Patents

Literature

508126 results about "Raw material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A raw material, also known as a feedstock, unprocessed material, or primary commodity, is a basic material that is used to produce goods, finished products, energy, or intermediate materials which are feedstock for future finished products. As feedstock, the term connotes these materials are bottleneck assets and are highly important with regard to producing other products. An example of this is crude oil, which is a raw material and a feedstock used in the production of industrial chemicals, fuels, plastics, and pharmaceutical goods; lumber is a raw material used to produce a variety of products including all types of furniture. The term "raw material" denotes materials in minimally processed or unprocessed in states; e.g., raw latex, crude oil, cotton, coal, raw biomass, iron ore, air, logs, or water i.e. "any product of agriculture, forestry, fishing and any other mineral that is in its natural form or which has undergone the transformation required to prepare it for internationally marketing in substantial volumes."

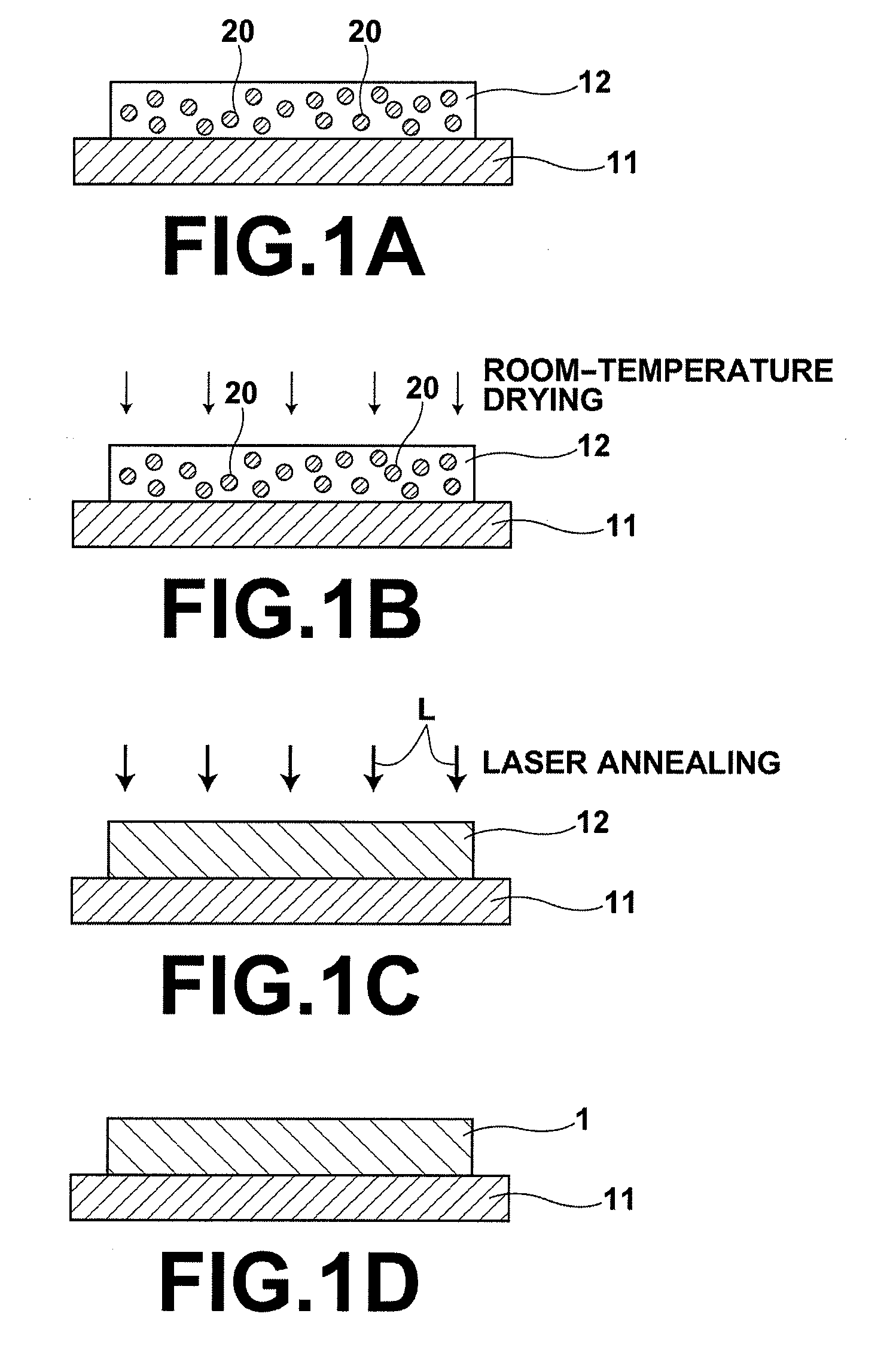

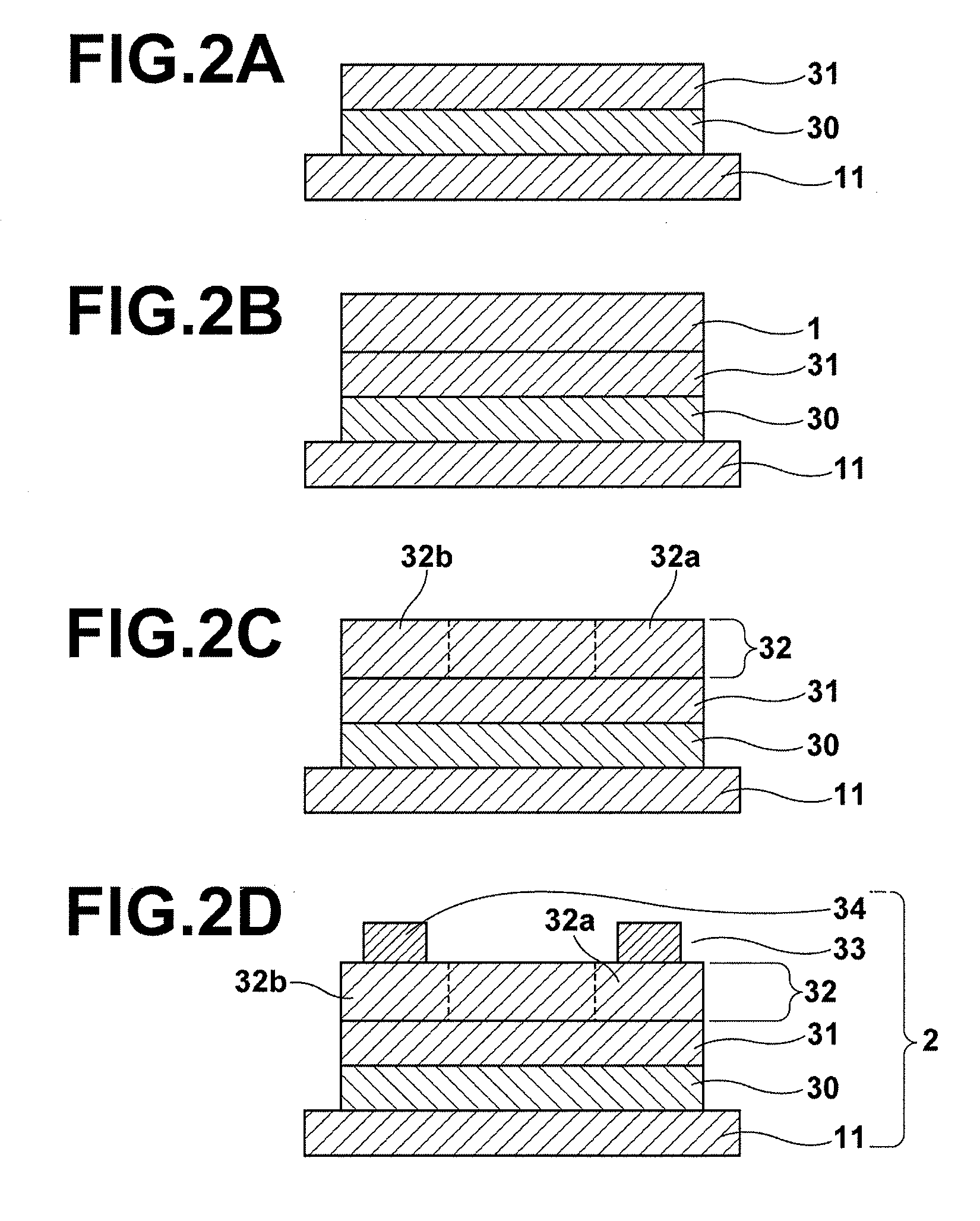

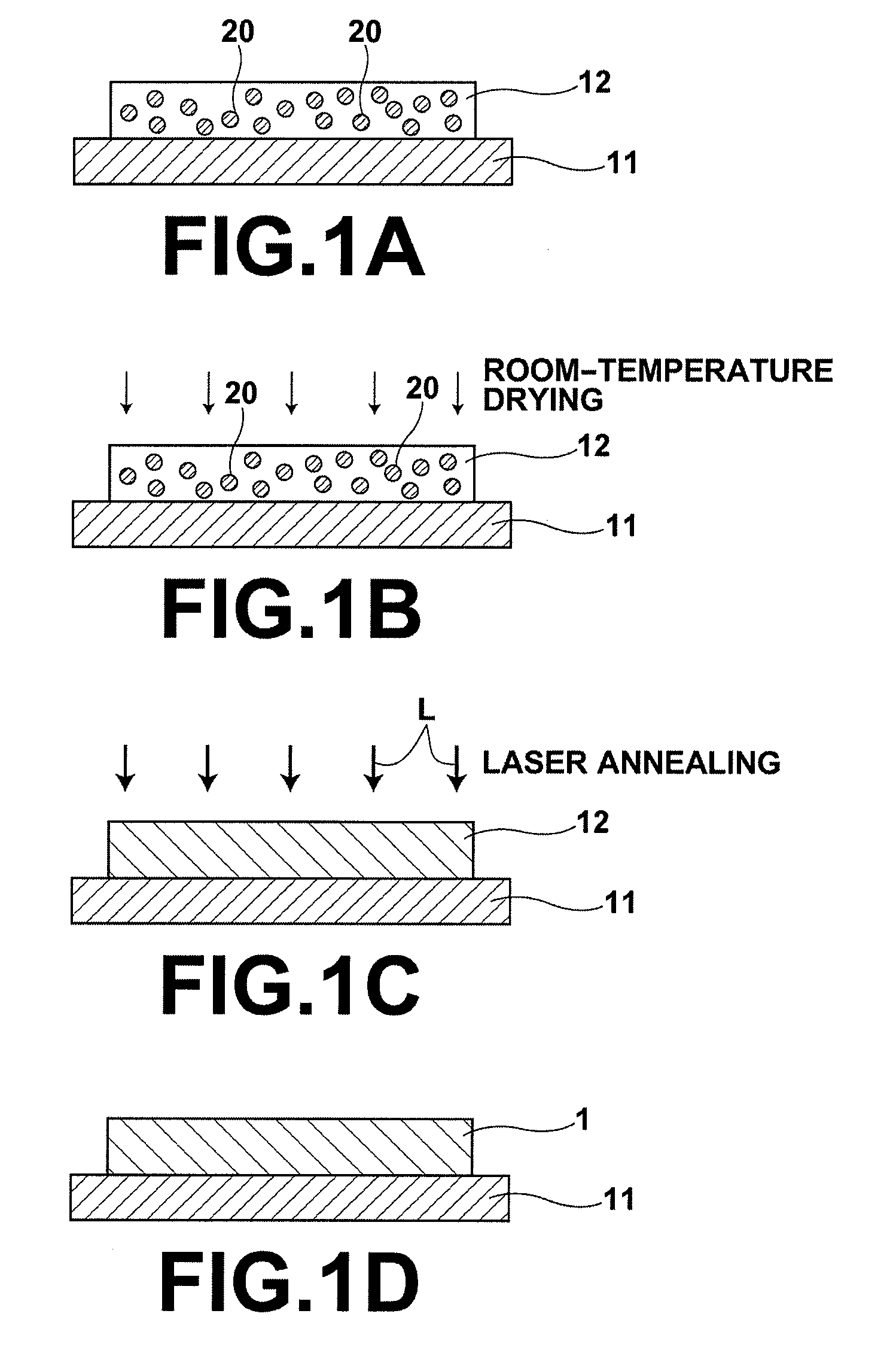

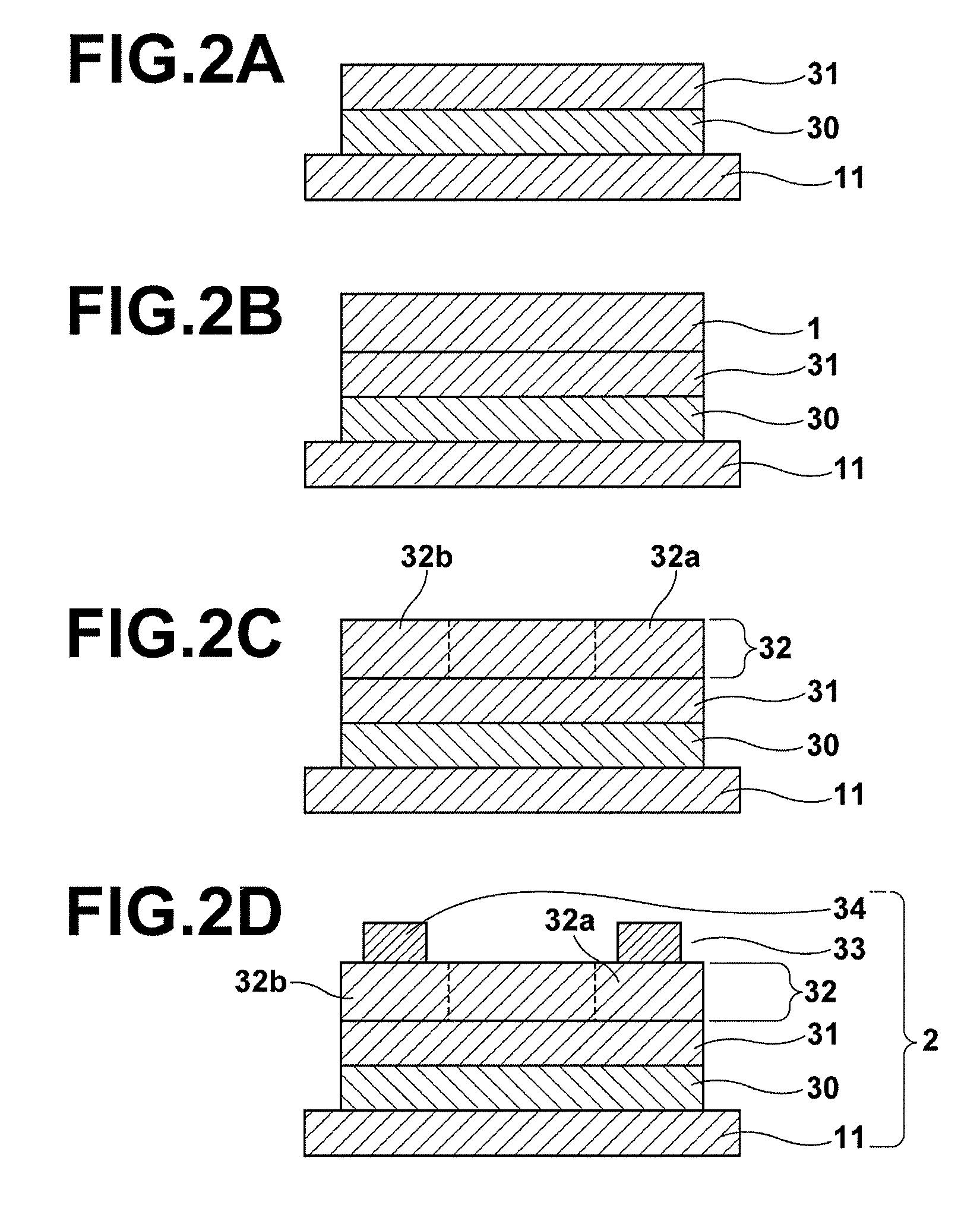

Process for producing oriented inorganic crystalline film, and semiconductor device using the oriented inorganic crystalline film

ActiveUS20090152506A1Orientation can be controlledLow costFrom gel stateFrom solid stateOrganic solventDevice material

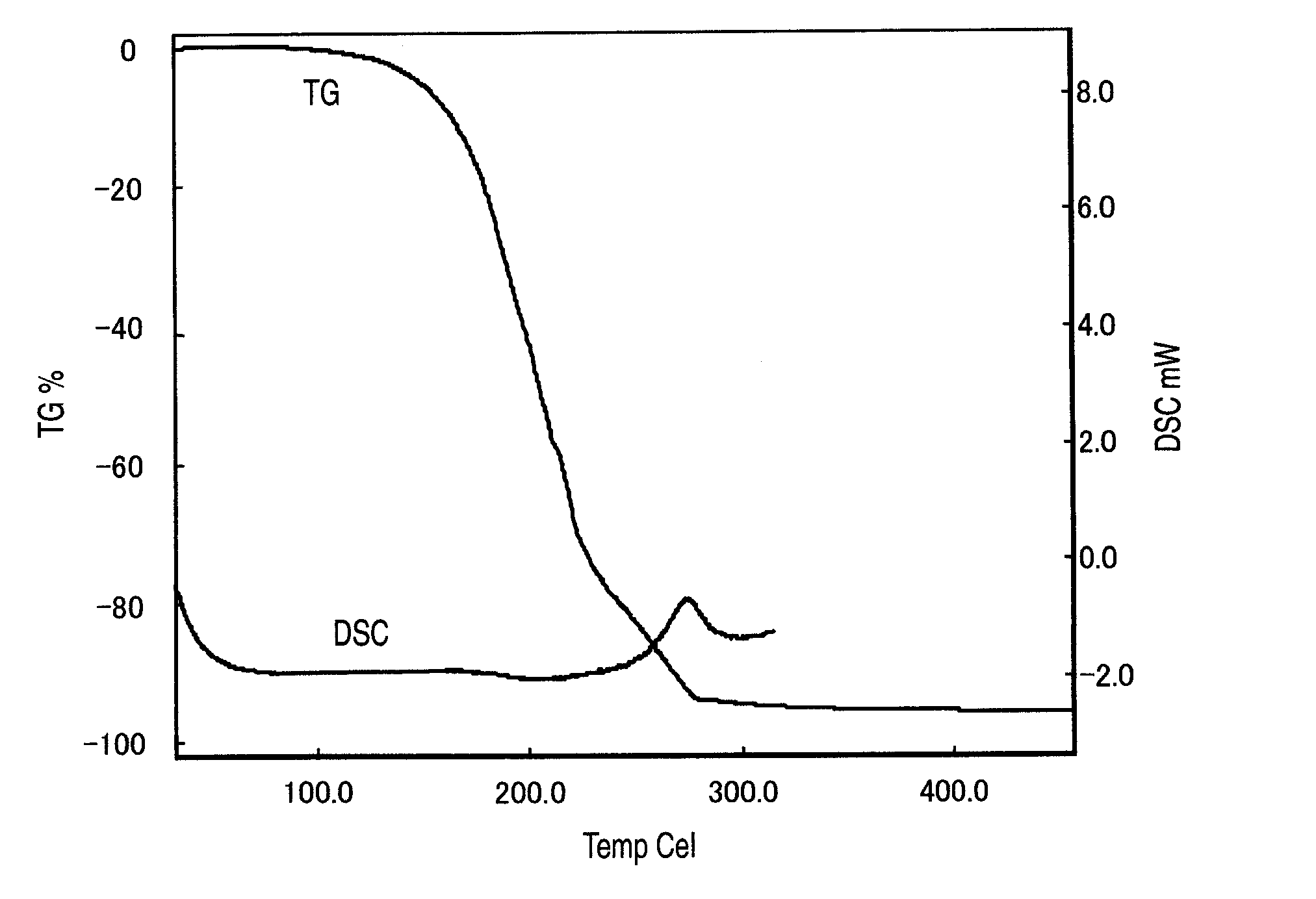

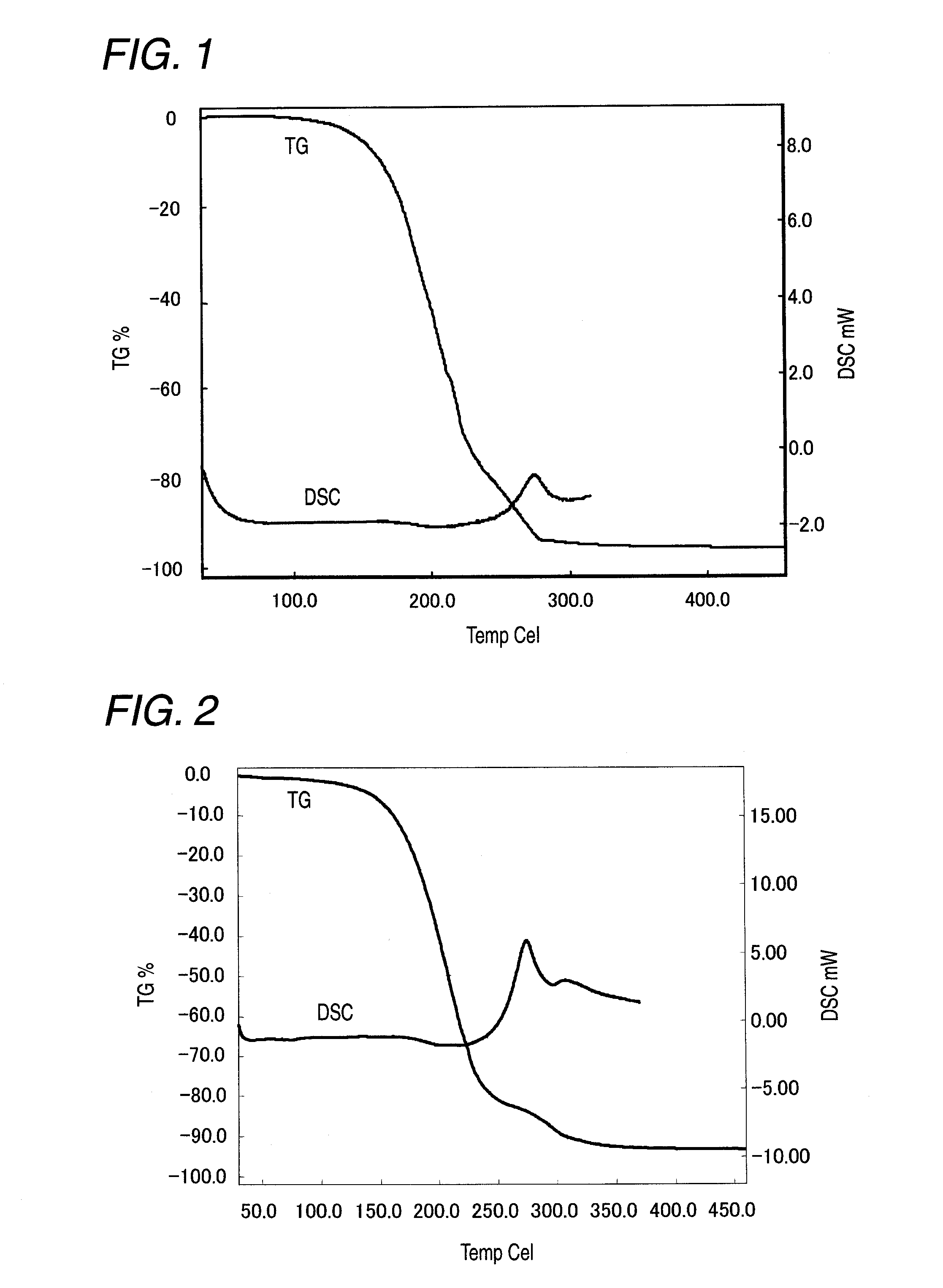

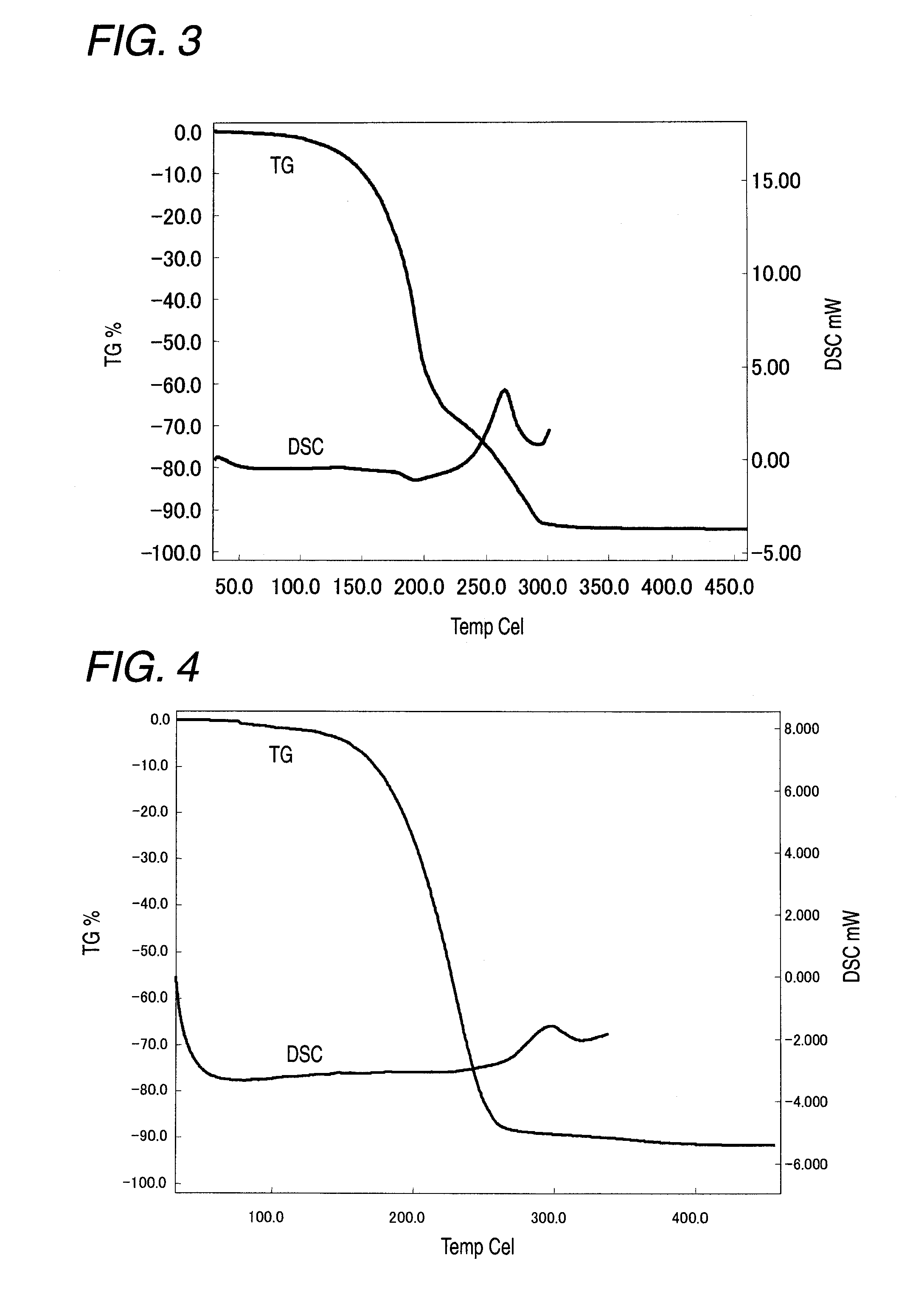

In a process for producing an oriented inorganic crystalline film, a non-monocrystalline film containing inorganic crystalline particles is formed on a substrate by a liquid phase technique using a raw-material solution which contains a raw material and an organic solvent, where the inorganic crystalline particles have a layered crystal structure and are contained in the raw material. Then, the non-monocrystalline film is crystallized by heating the non-monocrystalline film to a temperature equal to or higher than the crystallization temperature of the non-monocrystalline film so that part of the inorganic crystalline particles act as crystal nuclei.

Owner:FUJIFILM CORP

Process for producing oriented inorganic crystalline film, and semiconductor device using the oriented inorganic crystalline film

ActiveUS8202365B2Orientation can be controlledLow costFrom gel stateFrom solid stateOrganic solventCrystal structure

In a process for producing an oriented inorganic crystalline film, a non-monocrystalline film containing inorganic crystalline particles is formed on a substrate by a liquid phase technique using a raw-material solution which contains a raw material and an organic solvent, where the inorganic crystalline particles have a layered crystal structure and are contained in the raw material. Then, the non-monocrystalline film is crystallized by heating the non-monocrystalline film to a temperature equal to or higher than the crystallization temperature of the non-monocrystalline film so that part of the inorganic crystalline particles act as crystal nuclei.

Owner:FUJIFILM CORP

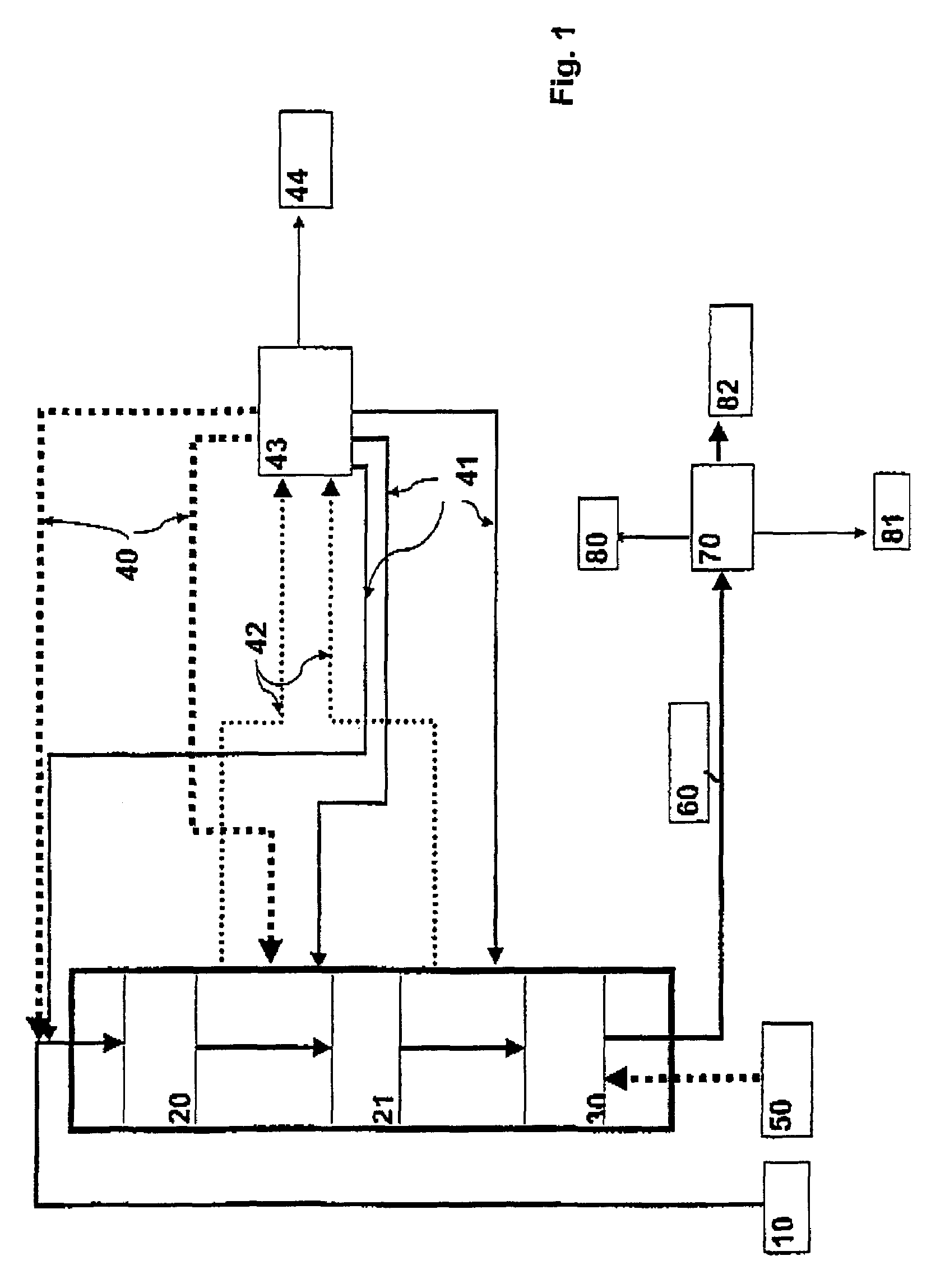

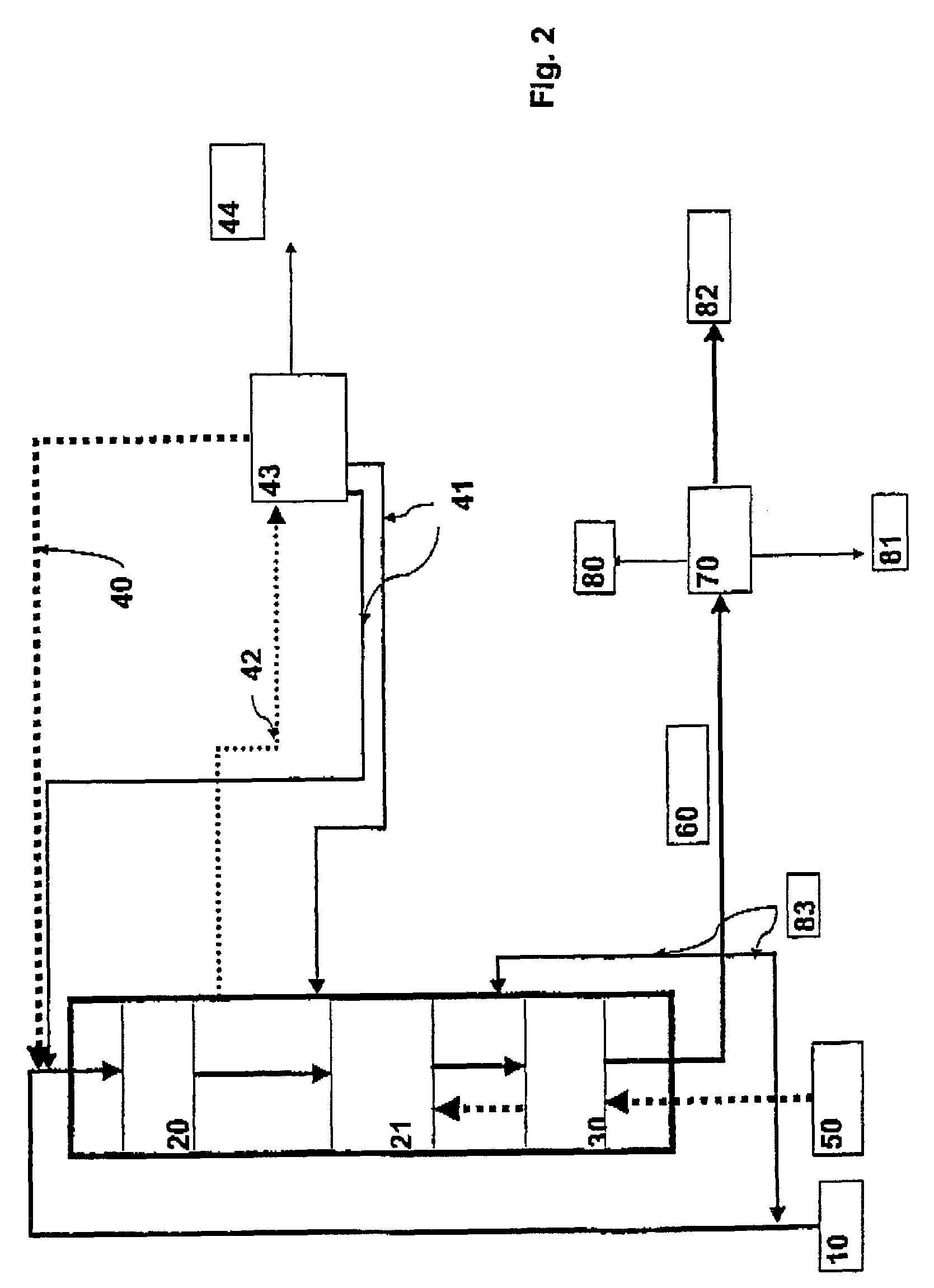

Process for producing a hydrocarbon component of biological origin

ActiveUS20040230085A1Improve performanceLow densityLiquid hydrocarbon mixture productionHydrocarbonsIsomerizationHydrocarbon

The invention relates to a process for producing a hydrocarbon component of biological origin. The process comprises at least two steps, the first one of which is a HDO step and the second one is an isomerization step operated using the counter-current flow principle. A biological raw material containing fatty acids and / or fatty acid esters serves as the feed stock.

Owner:OYJ NESTE OIL +1

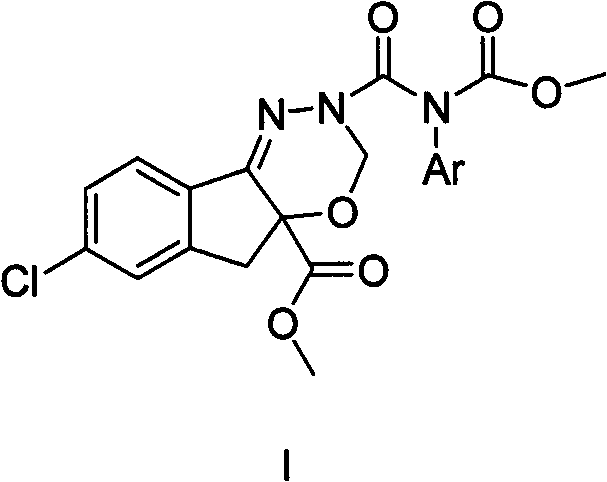

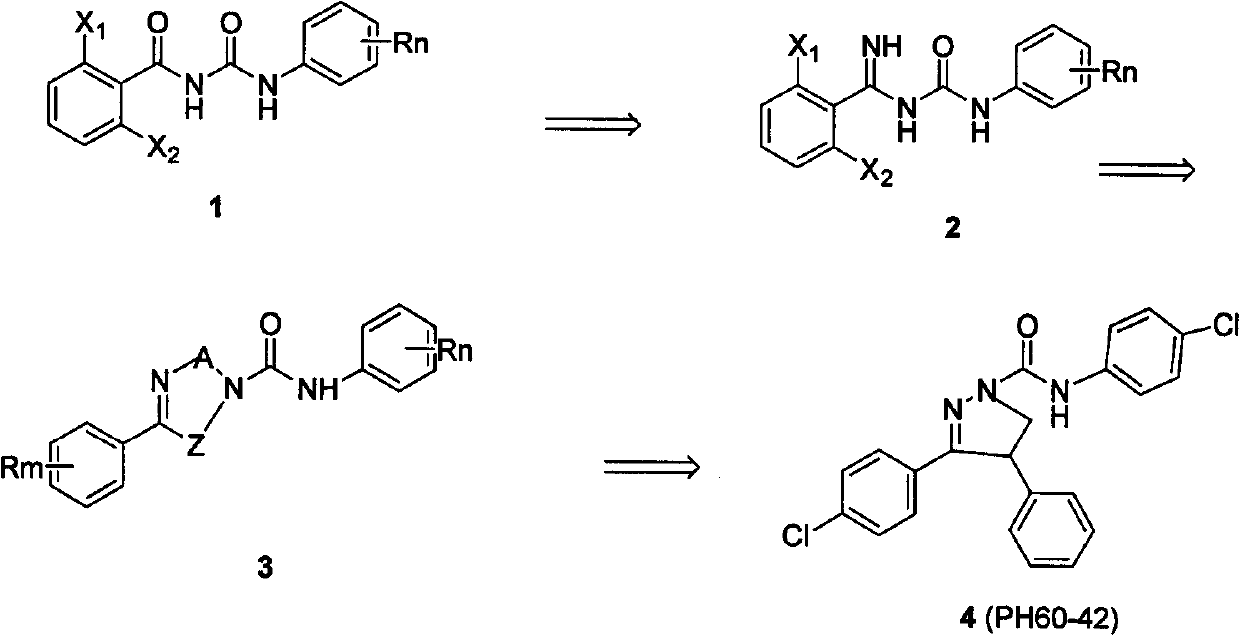

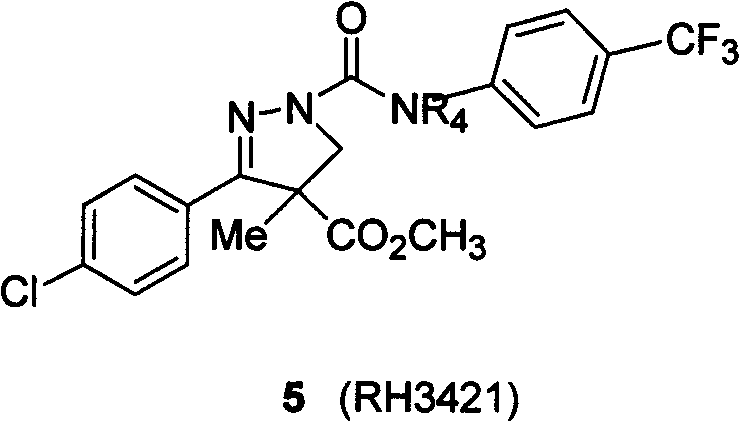

N-substituted dioxazine compound as well as preparation method and application thereof

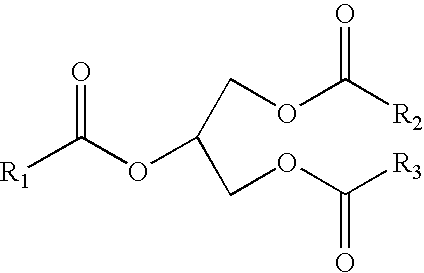

The invention relates to an N-substituted dioxazine compound as well as a preparation method and application thereof. The N-substituted dioxazine compound has the following chemical structure general formula (I), wherein Ar in the chemical structure general formula (I) is a benzene ring, a naphthalene ring, and a pyridine or pyrimidine ring system. The compound is prepared with the following two steps: (1) taking 2-(benzyl)-7-benzindene[1,2-e][1,3-4] dioxazine-2,4a(3H,5H)-dicarboxylic acid-4a-methoxycarbonyl group and hydrogen as raw materials, taking Pd / C in solvent a as catalyst a, and carrying out hydrogenation, thus obtaining an intermediate B after reaction is finished; (2) taking (carbonylchloride) (aryl) methyl carhamate as the intermediate C, and carrying out (carbonylchloride) (aryl) methyl carhamate with the intermediate B obtained in the step (1) in the presence of a catalyst b in the solvent b; and obtaining the product N-substituted dioxazine compound. Compared with the prior art, the insecticidalactivity on the armyworm by the N-substituted dioxazine compound is 80-100%.

Owner:SHANGHAI JIAO TONG UNIV +1

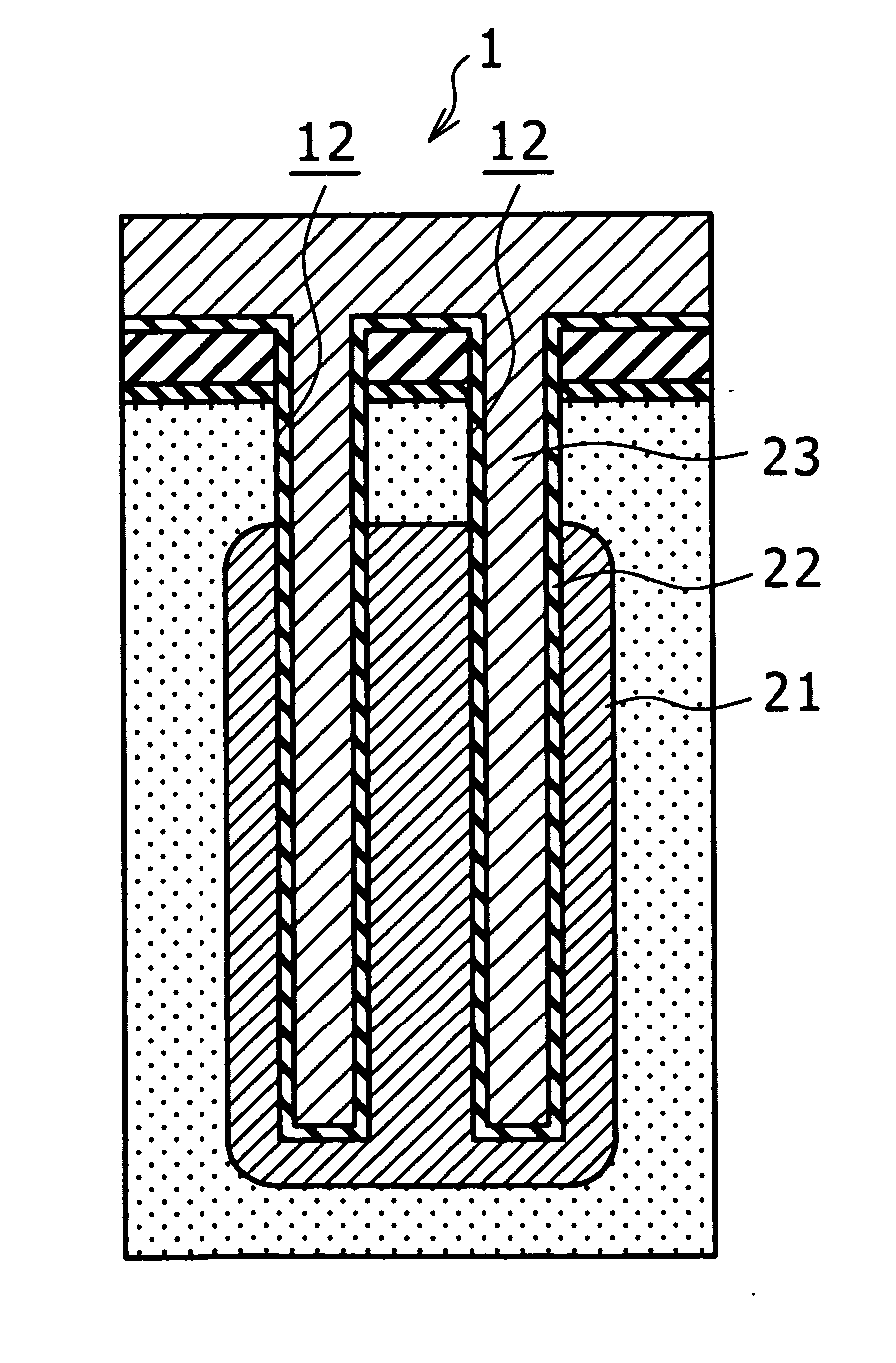

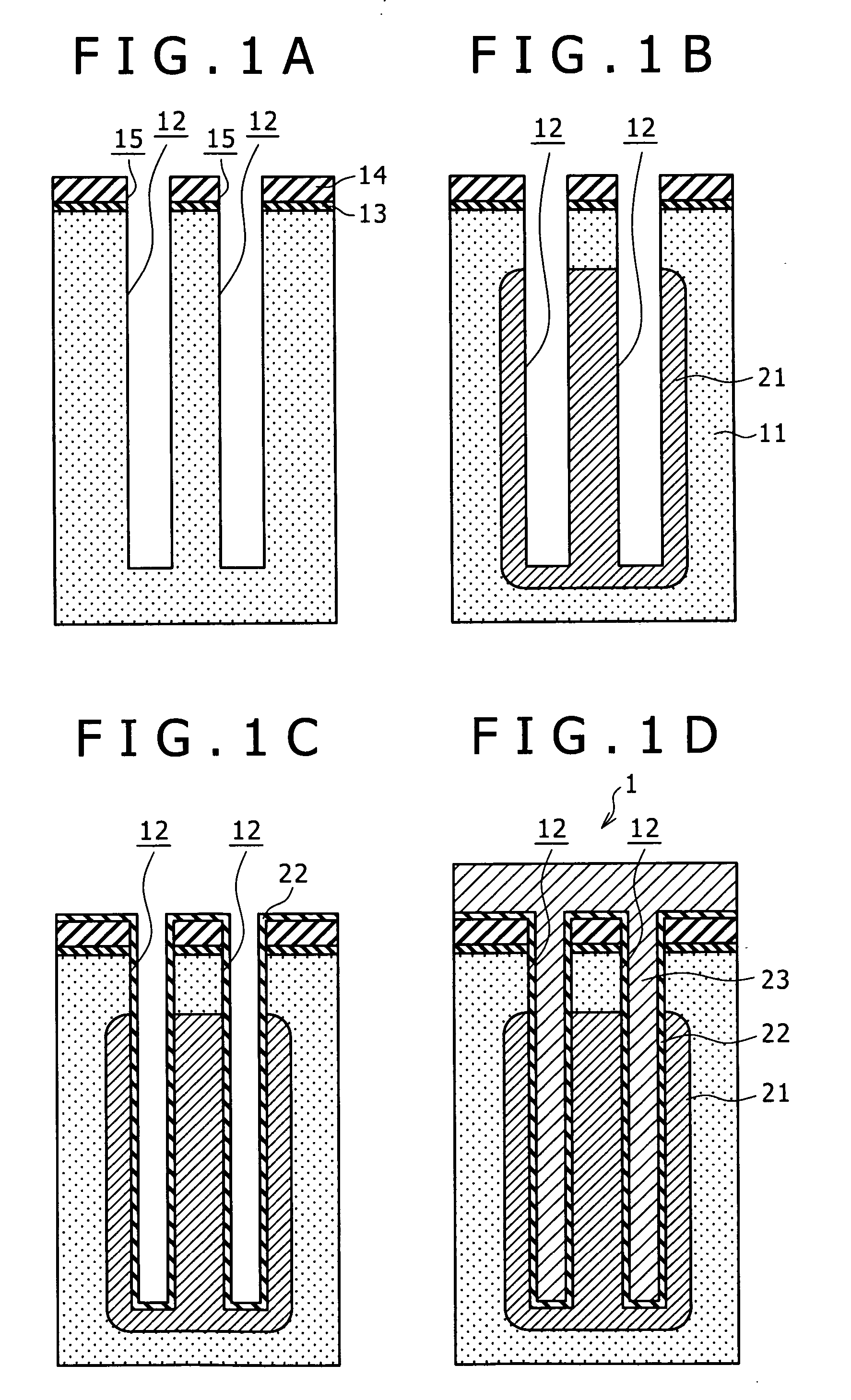

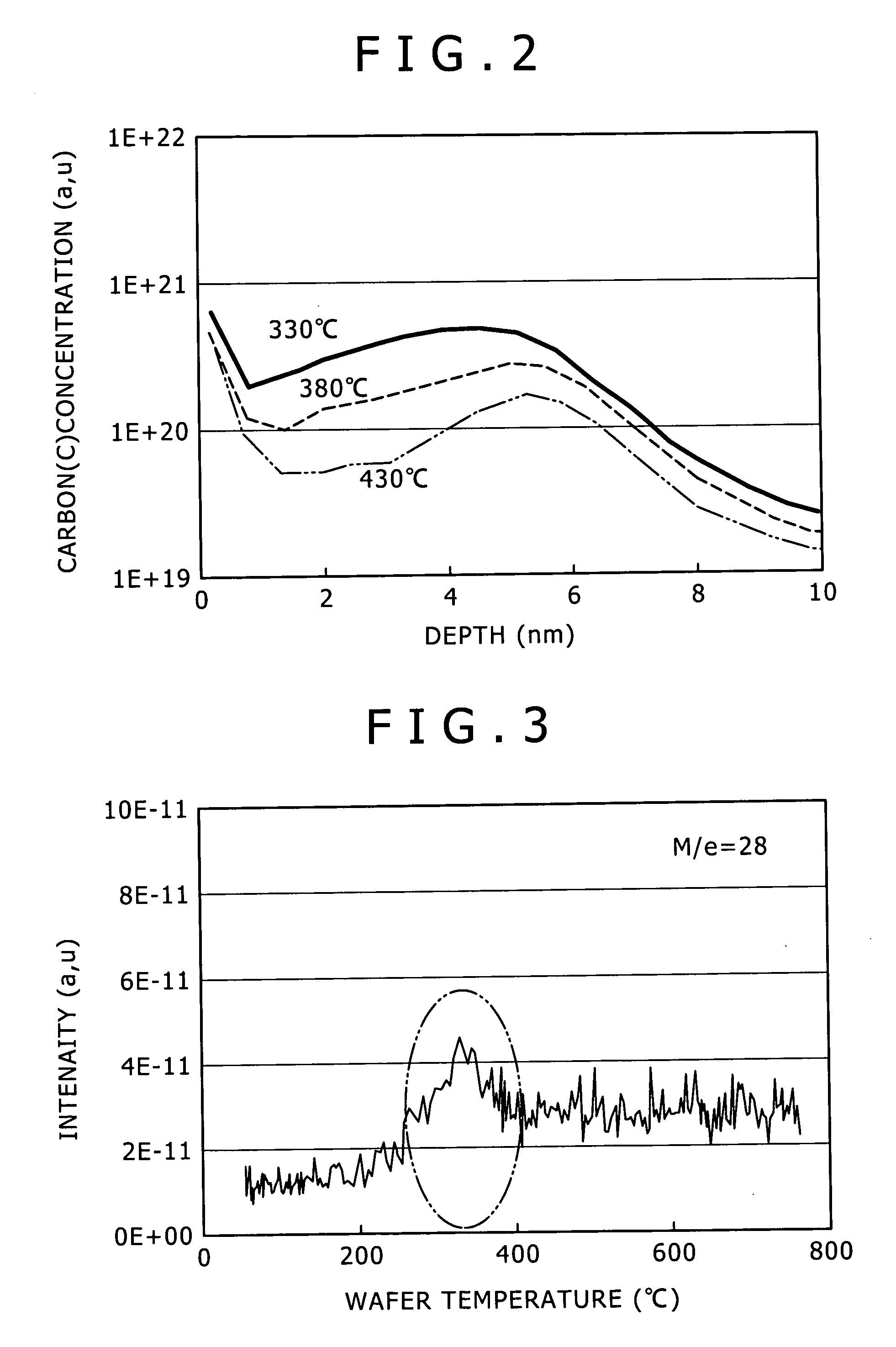

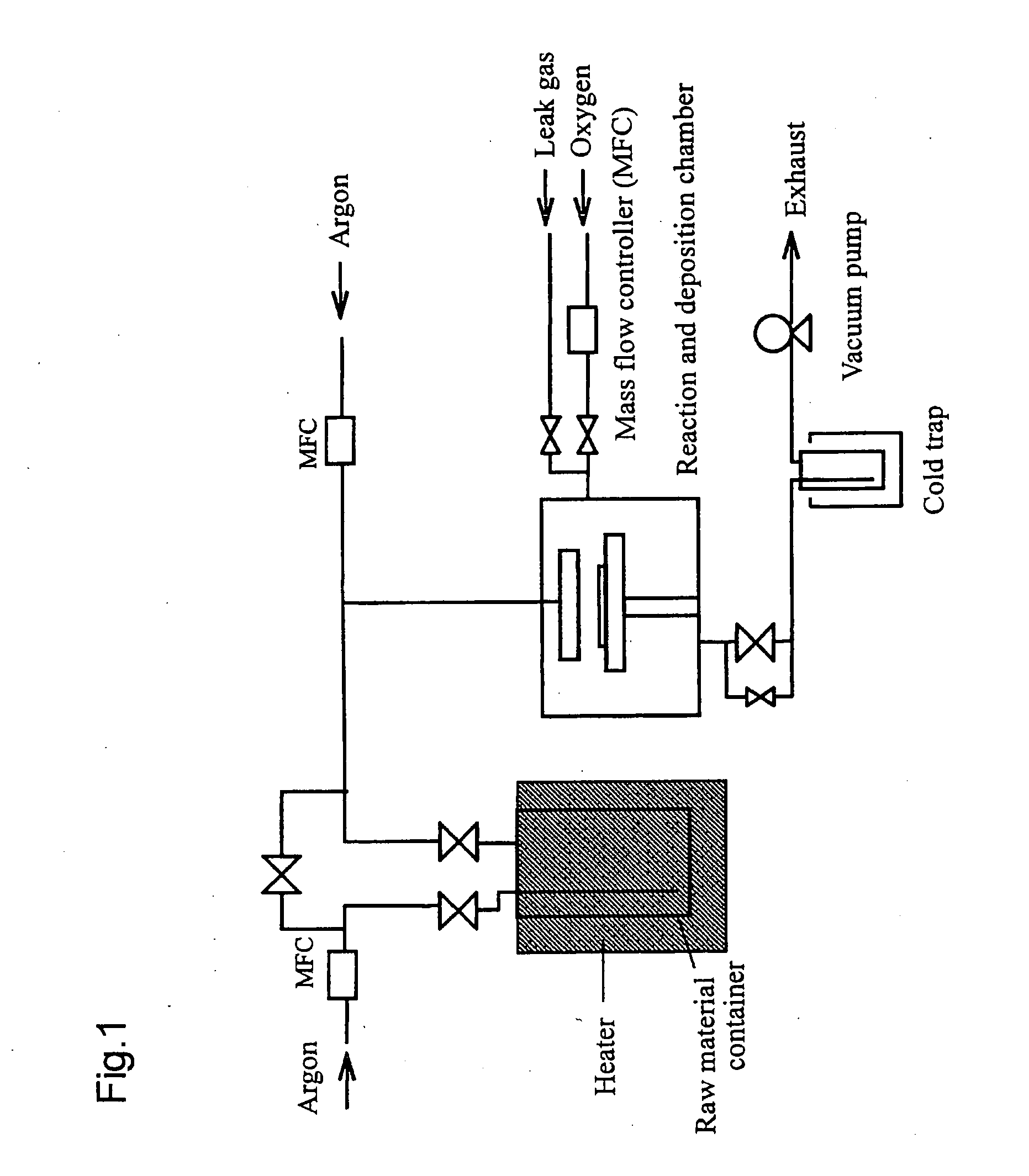

Method of manufacturing semiconductor device

InactiveUS20070066010A1Good step coverageReduce leakage levelTransistorSolid-state devicesDevice materialEvaporation

The invention aims at enabling leakage current characteristics and a step coverage property to be improved by depositing a hafnium silicate film by utilizing an atomic layer evaporation method using a hafnium raw material, a silicon raw material and an oxidizing agent. Disclosed herein is a method of manufacturing a semiconductor device having a trench capacitor including a first electrode formed on an inner surface of a trench, a capacitor insulating film formed on a surface of the first electrode, and a second electrode formed on a surface of the capacitor insulating film. The method includes the step of depositing the capacitor insulating film in a form of a hafnium silicate film by utilizing an atomic layer deposition method using a hafnium raw material, a silicon raw material and an oxidizing agent.

Owner:SONY CORP

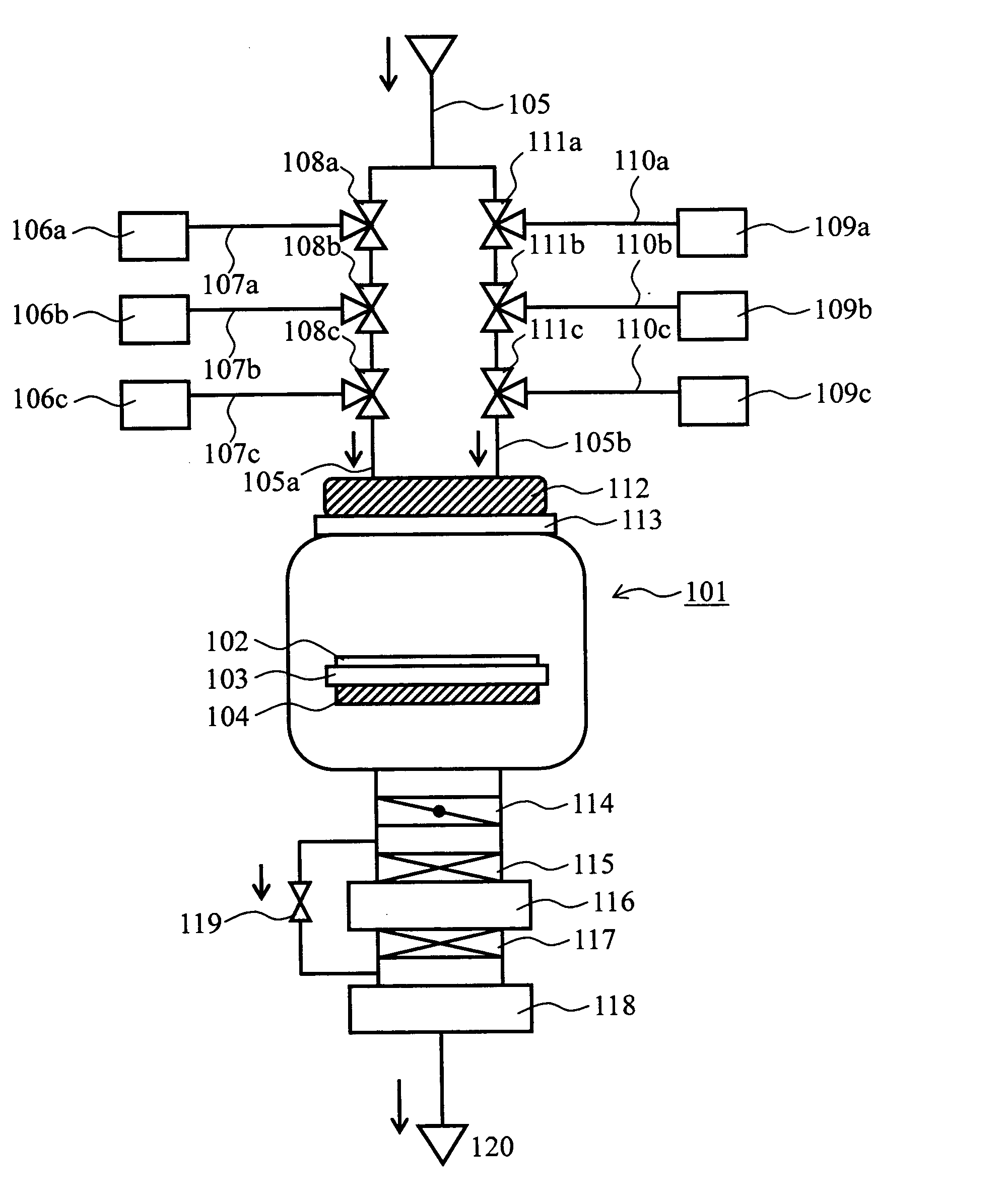

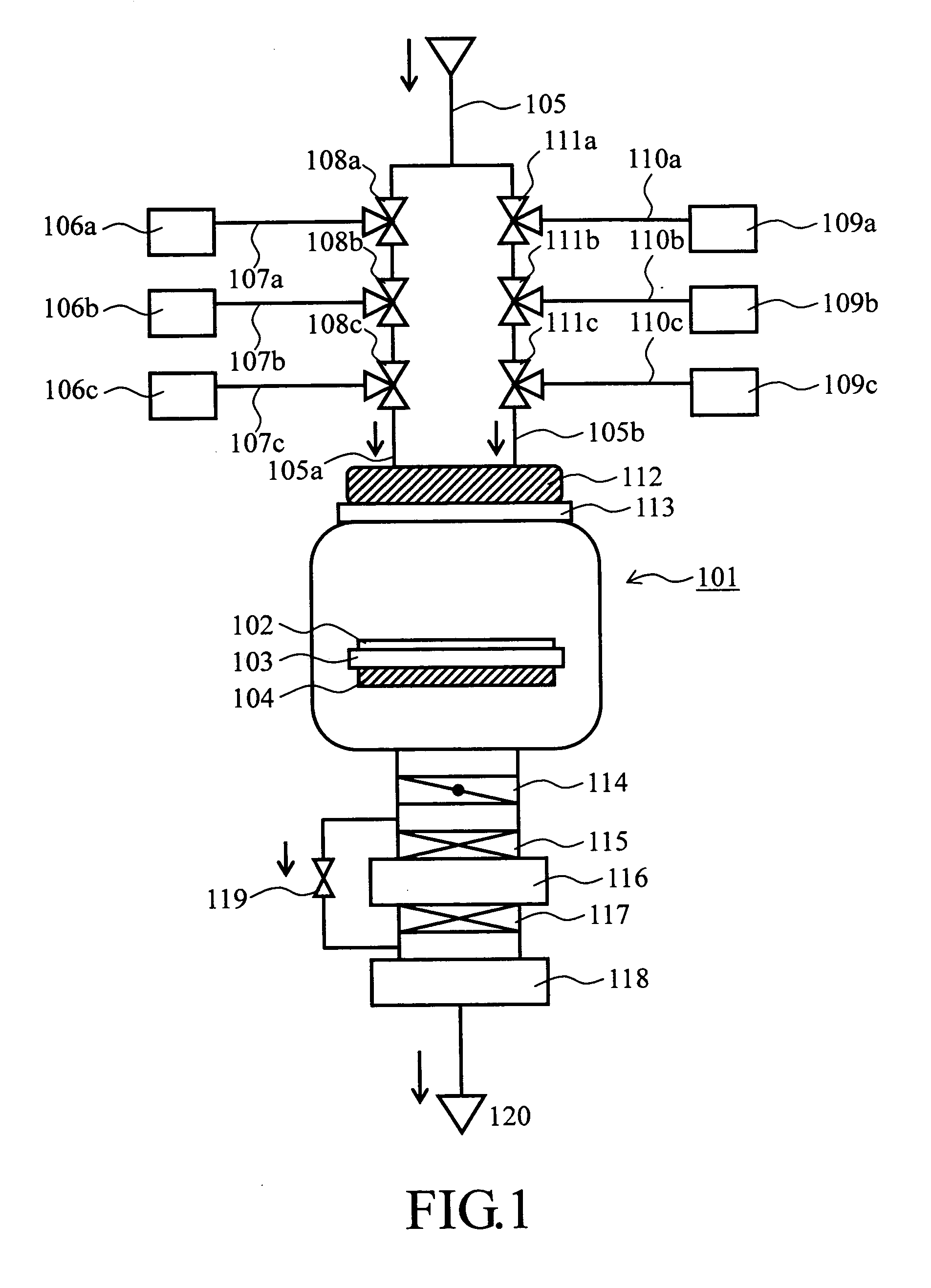

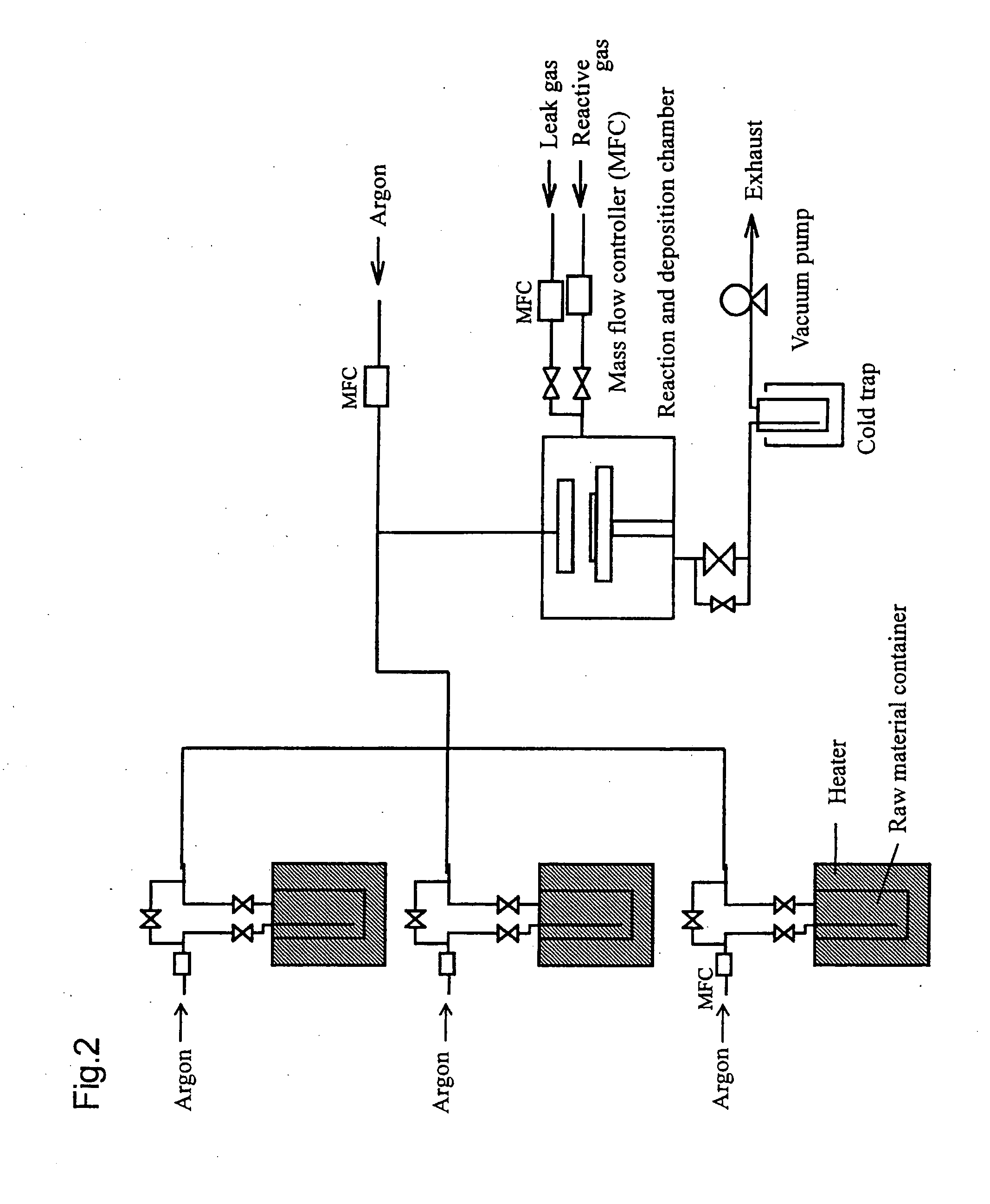

Film forming apparatus and method

InactiveUS20050249876A1Ameliorating the in-plane uniformity of an ALD filmTransistorSemiconductor/solid-state device manufacturingEngineeringReducer

An atomic layer deposition (ALD) apparatus capable of forming a conformal ultrathin-film layer with enhanced step coverage is disclosed. The apparatus includes an ALD reactor supporting therein a wafer, and a main pipe coupled thereto for constant supply of a carrier gas. This pipe has two parallel branch pipes. Raw material sources are connected by three-way valves to one branch pipe through separate pipes, respectively. Similarly, oxidant / reducer sources are coupled by three-way valves to the other branch pipe via independent pipes. ALD works by introducing one reactant gas at a time into the reactor while being combined with the carrier gas. The gas is “chemisorped” onto the wafer surface, creating a monolayer deposited. During the supply of a presently selected material gas from its source to a corresponding branch pipe, this gas passes through its own pipe independently of the others. An ALD method is also disclosed.

Owner:RENESAS TECH CORP

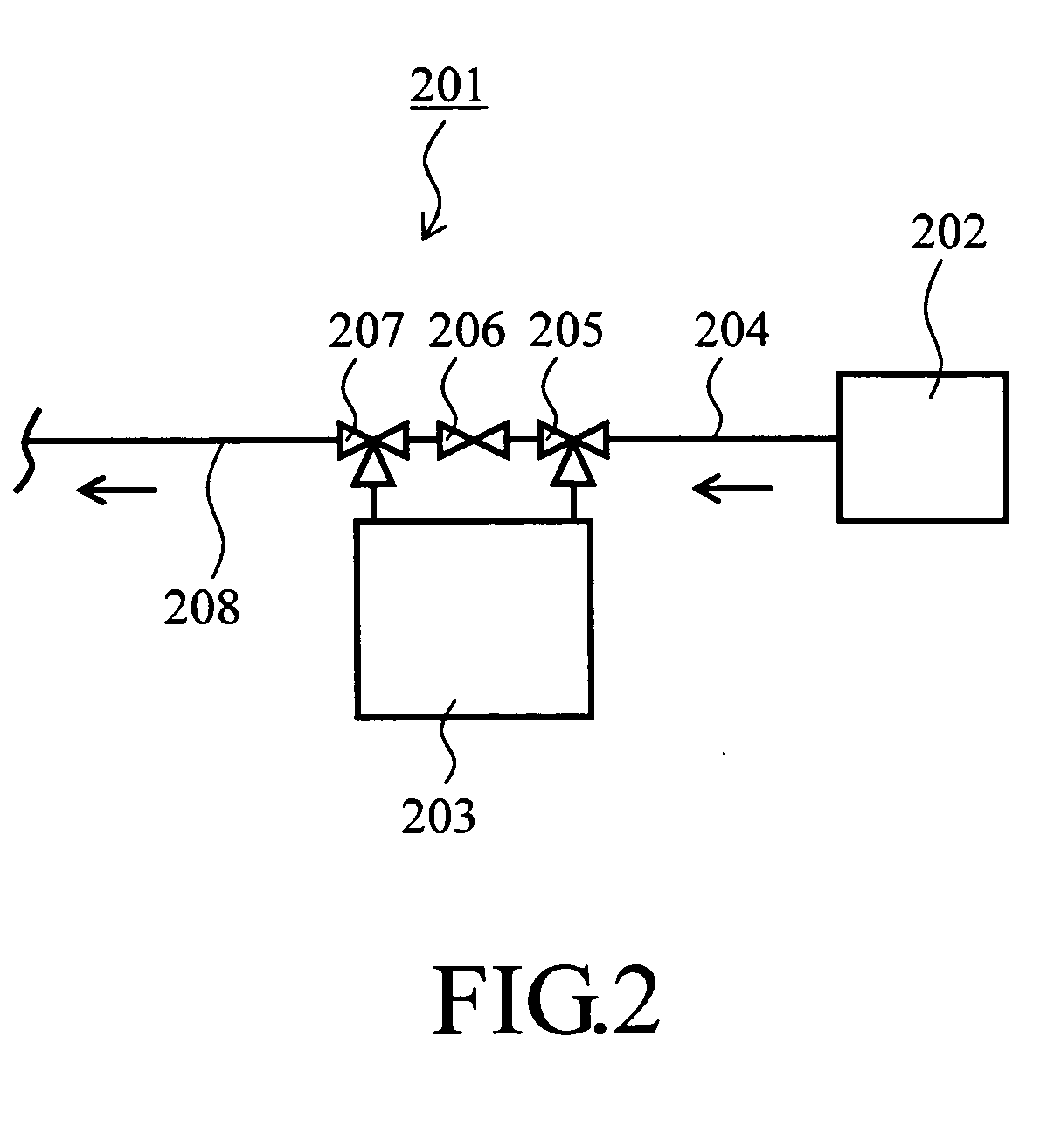

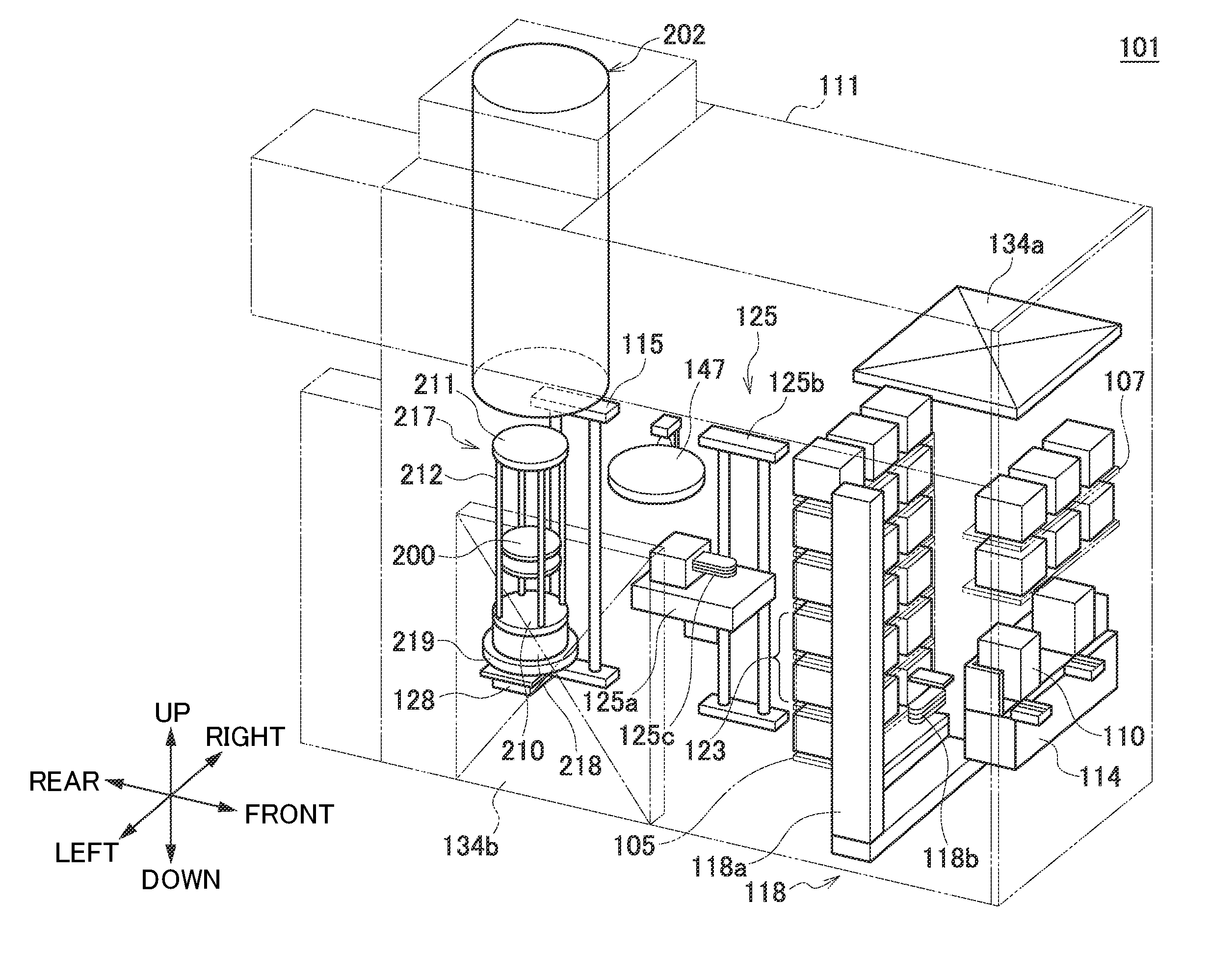

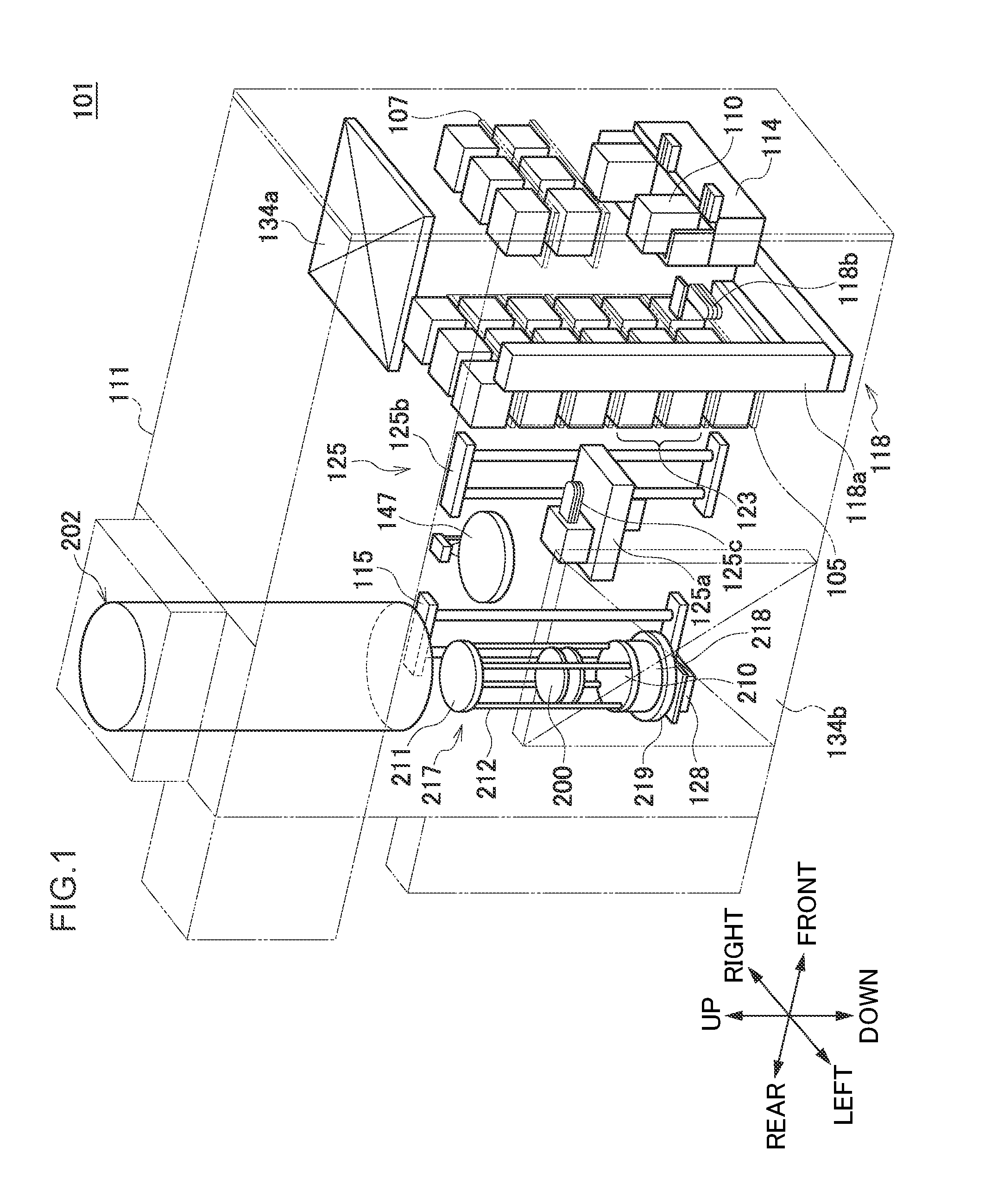

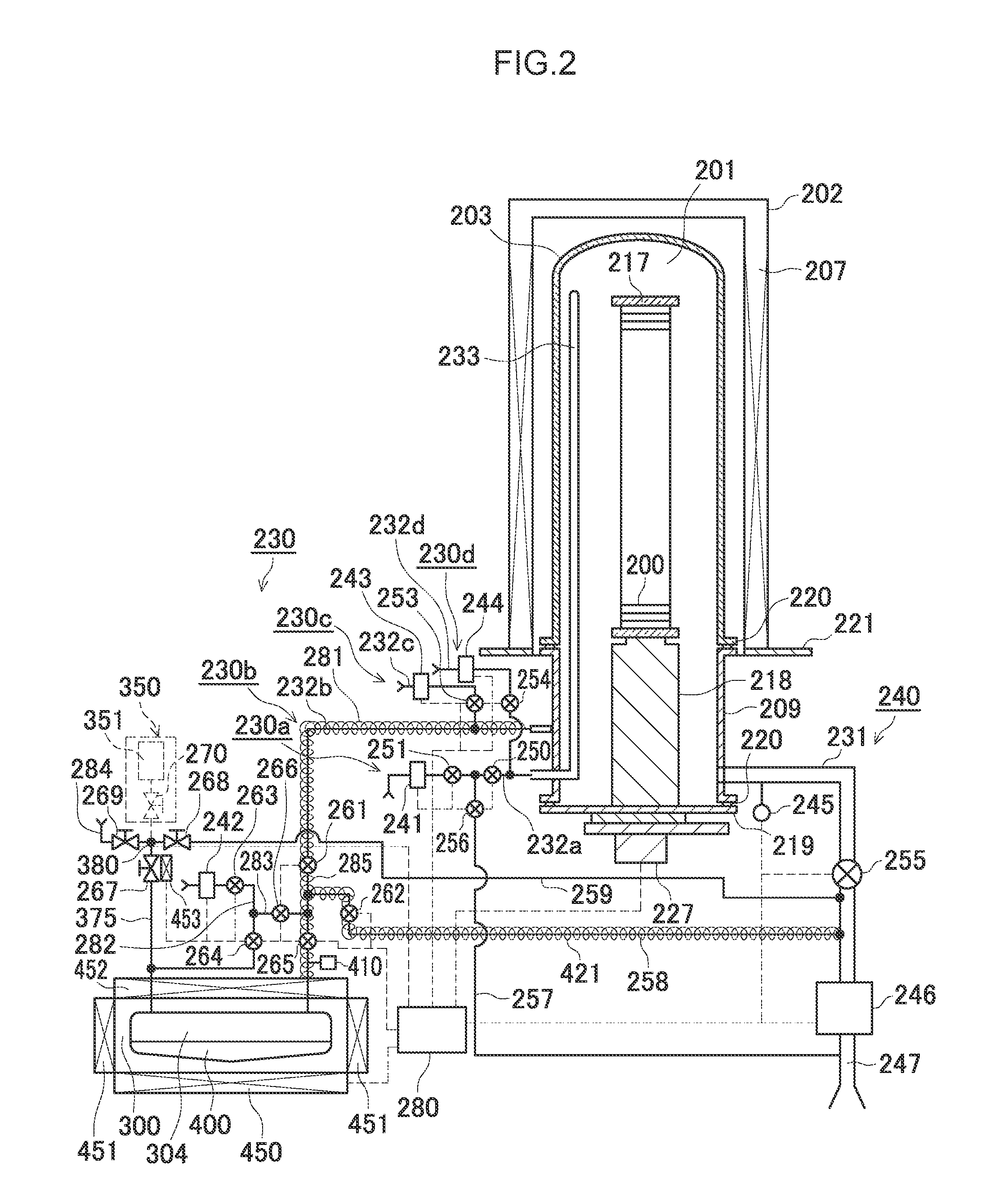

Substrate processing apparatus and solid raw material replenishing method

InactiveUS20120240858A1Simple configurationVacuum evaporation coatingSemiconductor/solid-state device manufacturingProduct gasProcess engineering

Disclosed is a substrate processing apparatus that includes: a processing chamber that accommodates a substrate; and a raw material supply system that sublimates a solid raw material to generate a gas raw material used for processing of the substrate, and supplies the generated gas raw material to the processing chamber. The raw material supply system includes: a solid raw material container that stores the solid raw material; a first piping connected between the solid raw material container and the processing chamber; and a second piping connected with the solid raw material container and equipped with an attachment portion to which a raw material replenishing container that holds the solid raw material for replenishment is attached.

Owner:KOKUSA ELECTRIC CO LTD +1

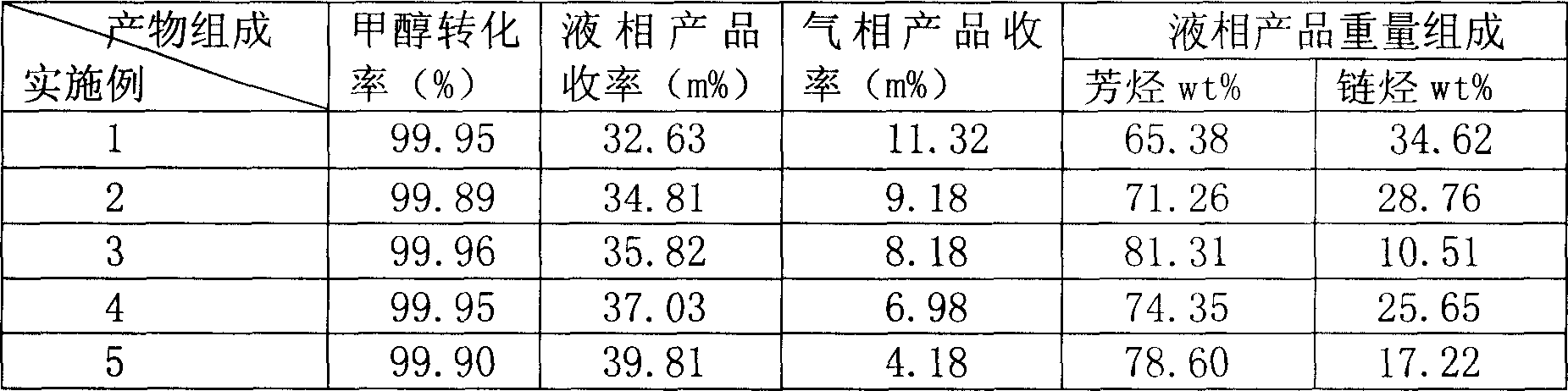

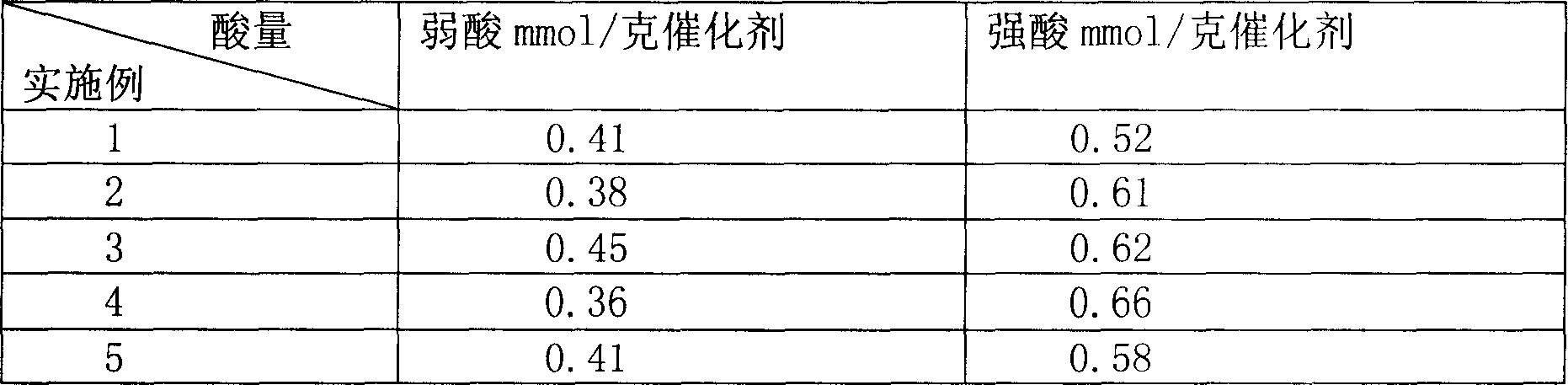

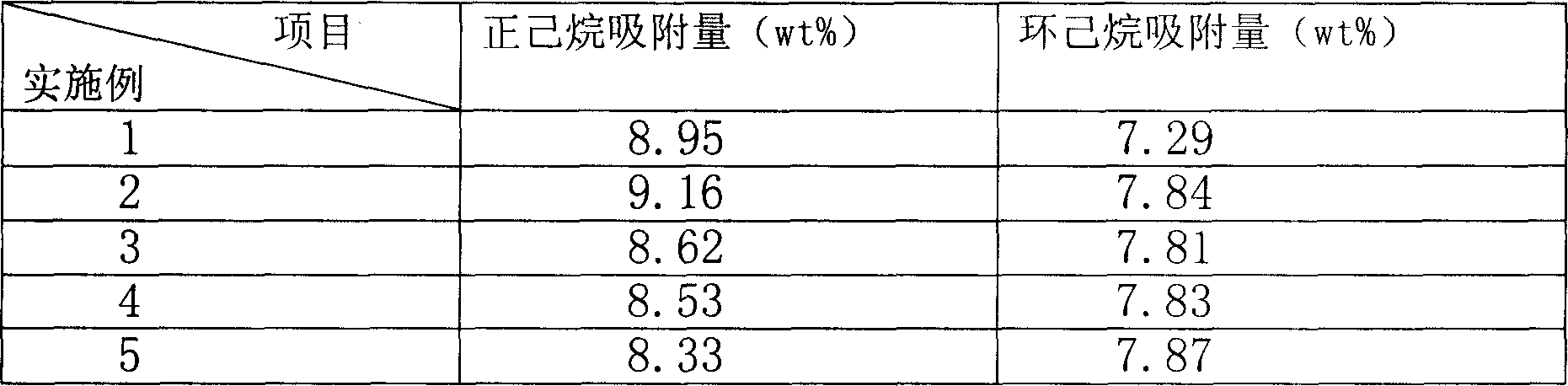

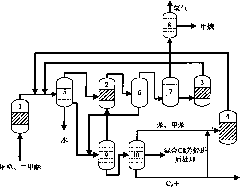

Process of methanol conversion for preparing arene and catalyst and catalyst preparation method

InactiveCN1880288AHigh selectivityHigh flexibility in process operationMolecular sieve catalystsHydrocarbonsGas phaseAromatic hydrocarbon

This invention relates to a process for transforming methanol to aromatic hydrocarbons, comprising: use methanol as raw material, with modified ZSM-5 molecular sieve as catalyst, under conditions of operation pressure 0.1-5.0Mpa, operation temperature 300-460Deg C, raw material liquid air speed 0.1-6.0h-1, transformed to products with aromatic hydrocarbons as main components; separate the gas-phase products lower carbon hydrocarbons from the liquid-phase C5+ hydrocarbons by cooling separation; the liquid-phase C5+ hydrocarbons then can be separated to be aromatic hydrocarbons and non-aromatic hydrocarbons by extracting separation. This invention is characterized of high total selectivity of aromatic hydrocarbons and flexible process operation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

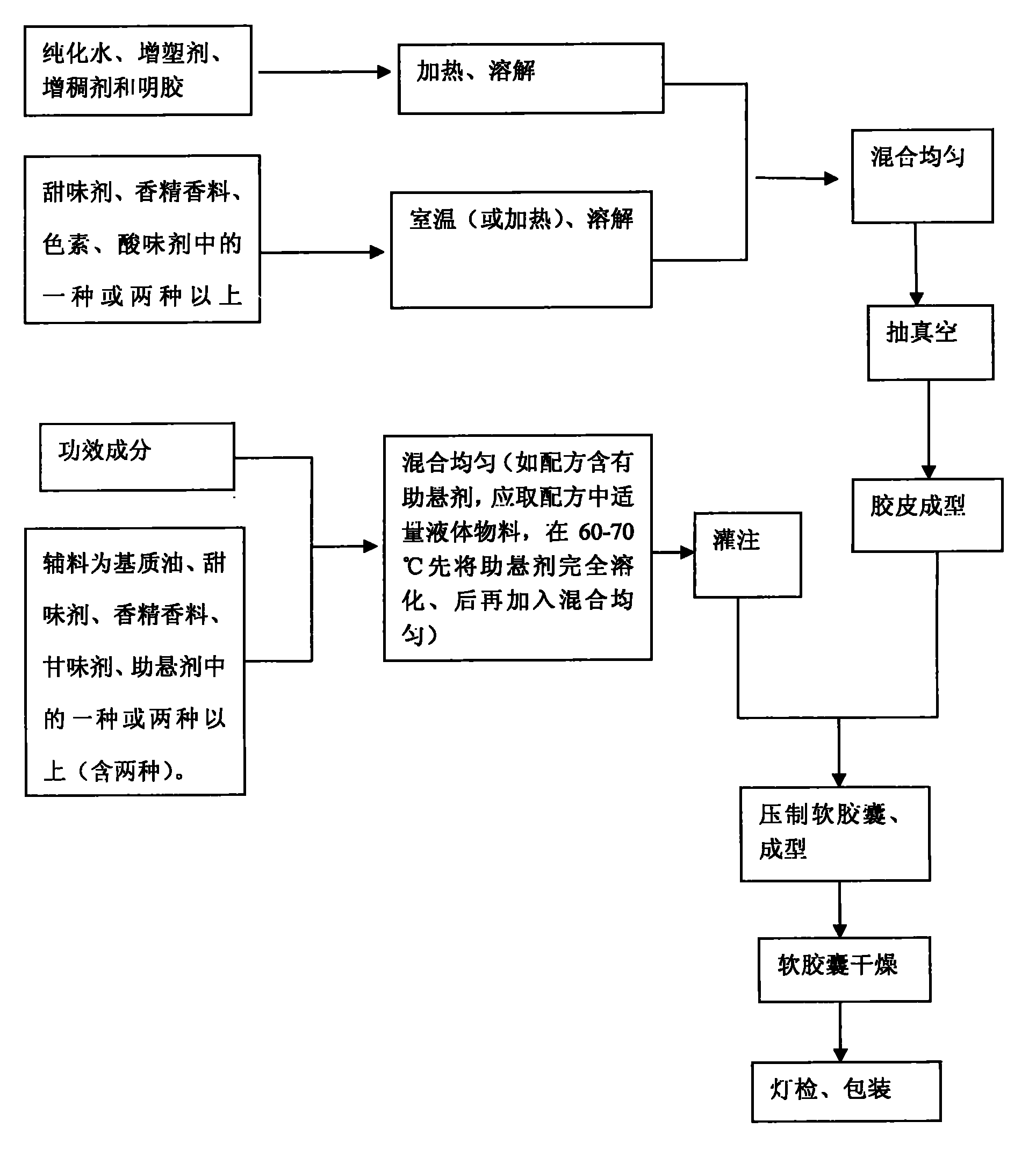

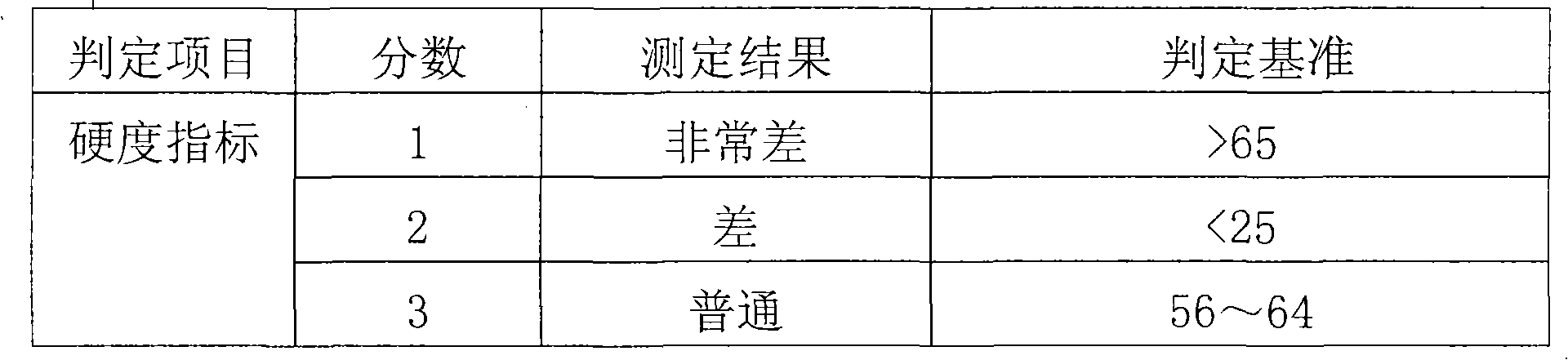

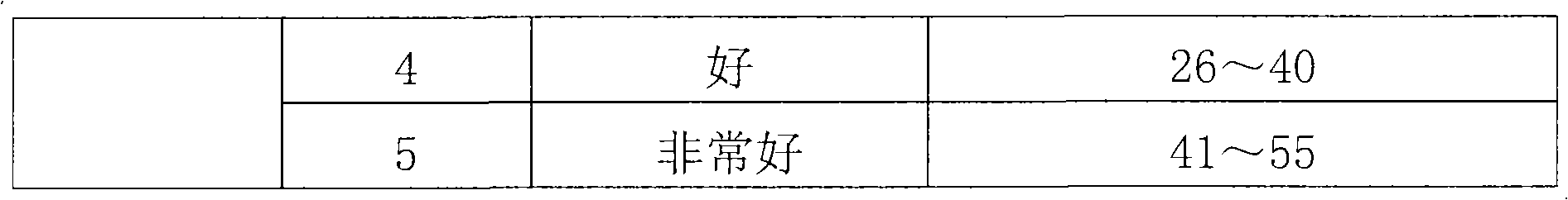

Chewable soft capsules and method for preparing same

ActiveCN101810336ADissolution stabilityRapid dissolutionFood shapingFood preparationFlavorPlasticizer

The invention discloses chewable soft capsules, which comprise capsule shells and contents sealed in the capsule shells. The chewable soft capsules are characterized by comprising the following raw materials in part by weight: 25 to 65 parts of glutin, 1 to 25 percent of thickening agent, 18 to 65 parts of plasticizer, 4 to 16 parts of water and a mixture containing one or more of 0.005 to 20 parts of sweetening agent, 0.005 to 2 parts of essence, 0.0001 to 10 parts of pigment and 0.0001 to 5 parts of acid additive. The invention also discloses a method for preparing the novel chewable soft capsules. The chewable soft capsules have the advantages of reasonable blending ratio, proper hardness, good temperature resistance, no adhesion, no deformation, stable storage, quick dissolution of effectively components and high chewiness; and when the chewing soft capsules are chewed, tastes of the capsule shells and the contents easily and uniformly spread in the mouth so as to cover up bad taste of raw materials.

Owner:SIRIO PHARMA CO LTD

Preparation method of plant enzyme food

The invention discloses a preparation method of plant enzyme food, belonging to the field of food processing technology. The method comprises the following steps of: performing twice fermentation and compounding on the natural plant raw materials of fresh fruits, vegetables, mushrooms, medicines, grains and flowers to obtain the secondary-fermentation stock solution or raw sauce, and storing; filling and sealing the secondary-fermentation stock solution or raw sauce to obtain liquid or sauce-type plant enzyme food or compound plant enzyme food; or performing low-temperature concentration and freeze drying to obtain solid plant enzyme food or compound plant enzyme food. Due the adoption of the preparation method, the obtained natural plant enzyme food has the functions of improving the immunity of human body, activating cells, promoting metabolism and the like.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

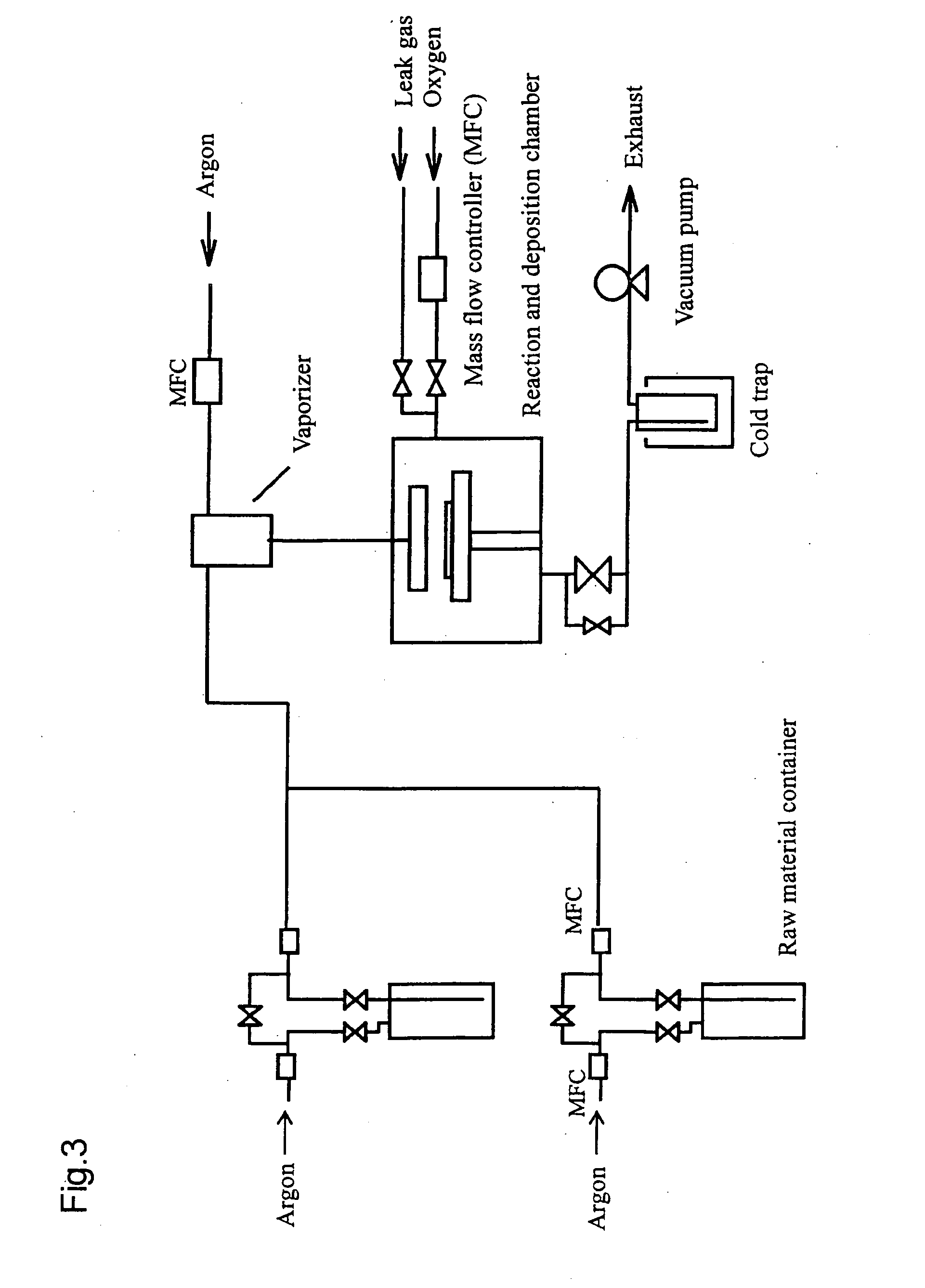

Thin film-forming material and method for producing thin film

InactiveUS20070178235A1Chemical vapor deposition coatingZinc organic compoundsZinc compoundsMaterials science

The thin film-forming material of the present invention comprises a bis(β-diketonato)zinc compound that is liquid at 25° C. and is suitable for forming a zinc-containing thin film. By using the thin film-forming material, a thin film can be produced with stable film-forming rate or stable film composition control without suffering from problems of raw material gas suppliability and in-line raw material transport. Preferred (β-diketonato)zinc compounds include, for example, bis(octane-2,4-dionato)zinc and bis(2,2-dimethyl-6-ethyldecane-3,5-dionato)zinc.

Owner:ADEKA CORP

Metal-containing compound, its production method, metal-containing thin film, and its formation method

ActiveUS20100105936A1Appropriate thermal stabilityAppropriate volatilityGroup 3/13 organic compounds without C-metal linkagesGroup 4/14 organic compounds without C-metal linkagesLithiumHydrogen

Owner:TOSOH CORP +1

Process for producing a hydrocarbon component of biological origin

ActiveUS7232935B2Improve performanceLow densityHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionIsomerizationHydrocarbon

The invention relates to a process for producing a hydrocarbon component of biological origin. The process comprises at least two steps, the first one of which is a HDO step and the second one is an isomerization step operated using the counter-current flow principle. A biological raw material containing fatty acids and / or fatty acid esters serves as the feed stock.

Owner:OYJ NESTE OIL +1

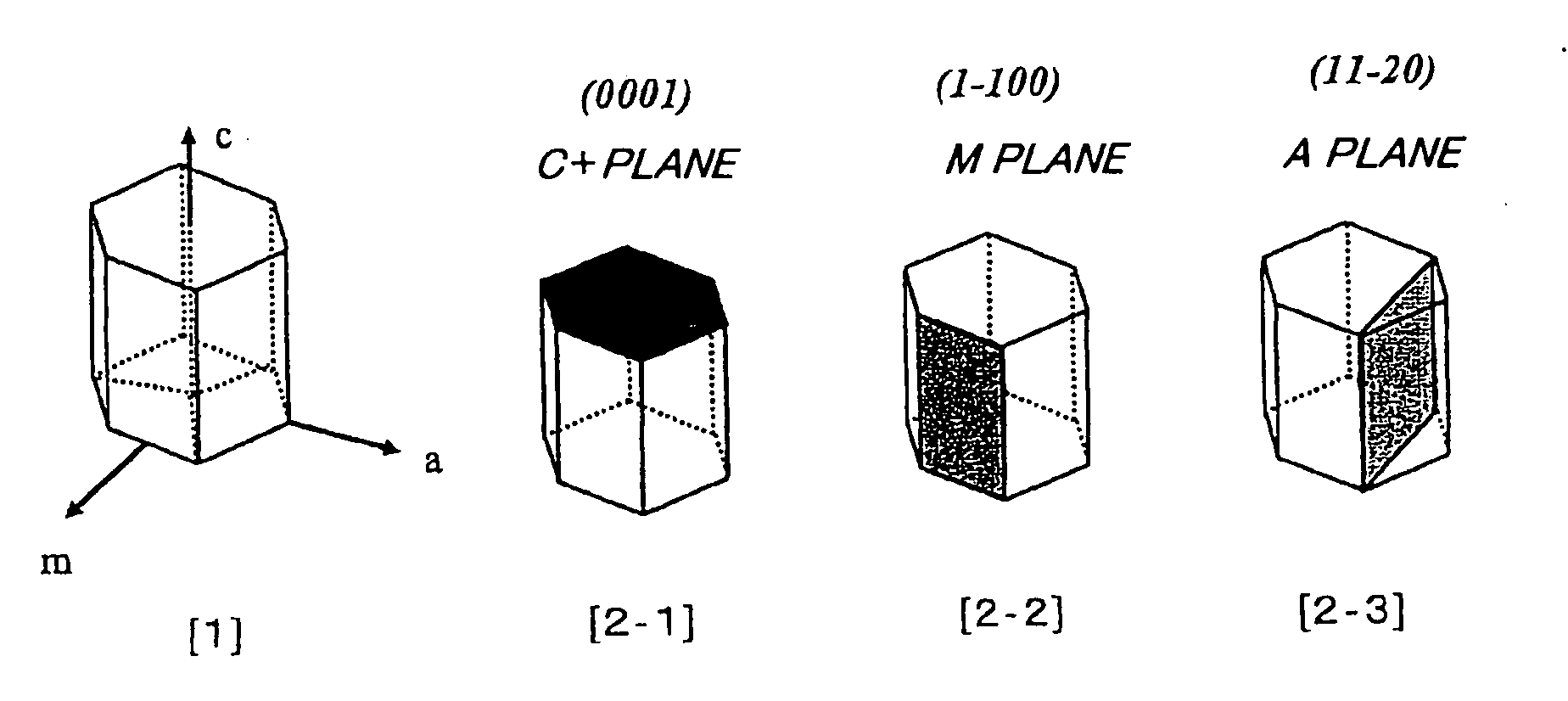

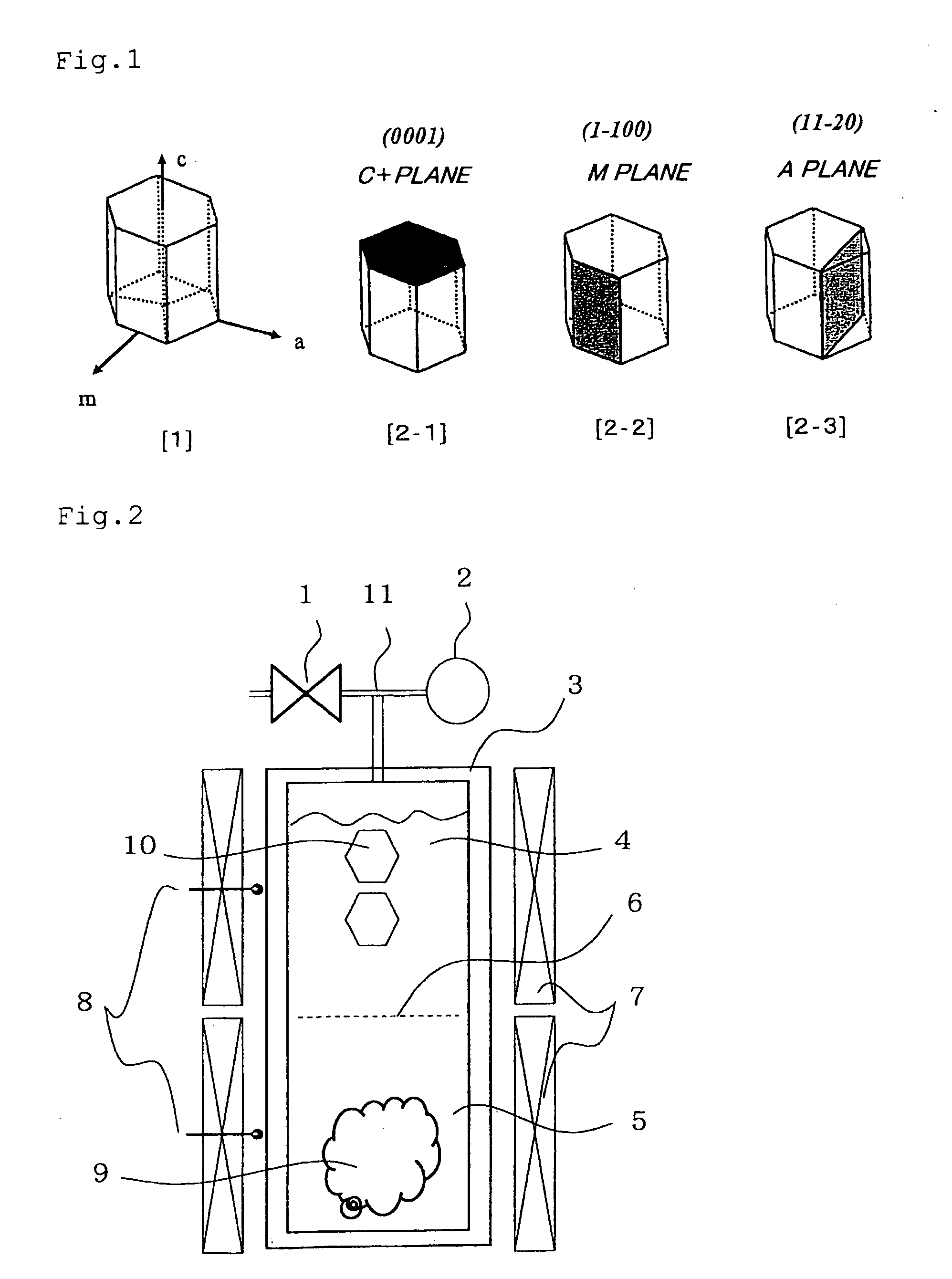

Method for producing nitride semiconductor, crystal growth rate increasing agent, single crystal nitride, wafer and device

InactiveUS20100104495A1Improve performanceIncrease probabilityPolycrystalline material growthFrom normal temperature solutionsNitrogenCrystal structure

A method for producing a nitride semiconductor, comprising controlling temperature and pressure in a autoclave containing a seed having a hexagonal crystal structure, a nitrogen element-containing solvent, a raw material substance containing a metal element of Group 13 of the Periodic Table, and a mineralizer so as to put said solvent into a supercritical state and / or a subcritical state and thereby ammonothermally grow a nitride semiconductor crystal on the surface of said seed, wherein the crystal growth rate in the m-axis direction on said seed is 1.5 times or more the crystal growth rate in the c-axis direction on said seed. By the method, a nitride semiconductor having a large-diameter C plane or a nitride semiconductor thick in the m-axis direction can be efficiently and simply produced.

Owner:MITSUBISHI CHEM CORP +1

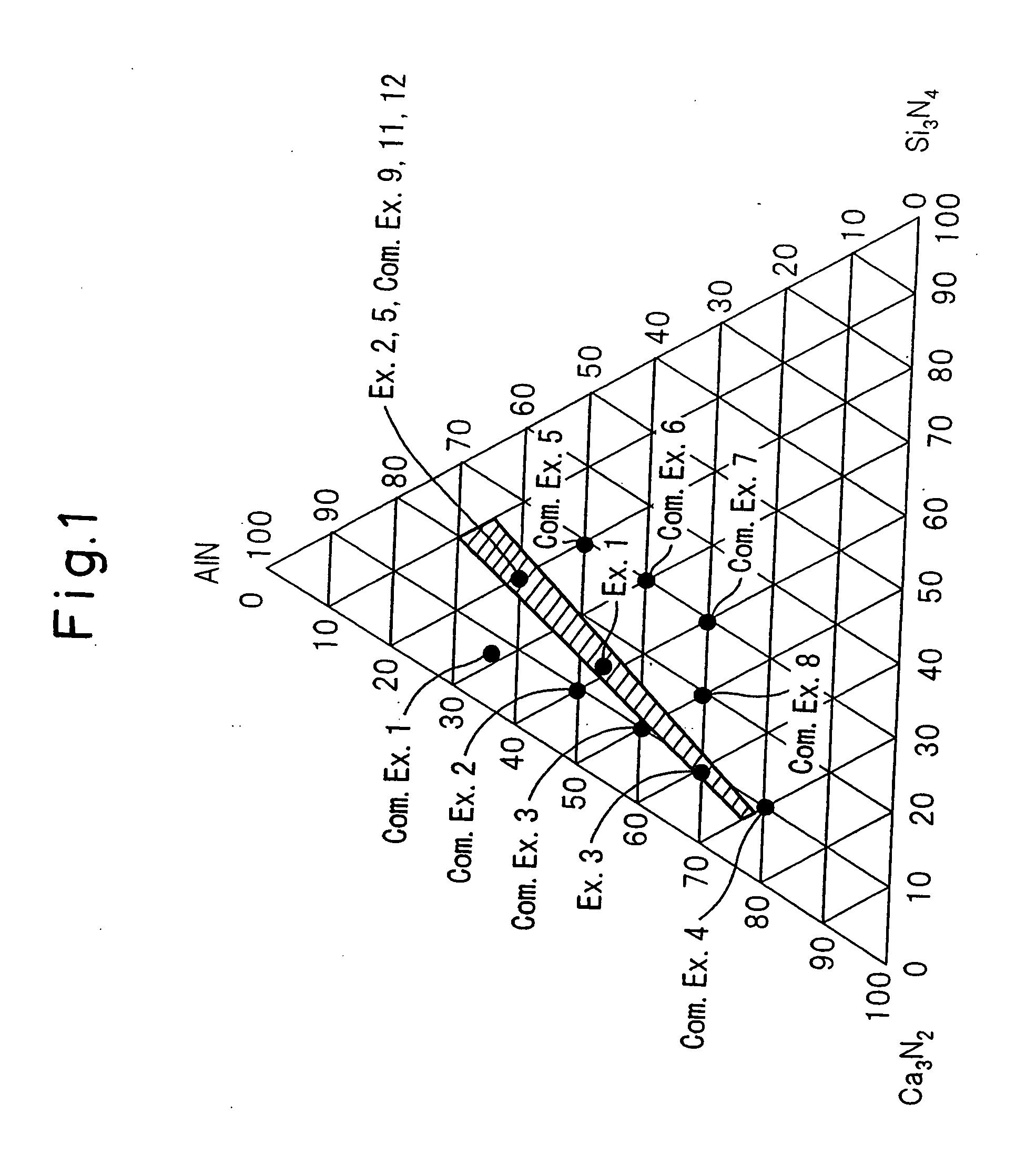

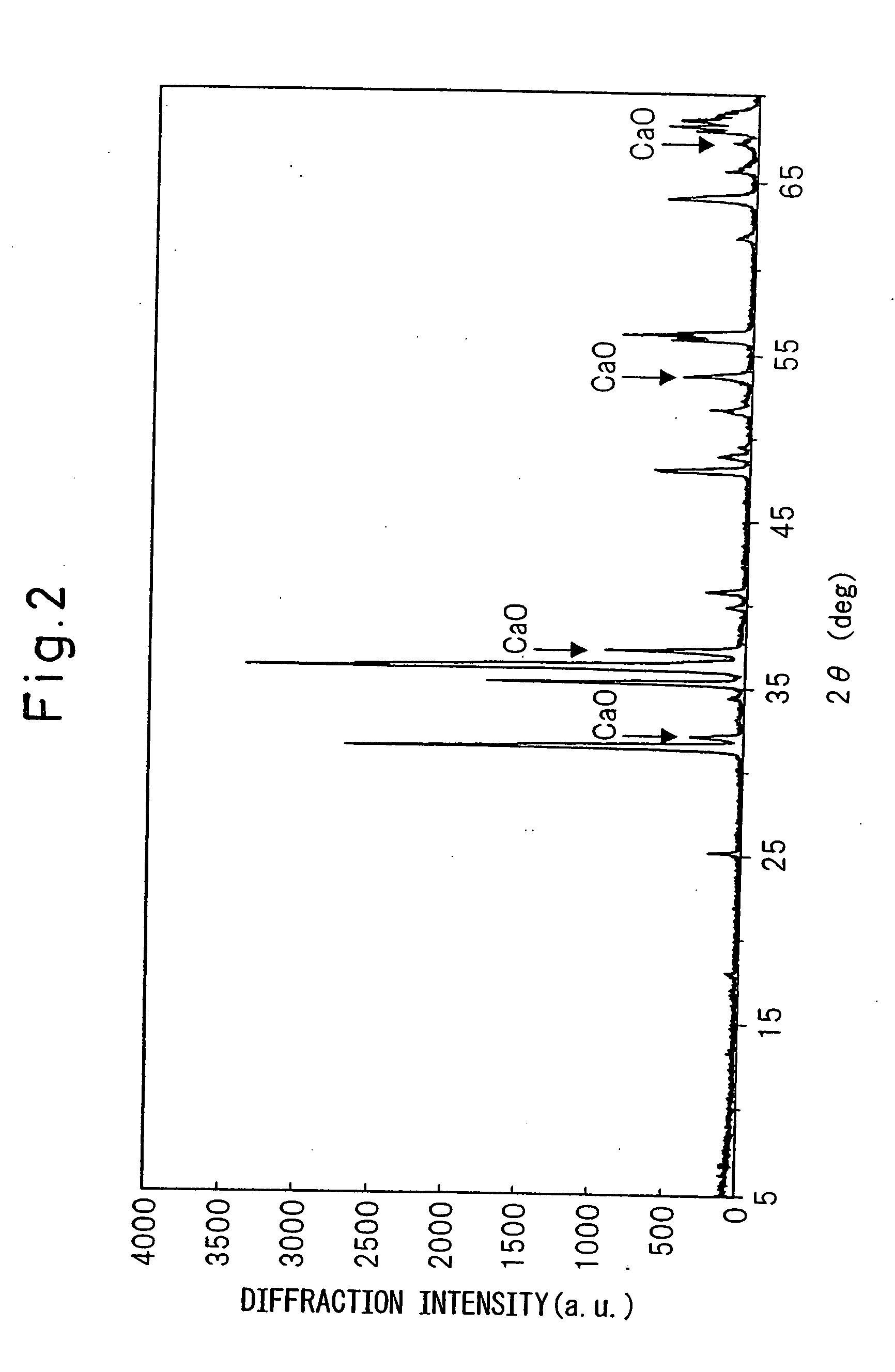

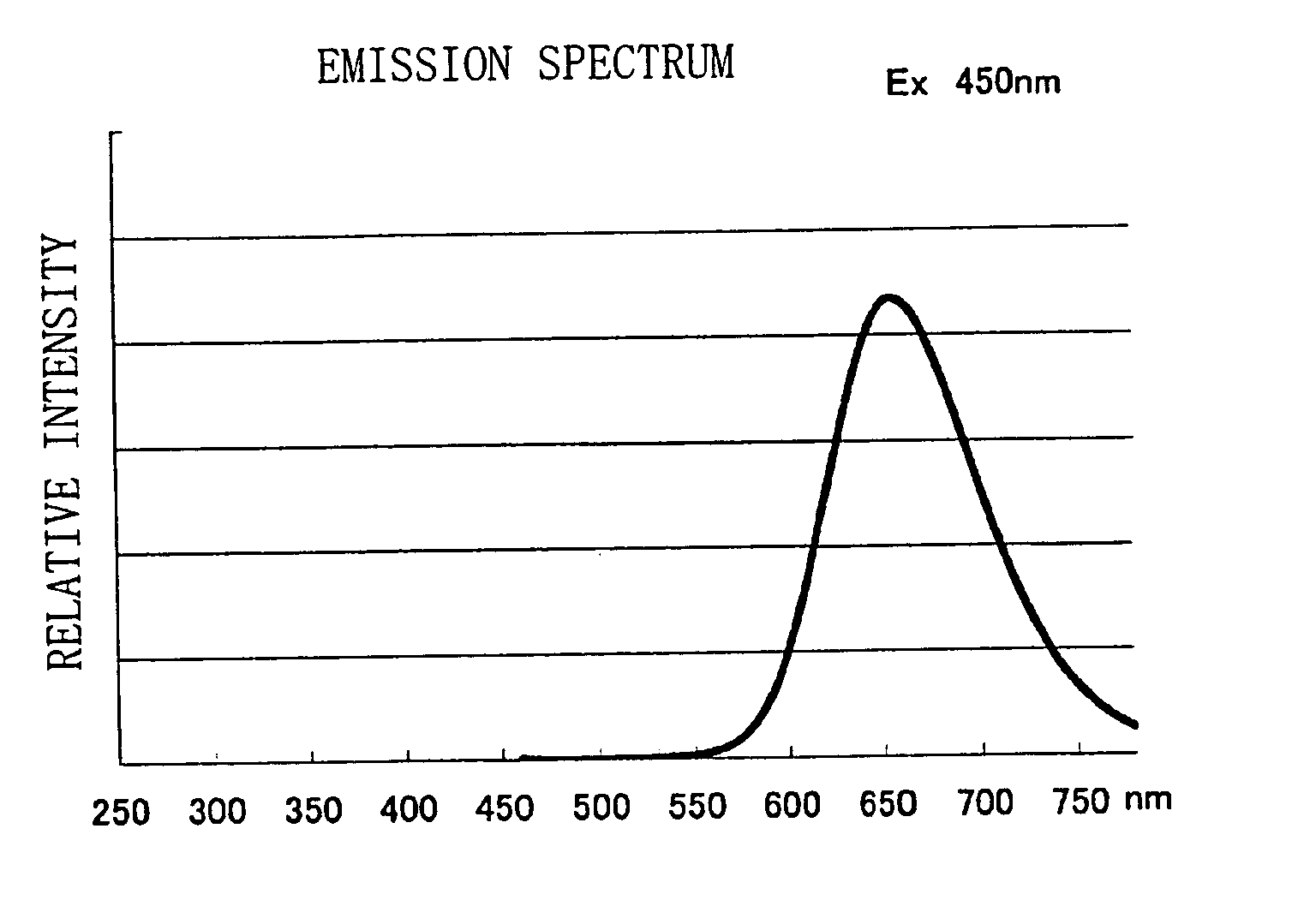

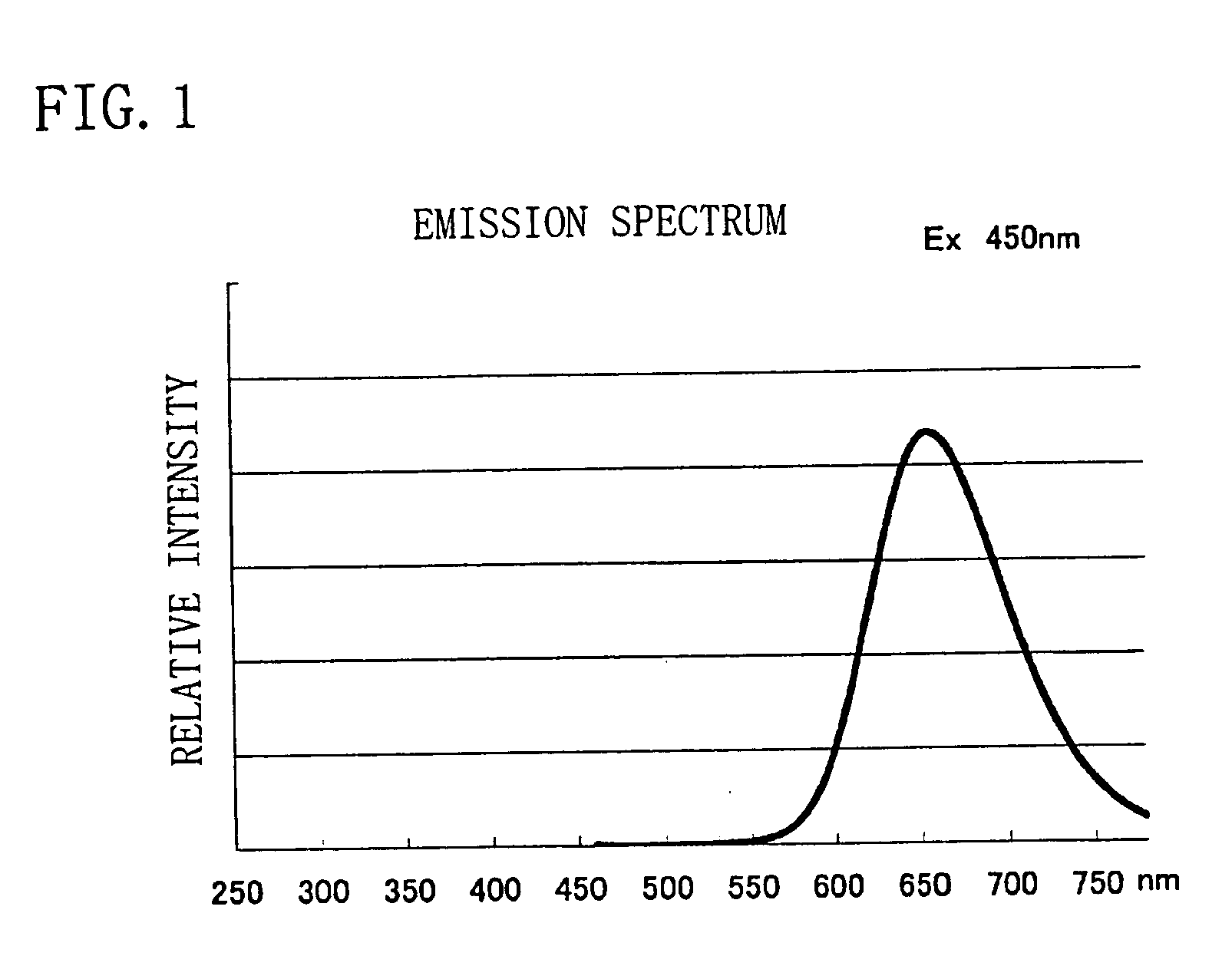

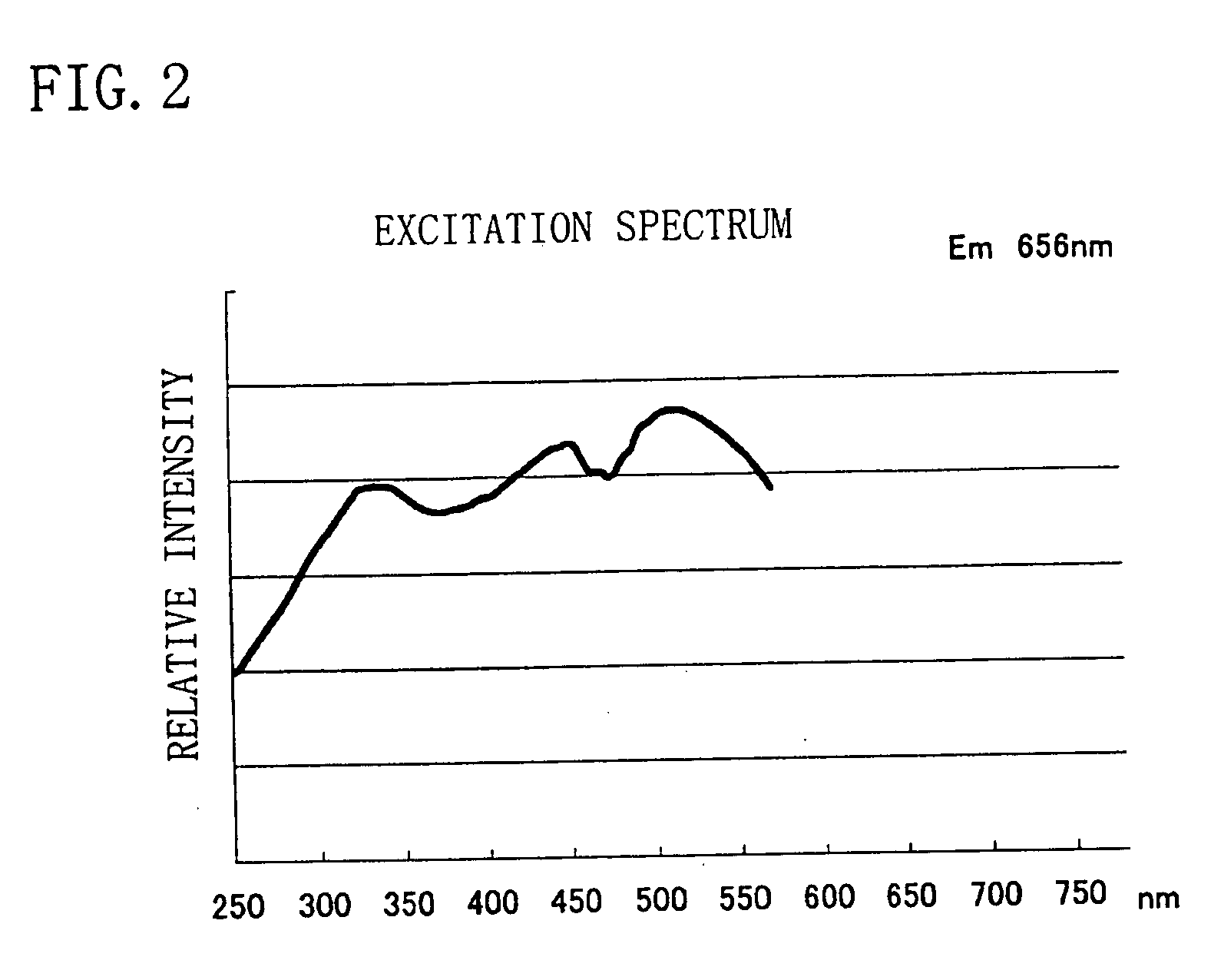

Red Nitride Phosphor and Production Method Thereof

A red phosphor where the crystal phase constituting the phosphor is monoclinic Eu-activated CaAlSiN3. A red phosphor which is Eu-activated CaAlSiN3 powder having an average particle diameter of 10 μm or less as measured in the non-pulverized state by the laser scattering particle size distribution analysis. A light-emitting device comprising a blue light-emitting element, a yellow phosphor capable of converting the blue light emitted from the blue light-emitting element into yellow light, and the above-described red phosphor capable of converting the blue light emitted from the blue light-emitting element into red light. A method for producing Eu-activated CaAlSiN3, comprising firing a raw material powder comprising Ca3N2, AlN, Si3N4 and EuN at 1,400 to 2,000° C. in a nitrogen-containing atmosphere, the Ca3N2, AlN and Si3N4 giving a composition falling in the region surrounded by a straight line connecting the following four points A to D in the composition diagram of FIG. 1 and EuN being contained in an amount of 0.01 to 10 parts by weight as Eu per 100 parts by weight in total of Ca3N2, AlN and Si3N4.

Owner:UBE IND LTD

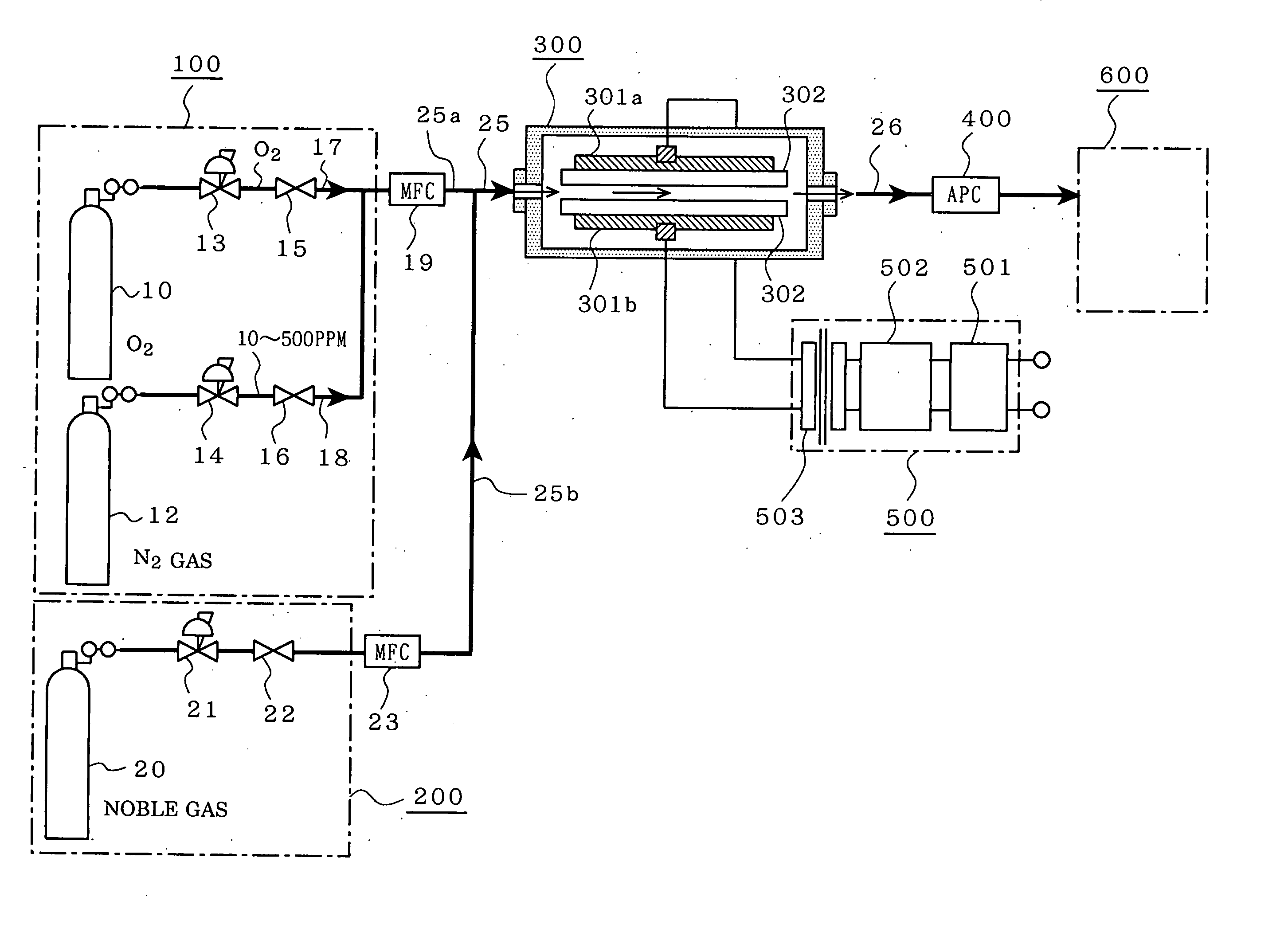

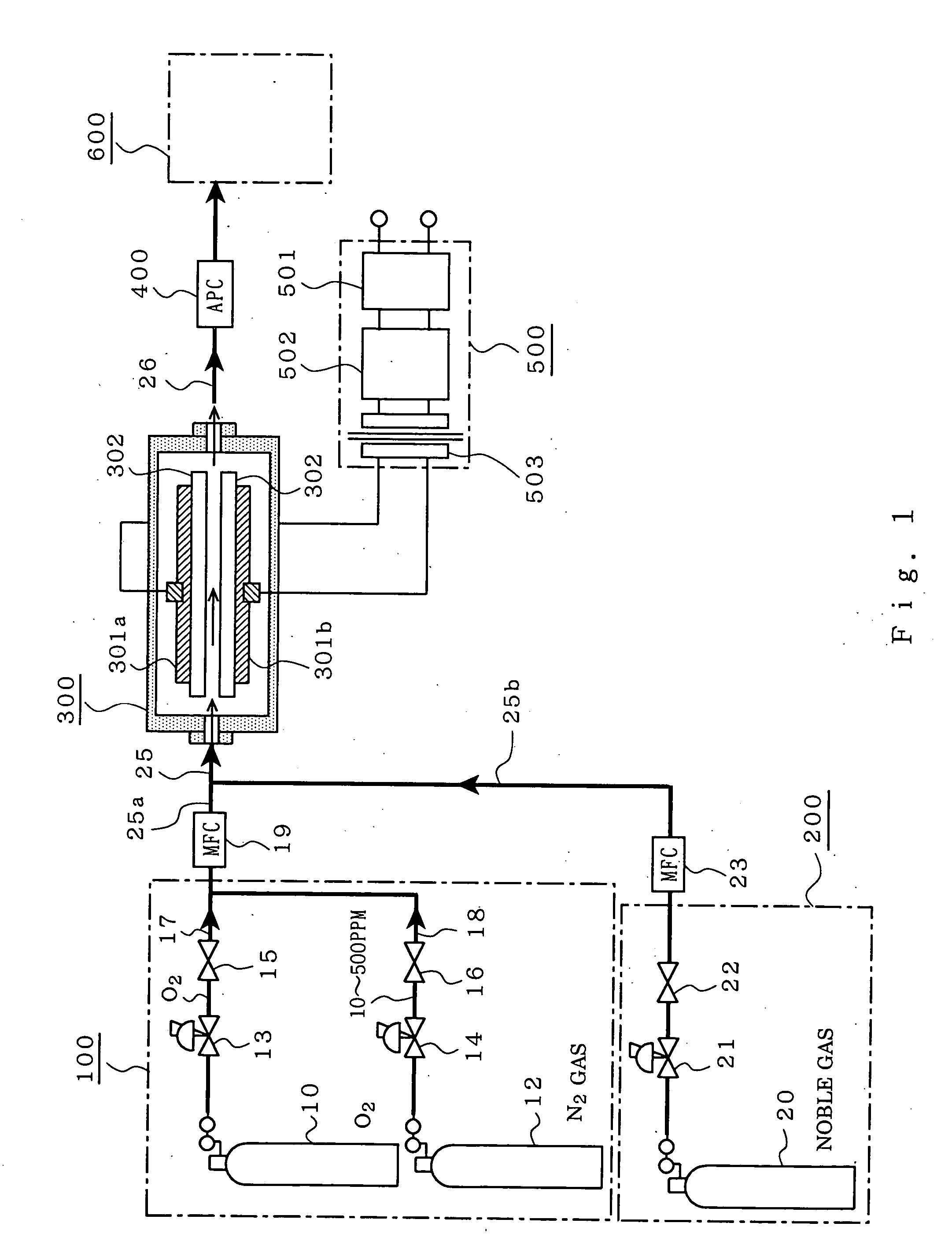

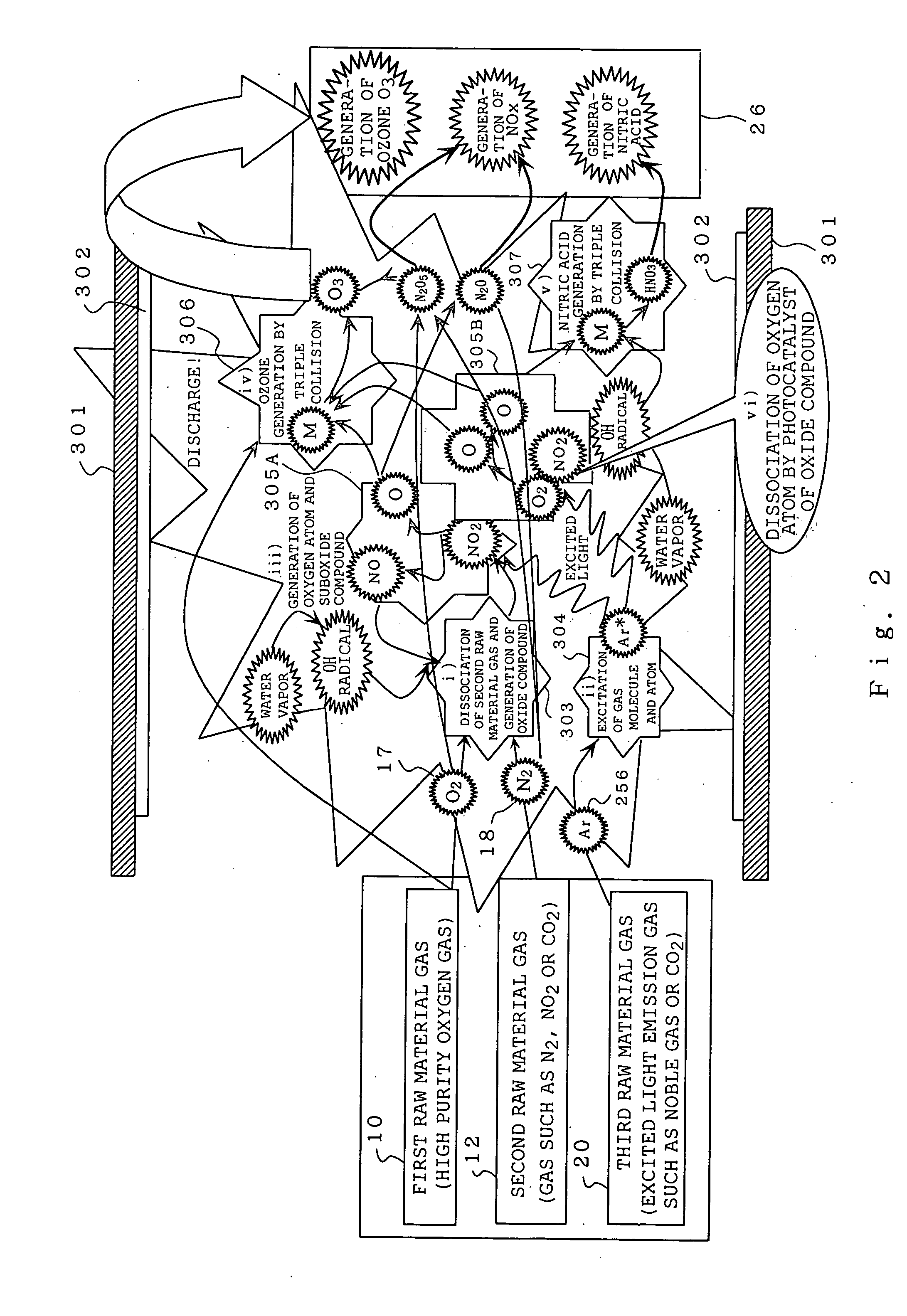

Ozone generator

ActiveUS20040223893A1Physical/chemical process catalystsElectrical discharge ozone preparationAtmospheric sciencesGas supply

An ozone generator for generating ozone by applying a specified process to oxygen by discharge includes a first raw material gas supply unit for supplying the oxygen as a first raw material gas, and a second raw material gas supply unit for supplying an oxide compound gas as a second raw material gas, in which, by excited light, excited and generated by a discharge in the oxygen and the oxide compound gas, the oxide compound gas is dissociated, or the oxide compound gas is excited accelerating dissociation of the oxygen, and ozone is generated. In this way, ozone generation efficiency is raised.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

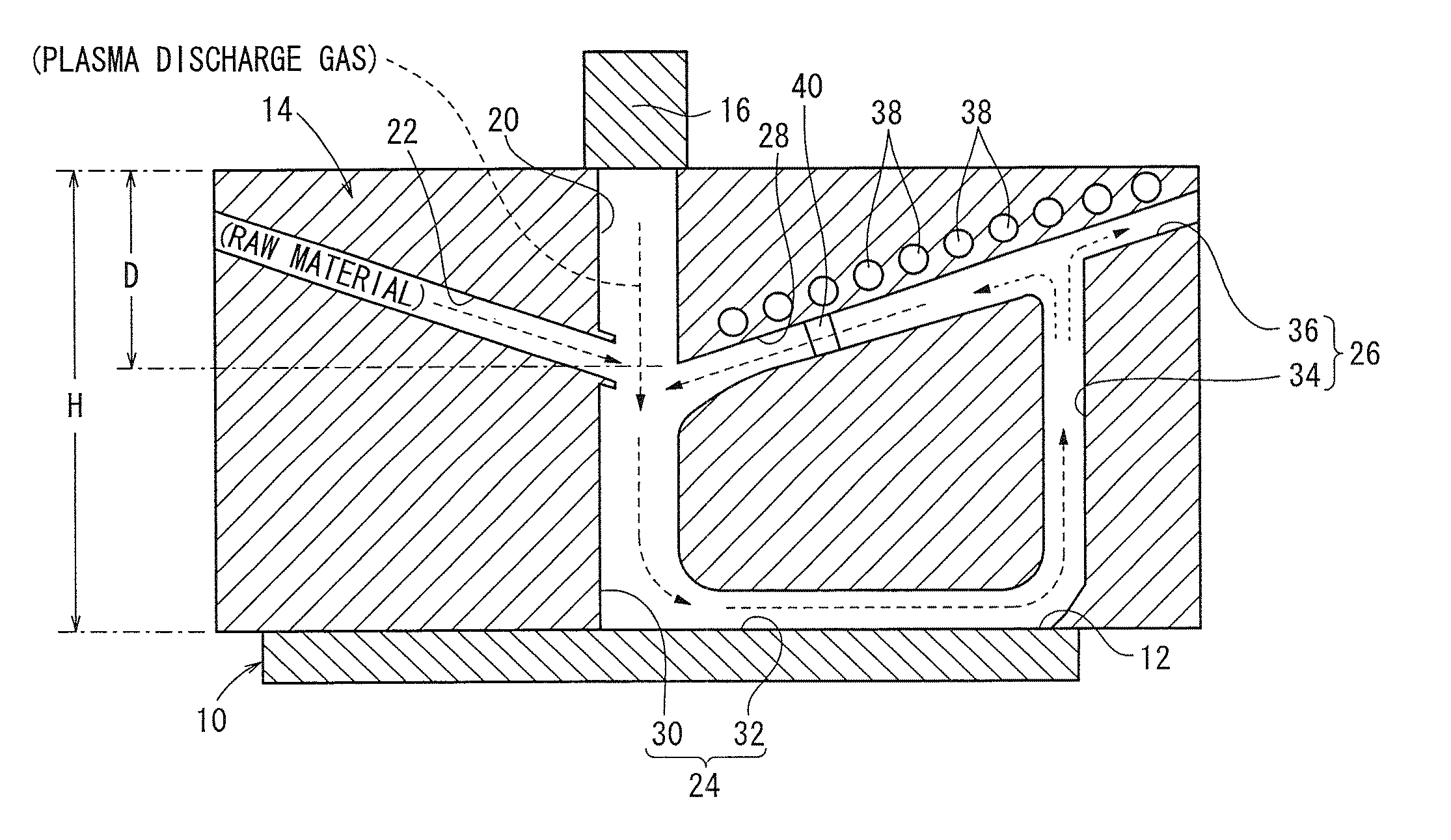

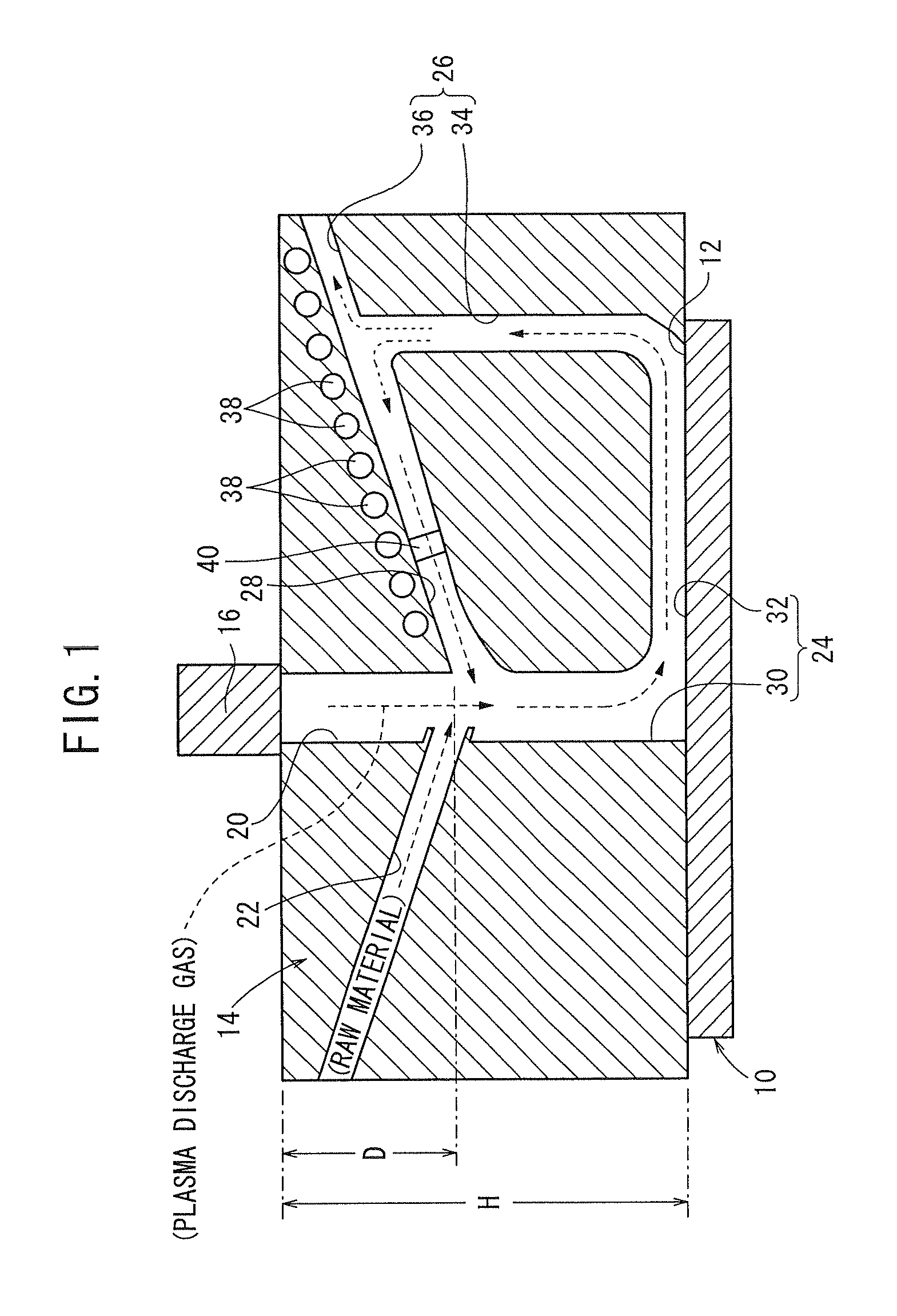

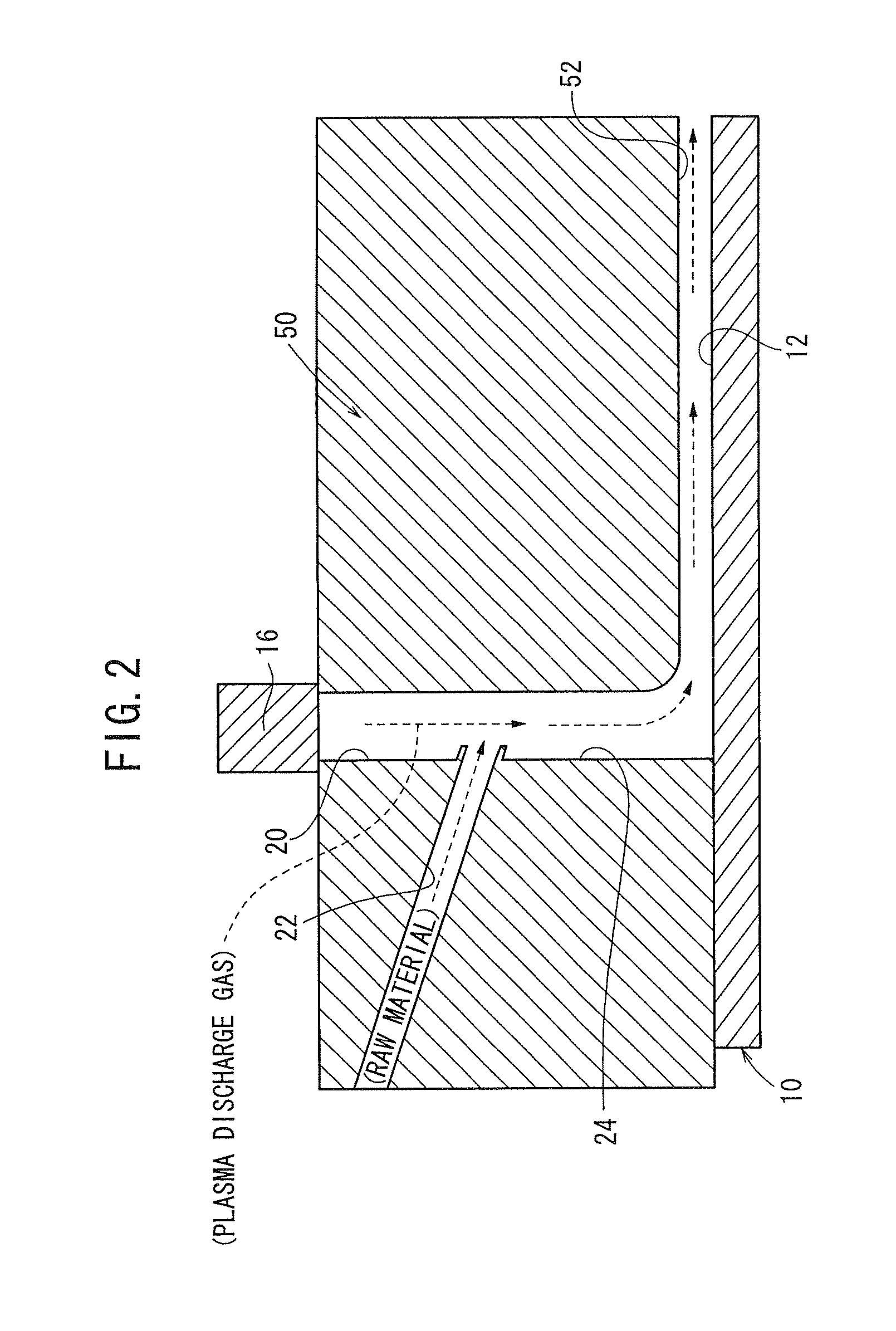

Plasma film forming apparatus

InactiveUS8573154B2Easy to useReduce material costsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringElectrical and Electronics engineering

The present invention relates to a plasma film forming apparatus. In the plasma film forming apparatus, a flow control jig is disposed between a plasma nozzle and a film formation region of a substrate. The flow control jig has a plasma supply path, a raw material supply path, a film formation joined path formed by combining the plasma supply path and the raw material supply path, an exhaust path for discharging a plasma discharge gas and an unreacted raw material transported from the film formation region, and a recovery path for returning the unreacted raw material in the exhaust path to the plasma supply path.

Owner:HONDA MOTOR CO LTD

Polycrystalline group iii metal nitride with getter and method of making

ActiveUS20100151194A1Simple and cost-effective to manufactureCost-effectiveConductive materialRecord information storageNitrogenNitride

A gettered polycrystalline group III metal nitride is formed by heating a group III metal with an added getter in a nitrogen-containing gas. Most of the residual oxygen in the gettered polycrystalline nitride is chemically bound by the getter. The gettered polycrystalline group III metal nitride is useful as a raw material for ammonothermal growth of bulk group III nitride crystals.

Owner:SLT TECH

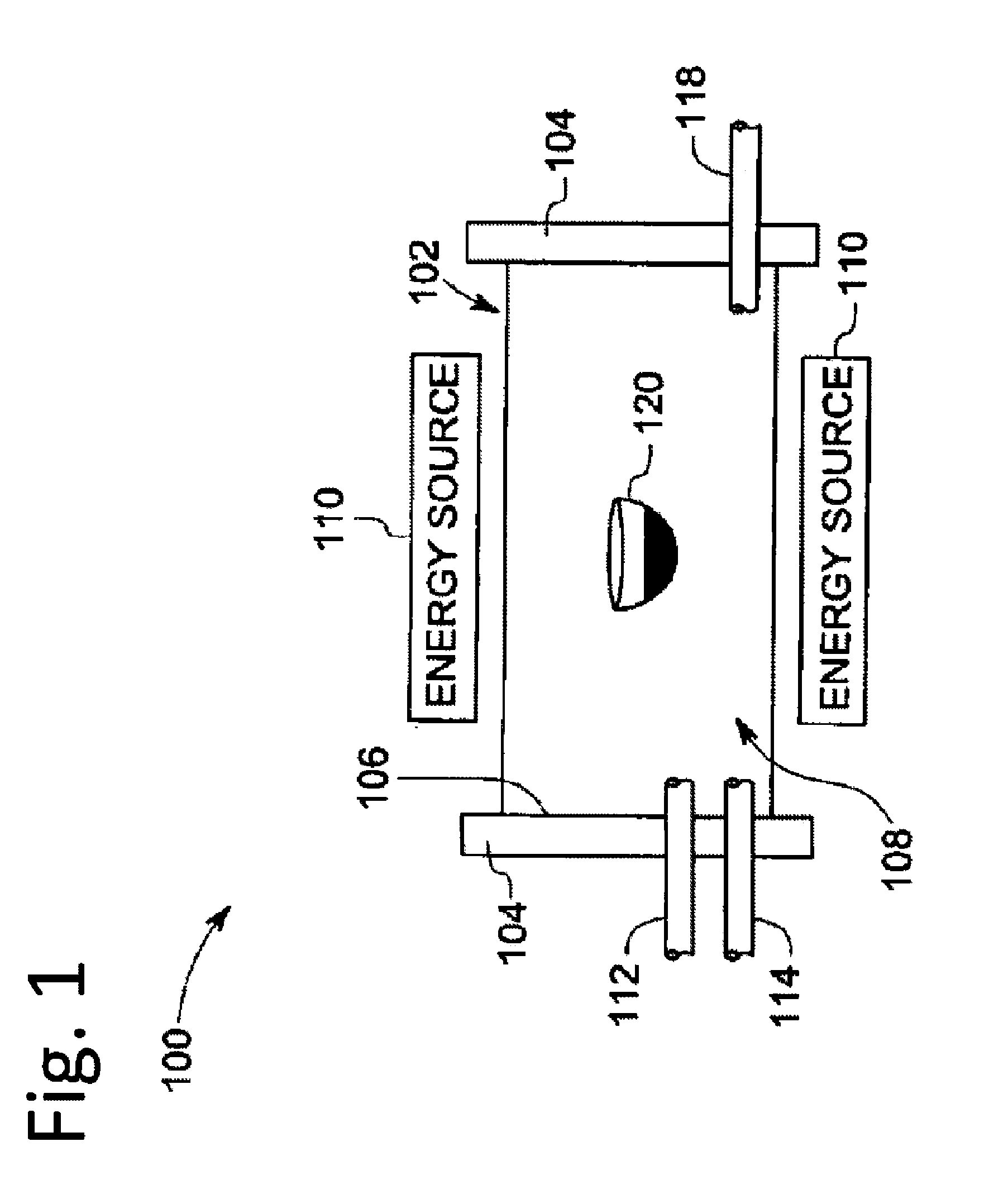

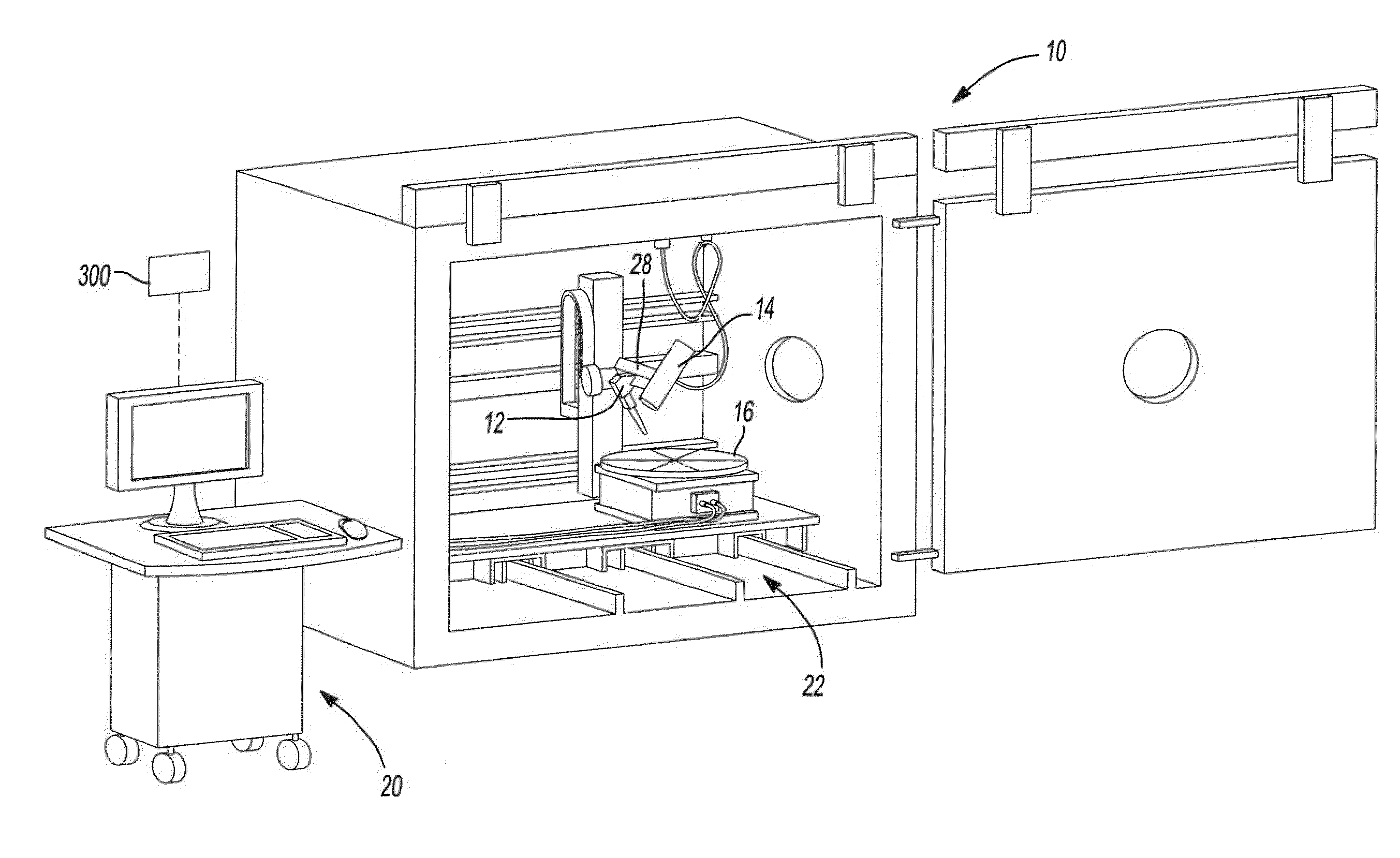

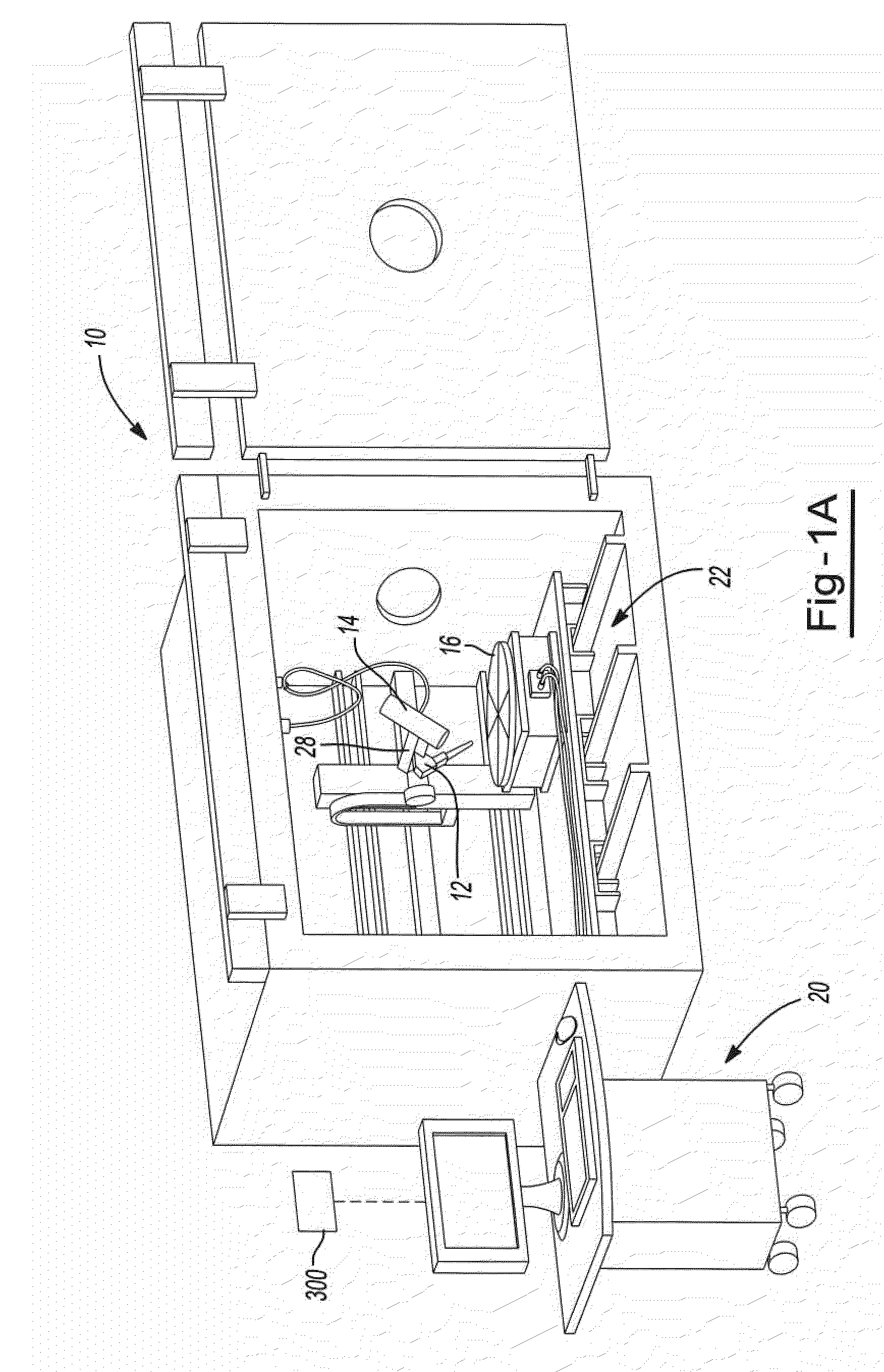

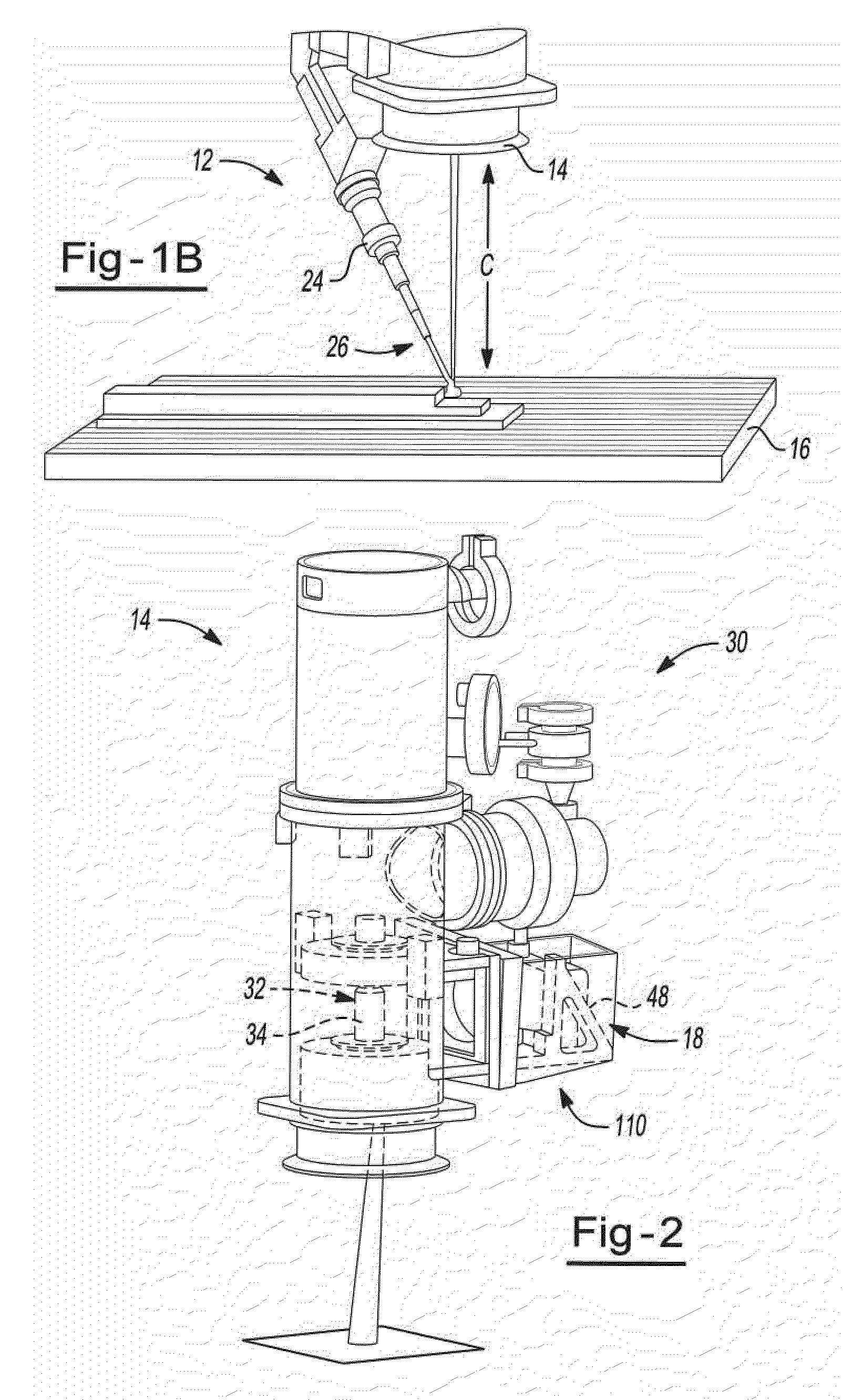

Electron beam layer manufacturing

ActiveUS20110061591A1Obstruct passageProgramme controlAdditive manufacturing apparatusFree formClosed loop

A process and apparatus for free form fabrication of a three-dimensional work piece comprising (a) feeding raw material in a solid state to a first predetermined location; (b) depositing the raw material onto a substrate as a molten pool deposit under a first processing condition; (c) monitoring the molten pool deposit for a preselected condition; (d) comparing information about the preselected condition of the monitored molten pool deposit with a predetermined desired value for the preselected condition of the monitored molten pool deposit; (e) solidifying the molten pool deposit; (f) automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step (d); and repeating steps (a) through (f) at one or more second locations for building up layer by layer a three-dimensional work piece. The apparatus is characterized by a detector that monitors a preselected condition of the deposited material and a closed loop electronic control device for controlling operation of one or more components of the apparatus in response to a detected condition by the detector.

Owner:SCIAKY SA

Method for producing aromatic amino compound

InactiveUS7250532B2High yieldEasy to eliminateOrganic compound preparationAmino compound preparationArylCompound a

A method for producing aromatic amino compound (V):by synthesizing intermediate compound (IV):by the reaction of compound (I): H2N—R1 with a mixture of halogenated aryl compounds (II): Ar1—X and (III): Ar2—X in the presence of a noble metal catalyst, followed by eliminating the substituent R1 from the nitrogen atom in compound (IV) under an acidic condition or an alkaline condition or by addition of a reducing agent or an oxidizing agent. (R1: a substituent having 2 to 50 carbon atoms; Ar1 and Ar2: a substituted or unsubstituted hydrocarbon group or heterocyclic group having 6 to 50 carbon atoms and the same with or different from each other; and X: a halogen group). The aromatic amino compound useful as the charge transporting material can be produced efficiently at a great yield without using highly toxic raw materials.

Owner:IDEMITSU KOSAN CO LTD

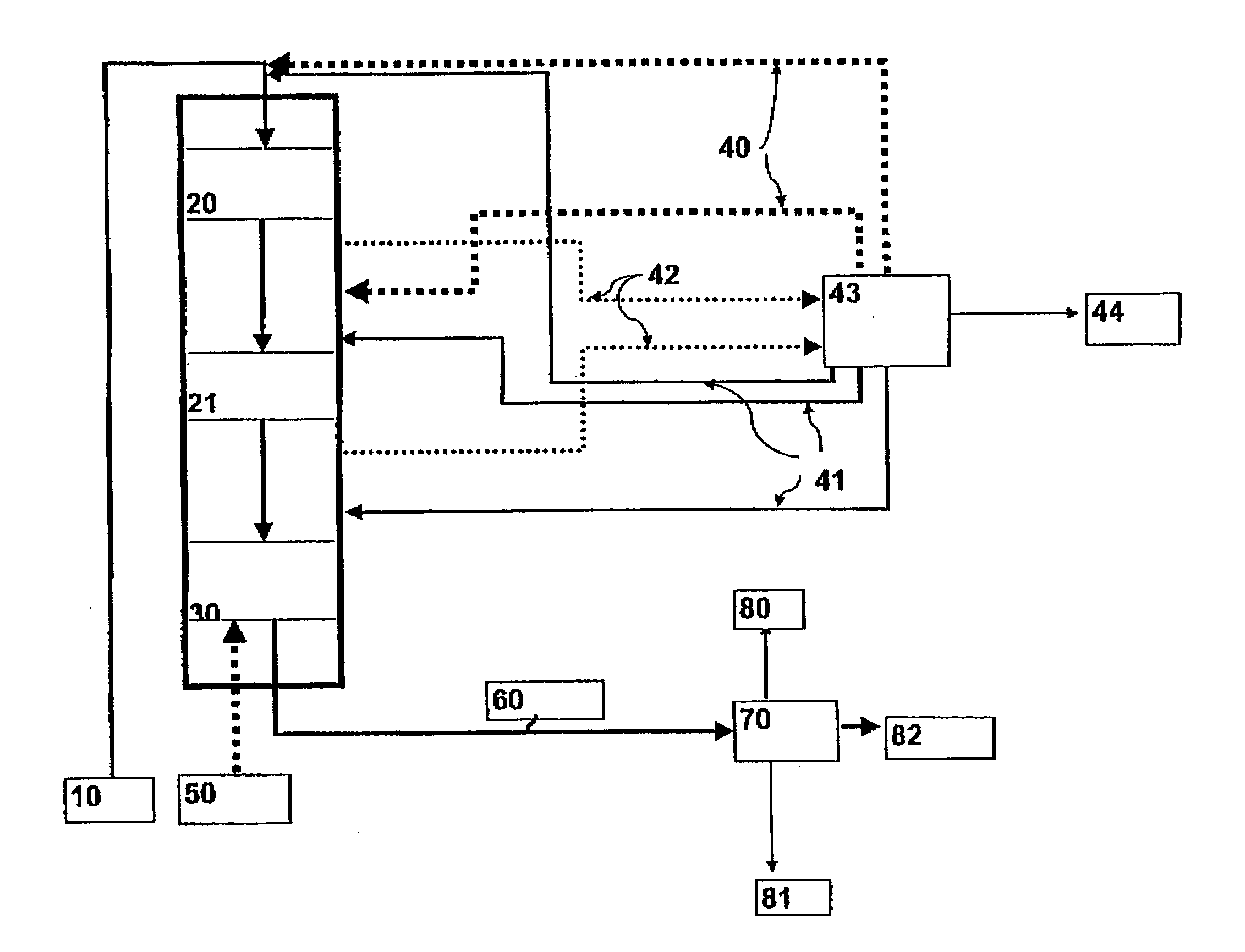

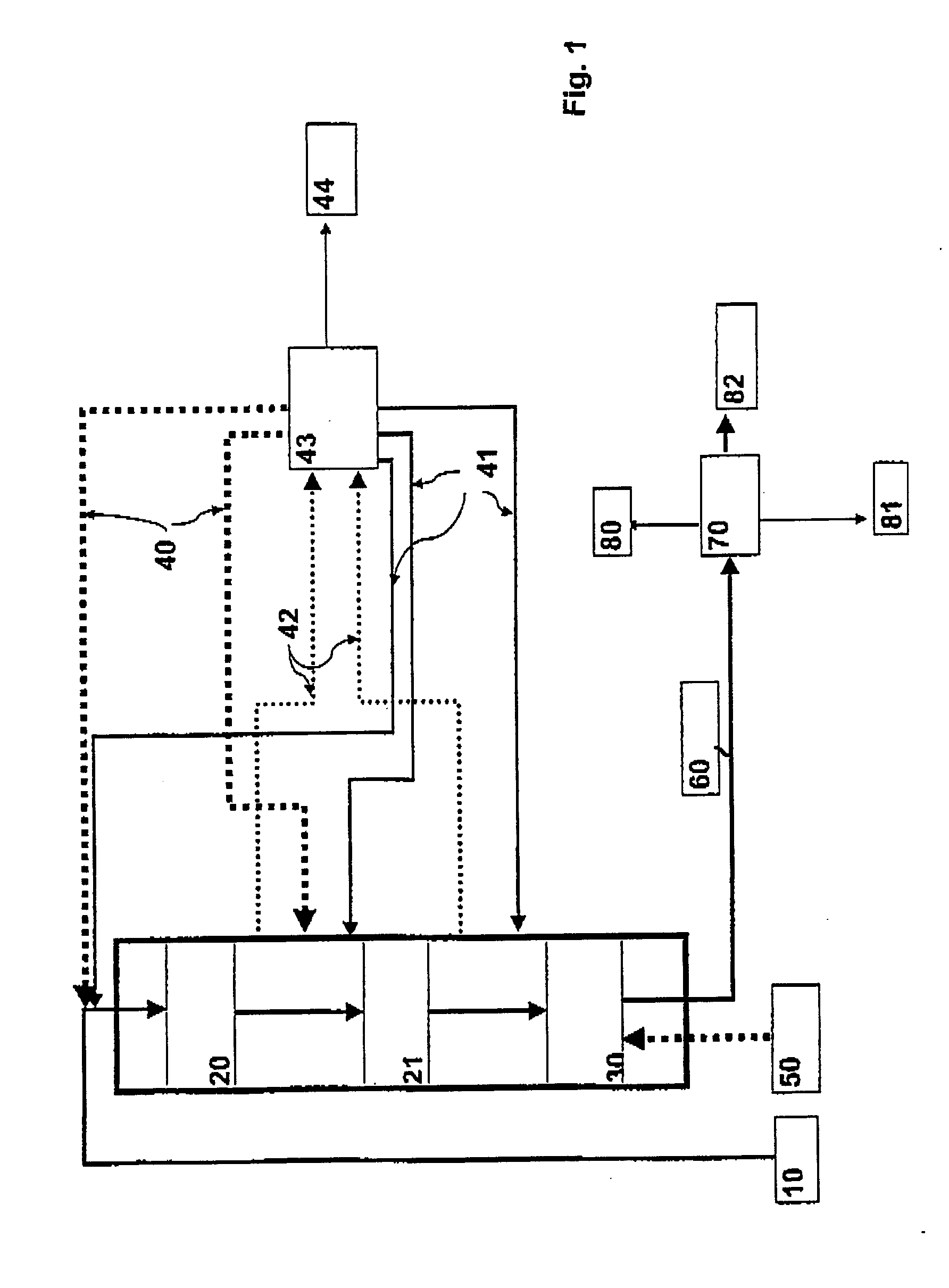

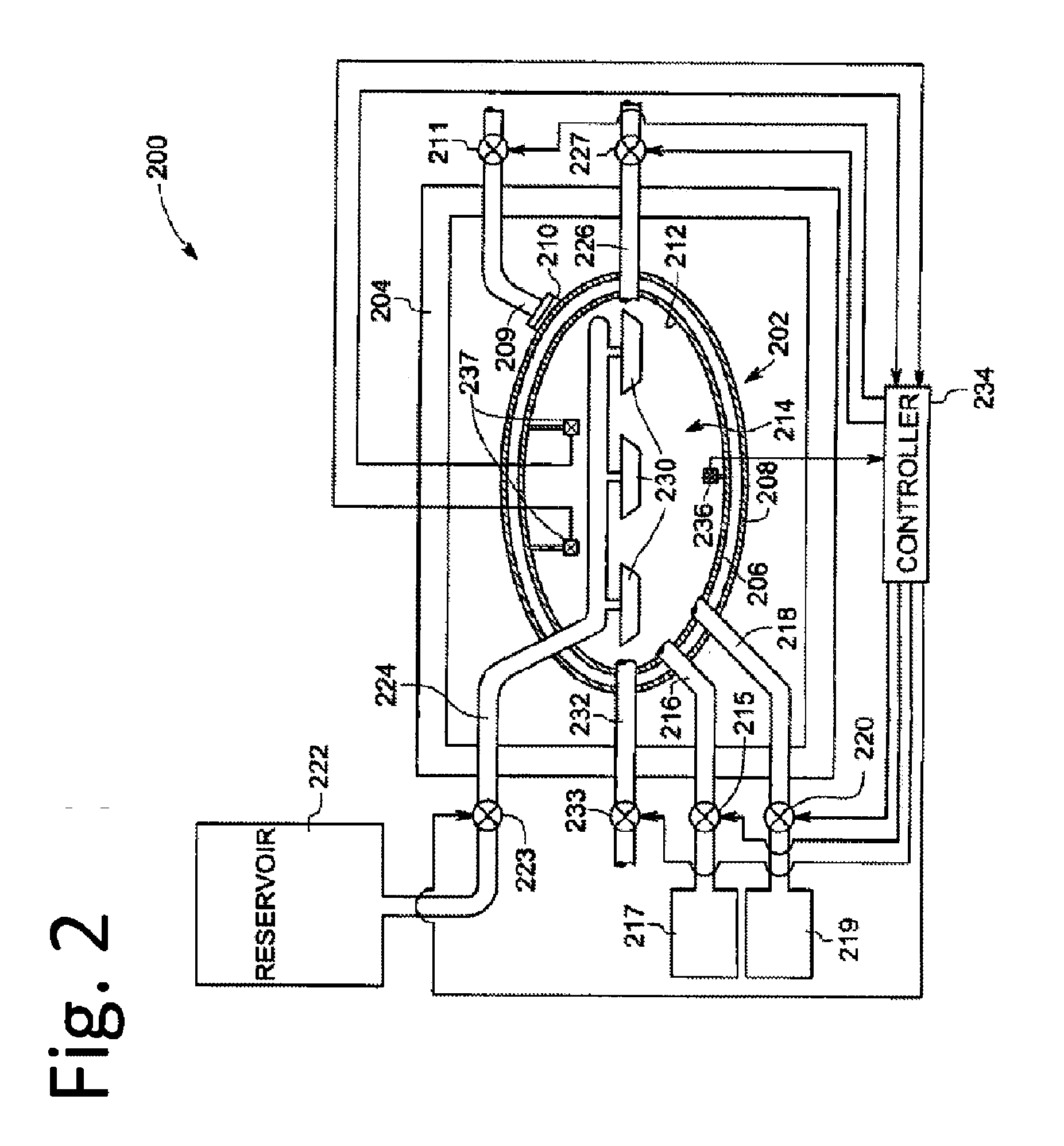

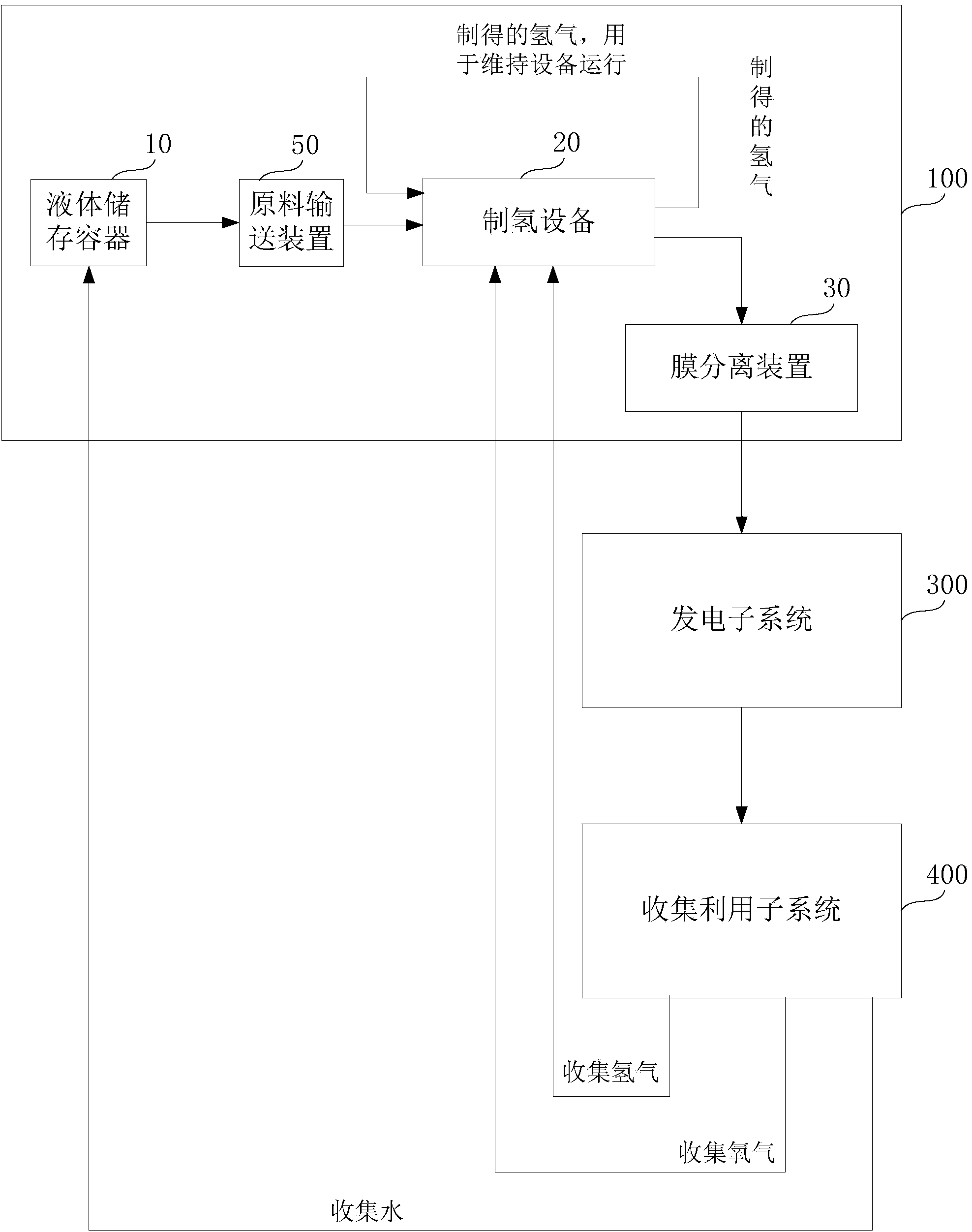

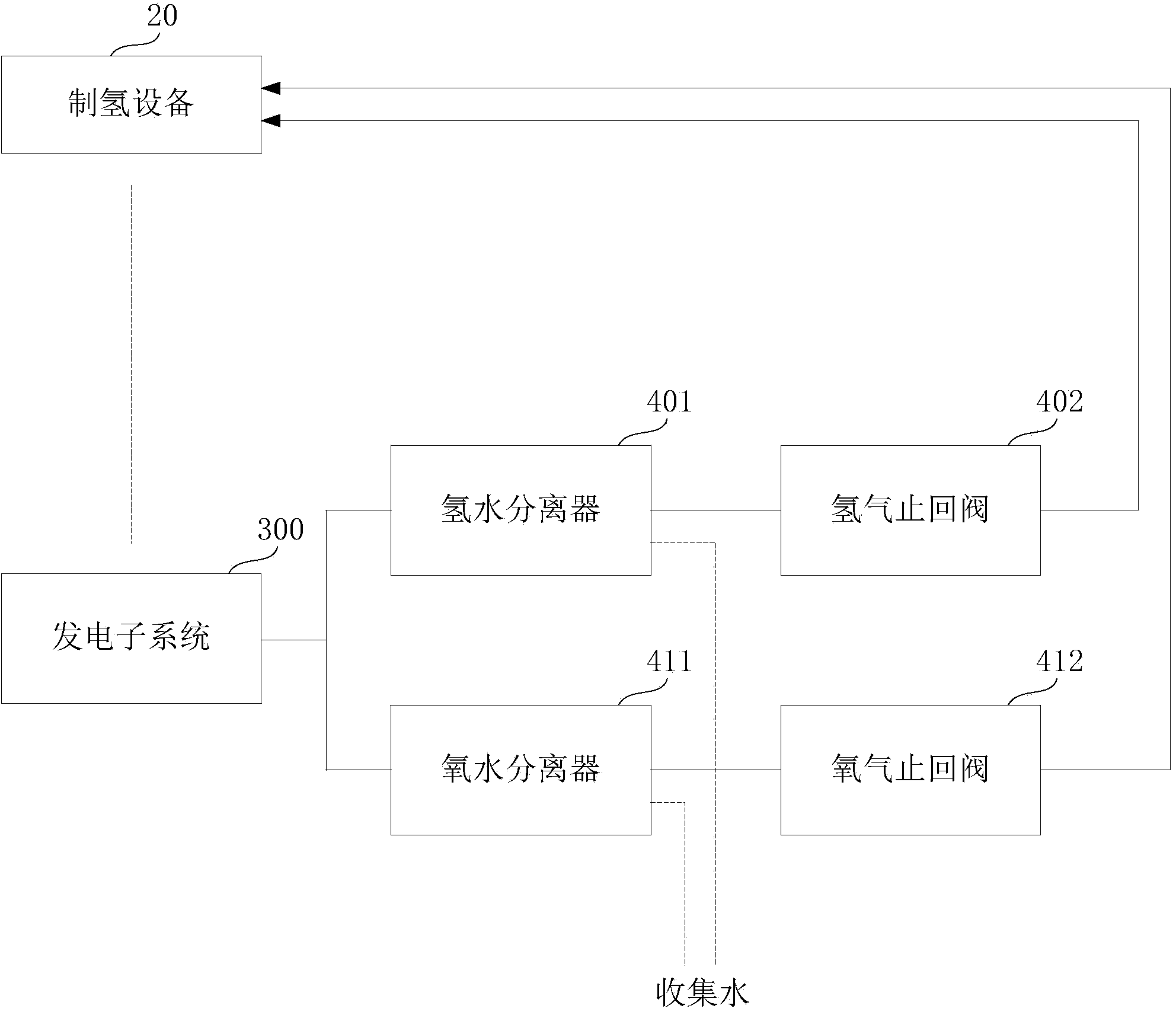

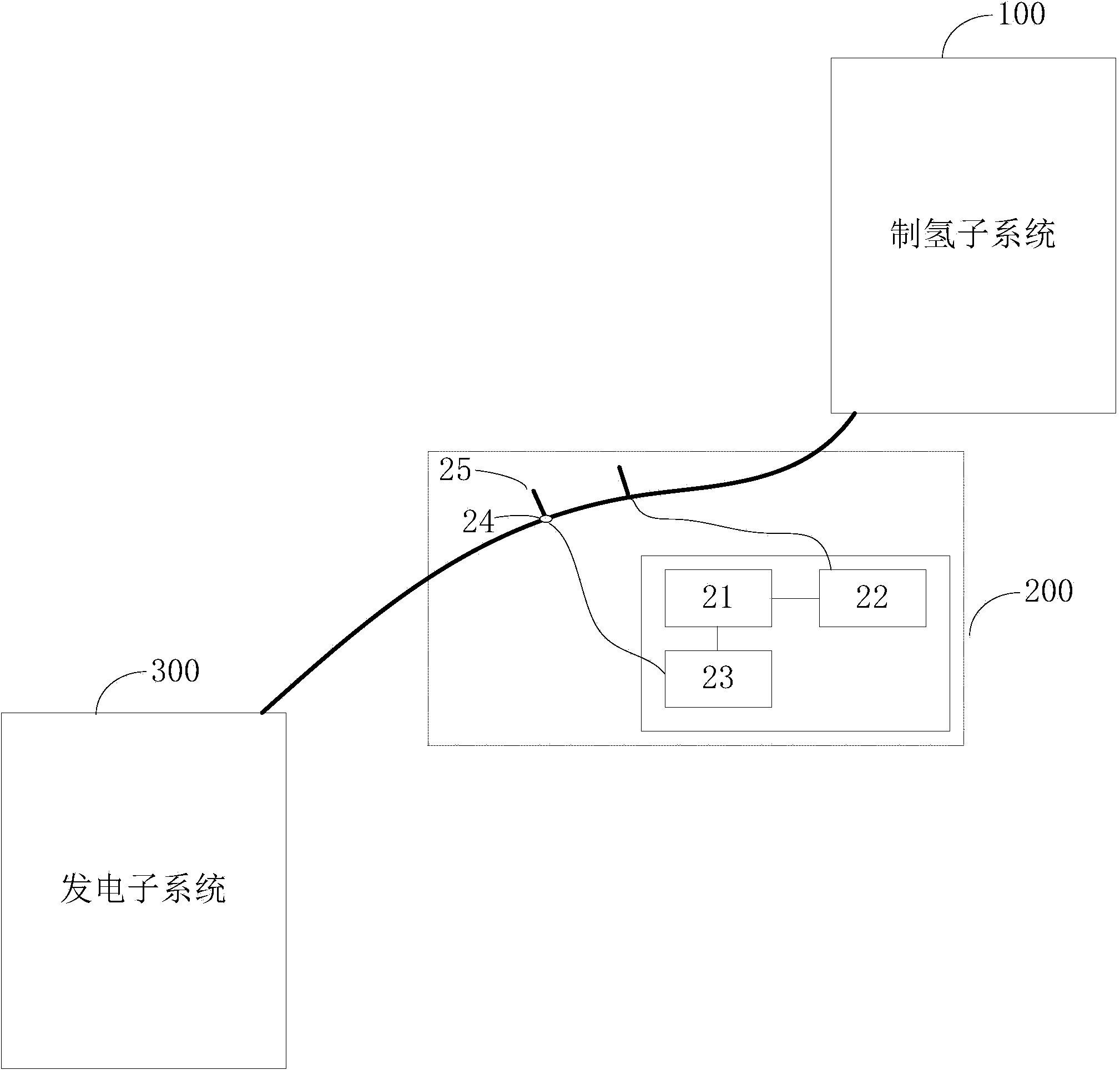

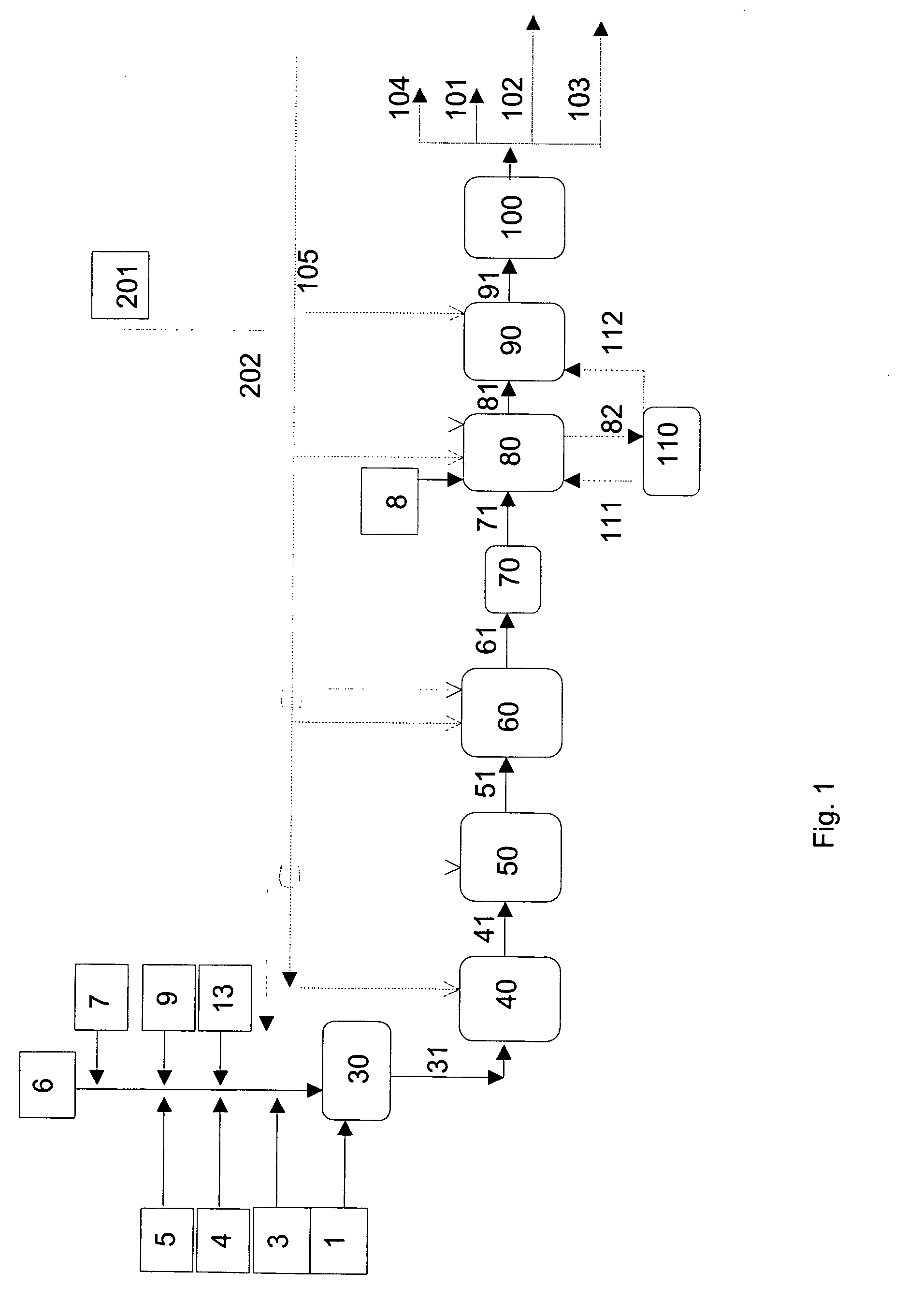

Instant hydrogen-production power generation system and method

InactiveCN103618100AImprove power generation efficiencySave energyReactant parameters controlMethanol waterWater source

The invention discloses an instant hydrogen-production power generation system and method. The system comprises a hydrogen-production subsystem, a power generation subsystem and a collection and utilization subsystem, wherein the hydrogen-production subsystem, power generation subsystem and collection and utilization subsystem are connected sequentially; the hydrogen-production subsystem uses methanol water to produce hydrogen, and transfers the produced hydrogen to the power generation subsystem in time through a transfer pipeline for power generation; and the collection and utilization subsystem is connected with an exhaust channel outlet of the power generation subsystem, and is used for collecting water from discharged gas or collecting water as the raw material of the hydrogen-production subsystem. The system and method can collect residual gas discharged from the power generation subsystem, and extract hydrogen, oxygen and water from the residual gas; and the hydrogen and oxygen can be combusted to release heat so as to provide heat energy for the power generation subsystem, and the water can be transferred to the hydrogen-production subsystem for cyclic utilization, so that the system does not need any additional water source. The system and method can enhance the power generation efficiency of the system and save the energy source.

Owner:广州市移电科技有限公司

Method for manufacturing alkylate oil with composite ionic liquid used as catalyst

ActiveUS20040133056A1Increase contentRaise the ratioOrganic chemistry methodsLiquid hydrocarbon mixtures productionAlkaneIonic liquid

The present invention pertains to a method for manufacturing alkylate oil using a composite ionic liquid as catalyst. A mixture of isobutane and C4 olefins is used as the raw material, and a composite ionic liquid is used as catalyst to carry out an alkylation reaction. The alkane / olefin ratio in the raw material is higher than 1:1. In the composition of the aforementioned composite ionic liquid catalyst, the cations come from a hydrohalide of an alkyl-containing amine or pyridine, while the anions are composite coordinate anions coming from two or more metal compounds. One of the metal compounds is an aluminum compound, while other metal compounds are compounds of Group IB and Group IIB elements of the Periodic Table and the transition metals. The present invention also provides a design of static mixer reaction apparatus that can realize the aforementioned manufacturing method. The method of the present invention increases the selectivity of the alkylation reaction to give the alkylation product a relatively high octane number and further increase the product yield. Also, the manufacturing operation is simplified, and the cost can be reduced. This method is an environmentally friendly method that will not pollute the environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

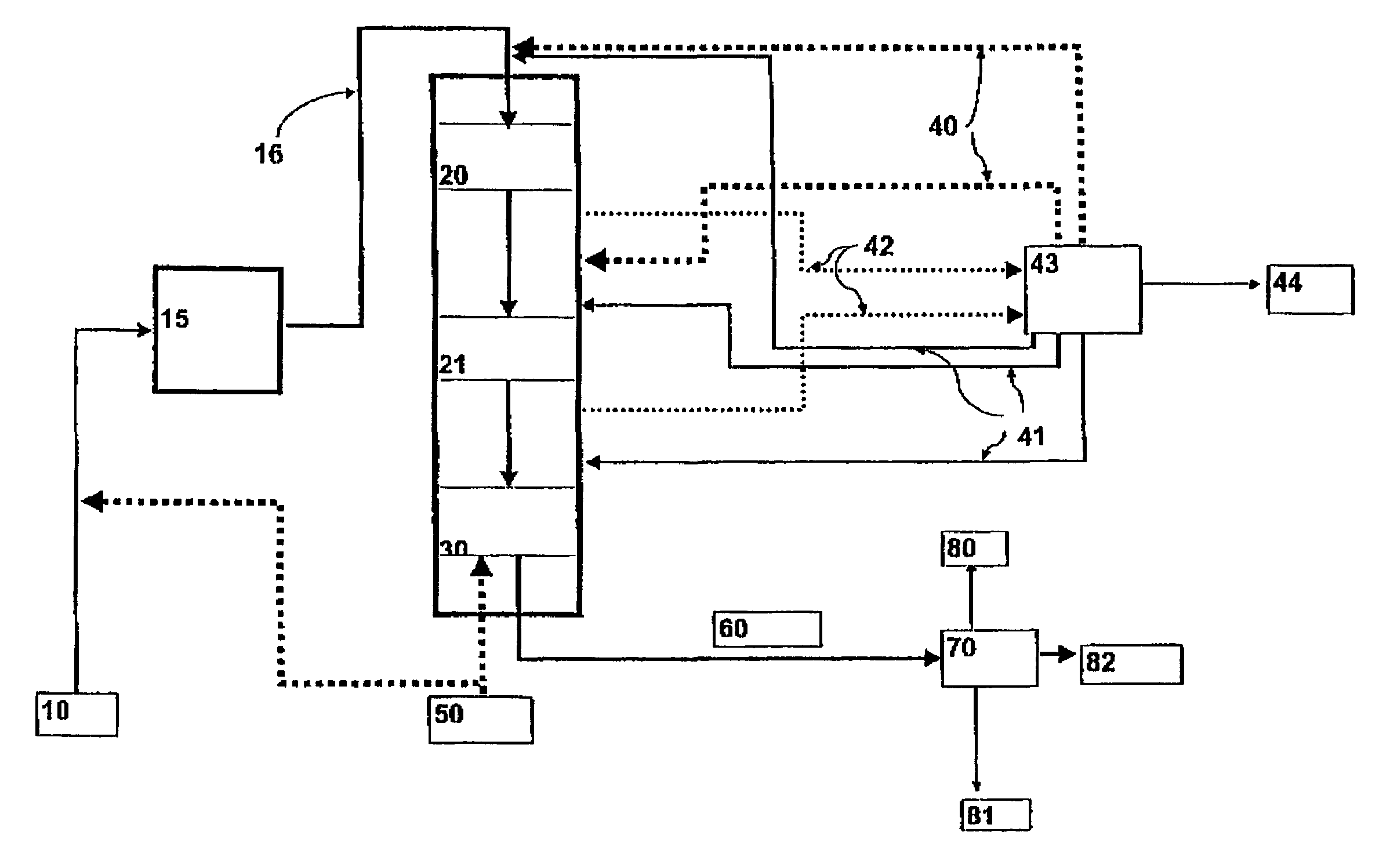

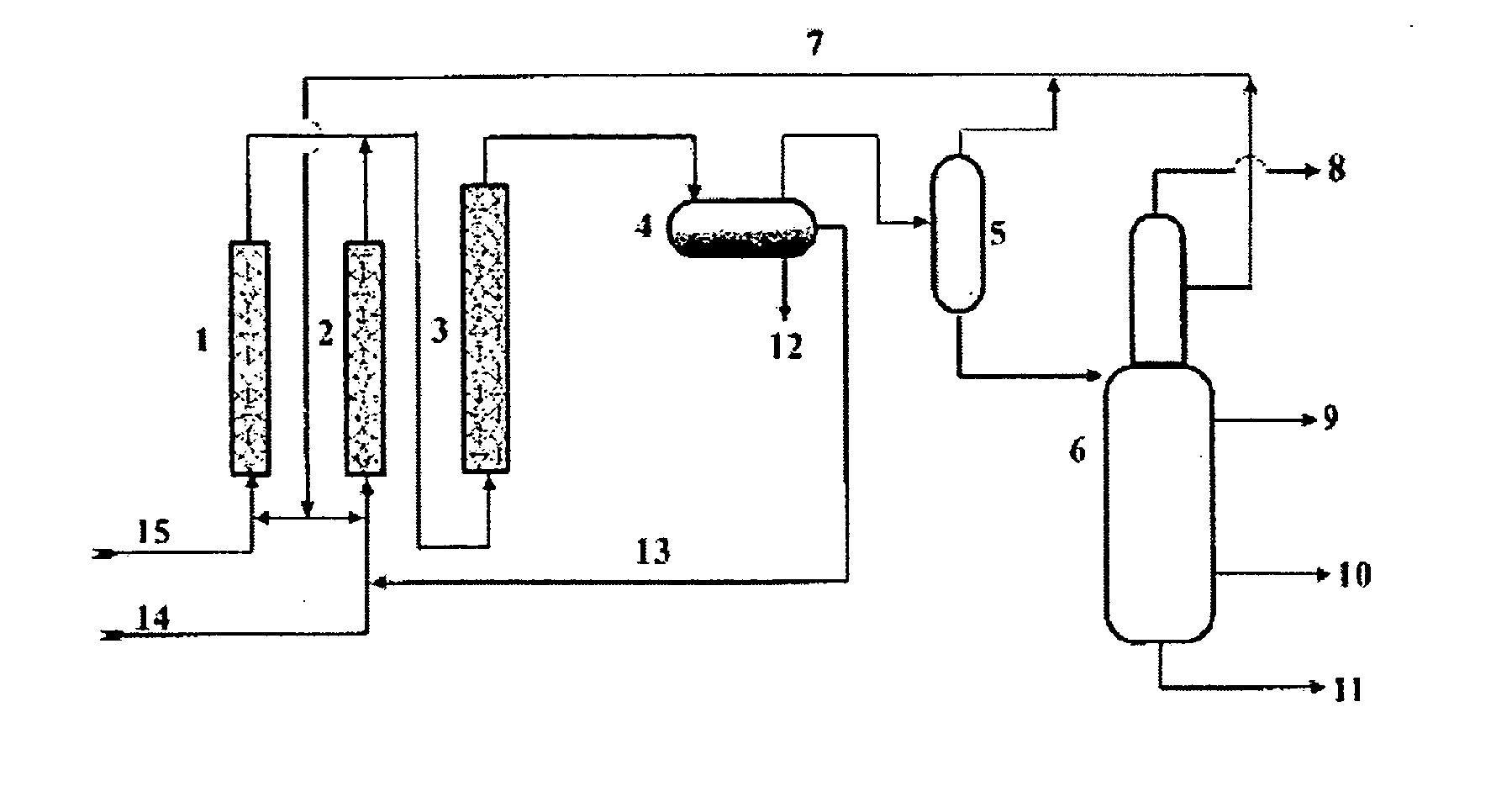

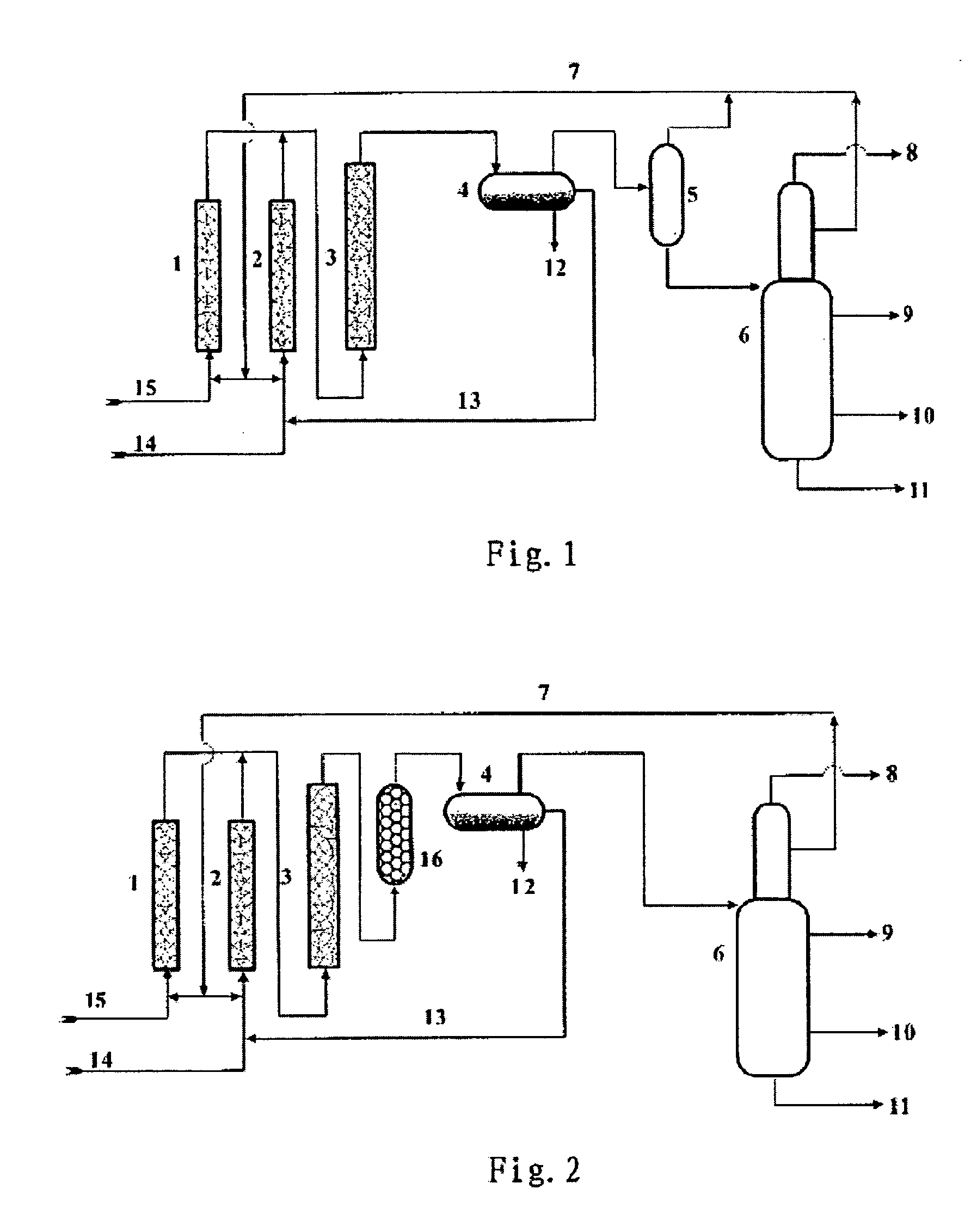

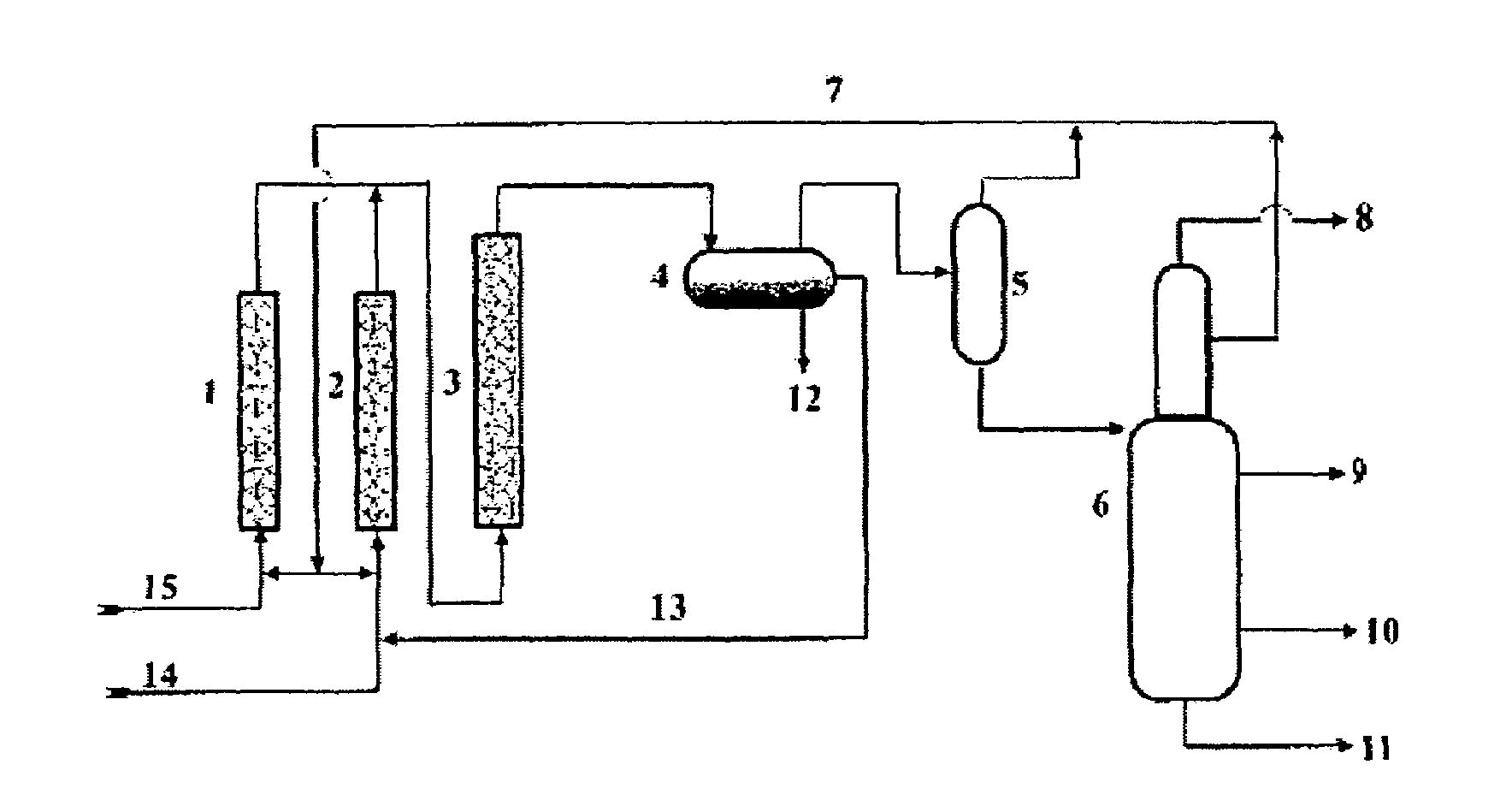

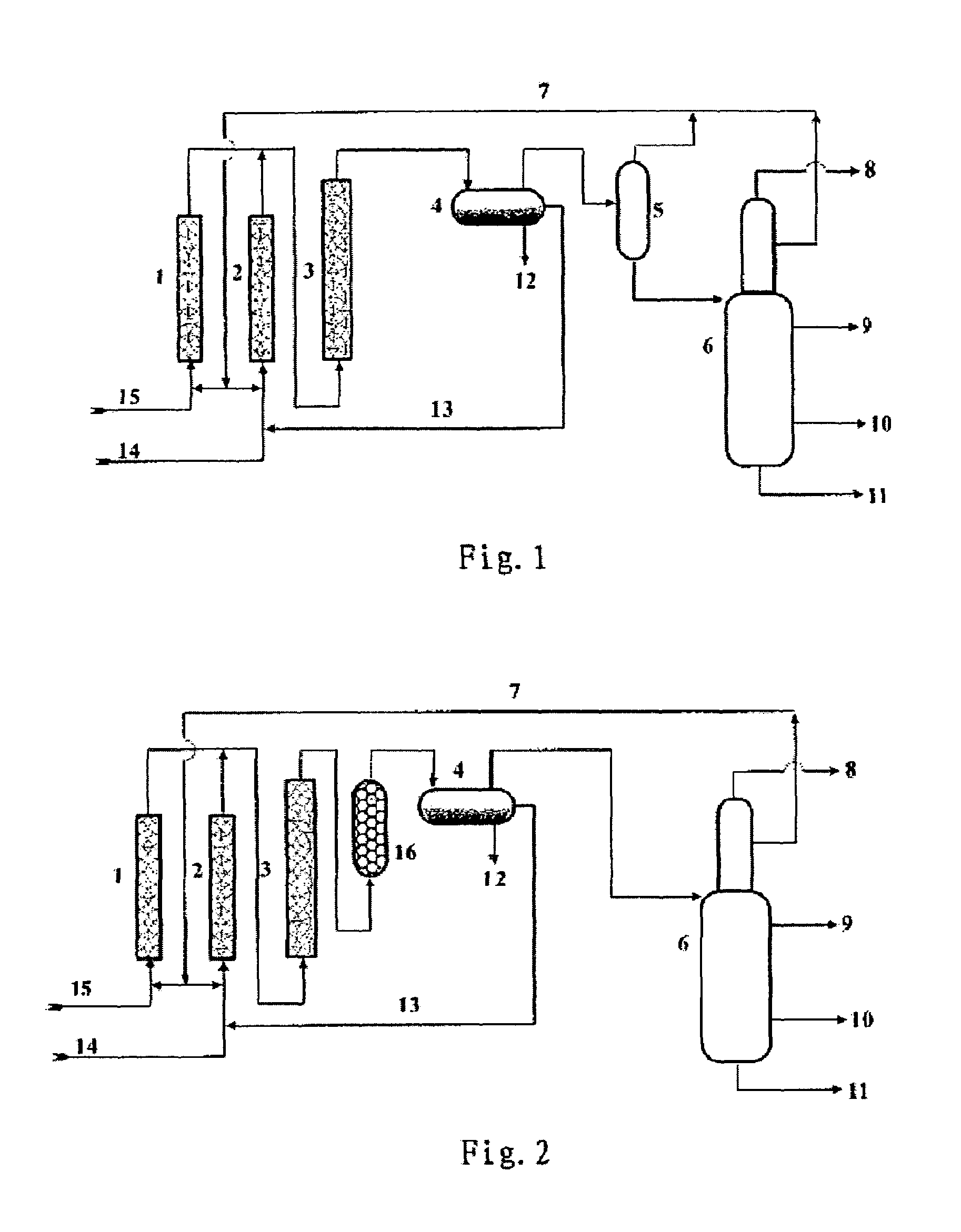

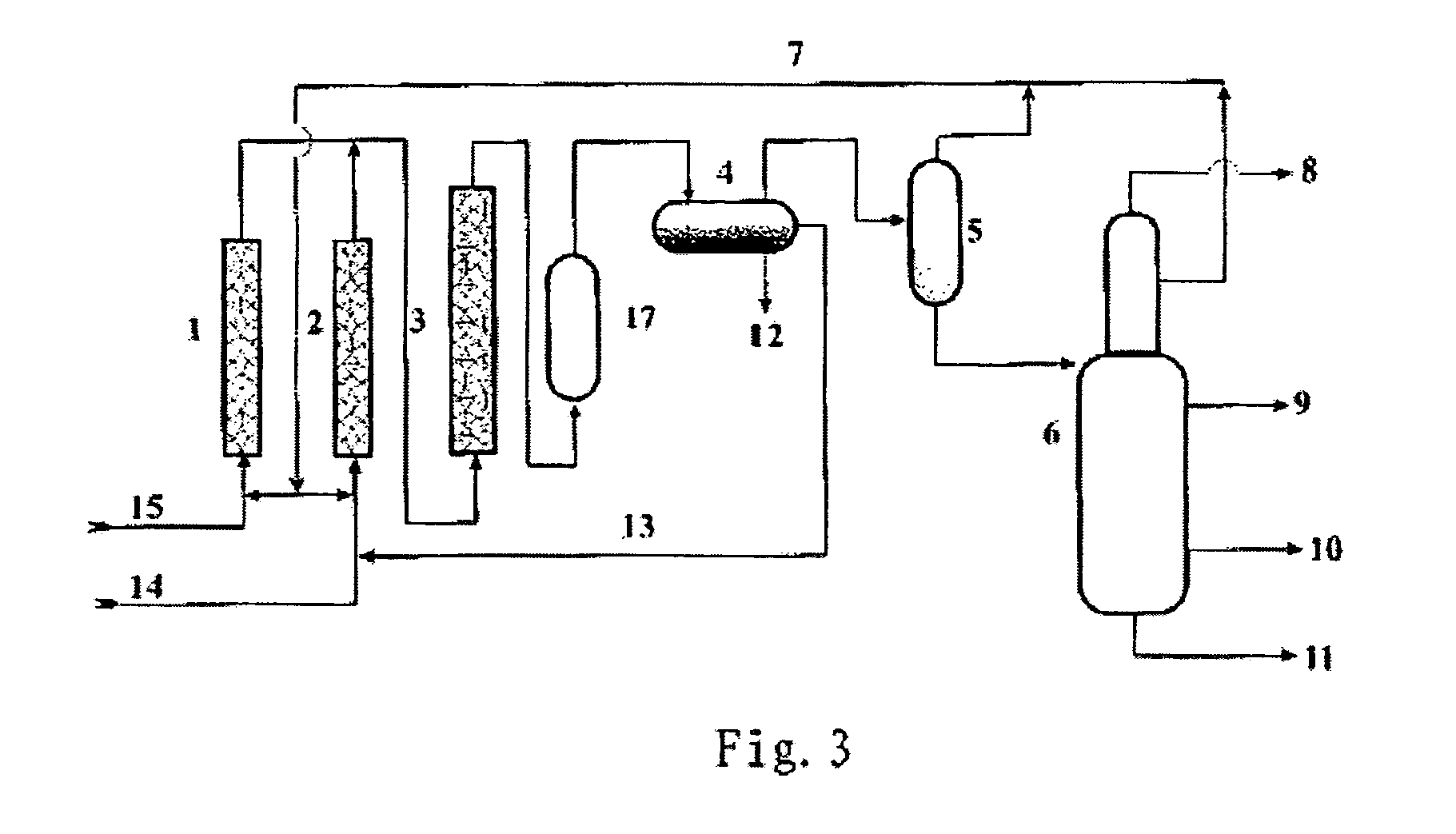

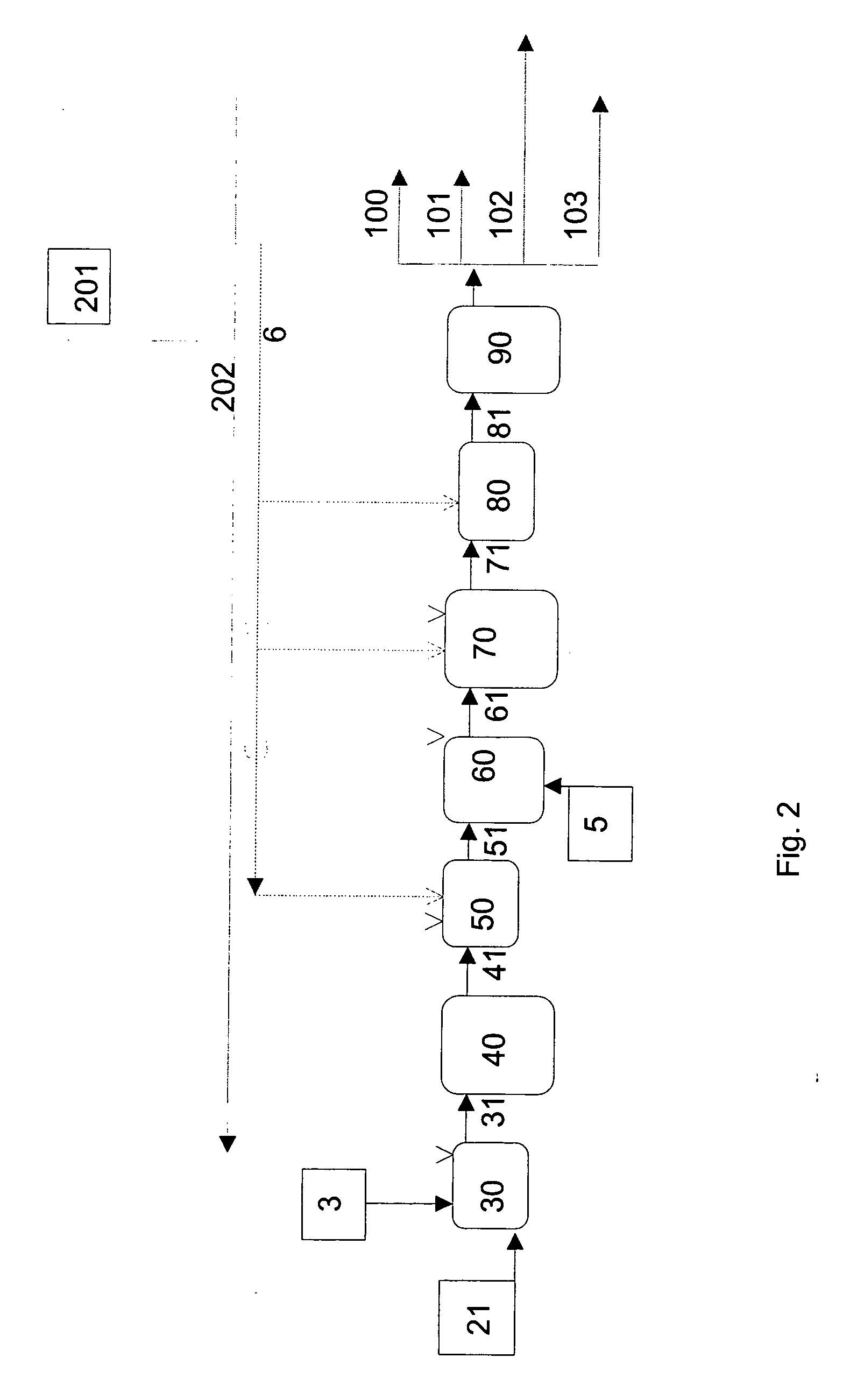

System and process for preparing aromatic hydrocarbon by converting methanol or dimethyl ether

ActiveCN101823929AHigh yieldHigh selectivityHydrogen separation using liquid contactHydrocarbon from oxygen organic compoundsAromatizationAromatic hydrocarbon

The invention relates to a system and a process for preparing aromatic hydrocarbon by converting methanol or dimethyl ether and belongs to the technical field of aromatic hydrocarbon production. The methanol or the dimethyl ether serving as a raw material firstly reacts in an aromatization reactor; a reaction product is separated; H2, methane, mixed C8 aromatic hydrocarbon and partial C9s + hydrocarbons serving as products are output from the system; and C2+ non-aromatic hydrocarbon and aromatic hydrocarbons except the mixed C8 aromatic hydrocarbon and the partial C9s + hydrocarbons are take as a circular material flow and return to corresponding reactors for further aromatization reaction. By separating and recycling the product obtained in the process of aromizing the methanol or the dimethyl ether, the system and the process improve the yield and selectivity of the aromatic hydrocarbon; and moreover, the process is flexible, and target products can be changed according to market demands.

Owner:TSINGHUA UNIV

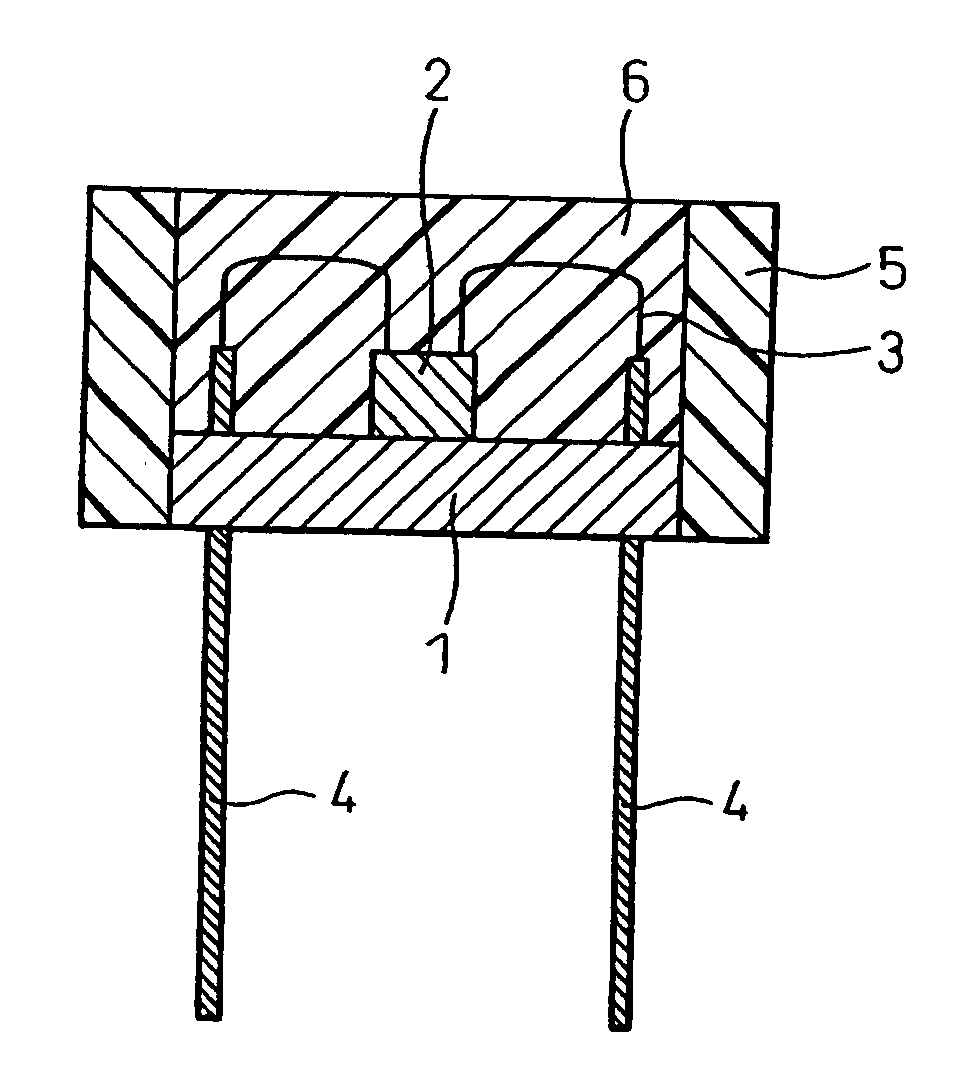

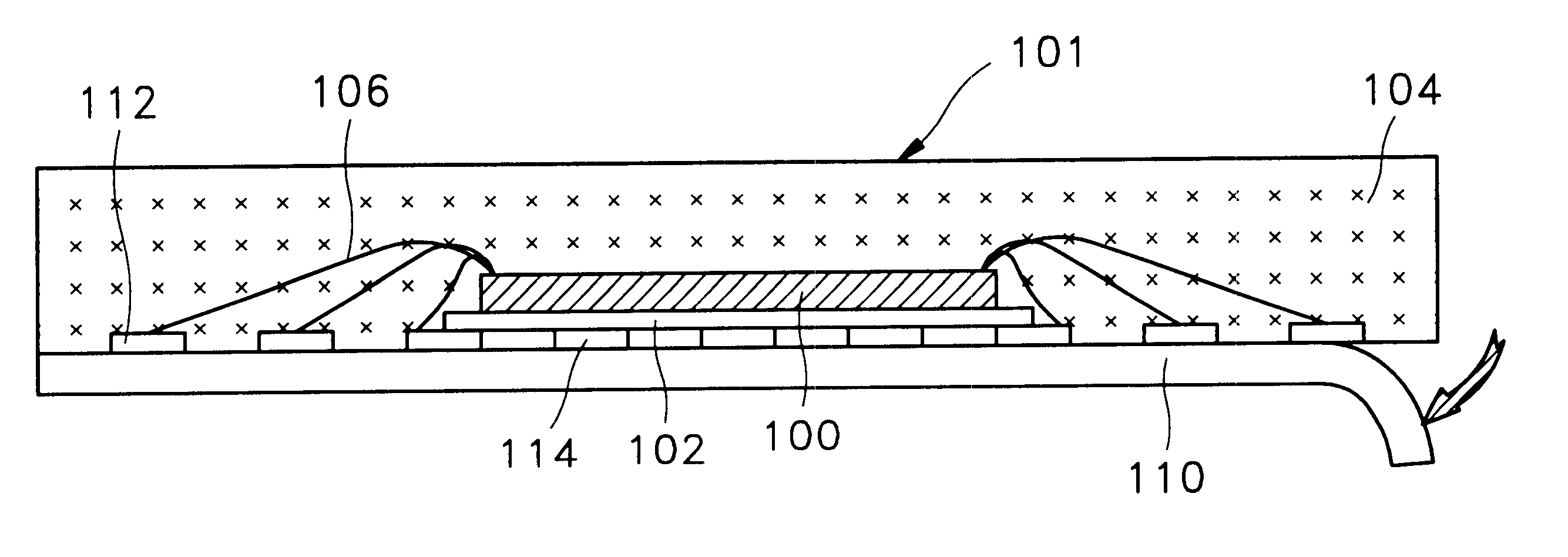

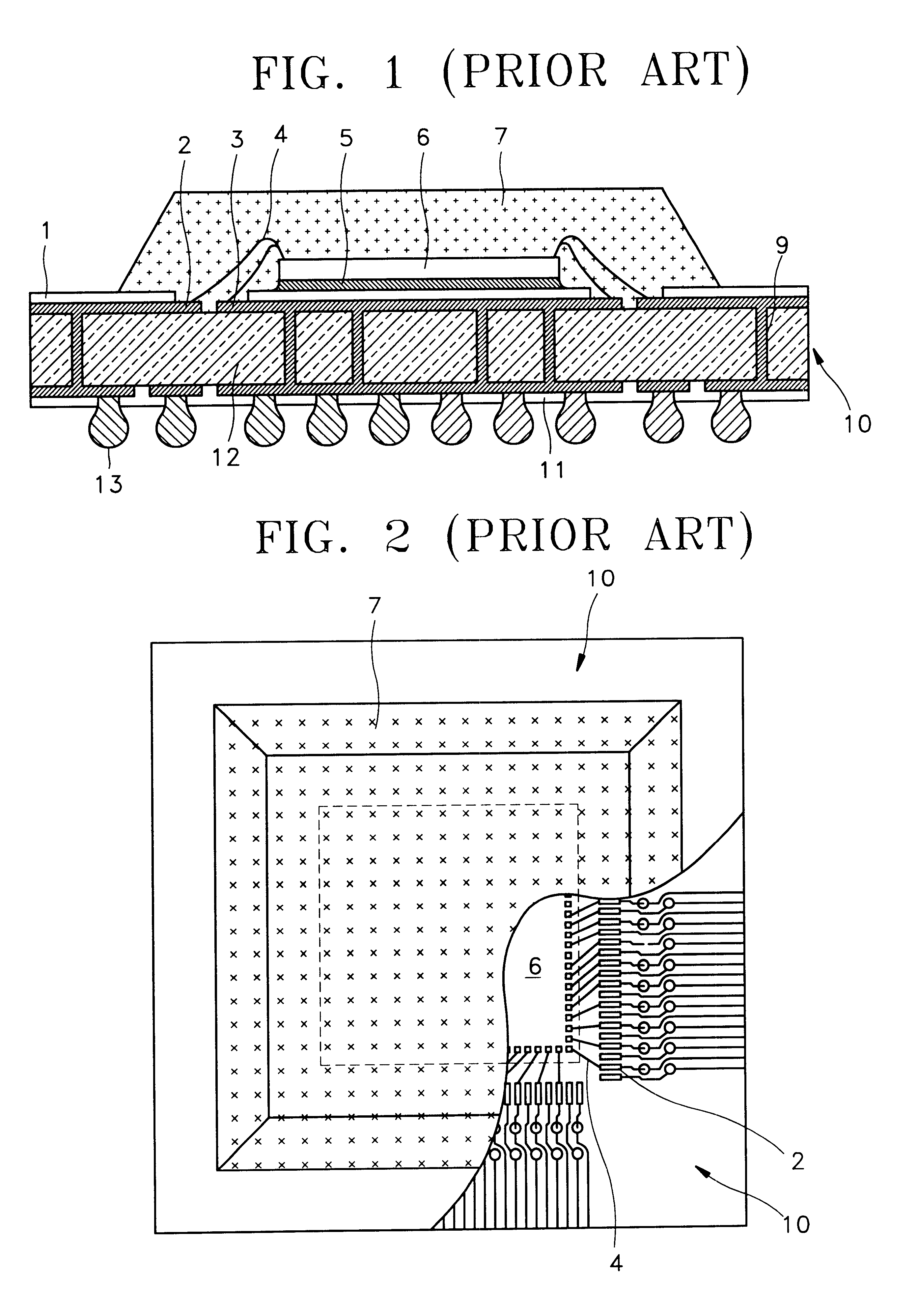

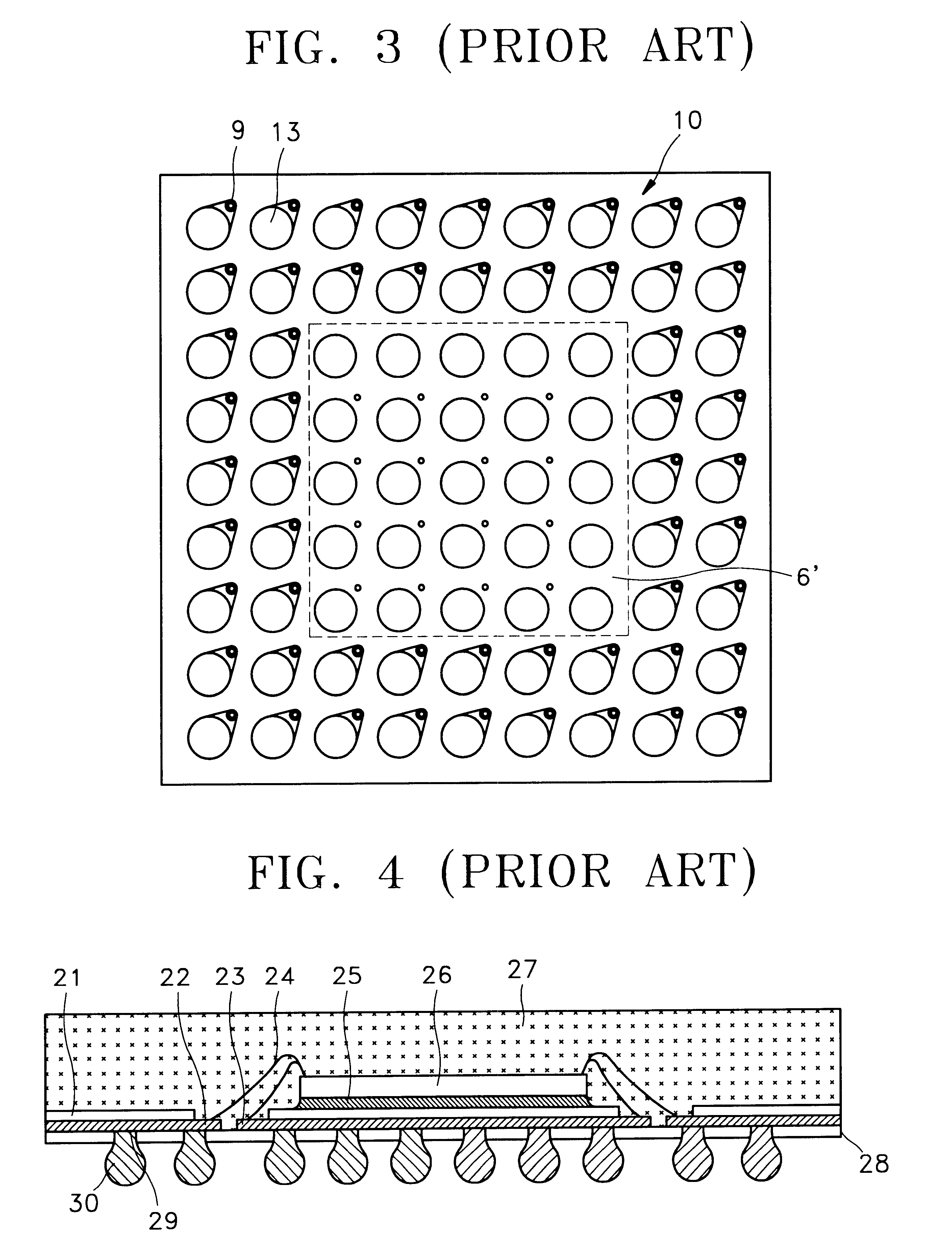

Semiconductor package having implantable conductive lands and method for manufacturing the same

InactiveUS6429508B1Semiconductor/solid-state device detailsSolid-state devicesManufacturing cost reductionSemiconductor package

Owner:KOSTAT SEMICON

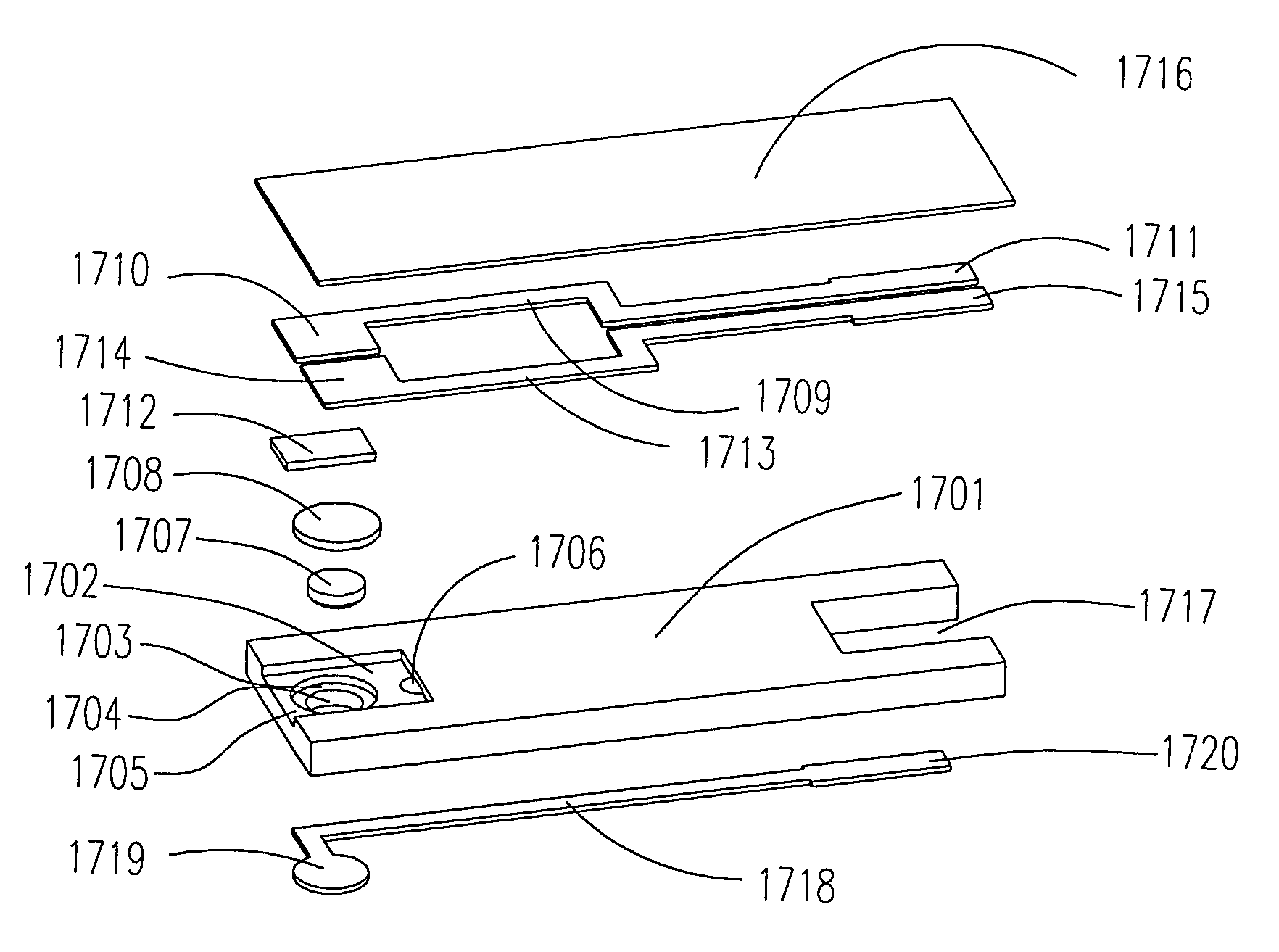

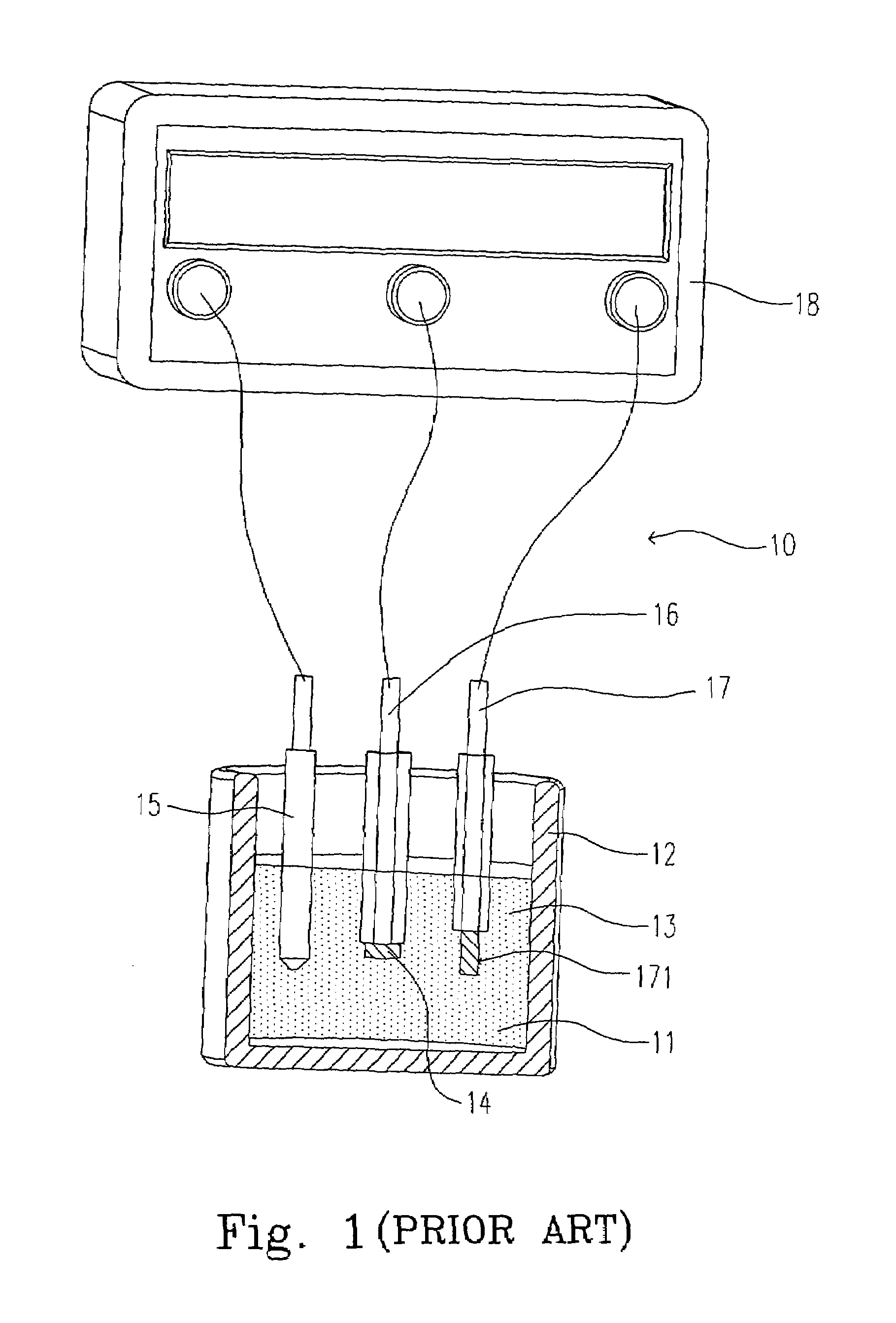

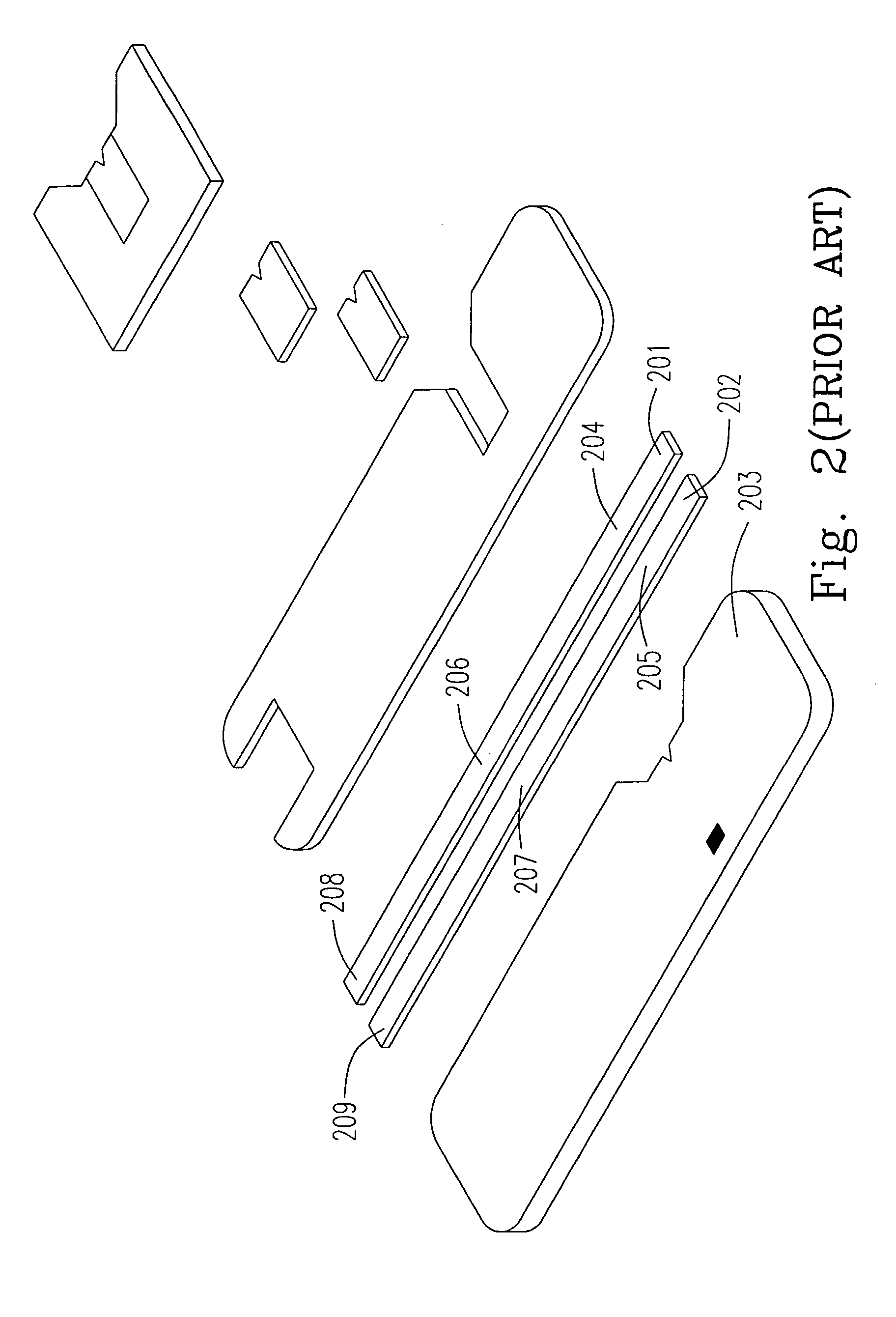

Structure and manufacturing method of disposable electrochemical sensor strip

ActiveUS7063776B2Reduce the amount requiredShorten production timeImmobilised enzymesBioreactor/fermenter combinationsMetalElectrical and Electronics engineering

A disposable electrochemical sensor strip is provided. The sensor strip includes an isolating sheet having at least a through hole, at least a conductive raw material mounted in the through hole, a metal film covered on the conductive raw material to form an electrode which comprises an electrode working surface for processing an electrode action, and an electrode connecting surface, at least a printed conductive film mounted on the isolating sheet and having a connecting terminal for being electrically connected to the electrode connecting surface, and a signal output terminal for outputting a measured signal produced by the electrode action.

Owner:HUANG CHUN MU

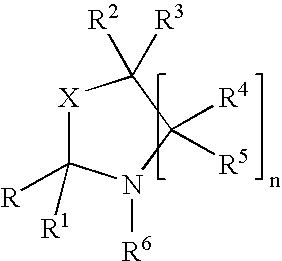

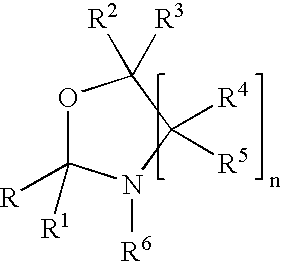

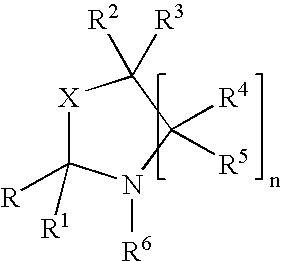

Fragrance pro-accords and aldehyde and ketone fragrance libraries

InactiveUS7018978B2Extend your lifeEasy to prepareCosmetic preparationsOrganic chemistryFlavorOxazolidine E

The present invention relates to novel heterocyclic pro-fragrances, preferably oxazolidines, tertahydro-1,3-oxazines, thiazolidines, or tetrahydro-1,3-thiazines, more preferably oxazolidines, or tertahydro-1,3-oxazines, most preferably oxazolidines, which are capable of sustained release of fragrance raw material ketones and aldehydes and to fragrance delivery systems which comprise said pro-fragrances.

Owner:THE PROCTER & GAMBLE COMPANY

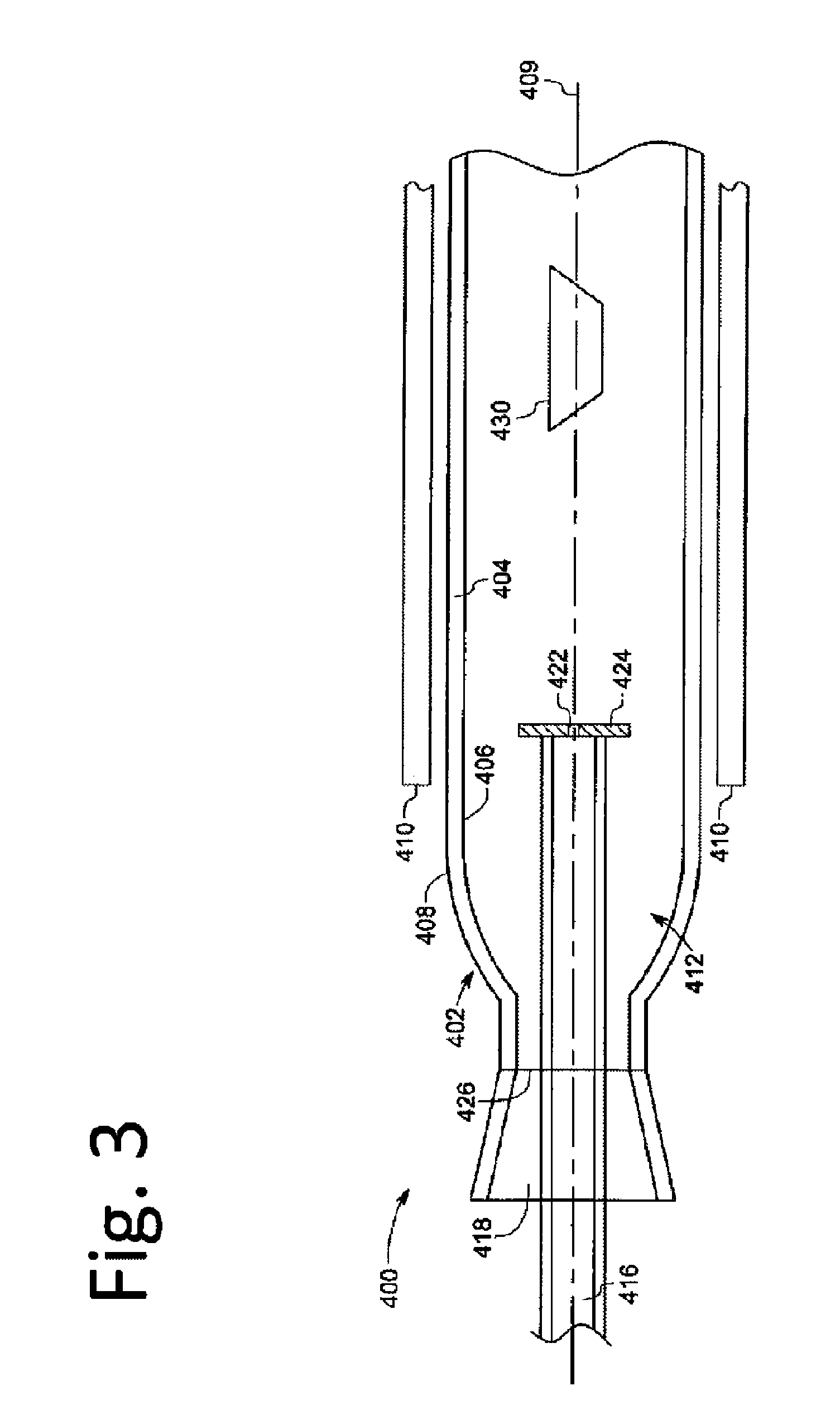

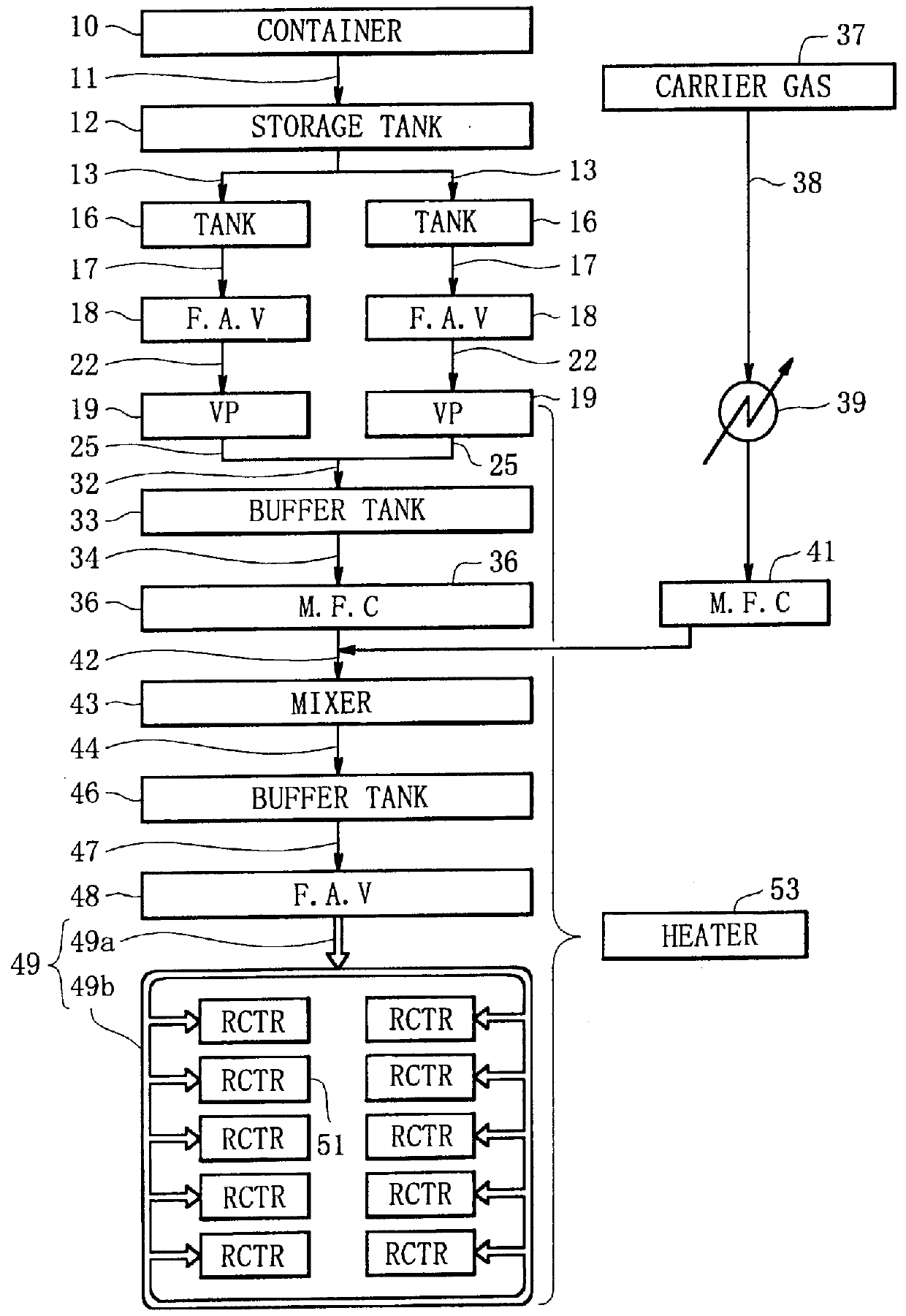

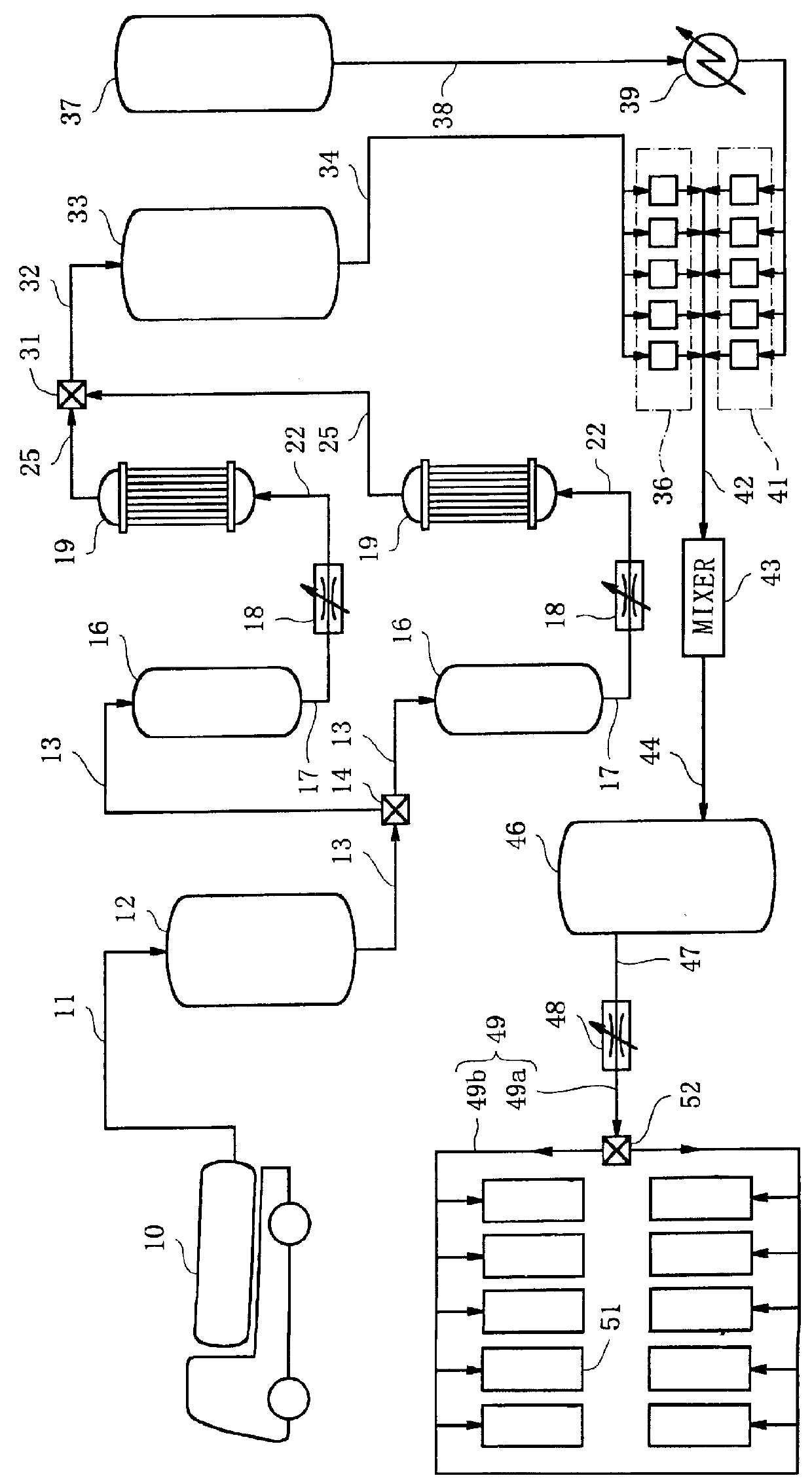

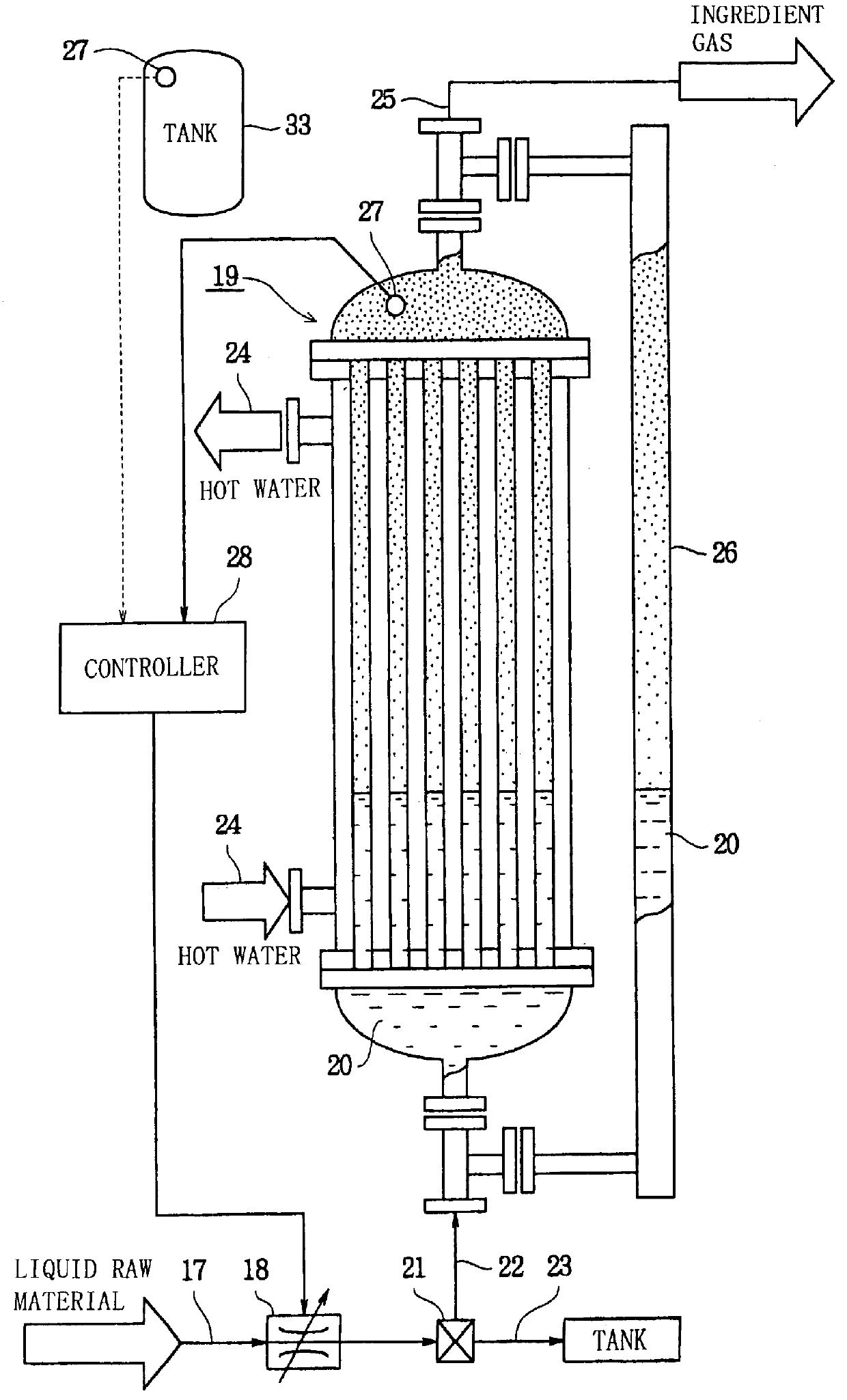

Method and apparatus for feeding a gas for epitaxial growth

InactiveUS6039809APolycrystalline material growthTransportation and packagingBoiling pointProduct gas

A liquid raw material is heated to its boiling point or higher at a vaporizer to mix the vaporized ingredient gas and a carrier gas at a mixer at predetermined concentrations. The flow of the mixed gas is adjusted while the mixed gas is heated to over its condensing point and the temperature thereof is kept. Subsequently, the mixed gas is fed to a reactor for epitaxial growth while the mixed gas is heated to over its condensing point and the temperature thereof is kept. When the temperature of a heating medium is kept constant at the vaporizer to vaporize the liquid raw material and the feeding amount of the liquid into the vaporizer is adjusted by the pressure of the gas inside the vaporizer, the liquid surface level can be controlled to be constant.

Owner:MITSUBISHI MATERIALS CORP

Method for manufacturing alkylate oil with composite ionic liquid used as catalyst

ActiveUS7285698B2High selectivityImprove production yieldOrganic chemistry methodsLiquid hydrocarbon mixtures productionAlkaneIonic liquid

The present invention pertains to a method for manufacturing alkylate oil using a composite ionic liquid as catalyst. A mixture of isobutane and C4 olefins is used as the raw material, and a composite ionic liquid is used as catalyst to carry out an alkylation reaction. The alkane / olefin ratio in the raw material is higher than 1:1. In the composition of the aforementioned composite ionic liquid catalyst, the cations come from a hydrohalide of an alkyl-containing amine or pyridine, while the anions are composite coordinate anions coming from two or more metal compounds. One of the metal compounds is an aluminum compound, while other metal compounds are compounds of Group IB and Group IIB elements of the Periodic Table and the transition metals. The present invention also provides a design of static mixer reaction apparatus that can realize the aforementioned manufacturing method. The method of the present invention increases the selectivity of the alkylation reaction to give the alkylation product a relatively high octane number and further increase the product yield. Also, the manufacturing operation is simplified, and the cost can be reduced. This method is an environmentally friendly method that will not pollute the environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Phosphor, light source and LED

InactiveUS20050189863A1Improve luminance of light lightImprove of visible light lightDischarge tube luminescnet screensLamp detailsPhosphorUltraviolet lights

A phosphor with high efficiency having an excitation band corresponding to light of the ultraviolet-visible (300 to 550 nm) wavelength region emitted from a light emitting portion which emits blue or ultraviolet light is provided. A nitride of Ca, a nitride of Al, a nitride QfSi, and an oxide of Eu are prepared, and respective raw materials are weighed so that a mol ratio of respective elements becomes Ca:Al:Si:Eu=0.985:3:1:0.015, mixed under a nitrogen atmosphere, and thereafter fired at 1500° C. in a nitrogen atmosphere to thereby produce a phosphor having a composition formula Ca0.985SiAlN3:Eu0.015.

Owner:NICHIA CORP

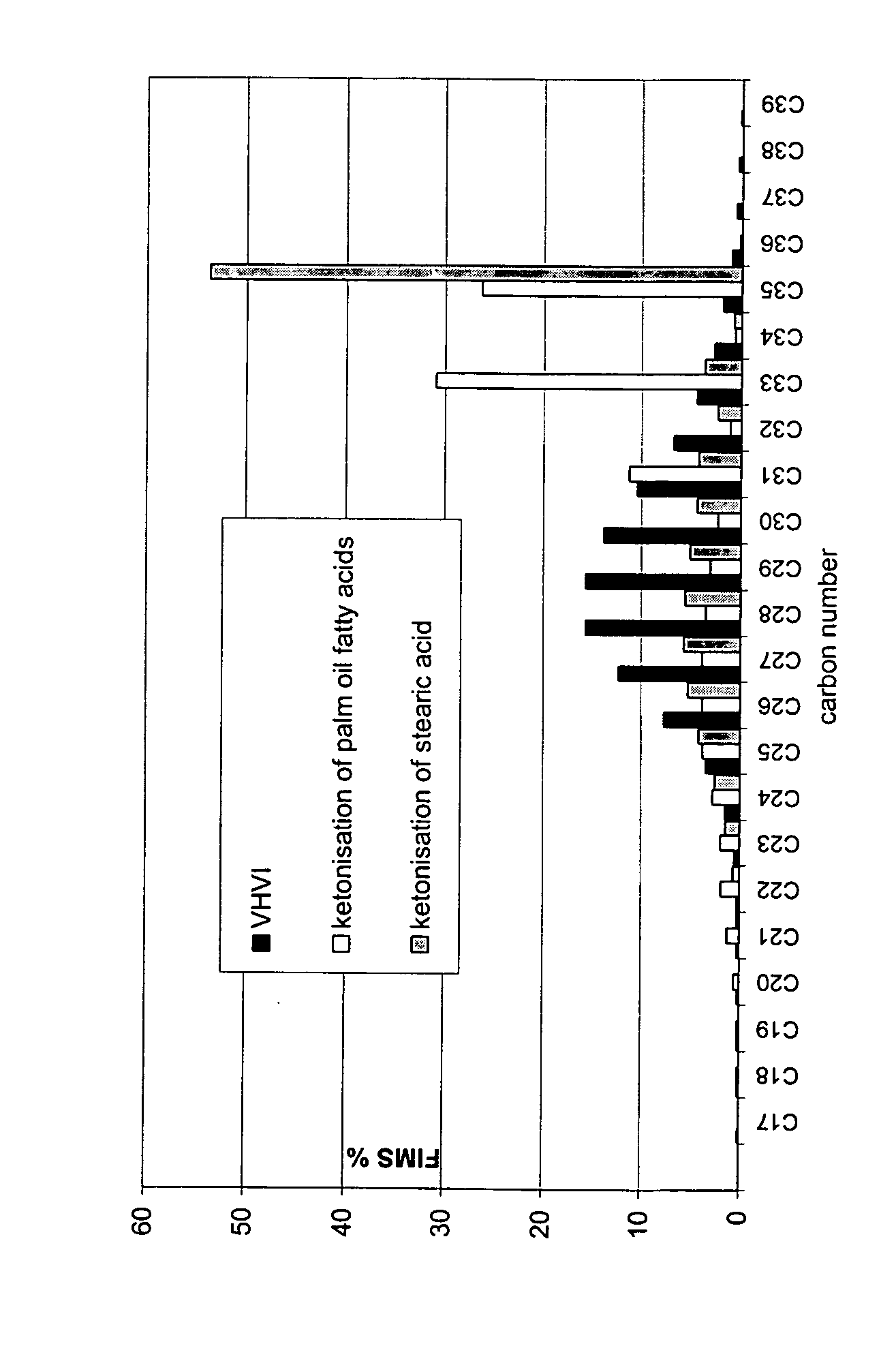

Process for producing a hydrocarbon component

ActiveUS20070161832A1Reduce carbon dioxide emissionsImprove low temperature performanceFatty oils/acids recovery from wasteFatty acid hydrogenationIsomerizationHydrodeoxygenation

The invention relates to a process for producing a new type of high-quality hydrocarbon base oil of biological origin. The process of the invention comprises ketonisation, hydrodeoxygenation, and isomerization steps. Fatty acids and / or fatty acid esters based on a biological raw material are preferably used as the feedstock.

Owner:NESTE OIL OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com