Reversal austenite toughened martensitic stainless steel and manufacturing method thereof

A martensitic stainless steel and manufacturing method technology, applied in the field of alloy steel, can solve the problems of ineffective regulation of austenite growth behavior, large scale, and damage to plasticity and toughness, and achieve good thermodynamic stability, dissipate deformation energy, and improve ductile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

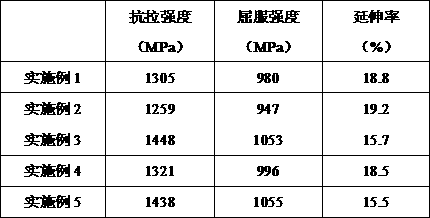

Embodiment 1

[0037] The chemical composition (wt%) of the slab obtained from smelting is C 0.15, Cr 13.60, Ni 3.74, Mo 0, Ti 0.16, Al0.08, Si 0.43, and the balance is Fe.

[0038] After hot rolling, the slab is austenitized at 1100°C for 60 minutes, cryogenically treated at -70°C for 30 minutes, and tempered at 700°C for 60 minutes.

Embodiment 2

[0040] The chemical composition of the slab obtained from smelting is C 0.001, Cr 16.89, Ni 12.0, Mo 0.57, Ti 1.10, Al0.85, Si 0.12, and the balance is Fe.

[0041] After hot rolling, the slab is austenitized at 1250°C for 45 minutes, cryogenically treated at -196°C for 10 minutes, and tempered at 500°C for 300 minutes.

Embodiment 3

[0043] The chemical composition of the slab obtained from smelting is C 0.40, Cr 11.1, Ni 1.0, Mo 2.99, Ti 0.96, Al0.18, Si 0.99, and the balance is Fe.

[0044] After hot rolling, the slab is austenitized at 880°C for 120 minutes, cryogenically treated at -50°C for 70 minutes, and tempered at 750°C for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com