Patents

Literature

4452results about "Pigment treatment with non-polymer organic compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

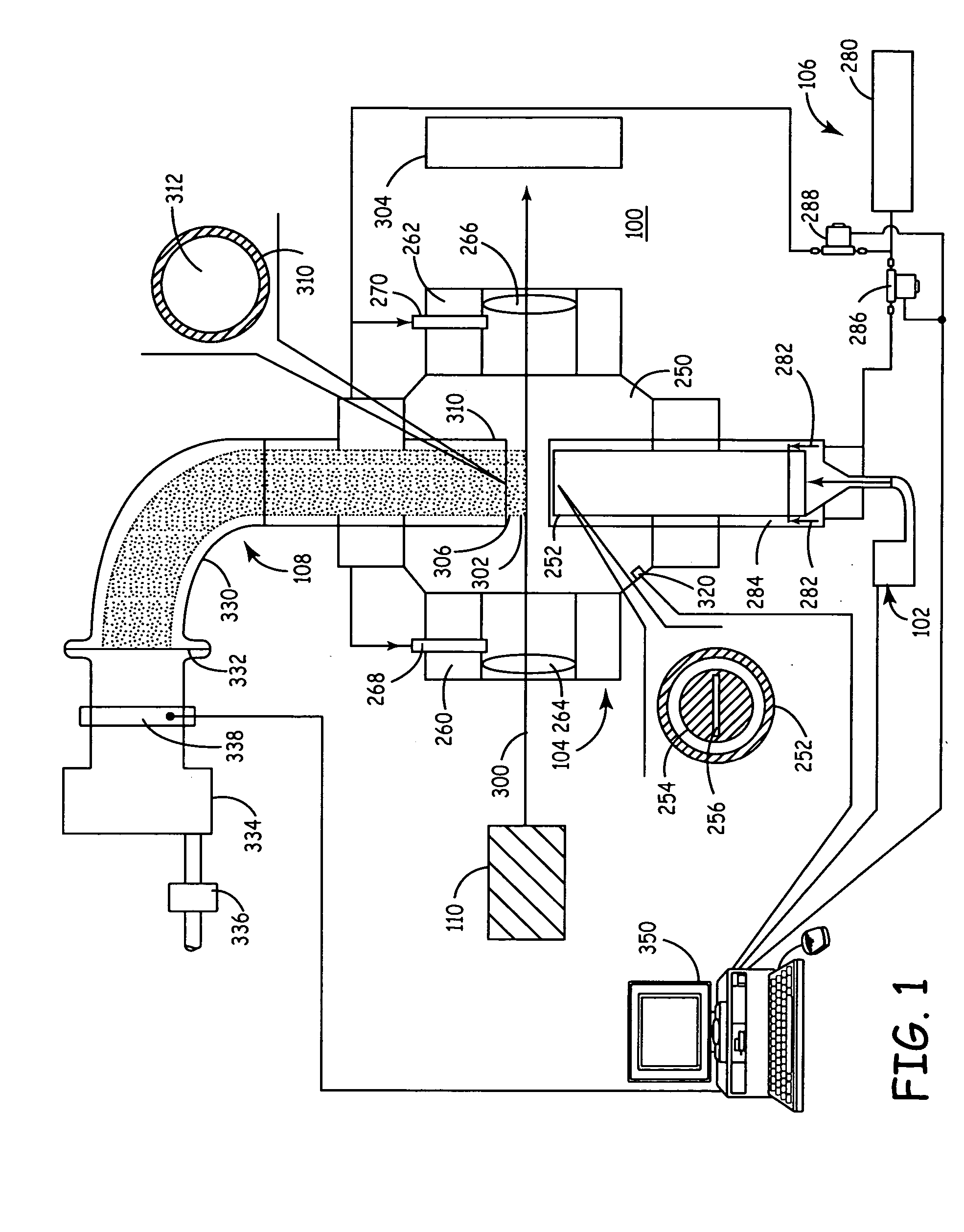

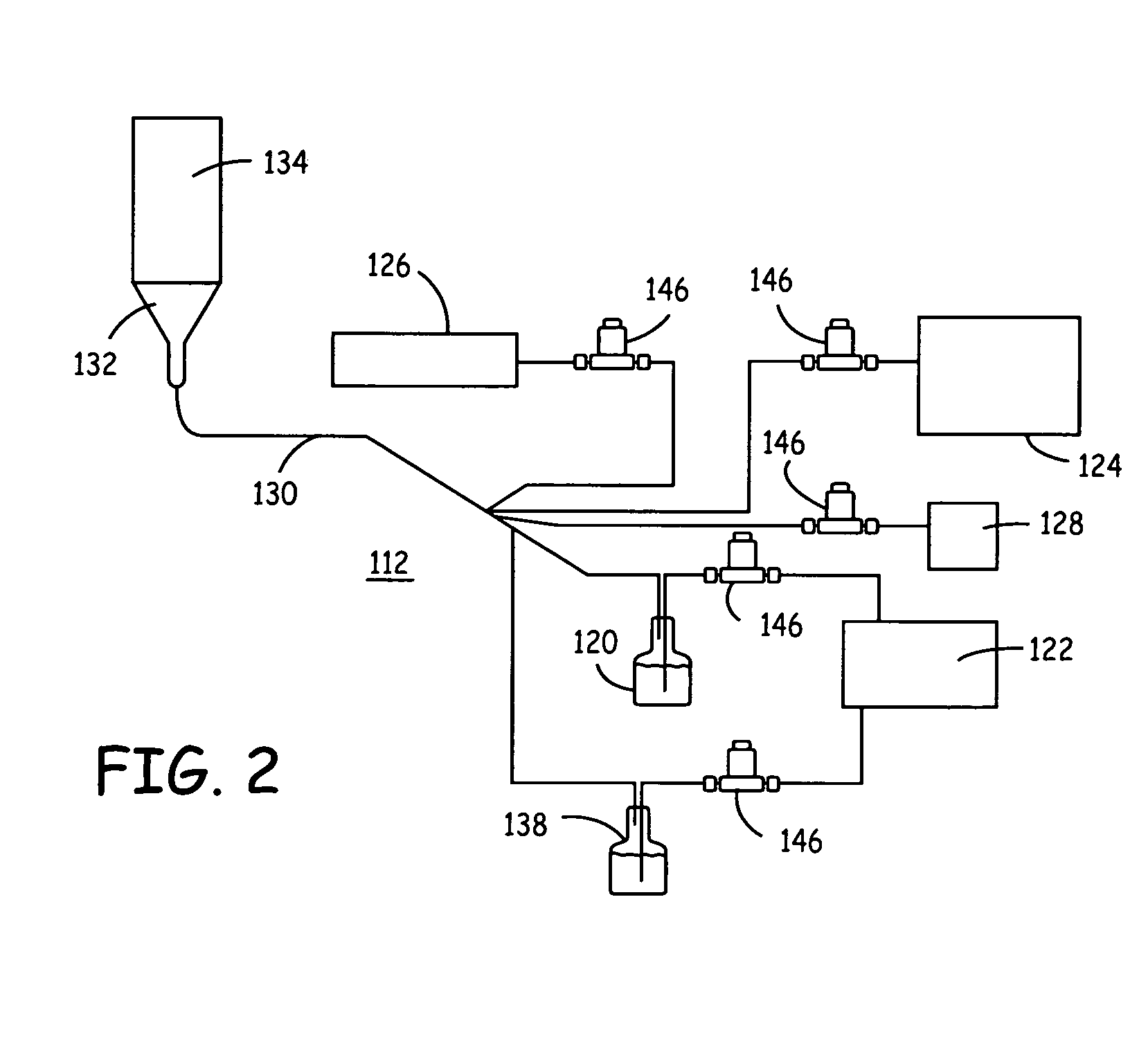

Sand aggregating reagents, modified sands, and methods for making and using same

ActiveUS7350579B2Improve propertiesImprove adhesionLiquid/gas jet drillingFluid removalMaterials scienceReagent

Owner:THE LUBRIZOL CORP

Carbon-containing material

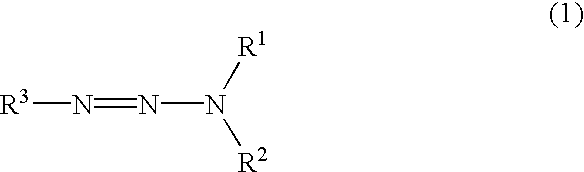

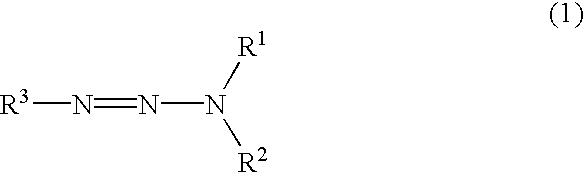

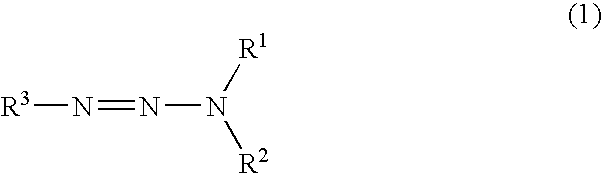

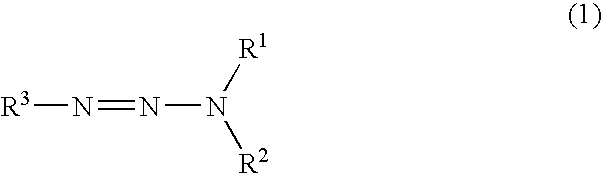

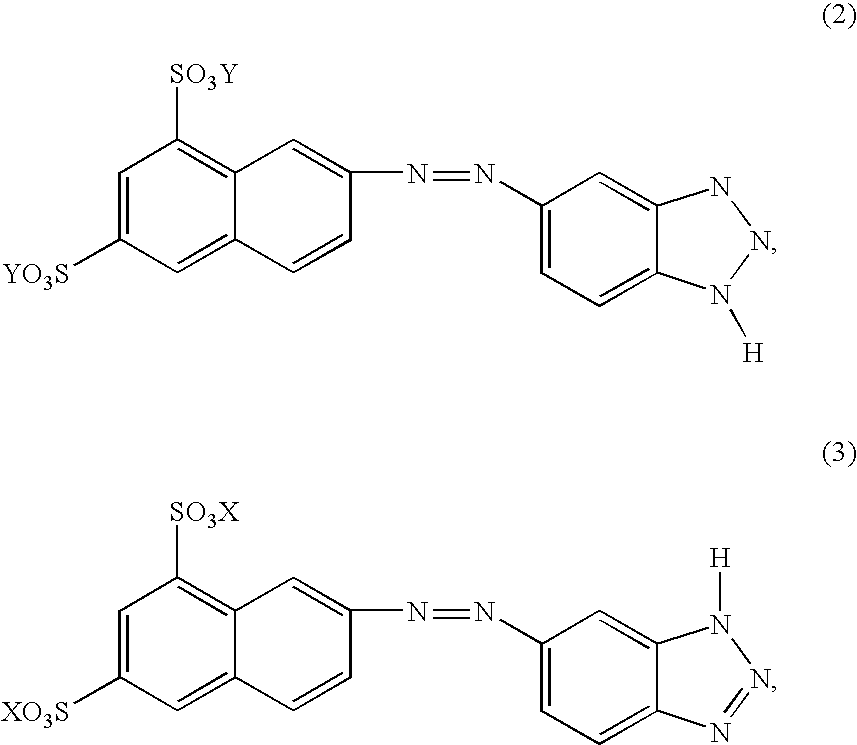

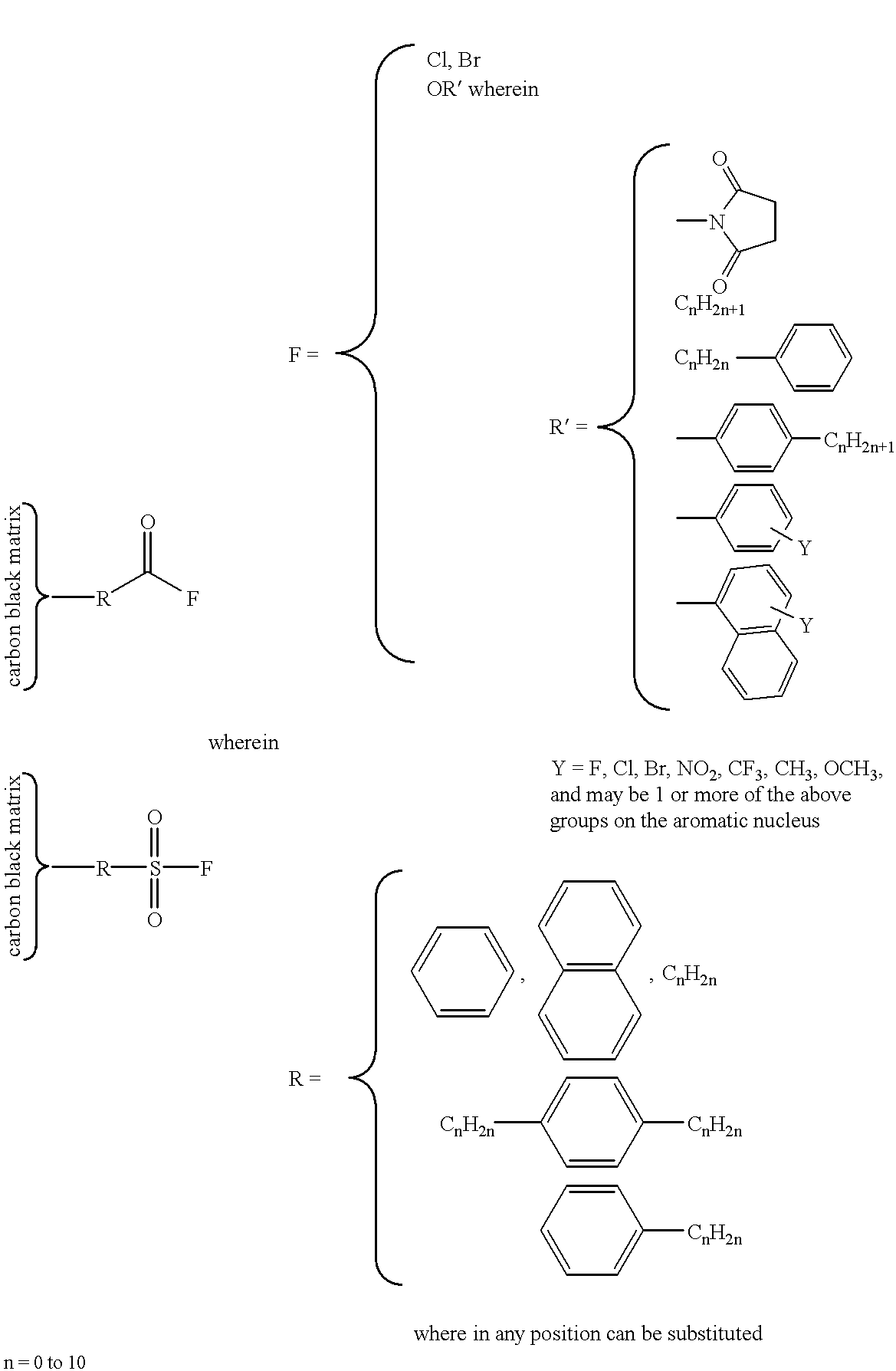

A carbon-containing material with organic groups, which is obtainable by reaction of the carbon-containing material with organic compounds of the general formula 1 A process for preparing the carbon-containing material according to the invention is also described. The carbon-containing materials according to the invention can be used as fillers, reinforcing fillers, UV stabilisers, conductivity carbon blacks or pigments.

Owner:UBS AG

Nanotechnology for drug delivery, contrast agents and biomedical implants

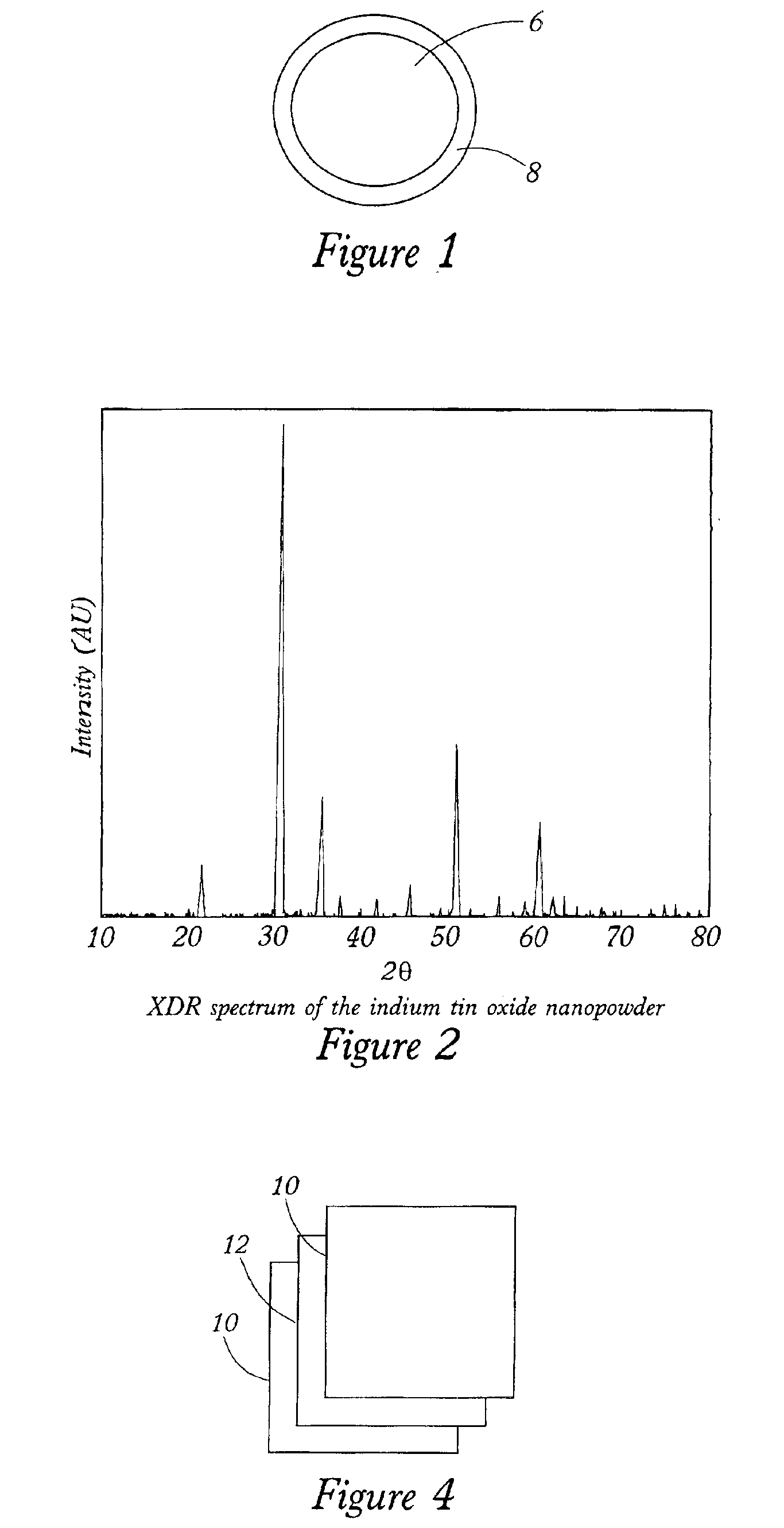

A nanocomposite structure comprising a nanostructured filler or carrier intimately mixed with a matrix, and methods of making such a structure. The nanostructured filler has a domain size sufficiently small to alter an electrical, magnetic, optical, electrochemical, chemical, thermal, biomedical, or tribological property of either filler or composite by at least 20%.

Owner:PPG IND OHIO INC

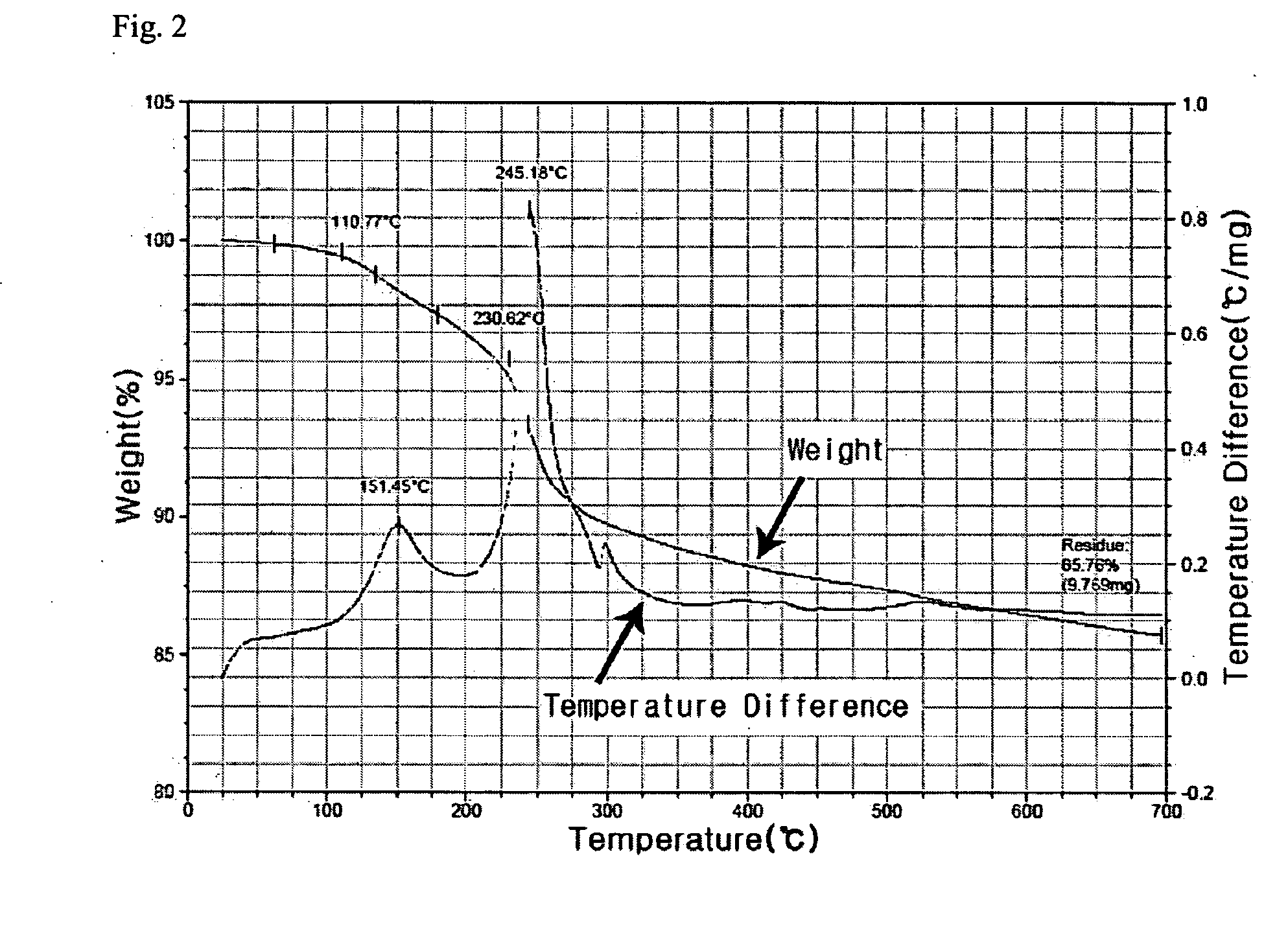

Conductive sintered layer forming composition and conductive coating film forming method and bonding method using the same

InactiveUS20080160183A1Low heating temperatureShorten heating timeSemiconductor/solid-state device detailsConductive materialHeating timeConductive coating

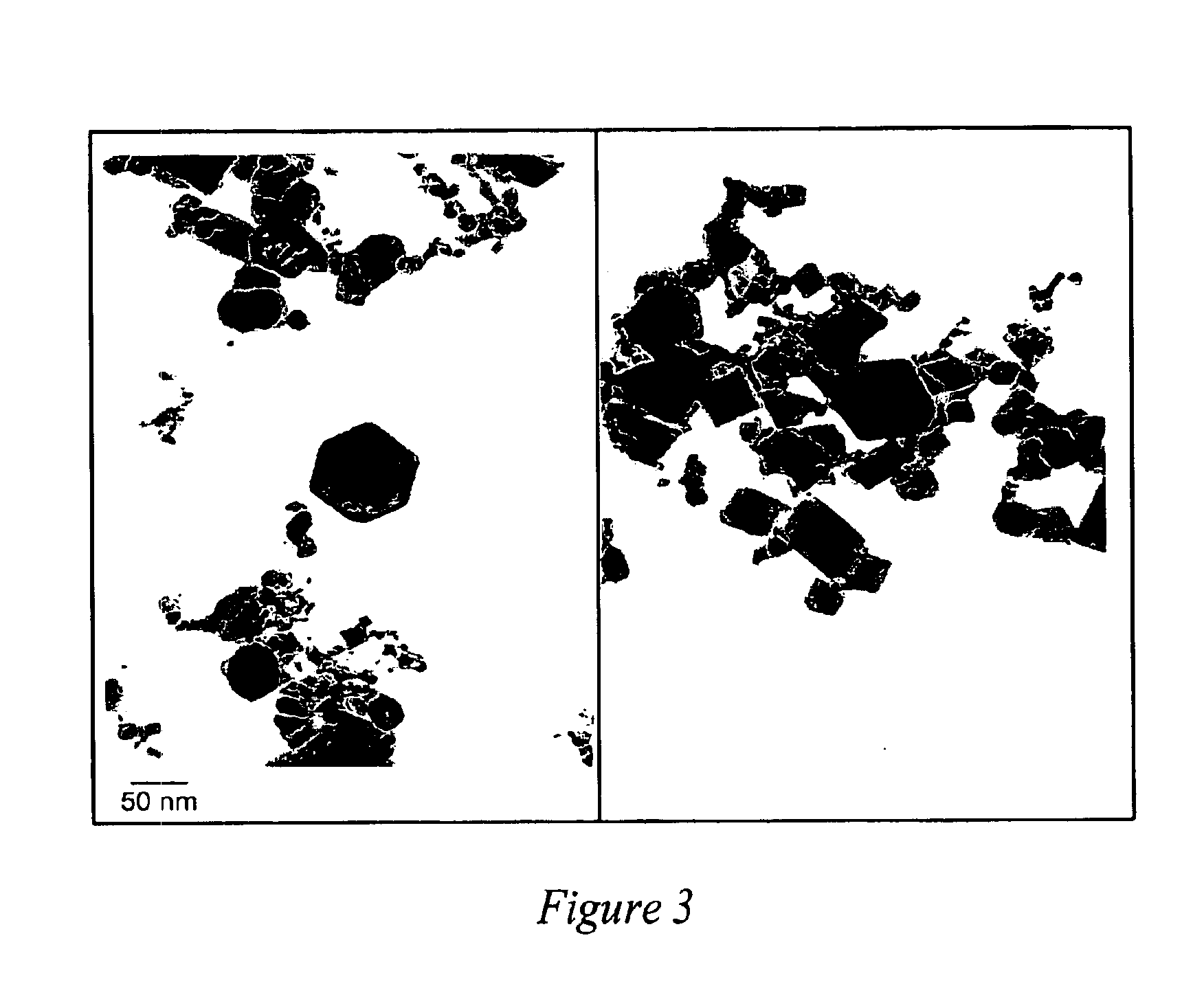

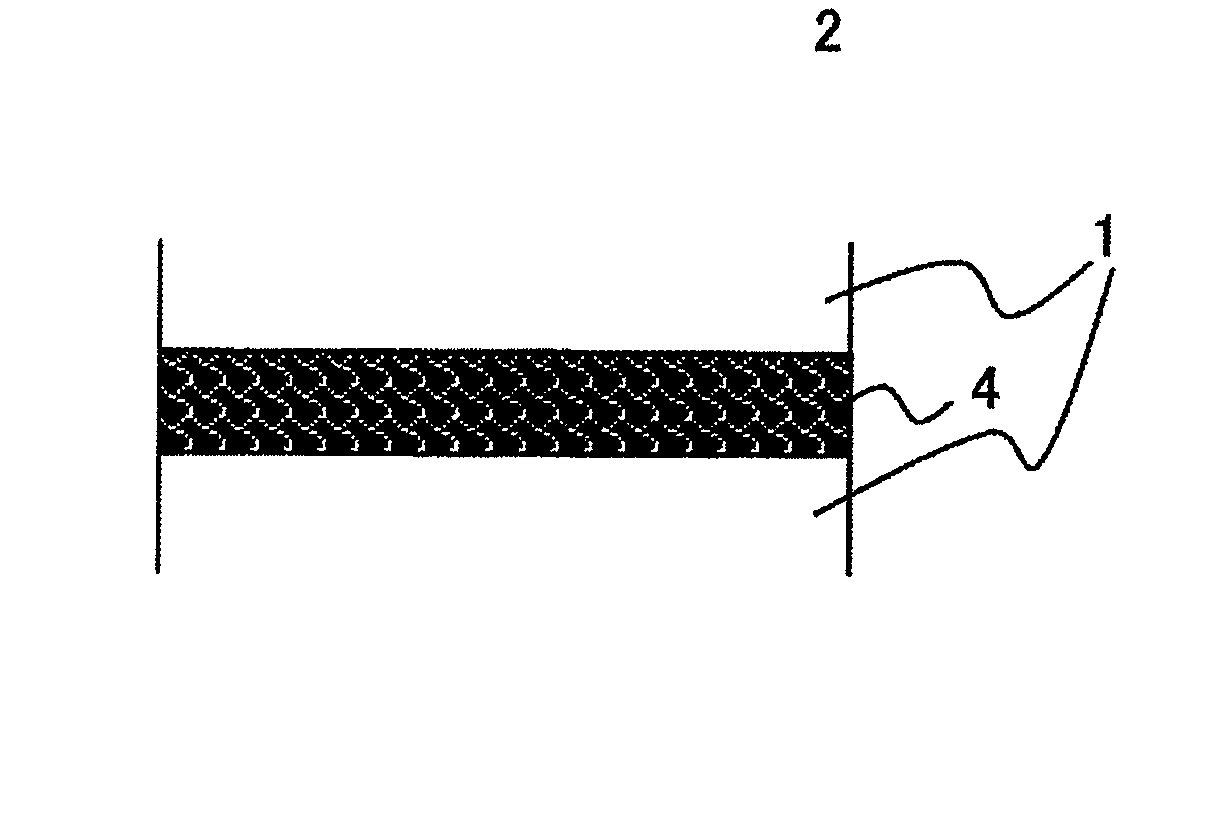

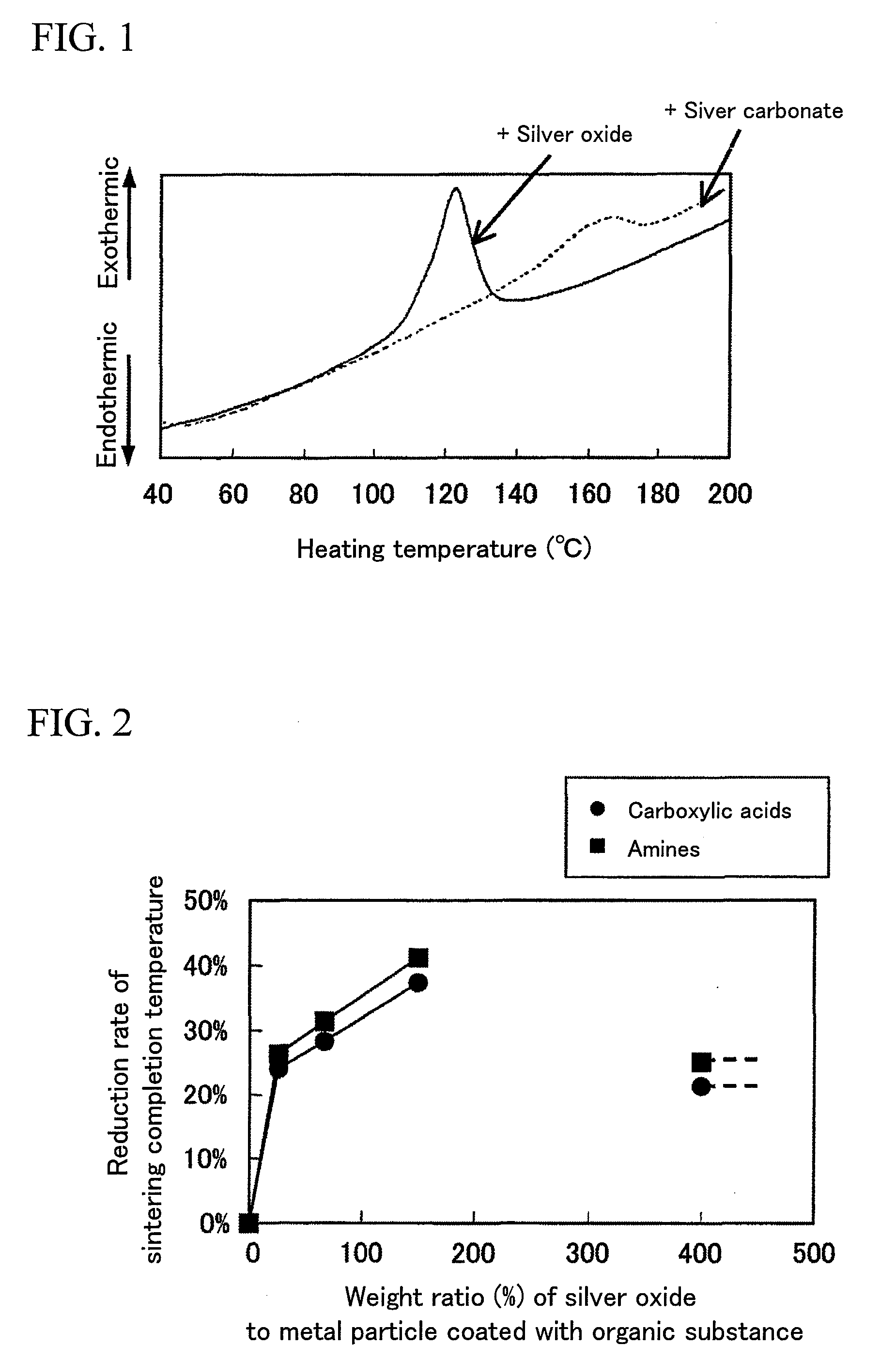

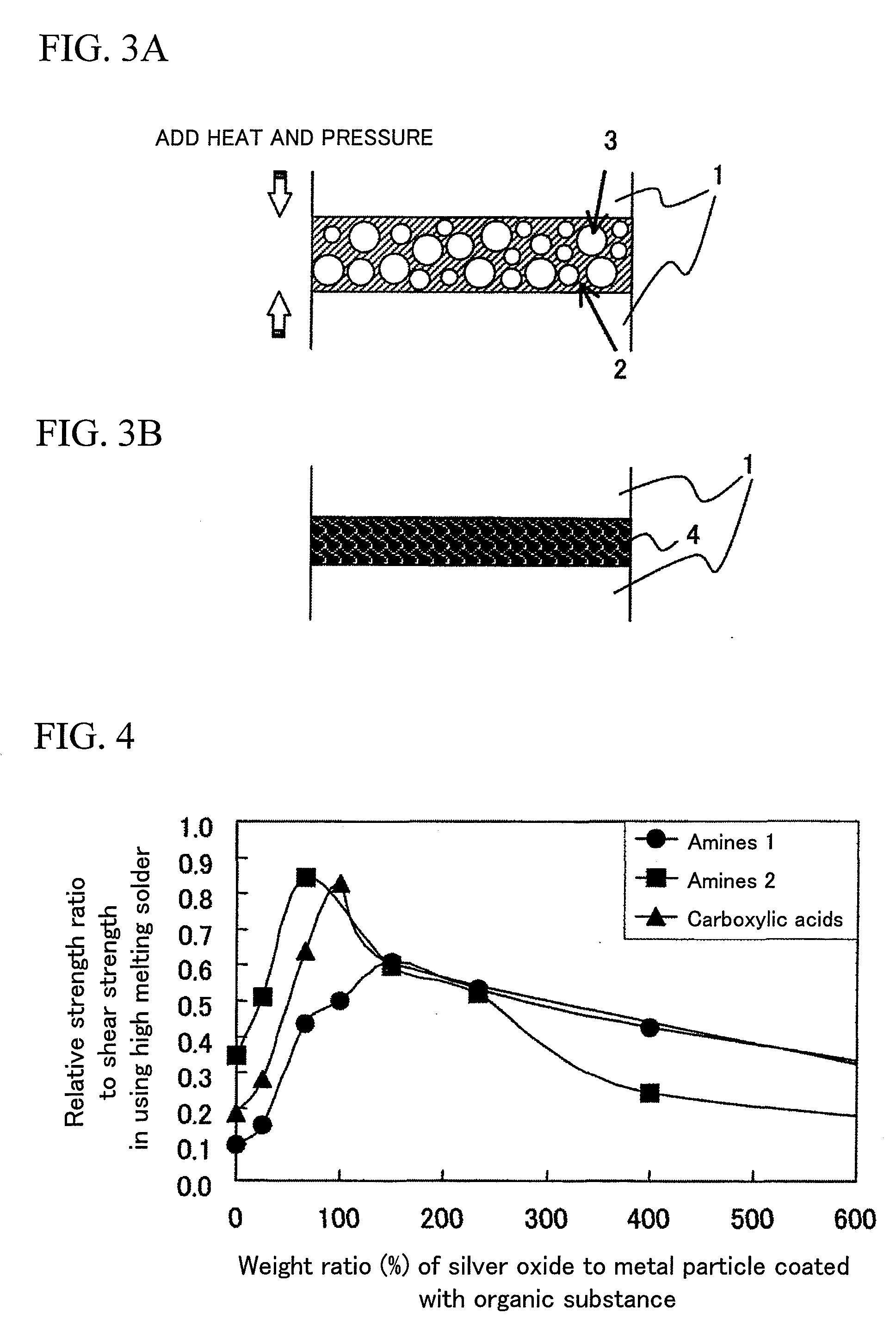

There is provided a conductive sintered layer forming composition and a conductive sintered layer forming method that can lower heating temperature and shorten heating time for a process of accelerating sintering or bonding by sintering of metal nano-particles coated with an organic substance. The conductive sintered layer forming composition may be obtained by utilizing a phenomenon that particles may be sintered at low temperature by mixing silver oxide with metal particles coated with the organic substance and having a grain size of 1 nm to 5 μm as compared to sintering each simple substance. The conductive sintered layer forming composition of the invention is characterized in that it contains the metal particles whose surface is coated with the organic substance and whose grain size is 1 nm to 5 μm and the silver oxide particles.

Owner:HITACHI LTD

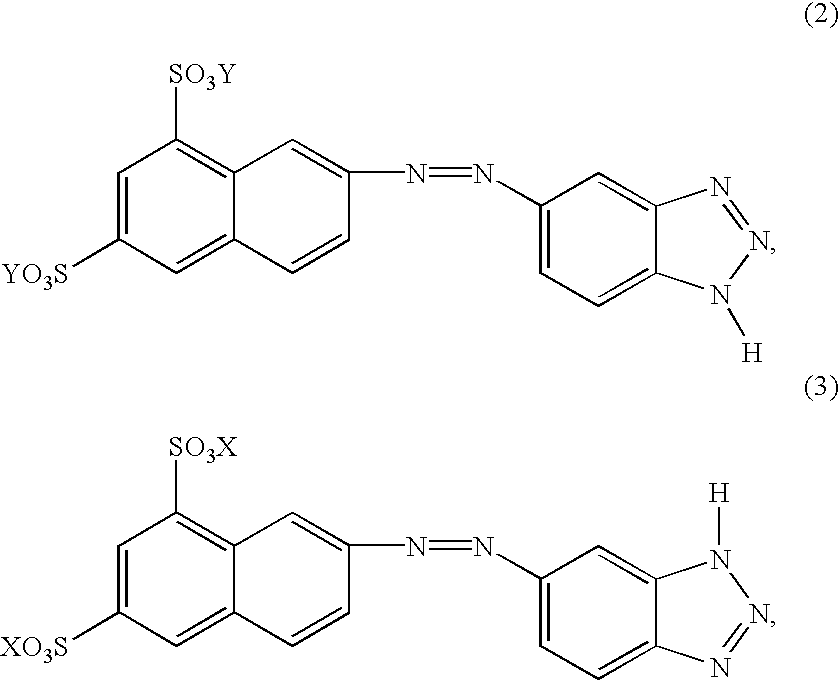

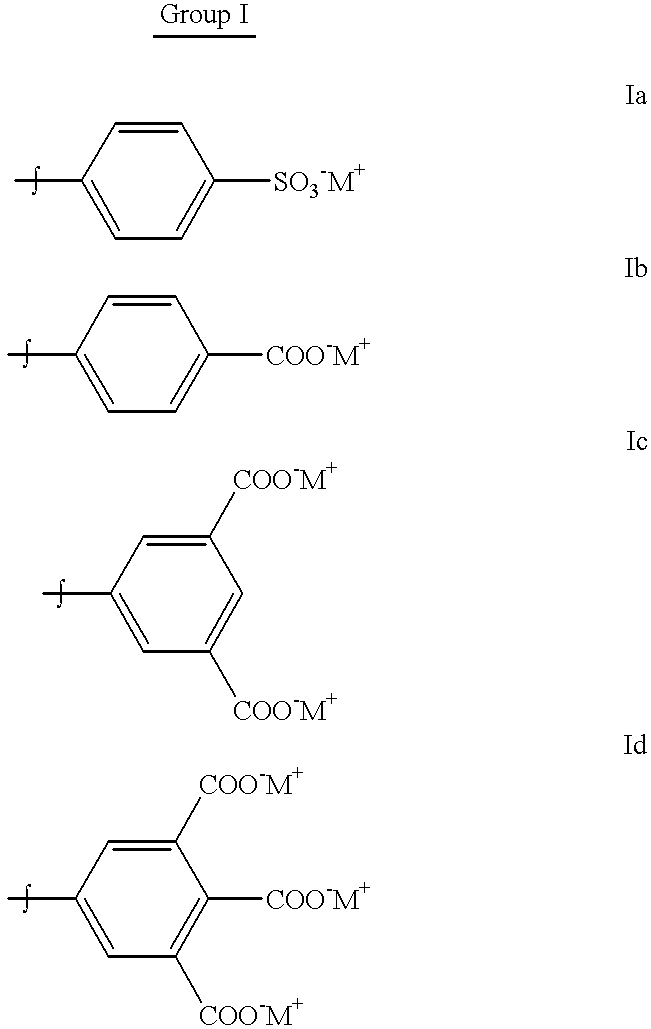

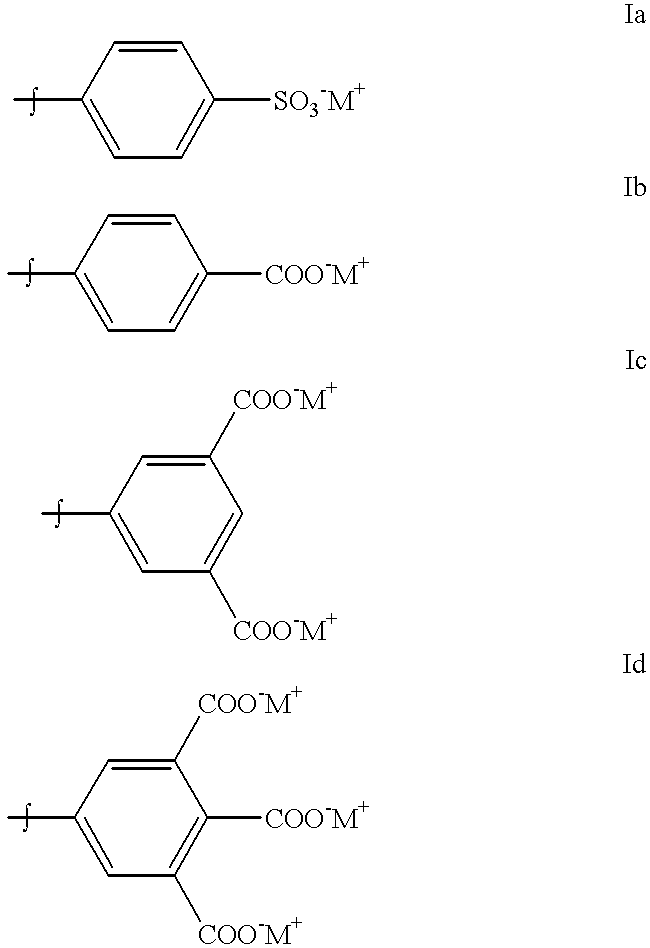

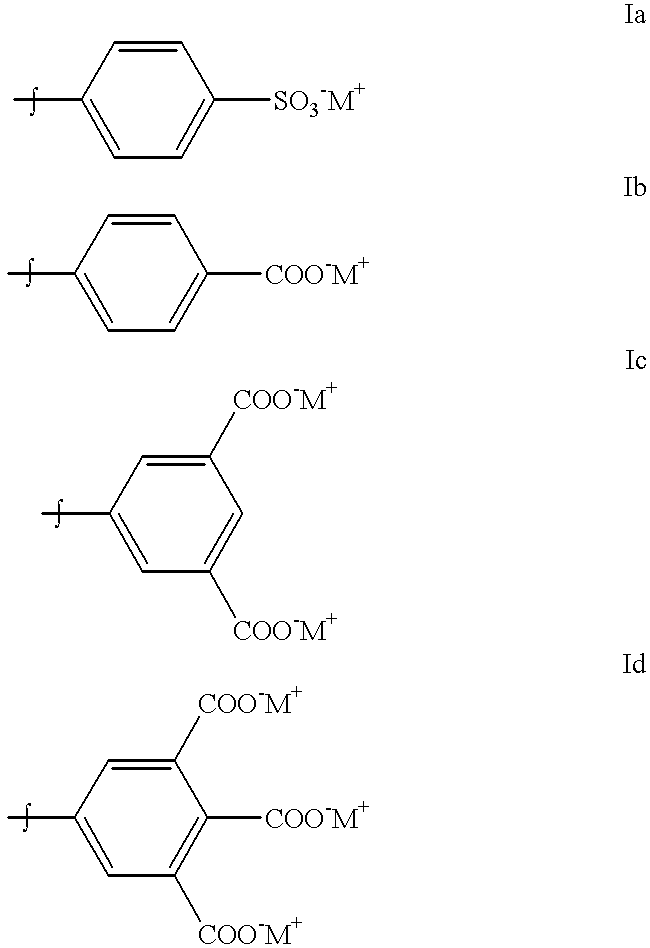

Superior waterfastness and bleed control with specifically treated pigments for ink-jet printing

InactiveUS6221142B1Improve printing effectGood colorMaterial nanotechnologyDuplicating/marking methodsWater insolubleWater soluble

The ink of the invention comprises a vehicle and a colorant. The colorant is a water-insoluble pigment that has been chemically modified to be water dispersable by addition of functional groups to the surface of the pigment resulting in water soluble colorant particles. The performance of these pigments is improved by the addition of specific functional groups which provide improved black to color bleed control and high waterfastness.

Owner:HEWLETT PACKARD DEV CO LP

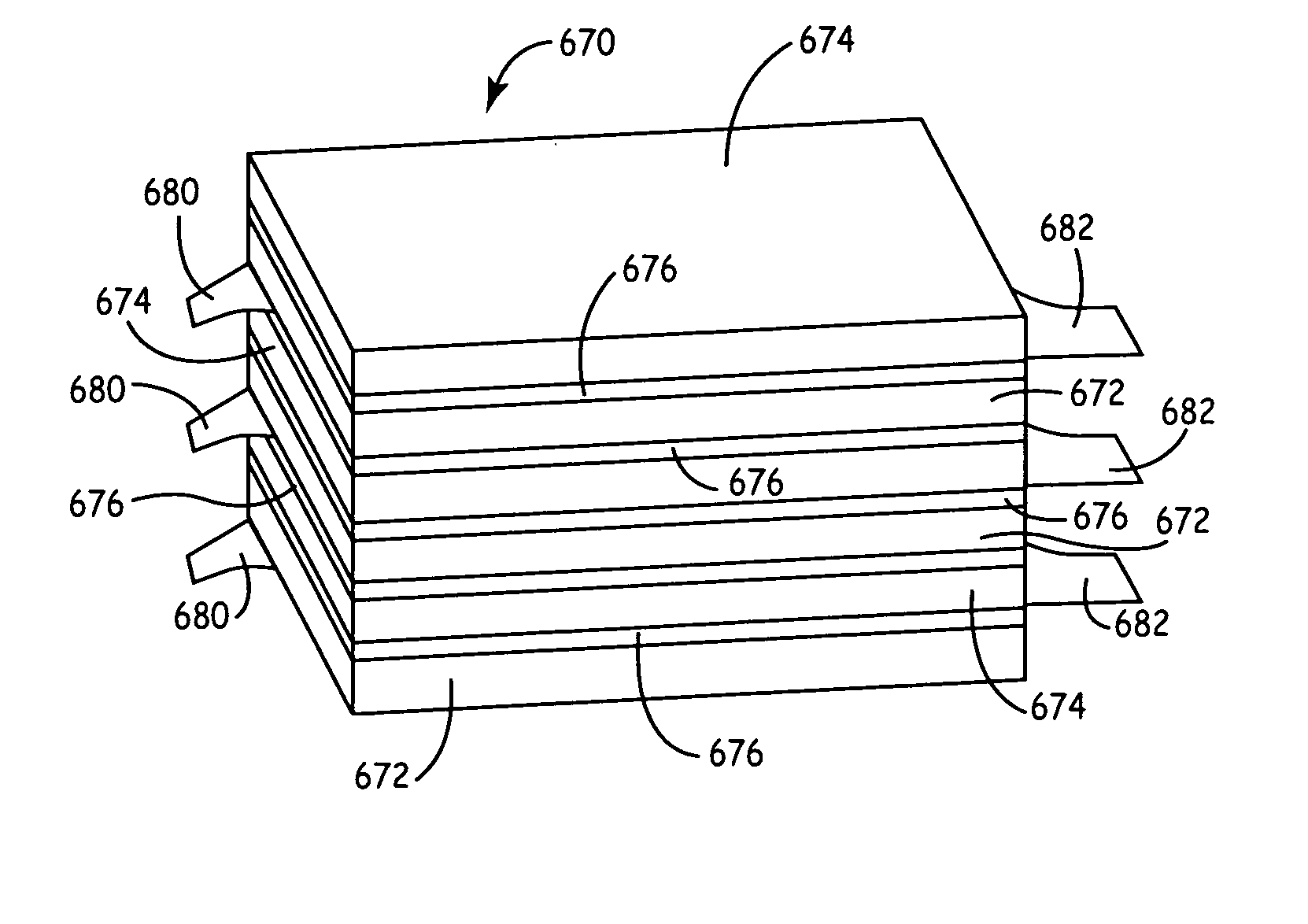

Medium rate and high rate batteries

Improved submicron carbon fluoride has increased graphite content and can also have improved uniformity. The increased graphite content and / or uniformity can result in improved battery performance, for example with respect to specific capacity. Desirable battery structures provide for use with implantable medical devices. Suitable batteries can be used for high rate, medium rate, low rate or a combination of rate applications.

Owner:GREATBATCH TECH ADVANCED RES LAB

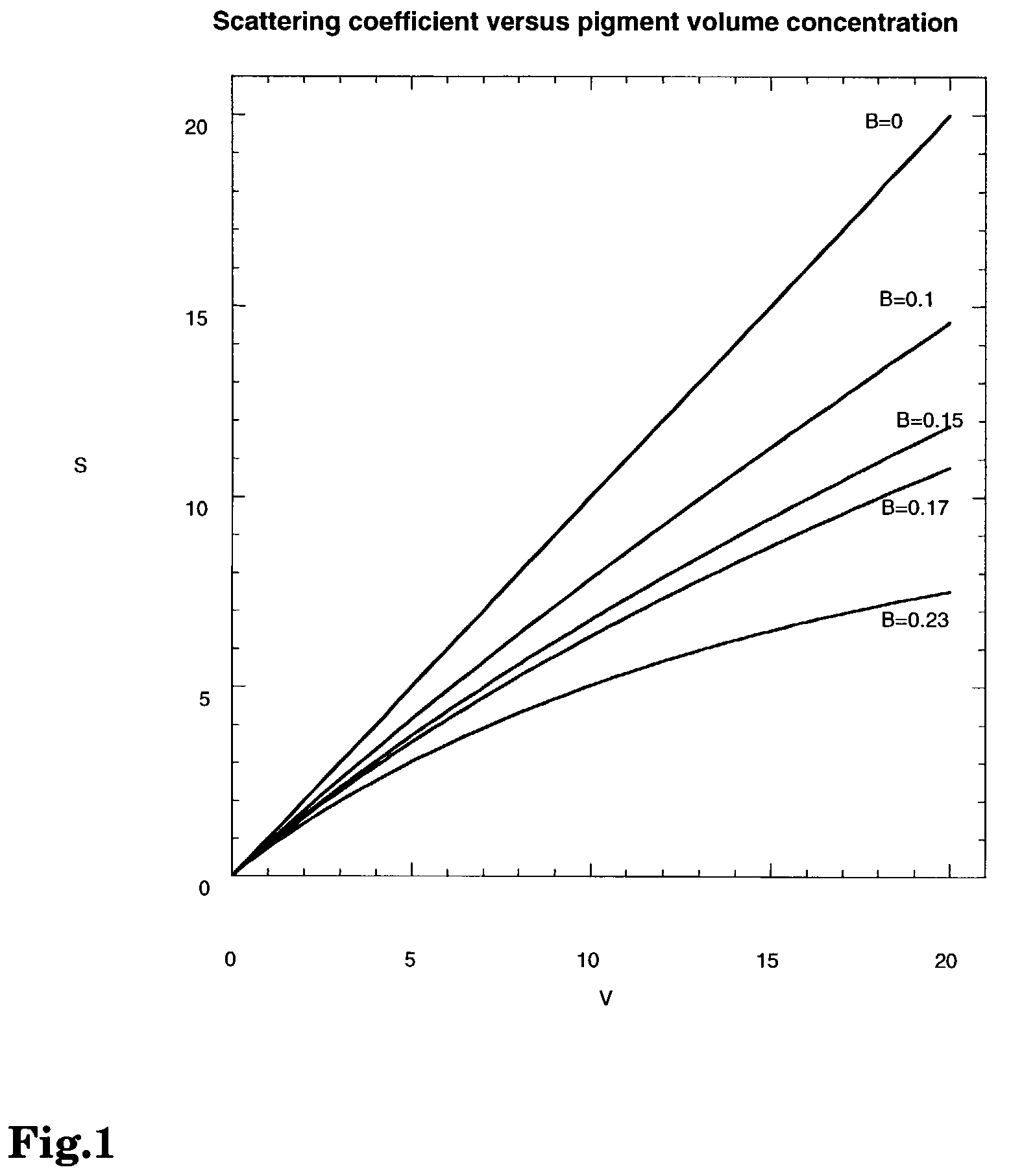

Coating with improved hiding, compositions prepared therewith, and processes for the preparation thereof

InactiveUS7081488B2Low levelIncreased hiding levelMaterial nanotechnologyConductive materialLinear relationshipVolume concentration

A coating containing pigment particles and a polymer matrix is provided. The coating contains pigment particles that have a scattering coefficient with a linear or quasi-linear relationship to the pigment volume concentration of those pigment particles. The coating has improved hiding and is useful as a protective coating or an aesthetic coating on an underlying substrate. Also provided are compositions useful for preparing the coating, including covalently bonded composite particles and aqueous dispersions containing composite particles. The composite particles each contain a pigment particle with a plurality of polymer particles attached by adsorption on the outer surface of the pigment particle or by covalent bonding to the pigment particle through a coupling agent. Methods to prepare the composite particles and coating compositions containing the composite particles are also provided.

Owner:ROHM & HAAS CO

Surface-modified zinc oxide for the production of nanoparticulate dispersions

InactiveUS20050048010A1Laborious grinding process can be avoidedEasy to separateCosmetic preparationsBiocideLiquid mediumPolyethylene glycol

The present invention relates to a surface-modified nanoscale zinc oxide, where the surface modification involves coating with an oligo- or polyethylene glycol acid. This surface-modified zinc oxide is characterized in that it forms stable dispersions in a liquid medium. In addition, the present invention relates to a process for the production of surface-modified zinc oxide, and also to a process for the production of nanoscale zinc oxide dispersions.

Owner:HENKEL KGAA

Carbon-containing material

A carbon-containing material with organic groups, which is obtainable by reaction of the carbon-containing material with organic compounds of the general formula 1A process for preparing the carbon-containing material according to the invention is also described. The carbon-containing materials according to the invention can be used as fillers, reinforcing fillers, UV stabilizers, conductivity carbon blacks or pigments.

Owner:UBS AG

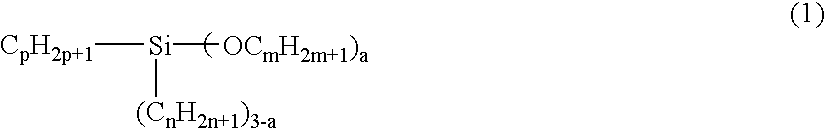

Silica coated carbon blacks

InactiveUS6197274B1Alkali metal halidesPigment treatment with organosilicon compoundsElastomerOrganic group

Silica coated carbon blacks are disclosed and can be prepared by coating a fine dispersion of carbon black, such as a carbon black having an attached organic group(s). Compositions and articles of manufacture, including elastomeric compositions, containing such carbon black are also disclosed.

Owner:CABOT CORP

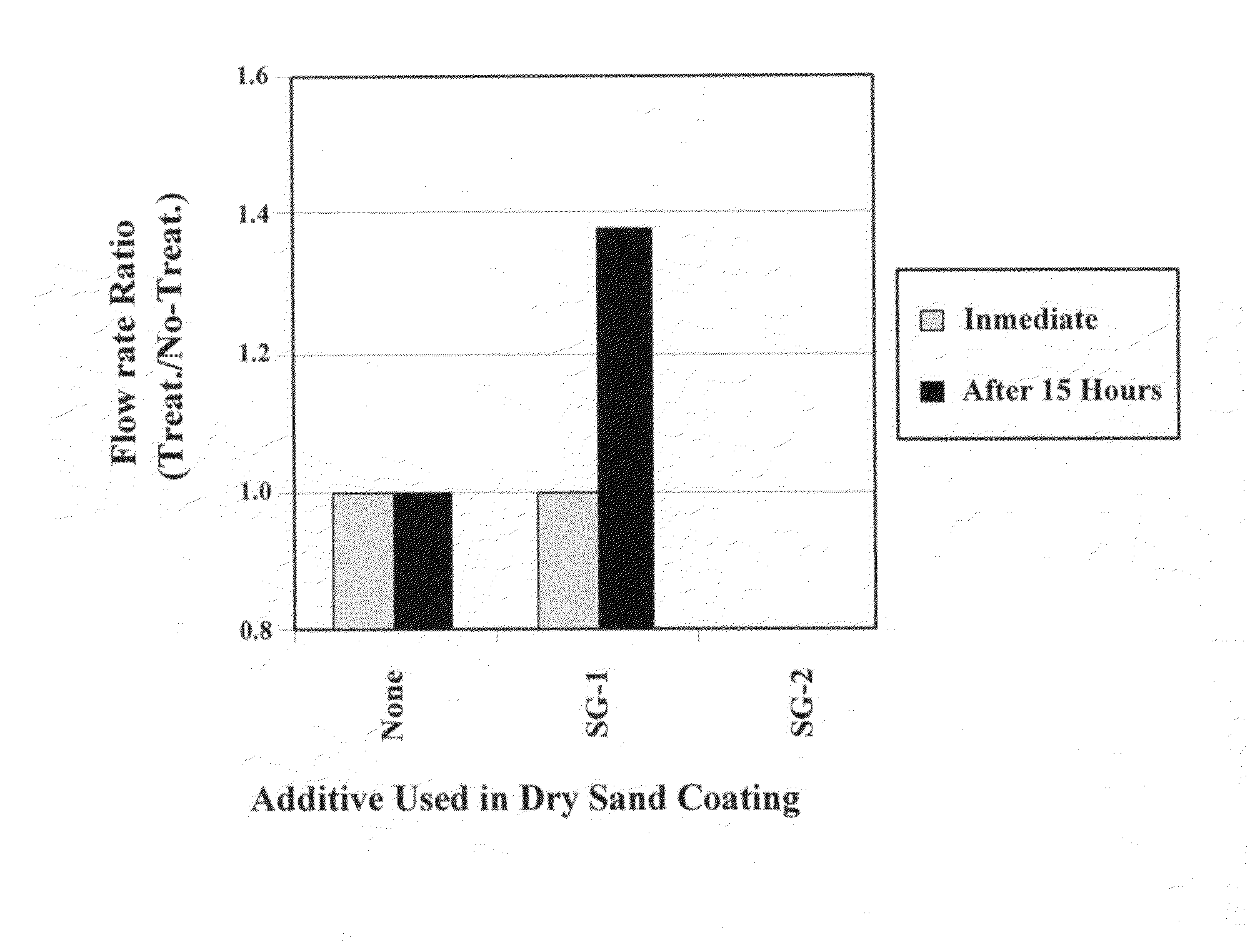

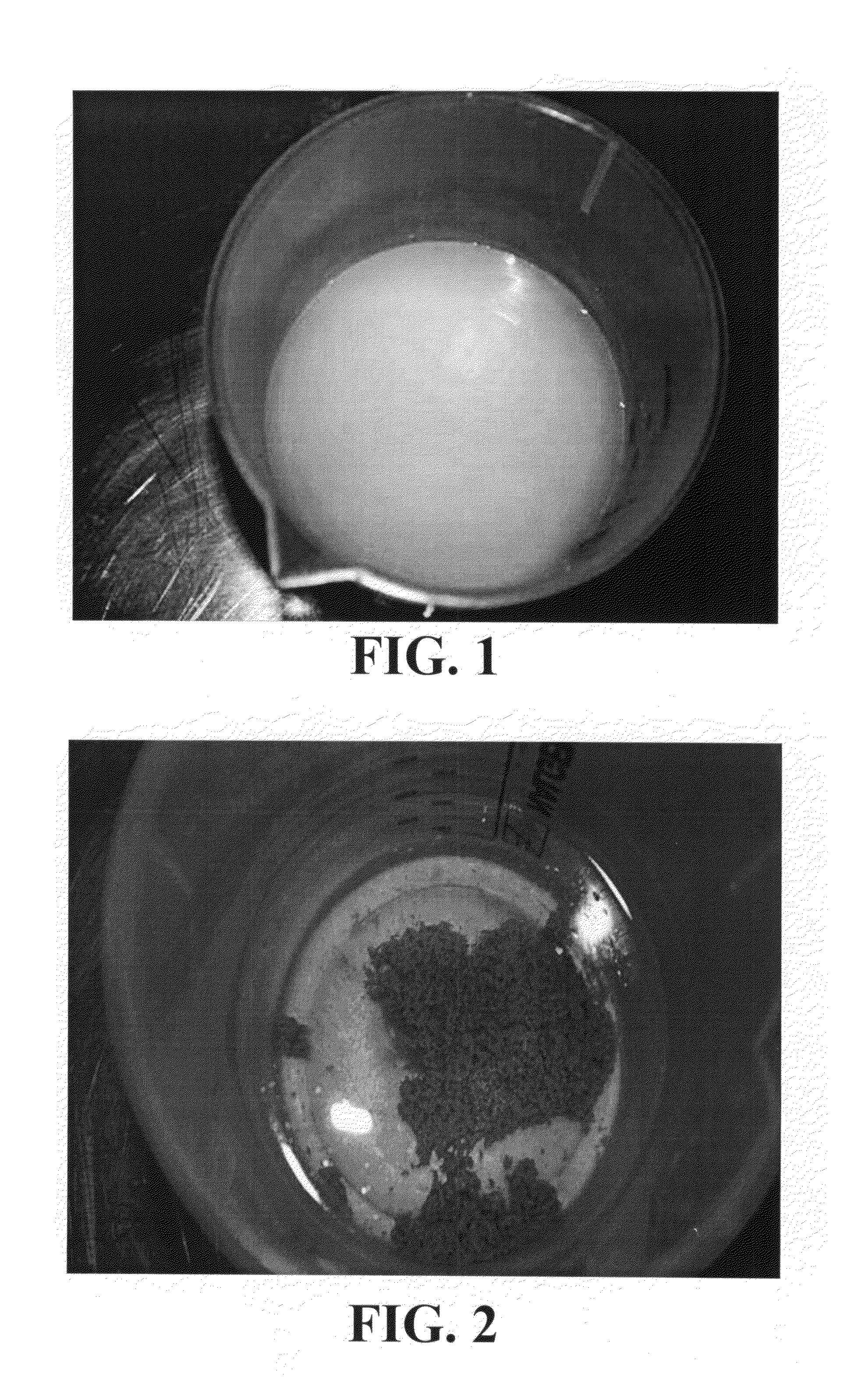

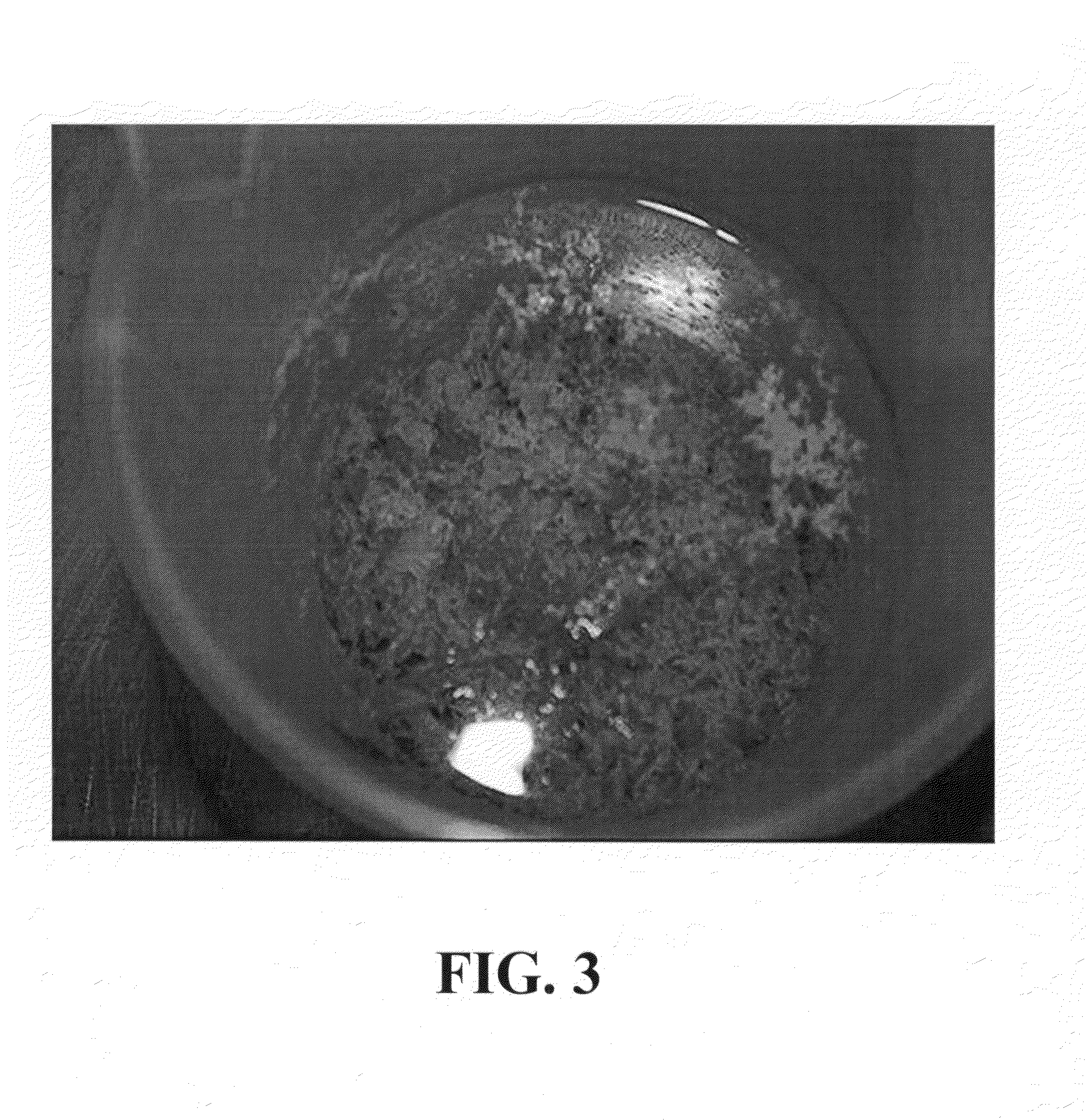

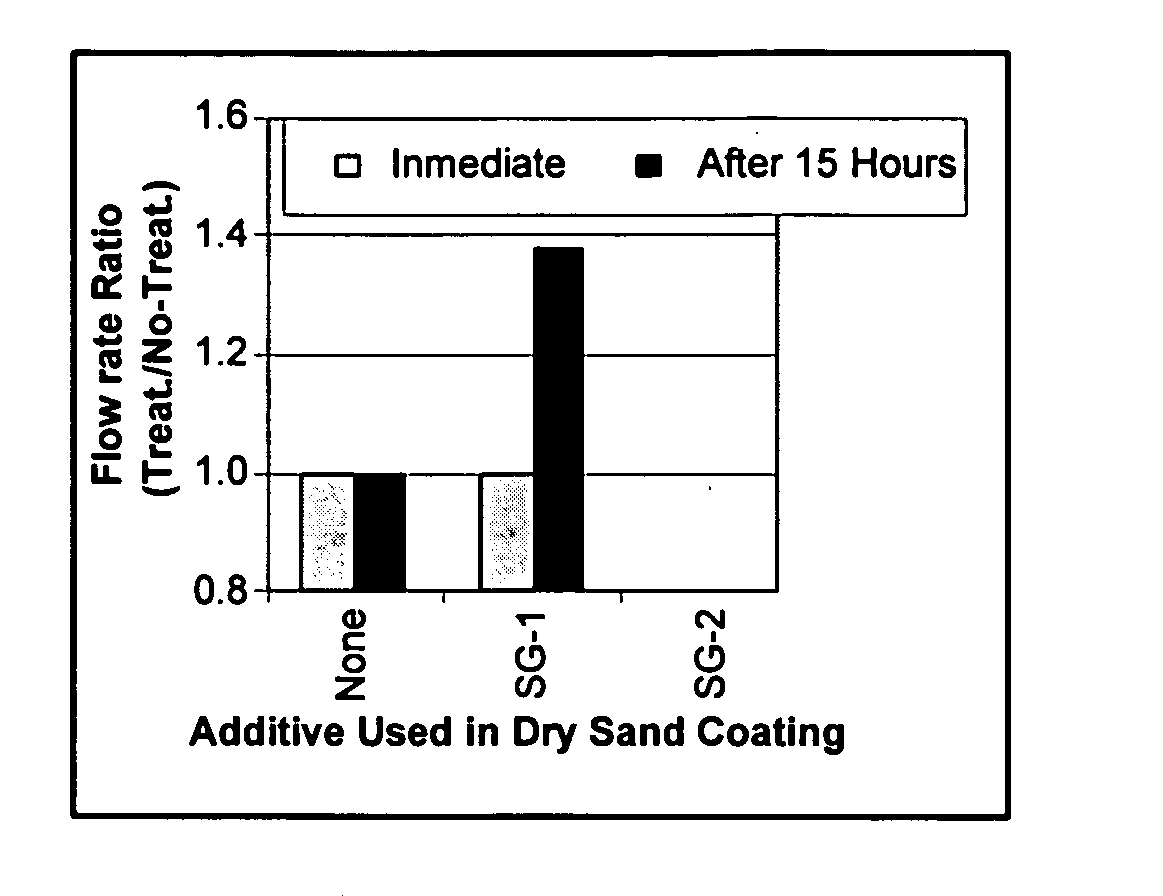

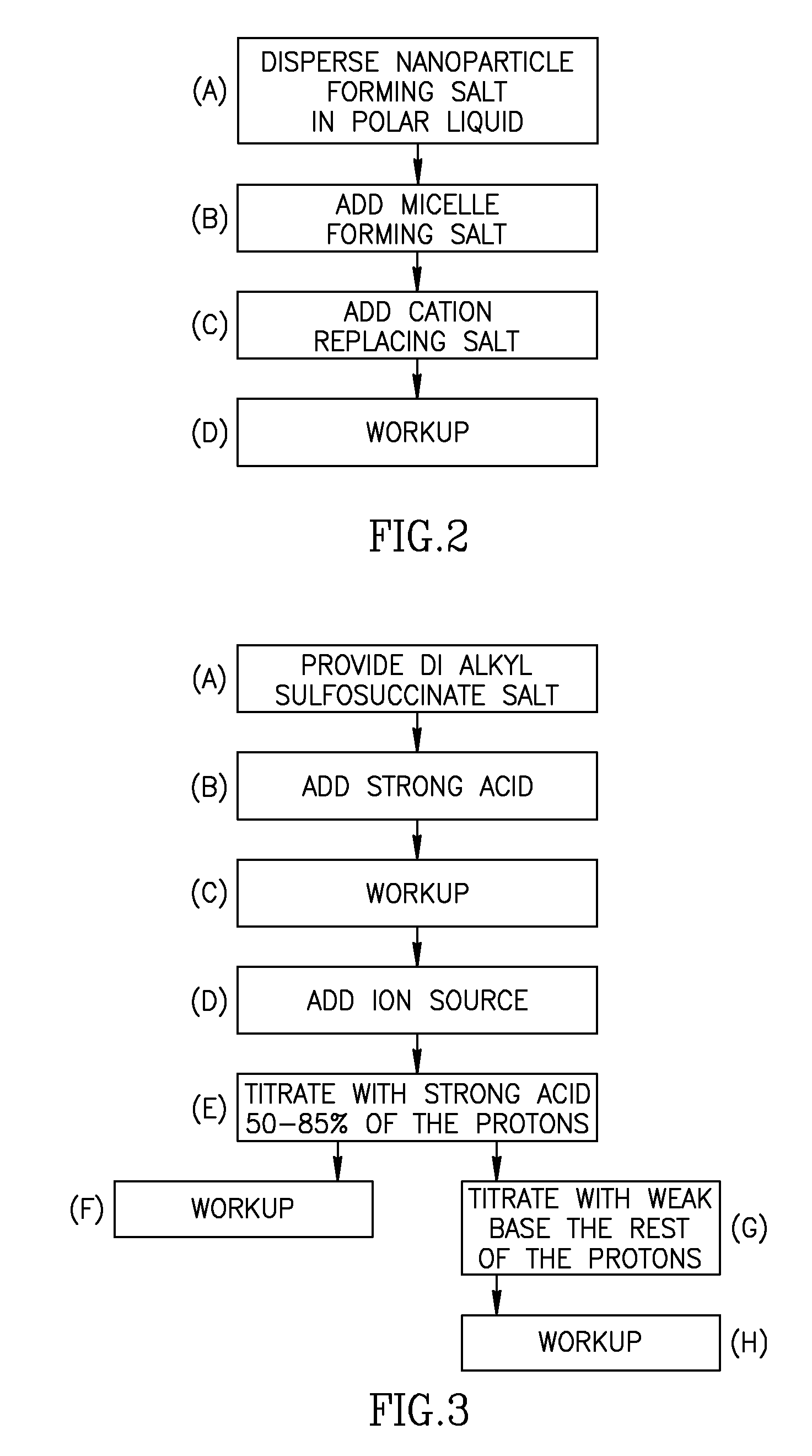

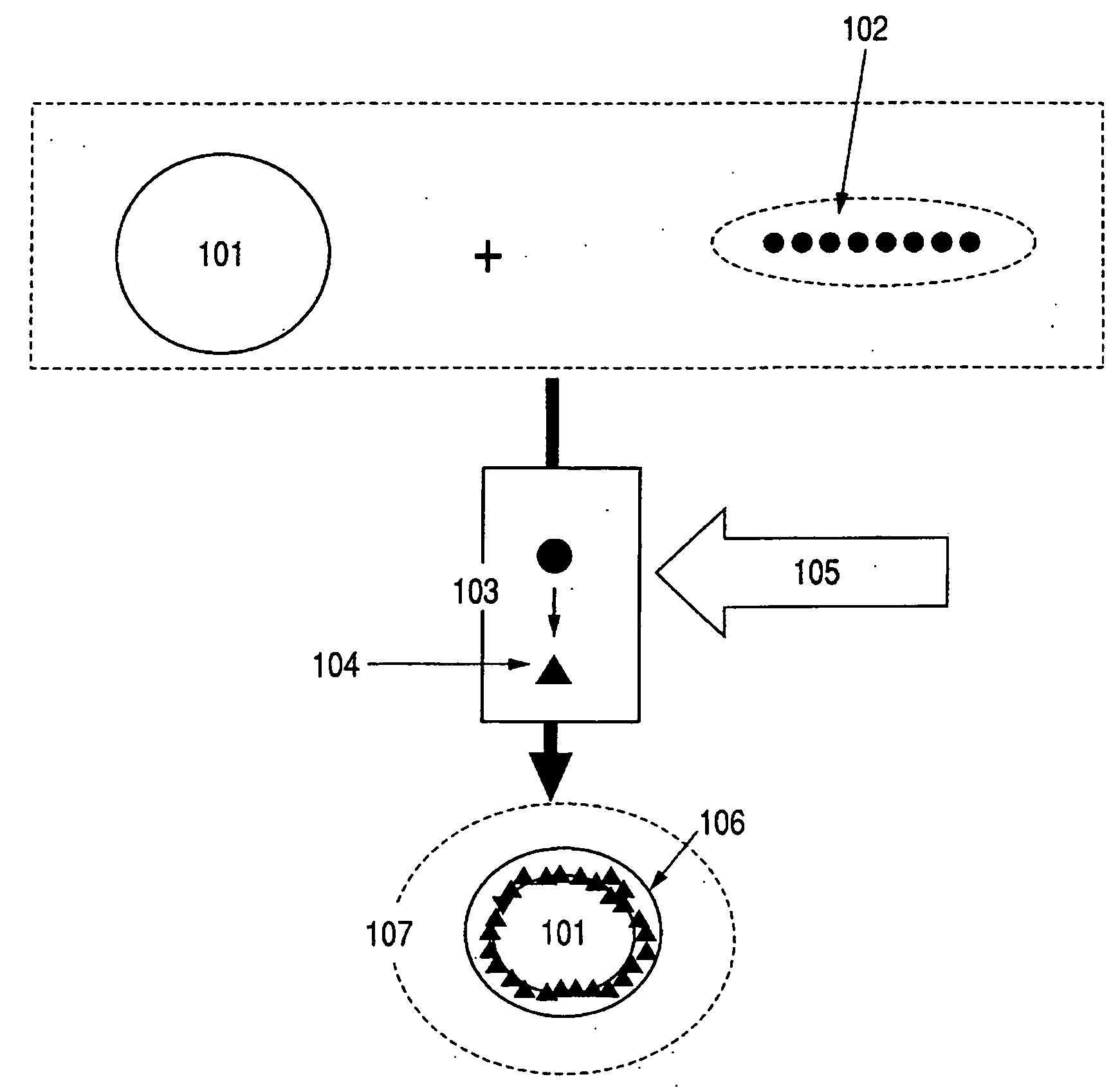

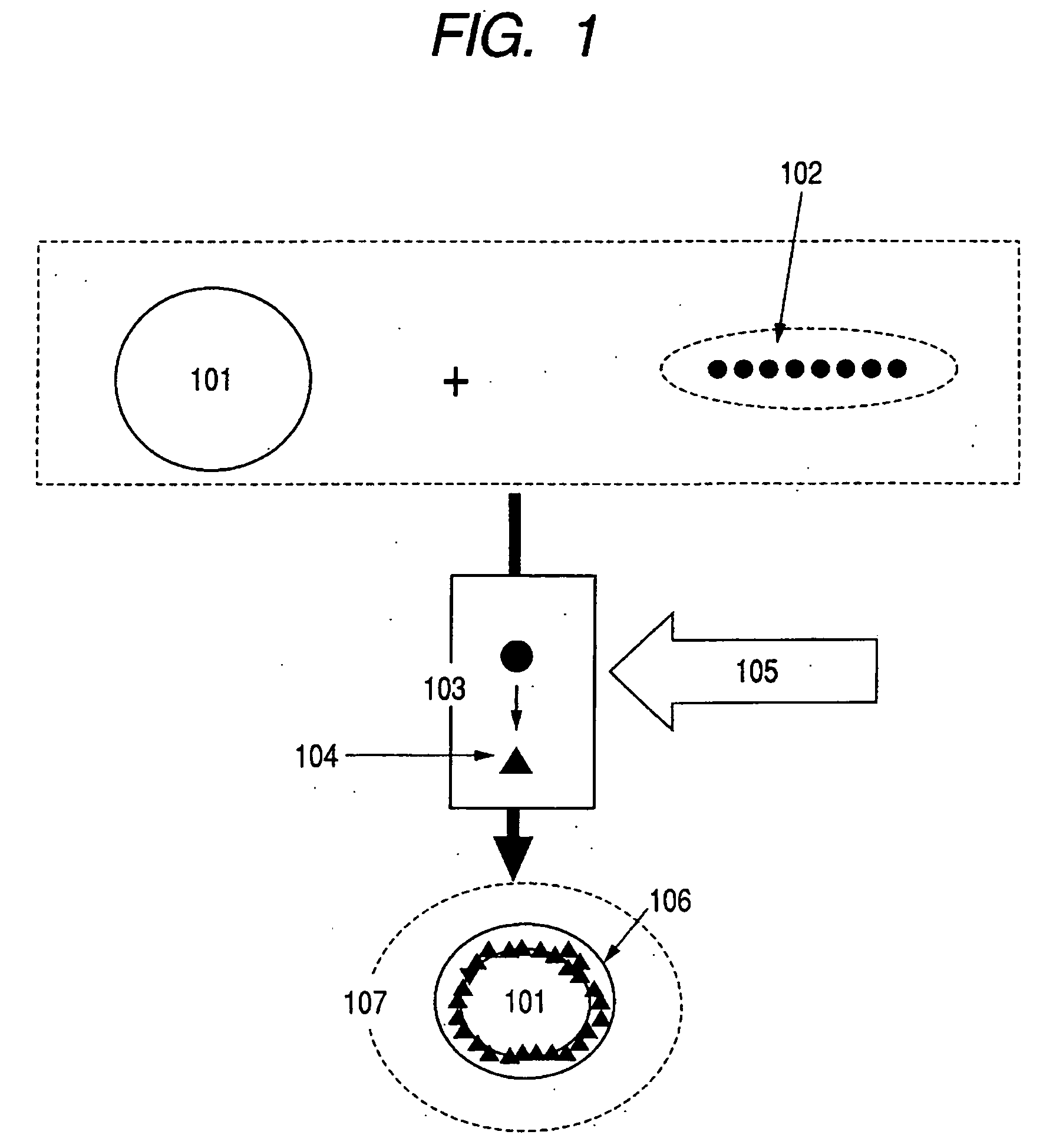

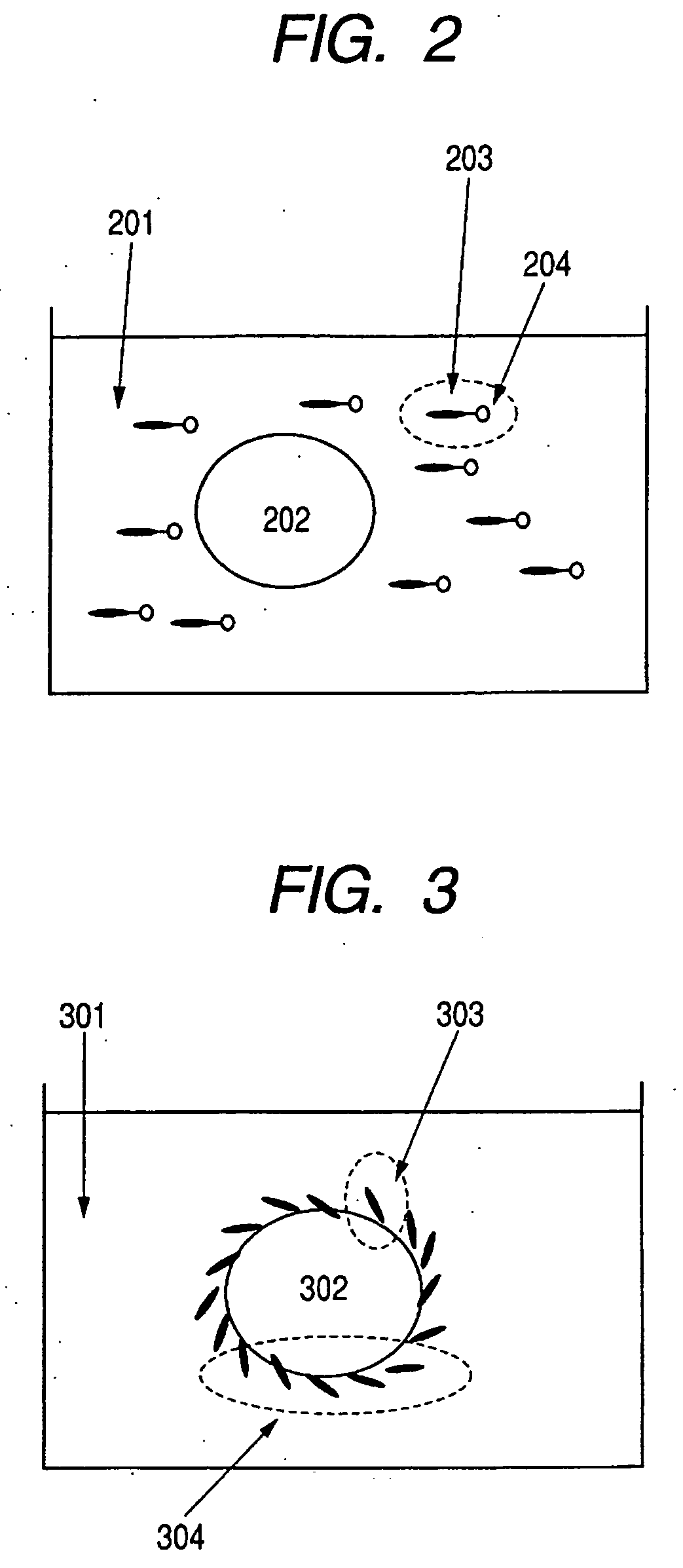

Sand aggregating reagents, modified sands, and methods for making and using same

ActiveUS20070131422A1Improve propertiesImprove adhesionLiquid/gas jet drillingFluid removalMaterials scienceReagent

A method for treating solid materials is disclosed, where the treating compositions coats surfaces or portions of surfaces of the solid materials changing an aggregation or agglomeration propensity of the materials. Treated solid materials are also disclosed. The methods and treated materials are ideally suited for oil field applications.

Owner:THE LUBRIZOL CORP

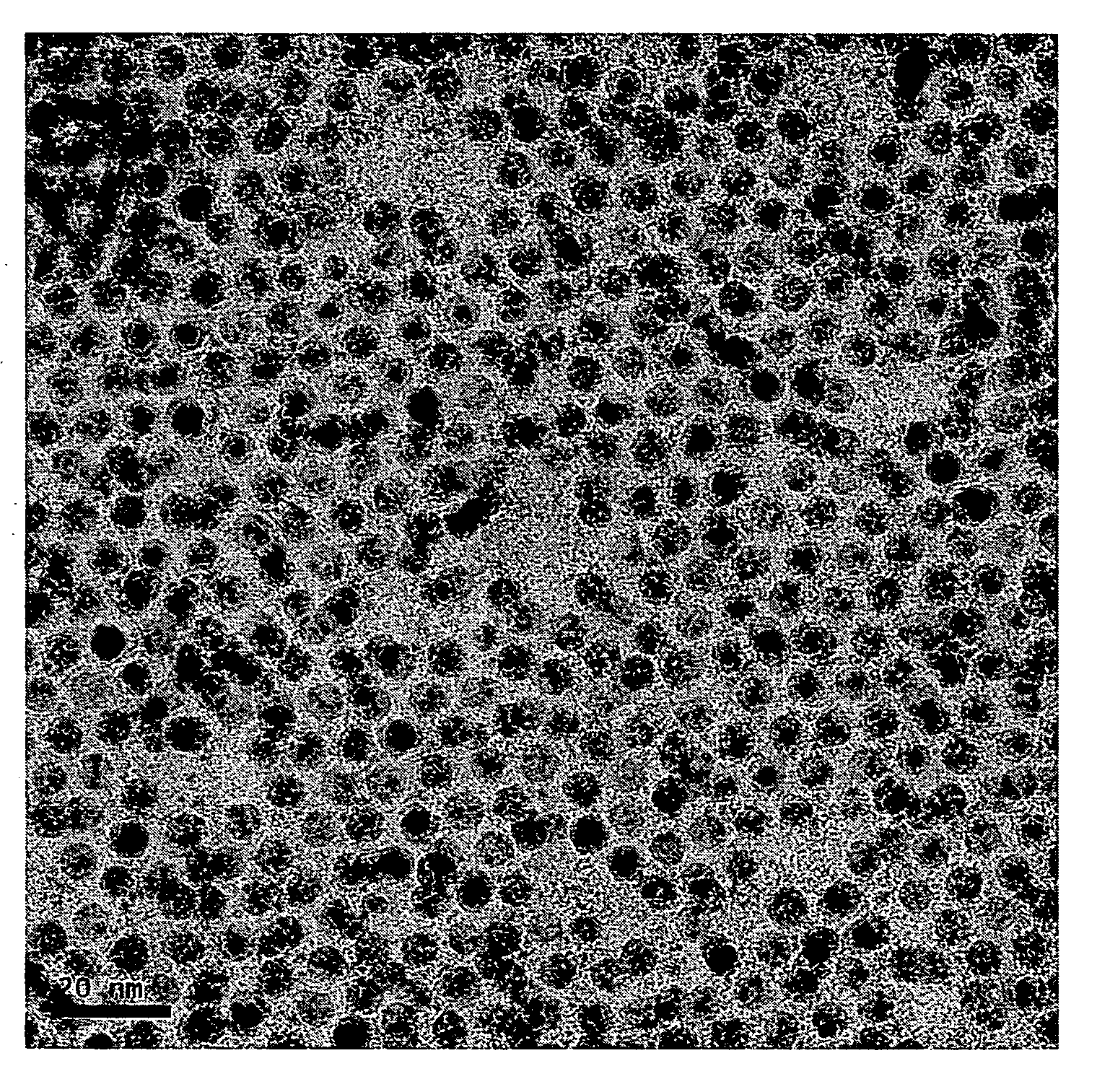

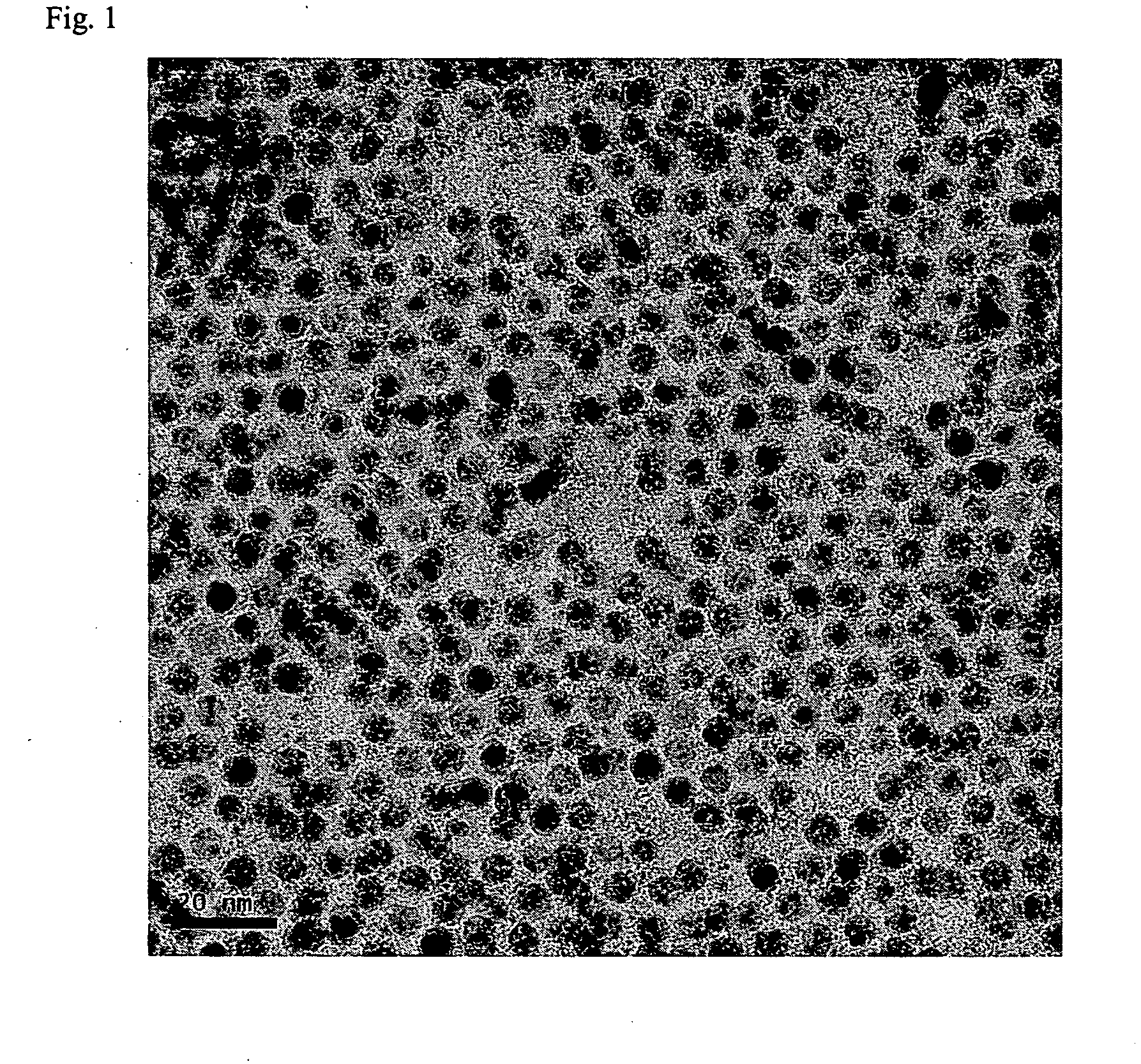

Method for producing silver nanoparticles and conductive ink

InactiveUS20090223410A1Uniform sizeHigh yield rateMaterial nanotechnologyMetal-working apparatusDispersion stabilityOxygen

A method of producing metal nanoparticles in a high yield rate and uniform shape and size, which is thus suitable for mass production. In addition, metal nanoparticles are provided that have superior dispersion stability when re-dispersed in various organic solvents, which thus suitable for use as a conductive ink having high conductivity. The method of producing nanoparticles includes mixing a metal precursor with a copper compound to a hydrocarbon based solvent, mixing an amine-based compound to the mixed solution of the metal precursor with copper compound and hydrocarbon based solvent, and mixing a compound including one or more atoms having at least one lone pair, selected from a group consisting of nitrogen, oxygen, sulfur and phosphorous to the mixed solution of the amine-based compound, metal precursor with a copper compound and hydrocarbon based solvent.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Covalent attachment of polymers onto macromolecular chromophores by nucleophilic substitution reaction for inkjet printing

InactiveUS6221932B1Easy to controlExceptional propertyDuplicating/marking methodsInksPolymer scienceOrganic solvent

The present invention relates to ink-jet ink compositions that comprise macromolecular chromophores having functional groups covalently attached for water solubility. Moreover, the MMCs have polymer chains covalently attached to the pigments by nucleophilic substitution to provide enhanced smearfastness, enhanced print quality, improved bleed control, and improved resistance to water when applied to the media. These inks have good viscosity and surface tension, are more soluble in organic solvents and are, therefore, useful in ink-jet printing, including thermal ink jet printing, piezoelectric ink jet printing, and continuous ink jet printing.

Owner:HEWLETT PACKARD DEV CO LP

Composite particle for dielectrics, ultramicroparticulate composite resin particle, composition for forming dielectrics and use thereof

InactiveUS20030151032A1High dielectric constantSmall dielectric loss tangentSemiconductor/solid-state device detailsSolid-state devicesInorganic particleResin-Based Composite

The dielectric-forming composition according to the invention is characterized by consisting of: composite particles for dielectrics in which part or all of the surfaces of inorganic particles with permittivity of 30 or greater are coated with a conductive metal or a compound thereof, or a conductive organic compound or a conductive inorganic material; and (B) a resin component constituted of at least one of a polymerizable compound and a polymer. In addition, another dielectric-forming composition according to the invention is characterized by containing: ultrafine particle-resin composite particles composed of (J) inorganic ultra fine particles with the average particle size of 0.1 mum or smaller, and (B) a resin component constituted of at least one of a polymerizable compound and a polymer, wherein part or all of the surfaces of the inorganic ultrafine particles (J) are coated with the resin component (B), and the ultrafine particle-resin composite particles contain 20% by weight or more of the inorganic ultrafine particles (J); and inorganic particles with the average particle size of 0.1 to 2 mum and permittivity of 30 or greater, or inorganic composite particles in which a conductive metal or a compound thereof, or a conductive organic compound or a conductive inorganic material is deposited on the part or all of the surfaces of the inorganic particles.

Owner:JSR CORPORATIOON

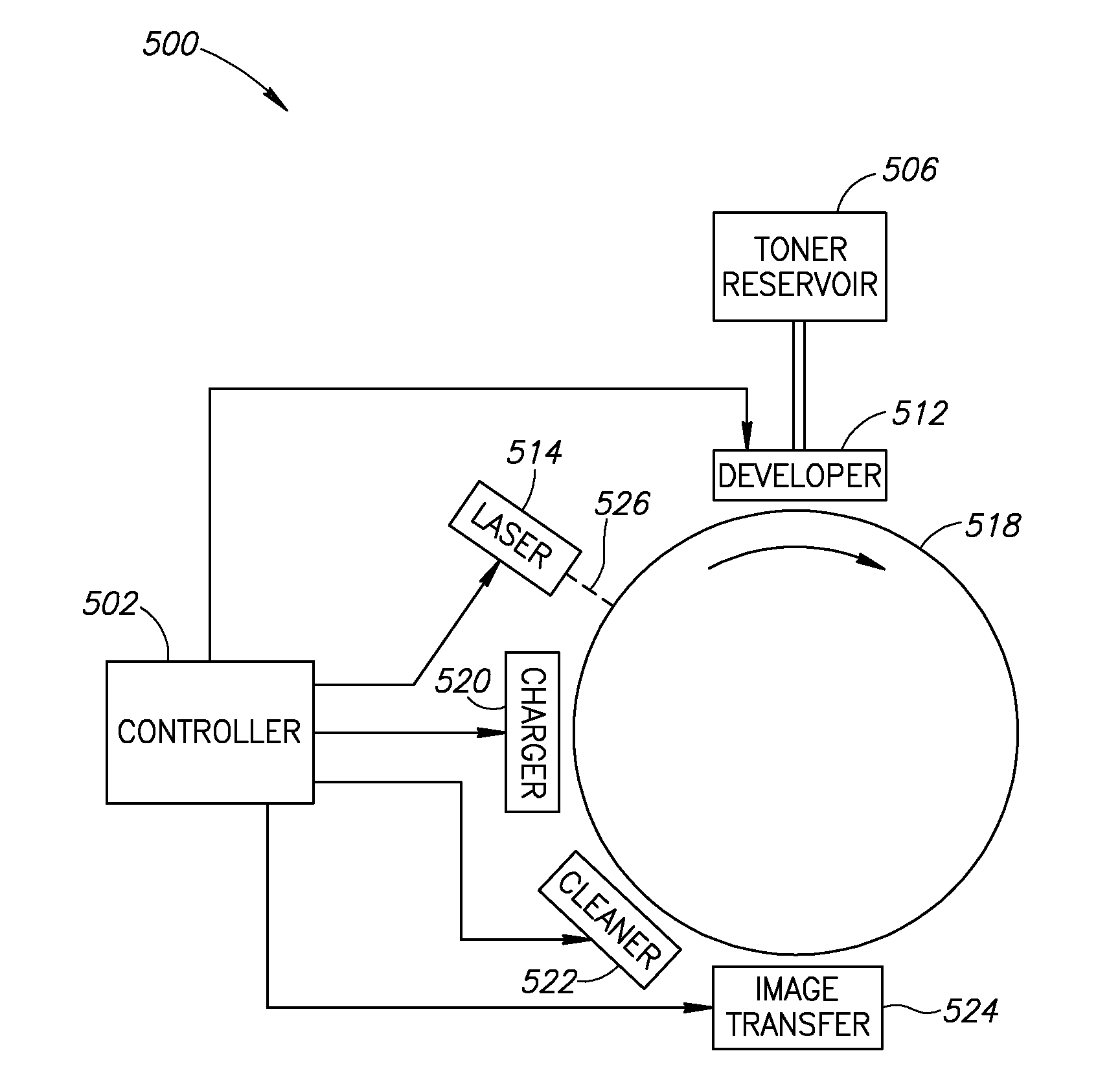

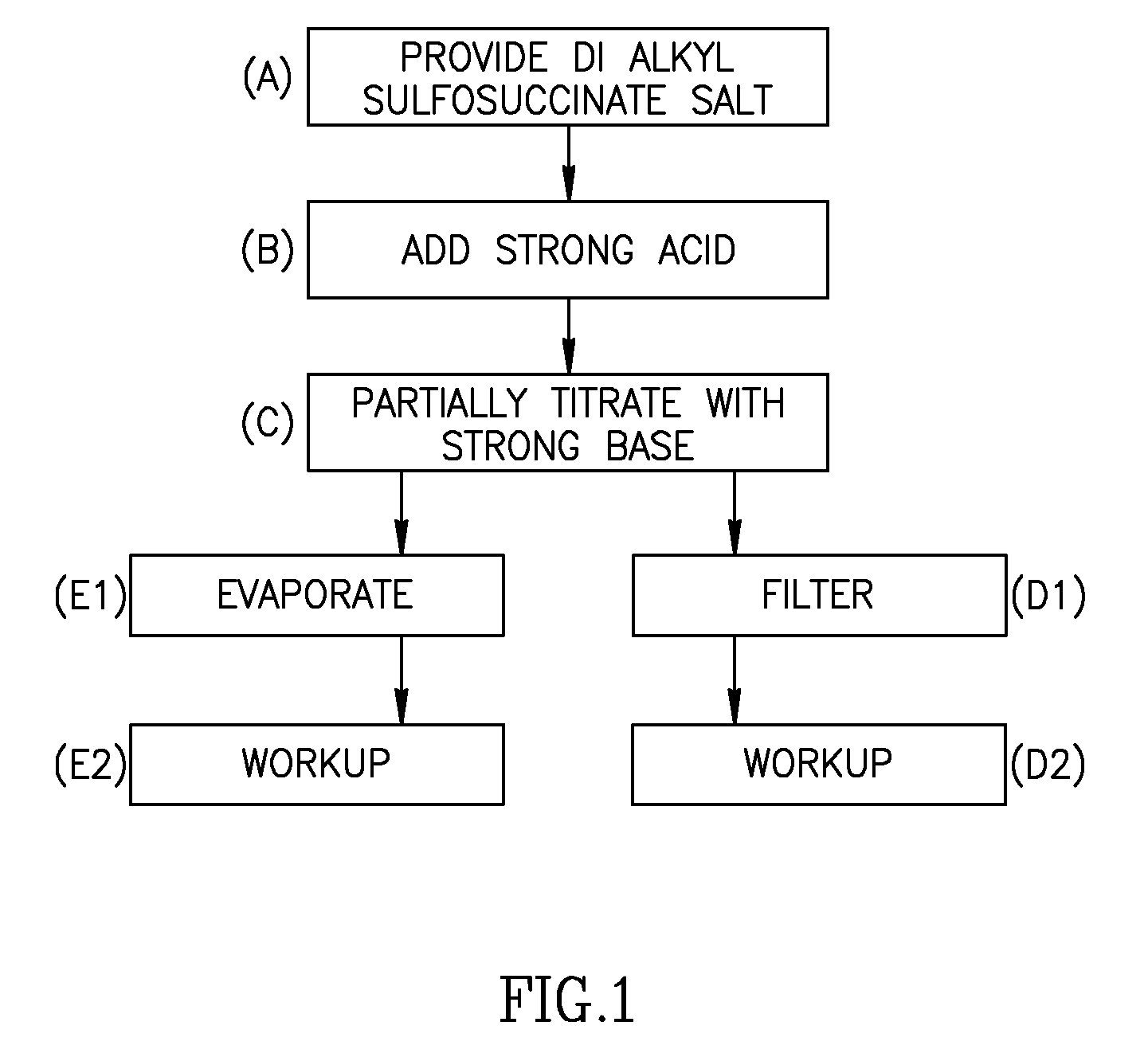

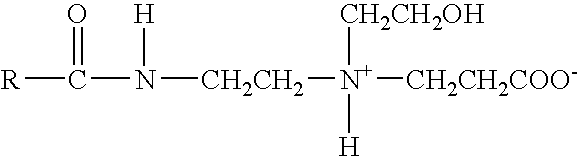

Charge Director for Liquid Toner

InactiveUS20090311614A1Less water-sensitiveEasy to controlMaterial nanotechnologyIndividual molecule manipulationHydrogenNanoparticle

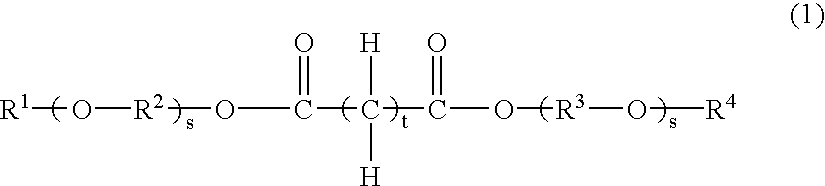

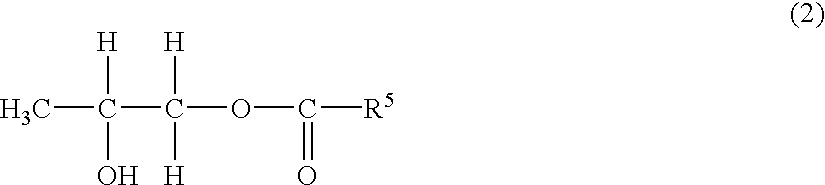

A charge director material for charging a liquid toner, the charge director material comprising (a) nanoparticles of a simple salt and (b) a sulfosuccinate salt of the general formula MAn, wherein M is a metal, n is the valence of M, and A is an ion of the general formula (I)[R1—O—C(O)CH2CH(SO3−)C(O)—O—R2], (I)wherein each of R1 and R2 is an alkyl group;said charge director material being substantially free of acids of the general formula (I),wherein one or both of R1 and R2 is hydrogen, and if only one of them is hydrogen, the other is an alkyl group,

Owner:HEWLETT PACKARD DEV CO LP

Treated filler and process for producing

The present invention is related to treated filler and processes for producing said treated filler. Untreated filler slurry can be treated with a treating material and, optionally, a coupling material and then subjected to conventional drying method(s), to produce the treated filler of the invention. Treated filler has a wide variety of applications including but not limited to battery separators and rubber compositions such as tires.

Owner:PPG IND OHIO INC

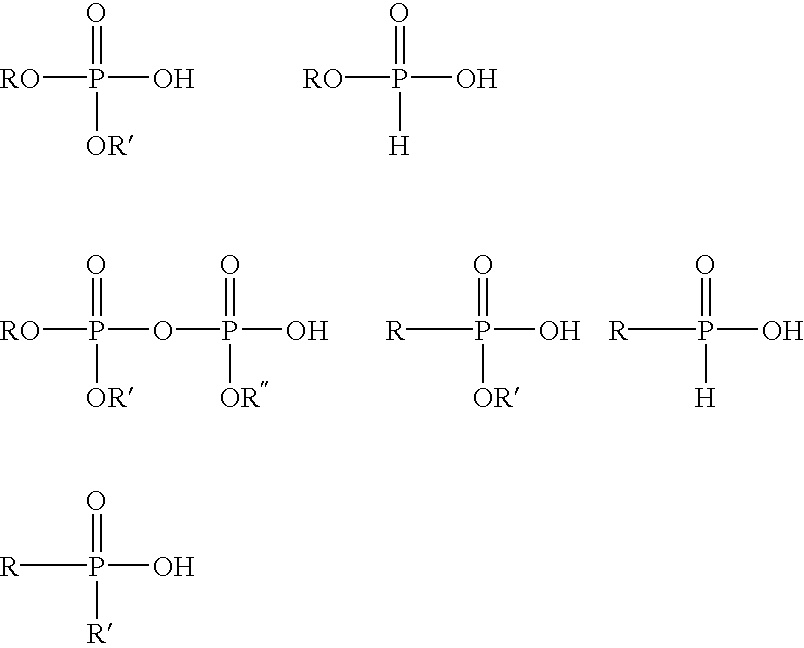

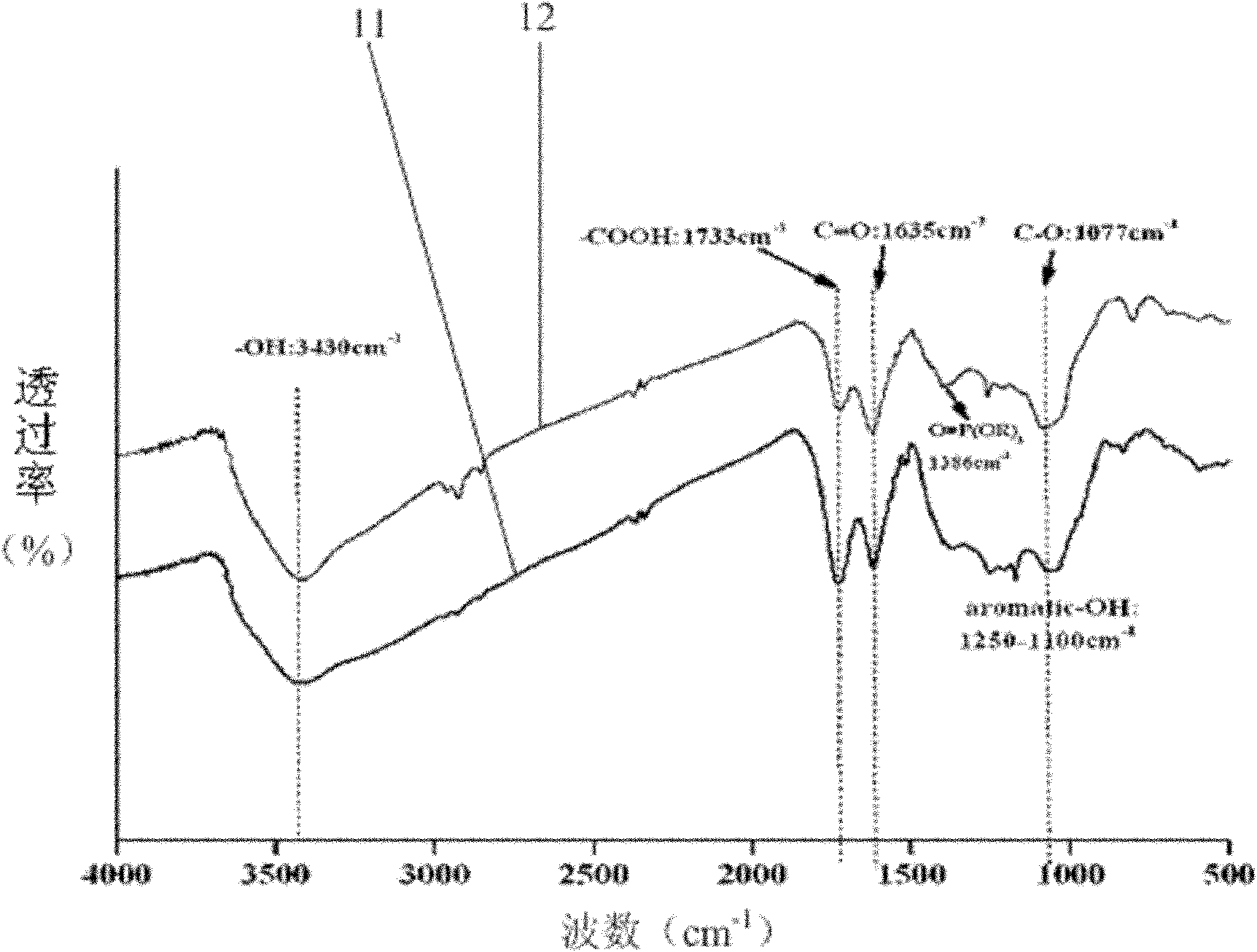

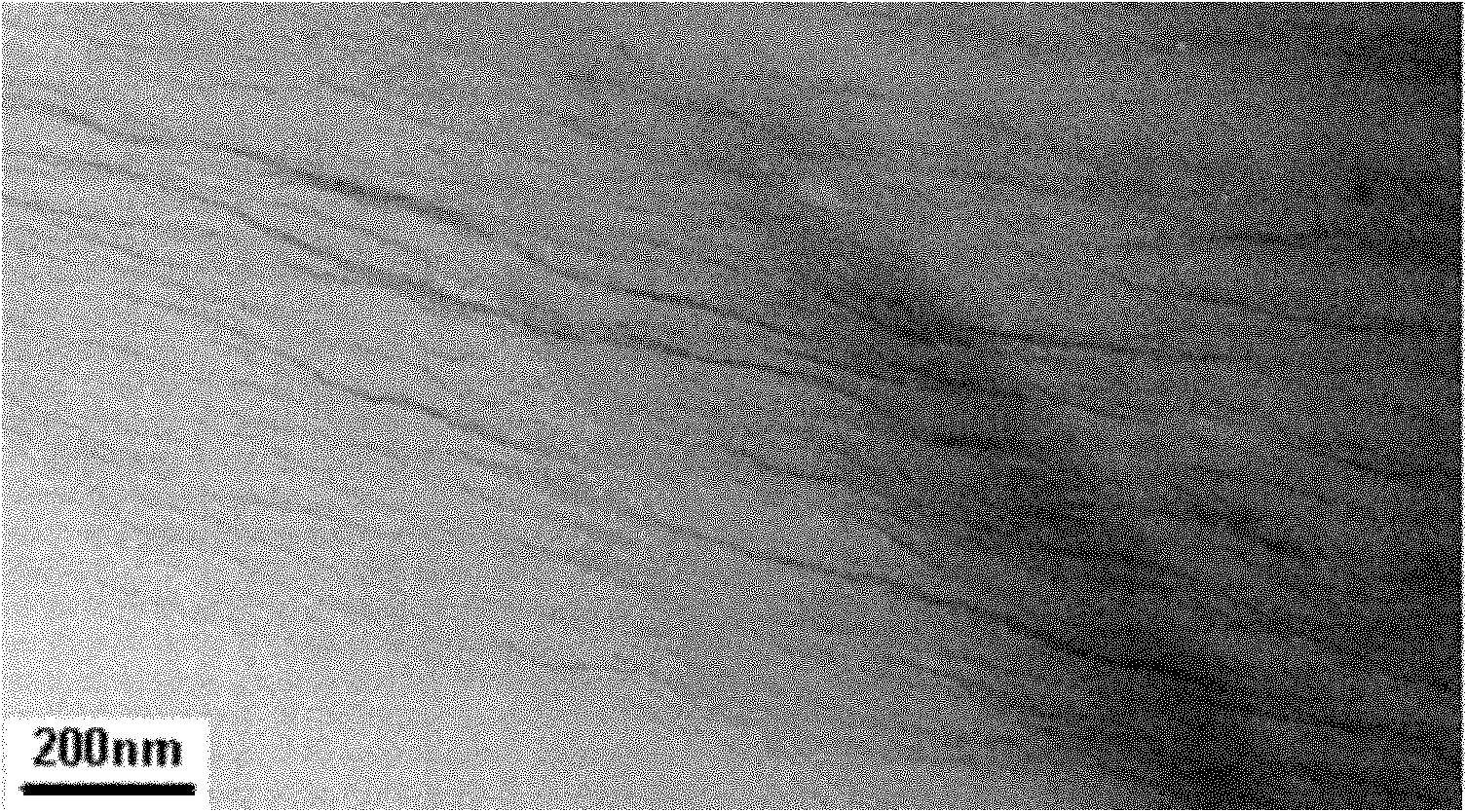

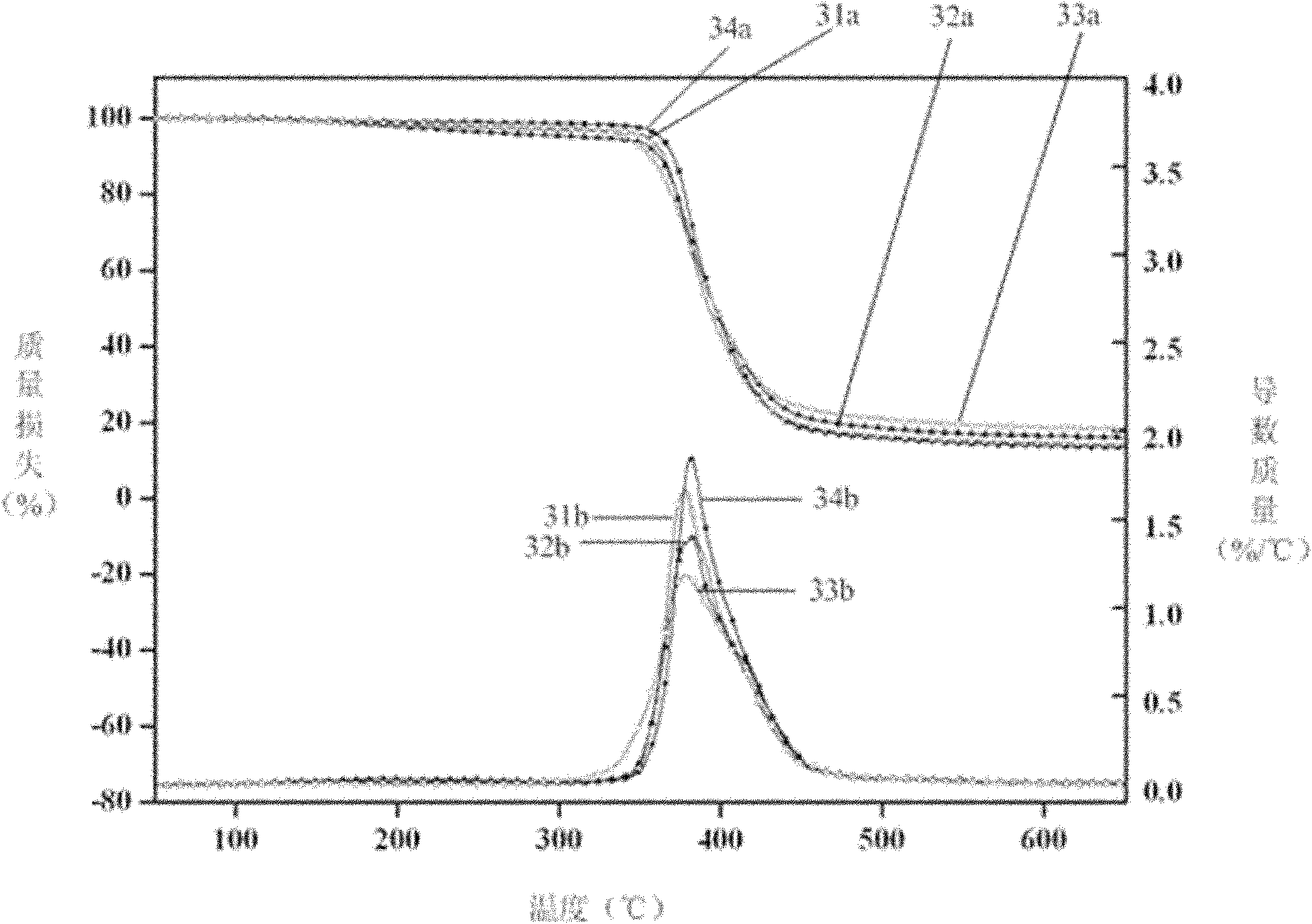

Preparation method of modified graphene oxide and preparation method of composite material containing modified graphene oxide

ActiveCN102127324AImprove flame retardant performanceEvenly dispersedPigment treatment with non-polymer organic compoundsEpoxyPolyamide

The invention provides a preparation method of a modified graphene oxide, comprising the following steps of: (a) reacting a phosphorus oxychloride compound, cyanuric chloride or diisocyanate with glycidol to obtain an intermediate product; and (b) dispersing graphite oxide in an organic solvent, dropwise adding to the intermediate product obtained through reaction, and reacting to obtain the modified graphene oxide. The invention also provides a preparation method of a composite material containing the modified graphene oxide, comprising the following steps of: dispersing the modified graphene oxide obtained through the preparation method in the technical scheme in an organic solvent, mixing the modified graphene oxide containing epoxide groups with epoxy resin oligomers and a polyamide curing agent, and curing to obtain the composite material containing the modified graphene oxide. In the composite material provided by the invention, the modified graphene oxide reacts with a resin substrate, is more uniform to disperse in the obtained composite material, and has better flame-retarding performance.

Owner:UNIV OF SCI & TECH OF CHINA

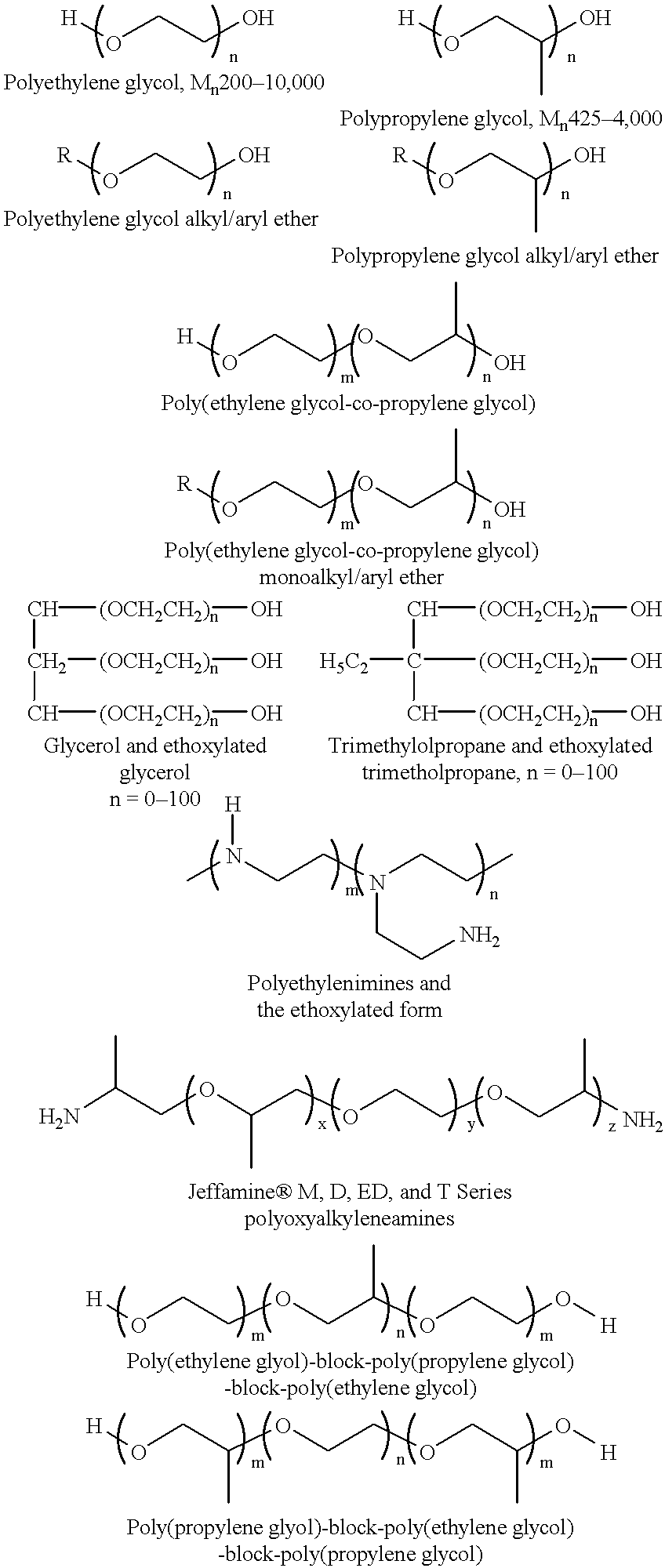

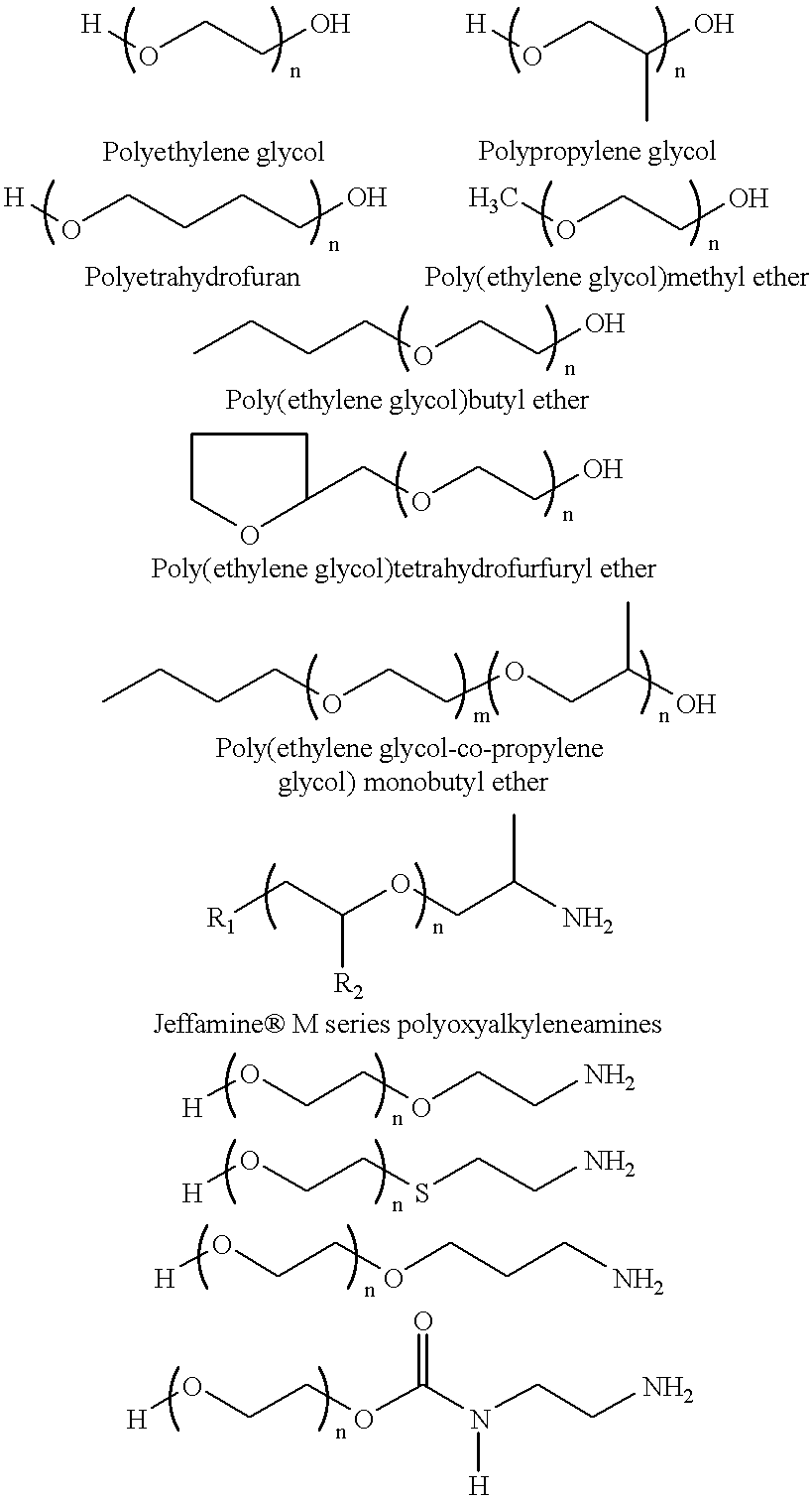

Modified pigments having improved dispersing properties

InactiveUS7056962B2Improving dispersibility and dispersion stabilityImprove dispersibility and dispersion stabilityPhotomechanical apparatusInksElastomerHydrogen

Various modified pigment products are described which are preferably capable of being dispersed in a variety of materials such as coatings, inks, toners, films, plastics, polymers, elastomers, and the like. The modified pigments are pigments having attached groups, such as polymeric groups, onto the pigment by means other than adsorption. A modified pigment product is described comprising a pigment having attached at least one group comprising the formula:—X—[NIon]pRwherein X comprises an aromatic group or an alkyl group, NIon comprises at least one type of non-ionic group, R represents hydrogen or comprises an aromatic group or an alkyl group, and p represents an integer of from 1 to 500. Modified pigment products are also described comprising a pigment having attached at least one alkylene oxide group or at least one polymeric group. In addition, other types of modified pigment products are described as well as their incorporation into inks, coatings, toners, films, plastics, polymers, elastomers, and the like. Methods of making the modified pigment products are also described.

Owner:CABOT CORP

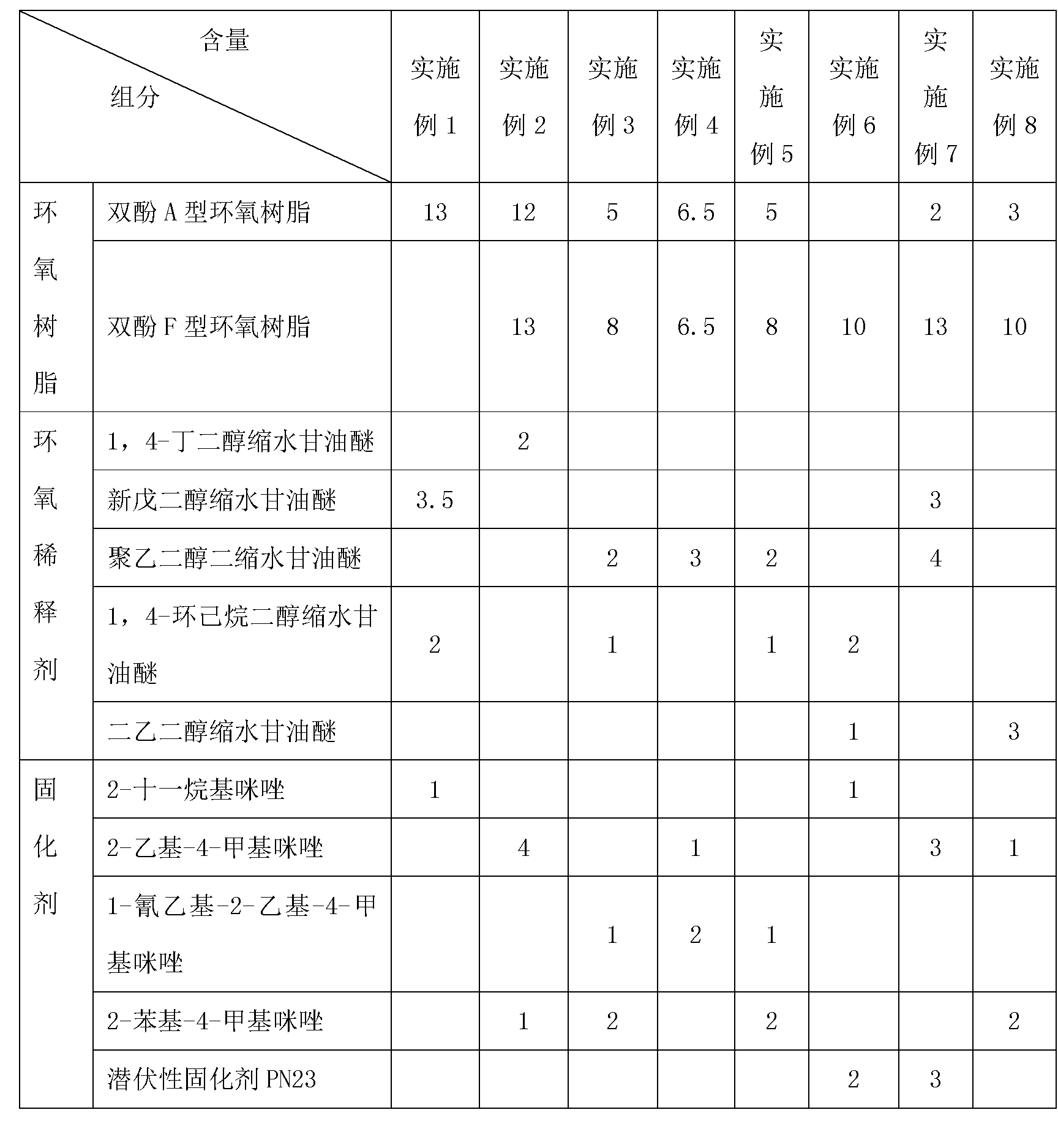

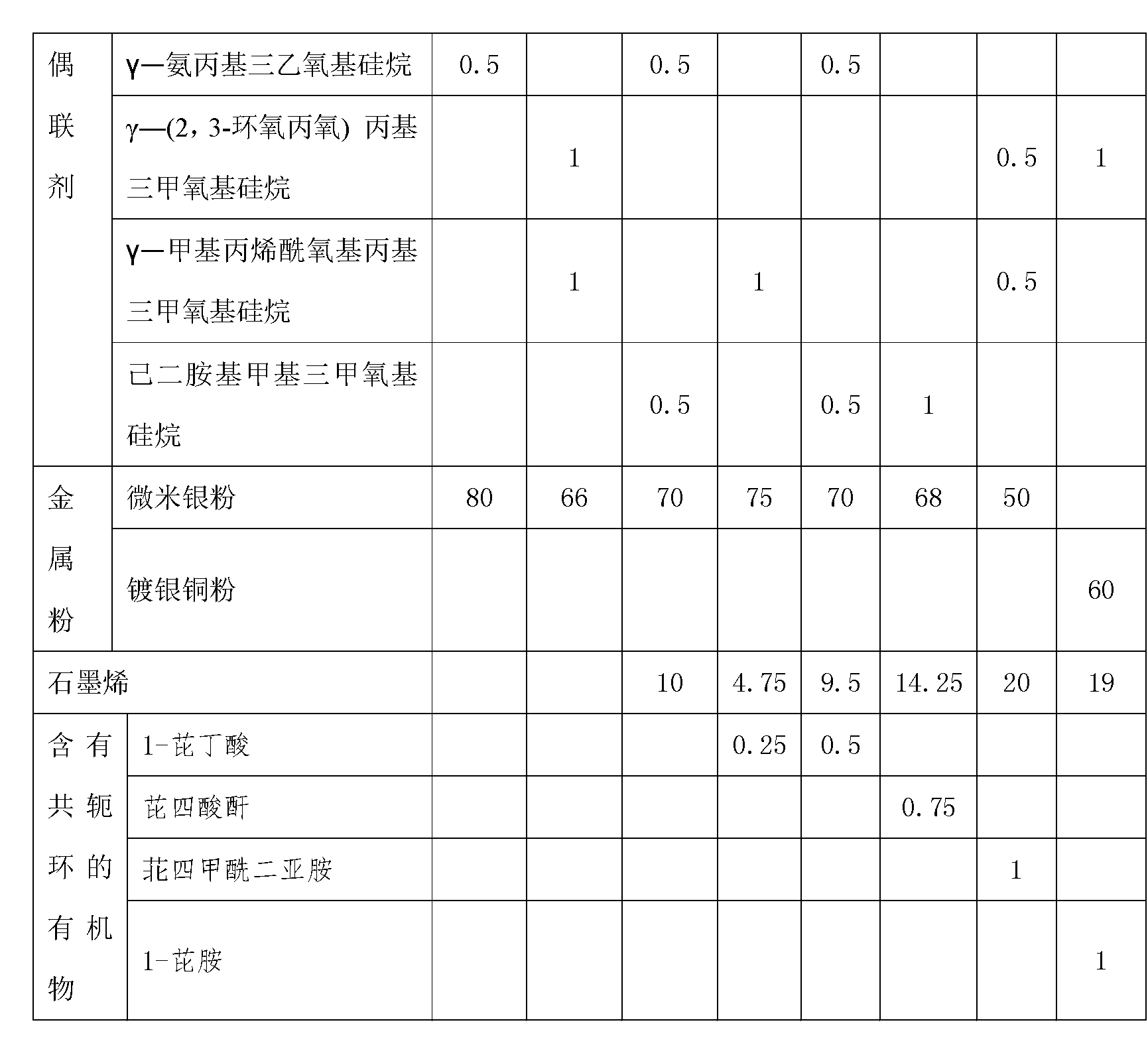

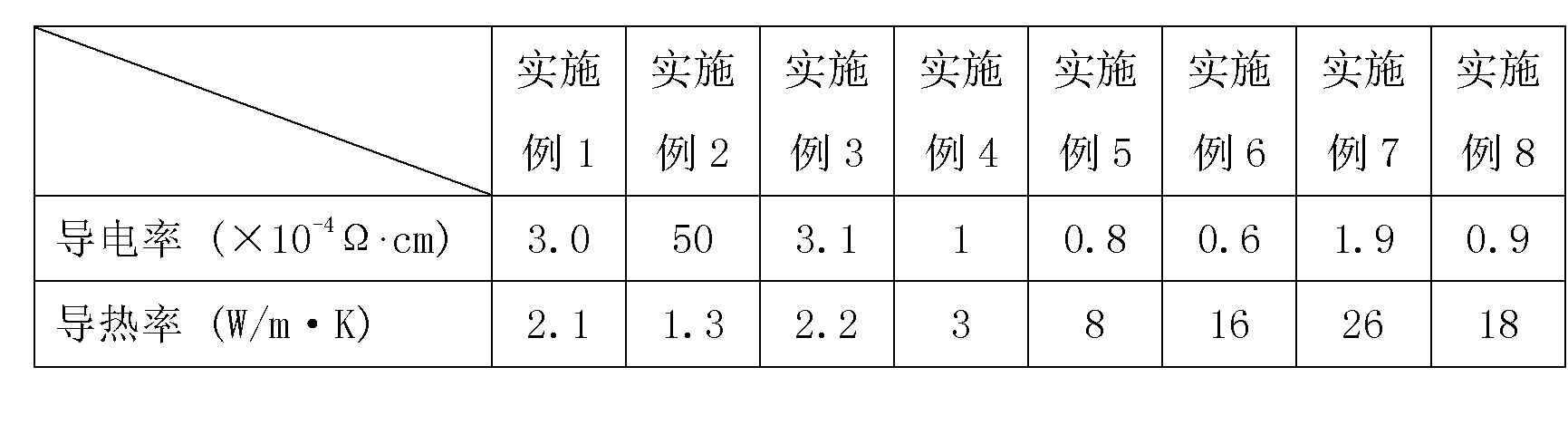

Method for preparing high-heat-conductivity conductive adhesive containing graphene

ActiveCN103194165AGood dispersionScatter to reachEpoxy resin adhesivesPigment treatment with non-polymer organic compoundsEpoxyAdhesive

The invention provides a method for preparing high-heat-conductivity conductive adhesive containing graphene. The method comprises the steps of (1) functionalizing surface of graphene, namely adding graphene to acetone solution of an organic matter containing a conjugate ring, and strongly ultrasonically shaking for 6-48 hours at 40-100 DEG C to form non-covalent modified graphene; (2) mixing epoxy resin with an epoxy diluent for 3-30 minutes at room temperature to obtain a mixture of epoxy resin and the epoxy diluent, and sequentially adding metal powder and a coupling agent to the mixture; (3) adding the non-covalent modified graphene prepared in the step (1) to the mixture in the step (2); and (4) adding a curing agent to the mixture in the step (3) to prepare the even conductive adhesive. The method has the advantages that dispersing and enhancing interface joint in an epoxy system are facilitated by functionalizing the surface of graphene by a non-covalent bond; and then graphene is mixed with metal powder to obtain the high-heat-conductivity conductive adhesive. The high-heat-conductivity conductive adhesive has the application prospect in a high-power apparatus.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

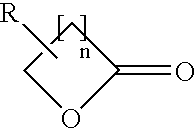

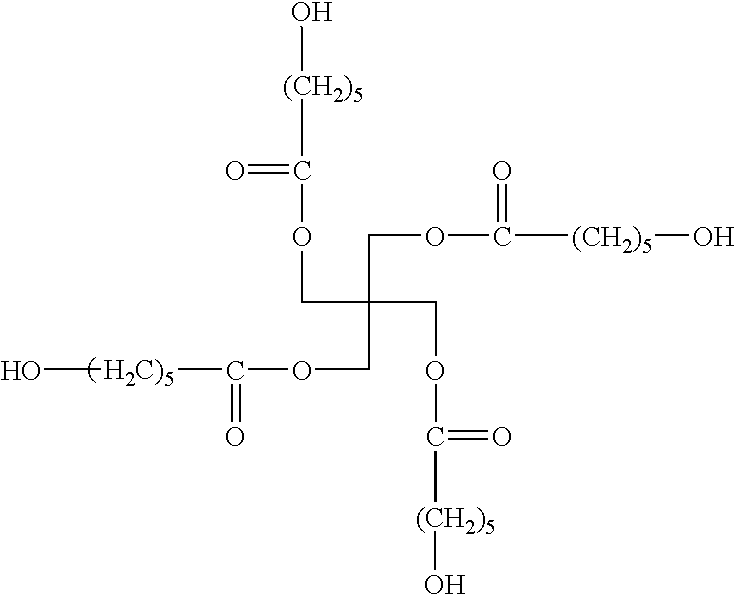

Polyester resin with carbamate functionality, a method of preparing the resin, and a coating composition utilizing the resin

InactiveUS7226971B2Increase flexibilityAcceptable appearanceTransportation and packagingMixingCarbamateCarboxylic acid

The present invention is directed to a polyester resin for use in a coating composition. The polyester resin is the reaction product of a first compound comprising a plurality of hydroxyl groups, a lactone compound, a carboxylic acid anhydride, an epoxy compound having at least one epoxy group, and a carbamate compound. The present invention is also directed to a coating composition including the polyester resin and to a method of preparing the resin.

Owner:BASF CORP

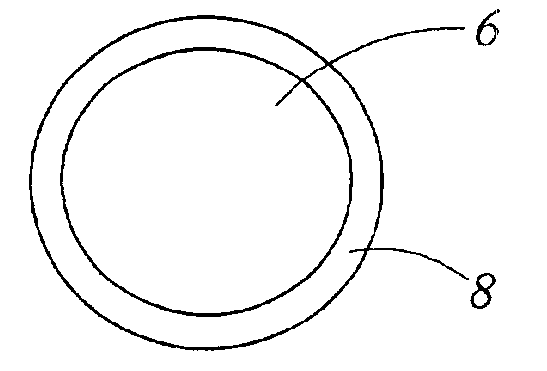

Coated fine particles, dispersed fine particles, method for producing coated fine particles, ink, recording method and recorded image

InactiveUS20060194056A1High fastnessQuality improvementMaterial nanotechnologyLiquid surface applicatorsChemistryOptics

An object of the present invention is to provide coated fine particles with a uniform particle size, having stable crystals on the surface, and to provide colored fine particles which exhibit good color development. A recorded image formed by a dispersion and an ink, using the coated fine particles, is provided with good color development and fastness. The present invention provides coated fine particles comprising fine particles as cores, the fine particles having a crystal layer on the surface, respectively.

Owner:CANON KK

Method for attachment of one or more organic groups onto a particle

InactiveUS6852158B2Reduce formationMaterial nanotechnologyPigment treatment with non-polymer organic compoundsOrganic groupRadical trapping

A method of attaching one or more organic groups onto a particle is described which involves reacting at least one radical with at least one particle wherein the radical is generated from the interaction of at least one transition metal compound with at least one organo-halide compound in the presence of one or more particles capable of radical capture. Variations of this method are also described.

Owner:CABOT CORP

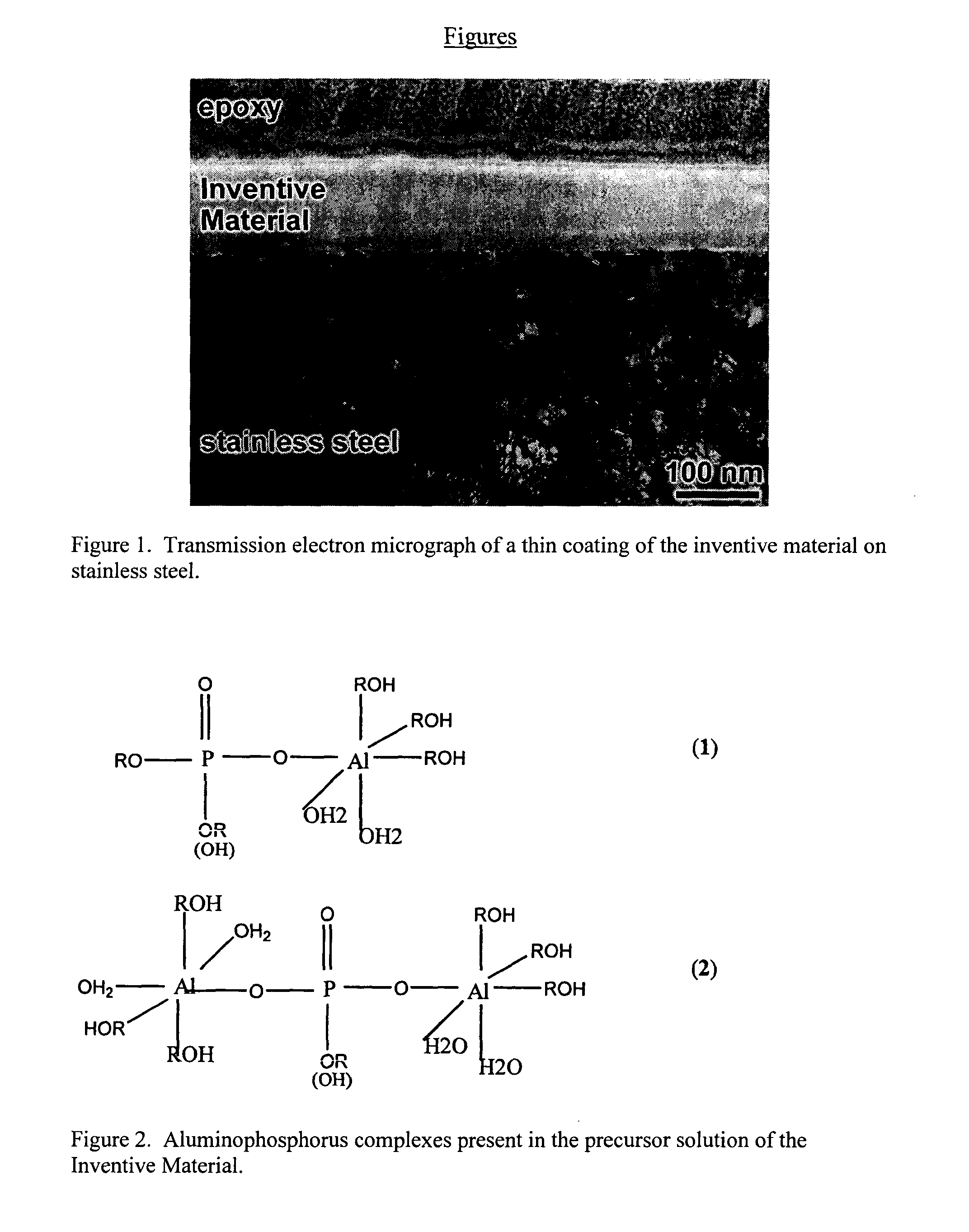

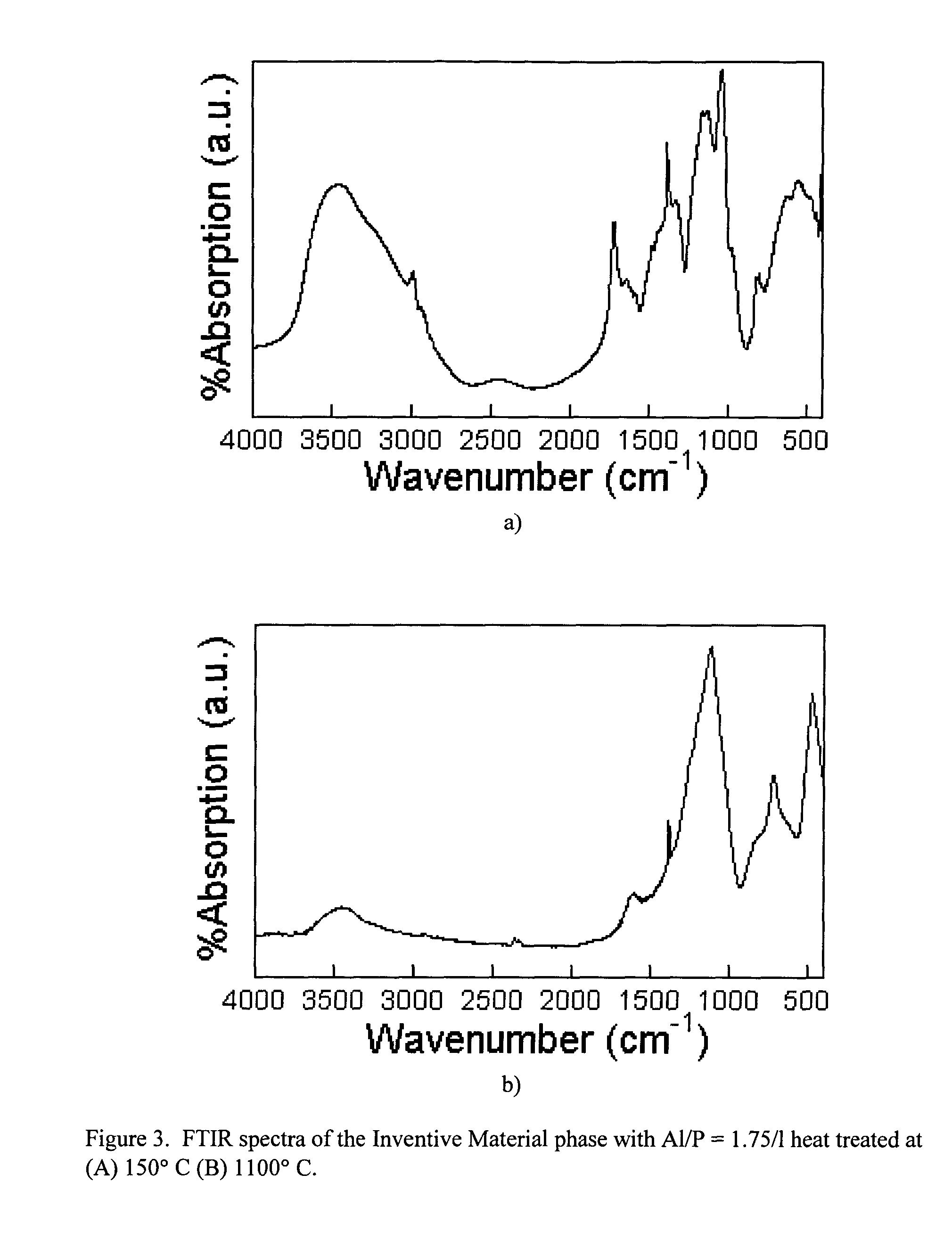

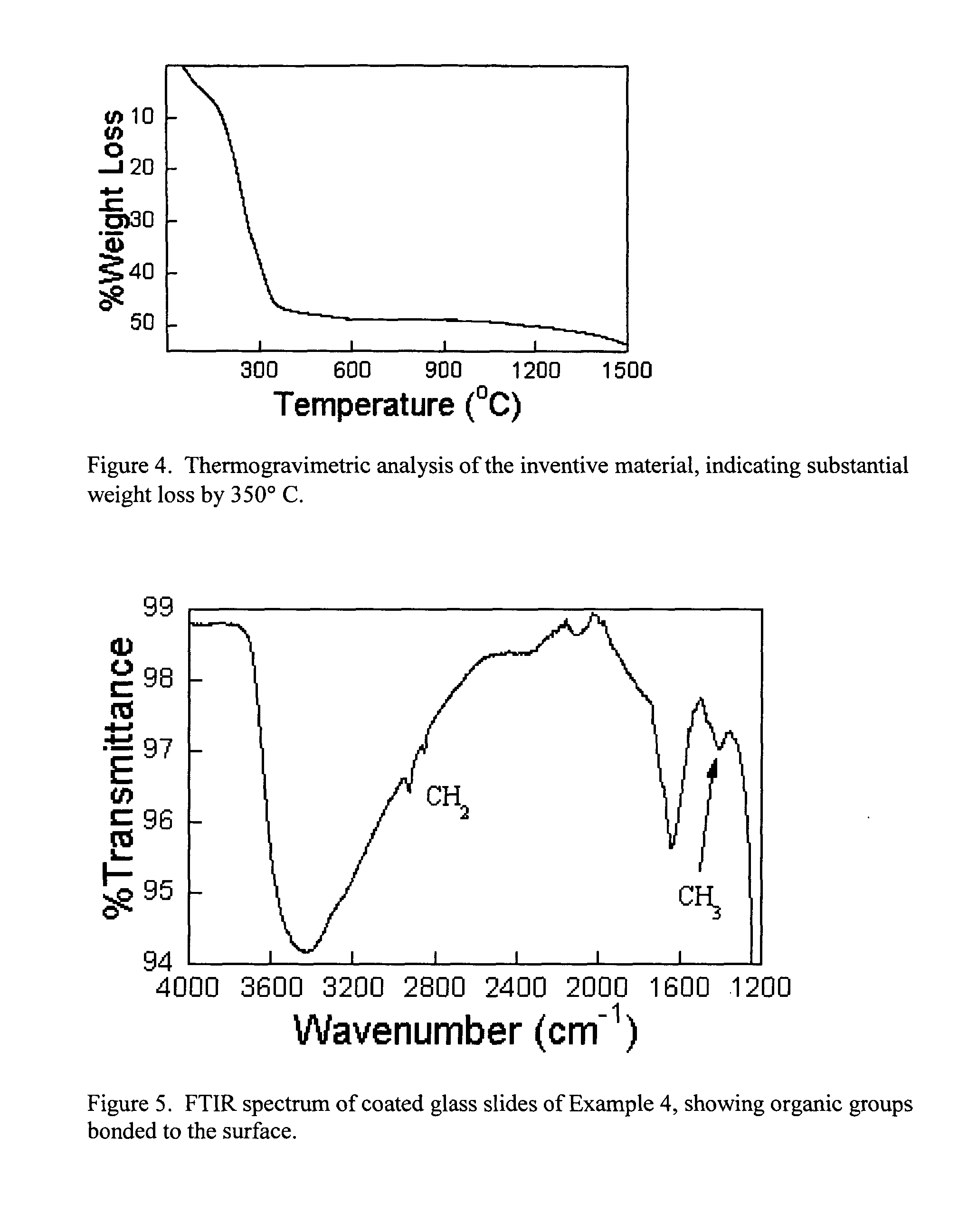

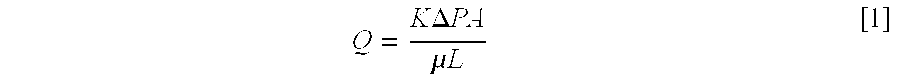

Aluminum phosphate compounds, compositions, materials and related composites

InactiveUS20050106384A1Control spreadImprove adhesionFilm/foil adhesivesPretreated surfacesNon oxide ceramicsMetallurgy

Owner:APPL THIN FILMS INC

Methods of using modified natural products as dewatering aids for fine particles

InactiveUS6375853B1Reduce moistureHigh degreeDrying solid materials without heatSolid fuelsNatural productTransesterification

Naturally occurring lipids of vegetable and animal origin are broken into smaller molecules, and used as dewatering aids. The process of breaking the molecules include transesterification, interesterification, and saponification followed by acidulation. The modified lipid molecules can adsorb on the surface of the particles to be dewatered and greatly enhance their hydrophobicity, which will help increase the rate of dewatering and hence reduce cake moisture. The modified lipids are more effective dewatering aids than the naturally occurring unmodified lipids, possibly because they can more readily form close-packed monolayers of hydrophobes on the surface of the particles.

Owner:YOON ROE HOAN

Method for producing special rutile type titanium white powder for power coating

ActiveCN101880479ALattice stabilizationGood dispersionPigment treatment with organosilicon compoundsPigment physical treatmentSlurryZircon

The invention discloses a method for producing special rutile type titanium white powder for power coating, which comprises the following steps of: preparing slurry of which titanium dioxide concentration is 300 to 400g / l by using bleached metatitanic acid, and adding a calcining auxiliary agent into the slurry; filtering the obtained metatitanic acid, then calcining solid, and grinding the solidto obtain a primary product; preparing titanium dioxide slurry of which titanium dioxide concentration is 650 to 850g / l by using the obtained primary product, adding a wetting agent into the titaniumdioxide slurry, and performing dispersion and grinding; heating the obtained titanium dioxide slurry to between 40 and 90 DEG C, adding dispersant, zircon salt or titanium salt, silicon salt and aluminum salt into the slurry in turn, adjusting the pH value to between 5 and 9, ageing the mixture, and adjusting the pH value to between 7 and 8; and then filtering, washing and drying the mixture, treating the dried product by an organic surface treatment agent, and vaporizing the product to obtain the rutile type titanium white powder. Compared with the prior art, the rutile type titanium white powder obtained by the method has the properties of stable crystal lattice, good dispersion, heat and yellowing resistance, and good oily whiteness, reducing power, covering power and weather resistance and the like; the appearance and properties of the rutile type titanium white powder are close to that of the rutile type titanium white powder prepared by a chlorination process; and the productionmethod has the advantages of easily obtained process raw materials and stable process control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

Novel nano calcium carbonate used for plastic film and preparation method thereof

InactiveCN101967298AImprove hydrophobicityAvoid reunionPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPolyolefinMechanical property

The invention discloses novel nano calcium carbonate used for a plastic film and a preparation method thereof. A Ca(OH)2 suspension and CO2 are carbonized in a reactor to generate the nano calcium carbonate, and then the obtained nano calcium carbonate is subjected to liquid phase coating treatment or is directly subjected to mixed coating by using dried nano calcium carbonate and a surfactant to obtain nano calcium carbonate powder which is highly dispersed and surface-activated. The invention has the advantages that: the process is simple, the nano calcium carbonate is effectively dispersed in a polymer and a remarkable enhancement effect can be achieved on the premise of ensuring the transparency. The nano calcium carbonate prepared by adopting the invention can remarkably improve the mechanical property of a polyolefin material; after the nano calcium carbonate is used for polyethylene plastic, the tension strength of the material is greatly improved; and after the nano calcium carbonate is used for a polyolefin film, a fish eye is free, and the high transparency of the film is maintained.

Owner:山东海泽纳米材料有限公司

Treated filler and process for producing

The present invention is related to treated filler and processes for producing said treated filler. Untreated filler slurry can be treated with a treating material and, optionally, a coupling material and then subjected to conventional drying method(s), to produce the treated filler of the invention. Treated filler has a wide variety of applications including but not limited to battery separators and rubber compositions such as tires.

Owner:PPG IND OHIO INC

Dopamine surface modified two-dimensional nano material and preparation method thereof

InactiveCN107216689AGood dispersionGood compatibilityPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsHeat conductingOrganic matter

The invention relates to a dopamine surface-modified two-dimensional nanometer material and a preparation method. A two-dimensional nanometer material wrapped with polydopamine is prepared through a one-step reaction. The invention solves the problem of poor dispersion of traditional two-dimensional nanometer materials in interstitium (water, organic matter). This characteristic preparation method provides a method for modifying the surface of two-dimensional nanomaterials with dopamine. After the surface of two-dimensional nanomaterials is modified by dopamine, functional groups (hydroxyl and amino groups) are successfully introduced. Compatibility between matter and two-dimensional nanomaterials. Therefore, this invention has great scientific significance, and has great practical application value in the production of friction-resistant composite materials, lubricating grease, and heat-conducting composite materials.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Reaction of carbon black with diazonium salts, resultant carbon black products and their uses

Processes for preparing a carbon black product having an organic group attached to the carbon black. In one process at least one diazonium salt reacts with a carbon black in the absence of an externally applied electric current sufficient to reduce the diazonium salt. In another process at least one diazonium salt reacts with a carbon black in a protic reaction medium. Carbon black products which may be prepared according to process of the invention are described as well as uses of such carbon black products in plastic compositions, rubber compositions, paper compositions, and textile compositions.

Owner:CABOT CORP

Method for preparing core-shell silicon dioxide-coated ammonium polyphosphate (APP)

ActiveCN101760049ALow water solubilityHigh strengthSilicaPigment treatment with non-polymer organic compoundsMass ratioSilicon dioxide

The invention relates to a method for preparing core-shell silicon dioxide-coated ammonium polyphosphate (APP), which is characterized by comprising the following steps successively: (1) adding ammonium polyphosphate into ethanol water solution, stirring and dispersing well; (2) adding silicate ester ethanol solution into the solution obtained in the step (1) while the mass ratio of silicate ester to ammonium polyphosphate is 0.05-10:1, adjusting the pH value of the solution to 9-12 by adding alkaline solution, and then performing complete reaction at room temperature; and (3) adding couplingagent into the grout obtained in the step (2) to carry out surface treatment, and then filtrating, washing and drying to obtain the silicon dioxide-coated ammonium polyphosphate. On one hand, the ammonium polyphosphate flame retardant utilizes the synergistic flame retardance of silicon and phosphorus elements to increase retardant effectiveness and reduce dosage, thereby bringing down the negative effects of APP; on the other hand, the ammonium polyphosphate flame retardant utilizes the advantages of silicon dioxide, such as excellent hydrophobicity, heat resistance, high strength and the like, to further solve the problems of APP such as infiltration and migration, influence on product strength, insufficient heat resistance and the like.

Owner:浙江富锦新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com