Patents

Literature

309results about How to "Change physical and chemical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

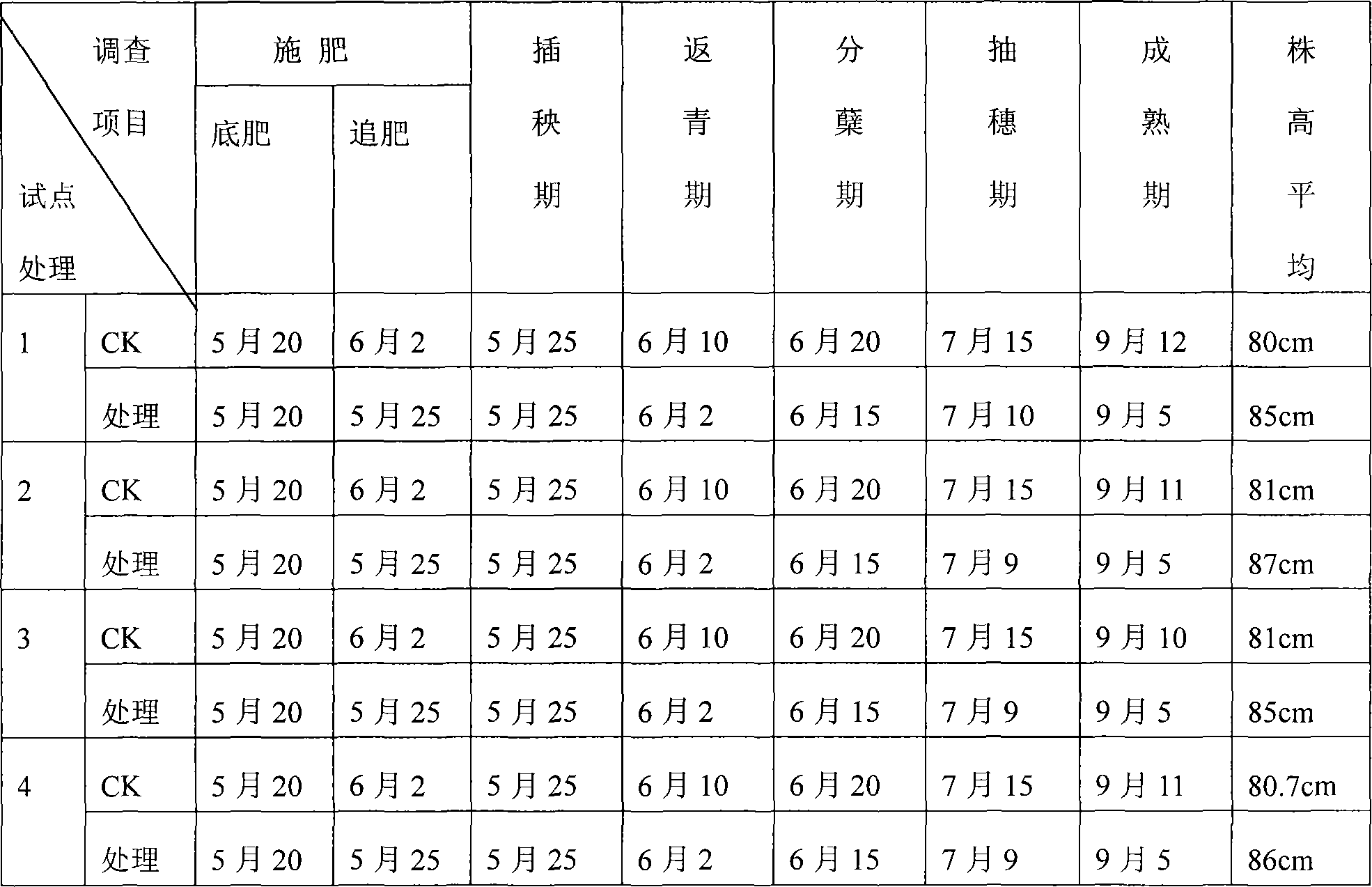

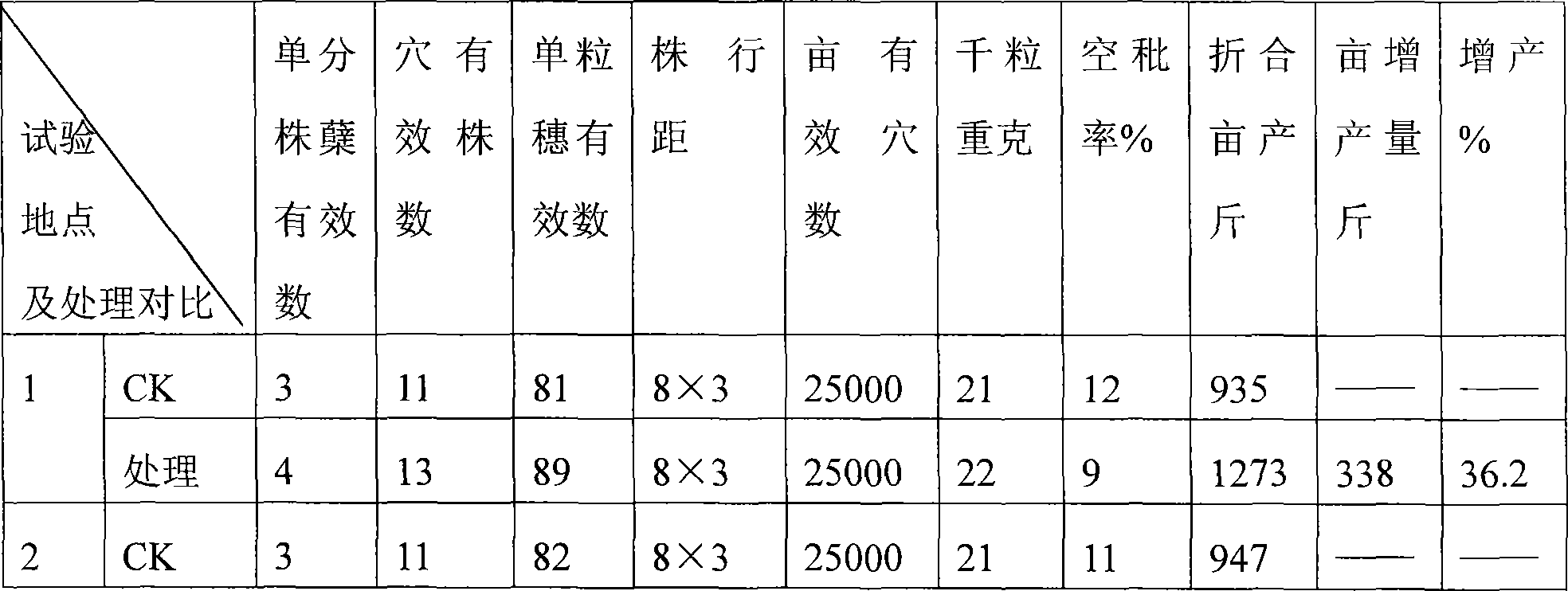

Soline alkali resisting rice fertilizer

InactiveCN101066901APromote growthImprove the growing environmentOrganic fertilisersFertilizer mixturesSulfurBiofertilizer

The present invention relates to one kind of saline alkali resisting rice fertilizer suitable for use in the saline alkali land in Heilongjiang area. The saline alkali resisting rice fertilizer contains effective components including nitrogen fertilizer 10-28 wt%, phosphate fertilizer 5-10 wt%, potash fertilizer 5-10 wt%, sulfur 10-25 wt%, amino acids 1-5 wt%, humic acid 1-10 wt%, medium and micro elements 0-5 wt%, and is prepared through mixing the said effective components with clay as the carrier mechanically and pelletizing. The saline alkali resisting rice fertilizer has scientific compounding of acid fertilizer and organic biofertilizer, and medium and micro elements, amino acids and humic acid easily absorbed by rice, and can change the physical and chemical characteristics of alkaline soil for rice to grow well and increase yield of rice greatly.

Owner:王淑娟

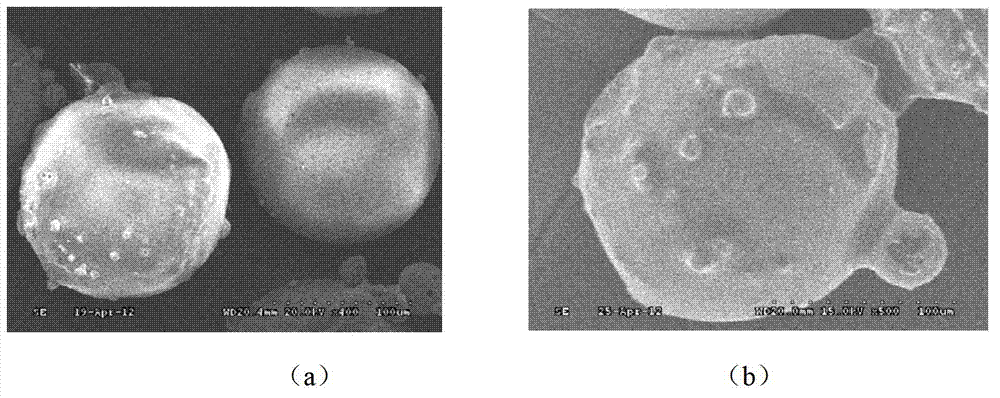

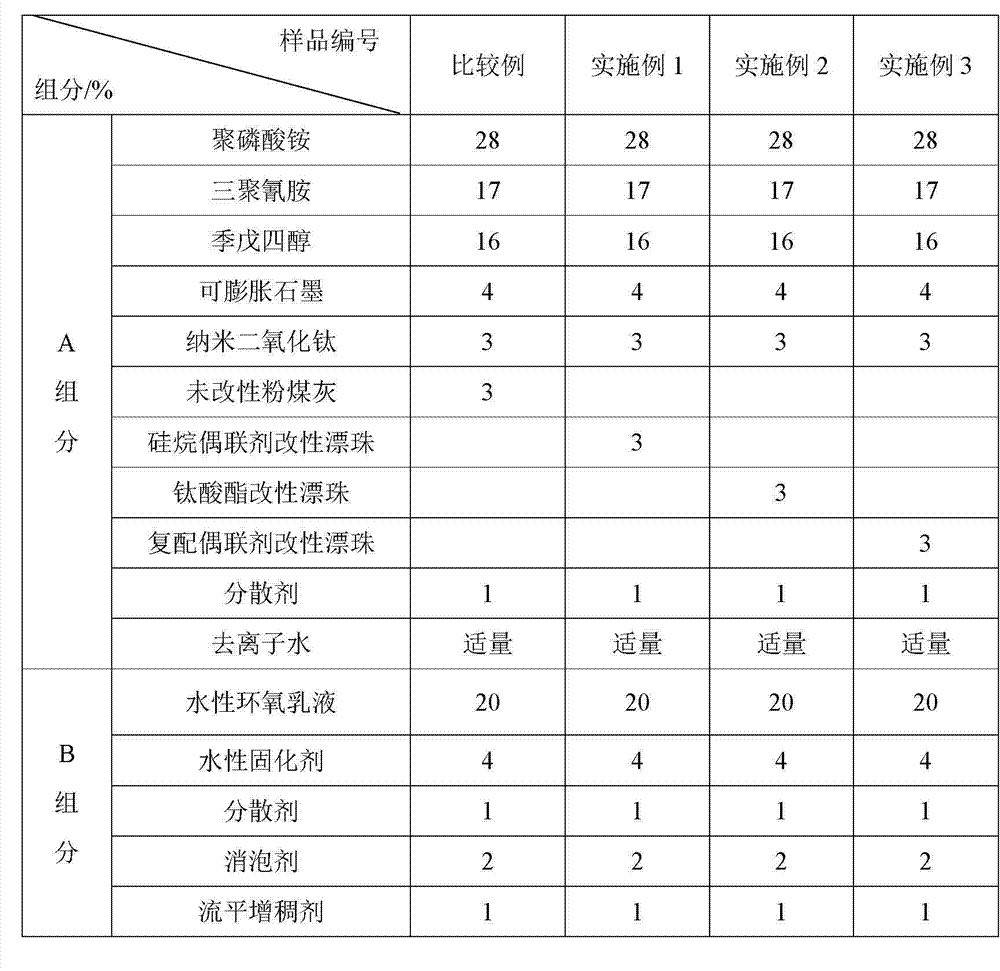

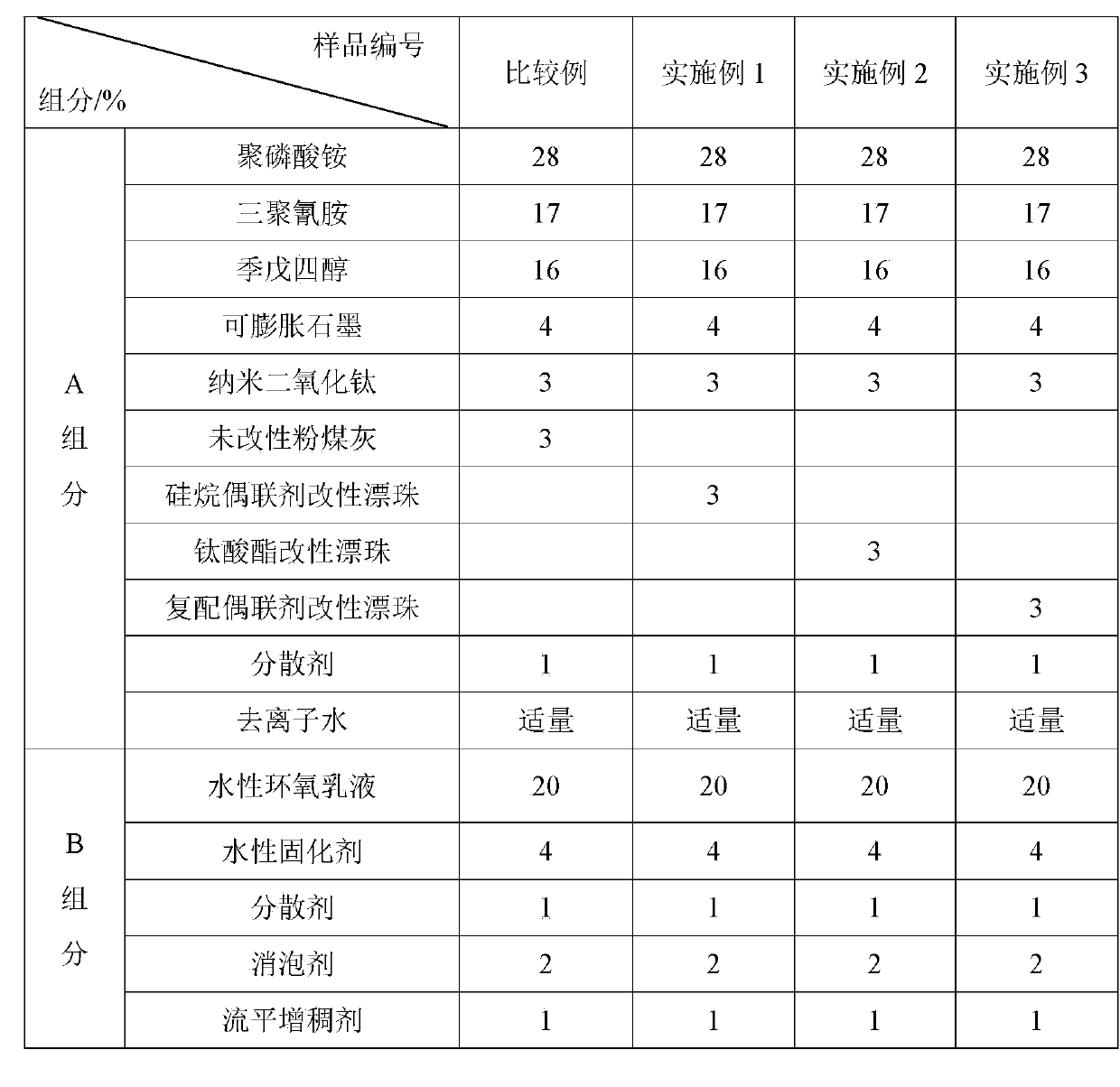

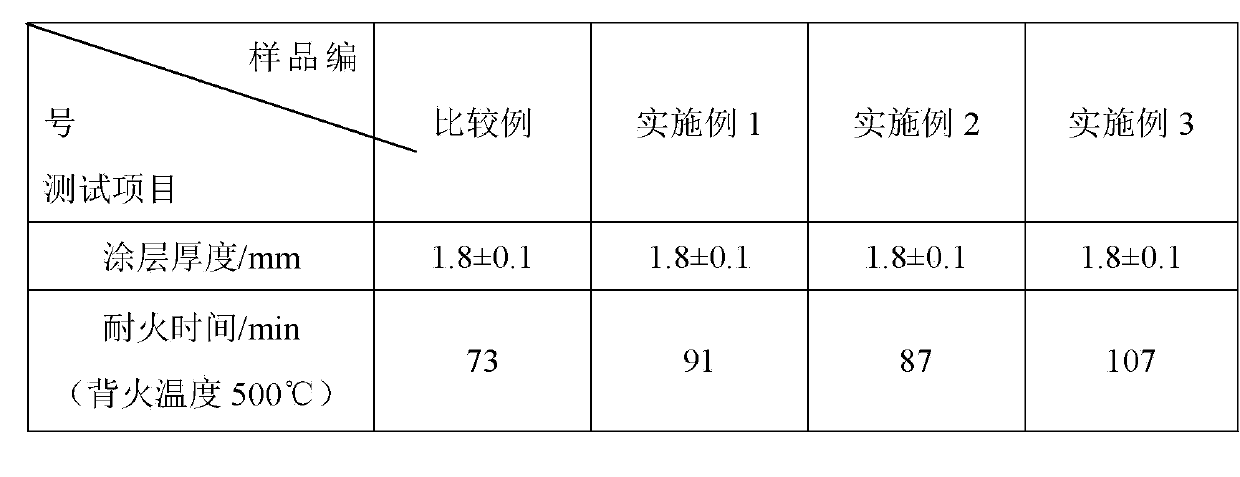

Method and application for carrying out fly ash floating bead surface modification by using compound coupling agent

InactiveCN102850825AEfficient removalOvercome the defect of poor modification effectFireproof paintsPigment treatment with organosilicon compoundsDispersityMechanical property

The invention relates to a fly ash floating bead surface modification technology, and specifically relates to a method for carrying out fly ash floating bead surface modification by using a compound silicane coupling agent. First, fly ash is subjected to sintering and acid-alkali pretreatments; and the pretreated fly ash is subjected to a surface modification treatment by using the compound coupling agent. When fly ash is processed through surface modification with the method provided by the invention, physical and chemical properties of obtained surface-modified fly ash floating beads are changed, dispersity of the beads in resin and organic polymers is improved, and compatibility of a filling material with interfaces of substrates such as resin is improved. Further, mechanical properties and other performances of high-molecular materials such as plastic, paint, and rubber are improved. Therefore, an improvement method is provided for better utilization of fly ash, and environment pollution is reduced.

Owner:ANHUI UNIV OF SCI & TECH

Green body of red soil ceramic and formula of transmutation glaze of red soil ceramic

The invention relates to a green body of red soil ceramic. The green body of the red soil ceramic is prepared from the following raw materials: red soil, quartz, talc, limestone and dolomite; the transmutation glaze of the red soil ceramic is prepared from the following raw materials: potassium feldspar, albite, calcium oxide, barium oxide, kaolin, quartz powder, sodium tripolyphosphate, titaniumoxide, rutile, zinc oxide and a coloring agent. By addition of other mineral raw materials, chemical raw materials and the like, the physical performance and the chemical performance of the green body are changed and the technical problems that the green body glaze of the red soil product is difficult to combine and the product is loose and fragile are solved; the firing temperature of the glaze is reduced from 1,310 DEG C to 1,230 DEG C, so thatthe firing temperature is reduced by 80 DEG C, the using amount of the fuel and the discharge quantity of harmful gas are reduced, environmental protection is contributed and production cost is greatly saved; and by development of the lead-free transmutation glaze, the lead-free transmutation glaze is suitable for being combined with the green body of the red soil ceramic, so that the problem of pollution to the ceramic decorative environment is solved fundamentally.

Owner:FUJIAN JIAMEI GRP +1

Nano-reinforced RTV long-lasting antifouling paint and producing process thereof

ActiveCN1690147AImprove thixotropyGood anti-sagAntifouling/underwater paintsPaints with biocidesUltravioletCross linker

An RTV long-acting anti-pollution flashover paint of nano intensive style used in the insulating surface outside the insulator of electric power appliances, and the method for producing it. The dispense comprises the following components (weight percent): nana SiO2 for 2-6 percent; hydroxy-terminated dimethyl silicone polymer for 20-40 percent; cross linker for 1-6 percent; catalyst for 0.02-1 percent; solvent for 30-70 percent; pigment for 1-2 percent. The producing steps as follows: mixed reacting hydroxy-terminated dimethyl silicone polymer and cross linker and catalyst; adding nano SiO2 into the autoclave for strring to 100-150 Deg.C, dewatering it in the condition of vaccum and loading it in the sealed metal drum; adding solvent and pigment to mix homogeneously, after a filtering treatment, placing it in an air-tight container. The coating by the invention is provided with fine thixotropic property, and the ability of ultraviolet absorption and infrared ray reflection, so the mechanical strength improved dramatically, the rate of hydrophobic mobility increased, and the property of anti-pollution flashover improved further.

Owner:STATE GRID CORP OF CHINA +1

Antibacterial natural latex product based on quaternary ammonium salt antibacterial agent and preparation technology of antibacterial natural latex product

The invention discloses an antibacterial natural latex product based on a quaternary ammonium salt antibacterial agent and a preparation technology of the antibacterial natural latex product, and belongs to the technical field of latex materials. The antibacterial natural latex product is prepared from the following components by weight: 90 to 100 parts of natural latex, 1 to 9 parts of sulfur, 1 to 5 parts of a vulcanization accelerator, 1.5 to 2 parts of an anti-aging agent, 1 to 6 parts of zinc oxide, 0.5 to 2 parts of sodium fluosilicate, 1 to 3 parts of potassium castorate, 0.1 to 2 parts of potassium oleate, 0.5 to 1 part of potassium permanganate and 0.1 to 3 parts of the quaternary ammonium salt antibacterial agent. The antibacterial natural latex product is based on the antibacterial characteristic of a low-concentration quaternary ammonium salt compound. The adopted quaternary ammonium salt compound has the advantage of stable performance, and the compound is tightly combined with latex polymer molecules and cannot permeate the skin of people or an animal by changing the physicochemical property of material surface. The latex product prepared in the invention has the advantages of high antibacterial property, hygiene, high practicability and the like, and has a broad market prospect.

Owner:江苏金世缘乳胶制品股份有限公司 +1

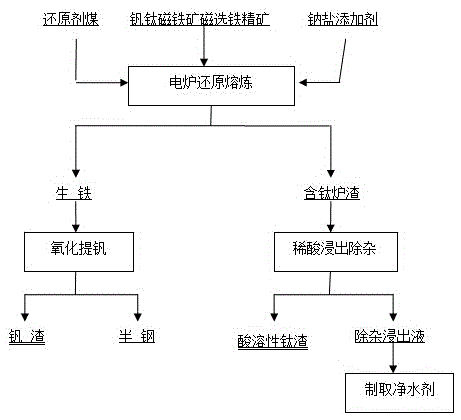

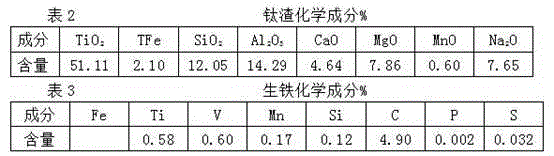

Method for extracting titanium from vanadium-titanium magnetite

InactiveCN105112689AEfficient and reasonable useSolve the technical problems of efficient separation and extractionProcess efficiency improvementElectric furnaceAluminateSmelting process

The invention discloses a method for extracting titanium from vanadium-titanium magnetite. The method comprises the following steps: adding sodium or potassium salt additive in the reduction smelting of an iron ore concentrate electric stove to obtain liquid iron and titanium-containing slag, wherein vanadium and iron are reduced to enter liquid iron, under a smelting high temperature condition, silicon and aluminum impurities form sodium aluminosilicate capable of being dissolved in dilute acid with the sodium or potassium salt additive, and enabling the sodium aluminosilicate and titanium and aluminum magnesium impurities to remain in the titanium-containing slag; purifying the titanium-containing slag by virtue of a wet-method metallurgical impurity removal method, to acquire a titanium slag product with TiO2 content more than 75 percent. For the application problem of titanium in the iron ore concentrate, the slag modification additive is added in the reduction smelting process, so that not only is the mobility of the slag improved, but also a condition is created for removing the later silicon-aluminum impurities of the slag, the high-efficiency separation and extraction problem of the titanium in the iron ore concentrate can be well solved, the resource utilization rate of the iron, titanium and vanadium is greatly increased, and the utilization rate of the titanium is increased about 3 times compared with the flow of a blast furnace.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Treating process of medium saline-alkali grassland

InactiveCN101020189AWell mixedChange physical and chemical propertiesContaminated soil reclamationHorticultureRevegetationGrassland

The treating process of moderately salinized grassland includes determining the salinized degree of the grassland; selecting seeds of saline-alkali tolerant plant including excellent pasture; tilling the soil shallowly; applying ecological preparation; and seeding through drilling and pressing for 1-3 times. The present invention can restore the vegetation fast and has the advantages of low cost, high efficiency and high adaptability.

Owner:倪红伟

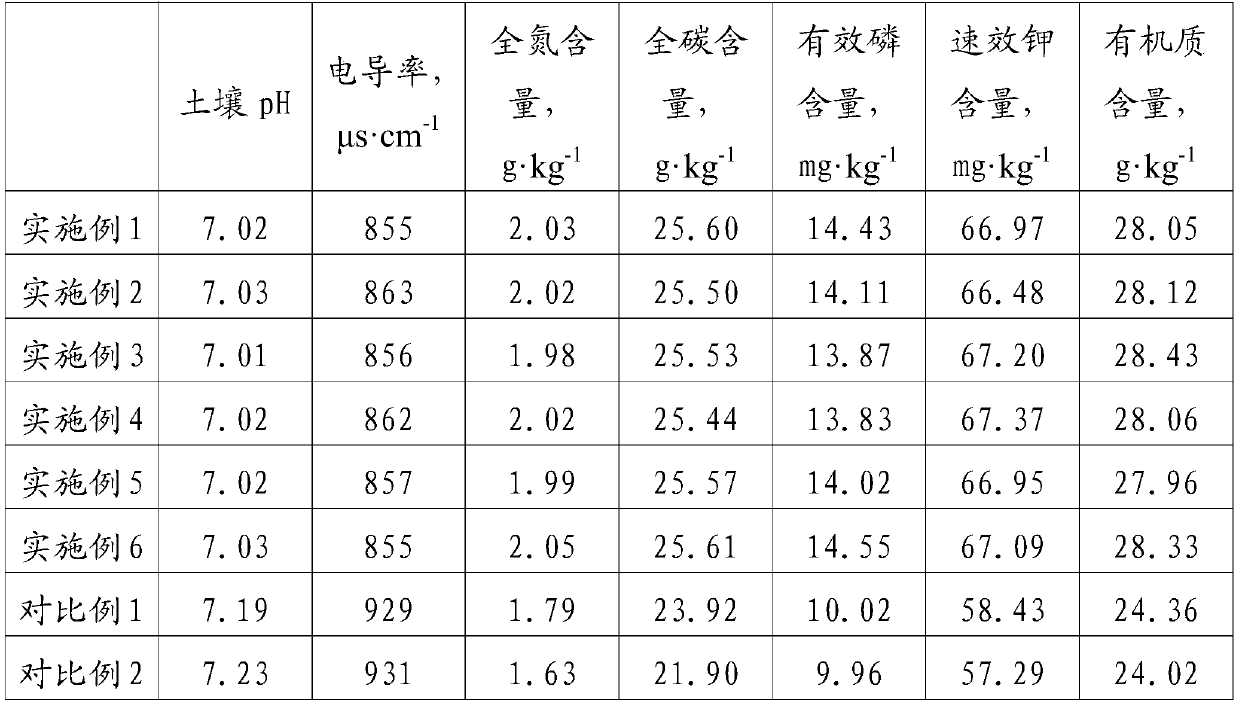

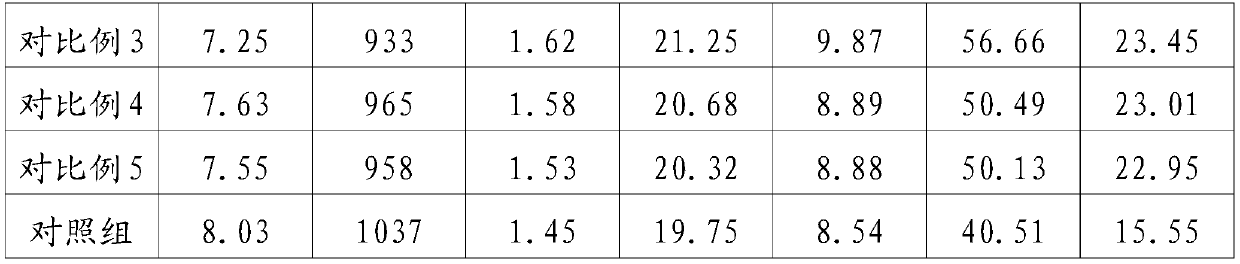

Comprehensive treatment method for saline-alkali land

InactiveCN109220036AHigh organic contentImprove physical structureSoil-working methodsLand improvementAlkali soil

The invention relates to the technical field of saline-alkali land improvement, in particular to a comprehensive treatment method for a saline-alkali land. The method consists of the following steps that 1, the saline-alkali land is deep ploughed and tilled loosely, an rice straw interlayer is laid and the surface is leveled, wherein the ploughing depth is 25-30 cm; 2, irrigation and salt washingare performed three times, wherein the water consumption is 60-160 m<3> per mu at a time, and the total water consumption is 300-400 m<3>; 3, a microbial organic fertilizer is applied to the saline-alkali land, tilling and leveling are conducted again; 4, salt-tolerant alkali-tolerant rice is planted for crop rotation with green manure plants. The method can improve the physical structure of soil,reduce the evaporation amount of water in the soil of the saline-alkali land, enhance the water-holding capacity of the soil, increase the content of organic matter, reduce the disasters of crop diseases and insects, increase the yield of crops, improve the economic benefits of the saline-alkali land and reduce the degree of soil salinization.

Owner:兴安盟隆华农业科技有限公司

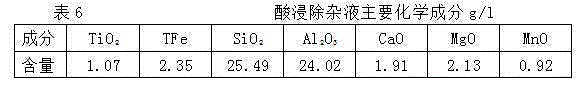

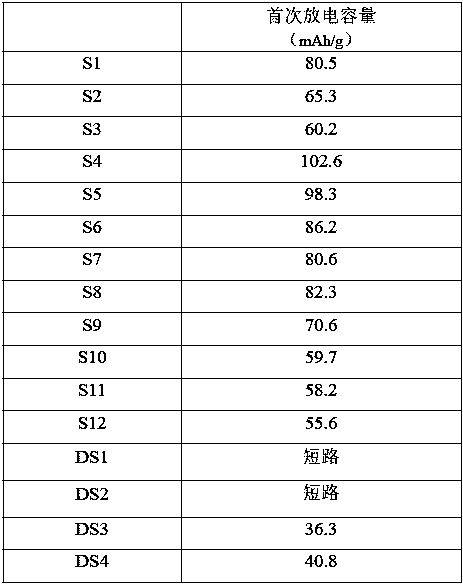

Solid electrolyte of lithium ion battery and preparation method of solid electrolyte as well as lithium ion battery

ActiveCN107666010AImprove ionic conductivityReduce crystallinitySecondary cellsSolid state electrolyteAluminium-ion battery

The invention provides solid electrolyte of a lithium ion battery and a preparation method of the solid electrolyte as well as the lithium ion battery. The solid electrolyte of the lithium ion batterycomprises a core material and a shell material coating the outer surface of the core material; the core material comprises Li1+xMxTi2-x(PO4)3, wherein M is selected from at least one of Al, La, Cr, Ga, Y or In, and 0.05fx f0.4; the shell material comprises Li0.6+yB0.8SiyP1-yO4, wherein 0.01fy f0.5; the Li 0.6+yB0.8SiyP1-yO4 shell material makes full surface contact with the core material, so thatthe ability of resistance between grains of the core material is obviously reduced; in addition, the solid electrolyte of the lithium ion battery has lower electronic conductivity and a complete anddense electronic shielding layer is formed on the surface of the core material, so that the problem that Ti<4+> is reduced into Ti<3+> is better solved. The prepared solid electrolyte has the characteristics of a wide electrochemical window (the electrochemical window is greater than 5V), relatively-high ionic conductivity and low electronic conductivity.

Owner:BYD CO LTD

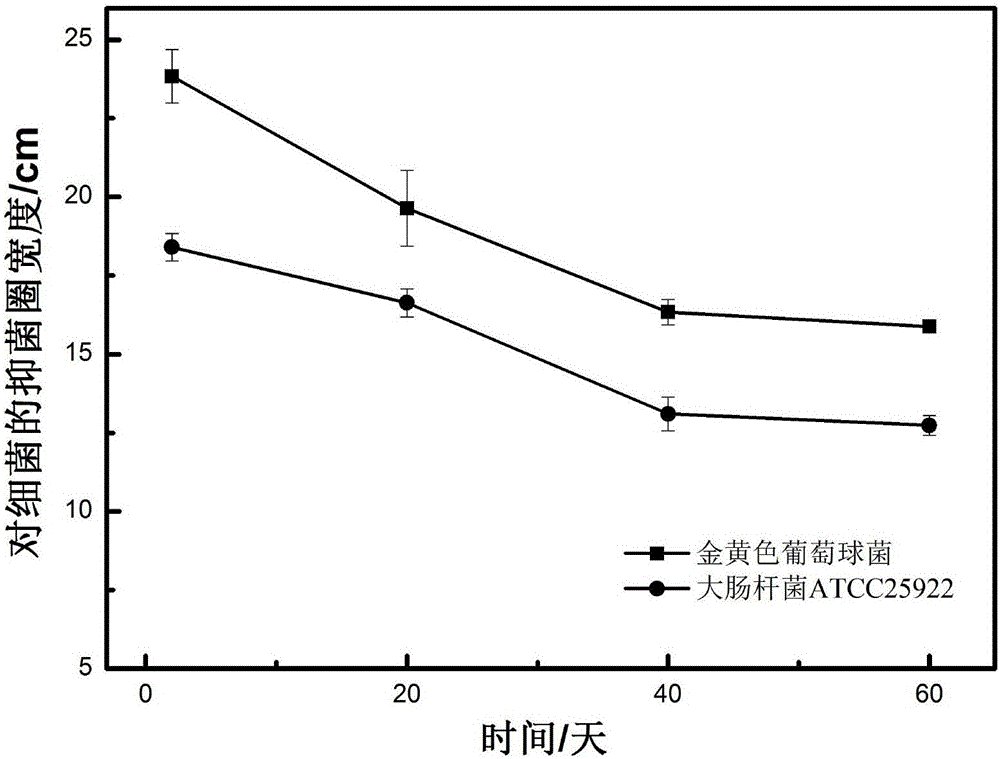

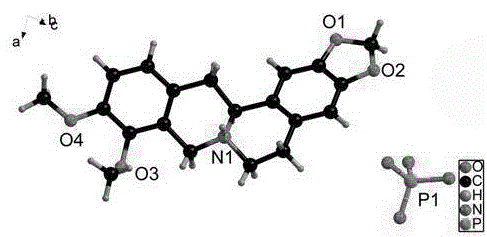

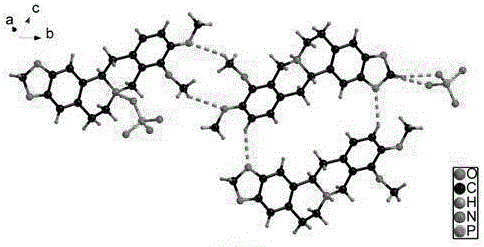

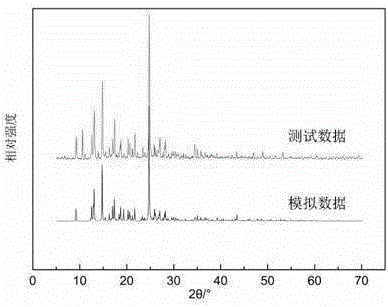

Phosphate tetrahydroberberine drug eutectic and preparation method thereof

InactiveCN106810547AEutectic Solubility EnhancementImprove bioavailabilityAntibacterial agentsOrganic chemistry methodsSpace groupPhosphate

The invention discloses a phosphate tetrahydroberberine drug eutectic and a preparation method thereof. The tetrahydroberberine and phosphate are added and mixed in isopropanol water solution, ethanol water solution or methanol water solution according to the molar ratio; the acquired mixed solution is volatilized under the room temperature. The prepared tetrahydroberberine drug eutectic is a triclinic system, and the space group is P-1, and its axial length (i) is FORMULA; the axial angle is FORMULA. The tetrahydroberberine drug eutectic prepared by the invention inherits the pharmacological activity of tetrahydroberberine, its solubleness, dissolution rate, antibiosis bacillus coli and staphylococcus aureus activities are significantly improved in relative to the tetrahydroberberine, thereby saving drug dosage; the method is good for developing to be drug preparation, and the tetrahydroberberine can be widely applied to the medicine field.

Owner:JIAMUSI UNIVERSITY

Special enhancing fertilizer for grape

InactiveCN103964925AReduce manufacturing costImprove qualityFertilizer mixturesSludgePhosphoric acid

The invention relates to a special enhancing fertilizer for grape. The special enhancing fertilizer is prepared from the following raw materials in parts by weight: 80-100 parts of biogas residue and biogas slurry, 20-30 parts of oilseed rape cake, 30-40 parts of river sludge, 10-15 parts of sawdust, 10-15 parts of plant ash, 10-15 parts of phosphatic fertilizer, 8-12 parts of nitrogen fertilizer, 5-10 parts of potassic fertilizer, 2-5 parts of calcium superphosphate, 0.5-2 parts of borax and 0.5-2 parts of trace element mixture. All the raw materials are stirred evenly, dried at a low temperature and pelletized by virtue of a pelletizer to obtain the enhancing fertilizer. The production cost of the special enhancing fertilizer for grape is low and the raw materials of the special enhancing fertilizer for grape are easily available; the special enhancing fertilizer for grape is capable of effectively increasing the organic matters of soil, changing the physical and chemical properties of soil, supplementing trace elements of the soil, preventing soil hardening, enhancing the soil fertility, and also reducing the production cost of grape, improving the quality of grape and increasing the income of the farmers.

Owner:沈金跃

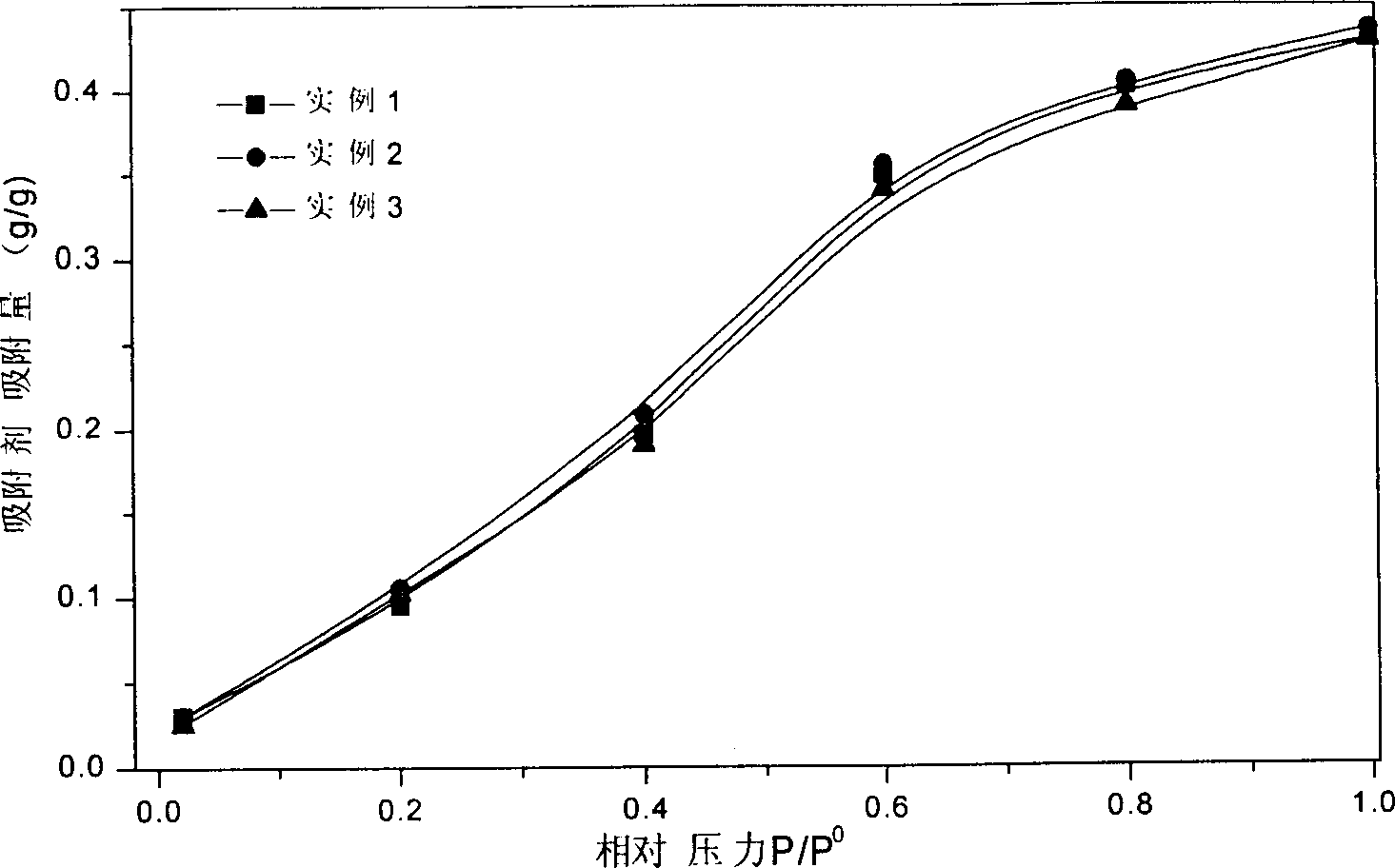

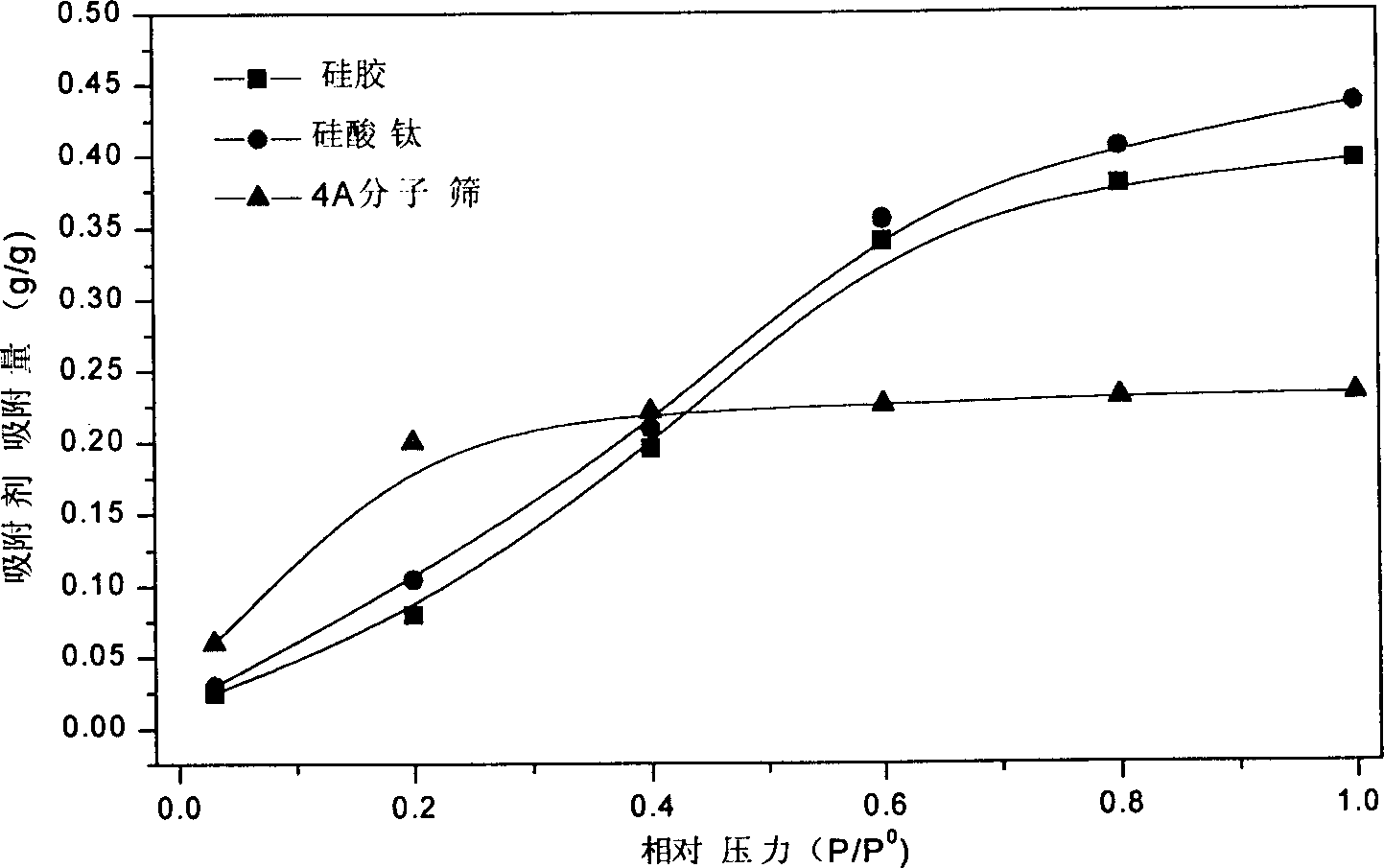

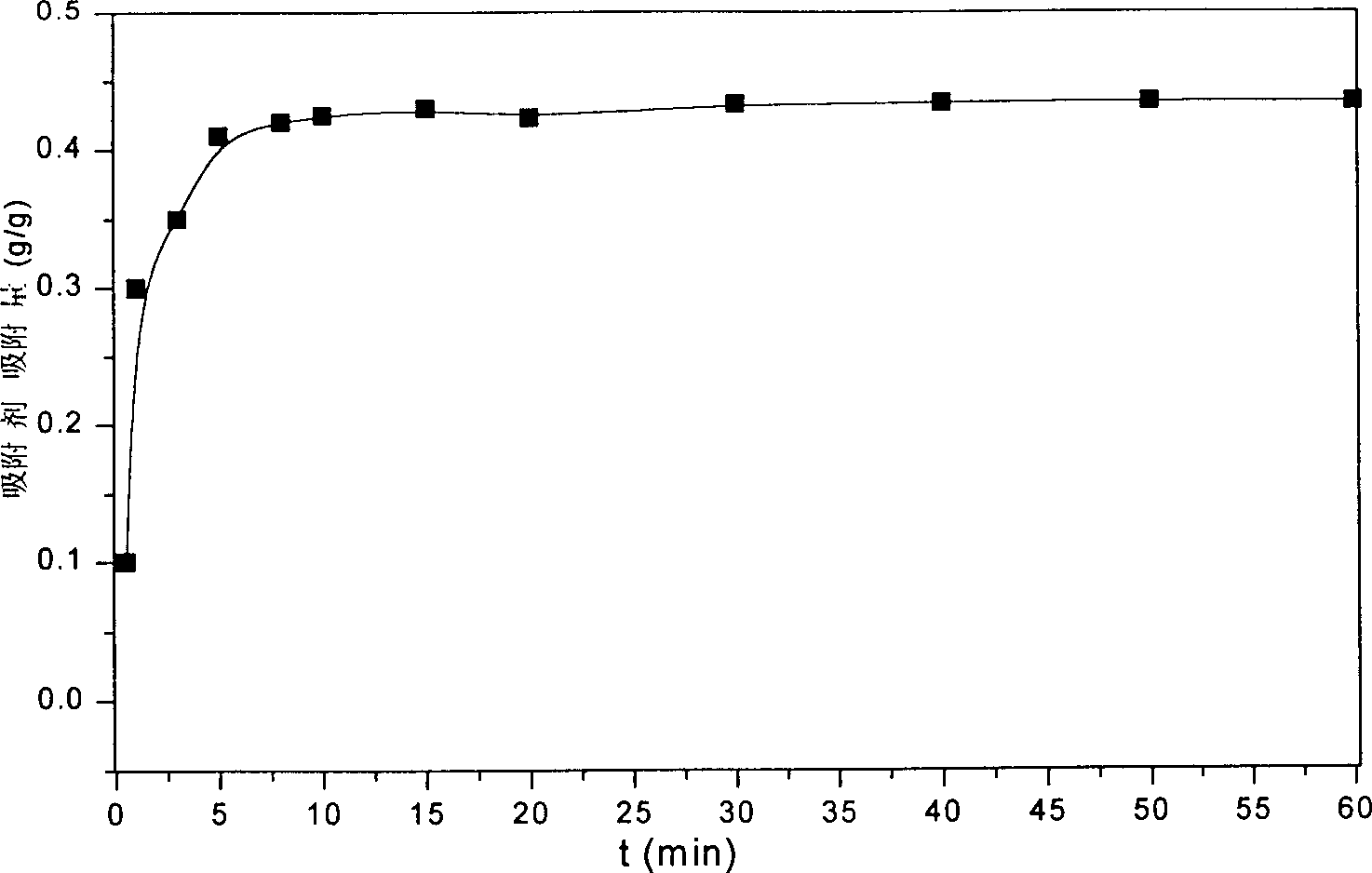

Prepn and application of titanium silicate adsorbent with high adsorption performance

InactiveCN1387942AImprove toughnessHigh rotational speed, corresponding energy requirements for turning the dehumidification wheelOther chemical processesSilicon compoundsPartial hydrolysisSorbent

The material for preparing titanium silicate adsorbent has molar ratio between Si and Ti of 8-20,and the proportion among alkoxide, water and polyethylene glycol of 1 to 5-15 to 0.002-0.005. The preparation includes the steps of sol preparation and titanium silicate preparation. The sol preparation includes partial hydrolysis of ethanol solution of silanolate, adding ethanol solution of titanic alkoxide while heating for complete hydrolysis; and adding polyethylene glycol for condensation to form sol. In the titanium silicate preparation, the sol is prepared into hydrogel through oil-free formation process and the hydrogel is then prepared into nano spherical titanium silicate via washing, drying and sieving. The titanium silicate product has high adsorption performance and is used in producing core of dehumidifying wheel.

Owner:SOUTH CHINA UNIV OF TECH

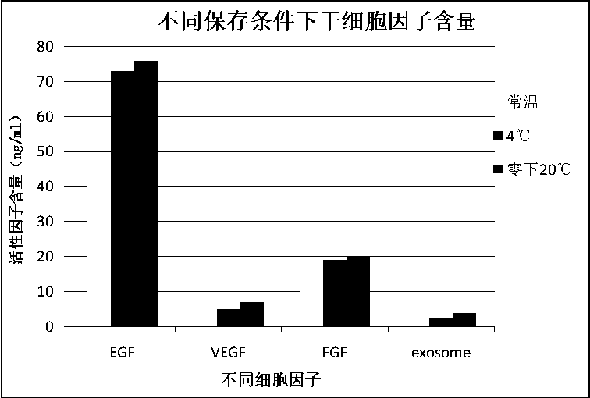

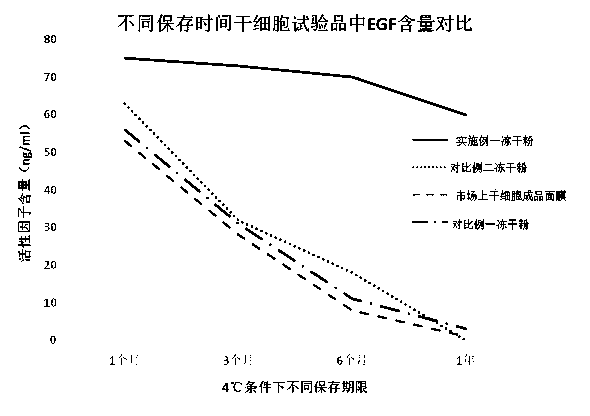

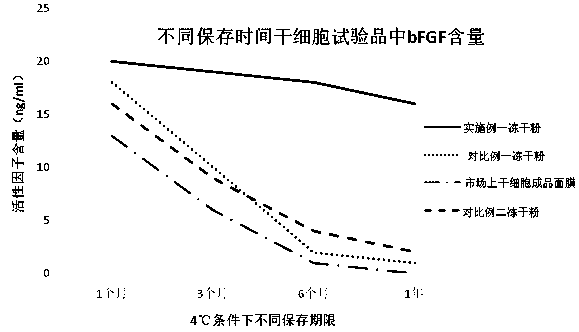

Cell growth factor freeze-dried powder, preparation method and application

InactiveCN108159078AChange physical and chemical propertiesChange biological characteristicsPowder deliveryUnknown materialsUmbilical cordGrowth cell

The invention provides cell growth factor freeze-dried powder, a preparation method and application. The cell growth factor freeze-dried powder is prepared by freezing cell culture supernate obtainedfrom subculture of umbilical cord mesenchymal stem cells, and is used as a protection agent after human albumin is added. The preparation method comprises the following steps: A, separating mbilical cord mesenchymal stem cells; B, performing subculture on the mbilical cord mesenchymal stem cells in a culture medium; C, collecting mbilical cord mesenchymal stem cell culture supernate of the step B,adding mannitol and human albumin, sucking the cell culture supernate into a centrifugal tube, placing in a low-temperature refrigerator or a liquid nitrogen tank, performing cryopreservation till asolid, completely freezing and solidifying the culture medium, putting the solid frozen culture medium into a cryopreservation bottle, performing freezing drying in a machine for 12-24 hours so as toobtain freeze-dried powder, and performing cold storage on the freeze-dried powder. As the human albumin is adopted as a protection agent, irritation and other rejection reactions are not easily caused, the powder can be relatively easily absorbed, a skin oxidation resistance effect is achieved, and skin aging can be further retarded.

Owner:深圳市新一仑生物科技有限公司

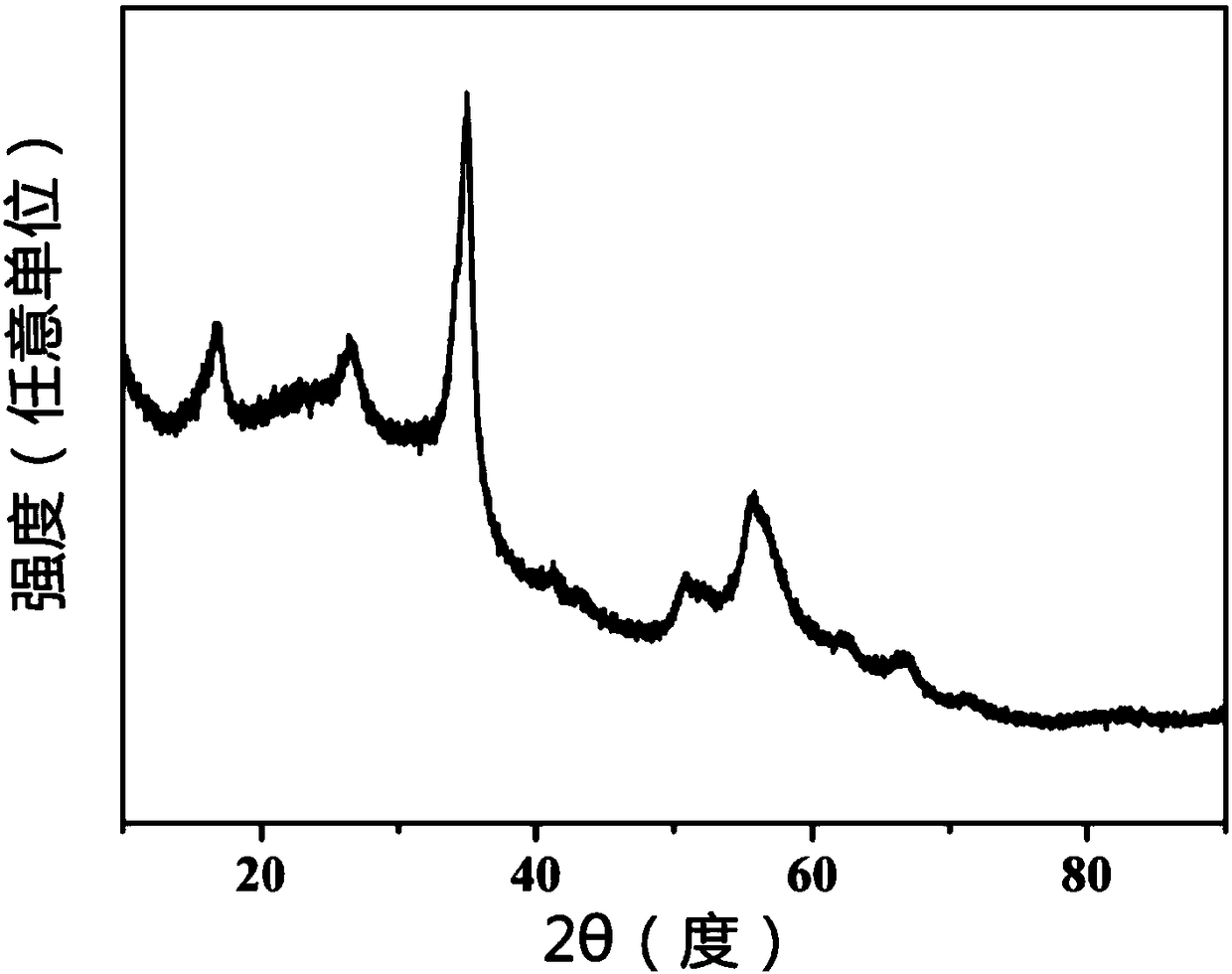

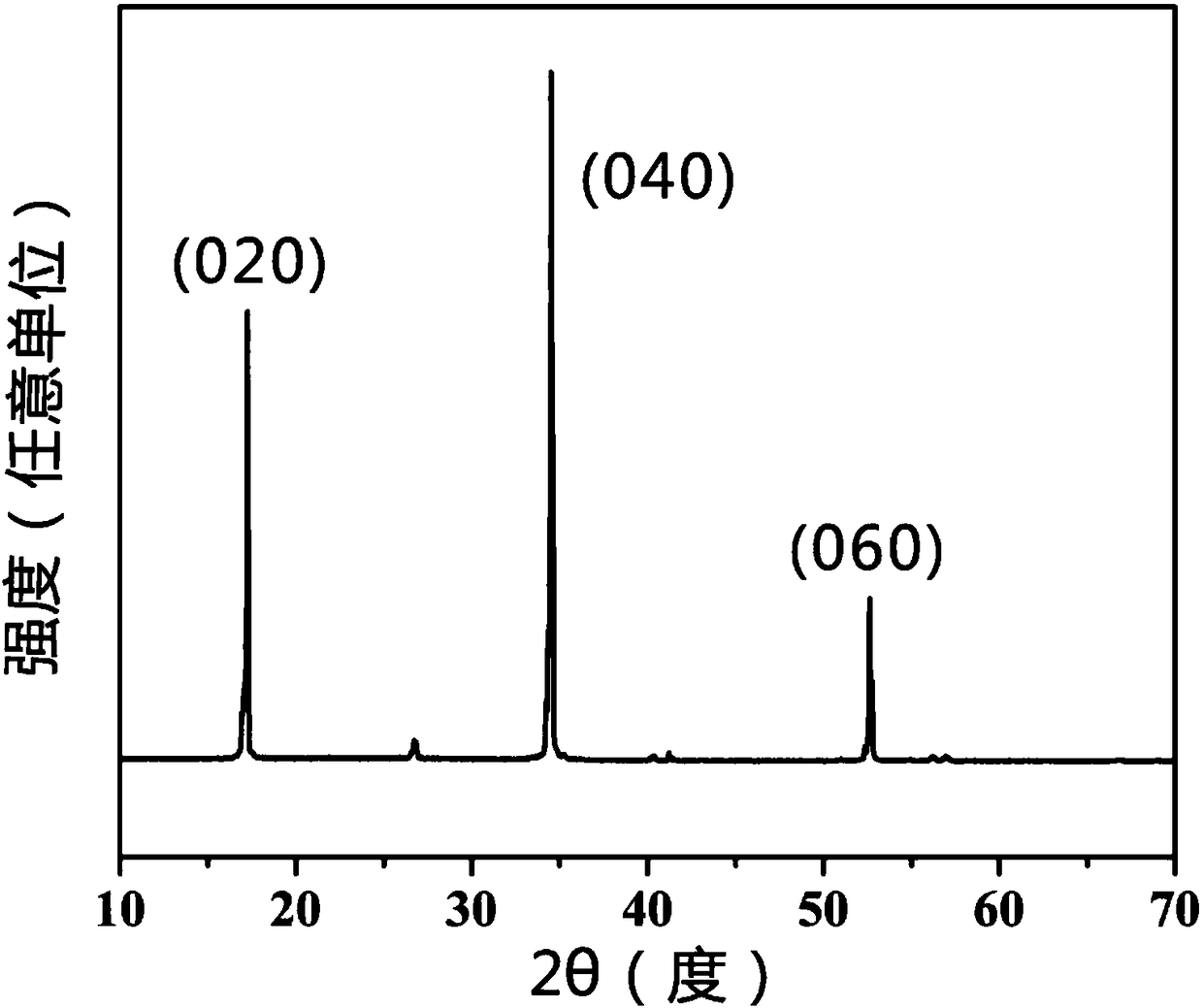

Low-energy-consumption preparation method for black phosphorus single crystals

The invention discloses a low-energy-consumption preparation method for black phosphorus single crystals. The method comprises the following steps that rough black phosphorus powder is used as a phosphorus raw material and subjected to a heating reaction with metal simple substance tin and mineralizer stannic iodide under the vacuum condition, and through programmed cooling, the black phosphorus single crystals with larger size and higher purity are obtained. According to the method, required equipment is simple, the reaction temperature is low, the obtained black phosphorus single crystals are good in crystal form, the energy consumption can be obviously lowered, and the method helps to achieve industrial large-scale preparation of the black phosphorus single crystals.

Owner:HUBEI MOPHOS TECH CO LTD

Saline-alkali soil improving method

InactiveCN108966718AImprove physical structureReduce salt contentSoil-working methodsWireless transmissionSoil science

The invention discloses a saline-alkali soil improving method. The saline-alkali soil improving method comprises the following steps of A, deep-ploughing and levelling saline-alkali soil; B, performing buried pipe salt removal on the leveled soil; C, after buried pipes are laid to irrigate the saline-alkali soil; D, applying soil targeted conditioning agent to the processed saline-alkali soil; E,planting saline-alkali tolerant rice. The saline-alkali soil improving method sets a wireless transmission mode inside a planting area to achieve remote rice growth monitoring, can significantly improve the physical structure of the saline-alkali soil, reduce the total salt content of the saline-alkali soil, activate soil, preserve water and fertilizer, increase the organic content of the soil, improve the physicochemical properties of the saline-alkali soil and further achieve long-term virtuous cycle of the saline-alkali soil.

Owner:青岛九天智慧资产管理有限公司

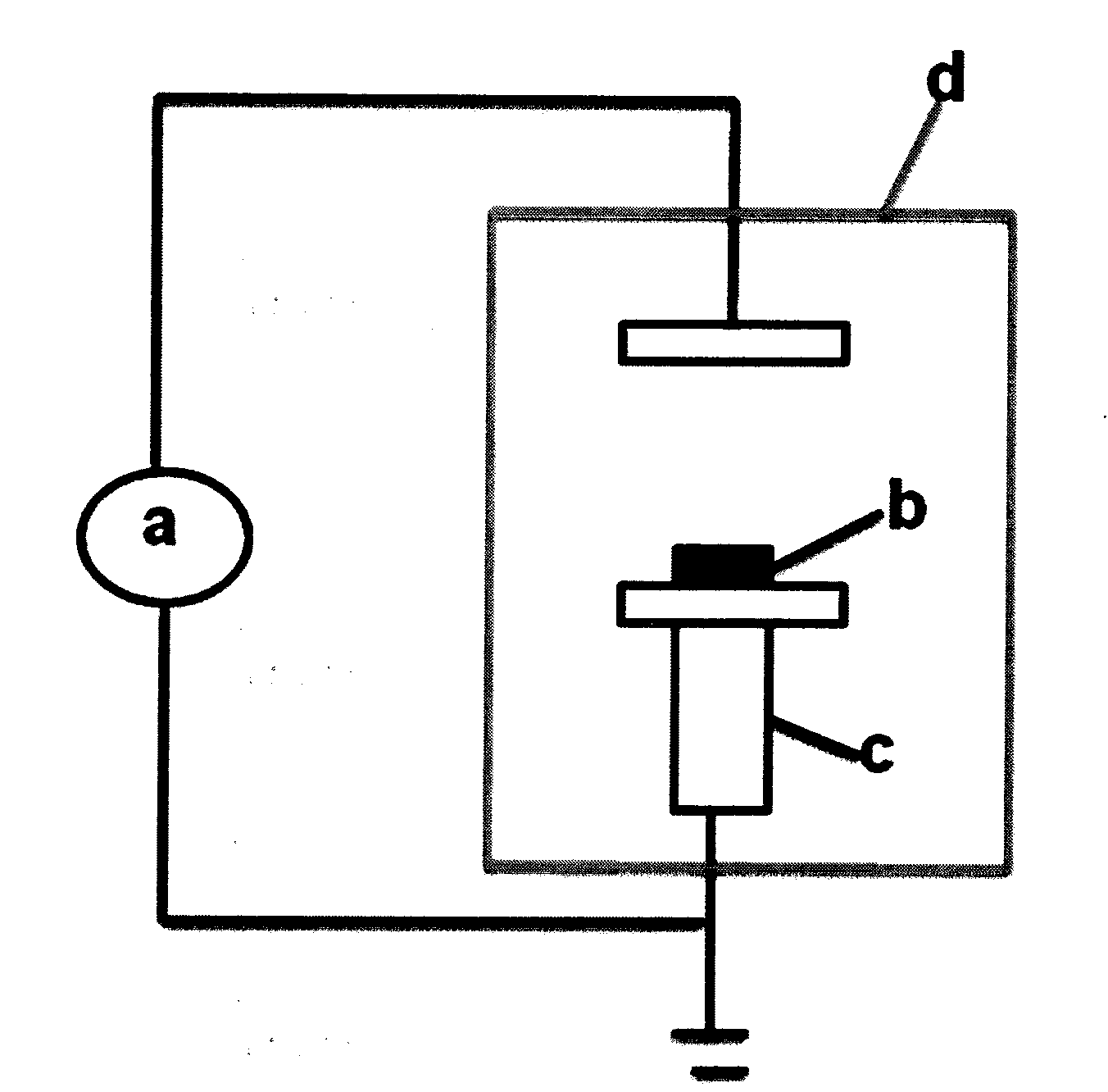

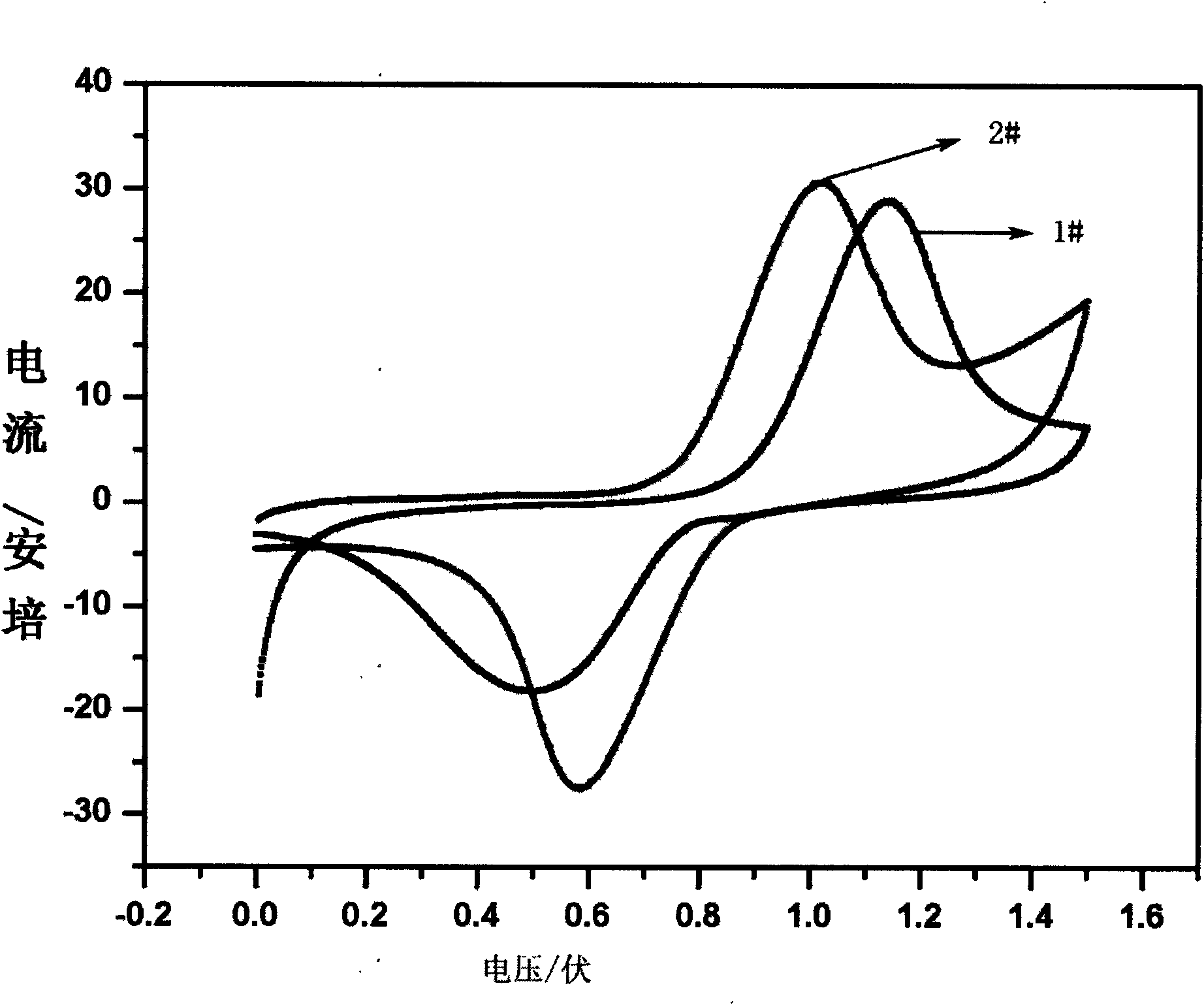

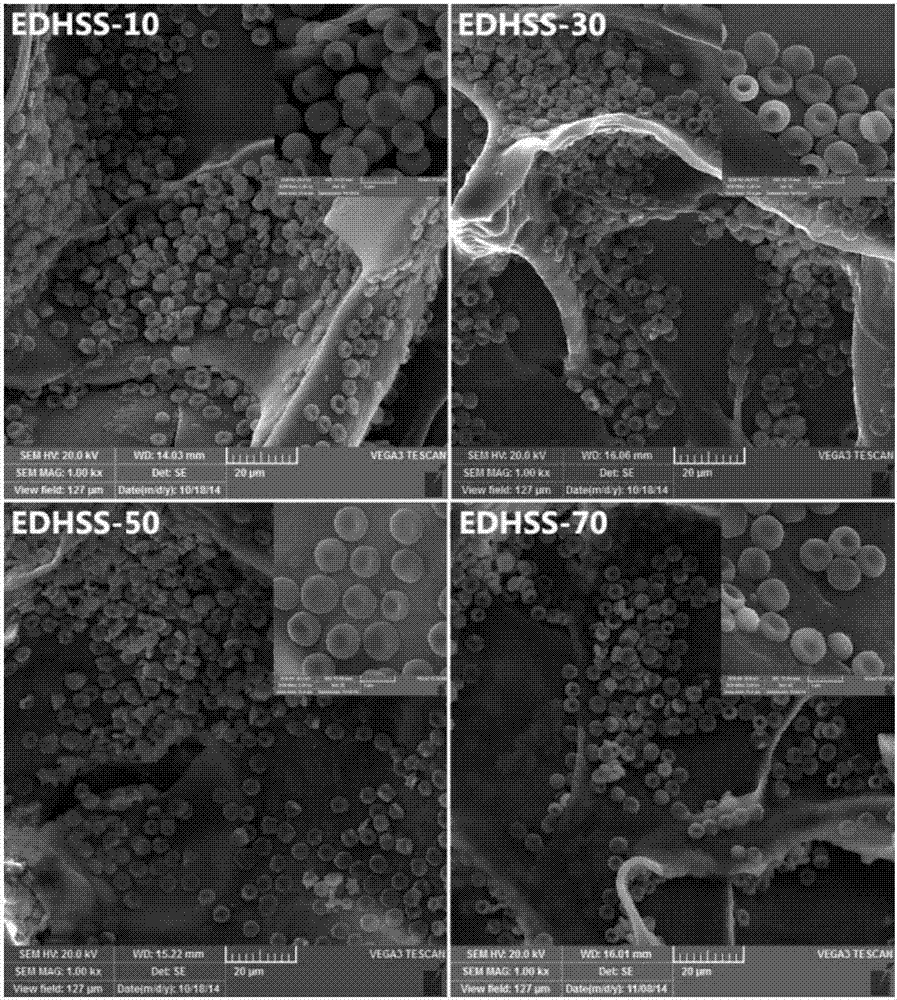

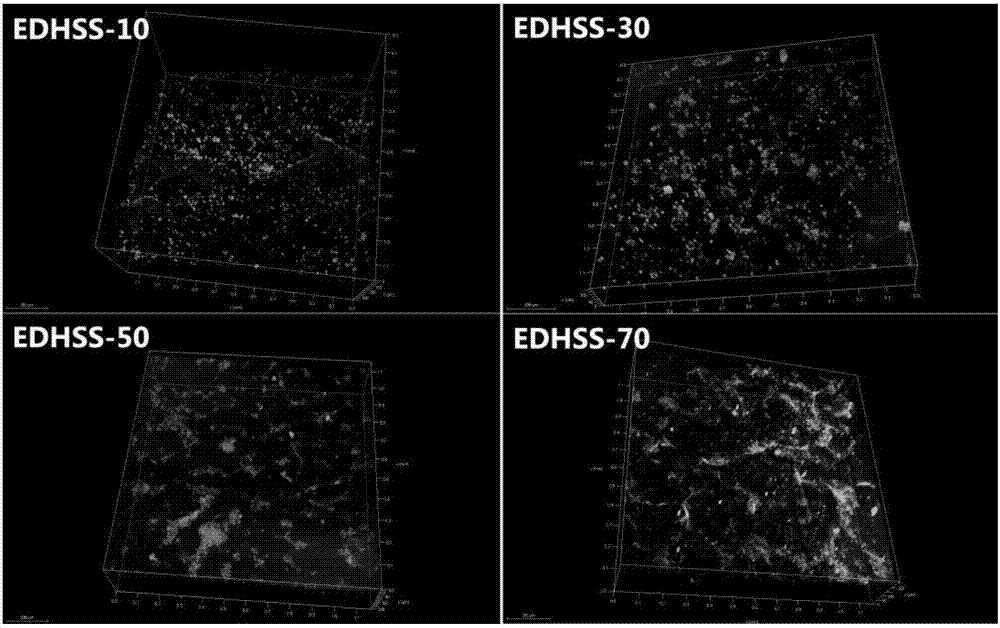

Surface modification method for raising activity of electrode material of vanadium cell

ActiveCN102723502AImprove energy storage efficiencyImprove hydrophilic propertiesCell electrodesCell fabricationElectrical polarity

The invention, relating to the field of cell manufacturing and energy storage, discloses a surface modification method for raising the activity of an electrode material of a vanadium cell, comprising the following steps: firstly cleaning the electrode material of the vanadium cell to remove surface impurities, then carrying out modification treatment of the electrode material by using plasma, reacting the gas which generates plasma with the electrode surface under ionization state to generate polar functional groups; and finally carrying out ultrasonic cleaning on the modified electrode material for 5-30 min and drying at 60-120 DEG C. According to the invention, by using the method of the invention to carry out surface modification on the electrode material of the vanadium cell, the hydrophilcity of the electrode surface is enhanced, partial polar functional groups has good catalytic influence on electrode reaction, and the energy storage efficiency of the cell is expected to increase. The method can be used for processing material surfaces with various morphologies and can keep mechanical properties and the like of material matrixes, the experiment condition are easy to control and the method has no pollution to environment. The method is efficient and environmentally friendly.

Owner:辽宁科京新材料有限公司

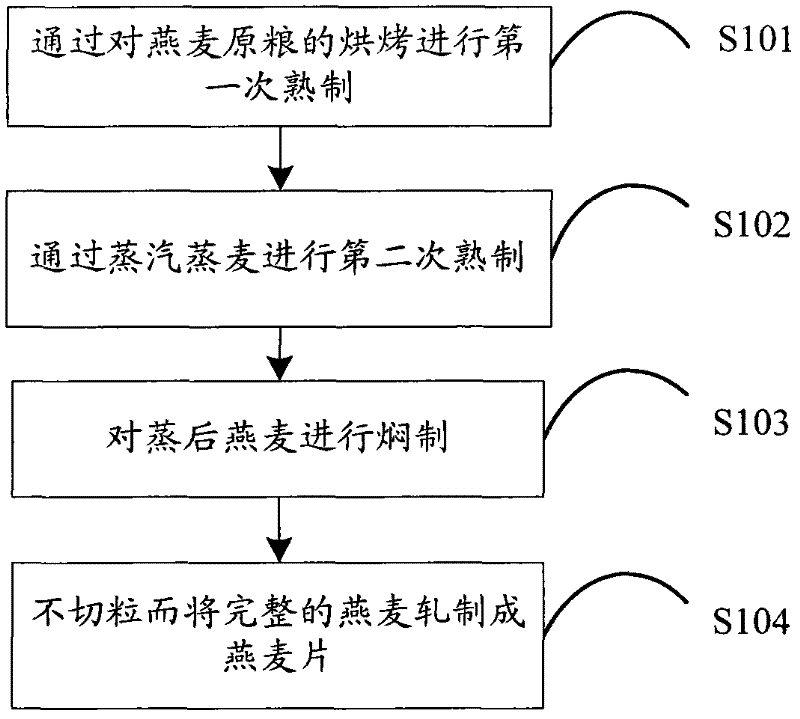

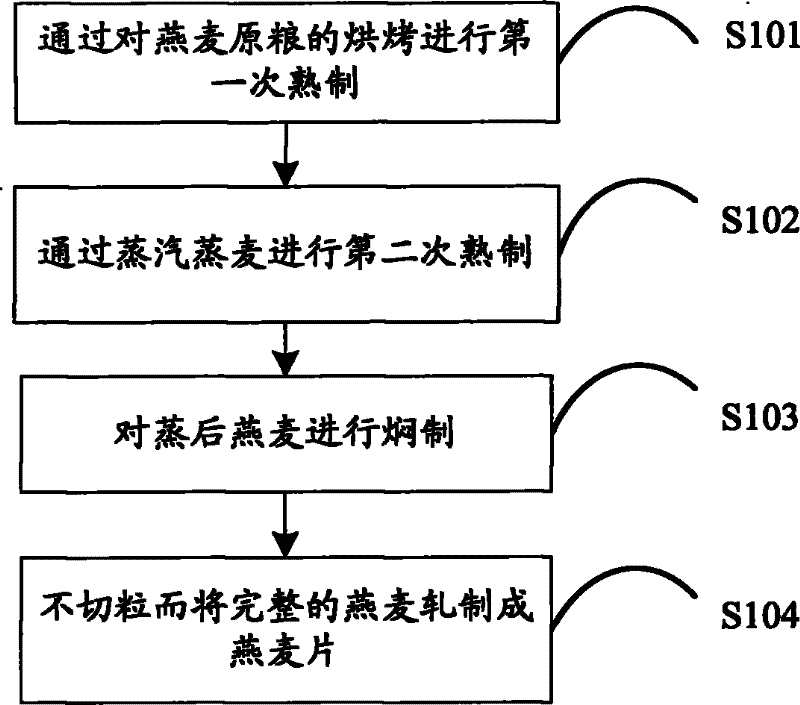

A kind of cooking method of oatmeal

The invention is applicable to the field of food processing, and provides an oatmeal cooking method; the method comprises the following steps: baking oat raw grains to perform first cooking; steaming oat by steam to perform second cooking; braising the steamed oat; rolling complete oat grains into oatmeal without grain cutting. According to the invention, while the oat grains is cooked, various enzymes in oat are passivated at high temperatures for several times in procedures such as oat baking, oat steaming, and oat braising; the product is guaranteed not to generate spoilage phenomenon under normal environment; the oatmeal is subject to third cooking during brewing; the oatmeal processed by the 'three cooking' processes has dense and lasting flavor, milk white soup, gloss, and high viscosity; and the oatmeal is chewy, is not sticky to teeth, and has smooth mouthfeel; the invention simultaneously adopts big-sheet rolling technology without grain cutting, and thus the prepared oatmeal has a complete shape, less fragments or fine powder, and good sensory quality.

Owner:INNER MONGOLIA SAIBAO OAT FOOD

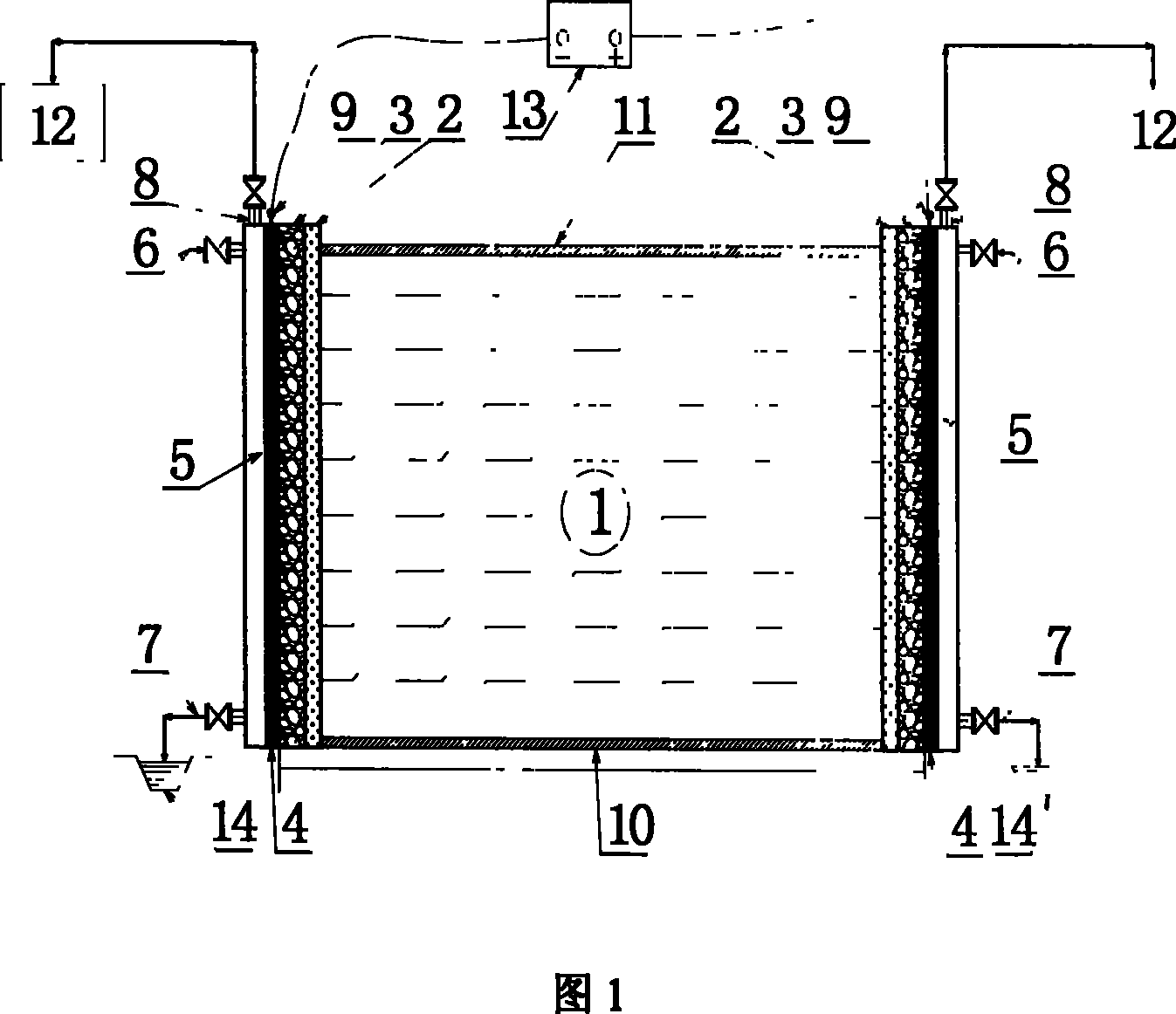

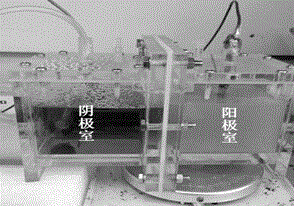

Process for united repairing heavy metal polluted soil by electric power and iron permeable reaction lattices

InactiveCN1899717BChange physical and chemical propertiesAvoid secondary pollutionContaminated soil reclamationMetal contaminationElectric power

The in-situ efficient heavy metal polluted soil repairing technology without secondary pollution is to combine electric power and in-situ PRB technology. Graphite electrodes are mounted on two sides of the polluted soil and PRB is set inside the soil between these two electrodes, so that under the action of the electric field, metal anions, such as Cr ion can migrate to anode, metal cations, suchas Cd2+ and Hg2+ can migrate to cathode and heavy metals can react with PRB to be adsorbed, reduced and precipitated. The said technology can eliminate polluting heavy metals from soil completely, avoid the secondary pollution to water and reduce the changes of soil in physical and chemical properties.

Owner:NANKAI UNIV

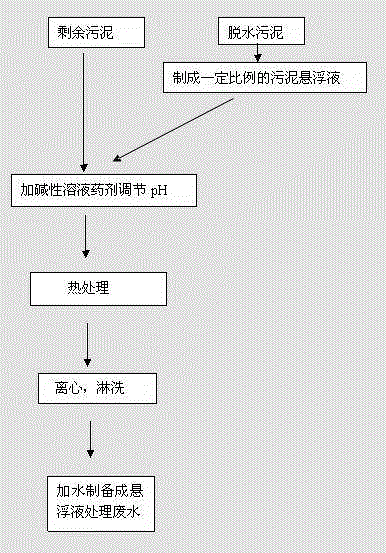

Method of preparing flocculating agent by utilizing sludge and application thereof

InactiveCN102976579AChange the body structureVarious ingredientsSludge treatmentWater/sewage treatment by flocculation/precipitationFlocculationMicroorganism

The invention relates to a preparation process of preparing a flocculating agent by utilizing sludge, and discloses a method of preparing flocculating agent by utilizing sludge and application thereof. The method comprises the following steps: mutually connecting the two pretreatments of the sludge in series to change the virtual structure of the sludge, changing physical and chemical properties of the sludge particles and microbial cells in the sludge, and enabling the sludge to possess higher adsorption property of the flocculating agent. The flocculation rate to kaolin can be up to 95% above. The processing method mainly comprises the steps of adjusting the pH value, heating and centrifuging and so on. The process has the characteristics of low cost, simple process, short preparation time, convenience in application and good processing effect and the like.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

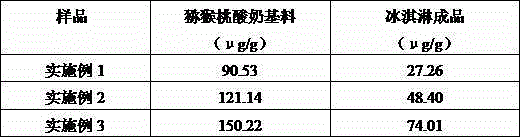

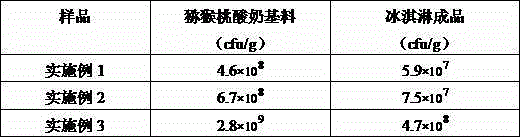

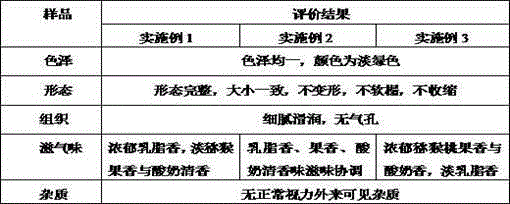

Preparation method of selenium-enriched kiwifruit yogurt ice cream

InactiveCN105028888AMaintain colorAroma components are stableFrozen sweetsNutrientSodium erythorbate

A preparation method of selenium-enriched kiwifruit yogurt ice cream comprises the steps that 1, selenium-enriched kiwifruits are selected for preparing kiwifruit concentrated juice, 0.01%-0.02% of sodium erythorbate and 0.2%-0.4% of beta-cyclodextrin are added, and the functions of maintaining the stabilization of color, aromatic components and nutrient substances of the kiwifruit concentrated juice are achieved; 2, milk is taken as the raw material, strain is added into the milk, yogurt is obtained through fermentation, and 10-15 parts of the selenium-enriched kiwifruit concentrated juice and 2-5 parts of a selenium-enriched yeast preparation basic material I are added; 3, an ice cream basic material II is prepared from whole milk power, skim milk power, maltodextrin, whey powder and single cream; 4, the basic material I and the basic material II are evenly mixed according to the proportion of 3-5 to 7-5, congelation is conducted, and a finished product is obtained. The ice cream prepared through the method has the functions of supplementing selenium and improving the intestinal function, the selenium content can reach 20 micrograms per gram, the viable count reaches over 107 cfu / g, the taste is delicate, and the fruity flavor is rich.

Owner:四川兴食尚科技有限公司

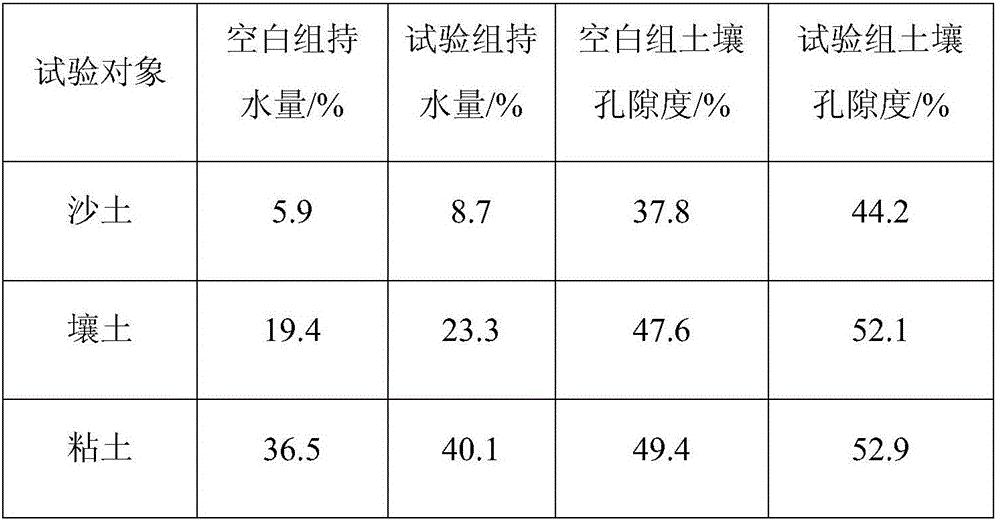

Saline and alkaline land improvement method

InactiveCN111083958AImprove adsorption capacityImprove physical and chemical propertiesSuperphosphatesNitrate fertilisersLand improvementAlkali soil

The invention discloses a saline and alkaline land improvement method. The improvement method comprises the following steps: crushing plant straw to prepare plant straw powder, then, scattering the plant straw powder into saline and alkaline land, and carrying deep ploughing and turning; applying a mixture consisting of soybean meal, furfural residues, activated biochar powder, a microbial agent,inorganic fertilizer, natural zeolite powder, mineral-sourced humic acid and modified calcium alginate aerogel to the surface layer of the saline and alkaline land, and using a rotary cultivator for rotary cultivation and mixing; flattening the soil surface layer of the saline and alkaline land, uniformly sowing alfalfa seeds on the flattened saline and alkaline land, then, performing earthing up,and controlling the sowing depth at 1-2 cm; during harvesting, keeping the stubble height of alfalfa at 5.5-7.5 cm; carrying out deep ploughing, turning and burying on the saline and alkaline land toturn and bury the alfalfa stubbles in the soil; and then, planting wheat or corn crops. The method can effectively reduce the soil alkalization degree and salt content, and the physiochemical properties of the soil are effectively improved.

Owner:WEIFANG YOURONG IND

Method for manufacturing high-tenacity ceramics through tricalcium phosphate

The invention belongs to the field of ceramic industry, and discloses a method for manufacturing high-tenacity ceramics through tricalcium phosphate. The method comprises the following steps that, by weight, 5%-15% of the tricalcium phosphate and 85-95% of ceramic blanks are evenly smashed, mixed, milled in the mode of wet ball milling, dried and ground into powder, green ceramic bodies are manufactured through dry pressing molding and the green ceramic bodies are sintered in a kiln to form the high-tenacity ceramics. According to the high-tenacity ceramic samples manufactured through the method, needle-shaped mullite and anorthite serve as the main crystalline phase, cristobalite serves as the auxiliary crystalline phase, and a Si-O system and P-O system composite glass phase serves as the binding phase. Through the structure, thermal expansion coefficients between the crystalline phases and between the crystalline phases and the glass phase are better matched, micro-cracks can be effectively reduced in the ceramic sintering process, and the tenacity of ceramic products is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

Hydroxyethyl cellulose/soybean protein composite sponge with water sensitive shape memory function and preparing method of composite sponge

The invention discloses a hydroxyethyl cellulose / soybean protein composite sponge with a water sensitive shape memory function and a preparing method of the composite sponge. The preparing method comprises the steps of firstly dissolving hydroxyethyl cellulose and soybean protein into deionized water and a weak NaOH solution respectively, and then preparing the composite sponge through freezing and a vacuum drying method. By changing the proportion of hydroxyethyl cellulose and soybean protein or conducting cross-linking modification on epichlorohydrin or ethylene glycol diglycidyl ether, composite sponge materials with different microstructures and properties can be obtained. The hydroxyethyl cellulose / soybean protein composite sponge has water sensitive type memory function, and the shape and structure before compression can be restored. A cell culture experiments in vitro and a blood compatibility experiment show that the composite material has good compatibility to cell, blood and tissue. The method is simple and practical, raw materials are wide in source, and a natural macromolecule biological medical material with an application prospect can be expected to be shaped.

Owner:WUHAN UNIV

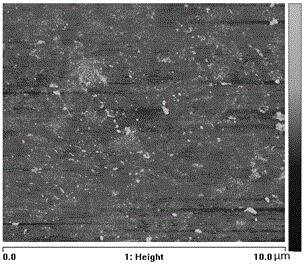

Technique for treating fermentation wastewater by microbial fuel cell

InactiveCN105140549AChange surface chargeChange hydrophilicityFinal product manufactureBiochemical fuel cellsSodium acetateChemical oxygen demand

The invention discloses a technique for treating fermentation wastewater by a microbial fuel cell, and relates to a technique for treating wastewater. The method comprises the steps as follows: with conductive glass, carbon cloth or a carbon felt as electrode materials, active groups, polyelectrolyte multilayer films or nanoparticles / polyelectrolyte multilayer films are respectively modified on the electrode materials by an alkaline hydrolysis method, an acid hydrolysis method and a layer-by-layer self-assembly technique; the series materials are applied to an anode of a microbial fuel cell reaction device to treat the fermentation wastewater; with sodium acetate and lotus pond sludge as substrates, a microbial fuel cell system with a relatively high electricity generating rate, relatively good chemical oxygen demand (COD) removal effects and relatively high coulombic efficiency is obtained. The microbial fuel cell system is good in process repeatability, safe and reliable; the fermentation wastewater is treated; meanwhile, a relatively high electricity generating quantity and a relatively high electricity generating rate are achieved; the problems that the traditional microbial fuel cell is low in electricity generating efficiency and low in sewage COD removal rate are effectively solved; and the technique has a good industrial application prospect.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Treating process of light saline-alkali grassland

InactiveCN101020187AWell mixedCultivation consistentContaminated soil reclamationHorticultureGranularityGrassland

The treating process of lightly salinized grassland includes tilling the soil in the depth of 8-10 cm, crushing weathered coal with humic acid content greater than 35 % and preparing ecological preparation of granularity of 0.1-5 mm, applying the ecological preparation in 30-50 kg / mou, seeding grass in the seed amount of 1.5-3 kg / mou and soil covering depth of 2-5 cm and pressing for 1-3 times. The present invention can improve salinized grassland completely and has the advantages of low cost, high efficiency and high adaptability.

Owner:倪红伟

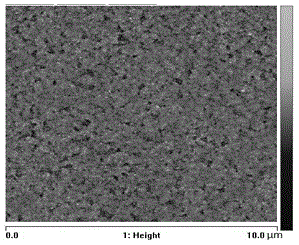

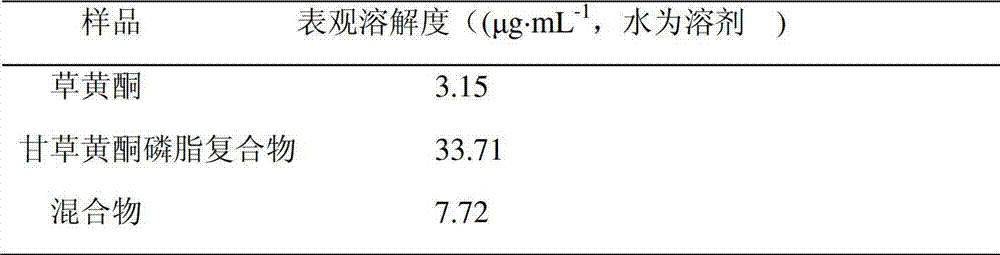

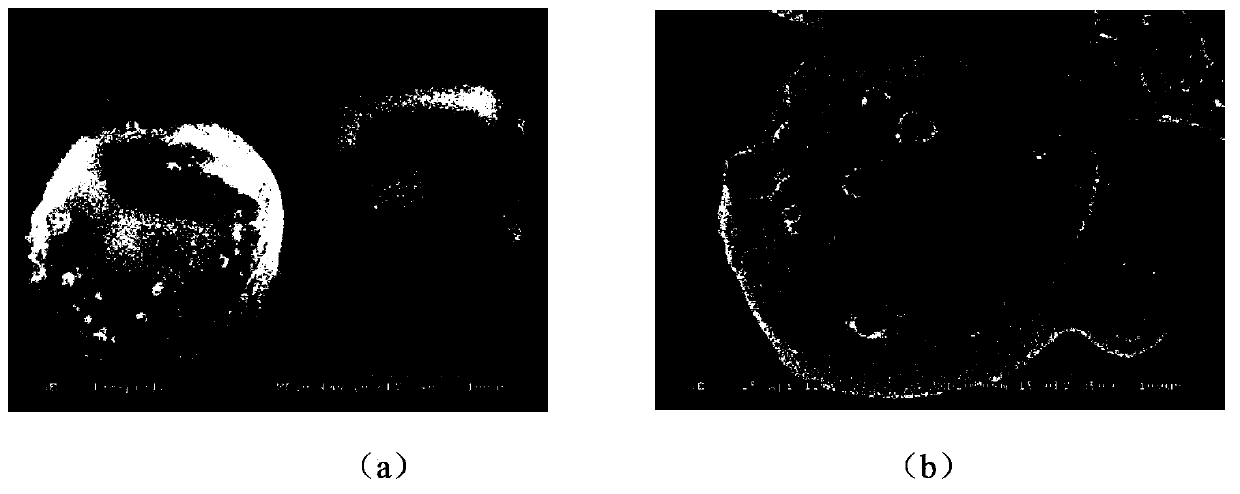

Licoflavone phospholipid complex and preparation method and application thereof

InactiveCN102949440ASimple preparation processGood reproducibilityAntiviralsAntineoplastic agentsOrganic solventFreeze-drying

The invention relates to a preparation method of a complex, in particular to a licoflavone phospholipid complex and a preparation method and the application of the licoflavone phospholipid complex; the licoflavone phospholipid complex comprises licoflavone and phospholipid by mass ratio of 1: 0.1-10; and the method comprises the steps of: according to the proportion, adding the licoflavone and the phospholipid into organic solvent, controlling the temperature to be within the range of 10-90 DEG C and carrying out reaction for 20min-8h until the reaction liquid is clear; carrying out pressure reduction or freeze drying to remove the organic solvent; after that, adding inert solvent to separate free drug which is not compounded; and removing the inert solvent and drying to obtain the licoflavone phospholipid complex. The invention is simple in preparation technology and good in reproducibility, and can improves the physicochemical properties including hydrophilic property and oleophylic property of the licoflavone by embedding the licoflavone by the phospholipid, so that the dissolving property of the licoflavone can be improved, the bioavailability of the licoflavone is increased, the problem that the licoflavone is not easily absorbed can be solved, the oxidation resistance of the licoflavone in different environments can be maintained or enhanced.

Owner:NINGXIA MEDICAL UNIV

Method and application for carrying out fly ash floating bead surface modification by using compound coupling agent

InactiveCN102850825BEfficient removalOvercome the defect of poor modification effectFireproof paintsPigment treatment with organosilicon compoundsDispersityMechanical property

The invention relates to a fly ash floating bead surface modification technology, and specifically relates to a method for carrying out fly ash floating bead surface modification by using a compound silicane coupling agent. First, fly ash is subjected to sintering and acid-alkali pretreatments; and the pretreated fly ash is subjected to a surface modification treatment by using the compound coupling agent. When fly ash is processed through surface modification with the method provided by the invention, physical and chemical properties of obtained surface-modified fly ash floating beads are changed, dispersity of the beads in resin and organic polymers is improved, and compatibility of a filling material with interfaces of substrates such as resin is improved. Further, mechanical properties and other performances of high-molecular materials such as plastic, paint, and rubber are improved. Therefore, an improvement method is provided for better utilization of fly ash, and environment pollution is reduced.

Owner:ANHUI UNIV OF SCI & TECH

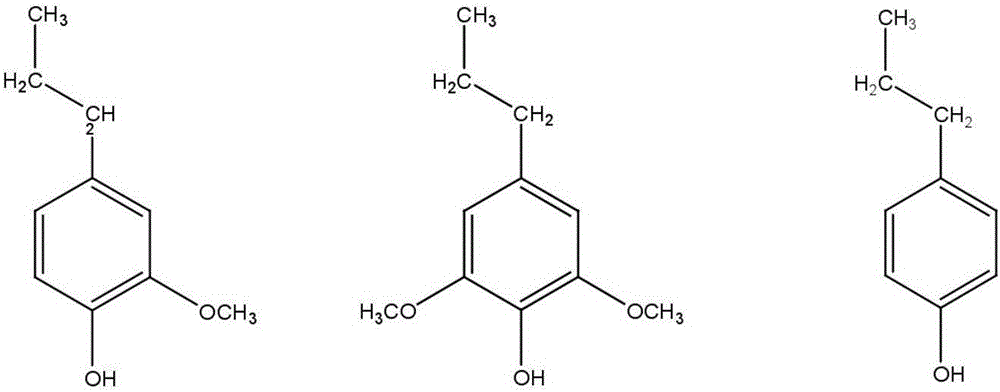

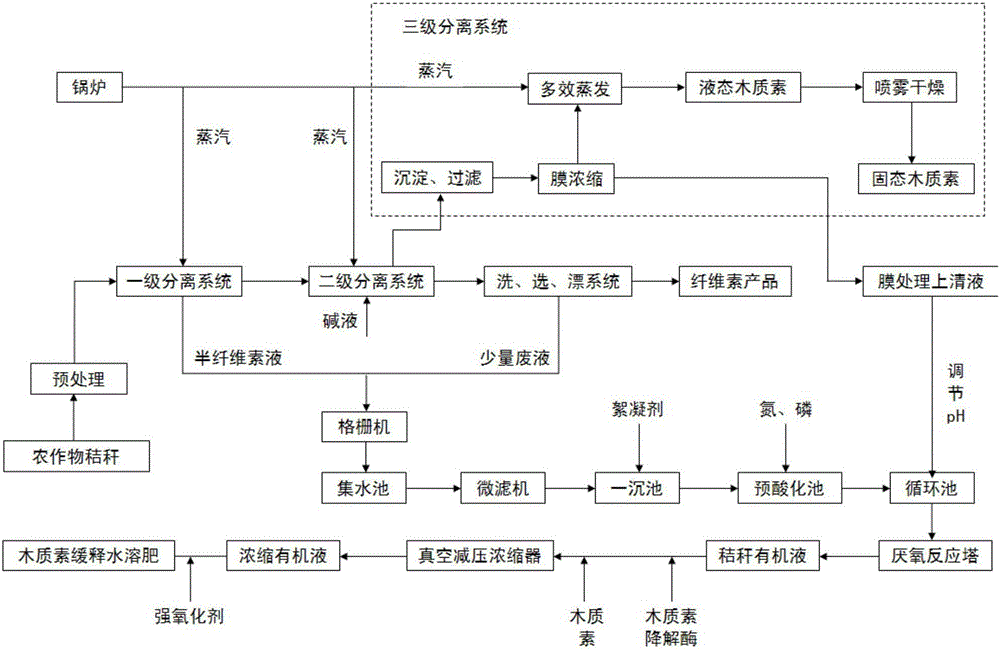

Lignin slow-release water-soluble fertilizer and preparation method thereof

InactiveCN106495847AHigh organic contentRaise quality standardsSewage/sludge fertilisersOrganic fertiliser preparationWater solubleEnzyme

The invention belongs to the technical field of fertilizers, and in particular relates to a lignin slow-release water-soluble fertilizer and a preparation method thereof. The lignin slow-release water-soluble fertilizer is prepared by adding a strong activating agent into an organic straw liquid, lignin, lignin-degrading enzyme; when the lignin is solid lignin, the weight parts of the organic straw liquid, the solid lignin and the lignin-degrading enzyme are 60-90 parts of the organic straw liquid, 10-40 parts of the solid lignin and 1-3 parts of the lignin-degrading enzyme; when the lignin is liquid lignin, the weight parts are 10-30 parts of the organic straw liquid, 70-100 parts of the liquid lignin and 1-3 parts of the lignin-degrading enzyme. The lignin slow-release water-soluble fertilizer provided by the invention has a slow-release function and water-soluble fertilizer properties as well, environmental pollution caused by comprehensive utilization of biomass raw materials is reduced, problems that a conventional slow-release water-soluble fertilizer is high in production cost, incomplete in nutrient component, relatively poor in fertility and the like can be solved, and modern organic planting of integral water and fertilizers can be achieved.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

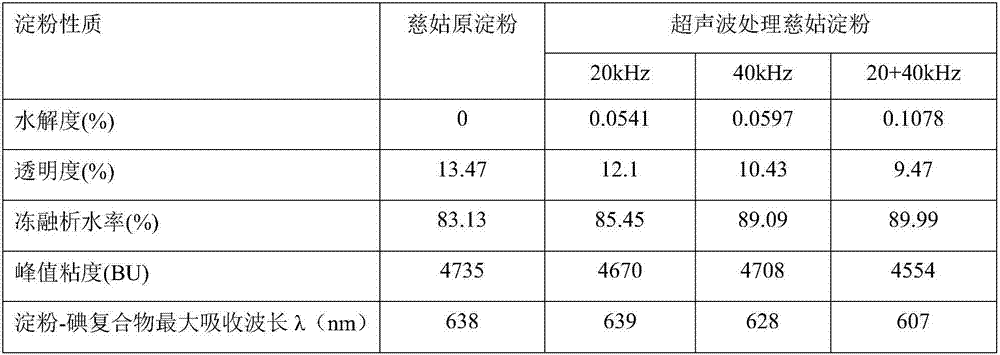

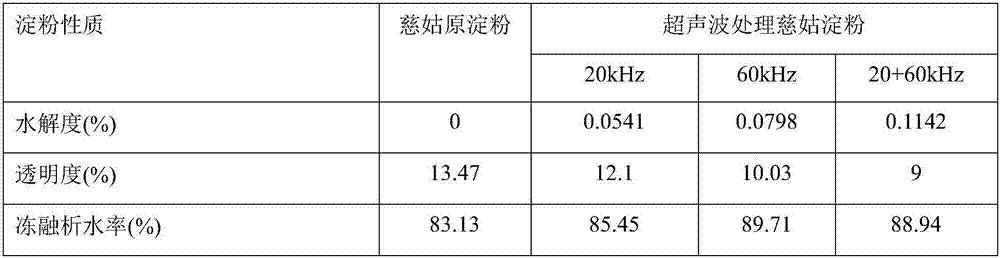

Double-frequency ultrasonic modification method of arrowhead starch

InactiveCN107337740AExpand the scope of applicationSimple processFood scienceChemistryDual frequency ultrasound

The invention discloses a double-frequency ultrasonic modification method of arrowhead starch, and belongs to the technical field of processing of agricultural products. A finished product is prepared from arrowhead starch through preparation, double-frequency ultrasonic modification treatment, drying and crushing. The structure and the physicochemical characteristics of the arrowhead starch undergoing the double-frequency ultrasonic modification treatment are greatly changed, so the application range of the arrowhead starch is greatly enlarged. Compared with traditional starch modification methods, the modification method disclosed in the invention has the advantages of short time, small energy consumption, convenience in operation, safety, no pollution, and easiness in industrial production.

Owner:JIANGSU UNIV

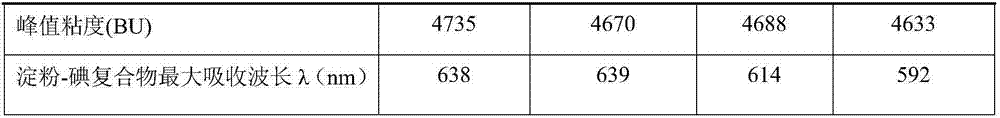

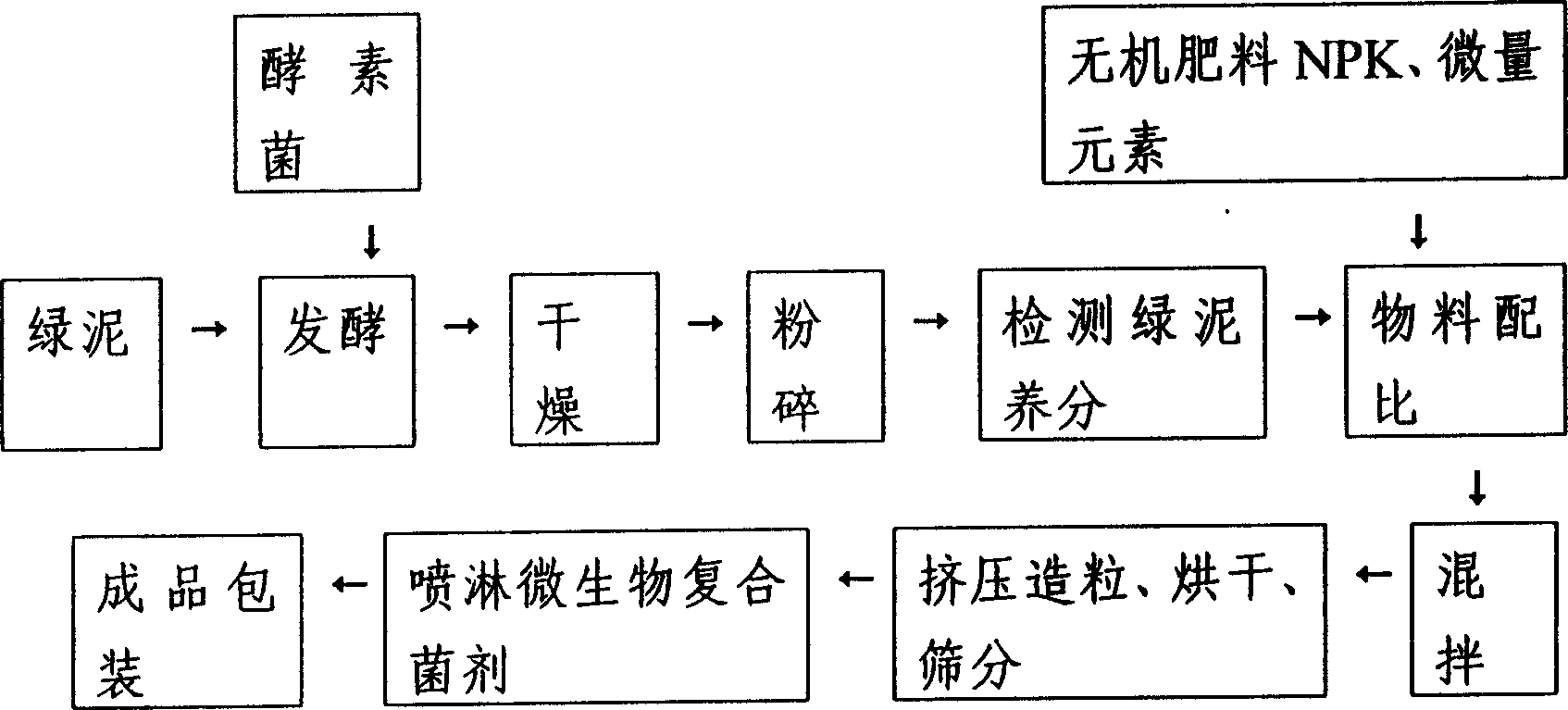

Green mud organic biological compound fertilizer and its preparation method

InactiveCN1521147ALow costSolve pollutionFertiliser formsOrganic fertilisersSoil organic matterTrace element

The present invention relates to fertilizer, and is especially one kind of biological organic composite green mud fertilizer and its preparation process. The green mud fertilizer consists of microbial fermented green mud 40-75 wt%, inorganic azophoska 20-55 wt%, trace elements 1-5 wt% and microbial preparation 0.1-0.5 wt%. The present invention has the following advantages: low cost, balanced nutrients, long fertilizing effect, obvious yield increasing effect, wide application range, capacity of raising organic matter content improvement of soil physical and chemical characters, raising water and fertilizer maintaining ability of soil, raising the quality of agricultural product and reducing pollution.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com