Patents

Literature

4571 results about "Autoclave" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An autoclave is a pressure chamber used to carry out industrial and scientific processes requiring elevated temperature and pressure different from ambient air pressure. Autoclaves are used in medical applications to perform sterilization and in the chemical industry to cure coatings and vulcanize rubber and for hydrothermal synthesis. Industrial autoclaves are used in industrial applications, especially regarding composites.

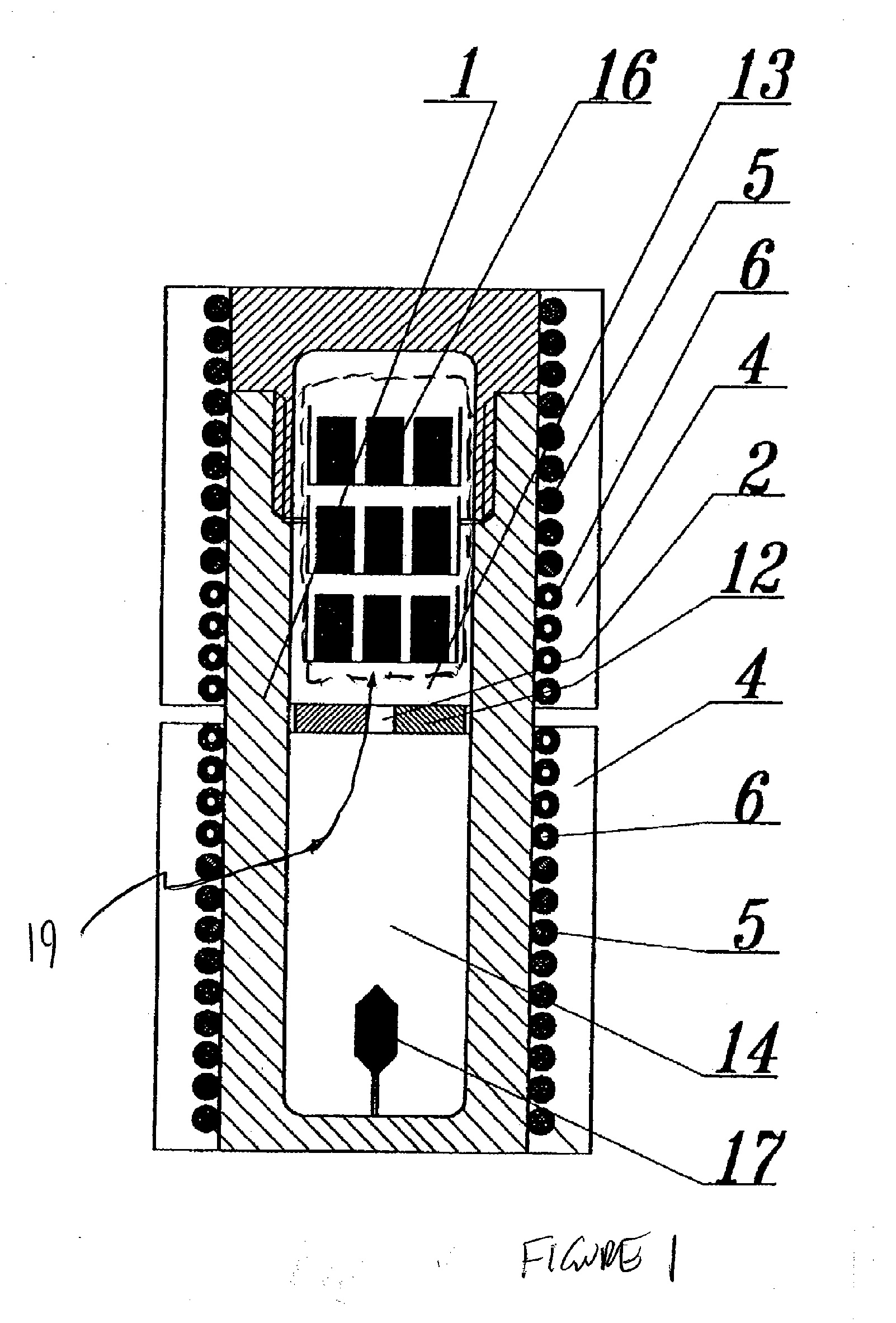

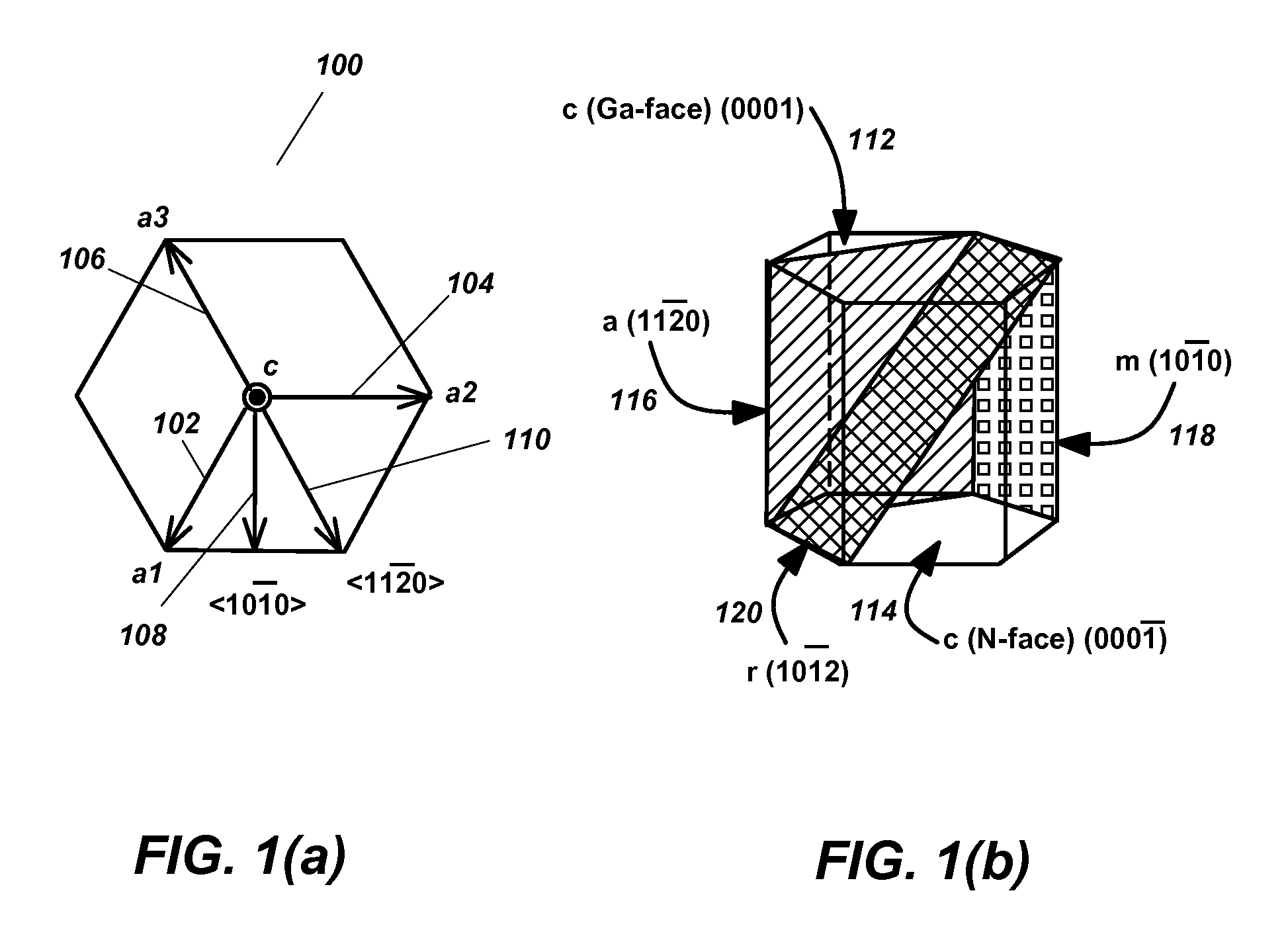

Method for producing nitride semiconductor, crystal growth rate increasing agent, single crystal nitride, wafer and device

InactiveUS20100104495A1Improve performanceIncrease probabilityPolycrystalline material growthFrom normal temperature solutionsNitrogenCrystal structure

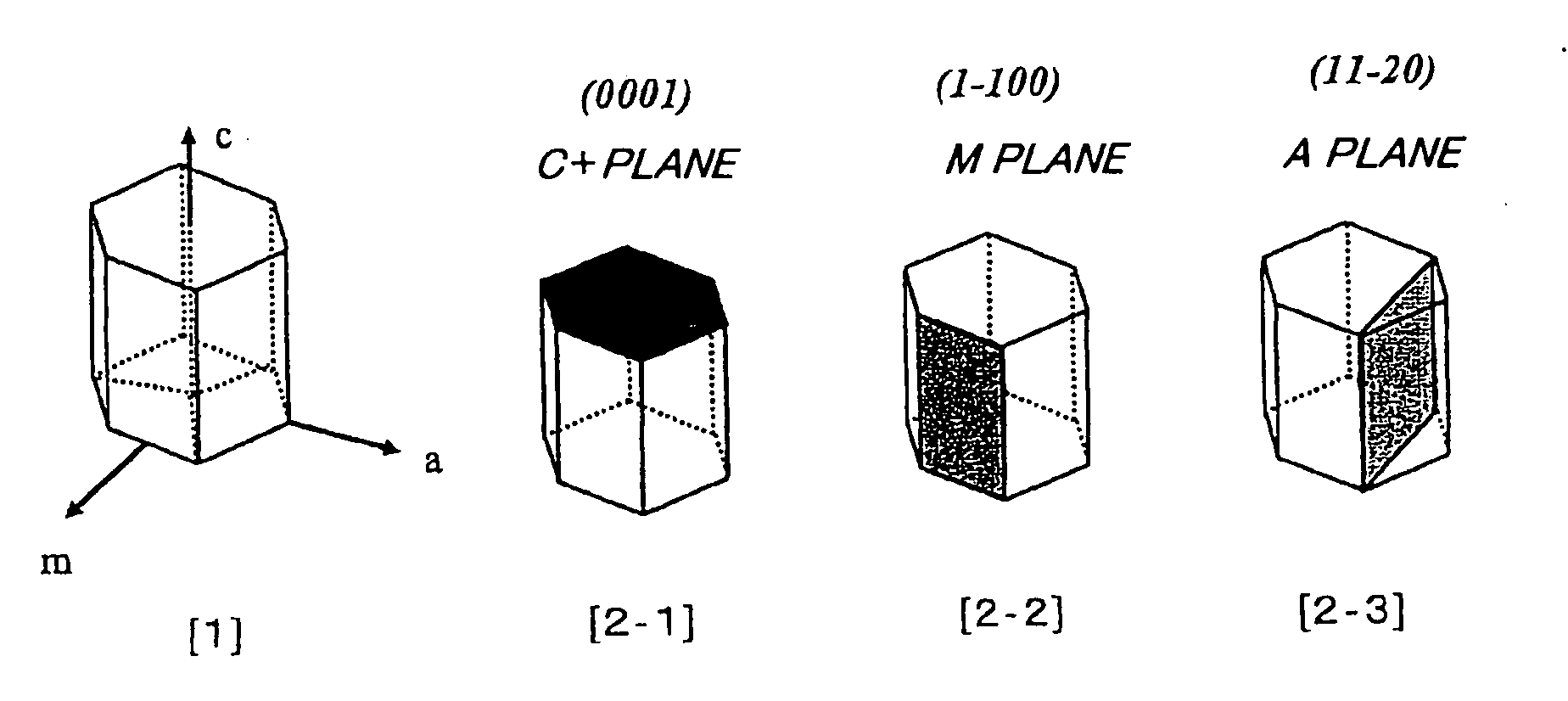

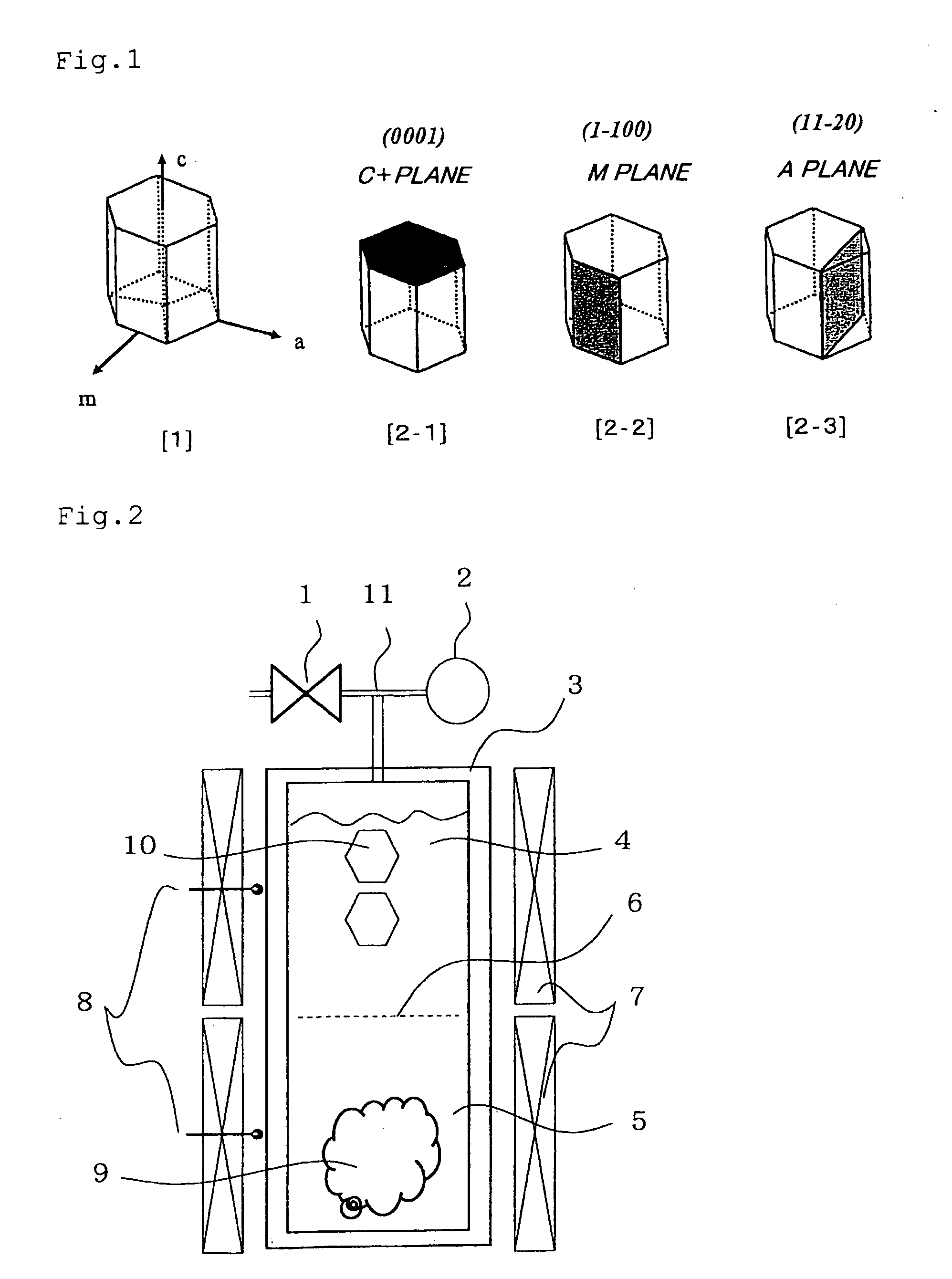

A method for producing a nitride semiconductor, comprising controlling temperature and pressure in a autoclave containing a seed having a hexagonal crystal structure, a nitrogen element-containing solvent, a raw material substance containing a metal element of Group 13 of the Periodic Table, and a mineralizer so as to put said solvent into a supercritical state and / or a subcritical state and thereby ammonothermally grow a nitride semiconductor crystal on the surface of said seed, wherein the crystal growth rate in the m-axis direction on said seed is 1.5 times or more the crystal growth rate in the c-axis direction on said seed. By the method, a nitride semiconductor having a large-diameter C plane or a nitride semiconductor thick in the m-axis direction can be efficiently and simply produced.

Owner:MITSUBISHI CHEM CORP +1

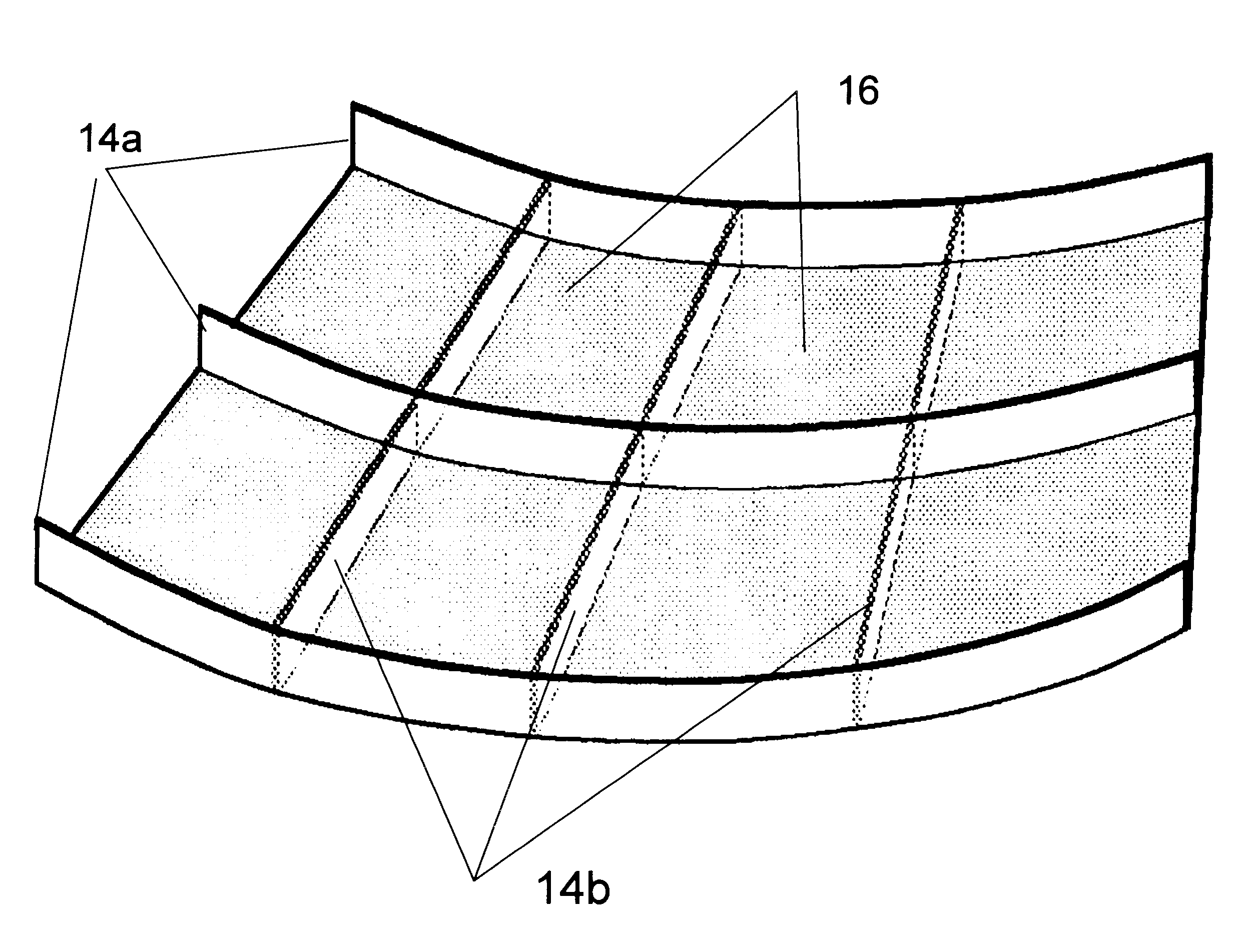

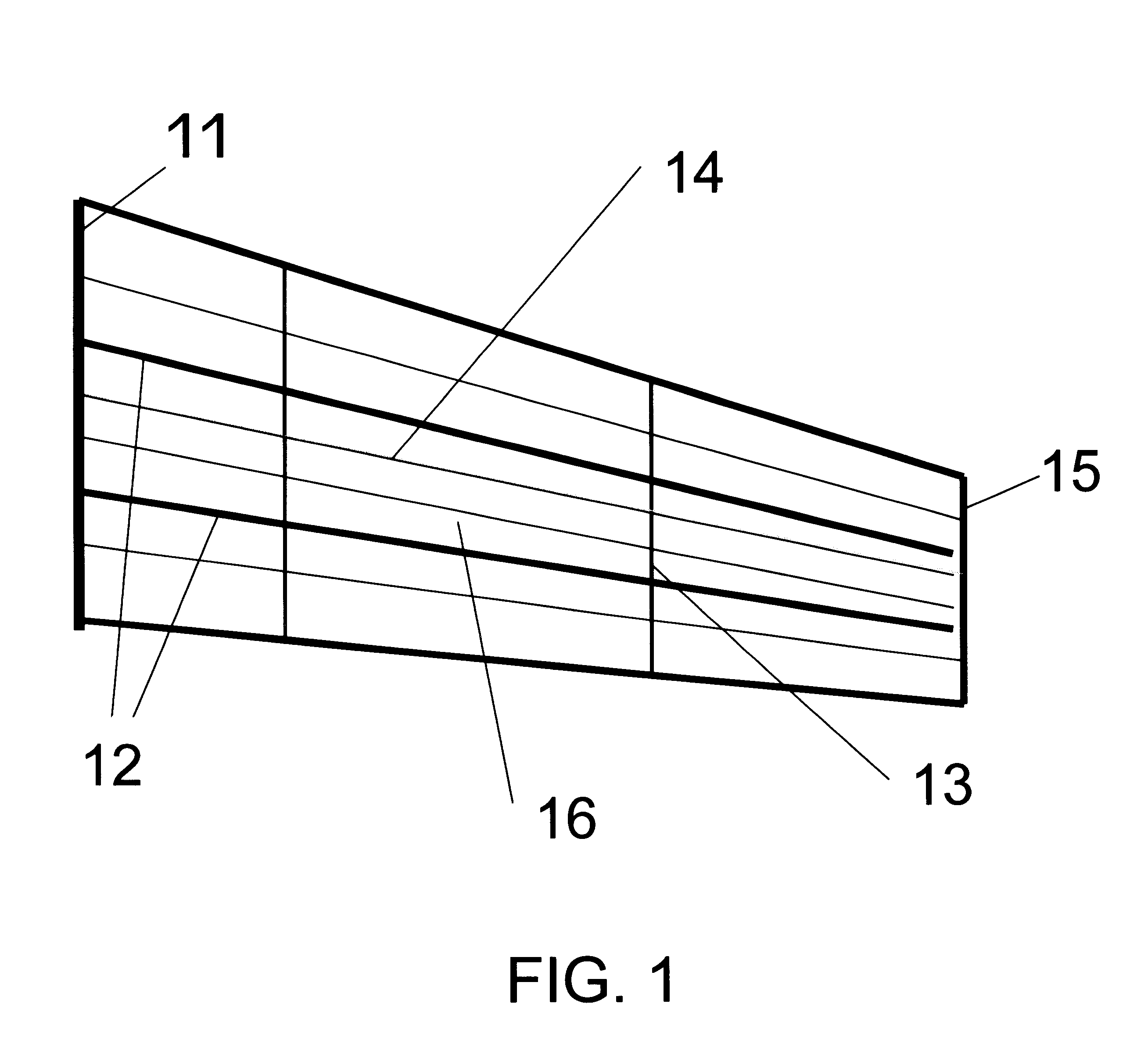

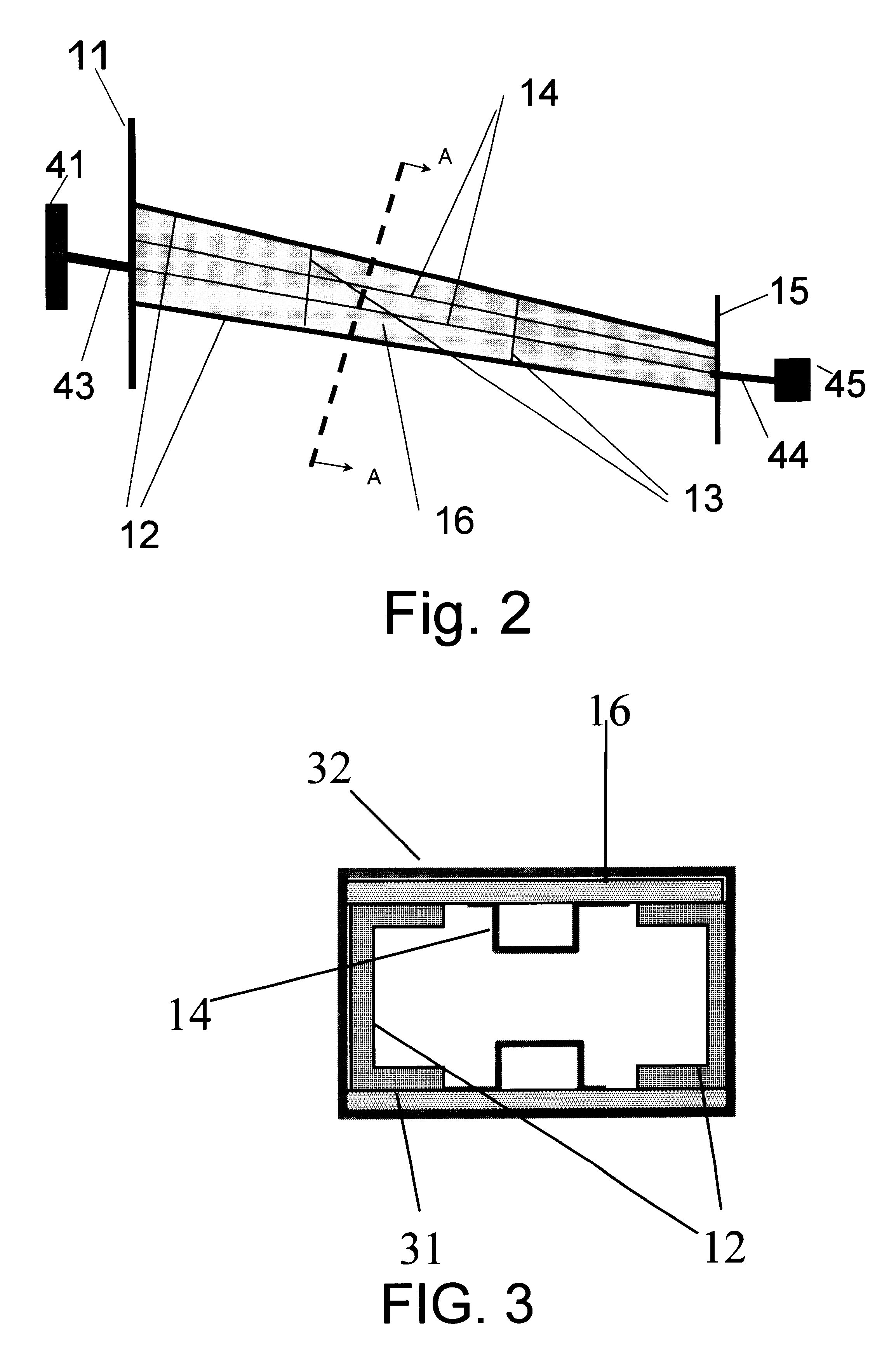

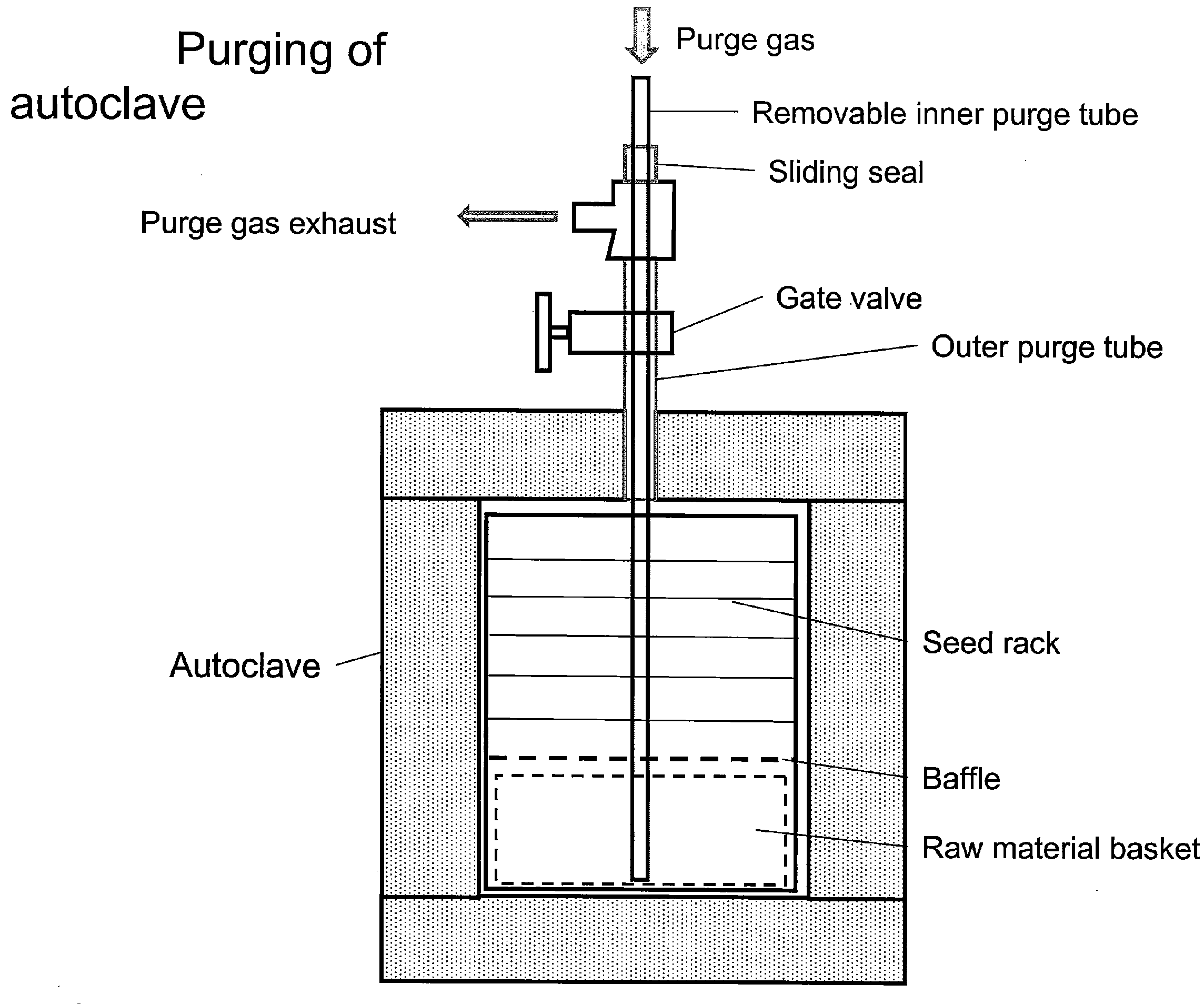

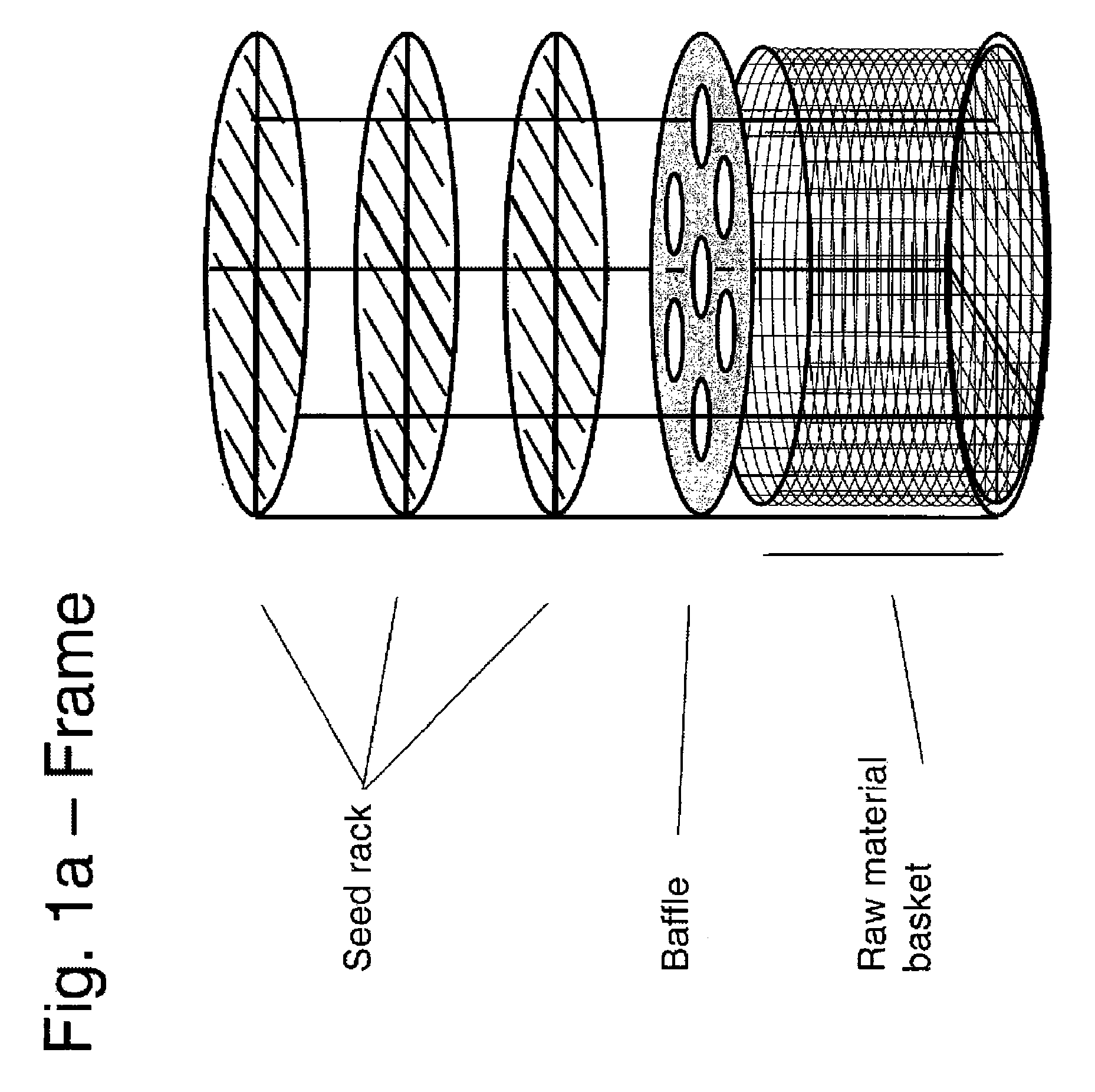

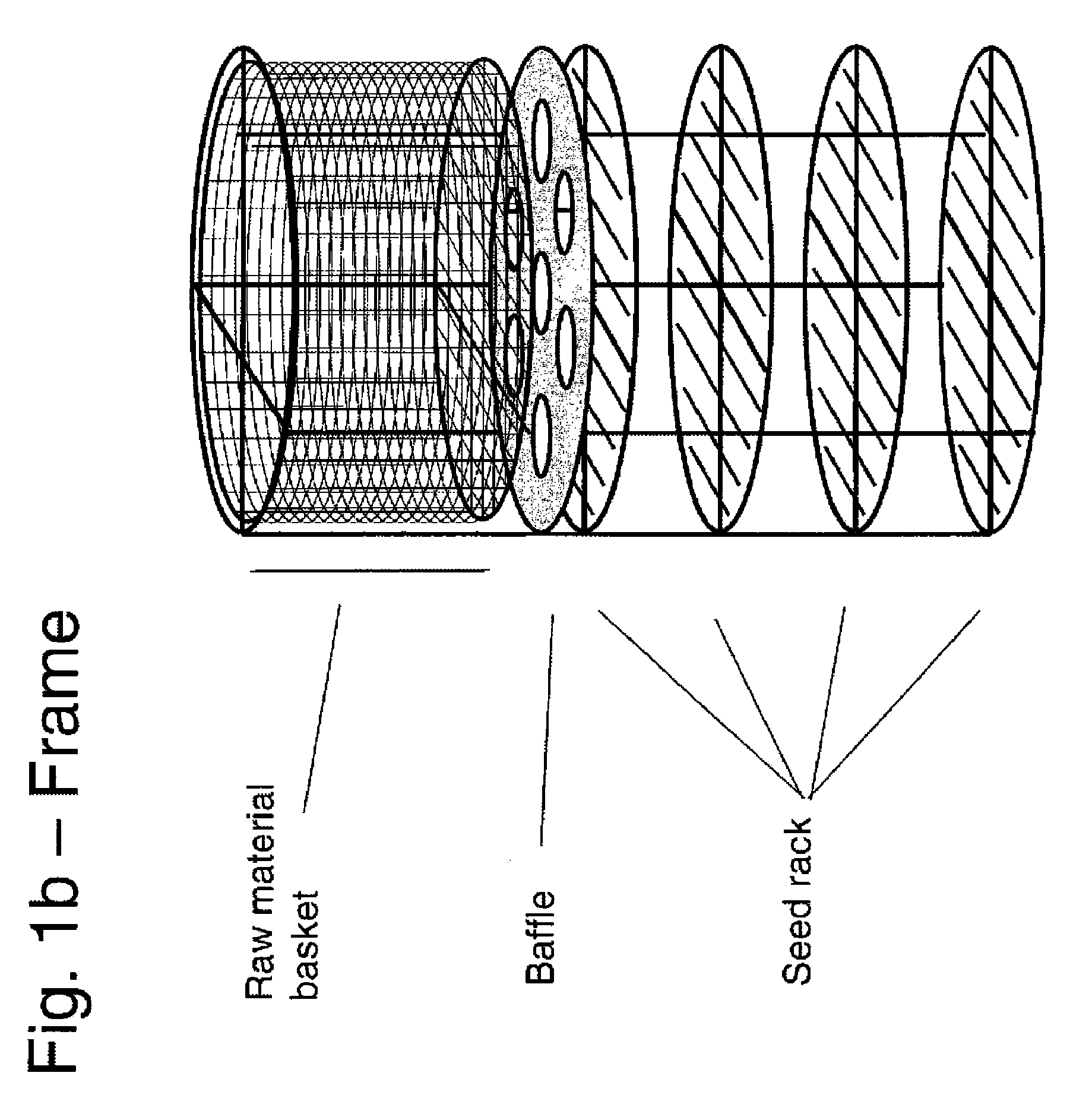

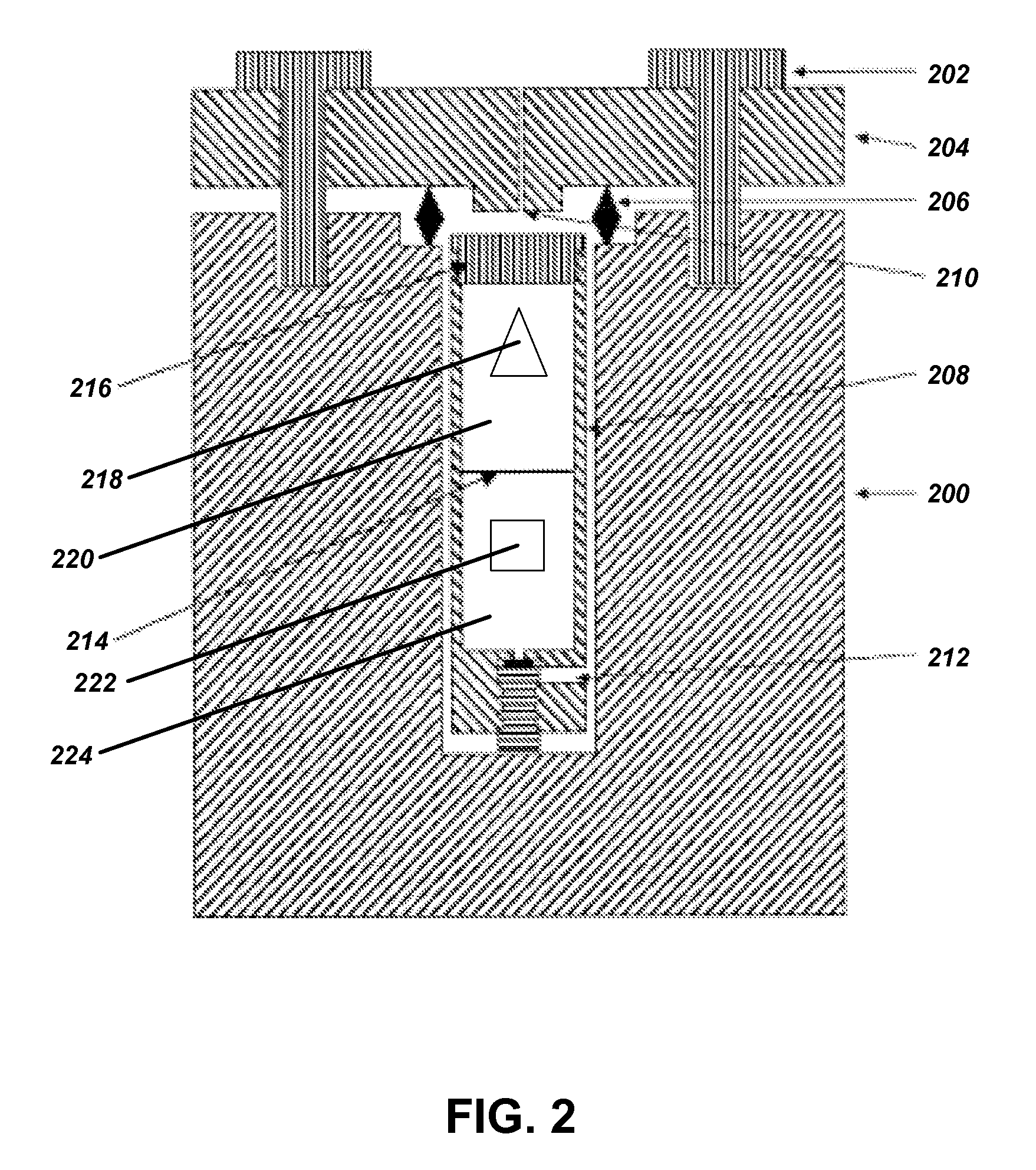

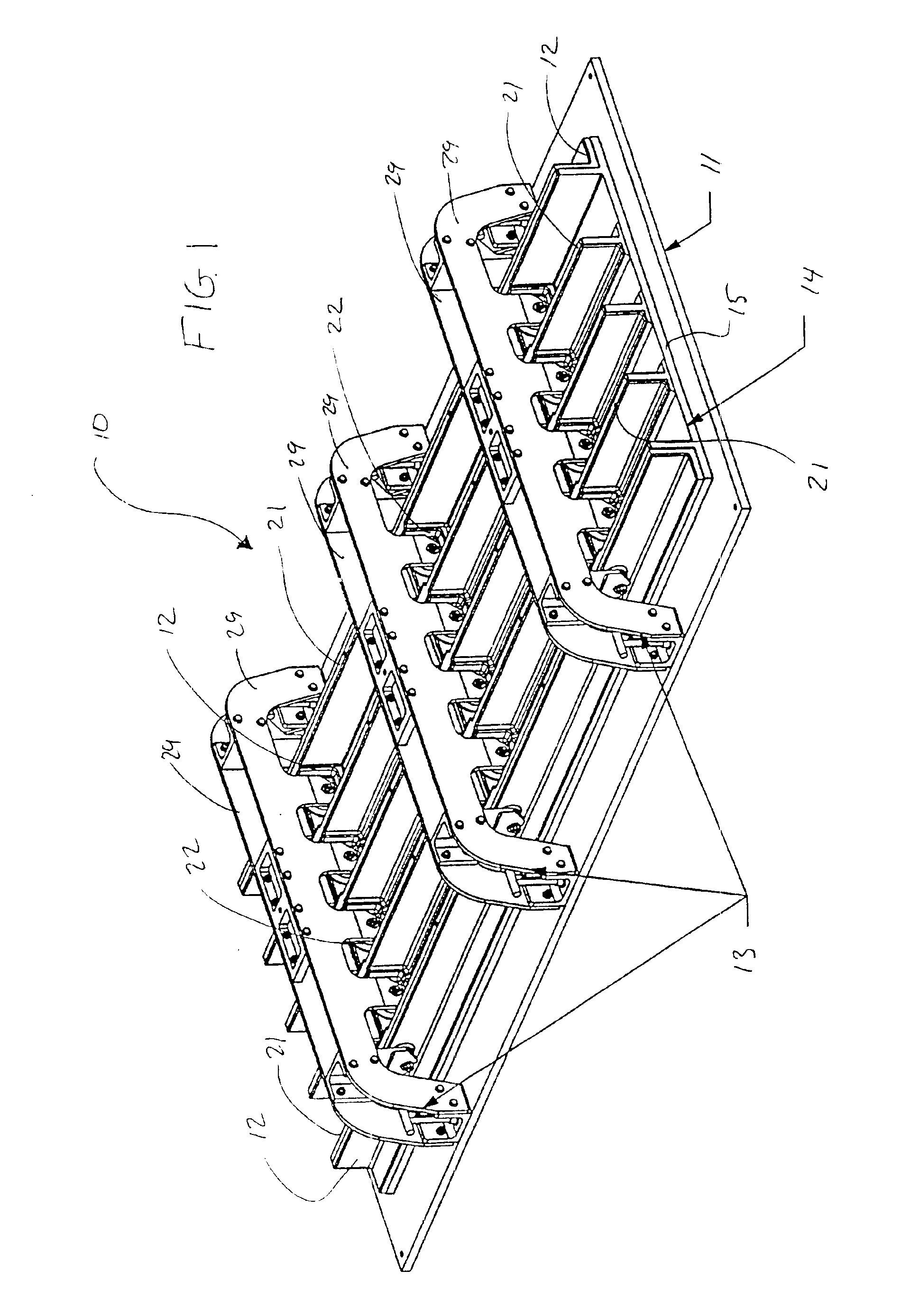

Process for large-scale ammonothermal manufacturing of gallium nitride boules

ActiveUS20100031875A1Cost-effectiveSimple and cost-effective to manufacturePolycrystalline material growthFrom normal temperature solutionsCost effectivenessEngineering

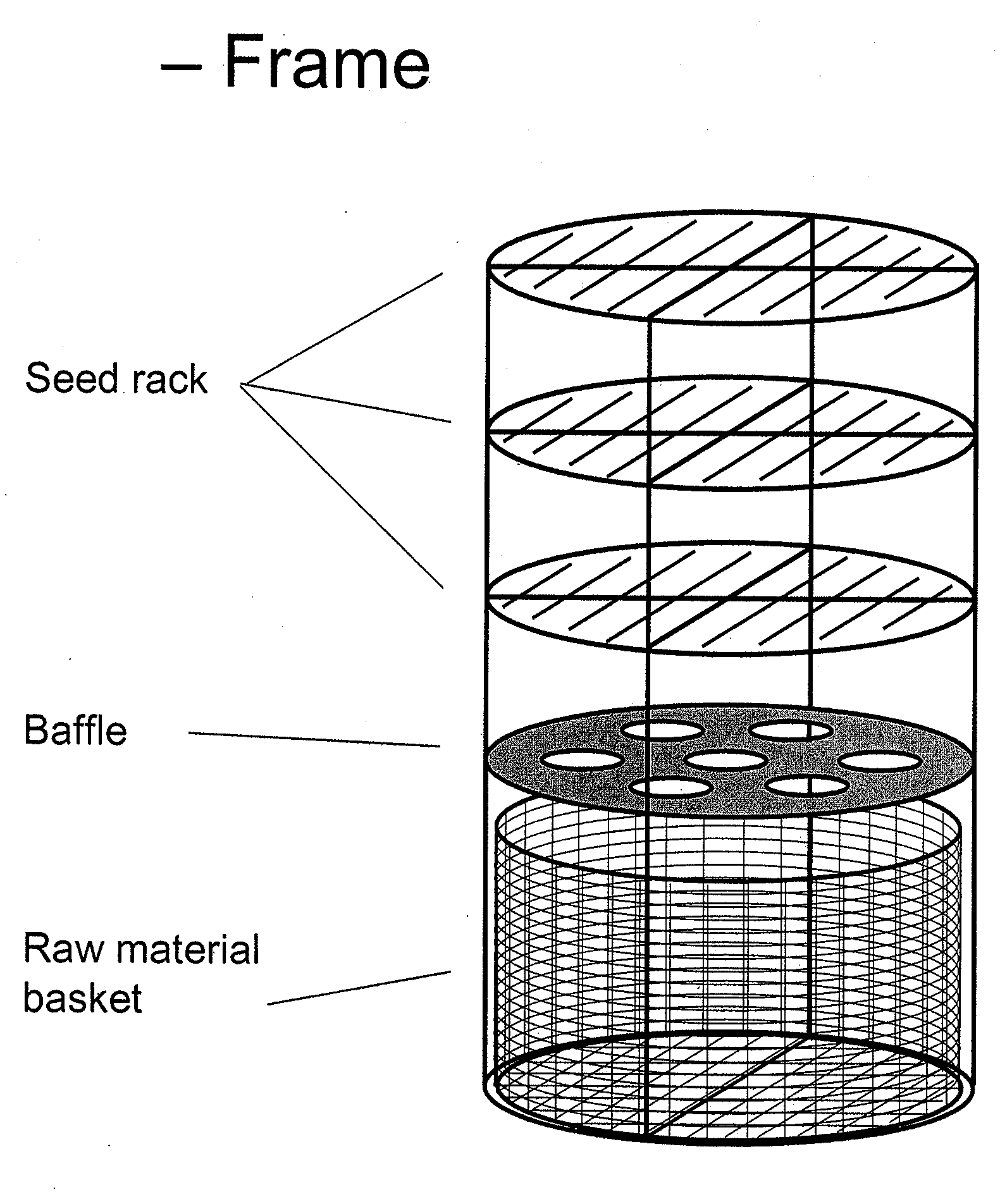

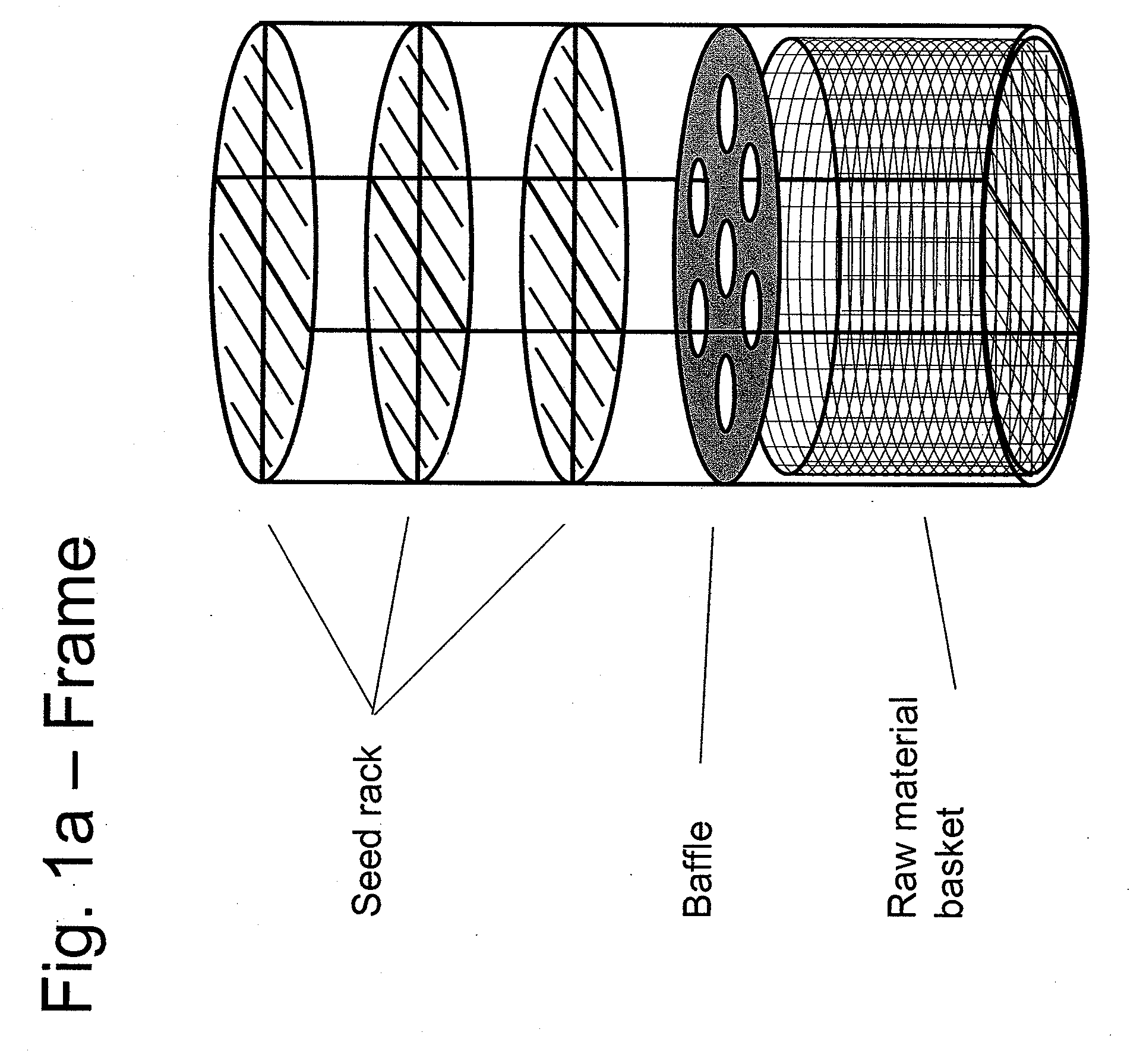

A method for large-scale manufacturing of gallium nitride boules. Large-area single crystal seed plates are suspended in a rack, placed in a large diameter autoclave or internally-heated high pressure apparatus along with ammonia and a mineralizer, and grown ammonothermally. The seed orientation and mounting geometry are chosen to provide efficient utilization of the seed plates and of the volume inside the autoclave or high pressure apparatus. The method is scalable up to very large volumes and is cost effective.

Owner:SLT TECH

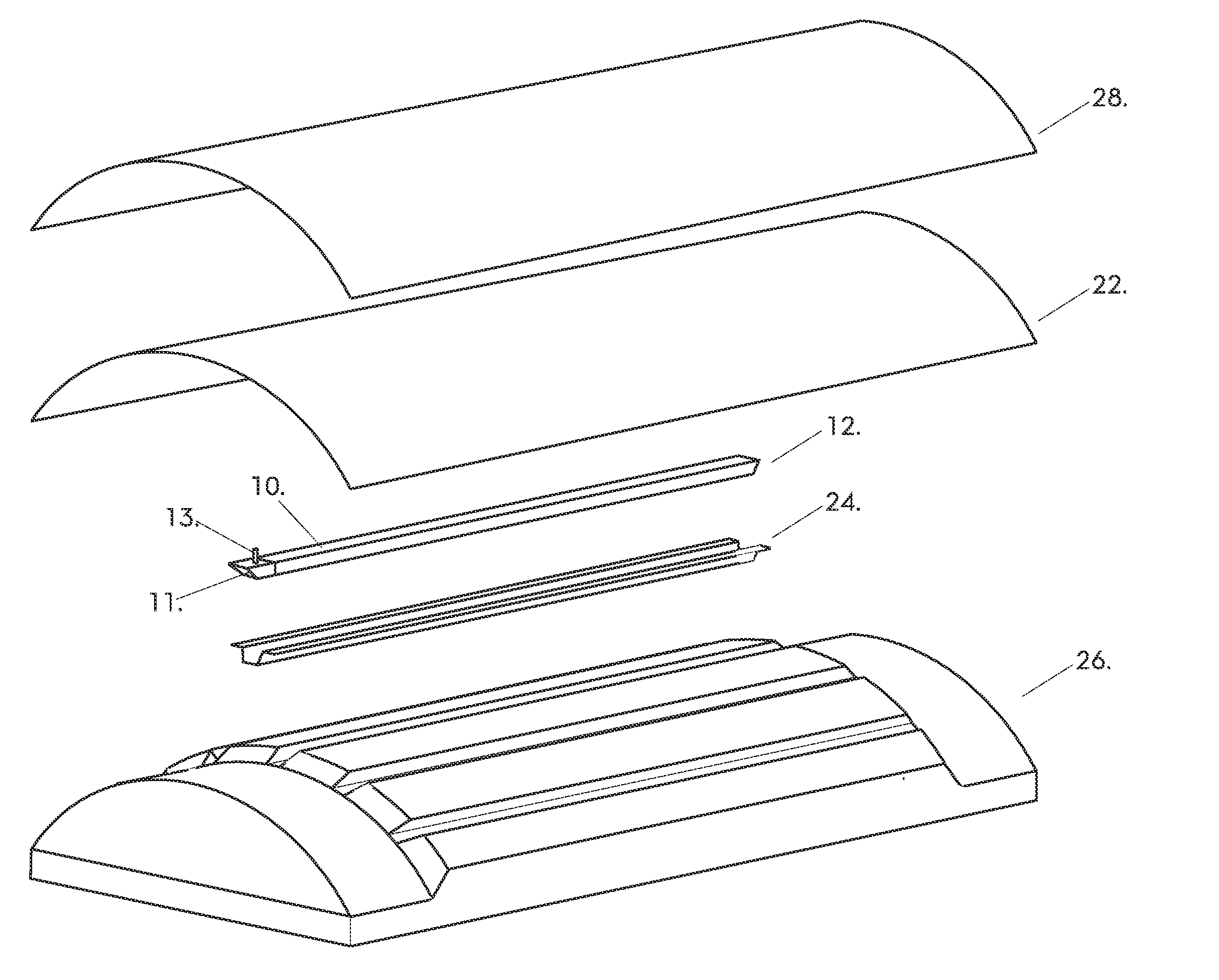

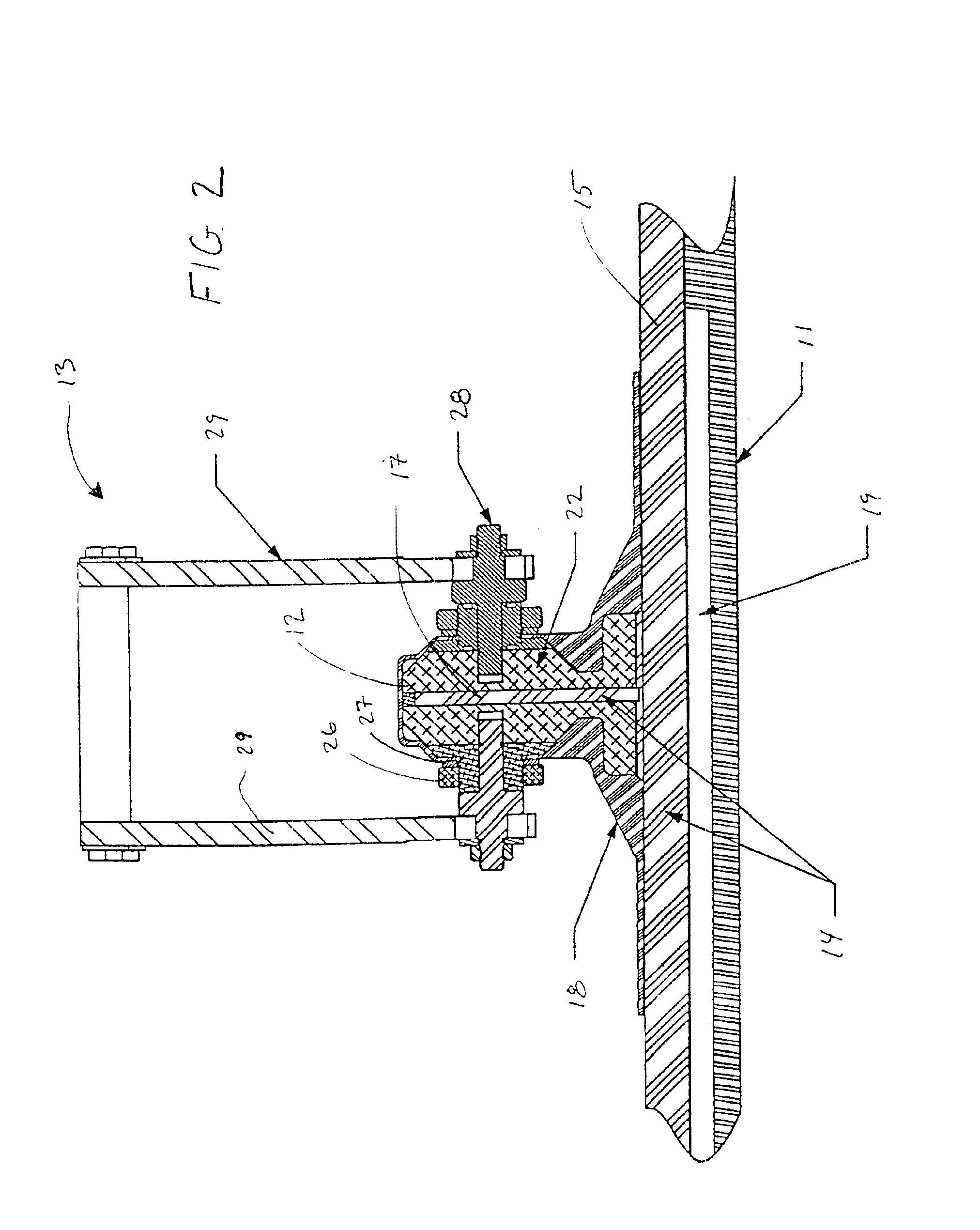

Monolithic composite wing manufacturing process

InactiveUS6190484B1Aircraft stabilisationPaper/cardboard wound articlesLeading edgeIncreased torsion

A method of manufacturing a monolithic composite wing without using mechanical fasteners is described. The process begins with the formation of a center wing box in combination with a pair of spars, riblets and a pair of skin-molds including the wrapping and binding of the box by means of resin impregnated composite tapes. Next, additional cells are adjoined contiguously on either side of the current framework and an overlap wrapping and bonding process is continued around the current framework. The overlap wrapping and binding procedure provides increased torsion stiffness and reduced structural weight. All cells up to the leading and trailing edges will be included in the assembly process. Conduits to convey fuel, hydraulic fluid and electrical wiring will also be installed in designated cells. Finally, the completed wing will be cured in an autoclave under uniform pressure and temperature.

Owner:APPA KARI

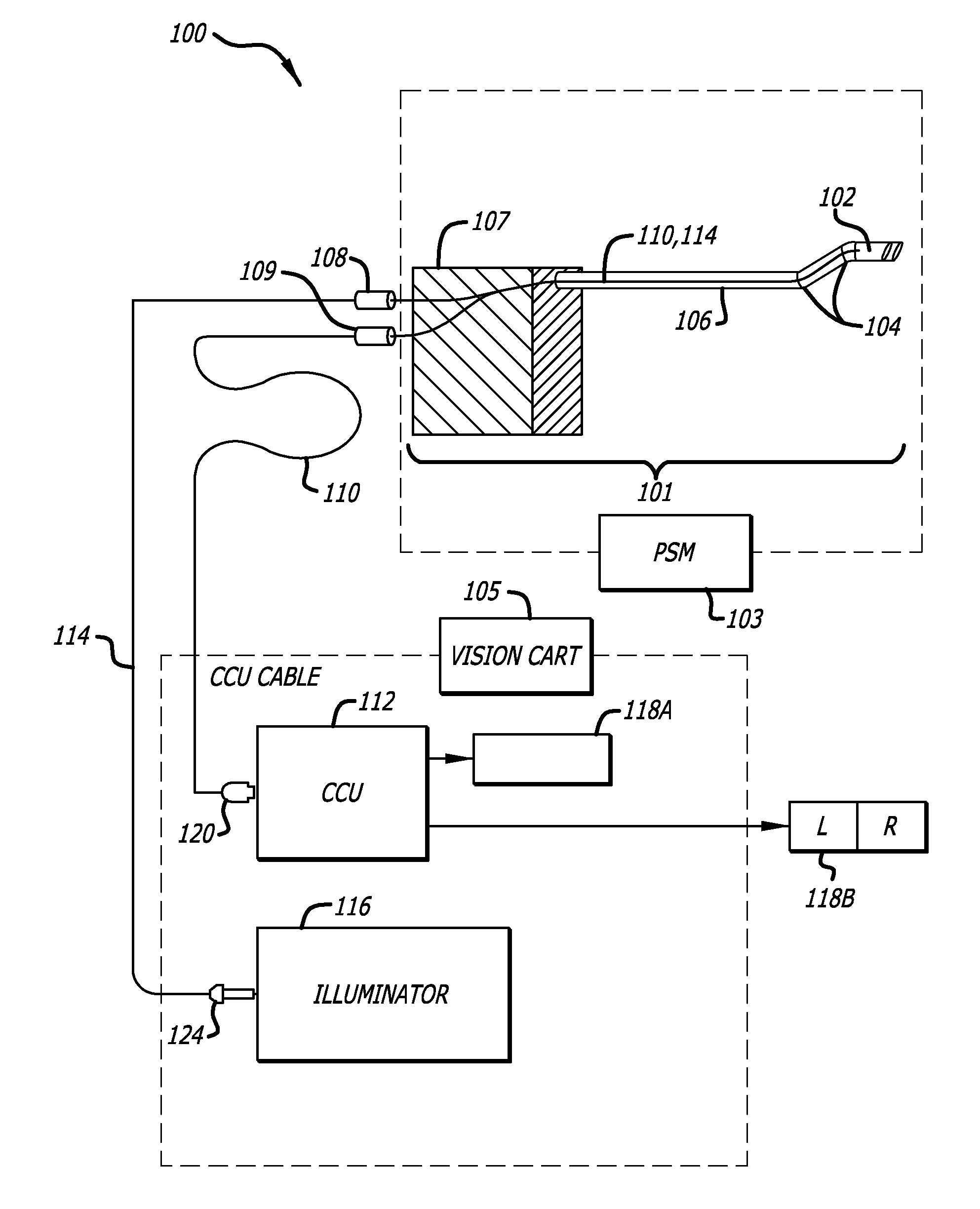

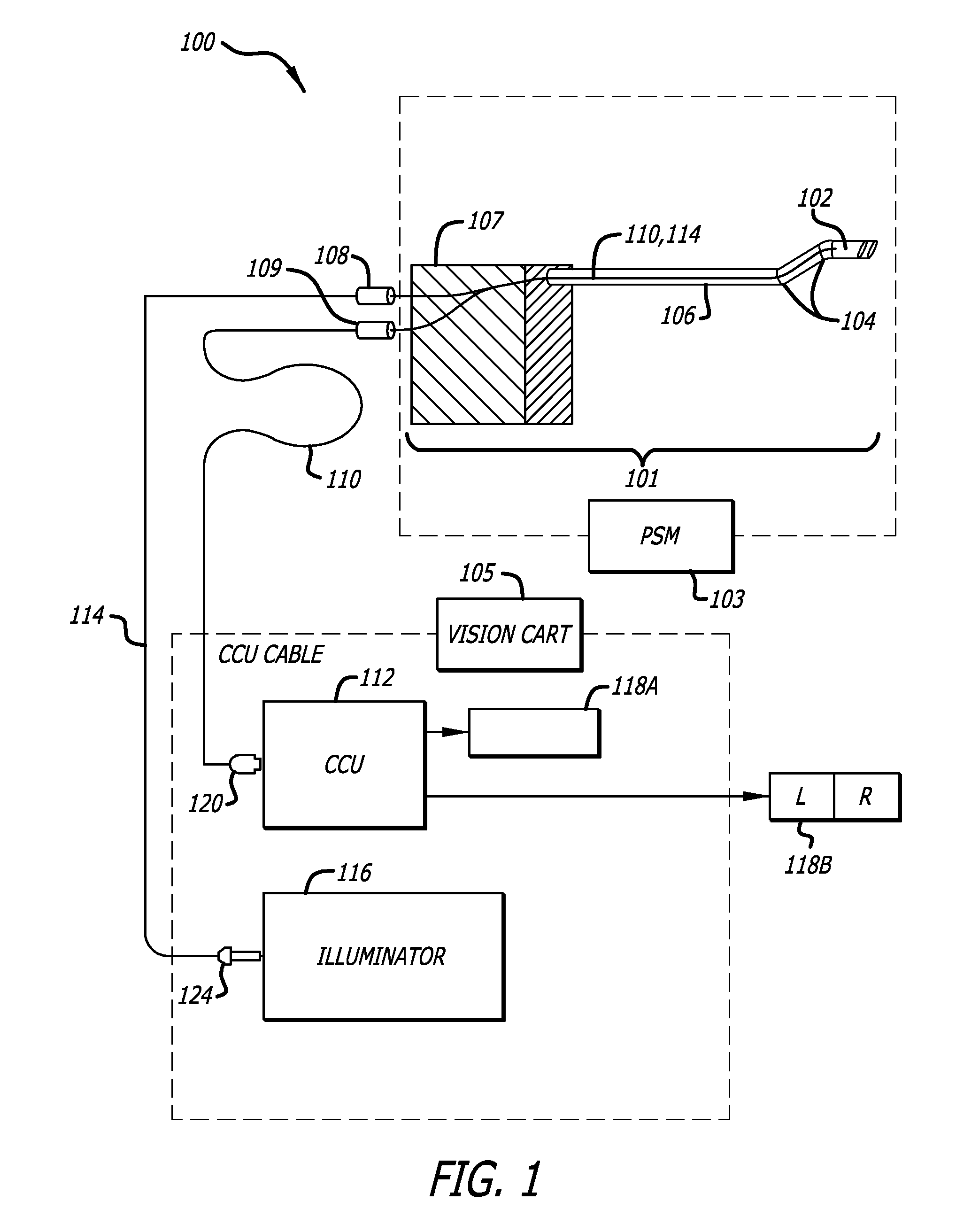

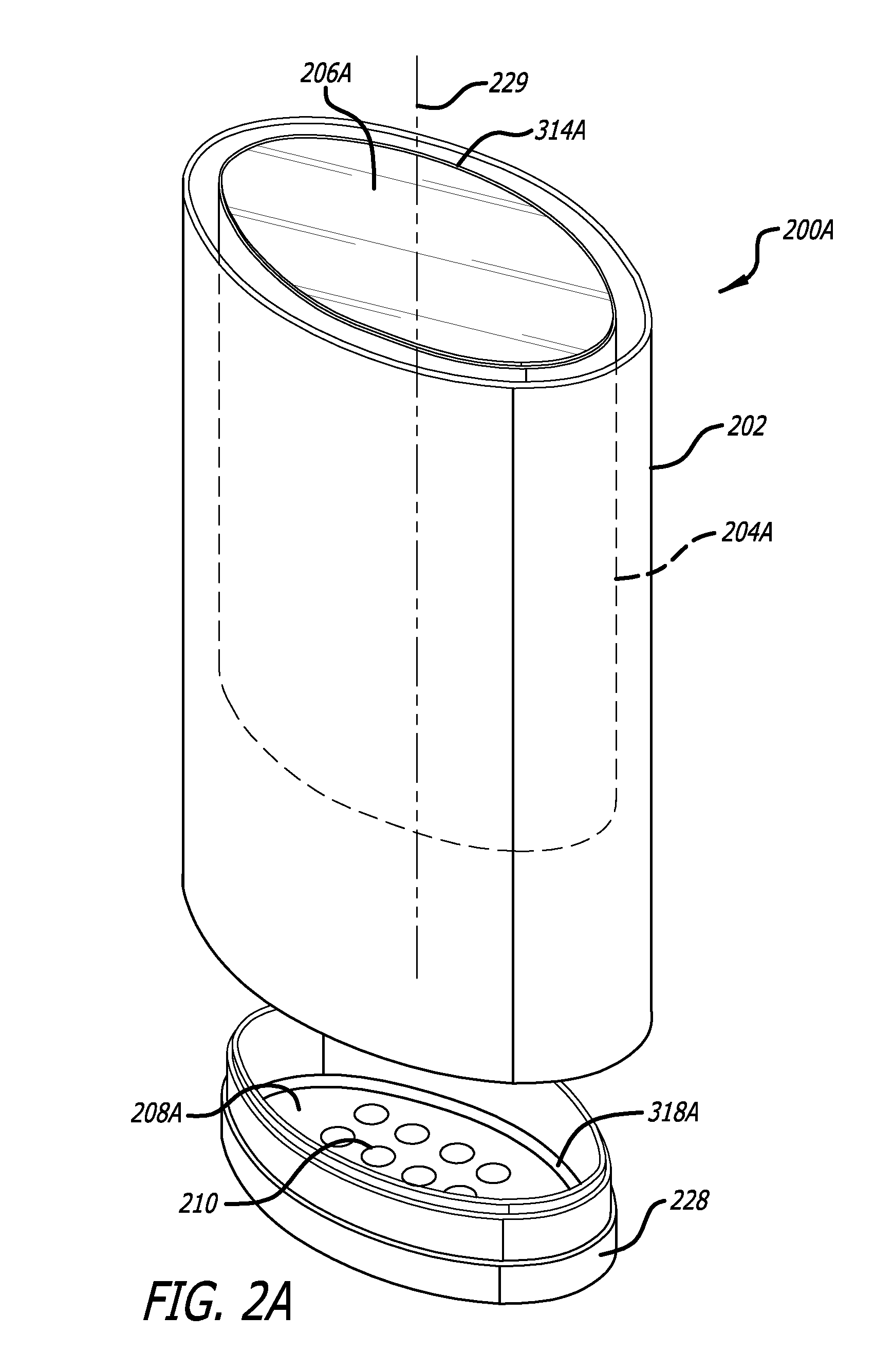

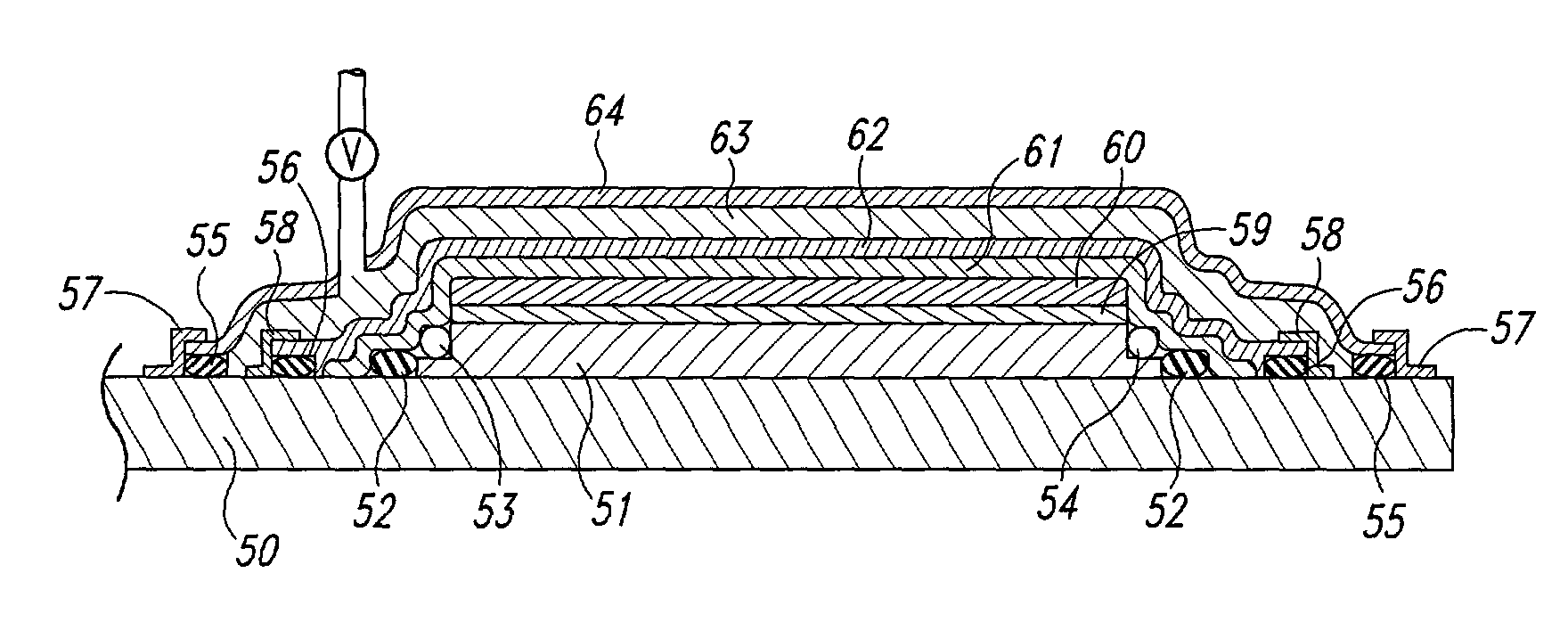

Hermetically sealed distal sensor endoscope

Owner:INTUITIVE SURGICAL OPERATIONS INC

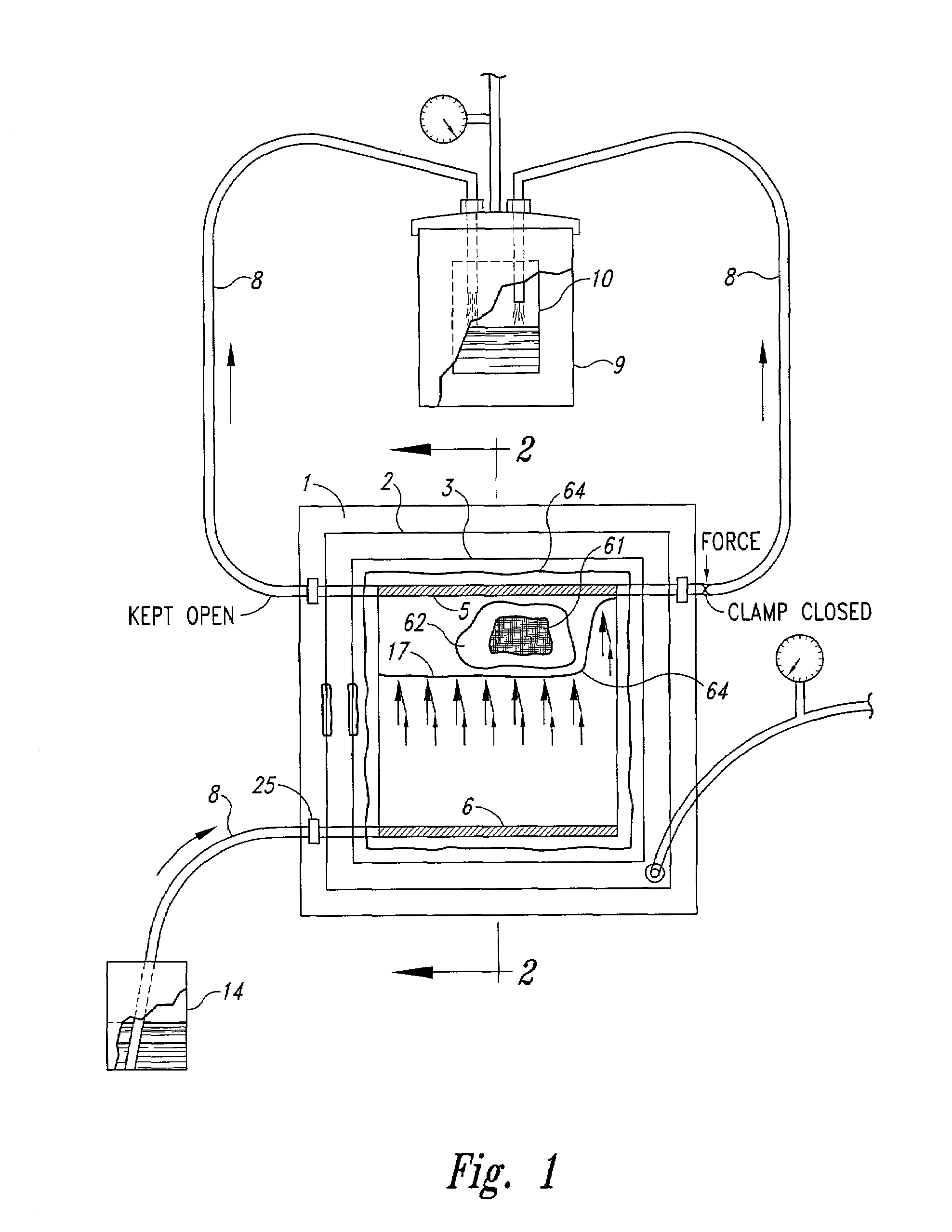

Double bag vacuum infusion process

InactiveUS7413694B2Reduce porosityMinimal surface porositySynthetic resin layered productsLaminationMedia controlsFiber

The double bag vacuum infusion process of the present invention provides a low cost method for producing complex composite assemblies without an autoclave. It also enables the production of highly innovative structures. The quality of the composites produced using such an infusion process are comparable to composites made using prepregs, hand layup or fiber placement, and autoclave curing. Double bagging provides vacuum integrity, controls bag relaxation while flow media controls the flow front to allow high quality aerospace-grade products.

Owner:THE BOEING CO

Process and apparatus for large-scale manufacturing of bulk monocrystalline gallium-containing nitride

ActiveUS20100031876A1Cost-effectiveSimple and cost-effective to manufacturePolycrystalline material growthFrom normal temperature solutionsCost effectivenessSingle crystal

A method for large-scale manufacturing of gallium nitride includes a process for reducing and / or minimizing contamination in the crystals, for solvent addition to an autoclave, for improving or optimizing the solvent atmosphere composition, for removal of the solvent from the autoclave, and for recycling of the solvent. The method is scalable up to large volumes and is cost effective.

Owner:SLT TECH

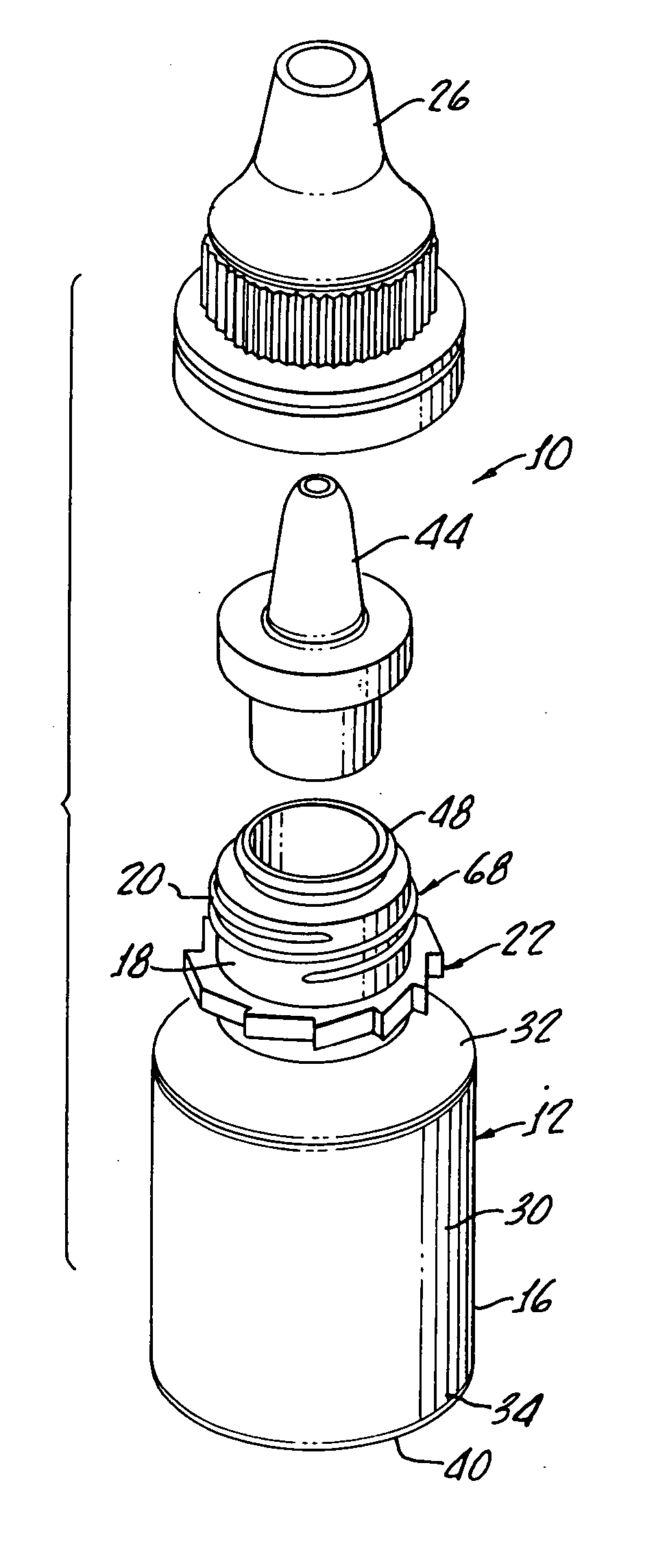

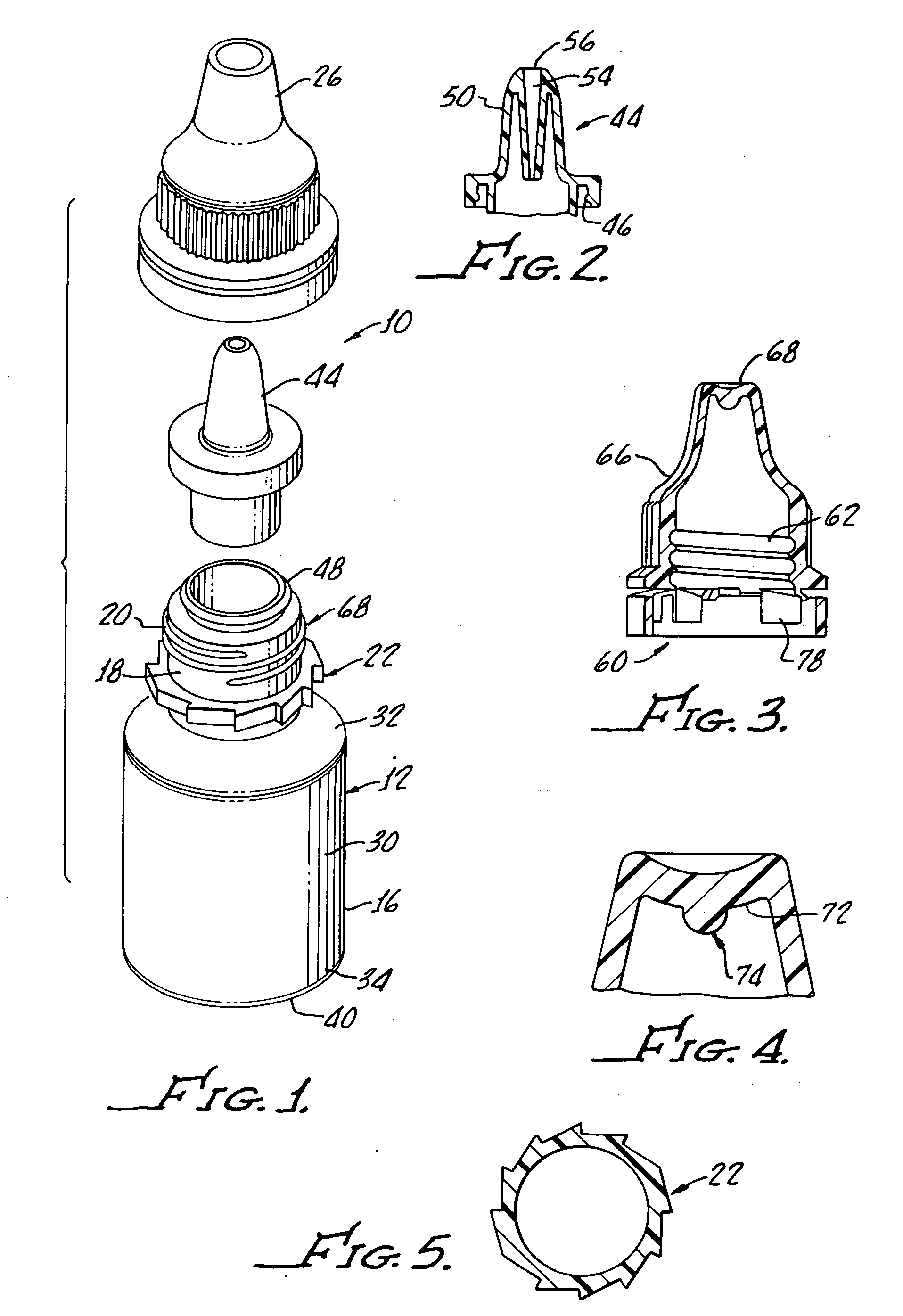

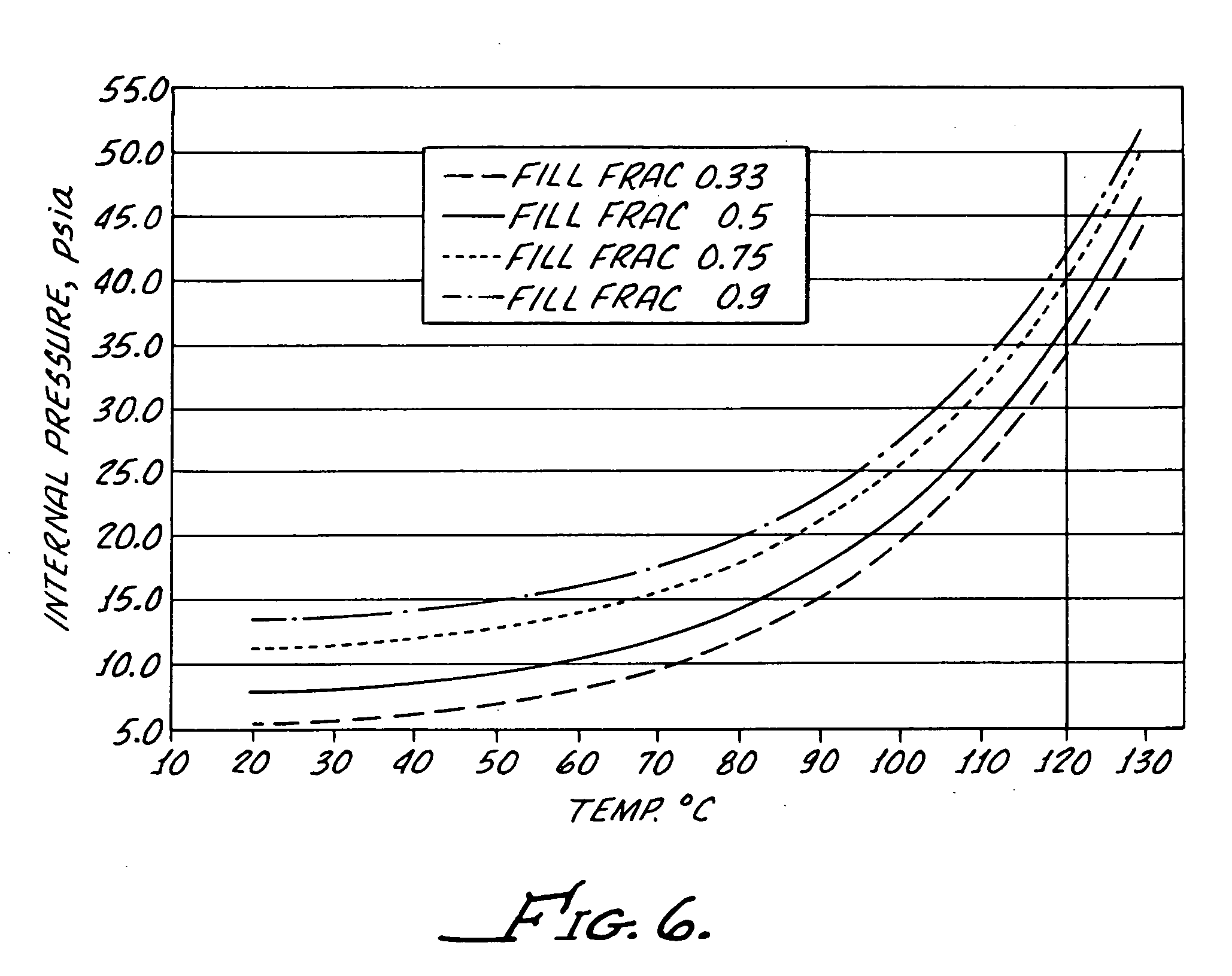

Autoclaveable small-volume dropper bottle

ActiveUS20060111680A1Short lifeLow acceptabilityClosuresLiquid flow controllersEngineeringHigh pressure

A terminally sterilizable container includes a polypropylene bottle having a body with a manually squeezable sidewall and a thickness preventing water loss. The bottle body includes shoulders for providing autoclave produced pressure distribution and deformation resistance along with an elongated tips outfitted to a neck of the body and having a lumen therethrough with a drop dispensing orifice. A cap enclosed the elongated tip and includes enclosed with a nub for sealing the orifice to prevent autoclave produced pressure leaks.

Owner:ALLERGAN INC

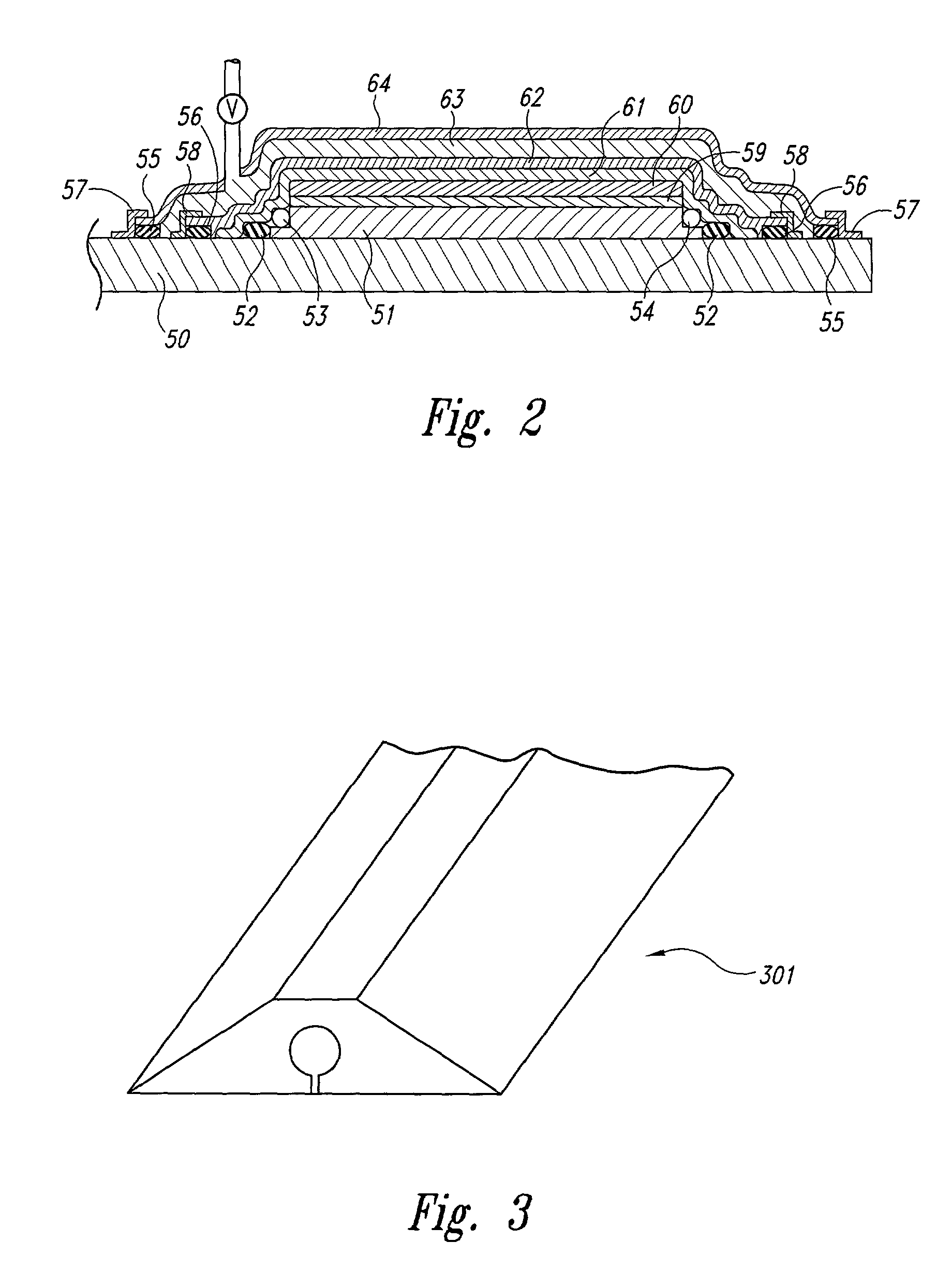

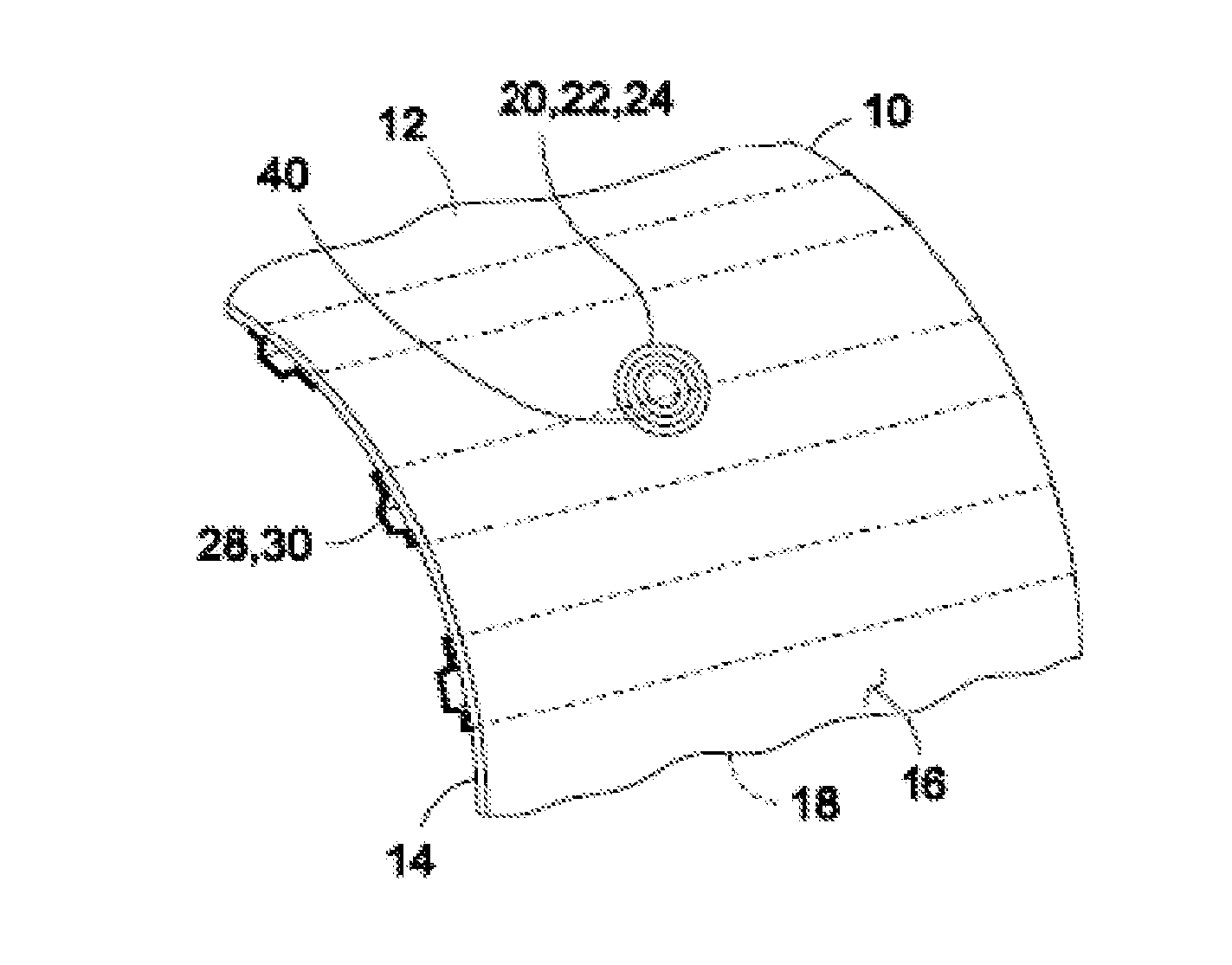

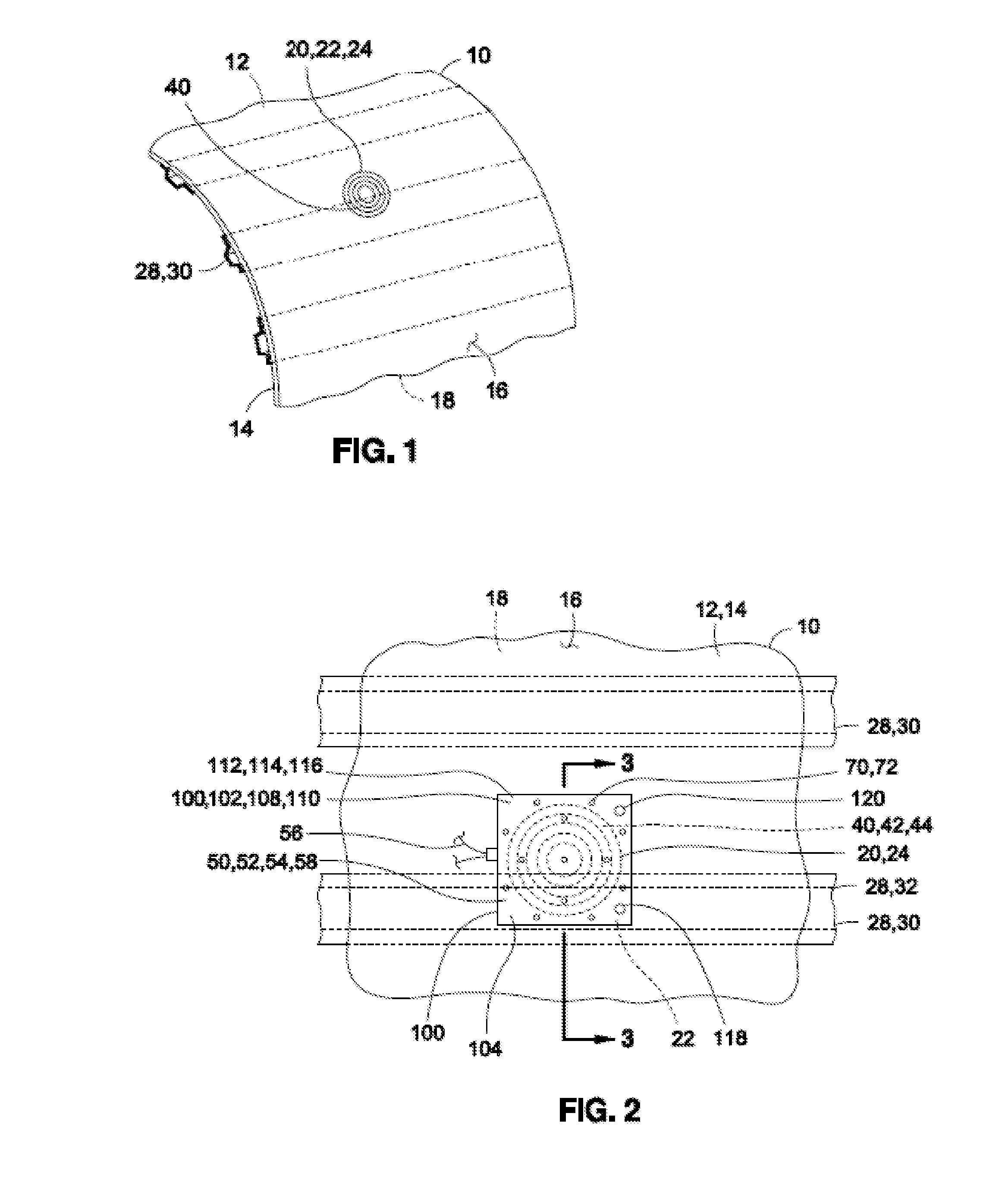

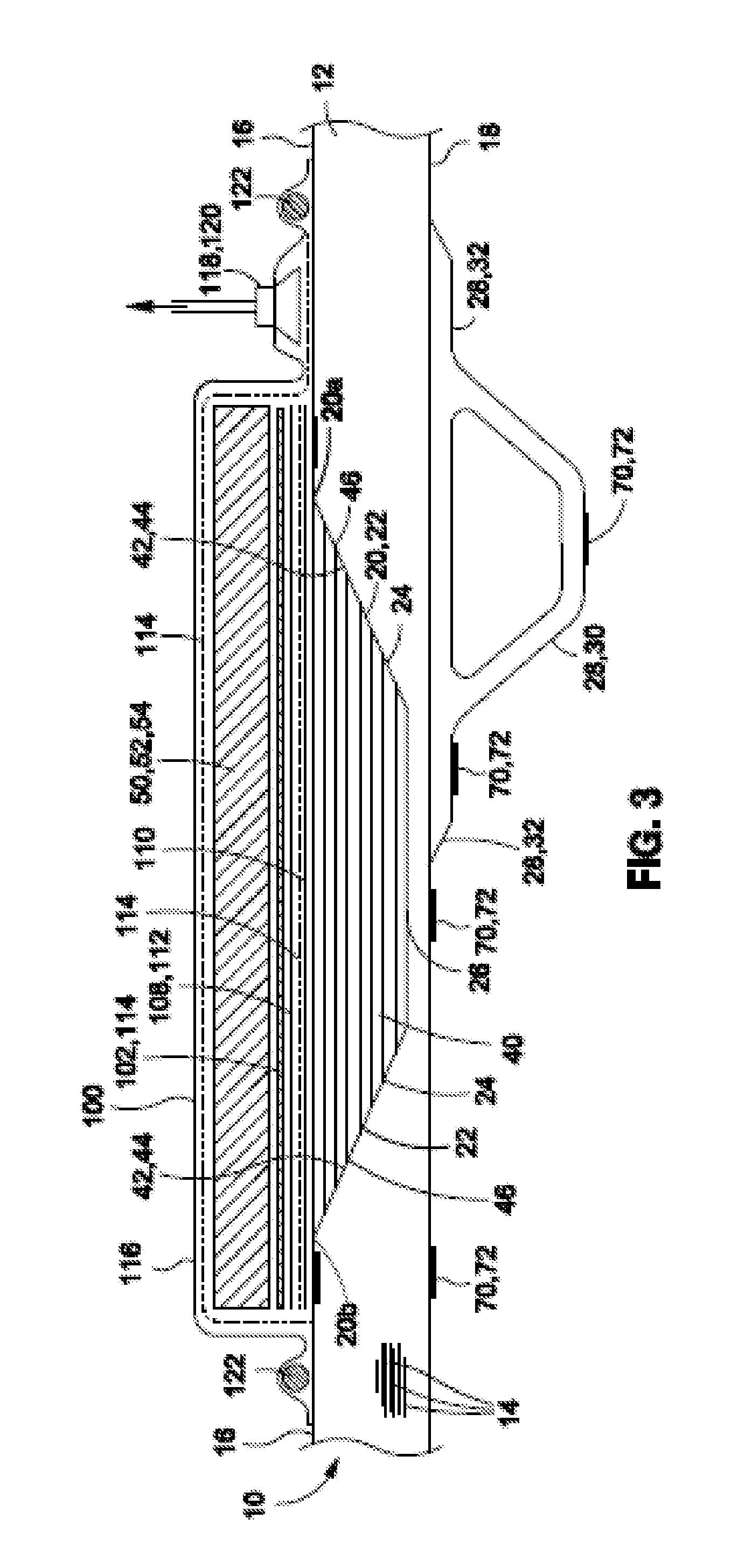

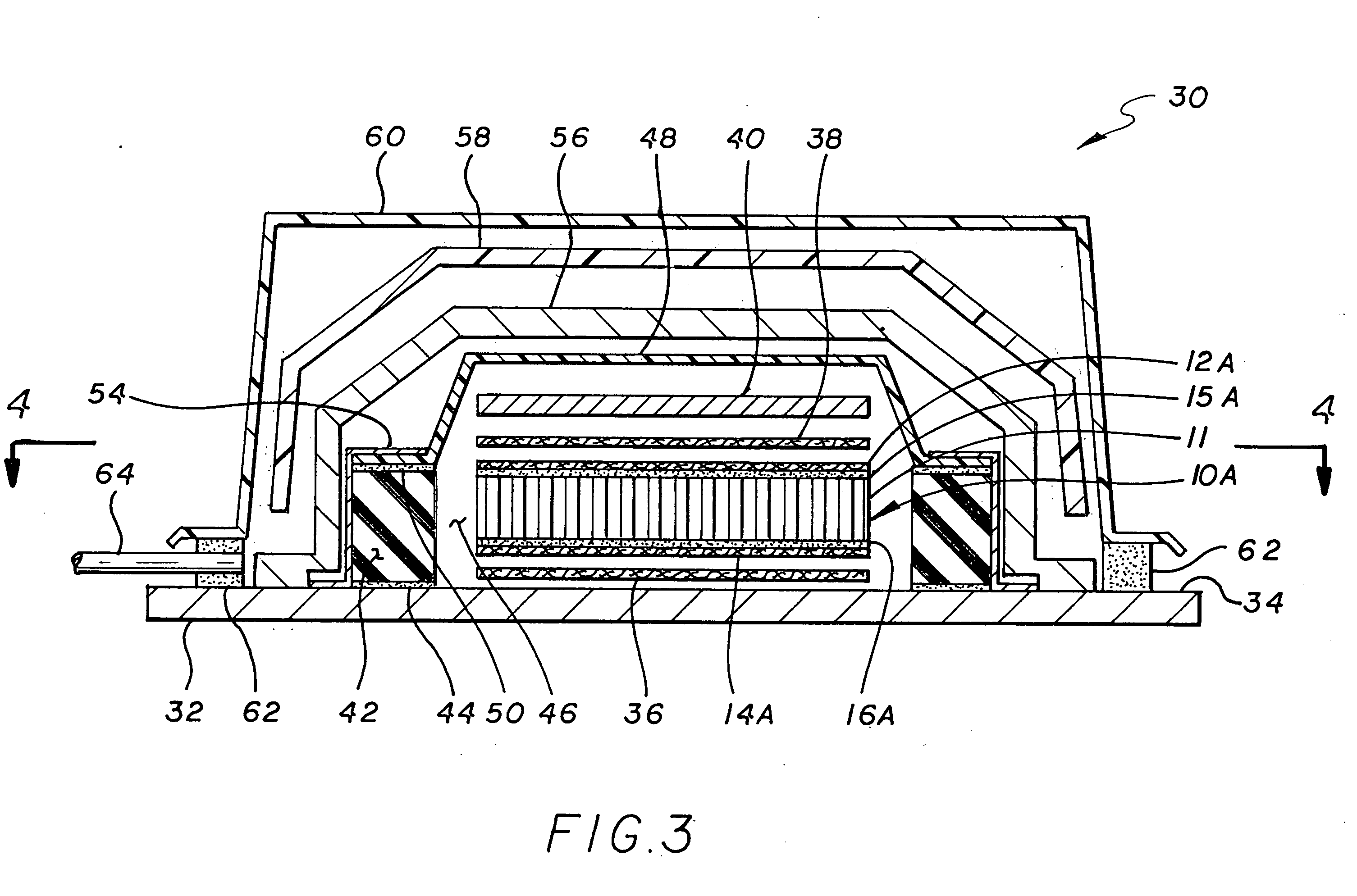

Curing Composites Out-Of-Autoclave Using Induction Heating with Smart Susceptors

ActiveUS20120145703A1Precise and uniform temperature controlSimple and relatively inexpensive to fabricateCoil arrangementsOhmic-resistance heatingSusceptorMaterials science

A composite part is cured out-of-autoclave using an inductively heated, stand-alone tooling. The part in placed on a tool and is covered by a heating blanket. One side of the part is heated by inductive coil circuits in the tool, and the other side of the part is heated by inductive coil circuits in the blanket.

Owner:THE BOEING CO

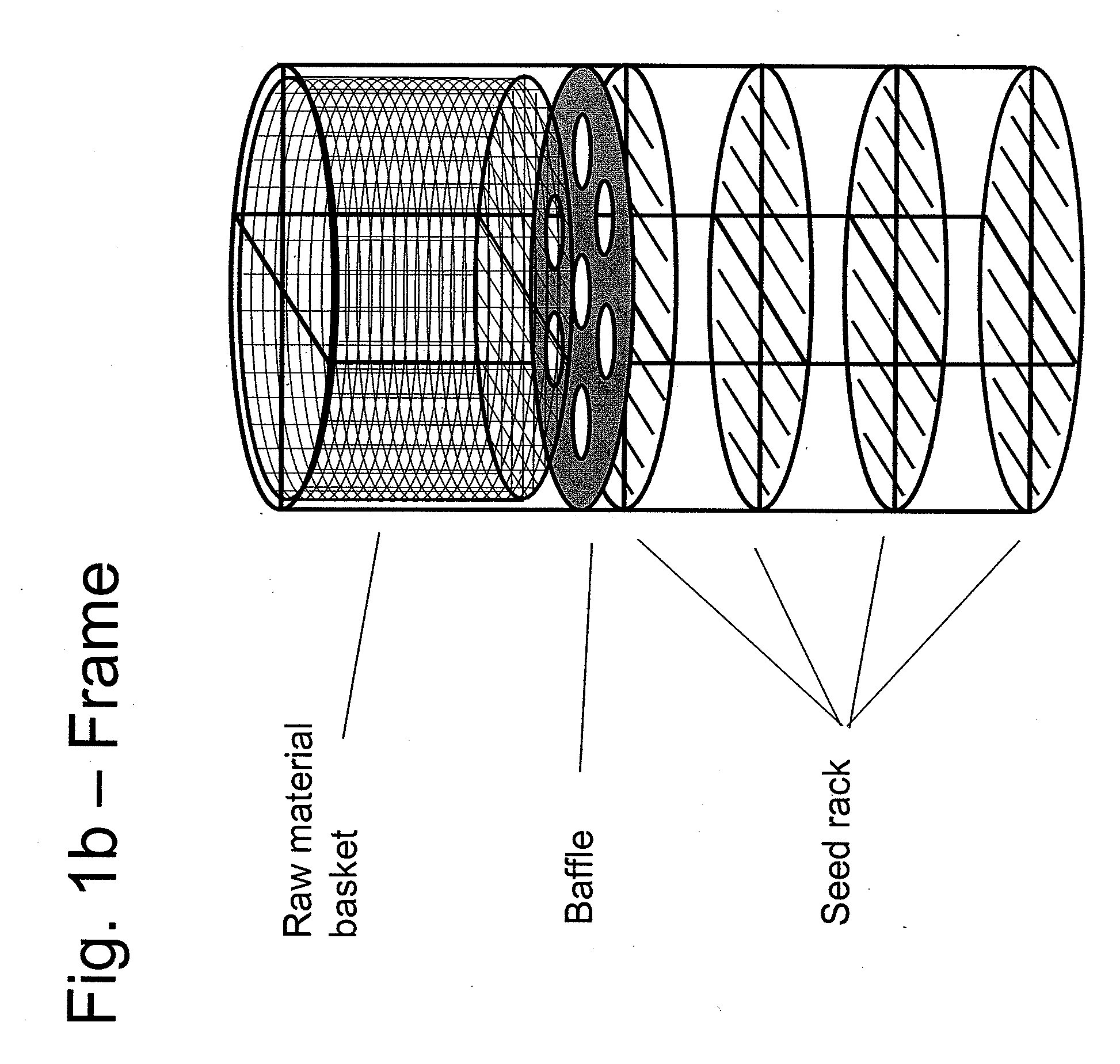

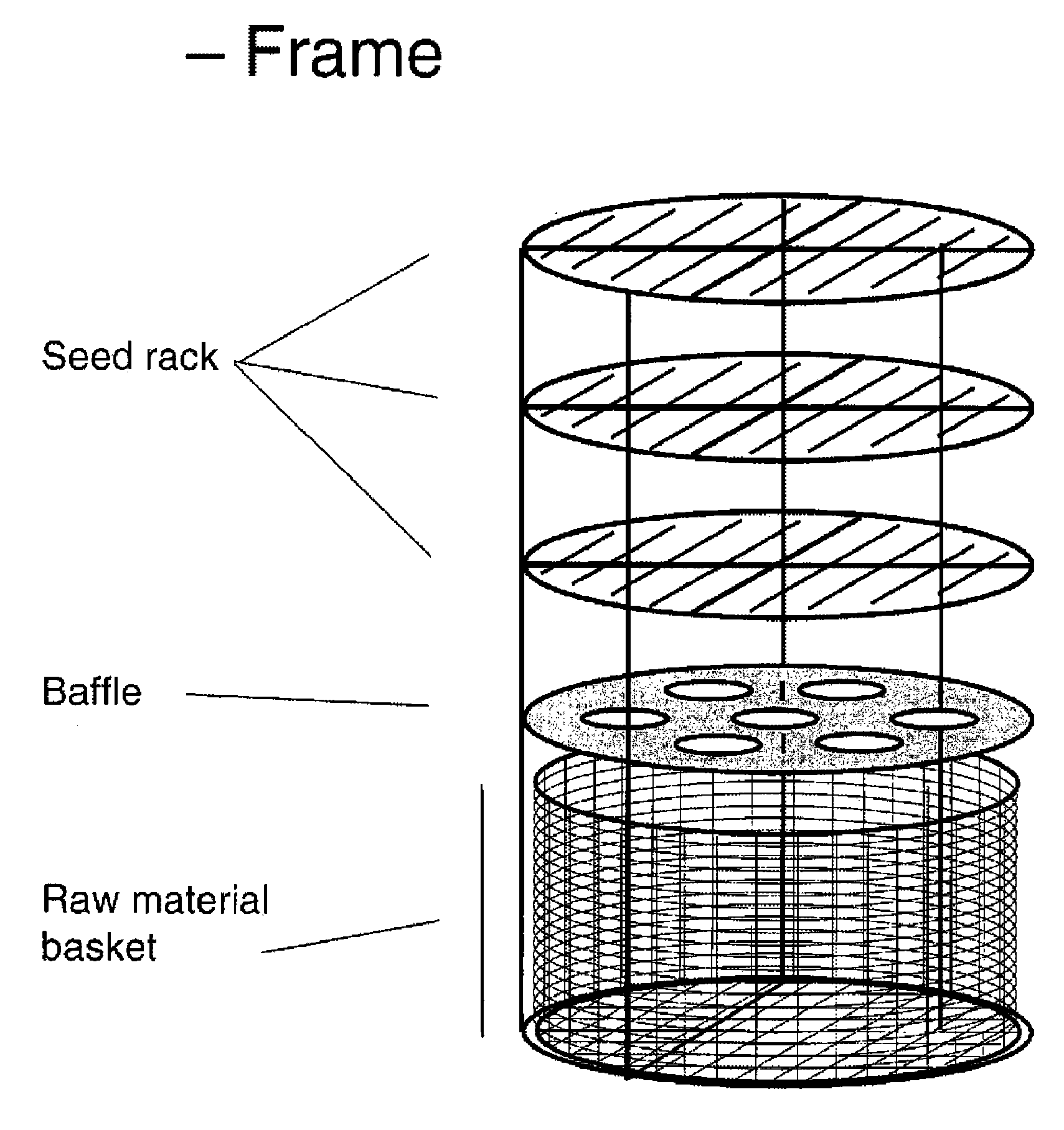

Basket process and apparatus for crystalline gallium-containing nitride

InactiveUS20100031873A1Avoid transportCost-effectivePolycrystalline material growthFrom normal temperature solutionsDopantCost effectiveness

An apparatus and associated method for large-scale manufacturing of gallium nitride is provided. The apparatus comprises a large diameter autoclave and a raw material basket. Methods include metered addition of dopants in the raw material and control of the atmosphere during crystal growth. The apparatus and methods are scalable up to very large volumes and are cost effective.

Owner:SORAA

Process and apparatus for growing a crystalline gallium-containing nitride using an azide mineralizer

ActiveUS20100031874A1Increase in sizeCost effectivePolycrystalline material growthFrom normal temperature solutionsDopantCost effectiveness

An apparatus and associated method for large-scale manufacturing of gallium nitride is provided. The apparatus comprises a large diameter autoclave and a raw material basket. Methods include metered addition of dopants in the raw material and control of the atmosphere during crystal growth. The apparatus and methods are scalable up to very large volumes and are cost effective.

Owner:SLT TECH

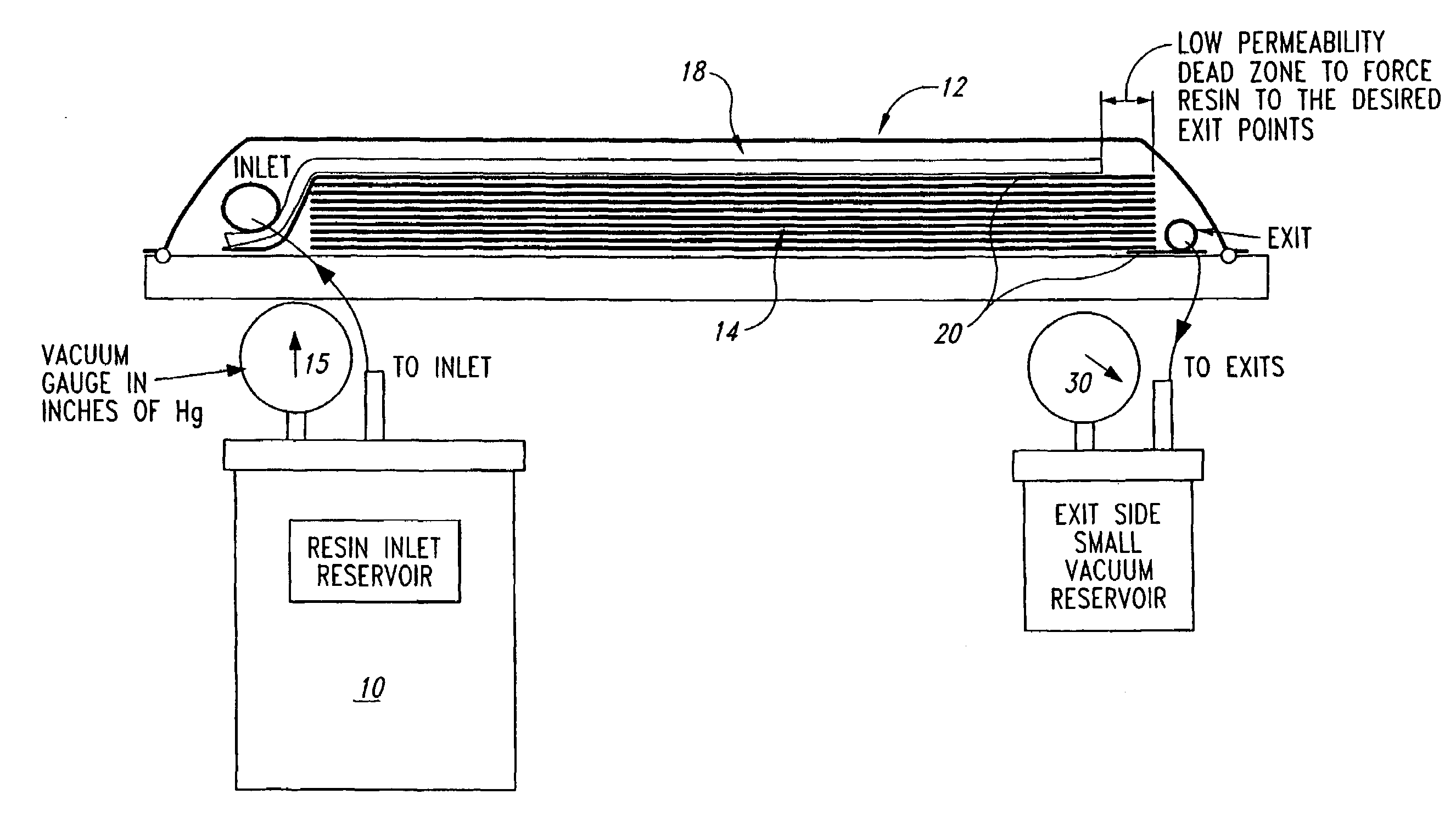

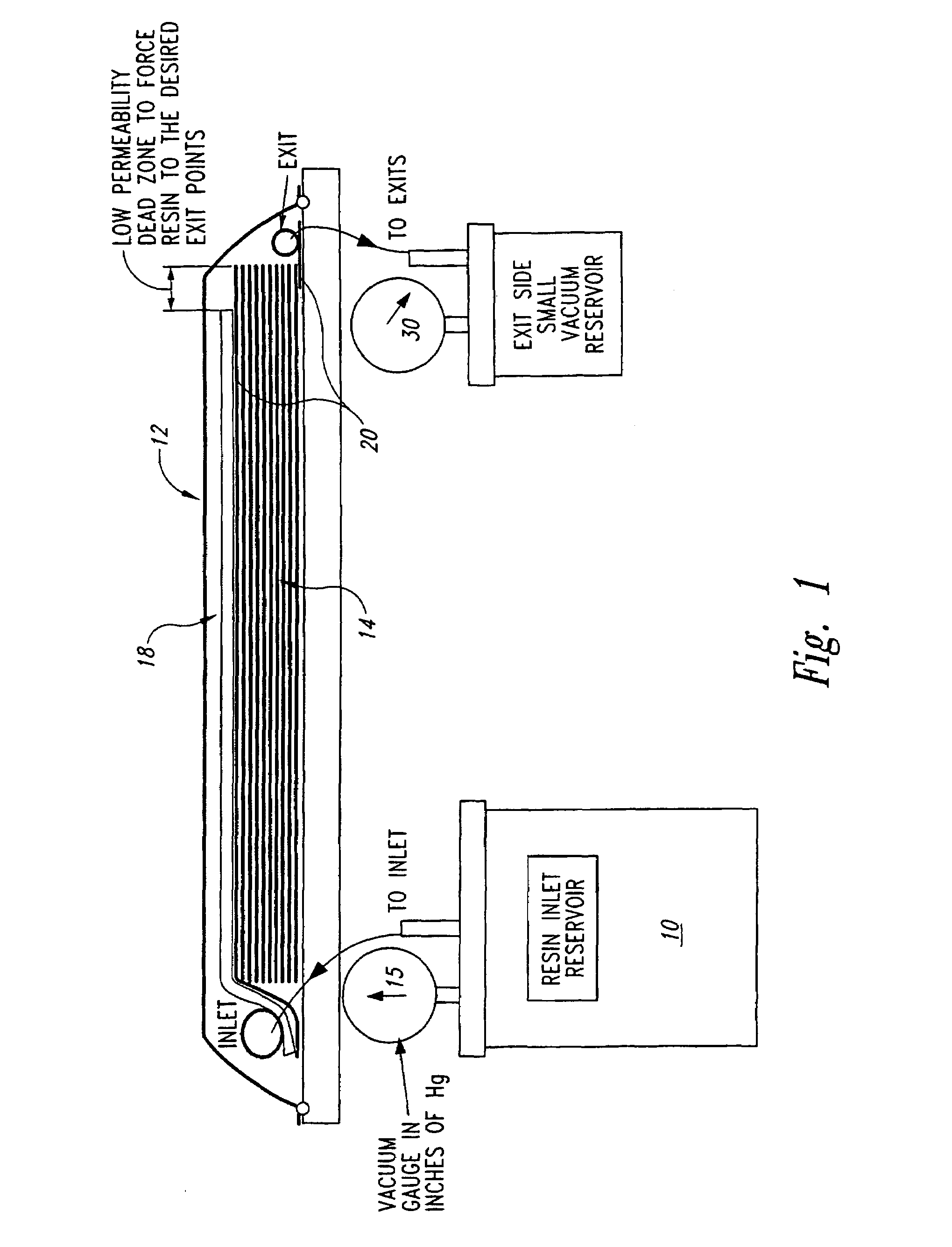

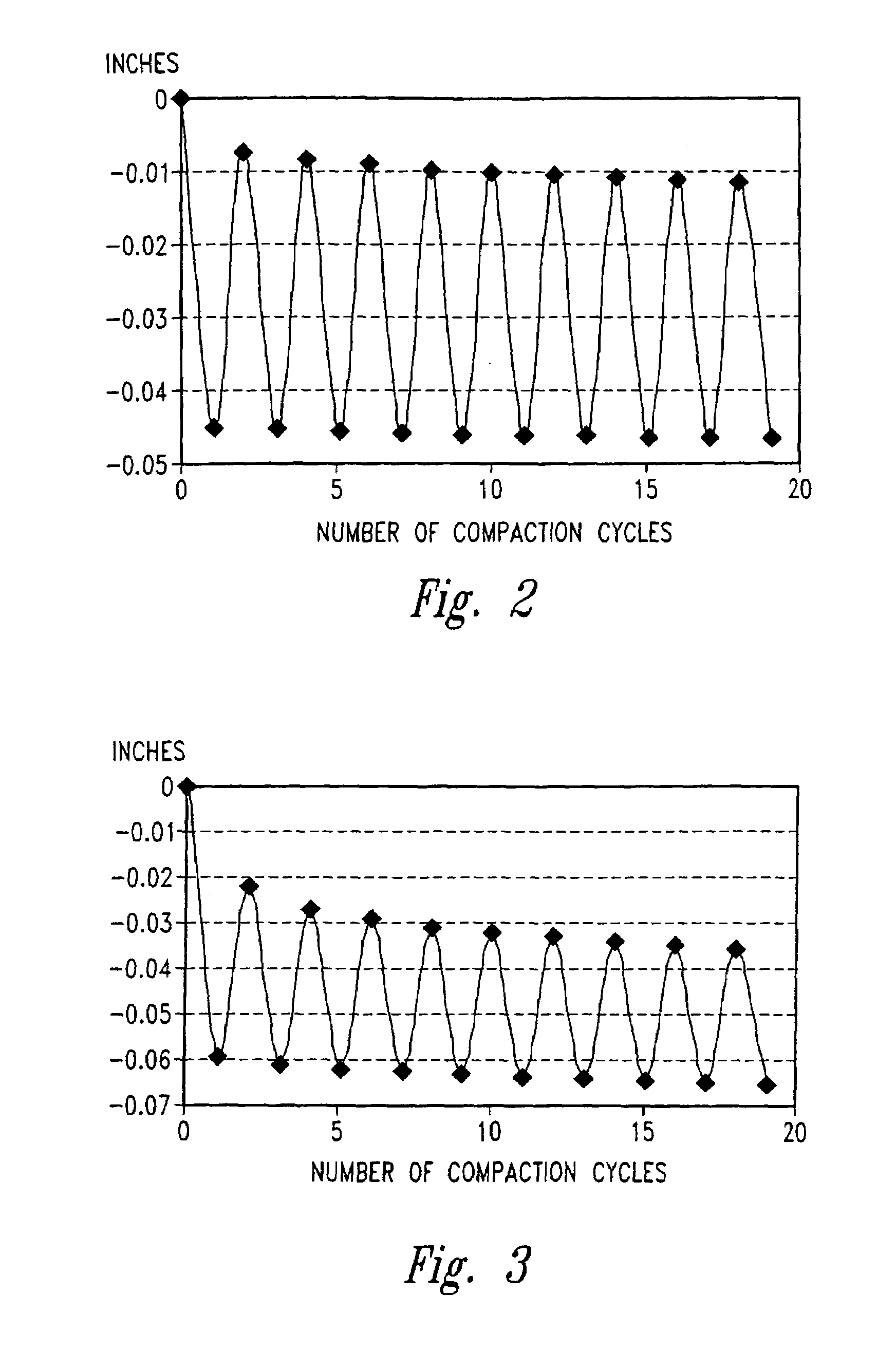

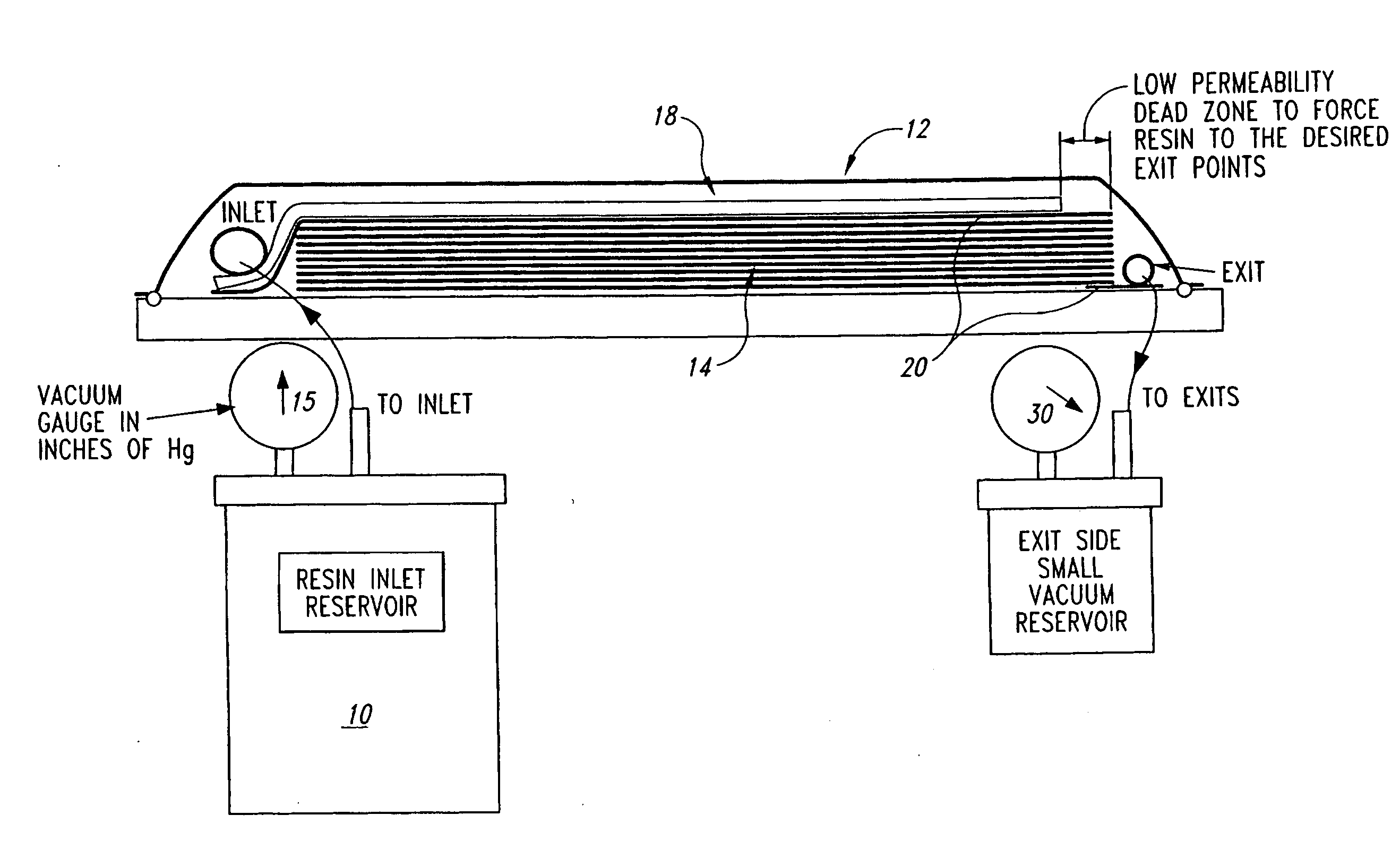

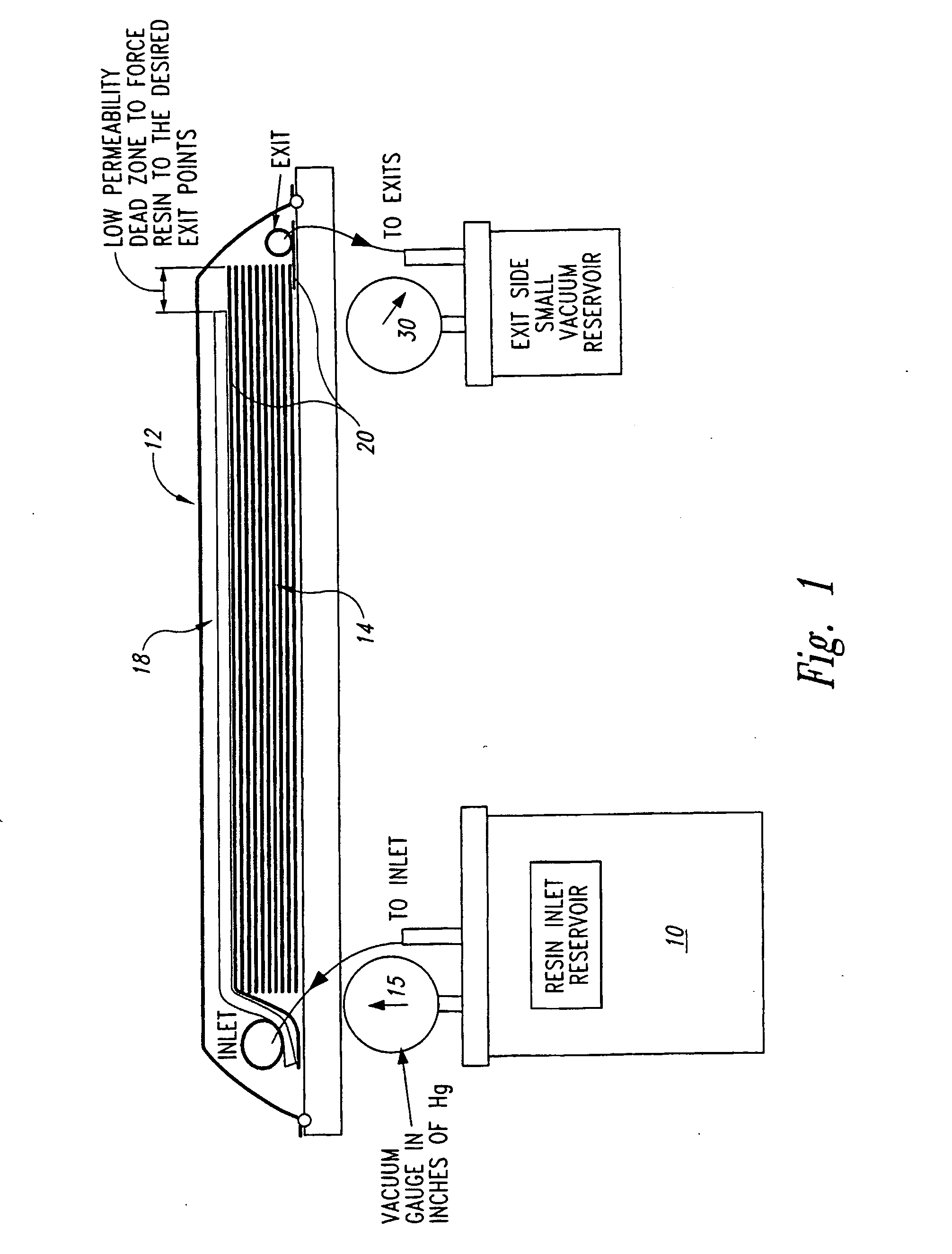

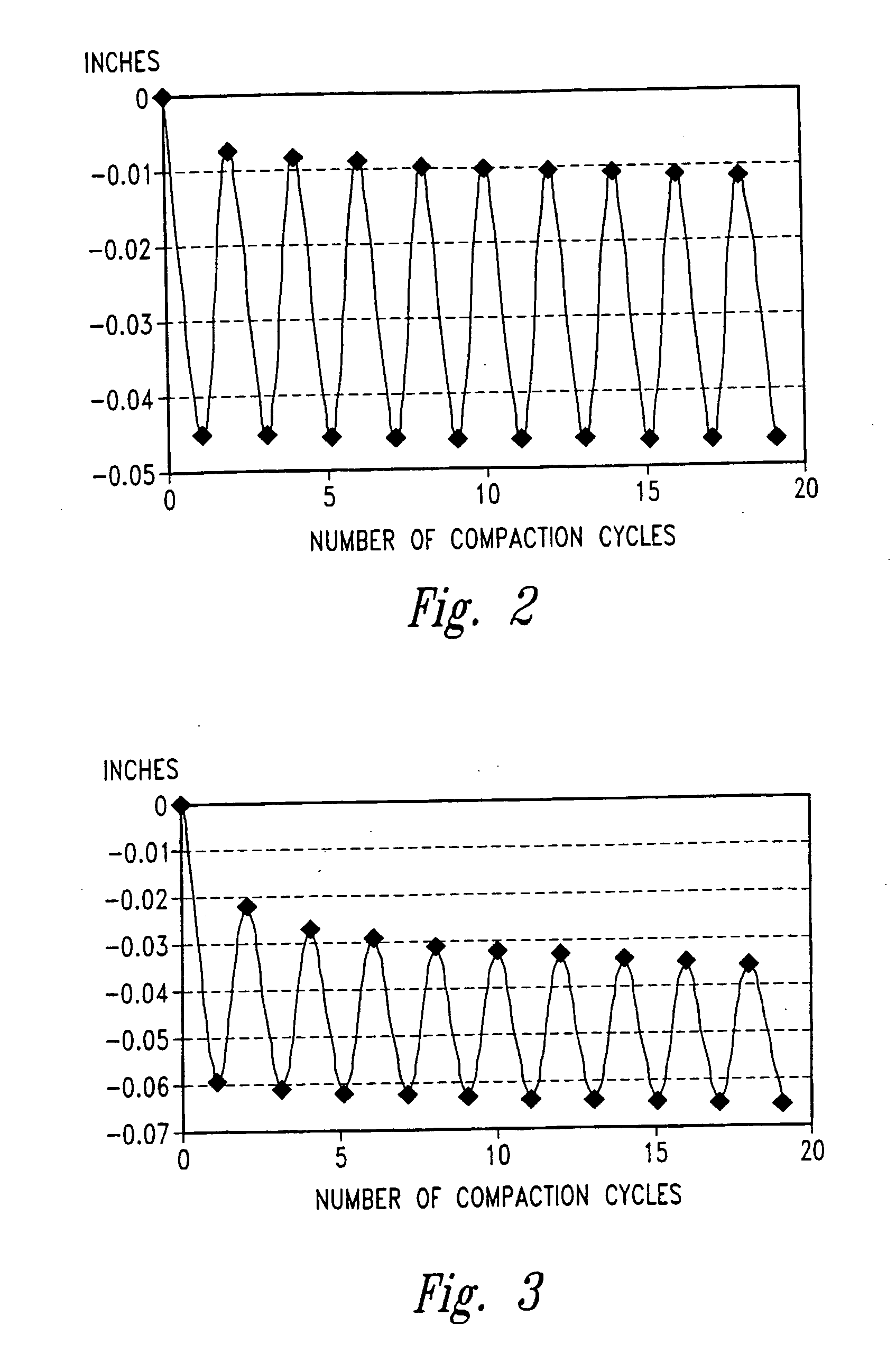

Controlled atmospheric pressure resin infusion process

By evacuating the resin feed tank to a pressure below atmospheric pressure, employing cyclic compaction, and controlling the net compaction pressure, we are better able to control a resin infusion process, particularly a vacuum assisted resin transfer molding process, and produce aerospace-grade fiber-reinforced resin composite having fiber volume fractions and tool-side surface finishes comparable to or exceeding those made using an autoclave.

Owner:THE BOEING CO

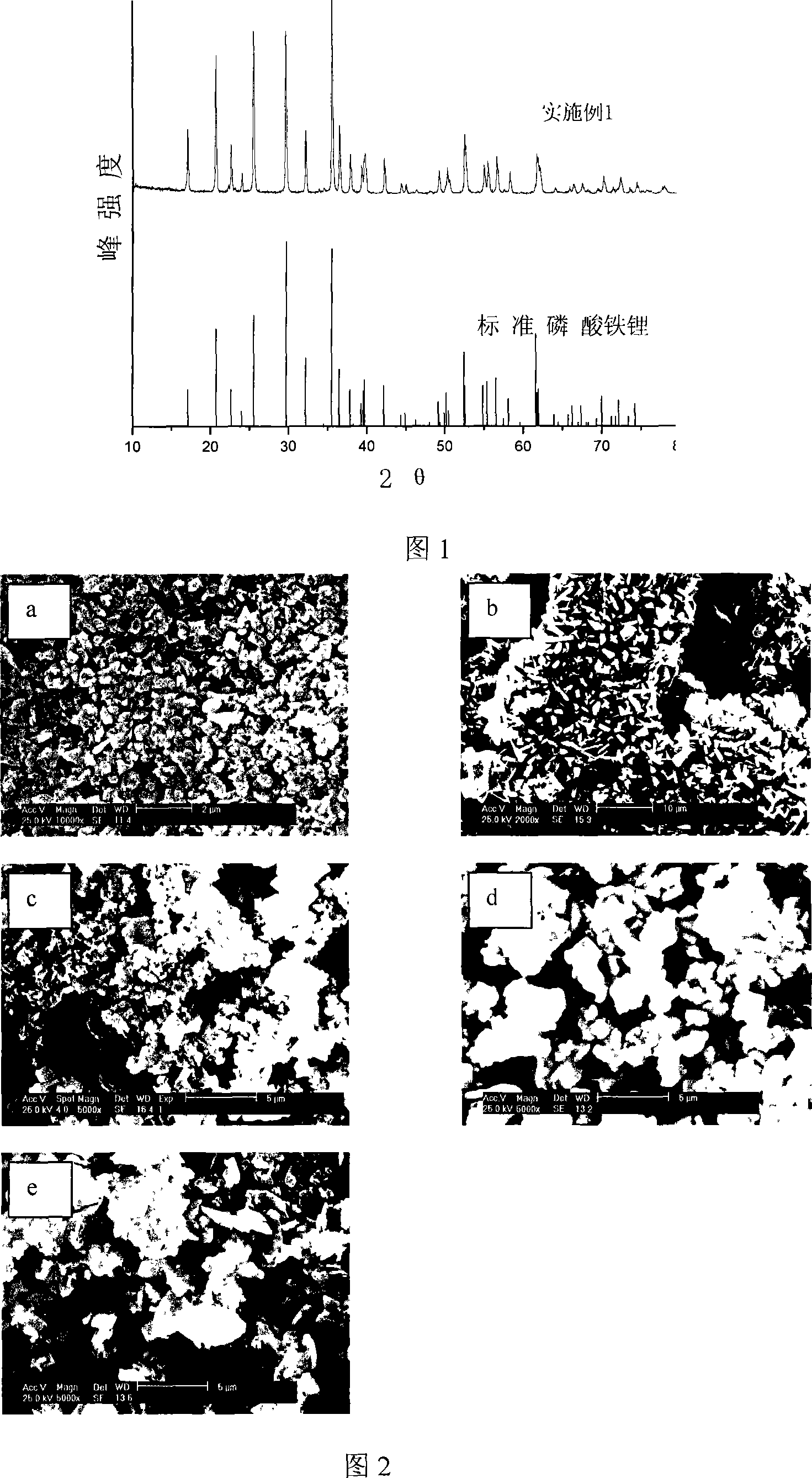

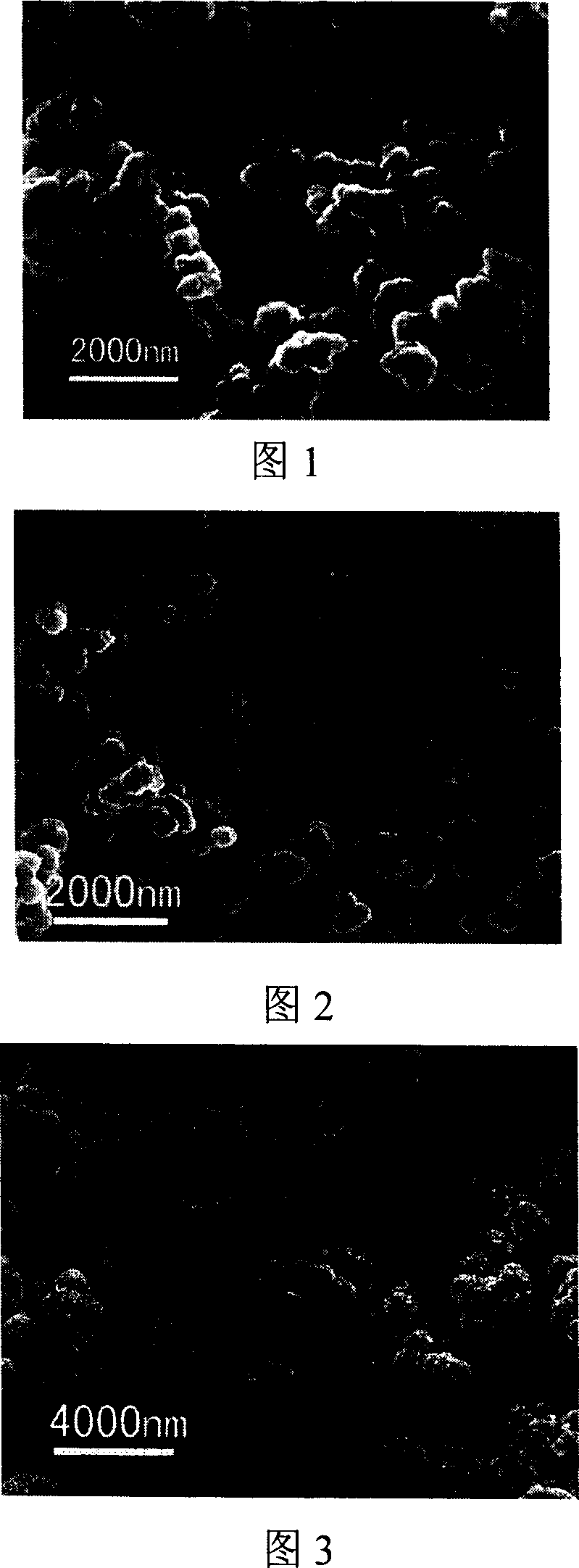

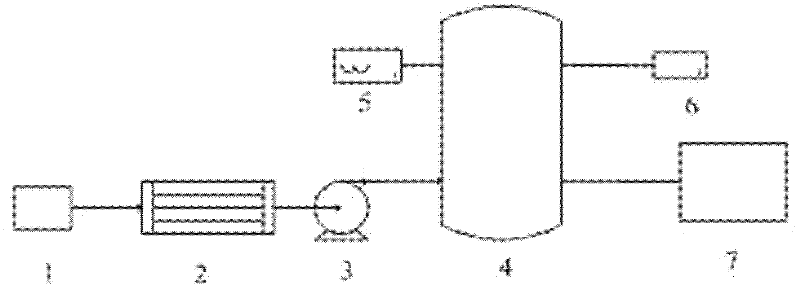

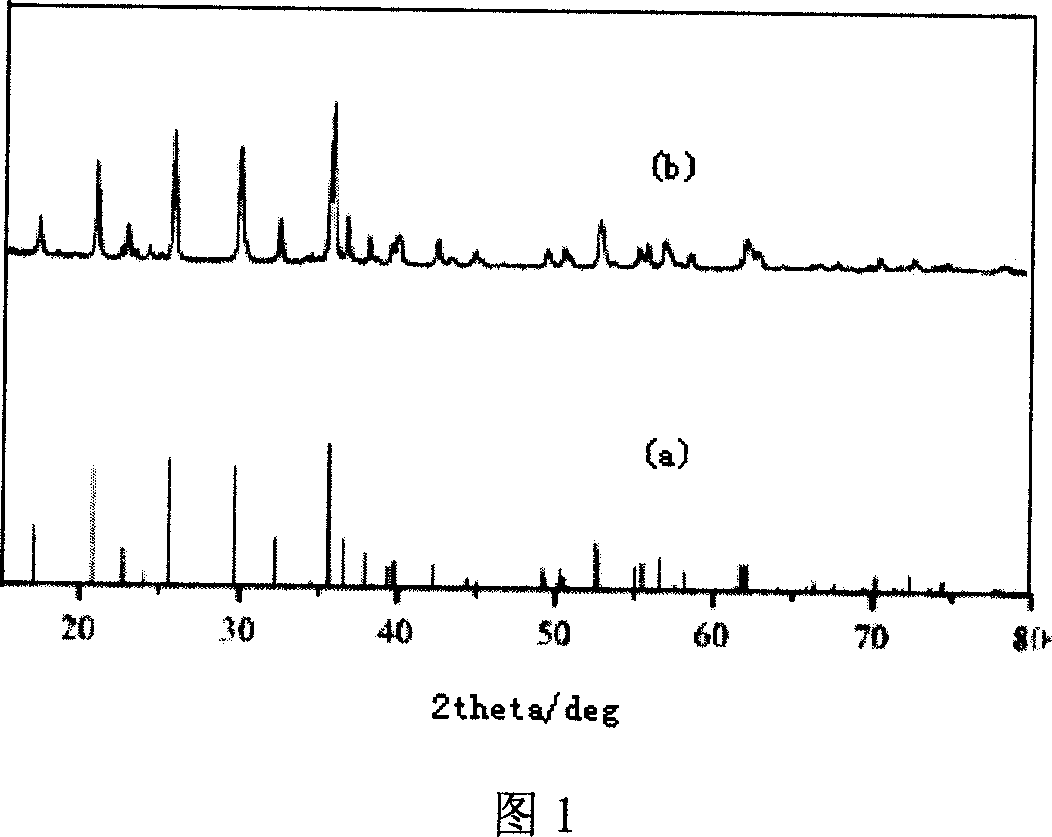

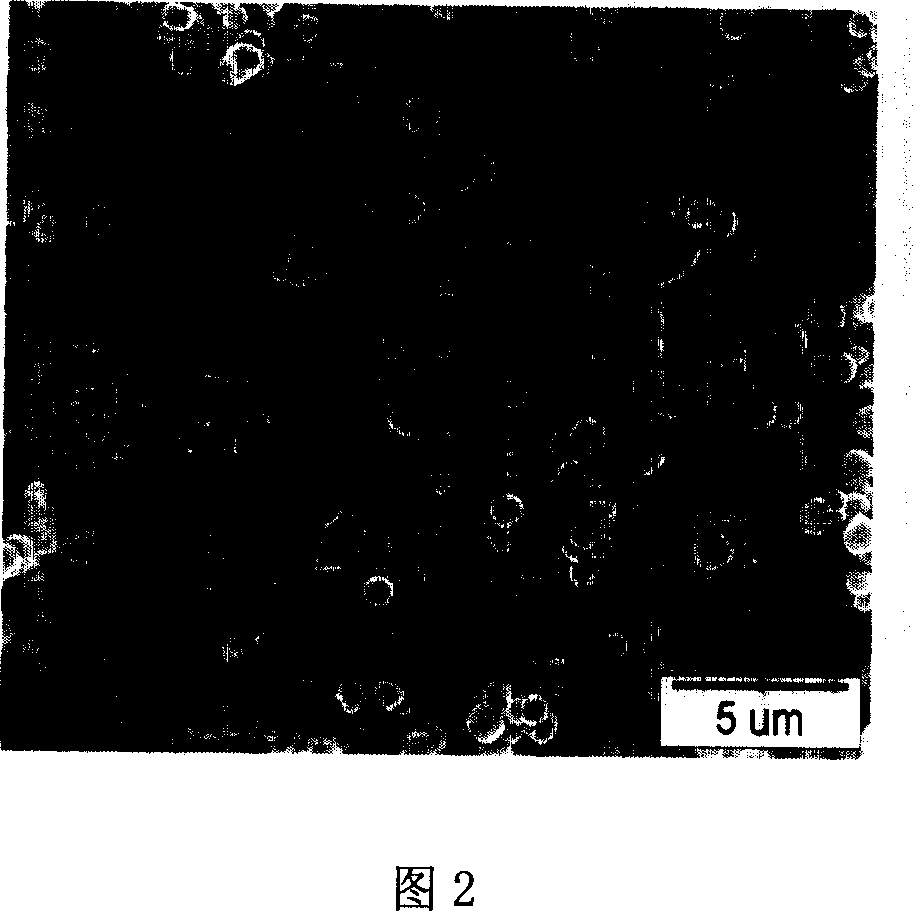

Hydrothermal synthesis method for lithium ion-cell anode material of ferric phosphate lithium

InactiveCN101117216AImprove electrochemical performanceShorten the diffusion pathCell electrodesPhosphorus compoundsExhaust valveDead volume

The invention discloses a hydrothermal synthesis method of lithium-ion battery anode material of lithium iron phosphate, relating two kinds of metal phosphate. The steps are as follows: lithium source and phosphorus source are dissolved in water or mixed with water, and added into the reaction autoclave, the quaternary cationic surfactants and the alkylphenols polyoxyethylene ethers nonionic surfactant is also added into the reaction autoclave, the air in the dead volume of the autoclave inside is purged by the inert gas, the autoclave is sealed and heated to 40-50 DEG C with stirring, a feed valve and an exhaust valve are opened, pure ferrous salting liquid is added into the autoclave, and then the autoclave is sealed for the reaction of the material at 140 to 180 DEG C for 30 to 480 minutes; the mixture ratio of the invention is set as follows: the molar ratio of Li, Fe and P is 3.0-3.15:1:1.0-1.15, and then the resultant is filtered, washed, dried and carbon-coated, thus the lithium iron phosphate is obtained. The lithium iron phosphate which is produced by the invention has the advantages that: the electrochemical performance is excellent, the particle size distribution of which the D50 is between 1.5 um to 2 um is even, the phase purity is above 99 percent and the electronic conductivity of the material is improved.

Owner:HEBEI LITAO BATTERY MATERIAL

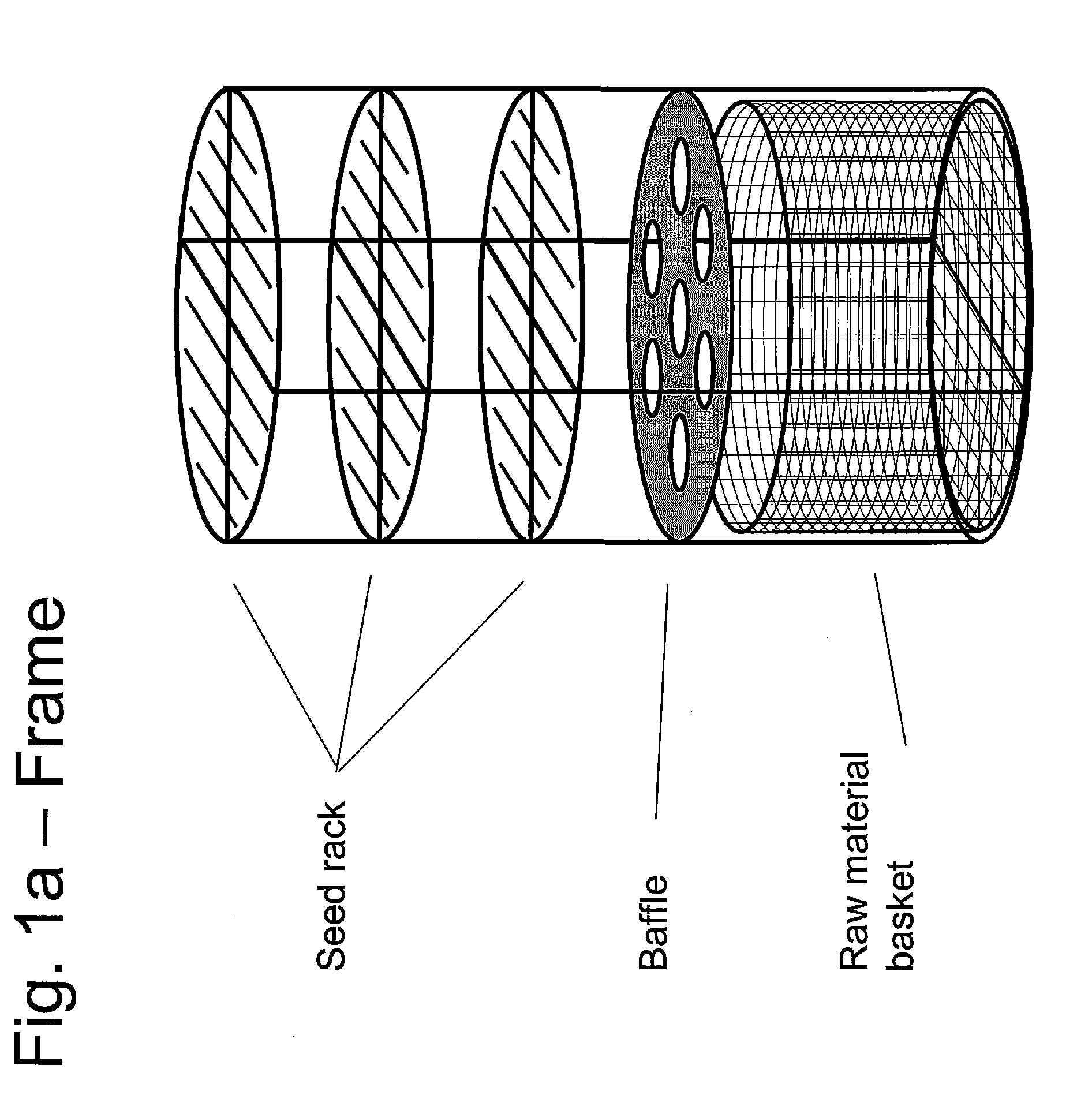

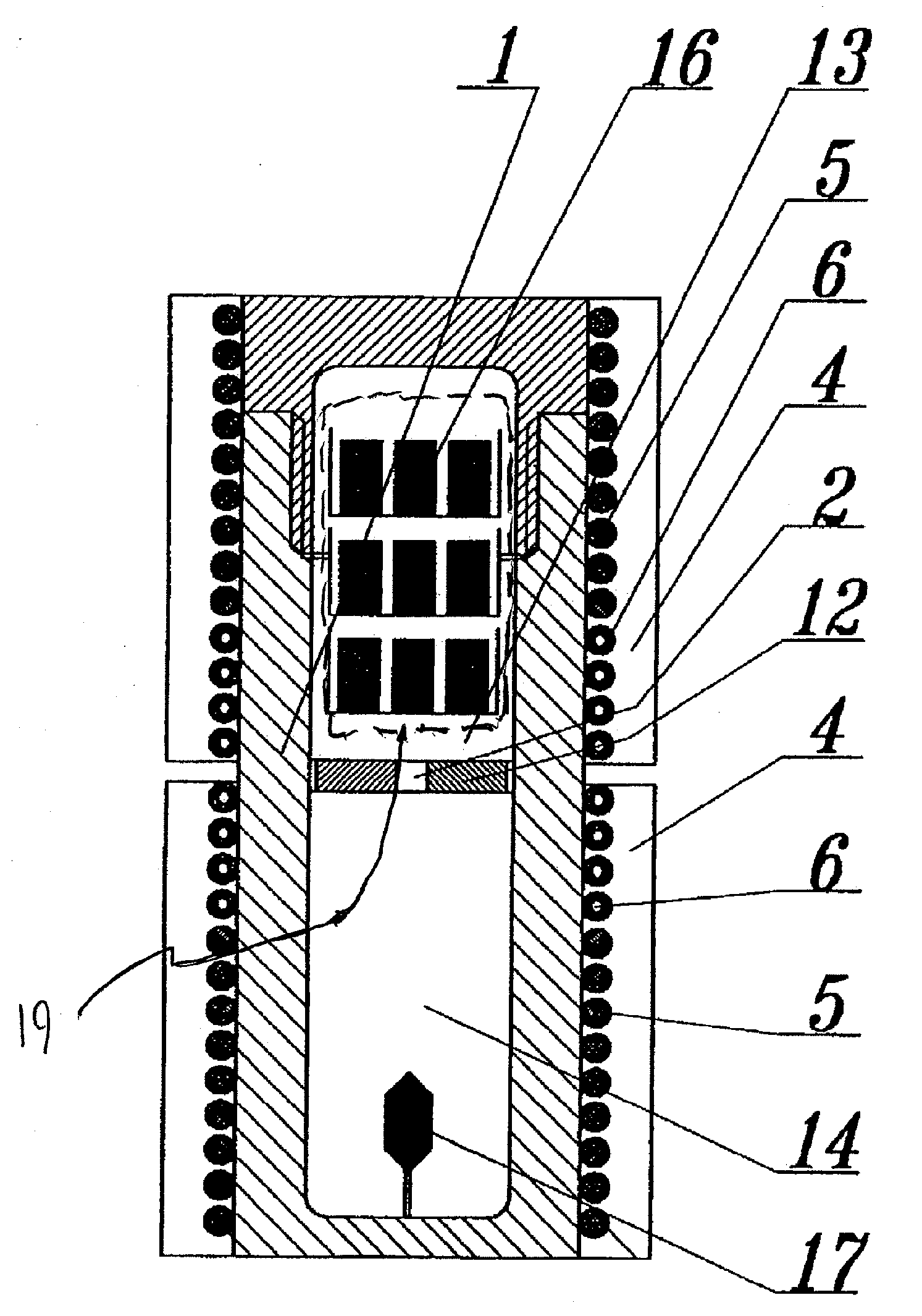

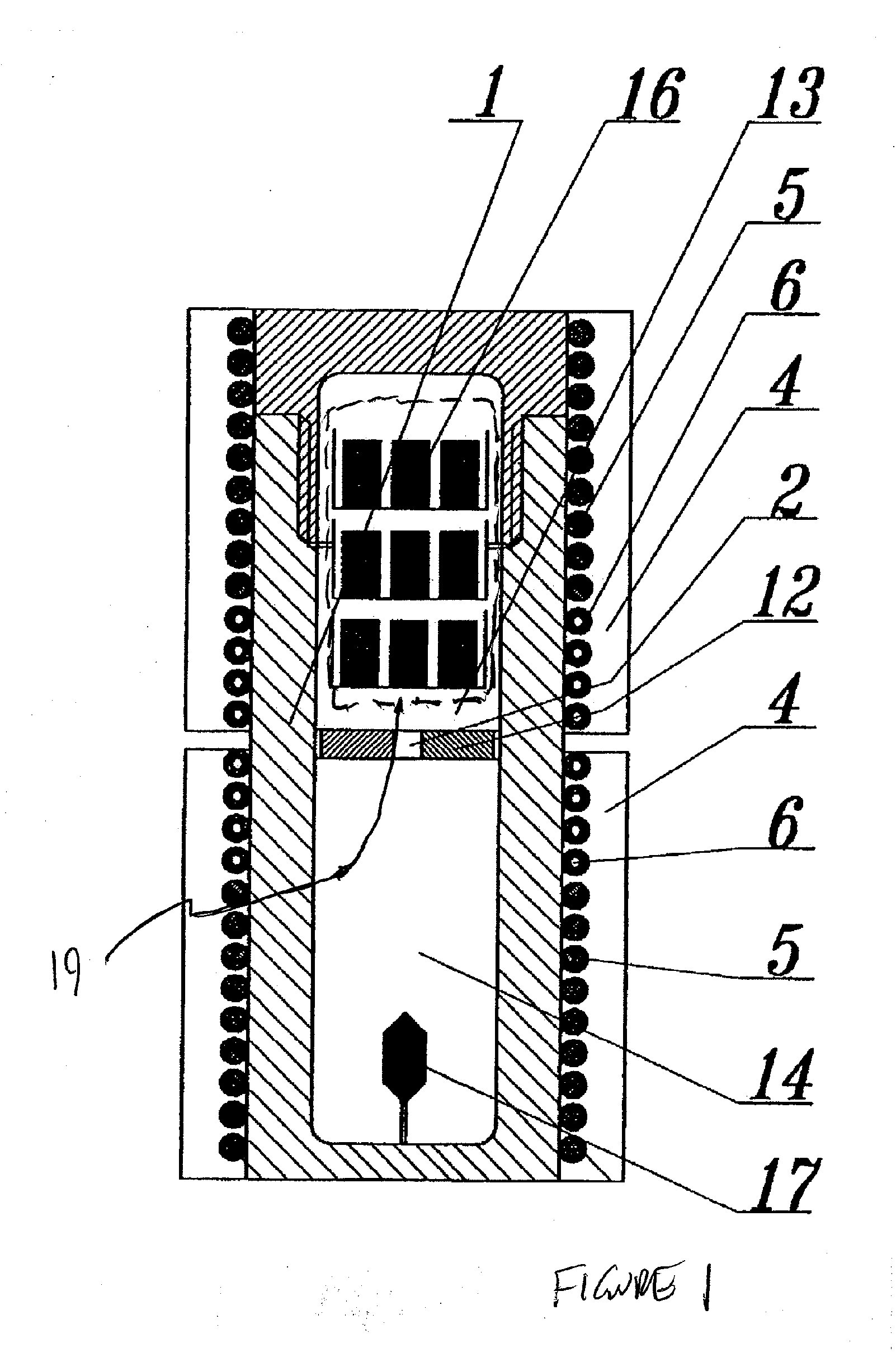

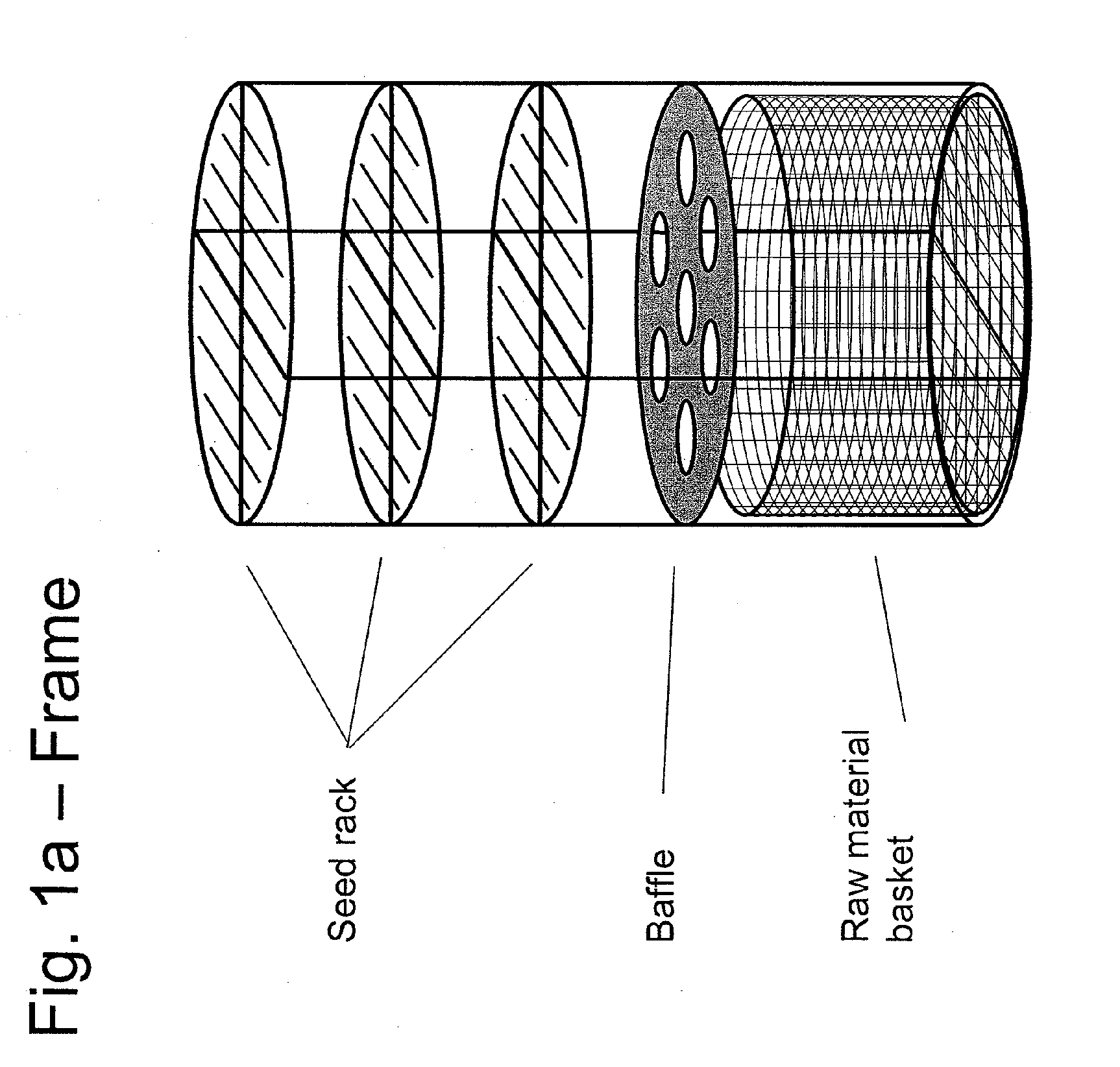

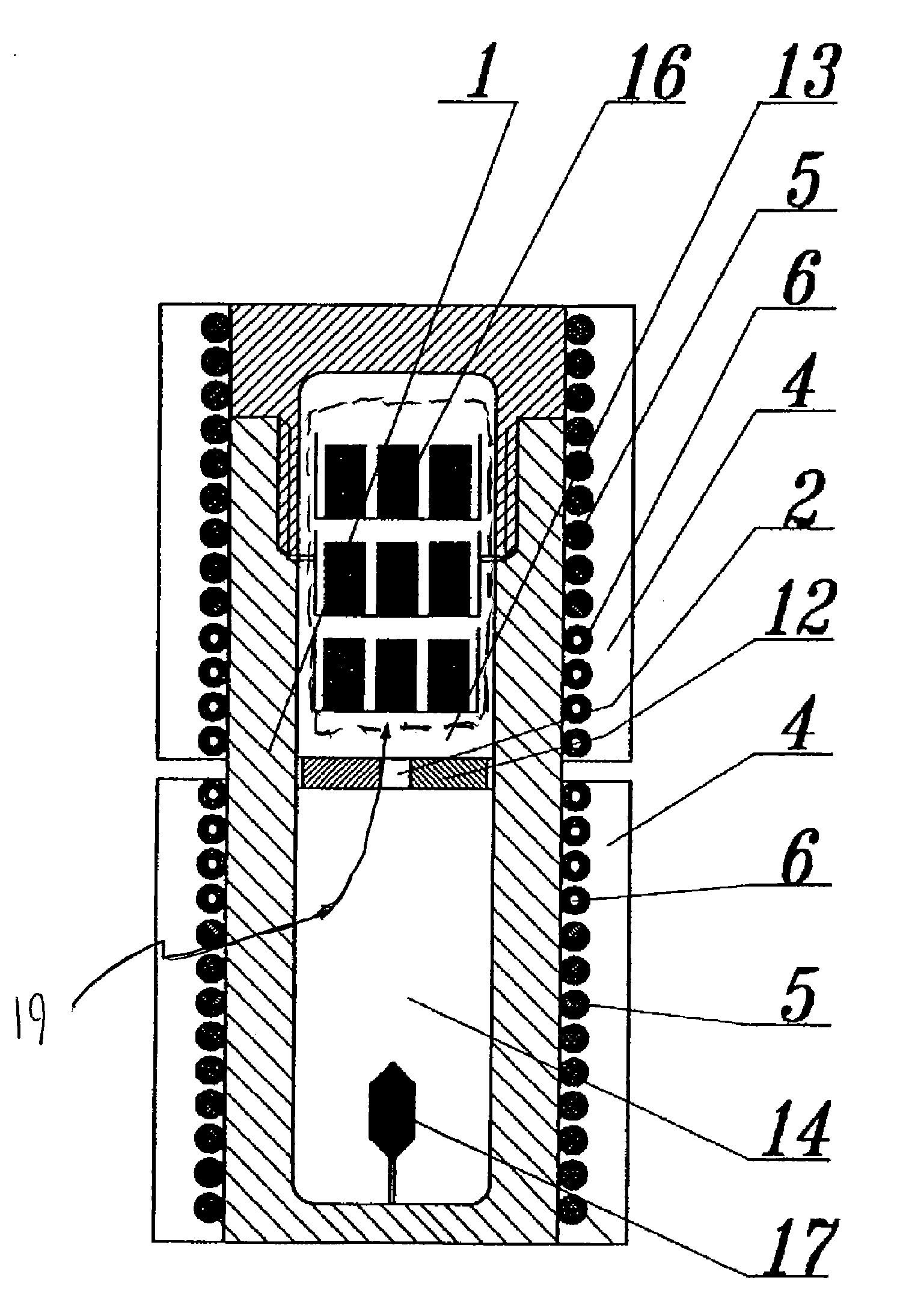

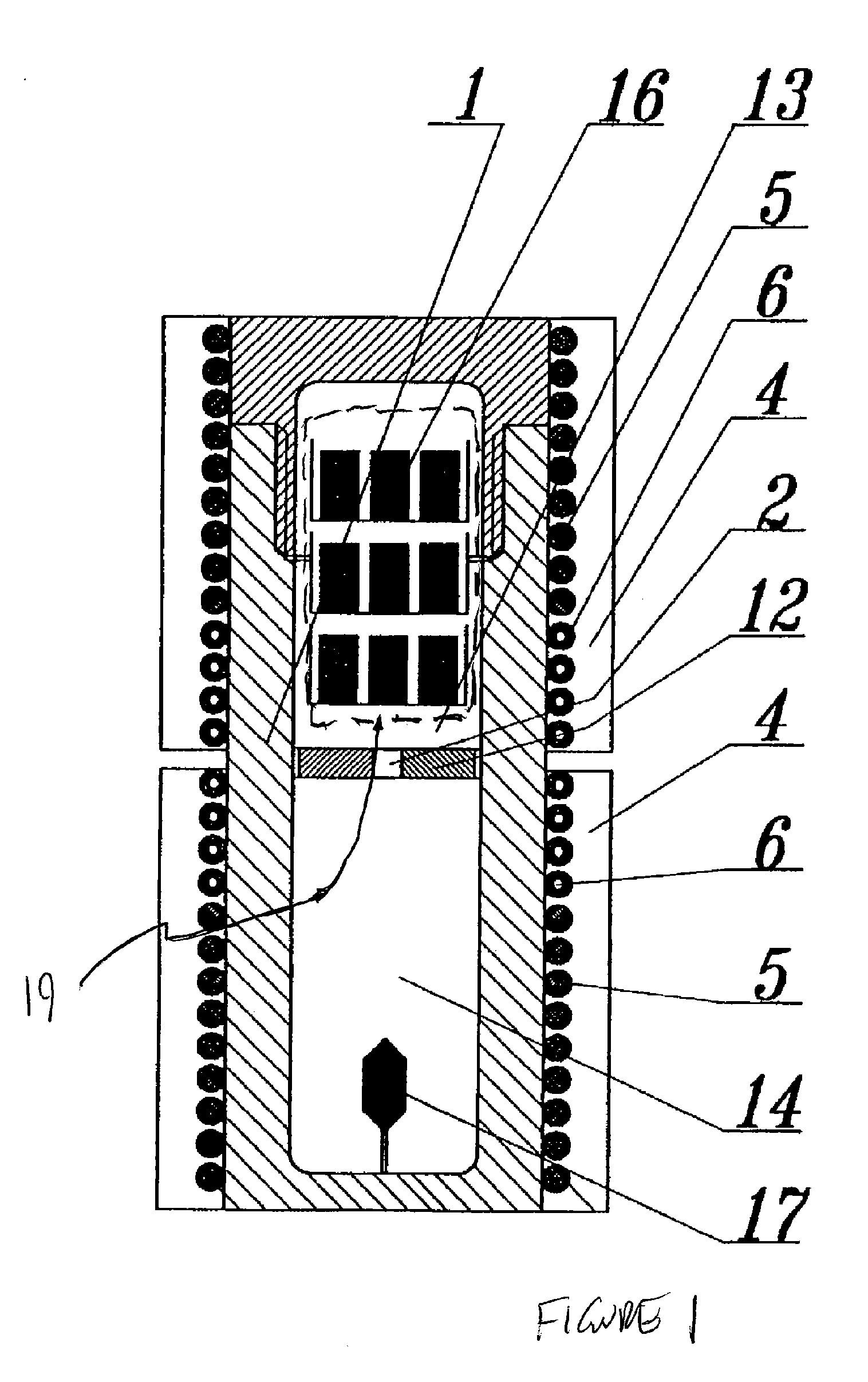

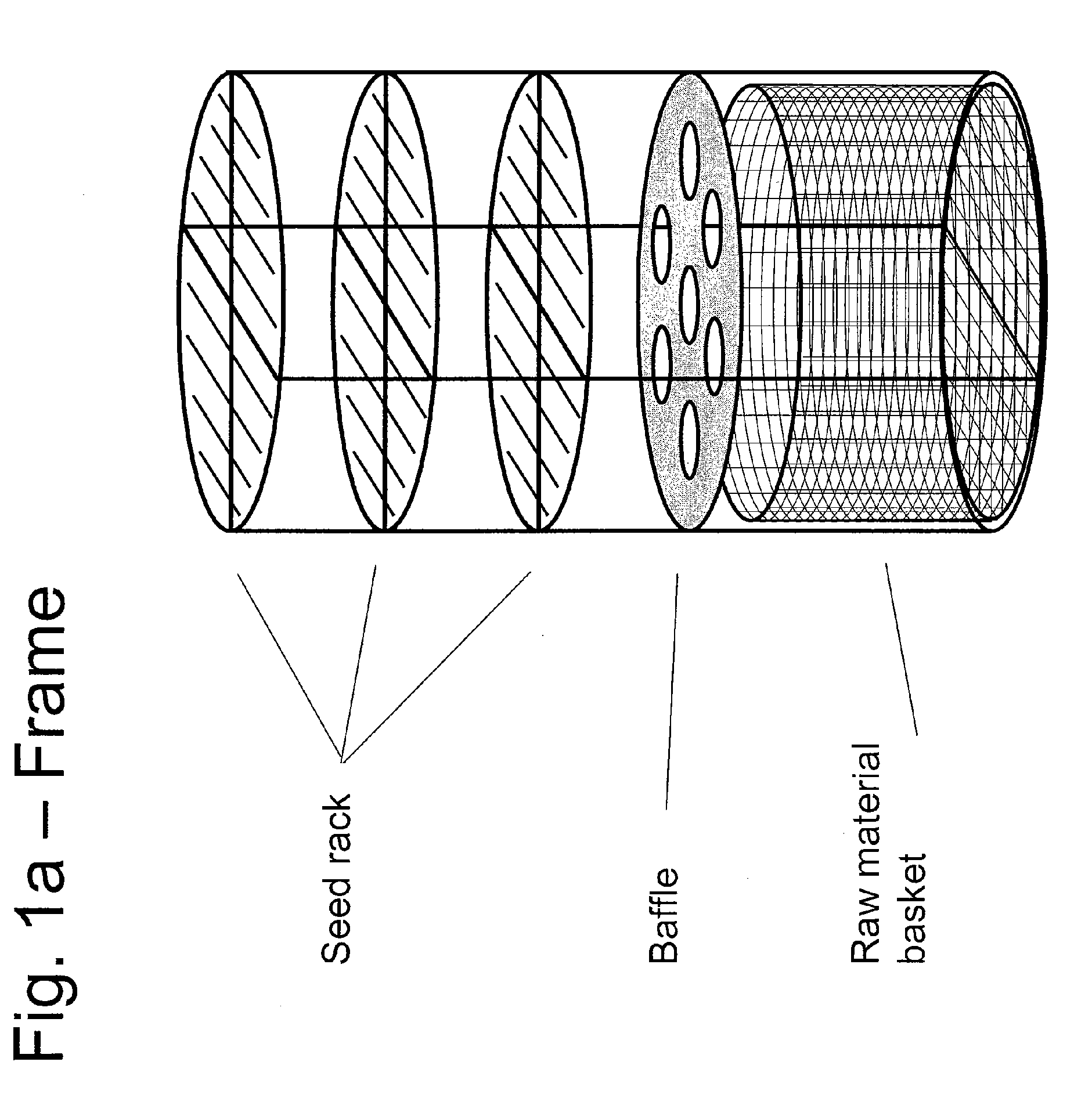

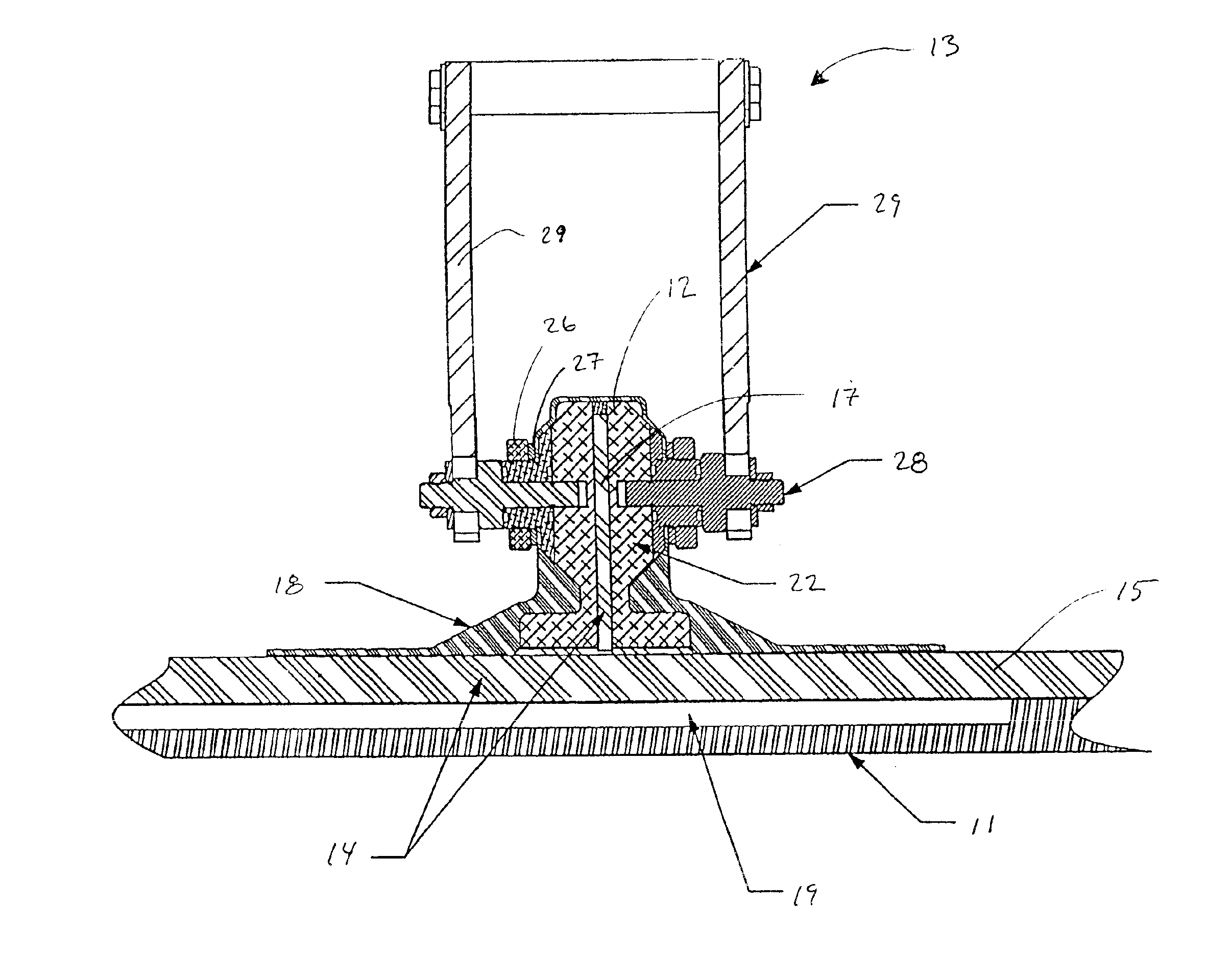

Apparatus and method for seed crystal utilization in large-scale manufacturing of gallium nitride

ActiveUS20100031872A1Cost-effectiveSimple and cost-effective to manufactureAfter-treatment apparatusPolycrystalline material growthCost effectivenessAdemetionine

An apparatus and associated method for large-scale manufacturing of gallium nitride. The apparatus comprises a large diameter autoclave or internally-heated high pressure vessel, a seed rack, and a raw material basket. Methods include effective means for utilization of seed crystals. The apparatus and methods are scalable up to very large volumes and are cost effective.

Owner:SLT TECH

OPTO-ELECTRONIC AND ELECTRONIC DEVICES USING N-FACE OR M-PLANE GaN SUBSTRATE PREPARED WITH AMMONOTHERMAL GROWTH

ActiveUS20080001165A1Improve performanceNot easy to growPolycrystalline material growthFrom normal temperature solutionsGallium nitrideOpto electronic

Owner:SILVERBROOK RES PTY LTD +1

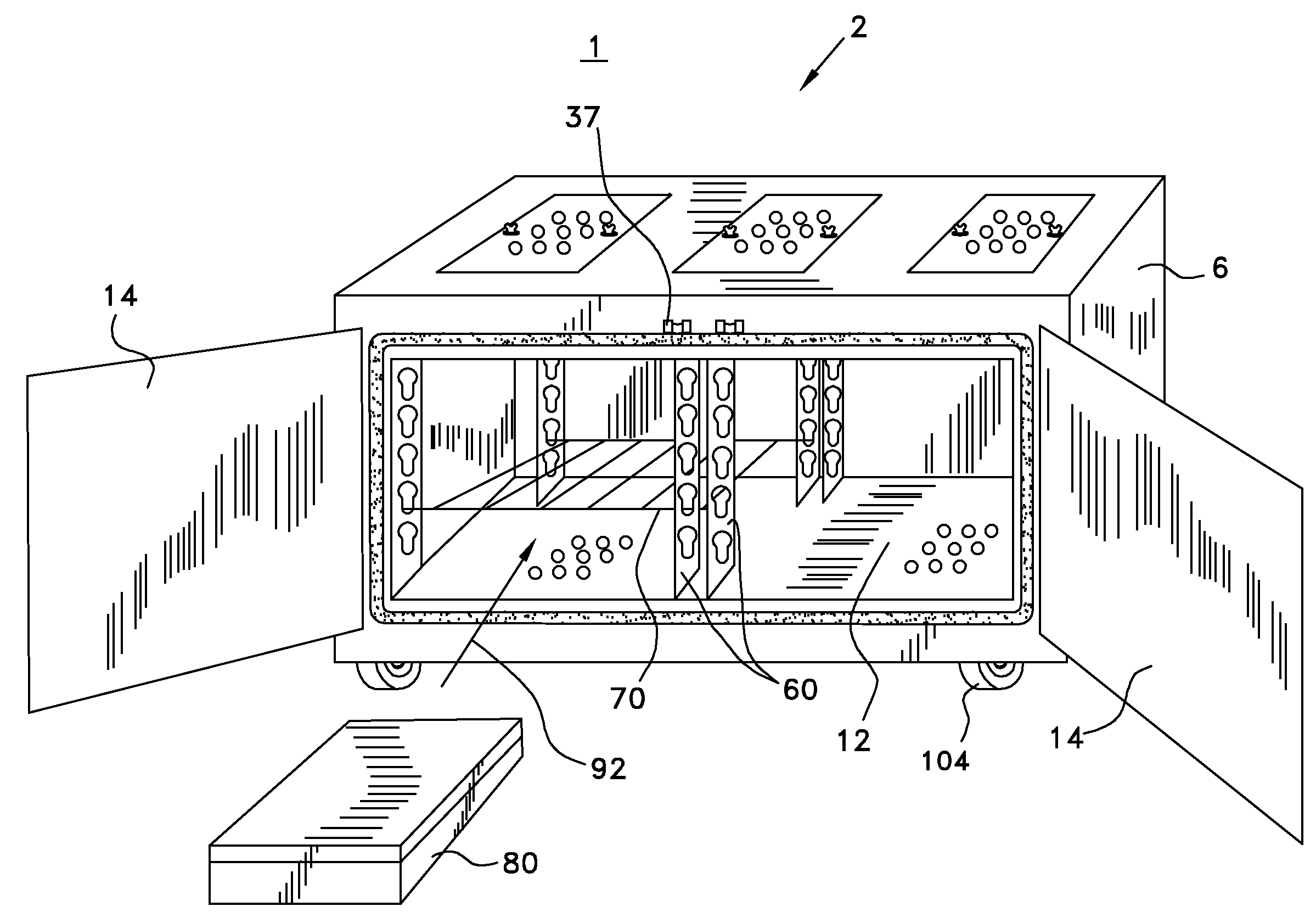

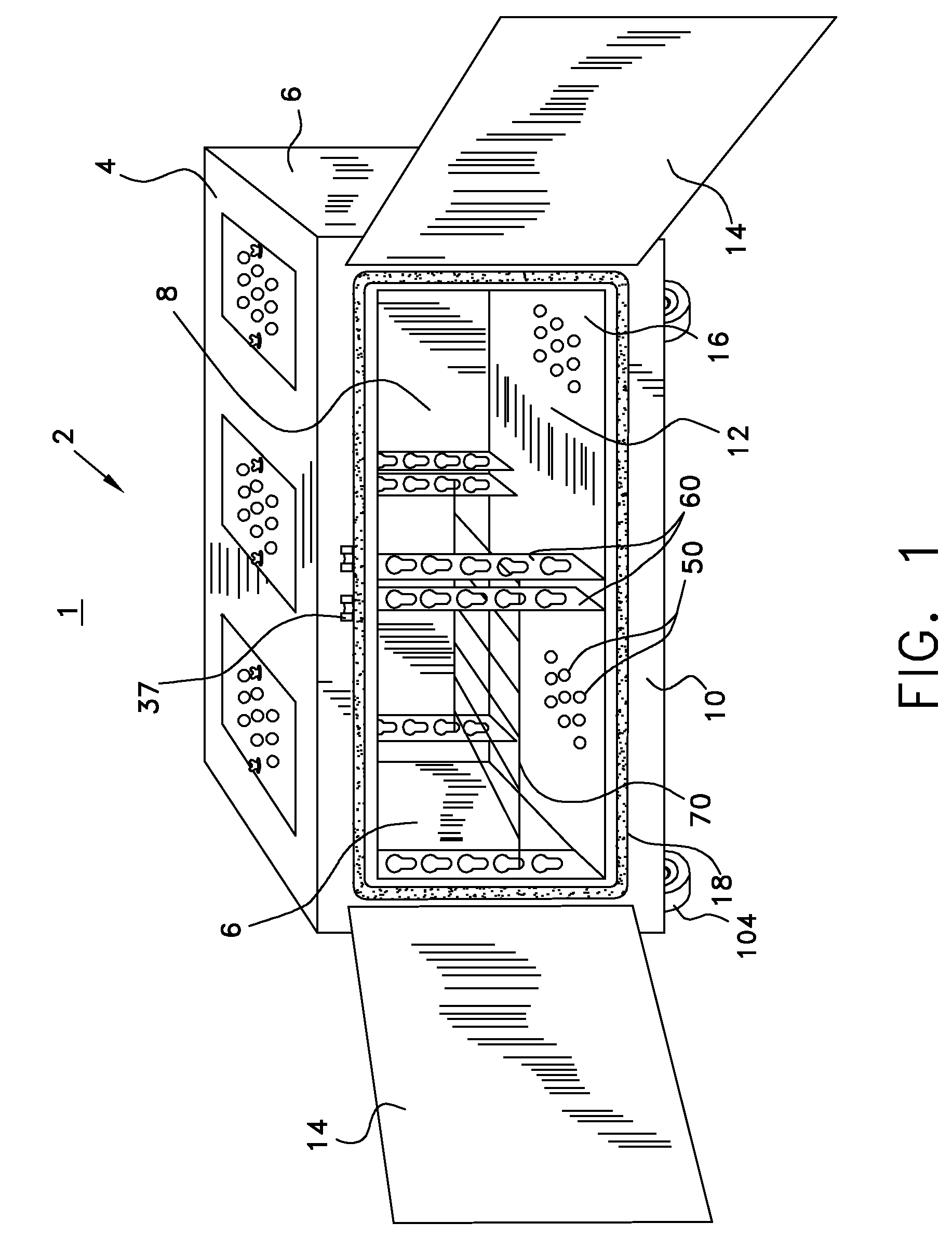

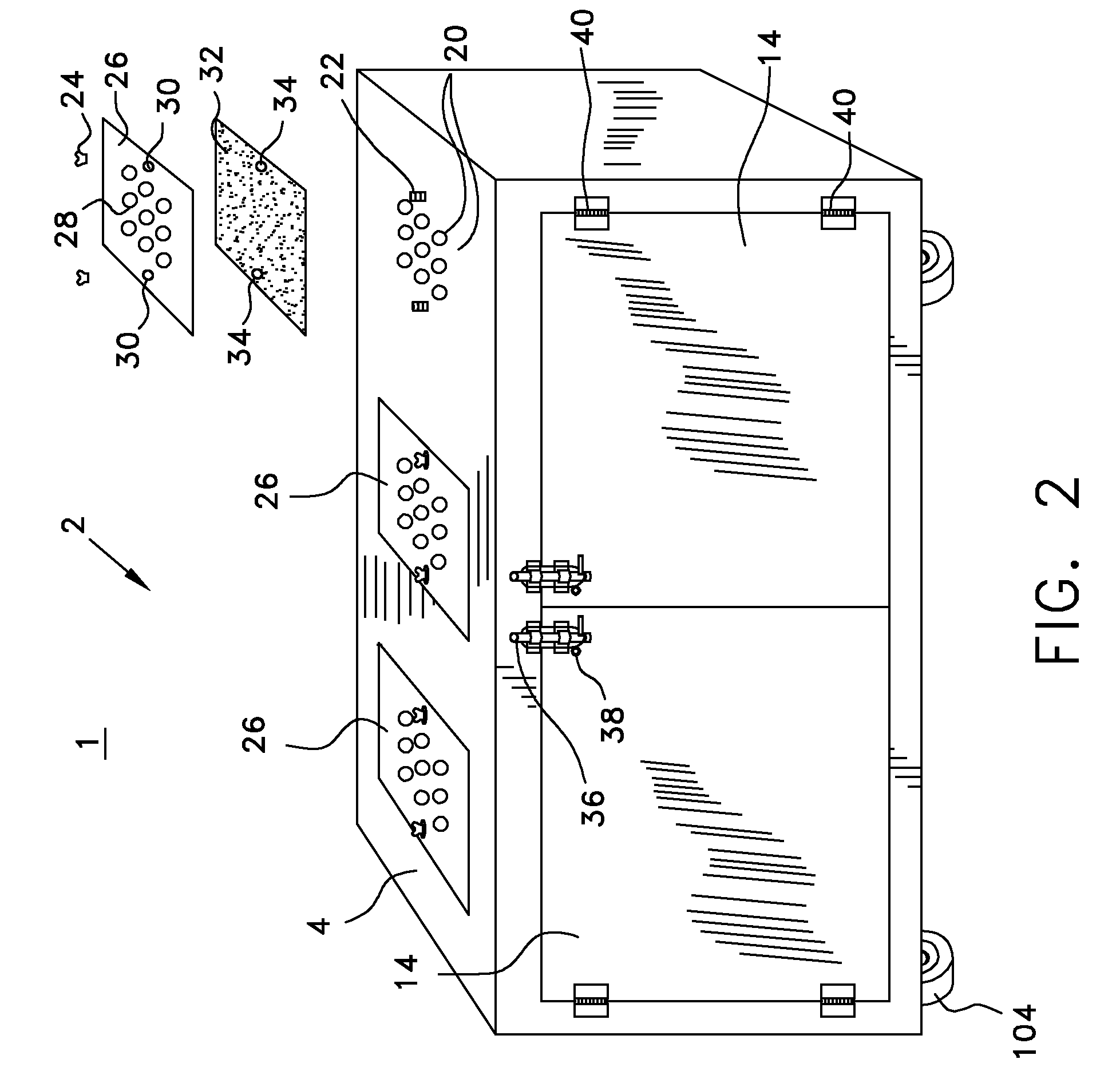

Mobile apparatus and method to sterilize surgical trays

A mobile apparatus and method to sterilize surgical trays. A cabinet has filtered cabinet roof vents, filtered cabinet floor vents, door(s) sealably covering a cabinet front aperture, shelves sized to support surgical trays, and wheels. Surgical trays are placed within the cabinet, the cabinet doors are closed, and the mobile apparatus is placed within an autoclave and sterilized. The cabinet doors are not unsealed until the cabinet is in the operating room, ready for use. During use in the operating room, doors are opened, trays removed, and their contents used. Wheels on the cabinet facilitate moving the cabinet from autoclave to storage or operating room. Chemical indicators and a locator card may be used to verify the sterilization status and autoclave history of the cabinet and its contents. Method steps include periodically replacing the filters and door gasket.

Owner:PROGRESSIVE STERILIZATION LLC

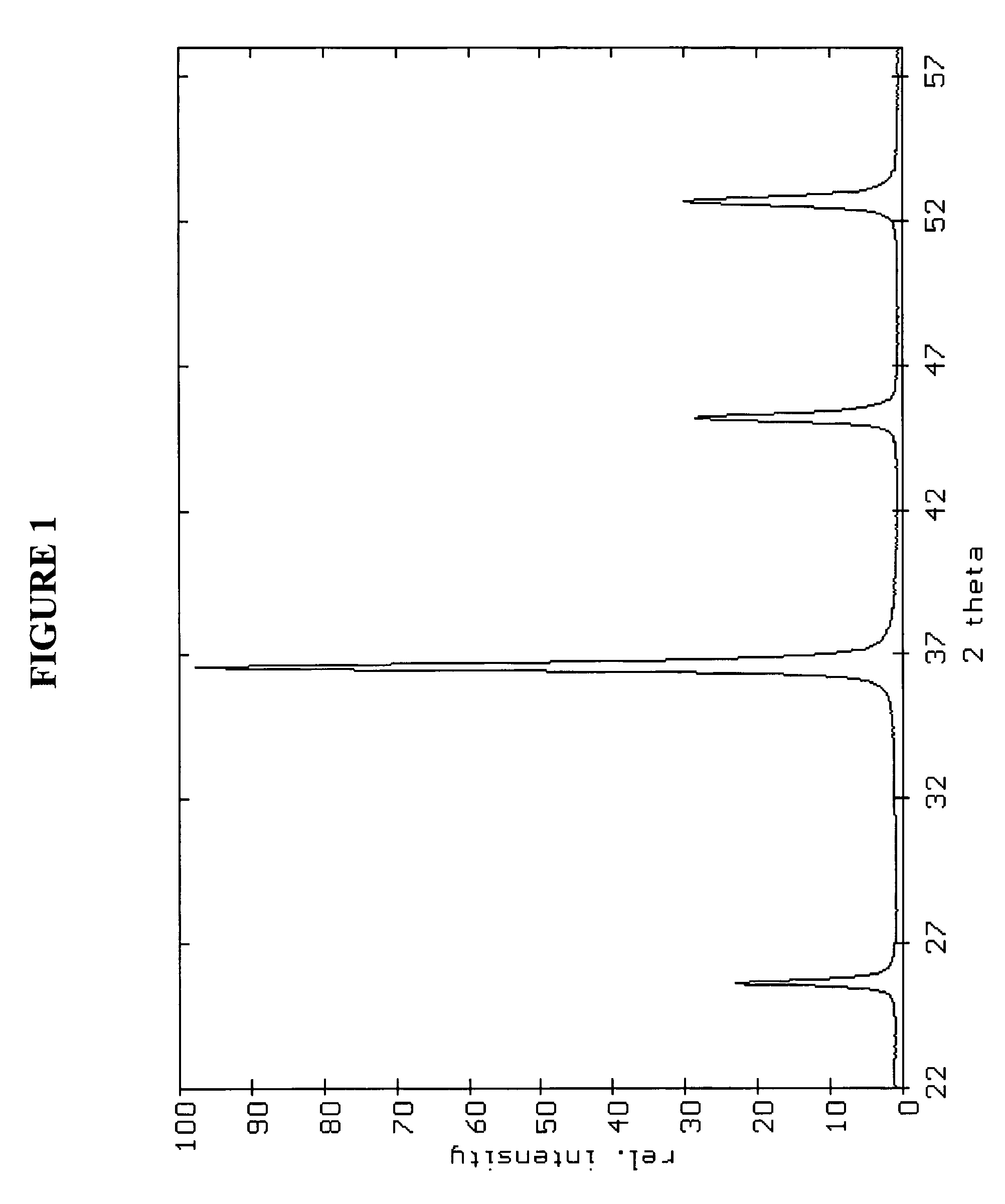

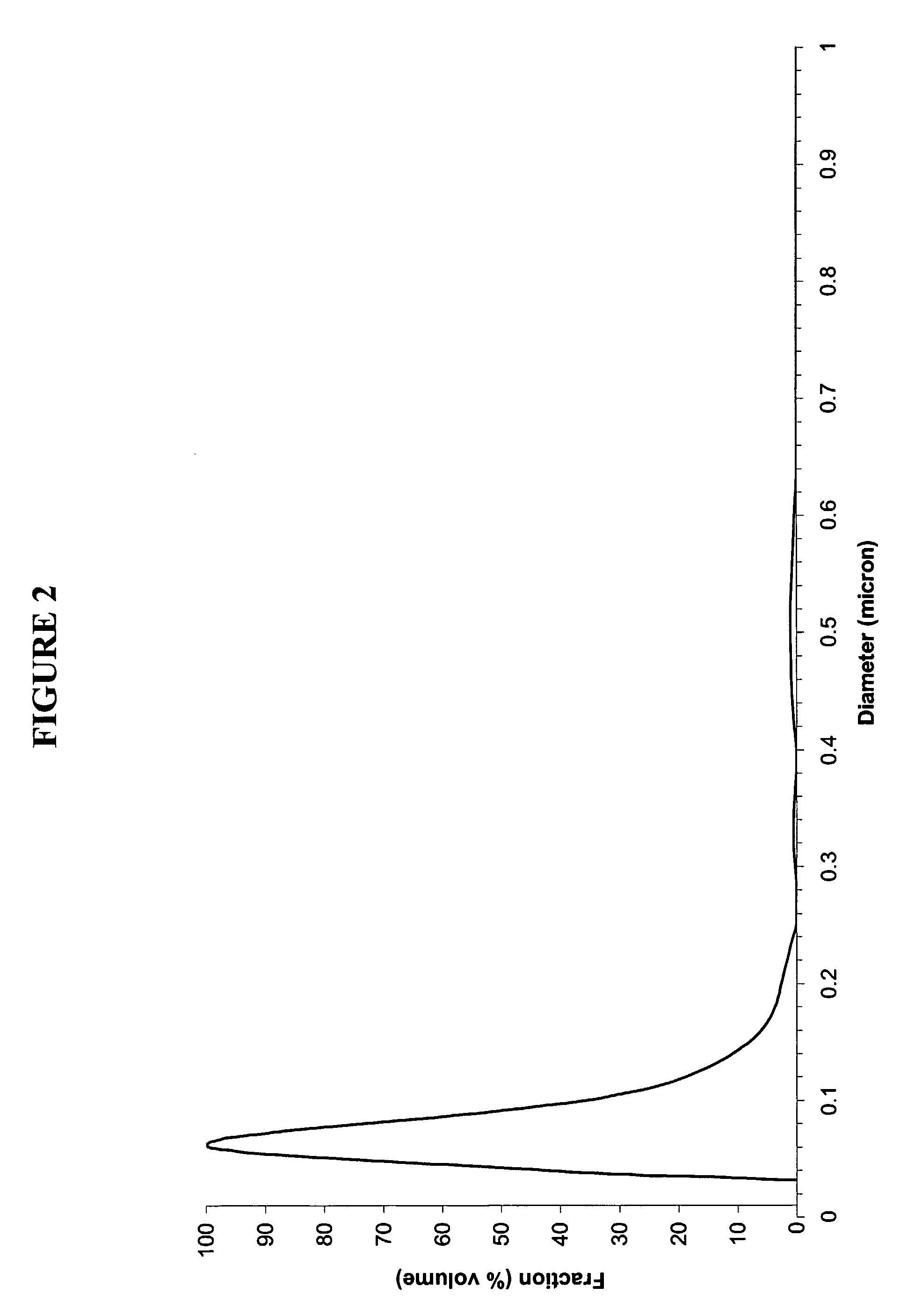

Production Of Barium Titanate Compounds

InactiveUS20070202036A1High purityLow costMaterial nanotechnologyAlkaline earth titanatesBarium titanateSpherical shaped

An ultrafine powder of barium titanate including solid solutions and doped compounds that meets up to specific characteristics is produced by method comprising two main steps. The first step is a reaction, typically in a Segmented Flow Tubular Reactor, between reactants to produce cubic-structure barium titanate composed of non-agglomerated ultrafine particles having a shape of given aspect ratio, usually a generally spherical shape, of low density corresponding at most to 90% of the intrinsic density, all particles being smaller than 1 micron and having a narrow particle size distribution and wherein the ratio of Ba:Ti including substitutents and dopants is very close to the ideal stoichiometry. This is followed by subjecting the powder produced in the first step to a second stage solvothermal post treatment typically in an autoclave at temperature less than 400° C. to convert the cubic-structure particles of low density to ultrafine tetragonal particles of increased density corresponding to at least 90% of the intrinsic density while maintaining the same aspect ratio, and maintaining the size of all particles below 1 micron, the narrow particle size distribution span, and the given ideal stoichiometry. The produced particles can have a non-spherical facetted shape such as cube-like.

Owner:JONGEN NATHALIE +1

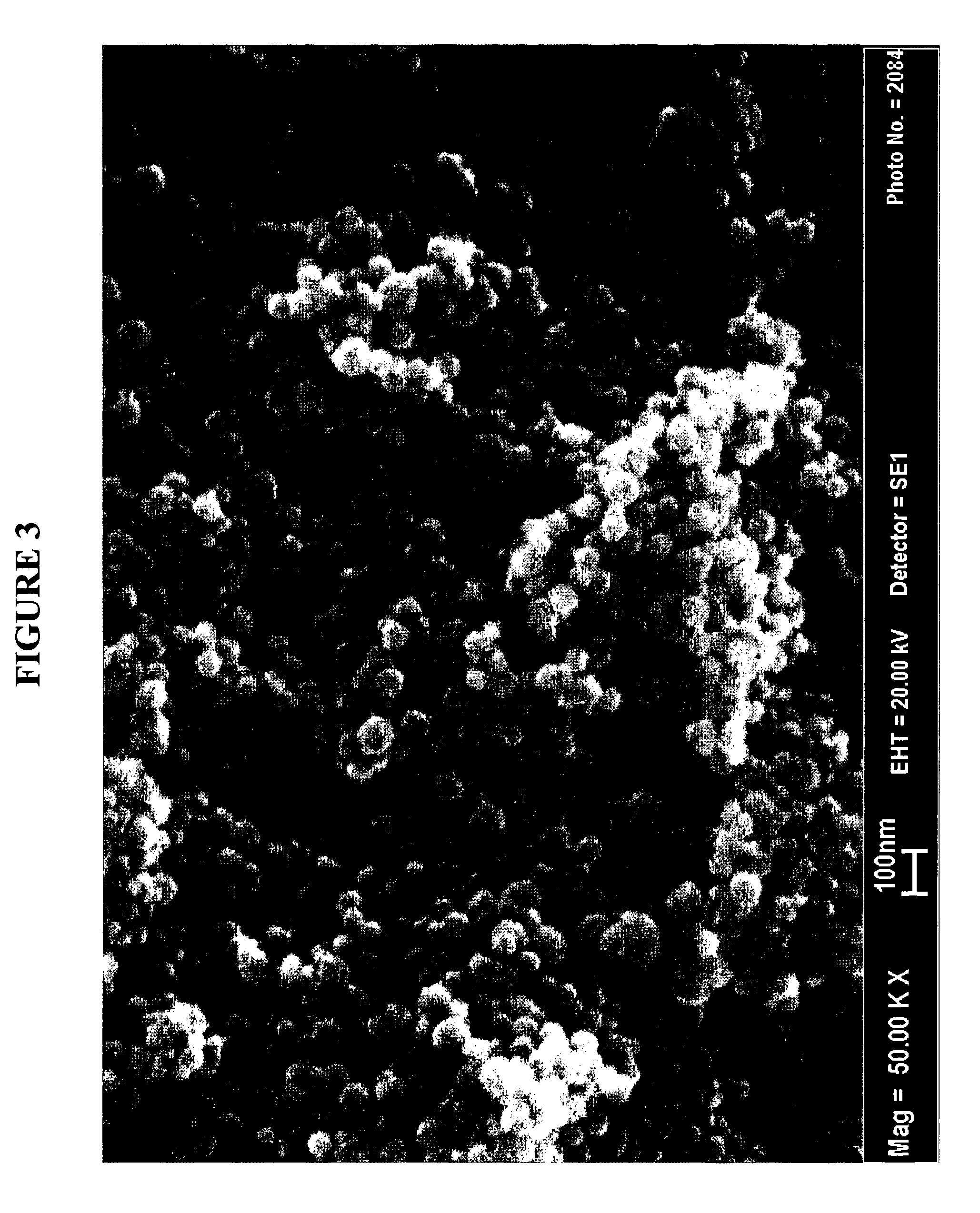

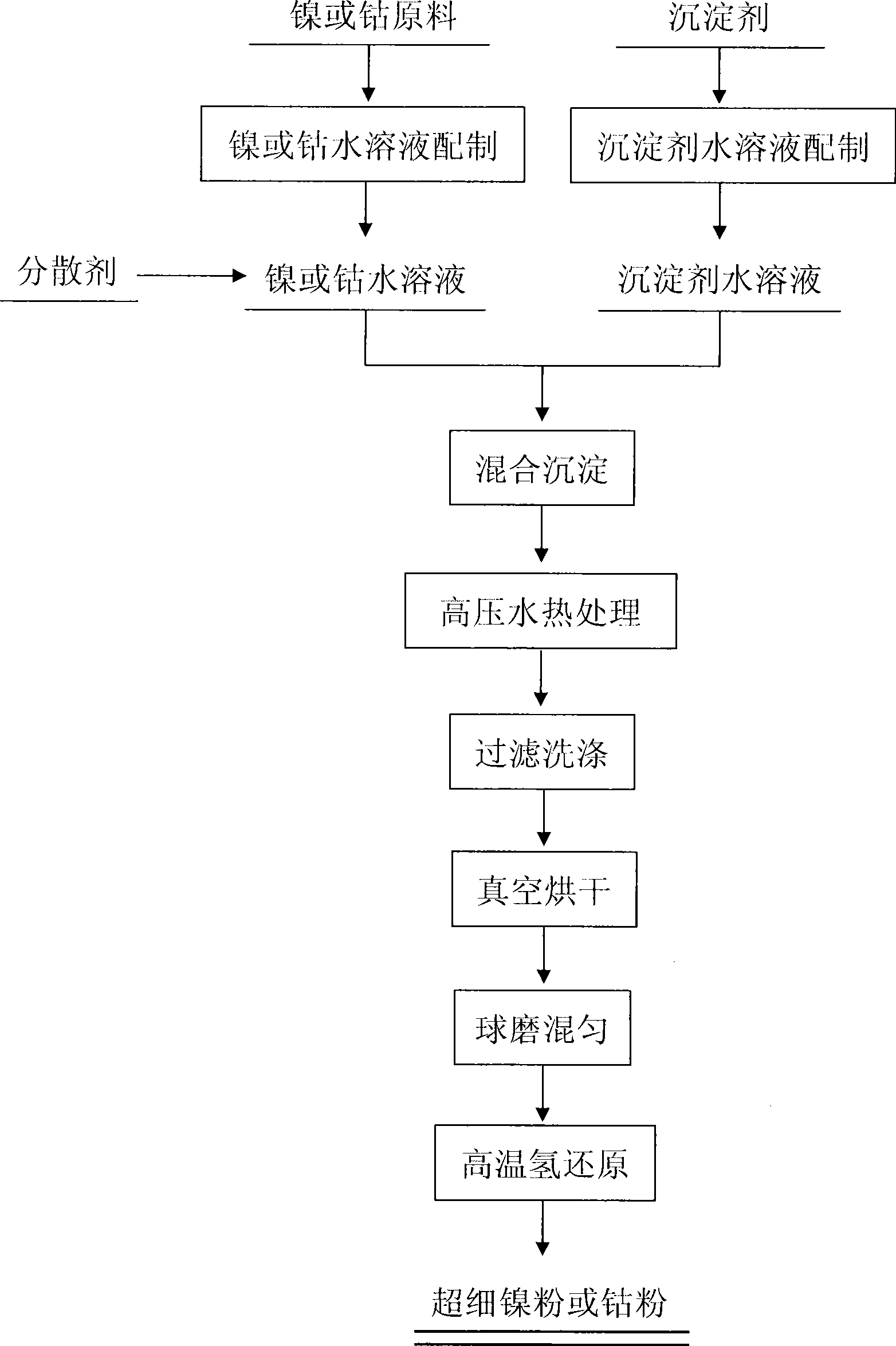

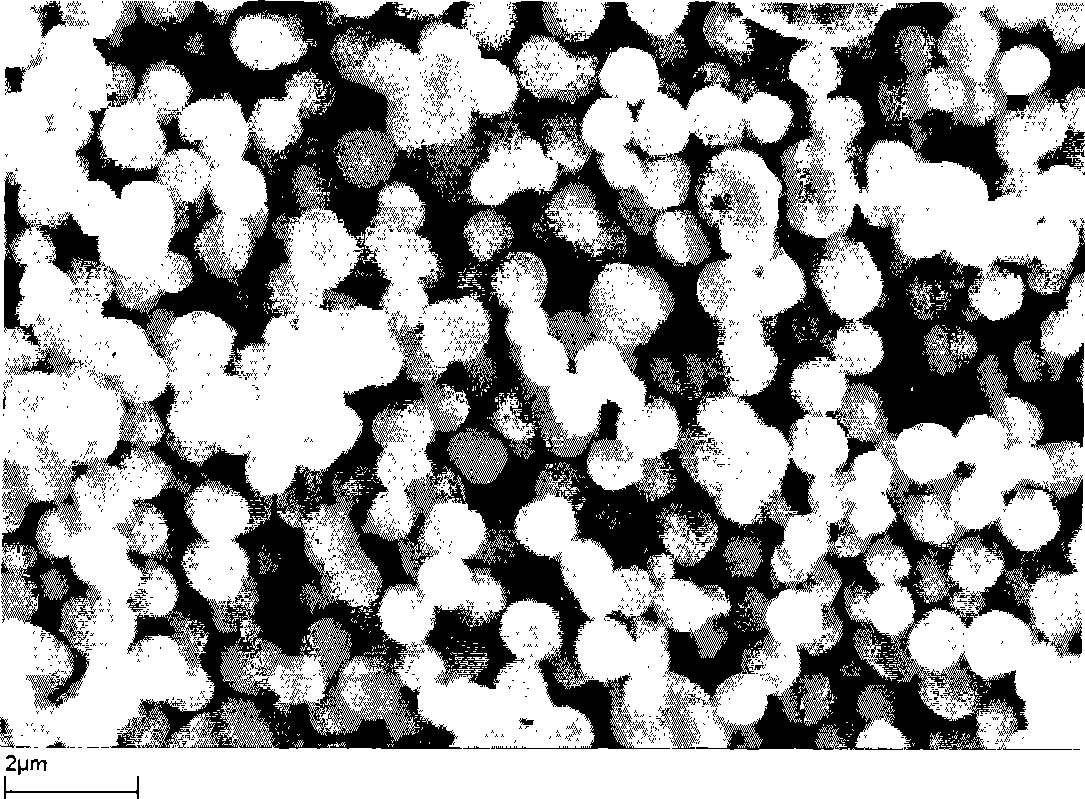

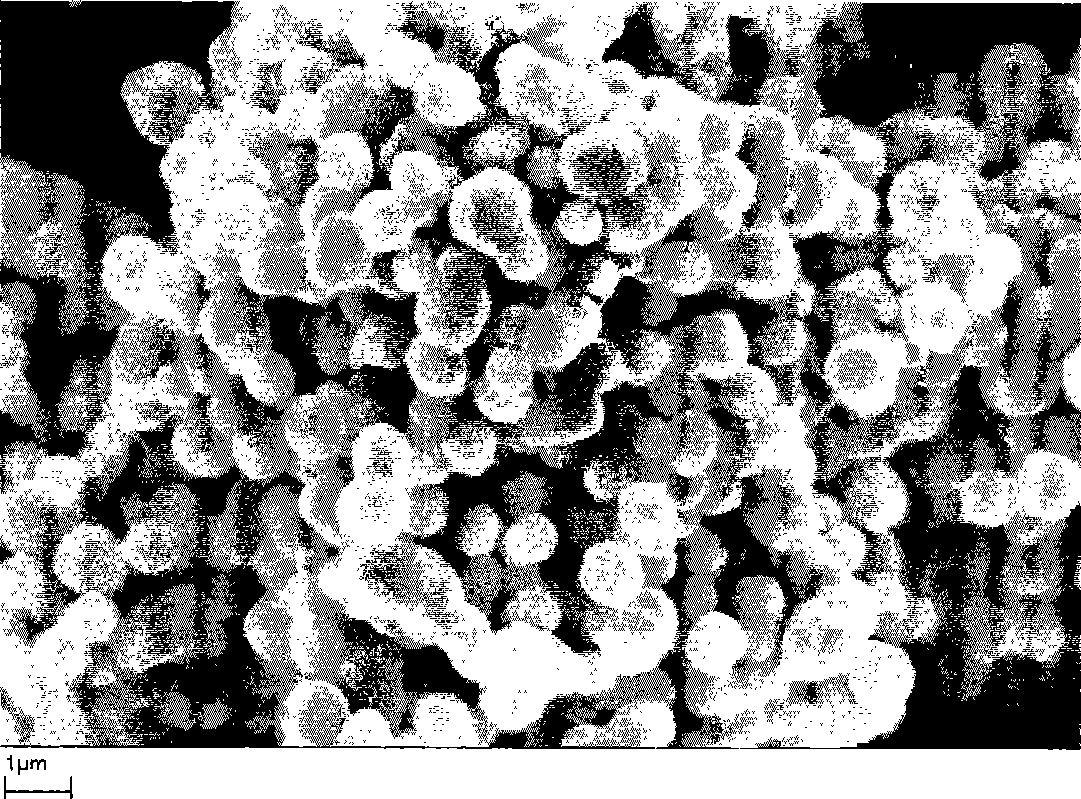

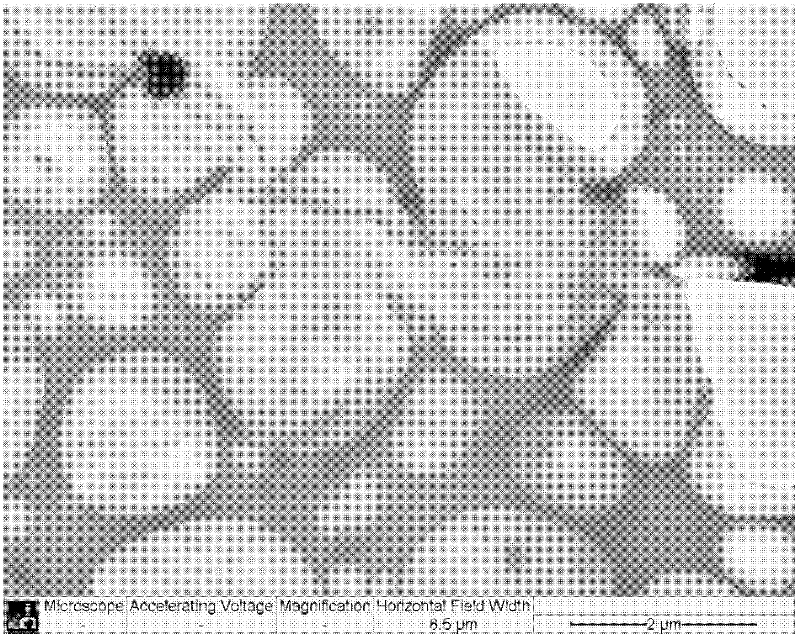

Process for producing spherical submicron metal with hydro-thermal treatment

The invention discloses a technological method for preparation of sphere-shaped ultrafine metallic powders through hydro-thermal treatment, which relates to a technological method for preparation of sphere-shaped ultrafine nickel powders or ultrafine cobalt powders through the procedures such as precipitation, dispersing agent surface finish, high-pressure hydro-thermal treatment, washing, drying and high-temperature hydrogen reduction and the like, and which belongs to the technical field for preparation of metal powder materials. The technological method adopts water soluble salts with nickel and cobalt, cobalt oxide, sub-carbonate, carbonate or hydroxide as raw materials, which are prepared into water solution after processing, the dispersing agent is added, then nickel ion and cobalt ion in the water solution are precipitated through alkali, carbonate, oxalic acid or ammonium oxalate and the like, the hydro-thermal treatment of water pulp of the precipitate is performed in an autoclave, and products of sphere-shaped ultrafine nickel powders or ultrafine cobalt powders with even graininess and good dispersibility can be obtained through washing, drying and high-temperature hydrogen reduction. The technological method is not only suitable for medium- and small-scale discontinuous-type manufacture, but also used for large-scale continuous manufacture, and the manufacturing cost is low.

Owner:张建玲

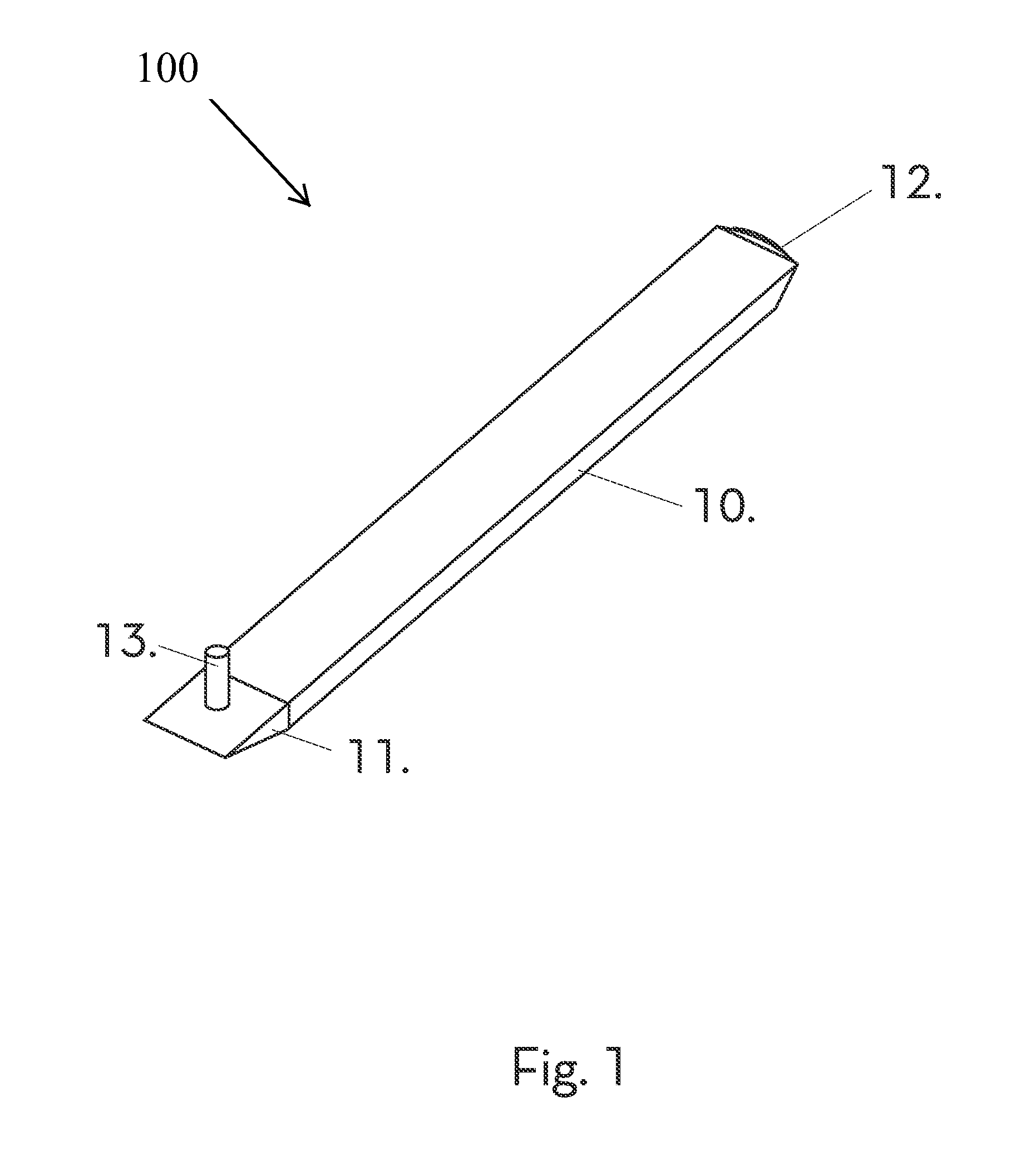

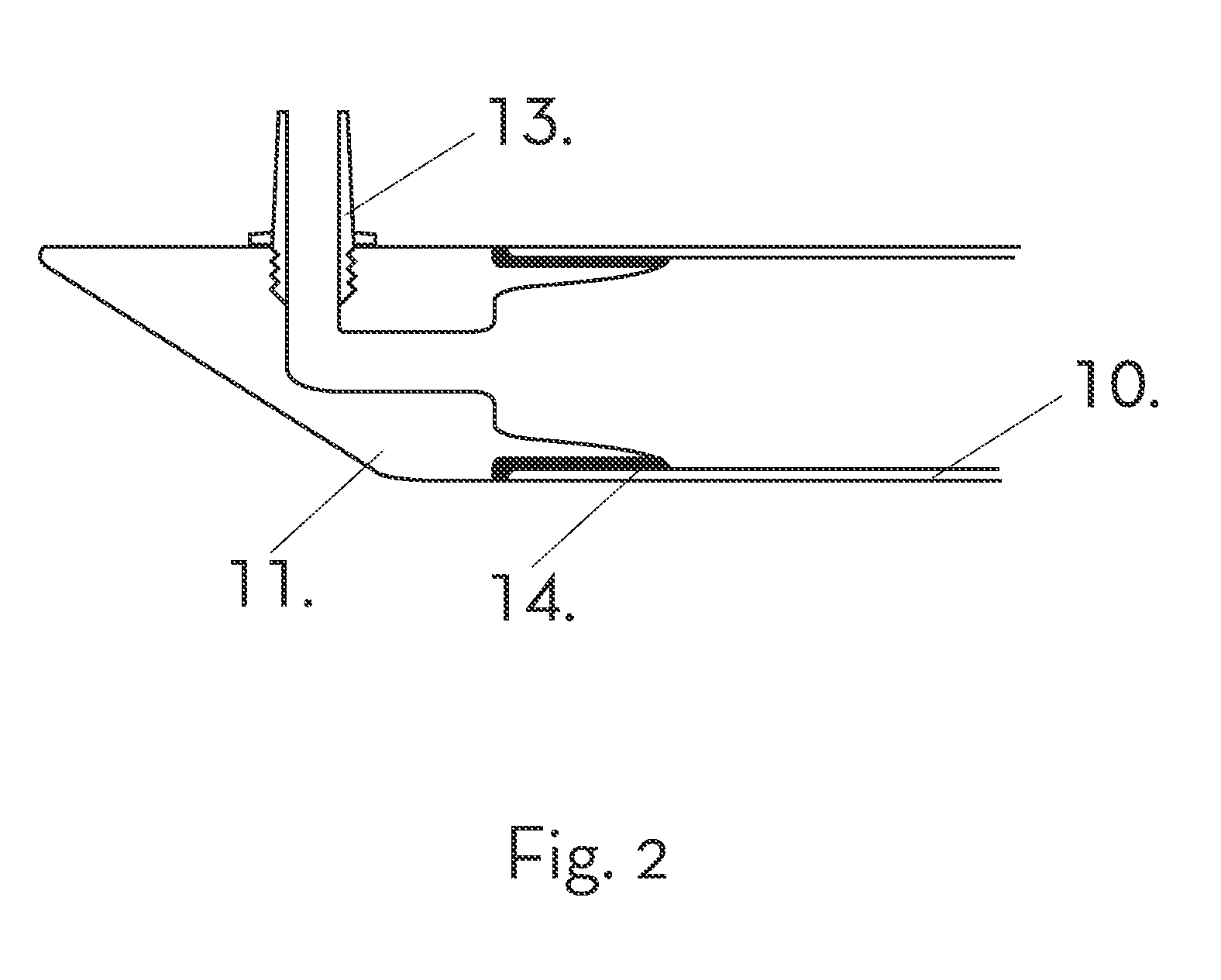

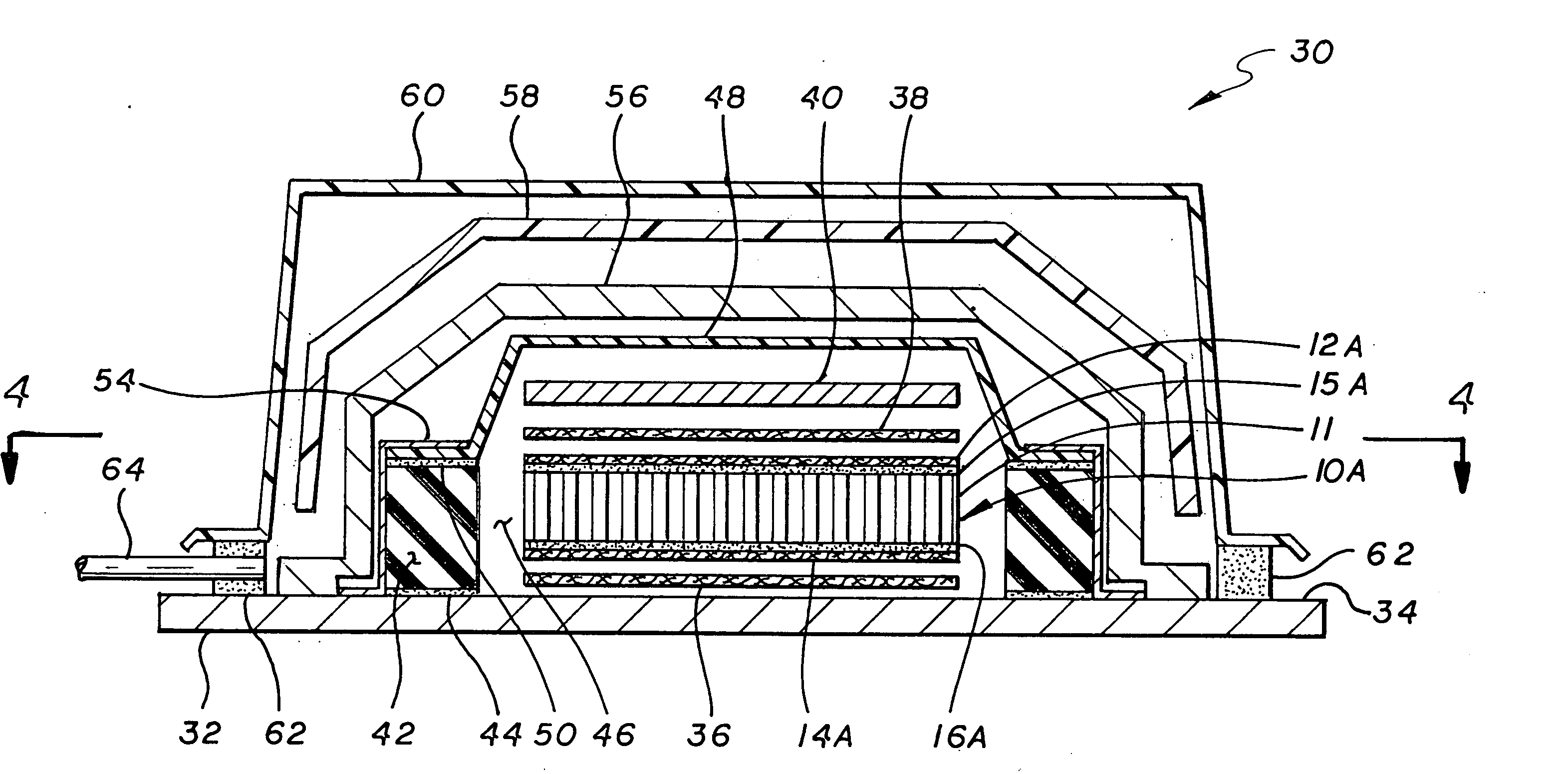

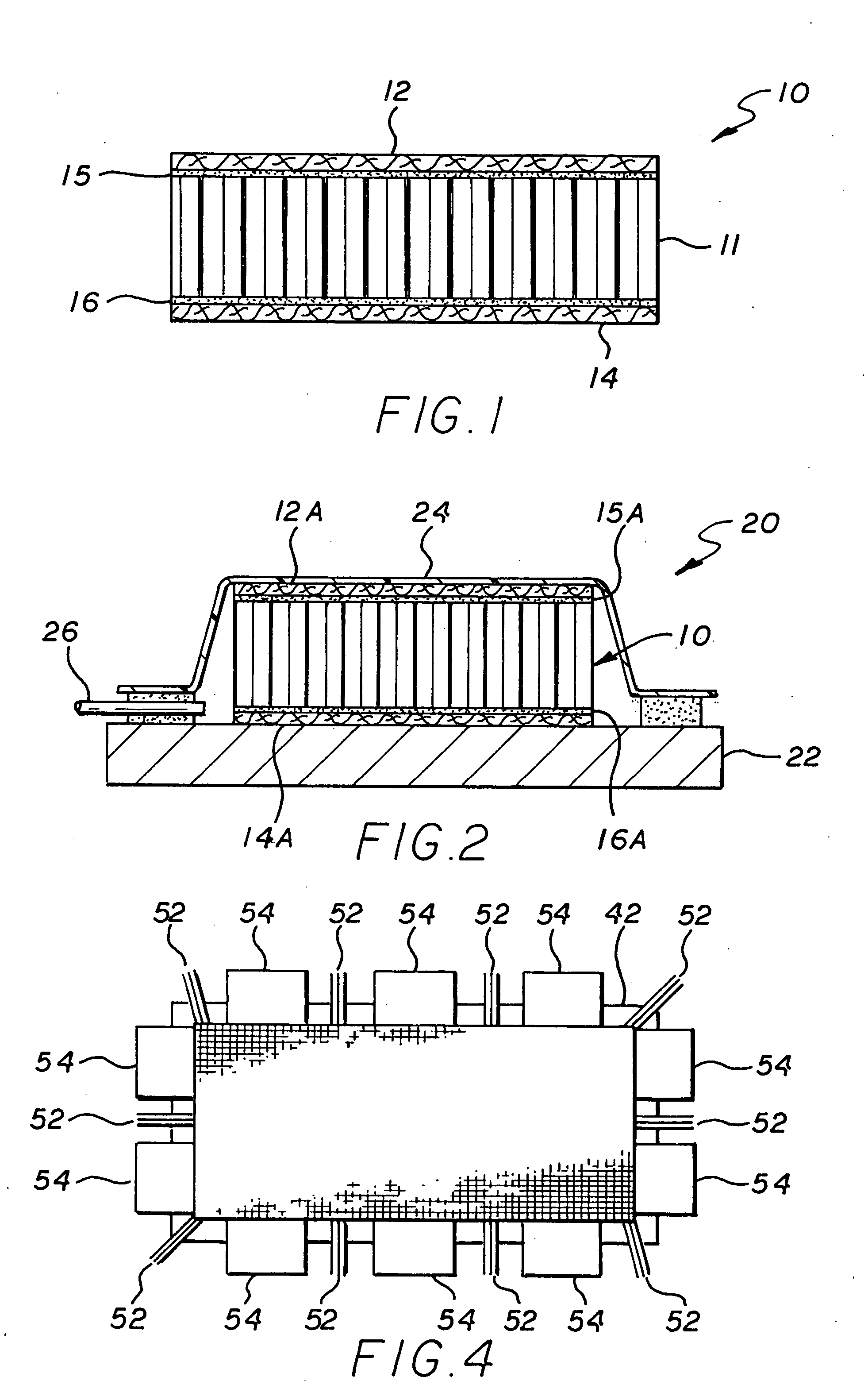

Thermoplastic mandrels for composite fabrication

InactiveUS20100186899A1Hollow filament manufactureFilament/thread formingEngineeringMechanical engineering

A mandrel assembly that includes an elongated hollow structure comprising a thermoplastic material that is extrudable having a first end and a second end. A first end cap attached to the first end. A vent tube attached to the first end cap, the vent tube extending from the first end cap. A second end cap attached to the second end. The mandrel assembly adapted to shape and form a composite structure in or outside an autoclave.

Owner:AIRTECH INT INC

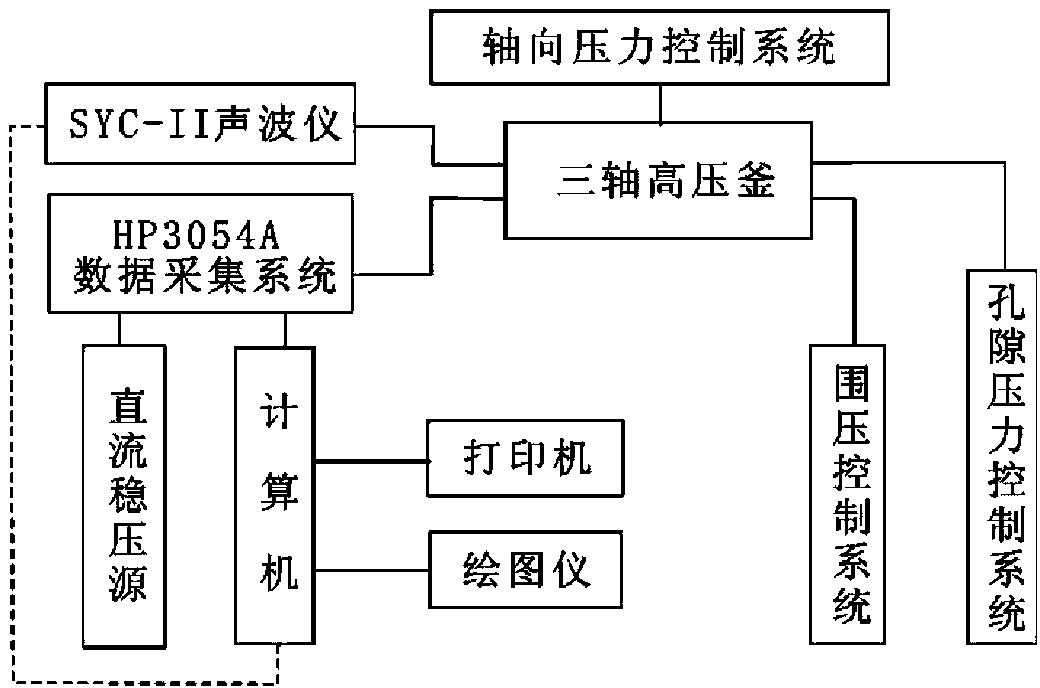

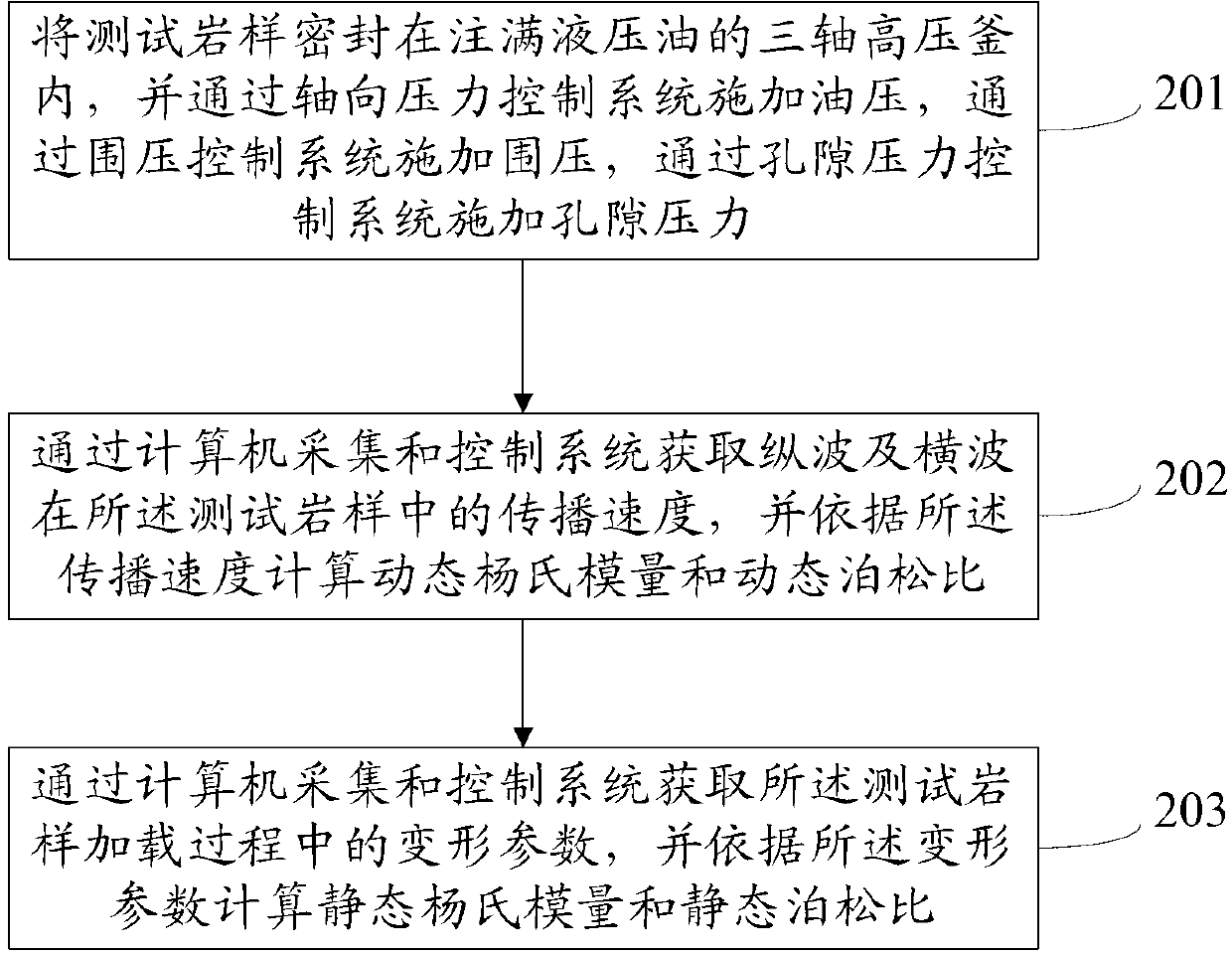

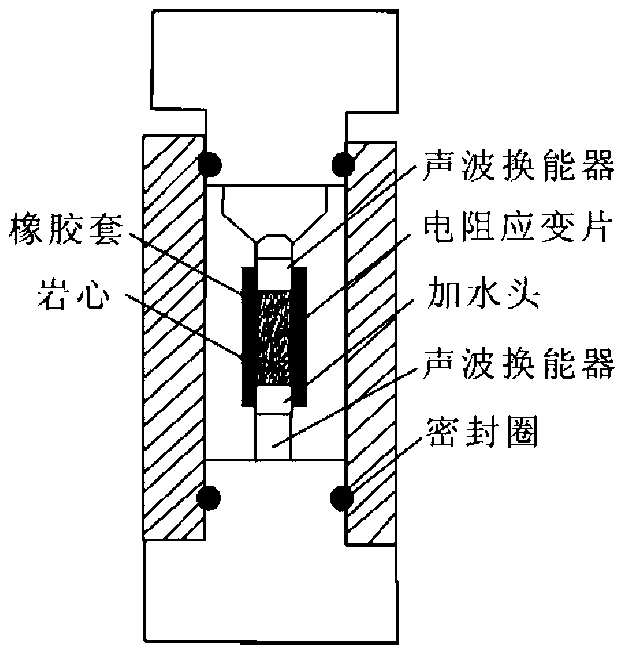

Method for synchronous measurements on dynamic and static elastic parameters of rocks

InactiveCN103278389AGuaranteed validityGuaranteed accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesControl systemAxial pressure

The invention provides a method and a device for synchronous measurements on dynamic and static elastic parameters of rocks by using a rock triaxial anti-compression testing device. The method comprises: sealing a test rock sample in a triaxial autoclave filled with hydraulic oil, applying an oil pressure by an axial pressure control system, applying a confining pressure by a confining pressure control system, and applying a pore pressure by a pore pressure control system; acquiring propagation speeds of longitudinal waves and transverse waves in the test rock sample by a computer acquisition and control system, and calculating the dynamic Young modulus and the dynamic Poisson ratio according to the propagation speeds; and acquiring deformation parameters of the test rock sample during a loading process by the computer acquisition and control system, and calculating the static Young modulus and the static Poisson ratio according to the deformation parameters. The method and the device can ensure validity and accuracy of hydrocarbon reservoir rock mechanical parameter measurements in thousands of meters deep underground and under the conditions of complex confining pressure, high temperature, high pore pressure and polyphase fluid.

Owner:PEKING UNIV

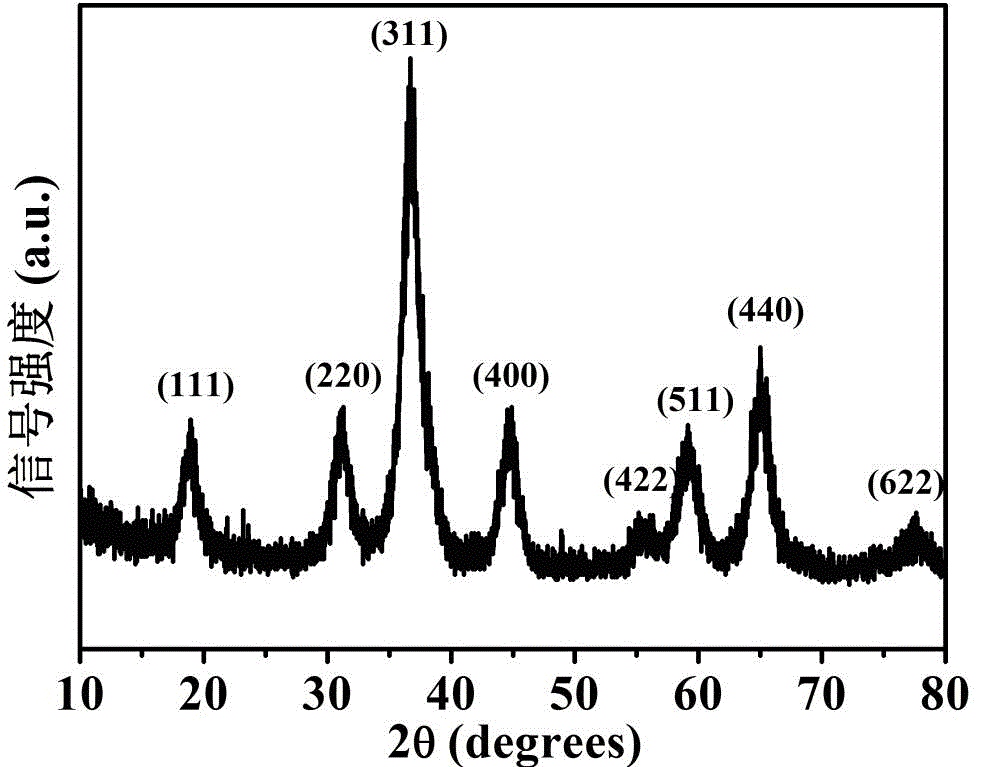

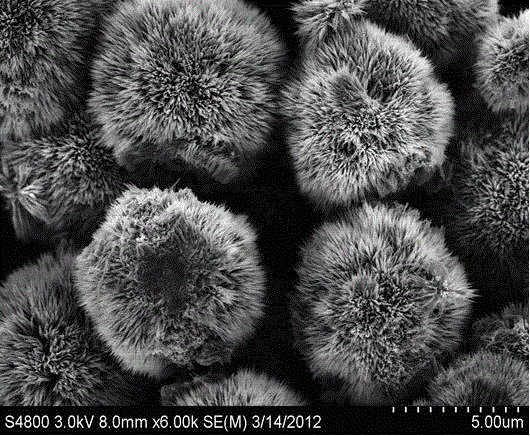

Method of synthesizing mesoporous nickel cobalt oxide nanowire using hydrothermal method and application thereof

InactiveCN102745752AHigh purityLarge specific surface areaMaterial nanotechnologyElectrolytic capacitorsCapacitanceAir atmosphere

The invention relates to a method of synthesizing nickel cobalt oxide electrode material using a hydrothermal method and an application thereof. The method comprises dissolving CoCl2.6H2O, NiCl2.6H2O and CO(NH2)2 into an appropriate amount of deionized water, wherein the mole ratio of CoCl2.6H2O to NiCl2.6H2O is 1 : 2; uniformly stirring the mixed solution by using a magnetic stirrer, transferring the solution into an autoclave, heating the solution to 100 DEG C and keeping the temperature constant for 10 hours; cooling the solution to room temperature, filtering, washing and drying reactants, and then annealing the reactants for 2 hours in an air atmosphere of 250 DEG C. The method is simple to operate and environmental-friendly. The prepared nickel cobalt oxide nanowire is a spinel-type cubic phase and porous, has high purity and relatively high specific surface area, and can be used as electrode materials for super capacitors, with specific capacitance thereof being 722 F / g.

Owner:TONGJI UNIV

Novel laminates for producing high strength porous sterilizable packaging

InactiveUS20060068674A1Solve Porosity InsufficiencyFine surfaceFlexible coversWrappersEthylene oxideEngineering

A novel approach is offered to produce a sterilizable medical package by laminating either a nonwoven fabric or a perforated film to a paper web. The laminate construction exhibits properties of heat stability, strength, microbial barrier, air / gas permeability and printability. The laminate construction becomes a self-sealing package that can be sterilized by various techniques, e.g. autoclave (heat), ethylene oxide or gamma radiation.

Owner:RUTHERFORD SALES & RECOVERY

Extrusion coating composition

Disclosed are polymer blends composed of from 25 to 75 wt % of ethylene homopolymer produced in a high pressure tubular reactor and from 75 to 25 wt % of ethylene homopolymer produced in a high pressure autoclave reactor, provided that each homopolymer is removed from the reaction zone prior to being blended together. The blends so formed have a good combination of neck-in and adhesion properties. A process for the extrusion coating of a substrate with these new polymer blends is also described.

Owner:NOVA CHEM (INT) SA

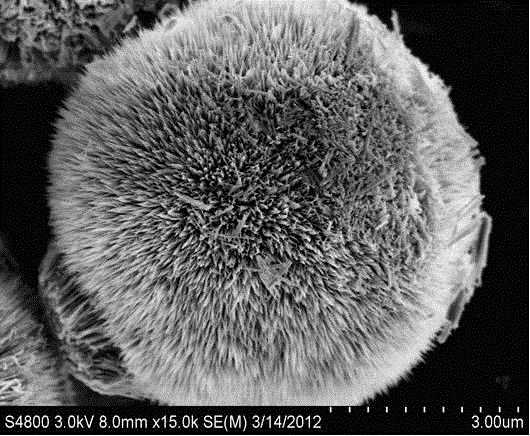

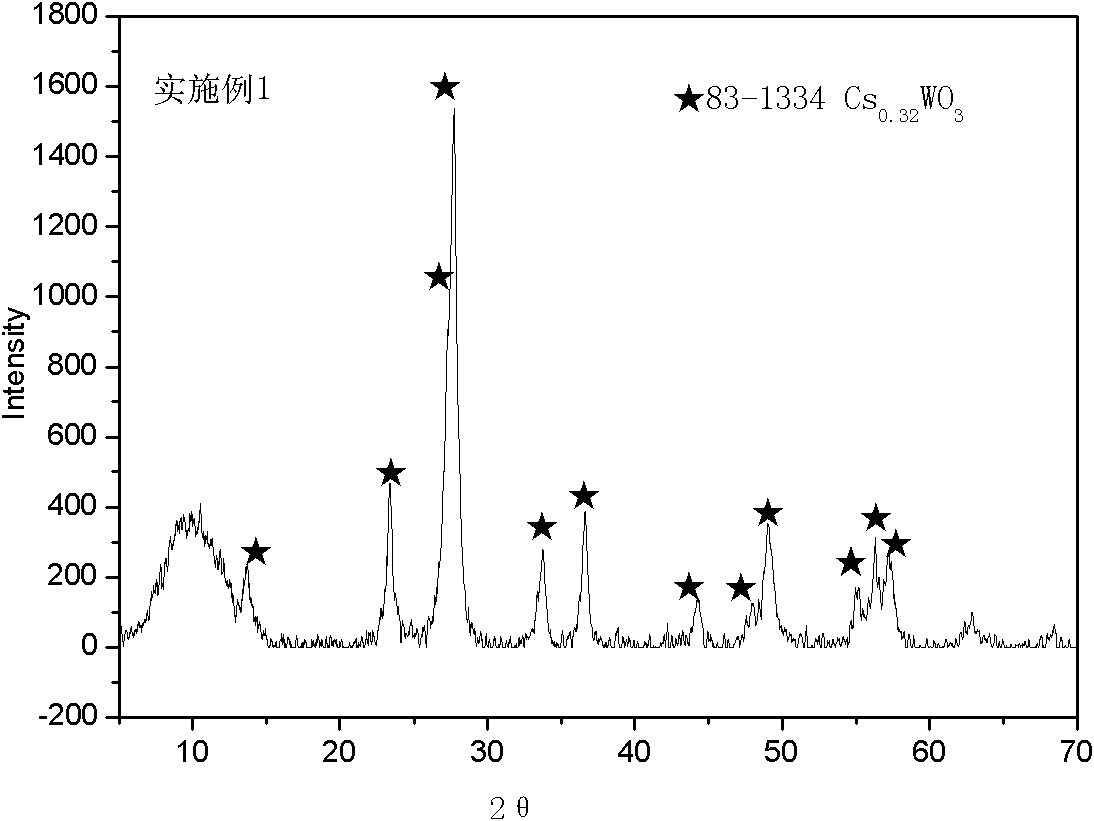

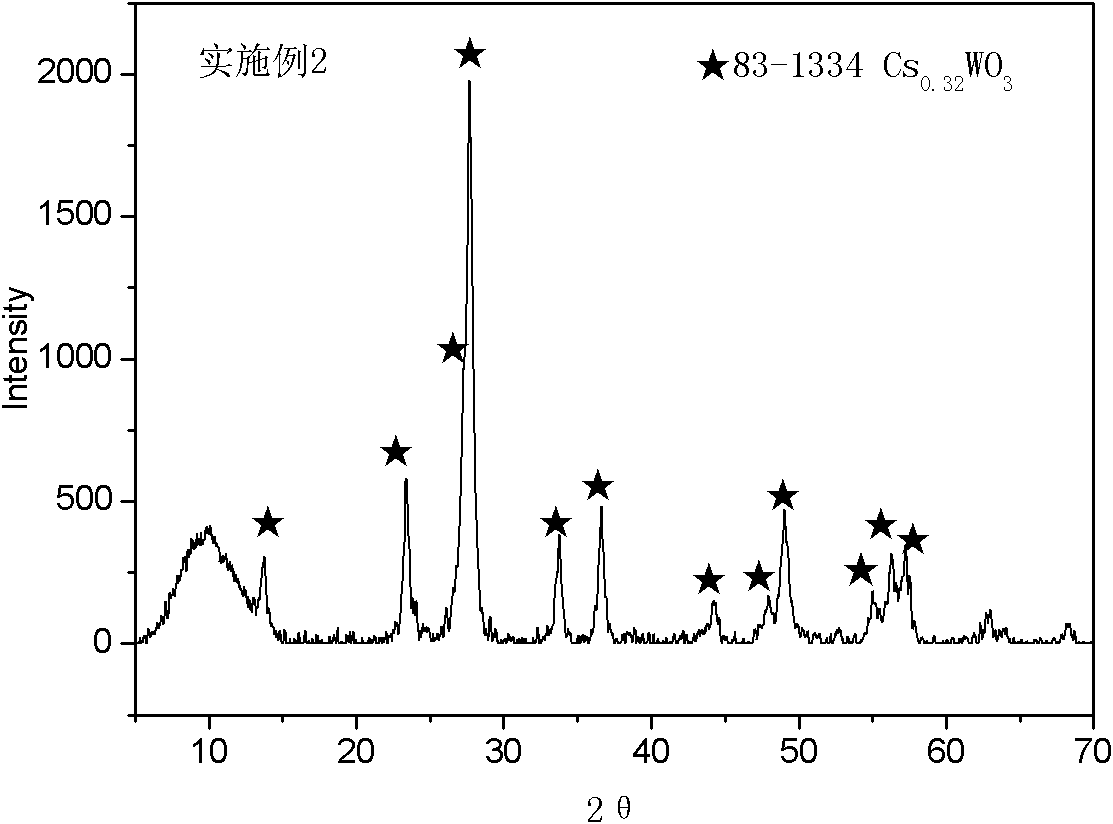

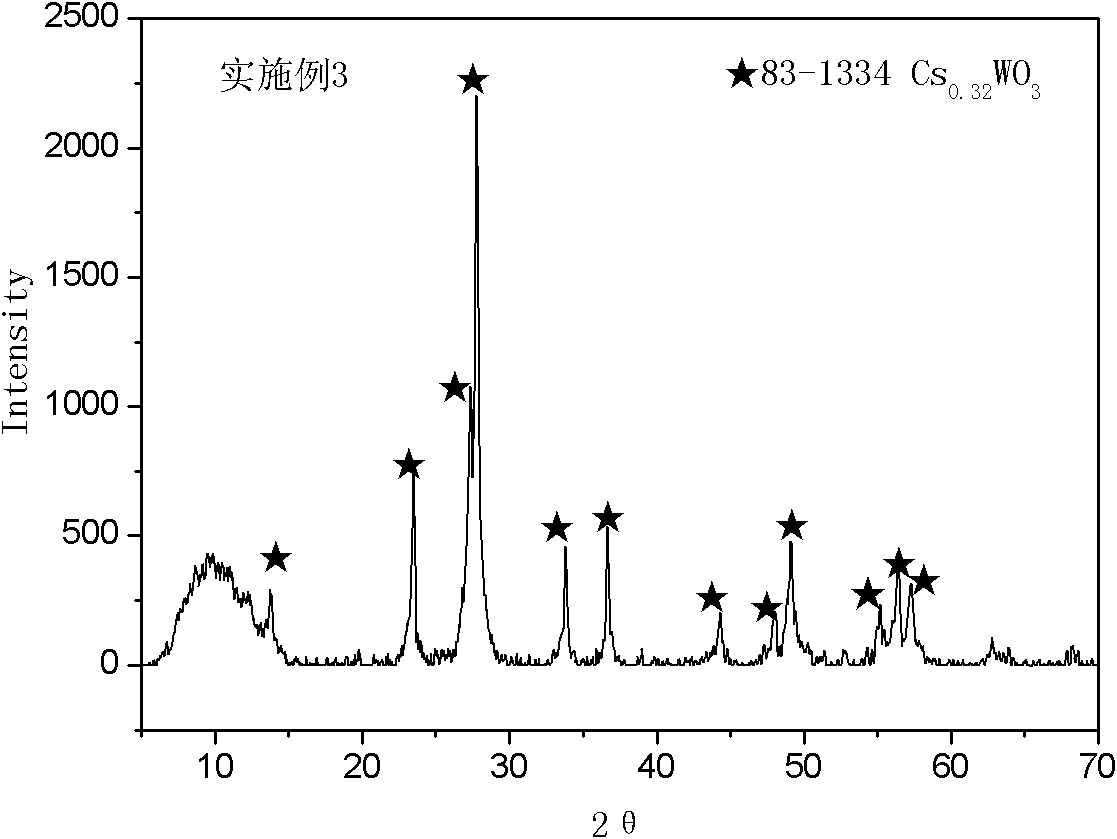

Cesium tungsten bronze powder and preparation method thereof

InactiveCN102320662AOptimal Control StructureReduce manufacturing costTungsten compoundsGranularitySolvent

The invention relates to cesium tungsten bronze powder and a preparation method thereof. The method comprises the following steps that: 1, precursor solution with tungstic acid, cesium carbonate and reducing substances is prepared according to a Cs / W mole ratio of 0.01 to 0.35 / 1, and the solvents are water or a mixture formed by ethanol and the water according to a volume ratio of 1 / 4 to 4 / 1; and 2, the precursor solution takes reaction for 1 to 3d under the condition of 180 to 200 DEG C in an autoclave, and the cesium tungsten bronze powder is obtained after the obtained precipitates are treated. The powder has the crystalline phase composition of Cs0.2WO3 or Cs0.32WO3, the size of the powder particle is 100 to 1300nm, and the specific surface area is 7 to 50m<2> / g. The synthetic process has the advantages that raw materials are cheap and mild, the operation is easy, the production cost can be reduced, in addition, the low-temperature (lower than or equal to 20 DEG C) synthesis is adopted, and the process is suitable for production and practical application. In addition, the product purposes are wide.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Process for the manufacture of composite structures

The invention is a process for making a composite structure having a honeycomb core and face sheets using vacuum bagging techniques without the use of an autoclave. In detail, the process includes the following steps: 1) forming a preform sandwich assembly having previously de-bulked cover sheets impregnated with a fiber-reinforced resin having a first curing temperature, a honeycomb core and sheets of adhesive between the cover sheets and core, the first layer of adhesive having a second curing temperature less than the first curing temperature; 2) vacuum bagging the preform and drawing a vacuum; 3) initially heating the vacuum bagged preform at a heating rate of between 0.5 degree and 2 degrees per minute until the gel temperature of said adhesive is reached; 4) holding the temperature at the gel temperature until the layer of adhesive has cured; 5) raising the temperature to the first curing temperature of the fiber-reinforced resin; and 6) maintaining the temperature at the first curing temperature until the fiber-reinforced resin has cured.

Owner:NORTHROP GRUMAN CORP

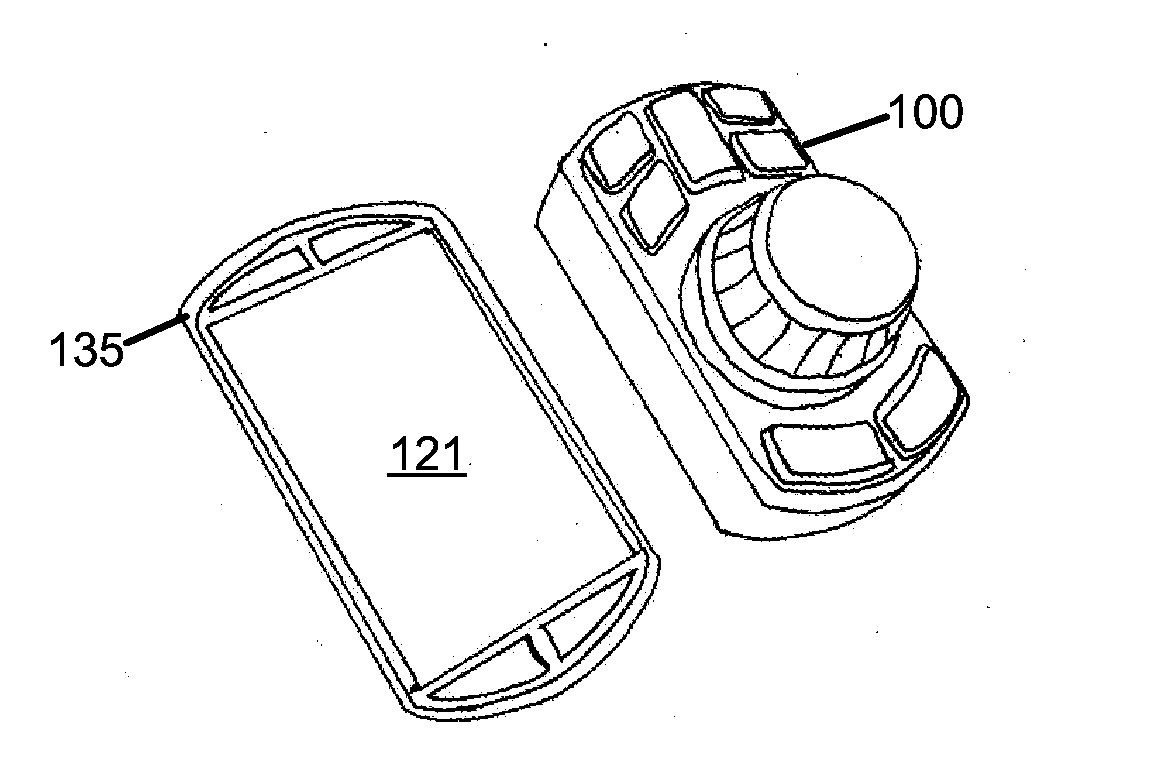

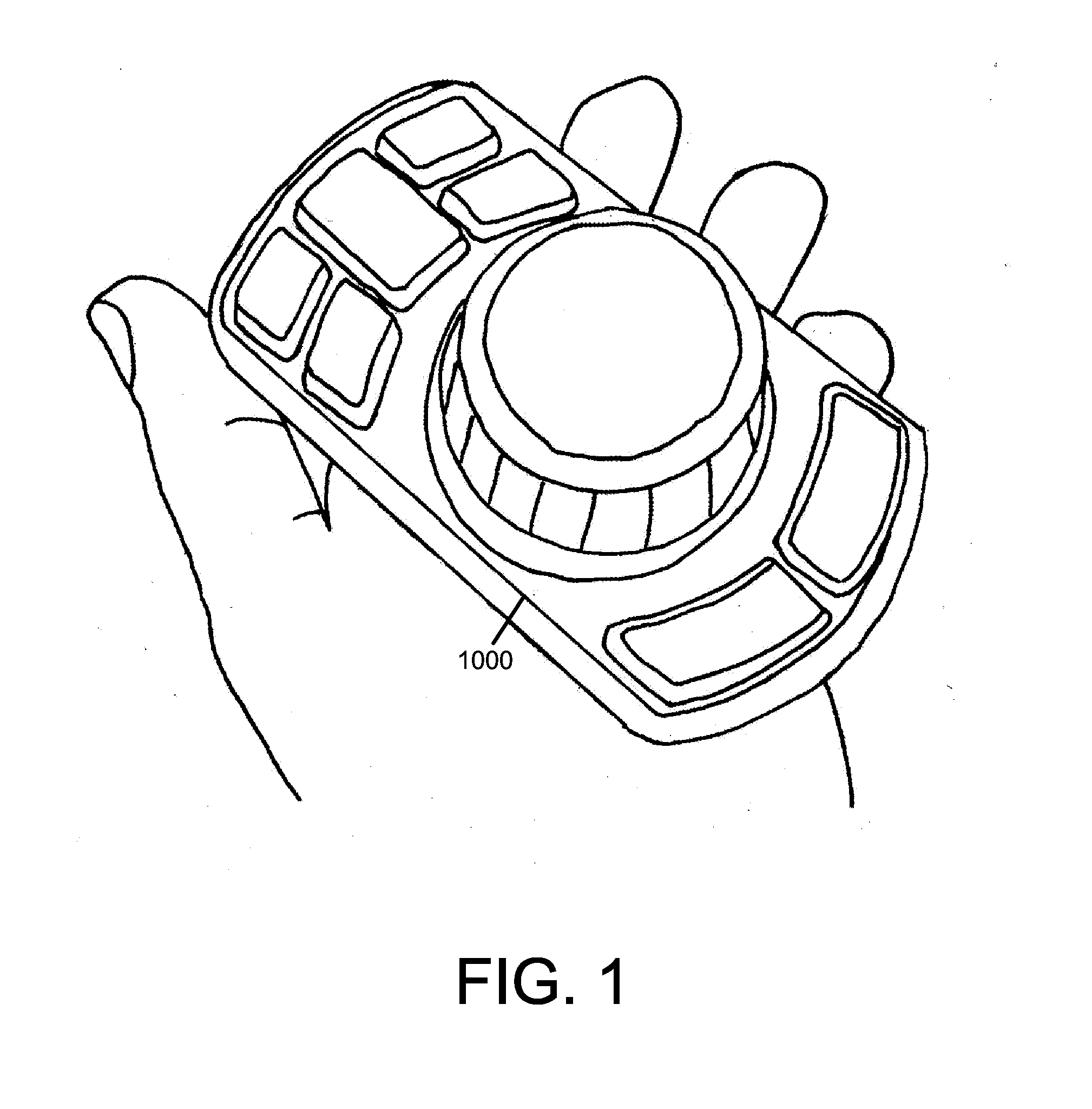

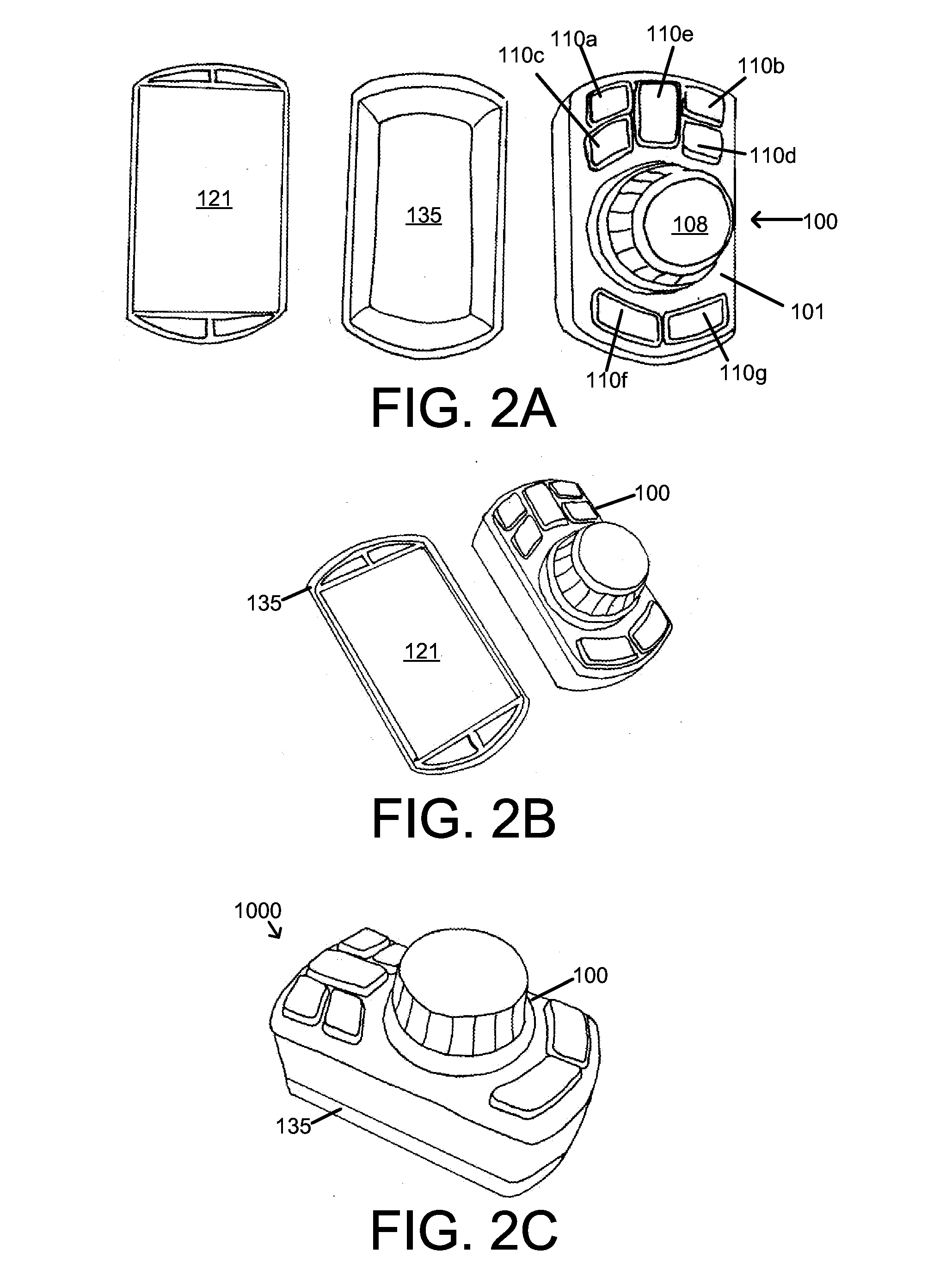

Autoclavable input devices

One embodiment describes a handheld, sterile input device to control one or more devices in the operating room. The embodiment's disposable component contains no electronics while its removable sensing module can be autoclaved and recharged for multiple procedures. Another embodiment describes a fully autoclaveable sterile input device with a detachable control assembly that enables thorough cleaning and disinfecting prior to steam sterilization in an autoclave.

Owner:PRYOR TIMOTHY +1

Resin infusion mold tool system and vacuum assisted resin transfer molding with subsequent pressure bleed

InactiveUS6840750B2Highly structuredHigh fiber volume fractionConfectioneryLaminationFiberLine tubing

A resin infusion mold tool system for use in a vacuum assisted resin transfer molding process with a subsequent pressure bleed step. The mold tool system includes a mold assembly having an outer mold line tool connected to resin supply lines and supplying resin to the preform. A plurality of inner mold line tools form a hard interface with the inner mold line of the fiber preform and are held to within tight tolerances by an external locating fixture. Excess resin is drawn out of the fiber preform using a vacuum bag connected to vacuum lines and disposed over the inner mold line tools but not between the tools and the fiber preform. The mold assembly is placed in an autoclave, the resin supply lines are detached and the autoclave pressurized to bleed additional resin out of the preform to raise the fiber volume of the composite structure.

Owner:THE BOEING CO

Preparation method of one-step hydrothermal synthesis of carbon/molybdenum disulfide composite microsphere

InactiveCN1994896AUniform particle sizeSimple methodVanadium oxidesMolybdenum sulfidesSucroseMicrosphere

The invention discloses a making method of carbon / molybdenum disulfide composite microball through water heat method, which comprises the following steps: dissolving molybdate in the deionized water to form 0.02-0.1m solution; adding thioacetamide or sulfourea as sulfur source with molar rate of thioacetamide or sulfourea and molybdate at 31-51; stirring evenly; adding glucose or sucrose as carbon source with the molar rate of glucose or sucrose and molybdate at 51-251; stirring completely; transmitting solution into water heat reacting autoclave to react under 200-240 deg. c for 20-24h; cooling naturally; separating; washing; drying to obtain the product.

Owner:ZHEJIANG UNIV

Method for preparing large-scale graphene through supercritical carbon dioxide exfoliation

ActiveCN102515155AReduce forceReduce the number of layersGrapheneBulk chemical productionMicrometerGraphite

The invention relates to a method for preparing large-scale graphene through supercritical carbon dioxide exfoliation. Supercritical carbon dioxide is adopted as an exfoliant, a surfactant is adopted as a dispersant, graphite powder and the dispersant are put in an autoclave, the carbon dioxide is pumped in the autoclave and circularly flows in a supercritical state, and then the pressure is reduced quickly to be normal pressure; the process is repeated so that the materials undergo pressure increment and pressure reduction several times; and the layers of the graphene is controlled by controlling the times of pressure increment and pressure reduction, so as to prepare the large scale graphene. Compared with the prior art, the invention has the advantages as follows: large-scale (hundreds of micrometers) high-quality graphene can be prepared; the method belongs to physical exfoliation, the treatment conditions are mild, and the quality of the graphene cannot be damaged; besides, the carbon dioxide used in the method is nontoxic, cheap and easy to obtain, and the technology is simple.

Owner:上海利物盛纳米科技有限公司

Controlled atmospheric pressure resin infusion process

ActiveUS20050073076A1Specific strength of partLow costLaminationLamination apparatusSurface finishEngineering

By evacuating the resin feed tank to a pressure below atmospheric pressure, employing cyclic compaction, and controlling the net compaction pressure, we are better able to control a resin infusion process, particularly a vacuum assisted resin transfer molding process, and produce aerospace-grade fiber-reinforced resin composite having fiber volume fractions and tool-side surface finishes comparable to or exceeding those made using an autoclave.

Owner:THE BOEING CO

Method for preparing equal dispersion ferric phosphate lithium nano crystal by hydrothermal synthetis method

InactiveCN101047242AExcellent inert environmentElectrode manufacturing processesPhosphateFerrous salts

A method for preparing uniformly scattered nanocrystal of iron-lithium phosphate by hydrothermal synthesis includes using ferrous salt and phosphoric acid as well as lithium hydroxide as raw materials to obtain reaction pioneer matter under temperature of 40-100deg.c first, then reacting on obtained pioneer matter in high pressure reactor with temperature of 150-200deg.c under hydrothermal condition and processing obtained product by high temperature under protection of inert gas to finally obtain said uniformly scattered nanocrystal with average particle diameter of 0.2-0.5micron.

Owner:胜利油田华鑫石油材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com