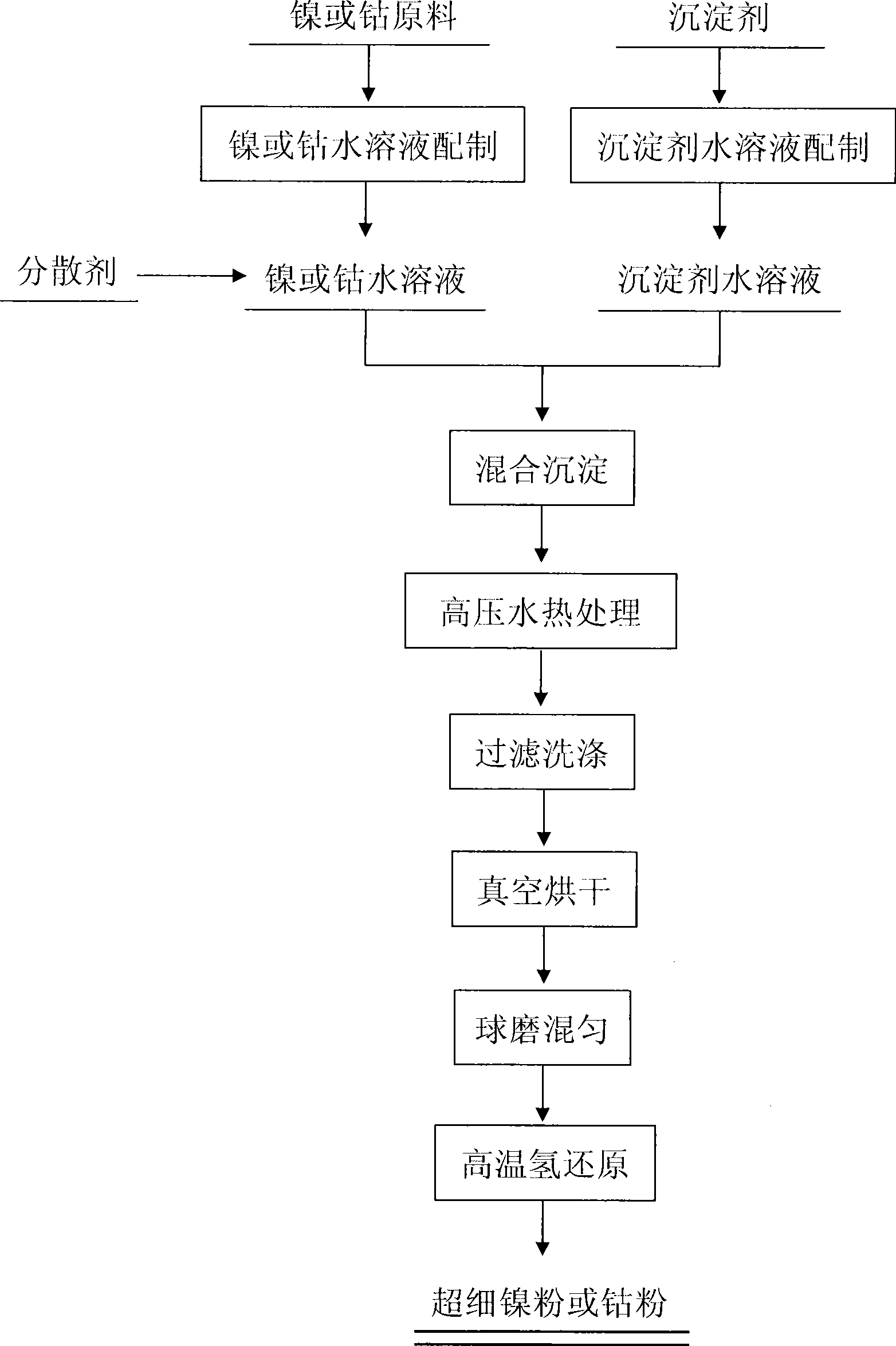

Process for producing spherical submicron metal with hydro-thermal treatment

A technology of ultra-fine metal powder and hydrothermal treatment, which is applied in the field of metal powder material preparation to achieve the effects of low production cost, low reduction temperature, and uniform and fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

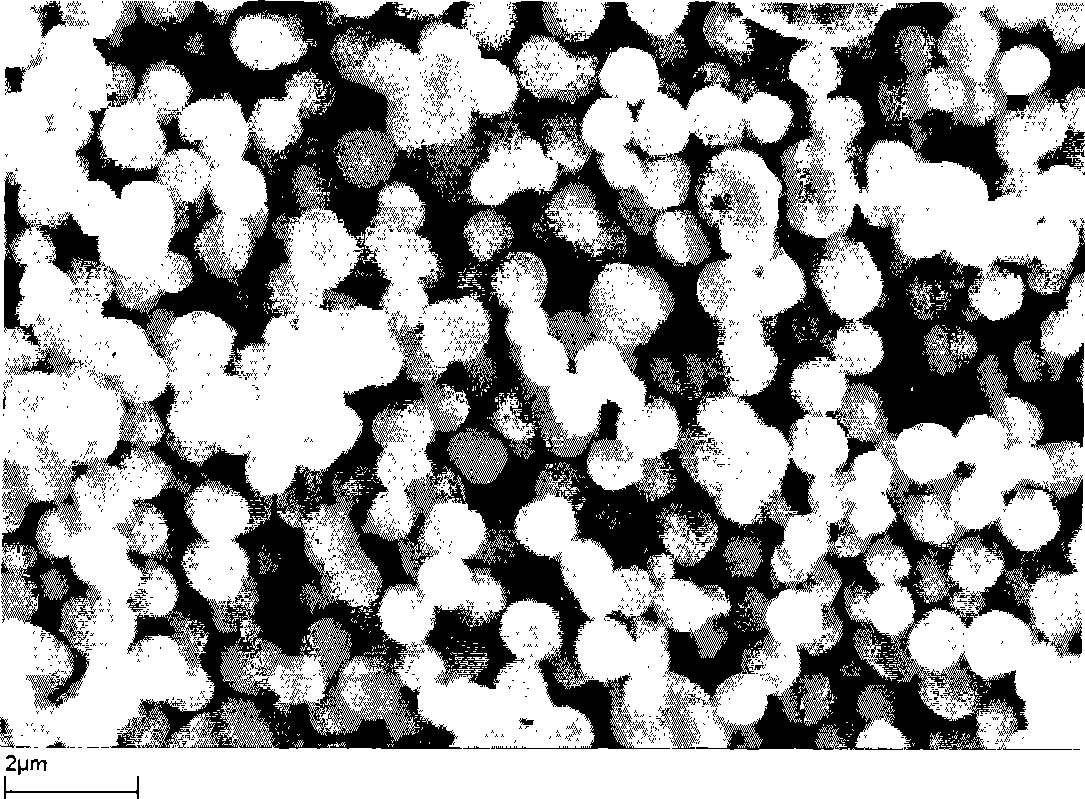

Embodiment 1

[0052] Nickel sulfate was used as raw material and ammonium bicarbonate was used as precipitant to prepare superfine nickel powder. Add 150L of deionized water into stirring tank A, heat up to 55°C; weigh 50kg of industrial pure nickel sulfate, add it into stirring tank A, stir to dissolve nickel sulfate; then add dispersant polyethylene glycol 1200g, oleic acid 700g, And dilute the nickel sulfate aqueous solution to a volume of 210L. Add 145L of deionized water to the stirring tank B, heat up to 50°C, then add 30.3Kg of industrial pure ammonium bicarbonate, stir to dissolve it completely, and dilute to a volume of 205L aqueous solution (concentration is about 1.8mol / L). Add the nickel sulfate aqueous solution containing the dispersant rapidly (within 3 to 4 minutes) into the ammonium bicarbonate aqueous solution under stirring conditions, and continue to stir for 12 minutes; after standing for 6 hours, remove part of the supernatant by suction filtration. The remaining sedim...

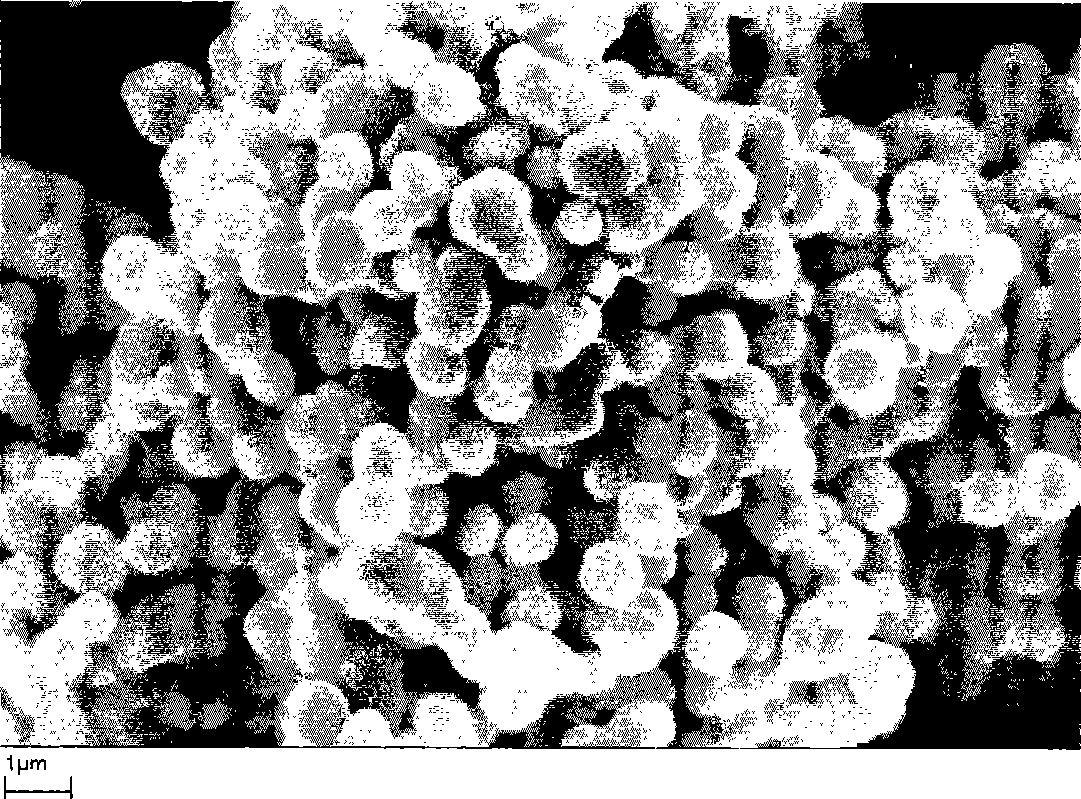

Embodiment 2

[0055] The superfine nickel powder was prepared by using nickel oxide as raw material and sodium hydroxide as precipitant. Add 100L of deionized water into stirring tank A, and heat up to 50°C; weigh 14.5kg of nickel oxide (containing 76.3% nickel), add it into stirring tank A, and stir to wet the nickel oxide; the concentration of 100L is 245.4g / L Add the aqueous nitric acid solution in the stirring tank A, and keep stirring to dissolve the nickel oxide aqueous slurry. After the nickel oxide is dissolved, filter the nickel nitrate aqueous solution with a 400-mesh acid-resistant filter cloth to remove insoluble matter, and dilute the solution volume to 260L. Then add dispersant polyvinylpyrrolidone 2000g, Tween-80 600g. In the stirring tank B, first add 160L of deionized water, then slowly add 15.8kg of industrial pure sodium hydroxide, and stir to completely dissolve it. Add the nickel nitrate aqueous solution containing the dispersant into the sodium hydroxide aqueous solu...

Embodiment 3

[0058] Cobalt sulfate was used as raw material and oxalic acid was used as precipitant to prepare superfine cobalt powder. Add 150L of deionized water into stirring tank A, and heat up to 50°C; weigh 56.3kg of industrially pure cobalt sulfate, add it to stirring tank A, and stir to dissolve cobalt sulfate; then add dispersant polyvinyl alcohol 1100g, polypropylene glycol 800g, 300g of oleic acid, and dilute the cobalt sulfate aqueous solution to a volume of 220L. First add 220L of deionized water into the stirring tank B, then add 24.8Kg of industrial pure oxalic acid, stir and heat to 50°C to completely dissolve it, and dilute to a volume of 245L of aqueous solution. Add the cobalt sulfate aqueous solution containing the dispersant into the oxalic acid aqueous solution rapidly under the condition of stirring, and continue to stir for 14 minutes; after standing still for 6 hours, part of the supernatant is removed by suction filtration. The remaining sediment water slurry was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com