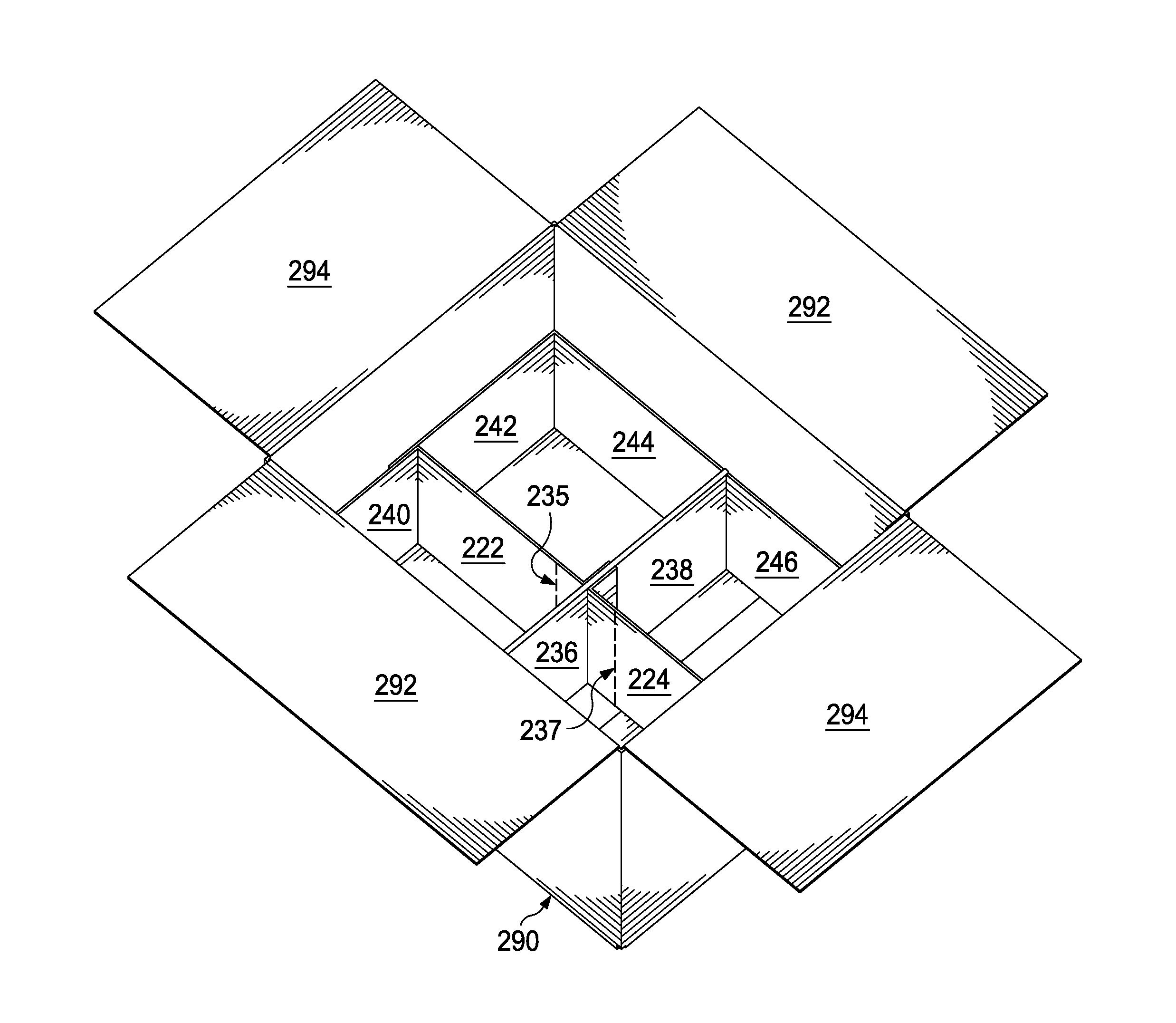

Force-resisting support assembly

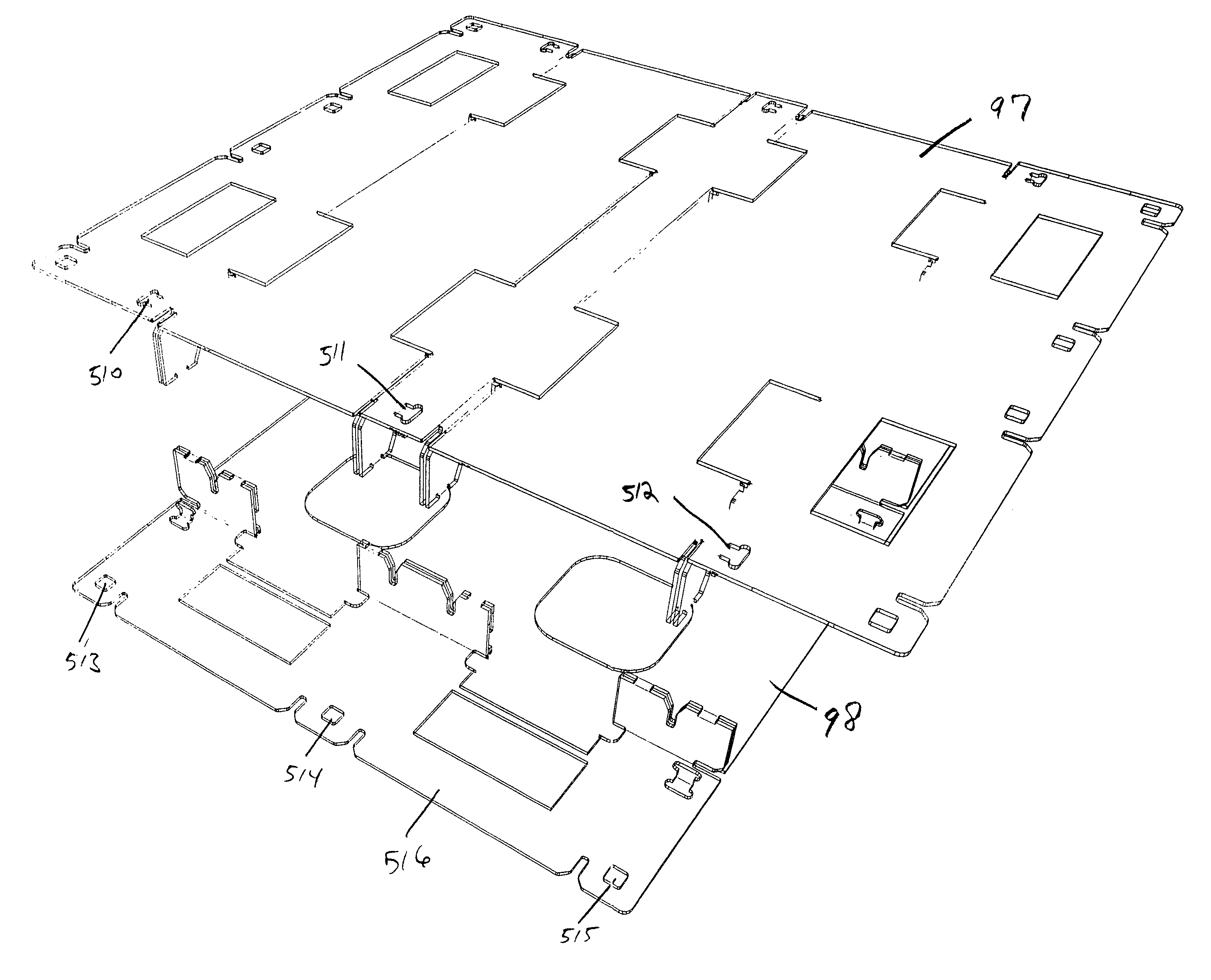

InactiveUS7426890B2Solve the complicated productionSimple stepsStands/trestlesKitchen equipmentCardboardEnvironment effect

The present invention is a force resisting assembly, and can be constructed into a pallet or dunnage support made from paperboard that minimizes adverse environmental impact, occupies little space before it is configured, and effectively saves production, storage and transportation costs. The present paperboard assembly can be shipped and stored as either one or more die-cut and scored paperboard pieces, thereby eliminating excess volume, with the pieces being readily interconnectable to form a complete pallet or dunnage support assembly. Preferably, the paperboard of the present invention further has a low moisture vapor transmission rate (MVTR), excellent glueability and recyclability.

Owner:OLVEY SUSAN

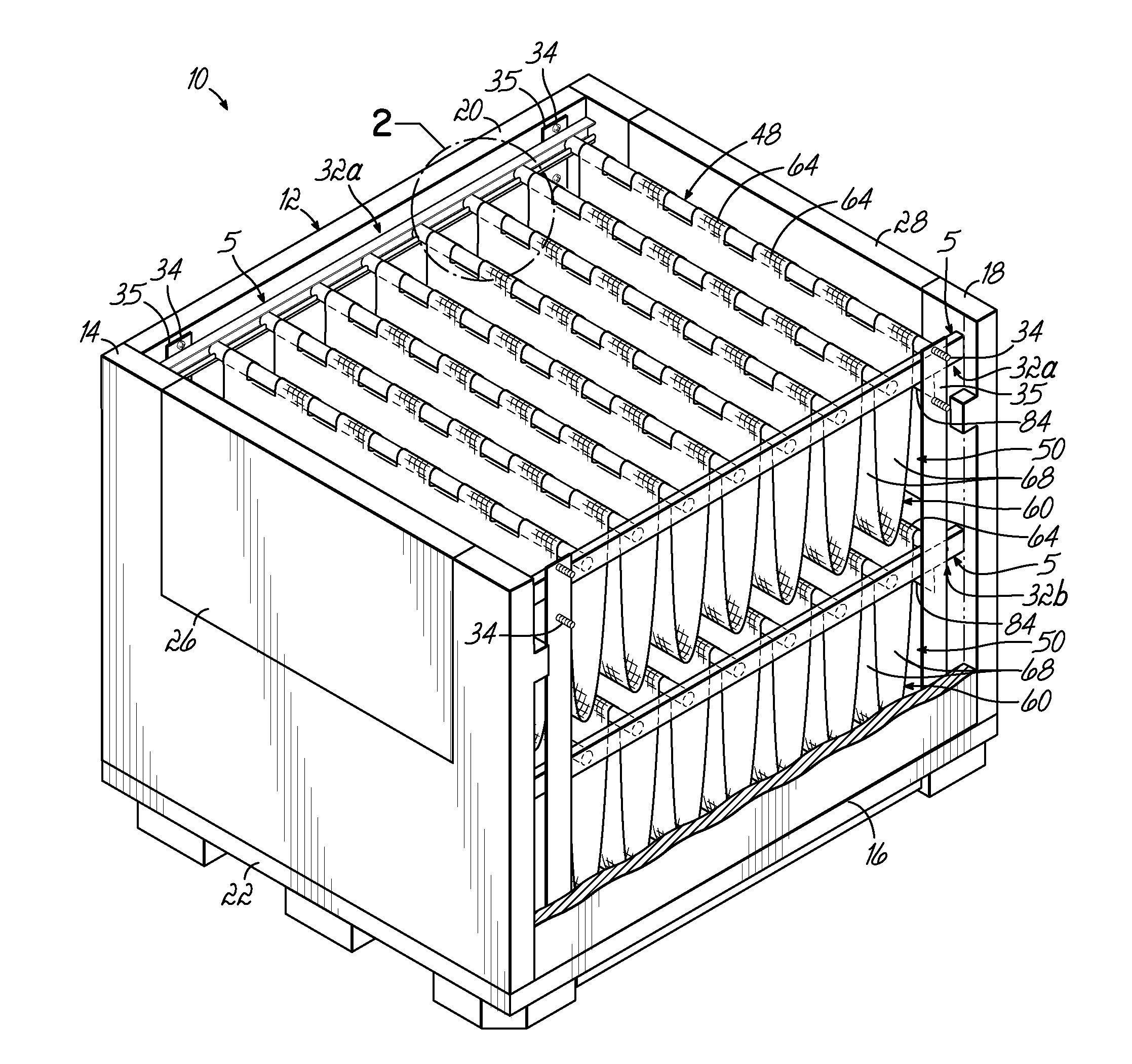

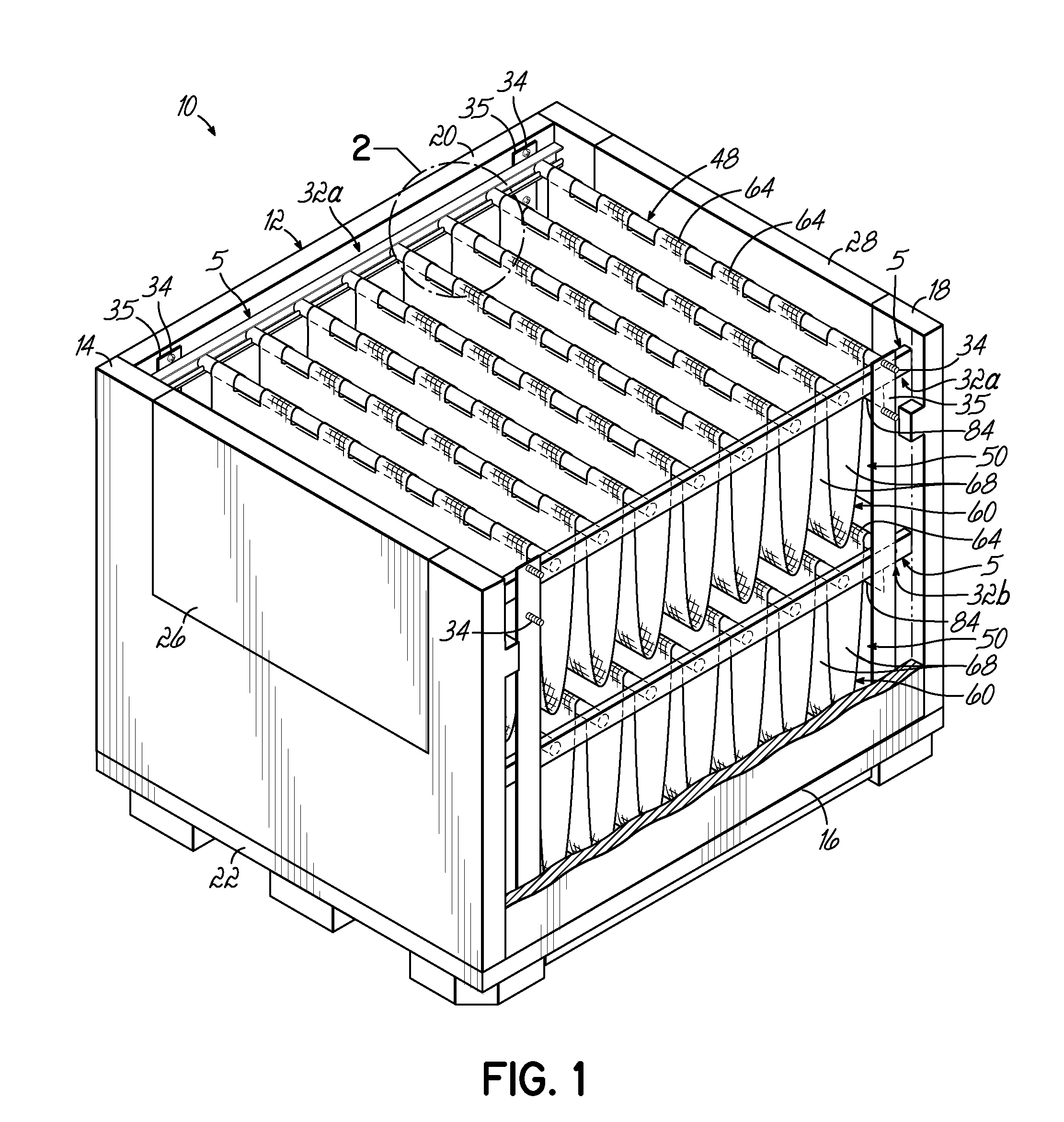

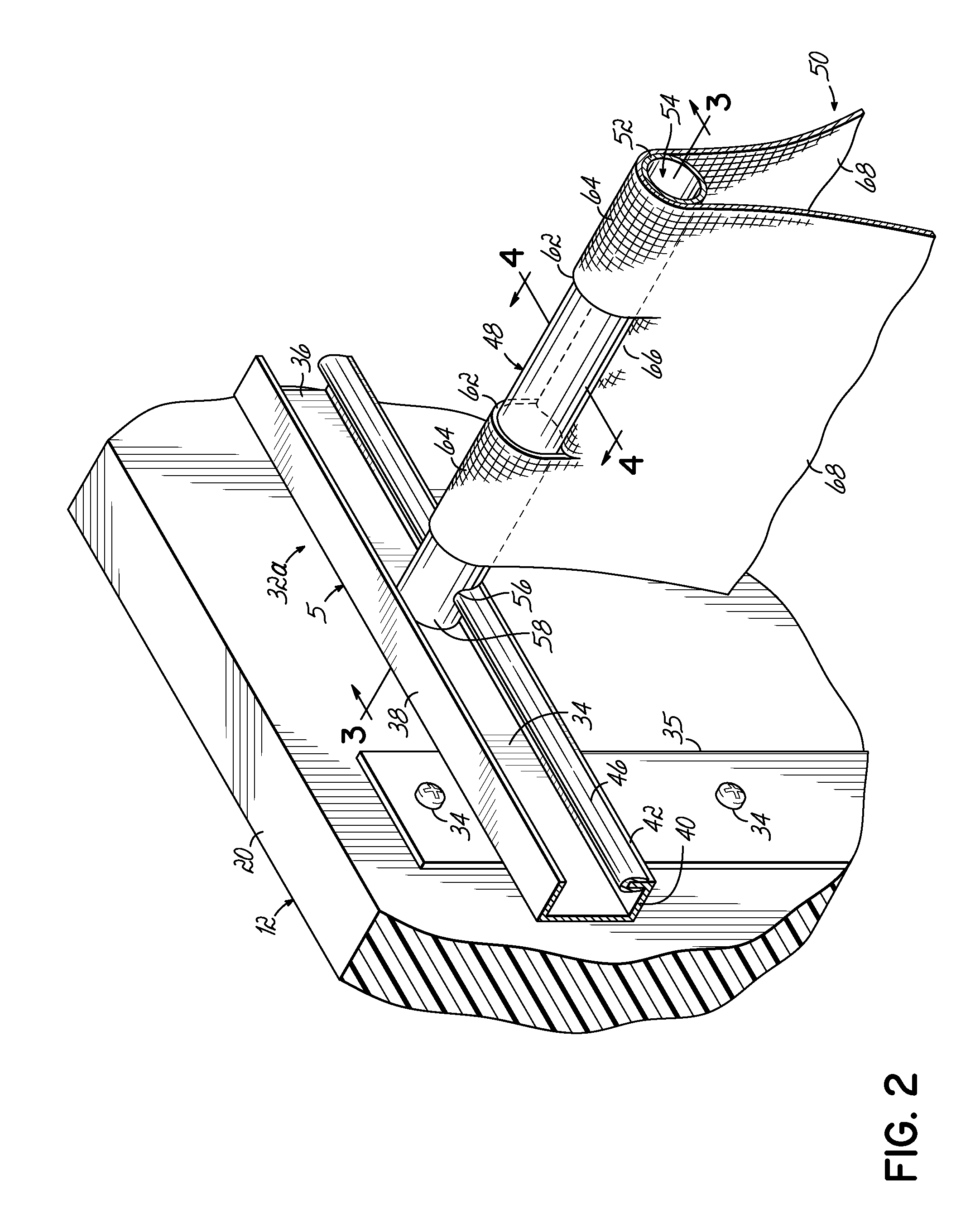

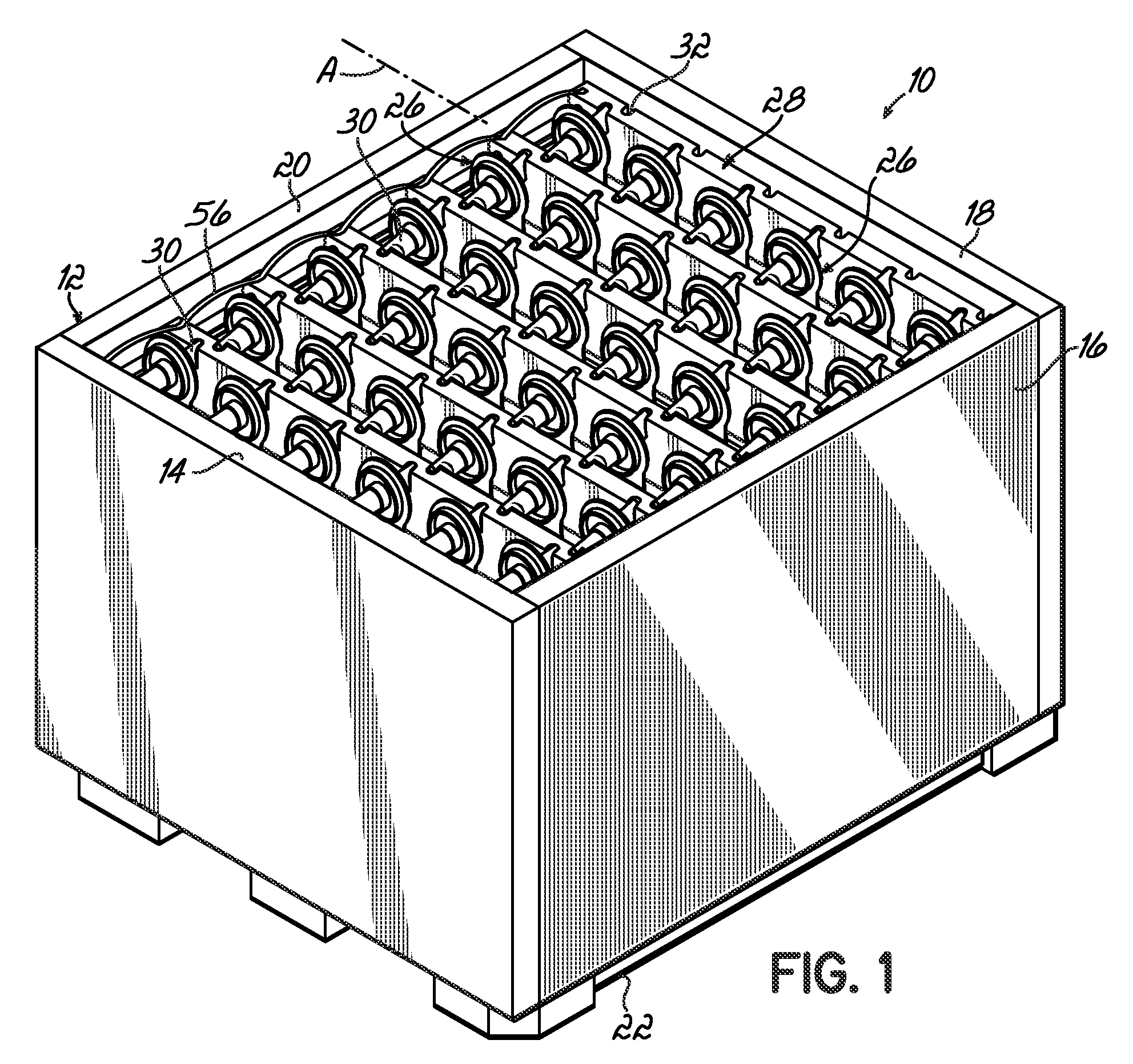

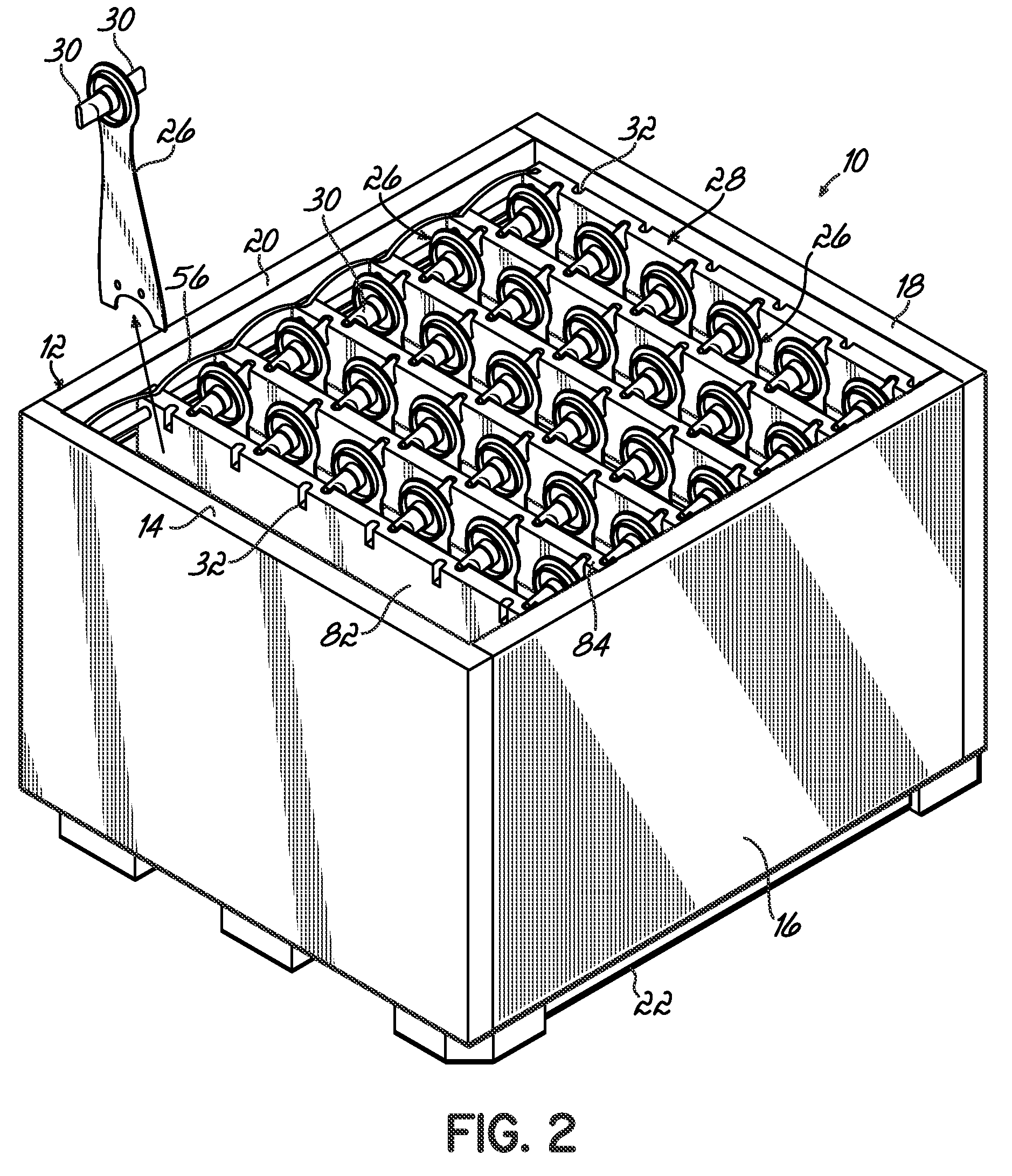

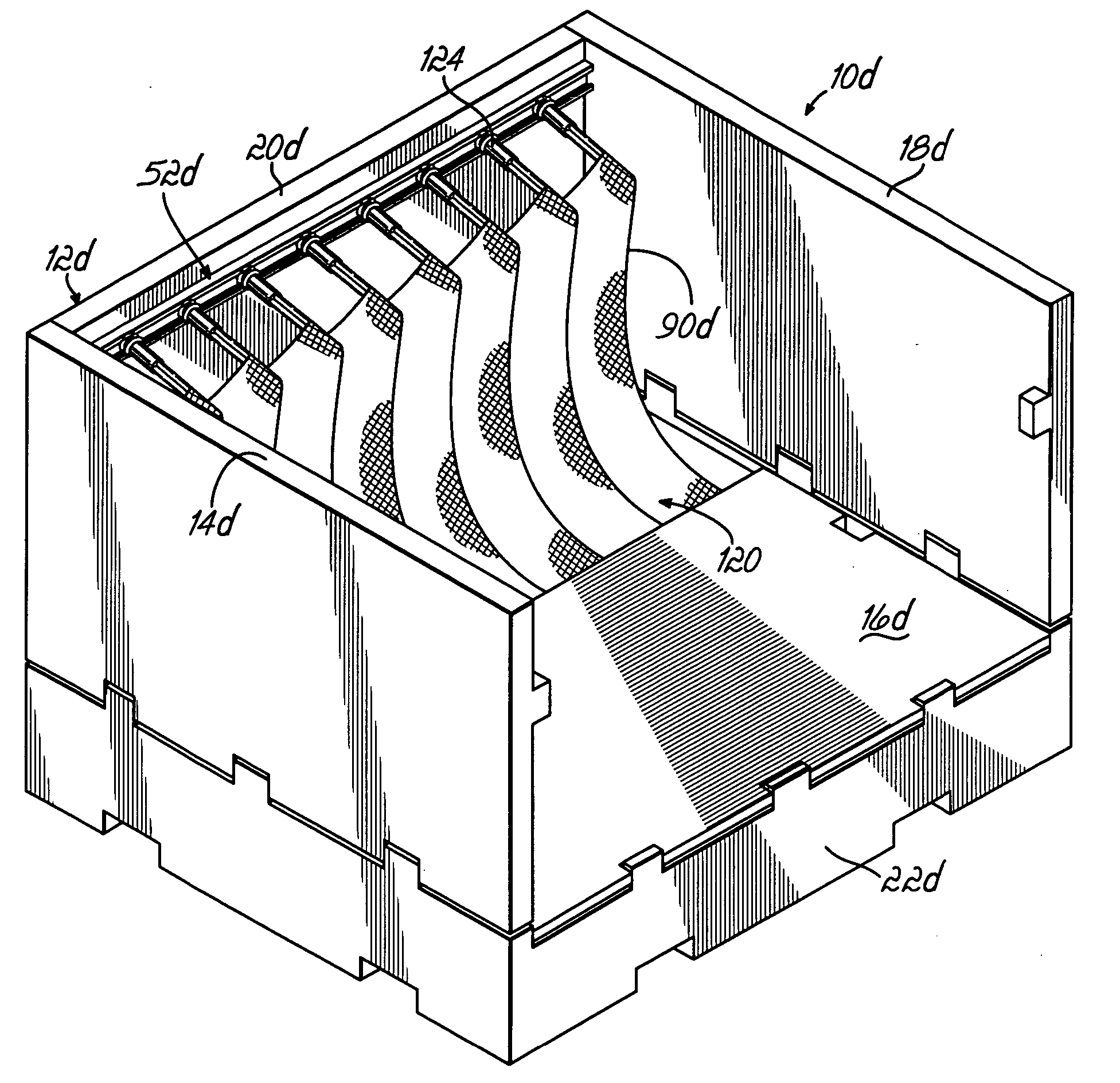

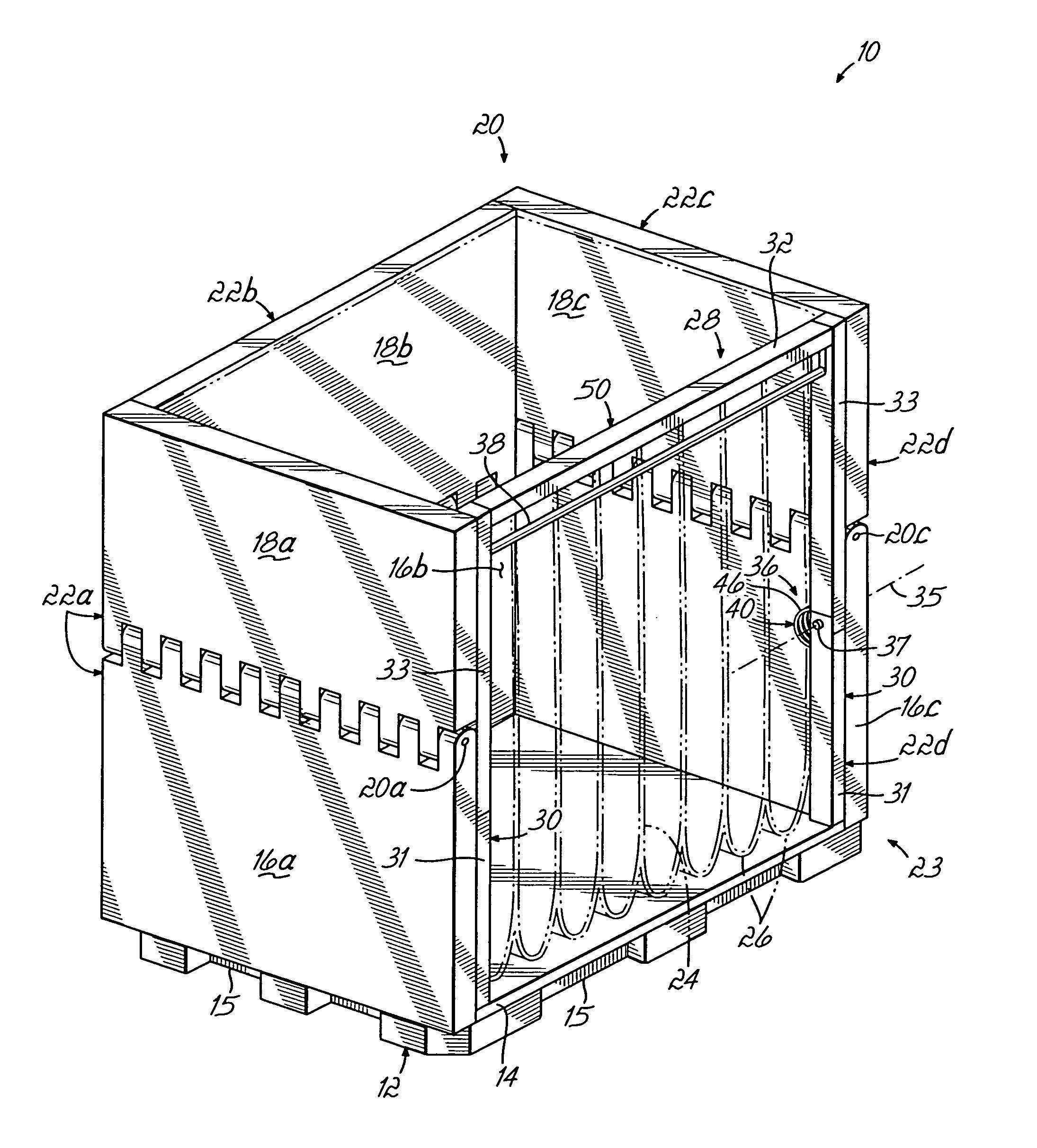

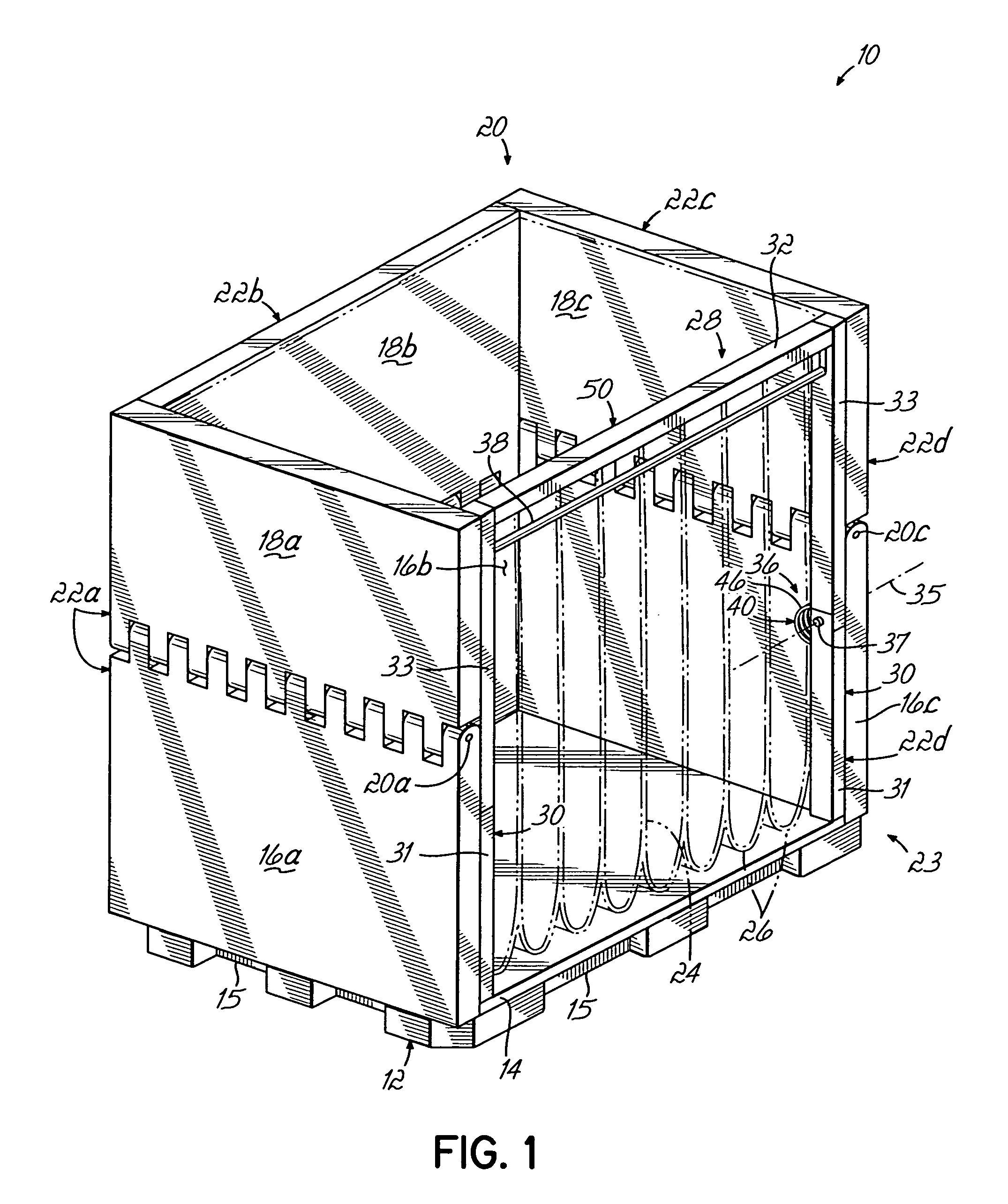

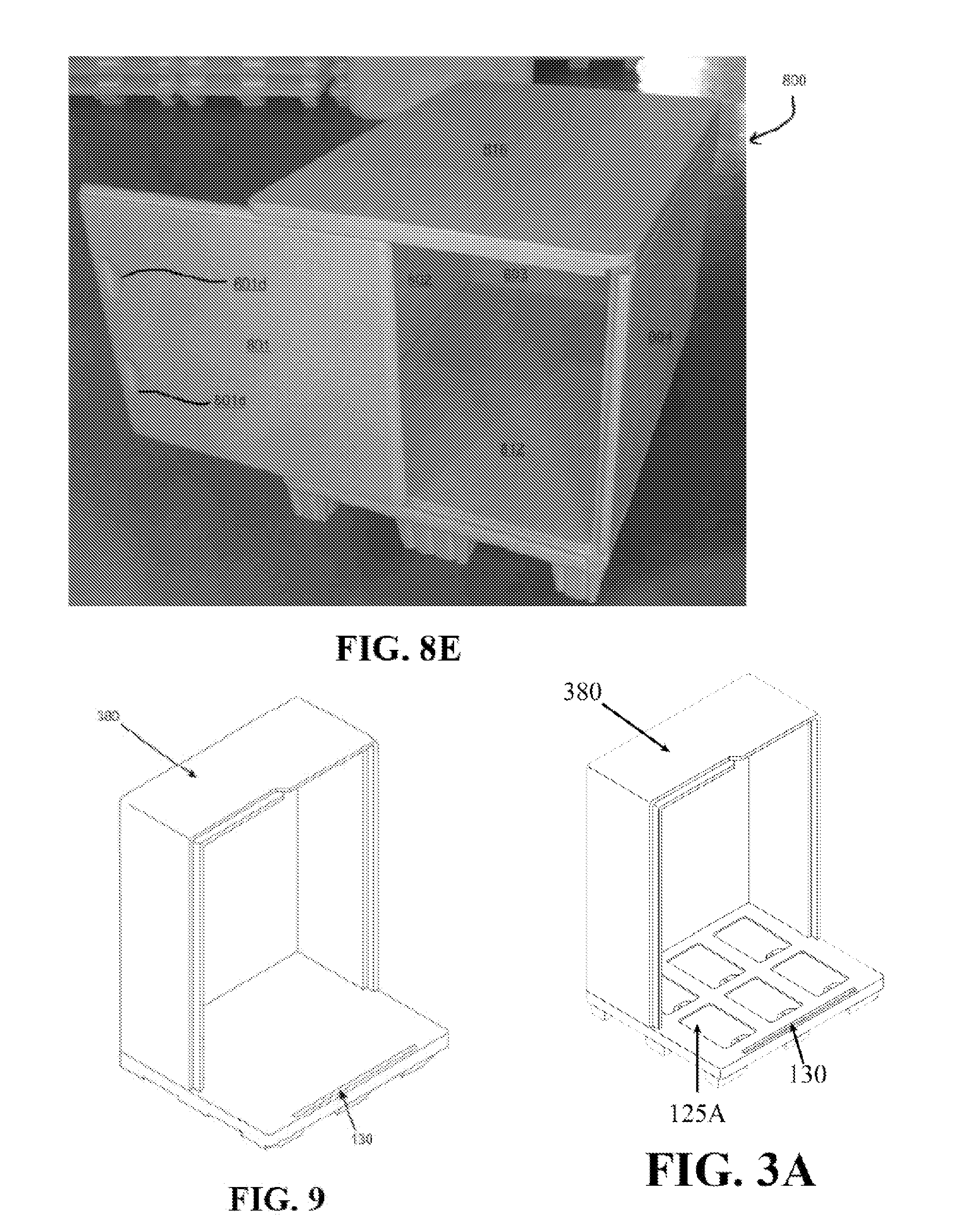

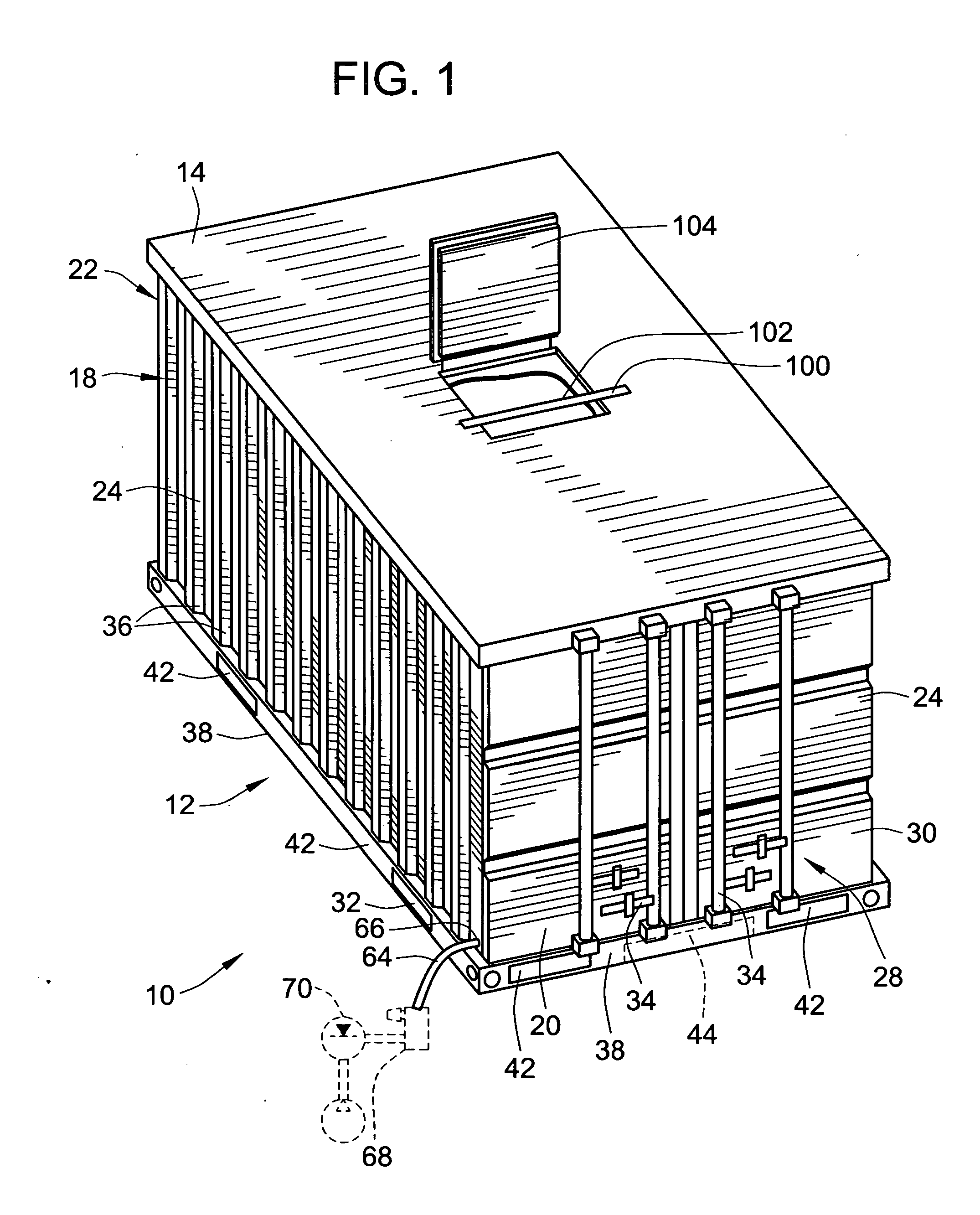

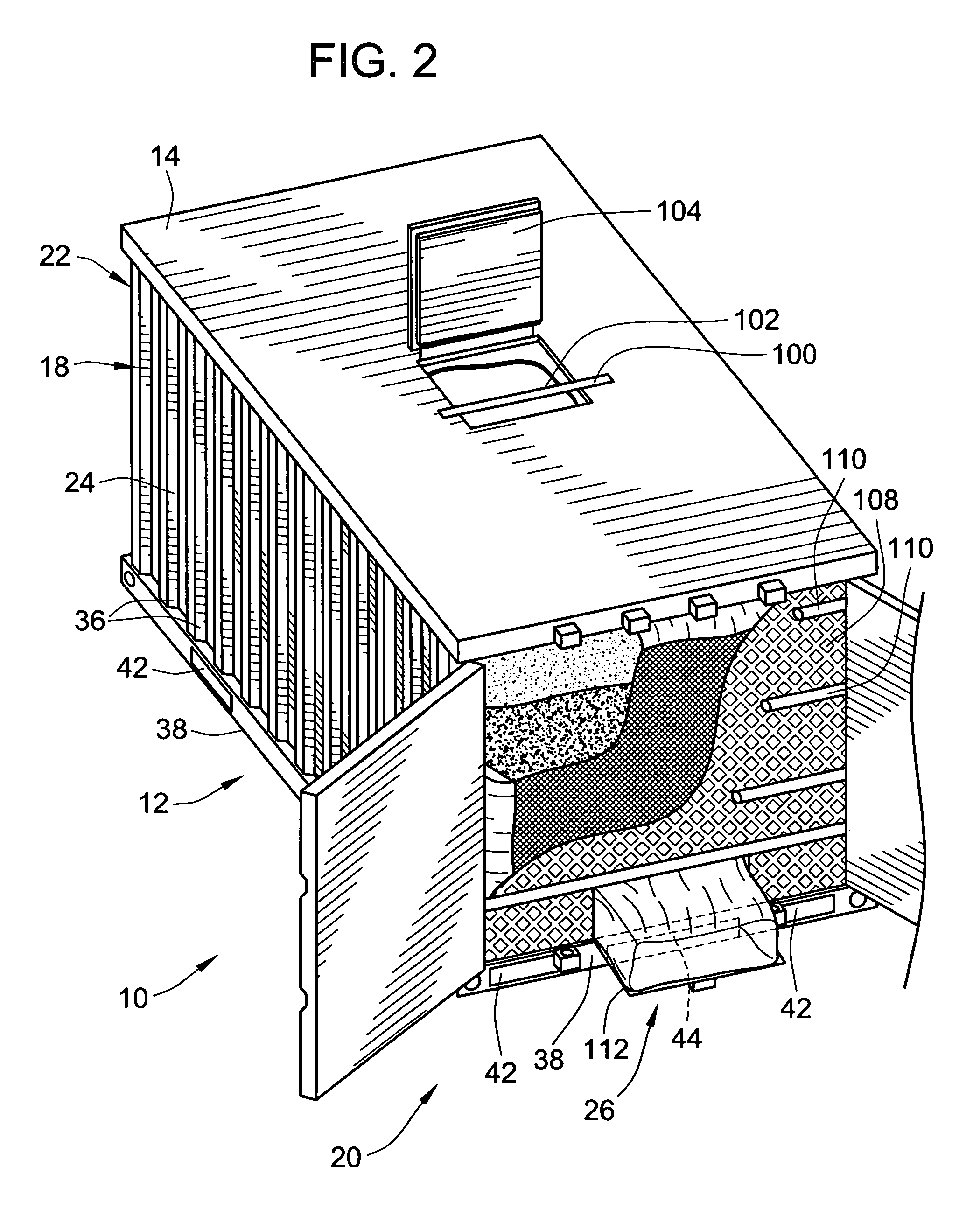

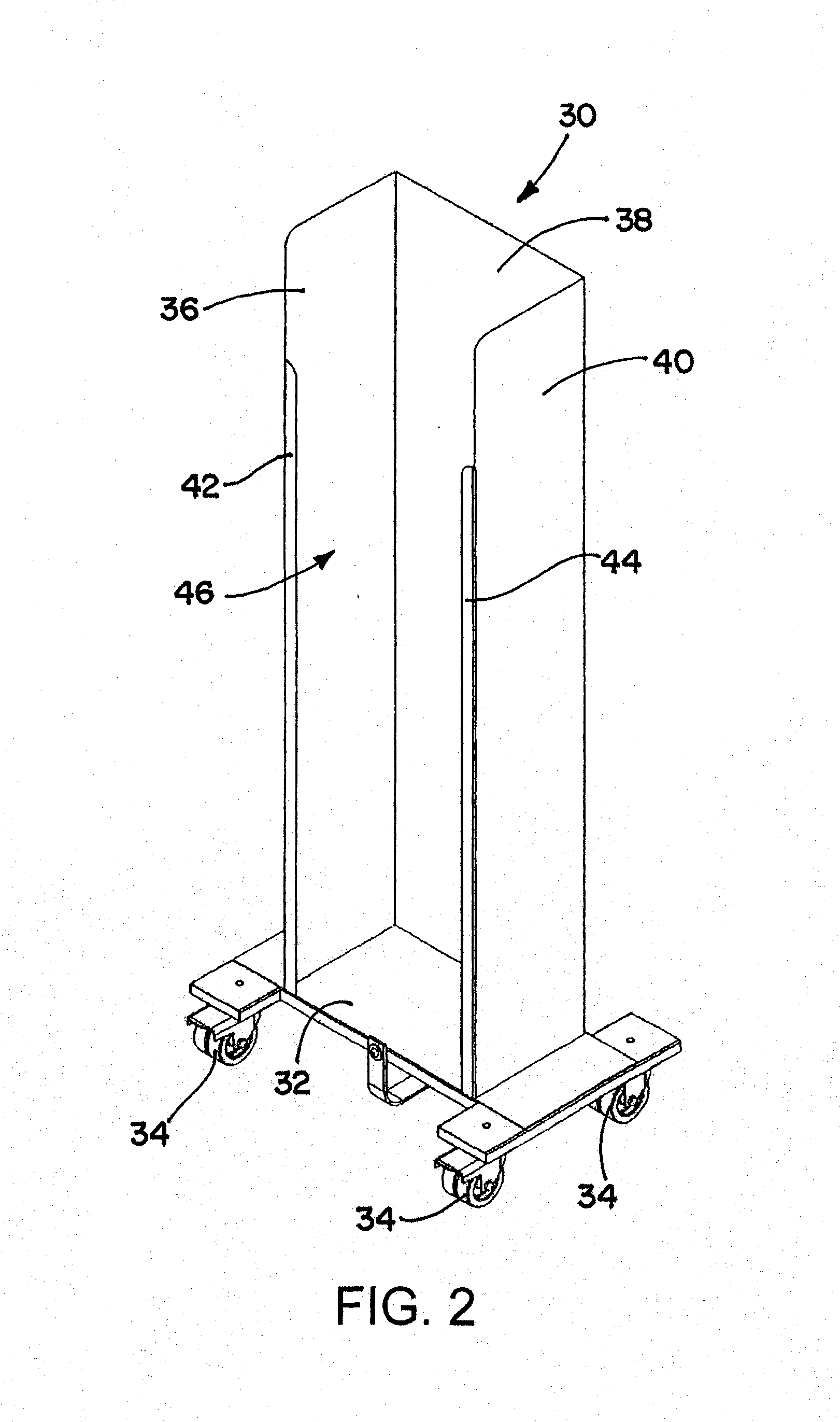

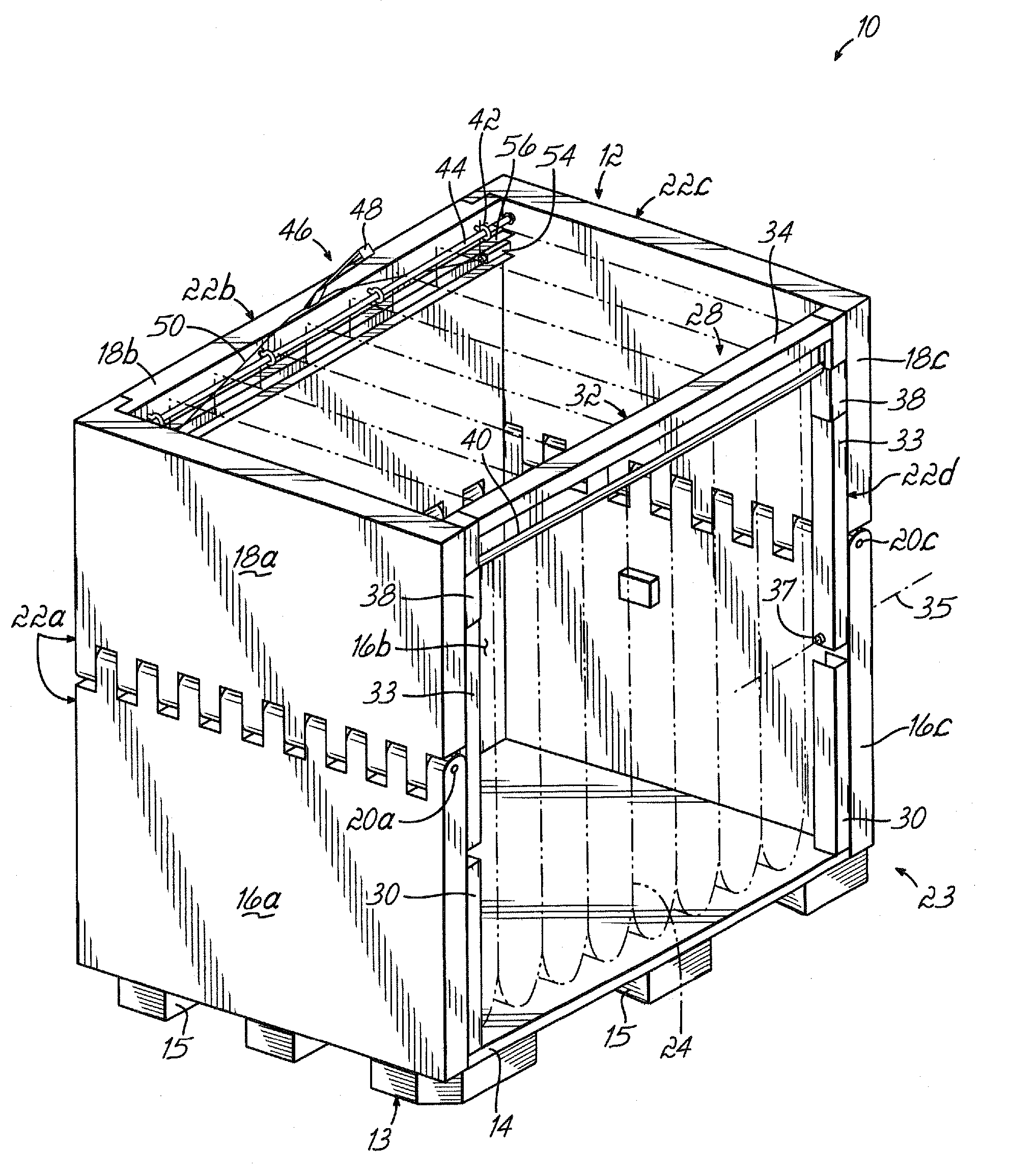

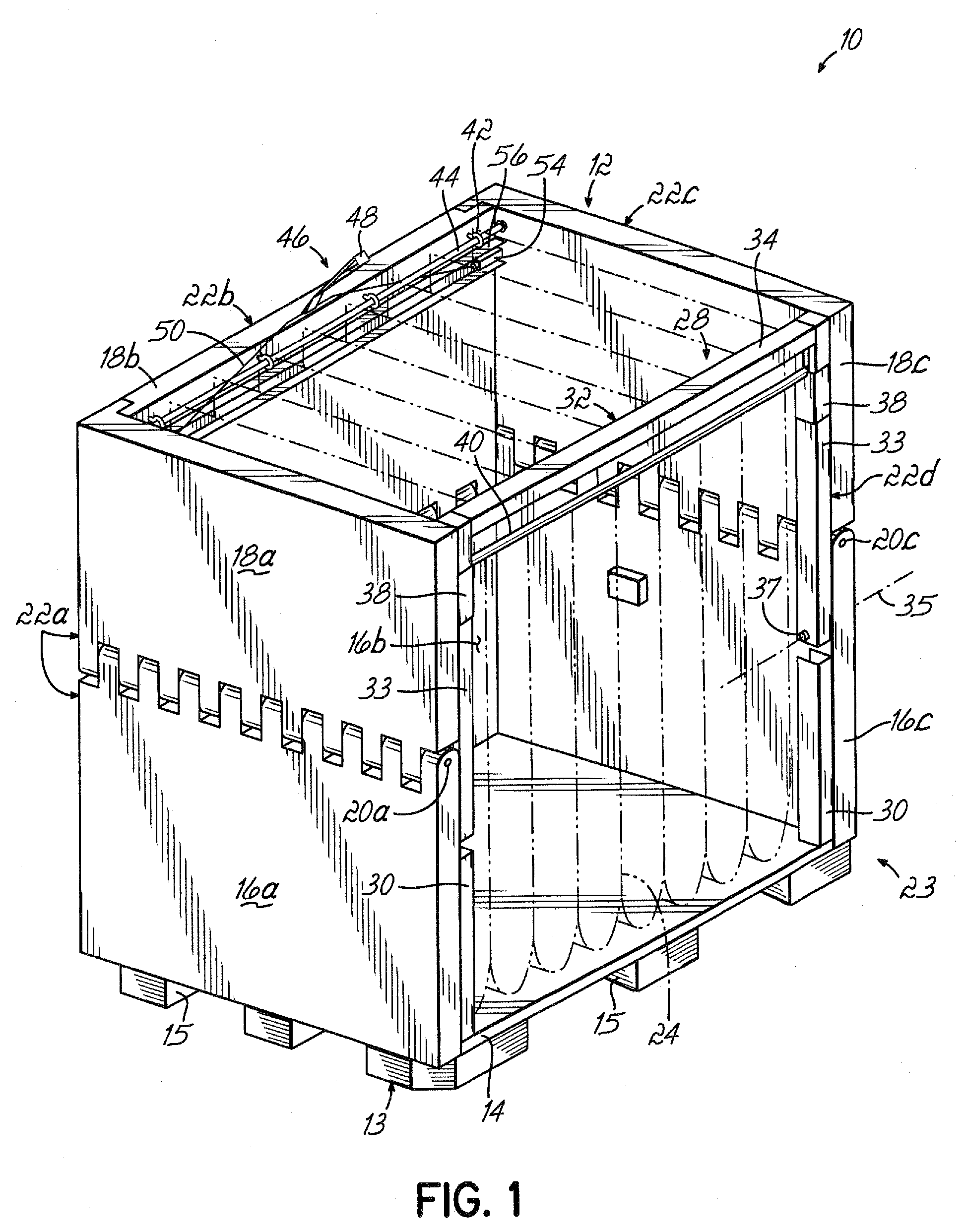

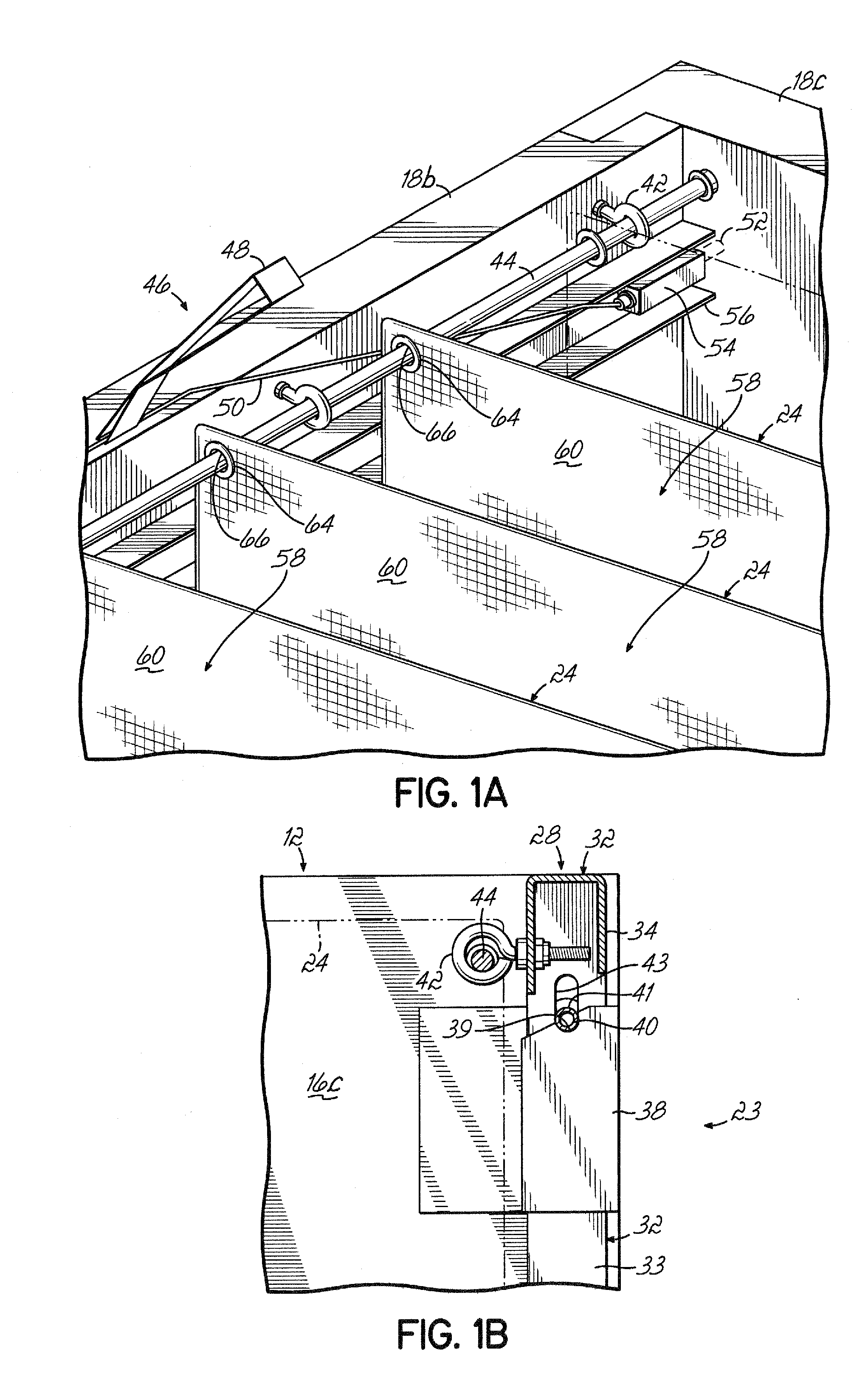

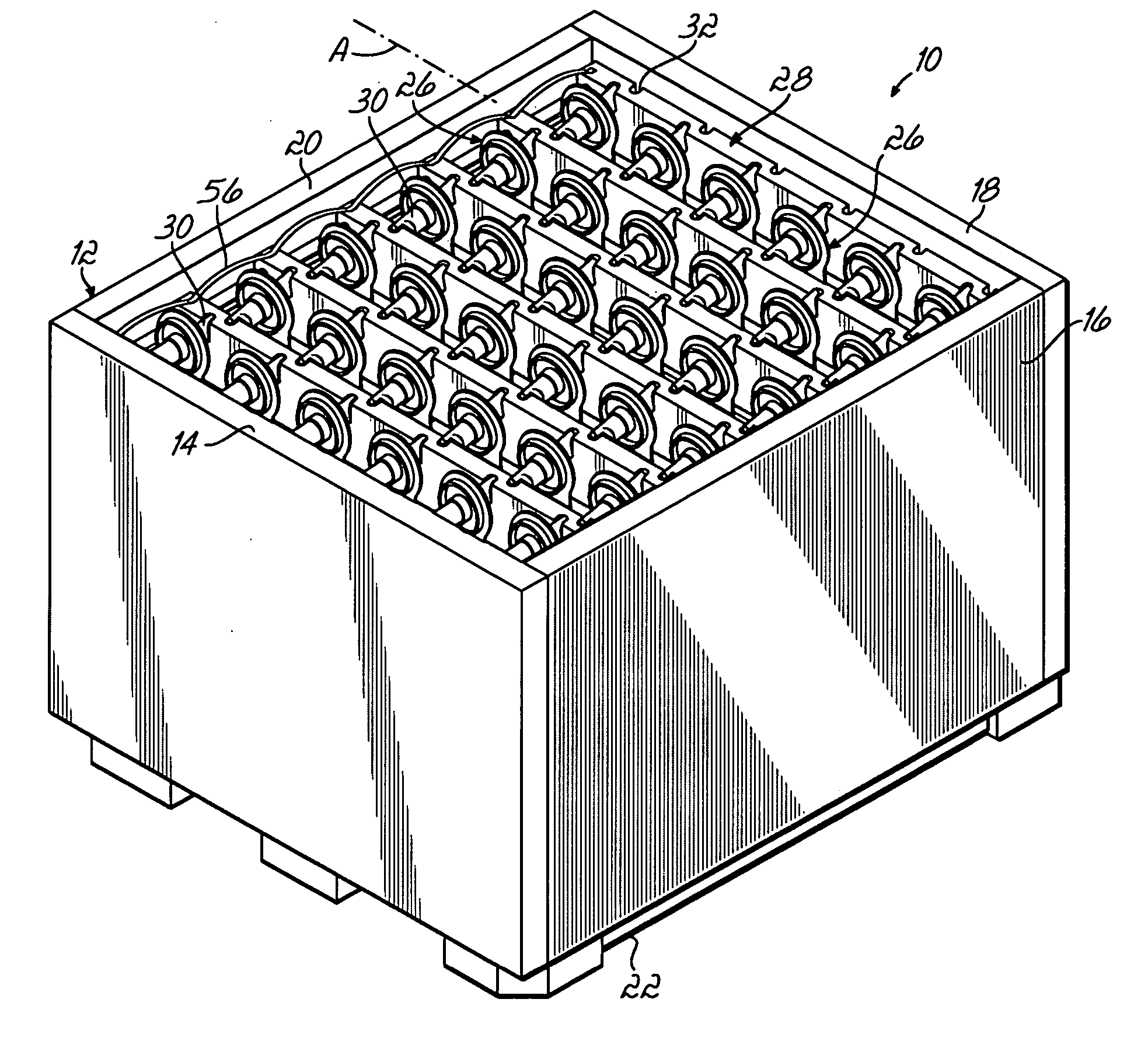

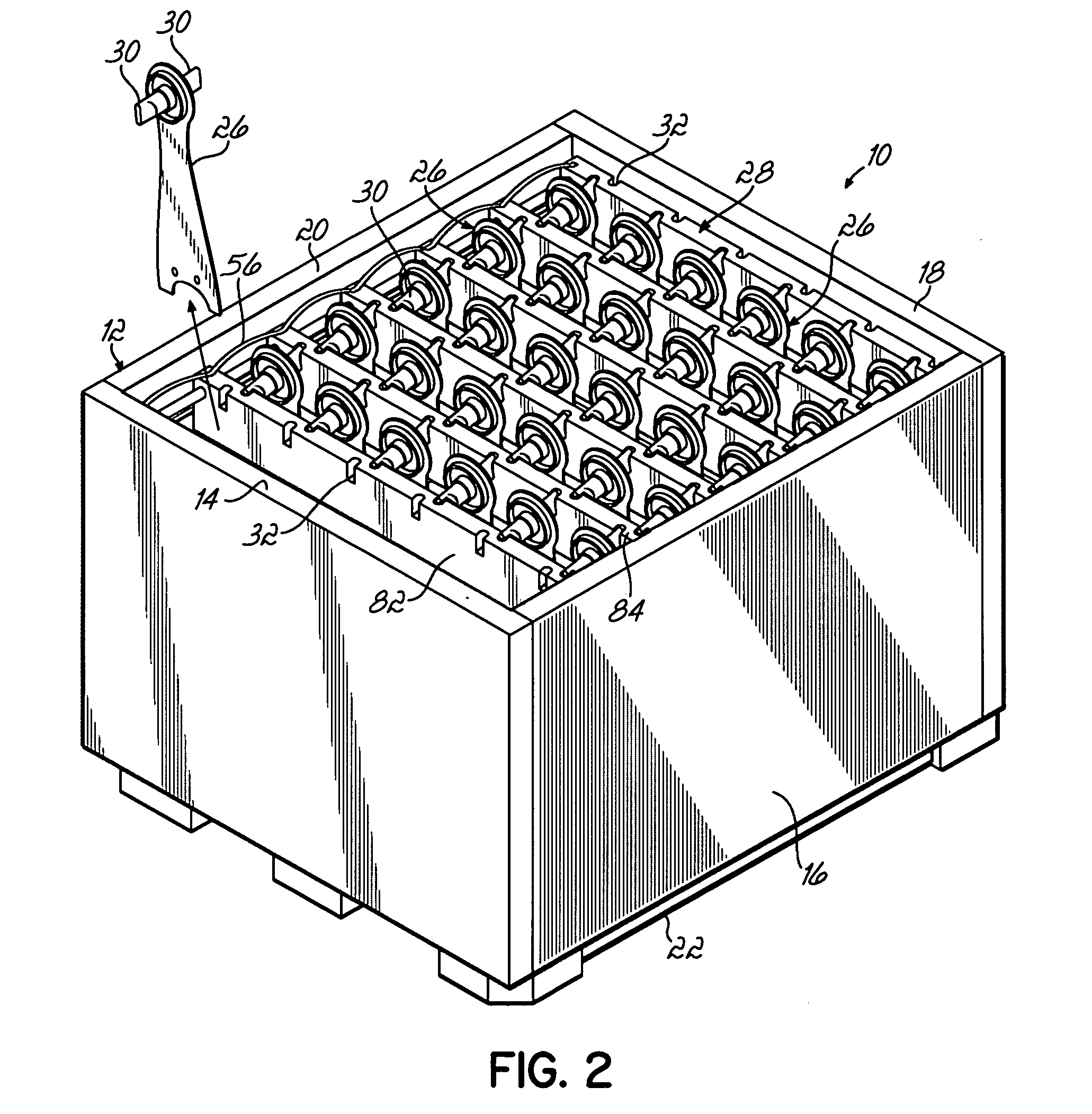

Container Having Sliding Support Members For Supporting Dunnage

The present invention provides a container for holding product therein during shipment and being returned for reuse that has a body, track assemblies attached to opposite sides of the body, and a plurality of tubular support members extending between the track assemblies. The tubular support members have notches which enable the support members to slide along track assemblies to move the support members. The tubular support members support dunnage for supporting product for storage or shipment.

Owner:BRADFORD CO

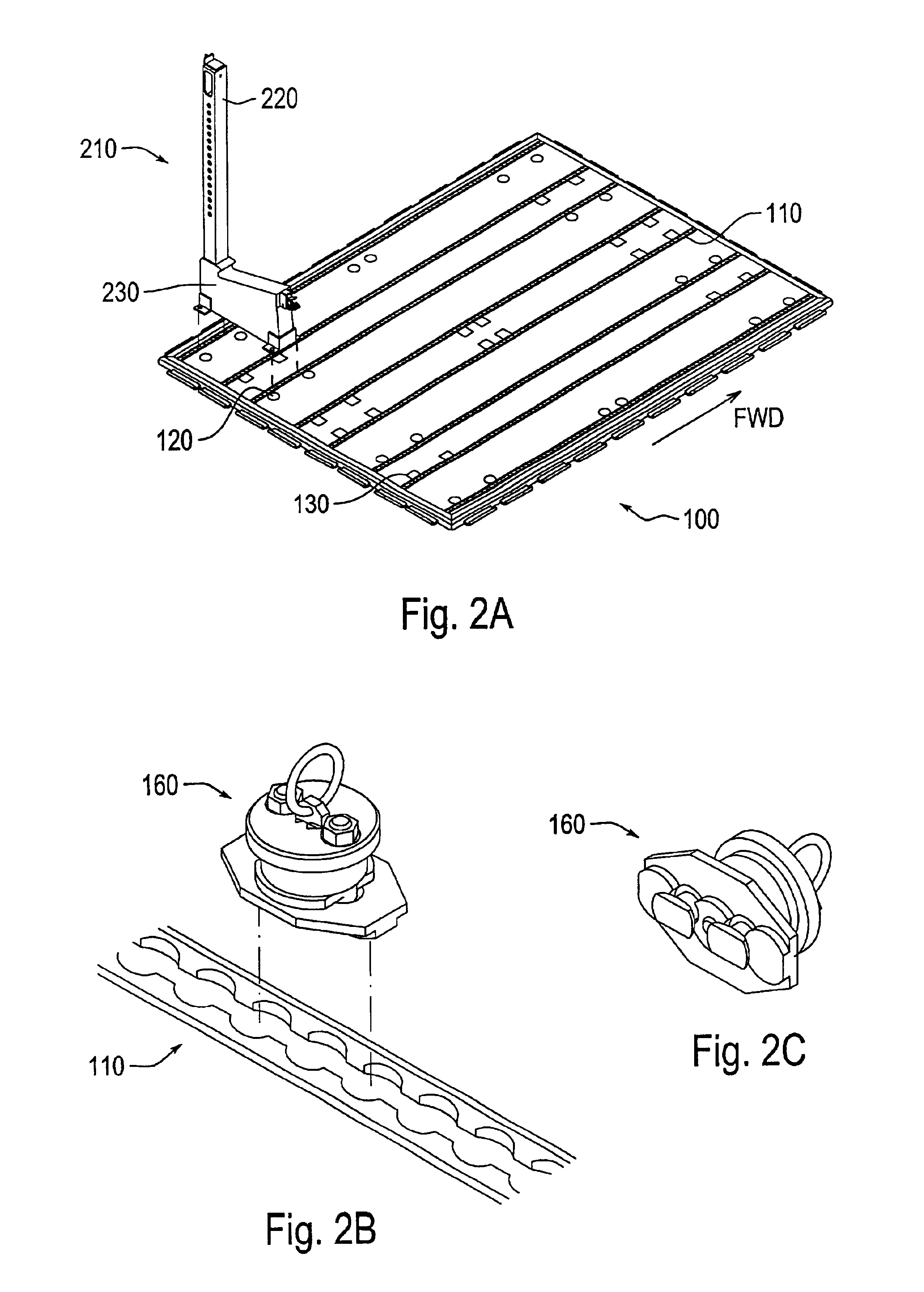

Medical evacuation patient support pallet

The invention provides a reconfigurable patient support pallet system for transporting patients on litters. The patient support pallet system includes a pallet mounted to the floor of a vehicle. The pallet has a plurality of track rails and attachment points for attaching a litter stanchion set, capable of holding a patient in a litter, and / or for attaching a seat to the surface of the pallet. The pallet also includes a plurality of pallet lips and cargo rings on the periphery which provide locations to attach one or more pallet extensions, pallet spacers and / or pallet ramps to increase the usable surface area of a pallet, as well as facilitate safe passage on, off and between pallets by reducing tripping hazards inherent in cargo aircraft.

Owner:ASES

Container having non-linear support members for supporting dunnage

A container for holding product therein during shipment and being returned for reuse that has a body, tracks supported by the body, and a plurality of support member assemblies, each having a pair of end members engaged with and moveable along the tracks and a non-linear support member extending between and connected to the end members. The support member assemblies support dunnage for supporting products for storage or shipment.

Owner:BRADFORD CO

Method for making paper dunnage

InactiveUS7651455B2Mechanical working/deformationPaper/cardboard articlesDunnagePulp and paper industry

Dunnage making machine and method in which a web of paper is drawn across a forming bar with curved end sections to roll the edge portions of the paper, then drawn through a first throat section to urge the rolled edge portions toward each other and cause them to gather, and thereafter through a second throat section of lesser dimension than the first to gather the central portion of the paper and further gather the edge portions. The gathered paper is then pressed with a roller to crumple it, following which the crumpled paper is perforated along a serrated tear line.

Owner:PREGIS INNOVATIVE PACKAGING INC

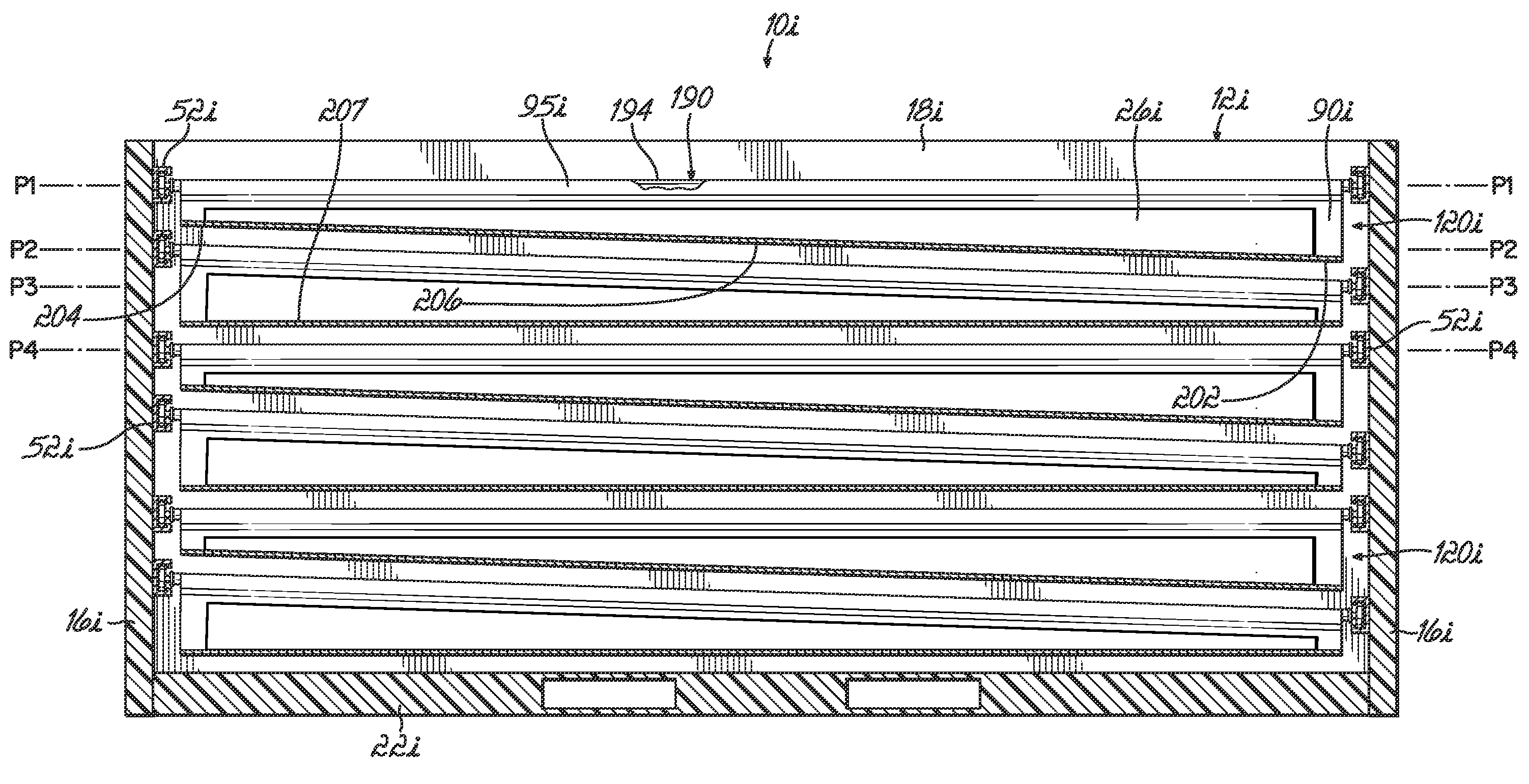

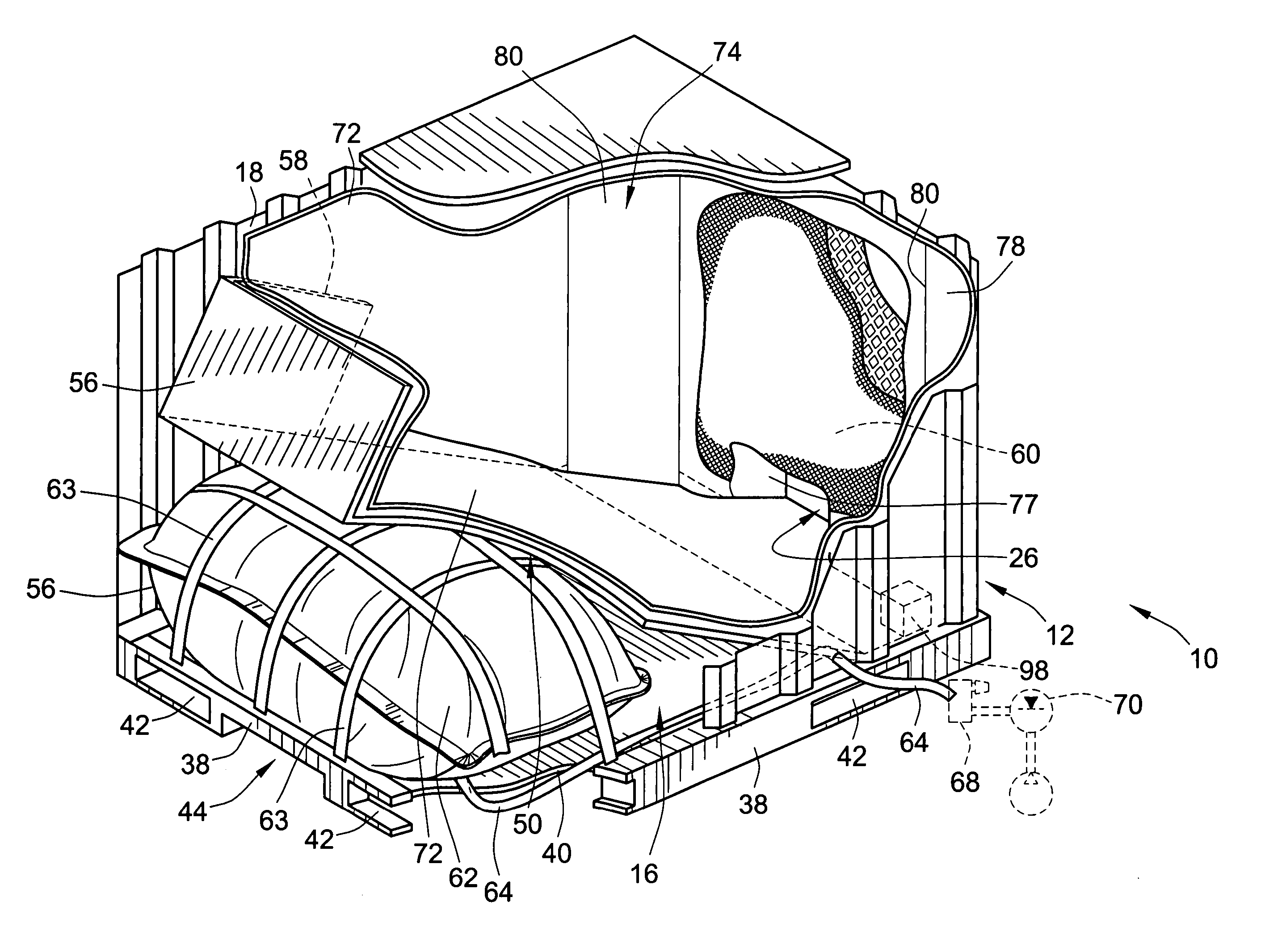

Container having sliding support member assemblies for supporting dunnage

InactiveUS20060249514A1DistanceHigh densityPackaging vehiclesContainers for machinesDunnageEngineering

The present invention provides a container for holding product therein during shipment and being returned for reuse that has a body, tracks attached to opposite sides of the body, and a plurality of support members extending between the tracks. Sliders are located at the ends of tubular supports, the sliders being slidable in the tracks to move the support members. The support members support dunnage for supporting products for storage or shipment.

Owner:BRADFORD CO

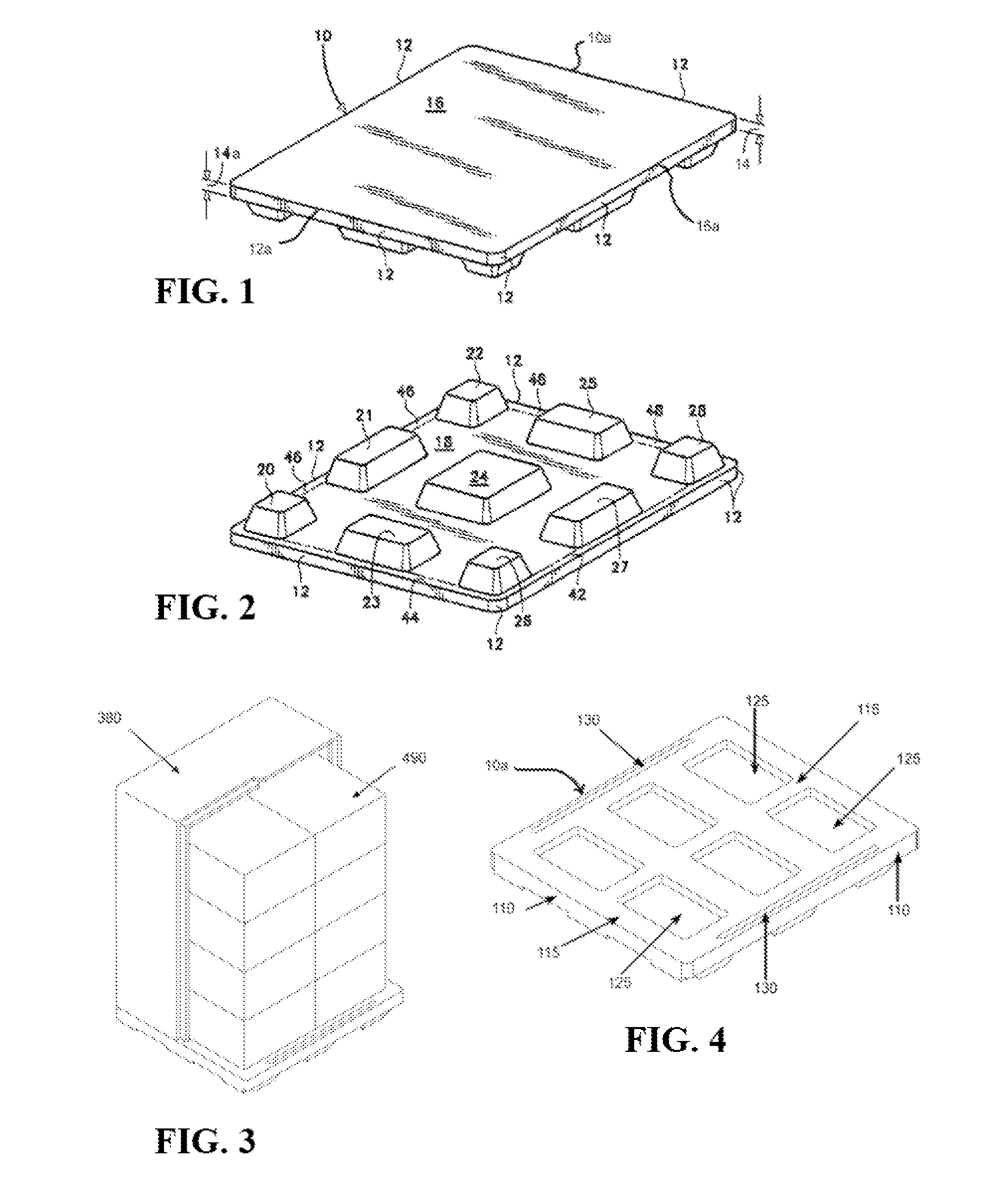

Collapsible container with dunnage erection biaser

InactiveUS7083369B2Reduce replacement costsReduce labor costsPackage recyclingLoad securingDunnageTorsion spring

A reusable and returnable container for holding product therein during shipment and subsequently being returned without product comprises a body having at least two opposed side structures, collapsible dunnage operably connected to the side structures, and a dunnage erection biaser operably connected to one of the side structures. The force needed to erect the dunnage is minimized due to the dunnage erection biaser. The dunnage erection biaser, in one embodiment is a pair of torsion springs. However, the biaser may be any elastic or non-elastic device to facilitate erection of collapsed dunnage.

Owner:BRADFORD CO

Load bearing structure having antimicrobial properties

InactiveUS20130014676A1Eliminating and preventing and retarding and minimizing growthMinimize cross-contaminationSynthetic resin layered productsLarge containersDunnageEngineering

The present invention provides a movable load bearing structure with a surface that includes antimicrobial agents capable of eliminating, preventing, retarding or minimizing the growth of microbes and also minimizing cross-contamination when the load bearing structure is being reused for cargos that differ from a previously transported cargo, for example, different food types, such as poultry, fresh vegetables, and fresh fruit. The load bearing structure may be a dunnage platform or a container for storing and / or shipping cargo.

Owner:AIRDEX INT

Apparatus for storing material

InactiveUS20060078412A1Raised and loweredLarge containersHand carts with one axisMoving floorDunnage

A new storage apparatus is provided which includes a rectangular box-like containment vessel in which a false movable floor is provided over the bottom floor. A dunnage bag or other actuator is provided to selectively raise and lower the false floor to facilitate self-evaluation and discharge of dry flowable material through a discharge port. The false floor structure may be removed to provide for versatility and different storage options. For example, the containment vessel can be left empty to provide for storage of other objects through openable doors or a pillow tank may be installed within the containment vessel to provide for liquid holding capabilities.

Owner:HAGEMANN MR RONALD T

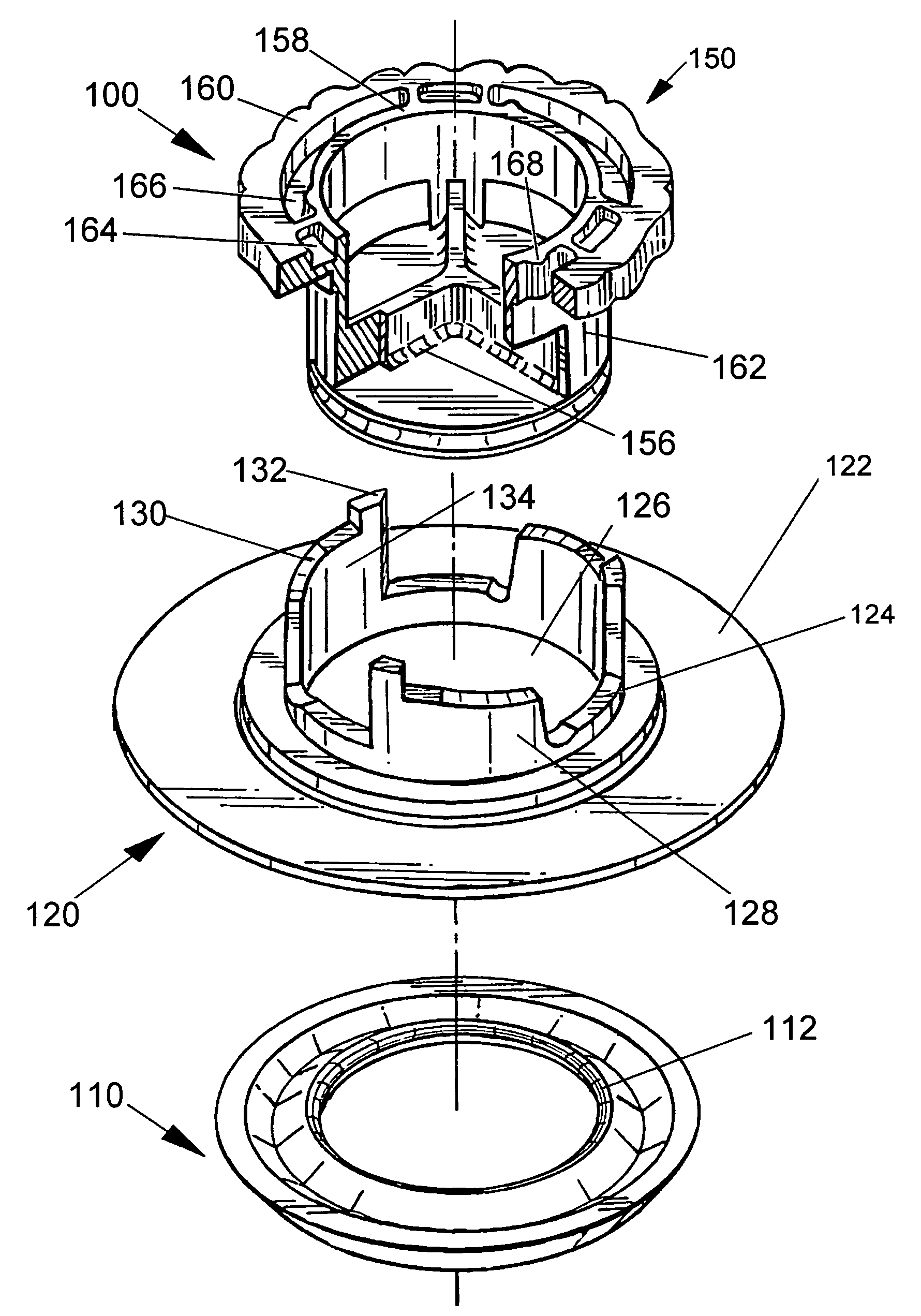

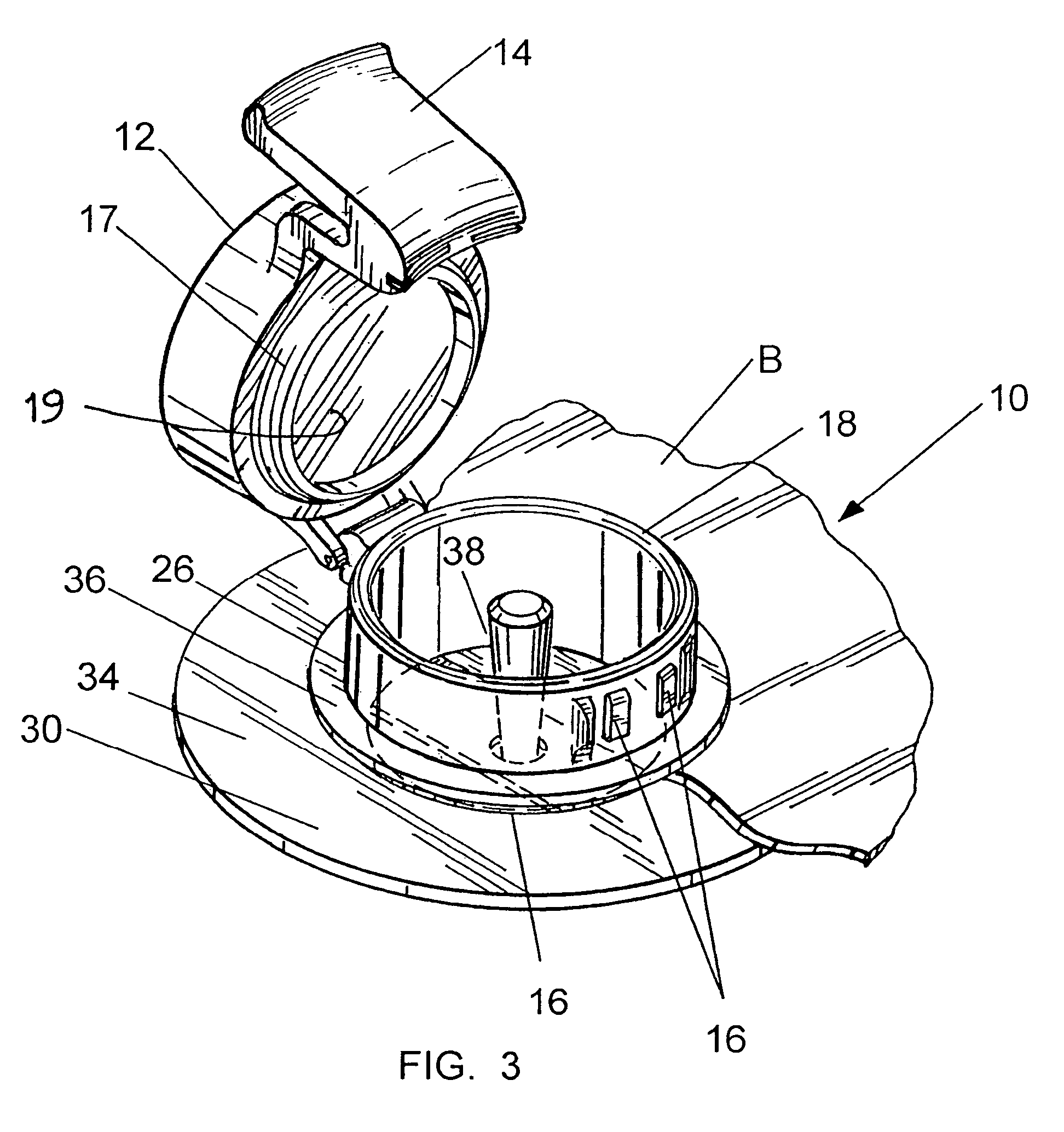

Inflation/deflation valve for cargo dunnage

InactiveUS7434594B1Facilitated releaseFunction increaseClosuresLiquid flow controllersDunnageEngineering

A valve assembly for a dunnage bag wherein in one embodiment of the valve a valve diaphragm is mounted on a shaft and is supported by a mounting bar such that the valve diaphragm may be reciprocally moved from the closed position to the open position by a simple axial push on the valve shaft. The valve shaft is retained in the mounting bar in an orifice and the shaft diameter is enlarged at its end distant from the valve diaphragm so as to generate a frictional force fit or lock in the open position to facilitate the removal of air from the bag. The valve may be released form the friction lock by the air pressure of a recharged bag and / or by the manual movement of the valve diaphragm and shaft axially toward the open end of the valve assembly. In an alternate embodiment, the valve diaphragm is mounted to a valve stem that it rotationally and axially moveably connected to the valve body. The valve may be frictionally locked in its open or closed position by rotation that valve stem no more than one quarter turn.

Owner:ROBBINS JAMES A +2

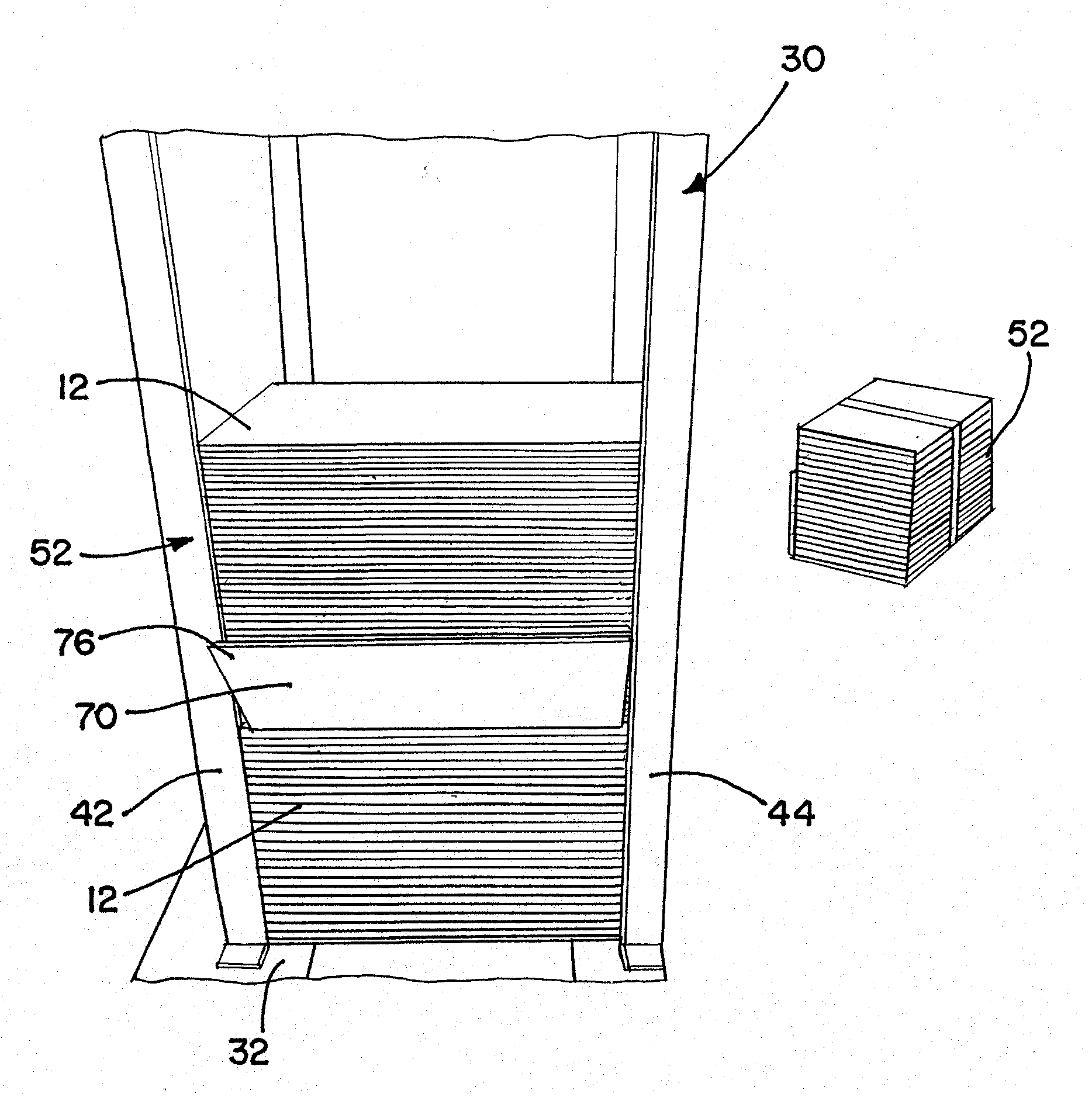

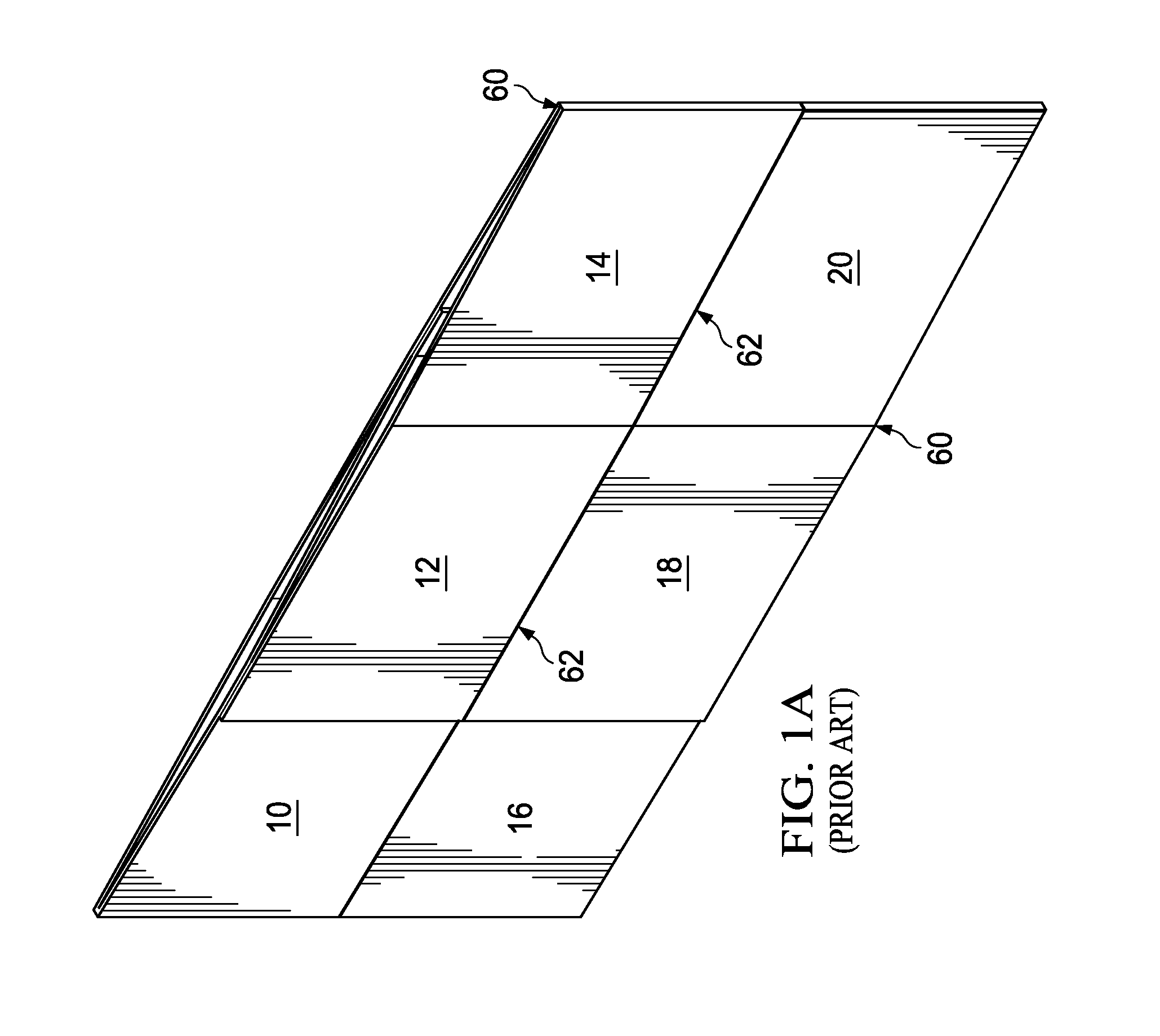

Carrier for a bundle of fan folded sheet material to be converted into dunnage

ActiveUS20150014205A1Low densityPrevent inwardly-folded cornerContainers for flexible articlesPaper/cardboard articlesDunnageSurface plate

A method of loading a stack of sheet stock material for use by a dunnage conversion machine, includes the following steps: (i) providing first and second stacks, the second stack being protected by a carrier having a central portion and longitudinally-spaced extensions that bound a central portion, the extensions and the central portion being joined along a weakened area defining a tear line, the central portion and the longitudinally-spaced extensions forming a planar bottom panel and a planar side panel, each panel extending substantially the length of the stack, and at a right angle to each other about a fold line over a bottom and an adjacent side of the stack, and one or more bale ties longitudinally inwardly of the tear lines holding the carrier to the stack; (ii) removing the extensions from the carrier; (iii) setting the second stack on top of the first stack; and (iv) removing the bale ties and the carrier, whereby an adhesive bonds the top page of the first stack to the bottom page of the second stack.

Owner:RANPAK CORP

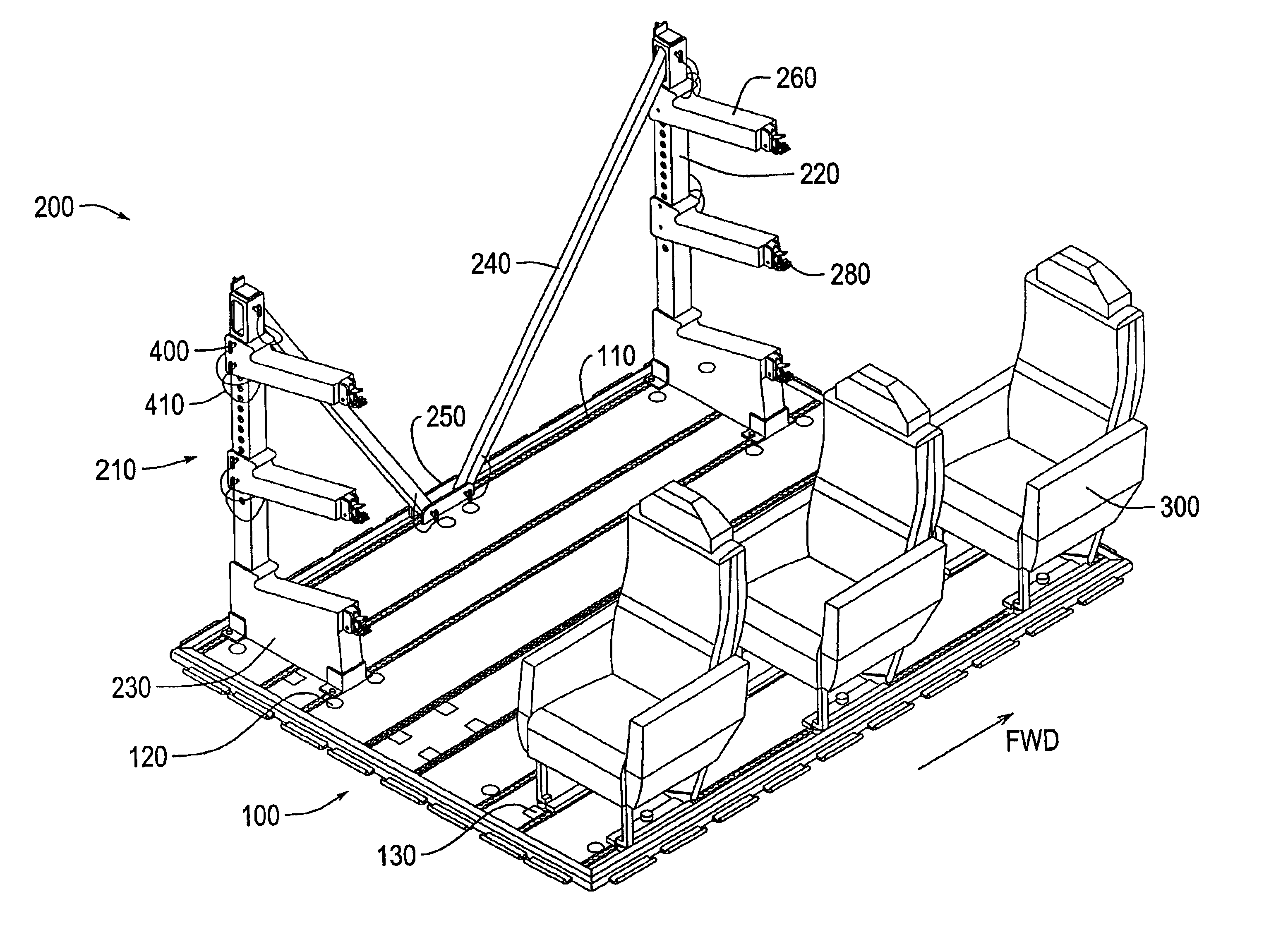

Container Having Dunnage With Integral Stabilizing Members

InactiveUS20080023470A1Easy and efficient transferUnnecessary lifting of the products is reduced and/or eliminatedLarge containersContainers to prevent mechanical damageDunnageEngineering

This invention provides a container for holding product therein during shipment and being returned for reuse that has a body including at least two side structures with support members attached thereto. Dunnage is suspended from the support members. The dunnage comprises a plurality of flexible members, at least some of the flexible members having stabilizers attached to the flexible member for stabilizing and protecting product being shipped. In one embodiment, tracks may be attached to opposite sides of the body, and support member assemblies extend between the tracks. Dunnage is suspended from the support member assemblies. Portions of the support member assemblies move in the tracks to move products suspended by the dunnage to a more ergonomically friendly position for loading or unloading.

Owner:BRADFORD CO

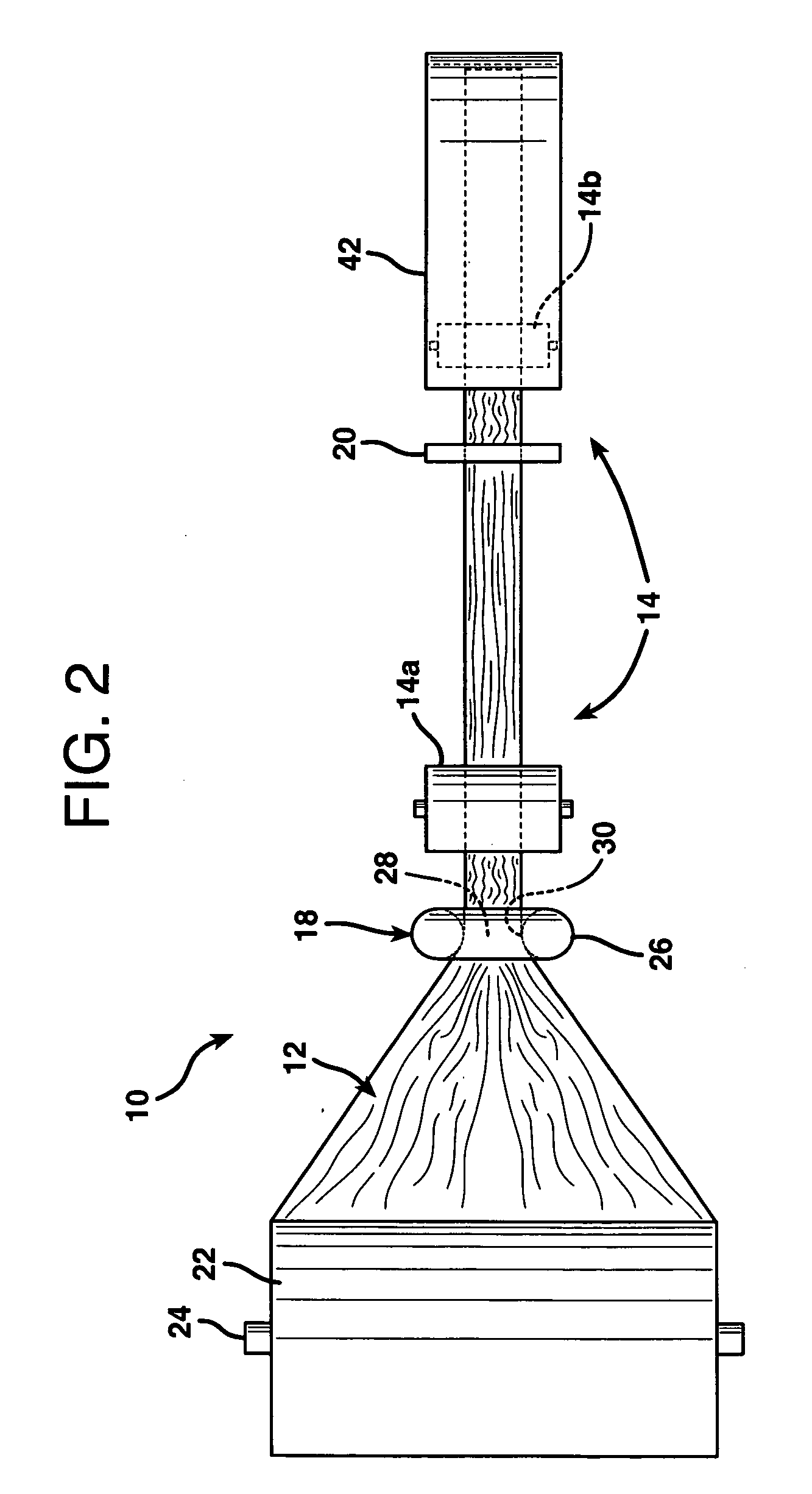

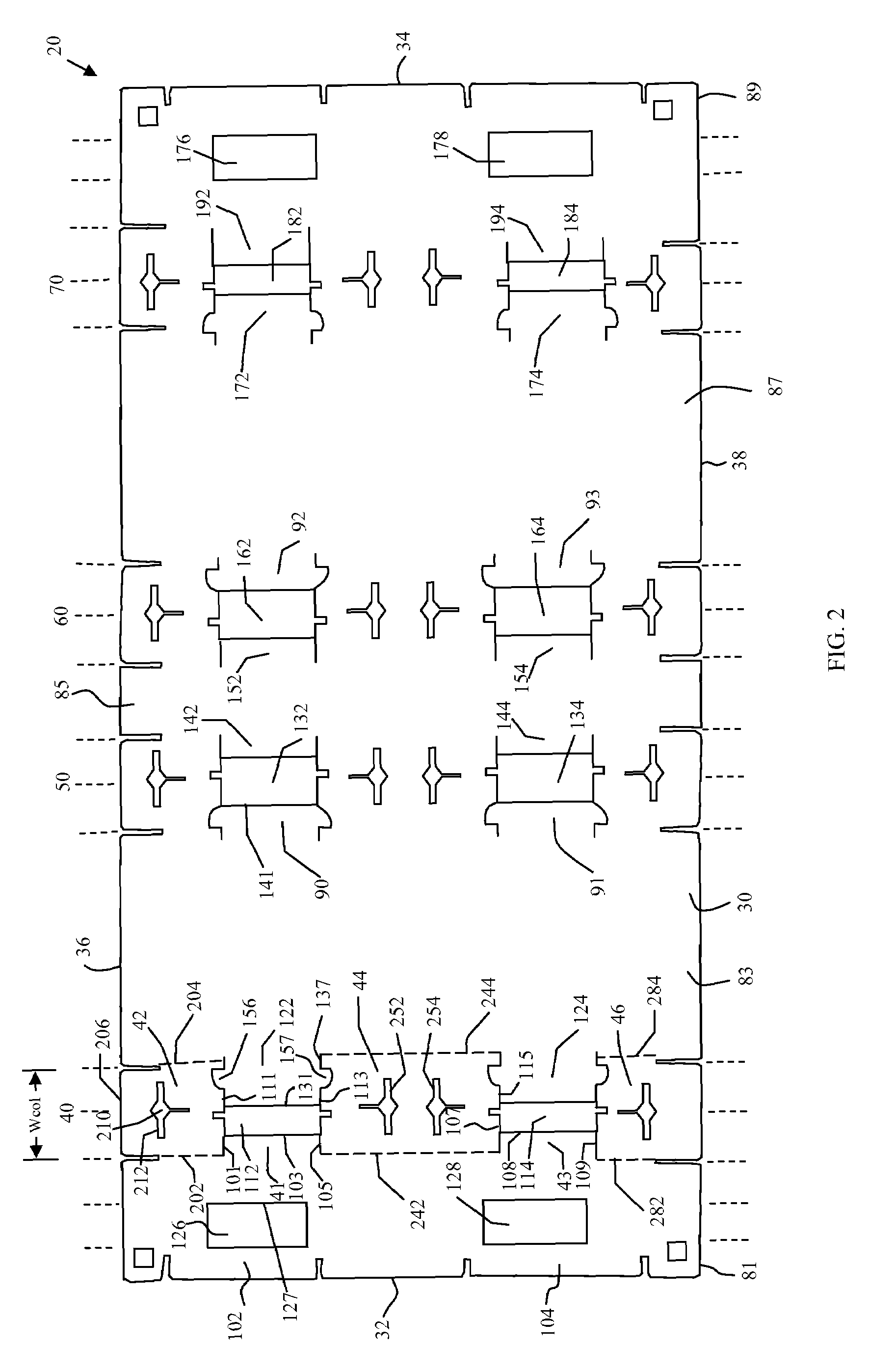

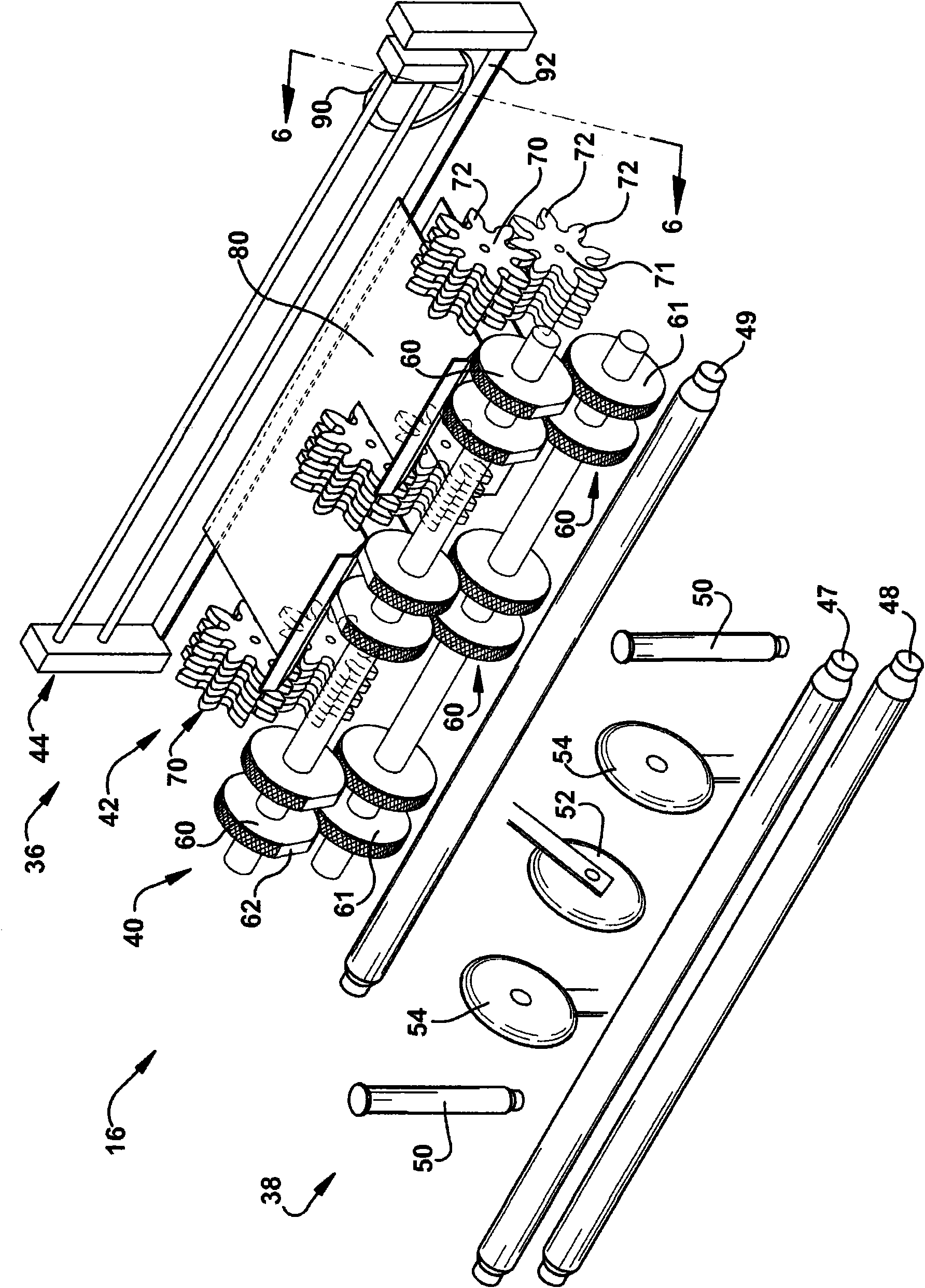

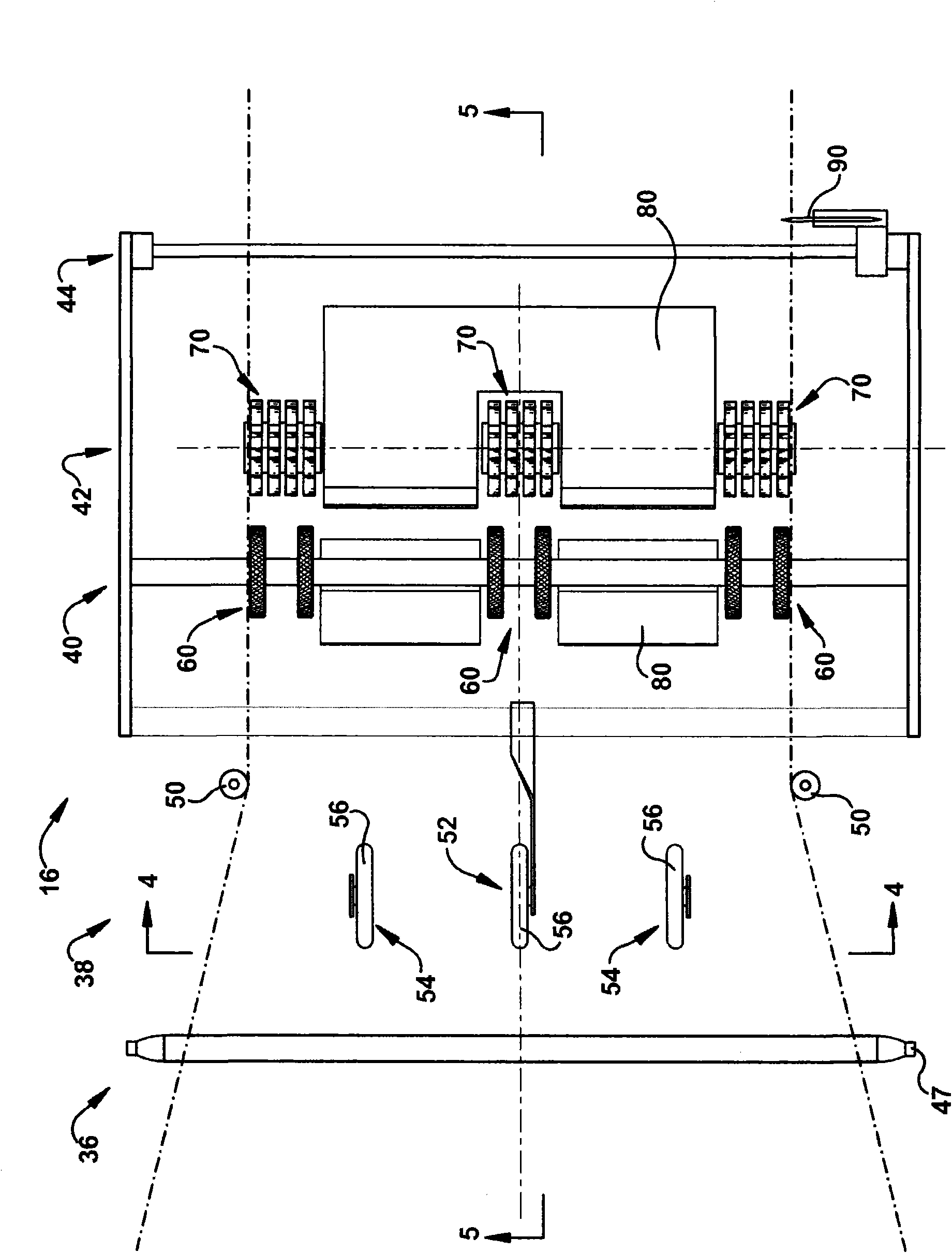

Dunnage conversion machine and method

A dunnage conversion machine (36) converts a sheet stock material into a dunnage product that is relatively thicker and less dense than the stock material, but is relatively thin and sufficiently flexible to function as a protective wrap. The conversion machine includes a feed mechanism (40) that advances a sheet stock material therethrough and a connecting mechanism (42) downstream of the feed mechanism. The connecting mechanism retards the passage of the sheet stock material therethrough by feeding the stock material therethrough at a slower rate than the feed mechanism feeds the stock material to the connecting mechanism. This causes the stock material to randomly crumple in a longitudinal space between the feed mechanism and the connecting mechanism. The connecting mechanism connects multiple overlapping layers of sheet stock material together as they pass therethrough, including connecting at least one crumpled sheet to one side of one other sheet.

Owner:RANPAK CORP

Container having non-linear support members for supporting dunnage

The present invention provides a container for holding product therein during shipment and being returned for reuse that has a body, tracks supported by the body, and a plurality of support member assemblies, each having a pair of end members engaged with and moveable along the tracks and a non-linear support member extending between and connected to the end members. The support member assemblies support dunnage for supporting products for storage or shipment.

Owner:BRADFORD CO

Packaging System

ActiveUS20160046404A1Easy to reconfigureOptimizationRigid containersInternal fittingsCardboardDunnage

A packaging system for a corrugated cardboard shipping container. The system uses two vertical compartmented inserts divided by a horizontal insert. The compartmented insert can be configured by a packer to consist of four to two rectangular compartments. The horizontal insert can be folded in half or have a quarter section folded away in order to accommodate a loading plan that requires items to protrude above the height of the bottom vertical compartmented insert. An optional diagonal divider and dunnage may be used prior to sealing the container.

Owner:PEPSICO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com