Method and application for carrying out fly ash floating bead surface modification by using compound coupling agent

A technology of fly ash floating beads and surface modification, which is applied in chemical instruments and methods, fibrous fillers, coatings, etc., to achieve the effects of good effect, improved dispersibility, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

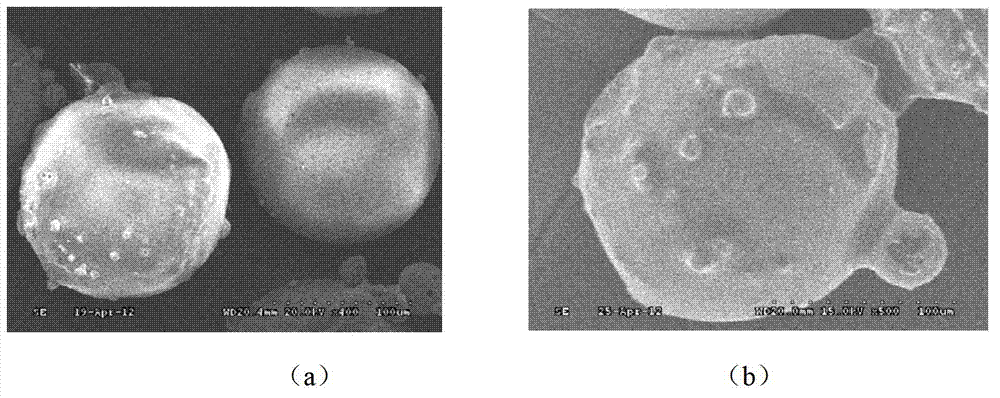

[0039] Surface treatment of fly ash floating beads produced by Huainan Pingwei Power Plant, wherein the particle size of fly ash floating beads is ≤140 mesh, and the main components include SiO 2 、Al2 o 3 , Fe 2 o 3 , CaO, etc., porosity 60-75%, specific surface area 0.3-0.45m 2 g -1 , loose dry density 600~1000kg / m 3 , compaction density 1300~1600 kg / m 3 , the specific operation is as follows:

[0040] 1. Pretreatment of fly ash

[0041] Since the raw powder of fly ash contains impurities such as unburned carbon, it must be pretreated before use. The treatment methods adopted in the present invention are sintering and acid-base treatment. The present invention has carried out twice processing to fly ash successively, and its processing step is as follows:

[0042] a. Take a certain amount of fly ash floating beads and sinter at 350-450°C for 48 hours to remove unburned carbon and other impurities;

[0043] b. Place the sintered fly ash in dilute acid and dilute alka...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com