Dunnage conversion machine and method

A technology of converting machine and dunnage, which is applied in the field of dunnage converting machine for dunnage products, which can solve the problems of speed limitation, environmental harm, slow process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

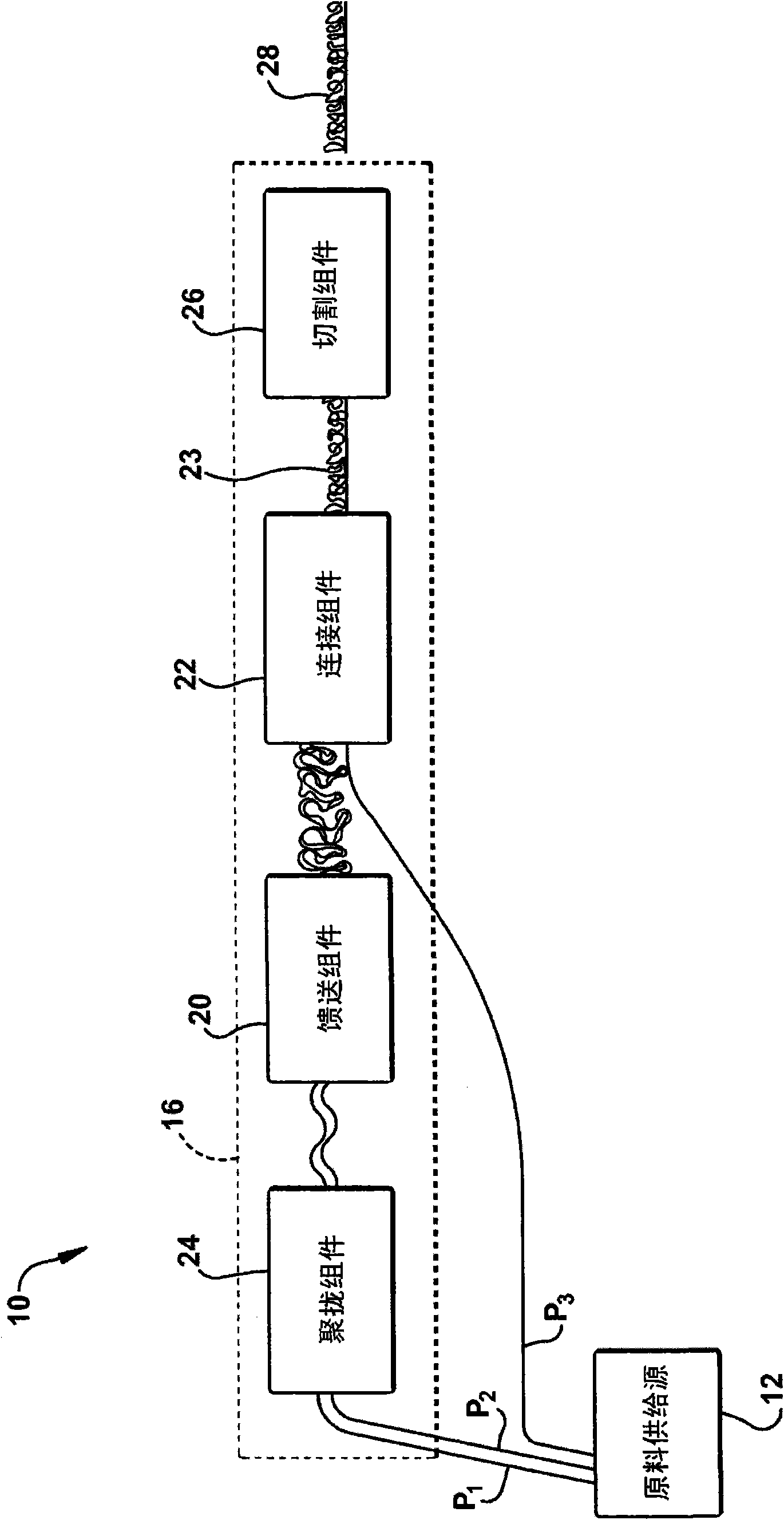

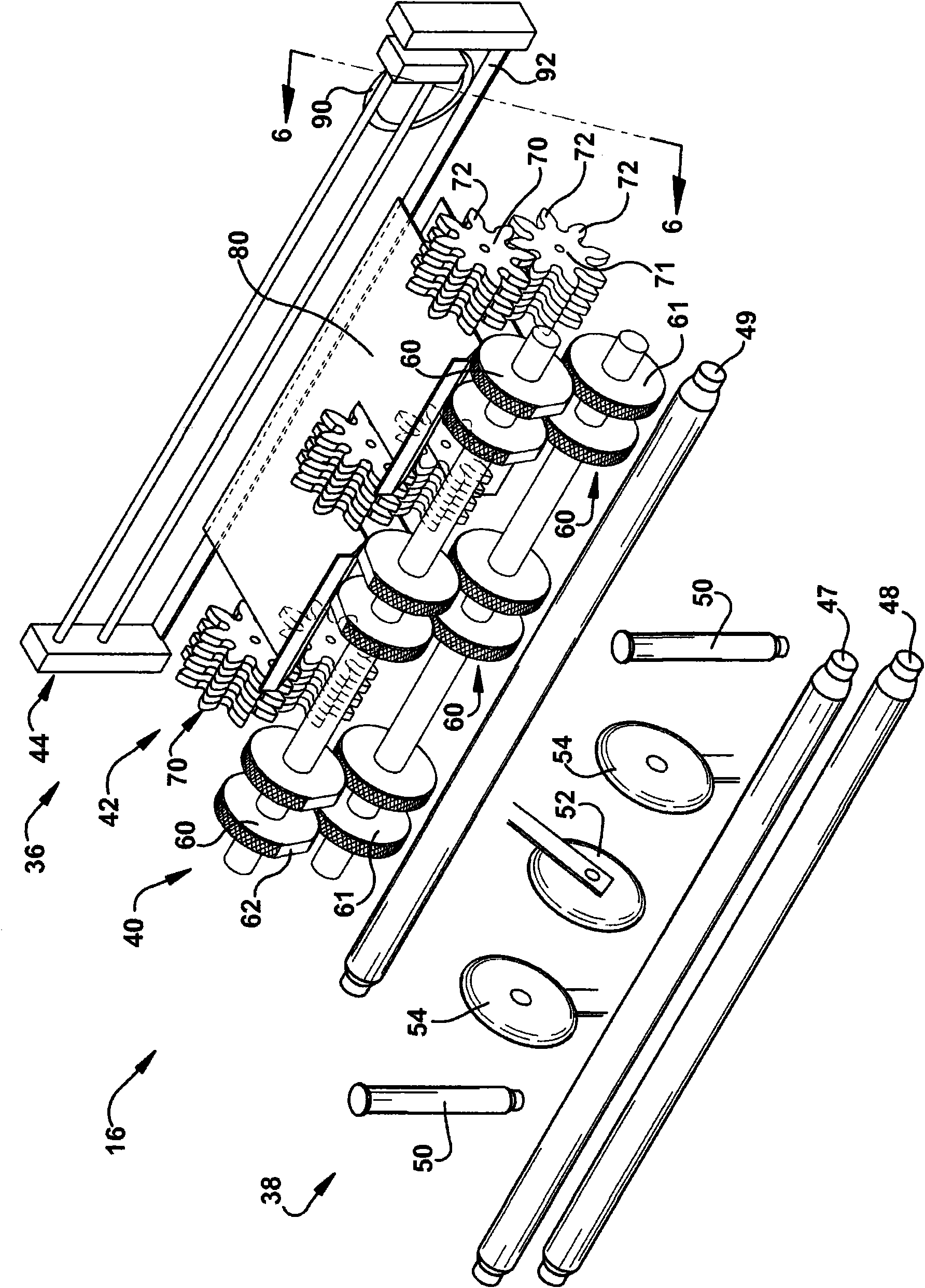

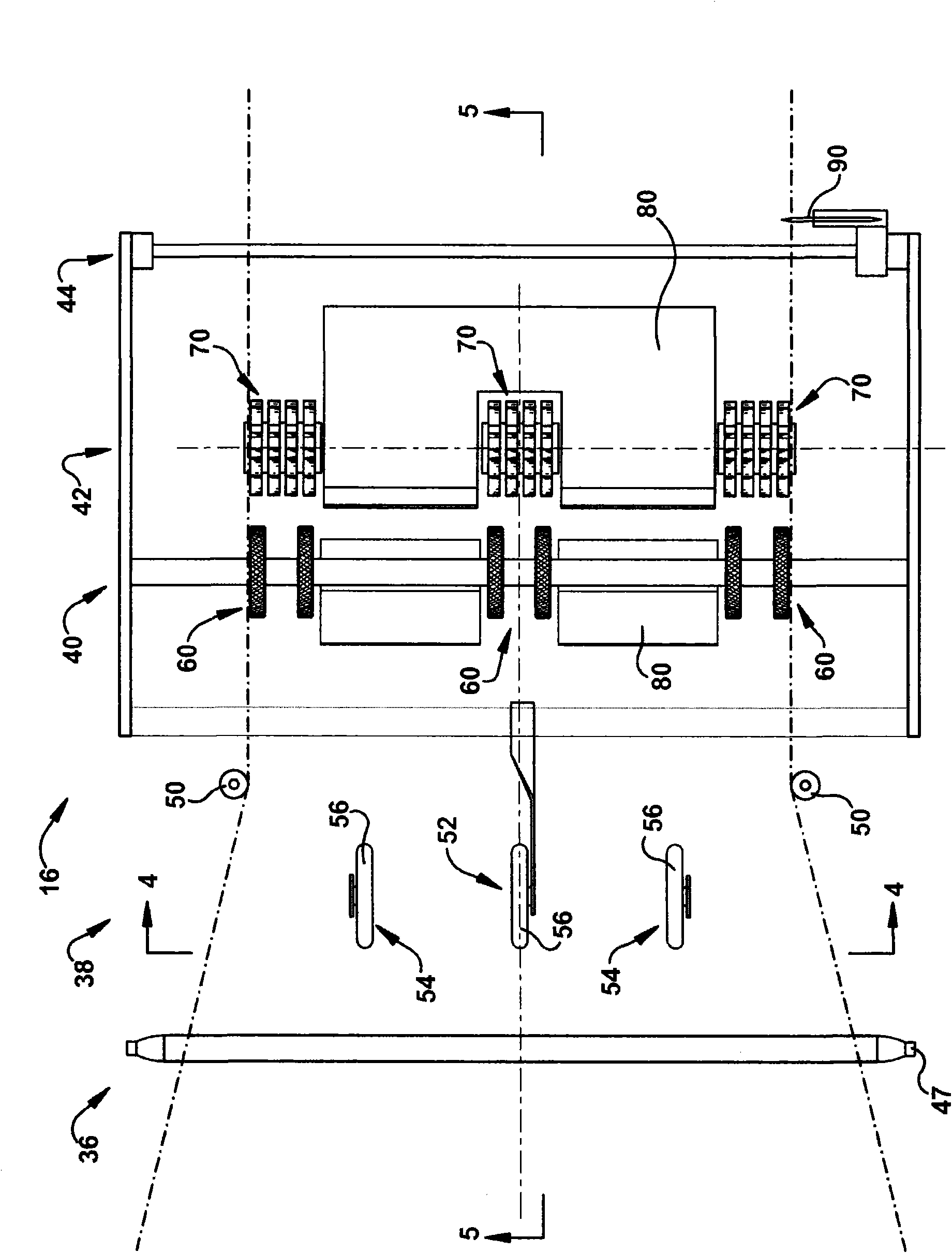

[0068] The present invention provides a dunnage conversion machine and method for forming sheet stock material into packable dunnage products, as well as a stock supply assembly and output chute for the dunnage conversion machine and corresponding method.

[0069] Packable dunnage

[0070] The present invention provides a packable dunnage product, a dunnage converter for converting a sheet stock material into a packable dunnage product, and a packable dunnage product for making a packable dunnage product that is relatively thicker and looser than the stock material. The corresponding method for the litter product. In particular, the present invention provides a multi-ply dunnage product having sufficient flexibility and thickness to be used as a protective layer or wrap. At least one ply of the dunnage product comprises a randomly creased web or sheet. Randomly creasing at least one sheet provides cushioning properties to the dunnage package. The crumpled sheet or sheets ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com