Patents

Literature

108 results about "Fine dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silica coated carbon blacks

InactiveUS6197274B1Alkali metal halidesPigment treatment with organosilicon compoundsElastomerOrganic group

Silica coated carbon blacks are disclosed and can be prepared by coating a fine dispersion of carbon black, such as a carbon black having an attached organic group(s). Compositions and articles of manufacture, including elastomeric compositions, containing such carbon black are also disclosed.

Owner:CABOT CORP

Continuous manufacturing method for rubber masterbatch, rubber masterbatch prepared by using continuous manufacturing method and rubber product

The invention relates to a continuous manufacturing method for rubber masterbatch, the rubber masterbatch prepared by using the continuous manufacturing method and a rubber product. The manufacturing method comprises the following steps: 1) adding a filling material into a rubber solution, carrying out stirring so as to form a rubber / filling material / solvent mixture and subjecting the rubber / filling material / solvent mixture to further fine dispersion and refined dispersion so as to improve the dispersion degree of the filling material in the rubber solution; 2) subjecting rubber and the filling material in the rubber / filling material / solvent mixture having undergone refined dispersion in step 1) to hetero-coagulation so as to obtain a mixture of a rubber / filling material compound and a solvent; and 3) removing the solvent and drying the mixture so as to obtain the rubber / filling material masterbatch. The invention further provides the masterbatch prepared by using the manufacturing method and the rubber product prepared from the masterbatch. Compared with a conventional wet rubber compounding technology, the invention has the following advantages: there are no special requirements on rubber and the filling material, the prepared masterbatch has a wide application scope, and dispersity of the filling material in a rubber compound is accordingly improved.

Owner:EVE RUBBER RES INST

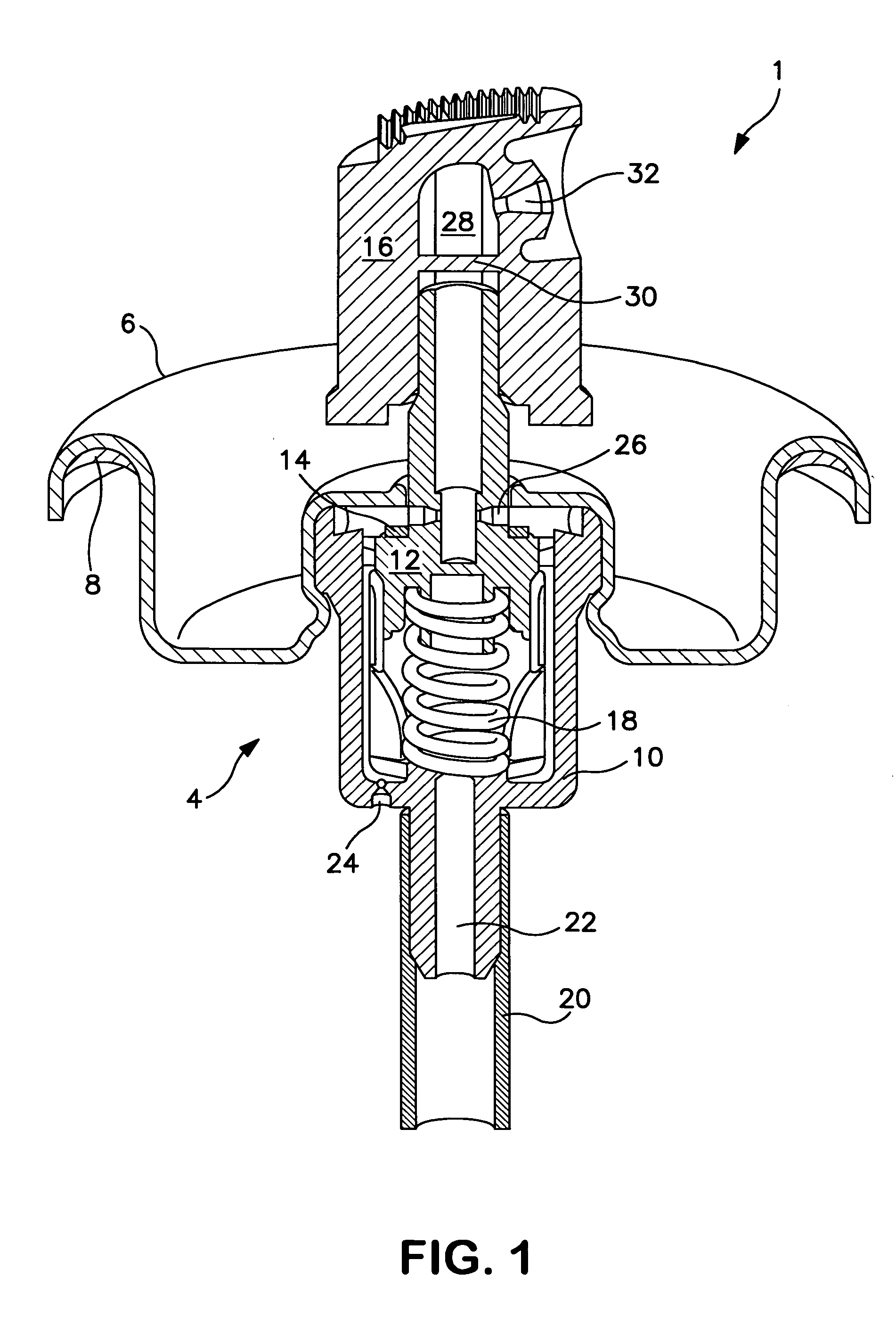

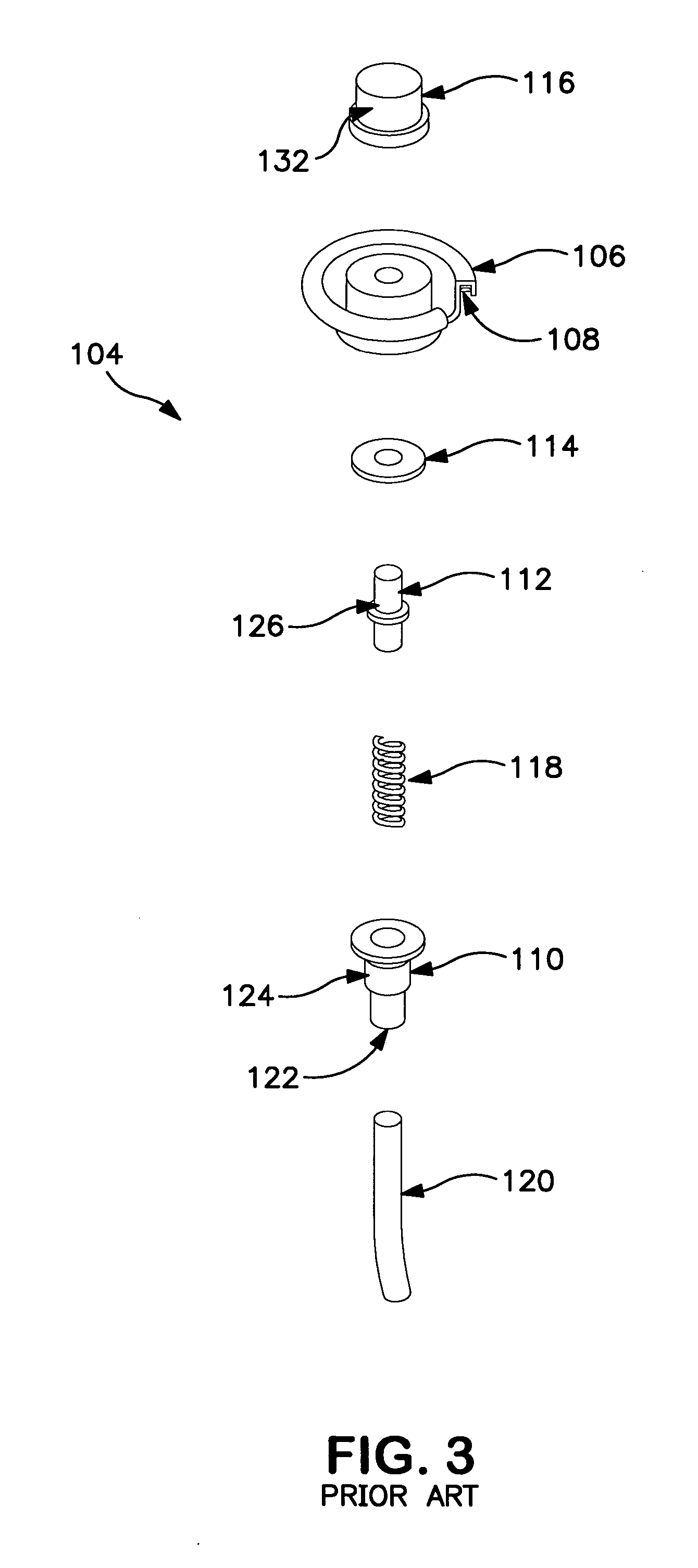

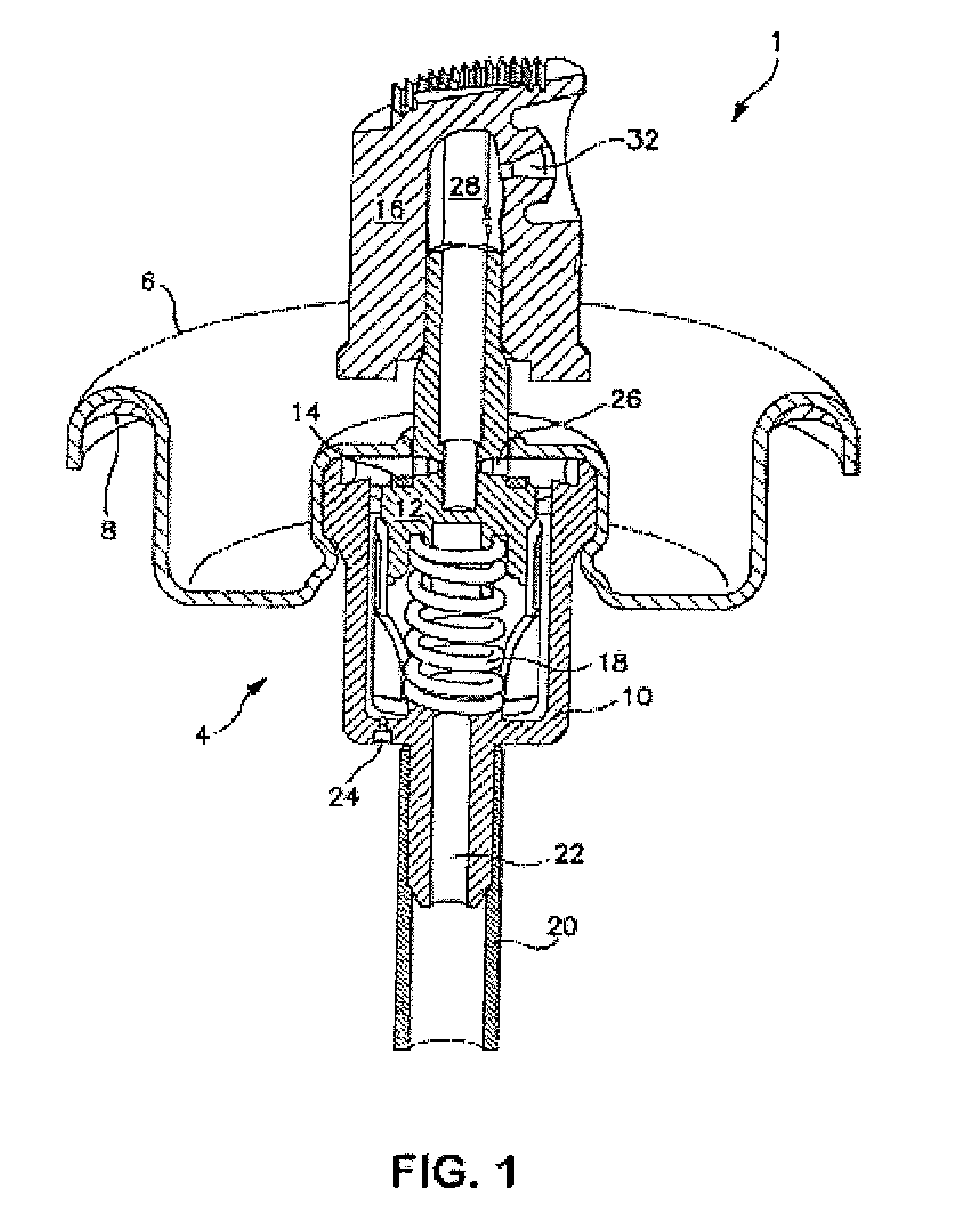

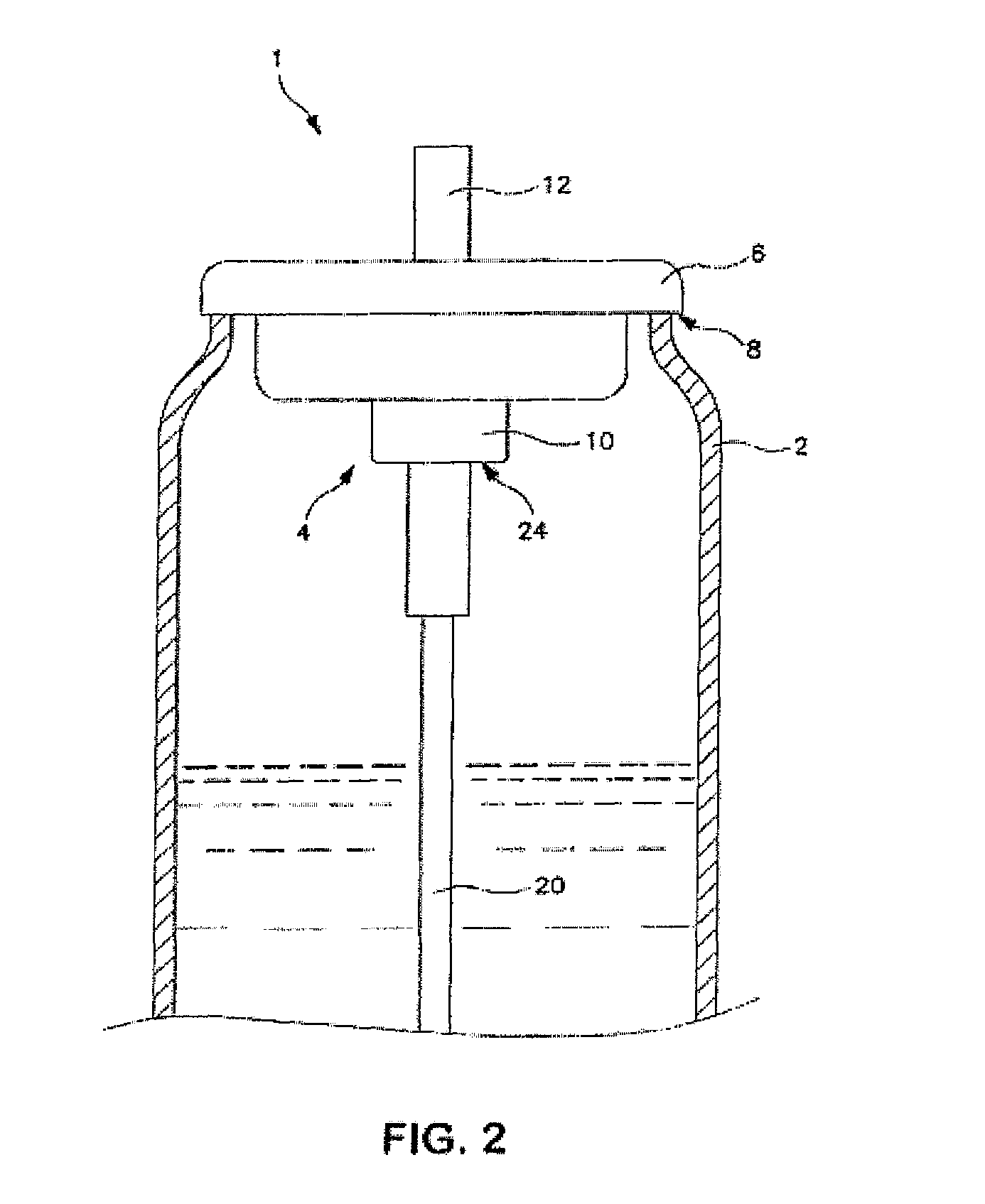

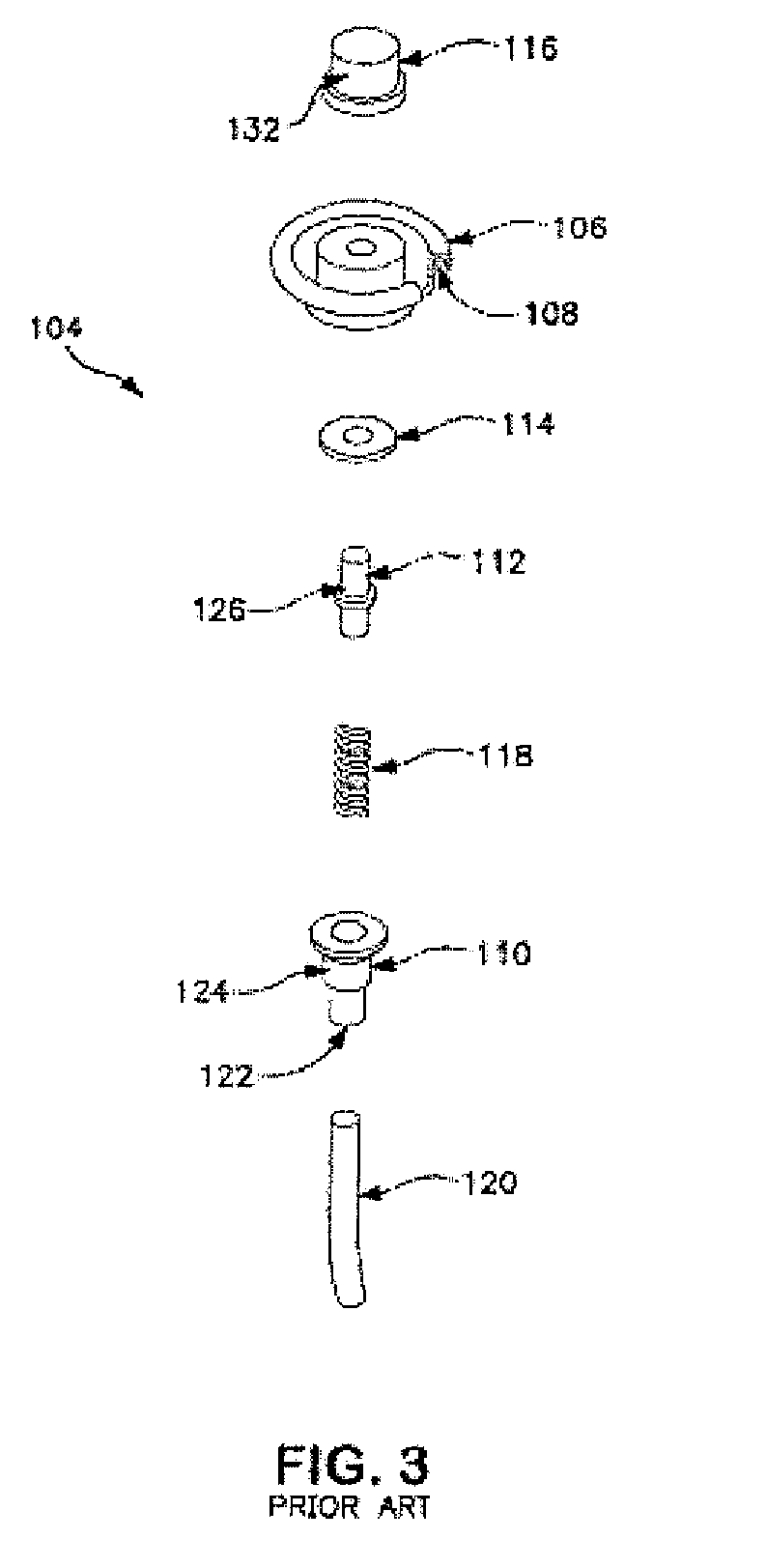

Composition and Aerosol Spray Dispenser for Eliminating Odors in Air

ActiveUS20070194040A1Fast absorptionGood dispersionOther chemical processesAerosol deliveryAdjuvantEngineering

An air treating composition for eliminating airborne malodors and / or sanitizing air in combination with a spray valve and actuator and spray performance parameters providing maximum dispersion of the composition is disclosed. The particles of the composition are small so that the active component is dispersed into air as a fine dispersion to provide more contact with malodors and to provide quick absorption of malodors and / or bacteria. The particle size of the composition is controlled through the valve and actuator dimensions, as well as the formulation requirements of the composition. The air treating composition includes water, a low molecular weight polyol, and a propellant The composition may also include one or more adjuvants such as an emulsifier, a co-solvent, a fragrance, a corrosion inhibitor, a pH adjusting agent and the like.

Owner:SC JOHNSON & SON INC

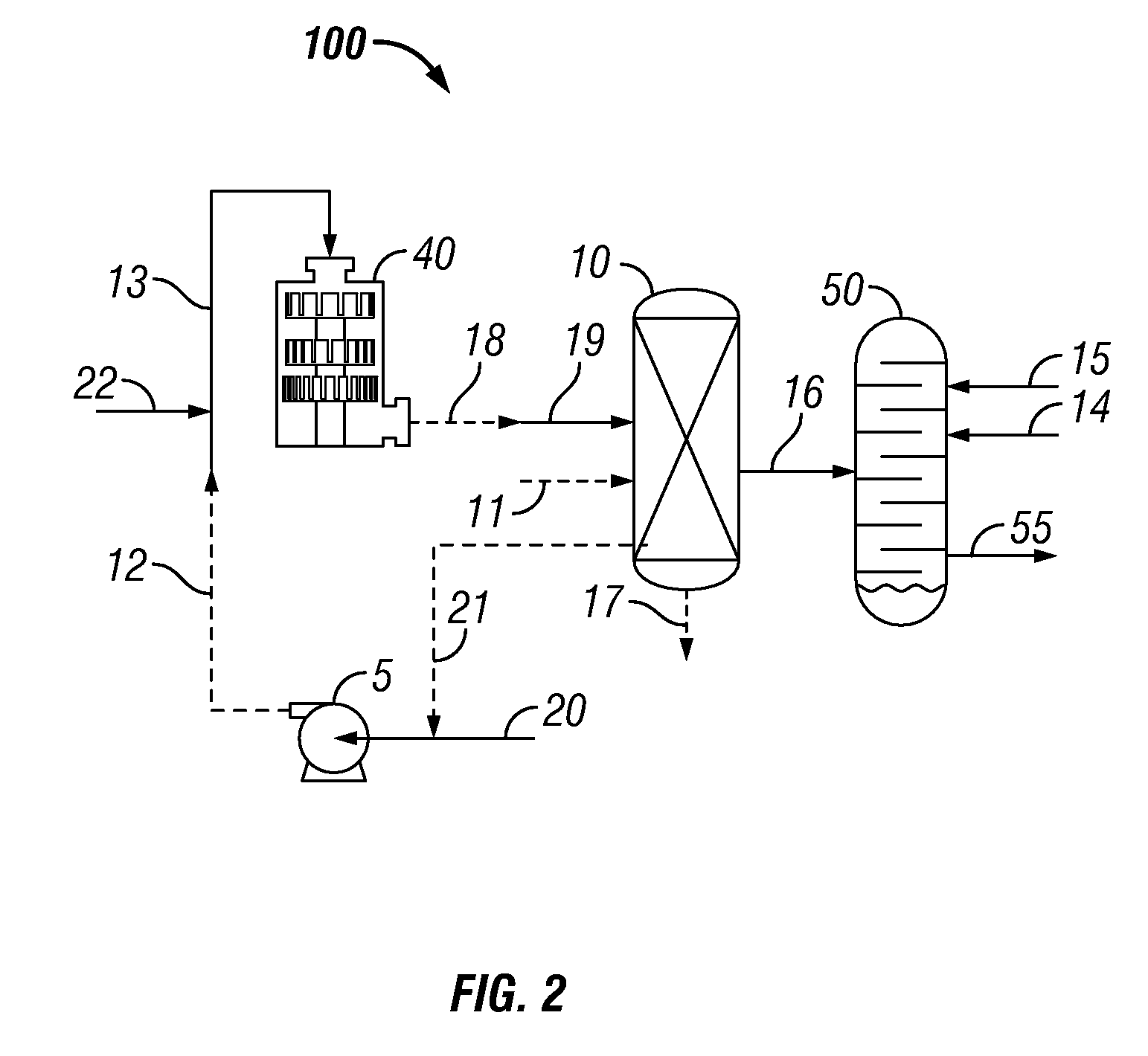

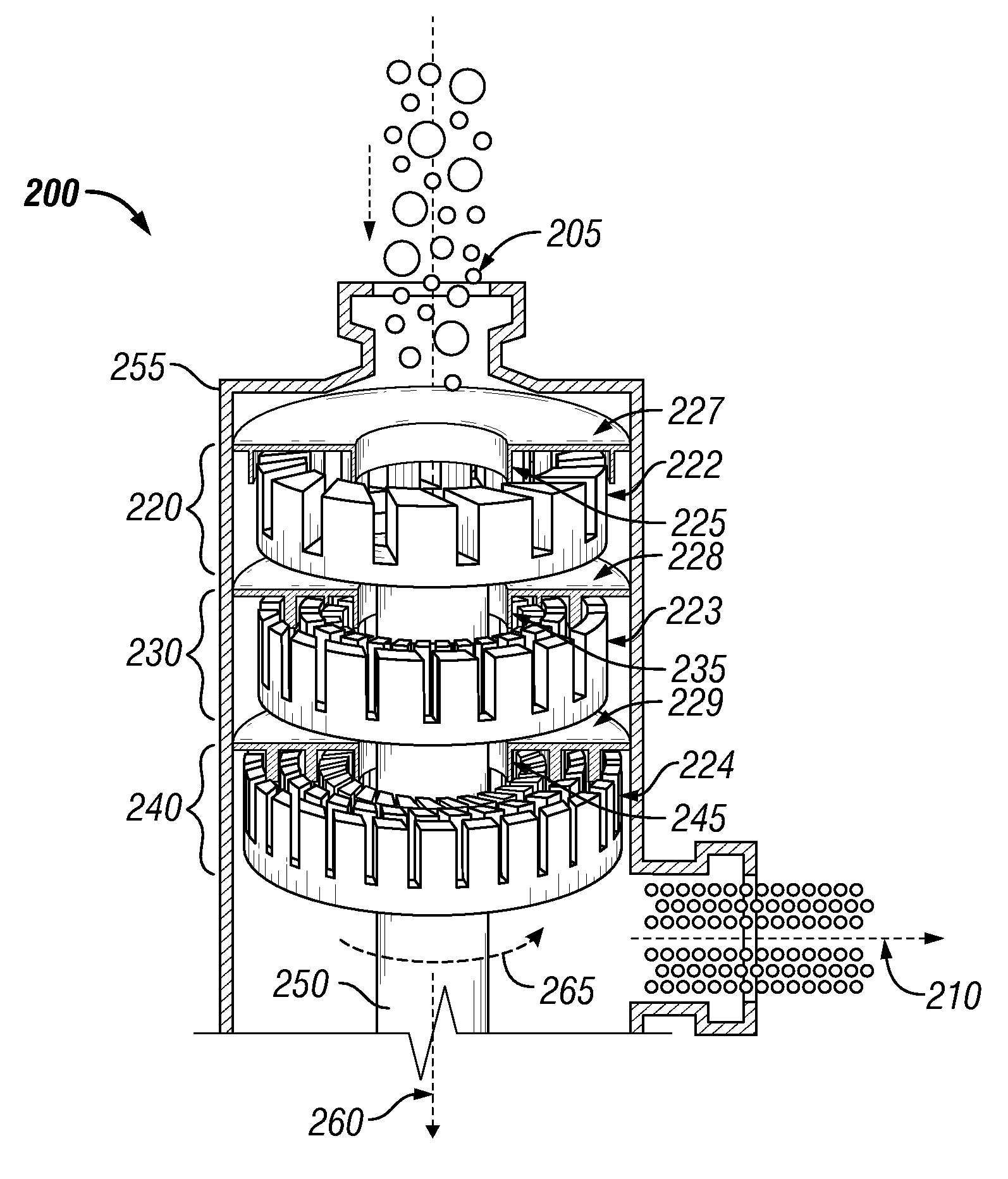

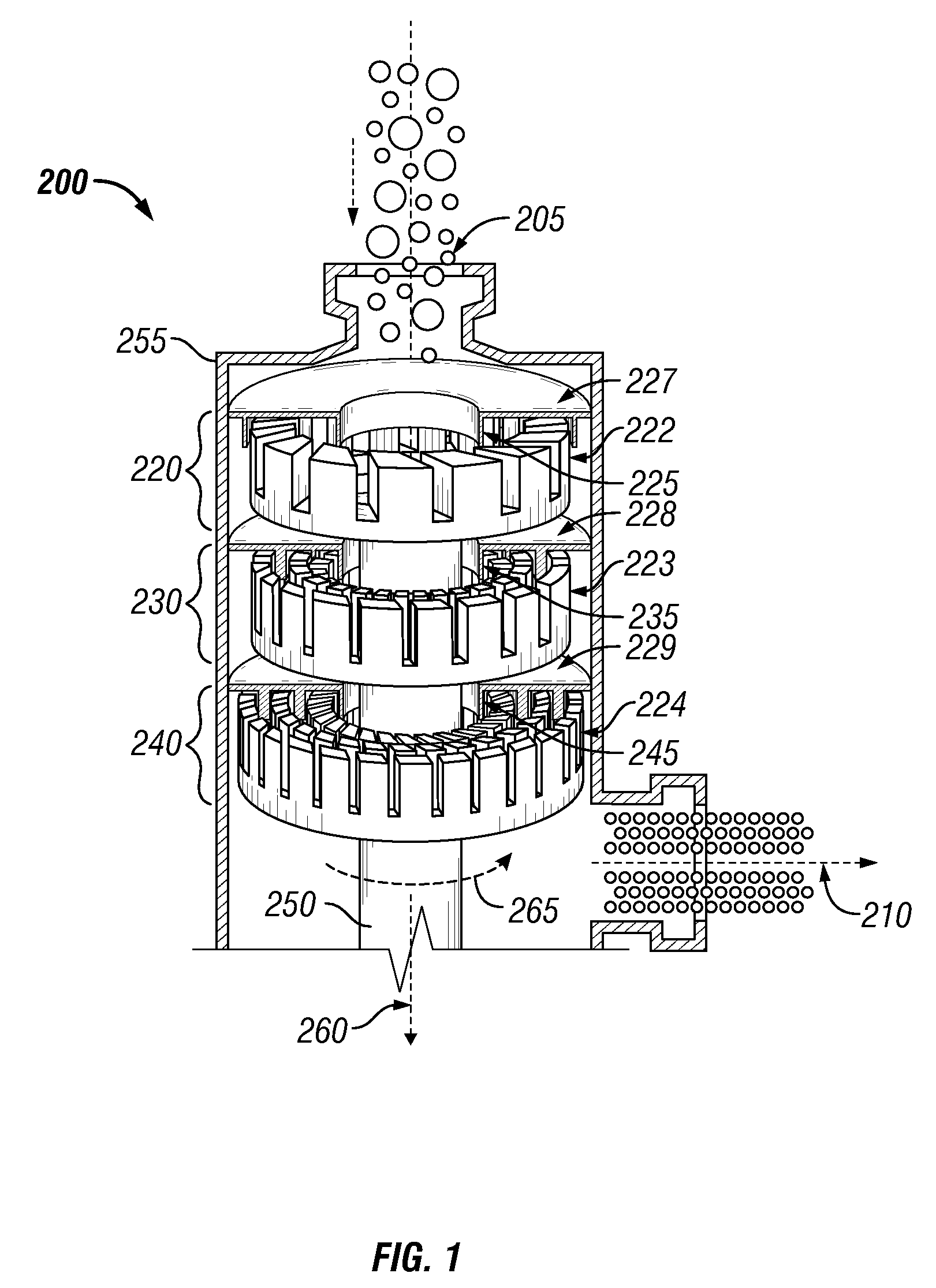

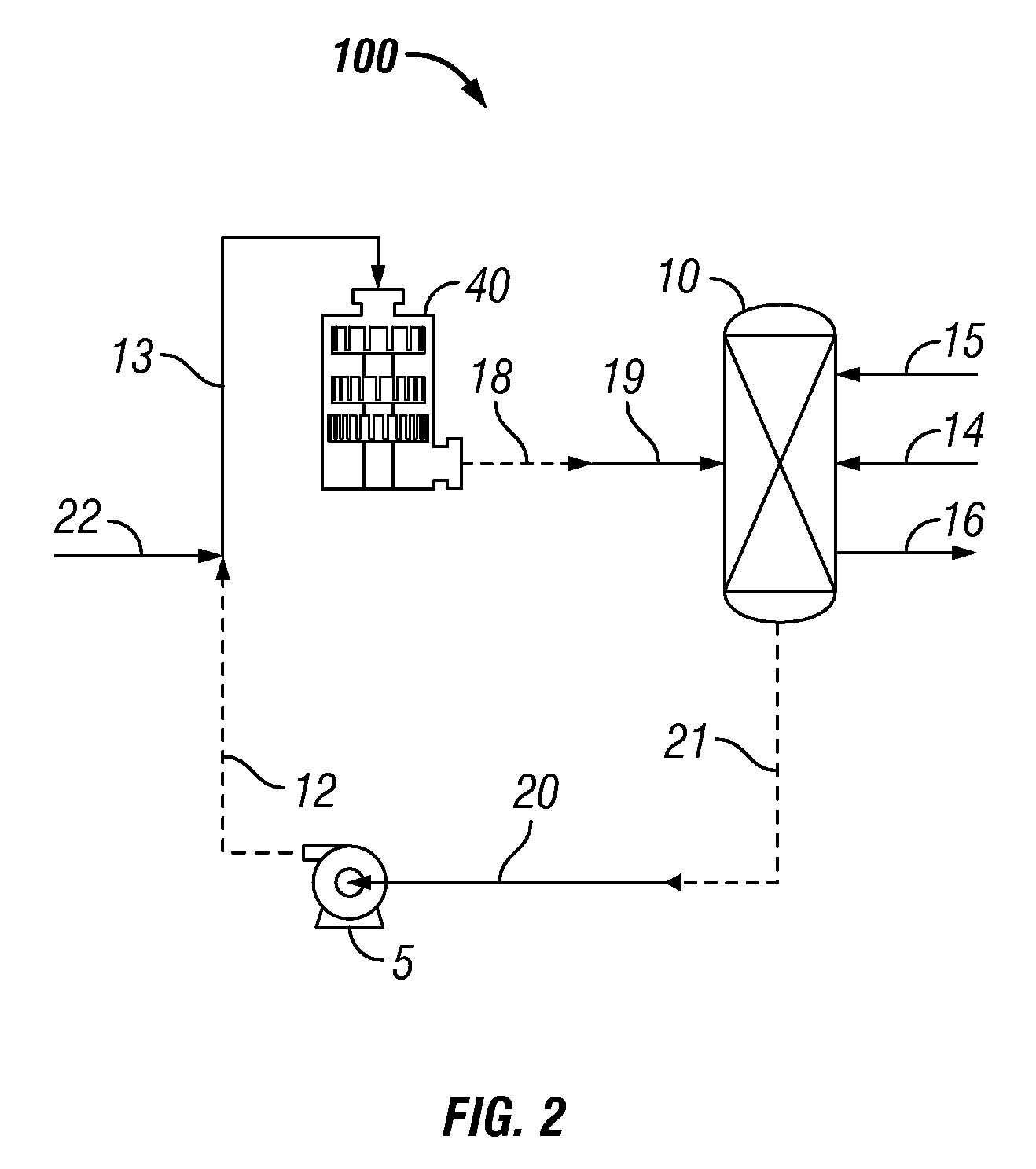

High shear process for dextrose production

InactiveUS20090005553A1Reduce the total massImprove production yieldSugar derivativesTransportation and packagingEmulsionHydrolysate

Use of a high shear mechanical device in a process for production of starch hydrolysate by reacting starch with a hydrolytic agent makes possible a decrease in mass transfer limitations, thereby enhancing production of starch hydrolysate. A system for production of starch hydrolysate is also provided in which a reactor is configured to receive the output from a high shear device, which is configured to receive a starch and lysing reagent. The high shear device is configured to generate a fine dispersion or emulsion of lysing.

Owner:HRD CORP

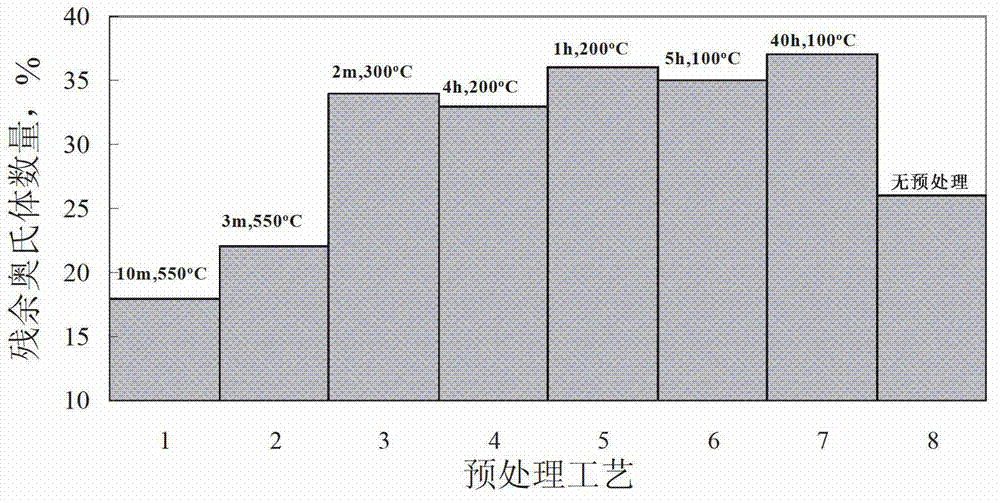

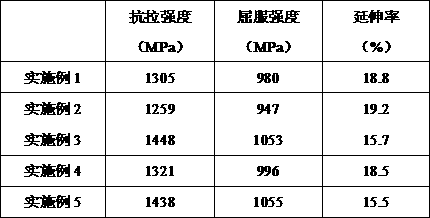

Method for producing high-strength and elongation product automobile steel plate by continuous annealing technology

The invention provides a method for producing a high-strength and elongation product automobile steel plate by a continuous annealing technology, belonging to the technical field of an automobile steel plate. The method comprises the following steps: based on the reasonable chemical component design and the alloy element partition, firstly, obtaining transition carbide with fine dispersion distribution by a cold rolled plate coil importantly, and promoting austenite inverse phase transformation through the solid solution of the fine carbide through two-phase region annealing, to obtain more and stable austenite phases to be remained. According to the method, the strict technological conditions for forming the finely-dispersed carbide and the strict interval for carrying out the technological parameters of the two-phase region annealing are given, so that the method has the advantages that the continuous annealing plate coil which is even in performance and good in surface quality can be obtained due to the short-time annealing of the existing continuous annealing production line of a steel factory, wherein the strength of the steel plate is 0.6-1.2GPa, the percentage elongation of the steel plate is 45-20%, and the product of strength and elongation is 25-40GPa%.

Owner:CENT IRON & STEEL RES INST

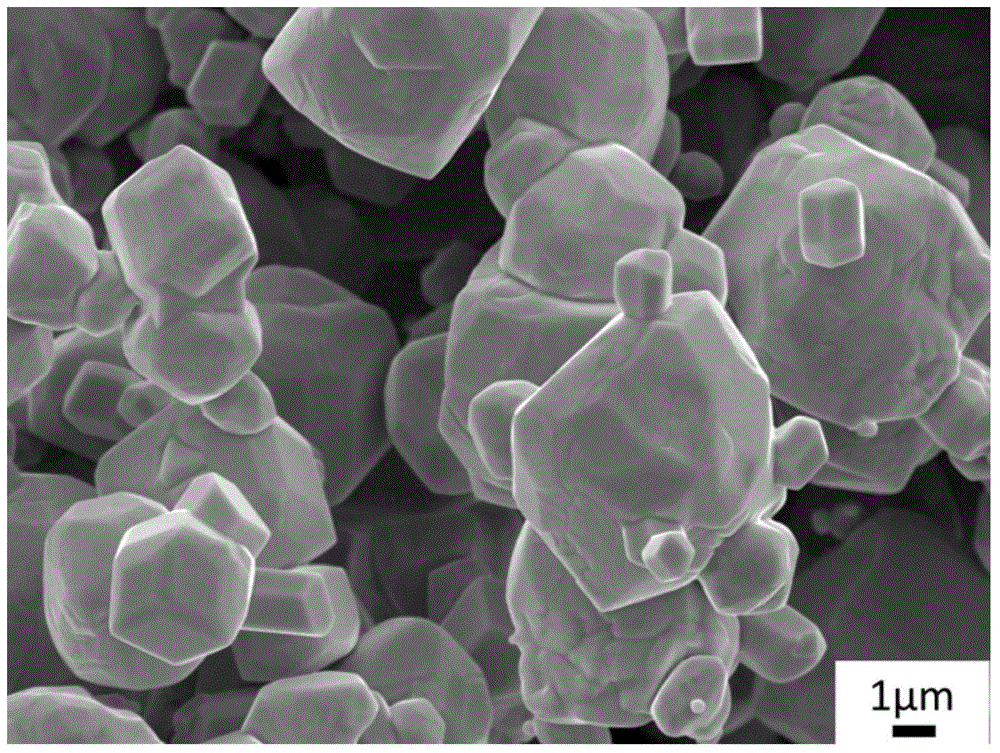

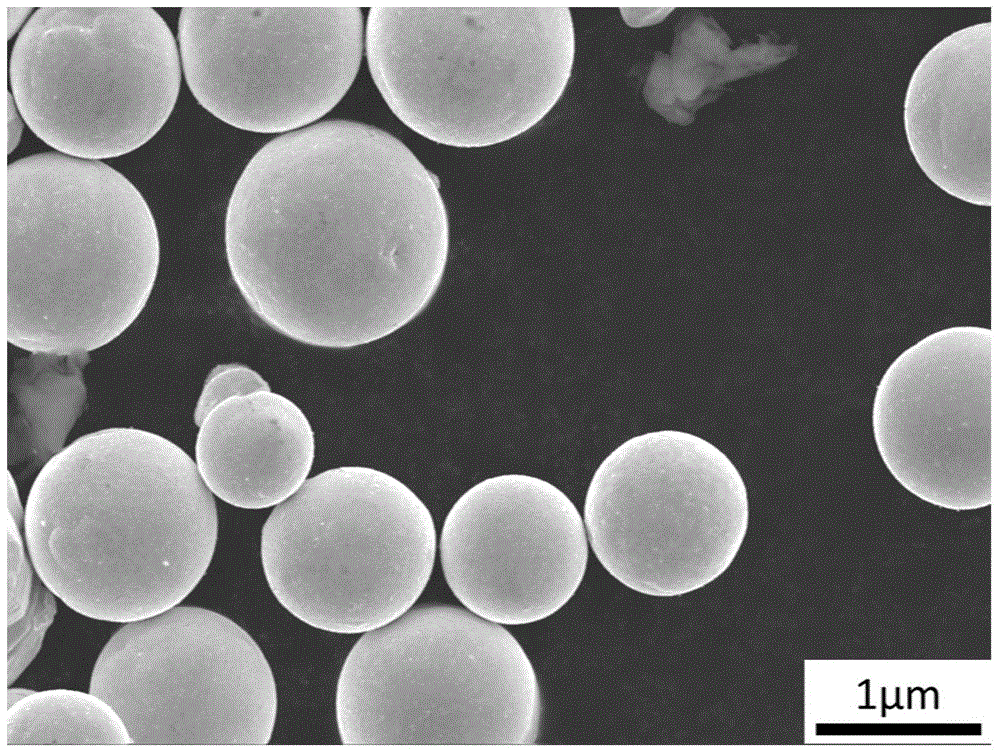

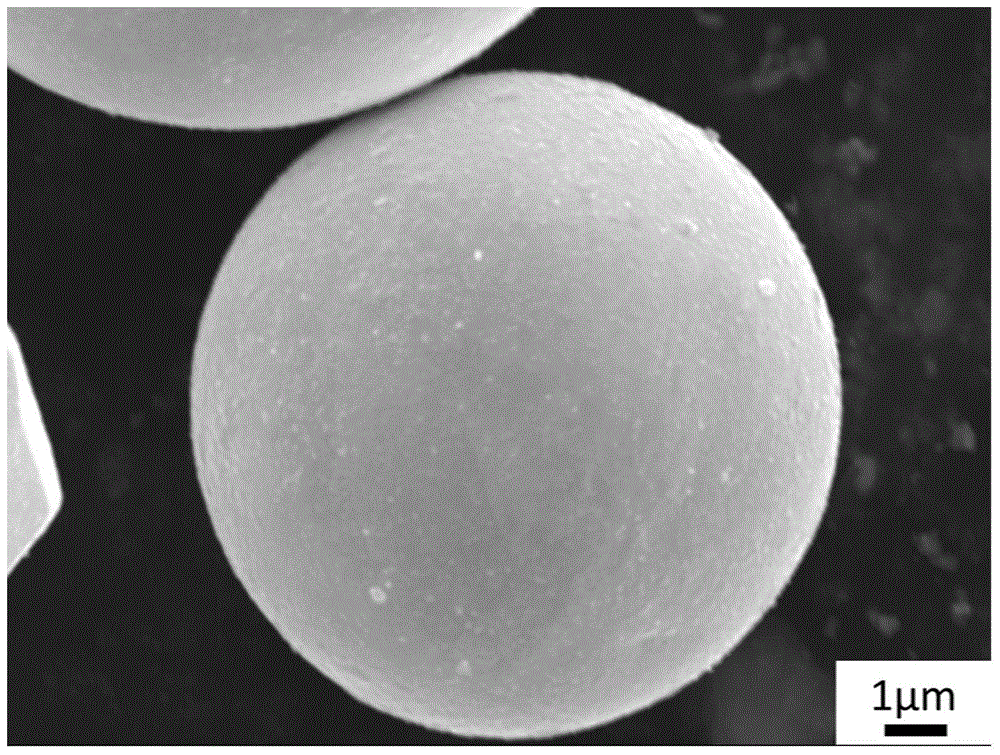

Spherical copper coating tungsten composite powder, preparation method and application thereof

The invention relates to a spherical copper coating tungsten composite powder, a preparation method and an application thereof. The copper coating tungsten composite powder is in a core-shell structure, the shell is a copper plating layer, the core is tungsten powder, and the weight ratio of the tungsten elements and copper elements of the copper coating tungsten composite powder ranges from 5 to 95 : 95 to 5; the spherical copper coating tungsten composite powder has the advantages of fine dispersion performance, high liquidity, even ingredients and high purity. The preparation method includes processing ordinary tungsten powder by a plasma spheroidizing technology, allowing the copper to deposit on the surface of the tungsten powder evenly by the intermittent copper electroplating process, and cleaning and drying the composite powder coated with copper. The spherical copper coating tungsten composite powder is prepared by combining the plasma spheroidizing and intermittent copper electroplating, the method is simple, reliable and easy to operate, the electroplating speed, the electroplated layer thickness and copper content range can be adjusted effectively, the copper-tungsten composite material comprehensive performances can be improved effectively, the expanded application prospect is provided, and the method can be applied to industrialized mass production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Composition and its physical requirements for eliminating odors in air

ActiveUS20060292111A1Reasonable delivery rateQuantity minimizationBiocideCosmetic preparationsAdjuvantEngineering

An air treating composition for eliminating odors from air in combination with specific spray valve and actuator requirements and spray performance parameters providing maximum dispersion of the active component in the composition into the air is disclosed. The particles of the composition are small so that the active component is dispersed into air as a fine dispersion to provide more contact with odors and to provide quick absorption of odors. The particle size of the composition is controlled through the selection of valve and actuator dimensions. The air treating and odor eliminating composition of the invention includes water, a low molecular weight polyol, an emulsifier, and a propellant. The composition may also include additional adjuvants such as solvent(s), fragrance(s), corrosion inhibitor, pH adjustor and the like.

Owner:SC JOHNSON & SON INC

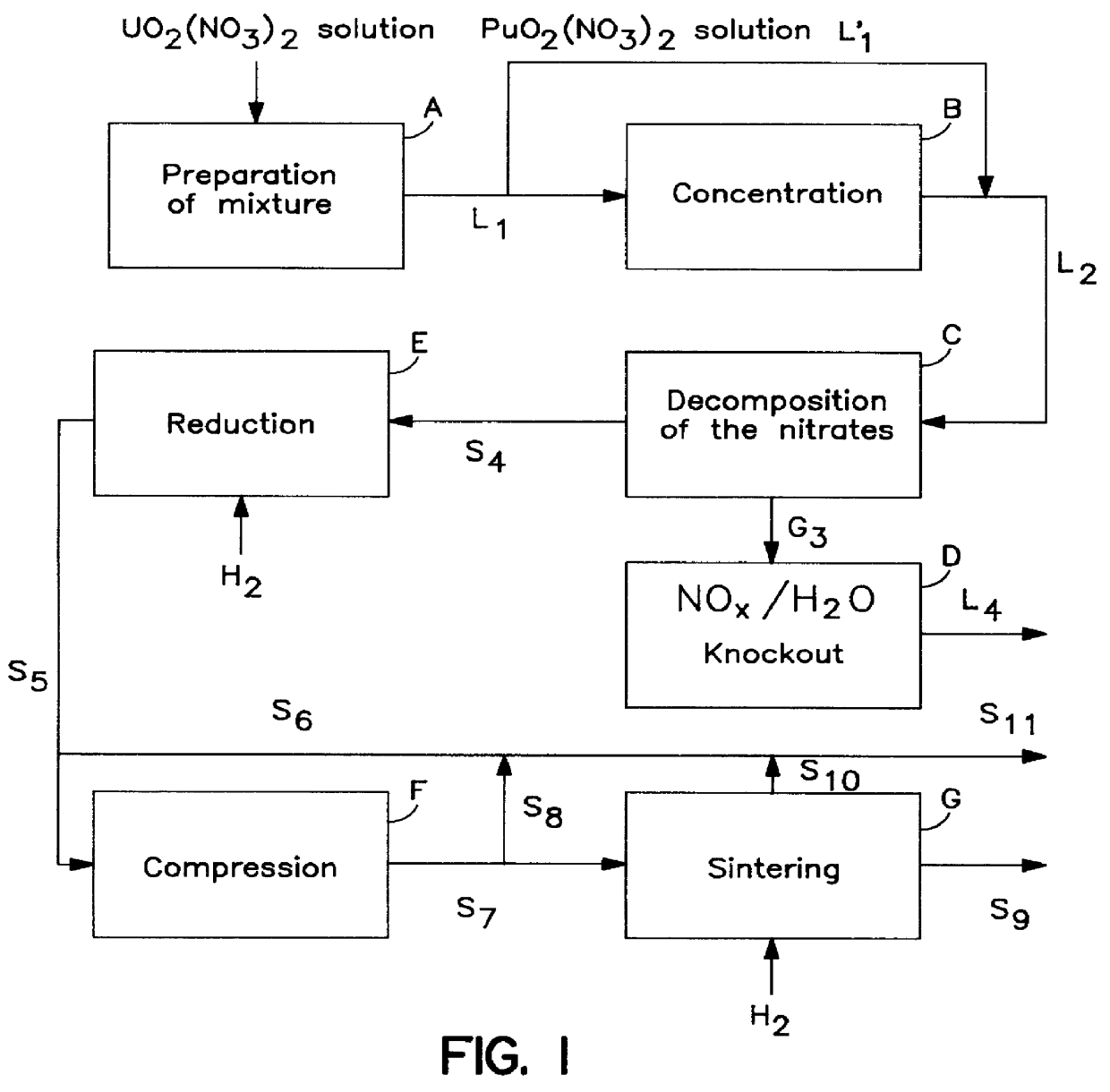

Method for preparing a mixture of powdered metal oxides from nitrates thereof in the nuclear industry

InactiveUS6110437AEasy to recycleImprove responseOxygen/ozone/oxide/hydroxideTransuranic element compoundsPowder mixtureNitrate

PCT No. PCT / FR96 / 01993 Sec. 371 Date Mar. 2, 1999 Sec. 102(e) Date Mar. 2, 1999 PCT Filed Dec. 12, 1996 PCT Pub. No. WO97 / 21629 PCT Pub. Date Jun. 19, 1997A thermal decomposition method useful in the nuclear industry for preparing a powdered mixture of metal oxides having suitable reactivity from nitrates thereof in the form of an aqueous solution or a mixture of solids. According to the method, the solution or the mixture of solids is thermomechanically contacted with a gaseous fluid in the contact area of a reaction chamber, said gaseous fluid being fed into the reaction chamber at the same time as the solution or mixture at a temperature no lower than the decomposition temperature of the nitrates, and having a mechanical energy high enough to generate a fine spray of the solution or a fine dispersion of the solid mixture, and instantly decompose the nitrates. The resulting oxide mixtures may be used to prepare nuclear fuels.

Owner:COMURHEX

Rock asphalt composite modifier and its preparation method and use

The invention discloses a rock asphalt compound modifier and a preparation method and use of the rock asphalt compound modifier. The rock asphalt compound modifier is composed of rock asphalt and polymer, wherein, the amount of the rock asphalt is 10 percent to 90 percent and the amount of the polymer is 10 percent to 90 percent in weight percentage. The preparation method is that the rock asphalt and the polymer are mixed together by a twin screw extruder in proportion, and then are granulated by a cold bracing and granulating equipment. The use of the rock asphalt compound modifier is that the rock asphalt compound modifier is put into an asphalt mixture mixing plant to be mixed with hot mineral aggregation for 5 to 20 seconds, and then basic asphalt is sprayed in to be mixed with the hot mineral aggregation for 20 to 60 seconds, at last the compound modified asphalt mixture is prepared. The rock asphalt compound modifier is in granular shape and has the advantages of accurate adding measurement, fine dispersion, uniform mixing and convenient construction. The compound modified asphalt mixture is suitable for paving the roads in high grade with further improved performance.

Owner:交通部公路科学研究院 +1

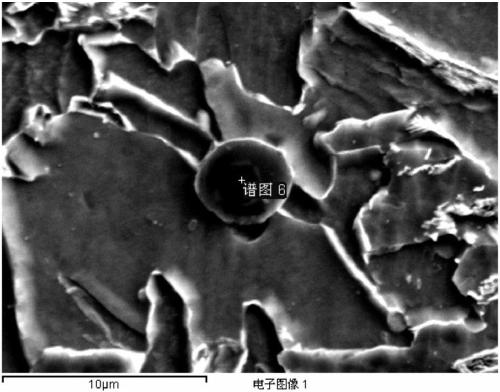

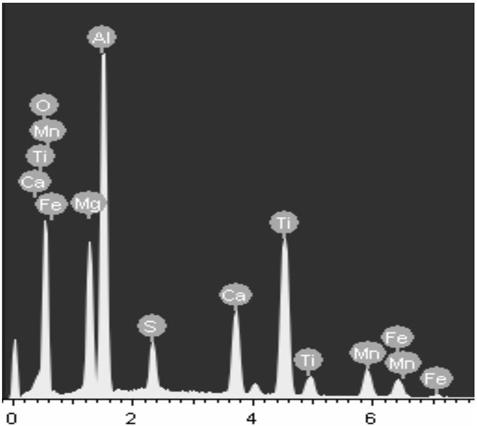

Thick steel plate suitable for large heat input welding in EH420 grade marine engineering and preparation method thereof

ActiveCN109321847AImprove nucleation abilityGood for fine dispersionMetal rolling arrangementsManganeseAlloy

The invention belongs to the technical field of low-alloy high-strength steel, and particularly relates to a thick steel plate suitable for large heat input welding in EH420 grade marine engineering and a preparation method of the thick steel plate. The steel plate comprises the following chemical components of, by mass percentage, 0.05-0.12% of C, 0.1-0.3% of Si, 1.0-1.7% of Mn, 0.001-0.01% of P,0.001-0.005% of S, 0.01-0.04% of Nb, 0.005-0.025% of Ti, 0.2-0.5% of Cu, 0.2-0.5% of Ni, 0.001-0.006% of N, 0.001-0.005% of O, 0.005-0.025% of Al, 0.0005-0.005% of Mg, 0.0005-0.005% of Ca and the balance of Fe. Al-Mg-Ti-Ca-Mn-O-S composite inclusions account for more than 10% of inclusions with the sizes of 0.5-5 [mu]m in the steel plate and have special compositions. The steel plate is preparedaccording to the steps of adding silicon and manganese when steel is discharged from a converter, and feeding calcium wires, titanium wires, magnesium wires and aluminum wires during LF and RH refining; and adopting two-stage controlled rolling and controlled cooling. Particles of the inclusions in the steel plate are favorable for fine dispersion and distribution, have a better capability of promoting acicular ferrite nucleation, and can obviously improve low-temperature toughness of large heat input welding.

Owner:NORTHEASTERN UNIV +1

High shear process for aspirin production

InactiveUS20090005592A1Simple reaction conditionsIncrease ratingsOrganic compound preparationRotary stirring mixersAspirinEmulsion

Use of a high shear mechanical device in a process for production of acetyl salicylic acid, by contacting acetic anhydride with salicylic acid in a high shear device. The disclosed process makes possible a decrease in mass transfer limitations, thereby enhancing production of acetyl salicylic acid. A system for production of acetyl salicylic acid is also provided in which a reactor is configured to receive the output from a high shear device, which is configured to receive, via one or more inlets, acetic anhydride, and salicylic acid and generate a fine dispersion or emulsion of reactants.

Owner:HRD CORP

Dispersed precipitated phase strengthened austenitic stainless steel with high Cr and high Ni and thermal processing method

InactiveCN103173698AImprove high temperature strengthImproved resistance to radiation swellingThermoformingCu element

The invention relates to dispersed precipitated phase strengthened austenitic stainless steel with high Cr and high Ni and a thermal processing method. The stainless steel component comprises the components in percentage by weight as follows: 0.2-0.8% of Si, not greater than 2% of Mn, 20-28% of Cr, 16-25% of Ni, not greater than 3% of Mo, 0-1% of Ti, 0-1% of W, 0-1% of Zr, 0-1% of V and the balance of Fe. The method comprises the following steps of: weighing according to the component proportion, refining and moulding; thermally forging, wherein the thermal rolling process is that rolling in four gates at 1180-1230 DEG C with the final rolling temperature over 1030 DEG C, wherein deformation is not less than 40% every time, and quenching and cooling; insulating for 20min to 1 hour at 1120-1200 DEG C; immediately quenching; performing high temperature annealing treatment at 950-1050 DEG C, insulating for 1.5-4 hours, then, furnace cooling or air cooling to room temperature, and directly quenching and quickly cooling. According to the invention, MC phase is separated out in the high temperature deformation process by comprehensively adding Ti, W, V, Zr and C elements. After thermal forming, relative materials are separated out through fine dispersion. Dimension of a second precipitated phase is controlled by the cooling rate through controlling subsequent thermal deformation processing parameters and the thermal treatment system.

Owner:UNIV OF SCI & TECH BEIJING

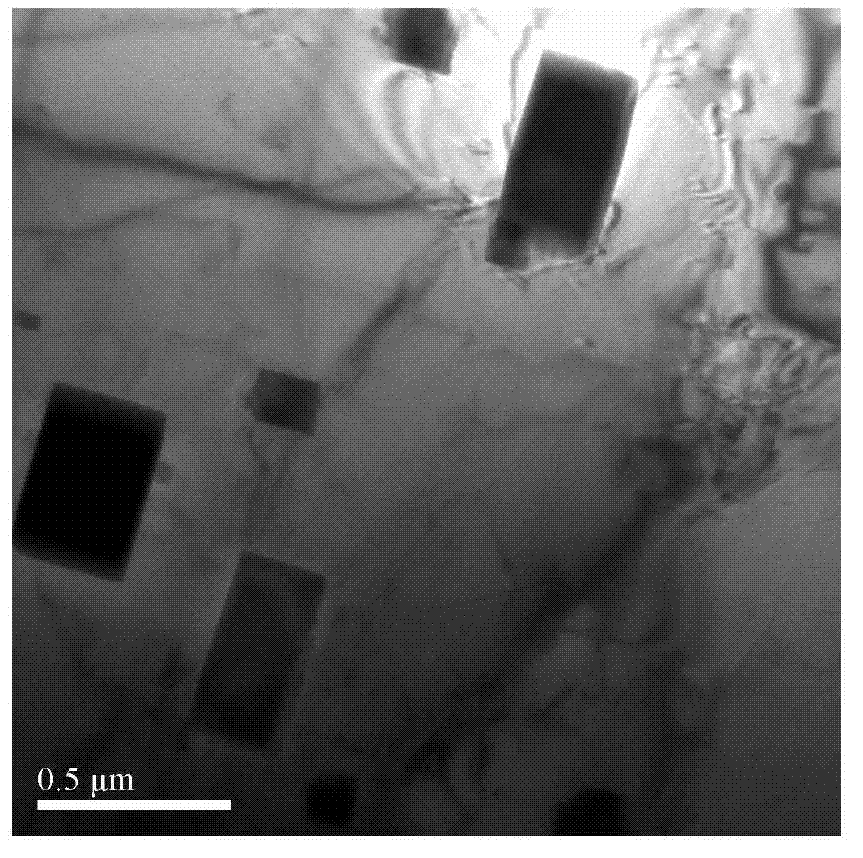

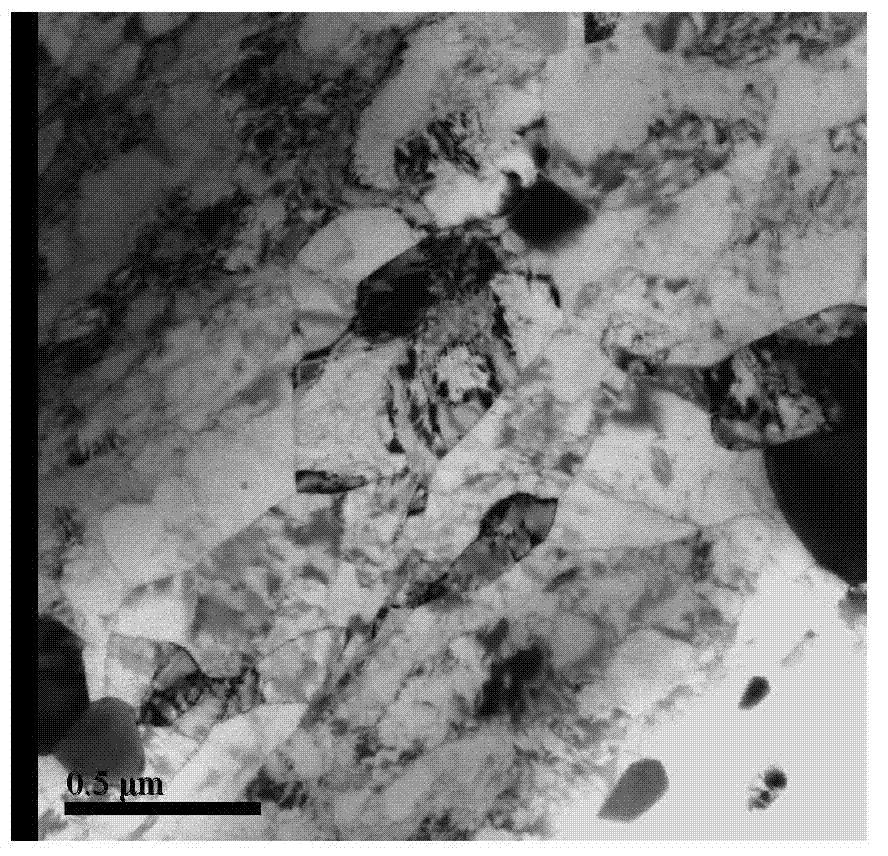

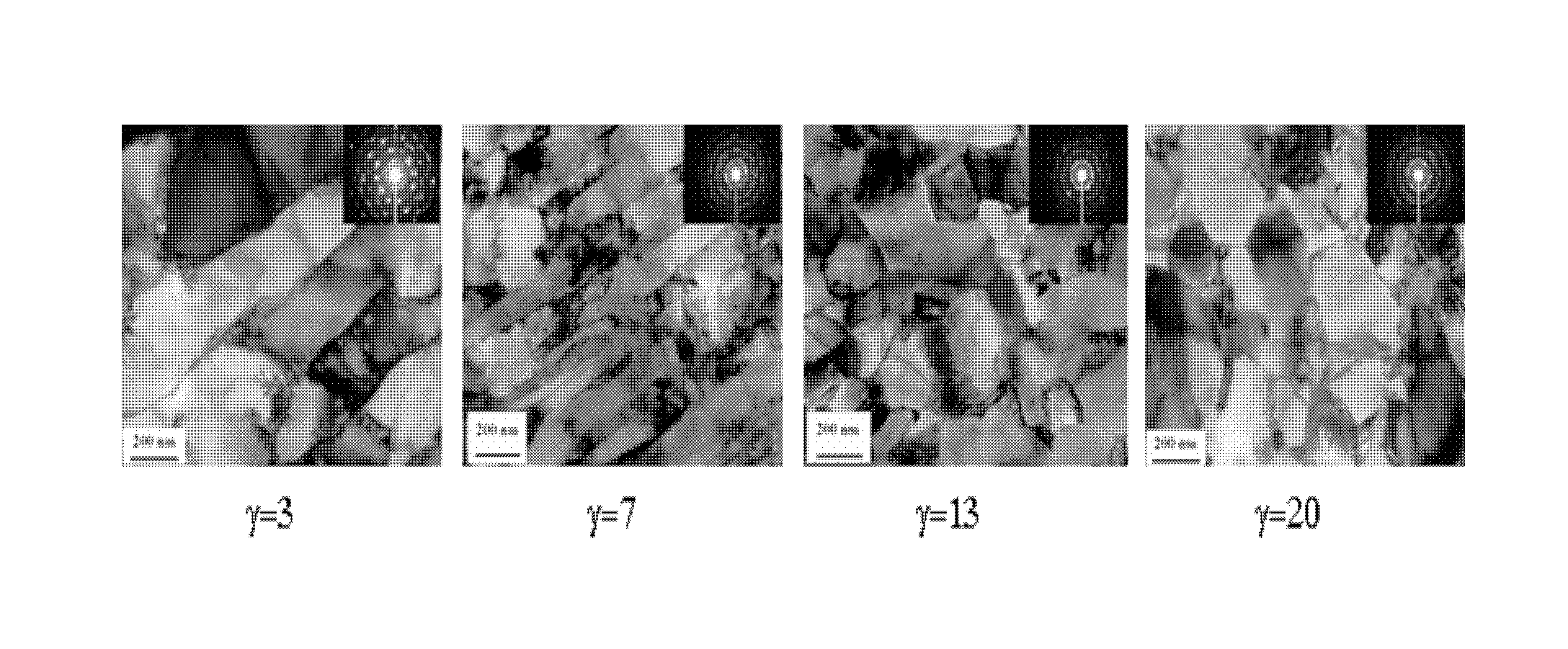

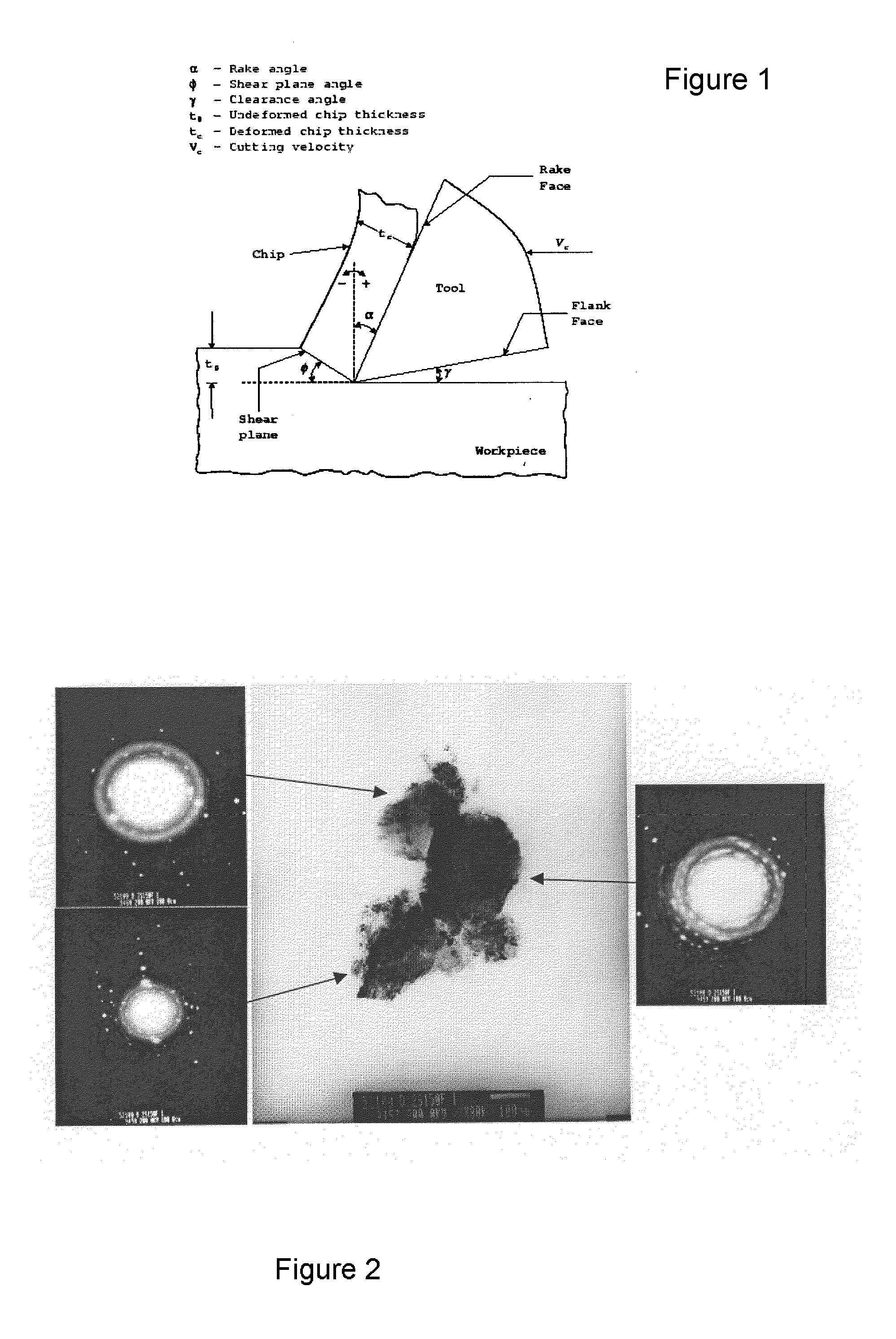

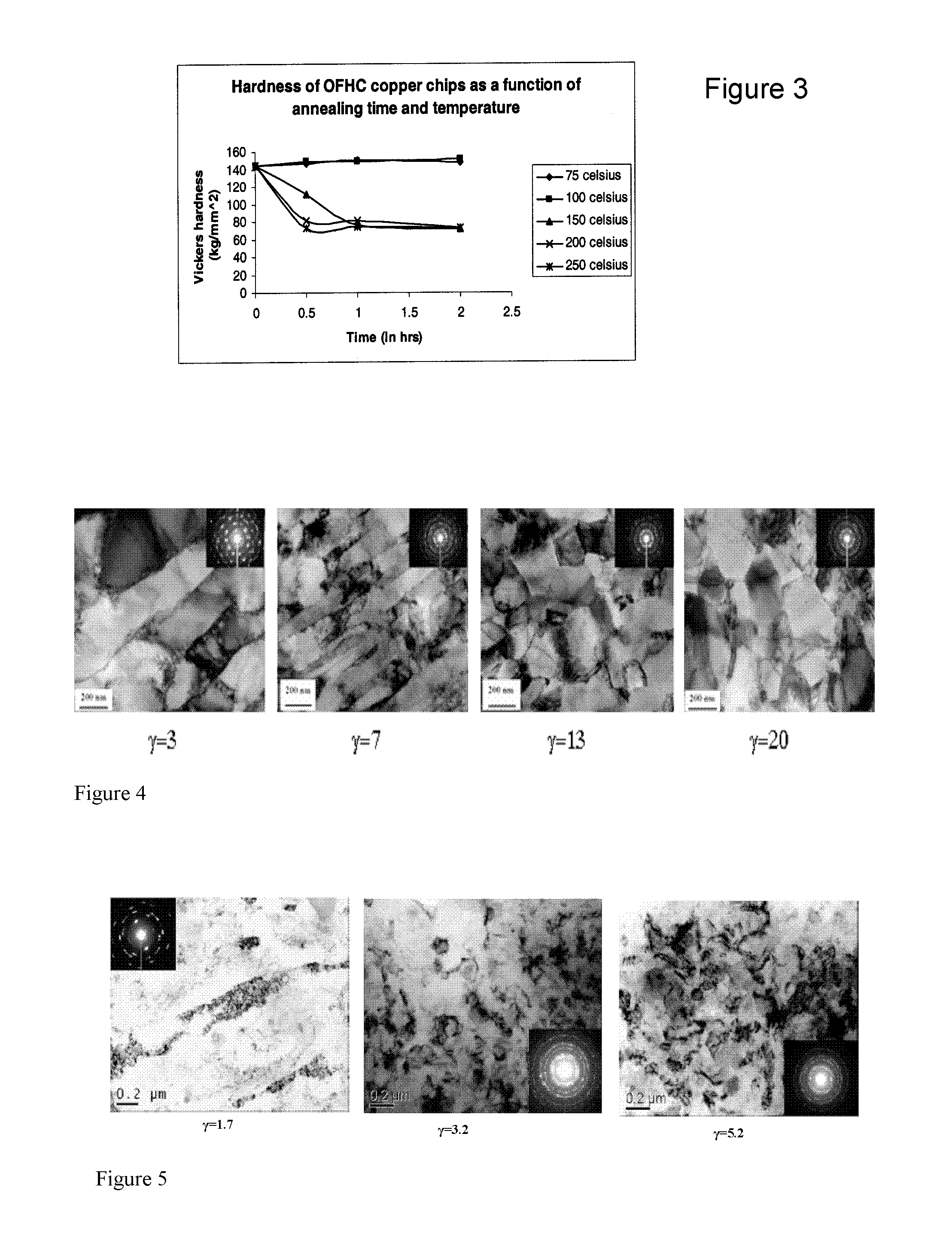

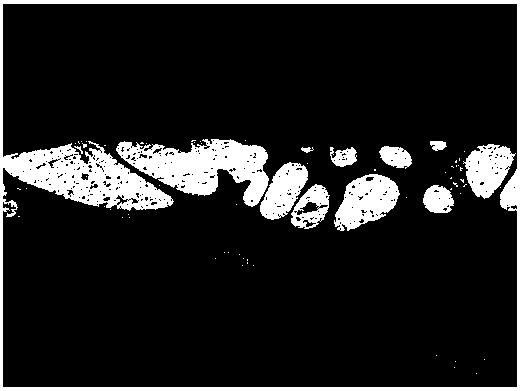

Method of consolidating precipitation-hardenable alloys to form consolidated articles with ultra-fine grain microstructures

InactiveUS20060278308A1Low costEasy to useTransportation and packagingMetal-working apparatusUltra fineSupersaturated solid solution

A method by which consolidated articles can be produced from nanocrystalline materials to have mechanical properties that can be improved through thermal treatment. The method entails machining a body to produce polycrystalline chips having nanocrystalline microstructures, and then consolidating the chips to form a consolidated article having mechanical properties that exceed that of the body from which the chips were formed. In particular, consolidation of nanocrystalline chips formed by machining a supersaturated solid-solution body causes precipitation of a fine dispersion of precipitates in the consolidated article, with the potential for certain properties to even improve during consolidation or subsequent thermal treatment of the consolidated article.

Owner:PURDUE RES FOUND INC

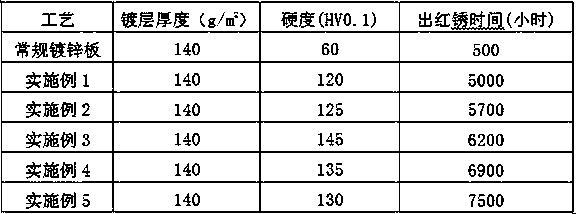

Zn-Al-Mg hot-dip steel plate with high corrosion resistance, and production method thereof

ActiveCN109536864AWon't dissolveDoes not dissolveHot-dipping/immersion processesSheet steelChemical composition

The invention discloses a Zn-Al-Mg hot-dip steel plate with high corrosion resistance, and a production method thereof. The Zn-Al-Mg hot-dip steel plate comprises a baseplate and a coating on the baseplate, and is characterized in that the chemical components of the coating comprise, by mass, 1.8%-2.3% of Al, 1.2%-1.8% of Mg, 0.01%-0.08% of Re, 0.003%-0.008% of Cu and the balance Zn and other inevitable impurities, wherein the Cu is added to plating solutions in a nanometer form during melting of the plating solutions. The Cu in the coating of the steel plate is added in a nano-copper form during melting of the plating solutions; since the temperature of Zn liquid is lower during adding of the Cu, the shape of Cu particles can be ensured; by taking advantage of the characteristic of fine dispersion of the Cu particles, the Cu particles play a role in strengthening of precipitation, so that the hardness of the coating is improved; and by adding of rare earth Re, the coating structure can be fined, and the fluidity of the plating solutions is improved, so that the corrosion resistance of the coating can be improved effectively. The coating structure of a product obtained with the method is primary Zn, Zn / MgZn2 binary eutectic, Zn / Al / MgZn2 ternary eutectic and nano-copper; and the corrosion resistance is equal to 10-15 times the corrosion resistance of a pure zinc plate of the same thickness.

Owner:HEBEI IRON AND STEEL

Use of nanoscalar water-soluble beta-(1,3) glucans

The invention relates to the use of nanoscalar water-soluble β-(1,3) glucans, which are essentially free from β-(1,6) links and have particle diameters ranging from 10 to 300 nm for producing cosmetic and / or pharmaceutical preparations. When applied topically, the especially fine dispersion of the particles, compared to prior art glucans, facilitates their rapid penetration of both the stratum corneum of the skin and the keratin fibres of the hair.

Owner:SANA PHARMA

Scale-shaped filmy fines dispersion

ActiveUS20120174824A1Good dispersionHigh degreePigmenting treatmentMaterial nanotechnologyAlloySolvent

Provided is a scale-shaped filmy fines dispersion. More specifically, scale-shaped filmy fines are subjected to a treatment for keeping the scale-shaped filmy fines from easily settling out. In the case of a metallic pigment using the scale-shaped filmy fines, the scale-shaped filmy fines are dispersed in the ink. As a result, nozzle clogging can be prevented, and the obtained print can achieve abundant metallic luster. The scale-shaped filmy fines dispersion contains, in a solvent, scale-shaped filmy fines obtained by finely grinding a simple metal, an alloy, or a metal compound. The scale-shaped filmy fines have a mean length of 0.5 μm or more and 5.0 μm or less, a maximum length of 10 μm or less, a mean thickness of 5 nm or more and 100 nm or less, and an aspect ratio of 20 or more.

Owner:OIKE IND

Heat and corrosion resistant cast CN-12 type stainless steel with improved high temperature strength and ductility

A cast stainless steel alloy and articles formed therefrom containing about 0.5 wt. % to about 10 wt. % manganese, 0.02 wt. % to 0.50 wt. % N, and less than 0.15 wt. % sulfur provides high temperature strength both in the matrix and at the grain boundaries without reducing ductility due to cracking along boundaries with continuous or nearly-continuous carbides. Alloys of the present invention also have increased nitrogen solubility thereby enhancing strength at all temperatures because nitride precipitates or nitrogen porosity during casting are not observed. The solubility of nitrogen is dramatically enhanced by the presence of manganese, which also retains or improves the solubility of carbon thereby providing additional solid solution strengthening due to the presence of manganese and nitrogen, and combined carbon. Such solution strengthening enhances the high temperature precipitation-strengthening benefits of fine dispersions of NbC. Such solid solution effects also enhance the stability of the austenite matrix from resistance to excess sigma phase or chrome carbide formation at higher service temperatures. The presence of sulfides is substantially eliminated.

Owner:UT BATTELLE LLC

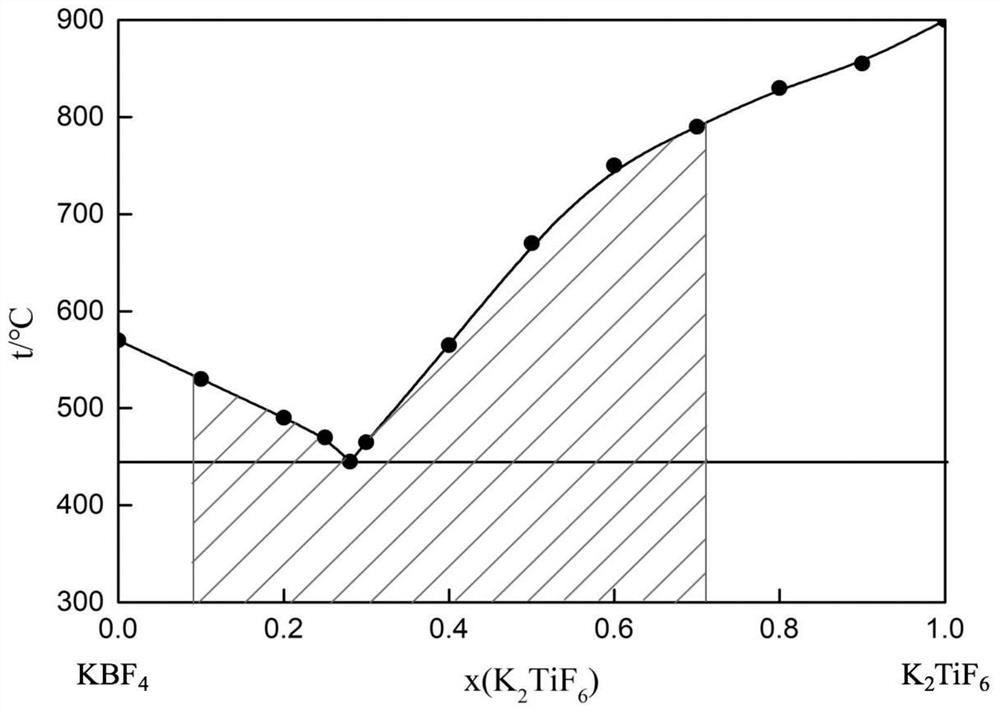

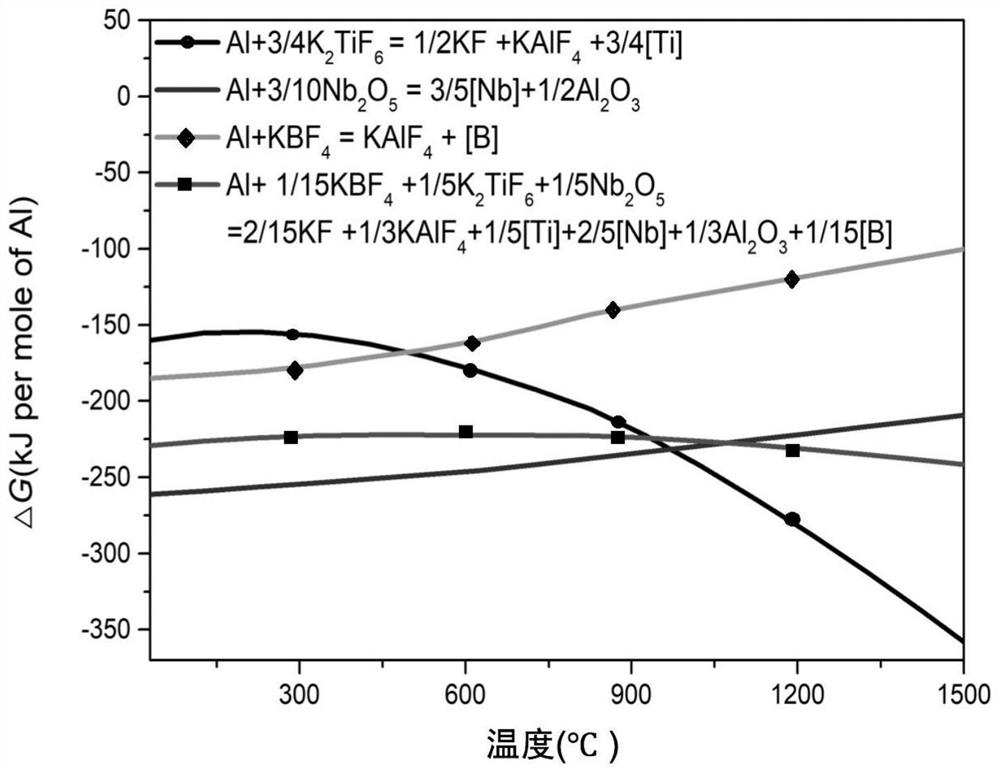

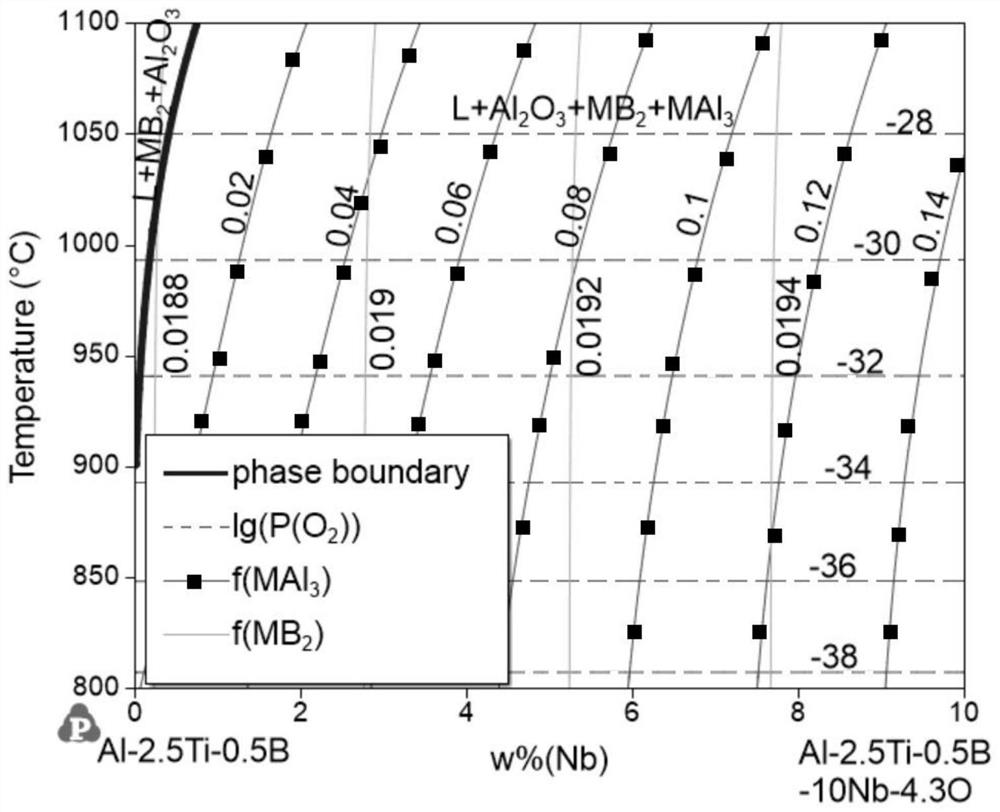

Preparation method of Al-Ti-Nb-B refiner for casting aluminum-silicon alloy

PendingCN112048629AImprove refinementMeet industry-accepted standardsFine dispersionAluminothermic reaction

The invention discloses a preparation method of an Al-Ti-Nb-B refiner for casting an aluminum-silicon alloy. The preparation method comprises the following steps that a, raw materials are weighted; and b, smelting of the Al-Ti-Nb-B refiner is carried out. According to the Al-Ti-Nb-B refiner prepared by the method, Nb2O5 is introduced as a Nb source, so that the raw material cost is greatly reduced; in the aspect of preparation effect, the grain size of alpha-Al in the aluminum-silicon alloy can be refined to 220 microns, and the industrial approval standard is met. Nb is introduced into the refiner through aluminothermic reaction, so that fine dispersion distribution of the second phases MB2 and MAl3 in the Al-Ti-Nb-B refiner is realized, and the refinement performance of the Al-Ti-Nb-B refiner is improved. The method can greatly reduce the preparation cost of the Al-Ti-Nb-B refiner, the preparation method is simple and convenient, and is suitable for industrial large-scale production.

Owner:SHANGHAI UNIV +1

High-strength, high-toughness rolled shape steel and method of producing the same

InactiveUS6364967B1Enabling effective texture grain refinementImprove toughnessFurnace typesHeat treatment furnacesTemperature controlSheet steel

A 590 MPa-class rolled steel shape of high strength and excellent toughness for use as a building structural member and a method of producing the high-tensile rolled steel shape are provided. Strength optimization by an alloy that elevates hardenability, texture refinement obtained by fine dispersion of Ti oxides and TiN owing to Ti addition, precipitation strengthening by Cu addition, and formation of a fine bainite texture by temperature-controlled rolling, cooling control and the like enable a high-strength, high-toughness rolled steel shape of high-strength and excellent toughness having mechanical properties of a tensile strength of not less than 590 MPa, a yield strength or 0.2% proof strength of not less than 440 MPa and a Charpy impact absorption energy at 0° C. of not less than 47 J, and method of producing the same.

Owner:NIPPON STEEL CORP

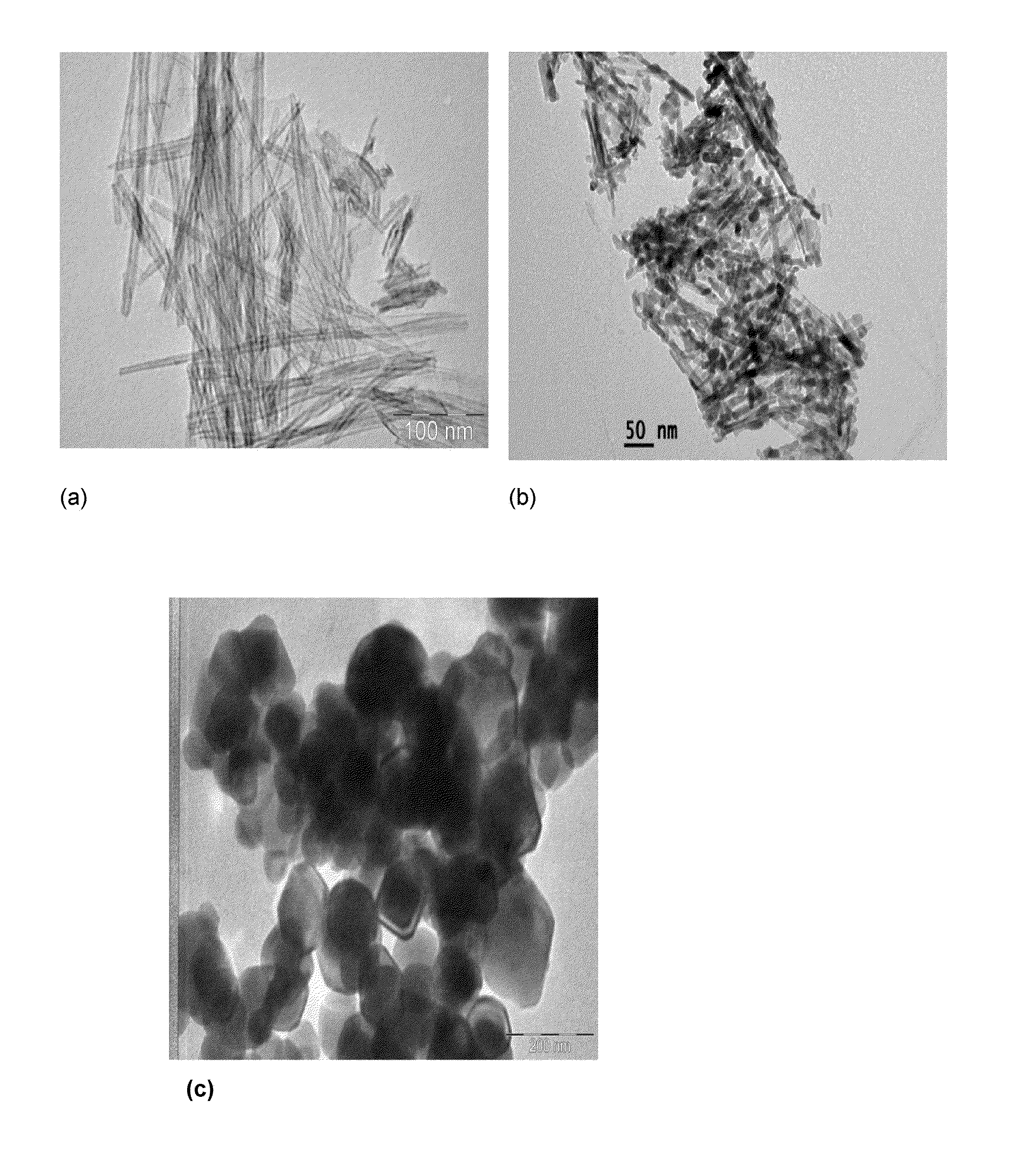

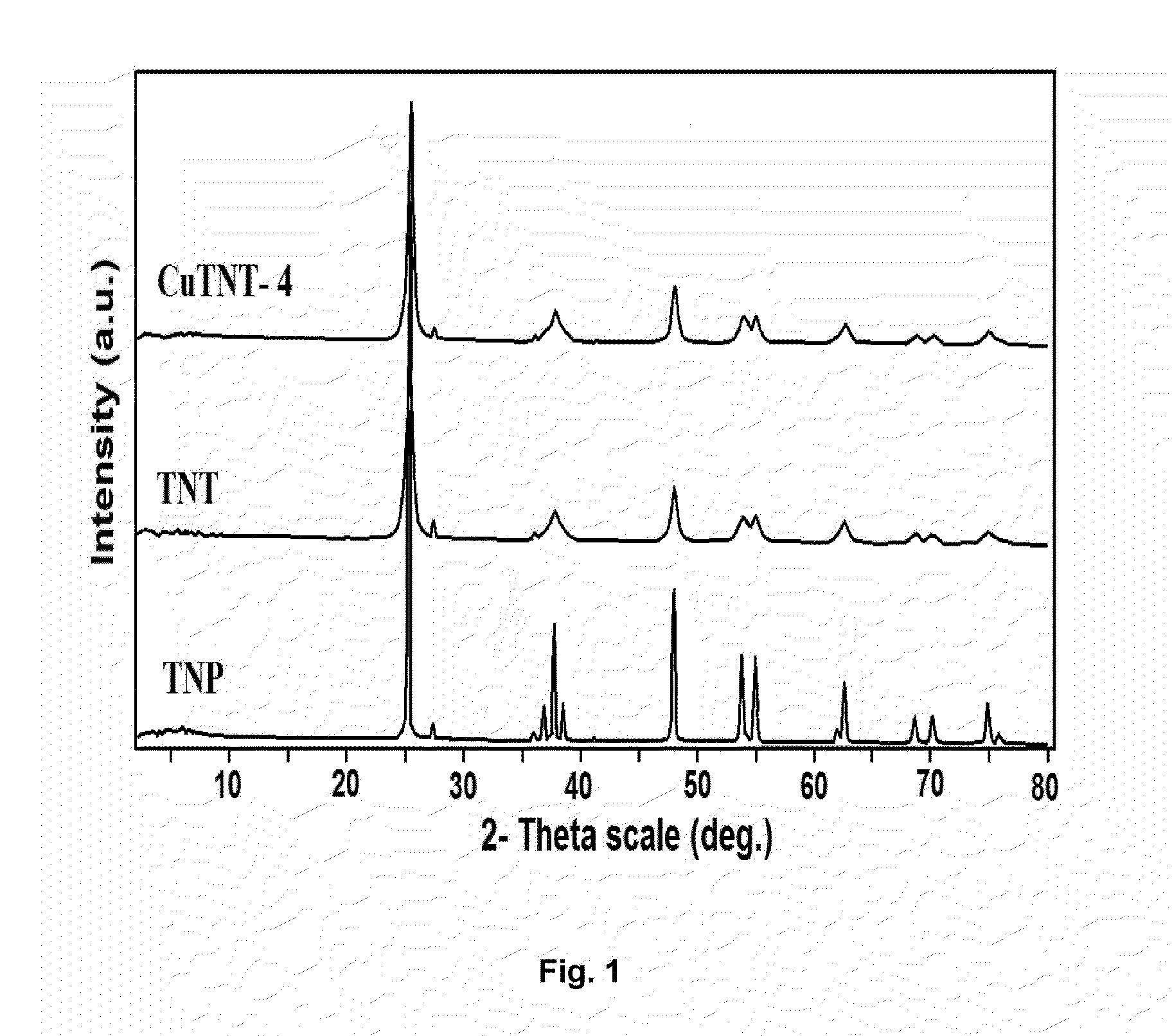

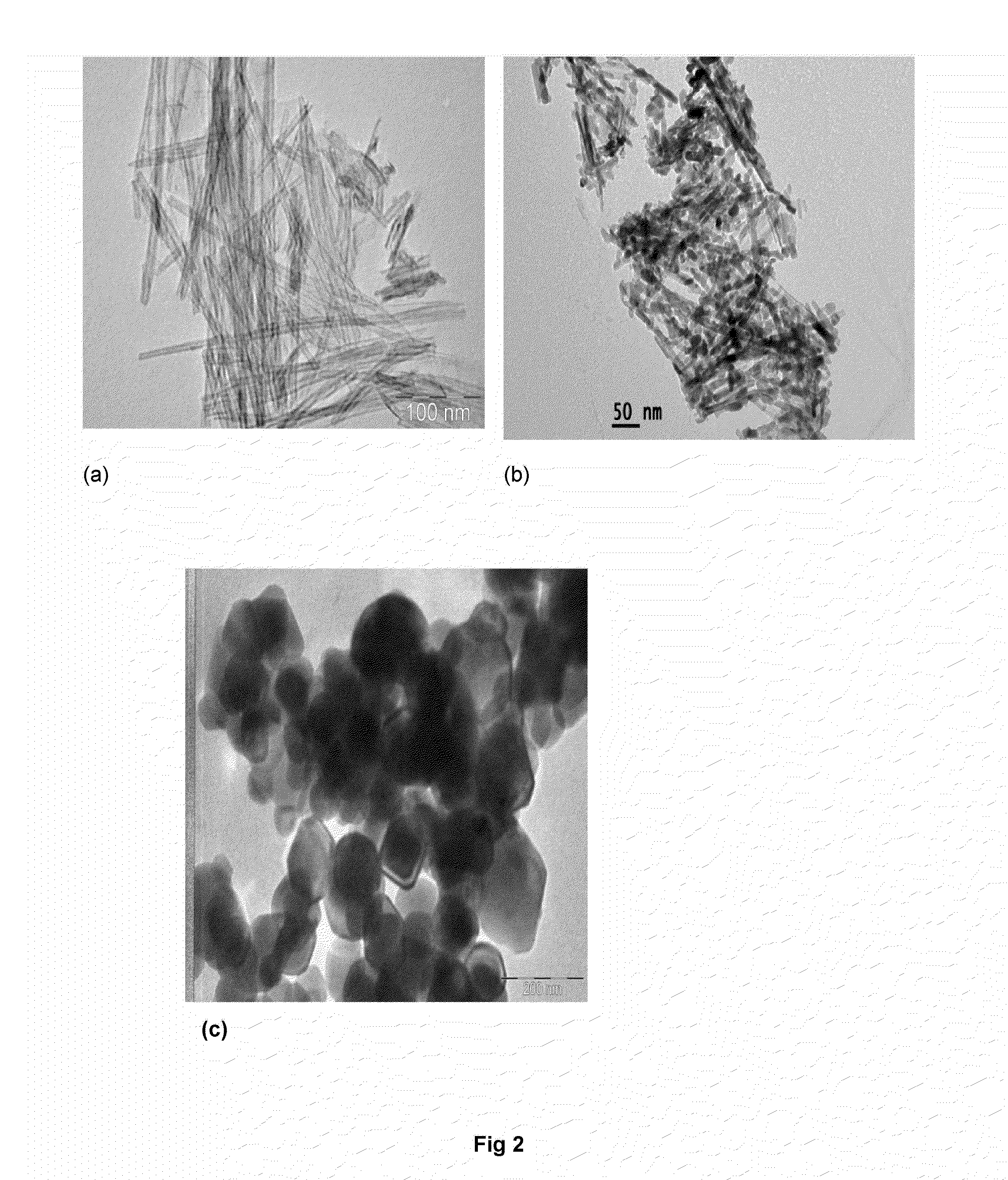

CuO - TiO2 NANOCOMPOSITE PHOTOCATALYST FOR HYDROGEN PRODUCTION, PROCESS FOR THE PREPARATION THEREOF

The present investigation is development of the TiO2 nanotubes concept of preparation of and their composite with fine dispersion of copper. The inventions also relates to identify a method for optimum amount of photocatalyst required for efficient and maximum hydrogen production reported than earlier (H2=99,823 μmol·h−1·g−1 catalyst) from glycerol-water mixtures under solar light irradiation. A method is disclosed to produce CuO / TiO2 nanotubes with high sustainability and recyclable activity for hydrogen production.

Owner:COUNCIL OF SCI & IND RES

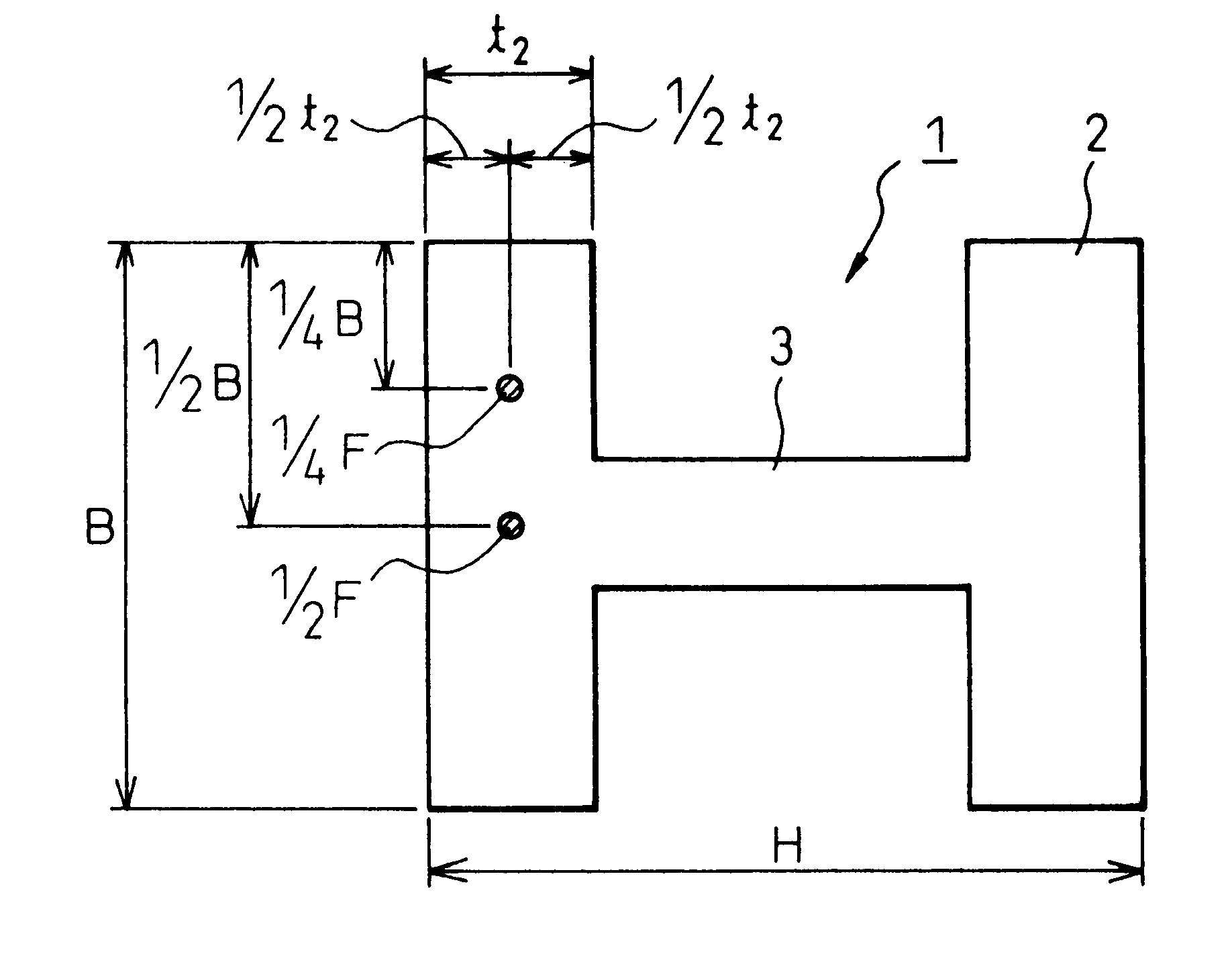

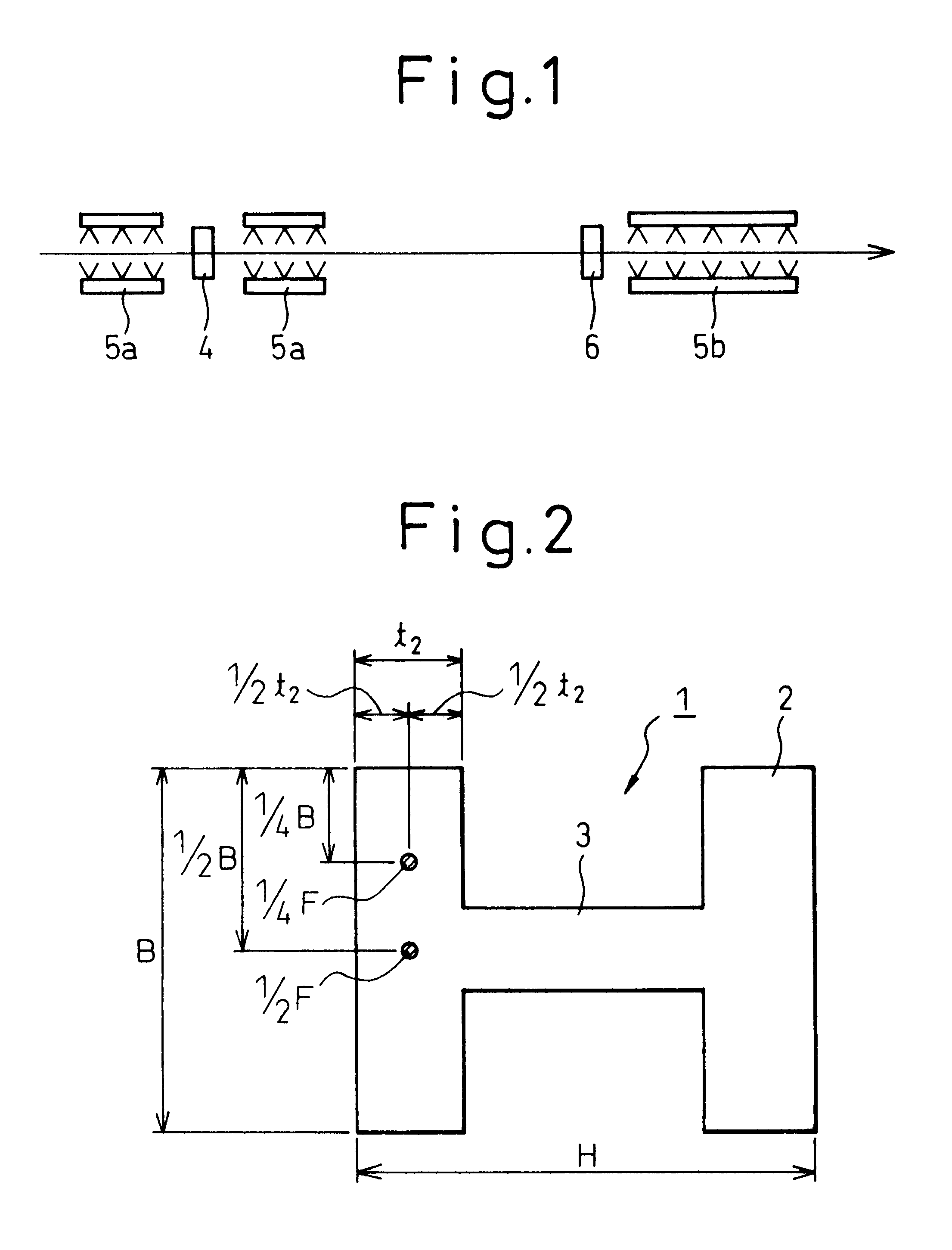

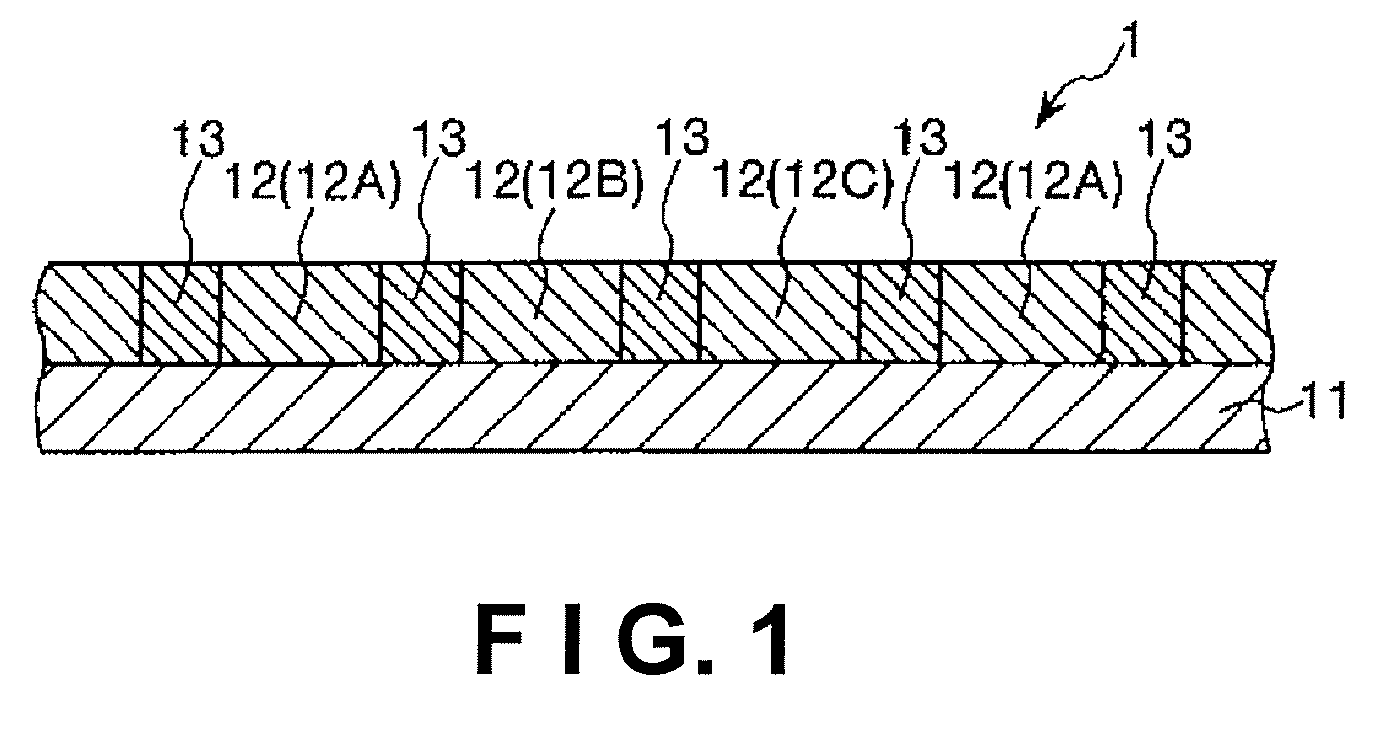

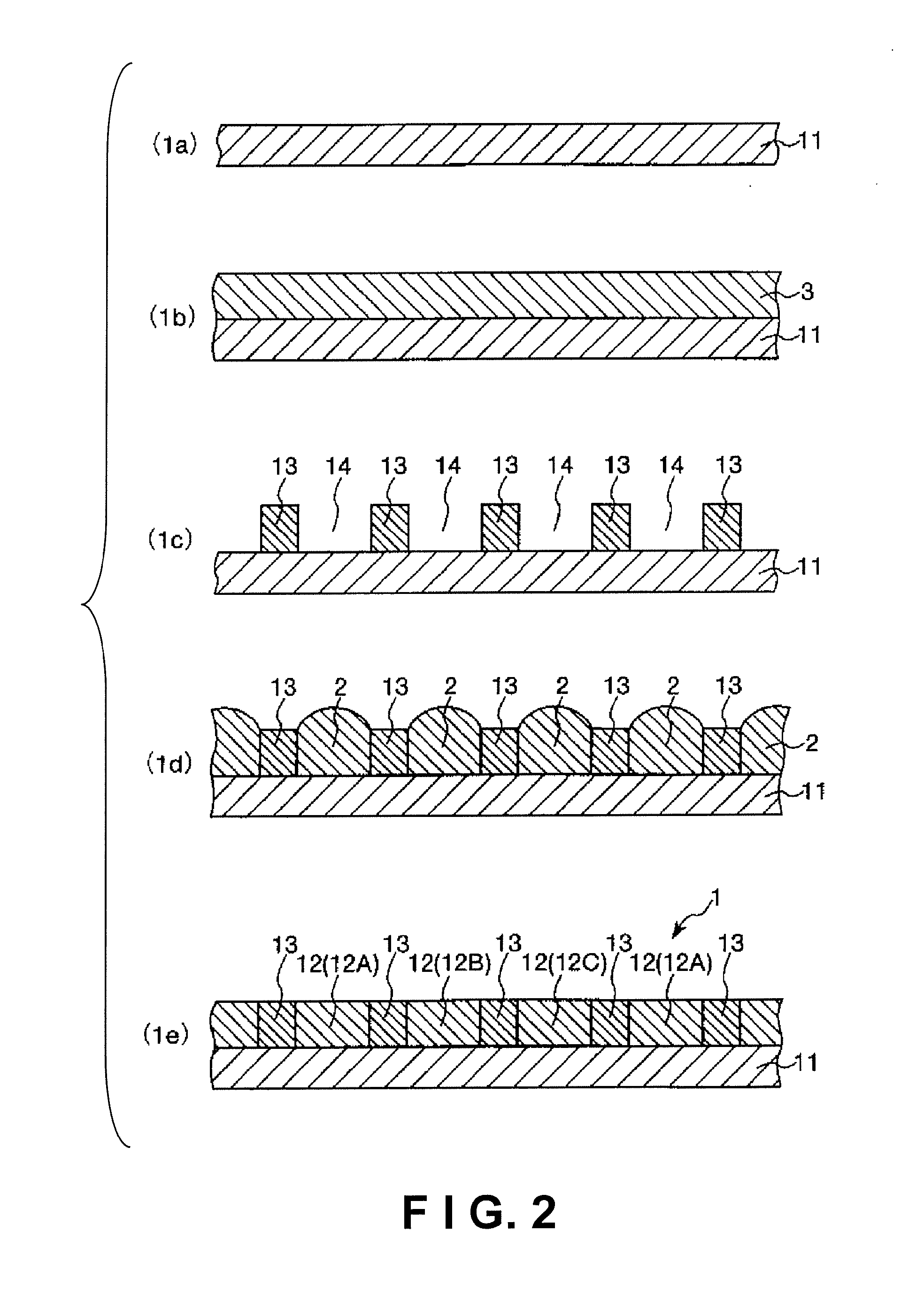

Method for manufacturing color filter ink, color filter ink, color filter, image display device, and electronic device

InactiveUS20090135349A1Increased durabilityImprove uniformityOrganic compound preparationOptical filtersSolventFine dispersion

A method for manufacturing a color filter ink is adapted to be used to manufacture a color filter by an inkjet method. The method includes dispersing a dispersing agent in a solvent to obtain a dispersing-agent-dispersed liquid by agitating a mixture of the dispersing agent, a thermoplastic resin and the solvent, performing a fine dispersion treatment to obtain a pigment dispersed material by adding a pigment to the dispersing-agent-dispersed liquid and by adding inorganic beads to the dispersing-agent-dispersed liquid in multiple stages, and mixing the pigment dispersed material with a curable resin.

Owner:SEIKO EPSON CORP

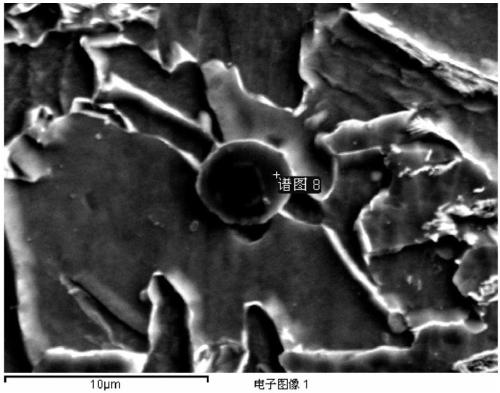

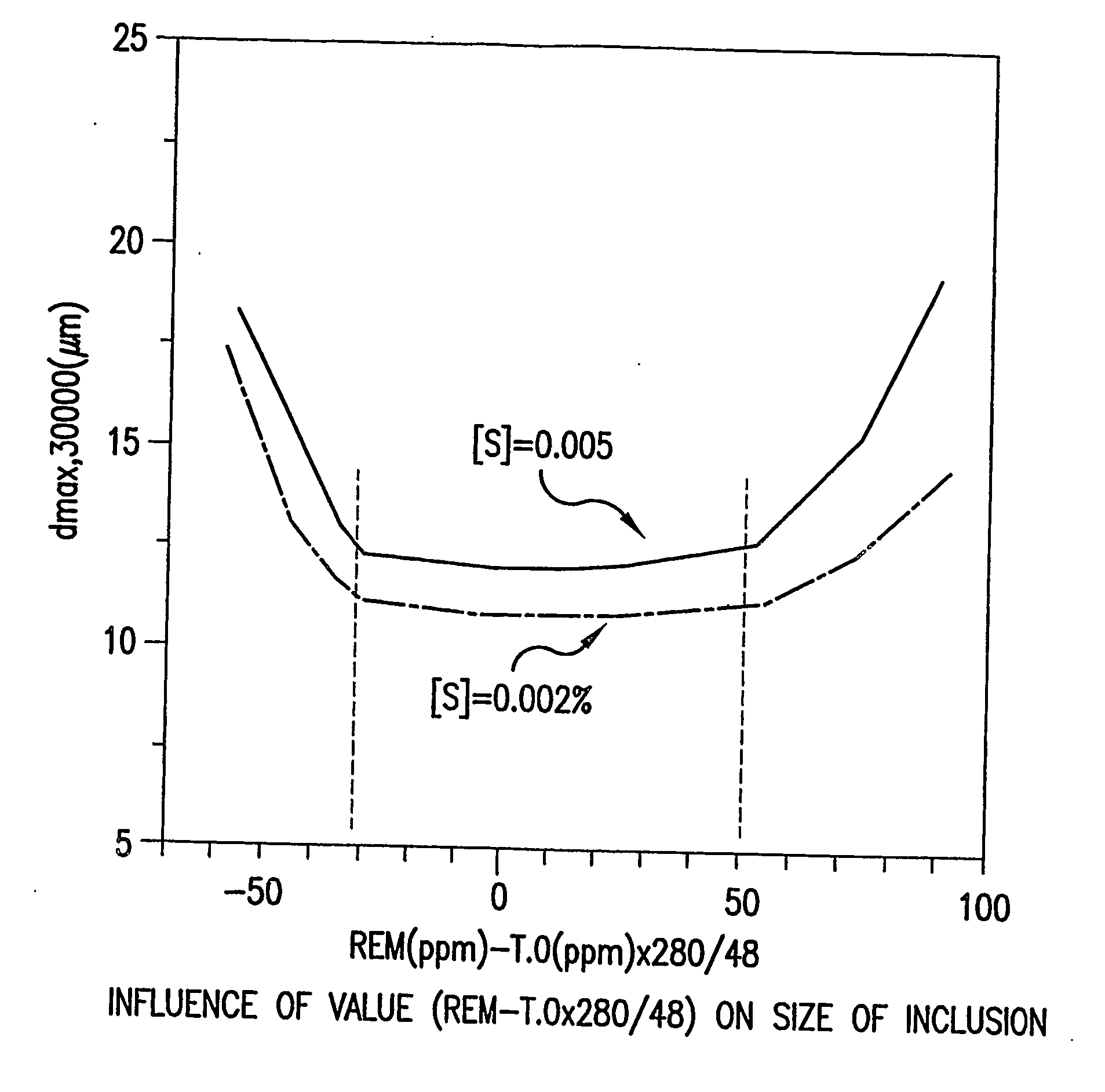

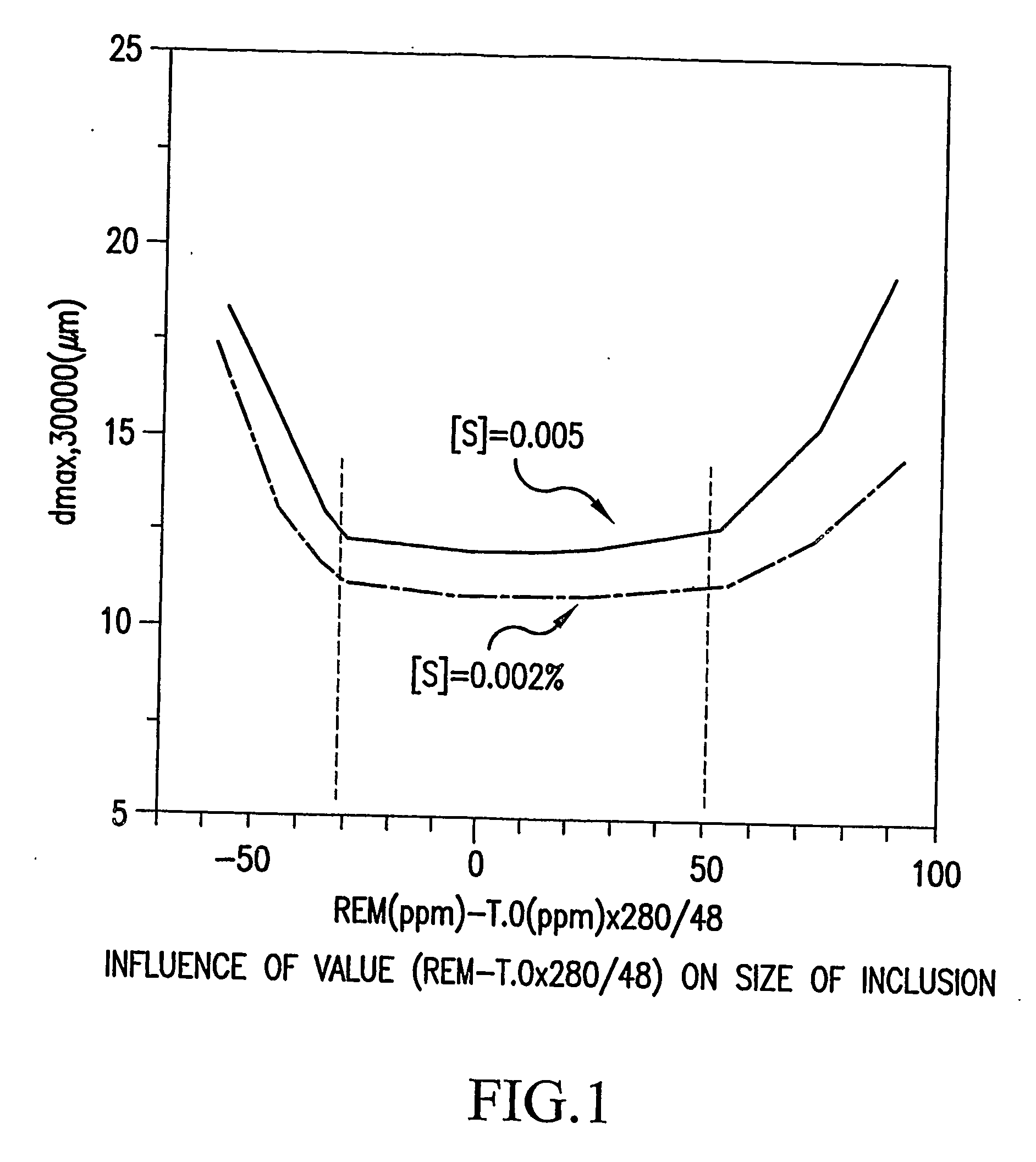

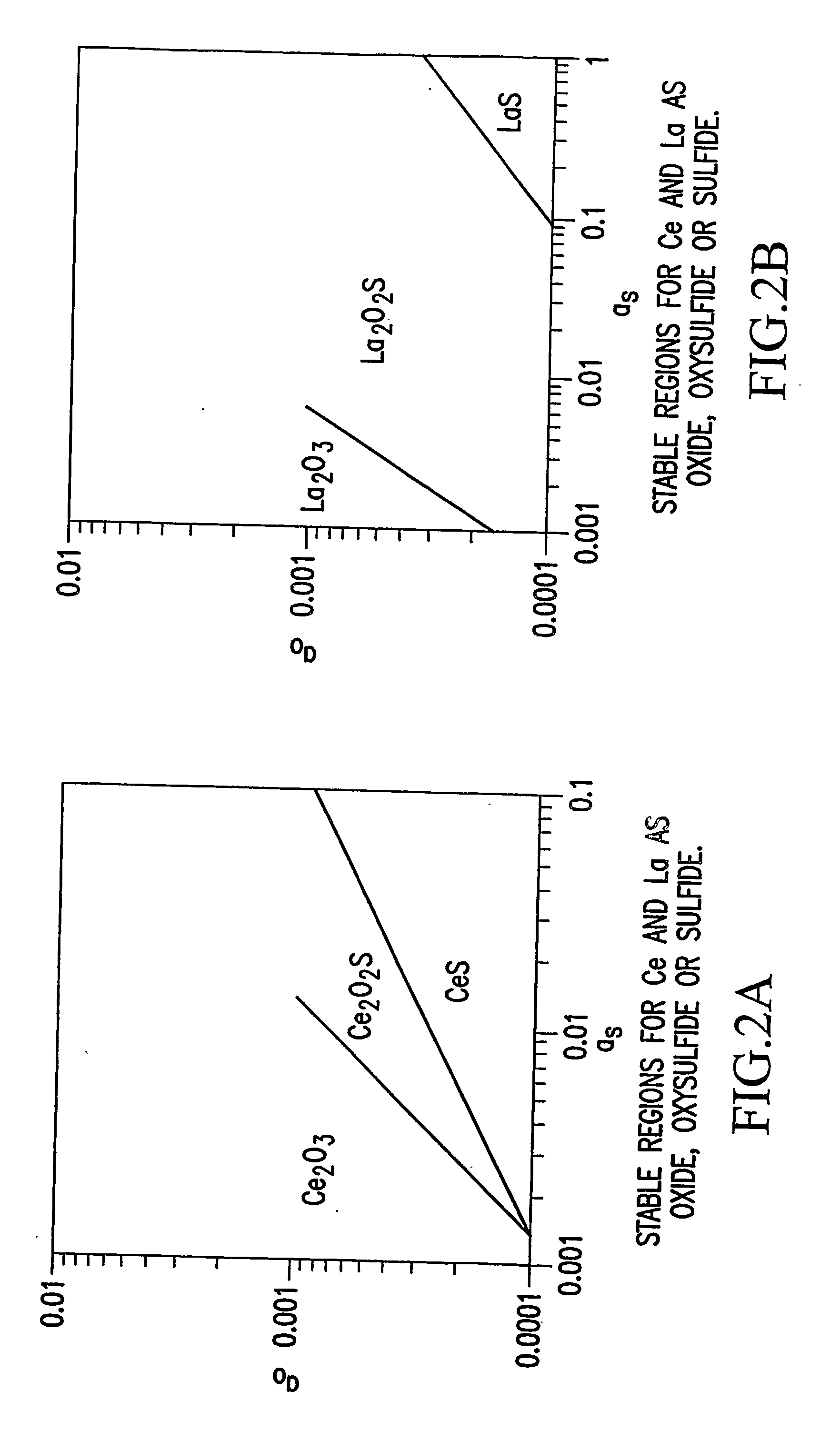

Steel having finely dispersed inclusions

InactiveUS20060157162A1Improved fatigue life and acoustic characteristicBearing componentsMetallic material coating processesFine dispersionMaterials science

An object of the invention is to provide a steel having good fatigue life characteristics and acoustic characteristics by eliminating the harmful effects of oxide based inclusions. The object is attained by the following steel. A steel having at least a part comprising: REM of which amount meets formula (1); and REM-containing inclusions of which number meets formula (2); wherein the concentration of Al203 in the REM-containing inclusions is 30 mass % or less (including 0%); Formula (1); −30<REM(ppm)−(T.O(ppm)×280 / 48)<50, Formula (2); number of REM-containing inclusions / total number of inclusions >0.8, wherein the inclusions of Formula (2) having an equivalent diameter of 1 μm or more.

Owner:NIPPON STEEL CORP

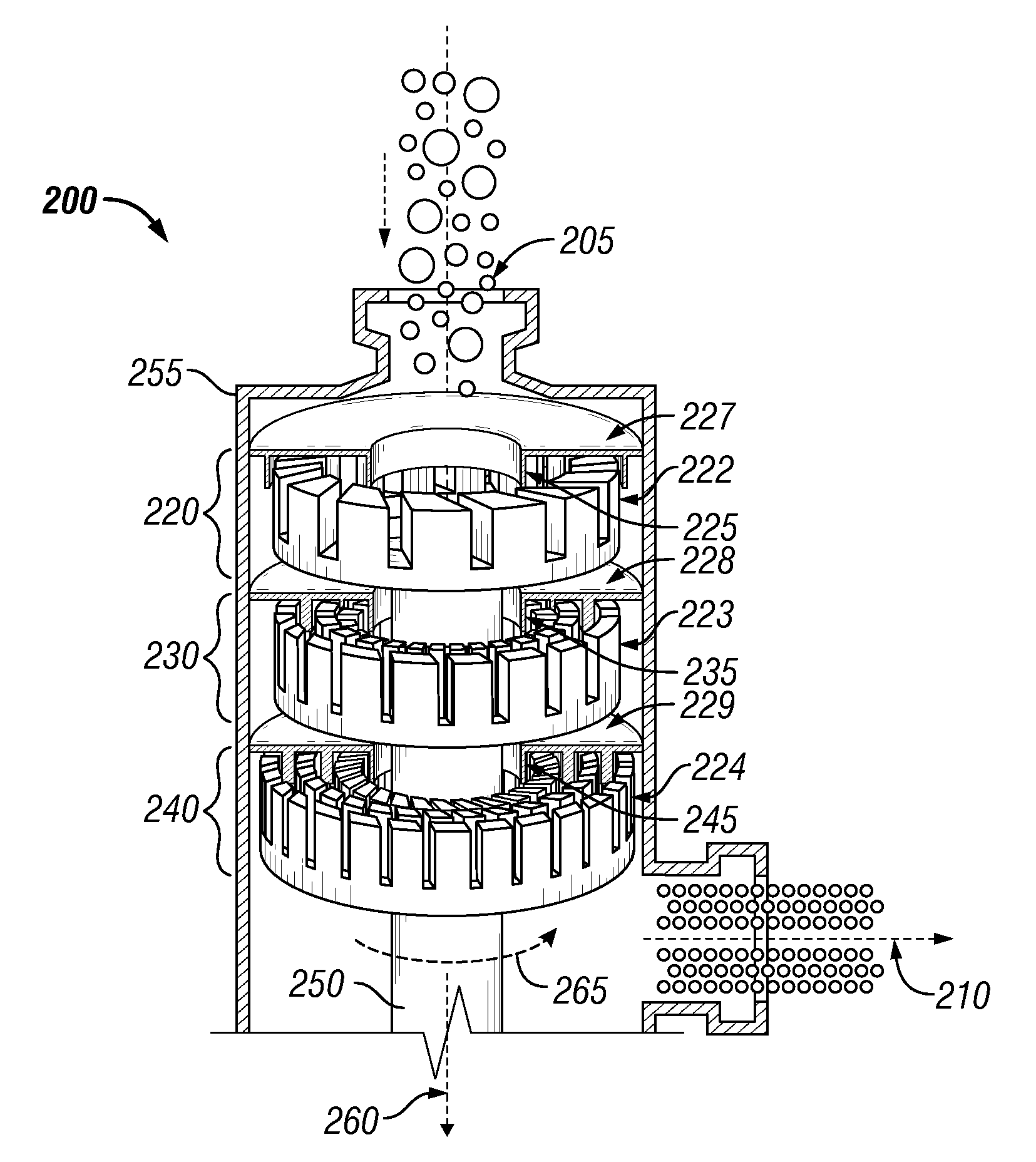

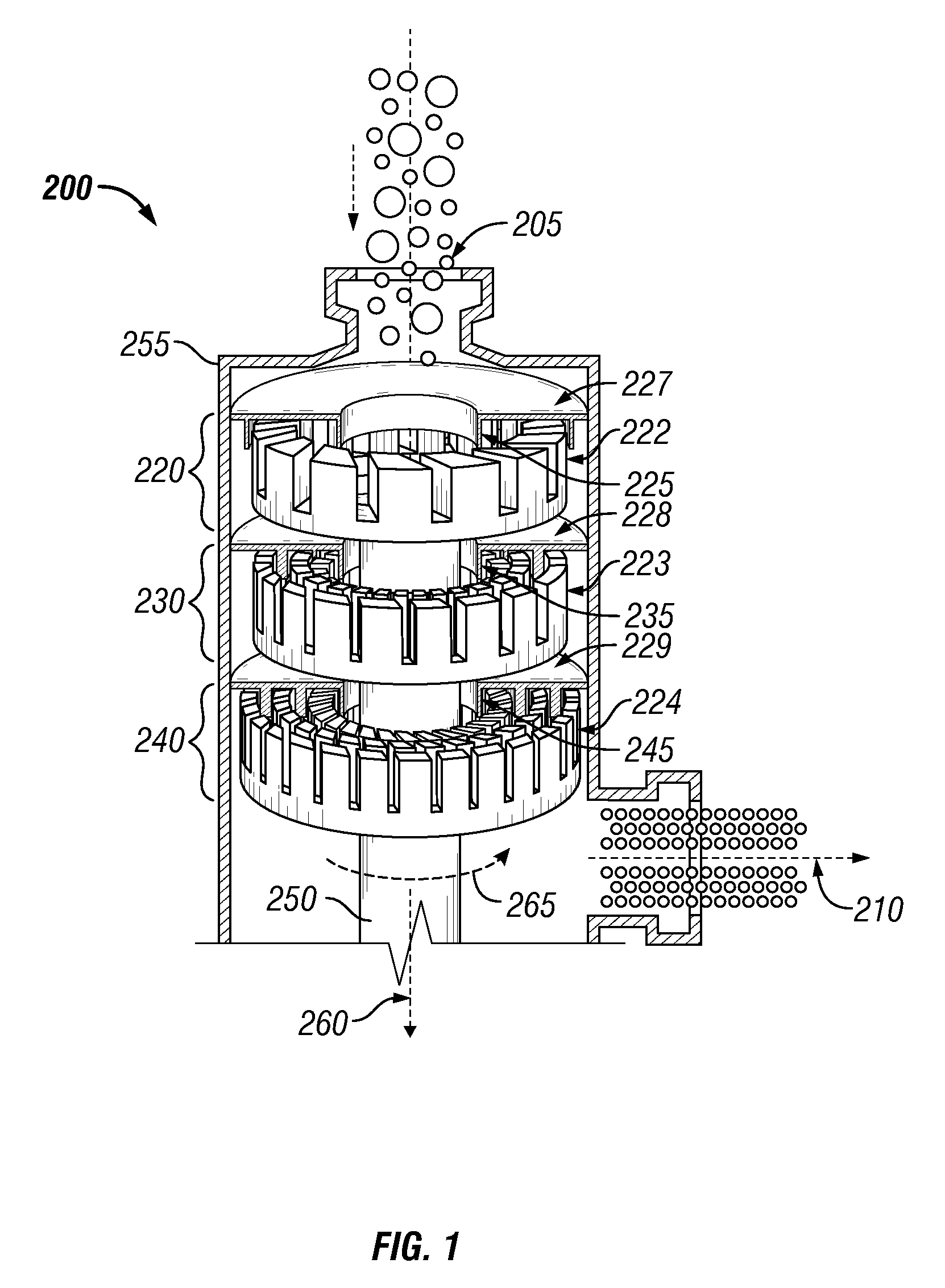

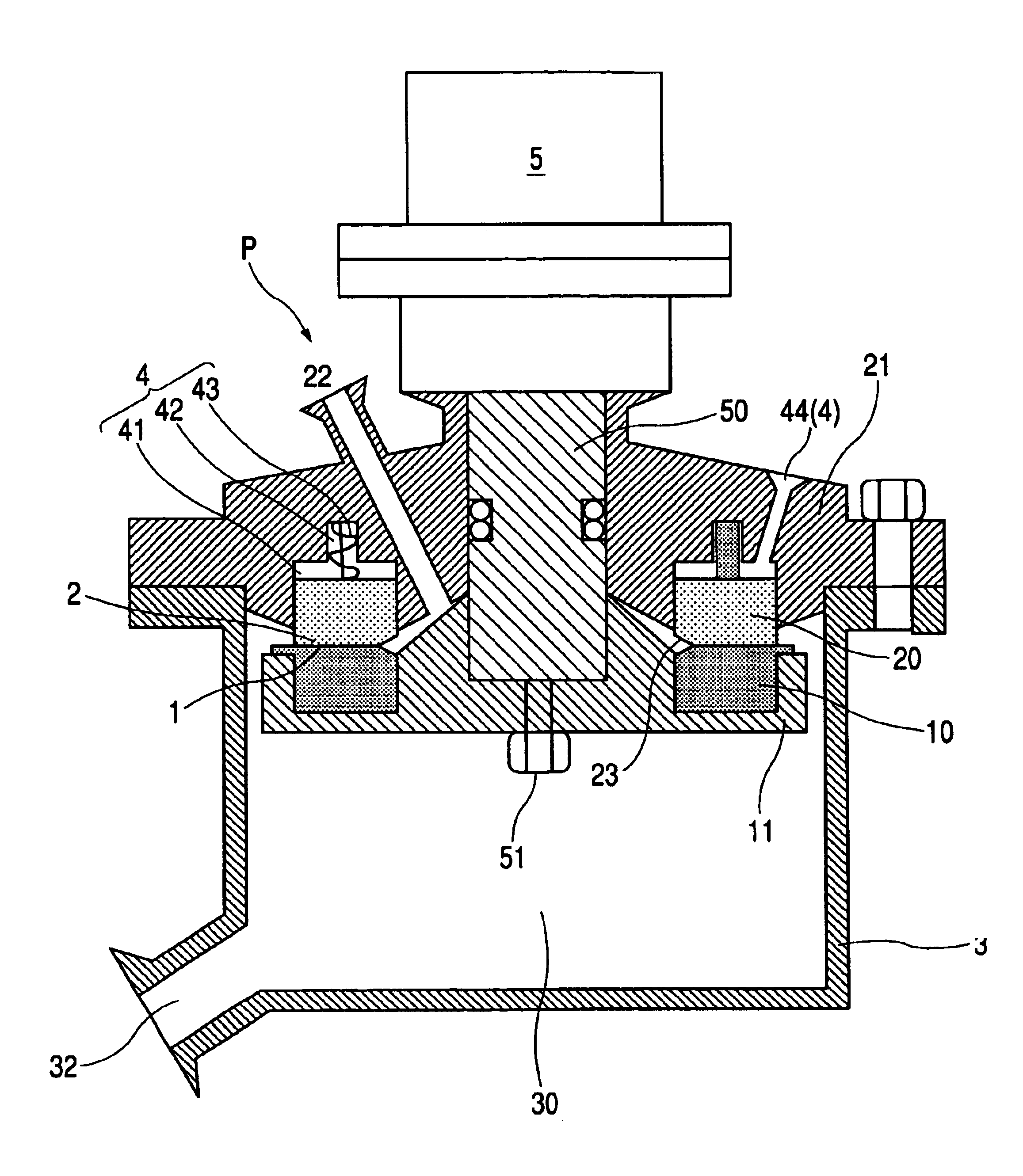

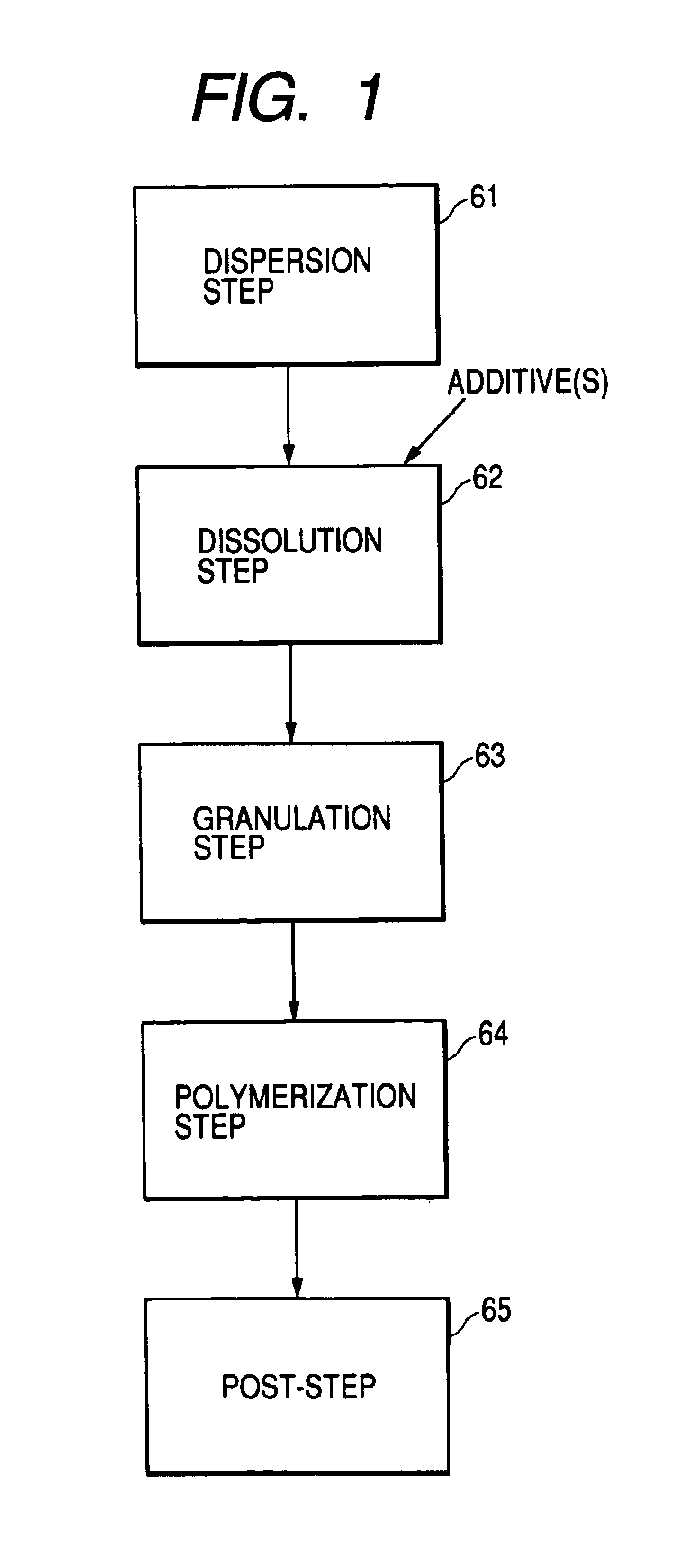

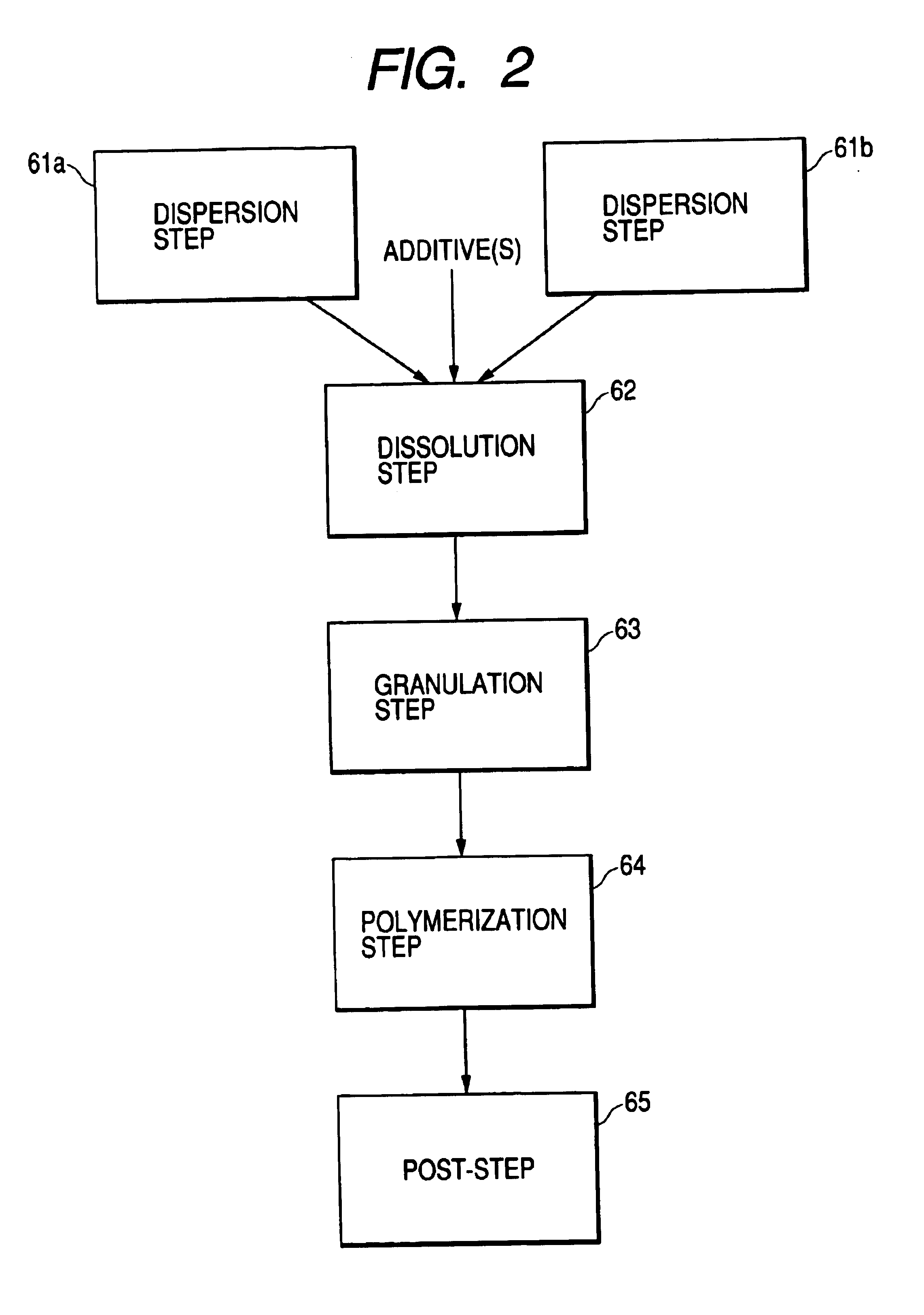

Process for producing toner particles

ActiveUS6951704B2Good anti-offset propertyHigh image densityDevelopersFine dispersionBiomedical engineering

In a process for producing toner particles by pre-dispersing at least a colorant and / or a release agent in a first dispersion medium to prepare a first fluid mixture, preparing a second fluid mixture from the first fluid mixture by means of a fine-dispersion machine, and forming toner particles from the second fluid mixture;(i) the fine-dispersion machine has at least a first treatment ring and a second treatment ring approachable to and separable from the former and a rotary drive mechanism which makes the former rotate relatively to the latter, and (ii) the first fluid mixture is introduced to the part between the first treatment ring and the second treatment ring to make the latter separate from the former, and the colorant and / or the release agent are dispersed in the form of fine particles by the rotation of the first treatment ring to obtain the second fluid mixture.

Owner:CANON KK

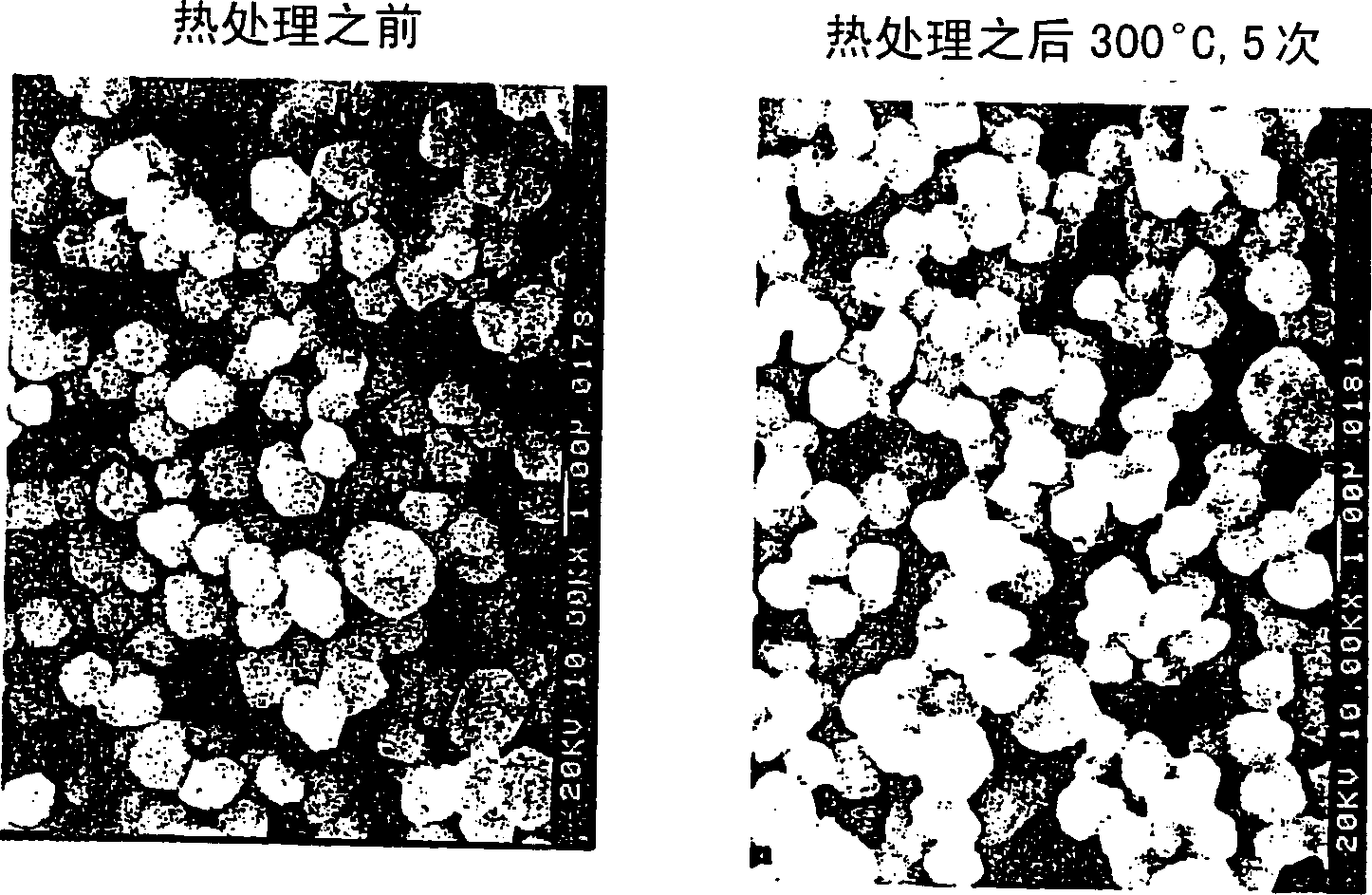

Method for forming fine copper particle sintered product type of electric conductor having fine shape, method for forming fine copper wiring and thin copper film using said method

ActiveCN1792127AInhibit open circuitLow heat resistanceSemiconductor/solid-state device manufacturingConductive pattern formationElectrical conductorReduction treatment

A method of forming a fine-shaped electrical conductor of the sintered product of fine copper particles, wherein a fine pattern is drawn by using a dispersion of copper particles having an oxide film on its surface, and then, at a relatively low temperature, on the surface of the resulting pattern The fine copper particles or the fine copper oxide particles having an oxide film layer are subjected to reduction treatment, and the resulting copper particles are then sintered. In one embodiment, a dispersion of fine copper particles or fine copper oxide particles having an oxide film layer on its surface (the particles have an average particle diameter of 10 μm or less) is coated on a substrate, and the resulting coating The fine particles in the layer are heated to a temperature of 350° C. or lower in an atmosphere containing a compound having reducing ability or gas, whereby the oxide film is reduced by reduction using the compound having reducing ability as a reducing agent, and then , performing a series of heating steps including repeated short-time oxidation treatment and re-reduction treatment combined with heating treatment, thereby forming a sintered product from the resulting copper particles. The finely formed electrical conductor of the sintered product of fine copper particles formed by the above method exhibits excellent electrical conductivity.

Owner:HARIMA CHEM INC

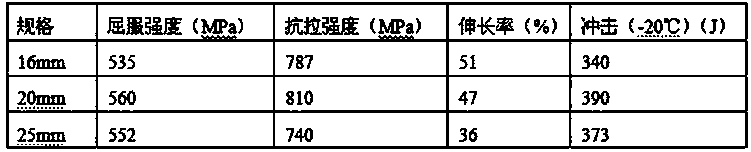

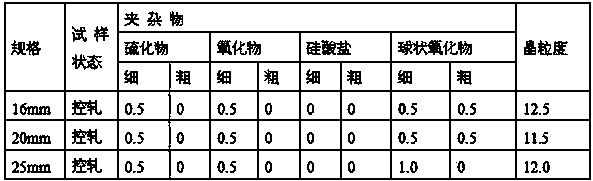

X 60 pipeline steel with thickness of 16-25 mm and production method of pipeline steel

The invention discloses X 60 pipeline steel with the thickness of 16-25 mm and a production method of the pipeline steel. The pipeline steel comprises chemical components as follows: 0.06 wt%-0.09 wt% of C, 0.25 wt%-0.35 wt% of Si, 1.55 wt%-1.69 wt% of Mn, 0.20 wt%-0.29 wt% of (Nb+Ti+V+Mo+Ni), no more than 0.010 wt% of P and no more than 0.003 wt% of S. The production method mainly comprises LF+VD, continuous casting and controlled rolling and controlled cooling. Obtained X 60 microstructure contains 42 %-46 % of lath-shaped ferrites, 32 %-38 % of acicular ferrites, 13 %-15 % of bainite, a small amount of M-A islands and fine dispersion precipitated phases; the phase interface bonding performance is good, the yield ratio is 0.66-0.76, and the grain size reaches 11.5-12.5 grades; and the welding performance is good, and the Bauschinger effect is low.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Composition and aerosol spray dispenser for eliminating odors in air

Owner:SC JOHNSON & SON INC

Preparation method of liquid ultra-fine dispersion dye

The invention provides a preparation method of a liquid ultra-fine dispersion dye, belonging to the field of fine chemical engineering and material science. The preparation method provided by the invention comprises the following steps of subjecting a dispersion dye into surface modification by means of microcapsule technology, so that the surface of the dispersion dye which is modified is coated with a polymer, the agglomeration of particles of the dispersion dye is prevented, and the dispersion dye with good flowability, easy dispersibility and stability is obtained; and when the dispersion dye is dispersed in a solvent, the liquid ultra-fine dispersion dye of which is particle size is less than 180 nm can be obtained. The method provided by the invention is suitable for the surface modification and the nanocrystallization of various dispersion dyes and is characterized by low device investment, simple preparation process and stable product quality and etc.

Owner:JIANGNAN UNIV

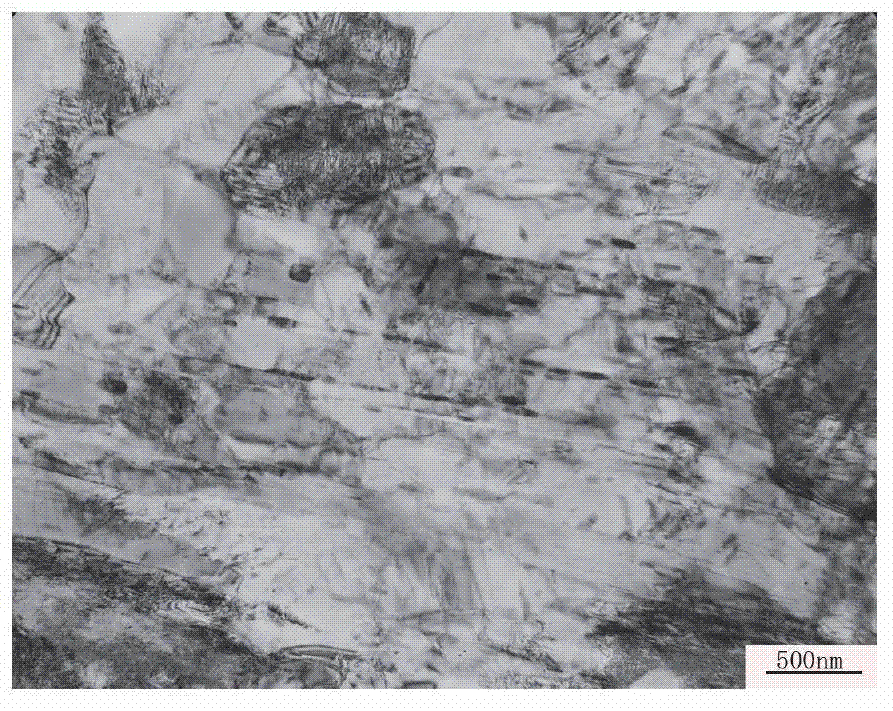

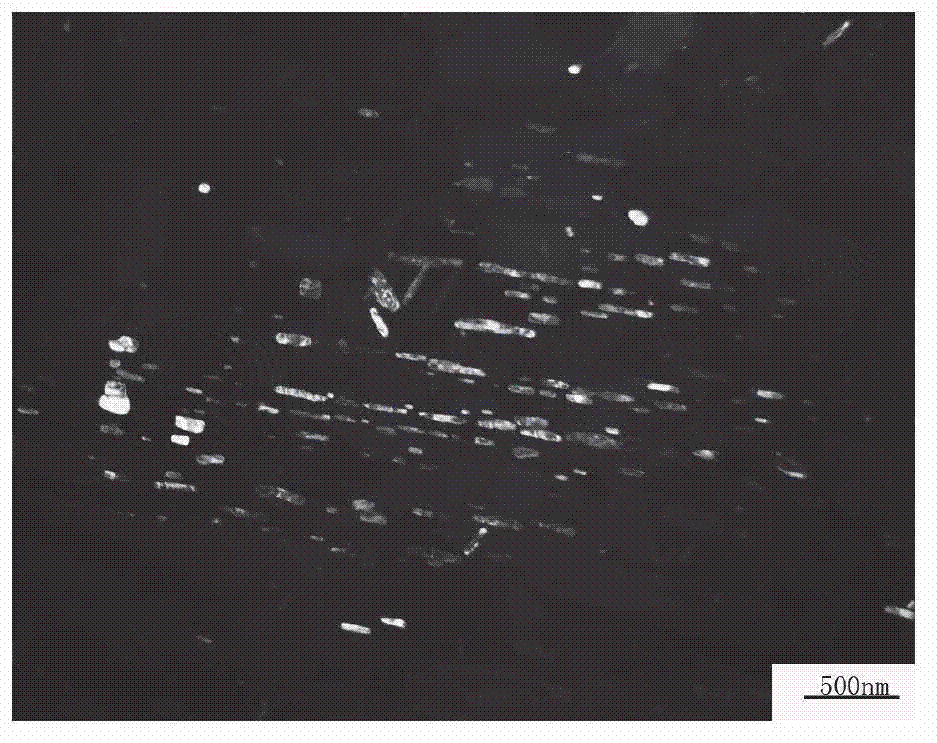

Reversal austenite toughened martensitic stainless steel and manufacturing method thereof

ActiveCN108251759AImprove toughness and plasticityHigh thermodynamic stabilityMartensitic stainless steelHeat stability

The invention discloses reversal austenite toughened martensitic stainless steel and a manufacturing method thereof. The stainless steel comprises, by mass percent, 0.001 to 0.40% of C, 11.0 to 22.0%of Cr, 1.0 to 12.0% of Ni, 0 to 3.0% of Mo, 0.07 to 1.50% of Ti, 0.05 to 1.50% of Al, 0.10 to 2.0% of Si and the balance Fe and inevitable impurities. The manufacturing method of the stainless steel comprises the steps that firstly, an electric furnace is used for smelting, and an AOD furnace is used for refining and casting to form a steel ingot; hot rolling or hot forging treatment is carried out; austenitizing is carried out, and air cooling quenching is carried out; deep cooling treatment is carried out; tempering is carried out. The thermodynamics condition formed by the reversal austenite and the martensite transformation principle serve as the reference, the fine dispersion nucleation position is created for the reversal austenite, the austenite heat stability is improved, a large amount of thin long strip reversal austenite is formed between martensite strips, and toughness plasticity of the martensite stainless steel can be obviously improved.

Owner:NANJING UNIV OF SCI & TECH

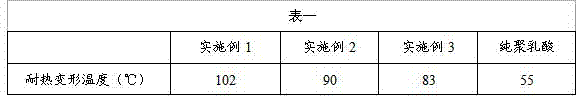

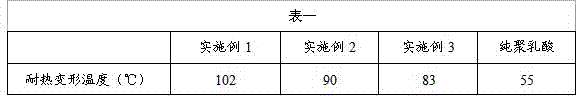

Nanometer high polymer polylactic acid composite material and preparation method thereof

The invention aims to provide a nanometer high polymer polylactic acid composite material with high heat resistance and a preparation method thereof. The nanometer high polymer polylactic acid composite material disclosed by the invention is prepared by mixing 88.9-96 percent by weight of polylactic acid, 1-10 percent by weight of high-performance nanometer high polymers, 0.5-1 percent by weight of a hydrolysis inhibitor, 0.1-1 percent by weight of an anti-ageing agent and 0.1-1 percent by weight of an antioxidant. Nano-grade fine dispersion of high-performance polymer components is realized in polylactic acid, so that the crystallization speed of polylactic acid is increased greatly, and the heat resistance of a polylactic acid material is enhanced.

Owner:CHERY AUTOMOBILE CO LTD

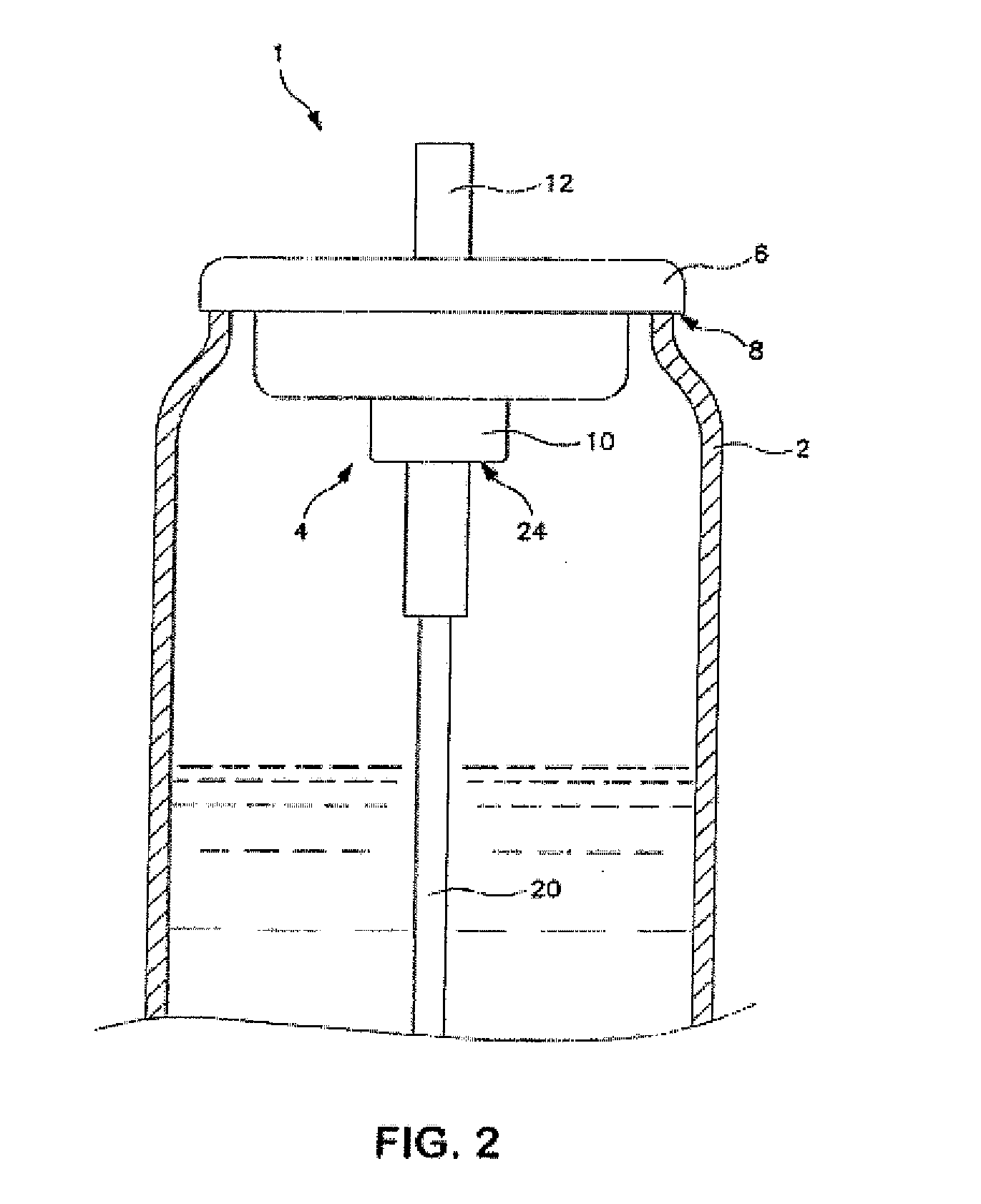

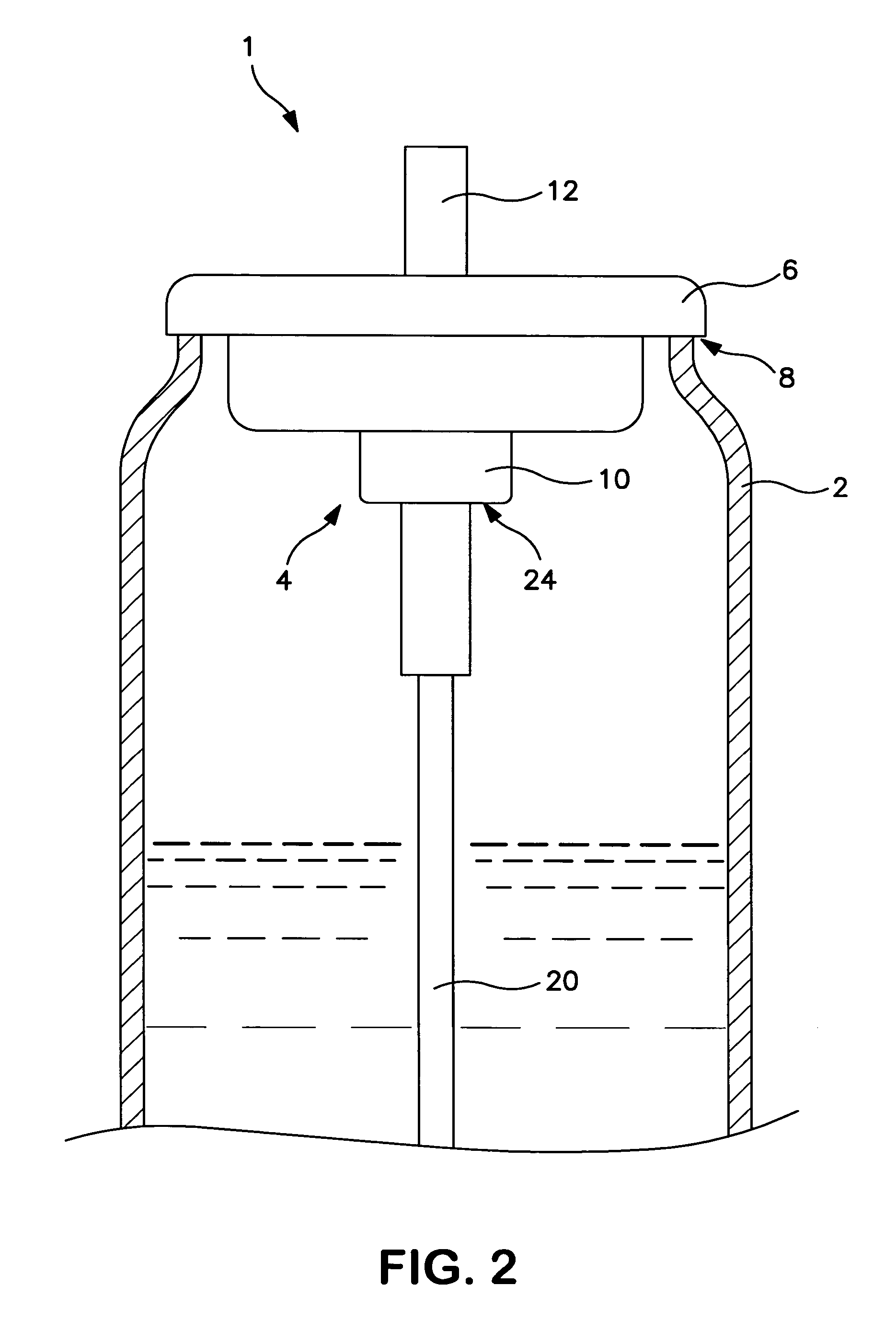

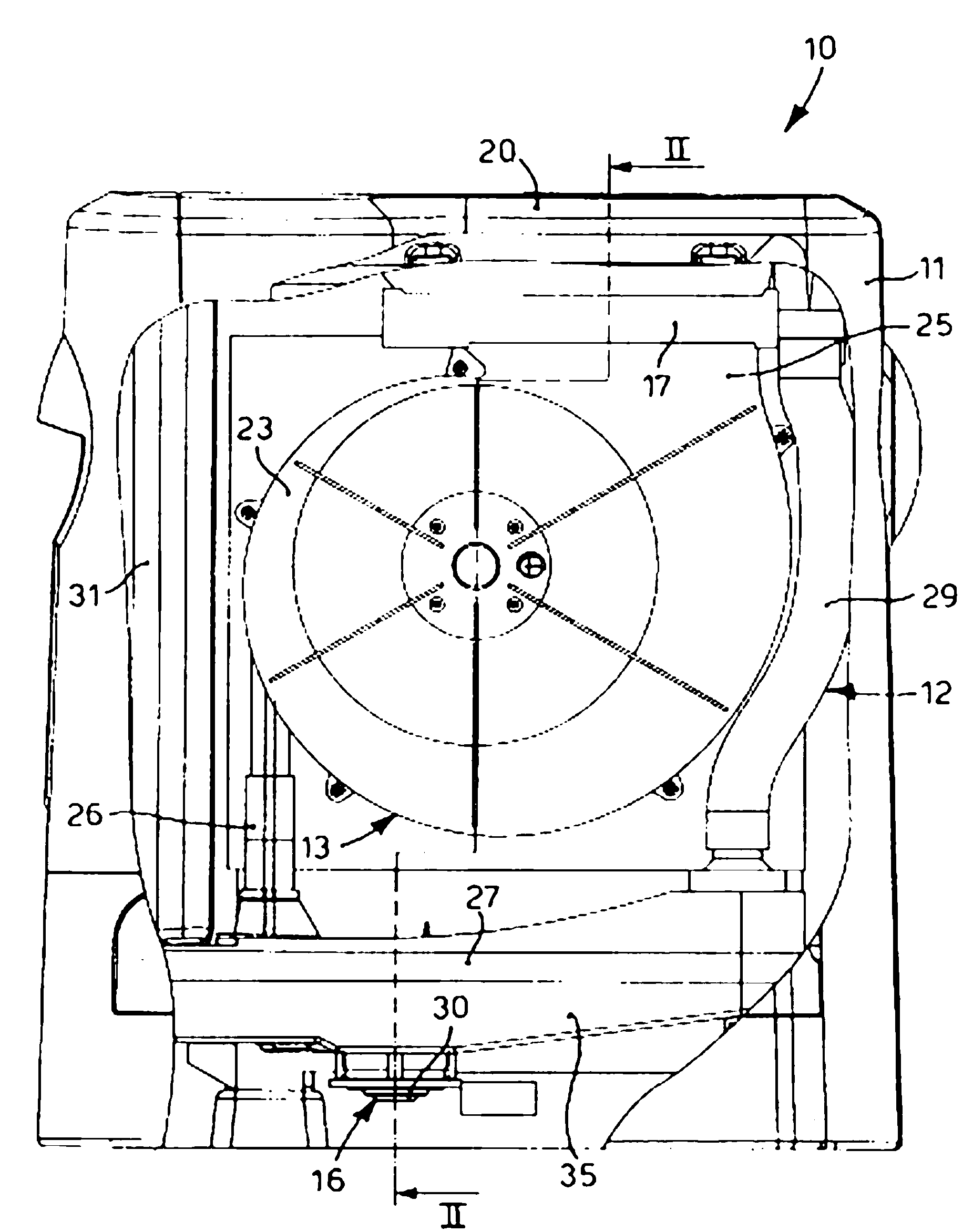

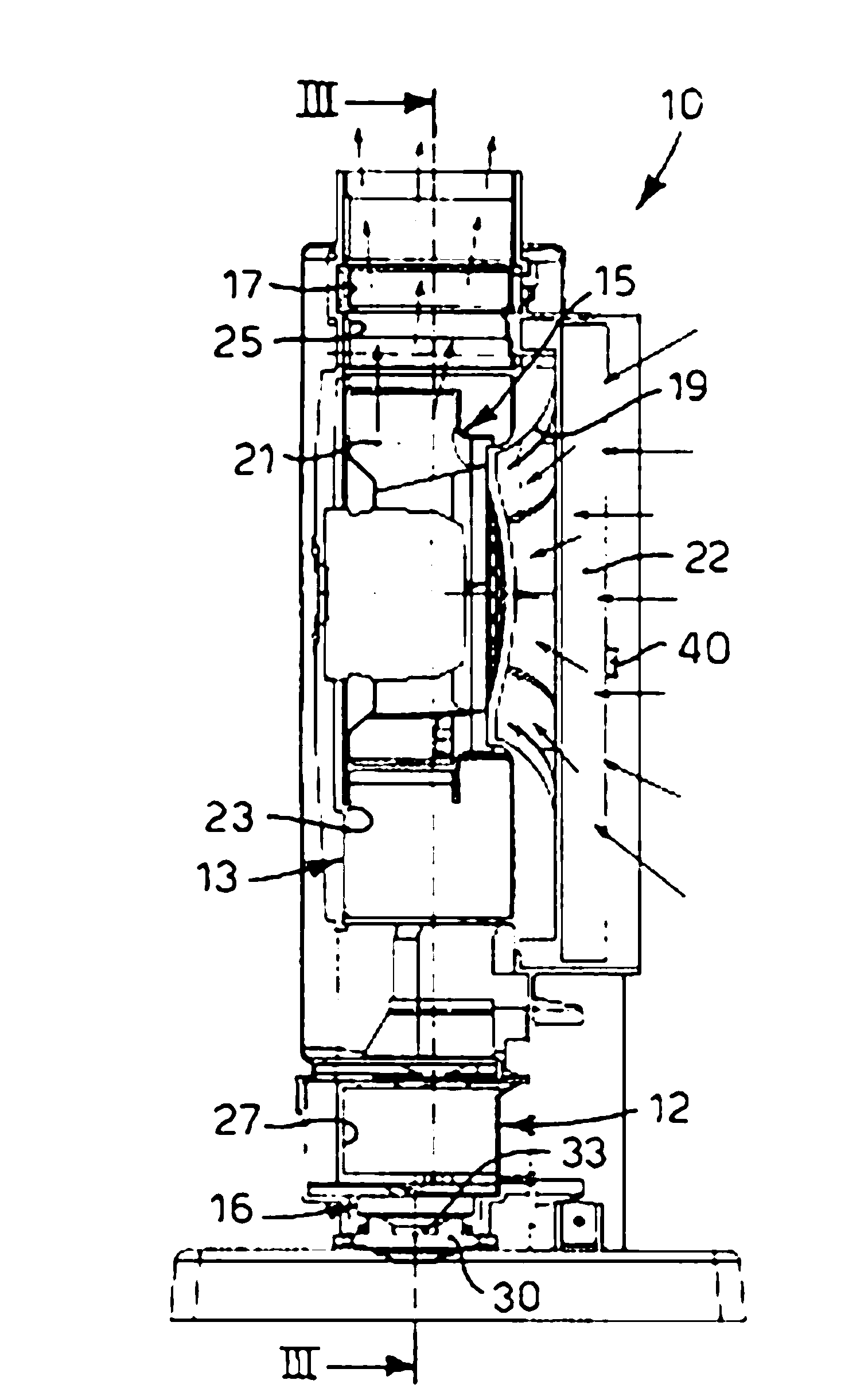

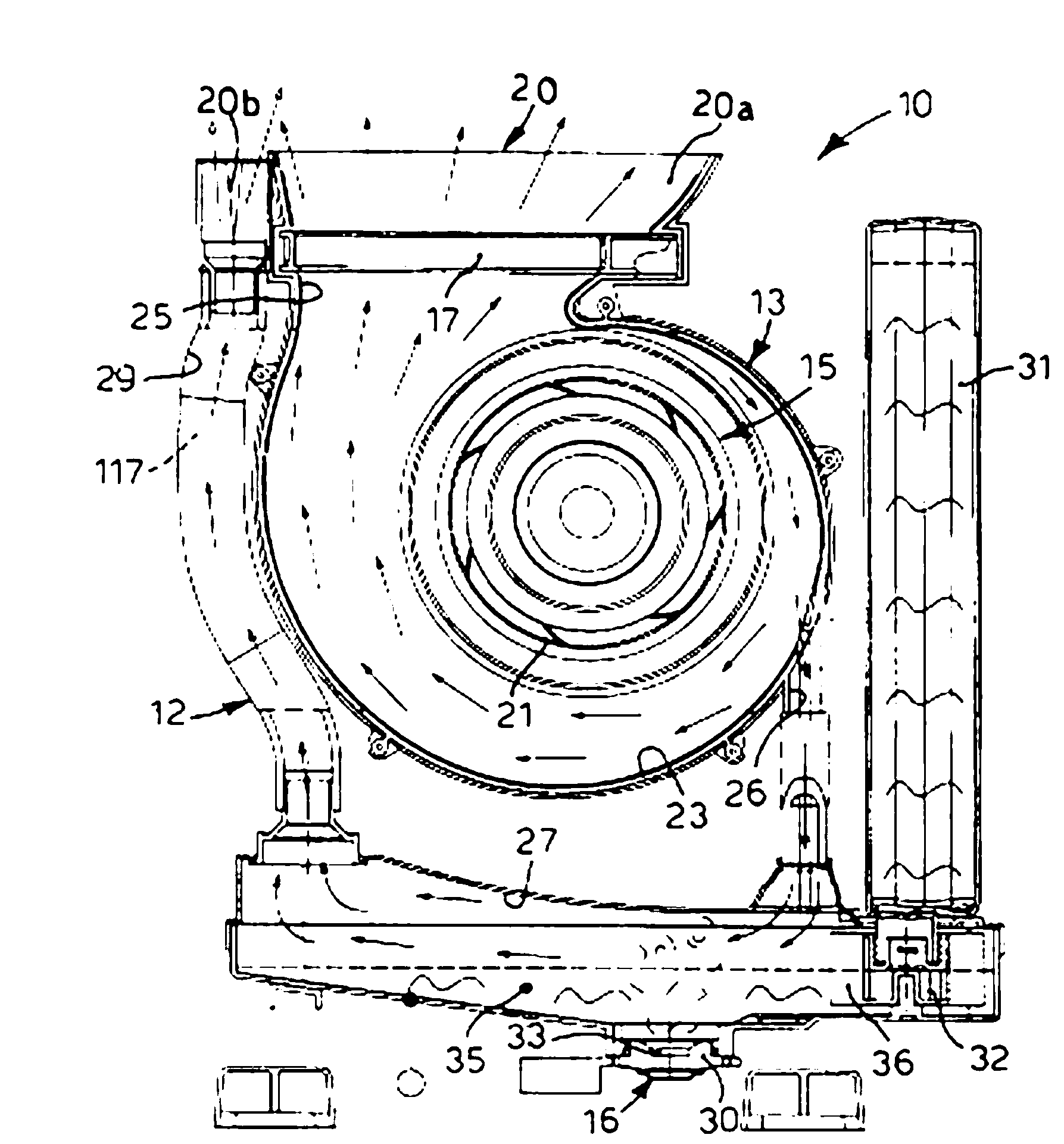

Apparatus to humidify a room

ActiveCN102713449ANo room temperature reductionNo change in room temperatureSpace heating and ventilation safety systemsSpace heating and ventilation control systemsAmbient humidityEnvironmental engineering

Apparatus to humidify a room, comprising an area containing water (35), a humidifier circuit (12) which passes through and / or laps the area containing water (35), at least a suction member (15), to take in ambient air and to introduce at least a fraction of the air inside the humidifier circuit (12) upstream of the area containing water (35), and a water fragmentation member (30, 33) able to form a fine dispersion of drops of water in the area containing water (35). The humidifier circuit (12) is configured, with respect to the area containing water (35), so that the fraction of air taken in by the suction member (15) meets the fine dispersion of drops of water and transports it toward the exit into the room of the humidifier circuit (12), to form a humidified and nebulized stream.; At least downstream of the area containing water (35), associated with the humidifier circuit (12), there are heating means (17, 1 17) to heat the humidified and nebulized fluid, able to supply to the stream a desired energy input.

Owner:DELONGHI APPLIANCES S R L CON UNICO SOCIO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com